Patents

Literature

717results about How to "Soft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin cleaning article

InactiveCN101427990ASoftIncrease elasticityCosmetic preparationsToilet preparationsBranSURFACTANT BLEND

The invention relates to a skin cleansing product. Mill offals are added to the cleansing product, and comprise components by the following contents (weight percentages): 0.01% to 99% of water, 0.01% to 99% of surfactant and 0.01% to 30% of mill offals. Mill offals are adopted as the abradant and the massage particles of the skin cleansing product, and compared with the prior art, the skin cleansing product has the advantages that the utilization value of the mill offals is increased; the mill offals originate from natural plants, are soft in texture, and have the advantages of environment protection, naturalness and temperateness; and simultaneously, the nutrient components in the mill offals of plants serve the functions of nutrient caring and nourishing.

Owner:上海蔻漫生物科技有限公司 +2

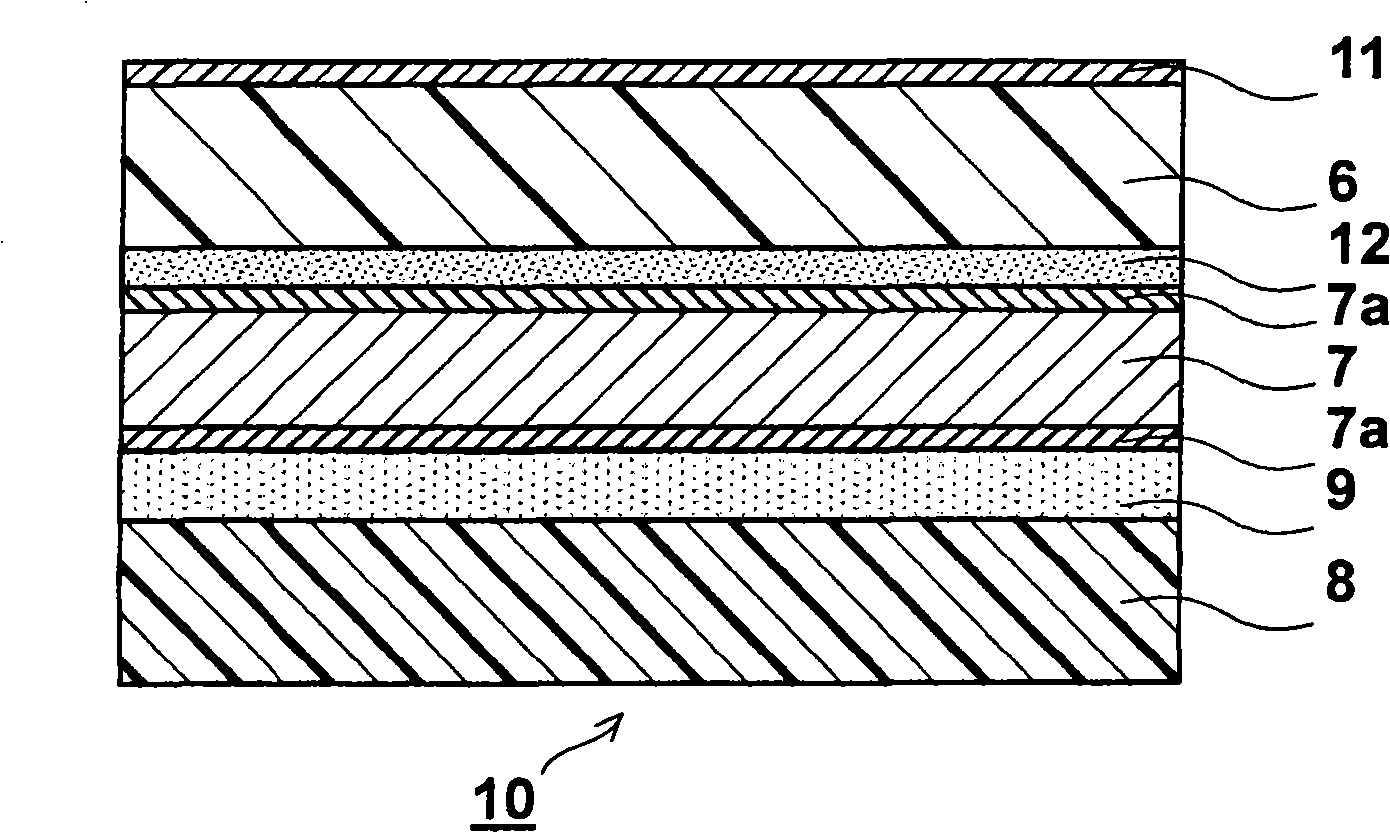

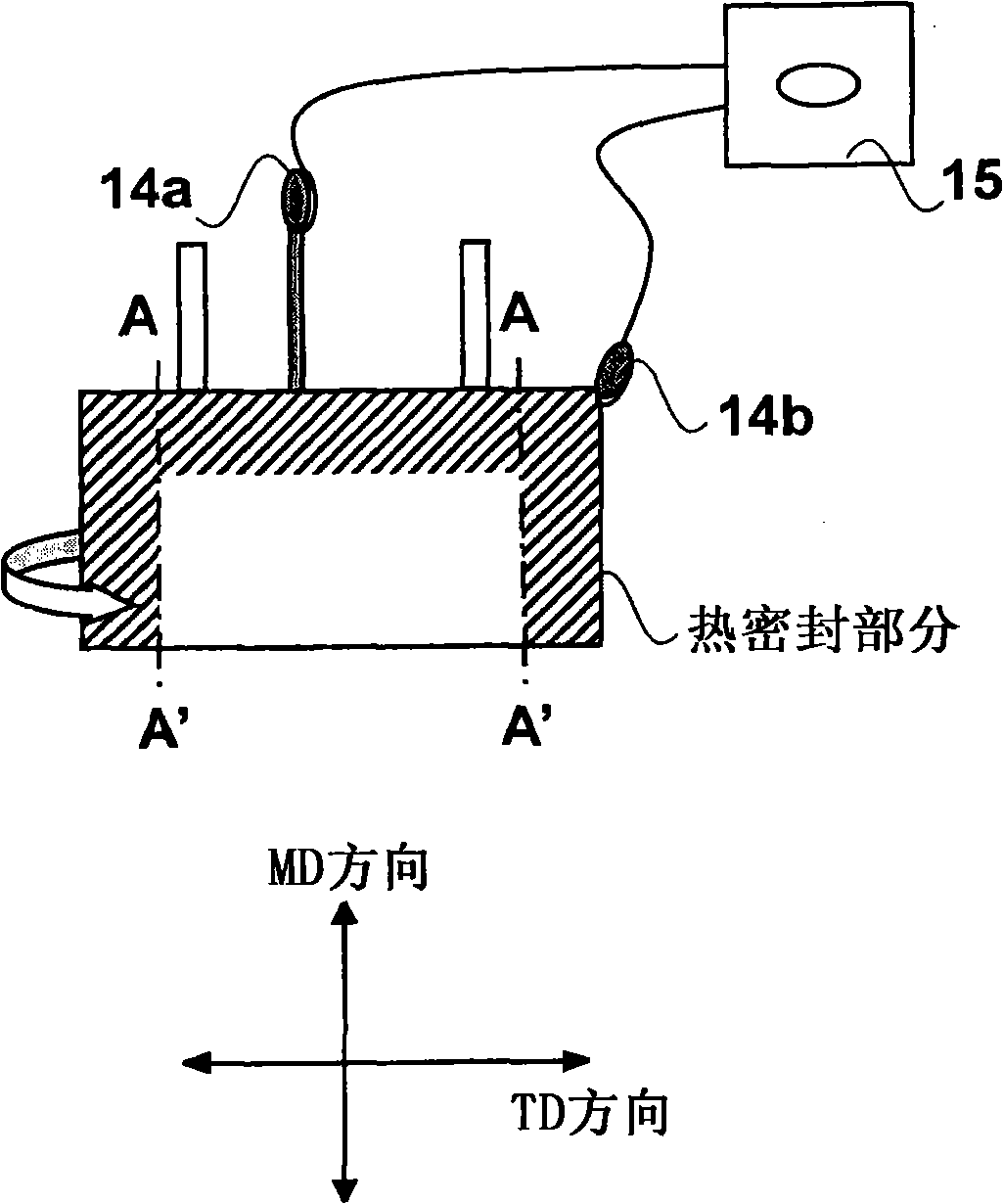

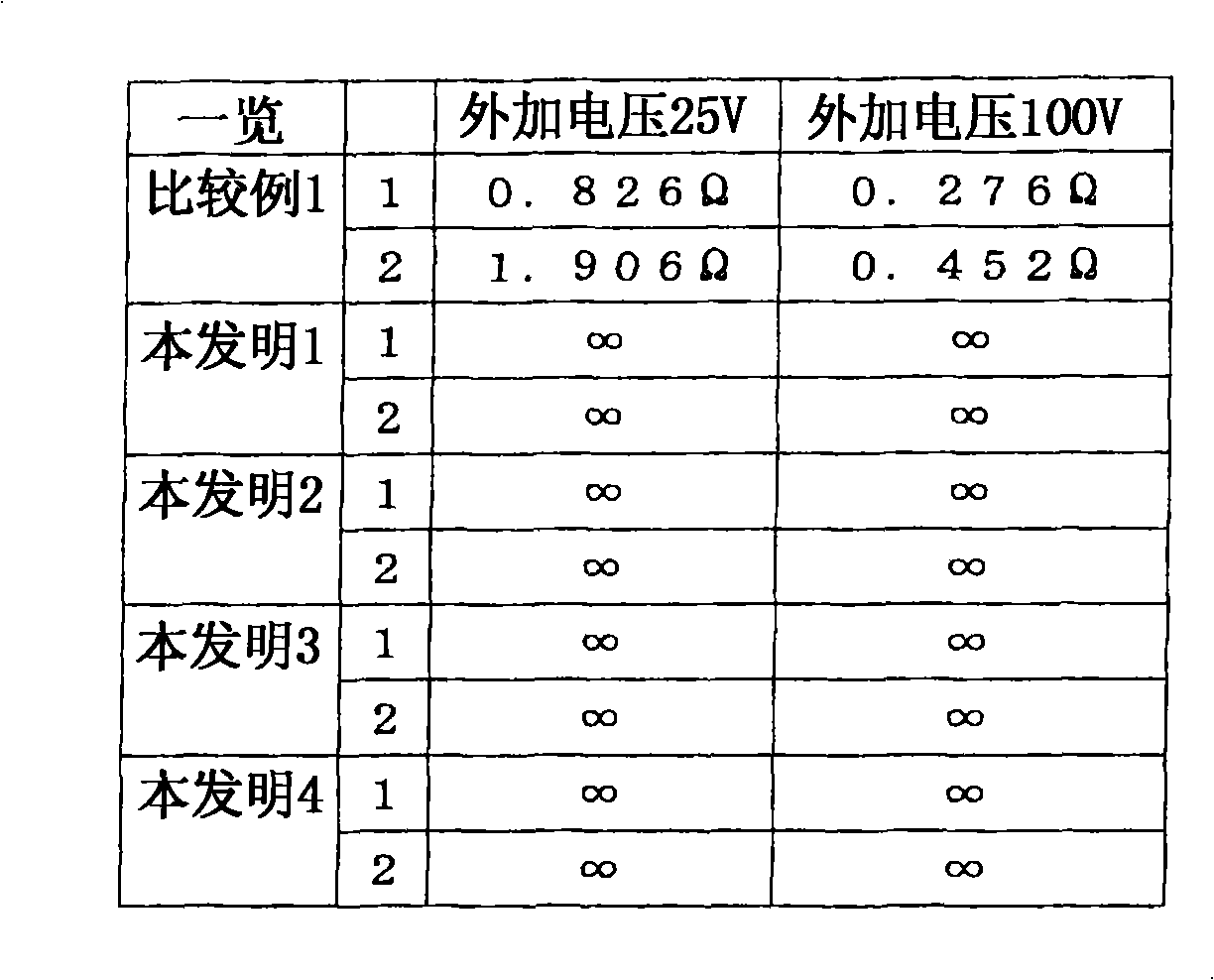

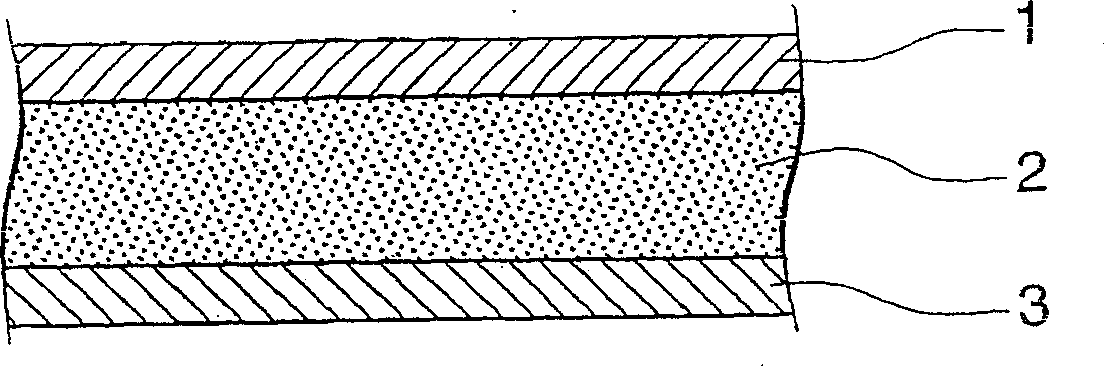

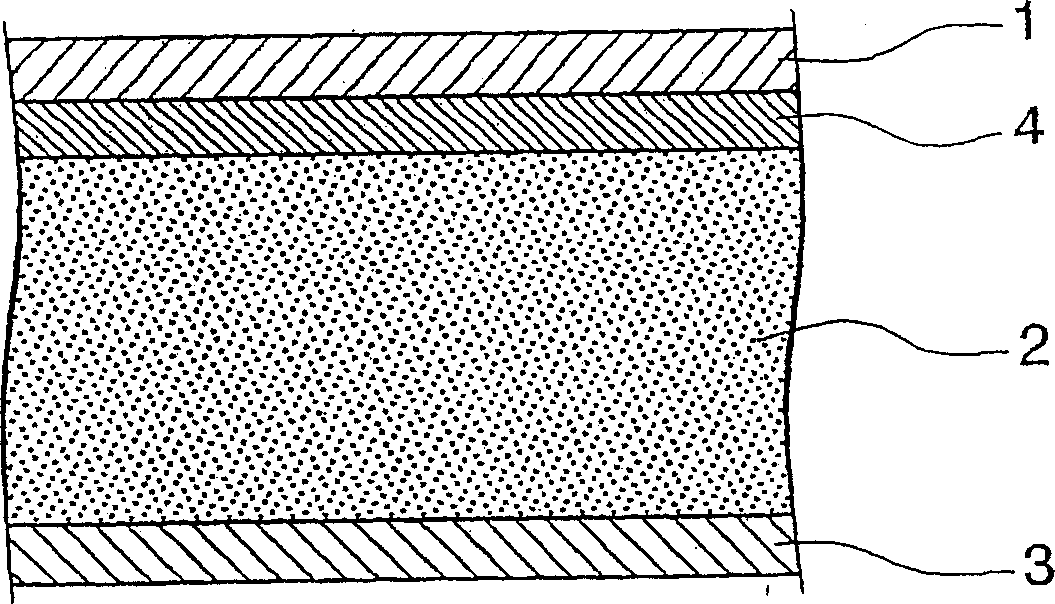

Packaging material for flat electrochemical cell

In a packaging material for electrochemical cell, a thermally adhesive resin layer is configured of a resin having a propylene based elastomer resin in a propylene based resin. This propylene based elastomer resin is a copolymer composed of a constitutional unit derived from propylene and a constitutional unit derived from an alpha-olefin having from 2 to 20 carbon atoms; when the total sum of the constitutional unit derived from propylene and the constitutional unit derived from an alpha-olefin is defined as 100% by mole, contains 50% by mole or more of the constitutional unit derived from propylene; and is satisfied with (a) a Shore A hardness (ASTM D2240) of from 65 to 90, (b) a melting point of from 130 DEG C to 170 DEG C, (c) a density (ASTM D1505) of from 860 to 875 kg / m3 and (d) a glass transition temperature as measured by DSC of from -25 DEG C to -35 DEG C.

Owner:DAI NIPPON PRINTING CO LTD +1

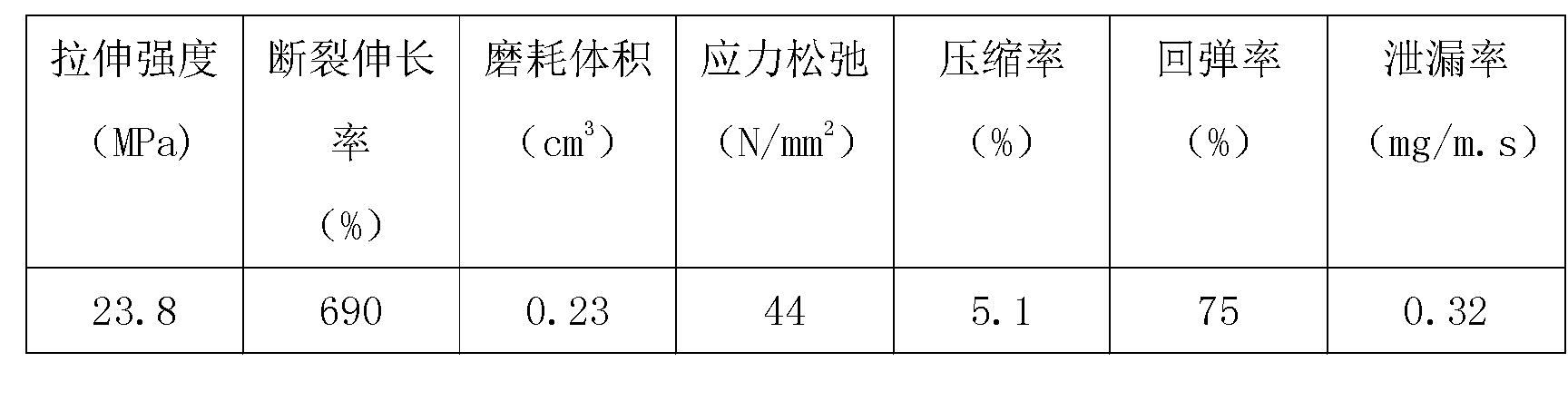

Nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket and preparation method thereof

The invention discloses a nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket. Raw materials for the nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket comprise, by weight, 135 to 145 parts of chlorosulfonated polyethylene rubber CSM2305, 10 to 15 parts of butyl rubber CBK139, 10 to 15 parts of Lanxess 2470 EPDM rubber, 2 to 5 parts of phthalate, 3 to 5 parts of propanediol sebacate polyester, 2 to 5 parts of n-butyl methacrylate, 3 to 4 parts of zinc oxide, etc. The gasket provided by the invention has the advantages of good high temperature resistance, sealing performance and flame resistance, excellent resistance to corrosion, small changes in its volume and hardness when working in mediums like an acid, an alkali and oil for a long time, no adherency onto the surface of a metal, a small friction coefficient, good wear resistance, flexibility of bonding with a sealing surface, good resistance to weathering ageing and ozone ageing, durability, etc.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

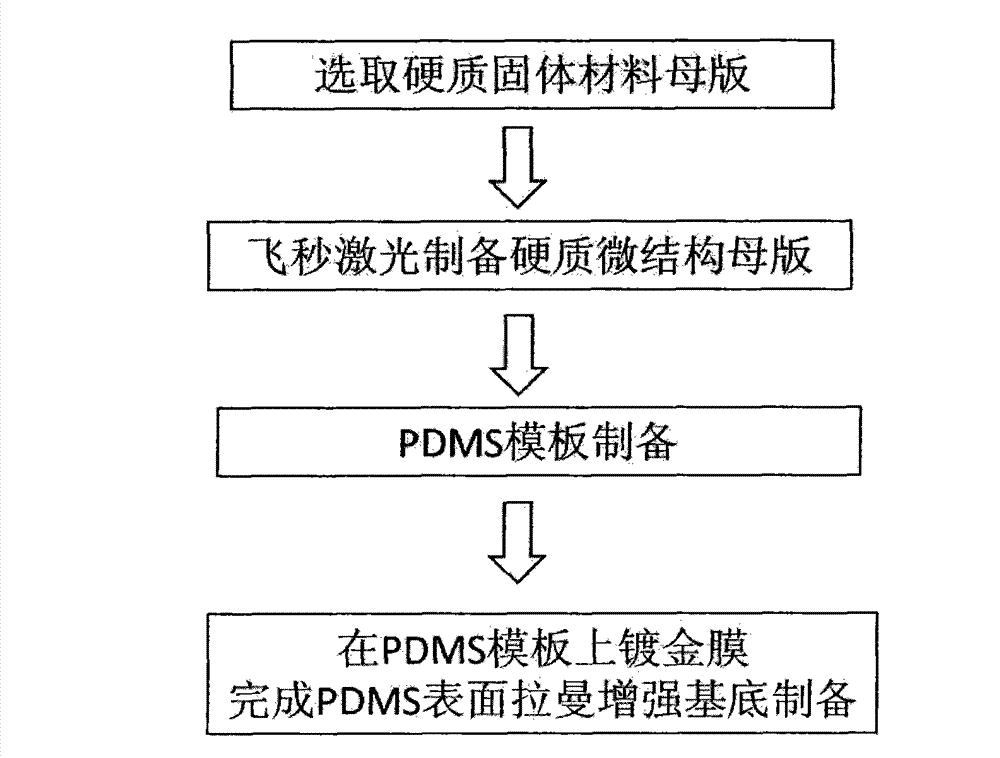

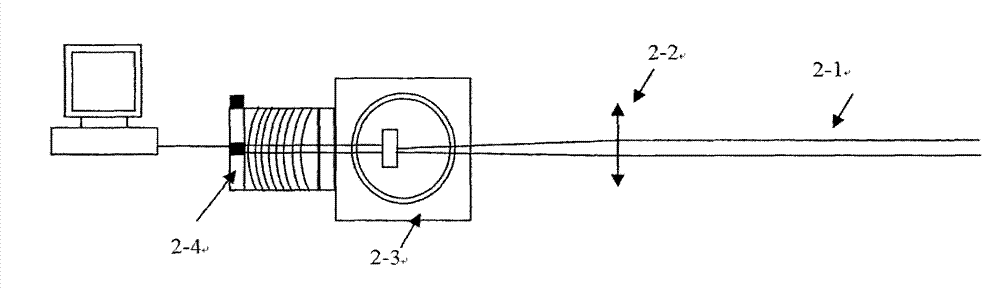

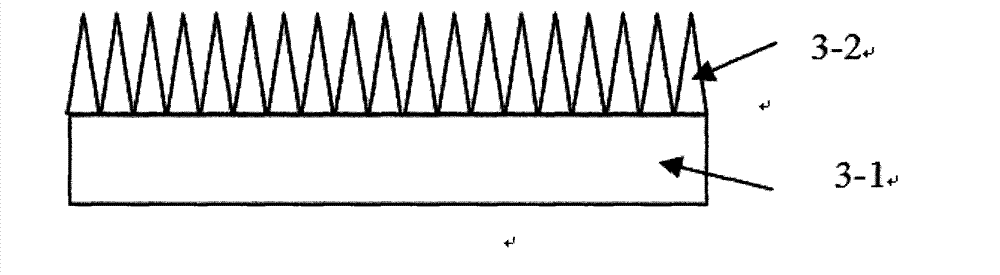

Preparation method of large-area surface enhancement raman scattering substrate

The invention discloses a preparation method of a large-area surface enhancement raman scattering substrate. The preparation method comprises the following steps: at first, the surface of a hard solid material is irradiated by femtosecond laser to prepare a large-scale hard microstructural mother set; then, polydimethylsiloxane (PDMS) is poured on the hard microstructural mother set by the nanoimprint lithography technology, and the structure on the hard microstructural mother set is copied to prepare a PDMS framework; and finally, a gold film is plated on the PDMS framework to prepare the PDMS surface enhancement raman scattering substrate. The experiment results show that the preparation method has the advantages that the enhancement factors are high, enhancement factors in different positions of the substrate have good uniformity, the large-area surface enhancement raman scattering substrate can be prepared, the mother set can be repeatedly imprinted, the production cost is reduced, and in addition, god is taken as raman enhancement metal, so that the defect that silver is oxidized very easily is avoided.

Owner:NANKAI UNIV

Soil repellency aqueous dispersions, soil repellant soft articles, and methods of making the same

ActiveUS20110311757A1Improve efficiencySoftMaterial nanotechnologyStain/soil resistant fibresFiberYarn

A soil repellency aqueous dispersion for treating various fibers, yarns, and textiles is disclosed. The dispersion provides superior soil resistance when compared to known fluorochemical and silicone fiber treatments. The dispersion comprises clay nanoparticle components and fluorochemicals that can be applied to the fibers, yarns, and textiles using known methods.

Owner:INV PERFORMANCE SURFACES LLC

Thermoplastic elastomeric resin composition and a process for the preparation thereof

InactiveUS20030017223A1Heat resistantSoftFilm/foil adhesivesCeramic shaping plantsElastomerThermoplastic

The invention provides a process for the preparation of a thermoplastic elastomeric resin composition comprising melt kneading (a) 100 parts by weight of a block copolymer consisting of at least two polymeric blocks (A) composed mainly of a vinyl aromatic compound and at least one polymeric block (B) composed mainly of a conjugated diene compound, and / or a hydrogenated block copolymer obtained by hydrogenating said block copolymer, (b) 20 to 300 parts by weight of a non-aromatic softening agent for rubber, (c) 1 to 150 parts by weight of a peroxide-crosslinking type olefinic resin and / or a copolymeric rubber containing said resin, and (d) 10 to 150 parts by weight of a peroxide-decomposing type olefinic resin and / or a copolymer containing said resin, characterized in that the process comprises a step of heat-processing component (a), component (b), at least a part of component (c), at least a part of component (d) and at least a part of 1.0 to 1,200 parts by weight of component (e) in the presence of an organic peroxide to cause crosslinking, wherein component (e) is at least one thermoplastic polymer selected from the group consisting of polyester type (co)polymers, polyamide type (co)polymers and polyurethane type (co)polymers, and a subsequent step of blending these with the remaining part of component (c), and, the remaining part of component (d) and component (e), if any. The obtained composition is soft and excellent in heat deformation resistance and mechanical strength, moldability and processability, particularly in oil resistance and stain resistance.

Owner:RIKEN TECHNOS CORP

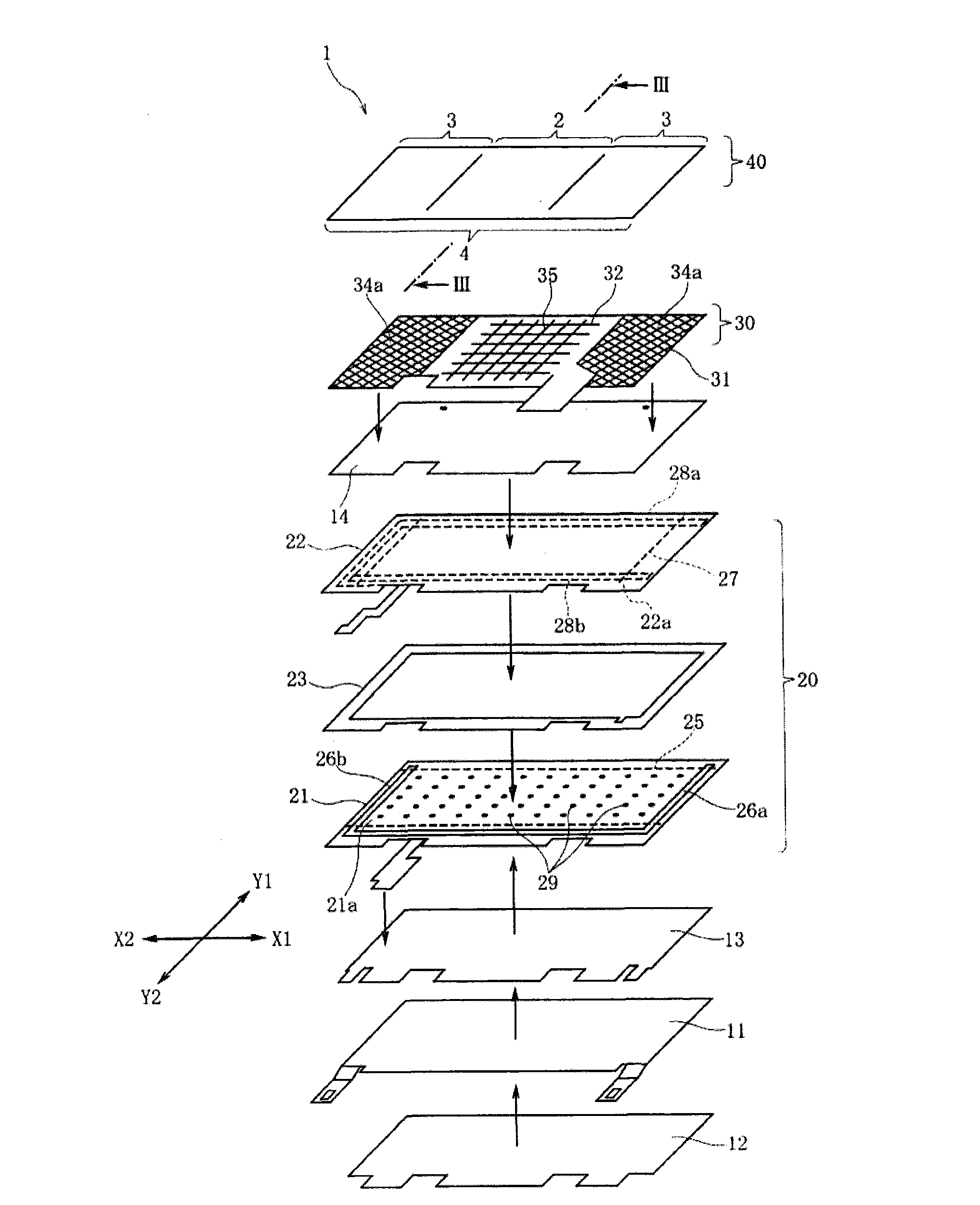

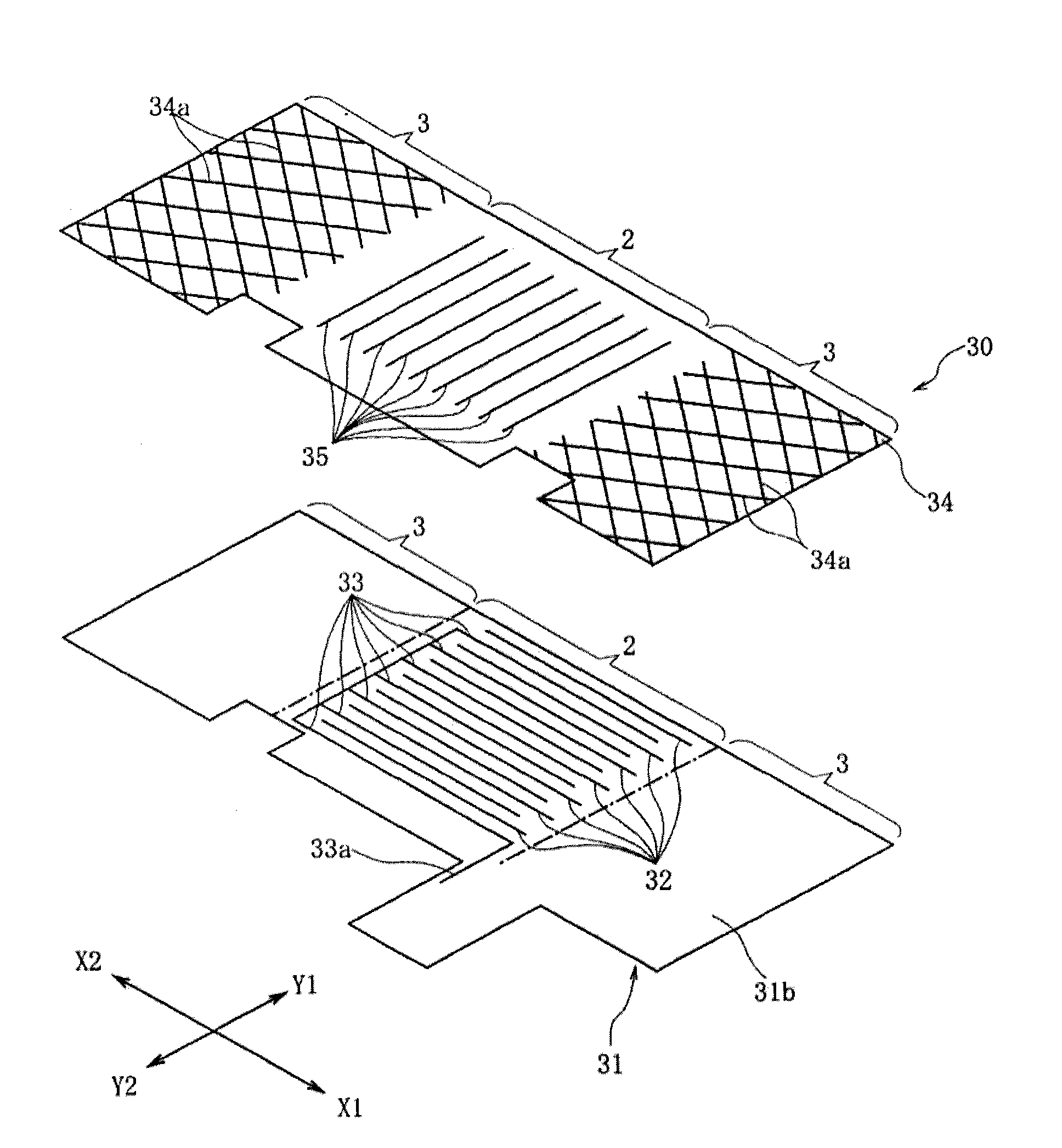

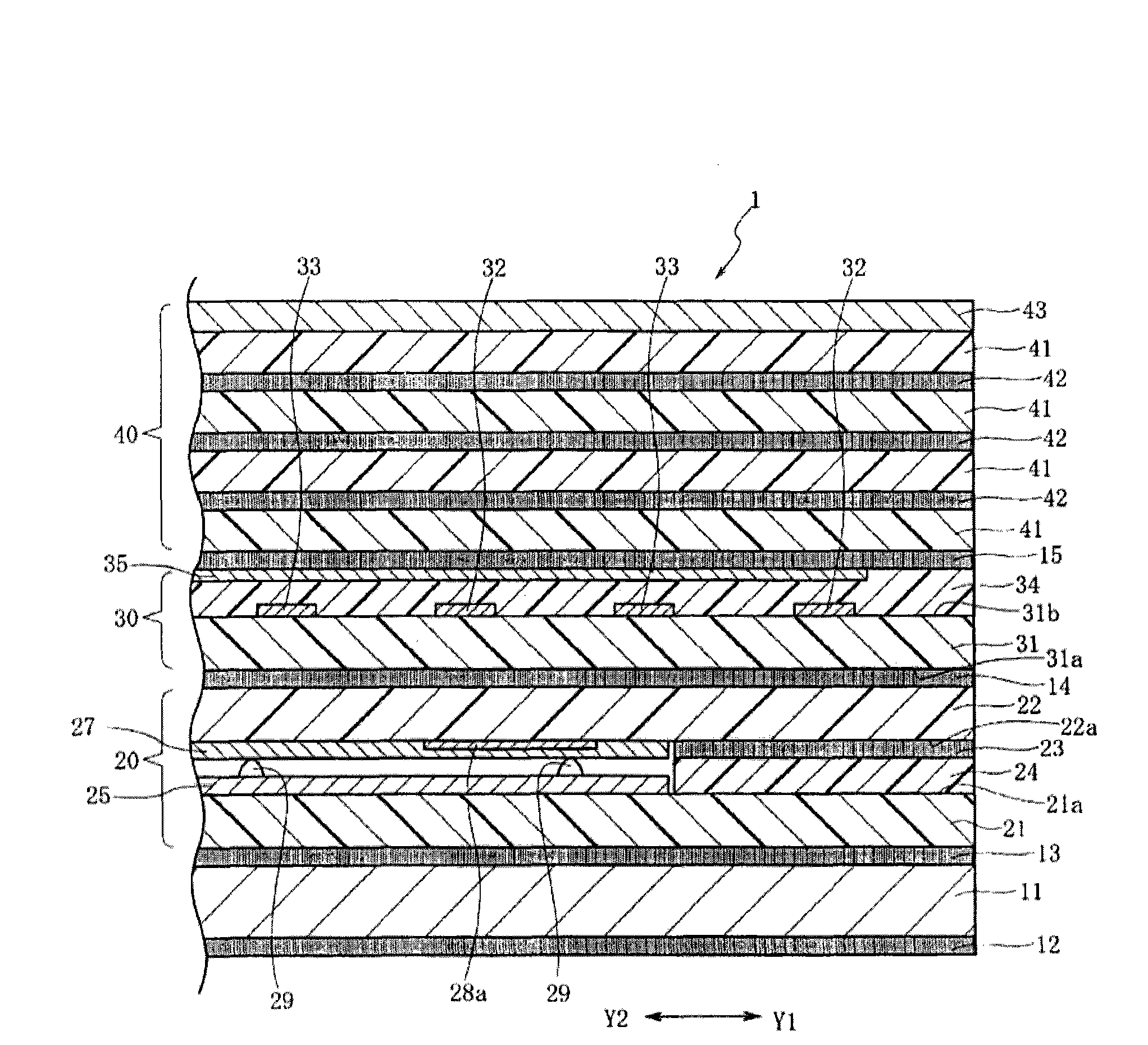

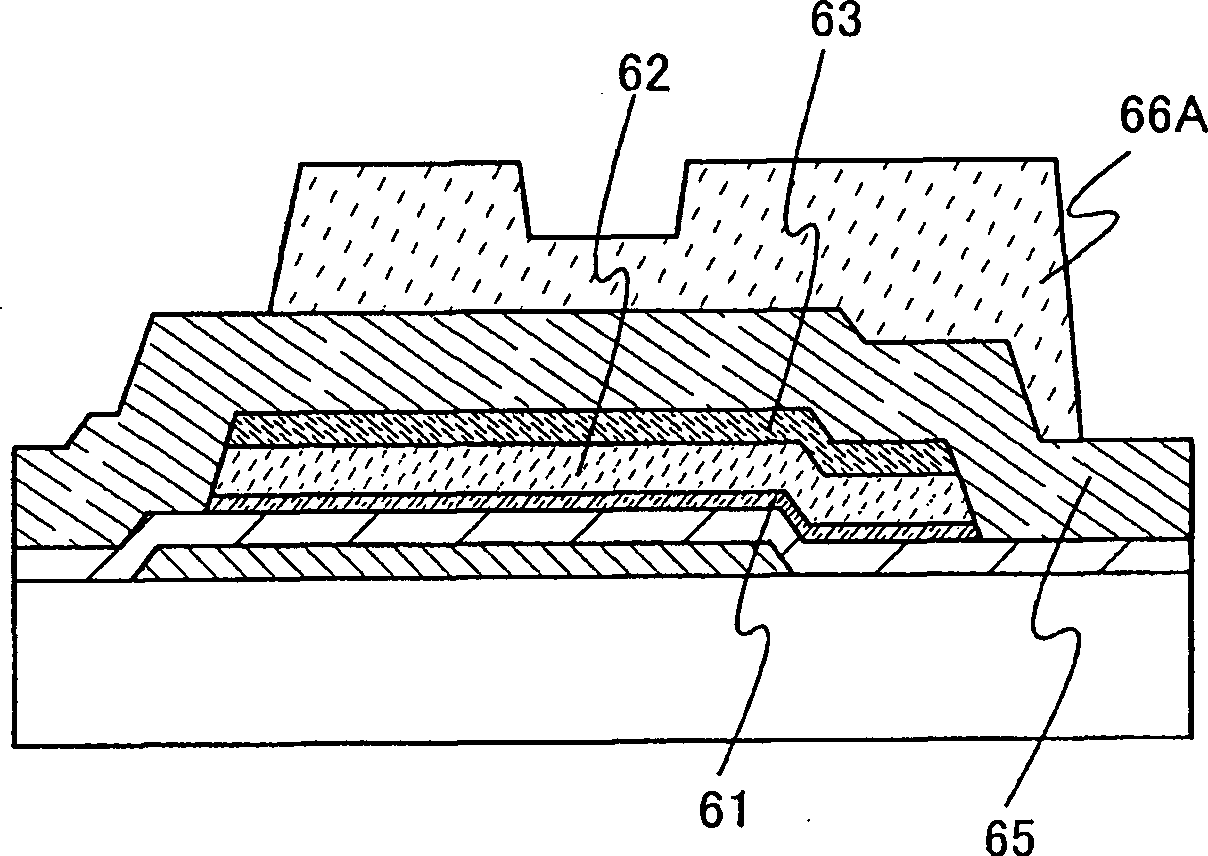

Input device

InactiveCN101515214ASolve the problem of extreme drop in detection accuracyReduce the number of layersInput/output processes for data processingManufacturing cost reductionCapacitance

Disclosed is an input device capable of decreasing the number of layers of a detecting portion to reduce manufacturing costs and easily deforming layers provided above a pressure sensitive detecting portion. A capacitance-type detecting portion that detects the contact position of a finger on the basis of a variation in capacitance is provided on a pressure sensitive detecting portion that includes a lower detection layer formed on a lower base sheet and an upper detection layer formed on an upper base sheet. A voltage is applied to the pressure sensitive detecting portion and the capacitance-type detecting portion such that the application times of the voltages do not overlap each other. Therefore, it is possible to prevent interference between the detection operations of the two detecting portions.

Owner:ALPS ALPINE CO LTD

Dyeing technology of nylon-imitating high-elastic polyester yarn

InactiveCN103498350AImprove featuresEnsure stabilityFibre typesHeating/cooling textile fabricsTextile printerPolyester

The invention relates to the technical field of textile printing and dyeing, and provides a dyeing technology of a nylon-imitating high-elastic polyester yarn. According to the dyeing technology, by combining of low-elastic polyester and twisting into high-elastic polyester, the nylon yarn dyeing problem can be solved and an elastic hand feeling effect of the nylon yarn can be achieved, and the dyeing technology comprises a polyester yarn dyeing preprocessing process, a yarn reeling process, high temperature preforming, a dyeing process, a reduction cleaning process, a finishing process and a dehydration drying process.

Owner:福建锦丰印染有限公司

Preparation method of composite terylene knitted fabric

The invention relates to a preparation method of a composite terylene knitted fabric, which comprises the following steps of: (1) using DTY (Draw Textured Yarn) yarns as terry of a single-sided velvet surface, using DTY yarns which are processed at a temperature of 120 to 130 DEG C as terry of a coral velvet surface, using FDY (Fully Drawn Yarn) yarns as bottom yarns and selecting blank cloth by a weaving machine structure and a coil; and (2) by processing of alkali weight reduction, respectively processing the terry of the single-sided velvet surface and the terry of the coral velvet surface to obtain the composite terylene knitted fabric. The preparation method has simple process and low cost and is environmental-friendly; two different napped style effects are formed by the variation of a tissues structure and different shrinkage principles of polyester yarns; and the prepared composite terylene knitted fabric has soft hand feeling, light gram weight and wide application prospect.

Owner:NINGBO DAQIAN TEXTILE

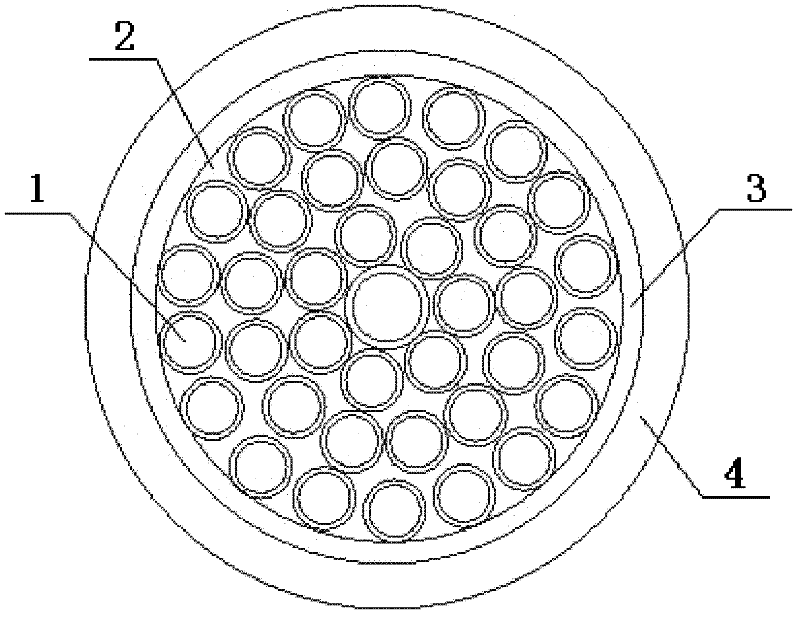

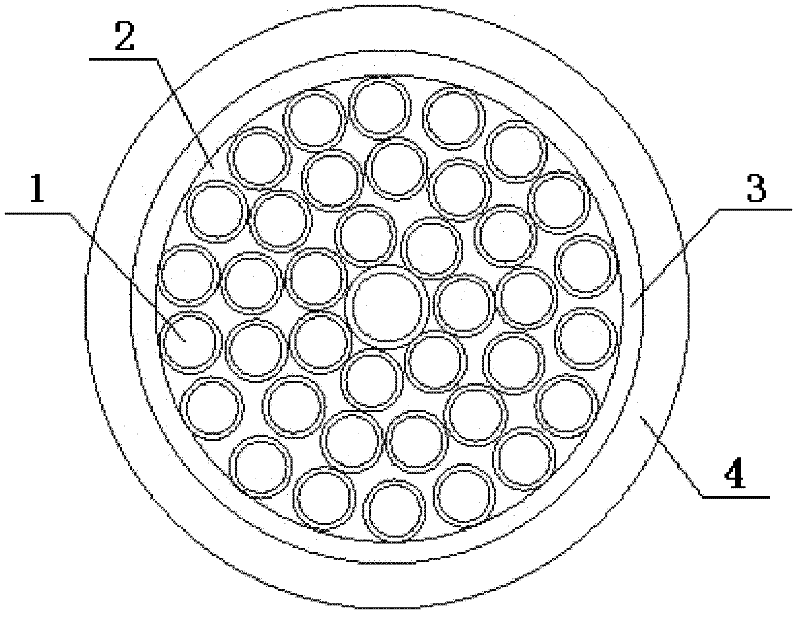

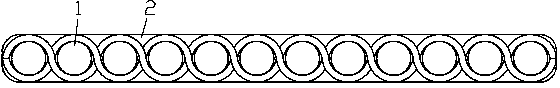

Rat-proof termite-proof low-smoke low-halogen leadless flame-retardant control cable for elevator shaft

ActiveCN102446586ACreate pollutionRodent proofPlastic/resin/waxes insulatorsInsulated cablesHalogenElectrical conductor

The invention relates to the technical field of cables and in particular relates to a cable for elevators, and provides a rat-proof termite-proof low-smoke low-halogen leadless flame-retardant control cable for elevator shafts, which comprises a sheath and a cable core arranged in the sheath, wherein the cable core comprises a conductor and an insulating layer arranged outside the conductor, the sheath is a polyvinyl chloride sheath made of a polyvinyl chloride insulating material, and the polyvinyl chloride insulating material has rat-proof, termite-proof, low-smoke, low-halogen, leadless and flame-retardant properties. By using the technical scheme, the cable has the rat-proof, termite-proof, low-smoke, low-halogen, leadless and flame-retardant effects, and also has the advantages of flexibility, elasticity and firm structure.

Owner:上海贝恩科电缆有限公司

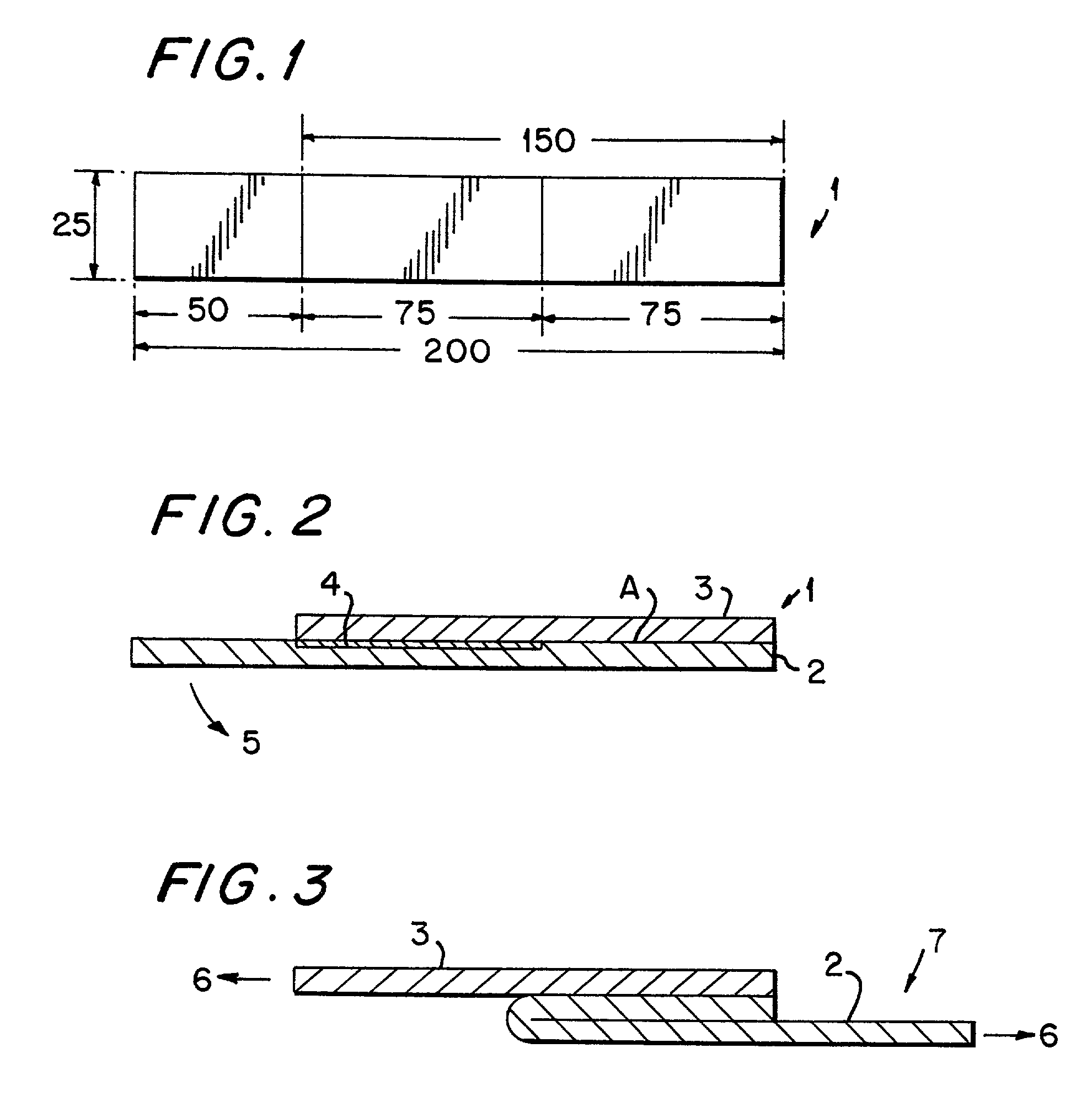

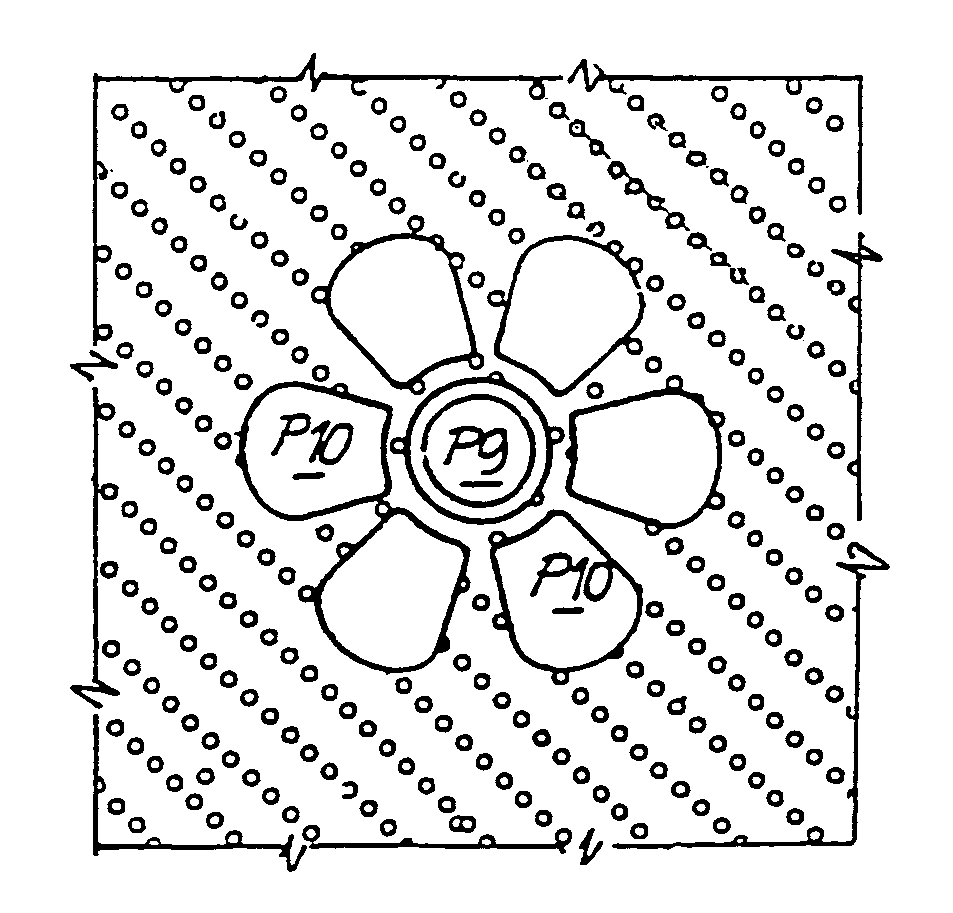

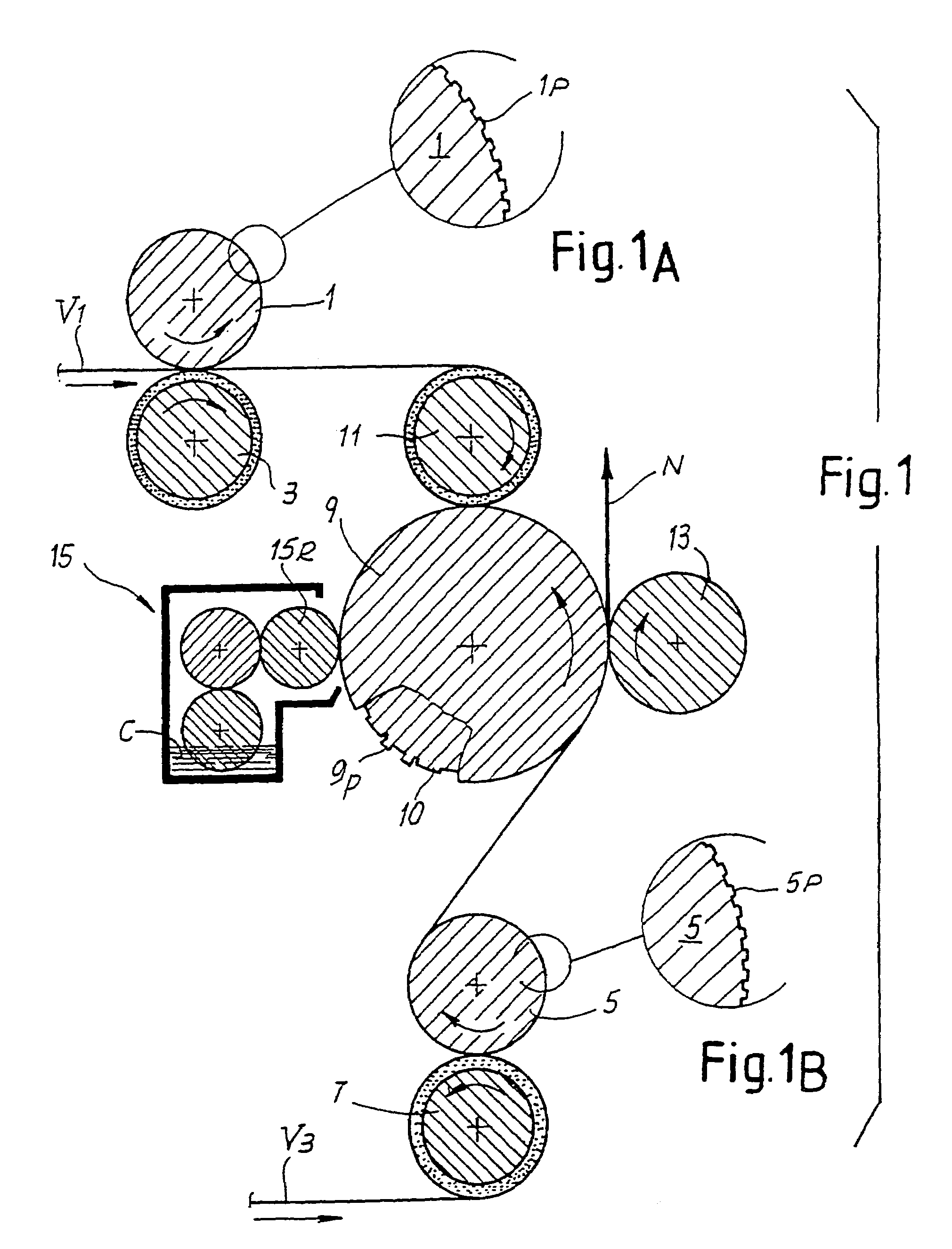

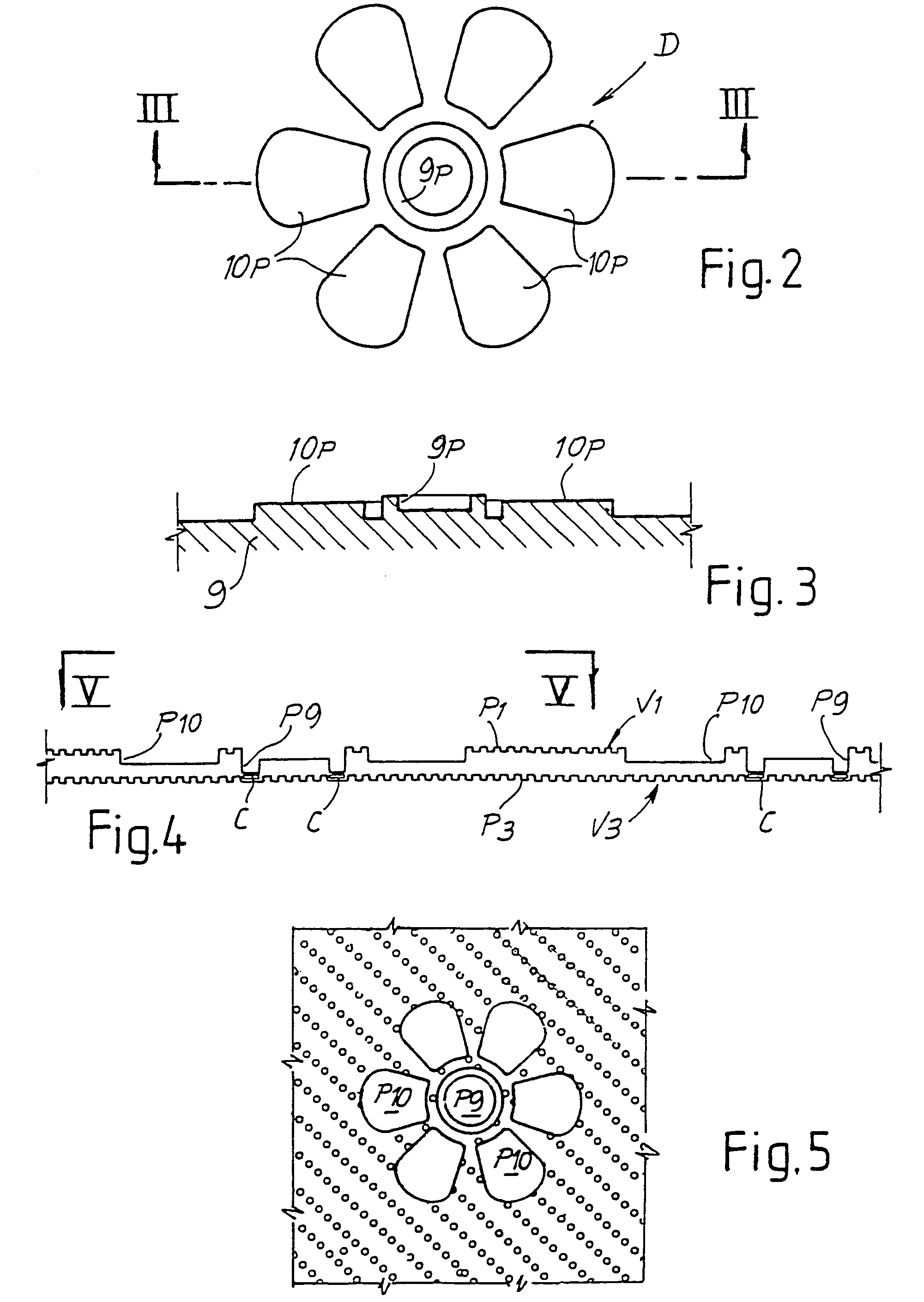

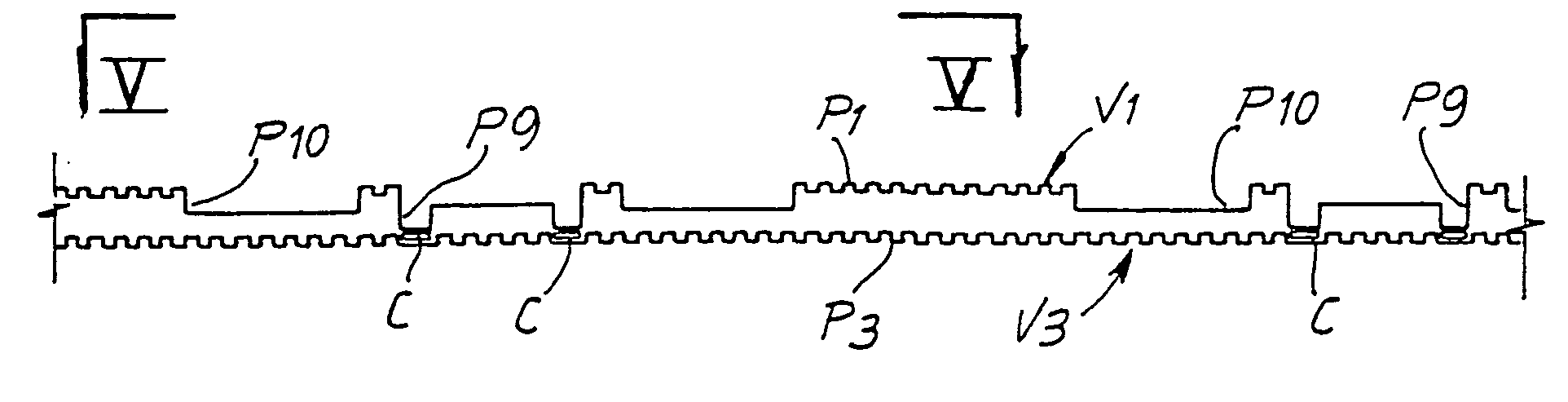

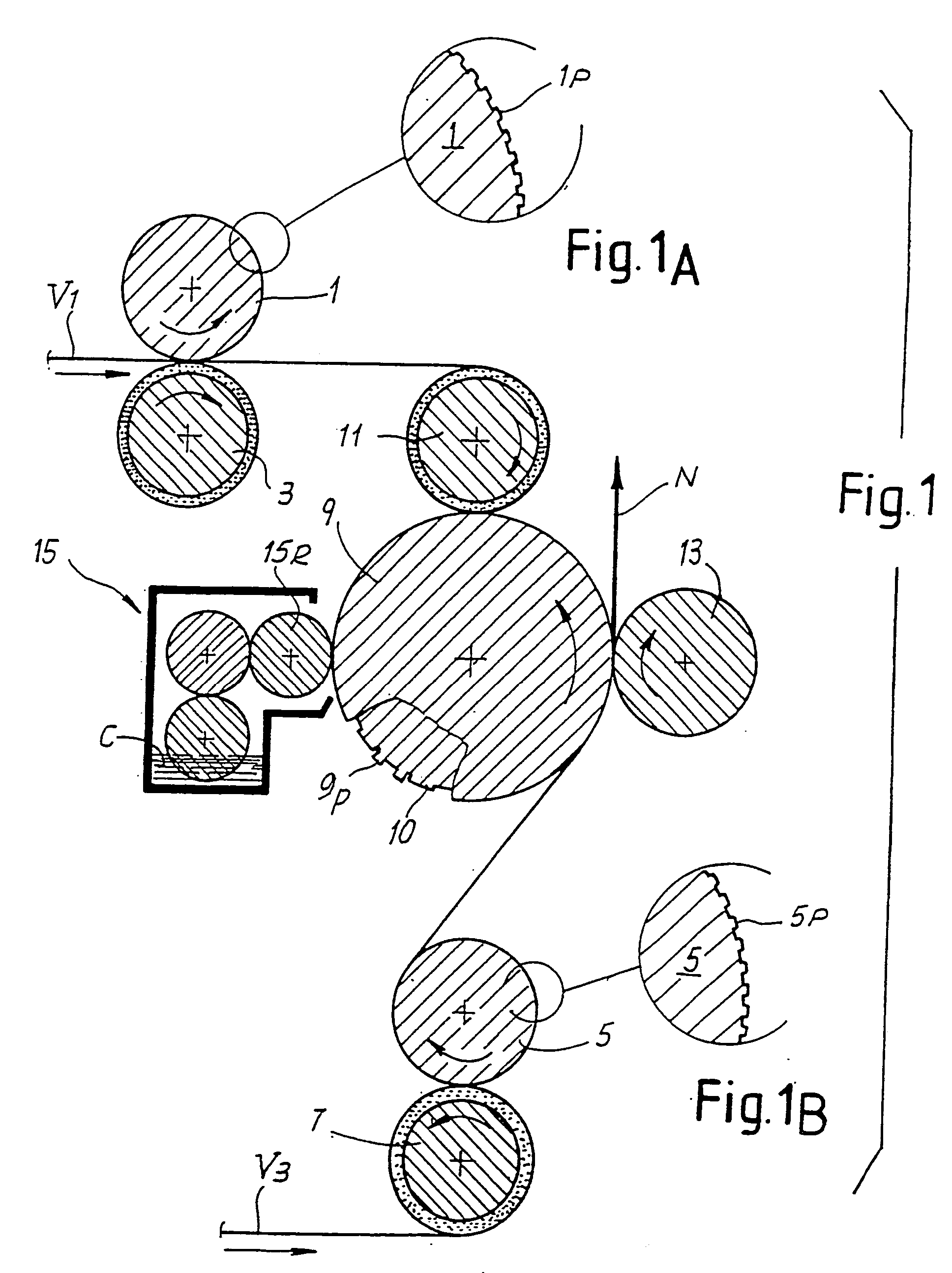

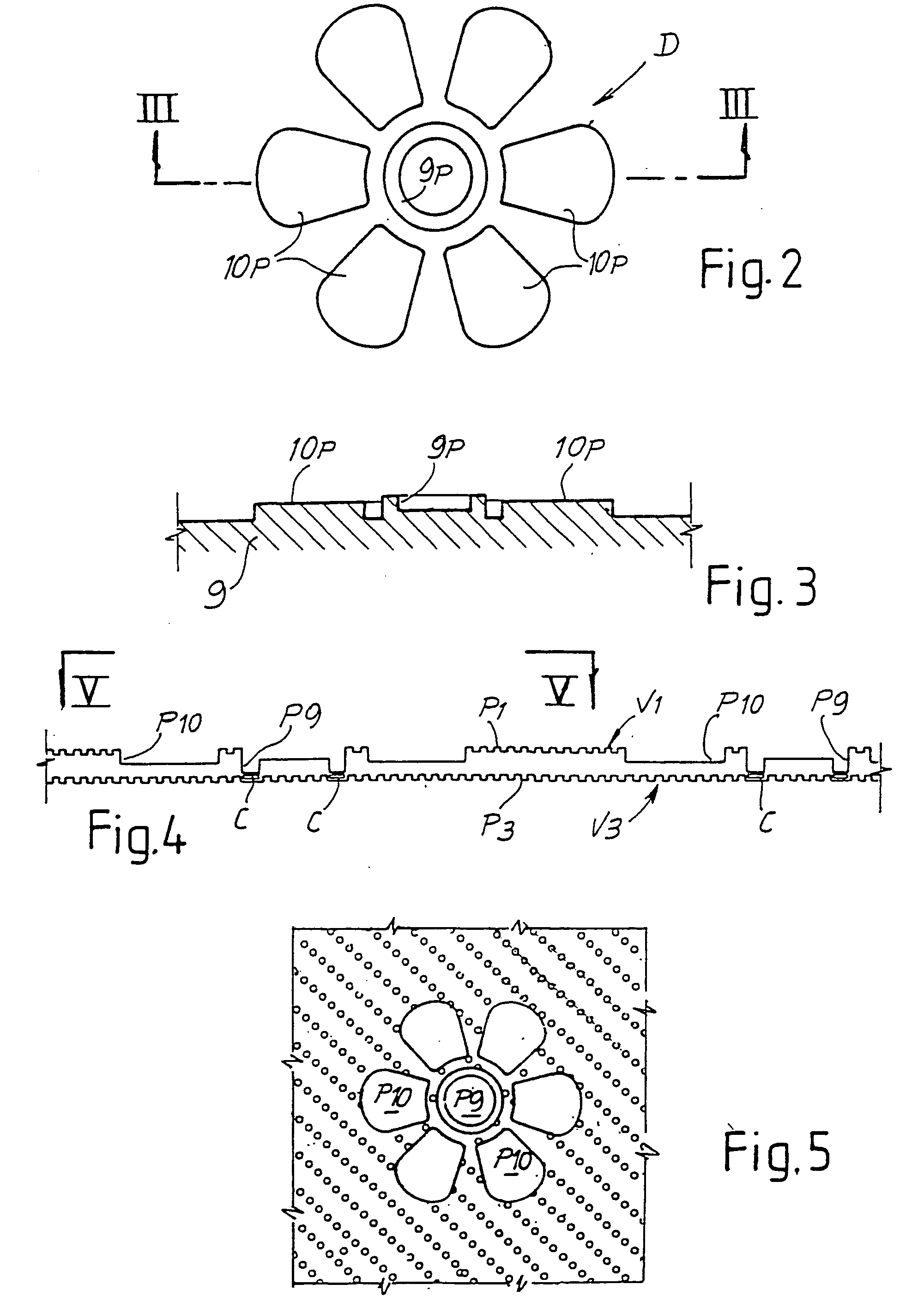

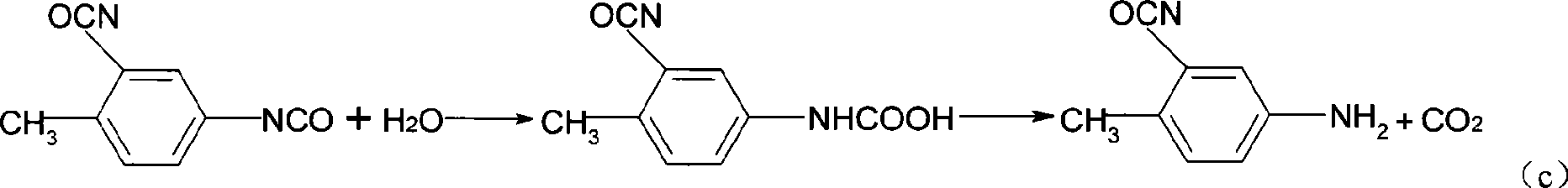

Method and device for producing an embossed web material and product obtained with said method

InactiveUS7285317B2Maintaining and improving technical characteristicEliminating reducing limitMechanical working/deformationSpecial paperAdhesiveEngineering

A method for producing an embossed web product comprising at least two plies (V1, V3) bone to one another by gluing, wherein: at least a first of said plies is embossed producing on it a first series of protuberances (P9) and a second series of protuberances (P10), the protuberances of the first series being of greater height than the protuberances of the second series; an adhesive (C) is applied to the protuberances of said first series; the first ply is glued to the second ply (V3), the protuberances (P9, P10) of the first ply projecting inside the web product, towards the second ply (V3). The protuberances of the first and of the second series form in combination with each other complex decorative patterns (D). Each complex decorative pattern is formed by at least a protuberance of the first series and at least a protuberance of the second series. Moreover, the complex decorative patterns are distributed with a density equal to or less than 2 patterns per cm2.

Owner:FABIO PERINI SPA

Bamboo fiber label tape and production method thereof

ActiveCN103590255ANot easy to wrinkleSoft touchSucessive textile treatmentsVegetal fibresAdhesiveEngineering

The invention relates to label tapes and production methods thereof, particular to a bamboo fiber label tape and a production method thereof. The label tape comprises a base cloth layer and an adhesive layer, the thickness of the label tape is in a range of 0.280-0.300 mm, the base cloth layer is made of a 100% bamboo pulp fiber material, the count of bamboo pulp fiber yarn forming the base cloth layer is 16-40, the warp density is 28-45 warps / cm, and the weft density is 19-35 wefts / cm. The production method comprises the steps of selecting a bamboo fiber semi-finished product as base cloth; performing anti-crease finishing; subjecting the base cloth to two-time immersion and two-time rolling treatment; performing pre-calendering treatment: a calendering surface is a stain-weave surface, the calendering temperature is 50 DEG C to 60 DEG C, the pressure is 10MPa to 12MPa, the calendering speed is 30 m / min to 35 m / min, and the thickness of the base cloth is calendered into 0.285 mm to 0.295 mm; performing coating treatment: a dry type coating method is adopted, coating a plain-weave surface of the base cloth with adhesive, scraping pulp by pulp scraping equipment, the adhesive spread is controlled within 5 g / m<2> to 10 gm<2>, and the total weight is 144 g / m<2> to 148 g / m<2>; and performing post-calendering treatment: the calendering temperature is 70 DEG C to 120 DEG C, the pressure is 10MPa to 12MPa, the calendering speed is 30 m / min to 35 m / min, and the thickness of the coated cloth is calendered into 0.280 mm to 0.300 mm. The label tape touches soft and can be used as a sewn-in label.

Owner:HUZHOU SINY LABEL MATERIAL

Method for preparing animal and plant specimen by plasticization

InactiveCN1826887ANot corrosiveNo pollution in the processDead plant preservationDead animal preservationPlasticizerPolyethylene glycol

The invention relates to a method for plasticizing animal and plant specimen, belonging to field of preserving animal and plant body or part of them. The invention is to provide a method for plasticising animal and plant specimen taking carbowax as plasticising agent. The project comprises sterilization, cleaning and plasticising, and during plasticising process, the expected specimen is immersed into carbowax, the concentration of which is increased gradually from 10% to 100%, to make the carbowax replace water in specimen. The invention is applied for preparing animal and plant specimen. The invention is characterized by the nontoxic and non-corrosive specimen and non use of preservative agent.

Owner:CHONGQING NORMAL UNIVERSITY

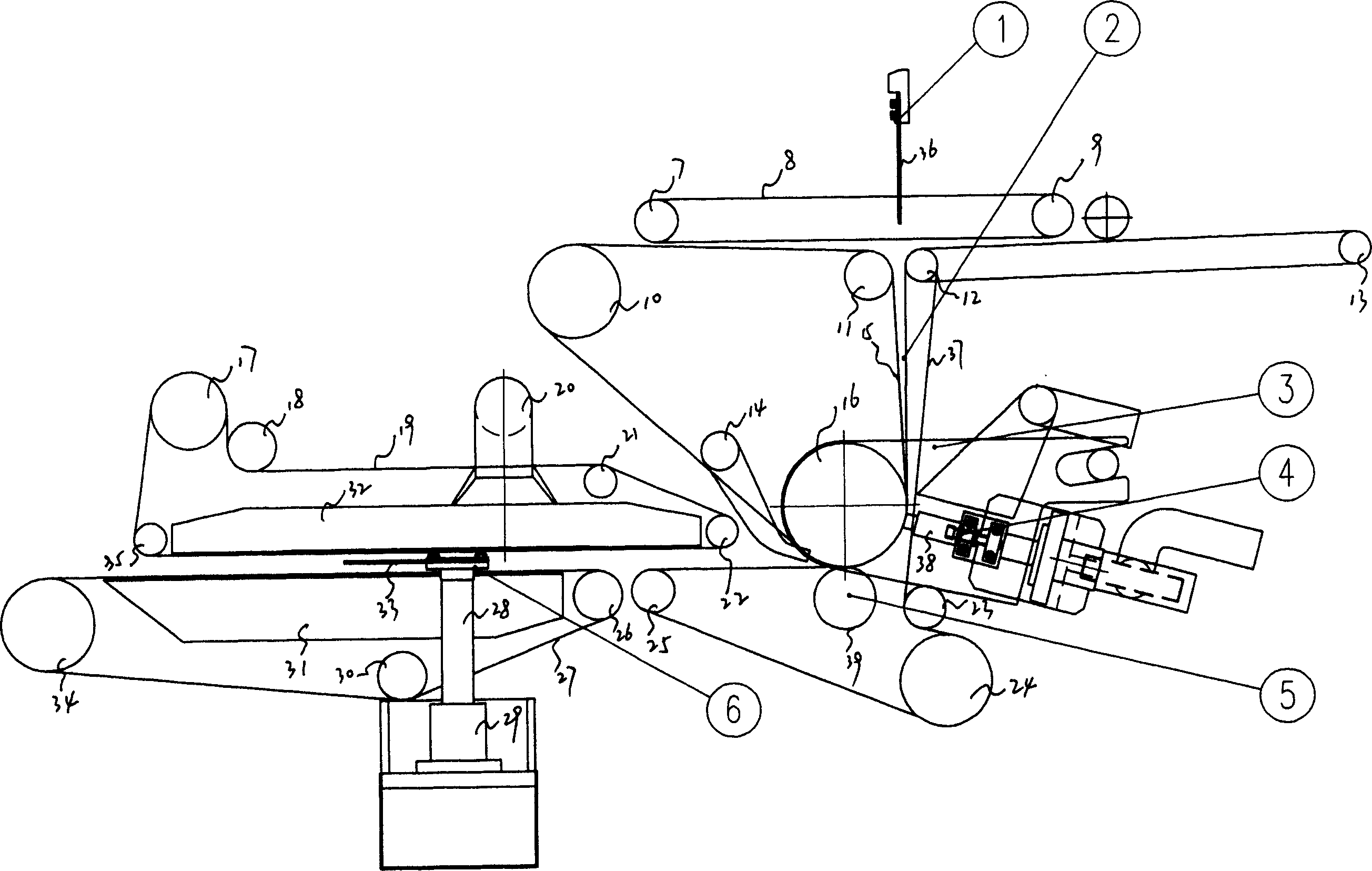

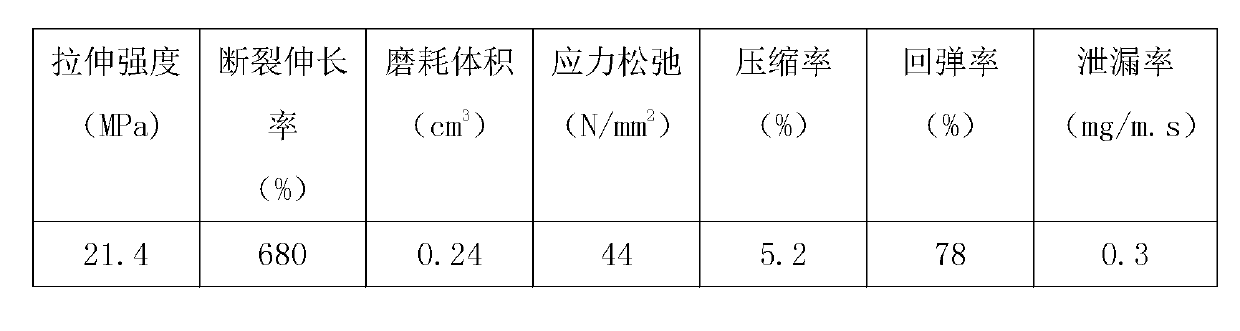

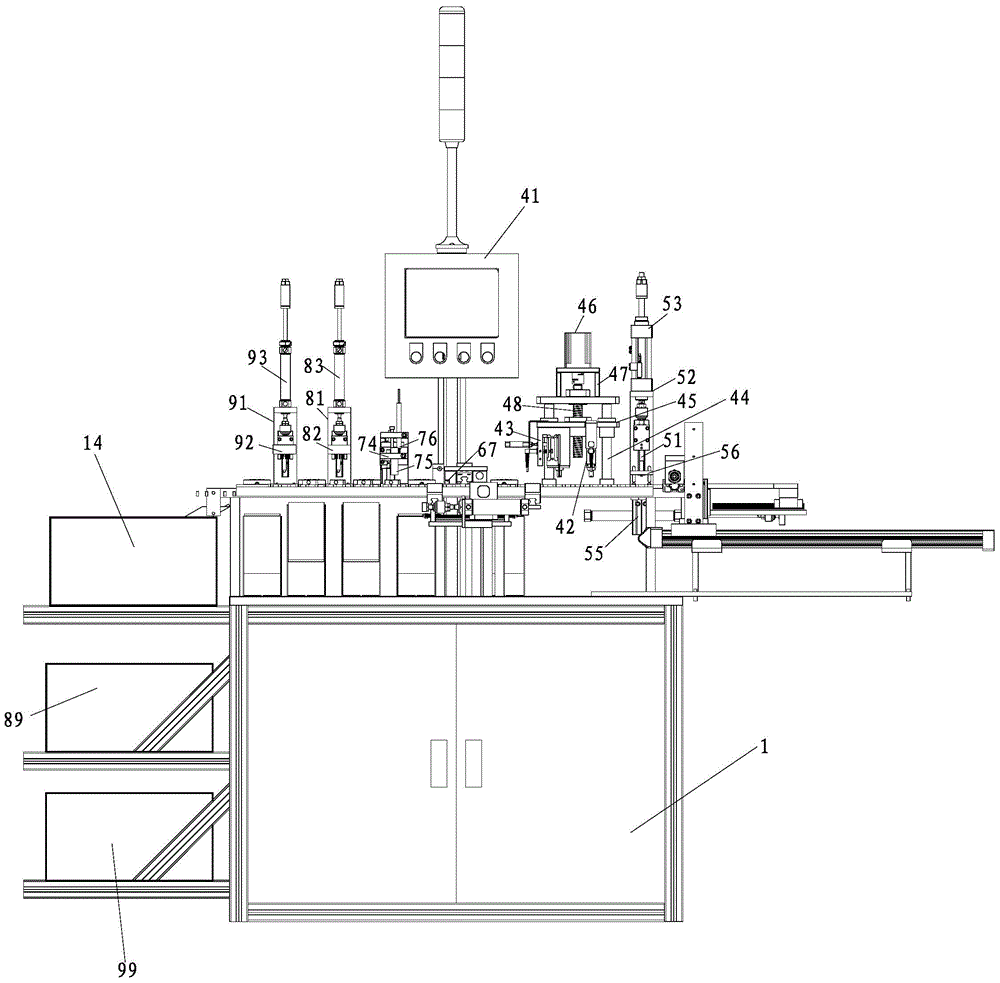

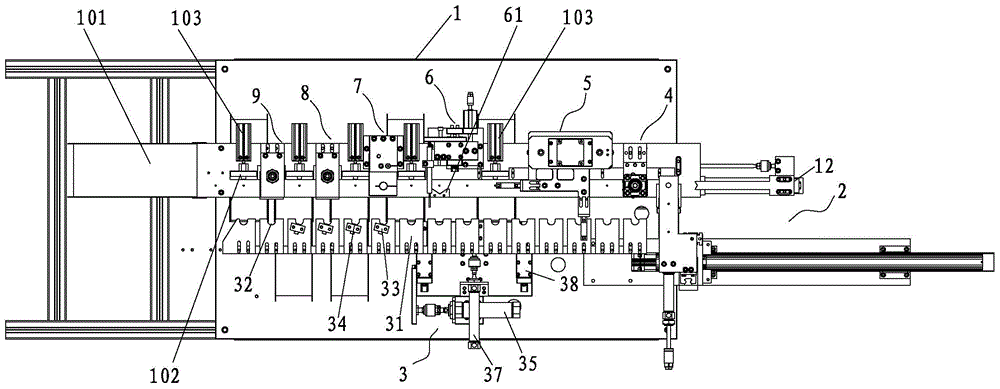

Infant and child training pants shaping derice and shaping method

A machine and method for forming the infantile training trousers are disclosed. An inserting plate can insert the training trousers in folding unit for symmetrically folding it. The two waist pieces of said training trousers are smoothed by a finishing unit. The pieces for waist and legs are welded by the patterning wheel or moulding roller and ultrasonic head in welding unit. The waist edge is cut by the trimming unit for making it neat. The left and right waist pieces are than curled by the edge curling unit.

Owner:ZHEJIANG ROBOT MACHINERY TECH

Manufacturing process of polyurethane foam sheet and layered sheet using the same

ActiveCN1732082AControllable shapeUniform shapeSynthetic resin layered productsLaminationWood veneerCushioning

A method of producing a polyurethane foam sheet, and a laminated sheet that uses such a foam sheet, that can be applied to artificial leather, synthetic leather, and cushioning materials used in all manner of applications. A polyurethane foam sheet is produced by applying a liquid mixture, obtained by mixing together a heated and melted hot melt urethane prepolymer (A) containing isocyanate groups at molecular terminals, and a compound (B) containing at least 2 active hydrogen atom-containing groups, onto a substrate in a sheet-like manner, and then water foaming the liquid mixture by bringing the sheet-like liquid mixture into contact with water vapor or moisture (water). A laminated sheet is produced by bonding a third substrate to the polyurethane foam sheet.

Owner:DIC CORP

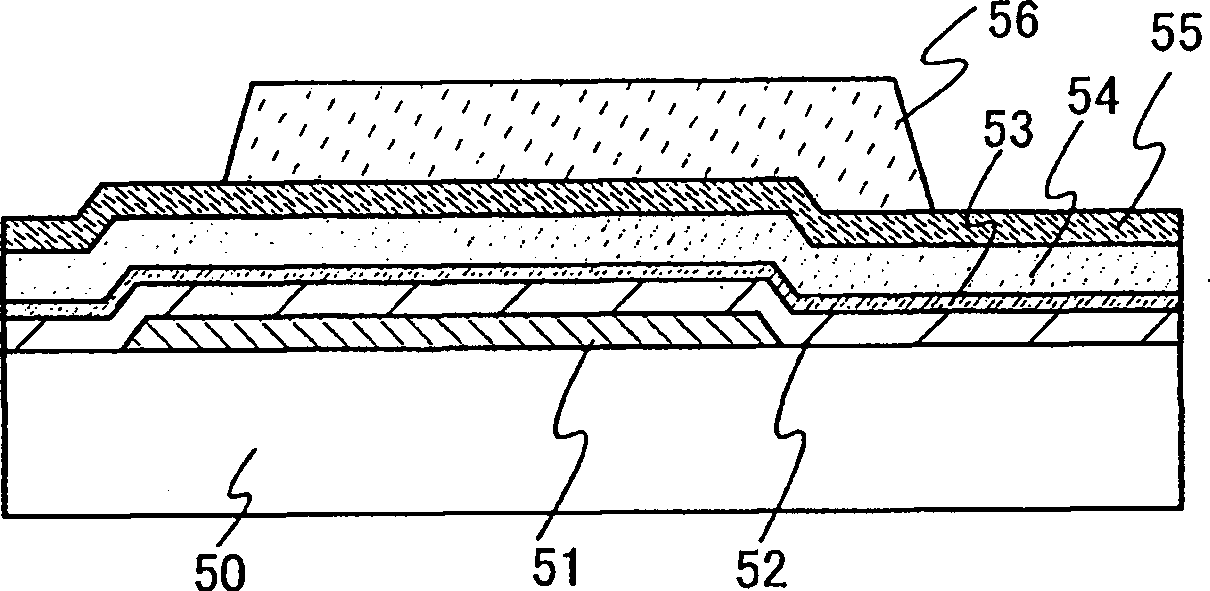

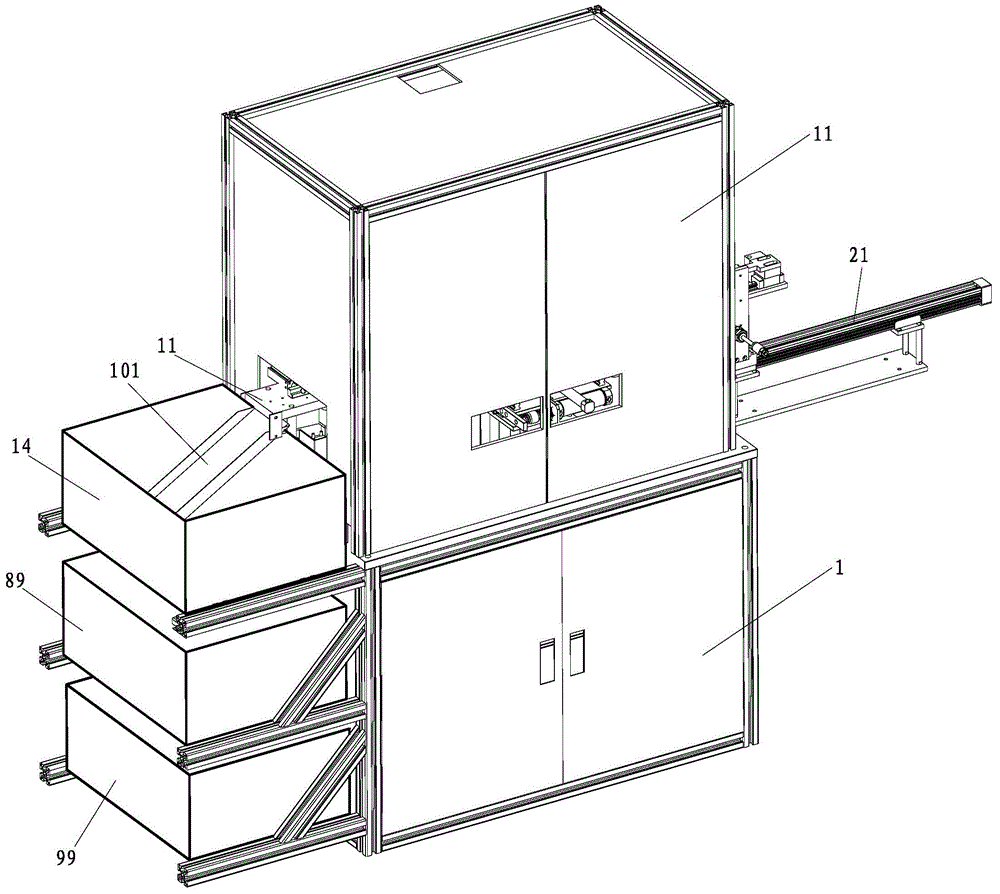

Electrophoretic display device and method for manufacturing thereof

InactiveCN101393370AImprove electrical characteristicsImprove reliabilitySolid-state devicesNon-linear opticsElectrophoresisDisplay device

It is an object to provide an electrophoretic display device having a thin film transistor which has highly reliable electric characteristics, lightweight, and flexibility. A gate insulating film is formed over a gate electrode, a microcrystalline semiconductor film which functions as a channel formation region is formed over the gate insulating film, a buffer layer is formed over the microcrystalline semiconductor film, a pair of source and drain regions are formed over the buffer layer, a pair of the source and drain electrodes in contact with the source and drain regions are formed. Then, the inverted-staggered thin film transistor is interposed between the flexible substrates, and the thin film transistor is provided with electrophoretic display element which is electrically connectedby the pixel electrode. Then, the electrophoretic display electrode is surrounded by the partition layer so as to cover the end portion of the pixel electrode and provided over the pixel electrode.

Owner:SEMICON ENERGY LAB CO LTD

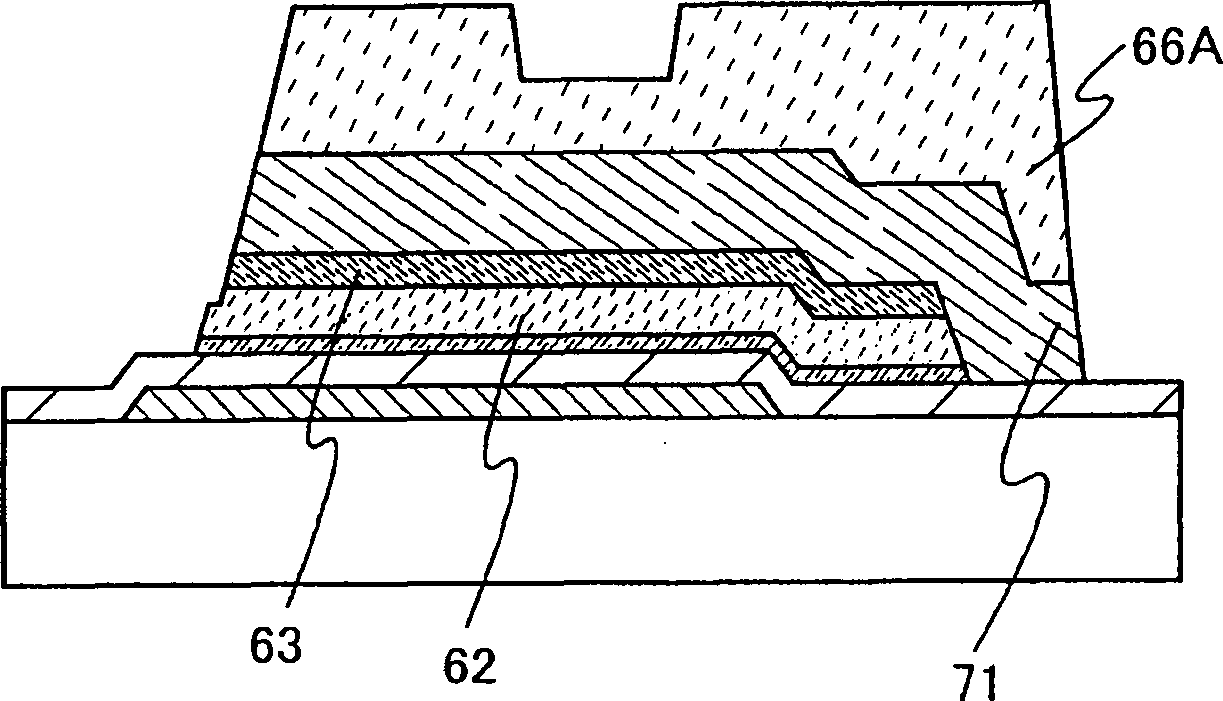

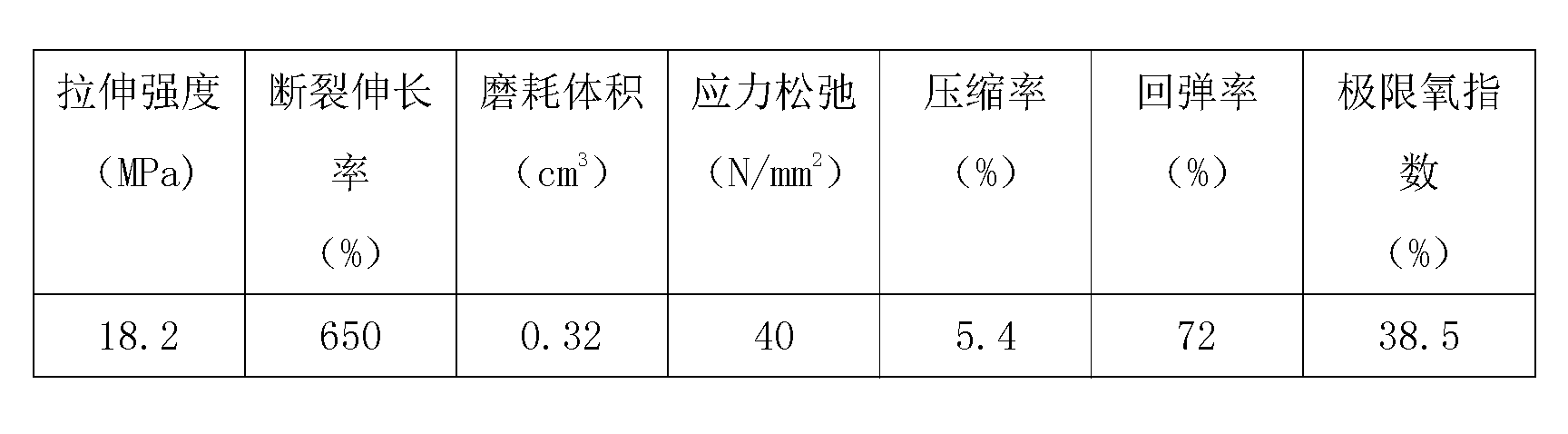

Chloroprene rubber gasket with high abrasion resistance and preparation method thereof

InactiveCN102993517AImprove flame retardant performanceAccelerated corrosionLow-density polyethylenePolymer science

The invention discloses a chloroprene rubber gasket with high abrasion resistance. The chloroprene rubber gasket comprises the following raw materials in parts by weight: 135-145 parts of chloroprene rubber (CR)121, 10-15 parts of butyl rubber CBK139, 20-25 parts of low density polyethylene, 3-5 parts of acetyl triethyl citrate, 2-5 parts of dibutyl maleate, 1-2 parts of isooctyl dimercaptoacetate di-n-octyl tin and the like. The chloroprene rubber gasket has the beneficial effects that the gasket has good high temperature resistance, sealability, flame retardance and corrosion resistance and can work in such medias as acid, alkali and oil for a long time; the volume and hardness of the gasket are small in variation; the gasket does not adhere to metal surfaces; and the gasket has small friction coefficient and good abrasion resistance and has the advantages of softness of bonding with sealing surfaces, good weathering aging and ozone aging resistance, durability and the like.

Owner:ANHUI RONGDA VALVE

Easy-adhesion copolyester fiber and fabric thereof

InactiveCN103184572AIncreased adhesion areaHigh bonding strengthMonocomponent copolyesters artificial filamentFiberAlcohol

The invention discloses easy-adhesion copolyester fiber. An acid component forming the copolyester fiber mainly has terephthalic acid structural units. In a dihydric alcohol component forming the copolyester fiber, the content of aliphatic diol structural units comprising side chain and carbon atom number under 6 is 20-90mol%. The fiber has no melting point or low melting point. When the fiber is prepared into fabric and when the fabric is heated by using a common iron or other heating devices, a partial fusion phenomenon occurs to the fabric, and an adhesion effect is provided. The fabric can be used in side locking of positions such as cuffs and trouser bottoms, and can be used in shaping of collars and the like, such that clothes can be provided with certain stiffness.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Integrated commutator detector and detection method thereof

ActiveCN104567997AImplement automatic categorizationEasy post-processingMeasurement devicesMechanical engineeringVoltage

The invention discloses an integrated commutator detector and a detection method thereof and belongs to the technical field of commutator detection. The detector comprises a base, and a feeding mechanism, a conveying mechanism, a gauge detecting mechanism, an inner diameter detecting mechanism, an outer diameter detecting mechanism, a height detecting mechanism, an inter-chip high-voltage-resistant detecting mechanism, a chip shaft high-voltage-resistant detecting mechanism and a discharging mechanism, which are mounted on the base. The integrated commutator detector and the detection method thereof can simultaneously detect the inner diameters, the outer diameters, the heights, the inter-chip high-voltage resistance and the chip shaft high-voltage resistance of commutators, can automatically classify the detected commutators, and has the characteristics of high measurement precision, great stability, low failure rate and the like.

Owner:绍兴中轴自动化设备有限公司

High-flame-retardation chloroprene rubber sealing gasket and its preparation method

InactiveCN102977432AImproved corrosion resistance and flame retardancyLow costCorrosionAging resistance

The invention discloses a high-flame-retardation chloroprene rubber sealing gasket. The sealing gasket comprises the following raw materials, by weight, 135-145 parts of chloroprene rubber CR121, 10-15 parts of butyl rubber CBK139, 20-25 parts of chlorhydrin rubber H75, 10-20 parts of an SG-5 PVC resin, 3-5 parts of tri(2-ethylhexyl)acetocitrate, 3-5 parts of di(2-ethylhexyl)-4,5-epoxy tetrahydrophthalate and 1-2 parts of propylene glycol sebacate. The sealing gasket has the advantages of good high temperature resistance, good sealing performance, flame retardation grade reaching UL94-V0 or higher, good corrosion resistance, realization of long-term working in mediums comprising acids, alkalis, oil and the like, small volume and hardness changes, no adhesion on the metal surface, small friction coefficient, good abrasion resistance, good combination flexibility with a sealing surface, good weather ageing and ozone ageing resistances, durability and the like.

Owner:ANHUI RONGDA VALVE

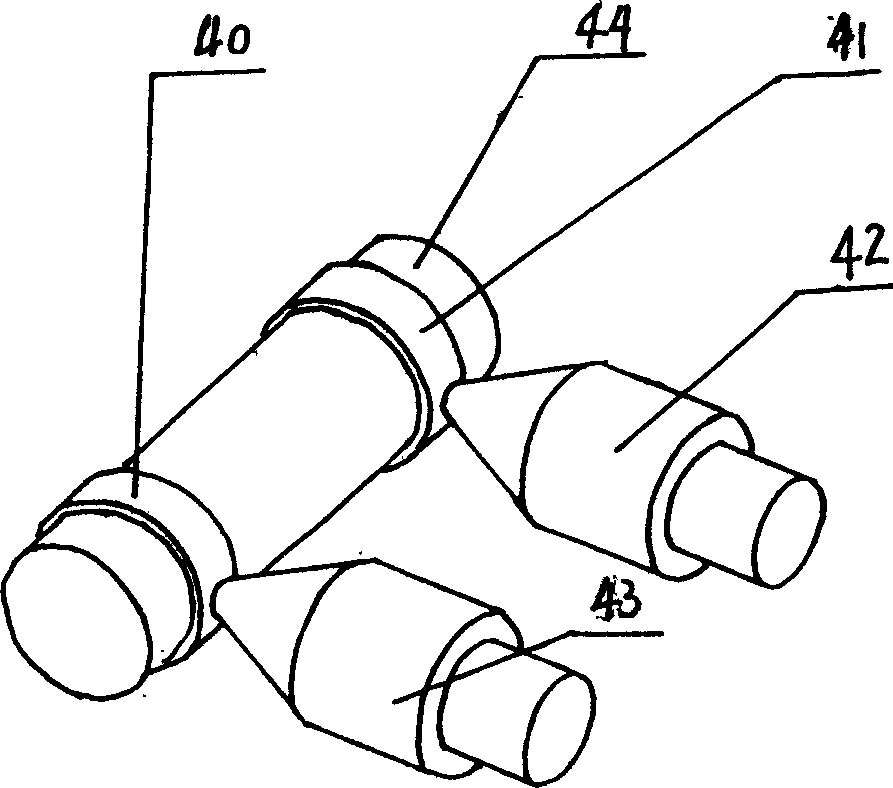

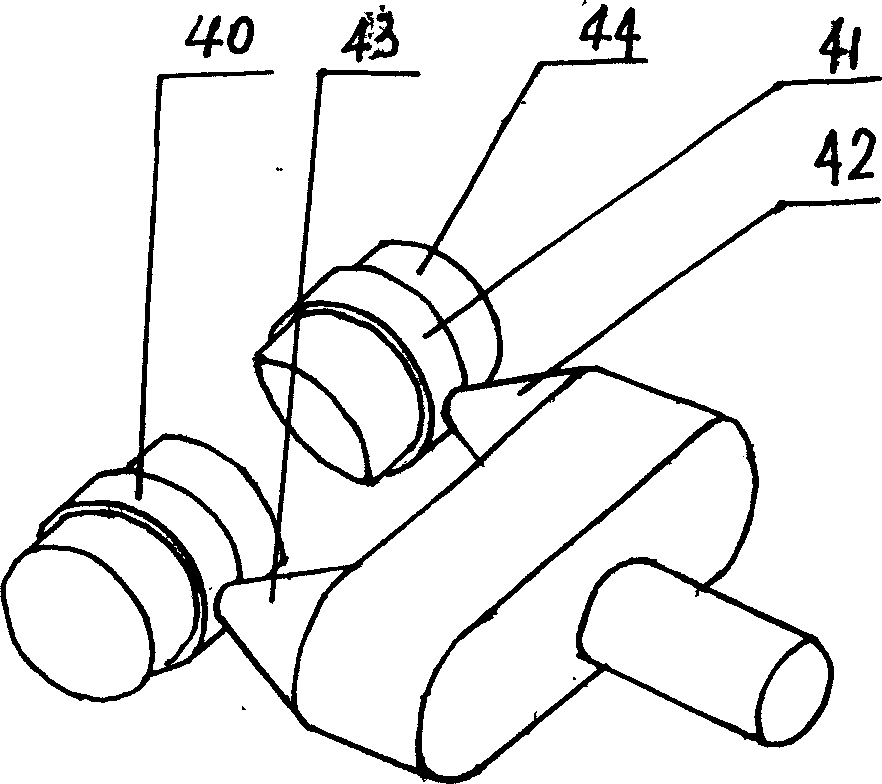

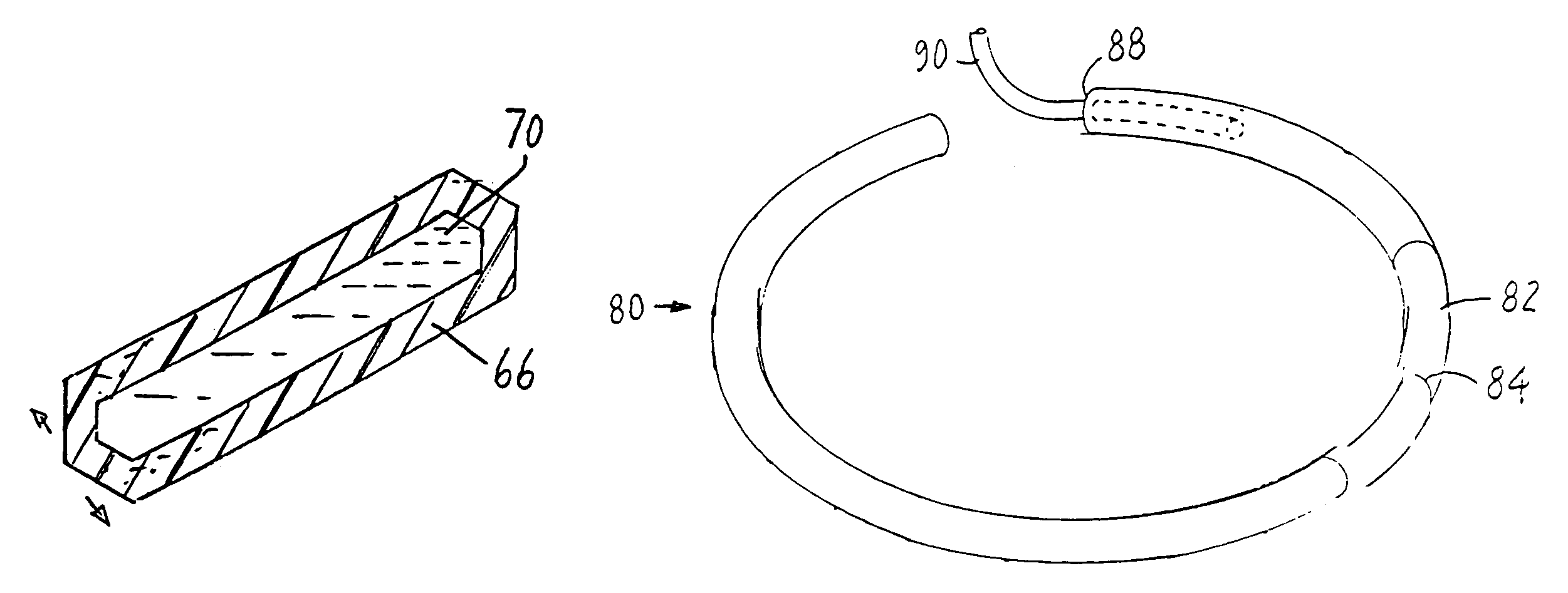

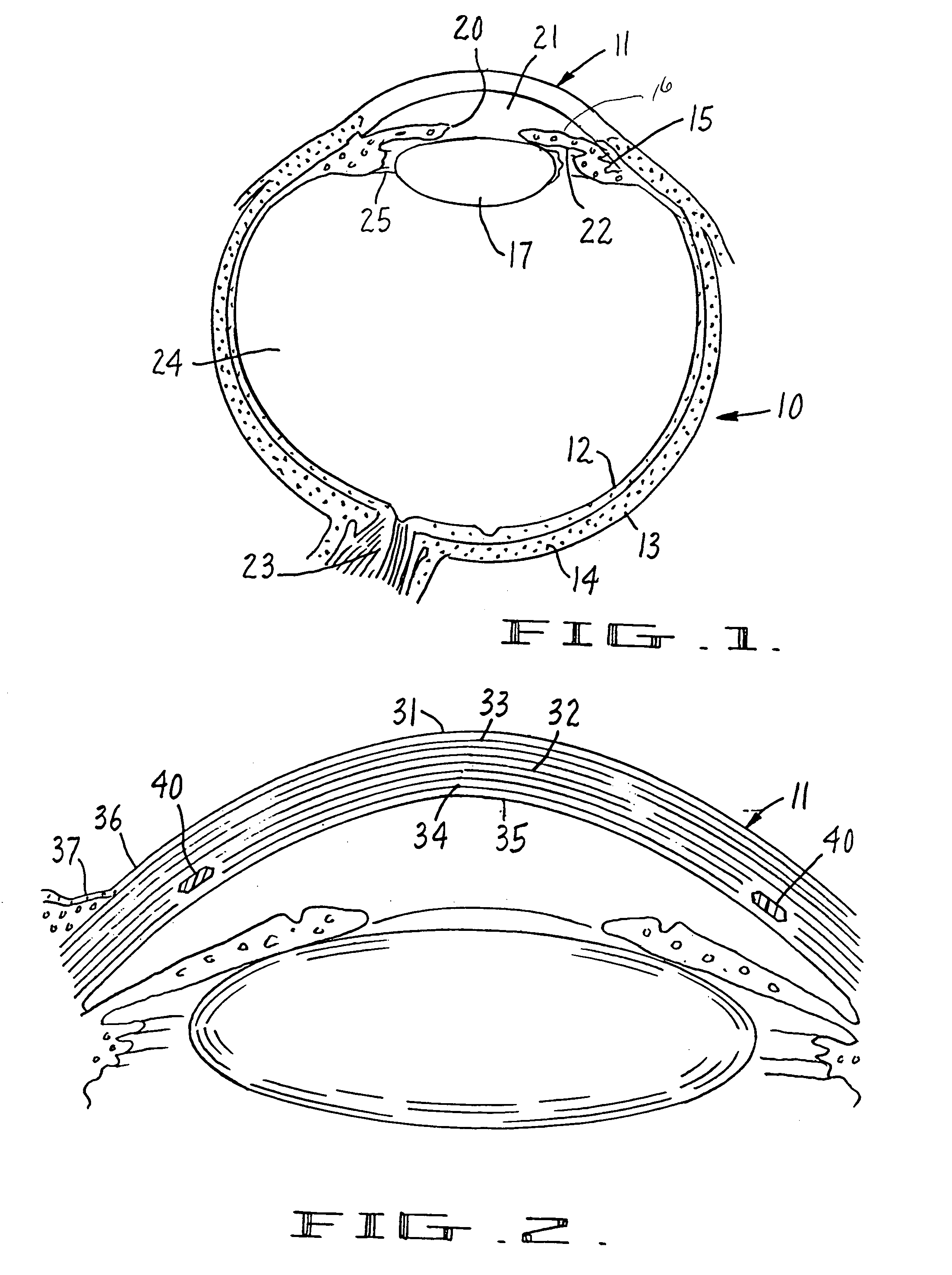

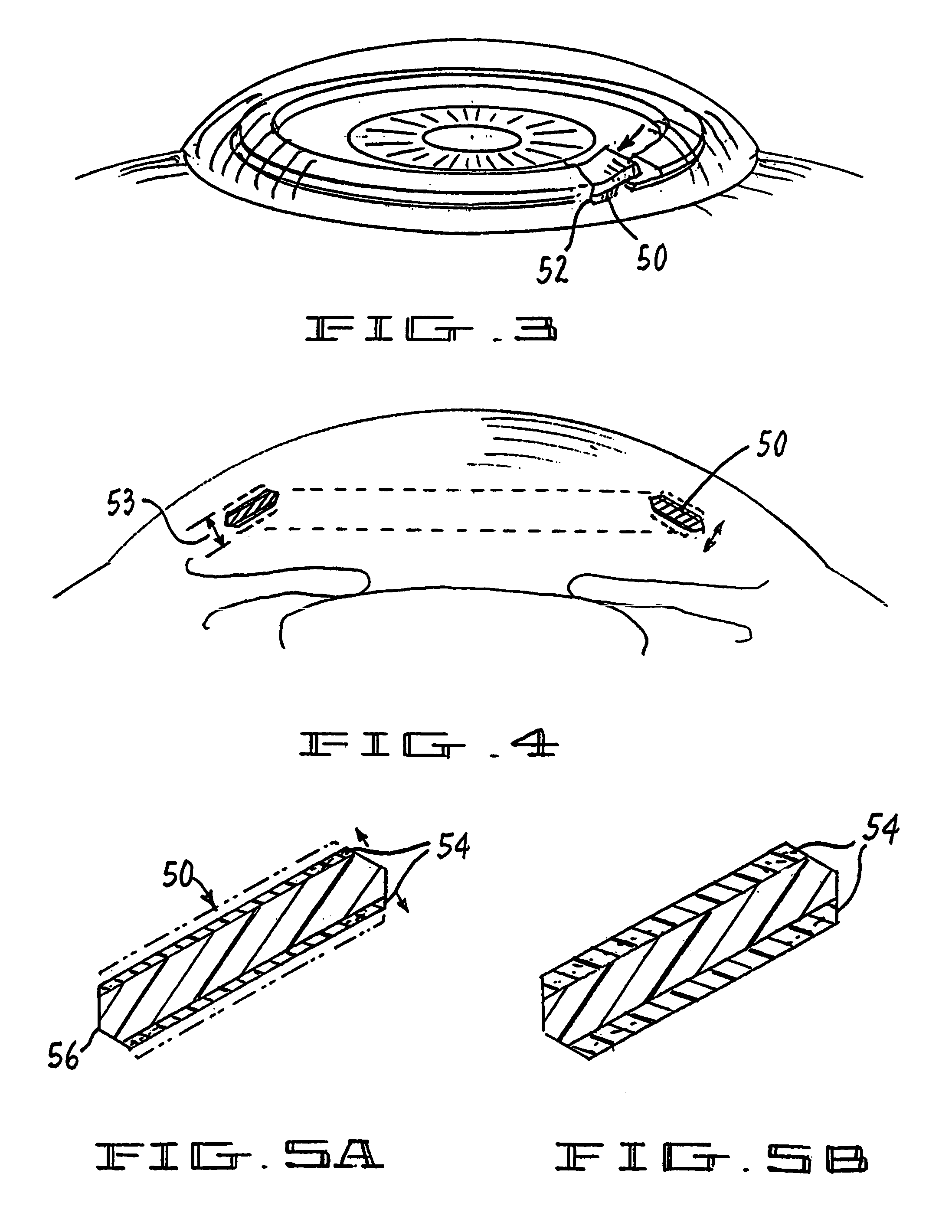

Hybrid intrastromal corneal ring

This invention is a hybrid intrastromal corneal ring (“ICR”) comprising at least one outer layer of a physiologically compatible polymer having a low modulus of elasticity, which polymer may be hydratable and may be hydrophilic. The inner portion of the ICR may be hollow or may contain one or more physiologically compatible polymers.

Owner:ADDITION TECH INC

Method and device for producing an embossed web material and product obtained with said method

InactiveUS20050170145A1Chromatic effectMaintaining and improving technical characteristicMechanical working/deformationSpecial paperAdhesiveEngineering

A method for producing an embossed web product comprising at least two plies (V1, V3) bone to one another by gluing, wherein: at least a first of said plies is embossed producing on it a first series of protuberances (P9) and a second series of protuberances (P10), the protuberances of the first series being of greater height than the protuberances of the second series; an adhesive (C) is applied to the protuberances of said first series; the first ply is glued to the second ply (V3), the protuberances (P9, P10) of the first ply projecting inside the web product, towards the second ply (V3). The protuberances of the first and of the second series form in combination with each other complex decorative patterns (D). Each complex decorative pattern is formed by at least a protuberance of the first series and at least a protuberance of the second series. Moreover, the complex decorative patterns are distributed with a density equal to or less than 2 patterns per cm2.

Owner:FABIO PERINI SPA

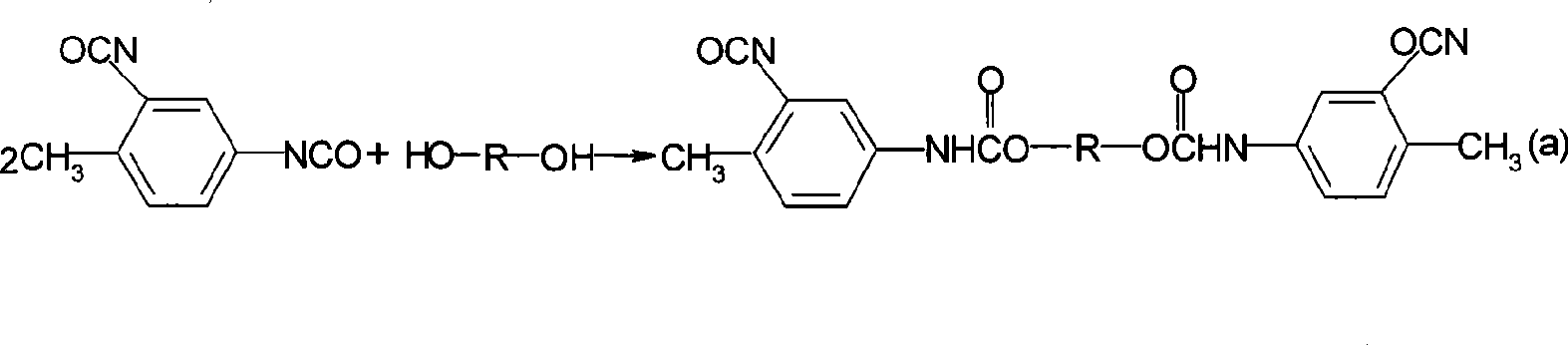

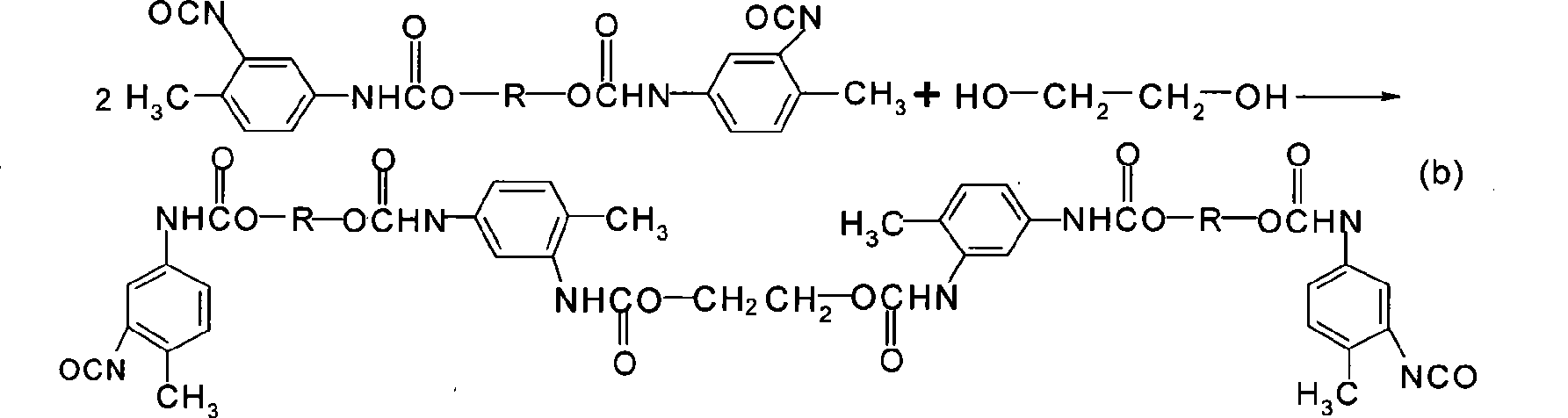

Method for preparing polyurethane skincare microcapsule

The invention relates to the field of function finishing of the fabrics, in particular to a method for preparing polyurethane skin-protecting micro-capsule. The method comprises the following steps: mixing the oil-soluble skin-protecting substance and fatty group or aromatic vulcabond according to the ratio of 1-3:1, and adding the mixture into water solution containing an emulsifying agent at the rotation speed of 1000-10000rpm, emulsifying until the solution becomes an even emulsified disperse system, then adding the poly-diatomic alcohol and catalyzer slowly, stirring for 20-40 minutes at the temperature of 0-30 DEG C, then heating to 60-90 DEG C, and adding 1-5ml chain-extension agent and keeping for 0.5-2 hours to obtain the micro-capsule solution. The synthetic method adopted by the invention does not use any organic solvent. The invention leads the fabrics to have functions of nourishing and moistening as the cosmetics. Furthermore, the raw materials are easy to acquire, the utilization rate is high, the reaction conditions are easy to satisfy and the operation is simple.

Owner:ZHEJIANG SCI-TECH UNIV

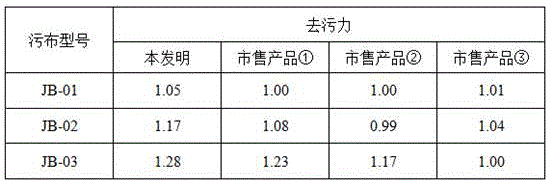

Antibacterial fabric detergent and preparation method thereof

InactiveCN105754753ADecontaminationWith sterilizationOrganic detergent compounding agentsPolymeric surface-active compoundsSoftened waterSurface-active agents

The invention relates to an antibacterial fabric detergent and a preparation method thereof. At present, few fabric detergents can achieve the effects of bacteriostasis and sterilization at the same time. The antibacterial fabric detergent is prepared from a nonionic surface active agent, an amphoteric ion surfactant, a solubilizer, a chelating agent, a dirt redeposition resisting agent, and softened water, and has double efficacies of decontamination and sterilization; besides, the antibacterial fabric detergent has the characteristics of removing peculiar smell of textile fabric, restraining peculiar smell from being generated, resisting dirt redeposition, being safe, non-toxic and non-irritating to human bodies, being pollution-free to environment, being low in production cost, and the like.

Owner:于文 +1

Hydrogel composition

InactiveUS20070020325A1Reduce stimulationAvoid changeAntipyreticAnalgesicsPolyvinyl alcoholWater soluble

A hydrogel composition containing as an active ingredient a drug that is transdermally or transmucosally absorbed to produce a drug effect, the hydrogel composition comprising polyvinyl alcohol with a saponification degree of 90-96 mol %, a water-soluble polymer and water, wherein the content of the water-soluble polymer is no greater than 25 wt % and the water content is at least 60 wt %, with respect to the total weight of the hydrogel composition.

Owner:HISAMITSU PHARM CO INC

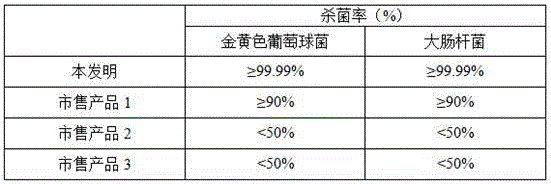

Semi-interpenetrating polymer cement-based flexible facing brick and manufacturing method thereof

The invention discloses a semi-interpenetrating polymer cement-based flexible facing brick, which comprises the following components, by weight part, 10-25 parts of a waterborne epoxy resin emulsion, 3-10 parts of a water-soluble epoxy resin curing agent, 1-5 parts of rubber elastomer, 1-5 parts of a fluorine-containing polyacrylate elastic emulsion, 15-25 parts of cement, 15-25 parts of stone flour, 30-50 parts of quartz sand, 5-15 parts of a fire retardant, 1-3 parts of inorganic pigment and 10-25 parts of water. A manufacturing method of the facing brick comprises: adding the components by weight part to a stirring vessel, performing full stirring to make a thick liquid, injecting the thick liquid to a die, and performing solidification and drying to obtain the facing brick. The manufacturing method is simple, and the obtained flexible facing brick is excellent in mildew resistance, water resistance, seepage resistance, wear resistance, thermal resistance and flexibility, is high in strength, and can be widely applied to building decoration materials.

Owner:万卓(武汉)新材料有限公司

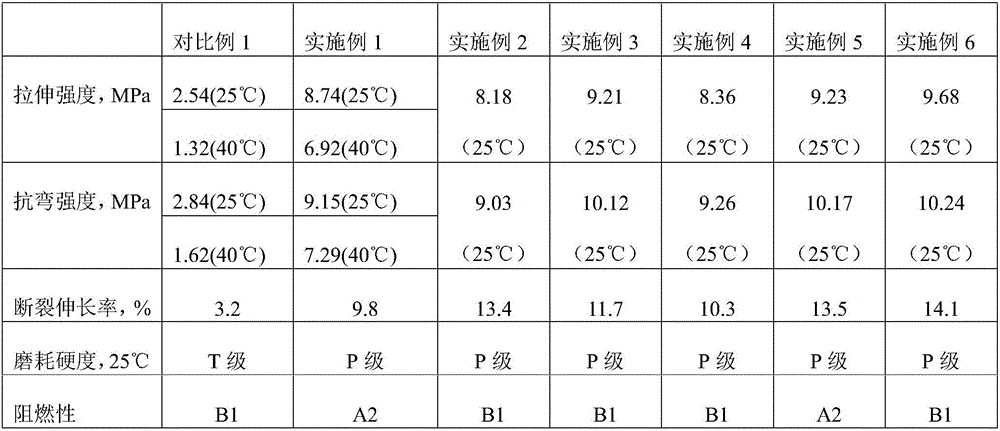

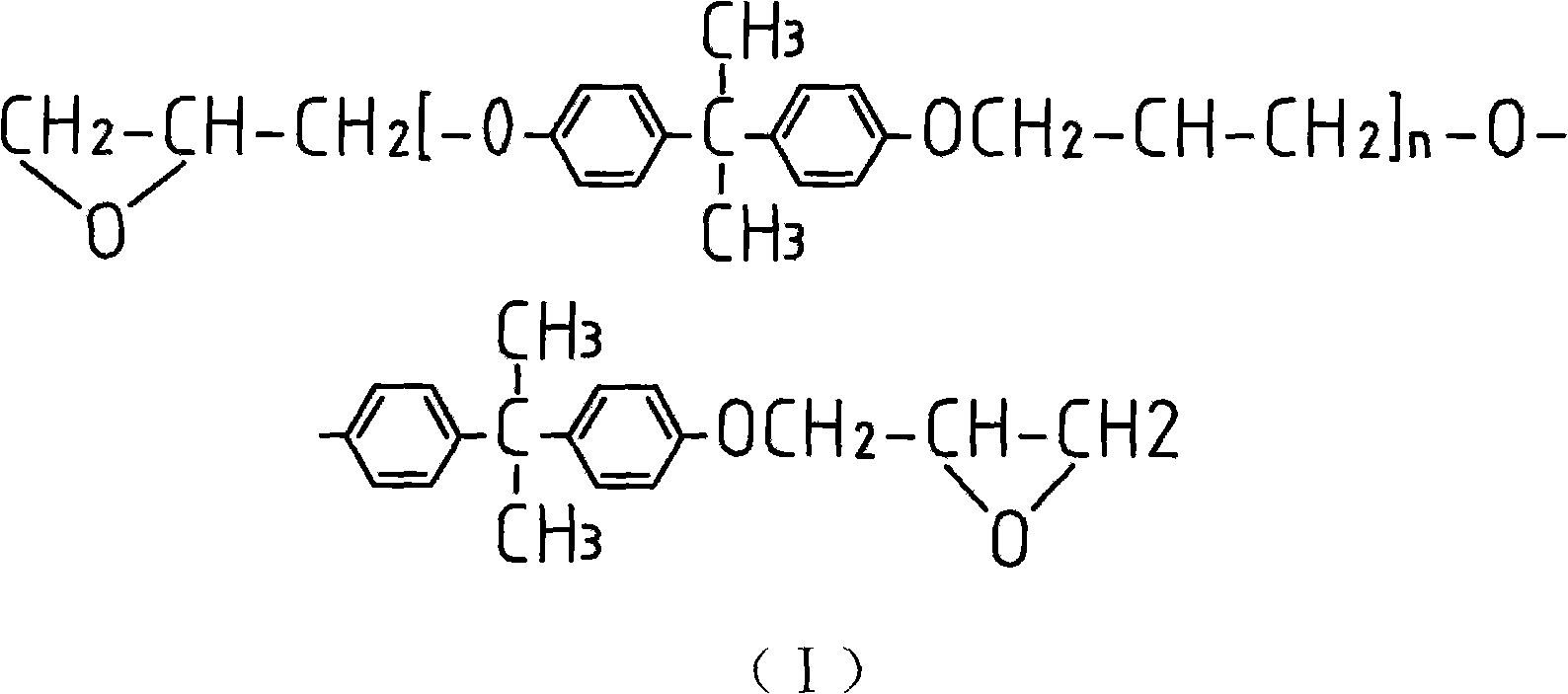

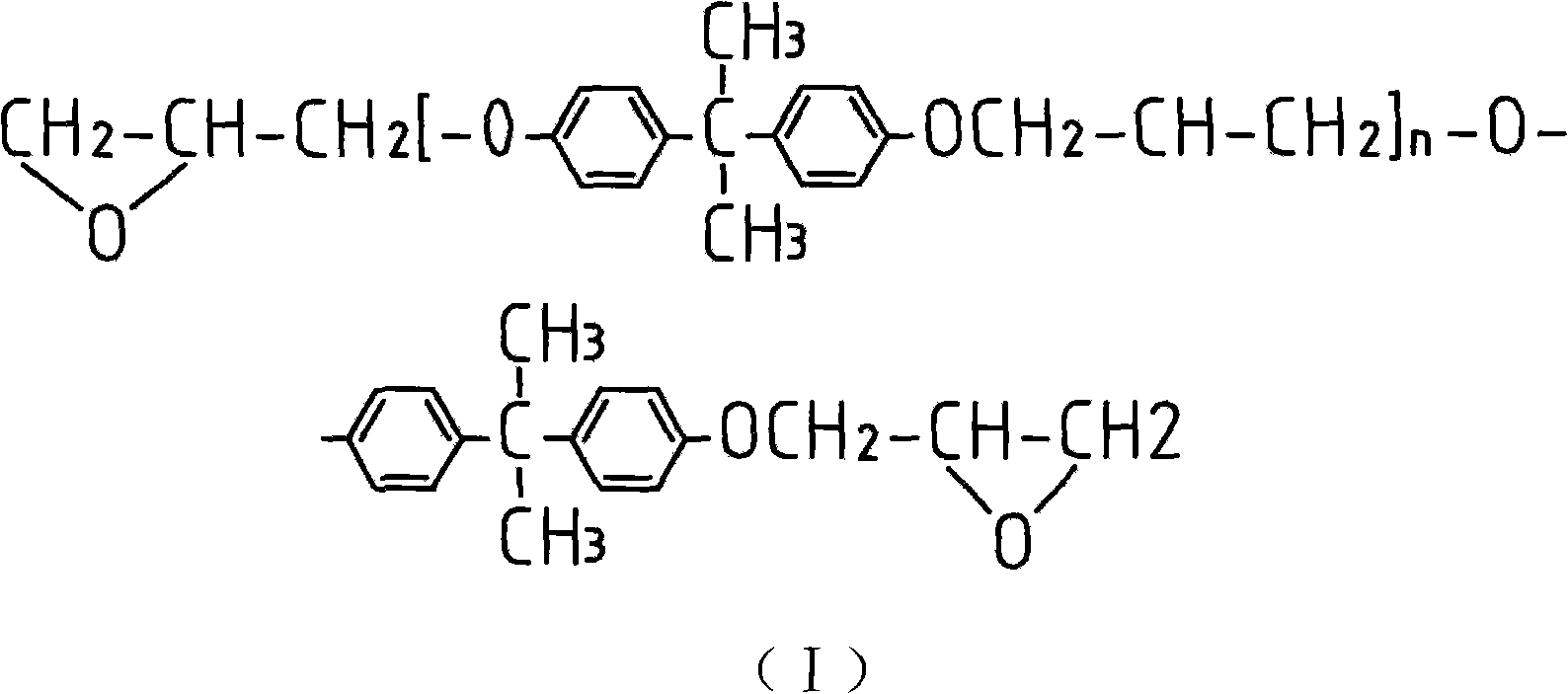

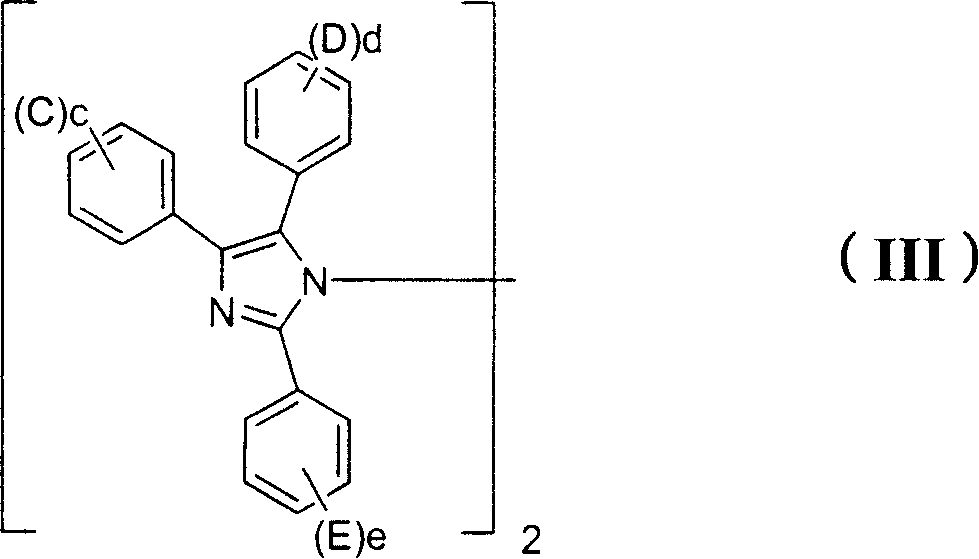

Epoxy resin composition for transformers and process for casting transformer by composition

The invention relates to the technical field of resin, in particular to an epoxy resin composition for transformers and a process for casting a transformer by the composition. The composition comprises epoxy resin, a curing agent, a toughening agent and an accelerating agent, the epoxy resin is a mixture of general formula (I), the epoxy groups on both terminals have reactive activity in the composition unit of the general formula (I), bisphenol A framework provides strong toughness and thermal endurance, a methylene chain has flexibility, ether bond has chemical resistance, and hydroxyl has reactivity and adhesiveness. Brominated epoxy resin of halogenated epoxy resin is taken as an fire retardant, and can be reactive fire retardant and also as flame retardant epoxy resin, thus fire resistance of the cast coil is good, and local discharge is small.

Owner:广东康德威电气股份有限公司

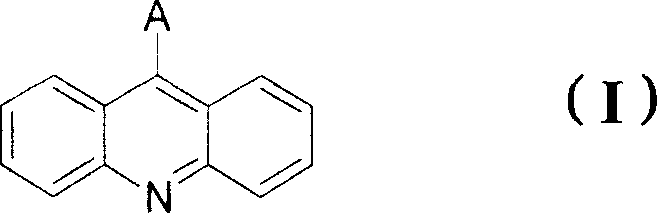

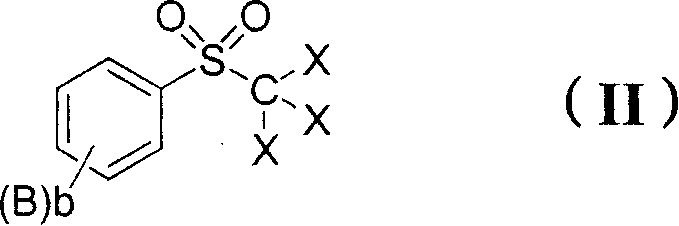

Photosensitive resin composition and laminating article thereof

ActiveCN1940723AImprove dispersion stabilityHigh resolution performanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPolymer scienceMeth-

The purpose of the present invention is to provide a photosensitive film with good resolution after development, excellent dispersion stability to the developer, no aggregates, excellent flexibility of the cured film, hole capping and good etchant resistance. A photosensitive resin composition, a photosensitive resin laminate having a photosensitive resin layer composed of the composition, a method of forming a resist pattern using the laminate, and a method of producing a conductive pattern. The present invention solves the above-mentioned problems by providing the following photosensitive resin composition, that is, a photosensitive resin composition characterized in that it contains (a) binder resin: 10 to 90% by mass, and its carboxyl group content is The acid equivalent is 100 to 600, contains benzyl (meth)acrylate as a copolymerization component, and has a weight average molecular weight of 5,000 to 500,000, (b) photopolymerizable unsaturated compound: 5 to 70% by mass, (c) as photopolymerizable unsaturated compound: The specific compound of the polymerization initiator is 0.1 to 20% by mass.

Owner:ASAHI KASEI KK

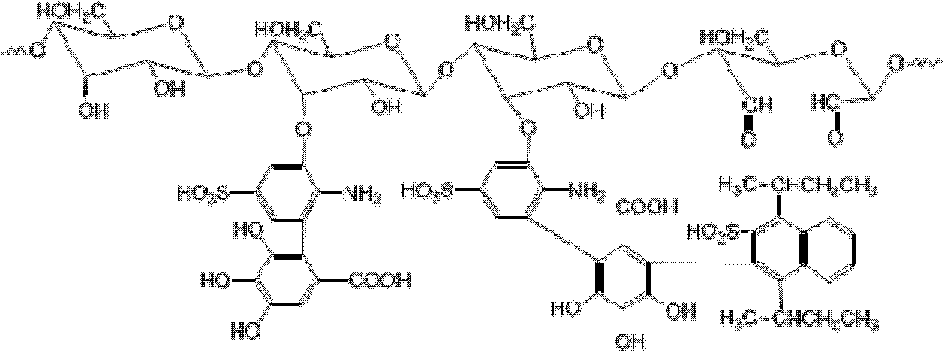

Method for preparing modified starch tanning agent

InactiveCN102020719AImprove absorption rateIncrease shrinkage temperatureTanning treatmentHigh absorptionGallic acid ester

The invention discloses a method for preparing a modified starch tanning agent, comprising the following steps of: firstly, degrading corn starch; in the presence of HRP (Horse Radish Peroxidase) / hydrogen peroxide (H2O2), grafting and modifying the degraded starch with sulfanilic acid, gallic acid and nekal; and then oxidizing the grafted starch with periodic acid. The invention has the innovation points that a nekal structure unit is introduced in the starch structure so as to improve the permeation wetting function of the modified starch tanning agent; the gallic acid structure unit is introduced to improve the tanning properties of the modified starch tanning agent, the sulfanilic acid is introduced to increase the dispersivity of the modified starch tanning agent, and dialdehyde action is used for improving the tanning properties of the modified starch tanning agent. The preparation method of the invention is peculiar and practical, and the obtained tanning agent is an environmentally-friendly leather tanning agent and is suitable for primary tanning and retanning. The shrinkage temperature (Ts) of pickled leather after primary tanning can be improved to 75-80 DEG C; and the retanned product has the advantages of wash resistance, high absorption rate on dyes and fatting agents and the like, is soft and plump.

Owner:SHAANXI UNIV OF SCI & TECH

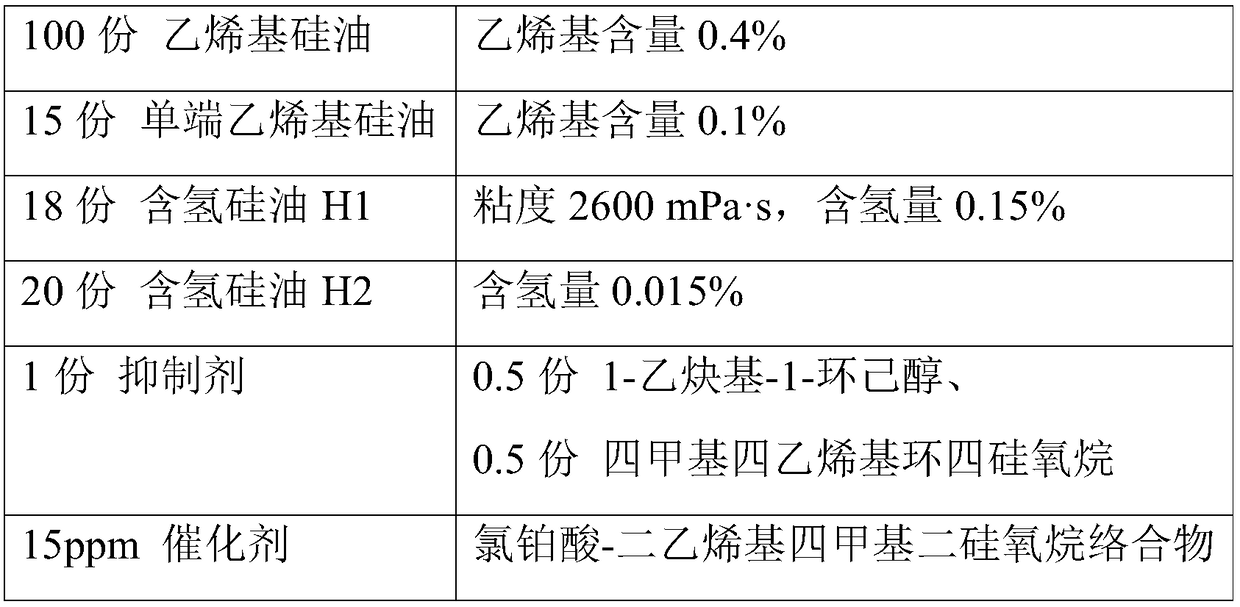

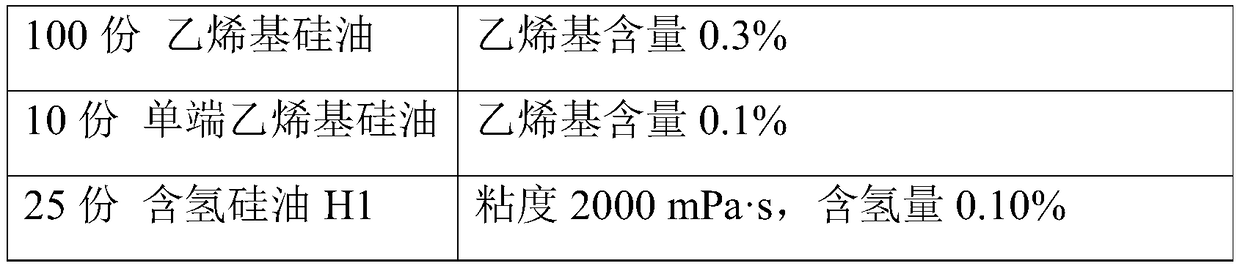

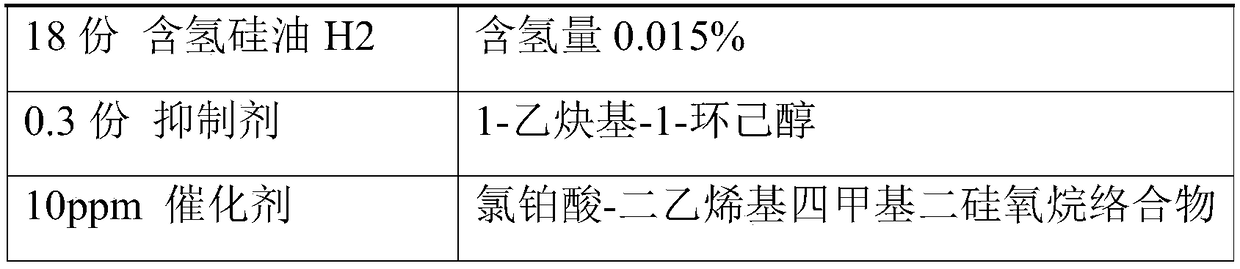

Low-oil-permeability high-strength addition-type silica gel and preparation method thereof

The invention relates to low-oil-permeability high-strength addition-type silica gel and a preparation method thereof. The addition-type silica gel is prepared from the following raw material components in parts by weight: 100 parts of alpha,omega-vinyl polydimethylsiloxane, 5 to 15 parts of single-ended vinyl polydimethylsiloxane, 15 to 30 parts of polymethylhydrosiloxane H1, 10 to 25 parts of polymethylhydrosiloxane H2, 0.01 to 2 parts of inhibitor, and platinum catalyst containing 0.5 to 50 ppm of platinum by mass, wherein nSi-H / nSi-Vi is greater than 1 in the addition-type silica gel. Theaddition-type silica gel has not only higher tensile strength and elongation at break, but superior oil permeability resistance, and stable adhesive performance and dielectric property, and can meet the encapsulating protection requirements of high-end precise electronic parts and components.

Owner:GUANGZHOU BAIYUN CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com