Environment-friendly laundry detergent bottle and preparation method thereof

A laundry detergent and environmentally friendly technology, applied in the field of plastic products, can solve the problems of unfavorable air environment due to smog, non-degradable laundry detergent bottles, human body hazards, etc., and achieve the effects of enhancing the stirring effect, improving the light stabilization effect and reducing the damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

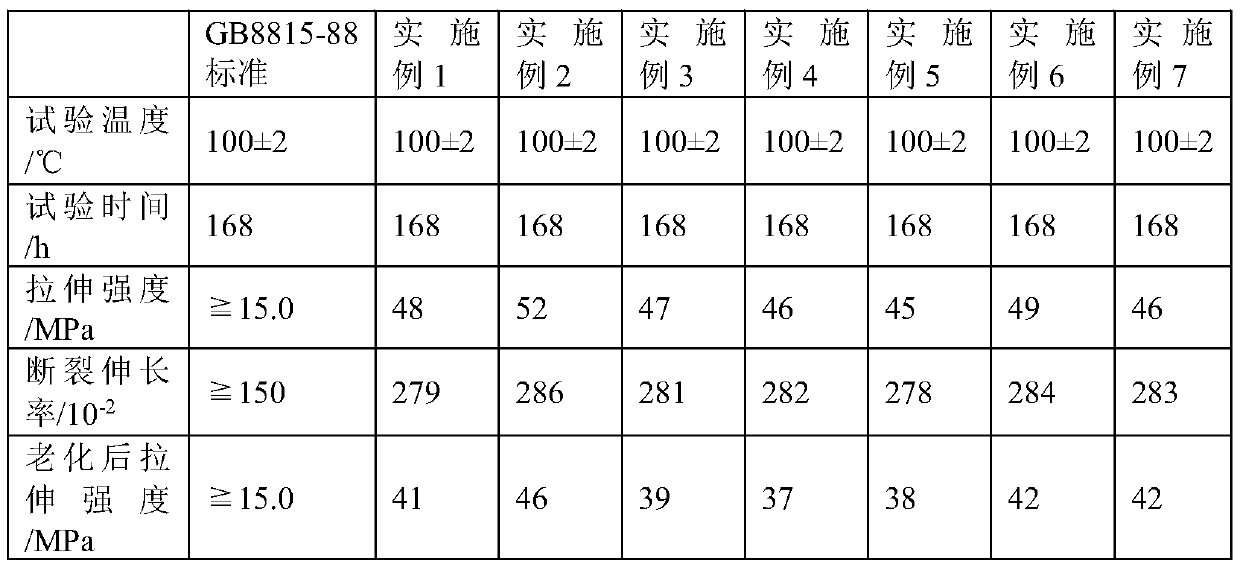

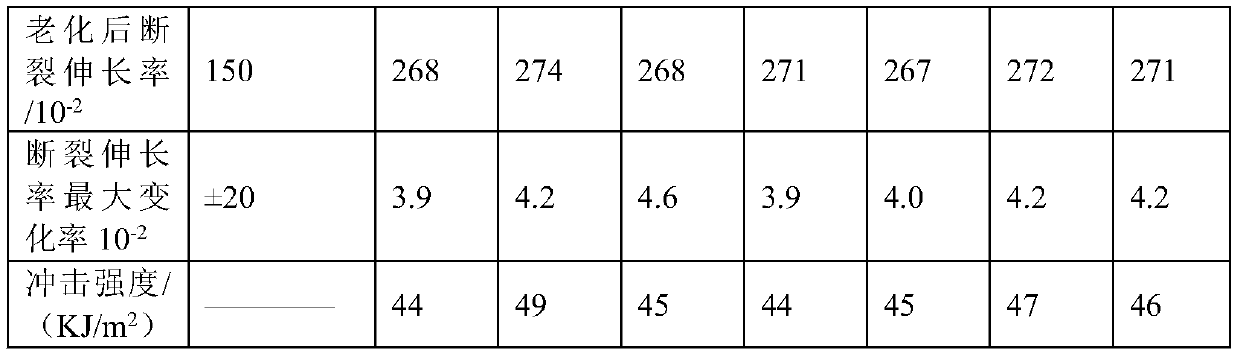

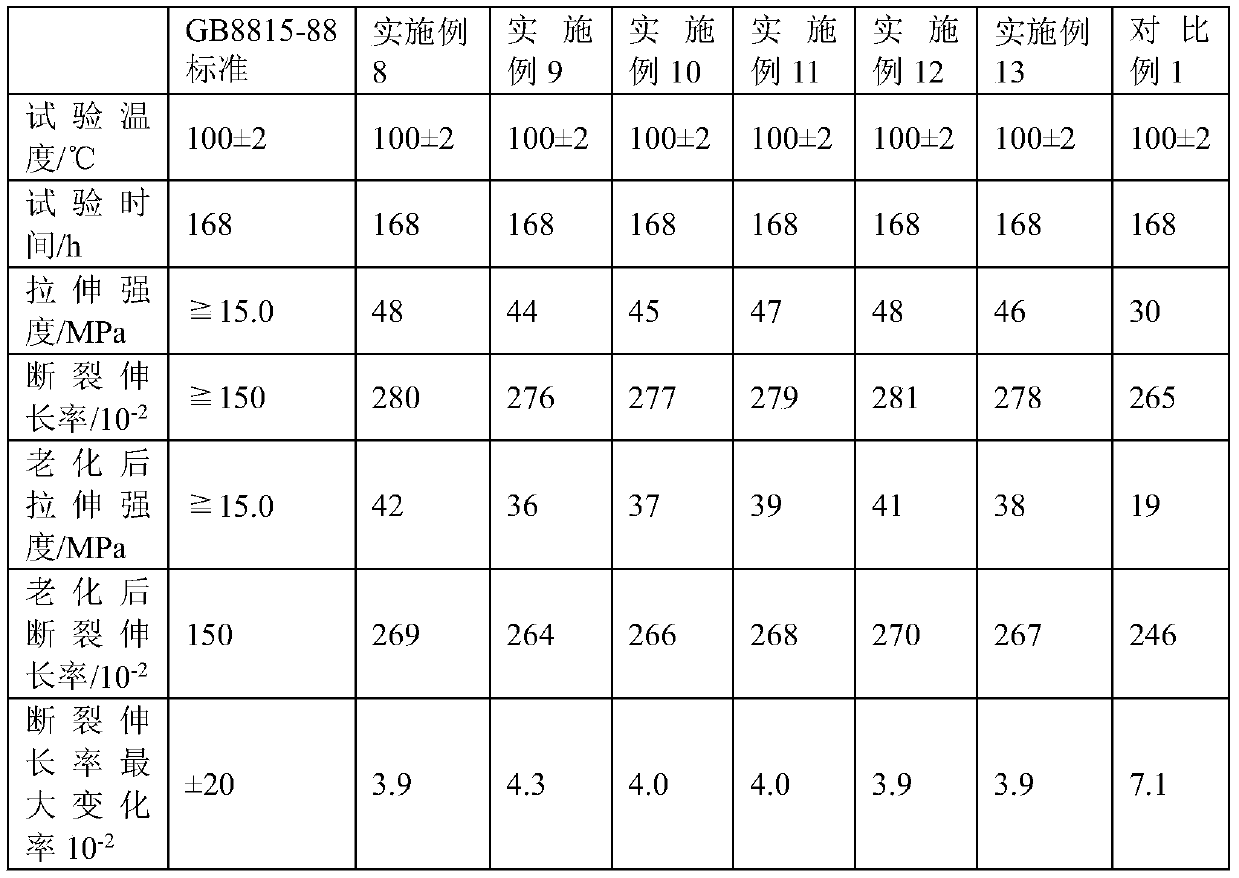

Examples

Embodiment 1

[0033] A kind of preparation method of environment-friendly type washing liquid bottle comprises the following steps:

[0034] Step 1: Preparation of the mixture: according to parts by weight, prepare 6 parts of basic components and 1 part of degradation enhancement components in advance, and then put 60 parts of high-density polyethylene in the basic components into the shearing equipment, linear 0.5 parts of low-density polyethylene, mixed uniformly at a speed of 1200 rev / min; then add 3 parts of methyl methacrylate-butadiene-styrene copolymer, 1.5 parts of zirconate coupling agent, 2 parts of masterbatch, 4 parts of castor oil, 0.1 part of zinc dialkyldithiophosphate, 4 parts of microencapsulated red phosphorus, 1 part of 2-hydroxy-4-n-octyloxybenzophenone, polyethylene wax 5 parts, stir evenly at a speed of 1500 rpm; then add 10 parts of acetate fiber, 6 parts of chitin fiber, 5 parts of wood flour, and 4 parts of aramid fiber in the degradation enhancement component, and ...

Embodiment 2

[0039] A kind of preparation method of environment-friendly type washing liquid bottle comprises the following steps:

[0040] Step 1: Preparation of the mixture: according to parts by weight, prepare 7 parts of basic components and 1 part of degradation enhancement components in advance, and then put 75 parts of high-density polyethylene in the basic components into the shearing equipment, linear 1 part of low-density polyethylene, mixed uniformly at a speed of 1400 rev / min; then add 4 parts of methyl methacrylate-butadiene-styrene copolymer, 3 parts of zirconate coupling agent, 3 parts of masterbatch, 6 parts of castor oil, 0.3 parts of zinc dialkyldithiophosphate, 6 parts of microencapsulated red phosphorus, 2 parts of 2-hydroxy-4-n-octyloxybenzophenone, polyethylene wax 7 parts, stir evenly at a speed of 1600 rpm; add 12 parts of acetate fiber, 7 parts of chitin fiber, 8 parts of wood flour, and 6 parts of aramid fiber in the degradation enhancement component, and mix at a s...

Embodiment 3

[0045] A kind of preparation method of environment-friendly type washing liquid bottle comprises the following steps:

[0046] Step 1: Preparation of the mixture: according to parts by weight, prepare 9 parts of basic components and 1 part of degradation enhancing components in advance, and then put 85 parts of high-density polyethylene in the basic components into the shearing equipment, linear 1.5 parts of low-density polyethylene, mixed uniformly at a speed of 1500 rev / min; then add 5 parts of methyl methacrylate-butadiene-styrene copolymer, 5.5 parts of zirconate coupling agent, 4 parts of masterbatch, 7 parts of castor oil, 0.5 parts of zinc dialkyldithiophosphate, 9 parts of microencapsulated red phosphorus, 3 parts of 2-hydroxy-4-n-octyloxybenzophenone, polyethylene wax 9 parts, stir evenly with the rotating speed of 1800 rpm; add 13 parts of cellulose acetate, 8 parts of chitin fiber, 9 parts of wood flour, and 7 parts of aramid fiber in the degradation enhancement com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com