Novel wallboard convenient to install

A new type of wallboard technology, applied in building components, buildings, building structures, etc., can solve problems such as poor thermal insulation ability, sound insulation ability, poor fire resistance, affecting construction quality and construction progress, a large amount of waste and debris, etc. Convenience, easy production operation and transfer installation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

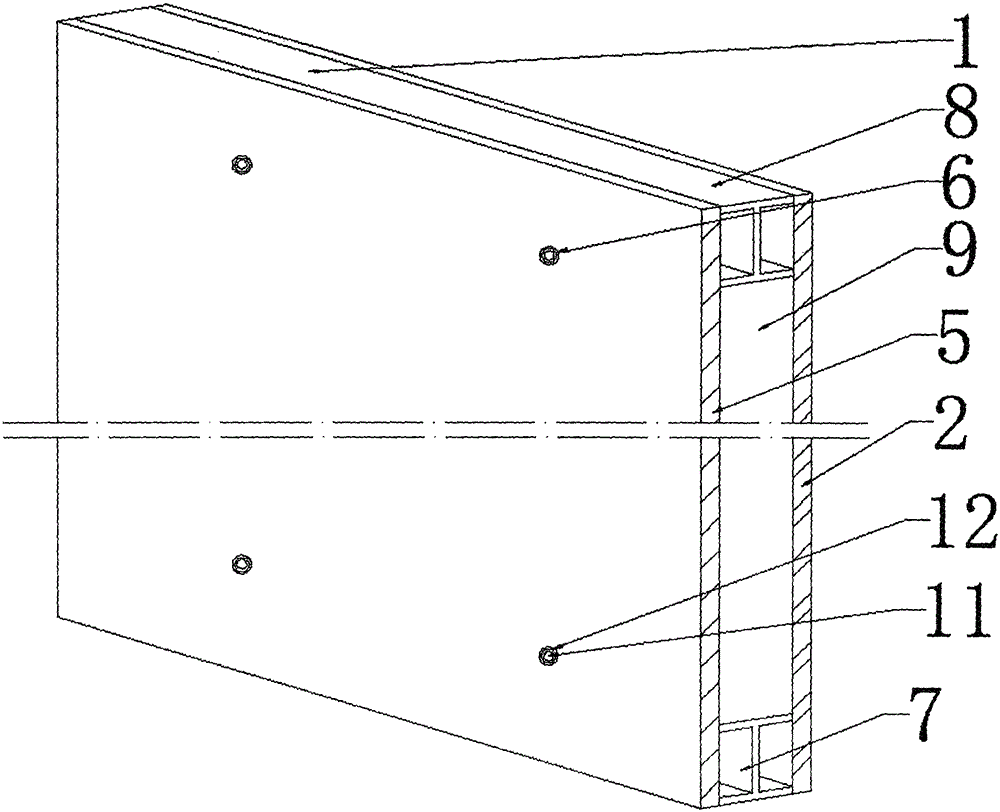

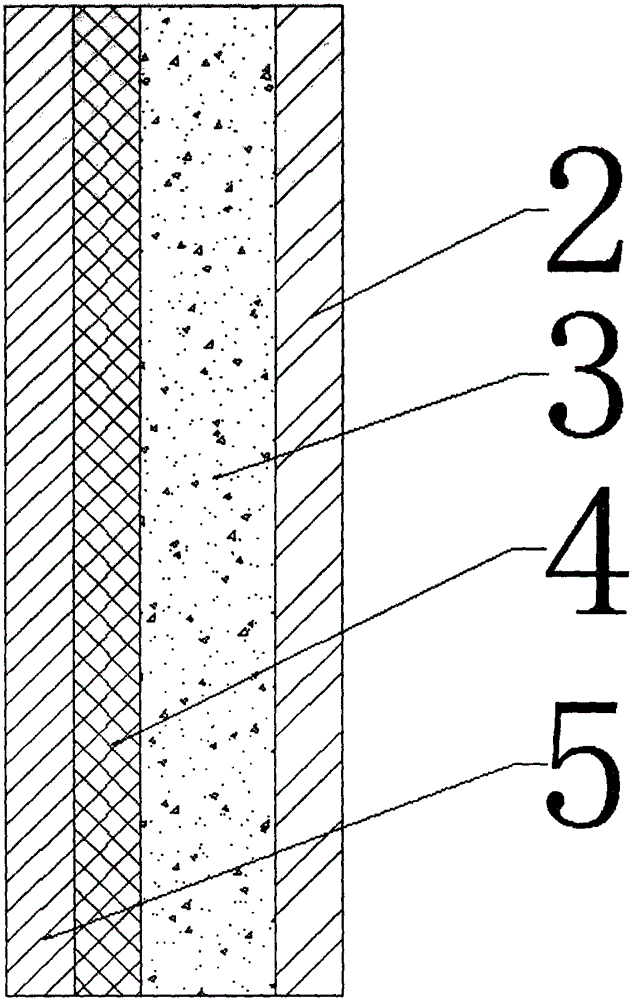

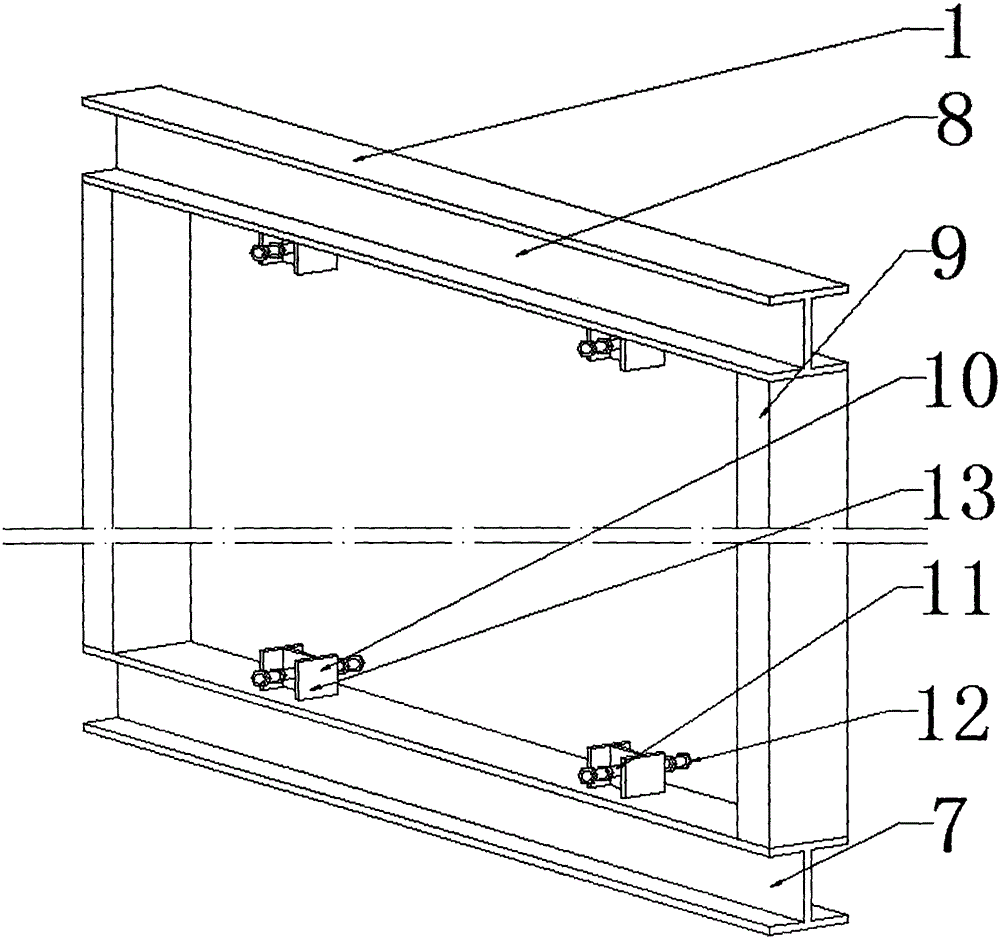

[0019] as attached Figure 1-4 As shown, a novel wall panel that is conveniently installed includes a bracket 1, an outer blade 5, and an inner blade 2. The bracket 1 is composed of a column 9, a top beam 7, a bottom beam 8, and a connector 13. The two ends of the upper side of the bottom beam 8 are fixed with columns 9 perpendicular to the upper side of the bottom beam 8. The columns 9 are two rectangular steels with the same height. The top beam 7, the lower side of the top beam 7 is provided with two connectors 13, the upper side of the bottom beam 8 is provided with two connectors 13, and the connectors 13 are fixedly welded on the beam. I-shaped steel 10, studs 11, and nuts 12. The center of the I-shaped steel 10 runs through a stud 11. Two nuts 12 are respectively provided at both ends of the described I-beam 11. The outer blades 5 and Bolt holes 6 are correspondingly provided on the inner leaf plate 2, the outer leaf plate 5 and the inner leaf plate 2 are fixed on the ...

Embodiment 2

[0023] as attached Figure 1-4 As shown, a novel wall panel that is conveniently installed includes a bracket 1, an outer blade 5, and an inner blade 2. The bracket 1 is composed of a column 9, a top beam 7, a bottom beam 8, and a connector 13. The two ends of the upper side of the bottom beam 8 are fixed with columns 9 perpendicular to the upper side of the bottom beam 8. The columns 9 are two rectangular steels with the same height. The top beam 7, the lower side of the top beam 7 is provided with two connectors 13, the upper side of the bottom beam 8 is provided with two connectors 13, and the connectors 13 are fixedly welded on the beam. I-shaped steel 10, studs 11, and nuts 12. The center of the I-shaped steel 10 runs through a stud 11. Two nuts 12 are respectively provided at both ends of the described I-beam 11. The outer blades 5 and Bolt holes 6 are correspondingly provided on the inner leaf plate 2, the outer leaf plate 5 and the inner leaf plate 2 are fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com