Patents

Literature

575 results about "Decreased carbon dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon Dioxide Capture and Mitigation of Carbon Dioxide Emissions

InactiveUS20080031801A1Pressure dropCalcium/strontium/barium carbonatesLiquefactionSorbentSolid surface

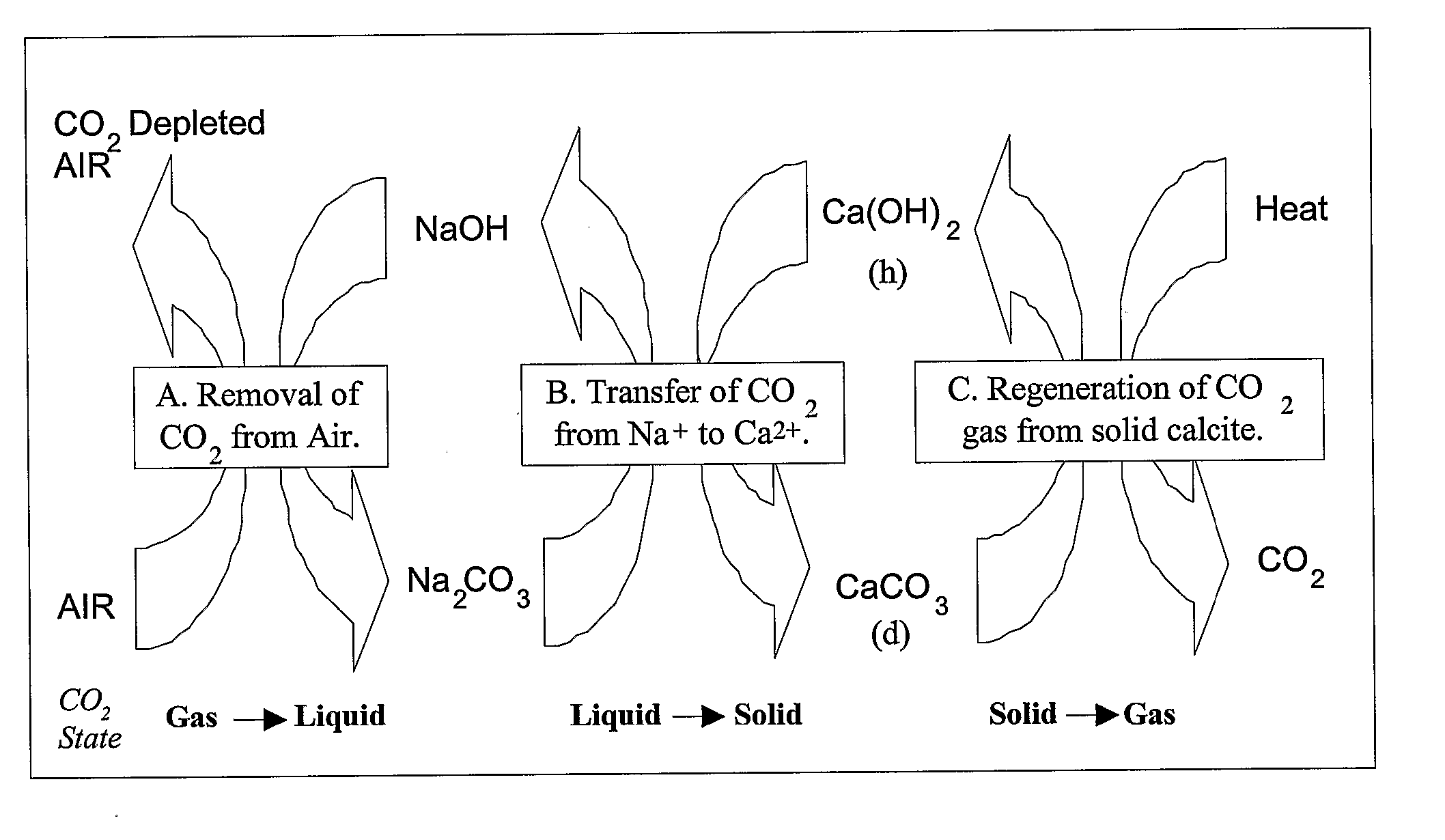

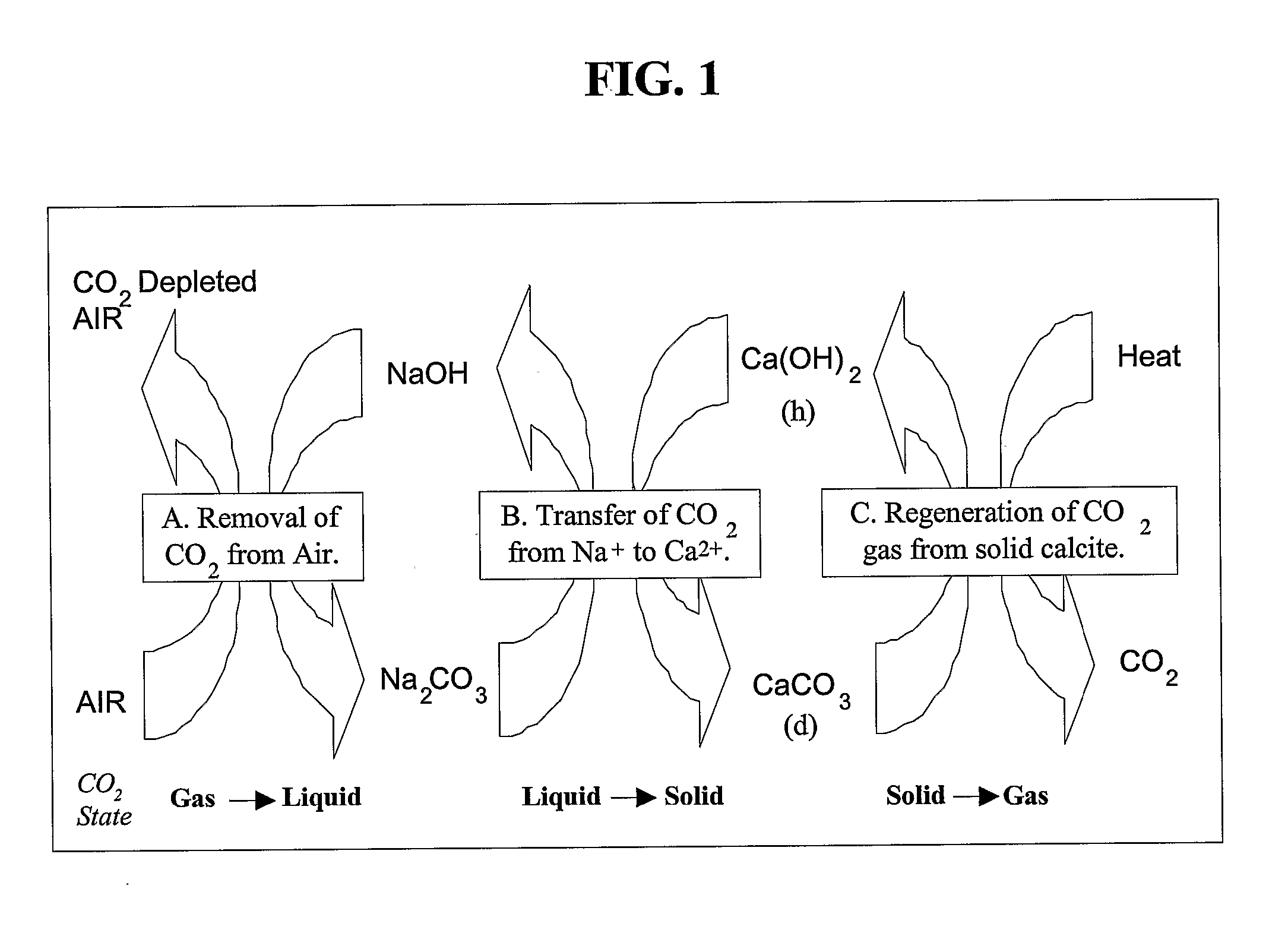

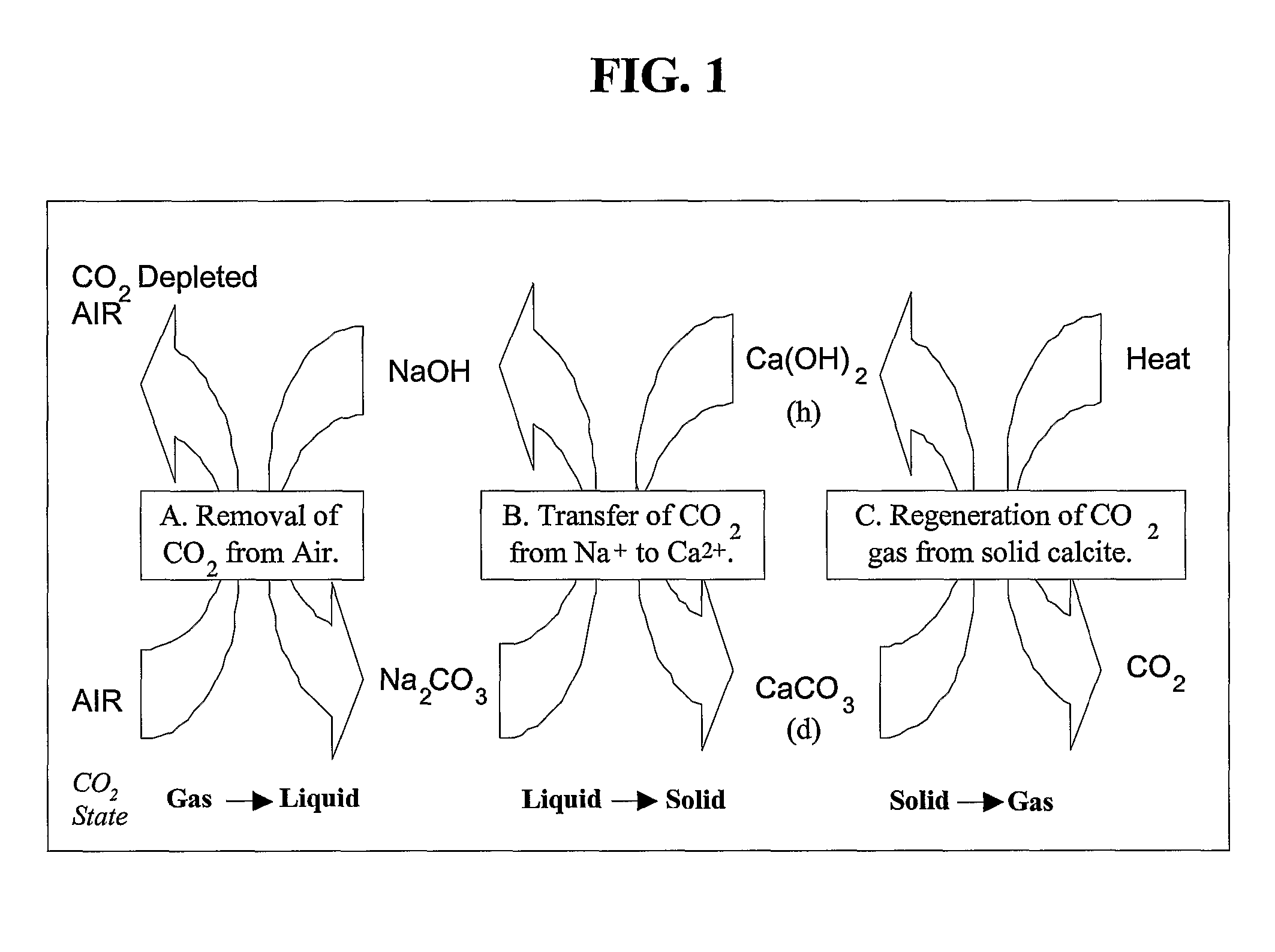

The present invention describes methods and systems for extracting, capturing, reducing, storing, sequestering, or disposing of carbon dioxide (CO2), particularly from the air. The CO2 extraction methods and systems involve the use of chemical processes, mineral sequestration, and solid and liquid sorbents. Methods are also described for extracting and / or capturing CO2 via condensation on solid surfaces at low temperature.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +1

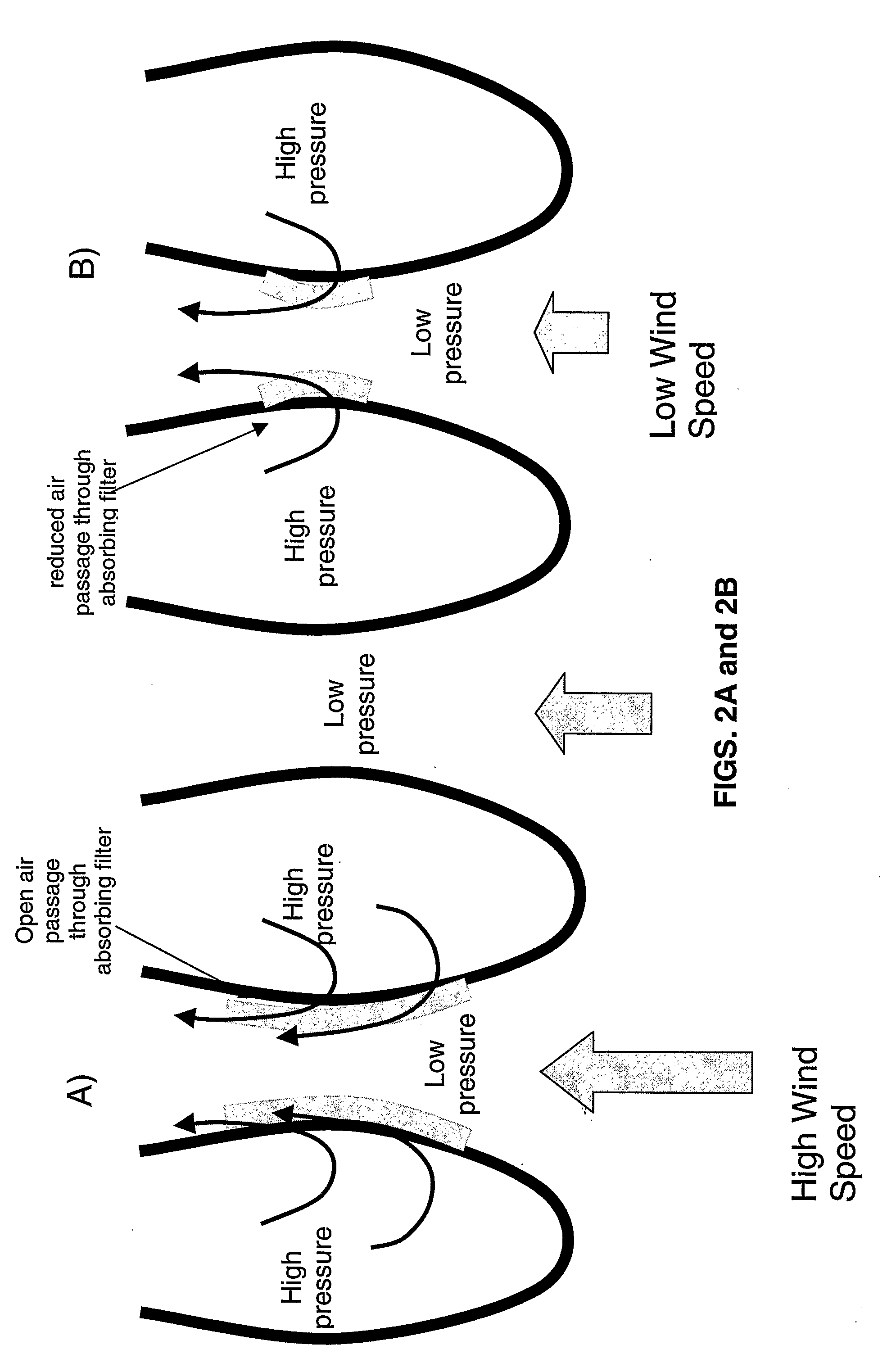

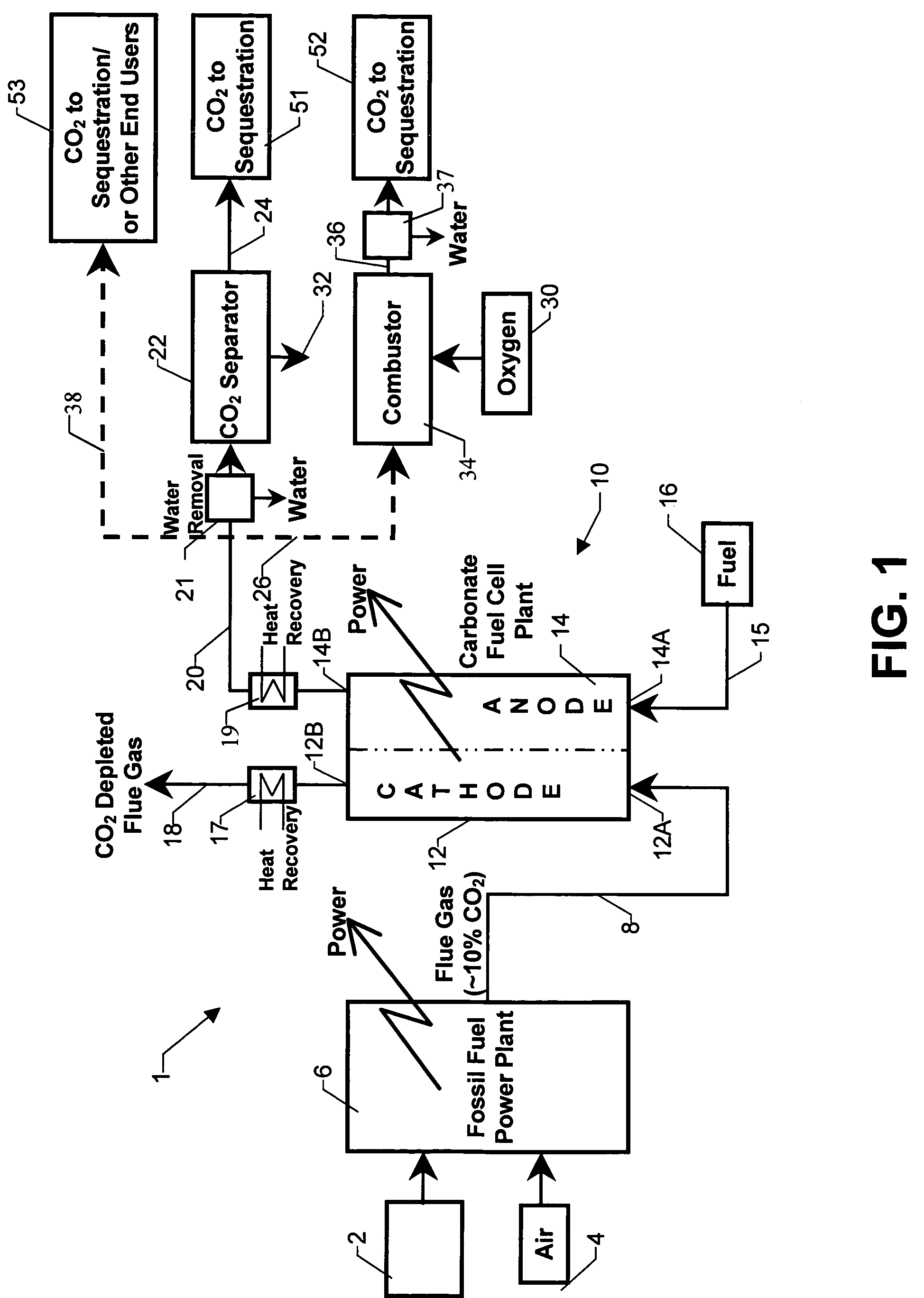

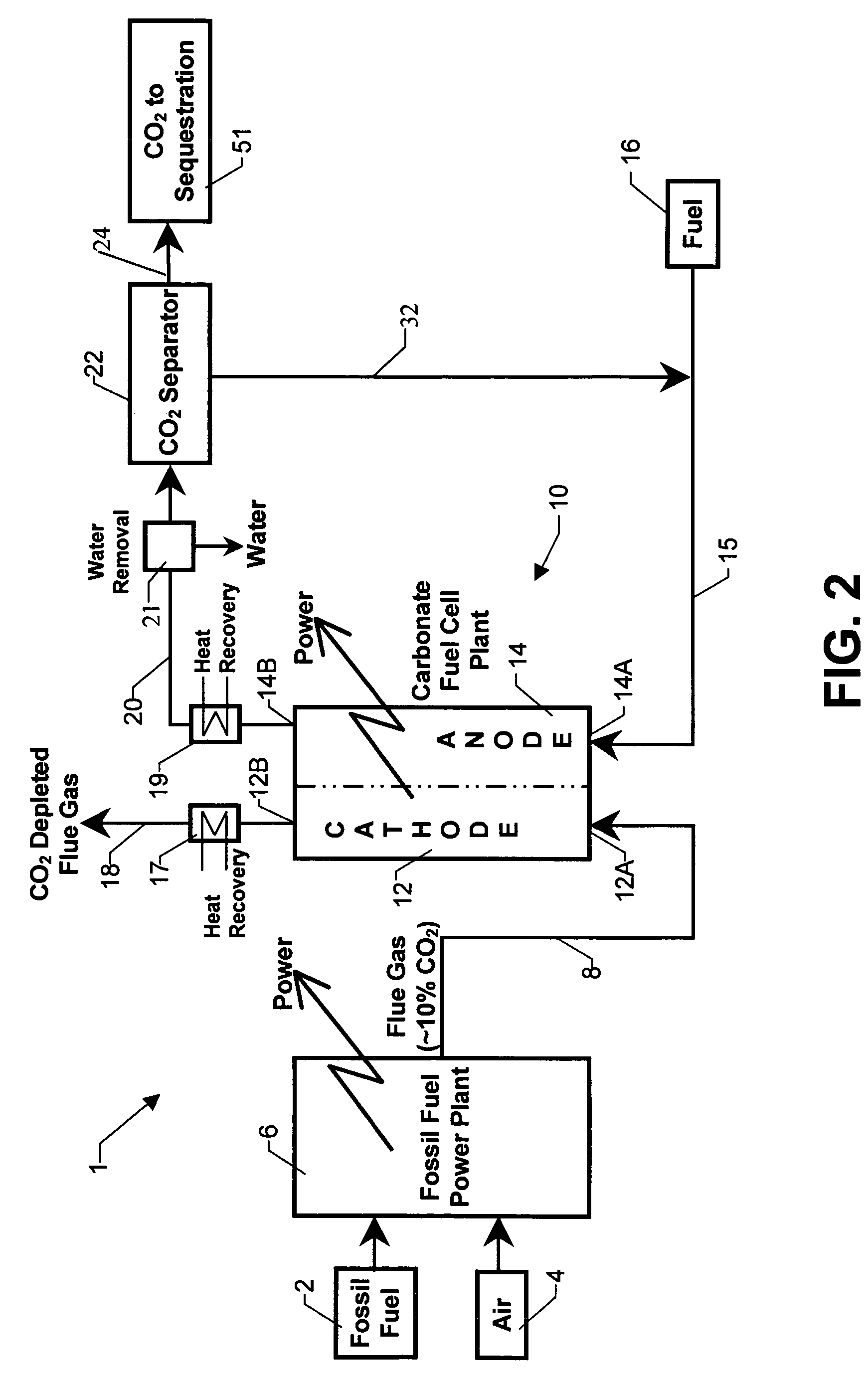

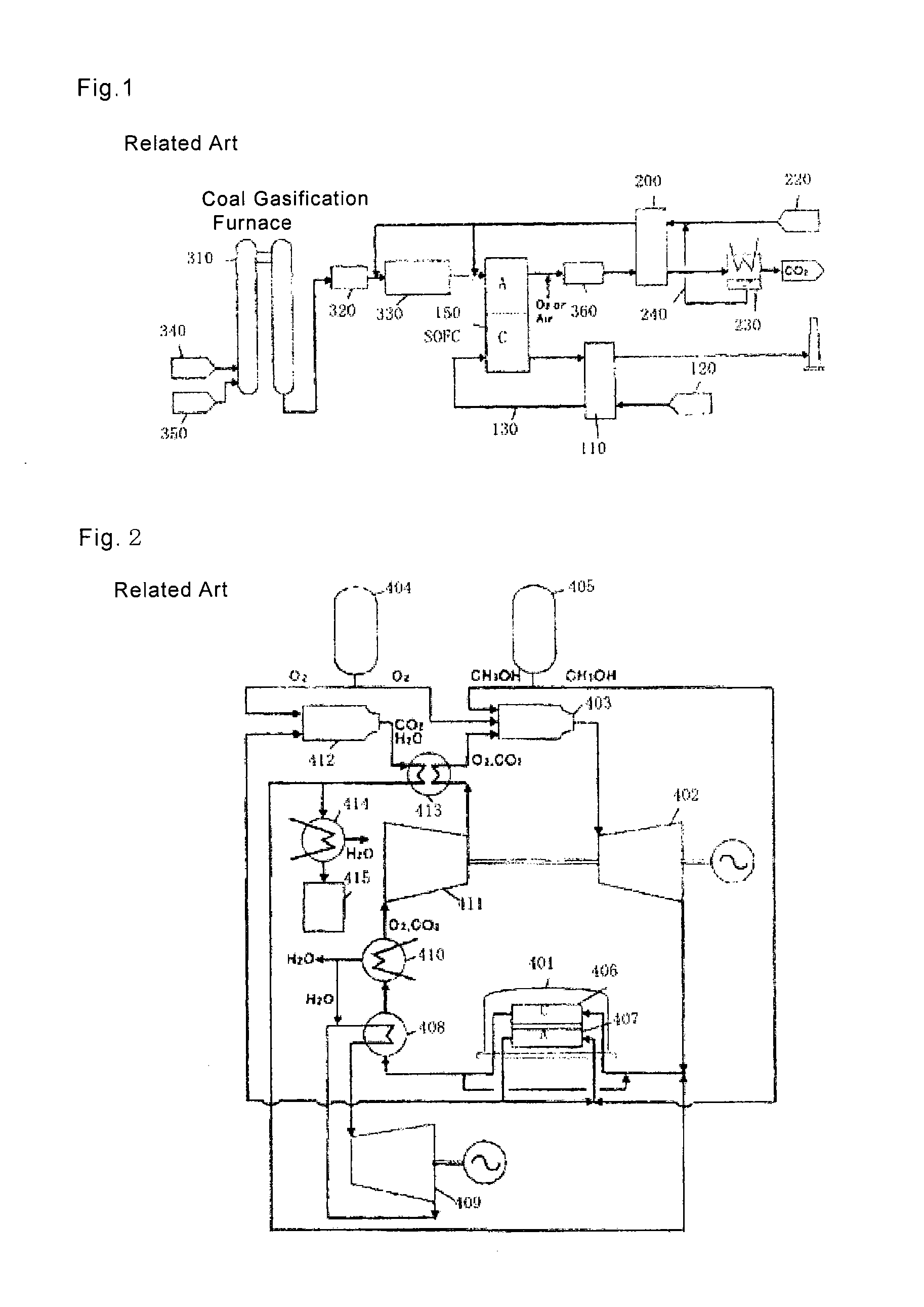

Integrated high efficiency fossil fuel power plant/fuel cell system with CO2 emissions abatement

ActiveUS7396603B2Fuel cell heat exchangeElectricity cogenerationNuclear engineeringEmission abatement

Owner:FUELCELL ENERGY INC

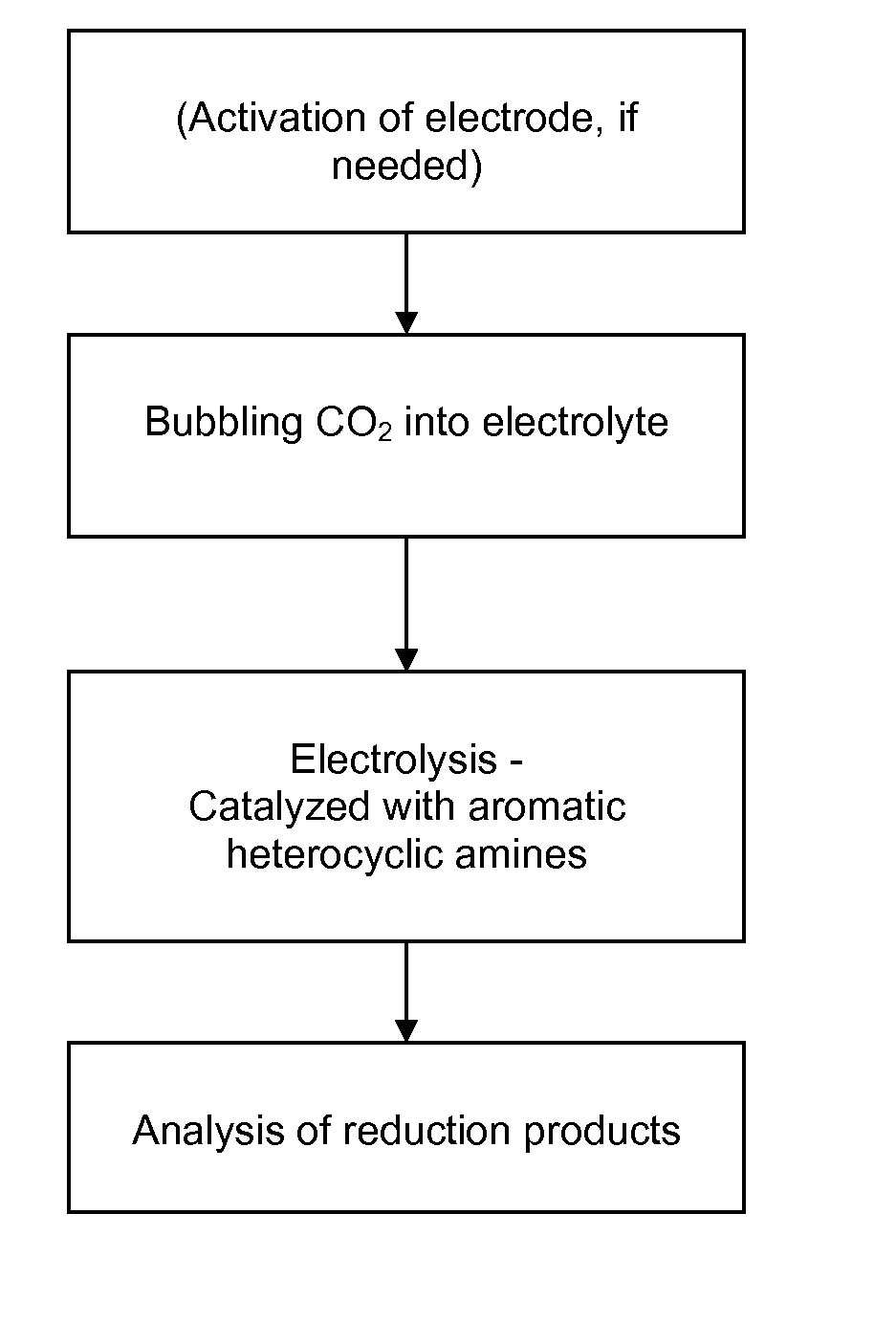

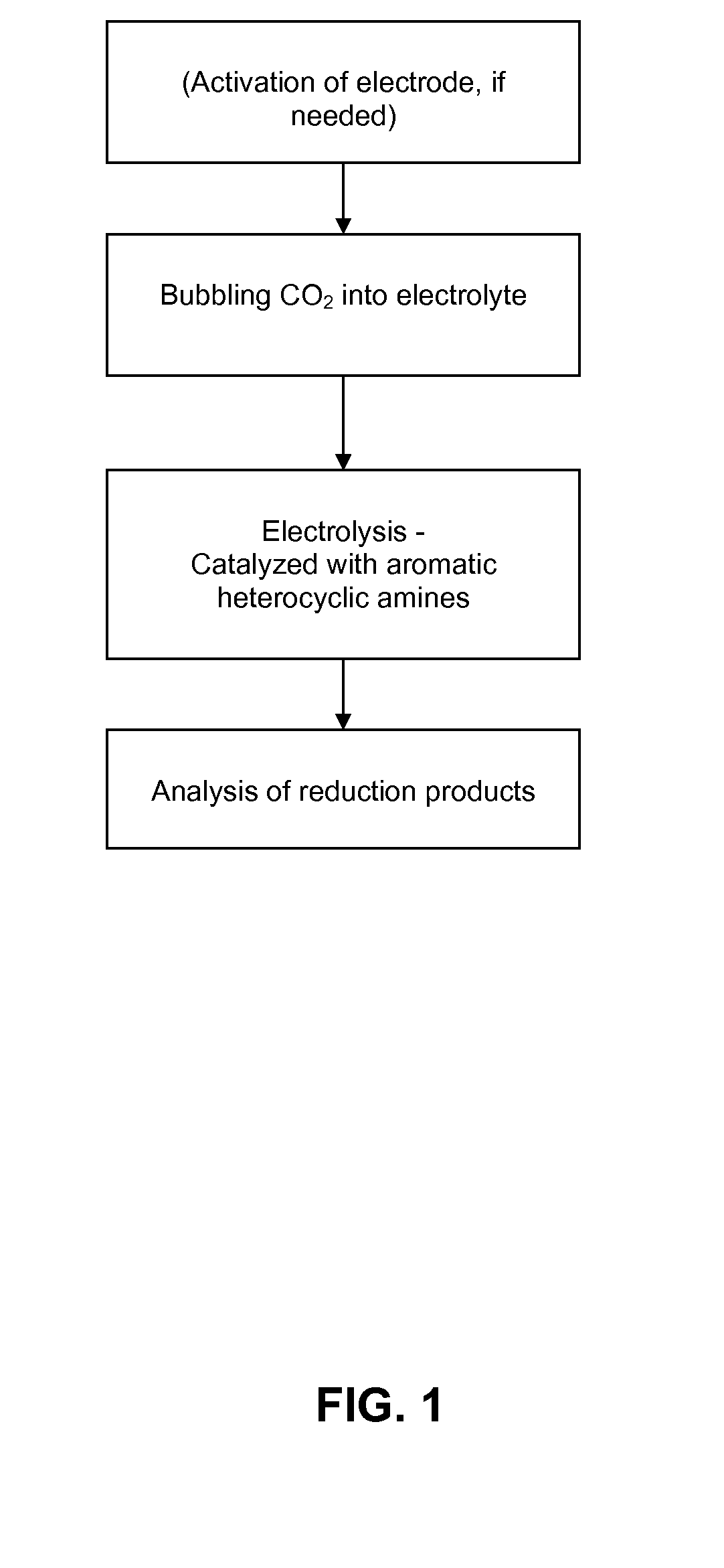

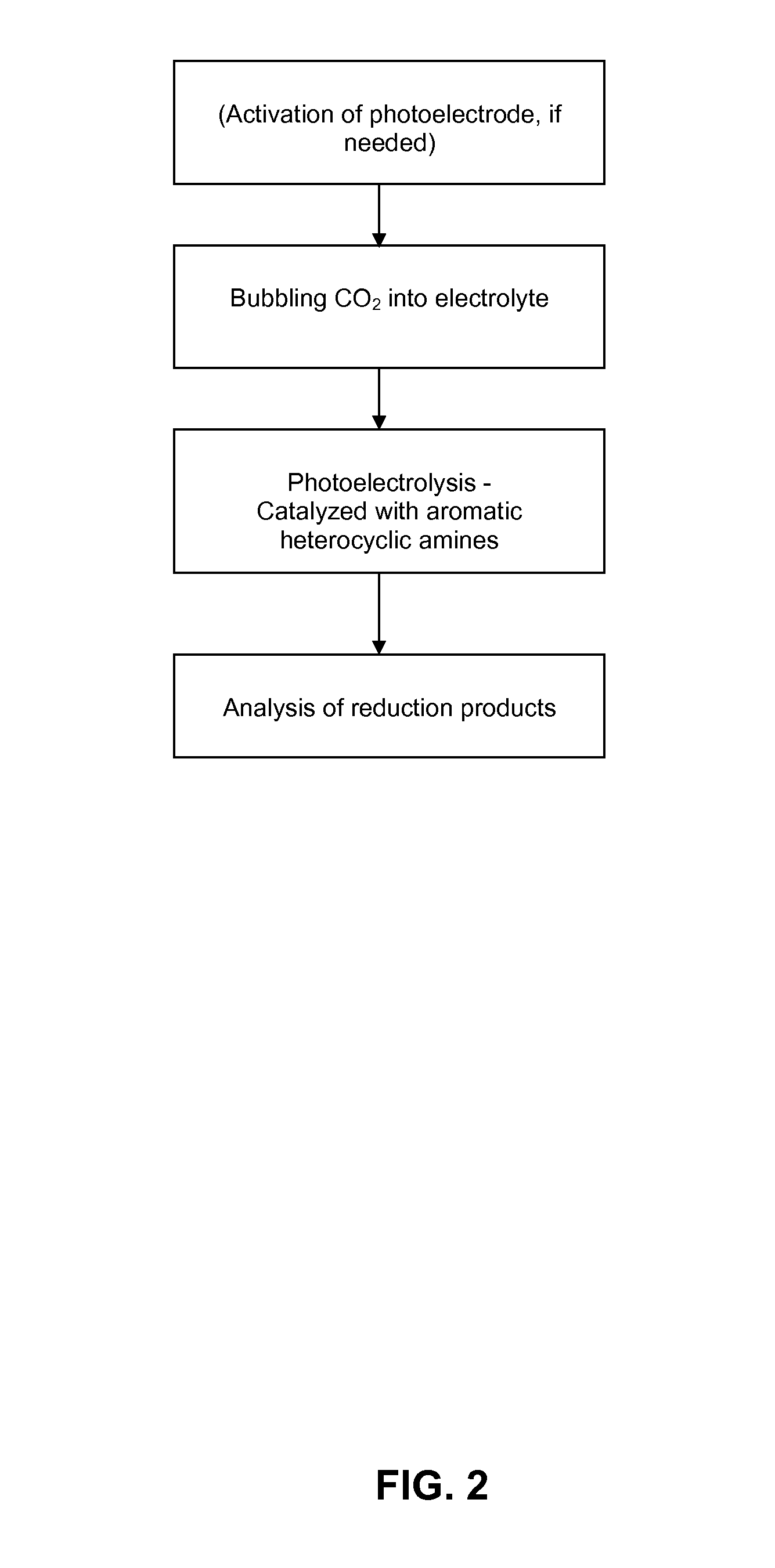

Conversion of carbon dioxide to organic products

ActiveUS20100187123A1Effective and stableReducing carbon dioxideCellsPhotography auxillary processesAqueous solutionElectrochemical cell

The invention relates to various embodiments of an environmentally beneficial method for reducing carbon dioxide. The methods in accordance with the invention include electrochemically or photoelectrochemically reducing the carbon dioxide in a divided electrochemical cell that includes an anode, e.g., an inert metal counterelectrode, in one cell compartment and a metal or p-type semiconductor cathode electrode in another cell compartment that also contains an aqueous solution of an electrolyte and a catalyst of one or more substituted or unsubstituted aromatic amines to produce therein a reduced organic product.

Owner:PRINCETON UNIV

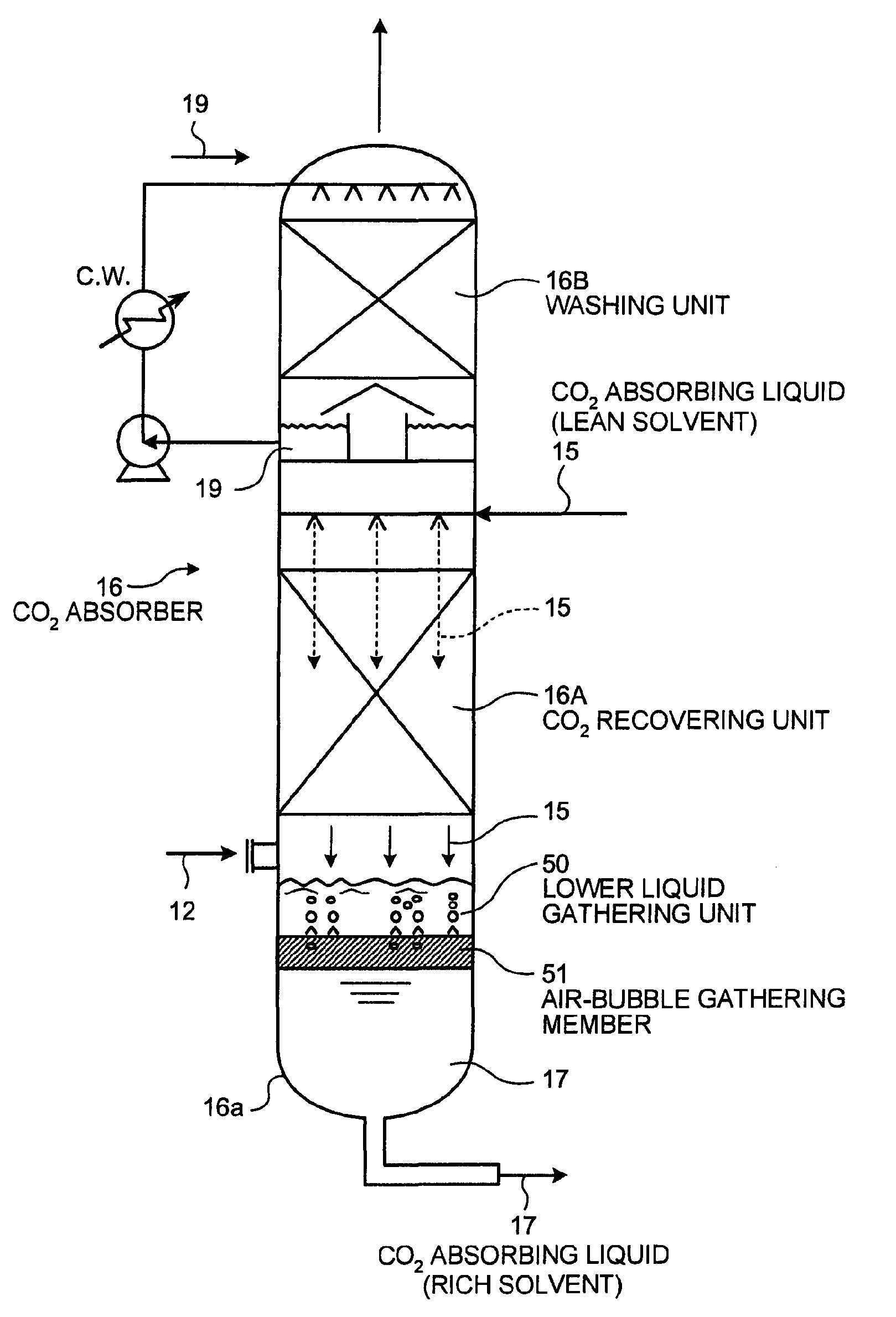

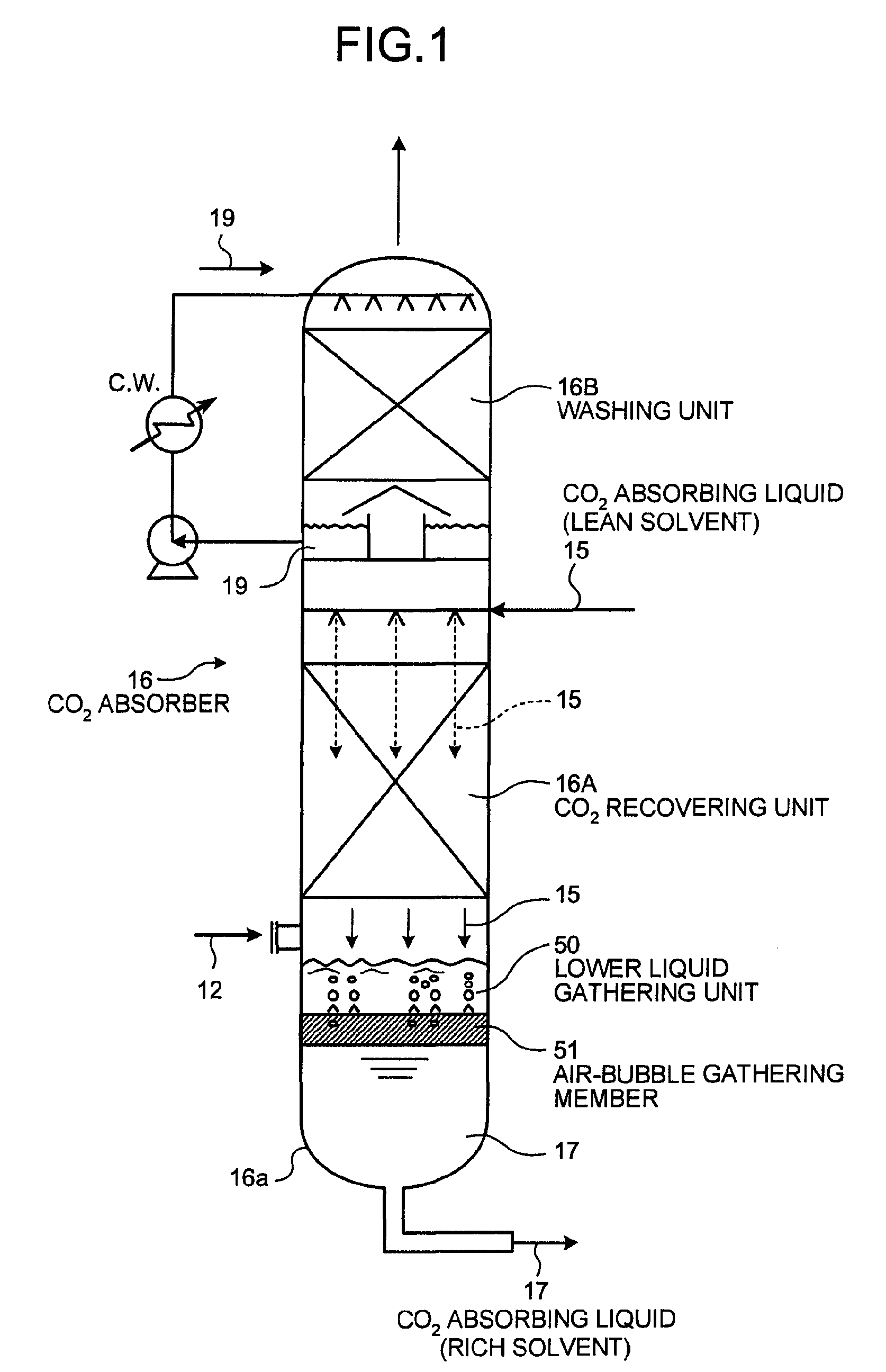

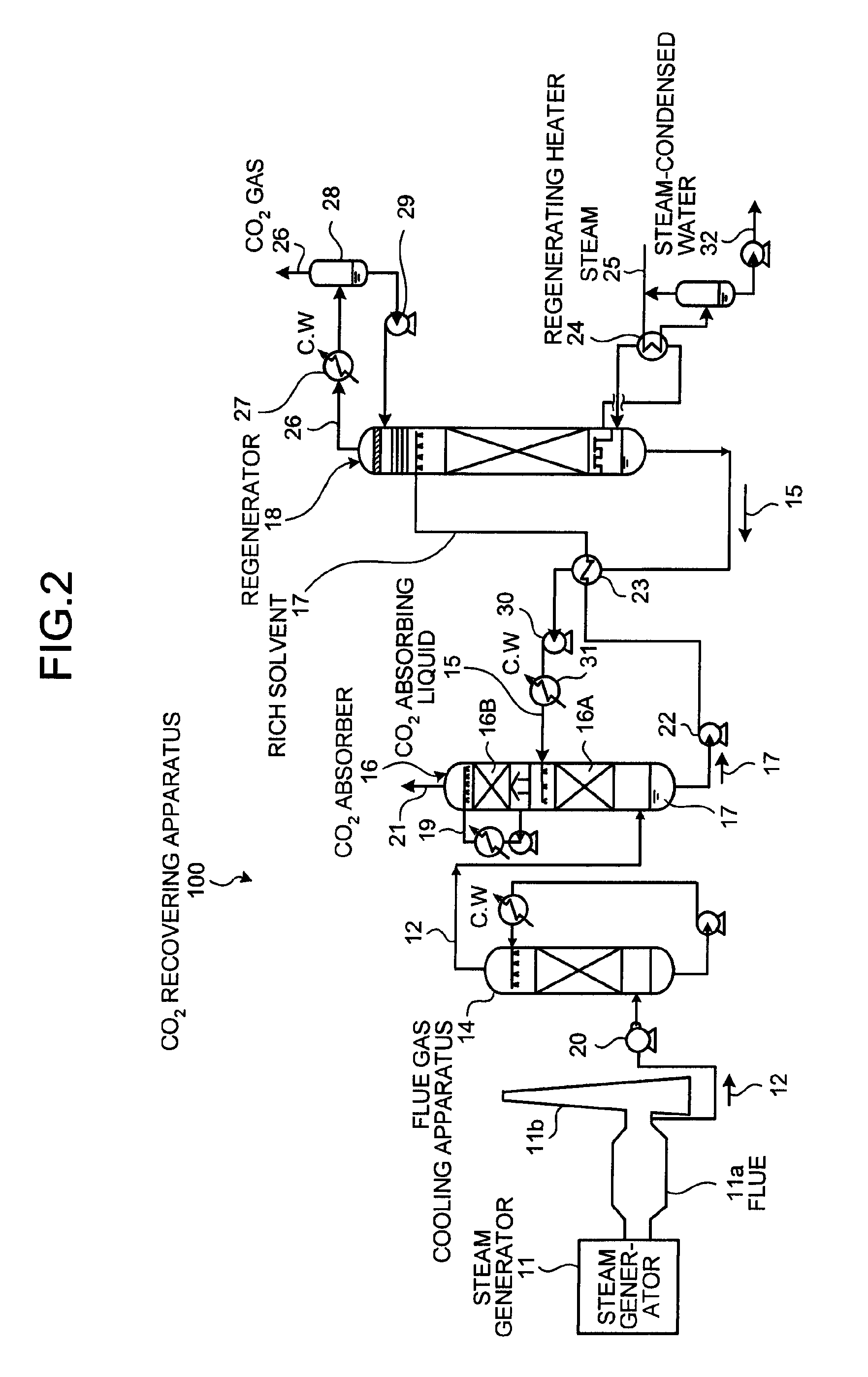

CO2 recovering apparatus

A CO2 recovering apparatus includes a CO2 absorber that brings flue gas containing CO2 and O2 into contact with CO2 absorbing liquid to reduce CO2 in the flue gas; and a regenerator that reduces CO2 in CO2 absorbing liquid (rich solvent) that absorbed CO2 in the CO2 absorber to regenerate the CO2 absorbing liquid, so that the regenerated CO2 absorbing liquid (lean solvent) having CO2 reduced in the regenerator is reused in the CO2 absorber. A lower liquid reservoir is located at the bottom of the CO2 absorber, and an air-bubble gathering member is arranged therein to gather air bubbles included in the absorbing liquid.

Owner:MITSUBISHI HEAVY IND LTD +1

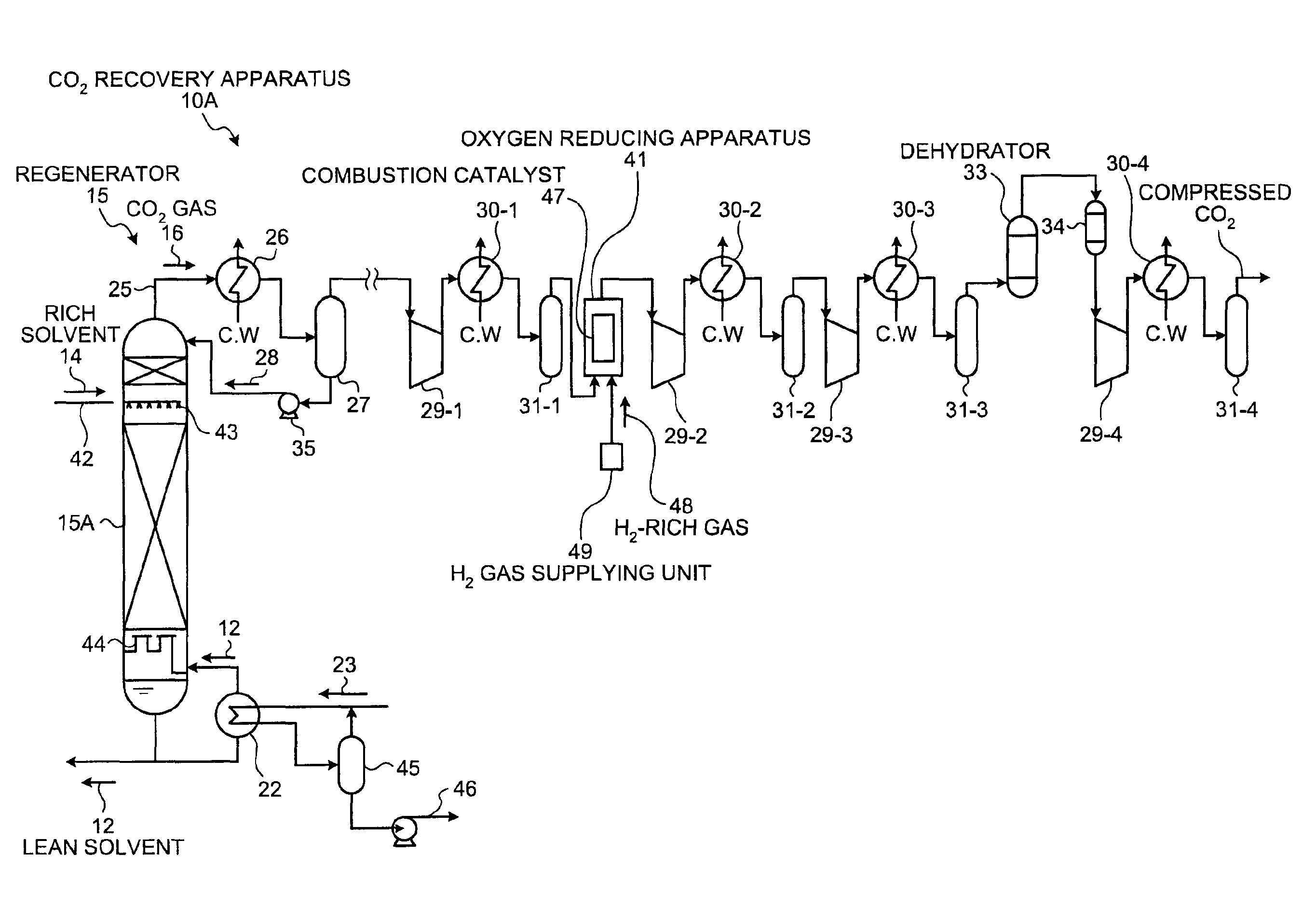

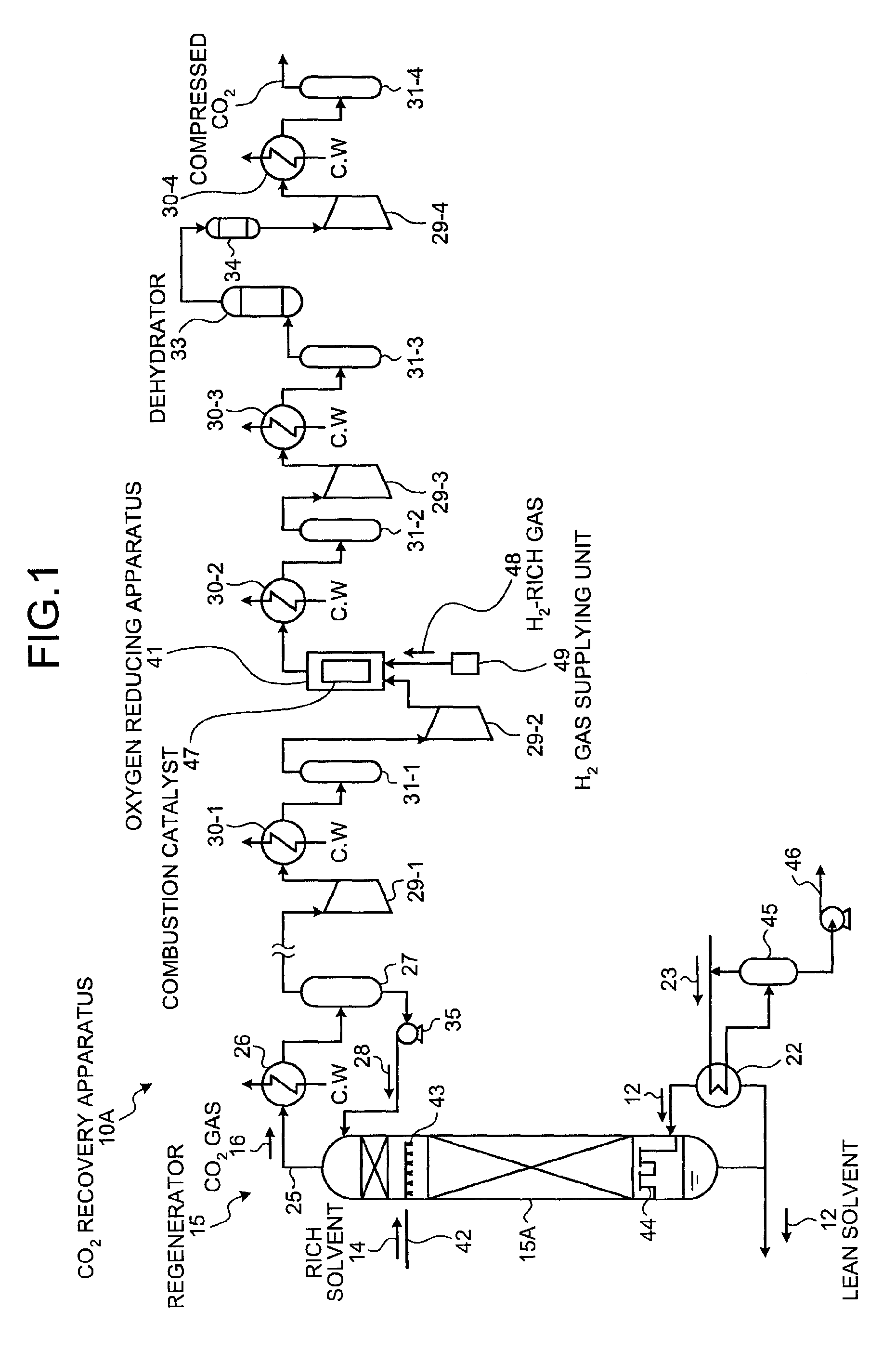

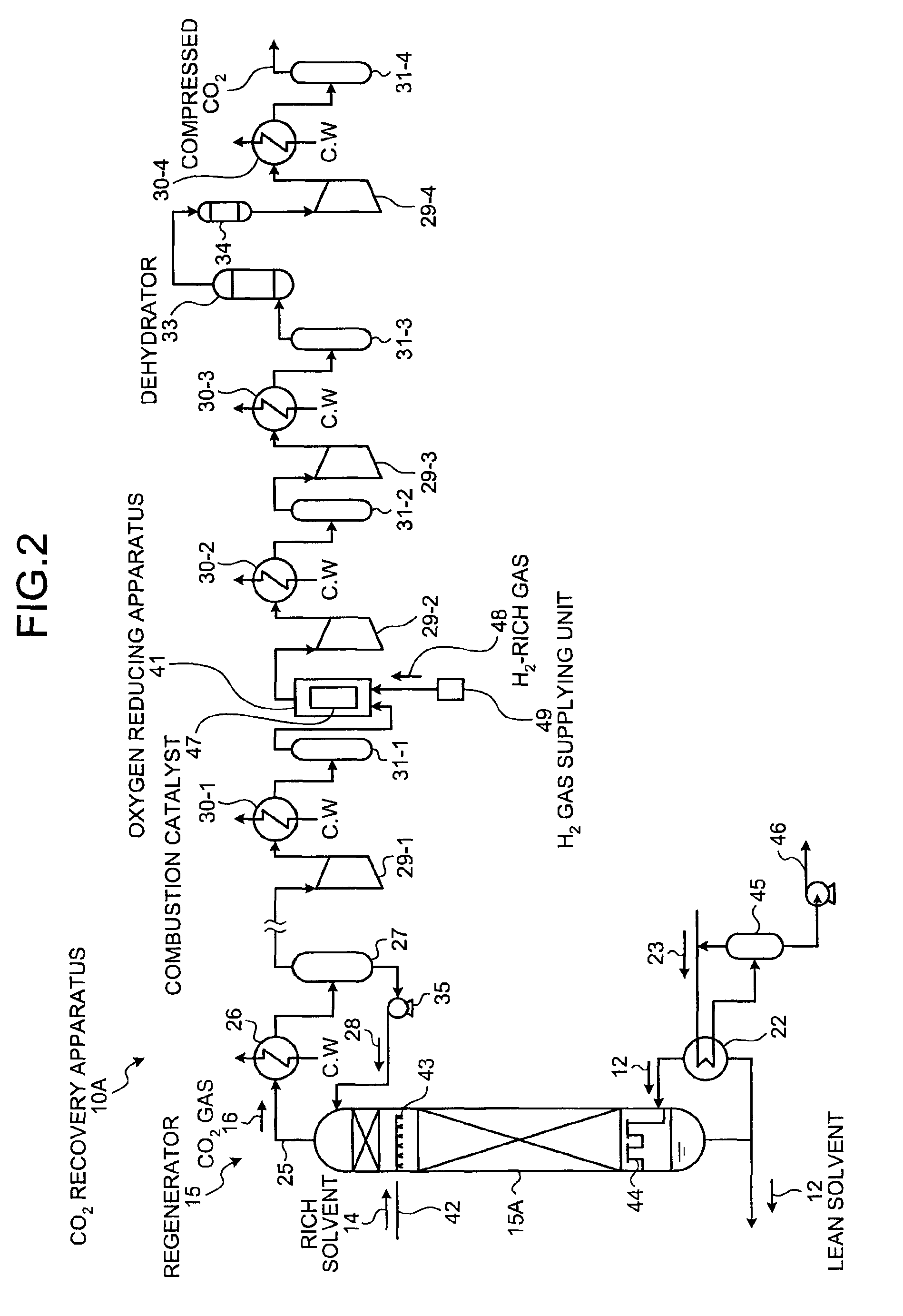

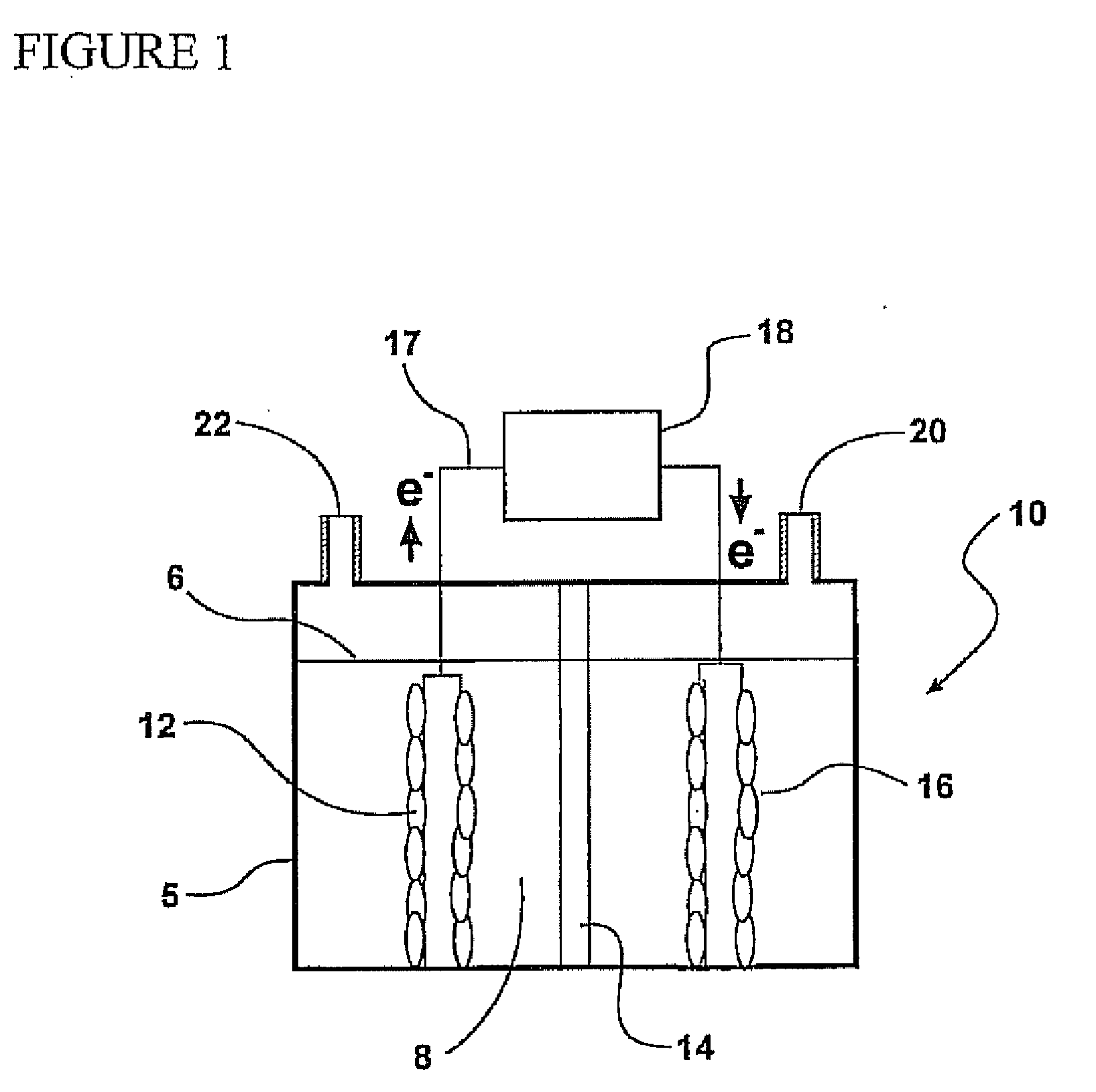

CO2 recovery apparatus and CO2 recovery method

ActiveUS8377184B2Reduce oxygen concentrationSuppression problemOxygen/ozone/oxide/hydroxideLiquid degasificationFlue gasCo2 absorption

A CO2 recovery apparatus according to a first embodiment of the present invention includes: a CO2 absorber that brings flue gas containing CO2 into contact with CO2 absorbing liquid to reduce CO2 in the flue gas; a regenerator that reduces CO2 in CO2 absorbing liquid (rich solvent) that has absorbed the CO2 in the CO2 absorber to regenerate the CO2 absorbing liquid, so that the regenerated absorbing liquid (lean solvent), having CO2 reduced in the regenerator, is reused in the CO2 absorber; a first compressor to a fourth compressor that compress the CO2 gas released from the regenerator; and an O2 reducing apparatus arranged between the second compressor and a second cooler to reduce O2 in the CO2 gas.

Owner:MITSUBISHI HEAVY IND ENG LTD

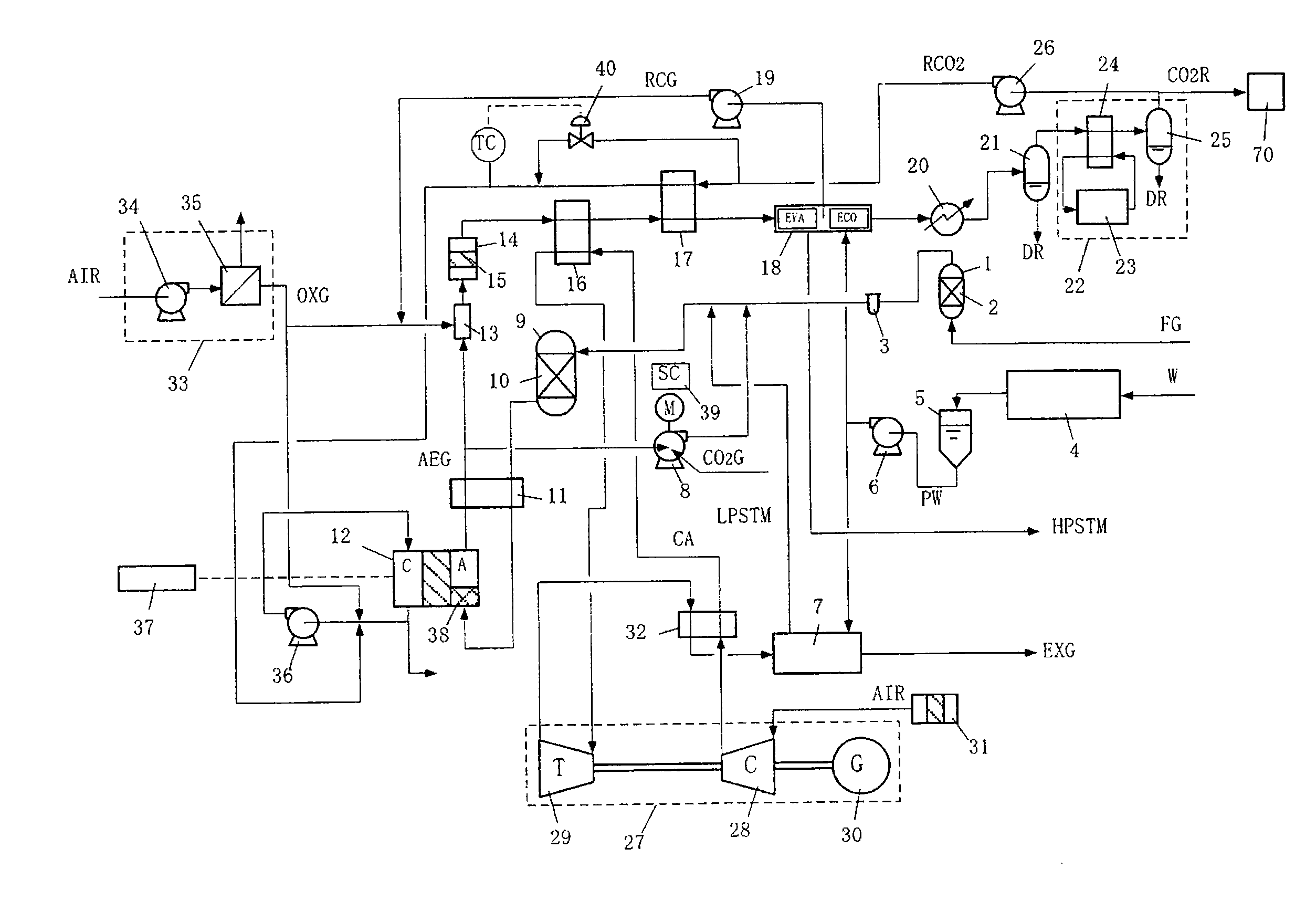

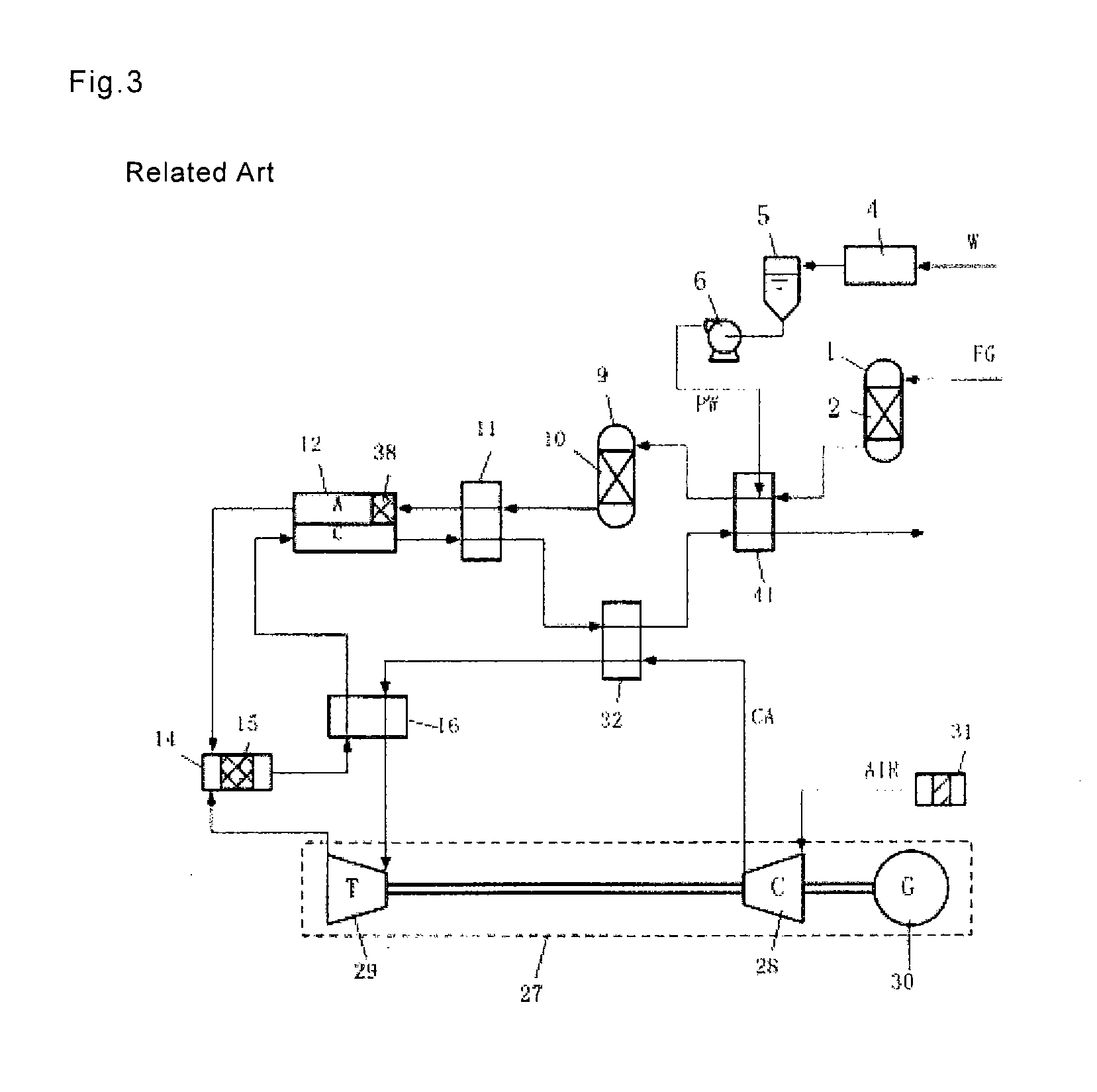

Mcfc power generation system and method for operating same

InactiveUS20110223500A1Reduce the amount of fuelReduce the amount requiredFuel cell heat exchangeRegenerative fuel cellsElectricityFuel cells

Disclosed is an MCFC power generation system and a method for operating the same enabling significant reduction of CO2 emission or substantially zero CO2 emission by minimizing the equipment added to a general power generation facility to a minimum, enabling both high power generation efficiency and high heat recovery efficiency, enabling adjustment of the voltage and output of the fuel cell in a certain range by adjusting the cathode gas composition, enabling great variation of the ratio between the heat and electricity, and thereby enabling variable thermoelectric operation. The MCFC generation system includes a cathode gas circulation system in which the cathode gas is circulated by a cathode gas recycle blower, and a closed loop is formed. Oxygen consumed by power generation is supplied from an oxygen supply plant, and CO2 is supplied from recycled CO2. Combustible components in anode exhaust are burned with oxygen, the resultant gas is cooled, and water is removed. The fuel gases in the anode exhaust is recycled.

Owner:TOKYO GAS CO LTD

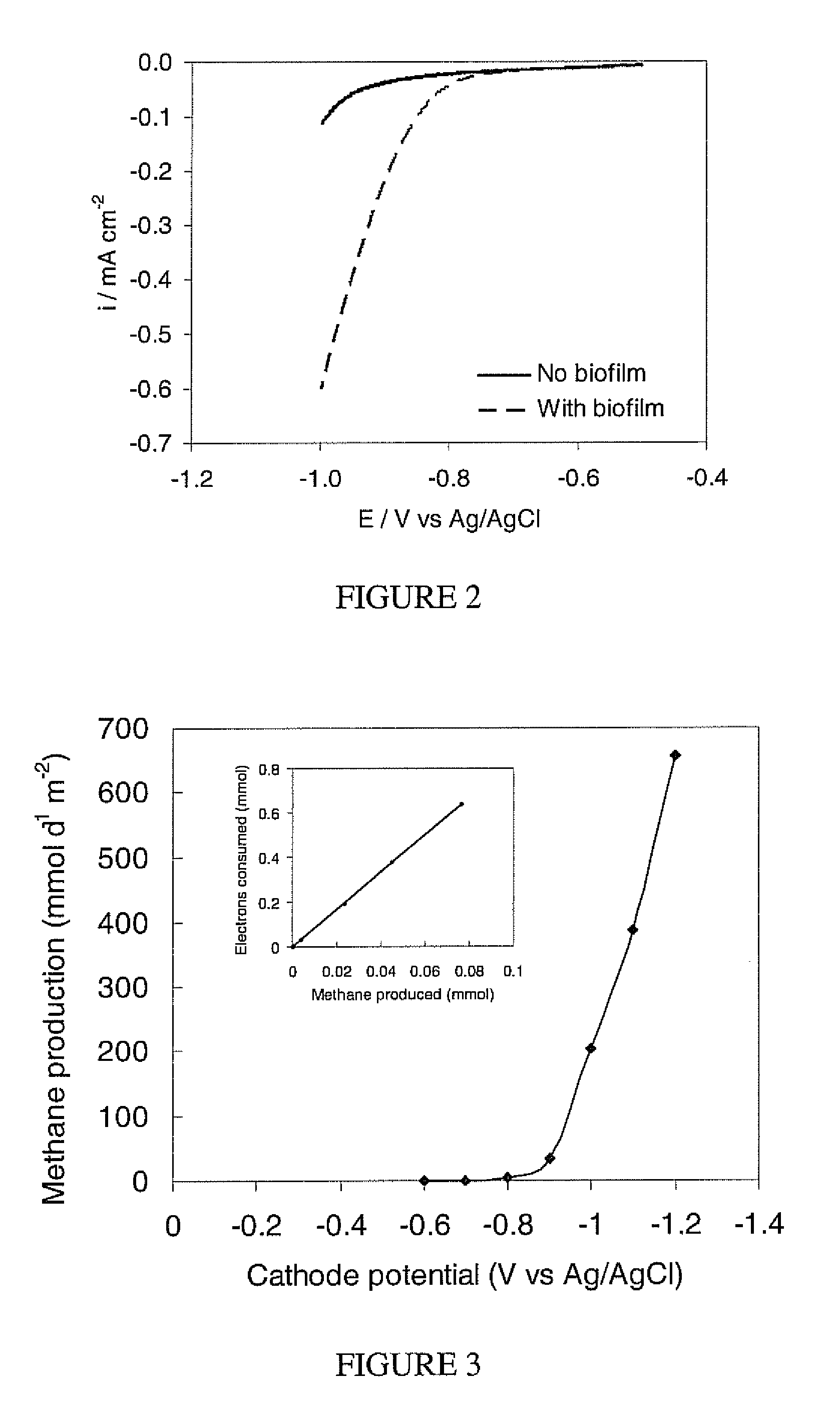

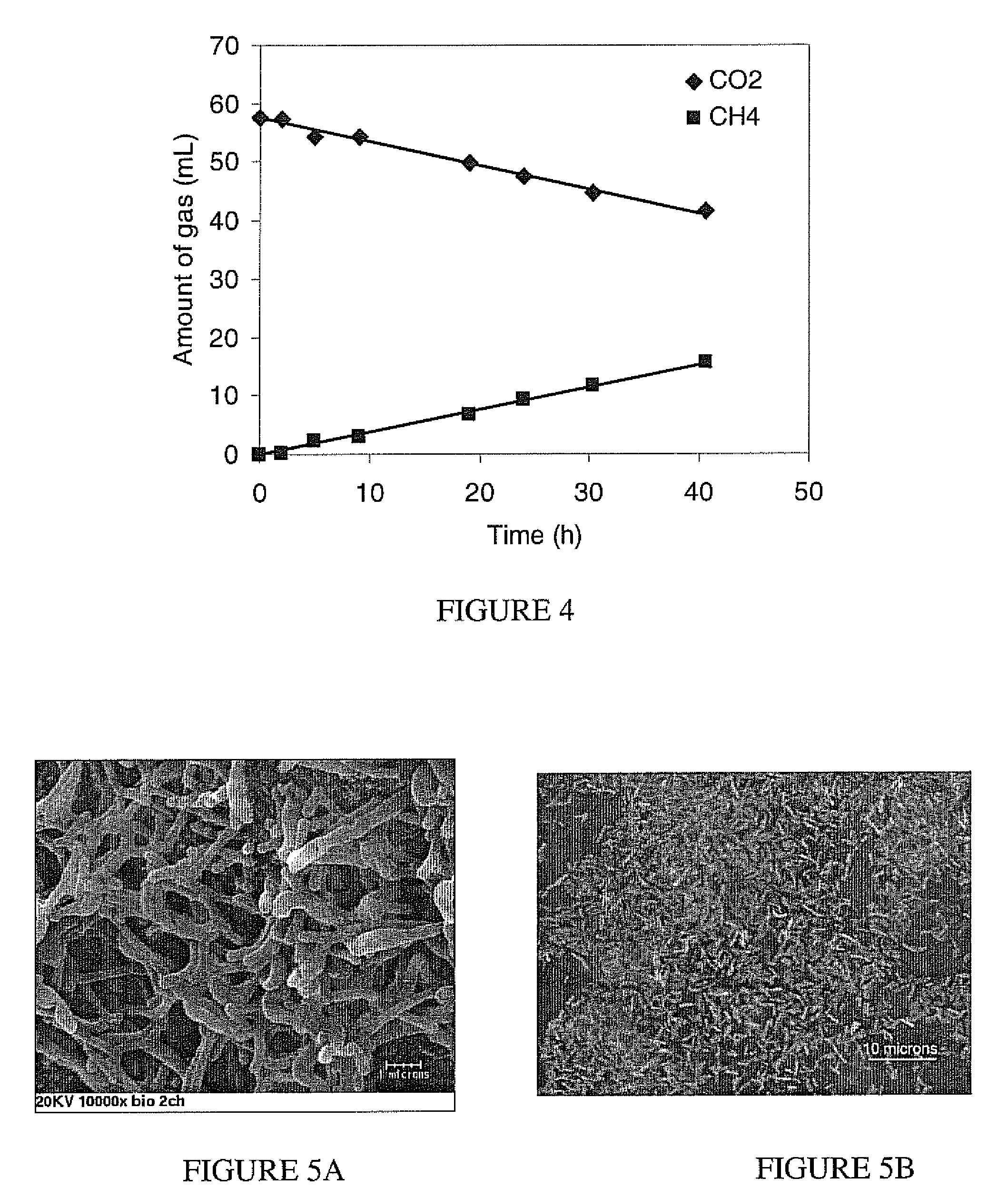

Electromethanogenic reactor and processes for methane production

ActiveUS20090317882A1Reduce deliveryImprove methane production efficiencyMicroorganismsGas production bioreactorsHydrogenCombustion

Increasing competition for fossil fuels, and the need to avoid release carbon dioxide from combustion of these fuels requires development of new and sustainable approaches for energy production and carbon capture. Biological processes for producing methane gas and capturing carbon from carbon dioxide are provided according to embodiments of the present invention which include providing an electromethanogenic reactor having an anode, a cathode and a plurality of methanogenic microorganisms disposed on the cathode. Electrons and carbon dioxide are provided to the plurality of methanogenic microorganisms disposed on the cathode. The methanogenic microorganisms reduce the carbon dioxide to produce methane gas, even in the absence of hydrogen and / or organic carbon sources.

Owner:PENN STATE RES FOUND

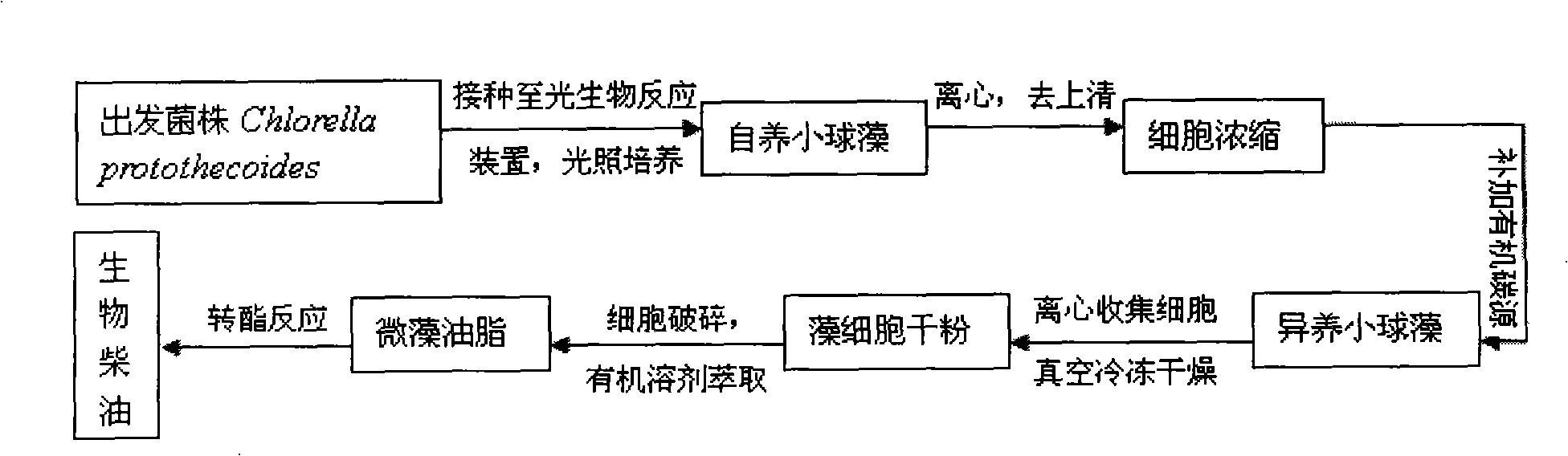

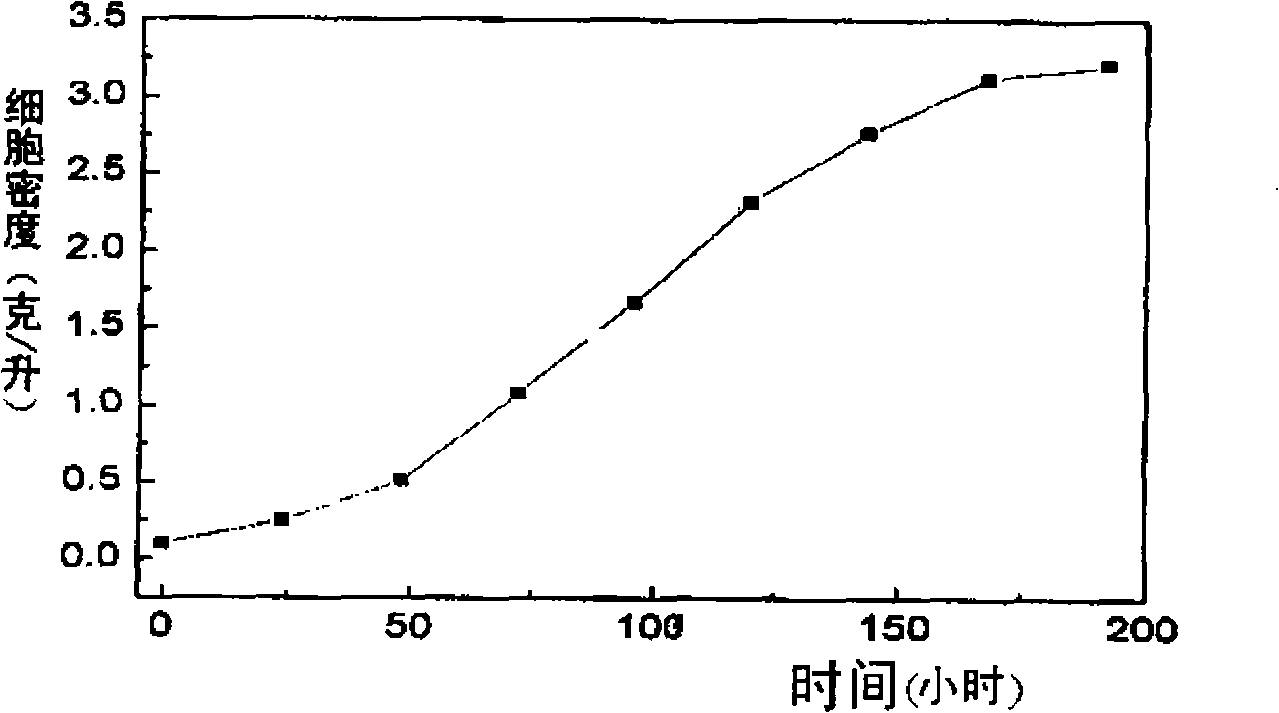

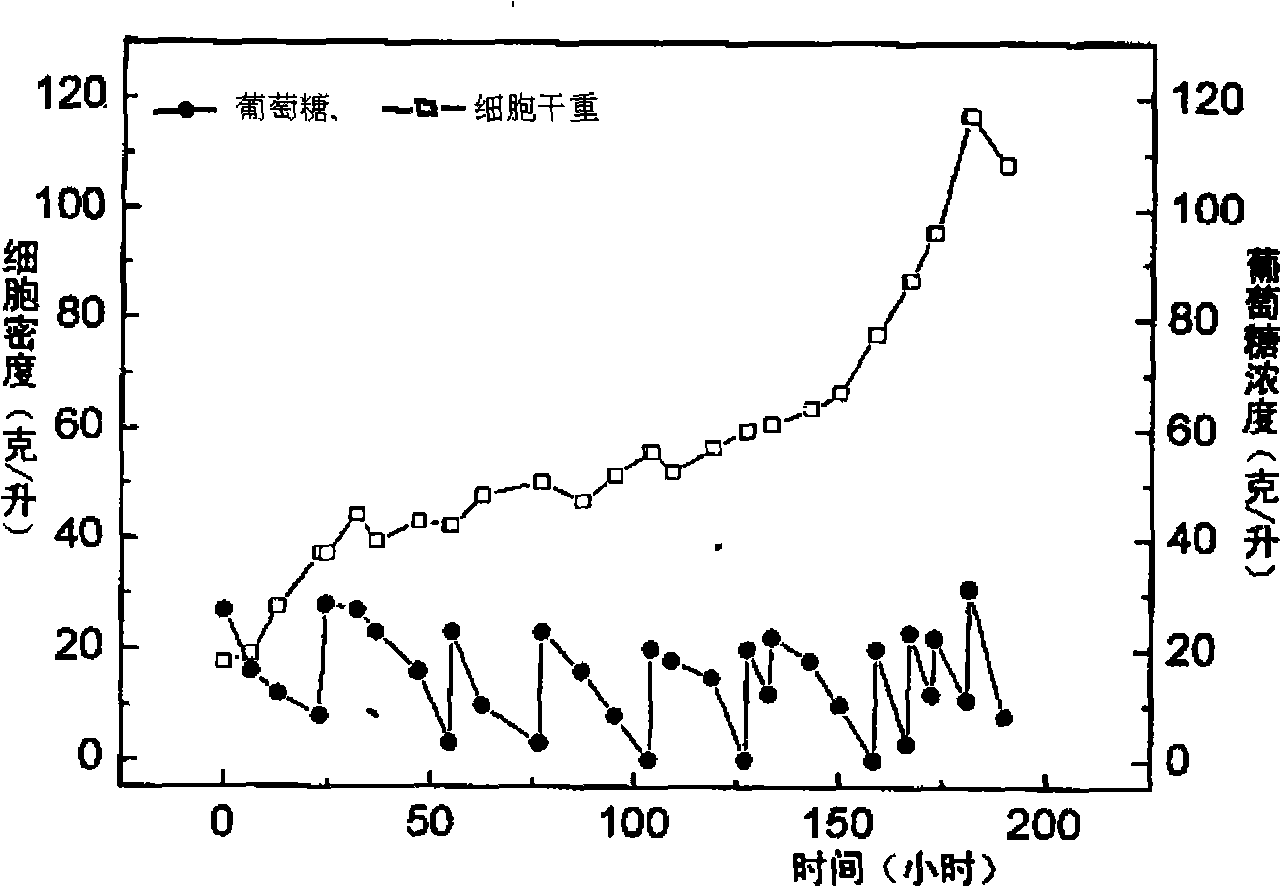

Method for producing biodiesel by autotrophic culture and heterotrophic culture of chlorella

InactiveCN101280328AReduce consumptionReduce releaseFatty acid esterificationUnicellular algaeBiodiesel feedstockOil and grease

The invention discloses a method for producing biological diesel oil by two steps of culture of chlorellas, namely, autotrophy and heterotrophy, which belongs to the renewable biological energy field. Concentrated autotrophic algae is put into a fermentation tank to perform heterotrophic growth from the processes of autotrophic culture, cell concentration and fermentation pollution controlling of the chlorellas, to ensure the chlorellas to be synthesized into neutral fat. Effective feeding strategy is established to ensure the fat to be synthesized into optimal after the optimization of the fermentation conditions and the process control. The biomass can reach 108g.L-1, and the grease content can reach 52 percent of cell dry weight. After the culturing is finished, biological diesel oil can be prepared after extracting algal oil and transesterification reaction. The cell concentration technology adopted by the invention can effectively avoid the problem of light restriction during the high density culture process Not only is the carbon dioxide emission reduced, but also the organic carbon source consumption is reduced, thus the preparation cost of the biological diesel oil material is saved. The whole technical line is environmental friendly, high efficient, and can meet the industrial application requirements of the microalgae biological diesel oil.

Owner:TSINGHUA UNIV

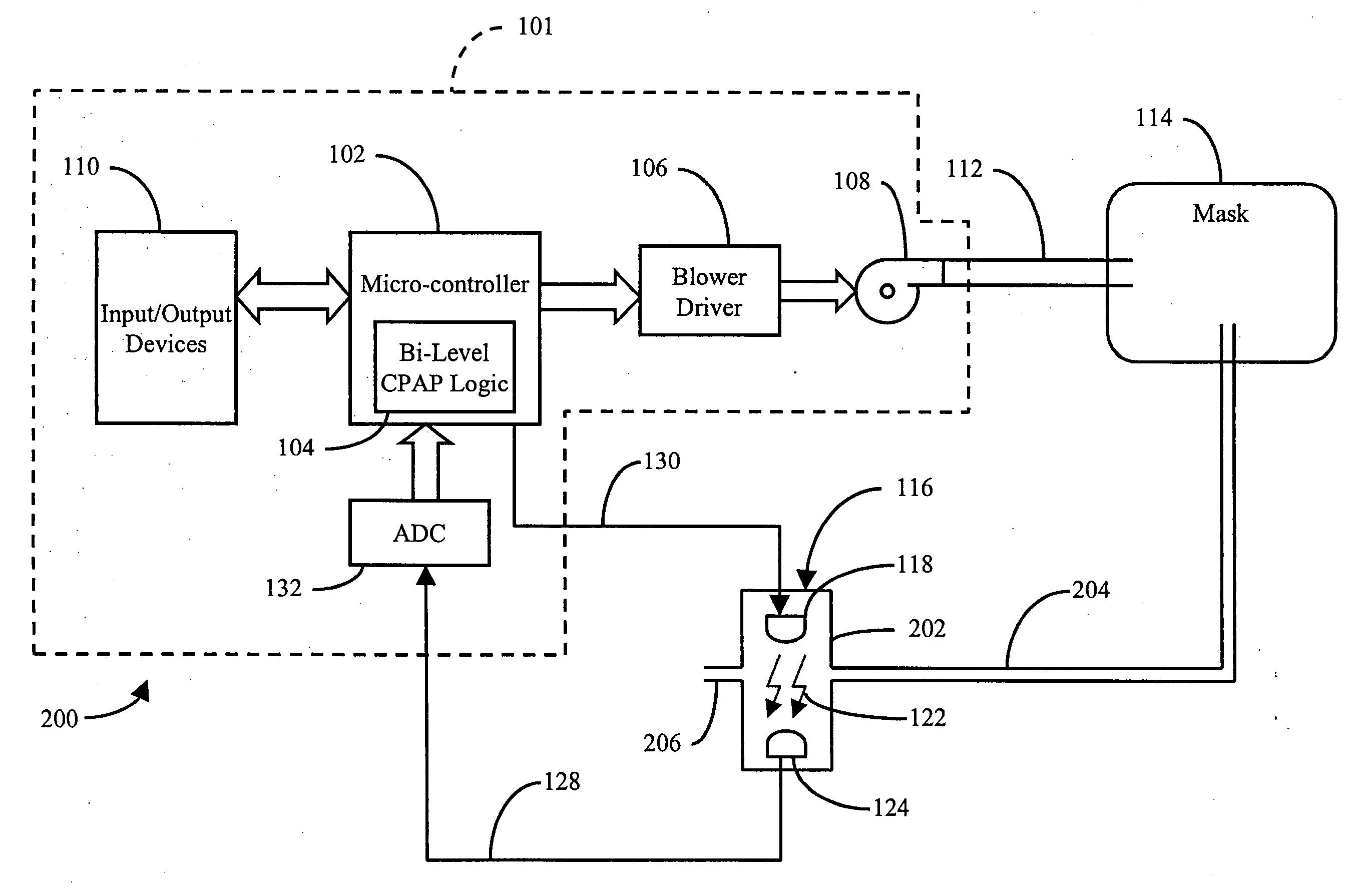

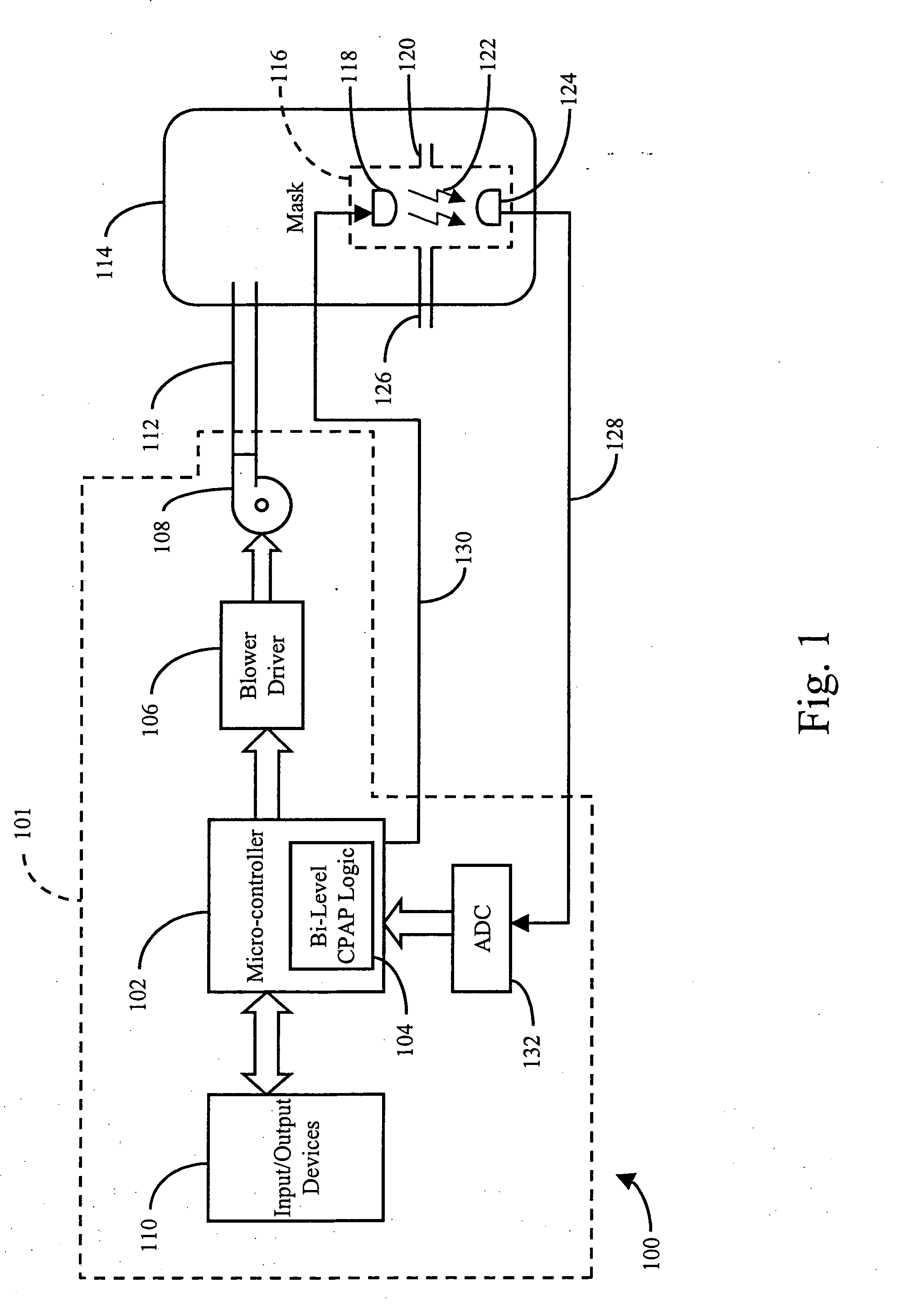

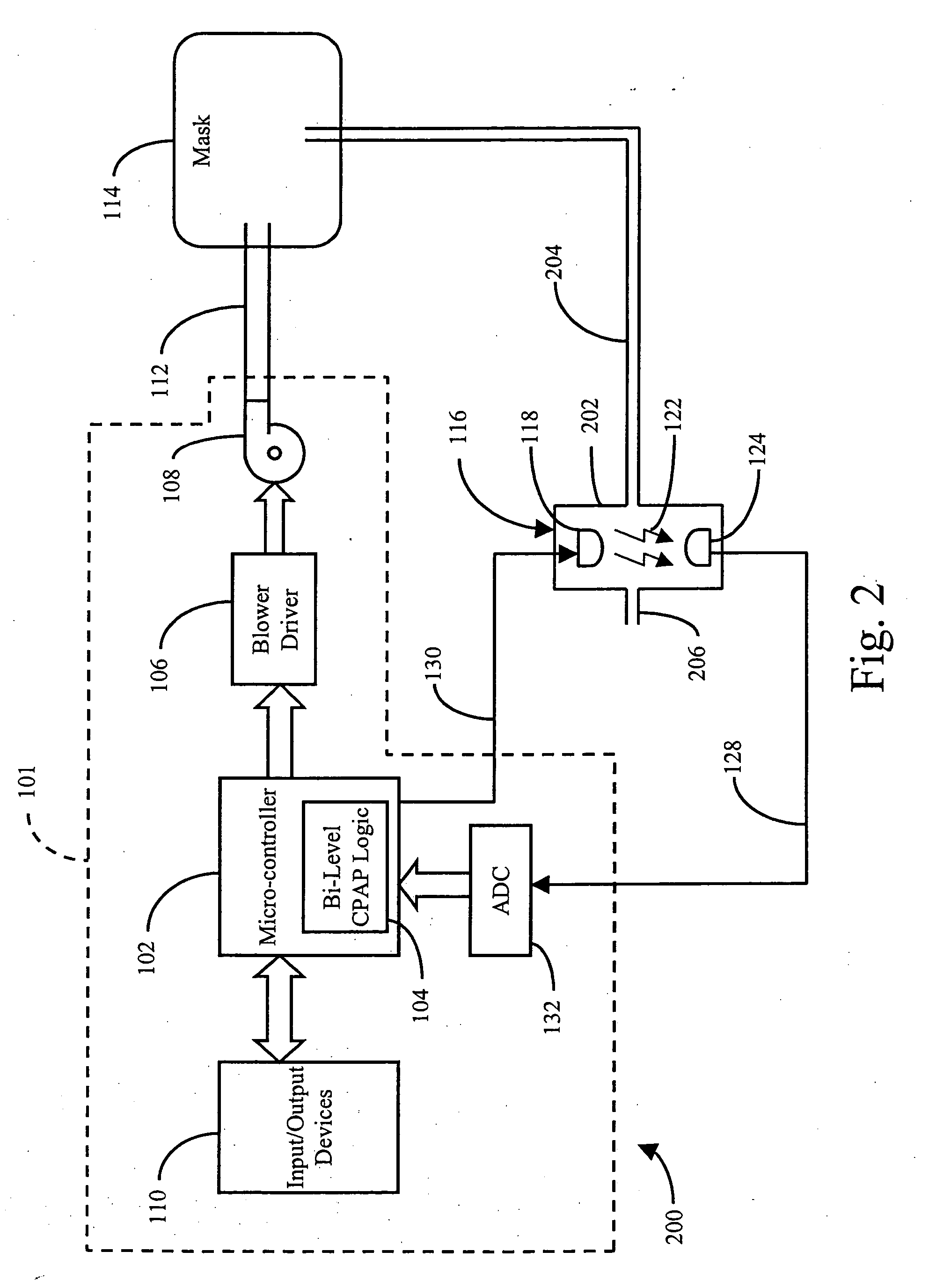

Carbon dioxide-based bi-level CPAP control

InactiveUS20050279358A1Few transmissionImprove pressure resistanceRespiratorsOperating means/releasing devices for valvesInhalationCo2 absorption

A system and method of providing bi-level CPAP therapy is provided that incorporates an infrared carbon-dioxide sensor to determine whether a patient is inhaling or exhaling. Patient exhalation causes the infrared light to be absorbed, while patient inhalation reduces the presence of carbon-dioxide causes little or no absorption of carbon-dioxide The level of carbon-dioxide in an associated patient breathing interface is monitored for thresholds that trigger higher CPAP pressure upon inhalation and lower CPAP pressure upon exhalation.

Owner:INVACARE CORP

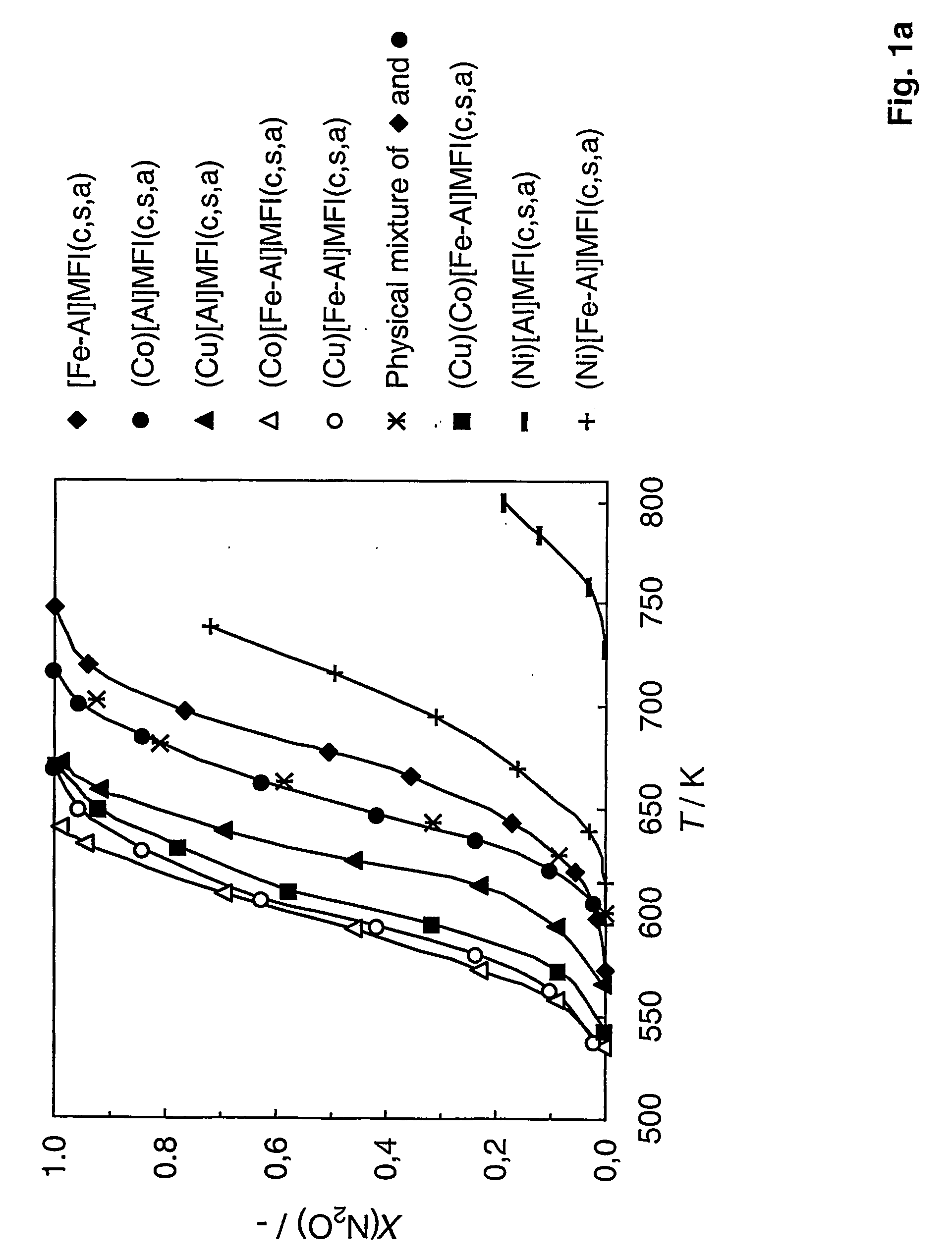

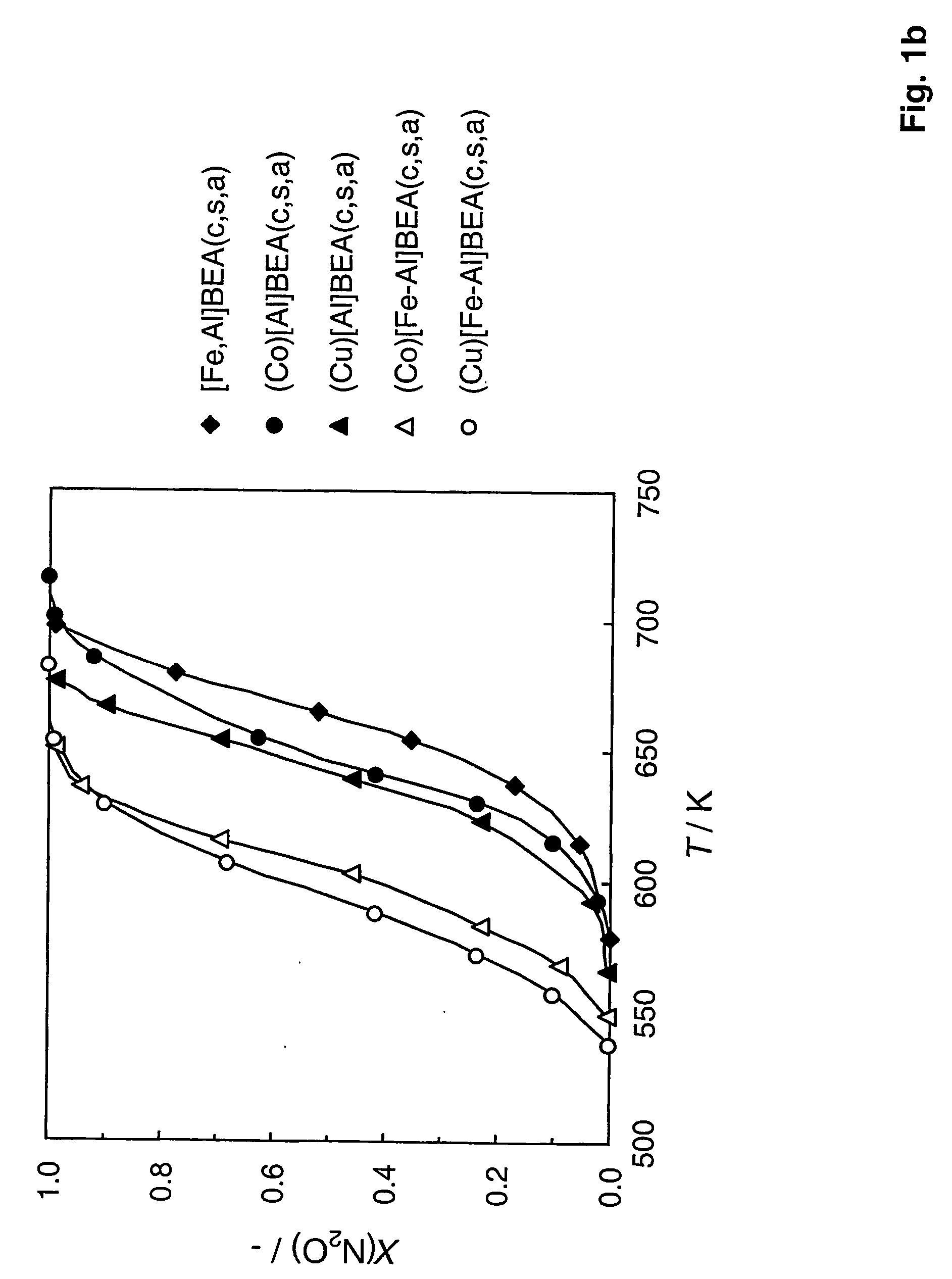

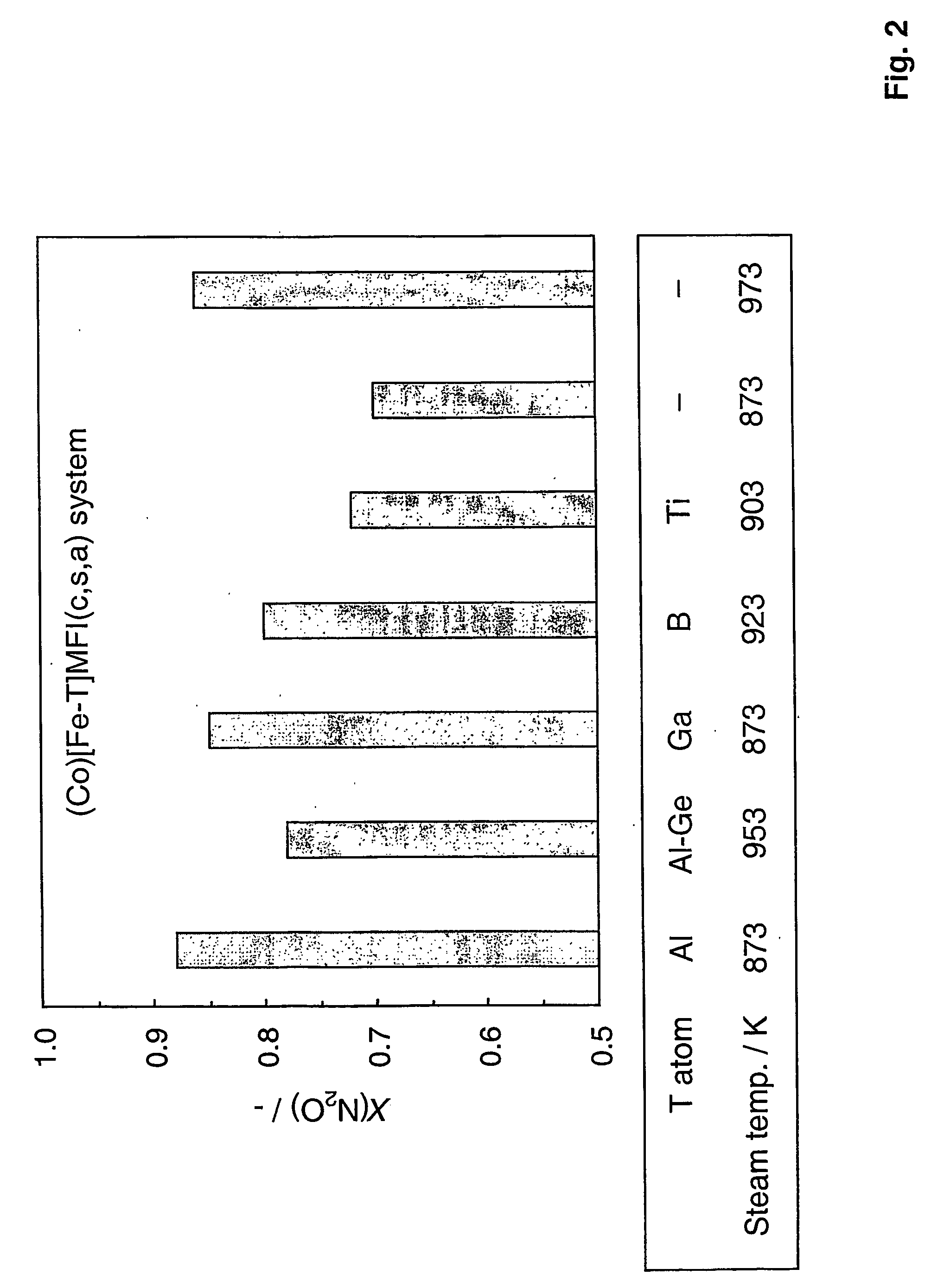

Method for preparation and activation of multimetallic zeolite catalysts, a catalyst composition and application for n2o abatement

InactiveUS20060088469A1High activityRemarkable stabilityNitrous oxide captureProductsBiological activationPilot scale

The present invention relates to the preparation and activation of multimetallic zeolites loaded with transition metals for N2O abatement in tail-gases from different sources. The N2O-containing gas is brought in contact with a catalyst comprising Fe and a second, third, or any additional transition metal (Cu, Co, Ni, Mn, Cr, V), with a total metal content ranging from 0.1-1.0 wt. %, on a zeolite support (MFI or BEA) at 523-873 K. Not 10 only the combination and loading of metals, but also the method of incorporation in the zeolite and its activation is essential to obtain active and stable catalysts. The synergy between metals was observed in Fe—Cu, Fe—Co, and Fe—Co—Cu systems, but not with combinations of iron with other transition metals. The optimal catalysts show high N2O conversions (>80%) at temperatures <623 K and stable behaviour for >2000 hours in pilot-scale tests with a zeolite-coated monolithic reactor.

Owner:YARA INT ASA

Carbon dioxide capture and mitigation of carbon dioxide emissions

The present invention describes methods and systems for extracting, capturing, reducing, storing, sequestering, or disposing of carbon dioxide (CO2), particularly from the air. The CO2 extraction methods and systems involve the use of chemical processes, mineral sequestration, and solid and liquid sorbents. Methods are also described for extracting and / or capturing CO2 via condensation on solid surfaces at low temperature.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +1

All electric LNG system and process

ActiveUS7114351B2Improve efficiencyReduce carbon dioxide emissionsSolidificationLiquefactionEngineeringProcess engineering

A reduced carbon dioxide emissions system and method for providing power for refrigerant compression and shared electrical power for a light hydrocarbon gas liquefaction process.

Owner:BP CORP NORTH AMERICA INC

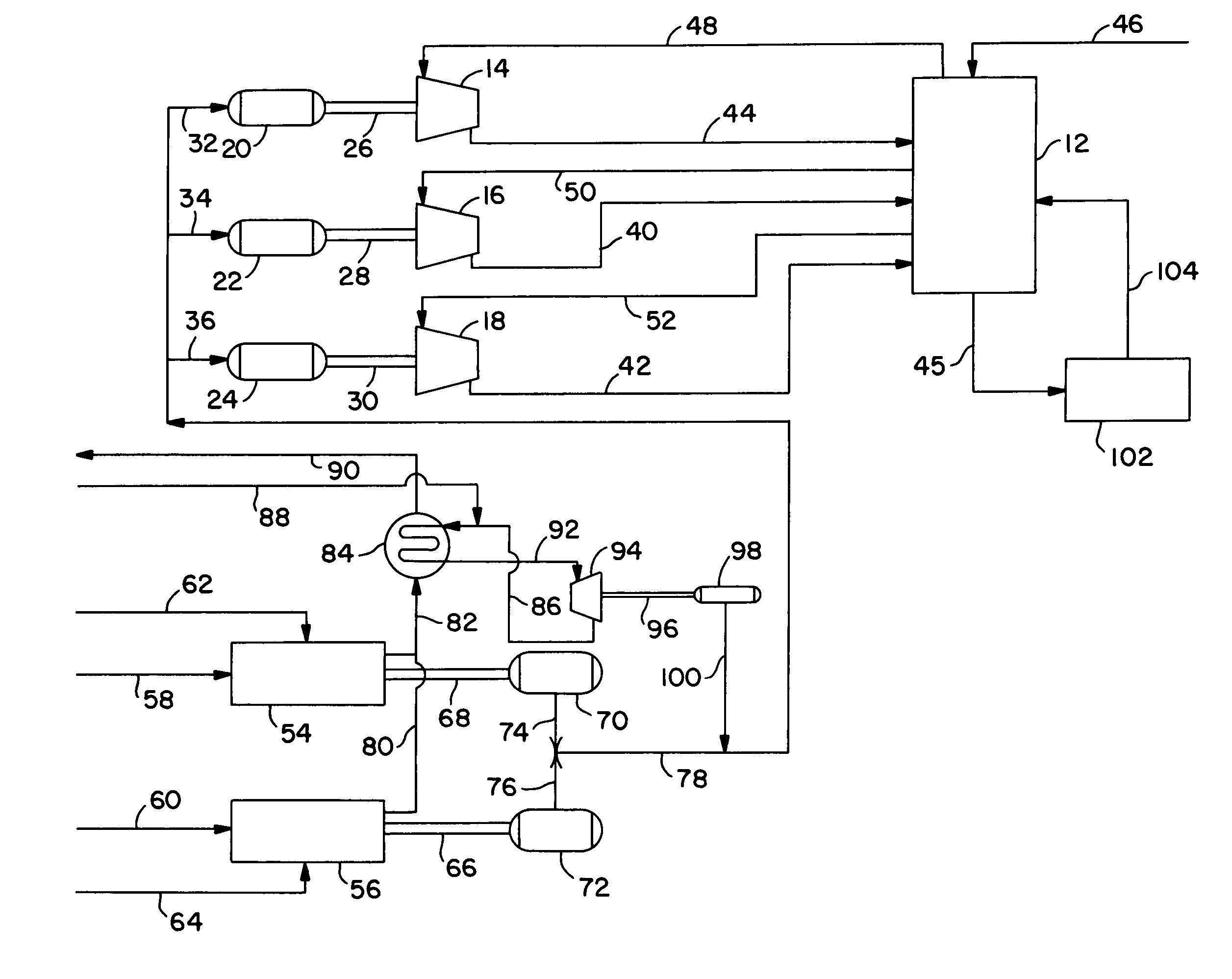

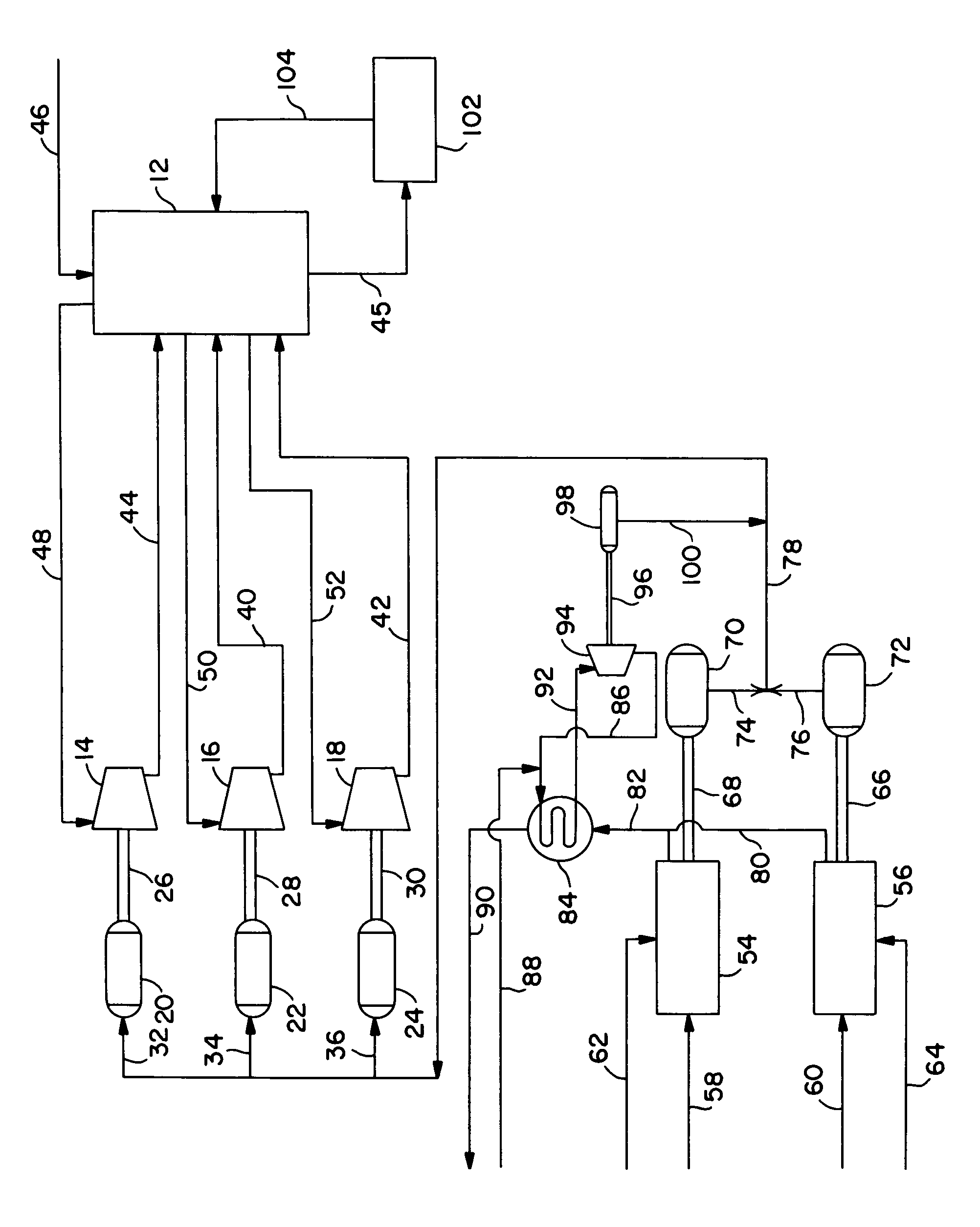

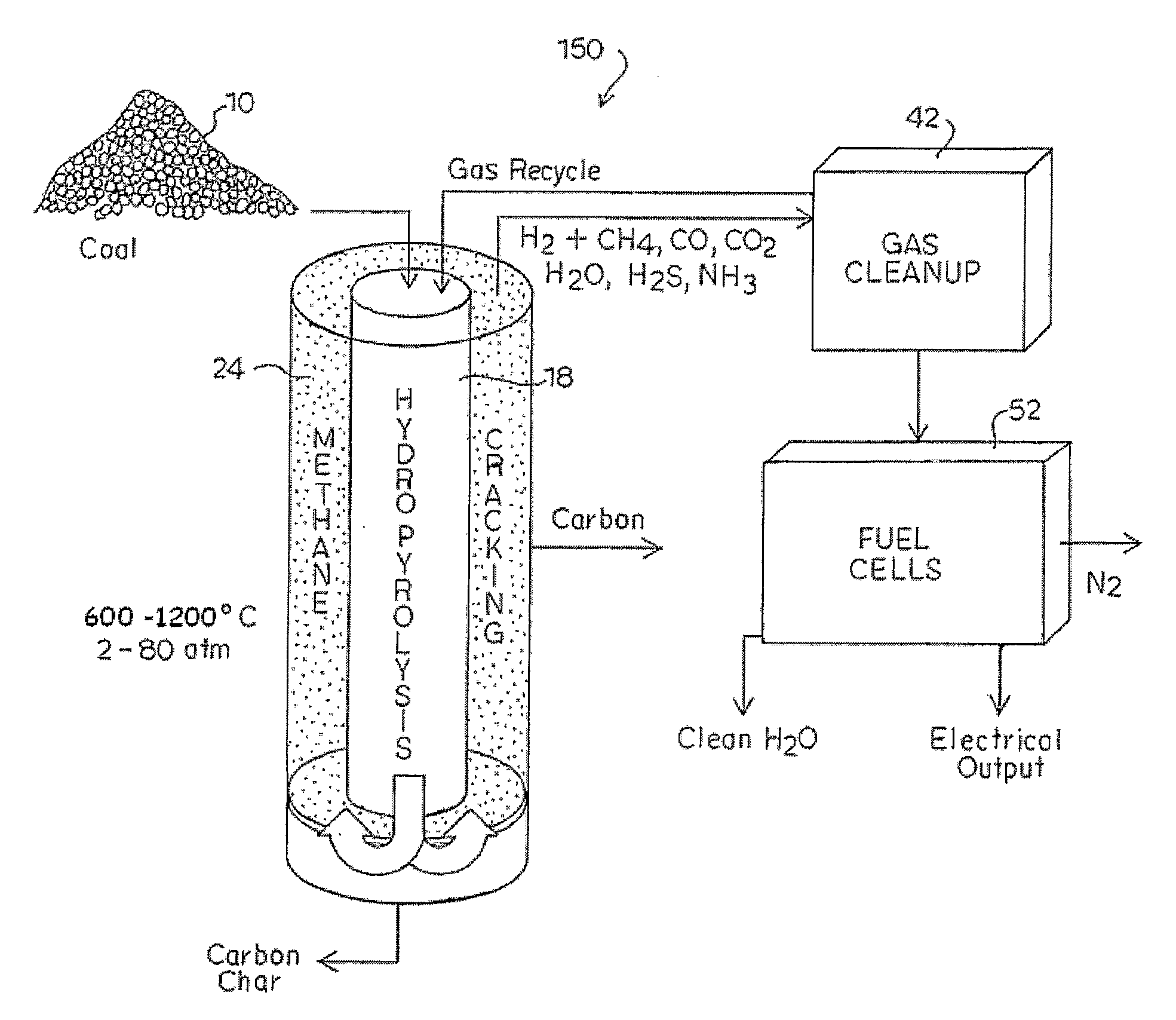

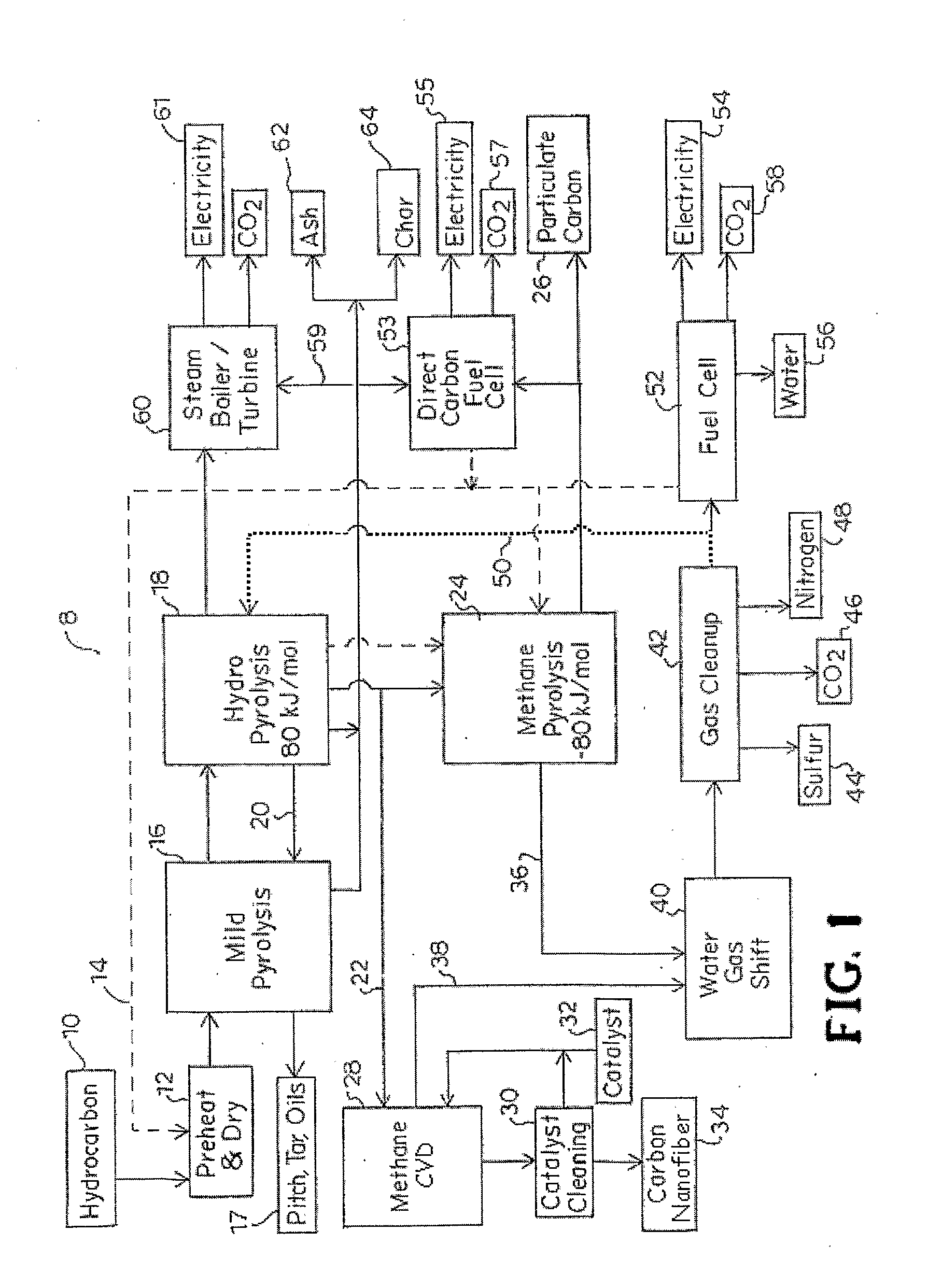

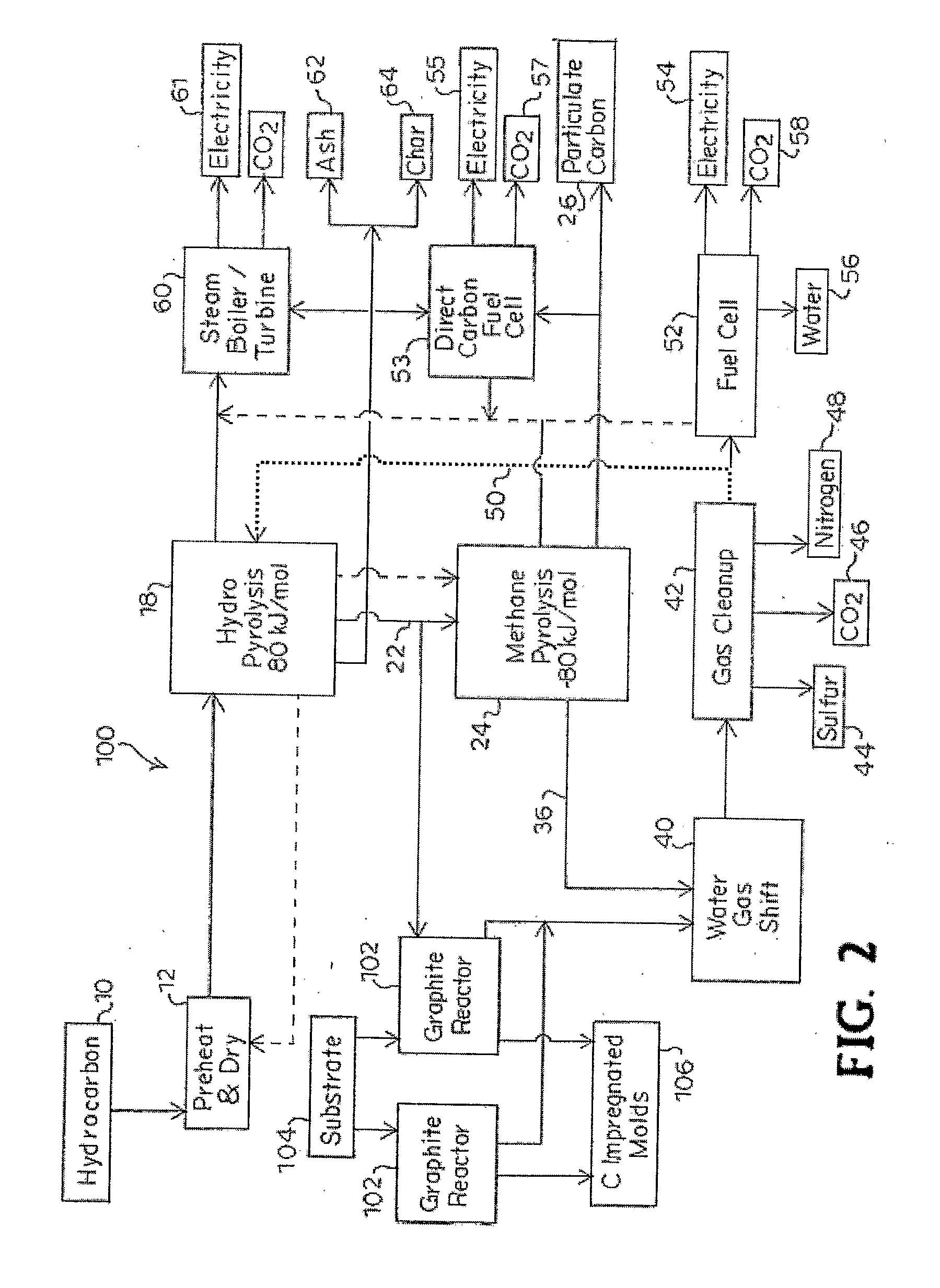

System and method for conversion of hydrocarbon materials

InactiveUS20110120138A1Improve responseGasifier mechanical detailsCombustible gas catalytic treatmentSolid carbonChemical reaction

A process for converting coal and other hydrocarbon solid fuel feedstocks comprises reacting the feedstock in a first stage exothermic hydropyrolysis reaction zone with a hydrogen-rich gas stream for producing methane. The methane from the first reaction zone is dissociated in a second endothermic reaction zone to produce solid carbon and hydrogen-rich gas using heat mainly from the first reaction zone. All heat to promote the desired extents of reaction in each reaction zone is provided solely from the exothermicity of chemical reactions in the process. The majority of the gas is recirculated from the second reaction zone to the first reaction zone. Hydrogen gas is recovered to produce electrical energy for reducing carbon dioxide emissions.

Owner:HYCET

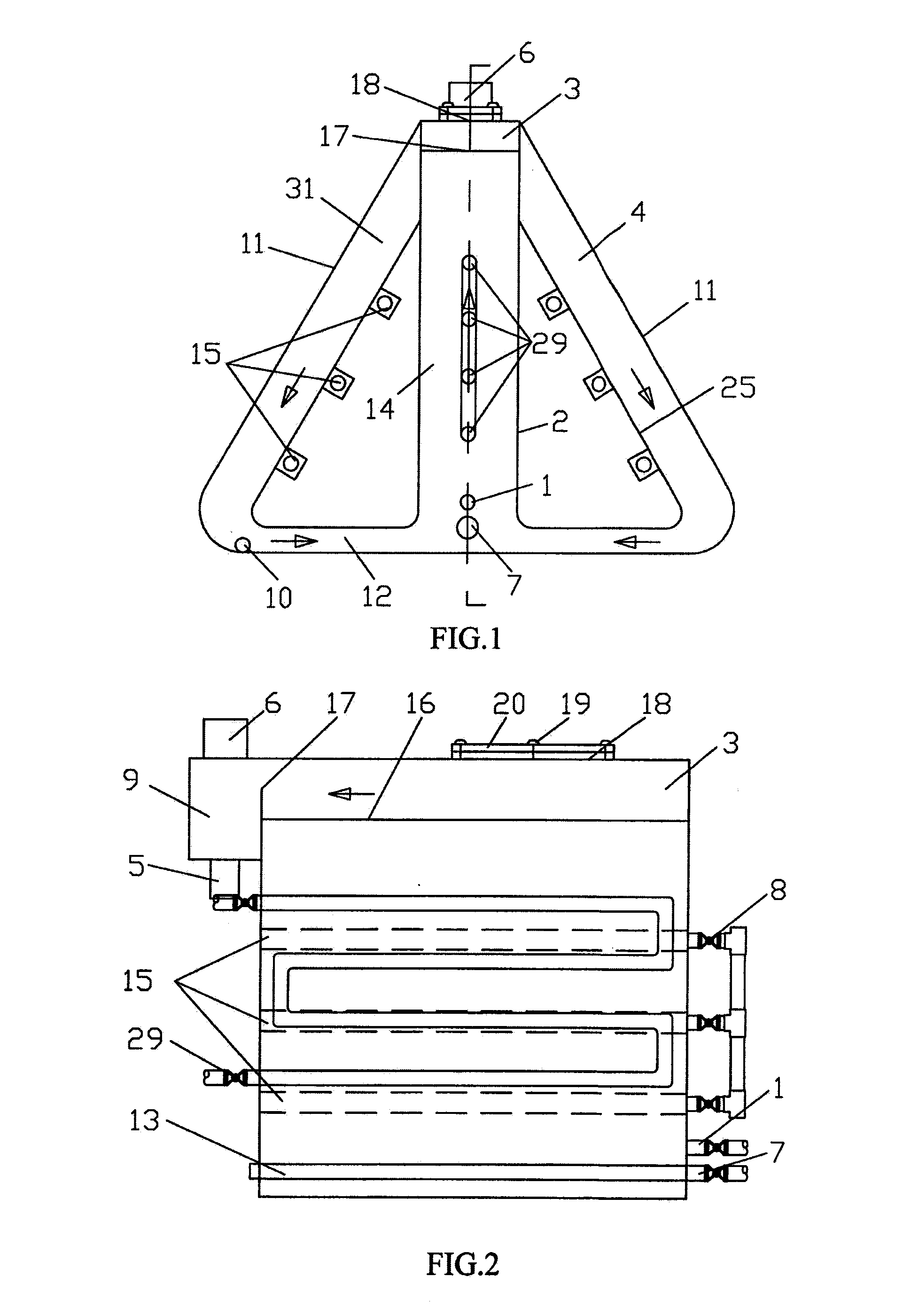

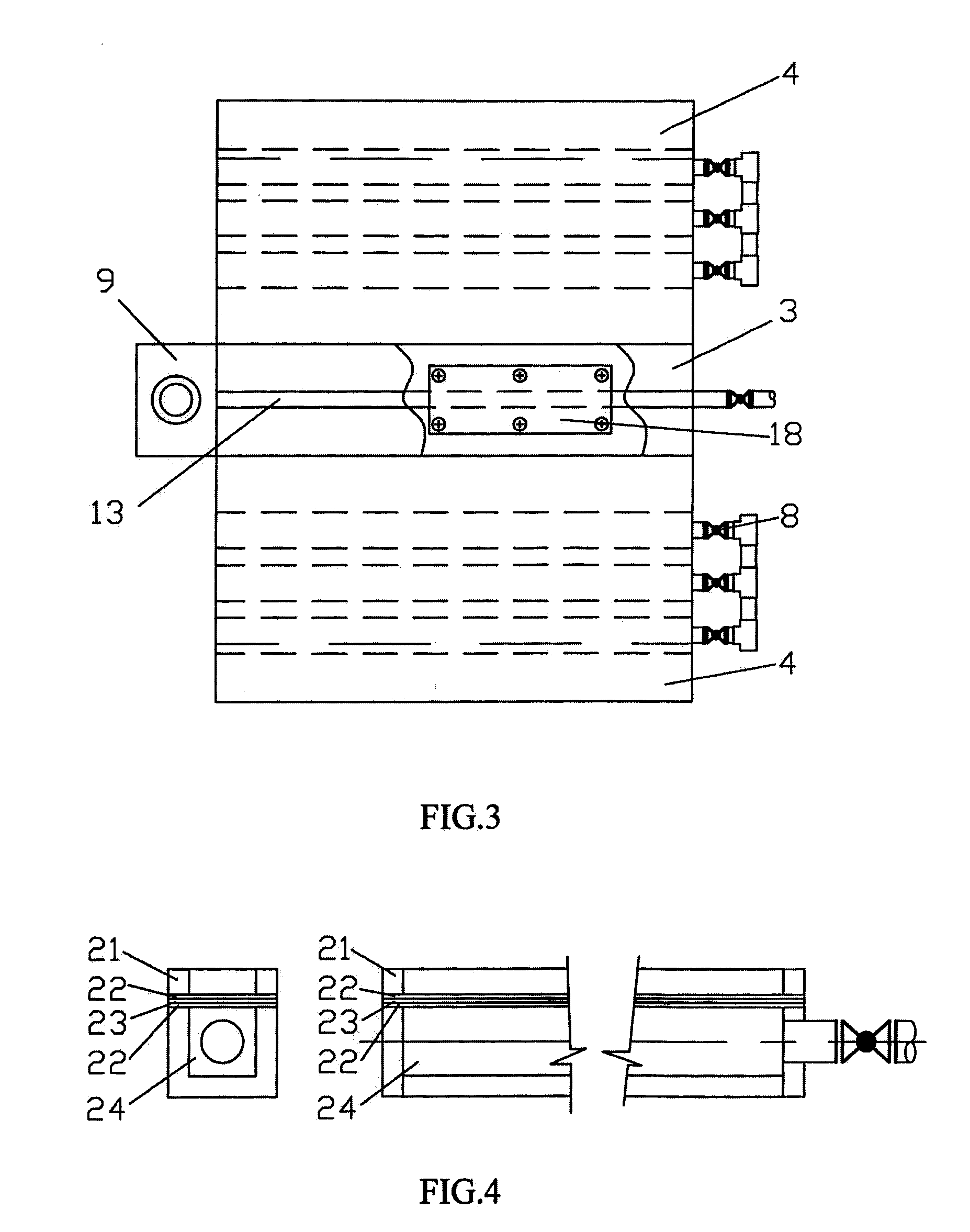

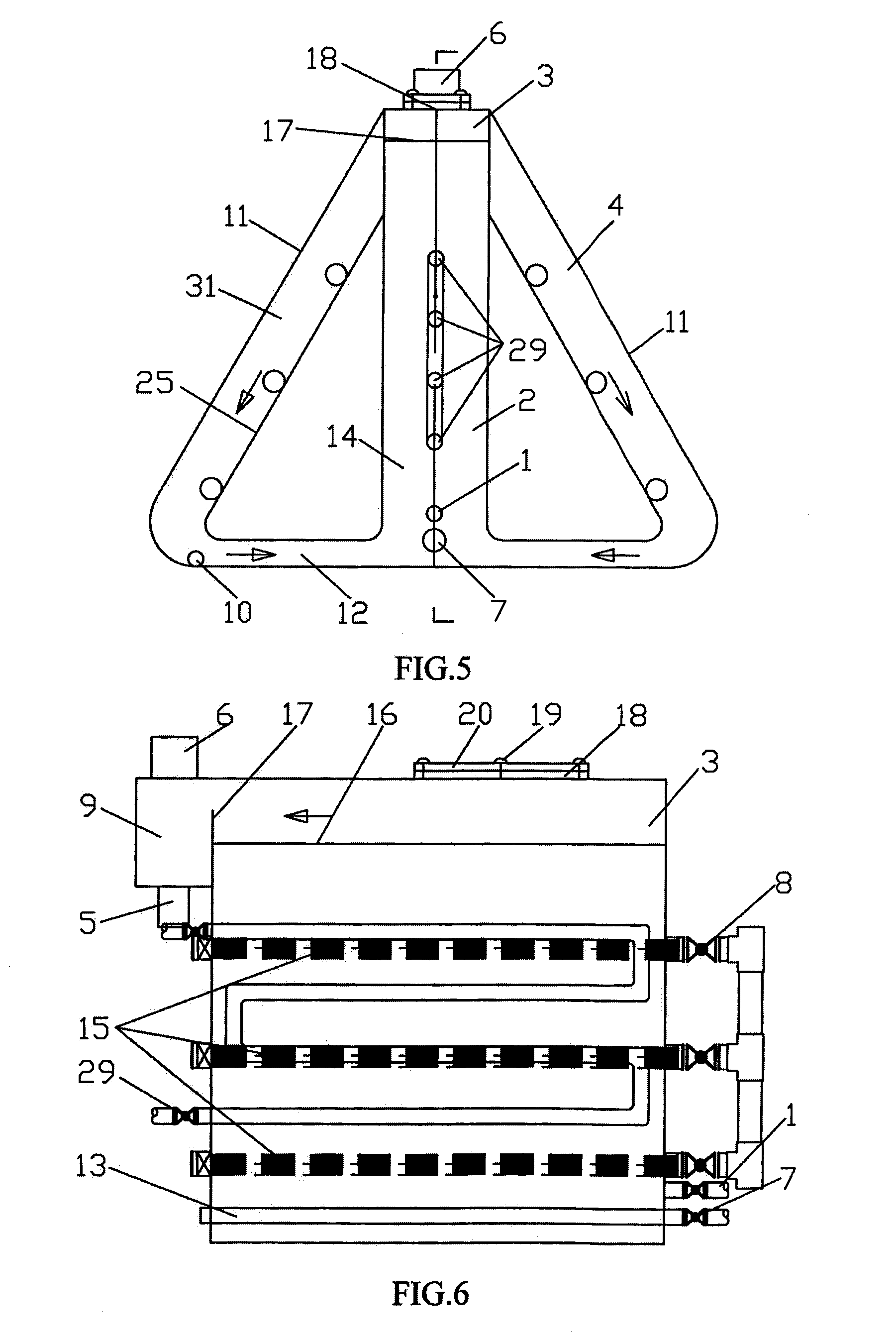

Photobioreactor for carbon dioxide mitigation in wastewater treatment

ActiveUS20110159581A1Increasing microalgae usage efficiency of light energyLarge light specific areaBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorBackflow

An airlift circulation micro-algae photoautotrophic-heterotrophic coupling photobioreactor for wastewater treatment carbon emission mitigation includes feeding pipe, micro-algae heterotrophic zone, gas-liquid separation chamber, micro-algae phototrophic zone, bottom backflow zone, discharge pipe, and the liquid drained zone.

Owner:TONGJI UNIV

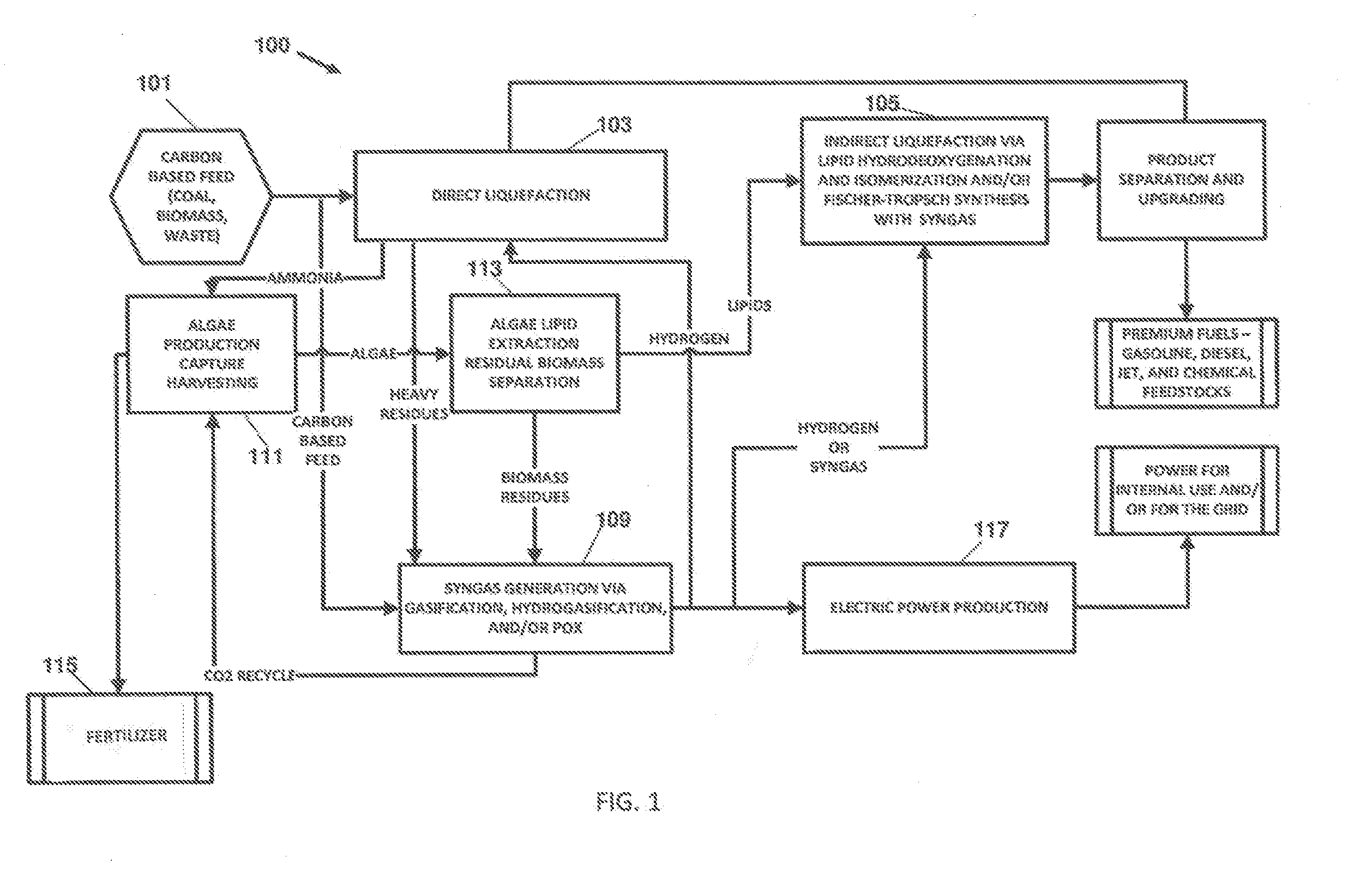

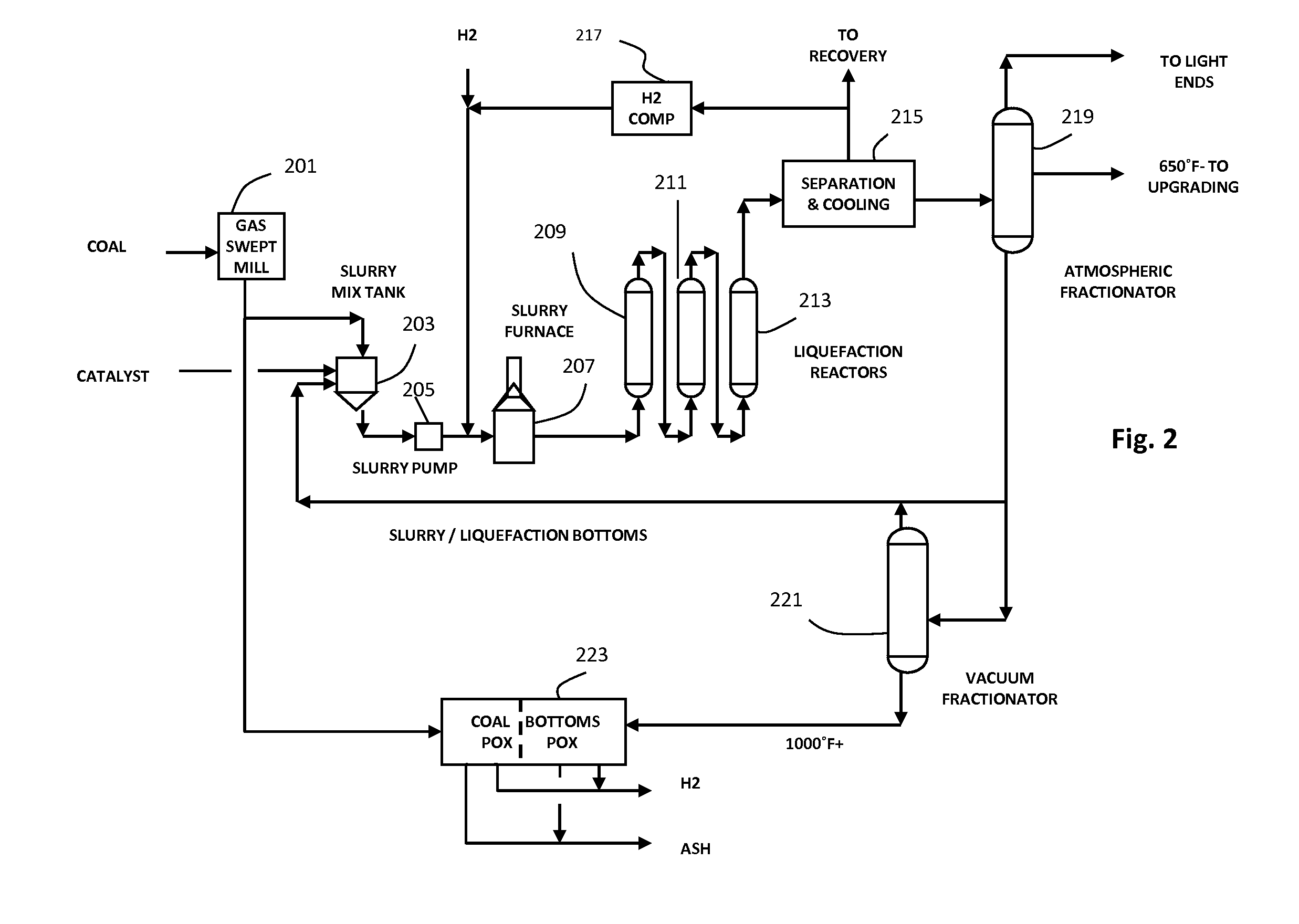

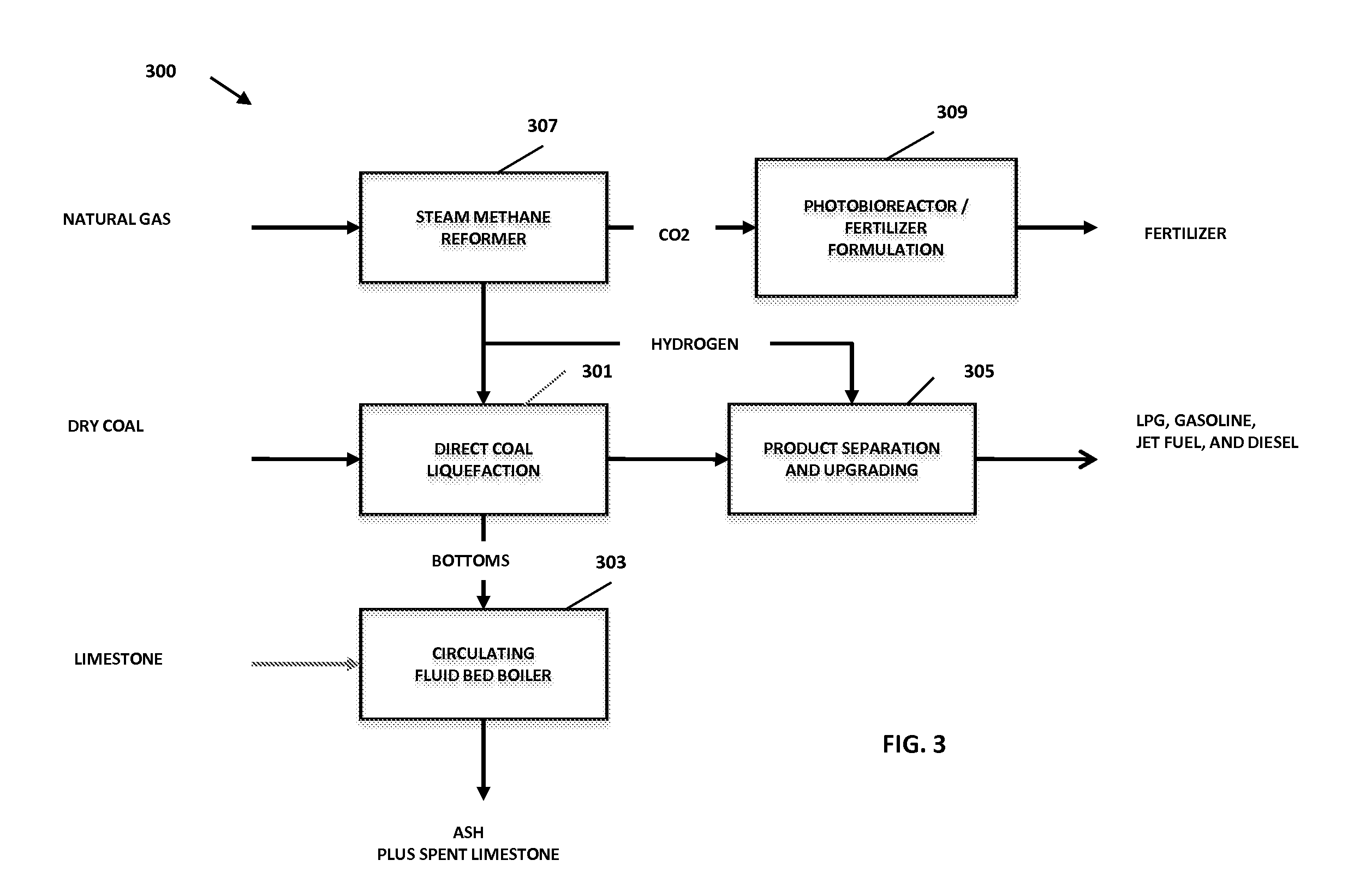

Integrated Coal To Liquids Process And System With Co2 Mitigation Using Algal Biomass

InactiveUS20120144887A1High thermal efficiencyReduced footprintBioreactor/fermenter combinationsBio-organic fraction processingMethane reformerSyngas

An ICBTL system having a low GHG footprint for converting coal or coal and biomass to liquid fuels in which a carbon-based feed is converted to liquids by direct liquefaction and optionally by indirect liquefaction and the liquids are upgraded to produce premium fuels. CO2 produced by the process is used to produce algal biomass and photosynthetic microorganisms in a photobioreactor. Optionally, lipids extracted from the some or all of the algal biomass is hydroprocessed to produce fuel components and biomass residues and the carbon-based feed our gasified to produce hydrogen and syngas for the direct and indirect liquefaction processes. Some or all of the algal biomass and photosynthetic microorganisms are used to produce a natural biofertilizer. CO2 may also be produced by a steam methane reformer for supplying CO2 to produce the algal biomass and photosynthetic microorganisms.

Owner:ACCELERGY CORP

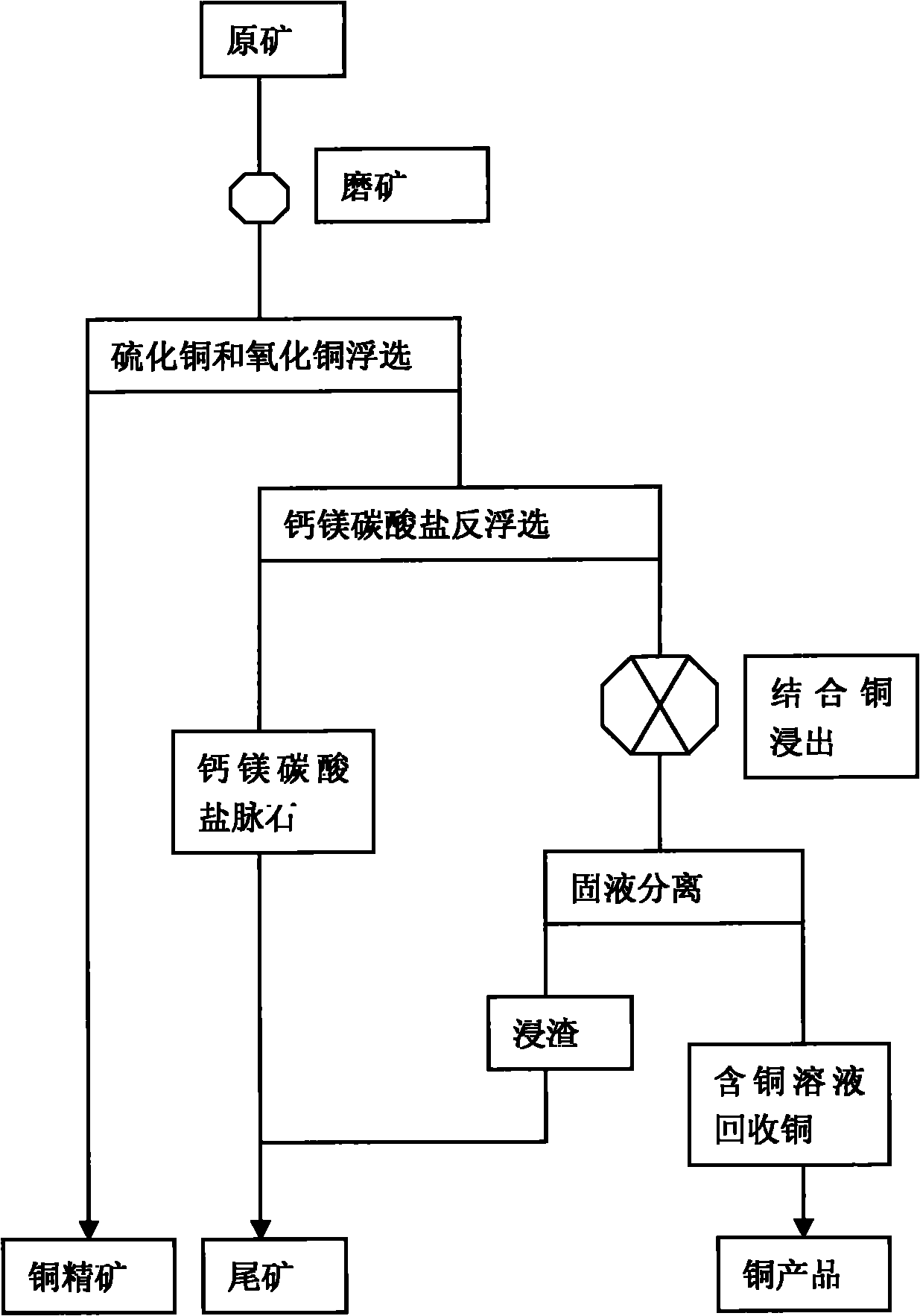

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

Combustion heating control device and method used for gas water heater

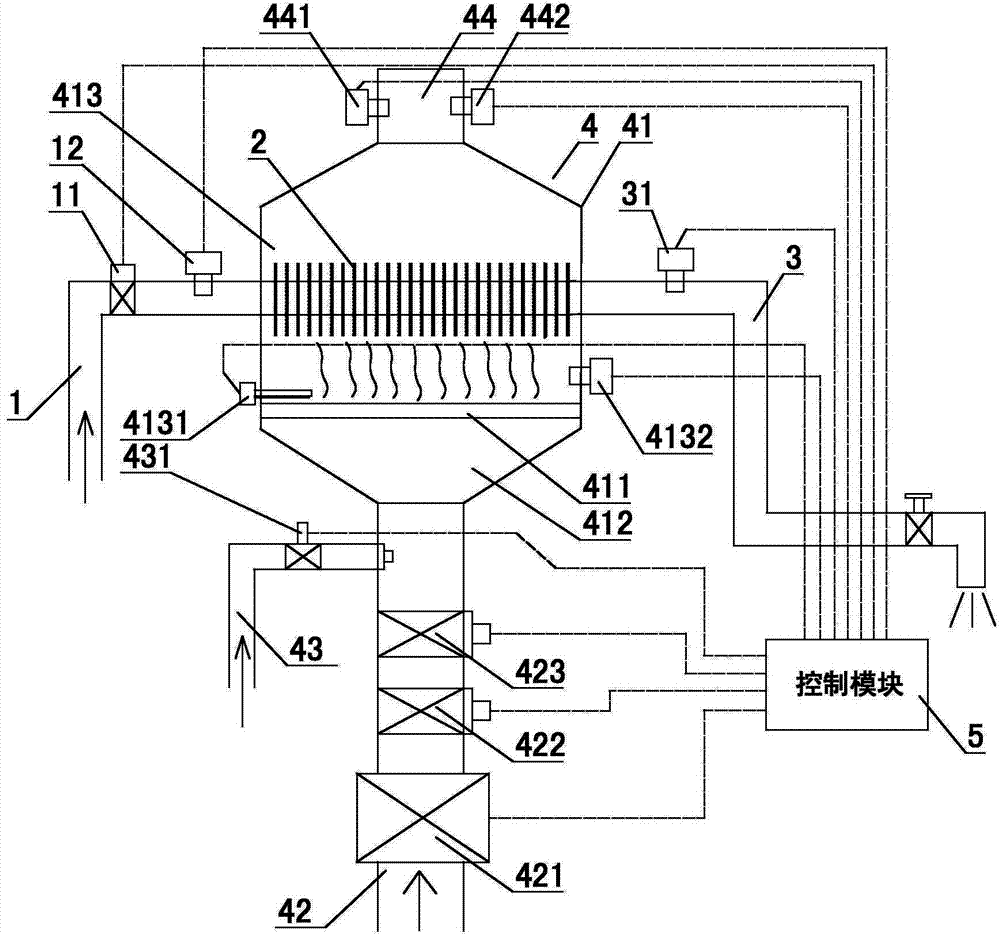

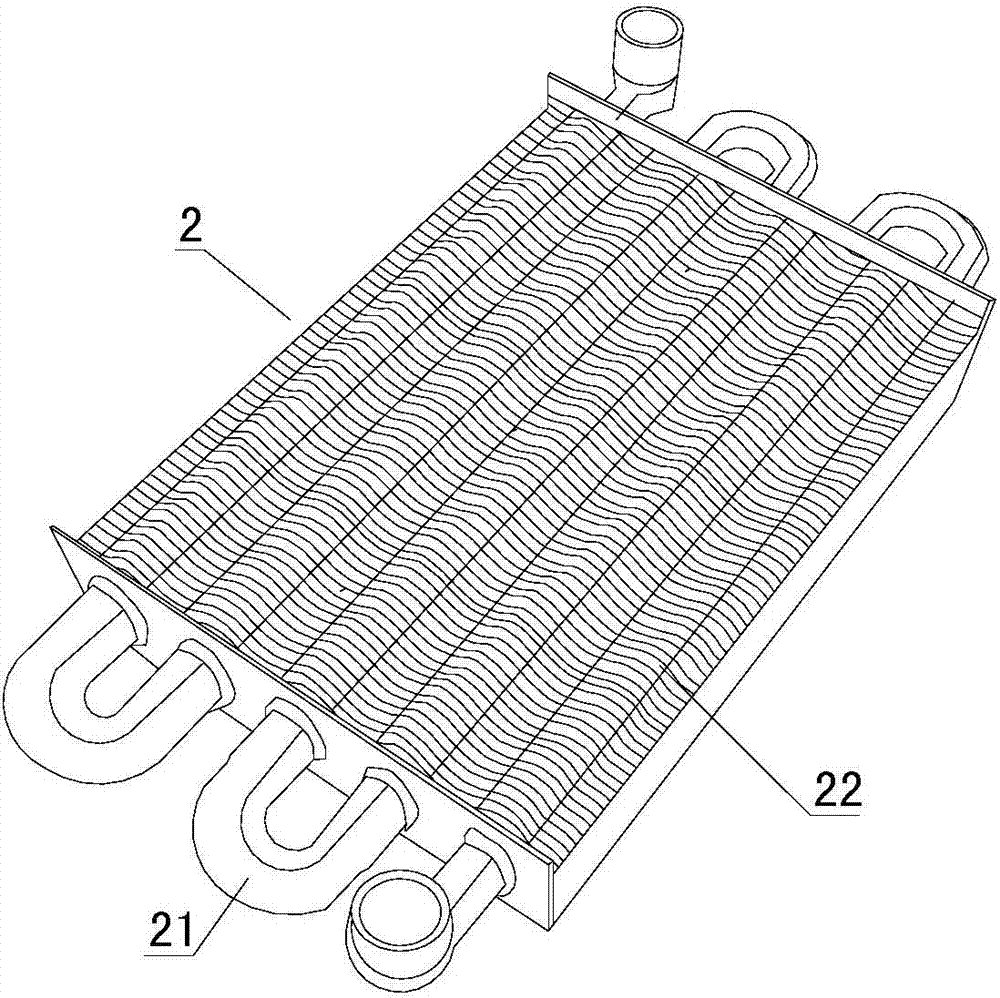

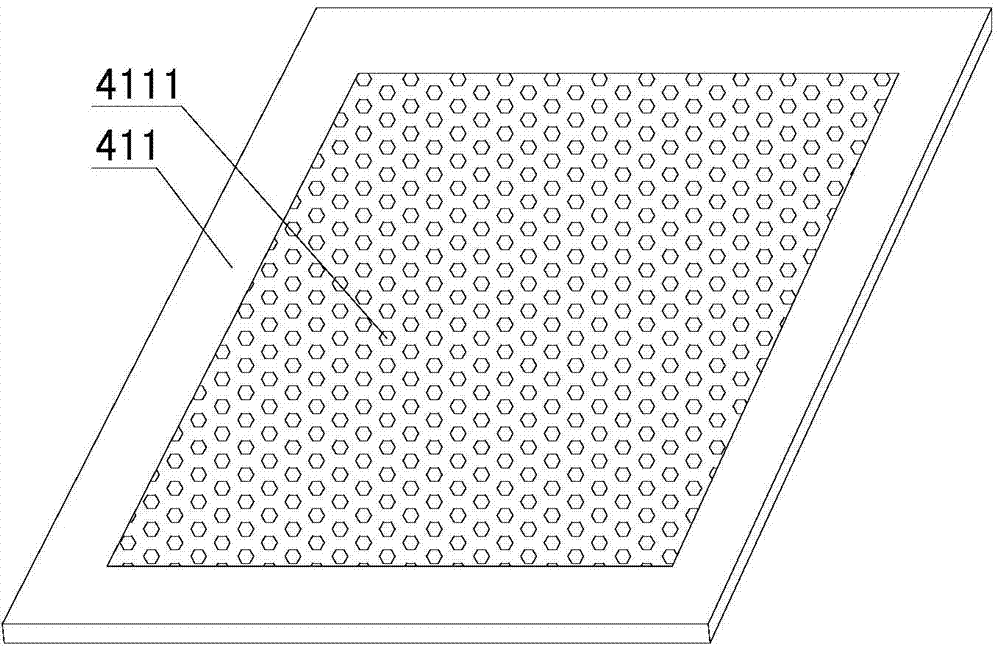

The invention discloses a combustion heating control device and method used for a gas water heater. The combustion heating control device comprises a water inlet pipe, a heat exchanger, a water outlet pipe, a heater and a control module. An air inlet pipe, a gas pipe and an exhaust pipe are arranged on a shell of the heater. An isolating and mixing bin and a combustion bin are arranged in the shell. A water inlet flow sensor and a water inlet temperature sensor are arranged on the water inlet pipe. A water outlet temperature sensor is arranged on the water outlet pipe. A vortex draught fan, an air proportional valve and an air flow sensor are arranged on the air inlet pipe. A gas proportion valve is arranged on the gas pipe. A tail gas temperature sensor and an air pressure sensor are arranged on the exhaust pipe. An igniter and an oxygen sensor are arranged in the combustion bin. The control module is connected with all the sensors, the vortex draught fan, the air proportion valve, the gas proportion valve and the igniter. An energy-saving control method of the combustion heating control device is included. The combustion heating control device has the advantages of being sufficient in gas combustion, low in manufacturing cost, concentrated in heat, and capable of saving gas, reducing carbon dioxide emission and reducing carbon monoxide poisoning.

Owner:广东奇林电气股份有限公司

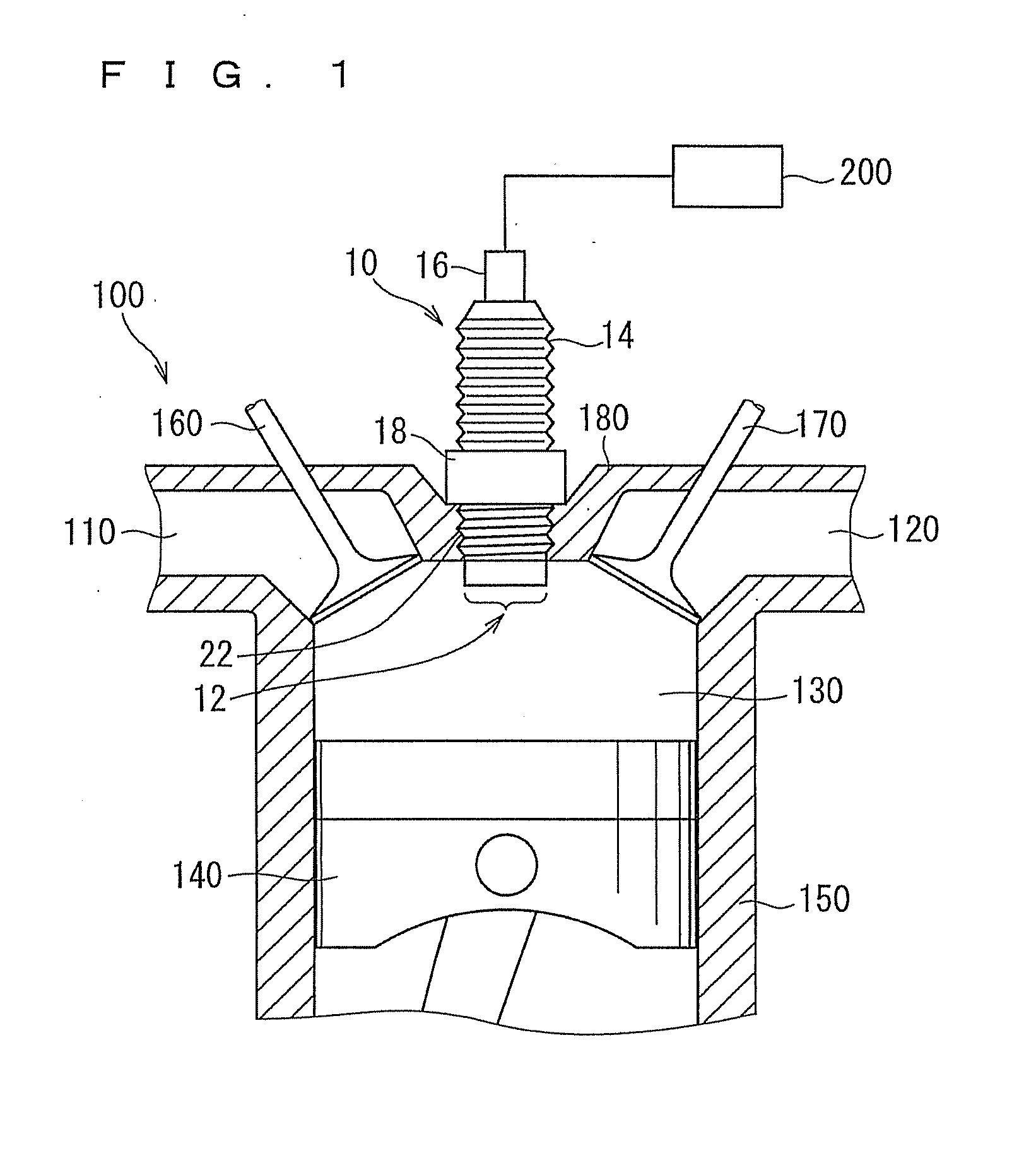

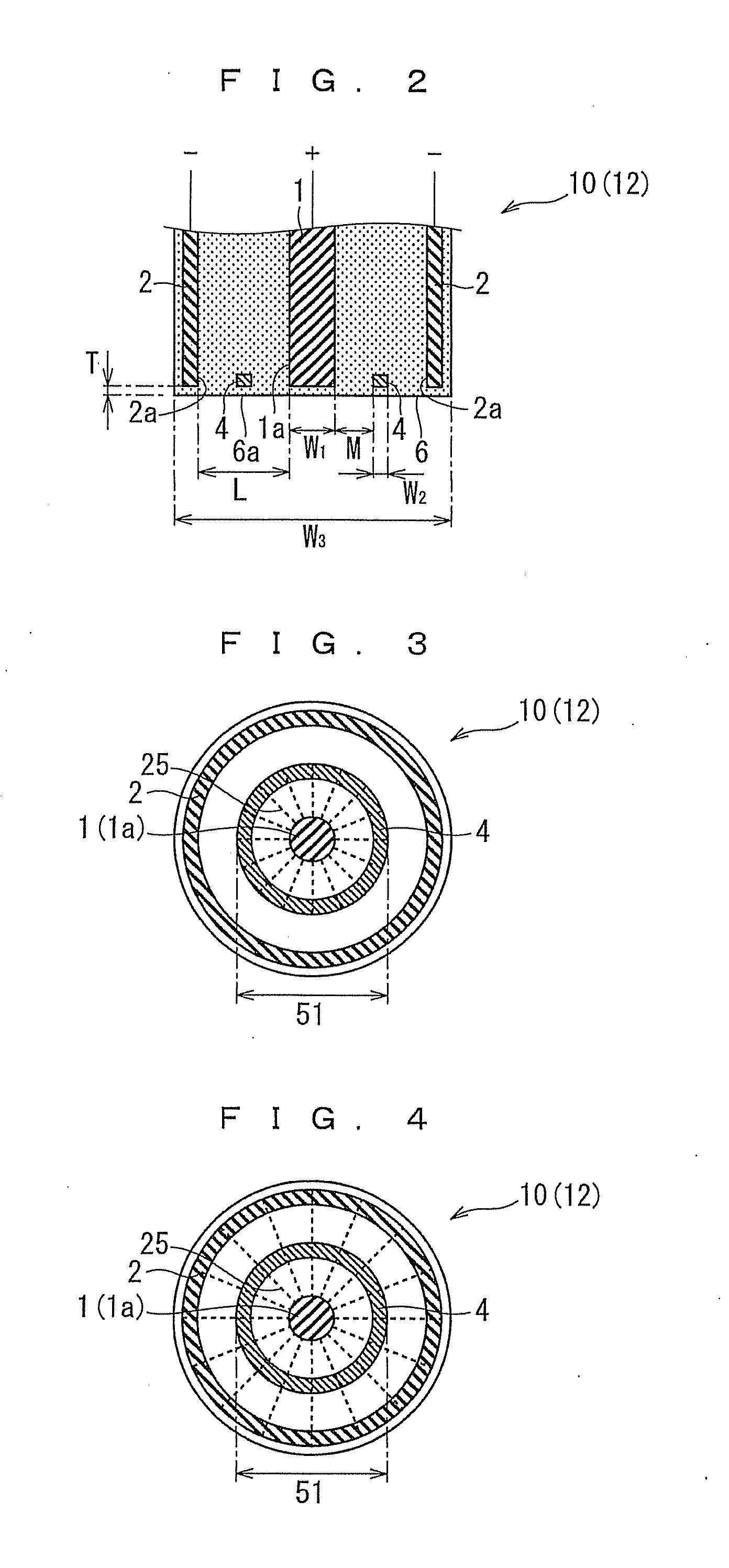

Plasma igniter and ignition device for internal combustion engine

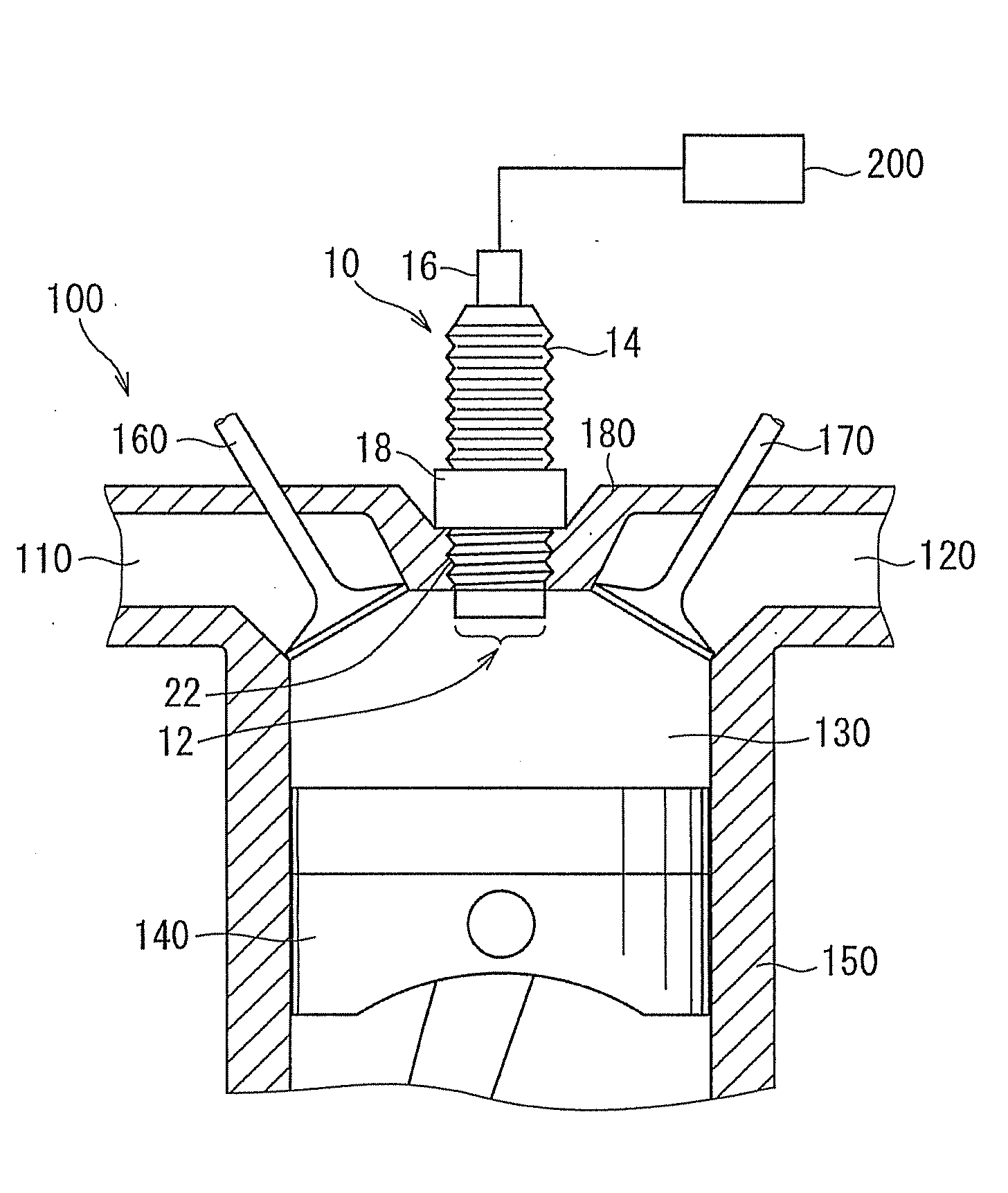

InactiveUS20100212620A1Reduced areaLow degreeSparking plugsCombustion enginesCombustion chamberLow voltage

To provide a plasma igniter capable of generating a discharge such as a pulse streamer discharge in a large region even by application of a low voltage, implementing powerful ignition by pulse voltage application in two or more stages, improving an air-fuel ratio (A / F), and reducing a CO2 emission amount.A plasma igniter includes an igniter part having a combustion chamber, and a discharge part arranged in such a manner that its discharge tip end is exposed to the combustion chamber. The discharge tip end has a column-shaped anode, an annular cathode arranged to be a predetermined interval away from an anode tip end part, and an annular floating electrode arranged between the anode tip end part and the cathode.

Owner:NGK INSULATORS LTD

Preparation method for zirconium-contained rare-earth composite oxide

ActiveCN102417352AExpand industrial applicationsHigh surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryCalcium bicarbonate

The invention relates to a preparation method for a zirconium-contained rare-earth composite oxide. At a certain ratio, rare earth (cerium, yttrium, praseodymium or terbium) is mixed with zirconium to burden, or rare earth (cerium, yttrium, praseodymium or terbium) and zirconium are mixed with at least one of other metal ions (aluminum, barium, magnesium, strontium, titanium, manganese, ferrum, copper and hafnium) to burden. A magnesium bicarbonate or / and calcium bicarbonate aqueous solution prepared from raw materials of magnesium or / and calcium minerals or oxides and hydroxides by at least one working procedure of roasting, digesting, mixing size, carbonizing and the like can serve as a precipitator to carry out precipitation so as to obtain at least one of rare earth and zirconium composite carbonate and subcarbonate, and the at least one of rare earth and zirconium composite carbonate and subcarbonate is further roasted to obtain a zirconium-contained rare-earth composite oxide product. In the preparation method, cheap calcium or / and magnesium minerals or low-purity oxides and hydroxides can serve as initial raw materials to replace common chemical industry precipitators, such as ammonia water, ammonium bicarbonate, sodium carbonate, sodium hydroxide and the like, substances, such as magnesium, calcium, carbon dioxide and the like can be effectively circulated and utilized so as to greatly lower the production cost of the zirconium-contained rare-earth composite oxide, such as ceria-zirconia, yttrium zirconium, praseodymium zirconium, terbium zirconium and the like. In addition, in the production technology disclosed by the invention, no ammonia nitrogen wastewater, high-salinity wastewater and the like are generated, carbon dioxide greenhouse gas emission amount is reduced, the preparation technology is environmentally-friendly, and environment pollution is avoided.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Technique for synthesizing methanol by hydrogen and carbon dioxide

ActiveCN101386564AImprove conversion rateSimple processOrganic compound preparationHydroxy compound preparationVapor–liquid separatorHydrogen

The invention discloses a technological method for synthesizing methanol by using hydrogen and carbon dioxide. The method mainly comprises the following steps that the hydrogen and the carbon dioxide are subjected to catalytic reaction which is the first step in a first reactor under the action of copper-based hydrogenation catalyst, so as to obtain methanol, water and carbon monoxide; separation is performed in a gas-liquid separator; liquid methanol and water are separated out; gaseous carbon monoxide, hydrogen and carbon dioxide enter a second reactor; and under the action of a methanol synthesis catalyst, synthesis reaction which is the second step is carried out, so as to obtain crude methanol and water. The method has the advantages that the method uses the hydrogen and the carbon dioxide as raw materials to synthesize the methanol, can fully utilize carbon dioxide resource which is generally regarded as waste gas to be discharged to synthesize the methanol easily, is low in reaction temperature, high in carbon dioxide conversion rate, simple in technological process, low in energy consumption and easy to realize industrialization, and develops a new way to produce methanol raw materials while reducing carbon dioxide emission into atmosphere.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

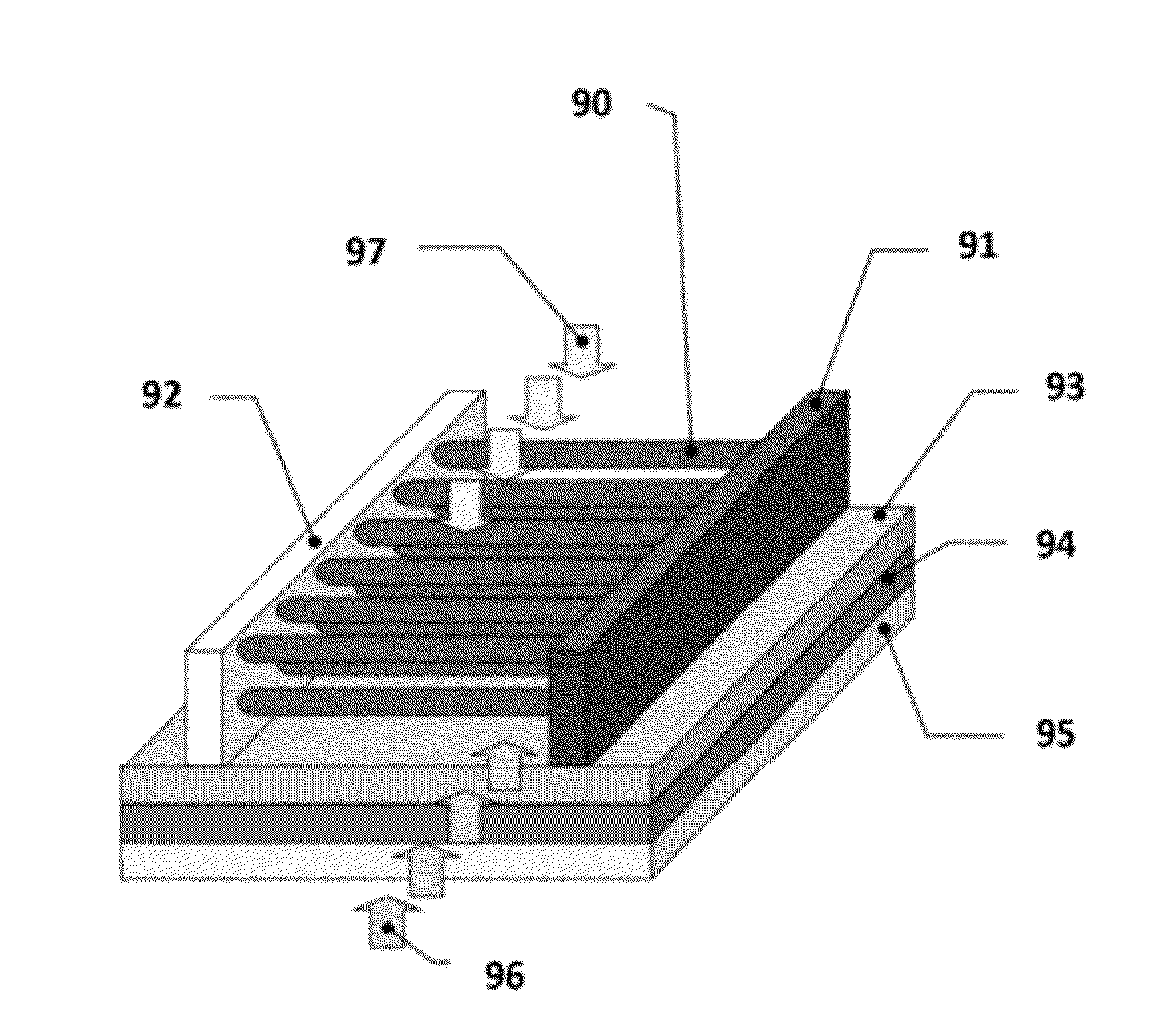

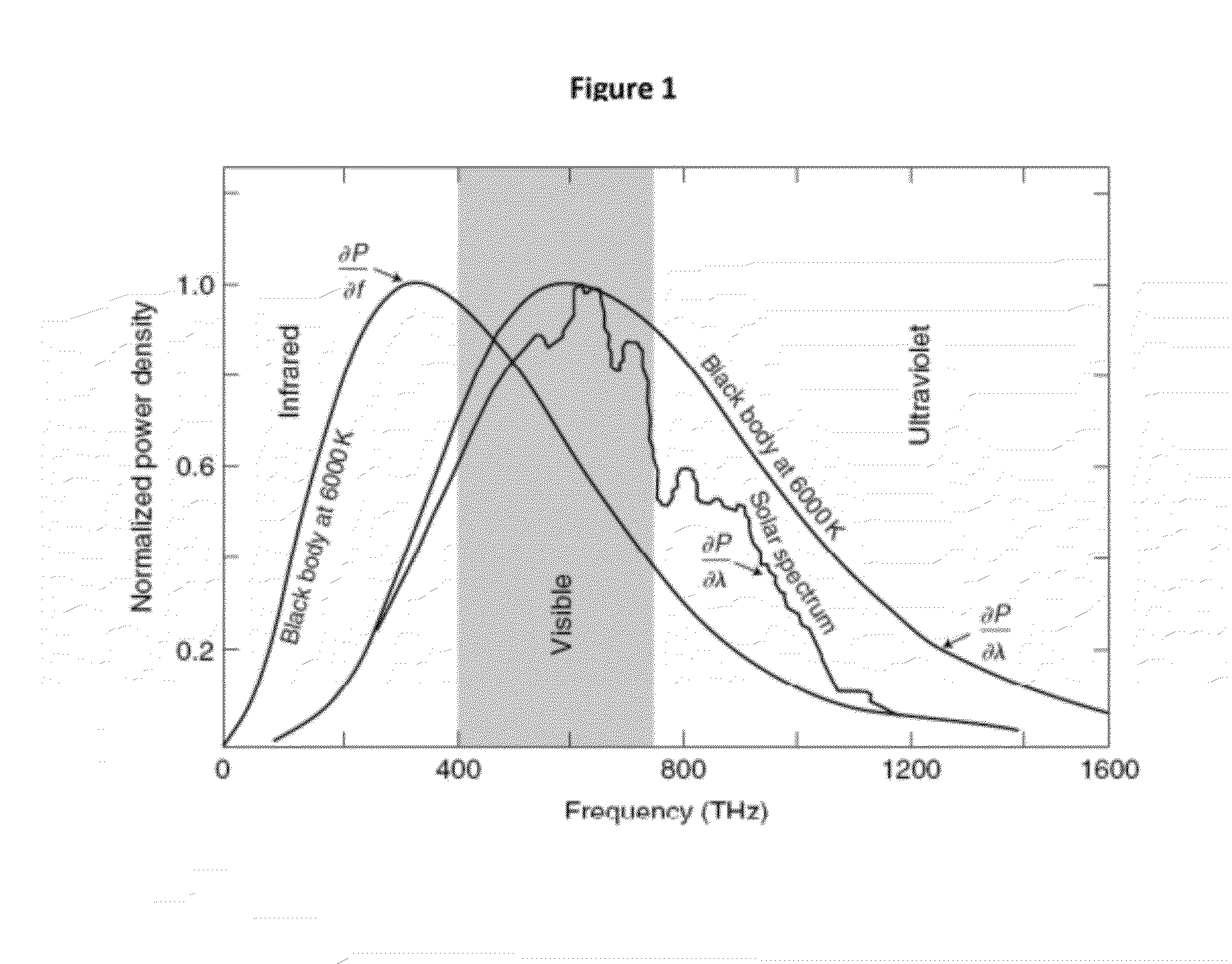

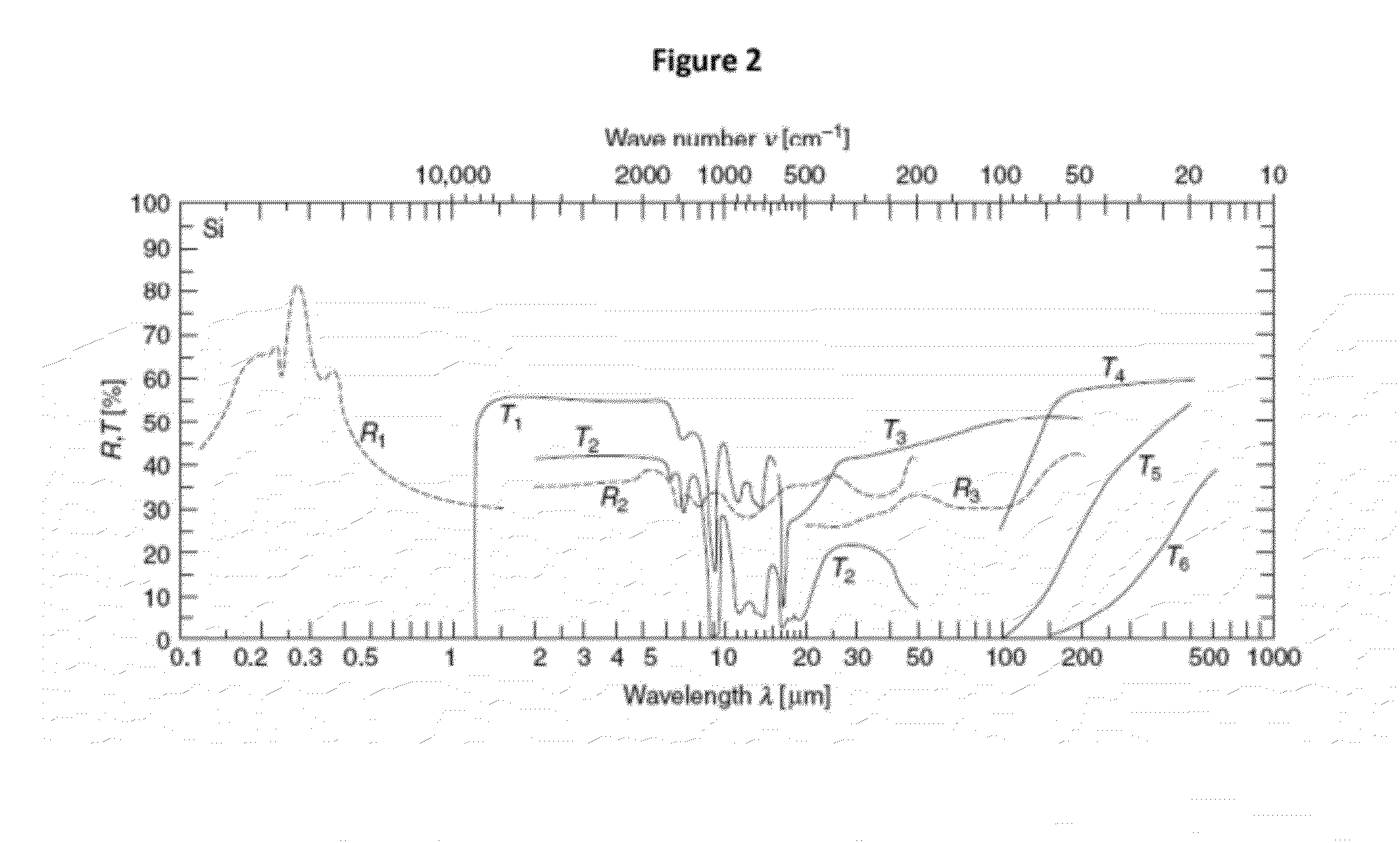

High efficiency electromagnetic radiation collection method and device

InactiveUS20120186635A1Improve efficiencyReduced footprintMaterial nanotechnologyNanoopticsNanowireWavelength

Devices and methods are described for more effectively collecting solar energy, including both visible and non-visible electromagnetic radiation to be converted into electrical energy. For example, a nanotube / nanowire device, comprising an electrical contact layer, semi-conductive layer, insulating layer, source electrode, drain electrode and semi-conducting nanotubes / nanowires can be used to collect solar energy from the UV to the infrared electromagnetic spectrum. Another example comprises a device that is capable of adjusting its frequency response to maximize power output according to the wavelength of electromagnetic radiation present. These devices and related methods are useful, for example, to provide an alternative electrical energy source, harness unused renewable energy, reduce carbon dioxide emissions, counteract global warming, and provide a carbon neutral energy source. The devices and methods are also useful, for example, to cool the interior of buildings, automobiles, airplanes, electronic devices / systems, etc.

Owner:PRINCIPLE ENERGY SOLUTIONS

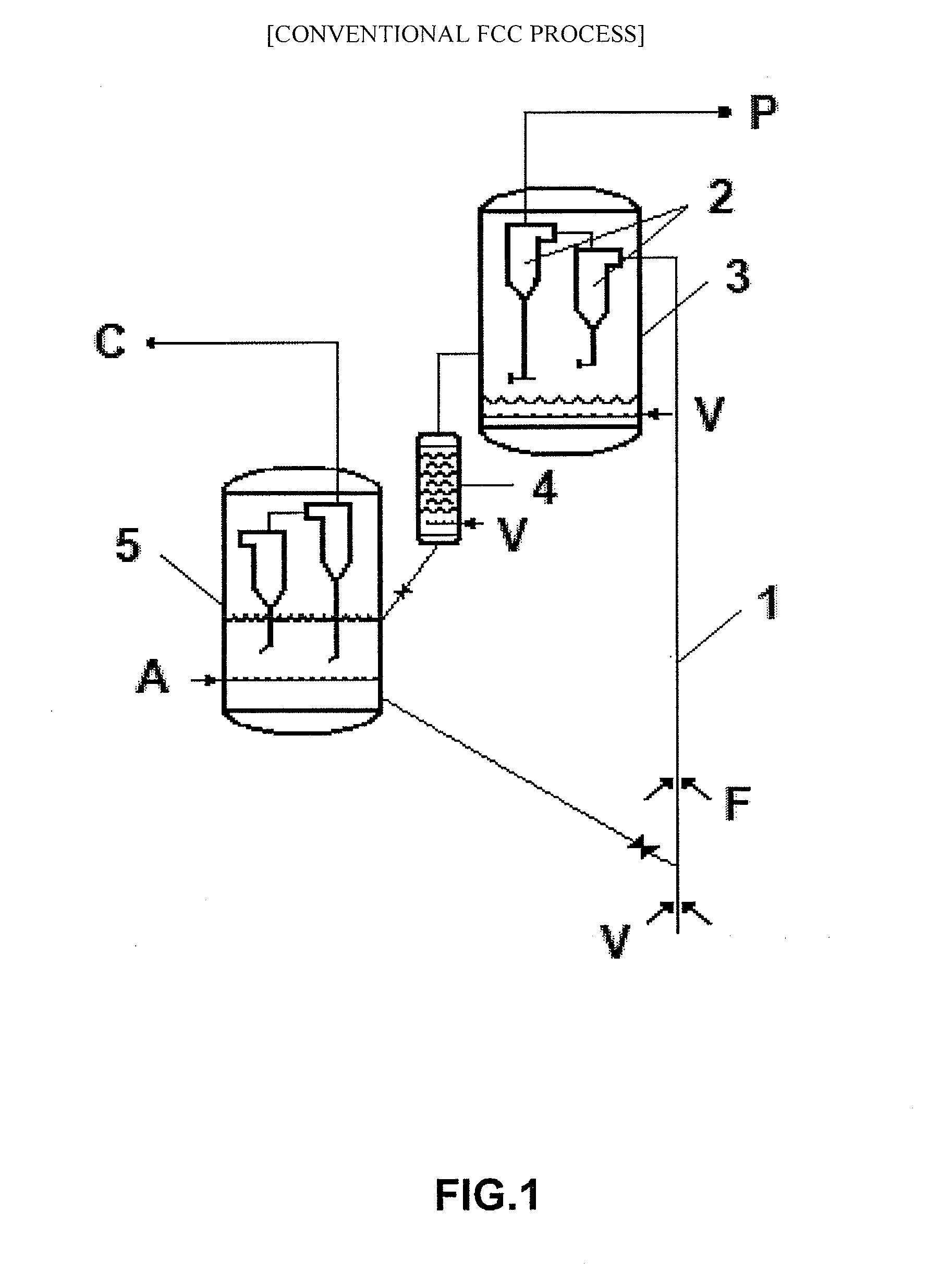

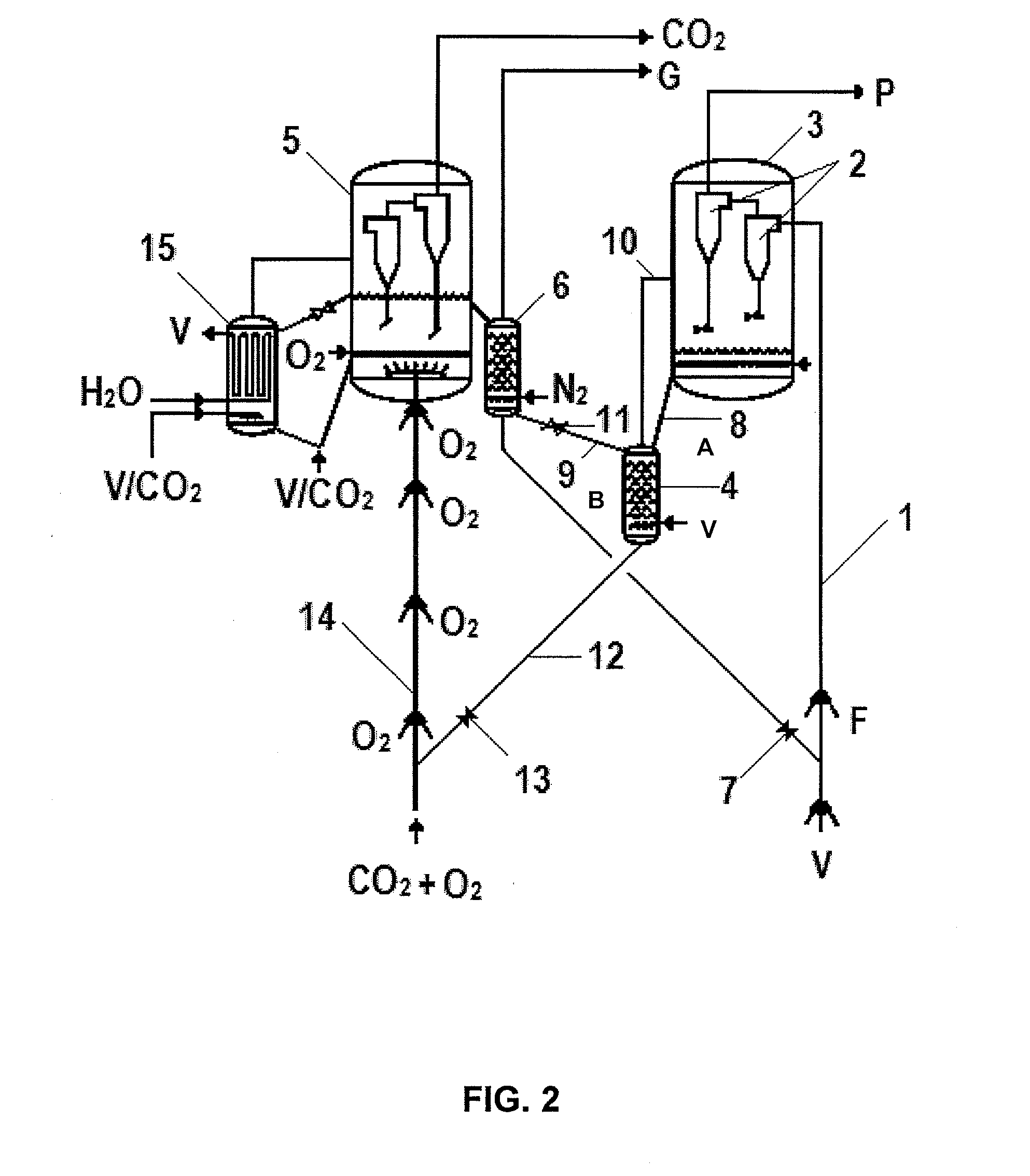

Fluid catalytic cracking process with reduced carbon dioxide emission

InactiveUS20110155642A1Simple processAvoid emissionsCatalytic crackingEthylene productionNitrogenNitrogen gas

This invention concerns a fluid catalytic cracking (FCC) process with reduced carbon monoxide emission which modifies the regeneration phase of the spent catalyst by using pure oxygen without the need for dilution when burning coke adhering to the catalyst. In addition, this invention improves the reconditioning stage of the catalyst, incorporating a reconditioner supplementary to a conventional reconditioner which employs nitrogen as a carrier gas in the reconditioning of the already regenerated catalyst.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

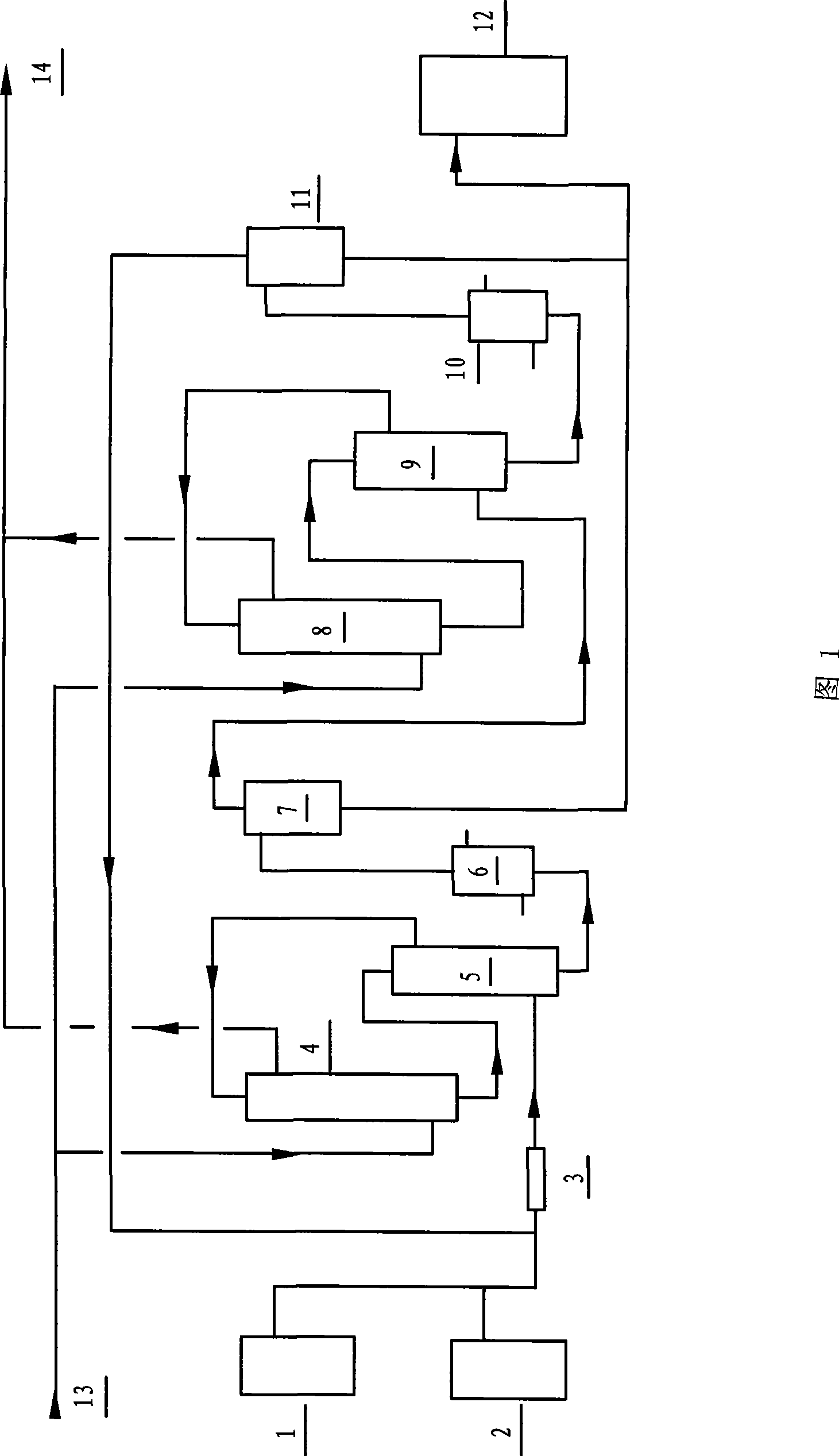

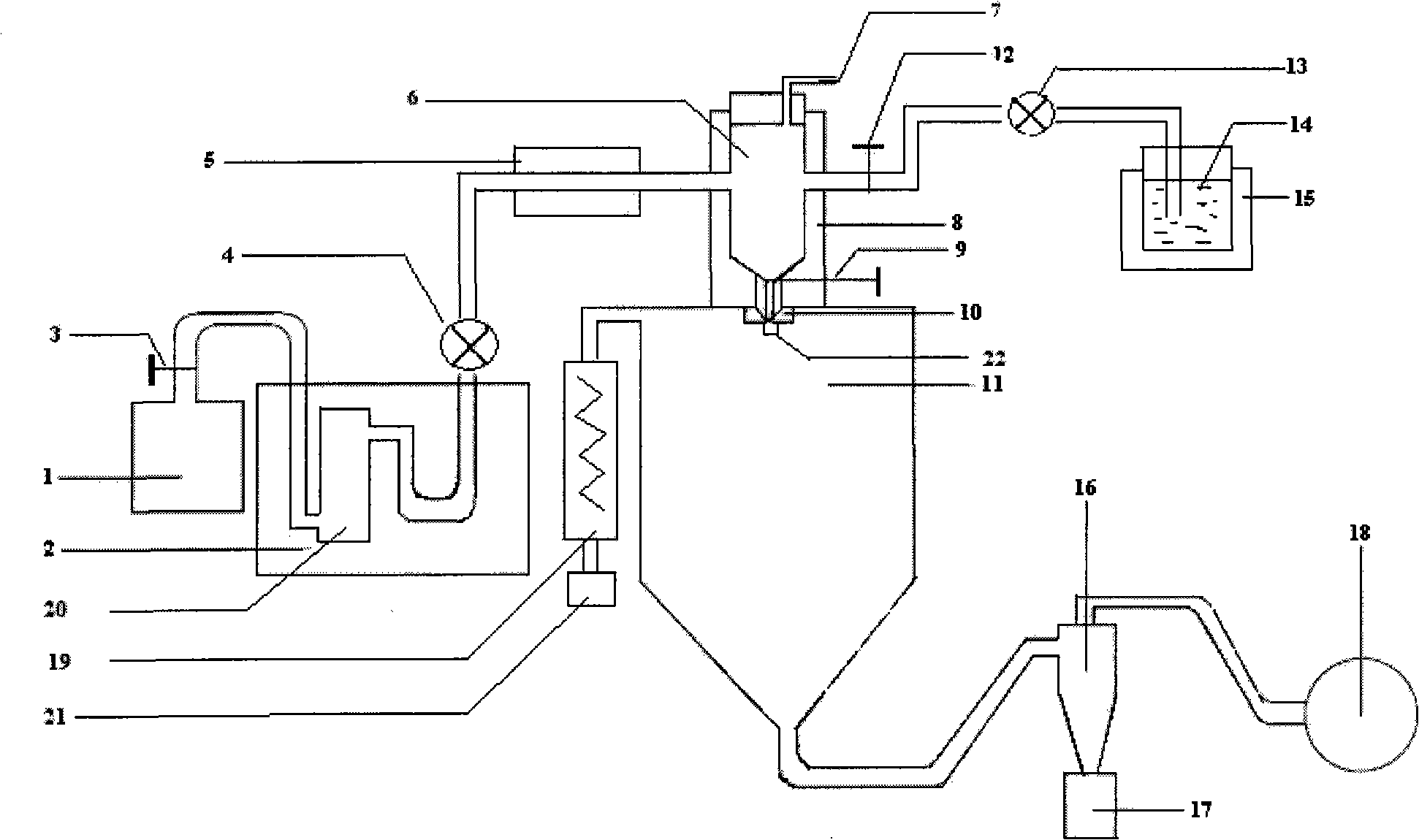

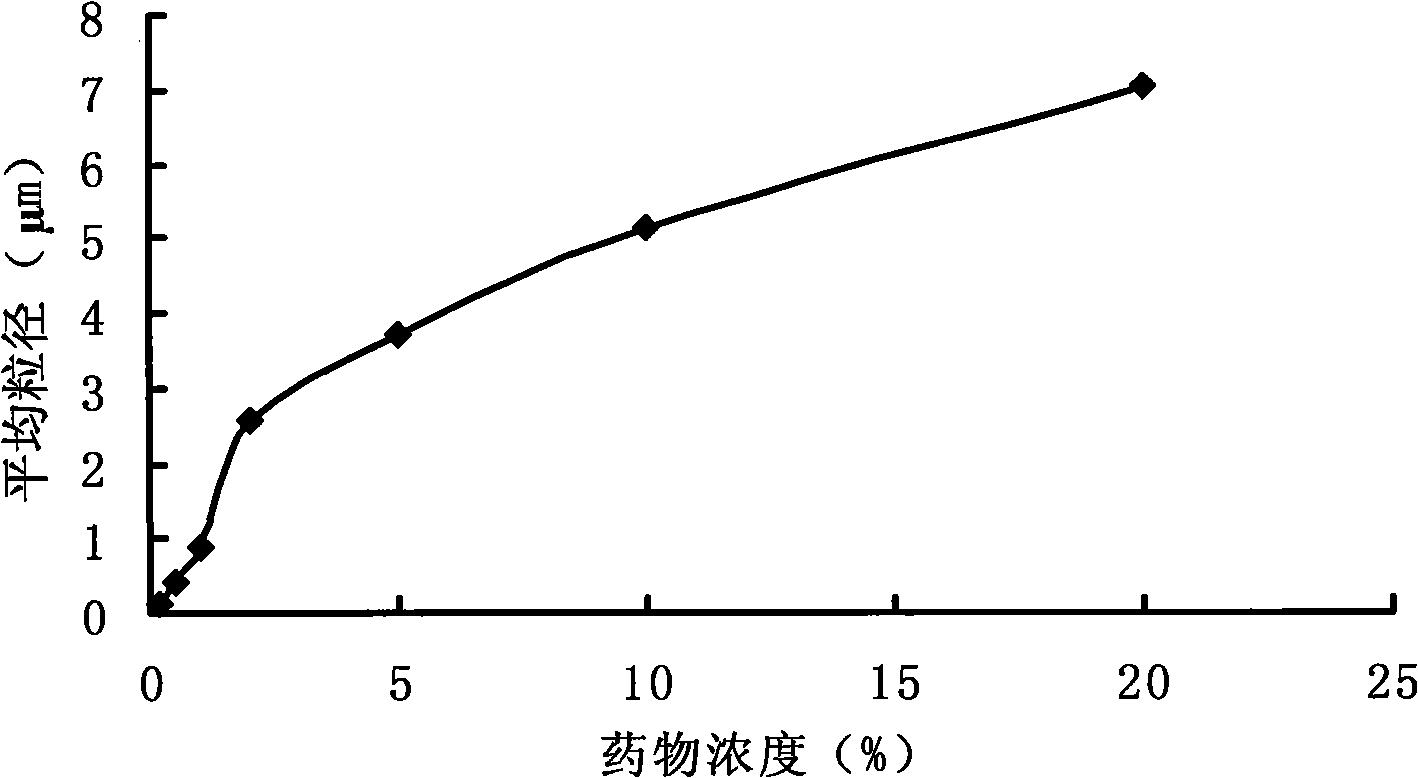

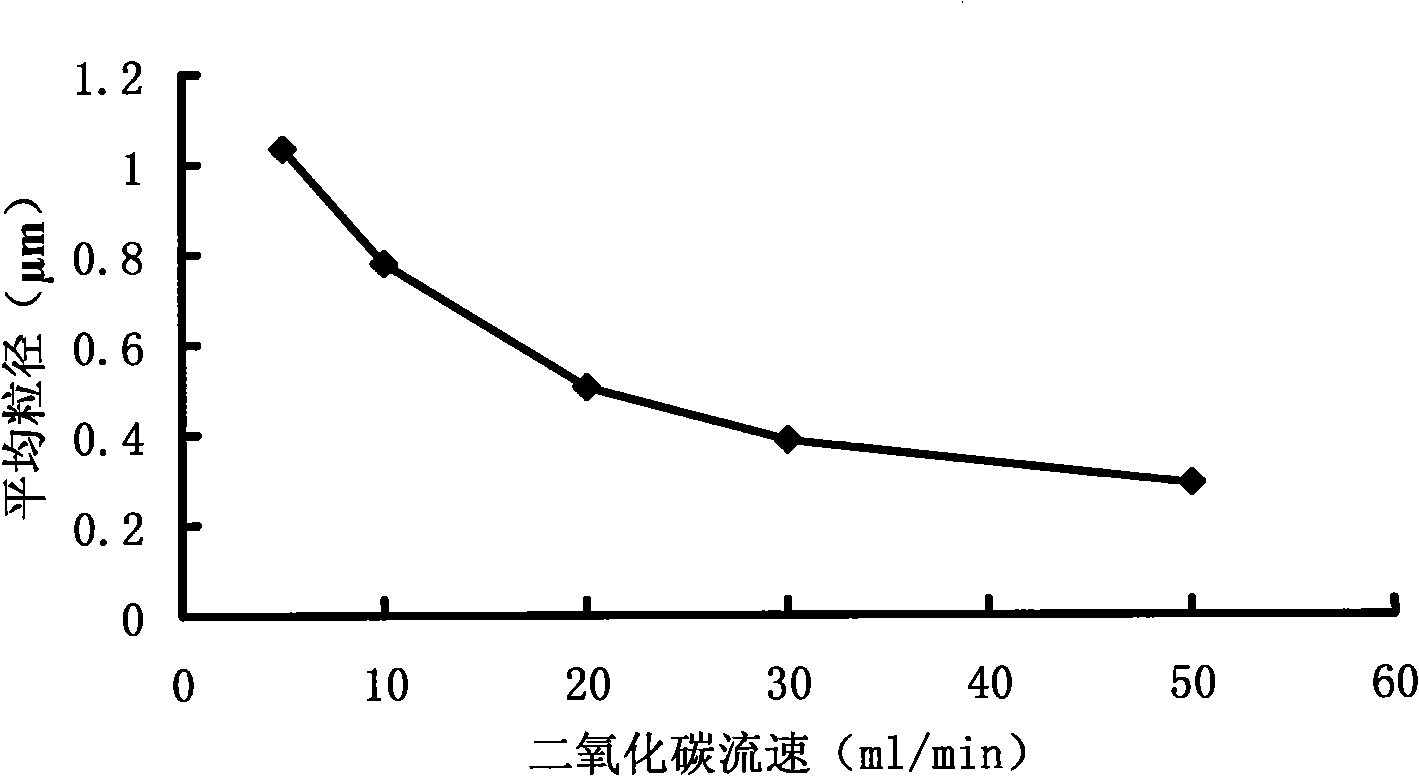

Device for preparing particulates using supercritical fluid assistant spray and use thereof

InactiveCN101357310ASlow coolingReduce size variationGranulation by liquid drop formationMicroballoon preparationParticulatesAir filter

The invention provides a device for producing microparticles by supercritical fluid auxiliary spray. The device consists of a carbon dioxide cylinder, a cooling water tank, a valve, a plunger pump, a heater, a gas-liquid mixing chamber, a pressure monitoring system, a heating jacket, a valve, a nozzle base, a drying box, a valve, a constant flow pump, a solvent storage tank, a heating jacket, a cyclone separator, a collection tank, an air pump, an air heater, a supercritical carbon dioxide storage tank, an air filter and a nozzle. The device provided by the invention can be applied to the preparation of pharmaceutical microparticles or nanoparticles, and drug-loaded microparticles or nanoparticles containing carriers. The device is characterized by reasonable design and low cost and adopts the integrated insulation design of the gas-liquid mixing chamber and the nozzle, which can reduce the nozzle temperature drop caused by the injection of the mixture of carbon dioxide and solvent, can ensure the spray to go smoothly; can decrease the change of particle sizes caused by temperature fluctuation, can continuously, efficiently and conveniently prepare and collect microparticles, and can be applicable to industrialized continuous production.

Owner:ZHEJIANG UNIV

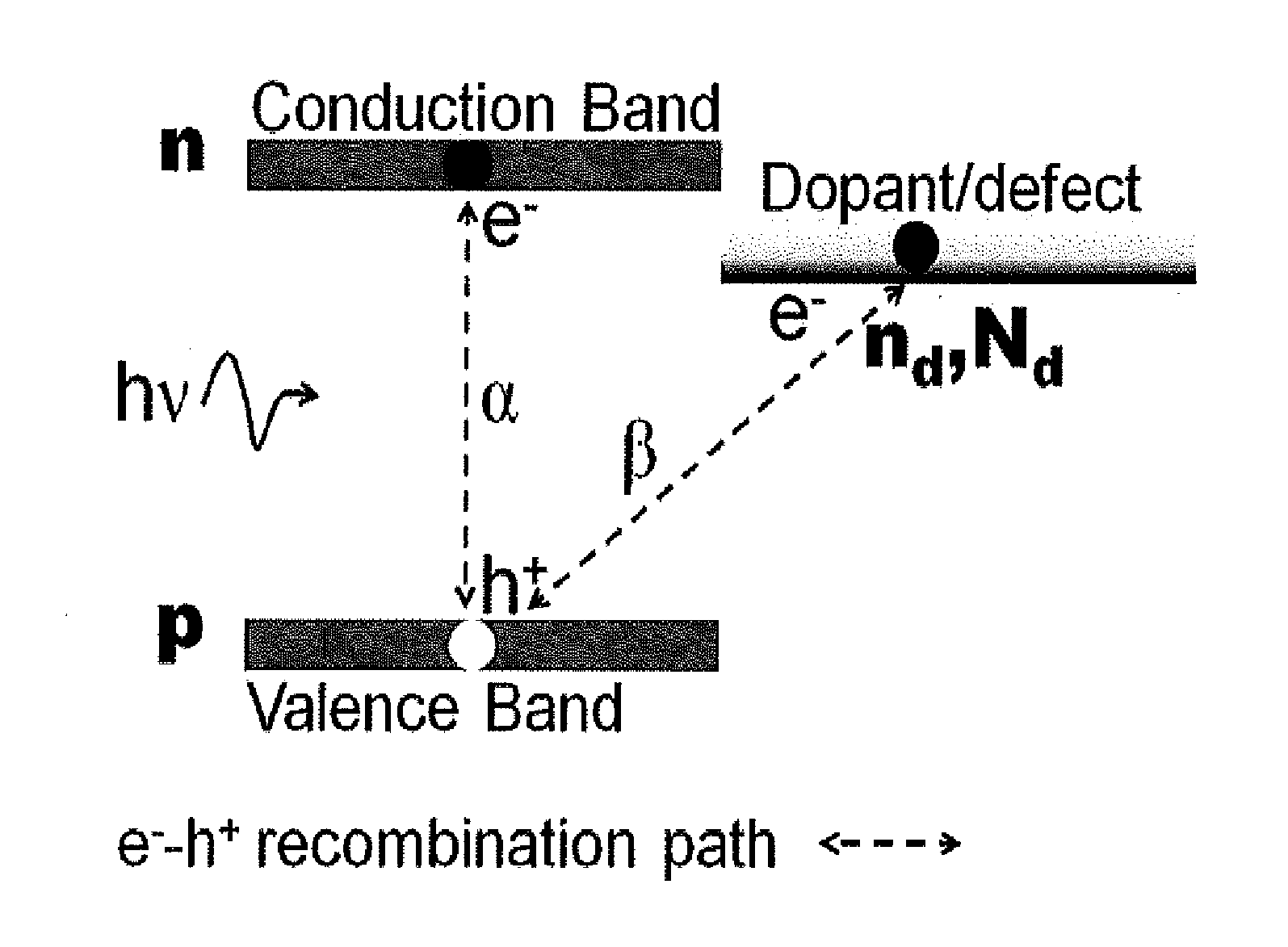

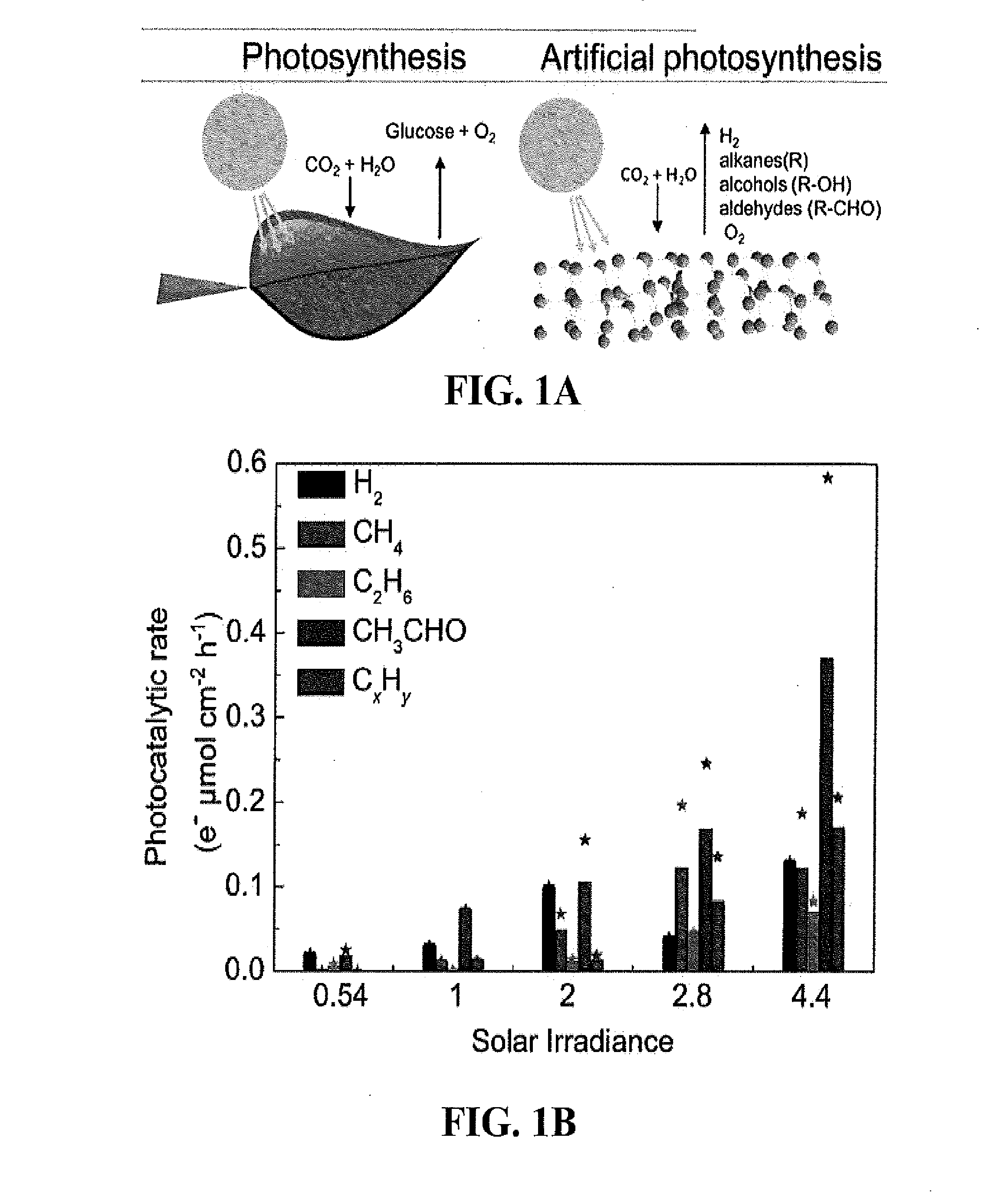

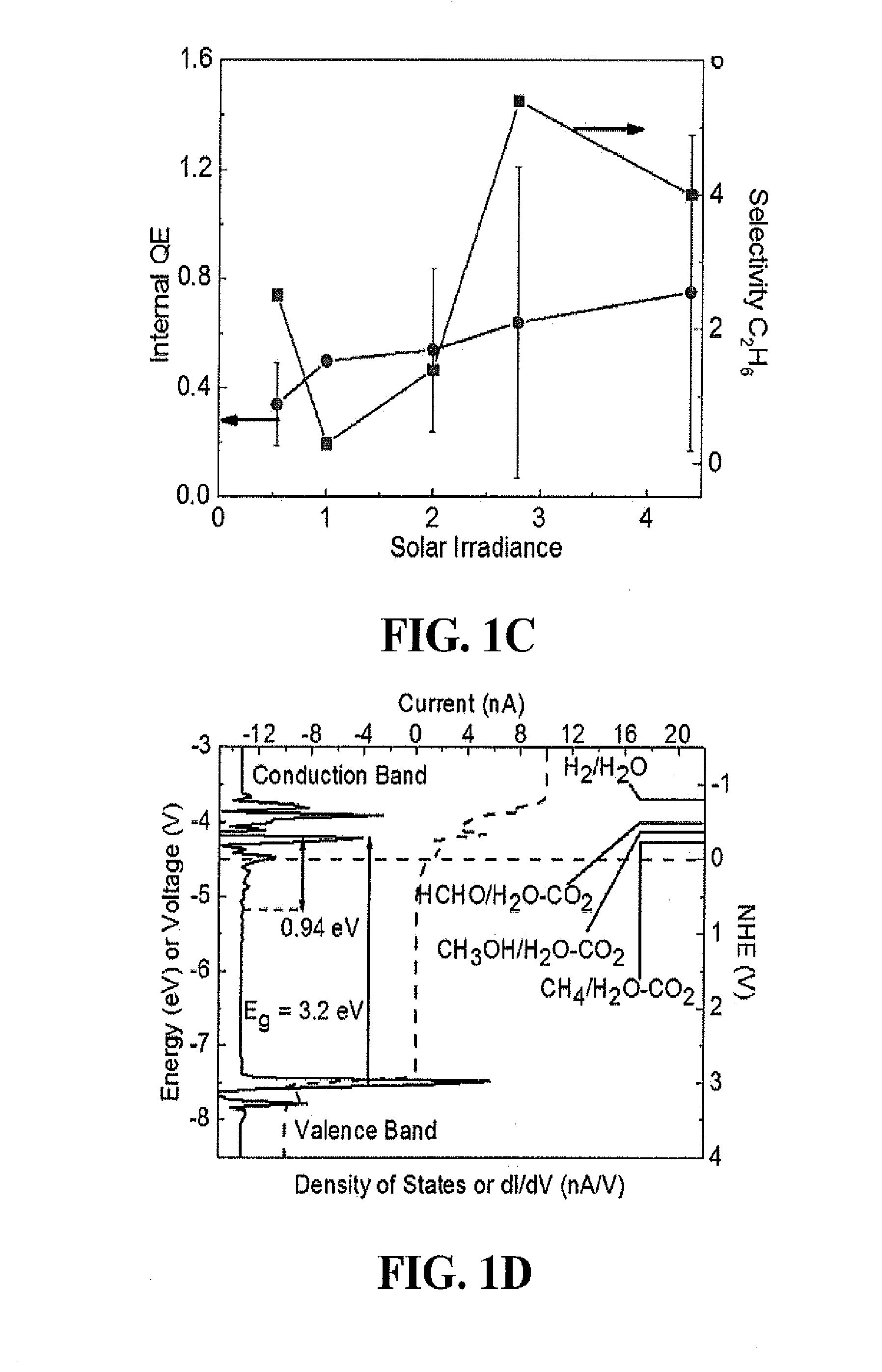

Nanostructured photocatalysts and doped wide-bandgap semiconductors

ActiveUS20160193595A1Easy to operateImprove photocatalytic activityCadmium sulfidesEnergy inputSynthesis methodsDisplay device

Photocatalysts for reduction of carbon dioxide and water are provided that can be tuned to produce certain reaction products, including hydrogen, alcohol, aldehyde, and / or hydrocarbon products. These photocatalysts can form artificial photosystems and can be incorporated into devices that reduce carbon dioxide and water for production of various fuels. Doped wide-bandgap semiconductor nanotubes are provided along with synthesis methods. A variety of optical, electronic and magnetic dopants (substitutional and interstitial, energetically shallow and deep) are incorporated into hollow nanotubes, ranging from a few dopants to heavily-doped semiconductors. The resulting wide-bandgap nanotubes, with desired electronic (p- or n-doped), optical (ultraviolet bandgap to infrared absorption in co-doped nanotubes), and magnetic (from paramagnetic to ferromagnetic) properties, can be used in photovoltaics, display technologies, photocatalysis, and spintronic applications.

Owner:UNIV OF COLORADO THE REGENTS OF

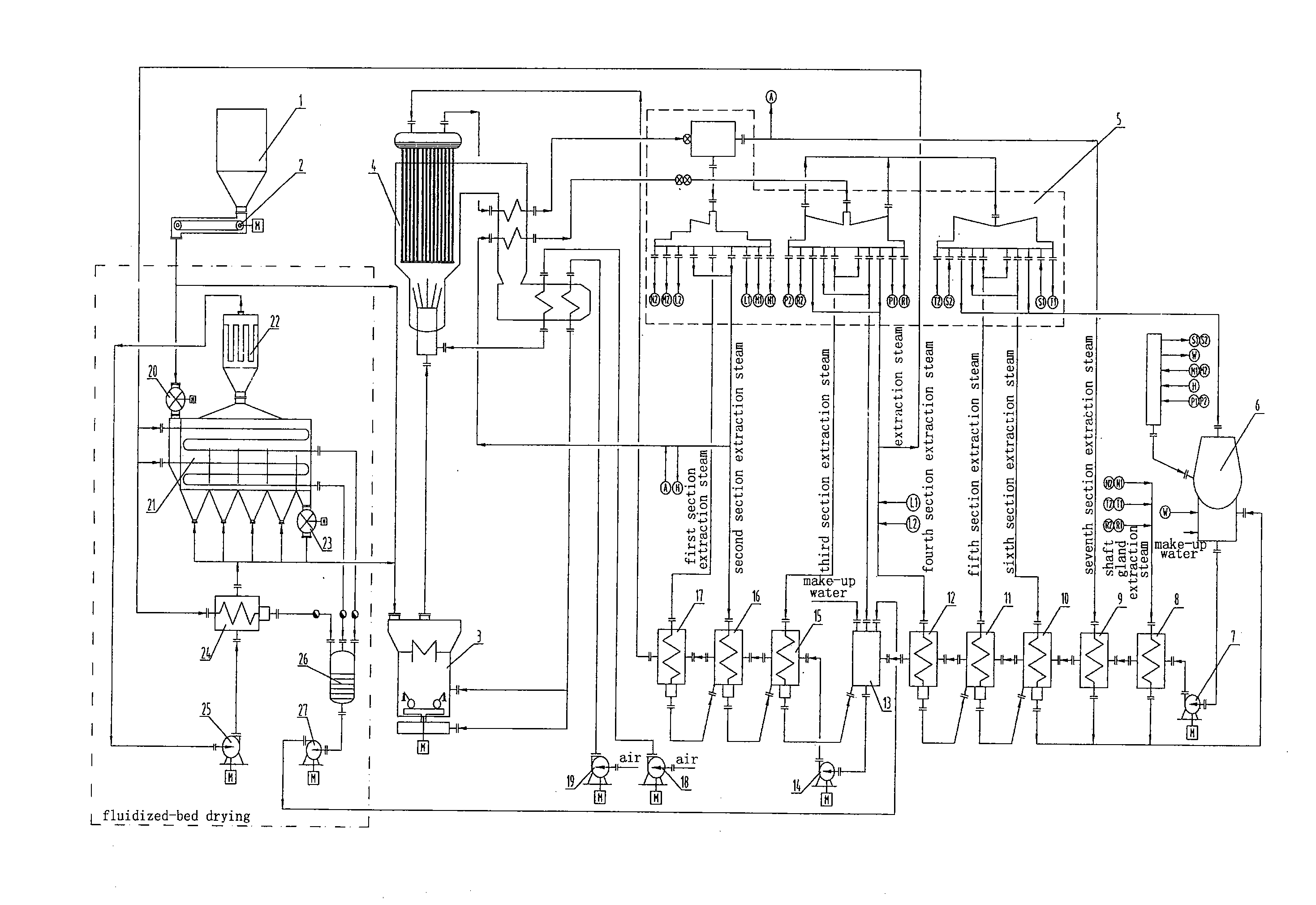

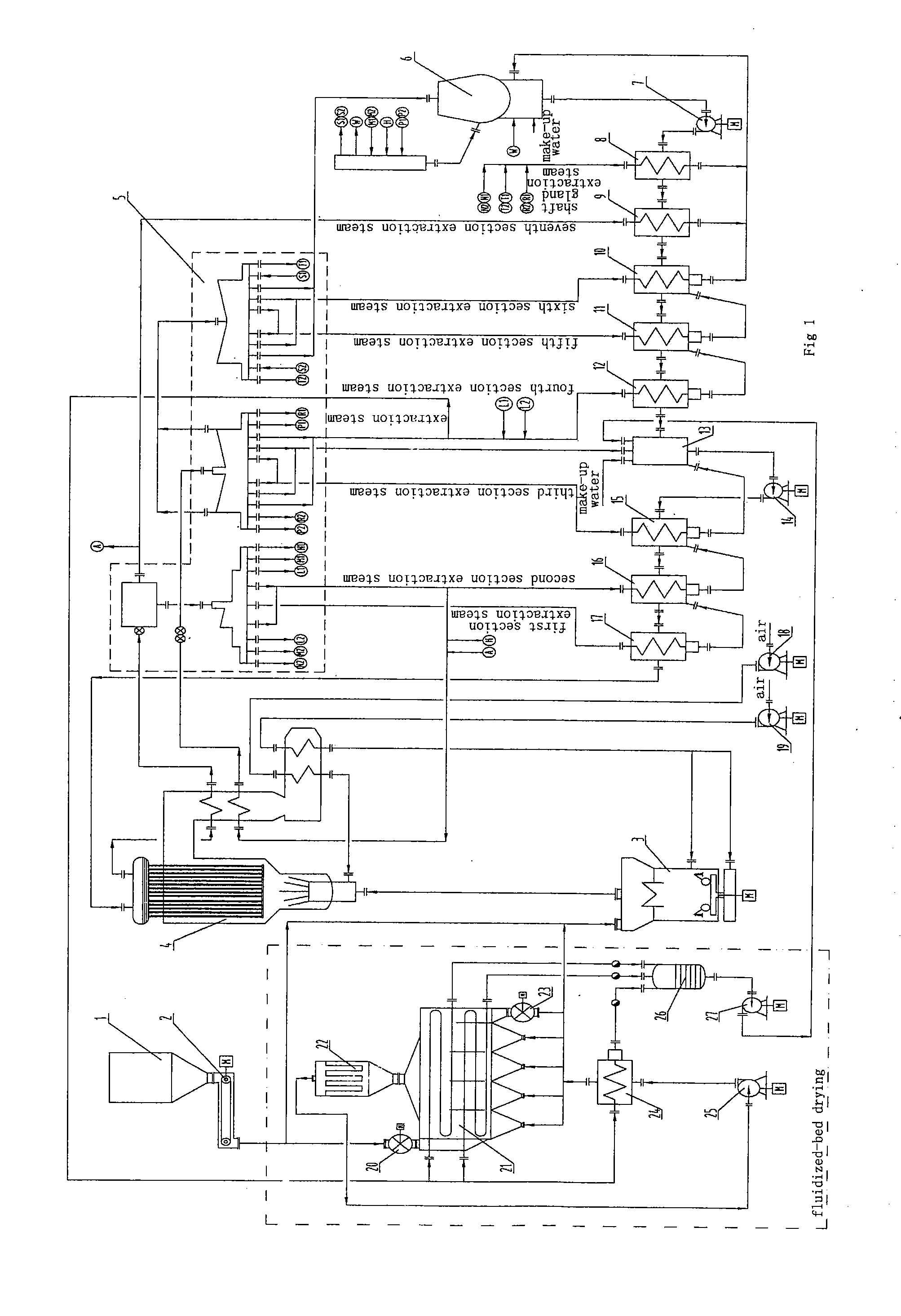

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS20110220744A1Reduce coal consumptionRemarkable effectFuel feeding arrangementsDrying solid materials with heatFluidized bed dryingProcess engineering

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

Carbon dioxide emission reduction method

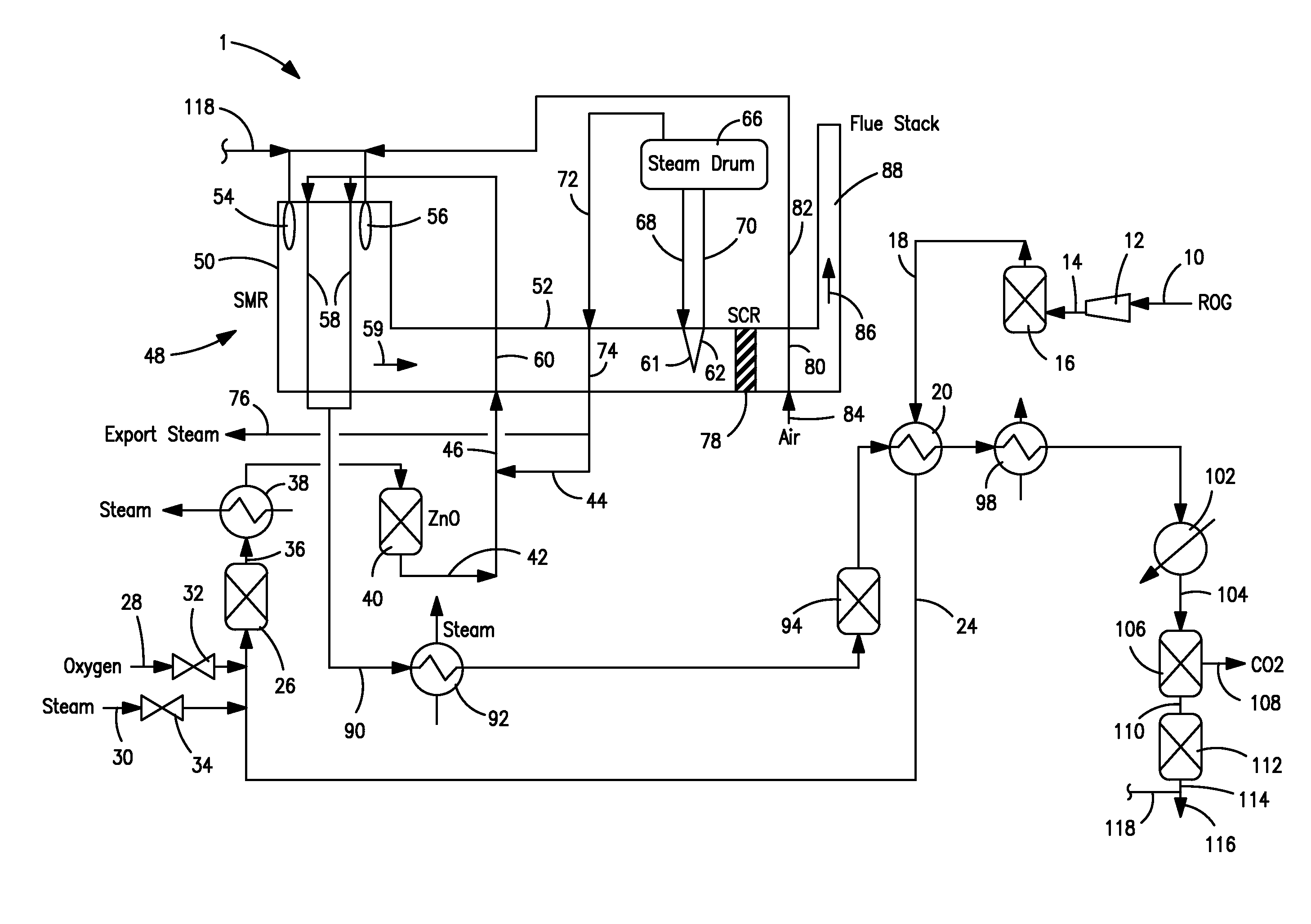

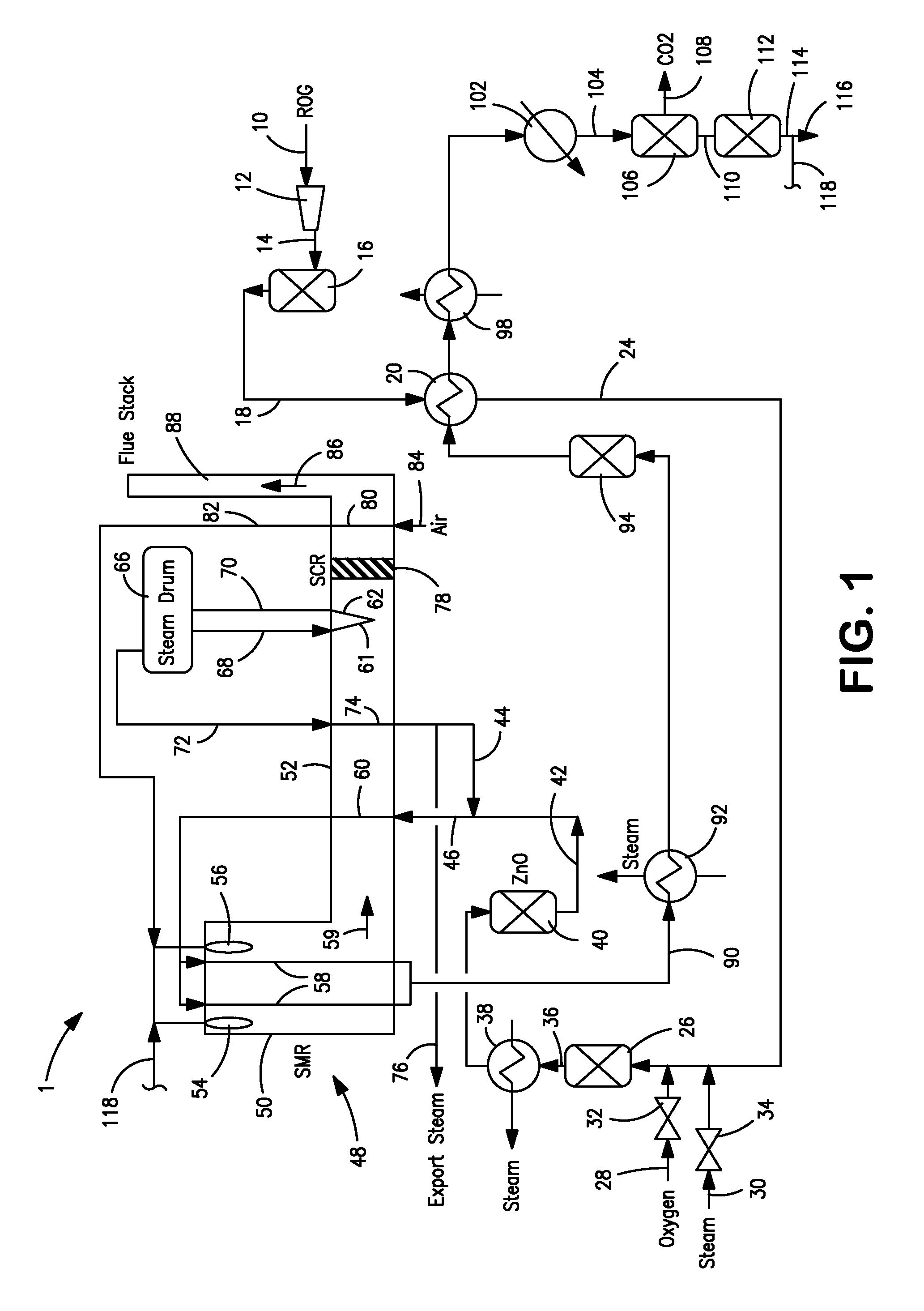

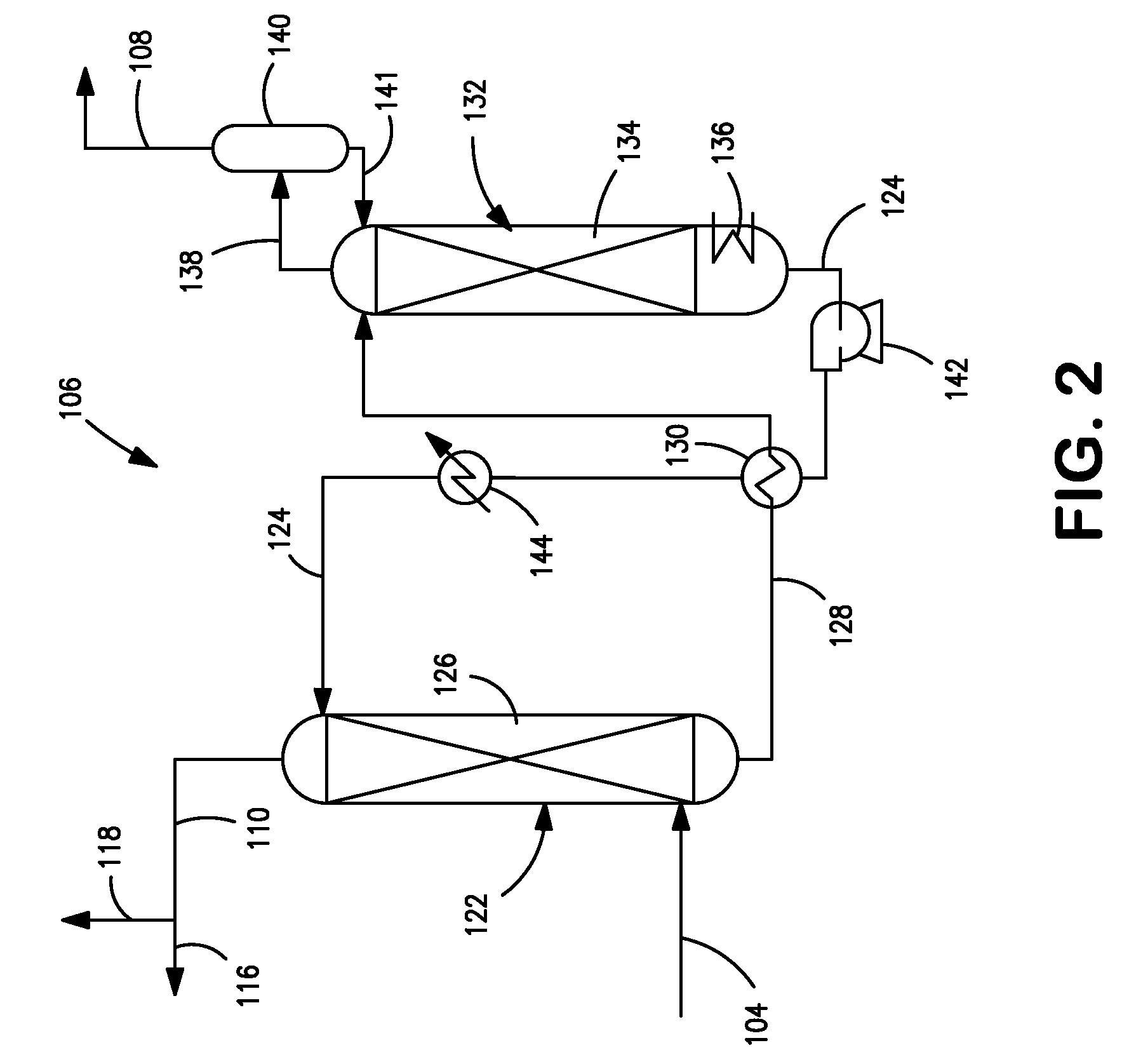

InactiveUS20100158776A1Increase productionLess carbonSolidificationLiquefactionMethane reformerMethane

Carbon dioxide emissions within a refinery are reduced by reforming a hydrocarbon containing feed at low pressure to enhance the conversion of methane to hydrogen and carbon monoxide and thereby reduce methane slip. The hydrocarbon containing feed is composed entirely or at least in part of a refinery off gas. The resulting reformed stream is then subjected to water-gas shift conversion to form a shifted stream from which carbon dioxide is separated. As a result of the separation and the low pressure reforming, hydrogen containing fuel gas streams, that are thereby necessary lean in carbon dioxide and methane, are used in firing the steam methane reformer and other fuel uses within the refinery to reduce carbon dioxide emissions. The carbon dioxide that is separated can be sequestered or used in other processes such as enhanced oil recovery.

Owner:PRAXAIR TECH INC

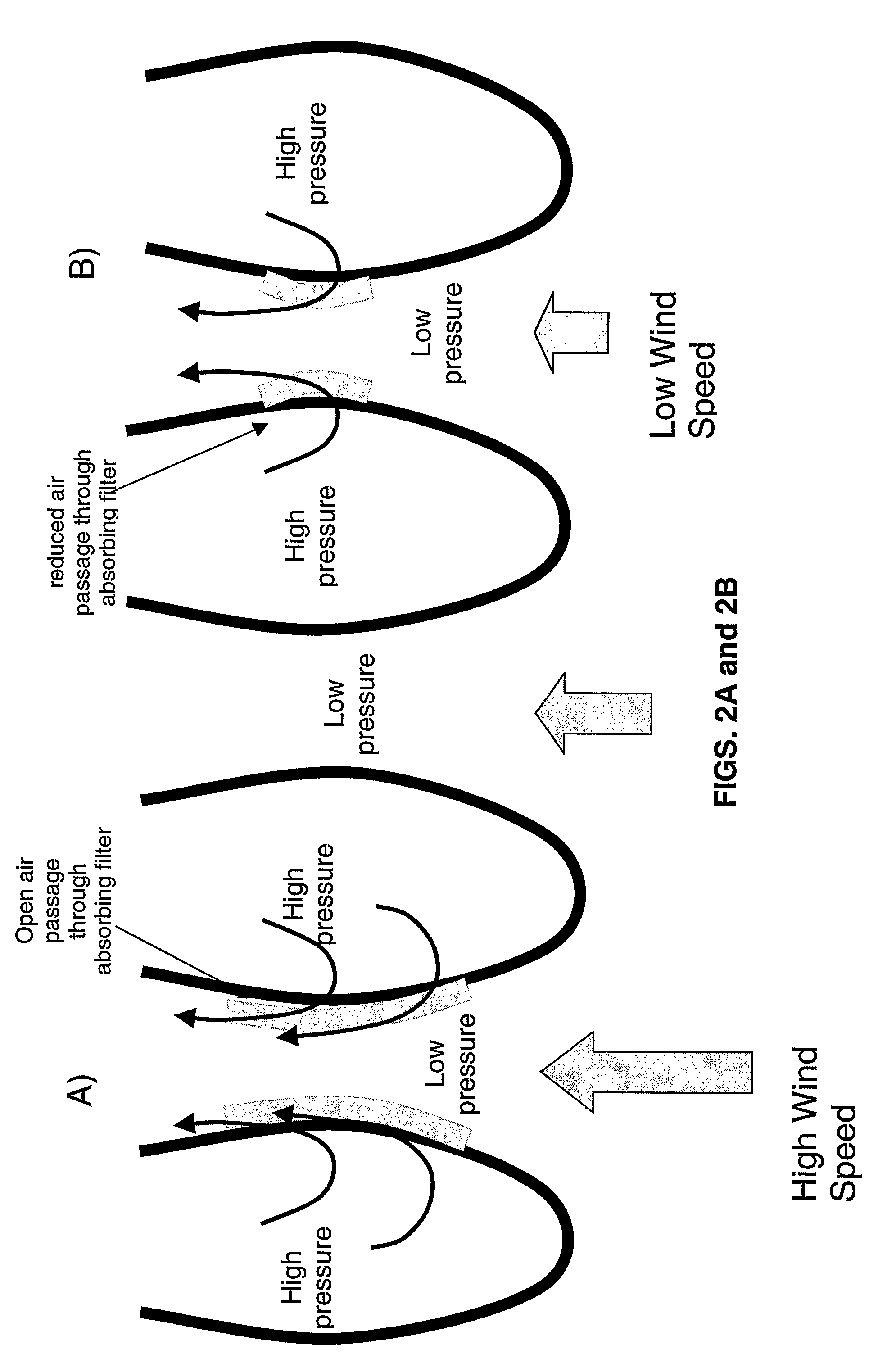

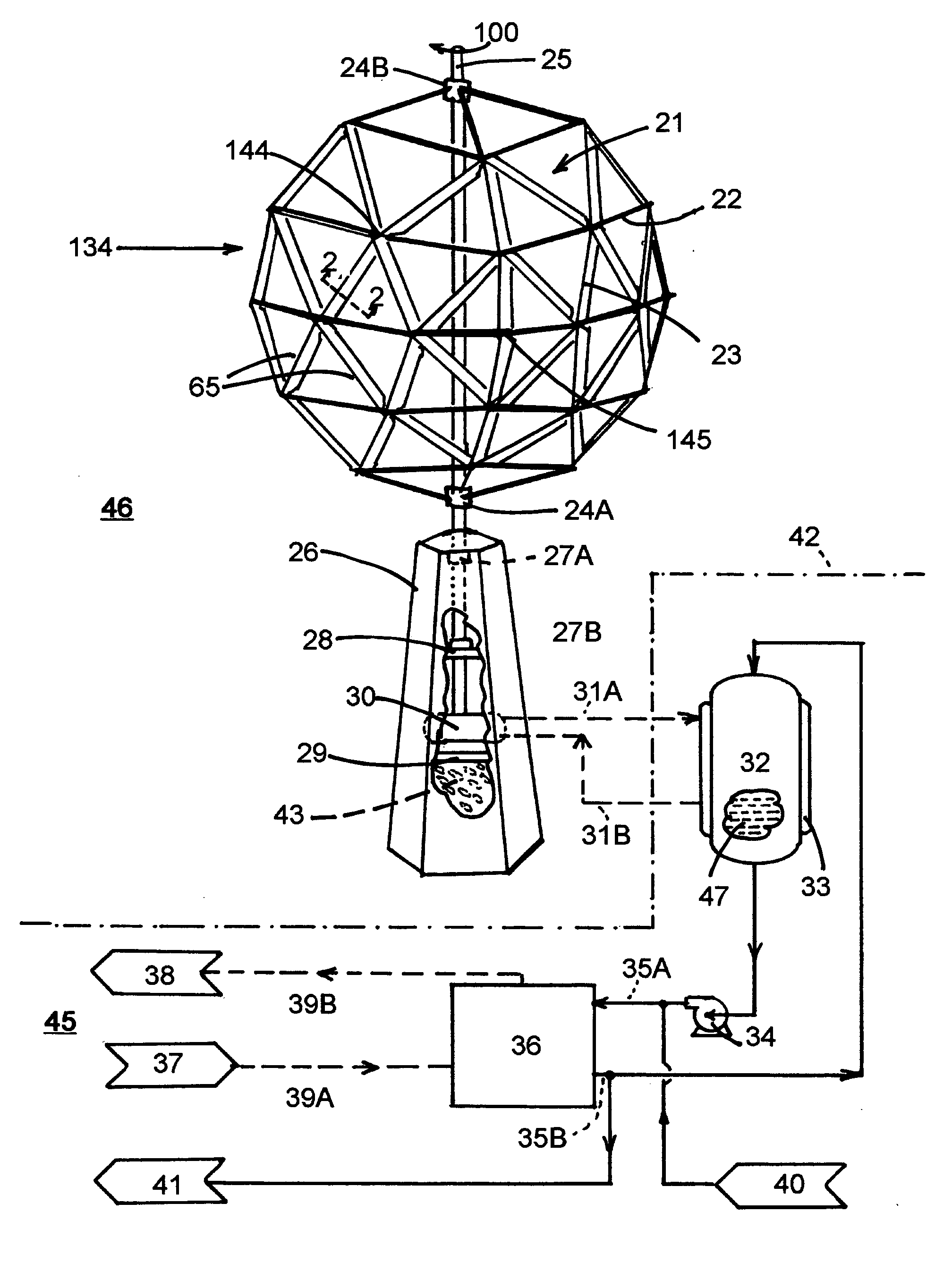

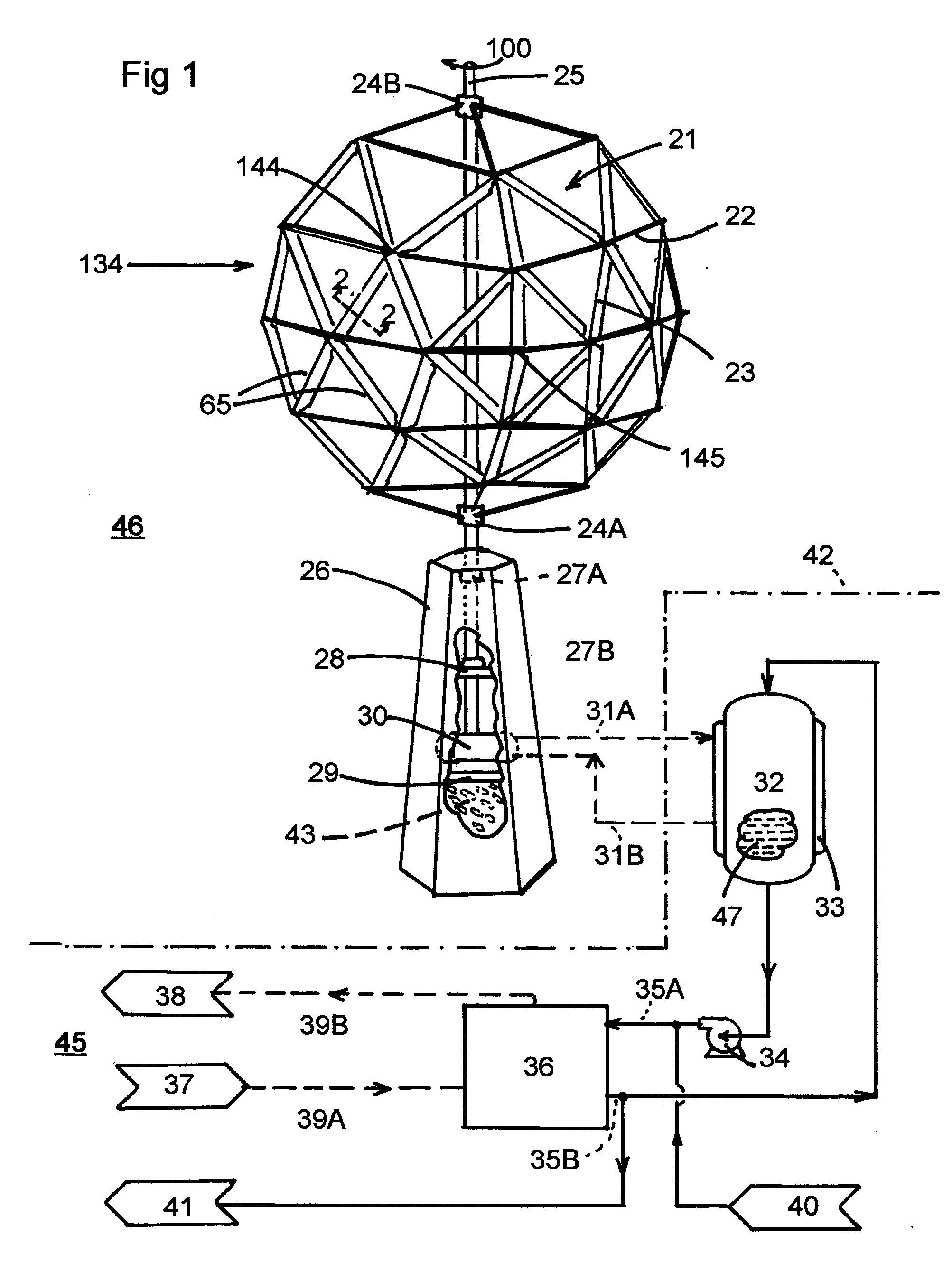

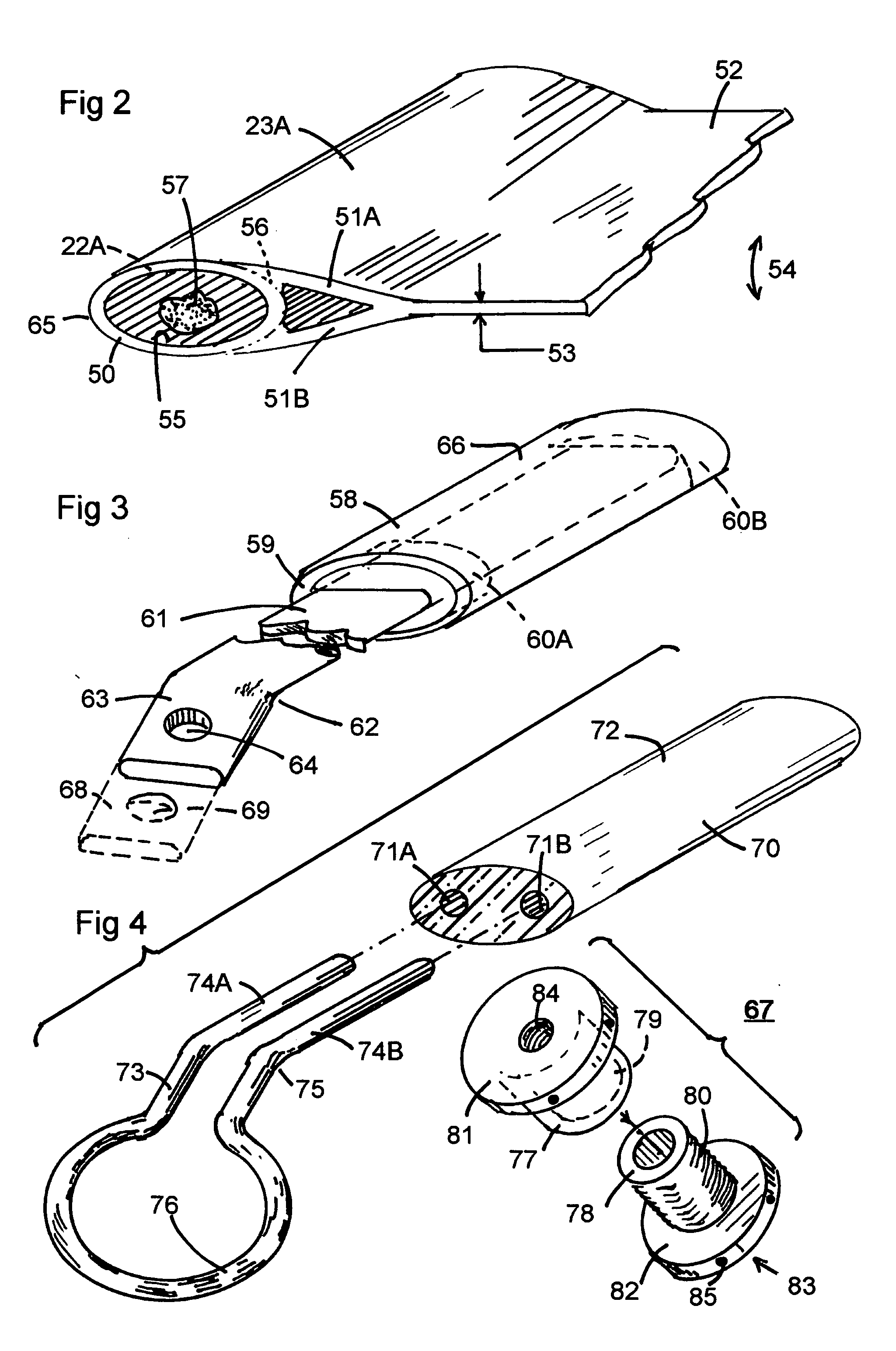

Wind turbine and energy distribution system

A new design of vertical axis wind turbine is disclosed based on a dome structure using dome struts as blades that work in concert to produce rotational motion. The stability and low cost of the new design allows the turbine to function in low wind speed regimes as well as high speed winds that would be encountered in off-shore wind installations. The large stresses and structural requirements of mounting large horizontal axis wind turbines, particularly off-shore, are avoided with the new system. A new energy distribution system is proposed that will capture abundant off-shore wind energy, store it aboard a generator / delivery ship in the form of Hydrogen gas, and deliver it to an existing shore based power plant to produce electricity using a conventional gas turbine. Alternatively, the Hydrogen can be used to produce methane from coal using known processes to add natural gas to pipelines in areas that would normally be consuming the material. Both applications, and the direct production of heat by the new turbines, would stabilize our national energy grid while reducing CO2 emissions.

Owner:HARTMAN PAUL HARVEY

Method for the production of humus- and nutrient-rich and water-storing soils or soil substrates for sustainable land use and development systems

ActiveUS20100199734A1Improve fertilityBioreactor/fermenter combinationsBio-organic fraction processingTerra pretaAir cleaning

The present invention relates to a method for the production of stable humus- and nutrient-rich and water-storing soil substrates with properties of anthropogenic soil types (Terra Preta) in which pyrogenic carbon, organic biomass, and / or natural mineral materials are used as initial materials in a fermentation process. The soil produced or treated according to the invention leads to a sustainably high soil yield such that mineral fertilizers are no longer needed for agricultural use. Moreover, the soil is suitable for use as a soil substitute, for use as a soil supplement, for greening developments, for preventing erosion, for improving regional water supplies, for preventing floods, for preventing climate change, for reducing carbon dioxide content in the atmosphere, for waste water cleaning and treatment, for exhaust air cleaning and building air purification, for creating material flow cycles from biogenic waste and / or waste water in order to develop and utilize land use and development systems.

Owner:RICION AG

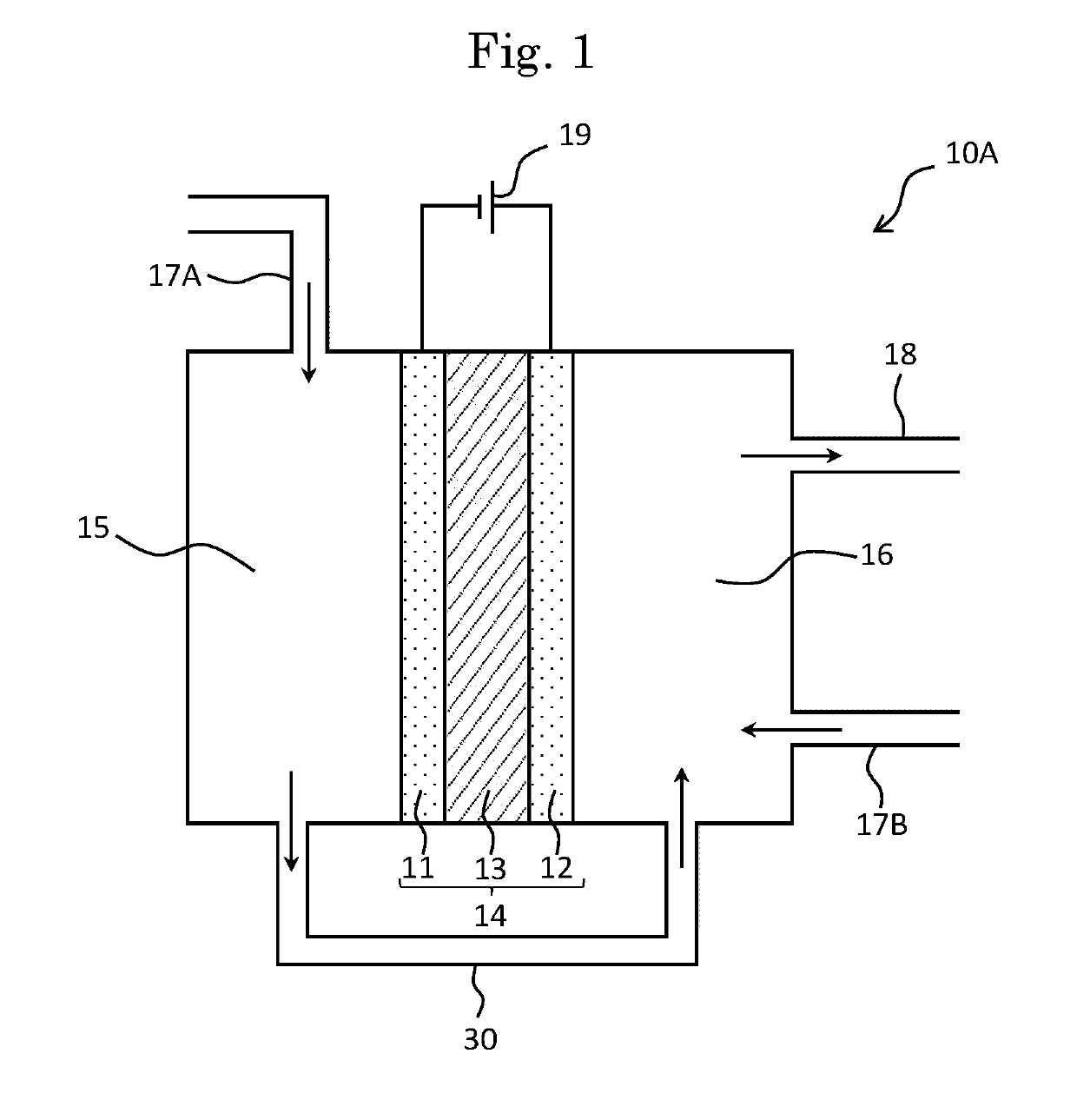

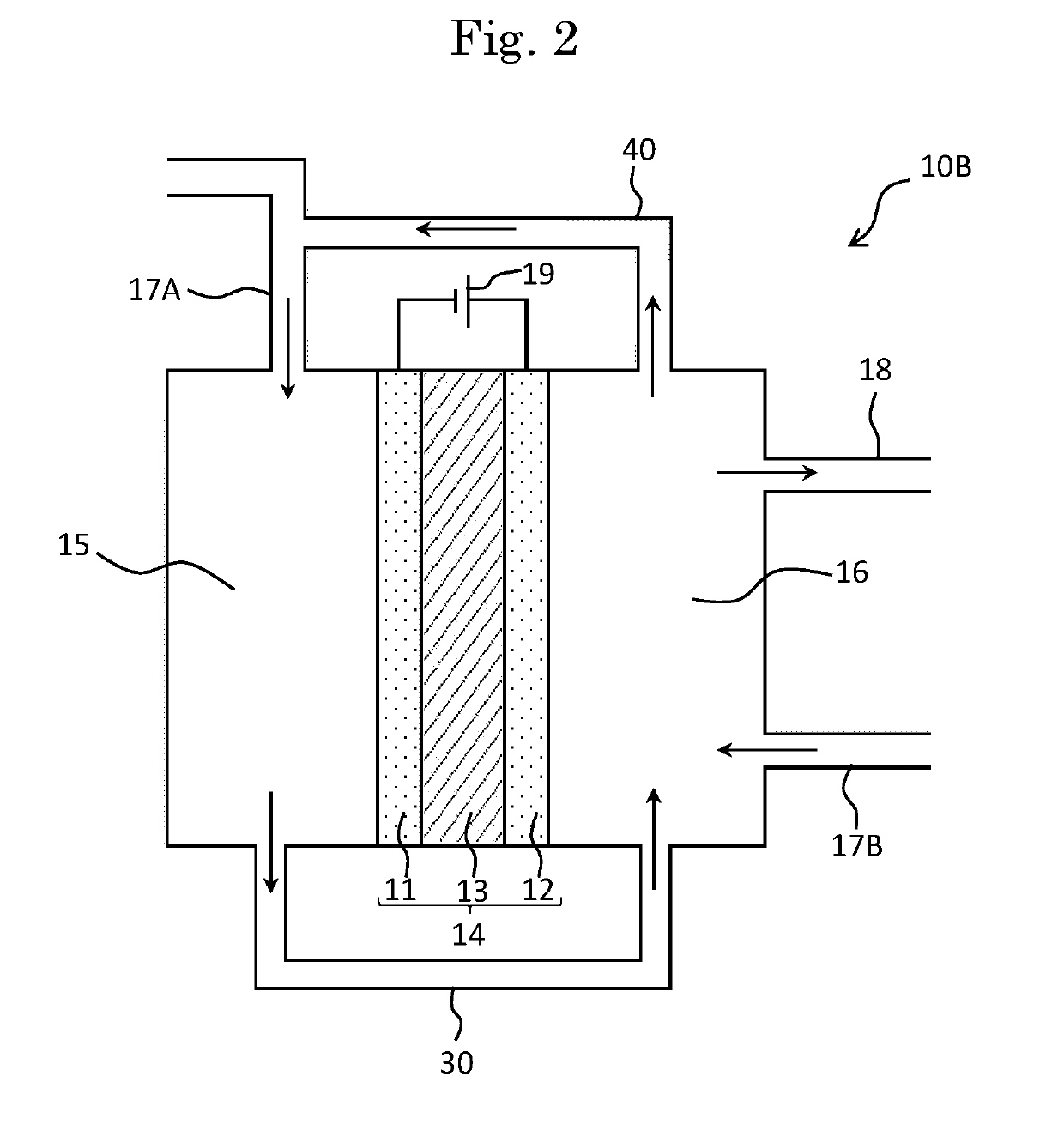

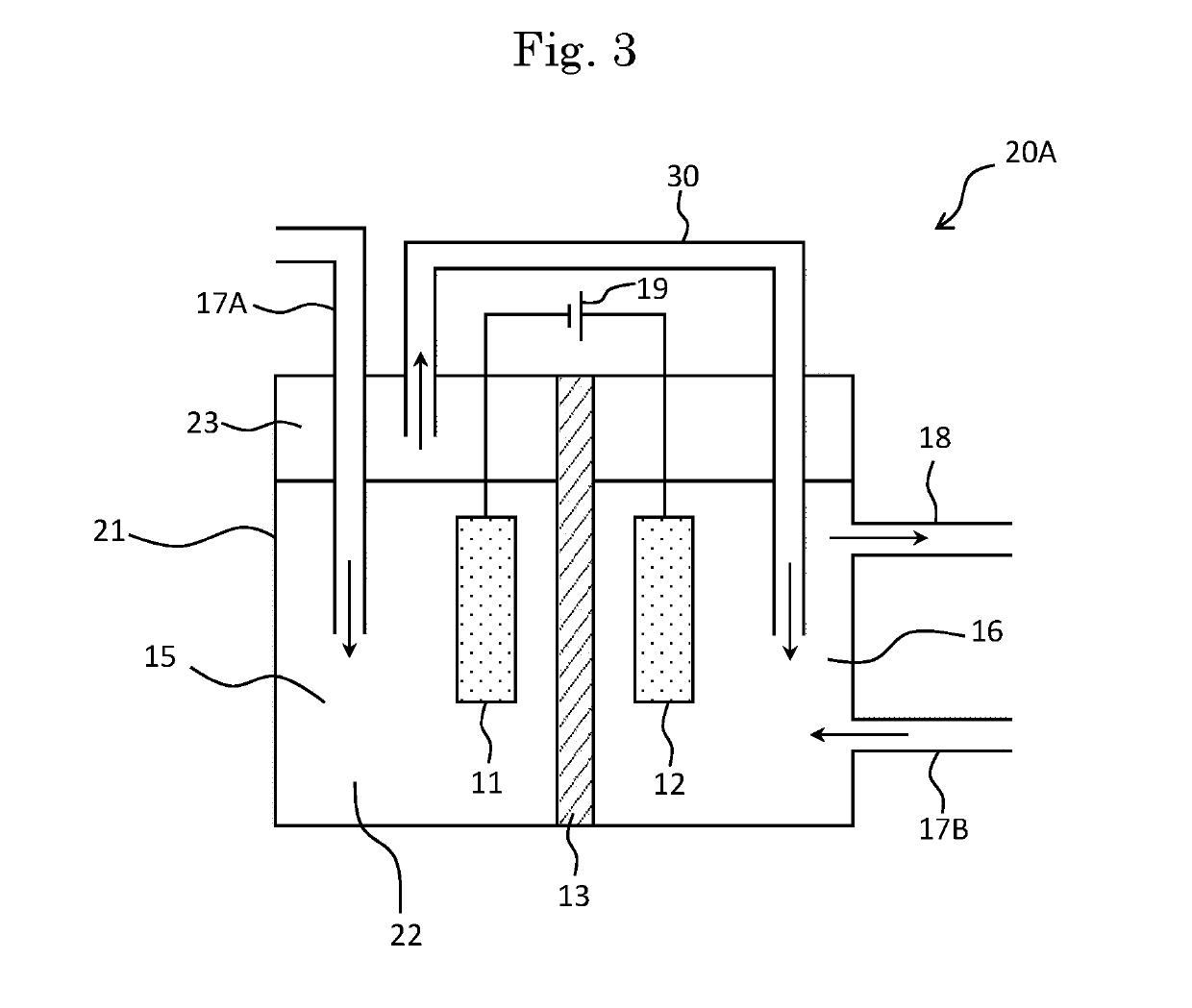

Carbon dioxide reduction apparatus and method of producing organic compound

ActiveUS20190292668A1Efficient use ofCellsElectrolytic organic reductionSimple Organic CompoundsPtru catalyst

A carbon dioxide reduction apparatus comprises a first electrochemical compartment provided with a first electrode, a second electrochemical compartment provided with a second electrode, an ion conducting membrane which demarcates the first electrochemical compartment from the second electrochemical compartment, and a first connecting path which connects the first electrochemical compartment with the second electrochemical compartment. The first electrode contains a first catalyst which catalyzes a reduction of carbon dioxide to a reduced product, and the second electrode contains a second catalyst which catalyzes a reaction between the reduced product and a reactant. The first connecting path is a connecting path which allows the reduced product in the first electrochemical compartment to flow out to the second electrochemical compartment.

Owner:SEKISUI CHEM CO LTD

Biological carbon soil conditioner and preparation method thereof

ActiveCN101818067AHigh porosityImprove adsorption capacityAgriculture tools and machinesOrganic fertilisersSodium BentoniteSoil organic matter

The invention discloses a biological carbon soil conditioner and a preparation method thereof. The biological carbon soil conditioner mainly comprises the following components in parts by weight: 40-60 parts of biological carbon, 10-25 parts of pumice and 20-45 parts of bentonite, wherein the biological carbon is obtained by performing anaerobic carbonization on at least one of crops straw, wooden meal, deadwood or deciduous leaves at the temperature of 300-1000 DEG C; and the biological carbon soil conditioner is prepared by the following the steps: mixing the raw materials, adding 15-35 parts of water by weight, stirring, extruding, pelletizing and packaging components. The invention can improve soil physicochemical property, enhance soil organic matter content and fertilizer utilization rate, and reduce carbon dioxide burst size.

Owner:沃达农业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com