Patents

Literature

40results about How to "Improve methane production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bio-recycling of carbon dioxide emitted from power plants

InactiveUS20070298478A1Enhance biogas methane productionReduce carbon dioxide emissionsBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationFossil fuel

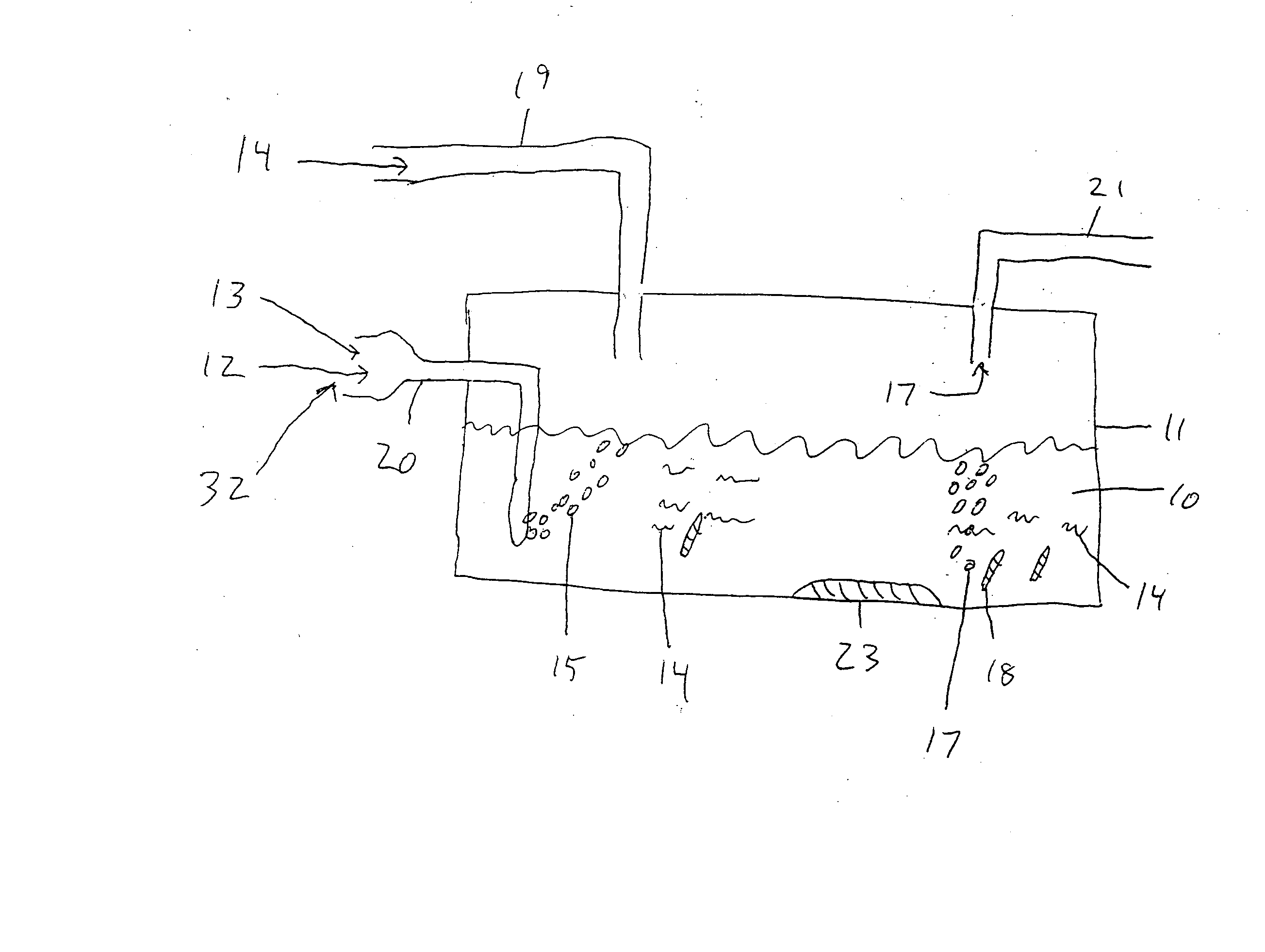

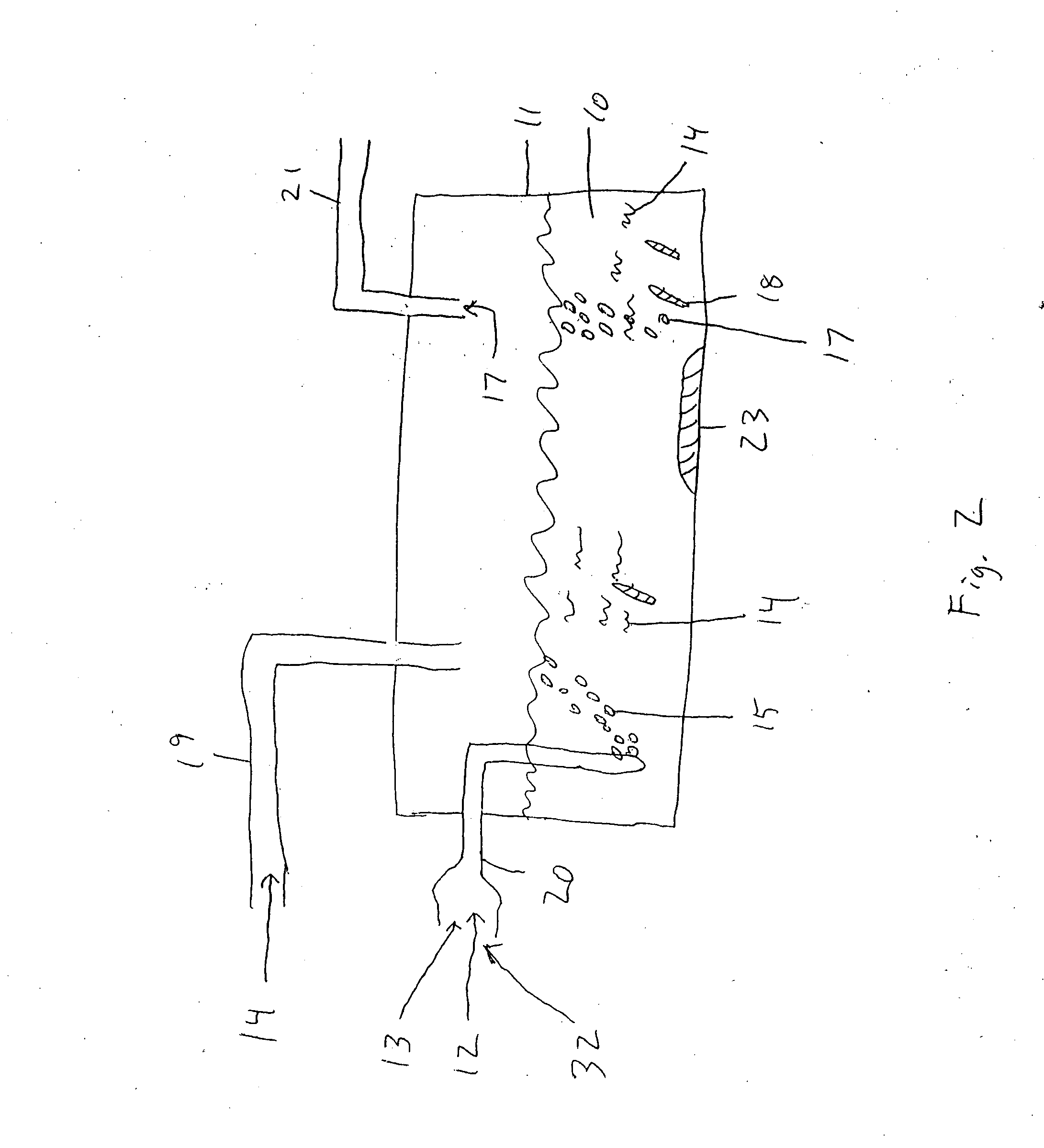

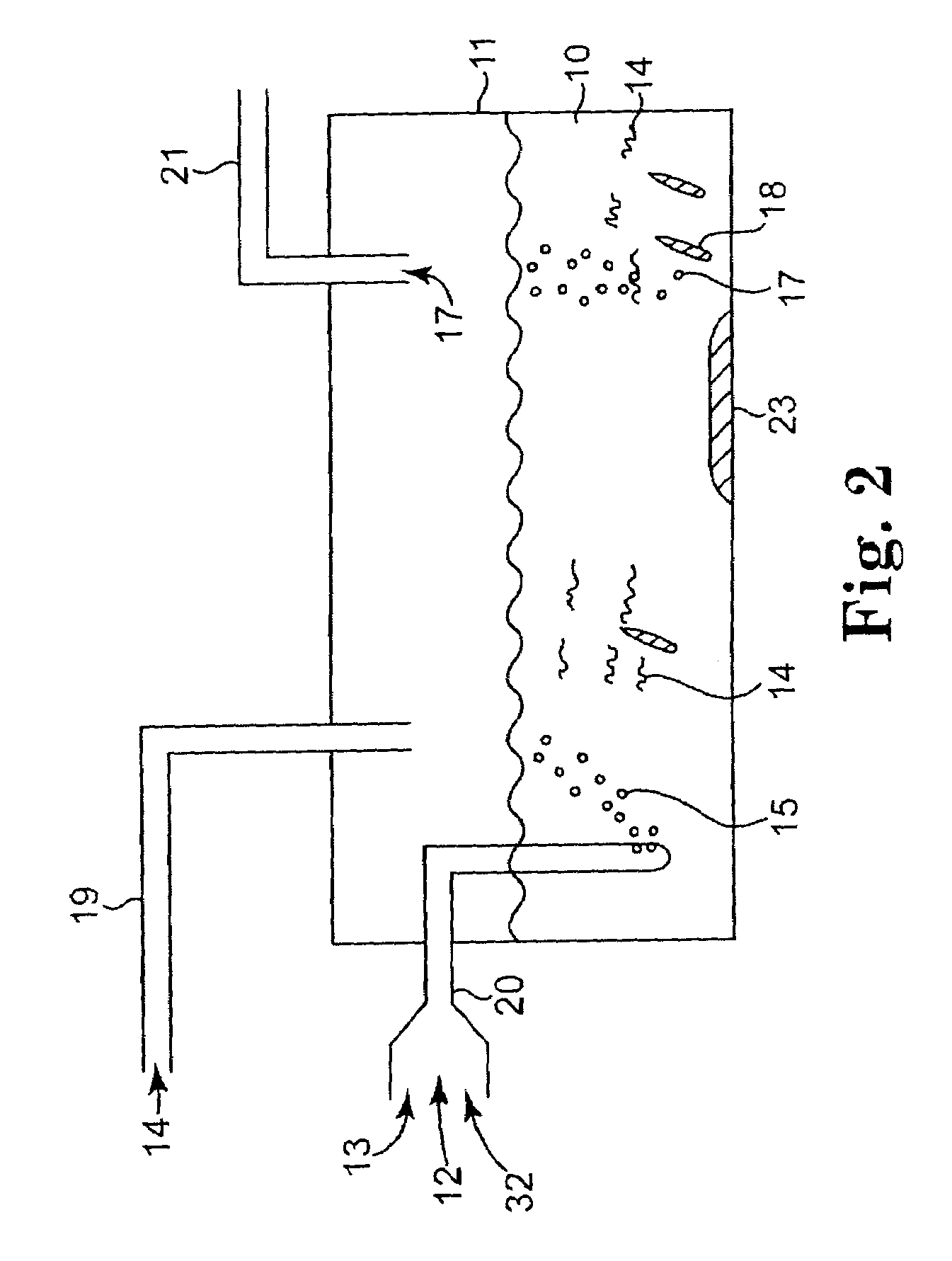

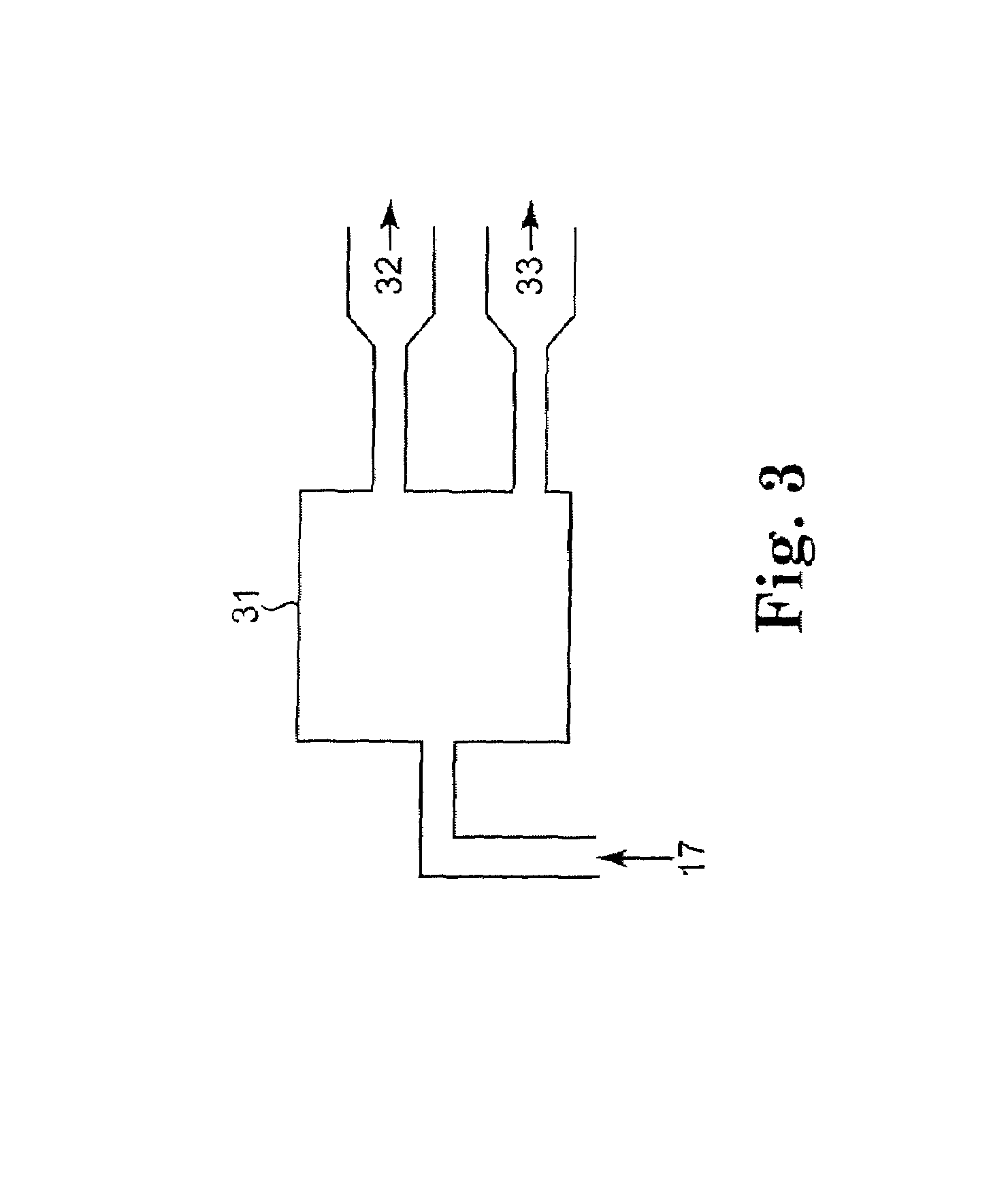

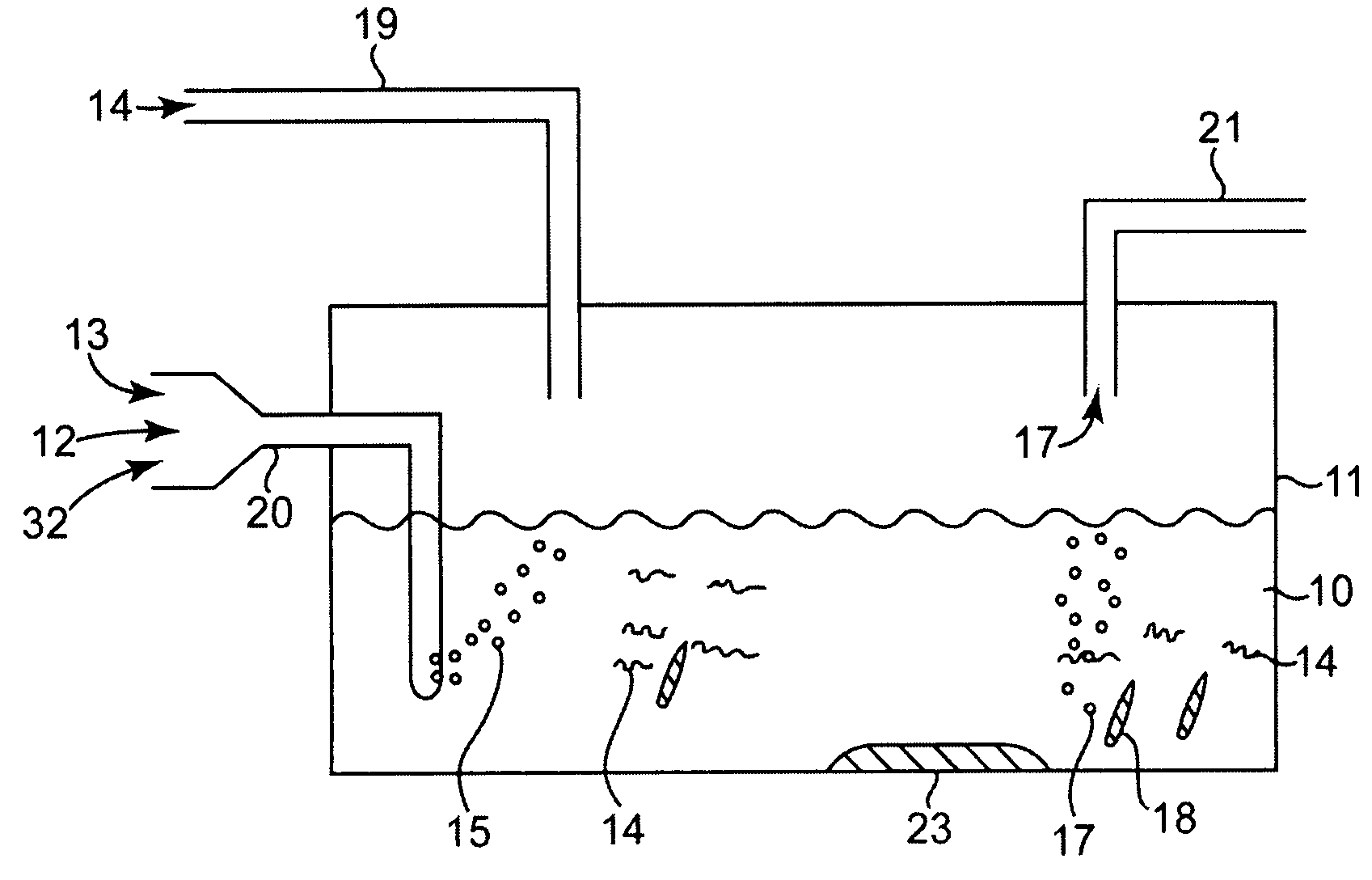

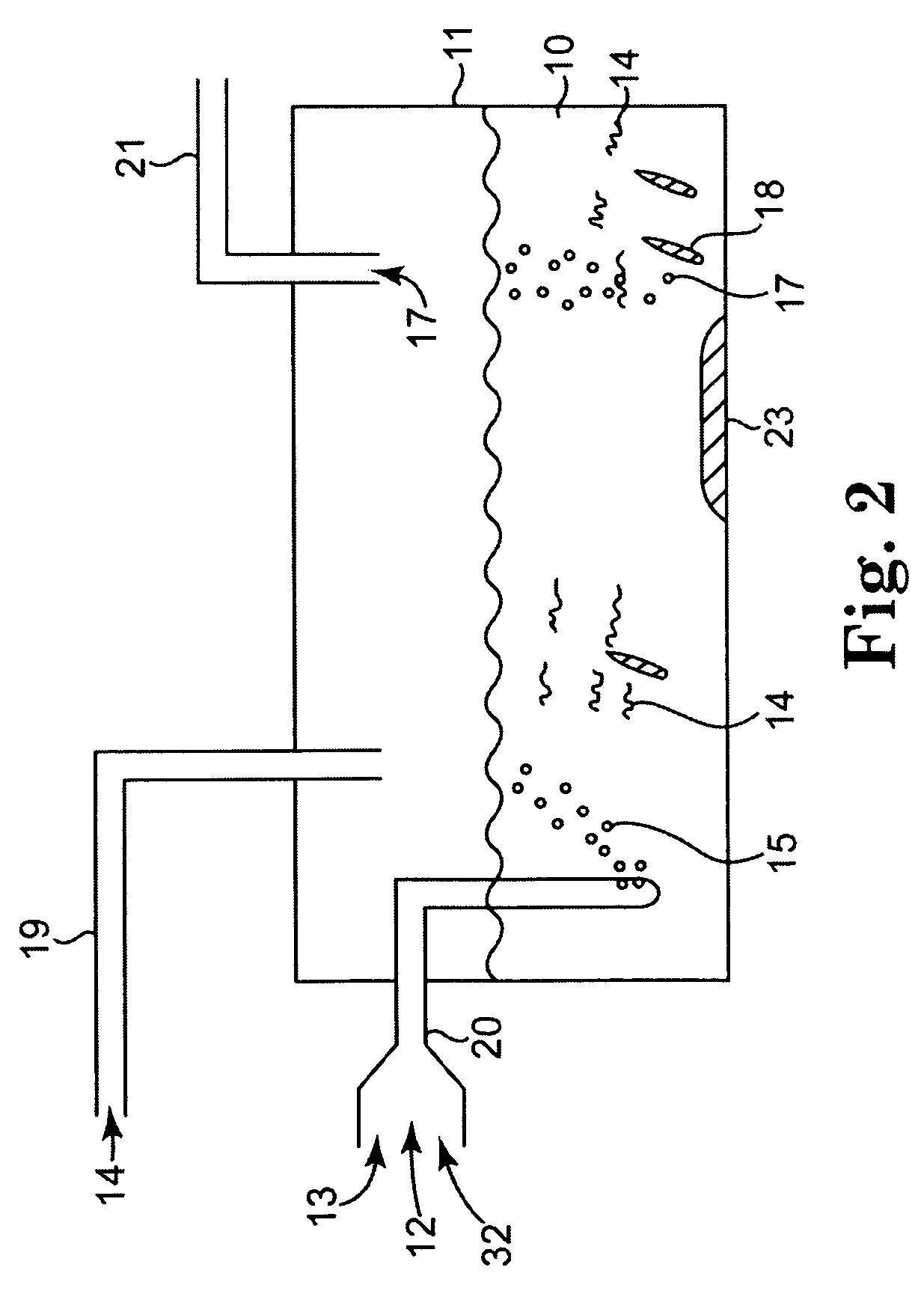

The invention provides a method to decrease emission of carbon dioxide from combustion of fossil fuels or other hydrocarbons and to enhance the efficiency of methane production from anaerobic biodigesters. The invention involves feeding carbon dioxide from the exhaust gas of hydrocarbon fuel combustion to an anaerobic biodigester where biomass is anaerobically fermented to produce methane. Carbon dioxide is an electron acceptor for anaerobic fermentation, and thus some of the carbon dioxide is reduced to methane, which can again be used for fuel. In this way, at least a portion of the exhaust gas CO2 is recycled to form fuel methane instead of being released into the atmosphere. Thus, the net CO2 emission from burning a given amount of fossil fuel is decreased. Adding carbon dioxide to an anaerobic fermentation also increases the efficiency and amount of methane production in the fermentation.

Owner:VIRESCO AD LLC

Bio-recycling of carbon dioxide emitted from power plants

InactiveUS7608439B2Reduce carbon dioxide emissionsImprove methane production efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationFossil fuel

The invention provides a method to decrease emission of carbon dioxide from combustion of fossil fuels or other hydrocarbons and to enhance the efficiency of methane production from anaerobic biodigesters. The invention involves feeding carbon dioxide from the exhaust gas of hydrocarbon fuel combustion to an anaerobic biodigester where biomass is anaerobically fermented to produce methane. Carbon dioxide is an electron acceptor for anaerobic fermentation, and thus some of the carbon dioxide is reduced to methane, which can again be used for fuel. In this way, at least a portion of the exhaust gas CO2 is recycled to form fuel methane instead of being released into the atmosphere. Thus, the net CO2 emission from burning a given amount of fossil fuel is decreased. Adding carbon dioxide to an anaerobic fermentation also increases the efficiency and amount of methane production in the fermentation.

Owner:VIRESCO AD LLC

Method for increasing methane production efficiency in organic waste anaerobic process

ActiveCN102140001APromote hydrolysisImprove metabolic activityGas production bioreactorsWaste based fuelGeneration rateFeces

The invention discloses a method for increasing methane production efficiency in organic waste anaerobic process. The method is characterized in that powder containing no less than 15% of free ferric iron oxides is added into an anaerobic biochemical system to be uniformly blended, wherein the anaerobic biochemical system produces methane by utilizing organic wastes; and ferric ions released when microbes reduce the ferric iron oxides in the anaerobic process can promote the activity of anaerobic bacteria such as methane bacteria and the like, thus increasing the production rate and yield of methane by utilizing organic wastes. The method can be widely used for increasing the methane production rate and yield of an energy utilization system for biogas production of municipal domestic waste, agriculture product processing wastes, excess sludge of sewage treatment plants, feces of intensifying raising farms and the like and improves the utilization rate of renewable energy sources of organic wastes.

Owner:HEFEI UNIV OF TECH

Bio-recycling of carbon dioxide emitted from power plants

InactiveUS20090162914A1Reduce carbon dioxide emissionsImprove methane production efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsFermentationFossil fuel

The invention provides a method to decrease emission of carbon dioxide from combustion of fossil fuels or other hydrocarbons and to enhance the efficiency of methane production from anaerobic biodigesters. The invention involves feeding carbon dioxide from the exhaust gas of hydrocarbon fuel combustion to an anaerobic biodigester where biomass is anaerobically fermented to produce methane. Carbon dioxide is an electron acceptor for anaerobic fermentation, and thus some of the carbon dioxide is reduced to methane, which can again be used for fuel. In this way, at least a portion of the exhaust gas CO2 is recycled to form fuel methane instead of being released into the atmosphere. Thus, the net CO2 emission from burning a given amount of fossil fuel is decreased. Adding carbon dioxide to an anaerobic fermentation also increases the efficiency and amount of methane production in the fermentation.

Owner:OFFERMAN JOHN D +1

Electromethanogenic reactor and processes for methane production

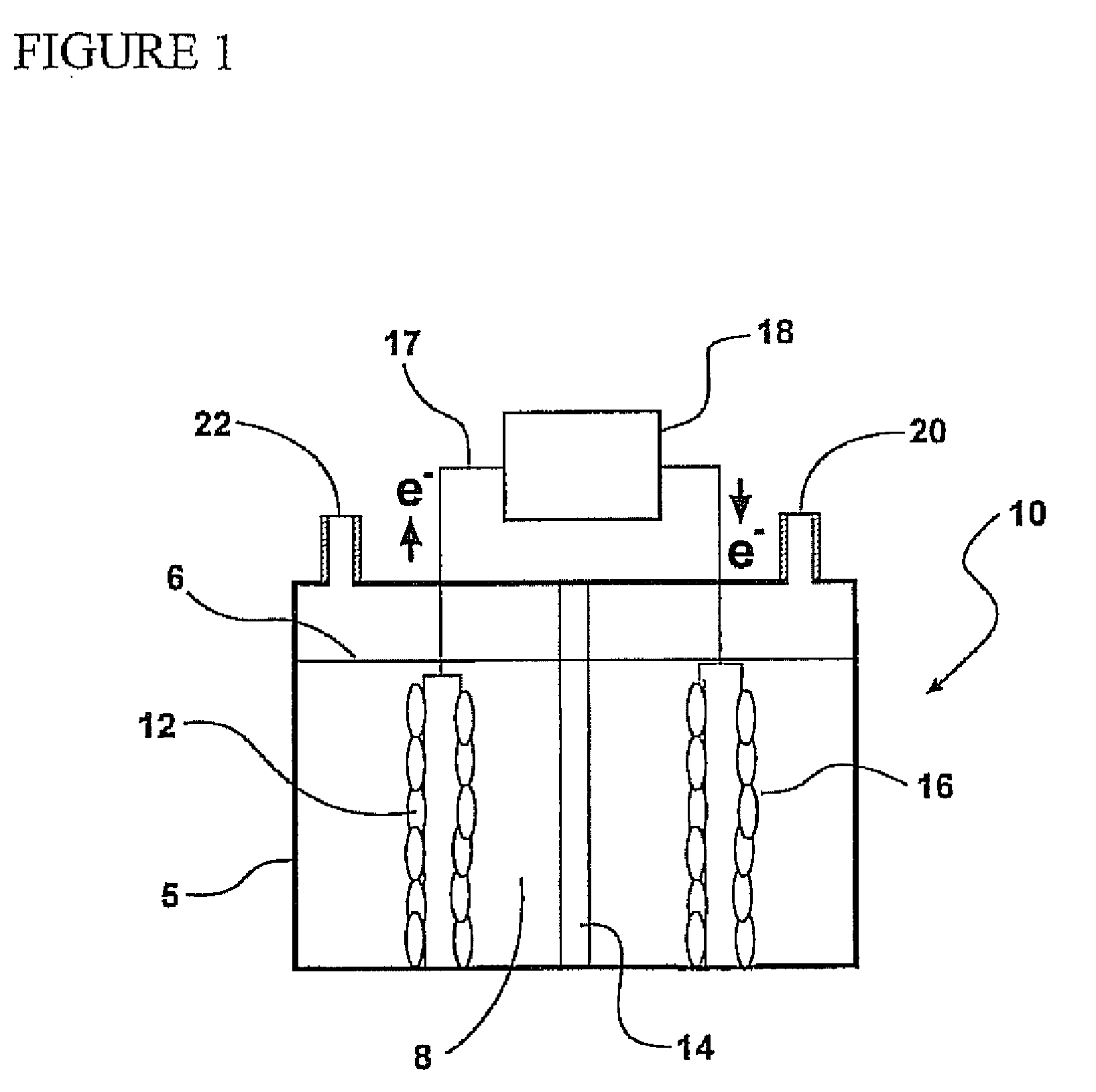

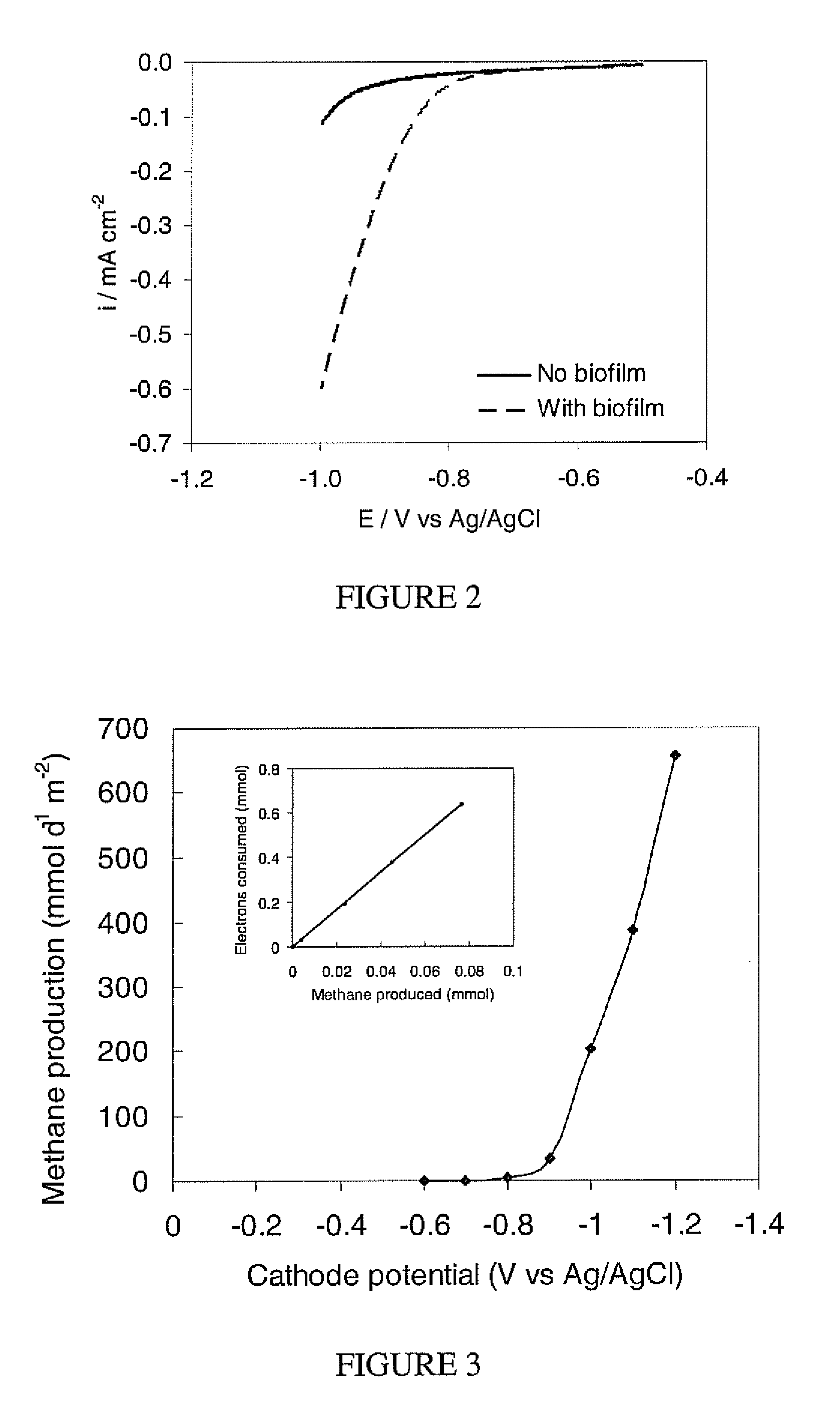

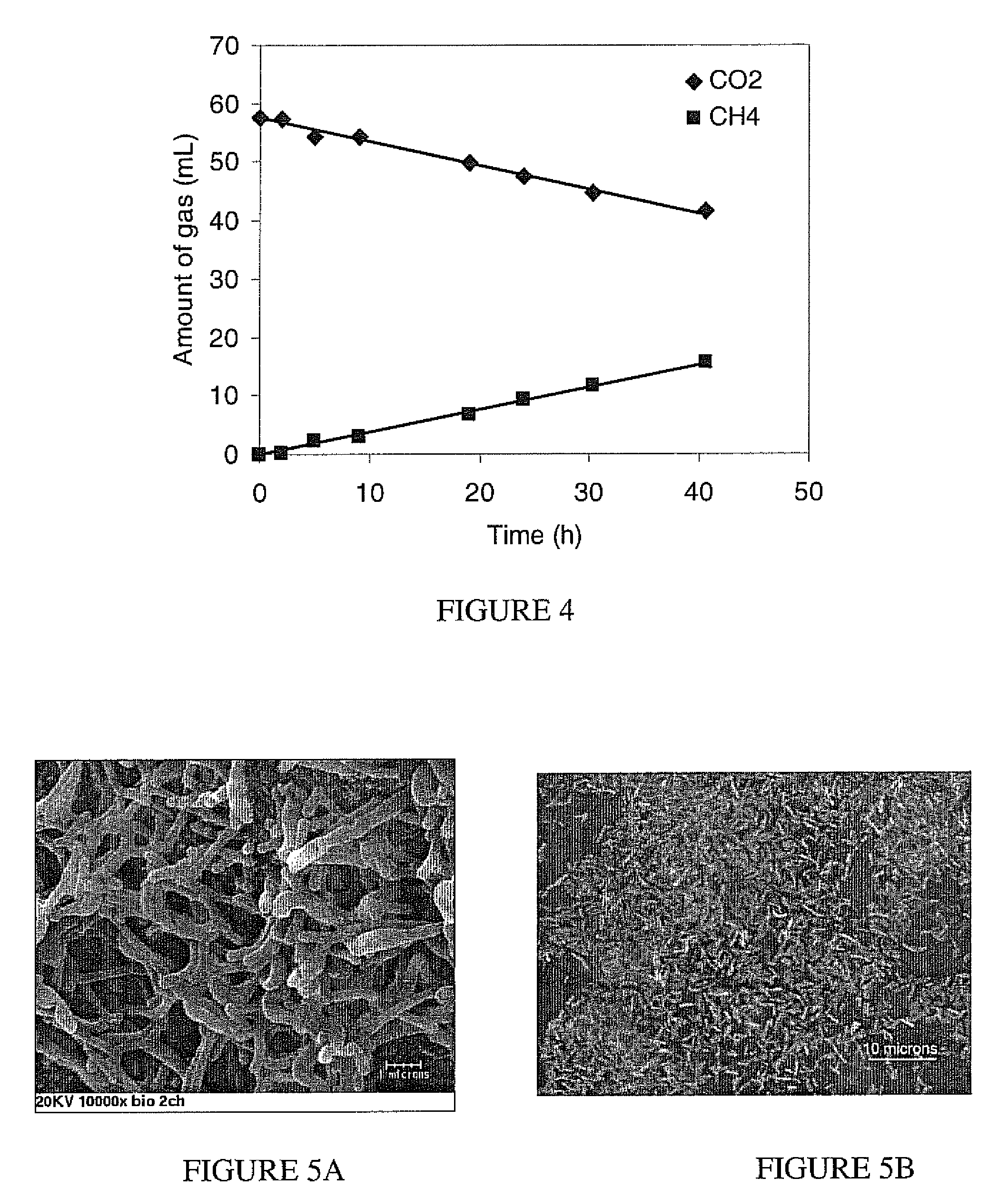

ActiveUS8440438B2Increasing methane gas production rateReduce deliveryMicroorganismsGas production bioreactorsMethane gasElectron

Increasing competition for fossil fuels, and the need to avoid release carbon dioxide from combustion of these fuels requires development of new and sustainable approaches for energy production and carbon capture. Biological processes for producing methane gas and capturing carbon from carbon dioxide are provided according to embodiments of the present invention which include providing an electromethanogenic reactor having an anode, a cathode and a plurality of methanogenic microorganisms disposed on the cathode. Electrons and carbon dioxide are provided to the plurality of methanogenic microorganisms disposed on the cathode. The methanogenic microorganisms reduce the carbon dioxide to produce methane gas, even in the absence of hydrogen and / or organic carbon sources.

Owner:PENN STATE RES FOUND

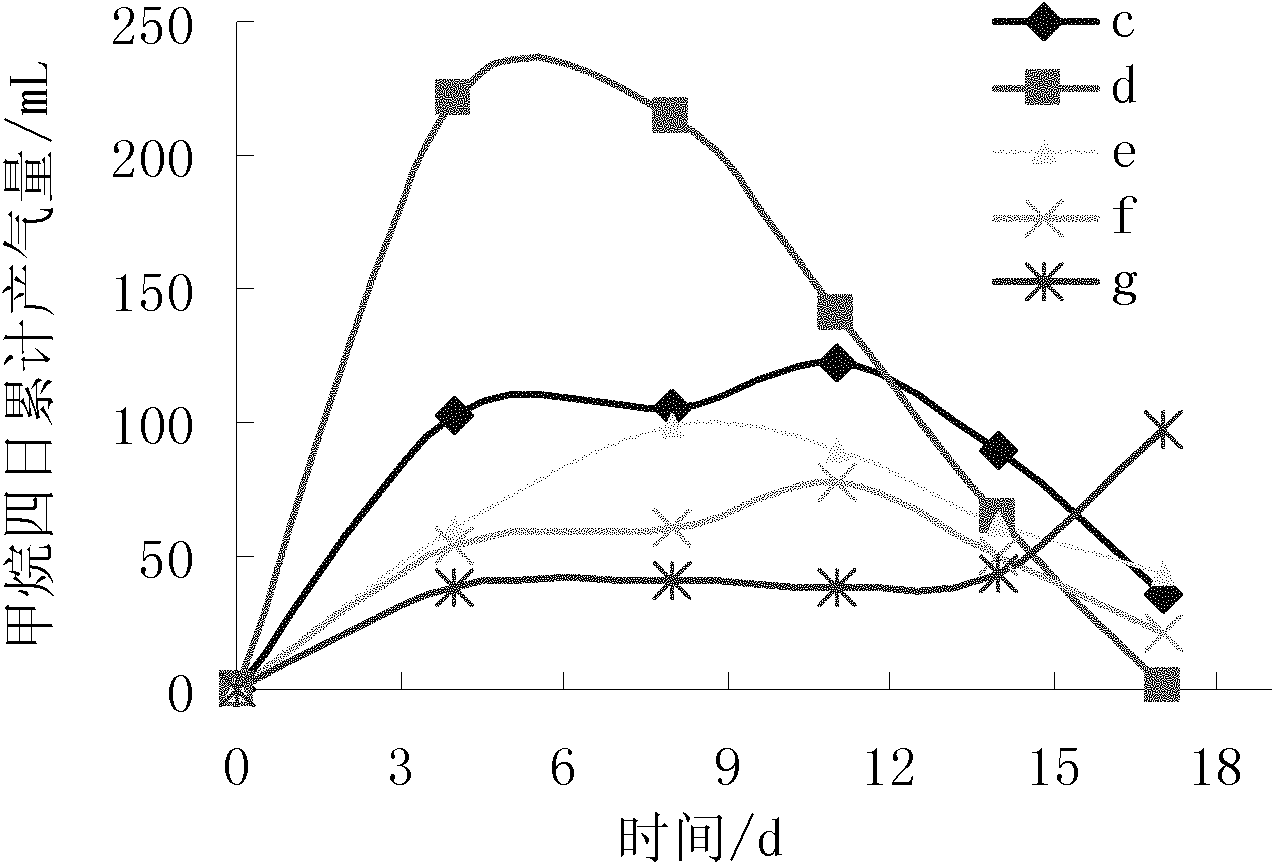

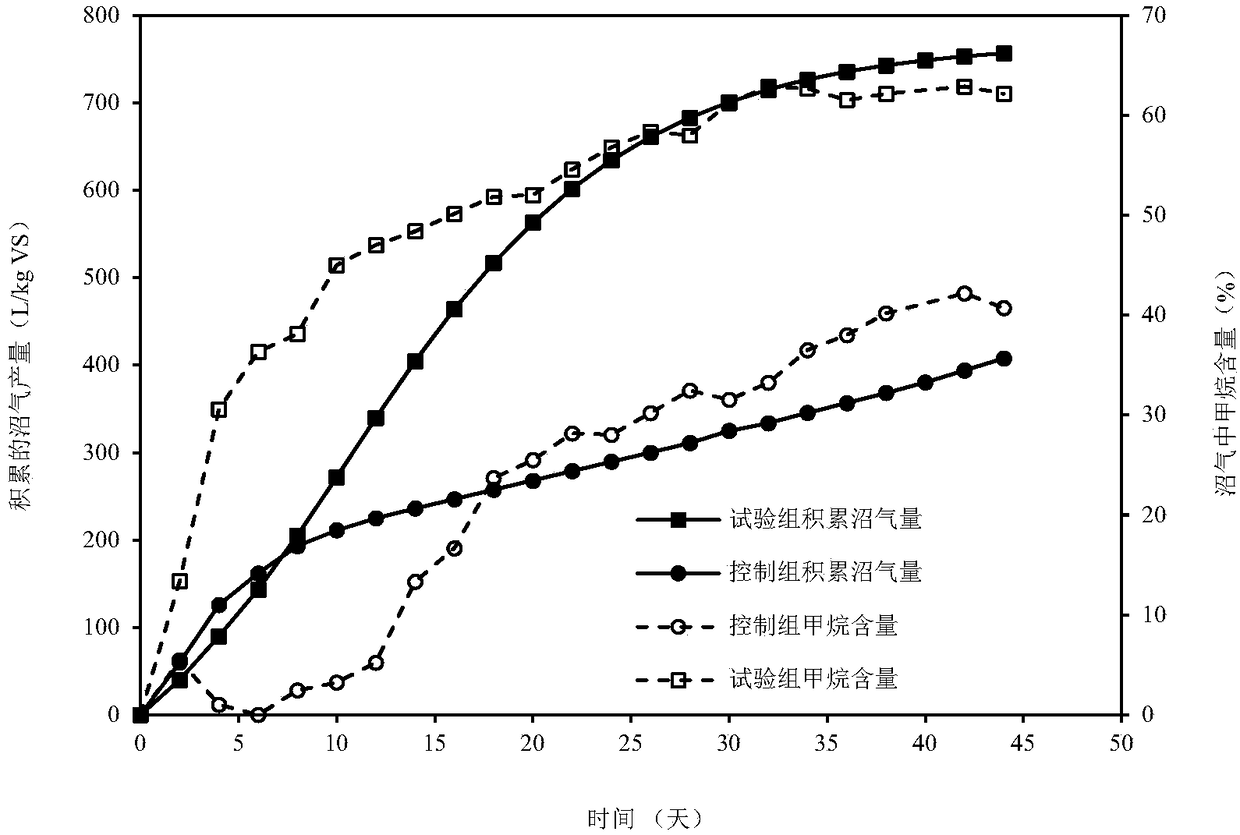

Method for improving efficiency of blue-green algae or straw anaerobic methane production process

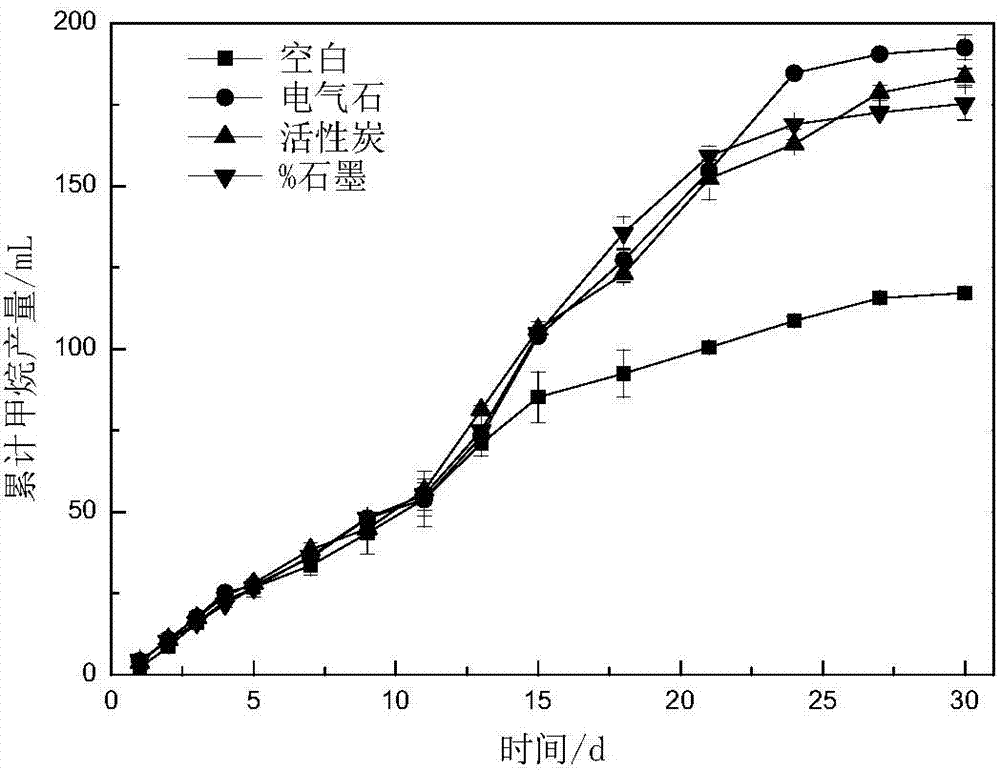

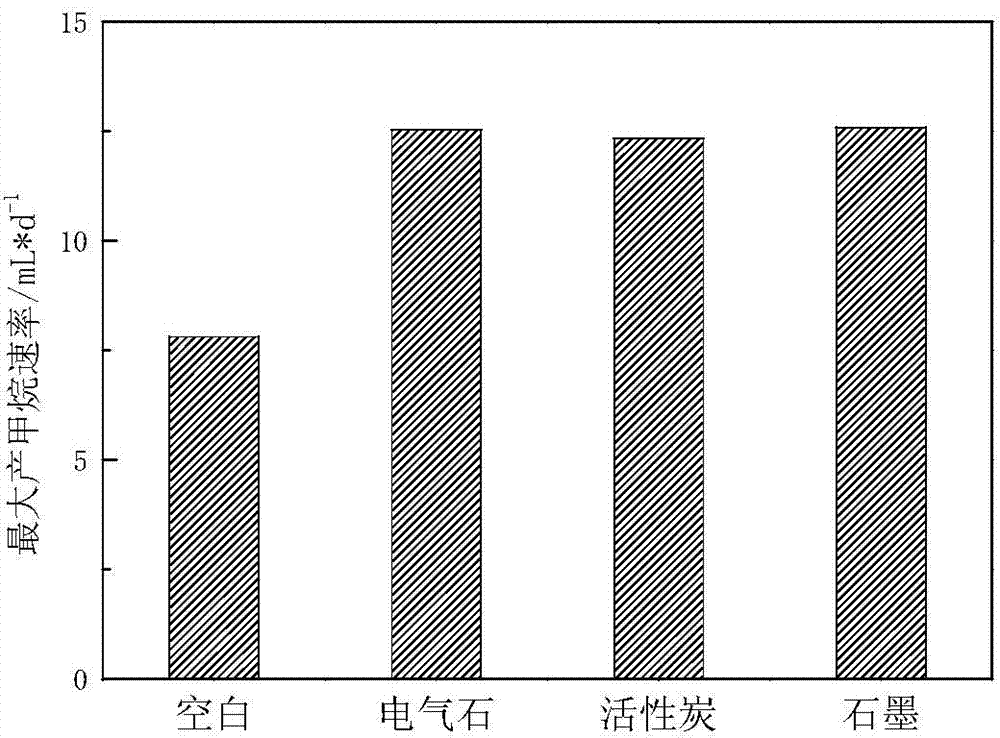

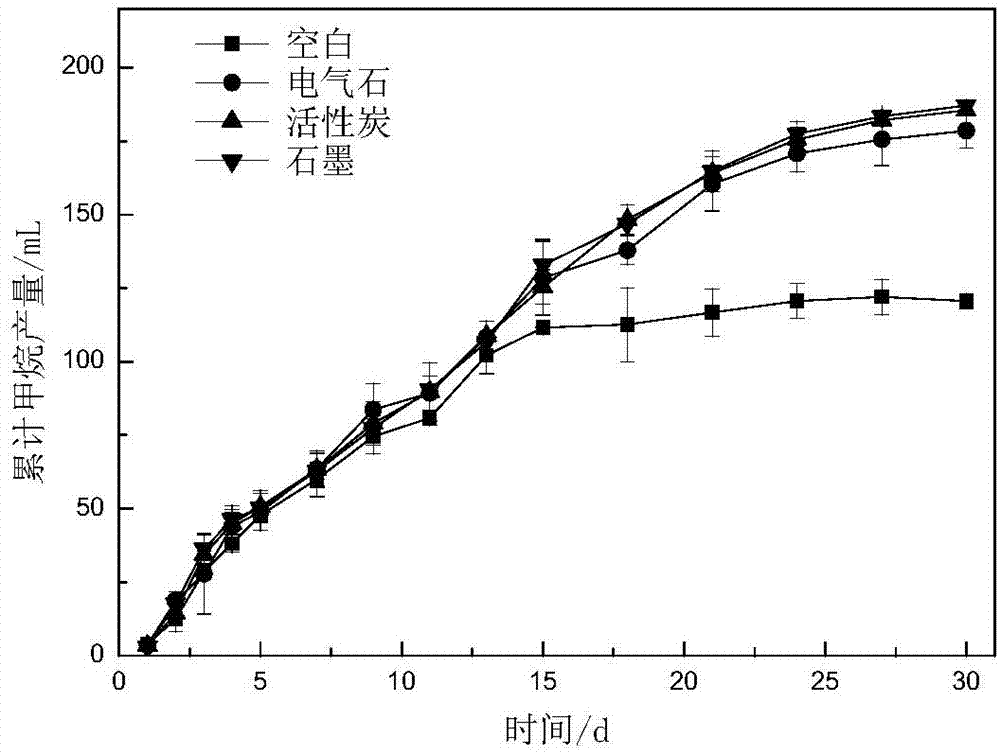

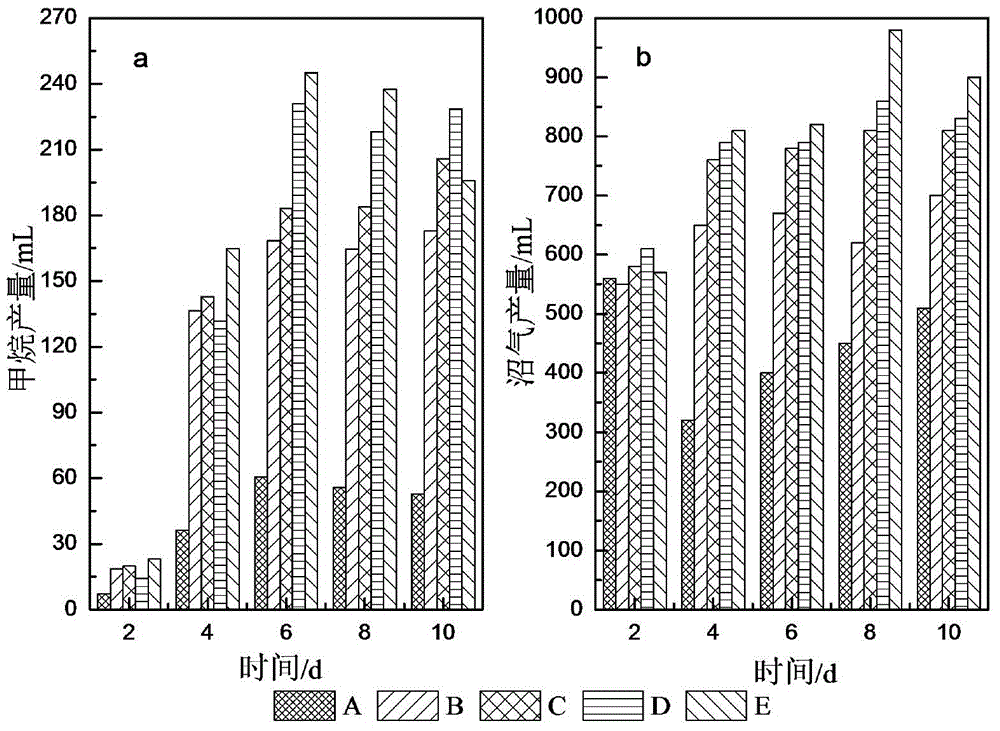

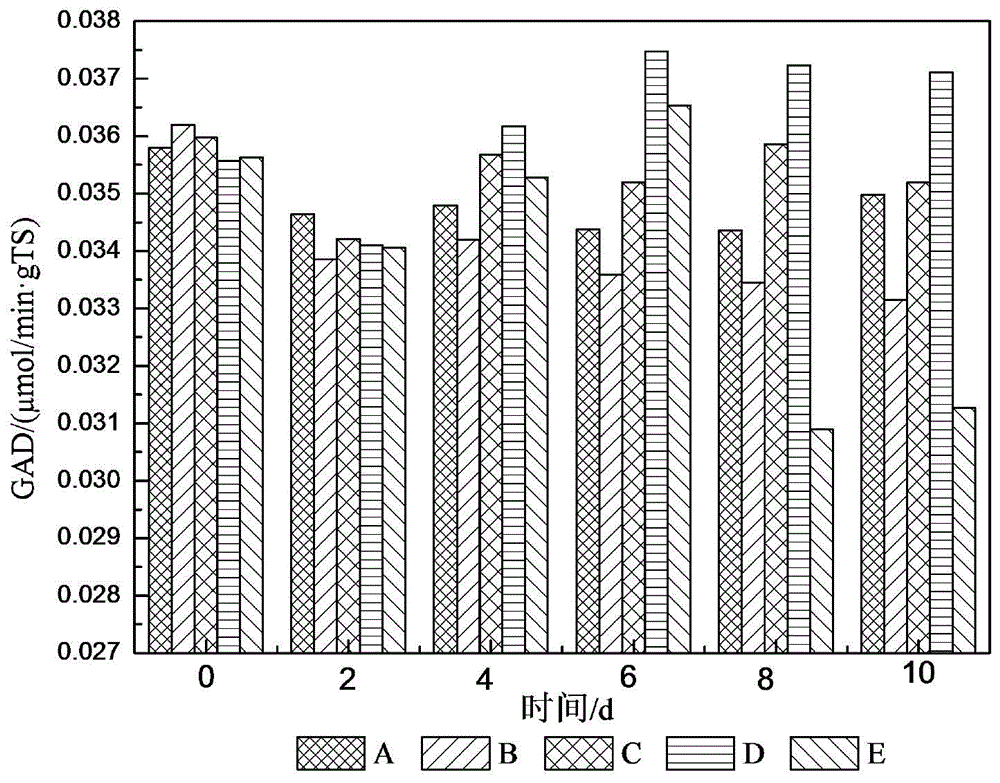

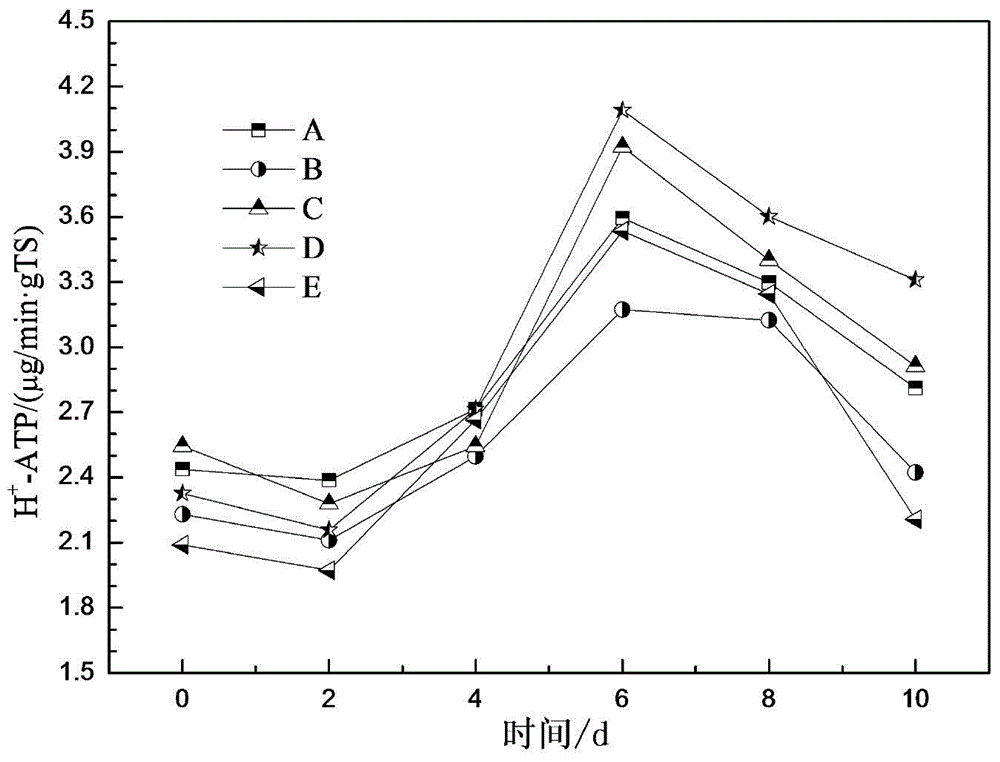

InactiveCN104762332AHigh activityIncrease productionWaste based fuelFermentationActivated carbonMethane yield

The invention discloses a method for improving the efficiency of a blue-green algae or straw anaerobic methane production process. The method is characterized in that tourmaline, activated carbon or graphite is adopted as an additive, the additive is respectively added into a blue-green algae or straw anaerobic fermentation system and is well mixed with anaerobic microbes and a fermentation substrate in the anaerobic fermentation system. With the method, blue-green algae or straw methane production efficiency and methane yield are improved during a process that the anaerobic microbes convert the blue-green algae or straw into methane.

Owner:HEFEI UNIV OF TECH

Efficient sludge resource utilization method

ActiveCN107434341AImprove dehydration effectImprove the efficiency of solid-liquid separationSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisResource utilizationSorbent

The invention belongs to the field of sewage treatment and specifically relates to an efficient sludge resource utilization method. The method mainly comprises links of sludge concentration, pretreatment, solid-liquid separation, anaerobic digestion, preparation of a sludge adsorbent and the like. The operation method comprises the following steps: sludge from a sewage treatment plant is firstly concentrated to a proper concentration; pretreatment of calcium and alkaline agents mixing combined with other methods is then carried out; and solid-liquid separation is conducted, the liquid part undergoes anaerobic digestion for production of methane, and the solid part undergoes anhydration or pyrolysis to prepare sludge charcoal. By the pretreatment including the calcium and alkali mixing treatment process, organic substances in the sludge can be released, and those organic substances can be subjected to anaerobic digestion through an effective anaerobic reactor for production of methane. By calcium and alkali mixing, on one hand, most of phosphorus in the sludge can be maintained in sludge solids to reduce release of phosphorus during the pretreatment process, and the content of phosphorus in the prepared sludge charcoal is high. On the other hand, the sludge solids can be activated and modified, and the prepared sludge charcoal has good adsorption characteristic.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Method for increasing kitchen waste high solid-state fermentation produced biogas

ActiveCN104911218AImprove toleranceIncrease alkalinityWaste based fuelFermentationOrganic acidMethanogenesis

The invention discloses a method for increasing kitchen waste high solid fermentative produced biogas, and belongs to the technical field of treatment control and environmentally-friendly purification treatment of solid waste. The biogas is produced in a high solid-state anaerobic fermentation way, so that not only can the kitchen waste be effectively treated and the harmless treatment, reduction and recycling of the solid waste be realized, but also the tolerance of methanogens to organic acid can be improved, and the methanogenesis efficiency of high solid-state anaerobic fermentation for the kitchen waste can be improved. A fermentation system is stable to operate, the kitchen waste treatment effect is good, and the energy recovery rate is relatively high.

Owner:JIANGNAN UNIV

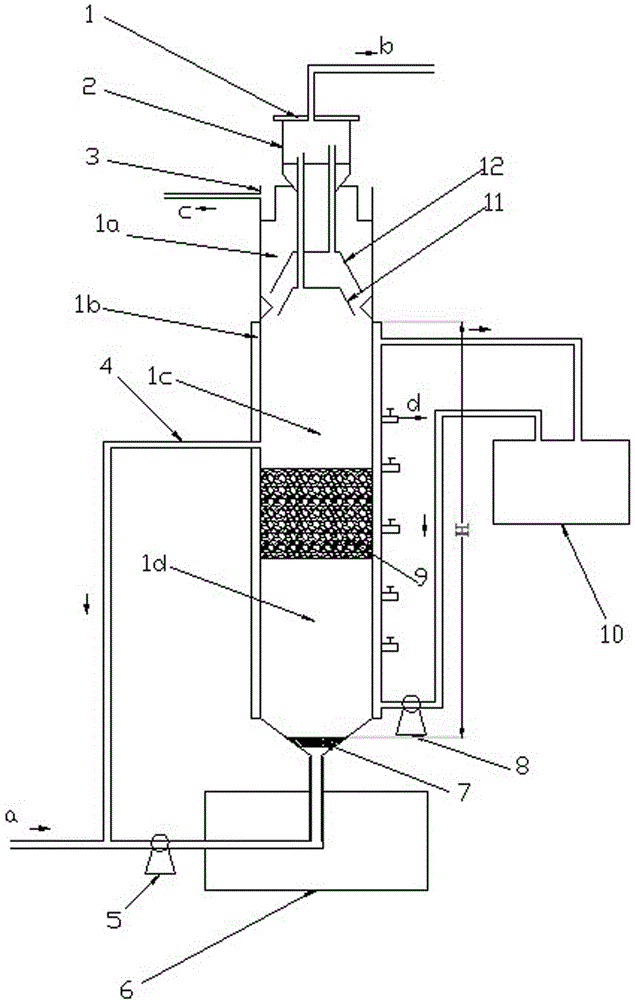

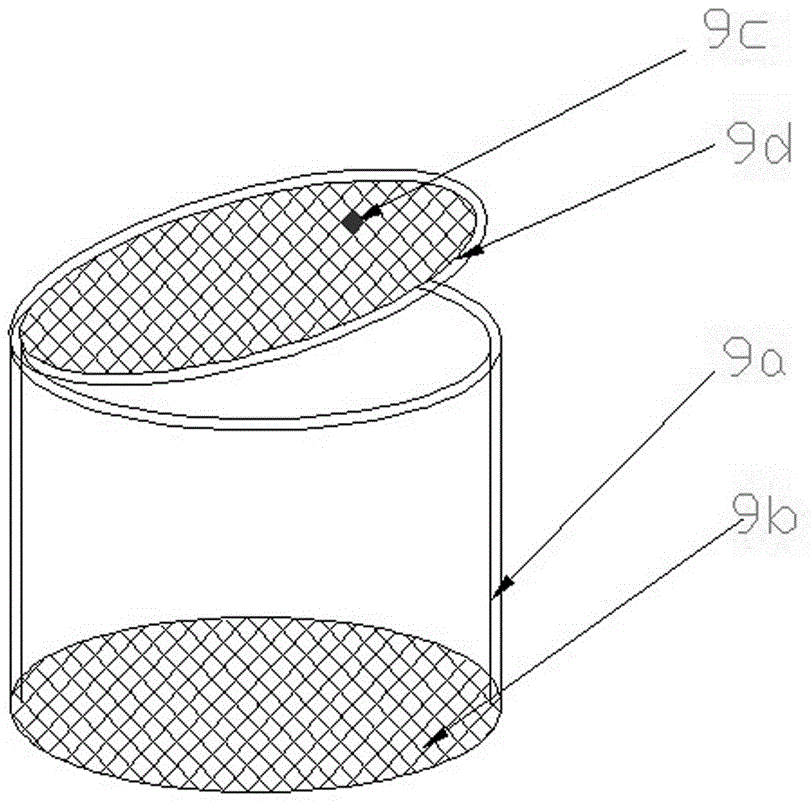

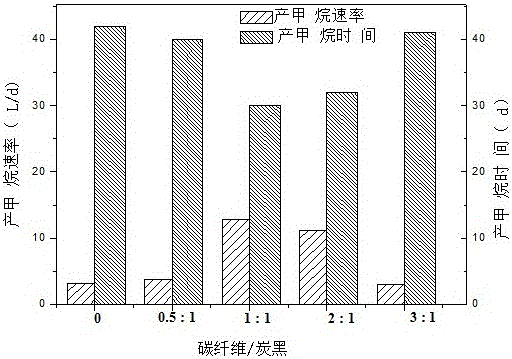

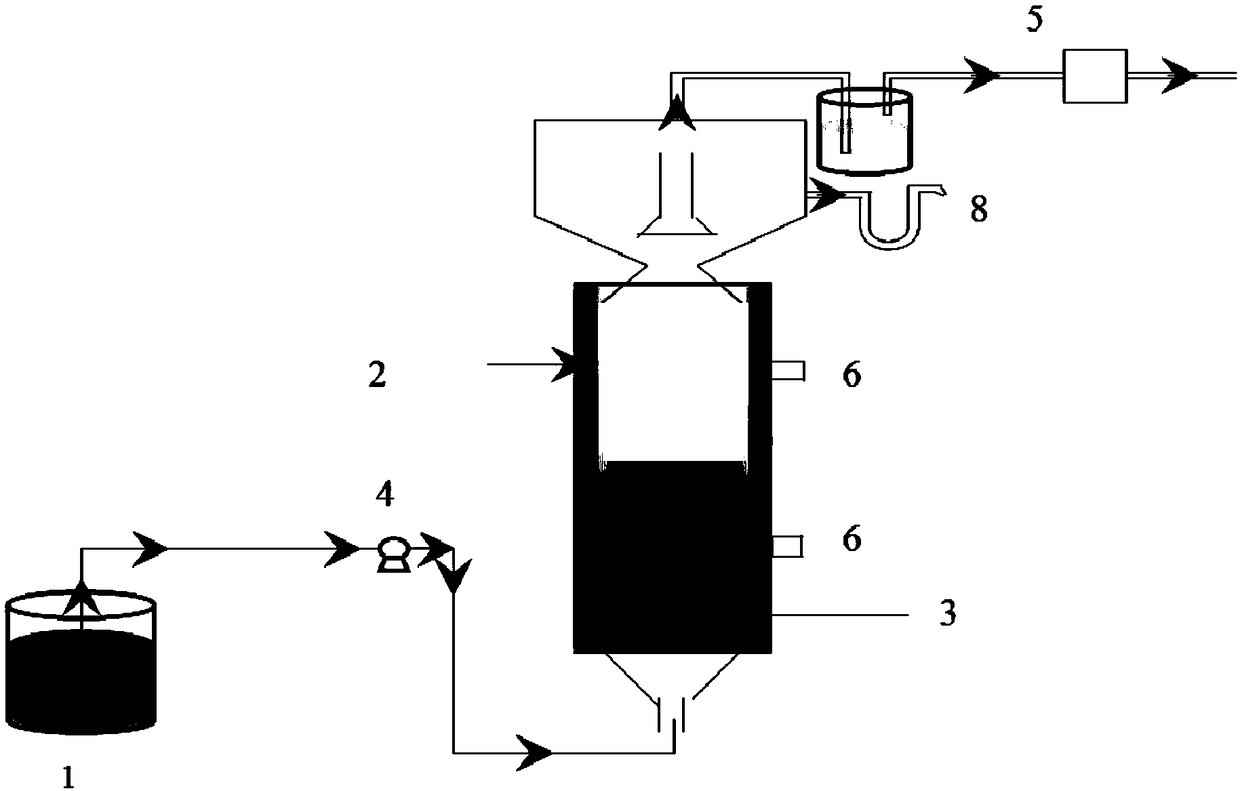

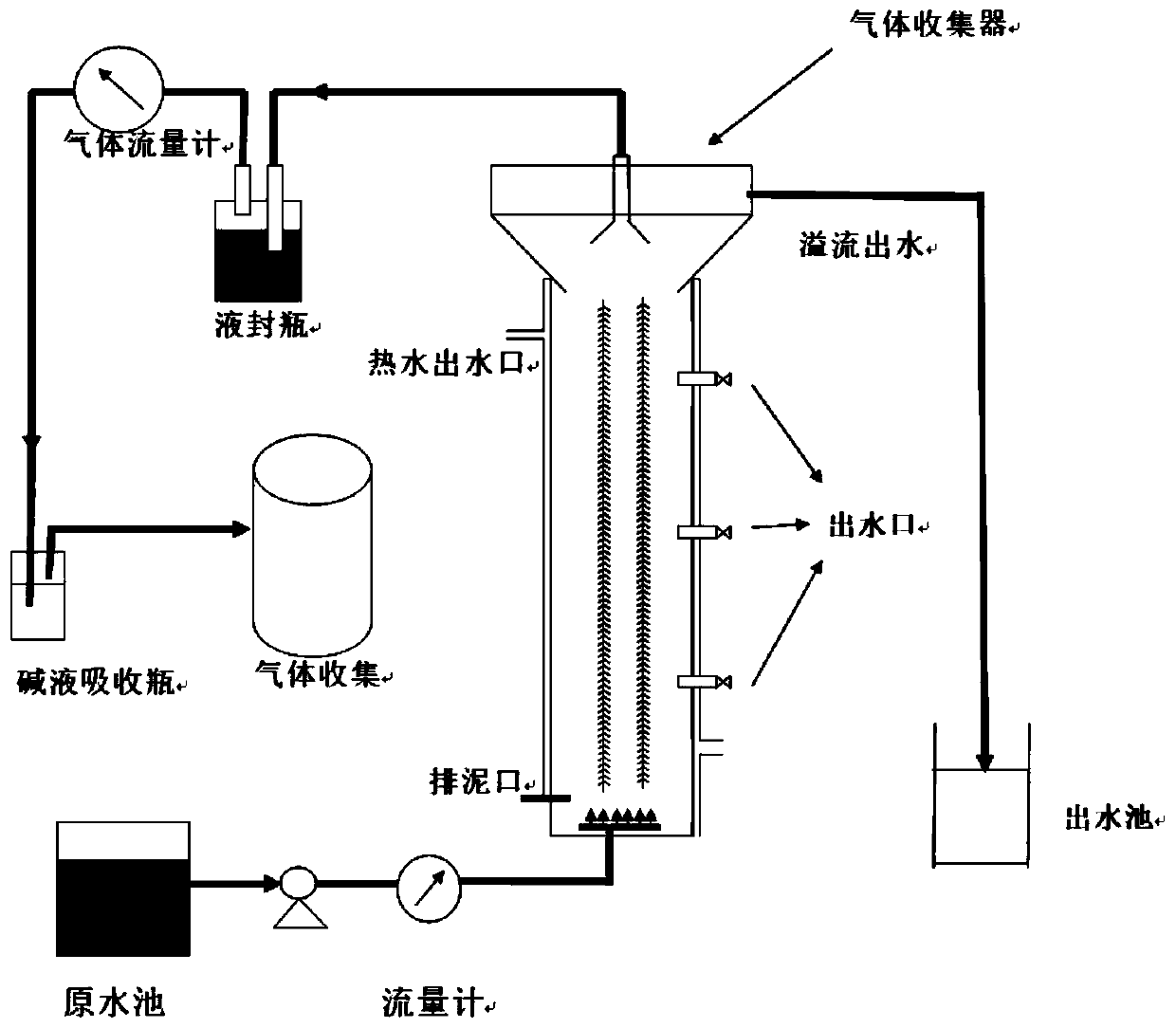

Device and process for producing methane by sludge removal filtrate

InactiveCN106145339AWay to increaseNot easy to loseTreatment by combined electrochemical biological processesBiological treatment apparatusCarbon fibersAnaerobic reactor

The invention discloses a device and a method for producing methane by sludge removal filtrate. The device comprises an anaerobic reactor, wherein the anaerobic reactor is divided into a sludge reaction area, a three-phase separation area and a gas chamber from top to bottom; the sludge reaction area is provided with a conductive carrier layer; a conductive carrier in the conductive carrier layer consists of carbon fibres and carbon black at the mass ratio of (1:1)-(2:1). The carbon fibres and the carbon black are arranged in the anaerobic reactor to serve as the conductive carrier layer, so that electrons are transferred between methanogenic archaea and syntrophism bacteria through electron carriers of hydrogen, methanoic acid or the like, and inter-specific electron transfer can also be performed directly; therefore, more methane producing ways are provided for producing methane bacteria; the conductive carrier layer is fixed to the anaerobic reactor so as not to lose easily along with the outflow of water flow, and the conductive carrier layer can also be in full contact with wastewater so as to improve the methane producing rate; the water penetrating load of the conductive carrier layer is increased by adopting wastewater cycling, and meanwhile, a fluidizing effect of sludge is also improved; therefore, the methane producing efficiency is improved.

Owner:POWERCHINA ZHONGNAN ENG +1

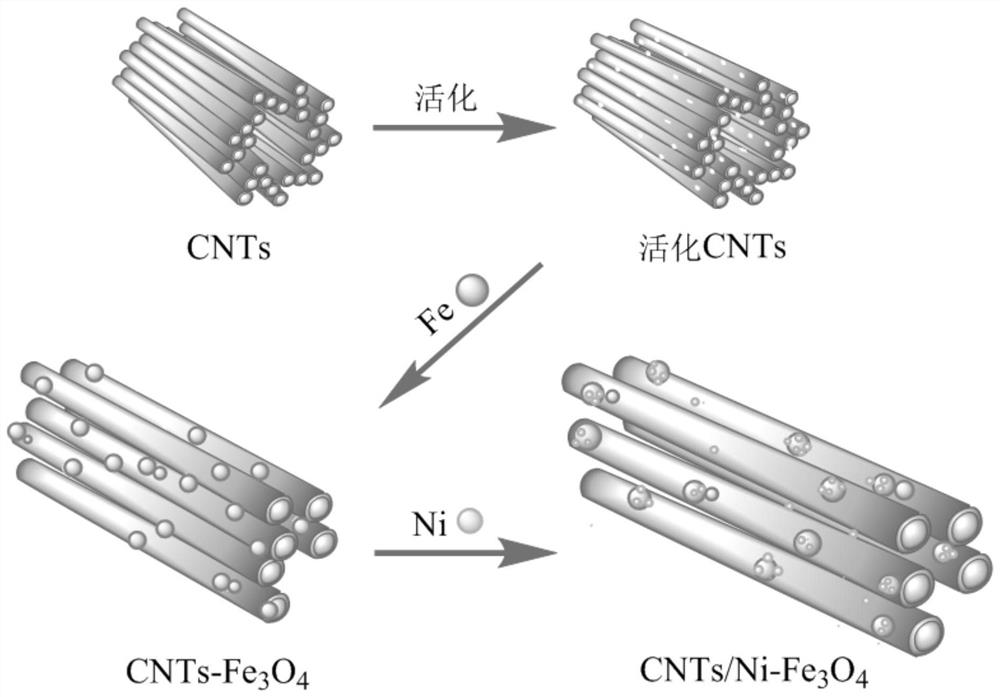

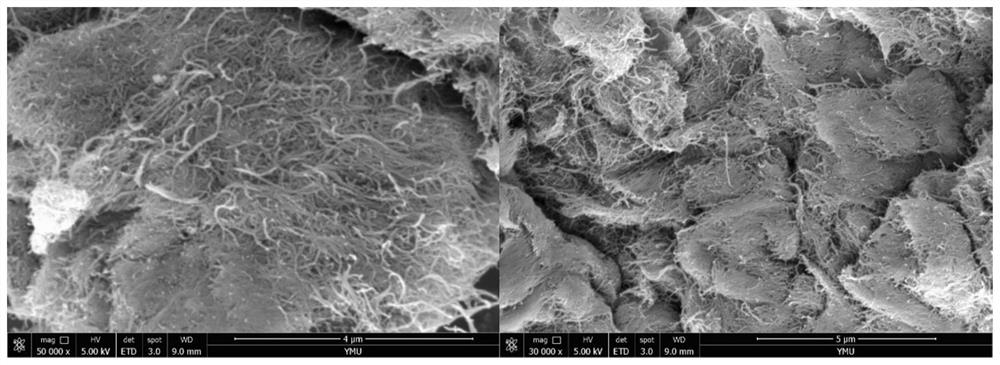

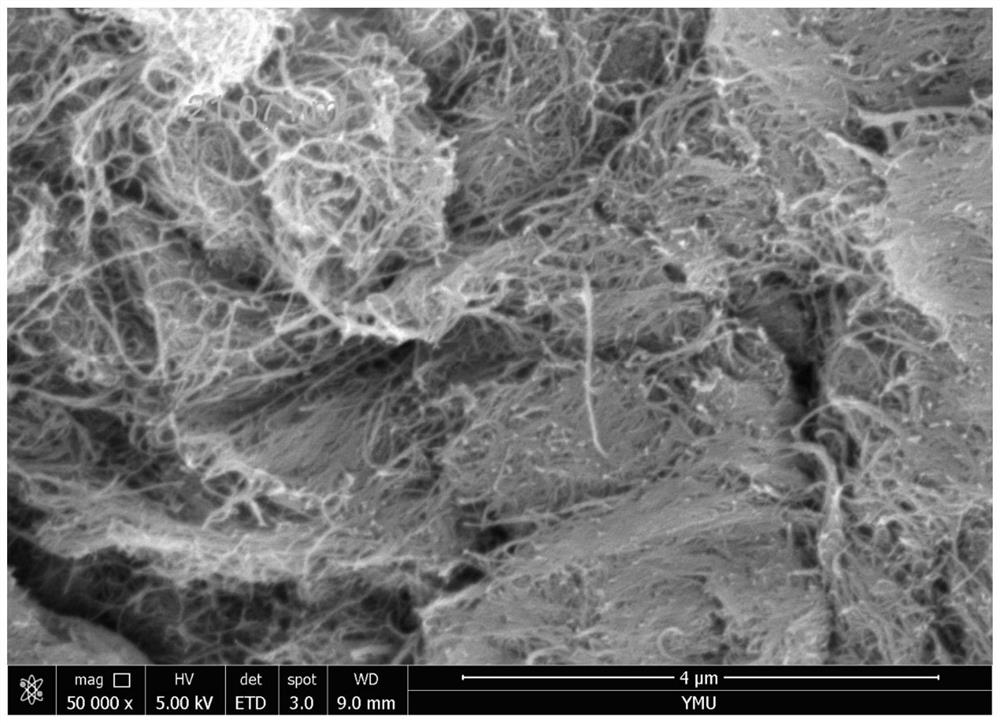

Preparation method of CNTs/Ni-Fe3O4 functional material

InactiveCN112185639AIncreased electron transport capacityHigh catalytic activityOther chemical processesMagnetic/electric field screeningPtru catalystMethane yield

The invention relates to a preparation method of a CNTs / NiFe3O4 functional material, and belongs to the technical field of functional nano composite materials and environmental biology. The preparation method of the CNTs / NiFe3O4 functional material comprises the following specific steps: purifying and activating multiwalled carbon nanotubes; preparing CNTsFe3O4: preparing the CNTs / NiFe3O4 nano composite material. The CNTs / NiFe3O4 functional material prepared by the invention is used as an efficient biological catalytic material and a wave-absorbing material, has the characteristics of promoting oxidation-reduction reaction and electron transfer, is used as a stabilizer and a catalyst in sewage treatment anaerobic digestion reaction, can improve the methane yield and produce biomass energy,can play a role once being added, and has a good application prospect. The catalyst is good in dispersity in a reactor and uniform and consistent in reaction, and can be recycled to save the cost.

Owner:KUNMING UNIV OF SCI & TECH

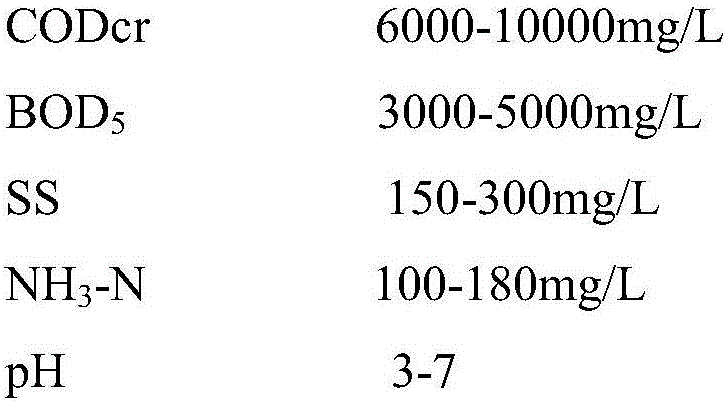

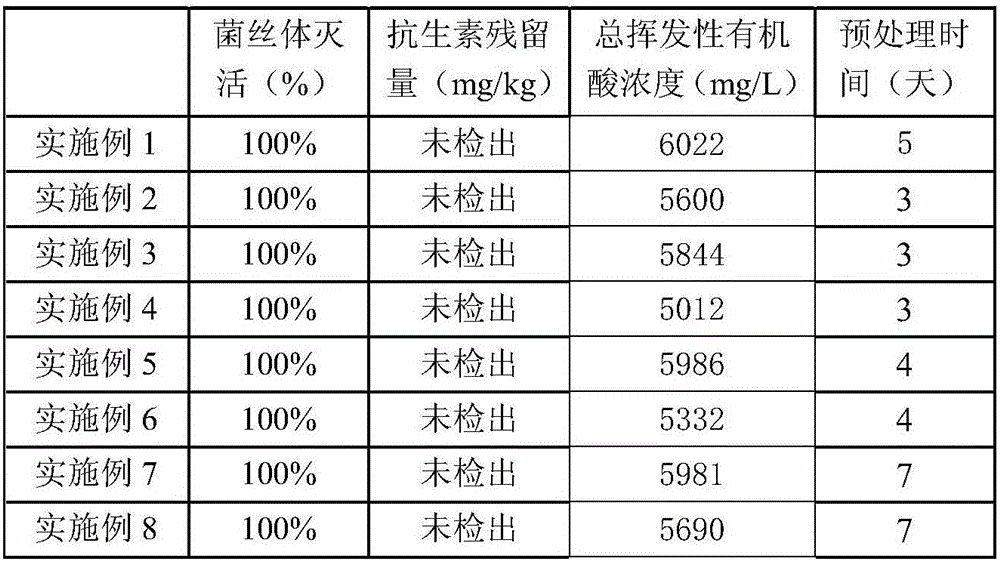

Pretreatment method of ferment antibiotic fungi residues

ActiveCN106480104AImprove metabolic activityAccelerated hydrolysis and acidificationWaste based fuelFermentationHigh concentrationMicroorganism

The invention discloses a pretreatment method of ferment antibiotic fungi residues. The pretreatment method comprises ultrahigh temperature reinforced acidogenic fermentation treatment of the ferment antibiotic fungi residues. Thermophilic hydrolysis acid-forming bacteria are used for performing high temperature anaerobic digestion treatment on the ferment antibiotic fungi residues, so that the fungi residues are hydrolyzed and acidified, antibiotic producing bacteria in the fungi residues are inactivated, and retained antibiotics are degraded. The fungi residues pretreated through the method can be directly subjected to subsequent biochemical treatment after being subjected to antibiotic removal. According to the method disclosed by the invention, the antibiotic producing bacteria can be completely killed, the antibiotics in the fungi residues can be removed, inhibition of high-concentration antibiotics to microorganisms is reduced, the difficulty in treatment of the fungi residues based on the subsequent biochemical method is reduced, generation of drug-resistant fungi and drug-resistant genes in the subsequent biochemical treatment is reduced, the harmless treatment efficiency of the antibiotic fungi residues is improved, and environmental protection is facilitated.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

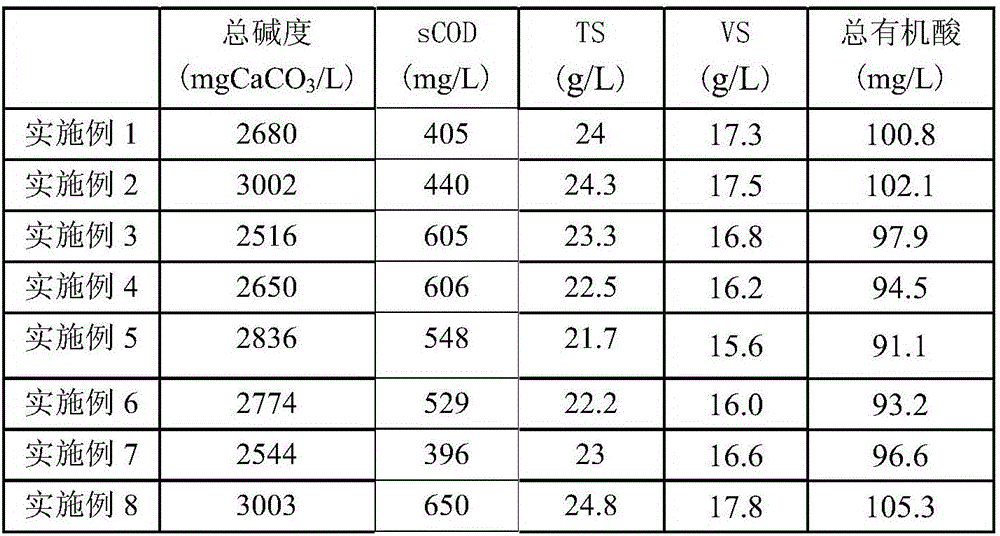

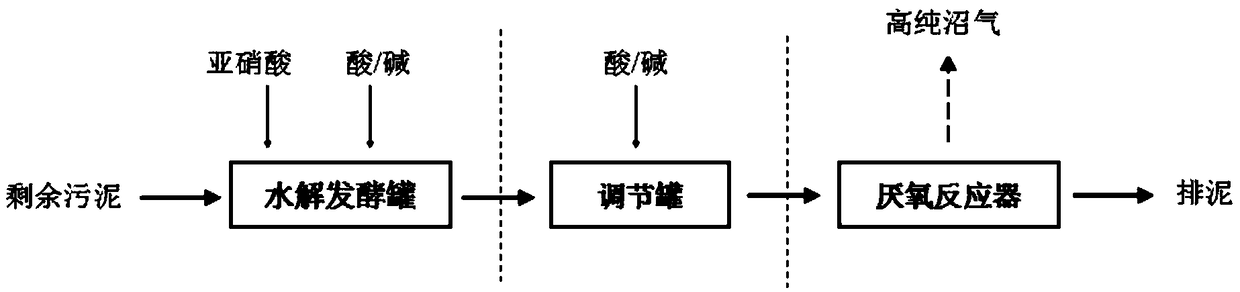

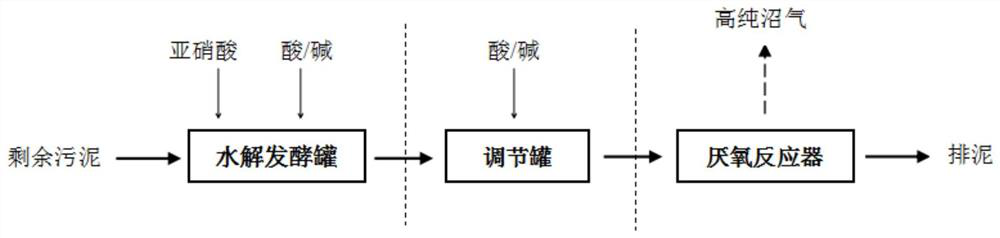

Method for improving methane purity in sludge anaerobic digestion generated biogas

ActiveCN108793656AImprove methane production efficiencyFacilitated releaseWater treatment parameter controlSludge treatment by oxidationLysisHydrogen

The invention provides a method for improving methane purity in a sludge anaerobic digestion generated biogas. The method comprises the following steps: concentrating organic sludge till a solid content is 20-40g / L; adding an additive, and controlling a pH value to 4.0-6.0, and carrying out a hydrolytic acidification reaction at 35-39 DEG C; adjusting the pH value of the sludge after hydrolytic acidification to 6.0-6.5, carrying out an anaerobic digestion reaction, and collecting a biogas. By adopting the method, calcium nitrite is adopted as the additive, so that sludge lysis and hydrolysis acidification can be improved, the anaerobic acid generation velocity of the sludge is greatly increased, furthermore, the sludge anaerobic digestion efficiency is improved; due to the addition of thecalcium nitrite, a function of blocking carbon is also achieved, the concentration of carbon dioxide in the biogas is also reduced, and the purity of methane is improved; as the pH value is adjusted twice, both acidic hydrolysis of the sludge under the action of the calcium nitrite is improved, and growth of hydrogen type methanogens in an anaerobic methanogenesis period is facilitated, the potential that the carbon dioxide is in reaction with hydrogen to generate the methane is improved, and the purity of the methane in the biogas is further improved.

Owner:SHANGHAI JIAO TONG UNIV

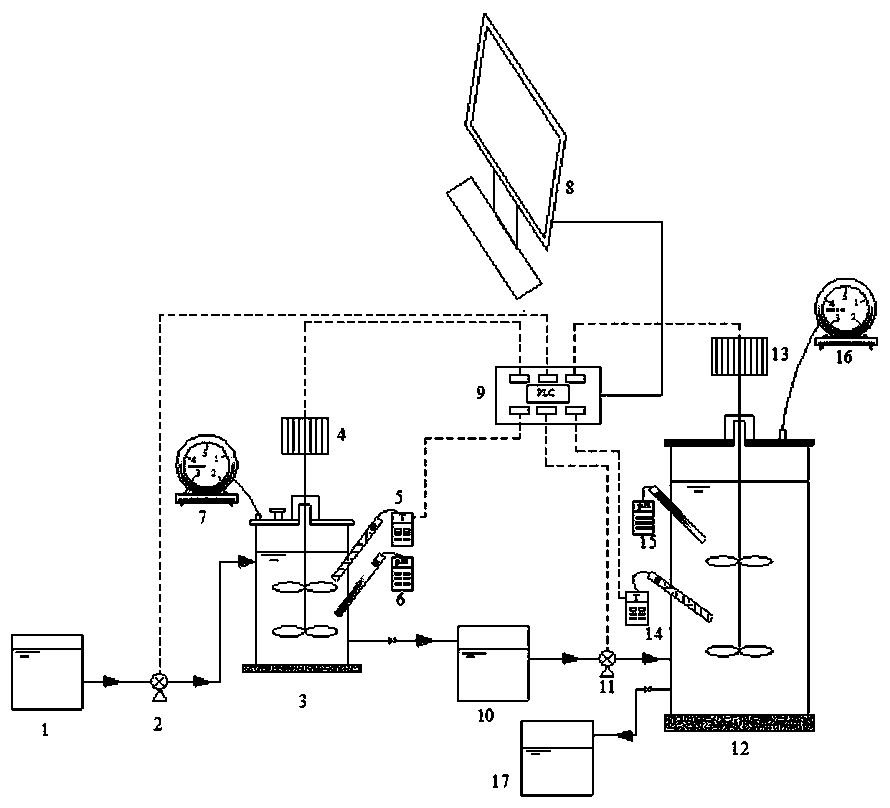

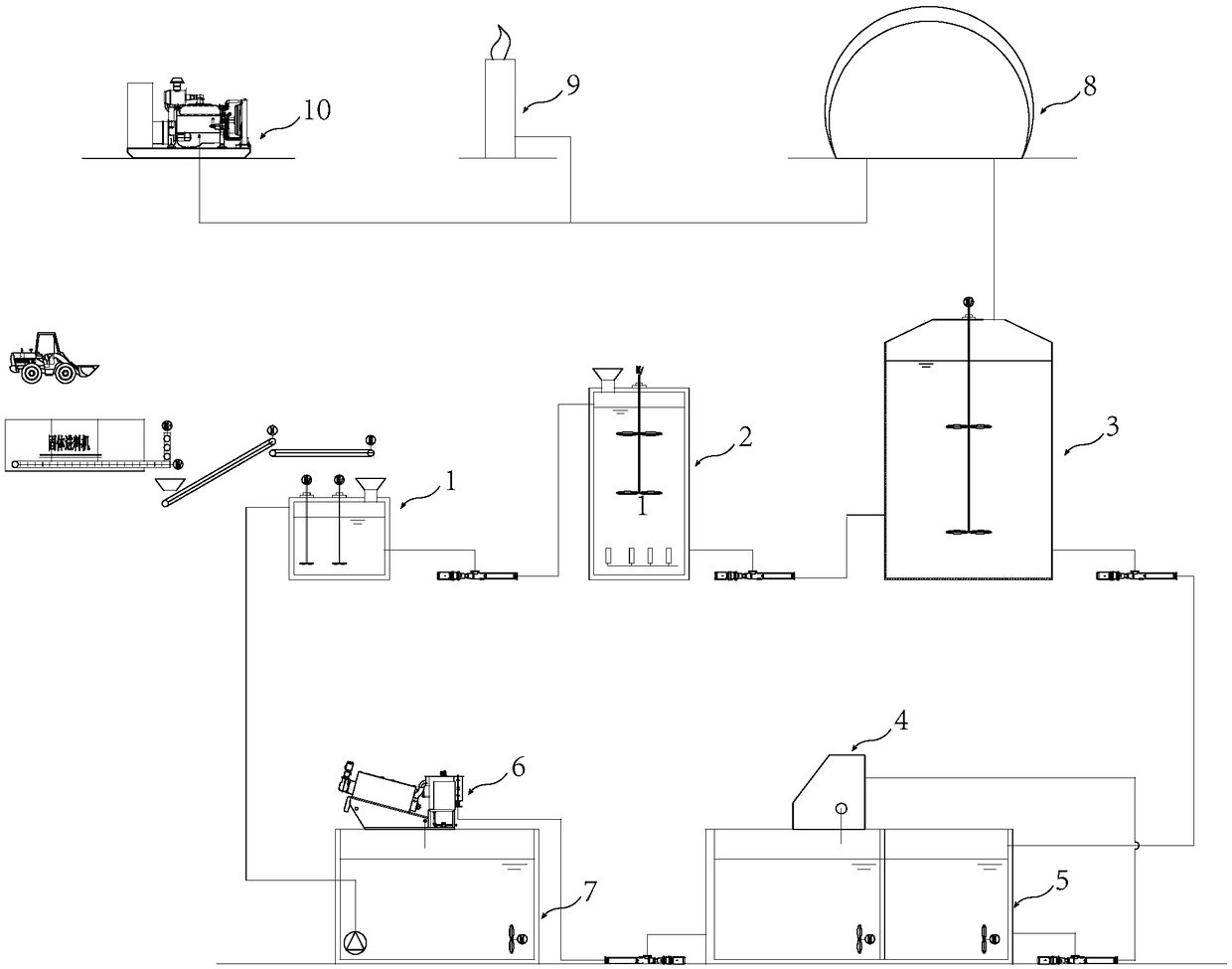

Sludge and kitchen waste co-digestion system and operation method thereof

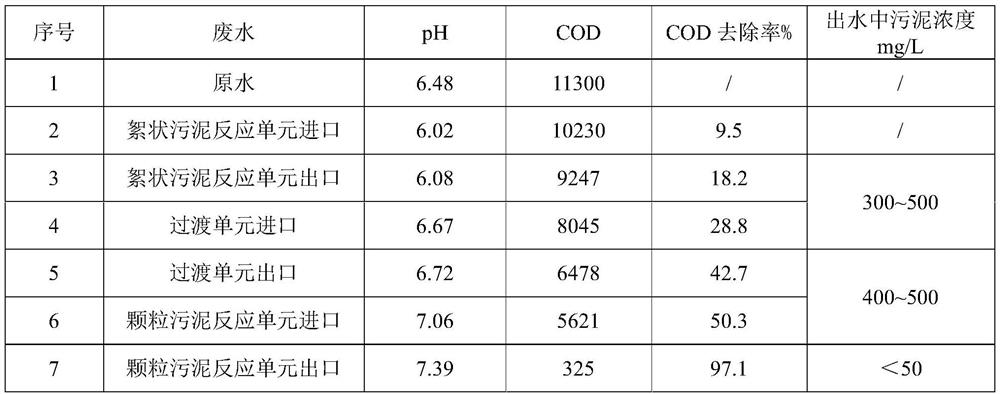

PendingCN109401947AHigh removal rateAccelerated hydrolysis acidificationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpSludge

The invention discloses a sludge and kitchen waste co-digestion system. A mixture storage tank is connected with a high-temperature fermentation tank through a first peristaltic pump; the high-temperature fermentation tank is connected with a cooling adjusting tank; the cooling adjusting tank is connected with a middle-temperature methane-producing reactor through a second peristaltic pump; the middle-temperature methane-producing reactor is connected with a digested mixture storage tank. According to the sludge and kitchen waste co-digestion system, sludge is uniformly mixed with kitchen waste at first; then an obtained mixture is pumped into the high-temperature fermentation tank to be subjected to hydrolytic acidification; finally, a sludge and kitchen waste fermentation mixture is pumped into the middle-temperature methane-producing reactor to produce methane. According to the method, a hydrolytic acid production phase and a methane production phase of a co-digestion process are carried out in two reactors; high temperature is controlled at the hydrolytic acid production phase and middle temperature is controlled at the methane production phase. The hydrolytic acid production efficiency is improved; meanwhile, an optimal living environment is provided for hydrolytic acid production bacteria and methane production bacteria; the inhibition, caused by the fact that sludge andkitchen waste single-phase co-digestion short-chain fatty acid (SCFAs) is excessively accumulated, on a methane production process is avoided.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

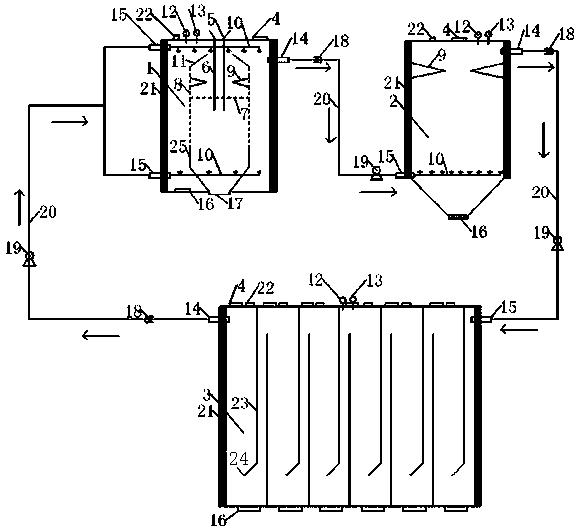

Reaction system suitable for organic solid waste resource utilization

ActiveCN108485945AAvoid accumulationAvoid competitionBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeResource utilization

The invention relates to a reaction system suitable for organic solid waste resource utilization and belongs to the field of solid waste anaerobic biological treatment. The problems that in the priorart, the reaction process is easy to acidify, and the fermentation efficiency and the gas producing efficiency are low can be solved. The reaction system suitable for organic solid waste resource utilization comprises a high-temperature hydrolysis fermentation reaction device, a medium-temperature acidification fermentation reaction device and a methane fermentation reaction device; a hydrolysis dominant bacterial community, an acid producing dominant bacterial community and a methane producing dominant bacterial community are formed in the three independent reaction devices respectively, andthe best conditions required by the growth of the communities respectively are provided, so that the fact that the reaction devices cannot operate normally caused by the acidification phenomenon can be avoided effectively. Each device injects biogas liquid into the next reaction device through a jet pump on a connecting pipe and through a water distribution device, so that the reaction devices canbe stirred completely, the contact area of reaction substrates and sludge is enlarged, the problems in mechanical stirring that failure is liable to occur and energy consumption is high are reduced,the biogas liquid circulating aim can be fulfilled, the organic solid waste can be fermented completely again, and biogas residues are reduced.

Owner:TAIYUAN UNIV OF TECH

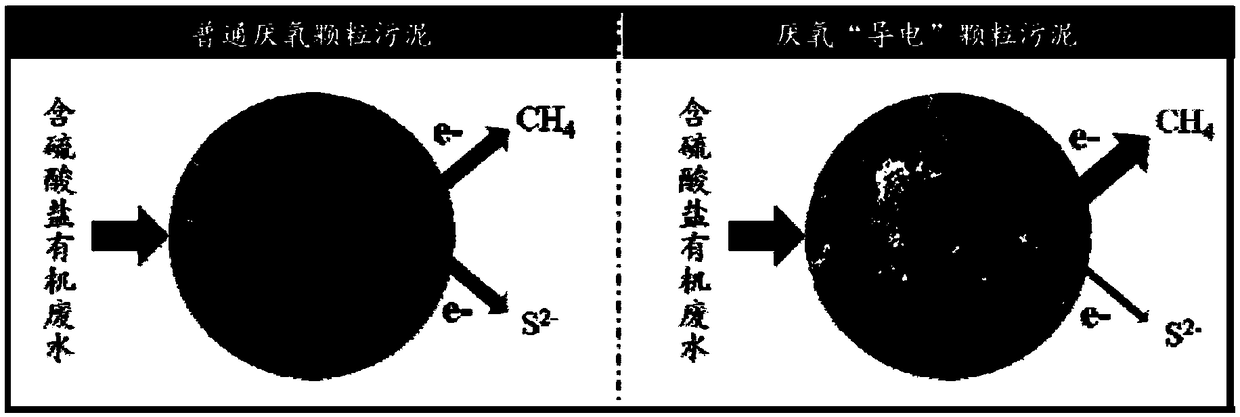

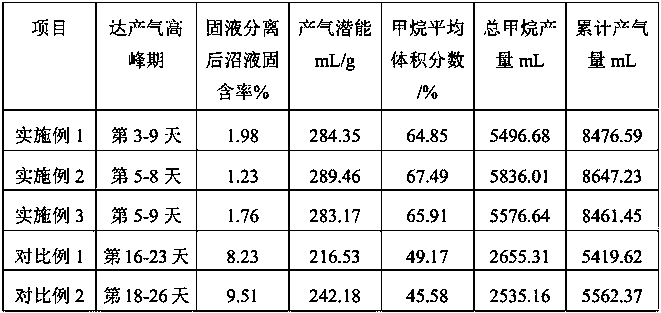

Method for improving methane production efficiency of sulfate organic wastewater

InactiveCN109231449AImprove methane production efficiencyEasy to solveTreatment by combined electrochemical biological processesWater contaminantsCarbon nanotubeEnvironmental chemistry

The invention discloses a method for improving methane production efficiency of sulfate organic wastewater. The method comprises the following steps: taking anaerobic sludge; adding single-wall carbonnanotubes into the anaerobic sludge to form a mixed layer; then enabling the sulfate organic wastewater to pass through the mixed layer under an anaerobic environment; recycling methane generated inthe wastewater. Compared with the prior art, the method disclosed by the invention has the advantages that the single-wall carbon nanotubes are added to from anaerobic conductive particle sludge, andthe methane production efficiency of the sulfate organic wastewater can be remarkably improved; the methane yield can be improved by 20 to 30 percent. Furthermore, operation characteristics of a UASB(Upflow Anaerobic Sludge Blanket) are utilized and the carbon nanotubes be remained in a reaction system for a long period; a procedure of continuously adding the carbon nanotubes is avoided, so thata technology is simplified and the maintenance cost is reduced.

Owner:NANJING NORMAL UNIVERSITY

Technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials

InactiveCN108866110ASolve efficiency problemsSolve concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseOxygen

The invention belongs to the technical field of a biogas preparation method, and provides a technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials. The technology method comprises the following steps of material pulping, biological treatment, facultative hydrolyzing and acid production, anaerobic fermenting, solid and liquid separating, refluxing and the like. The technology method solves the problems of low pretreatment efficiency of the lignocellulose-rich materials, overhigh concentration of reflux biogas, and low biogas productionefficiency in the prior art.

Owner:河北京安瑞能环境科技有限公司

Method for producing methane by reinforcing anaerobic fermentation of cow dung through heat-alkali combined pretreatment

PendingCN113387526AHigh methane contentImprove methane production efficiencySludge treatment by thermal conditioningSpecific water treatment objectivesBiotechnologyMethane yield

The invention belongs to the technical field of solid waste recycling, and relates to a method for producing producing methane by reinforcing anaerobic fermentation of cow dung through heat-alkali combined pretreatment. According to the method, after the cow dung is subjected to alkali pretreatment, degradation of refractory organics such as hemicellulose, cellulose and lignin which are not completely digested in the cow dung can be increased; and heat pretreatment is carried out while the alkali pretreatment is carried out, so the dissolution of organic matters such as protein and polysaccharide in the cow dung in water can be remarkably improved, and a large amount of soluble organic matters are provided for acid production and methane production stages of anaerobic fermentation of the cow dung. According to the method, the content of soluble organic matters can be increased by utilizing the heat-alkali combined pretreatment of the cow dung, and methane yield can be maximized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

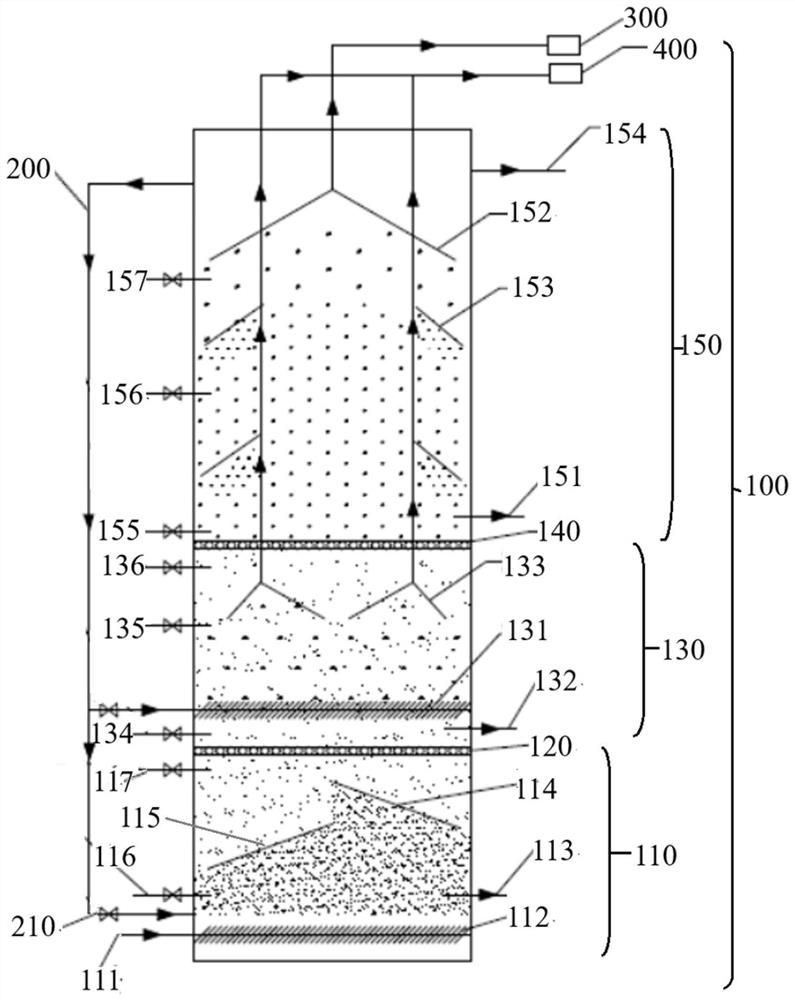

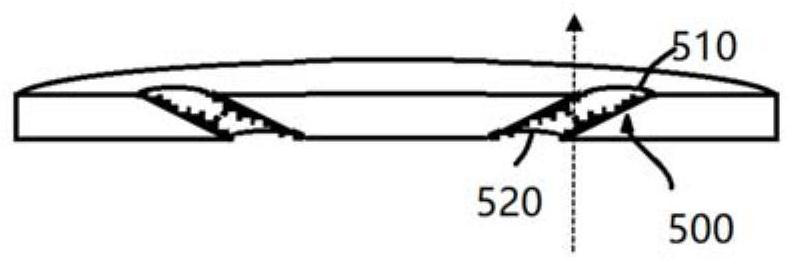

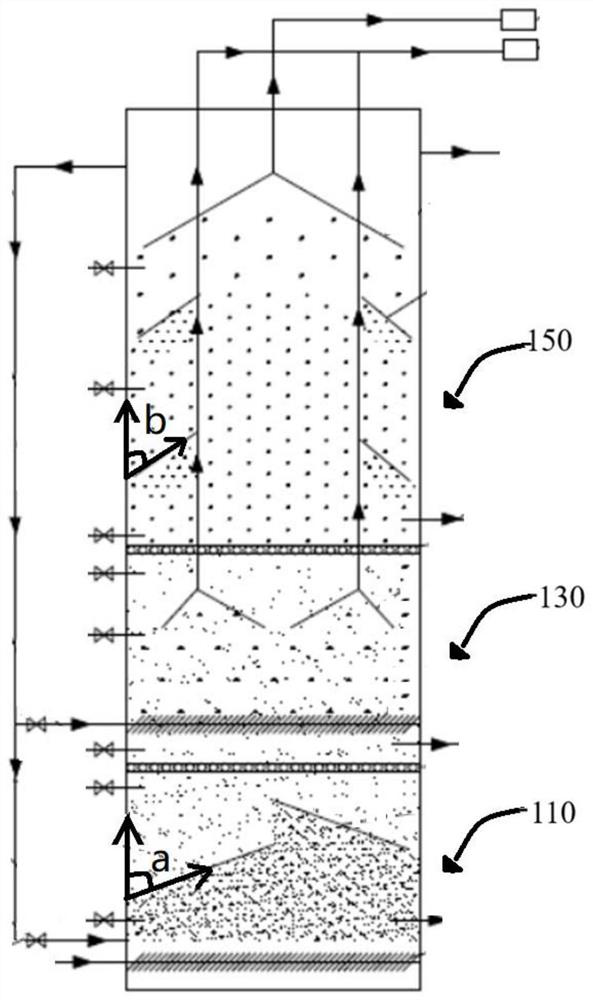

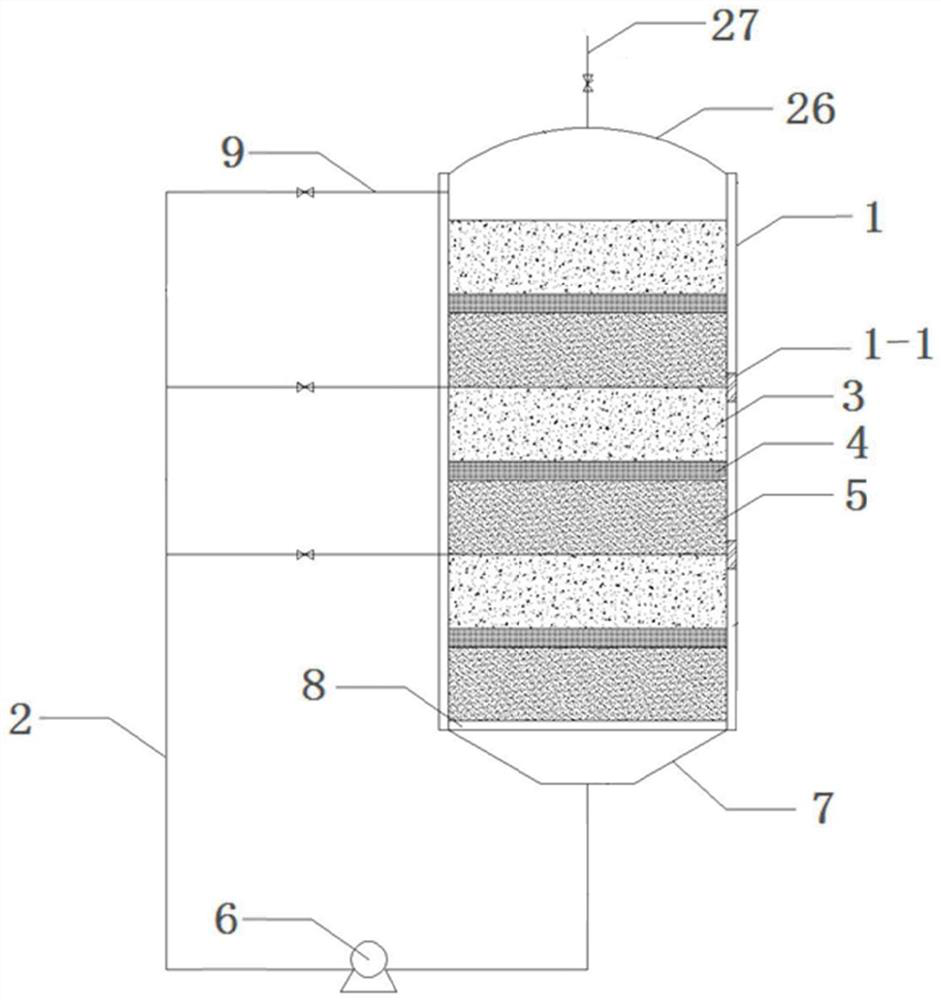

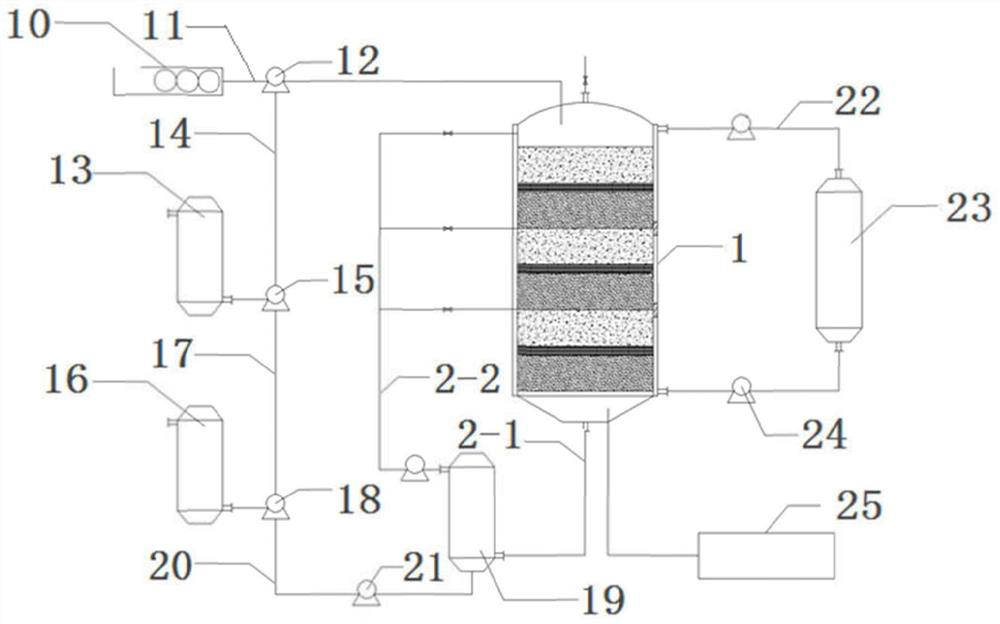

Built-in block anaerobic reactor for organic wastewater

ActiveCN112939216AImprove methane production efficiencyImprove reaction efficiencyBioreactor/fermenter combinationsWater treatment parameter controlAnaerobic reactorWater processing

The invention discloses a built-in block anaerobic reactor for organic wastewater, and belongs to the technical field of water treatment. The built-in block anaerobic reactor comprises a reactor and a circulating pipeline, a water inlet is formed in one end of the reactor, a water outlet is formed in the other end of the reactor, and a flocculent sludge area used for being filled with flocculent sludge, a transition area used for containing the flocculent sludge and granular sludge and a granular sludge area used for being filled with the granular sludge are sequentially arranged in the reactor in the direction from the water inlet to the water outlet; a three-phase separation system is arranged in each of the granular sludge area and the transition area; effluent of the reactor flows back to the flocculent sludge area or the flocculent sludge area and the transition area through a circulating pipeline; or the effluent of the reactor flows back to the flocculent sludge area or the flocculent sludge area and the transition area through a circulating pipeline provided with a metering pump.

Owner:NANJING UNIV +1

Method for producing methane from high-concentration phenol-containing wastewater

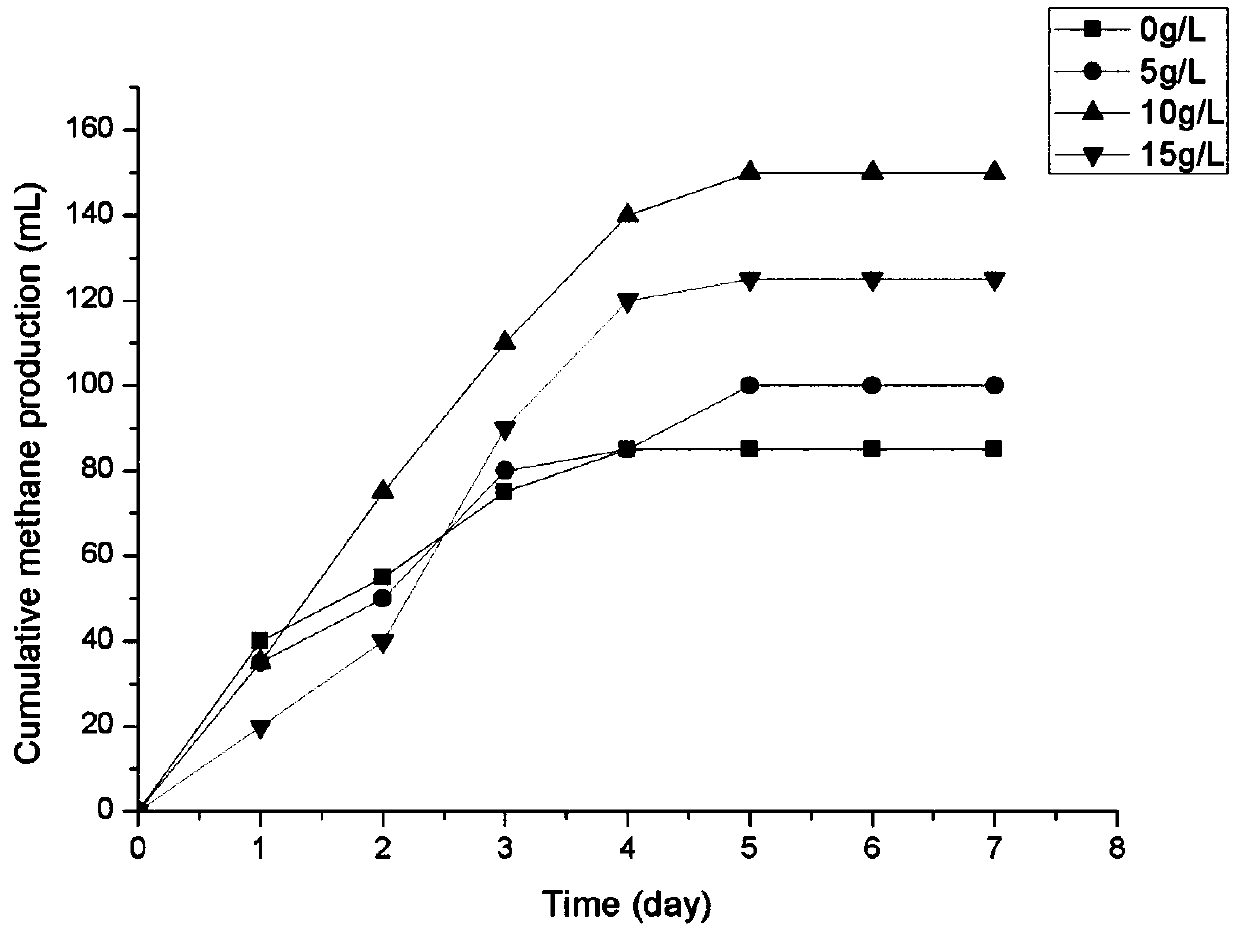

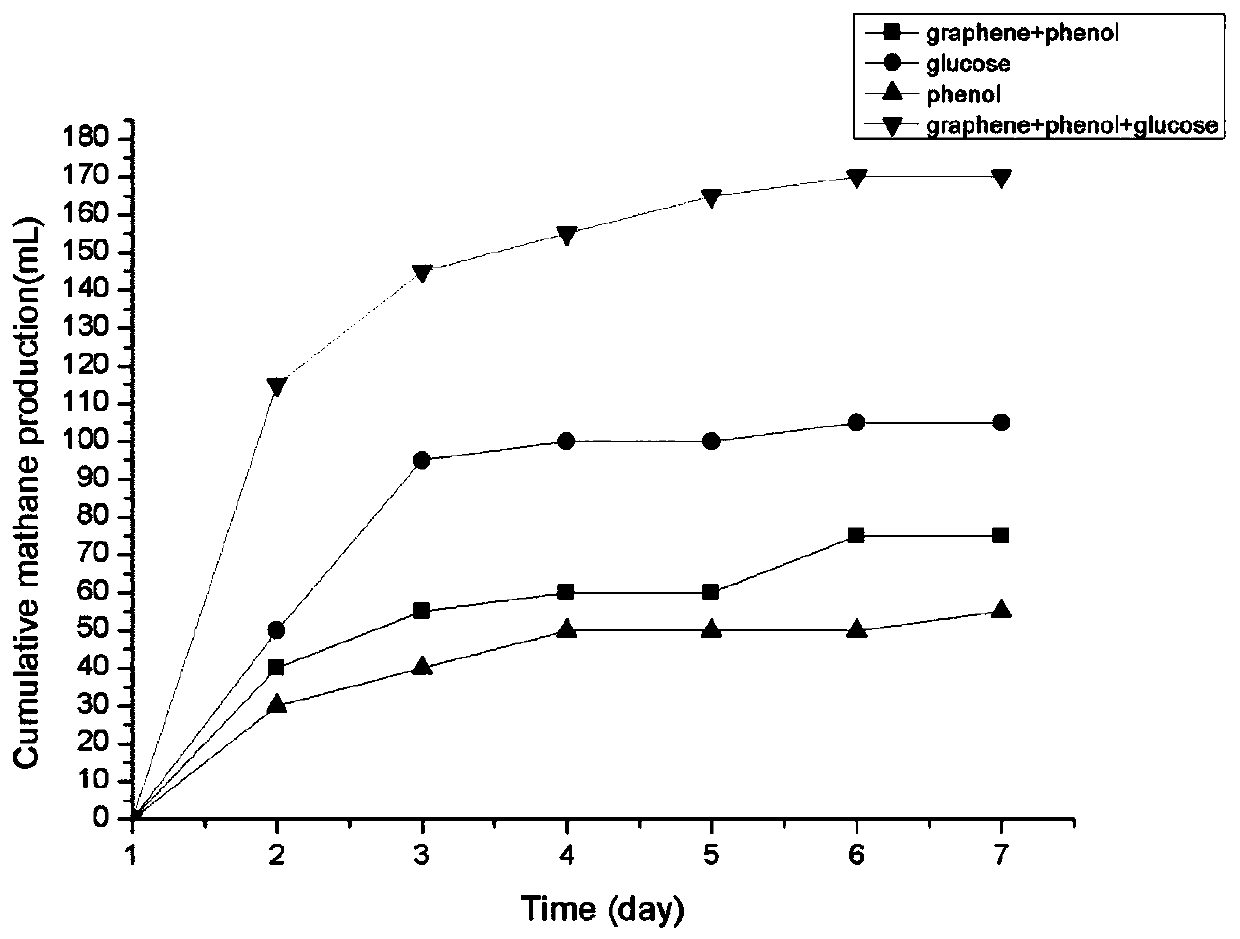

InactiveCN110606562AIncrease dosageEasy transferWater treatment parameter controlWater treatment compoundsHigh concentrationMethane yield

The invention discloses a method for producing methane from high-concentration phenol-containing wastewater. The method comprises the following steps: adding 9.8-10.5 g / L of graphene into an anaerobicbiofilter reactor; then with a mixed solution of high-concentration phenol-containing wastewater and a glucose solution as an inflow water sample, enabling the inflow water sample to enter the anaerobic biofilter reactor from the bottom and carrying out anaerobic digestion reaction, and collecting generated gas from the top; wherein the concentration of the glucose solution ranges from 1865 mg / Lto 2130 mg / L. According to the method for producing methane from high-concentration phenol-containing wastewater, an anaerobic co-metabolism enhancement technology and graphene are applied to anaerobic treatment of wastewater, so that the yield of methane produced by anaerobic digestion of phenol-containing wastewater is increased.

Owner:SUZHOU UNIV OF SCI & TECH

Method for improving straw high-solid anaerobic digestion to produce methane

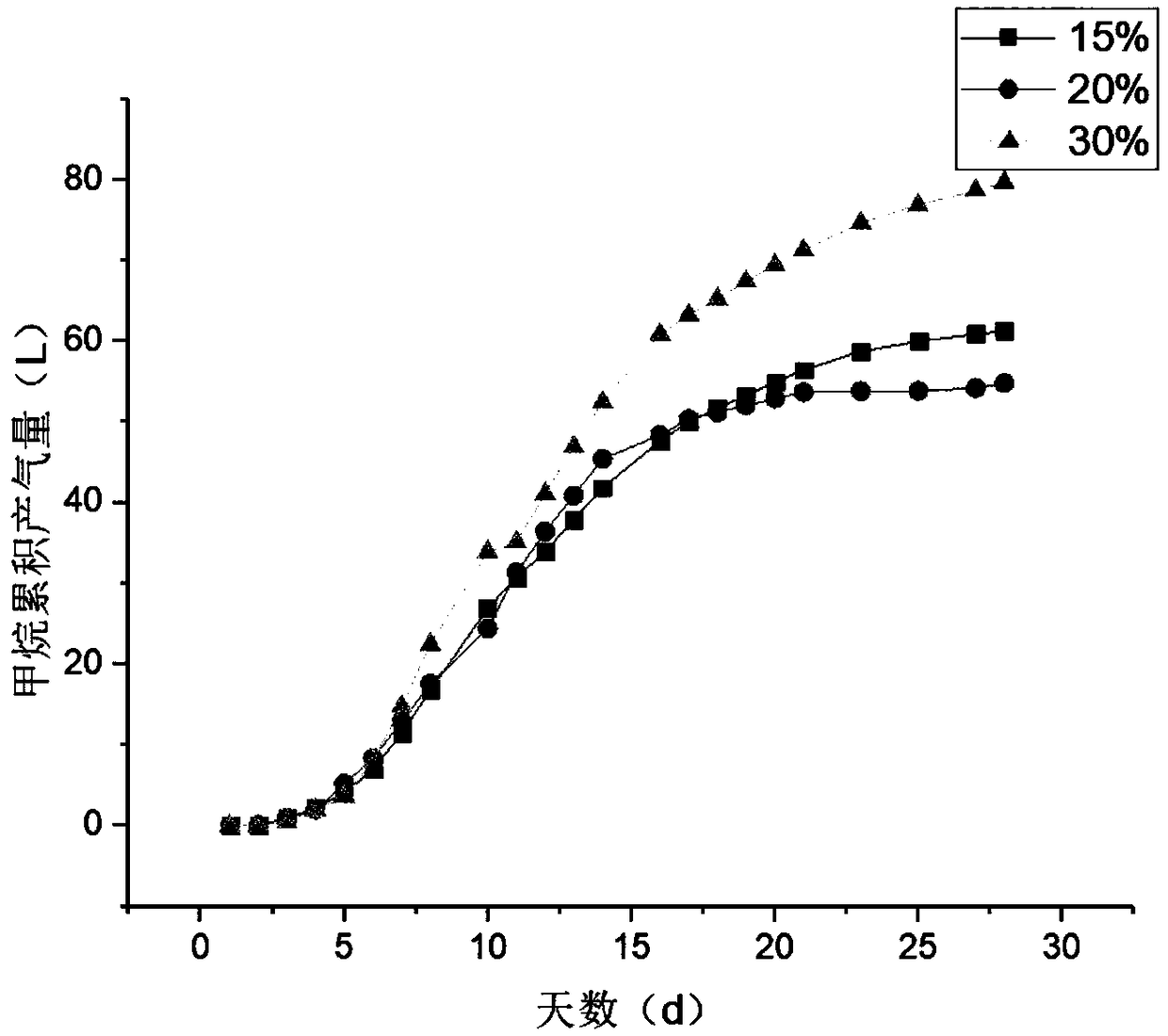

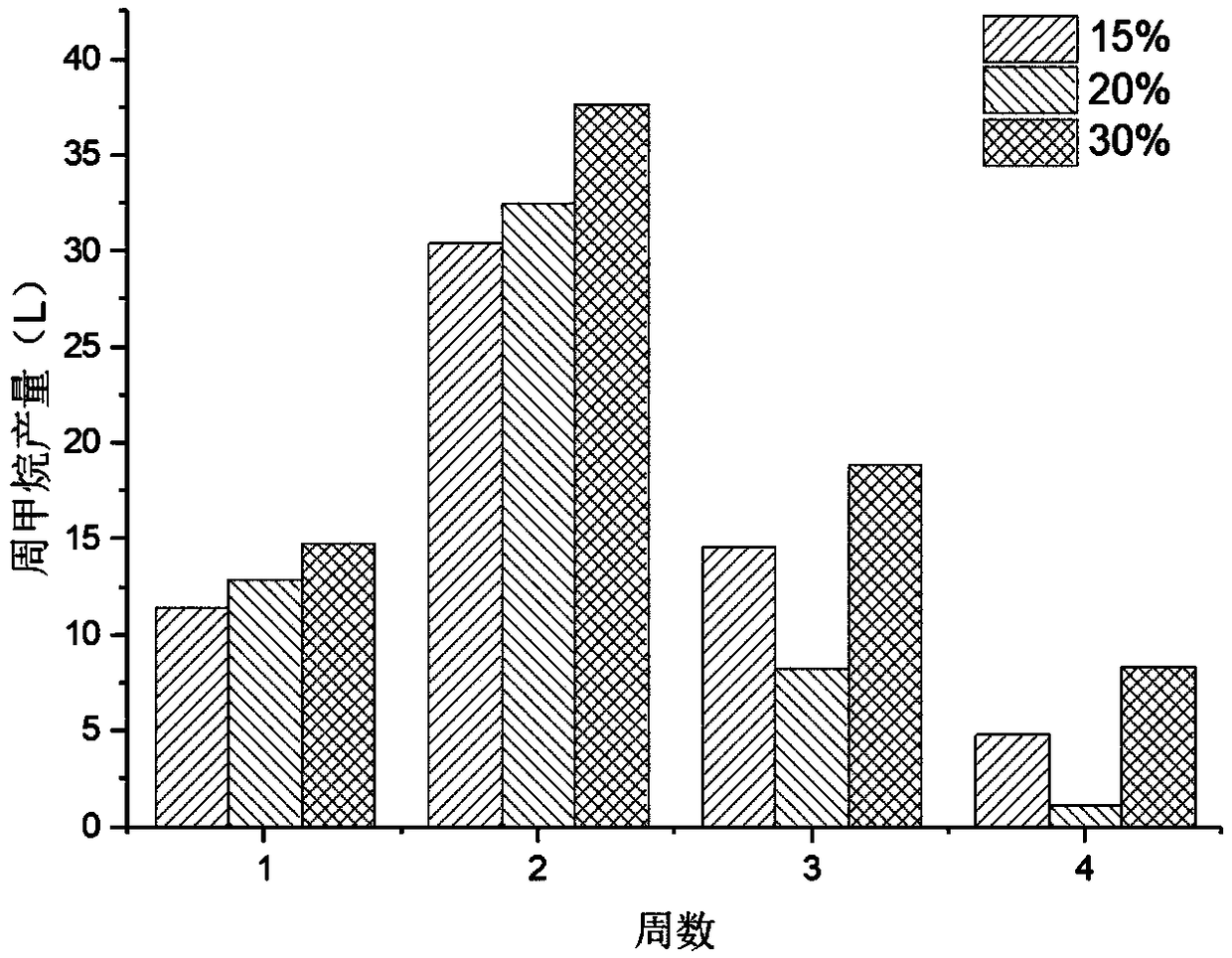

ActiveCN108949835AImprove methane production efficiencyOptimizing Process ParametersWaste based fuelFermentationMicroorganismAnaerobic reactor

The invention provides a method for improving straw high-solid anaerobic digestion to produce methane. The method comprises the following steps: (1) immersing ensiling straws into an inoculating solution and pre-mixing, wherein the solid content of the ensiling straws is 20 to 30 percent; (2) adding the mixture obtained by step (1) into a garage type anaerobic reactor, so as to carry out anaerobicdigestion on the mixture to produce the methane; and (3) refluxing biogas slurry back to the top of the garage type anaerobic reactor in an anaerobic digestion process, and spraying the biogas slurryinto the reactor to realize mass transfer. According to the method provided by the invention, a suitable spraying method is preferred for a refluxing system of a high-solid anaerobic digestion system, the mass transferring efficiency can be effectively improved, the contact between a substrate and a microorganism is reinforced and the growth and enrichment of the microorganisms in an anaerobic digestion system are promoted, so that the efficiency of producing the methane through the anaerobic digestion is improved. By adopting the method provided by the invention, energy consumption is reduced to the greatest extent; meanwhile, the water content in biogas residues is greatly reduced and subsequent composting and the like are convenient to realize.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A method for recycling agricultural waste straw

ActiveCN104445187BTake advantage ofPromote growthCarbon compoundsWaste based fuelActivated sludgePotassium

The invention discloses a method for recycling waste crop straw. The method comprises the following steps: (1) smashing crop straw, namely cutting the crop straw into sections, and blasting at the pressure of 0.2-2.0MPa for 0.5-1 minute with steam, wherein each section of the crop straw has a length of 3-15cm; (2) fermenting, namely adding ammonia, peptone, bran and chopped peanut shells into the blasted crop straw sections, regulating the molar ratio of carbon to nitrogen (C to N) to 20:30, adding activated sludge from a methane-generating pit, and carrying out solid state fermentation at a temperature of 20-55 DEG C for 10-20 days until combustible gases are generated; and (3) squeezing fermented waste residue to remove part of water, mixing with unfermented smashed crop straw, phosphoric acid or potassium chloride, drying a mixture until water left therein is not more than 10%, molding by extruding, carbonizing, activating with steam, cooling, and smashing to obtain activated carbon, wherein the raw materials molded by extruding contain 90-95% of fermented waste residue, 5-10% of unfermented smashed crop straw, 1-5% of phosphoric acid or potassium chloride and the balance of water, and the crop straw is wheat straw, rice straw, corn straw or soybean straw.

Owner:南通汉森农业科技有限公司

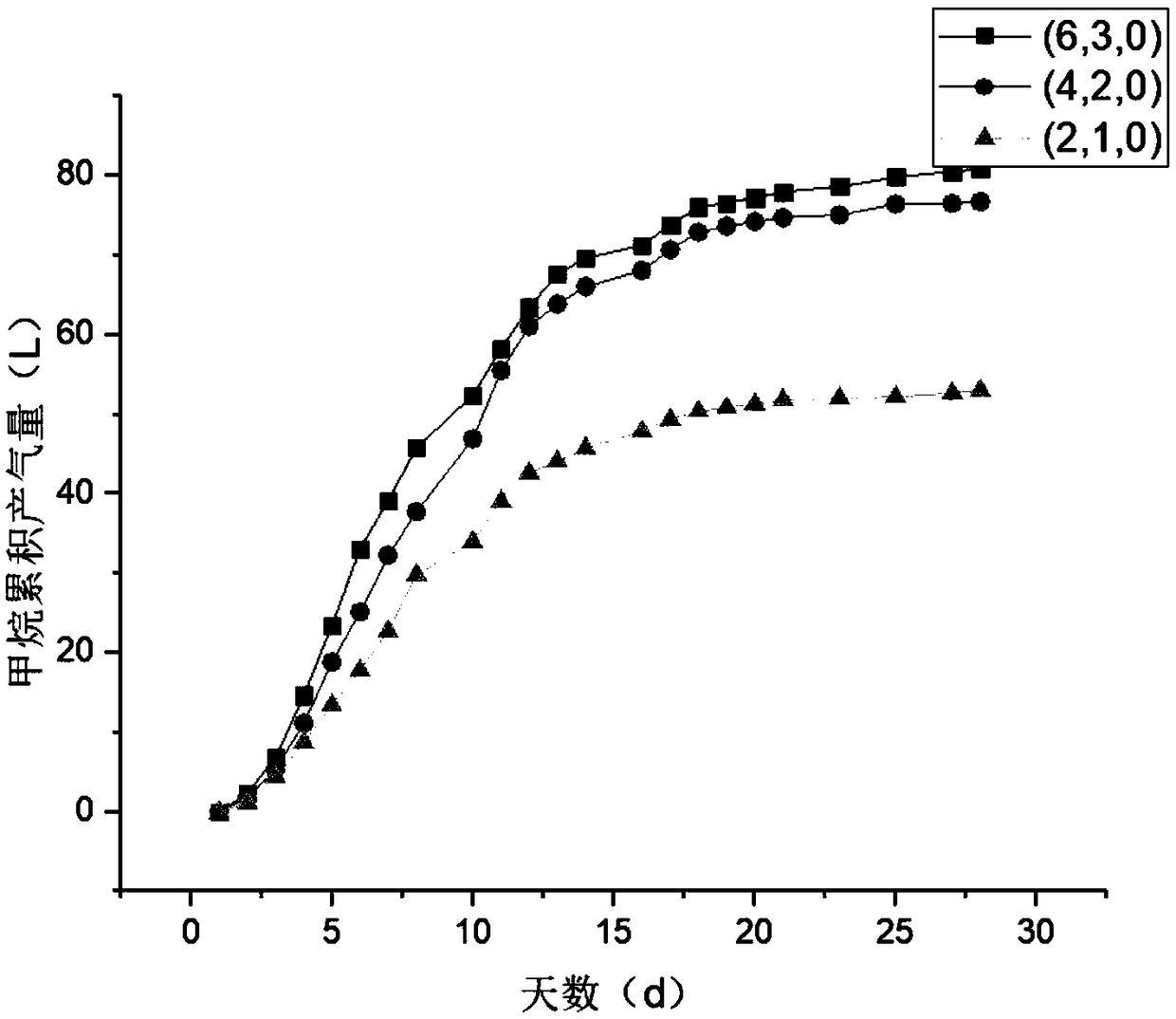

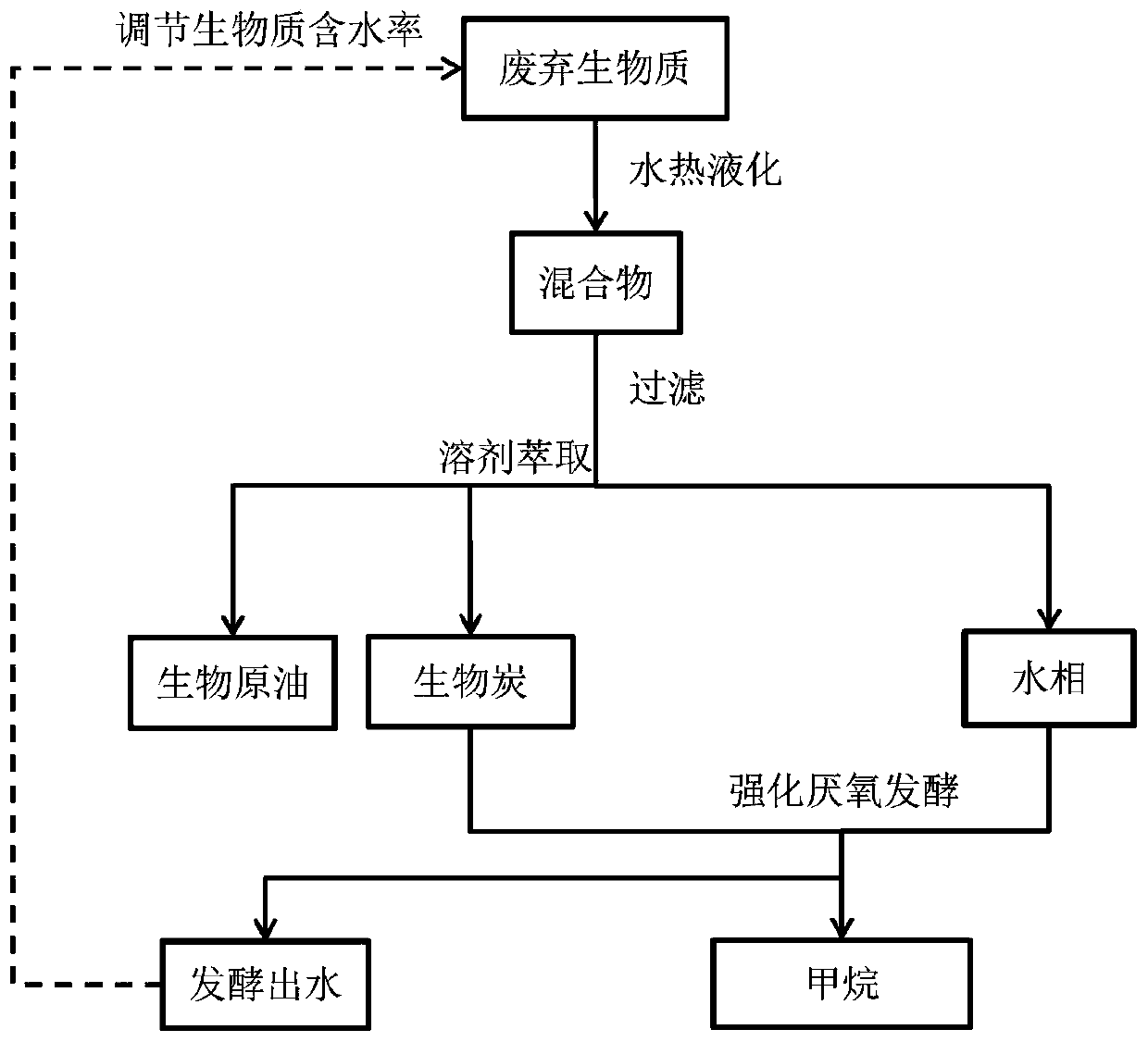

Method for producing bio crude oil and methane jointly from waste biomass

InactiveCN110551767AAchieve high valueEase the crisisWaste based fuelLiquid hydrocarbon mixture productionMethanationElectron transfer

The invention relates to the technical field of harmless treatment of waste biomass, in particular to a method for producing bio crude oil and methane jointly from waste biomass. Pathogenic bacteria in the waste biomass are killed through a hydrothermal liquefaction reaction in the method provided by the present invention, while high value of the biomass and harmless treatment are achieved; and atthe same time, the obtained biochar has more microporous structure in the hydrothermal liquefaction process. Through the enhanced anaerobic fermentation treatment of the aqueous phase through the above biochar, the acid inhibition and ammonia inhibition during the anaerobic fermentation process can be alleviated, the electron transfer during the fermentation process can be accelerated, the start-up period can be shortened, the stability of the system can be enhanced, the methanation process of anaerobic fermentation can be promoted, and the methane production efficiency can be improved to a large extent. Furthermore, the content of COD in the aqueous phase is effectively reduced, so that no waste is discharged in the whole process, full utilization of carbon resources is basically achieved, the energy crisis is relieved, air pollution is reduced, and the environment is protected.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

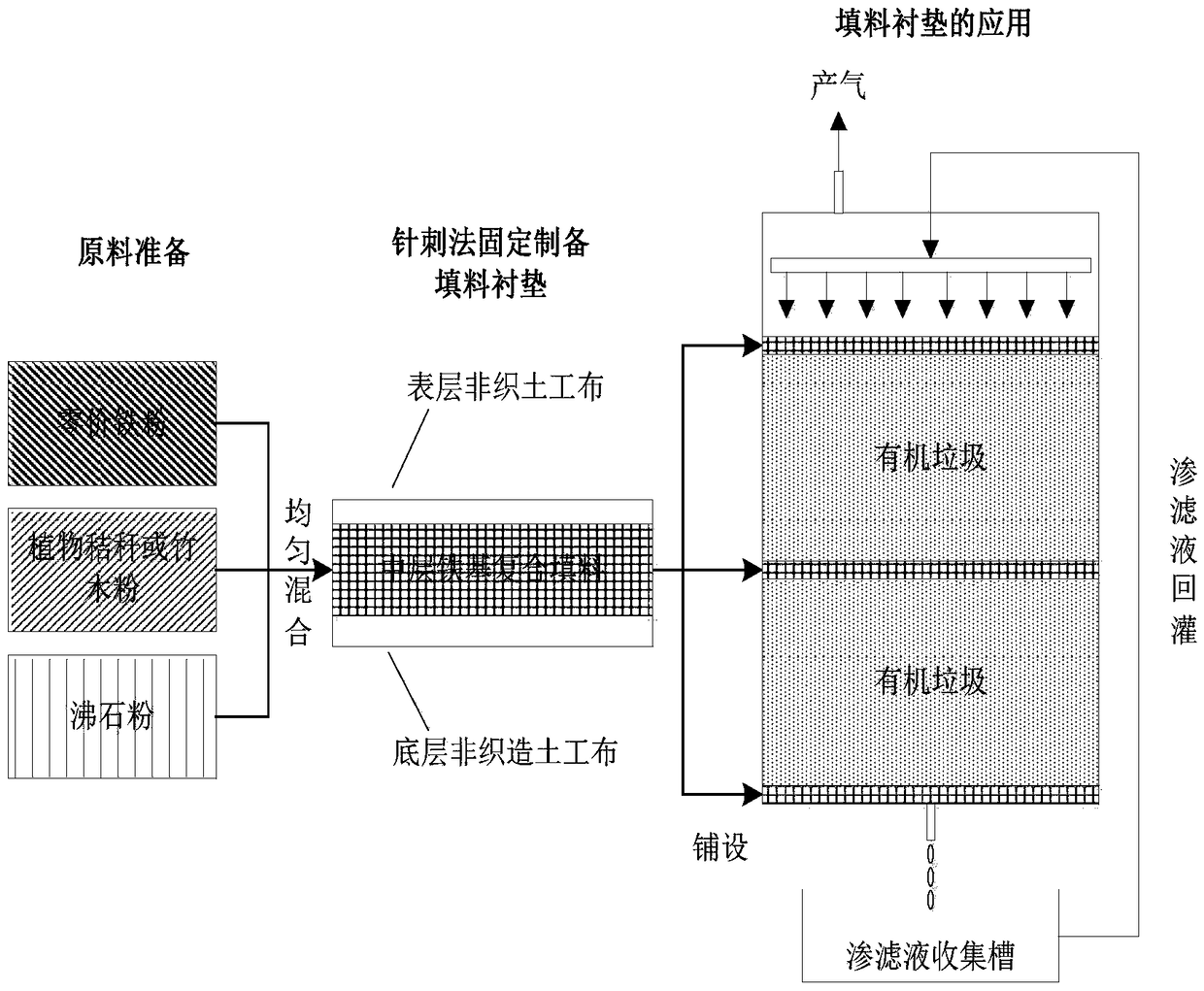

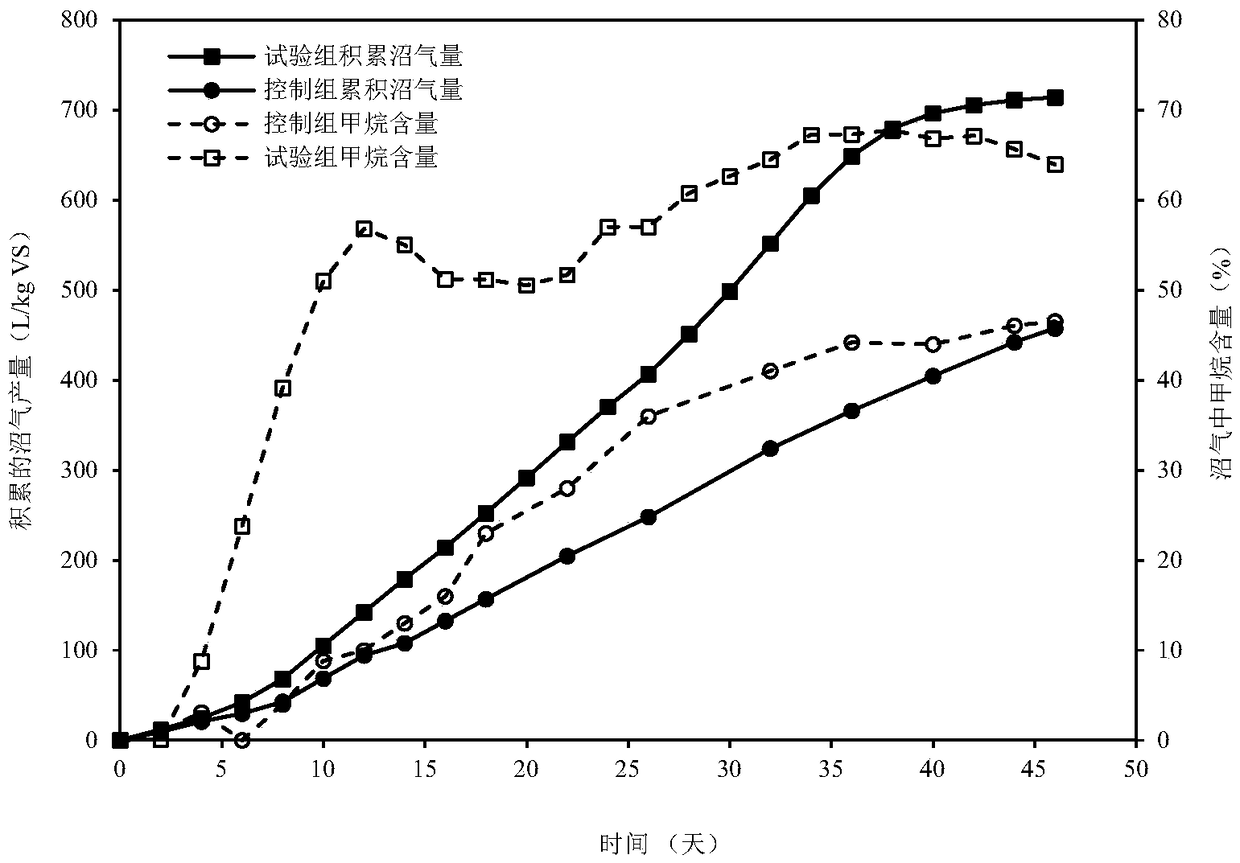

Packing liner for anaerobic dry fermentation of organic waste as well as preparation method and application of packing liner

InactiveCN109161564AImprove methane production efficiencyImprove metabolic activityWaste based fuelFermentationChemistryIron based

The invention discloses a packing liner for anaerobic dry fermentation of organic waste as well as a preparation method and an application of the packing liner. The packing liner is prepared by the step that nonwoven geotextiles wrap iron-based composite packing which is fixed with a needle-punching method, wherein the iron-based composite packing is prepared from 60%-65% by mass of zero-valent iron powder, 25%-30% by mass of crop stalks or bamboo powder and 5%-15% by mass of zeolite powder by mixed compounding. With the adoption of the packing liner, many defects of mixed addition of zero-valent iron in a traditional anaerobic dry fermentation process of the organic waste are overcome, the application is simple, the reliability is high, methane production efficiency of an anaerobic systemis effectively improved, and energy regeneration development of the organic waste is promoted.

Owner:BEIJING GEOENVIRON ENG & TECH

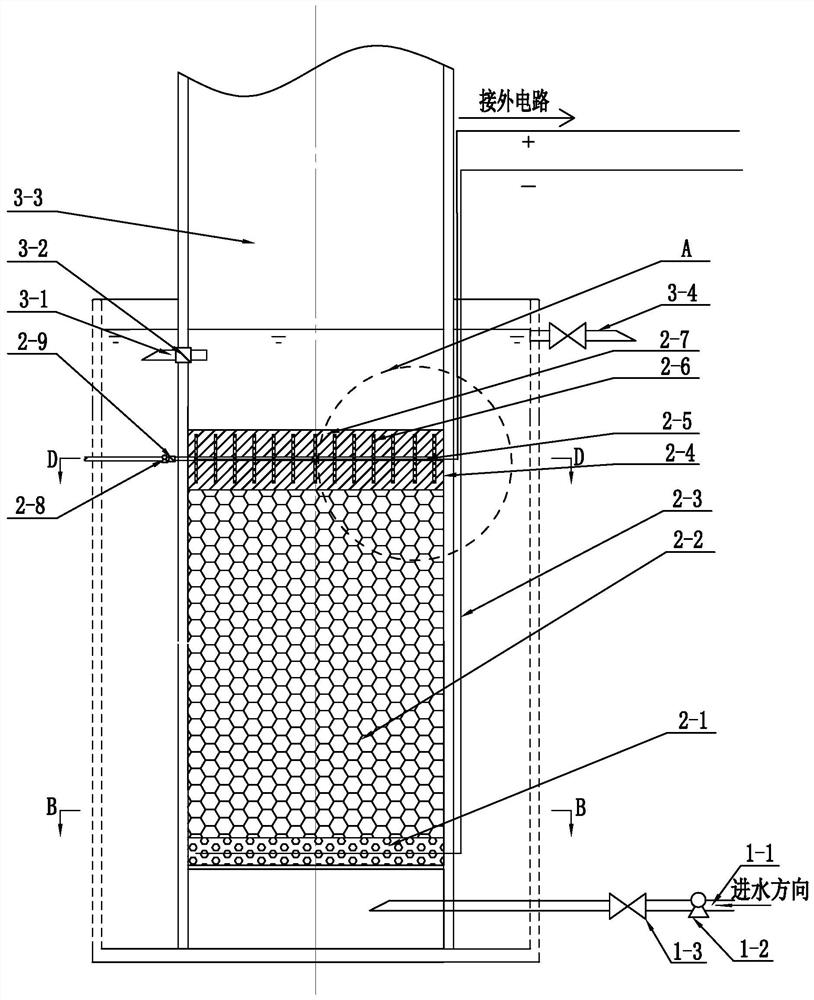

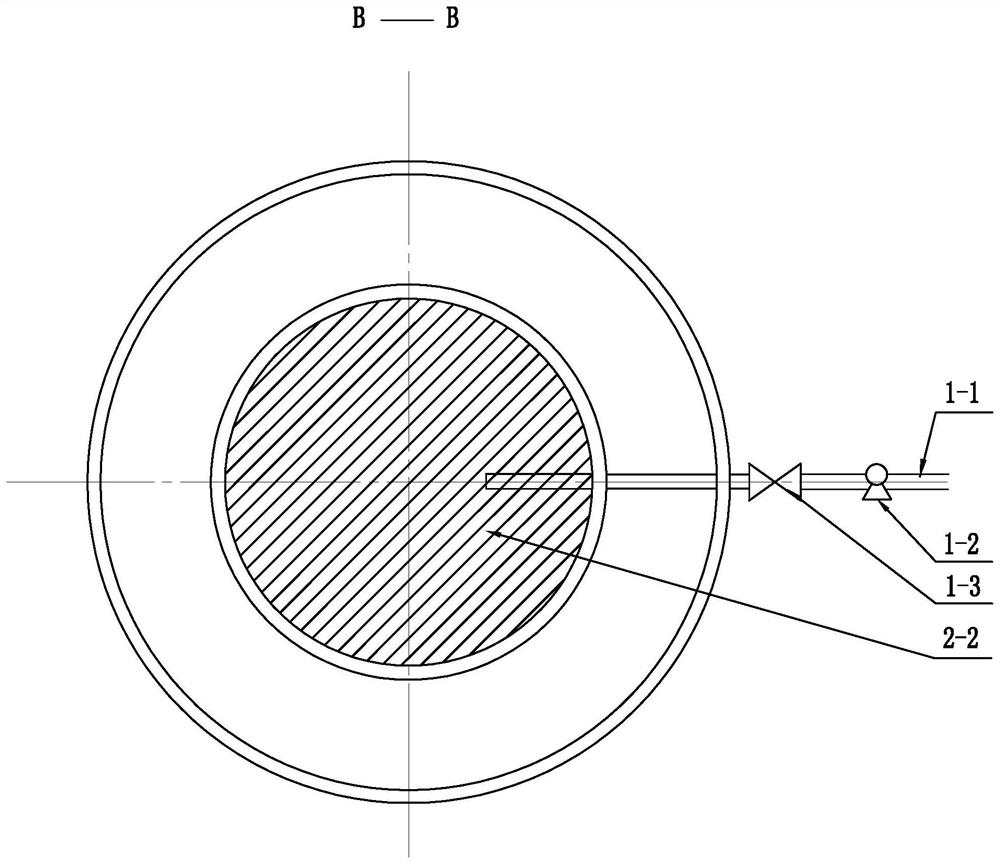

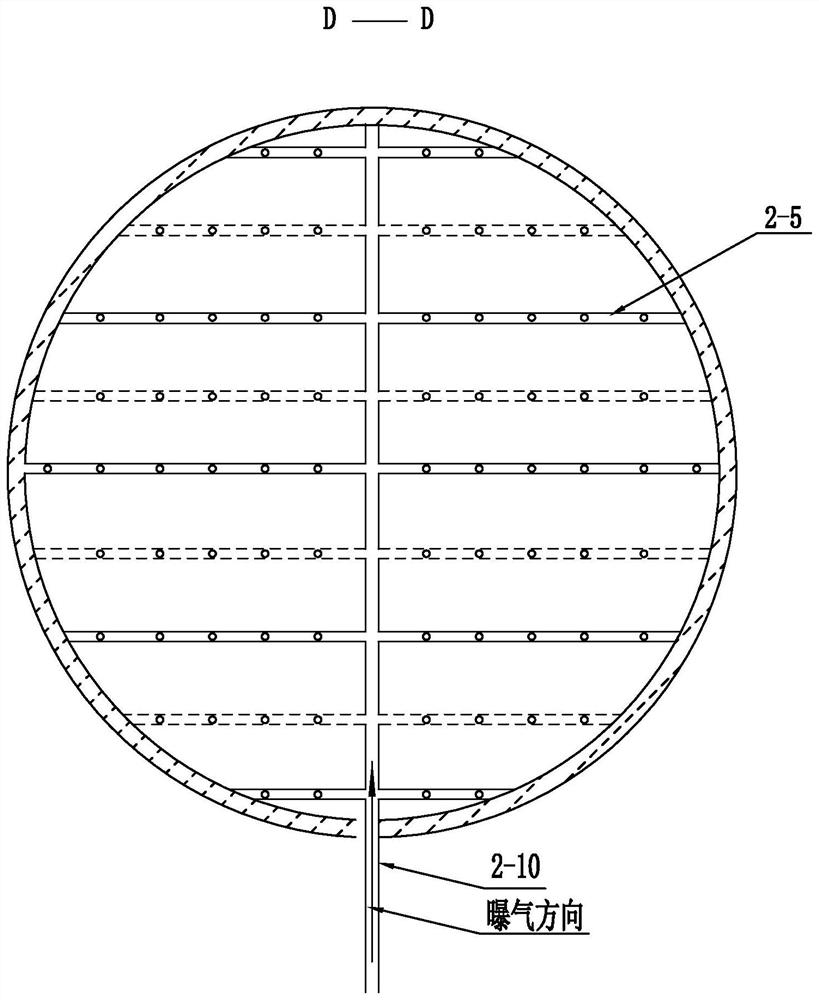

Device and method for biosynthesizing methane based on carbon emission reduction CO2

PendingCN114196534AAchieving Sustainable RecyclingImprove processing efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsCopper wireBiological filter

The invention discloses a device and a method for biosynthesizing methane based on carbon emission reduction CO2, and belongs to the field of carbon emission reduction and energy recovery. A main body of the biological filter is an annular tank body, an outer-layer tank body of the annular tank body is a clean water tank, a biological anode, a porous matrix and a biological cathode are sequentially arranged in an inner-layer tank body of the annular tank body from bottom to top, and the inner-layer tank body, the biological anode, the porous matrix and the biological cathode are combined to form a biological electrolytic tank filter. The biological anode and the biological cathode are connected with an external circuit through copper wires; the one-way drain pipe fixedly penetrates out of the upper part of the side wall of the biological electrolytic tank filter, the biological electrolytic tank filter is communicated with the clean water tank through the one-way drain pipe, the treated water drain pipe fixedly penetrates out of the upper part of the side wall of the clean water tank, and the upper part of the biological electrolytic tank filter is communicated with the exhaust flue; one end of the water inlet pipeline penetrates through the clean water tank and the side wall of the biological electrolytic tank and is communicated with the area below the biological anode. According to the invention, methane is produced by using CO2 and a sewage organic pollutant carbon source, so that the purposes of energy recovery and carbon emission reduction are achieved.

Owner:HARBIN INST OF TECH

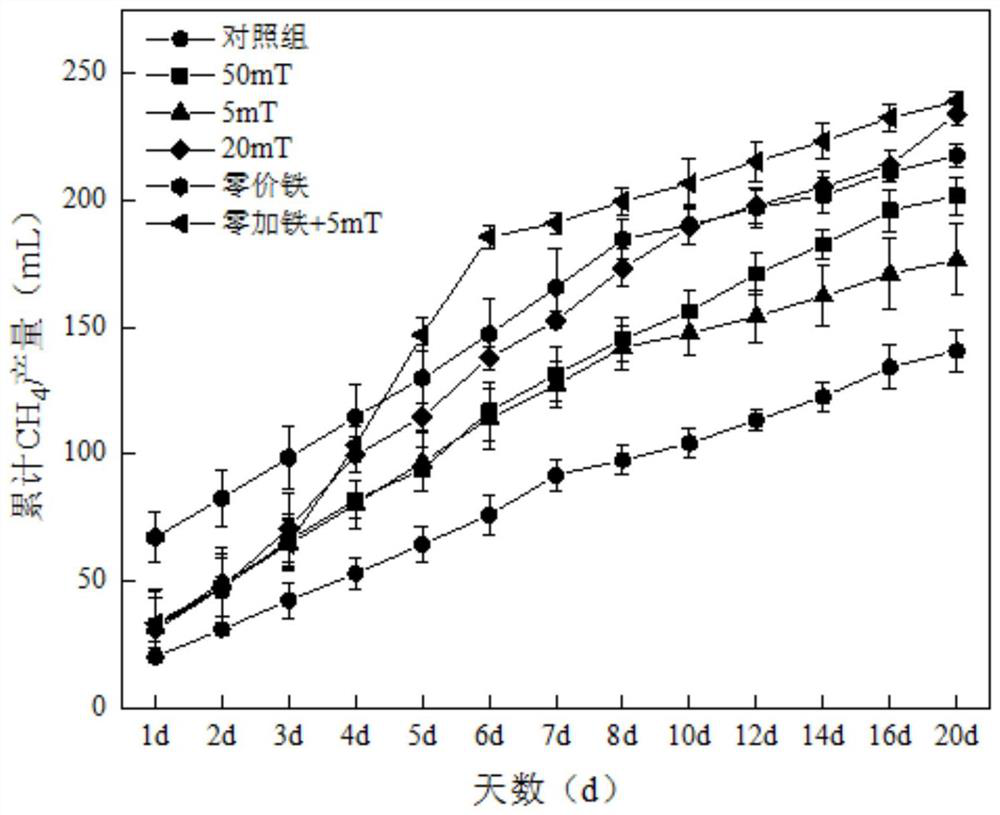

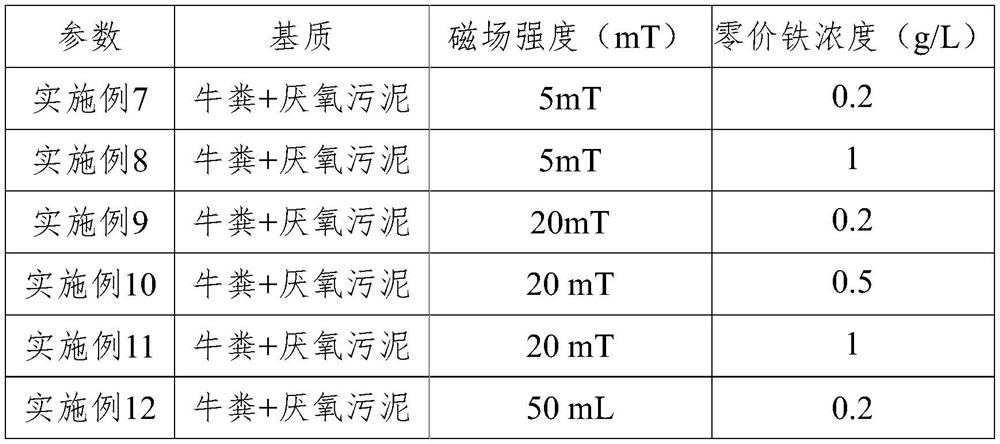

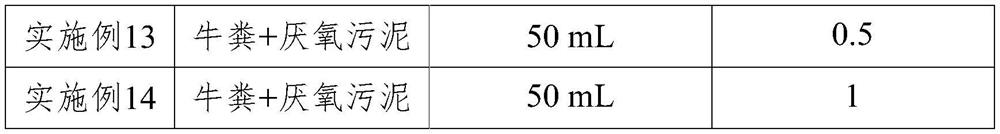

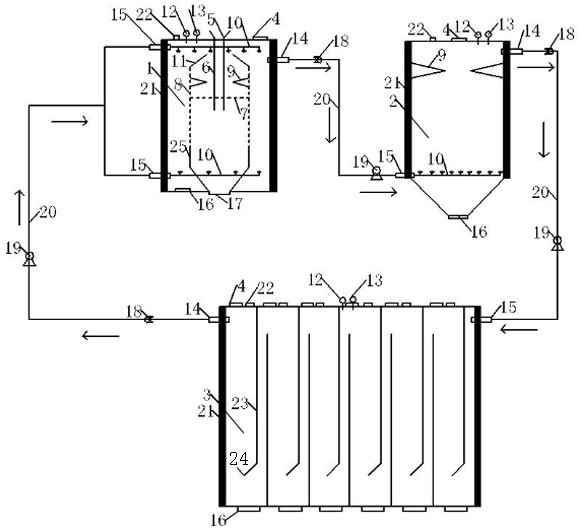

Method for anaerobic fermentation of livestock and poultry manure

PendingCN114835361AAccelerated corrosionProvide quicklyWaste water treatment from animal husbandryBiological synthesisBiotechnologyMicroorganism

The invention relates to the technical field of environmental protection, in particular to a method for anaerobic fermentation of livestock and poultry manure. The method at least comprises the following steps: mixing livestock and poultry manure with anaerobic sludge to obtain a fermentation raw material, and filling the fermentation raw material into an anaerobic reactor; adding zero iron into the anaerobic reactor, and applying a magnetic field; and carrying out anaerobic fermentation and recovering methane. The effect of a magnetic field on microorganisms is mainly utilized, so that the methane production efficiency of anaerobic digestion of the livestock and poultry manure is improved. The magnetic field can promote corrosion of zero iron, more electron donors can be provided more quickly, and the anaerobic digestion methane production potential of the livestock and poultry manure is effectively promoted.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A reaction system suitable for resource utilization of organic solid waste

ActiveCN108485945BAvoid accumulationAvoid competitionBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeMethane fermentation

A reaction system suitable for resource utilization of organic solid waste, which belongs to the field of anaerobic biological treatment of solid waste, can solve the problems of easy "acidification" in the reaction process of the prior art, low fermentation efficiency and gas production efficiency, including high temperature Hydrolysis fermentation reaction device, medium temperature acidification fermentation reaction device and methane fermentation reaction device, three independent reaction devices respectively form hydrolysis dominant bacteria group, acid production dominant bacteria group and methanogenic bacteria group and provide the best conditions for their growth , which can effectively avoid the phenomenon of "acidification" and cause the reaction device to fail to operate normally. Each device injects the biogas slurry into the next reaction device through the water distribution device through the jet pump on the connecting pipe, which can not only fully stir the reaction device, increase the contact area between the reaction substrate and the sludge, and reduce the failure of mechanical agitation, Problems such as high energy consumption can also achieve the purpose of biogas slurry circulation, so that organic solid waste can be thoroughly fermented again, and the generation of biogas residue can be reduced.

Owner:TAIYUAN UNIV OF TECH

A semi-continuous ammoniated straw and biogas residue sandwich mixed fermentation device

ActiveCN111849721BReduce deliveryEasy dischargeBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industrySlurry

The invention discloses a semi-continuous ammoniated straw and biogas residue sandwich mixed fermentation device, which includes a fermentation tank, a biogas slurry circulation pipeline and a fermentation feeding device. The fermentation unit is composed of vertically arranged fermentation units, and each fermentation unit includes an ammoniated straw layer, a biochar layer and a biogas residue layer arranged from top to bottom; Outlet; one end of the biogas slurry circulation pipeline is connected to the liquid outlet of the fermenter, and the other end is connected to the liquid inlet of the fermenter; the fermentation feeding device is connected to the feed port of the fermenter The feed pipe in turn transports biogas residue, biochar and ammoniated straw to the fermentation tank. The mixed fermentation device mixes and ferments biogas residue and ammoniated straw to optimize material ratio and improve gas production efficiency. At the same time, it adopts biogas slurry circulation spraying method, no need for stirring, simple operation and low input cost.

Owner:SOUTH CHINA AGRI UNIV

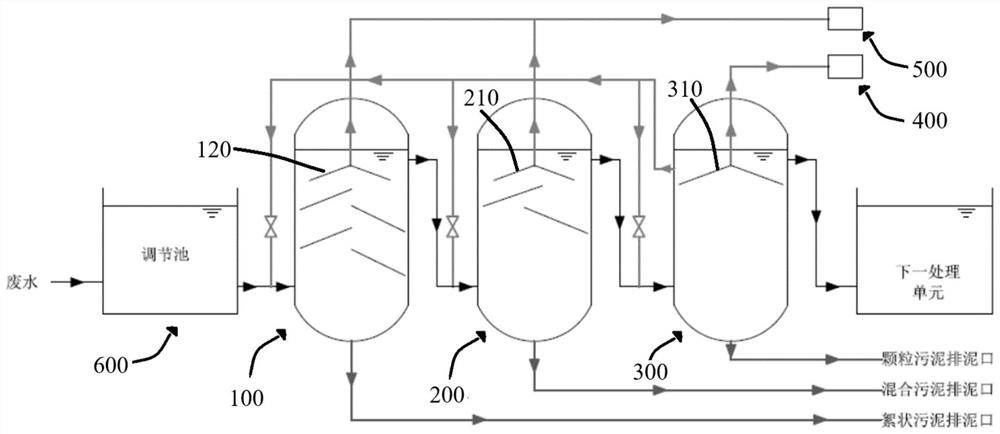

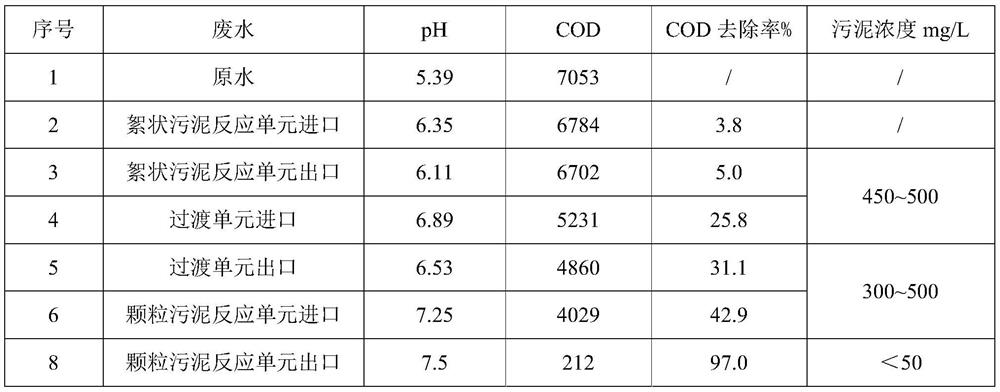

A block anaerobic treatment method for organic wastewater

ActiveCN112850886BImprove methane production efficiencyImprove reaction efficiencyWater treatment parameter controlBiological treatment regulationTreatment unitWater treatment

The invention discloses a block-based anaerobic treatment method for organic wastewater, which belongs to the technical field of water treatment. It includes the following steps: 1) passing the water body to be treated into a flocculent sludge treatment unit inoculated with flocculent sludge for treatment; 2) passing 1) effluent into a transition unit for treatment, and the transition unit contains flocculent Sludge and granular sludge; 3) passing 2) the effluent into a granular sludge treatment unit inoculated with granular sludge for treatment; wherein part of the effluent of the granular sludge treatment unit is returned to the flocculent sludge treatment unit and / or Or transition unit and / or granular sludge treatment unit. According to the advantages of different sludges, the present invention sets different sludge partitions, precisely controls the process parameters at different stages, greatly improves the treatment efficiency of the anaerobic process, and increases the output of granular sludge.

Owner:NANJING UNIV +1

Method for improving the purity of methane in biogas produced by anaerobic digestion of sludge

ActiveCN108793656BImprove methane production efficiencyFacilitated releaseWater treatment parameter controlSludge treatment by oxidationMethanobacterAcid hydrolysis

The invention provides a method for improving the purity of methane in biogas produced by anaerobic digestion of sludge, which comprises the following steps: after concentrating the organic sludge to a solid content rate of 20-40g / L, adding additives, and controlling the pH The value is 4.0-6.0, and the hydrolysis and acidification reaction is carried out at 35-39 °C; after the pH value of the hydrolysis-acidification sludge is adjusted to 6.0-6.5, the anaerobic digestion reaction is carried out to collect biogas. The present invention uses calcium nitrite as an additive, which promotes sludge lysis and hydrolysis to produce acid, greatly increases the rate of sludge anaerobic acid production, and further improves the efficiency of sludge anaerobic digestion; the addition of calcium nitrite also plays a role By sequestering carbon, it reduces the concentration of carbon dioxide in the biogas and improves the purity of methane; and adjusting the pH twice not only improves the acidic hydrolysis of sludge under the action of calcium nitrite, but also facilitates the hydrogen formation in the anaerobic methanogenesis stage. The growth of methanogens increases the potential of carbon dioxide and hydrogen to form methane, further improving the purity of methane in the biogas.

Owner:SHANGHAI JIAO TONG UNIV

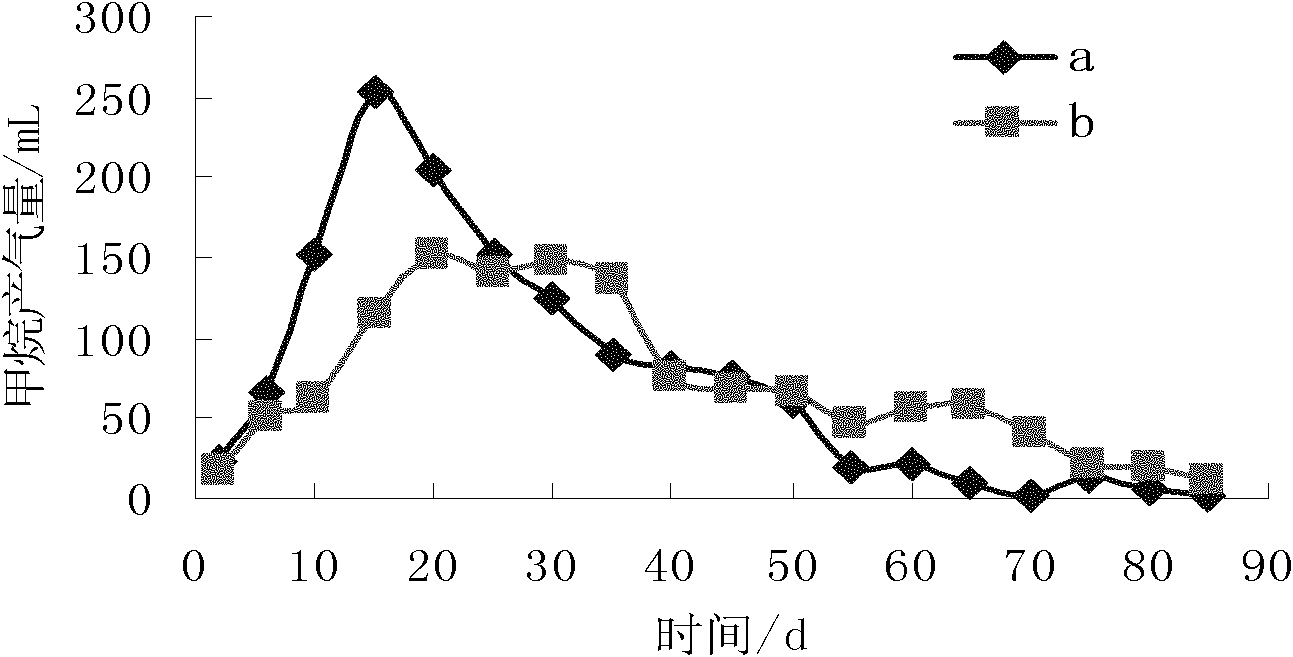

Method for producing methane by using anerobic fermentation of rumen microorganism

ActiveCN103484502BSolve processing problemsImprove efficiencyWaste based fuelFermentationResource utilizationSlurry

The invention relates to a method for pretreatment to biological substance waste materials and the biotechnology of resource utilization of the biological substance waste materials. Firstly, biogas slurry is used for pretreatment to the biological substance waste materials, and then rumen microorganism is used for anaerobic biotransformation; the fermentation process is that a rumen fluid is taken out of rumina of ruminants and inoculated into an anerobic fermentation reactor containing biological substance waste materials subjected to pretreatment and a buffer solution; the anerobic fermentation reactor runs to collect produced methane, and liquid phase and solid phase products. According to the invention, the dry matter digestion rate of biological substance waste material is improved by 10 to 20 percent, the fermentation time is shortened for 3 to 10 days, and the methane producing efficiency can reach 210 to 250 mL / g (moisture free weight). The biogas liquid produced by fermentation can be used for pretreatment in a recyclable way, and also can be used as an organic fertilizer after biogas residue treatment.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com