Patents

Literature

129results about How to "Uniform metallographic structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Swaging manufacturing method of light aluminum alloy rim

InactiveCN101653901ASimple structureEasy to manufactureShaping toolsRimsPerformance indexNational standard

The invention relates to a swaging manufacturing method of a light aluminum alloy rim. The method comprises the following processing steps: (1) baiting; (2) heating; (3) carrying out ring rolling; (4)manufacturing a spinning blank; (5) carrying out hot spinning; (6) carrying out head back hot spinning; (7) carrying out heat treatment; and (8) fine machining the blank into a rim product. The performance indexes of the rim all reach national standards. The method only needs a pair of spinning moulds, i.e. an upper spinning mould and a lower spinning mould for processing, wherein the moulds havesimple structure, easy manufacture and low manufacturing cost. High temperature and high speed hot spinning processing is adopted so as to ensure that the metallographic structure of the rim has uniformity, refined crystalline grain, light weight, thin thickness, mechanical property improvement of the rim, high precision and good quality, and compared with a rim processed by cold spinning, the rim of the invention cannot crack and generate pinholes and has long service life. The blank processed by the method is annular and has high material utilization rate, less waste and processing amount reduction. Meanwhile, the invention provides a new variety for the rims in the car accessory market. Consumers can conveniently replace and adjust the rims of different shapes and types as required atany time without dismantling a tire so as to quickly change the type of the whole tire.

Owner:丁松伟

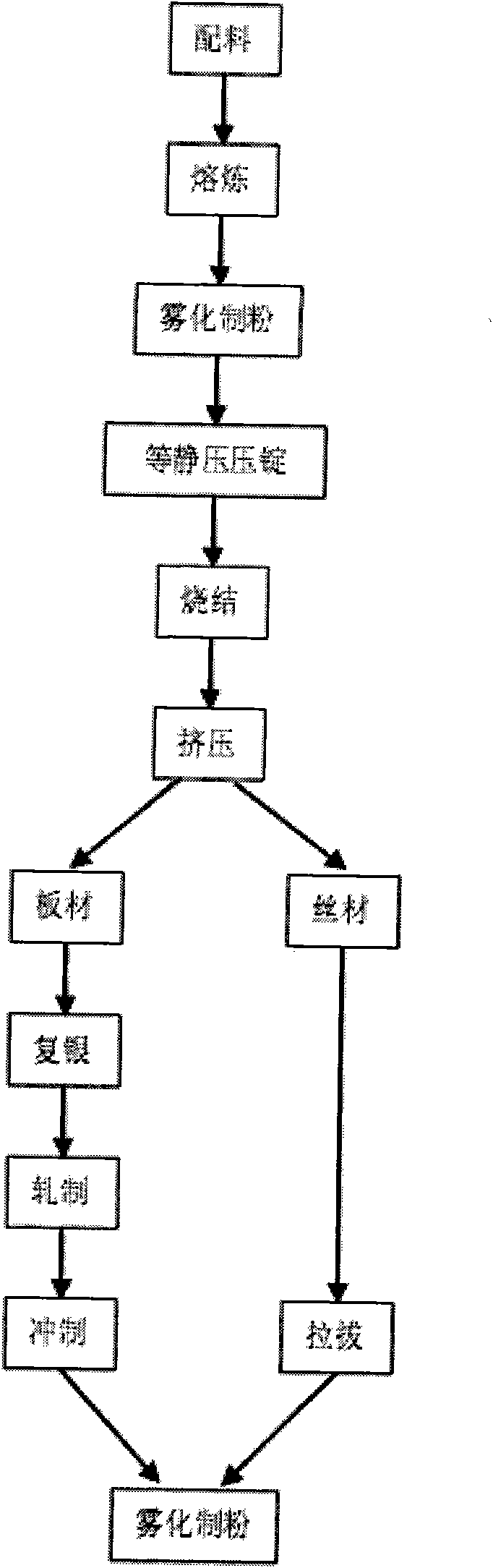

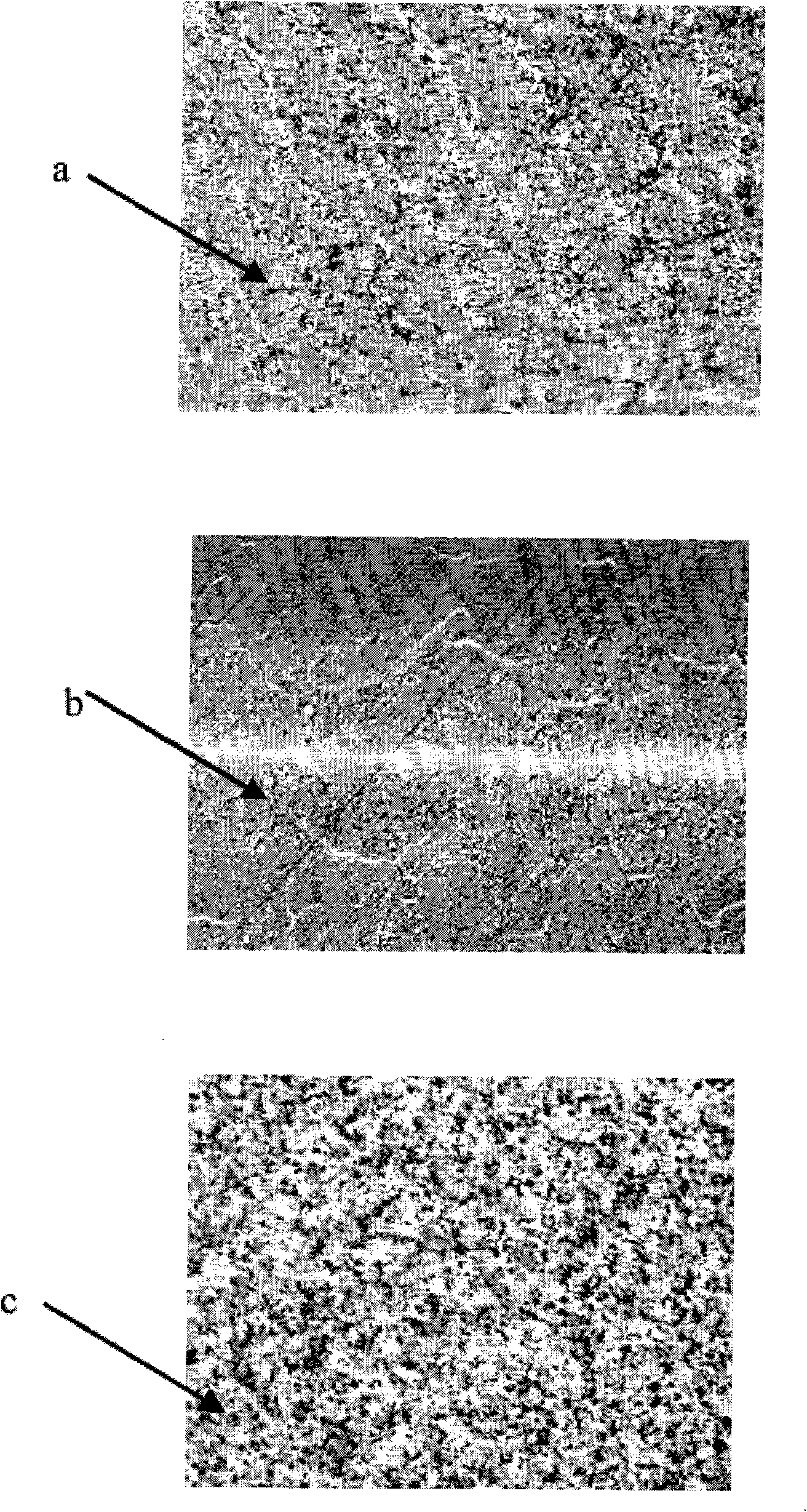

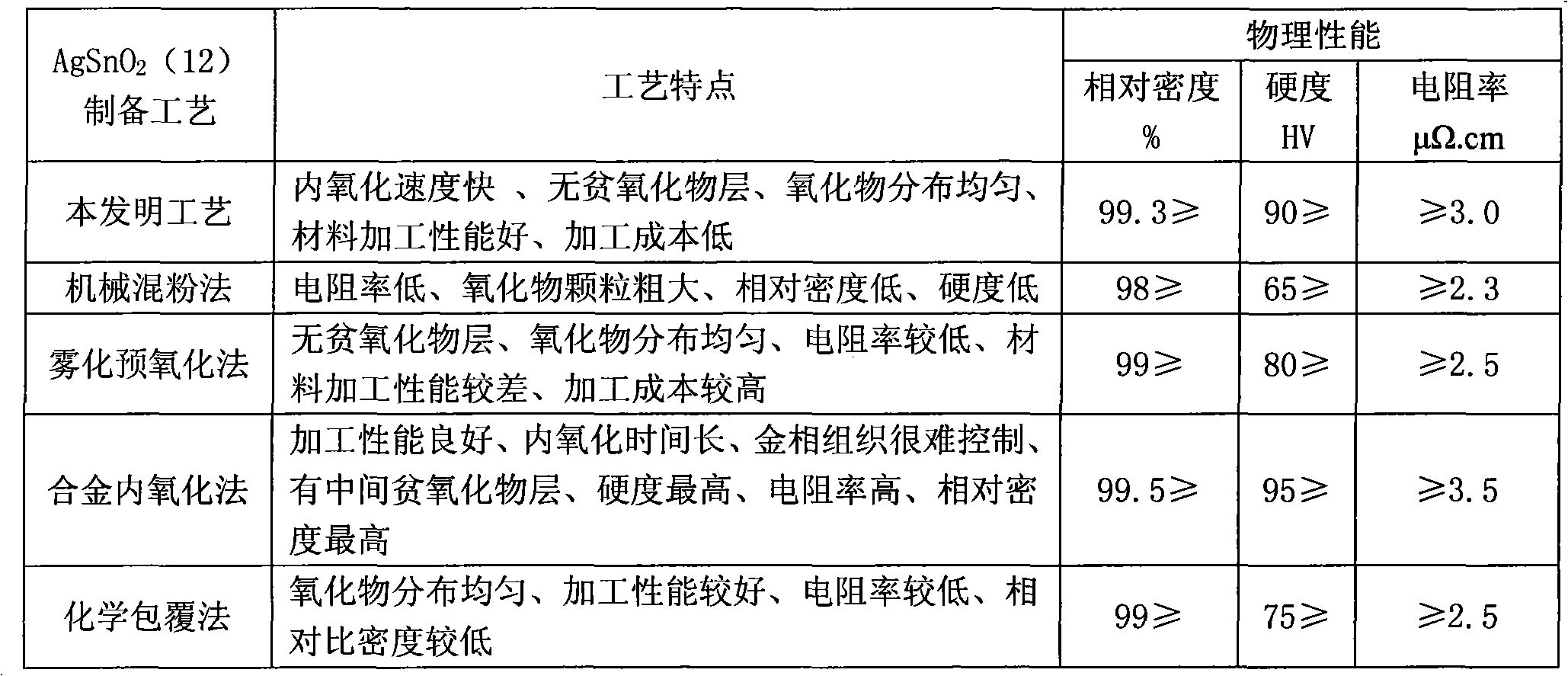

Preparation method for silver tin oxide electrical contact material

The invention discloses a preparation method for a silver tin oxide electrical contact material, which comprises the following steps: by taking a silver ingot, a tin ingot, an indium ingot and an additive ingot as raw materials, atomizing the raw materials to prepare a silver tin alloy powder; ingoting, sintering, extruding and drawing / rolling the silver tin alloy powder to prepare a wire material or a sheet plate or a belt material; and finally, carrying out internal oxidation to prepare the silver tin oxide electrical contact material. The preparation method for the silver tin oxide electrical contact material has the characteristics of uniform and stable contact material components, no conventional internally oxidized central lean oxidation zone, high density, high hardness and the like. The preparation method for the silver tin oxide electrical contact material has a simple process and is suitable for mass production. A prepared silver tin oxide product can be widely used for relays and contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

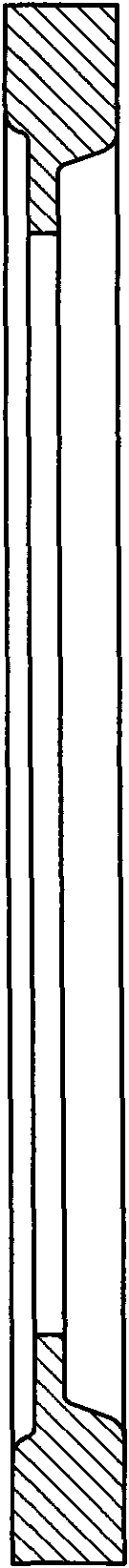

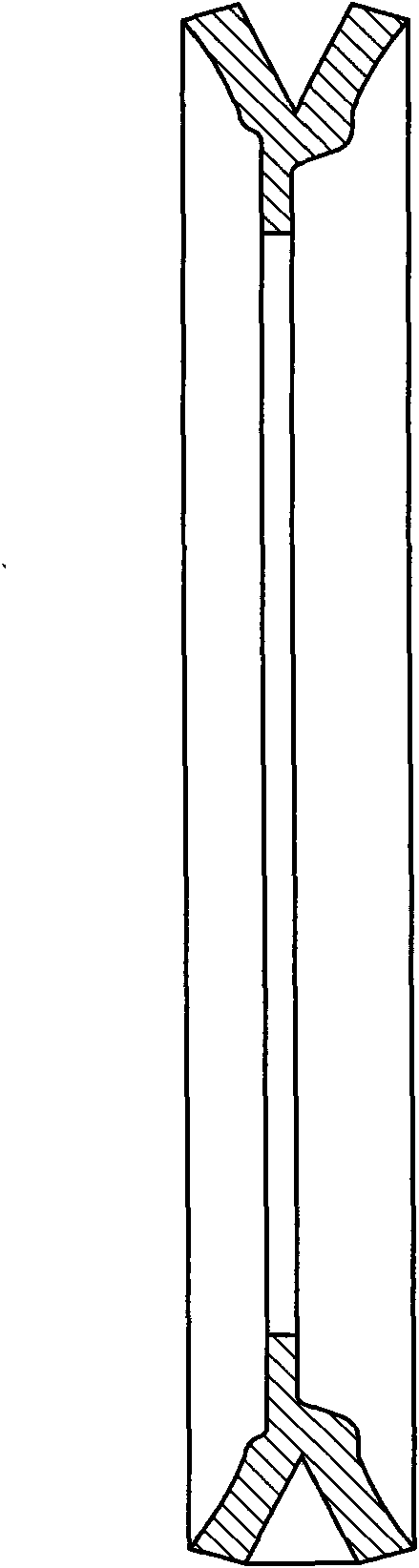

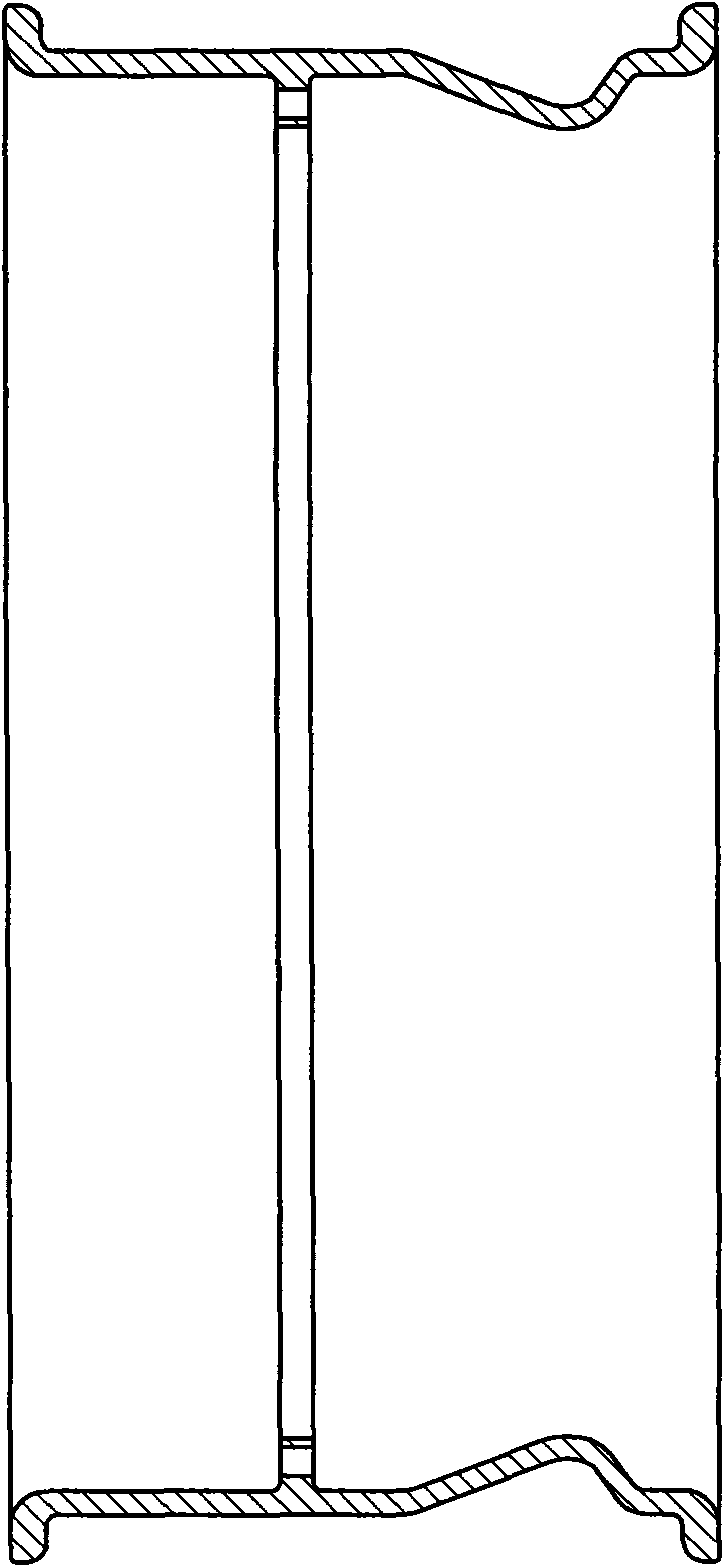

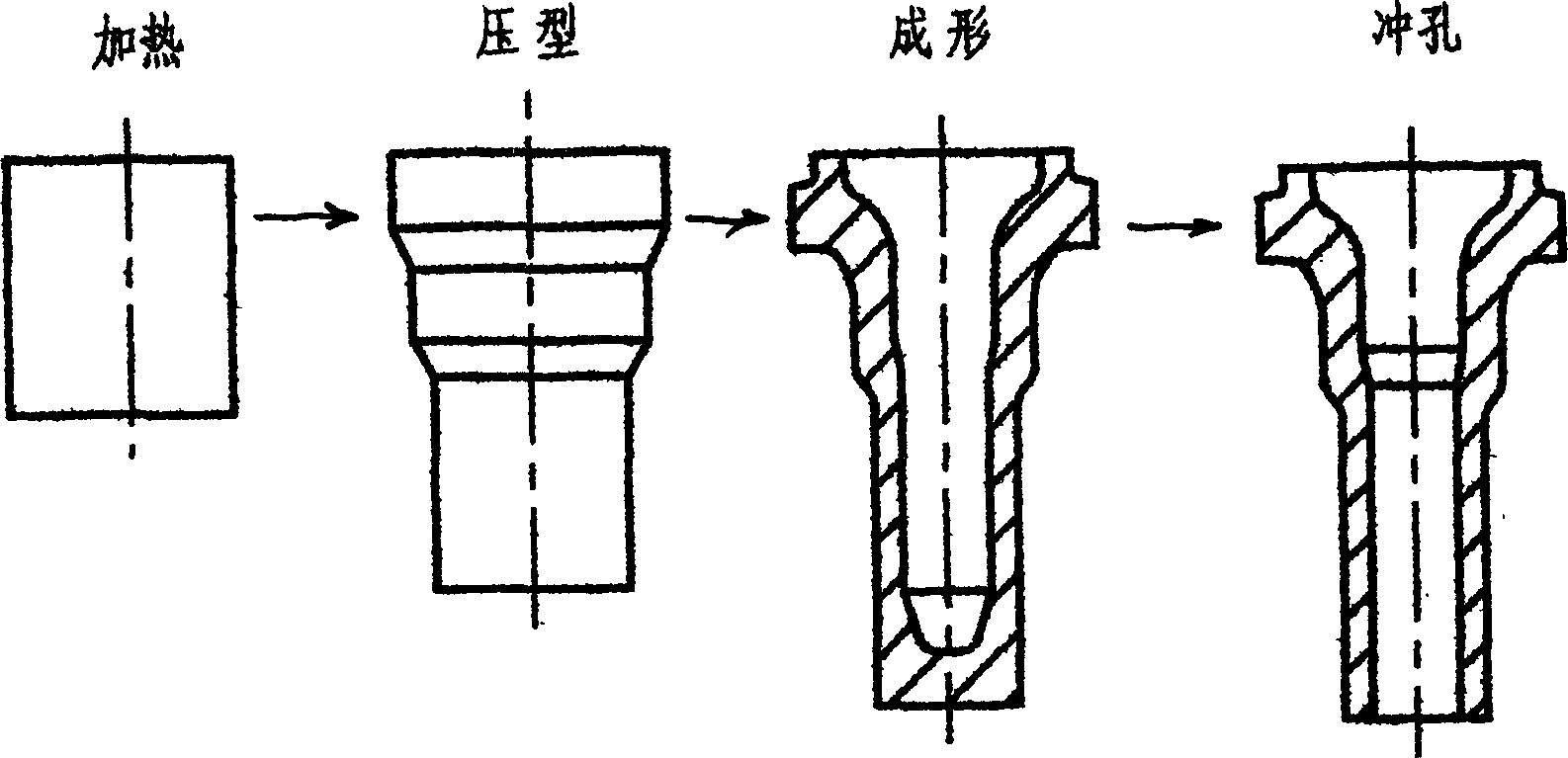

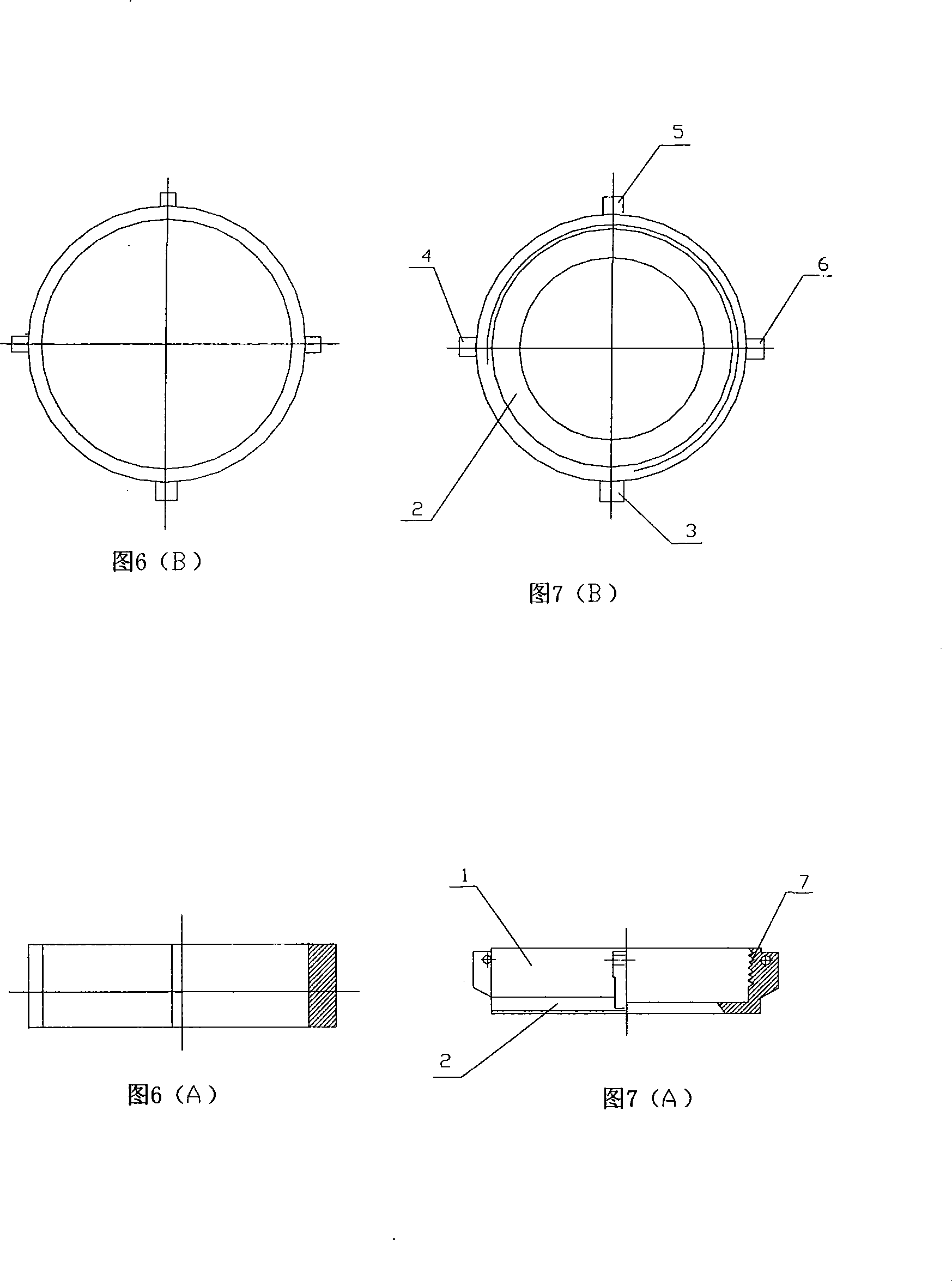

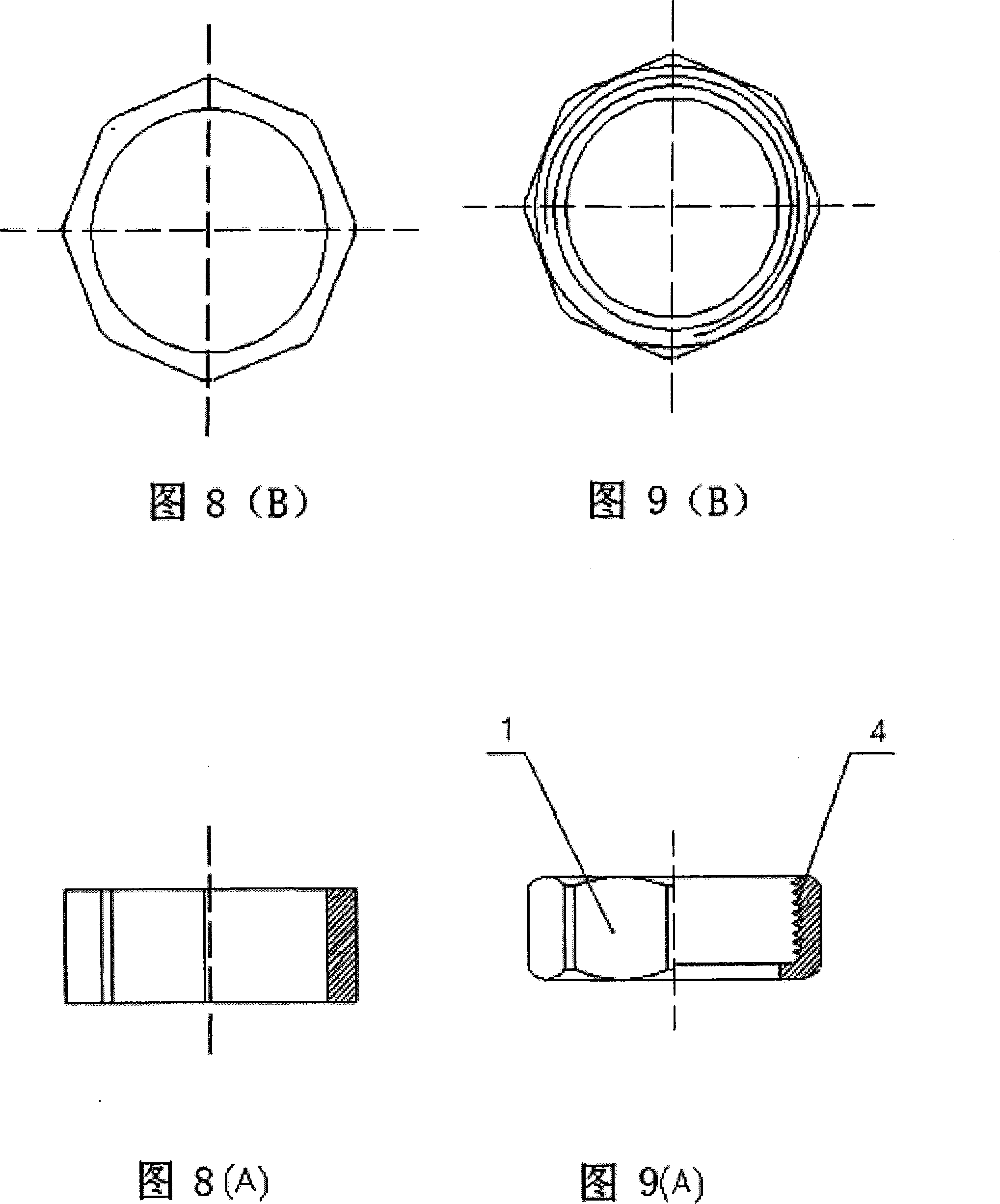

All fiber forging process for load-carrying vehicle hub axle and die therefor

InactiveCN1628921AHigh geometric accuracyGrain refinementForging/hammering/pressing machinesWheelsSurface finishFiber

This invention relates to a load automobile hub axle tube whole fiber forging and shaping process and its mould. It is characterized by the following: adopting solid material; finishing hub axle tube surface and deep hole extrusion shaping to get the whole fiber metal flow wire along axle direction and the inner hole is shaped by extrusion without process.

Owner:李克敏 +3

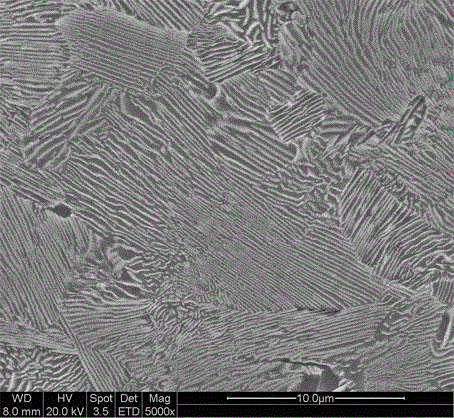

Wire with tensile strength>=2000MPa for bridge cable and production method

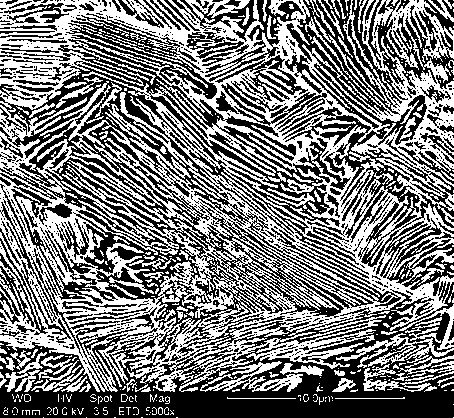

ActiveCN102936688AUniform metallographic structureUniform performanceMetal rolling arrangementsAir volumeRoom temperature

The invention discloses a wire with tensile strength>=2000MPa for a bridge cable and a production method. The wire comprises, by weight, 0.95-1.2% of C, 0.1-0.48% of Si, 0.6-1.0% of Mn, 0.1-0.5% of Cr, 0.01-0.05% of V, Cu<=0.05%, 0.05-0.15% of Al, 0.01-0.03% of N, P<=0.025% and S<=0.015%. The production method includes smelting and continuously casting into blanks; heating the casting blanks; rolling; heating again; high-speed rolling; spinning; air cooling to the room temperature; and placing for standby. According to the wire and the method, continuous casting of blooms, rolling starting of billets and high speed wire rolling are adopted, therefore a metallographic structure and the like of the wire for the bridge cable are even, and grains are better refined; and processes of rapid cooling with a large air volume and the like are adopted, therefore the tensile strength of the wire for the bridge cable is >=2000MPa and stable, a twist number reaches >=15, and wire fracture caused by the wire quality does not happen during cold drawing.

Owner:武汉钢铁有限公司

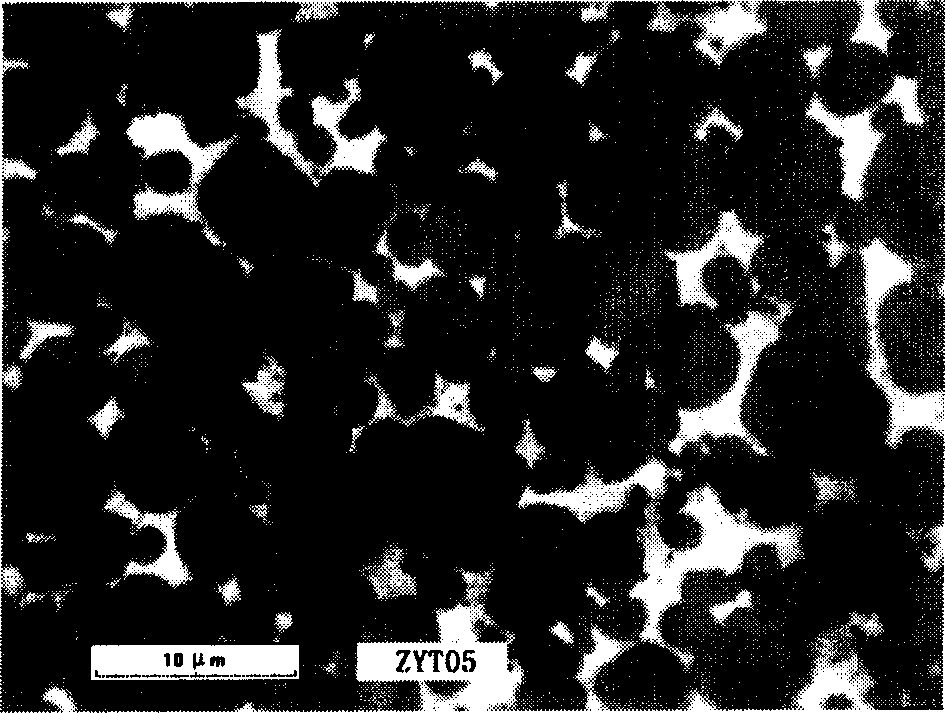

TiC-WC based alloy products

The invention discloses a TiC-WC base alloy guide roll and spool, valve seat in the metal ceramic and hard alloy manufacturing domain, which comprises the following parts: 30-60 wt percent TiC, 15-55 wt percent WC and 0-3 wt percent Ta as hard phase, 10-30 wt percent Co+Ni as adhesive phase and 0-3.0 wt percent Cr as grain growing inhibitor. The density of product is 0.3-0.5 times as WC base hard alloy density with 2500 N per mm2 anti-bending strength and 87.0-90.5 percent rigidity HRA, which possesses light quality, high rigidity and abrasion-proof property.

Owner:ZIGONG CEMENTED CARBIDE CORP

Silver zinc oxide electric contact material and preparation method thereof

InactiveCN101944441AEasy to oxidizeUniform metallographic structureFinal product manufactureContactsPunchingZinc alloys

The invention discloses a silver zinc oxide electric contact material and a preparation method thereof, and belongs to the technical field of electrical materials. The method comprises the following steps of: melting and ingoting silver, zinc and additives in a smelter according to a certain weight ratio, sintering and extruding into strips, and drawing to form a silver-zinc alloy wire material; oxidizing the silver-zinc alloy wire material to obtain a silver zinc oxide wire material; cutting the wire material into pieces by an open-back inclinable press, pressing the cut pieces in a steel die to manufacture an extruded stock, and sintering and extruding the cut pieces to manufacture a plate or a wire material; polishing the surface of the extruded plate, performing hot rolling on silver, rolling, punching and molding; and drawing, annealing and drawing the extruded wire material to a finished product wire material with phi of between 0.5 and 3.0mm to produce the rivet electric contact. In the method, the silver-zinc wire material is used for oxidation, so the alloy is easily oxidized without special oxidizing equipment; the metallographic phase of the material has uniform tissue without an oxidation zinc lean region or oxidation aggregation, and the consistency of the material performance, high compactness and good processing performance can be ensured; the method can realize mass production and has low production cost; and the production process and the material per se have no pollution to the environment.

Owner:YANGZHOU LEYIN ALLOY TECH

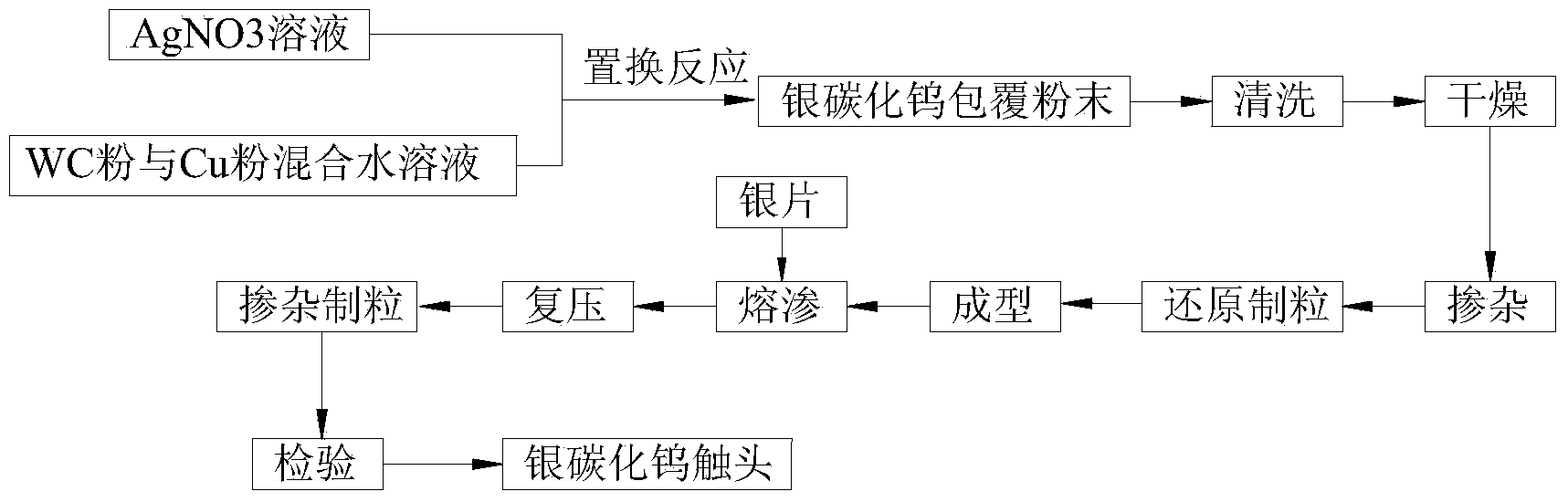

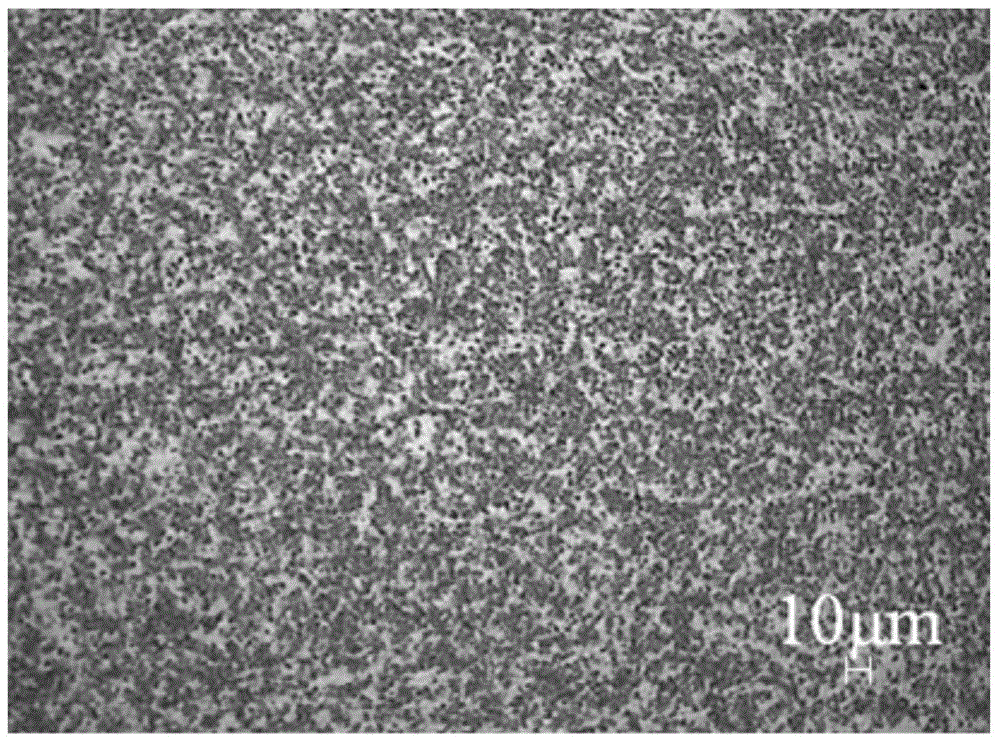

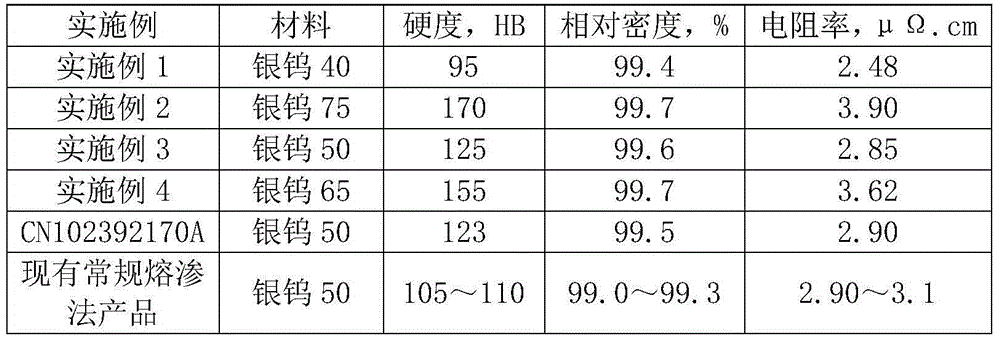

Method for preparing silver-tungsten carbide contact material from silver-coated tungsten carbide powder and silver-tungsten carbide contact material

ActiveCN103824710AHigh densityHigh hardnessContactsElectrical resistance and conductanceHigh density

The invention discloses a method for preparing a silver-tungsten carbide contact material from silver-coated tungsten carbide powder and the silver-tungsten carbide contact material. According to the technical scheme, a silver-tungsten carbide electrical contact is prepared from raw materials, i.e., a silver nitrate crystal and tungsten carbide powder, by a chemical coating powder preparation process and a liquid-phase infiltration process; the prepared silver-tungsten carbide electrical contact comprises the following components in percentage by weight: 38%-42% of tungsten carbide, 0-0.2% of additives and the balance being silver, wherein the additives are one or more selected from nickel, copper and zirconium. The silver-tungsten carbide contact material prepared by the method has the advantages of high density, high hardness, low and stable contact resistance, uniform metallographic structure, favorable high-temperature oxidation resistance, electric arc erosion resistance, wear resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

Preparation method of silver tungsten contact material

The invention discloses a preparation method of a silver tungsten contact material. The method comprises the following steps: mixing silver powder and tungsten powder, carrying out ball milling on the silver-tungsten mixed powder, high-purity nickel balls and water in a ball mill, and carrying out drying, annealing, molding and infiltration treatment on the silver-tungsten mixed powder subjected to ball milling, wherein the weight ratio of the high-purity nickel balls to the silver-tungsten mixed powder is (4-10):1, 120-200ml of water is added to every 1kg of silver-tungsten mixed powder, and the ball milling time is 12-50 hours. The silver-tungsten mixed powder, high-purity nickel balls and water are subjected to ball milling in the ball mill for special time in a specific proportion, so that the silver powder and tungsten powder are mixed more uniformly, the ball milling and additive nickel addition can be implemented at the same time, and the nickel lost on the high-purity nickel balls due to ball milling can be uniformly coated to the tungsten granule surface, thereby achieving the goal of effectively improving the wettability of the tungsten. The obtained material has the advantages of uniform structure, high density and low resistivity.

Owner:桂林金格电工电子材料科技有限公司

Processing method of silver tin oxide electrical contact material containing additives

The invention discloses a processing method of a silver tin oxide electrical contact material containing additives. The processing method specifically comprises the following steps: calculating the use level of metal tin, metal additives and silver required according to the material ratio of a silver tin oxide electrical contact required to be prepared, and smelting and atomizing one part with the metal tin and metal additives together in form of metal silver to prepare silver tin alloy powder; after mixing the other part with the prepared silver tin alloy powder in form of silver nitrate, carrying out reaction with sodium hydroxide to obtain composite powder of silver oxide and silver tin alloy; washing the obtained composite powder to be neutral, drying and crushing and putting in an oxygen atmosphere to be oxidized to obtain silver tin oxide composite powder containing the additives; and carrying out isostatic compaction and sintering on the composite powder, carrying out hot extrusion on a silver zinc oxide billet to process a strip or a wire rod, and then machining to obtain the silver tin oxide electrical contact material containing additives. The contact prepared by the method is uniform in metallographic structure and good in processing performance.

Owner:桂林金格电工电子材料科技有限公司

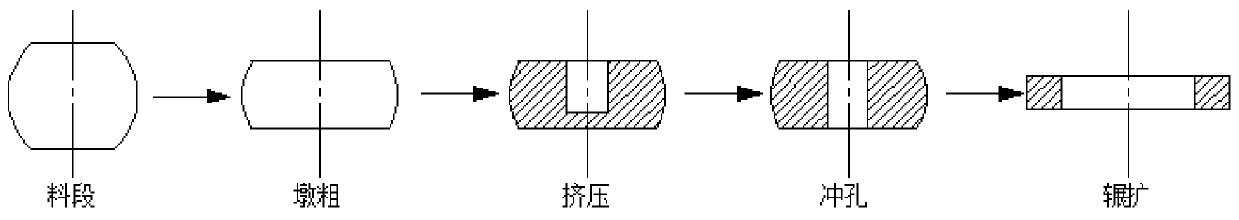

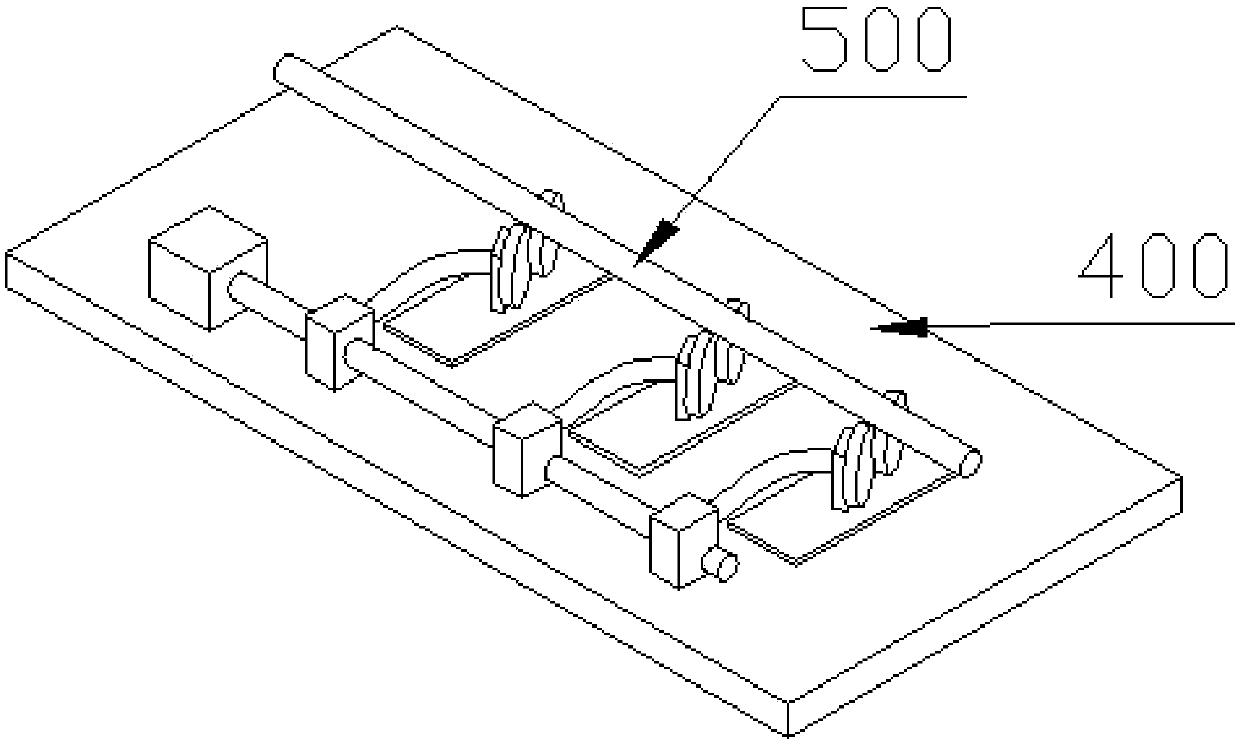

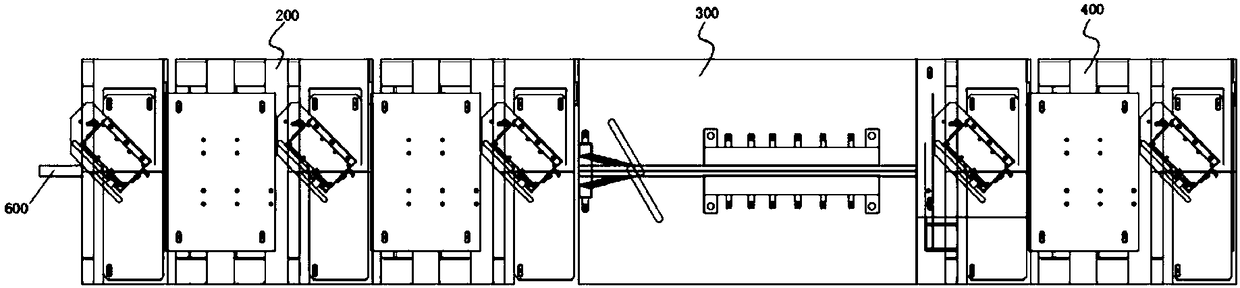

Bearing ring forging machining process and machining system

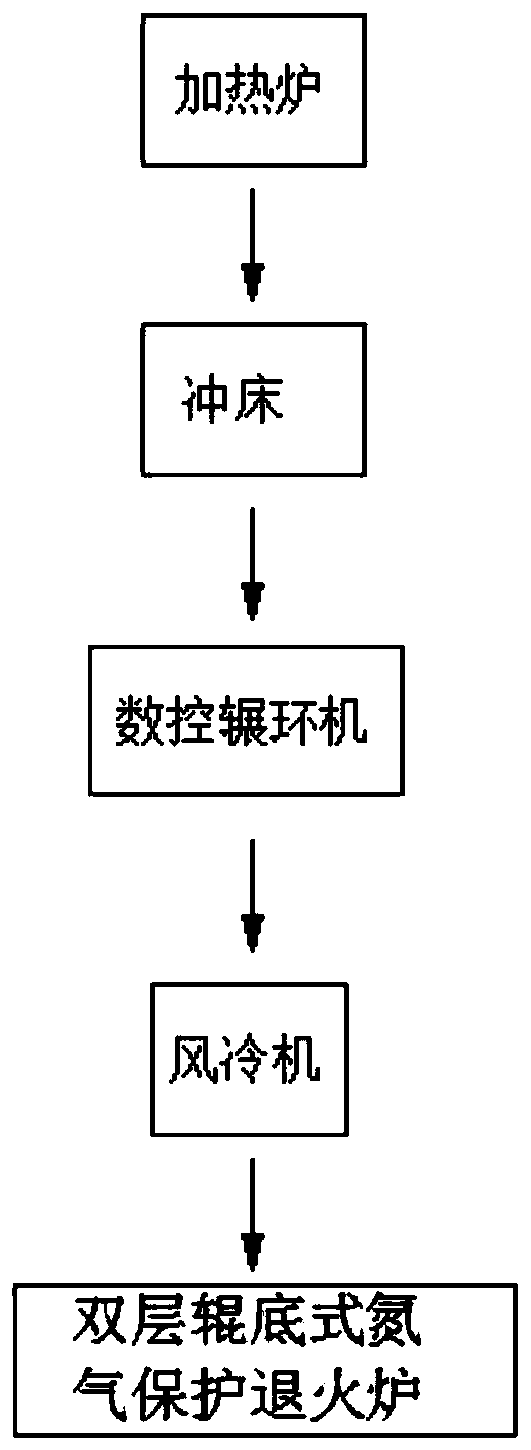

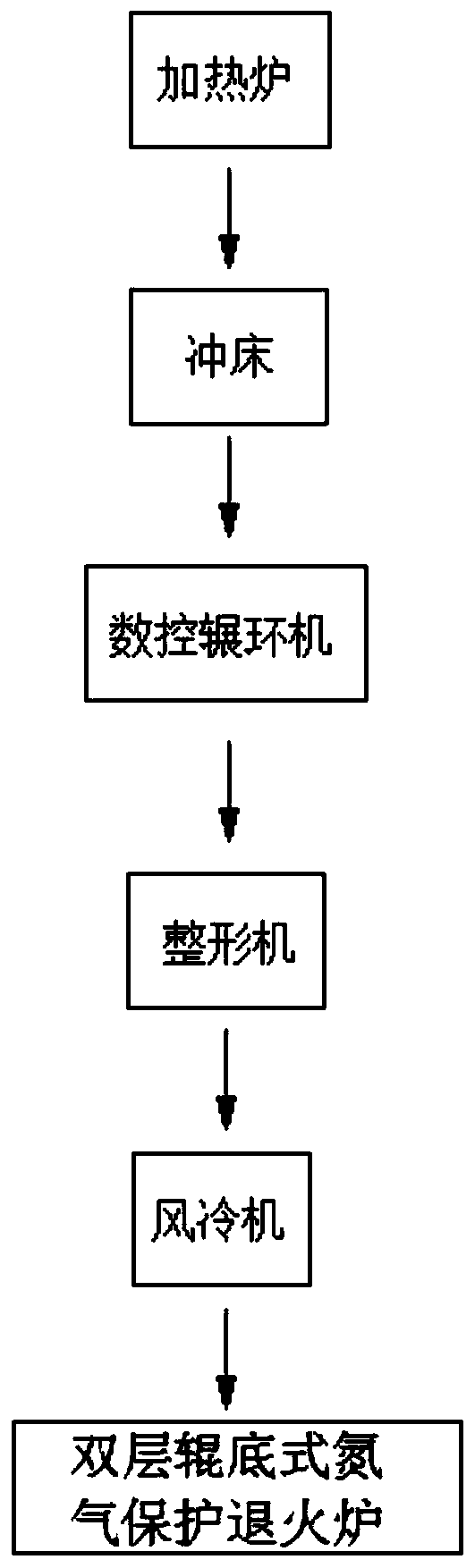

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

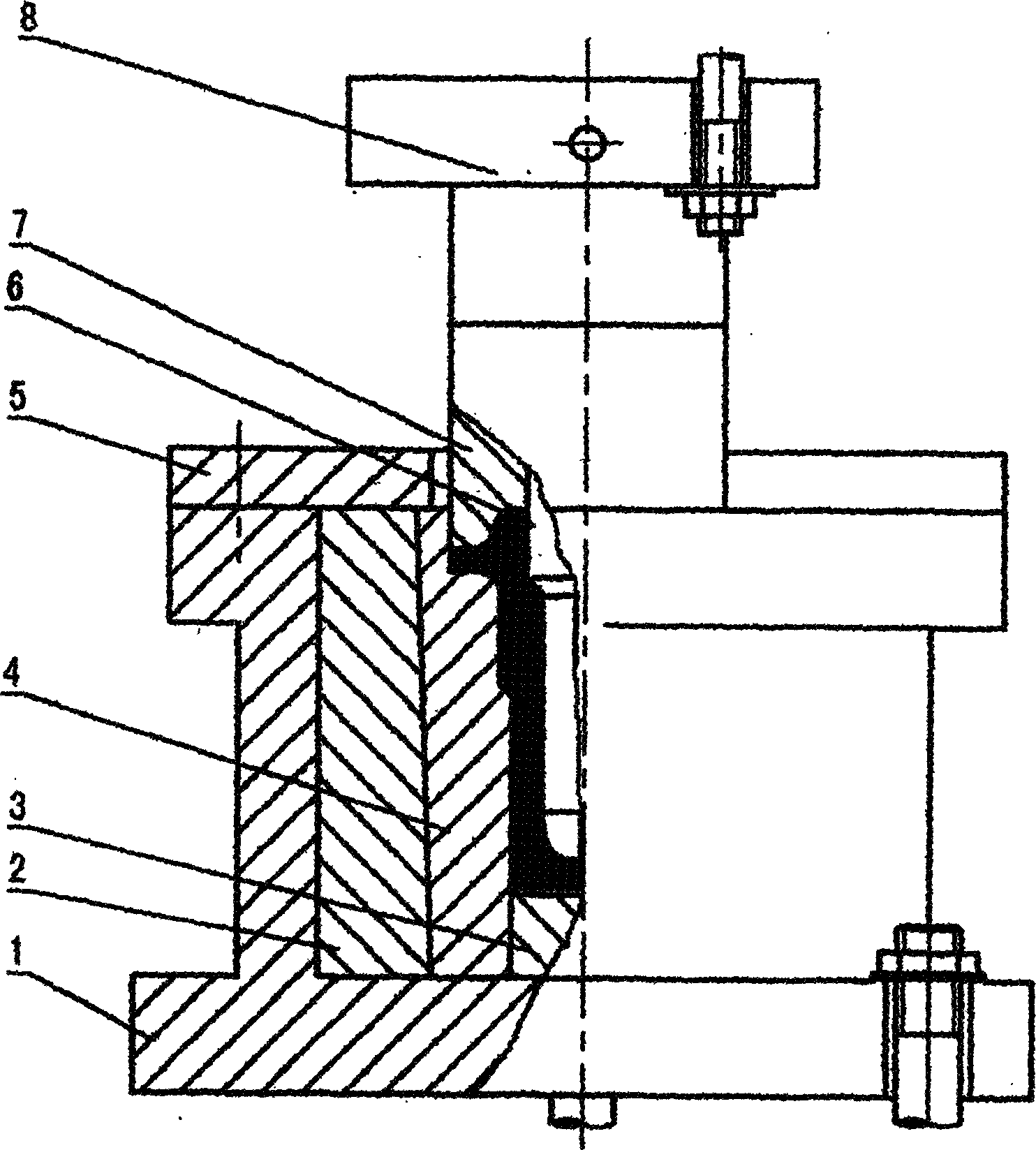

Impact extrusion forming technology for aluminum alloy water heating parts and products thereof

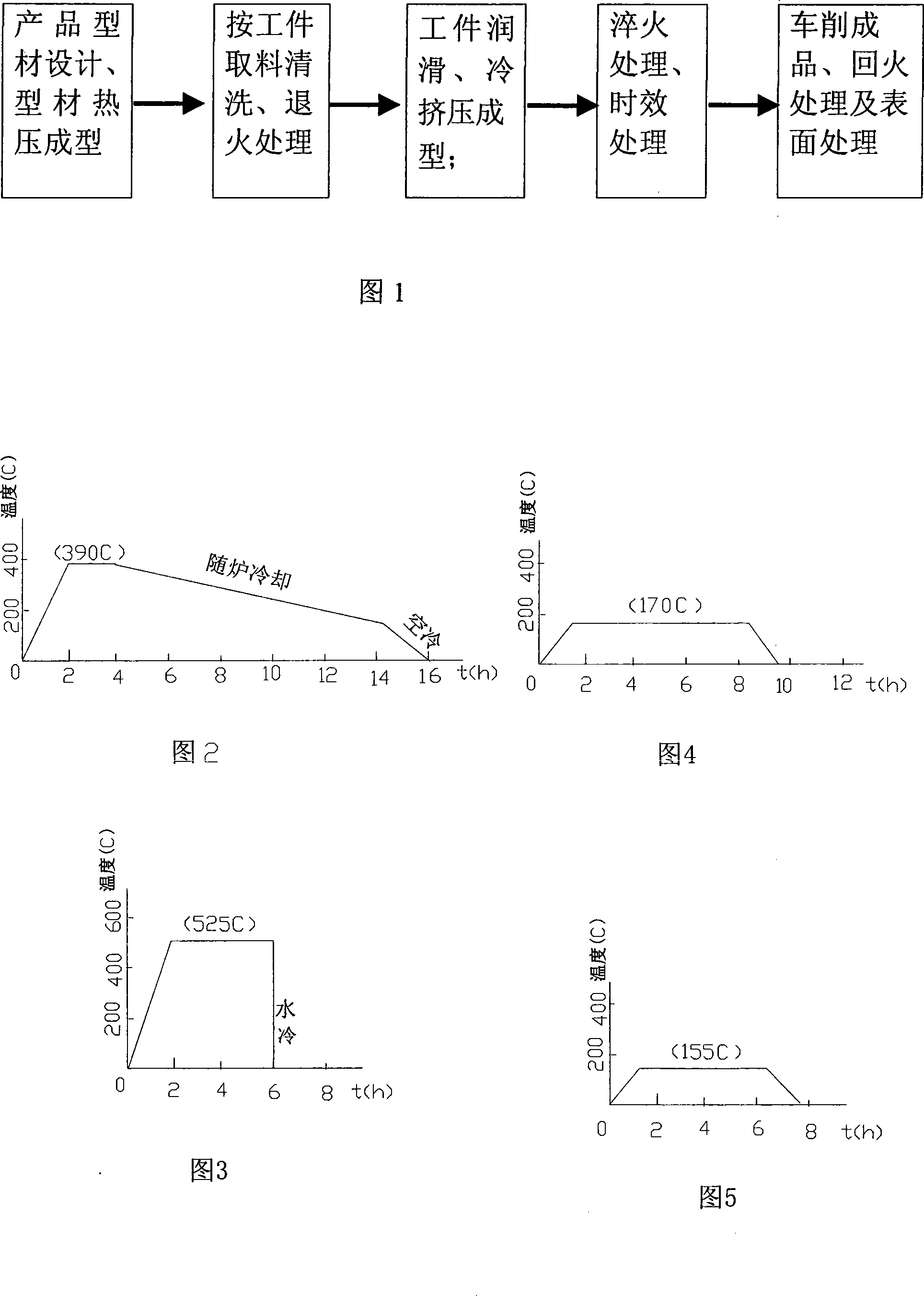

InactiveCN101224542AReduce hardnessImprove mechanical propertiesExtrusion diesExtrusion control devicesUltimate tensile strengthImpact extrusion

The invention relates to the water heating equipment field, in particular to a cold extrusion forming technique of an aluminium alloy water heating part and the water heating part product. The invention solves the problems that the existing product which takes the cast iron as the raw material is rough, has poor mechanical performance, low yield strength, and comparatively large brittleness, is easy to be broken during the construction installation and cracked during chilliness, and is not easy to resist the chilliness; furthermore, the product which takes the copper material as the raw material has high price, low mechanical performance and is not easy to resist the chilliness, and the cold extrusion technique of the aluminium alloy material can not be well formed; the detailed method of the invention can be seen in a manual; the product which is produced by the invention has the advantages of excellent mechanical performance, high hardness and tensile strength, high yield strength beyond comparison, comparatively small specific gravity, reducing the weight of the single part, beautiful appearance, no rust, no cracks, resisting the chilliness, long service life, high yield of the aluminium alloy cold extrusion forming product, and low cost of the products.

Owner:宁波炜兴特种铝制品有限公司

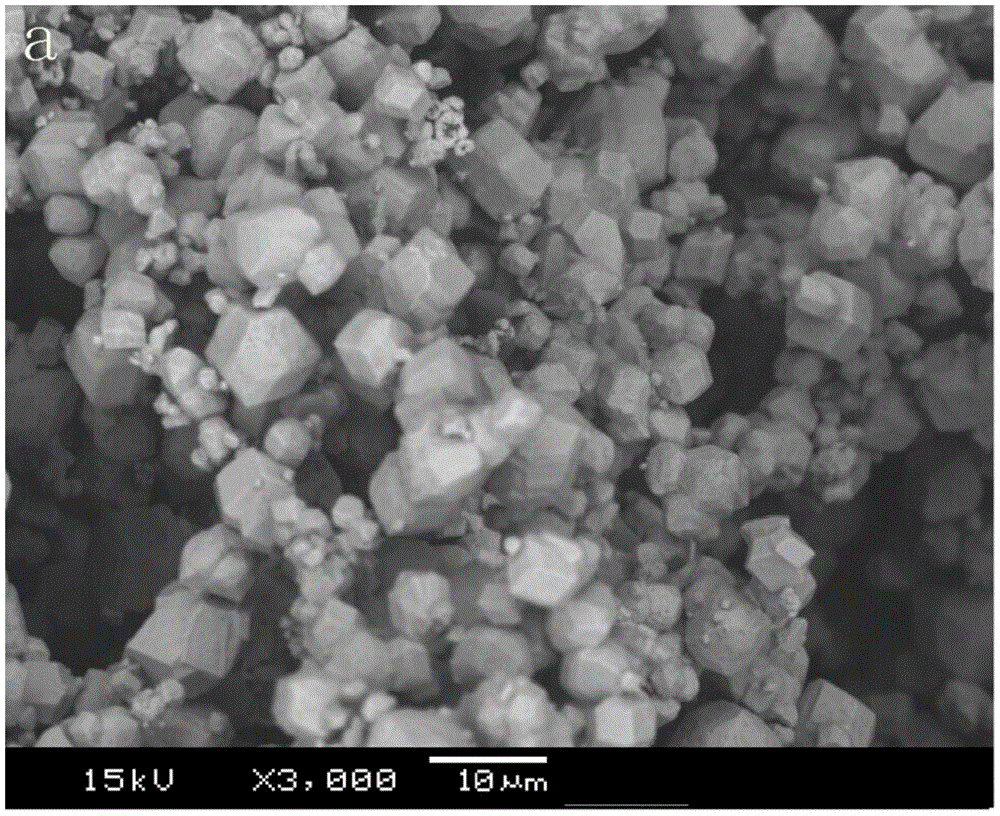

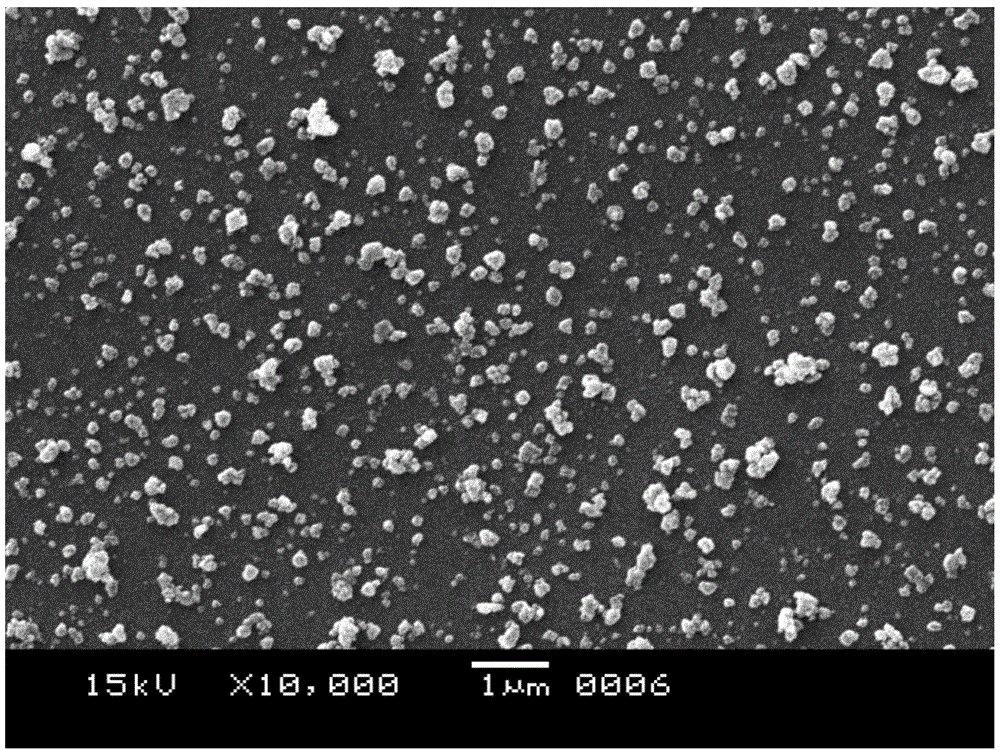

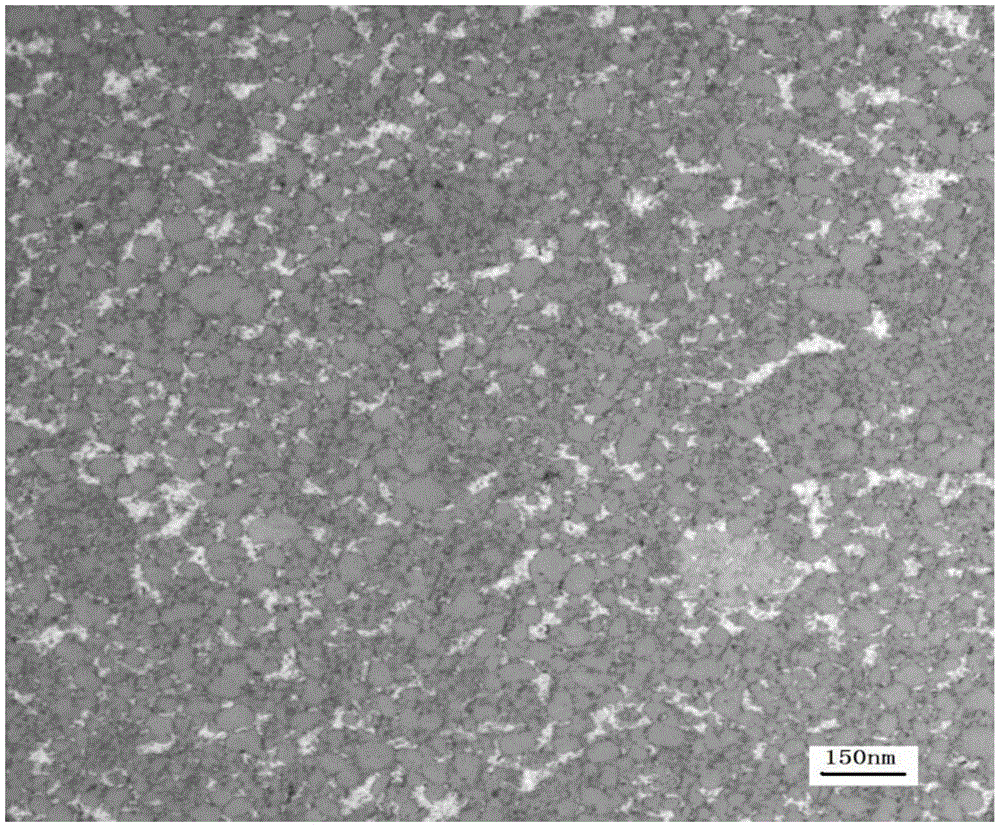

Nanometer tungsten carbide silver contact material and manufacturing method

A nano-tungsten carbide silver contact material and a preparation method thereof, wherein the tungsten carbide silver contact material is mainly composed of tungsten carbide powder, nickel powder, silver powder and stearic acid powder and is ball-milled to obtain a nano-WC / Ag composite powder, After reduction, pressing, sintering, re-pressing, and re-firing, nano-tungsten carbide silver electrical contacts are obtained. The weight ratio of tungsten carbide to silver is 40-80:20-60, and the particle size of the tungsten carbide phase is 50-500nm; The addition of the nickel powder is 0-2% of the mass percentage of the tungsten carbide powder; the addition of the stearic acid powder is 0.5-5% of the mass percentage of the tungsten carbide-silver-nickel mixed powder; the preparation method is: Weigh tungsten carbide powder and nickel powder, cemented carbide balls and alcohol according to the proportion and place them in a planetary high-energy ball mill for 12-72 hours. Take out the mixed powder and dry it, mix it with silver powder and stearic acid powder in a specific proportion and place it on a planetary ball mill. Milled in a high-energy ball mill for another 6-24 hours, the nano-WC / Ag composite powder obtained after ball milling is processed by reduction, pressing, sintering, re-pressing, and re-sintering to obtain uniform structure, high density, high hardness, and good electrical conductivity. , Nano-tungsten carbide silver electrical contacts with good anti-welding properties.

Owner:ZHEJIANG YATONG METAL CERAMICS

Preparation method for silver zinc oxide electrical contact

The invention discloses a preparation method for a silver zinc oxide electrical contact. The method comprises the following steps of: forming a pressed blank in a die pressing mode by adopting silver zinc alloy powder, wherein the relative density of the pressed blank is 65 to 80 percent; treating the formed pressed blank for 1 to 3 hours at the temperature of between 350 and 600 DEG C in hydrogen atmosphere, putting the treated pressed blank into an oxidation furnace with oxygen pressure of 0.02 to 1.5MPa and temperature of 500 to 750 DEG C, and performing oxidation; and for obtaining the high-compactness silver zinc oxide electrical contact, sintering the internal oxidized blank in the air at the temperature of between 700 and 900 DEG C, performing hot repressing on the blank at the temperature of between 500 and 900 DEG C, and thus obtaining an electrical contact product with relative density of over 99 percent. The silver zinc oxide granules prepared by the method are fine and uniform in metallographic structure; and the method has the advantages of an internal oxidation process and does not produce 'poor oxide bright bands'.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

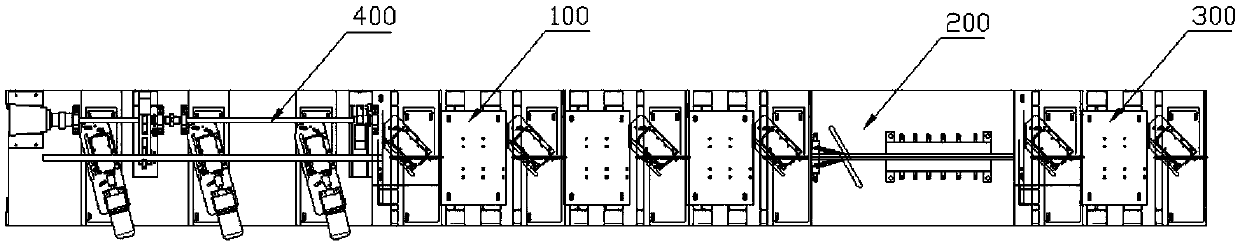

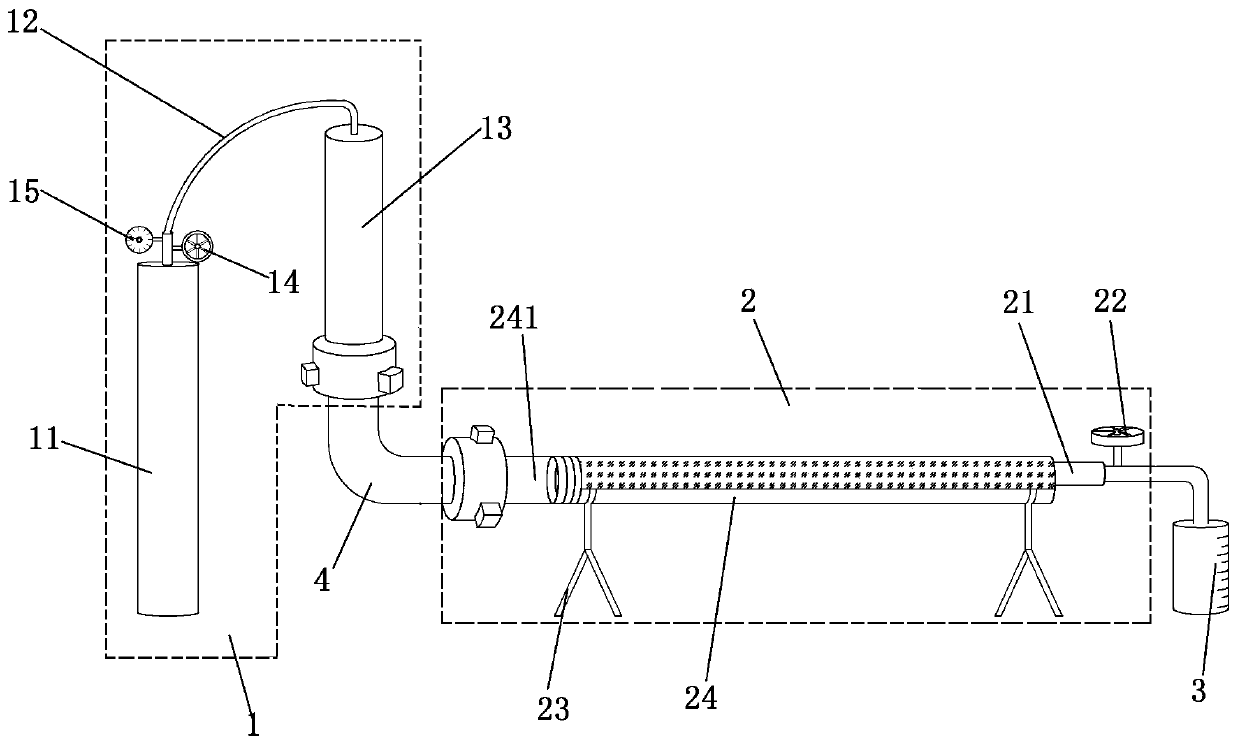

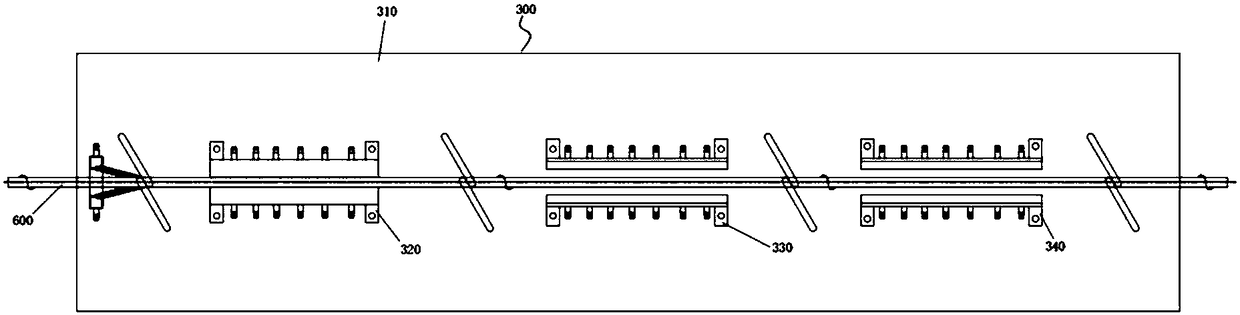

Large bar induction tempering technology and large bar induction tempering production line

InactiveCN107586934AHeating evenlyCool evenlyFurnace typesIncreasing energy efficiencyProduction lineFree cooling

The invention relates to the technical field of steel bar production, in particular to a large bar induction tempering technology and a large bar induction tempering production line. The large bar induction tempering technology comprises the steps as follows: the curvature of a raw material of rolled steel bars is inspected, the raw material of the steel bars is continuously moved on a conveying roller table and conveyed to a multi-stage induction heating zone, the steel bars subjected to multi-stage induction heating are conveyed to a quenching device for quenching, the quenched steel bars are conveyed to a multi-stage tempering induction heating zone, the tempered steel bars are conveyed to a blanking cold bed for natural cooling, and the cooled steel bars are packaged and stored. The steel bars are driven by the conveying roller table to move forwards continuously, so that the steel bars are gradually heated stage by stage, the induction heating tempering quality of the steel bars is improved, bending deformation is small, the steel bars are moved slowly while being treated, the steel bars are uniformly heated and cooled and has uniform hardness, metallographic structure and mechanical performance and small scattering difference. The large bar induction tempering production line has the advantages as compared with the prior art.

Owner:江苏南钢通恒特材科技有限公司

Silver-tungsten carbide-nickel contact material and preparation method thereof

The invention discloses a silver-tungsten carbide-nickel contact material and a preparation method thereof. The silver-tungsten carbide-nickel contact material is prepared from the following components in percentage by weight: 20-30% of tungsten carbide, 0.1-5% of nickel and the balance of silver. The preparation method of the material comprises the following steps: weighing tungsten carbide powder, nickel powder and silver powder, mixing evenly, putting the silver-tungsten carbide-nickel mixed powder, high-purity nickel balls and water into a ball mill for ball milling, and performing drying, annealing, forming, sintering, re-pressing and re-annealing on the ball-milled powder, thereby obtaining the silver-tungsten carbide-nickel contact material; the weight ratio of the high-purity nickel balls to the silver-tungsten carbide-nickel mixed powder is (4-10): 1; the dosage of the water is calculated according to that 130-220ml of water is added to the silver-tungsten carbide-nickel mixed powder per 1kg; the time of the ball milling is 12-48 hours; and as the nickel lost in ball milling is mixed with the powder, the weight of the weighed nickel powder is 0-92% of that of the nickel in the final silver-tungsten carbide-nickel mixed powder obtained after ball milling.

Owner:桂林金格电工电子材料科技有限公司

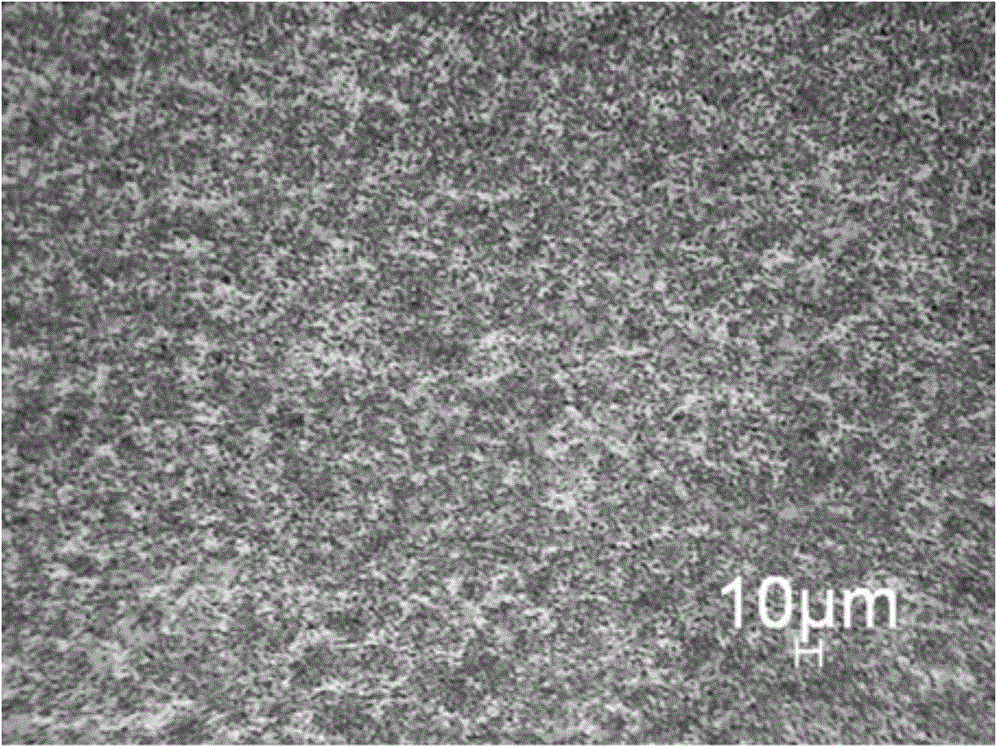

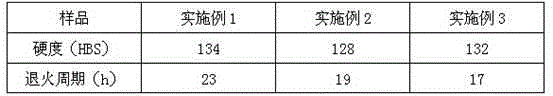

Spheroidized annealing process for shortening annealing cycle of hot rolled wire rods

The invention relates to a spheroidized annealing process for shortening the annealing cycle of hot rolled wire rods, belongs to the technical field of metal wire annealing process. The technical scheme of the spheroidized annealing process lies in that firstly, lamellar pearlites are heated to 770-790 DEG C, heat preservation is carried out for a certain time to enable the lamellar pearlite to be fused quickly, so that the undissolved carbide particles can promote the transformation of austenite into the spheroidized microscopic structure; the temperature is lowered to 710-730 DEG C, heat preservation is performed for 4-6 hours to enable the fused cementite to gather spherically, and along with the time extension of heat preservation, the rate of spheroidization of the cementite is gradually improved, and the uniformity is gradually improved. A slow three-stage cooling manner is adopted, so that the uniformity of the spheroidized structure is improved. According to the spheroidized annealing process for shortening the annealing cycle of hot rolled wire rods, the following advantages are achieved: the annealing effect is good, the technological process is simple, the annealing cycle is short, the production efficiency is high, and the cost is low. With the adoption of the spheroidized annealing process provided by the invention, the processed wire rods of fasteners are uniform in metallographic structure, high in toughness, high in malleability, low in harness, are suitable for subsequent moulding and processing forming, and the products are low in cold-forming cracking rate.

Owner:XINGTAI IRON & STEEL

Hollow drill steel rolling process

InactiveCN1544168AExtended service lifeUniform metallographic structureMetal rolling arrangementsMedium frequencyEngineering

The invention relates to a hollow drill steel rolling technique, including the working procedures of medium frequency induction heating, perforating by two roller inclined rolling, reducing diameter by three roller-core inclined rolling, fixing diameter and molding by three-roller vertical rolling, and controlling and cooling, and its character: behind working procedure of the medium frequency induction heating, there is an industrial frequency soaking working procedure and the adopted device is an industrial frequency soaking furnace. It adds industrial frequency soaking working procedure to the steel rolling technique, ensuring the inner gold phase tissue of finished product is uniform; it improves hollow drill steel gold-phase tissue and eliminates the inner-surface thread of the central hole and the roll defect, prolongs the service life of the drill steel.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

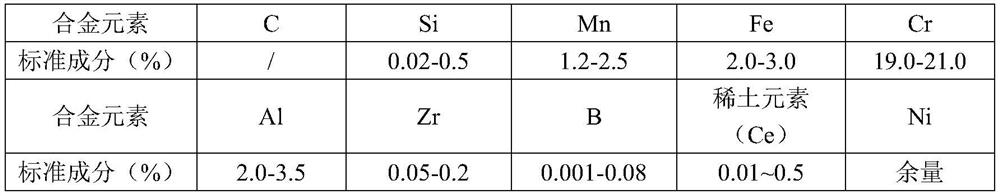

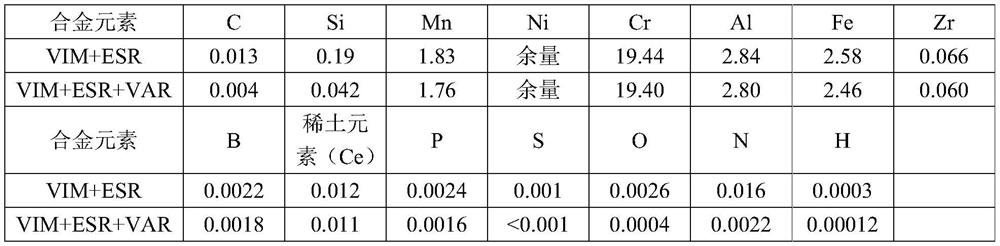

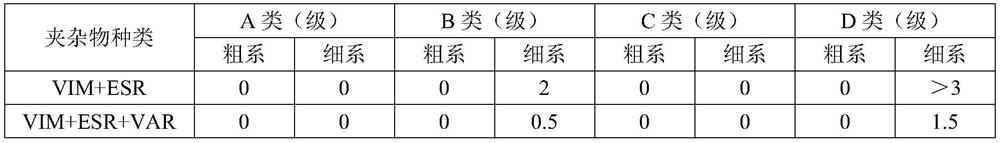

Preparation method of microalloyed high-strength precision nickel-chromium resistance alloy material

InactiveCN111621674AHigh temperature strengthImprove fatigue lifeIncreasing energy efficiencyNichromeMetallic materials

The invention belongs to the field of metal materials, and particularly relates to a microalloyed high-strength precision nickel-chromium resistance alloy material. A preparation method of the microalloyed high-strength precision nickel-chromium resistance alloy material comprises the steps of vacuum induction melting, electroslag remelting, vacuum consumable remelting and forging cogging. The material prepared by the method has high resistivity, low temperature coefficient of resistance, excellent heat resistance, corrosion resistance and mechanical properties, and good processing performance, can meet the processing requirements of high-precision foils and fine wires, improves the processing accuracy and surface quality of finished products, and is used for the production of high-precision electronic components, the products, namely precision resistance alloys, are made by the VIM+ESR+VAR smelting process, due to the precise control over the content of alloy elements, impurities andgas in the products, the electrical properties and the processing performance of the products meet the requirements, and the products can face the high-end precision resistance alloy market at home and abroad.

Owner:CHONGQING MATERIALS RES INST

Preparation method for silver cadmium oxide electrical contact

ActiveCN102319901ANo aggregationIncrease profitElectric switchesHydrogen atmosphereInternal oxidation

The invention discloses a preparation method for a silver cadmium oxide electrical contact. The method comprises the following steps of: forming a pressed blank in a die pressing mode by adopting silver cadmium alloy powder, wherein the relative density of the pressed blank is 65 to 80 percent; treating the formed pressed blank for 1 to 3 hours under the hydrogen atmosphere at the temperature of between 350 and 600 DEG C, putting the treated pressed blank into an oxidation furnace with oxygen pressure of 0.02 to 1.5MPa and temperature of 500 to 750 DEG C, and performing oxidation; for obtaining the silver cadmium oxide electrical contact with high compactness, sintering the internal oxidized blank at the temperature of between 700 and 900 DEG C in the air; and performing hot re-pressing on the blank at the temperature of between 500 and 900 DEG C, and thus obtaining an electrical contact product with relative density of over 99 percent. The silver cadmium oxide particles prepared by the method are fine and uniform in metallographic structure; and the method has the advantages of an internal oxidation process and does not produce a 'depleted oxide bright band'.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

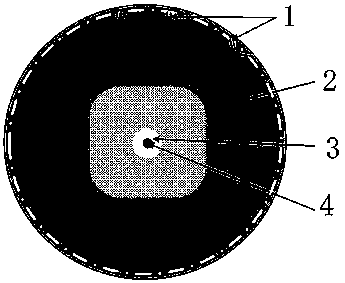

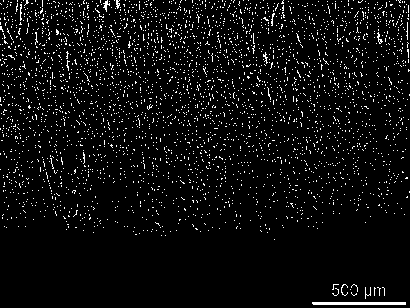

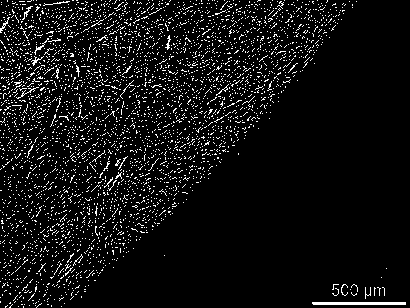

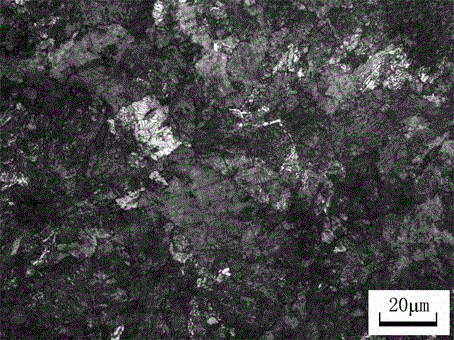

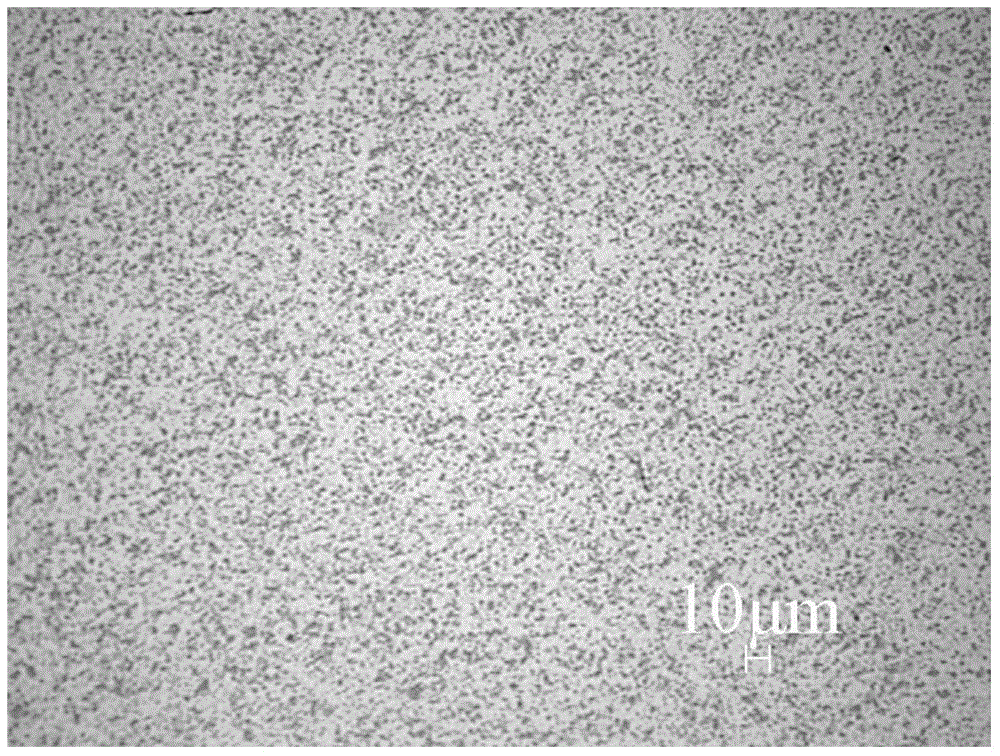

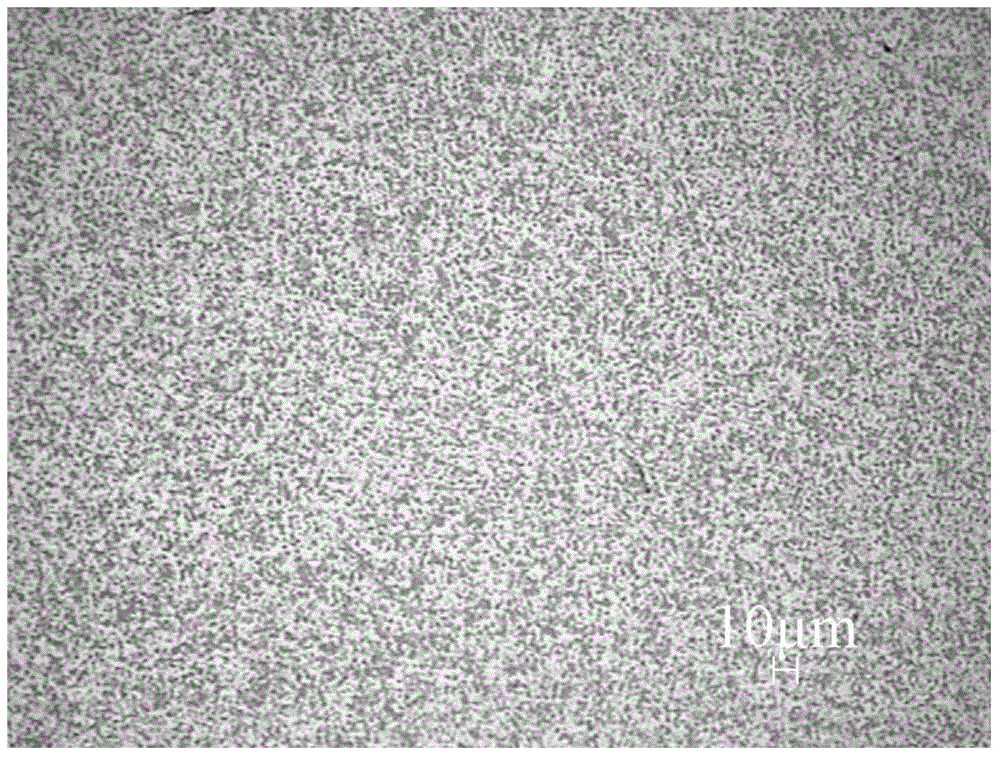

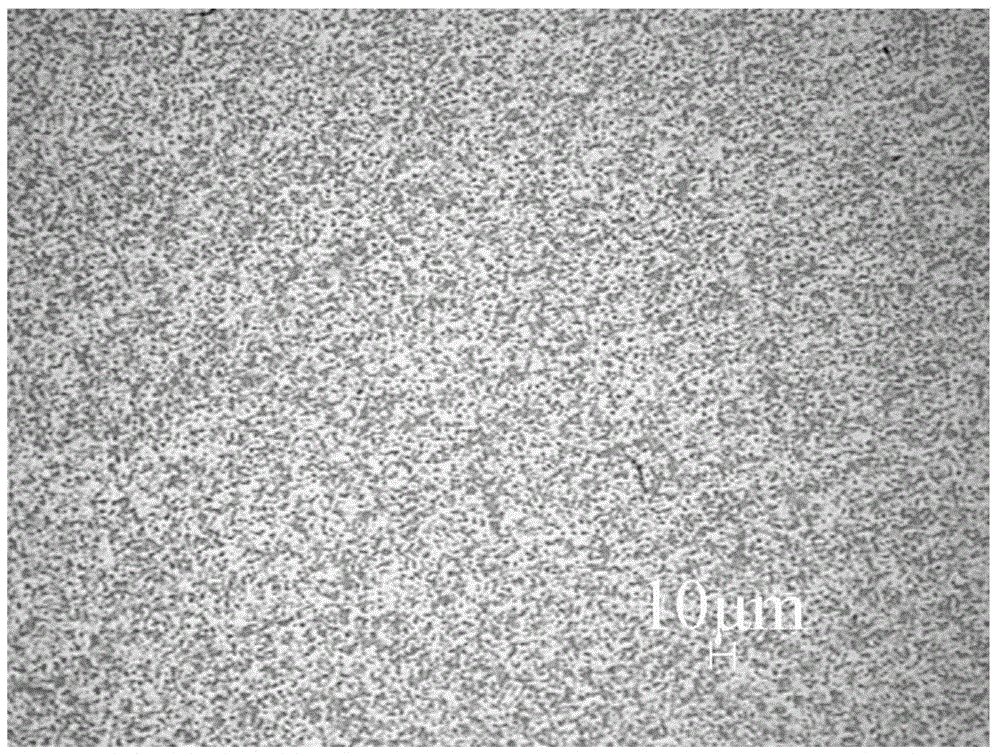

Continuous casting method for eliminating near-surface layer dendrite banded segregation of alloy spring steel wire rod

ActiveCN110508771AUniform metallographic structurePrevent early spring fatigue fracturePreparing sample for investigationTesting metal structuresElectromagnetic inductionCorrosion

The invention discloses a continuous casting method for eliminating near-surface layer dendrite banded segregation of an alloy spring steel wire rod. The continuous casting method comprises the processes of continuous casting tundish molten steel superheat degree control, continuous casting billet withdrawal speed control, crystallizer electromagnetic stirring control, crystallizer water inlet flow control and vibration parameter control; the tundish molten steel superheat degree is controlled to be 15-25 DEG C through tundish electromagnetic induction heating equipment; a crystallizer electromagnetic stirring part is mounted on the middle lower part of a crystallizer, the electromagnetic stirring current intensity is 150-300 A, and the electromagnetic stirring frequency is 1.5-2.5 Hz; andhydraulic vibration is adopted, the amplitude is 2.3-2.7 mm, the frequency of vibration is 100-130 cpm, and liquid level fluctuation is controlled to be + / -2 mm. The alloy spring steel wire rod, produced through the continuous casting method, of phi 5.5-20 mm is free of near-surface layer dendrite banded segregation through dendrite corrosion detection, after heat treatment, metallographic structures on a surface layer are uniform and consistent, and thus spring early fatigue break caused by dendrite banded segregation is effectively prevented.

Owner:XINGTAI IRON & STEEL

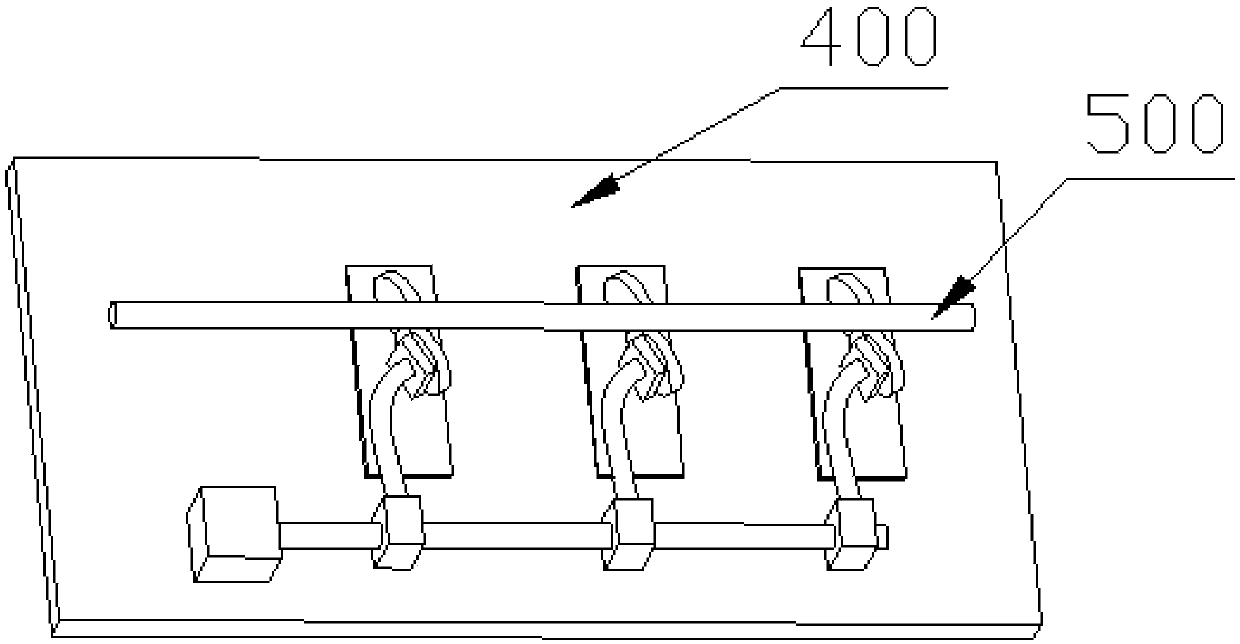

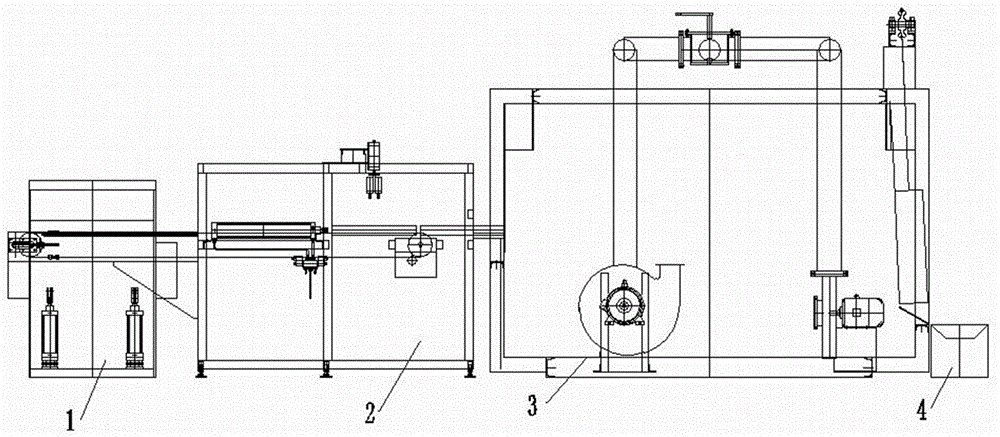

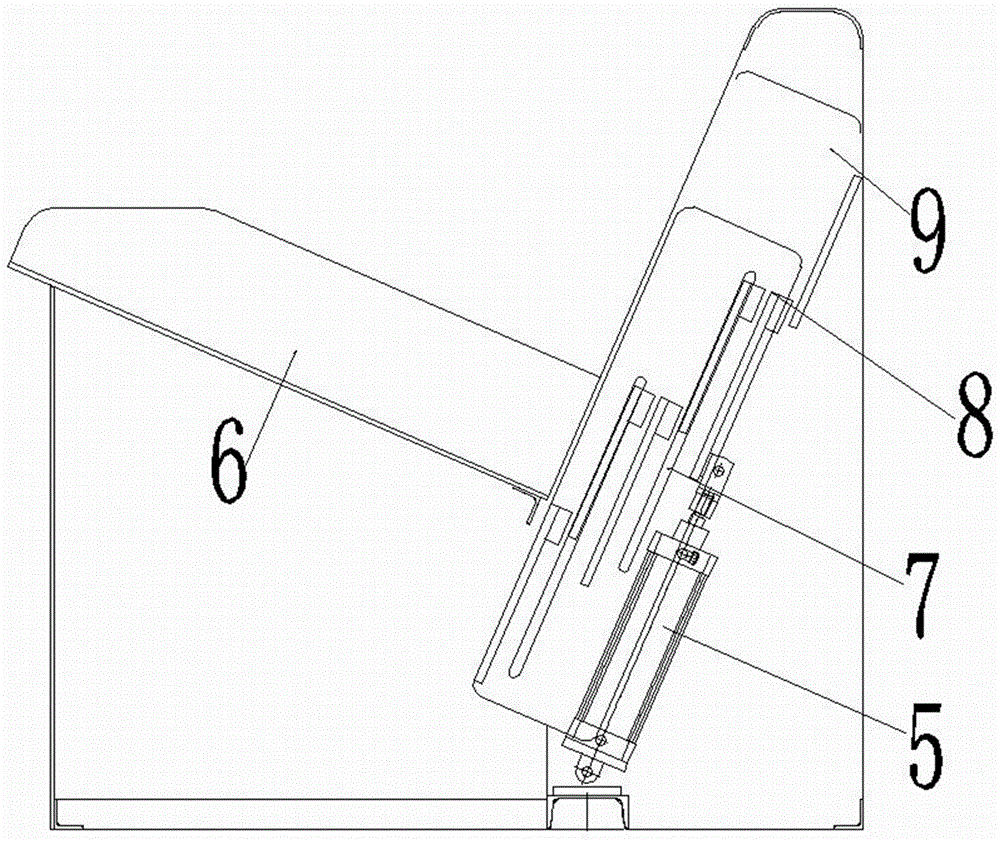

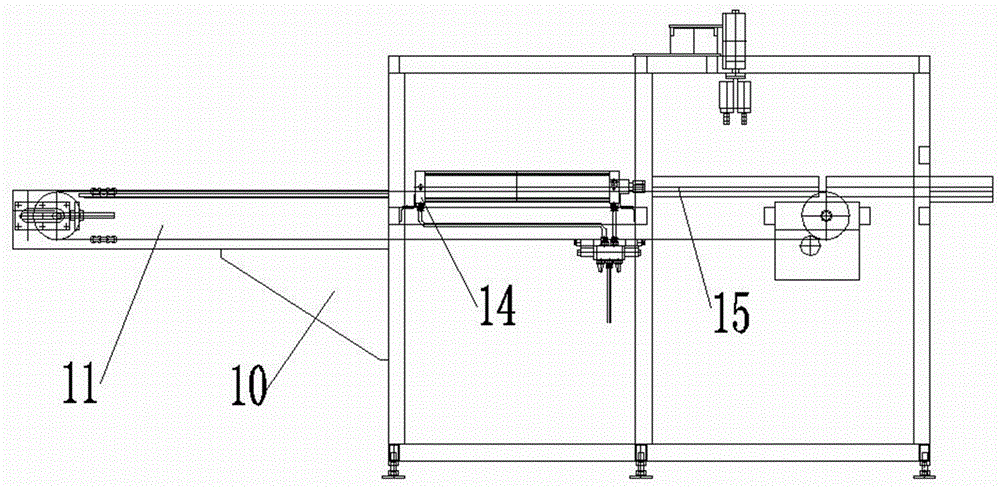

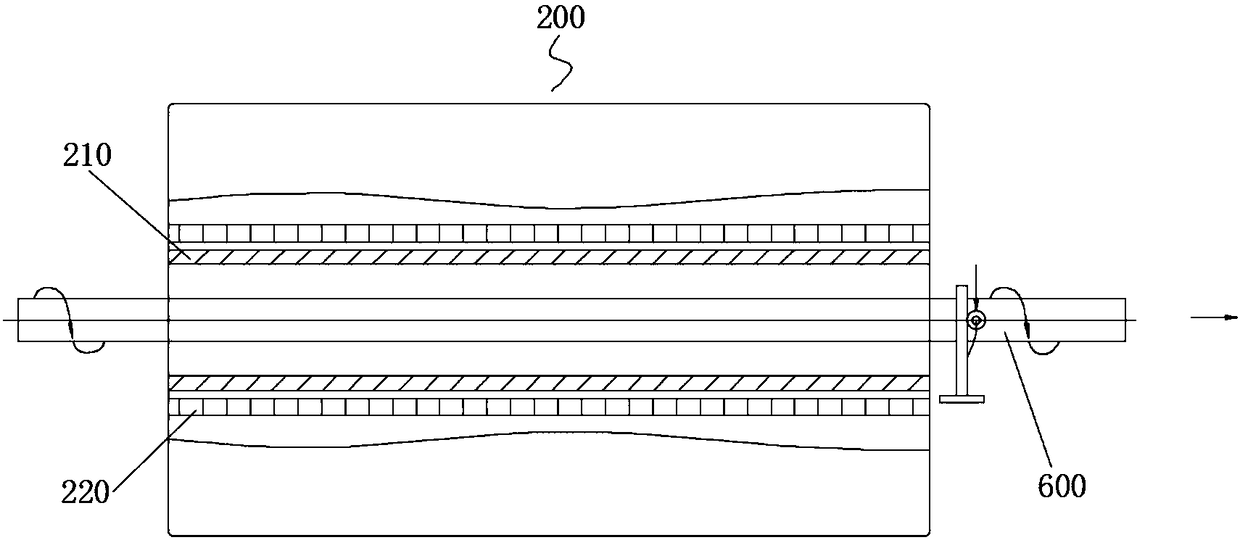

Fully-automatic continuous heating furnace for bars

InactiveCN106322993AIncrease productionSignificant energy savingCrucible furnacesGas emission reductionProcess engineeringRED MATERIAL

The invention provides a fully-automatic continuous heating furnace for bars and relates to the field of forging heating equipment. Through overcoming defects of a natural gas straight-flow furnace, the loading, furnace feeding and red material conveying of the bars for forging products are automatically finished, and the heating quality of the bars and the automation degree of equipment are improved. The fully-automatic continuous heating furnace for bars is characterized by sequentially comprising a storing and loading machine, a distributing and pushing machine, a natural gas heating furnace and a red material conveyer from front to rear according to an arrangement sequence. The working of the fully-automatic continuous heating furnace for bars, provided by the invention, is a continuous heating process, continuous forging can be realized, a periodic heating process of an old gas heating furnace is changed, the productivity is increased, natural gases are saved, and the production cost is reduced.

Owner:开封现代工业炉有限公司

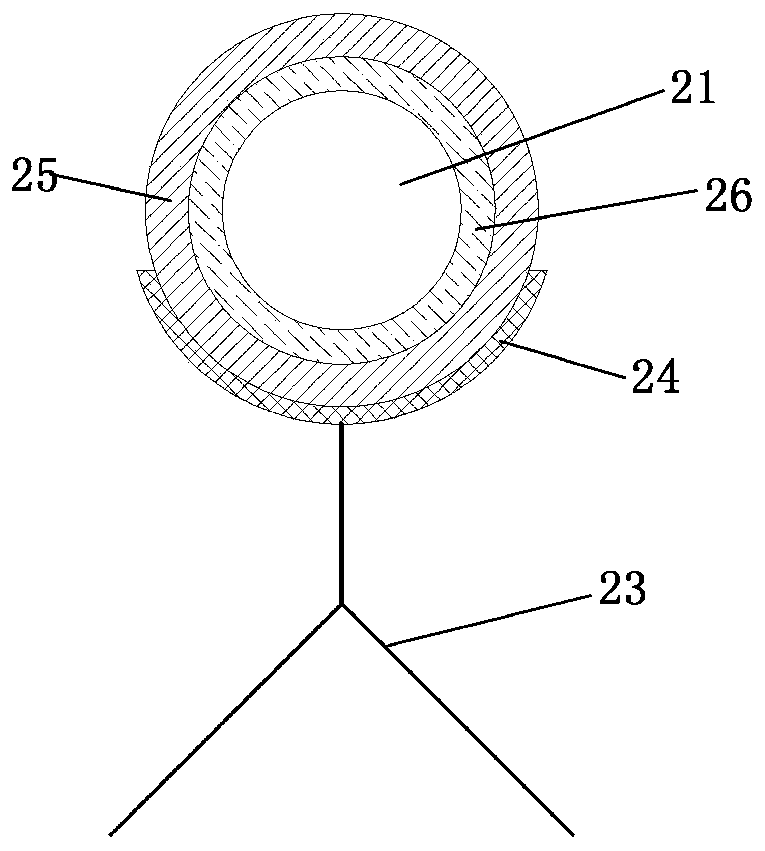

Visual plugging evaluation device and use method thereof

PendingCN110487971AUniform metallographic structureUniform pressure bearing capacityMaterial analysisCentrationDirect observation

The invention provides a visual plugging evaluation device and a use method thereof. The device comprises a simulated wellbore mechanism, a simulated formation mechanism and a measuring mechanism which are sequentially connected. The simulated wellbore mechanism comprises a compressed gas source, a compressed gas pipeline and a vertically arranged slurry pipe which are sequentially connected. Thesimulated formation mechanism comprises a visual pipe and an outlet valve which are horizontally arranged and sequentially connected. The measuring mechanism is connected with the outlet valve. The visual plugging evaluation device simulates different pore formations through particle fillers with different diameters, pressurized plugging is performed by using the plugging slurry of certain centration, the plugging process and results of the plugging agent bridging in the pores are observed and the effect of the plugging formula is evaluated. According to the plugging evaluation device, the plugging process can be directly observed and monitored anytime so as to be convenient and easy to use.

Owner:XINJIANG GRAND OILFIELD TECH

Wire with tensile strength>=2000MPa for bridge cable and production method

ActiveCN102936688BUniform metallographic structureUniform performanceMetal rolling arrangementsWire rodAir volume

The invention discloses a wire with tensile strength>=2000MPa for a bridge cable and a production method. The wire comprises, by weight, 0.95-1.2% of C, 0.1-0.48% of Si, 0.6-1.0% of Mn, 0.1-0.5% of Cr, 0.01-0.05% of V, Cu<=0.05%, 0.05-0.15% of Al, 0.01-0.03% of N, P<=0.025% and S<=0.015%. The production method includes smelting and continuously casting into blanks; heating the casting blanks; rolling; heating again; high-speed rolling; spinning; air cooling to the room temperature; and placing for standby. According to the wire and the method, continuous casting of blooms, rolling starting of billets and high speed wire rolling are adopted, therefore a metallographic structure and the like of the wire for the bridge cable are even, and grains are better refined; and processes of rapid cooling with a large air volume and the like are adopted, therefore the tensile strength of the wire for the bridge cable is >=2000MPa and stable, a twist number reaches >=15, and wire fracture caused by the wire quality does not happen during cold drawing.

Owner:武汉钢铁有限公司

Manufacturing process for silver zinc oxide copper oxide electrical contact and electrical contact product

InactiveCN104201019AUniform metallographic structureFine grainContactsElectrical resistance and conductanceIngot casting

The invention discloses a manufacturing process for a silver zinc oxide copper oxide electrical contact and an electrical contact product. In the manufacturing process, the electrical contact product is manufactured through smelting, ingot casting, hot extrusion, drawing into ally wires, forming of required specification of sheet through cold heading, then diffusion annealing and oxidation treatment. The electrical contact product produced by adopting the preparation method is characterized in that the electrical contact product is low in surface contact resistance, good in electrical property and arc extinguishing performance, high in welding resistance and good in combination property. The processing method is simple, the material utilization rate is high, the detrimental impurity is few, the production cost is low, and the production cycle is low. The economic benefit and social benefit are particularly obvious.

Owner:张树堂

Induction hardening and tempering production line

PendingCN108546804ATo achieve the effect of bending without deformationCool evenlyIncreasing energy efficiencyFurnace typesProduction lineSprayer

The invention belongs to the technical field of steel rod production and relates to an induction hardening and tempering production line. After a steel rod body enters a box, an all-around water sprayer achieves all-around quenching and cooling, so that the heated steel rod body can be quenched and cooled in an all-around manner, no quenching blind area exists, no soft spot exists, no soft zone exists, and deformation is tiny. A steel rod raw material is conveyed into a multi-grade quenching heating assembly to be heated, the heated steel rod is conveyed to a quenching cooling assembly to be quenched, the quenched steel rod is conveyed to the multi-grade tempering heating assembly, the tempered steel rod is conveyed to a cold bed through a discharging assembly, natural cooling is conducted, and packaging and storage are conducted. The steel rod is driven to continuously move frontwards through a conveying assembly, the steel rod is gradually heated in a graded manner, the induction heating and hardening and tempering quality is improved, and bending deformation is tiny; the steel rod is processed while slowly advancing, it is guaranteed that the steel rod is evenly heated and evenly cooled, the hardness, the metallographic structure and the mechanical property are uniform, and the scattering difference is small.

Owner:江苏南钢通恒特材科技有限公司

Preparation method of additive-containing silver zinc oxide electrical contact material

ActiveCN104593633AUniform metallographic structurePromote oxidationMetal/alloy conductorsSilver oxideSodium hydroxide

The invention discloses a preparation method of an additive-containing silver zinc oxide electrical contact material. The preparation method of the additive-containing silver zinc oxide electrical contact material comprises the following concrete steps: calculating usage amounts of the required metal zinc, metal additives and silver according to a ratio of a to-be-prepared silver zinc oxide electrical contact material, smelting one part of silver in a metallic silver form with the metal zinc and the metal additives, and atomizing to obtain silver-zinc alloyed powder; mixing the other part of silver in a silver nitrate form with the obtained silver-zinc alloyed powder, and then carrying out reaction on the obtained mixture and sodium hydroxide to obtain silver oxide and silver-zinc alloy composite powder; washing the obtained silver oxide and silver-zinc alloy composite powder to be neutral, drying, smashing, and oxidizing in the oxygen-containing atmosphere to obtain additive-containing silver zinc oxide composite powder; and moulding, sintering, repressing and resintering the obtained additive-containing silver zinc oxide composite powder, so that the additive-containing silver zinc oxide electrical contact material is obtained. A contact prepared by adopting the additive-containing silver zinc oxide electrical contact material has the advantages that a metallographic structure is more uniform, and the processability is better.

Owner:桂林金格电工电子材料科技有限公司

Spheroidizing annealing technology of high-tenacity fastener wire rod

InactiveCN104232858AUniform metallographic structureImprove toughnessFurnace typesHeat treatment furnacesFastenerHeat conservation

The invention discloses a spheroidizing annealing technology of a high-tenacity fastener wire rod. The spheroidizing annealing technology comprises the following steps: placing a fastener wire rod into a thermal treatment furnace, introducing a protective gas into the thermal treatment furnace, raising the temperature in the furnace to 720-740DEG C, and performing heat preservation for 1-3h; carrying out first-stage cooling: cooling the temperature in the furnace to 680-700DEG C at the speed of 10DEG C / h, and performing heat preservation for 2-4h; carrying out second-stage cooling: further reducing the temperature in the furnace to 630-650DEG C at the speed of 20DEG C / h; and carrying out third-stage cooling: naturally cooling the fastener wire rod to normal temperature. The fastener wire rod treated by adopting the technological method is uniform in metallographic structure, high in tenacity, high in ductility, low in hardness and suitable for subsequent high-difficulty repeated plastic machining forming, and the forming cracking rate of the product is low.

Owner:DONGGUAN KELEE STEEL WIRE

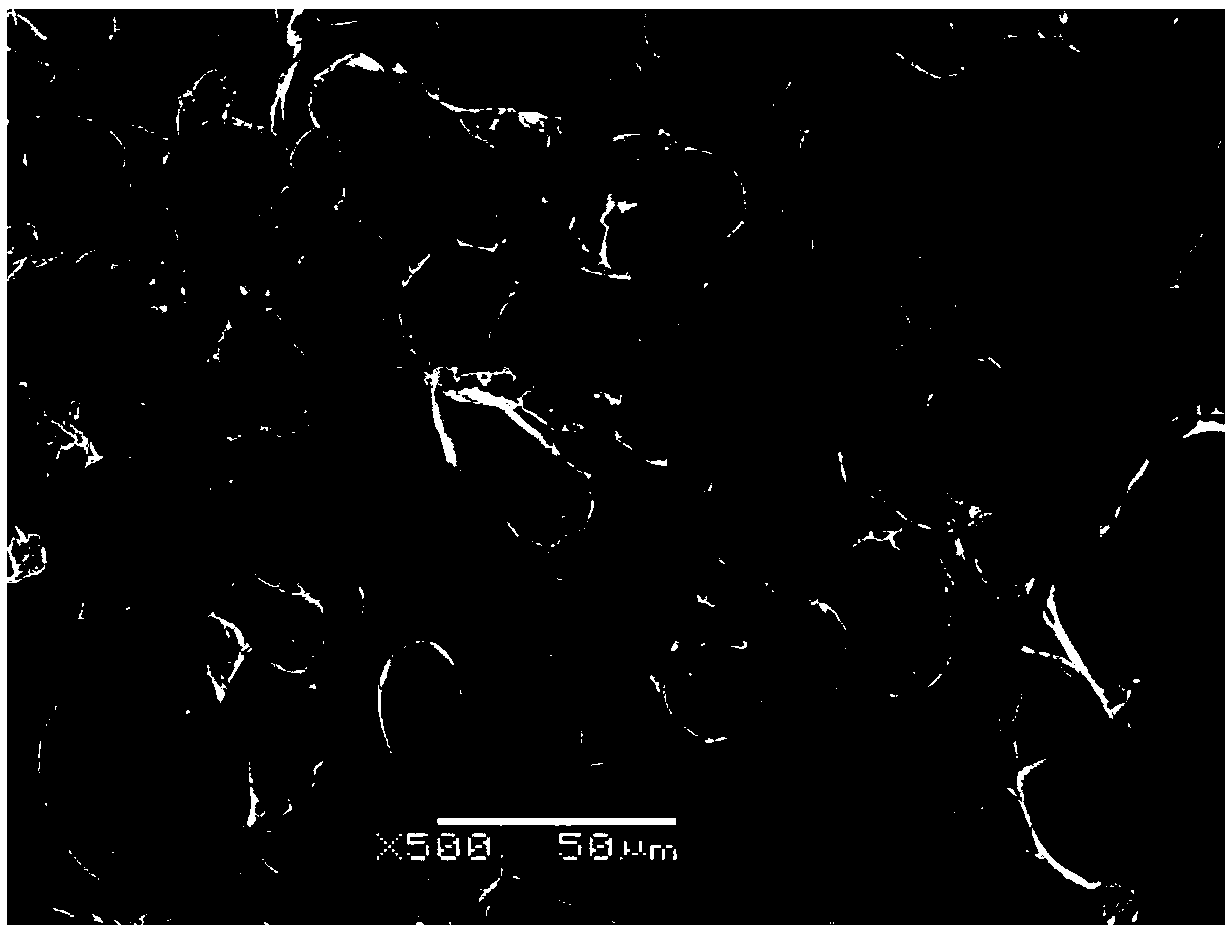

Production method of phosphor copper ball for electroplating

InactiveCN103741197AReduce consumptionUniform metallographic structureMetal rolling arrangementsElectrodesStructure analysisPhosphor

The invention discloses a production method of a phosphor copper ball for electroplating, and relates to a method which adopts a metallographic analysis method to control the quality of a phosphor copper ball for electroplating. The production method is characterized by adopting an up-drawn method; after the rolling of phosphor copper rods, metallographic analysis is carried out on the phosphor copper rods so as to judge whether the phosphor copper rods meet the preset metallographic structure analysis standards of finished phosphor copper rod on crystal particle fineness, tissue homogeneity, and compactness; the unqualified phosphor copper rods are returned to the rolling process by adopting the up-drawn method, and the rolling-judging-rolling process is continuously repeated until the phosphor copper rods meet the standards on crystal particle fineness, tissue homogeneity, and compactness so as to finish the preparation of phosphor copper balls. The production method utilizes metallographic analysis to observe the crystal particle size of phosphor copper ball, and has the advantages of directness, simplicity, and visualization. The prepared phosphor copper ball is used as a positive pole material for electroplating, and has the advantages of uniform and compact metallographic structure; moreover the fineness of the crystal particle size is strictly controlled to avoid the existence of crude and big crystal particles, and thus the consumption amount of phosphor copper ball during the electroplating process is effectively reduced.

Owner:JINCHUAN GROUP LIMITED

Preparation method of copper-chromium contact material

The invention belongs to the field of contact material manufacturing and particularly relates to a preparation method of a copper-chromium contact material. The preparation method comprises the following steps of mixing a part of copper powder as inductive copper powder with chromium powder, conducting ball milling to obtain ball-milled powder under the vacuum condition, adding the remaining copper powder to be mixed evenly to obtain mixed powder; pressing the mixed powder into a blank, pulling the pressed blank into a crucible and putting a copper sheet on the pressed blank; putting the crucible in a vacuum sintering furnace to be sintered and infiltrated and obtaining the copper-chromium contact material after annealing, wherein the chromium content of the material is 25-50 wt%. The copper-chromium contact material prepared through solid phase sintering and liquid phase copper infiltration is uniform in structure. Cr particles are nearly spherical and small in size. The material is good in compactness and low in gas content.

Owner:SHAANXI ZHONGTIAN ROCKET TECH CO LTD

Lead-free solder for soft soldering

InactiveCN101138813AGrain refinementUniform metallographic structureWelding/cutting media/materialsSoldering mediaSolderingMechanical property

The present invention relates to a lead-free solder for a soldering which is characterized in that the solder consists of materials with the following weight percentage: Cu from 0.1 percent to 1.0 percent, Ni from 0.1 percent to 0.2 percent, Ce from 0.01 percent to 0.10percent, Bi from 0.05percent to 2.0percent, Pr or / and Nd from 0.01percent to 0.10percent and the rest being Sn. The lead-free solder of the present invention, belonging to the environmental protecting products, has the advantages and effects of such as an anti-oxidation property, a mechanical property and corrosion resistance which can improve the performance of the solder, a uniform metallographic organization, refined grain, a good product quality, low cost and a proper reduction of the melting point.

Owner:郴州金箭焊料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com