Patents

Literature

94results about How to "Improve heat sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

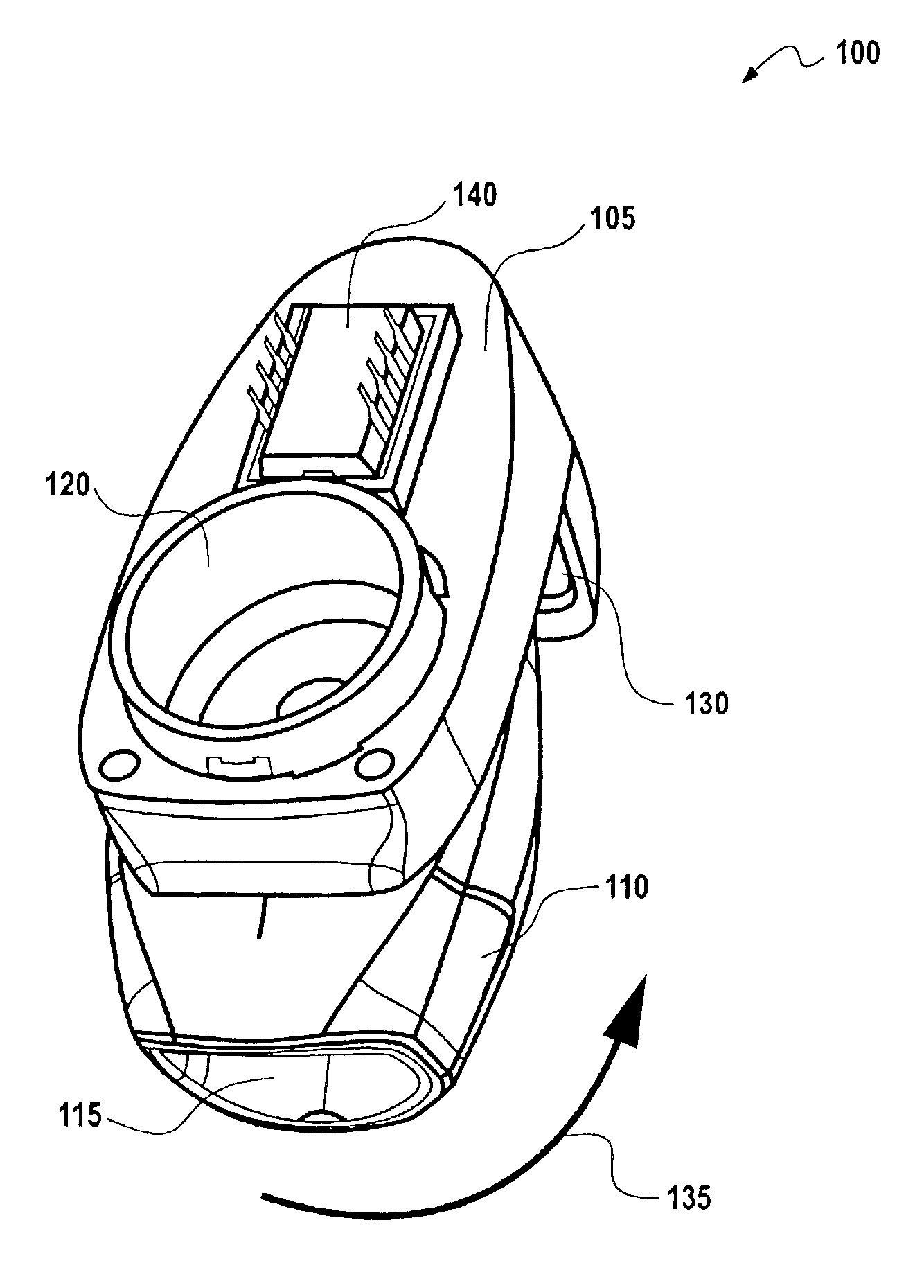

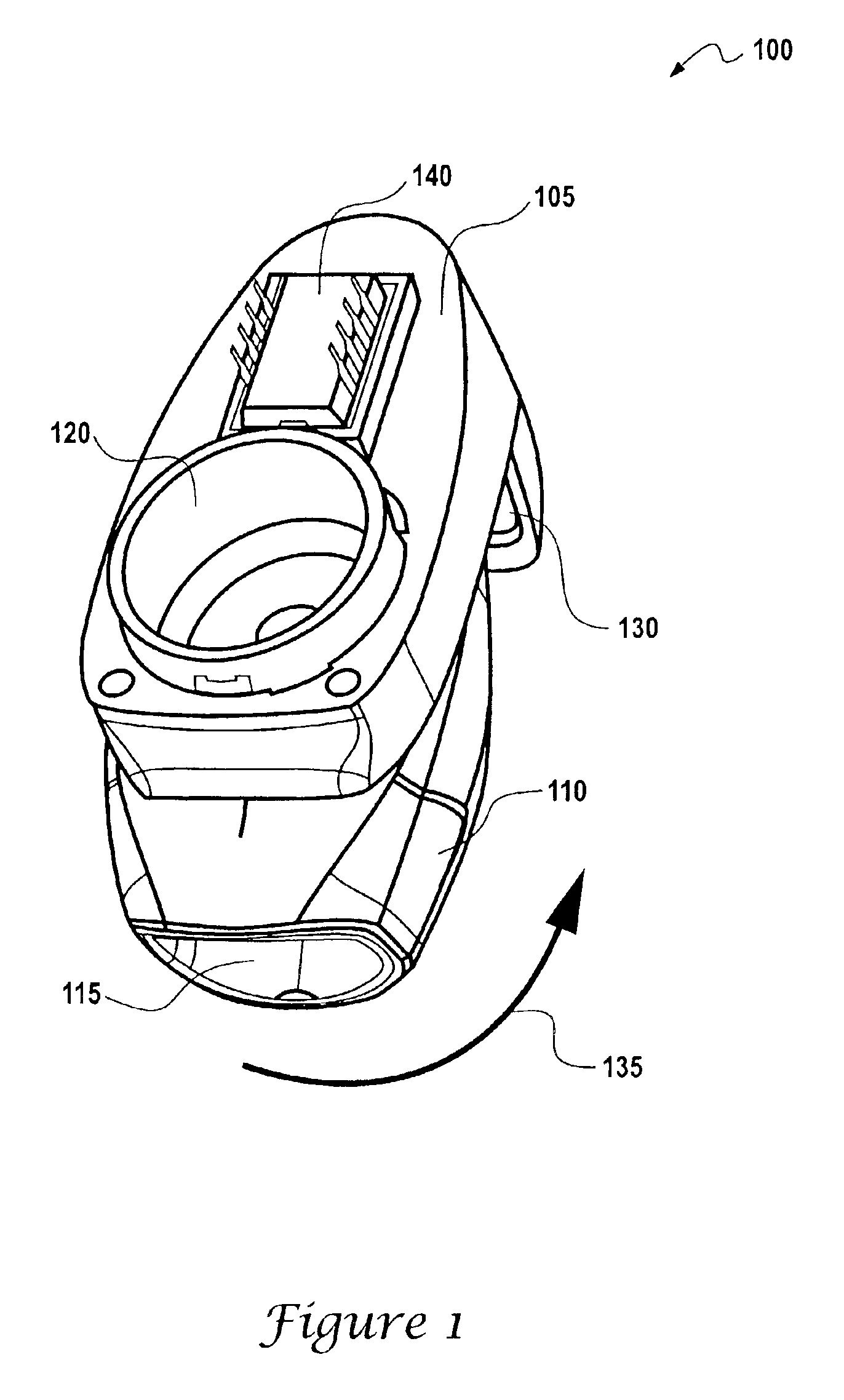

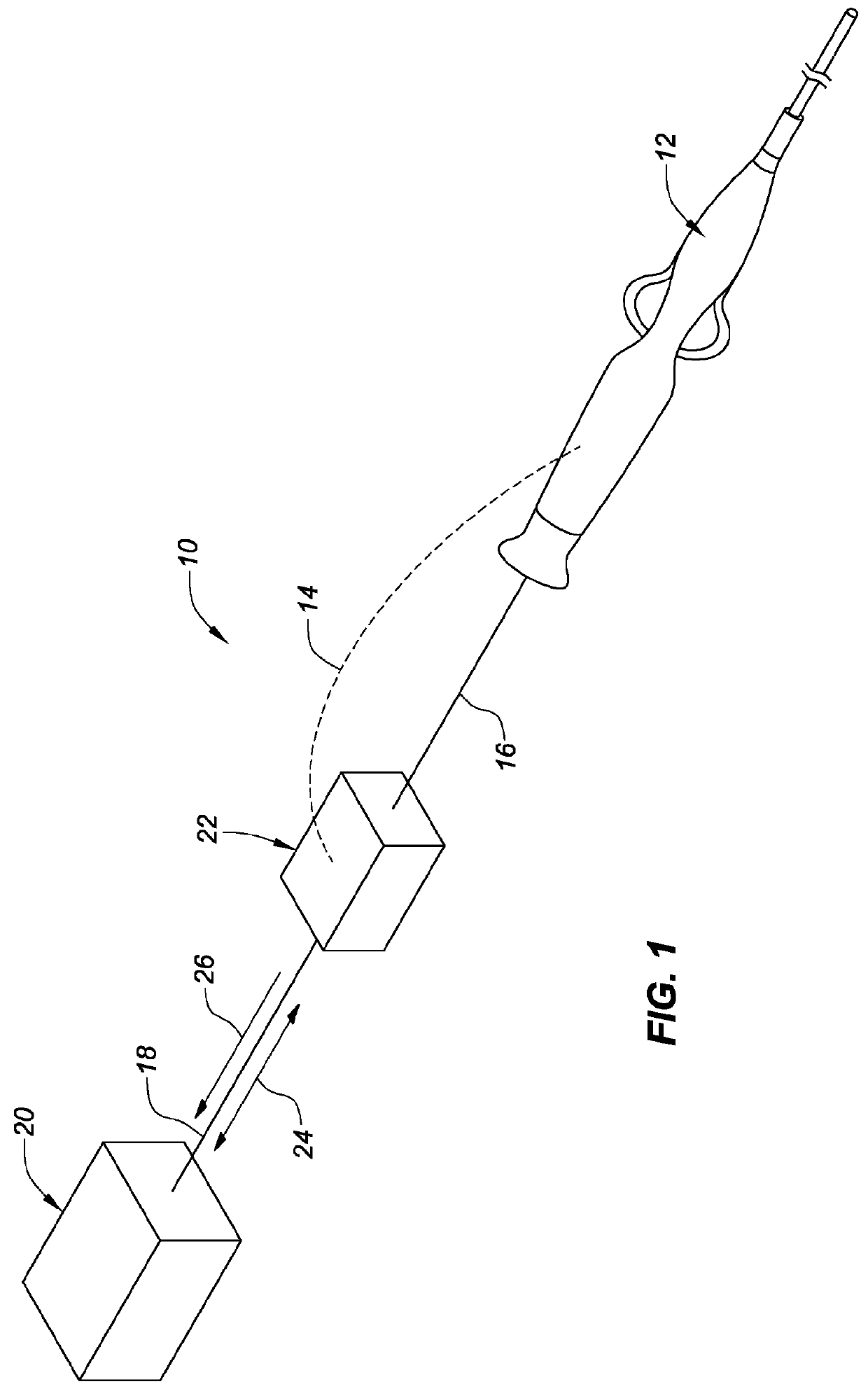

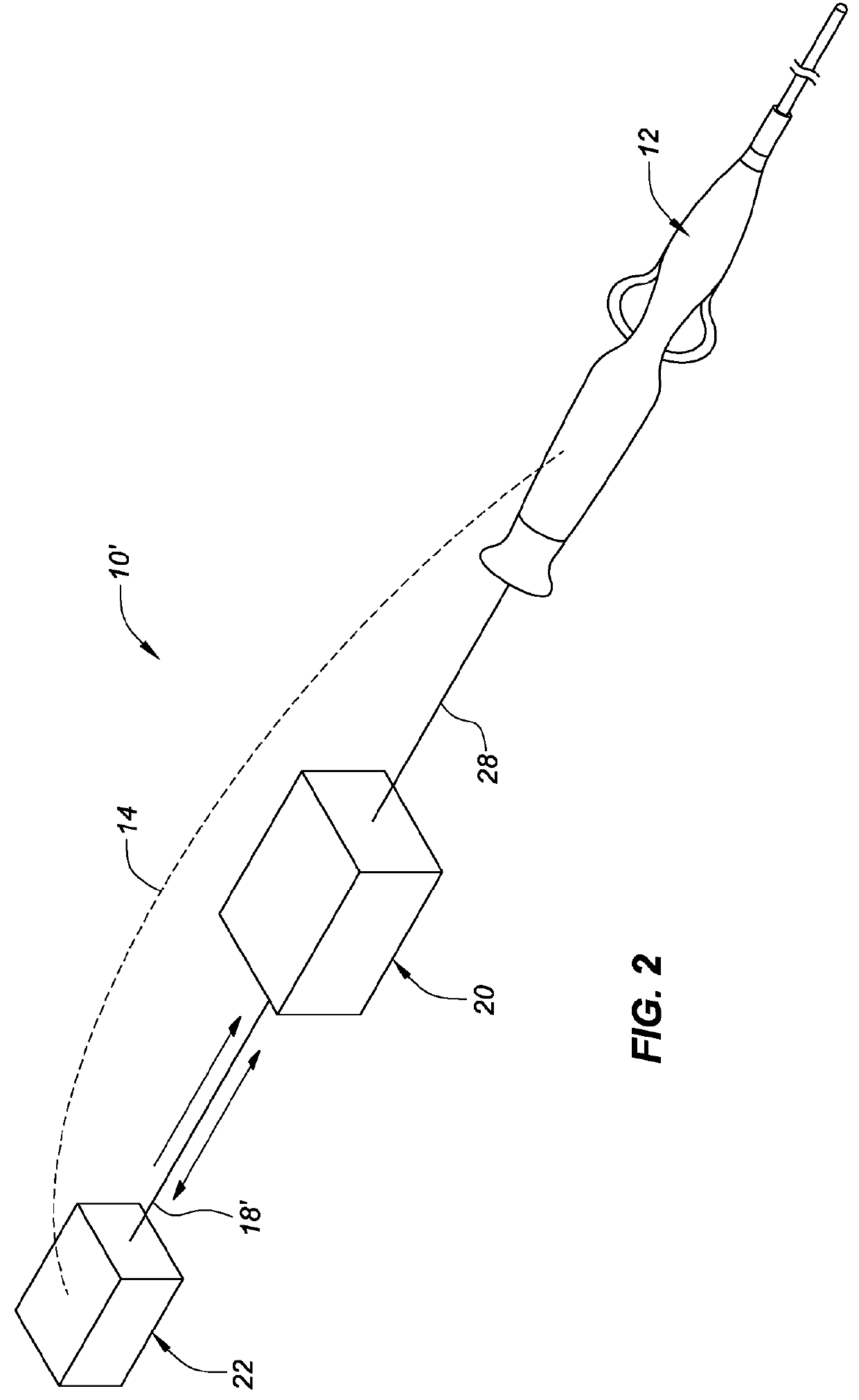

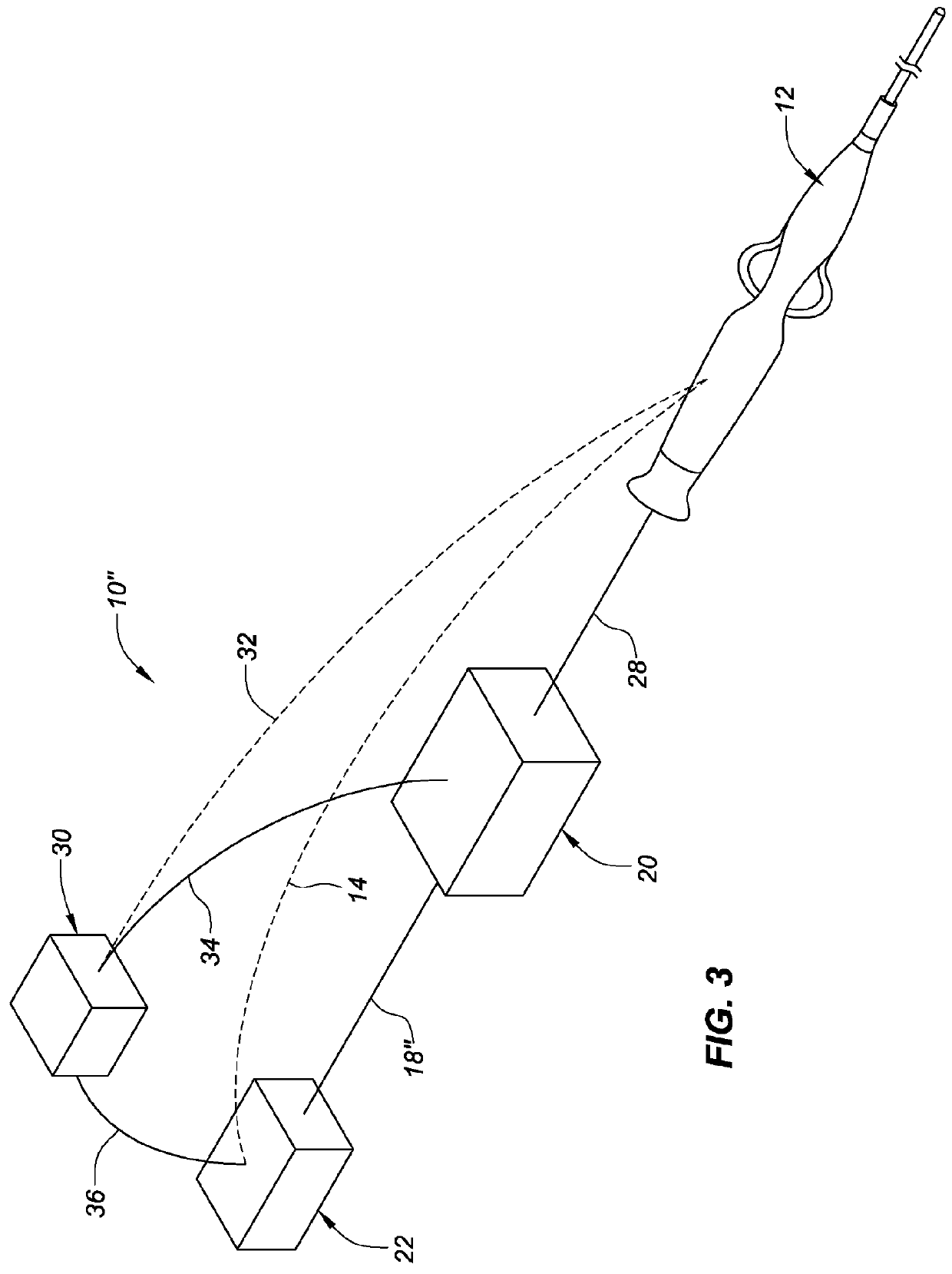

Indirect flow measurement through a breath-operated inhaler

Indirect airflow measurement through breath-operated device is accomplished by incorporating an airflow sensor into the inhaler device along a low resistance channel disposed away from the exhaust chamber of the device and having an input port in airflow communication with a low resistance channel and output input port and low resistance channel are formed in the main housing body of the device, and further incorporating an output port formed near the exhaust changer near the mouthpiece assembly, the output port also in airflow communication with the low resistance channel. A method of measuring airflow in an inhalation device is also described that measures air flowing through the low resistance channel. Another aspect of the invention provides a method that allows for the closure of the devices' airflow ports, by allowing for the rotation of the mouthpiece assembly from open to closed positions relative to the inhaling device's main housing body and towards handle assembly.

Owner:HONEYWELL INT INC

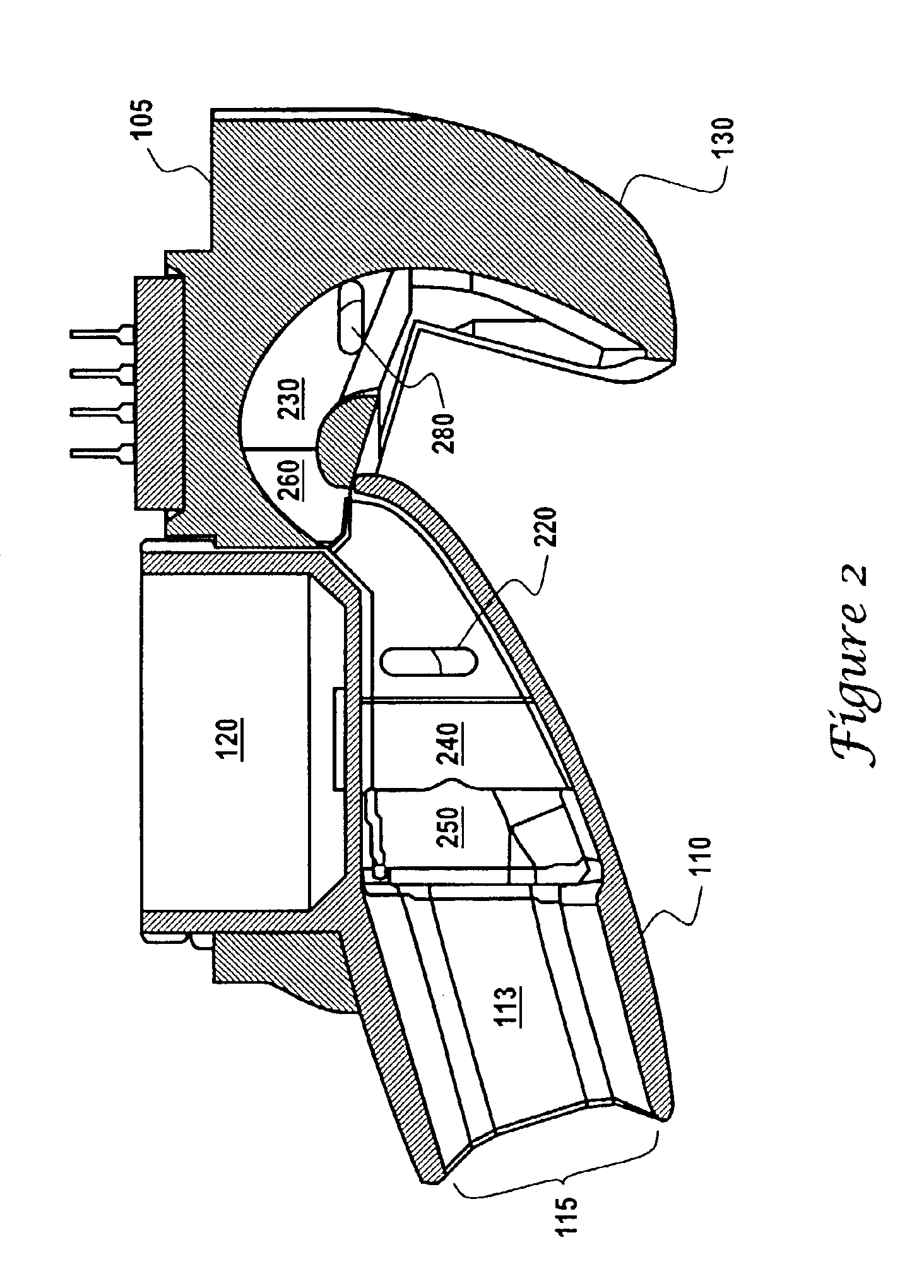

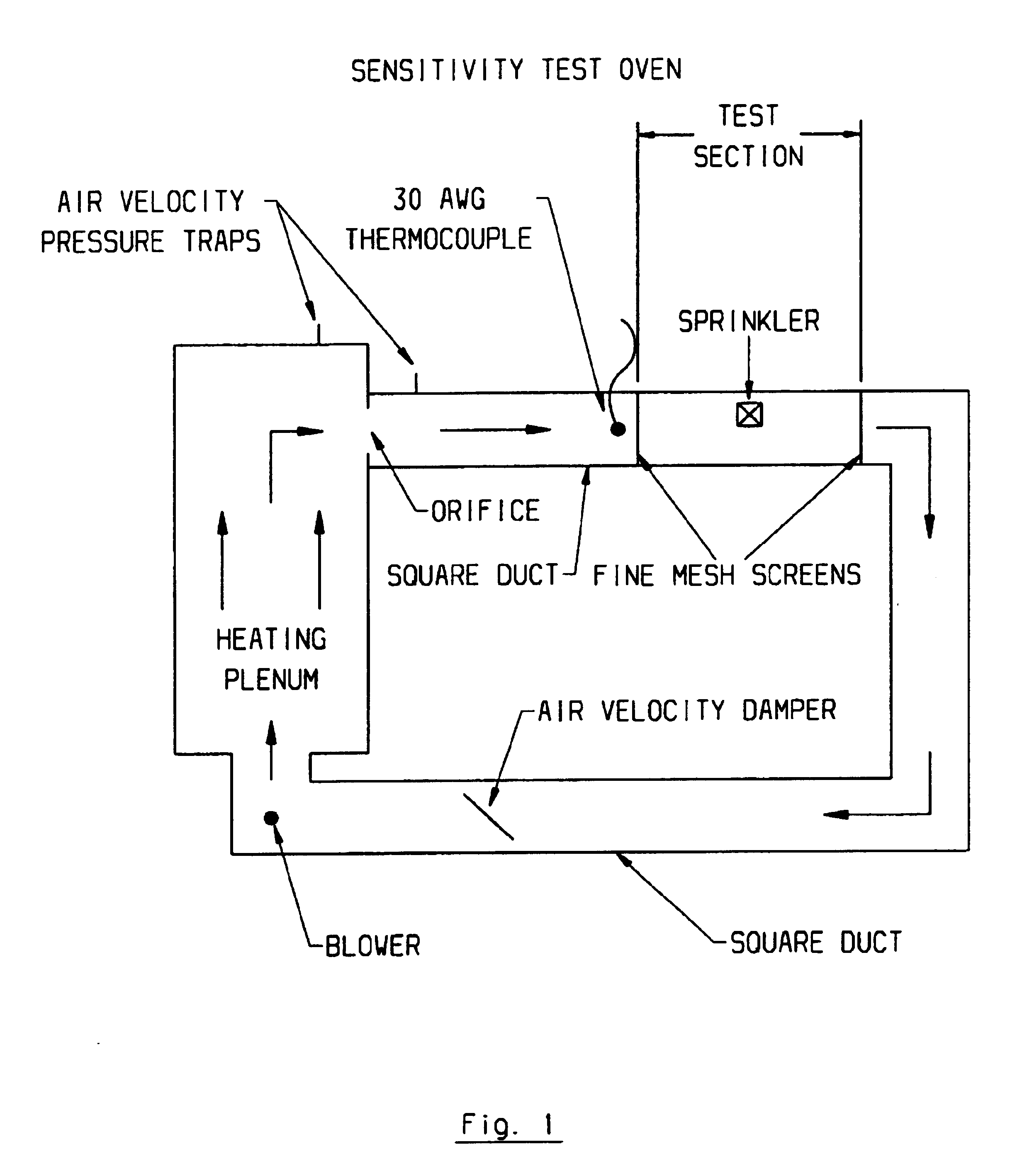

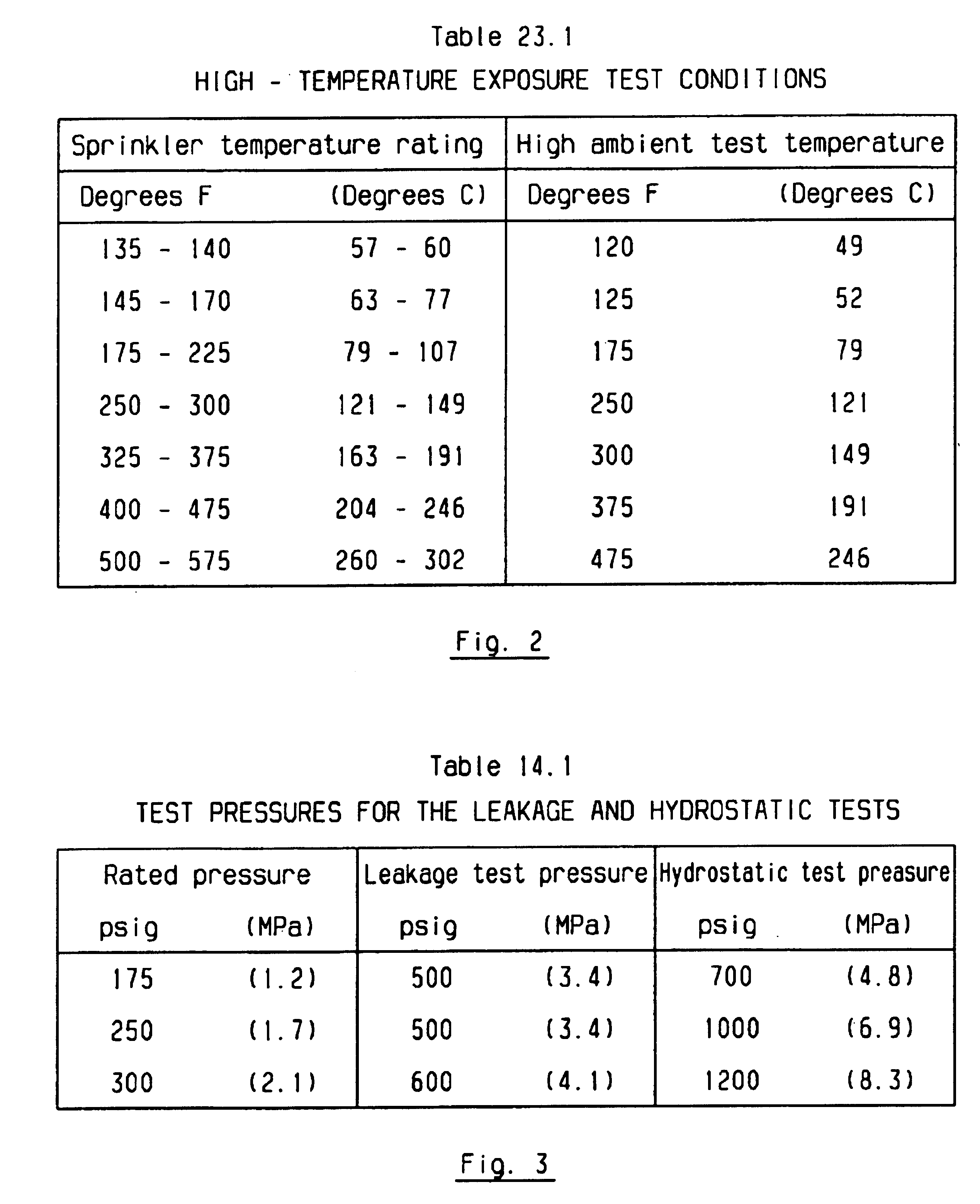

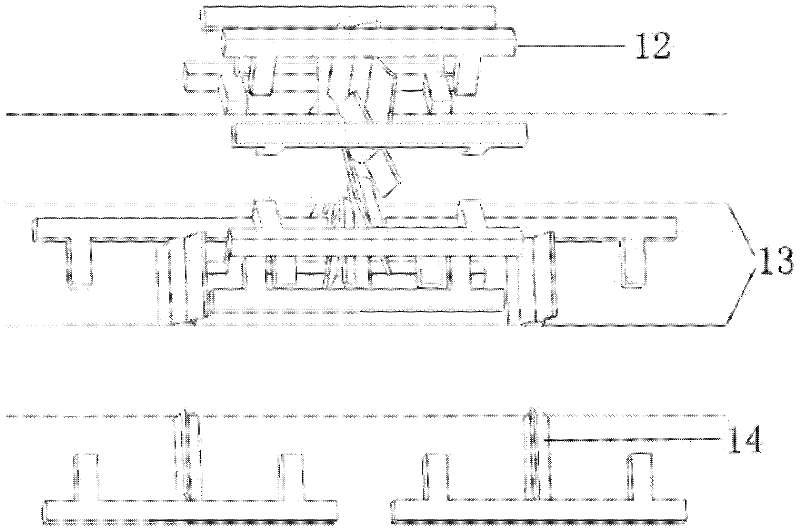

Sprinkler head trigger assembly

InactiveUS6918545B2Low costReduce manufacturing complexitySpraying apparatusTobacco devicesEngineeringMechanical engineering

A quick response trigger assembly for an automatic sprinkler head comprises an inherently unstable compression element positioned between the frame of the sprinkler body and sealing assembly. A thermal sensor surrounds the periphery of the compression element and includes at least one heat gathering element positioned a preselected distance from the compression element. The thermal sensor maintains the compression element in compression when the sprinkler head is in the non-activated condition. The presence of a heat gathering member spaced a preselected distance from the compression element increases the surface area through which conduction occurs, and thus, enables the trigger assembly to exhibit sufficient thermal sensitivity necessary to classify the sprinkler head as a quick response. Additionally, the thermal sensor is formed of two or more members which are substantially identical in configuration to thereby decrease manufacturing costs.

Owner:VIKING

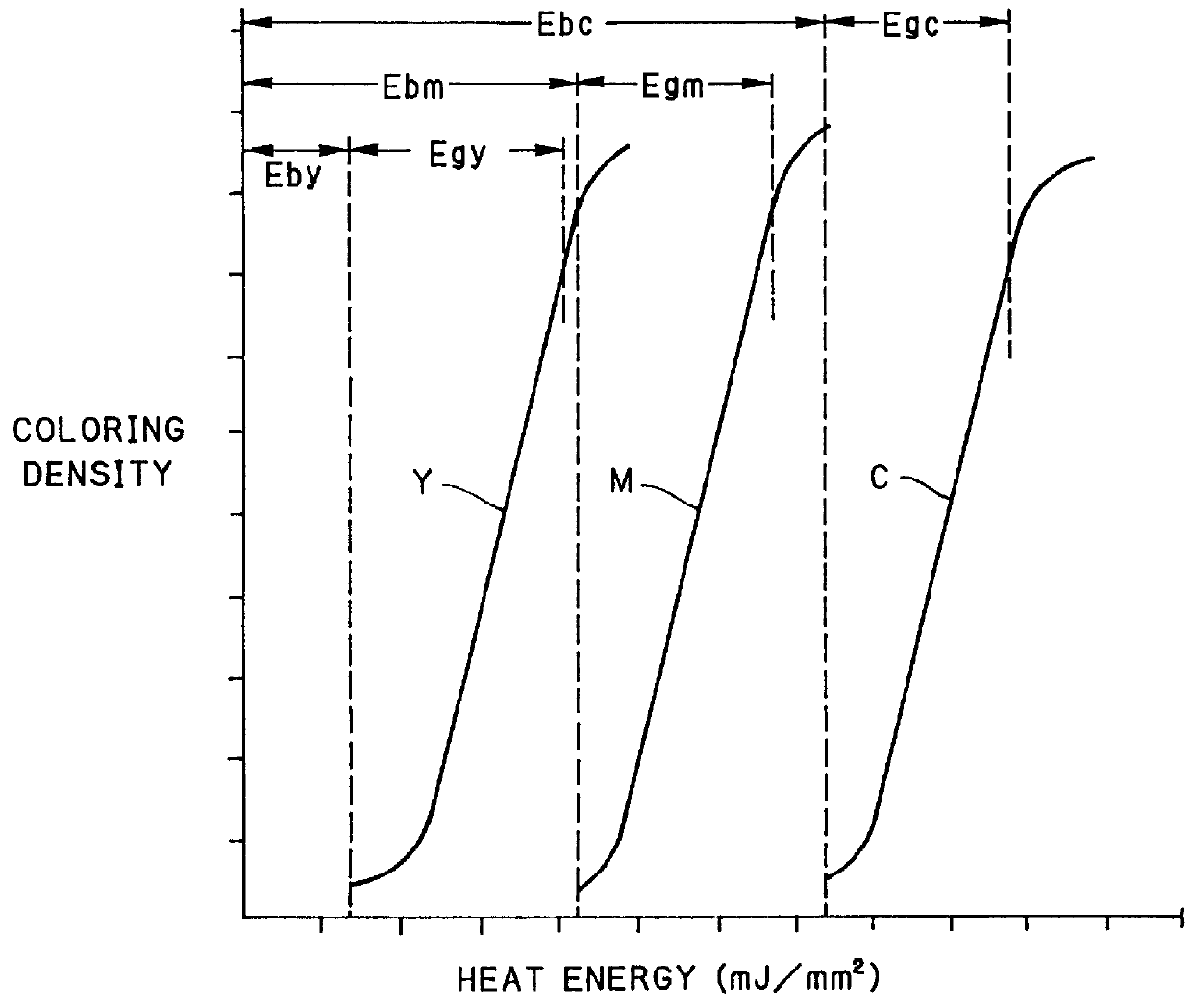

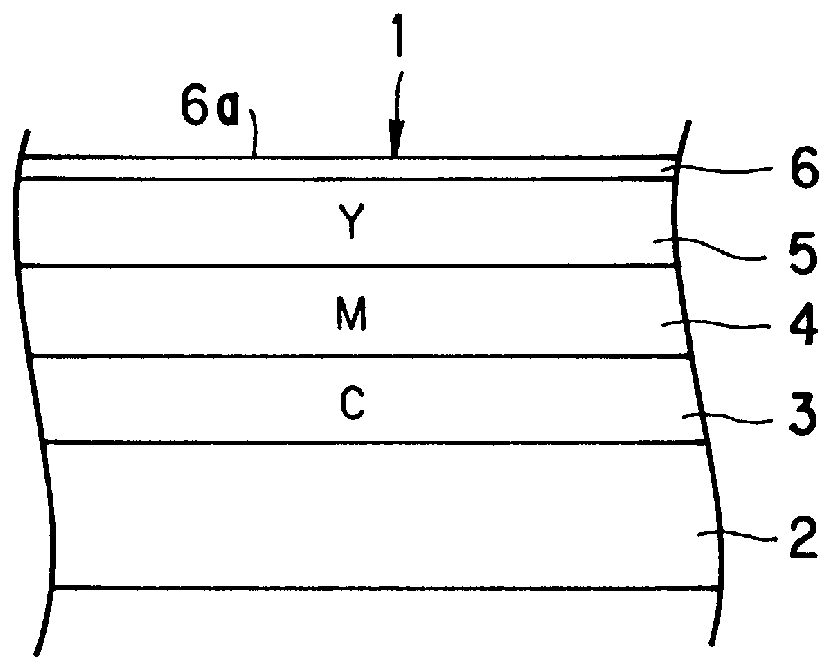

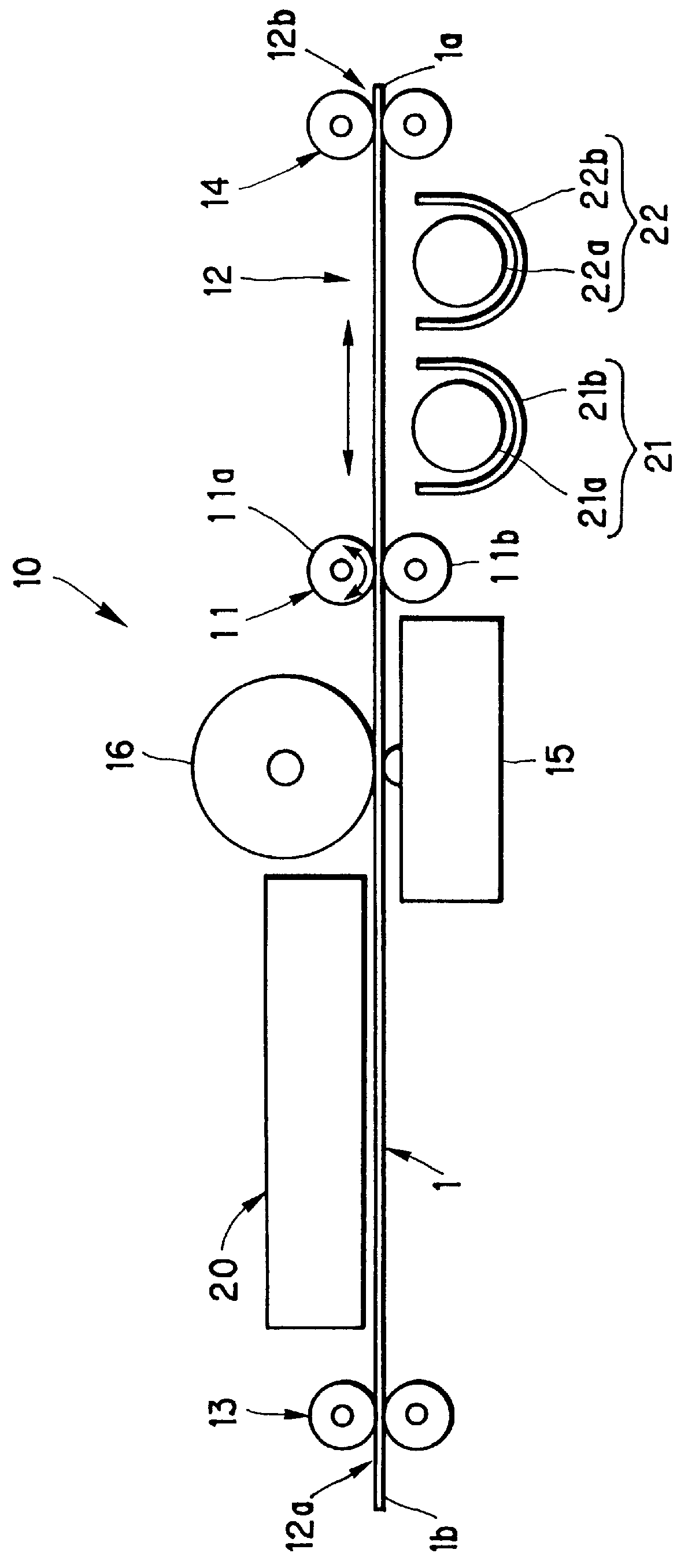

Thermal printing method and thermal printer

InactiveUS6037961AReduce heat sensitivityImprove heat sensitivityThermographyOther printing apparatusPaper sheetThermal energy

A thermosensitive recording sheet is conveyed relative to a thermal head. To effect thermal recording, the thermal head applies heat energy to the recording sheet. The recording sheet is preheated with preheating energy shortly before recording of the recording sheet with the thermal head. The preheating energy is lower than enough to color the recording sheet, but heightens temperature of the recording sheet upon movement of the recording sheet to the thermal head. The heat energy to be applied by the thermal head is reduced according to the preheating energy.

Owner:FUJIFILM CORP

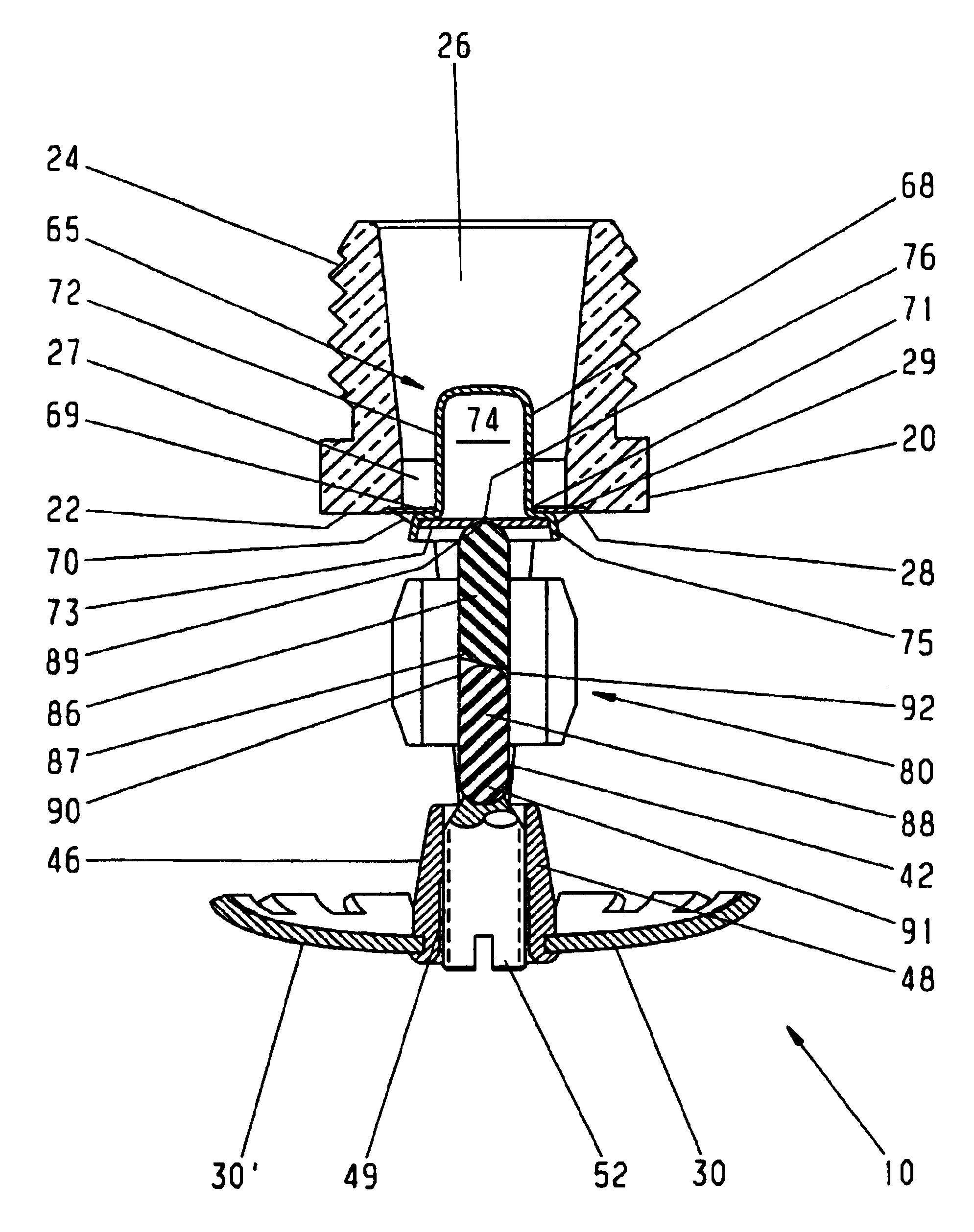

Ablation catheter tip with flexible electronic circuitry

PendingUS20180092688A1Facilitate near real-time temperature sensingImprove heat sensitivityElectrocardiographyCatheterElectricityForms of energy

Aspects of the present disclosure are directed to, for example, a high-thermal-sensitivity ablation catheter tip including a thermally-insulative ablation tip insert supporting at least one temperature sensor electrically coupled to a flexible electronic circuit and encapsulated, or essentially encapsulated, by a conductive shell. Also disclosed is a method of controlling the temperature of an ablation catheter tip while creating a desired lesion using various forms of energy and energy delivery.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

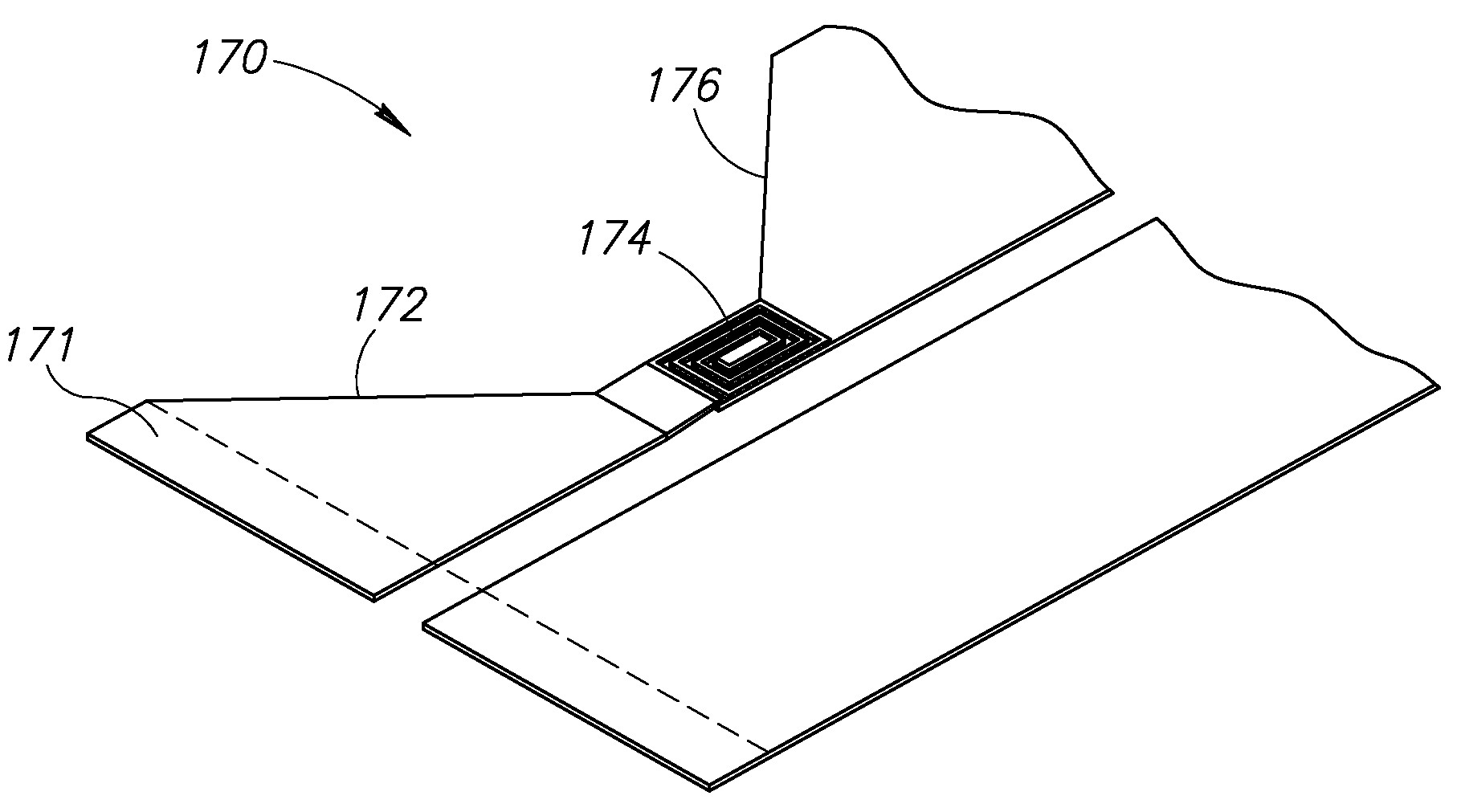

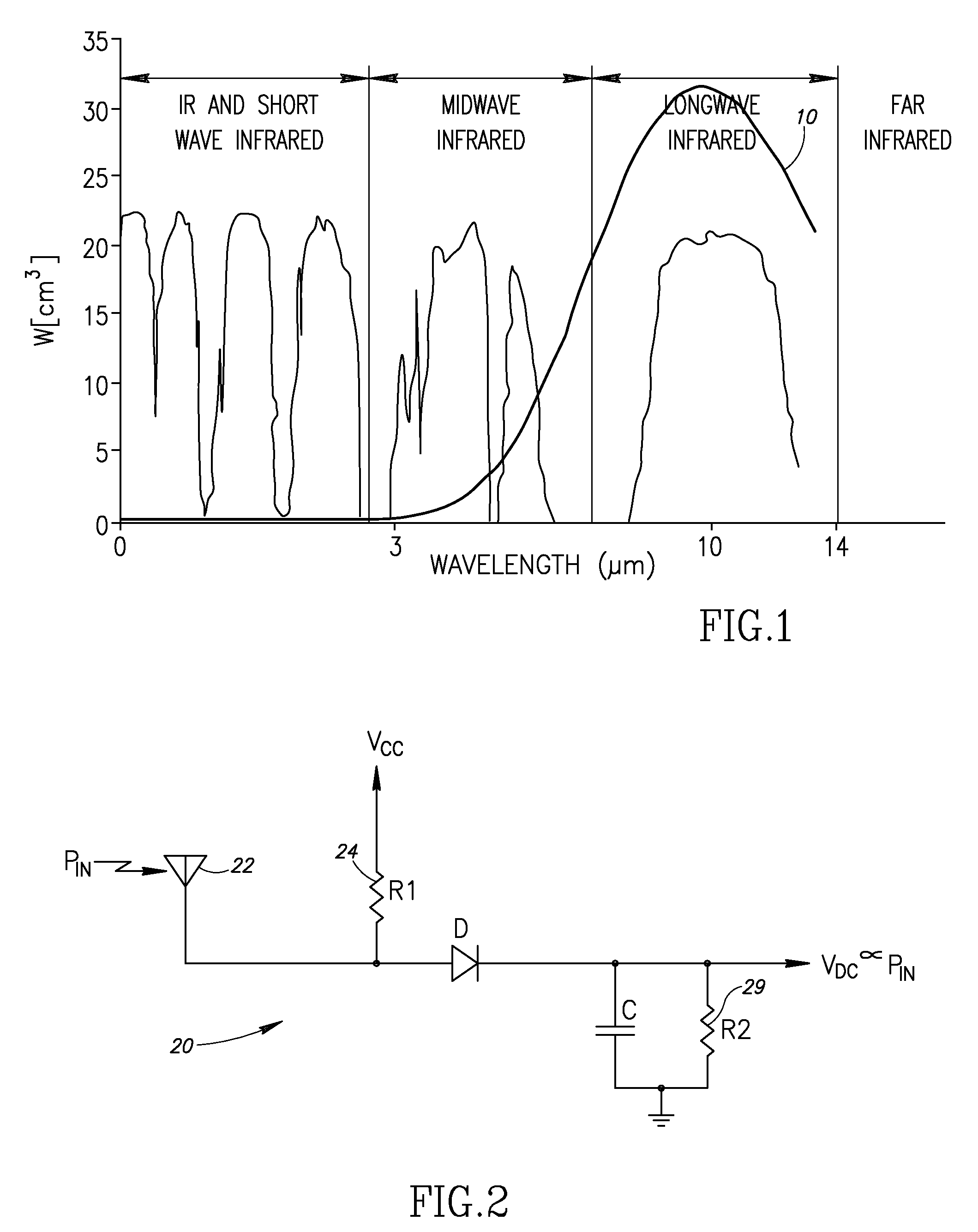

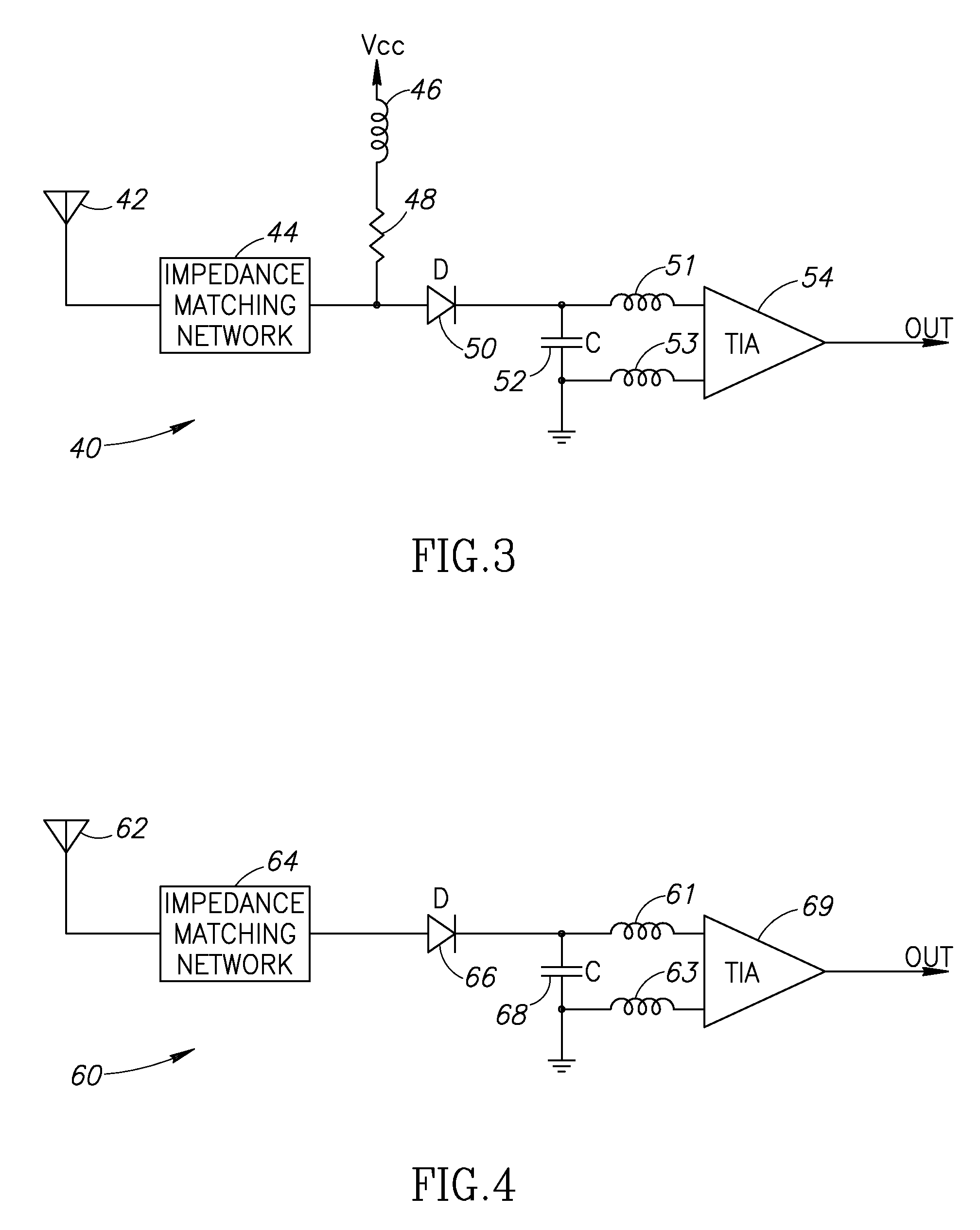

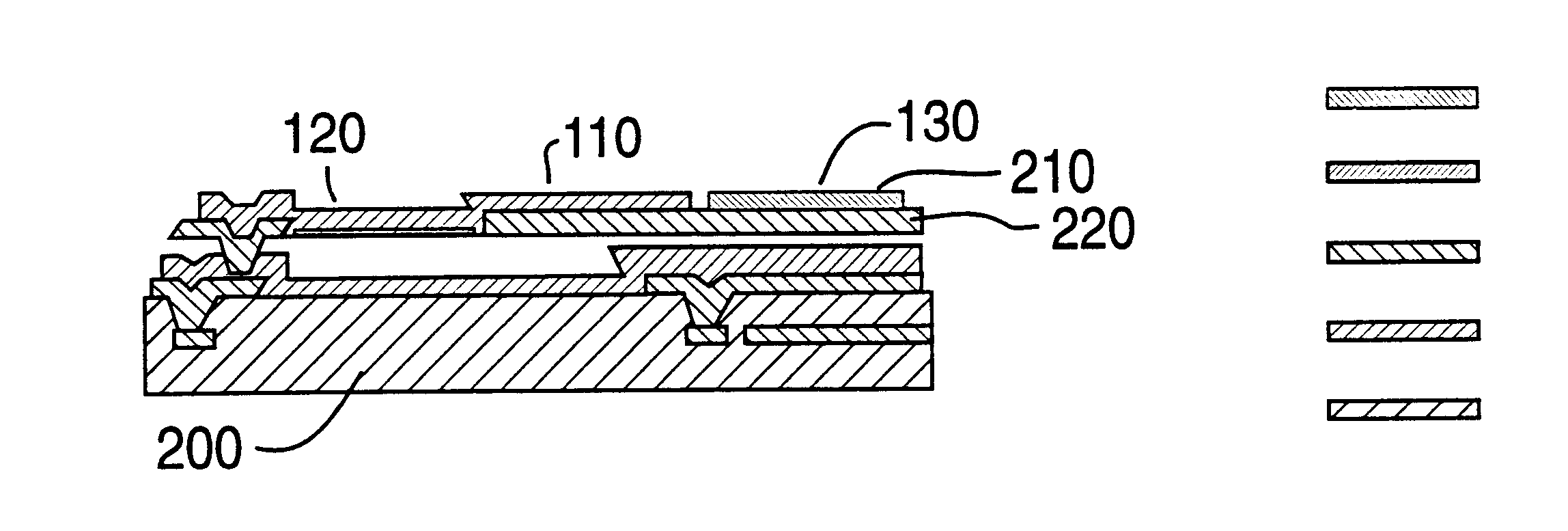

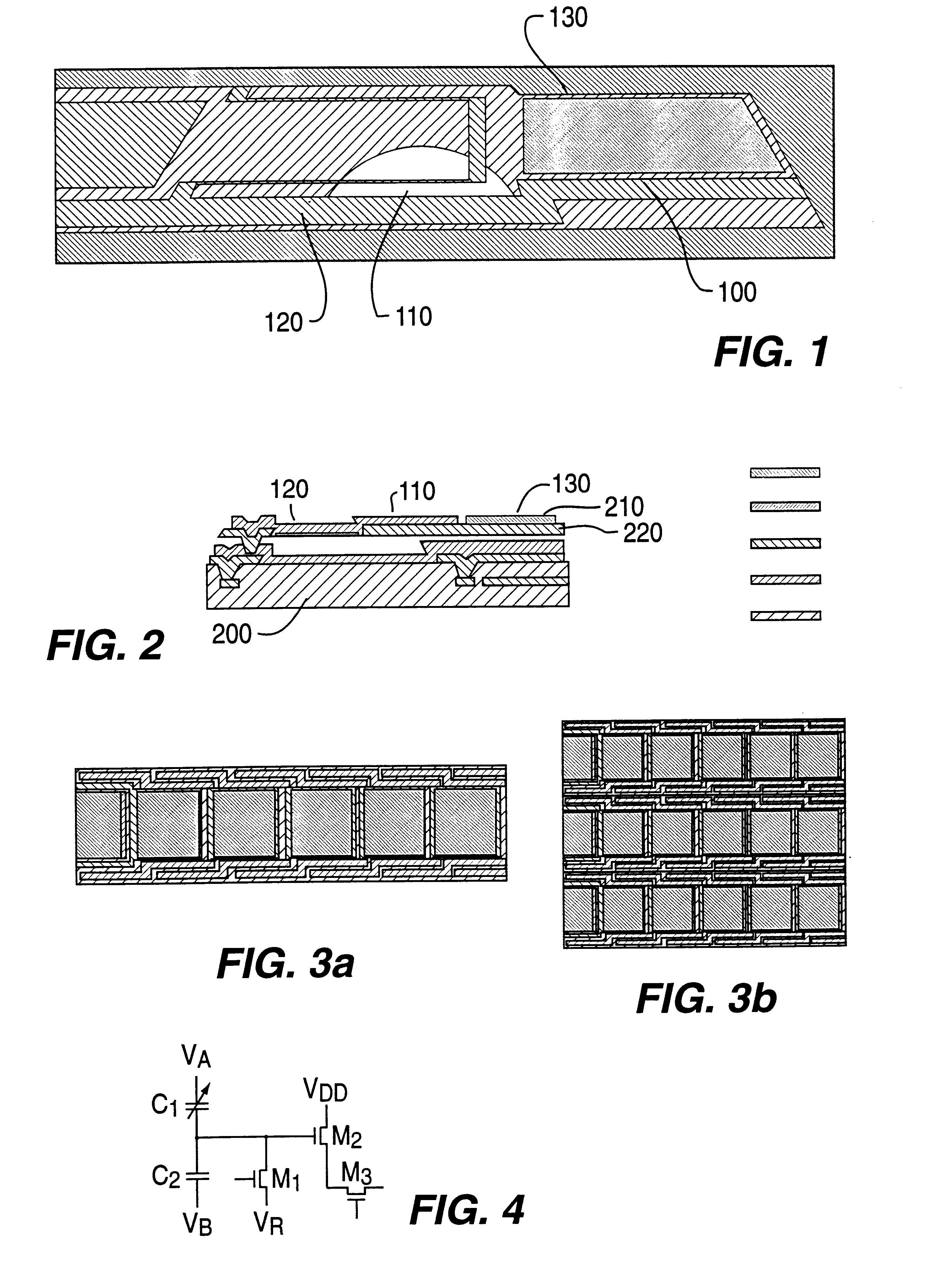

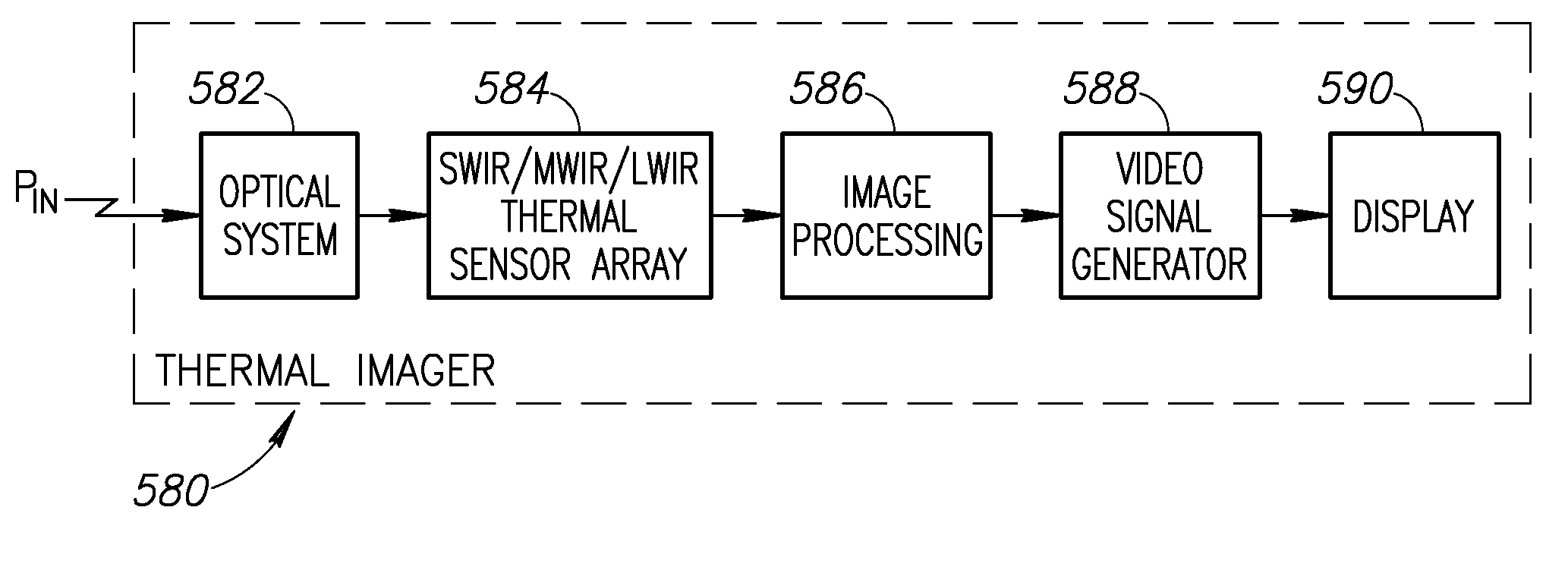

Electromagnetic based thermal sensing and imaging

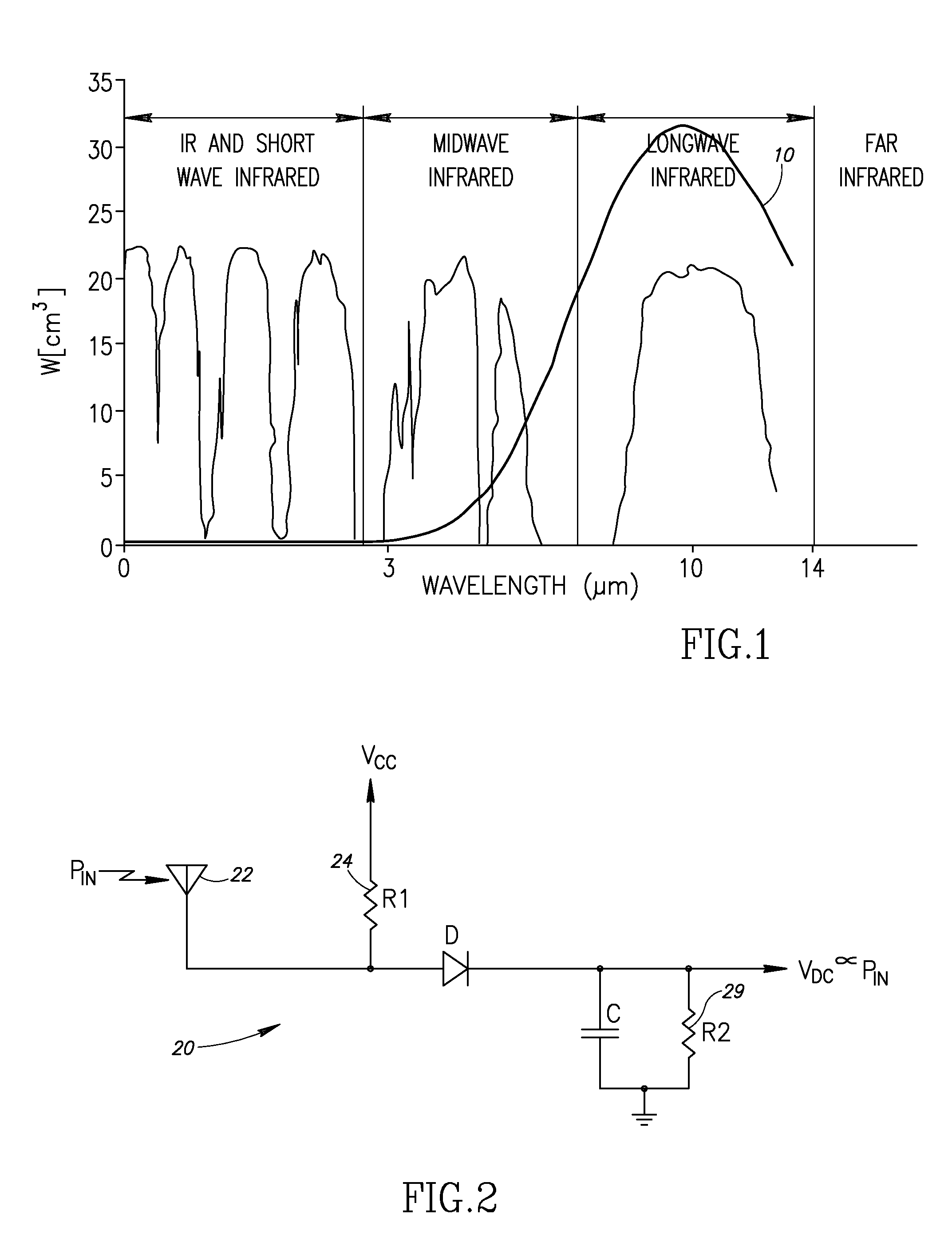

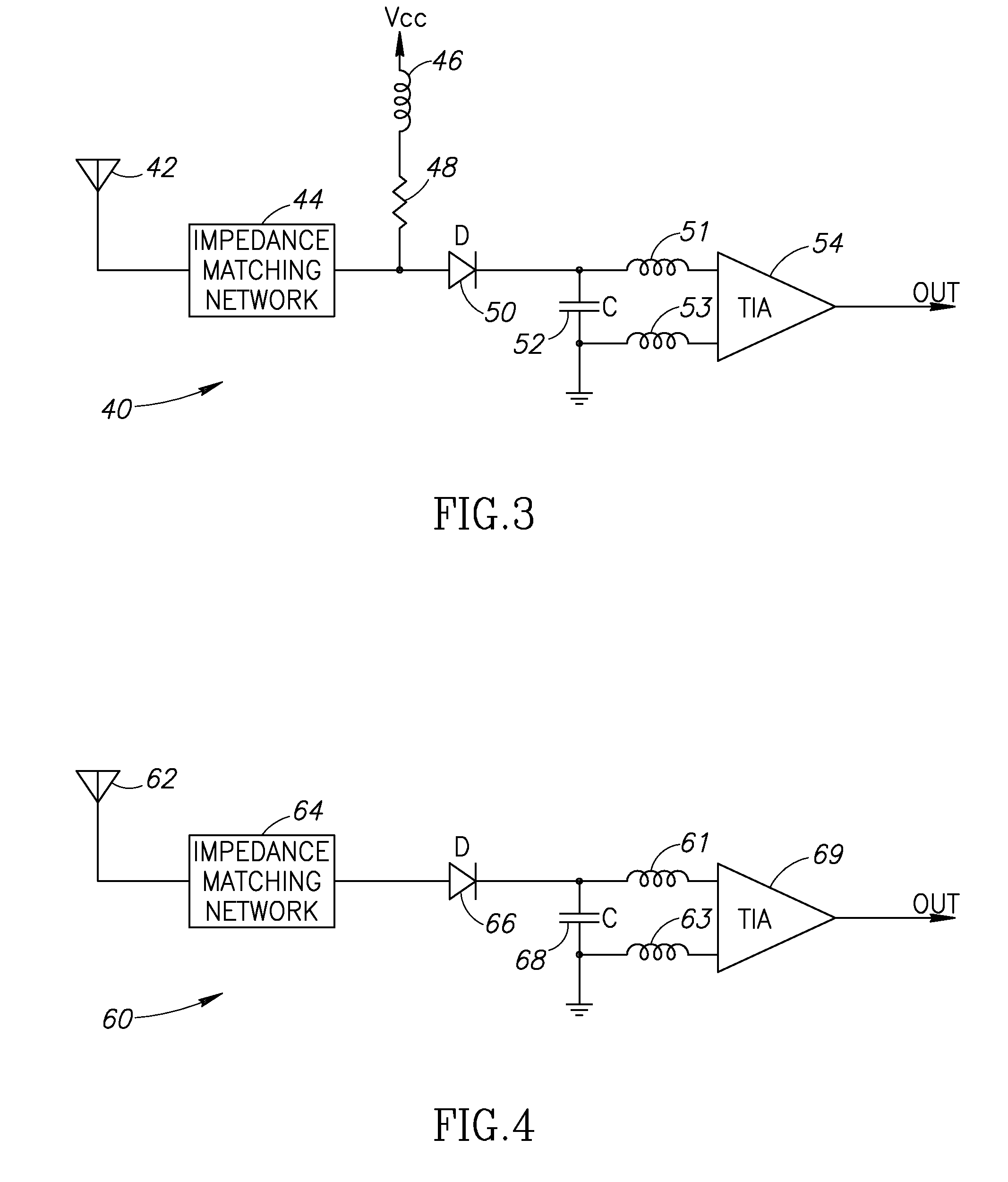

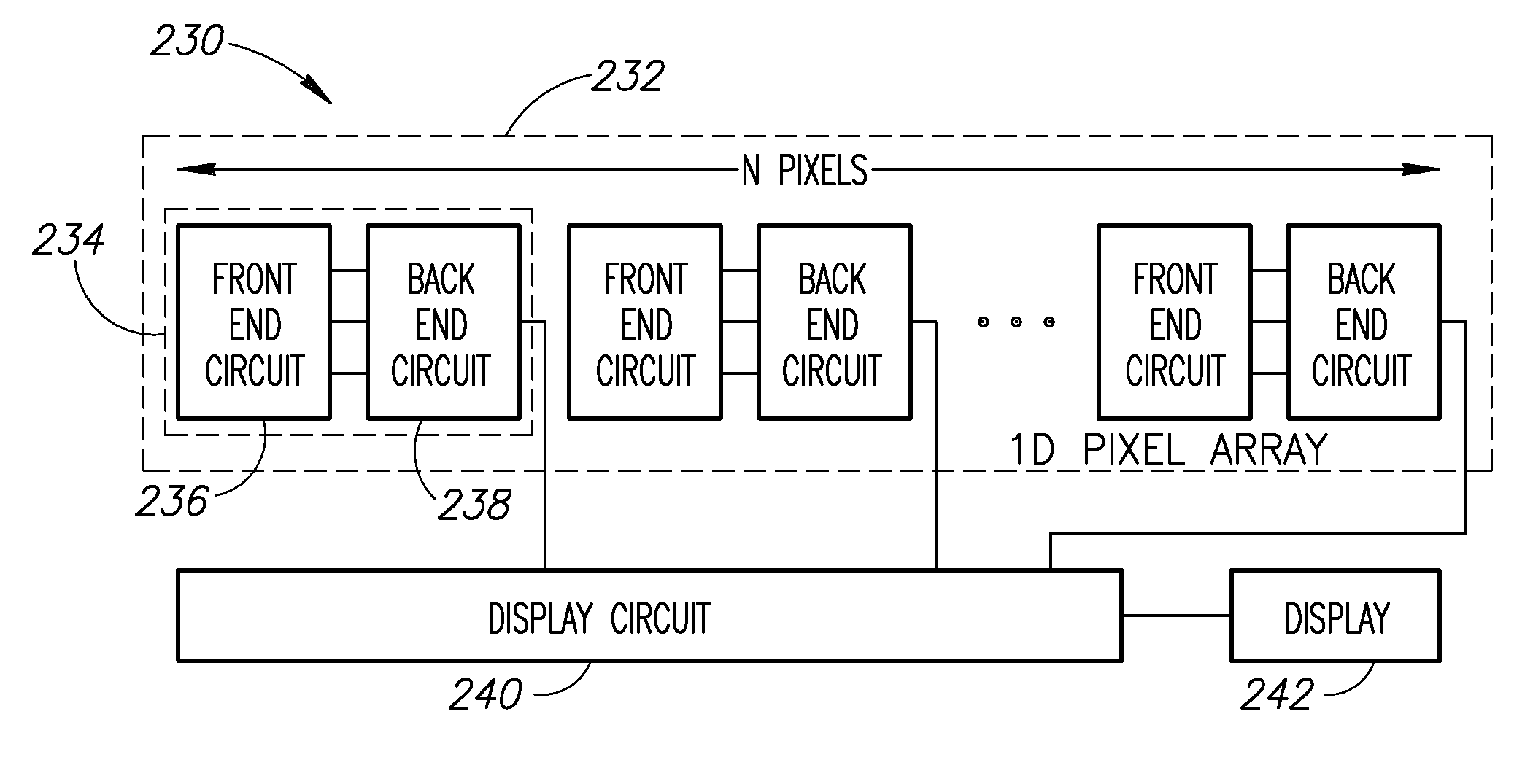

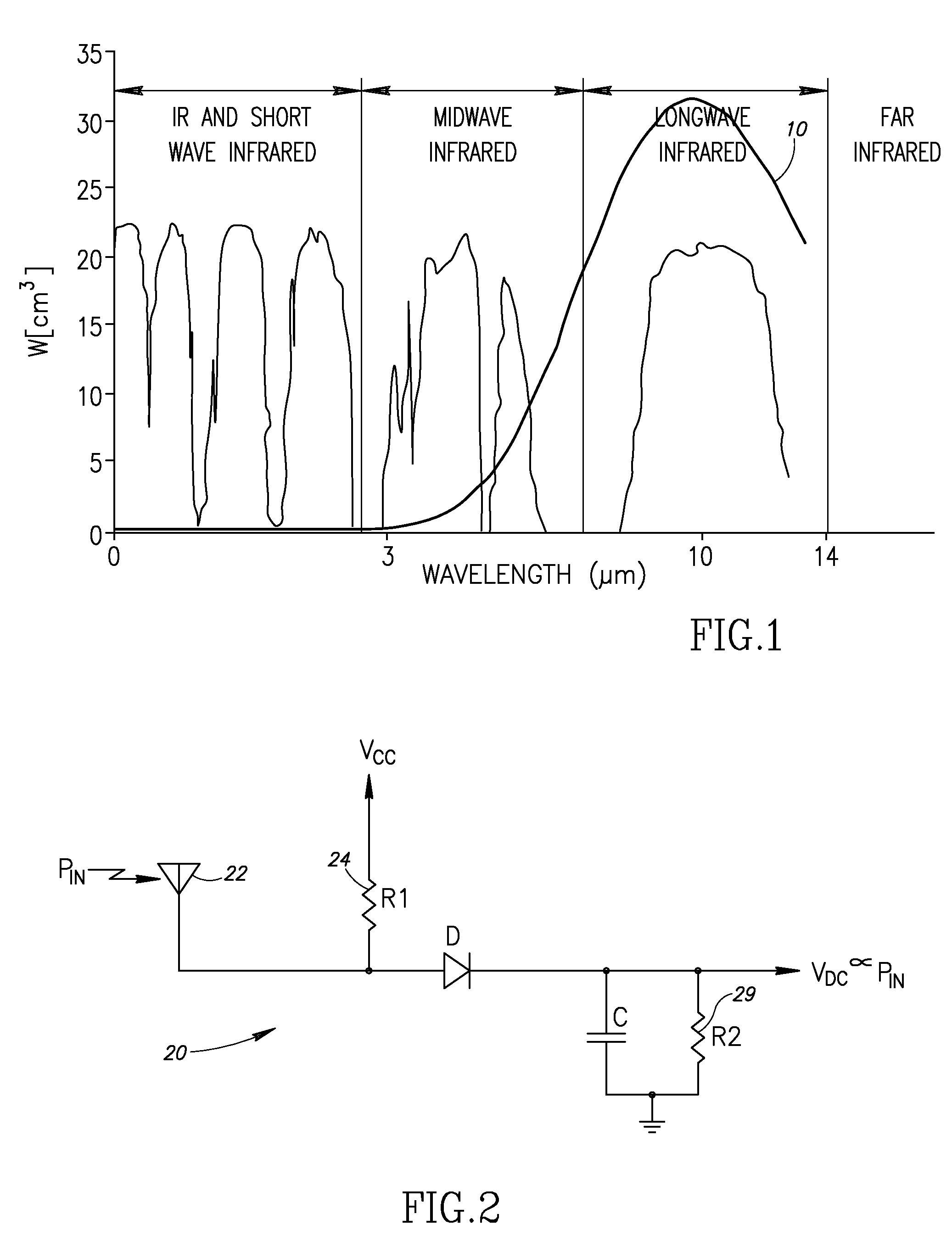

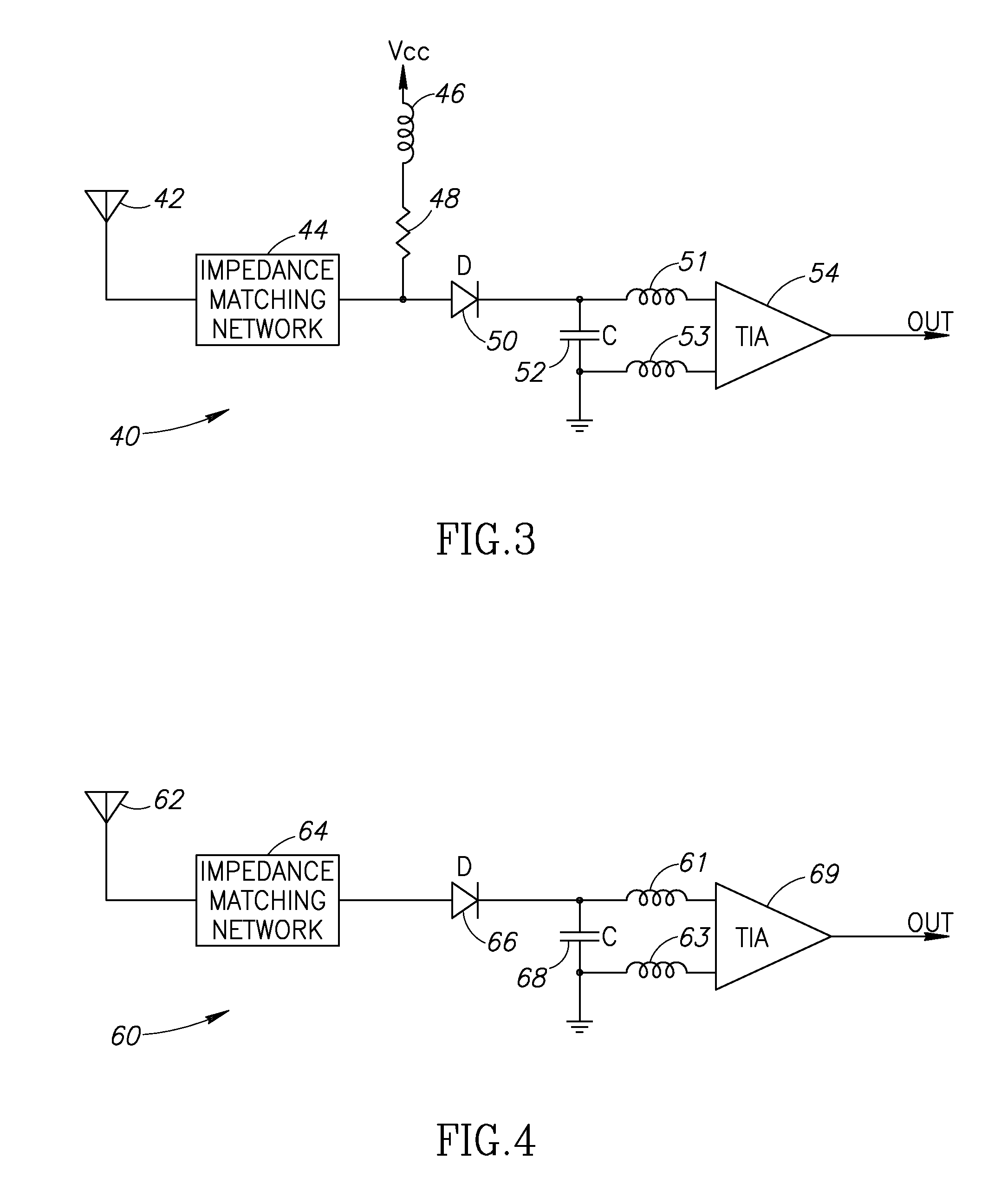

InactiveUS20110062329A1Improve heat sensitivityHigh sensitivitySolid-state devicesMaterial analysis by optical meansMetal-insulator-metalBlack-body radiation

A novel pixel circuit and multi-dimensional array for receiving and detecting black body radiation in the SWIR, MWIR or LWIR frequency bands. An electromagnetic thermal sensor and imaging system is provided based on the treatment of thermal radiation as an electromagnetic wave. The thermal sensor and imager functions essentially as an electromagnetic power sensor / receiver, operating in the SWIR (200-375 THz), MWIR (60-100 THz), or LWIR (21-38 THz) frequency bands. The thermal pixel circuit of the invention is used to construct thermal imaging arrays, such as 1D, 2D and stereoscopic arrays. Various pixel circuit embodiments arc provided including balanced and unbalanced, biased and unbiased and current and voltage sensing topologies. The pixel circuit and corresponding imaging arrays are constructed on a monolithic semiconductor substrate using in a stacked topology. A metal-insulator-metal (MIM) structure provides rectification of the received signal at high terahertz frequencies.

Owner:ORYX VISION LTD

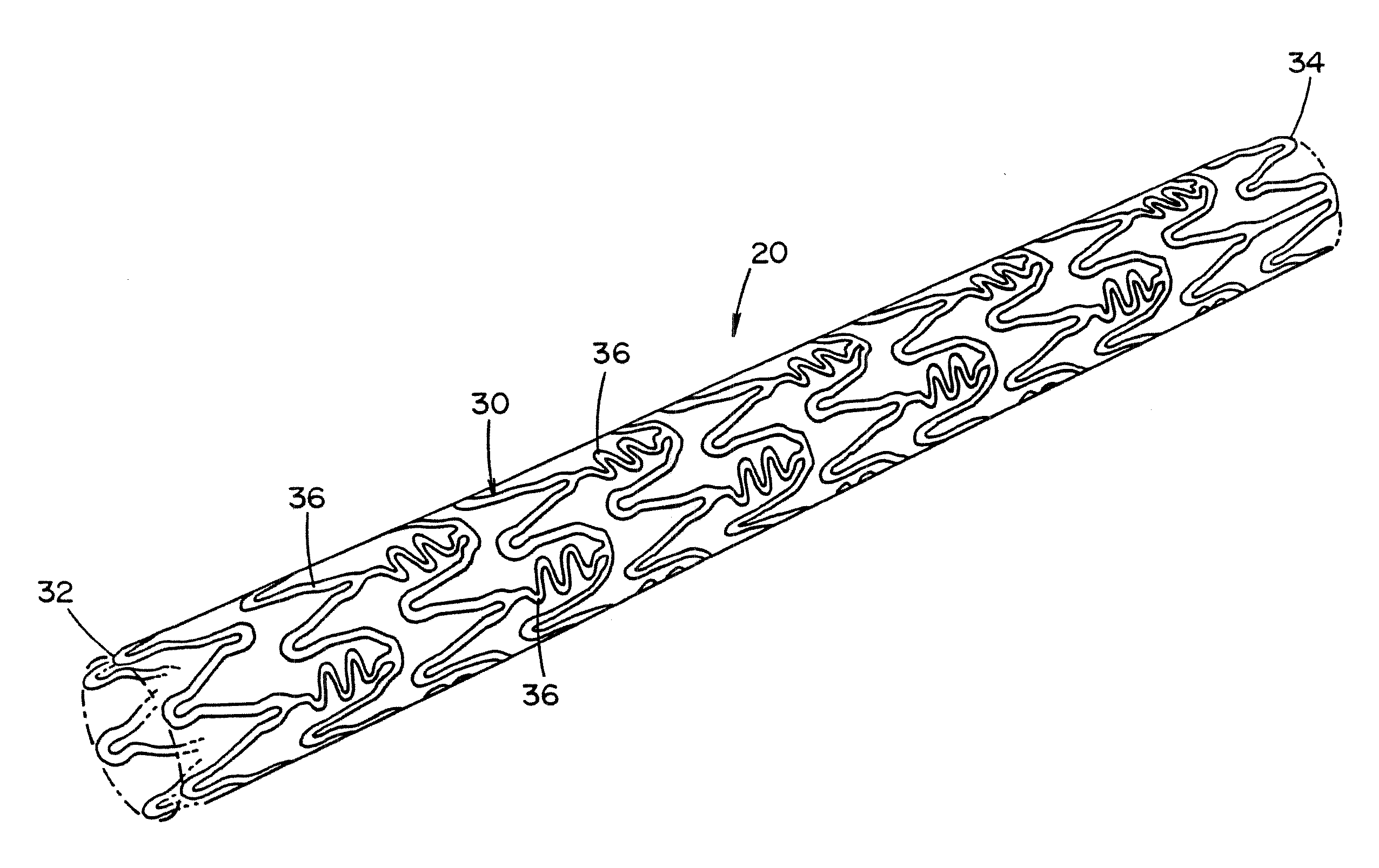

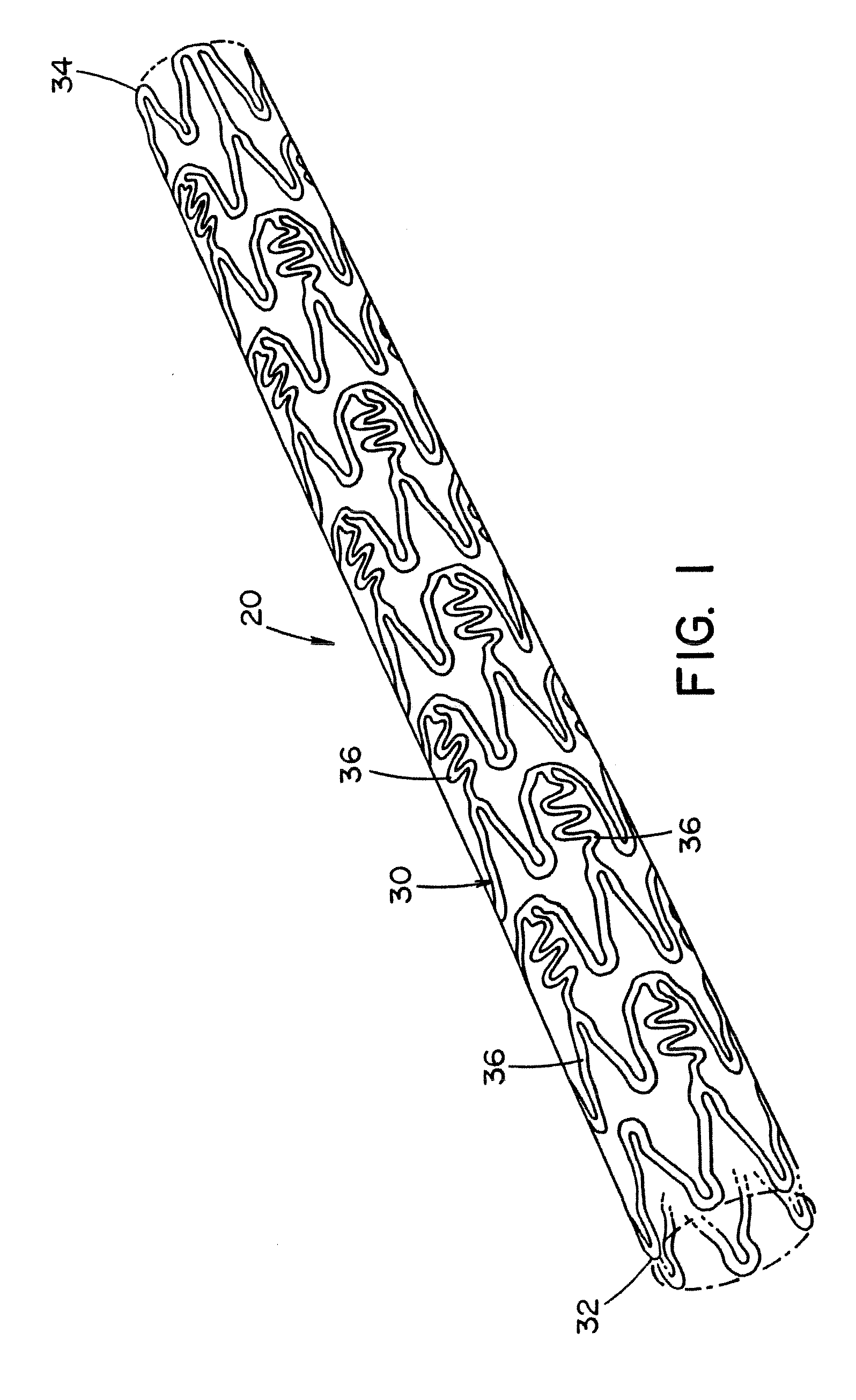

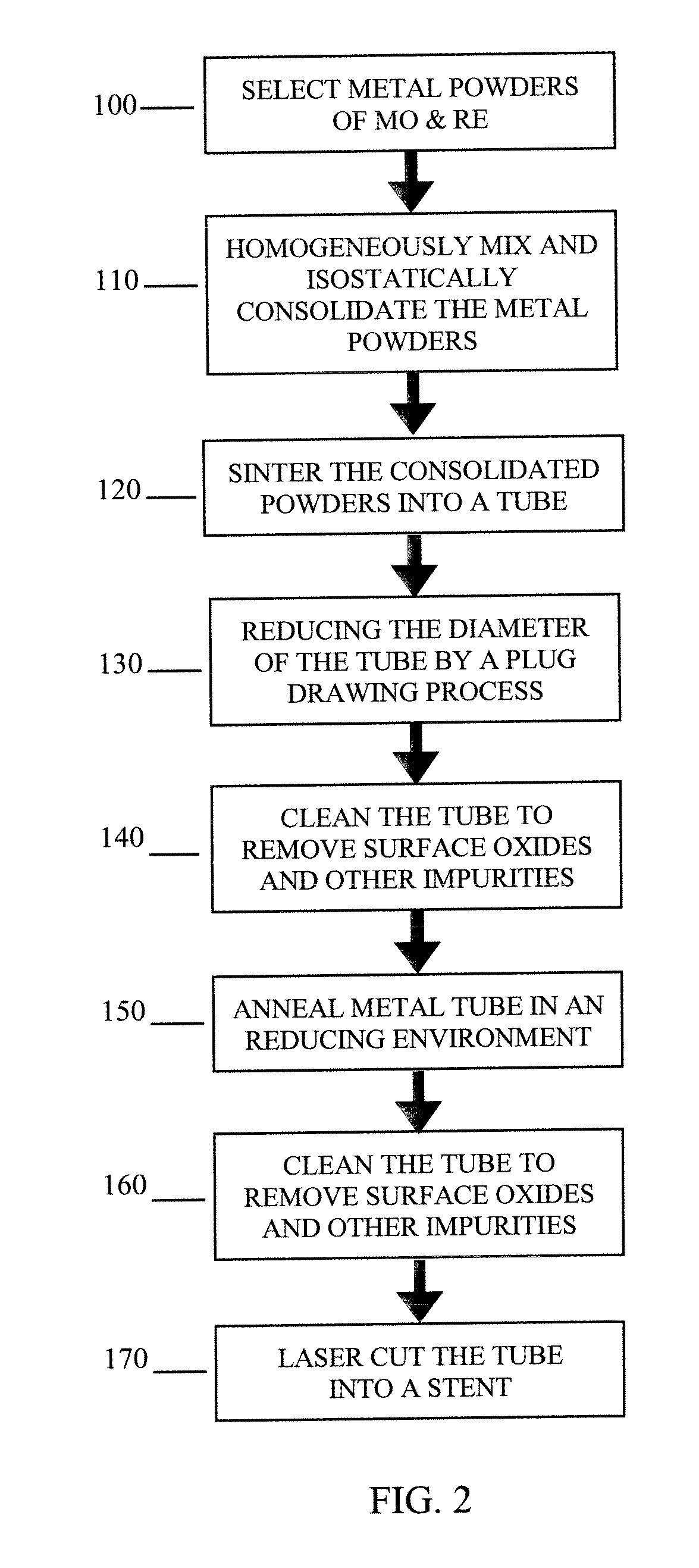

Method for forming a tubular medical device

A method and process for at least partially forming a medical device that is at least partially formed of a metal alloy which improves the physical properties of the medical device.

Owner:MIRUS LLC

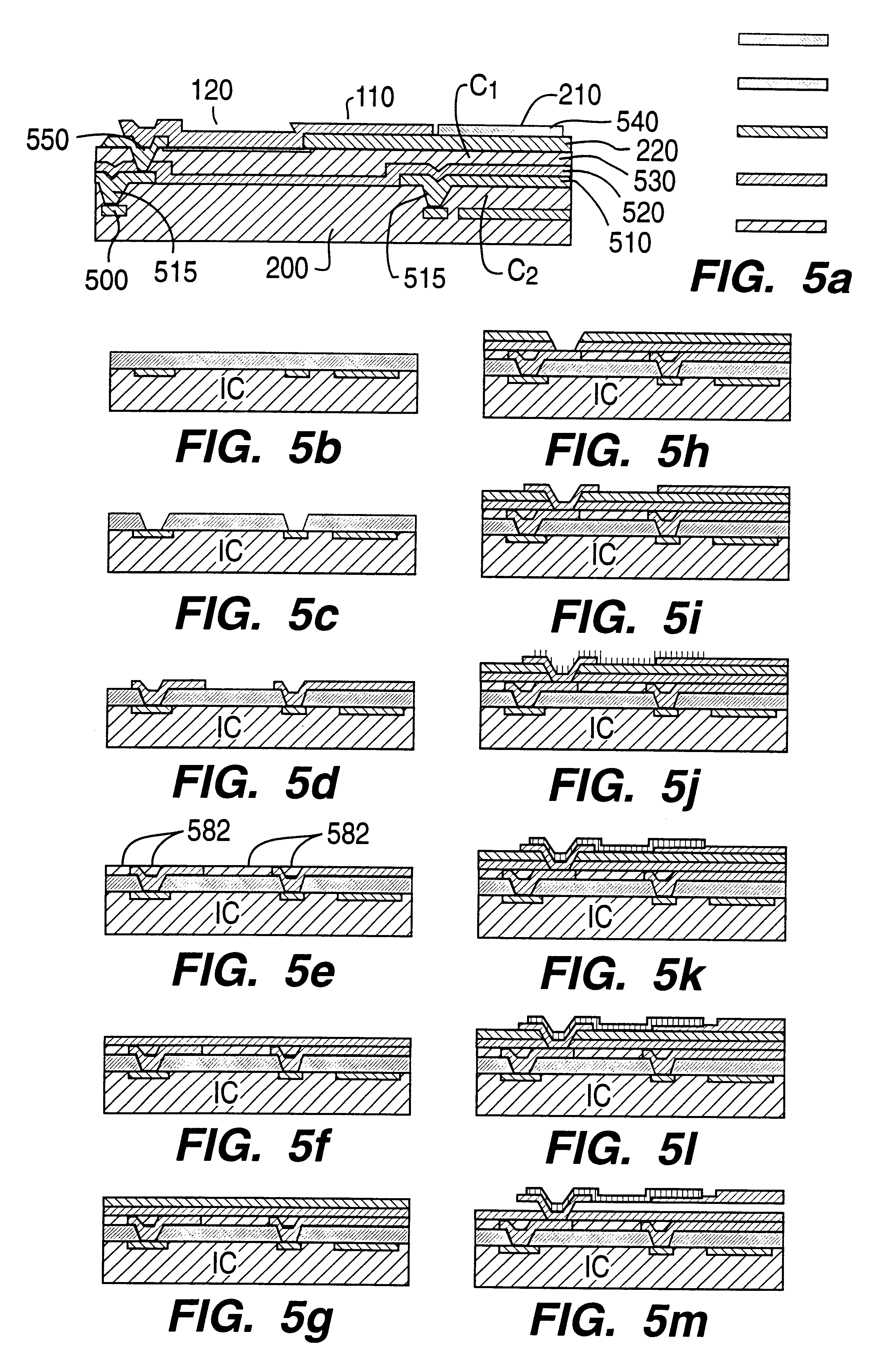

Infrared imager using room temperature capacitance sensor

InactiveUS6249001B1Increase resistanceImprove heat sensitivityTelevision system detailsOrganic chemistryRoom temperatureEngineering

An infrared imager includes an array of capacitance sensors that operate at room temperature. Each infrared capacitance sensor includes a deflectable first plate which expands due to absorbed thermal radiation relative to a non-deflectable second plate. In one embodiment each infrared capacitance sensor is composed of a bi-material strip which changes the position of one plate of a sensing capacitor in response to temperature changes due to absorbed incident thermal radiation. The bi-material strip is composed of two materials with a large difference in thermal expansion coefficients.

Owner:SRI INTERNATIONAL

High-performance cutter ring material and preparation method thereof

The invention discloses a high-performance cutter ring material and a preparation method thereof. The preparation method comprises steps of smelting, casting, electroslag remelting, uniform annealing,forging, spheroidizing annealing, quenching, tempering and the like, and the high-performance cutter ring material is prepared through following chemical elements in percentage: 0.55-0.70% of C, lessthan or equal to 0.40% of Si, less than or equal to 0.50% of Mn, 5.30-6.75% of Cr, 2.0-3.0% of Mo, 0.60-0.95% of V, less than or equal to 0.025% of S and P and the balance of iron. A high-performancecutter ring made of the material has the characteristics of being good in toughness, high in hardness, and the like, and compared with a cutter ring made of a conventional material, the cutter ring is remarkably good in wearing resistance, high in construction efficiency, long in service life and short in construction period.

Owner:中铁工程装备集团隧道设备制造有限公司

Production method of biobased solvent-free polyurethane synthetic leather

ActiveCN107012692AWith double foam technologyImprove controllabilityTextiles and paperProduction lineSolvent free

A production method of biobased solvent-free polyurethane synthetic leather comprising the steps of adding a hydroxyl containing component A and an isocyanate group containing component B into a reaction kettle, stirring for reaction to form foaming slurry, applying the foaming slurry to release paper in a scraping manner by using a dry synthetic leather production line to form a coating, laminating the coating with base cloth in a clearance laminating manner by using a laminating machine, putting in an oven for curing, and performing cooling and stripping to form the biobased solvent-free polyurethane synthetic leather. The biobased solvent-free polyurethane synthetic leather is produced by using a double foaming technology, an in-situ polyurethane polymerize technology, a heat-sensitive catalyst asynchronous catalysis technology and a single-knife constant temperature thermal scraping application technology; a production technology is environment-friendly, concise and stable; the product quality is good; biomass that is cheap and easy to obtain serves as a raw material; the use of a fossil raw material can be reduced; and environmental protection is facilitated.

Owner:聊城市鑫润达塑胶制品有限公司

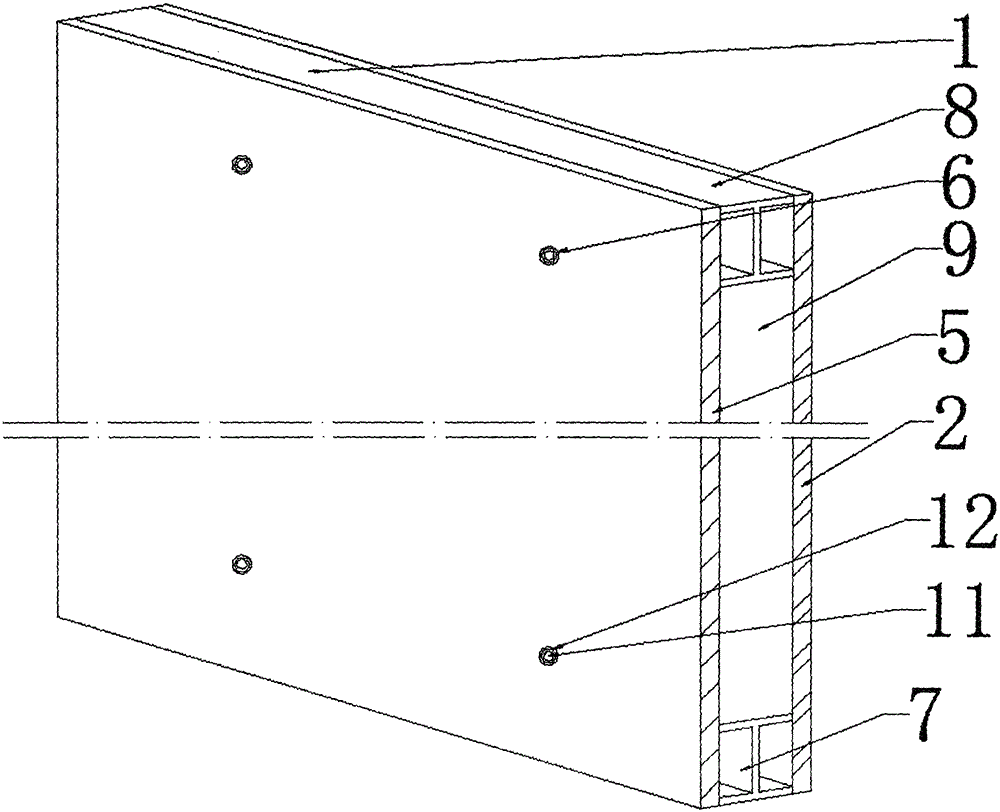

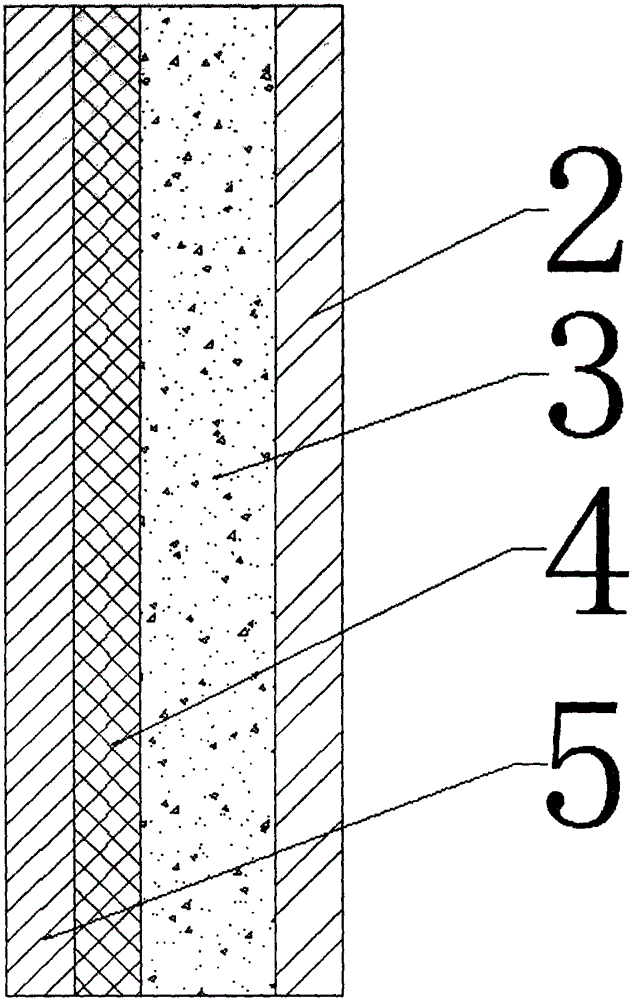

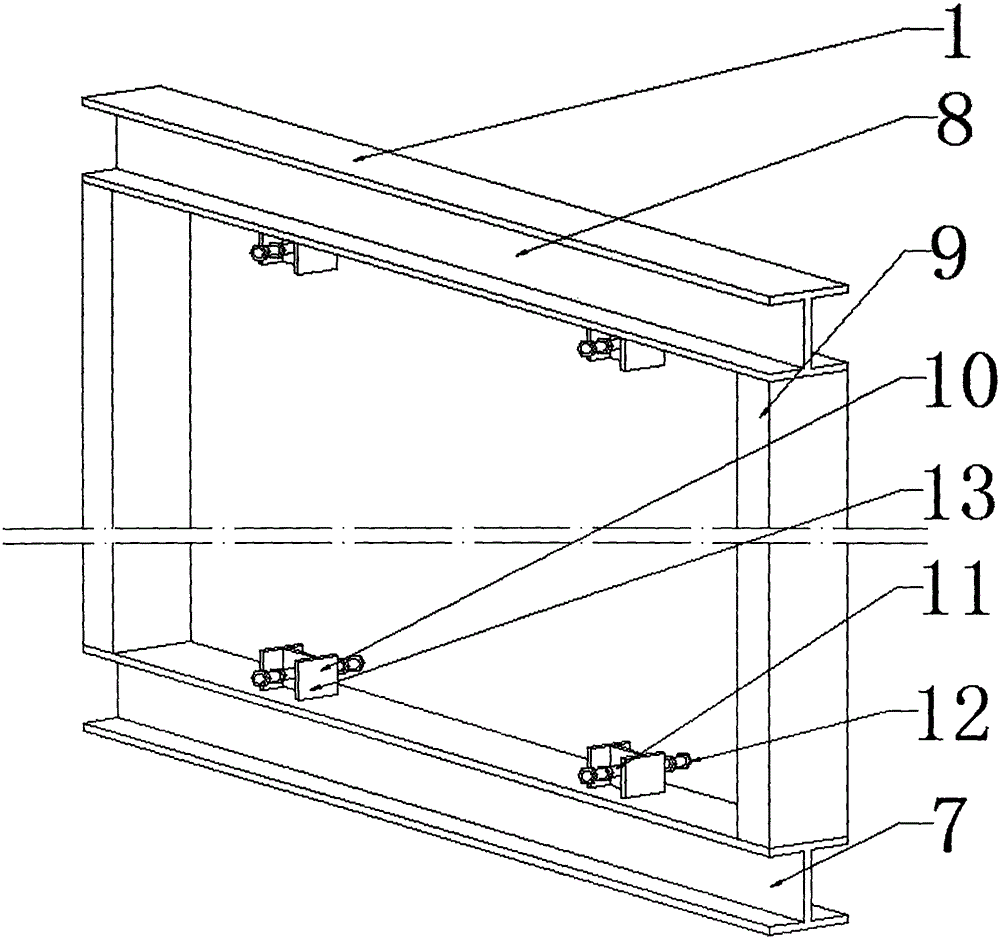

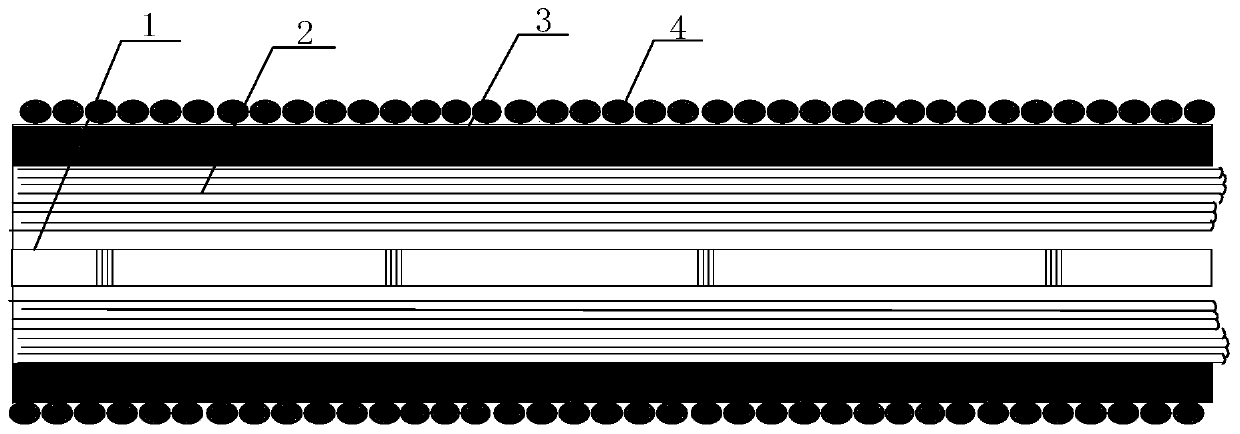

Novel wallboard convenient to install

InactiveCN105113709AQuick disassemblyImprove toughnessBuilding componentsEngineeringImpact resistance

The invention discloses a novel wallboard convenient to install. The novel wallboard convenient to install comprises a support, an outer leaf plate and an inner leaf plate. The support is composed of stand columns, a top beam, a bottom beam and connecting pieces. The stand columns perpendicular to the upper side face of the bottom beam are fixed to the two ends of the upper side face of the bottom beam, the top beam with the lower side face perpendicular to the stand columns is fixed to the top ends of the stand columns, the corresponding two connecting pieces are arranged on the lower side face of the top beam, and the corresponding two connecting pieces are arranged on the upper side face of the bottom beam. The connecting pieces are composed of joint steel fixedly welded to the beams, studs and nuts. The outer leaf plate and the inner leaf plate are fixed to the studs, a heat preservation cotton layer is arranged on the inner side of the outer leaf plate, a concrete layer is poured between the heat preservation cotton layer and the inner leaf plate, bolt holes correspond to the studs in position, and the thickness of the concrete layer can be adjusted by adjusting the positions of the nuts. Generally, the novel wallboard convenient to install has the advantages of being easy to manufacture, stable in quality, good in heat preservation, fire proofing, sound insulation and impact resistance capability and capable of being prefabricated, shortening the construction period of a building and saving production cost.

Owner:HENAN WANDAO JIEJIAN

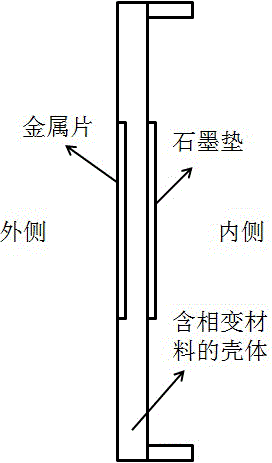

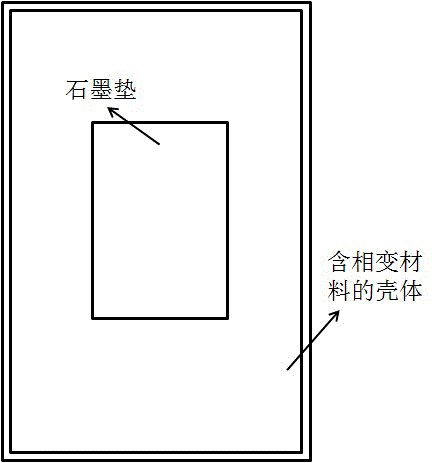

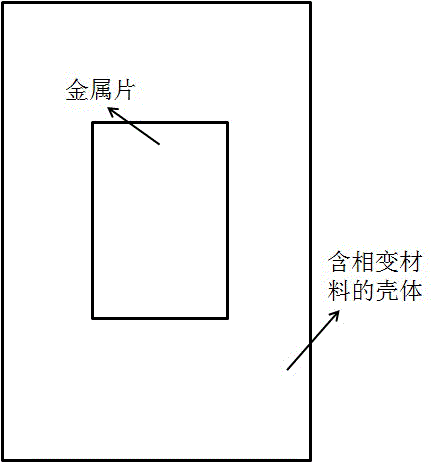

Phase-change temperature control mobile phone shell

InactiveCN104902041AFast thermal conductivityEasy to passTelephone set constructionsGraphiteMetal sheet

The invention relates to the technical field of a mobile phone protecting shell, specifically a phase-change temperature control mobile phone shell. The phase-change temperature control mobile phone shell comprises a graphite pad, a shell with phase-change material and a metal sheet. The graphite pad is closely stuck at the inner side of the shell with the phase-change material. The metal sheet is embedded at the outside of the shell with the phase-change material. The phase-change temperature control mobile phone shell of the invention integrates the functions of heat conduction, heat storage and heat dissipation and could ensure the temperature of a mobile phone to hold at the normally operated temperature when the mobile phone dissipates a lot of heat. The phase-change temperature control mobile phone shell of the invention not only adds the heat conduction and the heat dissipation of the mobile phone shell, but also improves beauty of the mobile phone shell by using the metal sheet simultaneously.

Owner:NINGBO GREENTECH ENERGY SAVING TECH

ELECTROMAGNETIC BASED THERMAL SENSING AND IMAGING INCORPORATING DISTRIBUTED MIM STRUCTURES FOR THz DETECTION

InactiveUS20110062334A1Improve heat sensitivityHigh sensitivitySolid-state devicesMaterial analysis by optical meansMetal-insulator-metalBlack-body radiation

A novel pixel circuit and multi-dimensional array for receiving and detecting black body radiation in the SWIR, MWIR or LWIR frequency bands. An electromagnetic thermal sensor and imaging system is provided based on the treatment of thermal radiation as an electromagnetic wave. The thermal sensor and imager functions essentially as an electromagnetic power sensor / receiver, operating in the SWIR (200-375 THz), MWIR (60-100 THz), or LWIR (21-38 THz) frequency bands. The thermal pixel circuit of the invention is used to construct thermal imaging arrays, such as 1D, 2D and stereoscopic arrays. Various pixel circuit embodiments are provided including balanced and unbalanced, biased and unbiased and current and voltage sensing topologies. The pixel circuit and corresponding imaging arrays are constructed on a monolithic semiconductor substrate using in a stacked topology. A metal-insulator-metal (MIM) structure provides rectification of the received signal at high terahertz frequencies.

Owner:ORYX VISION LTD

Modified polyolefin material for asphalt soft package

InactiveCN1566197AHigh tensile strengthImprove heat sensitivityPackaging corrosive chemicalsPolyethylene vinyl acetatePolyolefin

The invention relates to a modified polyolefin material for asphalt soft package which comprises polypropylene, polyethylene, polyethylene vinyl acetate copolymer, EPT rubber, and octadecanoic acid, the preparing process comprises the steps of, blending, granulating, blowing film, sealing, three-layer co-squeezing, and blowing film shaping.

Owner:PETROCHINA CO LTD +1

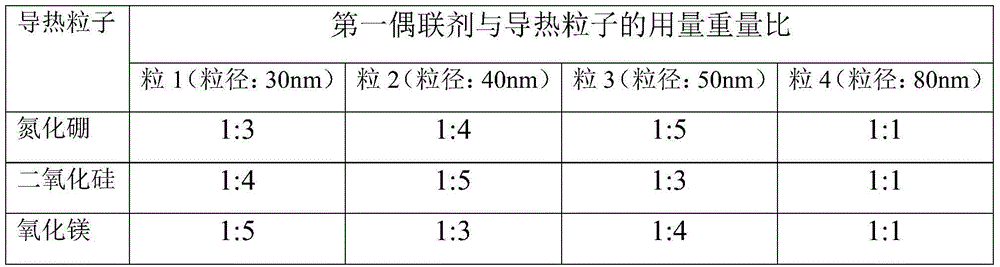

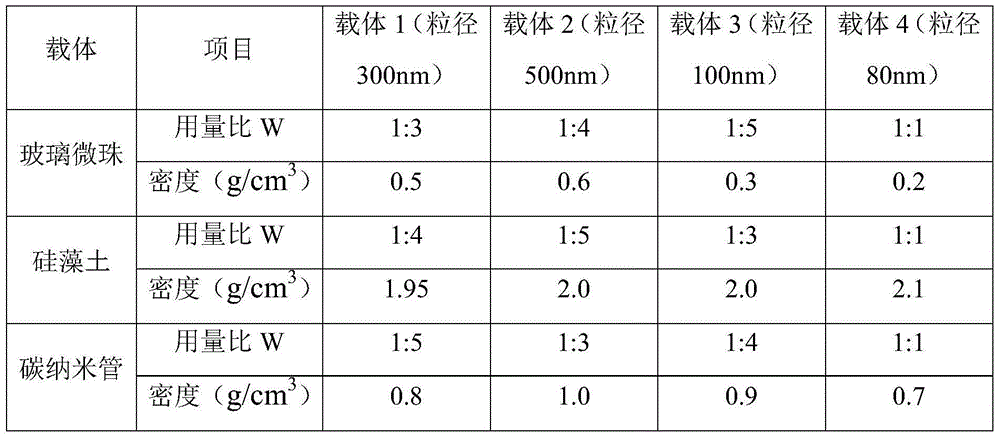

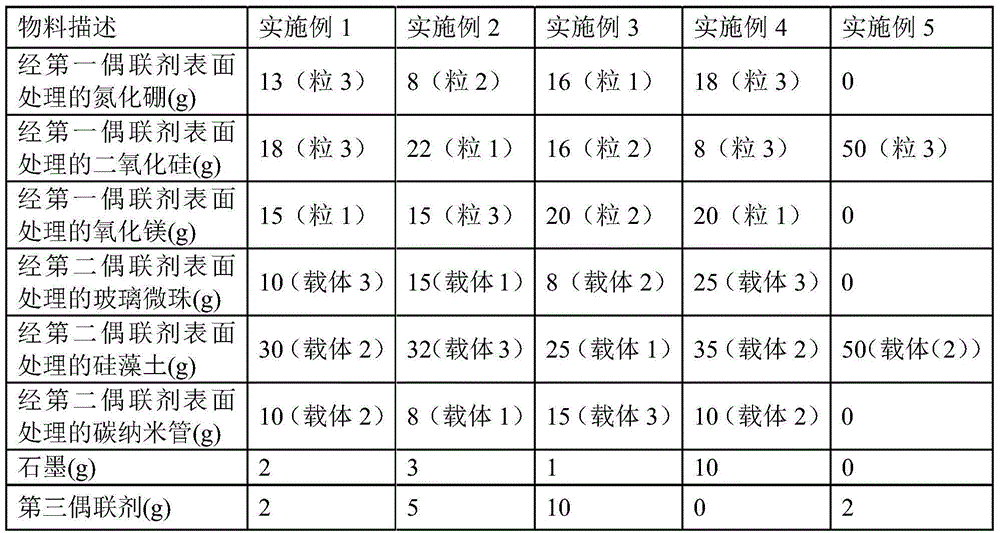

Heat-conducting composite material, rubber composition, pipe material for cooling media and preparation method for pipe material

The invention discloses a heat-conducting composite material, a rubber composition, a pipe material for cooling media and a preparation method for the pipe material. The heat-conducting composite material contains heat-conducting particles and a carrier, wherein the heat-conducting particles are subjected to surface treatment by a first coupling agent, and the carrier is subjected to surface treatment by a second coupling agent; and the heat-conducting particles which are subjected to surface treatment by the first coupling agent are at least partially filled in the carrier which is subjected to surface treatment by the second coupling agent, and the carrier is a porous, void or hollow granular matter. According to the heat-conducting composite material, the heat-conducting particles which are subjected to surface treatment by the first coupling agent and the carrier which is subjected to surface treatment by the second coupling agent are adopted, and the heat-conducting particles which are subjected to surface treatment by the first coupling agent are at least partially filled in pores of the carrier which is subjected to surface treatment by the second coupling agent, so that the compatibility of the heat-conducting composite material, containing the heat-conducting particles and the carrier, with base rubber is improved; and the heat-conducting composite material is added in the rubber composition, heat conducting channels are formed in milled rubber which is prepared through mixing the rubber composition containing the heat-conducting composite material, and then, the thermal sensitivity of the milled rubber is improved.

Owner:BYD CO LTD

Production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather

InactiveCN107268290AImprove controllabilityImprove waterproof performanceWaterborne vesselsTextiles and paperPolymer scienceIn situ polymerization

The invention discloses a production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather. The production method comprises the following steps: firstly, adding a component A containing hydroxyl and a component B containing an isocyanate group into a reaction still, and reacting by stirring to obtain foaming slurry; secondly, adopting a dry process production line of the synthetic leather, blade coating the foaming slurry on release paper to form a coating, and then laminating the coating with a base fabric by a gap fitting mode through a laminating machine; thirdly, feeding a mixture into a drying oven for cooking to obtain the waterproof organosilicon modified solvent-free polyurethane synthetic leather. According to the production method disclosed by the invention, the waterproof organosilicon modified solvent-free polyurethane synthetic leather is produced by adopting a double foaming technology, a polyurethane in-situ polymerization waterproof technology, a heat-sensitive catalyst asynchronous catalysis technology and a single-pole constant temperature heating scrape coating technology; the production technology is environmentally friendly, simple, and stable; the quality of a product is good; a contact angle of water droplets on the surface of the synthetic leather is as high as 107 degrees, and static water seepage prevention can be kept for 15 days; the waterproof organosilicon modified solvent-free polyurethane synthetic leather can be used as a high-end functional yacht seat covering material.

Owner:SHAANXI UNIV OF SCI & TECH

Pulsed tungsten argon arc welding method

InactiveCN103894709AReduce splashReduce distortionArc welding apparatusWelding/cutting media/materialsCurrent rangeShielding gas

A pulsed tungsten argon arc welding method comprises the following steps that (1) gas proportion of protective gas is determined; (2) composition of parent material is determined; (3) composition and diameter of a soldering wire is determined; (4) the welding is conducted according to the welding process specification. The welding process of the step (4) is characterized in that the requirements of the welding process comprise the steps that (a) the protective gas is the mixed gas of argon and oxygen, wherein at room temperature, the argon is 98% in volume, and the O2, namely the oxygen is 2% in volume; (b) it is guaranteed that the droplet transition is the one-pulse-one-droplet pulse jet flow transition in the welding process. According to the technical scheme, the pulsed tungsten argon arc welding method has the advantages that the welding spatter is small, bond area performance is improved, appearance of weld forms well, all position welding are applicable, and current range is wide.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

Temperature sensitive composite materials and preparing process thereof

InactiveCN1837288AFast thermal responseGood thermal expansion performanceHeat-exchange elementsCopperBall mill

The invention discloses a temperature-sensitive composite material and preparing method, which is characterized by the following: blending the copper and vax at inert gas protection; balling 50-150 h in the baler to produce temperature-sensitive composite material. The invention possesses good heat dilatability and easy manufacturing mould, which is benefit to do industrial production.

Owner:ZHEJIANG UNIV OF TECH

Electromagnetic based thermal sensing and imaging incorporating differential pixel topology

InactiveUS20110062330A1Improve heat sensitivityHigh sensitivityMaterial analysis by optical meansRadiation thermographyMetal-insulator-metalMulti dimensional

A novel pixel circuit and multi-dimensional array for receiving and detecting black body radiation in the SWIR, MWIR or LWIR frequency bands. An electromagnetic thermal sensor and imaging system is provided based on the treatment of thermal radiation as an electromagnetic wave. The thermal sensor and imager functions essentially as an electromagnetic power sensor / receiver, operating in the SWIR (200-375 THz), MWIR (60-100 THz), or LWIR (21-38 THz) frequency bands. The thermal pixel circuit of the invention is used to construct thermal imaging arrays, such as 1D, 2D and stereoscopic arrays. Various pixel circuit embodiments arc provided including balanced and unbalanced, biased and unbiased and current and voltage sensing topologies. The pixel circuit and corresponding imaging arrays are constructed on a monolithic semiconductor substrate using in a stacked topology. A metal-insulator-metal (MIM) structure provides rectification of the received signal at high terahertz frequencies.

Owner:ORYX VISION LTD

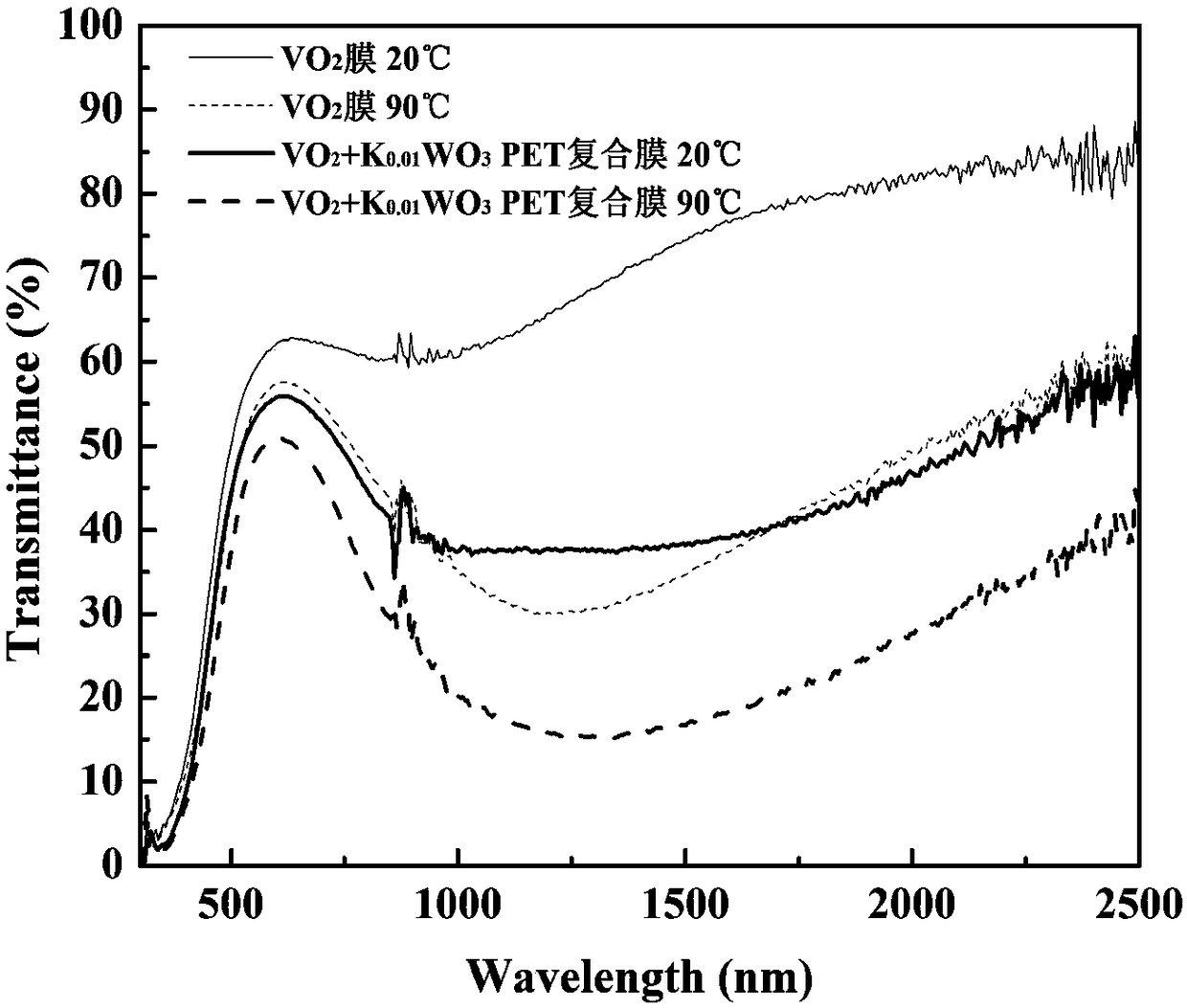

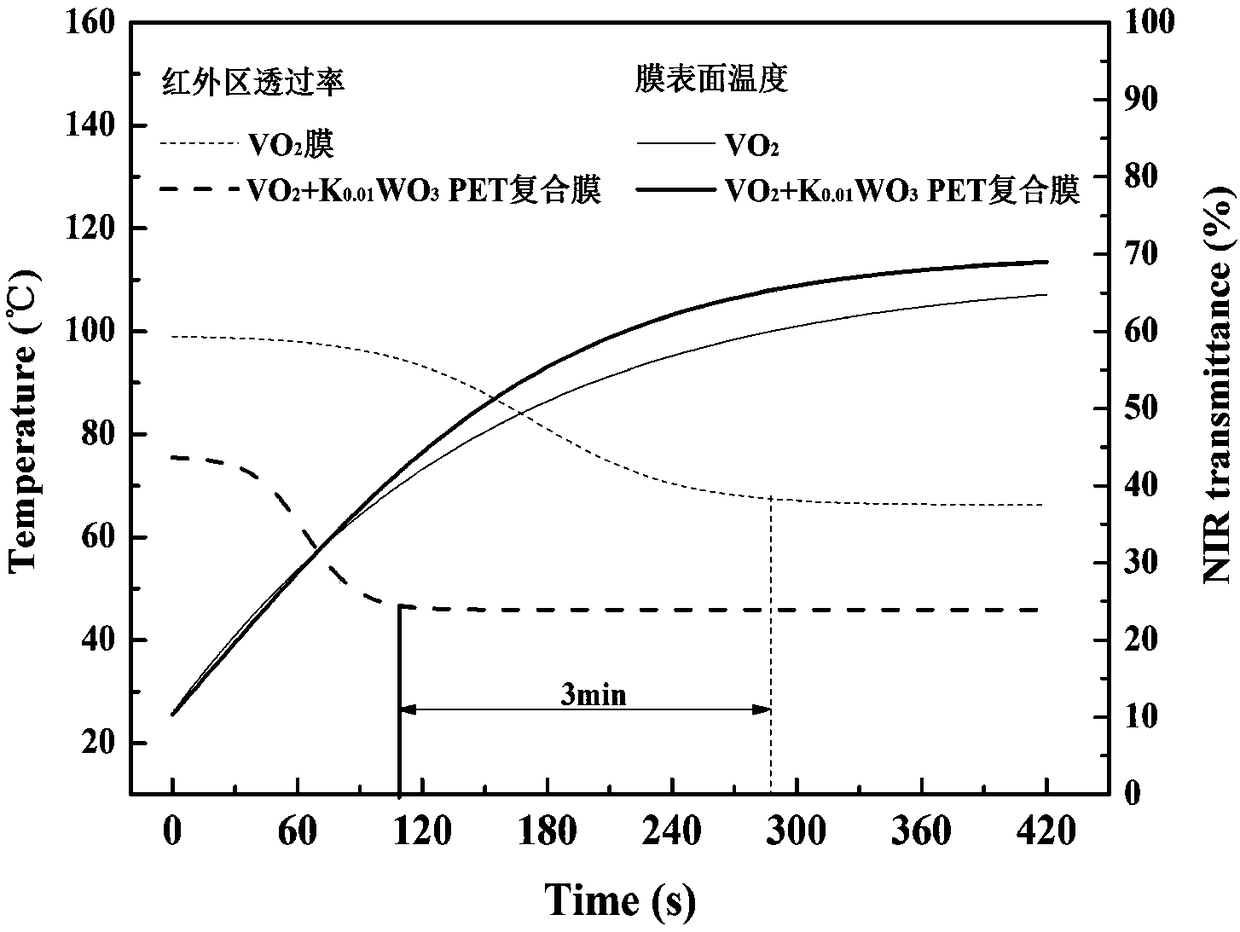

Preparation method of intelligent energy-saving composite film

ActiveCN108504271AComfort temperature rangeImprove heat sensitivityPolyurea/polyurethane coatingsRadiation-absorbing paintsWeather resistanceComposite film

The invention discloses a preparation method of an intelligent energy-saving composite film. The preparation method comprises the steps: mixing thermochromic slurry and tungsten bronze heat absorbingslurry to prepare composite slurry; then, adding a polymer film forming agent; and coating a substrate to prepare the intelligent energy-saving composite film. By utilizing the infrared absorption characteristic of tungsten bronze, the heat sensitivity of a thermochromic material is improved, the thermal response speed is increased, and the phase-change response time is shortened; meanwhile, due to the combination of the ultraviolet barrier property of the thermochromic material, the weather resistance of tungsten bronze is improved, the intelligent energy-saving composite film with high efficiency and high stability is obtained, and the intelligent energy-saving composite film can be widely applied to building glass, automotive glass and the like, can make the temperature inside a room ora vehicle reach a comfortable temperature range all the year round and has a good application prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

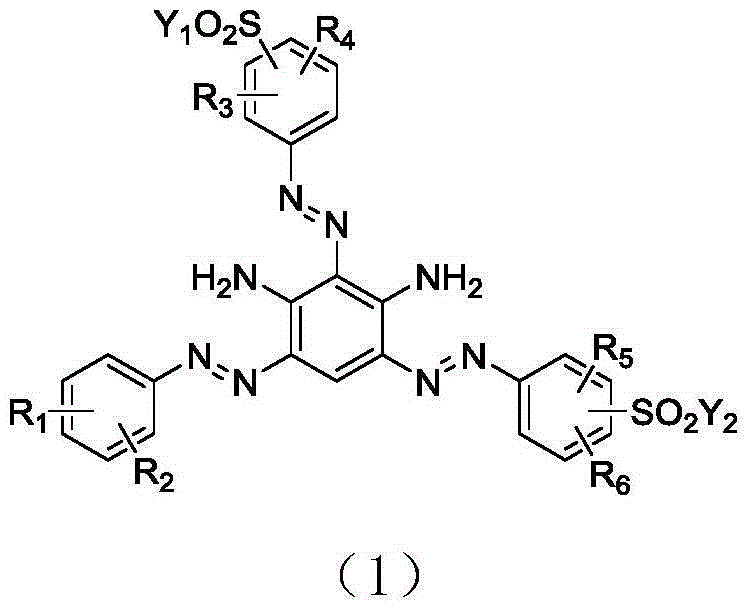

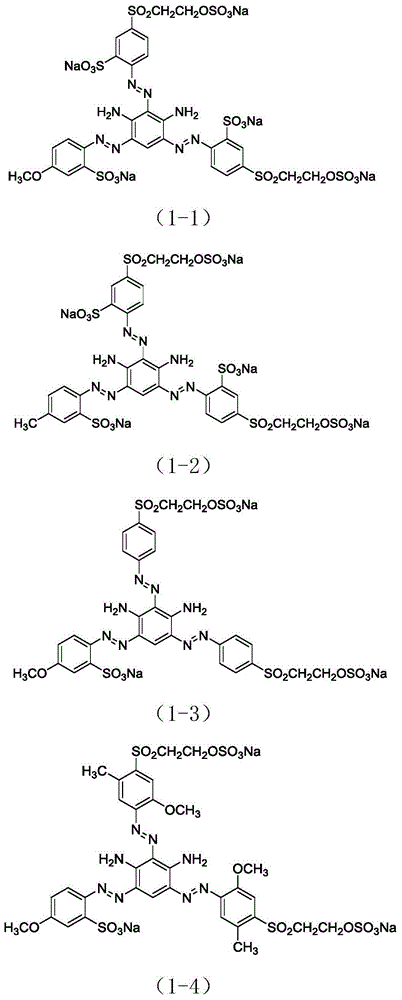

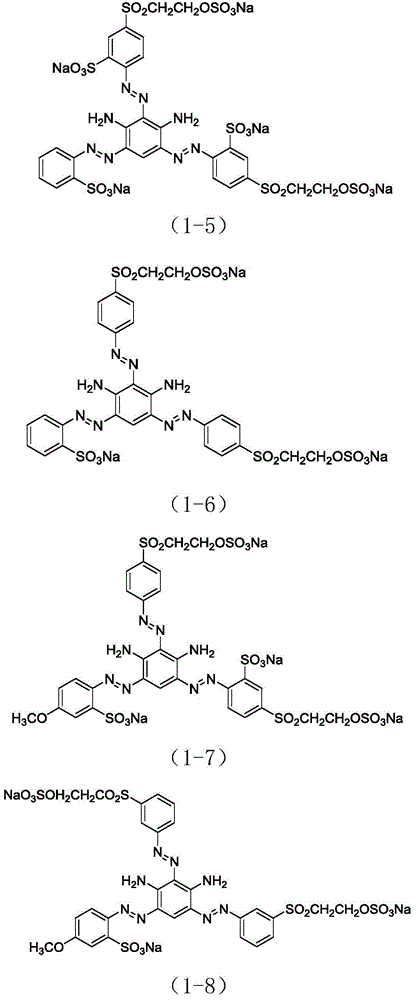

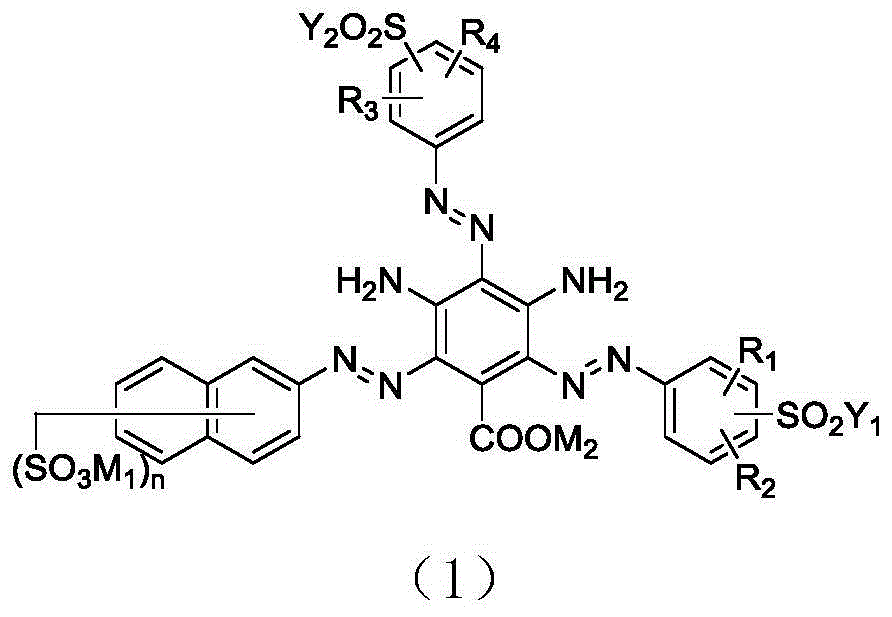

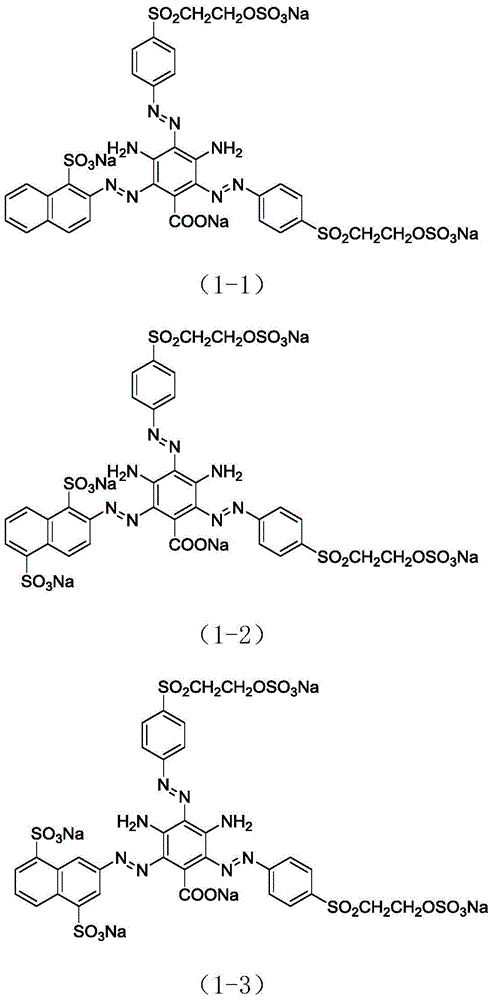

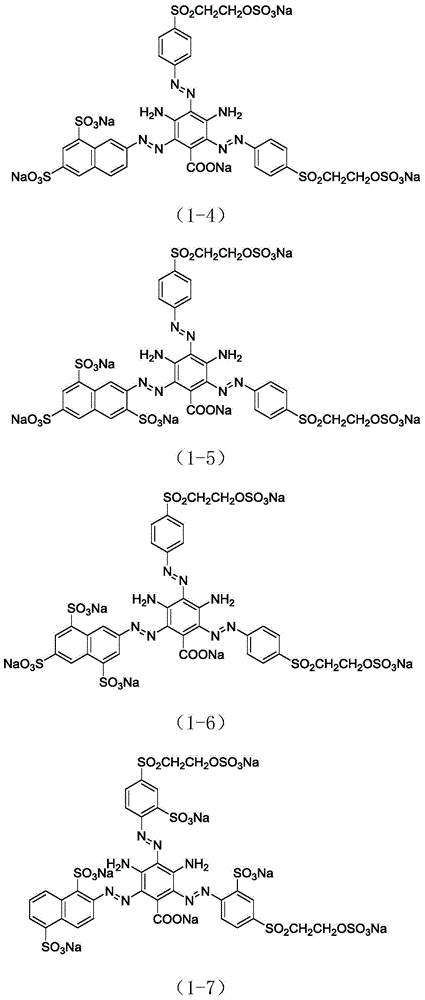

Yellowish-brown reactive dye and preparation method thereof

InactiveCN104830097AExcellent color synchronizationImprove dye uptake and color fixationOrganic chemistryOrganic compound preparationReactive dyePhotochemistry

A yellowish-brown reactive dye and a preparation method thereof. The invention relates to a yellowish-brown reactive dye and a preparation method thereof. The yellowish-brown reactive dye includes one compound selected from a general formula (1), or a mixture compounded by more than two compounds in the general formula (1) in any proportion. R1, R2, R3, R4, R5 and R6 in the formula (1) independently represent -H, -CH3, -OCH3 and -SO3M; Y1 and Y2 independently represent -CH=CH2 and -C2H4OSO3M; and M represents hydrogen or alkali metal. The yellowish-brown reactive dye has excellent coloration synchronization, high dye uptake and fixation rate, good levelness, and excellent solarization and friction fastness.

Owner:ZHEJIANG YIDE CHEM

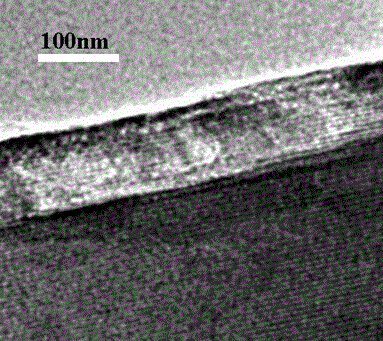

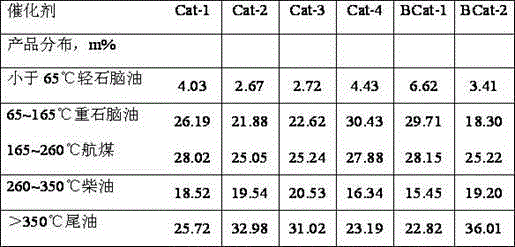

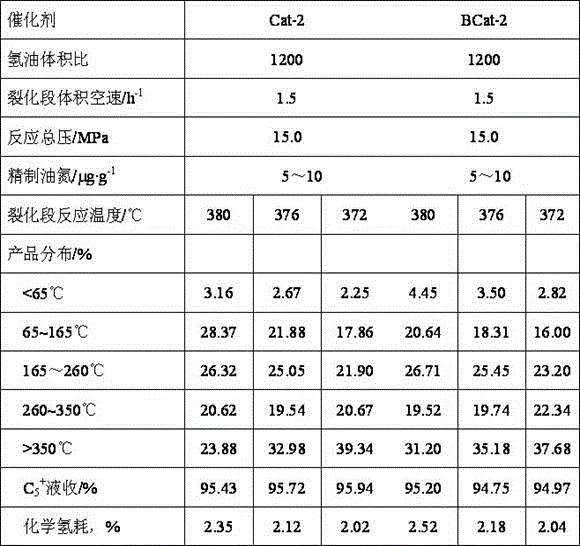

Method for preparing hydro-cracking catalyst composition

ActiveCN105618113AReduce the ratio of silicon to aluminumImprove heat sensitivityMolecular sieve catalystsHydrocarbon oil crackingPtru catalystOrganosolv

The invention discloses a method for preparing a hydro-cracking catalyst composition. The method comprises the following steps: 1, modified Y type molecular sieve, amorphous silica-alumina and / or aluminum oxide are well mixed according to a certain ratio; dilute nitric acid is added, such that a slurry is formed; extrusion molding is carried out; and drying and roasting are carried out, such that a silica-alumina carrier containing the modified Y type molecular sieve is obtained; and 2, the carrier obtained in the step 1 is impregnated with an impregnation solution containing active metals; after impregnation, the carrier is dried and the dried carrier is roasted, such that the hydro-cracking catalyst is obtained. A preparation method of the modified Y type molecular sieve comprises the following steps: NaY zeolite is adopted as raw powder; ammonium salt ion exchange, ammonium fluorosilicate dealumination and silicon reinsertion treatment, hydrothermal treatment, and aluminum salt solution treatment are carried out; impregnation is carried out in organic solvents; and fast drying, alkali desilication, drying and roasting treatments are carried out, such that the modified Y type molecular sieve is obtained. The hydro-cracking catalyst composition provided by the invention has good temperature increase sensitivity and operation flexibility. The composition can be widely used in hydro-cracking reaction processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

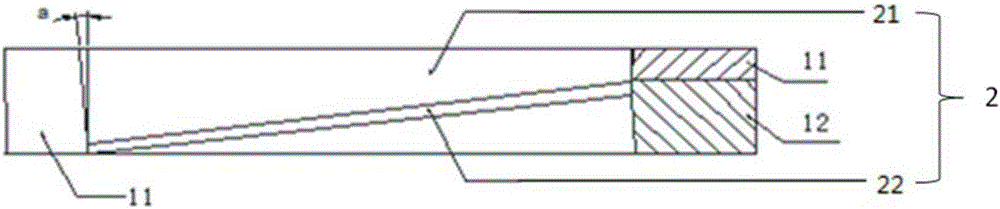

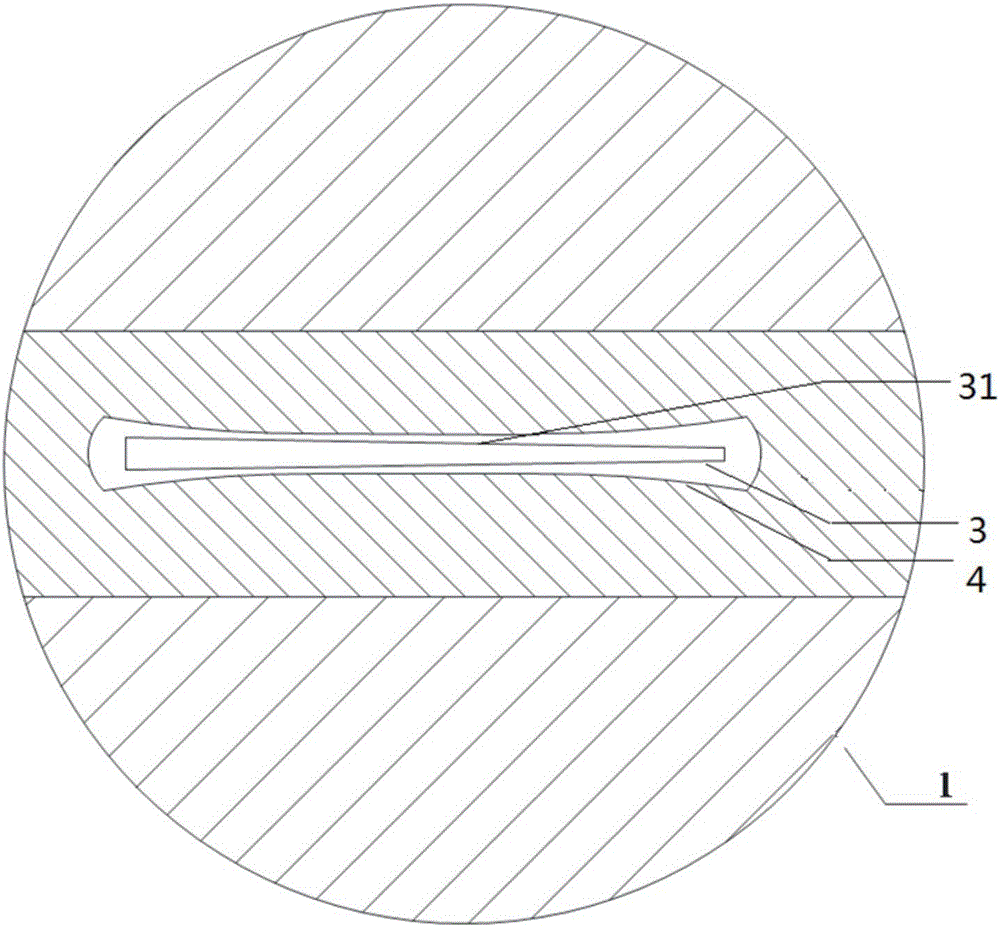

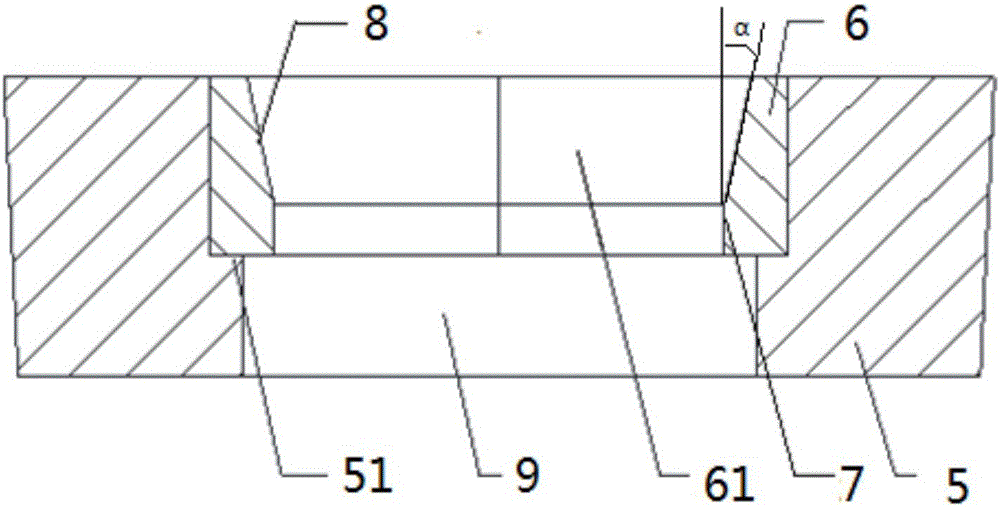

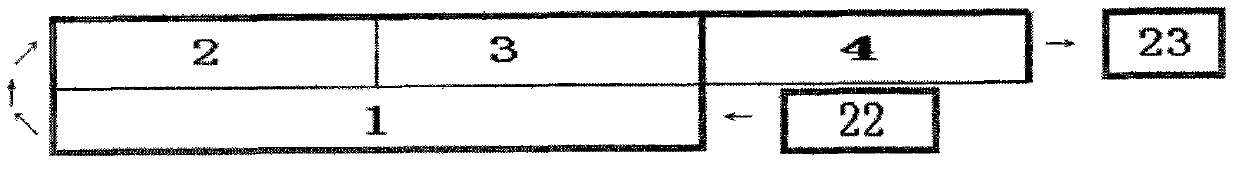

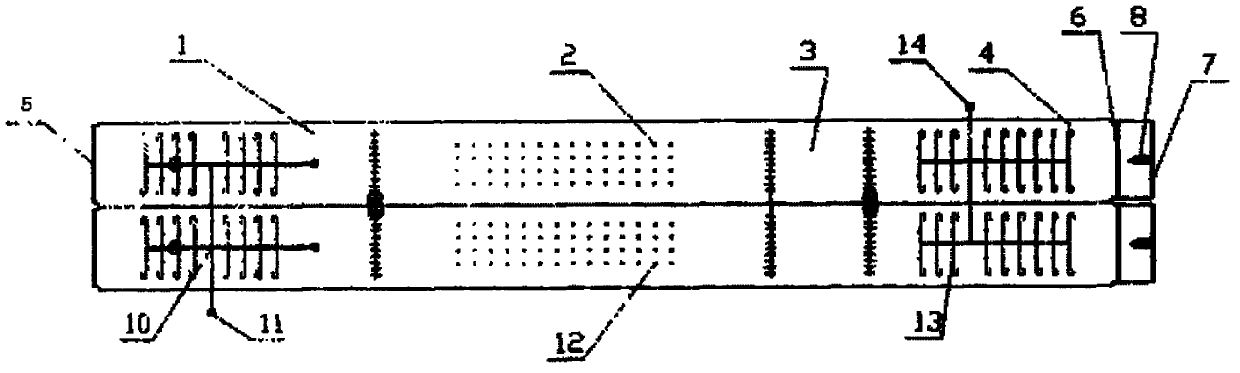

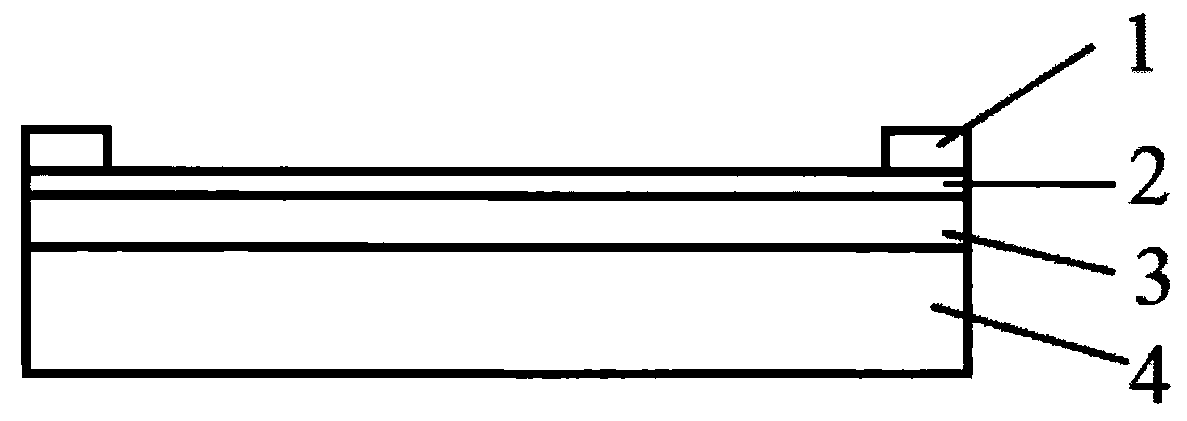

Production process for special-shaped silver-copper busbar and special-shaped silver-copper busbar

ActiveCN105032972AGuaranteed accuracy and mechanical propertiesGuaranteed uniformityDrawing diesExtrusion diesBusbarSilver copper

The invention provides a production process for a special-shaped silver-copper busbar and the special-shaped silver-copper busbar. In the step of conducting continuous extrusion on a silver-copper alloy rod so as to manufacture a special-shaped silver-copper alloy busbar blank, a sizing belt 22 of an extrusion die 1 which is adopted is in a protruding shape, and the portion, located on the central area of the die, of the sizing belt 22 is bent outwards in the radial direction to form an arc-shaped outwards-protruding part 31. After a whole base body of the die deforms inwards through high temperature and high pressure, the inward deformation range of the central area is the maximum, and therefore the central area is designed into the arc-shaped protruding part, the size of the central area can be large than that of the two sides, the whole area of an outlet can more tend to the straight state, copper products can evenly flow in the deformation process, straightness of appearance of extruded products coming out of the outlet is ensured, and accuracy of the extruded products and uniformity of the mechanical property are ensured.

Owner:JIANGXI GUANGXIN COPPER IND

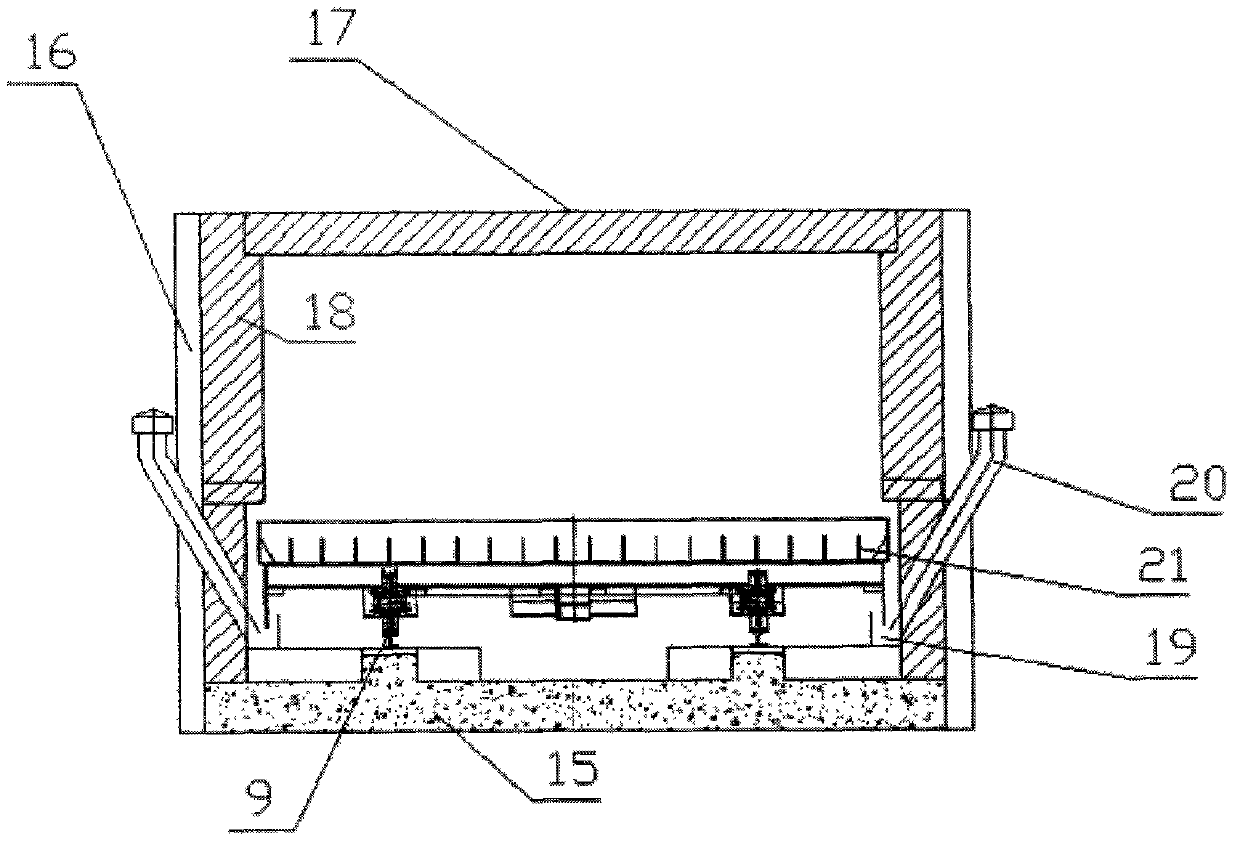

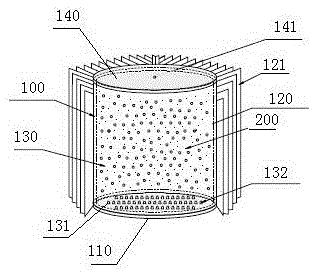

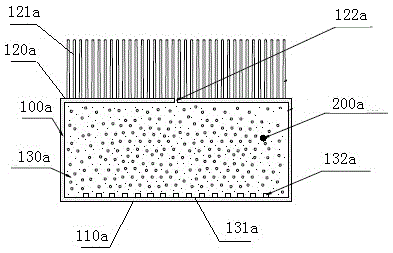

Assembled type tunnel kiln

InactiveCN103629925AShort construction periodShorten the production periodFurnace typesTunnel kilnFiber

The invention provides an assembled type tunnel kiln. The assembled type tunnel kiln comprises a bottom foundation, steel structure kiln walls, a kiln top and thermal insulation fireproof layers, wherein the steel structure kiln walls are fixedly arranged on the two sides of the bottom foundation, the thermal insulation fireproof layers are arranged inside the steel structure kiln walls, the kiln top is arranged on the top portions of the steel structure kiln walls, a kiln car rail is arranged on the bottom foundation, sand sealing grooves are formed in the two sides of the kiln car rail, sand adding pipes are arranged on the kiln walls and the thermal insulation fireproof layers in a penetrating mode, and the sand adding pipes are communicated with the sand sealing grooves. The assembled type tunnel kiln has the advantages that steel frame modules and refractory fibers replace tiles and mortar to be used for the assembled type tunnel kiln, ignition production can be conducted on the same day when the assembled type tunnel kiln is completely assembled, the production construction period is greatly shortened, and quality of the kiln is ensured.

Owner:巨野县大鹏窑炉有限公司

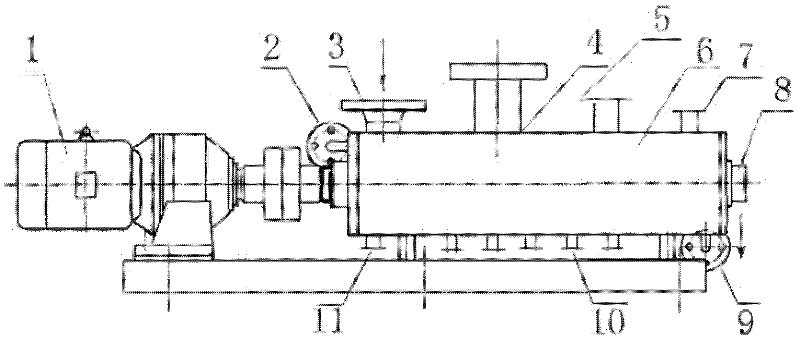

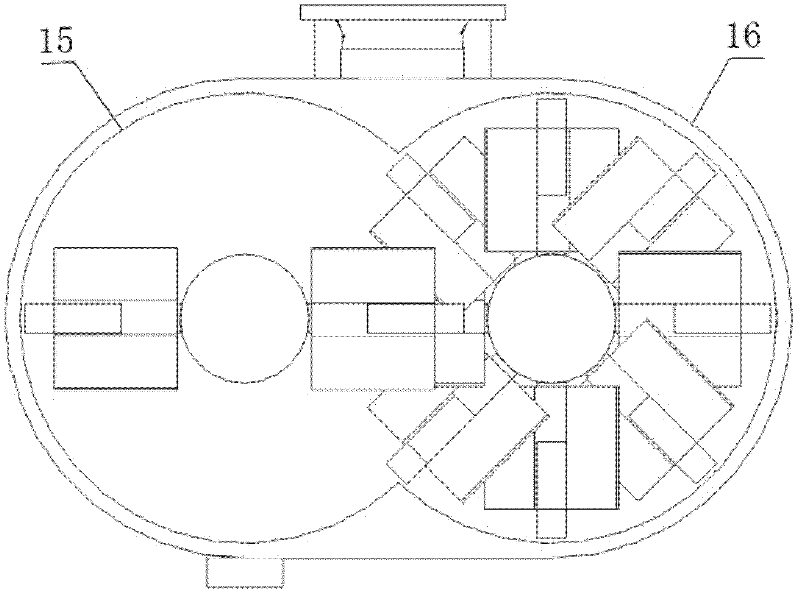

Rod fin-type horizontal double-shaft stirring reboiler with propulsion blades

The invention discloses a rod fin-type horizontal double-shaft stirring reboiler with propulsion blades. The rod fin-type horizontal double-shaft stirring reboiler with propulsion blades comprises a kettle body, a motor and a speed reducer connected to the motor. The top of the kettle body is provided respectively with a material inlet, a gas outlet and a manhole. Multiple material outlets are arranged at the bottom or a side wall of the kettle body. Two rotating shafts connected to an output shaft of the speed reducer are arranged in the kettle body. The two rotating shafts are respectively provided with multiple rod-type stirring fins at intervals. Each one of the rod-type stirring fins is provided with a propulsion blade. The rod-type stirring fins and the propulsion blades of the two rotating shafts are arranged crisscross. The rod fin-type horizontal double-shaft stirring reboiler with propulsion blades eliminates stirring blind angles and enhances stirring effects. Through the action between the rod-type stirring fins and the action between the rod-type stirring fins and the inner wall of the kettle body, materials bonded to the rod-type stirring fins and the inner wall of the kettle body can be scraped. Therefore, the rod fin-type horizontal double-shaft stirring reboiler with propulsion blades has strong self-cleaning effects and can avoid that materials are bonded to the interior of the kettle body.

Owner:TIANJIN UNIV

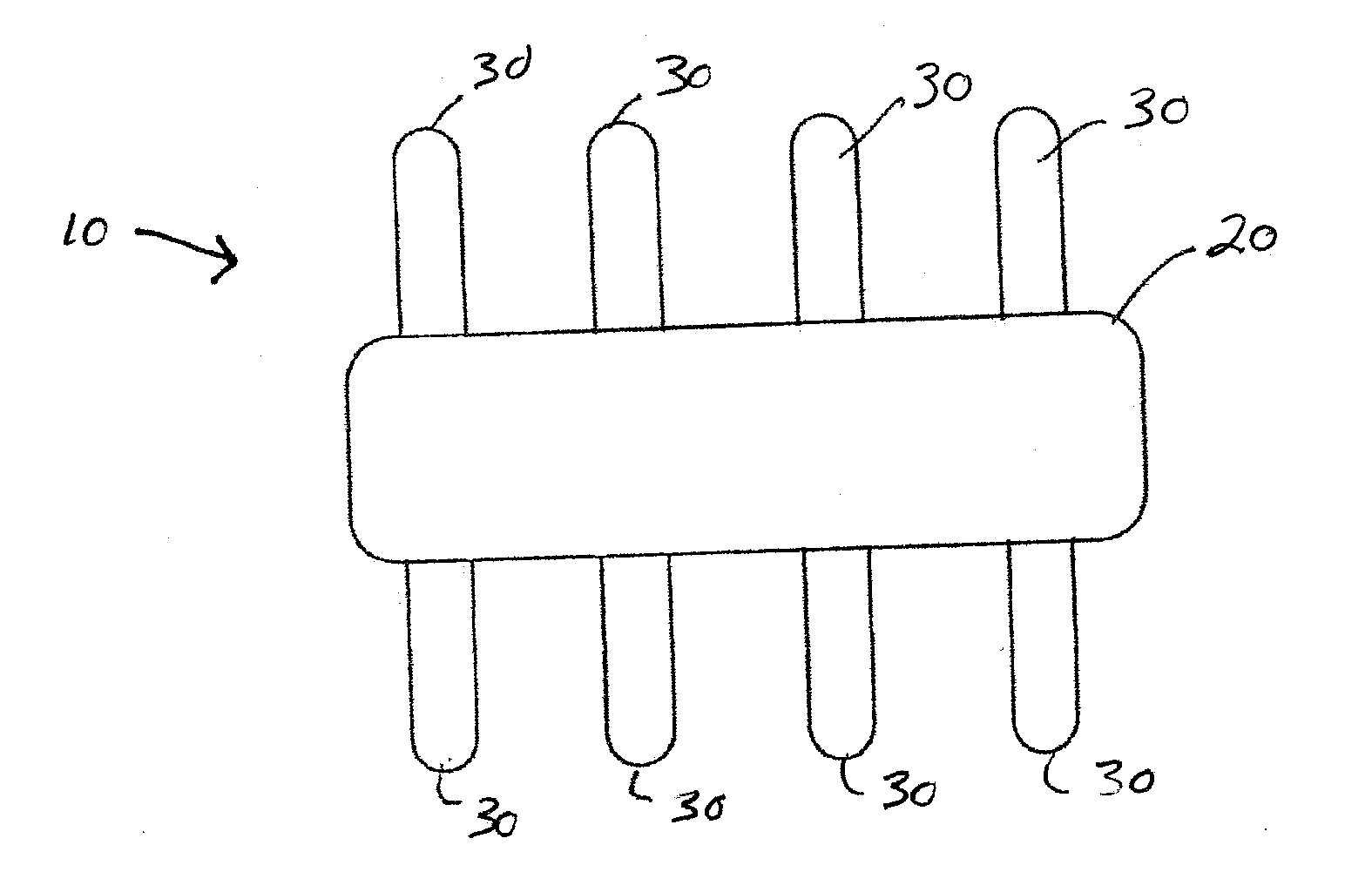

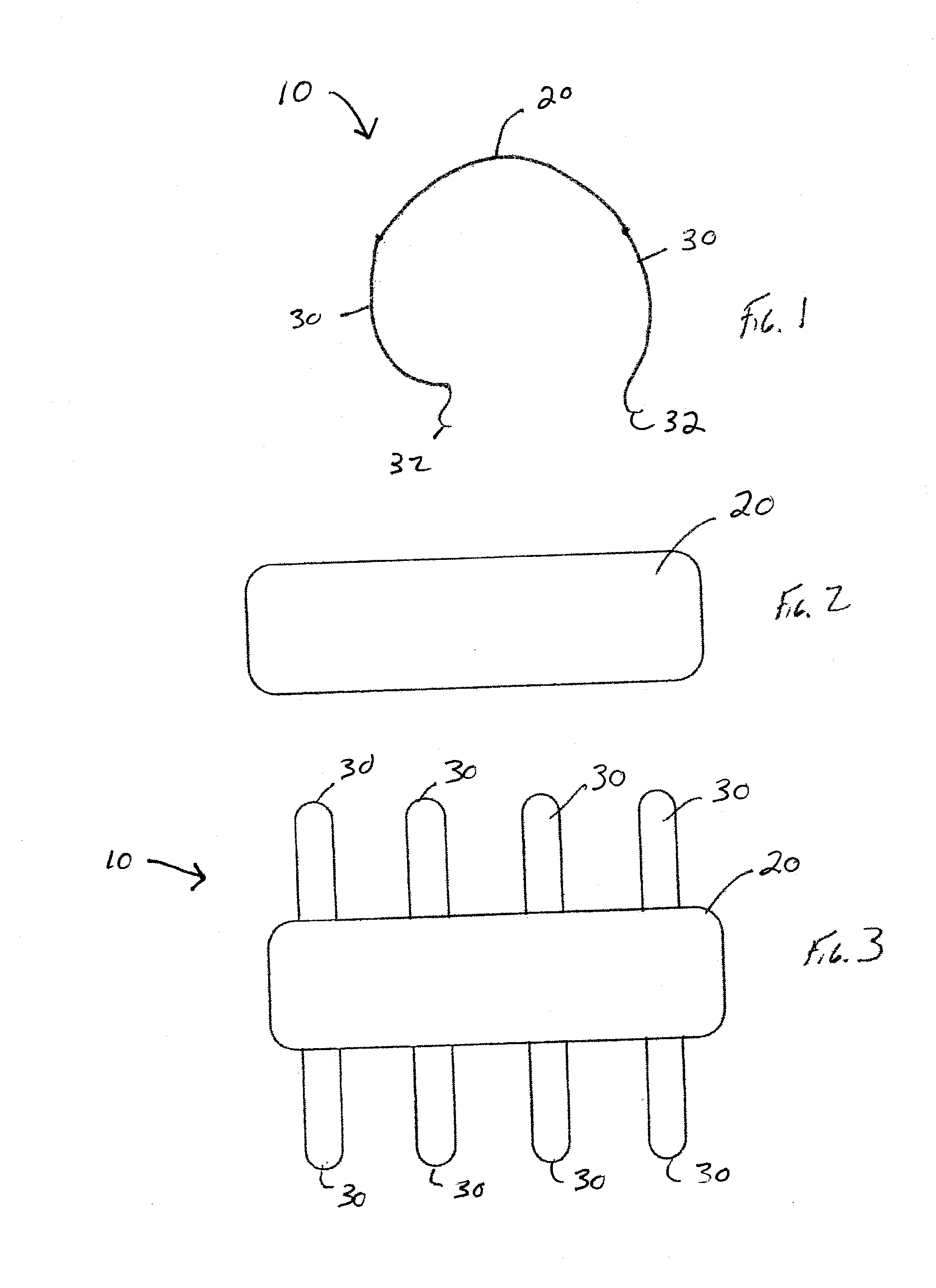

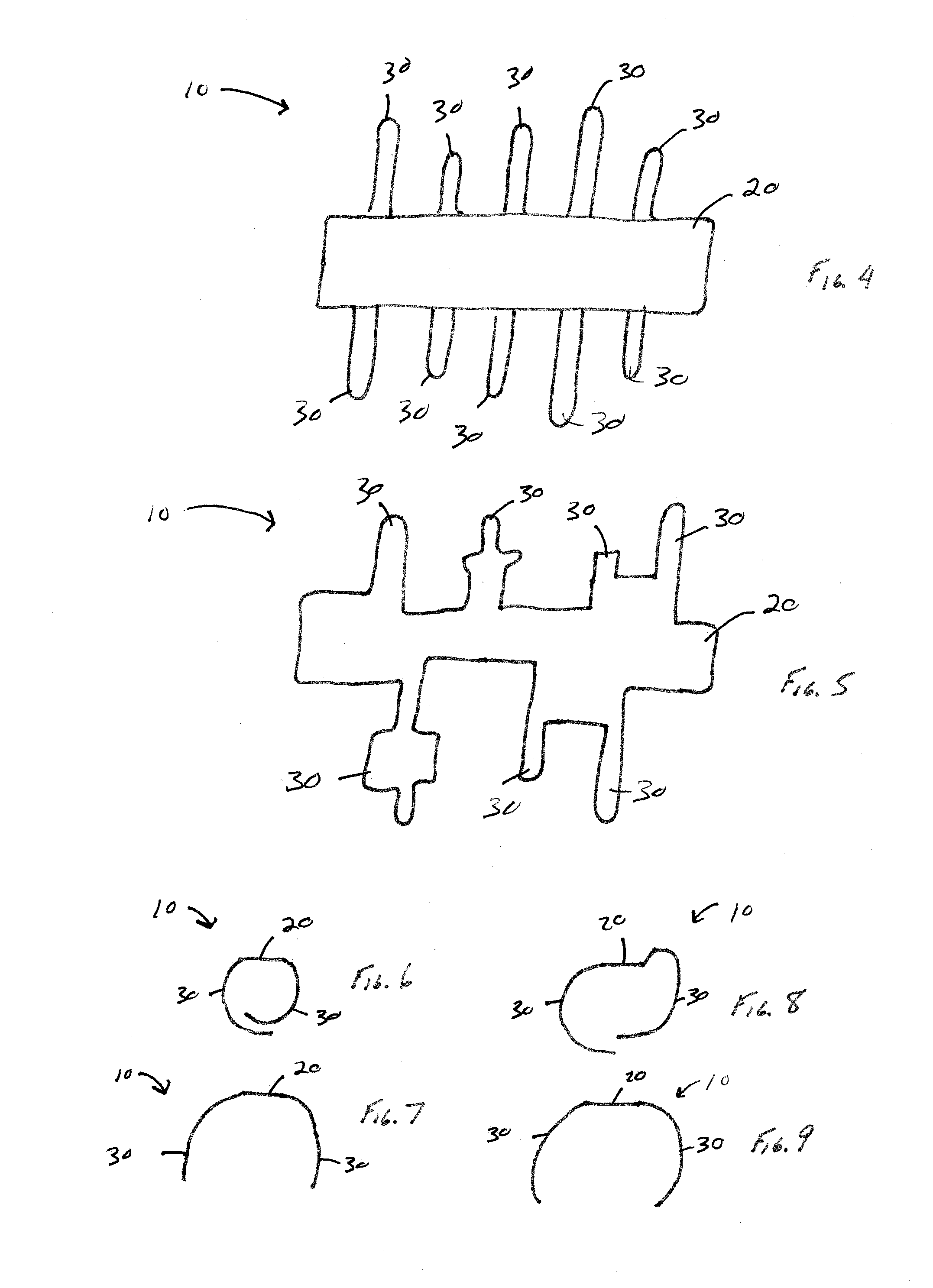

Expandable Device

InactiveUS20150272750A1Low ductilityMore coefficientStentsBlood vesselsMedical deviceBiomedical engineering

A medical device that is formed of a backbone portion and a plurality of ribs. The ends of one or more of the ribs are not connected together when the medical device is in the expanded position.

Owner:MIRUS LLC

Microgravity molecule heat-transferring heat conductor and application

InactiveCN105091645AImprove heat sensitivityAchieve heat transfer effectPoint-like light sourceLighting heating/cooling arrangementsHeat resistanceHeat energy

The invention discloses a microgravity molecule heat-transferring heat conductor. The microgravity molecule heat-transferring heat conductor comprises a radiator. The radiator is provided with a heat absorbing surface and at least one heat dissipating surface. A vacuum sealed cavity is arranged in the radiator. Microgravity molecule heat-transferring media with the volume being smaller than that of the vacuum sealed cavity are arranged in the vacuum sealed cavity. The microgravity molecule heat-transferring media are gasified rapidly when encountering a heat source under the microgravity condition, the whole sealed space is filled with the microgravity molecule heat-transferring media, part of heat energy is converted into molecule movement kinetic energy rapidly, and thus part of the heat energy is consumed; meanwhile, constant temperature is formed in the whole space rapidly, almost no heat resistance exists in the space, and a point heat source is changed into a body heat source instantly. The microgravity molecule heat-transferring heat conductor has the beneficial effects that the problems of high-power heat dissipation and high-heating-flux heat conduction are solved completely, manufacturing is convenient, the weight is low, cost is low, the conductor can be in any shape and be installed freely, and burning explosion hidden dangers are avoided. The microgravity molecule heat-transferring heat conductor is used for manufacturing high-power LED radiators or high-heating-flux integrated circuit board radiators.

Owner:胡祥卿

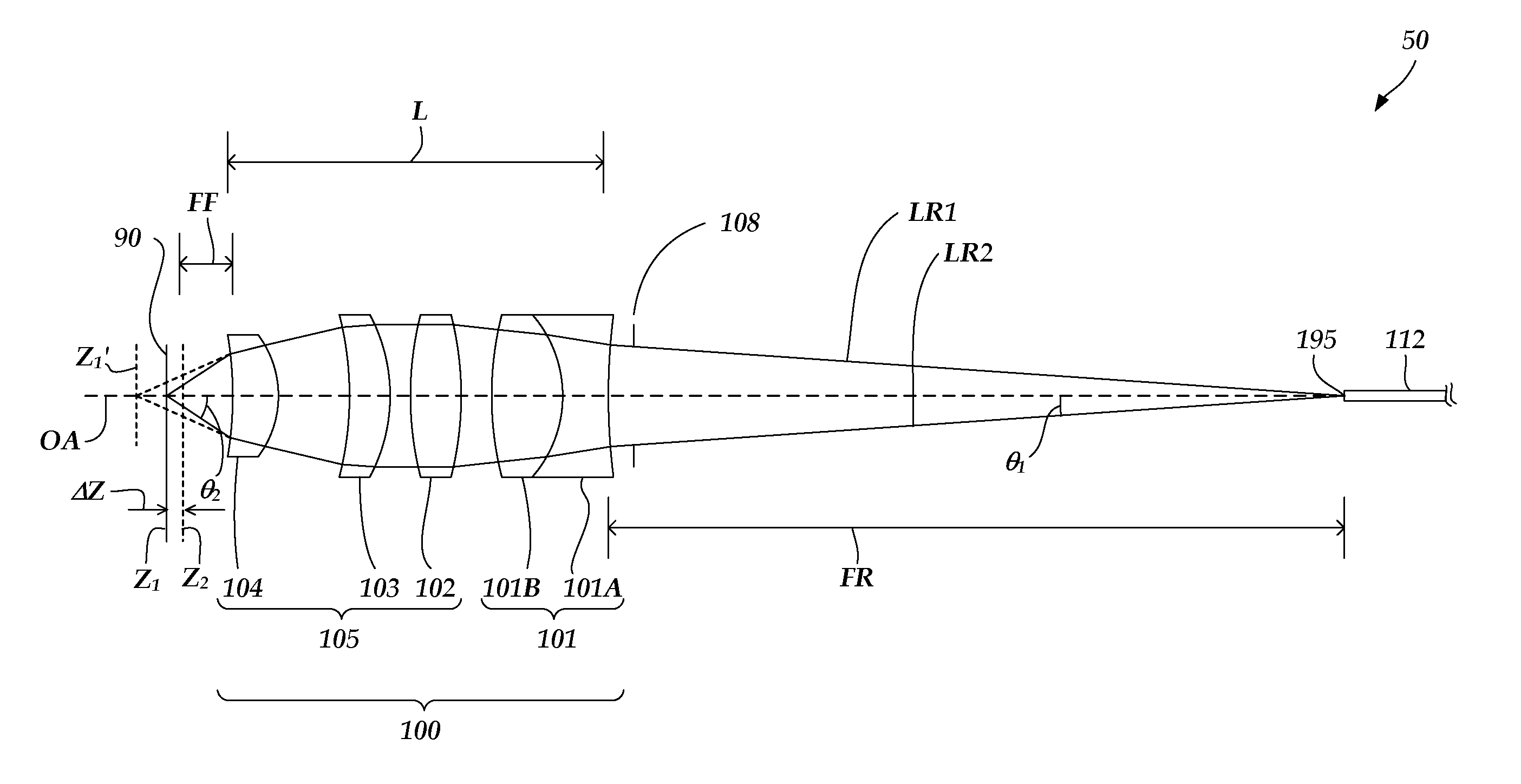

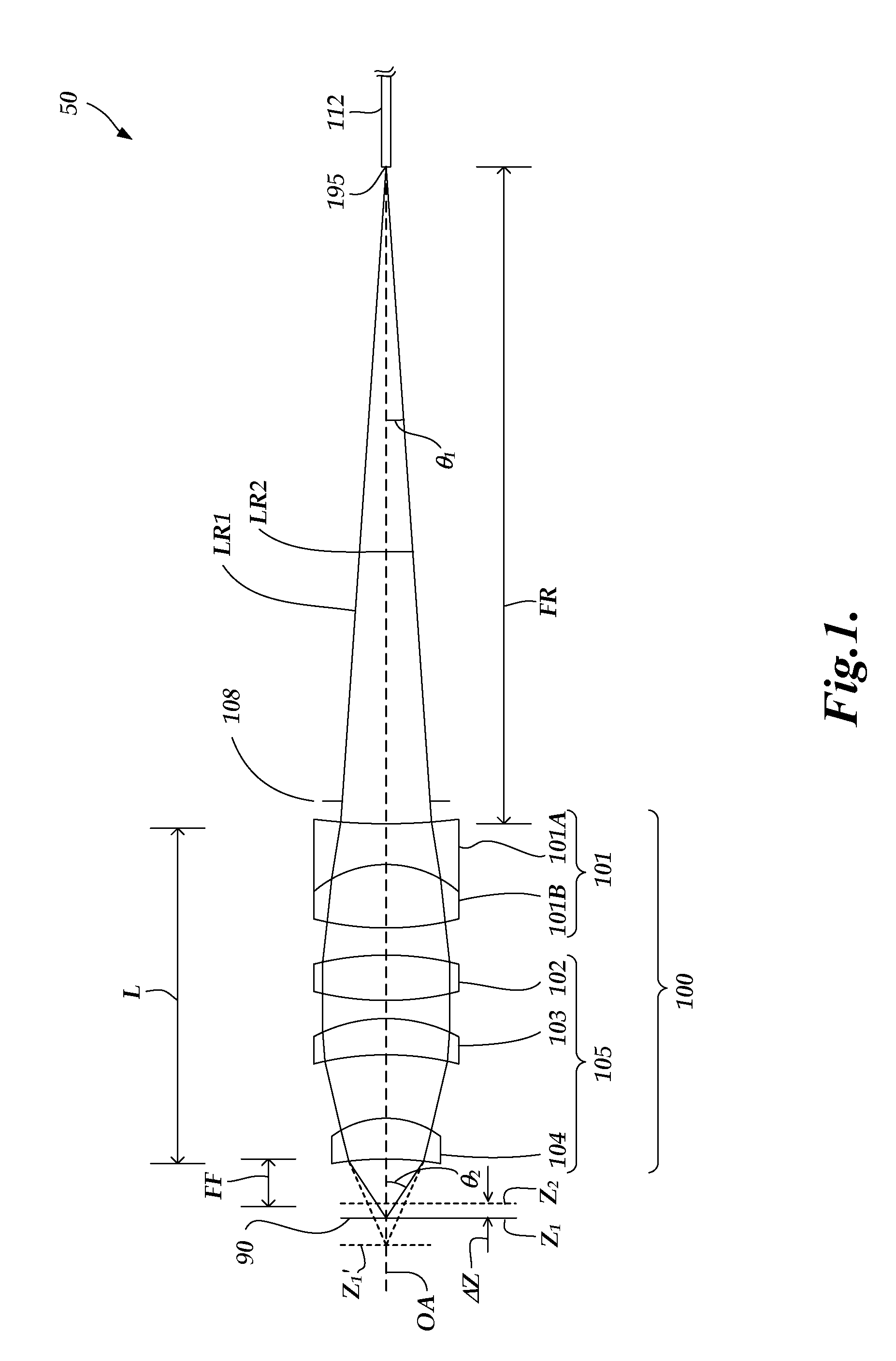

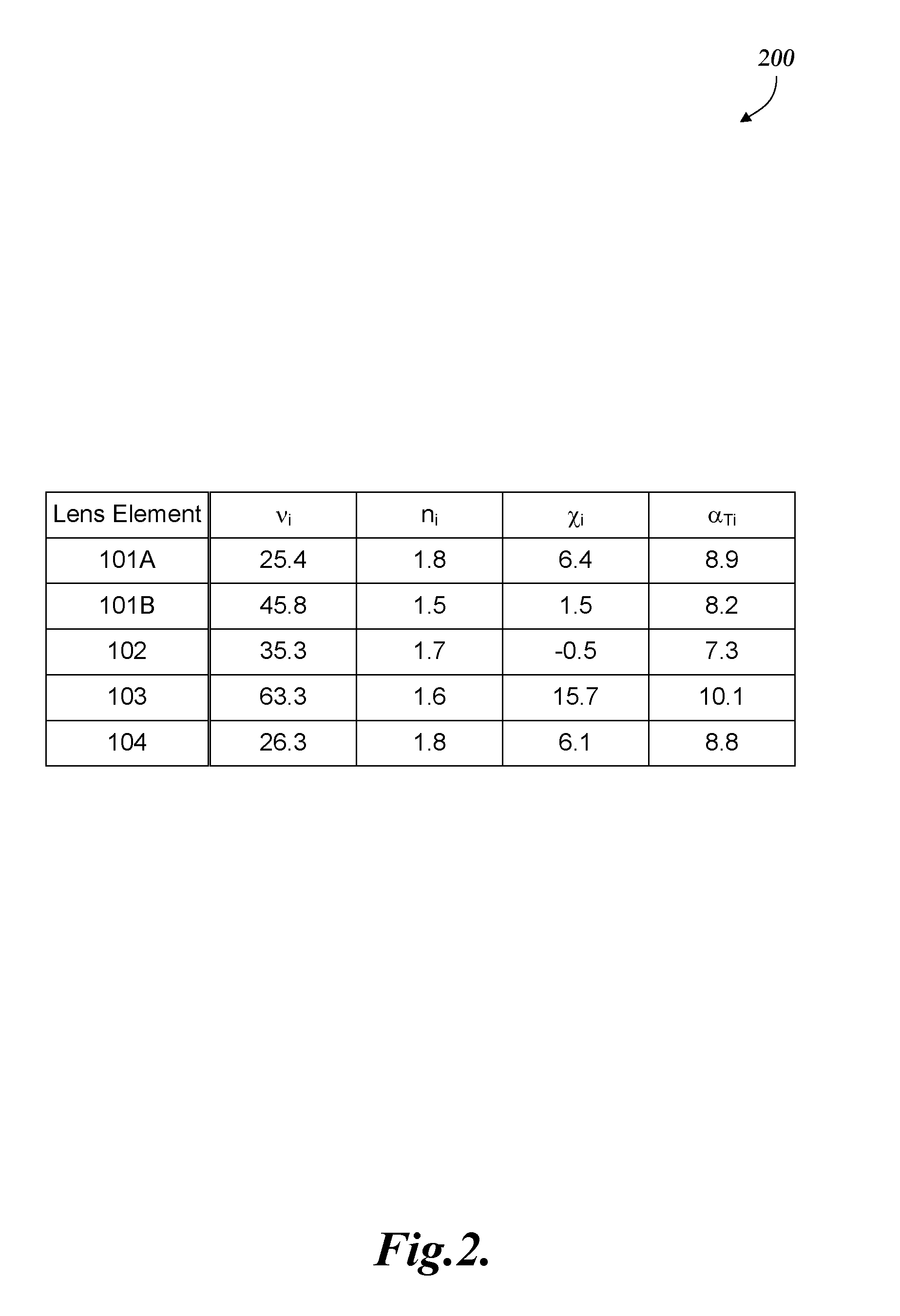

Lens configuration for a thermally compensated chromatic confocal point sensor

ActiveUS20110228250A1Reduce complexityReduce expensesOptical rangefindersHeight/levelling measurementCamera lensNegative power

A chromatically dispersive lens configuration including thermal compensation may be utilized in chromatic confocal point sensor optical pens for chromatic range sensing. The lens configuration may include a negative power doublet lens and a positive power lens portion. The positive power lens portion comprises at least two lens elements which compensate for the overall thermal sensitivity of a chromatic confocal point sensor optical pen. The lens elements of the positive power lens portion which compensate for thermal sensitivity have an average coefficient of thermal defocus which is in a range that is at lowest 10 ppm per 10° C. The lens configuration can be implemented with dimensions which fit a standard commercial chromatic confocal point sensor optical pen, while maintaining a level of optical performance sufficient for chromatic range sensing.

Owner:MITUTOYO CORP

Yellow reactive dye and preparation method thereof

InactiveCN104893357AGood lifting effectGood dyeing depthReactive dyesPolymer sciencePolymer chemistry

The invention relates to a yellow reactive dye and a preparation method thereof. The reactive dye comprises any one compound selected from a general formula (1) or a mixture of any more than two compounds with any proportion selected from the general formula (1) through complex formulation; wherein in the formula (1), R1, R2, R3, R4 are respectively and independently represented as -H, -CH3, -OCH3 or -SO3M1; Y1 and Y2 are respectively represented as -CH=CH2 or -C2H4OSO3M1; M1 and M2 are respectively and independently represented as hydrogen or alkali metal, and n is 1, 2, 3. The yellow reactive dye has excellent coloring synchronicity, high dyeing rate and color fixing rate, good level-dyeing property, excellent solarization and excellent friction fastness.

Owner:华新珍

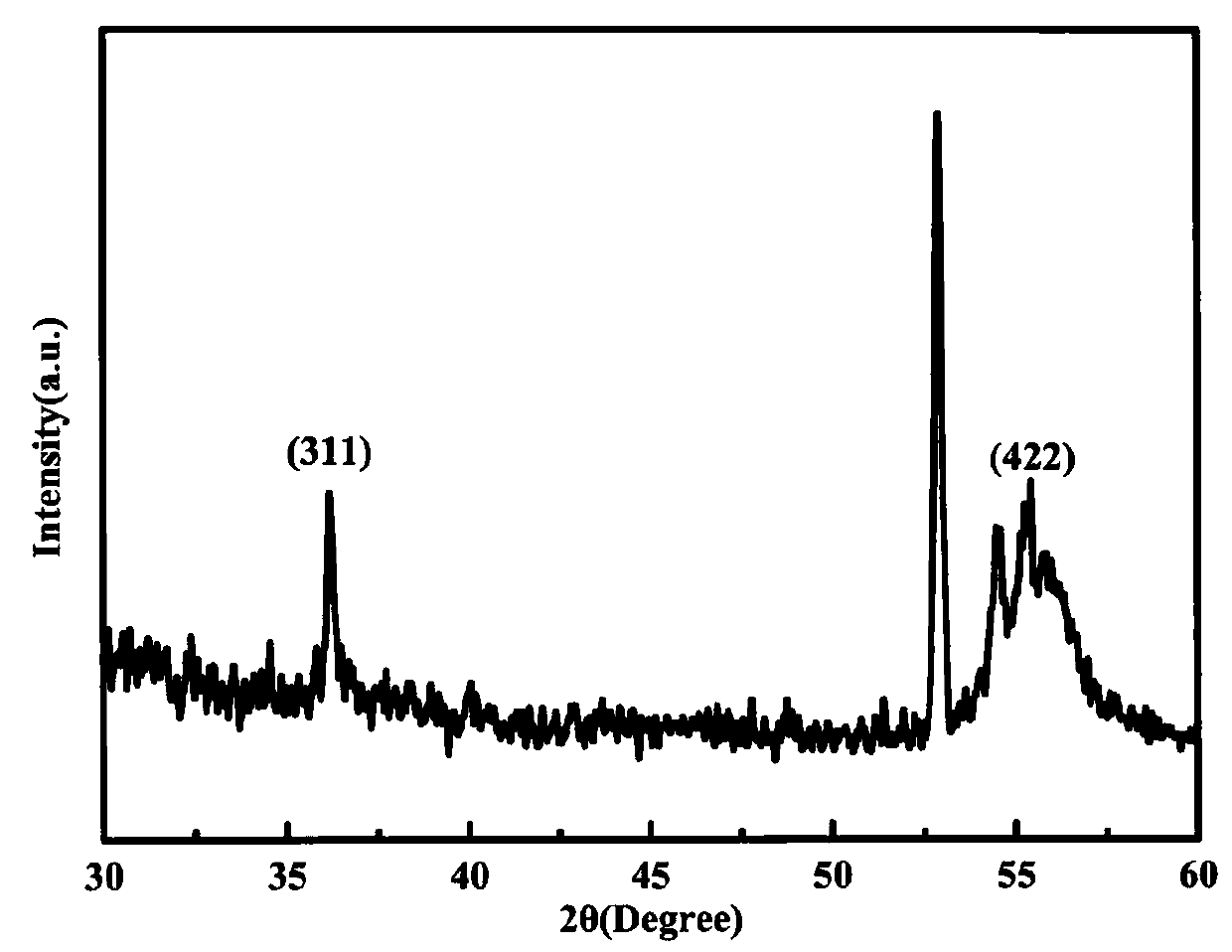

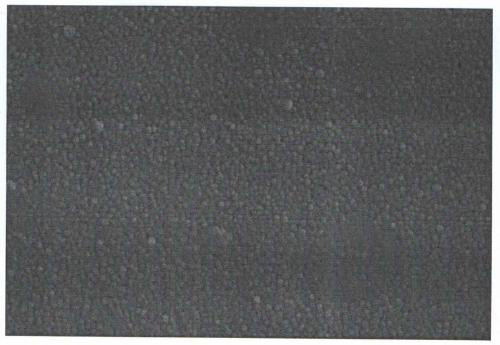

Negative temperature coefficient thermosensitive film and preparation method thereof

ActiveCN110106485AEasy to useHigh negative temperature coefficientVacuum evaporation coatingSputtering coatingOctahedronOxygen vacancy

The invention relates to a negative temperature coefficient thermosensitive film and a preparation method thereof, wherein the film is prepared from an Au / Ti double-layer electrode, a Mn-Co-Ni-Mg-Al base film, insulating silicon dioxide and a silicon substrate; a plurality of oxygen vacancies are generated while grains of the Mn-Co-Ni-Mg-Al base film grow through a first annealing treatment in a protective atmosphere; the oxygen vacancies not only provide two additional electrons, but also cause the deviation of the stoichiometric ratio of the material, the change of the valence state of the metal cation and the distortion of the oxygen octahedron, and then the oxygen element deleted in the film is supplemented through the second annealing treatment in an oxygen-containing atmosphere, so that the stability of the film structure is ensured under the condition of the deviation of the stoichiometric ratio, the change of the valence state of the metal cation and the distortion of the oxygen octahedron, and the thermosensitive performance of the film is further improved. Experiments show that the thermosensitive constant of the negative temperature coefficient thermosensitive film can reach 7127-8518 k; and the negative temperature coefficient thermosensitive film has higher negative temperature coefficient and high thermosensitive performance, guarantees the using effect of a thermistor, and can be applied advantageously.

Owner:中科传感(佛山)科技有限公司

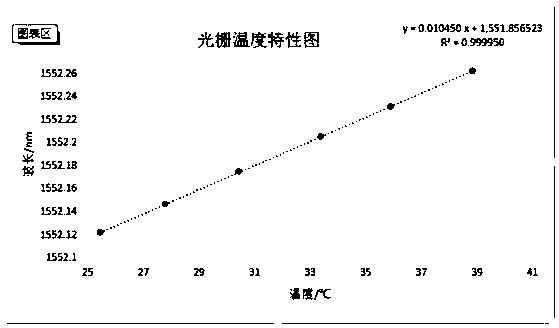

Stress-packaging-free temperature-sensing optical fiber cable and preparation method thereof

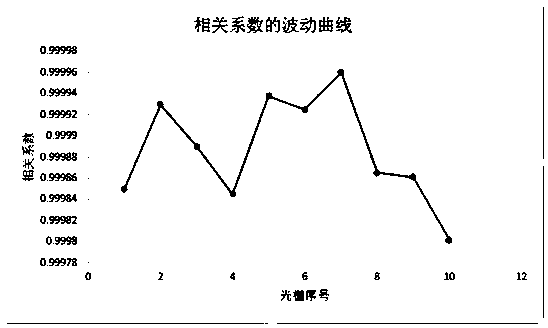

PendingCN110596837AEliminate the effects ofImprove temperature sensing accuracyThermometers using physical/chemical changesFibre mechanical structuresGratingLinear correlation

A stress-packaging-free temperature-sensing optical fiber cable and a preparation method thereof are provided, wherein the stress-packaging-free temperature-sensing optical fiber cable comprises: an ultra-weak optical fiber grating array positioned in the center; fiber bundles uniformly distributed around the ultra-weak optical fiber grating array in parallel, wherein the ultra-weak optical fibergrating array and the fiber bundles are freely combined; a metal tube wrapping the peripheries of the ultra-weak optical fiber grating array and the fiber bundles along the axial direction; and a reinforcement which is twisted and surrounded in a spiral form around the metal tube. According to the stress-packaging-free temperature-sensing optical fiber cable of the invention, the ultra-weak optical fiber grating array and the multiple fiber bundles are freely combined, then the metal tube is adopted for direct packaging, the extra length of the optical fiber is absorbed by adoption of a beam expanding effect after the optical fiber rebounds, the friction between the optical fiber and the tube wall of the metal tube is reduced, accumulated distribution of the extra length is inhibited, batch calibration is facilitated, the linear correlation degree of a temperature curve of the optical fiber is up to more than 0.999, the temperature sensitivity fluctuation is less than 0.3pm / DEG C, andthe temperature measurement precision of the optical cable is improved.

Owner:宜昌睿传光电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com