Antibacterial paint, anticorrosive paint, antibacterial and anticorrosive coating and oil transportation pipeline

A technology for antibacterial coatings and oil pipelines, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of poor antibacterial effect and short antibacterial life of oil pipelines, achieve improved adhesion, excellent anti-corrosion effect, and overcome antibacterial bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

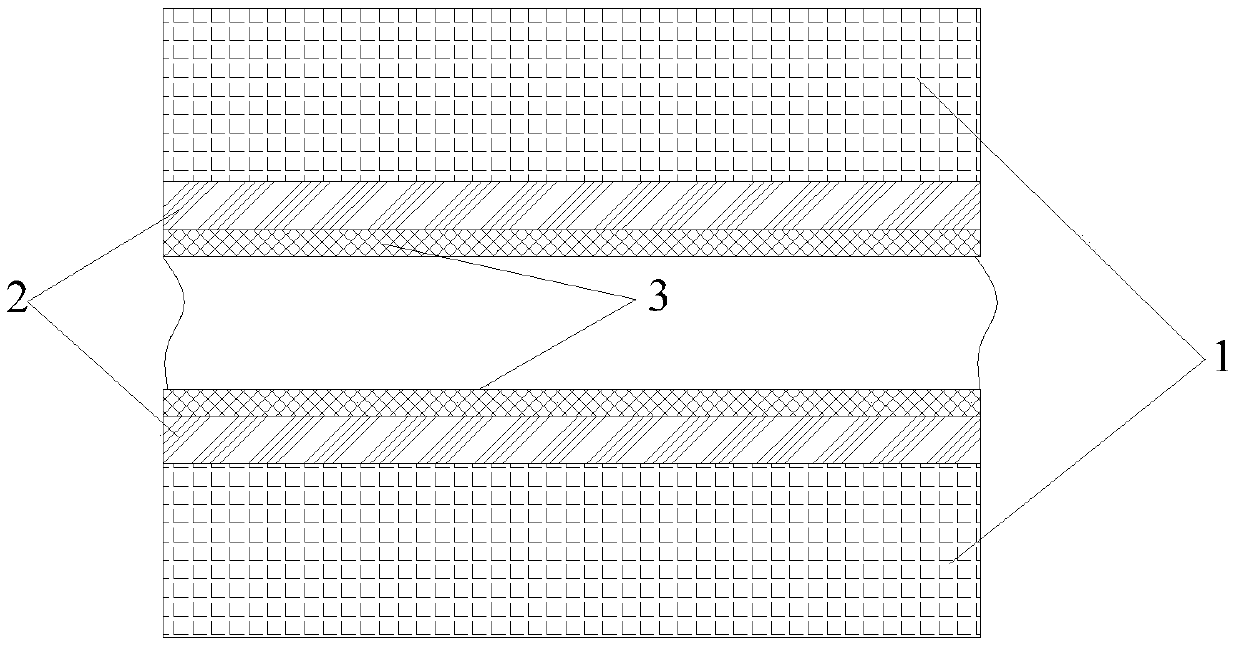

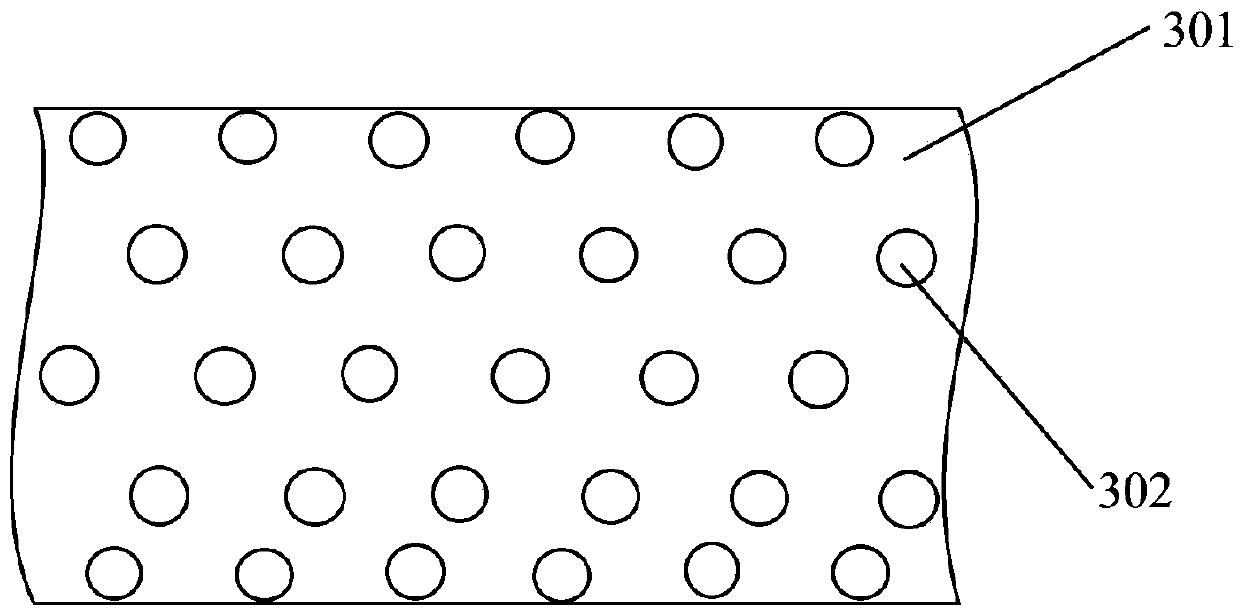

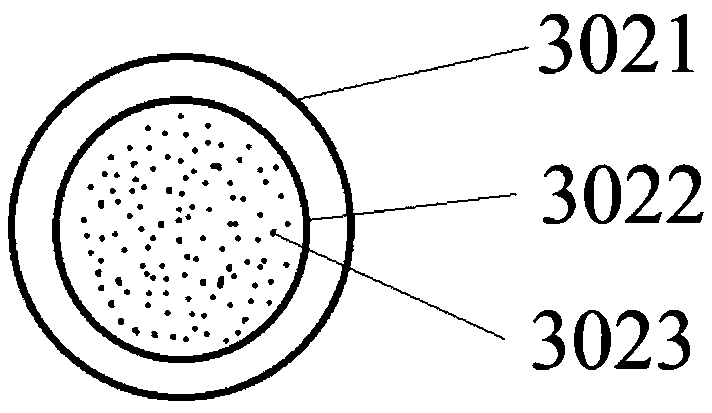

[0044] Please see attached figure 1 , 2 3. The present invention is described in detail; the preparation of the antibacterial and anticorrosion coating includes the preparation of heavy anticorrosion coating and the preparation of slow-release antibacterial coating.

[0045] A kind of preparation method of heavy-duty anticorrosion coating, it comprises the steps:

[0046] Dissolve the epoxy resin in a part of solvent A to obtain an epoxy resin solution, add the auxiliary agent, nano-zinc oxide and modified zinc powder to the remaining solvent A to obtain an auxiliary agent solution, and combine the epoxy resin solution and the auxiliary agent After the agent solution is mixed, add the curing agent and mix evenly to obtain the heavy-duty anti-corrosion coating.

[0047] A kind of heavy-duty anticorrosion paint, it comprises the following components by weight percentage:

[0048]

[0049]

[0050] As a preferred version, the epoxy resin is a water-soluble epoxy resin mo...

Embodiment 2

[0062] The preparation of the antibacterial and anti-corrosion coating includes the preparation of heavy-duty anti-corrosion coating and the preparation of slow-release anti-bacterial coating.

[0063] A kind of preparation method of heavy-duty anticorrosion coating, it comprises the steps:

[0064] Dissolve the epoxy resin in a part of solvent A to obtain an epoxy resin solution, add the auxiliary agent, nano-zinc oxide and modified zinc powder to the remaining solvent A to obtain an auxiliary agent solution, and combine the epoxy resin solution and the auxiliary agent After the agent solution is mixed, add the curing agent and mix evenly to obtain the heavy-duty anti-corrosion coating.

[0065] A kind of heavy-duty anticorrosion paint, it comprises the following components by weight percentage:

[0066]

[0067] As a preferred version, the epoxy resin is a water-soluble polyether-modified water-soluble epoxy resin, and the molecular weight of the polyether segment in the...

Embodiment 3

[0079] The preparation of the antibacterial and anti-corrosion coating includes the preparation of heavy-duty anti-corrosion coating and the preparation of slow-release anti-bacterial coating.

[0080] A kind of preparation method of heavy-duty anticorrosion coating, it comprises the steps:

[0081] Dissolve the epoxy resin in a part of solvent A to obtain an epoxy resin solution, add the auxiliary agent, nano-zinc oxide and modified zinc powder to the remaining solvent A to obtain an auxiliary agent solution, and combine the epoxy resin solution and the auxiliary agent After the agent solution is mixed, add the curing agent and mix evenly to obtain the heavy-duty anti-corrosion coating.

[0082] A kind of heavy-duty anticorrosion paint, it comprises the following components by weight percentage:

[0083]

[0084]As a preferred version, the epoxy resin is a water-soluble polyether-modified water-soluble epoxy resin, and the molecular weight of the polyether segment in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com