Patents

Literature

3083results about How to "Increase production speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

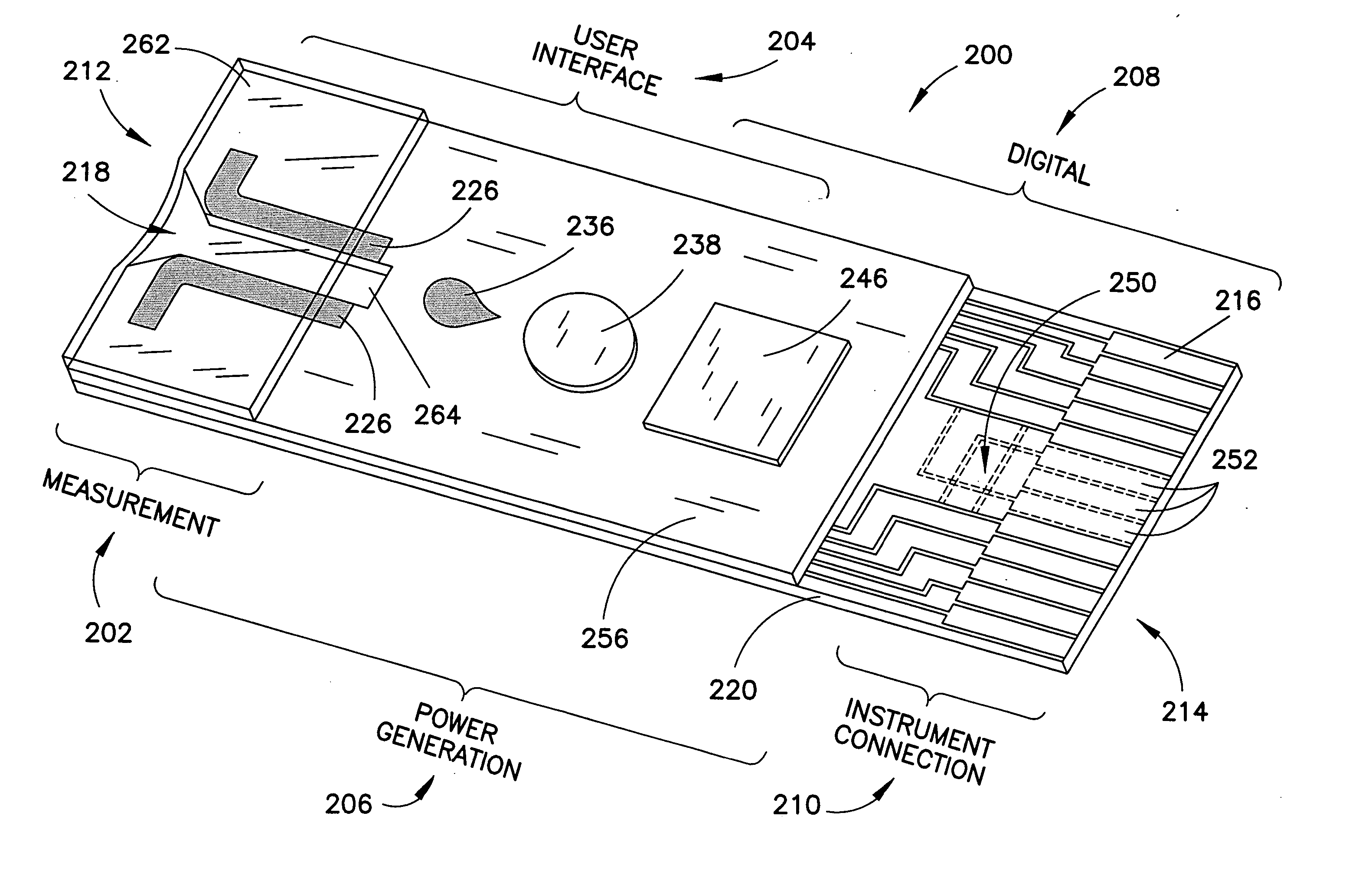

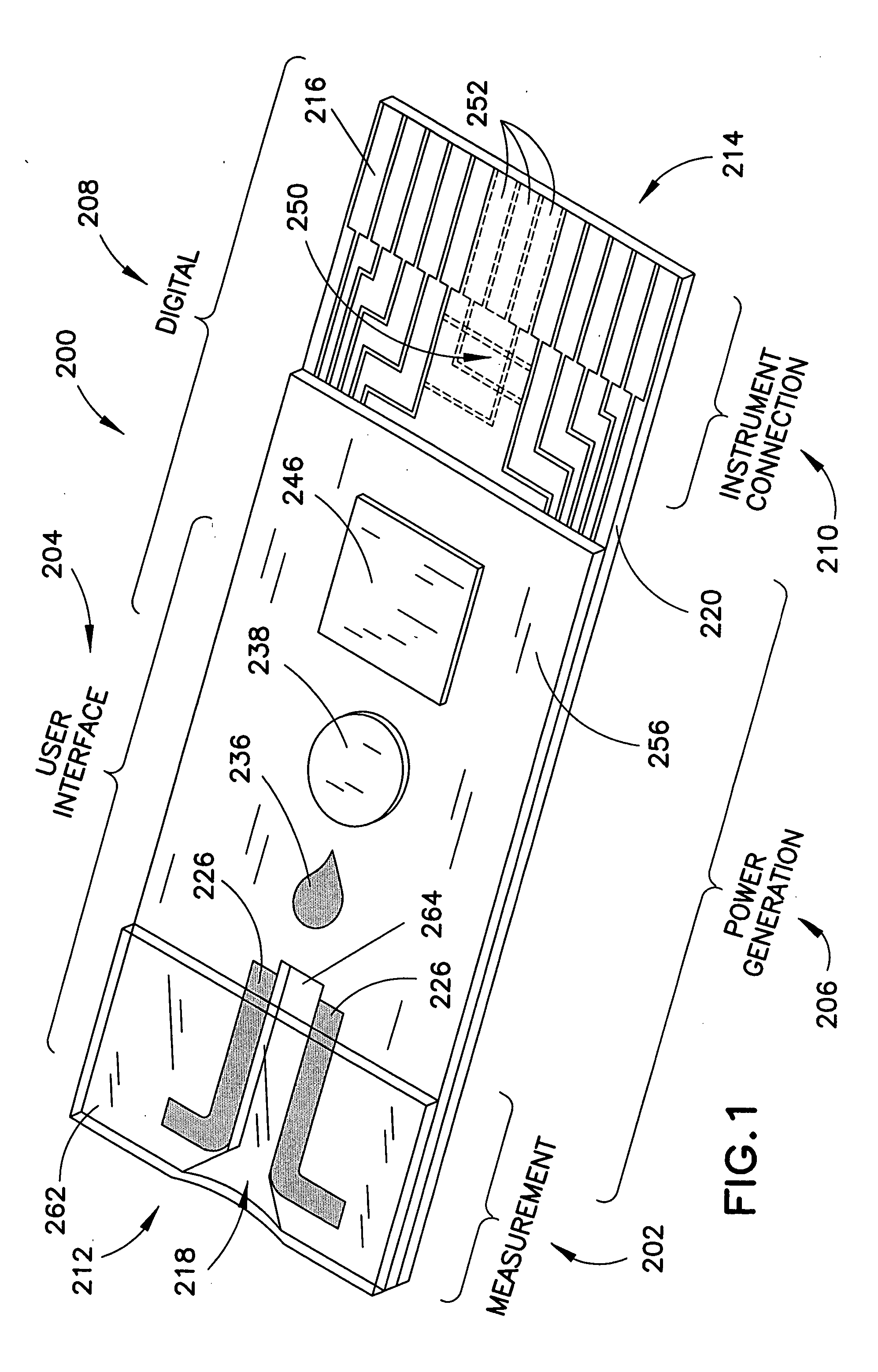

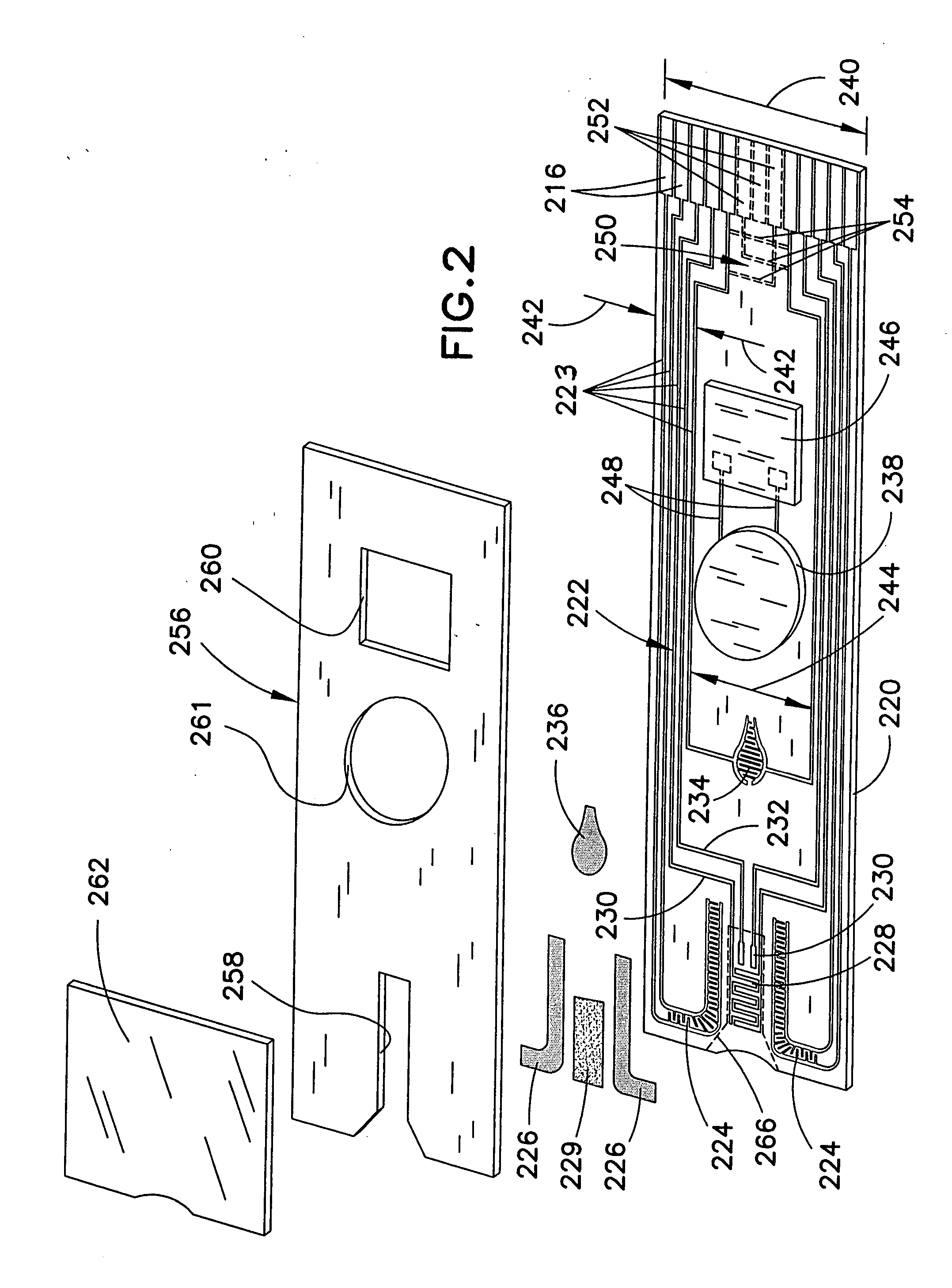

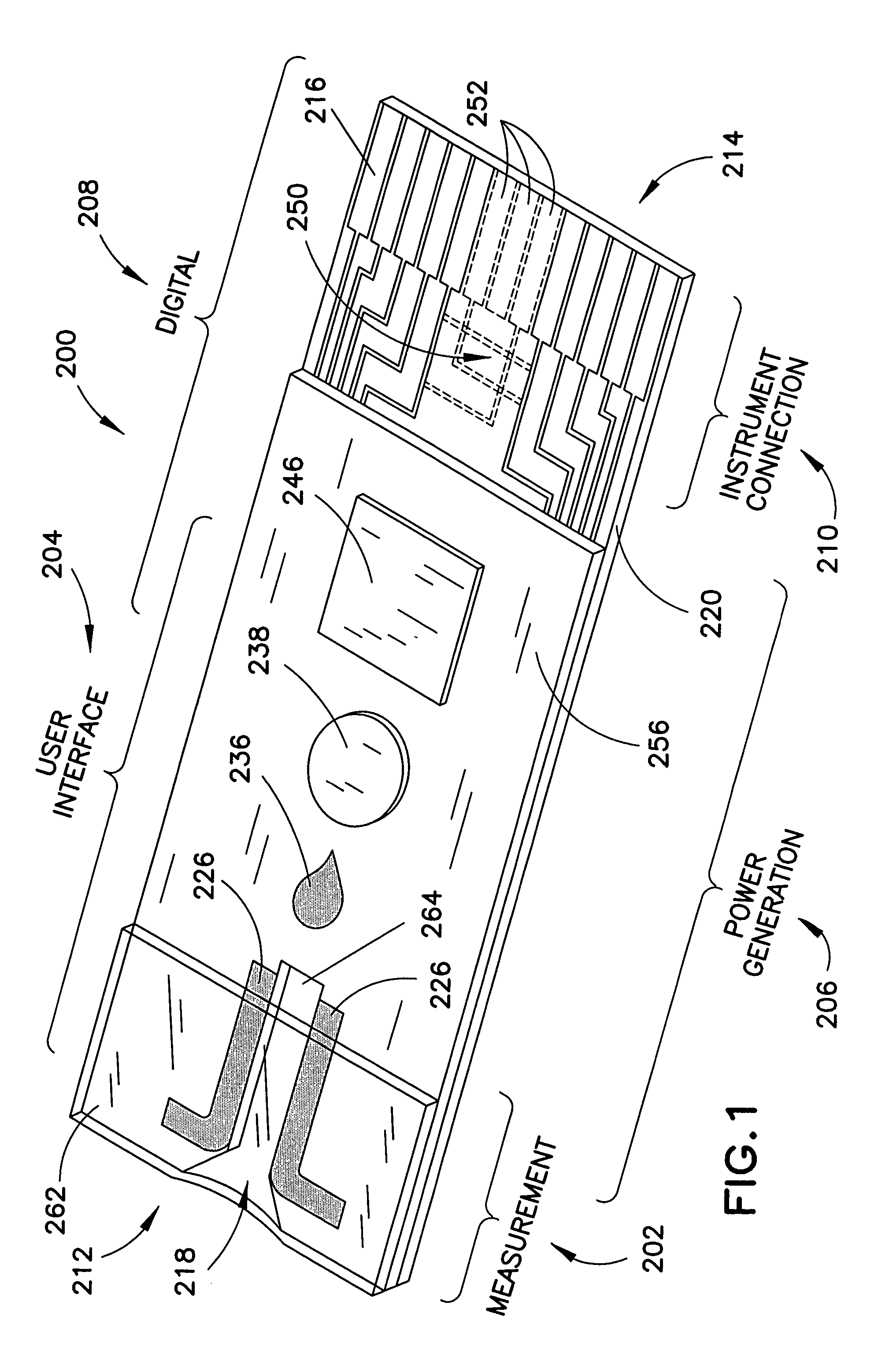

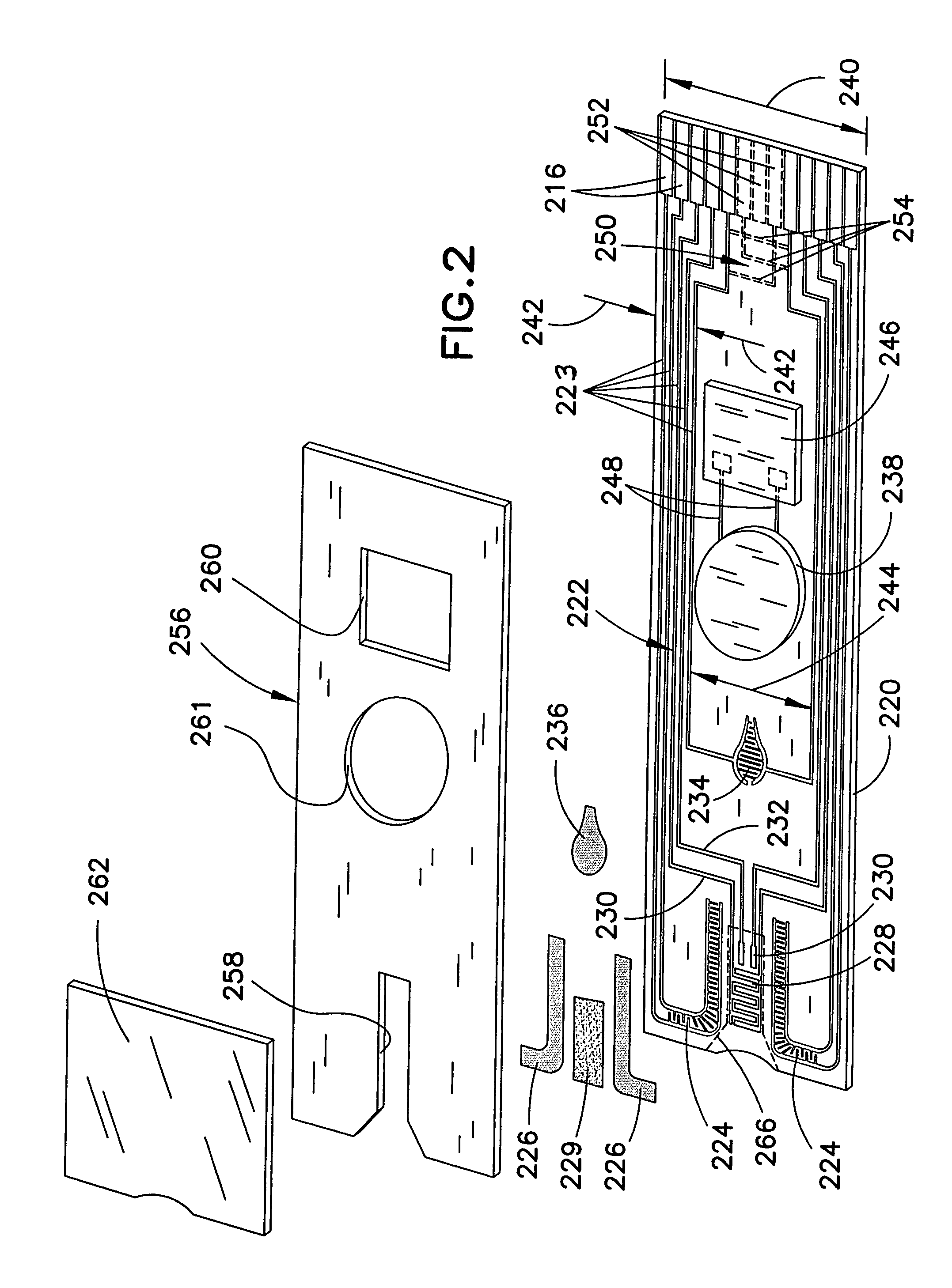

Biosensor with multiple electrical functionalities

InactiveUS20050023137A1Increase in production speedAdditional functionalityImmobilised enzymesBioreactor/fermenter combinationsRelevant costInstrumentation

A biosensor having multiple electrical functionalities located both within and outside of the measurement zone in which a fluid sample is interrogated. Incredibly small and complex electrical patterns with high quality edges provide electrical functionalities in the biosensor and also provide the electrical wiring for the various other electrical devices provided in the inventive biosensor. In addition to a measurement zone with multiple and various electrical functionalities, biosensors of the present invention may be provided with a user interface zone, a digital device zone and / or a power generation zone. The inventive biosensors offer improved ease of use and performance, and decrease the computational burden and associated cost of the instruments that read the biosensors by adding accurate yet cost-effective functionalities to the biosensors themselves.

Owner:ROCHE DIABETES CARE INC

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

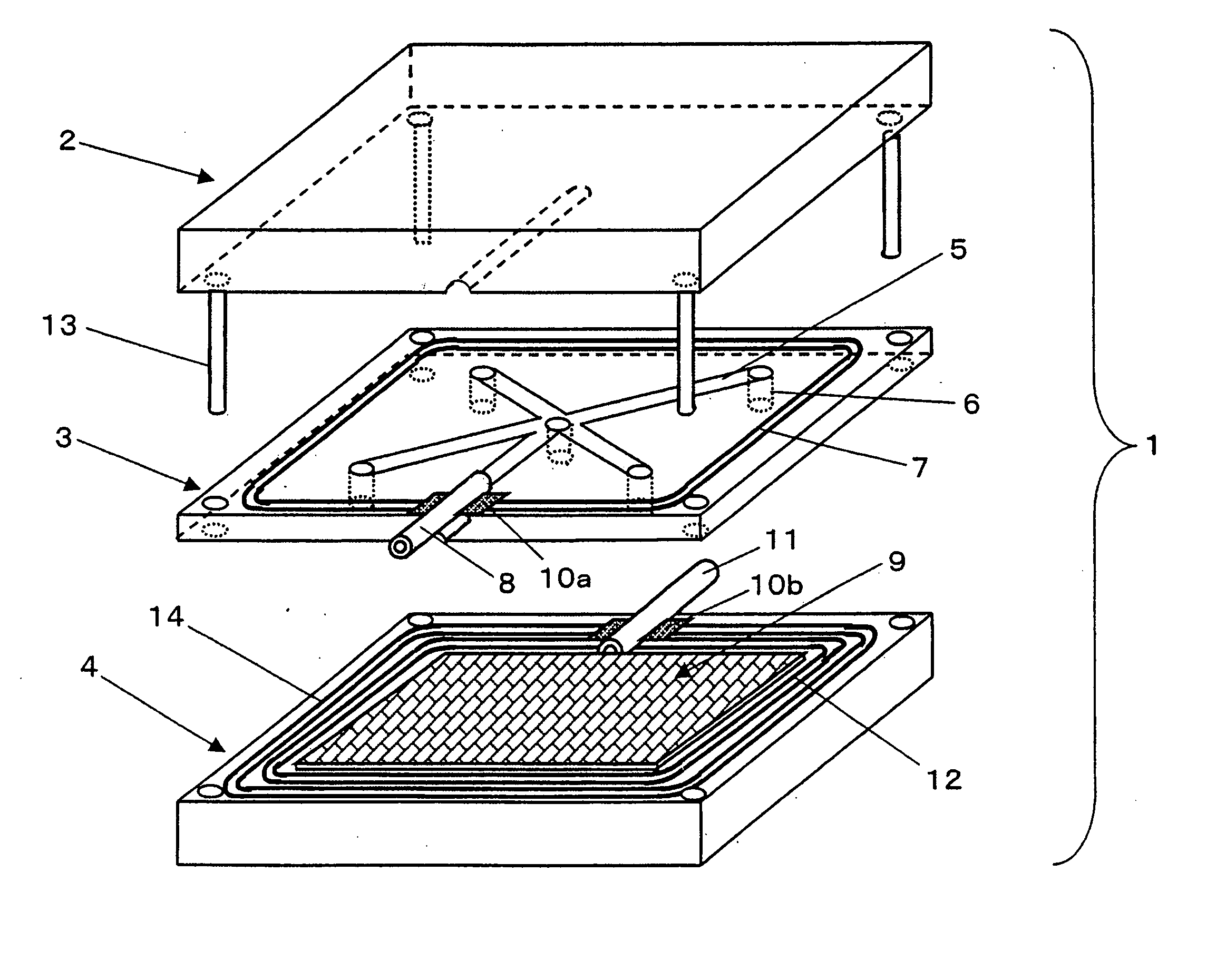

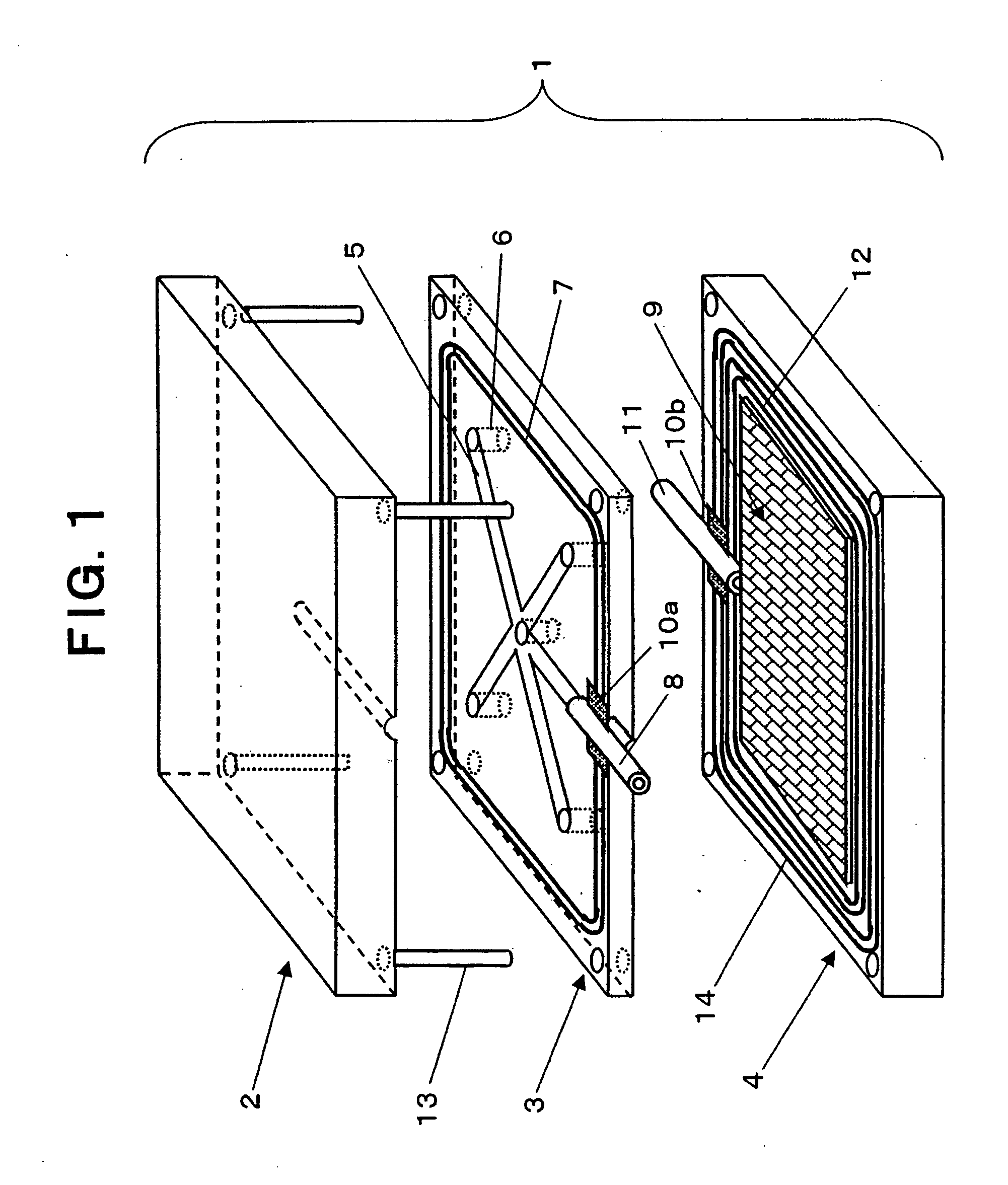

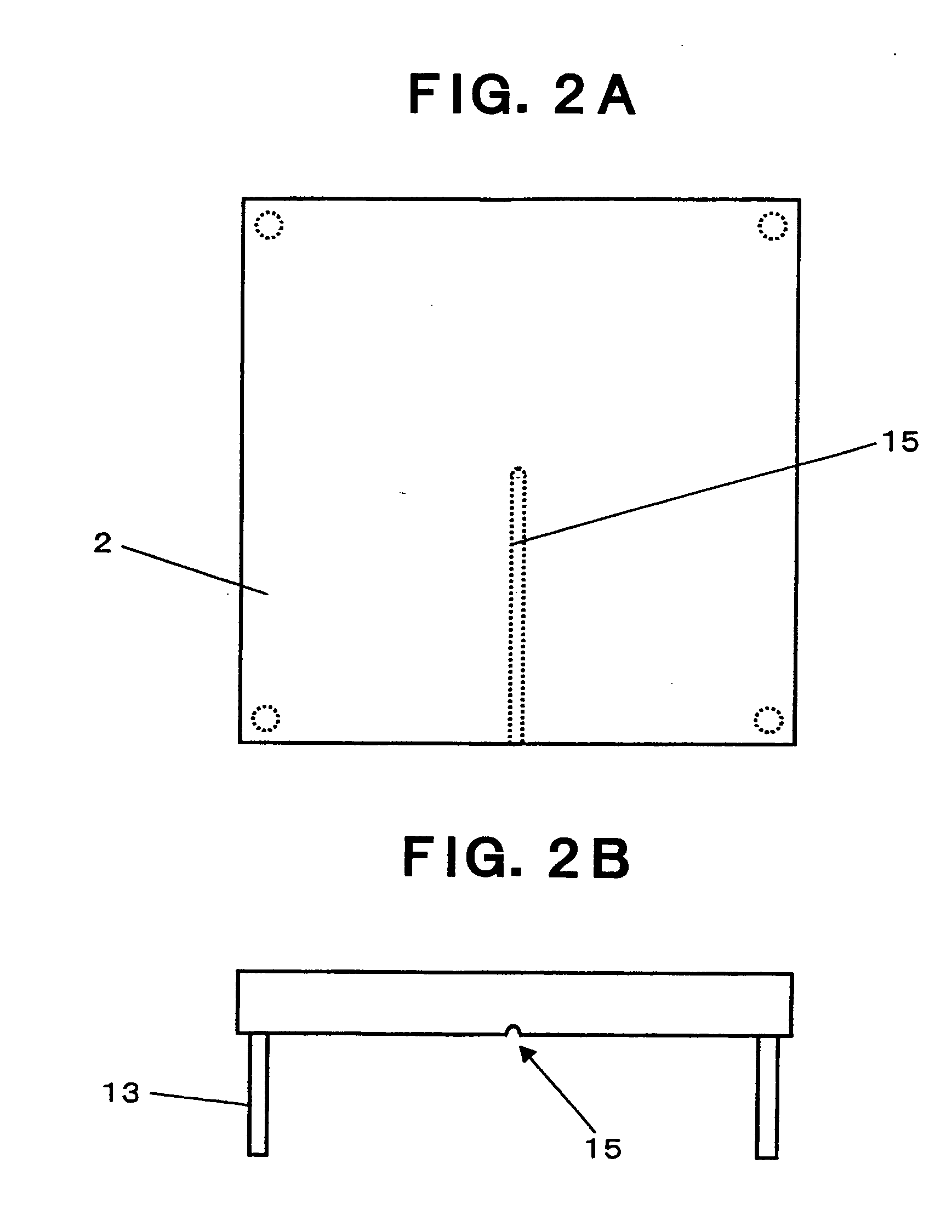

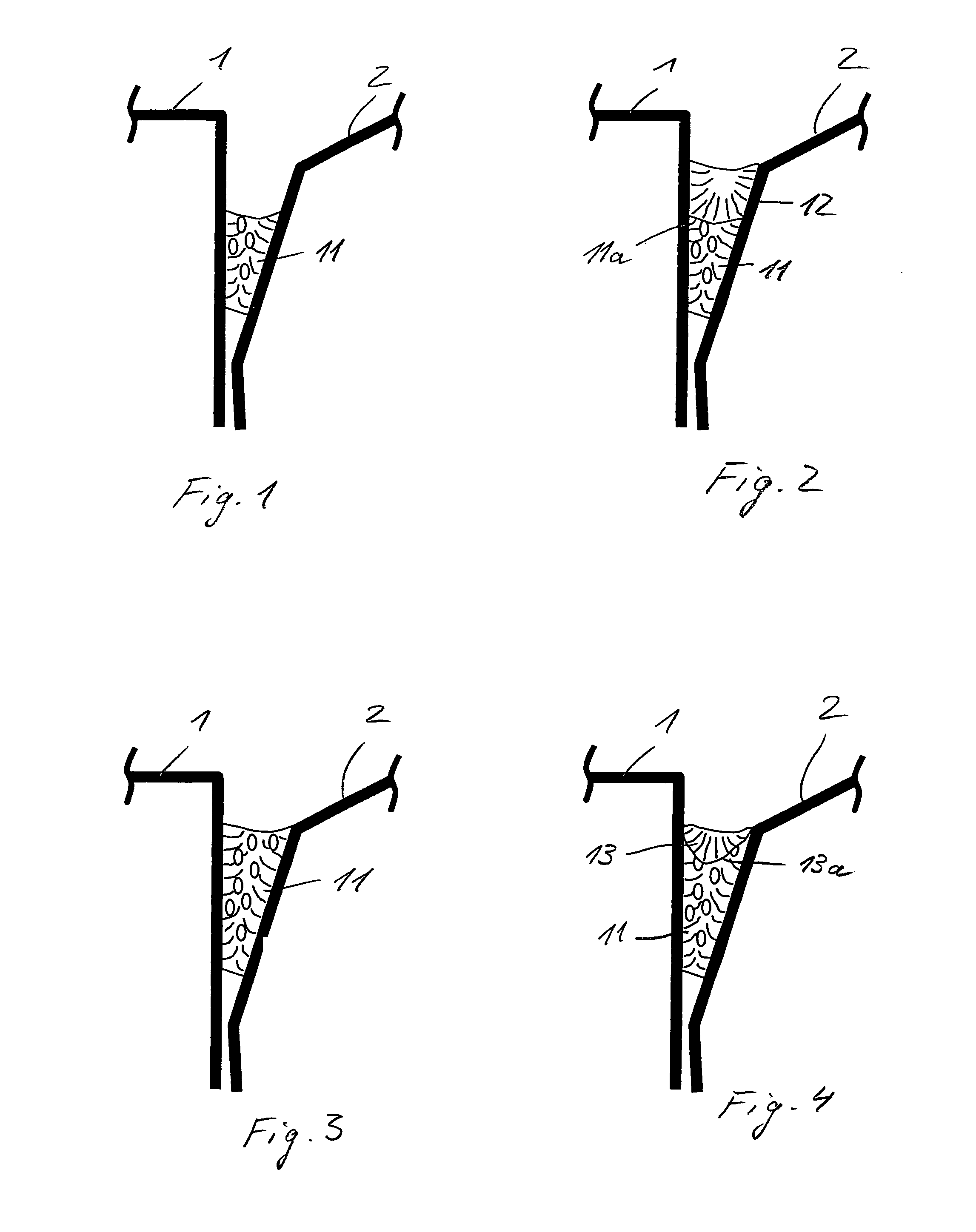

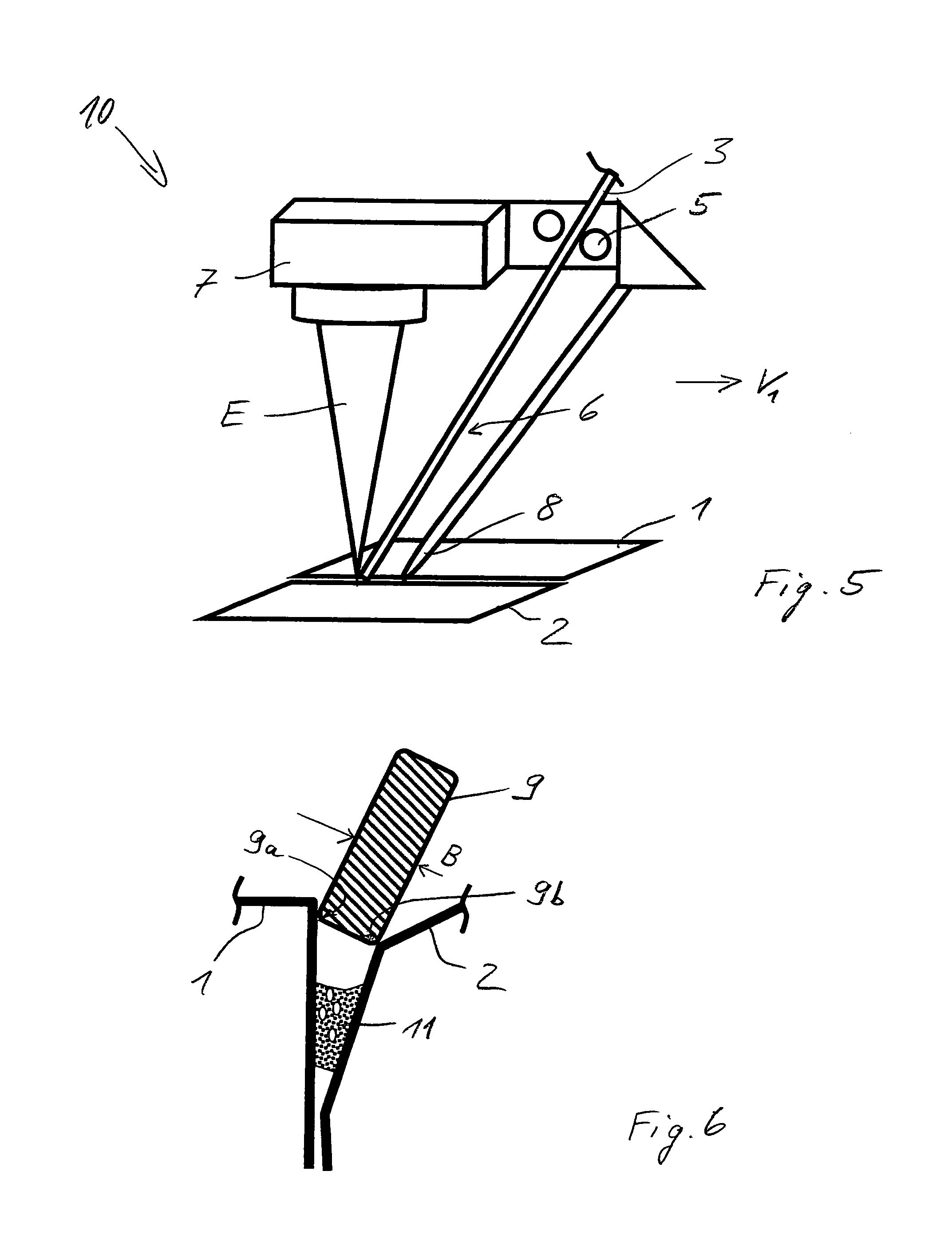

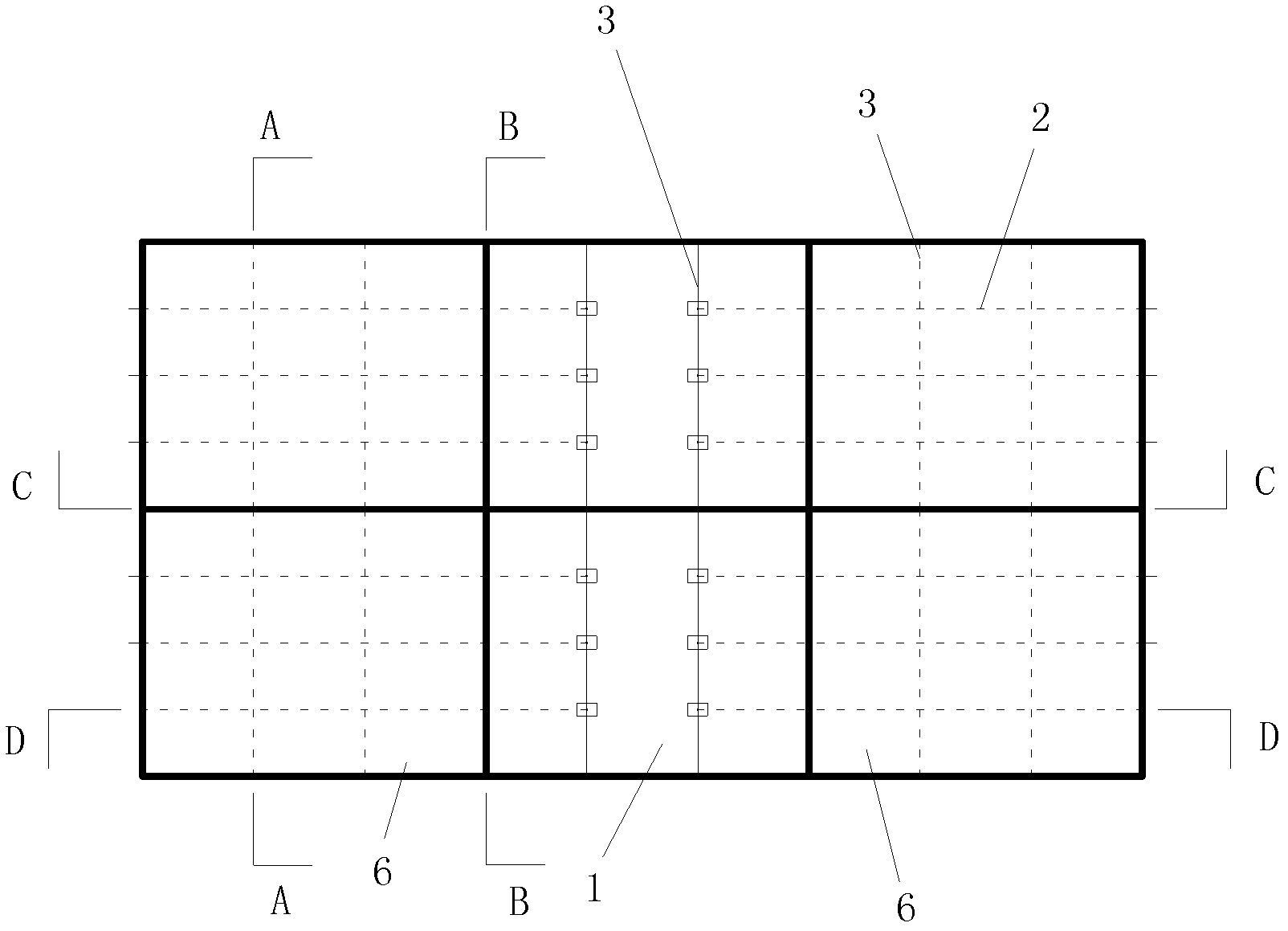

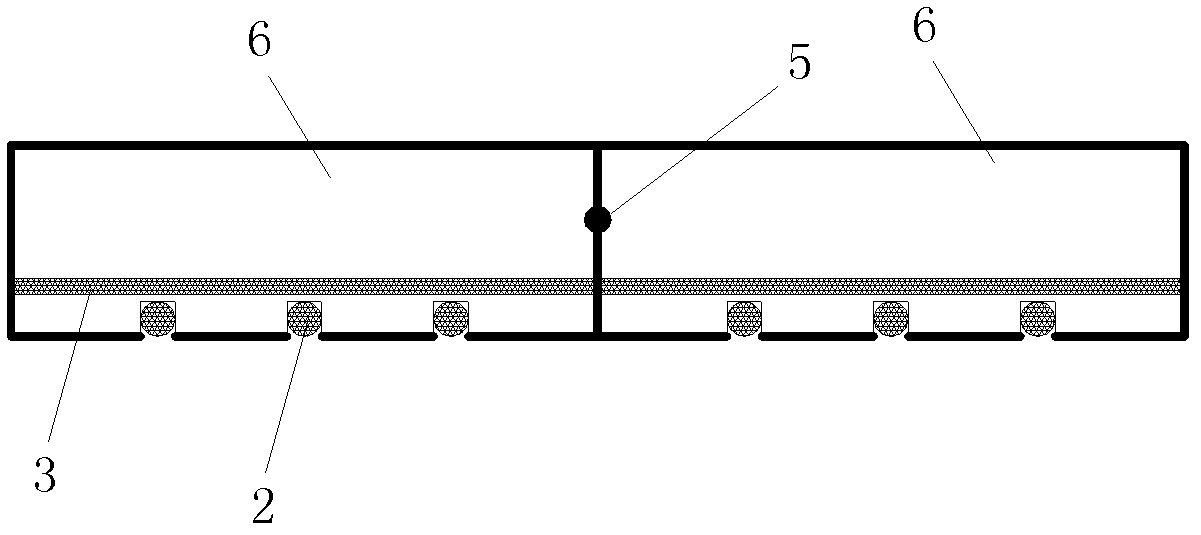

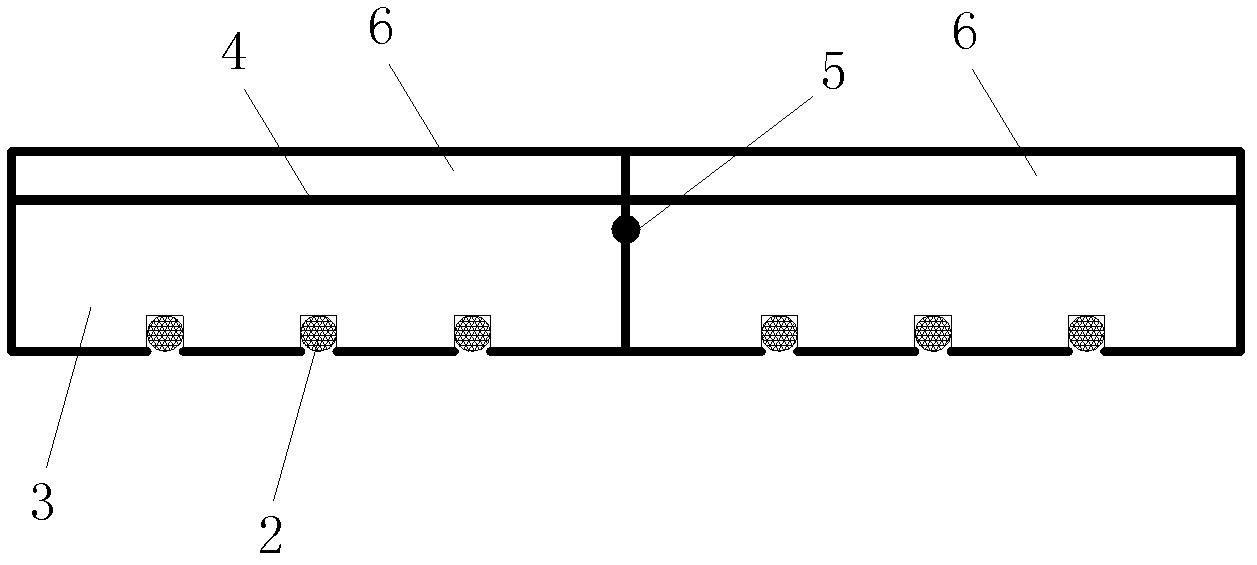

Rtm molding method and device

InactiveUS20070182071A1Shorten molding timeReduce the amount of solutionConfectioneryWood working apparatusFiber

An RTM molding method comprising disposing a reinforcing fiber substrate in a cavity of a mold consisting of a plurality of dies, clamping the mold, and thereafter injecting resin to complete molding, characterized in that divided areas with respect to the surface direction of the reinforcing fiber substrate are assumed, each divided area is one in which injected resin expands over the entire surface in the area and can be substantially uniformly impregnated in the thickness direction of the substrate, and resin introducing paths are formed for respective assumed divided areas for introducing the injected resin into the respective divided areas; and an RTM molding device. When a relatively large molded product is to be molded, a molding step from resin injection to impregnating / curing can be implemented at high speed without generating a non-resin-flowing area, thereby enabling a high-quality molded product to be produced free from voids, etc., with a molding time shortened and production speed and volume increased.

Owner:TORAY IND INC

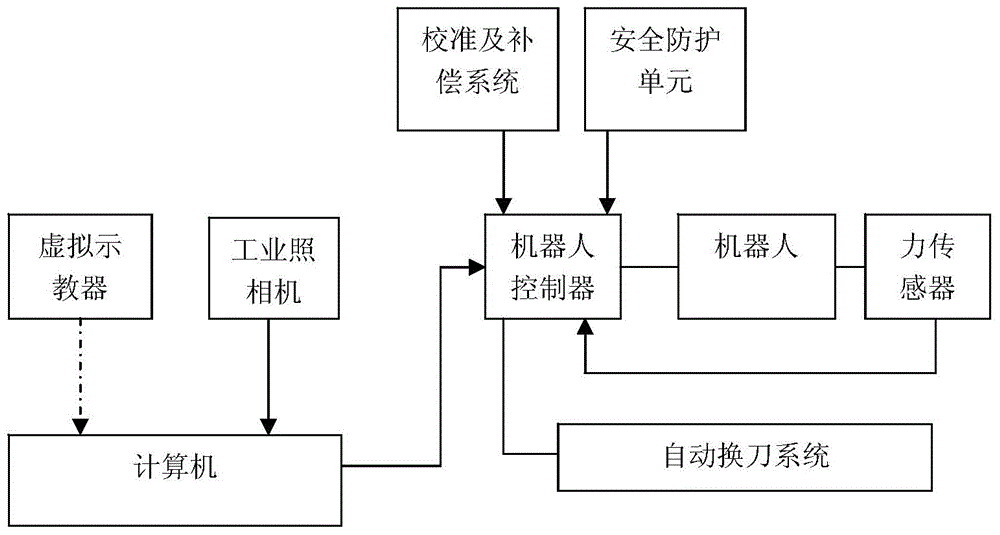

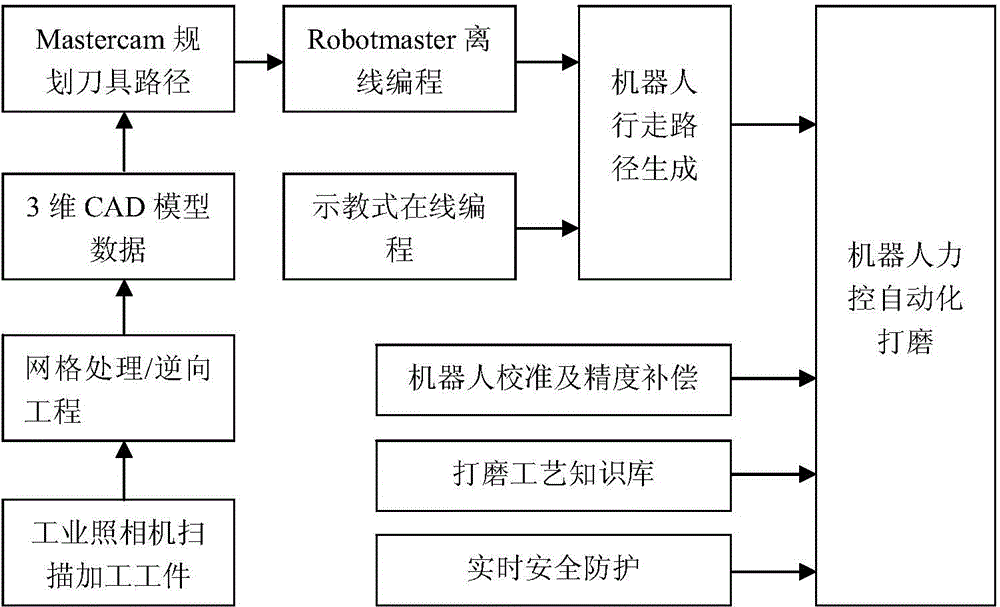

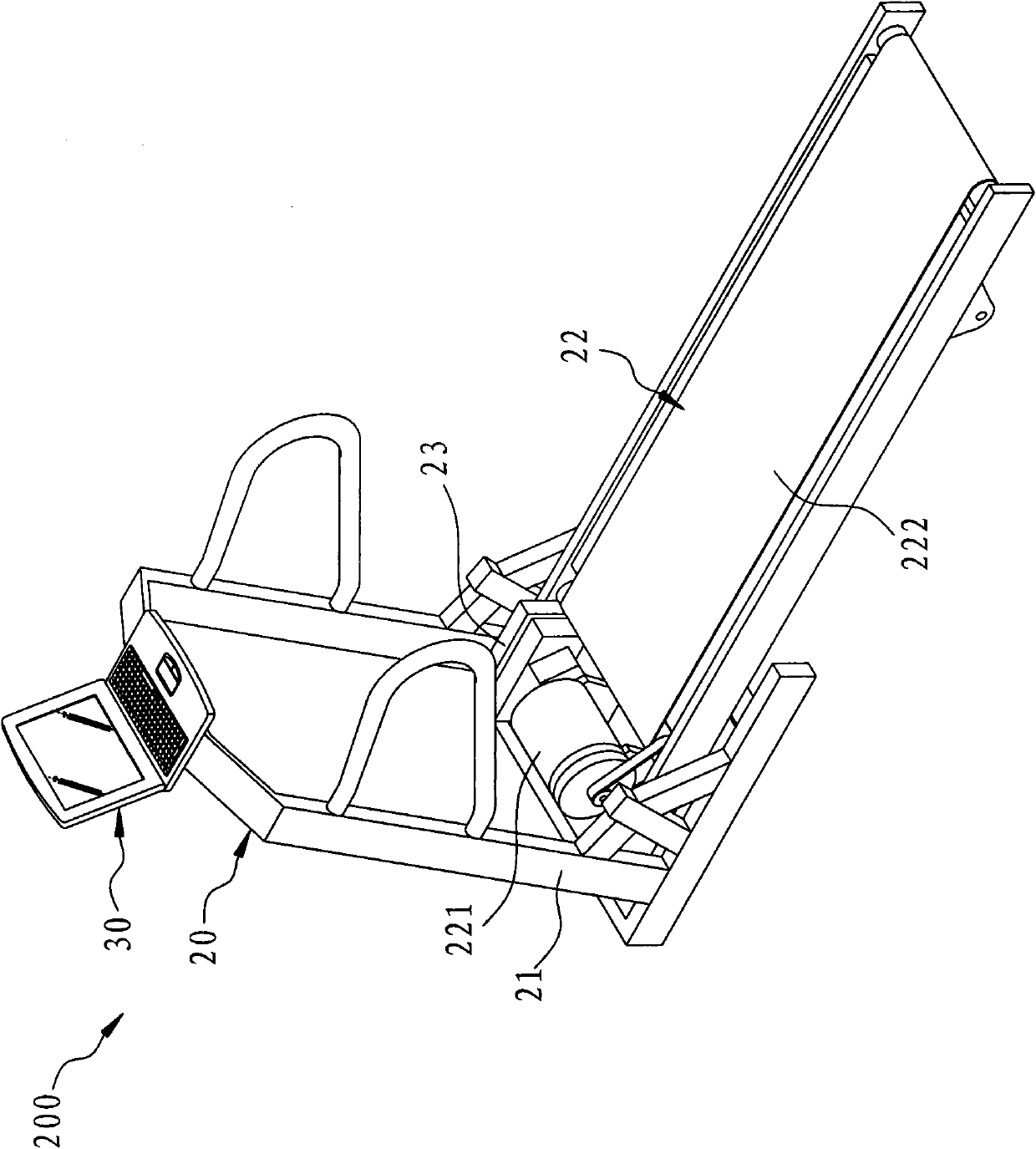

Intelligent force control robot grinding system and method

ActiveCN104972362ARealize automatic processingImprove machining accuracyAutomatic grinding controlSurface finishControl theory

The invention relates to an intelligent force control robot grinding system. The intelligent force control robot grinding system comprises a computer, an industrial camera, a robot, a robot controller, a calibration and compensation system, a safety protection unit, a force sensor and an automatic knife changing system. The computer is connected with the industrial camera. The robot controller is connected with the computer, the robot, the calibration and compensation system, the safety protection unit, the force sensor and the automatic knife changing system. A method comprises the steps that the computer receives workpiece scanning data collected by the industrial camera, generates a knife path and converts the knife path into the robot posture and the tail end path; calibration and compensation are carried out; the robot controller controls all joints to move while the robot posture and the tail end path are adjusted. Hardware of a high-precision force control grinding system is achieved, the path self-calibration and online compensation technology is adopted, and the machining of a complex hook face with the high requirements for machining precision and surface smoothness can be finished.

Owner:宏阔(南通)智能装备有限公司

Method of soldering or welding components

ActiveUS8686314B2Increase speedIncrease production speedWelding/cutting auxillary devicesVehicle componentsEngineeringSoldering

Owner:FFT PRODIONSSYST

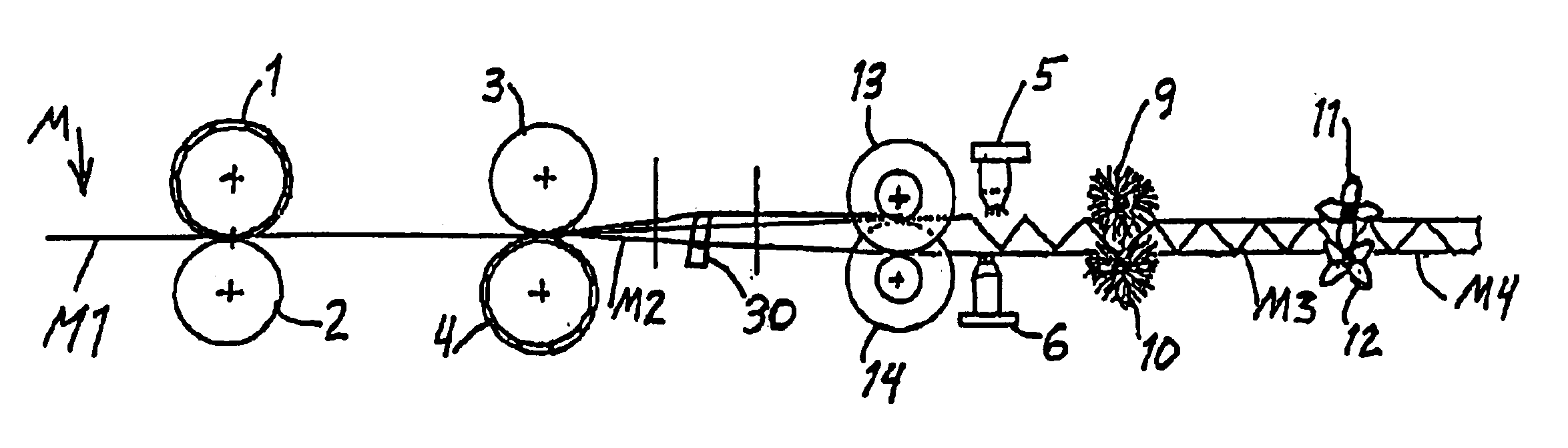

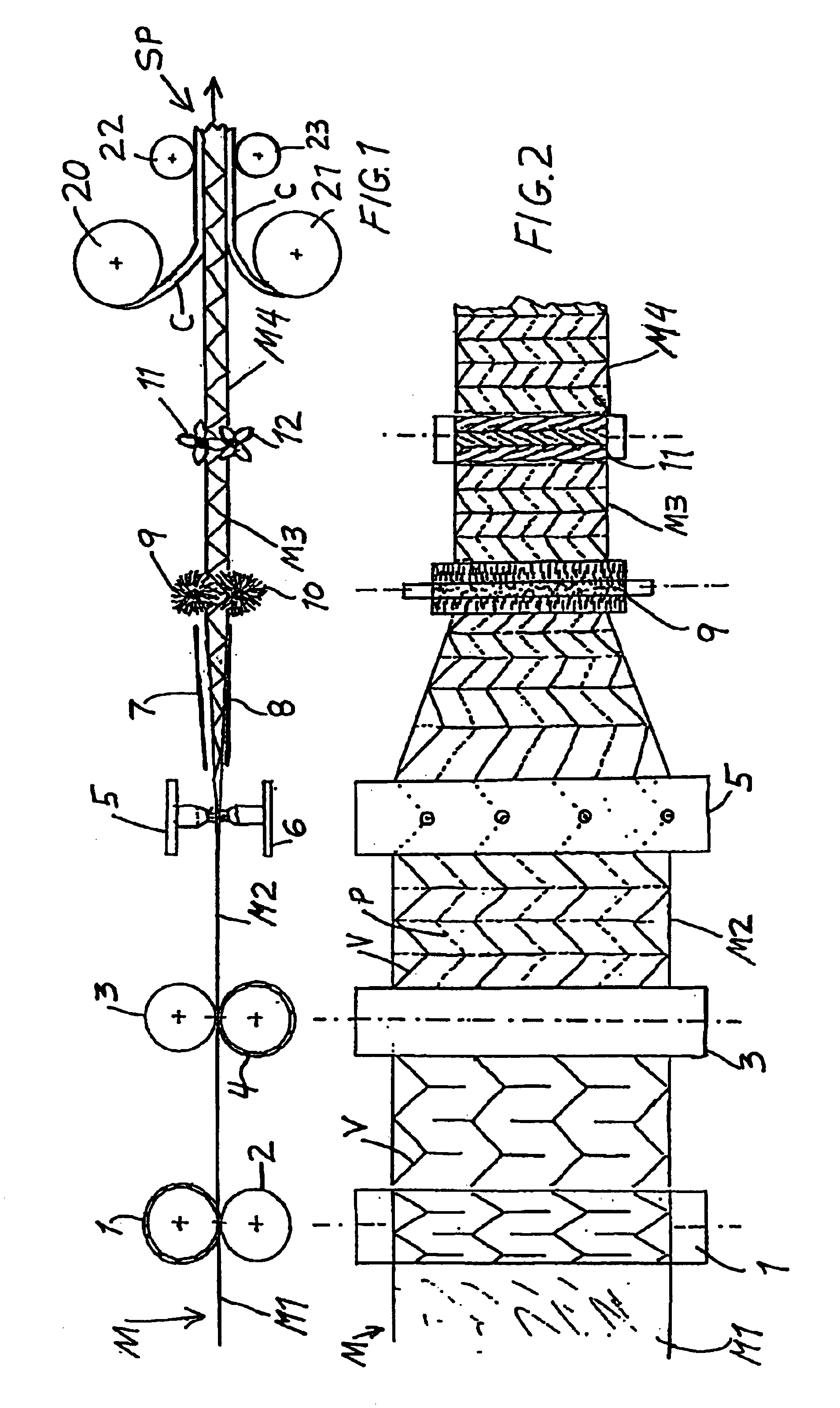

Method and apparatus for producing a composite structural panel with a folded material core

InactiveUS6913570B2Low densityIncrease stiffnessMechanical working/deformationPaper/cardboard articlesBristleEngineering

A folded core structure is produced by embossing fold lines into a flat planar material web, initiating folds along the fold lines on the upper and lower surfaces of the material web, proceeding with the formation of the folds along the fold lines to deform the material web from its two-dimensional starting configuration to a three-dimensional folded configuration, and post-processing the folded material web to stabilize or fix the folded configuration thereof. A composite structural panel is produced by bonding a cover layer onto at least one surface of the folded core structure. An apparatus preferably includes embossing or creasing rolls to form the fold lines in the material web, air nozzles or folding rolls to initiate the folding process, bristle brush rolls to complete the folding process, and further folding rolls to enhance and fix the folded configuration, optionally in connection with heating, cooling, applying a coating onto, or impregnating a resin or binder into the material web.

Owner:AIRBUS OPERATIONS GMBH

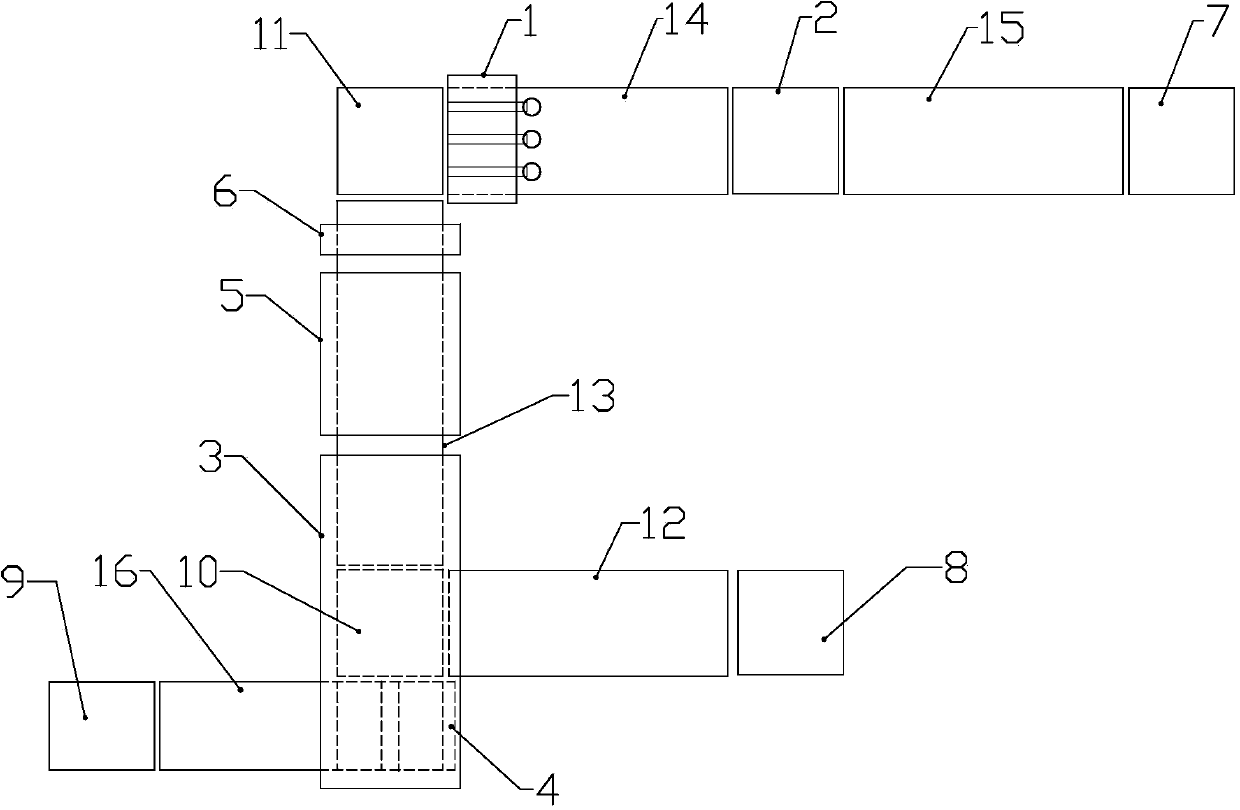

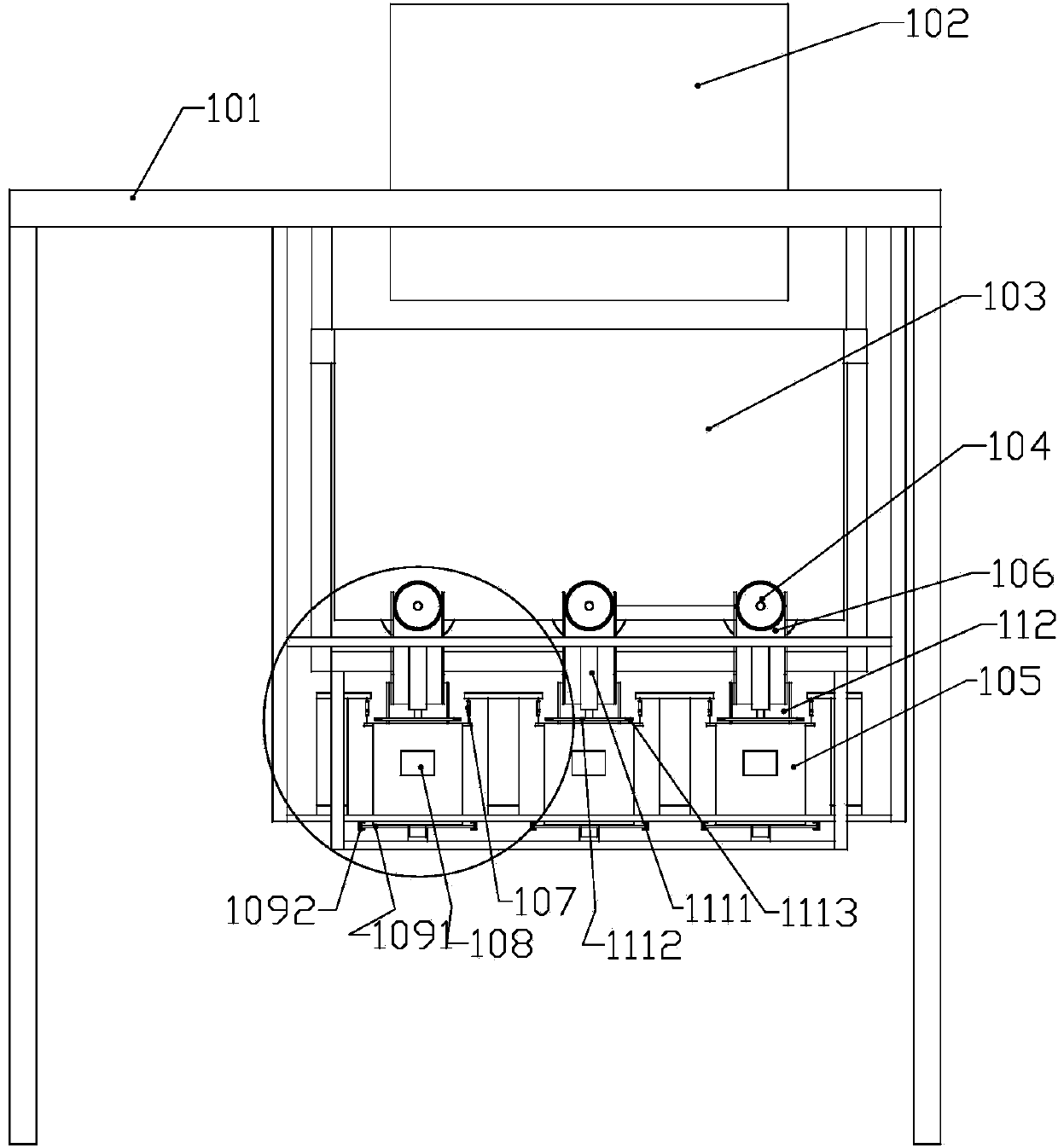

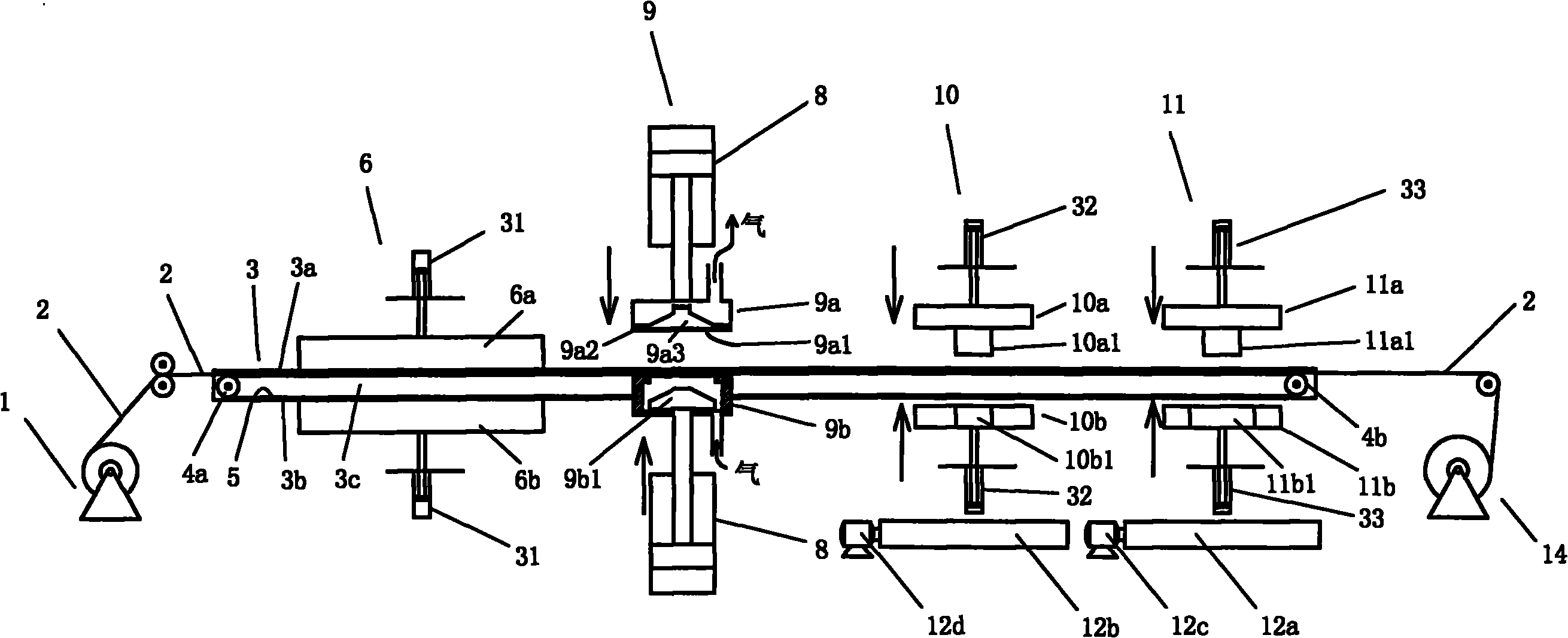

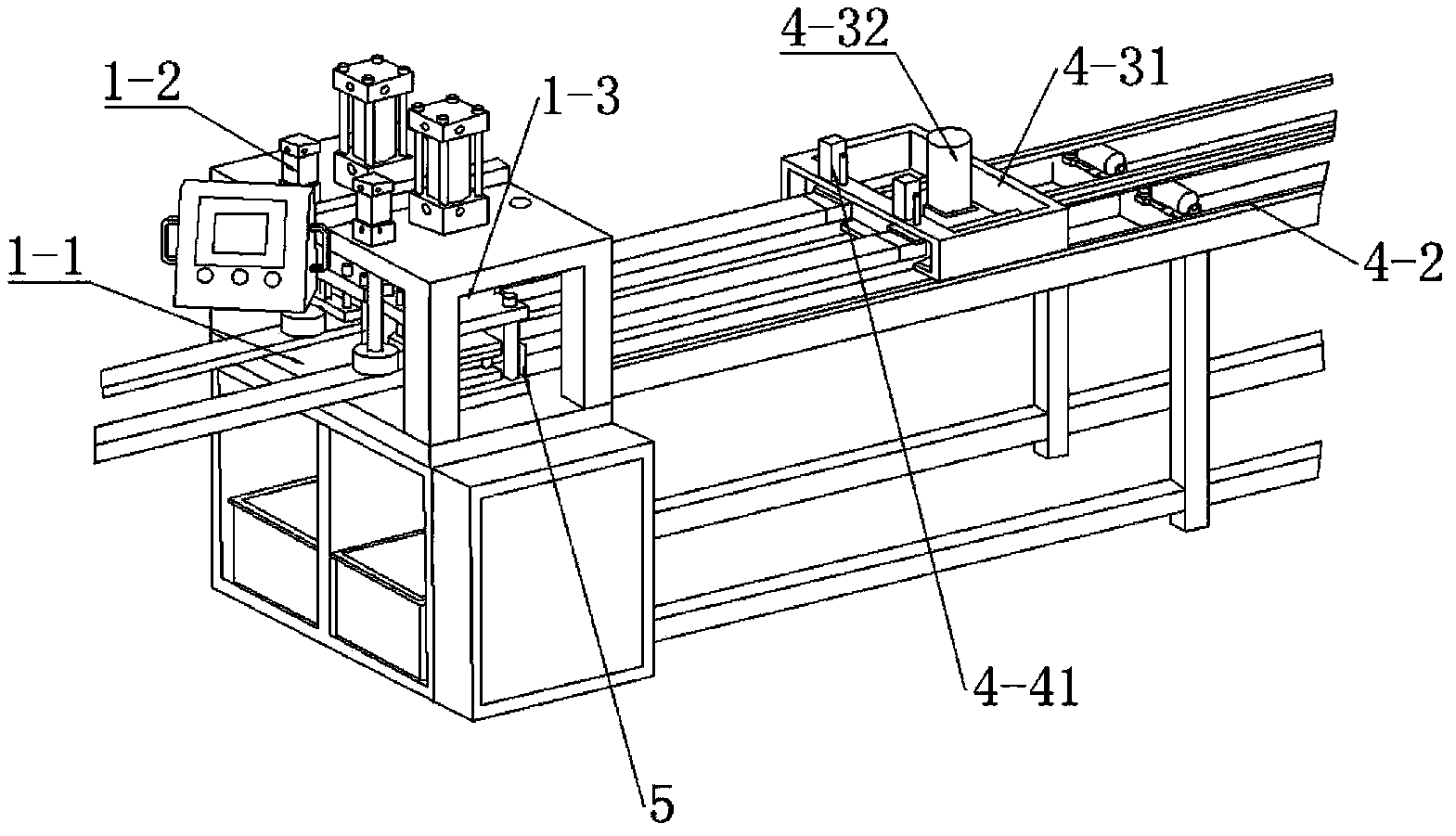

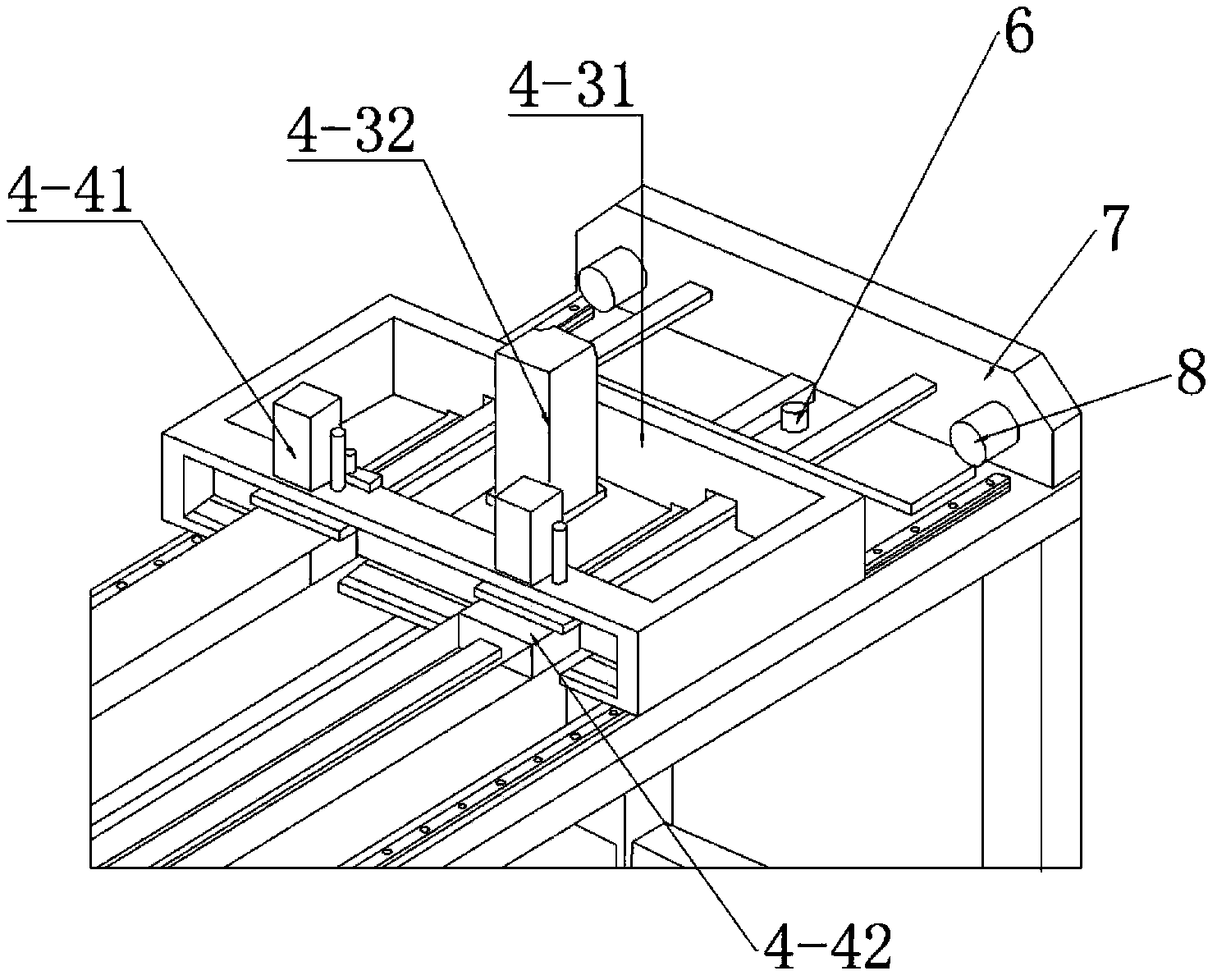

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

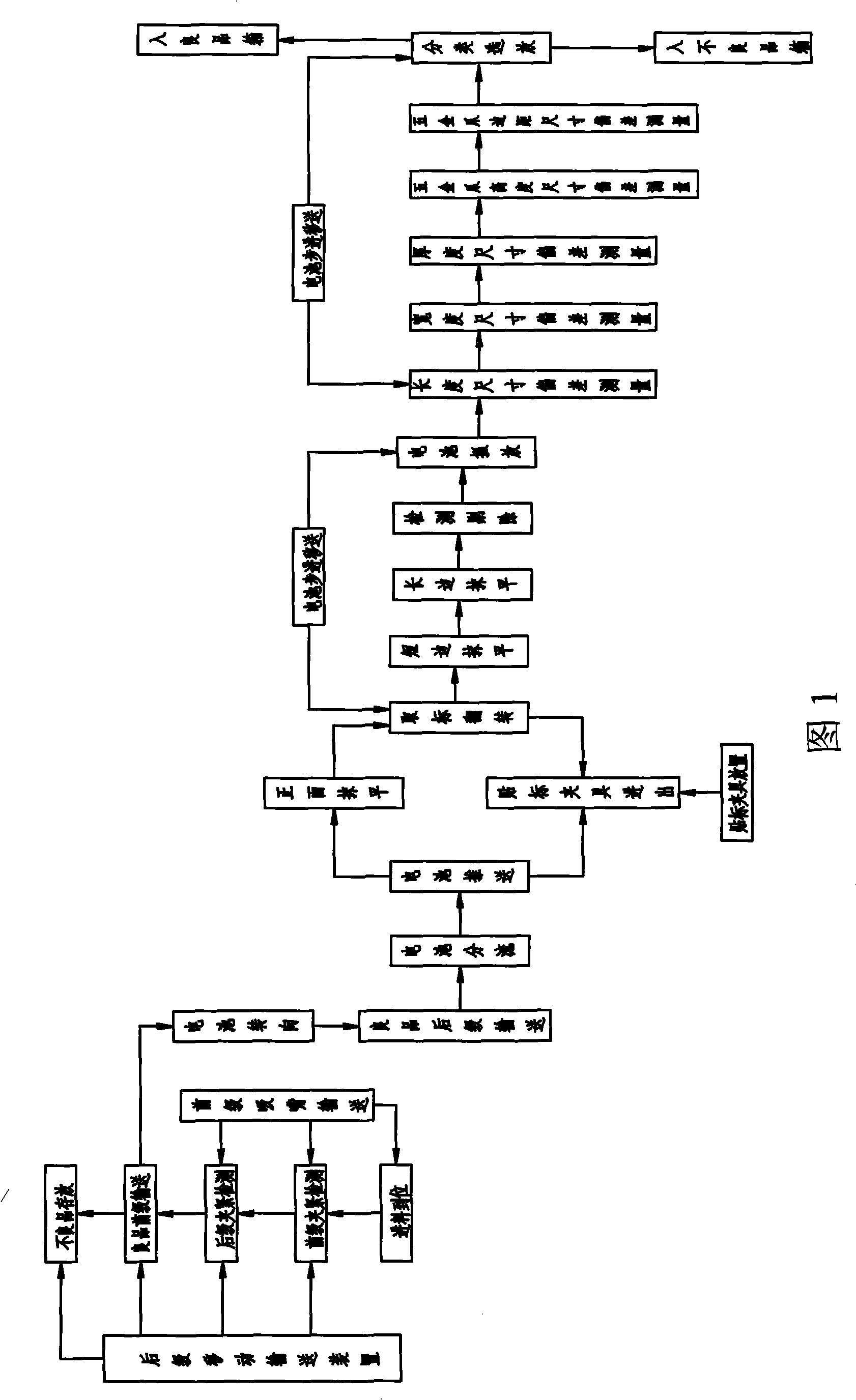

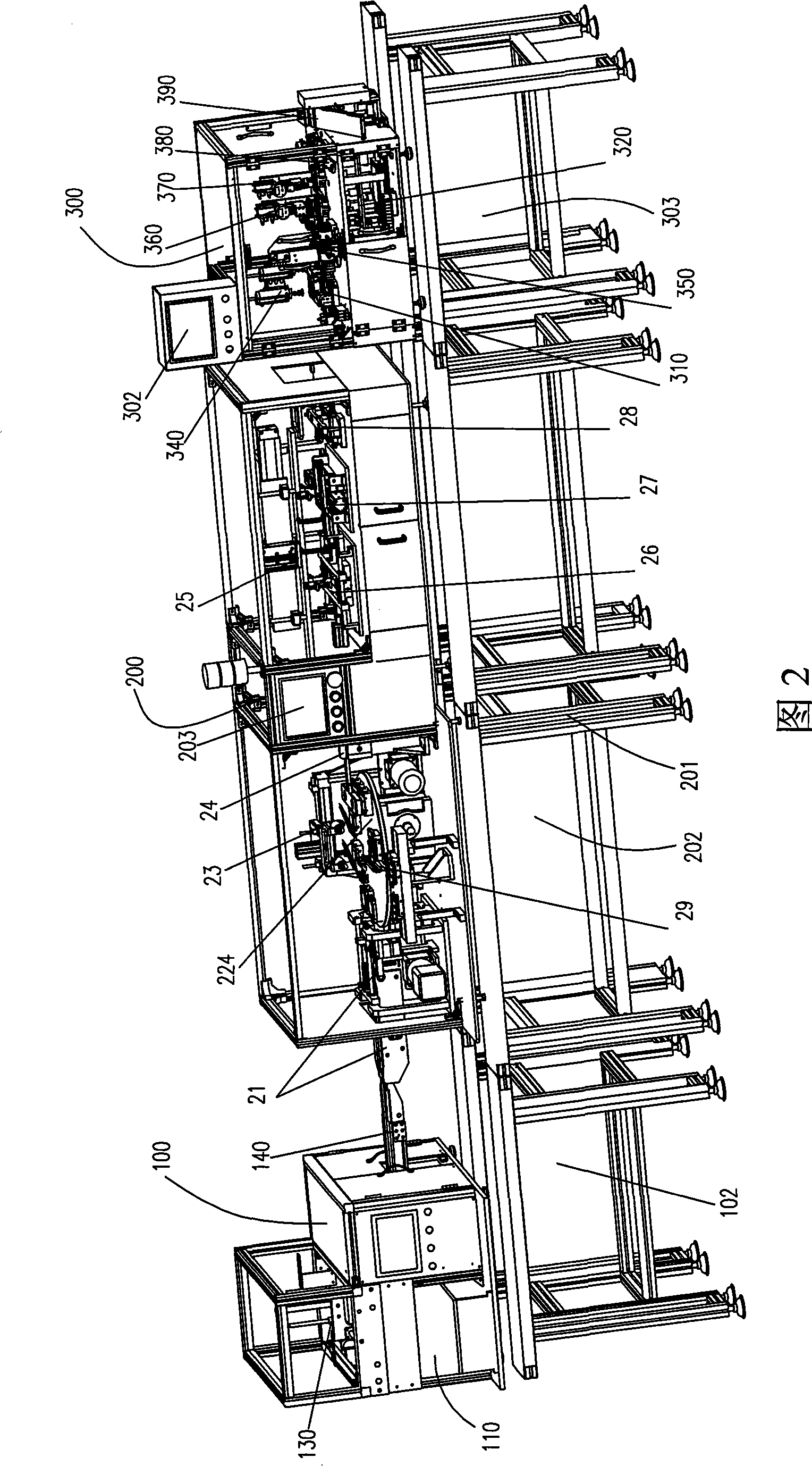

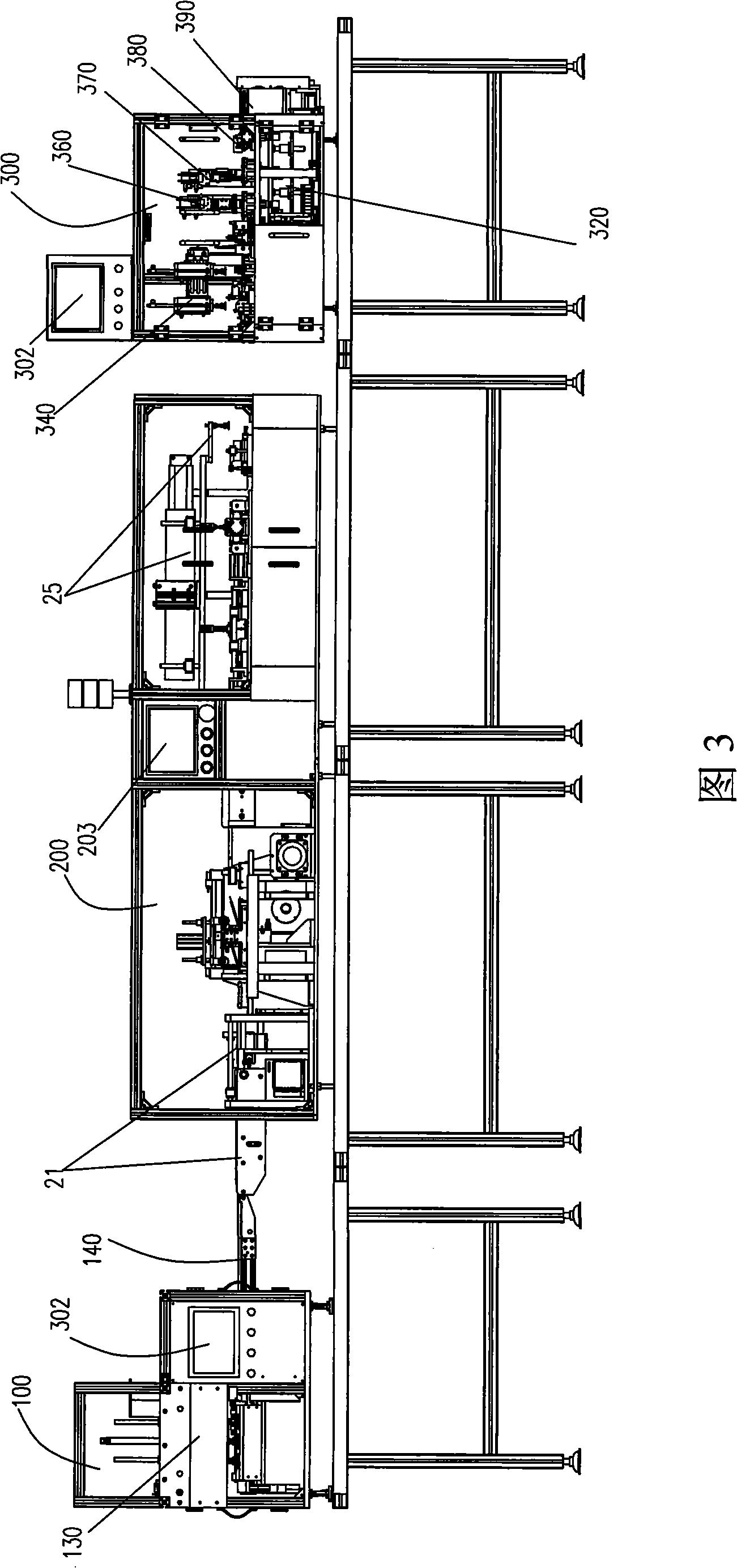

Detection, mark-wrapping, measurement automatic production line and process flow of mobile phone cell

InactiveCN101276929AReduce labor intensityImprove the wrapping effectFinal product manufacturePrimary cellsEngineeringAutonomation

The invention relates to a mobile phone detecting, mark wrapping, measuring automatic product line and technical flow. The product line comprises an orderly arranged mobile phone inside parameter automatic detector, a mobile phone automatic mark wrapper and a mobile phone cell size difference automatic measurer. A discharge port end of the mobile phone inside parameter automatic detector is connected with an inlet point end of the mobile phone automatic mark wrapper. A discharge port end of the mobile phone automatic mark wrapper is connected with an inlet point end of the mobile phone cell size difference automatic measurer that is connected electrically. In the invention, the cell feed in, position, clamp detection, mark wrapping and difference measurement after the mark wrapping are completed automatically. The mark wrapping effect is good, stable, and strongly reliable. The invention is simple in operation, high in efficiency and automatic level, which reduces the product manufacturing cost greatly and improves product quality and manufacturing speed, work efficiency as well as lightens labor intensity of the workers and improves labor capacity.

Owner:GRAND TECH SHENZHEN

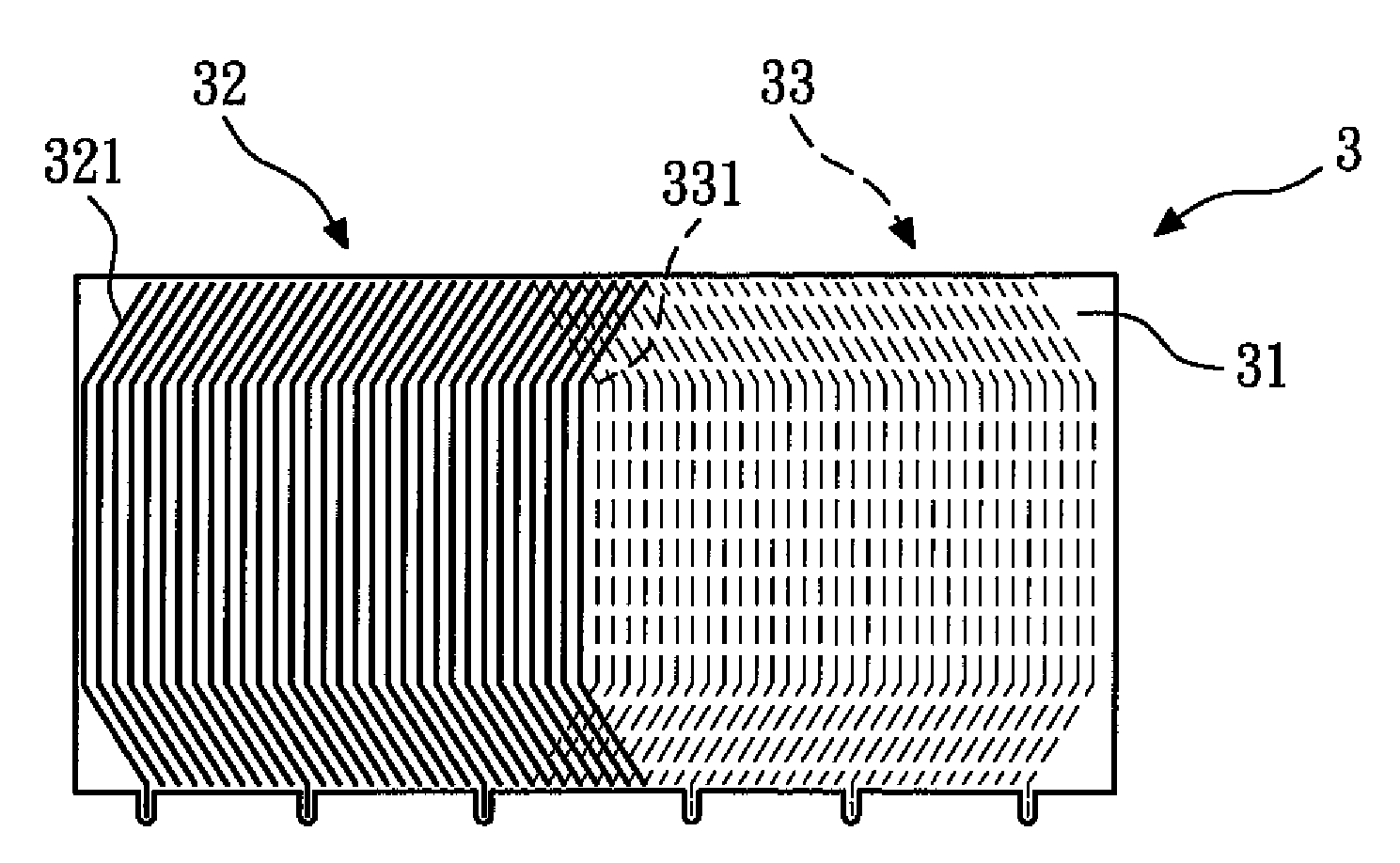

Slotless winding for rotating electric machine and manufacturing method thereof

InactiveUS20090072651A1Improve applicabilityImprove performanceMagnetic circuitTransformers/inductances coils/windings/connectionsElectric machineBarrel Shaped

The present invention relates to a slotless winding for a rotating electric machine and a manufacturing method thereof. The slotless winding includes at least one flexible printed circuit board having at least one circuit, and one piece of flexible printed circuit board(s) is curved or a plurality of pieces of flexible printed circuit board(s) is mutually combined to form a barrel shape, thereby simplifying the procedure of manufacturing the slotless winding, improving production speed and reliability, and enabling diversified designing schemes to meet the demands of the rotating electric machine. In addition, it is not necessary for the coil winding to be cured for assembling, and assembling yield is thus enhanced.

Owner:METAL INDS RES & DEV CENT

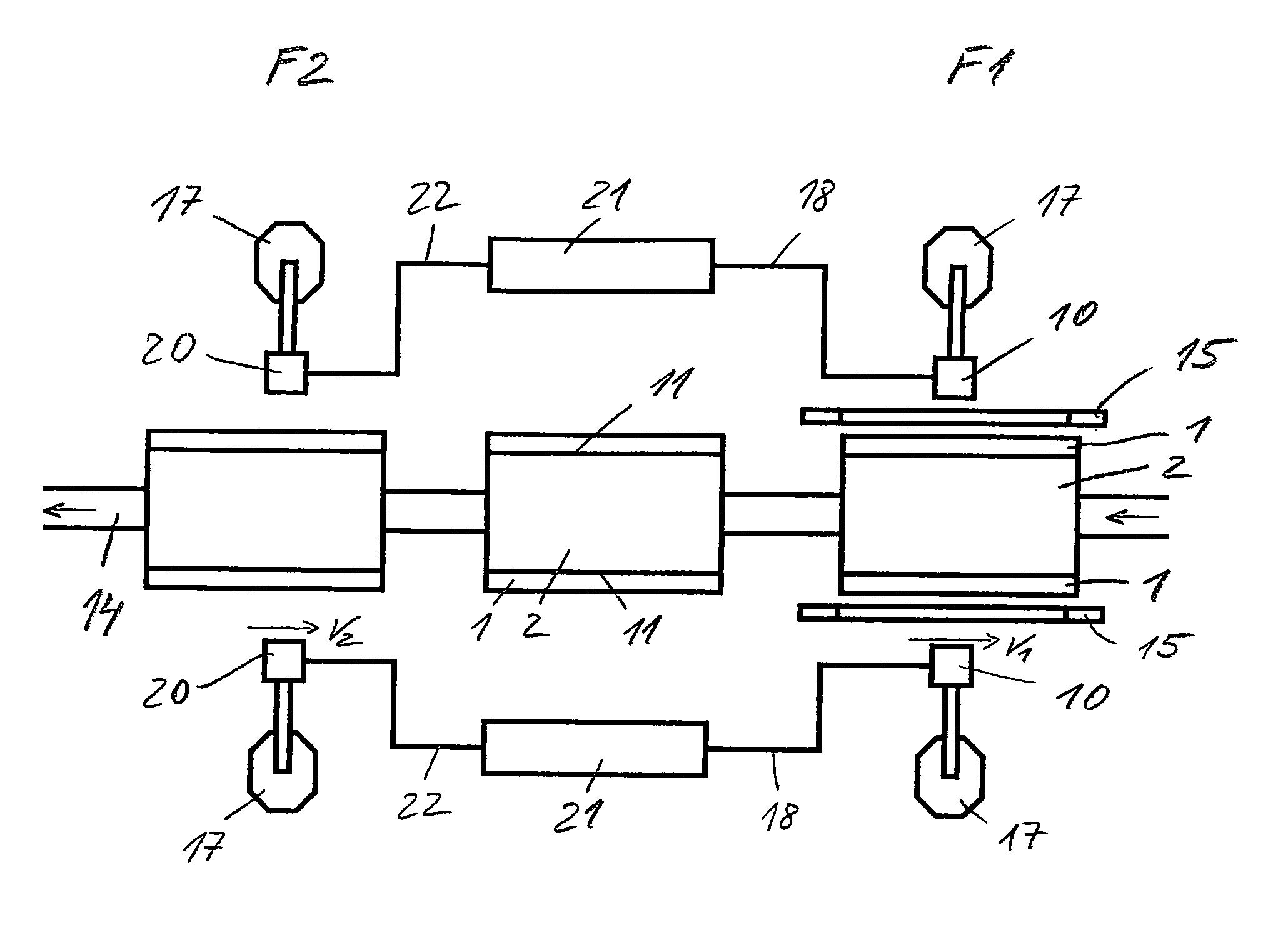

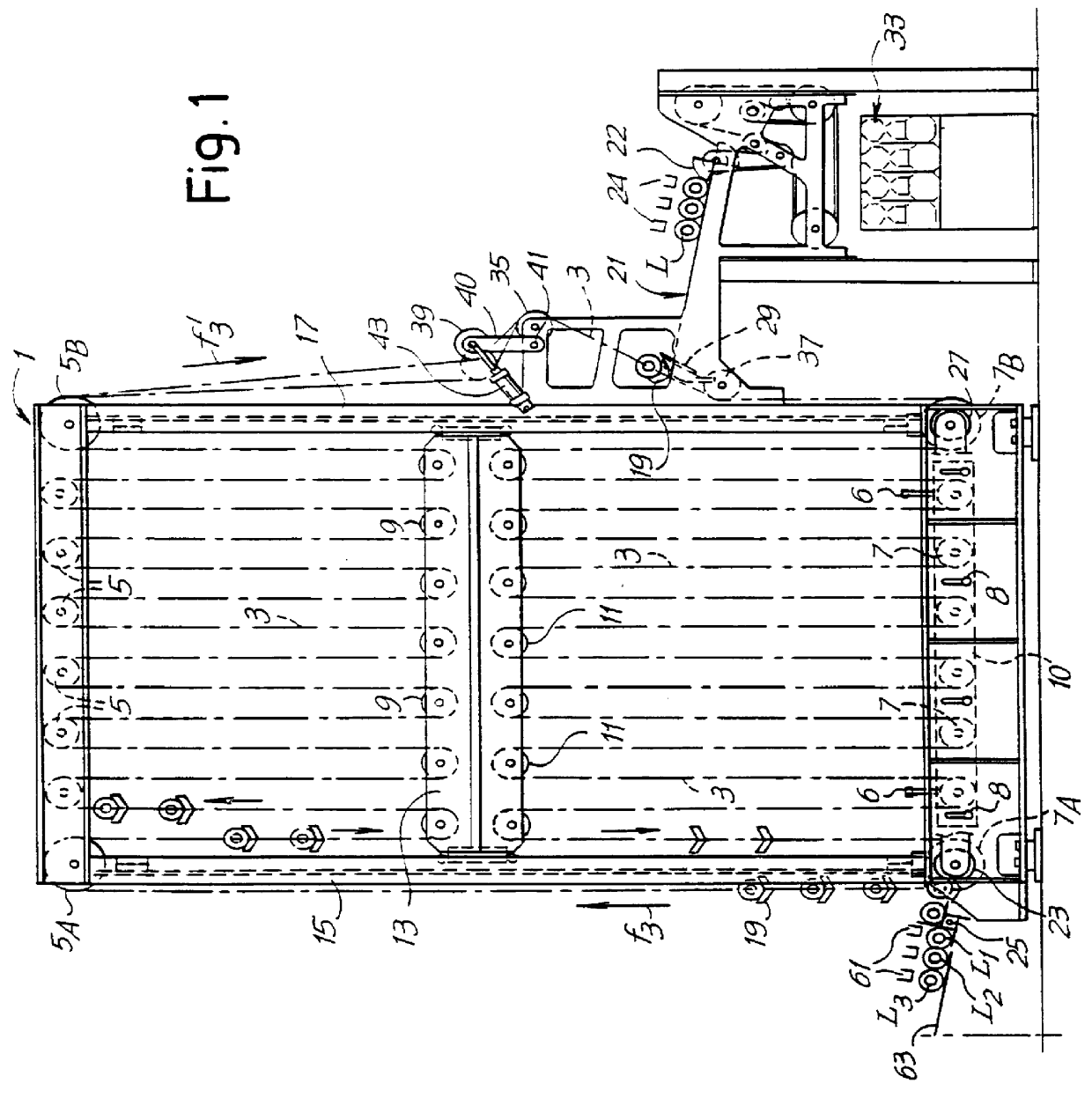

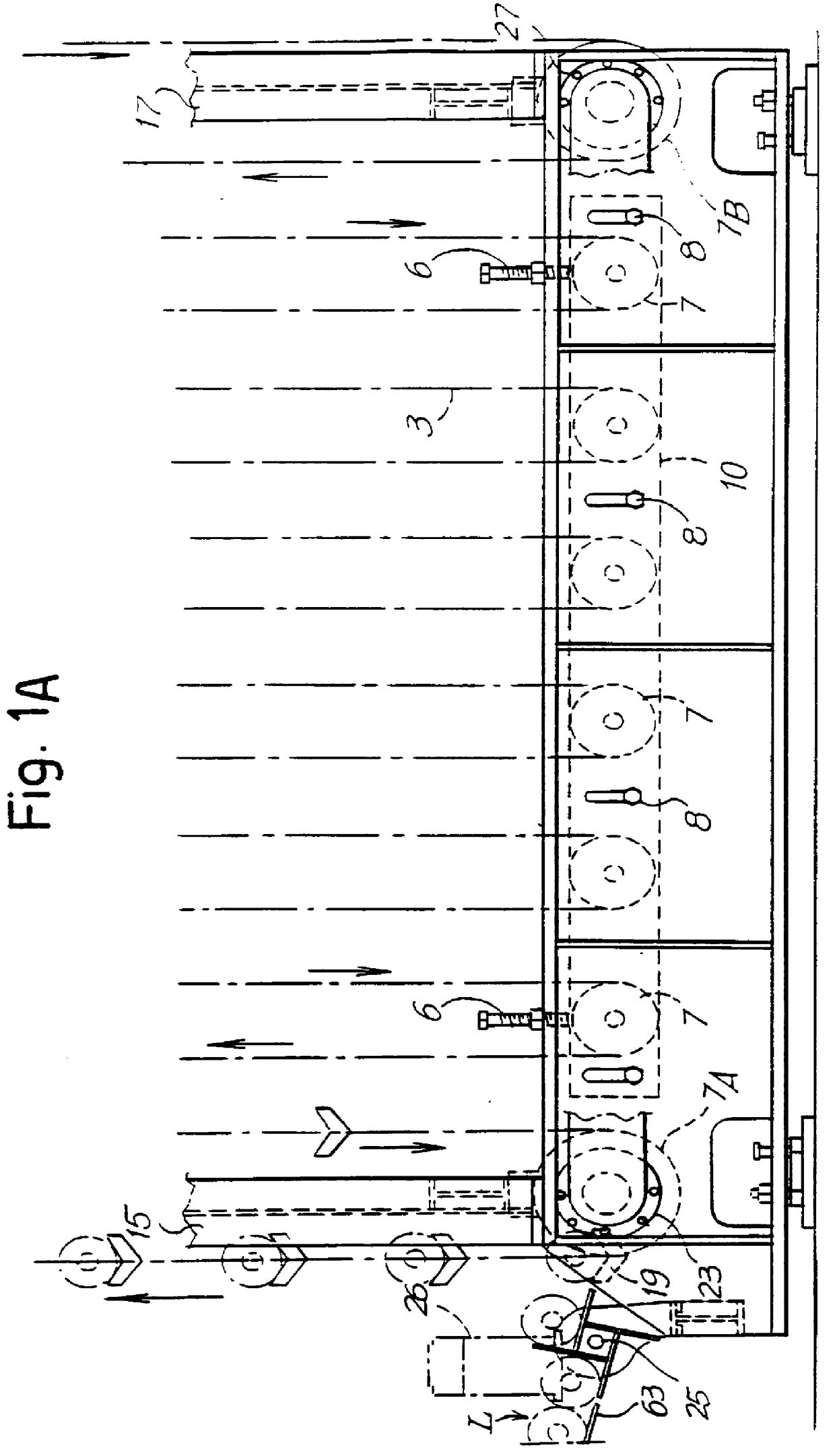

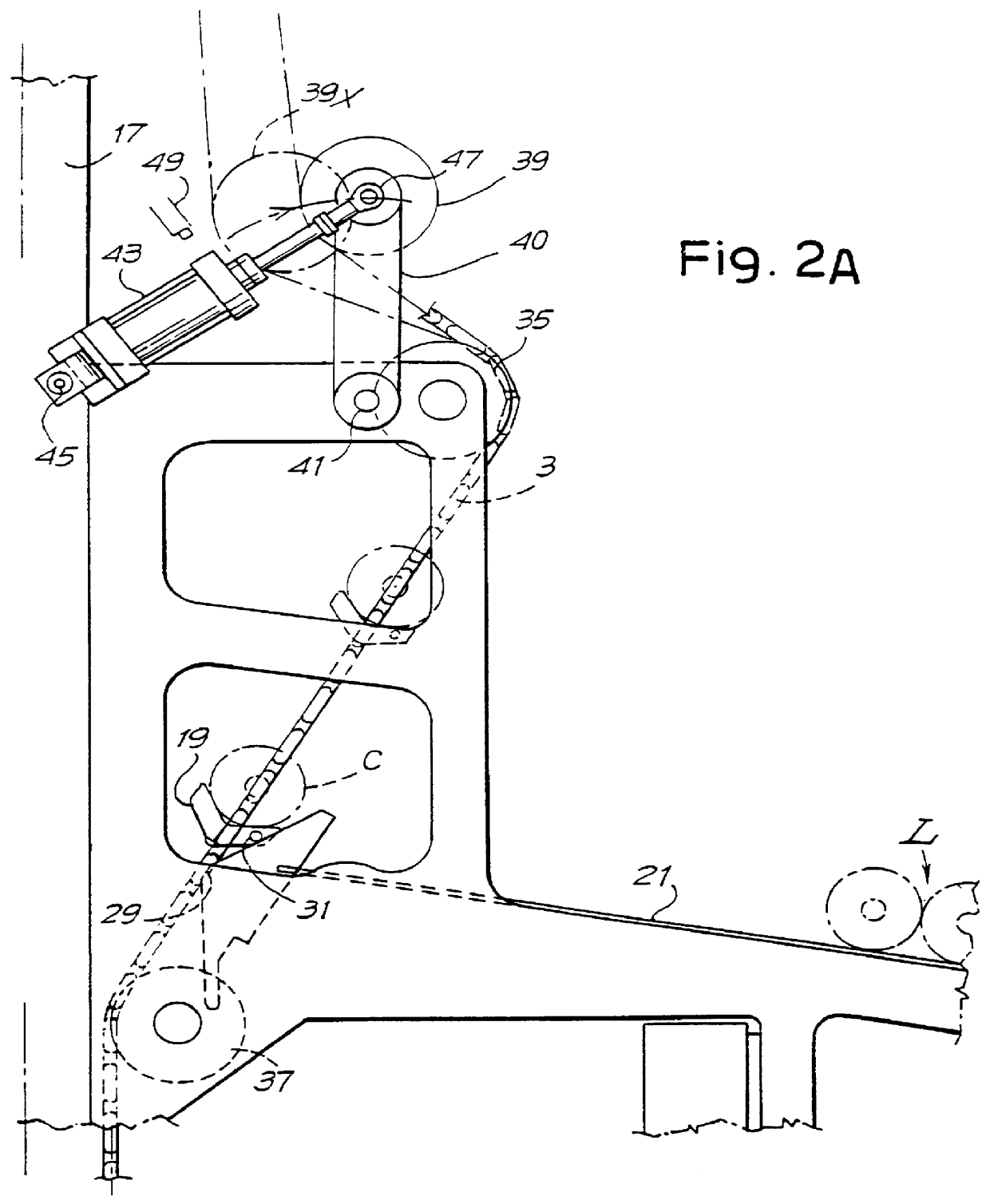

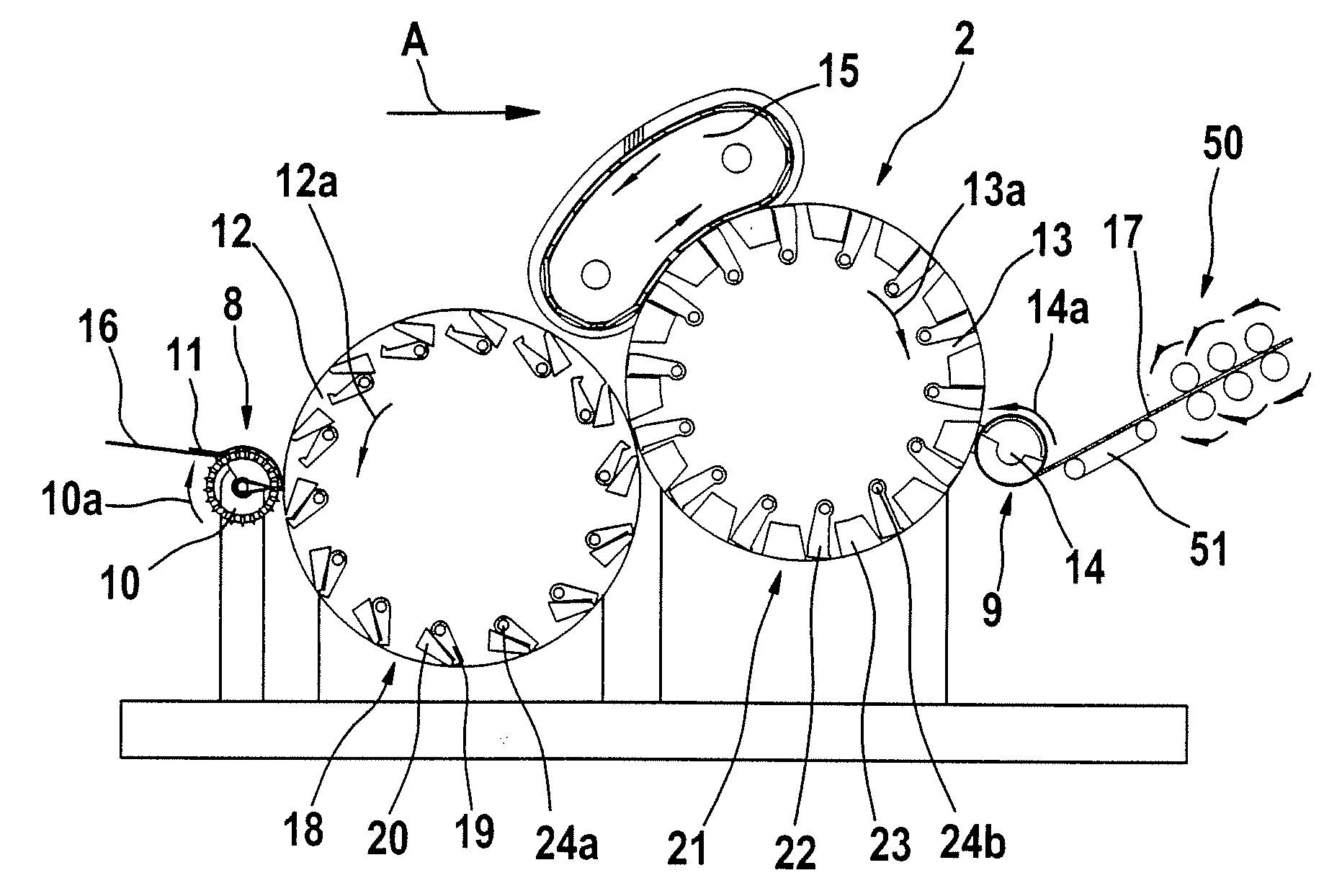

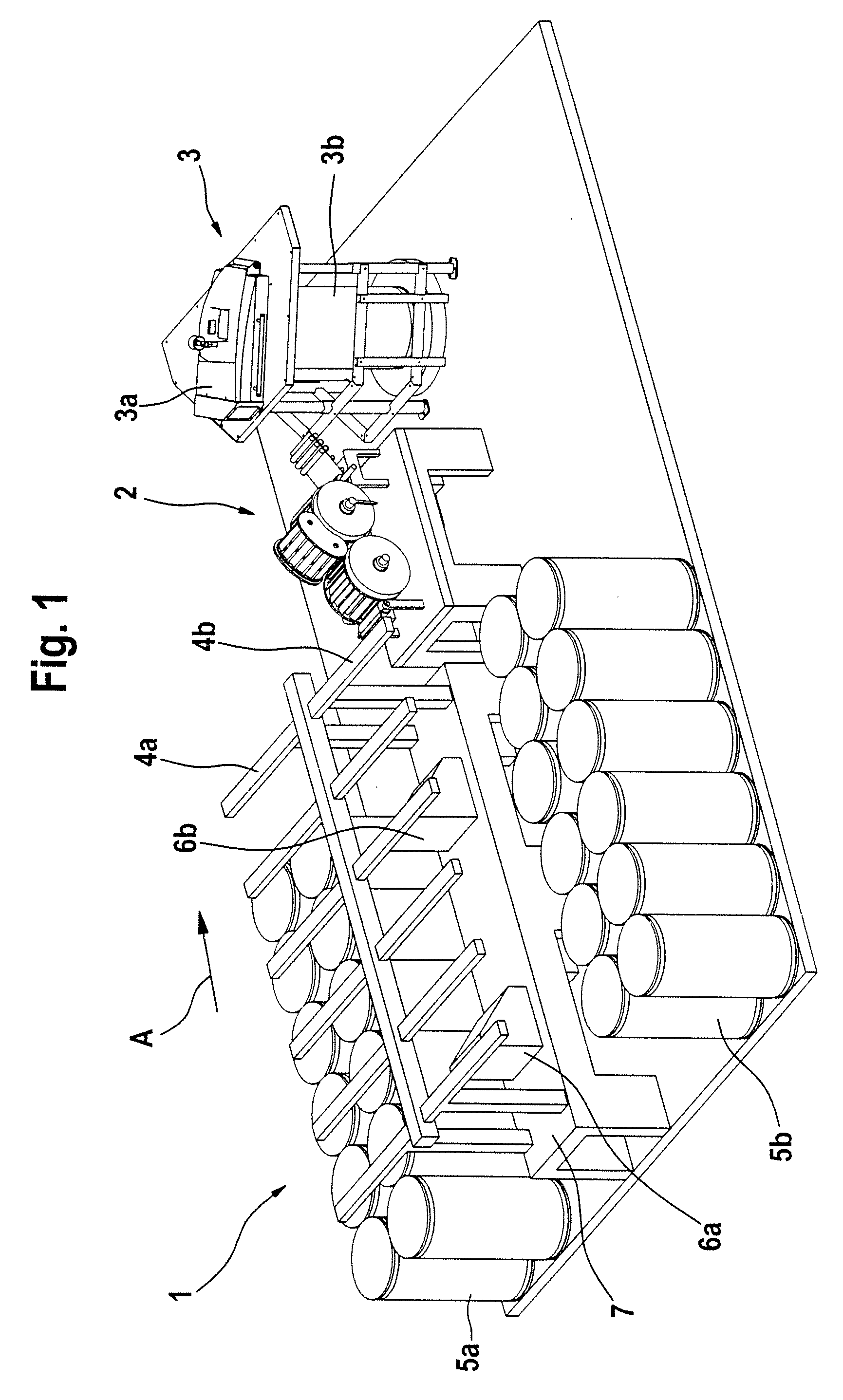

Storage unit with rates of advance dependent on upstream and downstream rates

InactiveUS6053304AReduce mechanical stressEliminate disadvantagesControl devices for conveyorsStorage devicesProduction lineEngineering

PCT No. PCT / IT96 / 00075 Sec. 371 Date Oct. 8, 1997 Sec. 102(e) Date Oct. 8, 1997 PCT Filed Apr. 16, 1996 PCT Pub. No. WO96 / 33114 PCT Pub. Date Oct. 24, 1996A storage unit for the temporary storage of rolls, arranged between a first section and a second section of a production line, is described which includes an endless flexible member defining a closed path within the storage unit and bearing a plurality of seats for the rolls, the seats being subdivided into a first group of empty seats and a second group of full seats; an input feeder for controlled distribution of rolls arriving from the first section to the seats of the first group; an output feeder for controlled discharge of rolls from the seats of the second group toward the second section; a first motor for advancing the seats of the first group toward the input feeder and; a second motor for advancing the seats of the second group toward the output feeder. The first and second motors have first and second independently adjustable continuous speeds, respectively. Further, the first and second motors move the flexible member at a continuous but variable speed. The first and second speeds are dependent on the rate of roll arrival from the first section and the rate of roll request from the second section, respectively.

Owner:FABIO PERINI SPA

Plastic sucking production line and production process thereof

The invention belongs to plastic sucking equipment and the technical field of a plastic sucking process, and relates to a plastic sucking production line. The production line comprises two mutually-parallel guide rails of which the opposite side is provided with an opening, wherein an annular conveying device for conveying sheet raw materials is arranged in the opening of each guide rail; a heating drying oven, a plastic sucking molding and in-mould die cutting device, a punching device and a stacking device are sequentially arranged between the two guide rails from one side to the other side; the heating drying oven is in an annular sealing type; and the plastic sucking molding and in-mould die cutting device has an integral structure. The plastic sucking production line comprises the production process of preparation, heating, molding, die cutting, stacking and discharging. The plastic sucking production line has the advantages of simple structure, high utilization factor of the raw materials, simple, convenient and quick operation, high automaticity, capability of saving electricity by over 65 percent and replacing required product dies according to the requirements of producing different products and wide application.

Owner:林士顺

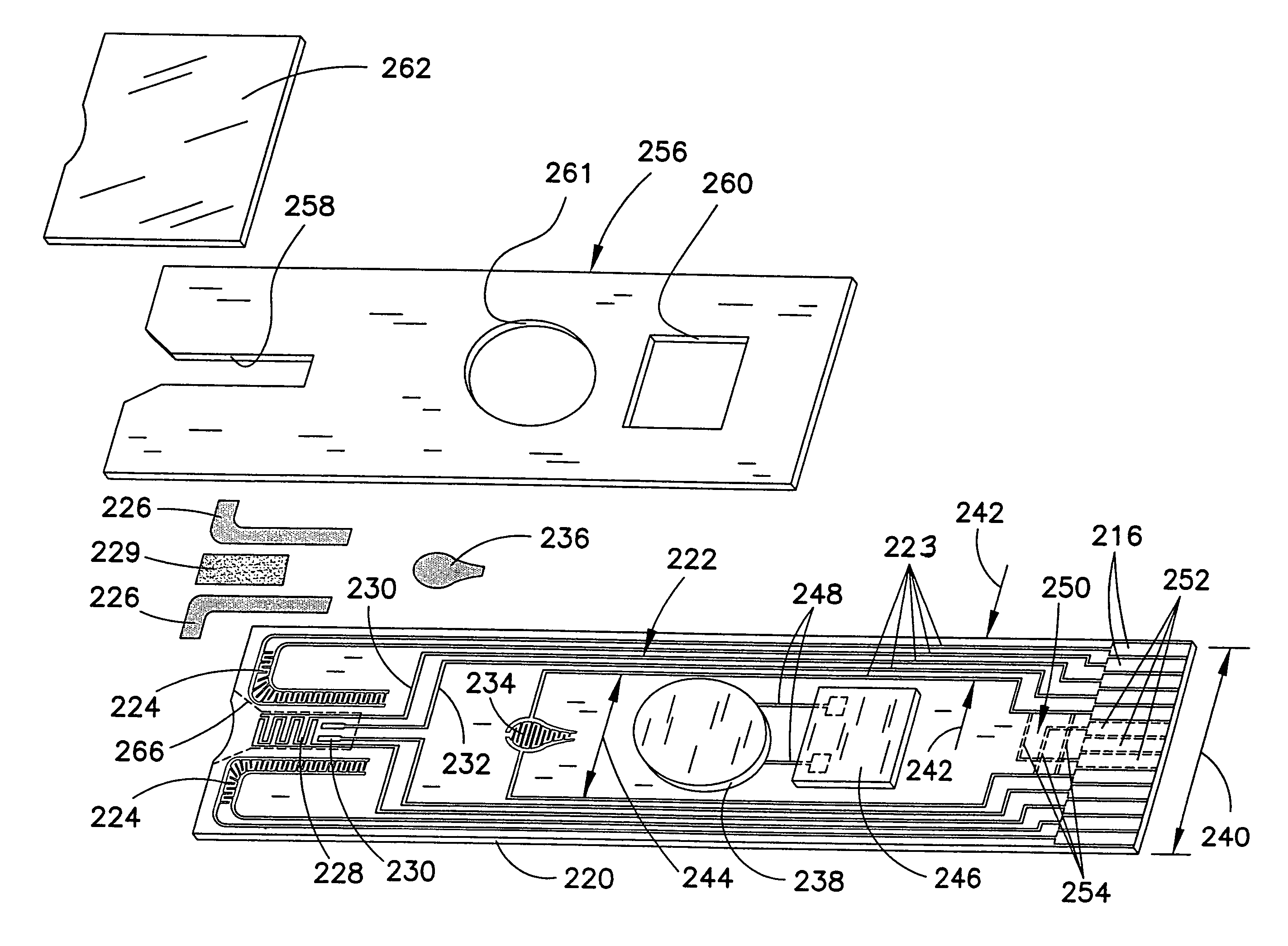

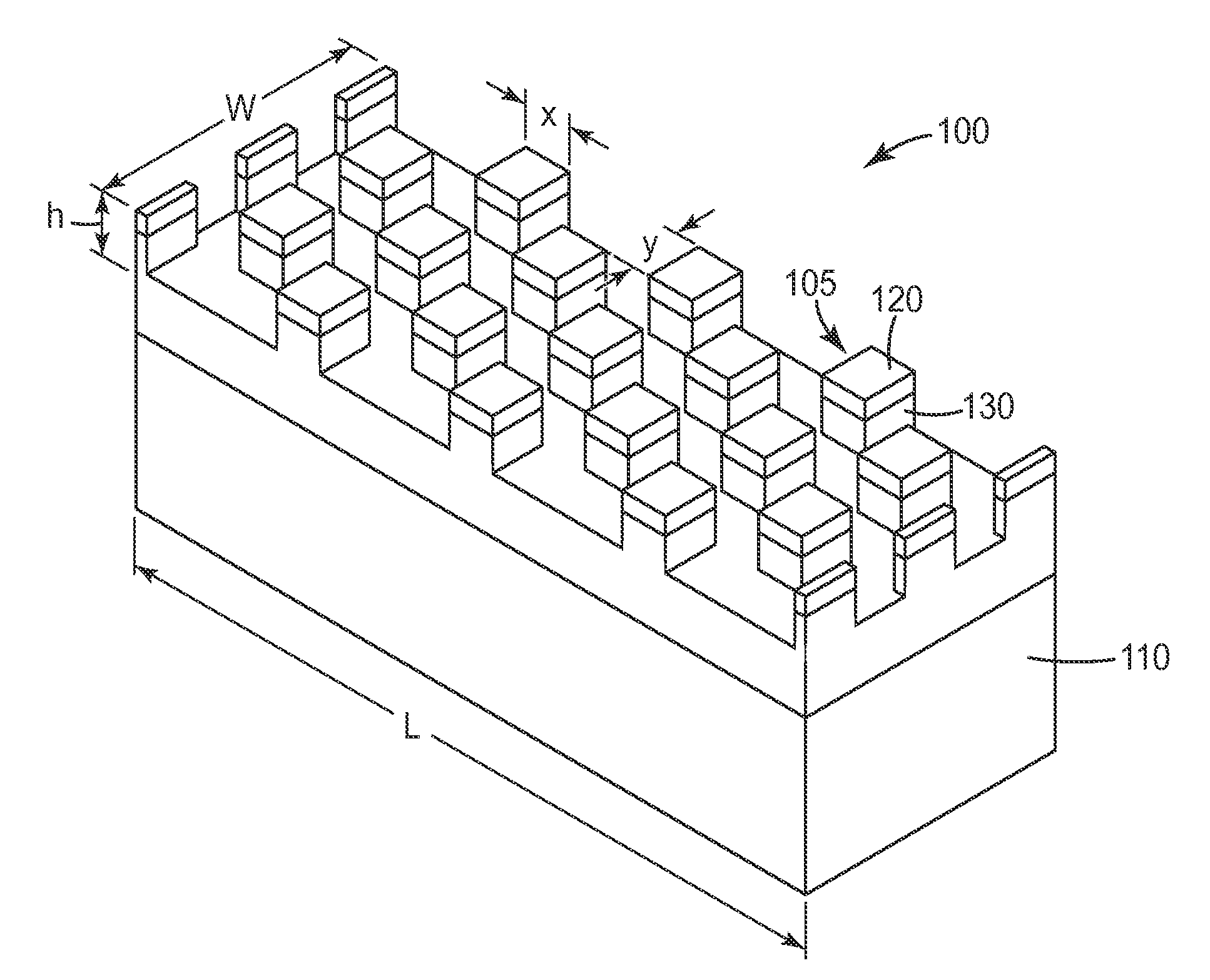

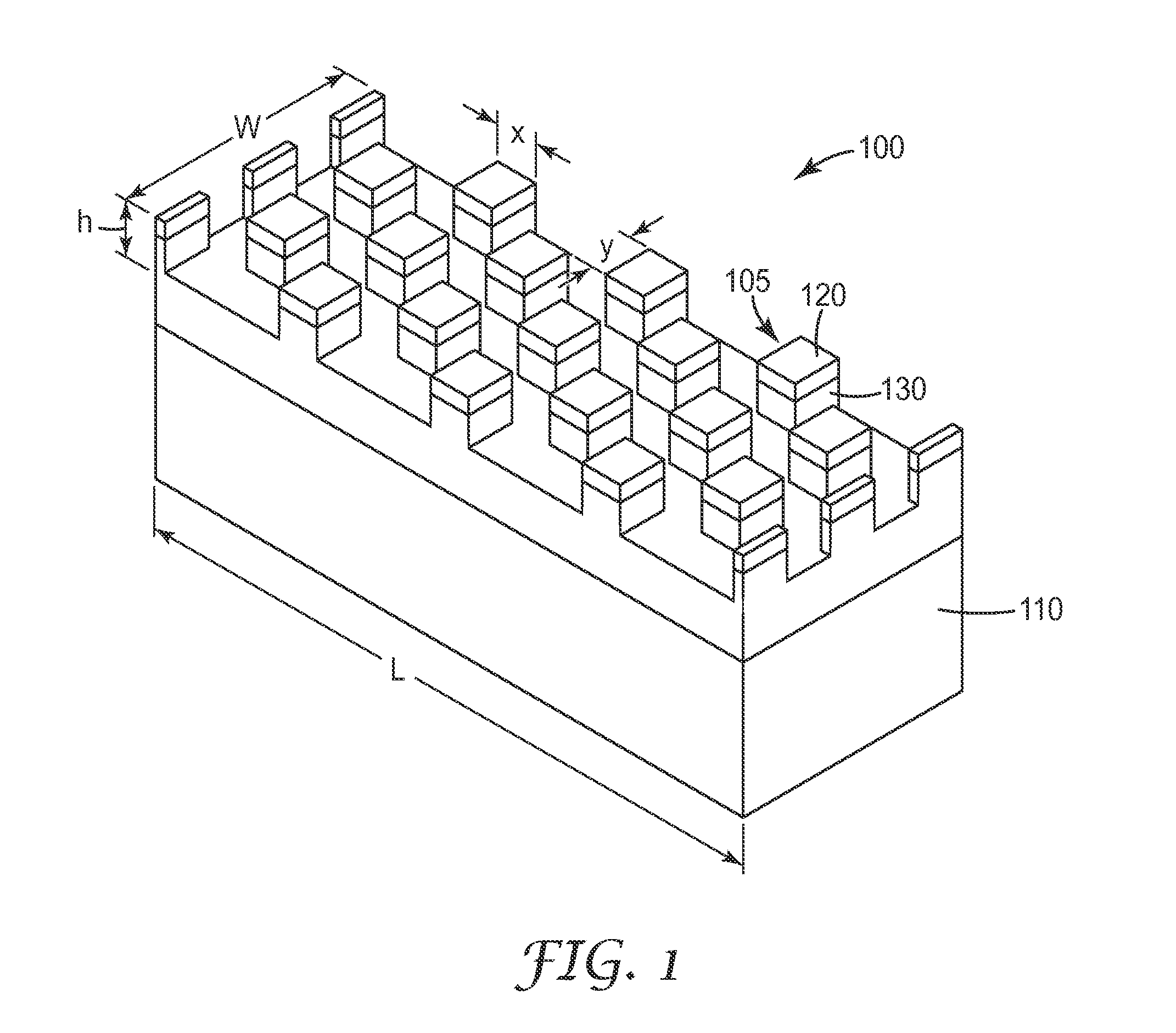

Biosensor with multiple electrical functionalities

InactiveUS7867369B2Enhancing quality and complexityDecreases computational burden and associated cost of instrumentImmobilised enzymesBioreactor/fermenter combinationsElectrical devicesUsability

A biosensor having multiple electrical functionalities located both within and outside of the measurement zone in which a fluid sample is interrogated. Incredibly small and complex electrical patterns with high quality edges provide electrical functionalities in the biosensor and also provide the electrical wiring for the various other electrical devices provided in the inventive biosensor. In addition to a measurement zone with multiple and various electrical functionalities, biosensors of the present invention may be provided with a user interface zone, a digital device zone and / or a power generation zone. The inventive biosensors offer improved ease of use and performance, and decrease the computational burden and associated cost of the instruments that read the biosensors by adding accurate yet cost-effective functionalities to the biosensors themselves.

Owner:ROCHE DIABETES CARE INC

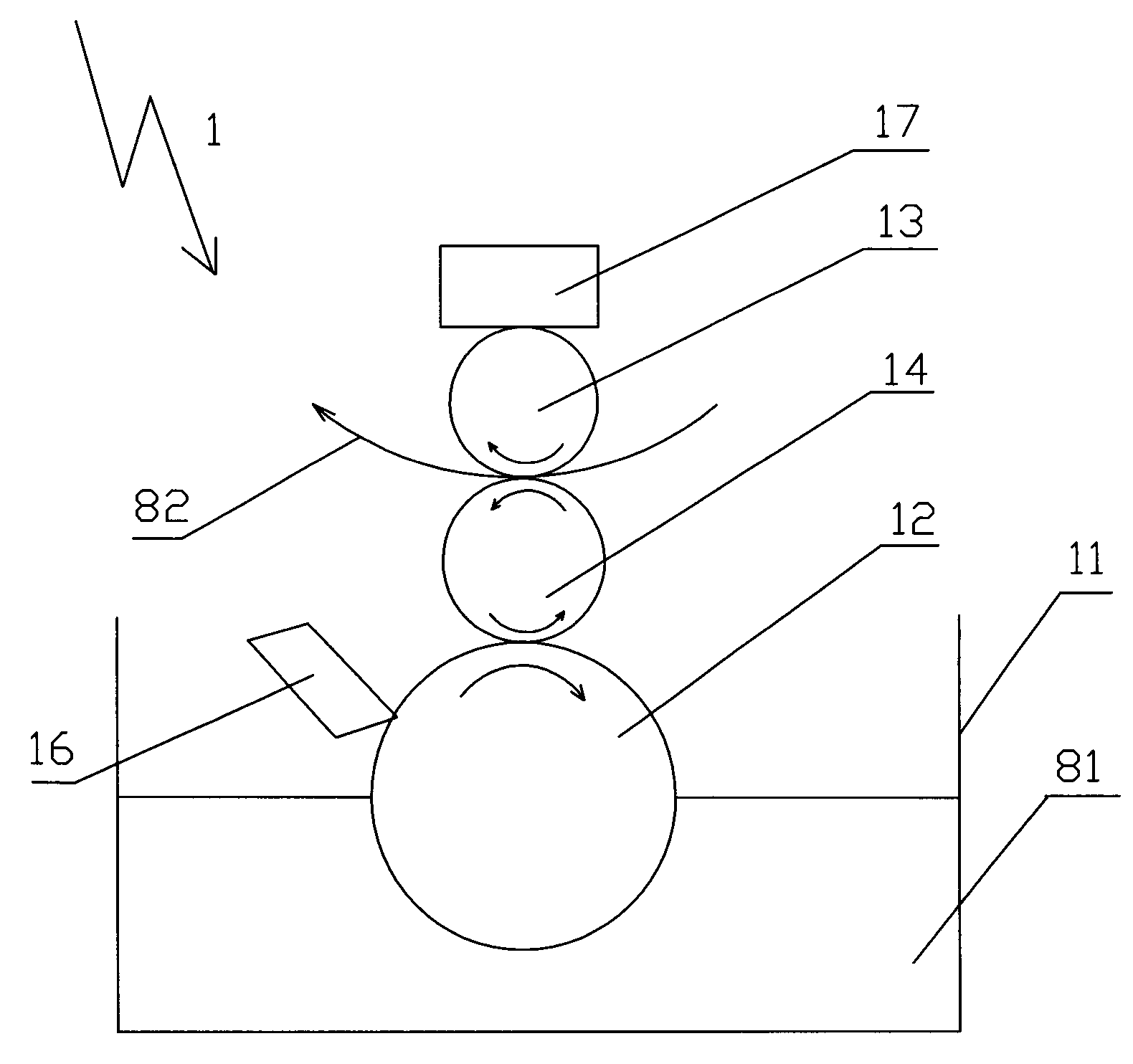

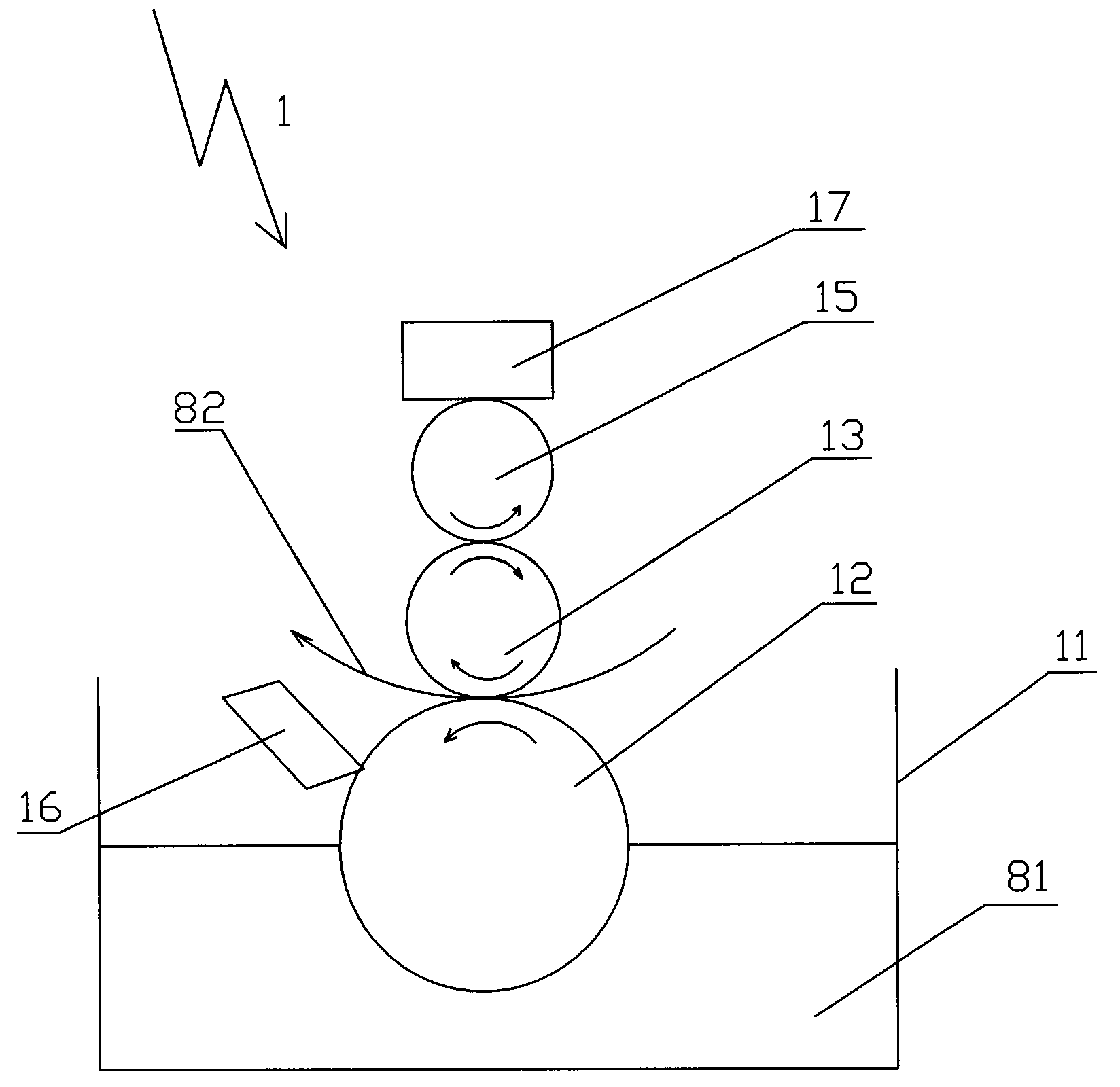

Apparatus for producing reflective membrane with microprism array structure

ActiveCN101672939AImprove work efficiencyImprove performanceOptical elementsUV curingHeat resistance

The invention relates to an apparatus for producing a reflective membrane with a microprism array structure and solves the defects in the prior art that the hardness, scratch resistance, heat resistance and solvent resistance of microprisms are disappointing, the product consistency is poorer, the production speed is lower, the work efficiency is not high, and the like. The apparatus comprises anannular strip-shaped mould, a heating membrane pressing device and a cooling device, wherein the annular strip-shaped mould is provided with an inner surface and an outer surface which is provided with a convex continuous precise microprism array structure. The apparatus also comprises a coating device, a drying device and a UV curing device. By adding the coating device, the drying device and theUV curing device, the microprism structure is formed after the UV curing of photosensitive resin, the hardness, scratch resistance, heat resistance and solvent resistance of microprism of the microprism structure are greatly improved, and the product consistency is fine. In addition, the apparatus can also obviously improve the production speed and the work efficiency.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

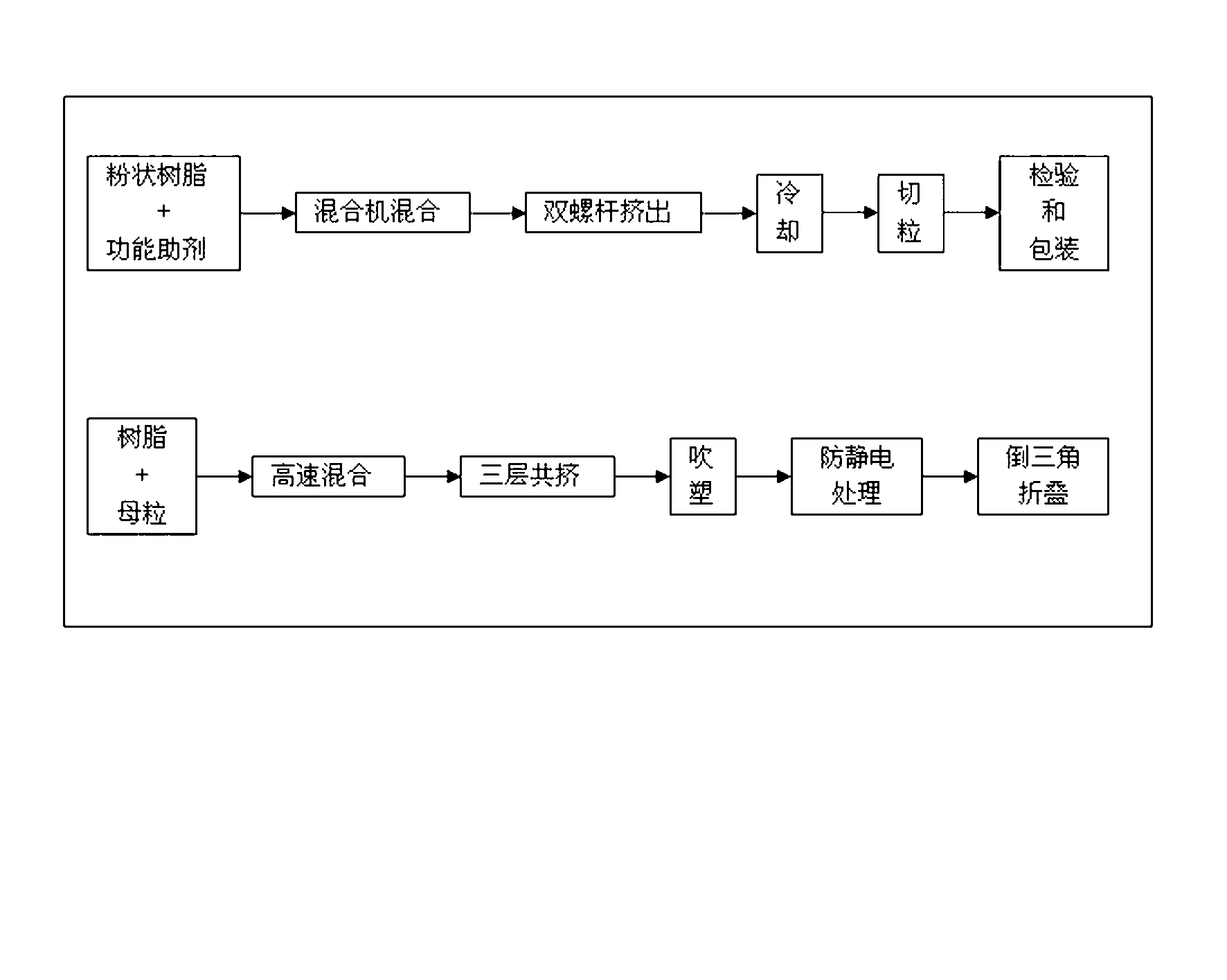

Three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film

ActiveCN103264563AGood colorEasy to processClimate change adaptationSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a nano fog-dissipation multifunctional greenhouse agricultural film, and in particular relates to a three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film, belonging to the field of agricultural mulching films. The raw material formula of an outer layer comprises the following components in percentage by weight: 20-50% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE), 10-20% of metallocene polyethylene (mPE) and 5-10% of double-prevention masterbatch; the raw material formula of a middle layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 20-40% of linear low-density polyethylene (LLDPE), 20-40% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; the raw material formula of an inner layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 10-20% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; and the formulas of the outer layer, the middle layer and the inner layer are uniformly mixed respectively, master batches are prepared by using a double-head thread screw double-screw extruding machine, a three-layer film is formed through a co-extrusion die head and is extruded out to prepare the multifunctional agricultural greenhouse film. Every quality technical index of the film reaches or exceeds a national standard, and a small part of the indexes is more than 2 times better than the national standard, so that the film is excellent in antiaging performance and cannot generate fog drops, and the service life of the film reaches more than 3 years.

Owner:HENAN YINFENG PLASTIC

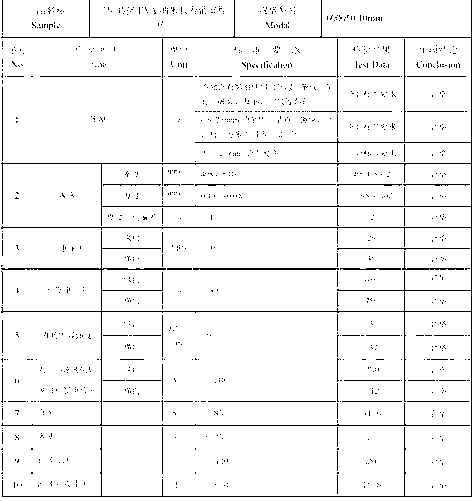

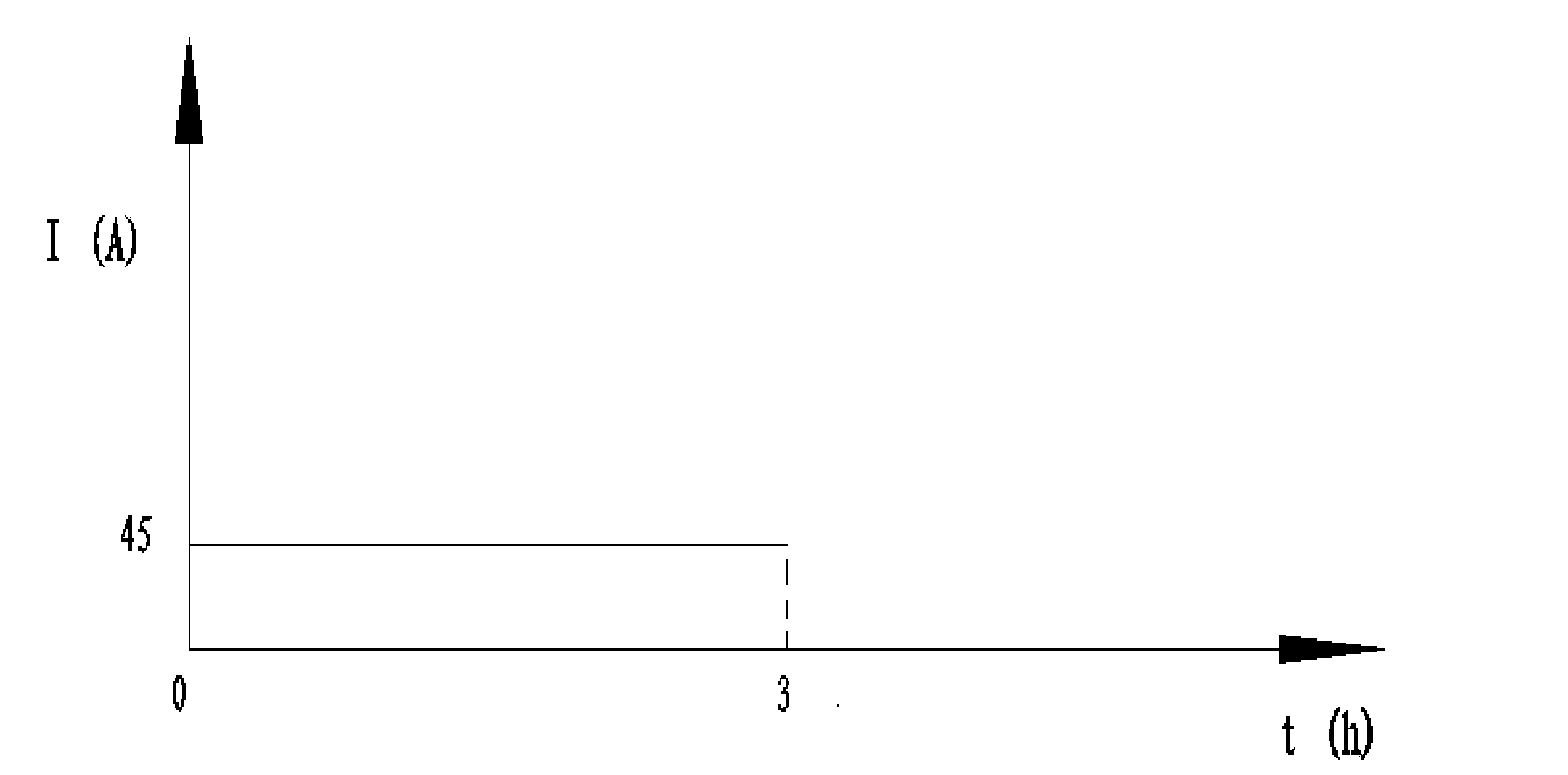

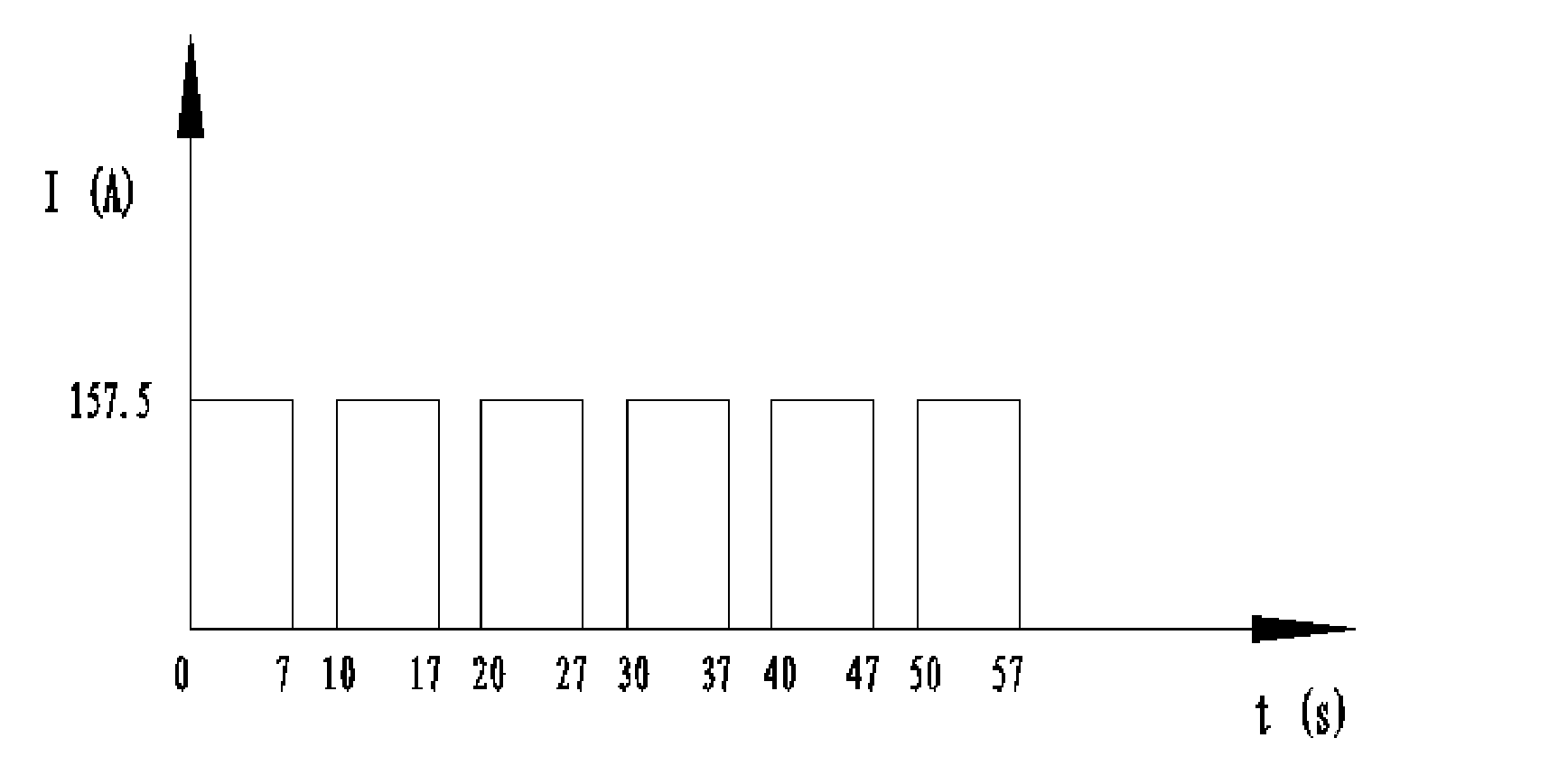

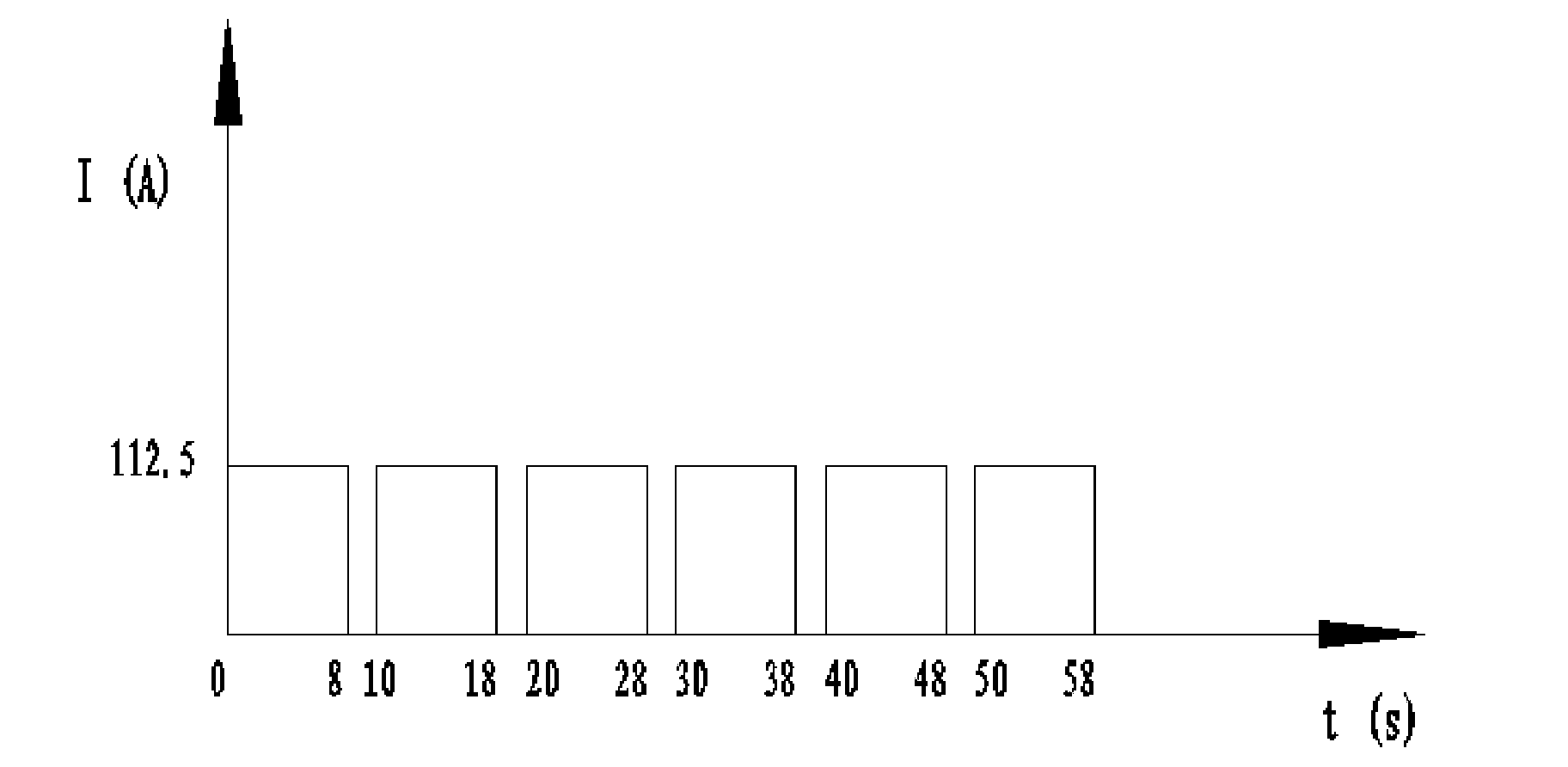

Pulse container formation method for high-capacity lead-acid battery

ActiveCN101877425AReduce shockImprove uniformityFinal product manufactureSecondary cells charging/dischargingEngineeringLow frequency

Owner:HUNAN FENGRI ELECTRIC GROUP

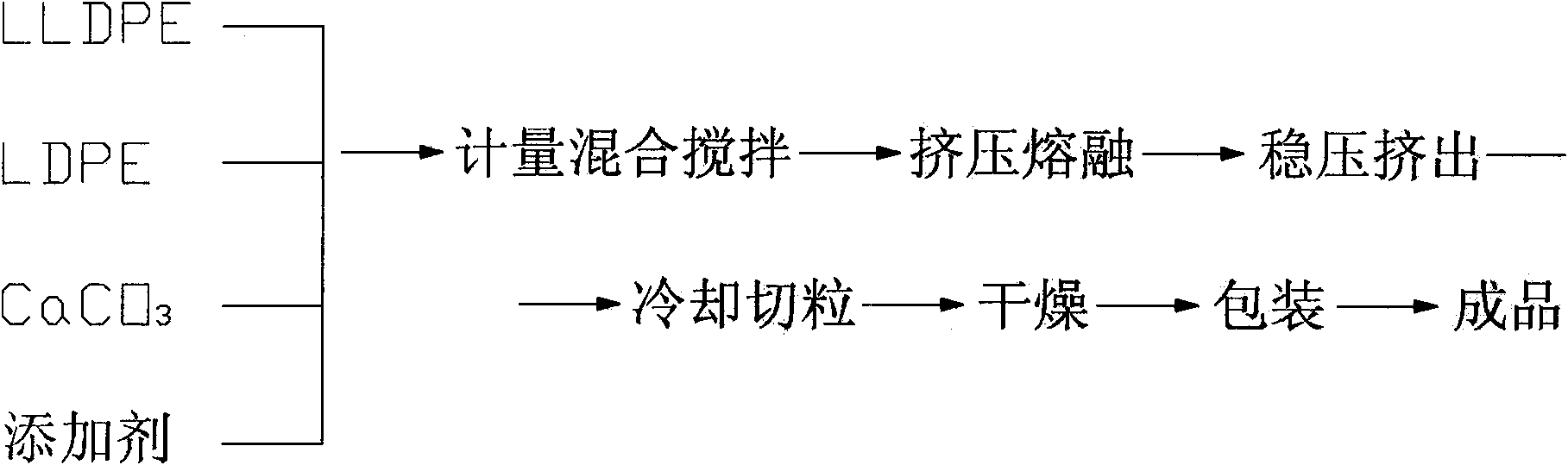

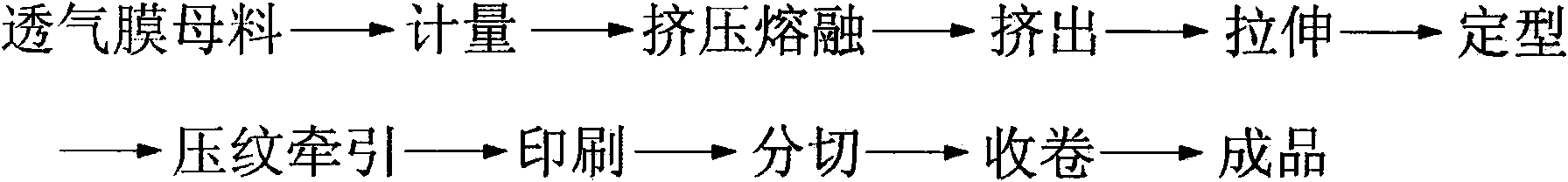

Ultrathin high porosity film and preparation method thereof

The invention discloses an ultrathin high porosity film and a preparation method thereof. The film comprises the following components by weight percent: 40-50% of : PE(LLDPE / LDPE), 45-55% of calcium carbonate and 3-5% of modified additives (plastic additive and film forming additive). The preparation method of the invention comprises the following steps: (1) breathable film master batch process flow and (2) breathable film process flow. The product of the invention can replace imported products, thus reducing the production cost of the breathable film, improving the current dilemma of foreignmonopoly, filling the domestic blank to develop and produce the breathable film material with independent intellectual property rights and having practical and great economic benefit and social benefit.

Owner:ZHEJIANG YUEHAN TECH BREATHABLE MATERIAL

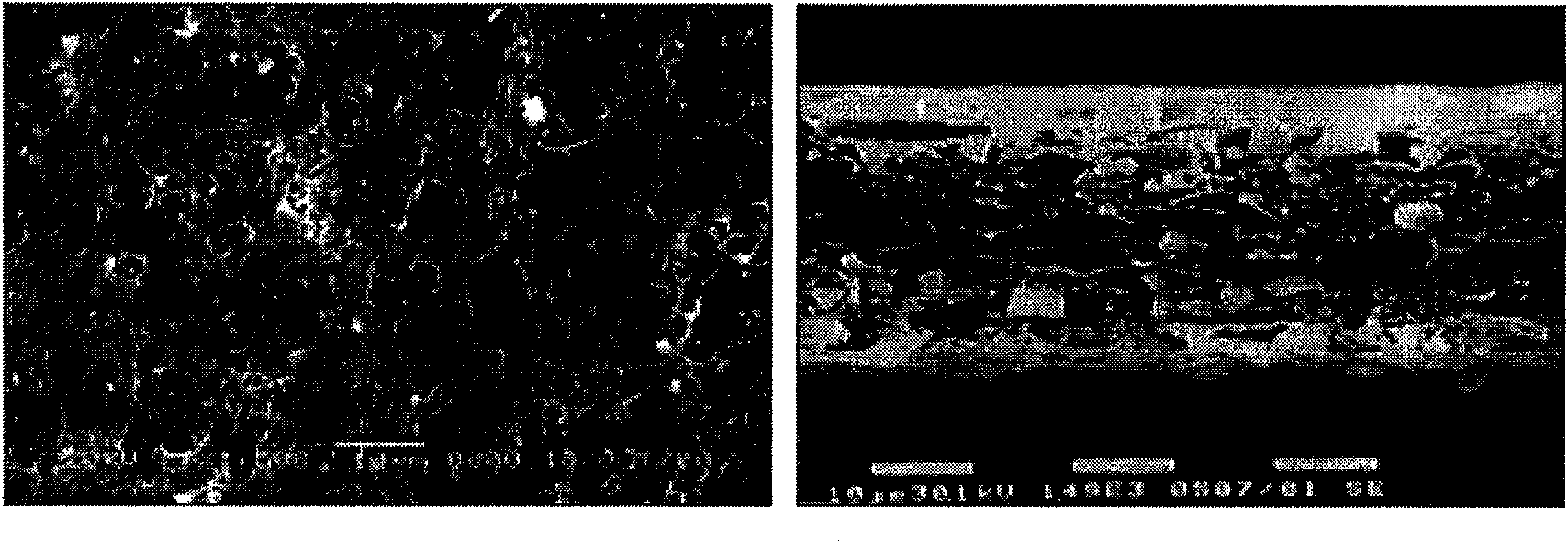

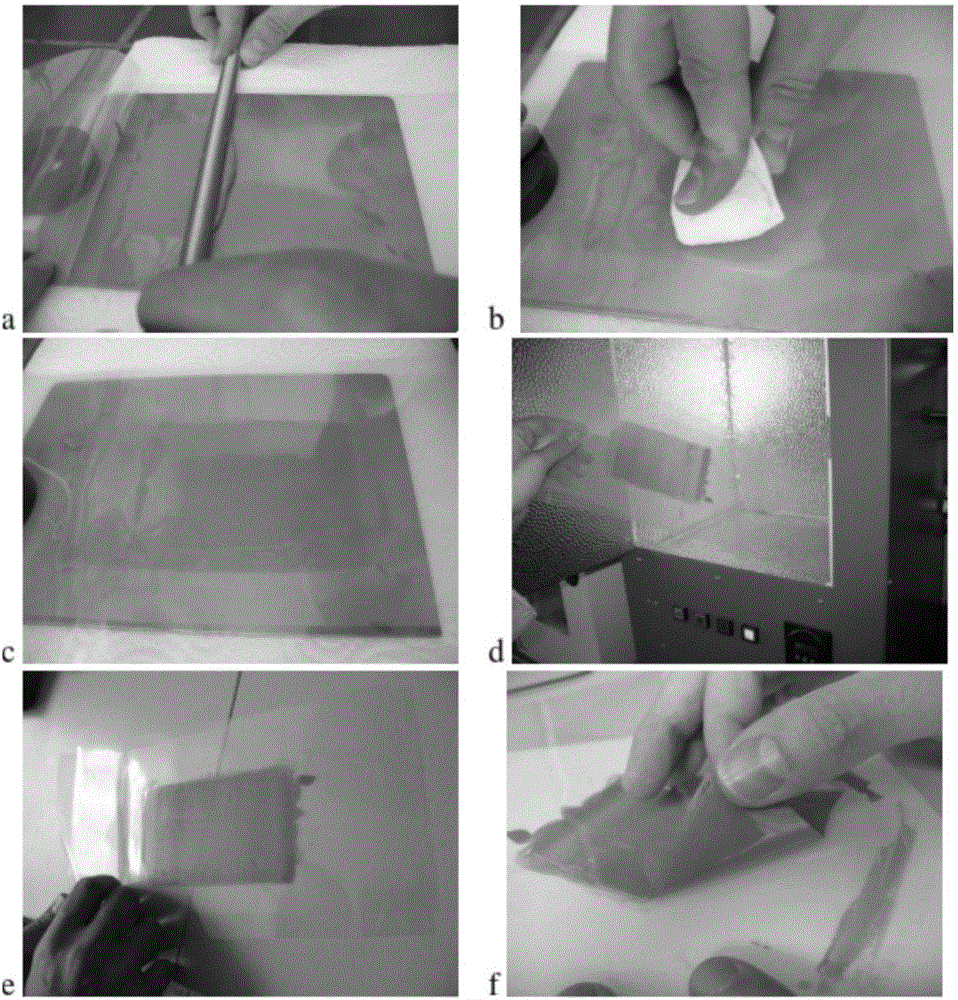

Cutting wire with composite structure, and manufacturing method and manufacturing equipment thereof

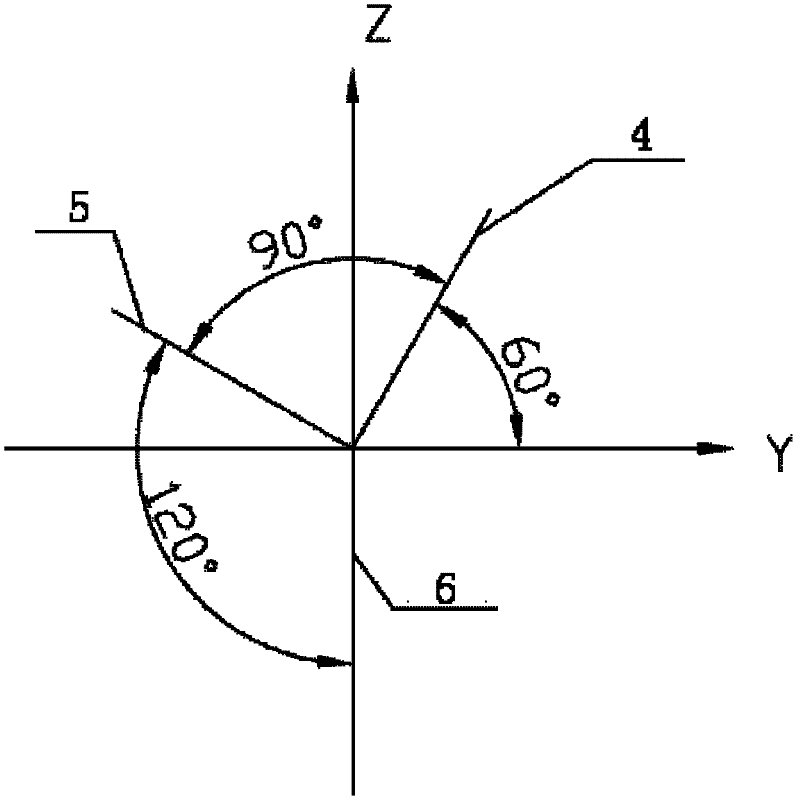

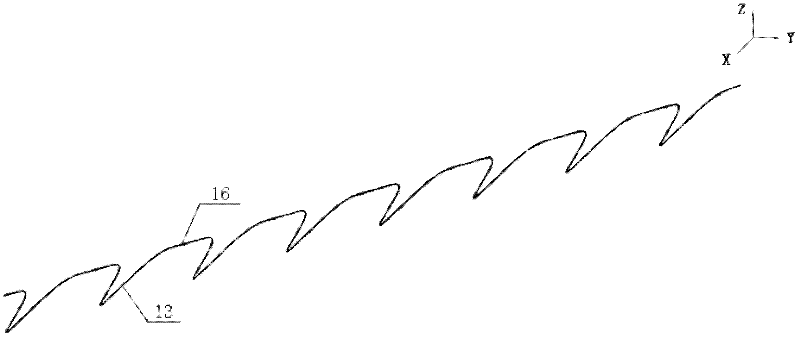

InactiveCN102310489ANot easy to peel offIncrease production speedFine working devicesThree-dimensional spaceEngineering

The invention discloses a cutting wire with a composite structure, and a manufacturing method and manufacturing equipment thereof. The cutting wire comprises a plurality of bent parts and curve parts, wherein adjacent bent parts are connected through the curve parts. The method comprises the following steps of: processing a metal wire into a linear metal wire; unwinding the linear metal wire along a central axis, passing through a first limiting group wheel, winding on a first deformed guide roller, applying pulling force, and bending the metal wire; and making the bent metal wire pass through a guide wheel, and unwinding the metal wire along the central axis. In the equipment, an unwinding disk, the limiting group wheel, the guide wheel, the deformed guide roller and a winding disk are arranged in sequence. In the invention, a plurality of concave regions are formed in a three-dimensional space through a three-dimensional structure of the cutting wire, thereby mortar grinding materials can be wrapped and carried efficiently and are prevented from easily falling off from the cutting wire, so that the production speed and efficiency of the cutting and fragmenting processes of silicon materials, jewels and the like are greatly increased, and the surface quality of fragmented materials can be effectively improved.

Owner:ZHENJIANG NAISI ADVANCE MATERIALS

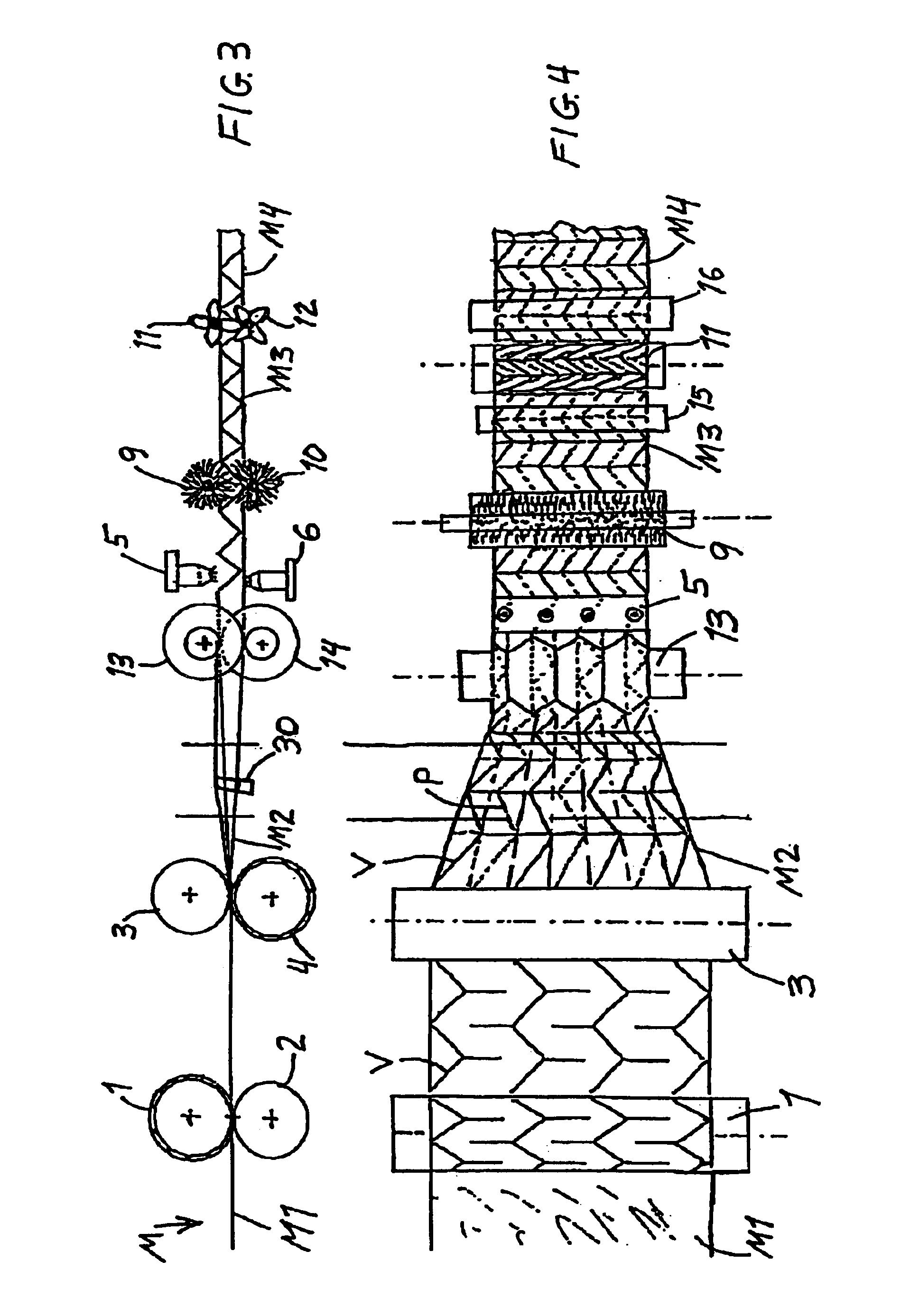

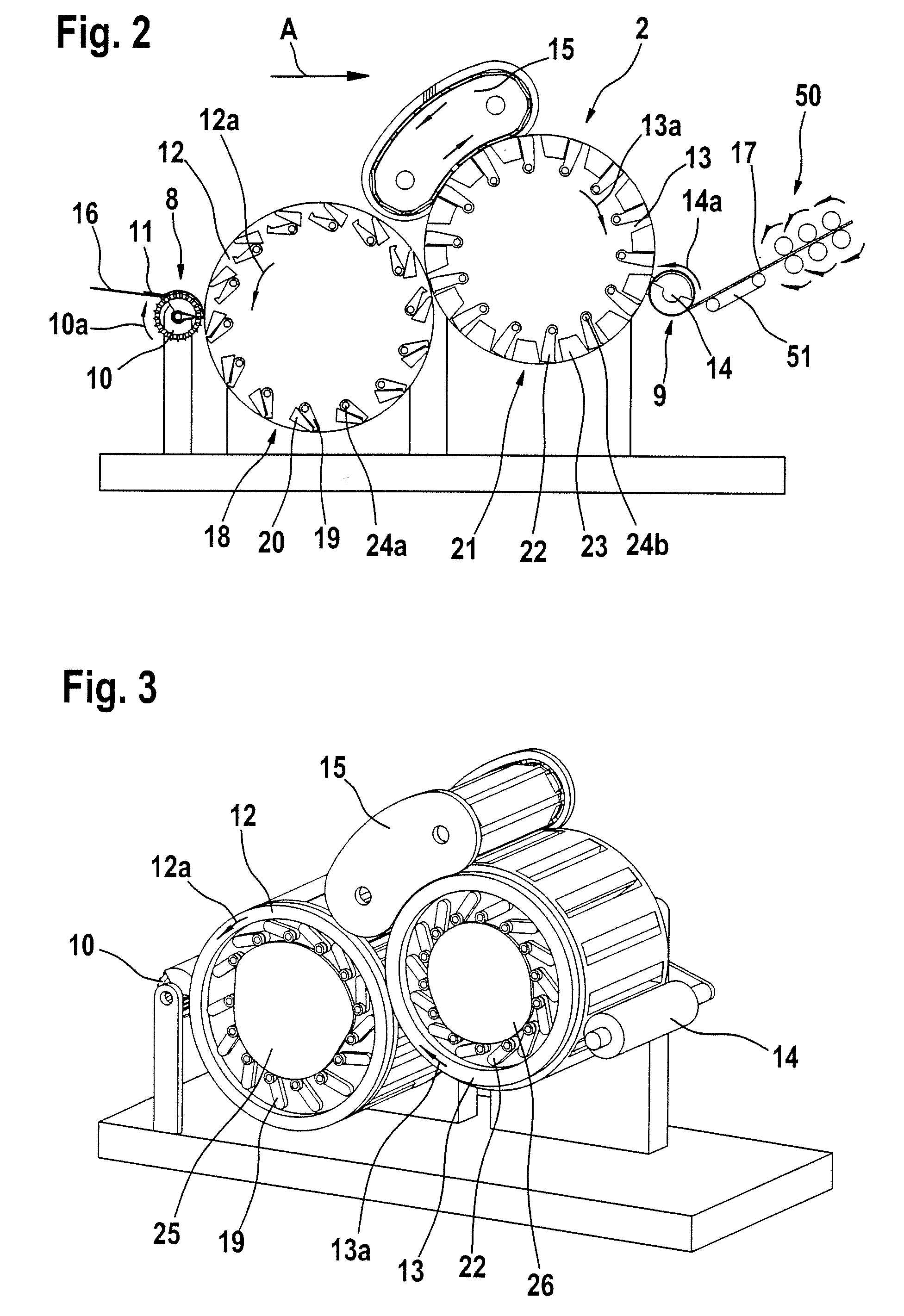

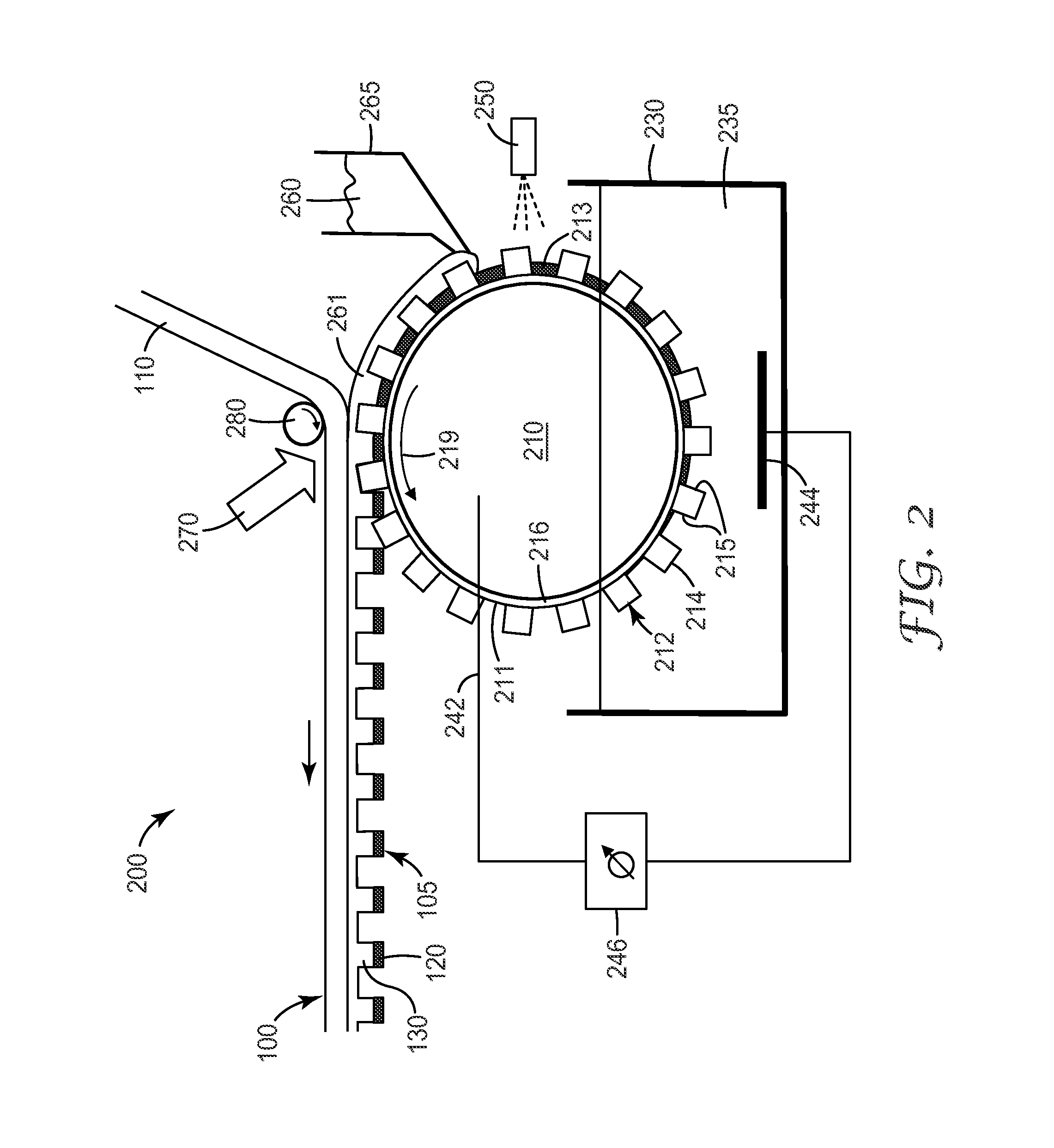

Apparatus for the fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing

InactiveUS20090000072A1Increase volumeImproved combed sliverCombing machinesProduction rateFiber bundle

In an apparatus for fibre-sorting or fibre-selection of a fibre bundle comprising textile fibres, especially for combing, the fibre bundle is supplied to a fibre-sorting device, clamping devices are provided, which clamp the fibre bundle at a distance from its free end, and mechanical device is present, which generates a combing action from the clamping site to the free end of the fibre bundle. To increase productivity in a simple manner and obtain an improved combed sliver downstream of the supply device there are at least two rotatably mounted rollers rotating rapidly without interruption, the combing device are associated with a said roller, and an arrangement for optimum feed and / or positioning of the fibre material to be combed is associated with the combing device.

Owner:TRUETZSCHLER GMBH & CO KG

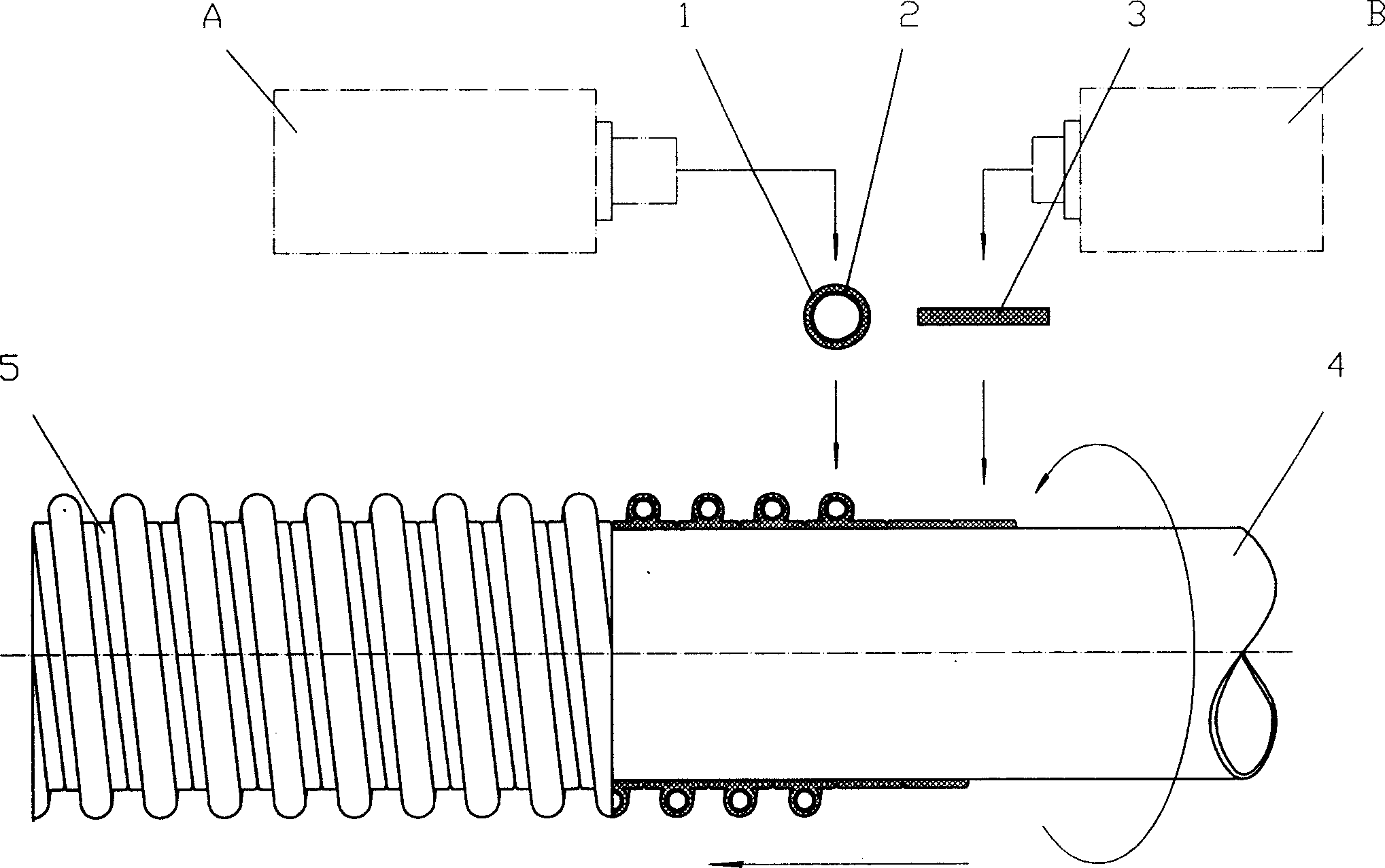

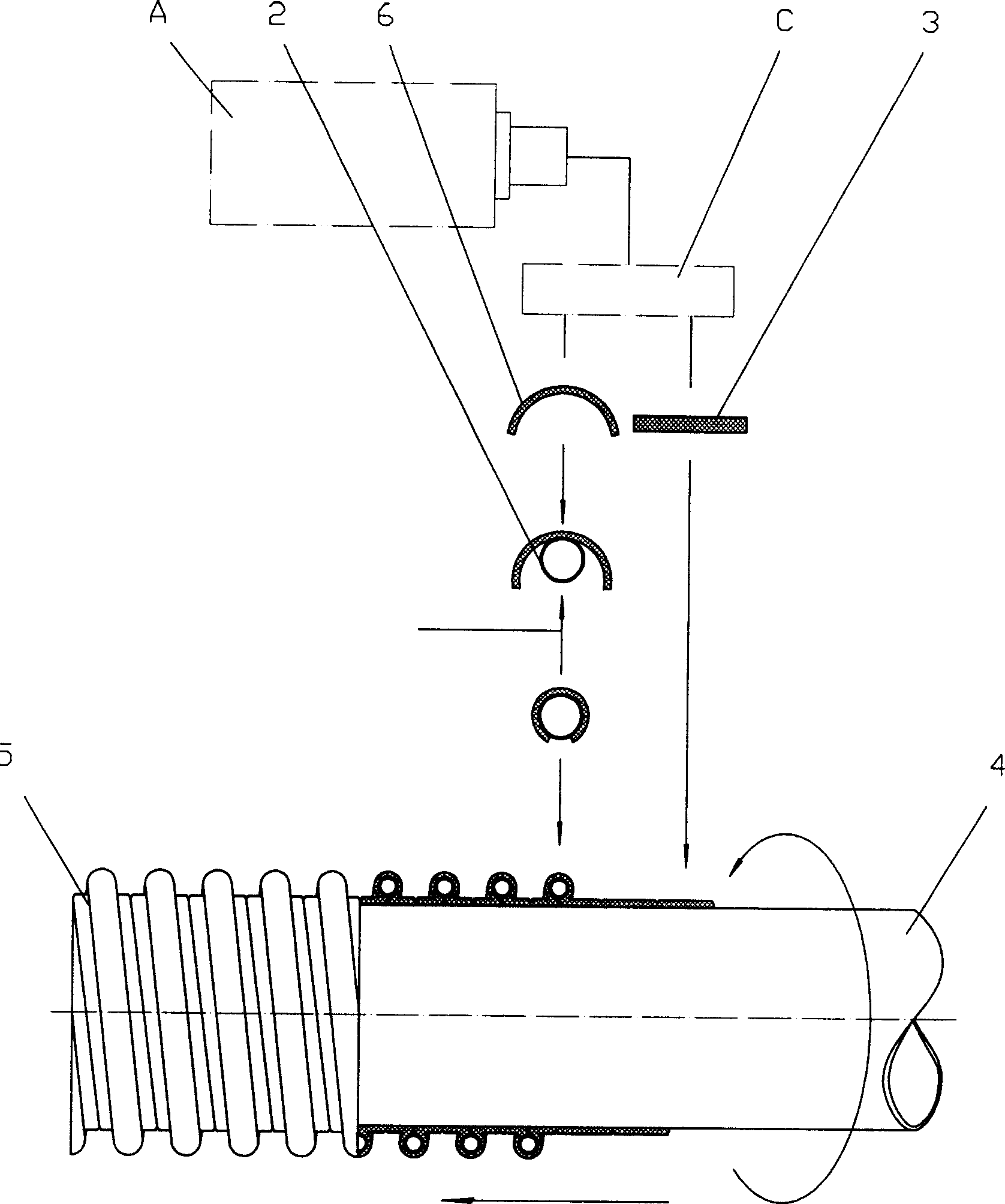

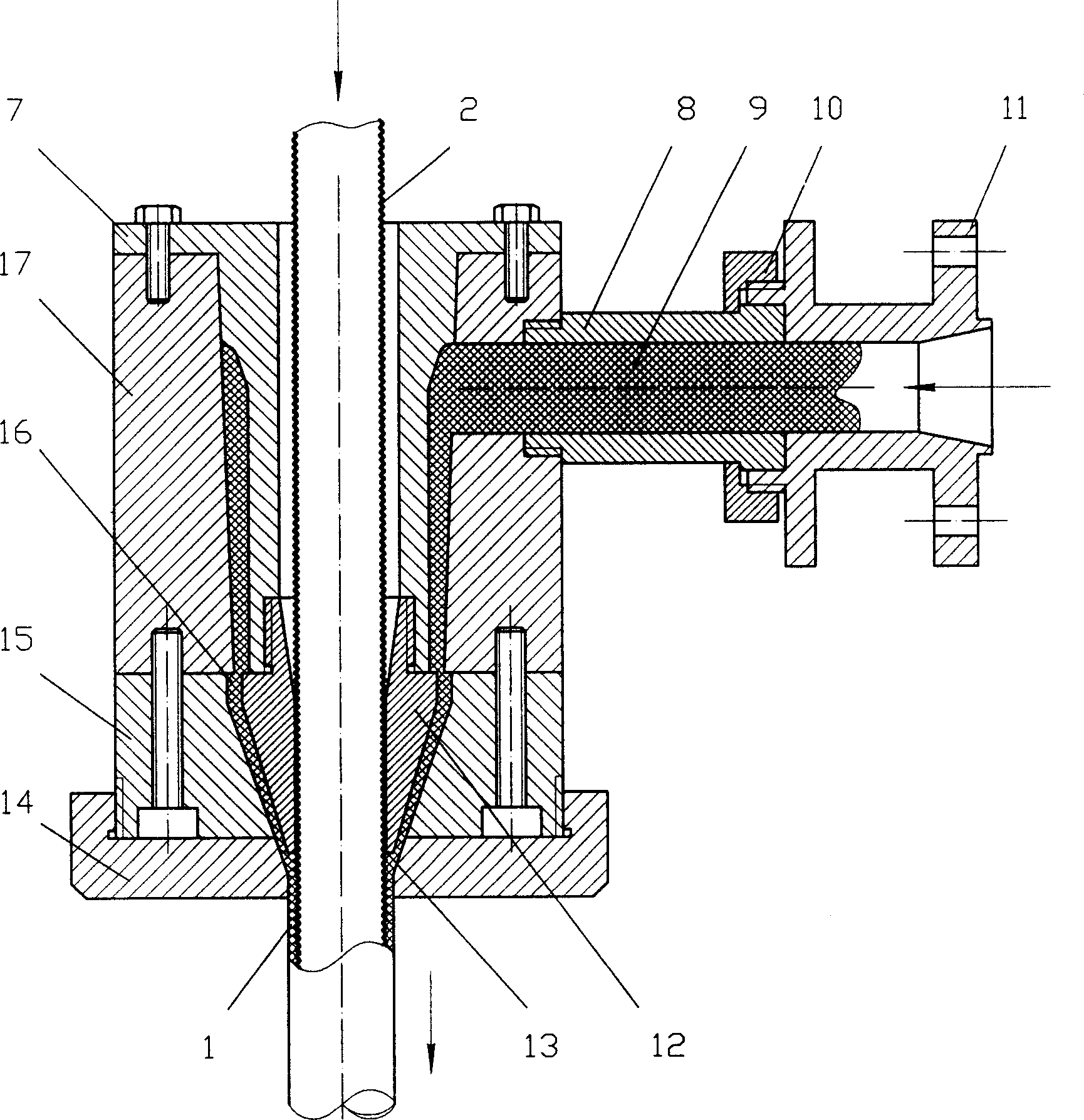

Coextruding heat winding structure wall pipe, processing method and method

ActiveCN1749626AHigh strengthIncrease stiffnessRigid pipesTubular articlesMaterial consumptionEngineering

The present invention provides a kind of hot wound and extruded pipe and its production process and forming mold, and the new product with low material consumption and high annular rigidity is produced based on equivalent wall thickness principle. The hot wound and extruded pipe is produced through hot screw winding plastic belt onto mold core and extruding to coat with the same kind of material. The present invention can produce co-extruded polyethylene pp pipe and polyethylene coated polypropylene single wall corrugated pipe with high strength and capable of being used as the reinforcing pipe for great caliber pipe. The present invention has high production efficiency.

Owner:福建纳川管业科技有限责任公司

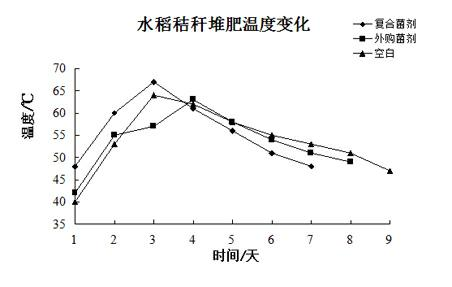

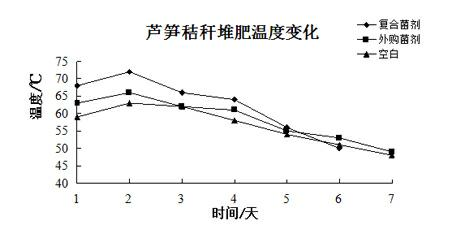

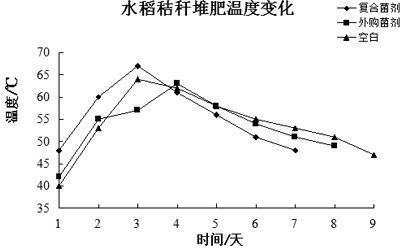

Efficient straw degrading composite fungicide and organic fertilizer preparing method thereof

ActiveCN102676492AFully degradedIncrease productivityBio-organic fraction processingMicroorganism based processesInsect pestFermentation

The invention relates to an efficient straw degrading composite fungicide (JFB-1) and an organic fertilizer preparing method thereof. The composite fungicide comprises composite bacteria and a carrier, wherein the carrier is wheat bran, and the composite bacteria include composite bacteria I, composite bacteria II, composite bacteria III and auxiliary bacteria. The composite bacteria I, II and III account for 1-1.5% of the weight of straws, wherein the composite bacteria I account for 20-25%, the composite bacteria II account for 45-50%, the composite bacteria III account for 30-35%, and the composite bacteria are added uniformly in compost fermentation so as to effectively improve the maturation speed and the quality of an organic fertilizer. The fungicide is fully mixed with straws of rice, asparagus and other crops to carry out compost fermentation, the straws can be degraded rapidly through the synergistic effect of the bacteria, the degradation efficiency is improved, the degradation time is shortened, and insect pests are effectively killed and are rapidly transformed into the organic fertilizer for improving soil. The efficient straw degrading composite fungicide can be used for effectively solving the problem of land occupation caused by landfill, or the problems of fire, traffic dangers, environment pollution and the like caused by burning.

Owner:SHANGHAI JIAO TONG UNIV

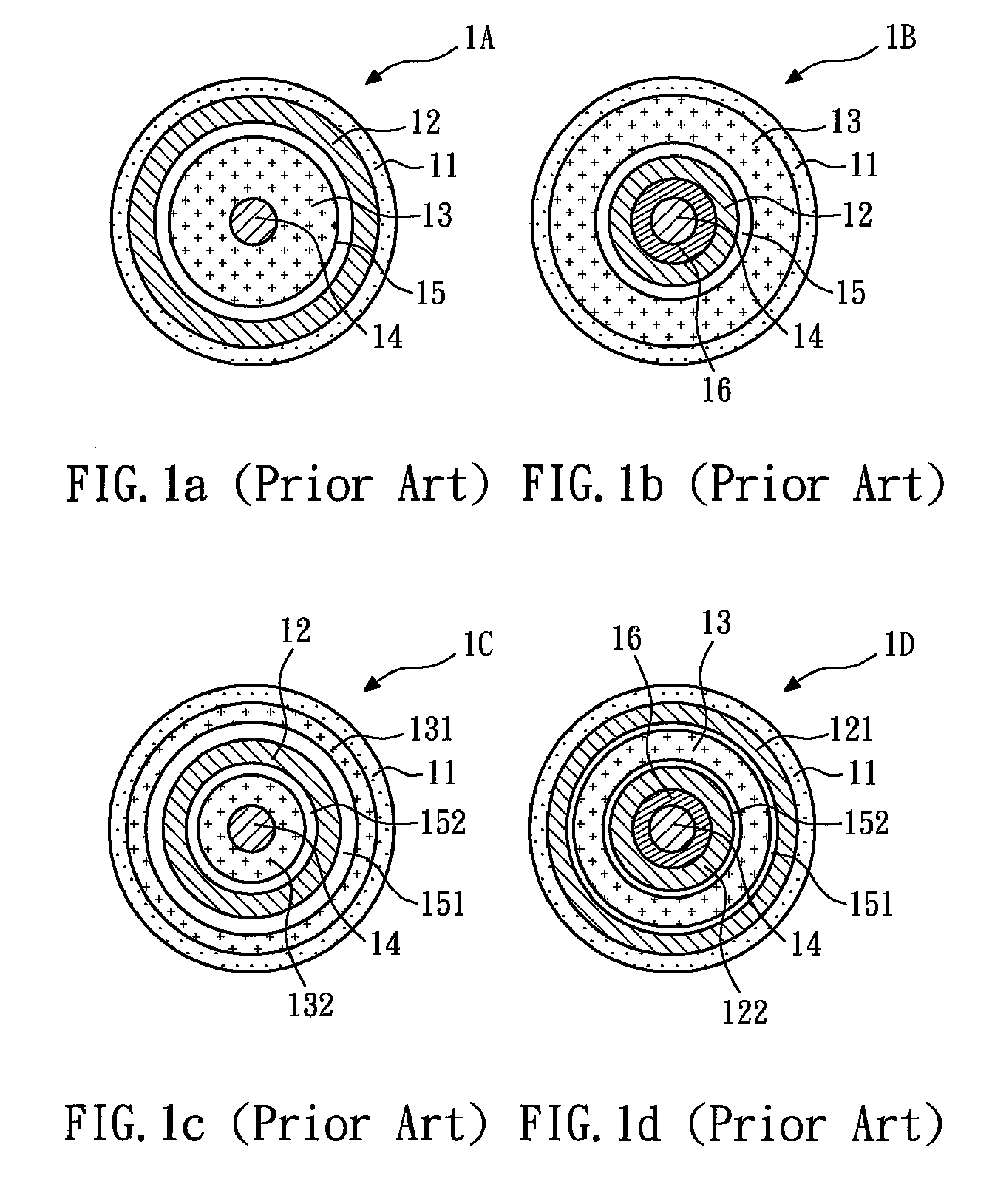

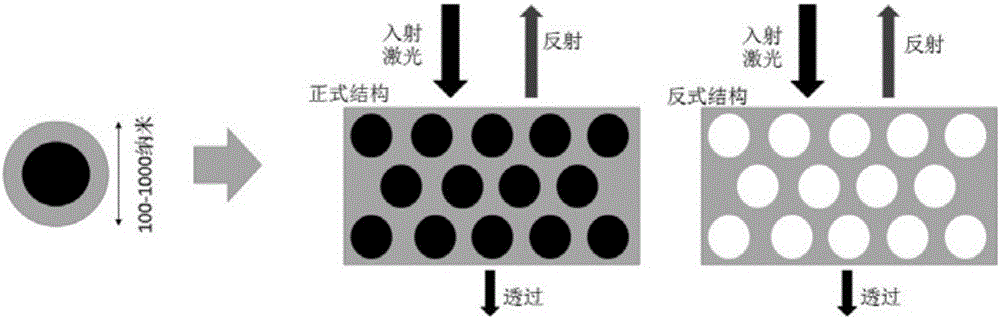

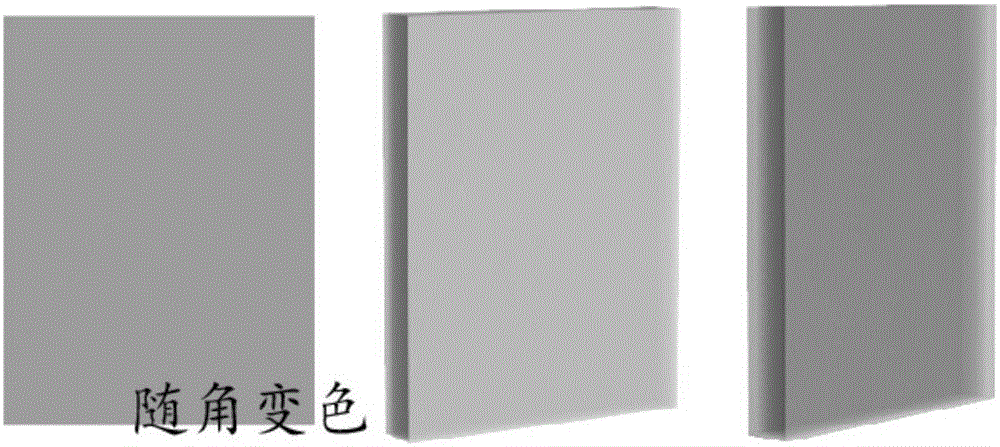

Nanoparticle, surface optical material and preparation method of surface optical material

ActiveCN105949379AImprove brittlenessEasy to controlCoatingsMicroballoon preparationElastomerNanoparticle

The invention relates to a nanoparticle, a surface optical material and a preparation method of the surface optical material. The nanoparticle adopts a core-shell structure and is characterized in that a core material of the nanoparticle comprises an organic or inorganic material, a shell material of the nanoparticle comprises an elastomer polymer material, and the nanoparticle has the size ranging from 100 nanometers to 1,000 nanometers. The material adopts entirely different preparation technologies and nanoparticle structures, the excellent strain discoloration function and monochromaticity are guaranteed, the production speed of the material is greatly increased, the yield in unit time is increased by ten times or above, and meanwhile, production of thinner optical films is facilitated.

Owner:PHOMERA METAMATERIALS INC

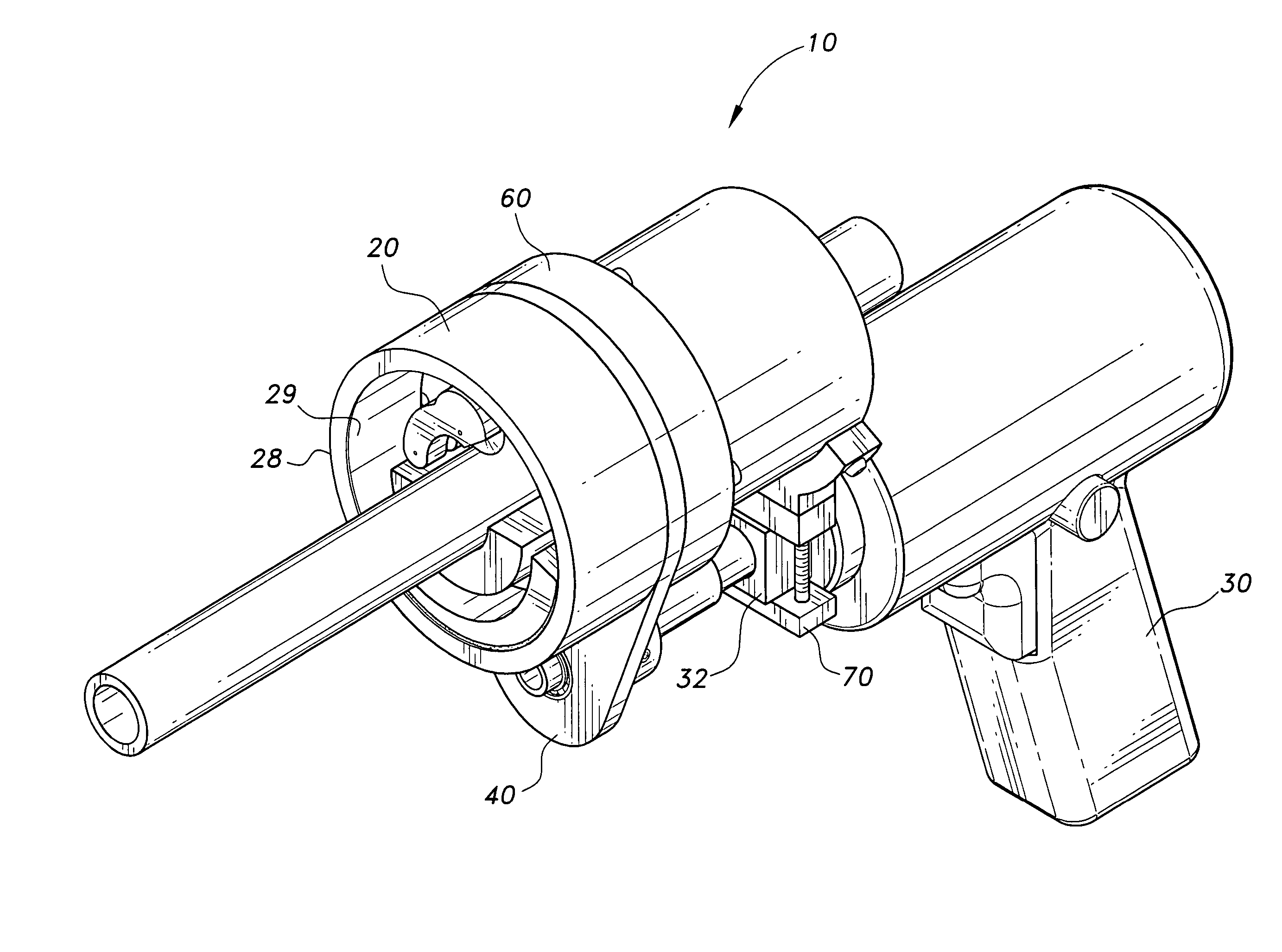

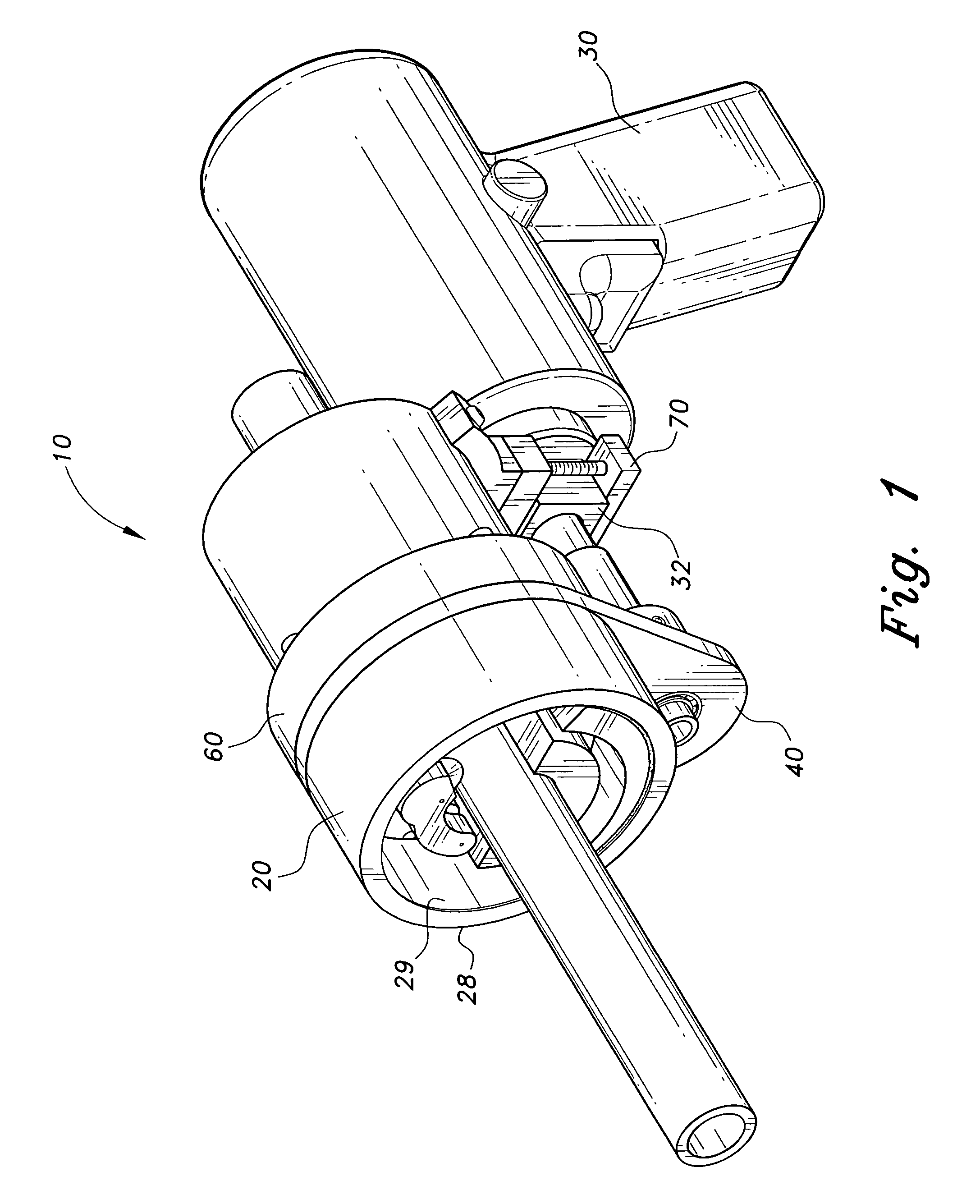

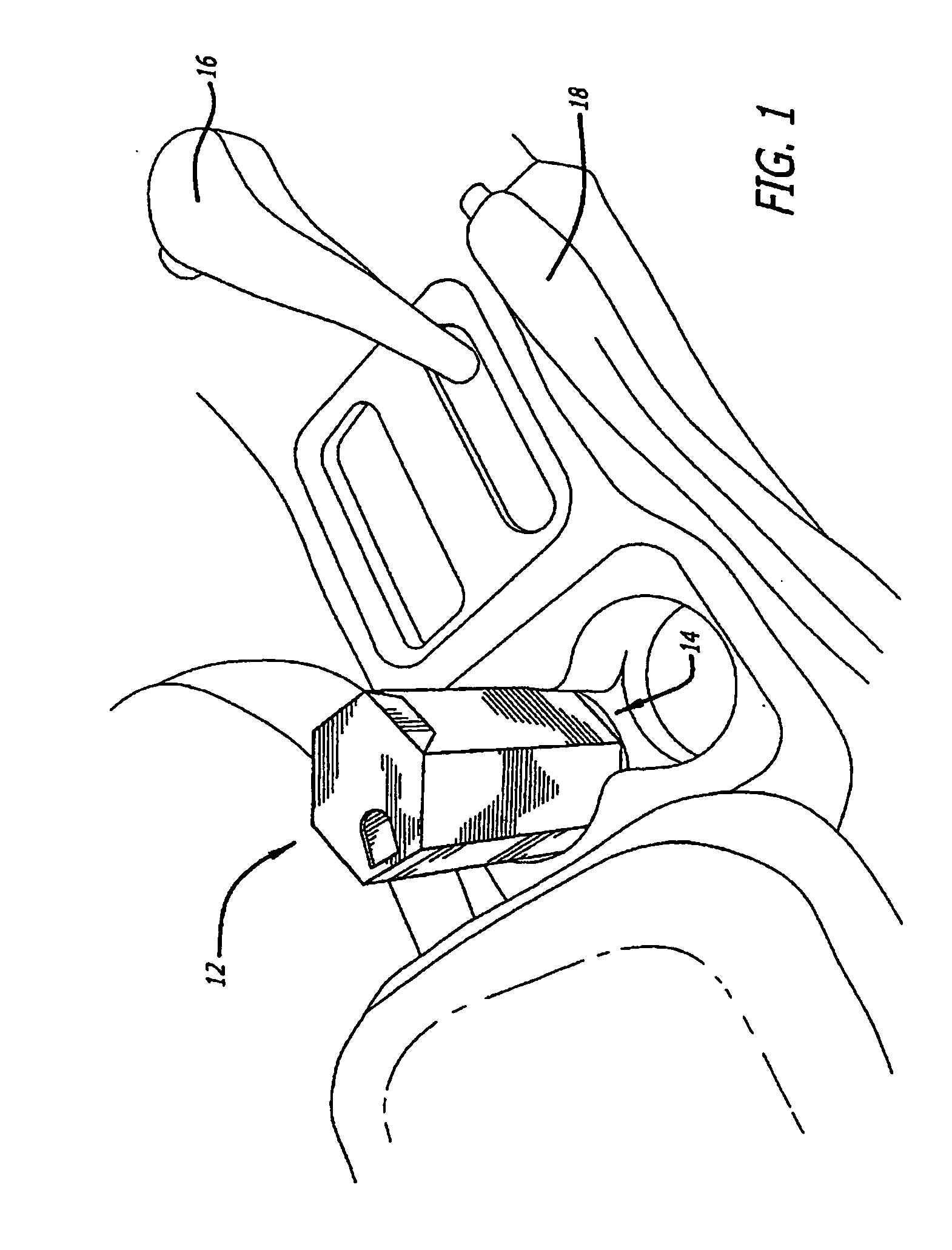

Powered tubing cutter

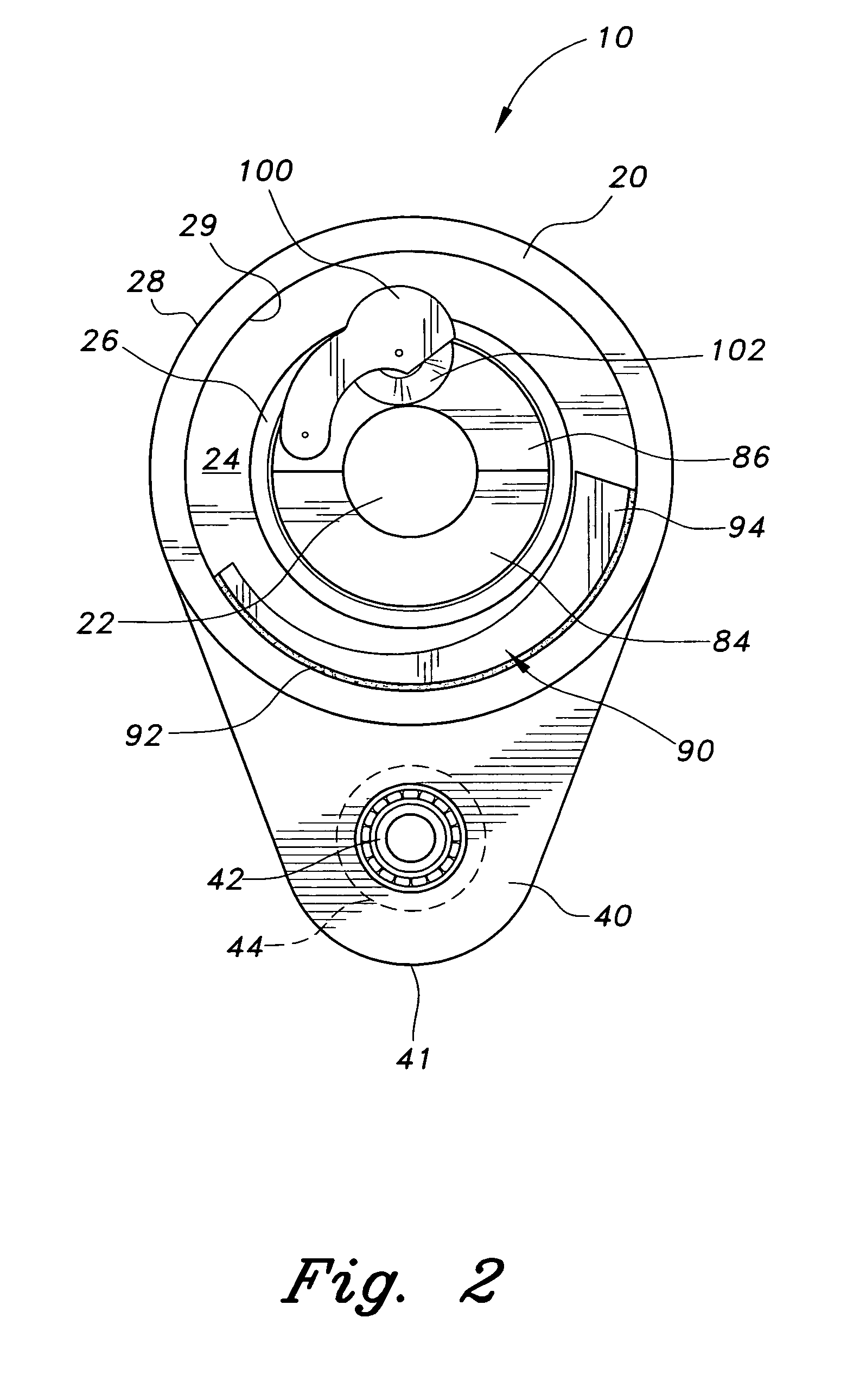

InactiveUS7152325B2Increase production speedPortable power-driven toolsTube shearing machinesDrive shaftHand held

The powered tubing cutter is a hand held, mechanical device driven by a motor for cutting tubing / piping. The device comprises a housing, a drive plate, a main drive shaft, a cutting assembly having a cutting blade, a cam plate and a chain drive secured to a motor housing, having a handle, by a mounting bracket. The chain drive is powered by the motor, which causes the main drive shaft to rotate. The cutting assembly is pivotally secured to a pin on the main drive shaft. The pipe / tube to be cut is placed into the hole in the center of the housing and the main drive shaft. As the cutting assembly rotates with the main drive shaft the cam plate forces the cutting blade into cutting engagement with the tube / pipe.

Owner:GREEN CARROLL D +1

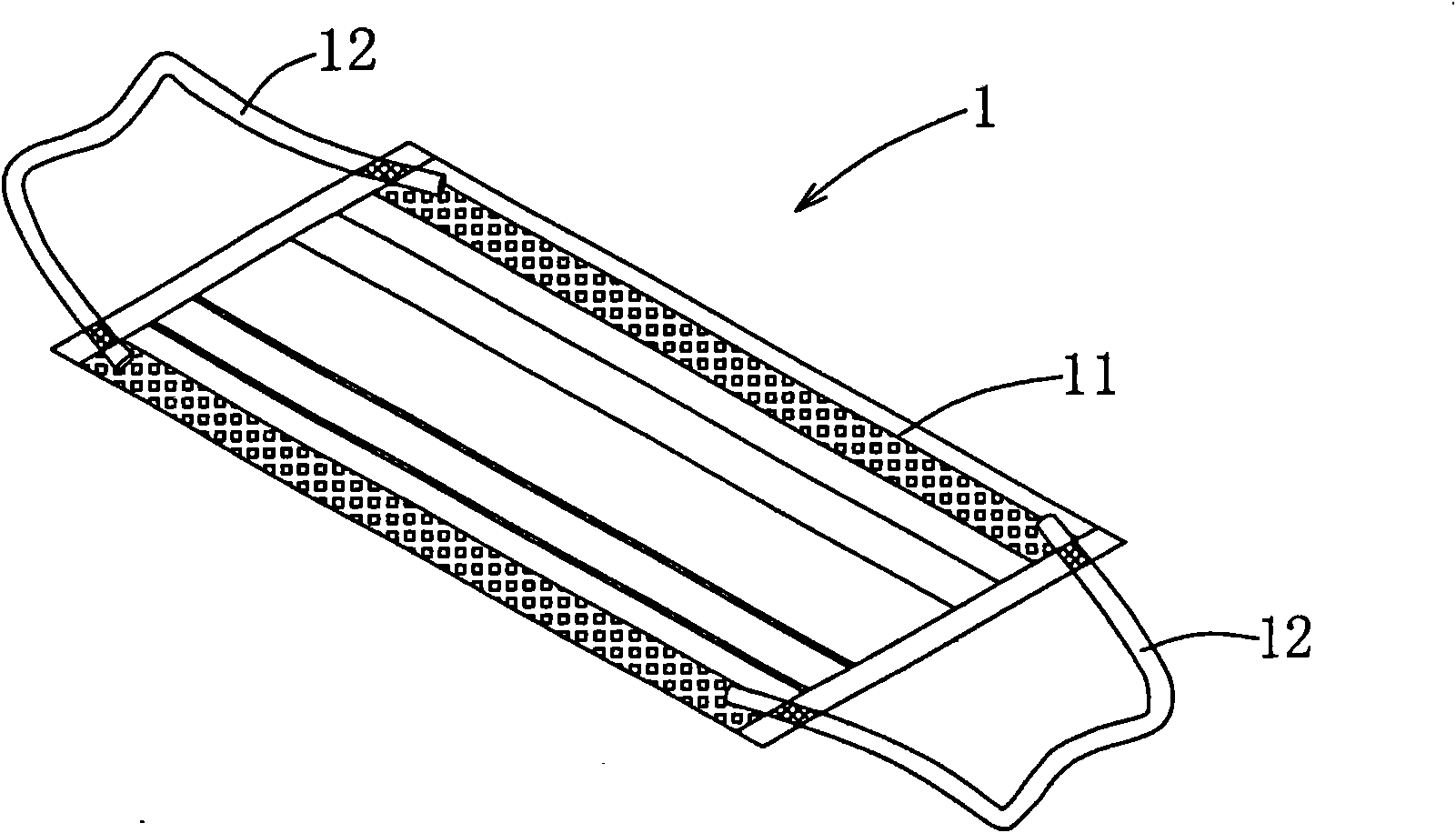

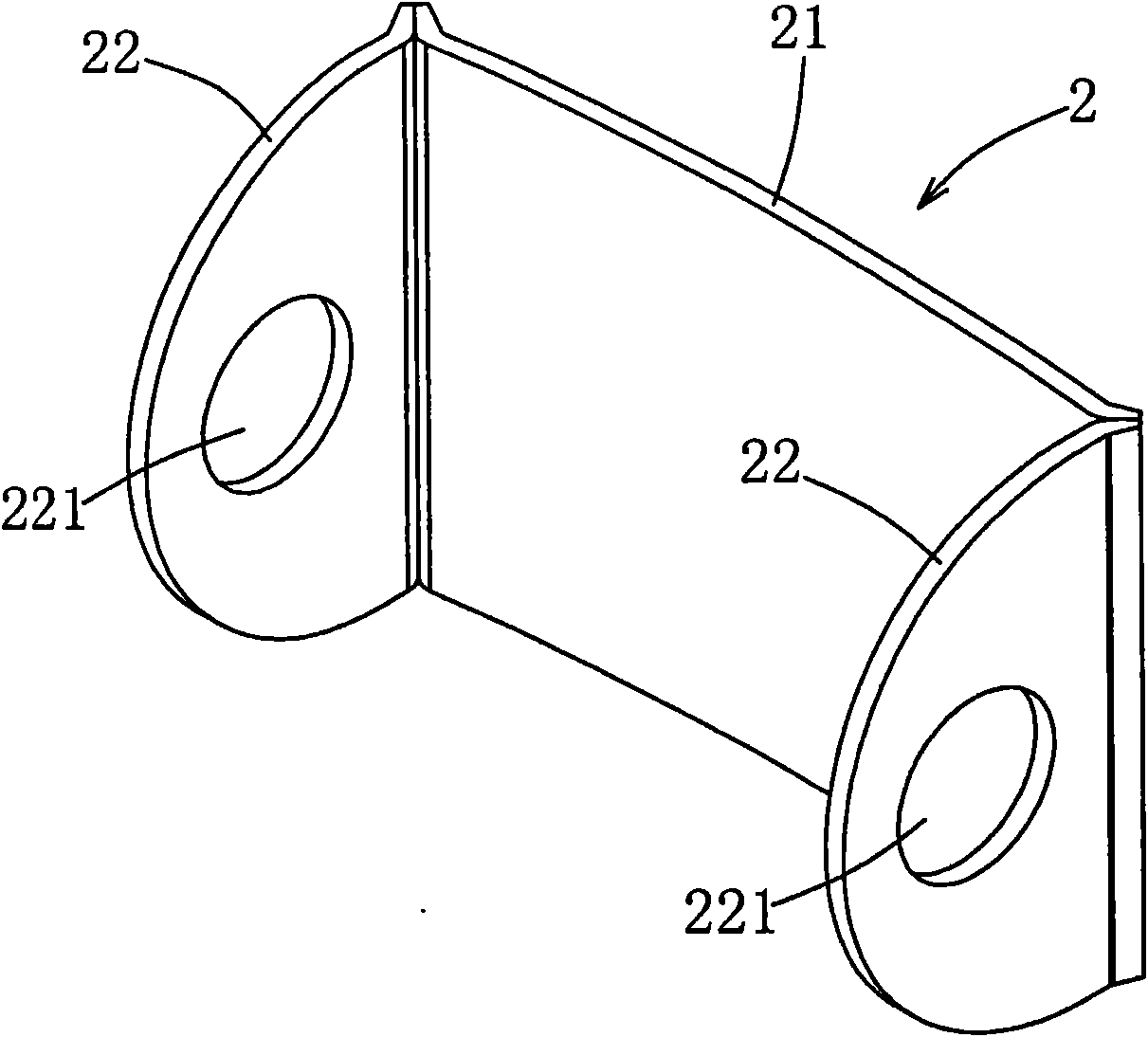

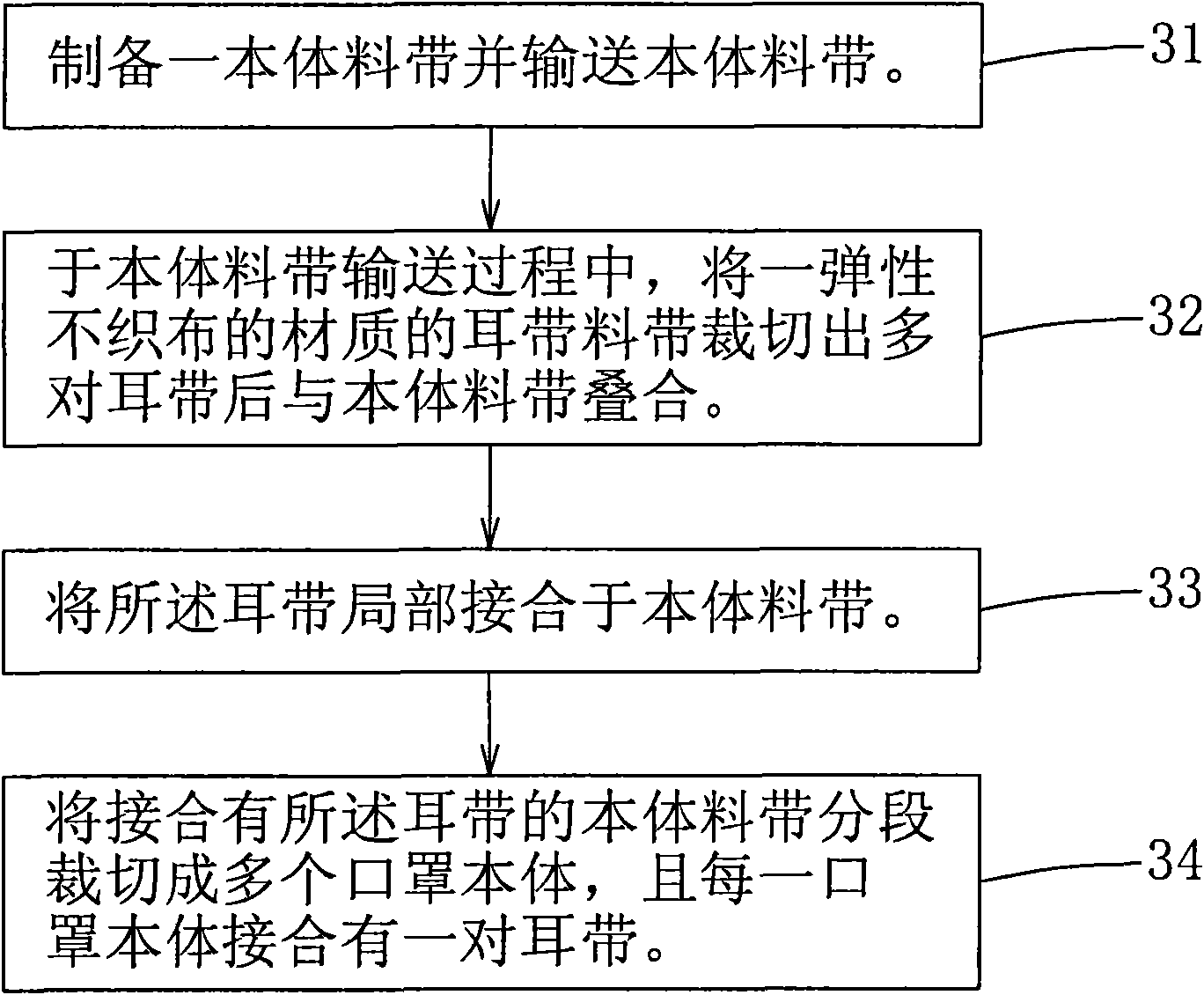

Mouth mask provided with elastic non-woven fabric ear bands and method for manufacturing same

The invention relates to a method for manufacturing a mouth mask provided with elastic non-woven fabric ear bands, which comprises the following: step (A), preparing a body material strip and conveying the body material strip; step (B), in the conveying process of the body material strip, cutting an elastic non-woven fabric ear band material strip into a plurality of pairs of ear bands and then superposing the ear bands with the body material strip; step (C), combining local parts of the ear bands with the body material strip; and step (D), sectionally cutting the body material strip combined with the ear bands into a plurality of mouth mask bodies each of which is combined with a pair of ear bands. The method integrates the manufacturing of the body and the combination with the ear bands into an operation mode finished at one time; thus, the production rate and yield are improved, and because the ear bands of the mouth mask are made of elastic non-woven fabrics, the material cost can be saved.

Owner:KANG NA HSIUNG ENTERPRISE CO LTD

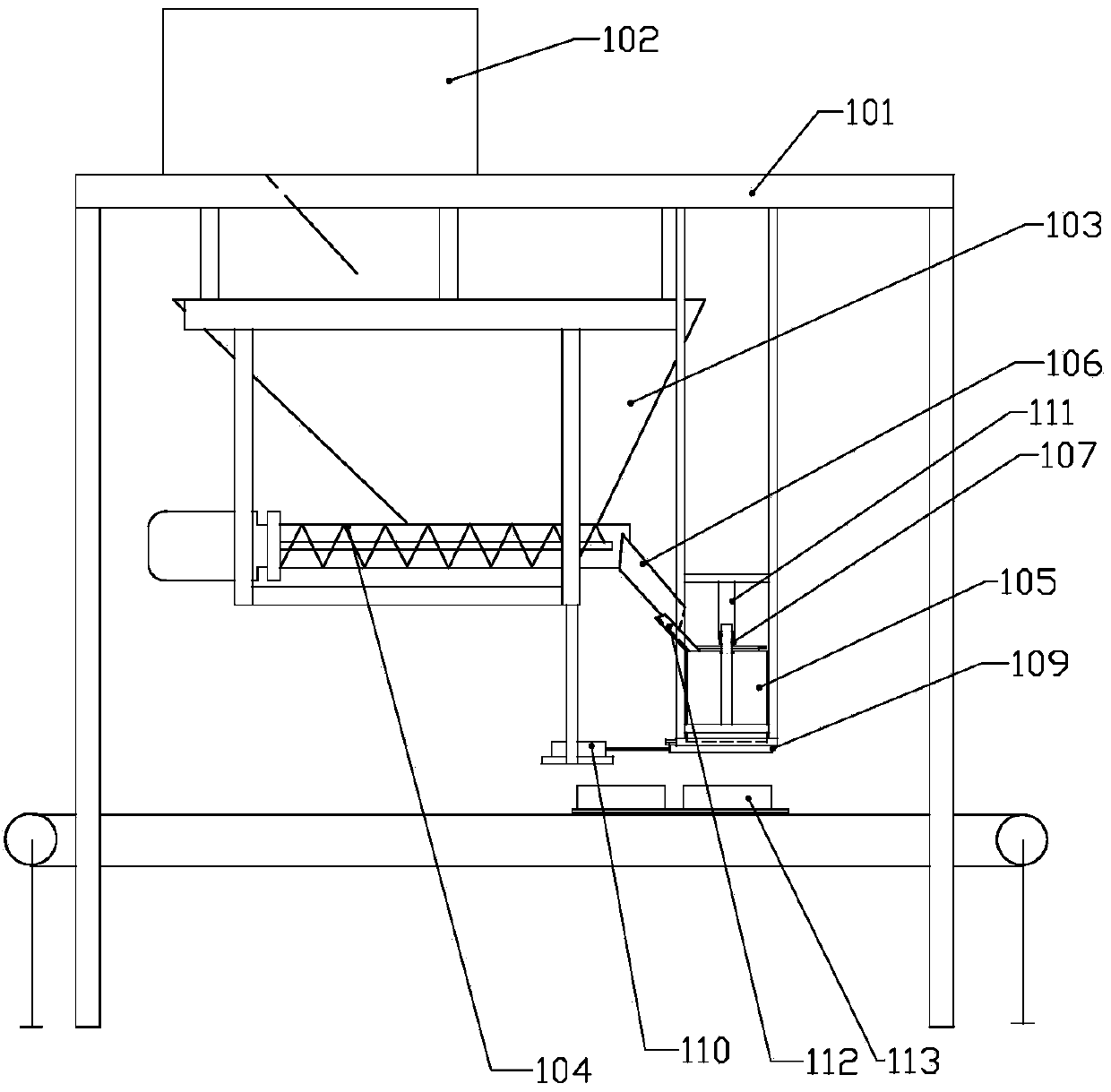

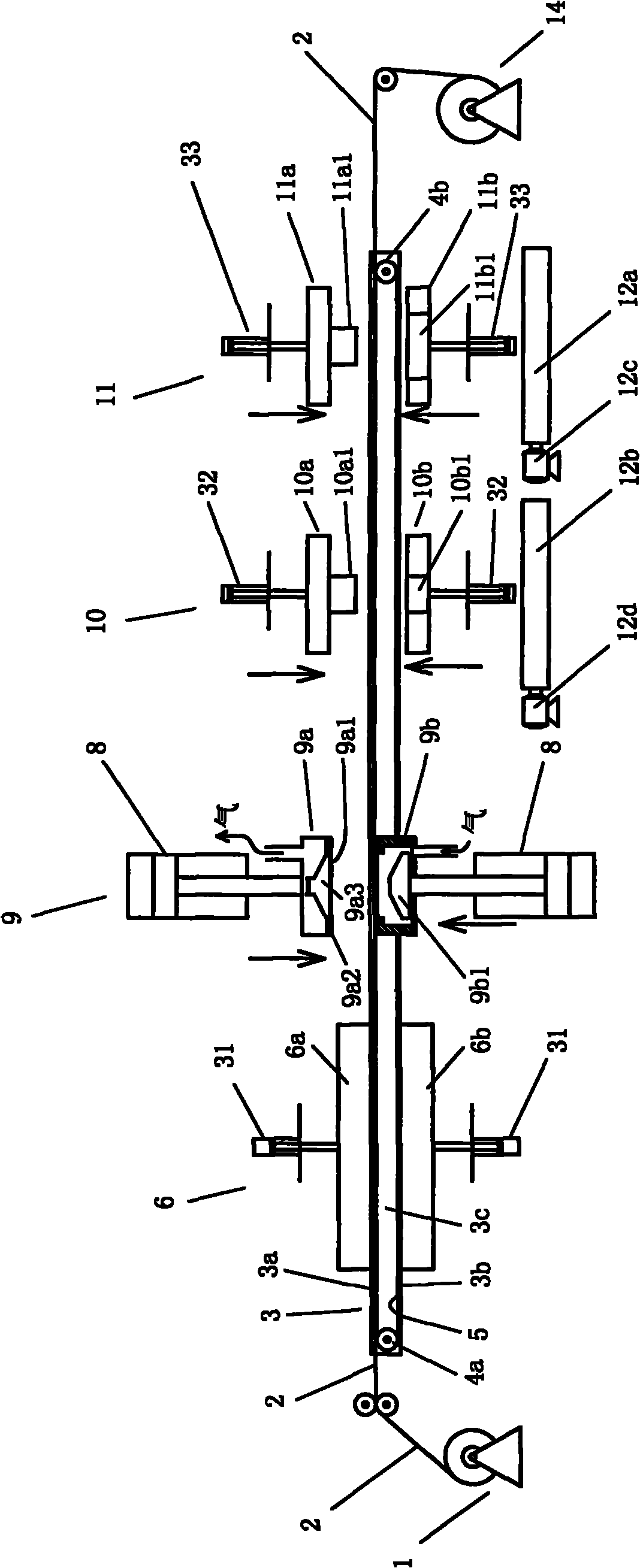

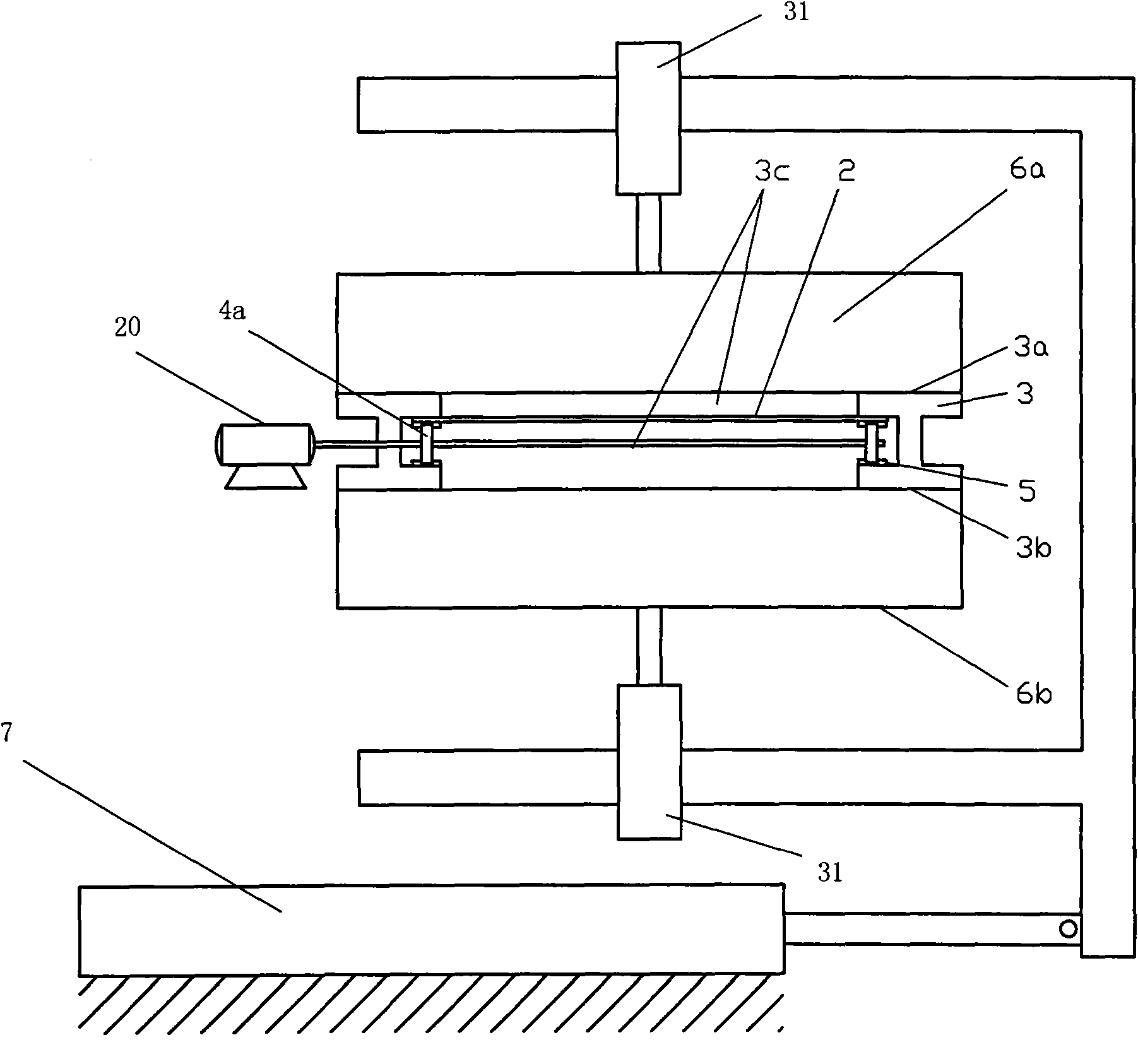

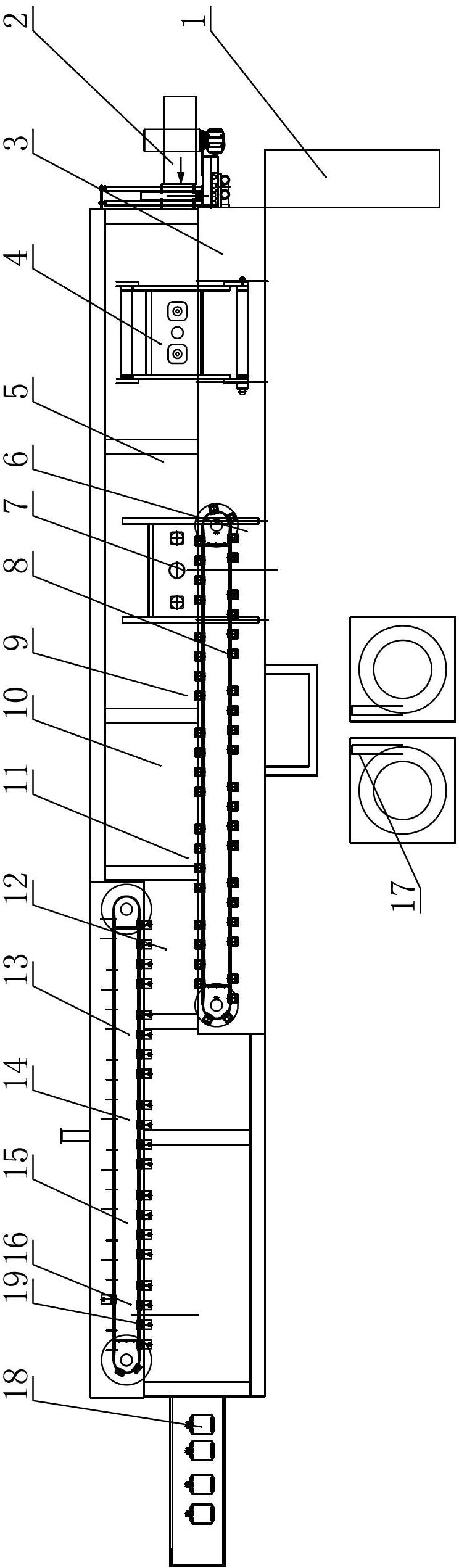

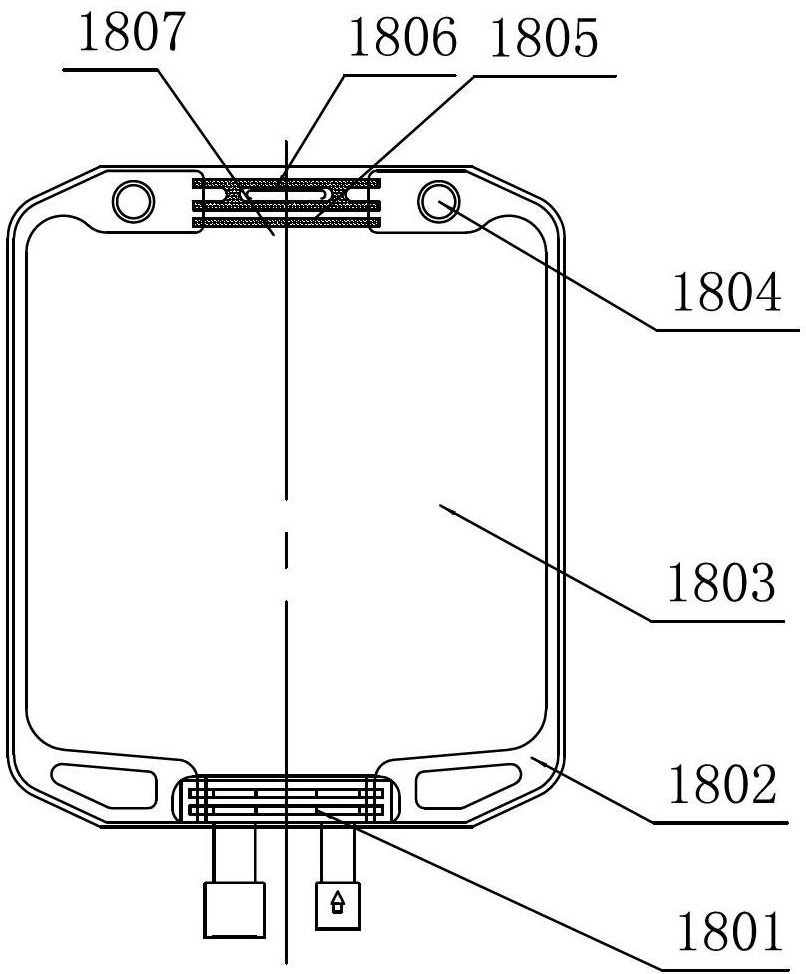

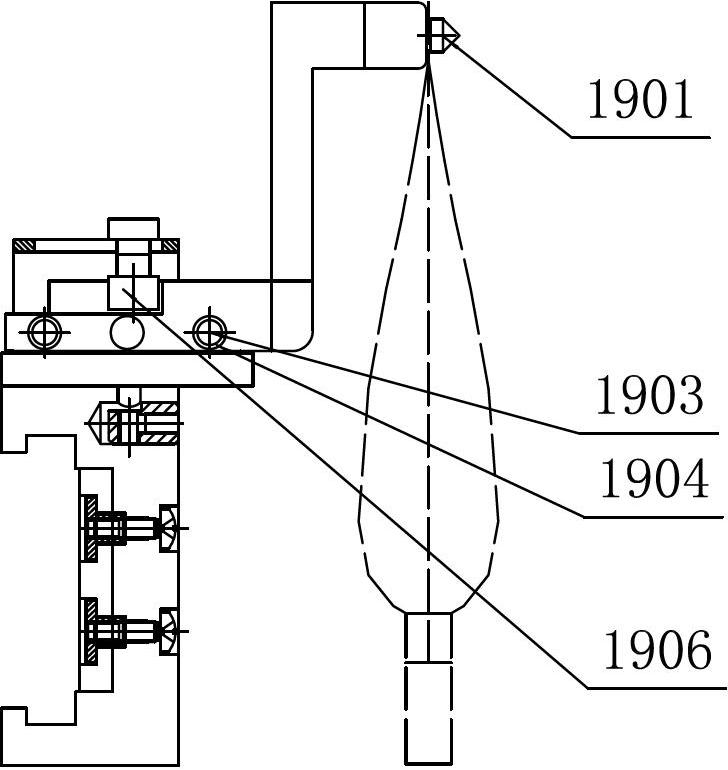

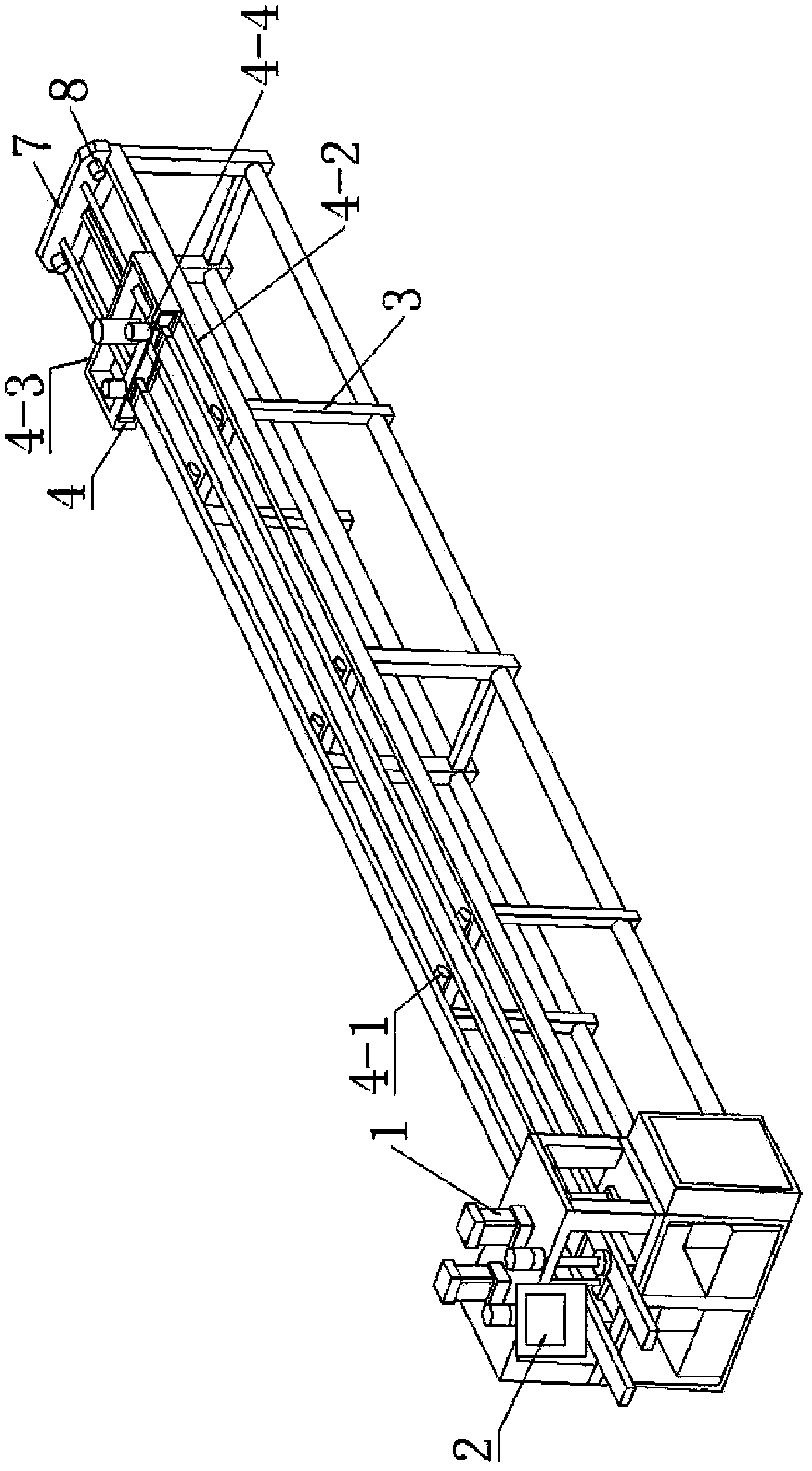

Full-automatic bag making and filling and sealing machine of bag tail filling non-PVC membrane transfusion soft bag

ActiveCN102642630ARealize automated productionSimple working principleWrapper twisting/gatheringLiquid materialFailure ratePolyvinyl chloride

The invention relates to a full-automatic bag making and filling and sealing machine of a bag tail filling non-PVC (polyvinyl chloride) membrane transfusion soft bag, which belongs to the technical field of pharmacy packing machine. The full-automatic bag making and filling and sealing machine comprises a machine body which consists of a frame component (3), wherein a distribution box (1) is arranged at one side of the machine body, and a bag making machine and a filling and sealing machine are arranged on the upper part of the machine body. The machine is characterized in that a bag body transfer mechanism (12) is arranged between the bag making machine and the filling and sealing machine, a connector supply mechanism (17) and a preheating mechanism (6) are arranged at one side of the bag making machine, the bag making machine is provided with a made bag annular conveying component (8), the made bag annular conveying component is provided with a connector fixture, the filling and sealing machine is provided with an annular conveying belt, and the annular conveying belt is provided with a bag fixture (19). According to the invention, full-automatic production of the tail filling non-PVC membrane transfusion soft bag is realized through improving the bag, the working principle is simple, the structure is reliable, the operation is stable, the failure rate is low, the occupied space is small, and according to the characteristics of the soft bag, the production cost can be obviously reduced. The action of the machine is fast, and the production efficiency is high.

Owner:SHINVA MEDICAL INSTR CO LTD

Punching machine with automatic feeding function

ActiveCN103350152AIncrease production speedImprove machining accuracyMetal-working feeding devicesPositioning devicesEngineeringMotor drive

The invention discloses a punching machine with an automatic feeding function. The punching machine with the automatic feeding function is characterized in that the punching machine comprises a punching mechanism, a control device, a feeding machine frame and an automatic feeding mechanism arranged on the feeding machine frame, the automatic feeding mechanism comprises a carrying roller installed on the feeding machine frame, a linear guideway, and a traveling mechanism arranged on the linear guideway, a clamping mechanism is arranged on the traveling mechanism, the traveling mechanism comprises a trailer wagon and a servo motor driving the trailer wagon to move along the linear guideway, the servo motor is connected with the control device, the control device controls the moving state of the trailer wagon, the punching mechanism comprises a supporting platform, a pressing cylinder, an upper puncher pin, and a lower die core arranged in the inner cavity of a sectional material, a recess corresponding to the upper puncher pin is formed in the upper surface of the lower die core, a die inner core pulling rod is arranged on the feeding machine frame, the lower die core is fixed at one end of the die inner core pulling rod, and the die inner core pulling rod is parallel to the linear guideway and penetrates through the trailer wagon. The punching machine with the automatic feeding function is simple in operation, high in production efficiency, and high in product accuracy.

Owner:广东澳美高新科技有限公司

Fabrication of conductive nanostructures on a flexible substrate

InactiveUS20110240476A1Reduce manufacturing costIncrease production speedIndividual molecule manipulationNanoopticsOptoelectronicsSurface layer

Provided is a method of fabricating a continuous nanostructured material having an electrodeposited surface layer. A conductive master drum having a relief pattern on its surface that exposes only a portion of the master drum surface is immersed into a plating bath. An electrodepositable material is coated onto the exposed surface of the drum. A support material is coated over the deposited layer and the relief structure. Removal from the drum yields the nanostructured material.

Owner:3M INNOVATIVE PROPERTIES CO

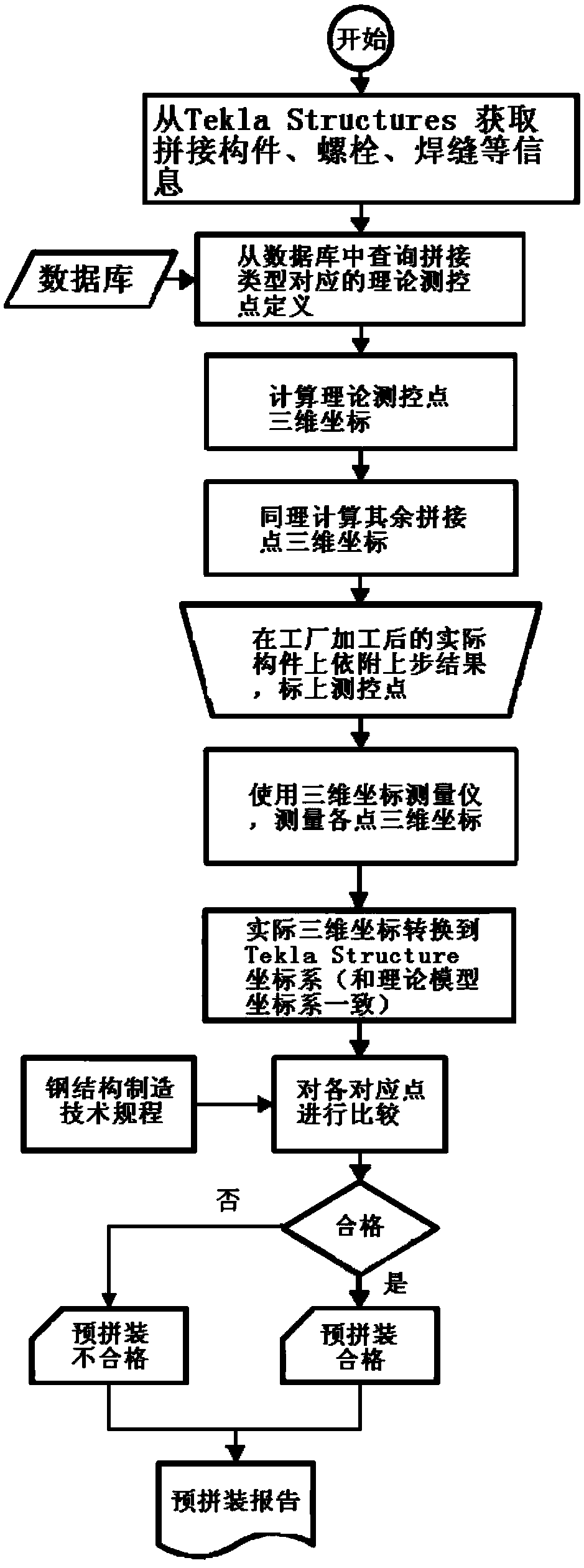

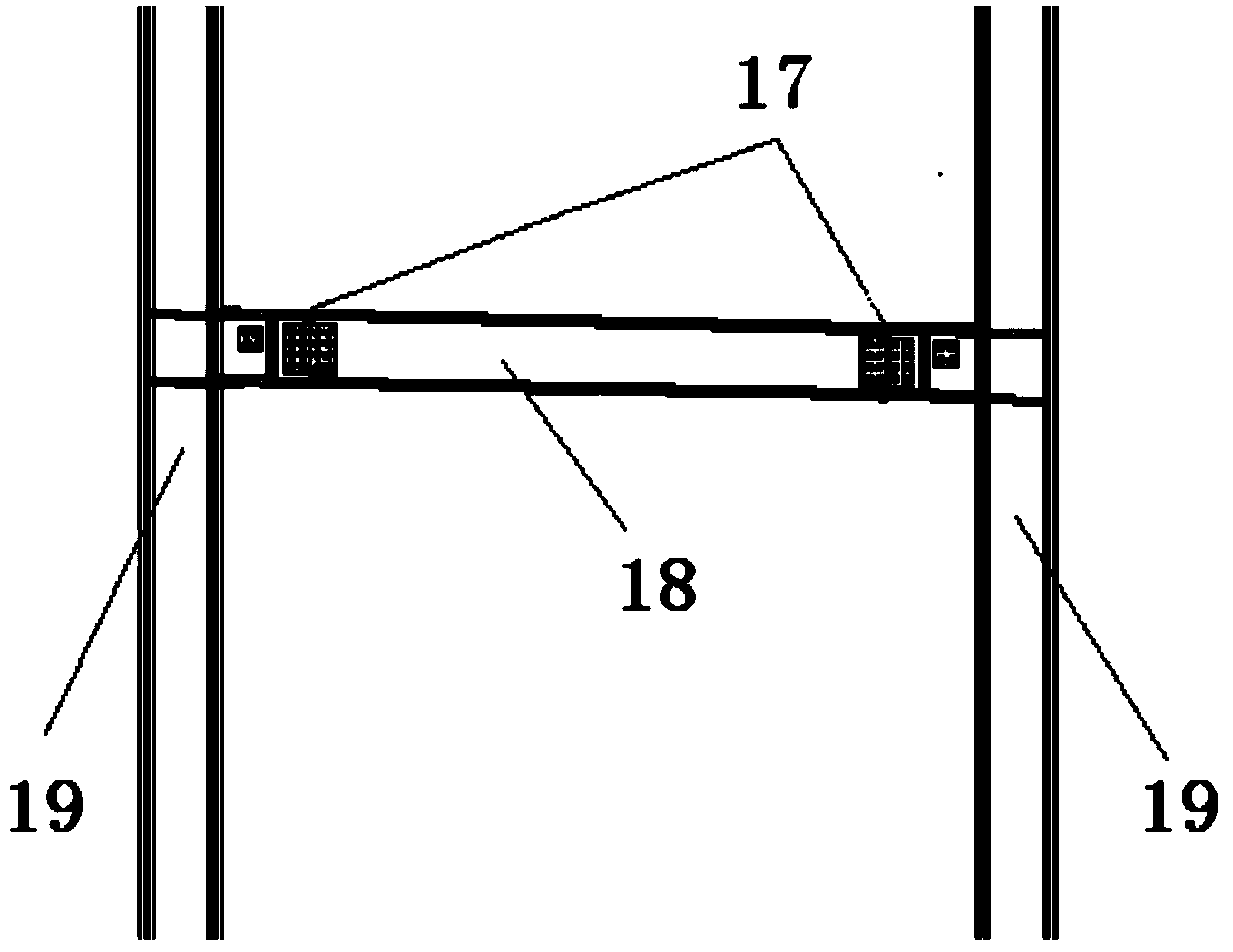

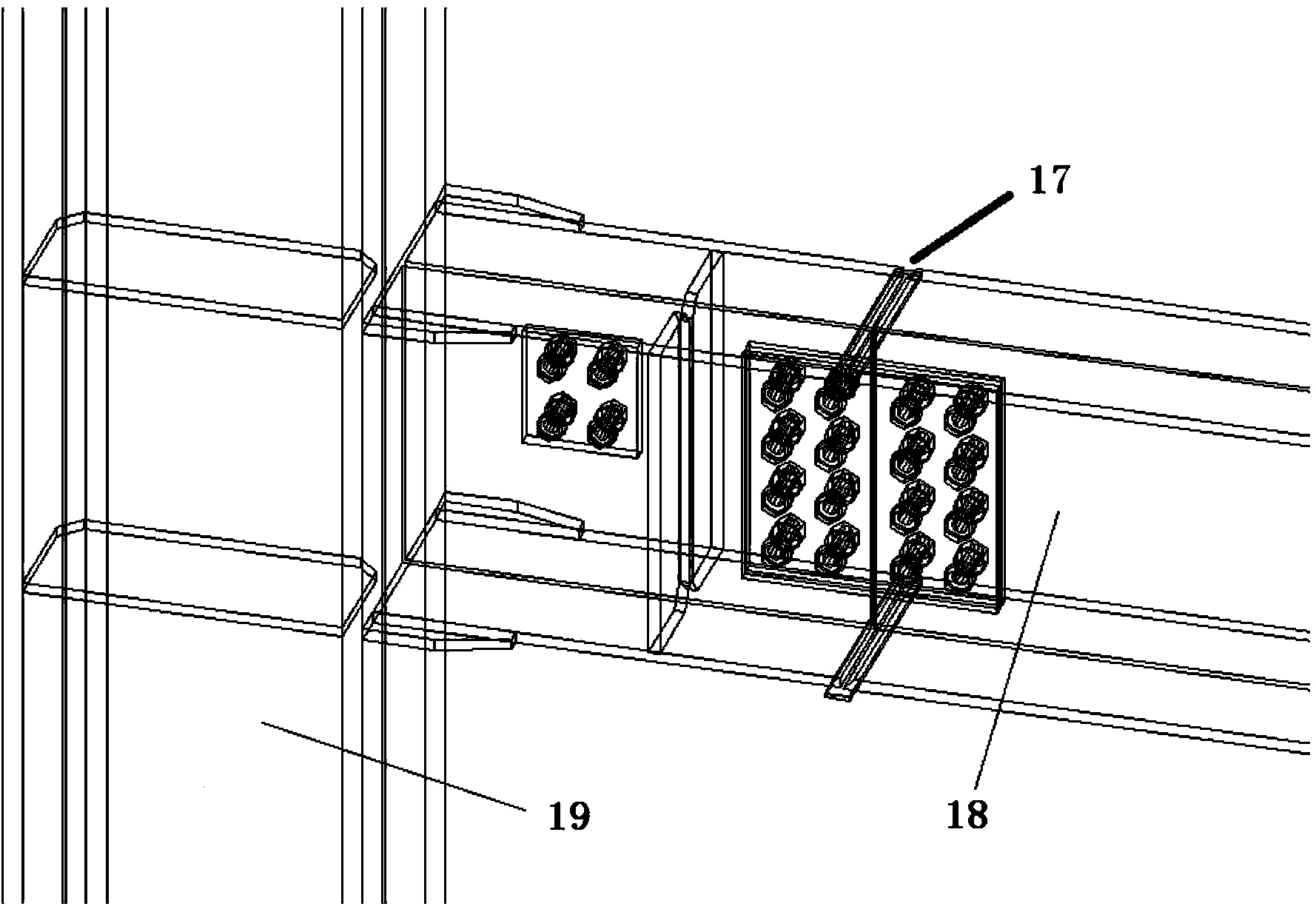

Method for achieving steel structure pre-assembling through computer simulation

InactiveCN103870657AFast and accurate error detectionImprove detection efficiencySoftware simulation/interpretation/emulationSpecial data processing applicationsSolid componentMeasuring instrument

The invention relates to a method for achieving steel structure pre-assembling through computer simulation. The method includes the following steps: (1) obtaining assembled components according to a steel structure detail drawing model, and automatically compiling component splicing numbers, (2) extracting feature information of the assembled components in the detail drawing model, calculating actual coordinates of the assembled components according to extracted features, generating theoretical measurement and control point three-dimensional coordinates of the components, and automatically naming the numbers, (3) according to the theoretical measurement and control point numbers, positioning and marking the solid components, (4) conducting three-dimensional coordinate measurement on positioning marks through a three-dimensional coordinate measuring instrument, and obtaining actual measurement three-dimensional coordinates of positioning points, and (5) conducting contrastive analysis on theoretical coordinates and the actual measurement coordinates of control points, and providing a rectification report or a pre-assembling examining report according to national steel structure manufacturing technical regulations and technological requirements, the rectification report or the pre-assembling examining report serves as an evidence of the quality control link. The method has the advantages that the theoretical control points are intelligently and automatically generated, errors caused by manually drawing up the theoretical control points can be greatly reduced, and the machining and production efficiency is high.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Fabricated prestressed heat-resistant cement concrete pavement and construction process thereof

ActiveCN102535295AReasonable structural designEasy to laySingle unit pavingsPaving detailsHeat resistancePre stress

The invention discloses a fabricated prestressed heat-resistant cement concrete pavement and a construction process thereof. The pavement is formed by splicing a plurality of fabricated prestressed heat-resistant pavement plates which are parallelly paved and connected into a whole through transverse prestressed steel stranded wires, wherein each fabricated prestressed heat-resistant pavement plate comprises a fabricated prestressed pavement plate which consists of a plurality of pavement plate blocks connected through connecting plates, and a vermiculite concrete heat-resistant paving layer which is paved on the fabricated prestressed pavement plate; each pavement plate block comprises a plurality of common plates which are connected into a whole through longitudinal prestressed steel stranded wires; and the connecting plates and the common plates are cement concrete prefabricated plate blocks. The construction process comprises the following steps of: 1, prefabricating the cement concrete prefabricated plate blocks; 2, transporting the cement concrete prefabricated plate blocks; and 3, paving the pavement. The pavement is reasonable in structural design, convenient to construct, low in input cost and short in construction period, and has heat resistance, construction quality is easy to ensure, and various practical problems of the traditional fabricated cement concrete pavement can be solved.

Owner:CHANGAN UNIV

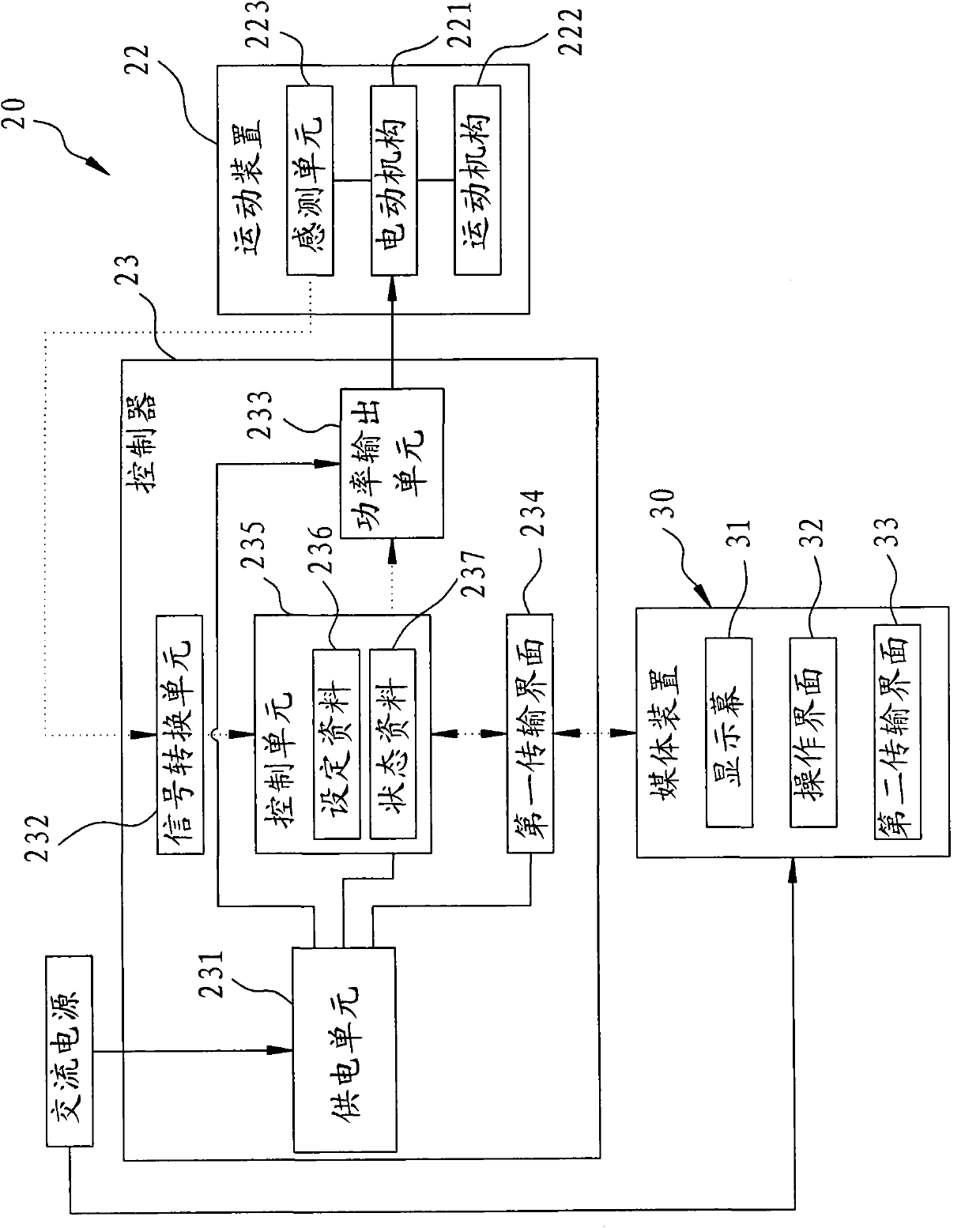

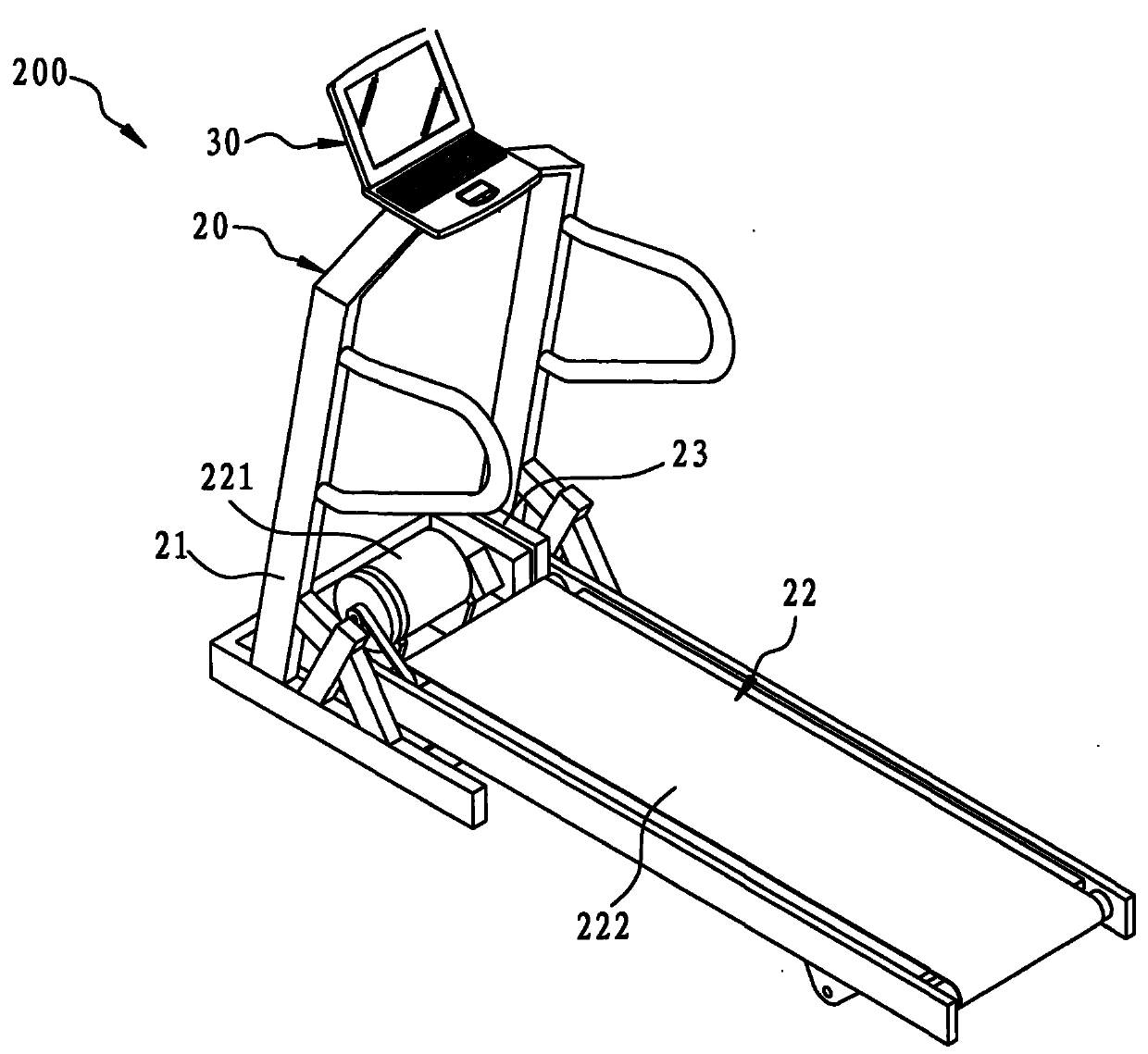

Motion control system, motion platform and controller for motion platform

InactiveCN101766891ATo achieve the effect of one thing with two purposesReduce manufacturing costMovement coordination devicesCardiovascular exercising devicesEngineeringPersonal computer

The invention relates to a motion control system, a motion platform and a controller for the motion platform. The motion control system comprises the motion platform and a media device. The motion platform comprises a motion device and the controller. The motion device is used for outputting a sensing signal changing with the operating condition of an electric mechanism. The controller is provided with a control unit for temporarily storing set data and state data. The sensing signal is transformed into the state data. The controller drives the electric mechanism to make the state data correspond to the set data. The control unit and the media device adopt the operation technology compatible with the personal computer. The set data is changed by the operation of the media device. The state data is transmitted to be responded to the media device.

Owner:PAN WORLD CONTROL TECH

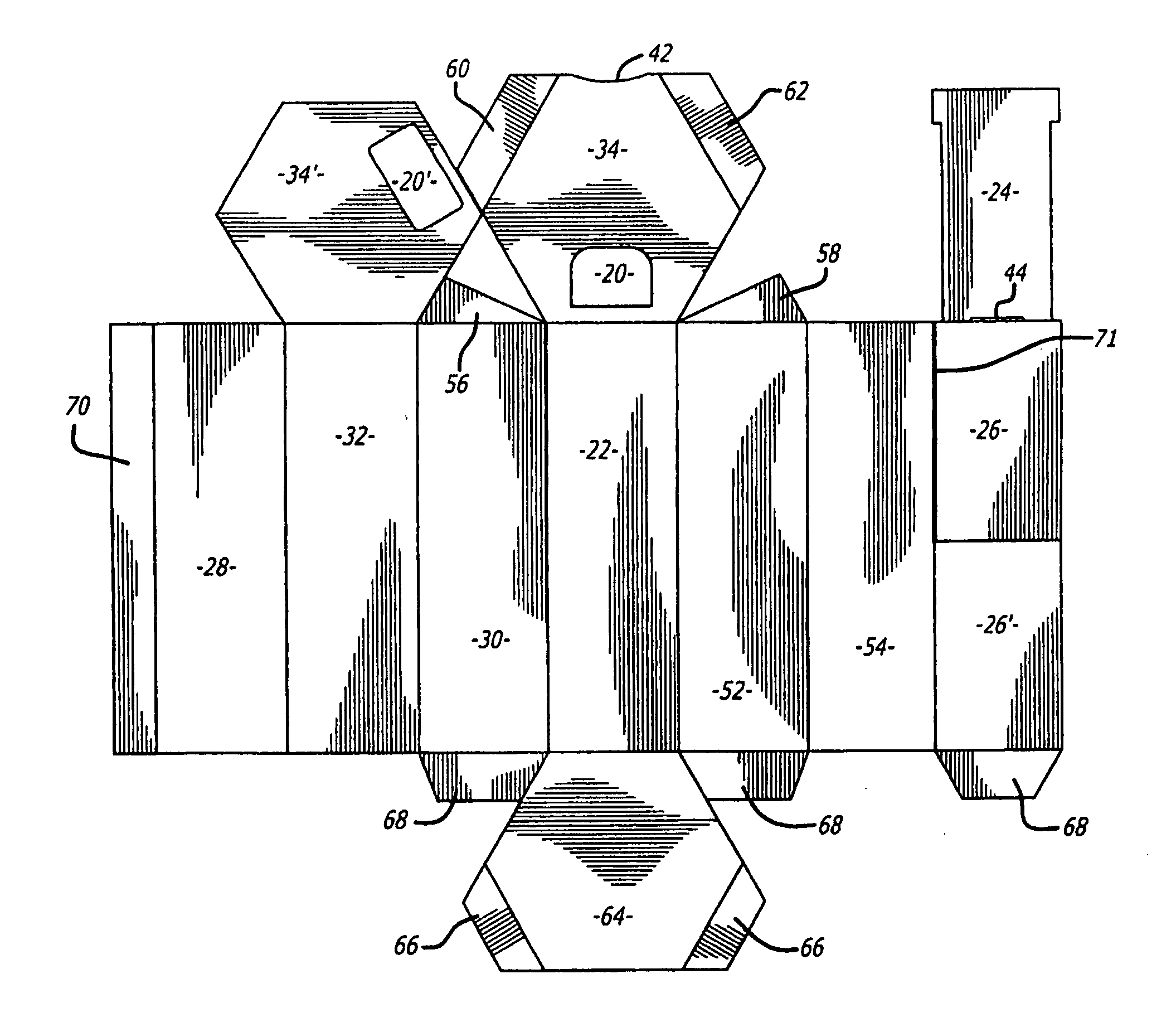

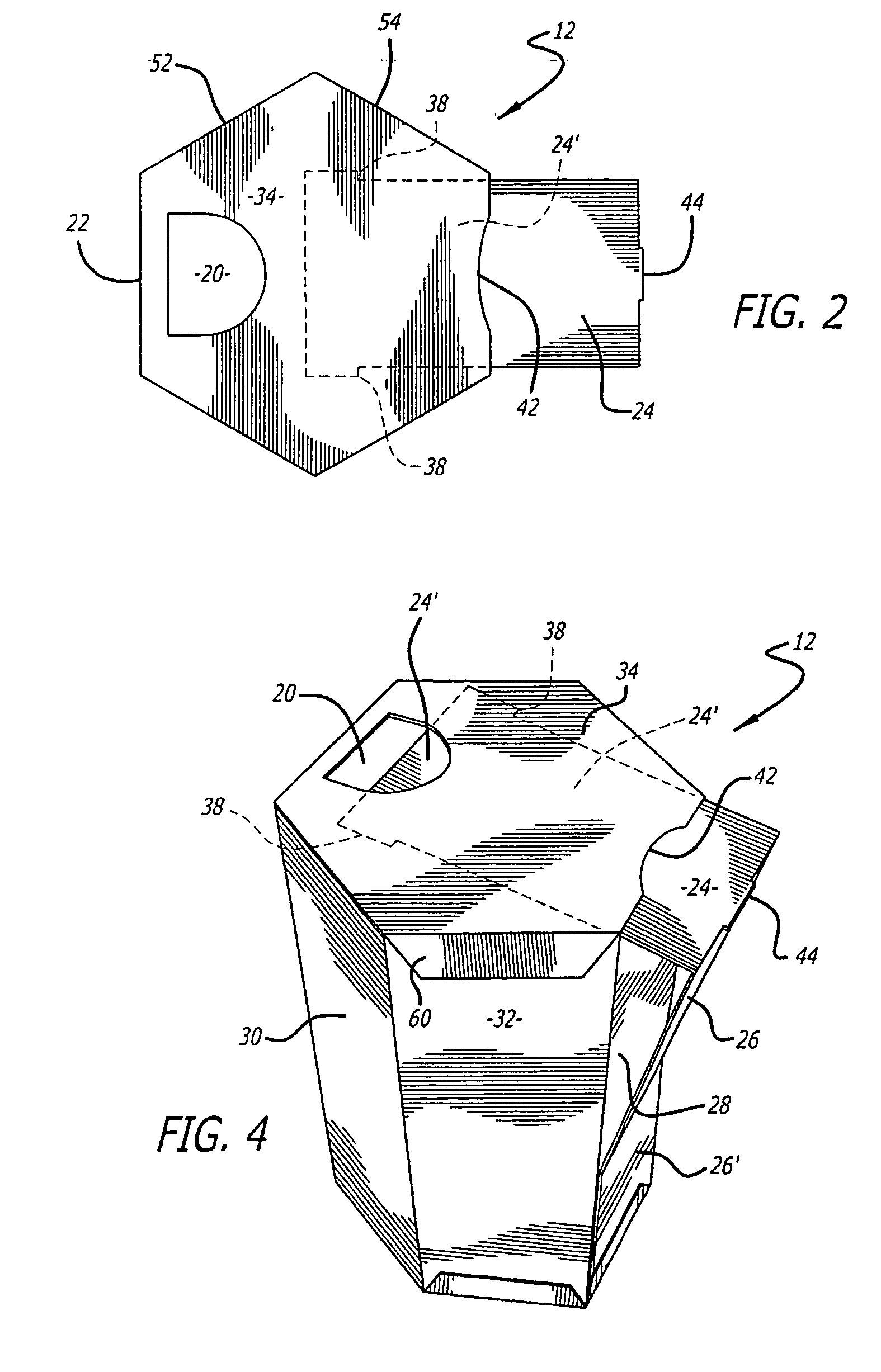

Convenient solid product dispensing package

InactiveUS20060124709A1Conveniently stored in vehicleEasy to manufactureRigid containersFace sheetMechanical engineering

Owner:HENGAMI DAVID TODJAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com