Patents

Literature

47results about How to "Improve extrusion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength polyethylene film

InactiveUS6248831B1Close tolerance in film thicknessGood high speed extrusion bubble stabilitySolubilityAlpha-olefin

A process for production of a polyethylene blend in situ comprising contacting ethylene and at least one alpha-olefin with a magnesium / titanium based catalyst system including a partially activated precursor and a cocatalyst in each of two fluidized bed reactors connected in series, one of the provisos being that the precursor is formed by contacting an alkylaluminum halide with a solid reaction product prepared from a magnesium alkoxide, a titanium tetraalkoxide, and a solubility enhancing agent.

Owner:UNION CARBIDE CORP

Pelletizing of broad molecular weight polyethylene

InactiveUS6454976B1Increased effect on polymer temperatureLow costFlat articlesPolymer scienceProduct gas

Polyethylene having a broad molecular weight distribution is extruded in pellet form using a pelletizing extruder having one or more zones essentially filled with the polyethylene and two or more zones partially filled with the polyethylene. The polyethylene is fed into the extruder at a temperature sufficient to melt the polyethylene, and a mixture of an inert gas and oxygen is fed into at least one partially filled zone of the extruder with the exception of the feed zone. The mixture contains about 1 to about 21% by volume oxygen based on the volume of the gas mixture.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

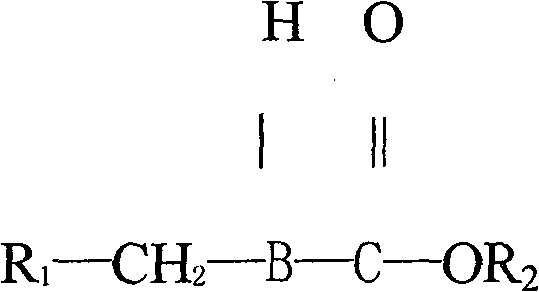

Cellulose reinforced resin compositions

InactiveUS20060094802A1Improve extrusion rateHigh tensile strengthNon-fibrous pulp additionPaper/cardboardWaxPolymer chemistry

The present invention provides an extrudable reinforced resin-containing composition comprising resin capable of plastic flow, reinforcing material, and a lubricant composition comprising oxidized polyethylene wax, ester wax, and amide wax. Also provided are the lubricant composition, and extrusion methods and extruded products based on the present compositions.

Owner:HONEYWELL INT INC

Aluminum alloy extruded product for heat exchangers and method of manufacturing the same

InactiveUS20050189047A1Reduce resistanceReduce the amount requiredHeat exchange apparatusSiluminHigh intensity

A high-strength aluminum alloy extruded product for heat exchangers which excels in extrudability, allows a thin flat multi-cavity tube to be extruded at a high critical extrusion rate, and excel in intergranular corrosion resistance at a high temperature, and a method of manufacturing the same. The aluminum alloy extruded product includes an aluminum alloy including 0.2 to 1.8% of Mn and 0.1 to 1.2% of Si, having a ratio of Mn content to Si content (Mn % / Si %) of 0.7 to 2.5, and having a content of Cu as an impurity of 0.05% or less, with the balance being Al and impurities, the aluminum alloy extruded product having an electric conductivity of 50% IACS or more and an average particle size of intermetallic compounds precipitating in a matrix of 1 μm or less.

Owner:FURUKAWA SKY ALUMINUM CORP +2

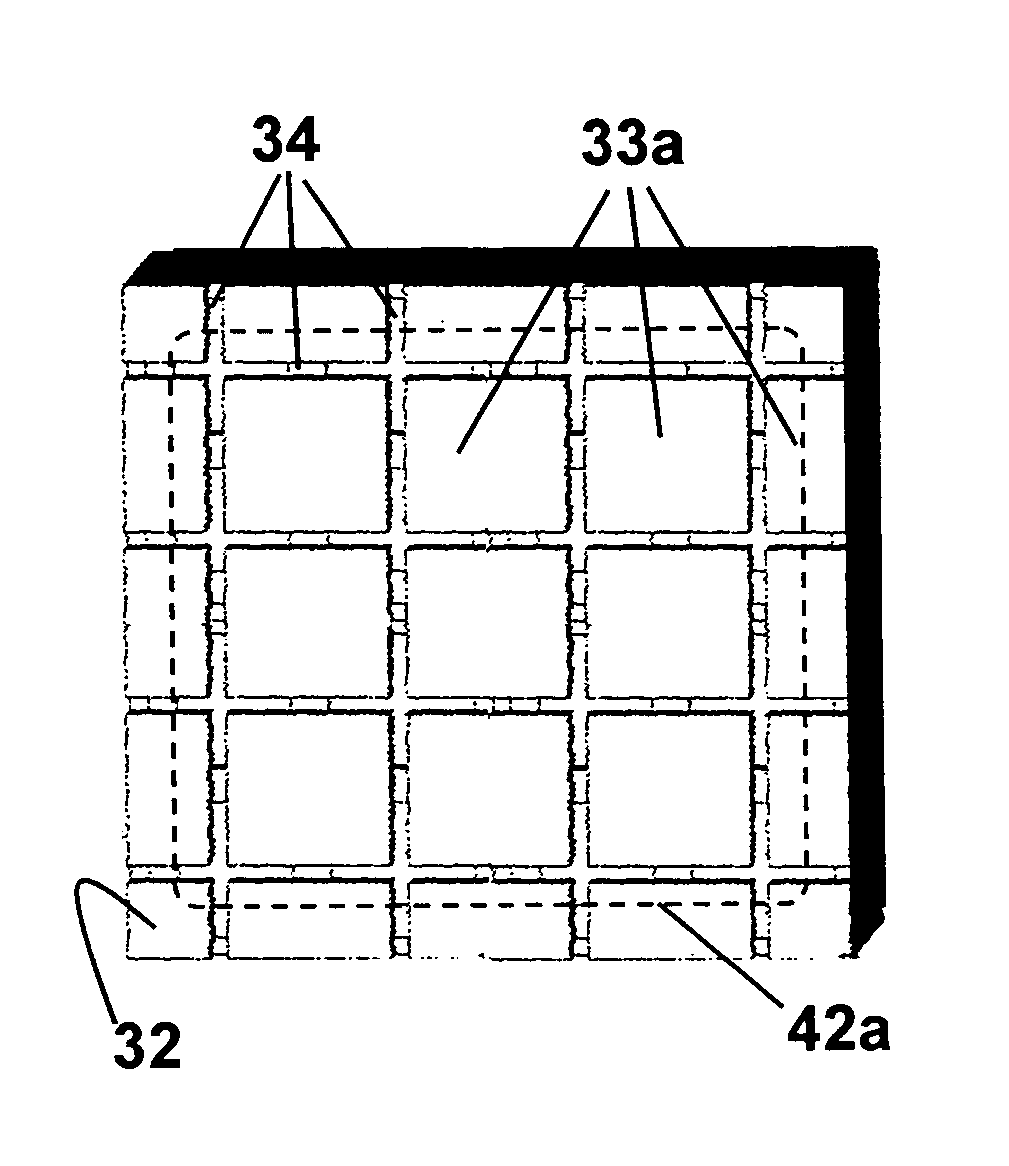

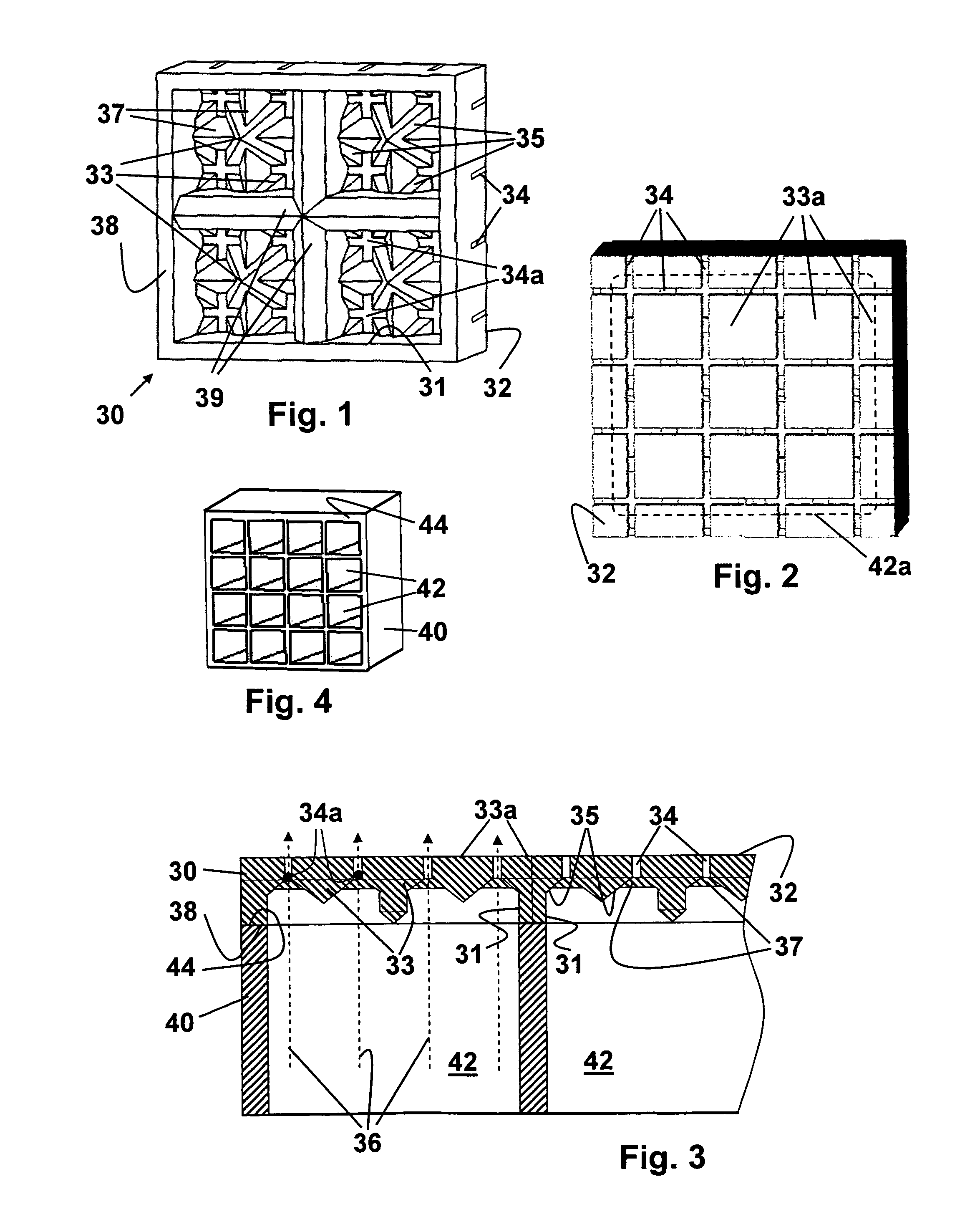

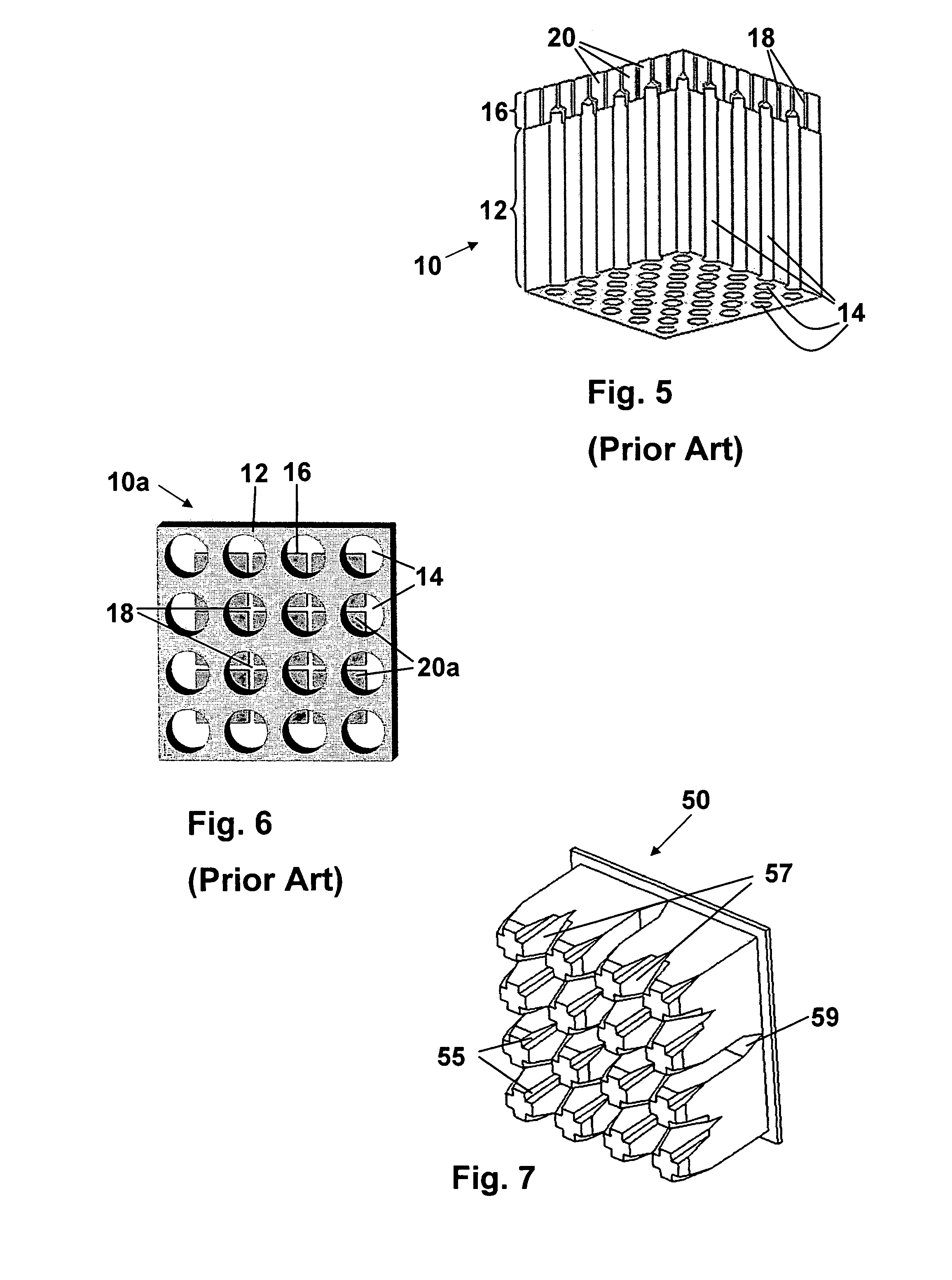

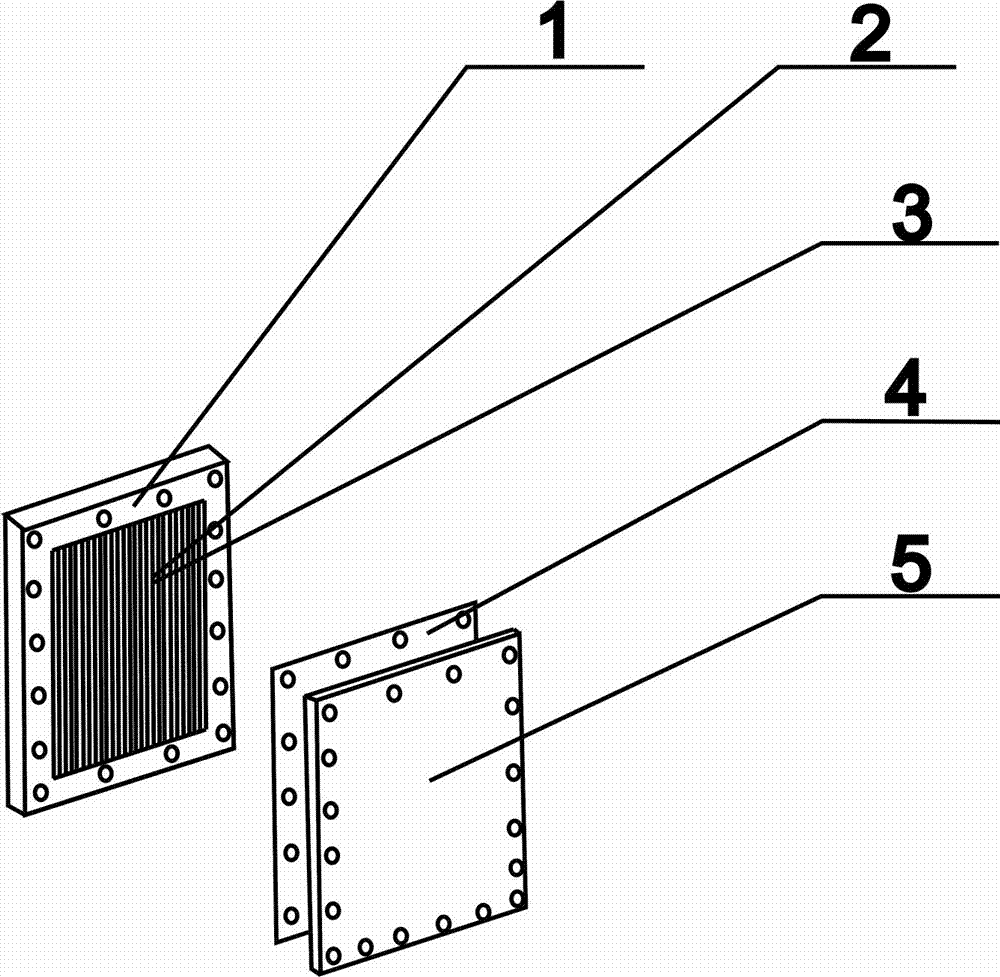

Open cavity extrusion dies

InactiveUS6991450B1Minimal pressure dropIncrease pressure dropConfectionerySweetmeatsEngineeringHoneycomb structure

Honeycomb structures are formed at reduced extrusion pressures and high extrusion rates via extrusion through open cavity honeycomb extrusion dies incorporating large, closely spaced feed channels delivering extrudable material to die honeycomb forming sections incorporating extrudate distribution means in the form of inverted conical or pyramidal flow dividers incorporating inclined flow-guiding surfaces that guide the extrudate into the base ends of plural discharge slot intersections and / or slot segments in direct line with the feed channels.

Owner:CORNING INC

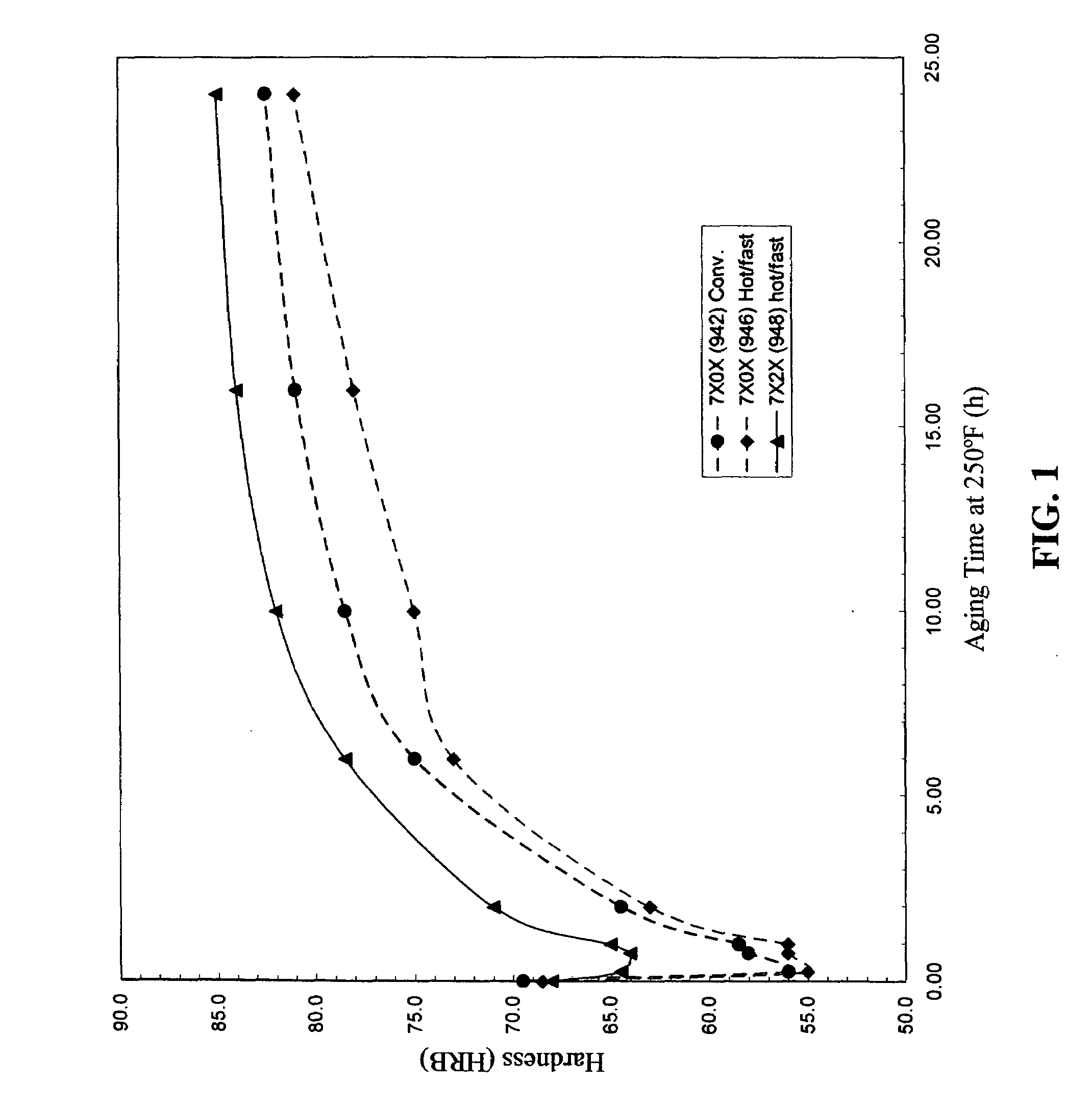

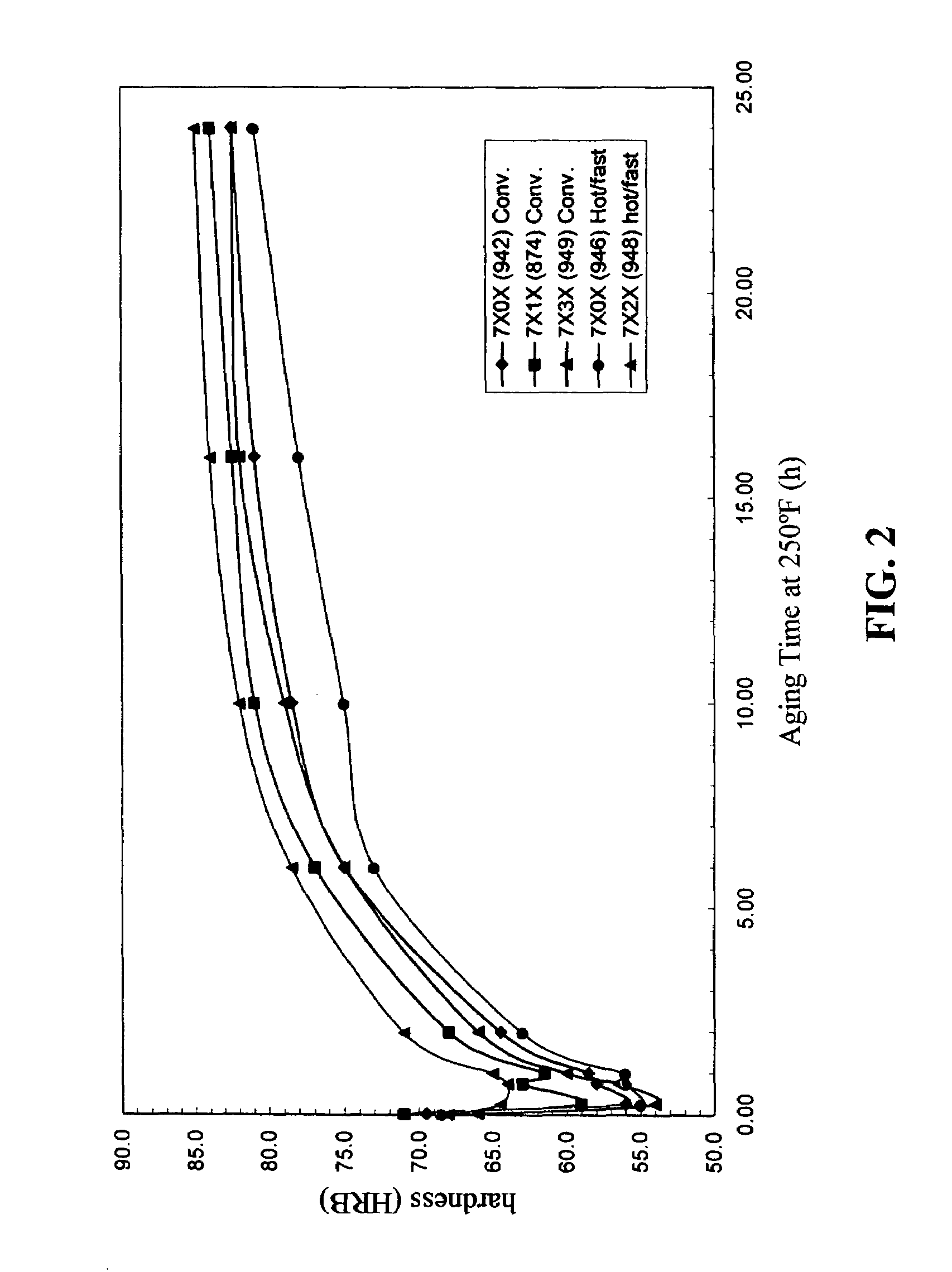

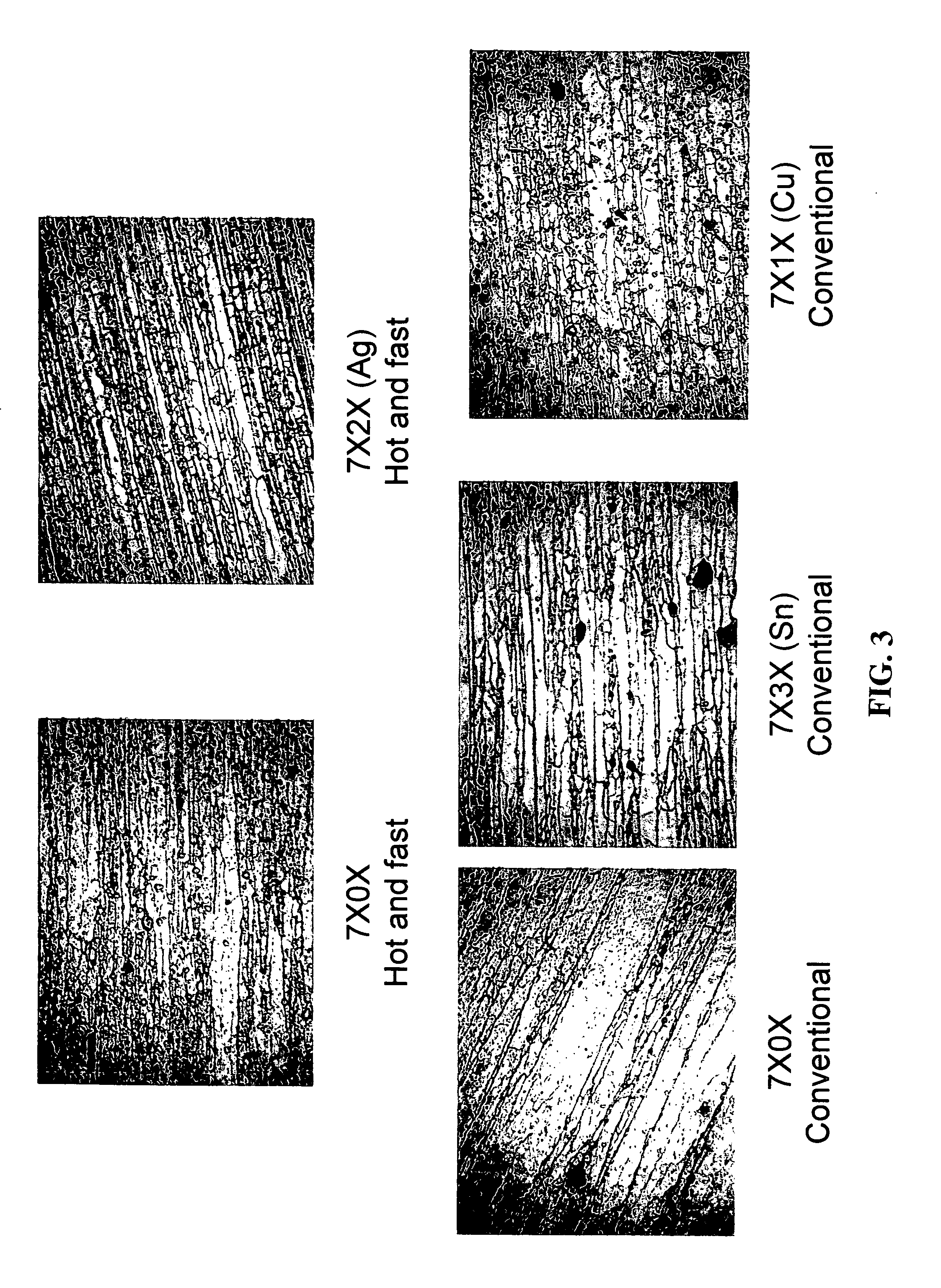

Aluminum-zinc-magnesium-scandium alloys and methods of fabricating same

Aluminum-zinc-magnesium-scandium alloys containing controlled amounts of alloying additions such as silver and tin are disclosed. The presence of Ag and / or Sn alloying additions improves fabrication characteristics of the alloys, such as the ability to be extruded at high temperatures and very high extrusion rates. The Al—Zn—Mg—Sc alloys may optionally include other alloying additions such as Cu, Mn, Zr, Ti and the like. The alloys possess good properties such as relatively high strength and excellent corrosion resistance. The alloys may be fabricated into various product forms such as extrusions, forgings, plate, sheet and weldments.

Owner:SURFACE TREATMENT TECH INC

Process for extrusion

InactiveUS20020074682A1Increased effect on polymer temperatureReduce capacityWood working apparatusDomestic articlesPolymer scienceProduct gas

A process for the extrusion of polyethylene having a broad molecular weight distribution wherein the polyethylene is prepared in pellet form, said extrusion taking place in a pelletizing extruder having one or more zones essentially filled with polyethylene and two or more zones partially filled with polyethylene including a feed zone comprising (i) introducing the polyethylene into the extruder at a temperature sufficient to melt the polyethylene; (ii) introducing a mixture of an inert gas and oxygen into at least one partially filled zone with the exception of the feed zone, said mixture containing about 1 to about 21 percent by volume oxygen based on the volume of the gaseous mixture; (iii) passing the molten polyethylene through each zone at melt temperature; and (iv) extruding the polyethylene into pellets and cooling same.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

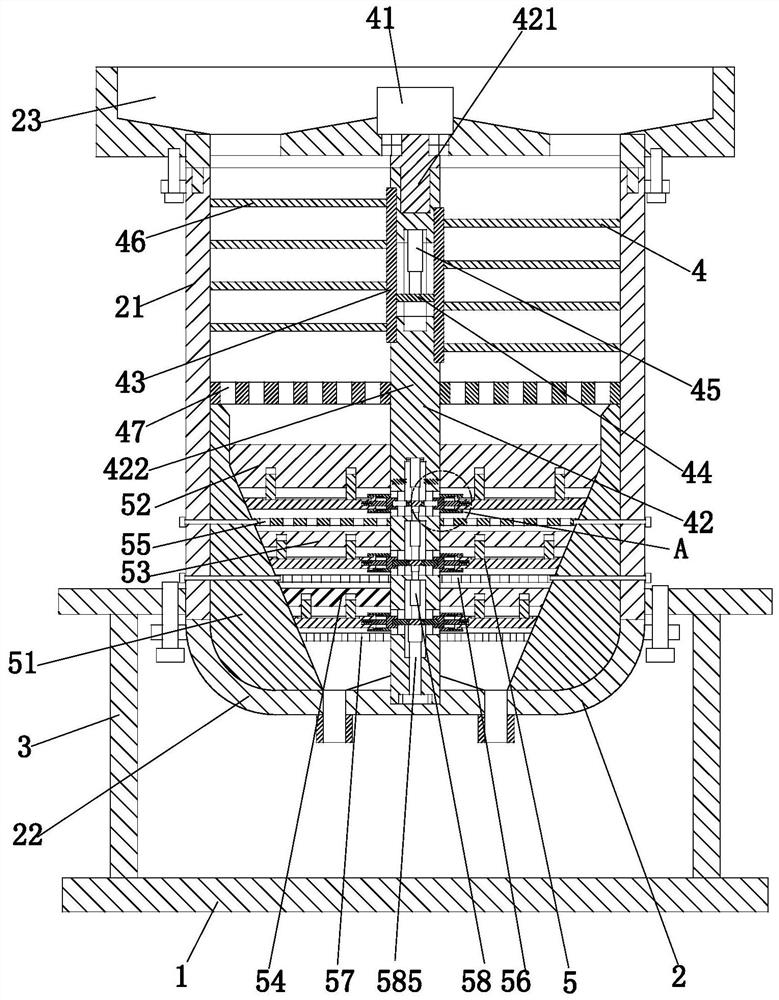

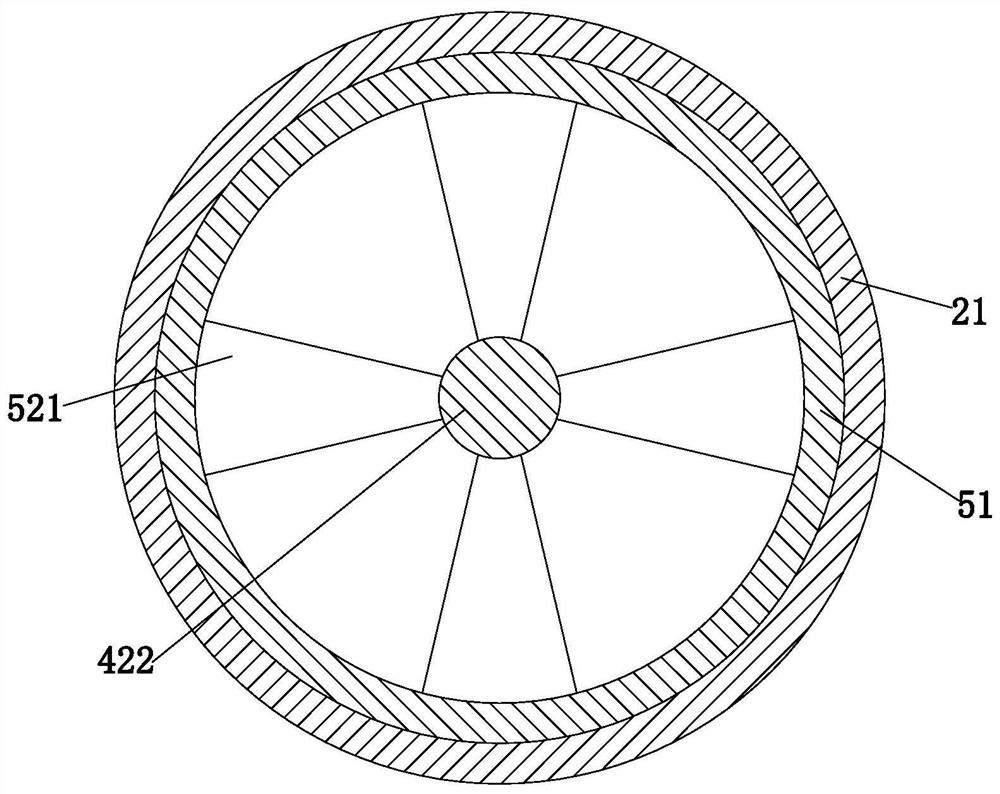

Cosmetic additive natural plant essential oil preparation technology

InactiveCN111790496ASmall sizeImprove extrusion rateEssential-oils/perfumesGrain treatmentsProcess engineeringCitrus plant

The invention relates to a cosmetic additive natural plant essential oil preparation technology. Essential oil preparation equipment is used and comprises a bottom plate, a shell, an installation frame, a cutting device and an extrusion device. The specific technological process for preparing citrus plant essential oil through the essential oil preparation equipment are as follows of raw materialpreparation, chopping treatment, grinding extrusion and essential oil collection. The extrusion device comprises a standing ring, a first extrusion mechanism, a second extrusion mechanism, a third extrusion mechanism, a first sieve plate, a second sieve plate, a third sieve plate and an auxiliary mechanism. According to the cosmetic additive natural plant essential oil preparation technology, essential oil is prepared from citrus peel in a mode that extrusion is conducted after cutting, the cut peel is small in size, thus the overall contact area of the peel and the extrusion device is increased, the extrusion effect can be improved, the cut peel is extruded repeatedly in a graded extrusion mode, the extrusion rate of the essential oil can be increased, and waste of raw materials is avoided.

Owner:上海肤徕生物高科技有限公司

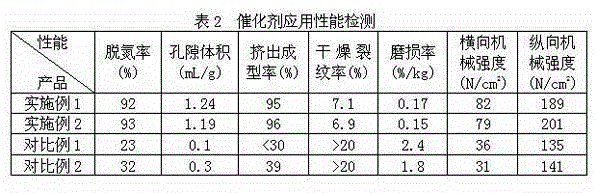

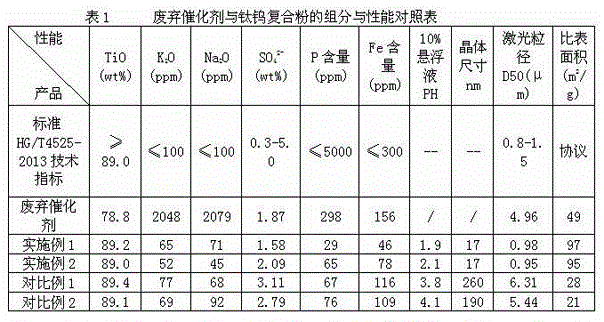

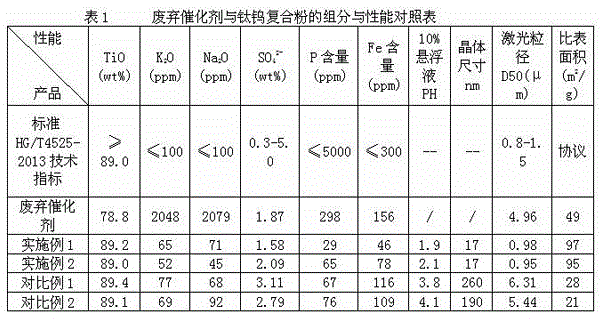

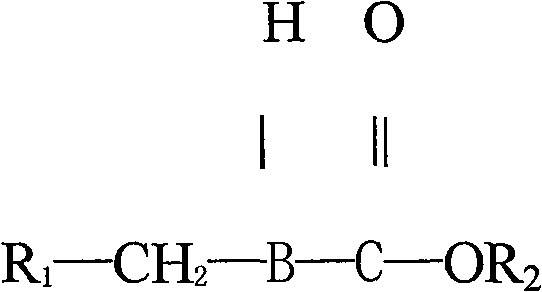

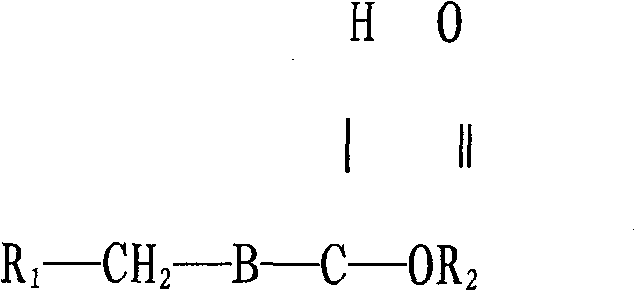

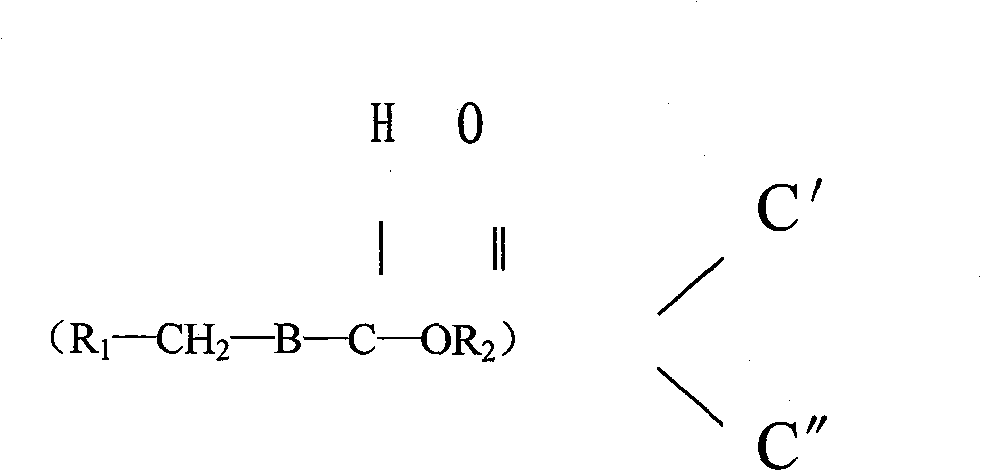

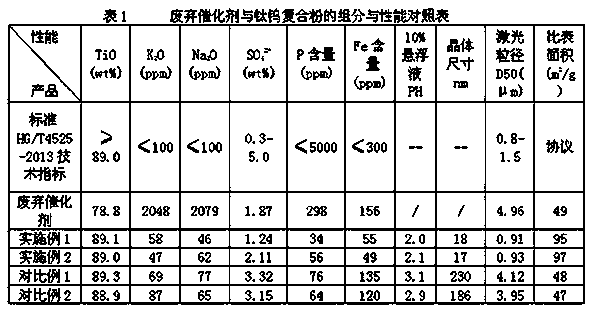

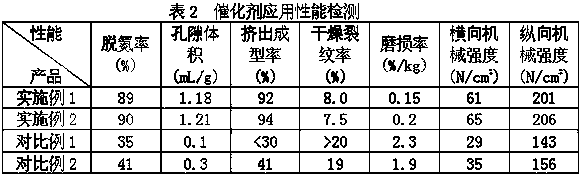

Low cost recovery and regeneration method of waste SCR catalyst, and regenerated SCR catalyst carrier

ActiveCN104368361AEfficient separationMeet the technical requirements of titanium dioxideCatalyst carriersCatalyst regeneration/reactivationSlurryEngineering

The present invention discloses a low cost recovery and regeneration method of a waste SCR catalyst, and a regenerated SCR catalyst carrier. According to the low cost recovery and regeneration method of the waste SCR catalyst, a catalyst is subjected to a primary treatment and then is mixed with a metatitanic acid slurry to co-prepare titanium-tungsten powder, harmful components in the waste catalyst are removed, and the active ingredients in the catalyst are retained so as to obtain the low cost and environmental protection recovery and regeneration method. In addition, various performance effects of the regenerated SCR catalyst carrier can achieve the standard for preparing the SCR catalyst, and the excellent performance is provided.

Owner:PANZHIHUA ZHENGYUAN TECH

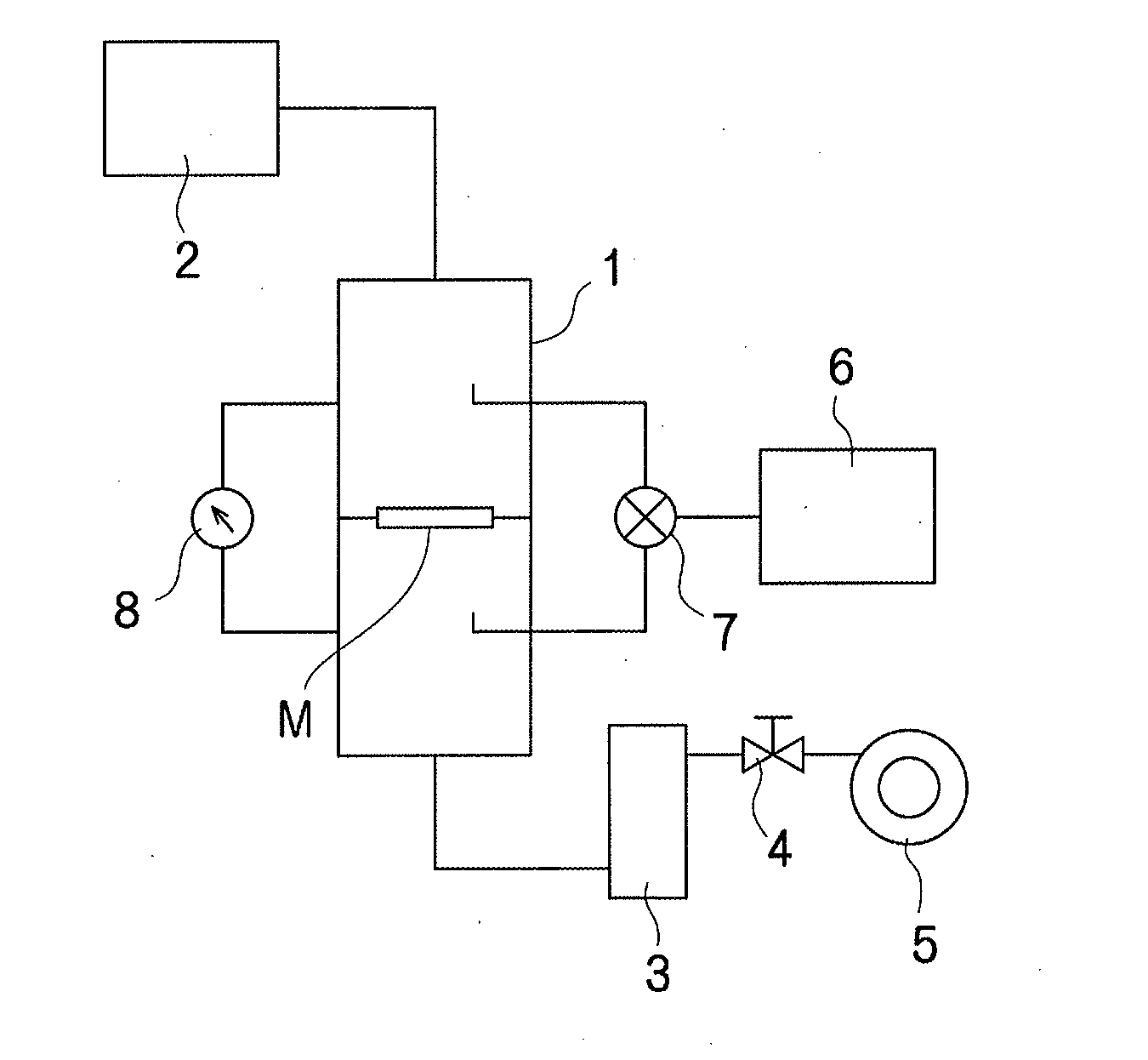

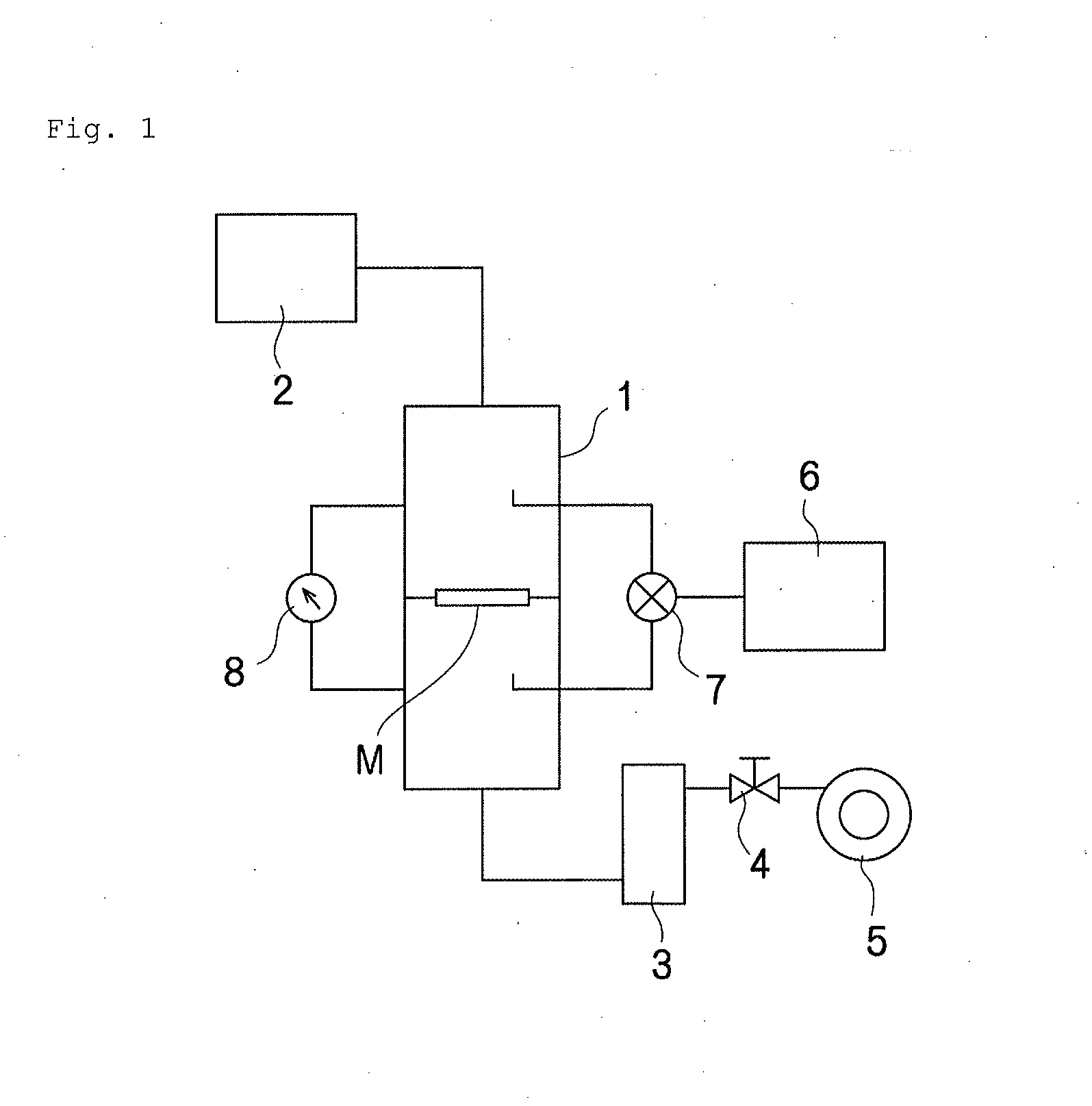

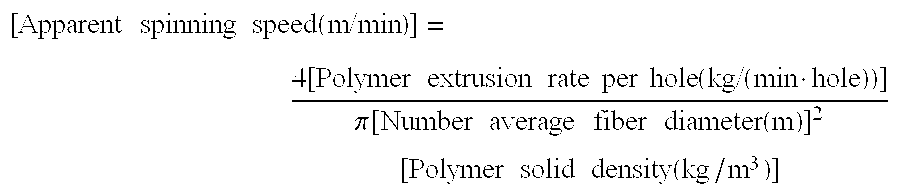

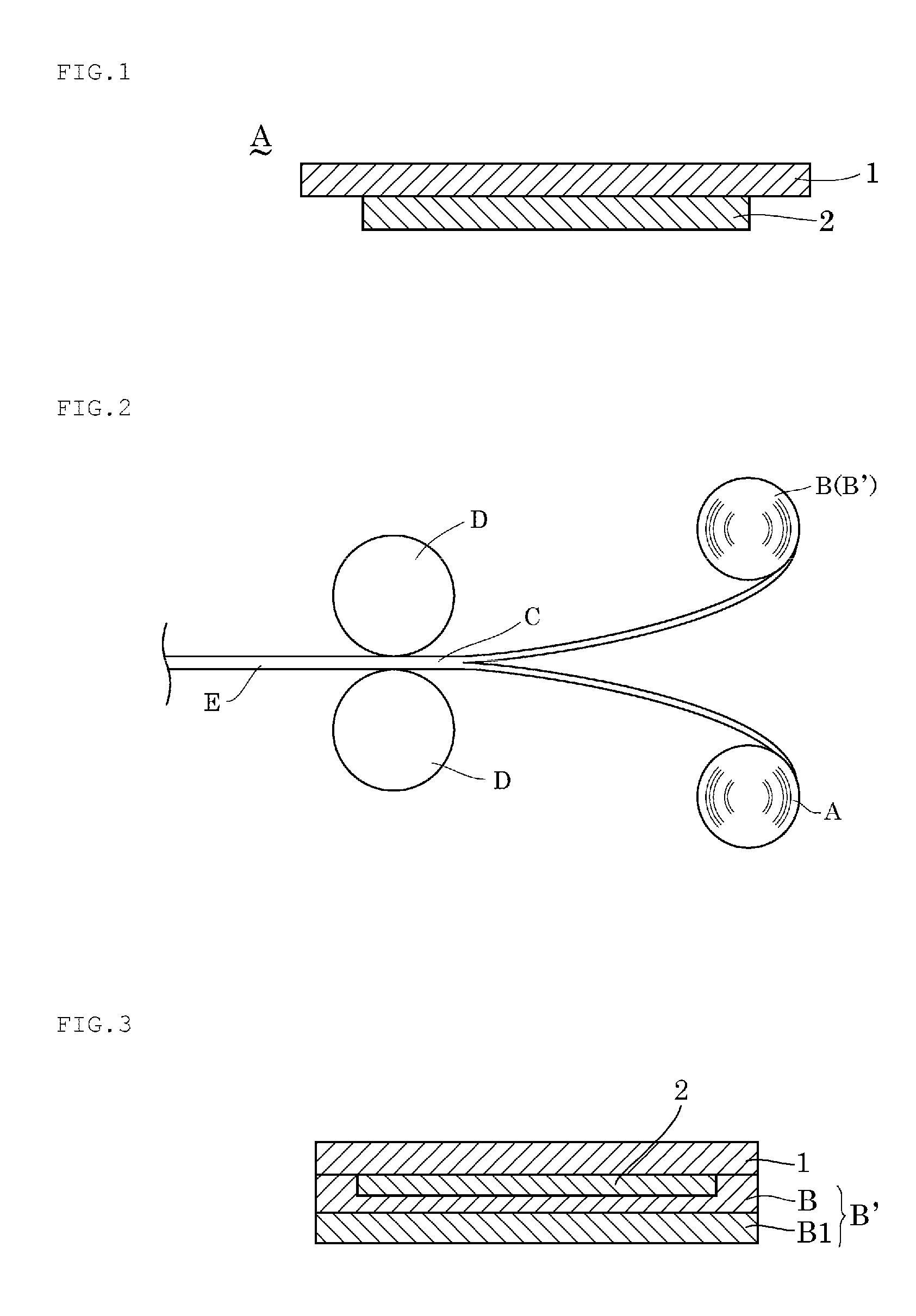

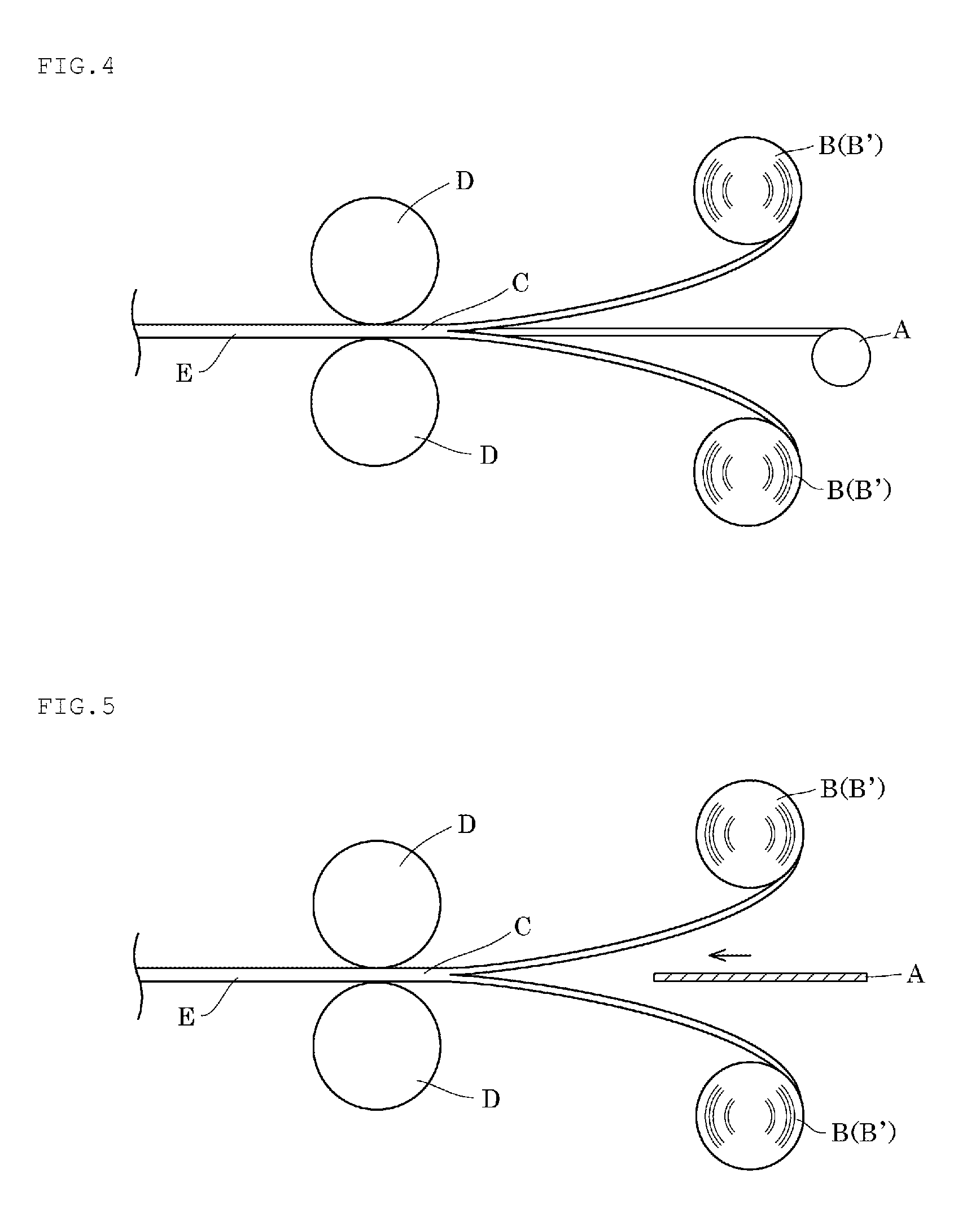

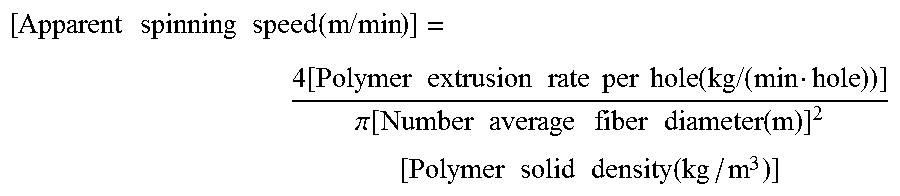

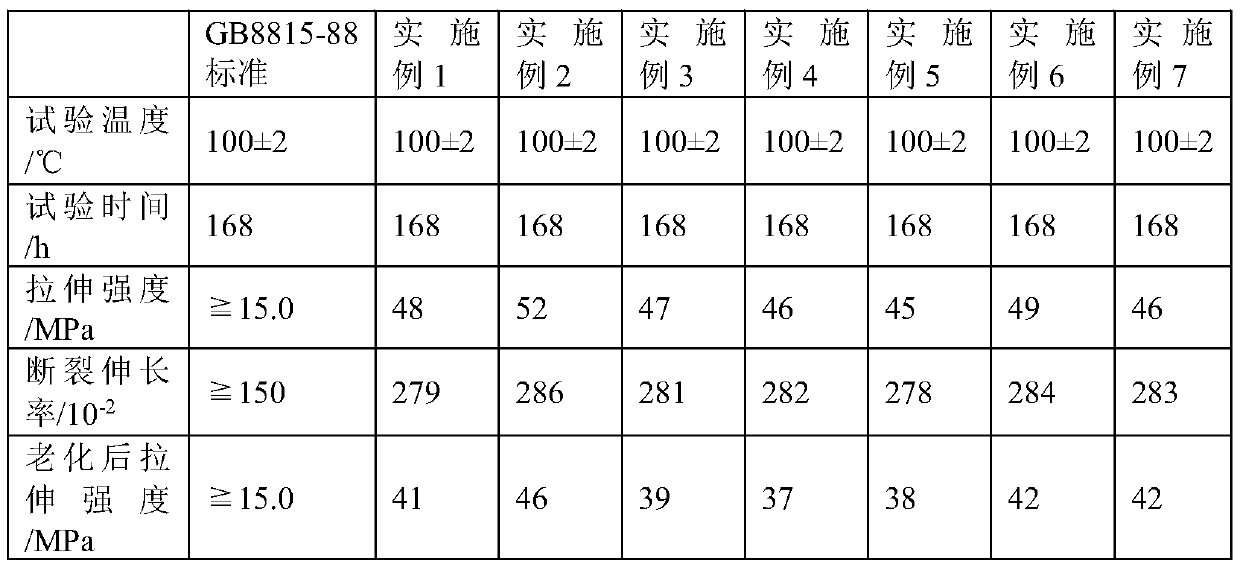

Mixed-fiber nonwoven fabric, laminated sheet and filter, and process for producing mixed-fiber nonwoven fabric (as amended)

ActiveUS20140305090A1Reduce deformationReduce fusionLoose filtering material filtersNon-woven fabricsPolyolefinPolymer science

Provided are a mixed-fiber nonwoven fabric suitable for air filters and a filter medium using the mixed-fiber nonwoven fabric. The nonwoven fabric includes at least two types of fibers having different melting points, which fibers are low melting point fibers made of a polyolefin resin component A, and high melting point fibers made of a high melting point resin component B having a higher melting point than that of the polyolefin resin component A. The number average fiber diameter of the high melting point fibers is larger than that of the low melting point fibers. At least one high melting point fiber having a fiber diameter of 20 μm to 100 μm is present per 1.00 mm of the length of the cross section of the nonwoven fabric. The number average fiber diameter of all fibers constituting the nonwoven fabric falls within the range of 0.3 μm to 10 μm.

Owner:TORAY IND INC

Aluminum alloy extruded product for heat exchangers and method of manufacturing the same

InactiveUS7767042B2Reduce resistanceReduce the amount requiredHeat exchange apparatusHigh intensityImpurity

A high-strength aluminum alloy extruded product for heat exchangers which excels in extrudability, allows a thin flat multi-cavity tube to be extruded at a high critical extrusion rate, and excels in intergranular corrosion resistance at a high temperature, and a method of manufacturing the same. The aluminum alloy extruded product includes an aluminum alloy including 0.2 to 1.8% of Mn and 0.1 to 1.2% of Si, having a ratio of Mn content to Si content (Mn % / Si %) of 0.7 to 2.5, and having a content of Cu as an impurity of 0.05% or less, with the balance being Al and impurities, the aluminum alloy extruded product having an electric conductivity of 50% IACS or more and an average particle size of intermetallic compounds precipitating in a matrix of 1 μm or less.

Owner:FURUKAWA SKY ALUMINUM CORP +2

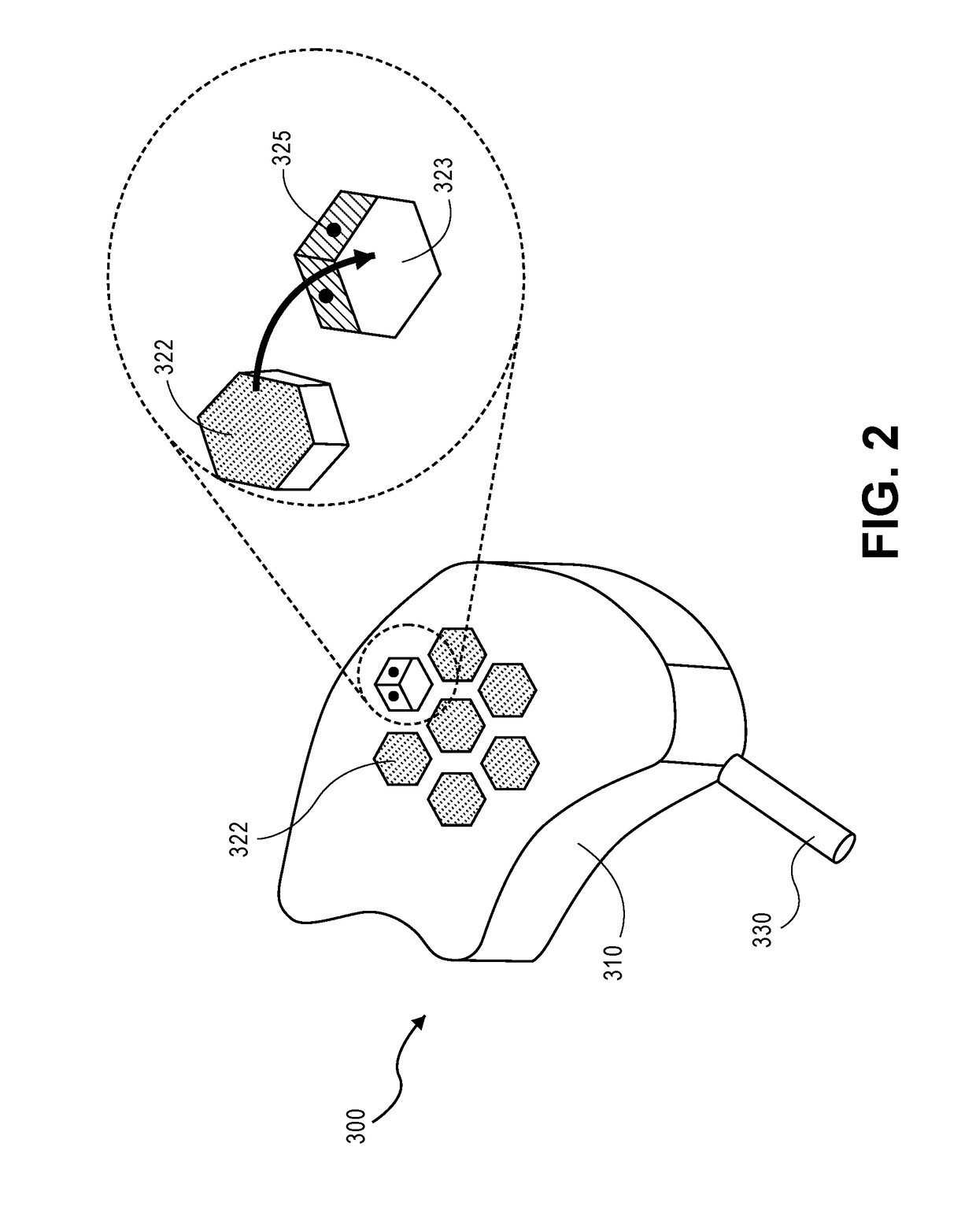

Low-profile intercranial device

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Low-profile intercranial device

ActiveUS11058541B2Good curative effectTotal current dropImage enhancementImage analysisBiochemical engineeringPharmaceutical drug

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

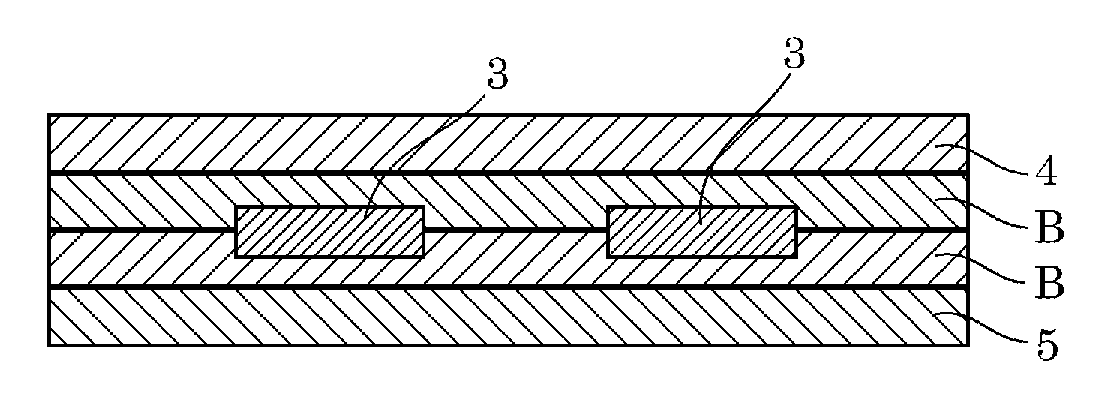

Sealing material for solar cell, protective sheet for solar cell, and process for production of solar cell module

ActiveUS20130005071A1Easily and efficiently producedSuppress sealing materialSemiconductor/solid-state device manufacturingOrganic dyesSilane compoundsButene

The present invention provides a sealing material for a solar cell that seals a solar cell element of a solar cell in a short time in the production of a solar cell module, thereby enabling efficient production of solar cell modules. The sealing material for a solar cell of the present invention has a feature of containing 100 parts by weight of a modified butene-based resin that is produced by graft-modifying a butene-ethylene copolymer having a butene content of 1 to 25% by weight with maleic anhydride and has a total content of the maleic anhydride of 0.1 to 3% by weight, and 0.1 to 15 parts by weight of a silane compound having an epoxy group.

Owner:SEKISUI CHEM CO LTD

White carbon black dispersant for rubber products and preparation method of dispersant

The invention discloses a white carbon black dispersant for rubber products. The white carbon black dispersant is characterized by being prepared from the following raw materials in parts by weight: 45-50 parts of C16-C18 natural fatty alcohol and 50-55 parts of 12-hydroxystearic acid. A preparation method of the white black dispersant comprises the following steps: partially melting, co-melting, blending, cooling, crushing and packaging. According to the white carbon black dispersant, white carbon black is uniformly dispersed in mixed rubber, so that the agglomeration caused by adhesion is solved, the product quality is improved, energy sources are saved, and meanwhile, the cost is reduced.

Owner:山东迪科化学科技股份有限公司

Method for preparing air-tight promoter

The invention relates to a method for preparing a promoter, in particular to a method for preparing an air-tight promoter. The method for preparing the air-tight promoter is characterized by comprising the following steps of: 1, adding short fibers, asphalt, silicon and alumina powder into coal powder, proportioning and mixing, wherein the adding amount of the short fibers is in an amount which is 15 percent based on the input amount of materials; 2, adding a mixture which is metered and mixed in the step 1 into a pulverizing mill for grinding, and performing vibration sieving purification by using a screen sieve; and 3, adding treated distillate aromatic extract (TDAE) into the mixture obtained in the step 2, putting into a mixing machine at the temperature of between 40 and 45 DEG C, rotating and mixing for 1 to 10 minutes, and discharging. The method has the advantages that: the content of rubber in butyl rubber is reduced, specific gravity is low, Mooney viscosity is reduced, and extrusion rate is improved, so that the production speed and the production efficiency of a product are increased; and return rate is reduced, namely product yield is improved.

Owner:山东迪科化学科技股份有限公司

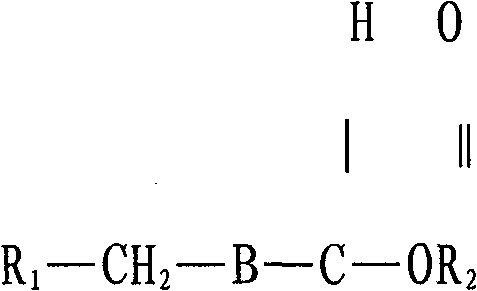

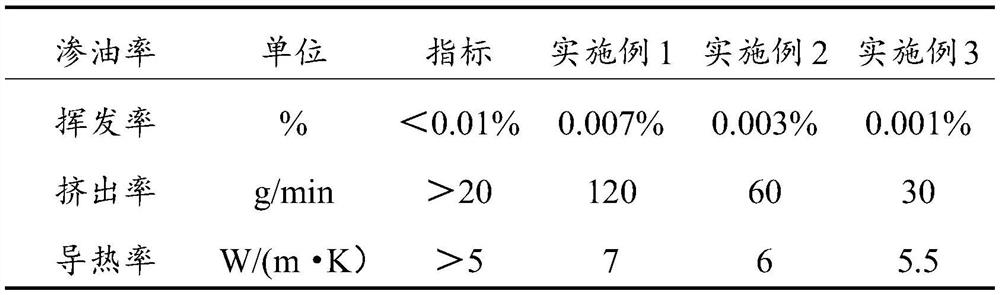

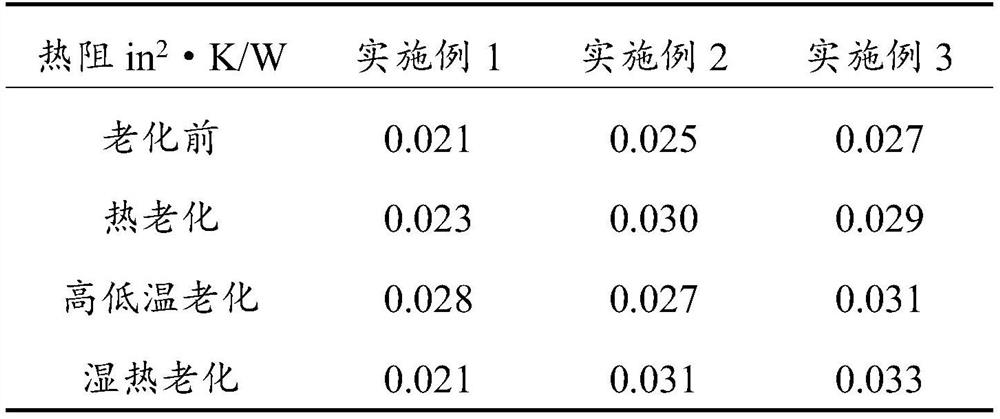

Preparation method of single-component high-fluidity high-thermal-conductivity gel

InactiveCN113024164AImprove extrusion rateNo pollutionHeat-exchange elementsPolymer sciencePtru catalyst

The invention relates to a preparation method of a single-component high-fluidity high-thermal-conductivity gel, the preparation method of the single-component high-fluidity high-thermal-conductivity gel comprises the following production steps: firstly adsorbing a platinum catalyst by using nano fumed silica, then wrapping the platinum catalyst with polymer resin, mixing 0.1-1 part of pretreated platinum catalyst and 80-95 parts of heat-conducting powder, wherein the heat-conducting powder is a mixture of spherical aluminum oxide, silicon nitride and boron nitride, and then mixing with 4-20 parts of silicone oil uniformly, wherein the silicone oil is a mixture of vinyl silicone oil and hydrogen-containing silicone oil, and the ratio of the vinyl silicone oil to the hydrogen-containing silicone oil is (10-20): 1. The gel is stable at normal temperature, and can be quickly cured after being heated to 100-150 DEG C to form an elastic film. The gel can be stored at room temperature for a long time and is stable, good in fluidity, high in automatic dispensing extrusion rate, easy to peel after being heated and cured, free of polluting components and convenient for later repair.

Owner:福建臻璟新材料科技有限公司

Method for manufacturing an extruded material of heat treatment type Al—Zn—Mg series aluminum alloy

Owner:KOBE STEEL LTD

Cellulose reinforced resin compositions with wax blend

InactiveUS7432317B2Improve extrusion rateHigh tensile strengthNon-fibrous pulp additionPaper/cardboardWaxCellulose

The present invention provides an extrudable reinforced resin-containing composition comprising resin capable of plastic flow, reinforcing material, and a lubricant composition comprising oxidized polyethylene wax, ester wax, and amide wax. Also provided are the lubricant composition, and extrusion methods and extruded products based on the present compositions.

Owner:HONEYWELL INT INC

Low-volatility double-cross-linking heat-conducting phase change gel and preparation method thereof

ActiveCN112812570AImprove extrusion rateLow viscosityHeat-exchange elementsPolymer sciencePtru catalyst

The invention discloses low-volatility double-cross-linking heat-conducting phase-change gel, which is characterized by comprising the following components in parts by weight: 1-30 parts of a resin A, 0.01-5 parts of a curing agent, 1-10 parts of a phase-change material, 0.1-2 parts of an antioxidant, 1-30 parts of a resin B, 0.01-5 parts of a cross-linking agent, 0.01-1 part of a catalyst and 100-300 parts of a heat-conducting filler. According to the invention, on the basis of silicone rubber and filler of original heat-conducting gel, an additional cross-linking curing system is introduced to achieve double-network cross-linking, and silicone rubber of different networks has a mutual dragging effect, so that volatilization of small molecules can be inhibited while it is guaranteed that the extrusion rate of the heat-conducting gel is high; a curing system of peroxide and silicone rubber is adopted, after a manufacturer completes curing to a certain degree, the product is made to be used at a client side, and the residual peroxide can still promote curing; and the phase change substance is introduced, and after phase change, the viscosity of the system is reduced, so that curing is promoted, the curing degree is improved, and volatilization of small molecules is further inhibited.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

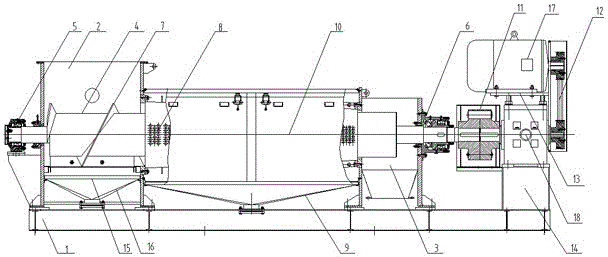

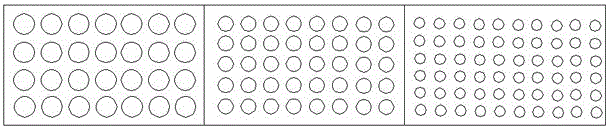

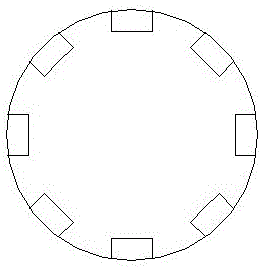

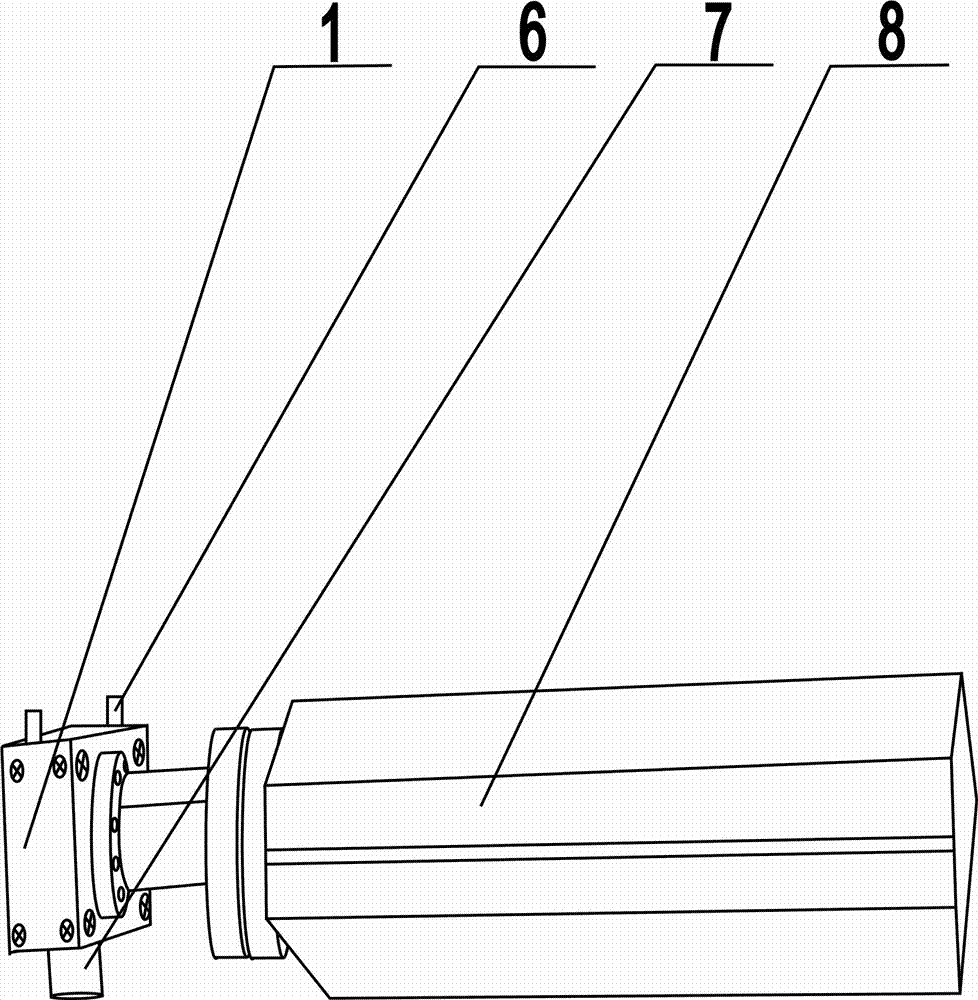

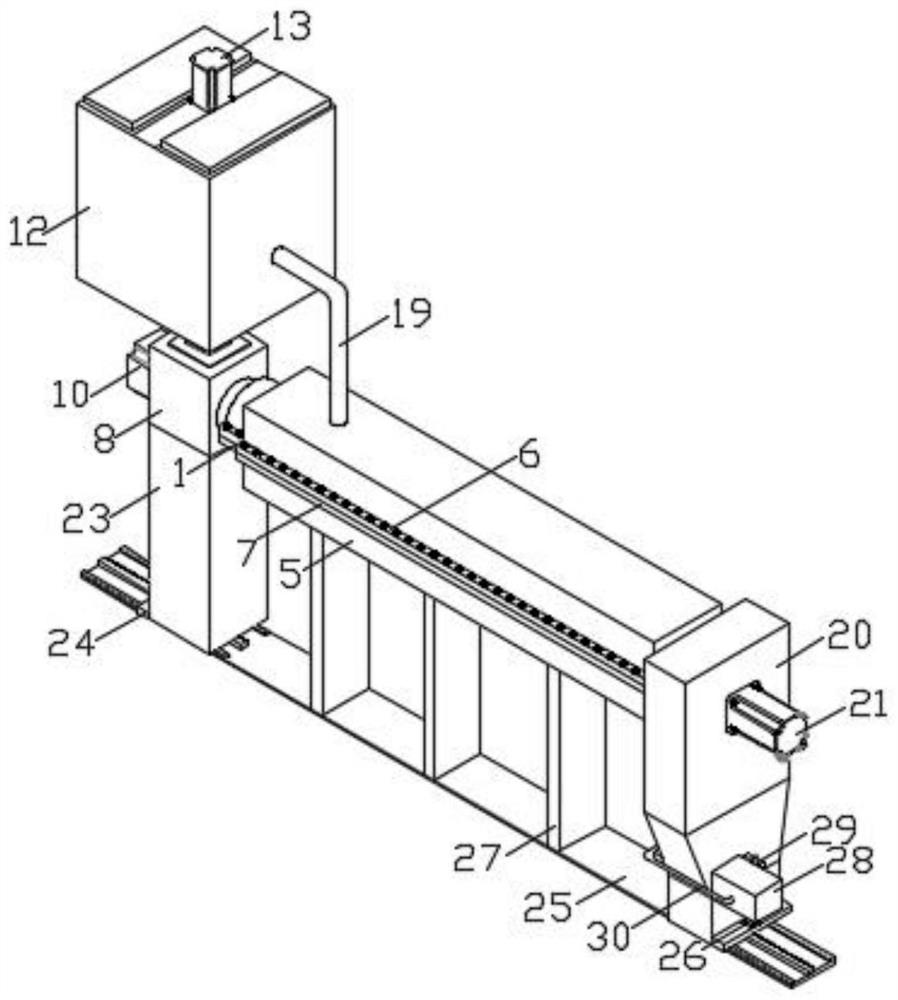

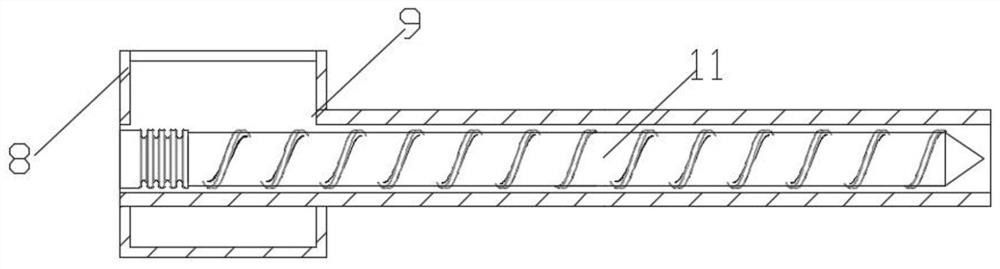

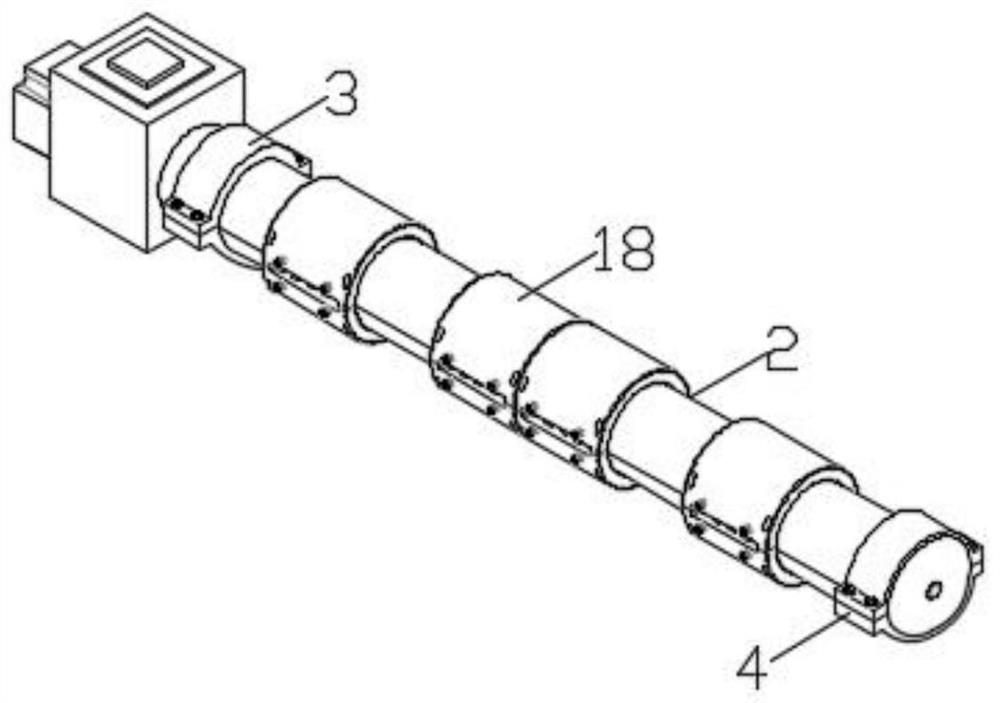

Single-rod spiral drying extruder

InactiveCN105972940AIncrease water speedImprove drainage fluencyDrying solid materials without heatWater filterEngineering

The invention discloses a single-rod spiral drying extruder, and is suitable for dehydration of wet materials with high water content in such industries as starch and feeds. The single-rod spiral drying extruder comprises a base, a feed box, a discharge box, a spiral main shaft, a water filter system and a transmission system. The single-rod spiral drying extruder adopts continuous production, is high in dehydration efficiency, simple in structure, convenient for use and maintenance, compact in whole structure, small in floor area and convenient for transportation, can recycle starch-contained residual liquid, and can reduce the cost and improve the economic efficiency.

Owner:江苏格兰特干燥浓缩设备有限公司

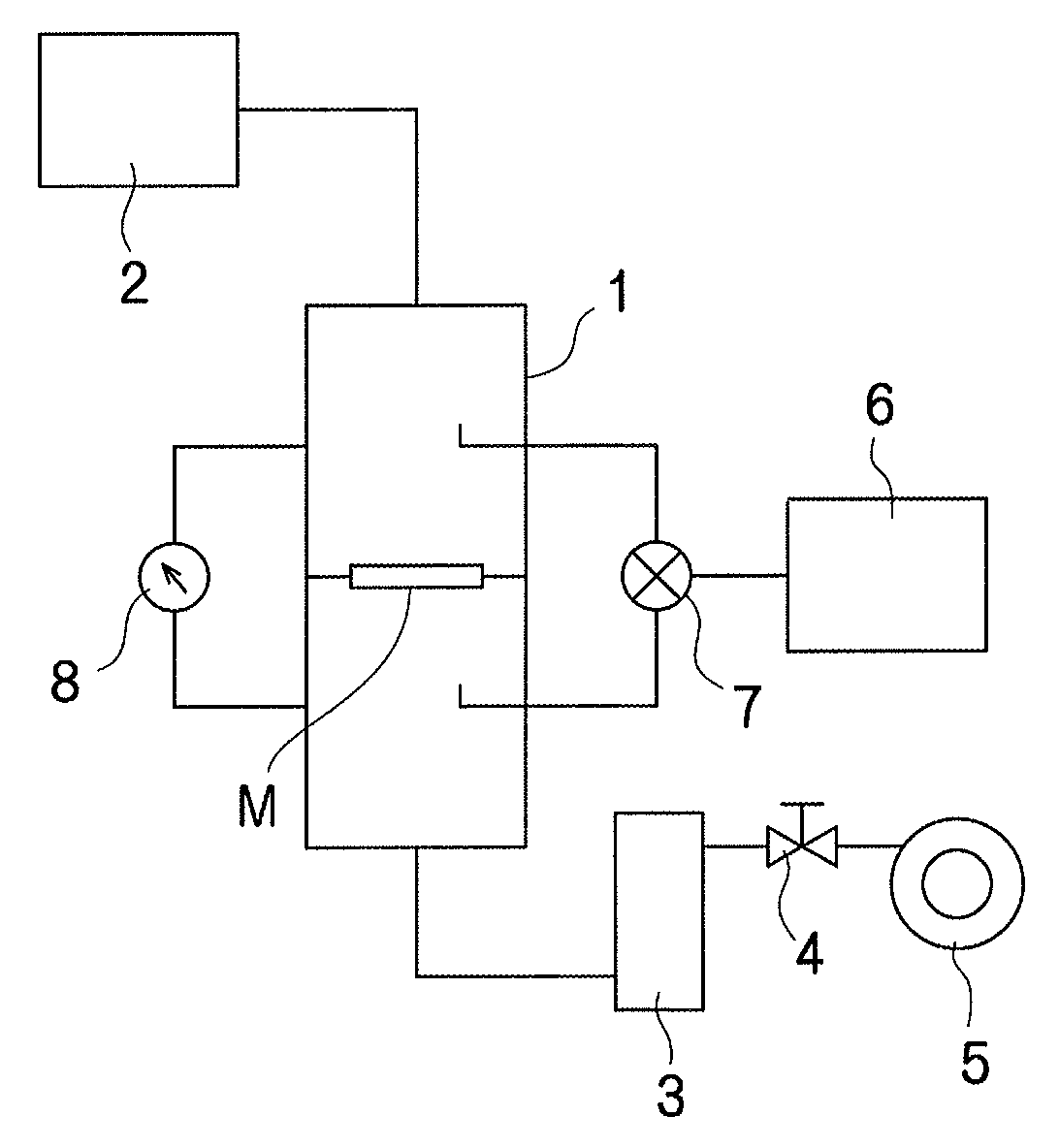

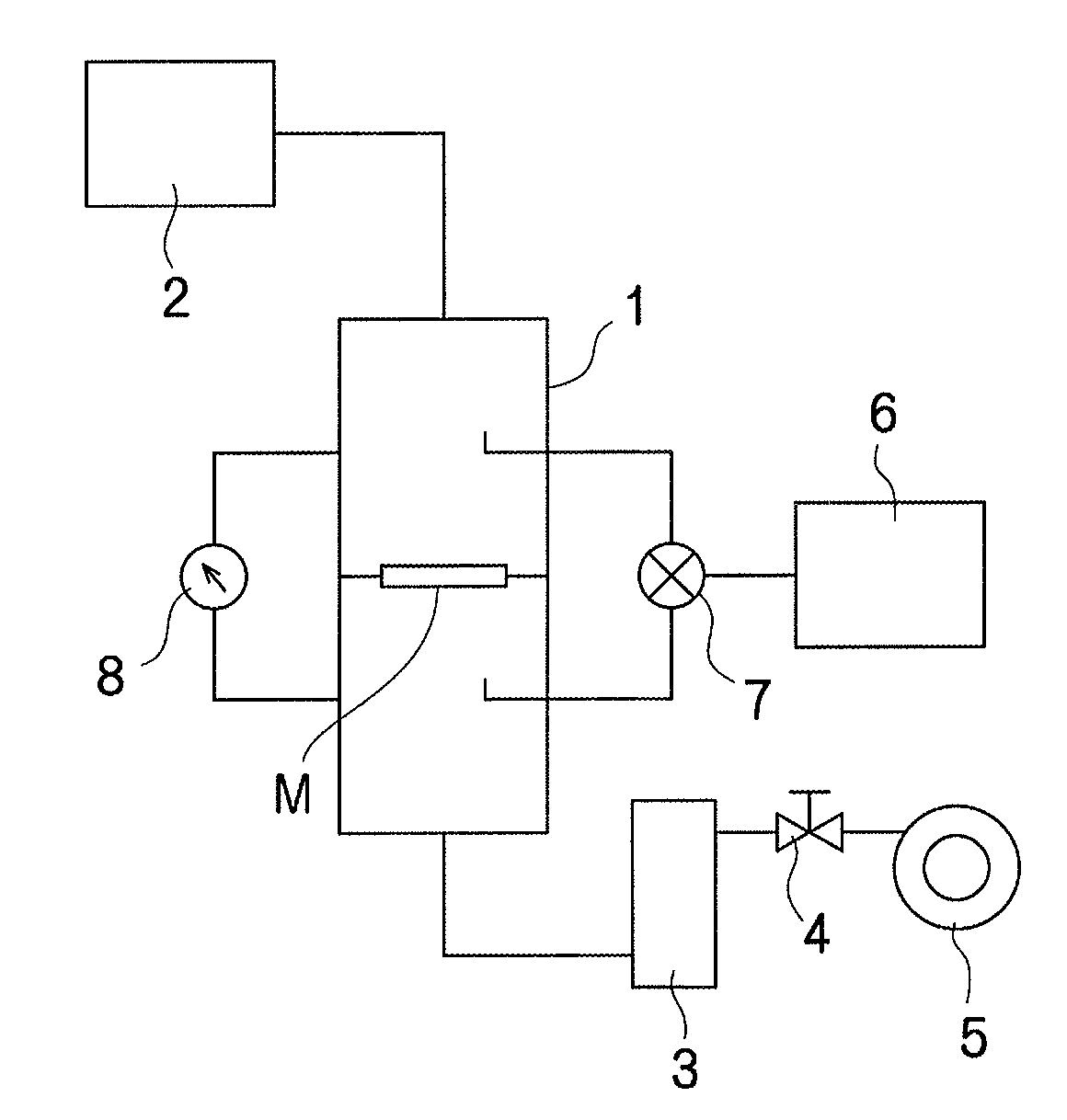

Heating device for wire drawing machine metering pump

InactiveCN107297877ASolve the problem of short service life and uneven heatingImprove uniformityElectricityFiber

The invention discloses a heating device for a wire drawing machine metering pump. The heating device comprises heating plates, electric heating wires and electric heating grooves; four heating plates are fixedly arranged at the periphery of a flowmeter, and one heating plate is fixed at each of the upper side and the lower side of the flowmeter; each heating plate is composed of the electric heating wires used for heat generation; the electric heating grooves are uniformly arranged on the inner surface of each heating plate vertically; heating wires are fixedly arranged in the electric heating grooves respectively; a sealing cushion is arranged at the externals of the corresponding electric heating wires; a cover plate is arranged at the external of each sealing cushion; one conductive column is fixedly arranged at each of the left part and the right part on the heating plate on the top of the flowmeter and is fixedly connected with the electric heating wires of the corresponding heating plate. By adopting the heating device for the wire drawing machine metering pump, the heating uniformity to the flowmeter is greatly improved, accurate control to polypropylene or polyethylene molten liquid is improved, and the extrusion rate of polyethylene or polypropylene flat fibers is increased.

Owner:洛阳市大资塑业有限公司

Energy-saving and environment-friendly plastic machining extruder

InactiveCN111844508AImprove cooling efficiencyAvoid enteringCoatingsProcess engineeringManufacturing engineering

The invention discloses an energy-saving and environment-friendly plastic machining extruder which comprises an extrusion pipe. The extrusion pipe comprises two arc pipes. The two arc pipes are arranged oppositely up and down and are cooperation components. The two ends of the extrusion pipe penetrate through the two sides of a heat insulation box correspondingly. The heat insulation box comprisesan upper box body and a lower box body. Through the arrangement of a rectangular frame capable of ascending and descending, a blade on the rectangular frame can scrape off raw materials on the innerwall of a feeding box, and the raw material extrusion rate is increased; through the design of filter screens, raw materials which do not reach the molten degree are prevented from entering the extrusion pipe, and the situation that inferior-quality products obtained through insufficient melting and extrusion happen to extrusion objects is avoided; through the design of the heat insulation box anda heat exchange pipe, redundant heat of cast aluminum heaters is conducted into the feeding box, raw materials in the feeding box are subjected to melting treatment in advance, the extrusion effect and extrusion efficiency are improved, and the energy saving and environmental protection effects are good; and the technical problems that in the prior art, the energy saving and environmental protection effects of plastic extruders are not good, and inferior-quality products are prone to happening in extrusion objects are solved.

Owner:界首市鸿鑫塑业有限公司

Mixed-fiber nonwoven fabric, laminated sheet and filter, and process for producing mixed-fiber nonwoven fabric

ActiveUS9266046B2Reduce deformationReduce fusionDispersed particle filtrationElectrostatic separationPolyolefinPolymer science

Provided are a mixed-fiber nonwoven fabric suitable for air filters and a filter medium using the mixed-fiber nonwoven fabric. The nonwoven fabric includes at least two types of fibers having different melting points, which fibers are low melting point fibers made of a polyolefin resin component A, and high melting point fibers made of a high melting point resin component B having a higher melting point than that of the polyolefin resin component A. The number average fiber diameter of the high melting point fibers is larger than that of the low melting point fibers. At least one high melting point fiber having a fiber diameter of 20 μm to 100 μm is present per 1.00 mm of the length of the cross section of the nonwoven fabric. The number average fiber diameter of all fibers constituting the nonwoven fabric falls within the range of 0.3 μm to 10 μm.

Owner:TORAY IND INC

Environment-friendly laundry detergent bottle and preparation method thereof

InactiveCN109929171AImprove breathabilityPromote degradationLinear low-density polyethyleneAntioxidant

The invention relates to an environment-friendly laundry detergent bottle and a preparation method thereof, and belongs to the technical field of plastic products. The laundry detergent bottle comprises a basic component and a degradation enhancing component. The basic component is prepared from the following raw materials: high-density polyethylene, linear low-density polyethylene, a flexibilizer, a coupling agent, color master batch, castor oil, a flame retardant, an antioxidant and an ultraviolet absorbent. The preparation raw materials of the degradation reinforcing component comprise cellulose acetate, chitin fiber, wood powder and aramid fiber. The preparation method comprises the following steps of (1) preparation of a mixture; (2) blow molding; (3) polishing; and (4) leakage detection. The prepared laundry detergent bottle has good impact resistance, good tensile property, good anti-aging capability and good biodegradability.

Owner:厦门市宏世发工贸有限公司

A kind of carbon black dispersant for rubber products and preparation method thereof

The invention discloses a carbon black dispersing agent for rubber products and a preparation method thereof. The invention is characterized in that the carbon black dispersing agent is prepared from the following raw materials in parts by weight: 25-35 parts of pentaerythritol, 15-25 parts of oxidized polyethylene wax, 12-18 parts of zinc stearate, 18-25 parts of talcum powder, 8-15 parts of third-line oil and 1-5 parts of anti-aging agent 998-A. The preparation method comprises the following steps: primary mixing, secondary mixing, metering and packaging. The materials with certain activity capable of enhancing high-speed flowability of carbon black in the compounding process are supplemented to solve the actual state that the flowability of the existing carbon black dispersing agent can not satisfy the technical requirements of users; and the consumption of the carbon black in the rubber is low (only 2-3 parts), and the carbon black can be uniformly dispersed in the compounded rubber, thereby enhancing the production efficiency and rubber extrusion ratio and saving the labor cost and product rejection loss.

Owner:山东迪科化学科技股份有限公司

Low-cost recovery and regeneration method of waste scr catalyst and regenerated scr catalyst carrier

ActiveCN104368361BEfficient separationMeet the technical requirements of titanium dioxideCatalyst carriersCatalyst regeneration/reactivationPtru catalystProcess engineering

The invention discloses a low-cost recovery and regeneration method for a waste SCR catalyst and a regenerated SCR catalyst carrier. The recovery and regeneration method of the waste SCR catalyst is to mix the catalyst with metatitanic acid slurry to prepare titanium tungsten powder after preliminary treatment, remove the harmful components in the waste catalyst, and keep the active components in the catalyst, so as to obtain a low The recovery and regeneration method is cost-friendly and environmentally friendly, and the performance effects of the regenerated catalyst carrier in all aspects can reach the standard for preparing SCR catalysts, and has excellent performance.

Owner:PANZHIHUA ZHENGYUAN TECH

Method for preparing air-tight promoter

Owner:山东迪科化学科技股份有限公司

Carbon black dispersing agent for rubber products and preparation method thereof

The invention discloses a carbon black dispersing agent for rubber products and a preparation method thereof. The invention is characterized in that the carbon black dispersing agent is prepared from the following raw materials in parts by weight: 25-35 parts of pentaerythritol, 15-25 parts of oxidized polyethylene wax, 12-18 parts of zinc stearate, 18-25 parts of talcum powder, 8-15 parts of third-line oil and 1-5 parts of anti-aging agent 998-A. The preparation method comprises the following steps: primary mixing, secondary mixing, metering and packaging. The materials with certain activity capable of enhancing high-speed flowability of carbon black in the compounding process are supplemented to solve the actual state that the flowability of the existing carbon black dispersing agent can not satisfy the technical requirements of users; and the consumption of the carbon black in the rubber is low (only 2-3 parts), and the carbon black can be uniformly dispersed in the compounded rubber, thereby enhancing the production efficiency and rubber extrusion ratio and saving the labor cost and product rejection loss.

Owner:山东迪科化学科技股份有限公司

Recovery and regeneration method of waste scr denitrification catalyst and regenerated scr catalyst carrier

ActiveCN104275178BEfficient separationMeet the technical requirements of titanium dioxideDispersed particle separationCatalyst regeneration/reactivationPtru catalystEnvironmental engineering

The invention discloses a method for recovering and regenerating a waste SCR denitrification catalyst and a regenerated SCR catalyst carrier. The method for recovering and regenerating the waste SCR denitrification catalyst is to add the catalyst to the production process of metatitanic acid to produce titanium dioxide after preliminary treatment, remove the harmful components in the waste catalyst, and retain the active components in the catalyst, so as to obtain a It is a low-cost and environment-friendly recovery and regeneration method, and the performance effects of the regenerated catalyst carrier in all aspects can reach the standard for preparing SCR catalysts, and has excellent performance.

Owner:PANZHIHUA ZHENGYUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com