Patents

Literature

127results about "Carbon disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

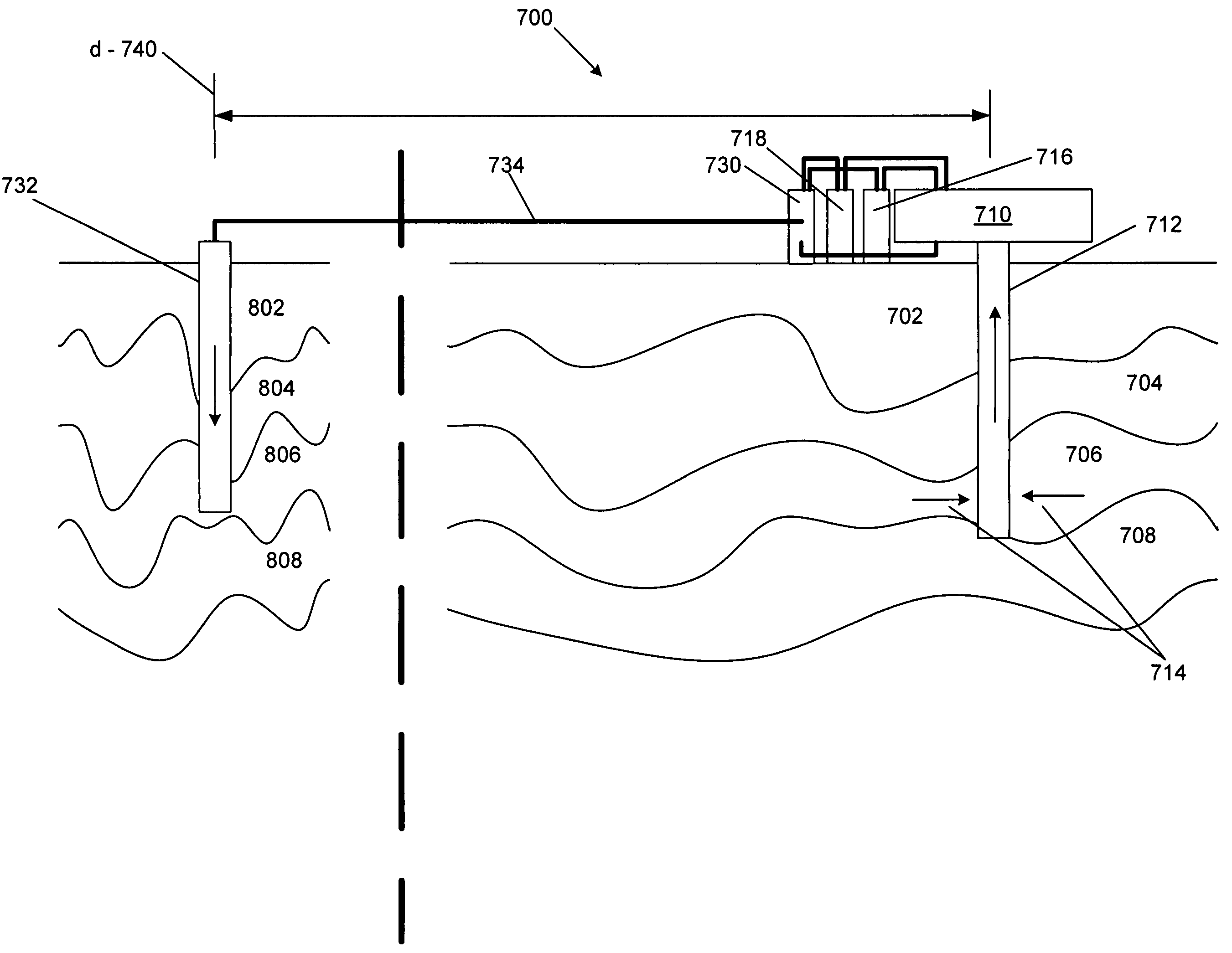

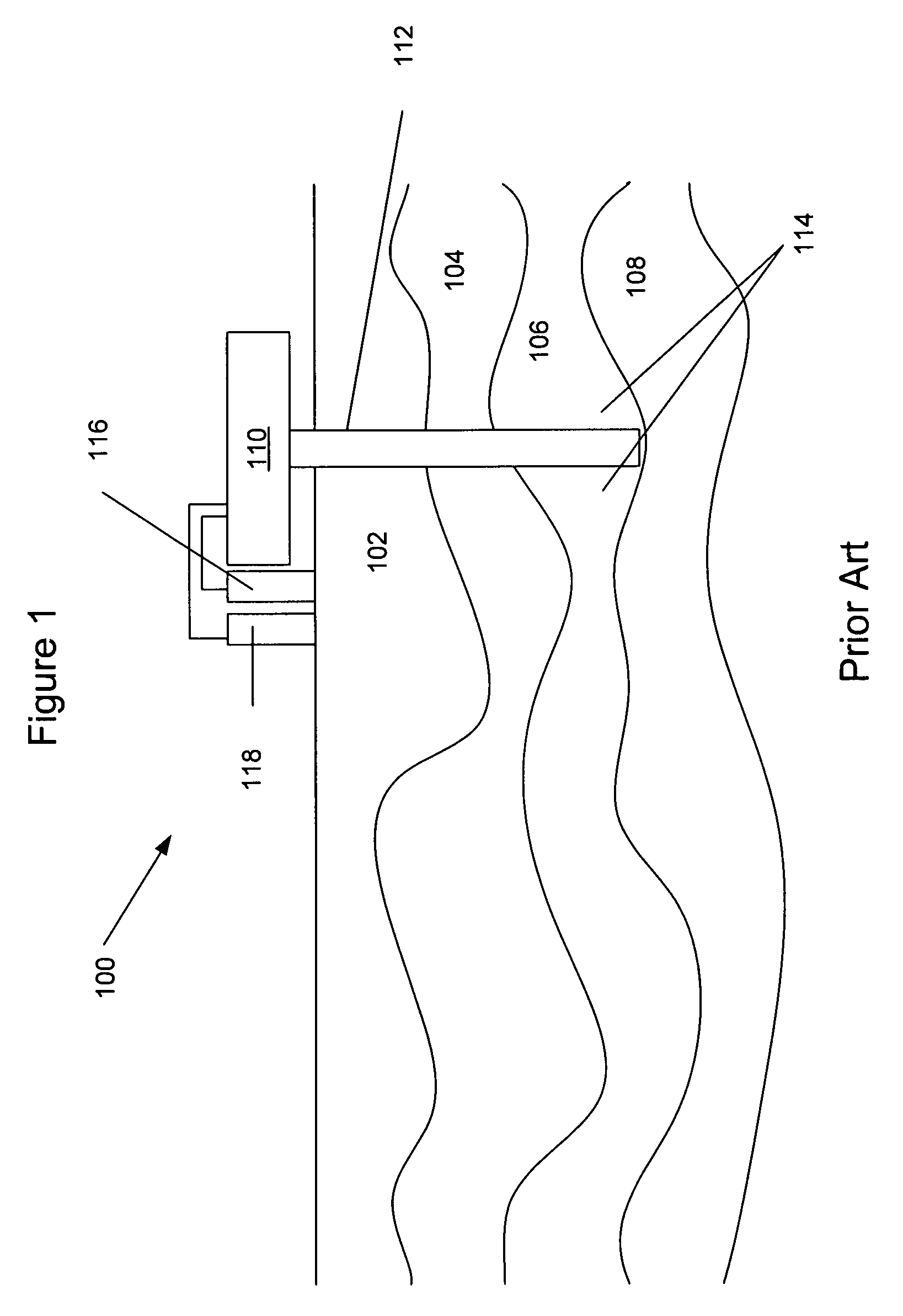

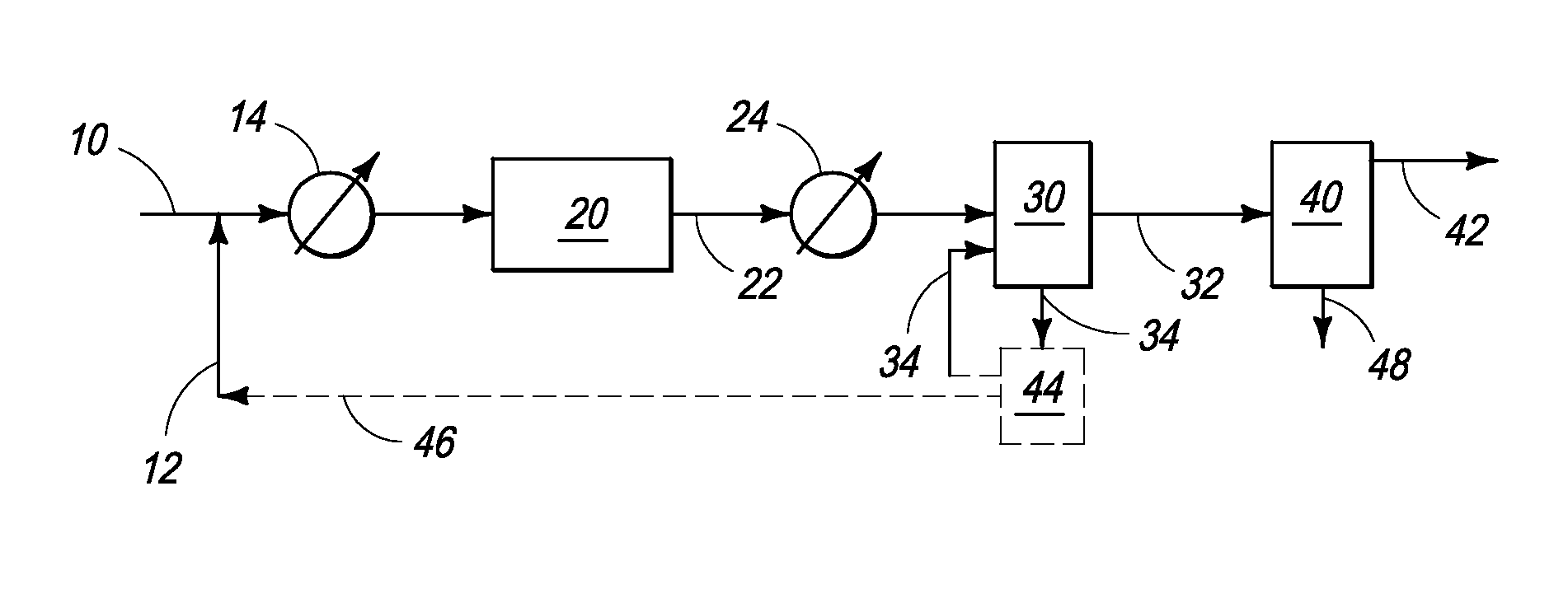

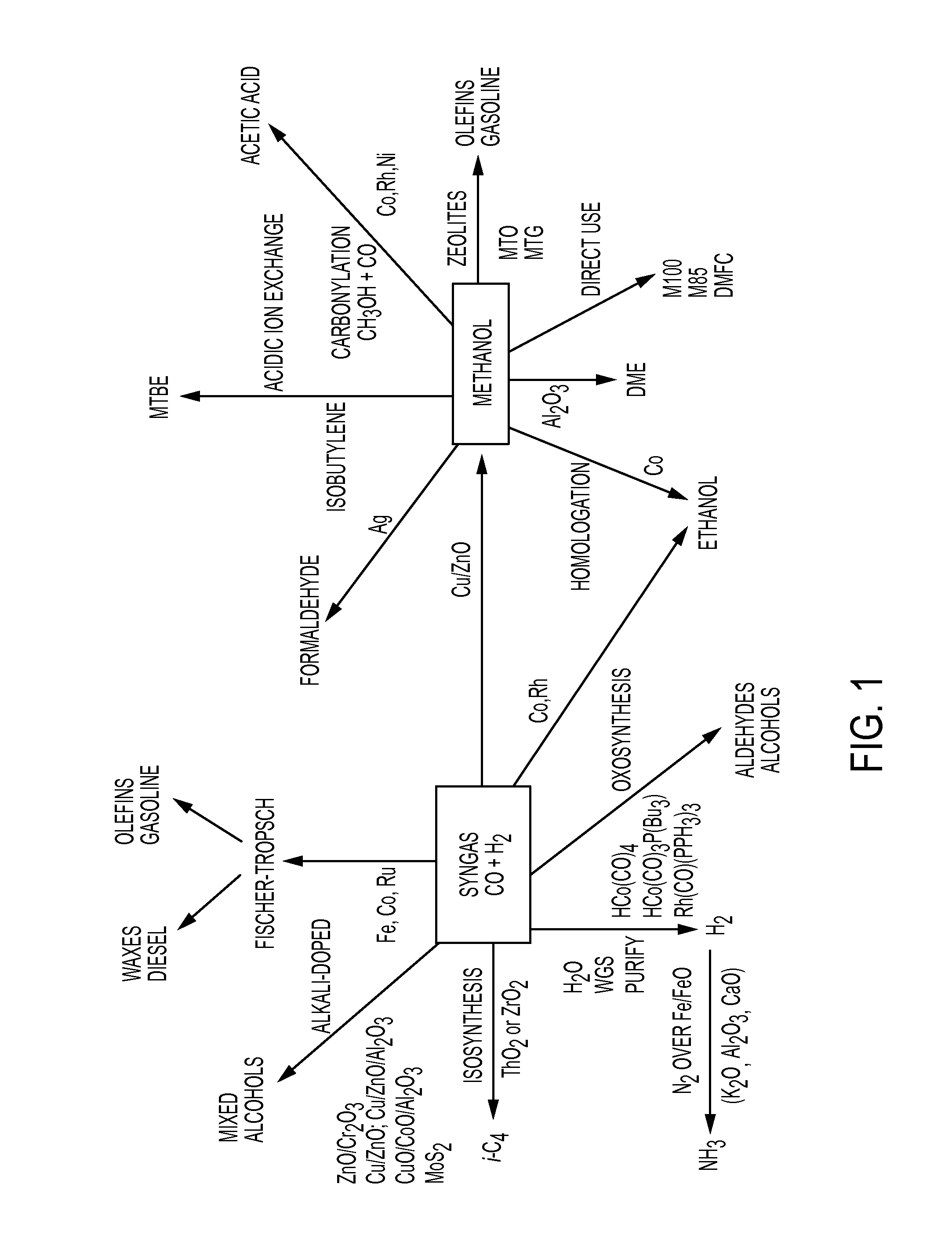

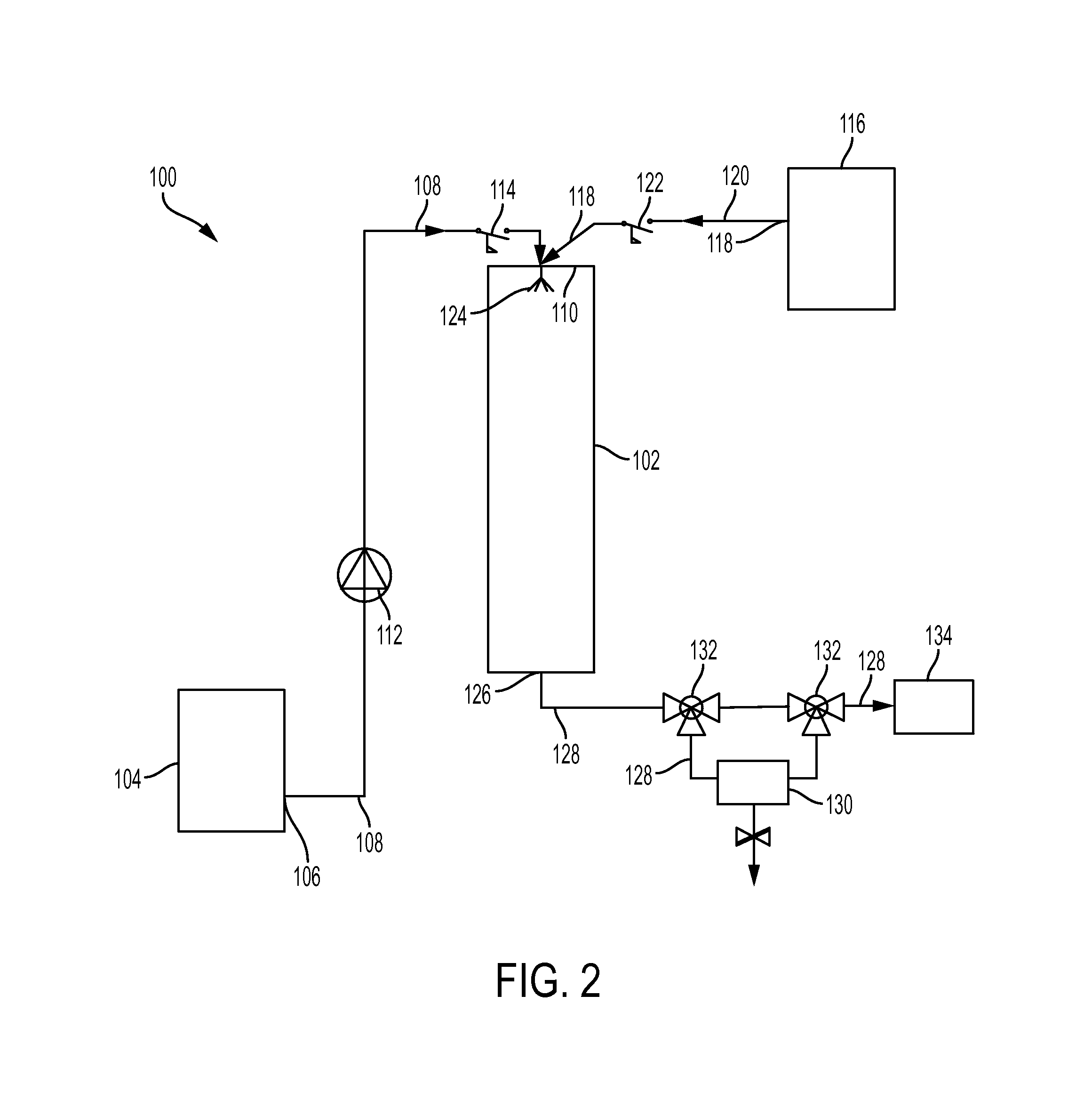

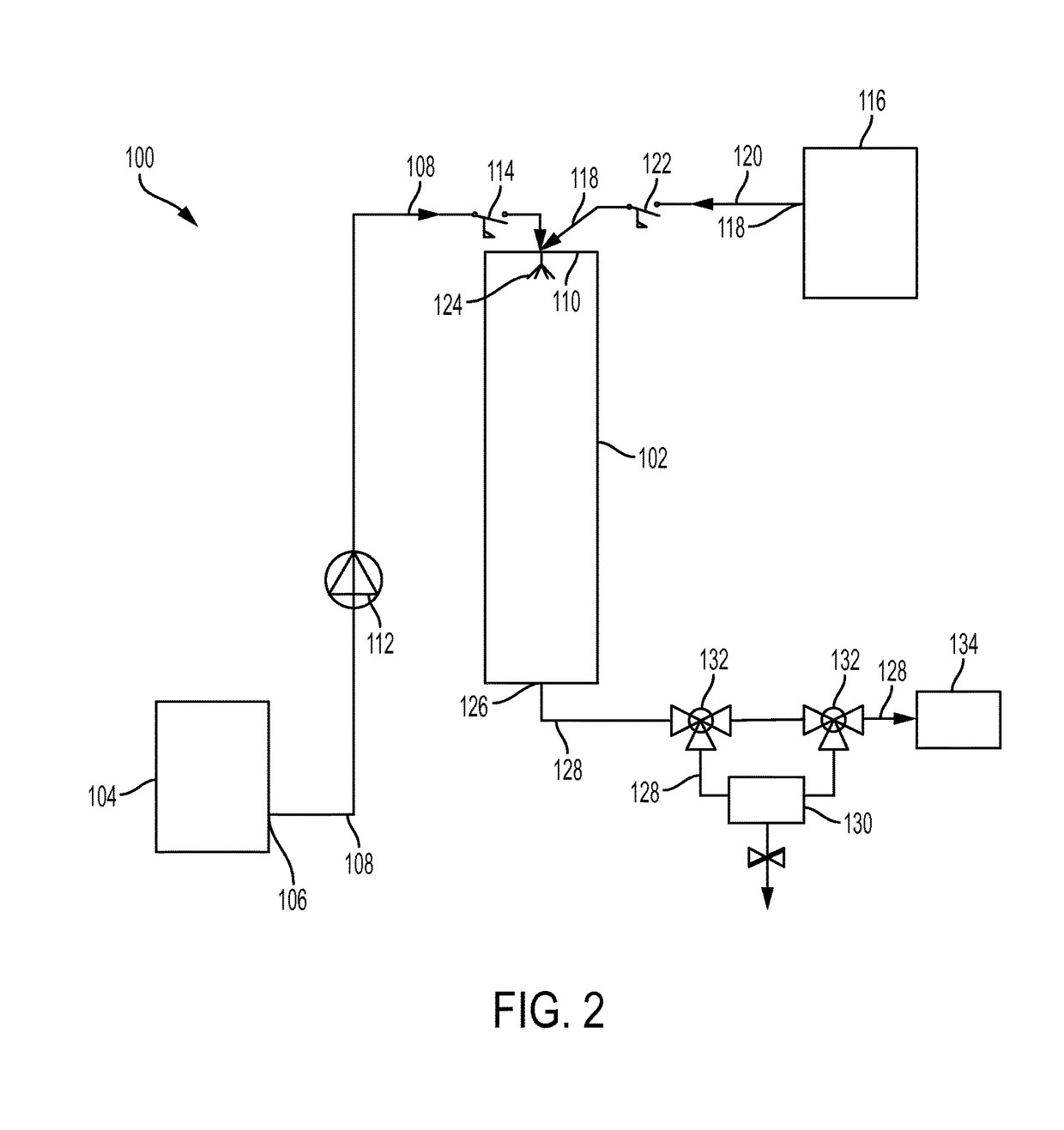

Systems and methods for producing oil and/or gas

A system including a mechanism for recovering oil and / or gas from an underground formation, the oil and / or gas comprising one or more sulfur compounds; a mechanism for converting at least a portion of the sulfur compounds from the recovered oil and / or gas into a carbon disulfide formulation; and a mechanism for releasing at least a portion of the carbon disulfide formulation into a formation.

Owner:SHELL OIL CO

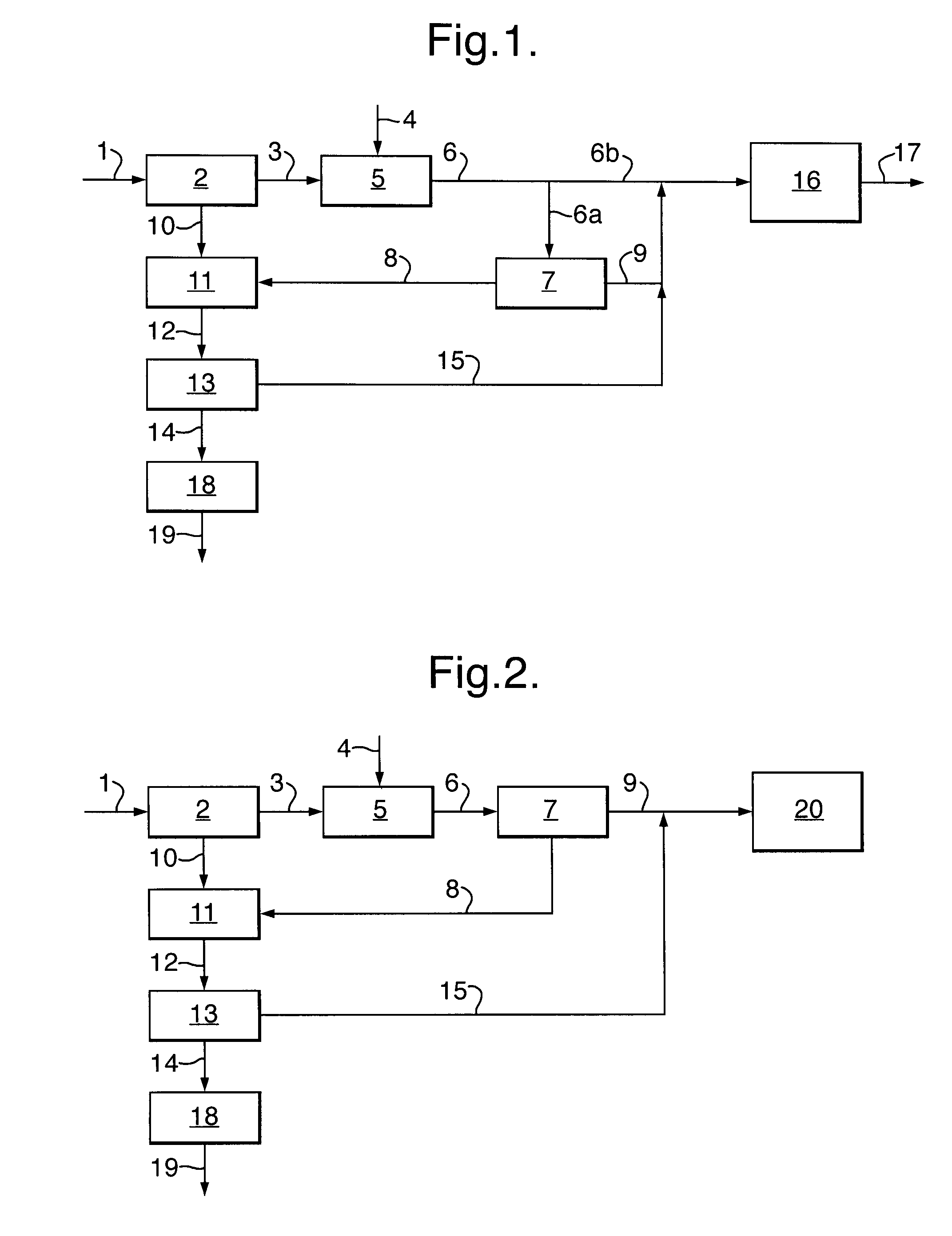

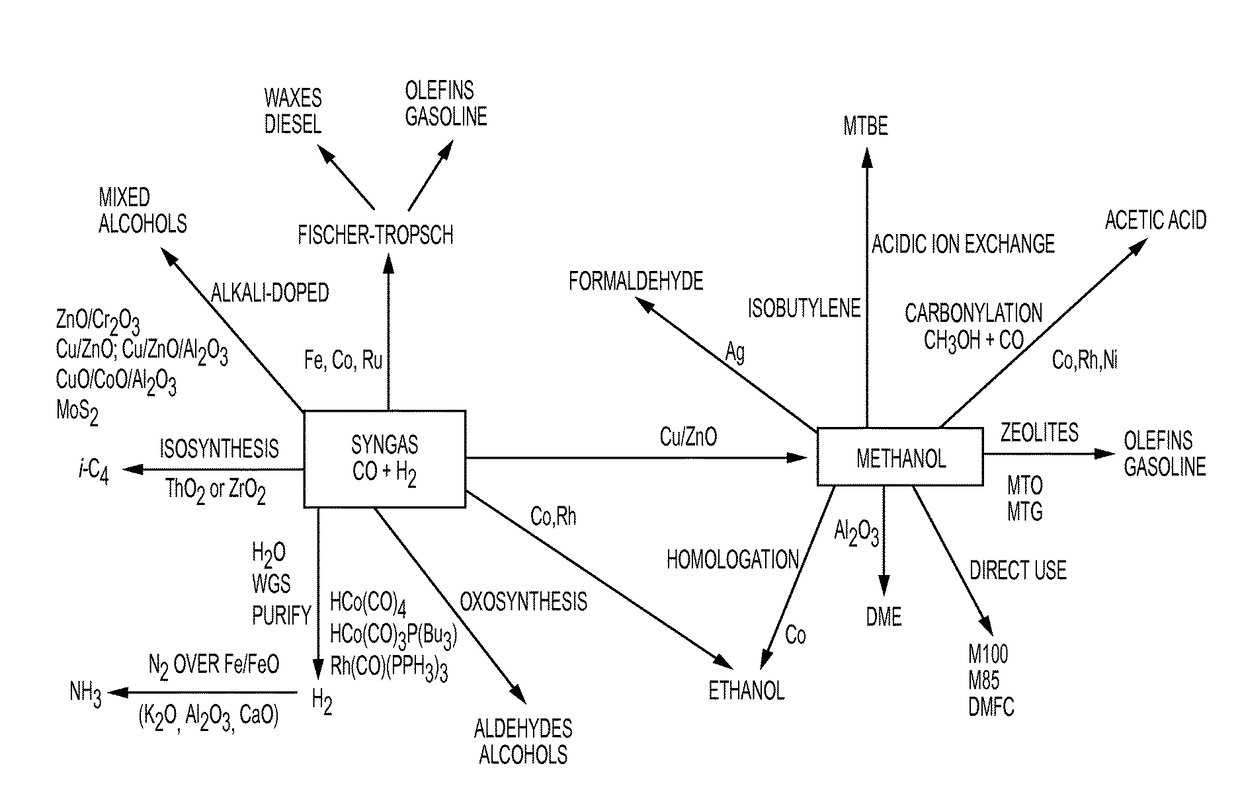

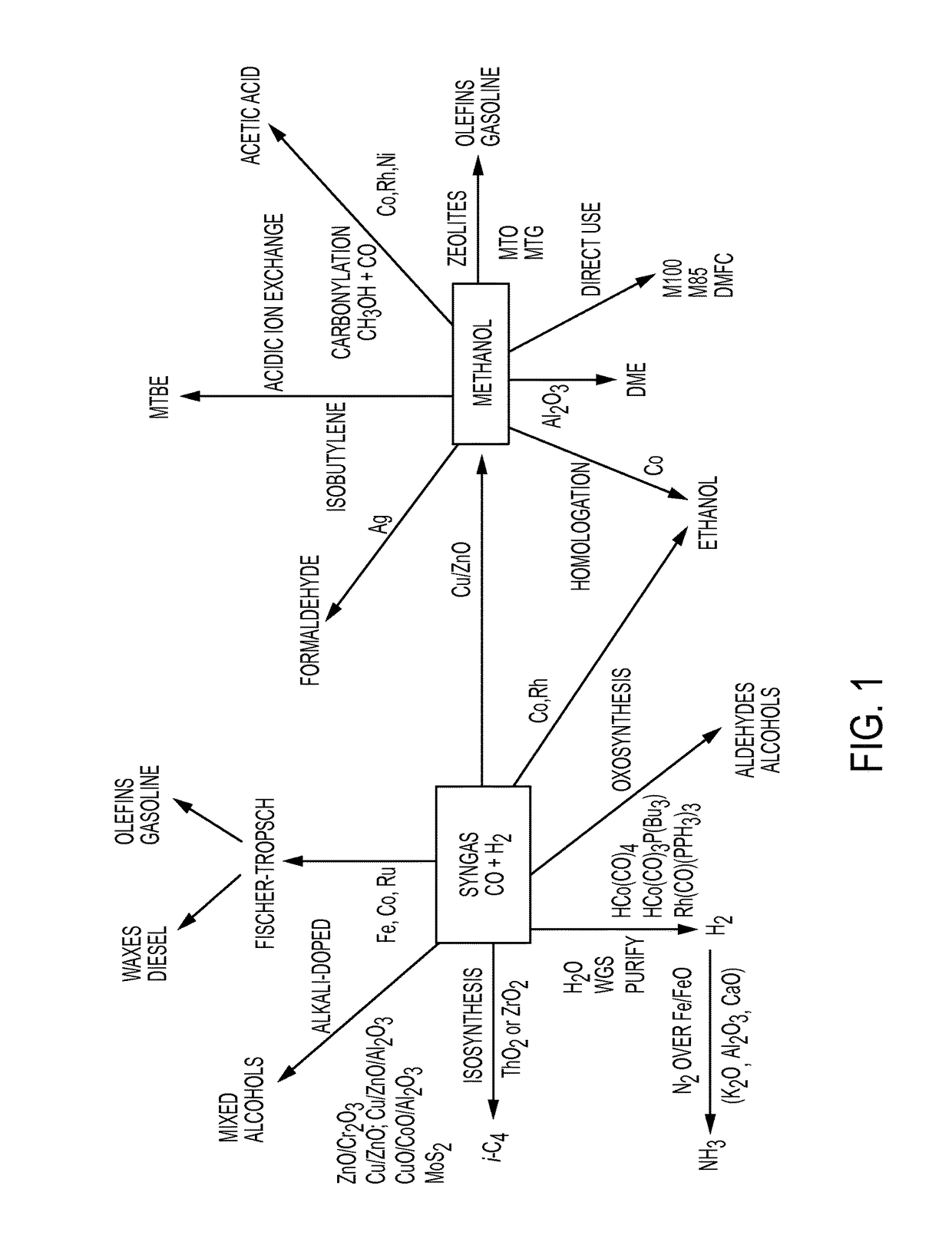

Process for the manufacture of carbon disulphide and use of a liquid stream comprising carbon disulphide for enhanced oil recovery

InactiveUS8097230B2Less carbon dioxideReduce rateCarbon disulfidePhysical/chemical process catalystsSulfurCarbon disulfide

The invention provides a process for the manufacture of carbon disulphide by reacting carbon monoxide with elemental sulphur to form carbonyl sulphide and disproportionating the carbonyl sulphide formed into carbon disulphide and carbon dioxide, the process comprising contacting a gaseous stream comprising carbon monoxide with a liquid elemental sulphur phase containing a solid catalyst at a temperature in the range of from 250 to 700° C. to obtain a gaseous phase comprising carbonyl sulphide, carbon disulphide and carbon dioxide. The invention further provides the use of a liquid stream comprising carbon disulphide, carbonyl sulphide and carbon dioxide obtainable by such process for enhanced oil recovery.

Owner:SHELL OIL CO

Process for the manufacture of carbon disulphide

InactiveUS7763227B2Significant costSignificant designCarbon disulfideHydrocarbon from carbon oxidesHydrogenCarbonyl sulfide

A process for the manufacture of carbon disulfide comprising the following steps: (a) reacting carbon monoxide with hydrogen sulfide to form carbonyl sulfide and hydrogen; (b) contacting the carbonyl sulfide formed in step (a) with a catalyst effective for disproportionating carbonyl sulfide into carbon disulfide and carbon dioxide.

Owner:SHELL OIL CO

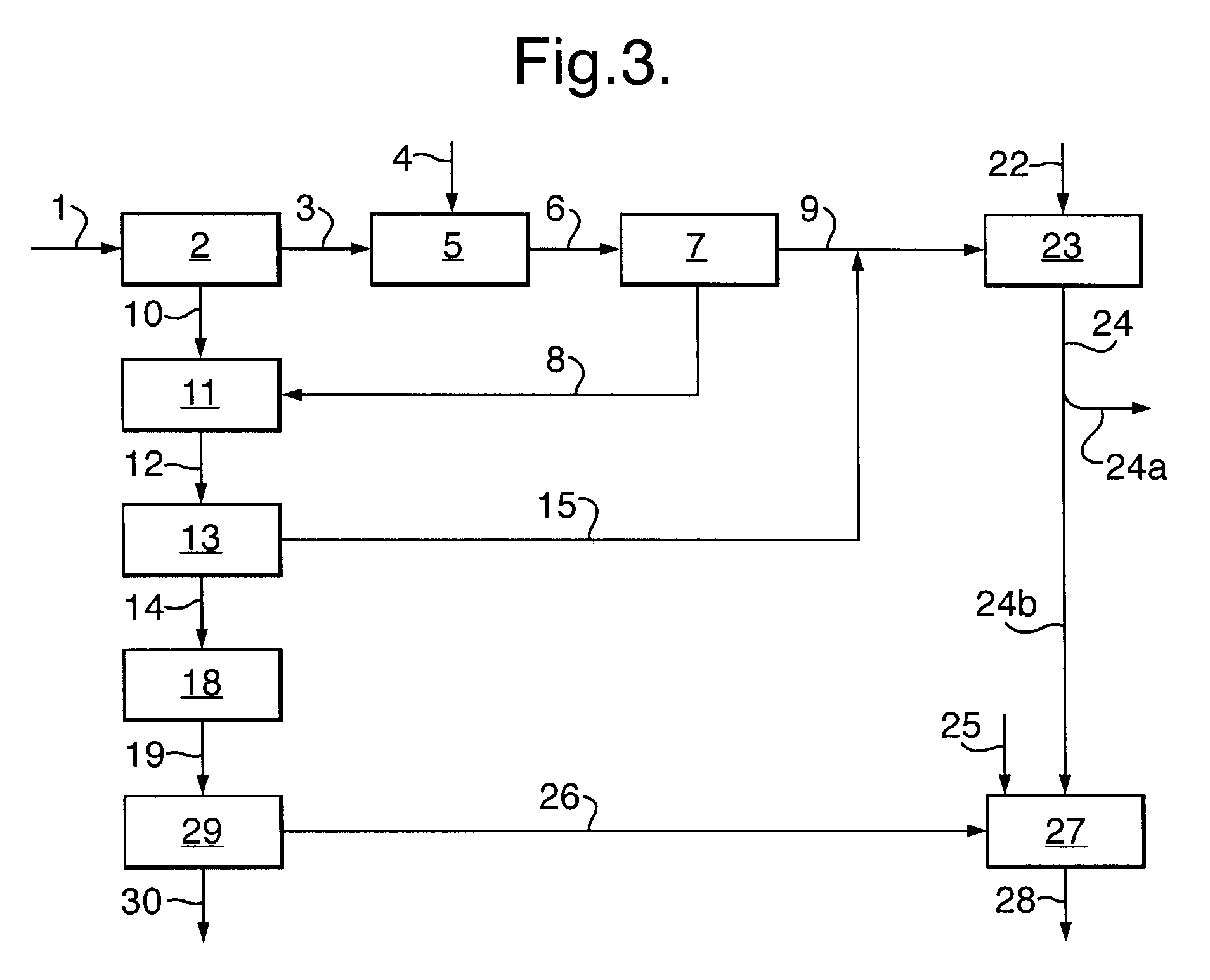

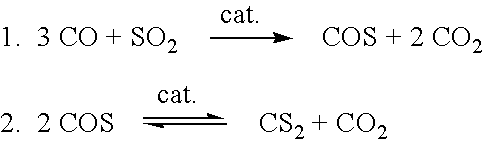

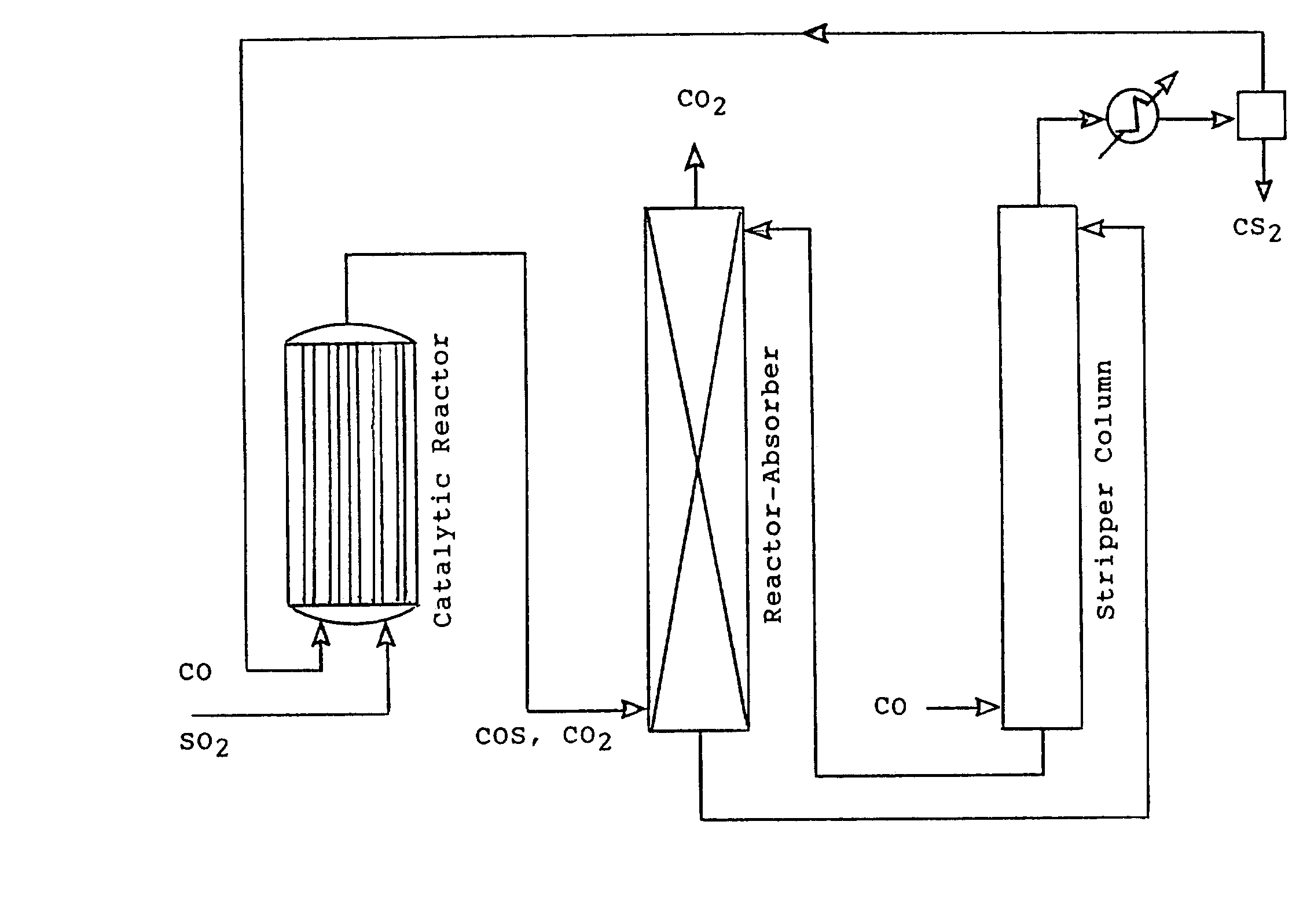

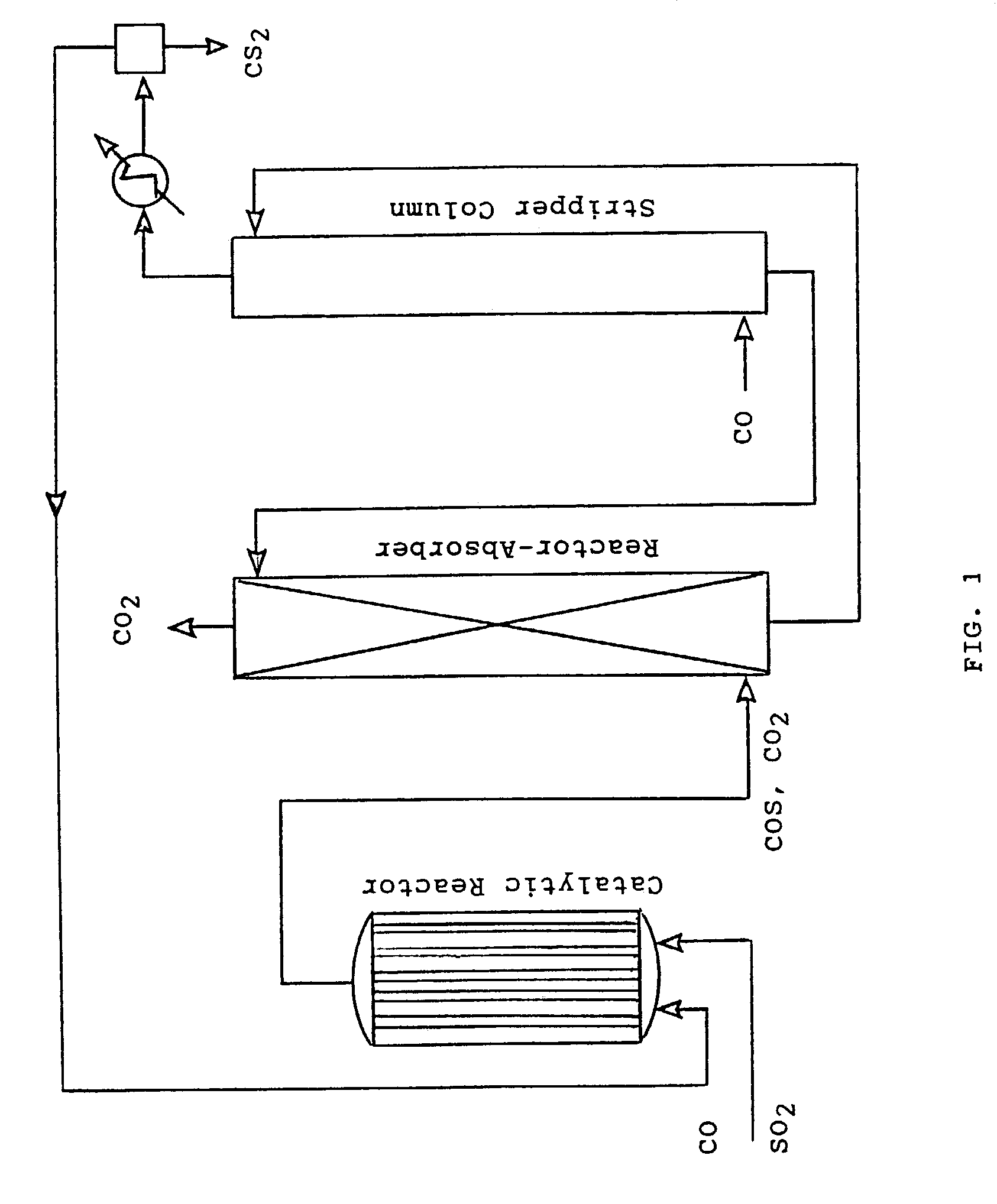

Carbon disulfide process

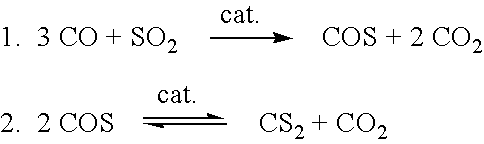

The specification discloses a process for the manufacture of carbon disulfide from sulfur dioxide and carbon monoxide comprising two catalytic reactions. In the first reaction, sulfur dioxide and carbon monoxide are converted to carbonyl sulfide and carbon dioxide. In the second reaction, carbonyl sulfide is disproportionated to carbon disulfide and carbon dioxide. The second reaction is conducted in the presence of a solvent, which continuously removes the carbon disulfide product so as to drive the reaction to completion.

Owner:JES TECH LLC

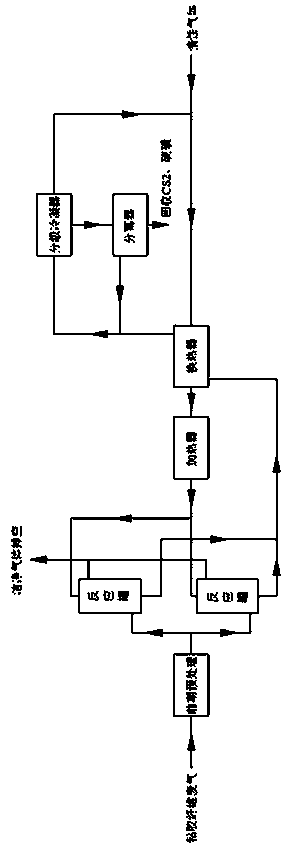

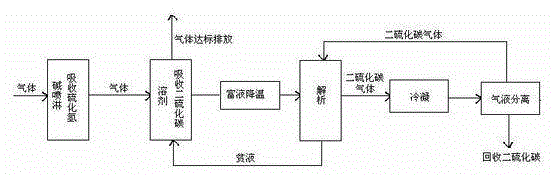

Recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber

InactiveCN103721524ANo emissionsSolving Corrosion ProblemsCarbon disulfideDispersed particle separationDesorptionSorbent

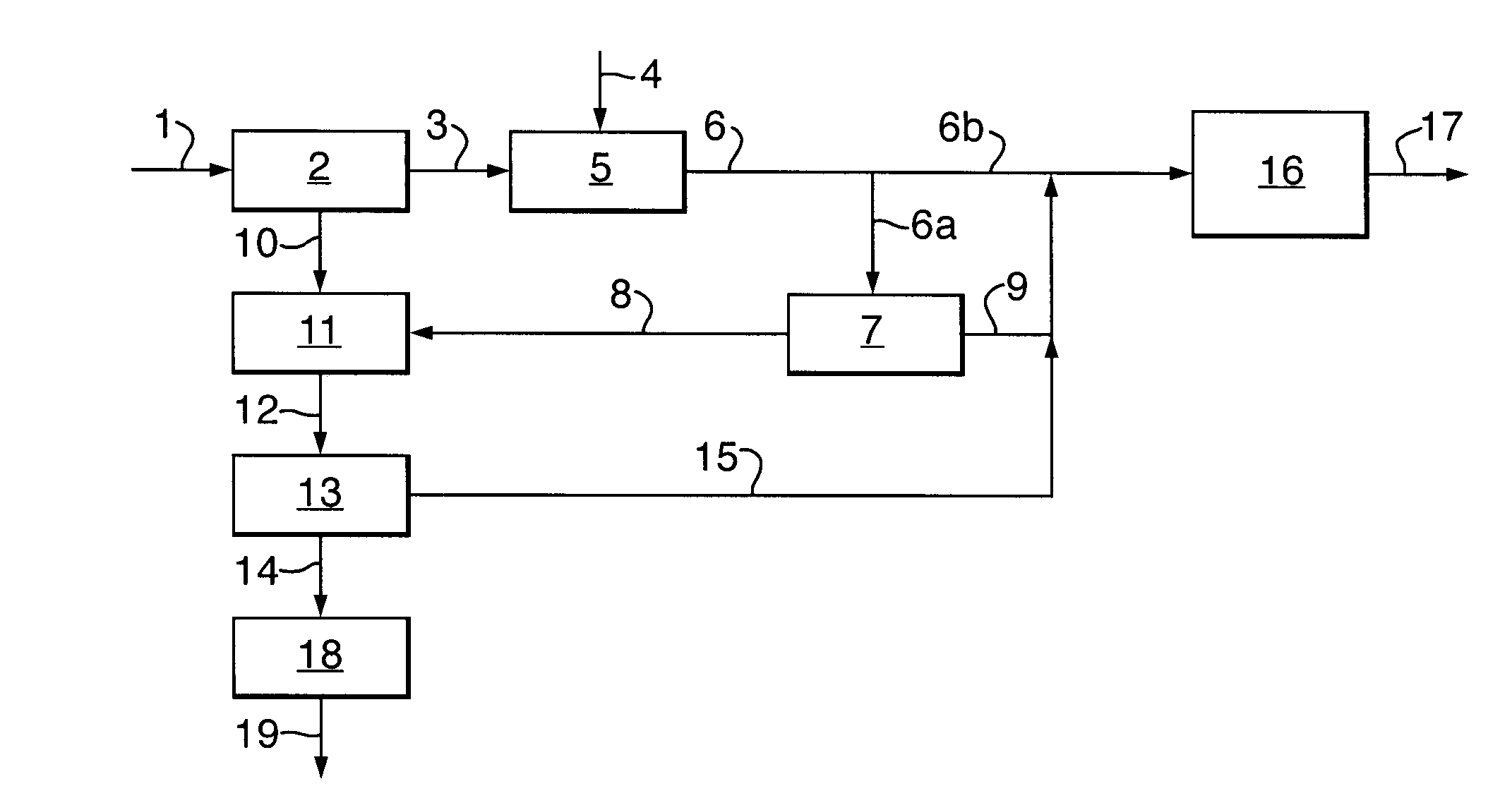

The invention relates to a recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber. The recycling treatment method comprises the four steps of pretreatment at the early stage, enrichment and thickening, desorption and regeneration and separation and recycling. The recycling treatment method particularly comprises the following steps: in the process of pretreatment at the early stage, carrying out dust removal, cooling and drying treatment on the waste gas; in the enrichment and thickening process, carrying out absorption and catching on two types of gases in a concentration-reaction tank filled with an absorbing agent; in the desorption and regeneration process, carrying out stepwise desorption on CS2 and H2S by adopting selected inert gas; and in the separation and recycling process, extracting CS2 and H2S respectively by adopting a fractional condenser. The recycling treatment method solves the problems that the equipment adopting steam as a desorbing carrier is corroded, the microporous surface of active carbon is calcified, and drying is needed after desorption and regeneration, and has the advantages that no waste gas is discharged, the service life of the absorbing agent is prolonged and high-efficiency and environmentally-friendly effects are achieved and the like.

Owner:石家庄科英化工技术有限公司

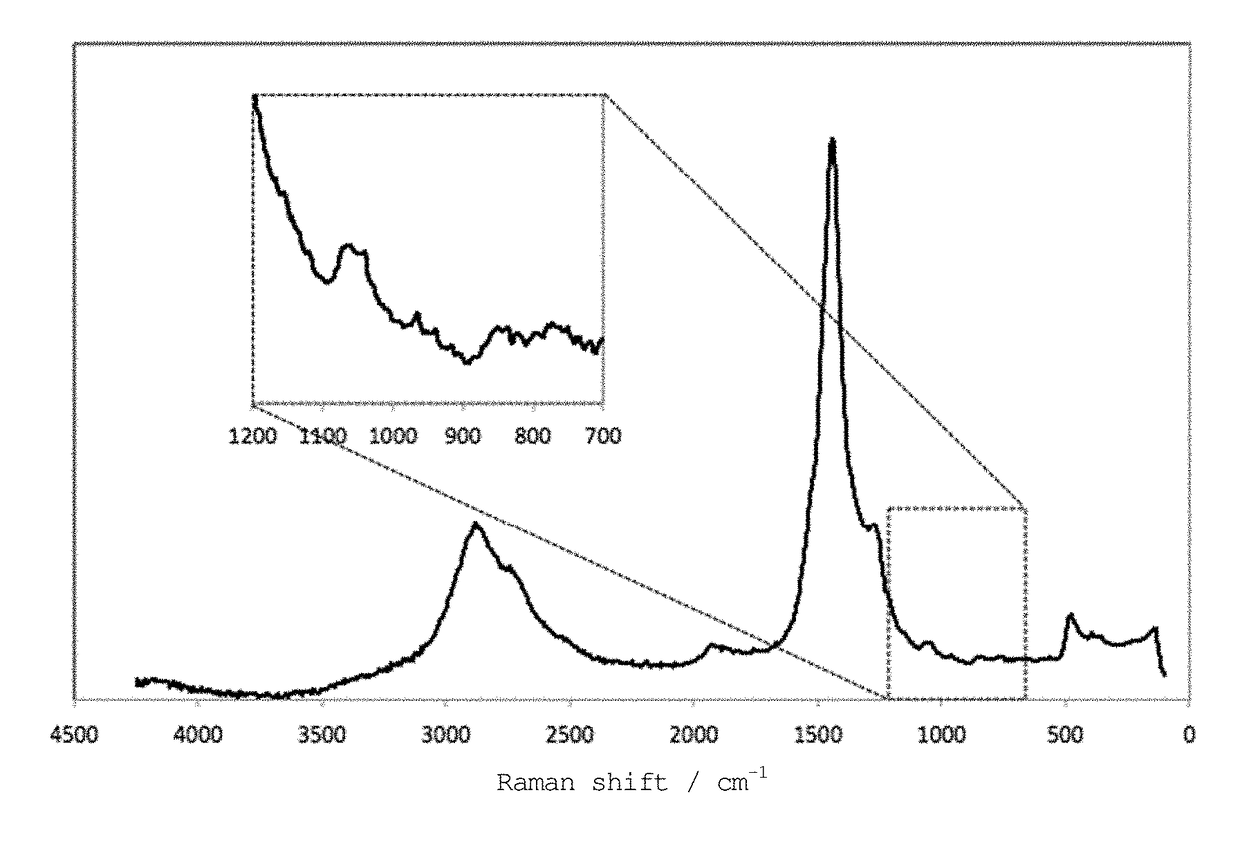

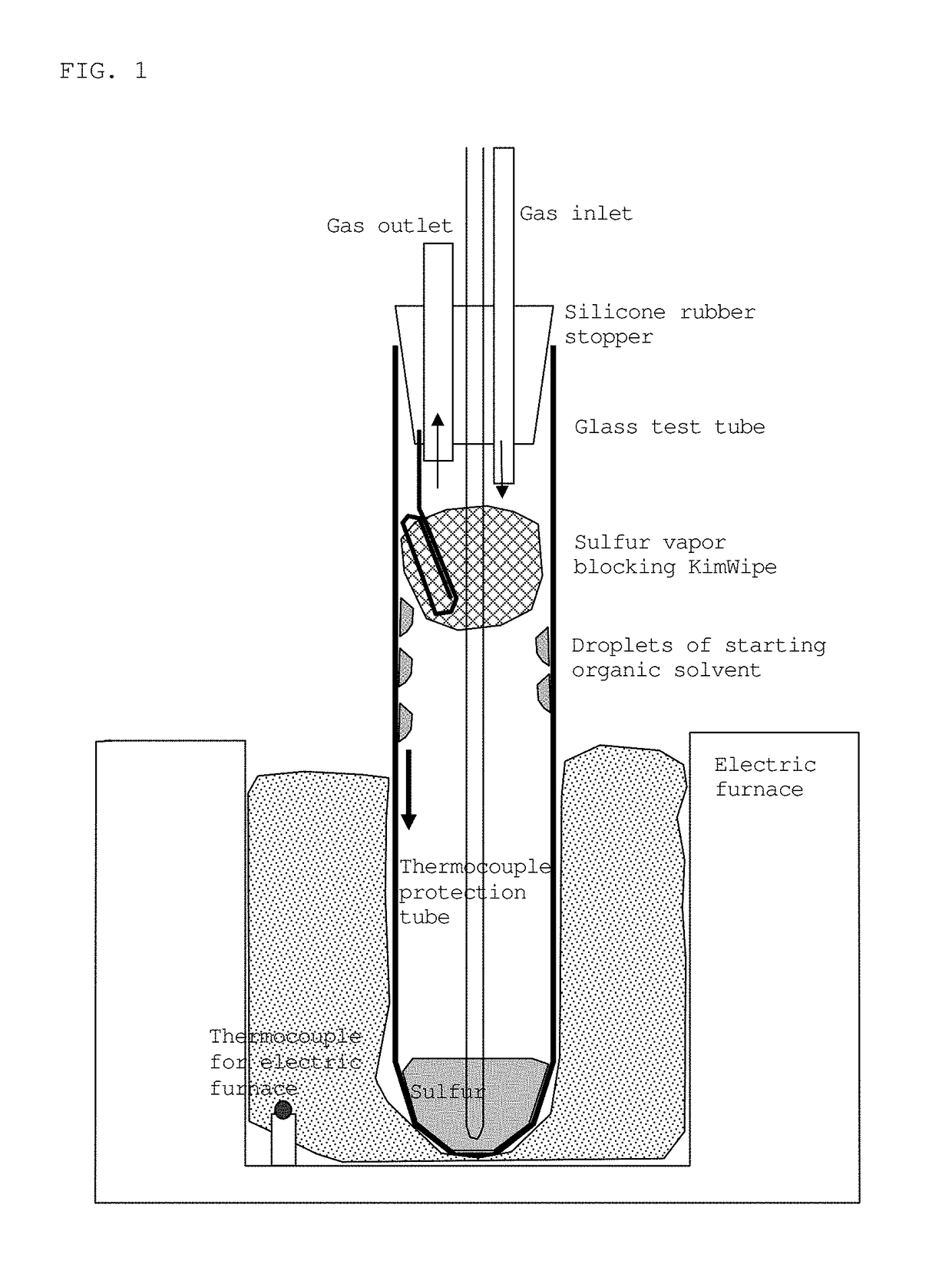

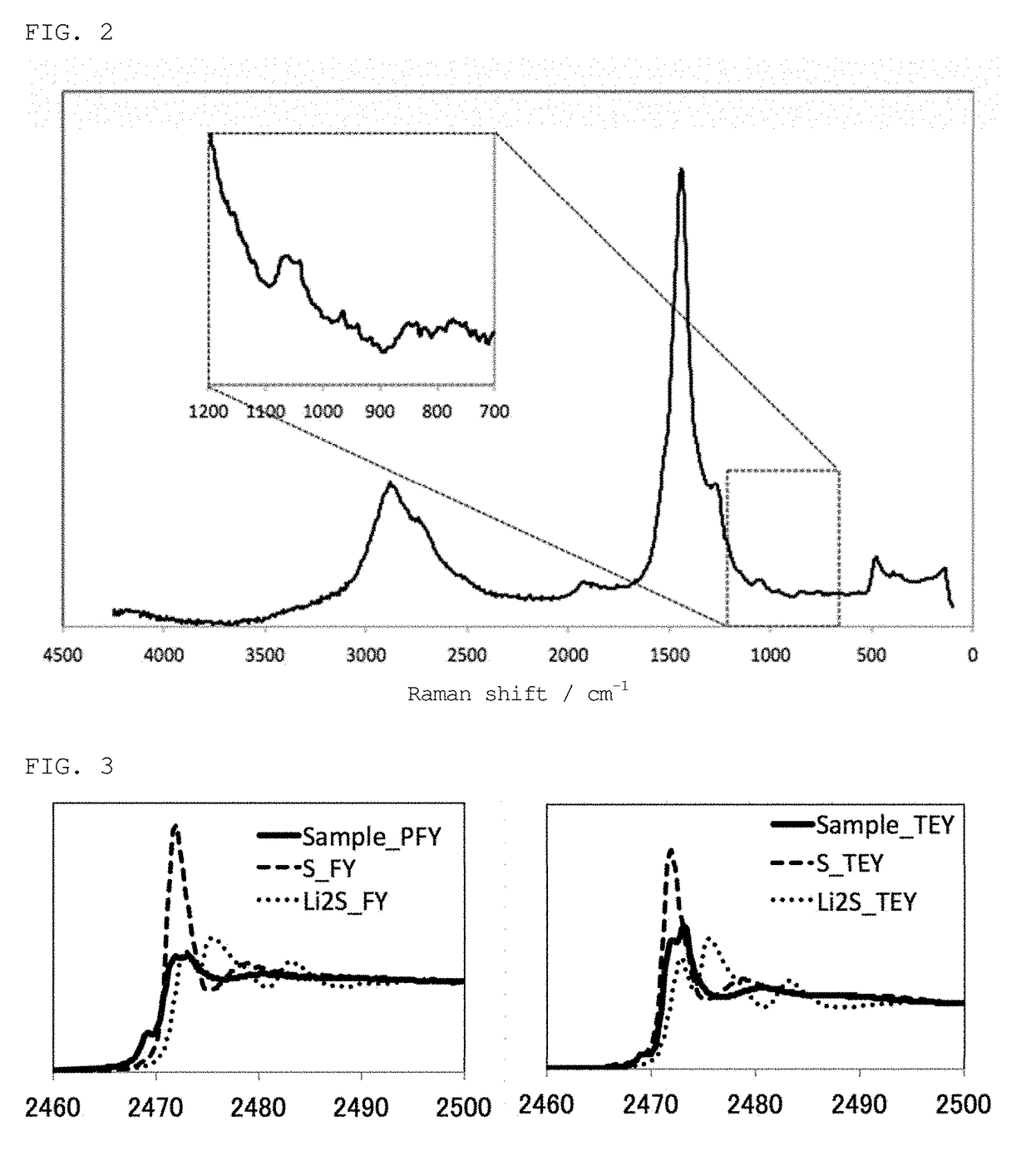

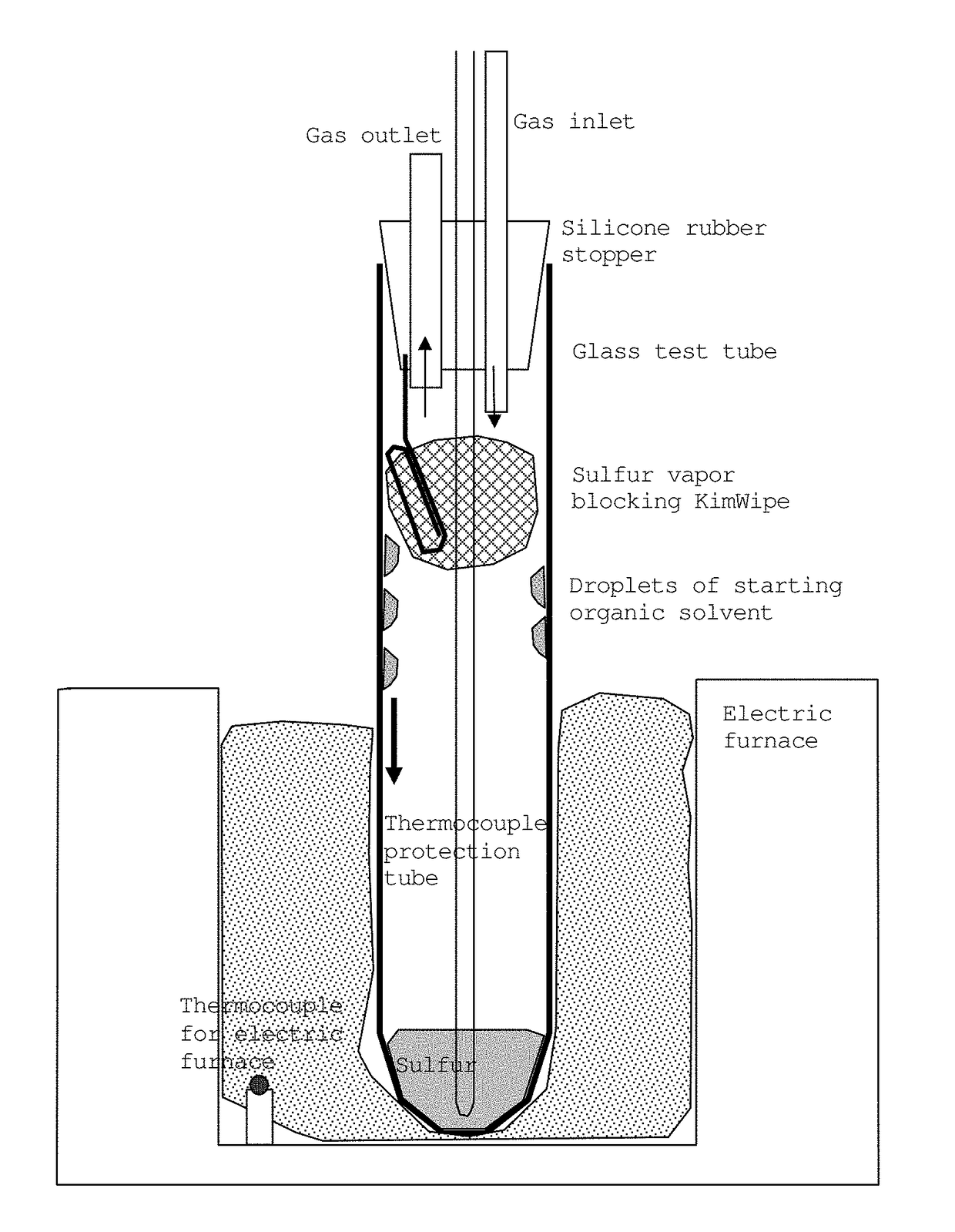

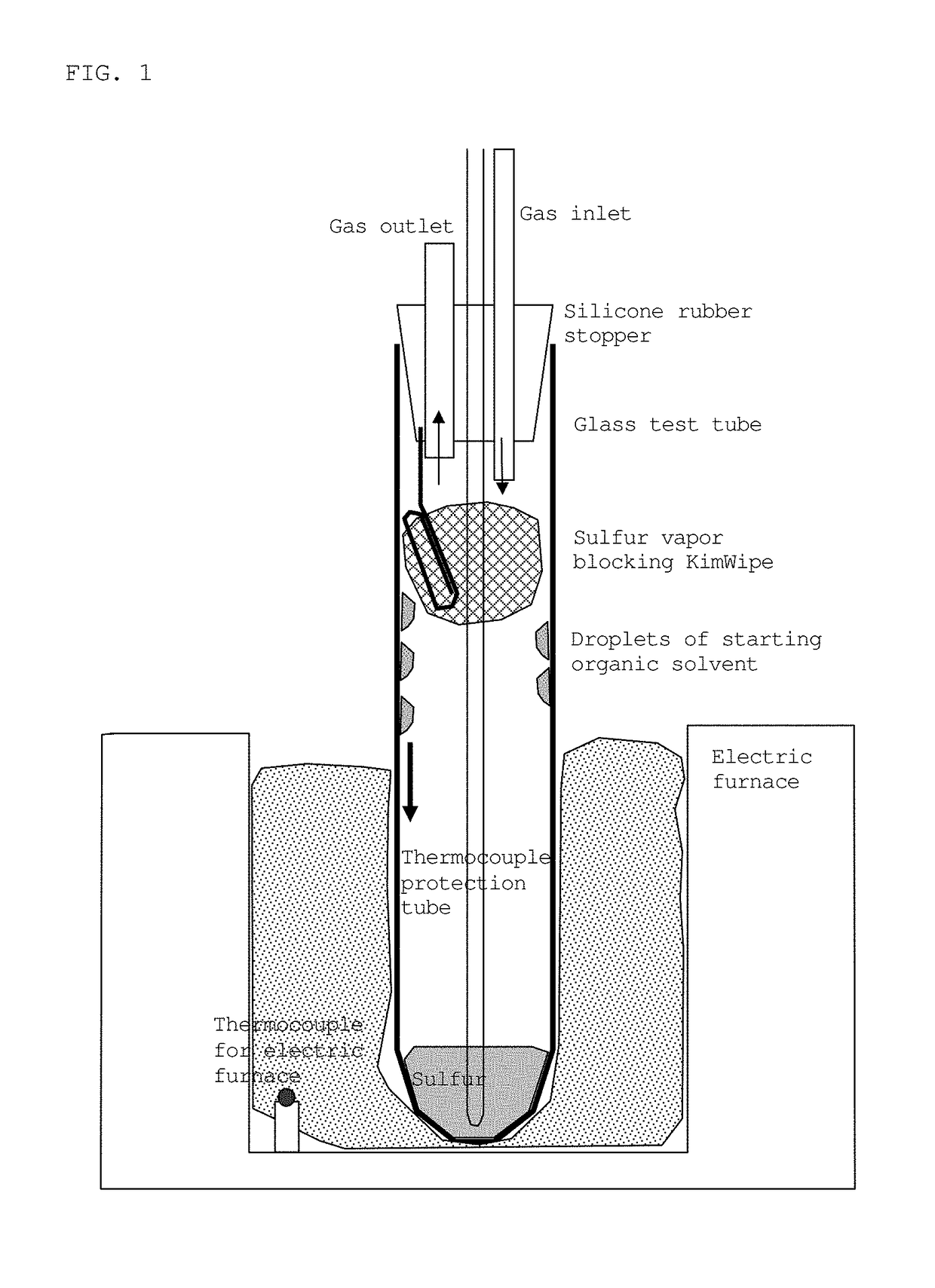

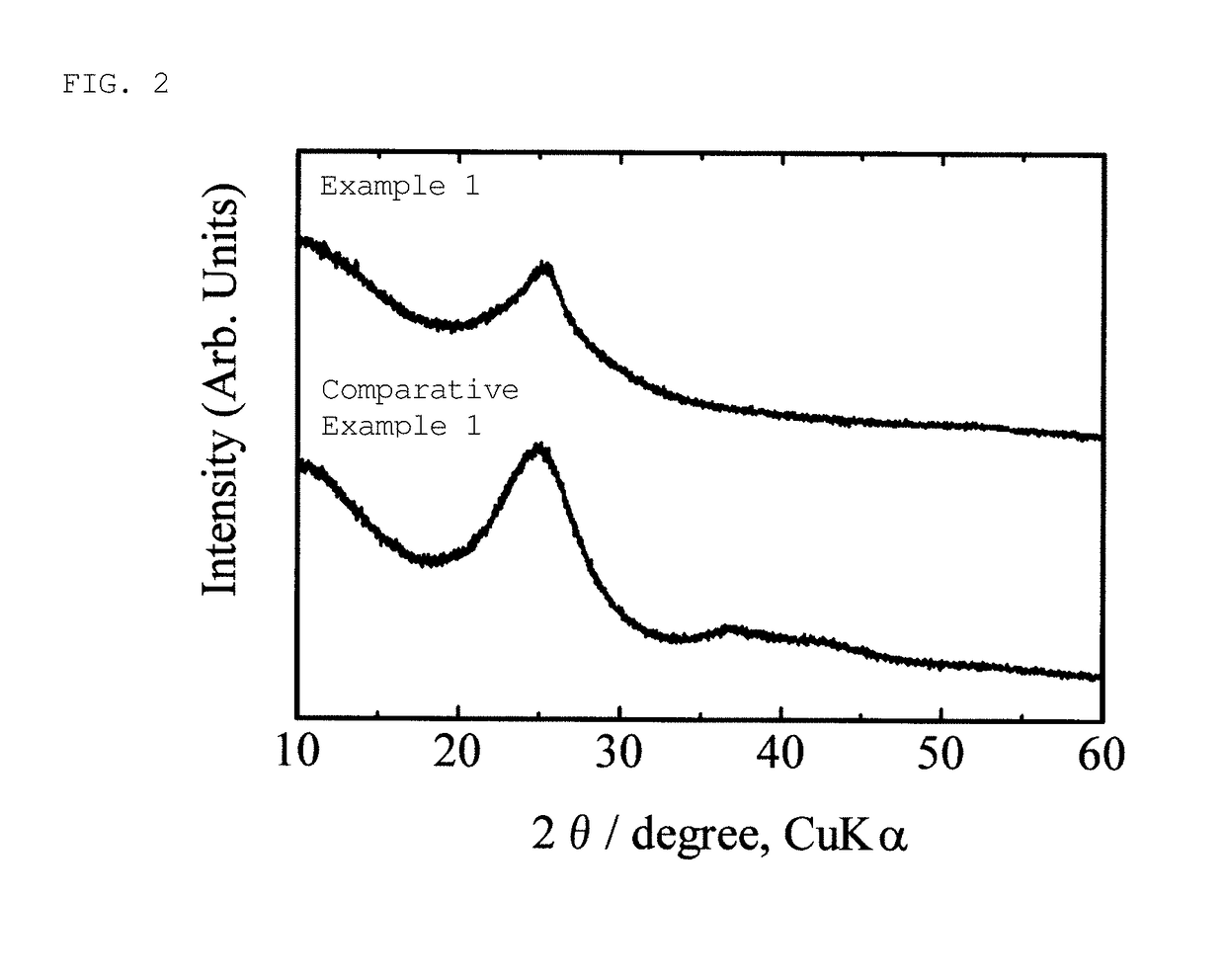

Organic sulfur material and method for producing same

ActiveUS20180065927A1Improve featuresExcellent cycle characteristicsCarbon disulfideOrganic chemistryHydrogenHeat resistance

An organic sulfur material comprising carbon, hydrogen, oxygen, and sulfur as constituent elements, and having peaks in the vicinity of 482 cm−1, 846 cm−1, 1066 cm−1, 1279 cm−1, and 1442 cm−1 in a Raman spectrum detected by Raman spectroscopy, the peak in the vicinity of 1442 cm−1 being most intense, has a high capacity and high heat resistance, although a liquid organic starting material is used.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Technology for recovery of carbon disulfide in viscose fiber production

ActiveCN103331083AInhibition releaseImprove absorption rateCarbon disulfideDispersed particle separationHigh absorptionDesorption

Relating to the field of exhaust gas recovery in the viscose fiber industry, the invention provides a technology for recovery of carbon disulfide in viscose fiber production. The technology is characterized in that: the hydrogen sulfide in carbon disulfide exhaust gas produced in viscose fiber production is removed by alkali spraying, then carbon disulfide is recovered through the steps of: A) taking white oil as an absorbent to absorb carbon disulfide in the exhaust gas, cooling an absorption saturated carbon disulfide-rich solution to 15-35DEG C; B) pumping the absorption saturated carbon disulfide-rich solution into a desorption tower, passing the solution through a liquid distributor, then heating the solution to 150DEG C-170DEG C, boiling the solution so as to separate the carbon disulfide gas and a barren solution; and C) subjecting the carbon disulfide gas to condensation and gas-liquid separation, and recovering the condensed carbon disulfide. The recovery technology involved in the invention has the advantages of high absorption rate, and low investment and operation cost.

Owner:YIBIN HIEST FIBER +2

Carbon disulfide process

The specification discloses a process for the manufacture of carbon disulfide from sulfur dioxide and carbon monoxide comprising two catalytic reactions. In the first reaction, sulfur dioxide and carbon monoxide are converted to carbonyl sulfide and carbon dioxide. In the second reaction, carbonyl sulfide is disproportionated to carbon disulfide and carbon dioxide. The second reaction is conducted in the presence of a solvent, which continuously removes the carbon disulfide product so as to drive the reaction to completion.

Owner:JES TECH LLC

Organic sulfur material and method for producing same

ActiveUS20180072665A1Excellent charge and discharge characteristicsImprove conductivityCarbon disulfideOrganic chemistryHydrogenSulfur

The present invention provides an organic sulfur material comprising carbon, hydrogen, and sulfur as constituent elements, and having peaks in the vicinity of 480 cm−1, 1250 cm−1, 1440 cm−1, and 1900 cm−1 in a Raman spectrum detected by Raman spectroscopy. The peak in the vicinity of 1440 cm−1 is the most intense peak. This organic sulfur material, which is produced by using a liquid organic starting material, achieves high capacity. This organic sulfur material preferably does not have peaks in the vicinity of 846 cm−1 or 1066 cm−1.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for recovery processing sulfur-containing mixed waste gas in production of viscose

InactiveCN103772250AAchieve the purpose of reuseEfficient use ofCarbon disulfideOrganic chemistrySocial benefitsExhaust fumes

The invention relates to a method for recovery processing sulfur-containing mixed waste gas in the production of viscose, which belongs to the technical field of the treatment of sulfur-containing waste gas in the production of viscose. The invention provides a novel technical route for the existing waste gas treatment situation of the viscose production enterprise, the sulfur-containing waste gas of low concentration is pretreated firstly, then the sulfur-containing waste gas is selectively absorbed by adopting the spraying absorption technology, then the absorption liquid is treated, and finally a product with high cost performance is obtained. The technical route is high in industrialization degree, the mixed waste gas consisting of low-concentration H2S, CS2, vast air and little solid waste in the production process of viscose industry can be effectively treated in time, certain economic benefit and social benefit also can be obtained, the technical feasibility and economical feasibility are good, and the sustainable development requirement of the society can be met.

Owner:YIBIN GRACE +2

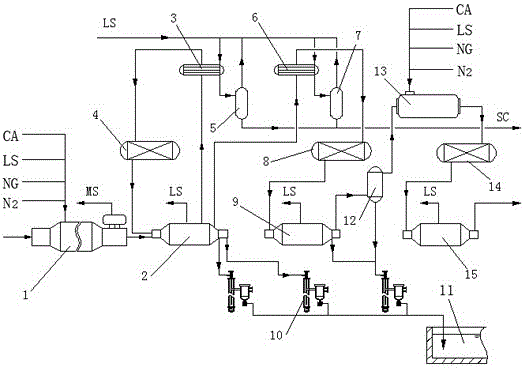

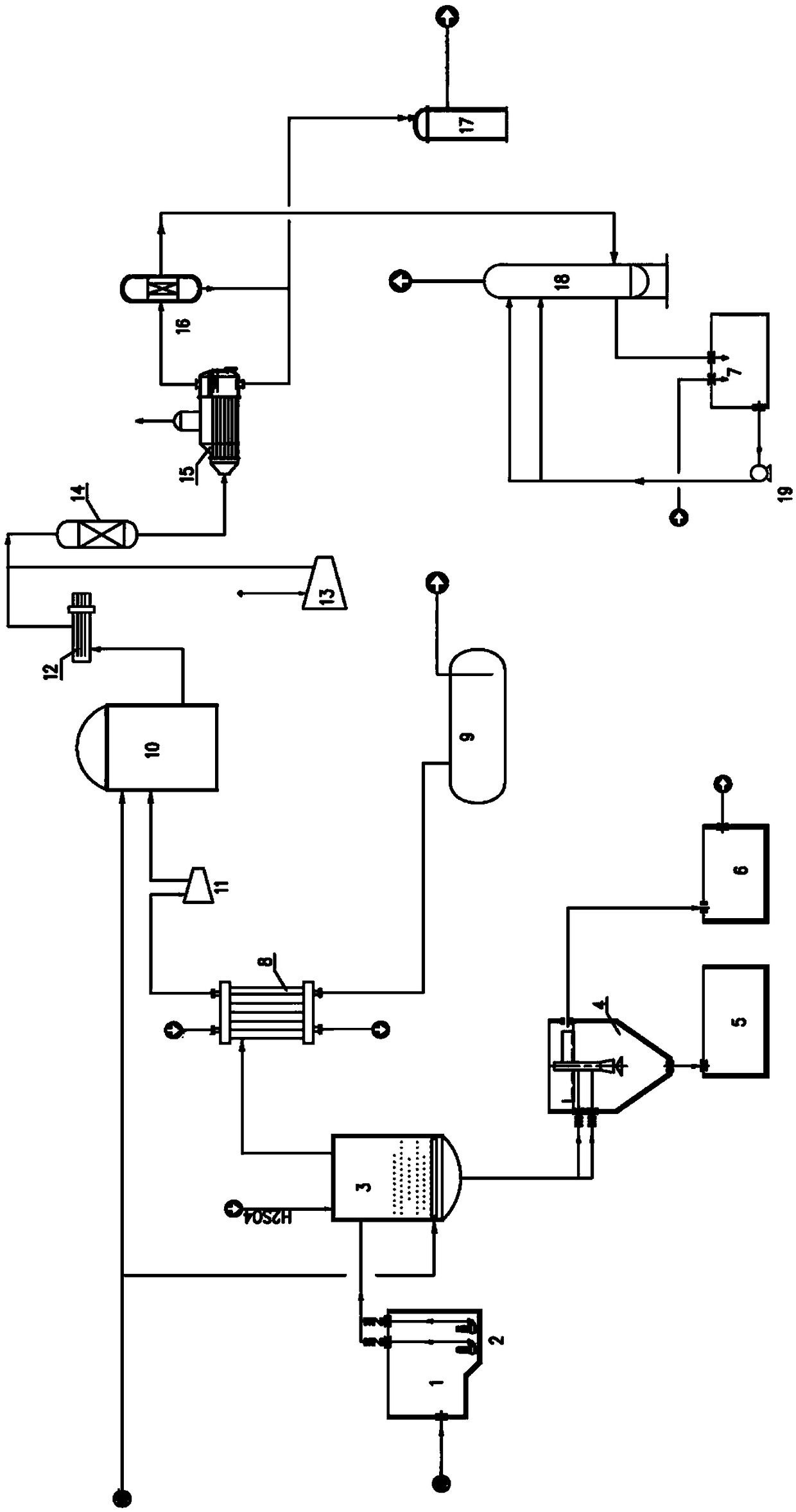

Treatment technology and equipment for carbon disulfide production process gas

InactiveCN106829875AEfficient recyclingSolve the problem that the catalytic conversion temperature is difficult to controlCarbon disulfideChemical industryNational standardFuel gas

The invention discloses a treatment technology and equipment for carbon disulfide production process gas. The treatment technology comprises the specific steps that 1, acid gas, fuel gas and air are fed into an acid gas combustion furnace for a combustion reaction; 2, process gas generated inside the acid gas combustion furnace is introduced into a converter reactor; 3, sulphur is separated out from the process gas generated after a reaction of the converter reactor, sulphur dioxide and elemental sulphur in generated tail gas are subjected to a hydrogenation reduction to obtain hydrogen sulfide, and organic sulphur is hydrolyzed into hydrogen sulfide; 4, H2S and CO2 are recycled circularly from the tail gas containing hydrogen sulfide generated in the step 3 through an amine solution, and the purified tail gas enters a tail gas burning furnace to be burnt and exhausted. By improving the technology and the equipment, sulphur in the process gas containing hydrogen sulfide is efficiently recycled, the total sulphur recycling rate reaches 99.8% or above, the problem that the catalytic conversion temperature of a traditional technology is hard to control is solved, and the SO2 content in the finally-exhausted tail gas is much lower than the concentration of the national standard.

Owner:安徽宣城金宏化工有限公司

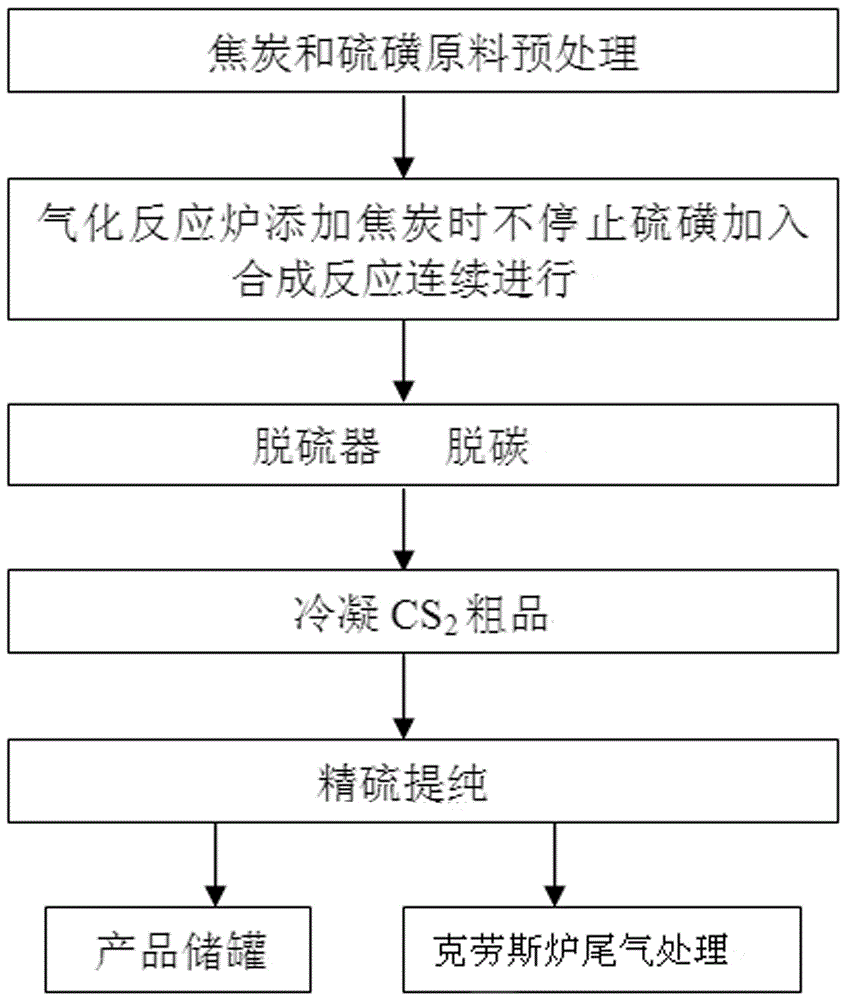

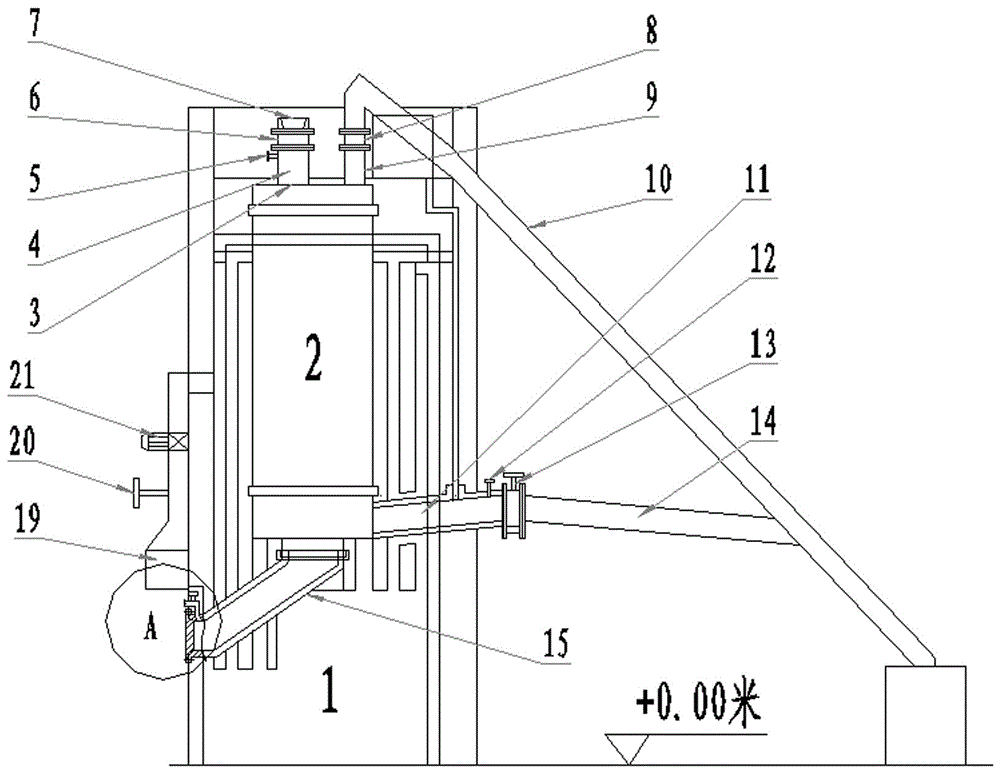

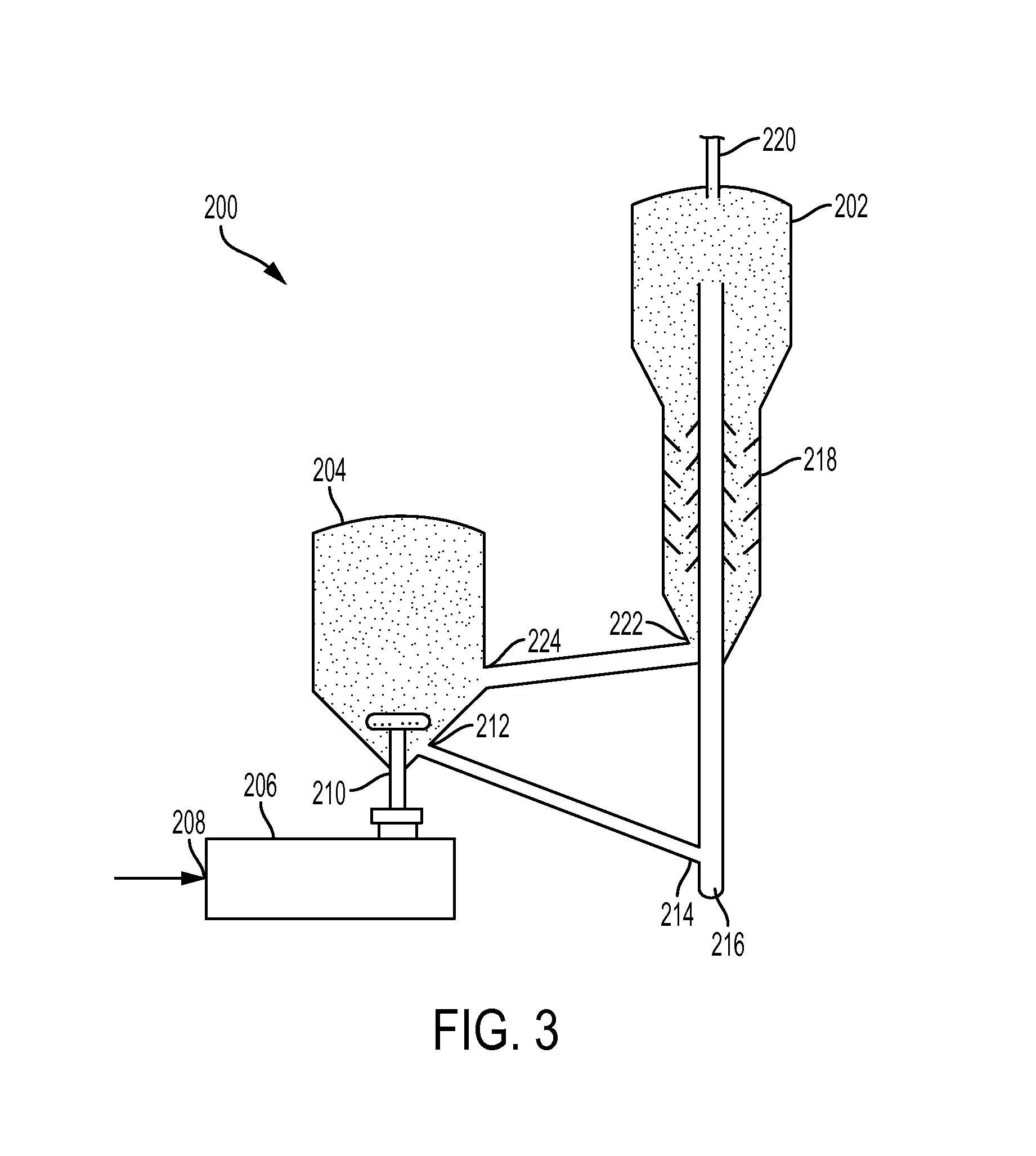

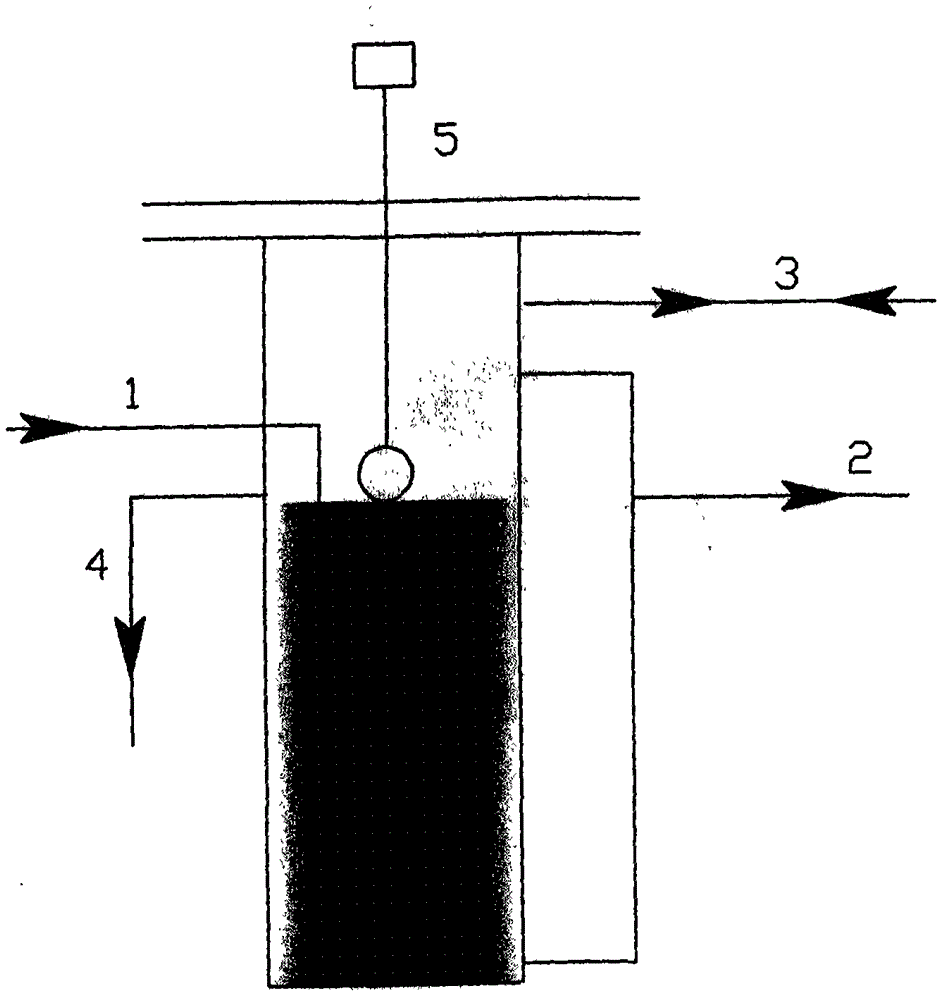

Continuous carbon disulfide production process and device adopting coke method

ActiveCN106395824AStop the leakNo emission problemsCarbon disulfideEnergy inputSlagMaterials science

The invention belongs to the technical field of carbon disulfide production by coke methods and aims to solve the problems that in an intermittent carbon disulfide production process adopting a traditional coke method, when coke raw materials are added, sulfur needs to stop adding, and environmental safety is caused during material adding and slag discharging. The invention provides a continuous carbon disulfide production process adopting the coke method. The process flow comprises the steps of pretreatment of raw materials, synthetic reaction, desulfuration, condensation, purification by rectification and tail gas treatment. According to the continuous production process disclosed by the invention, when the coke raw materials are added in a reaction furnace in working procedures of the synthetic reaction or slag is discharged from the reaction furnace, gases such as CS2 in the reaction furnace are displaced by inert gases and cannot leak out of the furnace. According to the continuous production process, when the coke raw materials are added into the gasification reacting furnace in working procedures of the synthetic reaction after a cover of the gasification reacting furnace is opened, intermittent production subjected to sulfur addition stopping is eliminated, so that the problem that environmental safety is caused due to unorganized emission of poisonous and harmful gases such as H2S and SO2 when the cover of the reaction furnace is opened for adding the coke raw materials and removing furnace slag, and clean production and continuous production are realized.

Owner:阳城县绿色科技研发中心 +1

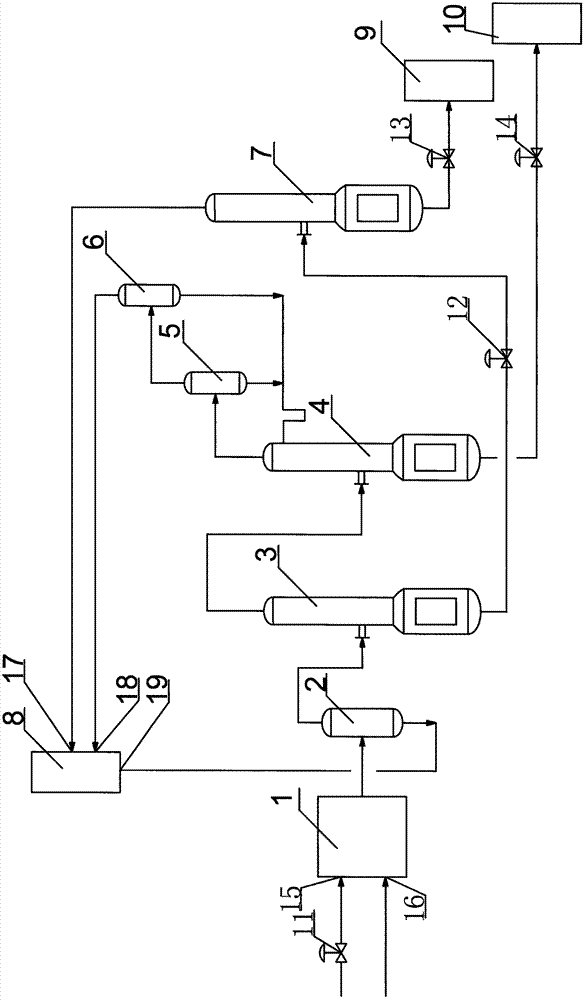

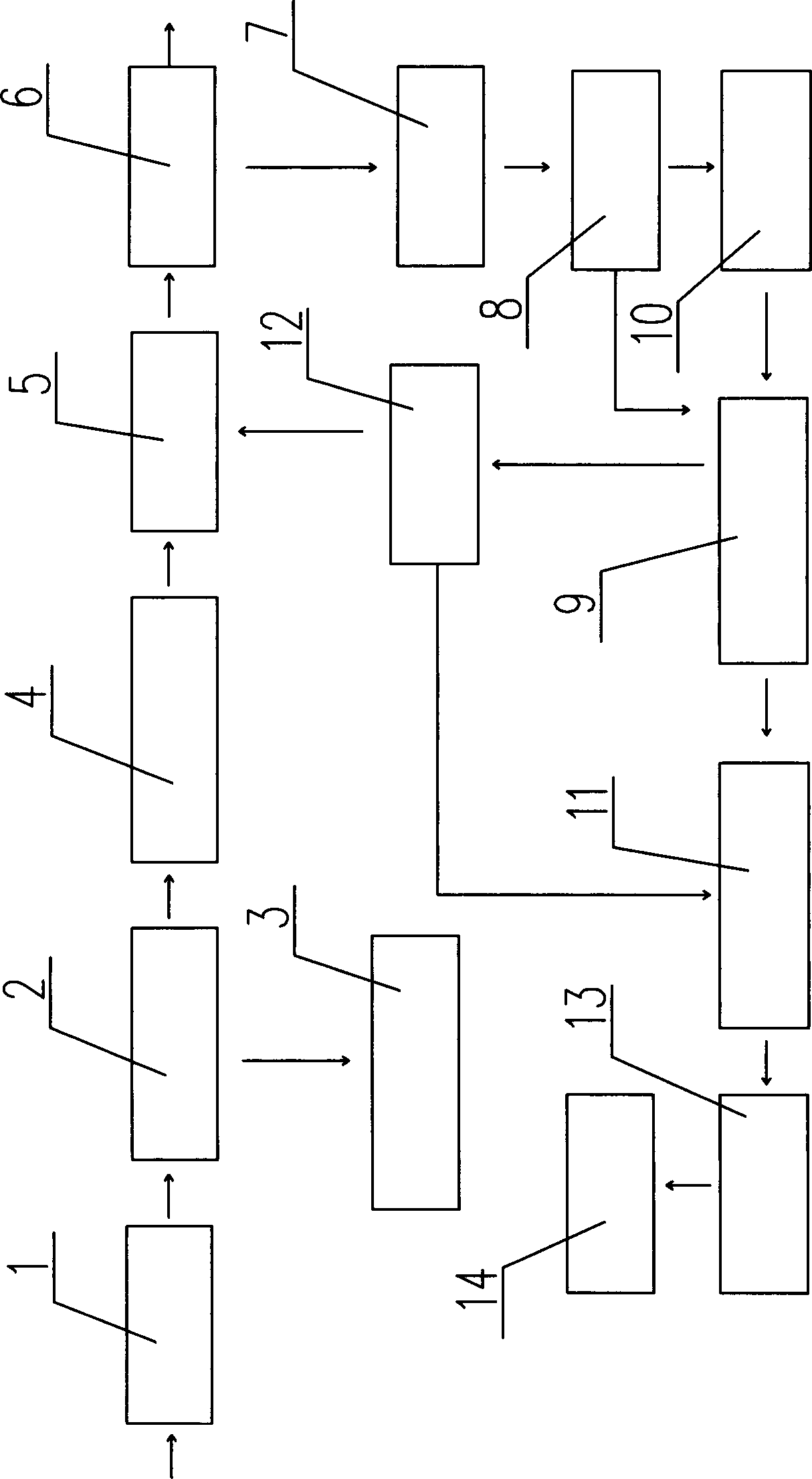

Device and method for simultaneously producing ultra-high-purity carbon oxysulfide and high-purity carbon disulfide

PendingCN107986277AEasy to integrateEasy to recycleCarbon disulfideCarbon oxysulideGas phaseBuffer tank

The invention belongs to a device and a method for simultaneously producing ultra-high-purity carbon oxysulfide and high-purity carbon disulfide. The device comprises a carbon monoxide raw material gas pipeline provided with a first regulating valve, a sulphur raw material pipeline, a carbon disulfide product tank and a carbon oxysulfide product tank, wherein the carbon monoxide raw material gas pipeline and the sulphur raw material pipeline are respectively connected with a first raw material inlet and a second raw material inlet of a reactor; an outlet of the reactor is connected with a buffer tank; a gas outlet formed in the top of the buffer tank is connected with an entrance of a first rectifying tower, a liquid phase outlet of the first rectifying tower is connected with an entranceof a third rectifying tower, and a liquid phase outlet of the third rectifying tower is connected with the carbon disulfide product tank; a gas phase outlet of the first rectifying tower is connectedwith a raw material inlet of a second rectifying tower, and a liquid phase outlet of the second rectifying tower is connected with the carbon oxysulfide product tank; the device and the method have the advantages that a three-tower type complex distillation process is used for extracting the carbon oxysulfide with the purity of not lower than 99.999%, and the purity of the carbon disulfide is improved to 99.99%.

Owner:HENAN XINLIANXIN SHENLENG ENERGY

Processes for converting hydrogen sulfide to carbon disulfide

Processes for forming carbon disulfide from a gas stream containing hydrogen sulfide. A gaseous stream comprising lower molecular weight alkanes and hydrogen sulfide may be contacted with sufficient bromine at a temperature of from about 250° C. to about 530° C. to convert substantially all of said hydrogen sulfide to carbon disulfide. The gaseous stream may contain from about 0.001 to about 20 mol % hydrogen sulfide. The molar ratio of bromine to hydrogen sulfide may be about 2:1.

Owner:GTC TECHNOLOGY US LLC

Preparation method of catalyst for preparing hydrogen from hydrogen sulfide

ActiveCN102773108ALow costImprove low temperature catalytic activityCarbon disulfidePhysical/chemical process catalystsSolubilityHydrogen

The invention relates to a preparation method of a catalyst for preparing hydrogen from hydrogen sulfide. The preparation method comprises a first step (1) of reacting a pre-precipitating agent aqueous solution and a precipitating agent aqueous solution to form a pre-precipitating turbid solution; a second step (2) of adding a metal salt-water solution into the pre-precipitating turbid solution of the first step (1), a precipitant being formed by a reaction, filtering, washing, drying and calcinating the precipitant to obtain a metal salt oxide; and a third step of (3) performing a sulphur treatment on the metal salt oxide of the second step (2), and thus a product is obtained. Cations of the pre-precipitating agent can form a precipitant with anions of the precipitating agent, wherein the solubility product of the precipitant is larger than that of a precipitant formed by metal ions and the anions of the precipitating agent; the precipitating agent is a material capable of producing materials such as OH<->, CO3 <2-> or -OOCCOO- in water; and the metal is one or more selected from VIB group and VIII group transition metals. The catalyst prepared by the method provided by the invention is a bulk phase catalyst consisting of metal sulfur oxides, is low in cost, and has high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for selectively desorbing carbon disulfide in coarse benzene

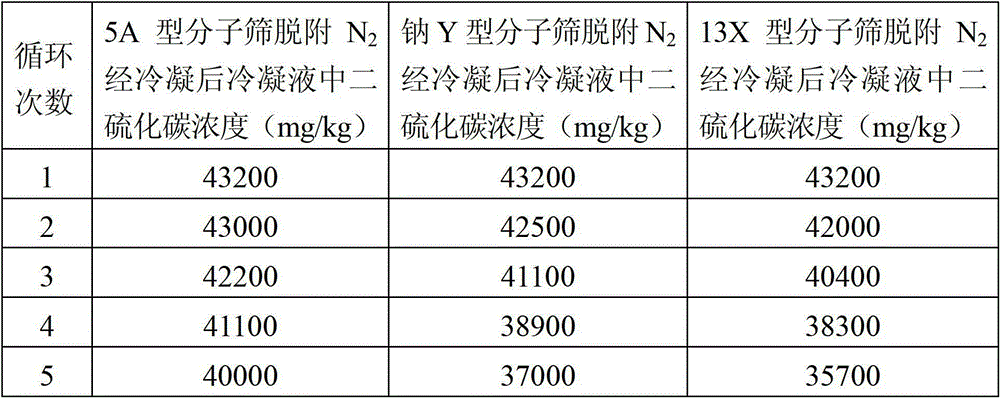

ActiveCN102718621APromote regenerationExtend the life cycleCarbon disulfideAdsorption purification/separationBenzeneMolecular sieve

The invention discloses a method for selectively desorbing carbon disulfide in coarse benzene. The nethod comprises the steps that a silicon-alumininm molecular sieve is utilized as adsorbent; at the temperature of 10-60DEG C, carbon disulfide in the coarse benzene is subjected to efficient selective adsorption under the normal-pressure condition; in addition, after adsorbent is adsorbed to be saturated, N2 is introduced in at the temperature of 200-400DEG C, and is purged for 2-6 hours, so the adsorbent can be regenerated and reused; and meanwhile, the adsorbed and desorbed carbon disulfide can be desorbed and reused. The method for selectively desorbing carbon disulfide in the coarse benzene has the advantages of moderate adsorption condition, simple equipment, easiness in operation, high selective adsorption and the like, and the adsorbent can be reused after being regenerated.

Owner:邢台旭阳科技有限公司

Carbon monoxide production from carbon dioxide reduction by elemental sulfur

ActiveUS20160107893A1Inhibit productionLower energy requirementsCarbon disulfideOther chemical processesSulfurDecreased carbon dioxide

Disclosed is a method of producing carbon monoxide (CO) and sulfur dioxide (SO2), the method comprising obtaining a reaction mixture comprising carbon dioxide gas (CO2(g)) and elemental sulfur gas (S(g)), and subjecting the reaction mixture to conditions sufficient to produce a product stream comprising CO(g) and SO2(g).

Owner:SABIC GLOBAL TECH BV

Method for recovery treatment of sulfur-containing mixed waste gas in production of viscose fiber

InactiveCN103772251AAchieve the purpose of reuseEfficient use ofCarbon disulfideOrganic chemistryProcess engineeringViscose fiber

The invention relates to a method for recovery treatment of sulfur-containing mixed waste gas in production of viscose fiber, belonging to the technical field of treatment of the sulfur-containing waste gas in the production of the viscose fiber. According to the method provided by the invention, the sulfur-containing mixed waste gas in the production of the viscose fiber is treated through the steps of pretreatment, absorption, synthesis and the like and converted to thiourea to achieve the purpose of reutilizing the waste gas. The invention provides a method for producing thiourea by adopting the waste gas produced in the production process of a viscose fiber enterprise, a thiourea product with relatively high market values is obtained, the waste gas of the viscose fiber enterprise is effectively controlled, waste alkali and waste acid in the production process of the viscose fiber enterprise are simultaneously effectively utilized, then the viscose fiber enterprise can obtain certain economic benefits in the control process of the waste gas, and very high market popularization values are realized.

Owner:YIBIN GRACE +2

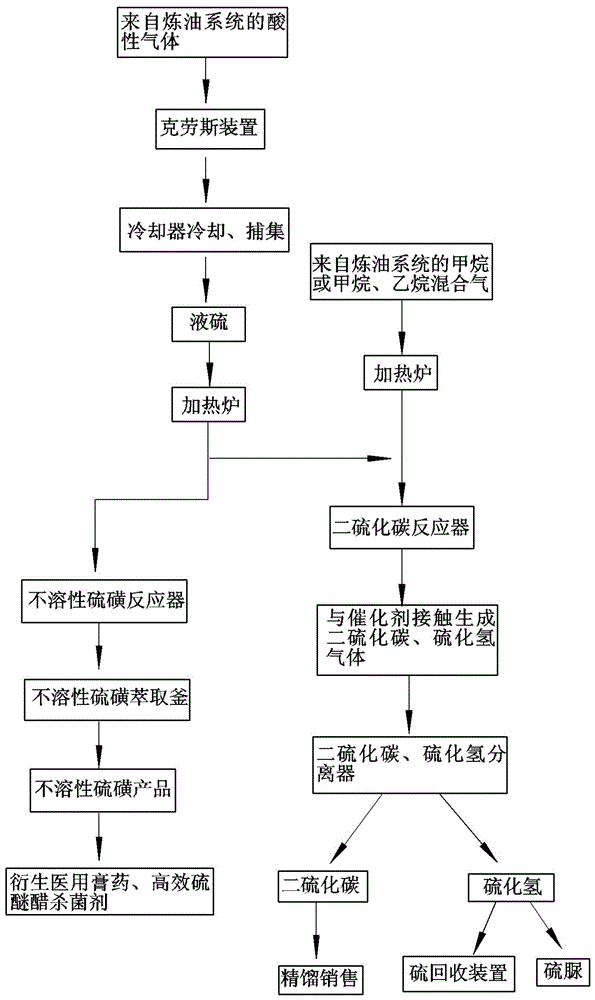

Recycling utilization method of oil refinery sulfur removal plant sulfur vapor

ActiveCN106829876ACompliant with comprehensive recyclingReduce pollutionCarbon disulfideOrganic chemistryThioureaMixed gas

The invention discloses a recycling utilization method of oil refinery sulfur removal plant sulfur vapor, and belongs to the field of fine chemical industry. The recycling utilization method of oil refinery sulfur removal plant sulfur vapor comprises the steps of firstly sending acid gas from an oil refining system into a claus device for sulfur recycling, conducting treatment at 1100-1300 DEG C and conducting heat extraction in a heat recovery steam generator to obtain mixed gas at 300-500 DEG C, and cooling the mixed gas through a cooler and catching the mixed gas through a catcher to obtain liquid sulfur at 160-170 DEG C; then directly sending liquid sulfur into a heating furnace, dividing sulfur vapor which is heated to be at 500-700 DEG C in the heating furnace into two paths, in one path, the sulfur vapor is used for preparing insoluble sulfur with high a heat resistant function, in the other path, sulfur vapor is mixed with methane or mixed gas of mixed gas of methane and ethane, and the mixture is then sent into a sulfur dioxide reactor to prepare carbon disulfide and hydrogen sulfide. According to the recycling utilization method of the oil refinery sulfur removal plant sulfur vapor, comprehensive utilization of energy resources is adopted, thus the production cost of producing the same kind of insoluble sulfur, carbon disulfide, hydrogen sulfide and derivative thiourea of the sulfur vapor is lowered by 33%-37%, the total amount of item investment is reduced by 31%-34%, energy is saved and environment is protected.

Owner:洛阳九成新材料技术有限公司

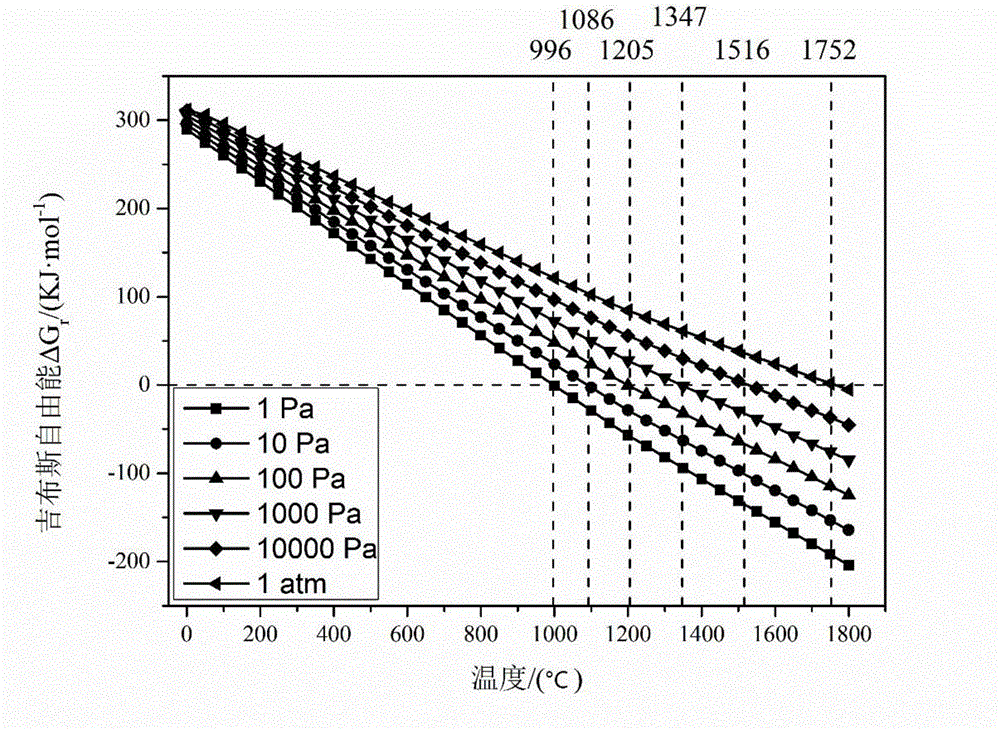

Method for preparing molybdenum-containing additive and carbon disulfide by vacuum carbon thermal reduction of molybdenum concentrate

ActiveCN106498264AEasy to handleEmission reductionCarbon disulfideMaterials preparationMaterials science

The invention discloses a method for preparing a molybdenum-containing additive and carbon disulfide by vacuum carbon thermal reduction of a molybdenum concentrate and belongs to the field of material preparation. According to the method disclosed by the invention, as raw materials, the molybdenum concentrate and carbon powder are proportioned according to a target ratio, are fully mixed and are subsequently treated at the temperature of 1200 to 1700 DEG C and at a vacuum degree of 1 Pa to 1000 Pa by adopting a vacuum carbon thermal reduction method to prepare an molybdenum-containing steel smelting additive of which the molybdenum content is as high as 90%; besides, a volatile product carbon disulfide is prepared; and the carbon disulfide is an important chemical raw material and is collected after being condensed. The method disclosed by the invention is free of generation of polluting gas sulfur dioxide and other pollutants, can be used for preparing the molybdenum-containing steel smelting additive and can also be used for preparing the carbon disulfide which has an extremely high value.

Owner:UNIV OF SCI & TECH BEIJING

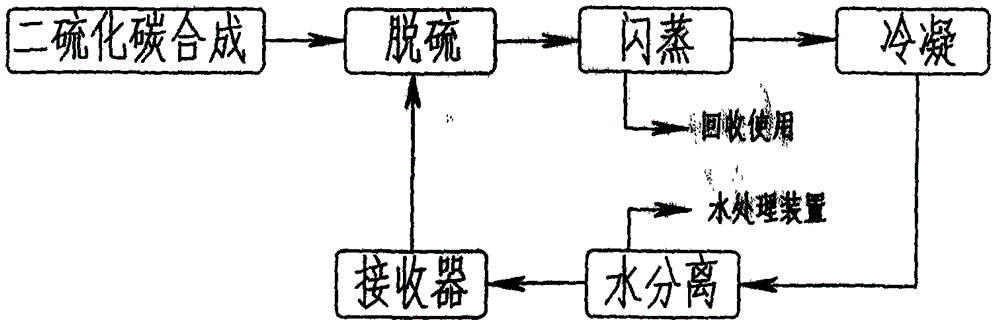

Method for avoiding forming hydrogen sulfide hydrate in carbon bisulfide production process

ActiveCN104016344AStable operating conditionsGuaranteed uptimeCarbon disulfideInorganic ChemicalTower

The invention belongs to the technical field of inorganic chemical industry, and relates to a method for avoiding forming hydrogen sulfide hydrate in a methane-process carbon bisulfide production process, which comprises the following steps: a sulfur-natural gas reaction mixture is subjected to primary condensation and desulfurizing tower desulfurization; the primary condensation product and desulfurizing tower bottom distillate together enter a flash tank; the flash-off carbon bisulfide gas is condensed and separated from water; the carbon bisulfide subjected to water separation is pumped back into the desulfurizing tower; and the desulfurizing tower overhead product enters a hydrogen sulfide rectification tower to implement separation of carbon bisulfide and hydrogen sulfide. The method solves the problem that water often exists in the hydrogen sulfide rectification tower and hydrogen sulfide outlet pipeline and forms the hydrogen sulfide hydrate, and provides insurance for safe operation of the carbon bisulfide device. The method is also suitable for solving the problem of some compounds which can easily form hydrocarbon hydrates with water.

Owner:吉林三源化工有限公司

Process for the manufacture of carbon disulphide and use of a liquid stream comprising carbon disulphide for enhanced oil recovery

The invention provides a process for the manufacture of carbon disulphide by reacting carbon monoxide with elemental sulphur to form carbonyl sulphide and disproportionating the carbonyl sulphide formed into carbon disulphide and carbon dioxide, the process comprising contacting a gaseous stream comprising carbon monoxide with a liquid elemental sulphur phase containing a solid catalyst at a temperature in the range of from 250 to 700 DEG C to obtain a gaseous phase comprising carbonyl sulphide, carbon disulphide and carbon dioxide. The invention further provides the use of a liquid stream comprising carbon disulphide, carbonyl sulphide and carbon dioxide obtainable by such process for enhanced oil recovery.

Owner:SHELL INT RES MAATSCHAPPIJ BV

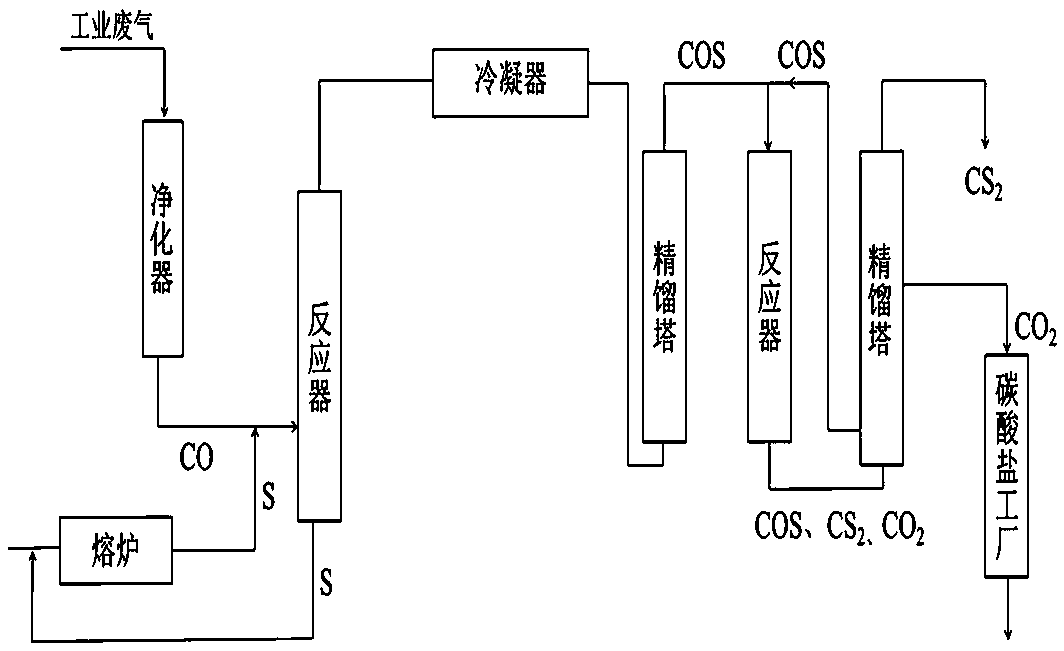

Method for preparing carbon disulfide from industrial tail carbon monoxide as raw material

InactiveCN107739033AIncrease profitHigh boiling pointCarbon disulfideCarbonate/bicarbonate preparationFertilizer plantDistillation

The invention relates to a method for simply preparing carbon disulfide CS2 from an industrial tail carbon monoxide CO as a raw material. By adopting the method, the carbon monoxide in tail gases of anitrogenous fertilizer plant is efficiently utilized, carbonyl sulfide is efficiently synthesized at relatively low temperature, and the yield of carbon disulfide is also relatively high; secondly, unreacted carbon disulfide can be introduced into a disproportionated reaction tower after condensation separation, so that the utilization rate of raw materials is sufficiently increased; furthermore,as carbonyl sulfide, carbon disulfide and carbon dioxide are separated by means of pressurized distillation, the normal boiling point of carbon disulfide is 46.2 DEG C, the boiling points of carbonylsulfide and carbon dioxide are 50.3 DEG C and 78.5 DEG C respectively, the boiling points of factions are increased through pressurization, and the separation effect is improved.

Owner:山西铁峰化工有限公司

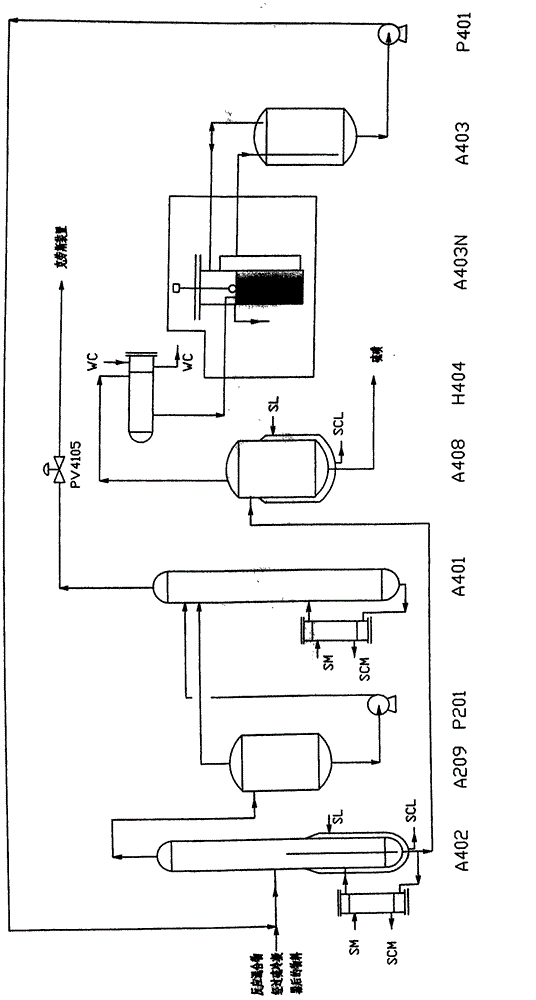

Process for simultaneous production of carbon disulfide, sulfur and insoluble sulfur

ActiveCN107572483ASolve pollutionTake advantage ofCarbon disulfideSulfur preparation/purificationSulfurPetrochemical

The invention provides a novel process for simultaneous production of carbon disulfide, sulfur and insoluble sulfur. The carbon disulfide, the sulfur and the insoluble sulfur can be produced in the same combined device. According to the invention, a conventional sulfur recycling device in a petrochemical enterprise is designed to be able to produce sulfur by using desulfurized gas in the petrochemical enterprise and waste gas of a carbon disulfide device; liquid sulfur is simultaneously used as a raw material for production of sulfur, carbon disulfide and insoluble sulfur; carbon disulfide isproduced through a reaction of methane and ethane in the petrochemical enterprise and gasified sulfur of an insoluble sulfur device; the insoluble sulfur is extracted with self-produced carbon disulfide; and extracted waste liquid returns to the carbon disulfide device for recycling, so a pure carbon disulfide product is obtained. The combined production process provided by the invention is linkedtogether and has the advantages of simple process, short flow, less equipment and convenient operation.

Owner:赵西营 +1

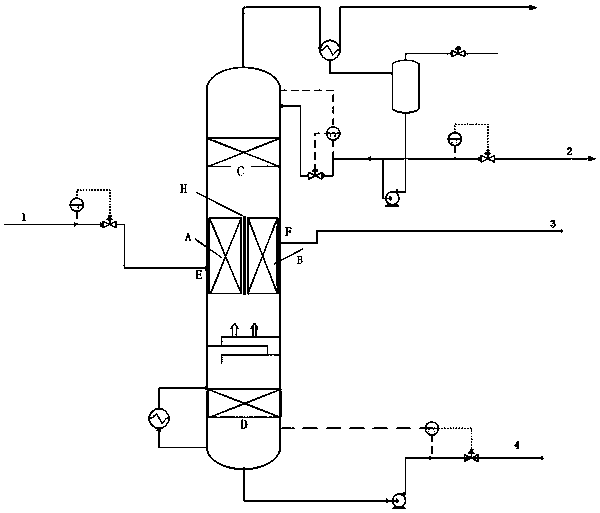

Method for purifying carbon disulfide with dividing wall column

ActiveCN109502587AReduce investmentReduce energy consumptionCarbon disulfideReboilerEnergy consumption

The invention provides a method for purifying carbon disulfide with a dividing wall column. The method comprises the following steps: feeding raw materials and performing separation in the dividing wall column. The dividing wall column comprises a public rectifying section, a separation section and a public stripping section; the separation section comprises a pre-separation zone, a separation plate and a pure product zone; the separation plate is located between the pre-separation zone and the pure product zone; the specific value of the cross sectional areas of the pre-separation zone and the pure product zone is (0.5-2):1. In the method, the carbon disulfide is purified by one column, one reboiler and a condenser. The equipment investment and energy consumption can be effectively reduced, and the covering area is reduced; with adoption of the method of the patent, a carbon disulfide product with the purity being near 100% is obtained. With adoption of the method of the patent, the energy consumption of a device is reduced by 45.6%.

Owner:SHANDONG XINHECHENG AMINO ACID

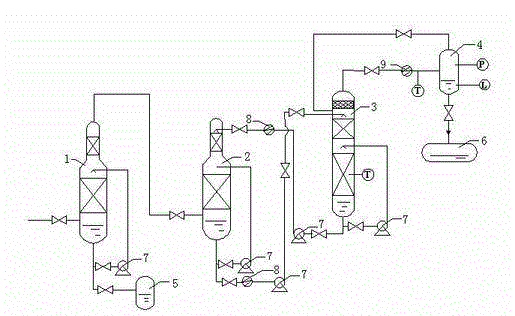

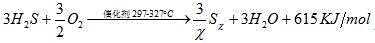

Waste gas recovery system for mucilage glue production

InactiveCN103341304AEfficient collectionCreate pollutionCarbon disulfideDispersed particle separationActivated carbonVapor–liquid separator

The invention discloses a waste gas recovery system for mucilage production with a good treatment effect. The recovery system comprises an alkali cleaning fan, an alkaline bath connected with the alkali cleaning fan, an Na2S and NaHS storage tank and a water scrubber which are connected with the alkaline bath, a draught fan connected with the water scrubber, an activated carbon adsorption tank connected with the draught fan, an evaporator connected with the activated carbon adsorption tank, a first condenser connected with the evaporator, a gas-liquid separator and a second condenser which are connected with the first condenser, a specific gravity separator and a safety can which are connected with the gas-liquid separator, and an after-cooler connected with the specific gravity separator, and a CS2 storage tank connected with the after-cooler. The second condenser is connected with the gas-liquid separator, and the safety can is connected with the specific gravity separator and the draught fan.

Owner:JIANGSU SHENJIANG ENVIRONMENT TECH

Carbon monoxide production from carbon dioxide reduction by elemental sulfur

ActiveUS9896339B2Lower energy requirementsAvoid complexityCarbon disulfideSulfur compoundsSulfurSulfur dioxide

Disclosed is a method of producing carbon monoxide (CO) and sulfur dioxide (SO2), the method comprising obtaining a reaction mixture comprising carbon dioxide gas (CO2(g)) and elemental sulfur gas (S(g)), and subjecting the reaction mixture to conditions sufficient to produce a product stream comprising CO(g) and SO2(g).

Owner:SABIC GLOBAL TECH BV

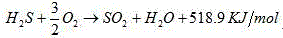

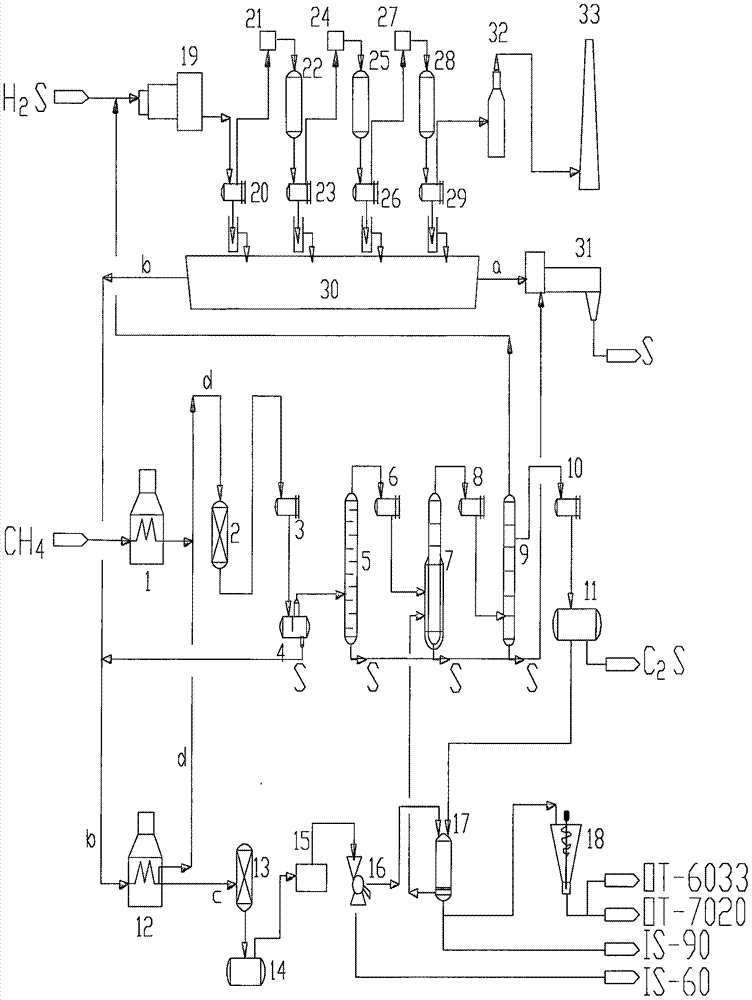

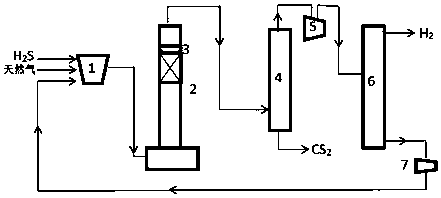

Method for preparing carbon disulfide with hydrogen sulfide as raw material

The invention discloses a method for preparing carbon disulfide with hydrogen sulfide as a raw material. The method includes the steps that mixed gas of natural gas and hydrogen sulfide reacts under the action of a novel catalyst, and carbon disulfide and hydrogen are generated; the generated mixed product with carbon dioxide, hydrogen and natural gas as main components, which contains a small amount of hydrogen sulfide, passes through a rectifying tower I, and carbon disulfide is condensed and separated; the separated mixed product with hydrogen, natural gas and hydrogen sulfide as main components is pressurized and enters a rectifying tower II for pressure rectification, and hydrogen is separated out from the top of the rectifying tower in the form of gas; unreacted natural gas and a small amount of non-completely-reacted hydrogen sulfide are recycled through a delivery pump to serve as raw materials again, and a circulating production process is realized. The raw materials in the preparation method are wide in source and low in price; besides, the reaction efficiency is high, less environmental pollution is caused, no industrial waste gas is discharged, the energy consumption islow, the economic benefit is good, and continuous safe production can be realized.

Owner:山西铁峰化工有限公司

CS2 reagent purification method

The invention discloses a CS2 reagent purification method, and relates to the technical field of biology and new medicine. The method comprises the following operation steps: (1) an organic impurity purification treatment, (2) a metal and heavy metal impurity purification treatment, and (3) 0.22 mum filtration packaging. According to the method, organic impurities, benzene substances, metals and heavy metals in industrial grade CS2 are removed, and the process does not require distillation so as to provide characteristics of safety and environmental protection, wherein the benzene substances, the metals and the heavy metals can not be removed through rectification and other purification means.

Owner:SHANGHAI ANPEL SCI INSTR

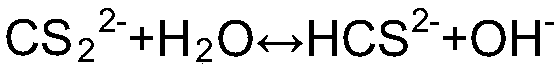

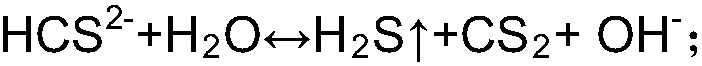

Device and method for sodium thiocarbonate containing sewage treatment and resource recovery

PendingCN108128921AMeet the needs of recyclingAchieve recyclingCarbon disulfideSulfur preparation/purificationSulfurResource recovery

The invention discloses a device and a method for sodium thiocarbonate containing sewage treatment and resource recovery. The device for sewage treatment and resource recovery comprises a sewage collection and reaction unit, a sewage treatment and circulation unit, CS2 recovery unit and a sulfur recovery unit, wherein the sewage collection and reaction unit is respectively connected with the sewage treatment and circulation unit and the CS2 recovery unit; and the CS2 recovery unit is connected with the sulfur recovery unit which is connected with the sewage treatment and circulation unit. Thedevice for sewage treatment and resource recovery provided by the invention can meet the demands of environmental protection, recovers resources, realizes cyclic utilization of the resources, reducesthe cost of production, and meets the needs of an enterprise for management and development.

Owner:JIANGSU HENGXIN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com