Patents

Literature

2095results about "Tanning treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

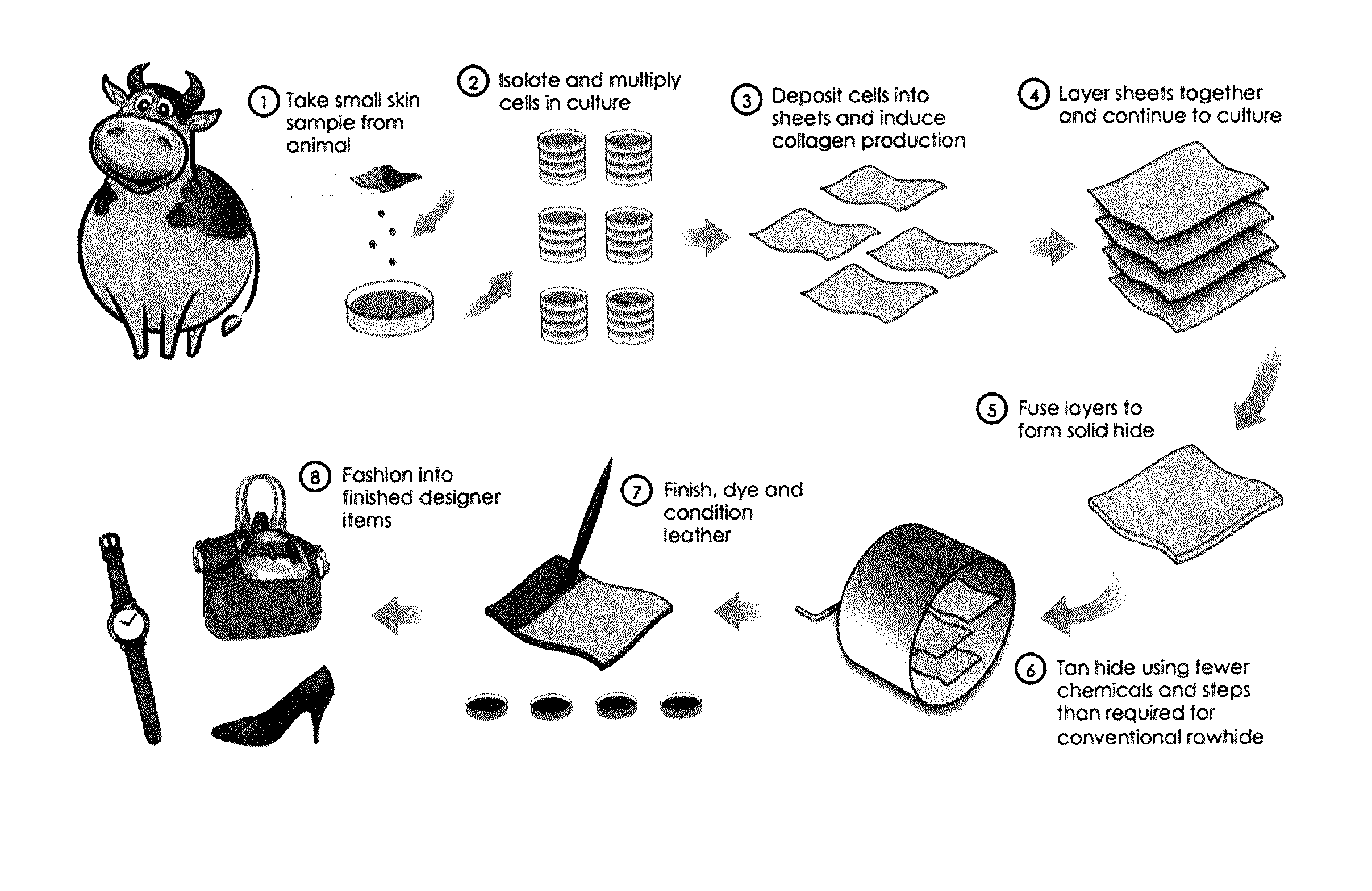

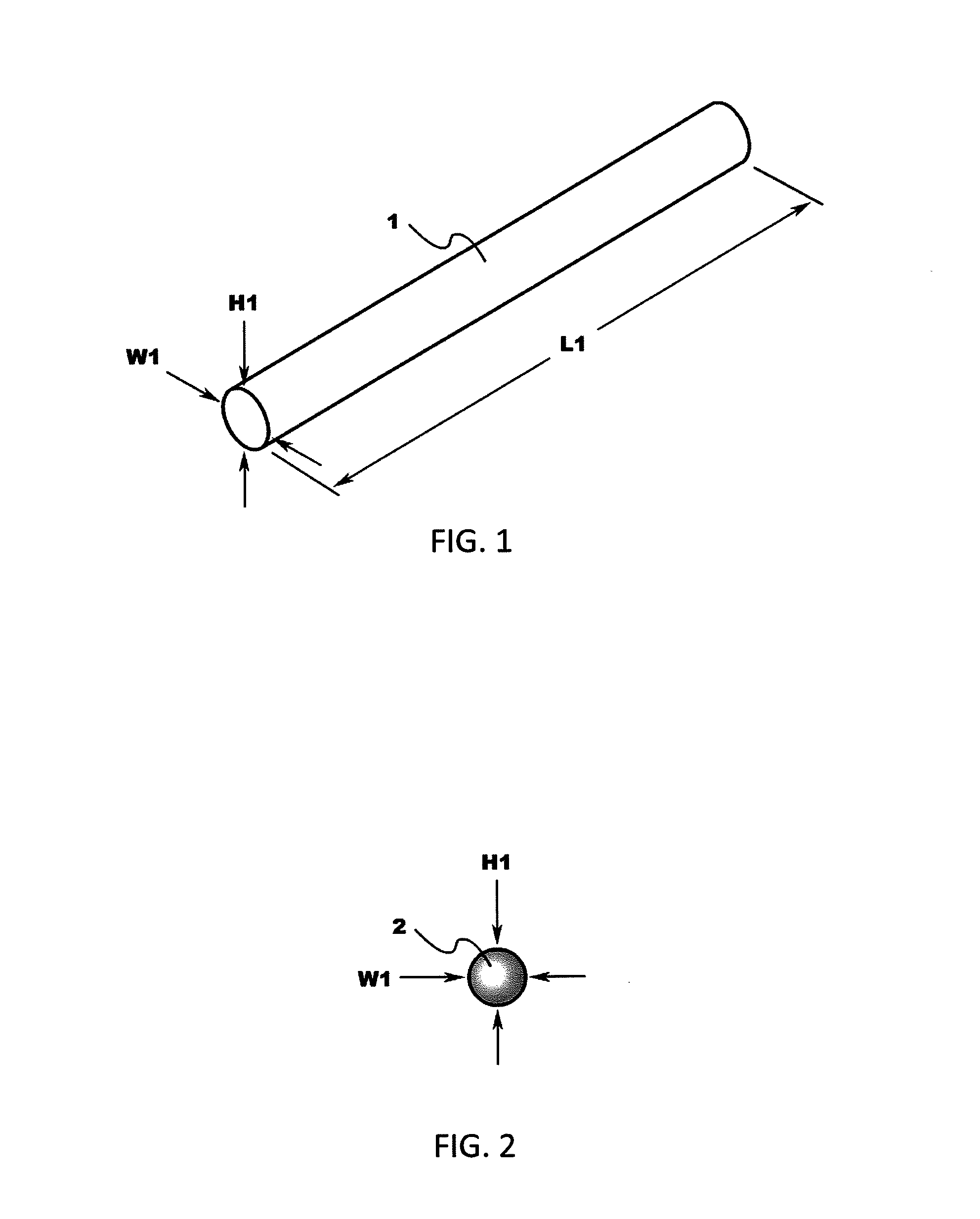

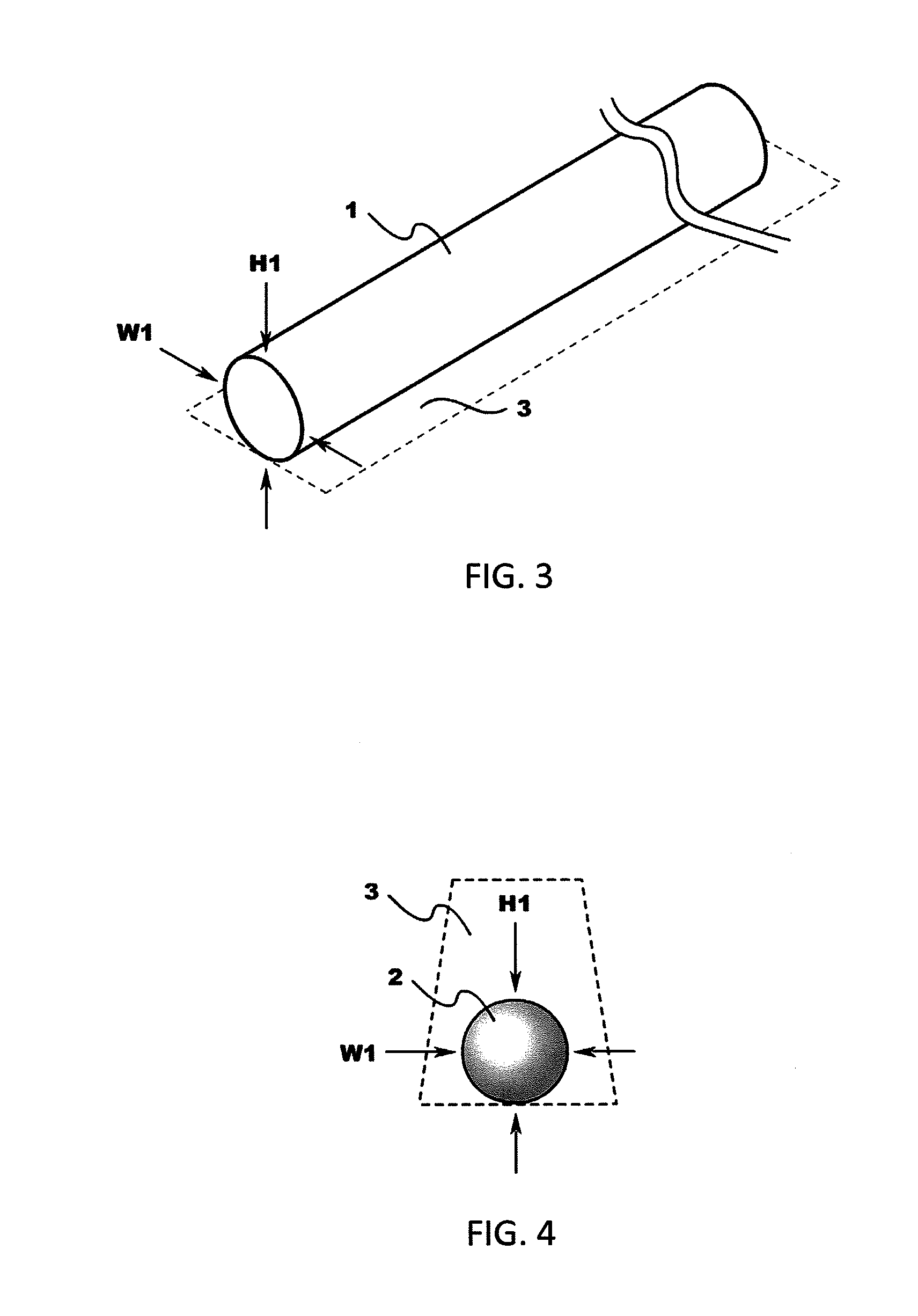

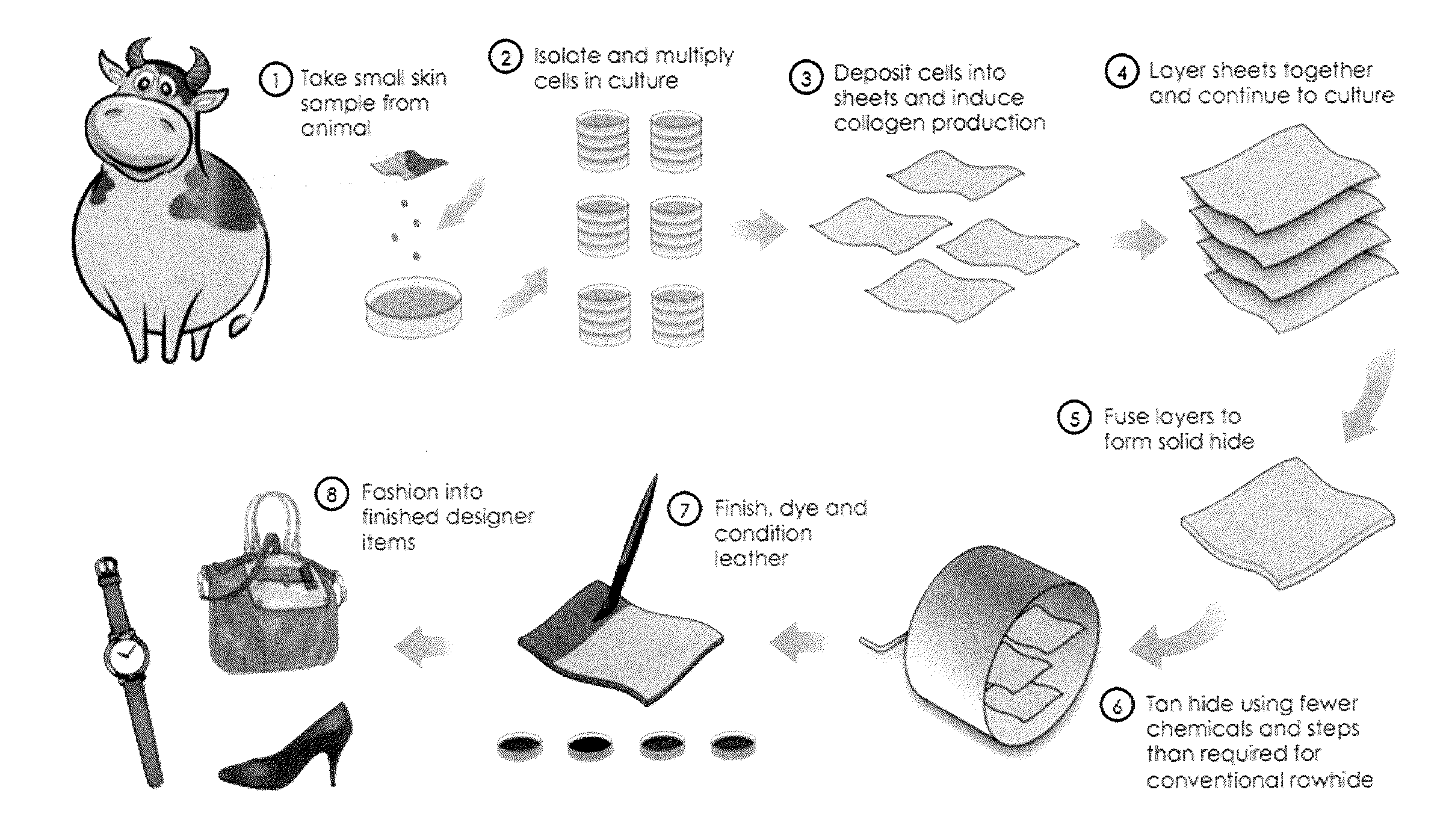

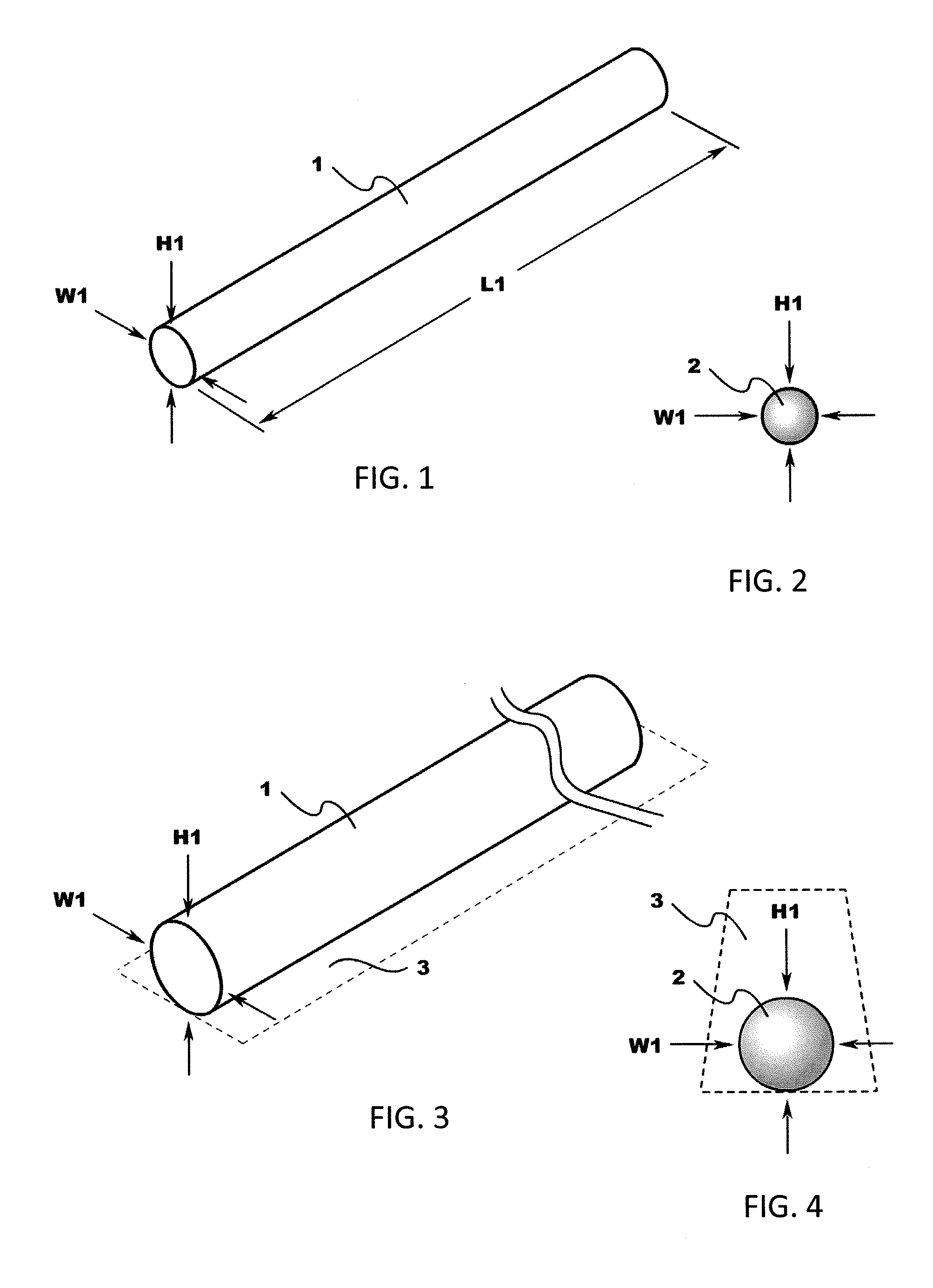

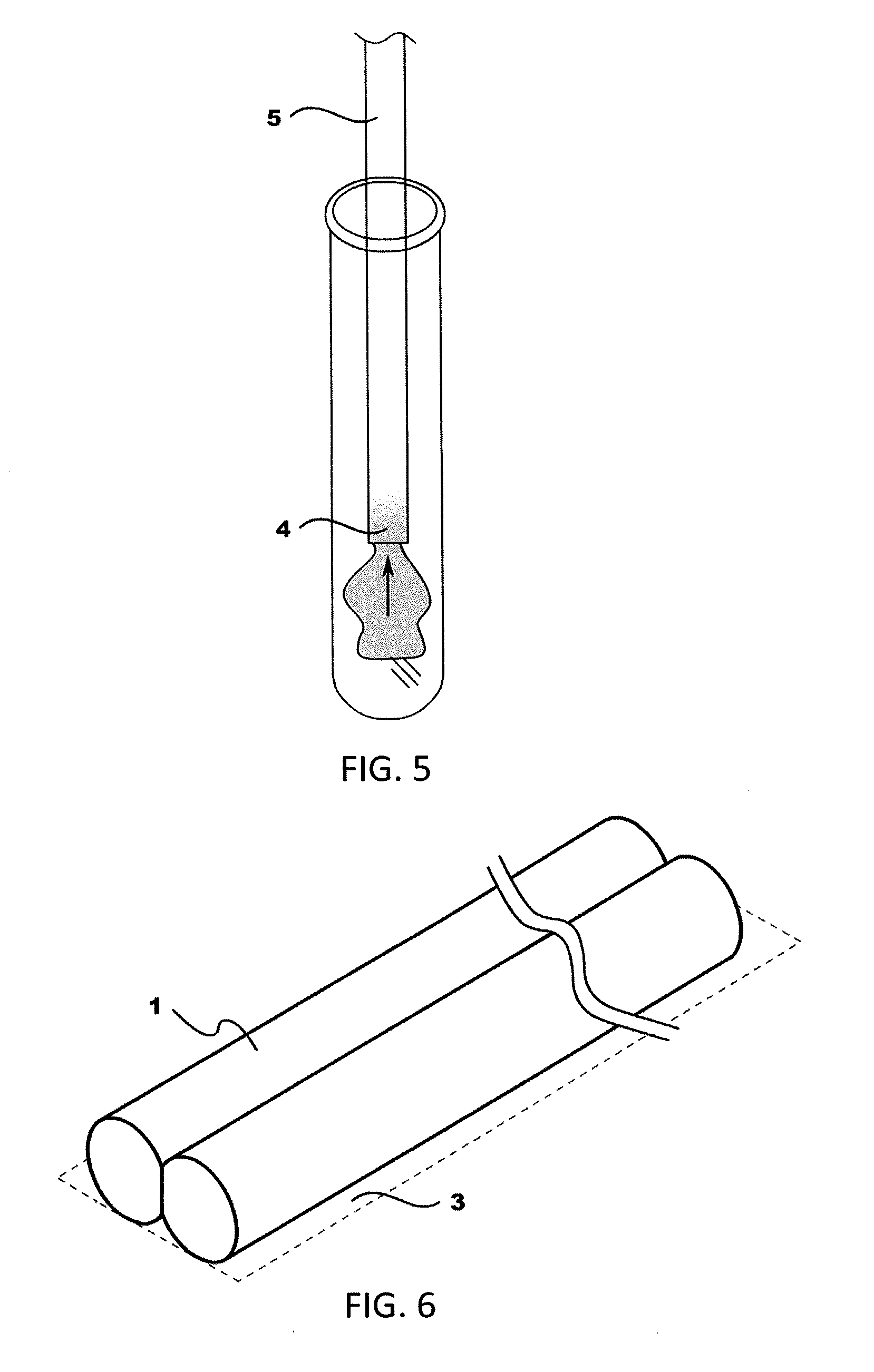

Engineered leather and methods of manufacture thereof

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

Engineered leather and methods of manufacture thereof

InactiveUS20160097109A1Increase heightEliminate needConnective tissue peptidesTanning treatmentAnimal skinBiology

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

Production technology of cow skin nappa leather

ActiveCN105132596AUniform leatherImprove leather yieldLeather manufacturingTanning treatmentFiberManufacturing technology

The invention relates to the technical field of the leather manufacturing technology, and provides a production technology of cow skin nappa leather. A series of problems that due to the fact that the structure of the abdomen and the part between the ribs and the hips of the cow skin is thin and fiber is woven loosely, in the processing process, the part of the abdomen and the part between the ribs and the hips are prone to being excessively loose, the part deviation is large, and face loosening is likely to happen are solved through the production process of the cow nappa soft-face leather. The integral procedure of the technology is simple, easy to achieve, convenient to operate and practical. The grain on the abdomen and the part between the ribs and the hips is easy to open in the tan preprocessing working section of the cow skin through tanning preprocessing, retanning processing and post-tanning mechanical processing, and the whole skin body fiber is even and loose. Even and slow tanning is carried out in the tanning working section, step-by-step and multi-time even filling is carried out in the retanning working section, the whole cow skin leather is even and consistent in the manner that filling is conducted after loosening, the leather is soft but not loose, and the leather yield and the utilization rate of finished cow skin are greatly increased.

Owner:XINGYE LEATHER TECH CO LTD

Chrome-free tannage producing technique for goat glove leather

The invention relates to a processing technique of leather, in particular to a chrome-free tannage manufacturing technique of goat glove leather, aims at solving the problem of heavy environment pollution caused by the chrome sewage in the prior art of chrome tannage. The processing technique of leather adopts a technical proposal that the chrome-free tannage manufacturing technique of goat glove leather comprises a plurality of successively steps as followings: softening, dipping in acid, organophosphor tanning, oxidation, stacking, sammying and extension, shaving, washing, degreasing, rinse, washing, retanning and stuffing, washing, and routine following chrome tanning technique. The processing technique of leather has the advantages of eliminating the environment pollution caused by the heavy metal chrome, reducing the cost of sewage treatment, producing environment-friendly goat glove leather with soft, plumpy, highly resilient, and flowing hand feeling, smooth grain, brilliant color, qualified formaldehyde content as ecological leather, over 88 DEG C shrinkage temperature, and completely same mechanical property as routine chrome tannage leather.

Owner:HAINING SHANGYUAN LEATHER

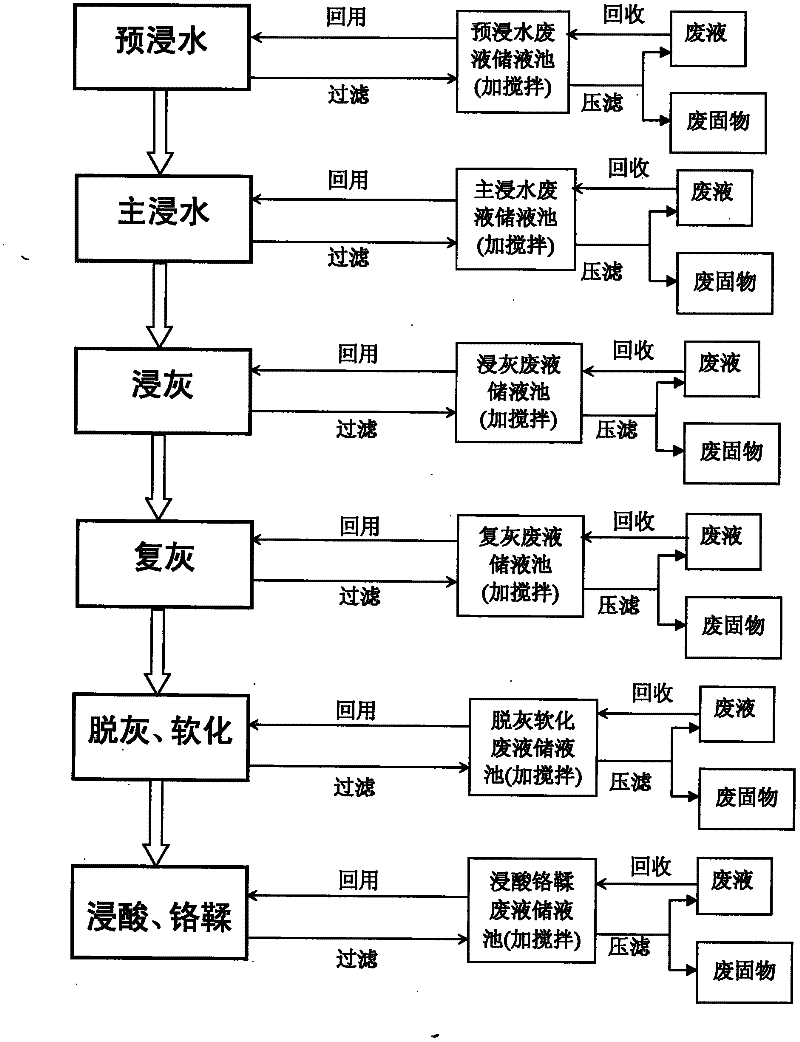

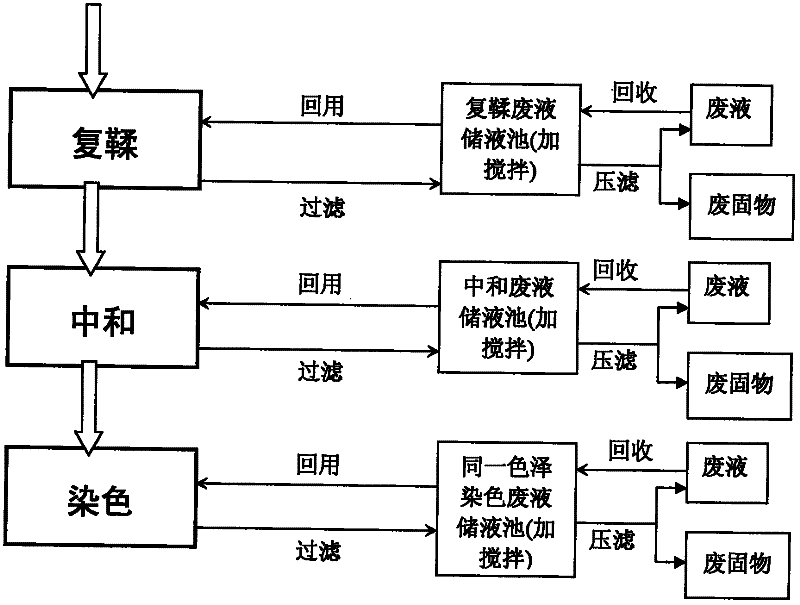

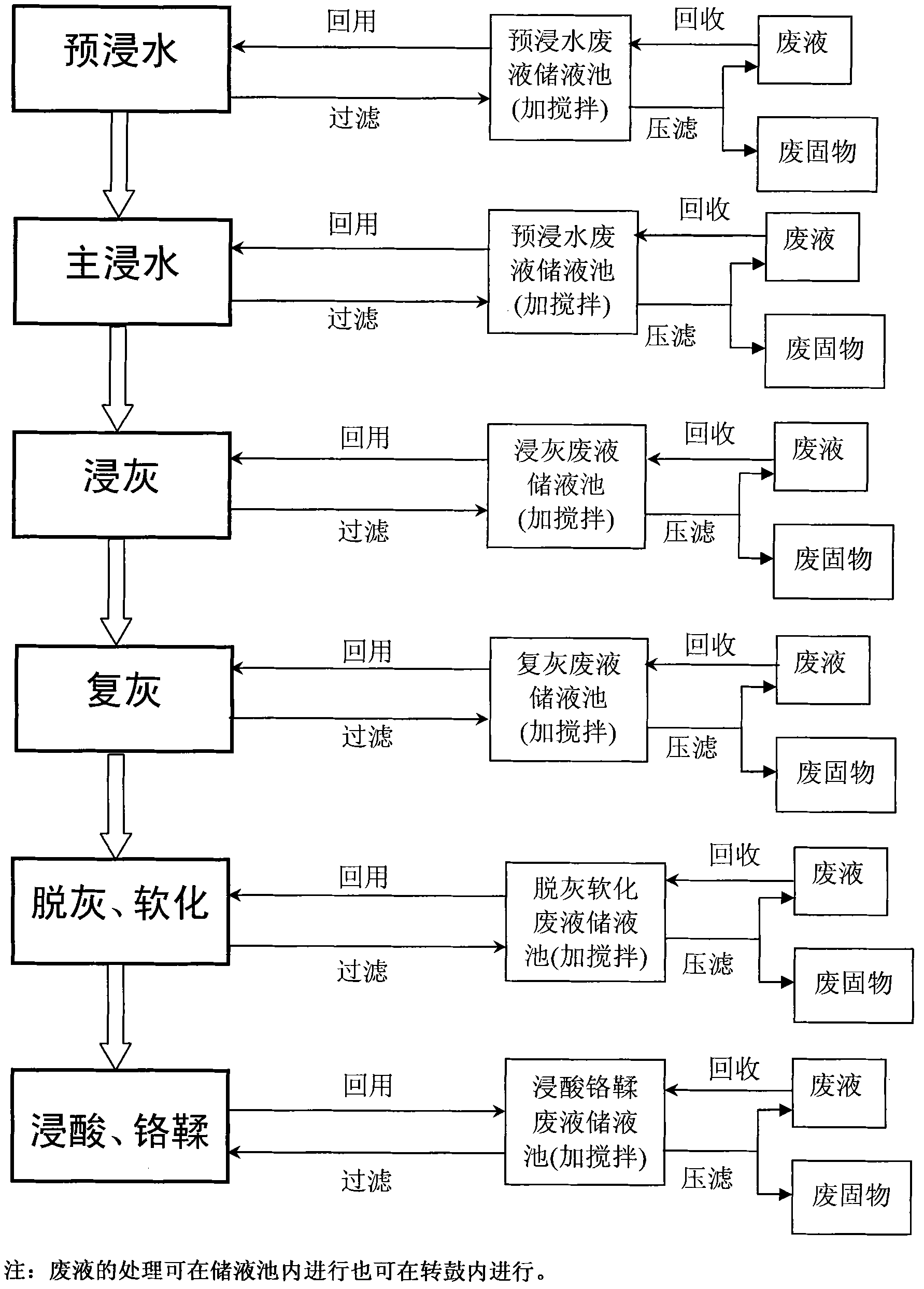

Tanning production process capable of recycling waste water repeatedly from soaking to dyeing

ActiveCN102534056AImprove firmnessHigh fullnessTanning treatmentPre-tanning chemical treatmentWastewaterSewage

The invention provides a tanning production process capable of recycling waste water repeatedly from soaking to dyeing, which is characterized in that waste liquid recycling is conducted in procedures of pre-soaking, main-soaking, liming, deliming and softening, pickling and chrome tanning, retanning, neutralizing and dyeing step by step, and waste liquid in all the procedures achieves full-closed circulation recycling. The technology is tested and verified in actual production in a tanning workshop of BIOSK (sq) Chemicals Co. Limited. The process achieves recycling of waste water from the pre-soaking to the dyeing, sewage discharging is greatly reduced, a problem of tanning pollution is solved thoroughly, quality of finished leather can be guaranteed simultaneously, loose side rate of the finished leather is effectively reduced, degree of compacting and fullness of the finished leather is improved, chemical materials can be saved by 15% to 55%, for example, chromium powder is saved by 35% to 65%, partial chemical materials can be saved by more than 90%, and exceptional chemical materials such as salt can be saved by 100%.

Owner:宝斯卡(商丘)化工有限公司

Biofabricated leather articles, and methods thereof

Owner:MODERN MEADOW INC

Manufacturing process of semi-vegetable tanned wrinkled leather of cow leather

InactiveCN102080134AQuality assuranceReduce contentTanning treatmentPre-tanning chemical treatmentPulp and paper industryHexavalent chromium

The invention relates to a manufacturing process of the semi-vegetable tanned wrinkled leather of cow leather, which comprises the working procedures of initial tanning, deacidifying, vegetable tanning, filling and dry finishing. In the method provided by the invention, firstly tanning is carried out on raw hide by a small quantity of chromium tanning agent and then by a vegetable tanning agent, thereby under the premise of guaranteeing the quality of the leather, greatly reducing the content of chromium in tanning waste liquid, lightening the pollution of the chromium to the environment and effectively inhibiting the generation of hexavalent chromium through the vegetable tanning agent in the leather; and meanwhile, the granule surface of the leather is tightened through the working procedures of dry finishing and coating, and natural winkles are formed on the granule surface, thereby covering the injury of the granule surface of the leather and improving the additional value of the leather.

Owner:锦兴皮业科技有限公司

Method for chrome-free tanning beach woolfell by adopting chrome-free tanning agent

InactiveCN102758029AHigh whitenessLow free formaldehyde contentTanning treatmentPre-tanning chemical treatmentSewageSewage treatment

The invention discloses a processing method for chrome-free tanning a beach woolfell by adopting a chrome-free tanning agent DESOTAN H30, which comprises the following steps: soaking, fleshing, degreasing, softening, pickling, tanning, extracting alkali, wet grinding, re-tanning, drying, wetting back, dry cleaning, staking, conditioning, reducing, oxidizing, drying, wetting back, staking, dry grinding, dedusting, and obtaining the finished product. The method is the technology for preparing the beach white woolfell, adopts the chrome-free tanning agent to process the beach white woolfell, uses no chrome during the tanning process, and obtains the finished product, which is pure white, slightly curled and distinctive in style, keeps the natural property, contains less than 150ppm of free formaldehyde, has a shrinkage temperature higher than 75 DEG C and has practical production significances. The technology can not only realize zero emission of waste chrome and lower the sewage treatment cost for an enterprise, but also obtain the finished product which is pure white, slightly curled and artistic in appearance, feels plump and soft, contains 130mg / kg of formaldehyde and has a shrinkage temperature of 75 DEG C.

Owner:SHAANXI UNIV OF SCI & TECH +1

Circularly-tanning technology for chrome tanning liquor of sheep garment leather

InactiveCN102586505APure white coatFull coatTanning treatmentPre-tanning chemical treatmentLeather industryFlocculation

The invention discloses a circularly-tanning technology for chrome tanning liquor of sheep garment leather. The circularly-tanning technology comprises the following steps: conditioning, drying, shearing, main-soaking, fleshing, degreasing, pickling, softening, disacidifying, softening, pickling, tanning, wet grinding, retanning, neutralizing, adding grease, retanning, dyeing hair, and dyeing plates. According to the circularly-tanning technology for chrome tanning liquor of sheep garment leather, the formation of hexavalent chromium can be effectively reduced, and the chrome waste liquor flocculation is omitted. According to the test on the chrome content after the chrome tanning liquor is utilized, the chrome waste liquor can be recycled repeatedly by supplementing corresponding chrome powder during next-time recycling, thereby realizing the clean production of tanned leather industry. According to the circularly-tanning technology, the sealed no-emission utilization of a chrome resource can be guaranteed so as to greatly reduce environmental pollution, effectively lower waste water emission and save enterprise waste treatment and production cost. In addition, the quality of the produced leather is consistent with that of the common chrome tanned leather, the shrinkage temperature is above 100DEG C, and a leather body is soft, plump and flexible, is colorful, has pure white hair and has no effect on the dyed hair and the dyed plates.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER +2

Environment-friendly type crust leather production method

ActiveCN103060488AEmission reductionCreate pollutionTanning treatmentPre-tanning chemical treatmentChromiumIon

The invention discloses an environment-friendly type crust leather production method, and aims at solving the problems that in a crust leather production method using conventional chrome tanning as basis, plenty of chromium ions are contained in waste water and cannot be effectively processed, plenty of leather wastes with chrome are also generated, and the environment is seriously polluted. The production method comprises the following steps of non-pickling tanning, retanning filling, dyeing fat liquoring and chrome retanning. The method adopts non-pickling non-chrome tanning technology, so solid wastes with the chrome cannot be generated. At the same time, through mutual matching with other procedures, finished leather shrinkage temperature and performance can be effectively improved so as to meet demands of leather production. At the last, the chrome retanning is adopted, only a path of waste water with the chrome is generated, waste water quantity is small, and the waste water is easy to recover and process. Therefore, compared with an existing crust leather production method using a chrome tanning method as basis, cleaning degree is high, the waste water quantity with the chrome can be effectively reduced, and the waste water is convenient to recover and process. At the same time, the leather wastes with the chrome cannot be produced, and the method is environment-friendly.

Owner:四川亭江新材料股份有限公司 +1

Preparation method of amphoteric retanning fatliquor

InactiveCN102757528AImprove absorption rateHas retanning effectTanning treatmentOrganic compound preparationSalt resistanceAqueous solution

The invention provides a preparation method of amphoteric retanning fatliquor. The preparation method comprises the steps of: carrying out amidate modification on oil; adding natural animal or vegetable oil, monoethanolamine and a first catalyst to a reactor which is provided with a mixer and a thermometer for being uniformly mixed, and then heating to react to obtain a system A; carrying out esterification modification, and adding maleic anhydride and a second catalyst in the system A, and uniformly mixing, and then heating to react, and cooling after the completion of the reaction, neutralizing the pH of the system into 7.0 through an alkaline aqueous solution, thus obtaining a system B; carrying out polymerization reaction, heating the system B, and synchronously dropwise adding acrylic acid derivatives, an amino cationic vinyl monomer aqueous solution and an initiator aqueous solution, and then heating to react, thus obtaining a system C; and compensating and metering water, and adjusting the content of effective solid in the system C to obtain the amphoteric retanning fatliquor. The amphoteric retanning fatliquor has high acid resistance, alkali resistance, salt resistance and electrolyte resistance, and is suitable for amphoteric retanning fatliquoring technologies under various conditions.

Owner:SHAANXI UNIV OF SCI & TECH

Reducing leather and preparation method thereof

ActiveCN101851828ARandom croppingNo location differenceNon-adhesive dressingsTanning treatmentFiberApparent density

The invention discloses reducing leather and a preparation method thereof. The leather is mainly and three-dimensionally weaved by collagenous fiber obtained by defibrination of leather materials, and the apparent density thereof is 0.35g / cm3-1.4g / cm3. The preparation method of the leather comprises the steps: carrying out defibrination on the leather materials to prepare the collagenous fiber, forming web, carrying out hydroentanglement and wet-hot shrinkage and forming. The leather is reducing leather, the weaving structure, the apparent density, all strength indexes and wear resistance of which are approximate to those of true leather. Compared with the true leather, the reducing leather has the advantages that the leather is large and tidy and can be cut randomly, the weaving apparent density is consistent without location difference; and simultaneously, the raw materials of the reducing leather mainly adopt corner wastes in the leather-working industry. The promotion of the method can enhance the circulation and reutilization of resources in the leather-working industry, and is beneficial to realizing transformation from the traditional leather-working industry to the energy-saving and environment-friendly industry.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Clean process for producing leather by using sturgeon skin

The invention discloses a clean process for producing leather by using sturgeon skin, which comprises the following steps of: immersing sturgeon into water, manual meat removing, degreasing, oil slick scratching, ash immersing, dying, ash immersing, oil slick scratching, ash restoring, oil slick scratching, deliming without ammonium, oxidation bleaching, acid etching, reduction bleaching, softening, organophosphorus tanning or oxazolidine tanning, dyeing and fat-liquoring, aluminum retanning or zirconium retanning, washing, hung airing and drying and finishing. According to the clean process, the sturgeon skin is tanned by adopting an organophosphorus tanning or oxazolidine tanning agent and a chrome-free tanning process; a less-sulfur liming and deliming without ammonium clean process is adopted in the tanning process, so that the harm of heavy metal chromium to the environment and a human body can be avoided, the emission of sulphide and the consumption of lime are reduced, the content of ammonia nitrogen in wastewater is reduced and the cost of sewage treatment of enterprises is saved; in addition, the produced environmentally-friendly sturgeon skin is soft in hand feeling, plump, rich in elasticity and flat and fine in particle surfaces, and keeps beautiful and complete natural squama.

Owner:王学川 +1

Dual-purpose modification process for native breed sheepskin leather

InactiveCN102839236AHas softnessIncrease shrinkage temperatureTanning treatmentPre-tanning chemical treatmentExtensibilityWork in process

The invention discloses a dual-purpose modification process for native breed sheepskin leather. The process sequentially comprises the following steps of processing native breed sheepskin semi-finished products: (1) classifying skin; (2) returning water; (3) soaking; (4) softening; (5) pickling; (6) performing chromium aluminum tanning; (7) performing tanning post-processing; (8) performing chrome retanning; (9) performing chrome retanning before dyeing; and (10) dyeing. According to the dual purpose modification process, commercially available native breed semi-finished skin (namely white skin) is processed, and the native breed semi-finished skin is tanned by increasing aldehyde aluminum tanning particularly, so that the extensibility of the native breed sheepskin can be effectively improved, the problem of dyeing defects is solved, and the uniformity in the post dyeing is ensured. The dual purpose modification process is matched with other steps and appropriate additives, and each additive is added according to reasonable additive amount, so that the final products have good handfeeling, high tearing resistance and high fullness, and the quality of the native breed sheepskin leather is greatly improved.

Owner:桐乡市雄鹰皮草股份有限公司

Polyurethane retanning filler

InactiveCN103030769APromote environmental protectionImprove hydrophobicityTanning treatmentPolymer scienceEmulsion

The invention relates to a polyurethane retanning filler. The preparation method of the polyurethane retanning filler comprises the following steps: preparing a prepolymer from raw materials IPDI (isophorone diisocyanate), PEG (polyethylene glycol), castor oil and DMBA (dimethylbenzanthracene); adding triethylamine to carry out neutralization reaction to generate salt; and adding an ethylenediamine water solution to carry out emulsification and chain extension to prepare the water-based polyurethane emulsion. The coated film of the water-based polyurethane emulsion has favorable water resistance and yellowing resistance.

Owner:QINGDAO WINCHANCE TECH

Sturgeon skin chrome tanning leather production process

InactiveCN102199676ALow fat contentImprove use valueTanning treatmentPre-tanning chemical treatmentSturgeonLeather production processes

The invention discloses a sturgeon skin chrome tanning leather production process, which comprises the following steps: immersing in water; removing meat manually; degreasing; scraping oil slick; liming; scraping oil slick; liming again; scraping oil slick; deliming and softening; bleaching by oxidization; pickling; bleaching by reduction; chrome tanning; dyeing and greasing; re-tanning; washing; hanging and drying; and coating. In the invention, when the sturgeon skin chrome tanning leather production is adopted, the grease content in the sturgeon skin can be reduced obviously and the color of particle surface of the back of the sturgeon skin can be lightened; and thus, dyeing or production of light leather can be facilitated, the finished leather retains the natural attractive scales and special textures of sturgeon skin, the utilization value of the sturgeon skin is improved greatly, and the added value of the product is increased obviously.

Owner:王学川 +1

Method for recovering collagen and chromium salts from chromium-containing scrap leather residues

ActiveCN103014191APromote hydrolysisQuick filterConnective tissue peptidesTanning treatmentStrong acidsAlkaline hydrolysis

The invention discloses a method for recovering collagen and chromium salts from chromium-containing scrap leather residues, which comprises the following steps: carrying out alkaline hydrolysis on chromium-containing scrap leather residues with strong alkali assisted by metal oxide and surfactant, recovering collagen from the filtrate, hydrolyzing the filter residues with strong acid, and sequentially carry out redox reaction to obtain a chrome tanning solution or drying to obtain a powdery chrome tanning agent. The invention has the advantages of fewer steps, short period, high efficiency and low production cost, is simple to operate, and can implement effective separation of chromium and hydrolyzed collagen; the recovered industrial collagen has low chromium content and high added value, and thus, can be used as a raw material for producing other fine industrial chemicals; the recovered chromium salts are free of calcium salts, and thus, can be used as a tanning agent for leather tanning again; and the invention does not generate tailings or wastewater, thereby avoiding secondary pollution.

Owner:SICHUAN UNIV

Novel process for recycling waste leather-making liquid step by step

ActiveCN101921881AReduce loose surface rateImprove firmnessTanning treatmentPre-tanning chemical treatmentWastewaterProcess engineering

The invention provides a novel process for recycling waste leather-making liquid step by step, which is characterized by carrying out waste liquid recycling step by step in the procedures of presoaking, soaking, liming, deliming for softening and pickling for chrome tannage. The waste liquid in all the procedures are recycled in a whole sealing way. The invention realizes the wastewater recycling from original leather to wet blue leather and can ensure the quality of the wet blue leather at the same time, greatly save cost on pollution control and material decomposing and greatly reduce sewage discharge.

Owner:宝斯卡(商丘)化工有限公司

Production method of negative oxygen ion multifunctional automotive trim leather

ActiveCN107312895AIncrease the fragranceFeel goodTanning treatmentPre-tanning chemical treatmentLiquid ratioKnurling

The invention relates to a production method of a negative oxygen ion multifunctional automotive trim leather. The production method comprises fleshing, liming, deliming, softening, pickling, tanning, retanning, neutralization, dyeing, fat liquoring, drying, softening, bottom coating, middle coating, knurling and top coating; in the pickling and tanning steps, salt is added for pickling, and aldehyde is added for tanning; the pickling by adding the salt is as follows: the leather is washed by softening water; the liquid ratio is 50%; by 100 mass parts of the leather, 50 parts of water are added; the temperature is controlled at 20+-2 DEG C; 7 parts of sodium chloride are added for reaction by 15 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; then, 0.5 part of 10 wt% of dilute formic acid is added for reaction by 30 minutes; 0.35 part of 5 wt% of dilute sulfuric acid is added for reaction by 30 minutes; sulfuric acid is added again by the same mode for reaction by 90 minutes; after dilute sulfuric acid is added, the pH value is controlled within 2.8+-0.1; and the reaction is performed by 60 minutes. The production method has the functions of constant release of negative oxygen ions, sterilization and bacteria resistance, achieves the effect of efficiently absorbing, decomposing and degrading such harmful gas as formaldehyde, and achieves softness and excellent shaping property.

Owner:HAINING SENDE LEATHER

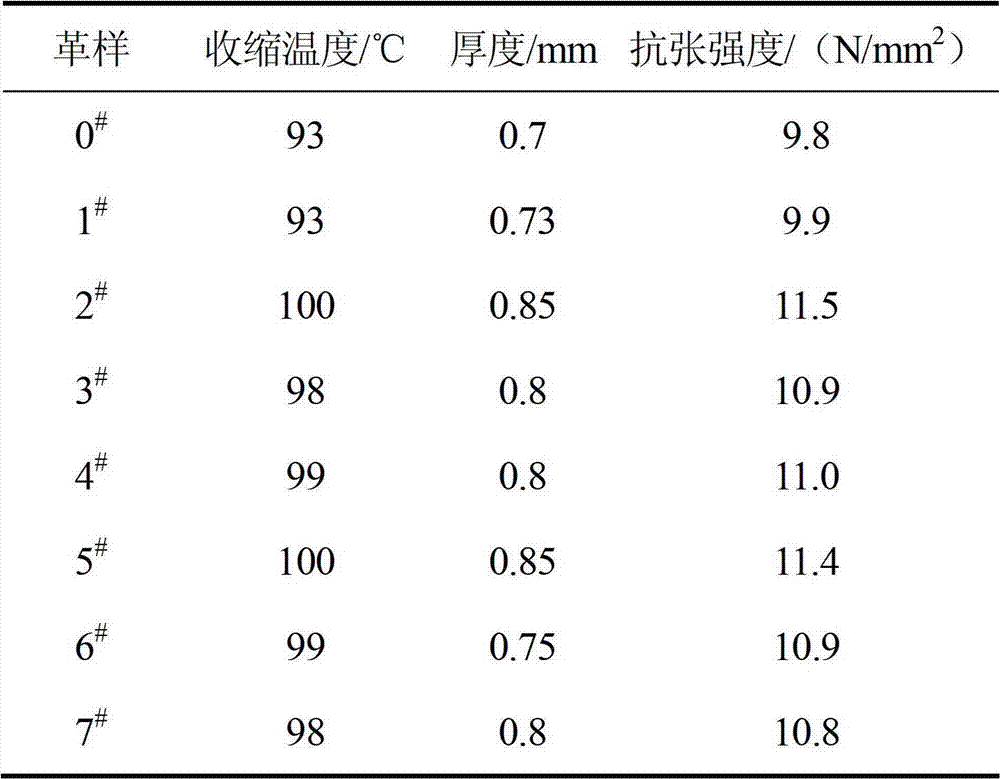

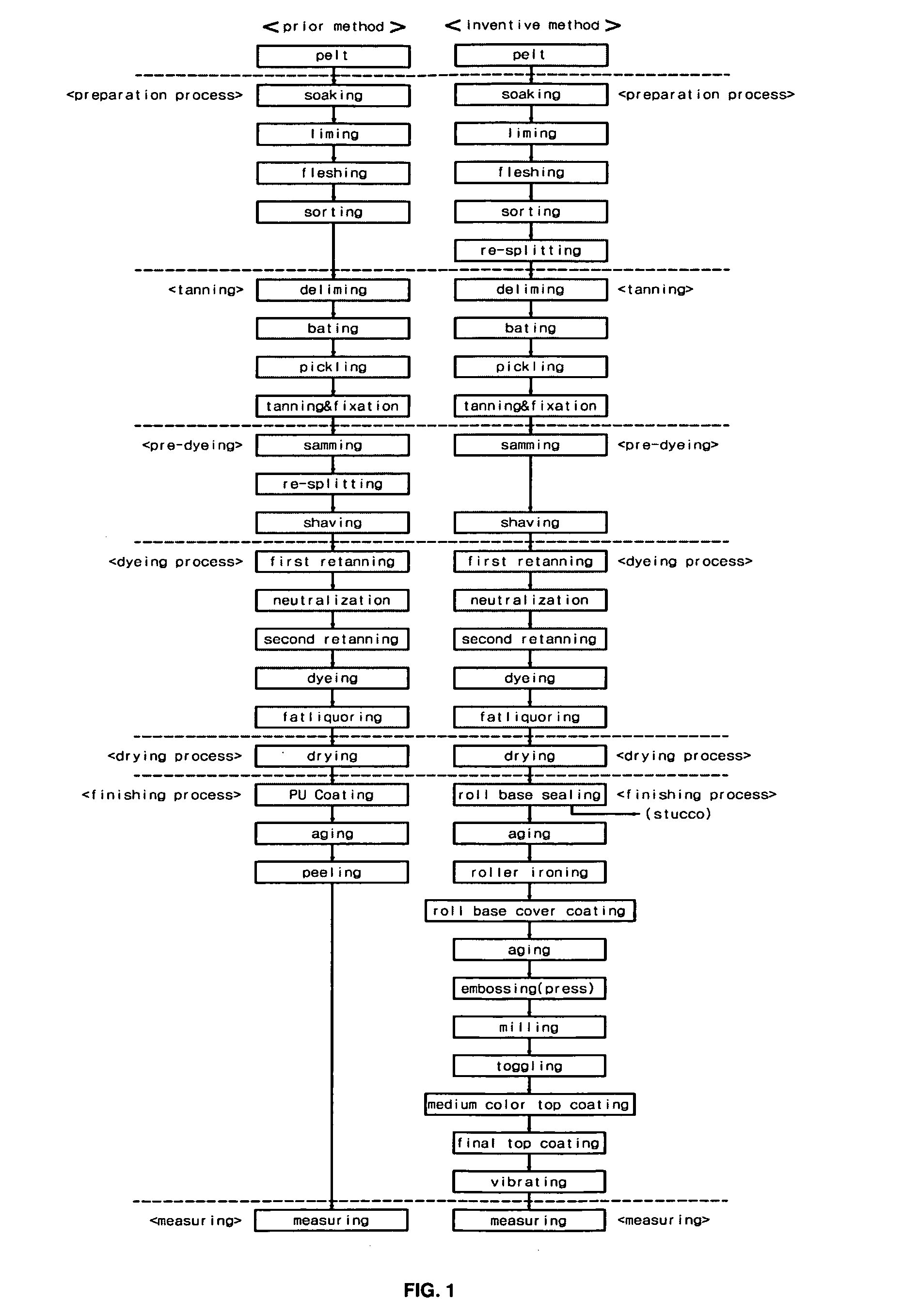

Split Leather for Car Seats and Manufacturing Method Thereof

InactiveUS20080299406A1Maximally maintain propertyCost advantageVehicle seatsTanning treatmentCar seatEngineering

Disclosed herein are split leather for car seats and a manufacturing method thereof. The method comprises a preparation process, a tanning process, a pre-dyeing process, a dyeing process, a drying process and a finishing process, wherein the method comprises, after the preparation process, but before the tanning process, a re-splitting process of splitting pelt into an upper grain layer and a split layer, having a thickness of 2.5-4 mm, and re-splitting the split layer to have a thickness of 1.8-2.5 mm starting from the upper side thereof, thus obtaining split leather, and the finishing process comprises sequentially forming a roll base sealing layer, a roll base cover layer, a medium color top coating layer and a final top coating layer on the split leather, thus treating the surface of the split leather. The split leather for car seats has a luxuriousness close to that of full-grain leather and a soft touch and feel, and can give customers a cost advantage. Also, the range of selection of raw material for manufacturing car seat leather can be widened, and waste can be recycled to thus reduce the generation of waste, thus being helpful to the environment. In addition, leather seats can be diversified and a new product group can be created.

Owner:NAM CHUNG

Method for preparing cleaned three-proofing cow split leather and prepared cleaned three-proofing cow split leather

ActiveCN102676710AGood flexibilityReduce Chromium PollutionTanning treatmentPre-tanning chemical treatmentWater solubleFluoride

The invention discloses a method for preparing cleaned three-proofing cow split leather and prepared cleaned three-proofing cow split leather. Cow split blue wet leather serving as a raw material is subjected to the steps of water return, preliminary fat-liquoring chromium-free retanning, neutralization, filling, dyeing, fat liquoring, fixing, fireproof treatment, drying and the like to prepare the cleaned three-proofing cow split leather. A waterproof anti-fouling agent and a flame retardant are added in the preparation process to enable the three-proofing cow split leather to have waterproof, anti-fouling and fireproof functions, wherein the waterproof anti-fouling agent is a water-soluble fluoride, and the flame retardant is an inorganic flame retardant. The method has the advantages of being high in cleaning degree, small in water discharge amount, short in production period and low in cost, and the three-proofing cow split leather is good in waterproof, anti-fouling and fireproof effects.

Owner:JINAN LURI JUNDA LEATHER

Clean production method of chromium-free automobile cushion leather

The clear production method for Cr-free vehicle seat cushion comprises: hair-saving, combing acid and base for expansion; ammonia-free deliming, dipping weak acid and low slat, Cr-free bating, composite batting, and adding strong-absorption fat for dyeing to treat skin from pig, cattle or sheep. The product has shrinkage temperature up to 110Deg, shows well hand feeling and resistance to thermal and age. This invention reduces material quantity and 30-50% sewage discharge, improves absorption rate, and brings a new way for Cr-free leather.

Owner:SICHUAN UNIV

Ecofriendly bio-process for leather processing

The present invention relates to an eco-friendly beam house process for de-hairing of leather using commercially available enzymes that obviates the use of lime and other alkalis. The present invention also provides an alternate process for opening the fibers of leather using commercially available enzymes. The present invention further provides a three-step process for tanning hide or skin in a narrow pH range of from about 7.5 to about 8.5.

Owner:COUNCIL OF SCI & IND RES

Double-bond saturation isomerism etherifying process for improving oxidation resistance and pouring point of plant oil

InactiveCN101792827AImprove antioxidant propertiesImprove pour pointTanning treatmentDouble bondFatty acid

The invention discloses a double-bond saturation isomerism etherifying process for improving oxidation resistance and a pouring point of plant oil. In the process, the plant oil is epoxidized by hydrogen peroxide, glacial acetic acid and catalyst sulfuric acid for saturating double bonds; and then, the etherification reaction is carried out by adopting fatty alcohol with a long chain under the participation of catalyst to obtain isomerized grease alcohol ether. The isomerized ether not only has stable oxidation but also reduces the pouring point. The obtained isomerized alcohol ether further generates esterification reaction with fatty acid anhydride to finally obtain synthetic grease with more stable oxidation and further reduction of the pouring point. The new improved oil has good oxidative stability, can be biologically degraded and is novel high-quality synthetic oil which has better oxidative stability, higher viscosity index, lower pouring point and better lubricating property than mineral oil, and part of performance of the synthetic oil is better than that of common market sold pentaerythritol ester.

Owner:SHANGHAI UNIV

Method for manufacturing washable cow split leather

ActiveCN107502685AFully rehumidifiedImprove washing resistanceTanning treatmentPre-tanning chemical treatmentSofteningChemistry

The invention relates to a method for manufacturing washable cow split leather and belongs to the technical field of manufacture of leather. The method comprises the following steps: taking a cow split leather blank subjected to wringing and shaving, and sequentially performing re-wetting, primary washing, retanning, neutralizing, secondary washing, filling, dyeing, stuffing, acid solidification, thrice washing, fixing, quartic washing, drying, hanging and airing, vibratory softening, leather fluffing and milling. The washable cow split leather manufactured by the method has favorable washability, and is high in leather yield.

Owner:漳州香洲皮革有限公司

Non-chromium leather tanning method

The invention provides a non-chromium leather tanning method. The non-chromium leather tanning method comprises the following steps of: (a) pre-treating animal skin, soaking in water and weighing, and soaking in gangue to obtain gangue skin; (b) carrying out deliming, softening and primary pickling onto the raw gangue skin to obtain raw skin; (c) carrying out secondary pickling onto the raw skin; (d) tanning the raw skin after the secondary pickling; (e) primarily fixing the tanned raw skin in formic acid for 30 minutes after carrying out oxidizing, aldehyde-removing and re-tanning; and carrying out neutralizing treatment after rinsing for 60 minutes by virtue of oxalic acid; and (f) getting out the raw skin after the neutralizing treatment from a rotary drum after carrying out fat liquoring, secondary fixing, and water-washing, drying the raw skin after primary stabbing, re-moistening for 20 hours, knocking and softening for 8 hours, and carrying out secondary stabbing and drying to obtain the tanned leather. The leather tanning method provided by the invention is free of chromium-containing preparation, so that the leather processing process is more environment-friendly, and the harms to the construction staffs are reduced.

Owner:何裕华

Manufacturing method of double-faced waterproofing pile-face dual-purpose leather of indumentum and leather boards

InactiveCN101445842AIn line with physical and chemical performance indicatorsComply with special chemical indicatorsTanning treatmentPre-tanning chemical treatmentDual purposeChemical index

The invention discloses a manufacturing method of double-faced waterproofing pile-face dual-purpose leather of indumentum and leather boards; the method comprises three parts that: manufacturing process of the pile-face dual-purpose crust leather and waterproofing treatment of the leather boards, the process of dyeing, retanning and stuffing, and indumentum waterproofing process. The physical andchemical indexes, specialty chemical index, waterproofing index, anti-washing index and dry cleaning resistant index of the manufactured double-faced waterproofing pile-face dual-purpose leather of indumentum and leather boards are all in accordance with international or industrial standards.

Owner:JIAXING UNIV +1

Reutilization method of chromium-containing leather production sludge

ActiveCN102363820ATake advantage ofAvoid secondary pollution of the environmentSludge treatmentTanning treatmentSludgeChromium

The invention relates to a reutilization method of chromium-containing leather production sludge. The method comprises steps that: the chromium-containing leather production sludge is dissolved by using acid, and is hydrolyzed; the obtained material is filtered, and a filtrate is used for producing a chrome tanning agent; the filter residue is used for producing a chromium-containing retanning agent, such that a secondary environmental pollution problem caused by filter residue produced during the reutilization of the chromium-containing leather production sludge is completely solved. When the filtrate is used for producing the chrome tanning agent, a powdery chrome tanning agent is produced.

Owner:BROTHER ENTERPRISES HLDG CO LTD

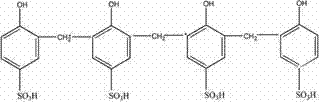

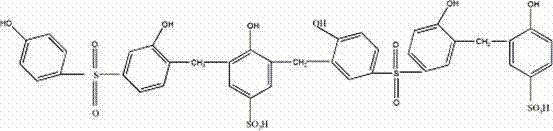

Process for the Preparation of Synthetic Tanning Agent for Improved Leather Characteristics

InactiveUS20080229511A1Improved leather characteristicImprove featuresTanning treatmentFiberLubrication

Generally, the tanned leathers are retanned with a combination of synthetic tanning agents to enhance the properties such as fullness, grain tightness, grain smoothness and roundness. Many of the chemicals that go into the preparation of such synthetic tanning agents are toxic and slow biodegradable. Further, in industrial practice, several synthetic tanning agents are combined to obtain a desired property. In the present invention, a synthetic tanning agent using natural and proteinous waste materials is disclosed, which provides to the leather the properties such as better fibre lubrication, filling of looser ends, softness, shape retention and fabrication comforts without combining with other synthetic tanning agents is reported.

Owner:COUNCIL OF SCI & IND RES

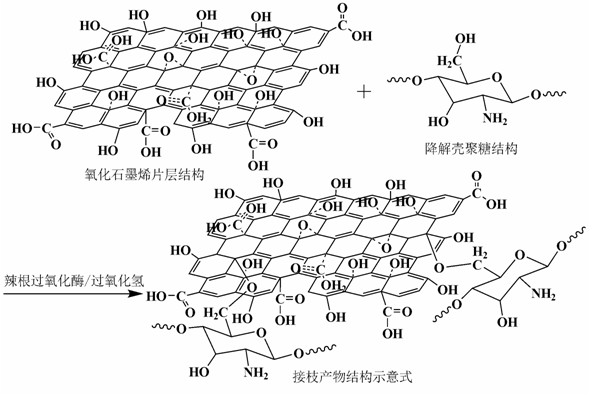

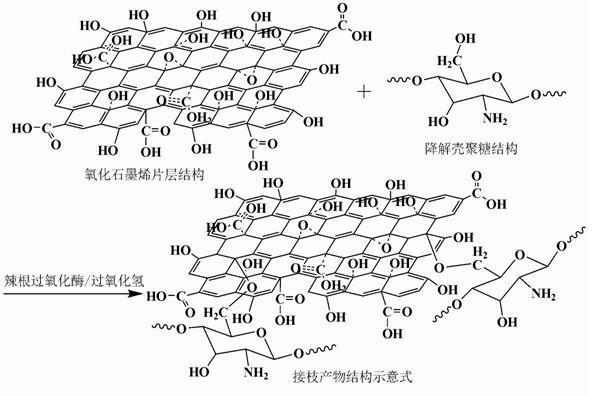

Preparation method of chitosan modified graphite oxide functional leather tanning agent

The invention relates to a preparation method of a chitosan modified graphite oxide functional leather tanning agent. Currently, the common leather tanning agents are chroming tanning agent, aluminum tanning agent, vegetable tanning agent, aldehyde tanning agent and synthetic tanning agent and the like, but the leather tanning agents can generate pollution problems hard to treat. The preparation method provided by the invention has the following steps of: mixing crystalline flake graphite powder, sodium nitrate and concentrated sulfuric acid and stirring uniformly, slowly adding potassium permanganate for oxygenation, and preparing a suspending liquid through washing, pH adjustment and ultrasonic treatment; and degrading chitosan with high-temperature alpha-amylase so as to obtain a degraded chitosan solution, modifying graphite oxide with the degraded chitosan under a horseradish peroxidase-hydrogen peroxide catalysis system, thus obtaining the chitosan modified graphite oxide functional leather tanning agent. The preparation method provided by the invention has the advantages of unique synthetizing preparation process and good tanning property, is suitable for main tanning and retanning; and the leather has excellent intensity and flexibility after main tanning.

Owner:JIANGSU BESCON PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com