Patents

Literature

120results about How to "Improve antioxidant properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite lithium-calcium base lubricating grease and preparation method thereof

ActiveCN102977979AGood mechanical stabilityGood extreme pressure and anti-wear propertiesThickenersWater resistanceLithium

The invention relates to lubricating grease and a preparation method thereof, particularly relates to composite lubricating grease and a preparation method thereof, and belongs to the technical field of chemistry. According to the invention, base oil, thickener and additive are prepared into lithium-calcium base lubricating grease according to a proper ratio; the lithium-calcium base lubricating grease has the characteristics of favorable high temperature property, shear stability, extreme pressure wear resistance, water resistance and the like; and the invention is simple in preparation method, stable in product performance, low in product comprehensive cost and is suitable for large-scale industrial production.

Owner:JIANGSU LOPALTECH

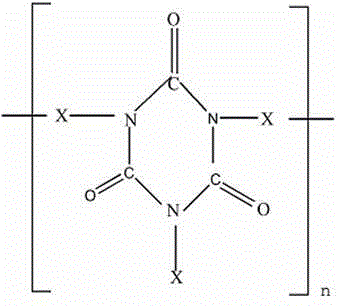

Crosslinked ethylene-tetrafluoroethylene copolymer insulating material

ActiveCN104629159ALow smoke productionHigh retention of tensile strength and elongation at breakPlastic/resin/waxes insulatorsInsulated cablesPrepolymerMineral oil

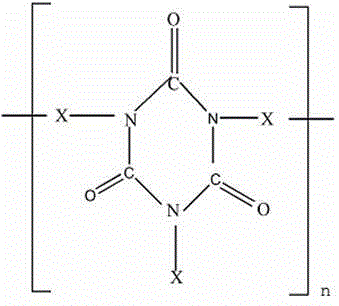

The invention is a crosslinked ethylene-tetrafluoroethylene copolymer insulating material. The crosslinked ethylene-tetrafluoroethylene copolymer insulating material comprises the following components in parts by mass: 100 parts of an ethylene-tetrafluoroethylene copolymer, 0.3-8 parts of a prepolymer crosslinking agent, 0.1-1 part of N, N'-bis[beta-(3,5-di-t-butyl-4-hydroxyphenyl) propionyl] hydrazine, 0.5-3 parts of 1,3,5-tris(3,5-di-tert-butyl 4-hydroxybenzyl)isocyanuric acid, 1-5 parts of antimony trioxide, 1-3 parts of antimony pentoxide, 0.1-2 parts of N, N'-ethylene bisstearamide, 0.1-0.5 part of pentaerythritol stearate and 0.1-3 parts of mineral oil, wherein the weight average molecular weight of the prepolymer crosslinking agent is 600-5000 and the weight part ratio of 1,3,5-tris(3,5-di-tert-butyl 4-hydroxybenzyl)isocyanuric acid to N, N'-bis[beta-(3,5-di-t-butyl-4-hydroxyphenyl) propionyl] hydrazine is 3: (0.9-1.2). By the crosslinked ethylene-tetrafluoroethylene copolymer insulating material, the problems that the smoke amount is high, the crosslinking agent is easy to self-polymerize and the requirements on the processing temperature is very rigorous during the processing of the current XETFE insulating material are solved and the domestic blank is filled up.

Owner:中广核三角洲(江苏)塑化有限公司

Carbonyl sulfur hydrolyzing catalyst

ActiveCN101239319AHigh catalytic activityImprove antioxidant propertiesMetal/metal-oxides/metal-hydroxide catalystsDesorptionSulphur compound

The present invention provides a carbonyl sulfur hydrolyst, including a carrier and an active component, characterized in that the active component of the catalyst includes an active component I and an active component II, the active component I is selected from sodium carbonate, potassium carbonate or their mixtures, the active component II is selected from following metal oxide: Be, Mg, Ca, Sr, Ba, or mixtures of their metal oxides, the catalyst carrier is selected from Al2O3 or mixture of Al2O3 and TiO2 or ZrO2, the percentage by weight in the catalyst: the active component I is 2wt%-15wt%, the active component II is 2wt%-15wt%, the carrier is 70wt%-96wt%. The catalyst is used for carboxide sulphur compound in desorption LPG, natural gas, refinery gas, catalytic cracking process gas, propylene and ethylene, the percent conversion is more than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Double-bond saturation isomerism etherifying process for improving oxidation resistance and pouring point of plant oil

InactiveCN101792827AImprove antioxidant propertiesImprove pour pointTanning treatmentDouble bondFatty acid

The invention discloses a double-bond saturation isomerism etherifying process for improving oxidation resistance and a pouring point of plant oil. In the process, the plant oil is epoxidized by hydrogen peroxide, glacial acetic acid and catalyst sulfuric acid for saturating double bonds; and then, the etherification reaction is carried out by adopting fatty alcohol with a long chain under the participation of catalyst to obtain isomerized grease alcohol ether. The isomerized ether not only has stable oxidation but also reduces the pouring point. The obtained isomerized alcohol ether further generates esterification reaction with fatty acid anhydride to finally obtain synthetic grease with more stable oxidation and further reduction of the pouring point. The new improved oil has good oxidative stability, can be biologically degraded and is novel high-quality synthetic oil which has better oxidative stability, higher viscosity index, lower pouring point and better lubricating property than mineral oil, and part of performance of the synthetic oil is better than that of common market sold pentaerythritol ester.

Owner:SHANGHAI UNIV

Nylon composite material special for electric wire and cable jacket and preparation method thereof

ActiveCN102020842AImprove heat resistanceImprove light aging resistanceInsulated cablesInsulated conductorsPropanoic acidPhenol

The invention provides a nylon composite material special for an electric wire and cable jacket, which is prepared from the following components by mass percent: 86-100% of nylon 6, 0.1-2.0% of main antioxygen, 0.1-2.0% of auxiliary antioxygen, 0.1-2.0% of lubricant release agent, 0.1-2.0% of light stabilizer, 0.1-2.0% of lubricant, 0.1-2.0% of nucleating agent and 0.3-2.0% of tackifier, wherein the main antioxygen is a hindered phenol antioxygen, the auxiliary antioxygen is thiodi-propionic acid diester or phosphite ester, the lubricant release agent is calcium stearate, the light stabilizer is a hindered amine light stabilizer, the lubricant is ethylene double hard ester amide (EBS), silicone powder or a compositor of the ethylene double hard ester amide (EBS) and silicone powder, the nucleating agent is nano talcum powder, and the tackifier is nylon 6 containing reactive groups. The nylon composite material has the advantanges of simple formula and cheap, easily available components and low cost, and the electric wire and cable jacket prepared from the nylon composite material can prevent white ants and mousse, has abrasion resistance and corrosion resistance, is durable in use and is non-toxic and environment-friendly.

Owner:辰东意普万新材料(广东)有限公司

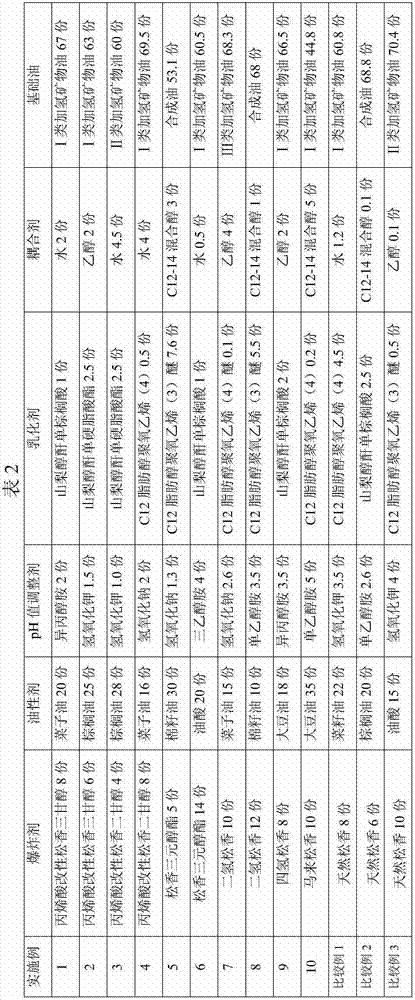

Emulsifying-type linear cutting operating fluid and uses thereof

ActiveCN103710075AImprove stabilityImprove antioxidant propertiesAdditivesHydrogenation reactionDouble bond

The invention relates to an emulsifying-type linear cutting operating fluid and uses thereof, and mainly solves the problem of short service life of the emulsifying-type electric-spark linear cutting operating fluid in the prior art. The emulsifying-type linear cutting operating fluid comprises the following components: by weight, a) 1-20 parts of a modified rosin blasting agent; b) 2-40 parts of a vegetable oilness agent; c) 0.2-5 parts of a pH adjustment agent; d) 0.1-10 parts of a coupling agent; e) 0.1-8 parts of an emulsifier; and f) 25-80 parts of base oil; the modified rosin blasting agent is selected from at least one from modified rosin prepared by esterification reaction or neutralization reaction of carboxyl in a molecular structure of rosin, or by addition reaction, hydrogenation reaction, disproportionation reaction or polymerization of double bonds of the molecular structure of the rosin, and the technical scheme solves the problem well, and can be used in the industrial production of the emulsifying-type electric-spark linear cutting operating fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

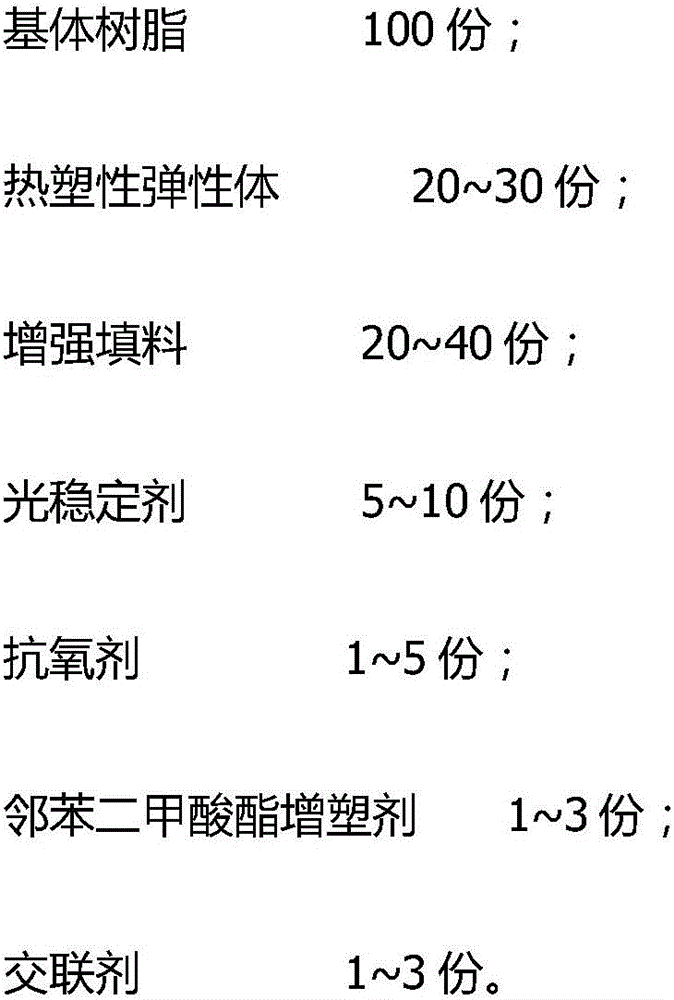

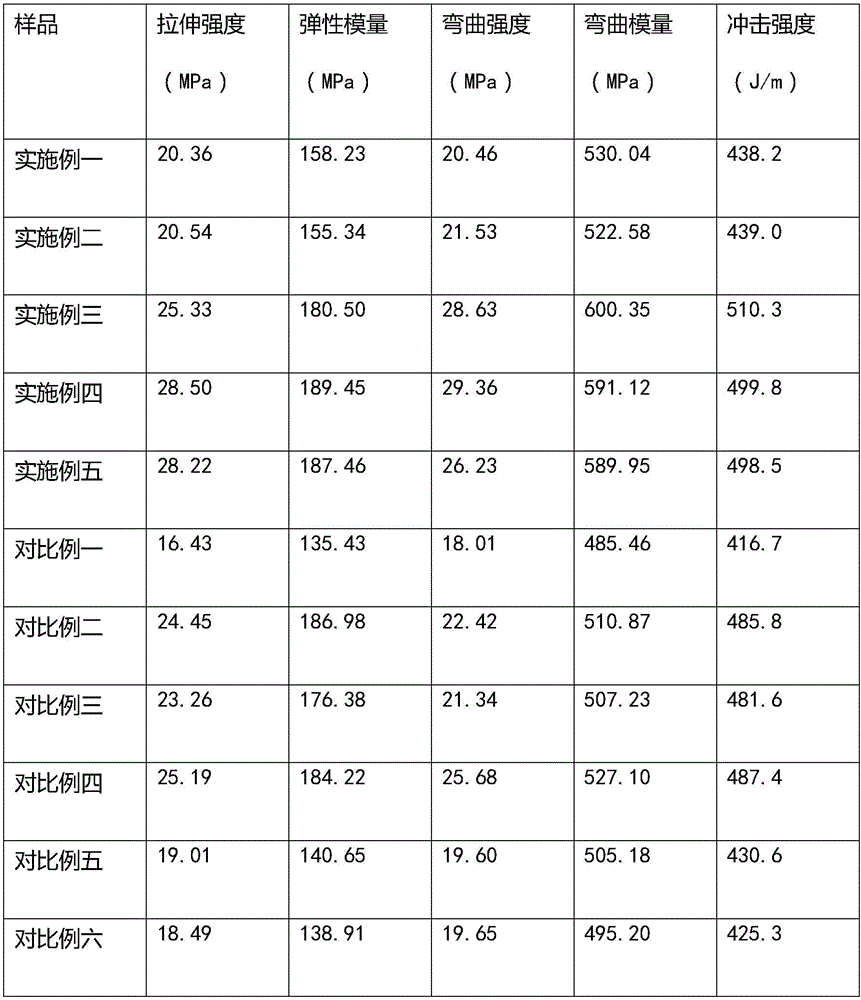

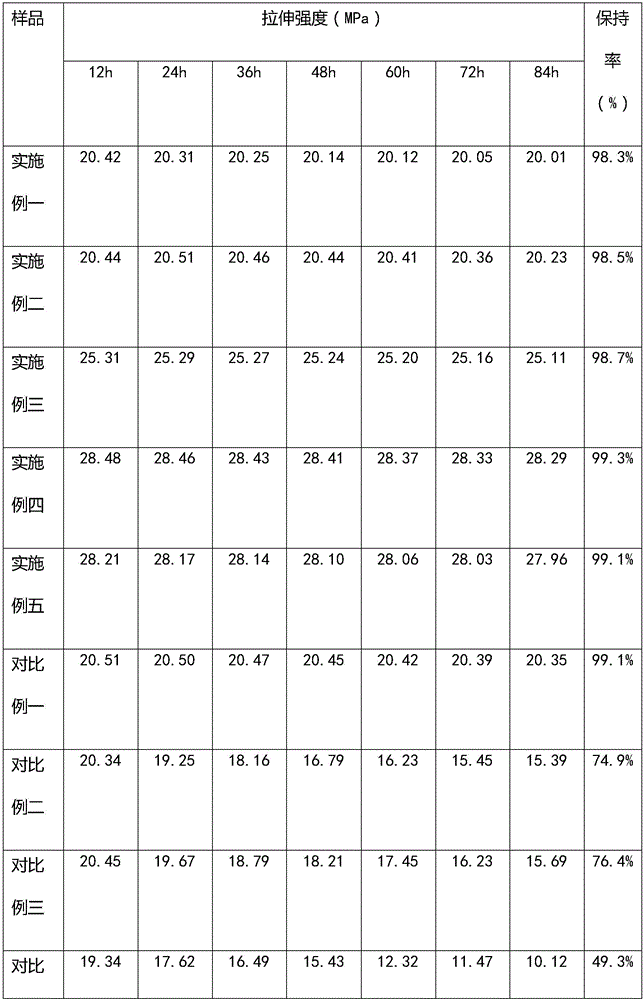

High-strength geogrid and preparation method thereof

The invention discloses a high-strength geogrid. The high-strength geogrid is prepared from, by weight, 100 parts of matrix resin, 20-30 parts of thermoplastic elastomer, 20-40 parts of reinforcing filler, 5-10 parts of a light stabilizer, 1-5 parts of an antioxidant, 1-3 parts of phthalate plasticizer and 1-3 parts of a crosslinking agent. The high-strength geogrid is excellent in light radiation resistance, tensile strength retention rate is about 98% after 84h light irradiation, ageing of the geogrid is remarkably decelerated, and deformation and damage of the geogrid are reduced.

Owner:天鸿建设集团有限公司

Compound preparation with effects of diminishing inflammation, resisting allergy and relieving itching as well as preparation method and application of compound preparation

InactiveCN107823472AReduce sensitivityRaise resistance thresholdCosmetic preparationsAntipyreticAllergyInflammation

The invention belongs to the field of natural product formulae, and relates to a compound preparation with effects of diminishing inflammation, resisting allergy and relieving itching as well as a preparation method and an application of the compound preparation. The compound preparation with the effects of diminishing inflammation, resisting allergy and relieving itching comprises raw materials in percentage by weight as follows: 1%-10% of herba portulacae extract, 20%-30% of moso bamboo leaf extract, 1%-30% of dendrobium candidum extract, 1%-10% of radix sophorae flavescentis extract, 1%-10%of radix glycyrrhizae extract, 1%-10% of flos lonicerae extract, 1%-10% of oat extract and the balance of auxiliary materials. With the adoption of an appropriate raw material ratio, effects of the components are brought into full play, the effect is better than that of each single component, the compound preparation has the good effects of diminishing inflammation, resisting allergy and relieving itching, and resisting threshold of skin to outside irritants is increased, so that skin allergy is relieved.

Owner:艾因特丽(苏州)生物科技有限公司

Halogen-free thermosetting epoxy adhesive and application thereof

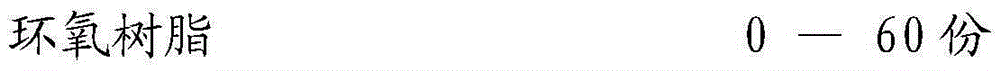

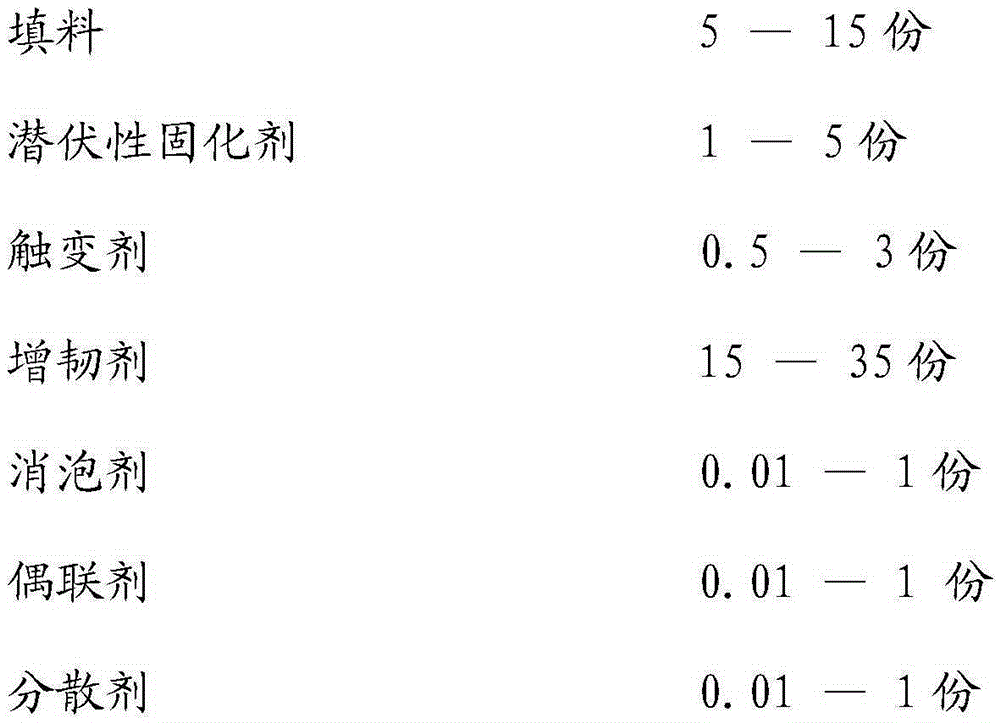

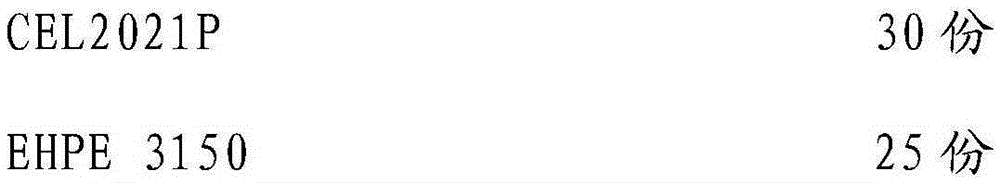

ActiveCN105385396AThere will be no excessive halogenHalogen-free requirements meetNon-macromolecular adhesive additivesMacromolecular adhesive additivesHalogenHeat resistance

The invention provides a halogen-free thermosetting epoxy adhesive. The halogen-free thermosetting epoxy adhesive comprises, by weight, 0-60 parts of epoxy resin, 5-15 parts of a filler, 1-5 parts of a latent curing agent, 0.5-3 parts of a thixotropic agent, 15-35 parts of a flexibilizer, 0.01-1 part of an antifoaming agent, 0.01-1 part of a coupling agent and 0.01-1 part of a dispersant. The halogen-free thermosetting epoxy adhesive can be applied in E-Paper edge sealing. The epoxy adhesive provided by the invention has the advantages of no halogen, realization of low-temperature rapid solidification, excellent bonding strength and flexibility, high heat resistance, low heat expansion coefficient and high water resistance.

Owner:深圳百丽春新材料科技有限公司

Thermal-conductive flame-retardant weatherproof anti-static environment-friendly insulating material for cables and preparation method of insulating material

InactiveCN107141624AImprove insulation performanceExcellent ozone aging resistancePlastic/resin/waxes insulatorsHeat-exchange elementsAntistatic agentUltraviolet lights

The invention discloses a thermal-conductive flame-retardant weatherproof anti-static environment-friendly insulating material for cables. The insulating material comprises, by weight, 50-60 parts of chlorinated polyethylene rubber, 7-11 parts of coupling agent, 2-4 parts of antistatic agent, 5-8 parts of antimony trioxide, 3-8 parts of calcium stearate, 5-10 parts of toughening agent, 1-2 parts of antioxidant, 2-6 parts of ultraviolet light absorber, 6-8 parts of flame retardant and 8-14 parts of insulating nanometer thermal conductive filler. The insulating material has good anti-oxygen effect, high stability and outstanding thermal conductivity, has high tensile strength and elongation at break, and also has good flame-retardant properties, anti-static performance and insulation performance, thereby being suitable for serving as the outer wrapping insulation material for cables; the preparation method of the insulating material has the advantages of low material cost, easy availability in raw materials, simple process, high practical value and good application prospects.

Owner:合肥市闵葵电力工程有限公司

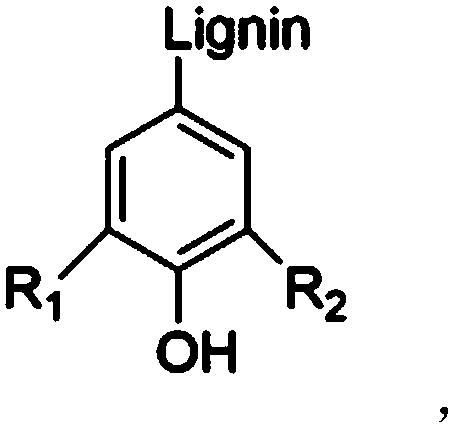

Multifunctional lignin arylamine macromolecular antioxidant and preparation method and application thereof

The invention provides a novel multifunctional lignin arylamine macromolecular antioxidant and a preparation method and application thereof in a polymer. Arylamine is introduced into lignin phenol ortho-position through a mannich reaction, a phenol functional group of the lignin is converted into a hindered phenol structure with the better anti-oxidant effect, and the anti-oxidant capability is improved; meanwhile, due to introduction of arylamine, the anti-oxidant effect is further enhanced, and the synergic anti-oxidant effect is achieved; compared with a common polymer antioxidant, the prepared lignin arylamine macromolecular antioxidant has the advantages of being non-toxic, high in molecular weight, not likely to be migrated, low in additive amount, simple in technology, mild in condition, capable of achieving industrial production easily and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

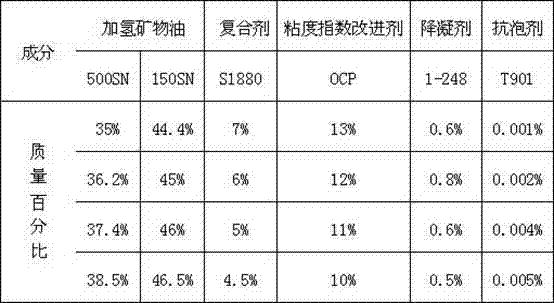

Formula as well as production technology of special lubricating oil for dual-fuel engine

InactiveCN104119992AGood antioxidant capacityGood lubricationLubricant compositionLubricationChemistry

The invention relates to a formula and a production technology of special lubricating oil for a dual-fuel engine. The lubricating oil is characterized by comprising base oil and an additive, wherein imported hydrogenated mineral base oil 500SN and 150SN are adopted as the base oil, the additive consists of a complexing agent S1880, a viscosity index improver OCP, a pour point depressant 1-248 and an anti-foaming agent T901, and the base oil and the additive are mixed according to a certain proportion. The lubricating oil is prepared by refining and blending hydrogenated base oil and special complex additives for imported dual fuels, and has better anti-oxidization capability and nitration resisting stability at higher temperature; the lubricating oil has protection and more excellent lubrication effects on parts difficult to lubricate, and can reduce the emission of harmful gas and generation of waste engine oil to purify the environment; the lubricating oil has excellent cleanliness and dispersion properties, and the generation of oil sludge and carbon deposit can be effectively inhibited, so that the engine can be cleaner, the oil is not easily aged, and the service life of the engine can be prolonged.

Owner:山东力牌石油化学有限公司

Rubber material for agriculture vehicle tire

InactiveCN104403140AHigh tensile strengthHigh tear strengthSpecial tyresRubber materialAluminium hydroxide

The invention discloses a rubber material for agriculture vehicle tires. The rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of natural rubber, 10-14 parts of epoxy natural rubber, 15-20 parts of silicon dioxide, 2-4 parts of a silane coupling agent, 20-30 parts of brominated butyl rubber, 20-30 parts of superfine glass bead, 30-40 parts of carbon black N660, 20-30 parts of light calcium carbonate, 1-2 parts of tetramethyl thiuram disulfide, 1-2 parts of diisopropylbenzene peroxide, 2-3 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 2-4 parts of zinc oxide, 1-2 parts of an accelerant DM, 0.5-1.0 part of an accelerant CZ, 1-2 parts of N-phenyl-N'-(1,3-dimethyl)-p-phenylenediamine, 1-2 parts of 2,2'-methylene-bi(4-methyl-6-tertiary butyl phenol), 1-2 parts of petroleum oil, 2-5 parts of stearic acid, 1-2 parts of protecting wax OK5194, 5-6 parts of rubber tackifying resin A-90, 5-8 parts of antimonous oxide, 5-10 parts of molybdenum trioxide and 20-30 parts of aluminium hydroxide.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

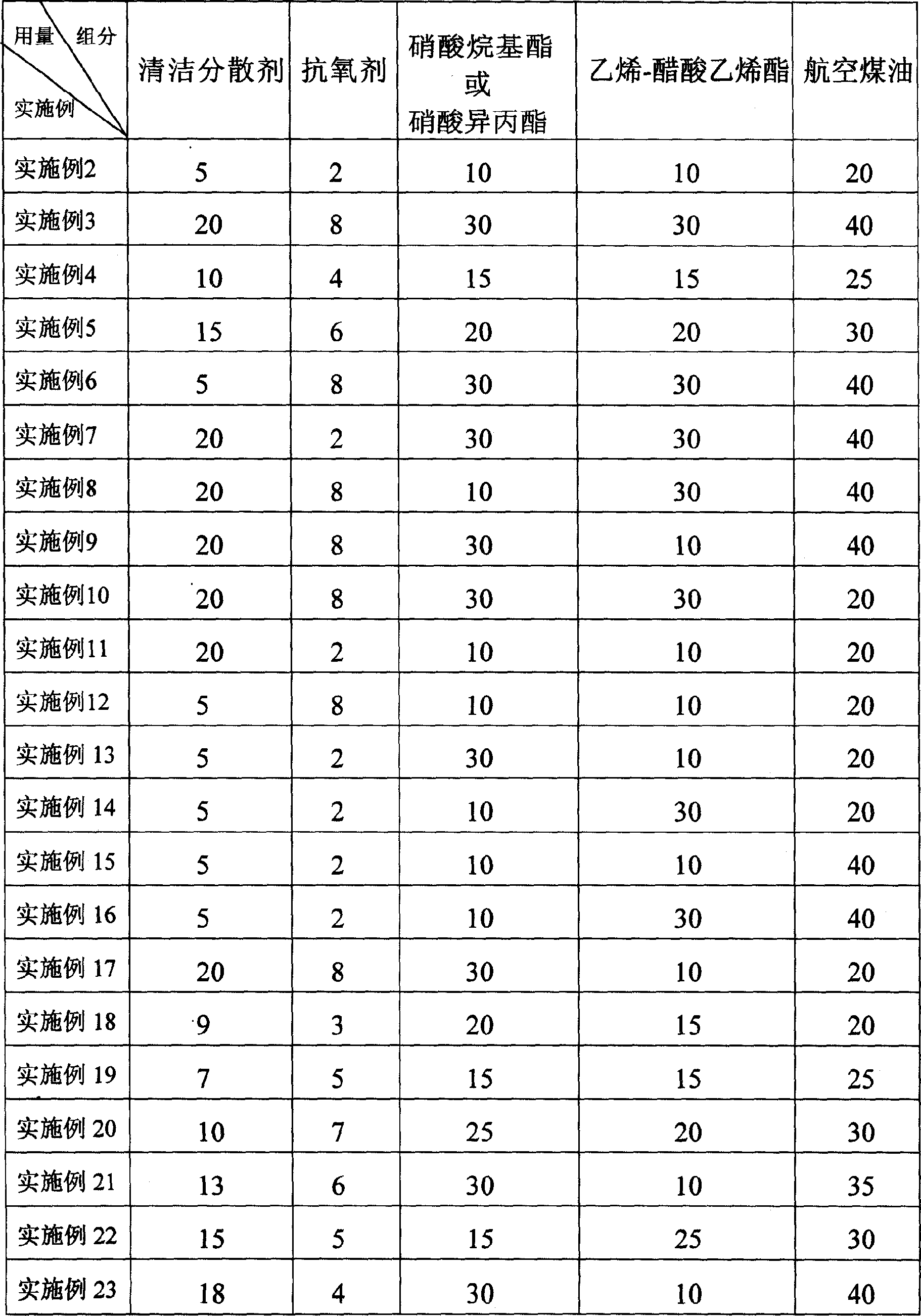

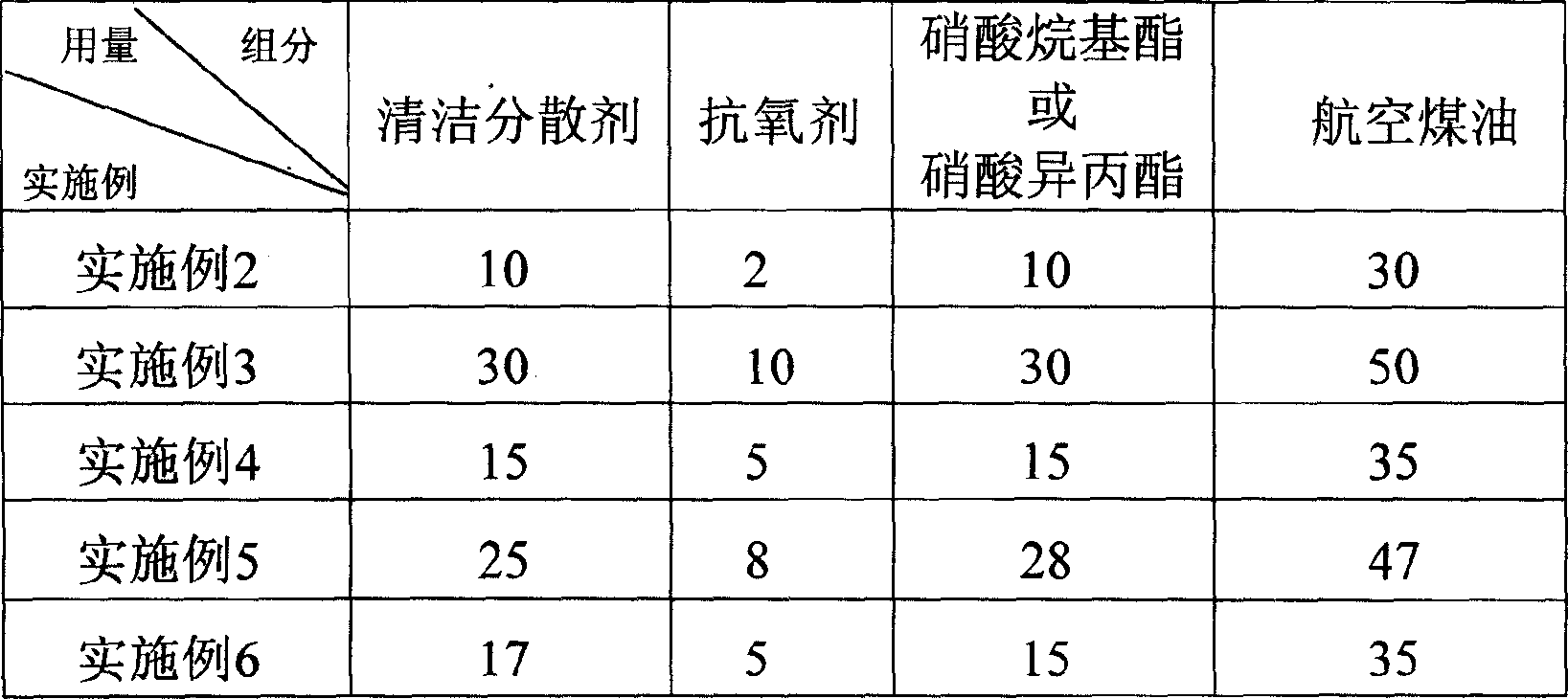

Smoke abatement anti-freeze agent for diesel fuel

The invention provides an environment-friendly type diesel smoke abatement and anti-freeze agent for purifying emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate or ethylene / vinyl acetate and high grade plane kerosene through high-shearing mixing and emulsion process. The invention can realize good intensified smoke abatement property and fluidity for diesel under low-temperature.

Owner:牛云龙

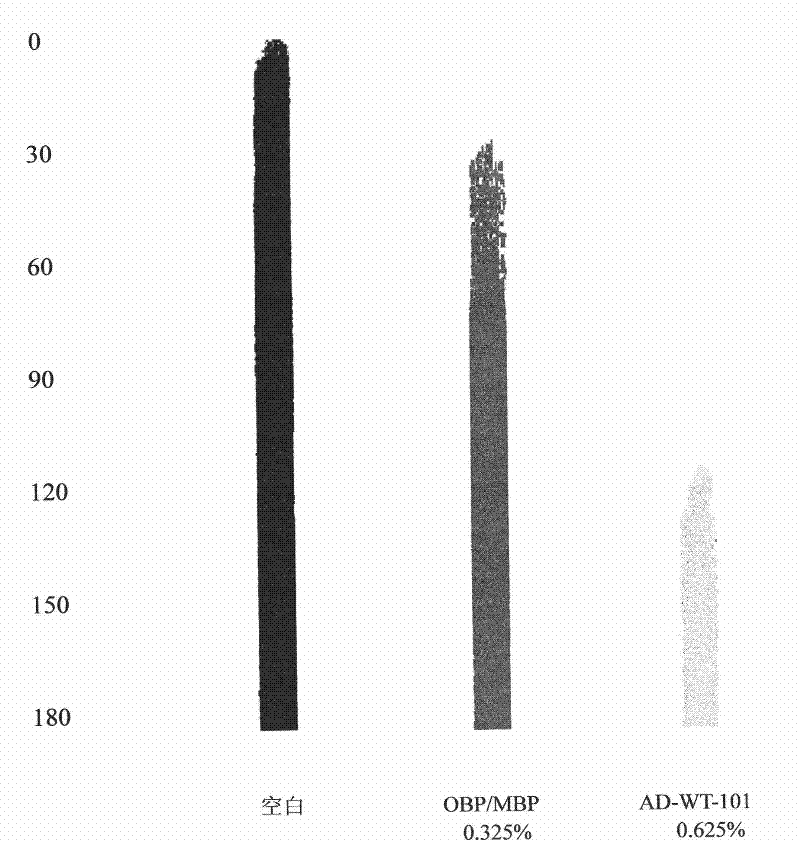

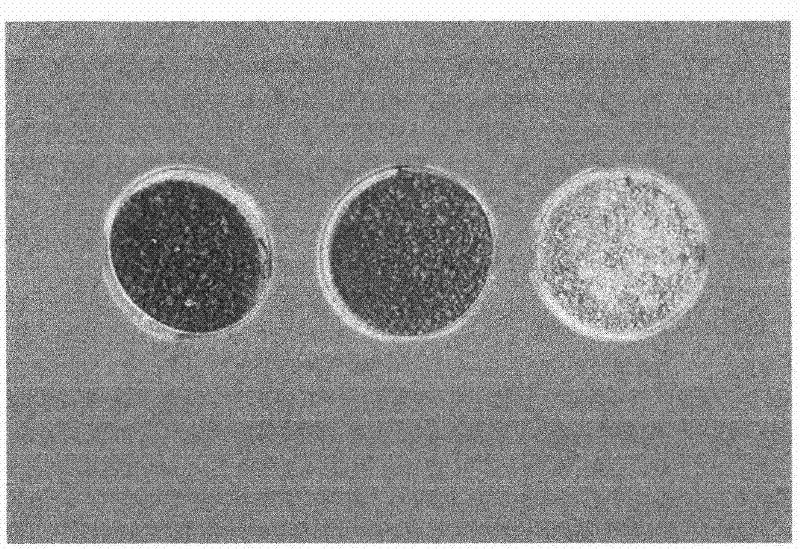

Emulsion antioxygen and preparation method thereof

The invention belongs to the field of antioxygen, in particular to an emulsion antioxygen and a preparation method thereof. The emulsion antioxygen is emulsified and compounded by the following raw material reagents at the proportion: main antioxygen, auxiliary antioxygen, emulsifying agent, dispersing agent and defoaming agent. The emulsion antioxygen has better oxidation resistance than other similar antioxygens and can achieve the optimal oxidation resistance effect, and the total solid content of the emulsion antioxygen is more than 52%. The emulsion antioxygen has the advantages of good oxidation resistance effect, big activity, low volatility, high durability, no pollution and the like and is especially suitable for protecting tint and pollution-free color polymer thereof. The emulsion antioxygen can be favorably dispersed in ABS (Acrylonitrile Butadiene StyreneAcrylonitrile Butadiene Styre) rubber latex, is ideal antioxygen used preparing ABS by emulsion polymerization and has excellent dispersibility. According to the emulsion antioxygen, the heating oxygen aging time of the ABS resin can be prolonged in the ABS production, the oxidation inducing temperature of the ABS resin is improved, the phenomenon that the ABS resin becomes yellows in the production and processing process thereof can be prevented, the strength of a product can be improved, and the oxidation resistance problem for preparing ABS by emulsion polymerization can be solved.

Owner:唐东波

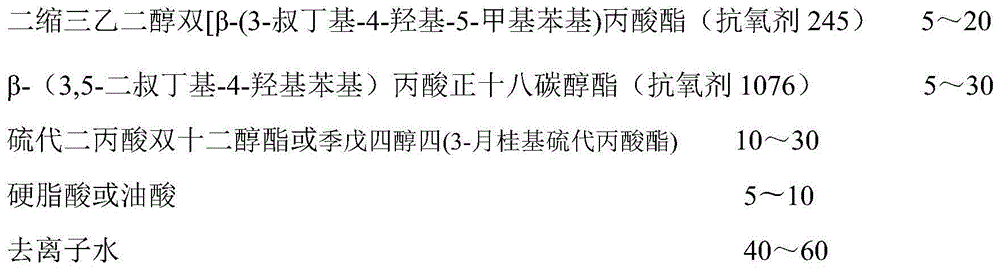

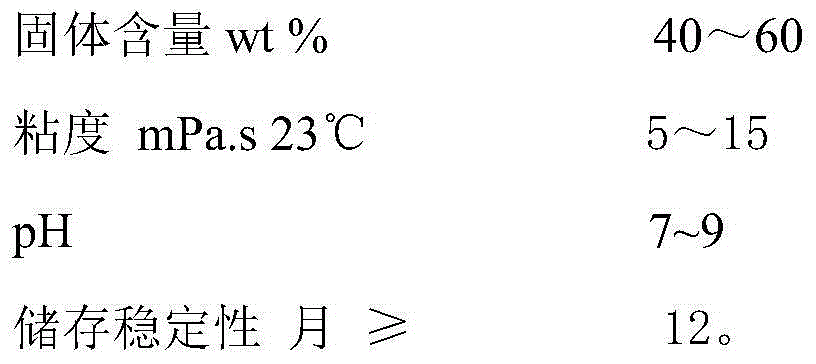

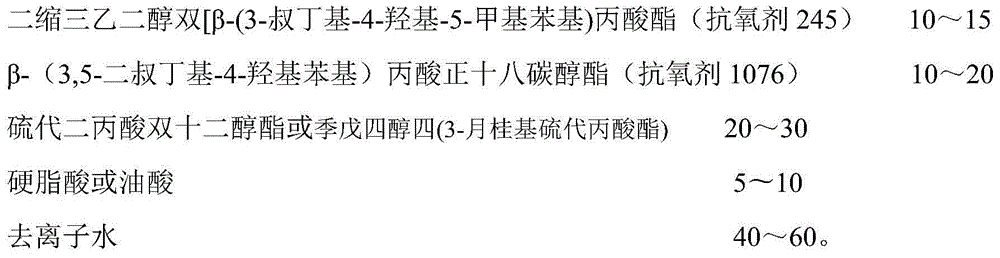

Dedicated emulsion-type composite anti-oxidant for MBS (methyl methacrylate-butadiene-styrene) and preparation method of the dedicated emulsion-type composite anti-oxidant

The invention provides a dedicated emulsion-type composite anti-oxidant for MBS (methyl methacrylate-butadiene-styrene) and a preparation method of the dedicated emulsion-type composite anti-oxidant, and belongs to compositions taking high-molecular compounds as binders. The dedicated emulsion-type composite anti-oxidant comprises the following raw materials by mass: 5 to 20 parts of triethylene glycol bis[beta-(3-tert-butyl-4-hydroxy-5-methyphenyl)propionate (anti-oxidant 245), 5 to 30 parts of n-octadecyl-beta-(4-hydroxy-3,5-di-tert-butyl-phenyl)propionate (anti-oxidant 1076), 10 to 30 parts of dilauryl thiodipropionate or pentaerythritol tetrakis(3-dodecyl-thiopionate), 5 to 10 parts of stearic acid or oleinic acid, and 40 to 60 parts of deionized water. The dedicated emulsion-type composite anti-oxidant has the advantages that the oxidative degradation prevention efficiency is high; the compatibility to MBS latex is high; adverse effects on other performances of a PVC product are avoided; the heat-proof and solvent extraction-proof capabilities are high; adverse reaction between the dedicated emulsion-type composite anti-oxidant and other additives is avoided; toxicity, peculiar smell and solvent evaporation are avoided; convenience is brought for environmental protection; the performance is ideal; the preparation technology is convenient to operate; the preparation cost is lower.

Owner:SHANDONG RUIFENG CHEM

Special protective adhesive for PS/CTP plates and preparation method thereof

The invention discloses a special protective adhesive for PS / CTP plates, which is prepared from the following components in parts by weight: 3-4 parts of Arabic gum, 2-3 parts of peach gum, 1-2 parts of pineapple pectin, 3-4 parts of hydroxyethyl fibers, 0.1-0.2 part of peppermint essential oil, 1-1.5 parts of polyvinyl alcohol, 1-2 parts of a compound additive, and 75-85 parts of deionized water; and in the process of preparation, components in a formula are added into hot water, and then fully stirred and filtered. The special protective adhesive for PS / CTP plates disclosed by the invention has a good uniform coating property, so that a smooth protective film can be formed after a small amount of the adhesive is used; the special protective adhesive for PS / CTP plates has an extremely strong protection ability, so that the service life of printing plates is prolonged; and the special protective adhesive for PS / CTP plates is aromatic in smell, so that the adhesive can improve the working environment, and improve the work efficiency.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

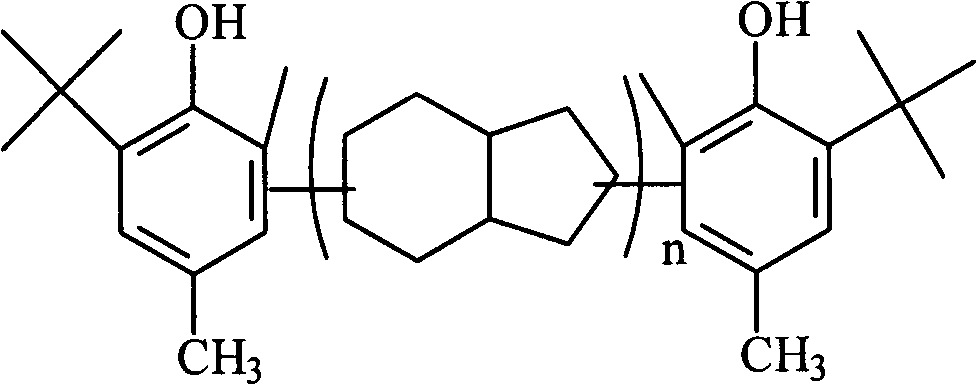

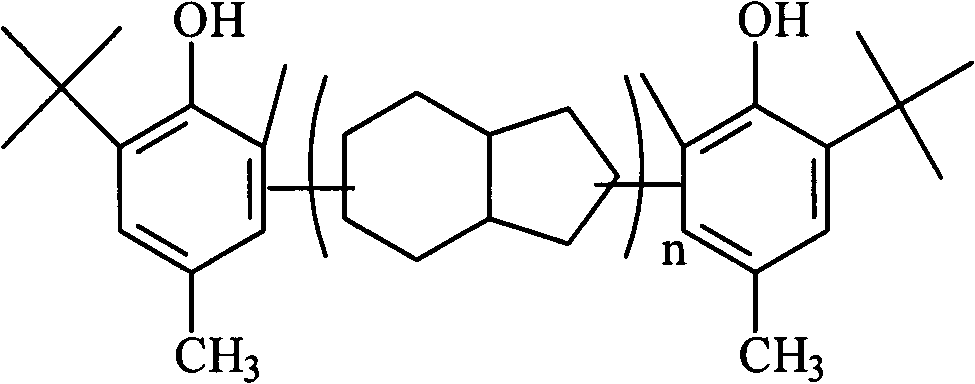

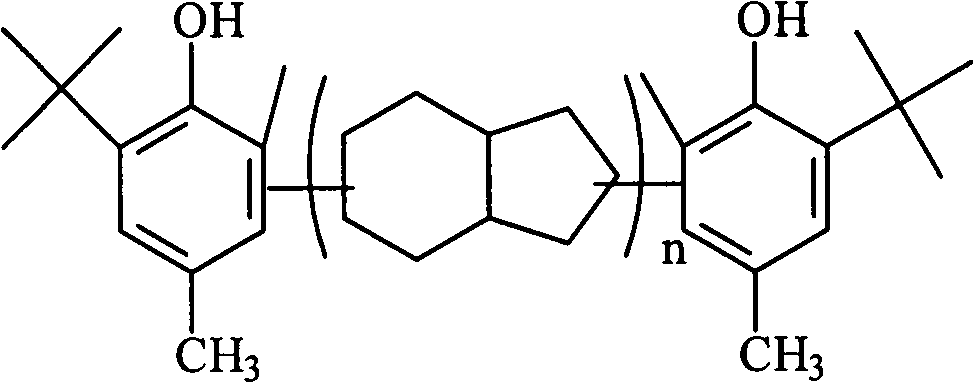

Preparation method for polymerization-type asymmetric hindered phenol anti-oxidant resins

InactiveCN103420810AHigh molecular weightImprove antioxidant propertiesOrganic chemistryOrganic compound preparationPolymer scienceO-Phosphoric Acid

Provided is a preparation method for polymerization-type asymmetric hindered phenol anti-oxidant resins. The preparation method comprises steps: with strong acid resins as catalysts, and benzene or cyclohexane as a solvent, 2-tert-Butyl-p-cresol and dicyclopentadiene are subjected to a polymerization reaction to form phenol-type petroleum resins; the phenol-type petroleum resins and saturated alcohols with one to three carbons are subjected to an alkylation reaction to form polymerization-type asymmetric hindered phenol anti-oxidant resins in presence of phosphoric acid and nickel-containing catalysts; the alkylation reaction products are subjected to reduced pressure distillation to remove the unreacted raw materials and solvent to obtain polymerization-type asymmetric hindered phenol antioxidant resin products. The preparation method has obvious positive effects, the polymerization reaction and the alkylation reaction have high selectivity and conversion rate, and the yield is about 80%. What is more important is that compared to traditional hindered phenol antioxidants, the synthesized polymerization-type asymmetric hindered phenol antioxidant resins are advantaged by high antioxidant activity, high heat stability, extracting resistance, compatibility, non-toxic and environmentally friendly characteristics.

Owner:CHINA PETROLEUM & CHEM CORP +1

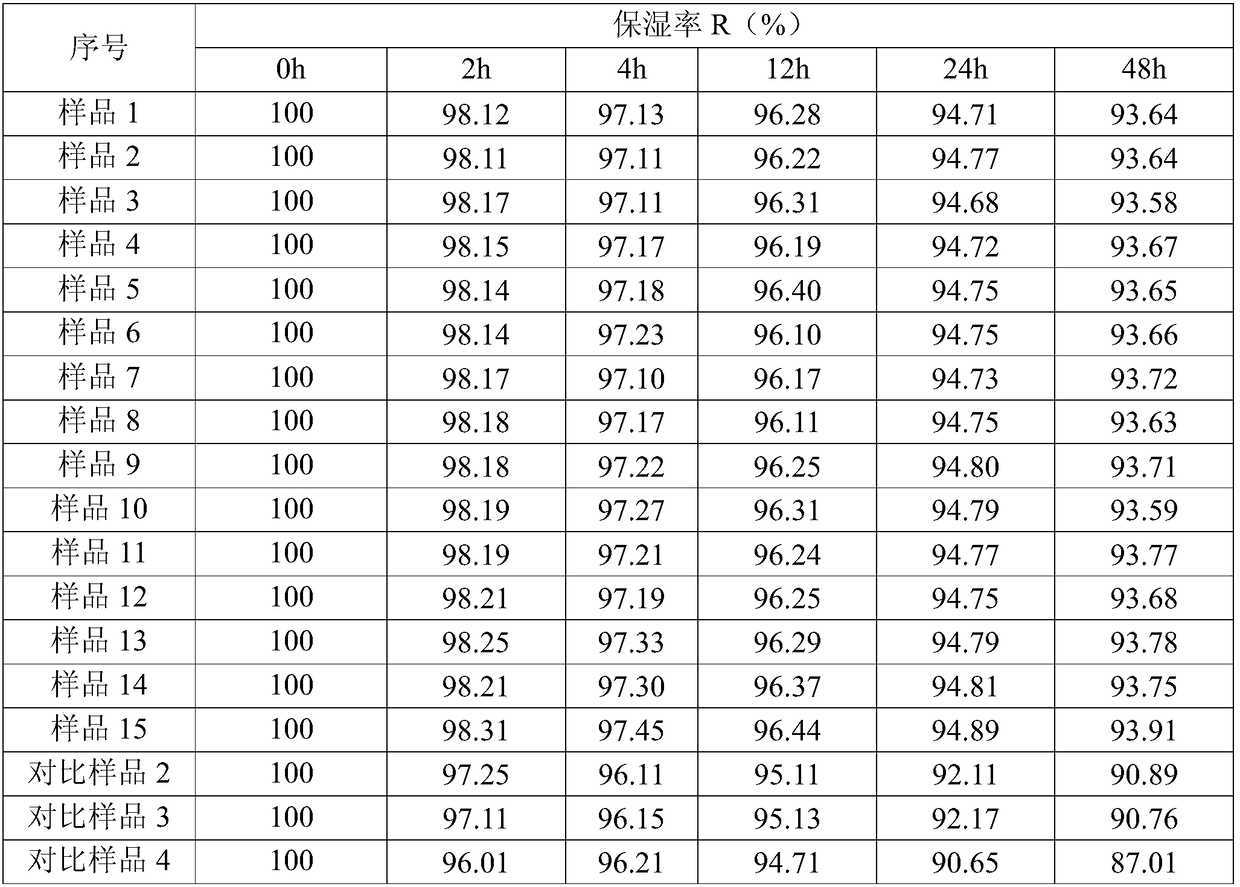

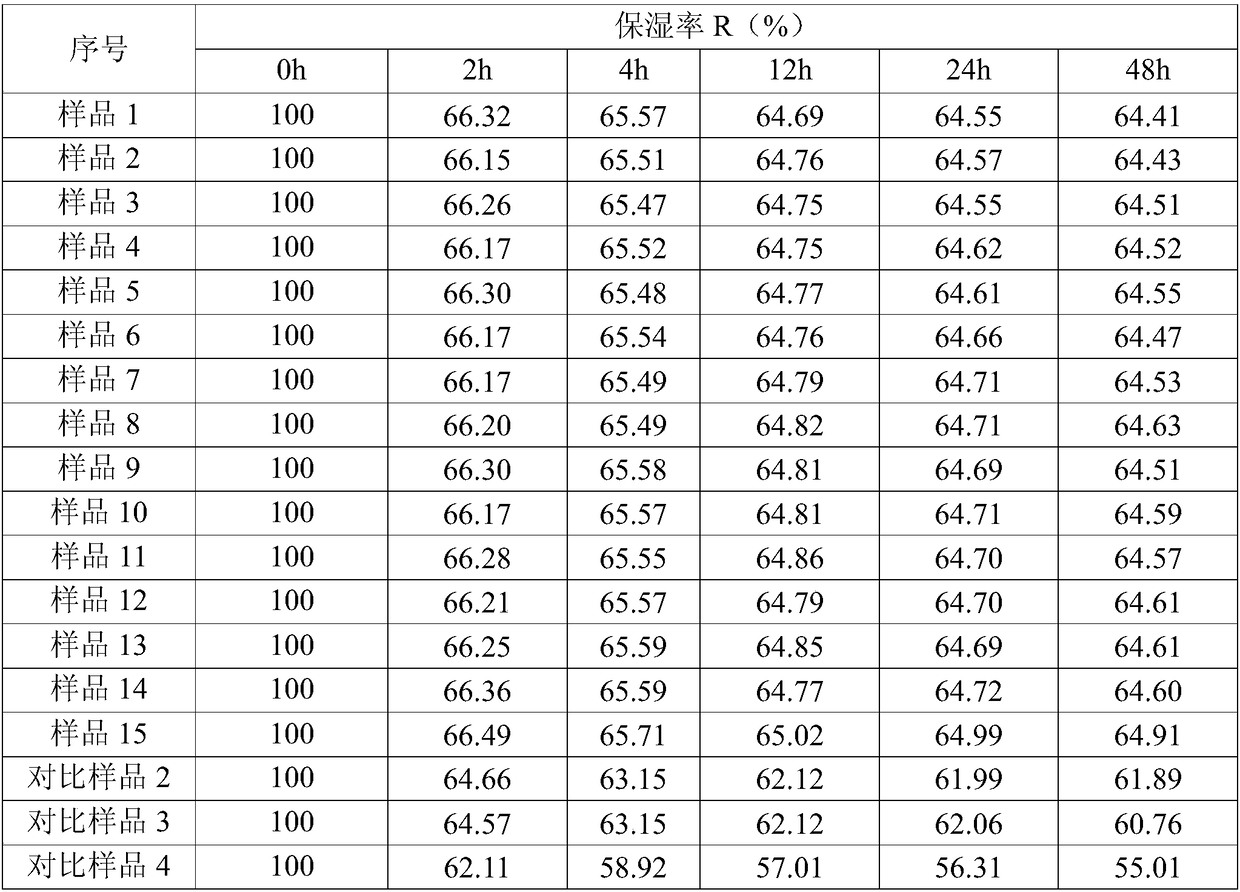

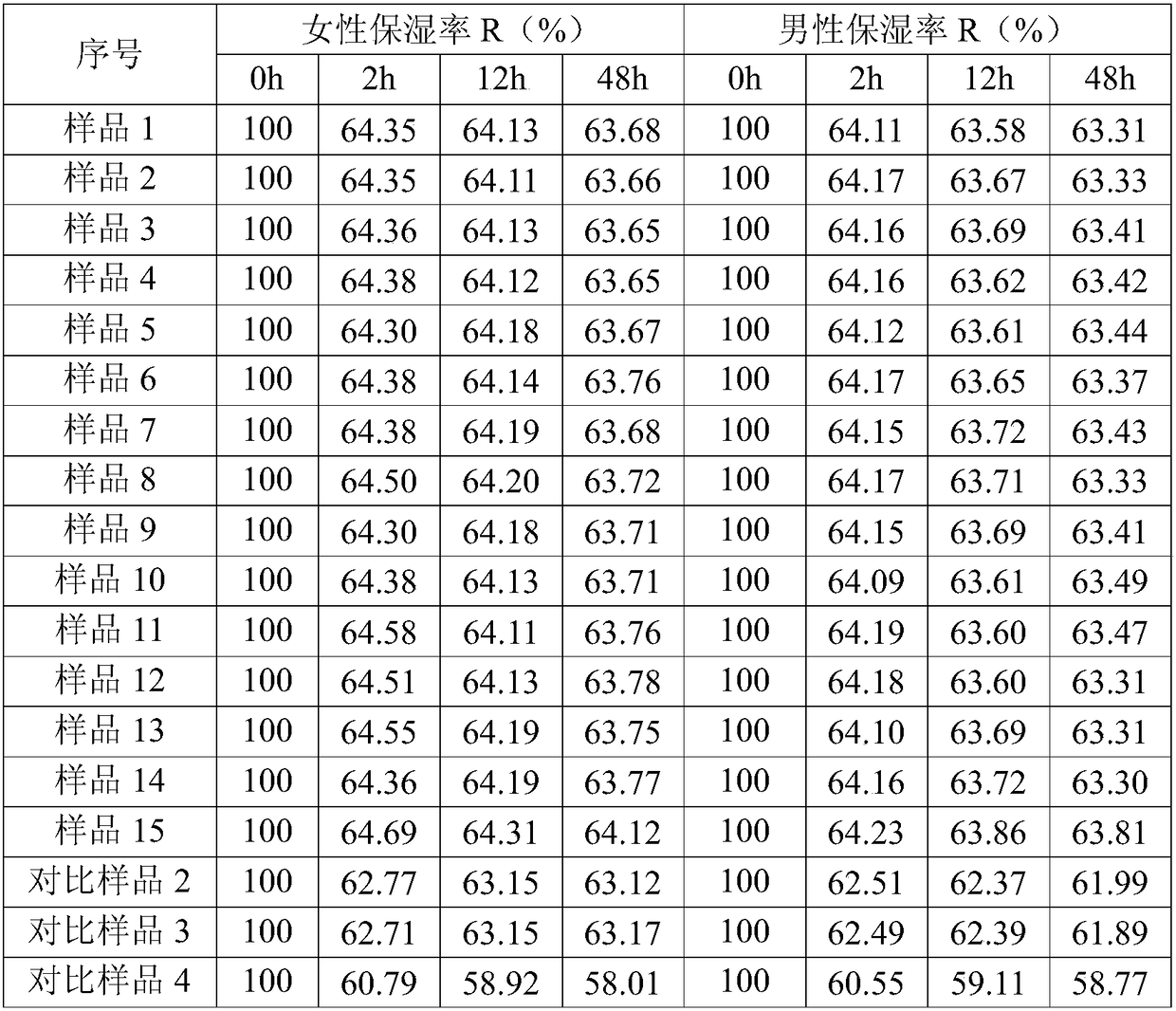

Skincare essence capable of moisturizing for 48 hours in long-acting mode

InactiveCN108451863ALong moisturizing durationGood moisturizing effectCosmetic preparationsToilet preparationsCuticlePreservative

The invention discloses skincare essence capable of moisturizing for 48 hours in a long-acting mode. The skincare essence is prepared from the following raw materials in parts by weight: 0.1-0.2 partof chia seed gel, 0.5-2 parts of chitosan, 3-5 parts of linseed oil, 6-8 parts of glycerin, 0.2-0.5 part of algal polysaccharides, 2-6 parts of plant fruit oil, 1-2 parts of plant essential oil, 0.2-0.5 part of panthenol, 0.05-0.2 part of preservative and 50-80 parts of deionized water. The skincare essence takes chia seed gel, algal polysaccharides, glycerin, aloe gel and chitosan as moisturizingcomponents, synchronously performs physical-layer moisturizing of chia seed gel, and water-absorbing moisturizing of algal polysaccharides and chitosan, is good in moisturizing effect, is long in moisturizing lasting time, and still can keep epidermis moisture content to be 50% or more after 48 hours.

Owner:四川四季莱源贸易有限公司

Preparation method of high-performance antioxidant of butyronitrile rubber latex

The invention relates to the technical field of antioxidant preparation methods, and in particular relates to a preparation method of a high-performance antioxidant of butyronitrile rubber latex. The preparation method disclosed by the invention comprises the following steps: mixing an emulsion type primary antioxidant of 2,2'-methylene-bis-(4-methyl-6-tert-butylphenol), paracresol and dicyclopentadiene butylated products with a tri[2,4-di-tertiary butyl-phenyl] phosphite ester emulsion type auxiliary antioxidant according to a certain proportion, and uniformly dispersing by stirring mechanically, wherein the viscosity of the formed emulsion is 0.2-2 pa.s, and the average particle size is less than or equal to 2 mu m. Compared with the prior art, firstly, the antioxidant prepared by the preparation method disclosed by the invention has the advantages of being good in antioxidant effect, high in heat-resistant stability, environment-friendly, convenient for use and the like; simultaneously, by adopting tri[2,4-di-tertiary butyl-phenyl] phosphite ester, the butyronitrile rubber latex can be effectively prevented from becoming aged and yellow; the instability effect of the rubber latex does not exist.

Owner:JIANGSU FEIYA CHEM IND

Preparation method for polymerization-type asymmetric hindered phenol anti-oxidant resins

InactiveCN103420808AHigh molecular weightImprove antioxidant propertiesOrganic chemistryOrganic compound preparationIsobutanolDistillation

Provided is a preparation method for polymerization-type asymmetric hindered phenol anti-oxidant resins. The preparation method comprises steps: with boron trifluoride complex as a catalyst and benzene or cyclohexane as a solvent, p-methylphenol and dicyclopentadiene are subjected to a polymerization reaction to form phenol-type petroleum resins; after alkali washing and water washing, the polymerization reaction products are subjected to reduced pressure distillation to remove unreacted p-methylphenol in the reaction liquid to obtain refined phenol-type petroleum resins; the phenol-type petroleum resins, saturated alcohols with one to three carbons and isobutanol are subjected to an alkylation reaction to form polymerization-type asymmetric hindered phenol anti-oxidant resins in a solvent in presence of phosphoric acid and nickel-containing catalysts; the alkylation reaction products are subjected to reduced pressure distillation to remove the unreacted raw materials and solvent to obtain polymerization-type asymmetric hindered phenol antioxidant resin products, and the yield is about 90%. The preparation method has obvious positive effects, through asymmetric substituent groups antioxidant effects are raised. Compared to traditional phenol antioxidants, the synthesized polymerization-type asymmetric hindered phenol antioxidant resins are advantaged by high antioxidant activity, high heat stability, extracting resistance, compatibility, non-toxic and environmentally friendly characteristics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic detersive of diesel fuel

The invention provides an environment-friendly type diesel catalysis detersive for cleaning emission of diesel automobiles, which is prepared from cleaning and dispersing agent, anti-oxidant, alkyl nitrite or isopropyl nitrate and high grade plane kerosene through high-shearing mixing and emulsion process. The agent can improve combustion efficiency according to the combustion conditions.

Owner:牛云龙

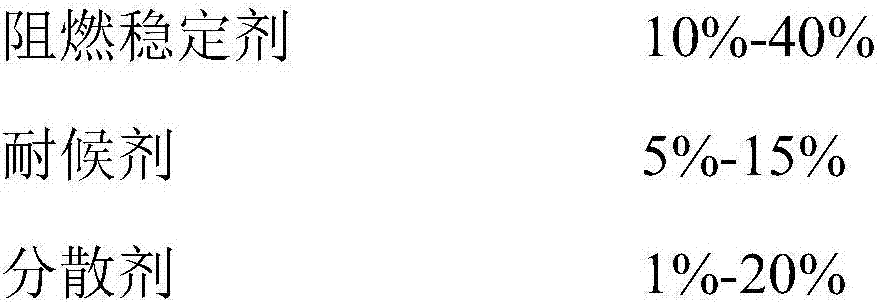

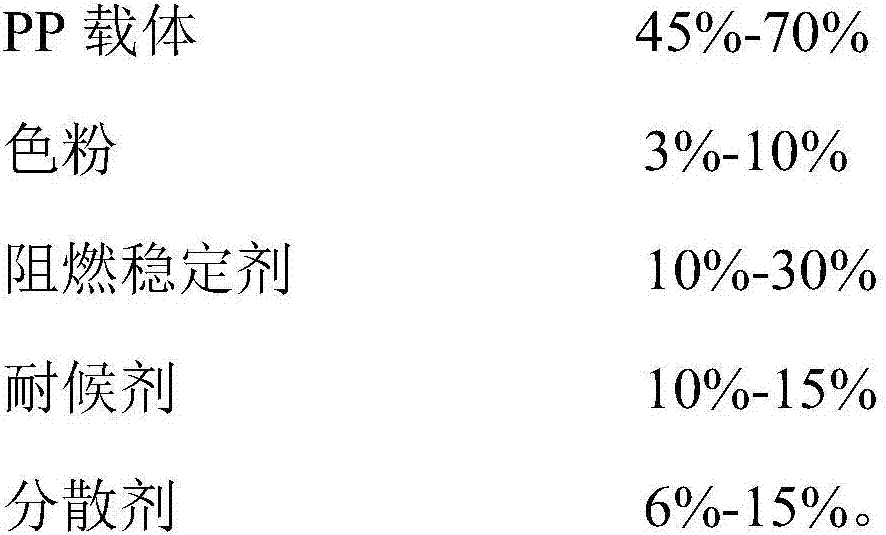

Weather-proof flame-retardant masterbatch for PP plate and preparation method of weather-resistant flame-retardant masterbatch

The invention discloses weather-proof flame-retardant masterbatch for a PP plate and a preparation method of the weather-resistant flame-retardant masterbatch. The masterbatch is composed of a PP carrier, toner, a flame-retardant stabilizer, a weather-resistant agent and dispersant. The masterbatch has good compatibility with polypropylene products, and has excellent performance in resisting weather and coloring flame retardant, bright color and high gloss, the outdoor service life of the masterbatch can reach 25 years without discoloration, and the flame retardant level can reach V0-level inthe UL94 standards; meanwhile, the masterbatch has the advantages of excellent UV resistance and oxidation resistance, and the outdoor service life of the masterbatch reach 5 years without pulverization.

Owner:恒永健(苏州)企业管理有限公司

HDPE pipe material and preparing method thereof

InactiveCN105670079AExcellent processing stability and heat resistance stabilityGood antioxidant effectWeather resistanceChemistry

The invention relates to an HDPE pipe material and a preparing method thereof. A formula of the HDPE pipe material contains hindered phenol quaternary ammonium salt modified imvite, the mass of which is 1-10% of the total mass of all components of the HDPE pipe material. The invention further provides a preparing method of the HDPE pipe material. The HDPE pipe material has excellent processing stability and thermal resistance stability, durable weather resistance and well color.

Owner:LIANSU TECH DEV GUIYANG

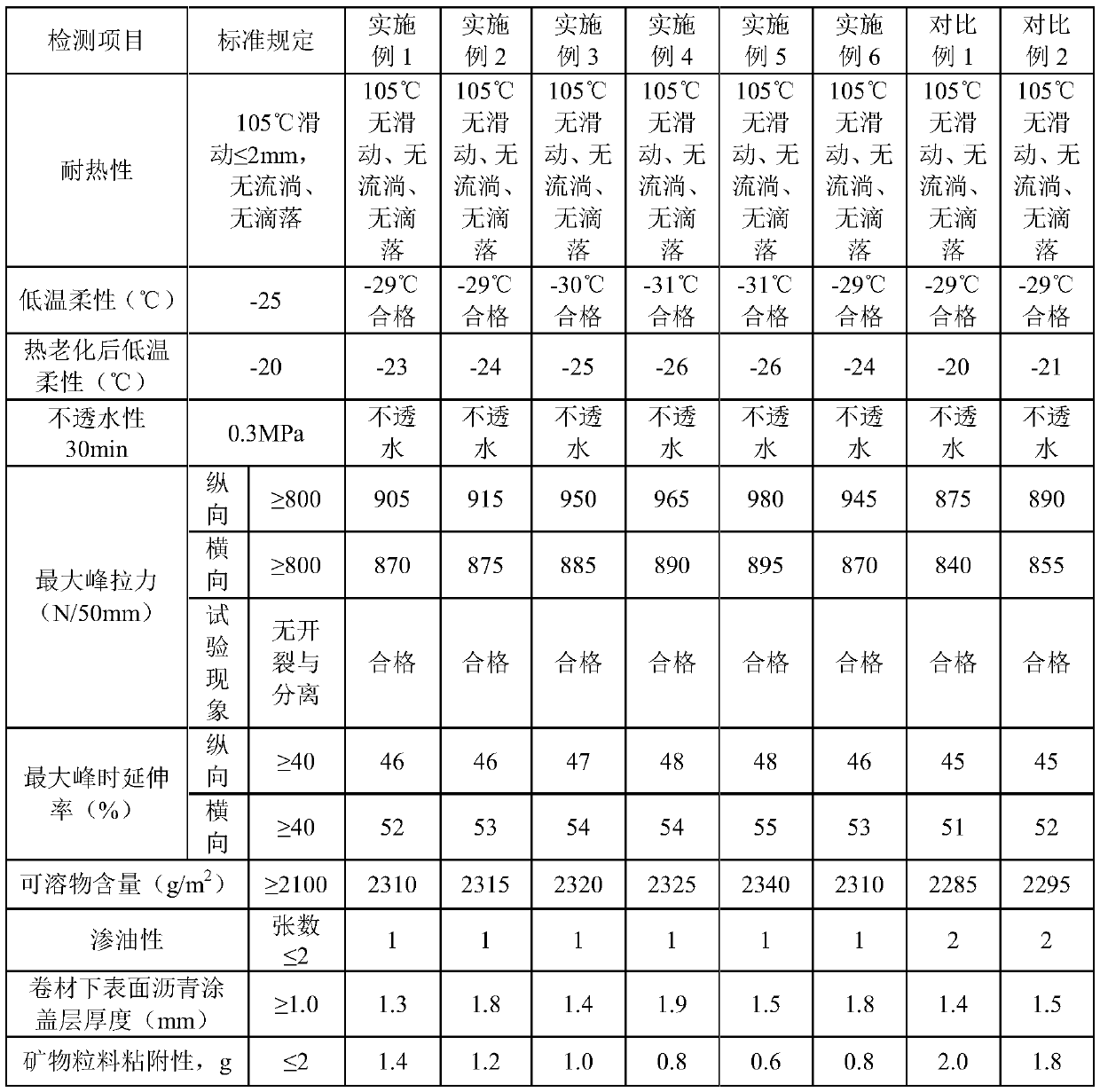

Modified asphalt coating, mineral granule surface modified asphalt waterproofing sheet material, preparation methods of coating and sheet material and mineral granule heating spreading device

InactiveCN109968776AGood stabilityDelay performance decayLiquid surface applicatorsSynthetic resin layered productsBituminous waterproofingMaterials science

The invention discloses a modified asphalt coating, a mineral granule surface modified asphalt waterproofing sheet material, preparation methods of the coating and the sheet material and a mineral granule heating spreading device. The modified asphalt coating comprises the following components, based on a total weight of the modified asphalt coating: 58-65 wt% of asphalt, 2-6 wt% of SBR, 8-14 wt%of SEBS, 3-6 wt% of tackifying resin, and 15-23 wt% of a filler, wherein the sum of weight fractions the components is 100%. According to the coating provided by the invention, a softening agent is not added, the coating does not contain the softening agent, so that the prepared mineral granule surface modified asphalt waterproofing sheet material has better stability, the performance degradationof the waterproof sheet material can be delayed, and adhesion of mineral granules can be improved; the SEBS is added, so that the prepared mineral granule surface modified asphalt waterproofing sheetmaterial has better UV-resistant stability, oxidation resistance and thermal stability, the performance degradation of the waterproof sheet material can be delayed, and the adhesion of the sheet material and the mineral granules can be improved.

Owner:河南东方雨虹建筑材料有限公司

Lead-free solder for soft soldering

InactiveCN101138813AGrain refinementUniform metallographic structureWelding/cutting media/materialsSoldering mediaSolderingMechanical property

The present invention relates to a lead-free solder for a soldering which is characterized in that the solder consists of materials with the following weight percentage: Cu from 0.1 percent to 1.0 percent, Ni from 0.1 percent to 0.2 percent, Ce from 0.01 percent to 0.10percent, Bi from 0.05percent to 2.0percent, Pr or / and Nd from 0.01percent to 0.10percent and the rest being Sn. The lead-free solder of the present invention, belonging to the environmental protecting products, has the advantages and effects of such as an anti-oxidation property, a mechanical property and corrosion resistance which can improve the performance of the solder, a uniform metallographic organization, refined grain, a good product quality, low cost and a proper reduction of the melting point.

Owner:郴州金箭焊料有限公司

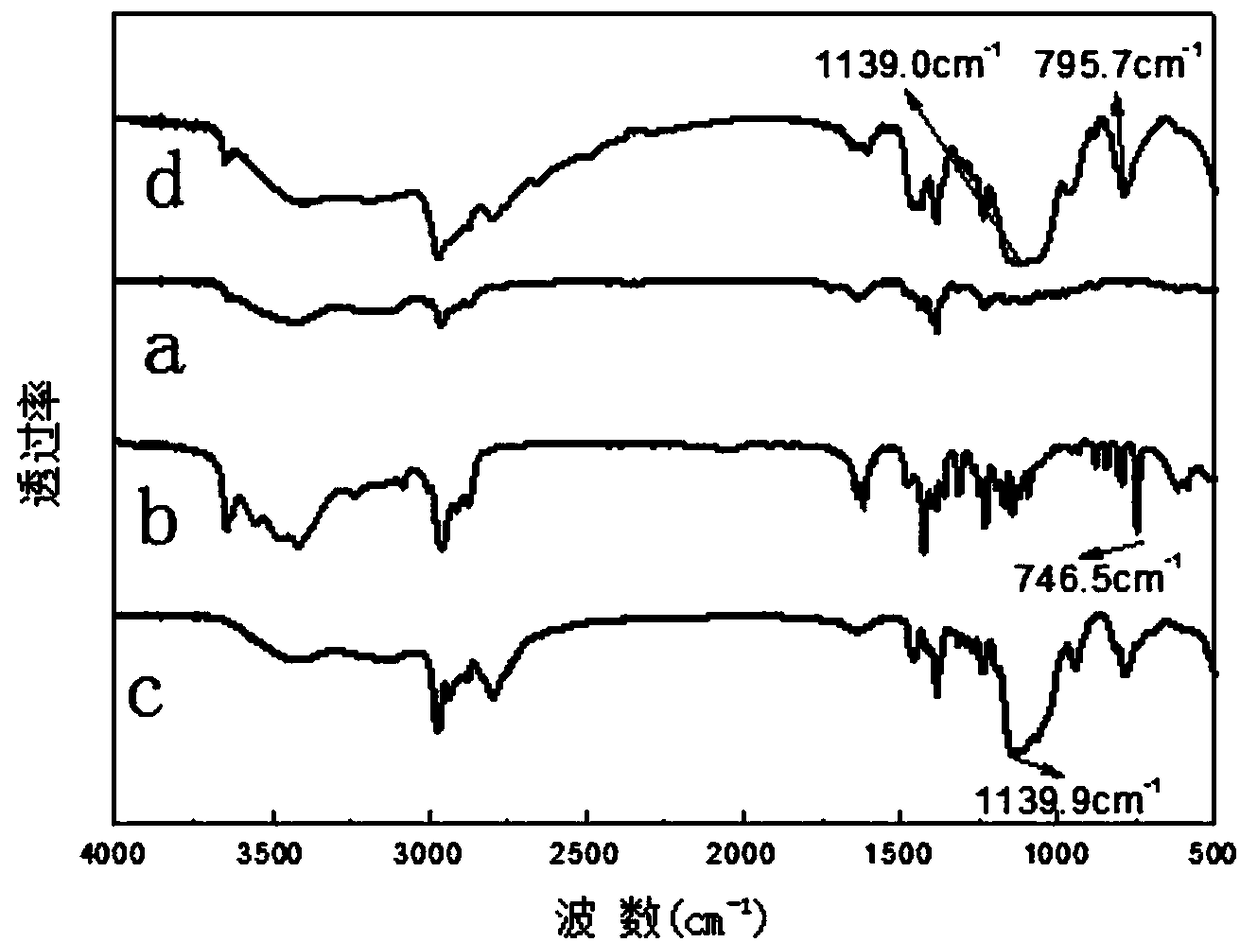

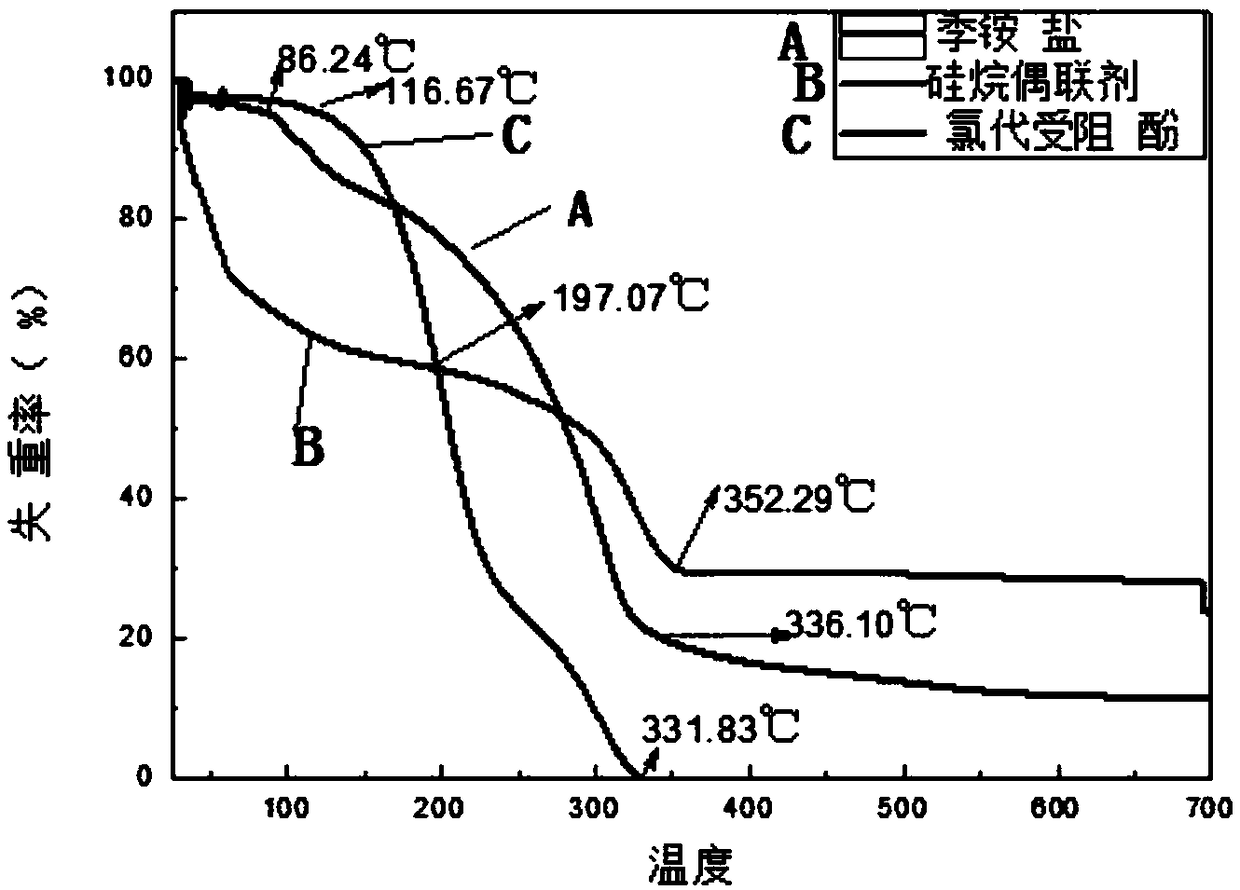

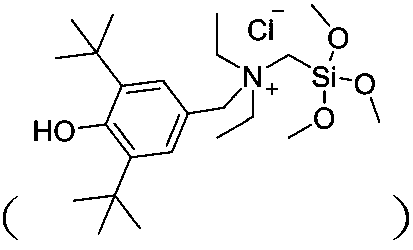

Novel antioxidation silane coupling agent containing hindered phenol structure and preparation method of novel antioxidation silane coupling agent

InactiveCN108440790ALower surface energyAntioxidant effectGroup 4/14 element organic compoundsDispersityNon toxicity

The invention discloses a novel antioxidation silane coupling agent containing a hindered phenol structure. The novel antioxidation silane coupling agent is characterized in that the structural formula of the silane coupling agent is shown in the description, wherein R<1> is methyl, ethyl or propyl; R<2> is methyl, ethyl, propyl or cyclohexyl; n is in a range of 1-4. Through combination of inorganic filler modification with antioxidant addition, the novel antioxidation silane coupling agent containing the hindered phenol structure not only has the advantages such as good antioxidation effect,little pollution, low probability of color change and low toxicity or non-toxicity of a hindered-phenol antioxidant, but also has the unique structure and performance such as adhesion, compatibility,dispersity and the like of the silane coupling agent, and compatibility of the antioxidant with a polymer material is improved greatly.

Owner:GUIZHOU NORMAL UNIVERSITY

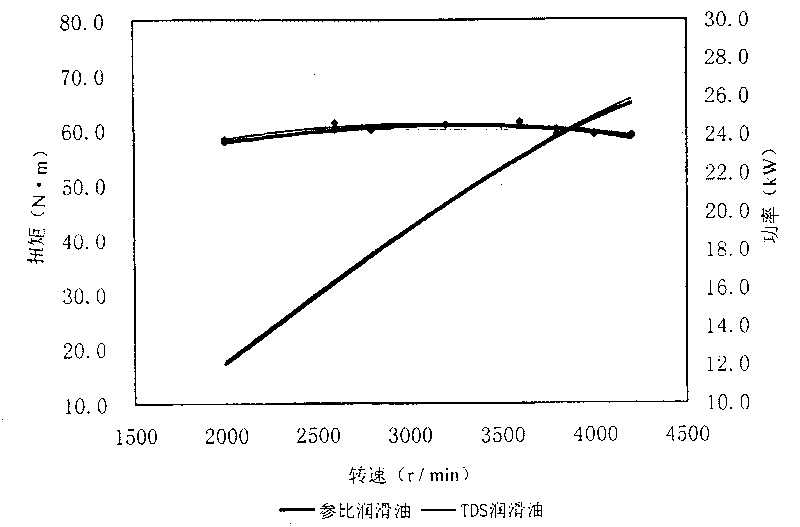

Combined energy-conserving synergistic agent composition of lubricating oil nanometer material

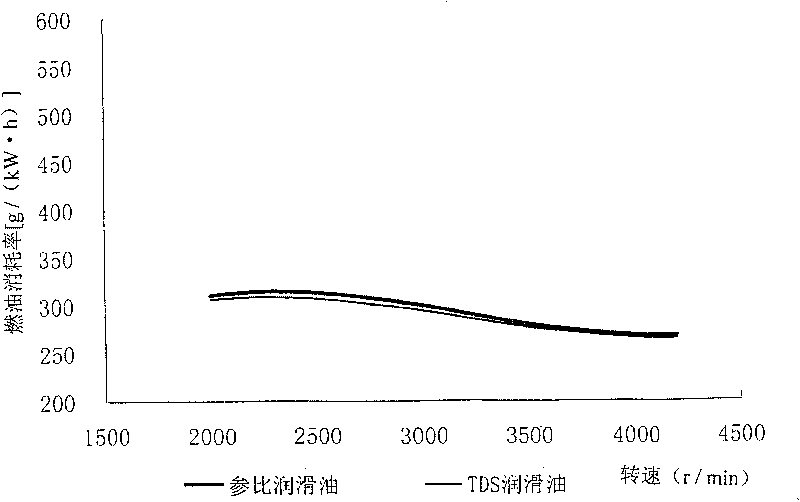

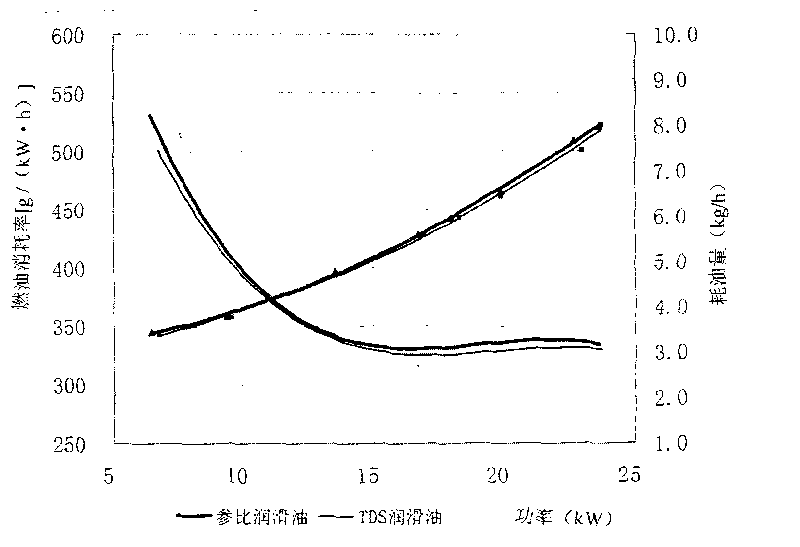

InactiveCN101760287AGive full play to the synergy effectReduce consumption rateAdditivesComparative testEmulsion

The invention discloses a combined energy-conserving synergistic agent composition of lubricating oil nanometer material, which is prepared by the following raw materials according to mass percent: 30-85 percent of nanometer-hydrocarbon particles, 3.0-30 percent of nanometer-copper particles, 3.0-30 percent of auxiliary antioxidant, and 3.0-30 percent of emulsion inhibitor. The invention adopts the optimized combination of multiple nanometer particles and adds the auxiliary antioxidant and the emulsion inhibitor to the optimized combination, meanwhile makes full use of the cooperation action between the additives and improves the lubricating oil performance in lubrication, detergent dispersion, anti-oxidation and anti-emulsification performance. The combined energy-conserving synergistic agent composition of lubricating oil nanometer material is added to the lubricating oil of the M-TCE engine to start an engine bench comparative test; the result indicates that the external characteristic power of the engine is increased, the effective specific fuel consumption is decreased averagely by 2.6 percent, and the load characteristic effective specific fuel consumption is averagely decreased by 2.8 percent; under the high-idle-speed working condition, the CO content is decreased from 0.03 percent to 0.02 percent and the HC content is decreased from 12ppm to 9ppm; under the idle-speedworking condition, the CO content is decreased from 0.05 percent to 0.04 percent and the HC content is decreased from 25ppm to 18ppm.

Owner:陕西天德节能技术有限责任公司

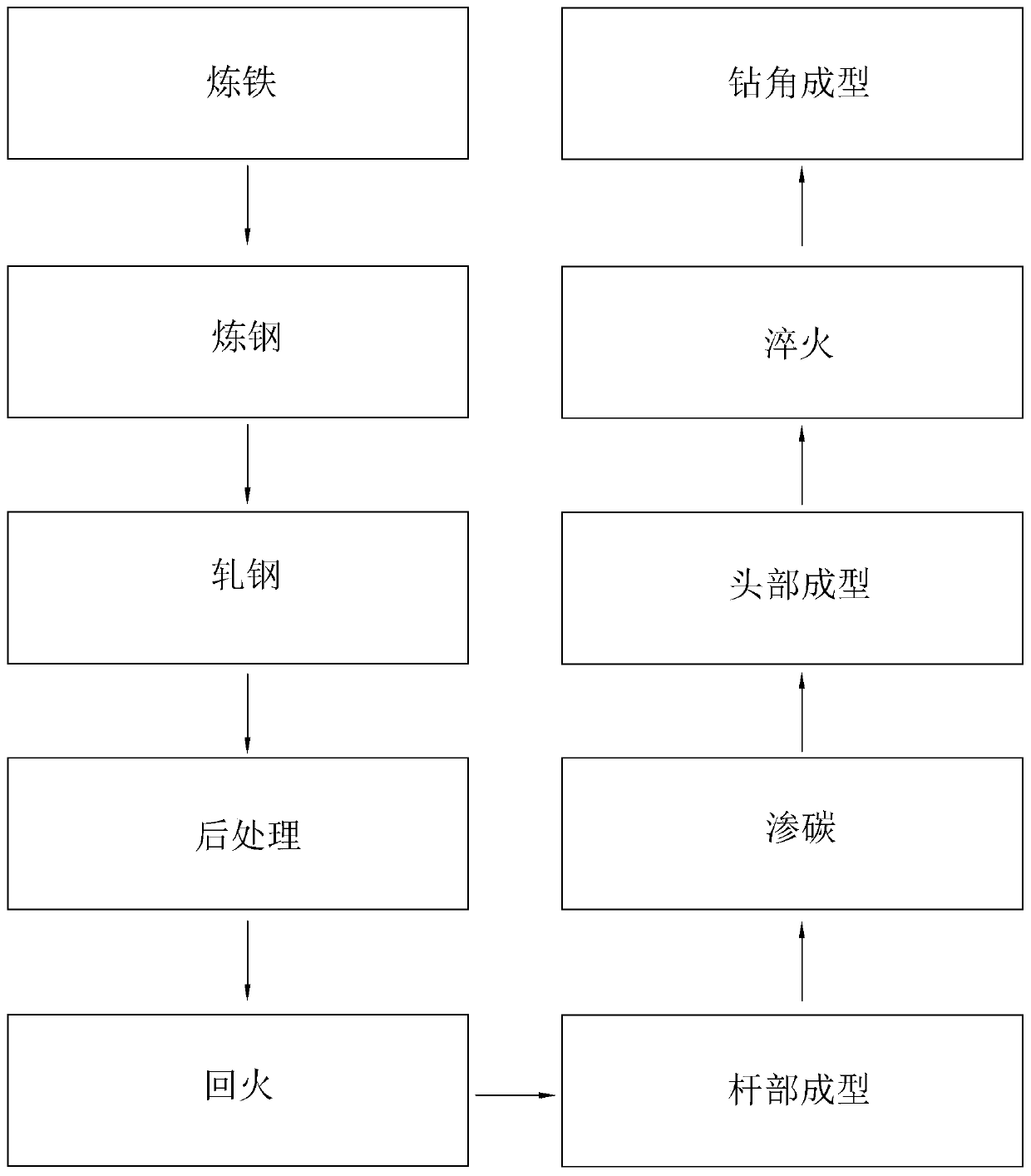

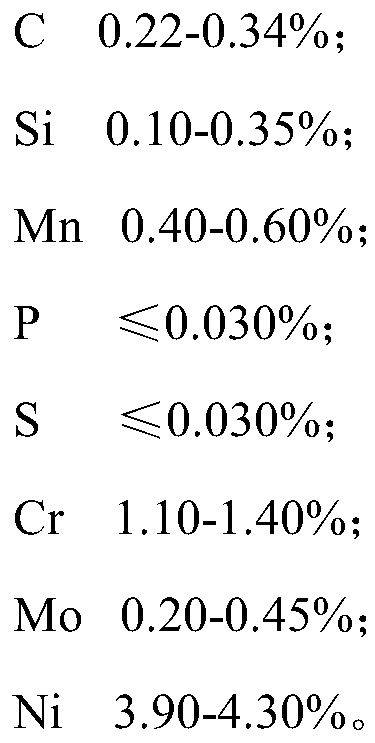

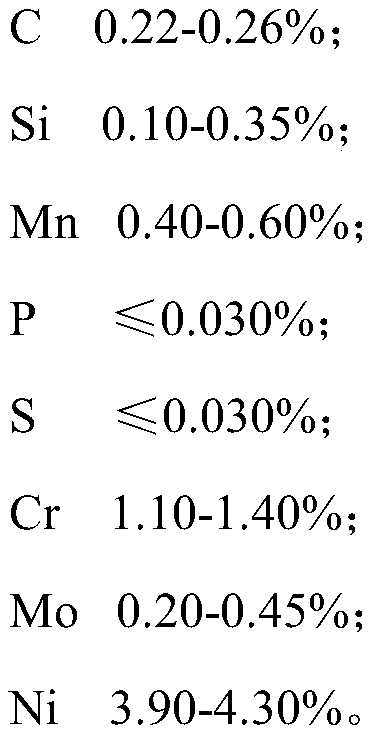

Drill bit housing steel and preparation method thereof

The invention discloses drill bit housing steel and a preparation method thereof, and relates to the technical field of rock drilling tools. The steel is prepared from the chemical components: 0.22-0.34% of C, 0.10-0.35% of Si, 0.40-0.60% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 1.10-1.40% of Cr, 0.20-0.45% of Mo and 3.90-4.30% of Ni. Chromium in the steel enhances the hardenability of the steel and has a secondary hardening effect, a drill bit housing has good corrosion resistance and oxygen resistance, and the hardness and wear resistance of high carbon steel are improved without embrittling the steel. Meanwhile, through the adoption of chromium, the high-temperature mechanical properties of the steel are improved, and the performance impact of high temperature generated in the rock drilling process on the drill bit housing is reduced. In terms of chemical components, vanadium is replaced with chromium, so that more uniform strength, toughness andfatigue strength of the drill bit housing are obtained, and better strength and wear resistance of the drill bit housing are obtained. Meanwhile, through the proportion adjustment of other metal elements, the drill bit housing is more suitable for rock drilling in limestone areas.

Owner:ZHEJIANG PULANKA ROCK TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com