TiC-WC based alloy products

A technology for base alloys and products, applied in the field of TiC-WC base alloy products, can solve the problems of low hardness and high temperature strength, excessive liquid phase, poor wear resistance, etc., and achieve strong corrosion resistance and oxidation resistance, strength And the effect of high hardness and uniform metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

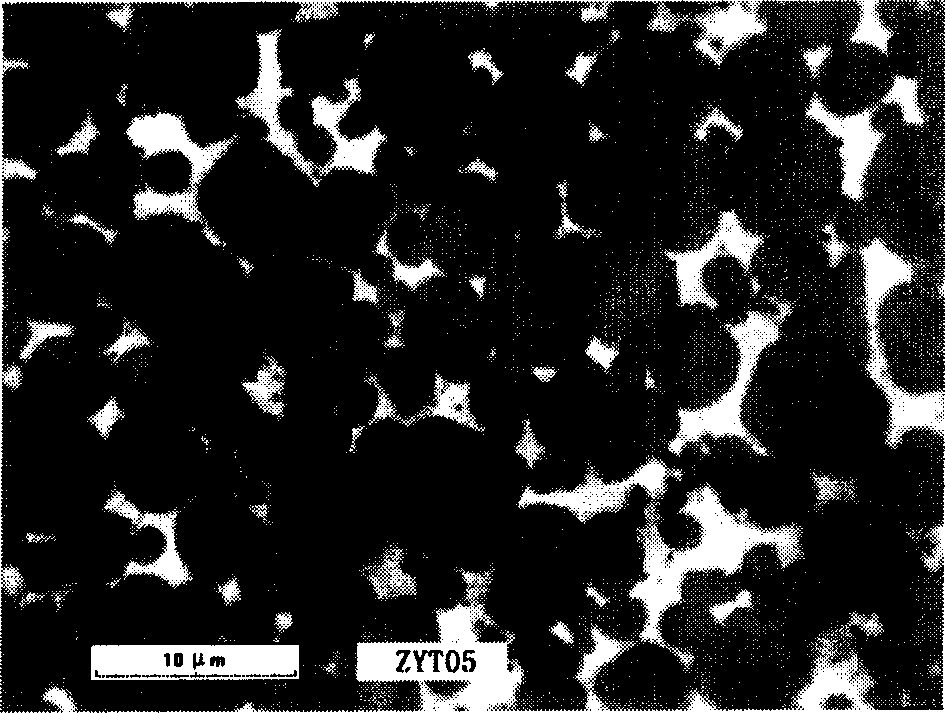

Image

Examples

Embodiment 1

[0008] Embodiment 1: the present embodiment is example (by every batch of 100kg batching) with the production of guide rollers for high-speed wire rod rolling:

[0009] A. Wet milling ingredients: put 56.5kgTiC, 18kgWC, 14kgNi, 10kgCo and 1.5kgCr powders that meet the industrial production standards in the ball mill, and after warm milling and mixing for 64 hours, add 2.0kg of paraffin and continue ball milling to mix evenly, and the slurry passes through 320 Mesh sieve, the resulting mixed powder is sent to a vacuum dryer and dried at a temperature of 100°C to remove the wet grinding medium, after cooling, the mixed powder is obtained through homogenization treatment; the wet grinding medium in this embodiment is hexane;

[0010] B. Compression molding and pre-sintering: Put the mixed powder into the mold and press it into the blank of the guide roller; then put it into the vacuum furnace and calcinate it at 500°C for 75 minutes to remove the paraffin and cool it with the furn...

Embodiment 2

[0013] Embodiment 2: Taking the production of wear-resistant and corrosion-resistant ball valve cores and valve seats as an example (by every batch of 100kg ingredients):

[0014] A. Wet grinding ingredients: 30kgTiC, 54kgWC, 7.5kgNi, 7.5kgCo and 1.0kgTa powders for industrial use are placed in the ball mill; the following processes and parameters (including steps B and C) are the same as in Example 1.

[0015] The product of this embodiment is tested: density 9.0g / cm 3 , hardness HRA≥90.5, bending strength 2000N / mm 2 , Porosity A 02 B 00 C 00 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com