Patents

Literature

202 results about "Polyethylene vinyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

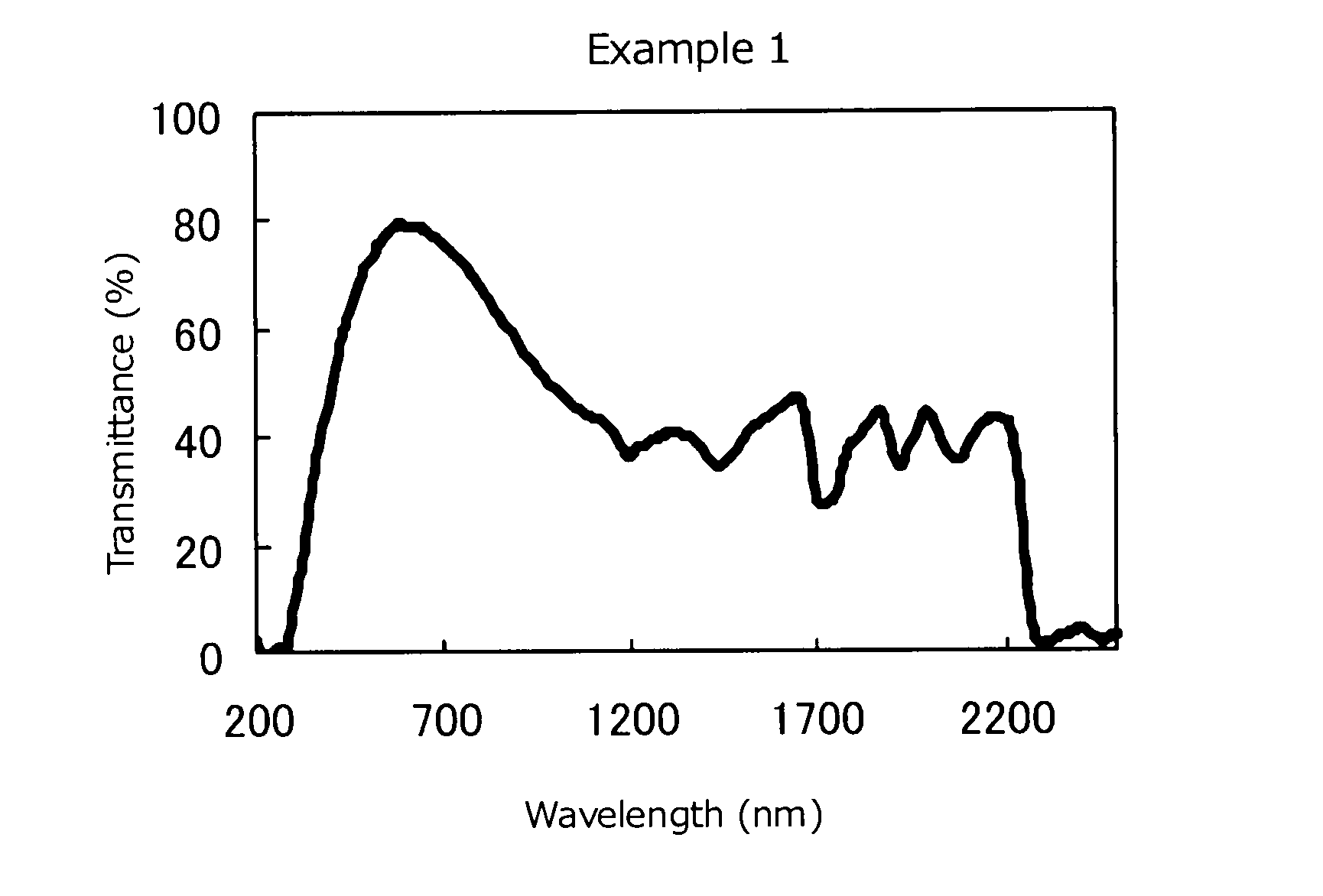

Gel polymer electrolyte of vinyl acetate

InactiveUS6268088B1Enhanced interactionImprove ionic conductivityOrganic electrolyte cellsSolid electrolyte cellsSolventFluid electrolytes

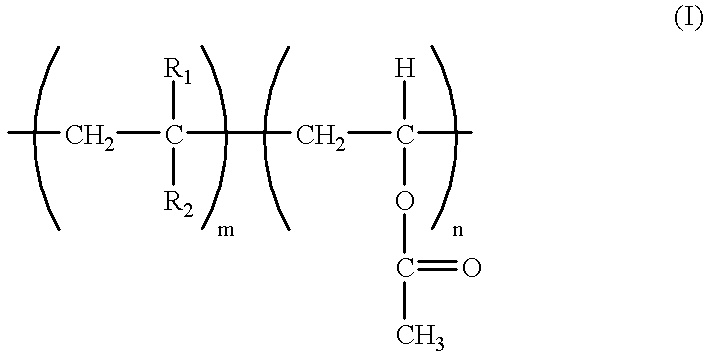

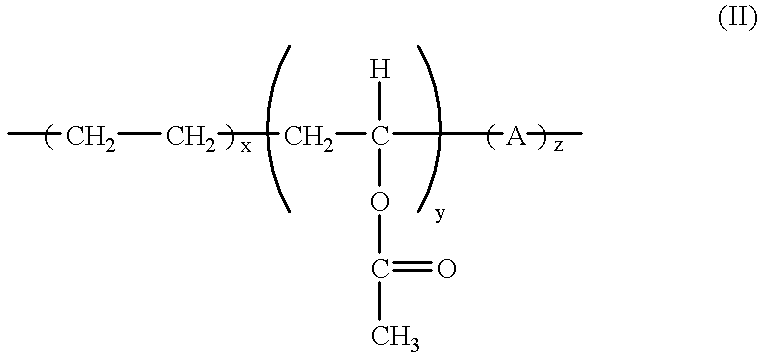

A gel polymer electrolyte according to the present invention comprises a polymer selected from the group consisting of vinyl acetate copolymer, poly(ethylene / vinylacetate / carbon oxide: EVACM), and poly(ethylene / vinylacetate / maleic acid anhydride: EVAMA); an inorganic filler; and a liquid electrolyte that a lithium salt is dissolved in an aprotic solvent. It is preferable that the polymer material in a gel polymer electrolyte according to the present invention is in the range of 20 to 30% by weight, the inorganic material filler is in the range of 5 to 20% by weight, and the liquid electrolyte is in the range of 60 to 80 % by weight. As a specific functional group which has a high compatibility with a liquid electrolyte in the present invention is contained in the polymer material, a lithium ion becomes to move with ease in electrolyte, and the ionic conductivity is over 0.5 mS / cm which is the demand level of a gel polymer electrolyte. Also, it provides the gel polymer electrolyte material with a high film formability, a good property of containing an electrolyte, a good adhesion, and a good mechanical strength.

Owner:CHEIL IND INC

Oxygen scavenger compositions

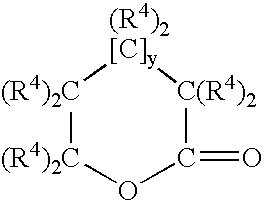

InactiveUS20050139806A1Sufficient viscosityReduce viscosityOther chemical processesSynthetic resin layered productsPolyesterPolyethylene vinyl acetate

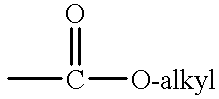

The present invention is directed to an oxygen scavenger composition comprising a mixture of (i) a polyester polymer composed of polymer segments containing cycloalkenyl group or functionality; and (ii) an ester type polymer selected from (a)a polyester having a high content of alkylene groups; (b) a polylactone; and (c) a polyvinylacetate having at least about 50 weight percent vinyl acetate mer units therein. The present polymer composition has been found to act as an oxygen scavenger agent under both ambient and refrigerated conditions, to be compatible with conventional film forming packaging materials, to provide compositions exhibiting low tack, and to be capable of being readily processed using conventional film forming equipment.

Owner:HAVENS MARVIN RUSSELL +1

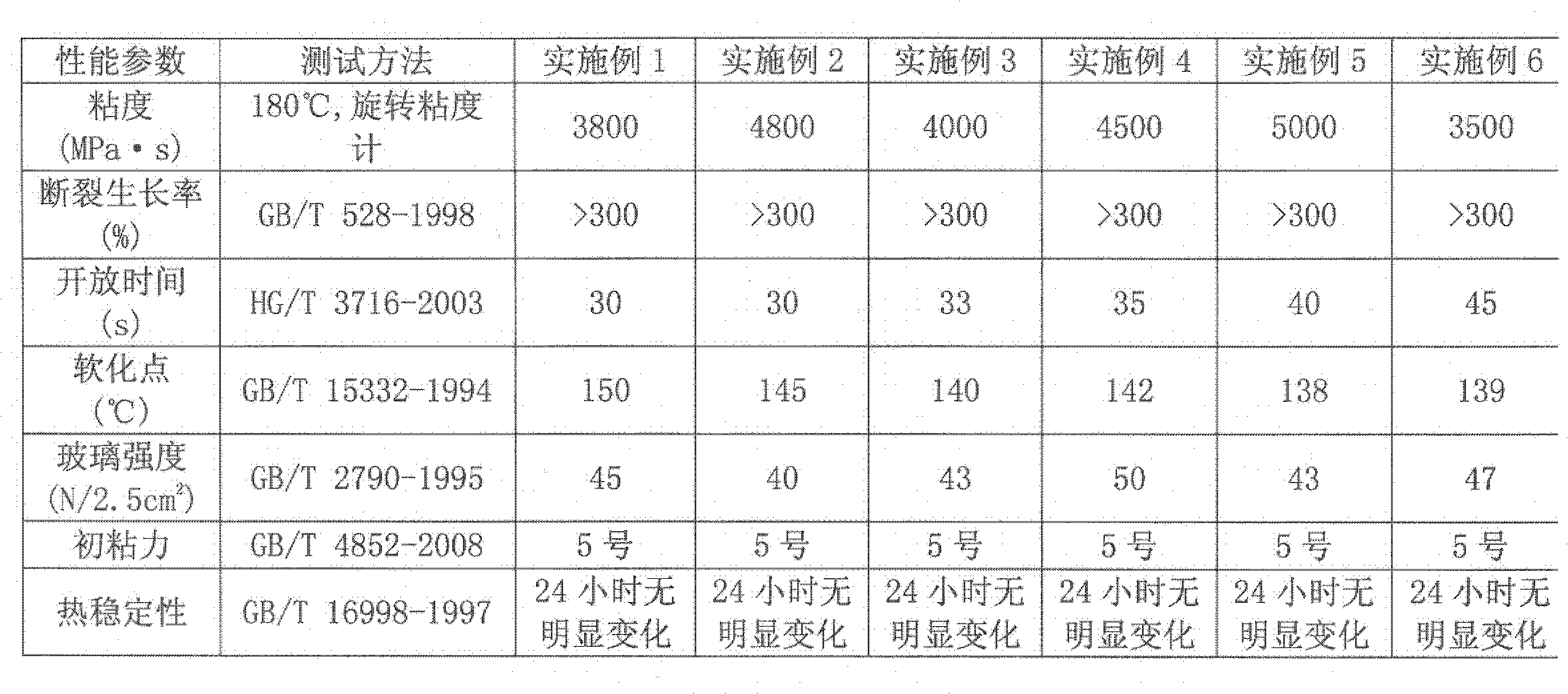

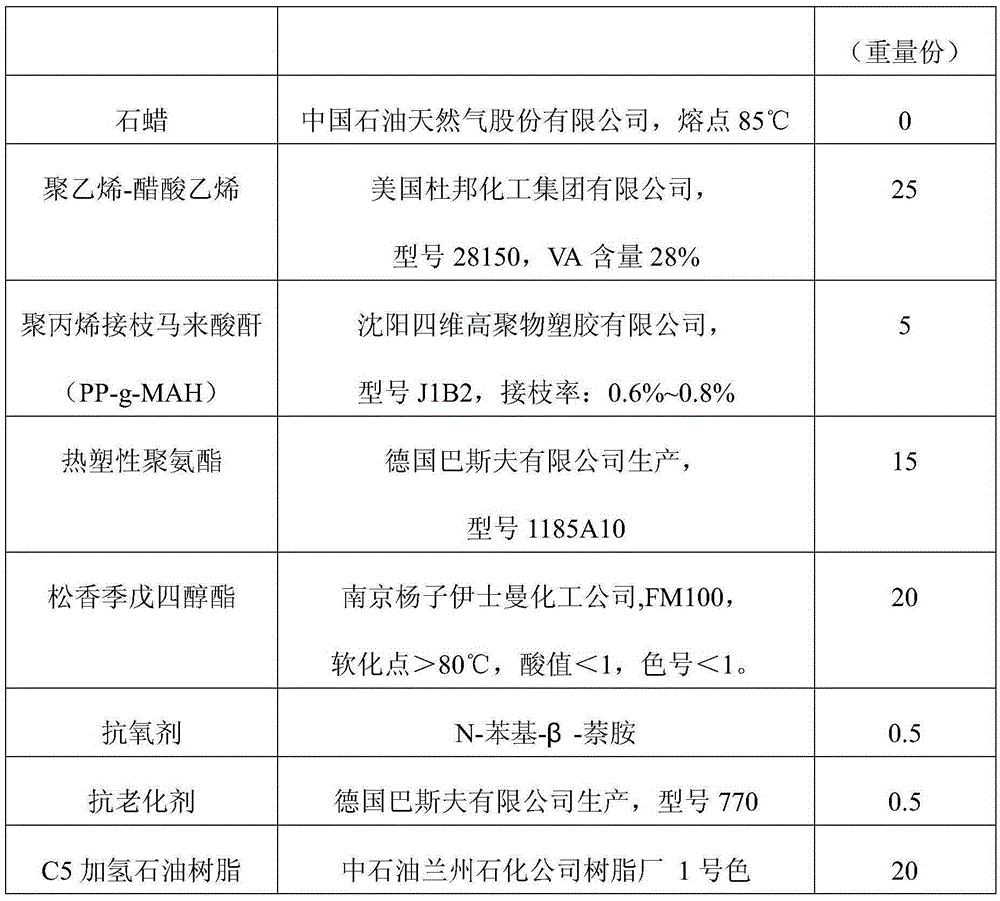

Hot melt adhesive used for automotive interiors, and preparation method of hot melt adhesive

InactiveCN102618211AHarmless to healthHigh bonding strengthWax adhesivesNatural resin adhesivesPolyethylene vinyl acetateParaffin wax

The invention discloses a hot melt adhesive used for automotive interiors, and a preparation method of the hot melt adhesive. The hot melt adhesive used for automotive interiors is characterized by comprising a proportion of paraffin, polyethylene wax, a thermoplastic elastic body SBS, random polyolefin, polyethylene vinyl acetate, C5 petroleum resin, rosin pentaerythritol ester, antioxygen, coupling agent and filler. The preparation method comprising the following steps: heating a stirring kettle to 140 to 160 DEG C, and adding the paraffin and the polyethylene wax; adding the thermoplastic elastic body SBS, vacuum-pumping and keeping warm, adding HMW(high molecular weight) random polyolefin I, HMW random polyolefin II and the antioxygen; adding the coupling agent and the filler; cooling, and adding polyethylene vinyl acetate I and polyethylene vinyl acetate II; cooling and adding the C5 petroleum resin; adding the rosin pentaerythritol ester and keeping warm; and emptying the stirring kettle, pressurizing, discharging and forming. No pollution or poison is produced during the production process of the hot melt adhesive; and the hot melt adhesive has the advantages of high adhesion strength, long opening time, good temperature resistance, strong ageing resistance, good tenacity, strong waterproofness and the like.

Owner:浙江固特新材料科技股份有限公司

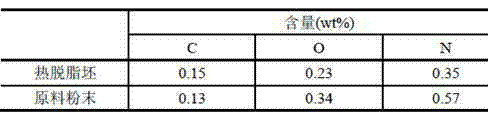

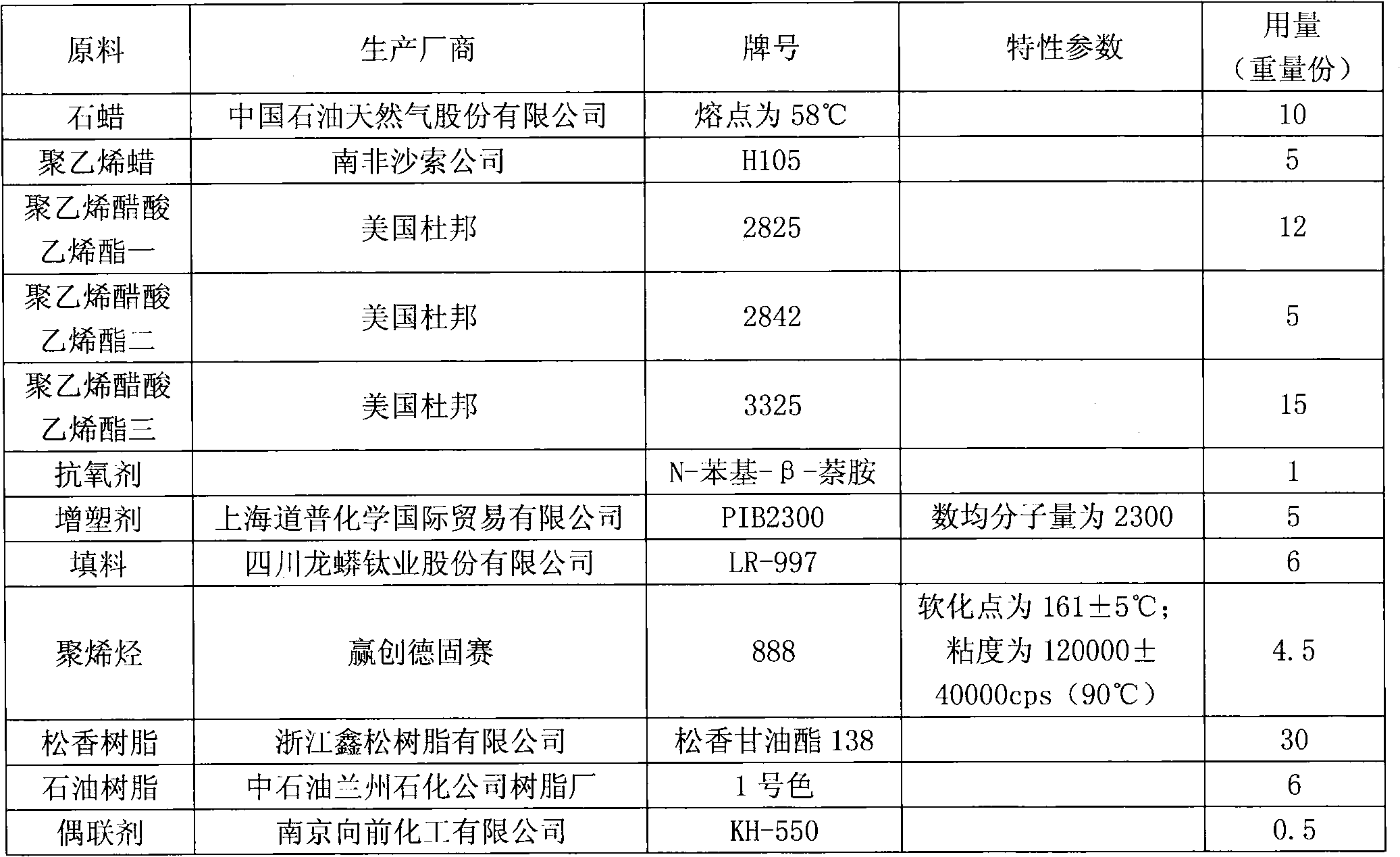

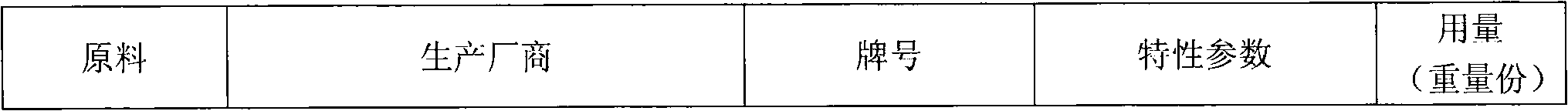

Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

ActiveCN103642253AGood compatibility of ingredientsEfficient mixingPolyethylene vinyl acetateParaffin wax

Owner:HUNAN UNIV

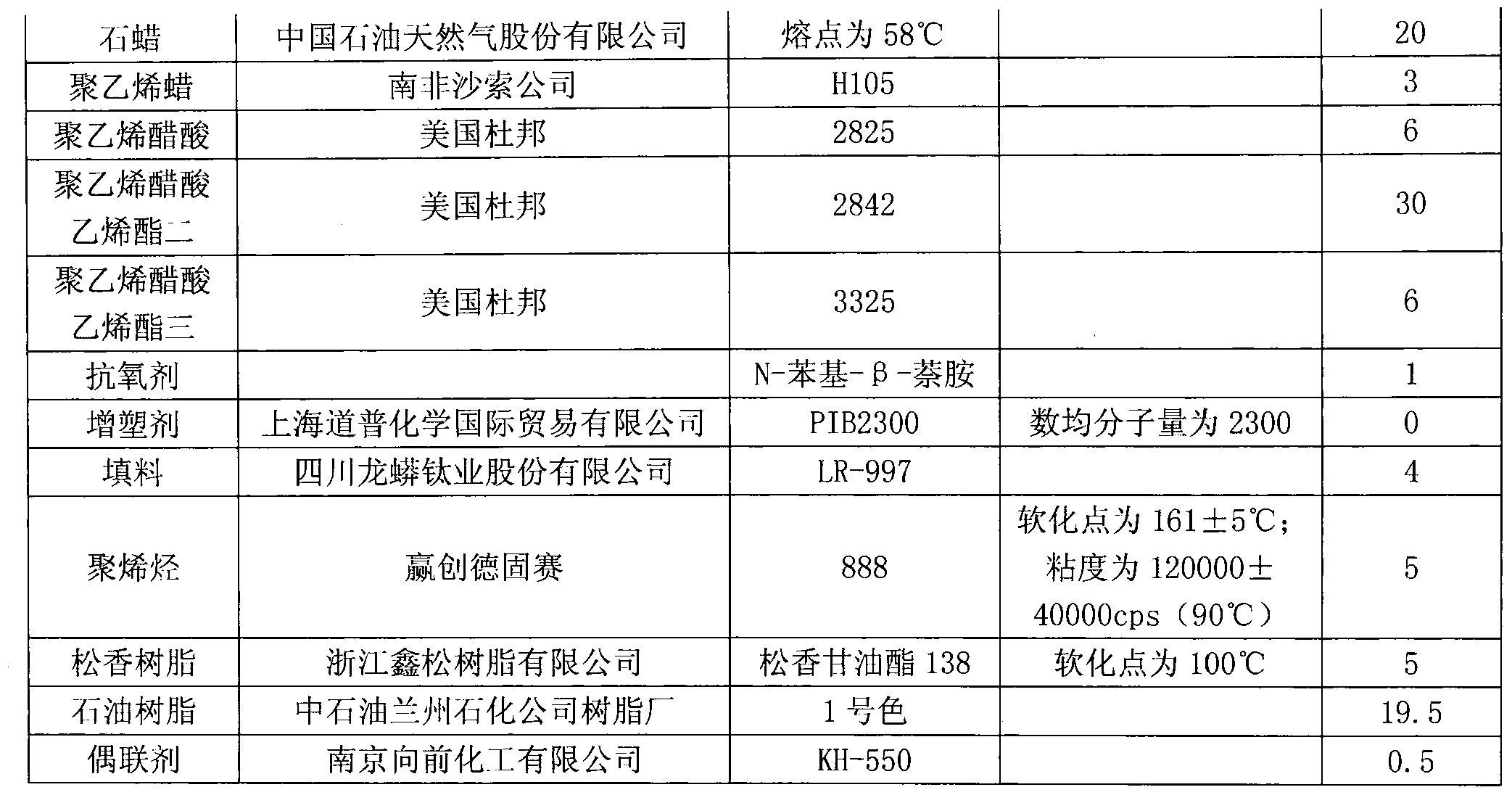

Back glue for books and magazines and production method thereof

InactiveCN102838949ASolve the difficulty of sticking, opp filmSolve the problem that the pet film cannot stickMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesParaffin waxPolyethylene vinyl acetate

The invention discloses back glue for books and magazines and a production method thereof. The back glue is characterized by comprising the following materials in parts by weight: 10-20 parts of paraffin wax, 0-10 parts of polyethylene wax, 5-30 parts of polyethylene vinyl acetate I, 5-30 parts of polyethylene vinyl acetate II, 5-30 parts of polyethylene vinyl acetate III, 0.1-1.5 parts of antioxidant, 0-5 parts of plasticizing agent, 1-10 parts of filler, 1-10 parts of polyolefin, 5-30 parts of rosin resin, 5-30 parts of petroleum resin and 0.1-1 part of coupling agent. The back glue is a hot-melt glue adopting EVA as a main material, is solvent-less and nontoxic, belongs to an environmentally-friendly product, solves the problems of difficult sticking to ink and incapability of opp membranes and pet membranes for long term by adding the polyolefin and special composite coupling agent, and can be used as back glue for unsewn binding of books, or materials such as high-grade paper, high-gram coated paper and dual laminating membranes.

Owner:浙江固特新材料科技股份有限公司

Acid, alkali, and salt corrosion resistant soft polychloroethylene cable sheath material and corrosion-resistant cable

InactiveCN101205341ALess intrusiveAvoid hydrolysisPlastic/resin/waxes insulatorsInsulated cablesPolyethylene vinyl acetatePolyvinyl chloride

The invention relates to a flexible polyvinyl chloride granula for cable with resistance to highly corrosive mediums comprised of acids, alkaline, saline, etc. The components of the invention: 100 shares of polyvinyl chloride resin, 10-30 shares of Polyethylene vinyl acetate or Di-octyl terephthalate and / or Dinonyl phthalate, 6-20 shares of dioctyl sebacate, 5-20 shares of dioctyl phthalate, 8-20 shares of chlorcosane with 52 percent chloride content, 0.3-1.5 shares of paraffin, 4-10 shares of stabilizing agent. Owing to the adapting of the insoluble or slightly dissolving in water, acid or alkali alkaline hydrolysis mixing plasticiser, the hydrolysis and extraction of the plasticiser are effectively prevented; the moisture content is decreased without adding hygroscopicity plugging compound; adding paraffin, the paraffin is dissolved out after the cooling, and then the waterproof membrane is formed at the surface of the plastic and the immergence of the moisture is prevented. The suction of the outside aqueous solution is decreased or avioded, the hydrolysis and extraction with plasticiser are decreased and avioded, and the acid resistance, the alkali resistance and the salt resistance are acheived, the service life in the saline and alkaline areas and coastal areas is prolonged. The invention can be led underground in saline and alkaline areas (inland) and coastal areas (tideland) and the safe service life can be prolonged one time to six times.

Owner:WUXI HUANCABLE +1

Powder metallurgy preparation method of compressor valve plate

ActiveCN103252494AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

The invention discloses a powder metallurgy preparation method of a compressor valve plate. The compressor valve plate comprises, by weight percent, 0.2-0.6% of graphite, 0.2-0.4% of chromium, 0.4-0.6% of manganese, 0.2-0.4% of nickel, 0.2-0.4% of quartz sand powder, 0.8-1% of aluminum, 1-2% of copper, 1-1.2% of modifier and the balance of iron. By the added modifier, ultrafine powder is provided in mixed raw materials, the ultrafine powder can be filled in gaps amount large particles, and apparent density of the mixed raw materials is increased. The ultrafine powder mainly comprises nano silicon dioxide and calcium stearate. The novel modifier obtained by modifiers such as silane coupling agents further increases physical indexes such as wear resistance of products. Polyethylene vinyl acetate and liquid paraffin which serve as lubricants are added to the modifier to increase hybrid pressing effect of the modifier, pressing strength, at the same pressing pressure, of powder metallurgy components is increased greatly, particle combination forms and pore shapes of raw materials are changed, and cracks are solved fundamentally.

Owner:海宁市钱江兴业投资开发有限公司

Light-splitting spectrum greenhouse film and preparation method thereof

ActiveCN102161249ALarge emission brightnessHigh color purityClimate change adaptationSynthetic resin layered productsLow-density polyethylenePolyethylene vinyl acetate

The invention relates to a light-splitting spectrum greenhouse film which comprises an inner film, a middle film and an outer film, wherein the master batch of the outer film comprises 2.8-3.4 parts of optical stabilizer, 0.8-1.1 part sof antioxidant, 0.8-1.2 parts of polyethylene wax, 0.8-1.2 parts of light-splitting assistant and 48-57 parts of polyethylene-vinyl acetate copolymer; the light-splitting assistant is the mixture of La<3+>, Y<3+> and Gd3<+>; the ratio by weight of the rare earth ions La<3+>, Y<3+> and Gd<3+> is (4-5):(8-9):(5-6); the ingredients comprise EVA (ethylene-vinyl acetate copolymer), LDPE (low-density polyethylene) and LLDPE (linear low density polyethylene); the ratio of parts by weight of the EVA, LDPE and LLDPE of the outer film and the master batch is (23-27):(23-27):(73-77):(11-17); the Eu<3+> ions in the rare earth assistant are partly displaced by non-fluorescent rare ions La<3+>, Y<3+> and Gd<3+> to form a heteronuclear multinuclear coordination compound, so as to strengthen the luminous intensity and overcome acute peaks; the half-width of the emission spectrum is 70nm; the excitation wavelength of the light-splitting spectrum greenhouse film is 290-390nm, the maximum wavelength is 332nm, and the emission spectrum is between 580-660nm; ultraviolet lights in solar radiation can be absorbed and transformed into red orange lights with large emission brightness and good colour purity; and the light conversion rate reaches 98%.

Owner:SHANDONG LONGXING PLASTIC FILM TECH CO LTD

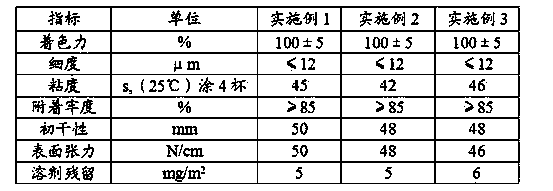

Novel environmentally-friendly high-speed gravure printing compound ink

ActiveCN103992690AImprove product qualityGood printing adaptabilityInksPolyethylene vinyl acetateDefoamer

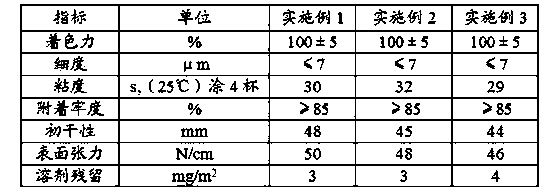

The invention discloses a novel environmentally-friendly high-speed gravure printing compound ink. The ink comprises, by mass, 25-40 parts of a polyurethane resin, 10-15 parts of polyethylene vinyl acetate, 30-45 parts of an ester alcohol solvent, 0.6-1 part of propylene glycol methyl ether acetate, 5-15 parts of a pigment, 0.3-0.6 parts of a dispersant, 0.3-0.6 parts of polyethylene wax powder, 0.8-1.5 parts of an adhesion promoter, 0.8-1.5 parts of an antistatic agent, 5-8 parts of a delustering liquid, 1-3 parts of delustring powder and 0.3-0.6 parts of an antifoaming agent. The ink has fine and uniform fineness, can adapt to a printing speed of 300m / min, and has the advantages of excellent light stability, excellent chemical drug resistance and no yellow stains.

Owner:SUZHOU ZHONGYA INK

Method for manufacturing automobile connecting rod through powder metallurgy

InactiveCN103223487AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateCadmium Cation

The invention discloses a method for manufacturing an automobile connecting rod through powder metallurgy. The method comprises the following step: the automobile connecting rod is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of graphite, 0.6-0.8 percent of zinc oxide powder, 0.4-0.6 percent of cadmium, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 4-6 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

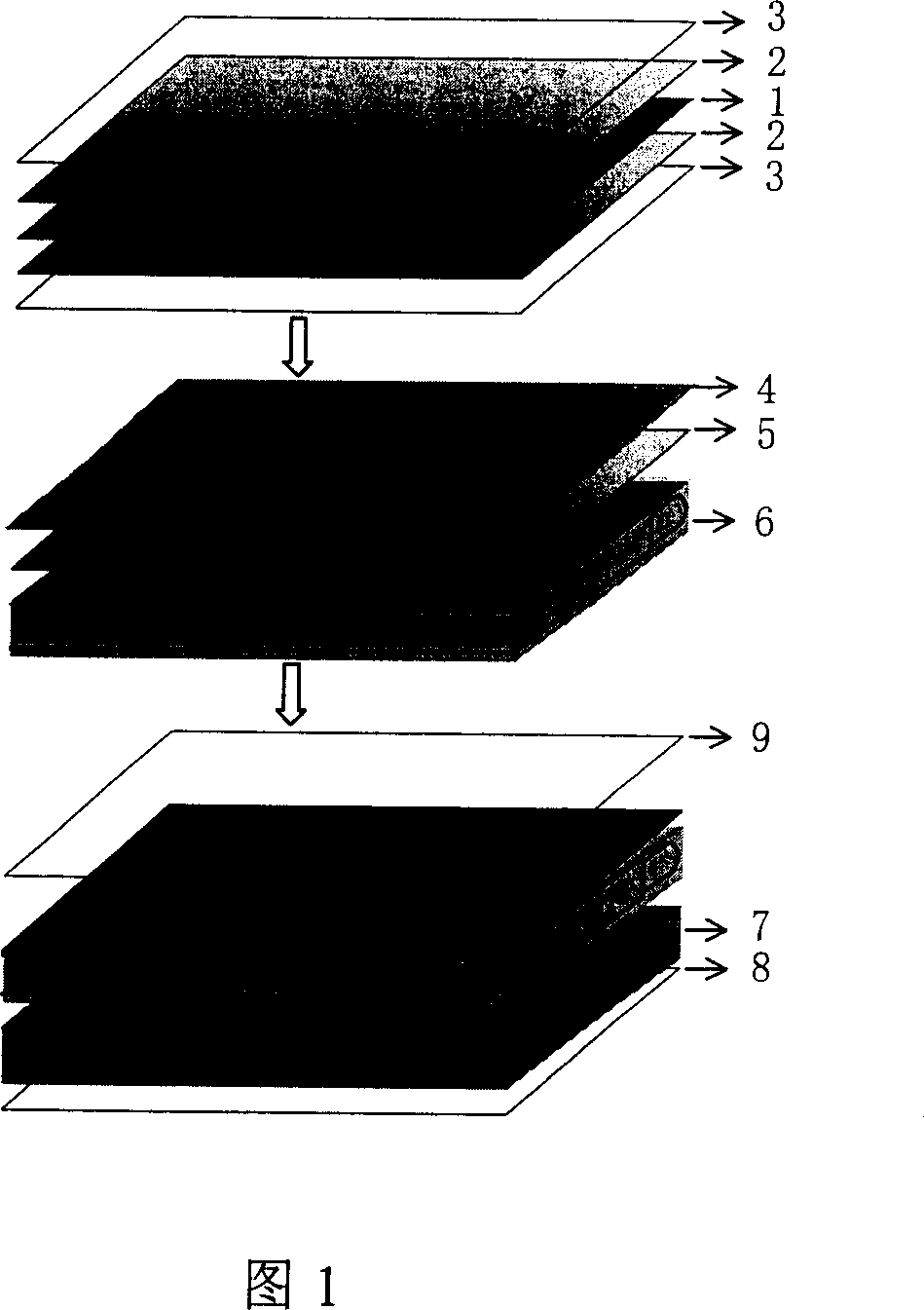

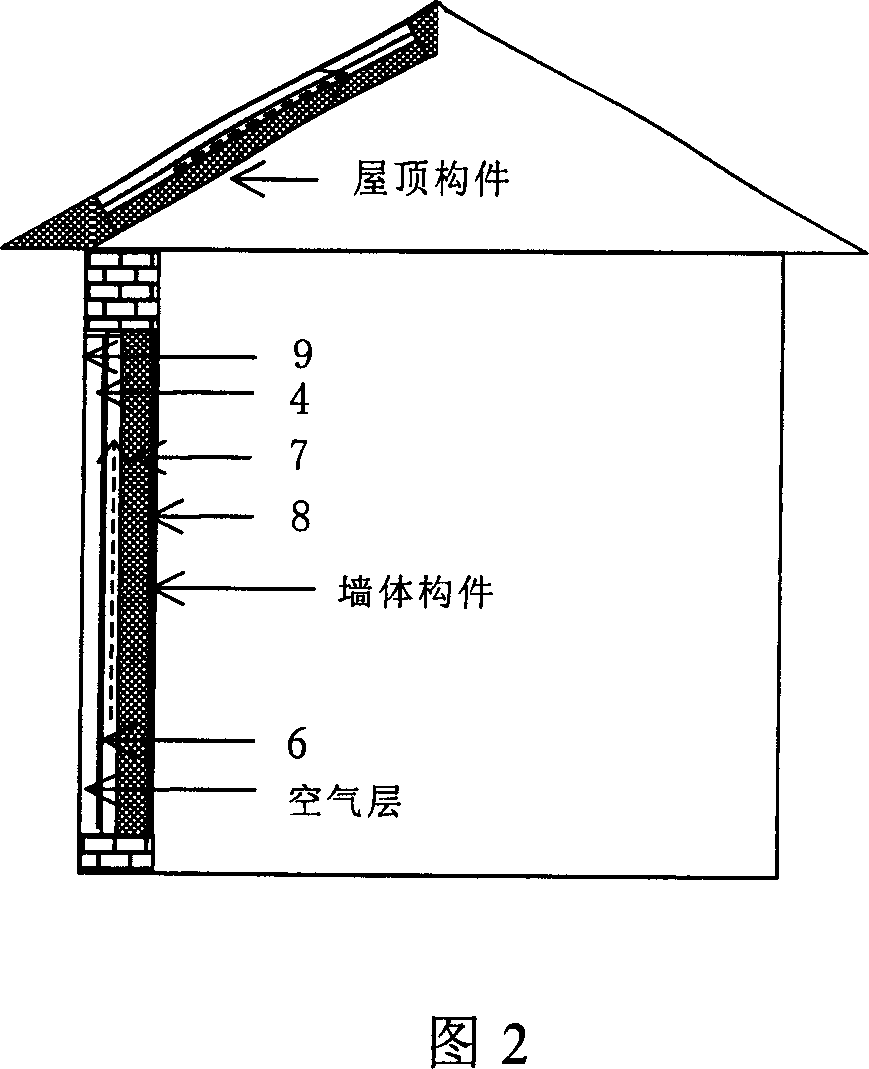

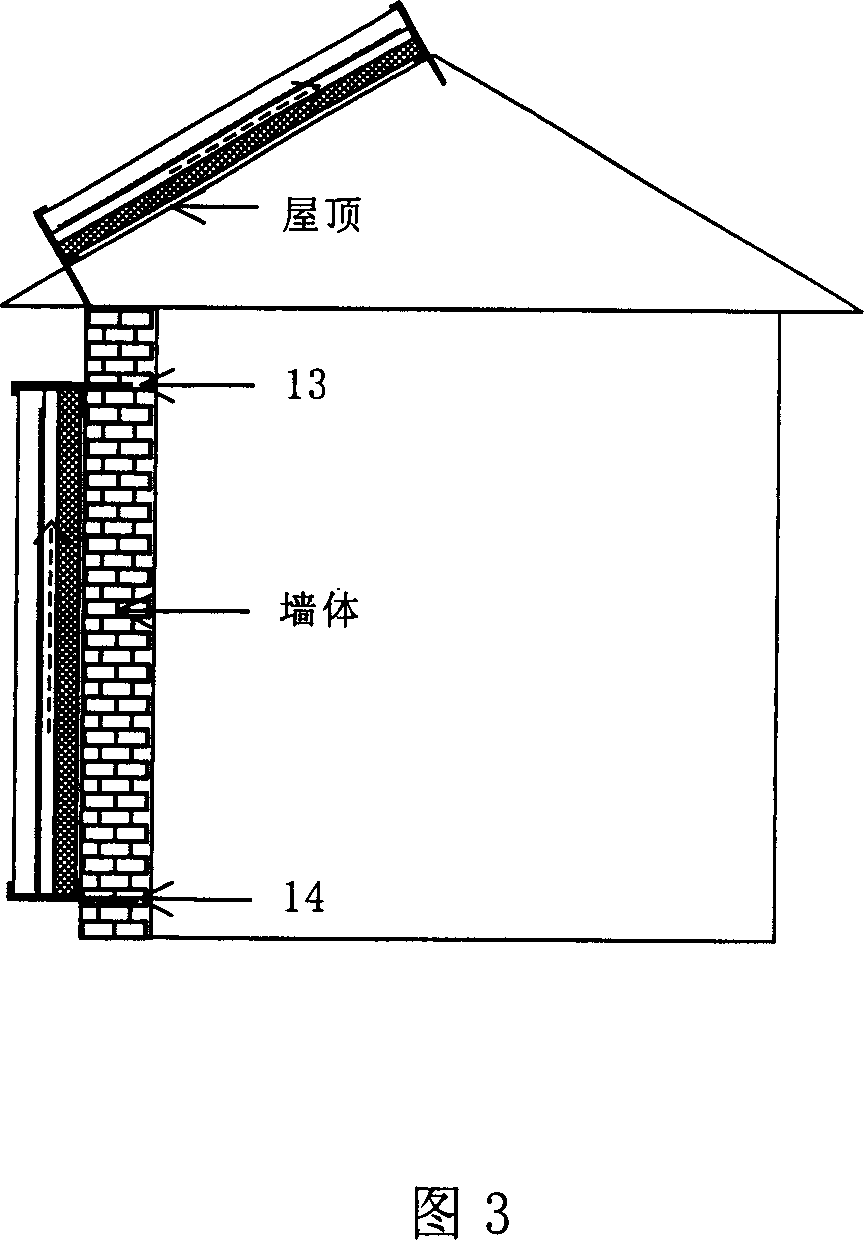

Composite photo voltaic hot water building integrated member and its producing process

InactiveCN1944911AImprove power generation efficiencySave materialRoof covering using slabs/sheetsRoof covering using tiles/slatesPolyethylene vinyl acetateCollector device

The present invention is composite photovoltaic water heating integrated building member and its production process. The composite photovoltaic water heating integrated building member includes photovoltaic assembly, heat collector, heat insulating layer and back plate laminated and fixed aluminum alloy frame. The production process includes the following steps: smearing polyethylene-vinyl acetate to photovoltaic cell, setting the photovoltaic cell between two layers of composite fluoric plastic film and pressing in a vacuum press to form; smearing silica gel to the heat absorbing surface of the heat collector and adhering the photovoltaic cell assembly; covering the other surface of the heat collector with heat insulating layer and back plate, fixing with frame and covering with glass plate. The integral member may be combined with wall or roof to produce electricity and hot water simultaneously in high efficiency.

Owner:UNIV OF SCI & TECH OF CHINA

Thermal insulation material and preparation method thereof

The invention relates to a thermal insulation material and a preparation method thereof. The thermal insulation material is prepared by mixing mica, vinyl alcohol, polyethylene vinyl acetate, polyvinyl alcohol, cement, saponite, butyronitrile, epoxy resin, hydroxypropyl methyl cellulose, sodium dodecyl benzene sulfonate, dibutyl phthalate, polyacrylamide and starch ether by adding water, wherein the mica is powder with particle size range from 1 micron to 0.6 millimetre. The preparation method comprises the following steps of: mixing the ingredients, adding water in the ingredients, uniformly stirring the ingredients, coating the obtained pulp on a surface needing thermal insulation, wherein the coating thickness is at least 1.5mm. The thermal insulation material is good in thermal insulation effect, simple to prepare, convenient to construct and low in construction cost, thereby being especially suitable for performing thermal insulation on old buildings.

Owner:美泰克(天津)矿物有限公司

Washable, waterproof, sealable and reusable storage bags

ActiveUS20150202832A1Strength and durabilityHigh strengthEnvelopes/bags making machineryPackage recyclingPolyethylene vinyl acetateEngineering

Disclosed are embodiments of a versatile storage bag and methods of making same. The versatile storage bag may have first and second sidewalls, a double-locking closure mechanism with a first closure element extending along the first sidewall and a second closure element extending along the second sidewall, each closure element having a channel and an elongated member configured for interlocking with one another. A double-seal along three sides of the first sidewall and the second sidewall form a gusset between two seals, leaving an opening through the double-locking closure mechanism. Corner seals may be formed at the corners of the first and second sidewalls, further reinforcing the double-locking closure mechanism for an airtight and hence waterproof seal. The versatile storage bag may be made of a food-grade polyethylene vinyl acetate blend, approximately 90% or less ethylene vinyl acetate and approximately 10% or less polyethylene.

Owner:REZIP CO

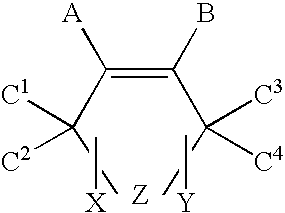

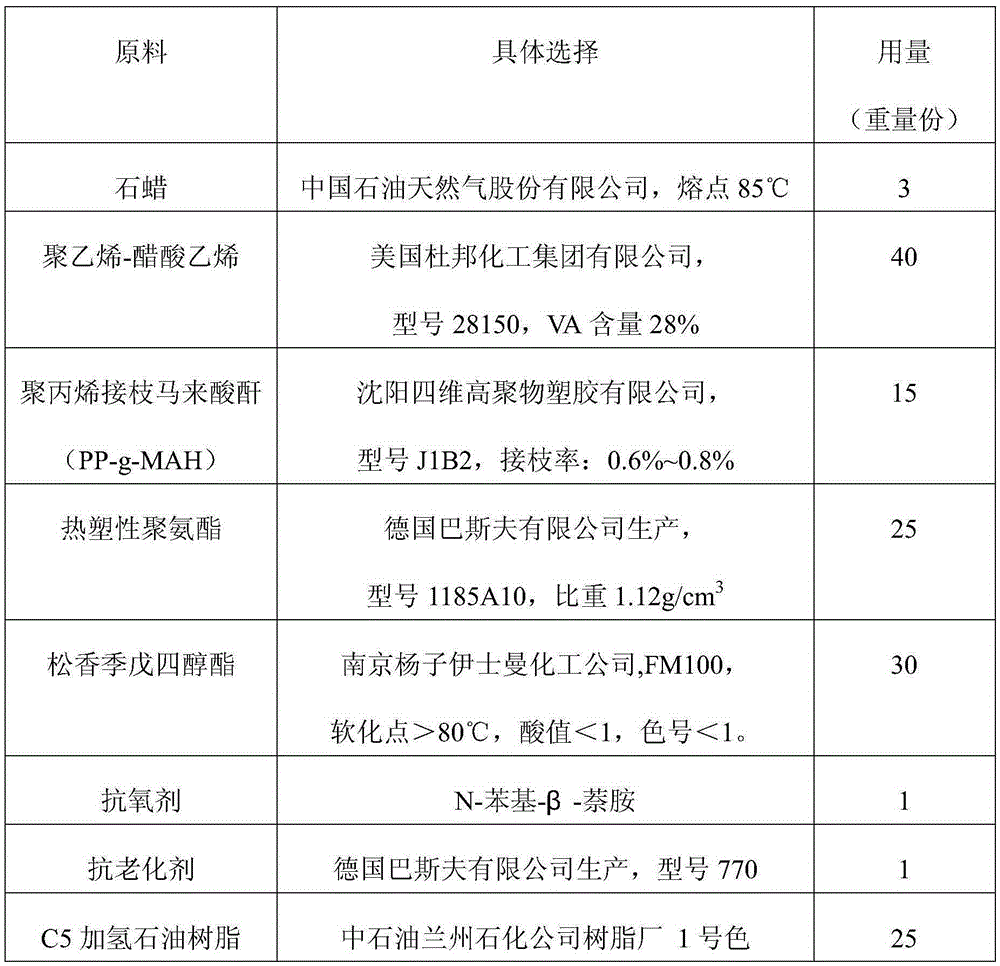

Polyethylene-vinyl acetate hot-melt adhesive and preparation method thereof

ActiveCN105238303AHigh strengthImprove toughnessMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesParaffin waxPolyethylene vinyl acetate

The invention relates to a polyethylene-vinyl acetate hot-melt adhesive and a preparation method thereof. The preparation method comprises the following steps: mixing 1 / 2-2 / 3 of polyethylene-vinyl acetate with 1 / 2-2 / 3 of thermoplastic polyurethanes by weight, heating the mixture, adding 0-3 parts of paraffin and 0.5-1 part of antioxidants into the heated mixture, adding the remaining polyethylene-vinyl acetate and the remaining thermoplastic polyurethanes after the added components are melted completely, and holding a temperature to be greater than or equal to 130 DEG C; and adding 5-15 parts of PP-g-MAH, holding the temperature to be greater than or equal to 120 DEG C, adding pentaerythritol rosin ester and a C5 hydrogenation petroleum resin, reducing the temperature to be 90-110 DEG C, adding an anti-aging agent after the pentaerythritol rosin ester and the C5 hydrogenation petroleum resin are melted completely, holding the temperature and stirring the mixture for 10-30 minutes to obtain the hot-melt adhesive. The polyethylene-vinyl acetate hot-melt adhesive provided by the invention is high in strength and good in toughness, and does not cause secondary pollution to the environment. An automobile-used hot-melt adhesive prepared from the adhesive has high adhesion ability and high chemical stability, and can be used in the field of automobile interior adhesion.

Owner:EAST CHINA UNIV OF SCI & TECH

Benzene and ketone free high temperature resistant table printing ink

The invention discloses a benzene and ketone free high temperature resistant table printing ink. The benzene and ketone free high temperature resistant table printing ink comprises, by mass, 25-40 parts of a polyurethane resin, 10-15 parts of polyethylene vinyl acetate, 30-45 parts of an ester alcohol solvent, 0.6-1 part of propylene glycol methyl ether acetate, 5-15 parts of a pigment, 0.3-0.6 parts of a dispersant, 0.3-0.6 parts of polyethylene wax powder, 0.8-1.5 parts of an adhesion promoter, 0.8-1.5 parts of an antistatic agent, 5-10 parts of a delustering agent, 0.3-0.6 parts of an antifoaming agent, 0.3-0.8 parts of a high temperature resistant assistant, and 1-2 parts of a curing agent. The adoption of a double liquid design increases the hardness and the adhesion of an ink film, effectively prevents offsetting or ink falling, realizes excellent high temperature and boiling resistances, and increases the shelf life of the printing ink.

Owner:SUZHOU ZHONGYA INK

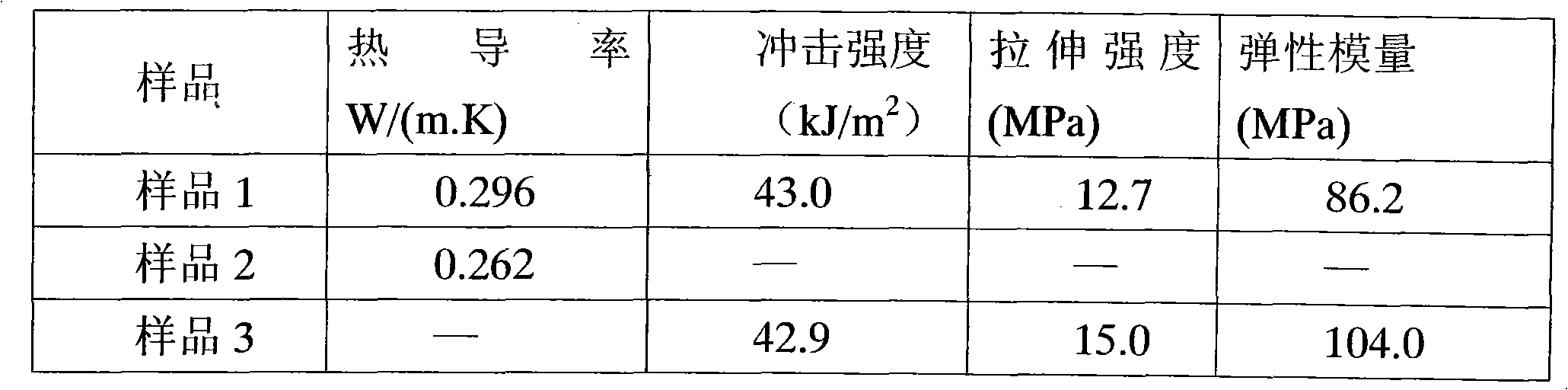

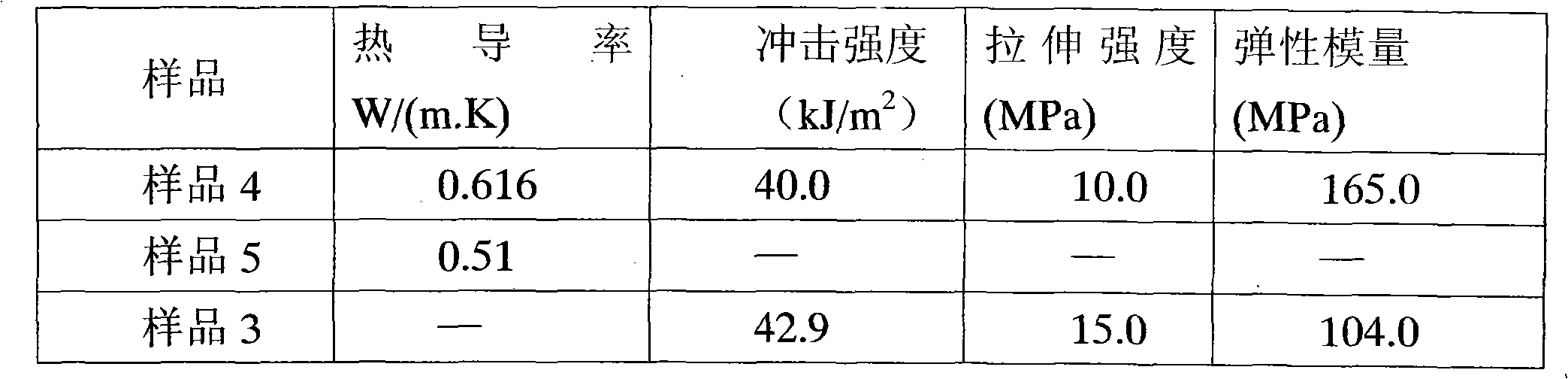

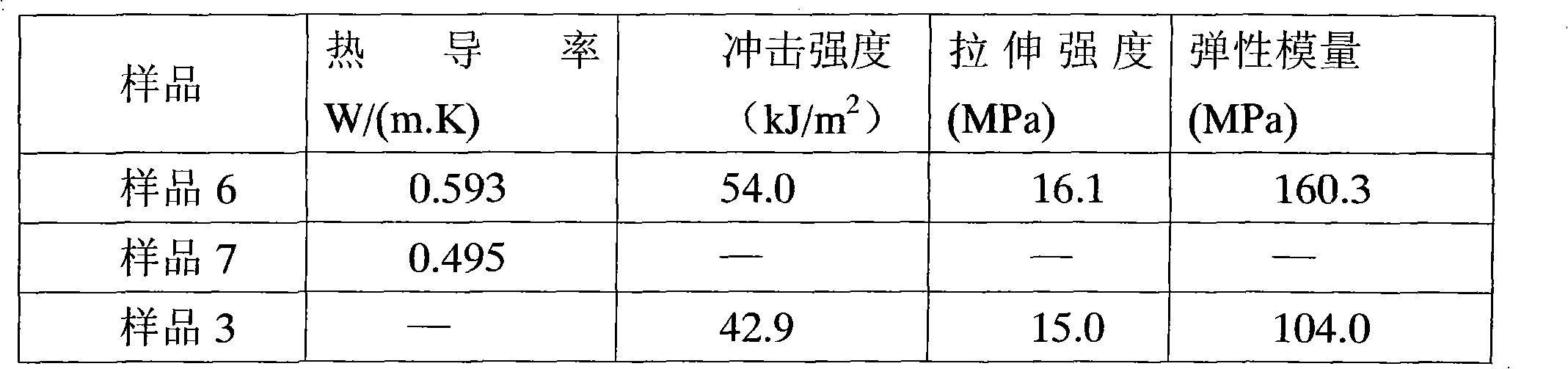

Heat conduction composite material and preparation method thereof

ActiveCN102311567AHigh thermal conductivityImprove mechanical propertiesHeat-exchange elementsPolyethylene vinyl acetateNano al2o3

The invention belongs to the field of macromolecular / inorganic nanometer composite materials, and particularly relates to a heat conduction composite material prepared by taking a blend of two polymers capable of forming two-phase structures as a matrix and adding an inorganic nanometer heat conduction filler, and a preparation method for the heat conduction composite material. The method comprises the following steps of: stirring and mixing 40 to 88 mass percentage of polyethylene and polyethylene-vinyl acetate, 1.5 mass percent of wetting agent and 0.5 mass percent of antioxidant uniformly in a mixer; adding 10 to 58 mass percent of nanometer aluminum oxide into the mixture, and stirring and mixing uniformly in the mixer; and melting and extruding the uniformly-mixed raw materials from a screw extruder, cooling, dragging and cutting into particles to obtain the heat conduction composite material, wherein a mass ratio of the polyethylene to the polyethylene-vinyl acetate is 1:1. The heat conduction composite material has the advantages of low filling, high heat conductivity and high mechanical property.

Owner:INST OF CHEM CHINESE ACAD OF SCI

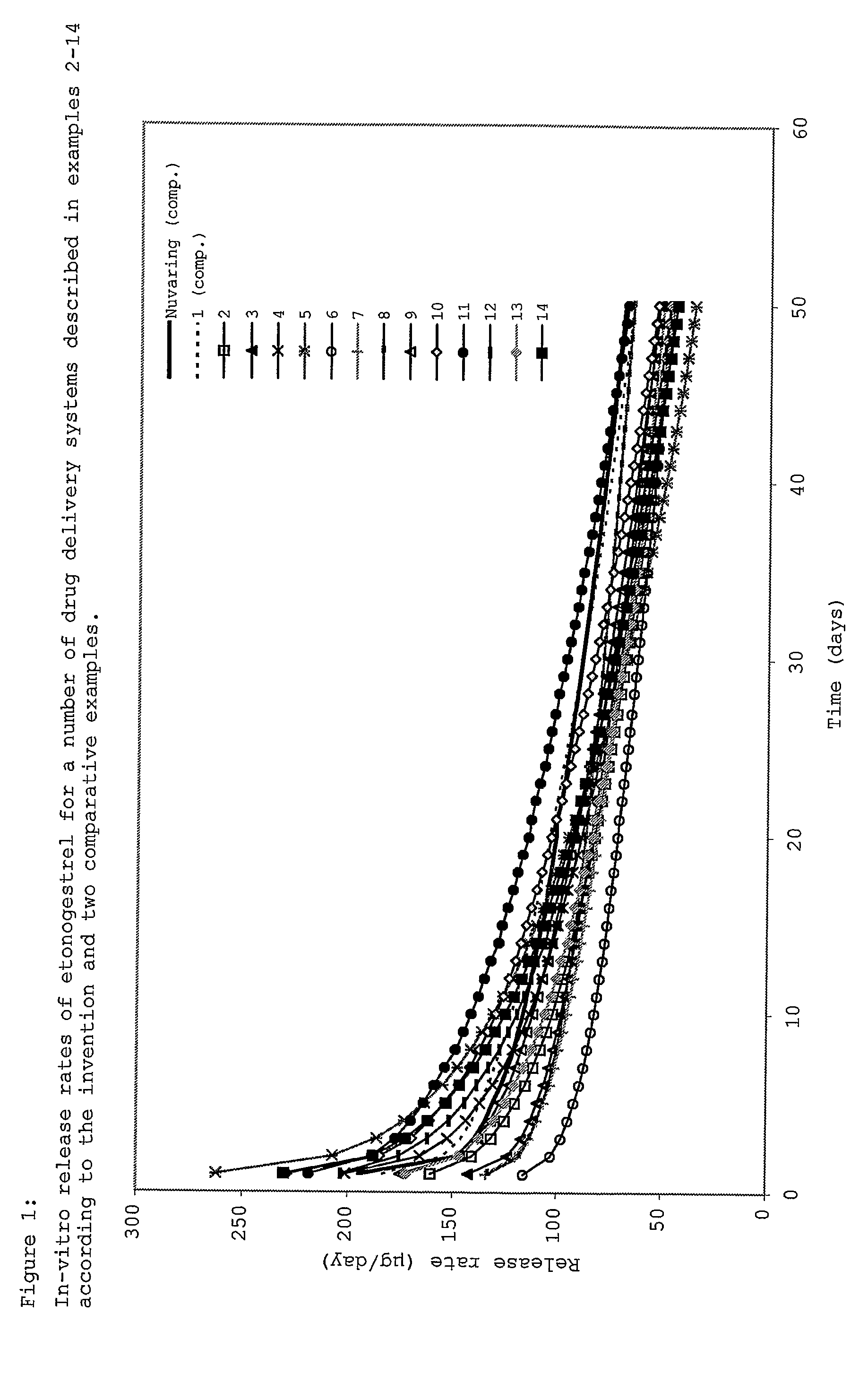

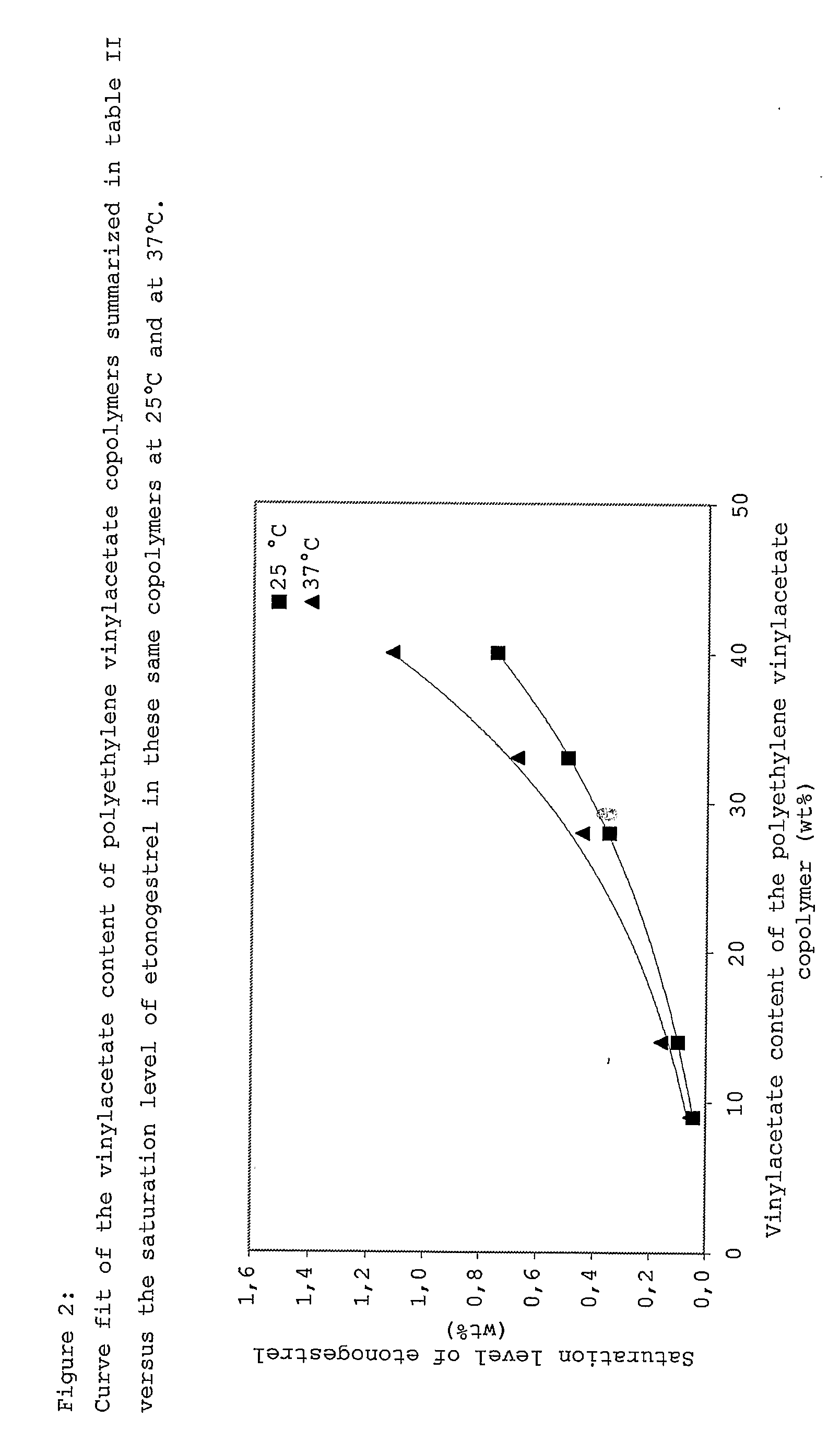

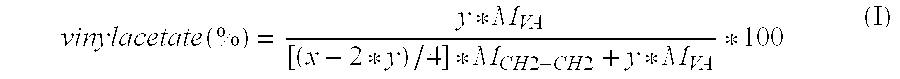

Drug delivery system based on polyethylene vinylacetate copolymers

ActiveUS20070141102A1Easy to prepareOrganic active ingredientsPowder deliveryPolyethylene vinyl acetateDisease

Disclosed herein is a drug delivery system consisting of one or more compartments and comprising a progestogenic compound dissolved in a thermoplastic polyethylene vinylacetate copolymer. Also disclosed are a contraceptive kit or hormone-replacement therapy kit comprising the drug delivery system, and a combination preparation that simultaneously provides contraception and treatment of a sexually transmitted disease comprising the drug delivery system.

Owner:MERCK SHARP & DOHME BV

Method for manufacturing eccentric wheel through powder metallurgy

ActiveCN103223489AEnhance the effect of mixing and pressingHigh bulk densityCranksEccentricsPolyethylene vinyl acetateMixed materials

The invention discloses a method for manufacturing an eccentric wheel through powder metallurgy. The method comprises the following step: the eccentric wheel is manufactured by the following raw materials in percentage by weight: 0.2-0.4 percent of nickel, 0.4-0.6 percent of molybdenum, 0.6-0.8 percent of tin, 0.3-0.5 percent of aluminium oxide powder, 0.8-1 percent of graphite powder, 0.4-0.6 percent of petroleum wax, 4-6 percent of copper, 1-2 percent of performance additive and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-zinc oxide powder and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Method for preparing powder metallurgy of engine piston pin

ActiveCN103252491AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateMixed materials

The invention discloses a method for preparing powder metallurgy of an engine piston pin. The method includes: the engine piston pin is made of following raw materials, by weight, 0.4-0.6% of nickel, 0.4-0.6% of magnesium, 0.6-0.8% of graphite powder, 0.4-0.6% of cadmium, 0.3-0.4% of zinc stearate, 1-2% of performance additive, 4-6% of copper, and the balance iron; via adding the performance additive, superfine powder is provided in the mixed raw materials and can fill in seams among large granules, so that density of the mixed materials is improved; main ingredients of the superfine powder include nano-silica and calcium stearate, the novel performance additive is obtained via agent like silane coupling agent, and physical properties like abrasion performance of prepared products is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricating agent are added in the performance additive, so that effect of the performance additive under mixed compression is strengthened, the strength of compaction of power metallurgy structural members is greatly improved under same compression force, combining shape and hole shape of the raw material granules is changed, and problem about generation of crack is solved basically.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

Method for preparing powder metallurgy of valve seat

ActiveCN103252498AEnhance the effect of mixing and pressingHigh bulk densityPolyethylene vinyl acetateAdditive ingredient

The invention discloses a method for preparing powder metallurgy of a valve seat. The method includes: the valve seat is made of following raw materials, by weight, 0.4-0.6% of nickel, 0.2-0.3% of carbon, 0.2-0.4% of manganese sulfide, 0.2-0.3% of vanadium, 0.6-0.8% of graphite powder, 0.1-0.2% of chrome, 0.3-0.4% of silicon, 1-2% of performance additive, 10-20% of copper, and the balance iron; via adding the performance additive, superfine powder is provided in the mixed raw materials and can fill in seams among large granules, so that density of the mixed materials is improved; main ingredients of the superfine powder include nano potassium feldspar powder and calcium stearate, and the novel performance additive is obtained via agent like silane coupling agent, physical properties like abrasion performance of prepared products is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricating agent are added in the performance additive, so that effect of the performance additive under mixed compression is strengthened, the strength of compaction of power metallurgy structural members is greatly improved under same compression force, combining shape and hole shape of the raw material granules is changed, and problem about generation of crack is solved basically.

Owner:浙江同力重型机械制造有限公司

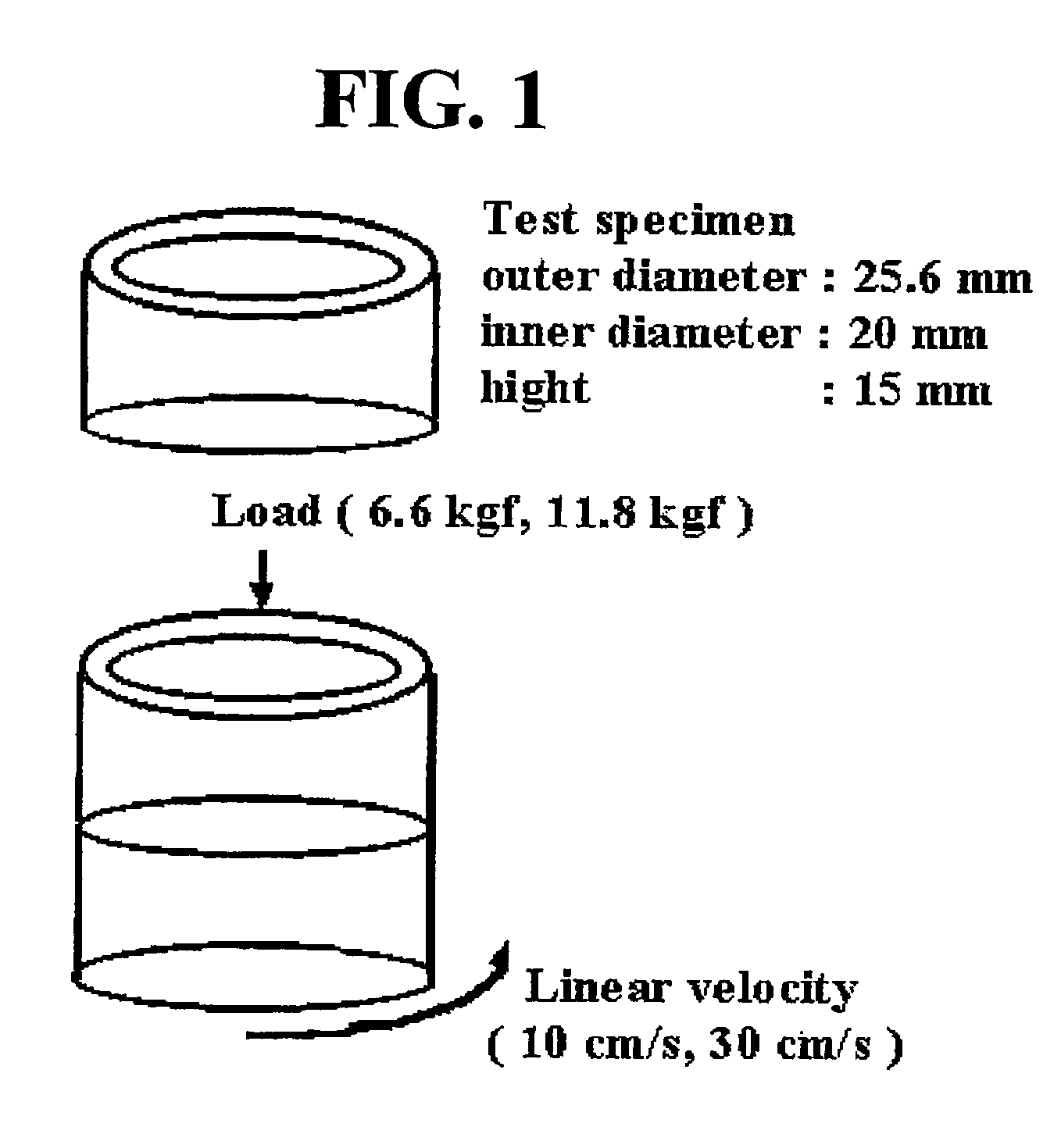

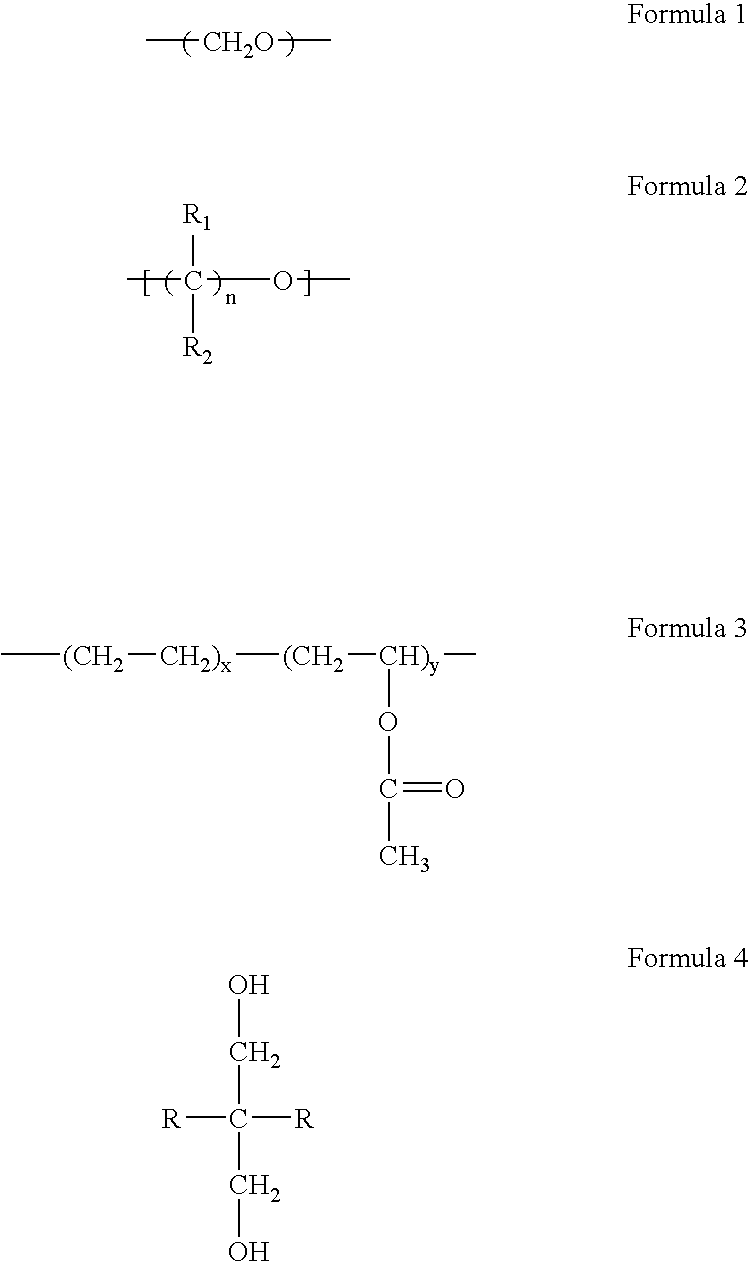

Polyacetal resin composition having excellent wear resistance and abruption-preventing effect

InactiveUS7098262B2Excellent friction and wear resistanceExcellent abruption-preventing effect upon moldingConveyorsOrganic compound preparationPolyethylene vinyl acetateHeat resistance

Disclosed is a polyacetal resin composition including a polyoxymethylene homopolymer or copolymer, an antioxidant, a thermal stabilizer, a polyethylene vinylacetate copolymer and hydroxyl pentacrythritol fatty acid ester. The polyacetal resin composition is excellent in mechanical properties, chemical resistance, heat resistance, dimensional stability, and electrical properties. Further, the composition is advantageous in terms of superior wear resistance and abruption-preventing effect.

Owner:KOREA ENG PLASTICS CO LTD

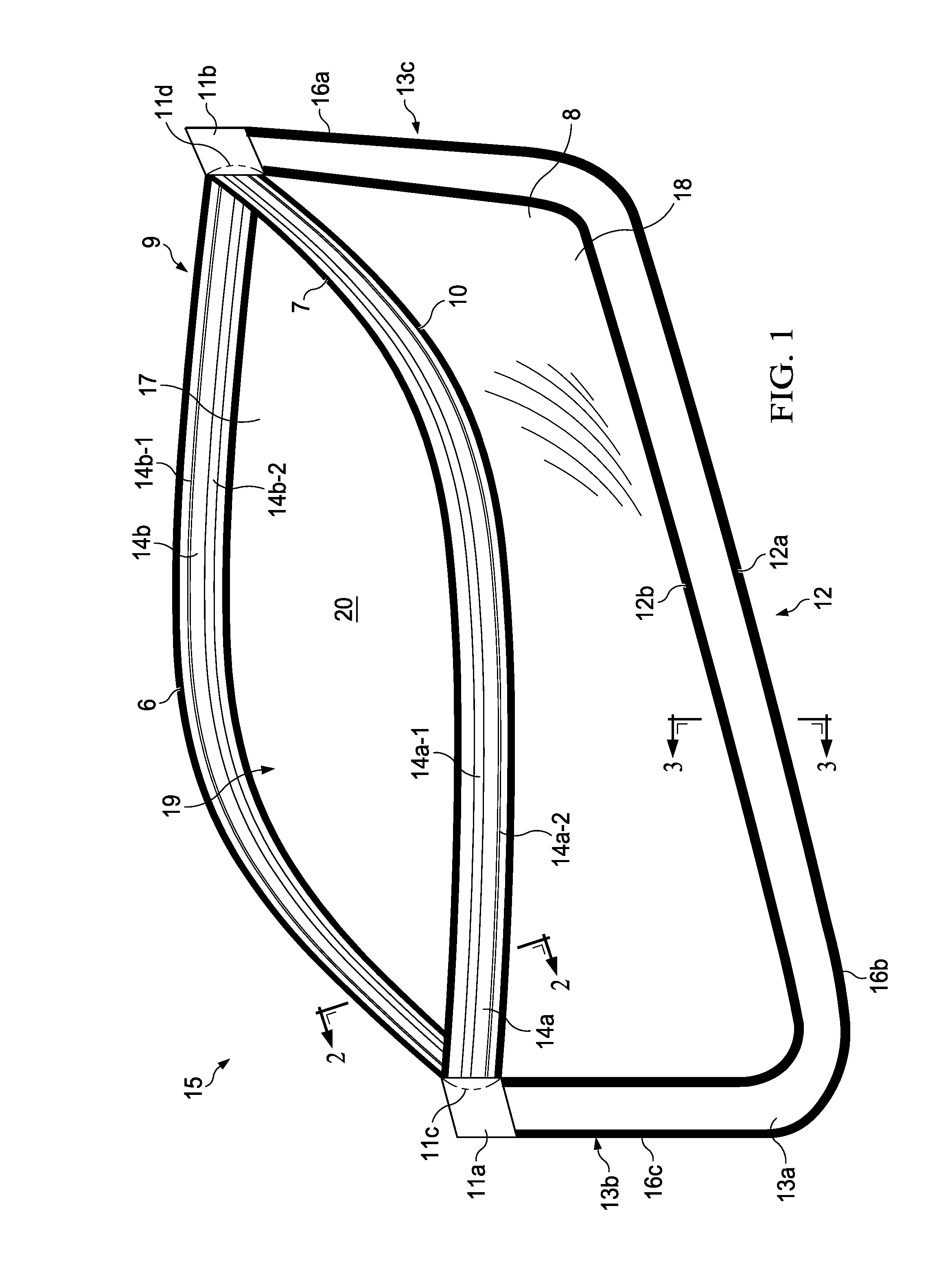

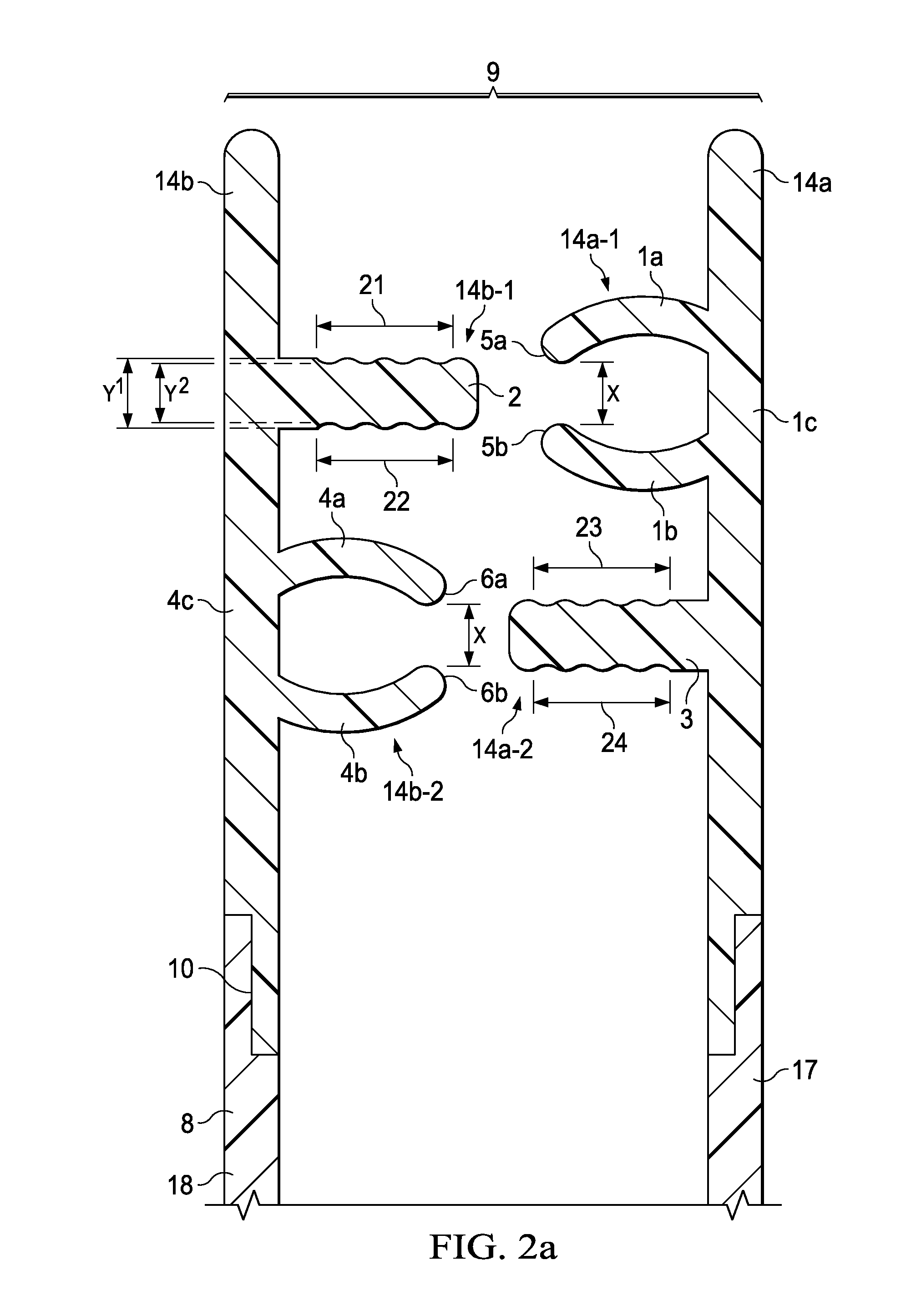

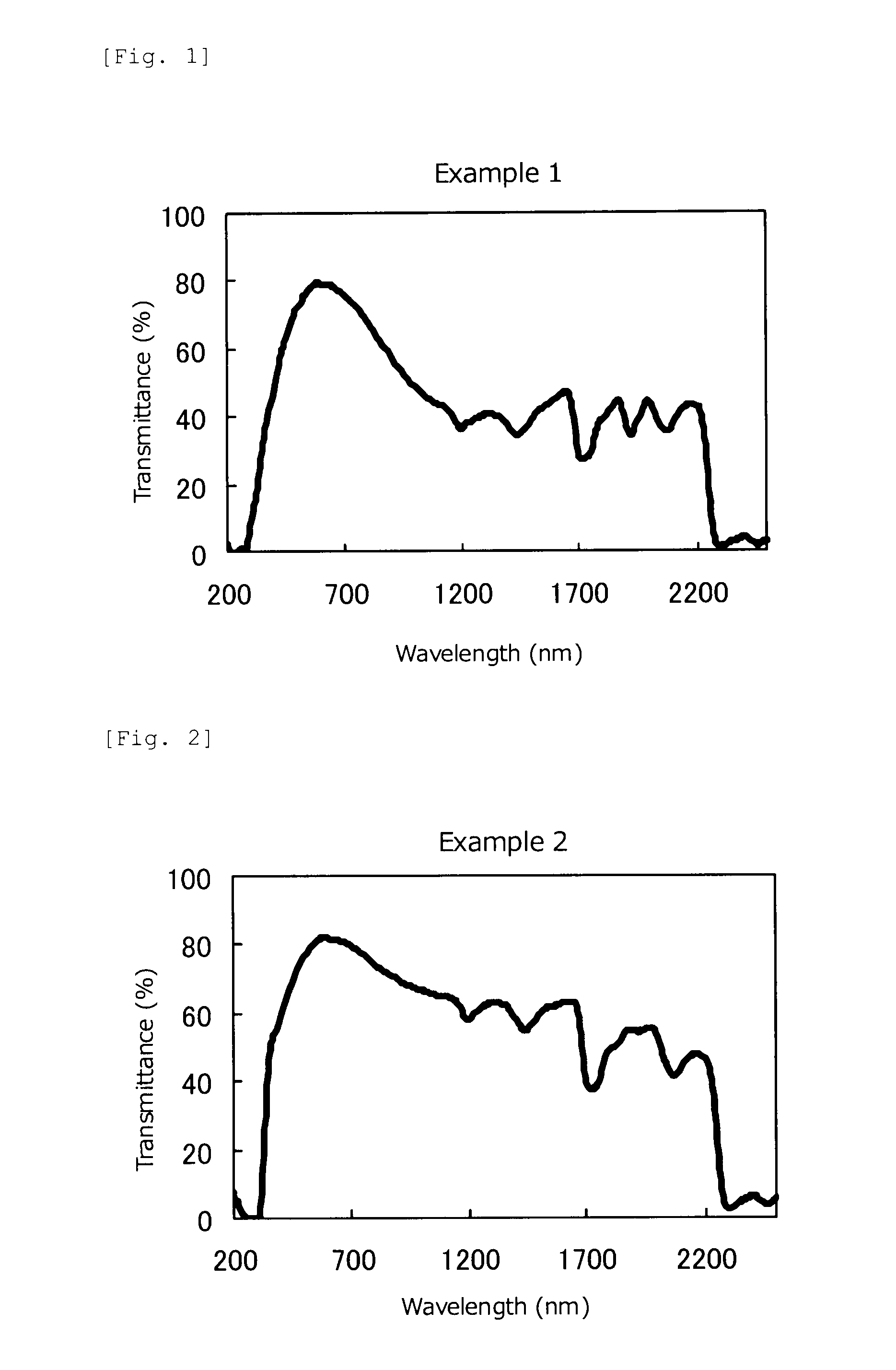

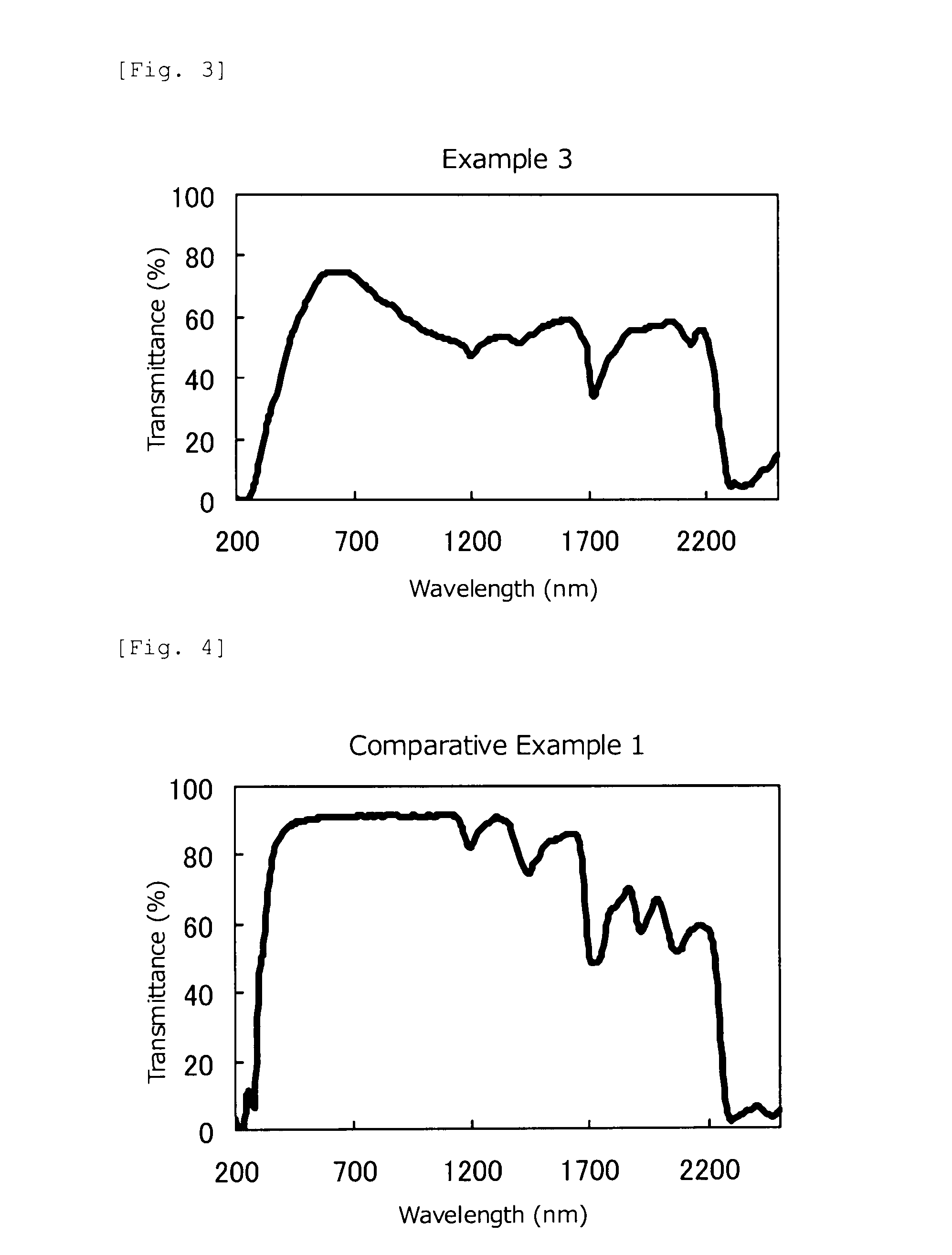

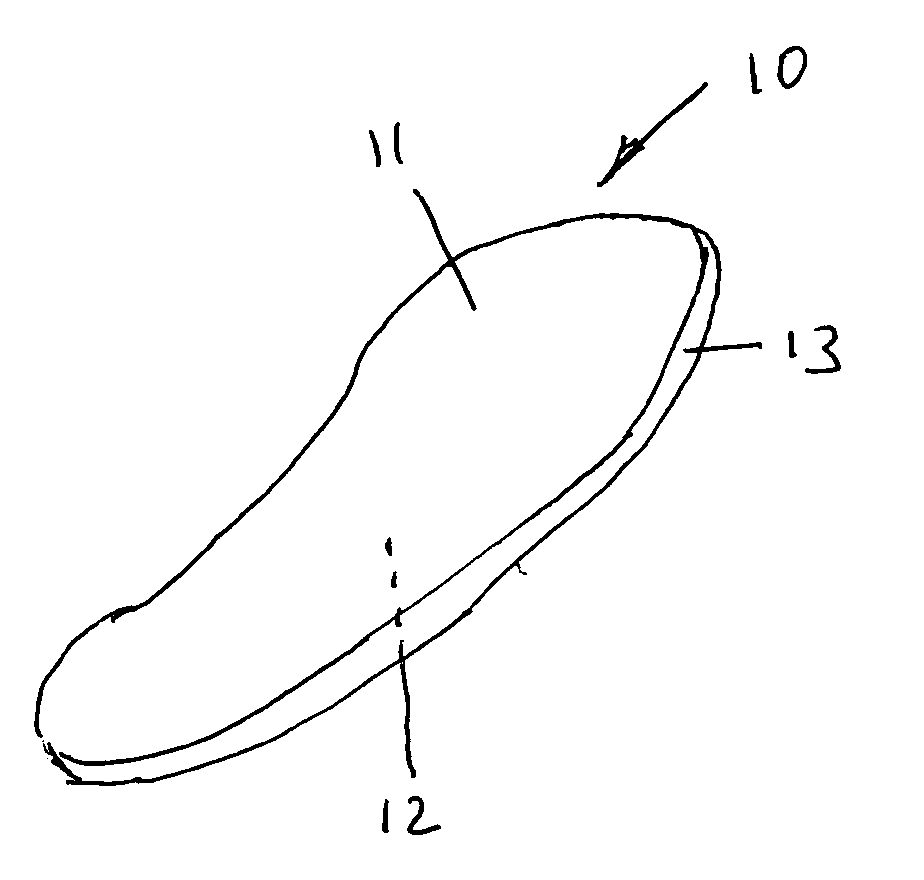

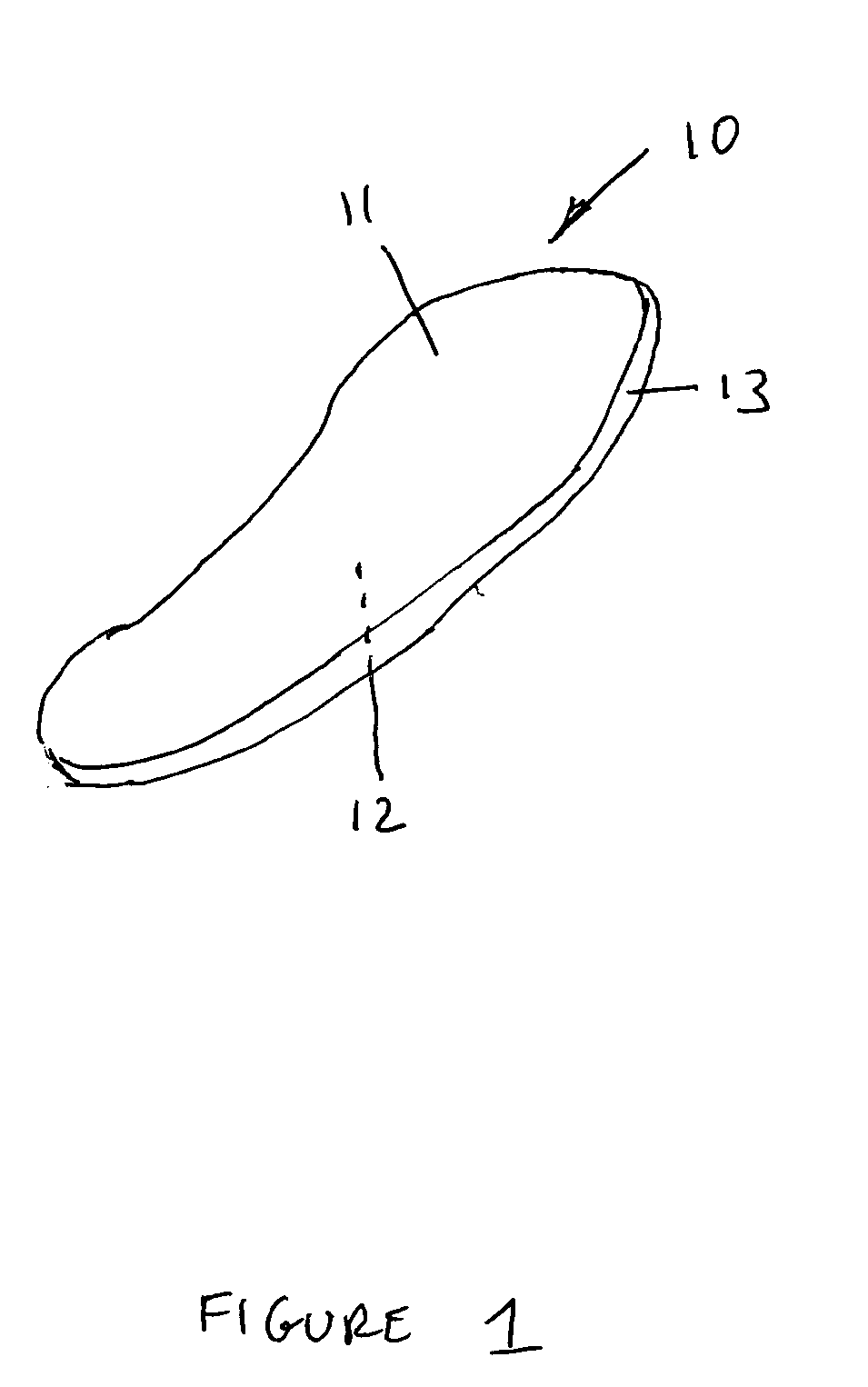

Film and intermediate film for laminated glass composed of the same

InactiveUS20100009172A1Good adhesion to glassIncreased durabilityWindowsWindscreensPolyethylene vinyl acetatePolyvinyl alcohol

A film is provided that is formed of at least one kind of a thermoplastic resin (A), selected from the group consisting of a polyvinyl acetal resin, a polyethylene vinyl acetate copolymer resin, a polyurethane resin, a polyester resin, and a polyacrylic resin, and contains microparticles of a copper compound (B) having an average particle diameter of 200 nm or less. The film is excellent in transparency, a heat-shielding property, electromagnetic wave permeability, and durability, so that it is suitable to be an interlayer film for laminated glass.

Owner:KURARAY CO LTD

Shoe insert pad

InactiveUS20050066545A1Comfortable supportExtended service lifeSolesInsolesPolyethylene vinyl acetateEngineering

A shoe insert pad is disclosed. The shoe insert pad includes a first planar surface and a second planar surface, wherein the first and second planar surfaces are defined by a shoe insert pad, comprising: a first planar surface; a second planar surface; and an edge defining the first planar surface and second planar surface substantially in the shape of a human foot; wherein the shoe insert pad is formed of a polyethylene vinyl acetate material having a density between 8 and 9 pounds per cubic foot.

Owner:PEOPLES WHEAD GORDON

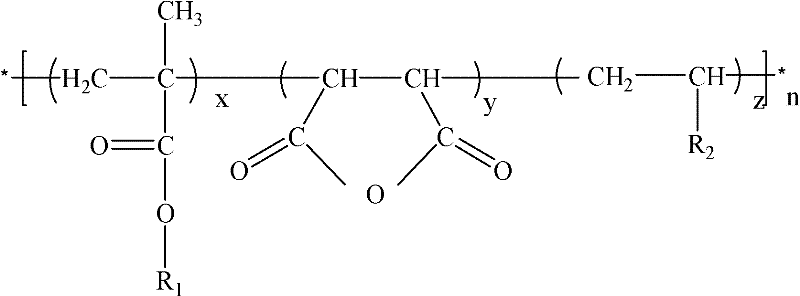

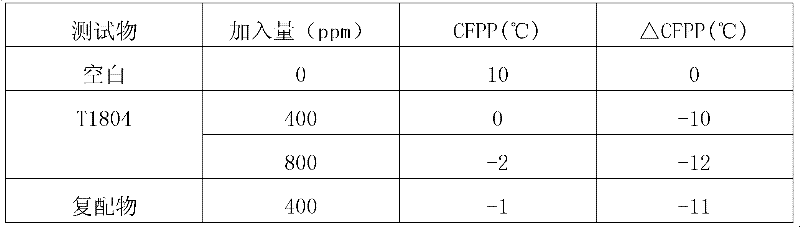

Novel diesel oil pour point depressant

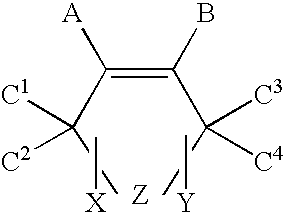

InactiveCN102382695ALower cold filter pointGood synergyLiquid carbonaceous fuelsPolyethylene vinyl acetateMethacrylate

The invention relates to a novel diesel oil pour point depressant. The novel diesel oil pour point depressant is prepared from 50-60% of polyethylene vinyl acetate (T1804), 20-30% of a hexadecyl methacrylate-maleic anhydride-alpha olefin (SMA-MA-alpha) copolymer and 15-20% of toluene, wherein the hexadecyl methacrylate-maleic anhydride-alpha olefin copolymer is a copolymer obtained by treating hexadecyl methacrylate, maleic anhydride and an alpha-olefin as raw materials and toluene as a solvent, and carrying out solution polymerization on the raw materials under the effect of a catalyst benzoyl peroxide. The prepared novel diesel oil pour point depressant of the invention can be applied to diesel oils refined from cycloalkyl crude oil and paraffin crude oil; and the hexadecyl methacrylate-maleic anhydride-alpha olefin and polyethylene vinyl acetate (T1804) which have a good synergistic effect allow the cold filter clogging temperature of diesel oils to be effectively reduced.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Method for manufacturing motorcycle crank shaft through powder metallurgy

InactiveCN103223490AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateParaffin wax

The invention discloses a method for manufacturing a motorcycle crank shaft through powder metallurgy. The method comprises the following step: the motorcycle crank shaft is manufactured by the following raw materials in percentage by weight: 0.4-0.6 percent of nickel, 0.4-0.6 percent of manganese sulfide powder, 0.4-0.6 percent of aluminium, 0.4-0.6 percent of manganese, 0.3-0.4 percent of zinc stearate, 1-2 percent of performance additive, 21-25 percent of copper and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-silicon dioxide and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

Owner:江门速龙机车制造有限公司

Modified polyolefin material for asphalt soft package

InactiveCN1566197AHigh tensile strengthImprove heat sensitivityPackaging corrosive chemicalsPolyethylene vinyl acetatePolyolefin

The invention relates to a modified polyolefin material for asphalt soft package which comprises polypropylene, polyethylene, polyethylene vinyl acetate copolymer, EPT rubber, and octadecanoic acid, the preparing process comprises the steps of, blending, granulating, blowing film, sealing, three-layer co-squeezing, and blowing film shaping.

Owner:PETROCHINA CO LTD +1

Special mortar for dry method construction of self-insulation aerated concrete and preparation method thereof

ActiveCN103739241AImprove thermal insulation performanceLight weightSolid waste managementPolyethylene vinyl acetateSlag

The invention relates to special mortar for dry method construction of self-insulation aerated concrete and a preparation method thereof, and belongs to a construction material technology field, wherein the mortar is characterized in that the mortar is composed of fly ash, phosphorus slag, cement clinker, phosphogypsum, carbide slag, graphite tailing sand, shale pottery sand, alkali lignin, polyethylene-vinyl acetate and hydroxypropyl methyl cellulose, and is prepared by the following steps of: (1) preparing an ecological composite gel material, which is prepared by mixing the following raw materials by weight: 35-45% of fly ash, 25-50% of phosphorus slag, 8-10% of cement clinker, 3-8% of phosphogypsum, and 2-6% of carbide slag; (2) preparing an additive by mixing and stirring the following raw materials by weight: 35-50% of alkali lignin, 15-30% of polyethylene- vinyl acetate, and 20-40% of hydroxypropyl methyl cellulose; and (3) preparing the plastering mortar by stirring according to a mass ratio of the ecological composite gel material, the graphite tailing sand, the shale pottery sand to the additive being 1:0.7:0.3:0.004.

Owner:湖北远固新型建材科技股份有限公司

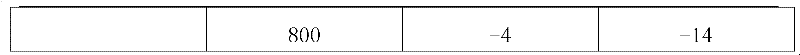

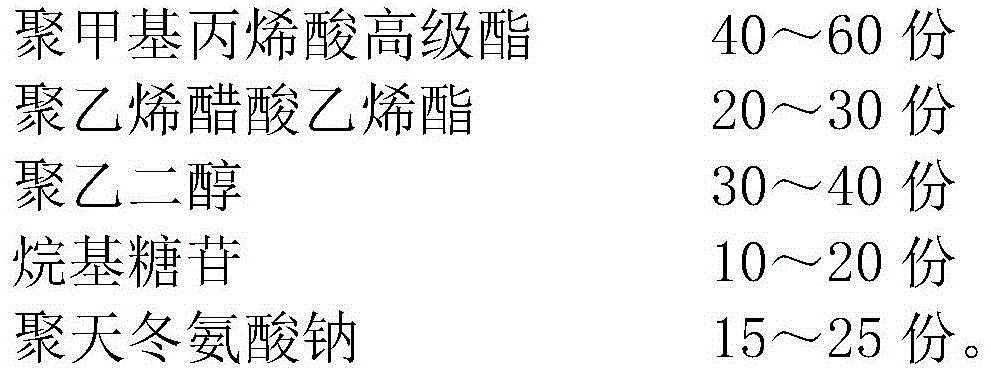

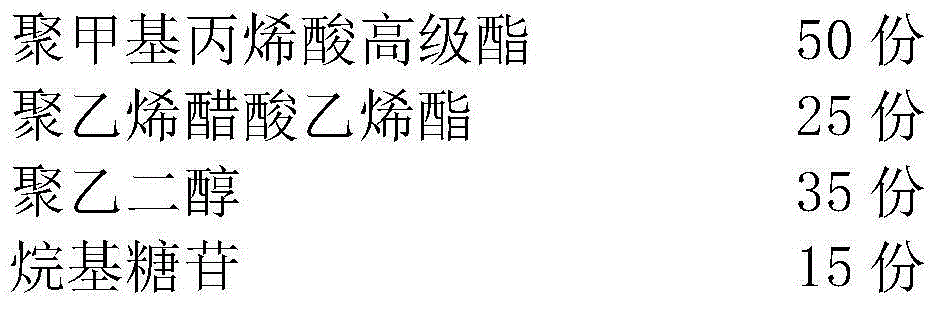

Diesel oil pour point depressant

InactiveCN104910977AGood dispersionLowering the freezing pointLiquid carbonaceous fuelsFuel additivesPolyethylene vinyl acetatePolyethylene glycol

The invention relates to the technical field of pour point depressants and particularly relates to the technical field of a diesel oil pour point depressant. The diesel oil pour point depressant is prepared from the following raw materials in parts by weight: 40-60 parts of high polymethacrylate, 20-30 parts of polyethylene vinyl acetate, 30-40 parts of polyethylene glycol, 10-20 parts of alkyl glycoside and 15-25 parts of sodium polyaspartate. According to the diesel oil pour point depressant disclosed by the invention, the pour point depression effect is remarkably improved, the cold filter plugging point and pour point of all diesel oil can be effectively lowered, particularly the sensitivity to high-wax-content and narrow-fraction diesel oil is relatively good, the flowing property of the high-wax-content and narrow-fraction diesel oil is better improved under low-temperature conditions, the diesel oil pour point depressant is environment-friendly and has an excellent market value, and the problems of the existing diesel oil pour point depressants in China petrochemical industry that the pertinence is high, the performance is single and the broad-spectrum performance is poor are solved.

Owner:马健

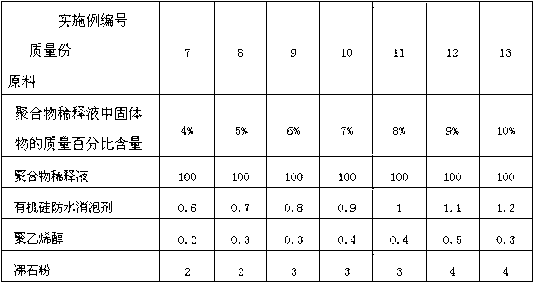

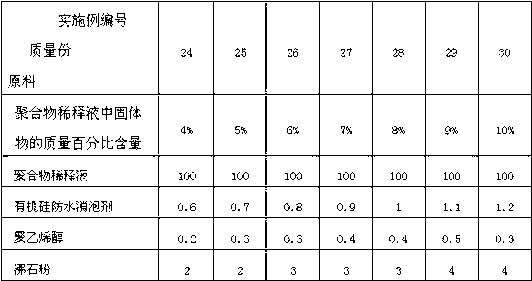

Modified high carbon ferro-chrome slag aggregate for road concrete and preparation method of modified high carbon ferro-chrome slag aggregate

ActiveCN103073210AFix bugsSolve hidden dangersSolid waste managementPolyethylene vinyl acetatePolyvinyl alcohol

The invention discloses a modified high carbon ferro-chrome slag aggregate for road concrete and a preparation method of the modified high carbon ferro-chrome slag aggregate. The modified high carbon ferro-chrome slag aggregate is characterized by being prepared from a high carbon ferro-chrome alloy slag aggregate and a chemical modifying agent accounting for 2-6 percent of the mass of the high carbon ferro-chrome alloy slag aggregate through mixing, wherein the chemical modifying agent is prepared from 100 parts by mass of polymer diluting solution, 0.5-1.2 parts by mass of organic silicon waterproof defoaming agent, 0.2-0.5 part by mass of polyvinyl alcohol and 2-4 parts by mass of zeolite powder through uniform mixing; the polymer diluting solution is prepared by diluting a polymer emulsion stock solution through adding water; and the polymer emulsion stock solution is any one of a butylbenzene emulsion, a polyacrylate emulsion, a polyethylene-vinyl acetate emulsion and a styrene-acrylic emulsion. By adopting the invention, waste alloy waste is used as a raw material, and thus building materials of carbon chromic slag can be recycled and efficiently utilized, and the defects and the hidden dangers of the carbon chromic slag as the concrete aggregate are solved; and the preparation method is simple and easy to realize and is strong in practicability.

Owner:李素娥

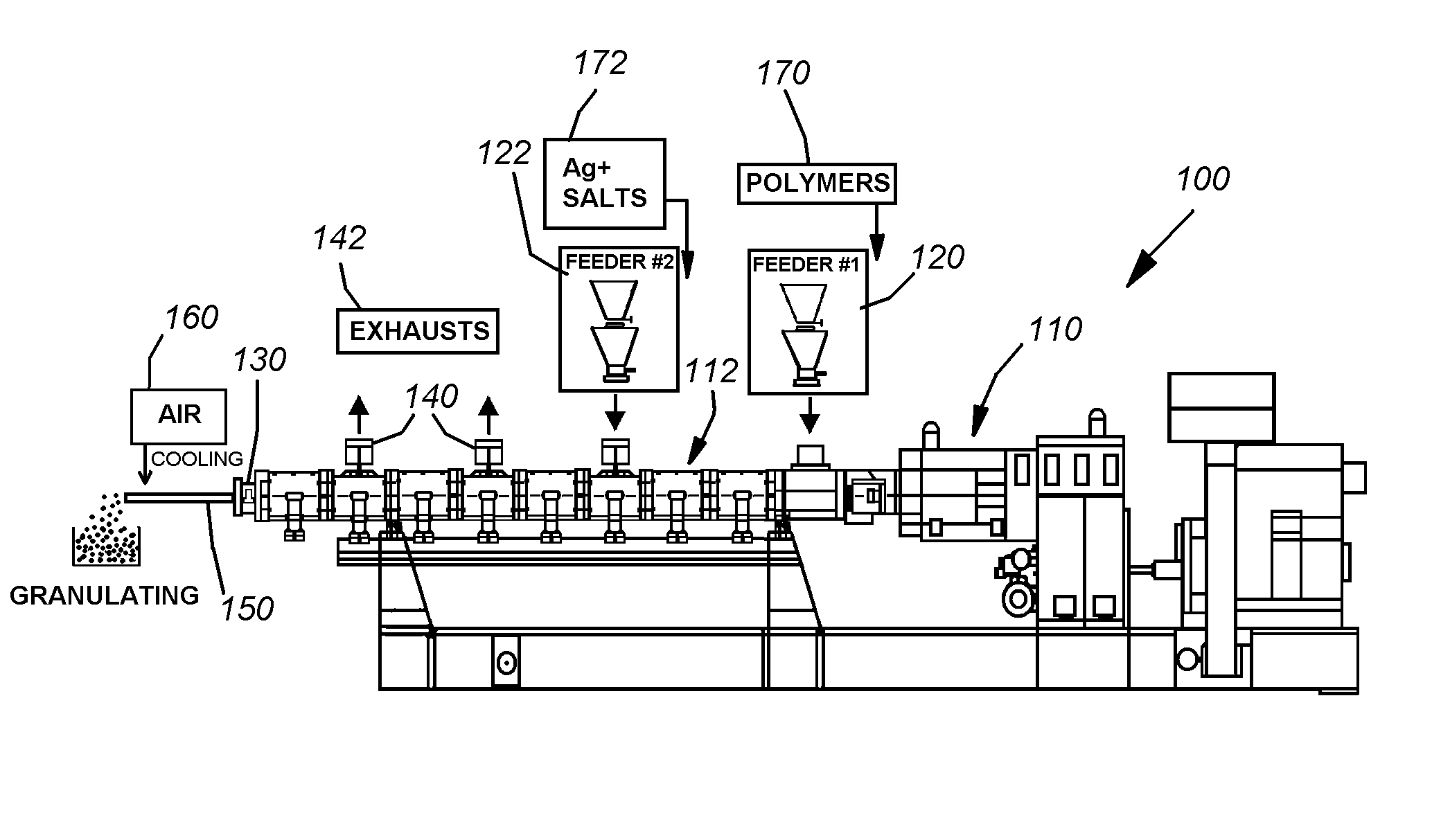

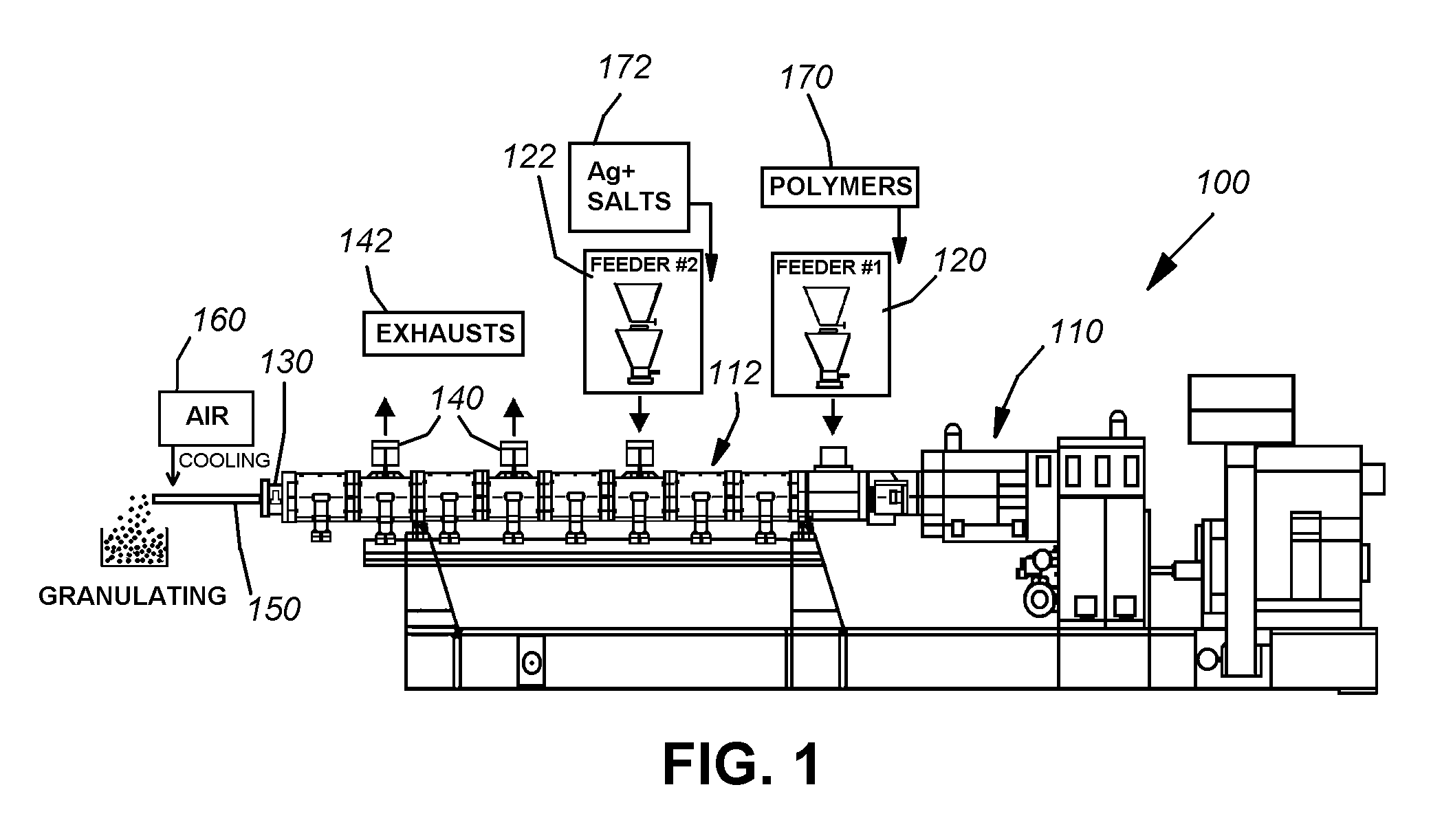

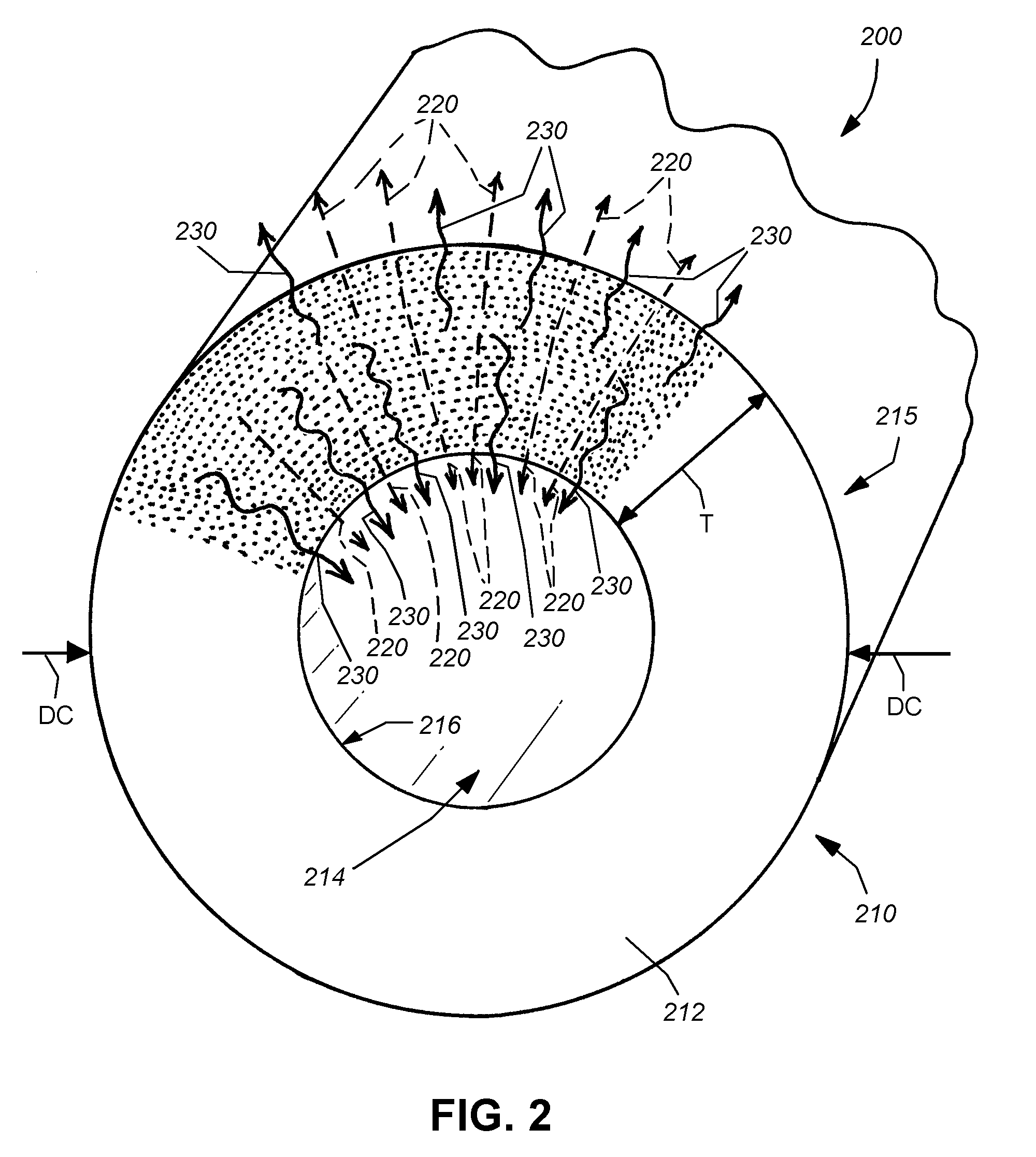

Antimicrobial material and method for making the same

InactiveUS7998498B2Reduce infectionSubstantial unmet needAntibacterial agentsBiocidePolyethylene vinyl acetateBurst effect

This invention provides a modified catheter biomaterial that provides both immediate, and long-term microbiocidal effects on otherwise antibiotic-resistant strains of microorganisms. The material, which exhibits good mechanical performance characteristics for medical devices, is composed of a hydrophobic polyurethane (PU), a hydrophilic polyethylene vinyl acetate (PEVA), a soluble silver salt and a sparsely-soluble silver salt. The hydrophobic polyurethane provides the good physical properties, the PEVA the hydrophilicity necessary to allow some water ingress into the catheter, the soluble silver salt for an immediate burst effect, and the sparsely-soluble silver salt for sustained-release over many months postimplantation.

Owner:SZYCHER MICHAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com