Packing liner for anaerobic dry fermentation of organic waste as well as preparation method and application of packing liner

A technology of organic waste and dry fermentation, which is applied in the field of organic waste treatment and recycling, can solve the problems of increasing the difficulty of fermentation residue, low material use efficiency, and difficult separation of zero-valent iron, so as to improve methane production efficiency, low cost, The effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

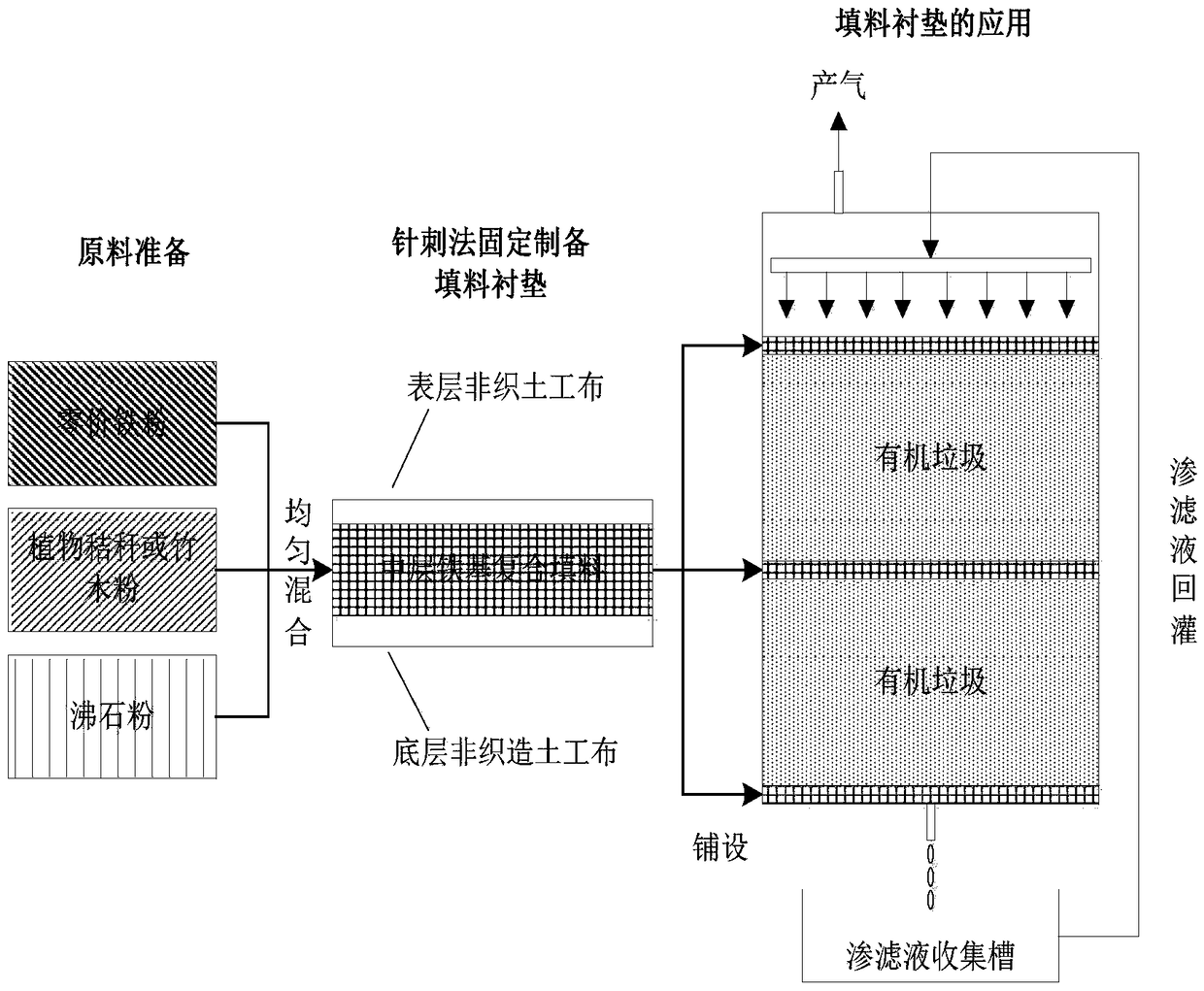

Method used

Image

Examples

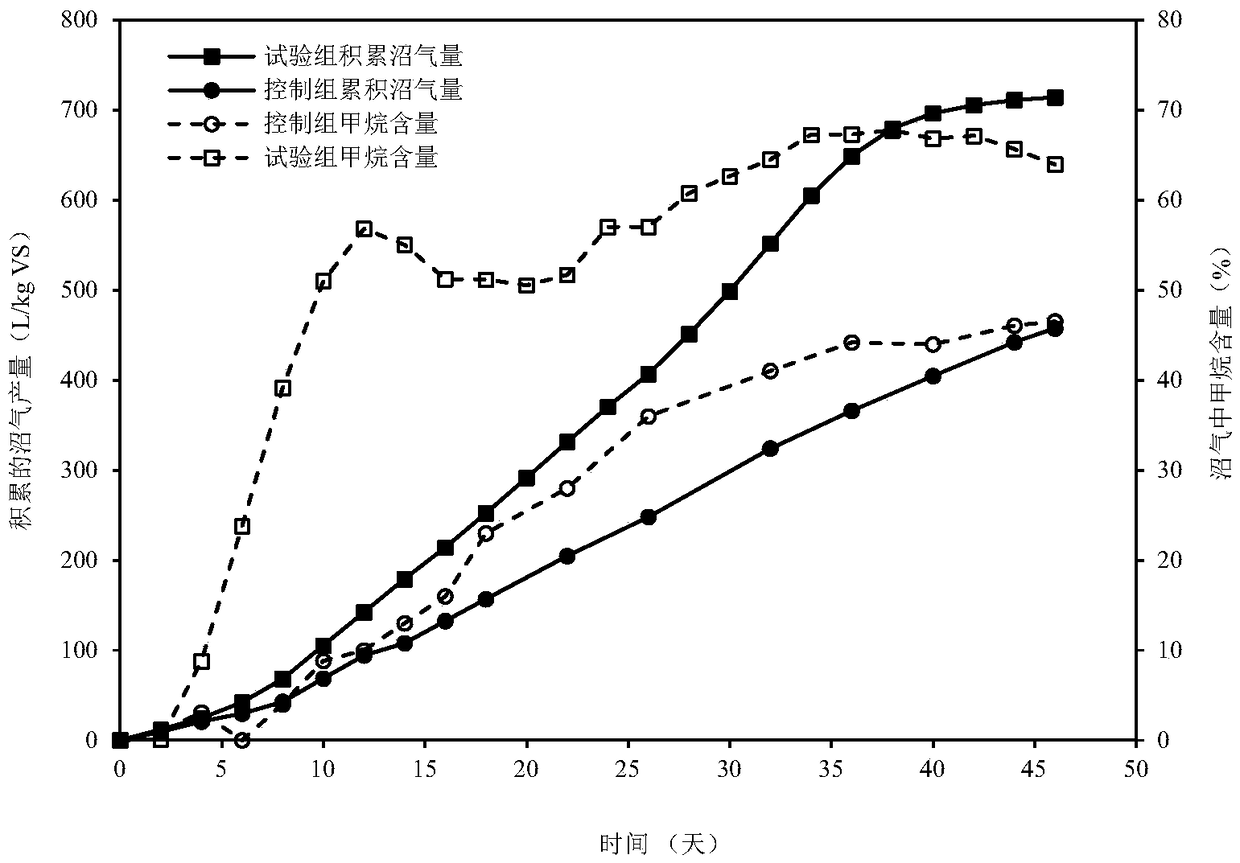

Embodiment 1

[0045] 1. Composition of organic waste

[0046]The domestic refuse used in the embodiment comes from the fresh refuse of a certain landfill in Beijing (see Table 1 for the specific composition). After manually removing inert substances such as stones, metals, plastics and porcelain, the remaining kitchen waste, paper, leaves and other parts that are not easy to sort are used as organic waste for the test. After the organic waste is crushed (<120mm) and uniformly mixed, it is ready for use.

[0047] Table 1: Basic composition of domestic waste (wet basis %)

[0048]

[0049] 2. The preparation of the test group packing liner in the present embodiment comprises the following steps:

[0050] (1) Raw material preparation: Grind the elemental iron powder to obtain 200 mesh zero-valent iron powder for later use; after natural air-drying and crushing of the obtained plant straw, pass through a 0.125mm sieve, and take the sieved part for later use; the obtained natural The zeoli...

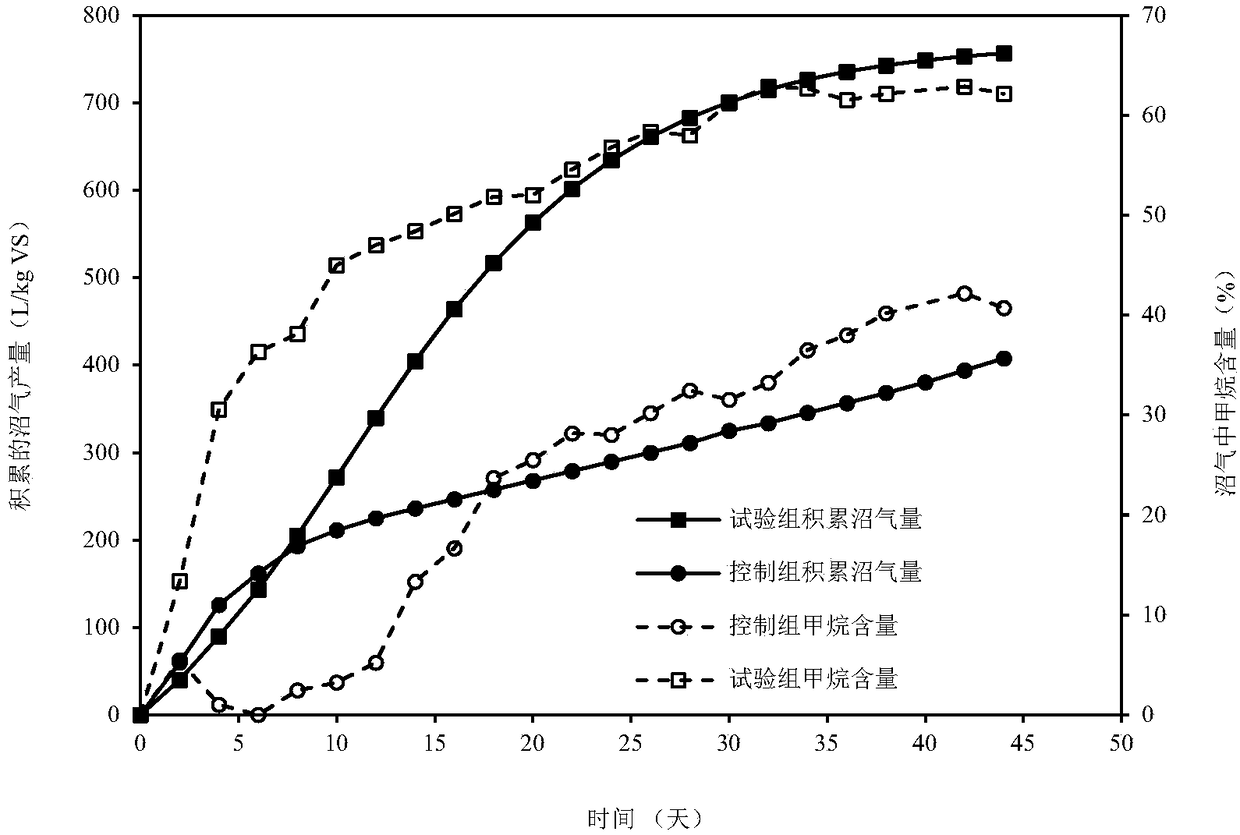

Embodiment 2

[0058] 1. Composition of organic waste

[0059] The configuration is the same as in Embodiment 1.

[0060] 2. The preparation of the test group packing liner in the present embodiment comprises the following steps:

[0061] (1) Prepare raw materials: Grind the elemental iron powder to obtain 80 mesh zero-valent iron powder for later use; air-dry and crush the obtained plant stalks naturally, pass through a 0.613mm sieve, and take the sieved part for later use; the obtained natural zeolite Sieve after crushing to obtain 80-mesh zeolite powder for subsequent use.

[0062] (2) The zero-valent iron powder with a mass percentage of about 65.0%, the plant straw with a mass percentage of about 30.0%, and the natural zeolite powder with a mass percentage of 5.0% are fully mixed and set aside.

[0063] (3) the iron-based composite filler obtained in step (2) is evenly spread on the nonwoven geotextile (200g / m 2 ). On the above-mentioned iron-based composite filler, spread one deck ...

Embodiment 3

[0068] Compared with Example 1, only the laid packing pads were recovered and reused, and the preparation and test methods of the rest of the packing pads were consistent with those of Example 1. A total of 6 cycles of dry anaerobic fermentation tests of organic waste have been completed for each layer of filler pads to verify its long-term effect and reliability of repeated use.

[0069] The measured gas production effect of the test group is as follows: Figure 4 shown. Since the fifth use of the packing liner, the gas production efficiency has decreased, only about 90% of the first use; and the sixth use, the gas production is only about 82% of the first use. Therefore, according to the application of the packing pad of the present invention, it is recommended that each layer of packing pad be used for 3-5 fermentation cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com