Patents

Literature

60results about How to "Low porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

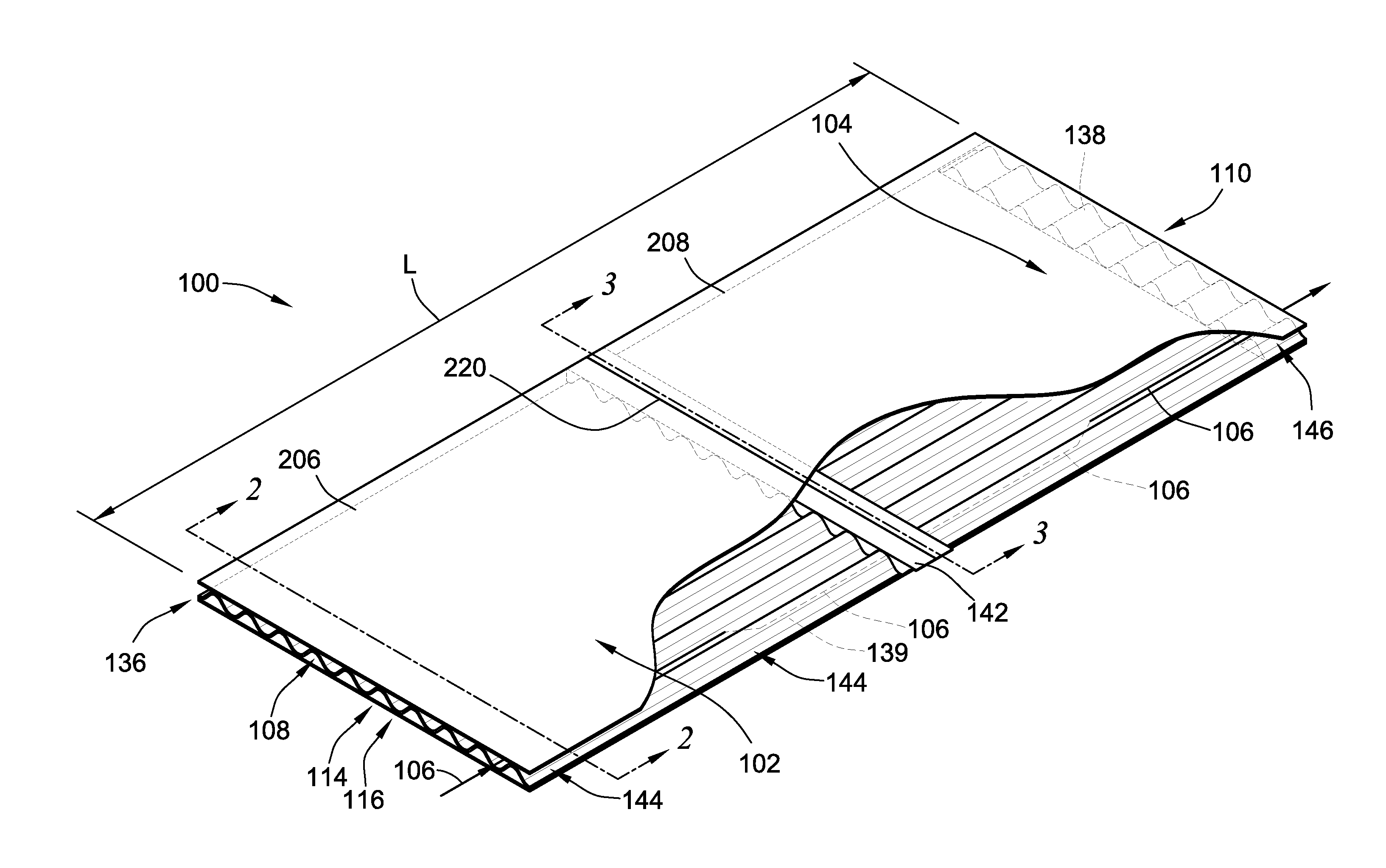

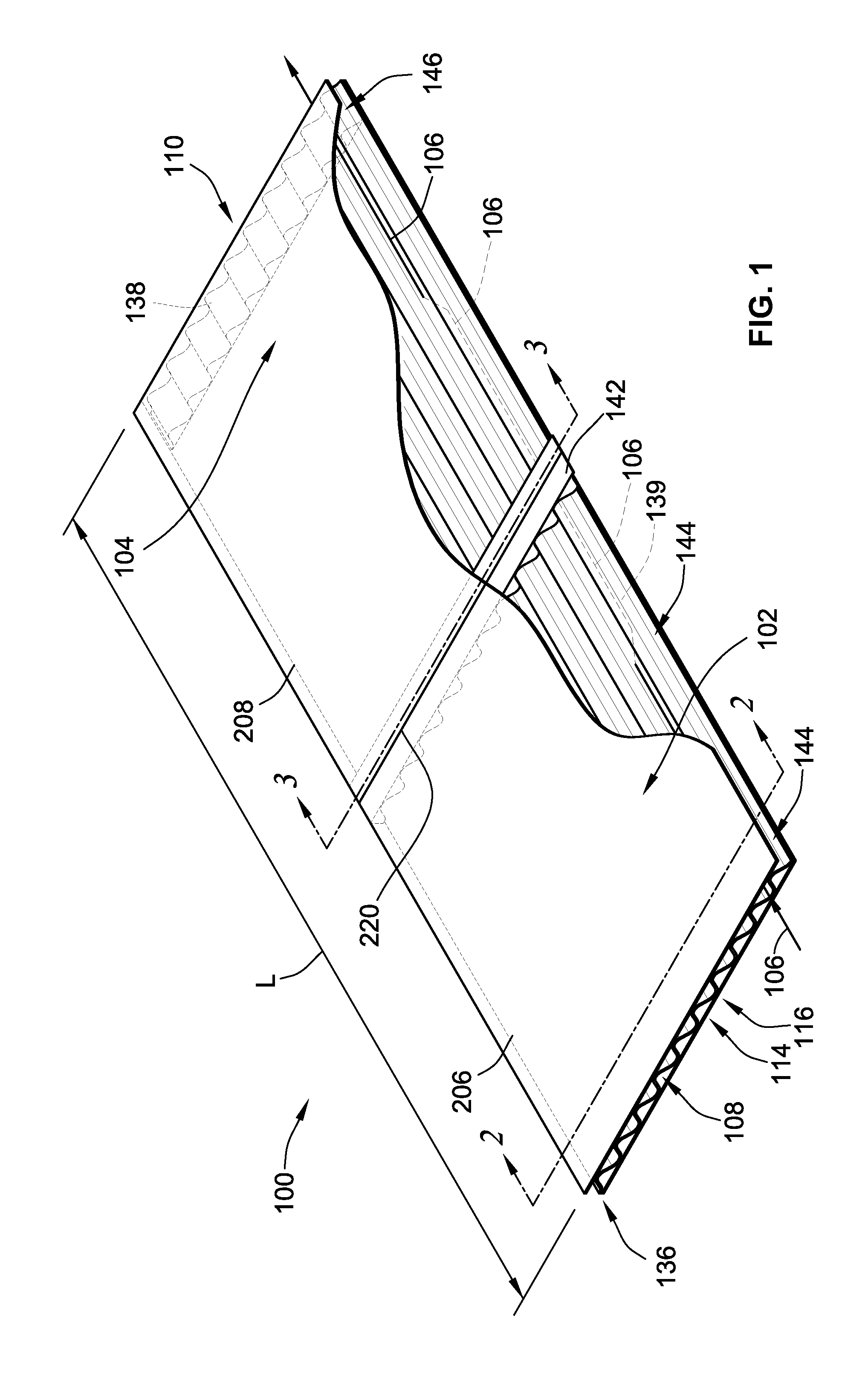

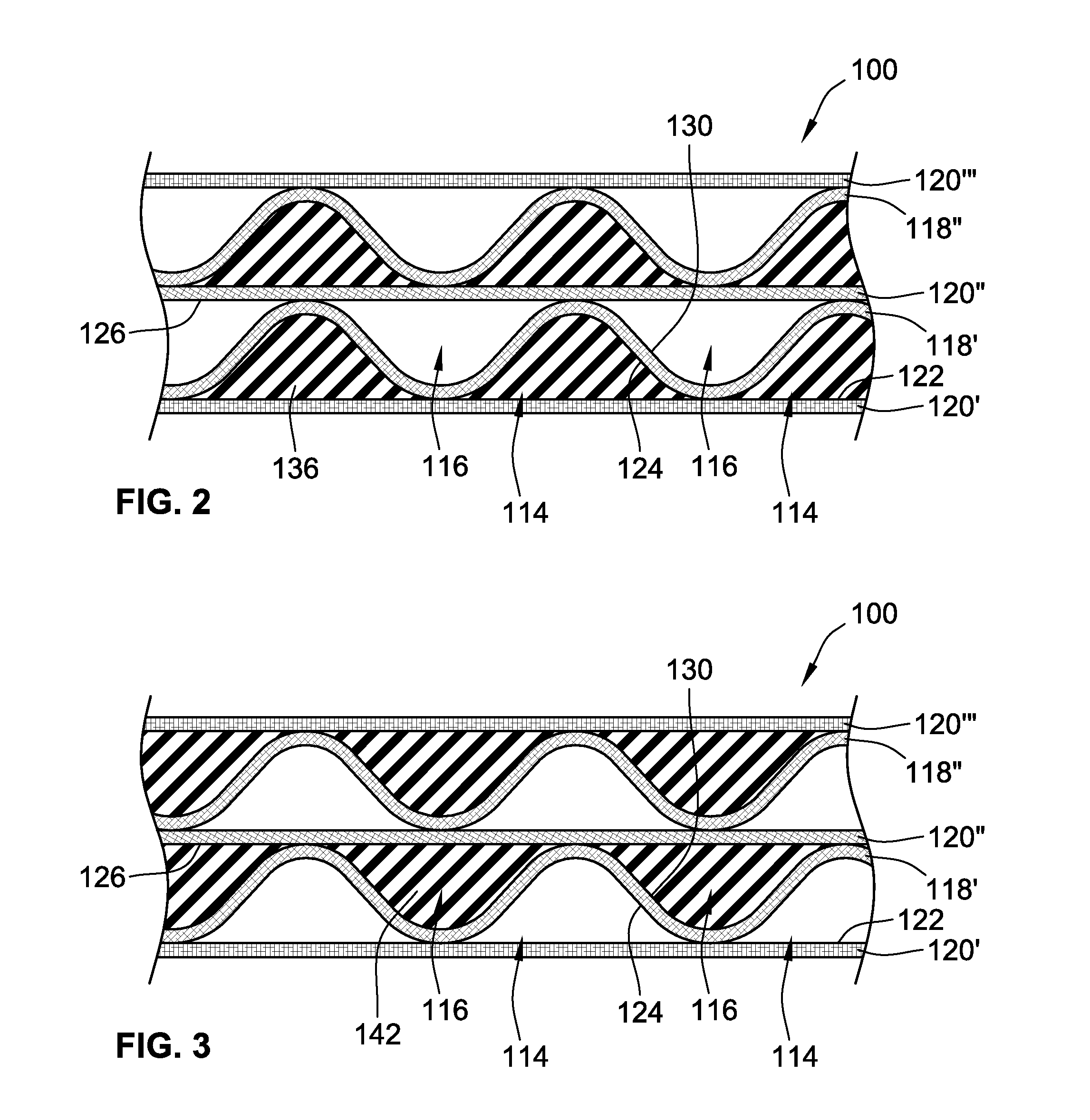

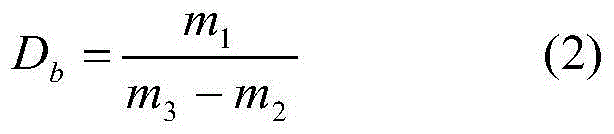

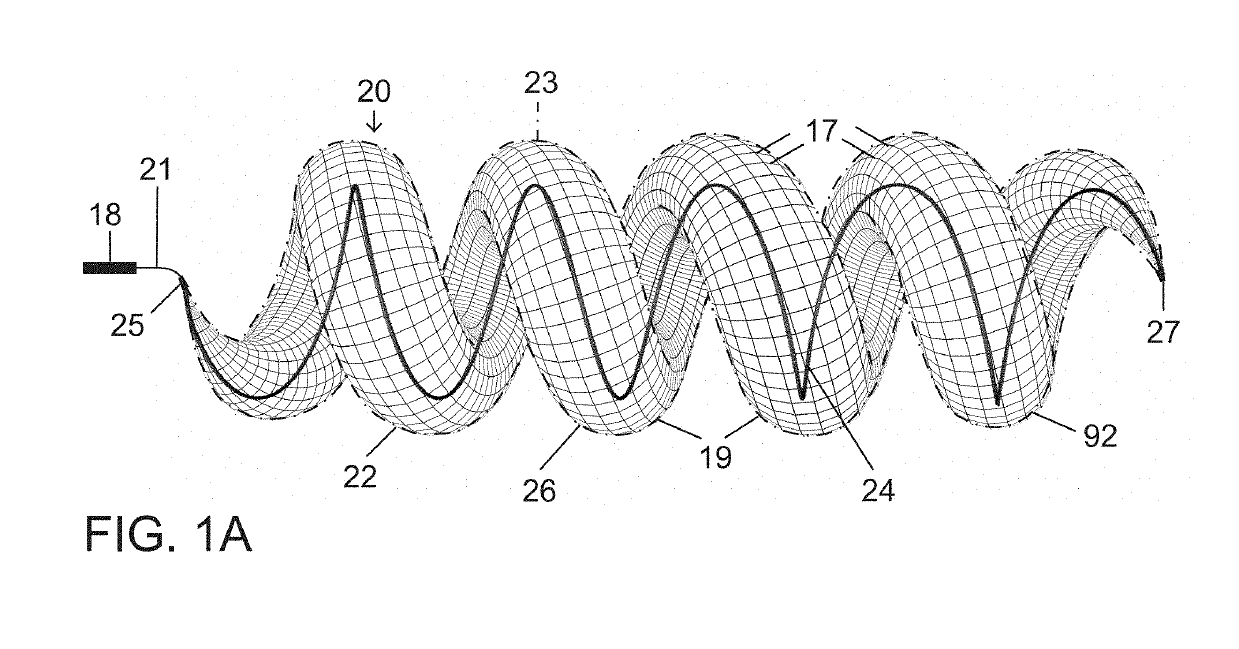

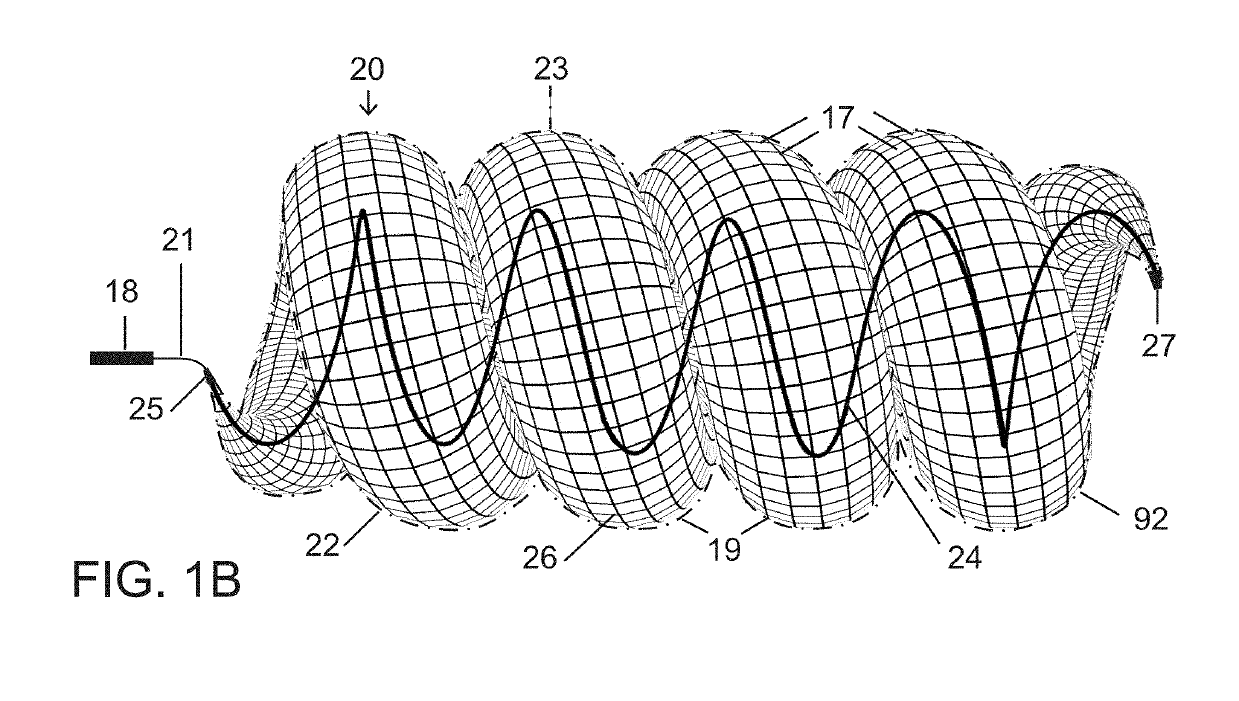

Mutli-Pass Fluted Filter

InactiveUS20140208705A1Low porosityHigh efficiencyCombination devicesDispersed particle filtrationFluteFilter element

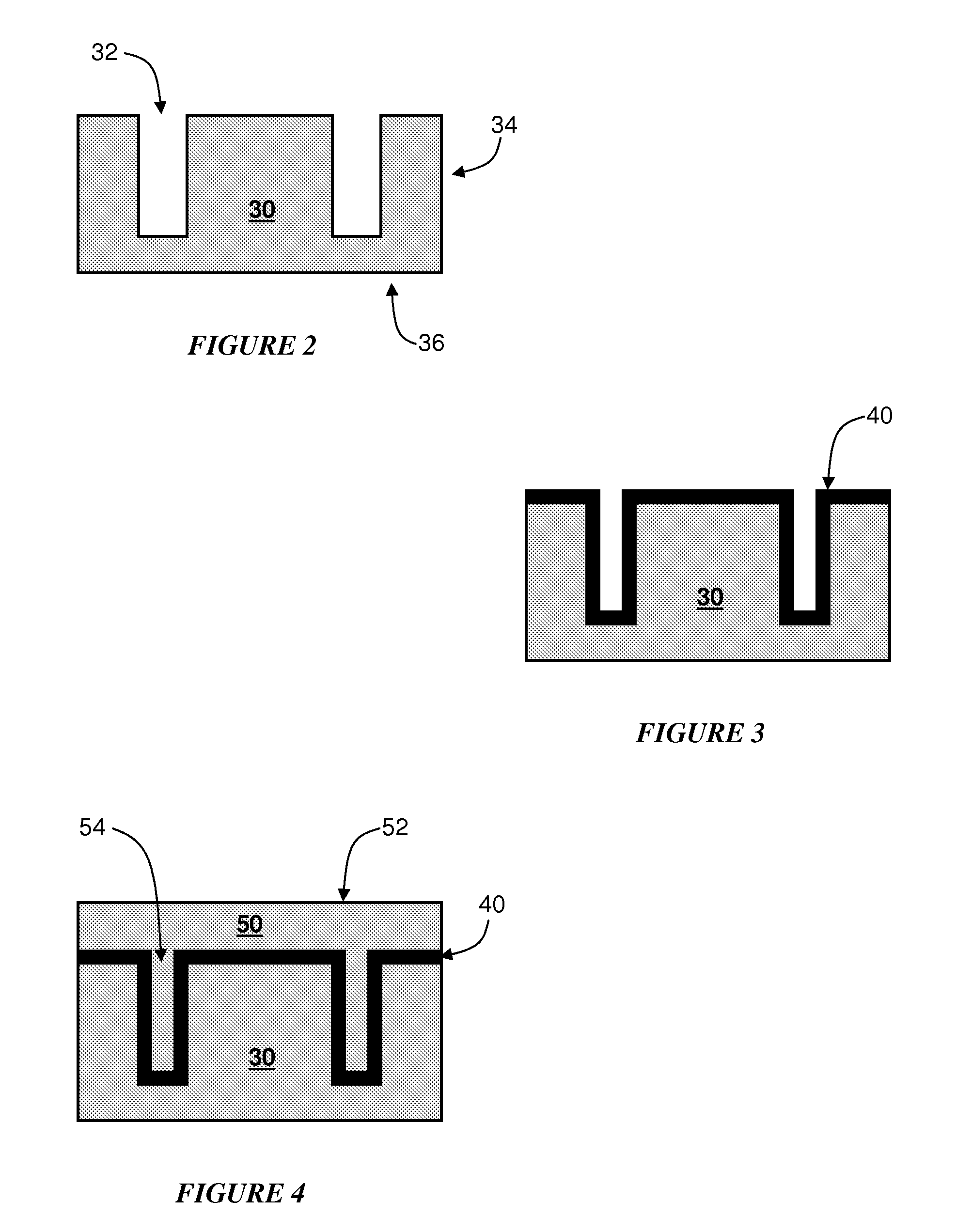

Filter media, filter elements, and method of forming filter media and filter elements are provided. The filter media and filter elements require filtered fluid to pass through filter media twice. The filter media and filter elements generally relate to fluted or similar style filter media. The filter media is formed from convoluted sheets coupled to face sheets to form first and second sets of flutes. At least one of the flute sets includes inlet and outlet seals and the other one of the flutes includes an intermediate seal interposed between the inlet and outlet seals of the other flute set. This forces the fluid to pass through the filter media at least twice.

Owner:BALDWIN FILTERS

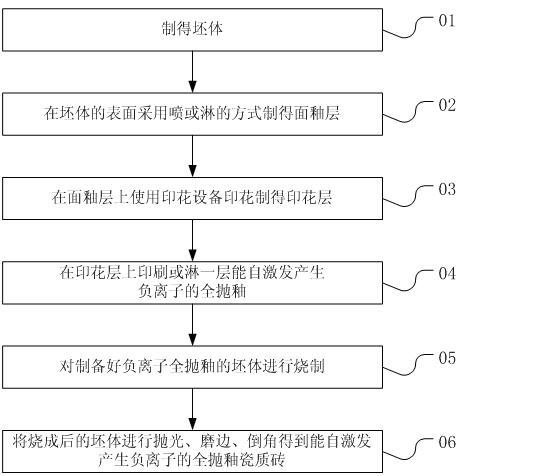

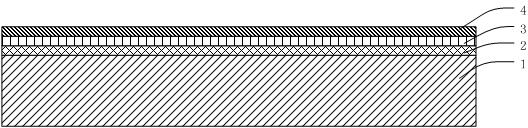

Full polished glaze porcelain tile capable of self-exciting to produce negative ions, and preparation method for full polished glaze porcelain tile

The invention discloses a full polished glaze porcelain tile capable of self-exciting to produce negative ions, and a preparation method for the full polished glaze porcelain tile. A negative ion material is added into the full polished glaze of the conventional full polished glaze porcelain tile, and the full polished glaze which is sintered at high temperature has the characteristics of high transparency, high gloss, high wear resistance, low porosity and good antifouling property, and has the function of exciting steam in air to produce negative oxygen ions. The full polished glaze porcelain tile can be widely applied to household and various engineering decoration, and has an obvious effect when used in a bathroom. In the environment of high air humidity, the negative ion full polished glaze can effectively excite the steam to form the negative ions which are beneficial to the health of a human body.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

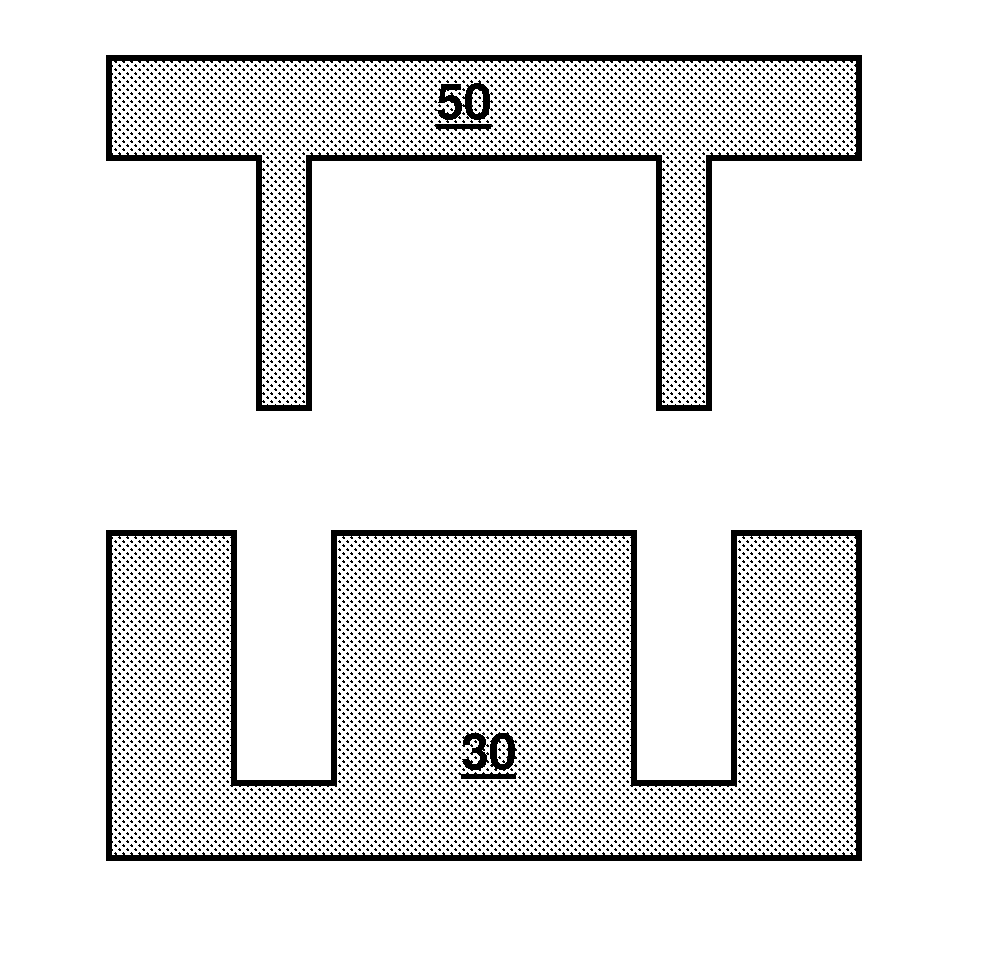

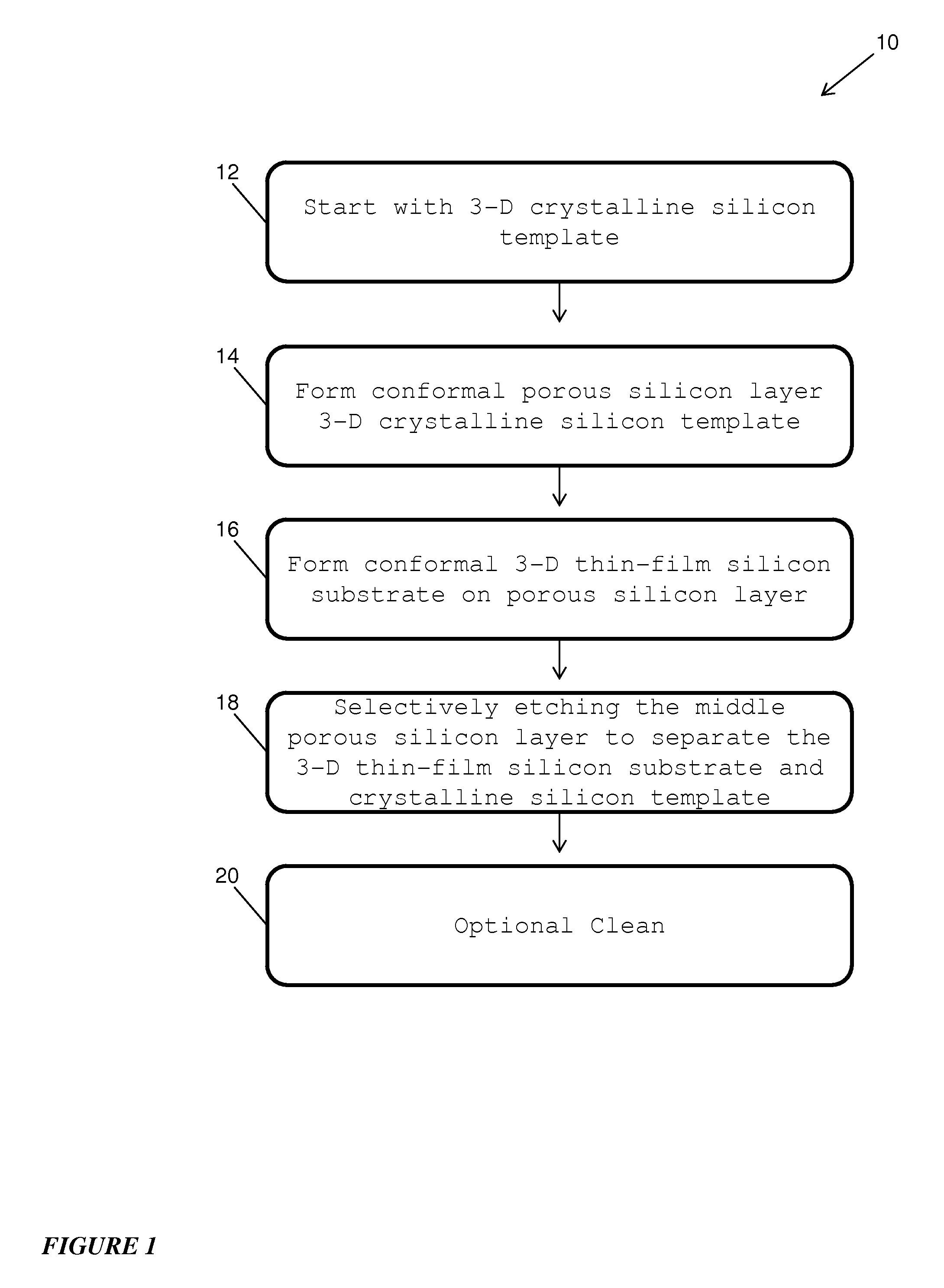

Method For Releasing a Thin-Film Substrate

ActiveUS20100279494A1Easily releaseLow porositySemiconductor/solid-state device manufacturingSemiconductor devicesPorous semiconductorsThin film semiconductors

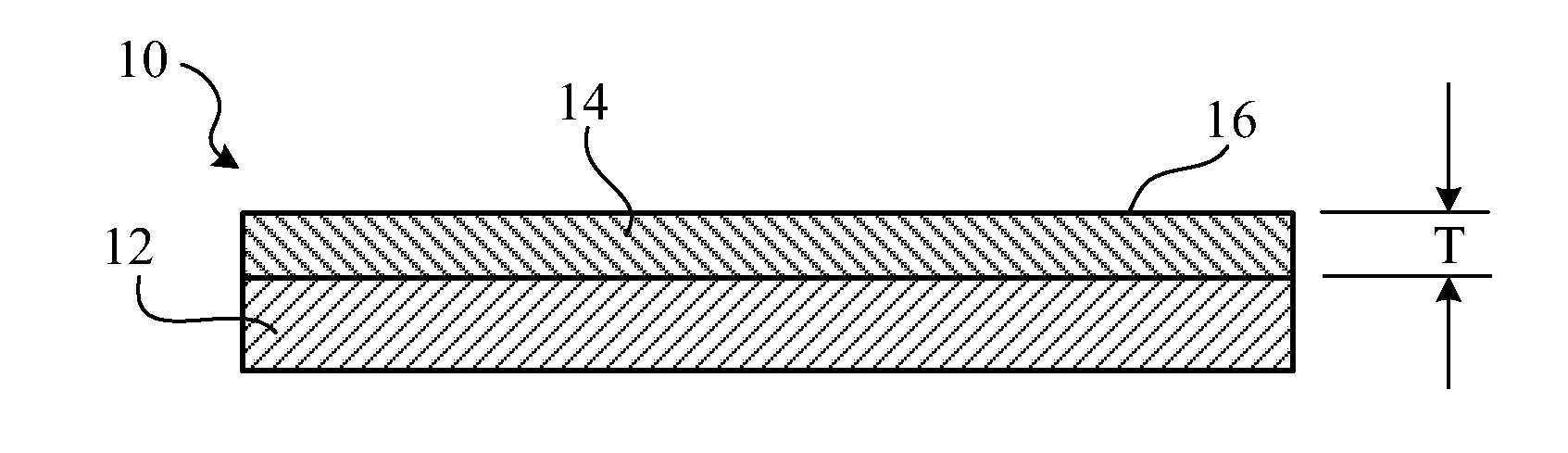

The present disclosure relates to methods for selectively etching a porous semiconductor layer to separate a thin-film semiconductor substrate (TFSS) having planar or three-dimensional features from a corresponding semiconductor template. The method involves forming a conformal sacrificial porous semiconductor layer on a template. Next, a conformal thin film silicon substrate is formed on top of the porous silicon layer. The middle porous silicon layer is then selectively etched to separate the TFSS and semiconductor template. The disclosed advanced etching chemistries and etching methods achieve selective etching with minimal damage to the TFSS and template.

Owner:BEAMREACH SOLAR INC

Small dense microporous solid support materials, their preparation, and use for purification for large macromolecules and bioparticles

InactiveUS20050269257A1High densityLow porosityBioreactor/fermenter combinationsBiological substance pretreatmentsMaceralOxide matrix

The present invention provides small, dense mineral oxide solid supports or microbeads, comprising dense microporous mineral oxides matrices in which a skin of polymers is rooted, and their use in downstream processing, especially for fluidized bed purification of bioparticles or high molecular weight macromolecules.

Owner:PALL CORP

Writable-erasable surfaces

InactiveUS20110300294A1Low porosityLow surface roughnessWriting boardsPretreated surfacesRadiationMetallurgy

Writable-erasable surfaces prepared by a powder coating process are provided. The coatings have many desirable attributes. For example, the coatings (e.g., powder compositions) cure rapidly at elevated temperatures or under radiation, have low VOC emissions, and have reduced tendency to form ghost images, even after prolonged and repeated normal use.

Owner:ICP CONSTR INC

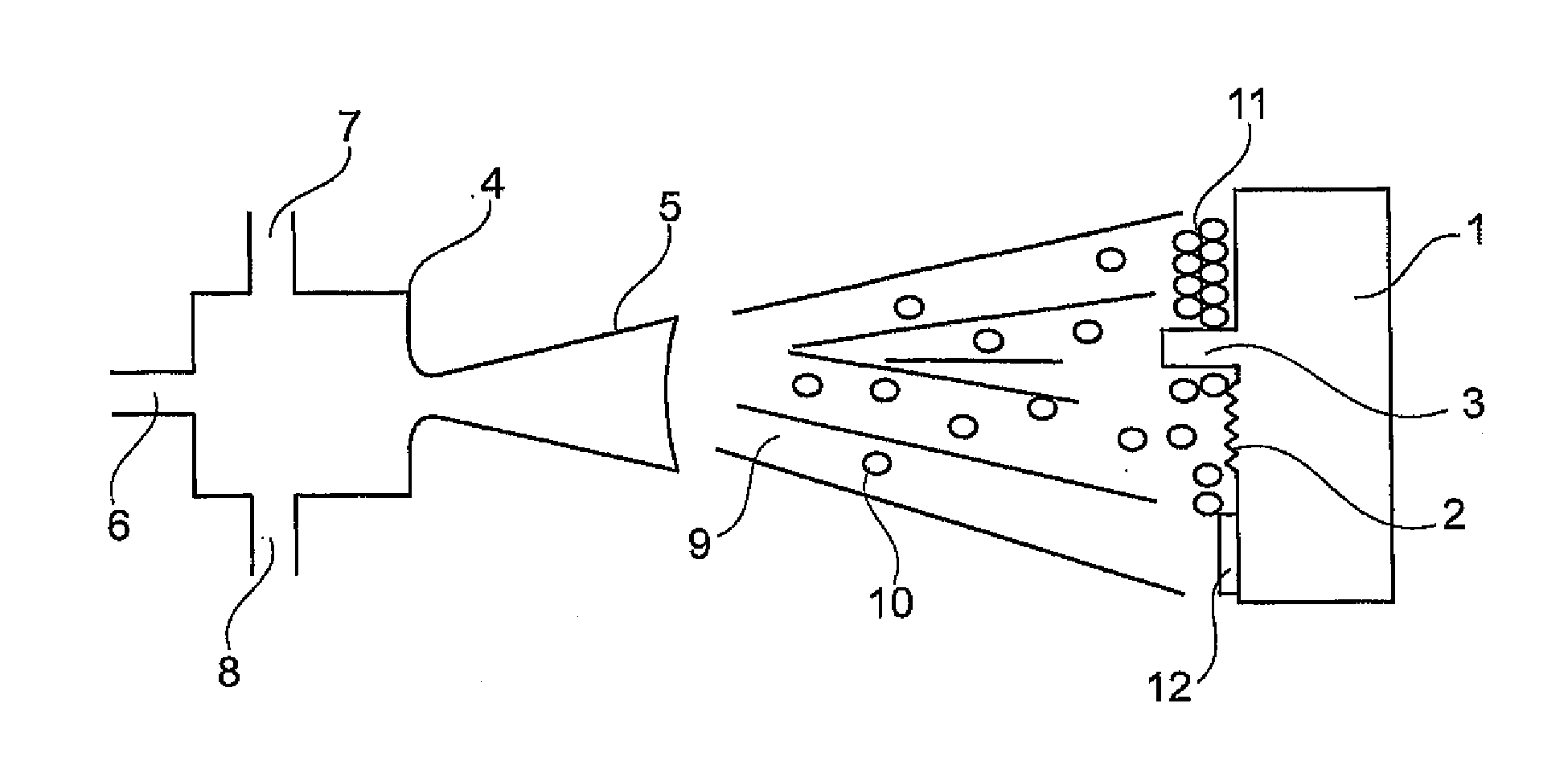

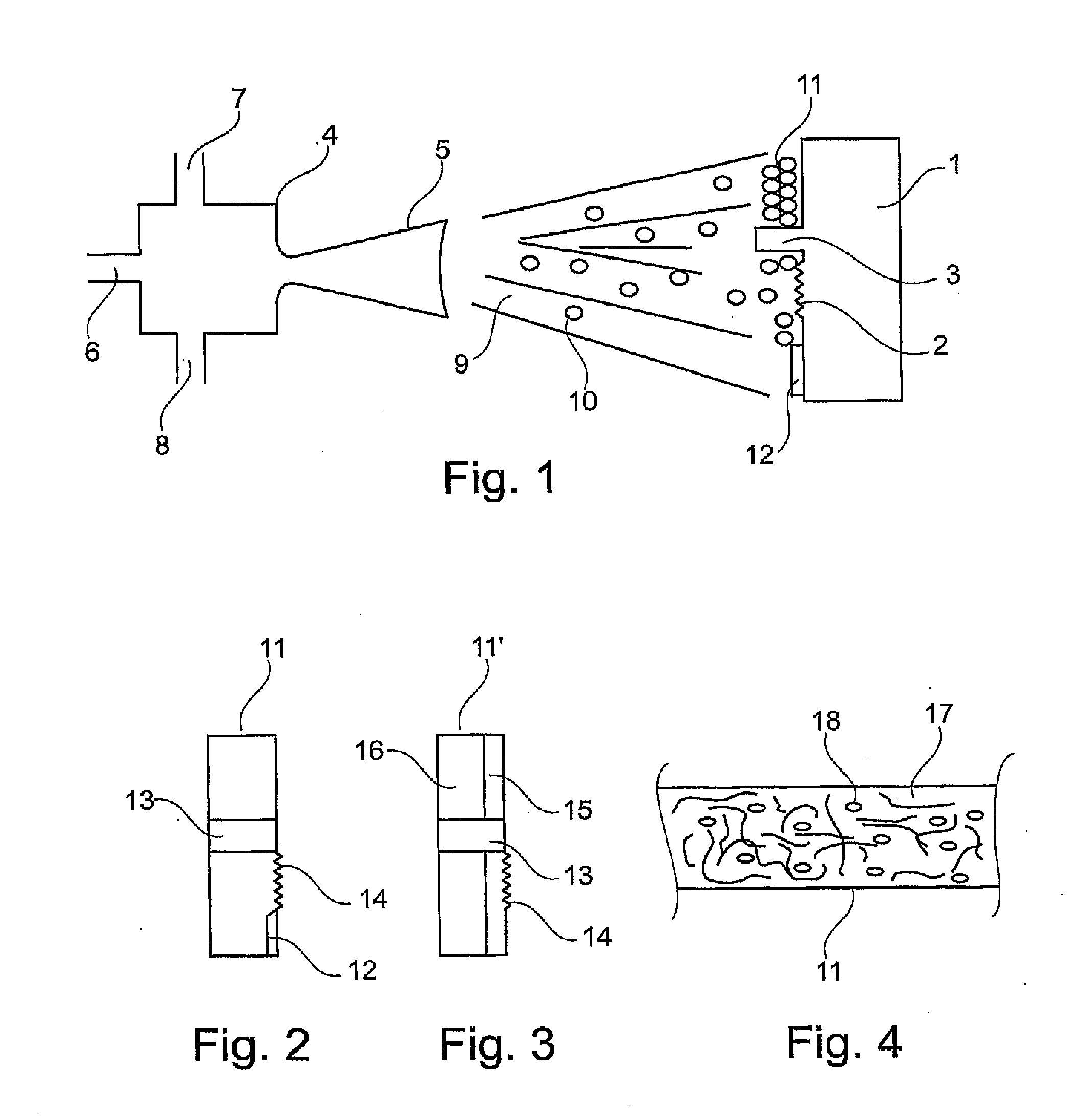

Thin-walled structural component, and method for the production thereof

InactiveUS20120171041A1High densityLow porosityBlade accessoriesPretreated surfacesThin walledStructural component

A method for producing a thin-walled structural component from a casting material. The casting material is supplied as a powder, and the powder is deposited on a support (1) by a kinetic cold gas spraying process so as to form the structural component (11, 11′). A structural component which is made of a casting material and in which the structure is formed from a plurality of particles (17) that are interlinked and deformed using a cold gas spraying process.

Owner:MTU AERO ENGINES GMBH

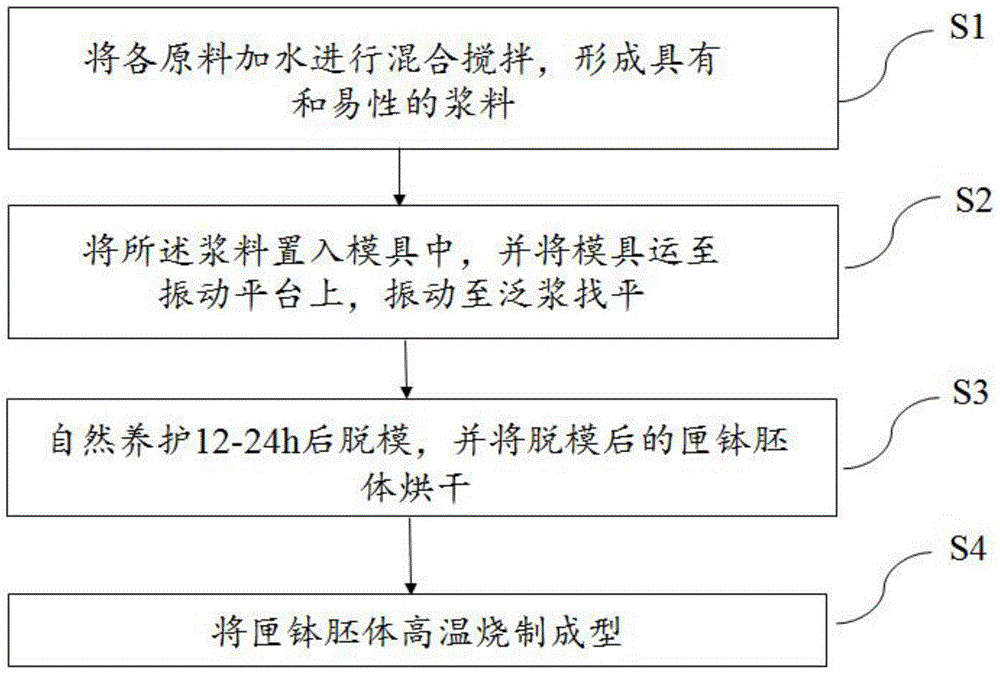

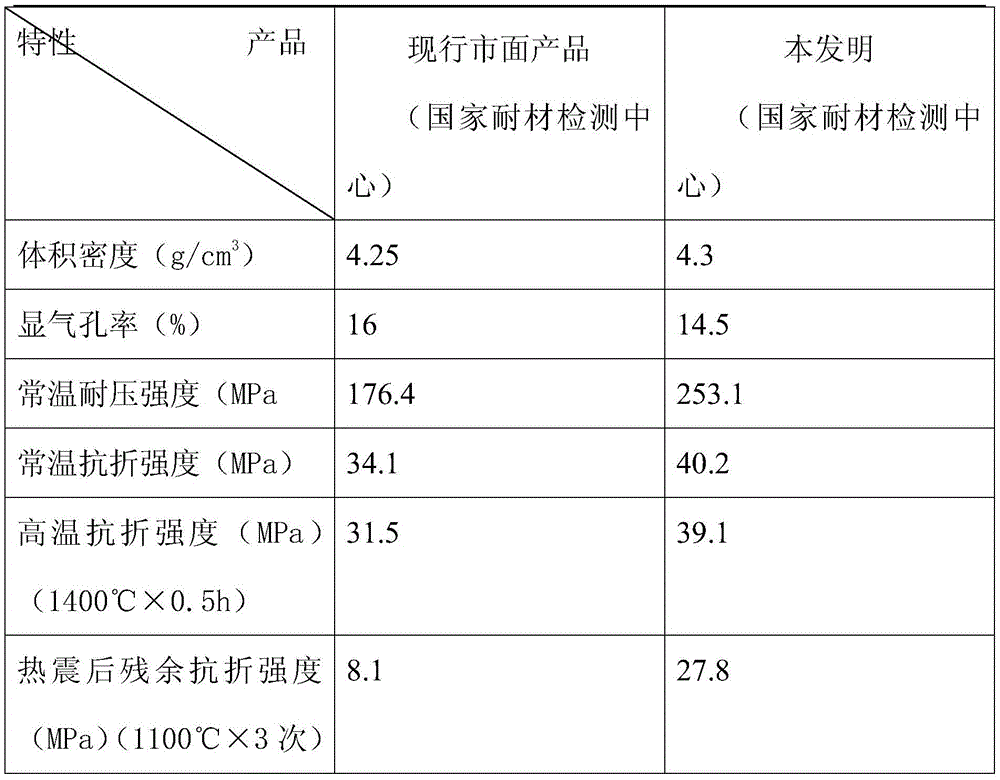

Sagger for lithium battery cathode material and preparation method thereof

The invention discloses a sagger for a lithium battery cathode material. The sagger is prepared from, by weight, tabular corundum 20-55%, cordierite 18-45%, aluminum titanate 6-30%, pure calcium aluminate cement 5-20% and alpha alumina micro-powder 6-8%. The invention further discloses a preparation method of the sagger for the lithium battery cathode material. The sagger preparation method adopts a casting molding process, and the defects of poor corrosion resistance, short service life, easy pollution of battery raw materials and the like existing in a traditional mechanical pressing molding process are overcome. Compared with the sagger prepared by adopting the existing mechanical pressing molding process, the sagger has higher bulk density and lower porosity by utilizing the self bonding and good liquidity of the micro-powder, the corrosion channels of the lithium battery cathode material to the fire-resistant sagger at high temperature are decreased, and the corrosion resistance of the sagger is improved.

Owner:苏州博立恒新能源科技有限公司

YAG lasing systems and methods

ActiveUS20050281302A1Low porosityMaterial nanotechnologyCeramic shaping apparatusYttriumYttrium aluminium garnet

Lasing systems utilizing YAG and methods for producing a YAG suitable for lasing are provided. The lasing system comprises a laser activator and a laser host material is provided. The laser host material comprises a transparent polycrystalline yttrium aluminum garnet material defined by a low porosity of less than about 3 ppm.

Owner:RAO UES

Micro-Macro Endovascular Occlusion Device and Methodology

ActiveUS20190142435A1Low porosityIncrease it throbogenicityOcculdersThree dimensional shapeVascular plug

A vascular plug comprises a superstructure expandable from a collapsed percutaneous insertion configuration to an expanded deployment or use configuration. The superstructure is comprised of both primary and secondary three-dimensional shapes allowing for the occlusion of a wide range of vessel sizes from small to large through a disproportionately small delivery catheter. The plug includes a shape memory element for the generation of radial force and the creation of the larger secondary three-dimensional twisting or helical superstructure as is needed for target vessel occlusion.

Owner:DEMERITT JOHN S

Durable silicon steel furnace bottom roller sleeve and preparation method thereof

The invention relates to a silicon steel furnace bottom roller sleeve and a preparation method thereof. The technical scheme of the invention is as follows: 2-10wt% of dense carbon material large particles, 2-10wt% of dense carbon material small particles, 80-95wt% of dense carbon material fine powder and 0.3-2.0wt% of Si micro powder are mixed together and are then ground for 20 to 30 minutes with the addition of 8-20wt% of bonding agent of the above materials; a silicon steel furnace bottom roller sleeve blank is manufactured after the mixed grinding and is baked for 4 to 8 hours after heat preservation under the temperature of 1,400 to 1,450 DEG C; then the silicon steel furnace bottom roller sleeve blank is placed in a pressure vessel and is maintained for 15 to 30 minutes under the pressure of 10,000 to 20,000Pa, tar is filled until the sleeve blank is completely soaked, and then the sleeve blank is pumped to the vacuum degree of 10,000 to 20,000Pa and is maintained for 15 to 30 minutes; finally, the sleeve blank is heat-preserved for 8 to 12 hours under the high temperature of 1,950 to 2,150 DEG C and is processed by machinery until the surface roughness is smaller than or equal to 12.5. The durable silicon steel furnace bottom roller sleeve has the characteristics of long service life, good oxidation resisting performance, high strength, good wear-resisting property, low porosity, no accretion and high quality of silicon steel plates.

Owner:WUHAN UNIV OF SCI & TECH

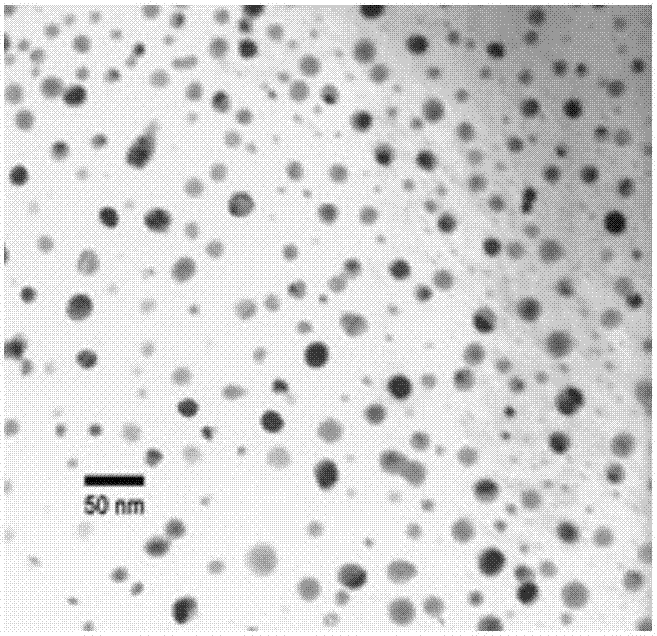

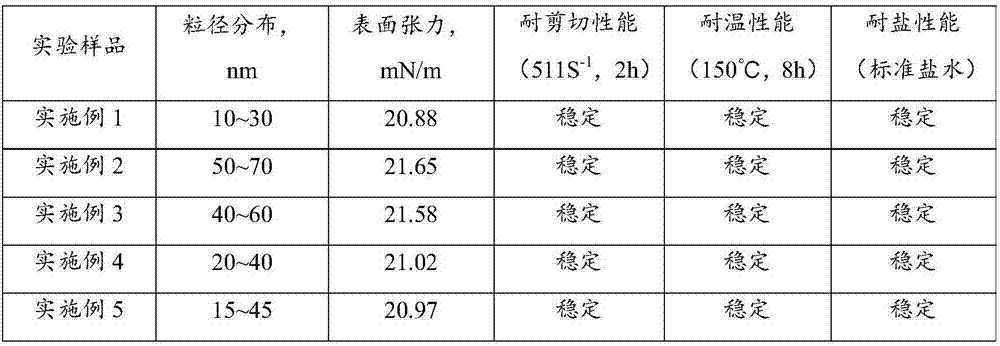

Nano-emulsion for fracturing water control and preparation method of nano-emulsion

The invention provides nano-emulsion for fracturing water control and a preparation method of the nano-emulsion. In a fracturing process of a tight gas well, the nano-emulsion for fracturing water control is injected into a tight gas reservoir along with fracturing fluid; the nano-emulsion for fracturing water control has hydrophobicity and stable adsorbability, after entering a stratum, the nano-emulsion for fracturing water control is adsorbed to surfaces of rock pores, and can resist water washing, water phase permeability can be reduced greatly, and the reduction amplitude reaches 70% or above; influence to gas phase permeability is quite low, the nano-emulsion has the characteristic of changing phase permeability selectively, and a water control effect is obvious; viscosity is low, surface tension is also low, the nano-emulsion is injected easily, and thus, the nano-emulsion is particularly suitable for the tight gas reservoir; and furthermore, the nano-emulsion is compatible to reservoir fluid well, and is good in shear stability, thermal stability and salt stability. Under the condition that influence to the gas phase permeability is quite low, the purpose of controlling water is achieved.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

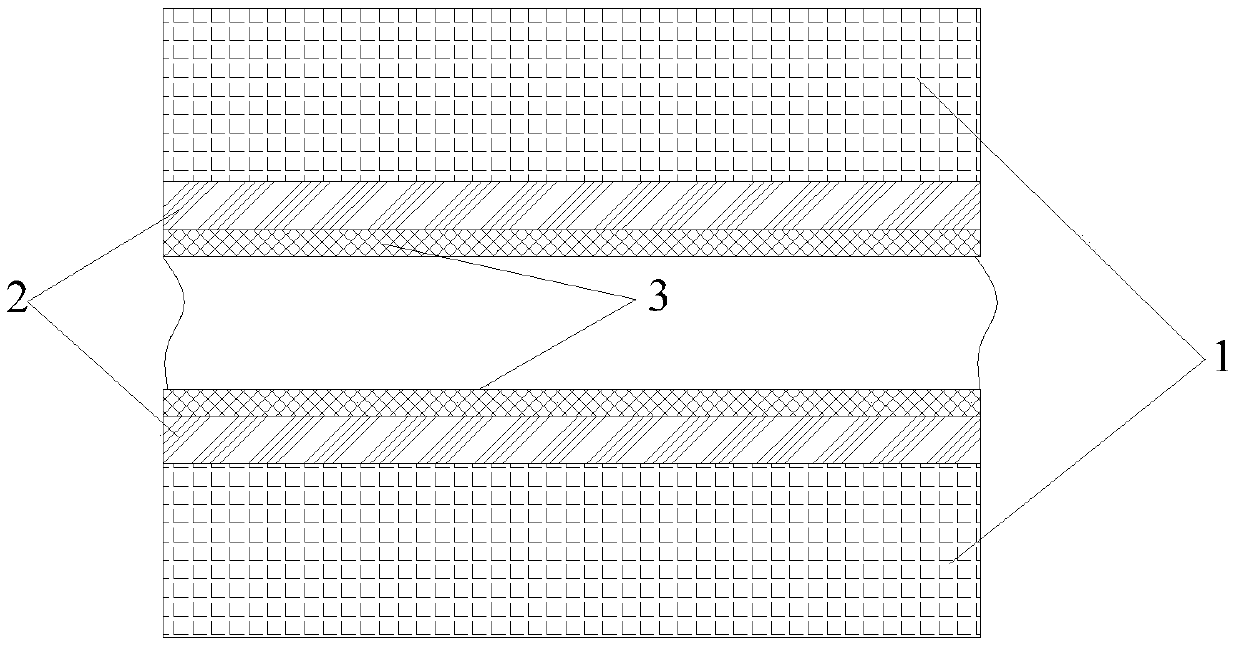

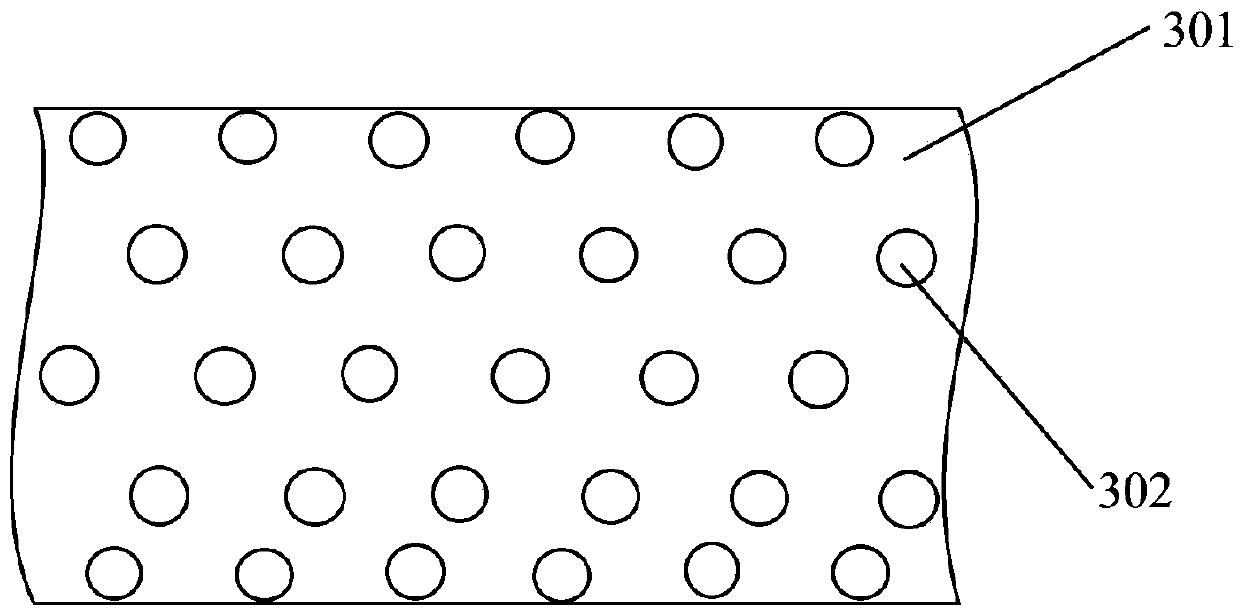

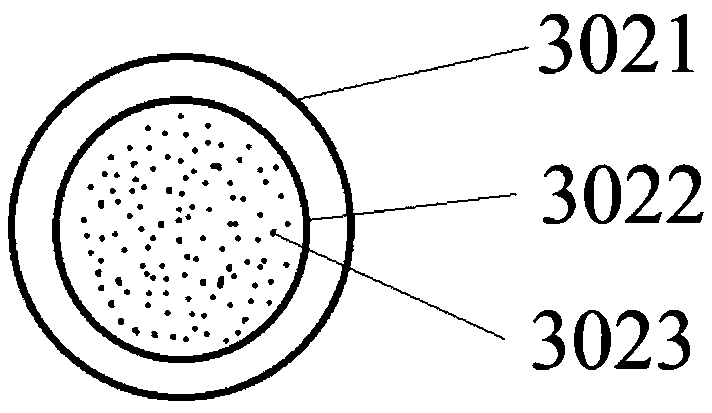

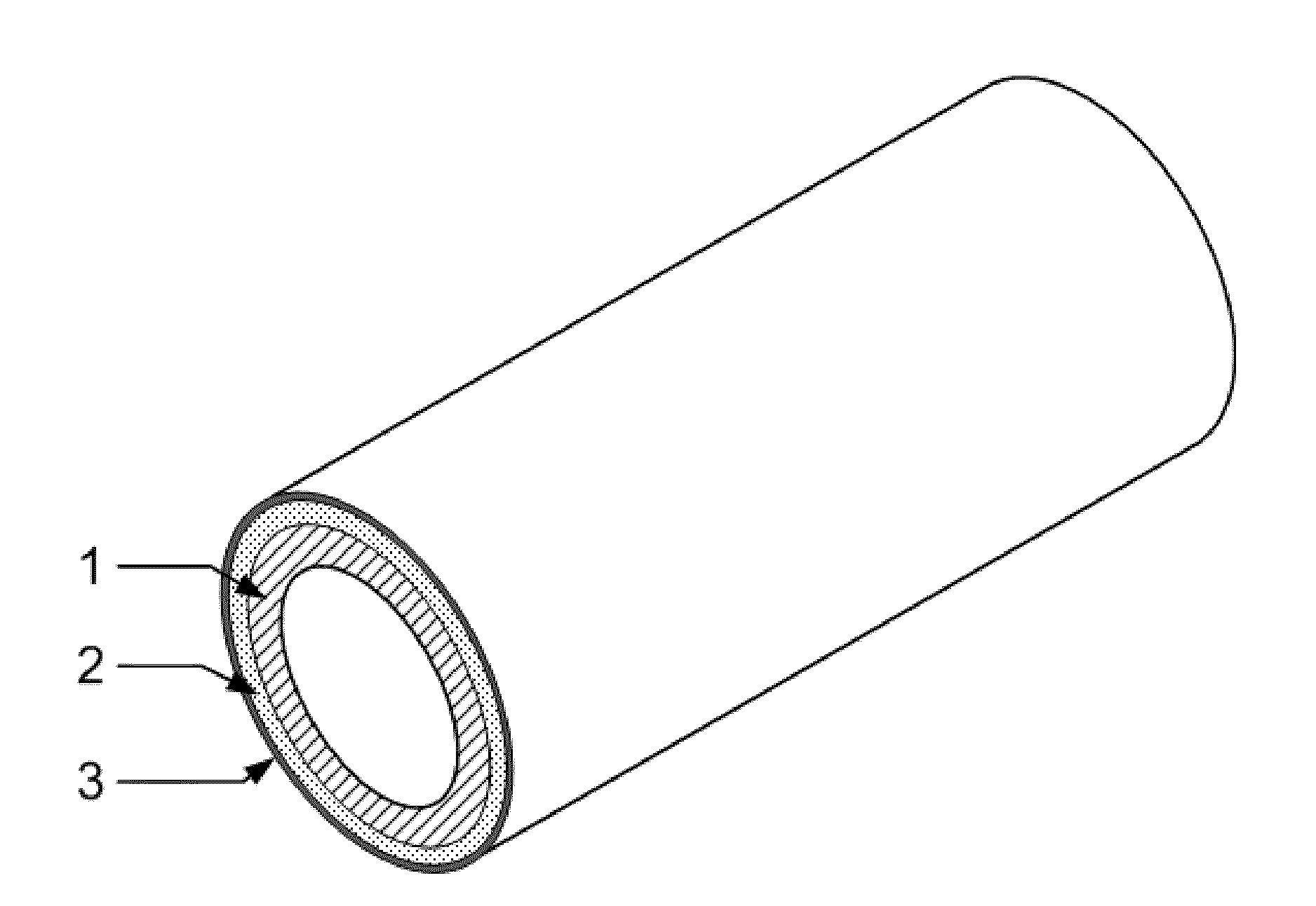

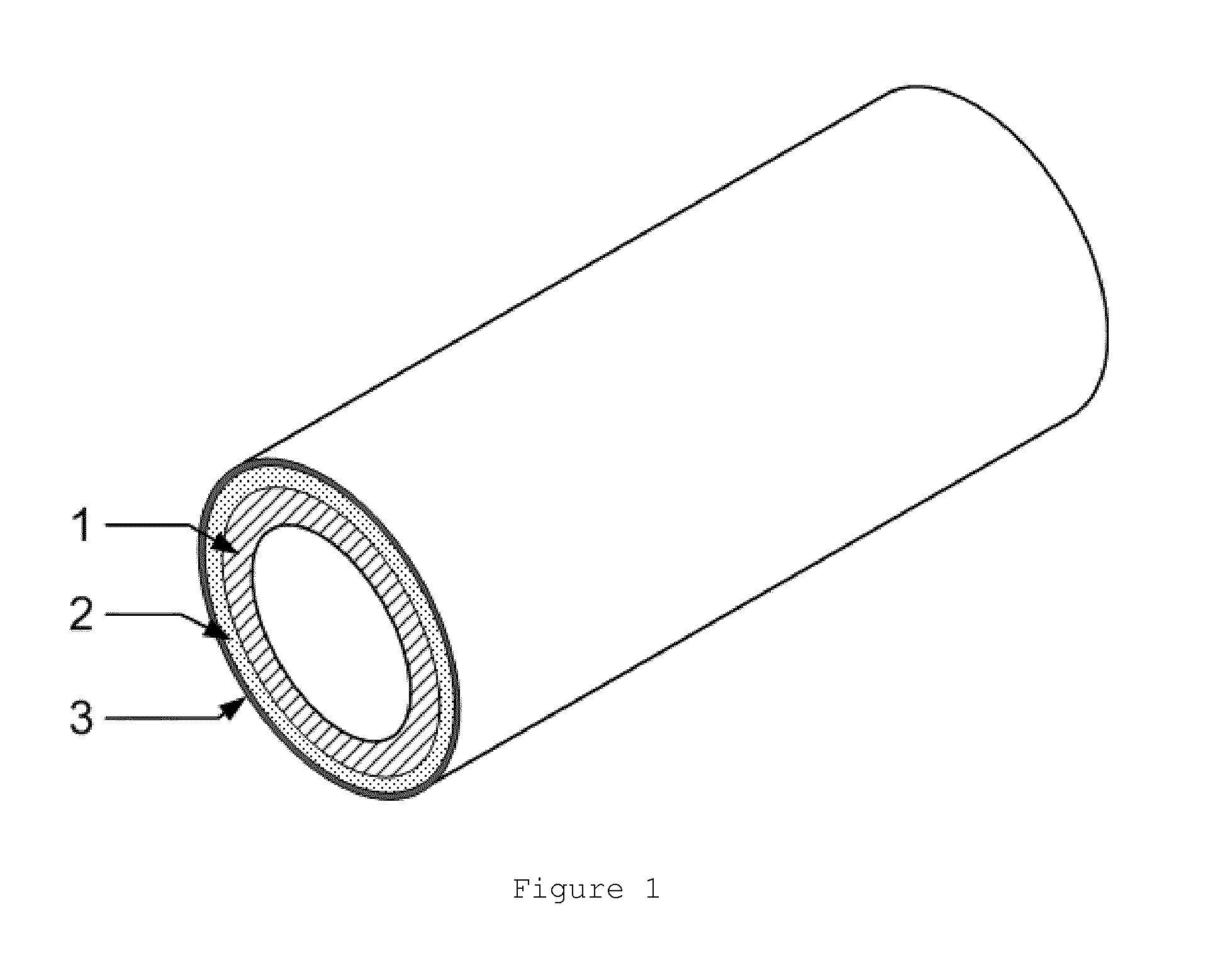

Antibacterial paint, anticorrosive paint, antibacterial and anticorrosive coating and oil transportation pipeline

InactiveCN105505112ASolve the problem of longevitySolve corrosionAntifouling/underwater paintsPaints with biocidesMicrometerOil transportation

The invention provides antibacterial paint, anticorrosive paint, an antibacterial and anticorrosive coating and an oil transportation pipeline. The antibacterial and anticorrosive coating comprises a slow-release antibacterial layer and a heavy anticorrosive layer, wherein the thickness of the heavy anticorrosive layer is 50-200 micrometers, and the thickness of the slow-release antibacterial layer is 20-80 micrometers. The inner wall of the oil transportation pipeline is coated with the heavy anticorrosive layer, and the surface of the heavy anticorrosive layer is coated with the slow-release antibacterial layer. Compared with the prior art, the slow-release antibacterial and anticorrosive oil transportation pipeline has the advantages that the defects that an oil transportation pipeline on the market is poor in antibacterial effect and high in cost, and an existing oil transportation pipeline with the antibacterial effect is short in antibacterial life and poor in anticorrosive property are overcome.

Owner:SHANGHAI WEIKAI CHEM +1

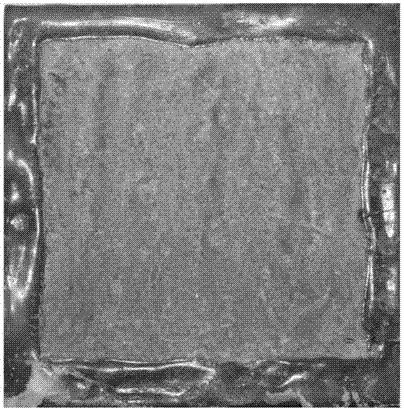

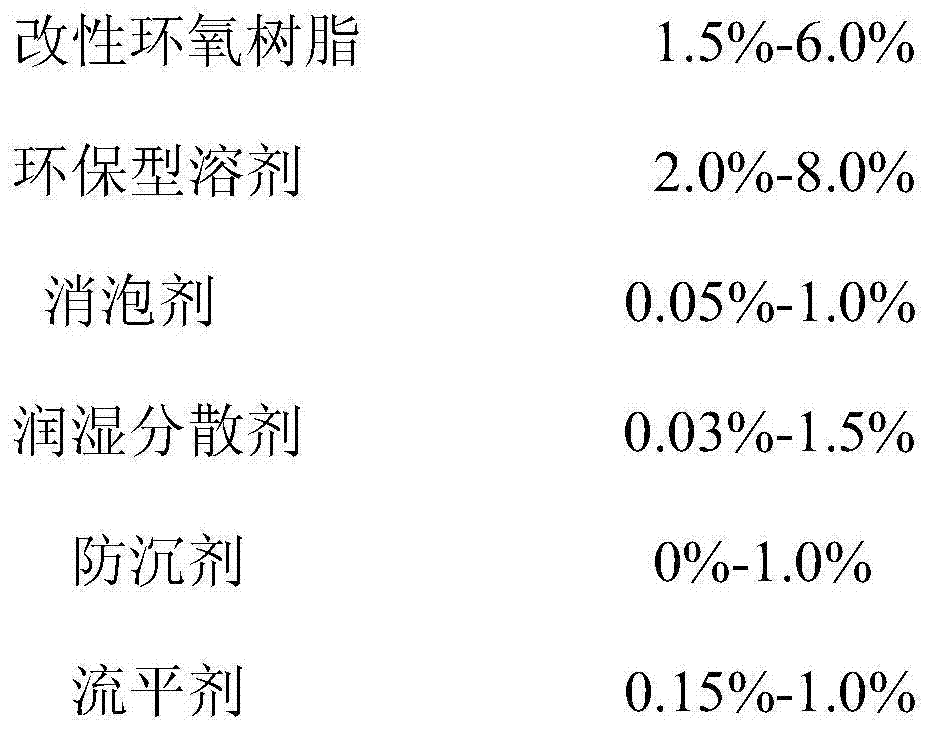

Cold galvanizing coating and preparation method thereof

InactiveCN104710850ALow porosityImprove shielding performanceAnti-corrosive paintsSolventDefoaming Agents

The invention provides a cold galvanizing coating and a preparation method thereof. The cold galvanizing coating is prepared by the following steps: adding an environment-friendly solvent and modified epoxy resin EPOKEY-868 into a paint mixing tank with a cooling device, and stirring for 5-15 minutes; continuing to add a wetting dispersant, a defoaming agent and an anti-setting agent, and stirring for 20-40 minutes; then adding zinc powder and a surface modifier, increasing the revolving speed and stirring for 30-50 minutes, and in the stirring process, adopting circulating water to keep the paint mixing tank to be cooled; after stirring, adding a flatting agent, and continuing to stir, so as to obtain the product, wherein the zinc powder is formed by mixing granulated zinc powder and flake zinc powder according to the weight ratio of 1:(2-4), and the surface modifier comprises a titanate coupling agent KB-36S, a silane coupling agent KH-560, and sodium dodecyl benzene sulfonate. The galvanizing coating prepared by the preparation method disclosed by the invention is environment-friendly, healthy, high in anti-precipitation performance, good in coating performance, and capable of improving the durability of the paint film; the coating layer is good in electrochemical protection performance.

Owner:STATE GRID CORP OF CHINA +2

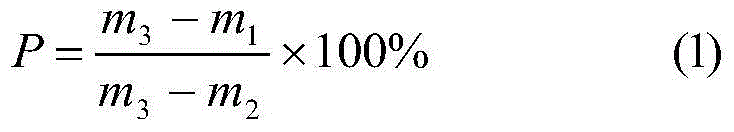

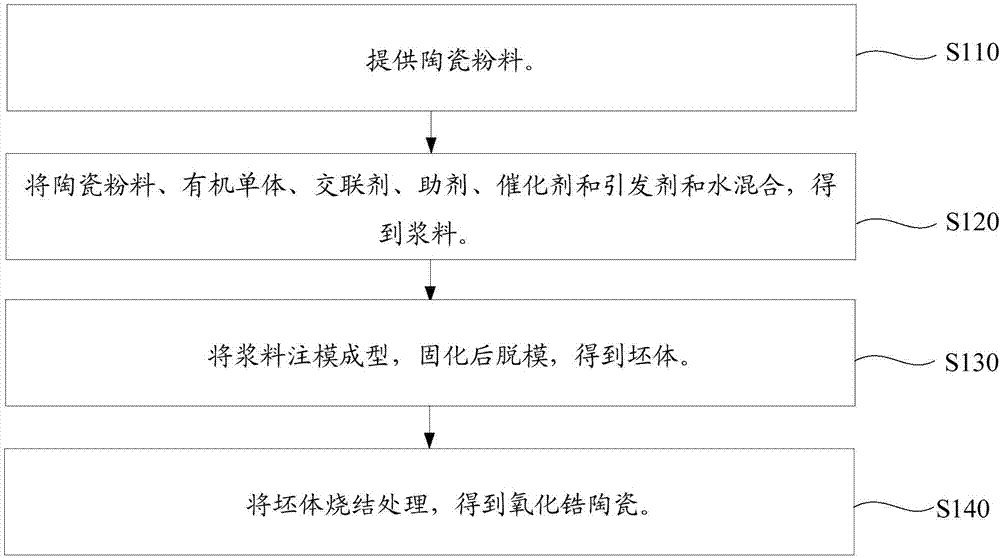

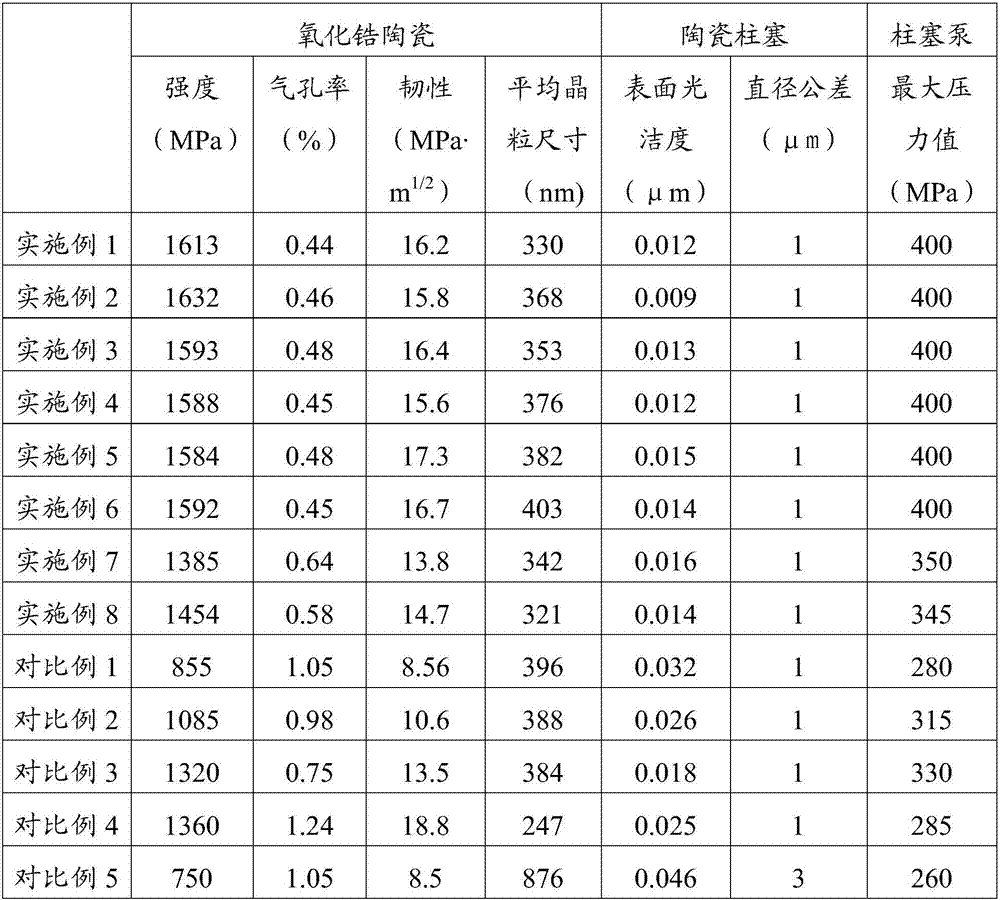

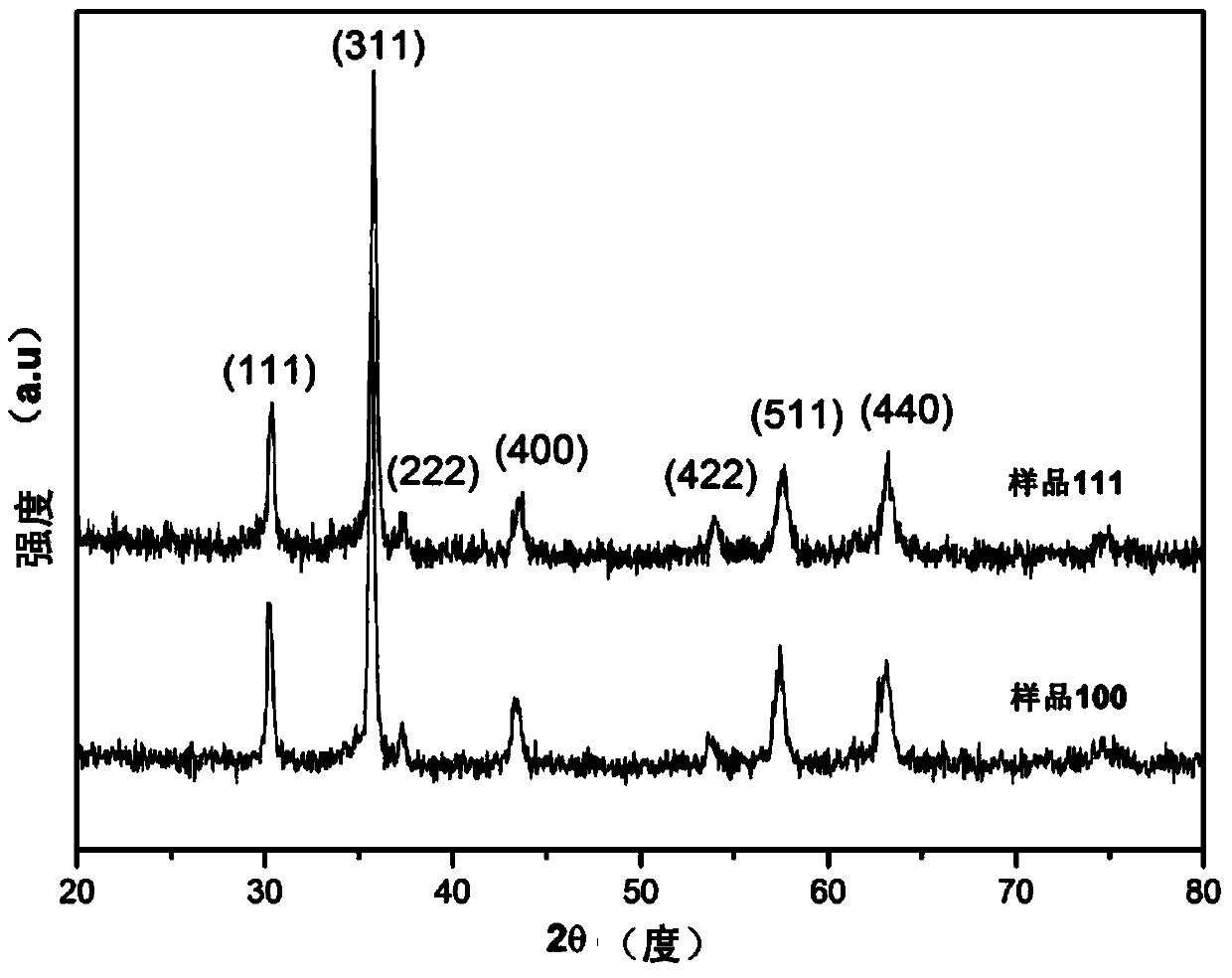

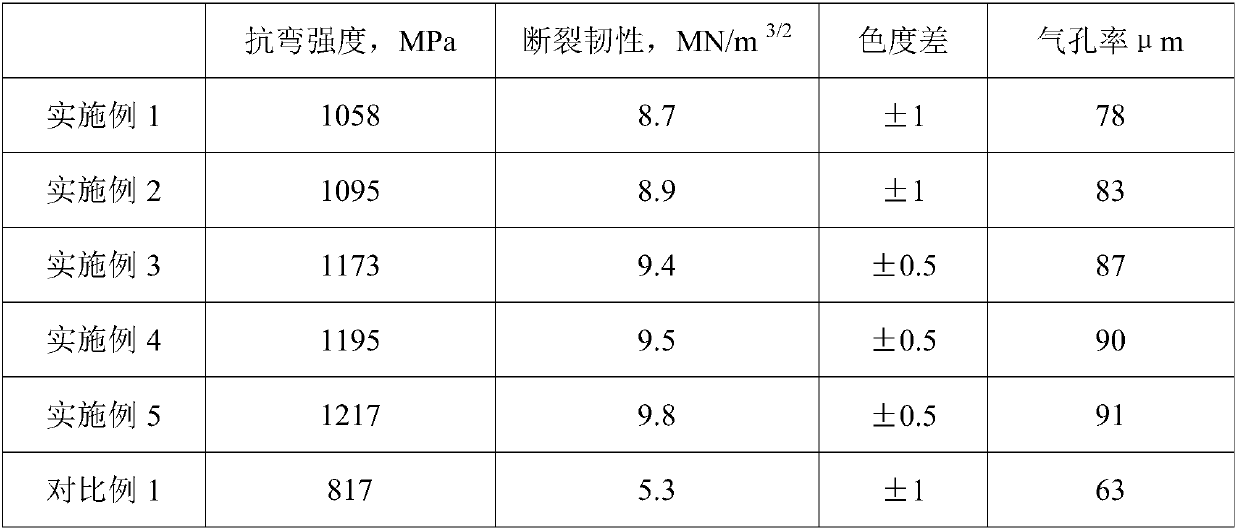

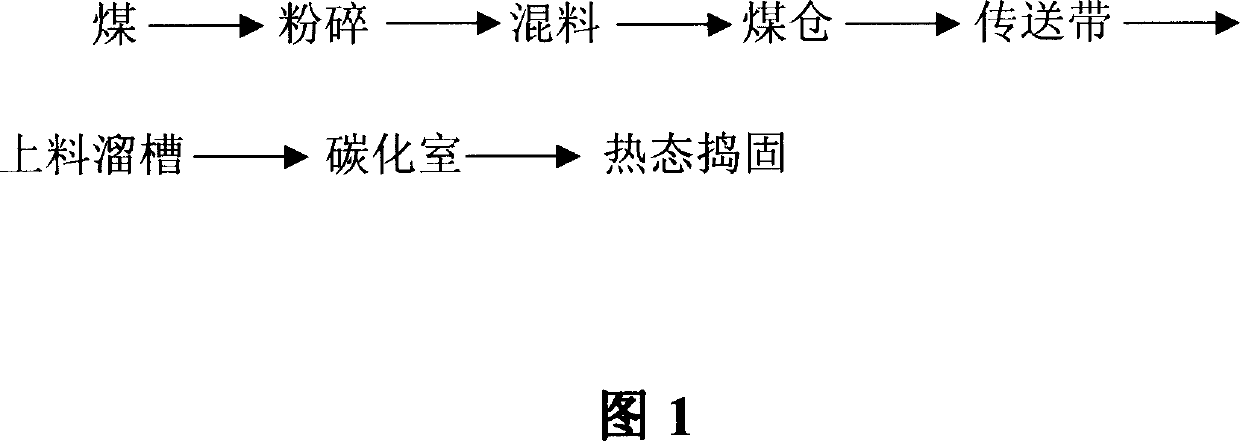

Zirconia ceramic, preparation method thereof, ceramic plunger and plunger pump

ActiveCN107445615AEasy to operateLow porosityPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpPorosity

The invention relates to zirconia ceramic, a preparation method thereof, a ceramic plunger and a plunger pump. The preparation method of the zirconia ceramic comprises the following steps: providing ceramic powder, wherein the ceramic powder contains the following components in percentage by weight: 94%-96% of zirconia, 3.5-5% of yttrium sesquioxide, 0.2%-1% of aluminum sesquioxide and 0.05%-0.2% of titanium dioxide, and the median particle diameter of zirconium dioxide is 0.1-0.5 micron; mixing the ceramic powder, an organic monomer, a cross-linking agent, and aid, a catalyst, an initiator and water, so as to obtain slurry; carrying out injection molding on the slurry, and carrying out curing demolding, so as to obtain a blank; and sintering the blank, so as to obtain the zirconia ceramic. The zirconia ceramic prepared by virtue of the preparation method is relatively high in strength, relatively low in porosity and relatively good in tenacity and has a relatively uniform internal structure; and after being polished, the zirconia ceramic has relatively high surface smoothness.

Owner:SHENZHEN SUNTECH ADVANCED CERAMICS

Method for preparing high-strength iron-making coke by using chemical waste

ActiveCN110699099ALow porosityReduce burning lossSpecial form destructive distillationCokeRoll bonding

The invention provides a method for preparing high-strength iron-making coke by using chemical waste. According to the method, pre-grinding, material mixing, pressure granulation, surface spray coating, rolling bonding, drying hardening and high-temperature coking manners are used to prepare the high-strength iron-making coke, especially the high-value reuse of the chemical waste including the coke powder is realized by using the cohesive effect of a liquid phase precipitated by a carbon-contained waste binder on the coke powder in the heating coking process and reduction of burning loss on the surface of a granulation material in the heating process by the coke powder adhered to the surface, the strength and quality of the coke are improved; and the crushing strength M40 of the coke obtained after coking in a high-temperature retorting device is >=91.2%, the abrasion resistance M10 is <=5.5%, and the coke post-reaction strength (CSR) is >=67%, all the above values reach a class I standard for coke for blast furnace ironmaking, and supply of ironmaking blast furnace raw materials is realized.

Owner:ANGANG STEEL CO LTD +1

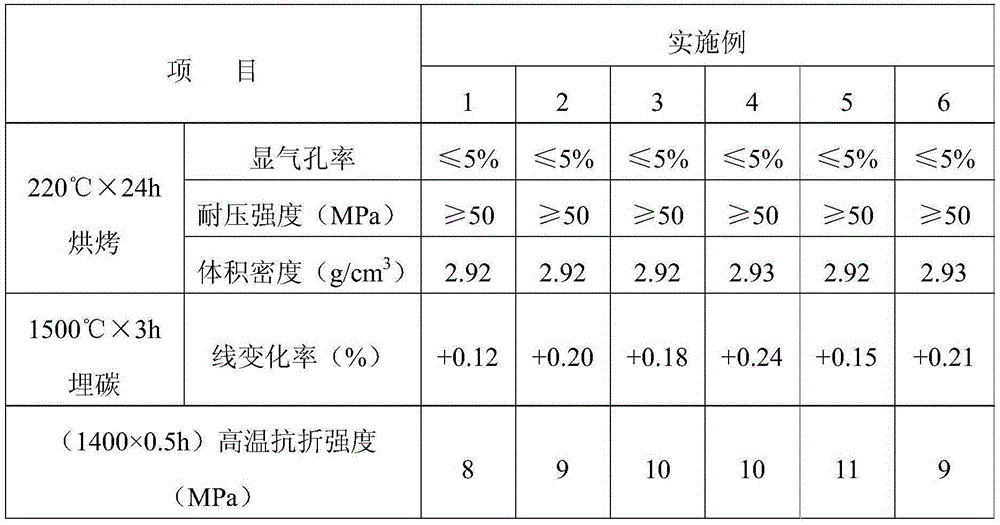

Chromium-alumina-carbon bricks and preparation method therefor

The invention discloses chromium-alumina-carbon bricks and a preparation method therefor and relates to the chromium-alumina-carbon bricks. The chromium-alumina-carbon bricks are prepared from the following ingredients in percentage by mass: 75-90% of electric-melted high-chromium sand materials, of which the granularity of each is 5-0 mesh and 240 meshes, 3-8% of alpha-Al2O3 micropowder, 0.1-6% of zirconia micropowder, 0.1-3% of metal aluminum powder material, of which the granularity is smaller than 180 meshes, 0.1-3% of graphite powder, 3-8% of chrome oxide green and 2-4% of additional binder. The chromium-alumina-carbon bricks are prepared through the preparing steps of carrying out material proportioning, carrying out fine-powder premixing, carrying out granule pre-wrapping, carrying out mixing, carrying out molding, carrying out drying and carrying out burning. According to the chromium-alumina-carbon bricks and the preparation method therefor, the aims of greatly improving thermal shock resistance and prolonging service lives are achieved.

Owner:洛阳利尔功能材料有限公司

Thermal sensitive ceramic material with low resistivity, high B value and negative temperature coefficient and preparation method thereof

The invention discloses a thermal sensitive ceramic material with low resistivity, high B value and negative temperature coefficient. MnO2, NiO and CuO are taken as main ingredients, and ZnO, Nb2O5, Y2O3 and Nd2O3 are taken as secondary ingredients; in the main ingredients, content of MnO2 is 65.0-70.4mol%, content of NiO is 16.3-18.3mol%, and content of CuO is 13.3-16.7mol%; amount of added ZnO is 3.3-13.3mol% of the amount of the main ingredients, amount of added Y2O3 is 0.3-0.7mol% of the amount of the main ingredients, amount of added Nb2O5 is 0.3-3.3mol% of the amount of the main ingredients, and amount of added Nd2O3 is 0.3-1.7mol% of the amount of the main ingredients. The invention also discloses a preparation method of the thermal sensitive ceramic material with negative temperature coefficient. The thermal sensitive ceramic material with negative temperature coefficient has superior characteristics of low resistivity and high B value.

Owner:SHANTOU XINCHENG ELECTRON TECH CO LTD

Aluminum-carbon carborundum brick for torpedo ladle and preparation method thereof

InactiveCN105272310AImproved oxidation resistance and thermal shock stabilityLow porosityAluminiumCorrosion

The invention discloses an aluminum-carbon carborundum brick for a torpedo ladle and a preparation method thereof. The aluminum-carbon carborundum brick for the torpedo ladle is prepared from, by weight, 62-74 parts of high-alumina bauxite clinker particles, 10-15 parts of high-alumina bauxite powder, 3-6 parts of silicon carbide micro powder, 2-5 parts of crystalline silicon, 10-15 parts of flake graphite and 3-5 parts of thermosetting phenolic resin. According to the method, firstly, the silicon carbide micro powder and the high-alumina bauxite powder are premixed; secondly, other raw materials are sequentially placed into a mixing mill to be mixed and ground, placed in a brick press for molding and heated at the temperature between 150 DEG C and 250 DEG C for 12-36h; finally, sorting, inspection, packaging and warehousing are conducted to obtain the aluminum-carbon carborundum brick for the torpedo ladle. The aluminum-carbon carborundum brick for the torpedo ladle has the advantages of low production cost, good oxidation resistance, good thermal shock resistance, good corrosion resistance performance, long service life and the like, thus can meet the market demand.

Owner:WUGANG REFRACTORY CO LTD

High density ceramic welding pad and production method thereof

The invention disclose a high density ceramic welding pad and production method thereof, wherein the pad comprises (by weight portion) silica dioxide SiO2 45-68%, aluminium trioxide Al2O3 20-39%, ferric oxide FeO 0.2-1.93%, calcium oxide CaO 0.2-1%, magnesium oxide MgO 0.3-13%, mixture of potassium oxide and sodium oxide K2O+Na2O 0.8-4.5%. The preparation process comprises the steps of disintegrating, batching, mixing, modeling, and burning.

Owner:大连金州明圆建材有限公司

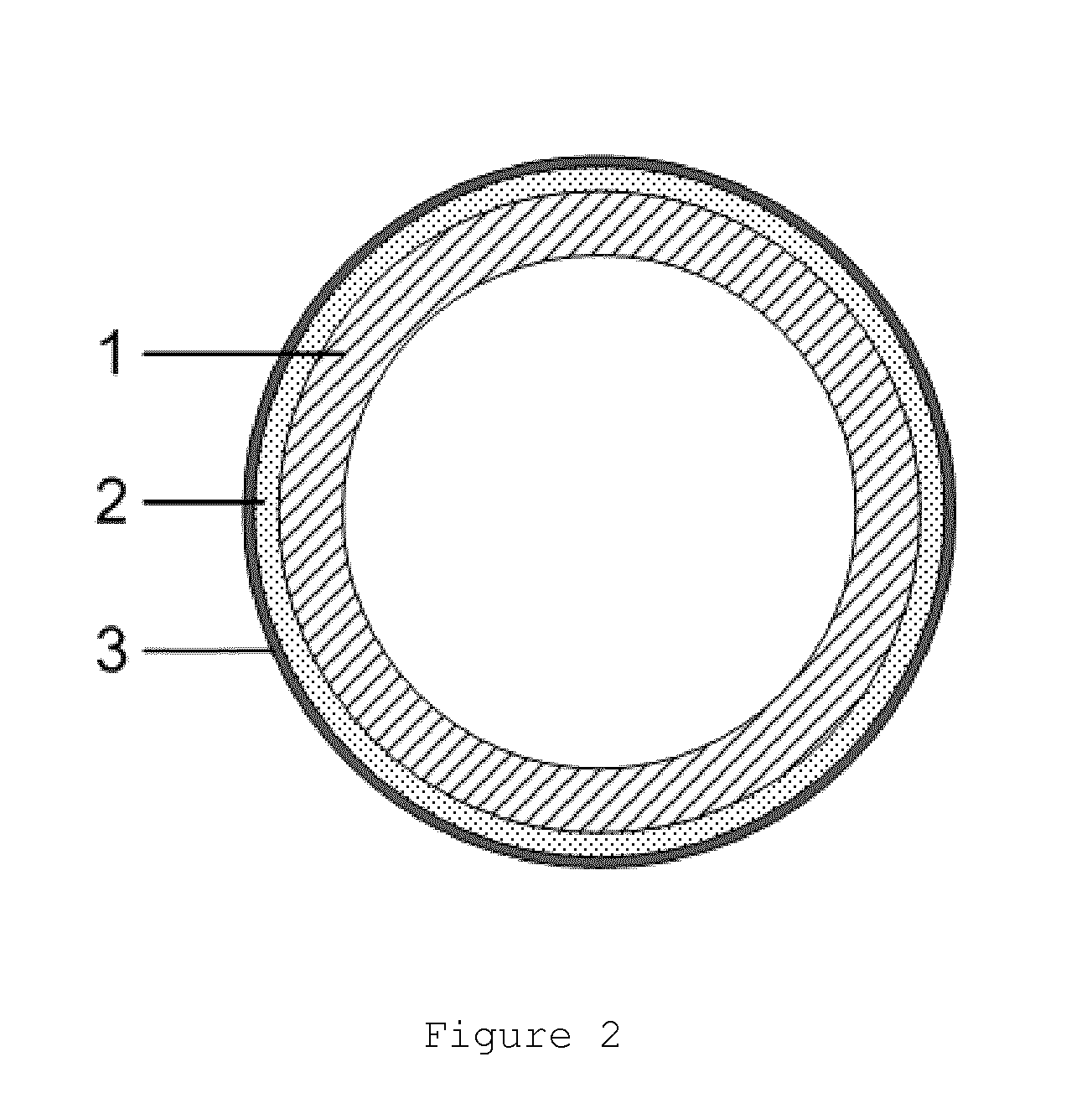

Hydrocyclone wear-resistant ceramic liner and preparation method thereof

The invention discloses a hydrocyclone wear-resistant ceramic liner and a preparation method thereof. The hydrocyclone wear-resistant ceramic liner is prepared from the following active ingredients in percentage by weight: 2%-8% of yttrium oxide, 2%-10% of aluminum oxide, 14%-20% of carbon fiber, and 65%-80% of silicon carbide. The ceramic liner adopts the technology of rare earth materials of aluminum oxide, yttrium oxide and the like, the low-temperature yttroalumite formed in the sintering process is beneficial to compactness of a silicon carbide liner, and the porosity of the product is reduced; simultaneously taking the large crispness characteristic of the silicon carbide, carbon fibers are added into active ingredients, so that the phenomena of deviating crack propagation, pulling out the fibers and the like can occur under the presence of the carbon fibers, and further the breakage tenacity of the product can be enhanced. The ceramic liner has the characteristics of being low in porosity, good in wear resistance and tenacity, and easy to produce, the service life of a heavy medium hydrocyclone applying the ceramic liner can be prolonged by more than one year which is far longer than three to five months of the conventional corundum liner, so that the service life of the heavy medium hydrocyclone is greatly prolonged; and the hydrocyclone wear-resistant ceramic liner can be widely applied in the field of mining industry and the like having higher requirement on wear resistance.

Owner:天地科技股份有限公司唐山分公司 +1

Preparation method of KSr2Nb5O15 transparent ferroelectric ceramic

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of micro-pore permeation resistance high-alumina brick

The invention belongs to the technical field of preparation of refractory materials and particularly relates to a preparation method of a micro-pore permeation resistance high-alumina brick. The preparation method comprises the following steps: firstly, ball-milling, preparation method and calcining raw materials: zirconite, bauxite and the like, so as to obtain zirconium nitride-based ceramic powder; smashing and sieving special grade high-alumina bauxite, mixing the special grade high-alumina bauxite, saccharose, alumina micro powder and the like and grinding the mixture; after grinding, screening out micro-pore high-alumina bauxite clinkers with all grades of granularity; mixing the micro-pore high-alumina bauxite clinkers with all grades of granularity, which is screened out, the zirconium nitride-based ceramic powder and the like, pressing the mixture into a green brick and calcining the green brick. The micro-pore permeation resistance high-alumina brick prepared by the invention is small in porosity and low in apparent porosity; the apparent porosity reaches 12-14%, so that the wear-resisting property is improved, and the abrasion loss at normal temperature is 5cm<3> or lower; the breaking strength at normal temperature reaches 29MPa or higher, and the pressure-resistant strength at normal temperature reaches 151MPa or higher.

Owner:吴迪

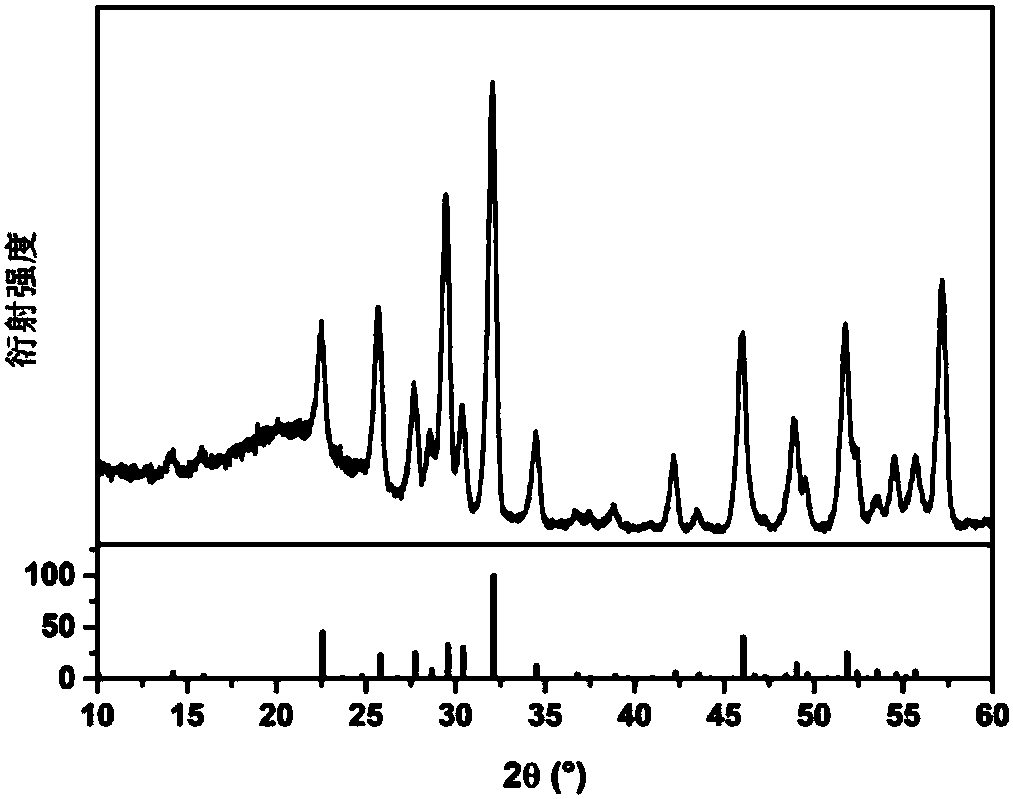

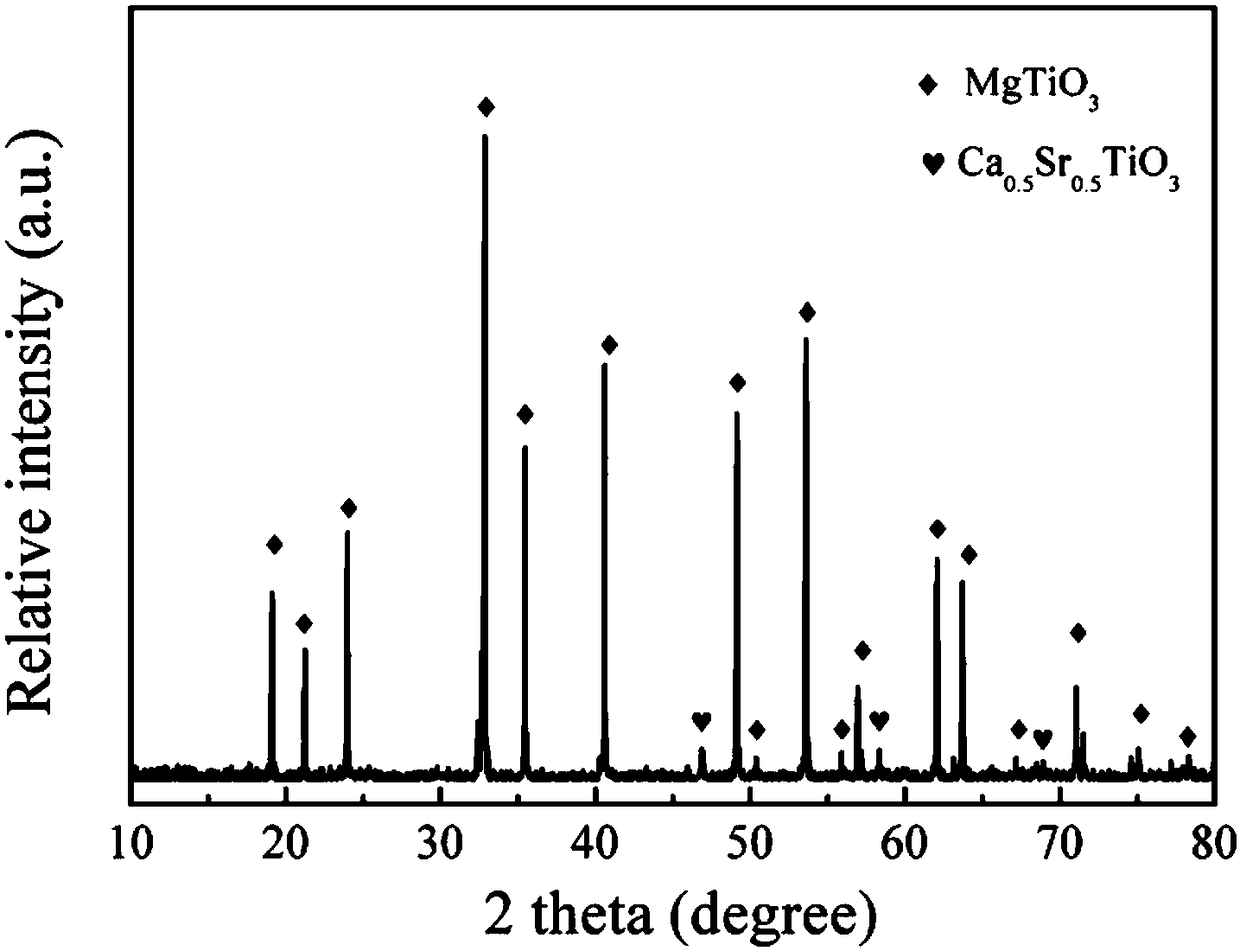

MgTiO3-Based microwave dielectric composite ceramic and preparation method thereof

The invention relates to MgTiO3-based microwave dielectric composite ceramic and a preparation method thereof and belongs to the field of high-tech functional ceramics and their application. The MgTiO3-based microwave dielectric composite ceramic is made by performing high temperature sintering and compounding on MgTiO3 as a base with one, as an additive, of Ca0.5Sr0.5TiO3 or mixture of Ca0.5Sr0.5TiO3 and LnAlO3 (Ln=Pr, Nd, La, Sm). The MgTiO3-based microwave dielectric composite ceramic is synthesized herein by a two-step process: MgTiO3, Ca0.5Sr0.5TiO3 and LnAlO3 (Ln=Pr, Nd, La, Sm) precursor powder are prepared separately through the molten-salt growth method, and the base is mixed with the additive before ball milling, drying, grinding, granulating, screening, dry shaping, and high temperature sintering to obtain the MgTiO3-based microwave dielectric composite ceramic. The MgTiO3-based microwave dielectric composite ceramic prepared herein has high density, low porosity, high dielectric constant, high quality factor, low dielectric loss and nearly zero resonant frequency temperature coefficient, and is particularly suitable for high frequency application in microwave dielectricresonators, filters and GPS (global positioning system) antennas.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

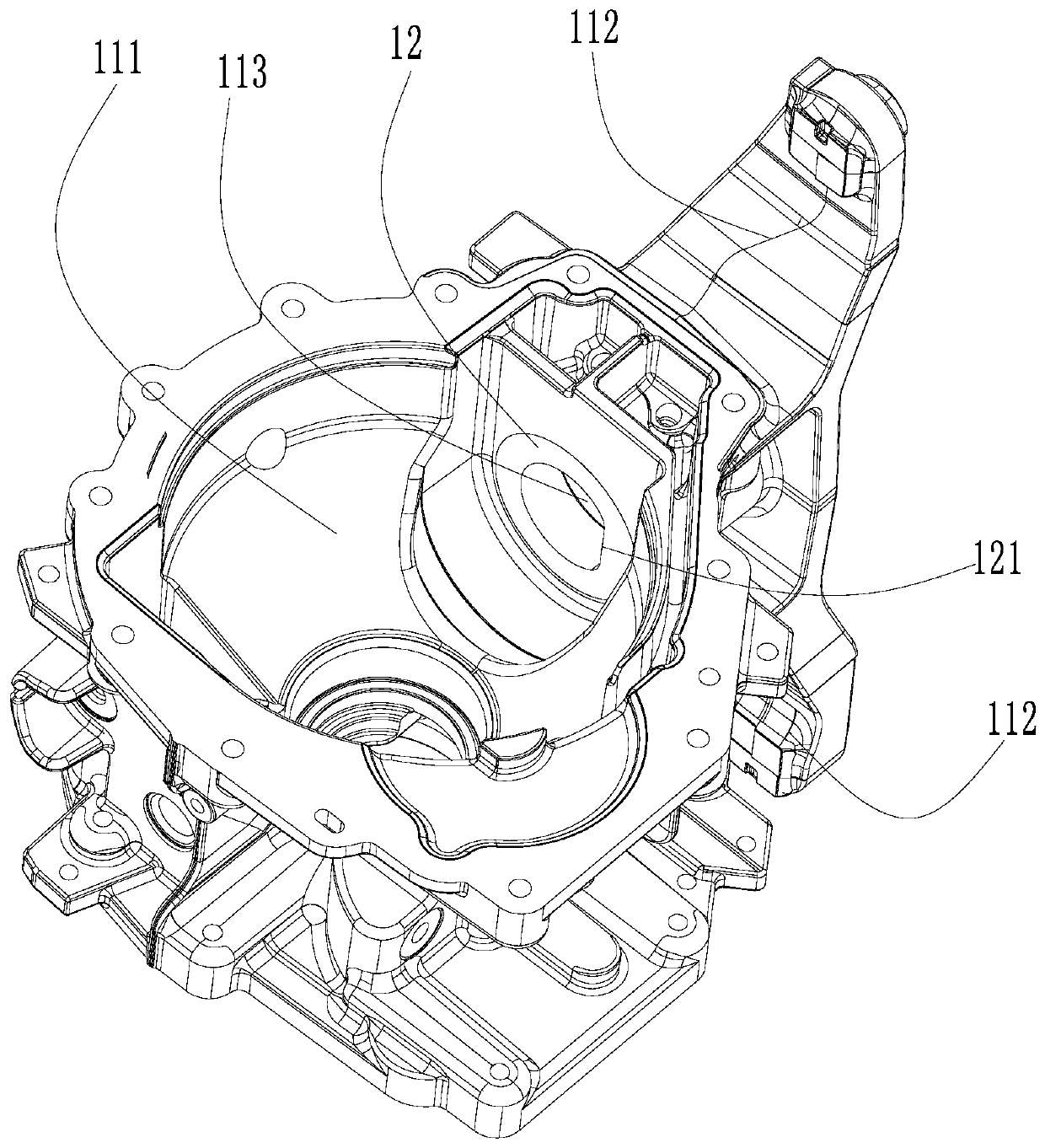

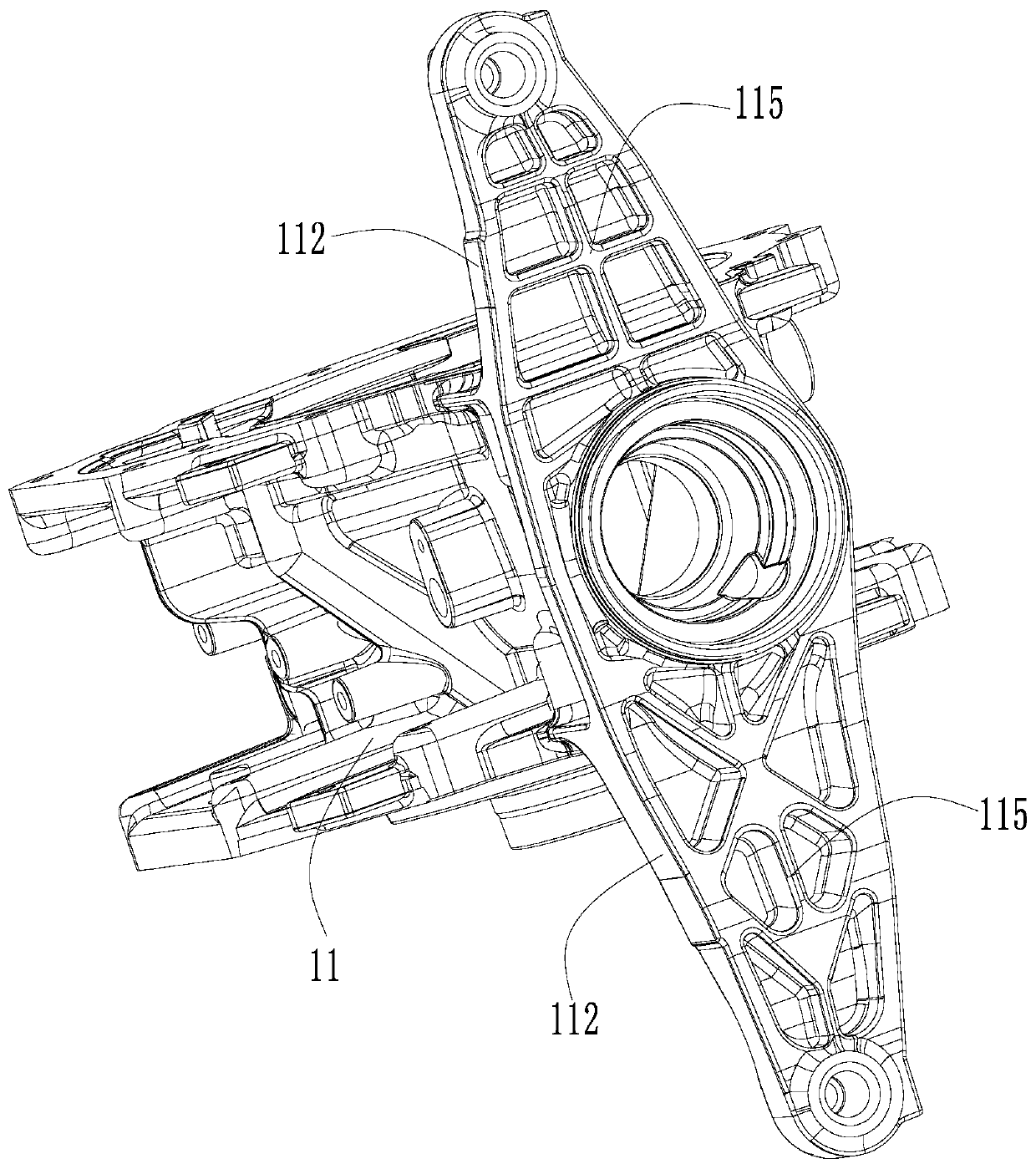

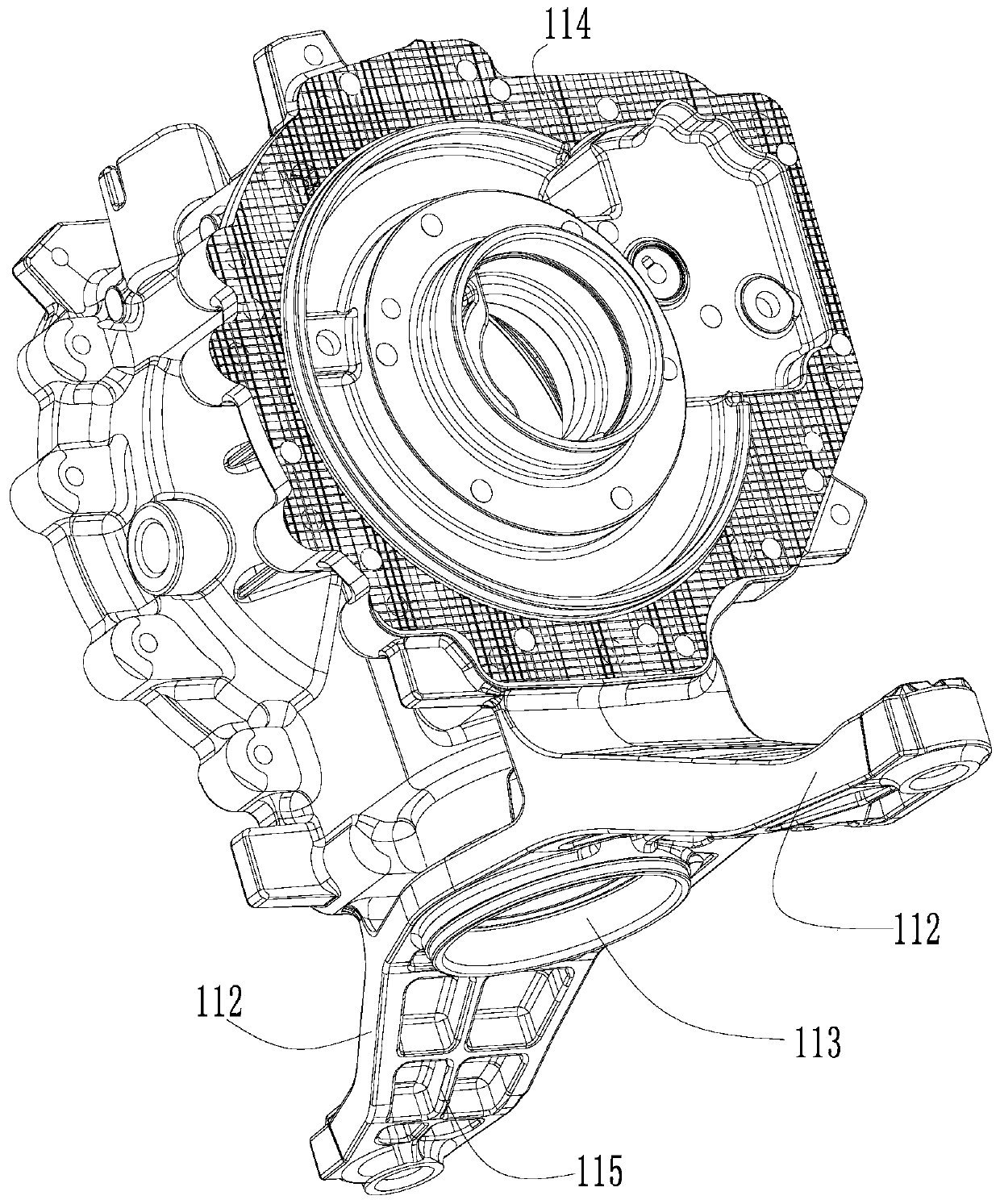

Automobile bracket with embedding part and die-casting die for forming automobile bracket

ActiveCN110126616ABracket product is of good qualityLow porosityControl devicesMechanical engineeringPorosity

The invention discloses an automobile bracket with an embedding part and a die-casting die for forming the automobile bracket. The automobile bracket comprises a body and the embedding part, a mounting cavity is formed in the upper part of the body, and the side face of the body protrudes to form two supports; a through hole is formed in the side face of the body and located between the two supports, and the through hole communicates with the mounting cavity; the embedding part is arranged in the through hole and located on the side close to the mounting cavity; the embedding part is providedwith a positioning surface. The die-casting die comprises a fixed die assembly, a movable die assembly, a core pulling assembly, a casting assembly, an ejecting assembly and a supporting assembly, wherein the core pulling assembly comprises a front sliding block, a rear sliding block, a left sliding block and a right sliding block, and a die cavity for forming the automobile bracket is defined bythe front sliding block, the rear sliding block, the left sliding block, the right sliding block, a first cavity and a second cavity; an embedding pin is arranged in the left sliding block, one end ofthe embedding pin stretches into the die cavity, and the embedding pin is sleeved with the embedding part; after the automobile bracket is formed, the embedding part and the automobile bracket are connected into a whole. The automobile bracket with the embedding part and the die-casting die for forming the automobile bracket have the advantages that the automobile bracket is low in porosity, andthe die structure arrangement is reasonable.

Owner:NINGBO HUASHUO MOLDING & MACHINE

Method of manufacturing rotogravure cylinders

ActiveUS20150259817A1Low porosityLarge porosityMolten spray coatingChromatisationCopper platingChromium

The present invention describes a method for manufacturing rotogravure cylinders with a cylinder base made of aluminum. The method involves the coating of the cylinder surface with high velocity spraying, the copper plating in an appropriate solution, the engraving of the cylinder, and the hardening of the cylinder by chromium plating. The spraying process is accomplished by High-Velocity Air-Fuel or High-Velocity Oxygen-Fuel thermal spraying which leads to less surface porosity, better adhesion of the copper substrate and better dimensional accuracy. The advantage of this method is the elimination of the surface roughening process and the elimination of the preplating process. In addition, the end plates are manufactured partly from aluminum and partly from steel which further reduces the total weight of the cylinder. The elimination of these processes reduces the weight of the cylinder and the overall manufacturing time considerably.

Owner:ICR IOANNOU SA

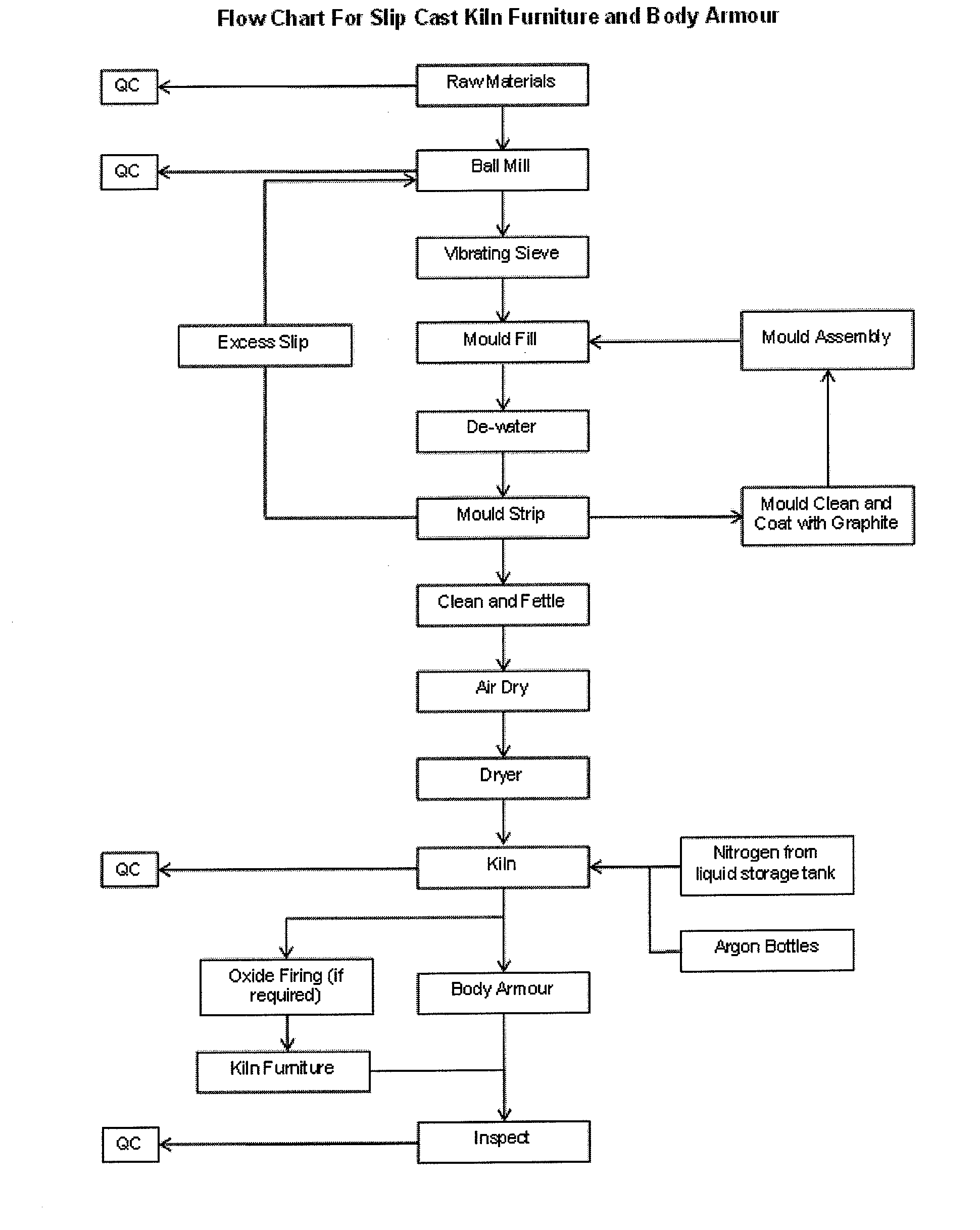

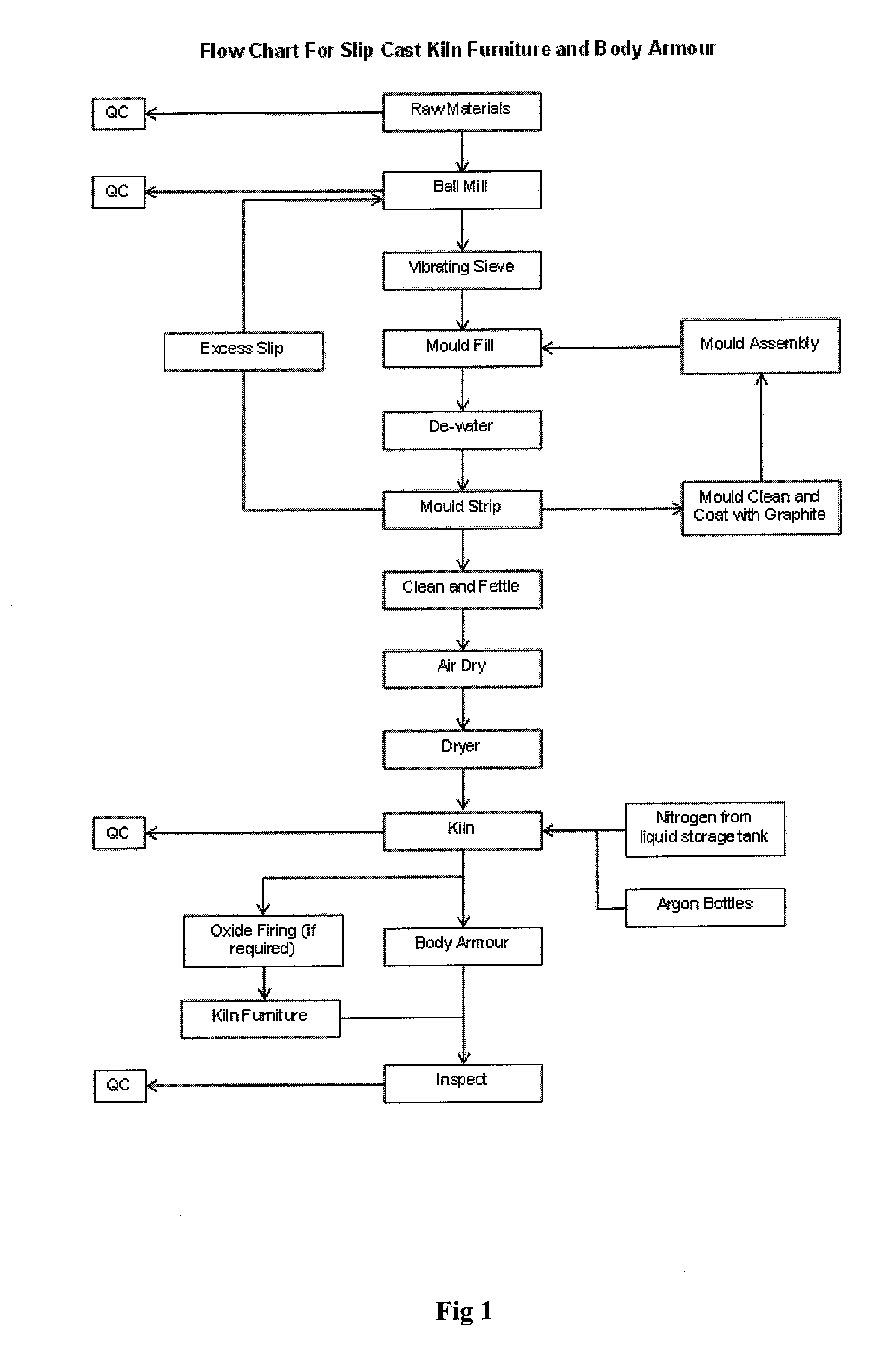

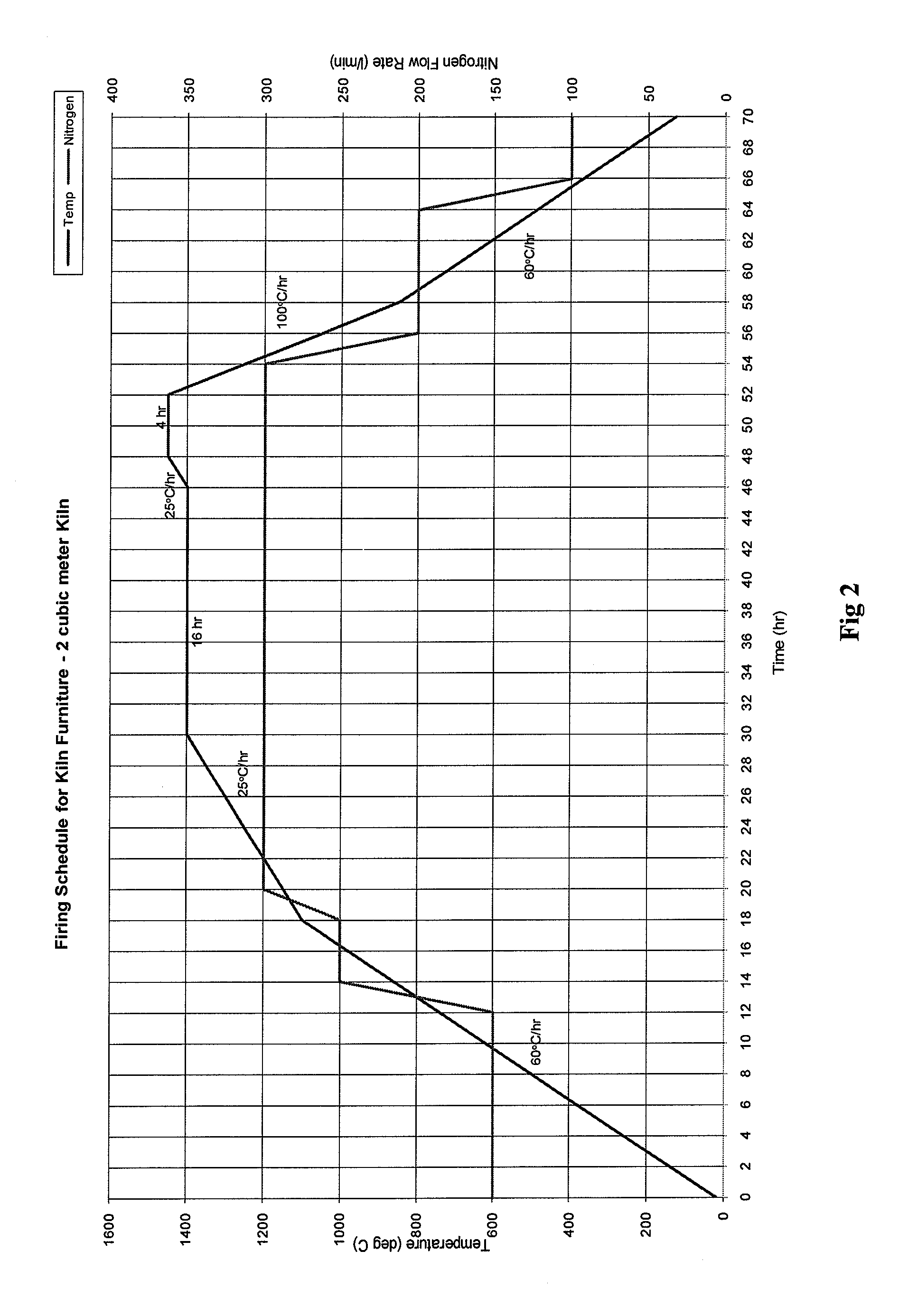

Sialon bonded silicon carbide material

A silicon carbide based material exhibiting high strength, good thermal shock resistance, high resistance to abrasion and being chemically stable to harsh environmental conditions is described. The carbide Ball Hill ceramic comprises a β-SiAlON bonding phase in which sintering is facilitated by at least one rare earth oxide sintering agents incorporated within the Vibrating Sieve batch admixture as starting materials. The residual rare earth sintering aid being chosen so as to impart good mechanical and refractory properties.

Owner:CAPITAL REFRACTORIES LTD

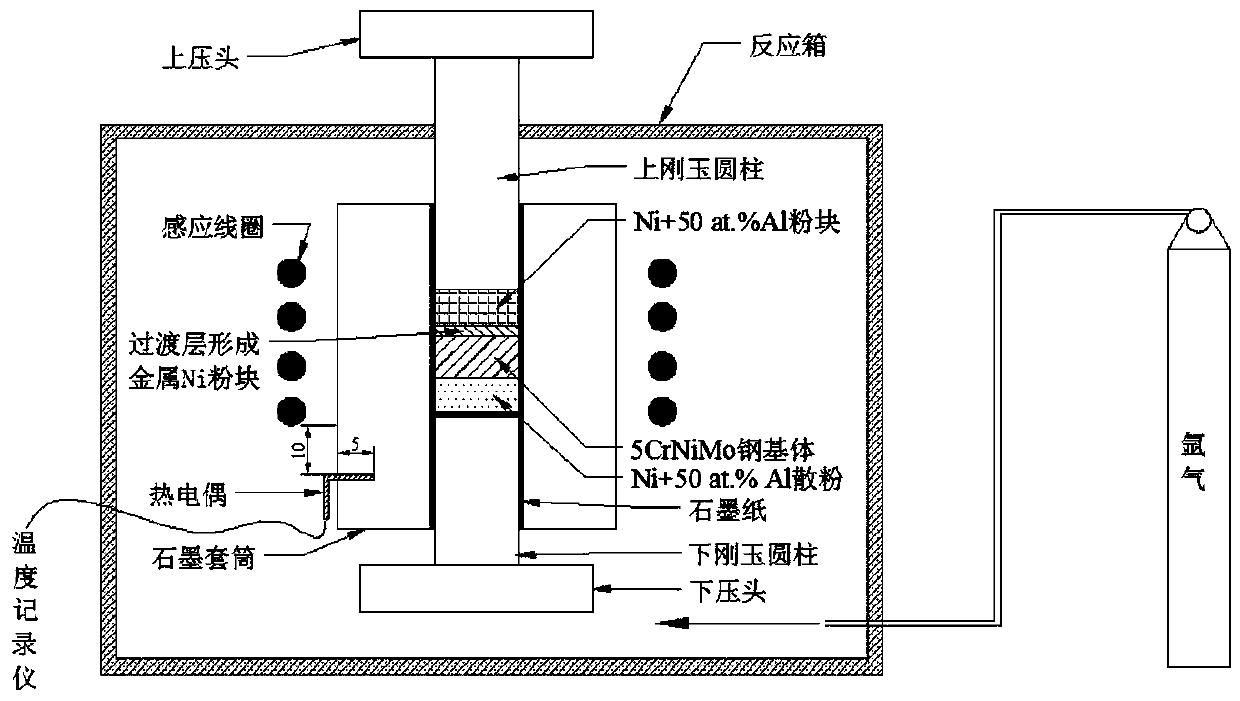

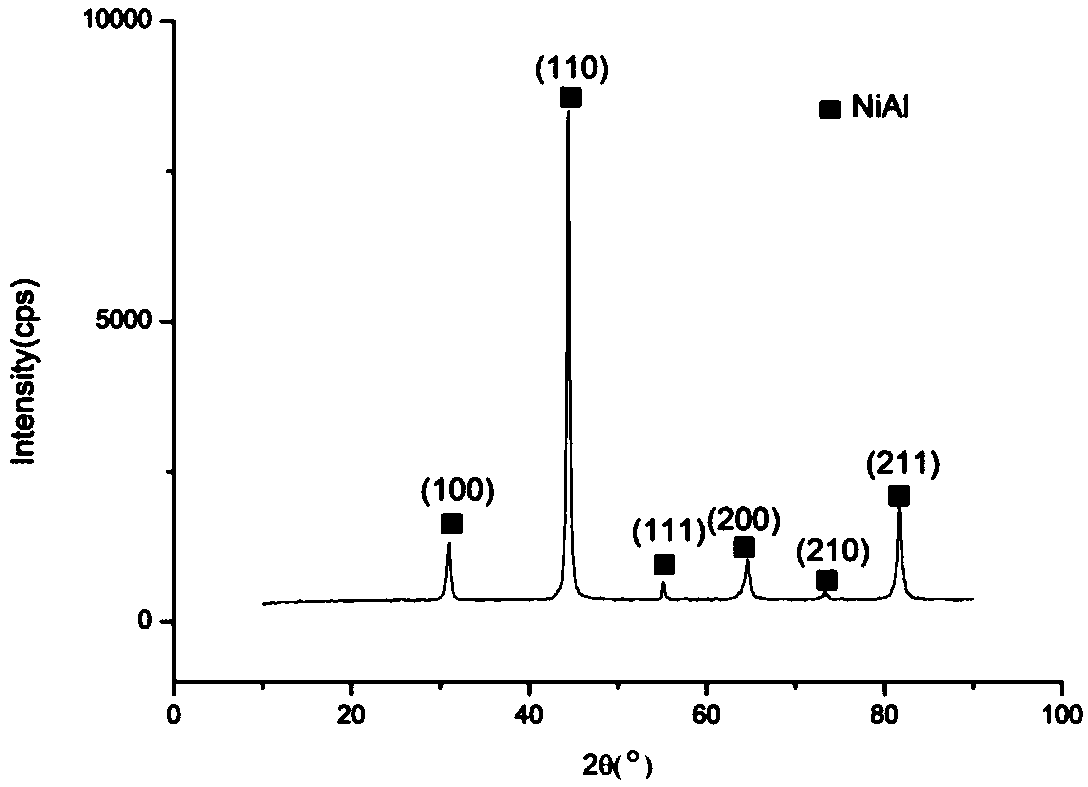

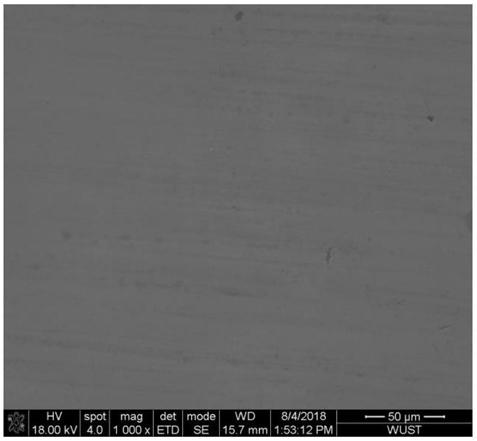

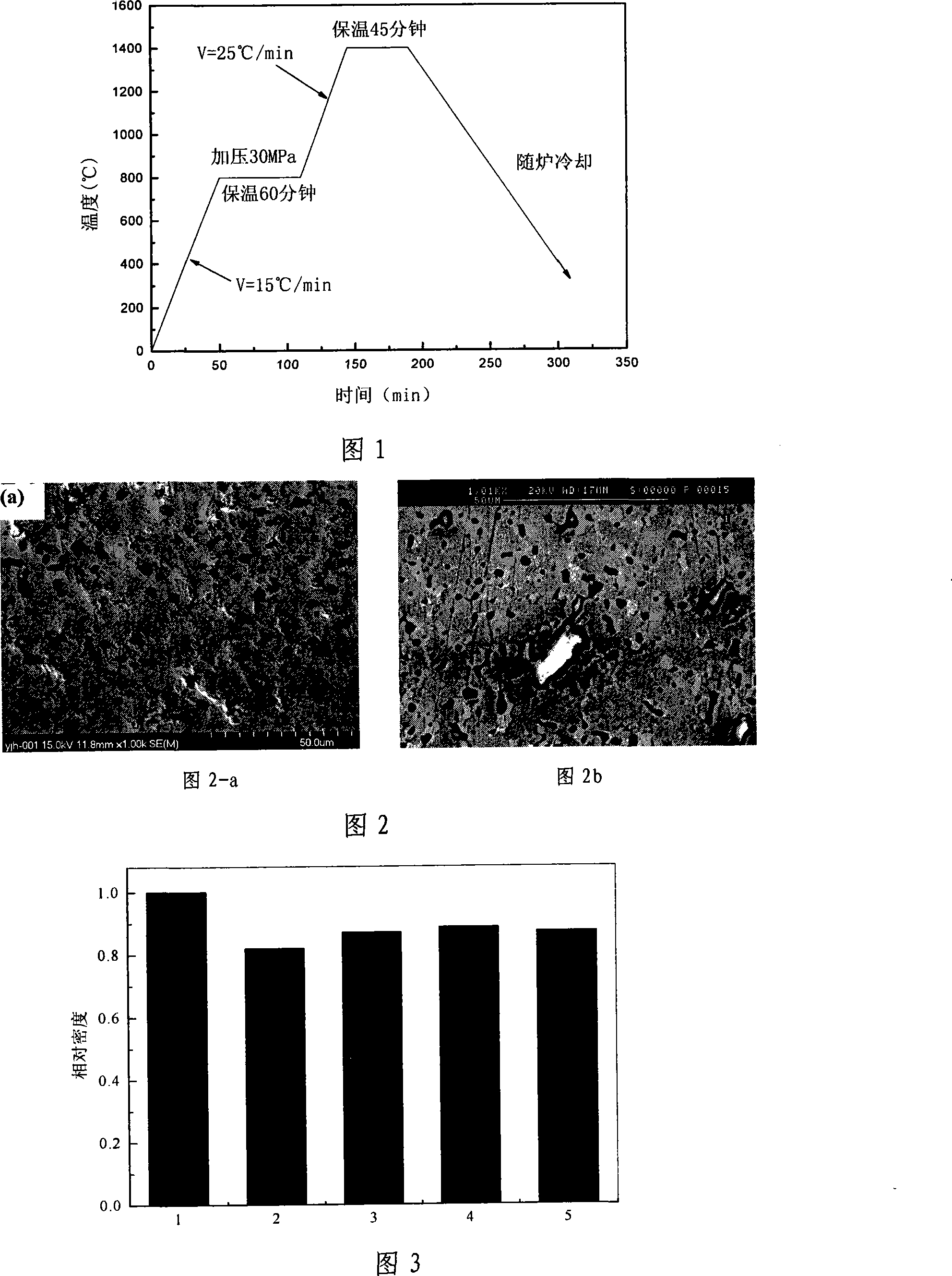

Preparation method of high-frequency induction assistant self-propagating NiAl intermetallic compound coating

The invention discloses a preparation method of a high-frequency induction assistant self-propagating NiAl intermetallic compound coating, and relates to the field of material surface engineering. Thepreparation method is characterized by comprising the following steps that 1, nickel powders and aluminum powders are pressed in proportion to make a preform; 2, the surface of a base body is polished by using abrasive paper; and 3, a high-frequency induction assistant self-propagating method is used for preheating the base body and a coating, and a self-propagating reaction is ignited to obtainthe NiAl intermetallic compound coating. The preparation method is simple in process, high in heating efficiency and low in cost, and the obtained coating is smooth, dense, low in porosity and high inbonding strength. The preparation method can be widely applied to surface treatment and remanufacturing of tools, dies, structural parts and the like so as to prolong the service life of the tools, dies, structural parts and the like.

Owner:WUHAN UNIV OF SCI & TECH

Tantalic oxide modified molybdenum disilicide based material and preparation method thereof

The invention relates to a tantalum pentoxide modified molybdenum disilicide-based composite material and a corresponding preparation method, wherein, the preparation method comprises following steps: equably mixing tantalum pentoxide and molybdenum disilicide according to a weight proportion that the tantalum pentoxide is 1% to 7% and molybdenum disilicide is 93% to 99%; dispersing by ultrasonic wave and ball milling and mixing to obtain a dry powder, sintering the dry powder in a vacuum heat pressing sintering furnace at a temperature of 1400 DEG C to obtain the antalum pentoxide modified molybdenum disilicide-based composite material. The invention has the advantages that: the Ta2O5 doped MoSi2 composite material has high specific strength, high temperature resistant performance and corrosion resistance performance, strong anti-high temperature oxidation performance and anti-heat shock ability, and good conductivity for electricity and heat.

Owner:HARBIN ENG UNIV

Abrasion-resistant ceramic material and preparation method and application thereof

ActiveCN107935623ALow porosityImprove mechanical propertiesImpression capsDentistry preparationsBiocompatibility TestingPorosity

The invention discloses an abrasion-resistant ceramic material and a preparation method and application thereof. The abrasion-resistant ceramic material is prepared from the following raw materials inparts by weight: 11 to 19 parts of zirconium oxide, 1 to 5 parts of dimeticone, 15 to 25 parts of levulinic acid, 22 to 30 parts of vermiculite, 3 to 7 parts of propylene carbonate, and 3 to 7 partsof ethyl cellulose. The preparation method comprises the following steps of mixing and grinding the zirconium oxide, the vermiculite and the ethyl cellulose, adding a levulinic acid solution, heating,and stirring under the sealing condition, so as to obtain a mixture A; adding the dimeticone and the propylene carbonate into the mixture A, cooling, stirring under the sealing condition, heating andstirring, treating by ultrasonic waves, centrifuging and separating, obtaining precipitate, washing and drying, preparing into a blank, firing and cooling, so as to obtain the ceramic material. The abrasion-resistant ceramic material has the advantages that the porosity is reduced, the mechanical property is improved, the good breaking toughness and bending strength are realized, the mechanical property is good, the chemical stability is strong, the biocompatibility is excellent, the color is also completely consistent with the color of teeth of a human body, and the simulation degree is veryhigh.

Owner:苏州新汉盛精密陶瓷科技有限公司

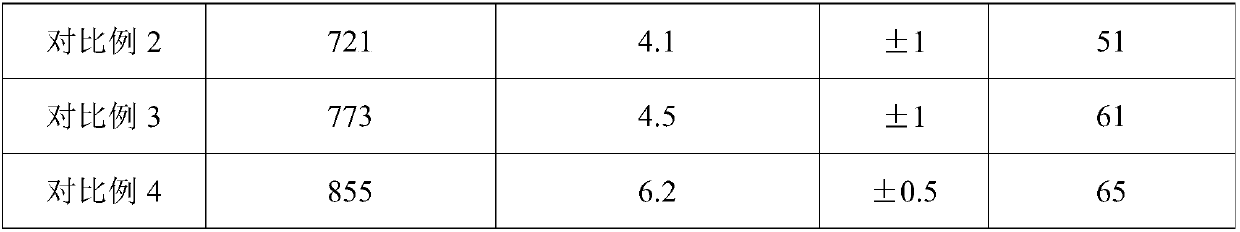

Thermal-state temping coking process

A thermal-state stamping coking process is carried out by crushing coal, mixing with raw materials, entering it into bunker, delivering it to additive channel at one side of carbonizing chamber by conveyor, heating coal at 200-450degrees C, stamping the melt coal by stamping mechanism at top of carbonizing chamber, and stamping the coal into high-density coal cake. It has higher stamping strength, can improve M40 to 8-10% and decrease coke porosity.

Owner:沈阳东方钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com