Patents

Literature

357 results about "Nanoimprint lithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

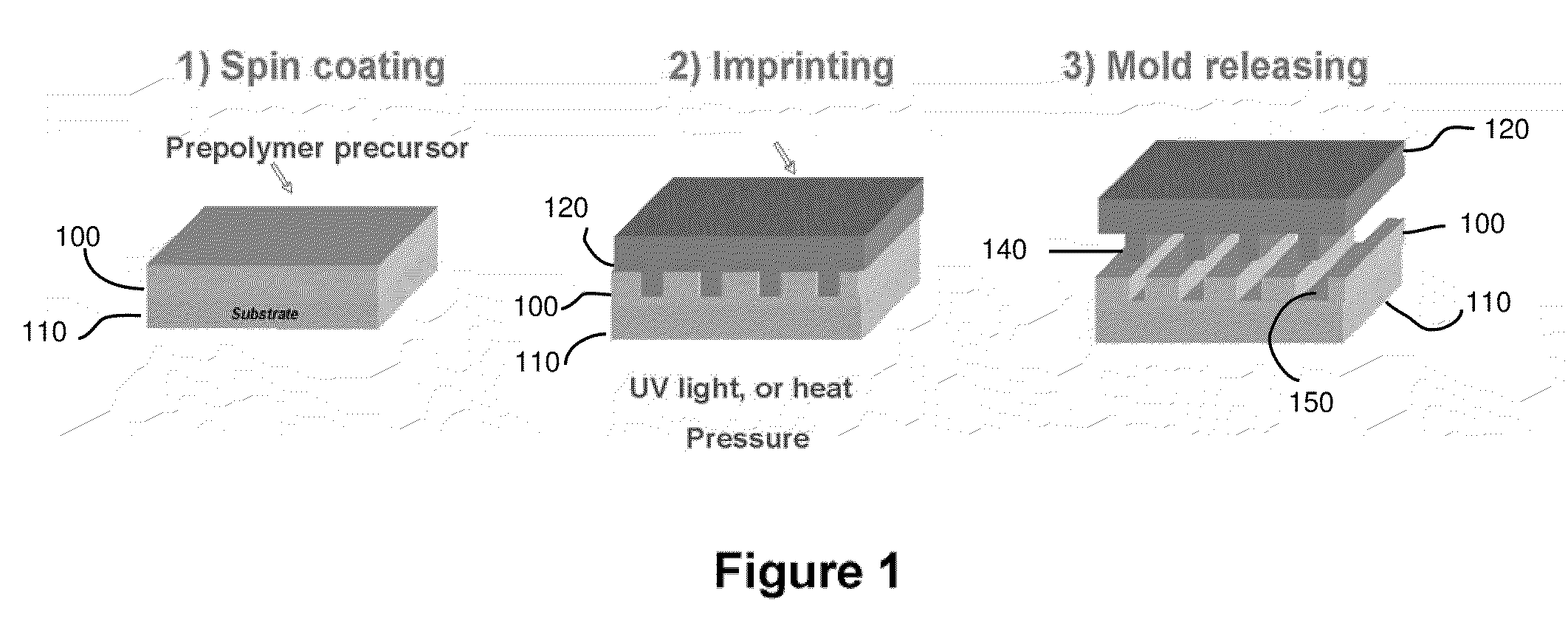

Nanoimprint lithography (NIL) is a method of fabricating nanometer scale patterns. It is a simple nanolithography process with low cost, high throughput and high resolution. It creates patterns by mechanical deformation of imprint resist and subsequent processes. The imprint resist is typically a monomer or polymer formulation that is cured by heat or UV light during the imprinting. Adhesion between the resist and the template is controlled to allow proper release.

Polymer solution for nanoimprint lithography to reduce imprint temperature and pressure

InactiveUS20040110856A1Reduce pressureReduce the temperatureNanostructure manufactureDecorative surface effectsCross-linkVitrification

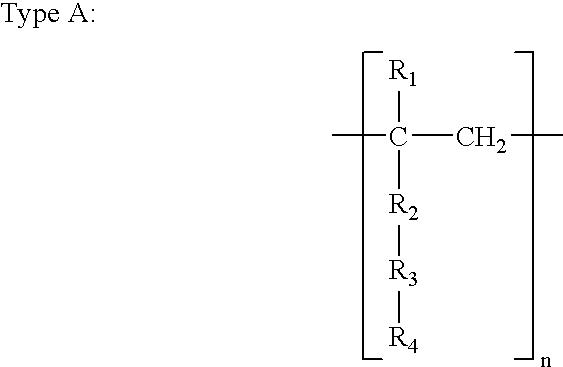

A method of forming features on substrates by imprinting is provided. The method comprises: (a) forming a polymer solution comprising at least one polymer dissolved in at least one polymerizable monomer; and (b) depositing the polymer solution on a substrate to form a liquid film thereon; and then either: (c) curing the liquid film by causing the monomer(s) to polymerize and optionally cross-linking the polymer(s) to thereby form a polymer film, the polymer film having a glass transition temperature (Tg); and imprinting the polymer film with a mold having a desired pattern to form a corresponding negative pattern in the polymer film, or (d) imprinting the liquid film with the mold and curing it to form the polymer film. The temperature of imprinting is as little as 10° C. above the Tg, or even less if the film is in the liquid state. The pressure of the imprinting can be within the range of 100 to 500 psi.

Owner:HEWLETT PACKARD DEV CO LP

Roll to roll nanoimprint lithography

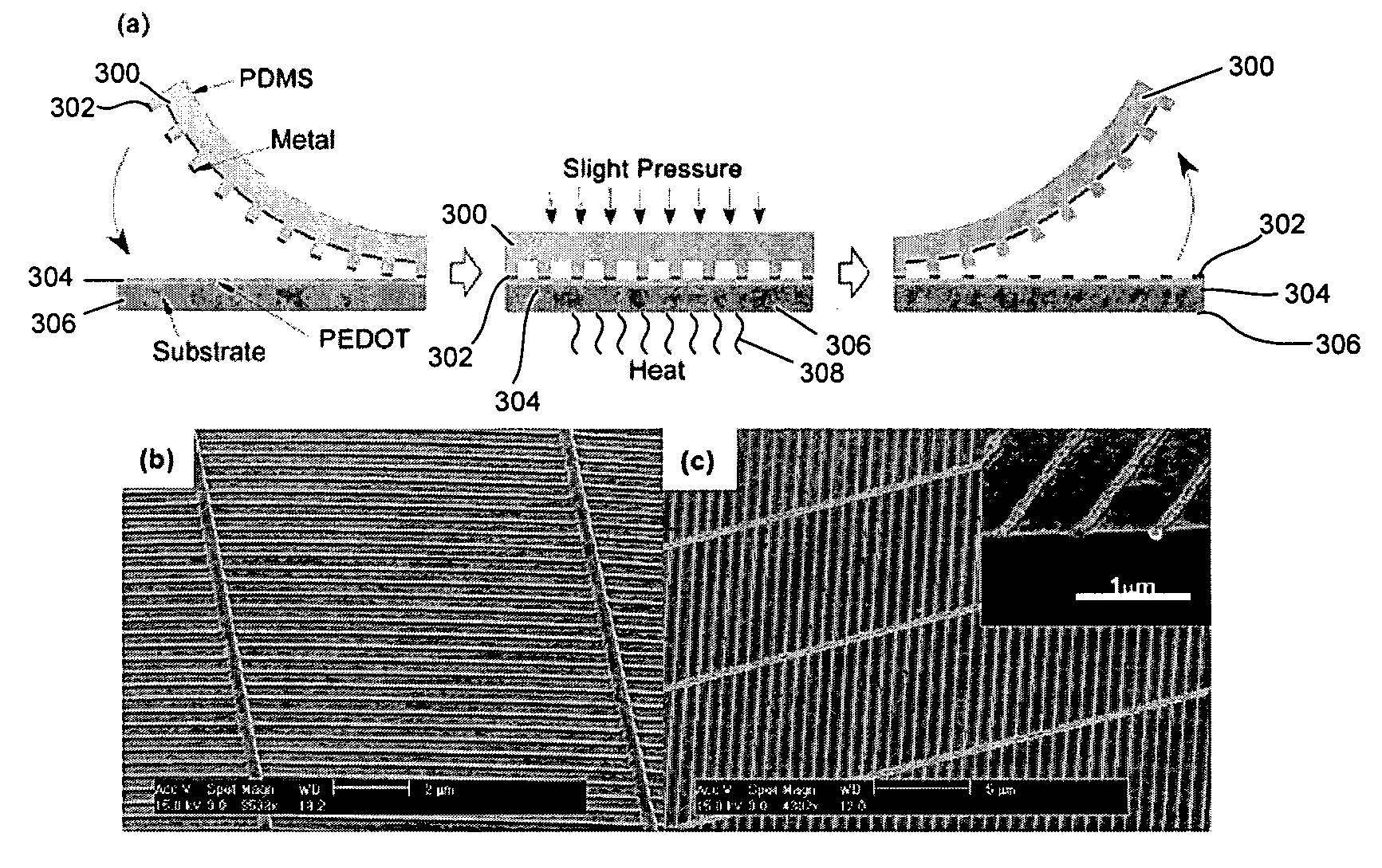

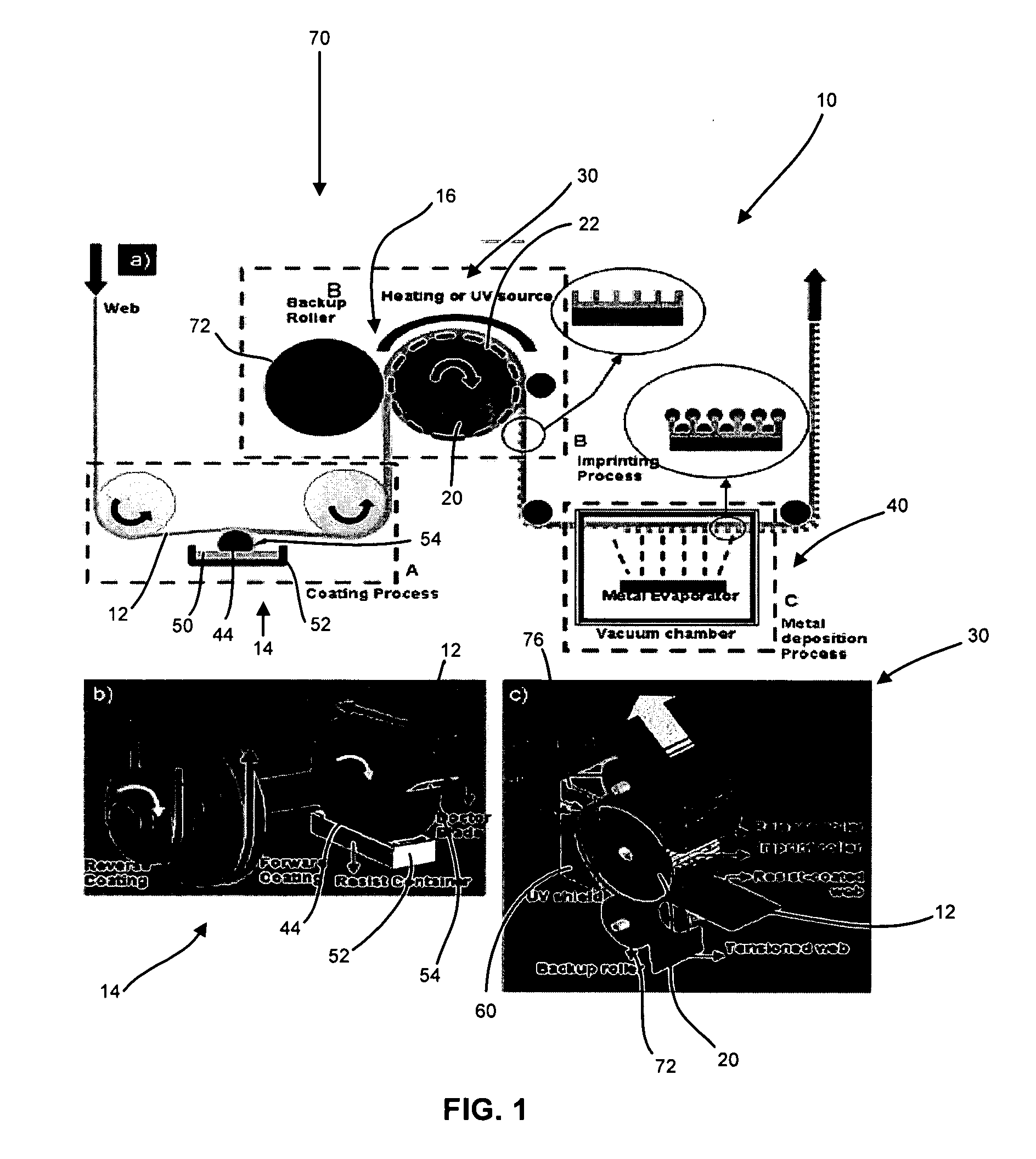

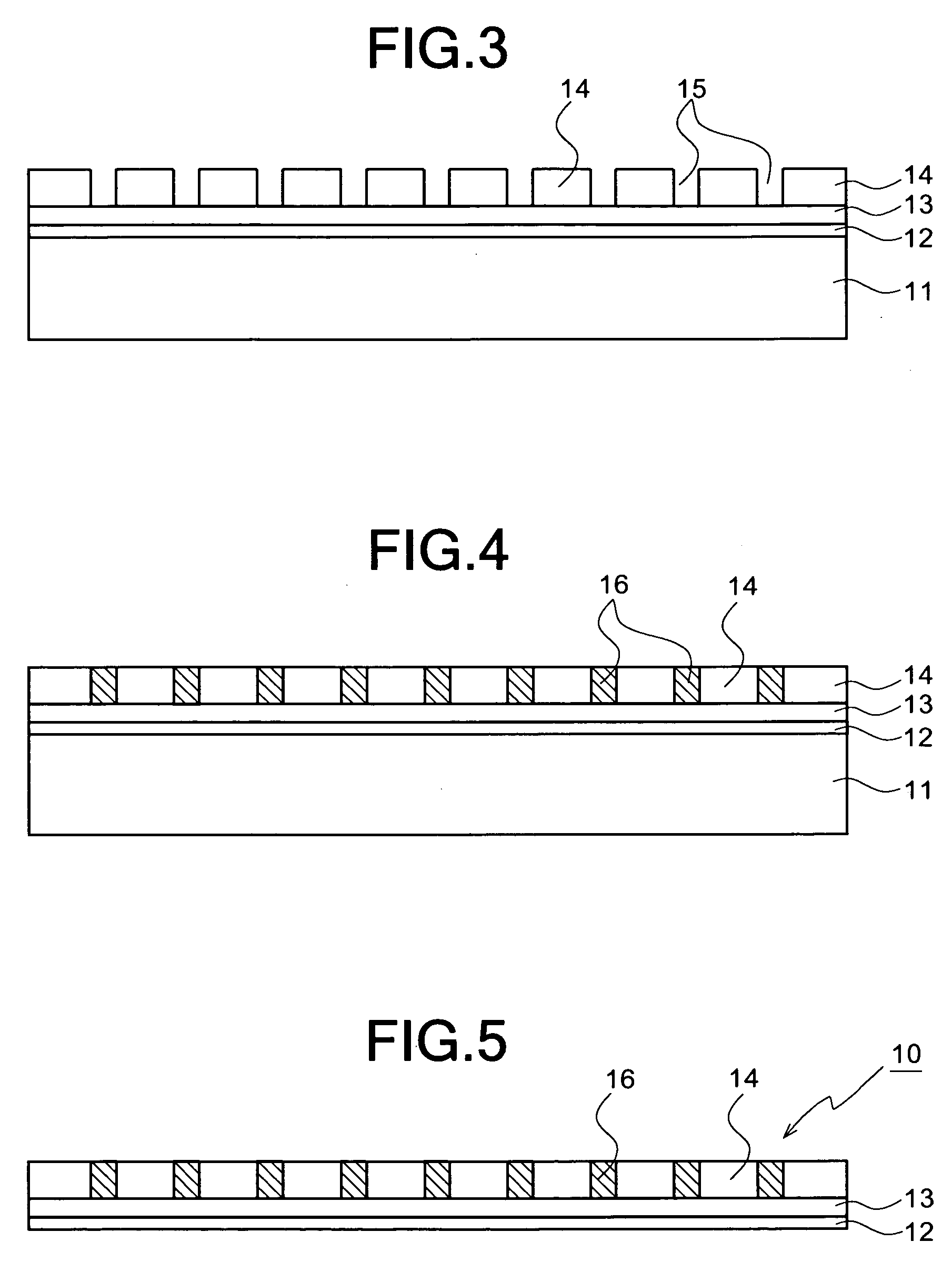

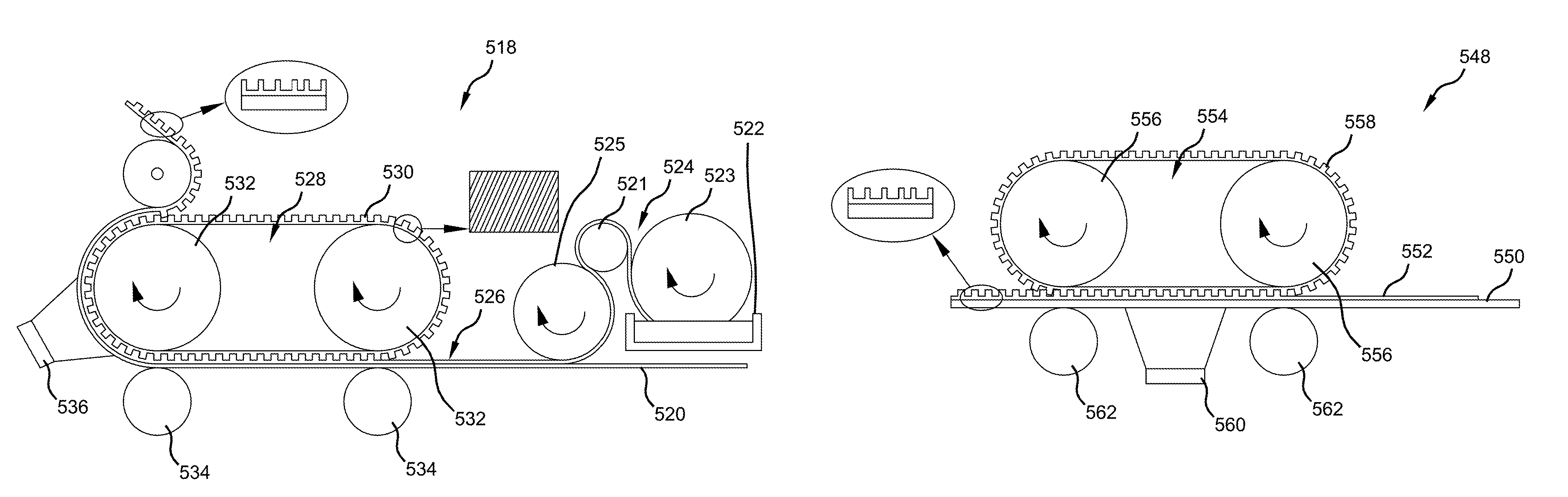

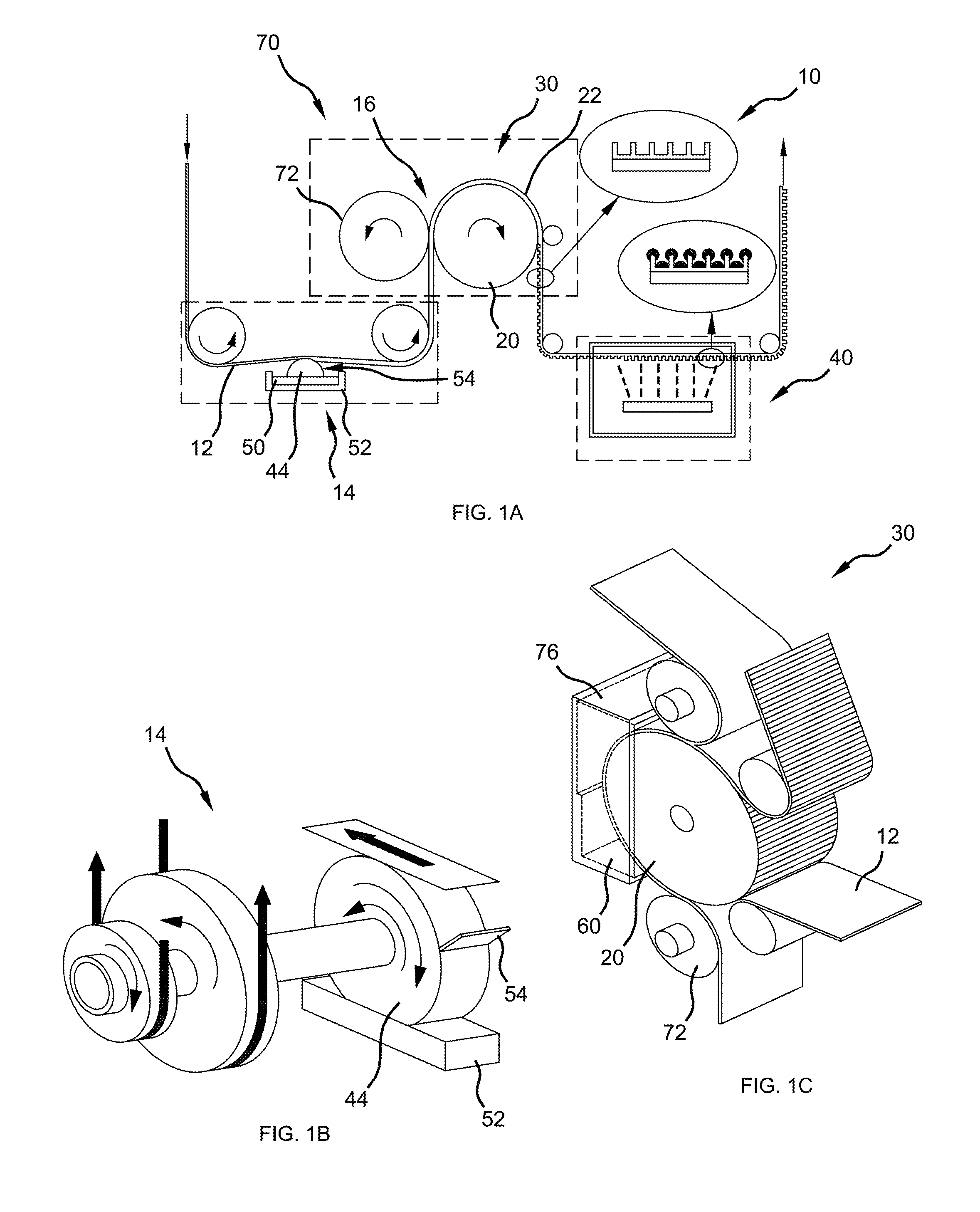

Apparatus and methods for a nano-patterning process to fabricate nanostructures. A roller type mold is used to continuously imprint nanostructures onto a flexible web or a rigid substrate. The process includes a coating and an imprinting module, which rotate the web synchronously. Liquid resist materials are used for imprinting and the patterns are set by thermal or UV curing. The process is used to produce bilayer metal wire-grid polarizers, organic solar cells, and organic light emitting diodes.

Owner:RGT UNIV OF MICHIGAN

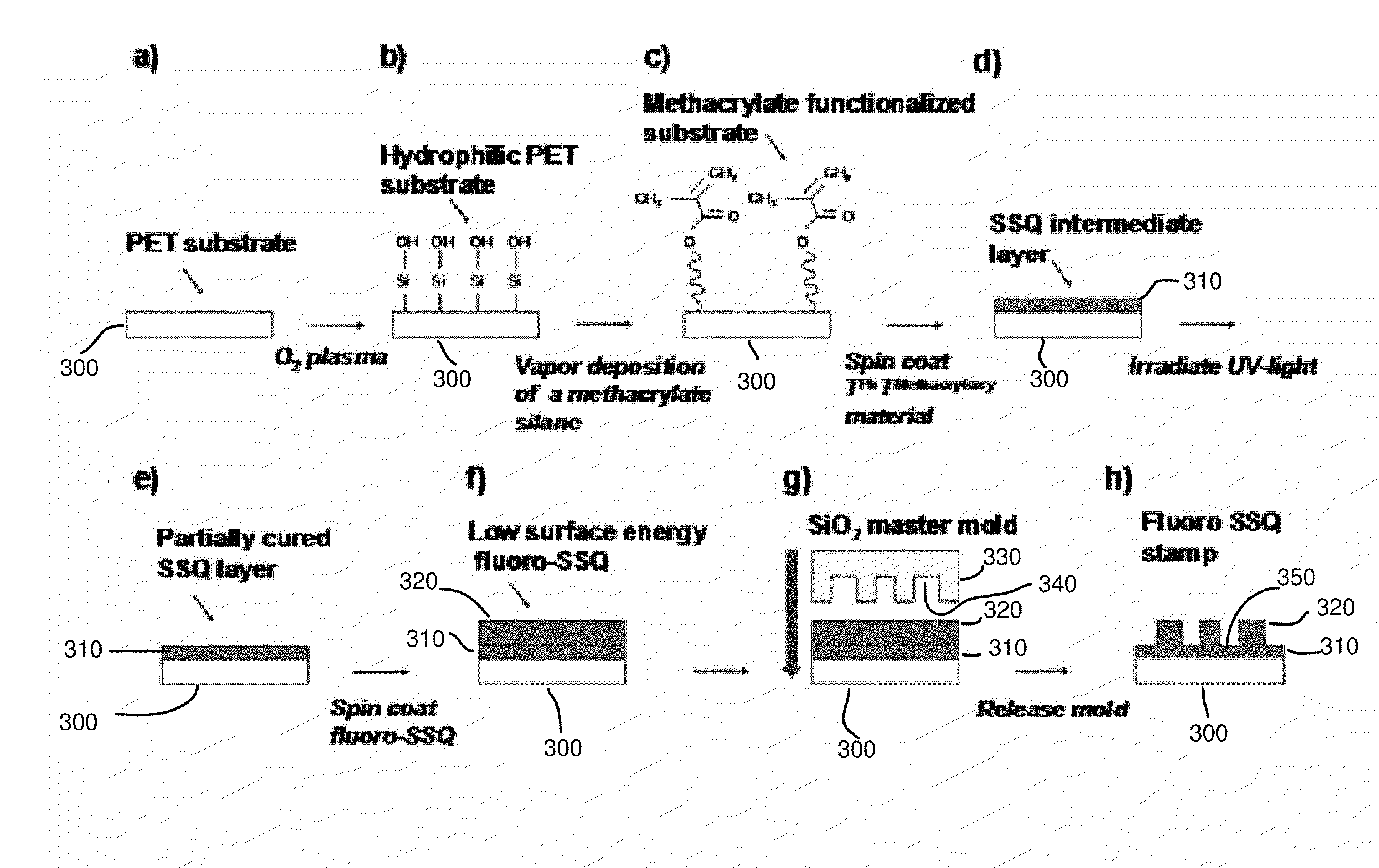

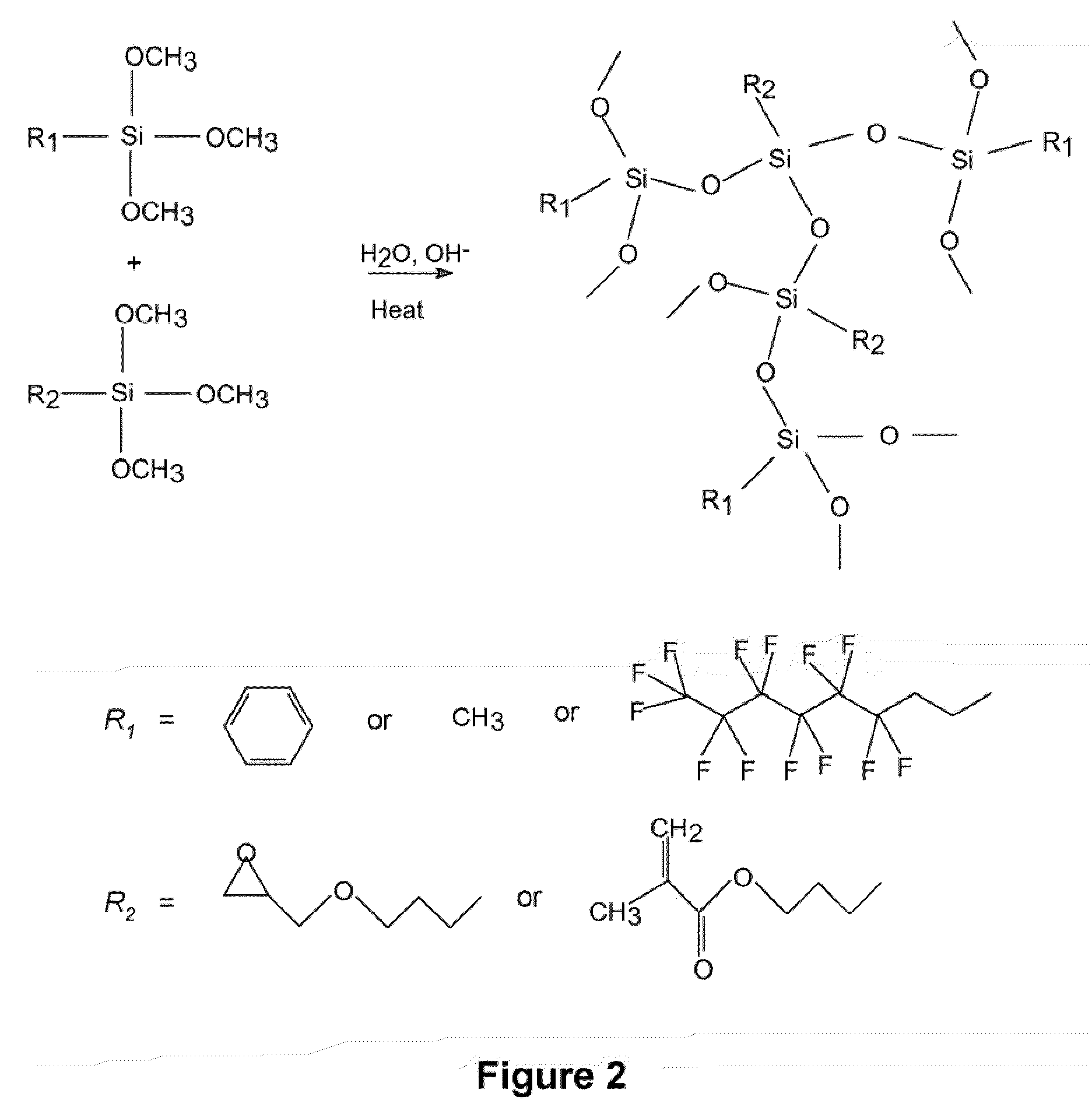

UV Curable Silsesquioxane Resins For Nanoprint Lithography

ActiveUS20090256287A1Simple compositionImprove methodPhotosensitive materialsNanoinformaticsNanolithographyResist

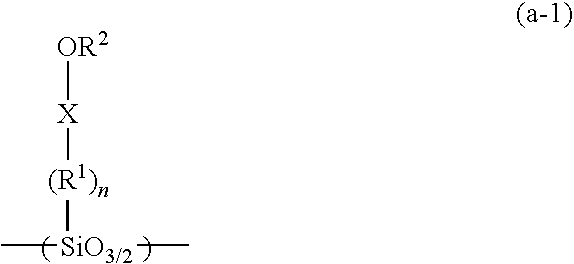

Radiation-curable silsesquioxane resin materials are employed for micro- and nanolithography. The resin materials can include a radiation-curable silsesquioxane resin and a photo-initiator having low viscosity. The low viscosity of the liquid system allows imprinting with low pressure and low temperature; e.g. room temperature. The resist's dry etching resistance is increased and the cured film is more easily separated from the mask. Due to its high modulus after cure, the material allows the fabrication of micro- and nano-features having high aspect ratios while providing a high throughput. Various pattern sizes, for example, ranging from tens of microns to as small as a few nanometers, may be achieved with the UV-curable material system.

Owner:RGT UNIV OF MICHIGAN

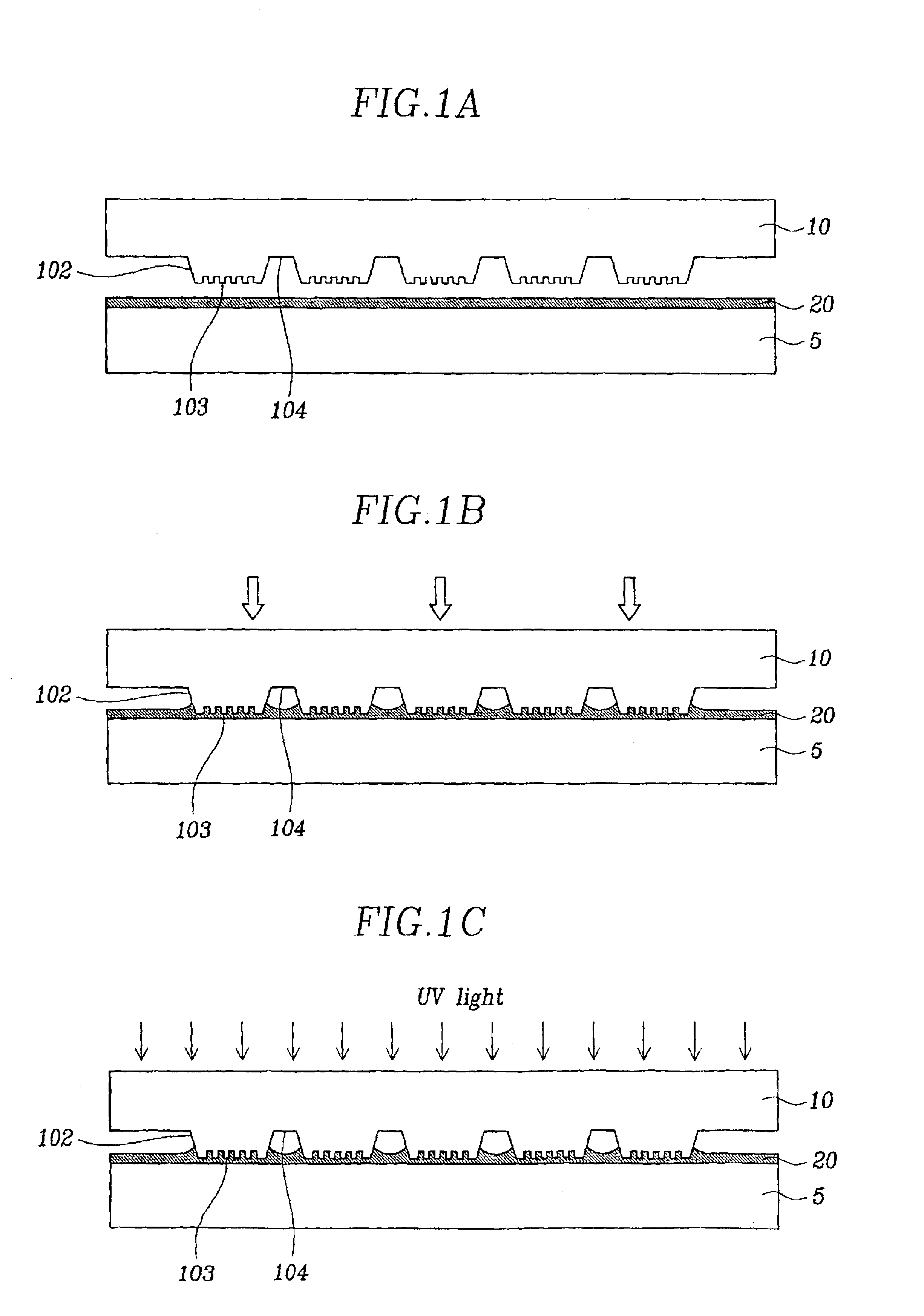

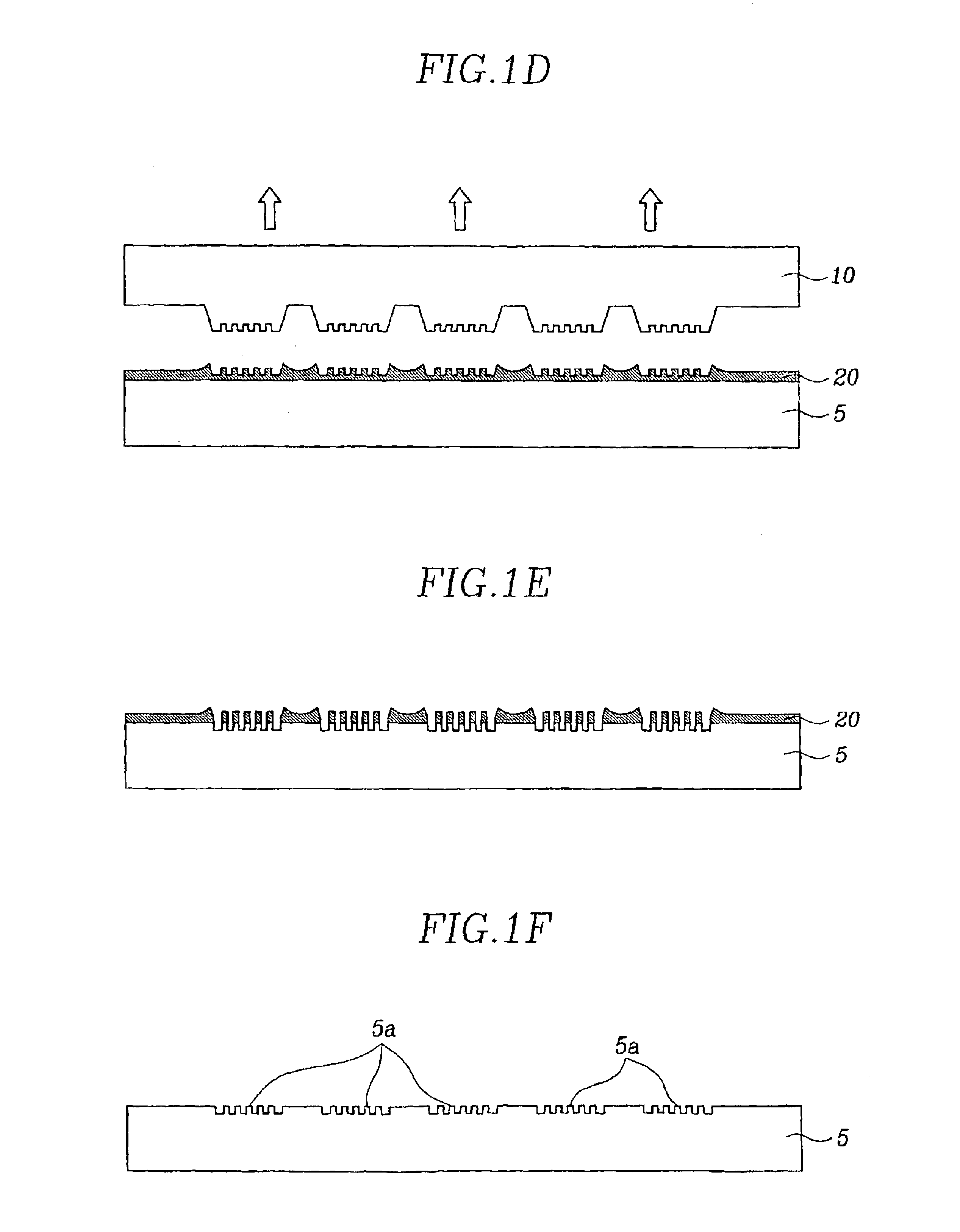

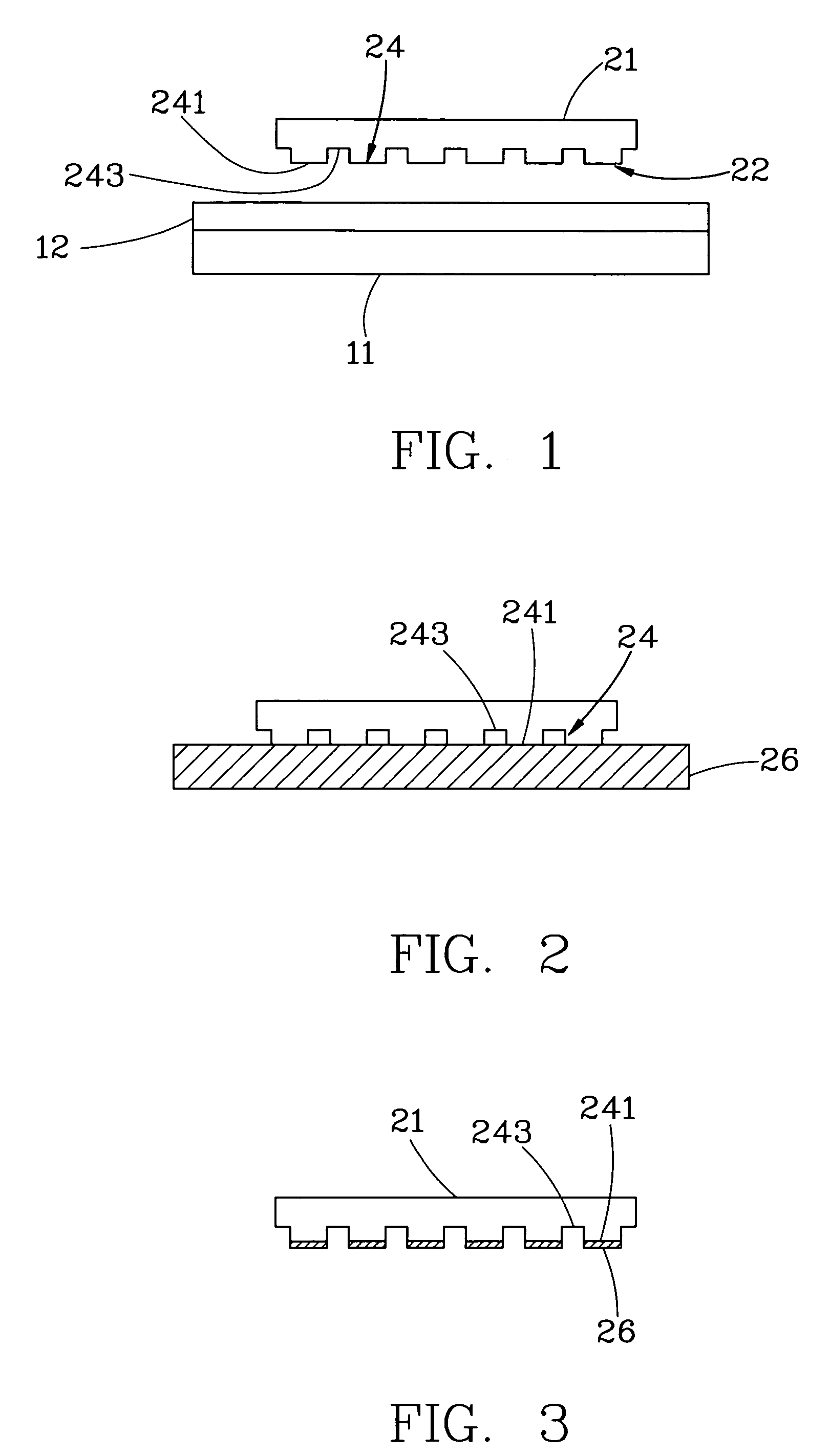

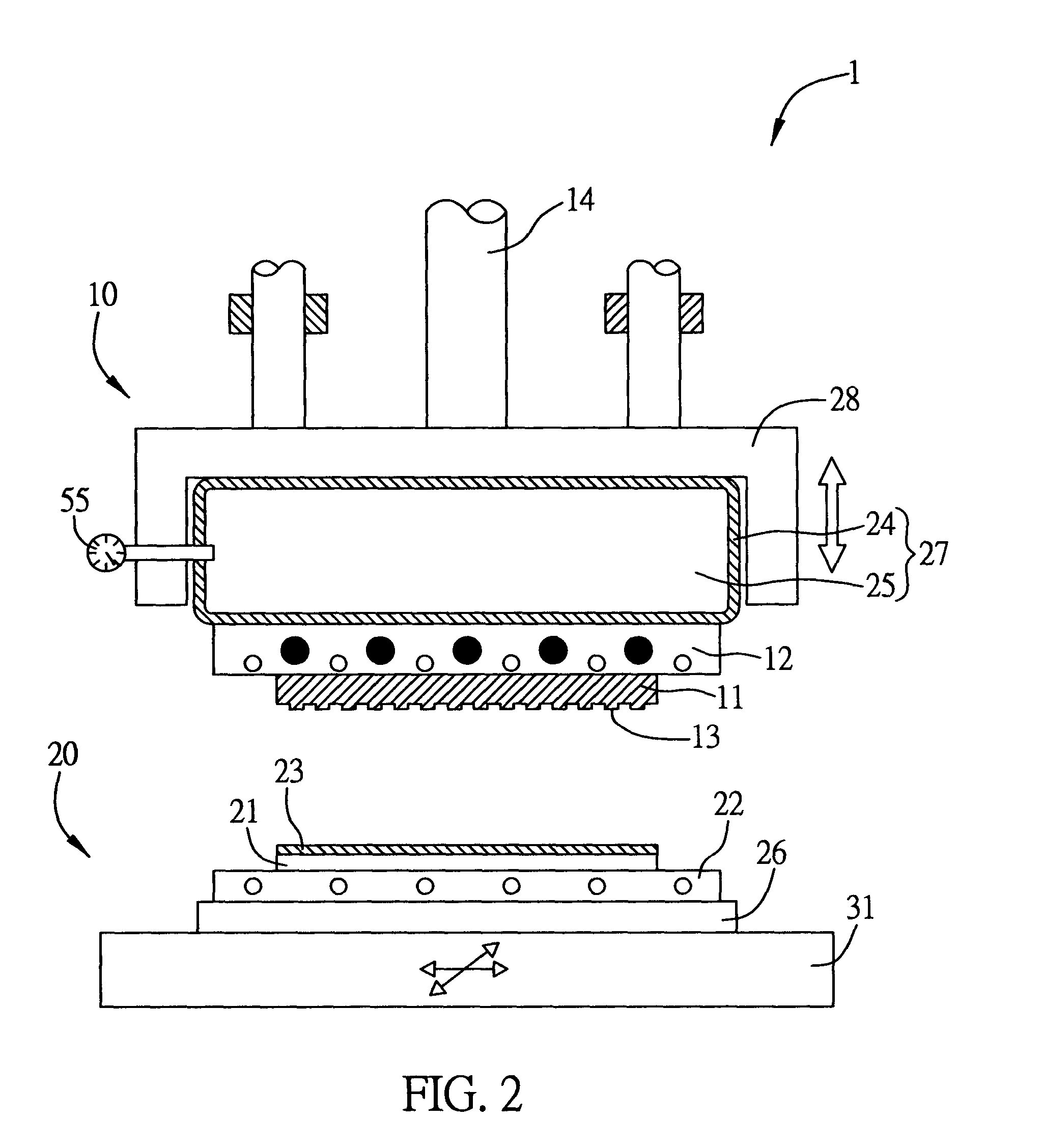

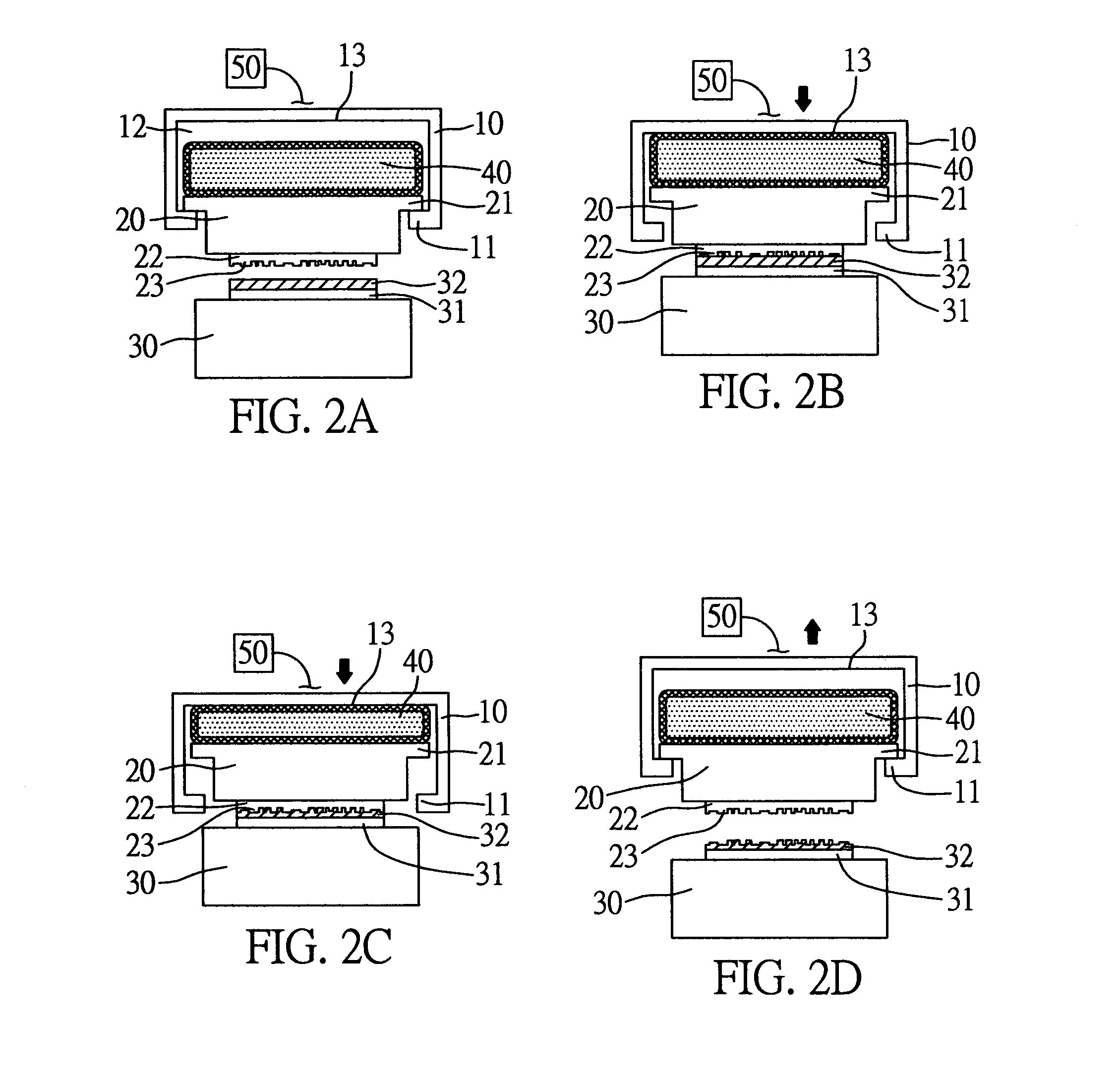

UV nanoimprint lithography process using elementwise embossed stamp and selectively additive pressurization

InactiveUS6943117B2High-precision and high-quality nanostructuresFast formingNanoinformaticsPhotomechanical apparatusResistRoom temperature

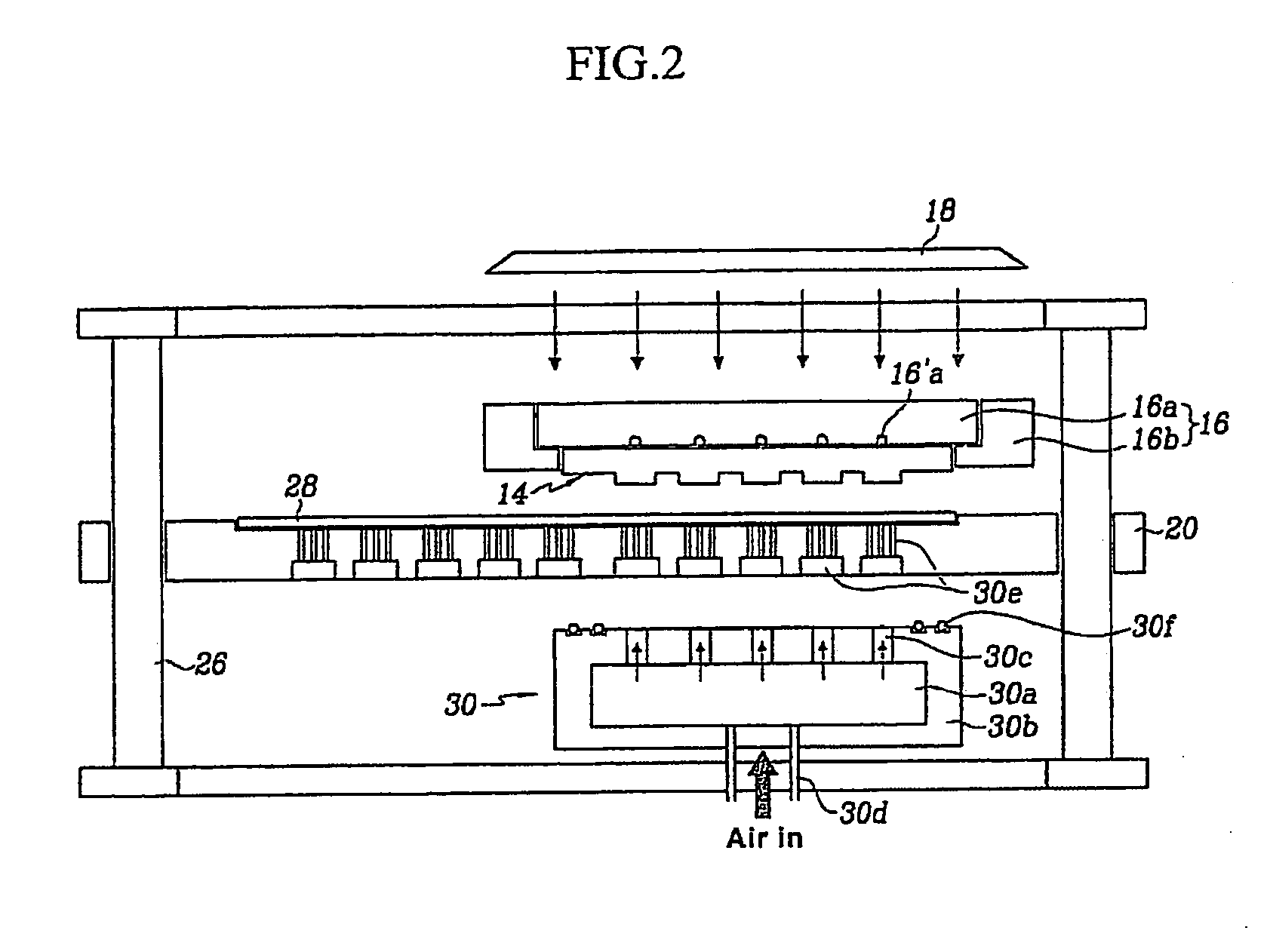

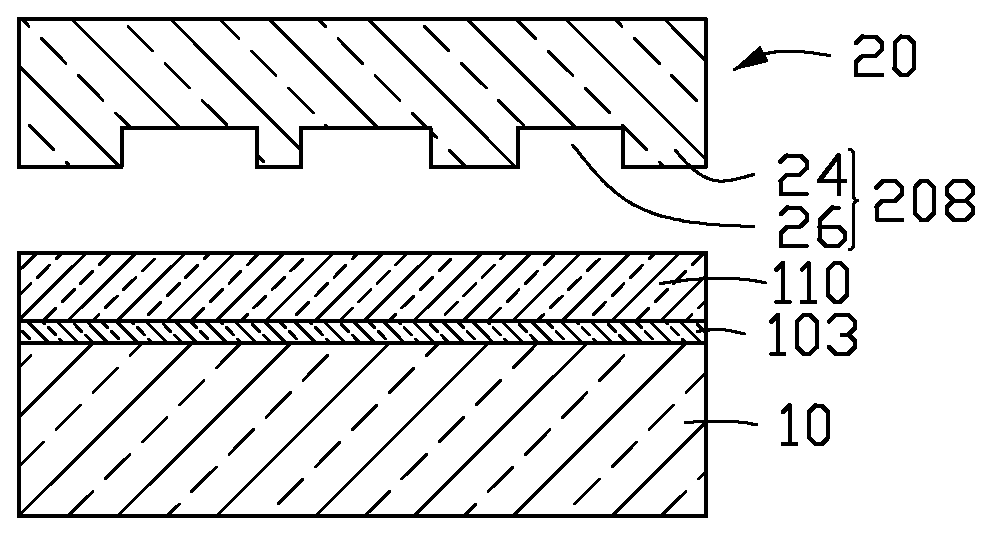

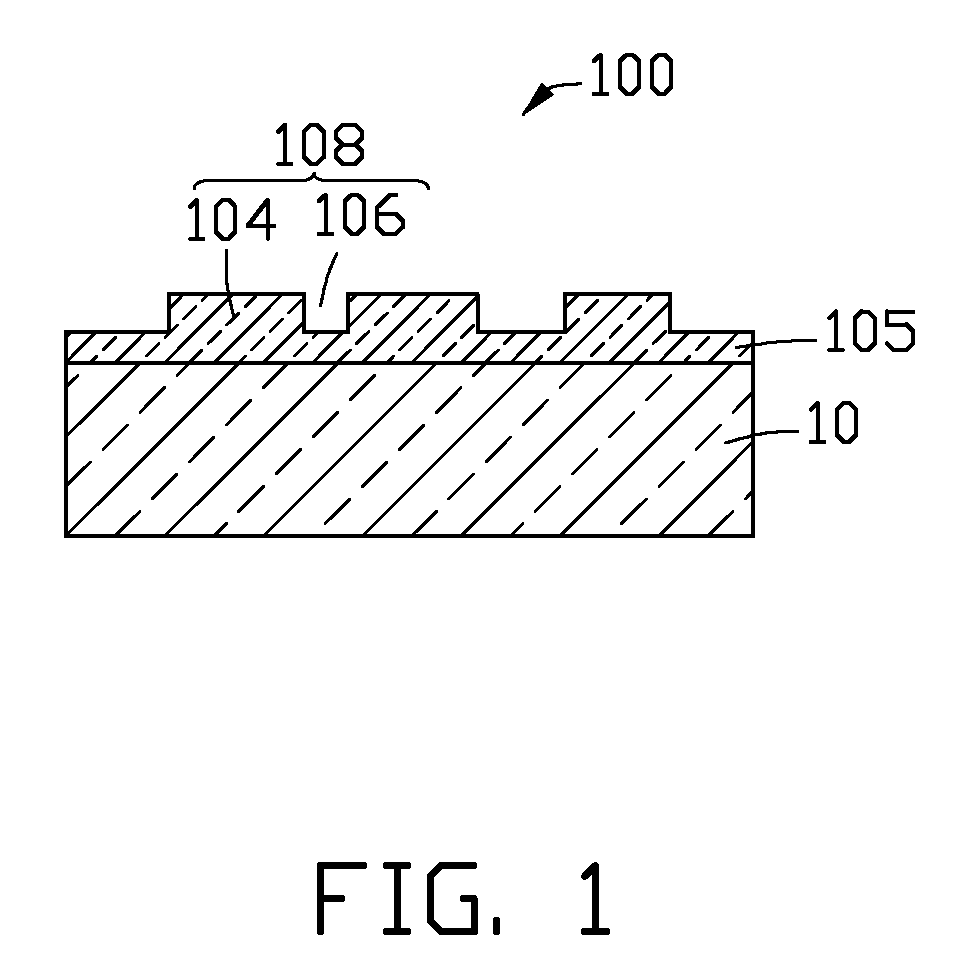

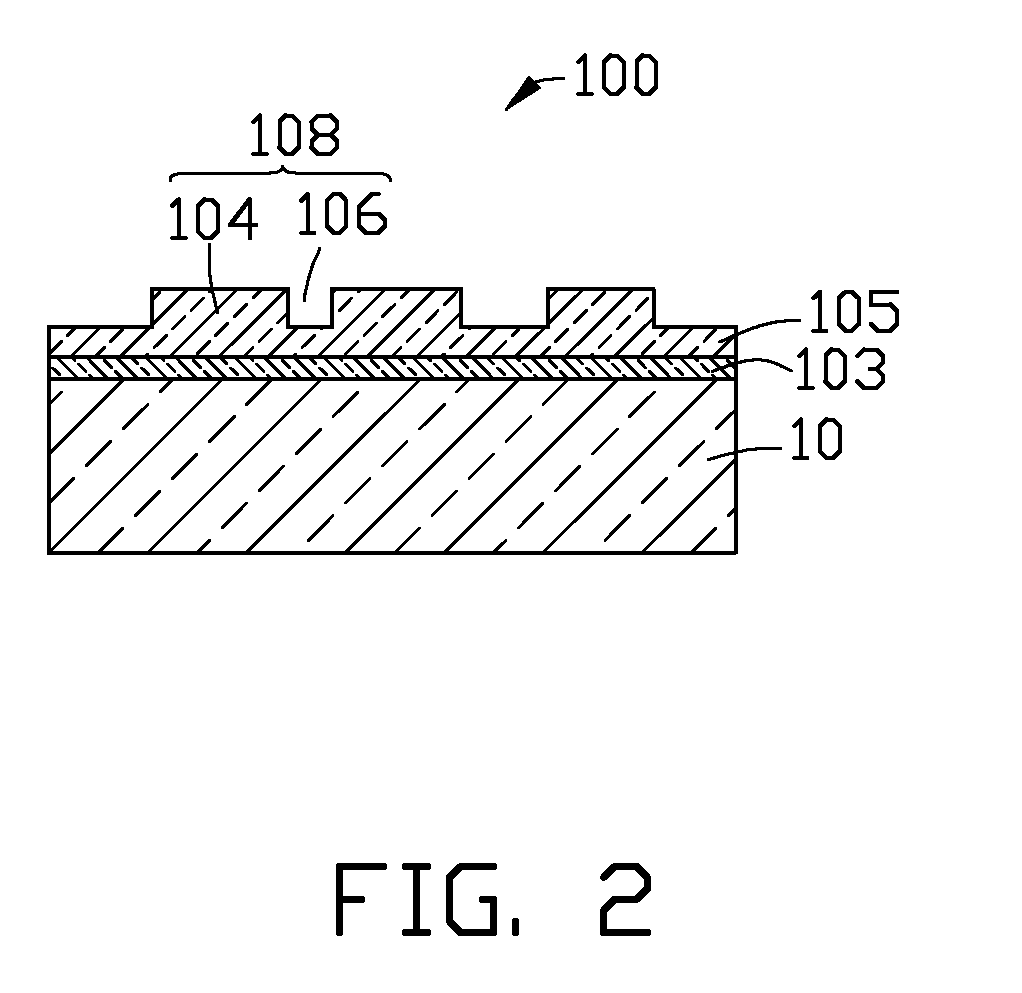

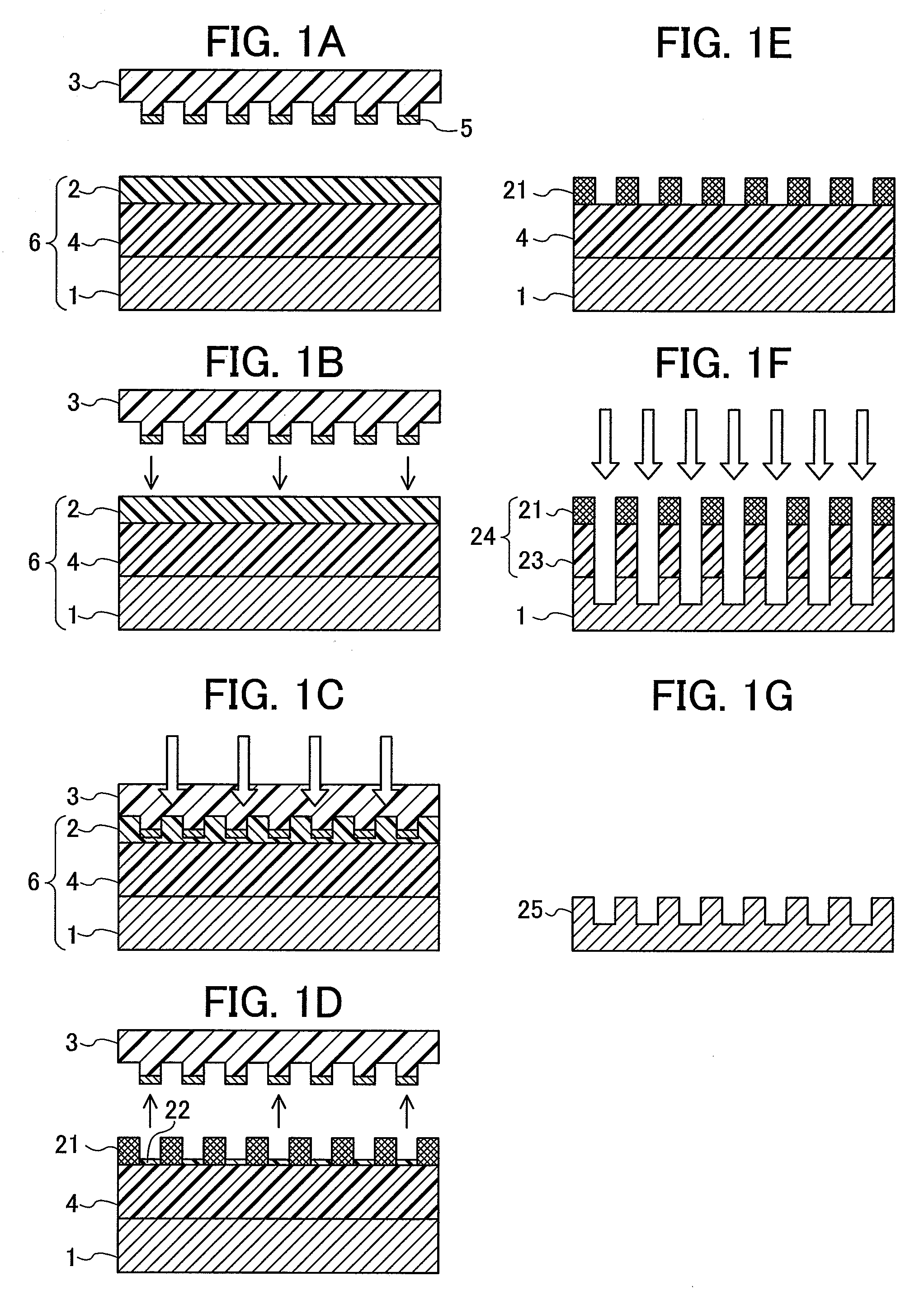

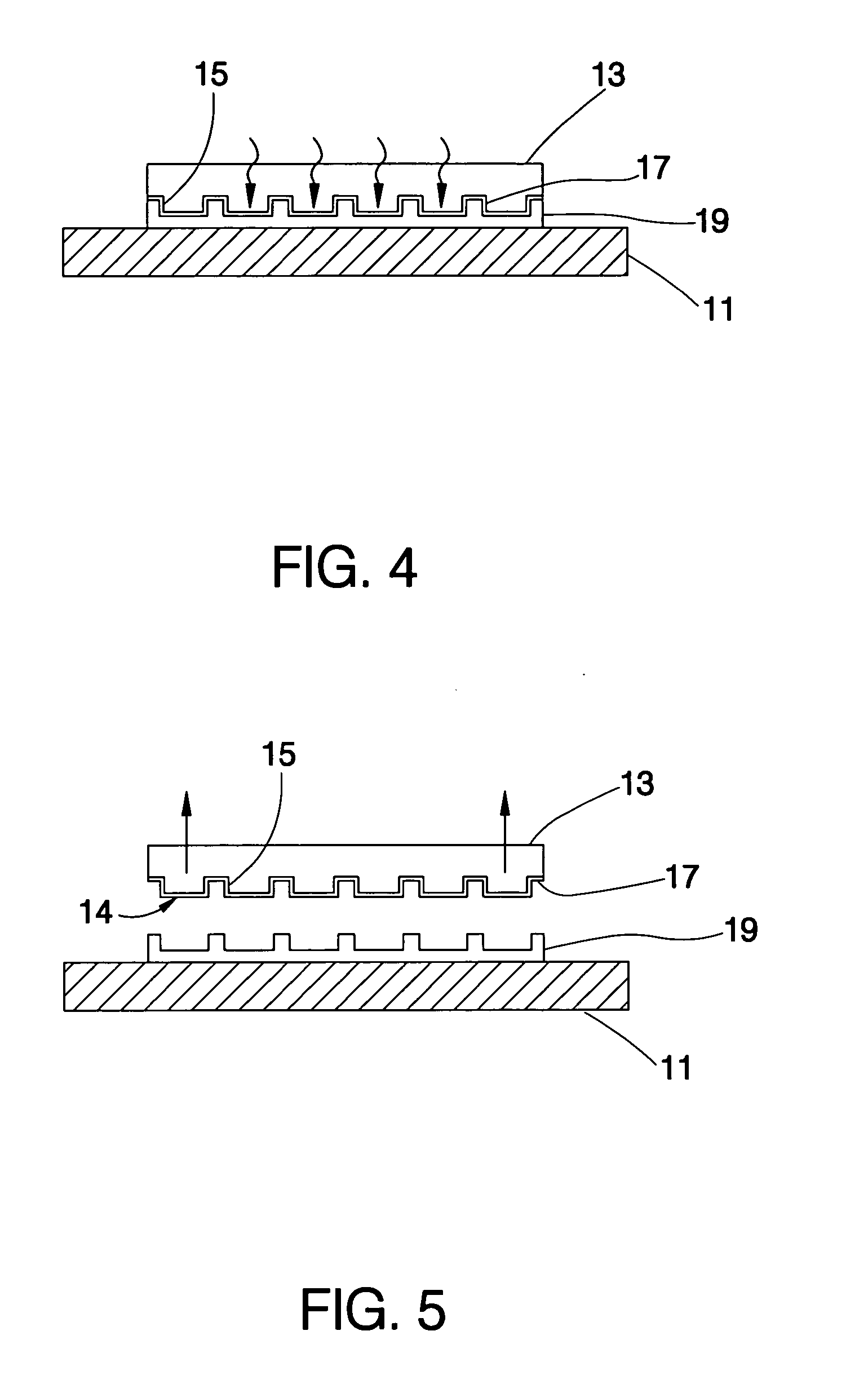

A UV nanoimprint lithography process for forming nanostructures on a substrate. The process includes depositing a resist on a substrate; contacting a stamp having formed thereon nanostructures at areas corresponding to where nanostructures on the substrate are to be formed to an upper surface of the resist, and applying a predetermined pressure to the stamp in a direction toward the substrate, the contacting and applying being performed at room temperature and at low pressure; irradiating ultraviolet rays onto the resist; separating the stamp from the resist; and etching an upper surface of the substrate on which the resist is deposited. The stamp is an elementwise embossed stamp that comprises at least two element stamps, and grooves formed between adjacent element stamps and having a depth that is greater than a depth of the nanostructures formed on the element stamps.

Owner:KOREA INST OF MASCH & MATERIALS

UV nanoimprint lithography process and apparatus

ActiveUS20050184436A1Efficiently formedLarge-area stampMaterial nanotechnologyConfectioneryLithography processUltraviolet

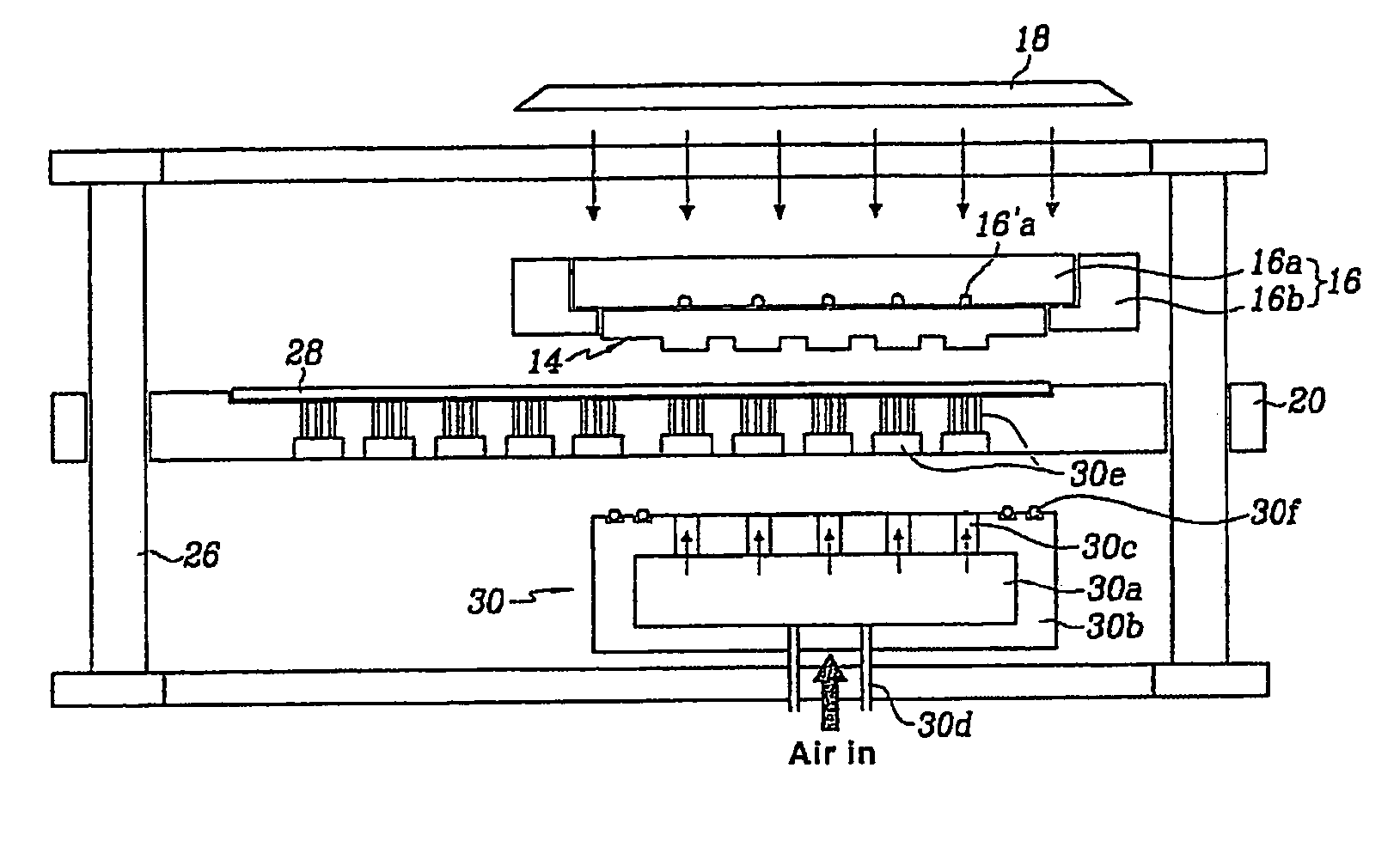

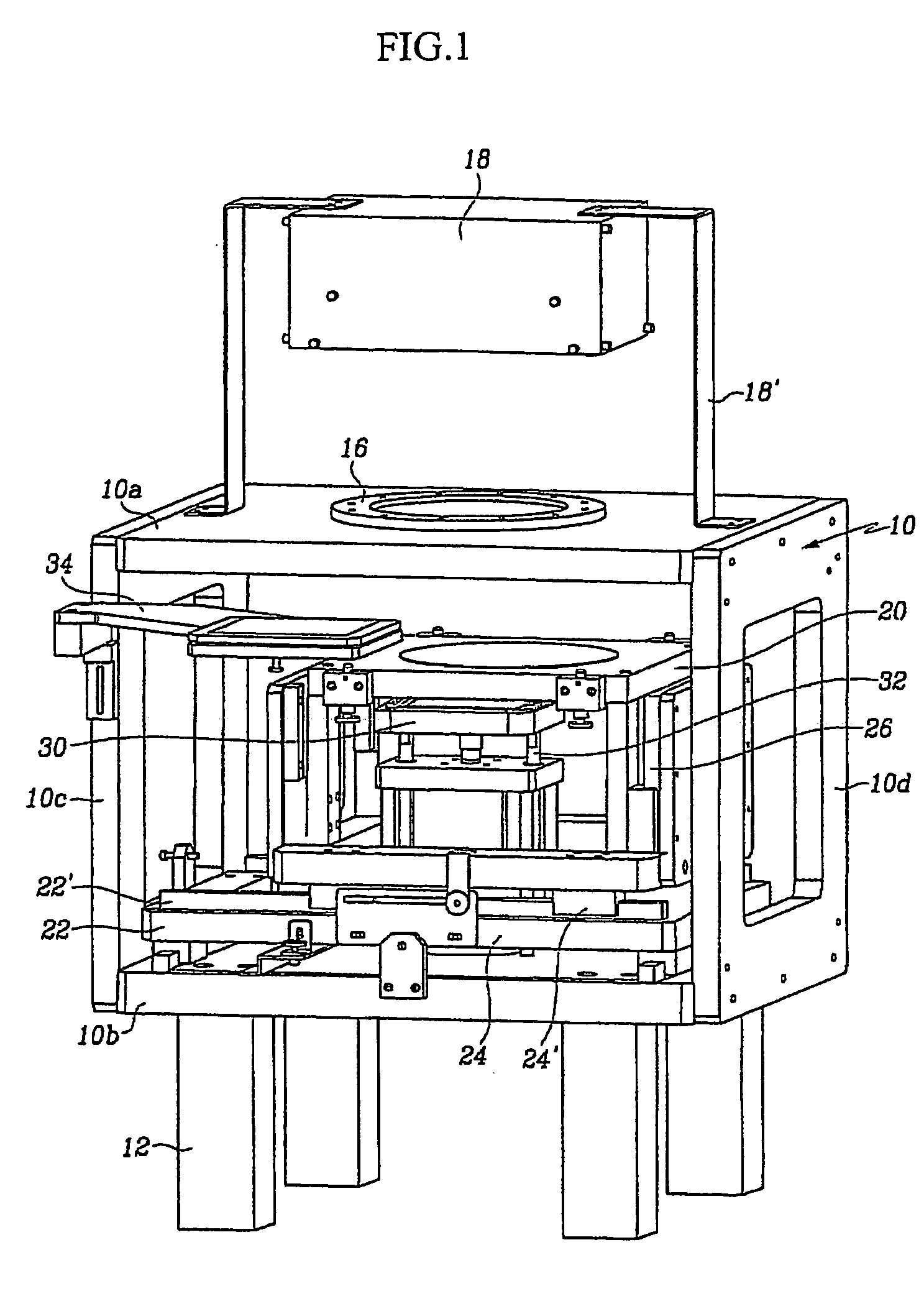

A UV nanoimprint lithography process and its apparatus that are able to repeatedly fabricates nanostructures on a substrate (wafer, UV-transparent plate) by using a stamp that is as large as or smaller than the substrate in size are provided. The apparatus includes a substrate chuck for mounting the substrate; a stamp made of UV-transparent materials and having more than two element stamps, wherein nanostructures are formed on the surface of each element stamp; a stamp chuck for mounting the stamp; a UV lamp unit for providing UV light to cure resist applied between the element stamps and the substrate; a moving unit for moving the substrate chuck or the stamp chuck to press the resist with the element stamps and substrate; and a pressure supply unit for applying pressurized gas to some selected regions of the substrate to help complete some incompletely filled element stamps.

Owner:KOREA INST OF MASCH & MATERIALS

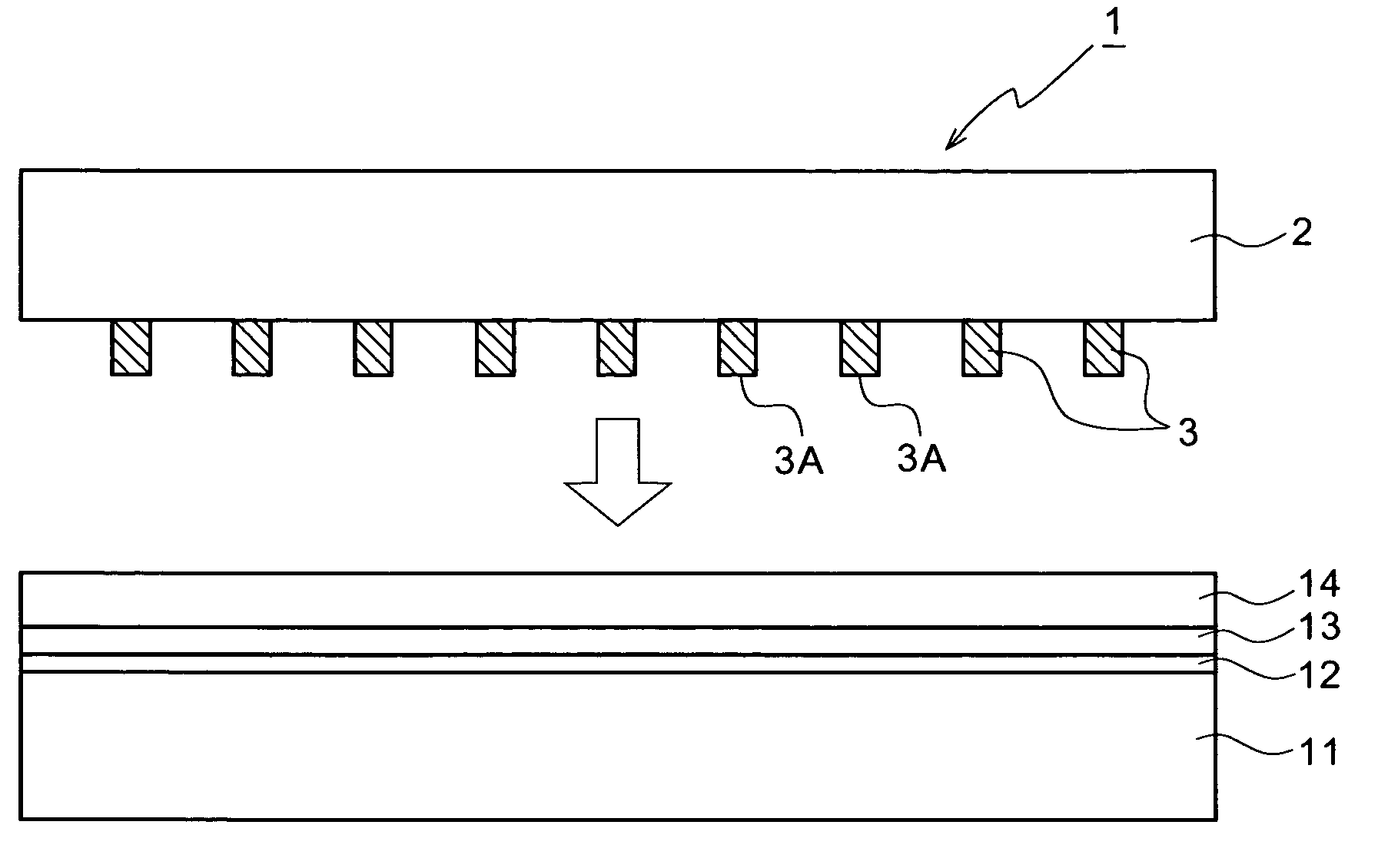

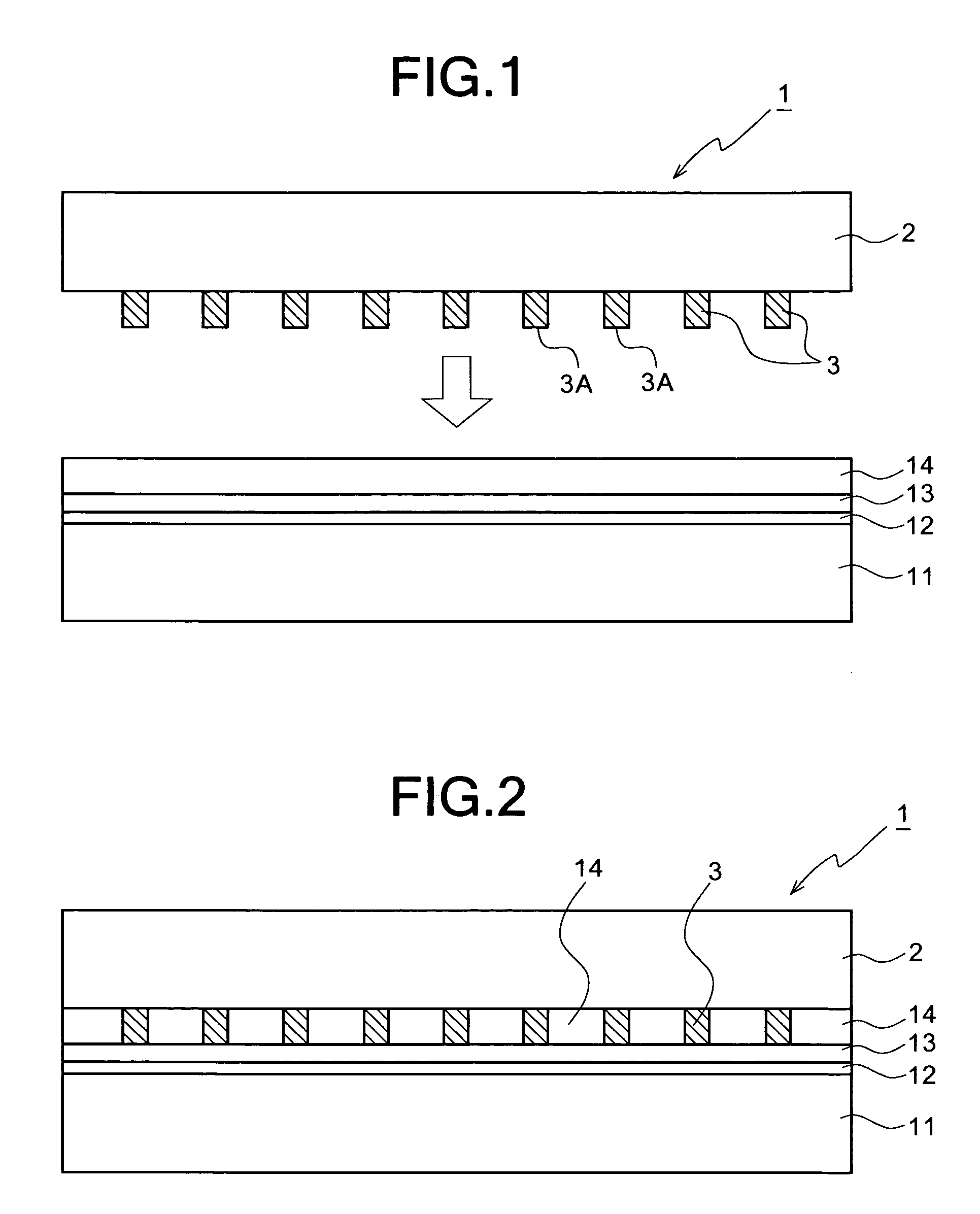

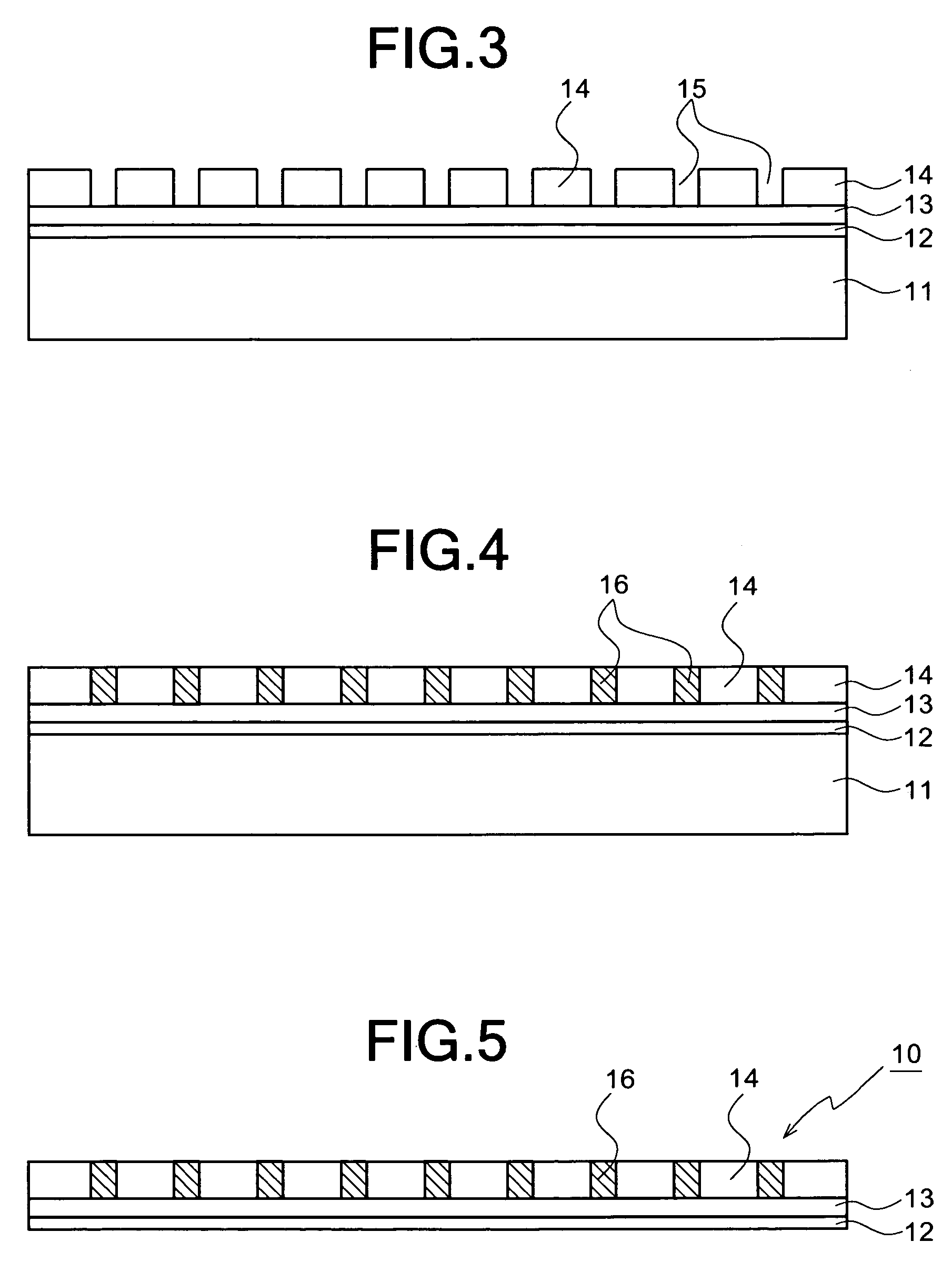

Wire grid polarizer and method for producing same

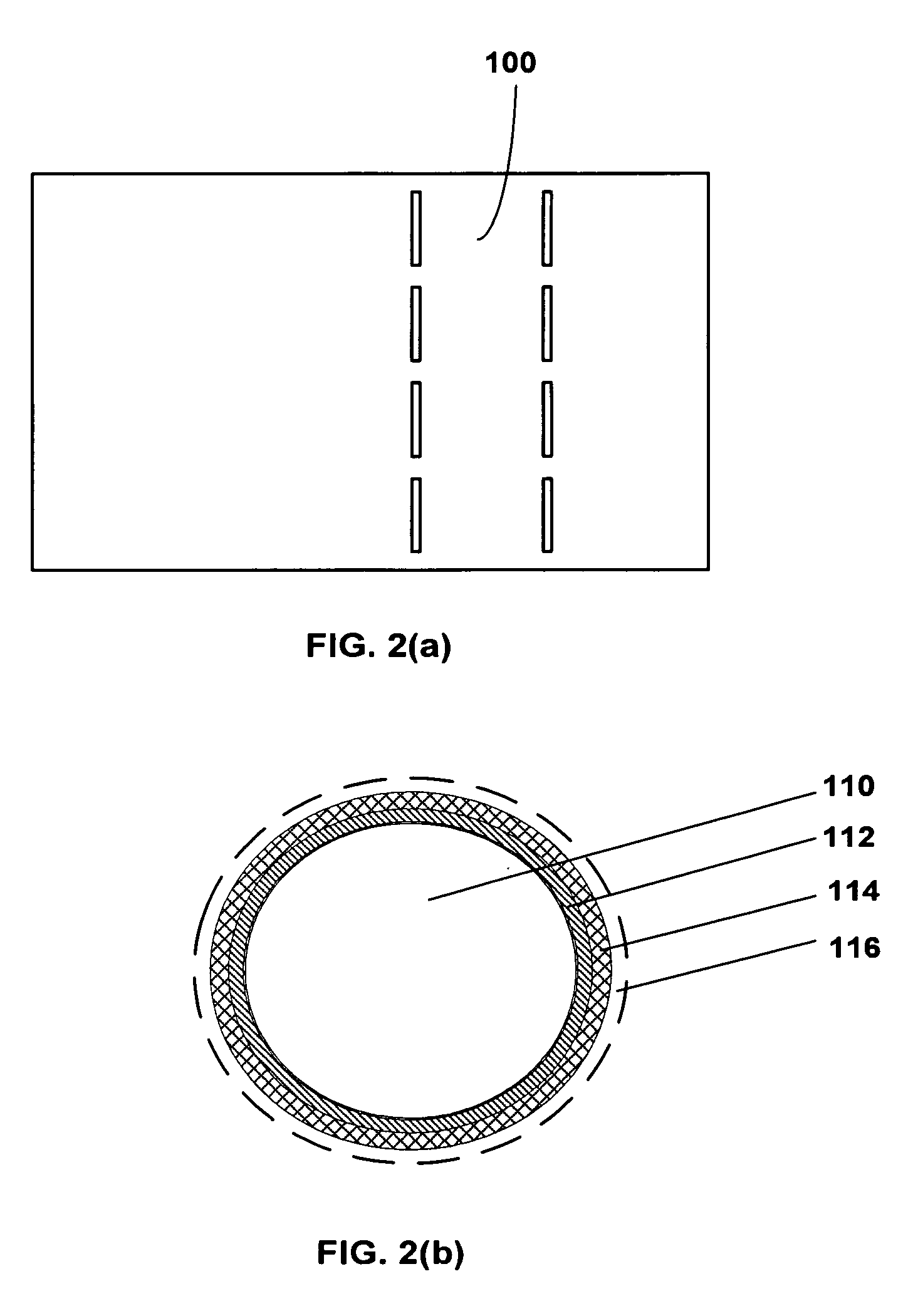

ActiveUS20050046943A1High light transmittanceLow costPolarising elementsOptical articlesWire gridLithographic artist

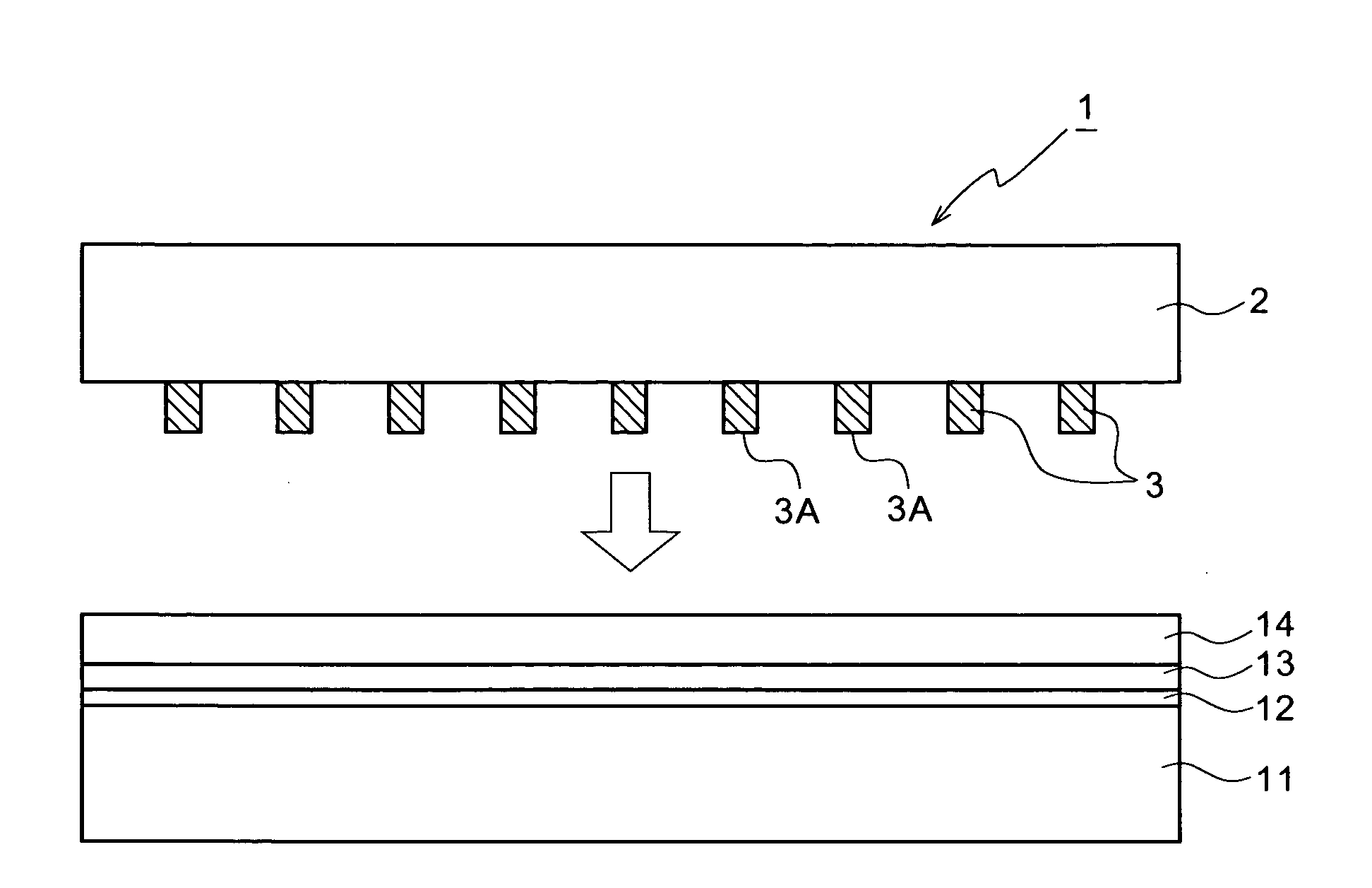

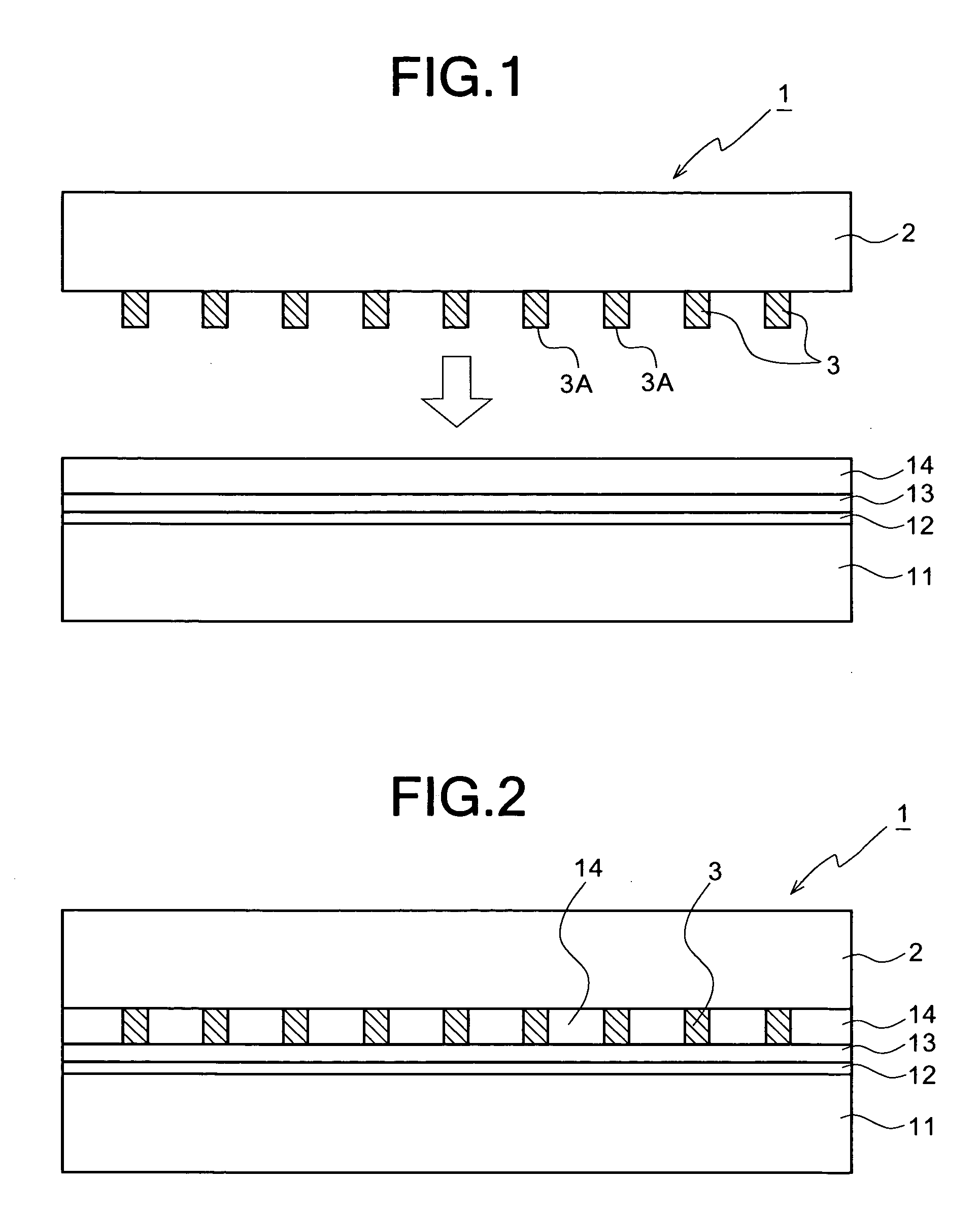

There are provided a thin wire grid polarizer having a high transmittance, a high quenching ratio and a high degree of polarization, and a method for producing the same at low costs. A fluoridated polyimide thin film 12, a hydrophilic thin film 13 and a hydrophobic thin film 14 are sequentially stacked on a glass substrate 11 to be pressed by a die 1 from the side of the hydrophobic thin film 14 to transfer the fine pattern of groove forming protrusions 3 of the die 1 to the hydrophobic thin film 14 and hydrophilic thin film 13 by the nano-imprinted lithography technique, and then, metal fine wires are caused to grow by plating.

Owner:ENPLAS CORP

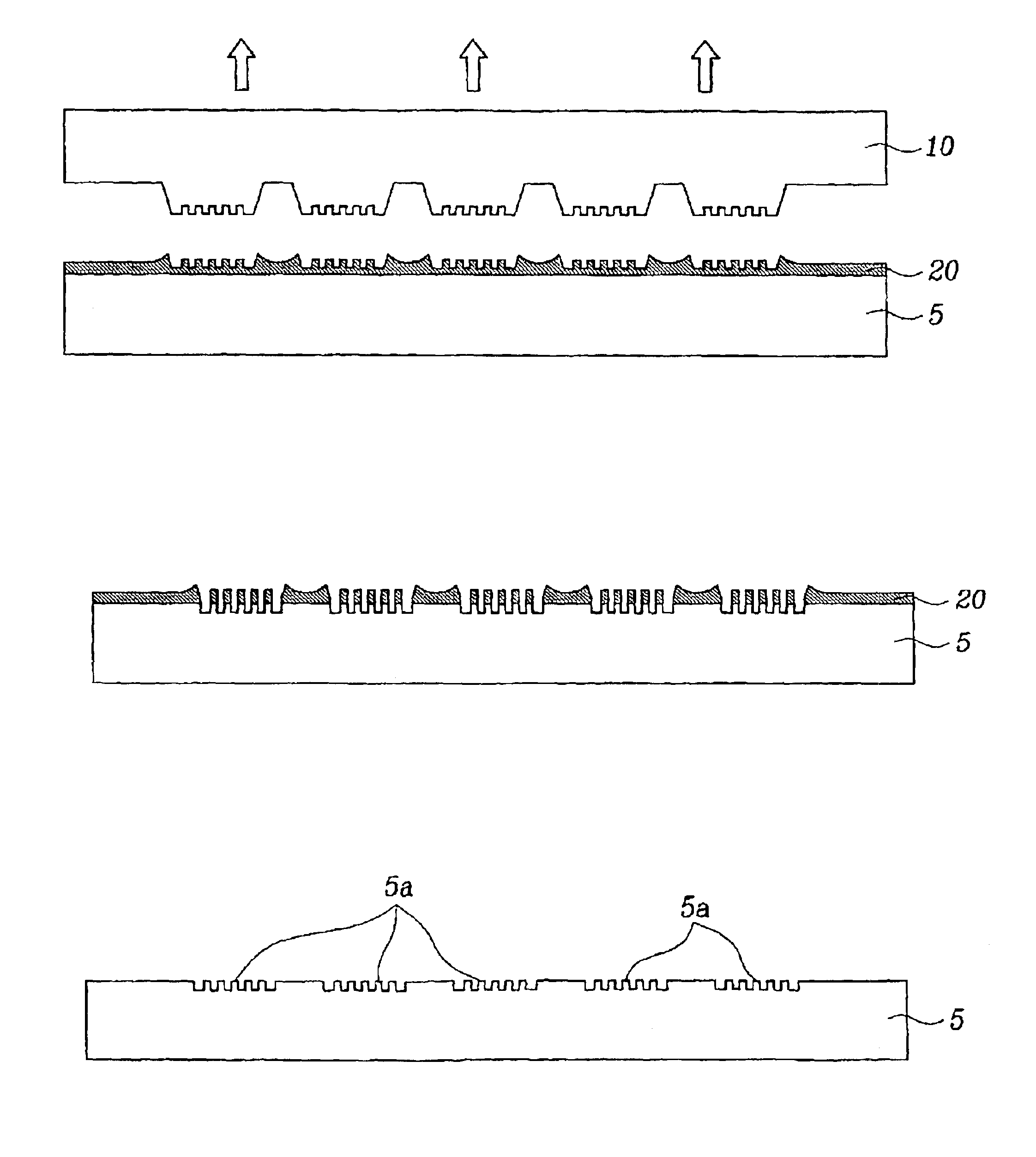

Roll to roll nanoimprint lithography

Apparatus and methods for a nano-patterning process to fabricate nanostructures. A roller type mold is used to continuously imprint nanostructures onto a flexible web or a rigid substrate. The process includes a coating and an imprinting module, which rotate the web synchronously. Liquid resist materials are used for imprinting and the patterns are set by thermal or UV curing. The process is used to produce bilayer metal wire-grid polarizers, organic solar cells, and organic light emitting diodes.

Owner:RGT UNIV OF MICHIGAN

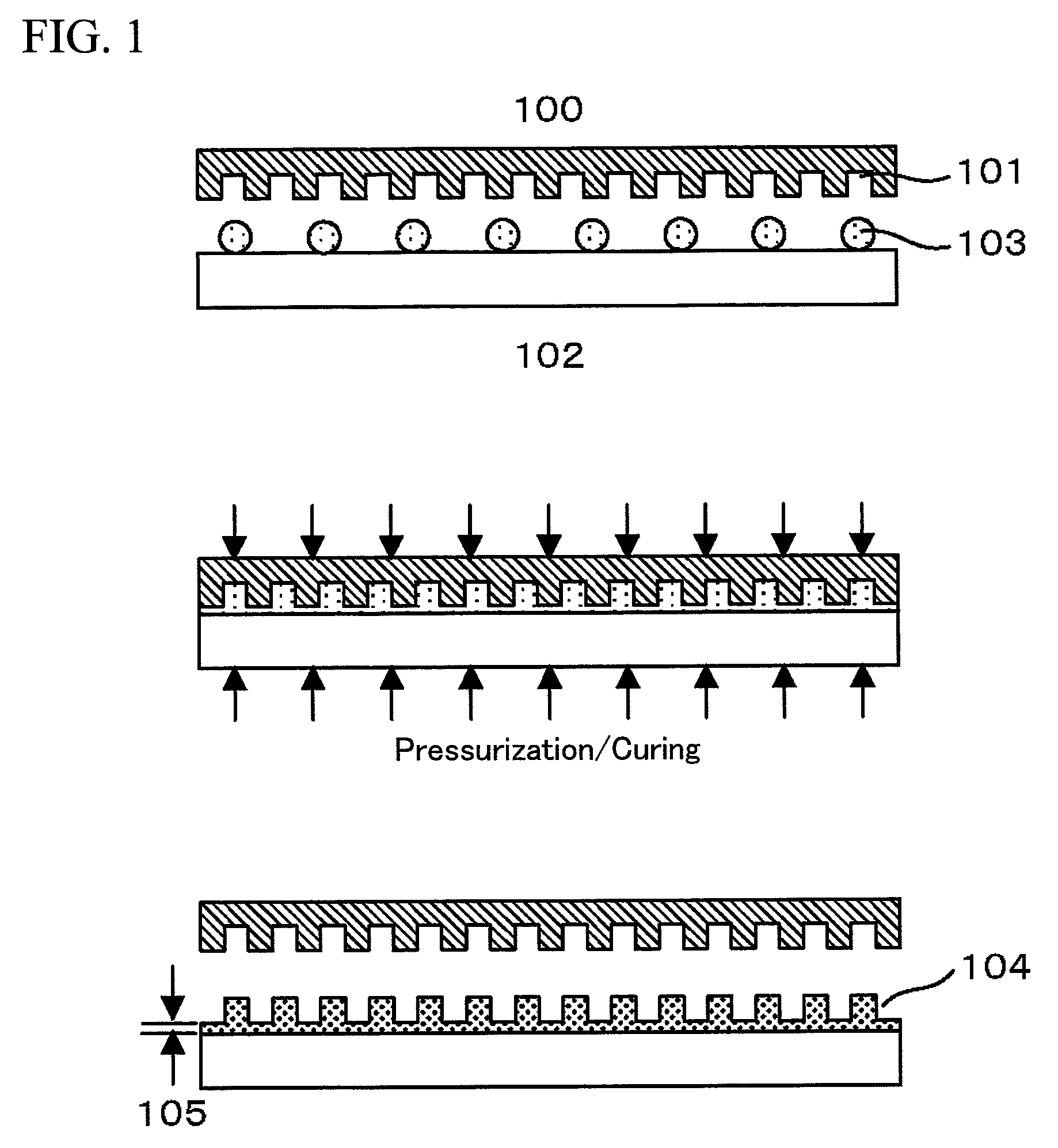

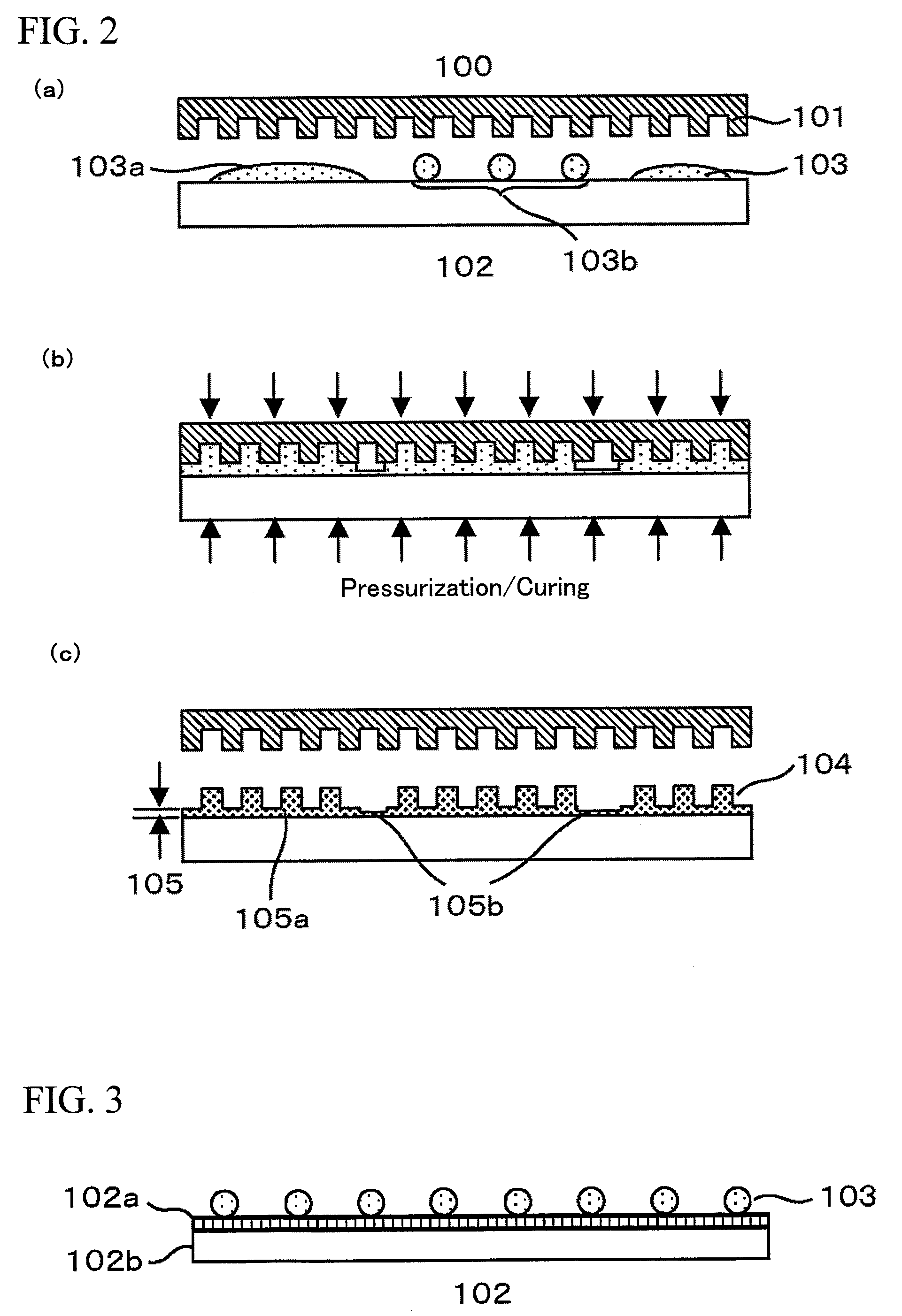

Photo nanoimprint lithography

InactiveUS20090085255A1Improve machining accuracyImprove positioning characteristicNanoinformaticsPhotomechanical apparatusResistNanoimprint lithography

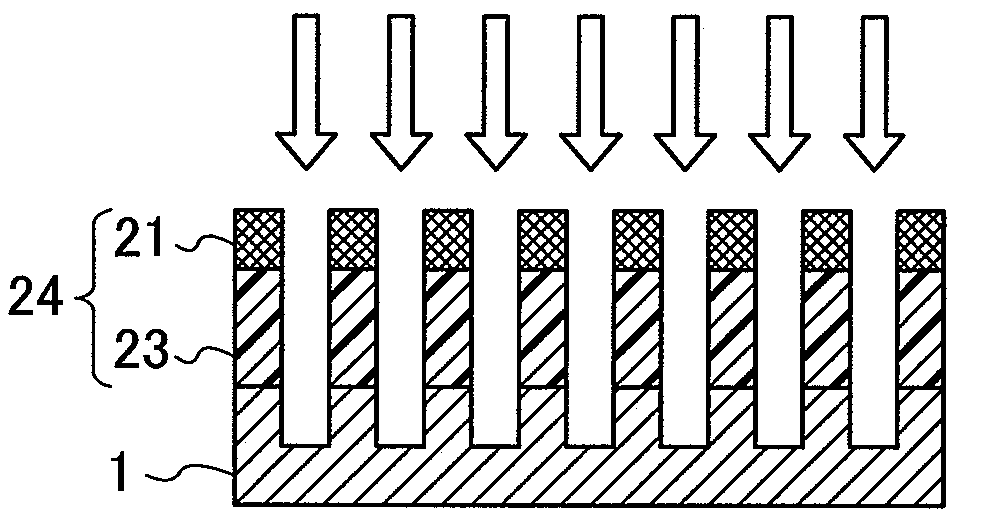

The present invention is directed to providing a photo nanoimprint lithography which can form a more uniform base layer. A photo nanoimprint lithography according to the present invention includes the steps of discretely applying a photo-curable resist drop-wise onto a substrate, filling an asperity pattern of a mold with the photo-curable resist by bringing the mold having the asperity pattern formed therein into contact with the photo-curable resist, curing the photo-curable resist by irradiating the resist with a light and releasing from the mold the photo-curable resist which has been photo-cured, wherein an intermediary layer is formed on a surface of the substrate for maintaining a discrete placement of the photo-curable resist that has been instilled drop-wise on the substrate until the mold is brought into contact with the photo-curable resist that has been instilled drop-wise on the substrate.

Owner:HITACHI LTD

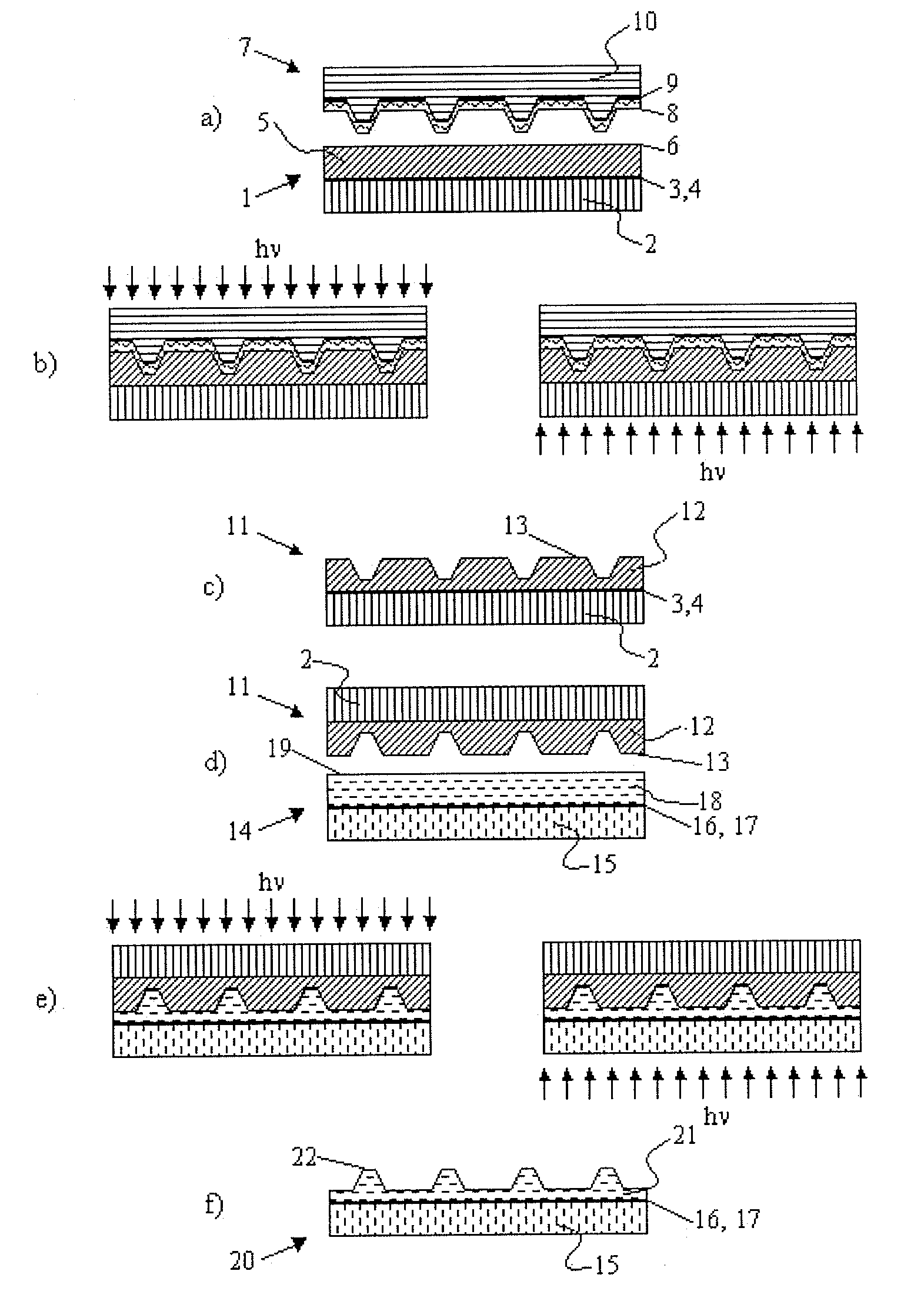

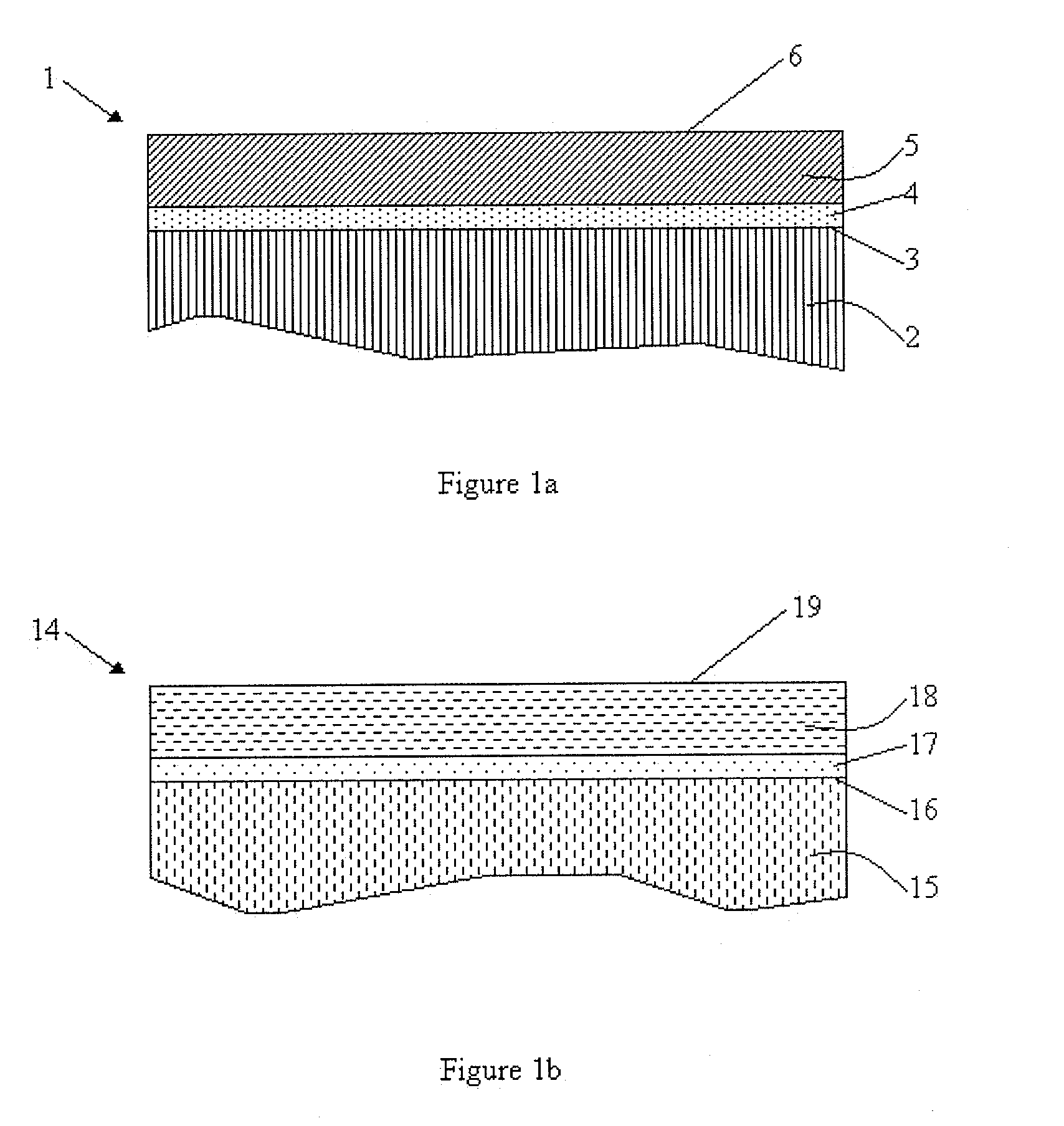

Substrate for and a process in connection with the product of structures

InactiveUS20040005444A1Easy to disassembleFacilitate NILSemi-permeable membranesFixed microstructural devicesResistMetallurgy

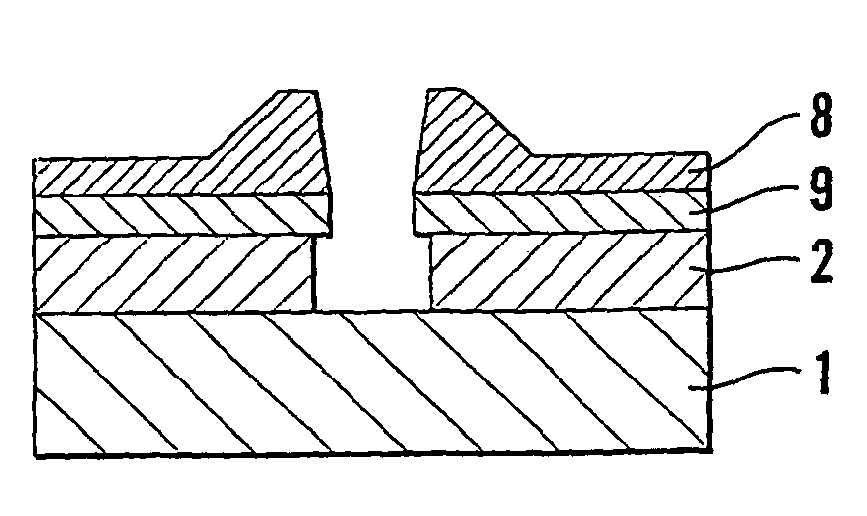

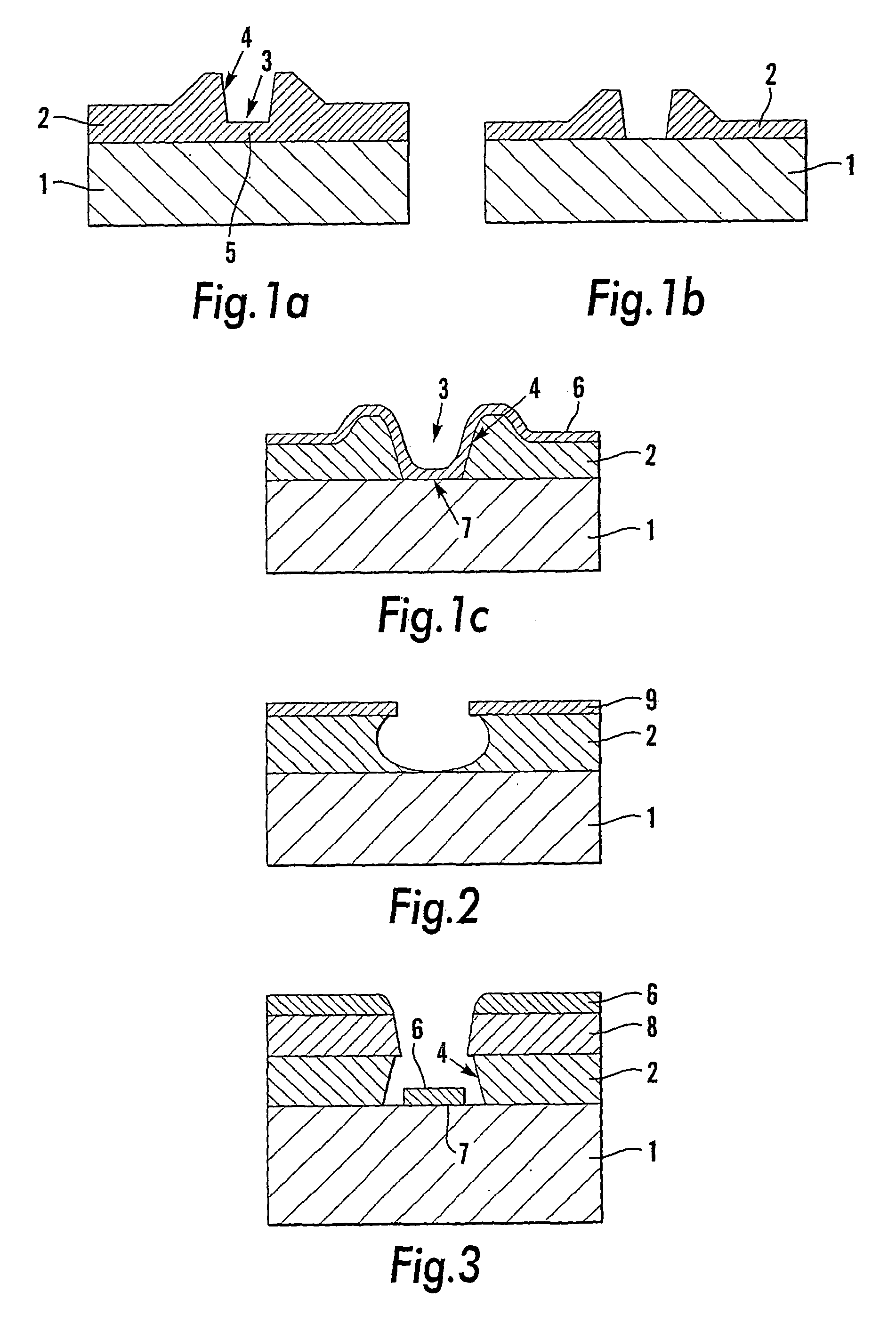

The invention relates to a substrate (1) comprising at least a first (2) and a second (8) coating layer on one surface of the substrate, for nanoimprint lithography, said first coating layer (2) consisting of a positive resist and said second (8) coating layer consisting of a negative resist. The invention also relates to a process in connection with nanoimprint lithography on the substrate (1), a pattern (3) of nanometre size being impressed in a first stage into the second coating layer (8) by means of a template (610), following which the first coating layer (2), in a second stage, is exposed to a chiefly isotropic developing method on surfaces thereof that have been exposed in connection with said first stage, a method for developing and material for said first and second coating layers being selected so that the first coating layer (2) is developed more quickly than the second coating layer (8), so that an undercut profile is obtained in the coating layers.

Owner:OBDUCAT AB SE

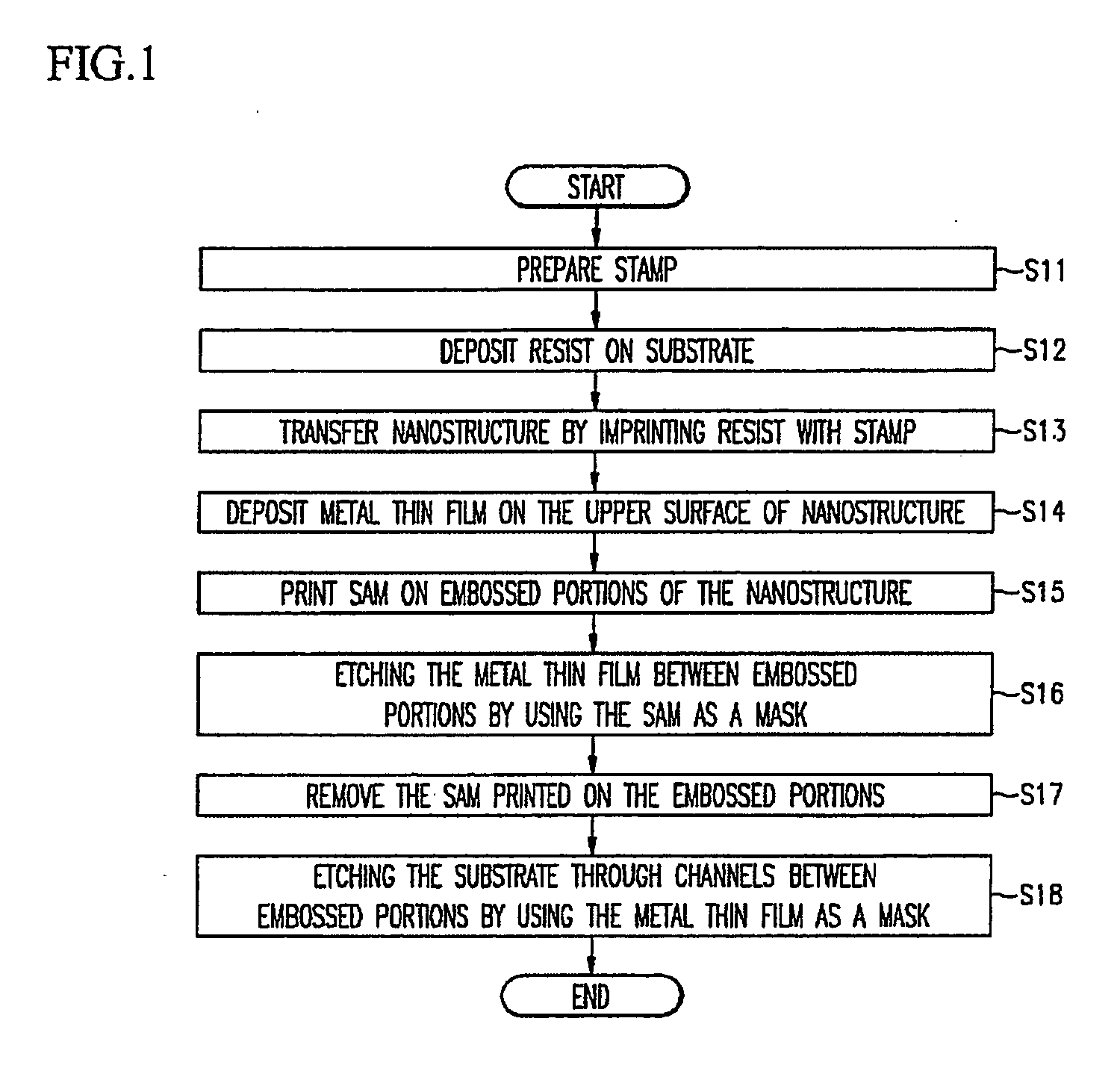

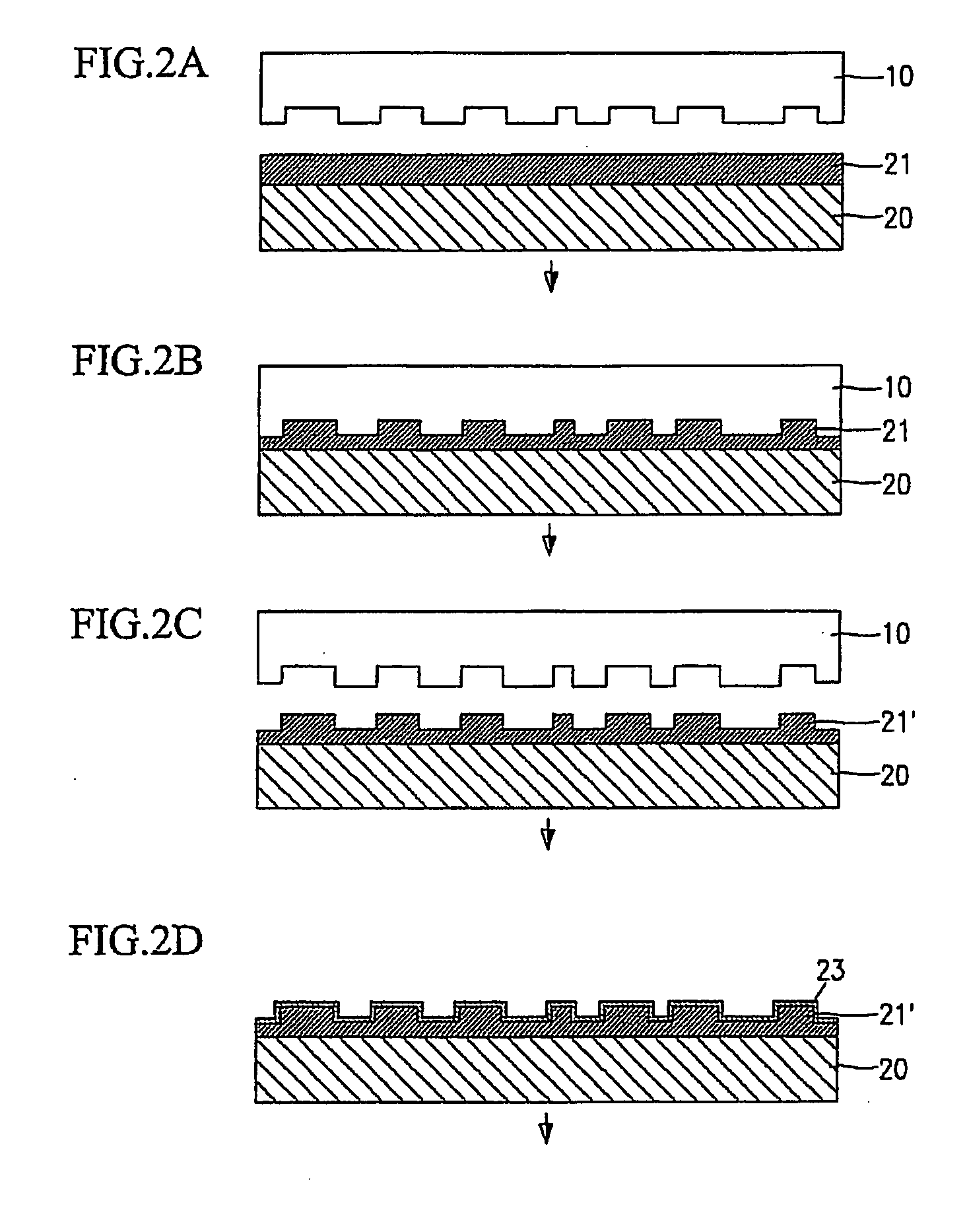

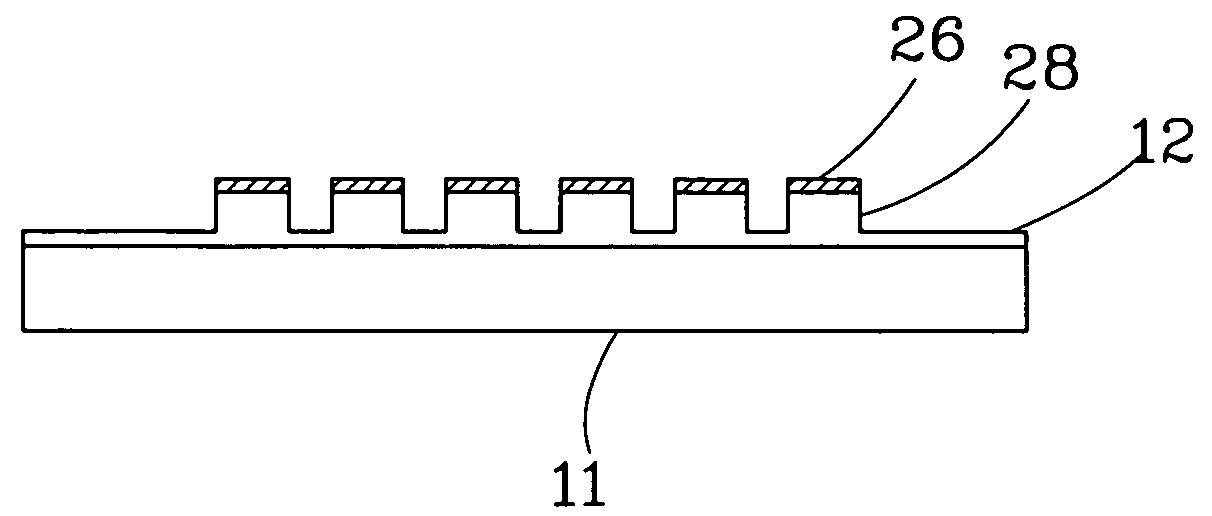

Microcontact printing method using imprinted nanostructure and nanostructure thereof

InactiveUS20050186405A1Material nanotechnologyDecorative surface effectsMicrocontact printingSelf-assembled monolayer

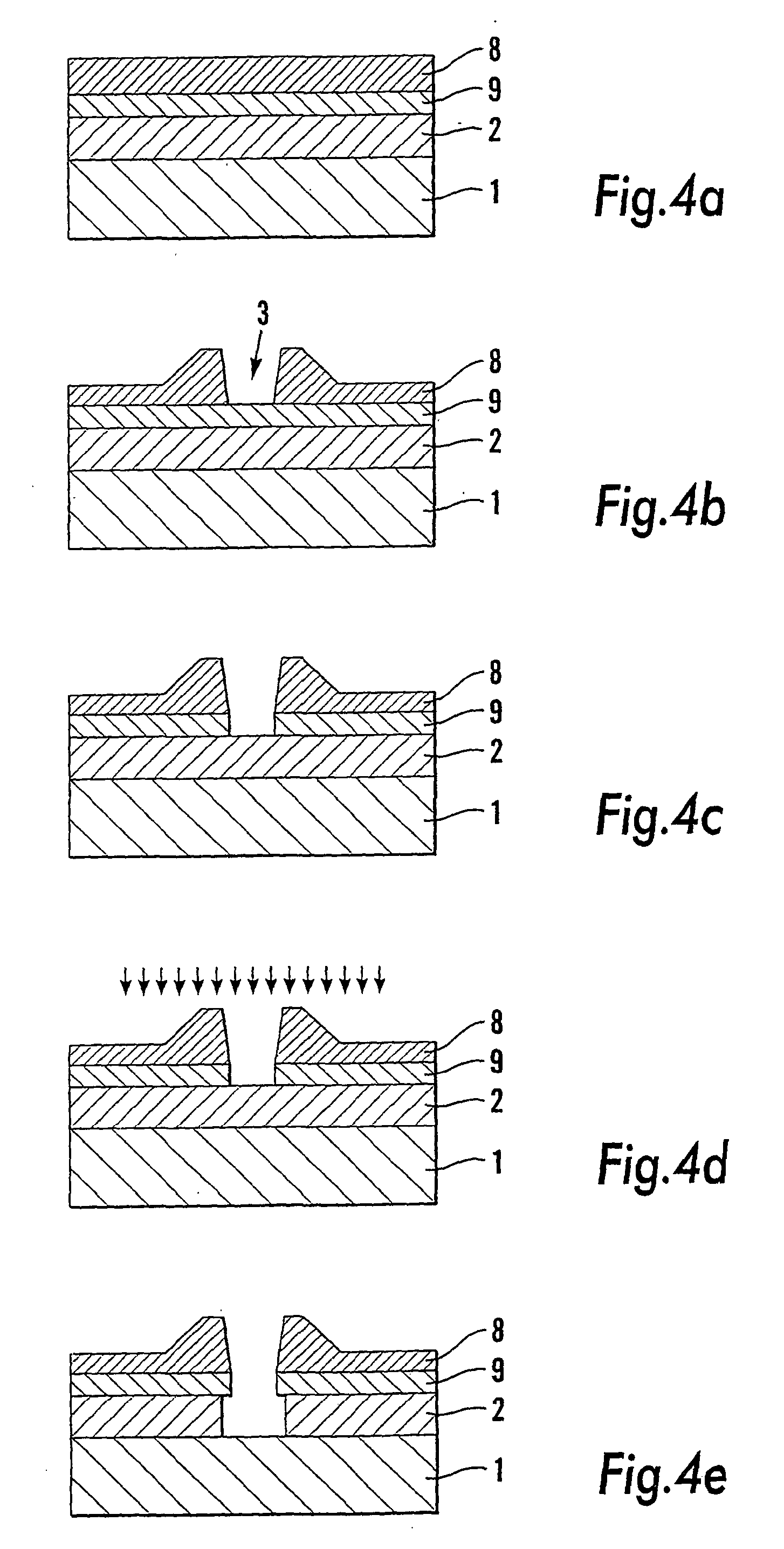

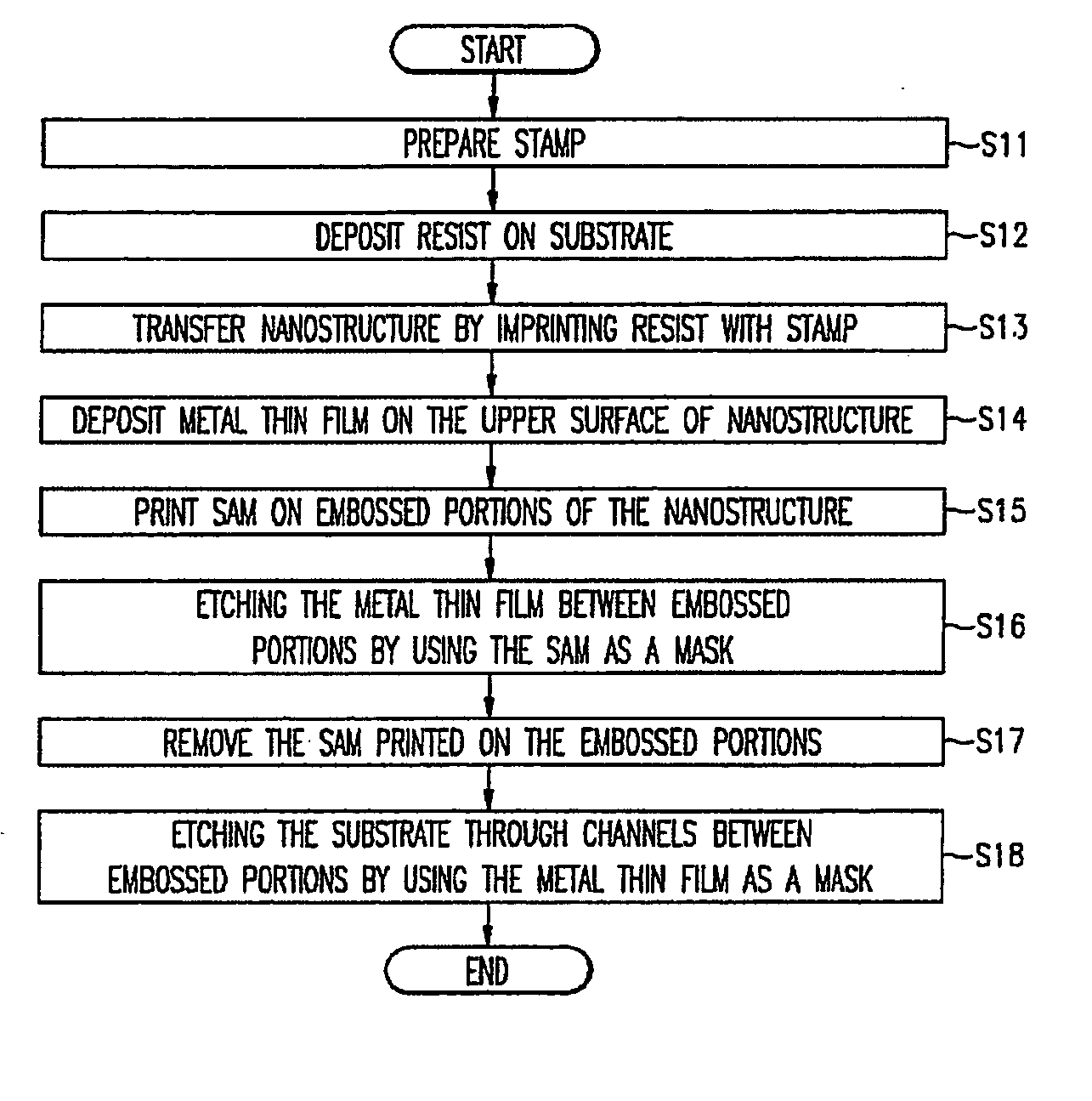

A microcontact printing method using an imprinted nanostructure is provided, wherein the microcontact printing is introduced to a nanoimprint lithography process to pattern a self-assembled monolayer (SAM) The method includes forming a nanostructure on a substrate by using the nanoimprint lithography process; and patterning the nanostructure with the microcontact printing method. The operation of patterning includes: depositing a metal thin film on the nanostructure; contacting a plate with the nanostructure to selectively print the SAM on the nanostructure, wherein the SAM is inked on the plate and the metal thin film is deposited on the nanostructure; selectively removing the metal thin film by using the SAM as a mask; removing the SAM from the nanostructure; and patterning the substrate by using the remaining metal thin film on the nanostructure as a mask.

Owner:KOREA INST OF MACHINERY & MATERIALS

Nanoimprint lithograph for fabricating nanoadhesive

InactiveUS20070018345A1Low costDecorative surface effectsDuplicating/marking methodsResistEngineering

A nanoimprint lithography method of fabricating a nanoadhesive includes steps of (a) preparing a substrate and a transfer stamp, said transfer stamp having a transfer face and nanometer-scale features formed on said transfer face, said nanometer-scale features having a plurality of convexities and concavities, said substrate having an etched layer; (b) proceeding a staining process to enable either of said convexities and concavities to be stained with a photoresist; (c) proceeding a transfer process to enable said nanometer-scale features to touch said etched layer to transfer said photoresist onto said etched layer; and (d) proceeding an etching process to enable parts of said etched layer that are not stained with the photoresist to be each etched for a predetermined depth. As the steps indicated above, the nanoadhesive can be produced with mass production and low cost.

Owner:CONTREL TECH CO LTD

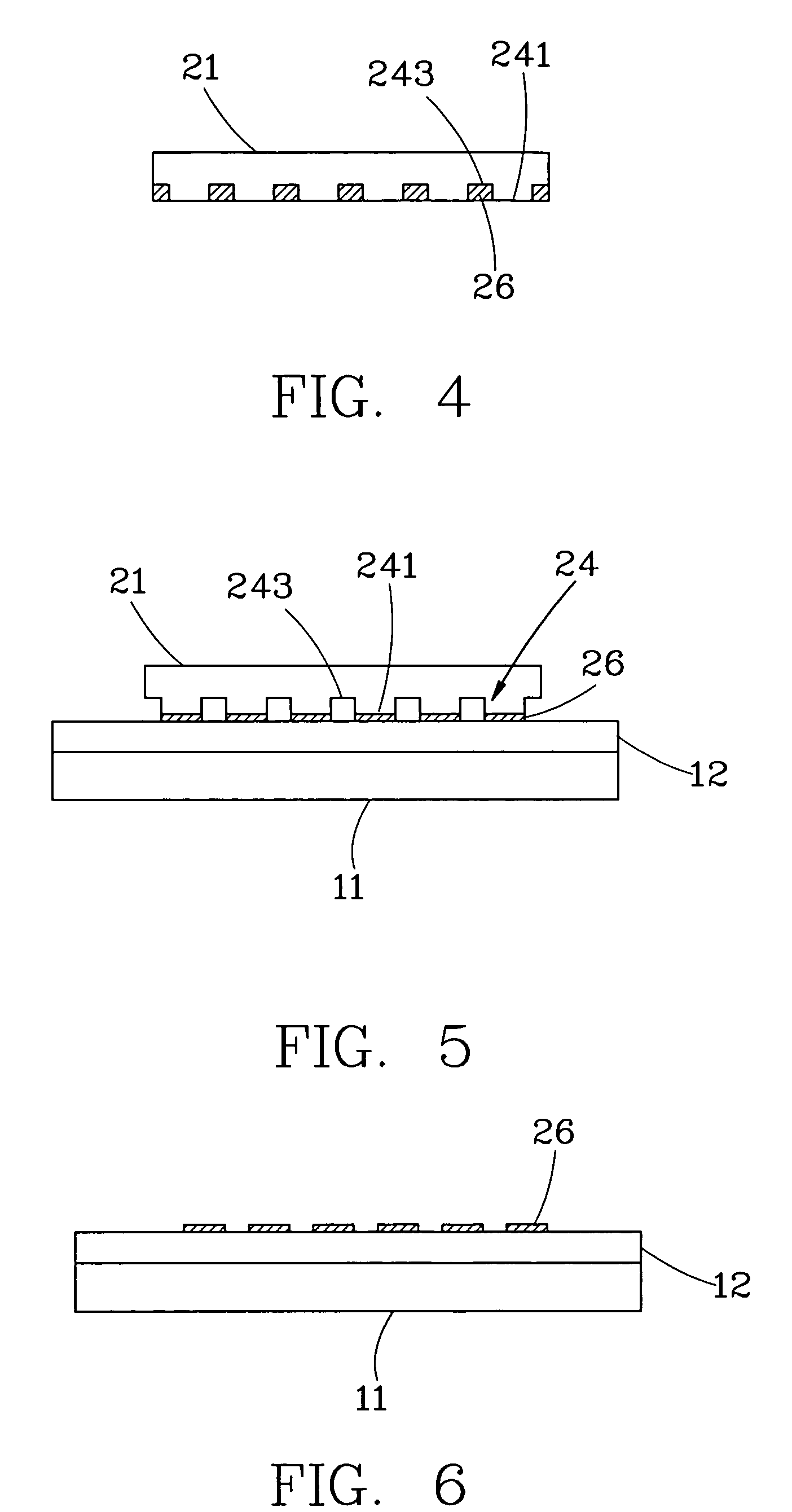

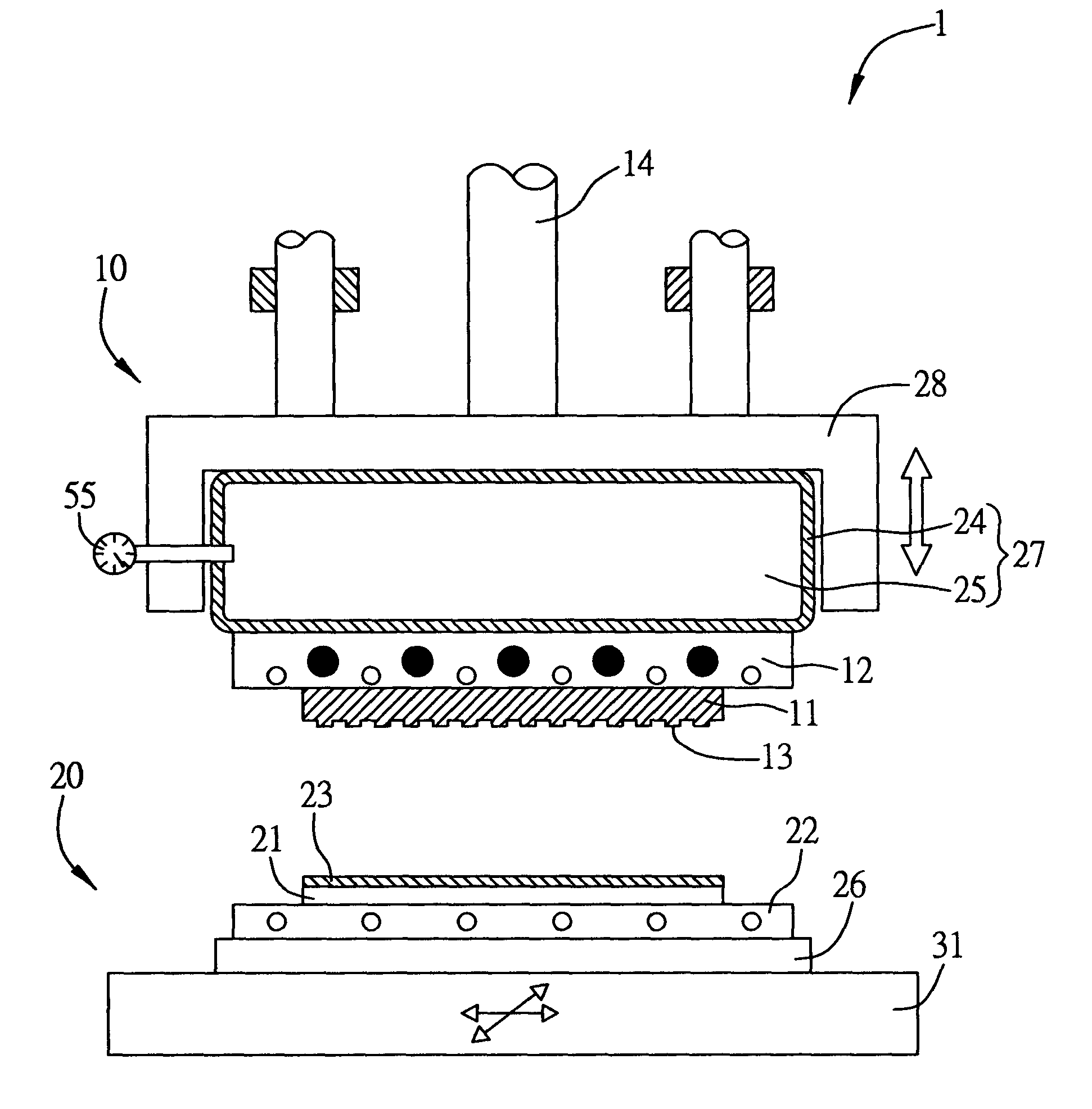

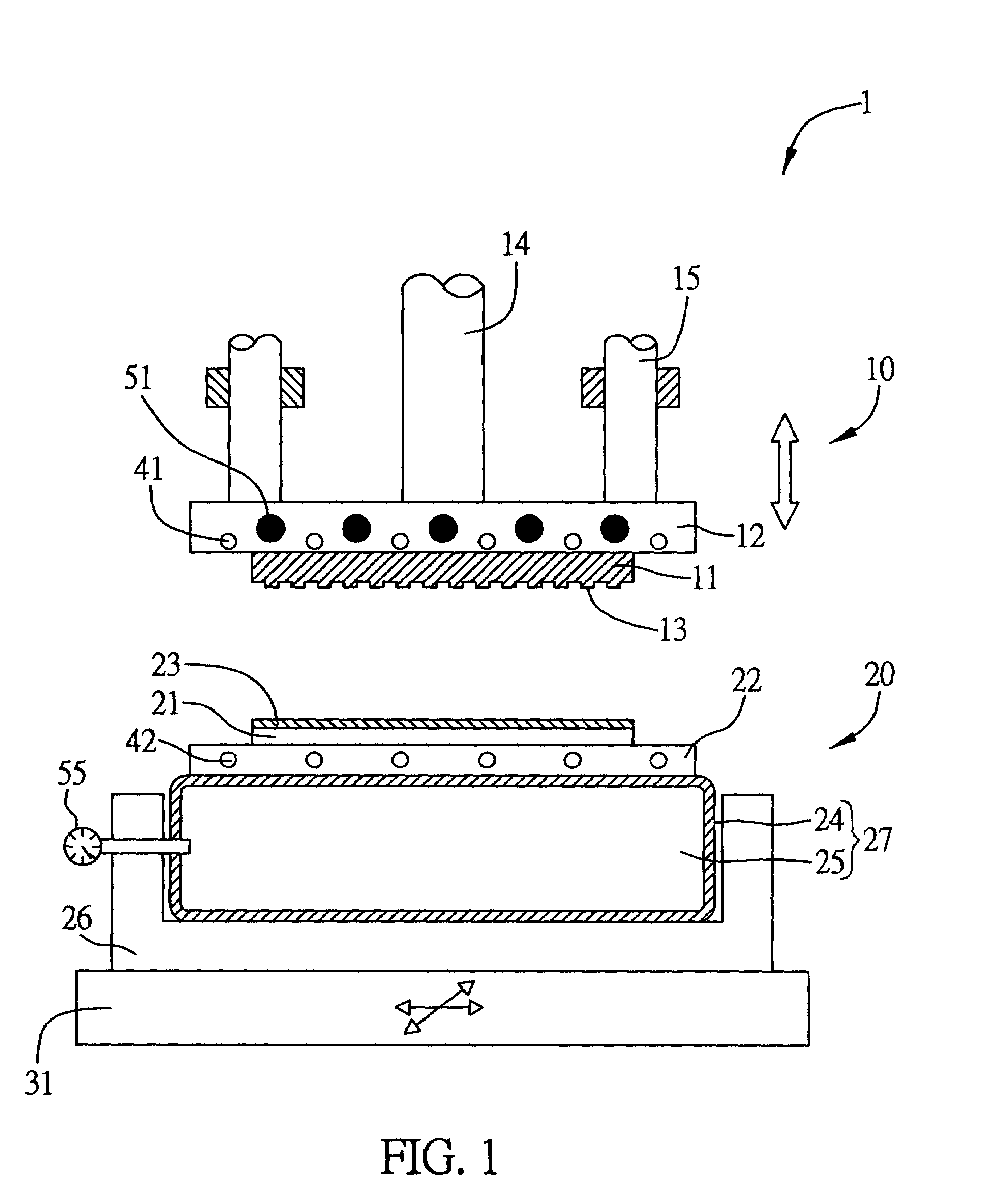

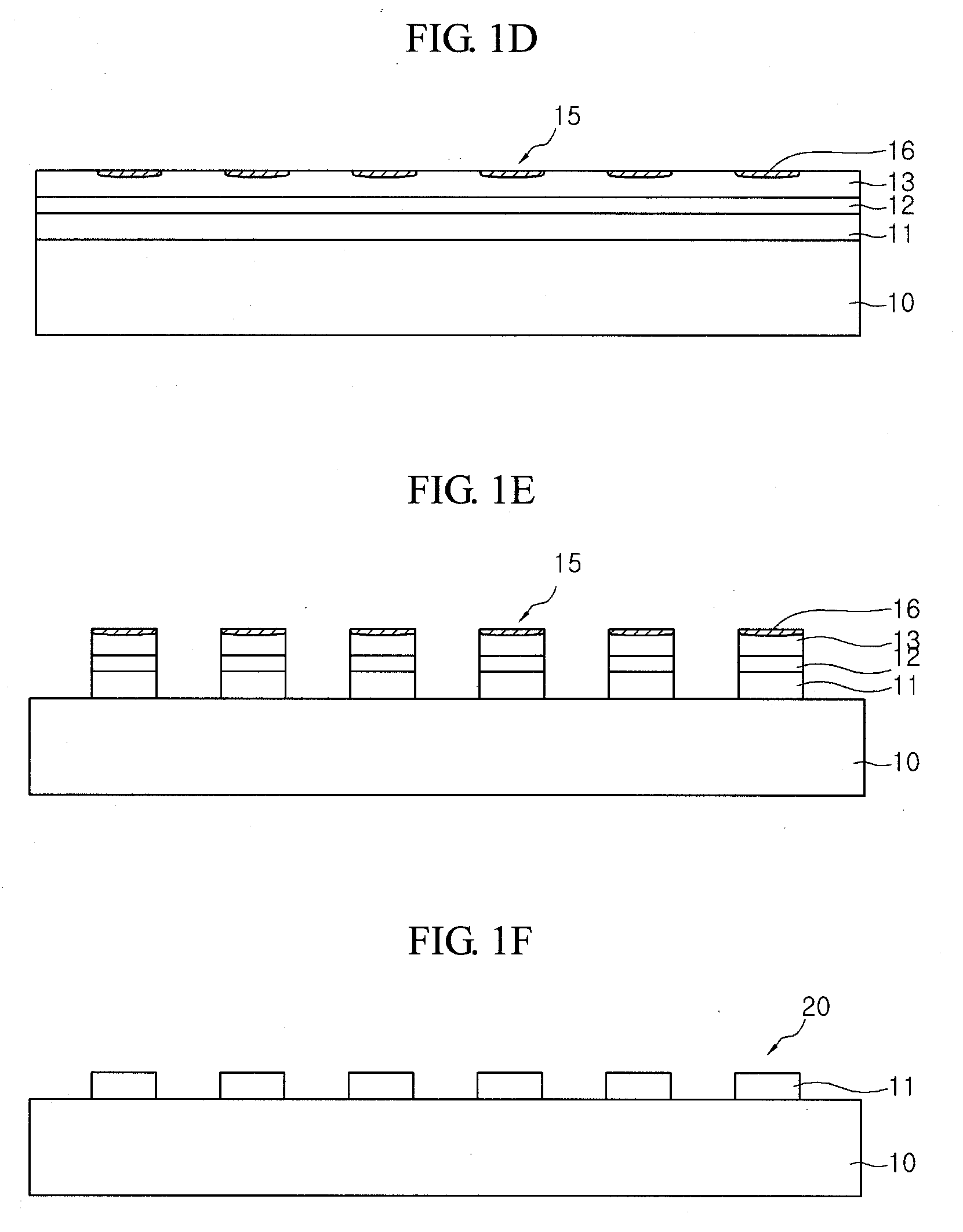

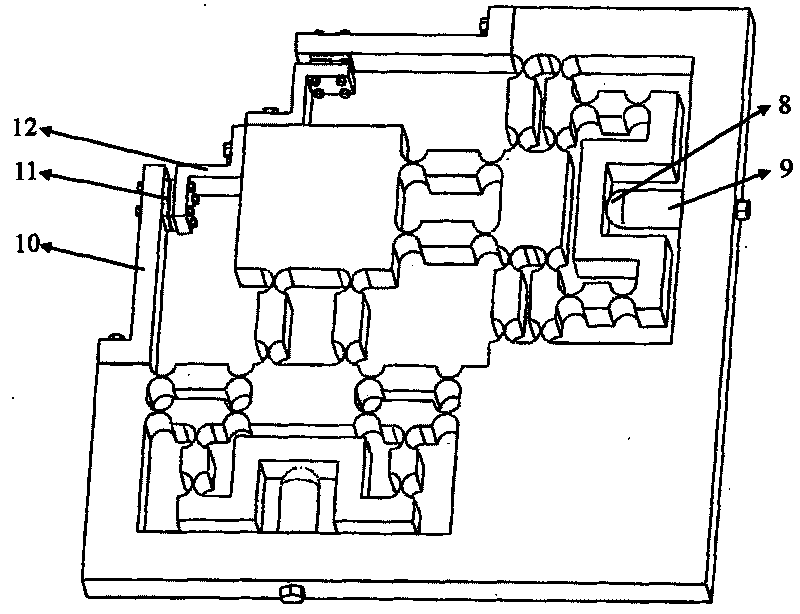

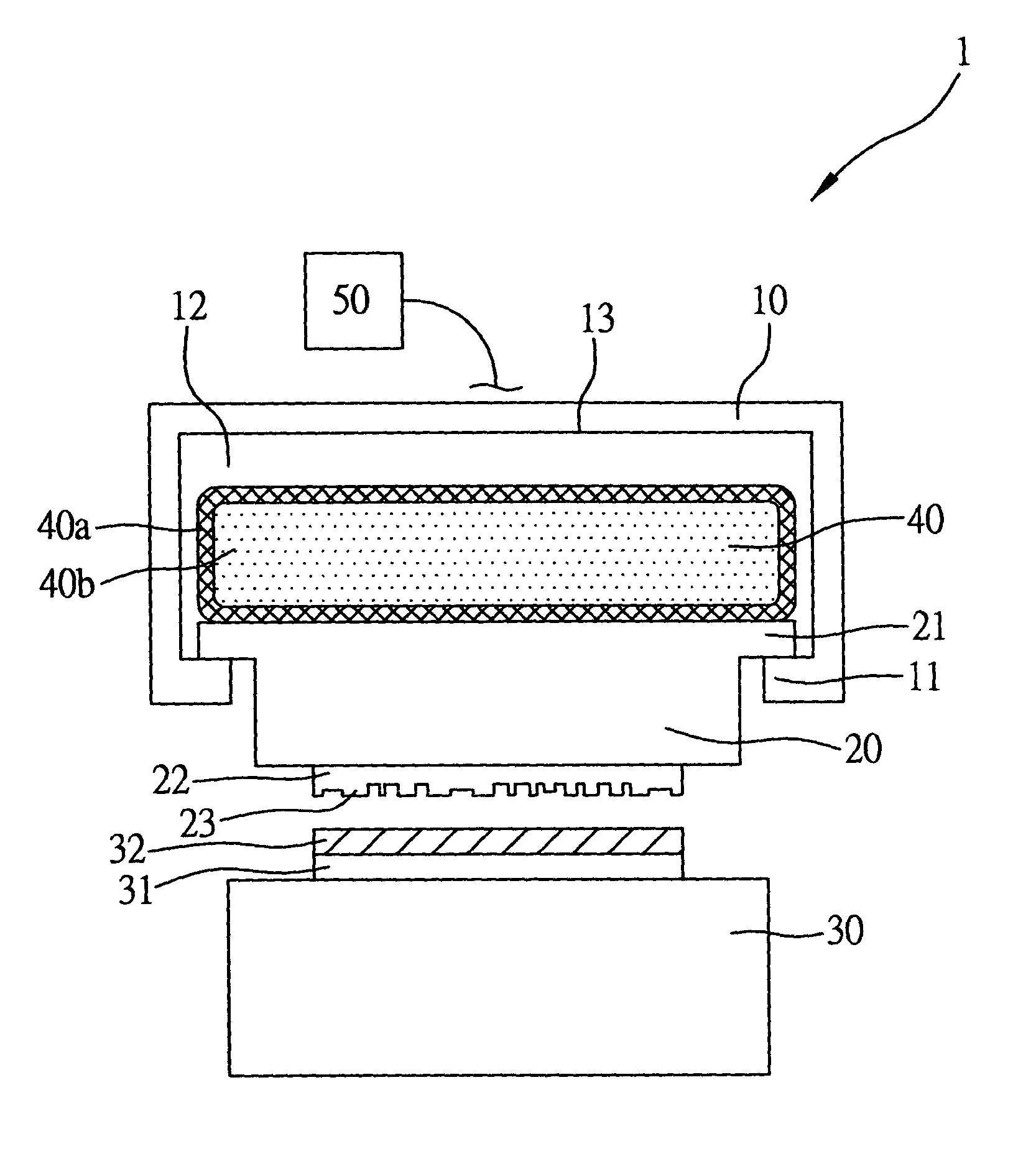

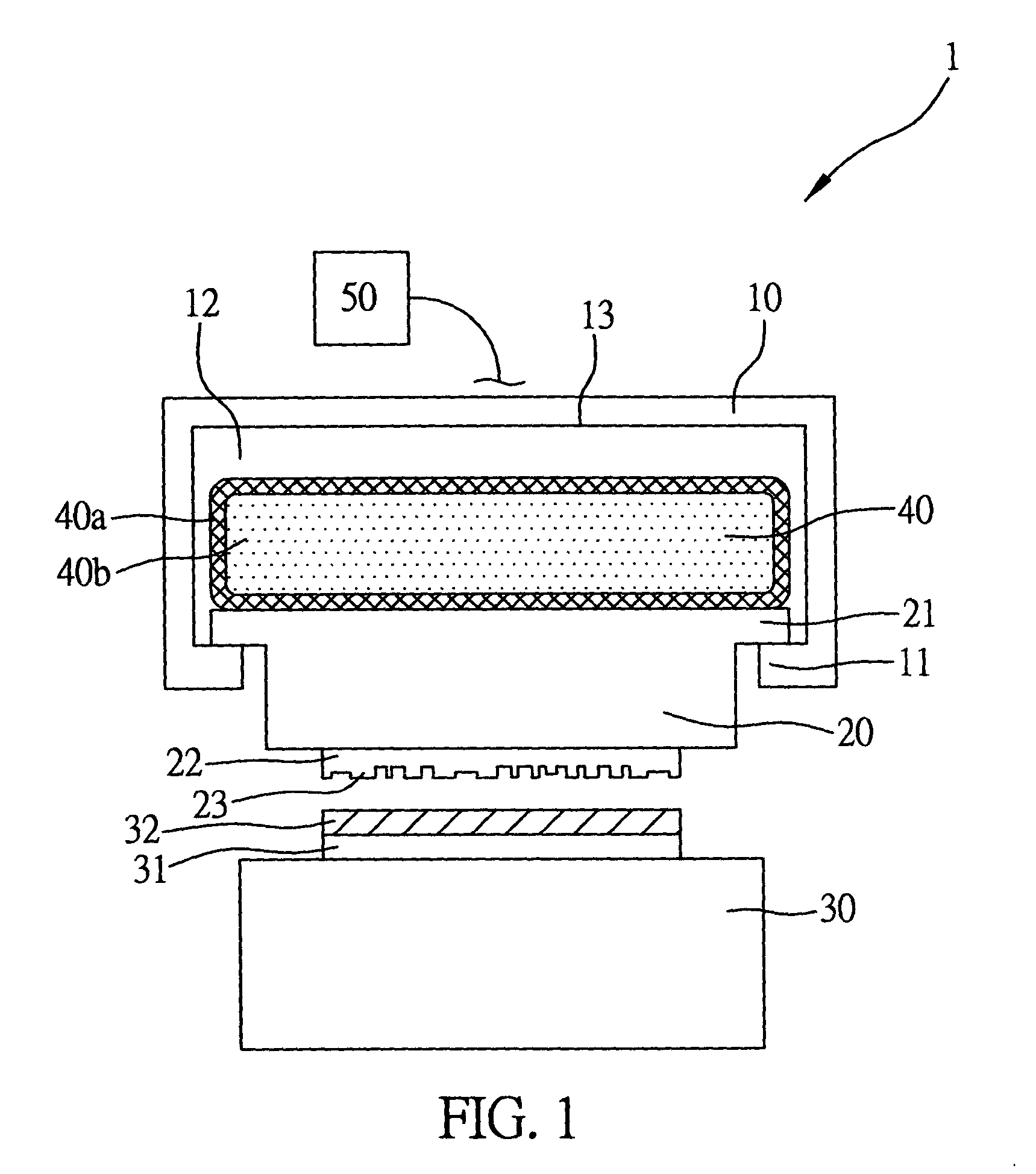

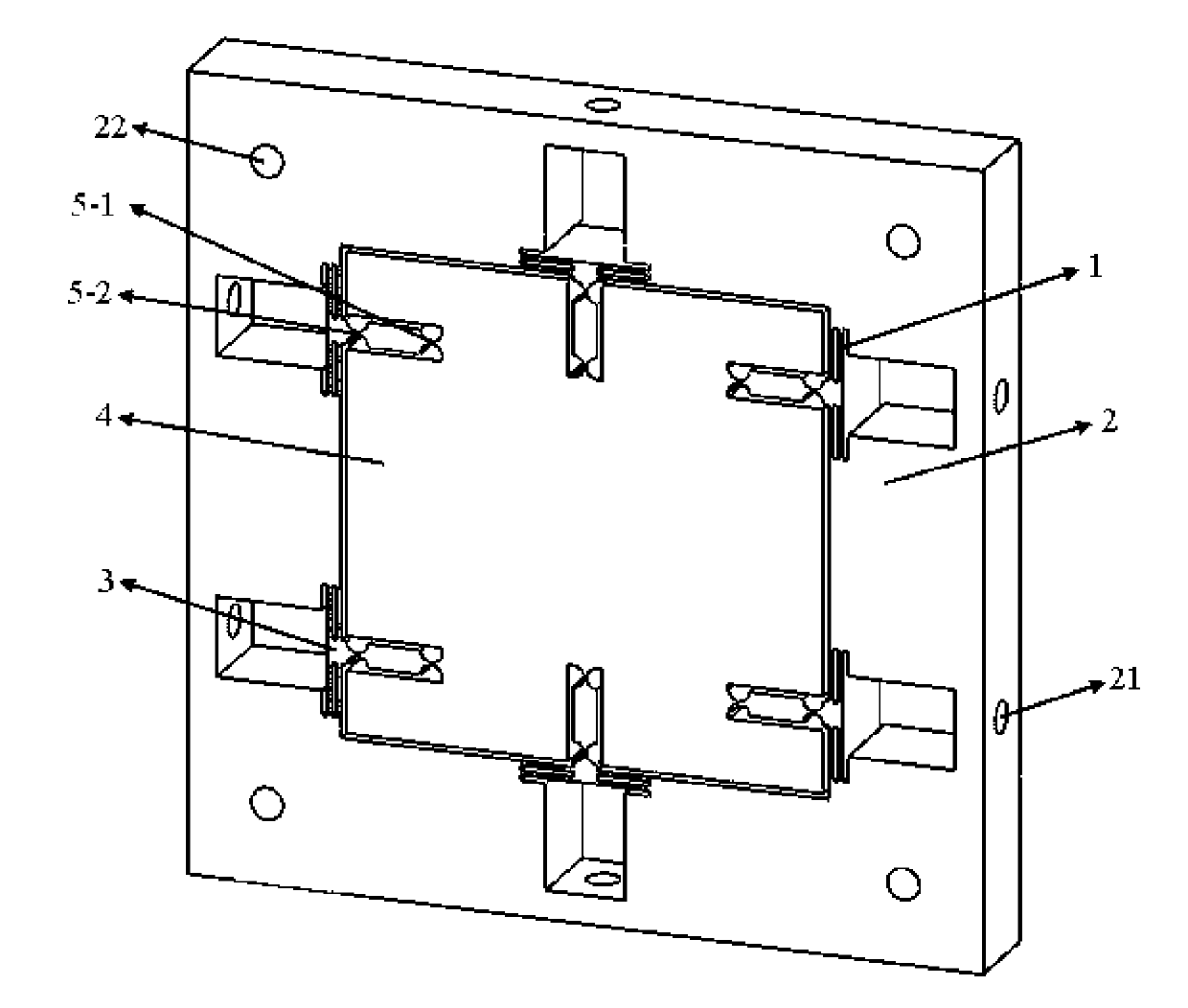

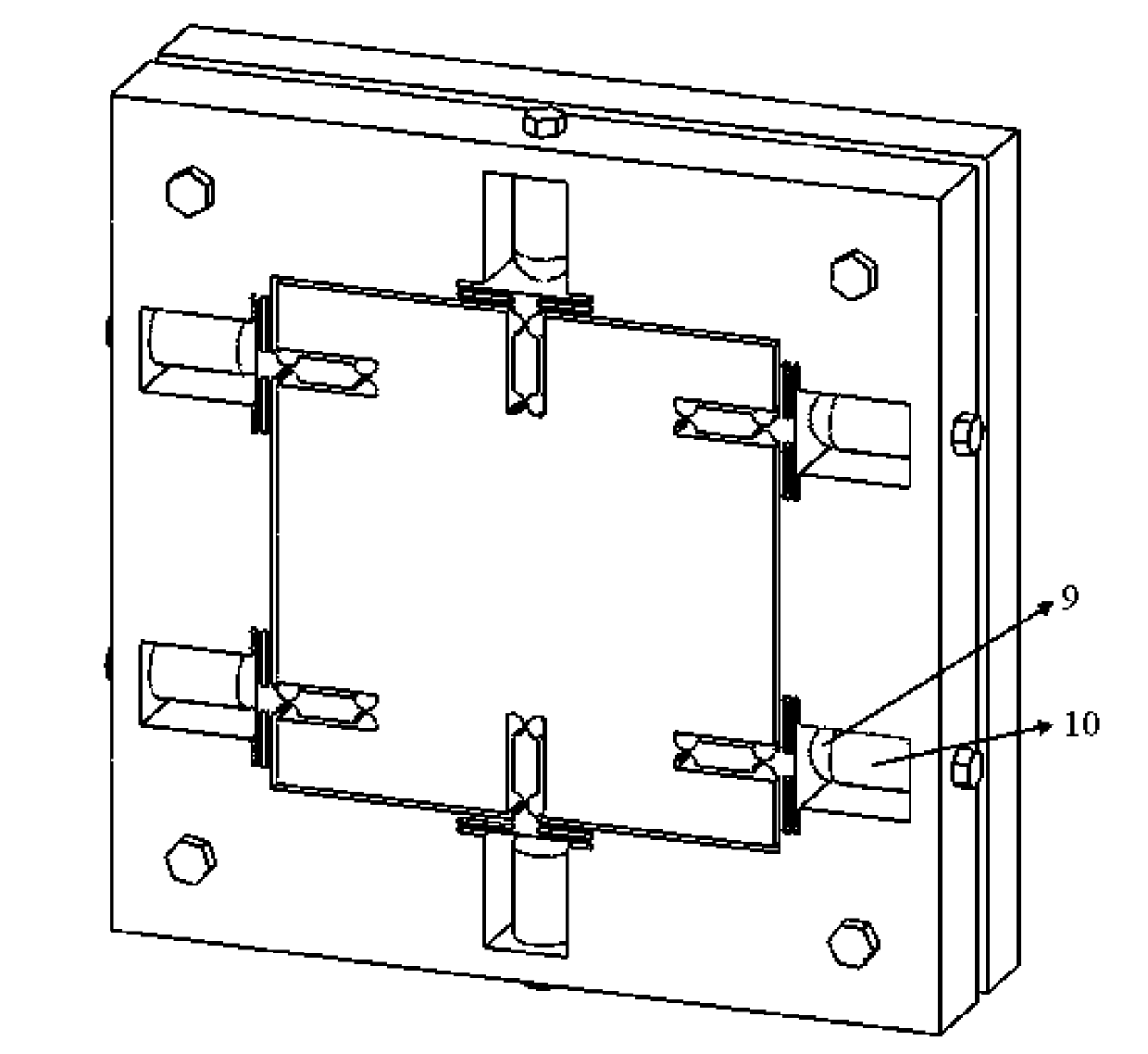

Parallelism adjustment device

InactiveUS7204686B2Enhance horizontal alignmentHigh level of freedomNanoinformaticsConfectioneryNanoimprint lithographyElectrical and Electronics engineering

A parallelism adjustment device applicable to nano-imprint lithography has an imprint unit, a carrier unit, a parallelism adjustment mechanism, and a driving source. The imprint unit has a first molding plate and an imprinting mold mounted on the first molding plate. The carrier unit has a second molding plate and a substrate mounted on the second molding plate. The parallelism adjustment mechanism has an enclosed resilient film and a fluid filled therein, and is coupled to at least one of the first and second molding plates. The driving source drives at least one of the imprint unit and the carrier unit to form contact between the mold and the moldable layer. The parallelism adjustment device is pressed via the contact to adjust parallelism for the imprint mold and the substrate and uniformly distributes the pressure between the mold and the substrate, making the molding quality of nano-imprint lithography significantly improved.

Owner:IND TECH RES INST

Process and method for modifying polymer film surface interaction

ActiveUS20100155988A1High replication fidelityEasy and suitable to employ industriallyNanoinformaticsSynthetic resin layered productsPolymer scienceLithography process

The invention provides a modification of a polymer film surface interaction properties. In this process a polymer carrier object is covered by a chemical composition, comprising photo-polymerizable compounds, photo-initiators or catalysts with the ability to initiate polymerization and semi-fluorinated molecules. The so-produced polymer mold contains semi-fluorinated moieties, which are predominantly located on the surface and on the surface near region of the patterned surface. The polymer mold is suitable as a template with modified properties in a nano-imprint lithography process.

Owner:OBDUCAT AB SE

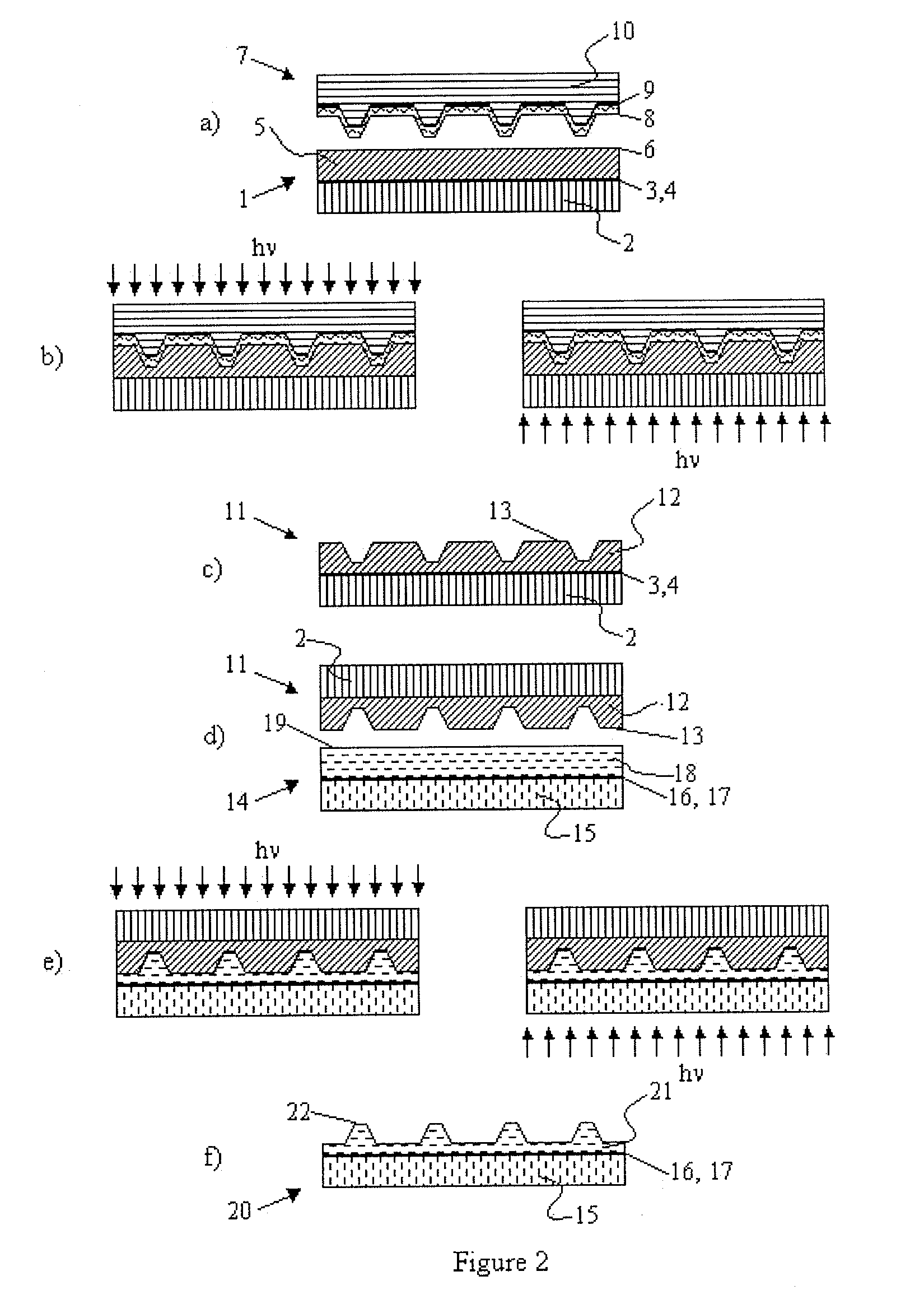

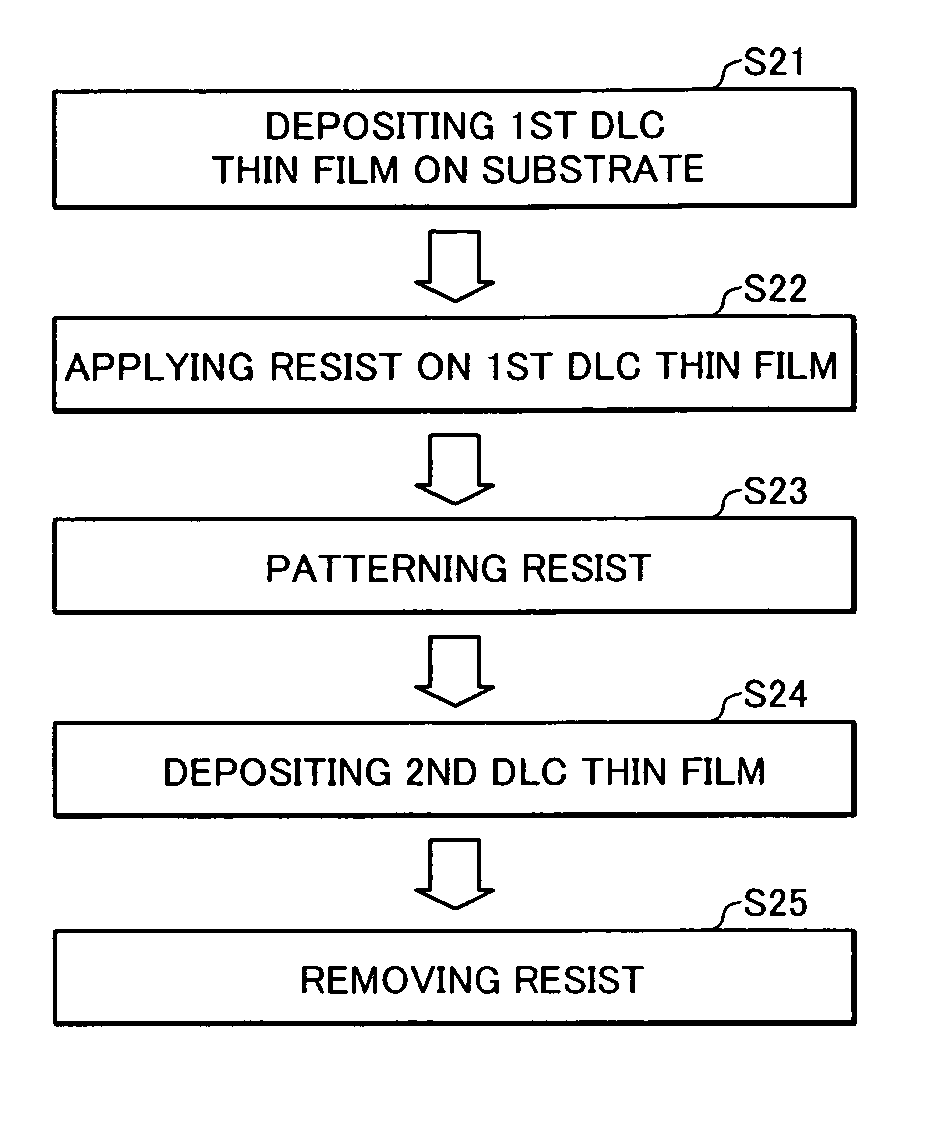

Stamp for micro/nano imprint lithography using diamond-like carbon and method of fabricating the same

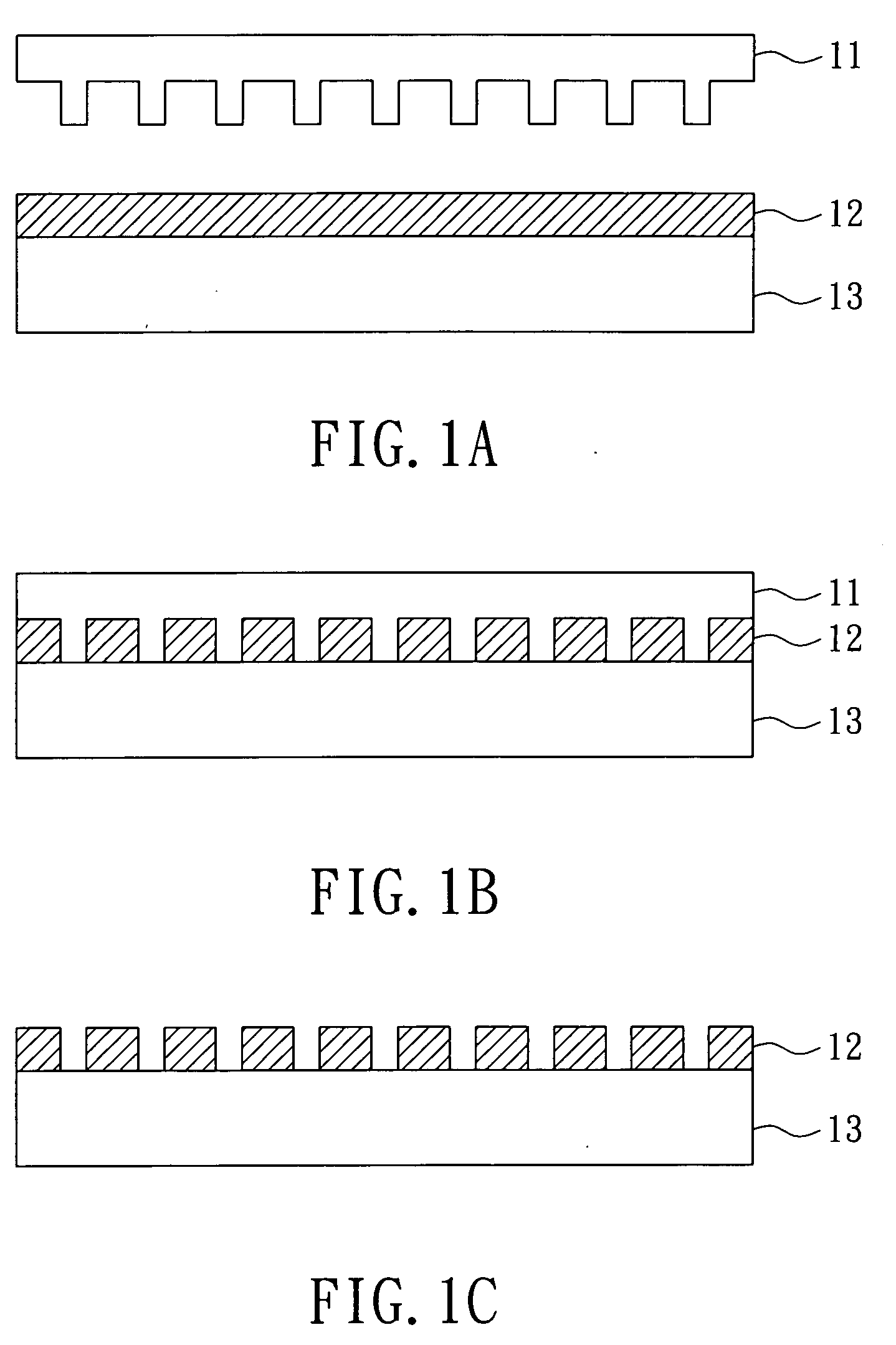

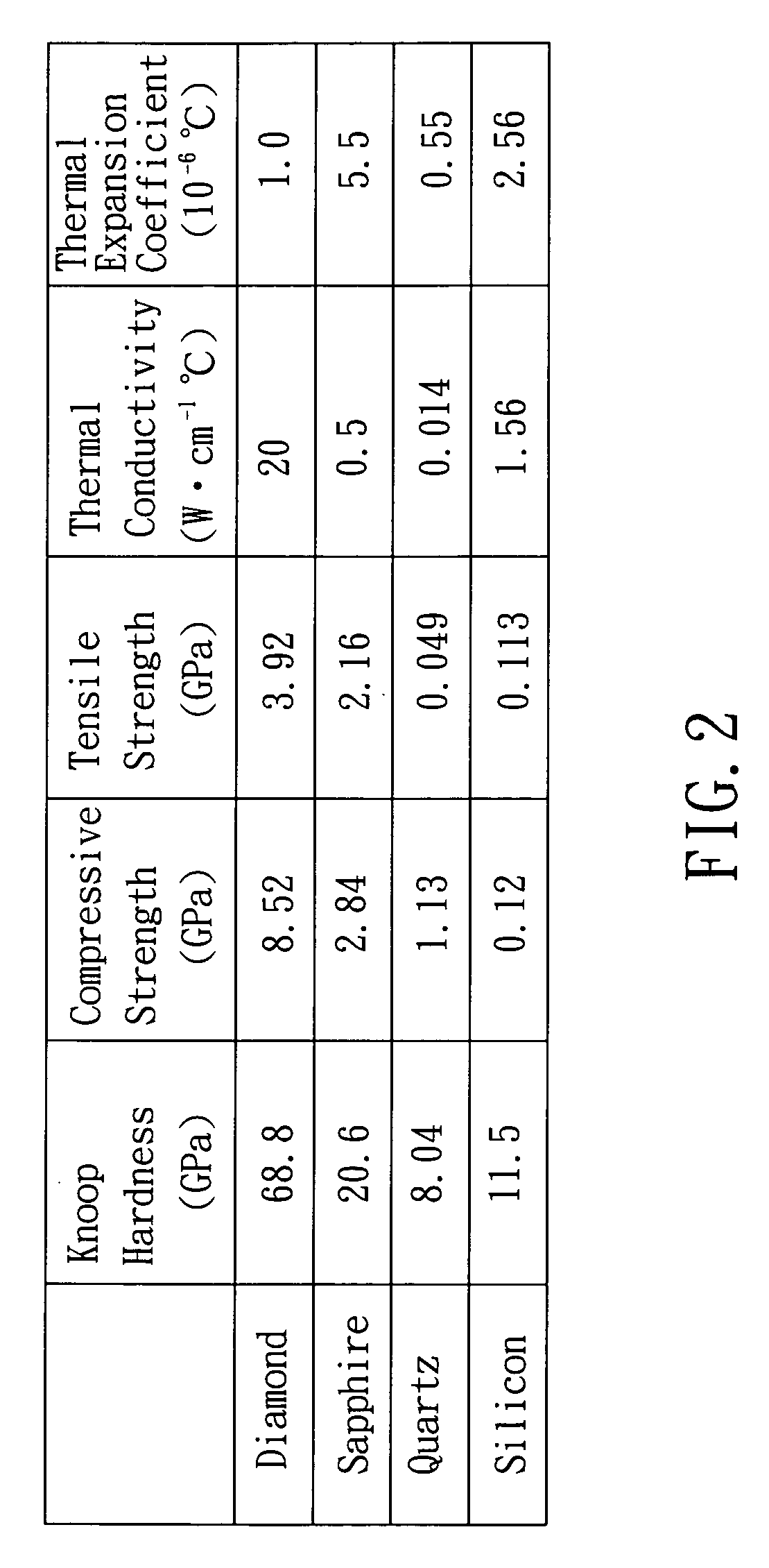

ActiveUS7914693B2Process stabilityDecorative surface effectsNanoinformaticsDiamond-like carbonLithography process

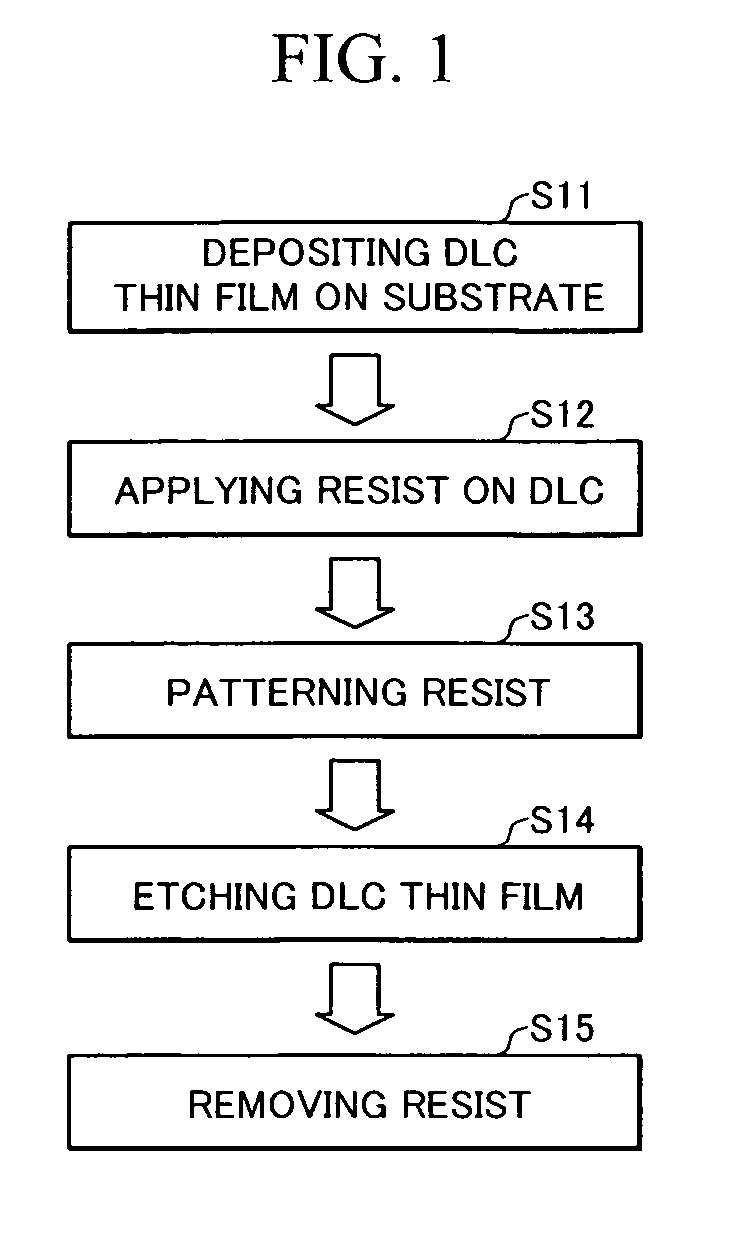

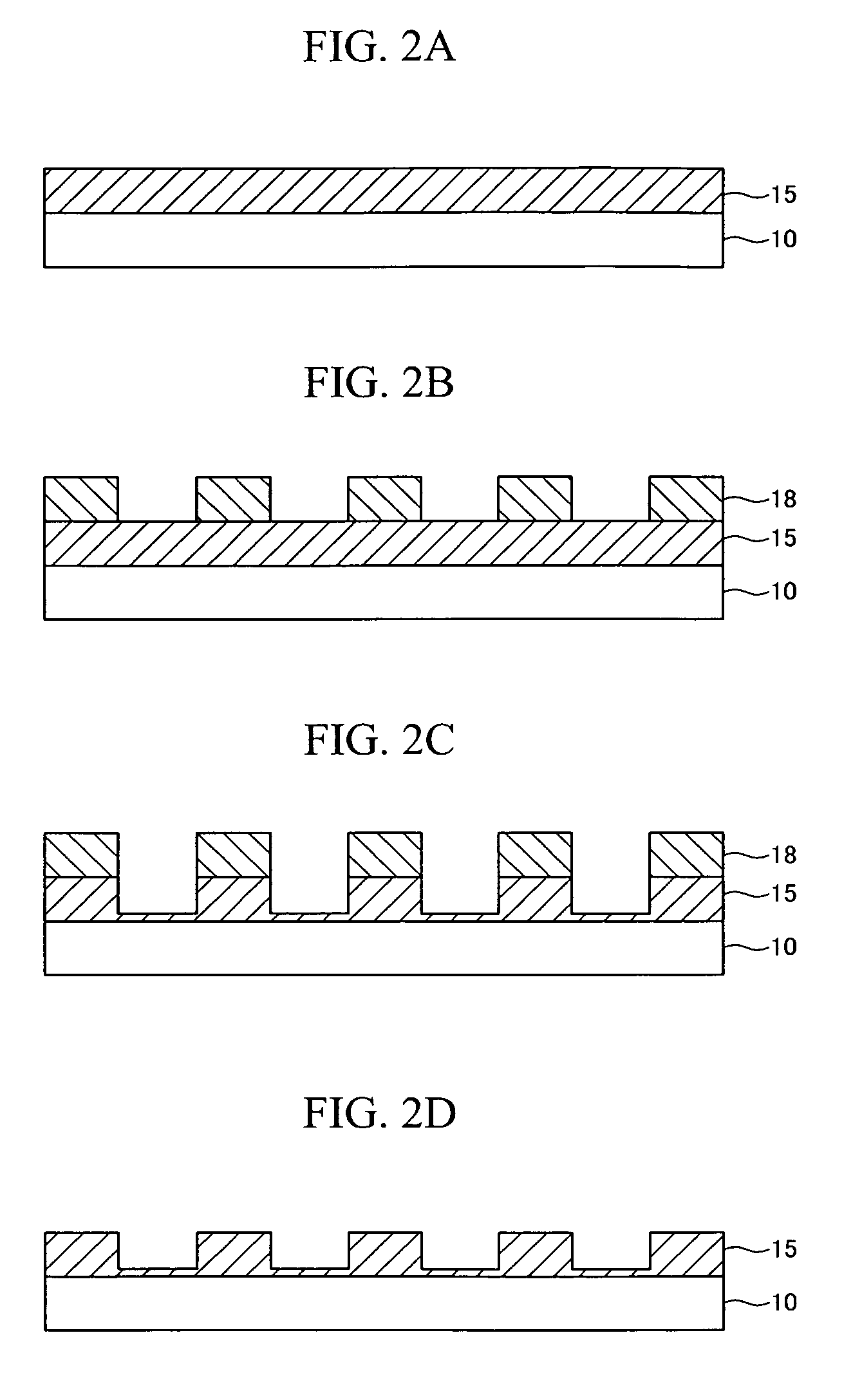

The present invention relates to a micro / nano imprint lithography technique and in particular, to a stamp that is used in an UV-micro / nano imprint lithography process or thermal micro / nano imprint lithography process and a method for fabricating the stamp.The method for fabricating a stamp for micro / nano imprint lithography of the present invention includes i) depositing a thin film of diamond-like carbon on a substrate, ii) applying resist on the diamond-like carbon thin film, iii) patterning the resist, iv) etching the diamond-like carbon thin film by using the resist as a protective layer, and v) removing the resist.

Owner:KOREA INST OF MACHINERY & MATERIALS

Molecular glass photoresist containing bisphenol A skeleton structure as well as preparation method and application thereof

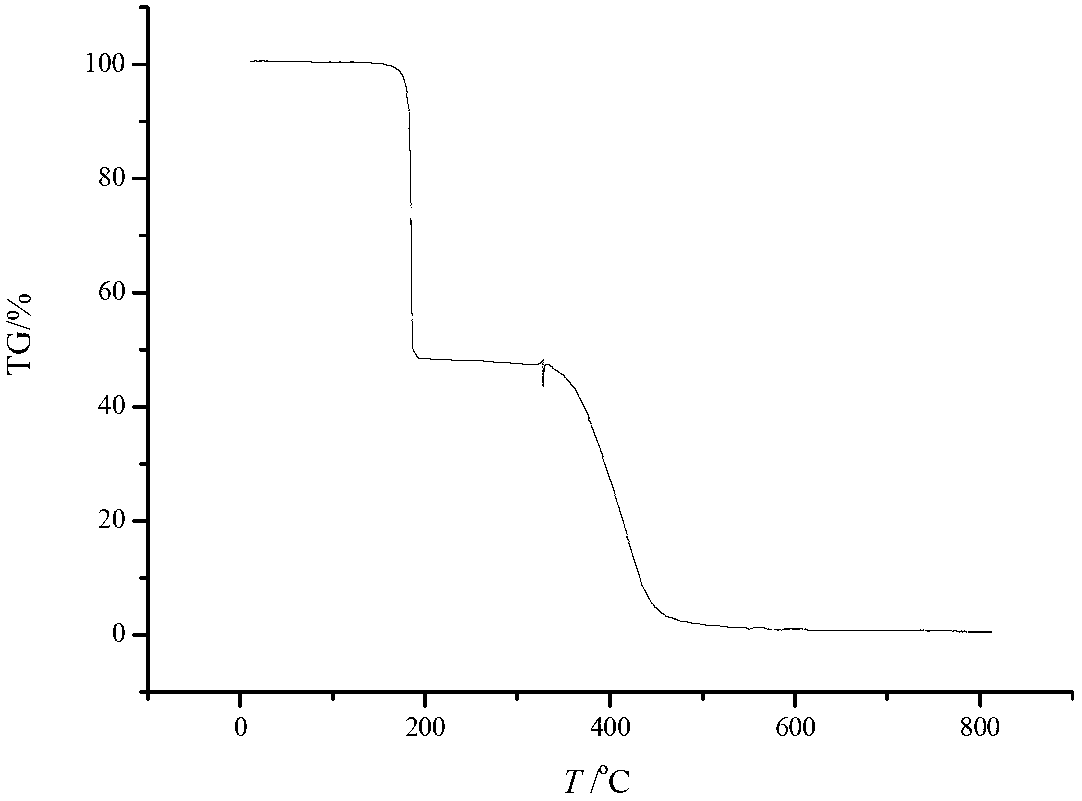

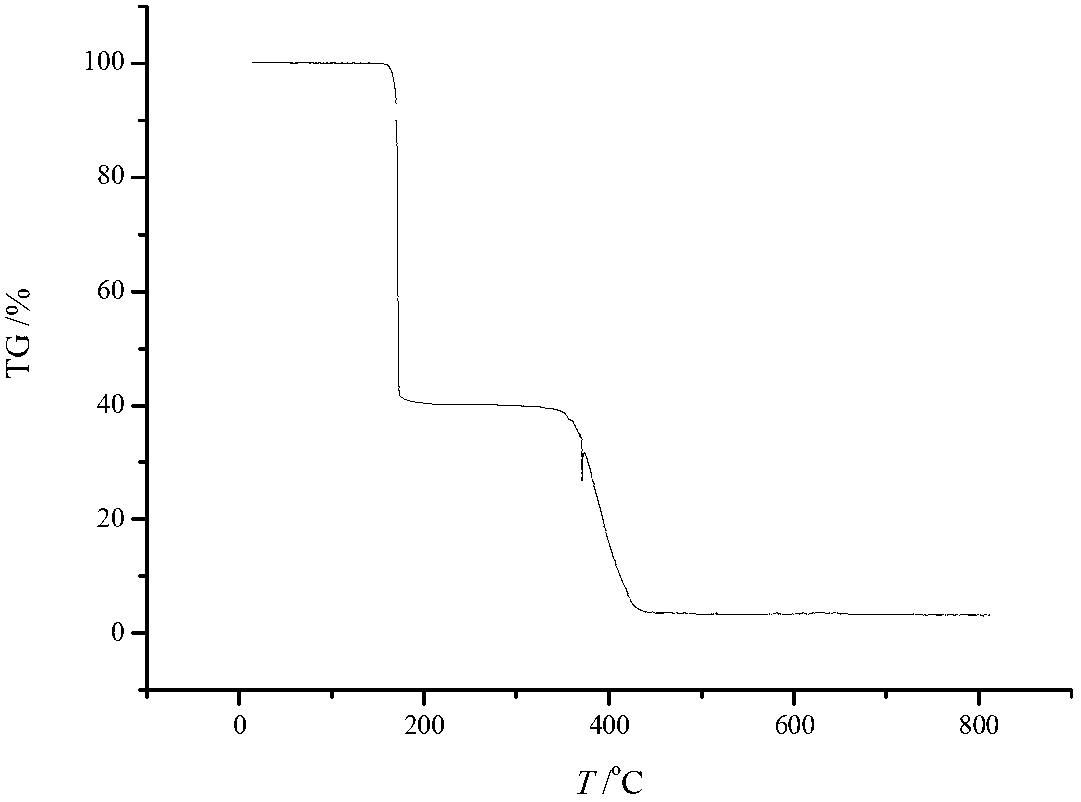

ActiveCN103304385AOrganic compound preparationPhotomechanical coating apparatusSolventNanoimprint lithography

The invention relates to a series of molecular glass photoresists (I and II) based on bisphenol A as a main body structure and a preparation method thereof. The molecular glass photoresists are compounded with a photo-acid generator, a crosslinking agent, a photoresist solvent and other additives to produce positive or negative photoresists; the positive or negative photoresists are placed on a silicon wafer through a spin coating method to prepare a photoresist coating layer with uniform thickness. The photoresist formula can be used in modern lithography technologies, such as 248nm lithography, 193nm lithography, extreme ultraviolet lithography, nanoimprinting lithography and electron beam lithography, and is especially suitable for an extreme ultraviolet (EUV) photo-lithographic process.

Owner:GUOKE TIANJI (BEIJING) NEW MATERIAL TECH CO LTD

Durable, heat-resistant multi-layer coatings and coated articles

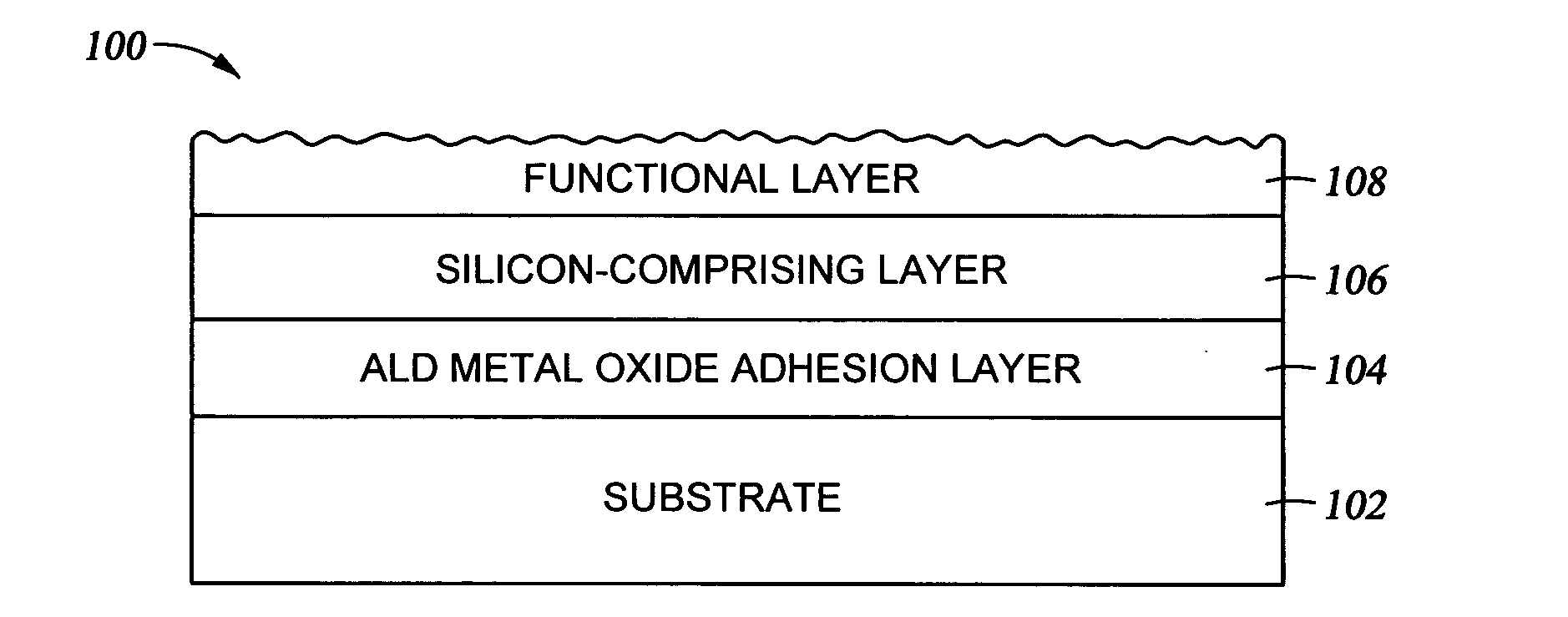

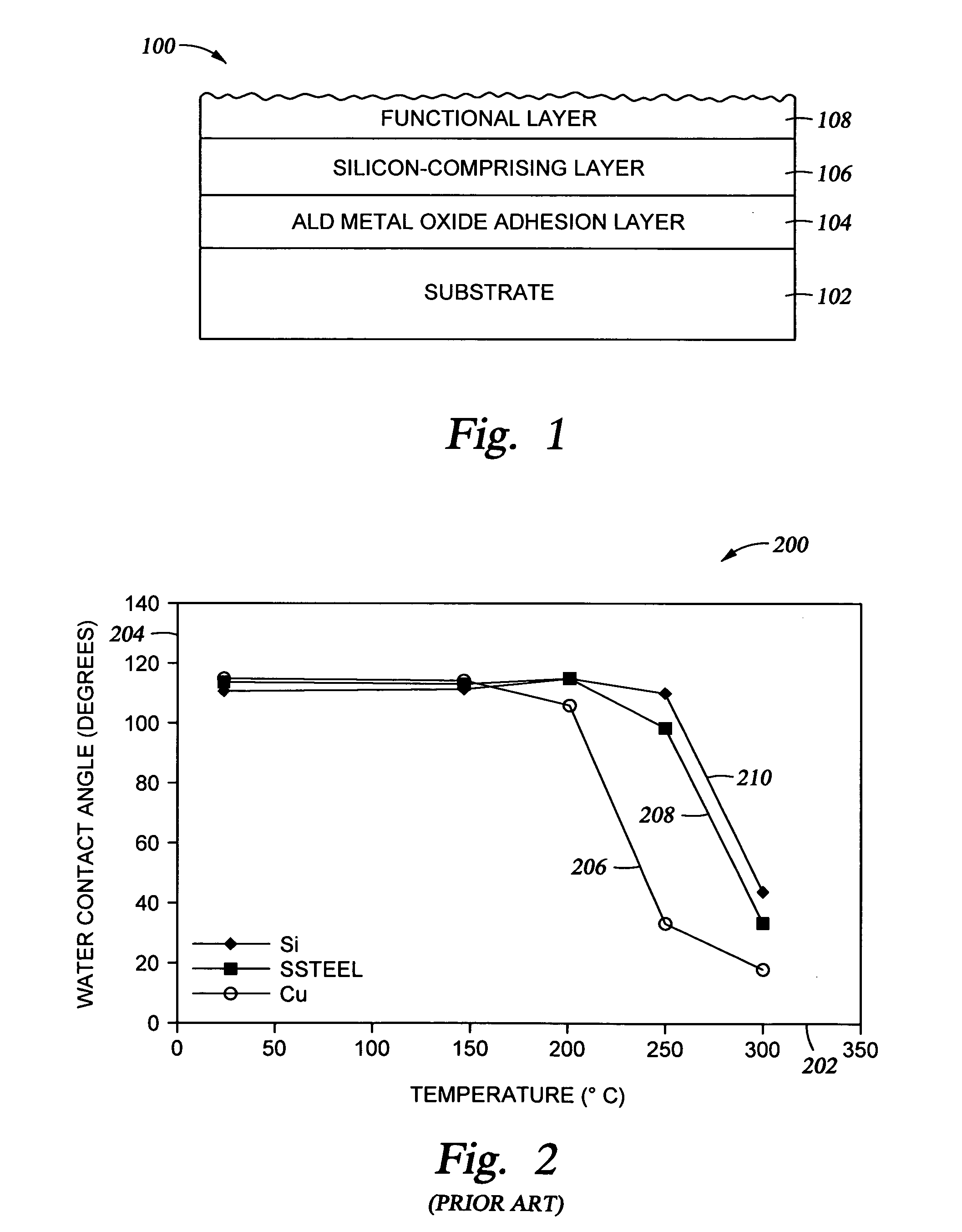

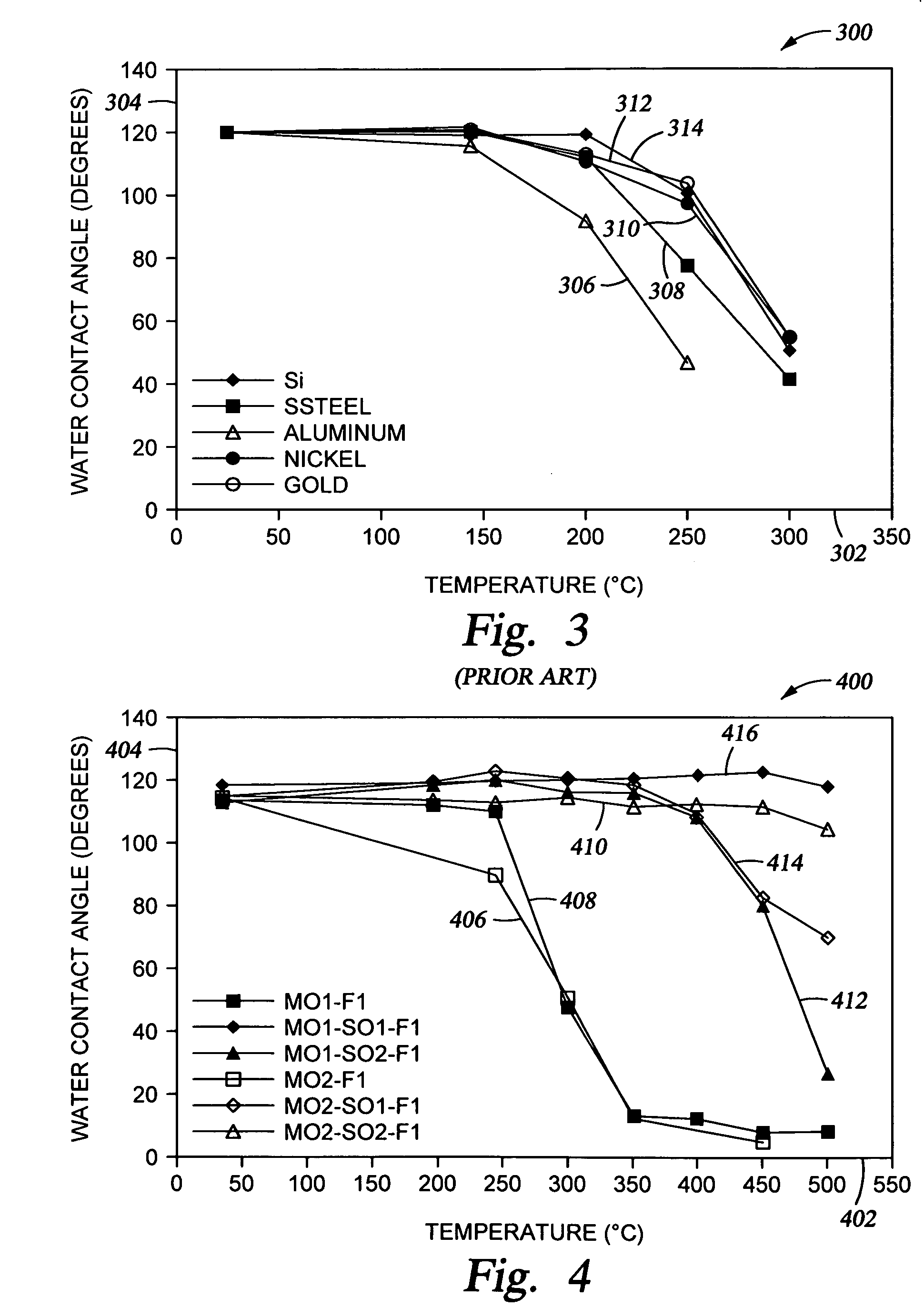

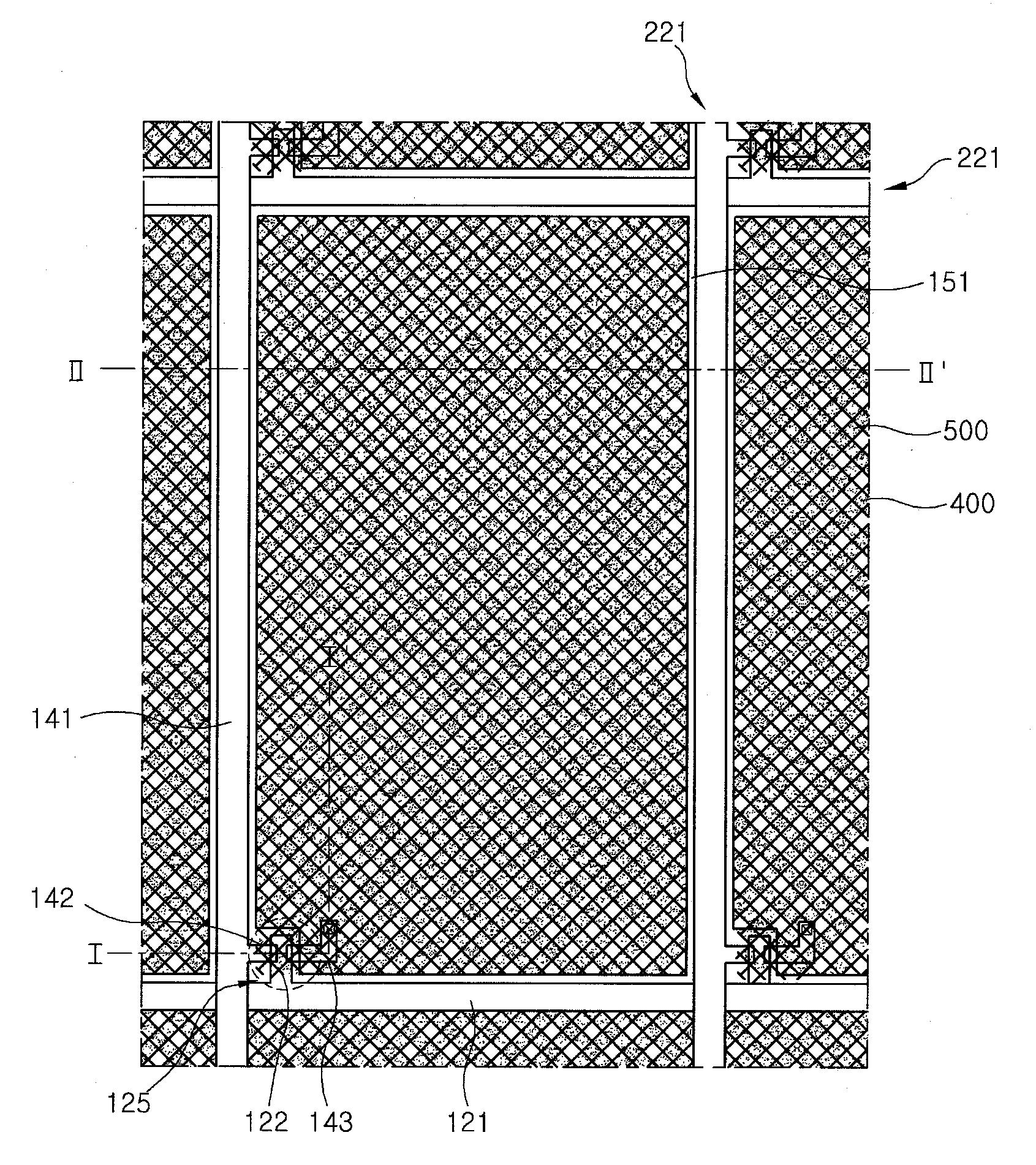

ActiveUS20080299288A1Improve adhesionIncreased durabilitySemiconductor/solid-state device detailsSolid-state devicesMetal oxide adhesionGas phase

A method of providing a durable protective coating structure which comprises at least three layers, and which is stable at temperatures in excess of 400° C., where the method includes vapor depositing a first layer deposited on a substrate, wherein the first layer is a metal oxide adhesion layer selected from the group consisting of an oxide of a Group IIIA metal element, a Group IVB metal element, a Group VB metal element, and combinations thereof; vapor depositing a second layer upon said first layer, wherein said second layer includes a silicon-containing layer selected from the group consisting of silicon oxide, silicon nitride, and silicon oxynitride; and vapor depositing a third layer upon said second layer, wherein said third layer is a functional organic-comprising layer. Numerous articles useful in electronics, MEMS, nanoimprinting lithography, and biotechnology applications can be fabricated using the method.

Owner:SPTS TECH LTD

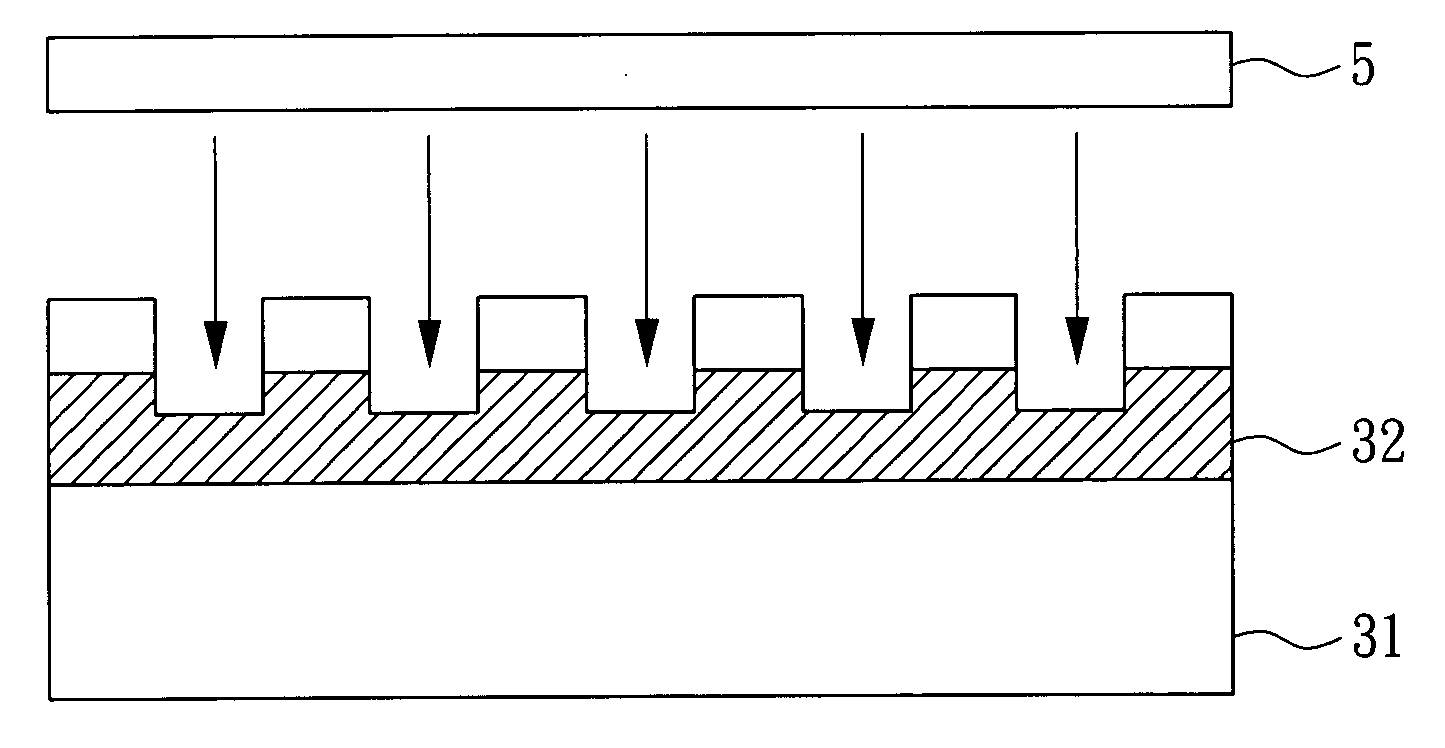

Method of forming an integrated optical polarization grid on an LCD subsrate and liquid crystal display manufactured to include the grid

ActiveUS20080100779A1Improve featuresReduce variationPhotomechanical apparatusOptical articlesWire gridLithography process

A method of forming a wire grid polarizing pattern across the relatively large surface area of a display substrate is disclosed where the method includes using a nano imprint lithograph process.According to the disclosure, in forming the wire grid polarizing patterns using nano imprint lithography process, wire grid polarizing patterns are formed by bonding a stamp having a stamping area substantially smaller than that of the substrate with successive reticle areas of the substrate, where the substrate has a photosensitive film deposited thereon and where the stamping is such that recesses having a predetermined depth are formed in the photosensitive film, and then filling the recesses with an insulating film and etching it using the insulating film as a mask.Accordingly, since a mechanical misalignment margin is acceptable from one reticle area to the next when patterning across the entire operational surface of the photosensitive film, a wire grid polarizing pattern with a uniform line width and spacings in each reticle area can be formed on a substrate having a large area for use with a liquid crystal panel.

Owner:SAMSUNG DISPLAY CO LTD

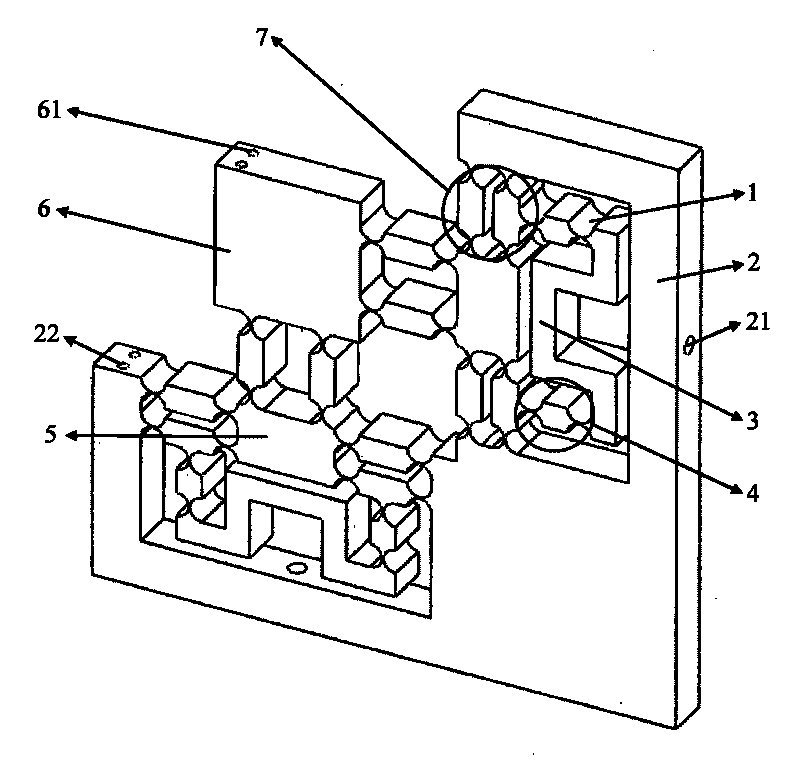

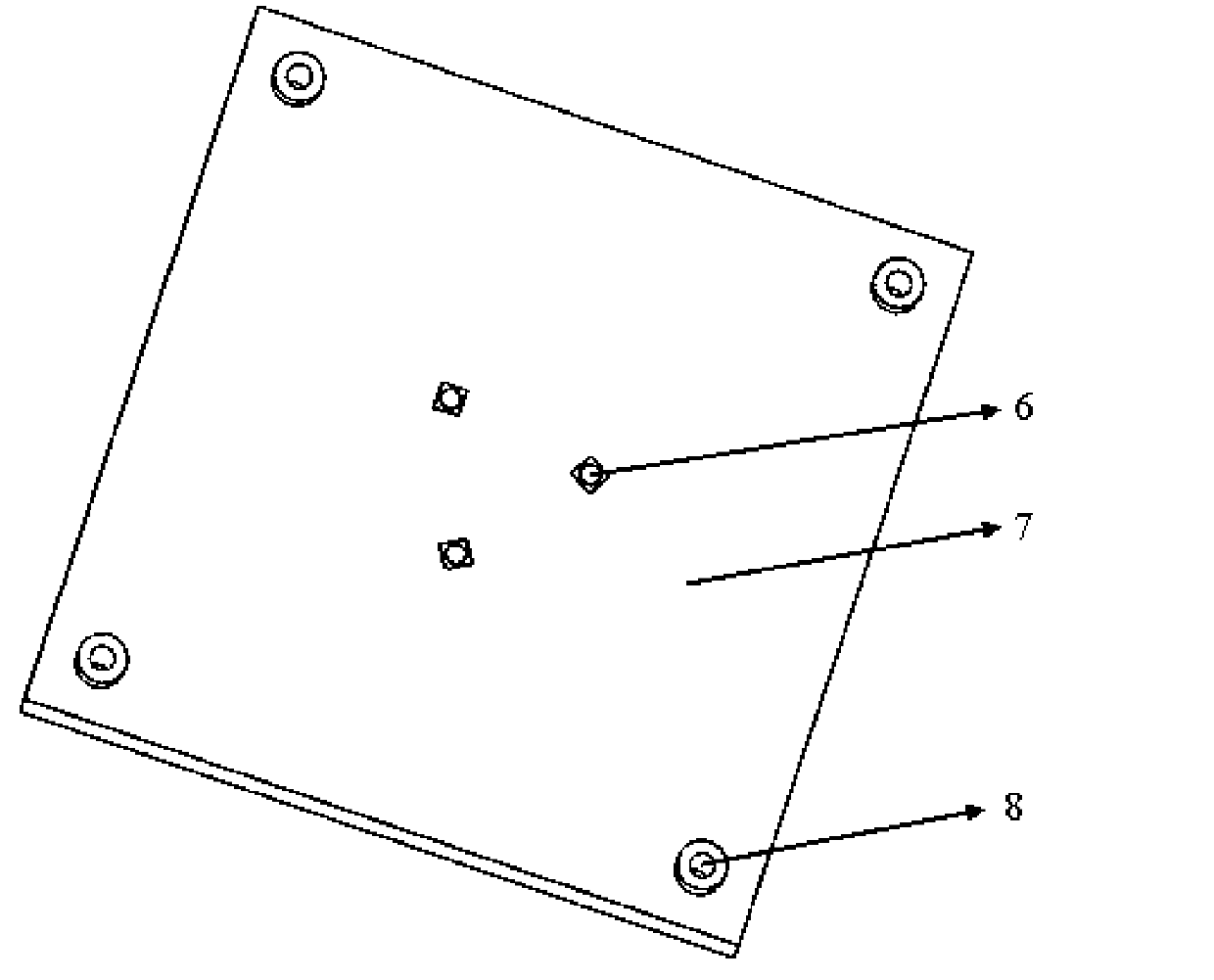

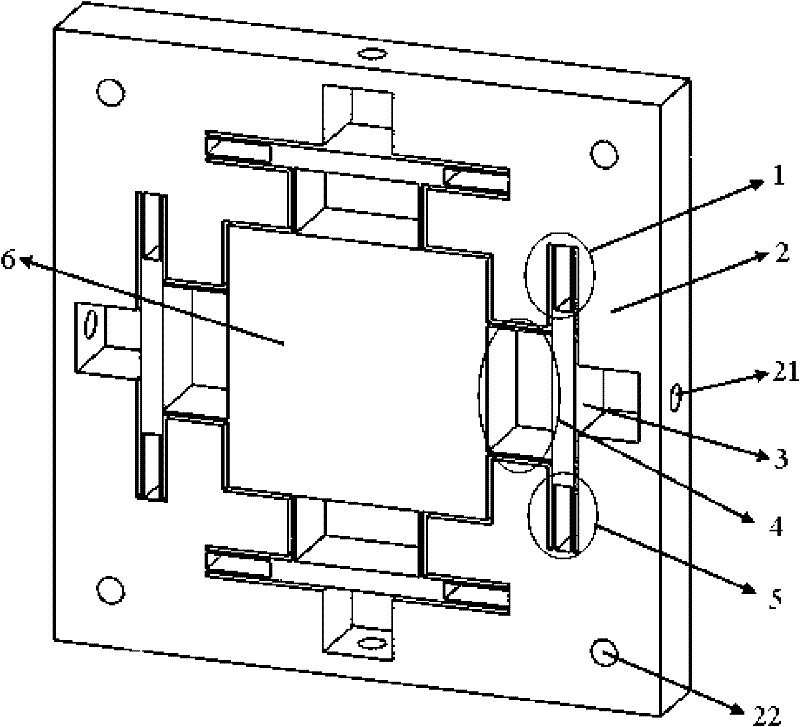

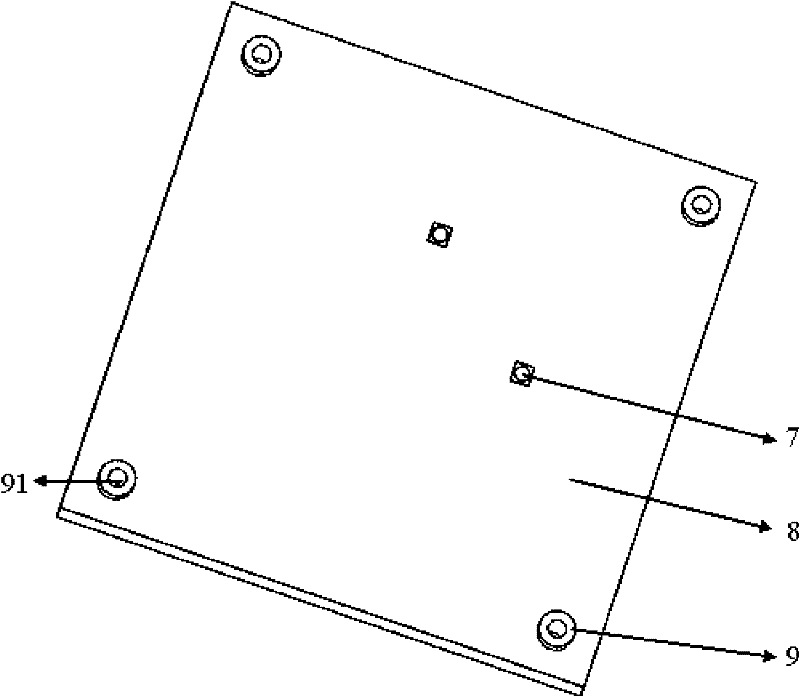

Flexible micro-positioning stage with two degrees of freedom

ActiveCN101738855AAvoid assemblyNo gapPhotomechanical apparatusFlexible MechanismsLithographic artist

The invention discloses a flexible micro-positioning stage with two degrees of freedom, the design of the flexible micro-positioning stage with two degrees of freedom comprises a flexible mechanism and an integral structure, two piezoelectric ceramic drivers are adopted in the structure, the tail part of each driver is connected with a base through a bolt, and the top end of each driver is connected with a spherical joint through a thread, thereby realizing Hertz contact. The flexible mechanism of the positioning stage mainly comprises three parts of the base, flexible branched chains with entirely consistent structures and a supporting movable platform thereof. Two displacement sensors are used for measuring actual output of the movable platform and respectively fixed between the base and the movable platform through an L-shaped support and a Z-shaped support. The flexible micro-positioning stage is characterized by high resolution and fast dynamic response speed, and can be taken as an auxiliary positioning platform of a nano-imprint lithography positioning system for realizing micro-feeding and precise positioning.

Owner:南通致远船舶设计有限公司

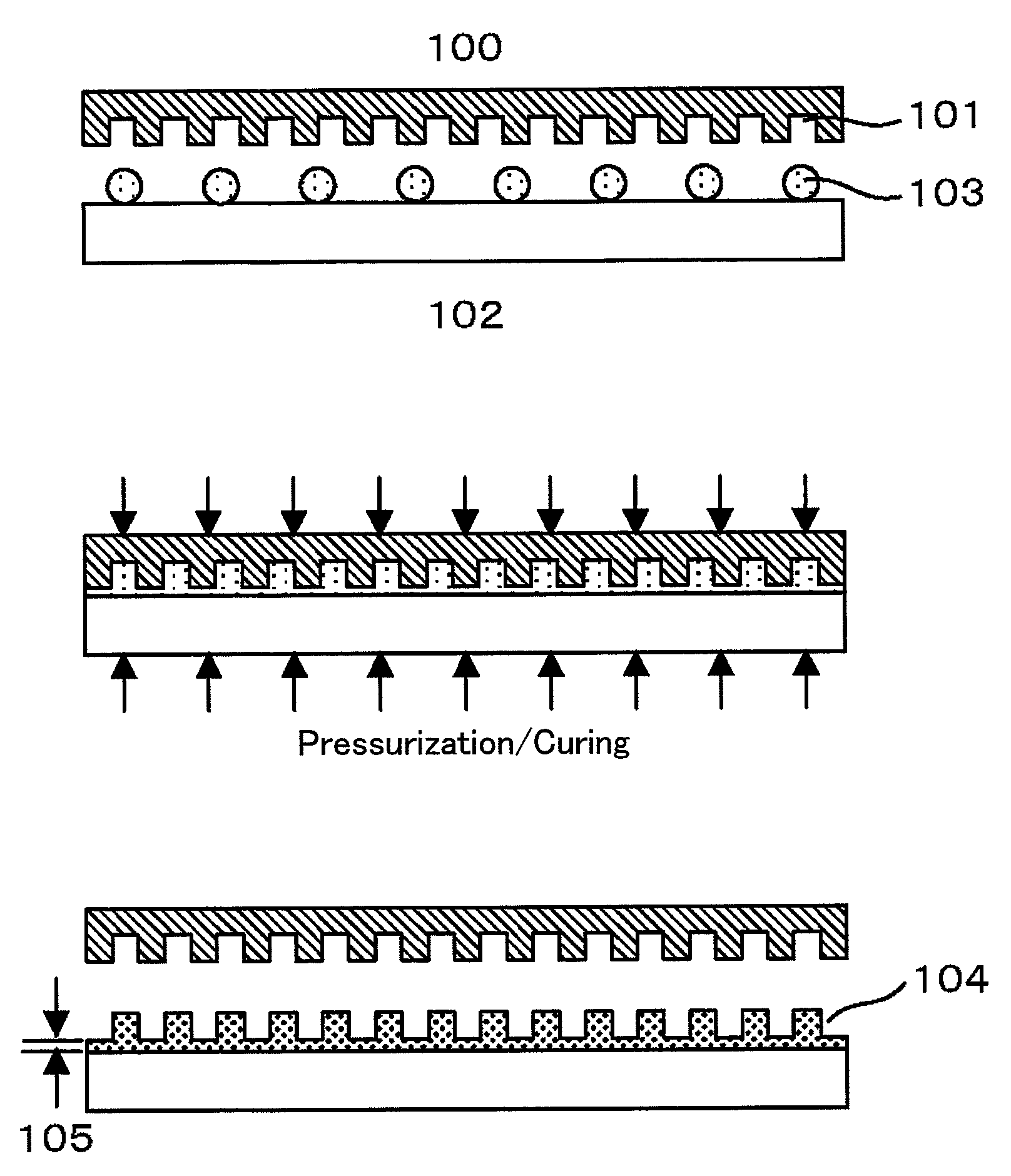

Wire grid polarizer and method for producing same

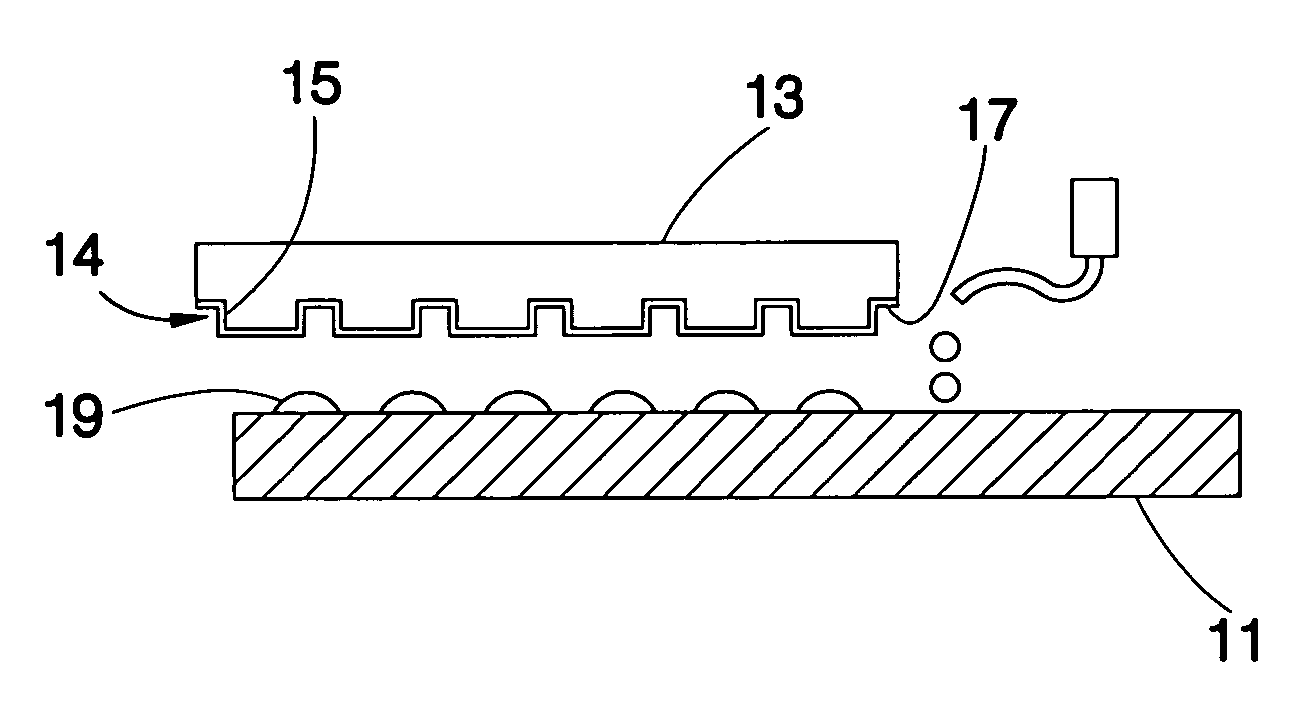

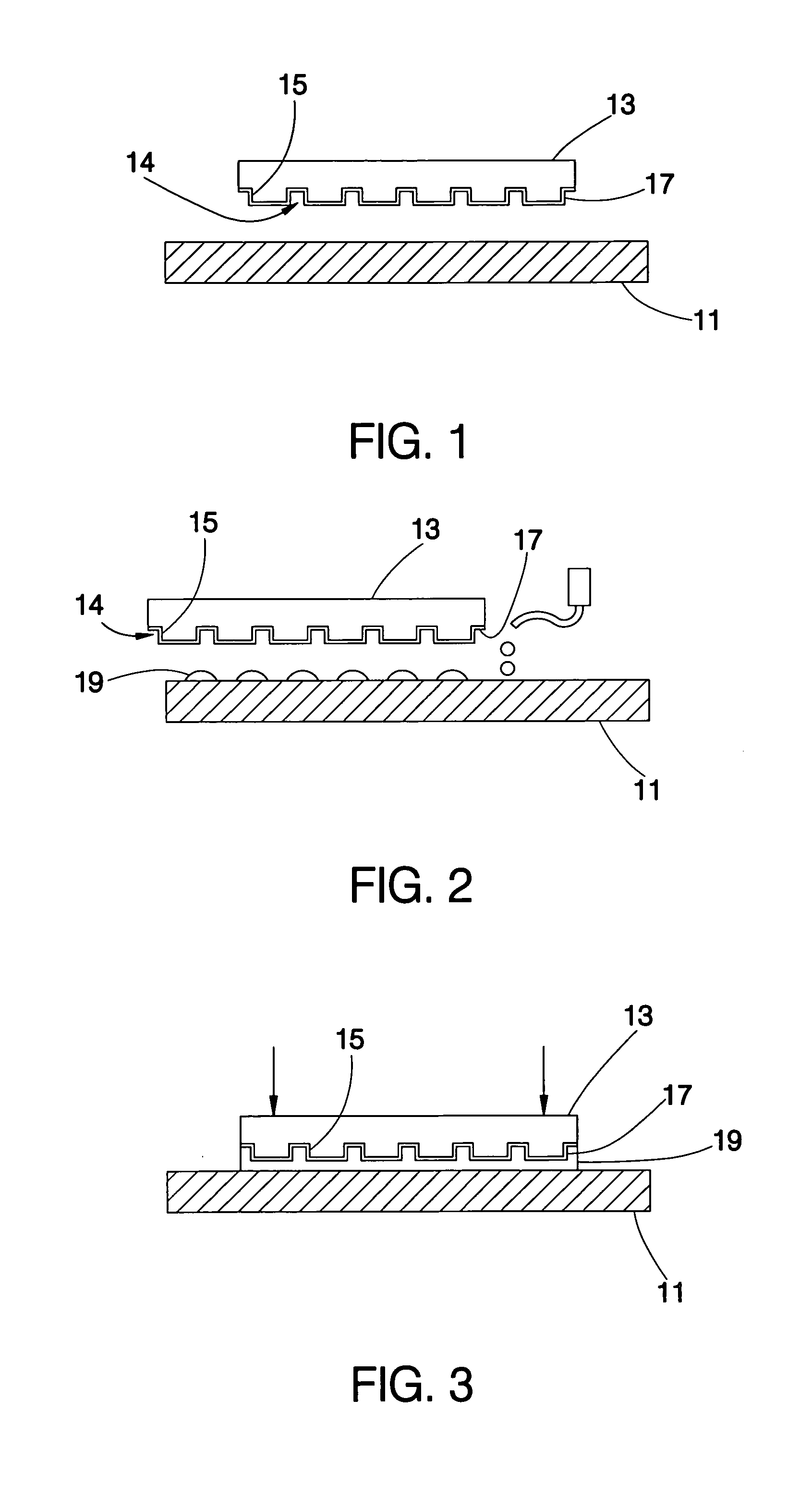

ActiveUS7220371B2High light transmittanceLow costPolarising elementsOptical articlesLithographic artistWire grid

There are provided a thin wire grid polarizer having a high transmittance, a high quenching ratio and a high degree of polarization, and a method for producing the same at low costs. A fluoridated polyimide thin film 12, a hydrophilic thin film 13 and a hydrophobic thin film 14 are sequentially stacked on a glass substrate 11 to be pressed by a die 1 from the side of the hydrophobic thin film 14 to transfer the fine pattern of groove forming protrusions 3 of the die 1 to the hydrophobic thin film 14 and hydrophilic thin film 13 by the nano-imprinted lithography technique, and then, metal fine wires are caused to grow by plating.

Owner:ENPLAS CORP

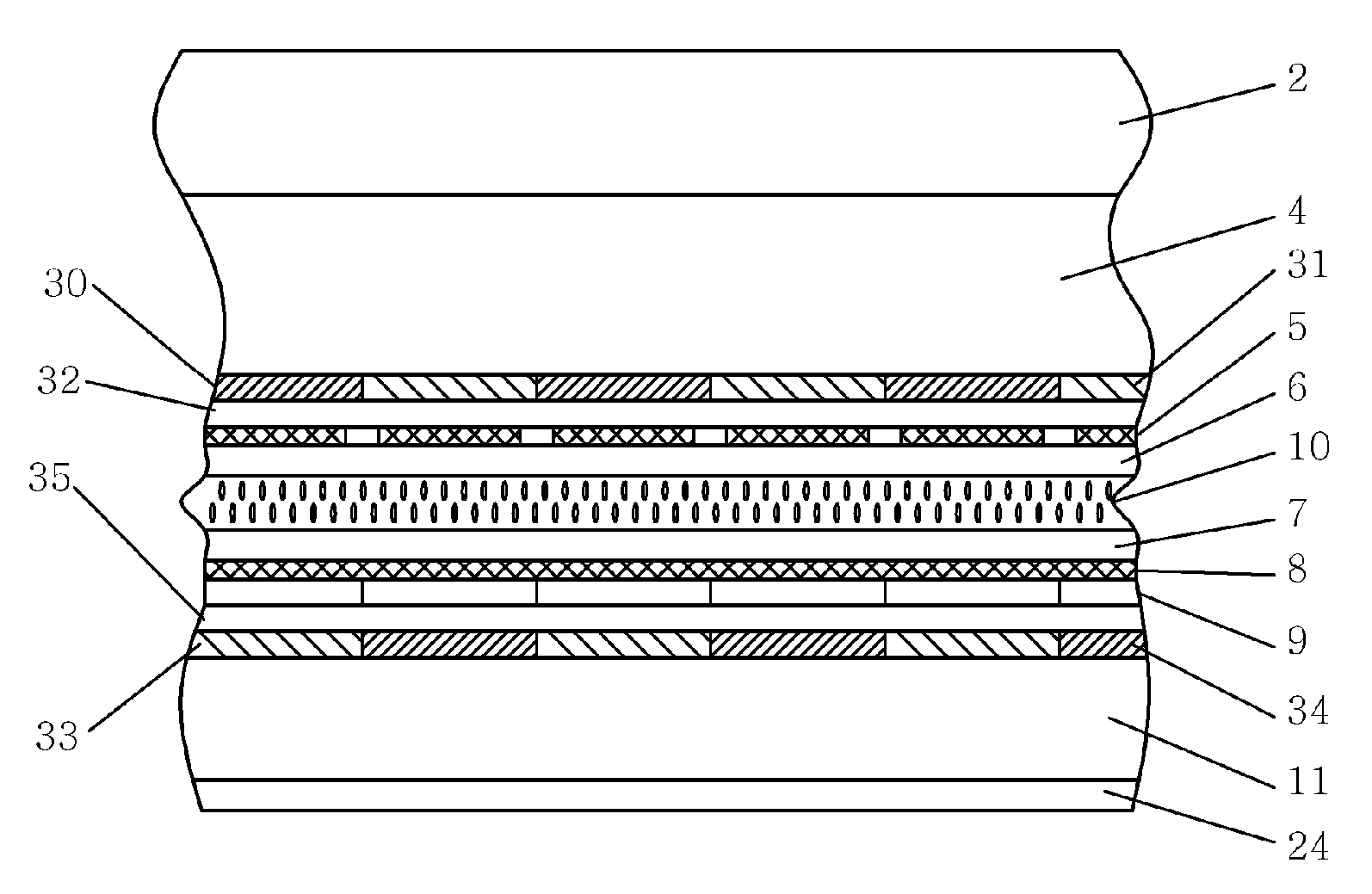

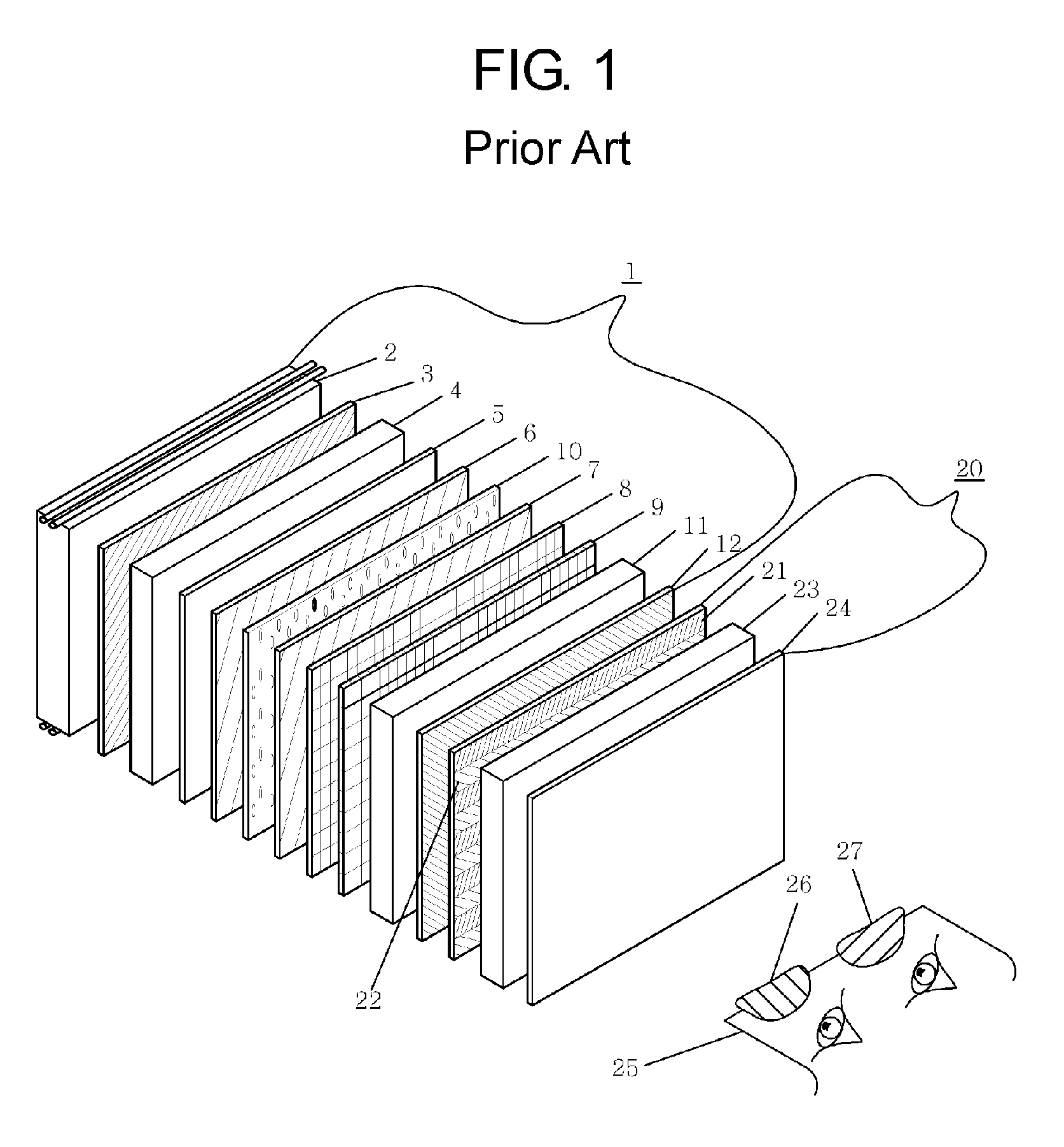

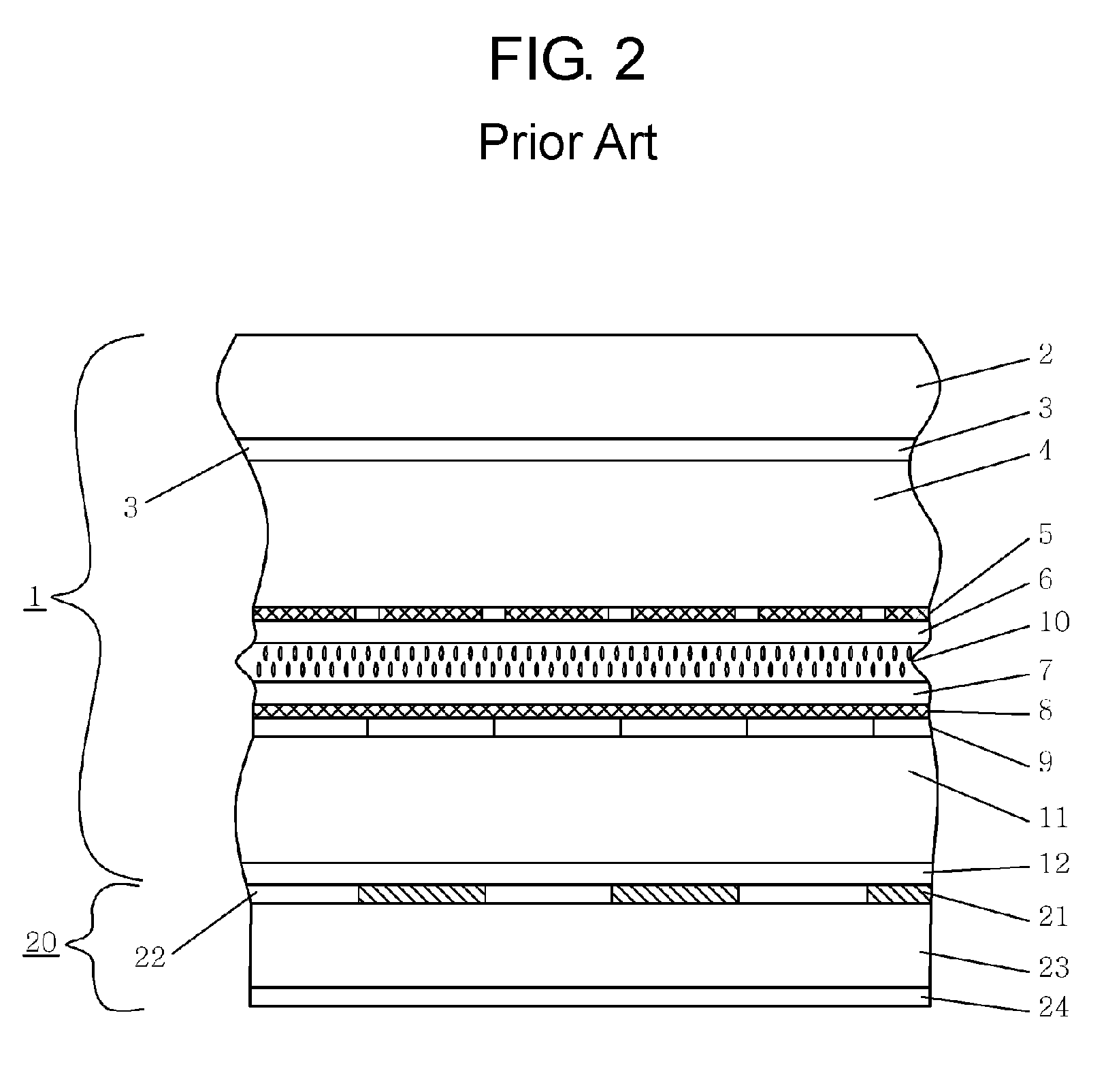

Liquid crystal display device having thin polarizing film and thin phase retardation film

InactiveUS20060023143A1Fabrication process can be shortenedReduce manufacturing costSteroscopic systemsNon-linear opticsPhase retardationLiquid-crystal display

A LCD device having a thin phase retardation film is disclosed, which is achieved using a thin film polarizing film formed by accurately processing a thin aluminum film, a polarizing film of a nano imprint lithography method that uses polymer, and a polarizing film and a liquid crystal material that form a polarizing nano material thin film by uniformly coating a polarizing nano material (TCF).

Owner:PAVONINE

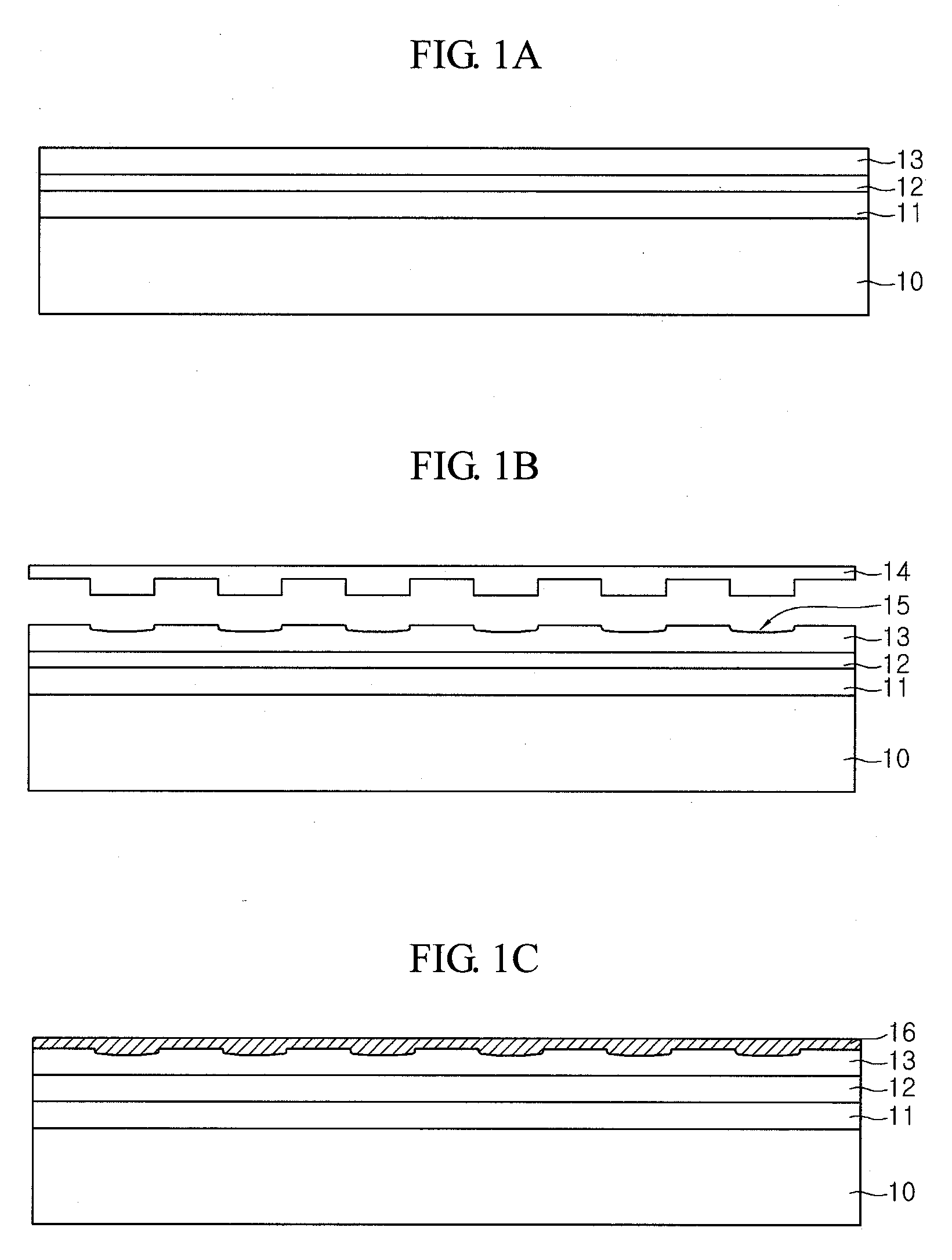

Structure of imprint mold and method for fabricating the same

InactiveUS20050170292A1Easy to carryGood anti-frictionLayered productsDecorative surface effectsLithographic artistNanoimprint lithography

The present invention is related to a structure of an imprint mold and a method for fabricating the same, which can be used in the field of nano-imprint lithography. Firstly, a diamond film and a photoresist film are successively formed onto a substrate; wherein the photoresist film is more capable of anticorrosion than the diamond film. Then an energy beam lithography system is provided to make the photoresist film form a photoresist mask with particularly arranged patterns. Because of the etching selectivity between the diamond film and the photoresist film, on the surface of the diamond film can be easily formed a pattern with recessions and protrusions according to the photoresist mask by dry etching method. Thus an imprint mold characterized as better antifriction and easily taking off from imprinted materials is completed.

Owner:IND TECH RES INST

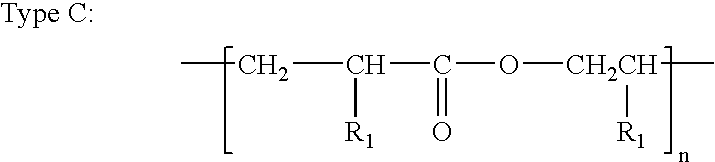

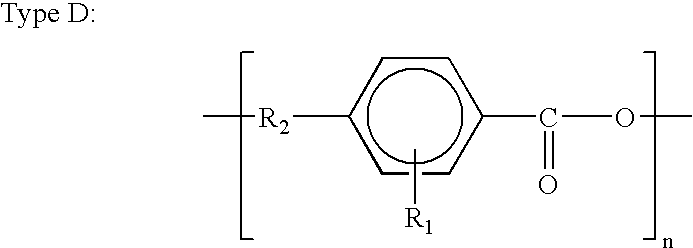

Compositions and processes for nanoimprinting

InactiveUS20080277826A1Mass productionImprove low temperature fluidityNanoinformaticsSynthetic resin layered productsResistNanoimprint lithography

The invention is directed to new nanoimprint resist and thin-film compositions for use in nanoimprinting lithography. The compositions permit economical high-throughput mass production, using nanoimprint processes, of patterns having sub-200 nm, and even sub-50 nm features.

Owner:CHOU +3

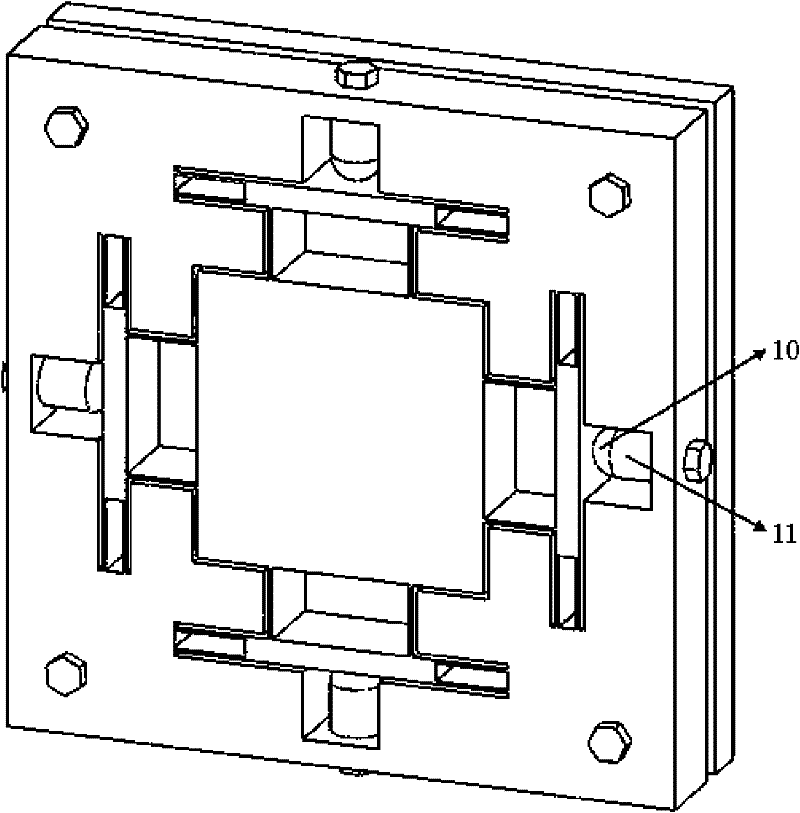

Uniform pressing apparatus

InactiveUS6994541B2Improve parallelismSimple structureConfectionerySweetmeatsEngineeringNanoimprint lithography

A uniform pressing apparatus used in nanoimprint lithographic process is proposed, including a housing having a first flange; a first carrier unit for carrying an imprint mold and having at least one second flange freely attaches to the first flange; a second carrier unit for carrying a substrate; at least one uniform pressing unit mounted on a imprint force transmission path; and a power source driving at least one of the housing and the second carrier unit to allow a contact to be formed between the mold and the moldable layer. Therefore, the nanoimprint lithographic process is achieved with good parallelism between the substrate and the mold and with uniform pressure distribution.

Owner:IND TECH RES INST

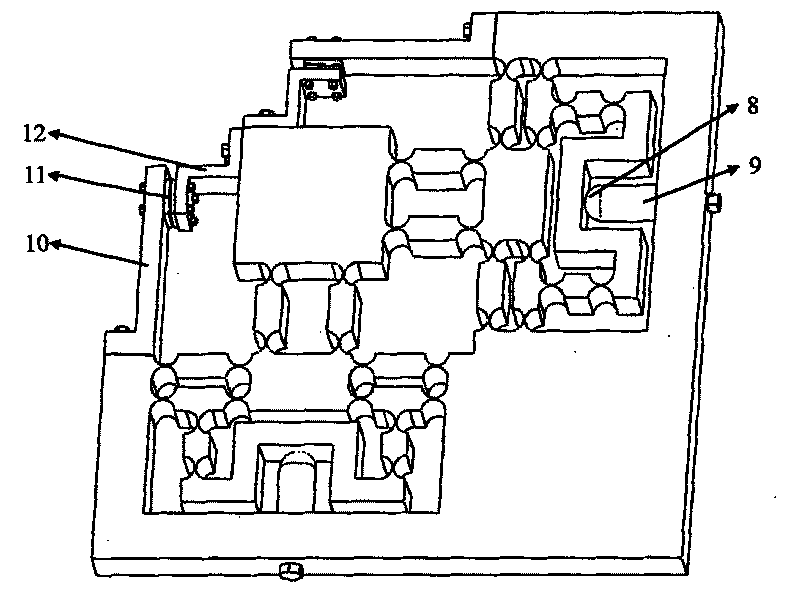

Three-degree of freedom flexible precision positioning workbench

InactiveCN101770182AAvoid assemblyNo gapPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistThree degrees of freedom

The invention discloses a three-degree of freedom flexible precision positioning workbench. In a structure of the workbench, six piezoelectric ceramic drivers are adopted, the tail of each driver is connected with a substrate through bolts, and the top end is in threaded connection with a ball joint to realize hertz contact; a flexible structure of the positioning workbench mainly comprises the substrate, six flexible branched chains with identical structures and a movable platform supported by the flexible branched chains; and three position sensors are used for measuring the actual output of the movable platform and are respectively fixed between a rigid support and the movable platform. The precision positioning workbench has the characteristics of high resolution ratio and high speed of dynamic response, and can be used as an assisted positioning platform of a nano-imprint lithography positioning system to realize microscale feeding and precision positioning.

Owner:TIANJIN UNIV

Nanoimprint resist, nanoimprint mold and nanoimprint lithography

ActiveUS20100308008A1Low modulusEasy to crushDecorative surface effectsNanoinformaticsResistOligomer

A nanoimprint resist includes a hyperbranched polyurethane oligomer (HP), a perfluoropolyether (PFPE), a methylmethacrylate (MMA), and a diluent solvent. A method of a nanoimprint lithography is also provided.

Owner:TSINGHUA UNIV +1

Method of forming resist pattern by nanoimprint lithography

ActiveUS20090189317A1Excellent etch resistanceImprove the immunityNanoinformaticsPhotomechanical apparatusResistOrganic layer

A method of forming a resist pattern of high aspect ratio excelling in etching resistance by the use of nanoimprint lithography. The method of forming a resist pattern by nanoimprint lithography comprises the steps of disposing organic layer (4) on support (1); providing resist layer (2) on the organic layer (4) with the use of chemical amplification type negative resist composition containing silsesquioxane resin (A); pressing light transmission allowing mold (3) with partial light shielding portion (5) against the resist layer (2) and thereafter carrying out exposure from the upside of the mold (3); and detaching the mold (3).

Owner:TOKYO OHKA KOGYO CO LTD

Nanoimprint lithograph for fabricating nanoadhesive

A nanoimprint lithography method of fabricating a nanoadhesive includes steps of (a) preparing a substrate and a mold under the vacuum environment, wherein at least one of the substrate and the mold is transparent, the mold is located over the substrate and has an oppressing portion having nanometer-scale features and a mold release agent located on the surface of the nanometer-scale features; (b) coating a liquid resist cast on the substrate, wherein the resist cast can be hardened by ultraviolet rays; (c) having the mold is pressed on the substrate to enable the resist cast to fill between the nanometer-scale features and the substrate; (d) irradiating the resist cast by the ultraviolet rays for hardening; and (e) releasing the mold from the substrate to enable the resist cast to produce a contrast pattern thereon corresponding to the nanometer-scale features, wherein the resist cast with the contrast pattern is the nanoadhesive.

Owner:CONTREL TECH CO LTD

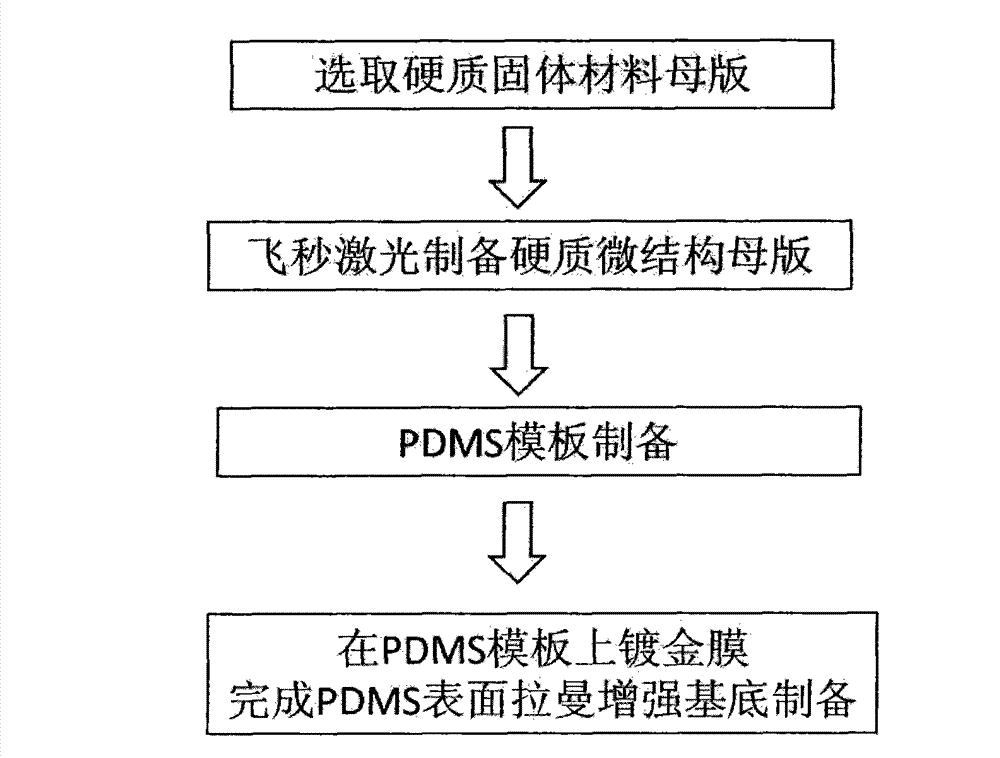

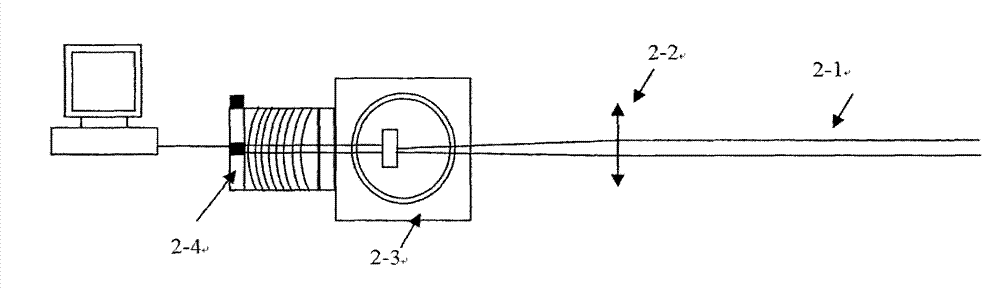

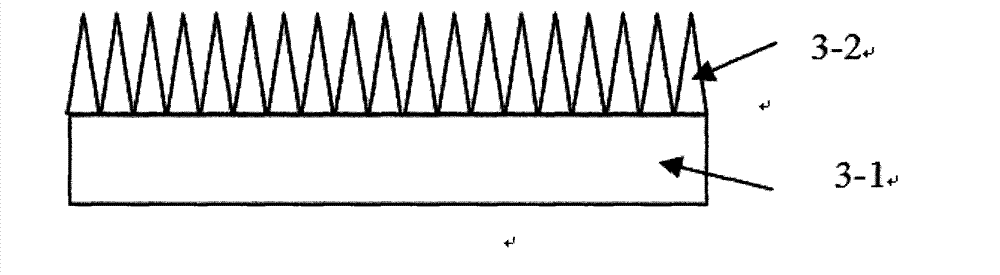

Preparation method of large-area surface enhancement raman scattering substrate

The invention discloses a preparation method of a large-area surface enhancement raman scattering substrate. The preparation method comprises the following steps: at first, the surface of a hard solid material is irradiated by femtosecond laser to prepare a large-scale hard microstructural mother set; then, polydimethylsiloxane (PDMS) is poured on the hard microstructural mother set by the nanoimprint lithography technology, and the structure on the hard microstructural mother set is copied to prepare a PDMS framework; and finally, a gold film is plated on the PDMS framework to prepare the PDMS surface enhancement raman scattering substrate. The experiment results show that the preparation method has the advantages that the enhancement factors are high, enhancement factors in different positions of the substrate have good uniformity, the large-area surface enhancement raman scattering substrate can be prepared, the mother set can be repeatedly imprinted, the production cost is reduced, and in addition, god is taken as raman enhancement metal, so that the defect that silver is oxidized very easily is avoided.

Owner:NANKAI UNIV

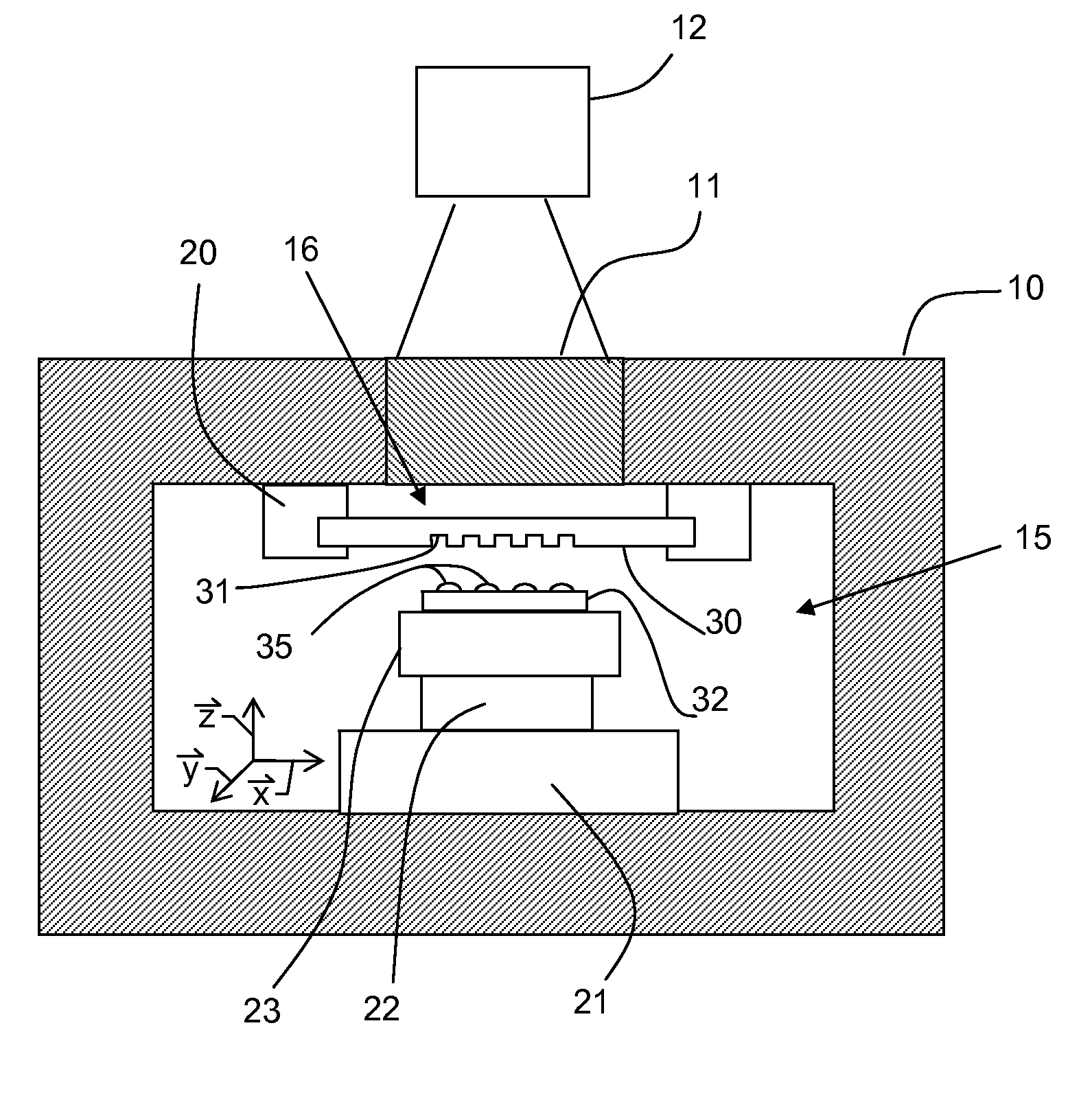

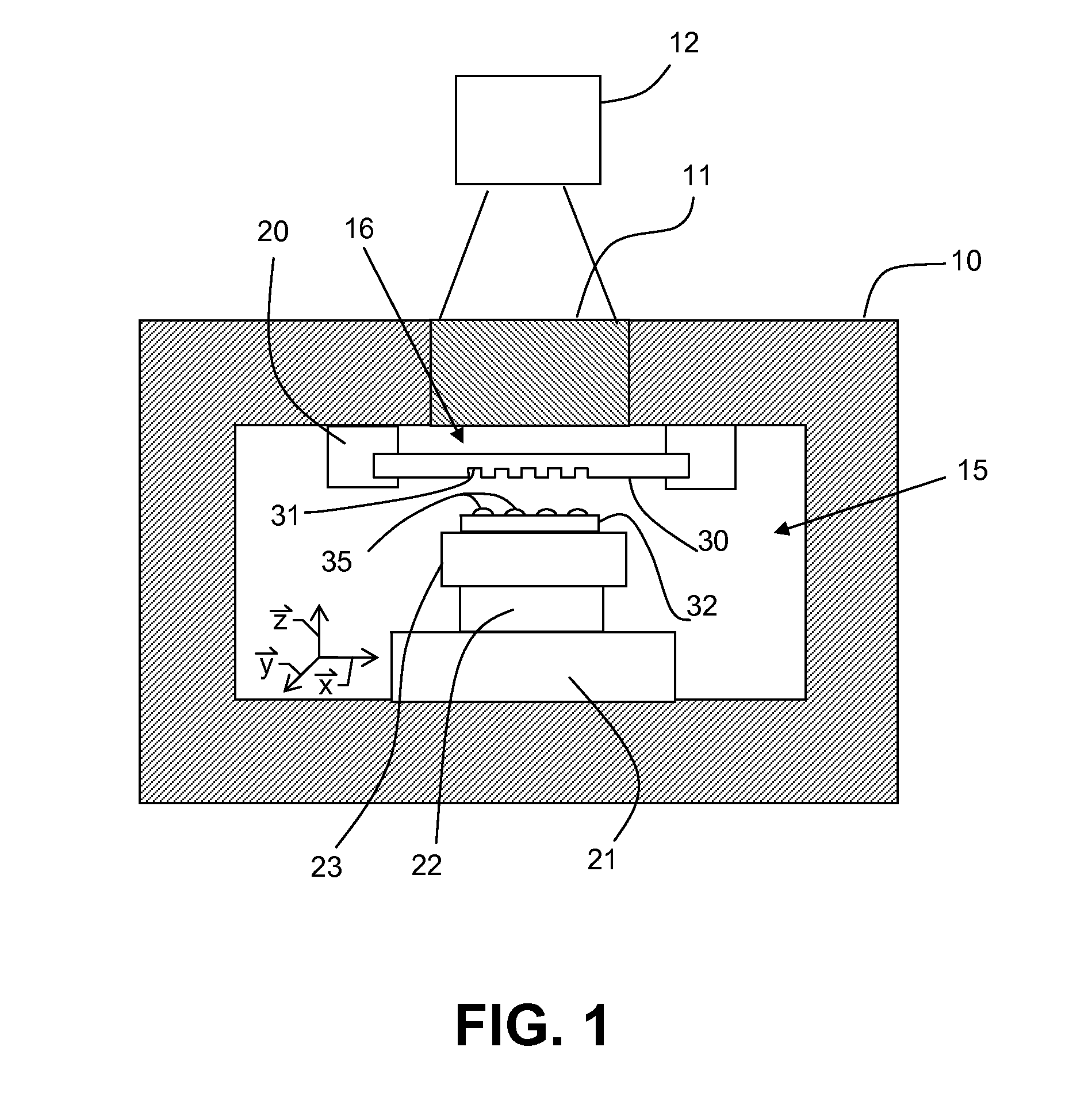

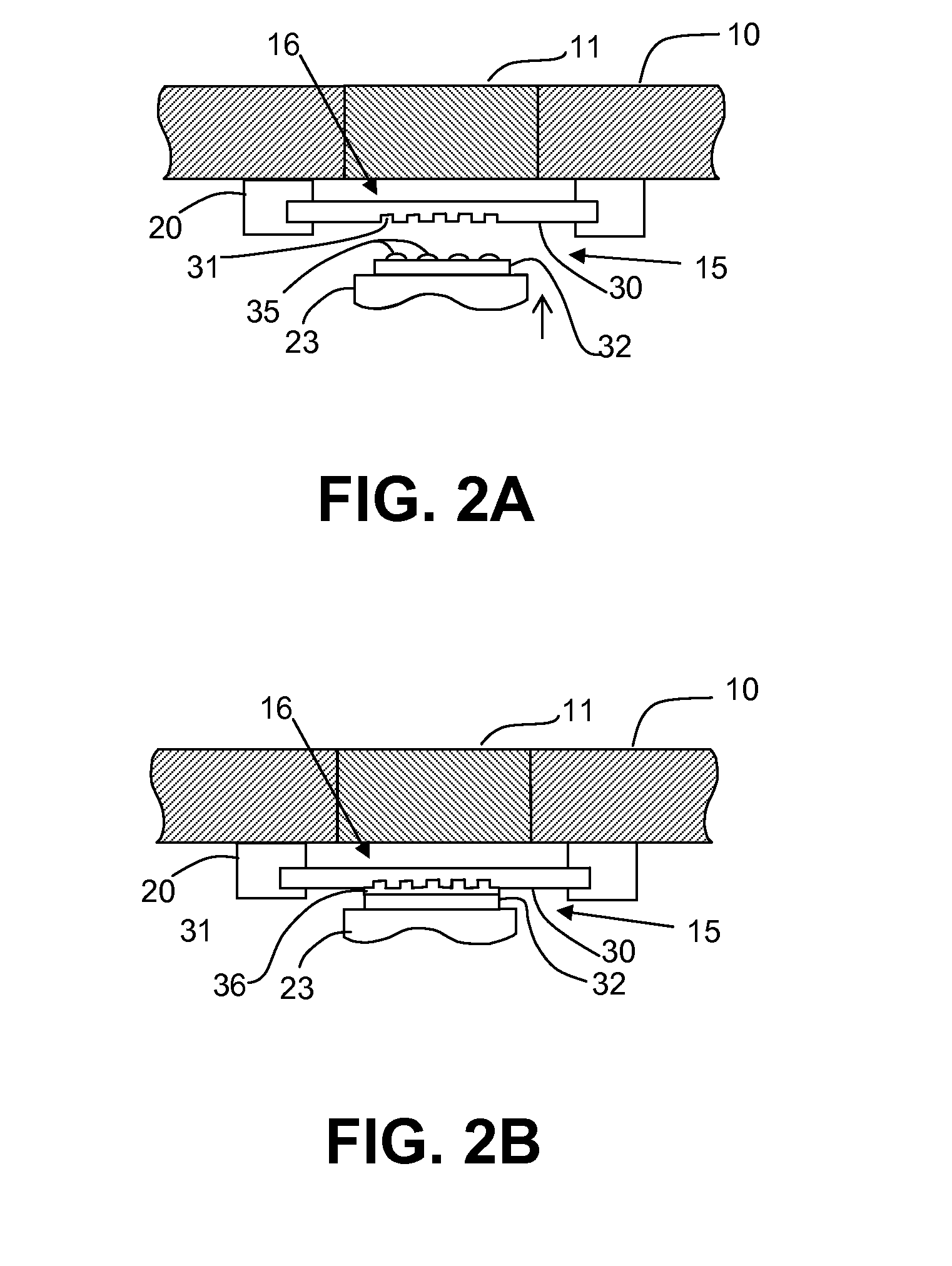

Fast nanoimprinting apparatus using deformale mold

The invention disclosed apparatuses and methods to do nanoimprint lithography using a deformable mold. Generally, the apparatus has a chamber with a transparent section on its top wall, which is capable of vacuuming and pressurizing. The deformable mold fixed firmly onto a hollow mold holder around its full periphery is attached to top inner surface of the chamber and positioned underneath the transparent section. The central area of the mold is freely accessible from underneath through the opening of the mold holder. An enclosed volume referring to mold mini-chamber is formed between the mold / holder and top wall of the chamber. Inside chamber, a stage assembly is installed. A chuck to vacuumly hold a substrate is mounted on top of the stage assembly. At beginning of the imprinting, the substrate with a layer of resist is positioned underneath the mold at a predetermined gap between them. Then, the substrate is moved up to contact with the mold either under vacuum or under atmosphere. The substrate and mold may be pressed further by introducing higher pressure inside the chamber. After consolidating the resist, the substrate is separated from the mold by either direct pull-down enabled by stage movement or deforming the mold enabled by differential pressure between the mold mini-chamber and the bulk volume of the chamber, or mixing of both.

Owner:NANONEX

Two-degree of freedom precise positioning work table

The invention discloses a two-degree of freedom precise positioning work table, which comprises a base, a moving platform, a rigid support which is connected with the bottom of the base, and four flexible branched chains which are connected between the moving platform and the base, wherein each flexible branched chain comprises a moving block and three groups of flexible plate spring structures; each flexible plate spring structure consists of two '-'-shaped flexible plate springs; a first group and a second group of the flexible plate spring structures are respectively positioned at the left side and the right side of the moving block; the lower ends of the two '-'-shaped flexible plate springs of a third group of the flexible plate spring structures are connected with the side wall of the upper end of the moving block, and the upper ends thereof are connected with the side wall of the moving platform; four piezoelectric ceramics driving devices are respectively horizontally arranged; a ball-shaped joint of each driving device is supported on the side wall of the lower end of the moving block; and conducting strips of two position sensors are respectively connected with the upper plane of the rigid support and the lower plane of the moving platform. The positioning work table can be taken as an auxiliary positioning platform of a nanometer embossing photoetching positioning system to realize the microscale feeding and the precise positioning.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com