Semi-interpenetrating polymer cement-based flexible facing brick and manufacturing method thereof

A semi-interpenetrating network and polymer technology, applied in the field of semi-interpenetrating network polymer cement-based flexible facing bricks and their preparation, can solve the problems of low elongation at break, insufficient flexibility, poor tear resistance, etc. Good flammability, excellent softness, excellent water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

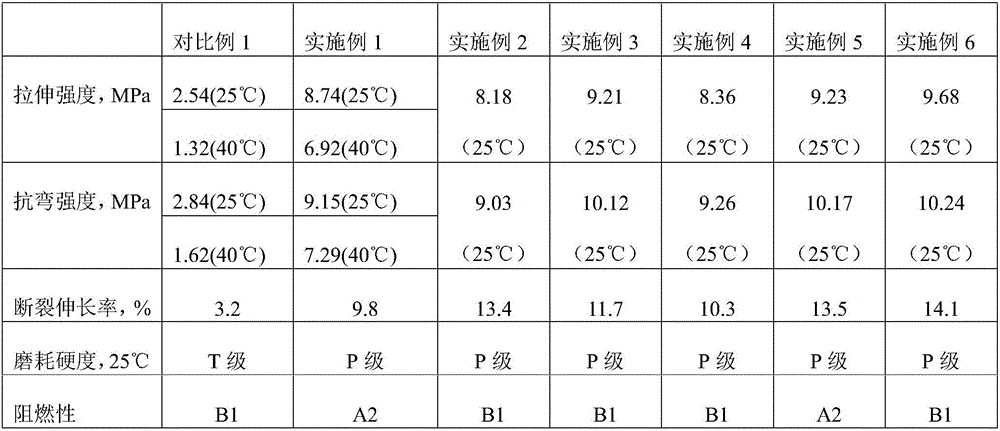

Examples

Embodiment 1

[0036] A kind of semi-interpenetrating network polymer cement-based flexible decorative brick, its preparation method comprises the steps:

[0037] 1) Weigh 25 parts of Portland white cement labeled 325#, 15 parts of 80-mesh stone powder and 50 parts of 300-mesh quartz sand in parts by weight, add them to a kneader, mix evenly, and obtain a mixed powder;

[0038] 2) Weigh 10 parts by weight of water-based epoxy resin emulsion (viscosity at 25°C is 500mPa.s, epoxy equivalent is 200g / mol), 2 parts of fluorine-containing polyacrylate elastic emulsion, 10 parts of flame retardant tripolyphosphoric acid 1 part, 1 part of inorganic pigment titanium dioxide and 10 parts of water are added to the stirring tank, and stirred evenly to obtain a mixed emulsion;

[0039] 3) Add the mixed powder obtained in step 2) to the mixed emulsion obtained in step 1), stir well, and after mixing evenly, add 1 part of polyethersulfone (PES), stir, react for 0.5 hours, and then add solidification 10 pa...

Embodiment 2

[0042] A kind of semi-interpenetrating network polymer cement-based flexible decorative brick, its preparation method comprises the steps:

[0043] 1) Weigh 20 parts of Portland white cement labeled 425#, 20 parts of 100-mesh stone powder and 40 parts of 150-mesh quartz sand, add them to a kneader, mix evenly, and obtain a mixed powder;

[0044] 2) Weigh 15 parts of water-based epoxy resin emulsion (viscosity at 25°C is 6,000mPa.s, epoxy equivalent is 1,400g / mol), 5 parts of fluorine-containing polyacrylate elastic emulsion, 3 parts of flame retardant melamine, poly Add 5 parts of ammonium phosphate, 2 parts of inorganic pigment carbon black and 15 parts of water into a stirring tank, and stir evenly to obtain a mixed emulsion;

[0045] 3) Add the mixed powder obtained in step 2) to the mixed emulsion obtained in step 1), stir well, and after mixing evenly, add 2 parts of polysulfone (PSF), stir, react for 1 hour, and then add curing agent 3 parts of polyamide (viscosity at 2...

Embodiment 3

[0048] A kind of semi-interpenetrating network polymer cement-based flexible decorative brick, its preparation method comprises the steps:

[0049] 1) Weigh 15 parts of Portland white cement labeled 525#, 25 parts of 300-mesh stone powder and 30 parts of 80-mesh quartz sand, add them to a kneader, mix evenly, and obtain a mixed powder;

[0050] 2) Weigh 20 parts of water-based epoxy resin emulsion (viscosity at 25°C is 2,000mPa.s, epoxy equivalent is 800g / mol), 2 parts of fluorine-containing polyacrylate elastic emulsion, and 5 parts of flame retardant melamine ammonium polyphosphate , 7 parts of ammonium polyphosphate, 1 part of inorganic pigment carbon black, 1 part of cadmium red and 10 parts of water are added to the stirring tank and stirred evenly to obtain a mixed emulsion;

[0051] 3) Add the mixed powder obtained in step 2) to the mixed emulsion obtained in step 1), stir well, and after mixing evenly, add 2 parts of polyether ketone (PEK), stir, react for 1 hour, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com