Patents

Literature

5914 results about "POLYETHYLENE WAX" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel wood plastic composite decorative building material and manufacturing method thereof

InactiveCN101955614AImproved performance characteristicsGood environmental characteristicsAntioxidantPolyvinyl chloride

The invention relates to a novel wood plastic composite decorative building material and a manufacturing method thereof. The novel wood plastic composite decorative building material comprises the following components in part by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 30 parts of mixture formed by mixing one or more of wood powder, bamboo powder, rice bran powder and crop straw powder in an arbitrary ratio, 30 parts of calcium powder, 5 to 10 parts of chlorinated polyethylene or MBS resin, 2 to 6 parts of rear earth compound stabilizer, 0.5 to 3 parts of polyethylene wax or oxidized polyethlene wax, 0.5 to 3 parts of stearic acid, 0.5 to 2.0 parts of foaming agent, 5 to 10 parts of blowing promoter, 0.5 to 1 part of antioxidant, 0.5 to 1 part of reinforcing agent, 1 to 3 parts of toner and 0.5 to 1 part of weather resistant agent. PVC plastic is modified by adding the auxiliaries, and the influence of unstable components (such as a vinyl chloride monomer, hydrogen chloride gas and the like) in the PVC on the performance of the building material is eliminated, so that the building material has better performance and environmental protection characteristics on the basis of keeping the original performance.

Owner:CHENGDU AOKINGTH TECH

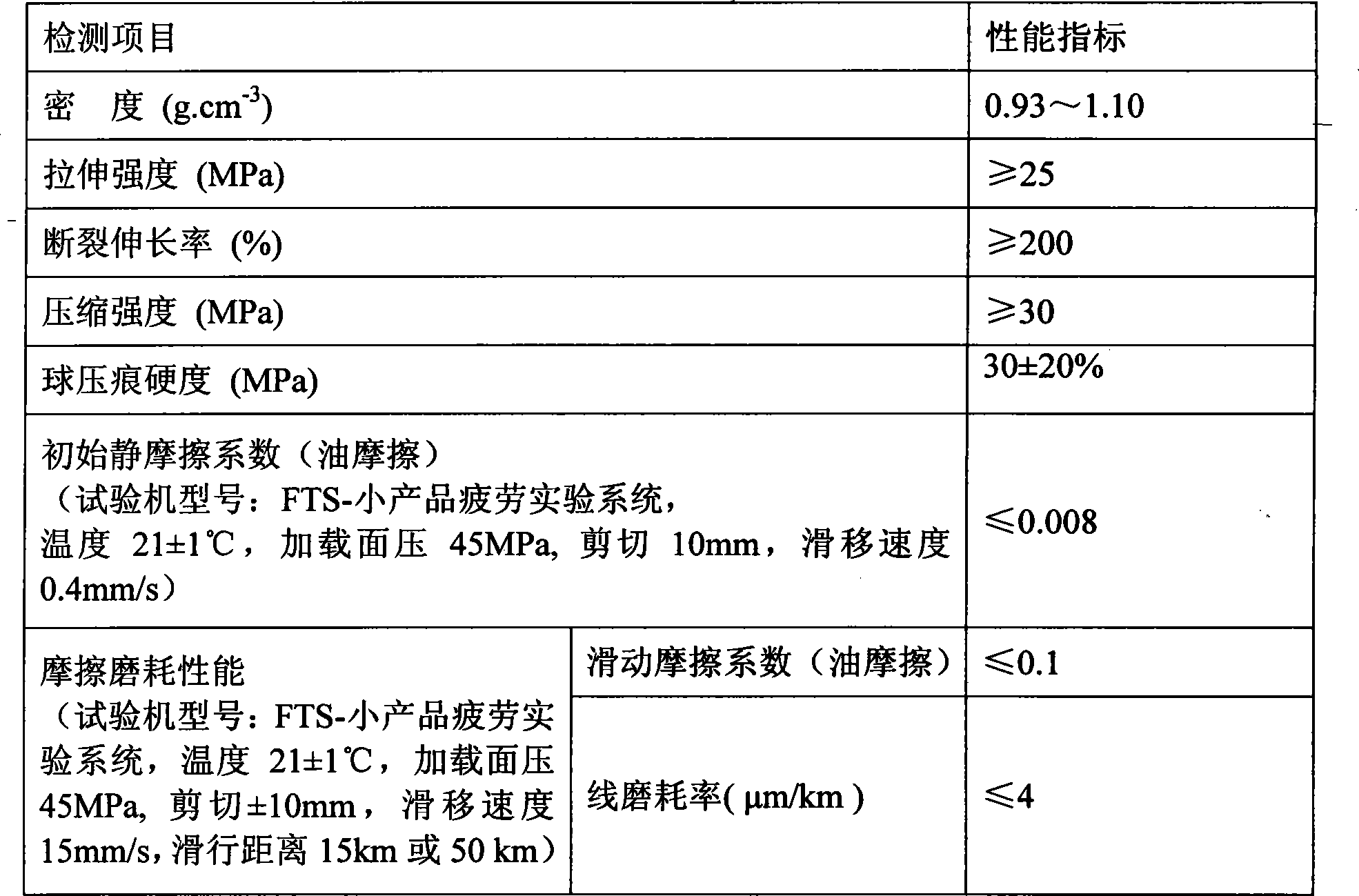

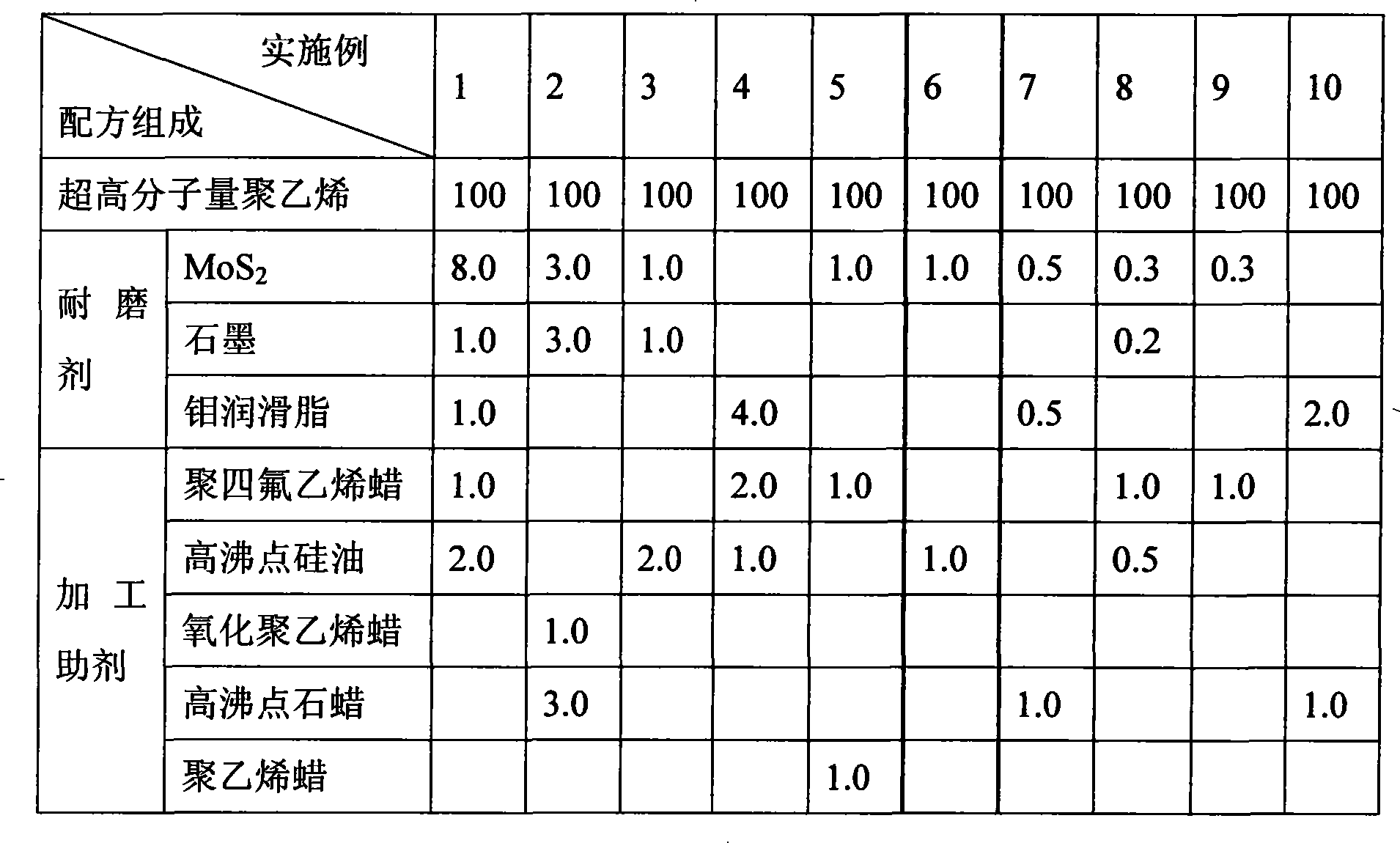

Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

InactiveCN101240092AImprove performanceExcellent formulaBridge structural detailsParaffin waxProcedure Agents

Ultra high molecular weight polyethylene composite with low molar mass and high friction resistance, preparation and application thereof. Raw materials of 100 parts by weight of ultra high molecular weight polyethylene, 0.1-10 parts by weight of wear-resisting agent, 0.1-5.0 parts by weight of processing aid is prepared into highly friction resistant composite by mixing, chill-pressing, heating to melt, compression molding, cooling for shaping and cutting. The mentioned utra high molecular weight polyethylene has a matrix molecular weight of greater than 6 millionl. The mentioned wear-resisting agent is MoS2 surface treated by coupling agent, black lead, lubricating grease of molybdenum, copper powder, or mixture of more than two of them. The mentioned processing agent is organic silicon oil with high boiling point, polytetrafluroethylene, oxidized polyethylene wax, olefin or polyethylene wax with high boiling point, or mixture of more than two of them.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

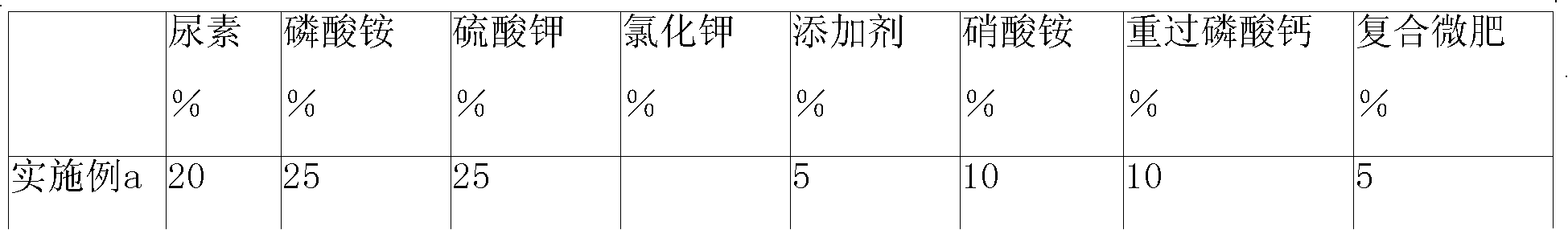

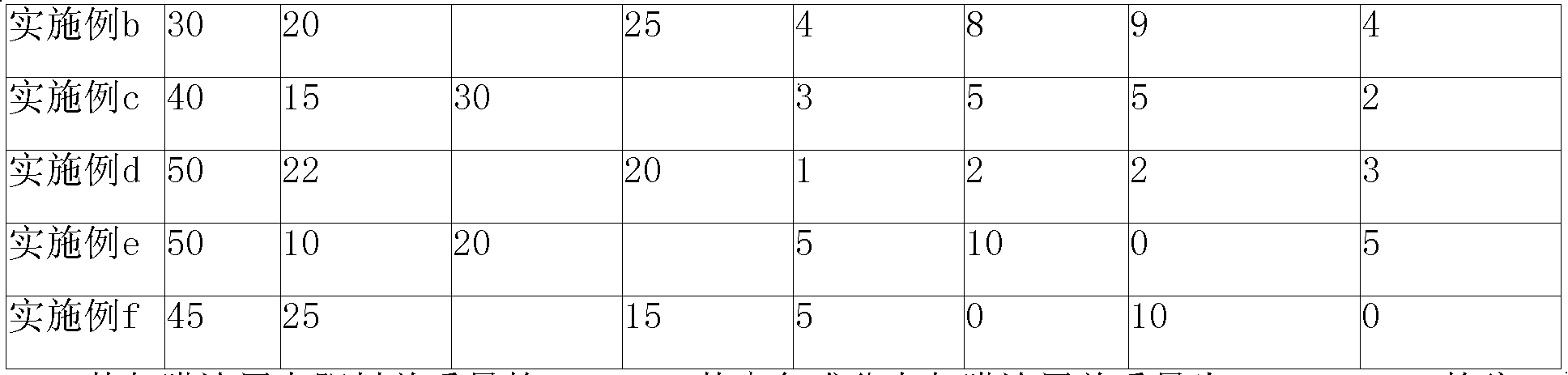

Long-acting special controlled release fertilizer for corn and preparation method thereof

InactiveCN101177365ALess hygroscopic expansion and contractionSimple preparation processFertilizer mixturesPotassiumNutrient

A special controlled-release fertilizer for long-acting corn and its preparation method. The fertilizer core accounts for 80-92% of the total weight of the fertilizer, wherein the weight sum of nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer calculated by pure nitrogen, phosphorus pentoxide and potassium chloride is the fertilizer 25%-50% of the total weight, the weight ratio is: 2-4:1-2:1-3; the coating coating accounts for 8-20% of the total weight of the fertilizer, including: 69.5-93% sulfur, 530 % polyethylene wax, 0.5-2% leveling agent. Melt sulfur, add montmorillonite and stir evenly, then add leveling agent, stir evenly to form molten sulfur. The molten sulfur and polyethylene wax are simultaneously sprayed on the surface of the fertilizer core to form a slow-release coating layer. The process occupies less land, requires less investment in equipment, and consumes less energy. It has the characteristics that one fertilization can meet the nutrient needs of corn throughout the growth period. The fertilizer effect is long and safe, and fertilization is simple.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

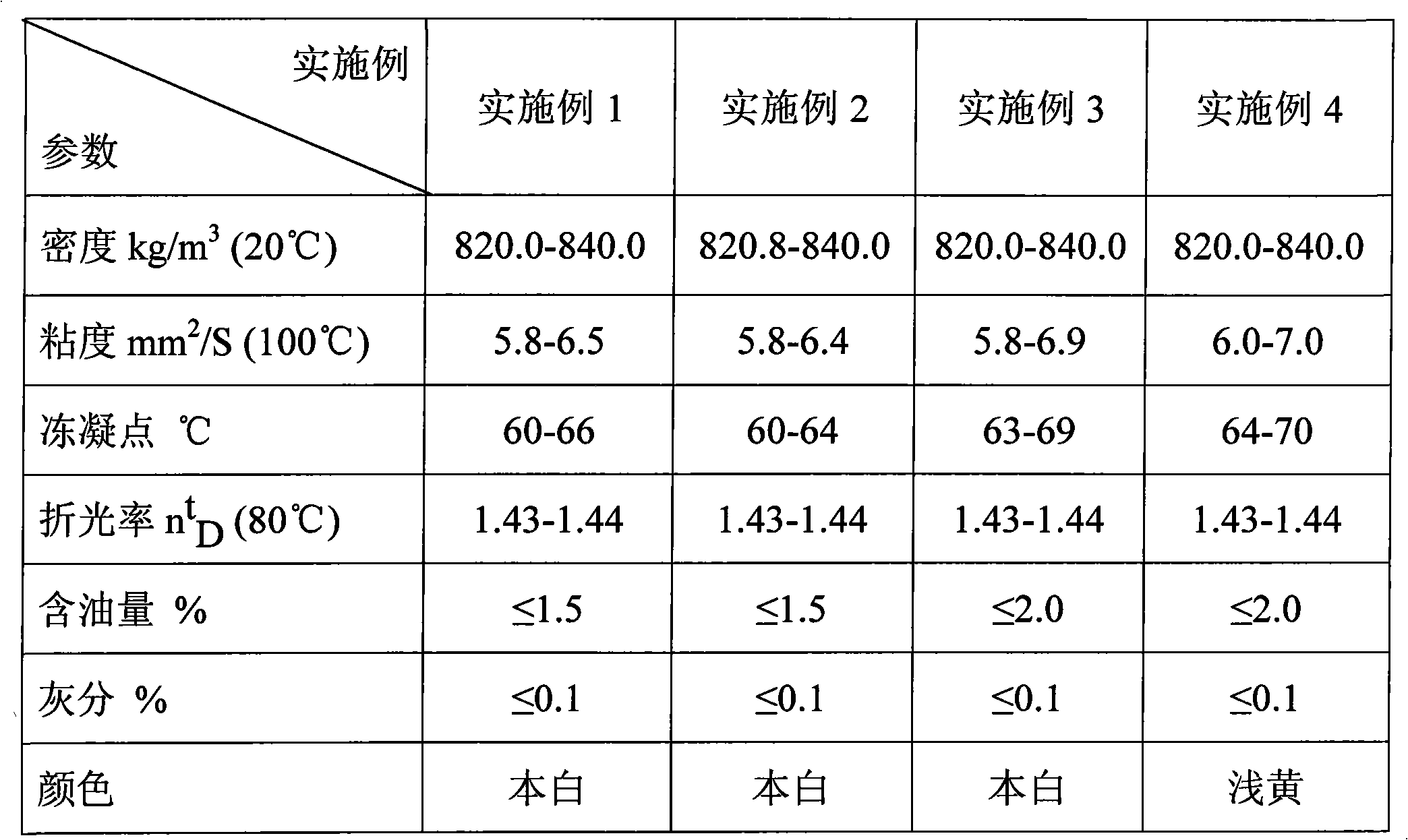

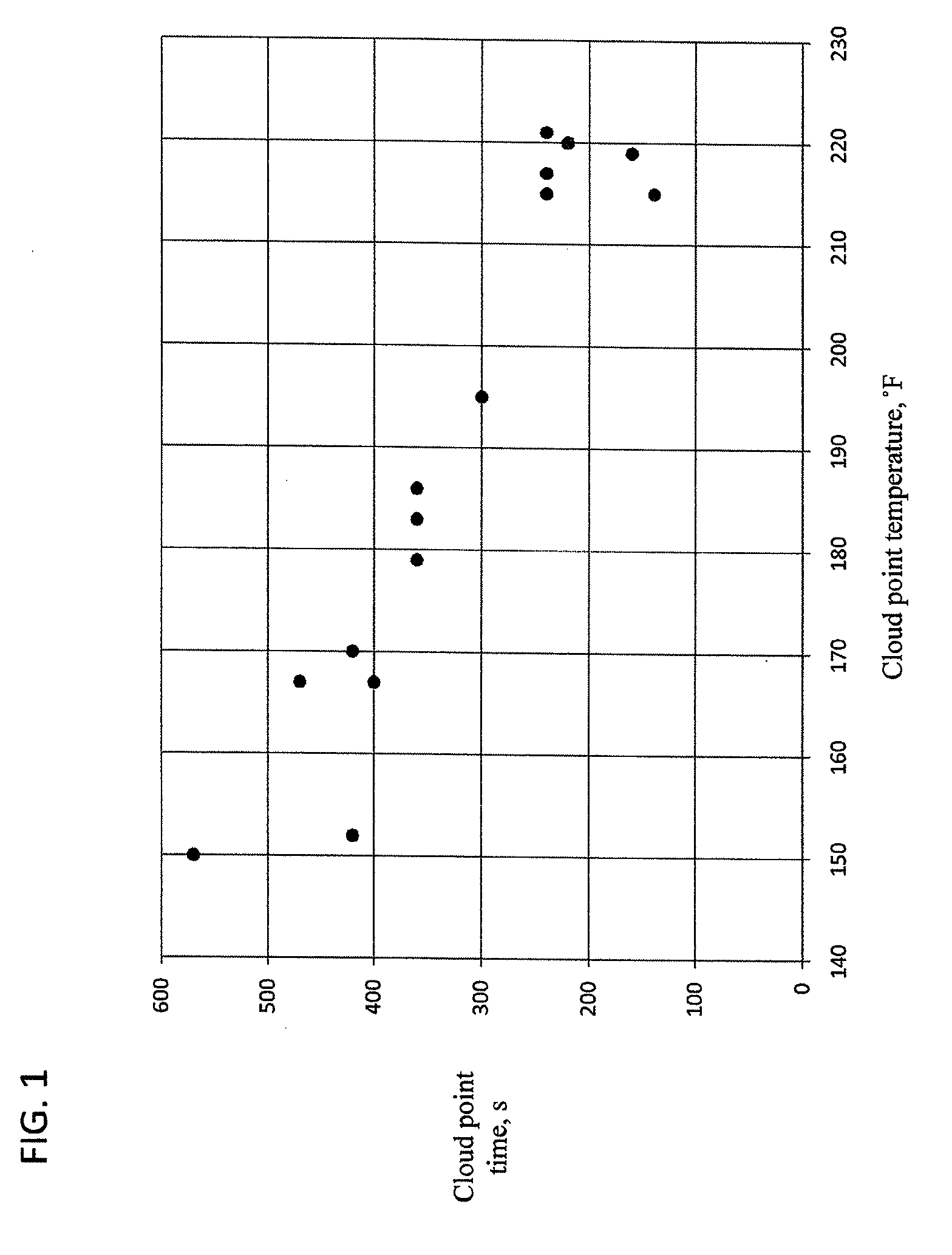

Method for separating polyethylene byproduct polyethylene wax

The invention provides a method for separating polyethylene byproduct polyethylene wax. In the method, a solvent is adopted to selectively dissolve components with a low melting point in the polyethylene wax, so that the separation between components with the low melting point and the components with a high melting point in the polyethylene wax is realized, and a polyethylene wax product with a high melting point and a polyethylene wax product with a low melting point are obtained. The melting point of the polyethylene wax with the high melting point is 82.6-96.3 DEG C, the polyethylene wax with the high melting point can be used for producing high-grade polishing wax for master batch, ink processing, automobiles and leather coats, and the price of the polyethylene wax with the high melting point per ton is increased by 3000-5000 RMB. The melting point of the polyethylene wax with the low melting point is 45.3-69.5 DEG C, and the product with the low melting point after being processed can be used for a phase-change capsule material and the cosmetics industry, so that the field of application of the polyethylene wax is widened, and the additive value of the product is increased; and in addition, the solvent which is recovered through depressurizing and distilling can be reused.

Owner:CHANGCHUN UNIV OF TECH

Method of separating polyethylene wax

A process for classifying the polyvinyl wax by molecular weights features that the C5-C12 paraffin, arylhydrocarbon or their mixture is used as solvent, the C2-C4 monoalcohol is used as precipitant, and the classifying procedure for each product includes changing the dissolving temp and solvent ratio, dissolving, concentrating, deposition, separating and drying.

Owner:刘喜军

Method for preparing trimeric high-strength and high-toughness energy-saving fishing net

ActiveCN102251303AMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer sciencePolyamide

The invention discloses a method for preparing a trimeric high-strength and high-toughness energy-saving fishing net, which is implemented by carrying out synthesis on polyethylene (1), polypropylene (2), polyamides (3), Nano silicon dioxide (4), polyethylene wax (5), a coupling / bulking agent (6), a UV (ultraviolet) resistant agent 173 (7), a coloring agent (8) and white mineral oil (9) accordingto five steps (namely, a step A, a step B, a step C, a step D and a step E).

Owner:HUNAN XINHAI CO LTD

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

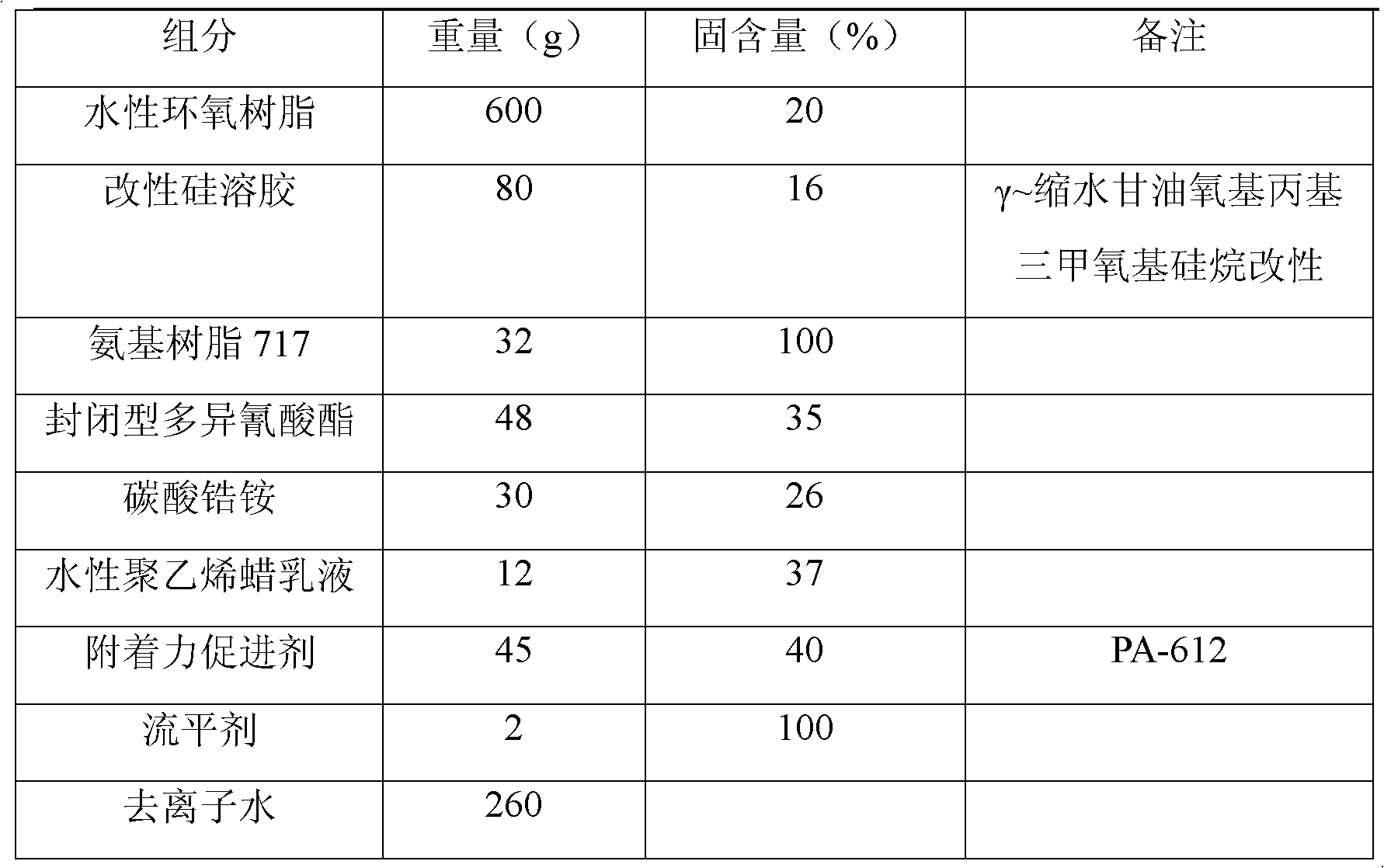

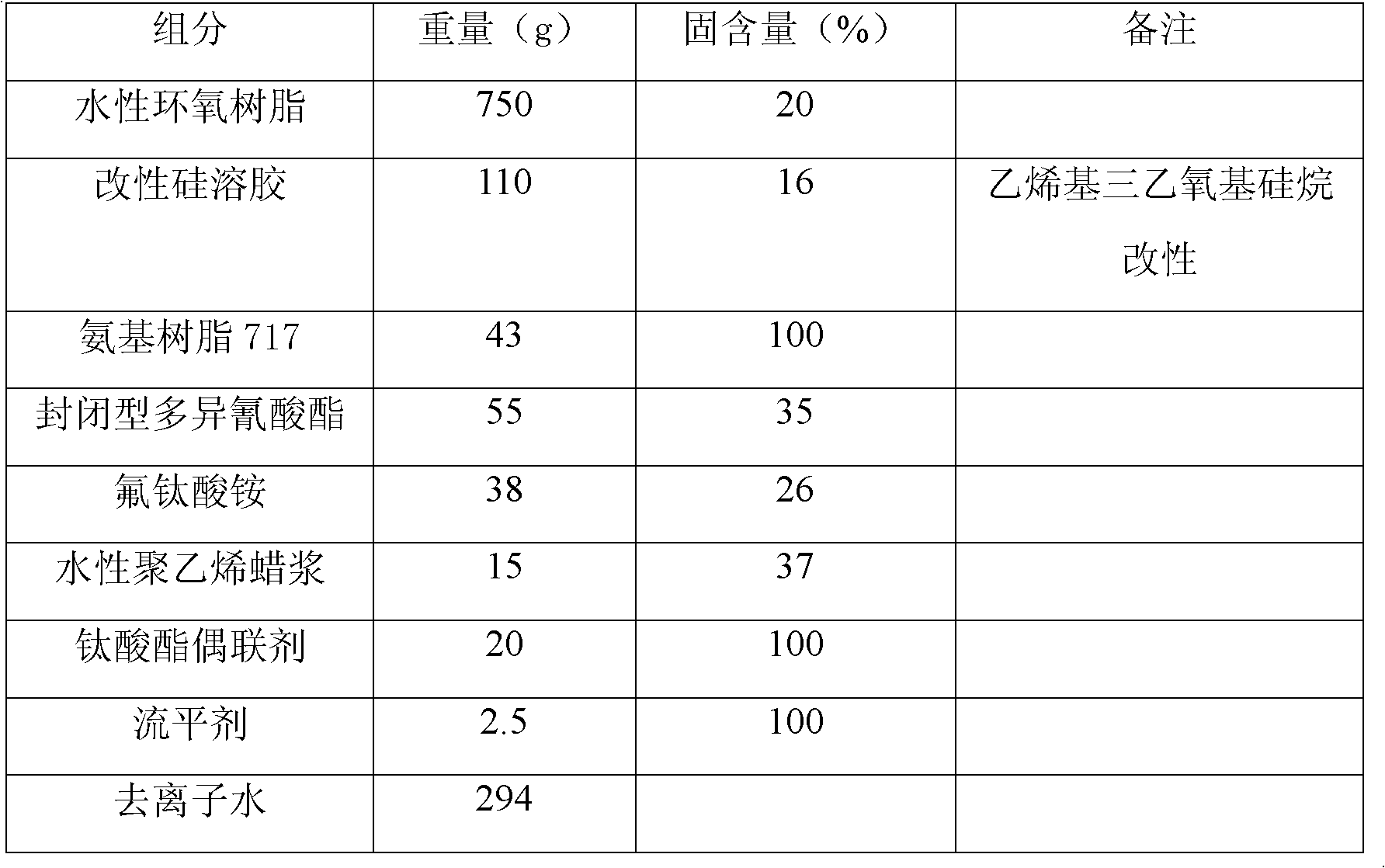

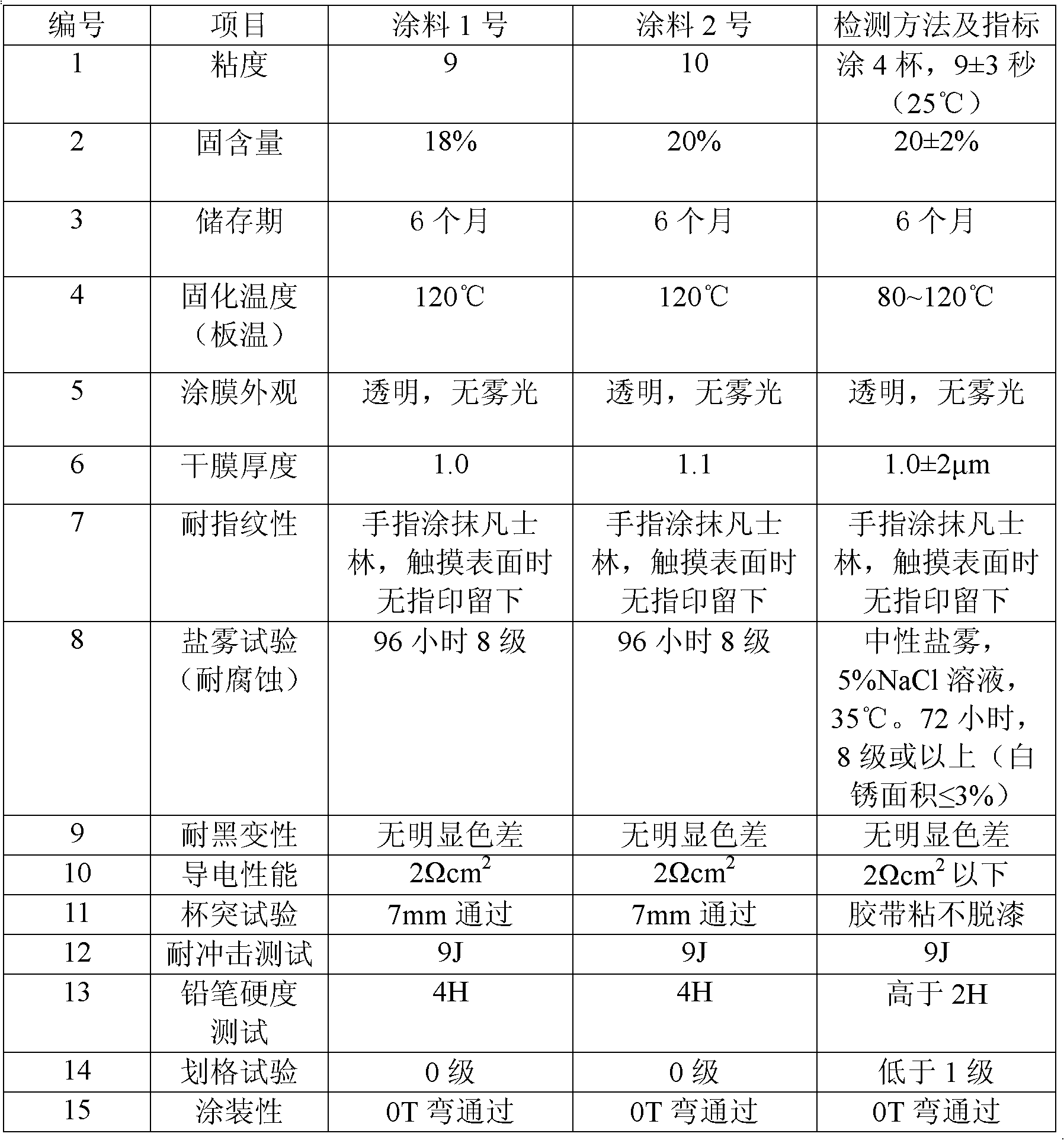

Organic and inorganic mixed fingerprint-resistance coating and preparation method thereof

The invention relates to an organic and inorganic mixed fingerprint-resistance coating and a preparation method thereof. The coating is prepared from the following chemical components in percentage by weight: 40 to 70 percent of aqueous resin, 3 to 10 percent of modified silica solution, 2 to 15 percent of amino resin, 2 to 10 percent of polyisocyanates, 1 to 5 percent of mineral salt, 1 to 6 percent of aqueous polyethylene wax pulp, 1 to 9 percent of adhesion promoter, 0.1 to 0.5 percent of flatting agent, and 10 to 40 percent of deionized water. And the total weight percentage of the raw materials is 100 percent. The organic and inorganic mixed fingerprint-resistance coating prepared by the method does not contain metal ions which cause pollution to the environment. The coating can be coated on an electrogalvanized steel sheet, hot-dip galvannealed sheet, tin-plated steel sheet or cold-rolled steel sheet, and after being coated, the coating can be baked for only 8 to 15 seconds to be solidified into a transparent coating with high fingerprint resistance, corrosion resistance, high hardness, scraping resistance, conductivity, self-lubricating performance, coating performance and the like.

Owner:SOUTHEAST UNIV

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

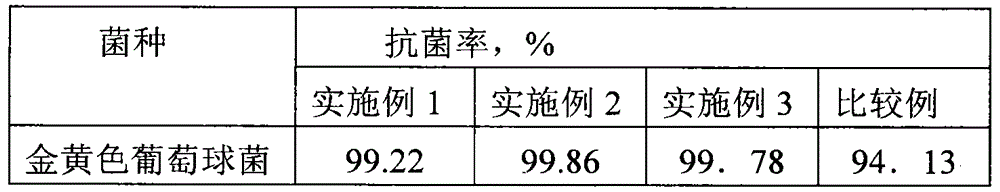

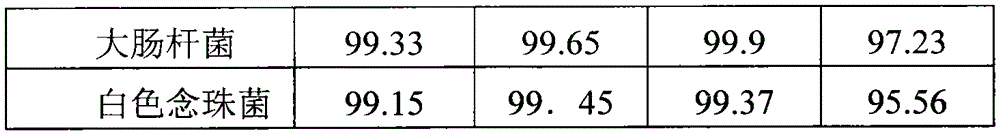

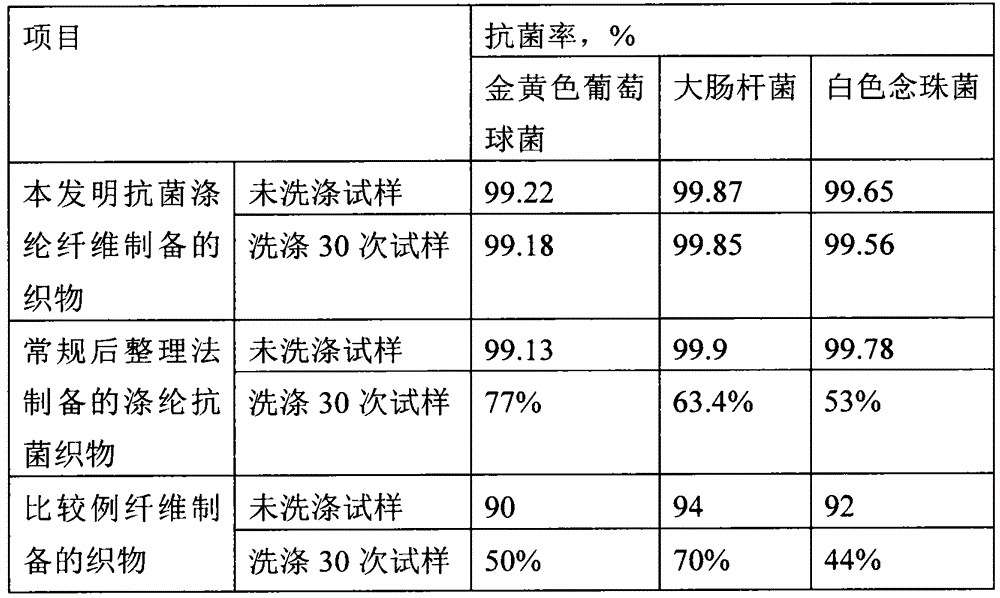

Antibacterial polyester fibers and preparation method for same

InactiveCN104963028ASolve the problem of uniform distribution of small particle sizeSimple methodMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterPolyethylene terephthalate glycol

The invention belongs to the field of textile, and particularly relates to antibacterial polyester fibers, which are prepared by melting-spinning the following materials in parts by weight: 100 parts of PET (polyethylene terephthalate) polyester chips and 2 to 5 parts of antibacterial polyester masterbatches, wherein the antibacterial polyester masterbatches are prepared by melt-blending and extruding the PET polyester chips, and 2 to 5 percent of a pre-treatment nanometer silver antibacterial agent, 2 to 3 percent of an antioxidant, 0.1 to 2 percent of a lubricant and 1 to 3 percent of a dispersant, which are counted based on the weight of the PET polyester chips; the pre-treatment nanometer silver antibacterial agent is a nanometer silver antibacterial agent obtained by wrapping treatment with polyethylene wax. According to the antibacterial polyester fibers, the small particle size uniform distribution of the nanometer silver antibacterial agent in a PET matrix is realized, the antibacterial polyester fibers are prepared by melt-spinning, and are efficient and long in service life, and the method is simple, easy and suitable for industrial popularization and application.

Owner:YIWU HUIHANG CHEM FIBER

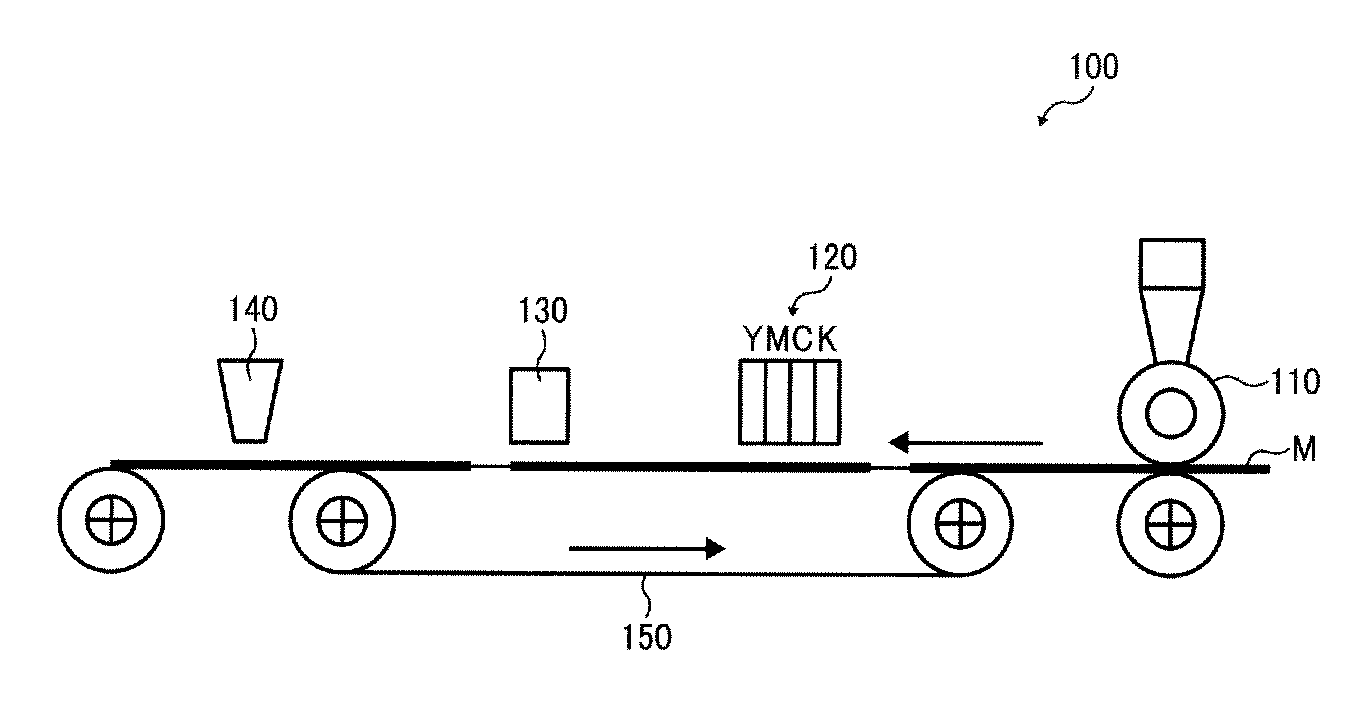

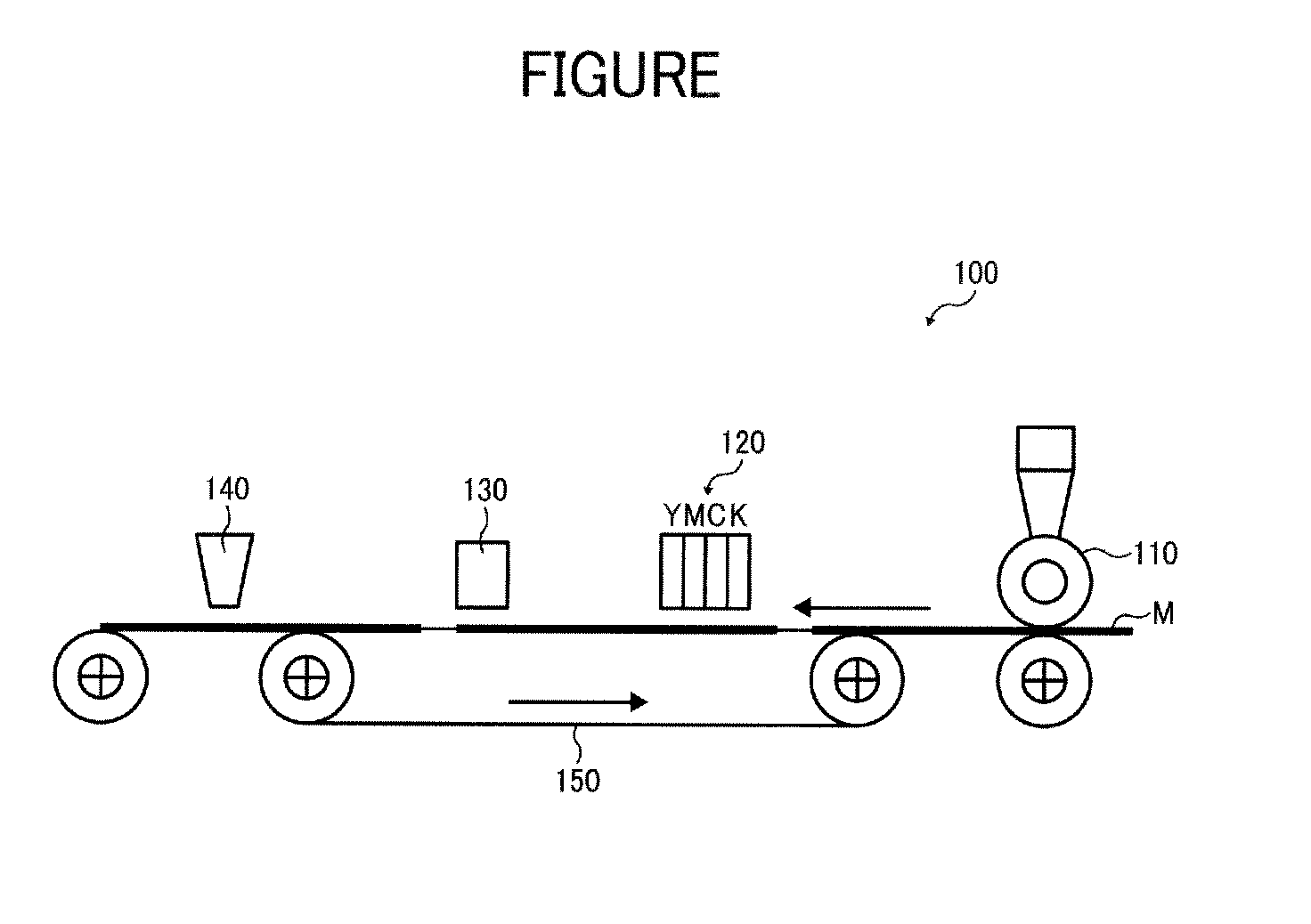

Image forming method and image forming apparatus

ActiveUS20140192112A1Good fixability and anti-blockingDuplicating/marking methodsPrinting after-treatmentParaffin waxWater dispersible

An image forming method includes discharging an inkjet ink including a water-dispersible colorant, a wetter, a surfactant, a penetrant water-dispersible polyurethane resin having a median diameter of from 0.01 to 0.10 μm water and at least one of a polyethylene wax and a paraffin wax on the surface of the recording medium on which the inkjet ink is discharged.

Owner:RICOH KK

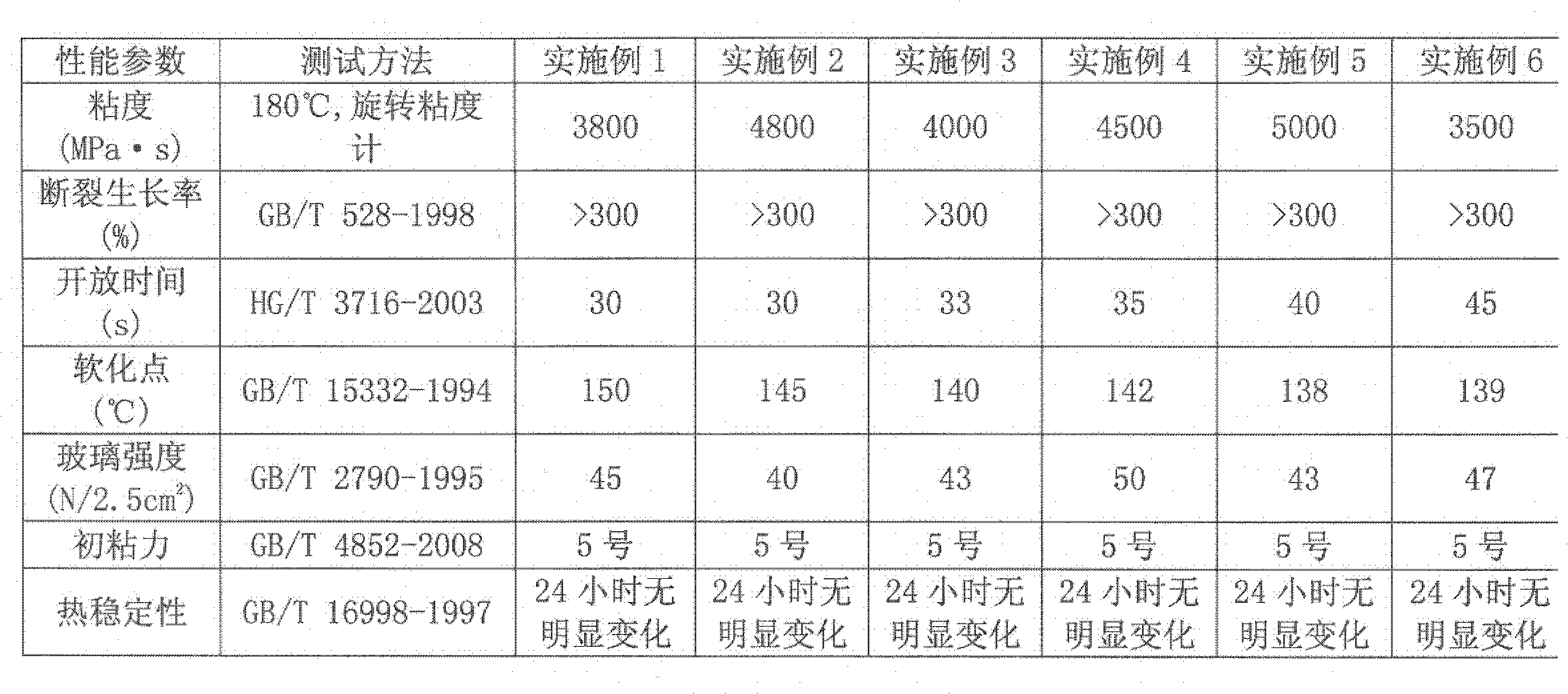

Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

InactiveCN102618211AHarmless to healthHigh bonding strengthWax adhesivesNatural resin adhesivesPolyethylene vinyl acetateParaffin wax

The invention discloses a hot melt adhesive used for automotive interiors, and a preparation method of the hot melt adhesive. The hot melt adhesive used for automotive interiors is characterized by comprising a proportion of paraffin, polyethylene wax, a thermoplastic elastic body SBS, random polyolefin, polyethylene vinyl acetate, C5 petroleum resin, rosin pentaerythritol ester, antioxygen, coupling agent and filler. The preparation method comprising the following steps: heating a stirring kettle to 140 to 160 DEG C, and adding the paraffin and the polyethylene wax; adding the thermoplastic elastic body SBS, vacuum-pumping and keeping warm, adding HMW(high molecular weight) random polyolefin I, HMW random polyolefin II and the antioxygen; adding the coupling agent and the filler; cooling, and adding polyethylene vinyl acetate I and polyethylene vinyl acetate II; cooling and adding the C5 petroleum resin; adding the rosin pentaerythritol ester and keeping warm; and emptying the stirring kettle, pressurizing, discharging and forming. No pollution or poison is produced during the production process of the hot melt adhesive; and the hot melt adhesive has the advantages of high adhesion strength, long opening time, good temperature resistance, strong ageing resistance, good tenacity, strong waterproofness and the like.

Owner:浙江固特新材料科技股份有限公司

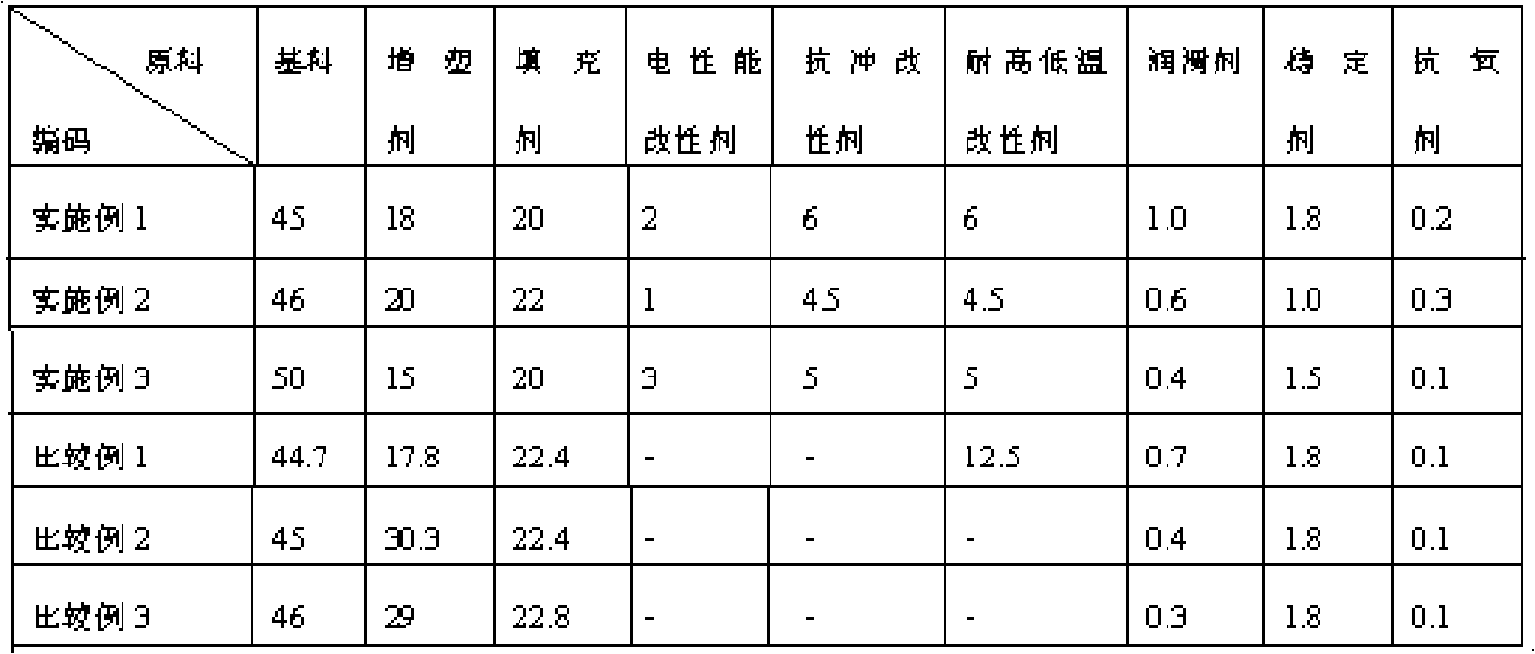

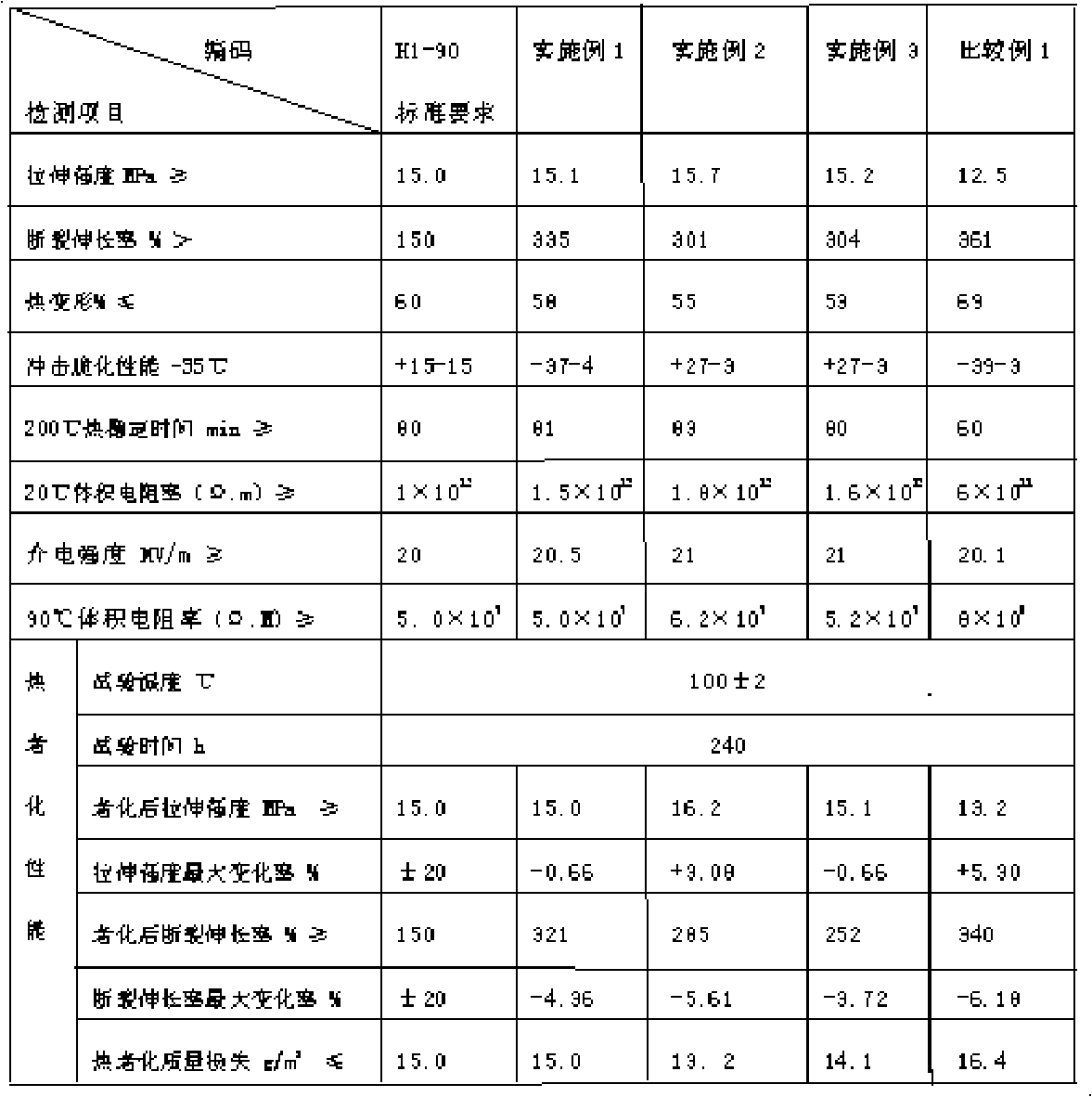

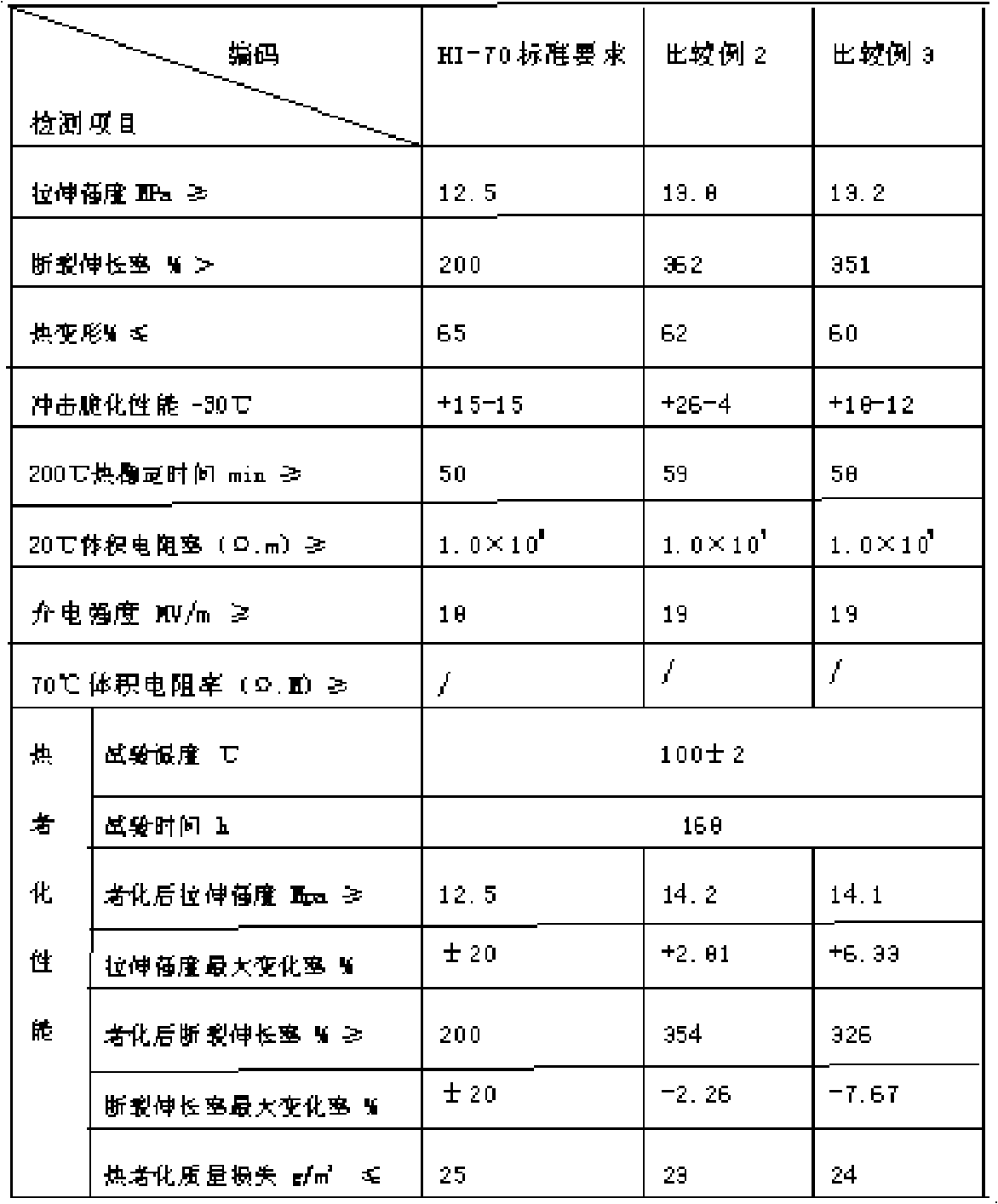

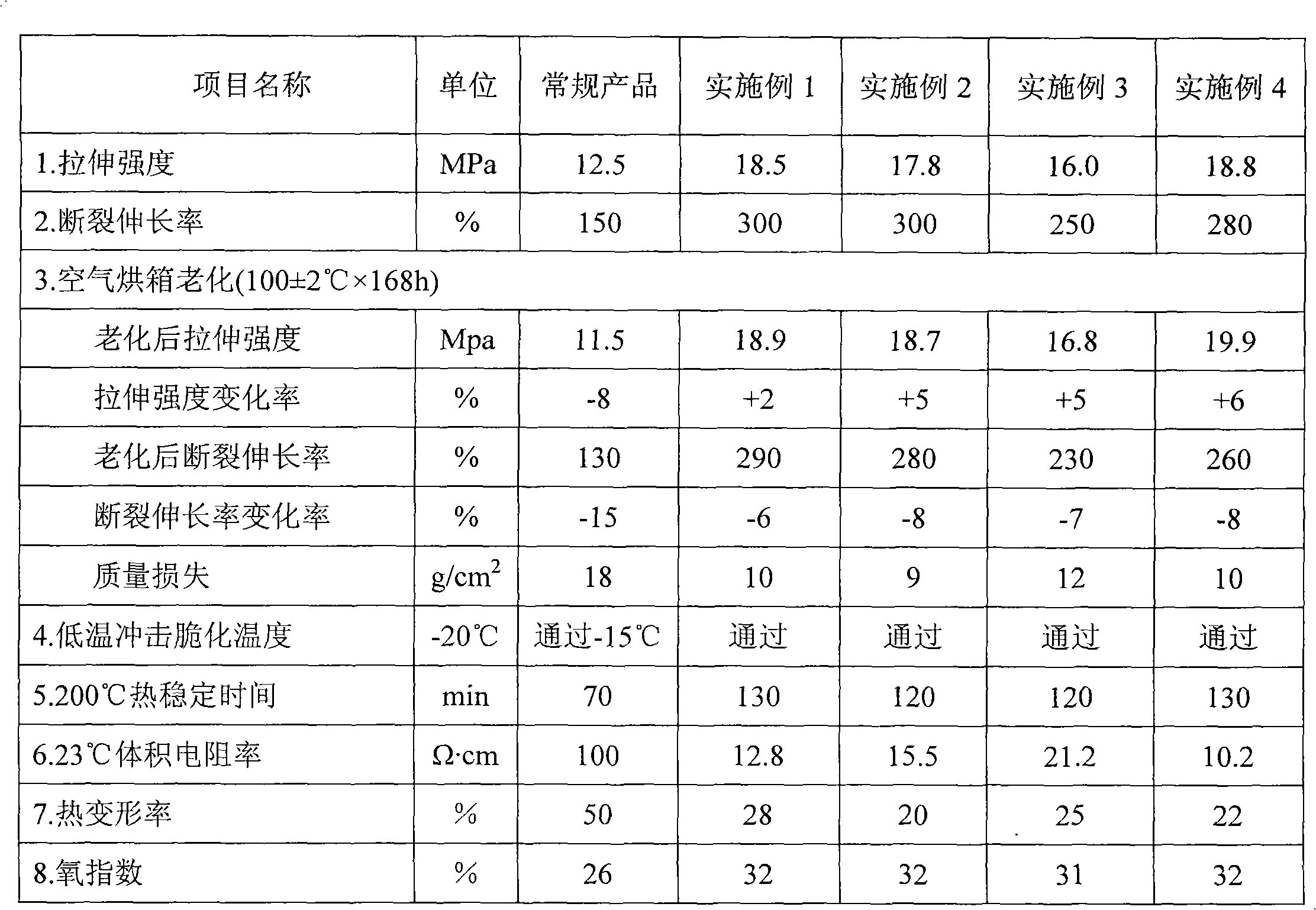

Ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material and preparation method thereof

ActiveCN101875747ALower embrittlement temperatureMeet construction requirementsPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

The invention discloses an ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material, belonging to the field of materials. The cable material is mainly prepared from the following raw materials in percentage by weight: 45-50% of PVC resin, 15-20% of plasticizer, 20-25% of filler, 1-3% of electrical property modifier, 9-15% of impact resistant and high and low temperature resistant modifier, 0.4-2.2% of lubricant, 1.0-2.0% of stabilizer and 0.1-0.3% of antioxidant, wherein the plasticizer is a mixture of more than two of phthalate, terephthalate or trimellitate; and the lubricant is a mixture of a composite lubricant and oxidized polyethylene wax. The invention also provides a preparation method of the cable material. The cable material provided by the invention has the advantages of low brittle temperature and good insulating property, wherein the brittle temperature can reach -35 DEG C; and simultaneously, the preparation method of the cable material is simple and is convenient for industrialized production.

Owner:ZHEJIANG DEYU TECH

Stone paper and manufacturing method thereof

The invention provides stone paper and a manufacturing method thereof. The stone paper comprises the following components in part by weight: 6 to 12 parts of low-density polyethylene, 6 to 12 parts of linear low-density polyethylene, 3 to 6 parts of hot melt adhesive, 5 to 10 parts of titanium dioxide, 65 to 75 parts of heavy calcium carbonate, 3 to 5 parts of silane coupling agent, 0.5 to 1.5 parts of stearic acid, 0.5 to 1.5 parts of epoxy plasticizer, and 0.2 to 0.6 part of polyethylene wax. In the method, high polymer is used as a base material, the calcium carbonate is subjected to compound modification, other additives are added, the characteristics of the surface chemical principle and modification of the high polymer are used and a special process is adopted; and the stone paper is prepared by mixing the polymer, performing composite modification on the filler, plasticizing the filler and polymer, extruding and casting, and performing calendaring molding. The stone paper and the method have great significance for saving energy, protecting natural resources and improving environment.

Owner:山东高旭新材料有限公司

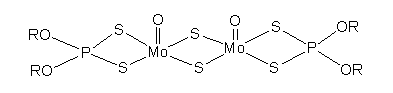

Chromium-free self-lubricating passivation solution and preparation method thereof

InactiveCN103290401AReduce coefficient of frictionImprove the lubrication effectMetallic material coating processesSilanesFirming agent

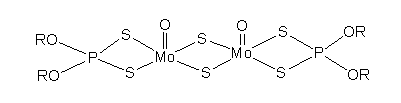

The invention discloses a chromium-free self-lubricating passivation solution and a preparation method thereof. The chromium-free self-lubricating passivation solution is formed by compounding the following compositions in percentage by weight: 8%-12% of water-borne epoxy resin, 0.5%-1% of curing agent, 10%-15% of silane coupling agent, 0.5%-1% of inorganic component, 2%-4% of solid lubricant, 1%-2% of friction modifier, 0.5%-1% of anti-wear agent, 0.5%-1% of anti-sinking agent, and 60%-75% of diluting agent. The inorganic component is one or a combination of Ce(NO3)3 and sodium molybdate, the solid lubricant is one or a combination of two or more of polytetrafluoroethylene, polyethylene wax, polyethylene, molybdenum disulfide and graphite, the friction modifier is self-synthesized molybdenum dialkyldithiophosphate, the anti-wear agent is one or a combination of nanosilicon dioxide and nano aluminum oxide, the anti-sinking agent is attapulgite, and the diluting agent is a mixture of water and ethanol. A plate product coated with passivation solution has the advantages of being pollution-free, low-friction, anti-oxidized, anti-wear and extreme pressure-resistant, corrosion-resistant, finger-resistant, having good mechanical performance and the like, and the passivation solution can be directly coated on the surfaces of a zinc-plated plate and parts of certain mechanical equipment for use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Polyolefin based hot melt adhesive composition

ActiveUS20130060215A1Improve rheologyShort effective set timePaper coatingCeramic layered productsPolyolefinPolymer science

A hot melt adhesive composition includes at least a semi-crystalline copolymer of propylene and a polyethylene wax having a Brookfield viscosity of about 20 cP to 500 cP at 140° C., a density of about 0.95 g / cm3 to 0.99 g / cm3 between 23° C. and 25° C., and a Mettler drop point of about 110° C. to 135° C., wherein the composition is characterized by a effective set time of about 0.1 second to 5 seconds. Articles including the composition and methods of making articles including the composition are described.

Owner:ADHERENT LAB

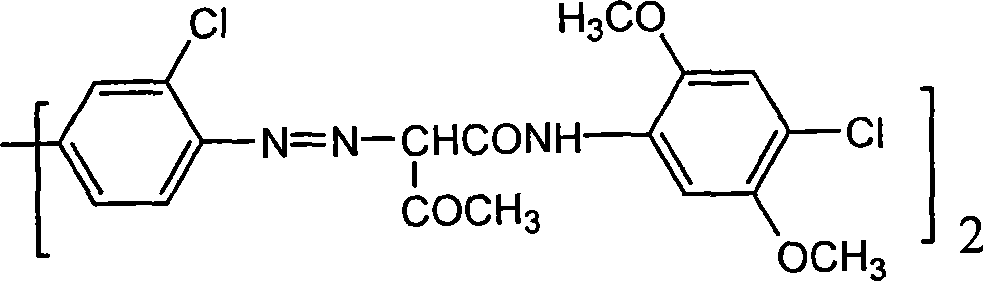

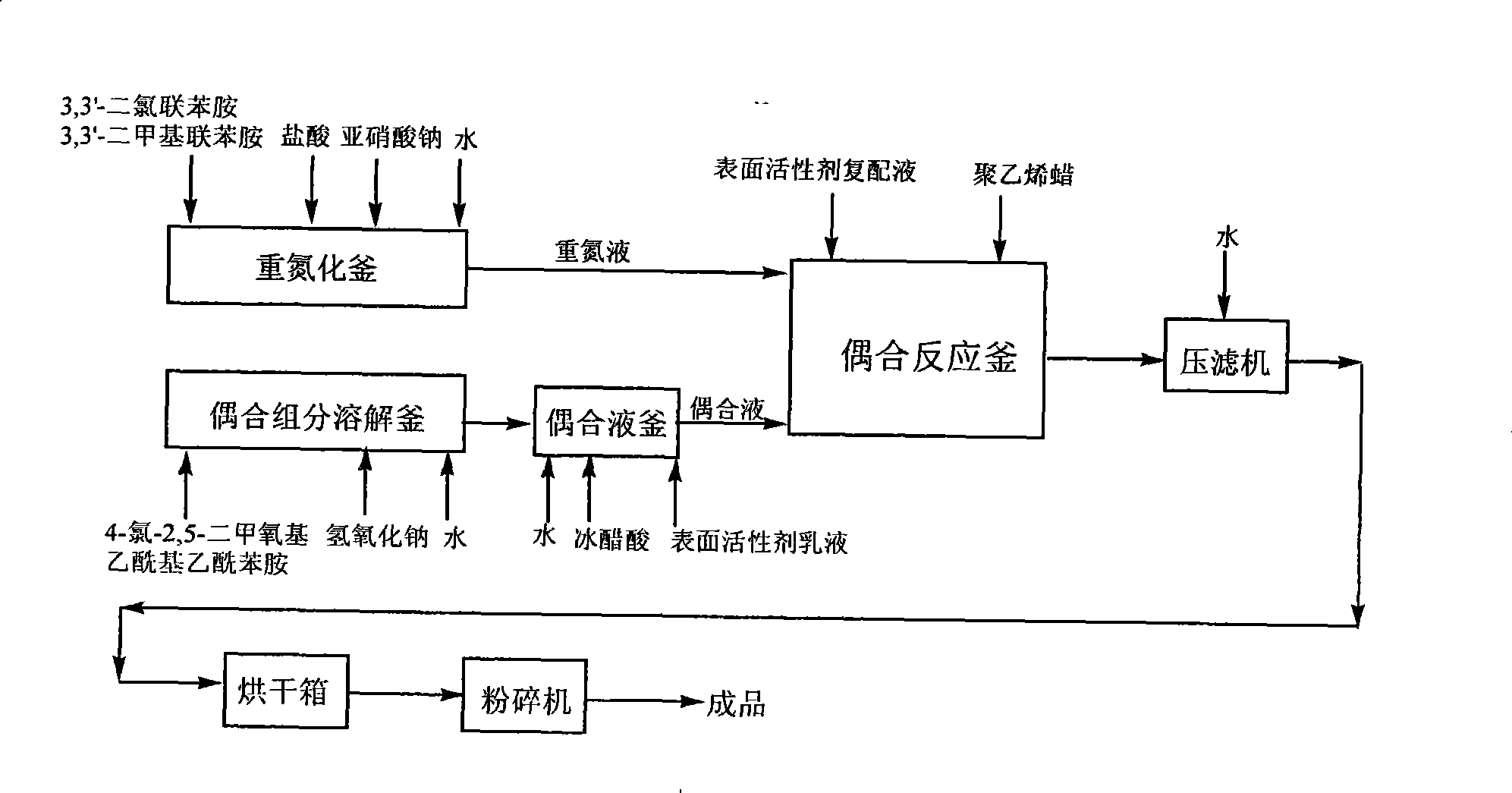

Method for preparing pigment yellow

The invention provides a method for preparing pigment yellow 83. The method comprises the following steps: 3, 3'-dichlorobenzidine, 3, 3'-dimethylbenzidine, hydrochloric acid and water are stirred, dissolved and added to sodium nitrite for diazotization, so as to obtain a diazonium solution; a sodium hydroxide solution containing 4-chlorine-2, 5-dimethoxy acetyl acetanilide is dripped into an acetic acid solution at the temperature between 20 and 40 DEG C, so as to prepare a coupling solution; the acetic acid solution contains an emulsion formed by well mixing anionic surfactant, nonionic surfactant, solvent and water; the diazonium solution is dripped into the coupling solution within 1 to 5 hours; the emulsion formed by compounding the anionic surfactant and non-polar hyper-dispersant is added to the coupling solution, reacts for 1 hour, and is heated to 90 to 100 DEG C; polyethylene wax is added in the mixture; and then the mixture, is insulated for 1 to 3 hours, pumped, filtered, washed, dried and ground, so as to obtain a finished product. The preparation method has the advantage of obtaining the pigment yellow 83 which is bright in color light, high in tinting strength, high in covering power and good in dispersibility.

Owner:宇虹颜料股份有限公司

Hot melt flexographic inks and method of preparing same

Solid, solvent-free inks are provided for use in hot melt flexographic printing. The ink is composed of a pigment; a thermoplastic binder which is an ethylene copolymer, a hydrocarbon resin, or a combination thereof; a wax which is a highly branched hydrocarbon wax, a polyethylene homopolymer wax, an oxidized polyethylene wax, an animal wax, a vegetable wax or combinations thereof; a solid linear alcohol; and, a dispersing agent. The ink may also contain a solid plasticizer. The solid ink has a melting point of about 75° C. or greater, and when heated to a temperature between about 90° C. and about 135° C., a molten ink is formed which has a viscosity between about 100 cps and about 1200 cps. The solid inks are used in melt flexographic printing by heating the ink to a temperature greater than about 90° C. to form a molten ink which has a viscosity between about 100 cps and about 1200 cps; applying the molten ink to the surface of a heated anilox roller in operational contact with a heated flexographic printing plate; and printing the applied molten ink from the printing plate onto a substrate such as conventional print stock, polymeric films, metal sheets, etc.

Owner:SUN CHEM CORP

Environment-friendly flame retardant semiconductive PVC sheathing compound used for ultra-pressure cable sheath

InactiveCN101633766APrevent agingImprove external lubricationInsulated cablesInsulated conductorsLow speedFire retardant

The invention relates to a cable sheathing compound and a preparation method thereof, in particular to an environment-friendly flame retardant semiconductive PVC sheathing compound used for an ultra-pressure cable sheath and a preparation method thereof. The semiconductive PVC sheathing compound in the invention comprises PVC resins, plasticizers, an antioxidant, polyethylene wax, ethylene- vinyl acetate resins, a flame retardant a, a compound environment-friendly heat stabilizer, a flame retardant b, conductive carbon black a, a high efficient lubricant, nano calcium carbonate, conductive carbon black b and conductive metal powder. The preparation method of the invention comprises the following steps: firstly, stirring the plasticizer a, conductive carbon black a, nano calcium carbonate, conductive carbon black b, conductive metal powder and antioxidant in a low speed kneading machine; then mixing other constituents and stirring the constituents in a high speed kneading machine. Compared with the existing products, the semiconductive PVC sheathing compound in the invention helps to fully restrain the aging of PVC, improve the intensity and the line extrusion speed of the product, lower the volume resistance rate and has the excellent conduction performance, thus can be widely applied to the outer sheaths needed by the environment-friendly flame retardant ultra-pressure cables.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Ink composition and ink jet recording method

An ink composition contains a pigment, first wax particles, second wax particles, and a resin emulsion, in which the first wax particles have a melting point of 120° C. or higher and 170° C. or lower, the second wax particles have a melting point of 70° C. or higher and less than 120° C., the resin emulsion has a glass transition point of 50° C. or higher and 150° C. or lower, the first wax particles contain one or more kinds of wax particles selected from the group consisting of polyethylene wax particles or polypropylene wax particles, and the second wax particles contain one or more kinds of wax particles selected from the group consisting of polyethylene wax particles.

Owner:SEIKO EPSON CORP

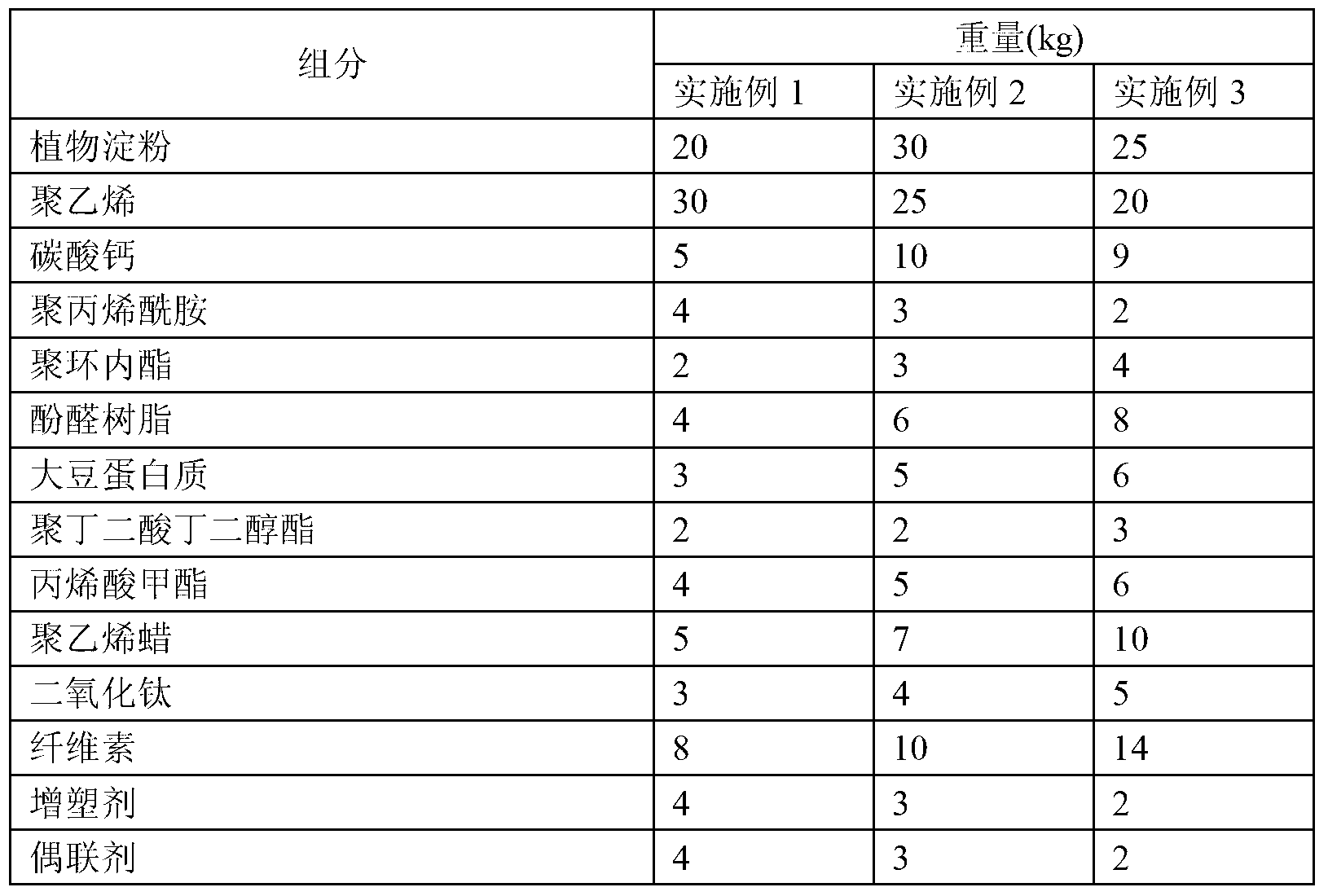

Degradable film containing starch and preparation method of degradable film

The invention provides an agricultural film material and particularly relates to a degradable film material containing starch serving as a raw material, belonging to the technical field of high molecular materials. The degradable film comprises the following raw materials in parts by weight: 20-30 parts of plant starch, 20-30 parts of polyethylene, 5-10 parts of calcium carbonate, 2-4 parts of polyacrylamide, 2-4 parts of poly cyclic lactone, 4-8 parts of phenol aldehyde resin, 3-6 parts of soybean protein, 2-3 parts of polybutylene succinate, 4-6 parts of methyl acrylate, 5-10 parts of polyethylene wax, 3-5 parts of titanium dioxide, 8-14 parts of cellulose, 2-4 parts of plasticizer and 2-4 parts of coupling agent. The degradable film provided by the invention has excellent strength, the tensile strength of the degradable film can be higher than 16MPa, the light transmittance can be higher than 88%, and the degradable film can be generally degraded within 4-6 months.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

High-pressure self-packing leather cup rubber for packer and preparation method thereof

The invention discloses high-pressure self-packing leather cup rubber for a packer. The high-pressure self-packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent, 2-3 parts of coupling agent DL-151 and 16-18 parts of epoxy linseed oil. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

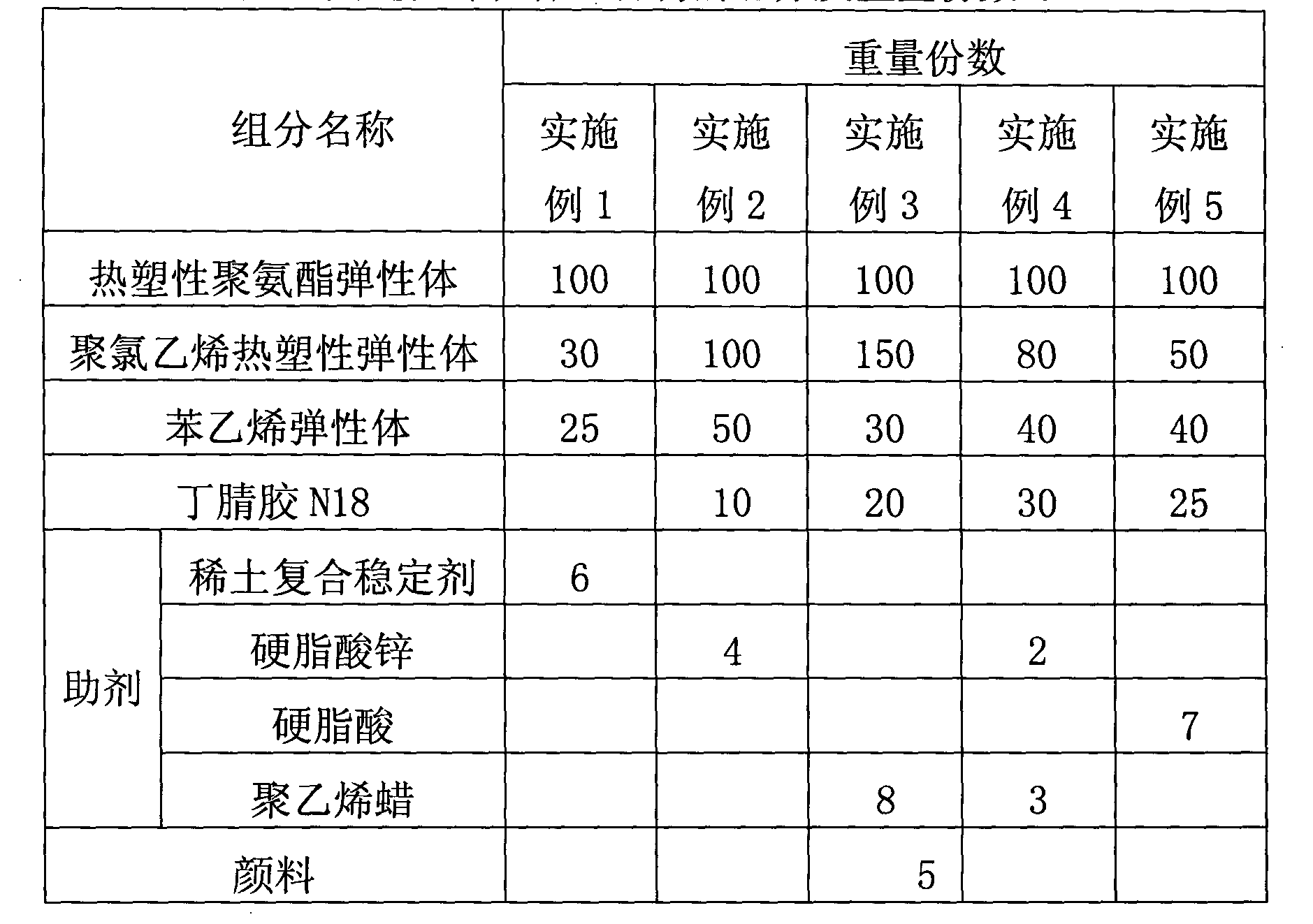

Thermoplastic elastomer composition

The invention discloses a thermoplastic elastomer composition which is plasticated by the following main components by weight: 100 parts of polyurethane thermoplastic elastomers, 30-150 parts of polyvinyl chloride thermoplastic elastomers, 25-50 parts of styrene elastomers, 0-30 parts of blend and 4-8 parts of auxiliaries, wherein the auxiliary is any one or more of a composite rare-earth stabilizer, zinc stearate, calcium stearate, stearic acid or polyethylene wax; and the blend is butyronitrile N18. The invention selects the thermoplastic elastomers with similar polarity and complementary properties to be synthesized and used and selects compatilizers to organically combine several best molecules with different structures, so that the generated novel thermoplastic elastomer has superior performance and appropriate price, can meet the requirements of market products and has wide application range because the product has the technical advantages of excellent oil resistance, resistance to low temperature of minus 35 DEG C, acid-alkali resistance, aging resistance and lower proportion than the vulcanized products with the same price.

Owner:营口巨成教学科技开发有限公司 +1

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

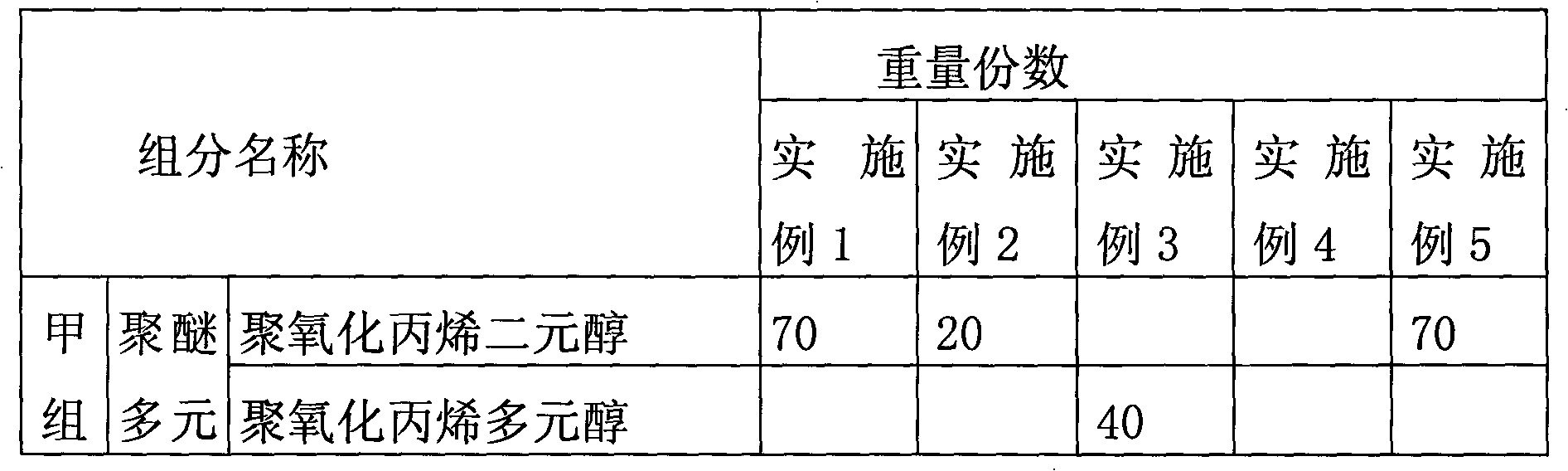

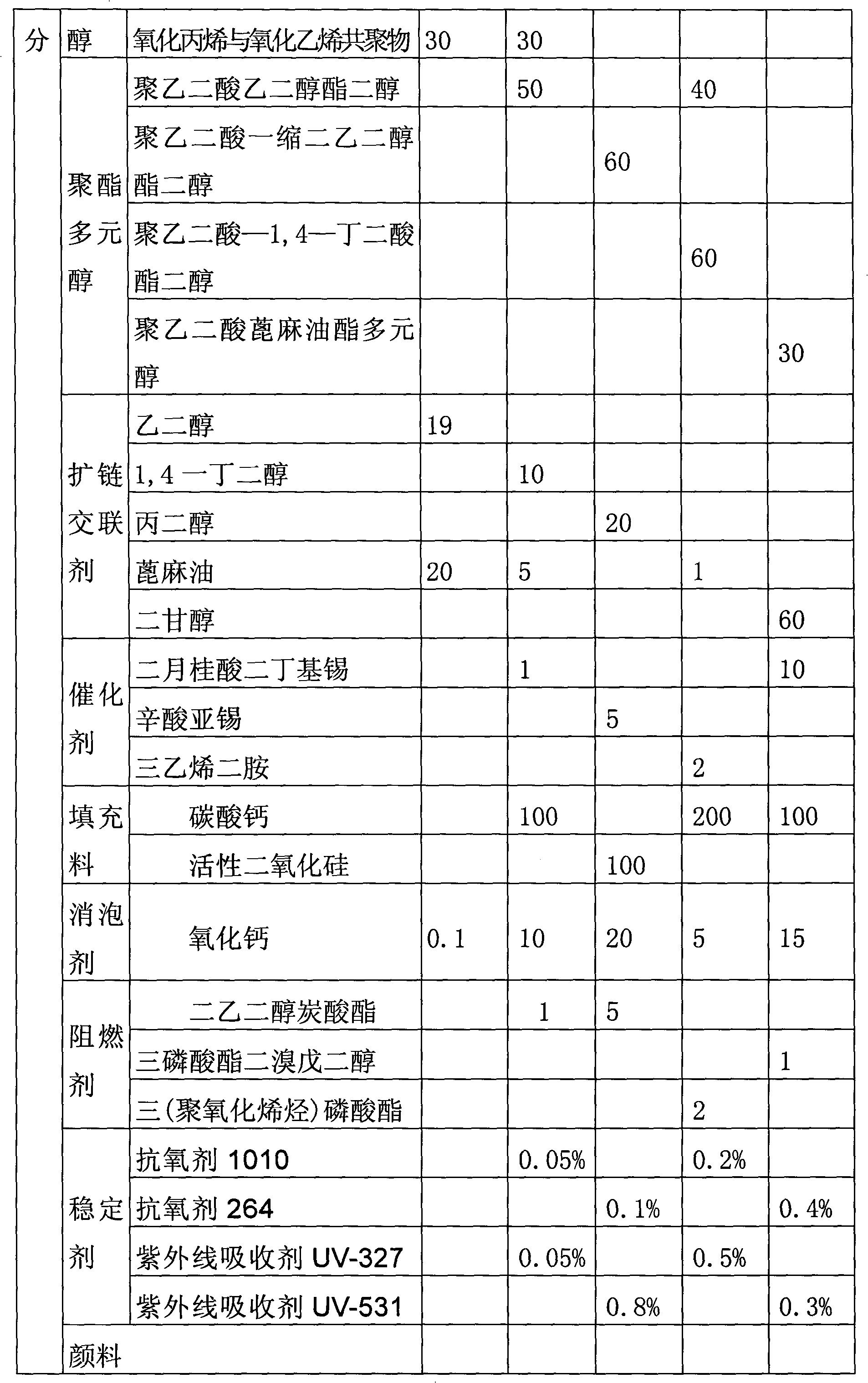

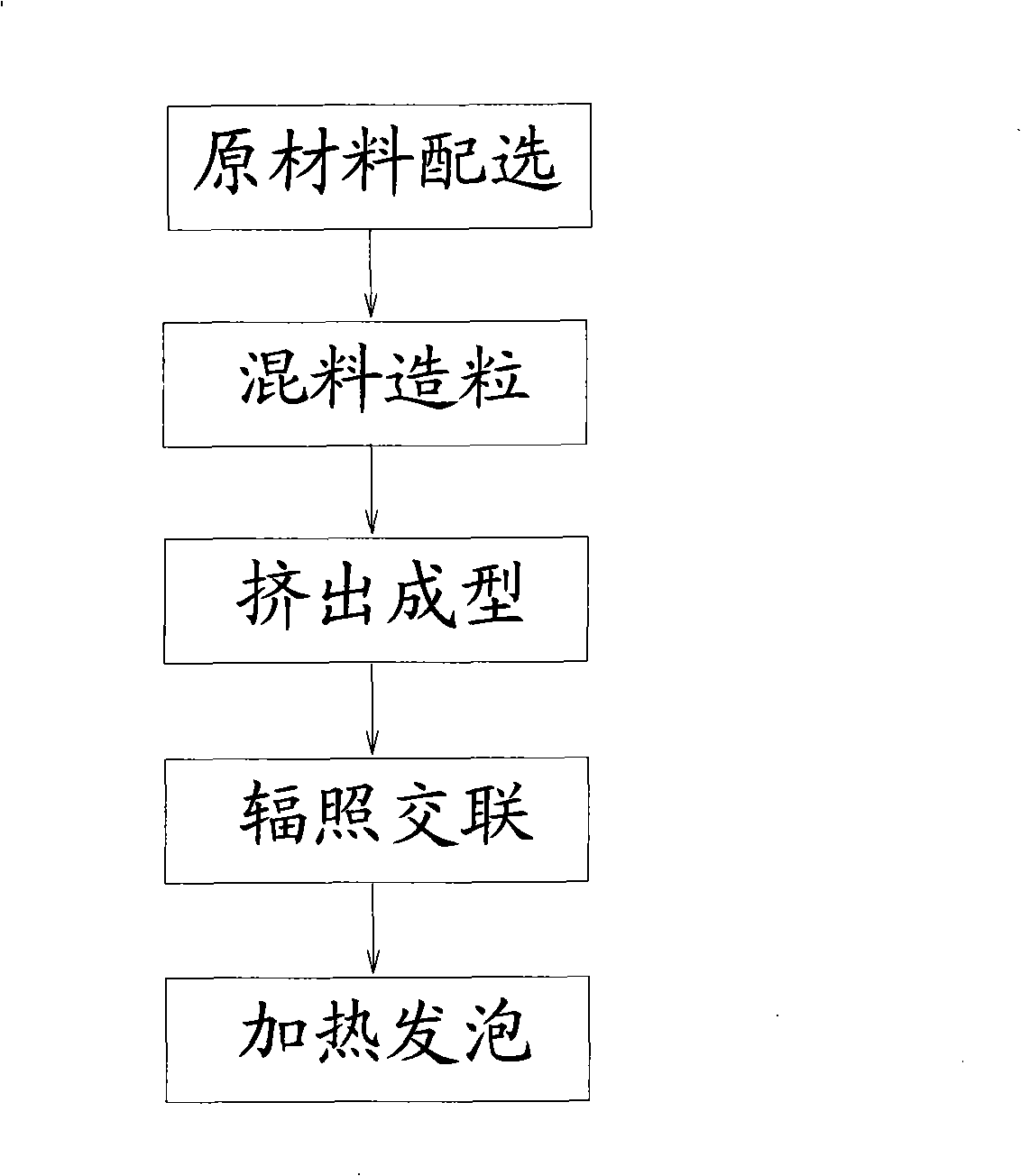

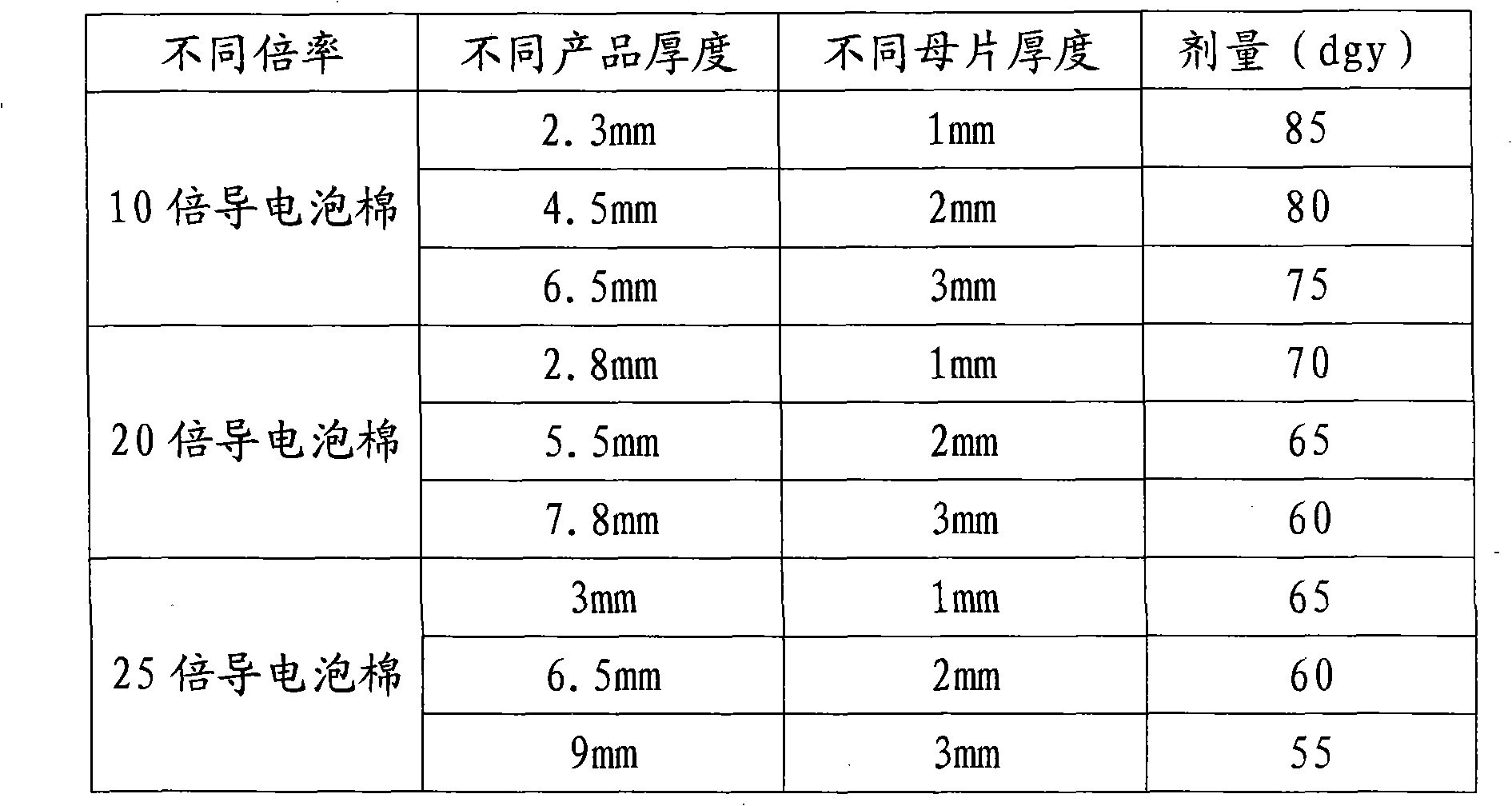

IXPE electron radiation on crosslinking polyethylene conductive foam and preparation method thereof

The invention relates to an IXPE electronic radiation crosslinked polyethylene conductive foam and a preparation method thereof. The IXPE electronic radiation crosslinked polyethylene conductive foam mainly contains the mother batch: low density polyethylene; accessories: ethylene-vinyl acetate copolymer, azodicarbonamide blowing agent, polyethylene wax lubrication additive, titanate ester coupling agent and conductive carbon black which are mixed for processing, extruded for molding, radiated for crosslinking, heated for foaming, and treated by secondary processing, etc, to produce the IXPE electronic radiation crosslinked polyethylene conductive foam. The crosslinking of the product of the invention can be easily controlled, the foaming process is stable, the foam pores are fine and even, the quality of the surface is high without unpleasant odor, the foam pores are obstructed, the production can be carried out continually, the electrical conductivity is stable, the product is lightweight, non-toxic, extremely less absorbent; the thermal conductivity is slow, aging resistant, chemical corrosion resistant, pulverization resistant, and a plurality of porous foam materials can be easily achieved; in addition, the product has good properties to be treated by the secondary processing procedures, such as bonding, machining, hot forming, etc.

Owner:SHENZHEN CHANGYUAN TEFA TECH CO LTD

Micro-foaming wood plastic composite material plate for building template and preparation method thereof

The invention discloses a micro-foaming wood plastic composite material plate for a building template and a preparation method thereof. The wood plastic composite material consists of polrvinyl chloride, wood powder, lightweight active calcium carbonate, a foaming agent, a foaming stabilizer, polyethylene wax, a titanate coupling agent, chlorinated polyethylene, an adsorbent nano calcium oxide, an auxiliary foaming agent nano zinc oxide, a silicone processing adjuvant and reinforced fiber alkali-free glass fiber. The preparation method comprises the following steps of: mixing the wood powder and the nano calcium oxide powder at a high speed; adding the titanate coupling agent and then mixing at the high speed; adding the rest materials; mixing at the high speed and then mixing at a low speed to obtain a premix; extruding the premixing by using an extruder; and cooling very quickly to obtain the product. The micro-foaming wood plastic composite material plate has the characteristics ofhigh surface hardness, high flowability, high strength, high toughness, high dimensional stability, long service life and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Silica products and UV curable systems

InactiveUS6039798AGood mattingReduce the numberPigmenting treatmentAlkali metal silicate coatingsUV curingSilicon dioxide

PCT No. PCT / EP96 / 03246 Sec. 371 Date Feb. 12, 1999 Sec. 102(e) Date Feb. 12, 1999 PCT Filed Jul. 20, 1996 PCT Pub. No. WO97 / 08250 PCT Pub. Date Mar. 6, 1997Wax coated silica matting agent wherein the silica is an amorphous silica having a pore volume of at least 1.5 cm3 / g, preferably at least 1.8 cm3 / g. The wax coating is present in the range from 6% to 15% by weight of the matting agent and comprises a synthetic polyethylene wax.

Owner:PQ SILICAS UK

High heat conducting nylon composite material and preparation method thereof

The invention discloses a high heat conducting nylon composite material and a preparation method thereof. The high heat conducting nylon composite material belongs to one of functional high molecules. The composite material is prepared from a thermoplastic nylon resin base body, heat conducting filler and other processing agents. The heat conducting coefficient is greater than 2.7W / m.K. The resin base body can be nylon 6 or a compound of nylon 6, nylon 9, nylon 66, nylon 610 and nylon 1010. The heat conducting filler can be one or more of magnesium oxide, aluminum oxide, aluminum nitride, boron nitride, silicon nitride, a multiwalled carbon nanotube and a graphite flake layer. The processing agents can be octadecanamide, polyethylene wax, liquid paraffin and the like. The method disclosed by the invention is simple to operate and low in cost, and can prepare the heat conducting composite material with excellent comprehensive performance by one step. The method is easy to realize industrialized production and can be widely applied to the fields of automobiles, household appliances, meter cases, circuit elements and the like.

Owner:BEIJING UNIV OF CHEM TECH

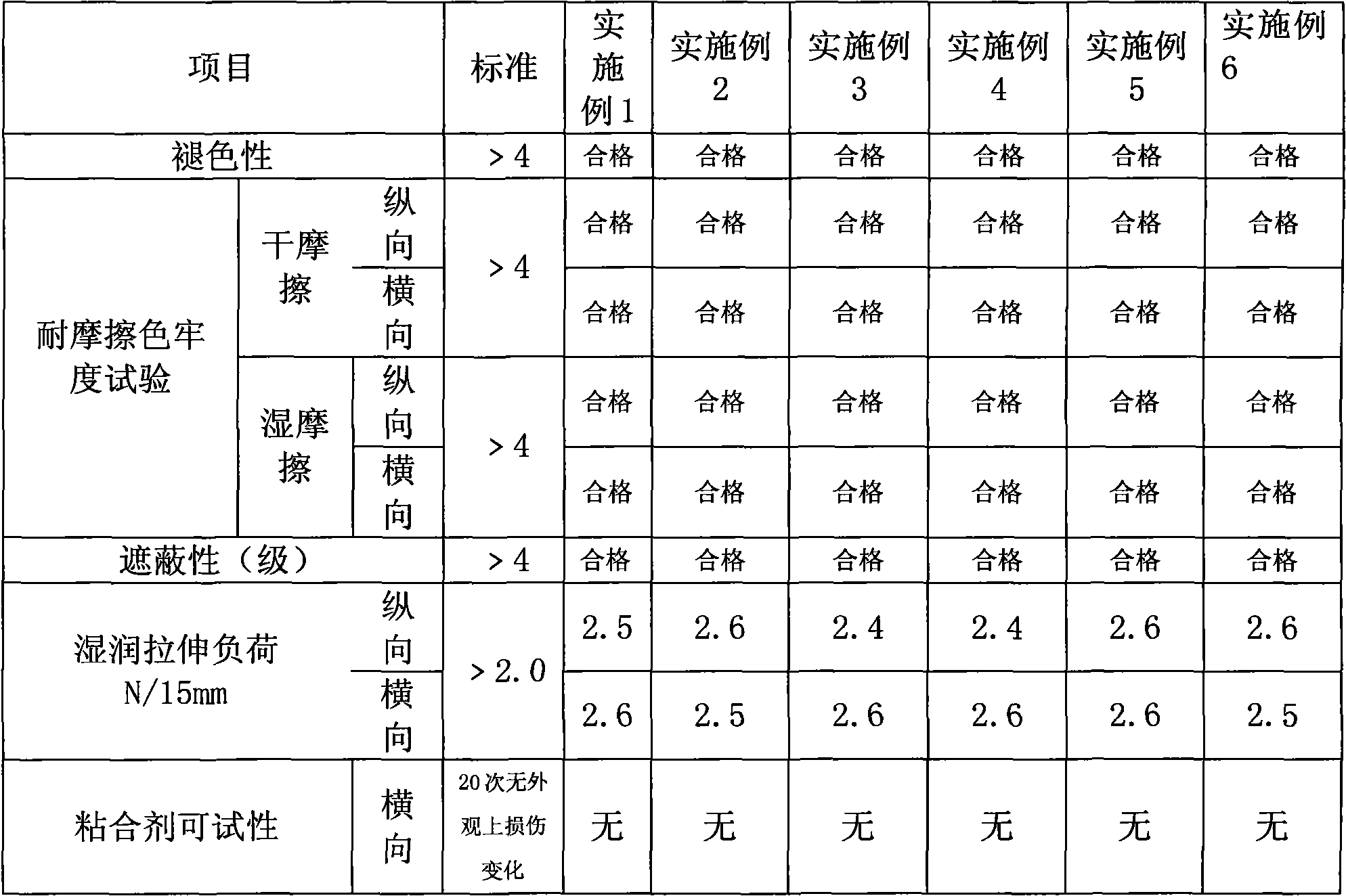

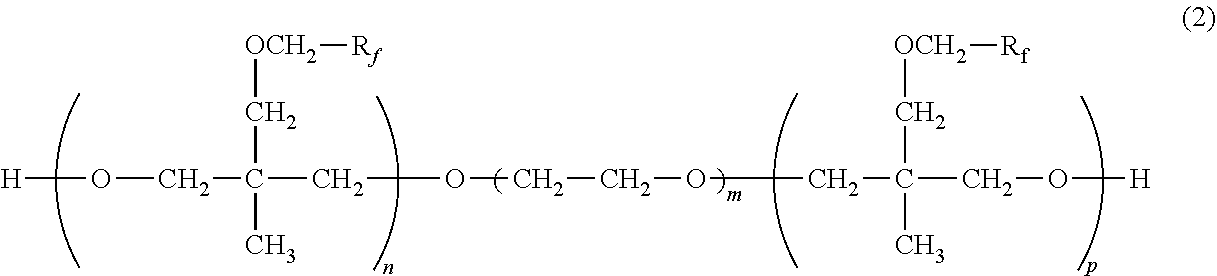

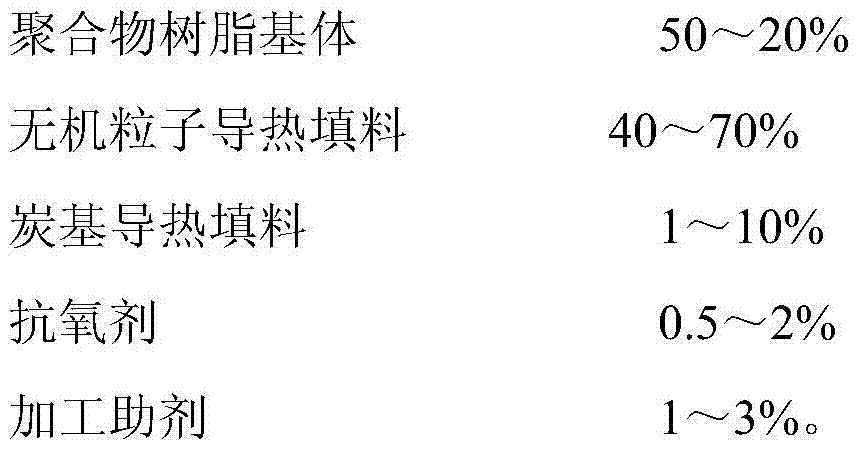

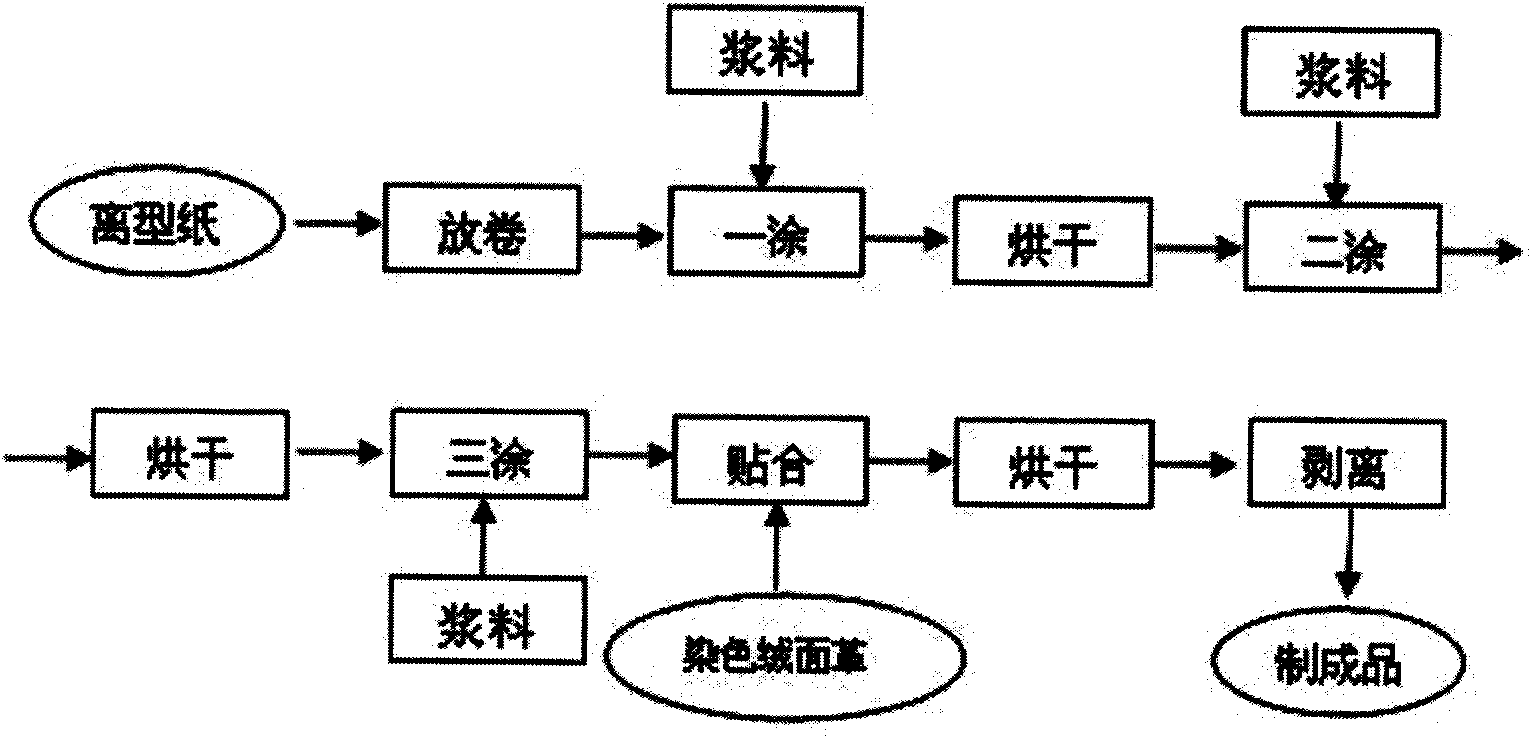

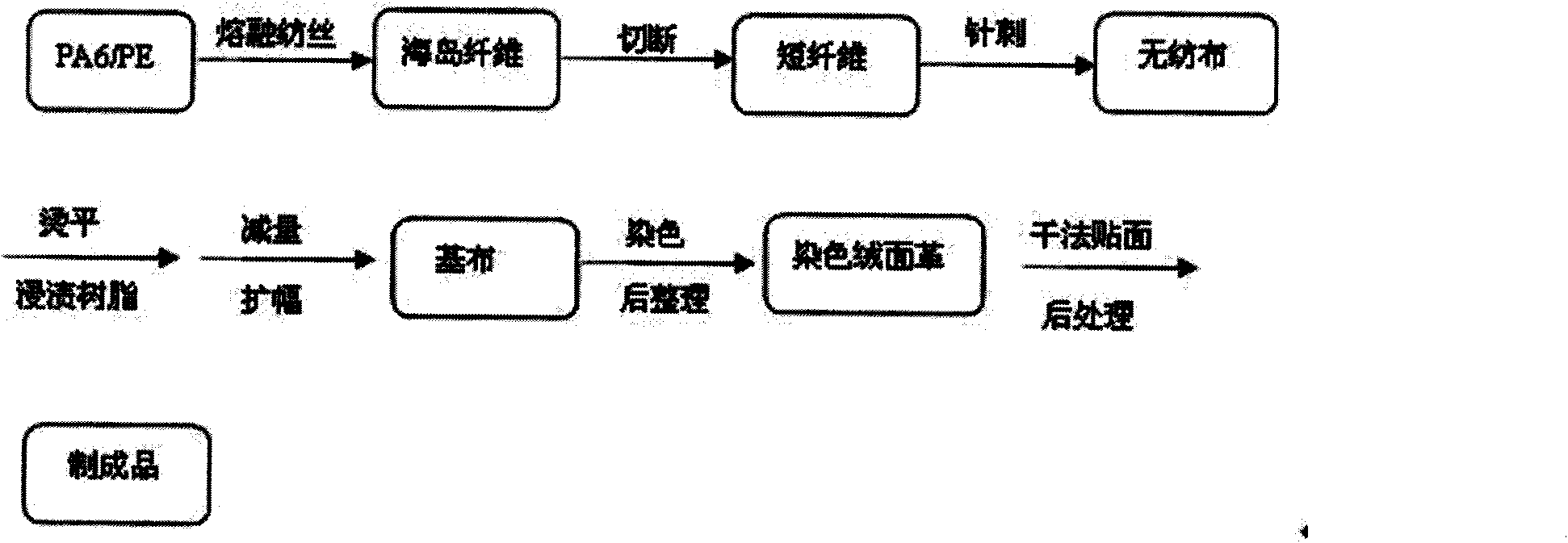

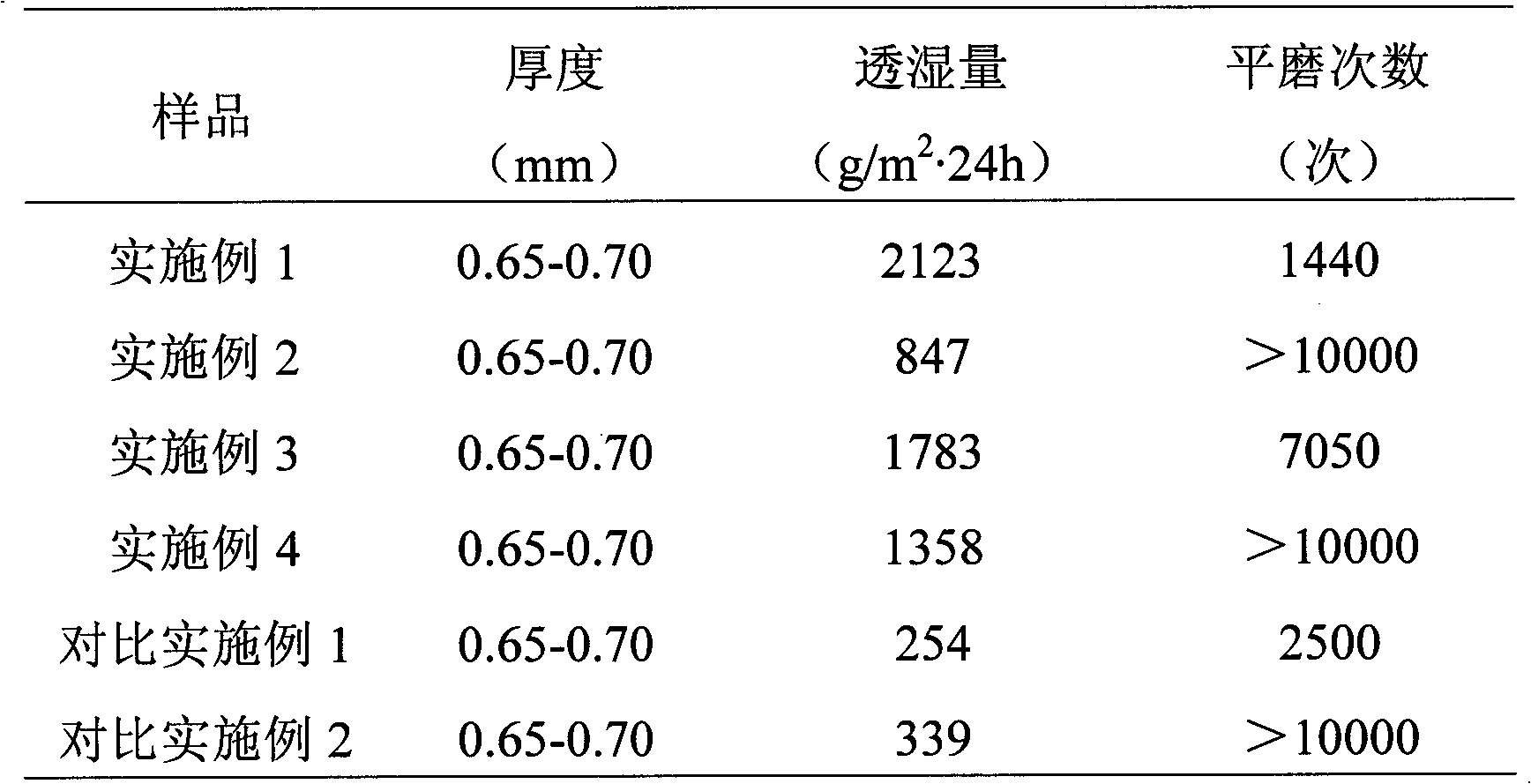

Superfine fiber leather and preparation method thereof

InactiveCN102102301AImprove comfortGood moisture permeabilitySynthetic resin layered productsTextiles and paperFiberWear resistant

The invention discloses a preparation method of superfine fiber leather, which comprises the steps of: coating a surface layer, a middle layer and an adhesive layer on a piece of release paper; laminating the release paper with dyed suede leather; drying; and removing the release paper to obtain the superfine fiber leather, wherein a sizing agent of the surface layer and the middle layer contains 100 parts of polyurethane resin, 10 to 60 parts of polar solvent, 1 to 6 parts of friction resistant additive and 0.5 to 5 parts of hydrophilic additive; a sizing agent of the adhesive layer contains 100 parts of polyurethane resin, 10 to 60 parts of polar solvent, 1 to 6 parts of friction resistant additive, 0.5 to 5 parts of hydrophilic additive and 70 to 90 parts of absorbent resin; a fluorine modified polyethylene wax substance is adopted as the friction resistant additive; and a hydrophilic organic silicon substance is adopted as the hydrophilic additive. The invention also discloses superfine fiber leather which has the moisture permeability higher than or equal to 850 grams per square meter for every 24 hours, which is higher than that of the natural leather. The preparation method disclosed by the invention can also improve the wear resistant time which is higher than 10000 times in the preferable embodiment of the invention.

Owner:HUAFON MICROFIBER SHANGHAI

Energy-storing self-luminescent road marking coating

InactiveCN101372598AGood Luminous RecognitionHigh luminous intensityLuminescent paintsTraffic signalsLuminous intensityMaterials science

The present invention relates to an energy storage self-lighting road marking dope which is characterized in that the raw materials of the dope consist of 15 to 16 portions of petroleum resin, 15 to 16 portions of quartz sand, 25 to 50 portions of calcium carbonate powder, 18 to 20 portions of glass bead, 0.8 to 1.2 portions of polyethylene wax, 0.8 to 1.5 portions of dioctylphthalate, 1.0 to 1.2 portions of EVA hot-melt adhesive, 2.0 to 4.0 portions of titanium pigment and 2.0 to 10 portions of energy storage luminescent material by weight proportion. All the raw materials of the energy storage self-lighting road marking dope are commercial universal industrial raw materials, the energy storage self-lighting road marking dope has low manufacturing cost and simple technology, also has good energy storage self-lighting and reflecting functions and ensures that a road marking has the characteristics of good luminescent recognizability, high luminescent intensity and long luminescent time no matter under the condition with light or without light; and the marking dope can be widely applied to various kinds of roads without illuminating device, such as highway, town road, village road, montane road, and the like, and can improve the traffic safety factor greatly.

Owner:BEIJING BRIDGE RUITONG MAINTENANCE CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com