Preparation method of large-area surface enhancement raman scattering substrate

A surface-enhanced Raman and large-area technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of complex process, high cost and loss, non-reusable use, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

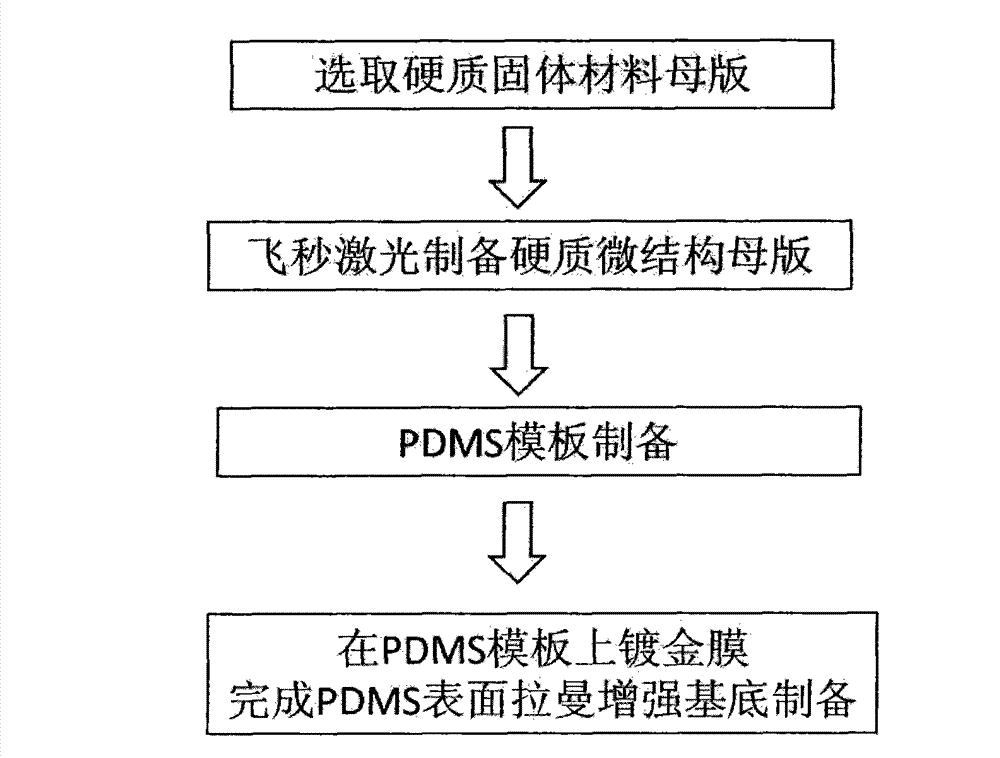

[0040] In the preparation method of the present invention, (1) choose a hard solid material as the master material, the hard solid material refers to a hard sheet or block material, and the material property can be a semiconductor material such as silicon, or a metal Materials such as copper, aluminum, etc., hard solid materials require flat surfaces, and the surface flatness means that the difference between the highest point and the lowest point on the surface of the material is less than or equal to 10 μm;

[0041] (2) Put the hard solid material into ethanol and acetone 1:1 mixed solution for ultrasonic cleaning for 15 minutes, then rinse with a large amount of deionized water to make the surface clean;

[0042] (3) The femtosecond laser irradiates the surface of the hard material to make a hard microstructure master;

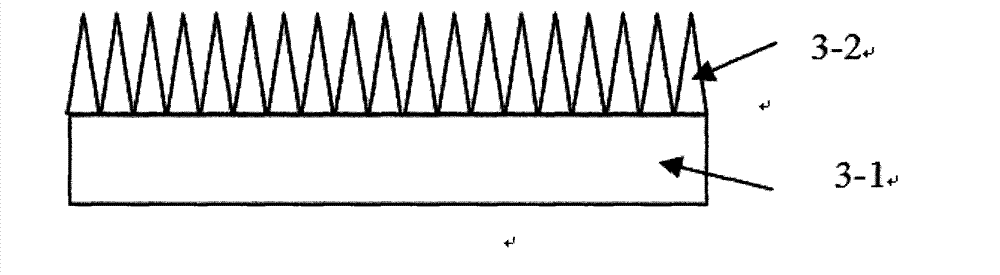

[0043] (4) Pouring liquid organic material polydimethylsiloxane (PDMS) on the surface of the processed hard microstructure master, so that PDMS covers the ...

Embodiment 1

[0052] The preparation method of PDMS surface enhanced Raman scattering substrate comprises the following steps:

[0053] 1. Select a silicon wafer with an n(110) resistivity of 2-10Ω*cm and a thickness of 400 μm as the hard master material.

[0054] 2. Ultrasonic clean the silicon wafer in ethanol, acetone 1:1 mixture for 15 minutes, and then rinse with a large amount of deionized water to make the surface clean.

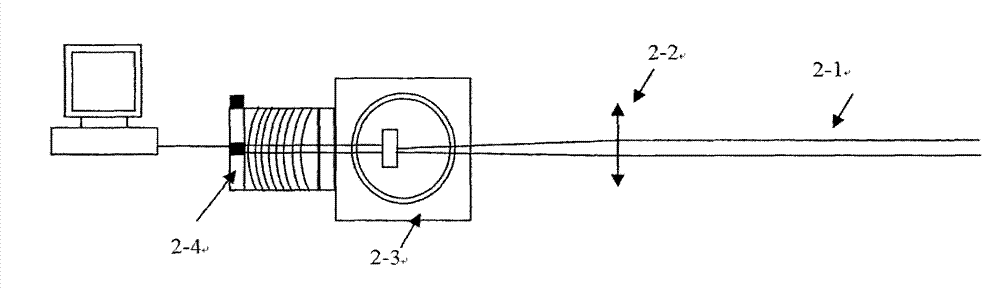

[0055] 3. Place the cleaned silicon wafer on the sample holder connected to the three-dimensional translation stage and fix it.

[0056] 4. Use a vacuum pump to evacuate the vacuum chamber, and then fill it with 0.6bar SF 6 gas, as a reactive gas.

[0057] 5. Adjust the incident femtosecond laser flux to 3kJ / m 2 .

[0058] 6. Through the control program, set the moving speed of the target piece to 1mm / s, and the row spacing to 100um, and perform surface scanning, and the scanning area is 3cm×3cm. After the scanning time is over, use a vacuum pump to remove the...

Embodiment 2

[0066] In order to detect the performance of the Raman-enhanced substrate on the PDMS surface, we add the step of measuring the Raman-enhanced substrate enhancement factor (EF) on the PDMS surface after step [6] in claim 1. The Raman-enhanced substrate on the PDMS surface is the substrate prepared in Example 1. The configuration concentration is 10 -1 M and 10 -6 M's R6G solution. drop by drop 10 -1 M R6G solution to the ordinary polished silicon surface, drop a drop of 10 -6 M R6G solution onto PDMS surface-enhanced Raman substrate. A Raman spectrometer from Renishaw Company was adopted, the magnification of the objective lens was 50×numerical aperture NA=0.5, the wavelength of the excitation light was 785 nm, and the integration time was 10 s.

[0067] EF=(I SERS ×N NR ) / (I NR ×N SERS )

[0068] where I SERS and N SERS Respectively represent the signal intensity of R6G Raman scattering on the SERS substrate and the number of molecules that the laser can irradiate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com