Fabrication of conductive nanostructures on a flexible substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

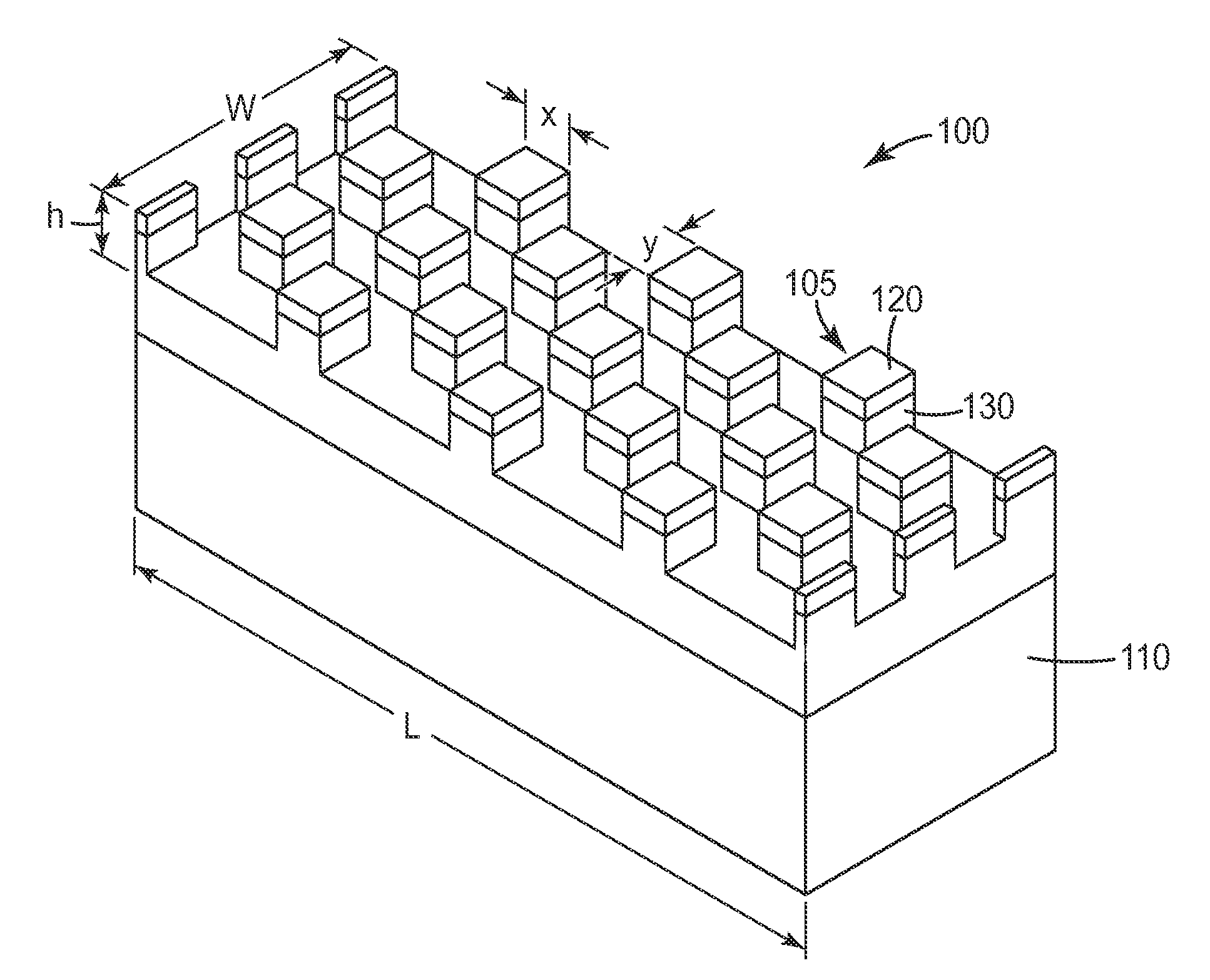

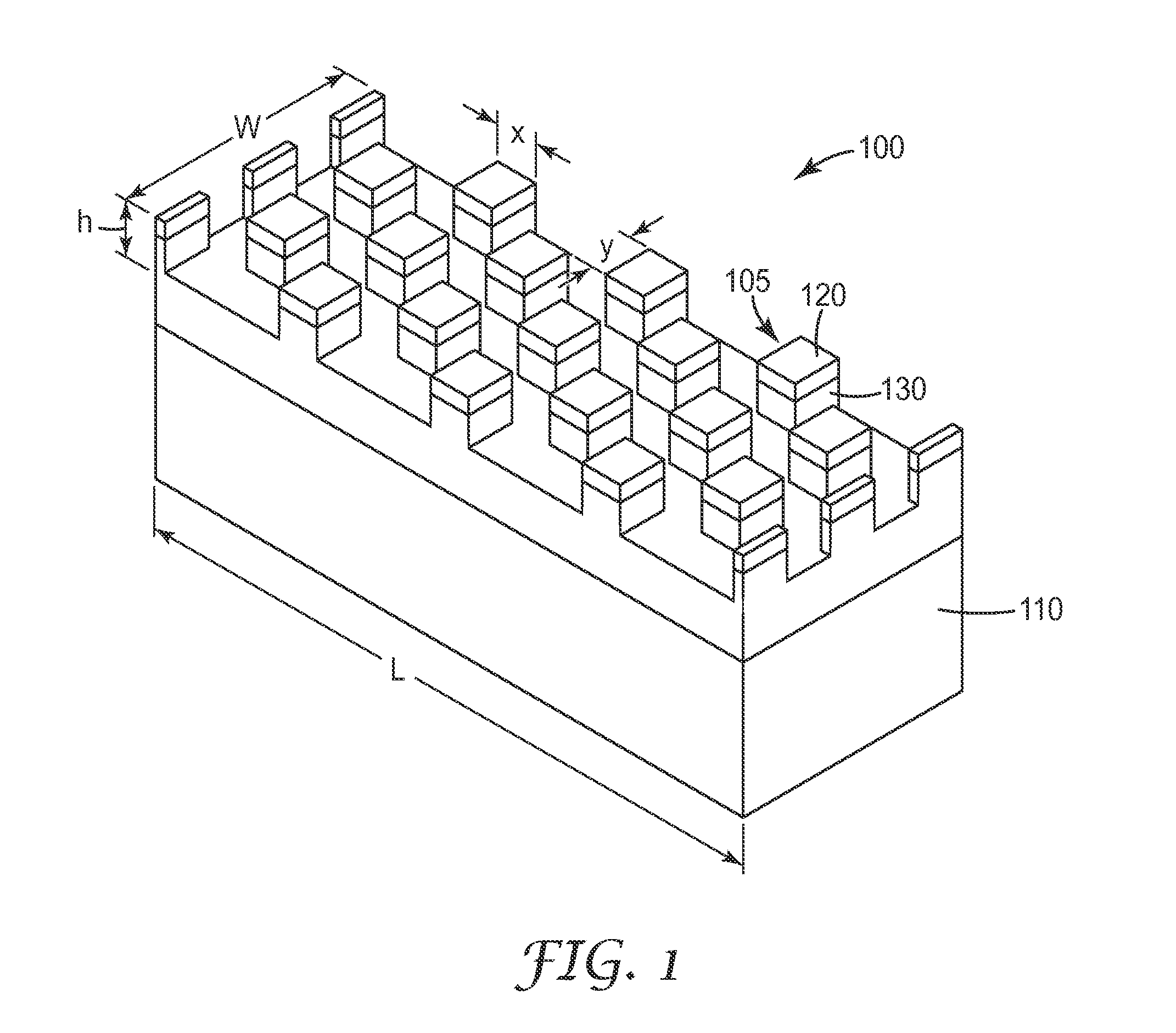

[0053]A nanostructured material 100′ having a sub-micron hole array structure was prepared utilizing the fabrication method previously described. FIGS. 3A-3G show a flow diagram of the fabrication method by which the nanostructured material 100′ was formed.

Preparing the Master

[0054]A thin layer of a positive UV5 photoresist 306 (available from Rohm and Haas Electronic Materials, Marlborough, Mass.) was applied to a glass master 300 having a conductive ITO surface layer 304 with a thin chromium tie layer (not shown) between the glass layer 302 and the ITO layer 304 as shown in FIG. 3A. The relief pattern 310 was made by interference lithography using a Innova Sabre FReD UV laser with an output of 270 mW (available from Company Coherent located at Santa Clara, Calif.) to pattern the photoresist layer 306 with an array of posts 314 (FIG. 3B). The exposed areas were then removed using a developing solution to dissolve the undesired photoresist.

[0055]The diameter, D, of the nanostructure...

example 2

[0061]A second replication master was made with a durable diamond-like carbon (DLC) relief structure on the surface of an ITO glass coated silicon master. A 200 nm DLC film was vacuum coated onto the surface of the ITO glass followed by application of a thin layer (about 50 nm) diamond-like glass (DLG) as described in U.S. Pat. Nos. 5,888,594; 6,015,597; and 6,696,157; herein incorporated by reference. A layer of photo resist (UV5 photoresist 306, available from Rohm and Haas Electronic Materials, Marlborough, Mass.) is applied to the to the DLG surface. The photo resist was patterned using interference lithography as generally described in U.S. Pat. No. 7,085,450, herein incorporated by reference. A 3-step reactive ion etching process utilizing perfluoropropane (C3F8), oxygen and argon gases was used to transfer the pattern from the photoresist into the DLC layer so that the surface of the ITO glass was exposed in selected areas. FIG. 5 shows a schematic cross-section of the silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Thermoplasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com