Patents

Literature

48results about How to "Avoid separation difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

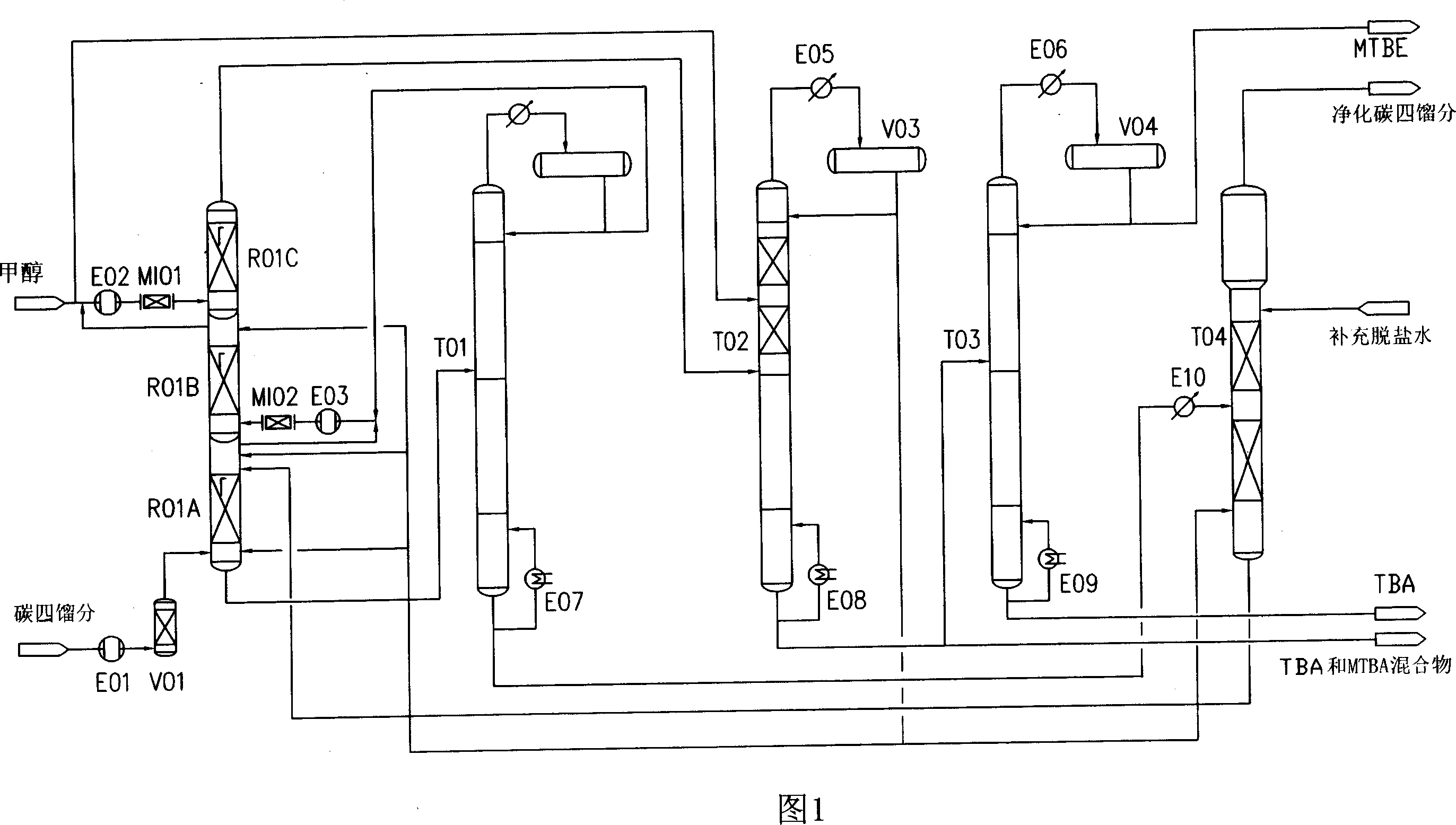

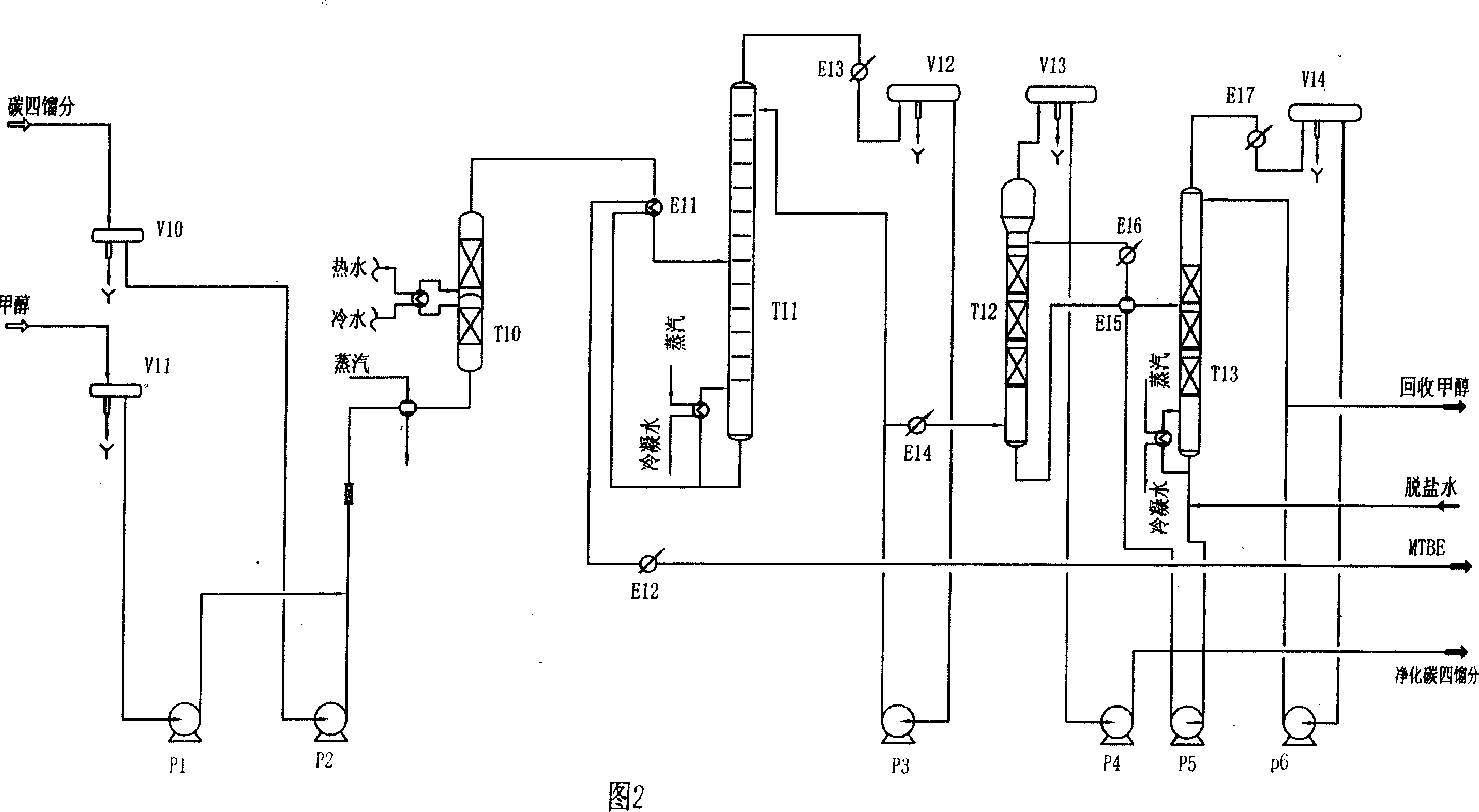

Phrcess of coproducing methyl tert-butyl ether and tert-butyl alcohol

InactiveCN101020622ASave energyLess investmentPreparation by hydroxy group additionEther preparation by compound additionMethanol waterMethyl t-butyl ether

The present invention relates to process of co-producing methyl tert-butyl ether and tert-butyl alcohol with isobutene and methanol in C4 fraction. The present invention features that two kinds of product are produced in an identical equipment with reduced investment, and that separation is completed through several reactions, resulting in simplified equipment and facilitated separation.

Owner:西安道特石化工程有限公司

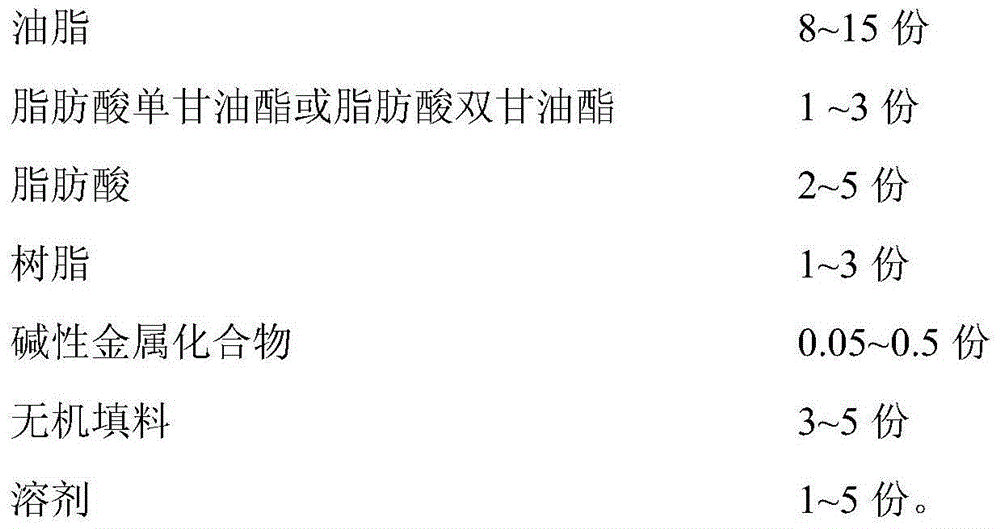

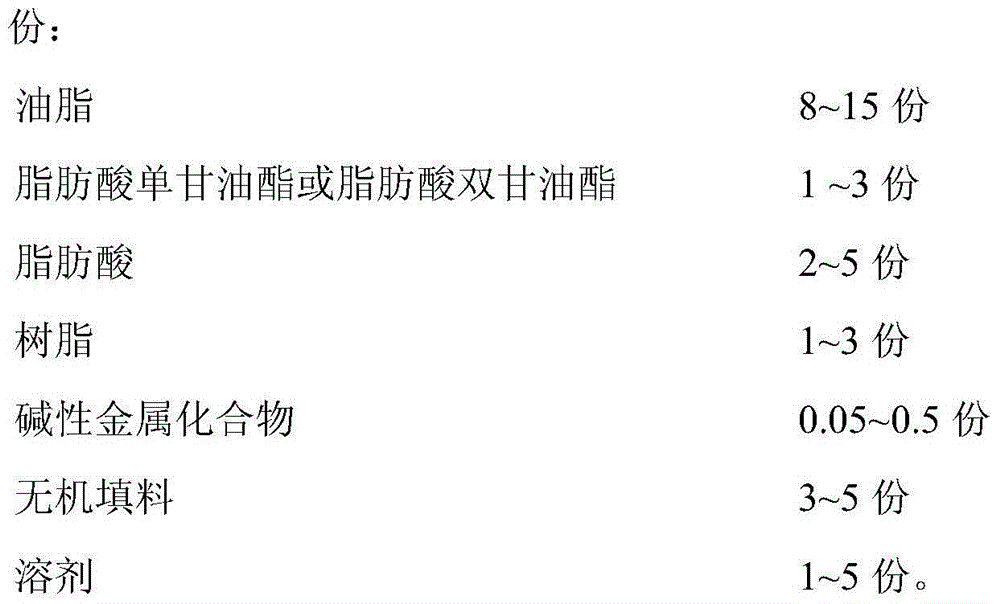

Concrete releasing agent for aluminum alloy template of building

InactiveCN104629885ABlock penetration throughAvoid destructionCeramic shaping apparatusLubricant compositionMonoglycerideDiglyceride

The invention provides a concrete releasing agent for an aluminum alloy template of a building. The releasing agent comprises the following components in parts by weight: 8-15 parts of grease, 1-3 parts of fatty acid monoglyceride or fatty acid diglyceride, 2-5 parts of fatty acid, 1-3 parts of resin, 0.05-0.5 parts of basic metal compound, 3-5 parts of inorganic filler and 1-5 parts of solvent. The releasing agent coats the aluminum alloy template of the building and is used in the concrete pouring technology, the concrete releasing quality is good without obvious blister, and the releasing agent residue surface matter is easily removed and the releasing agent is suitable for use for single or multiple times, and the service life of the template is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

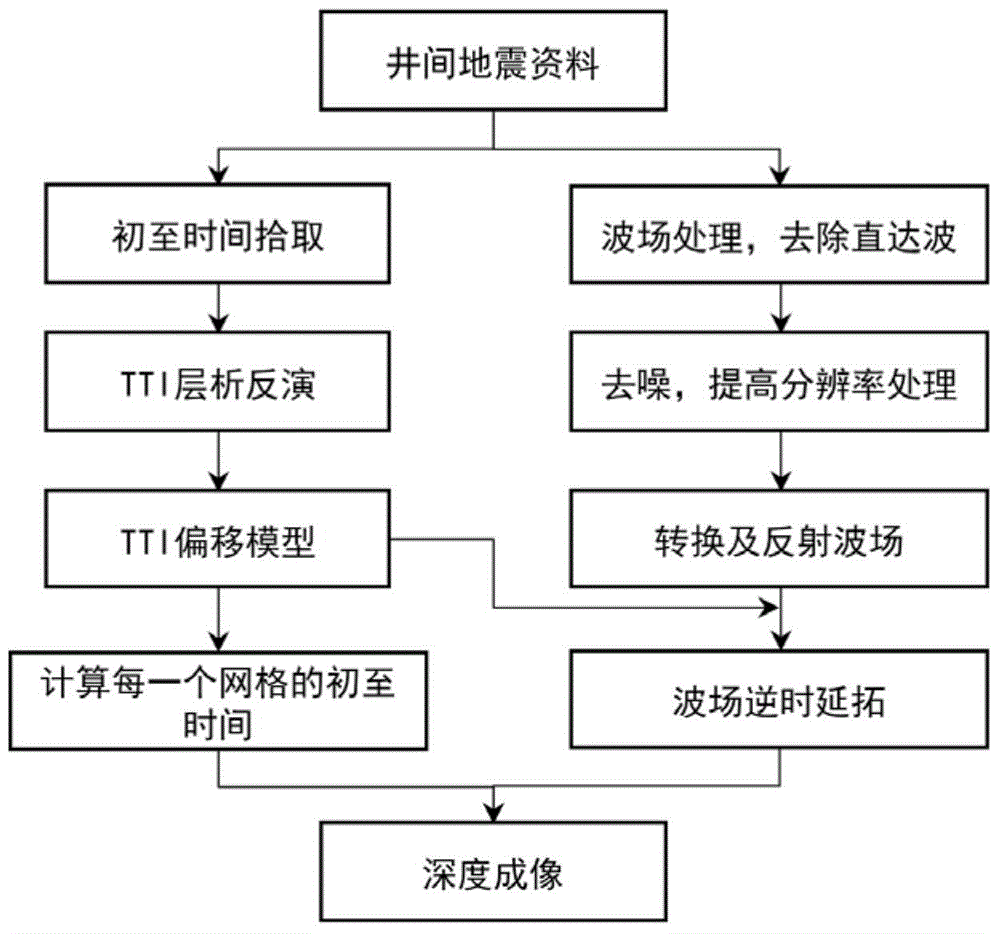

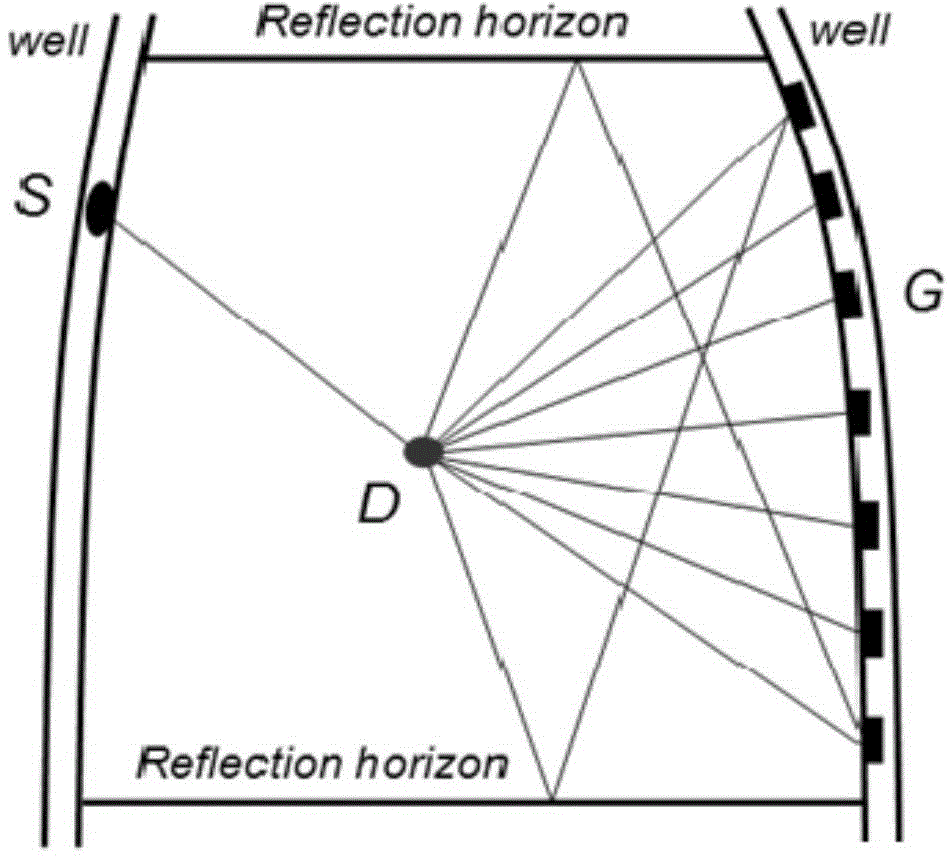

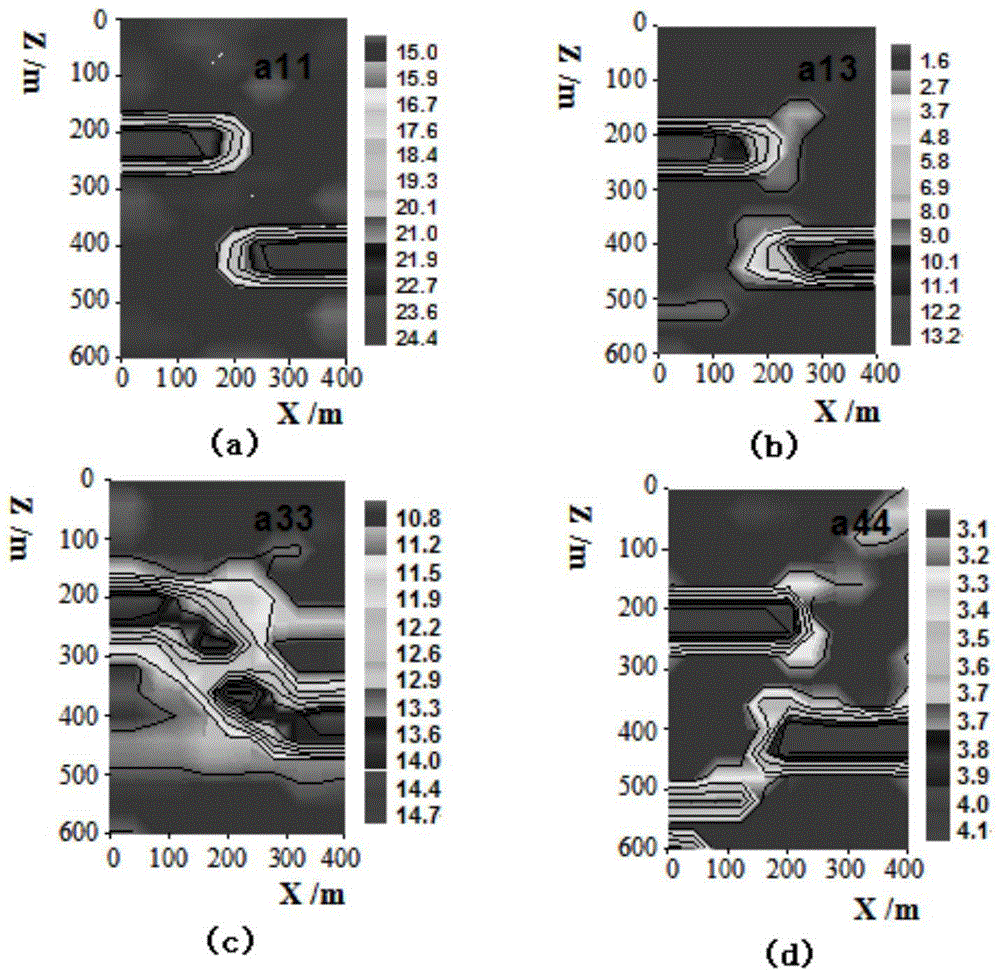

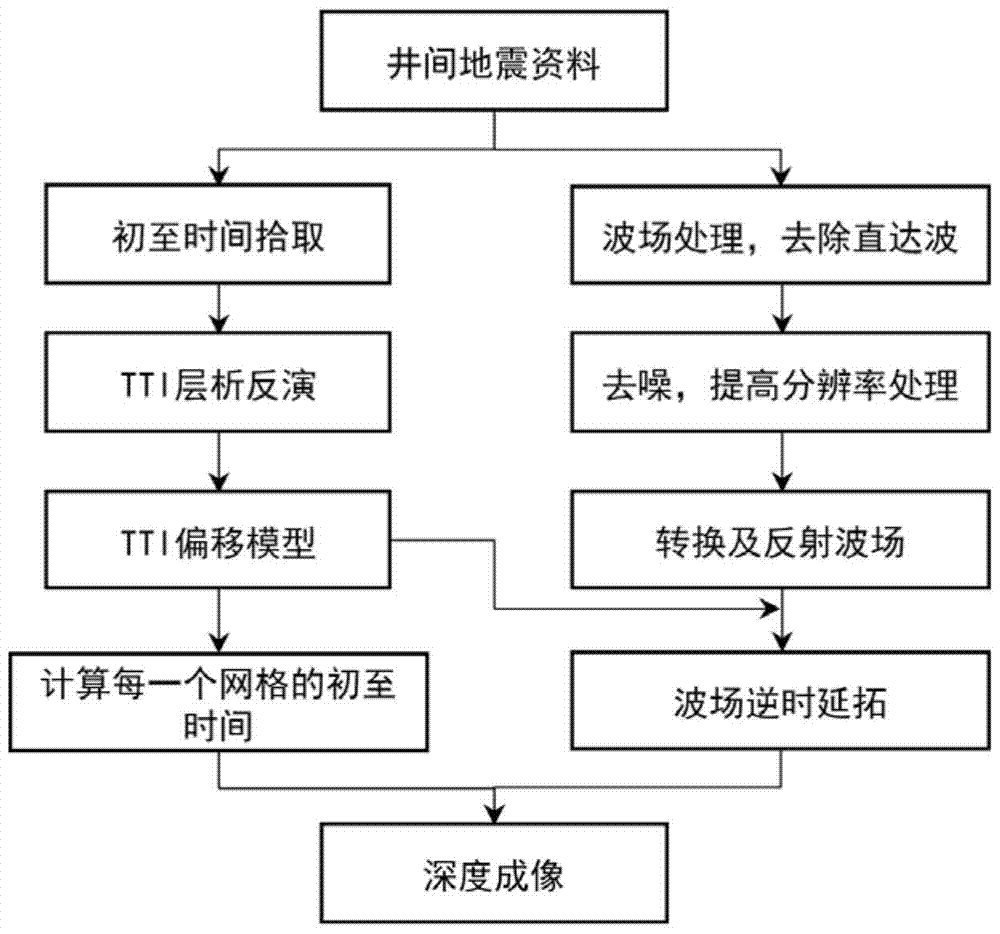

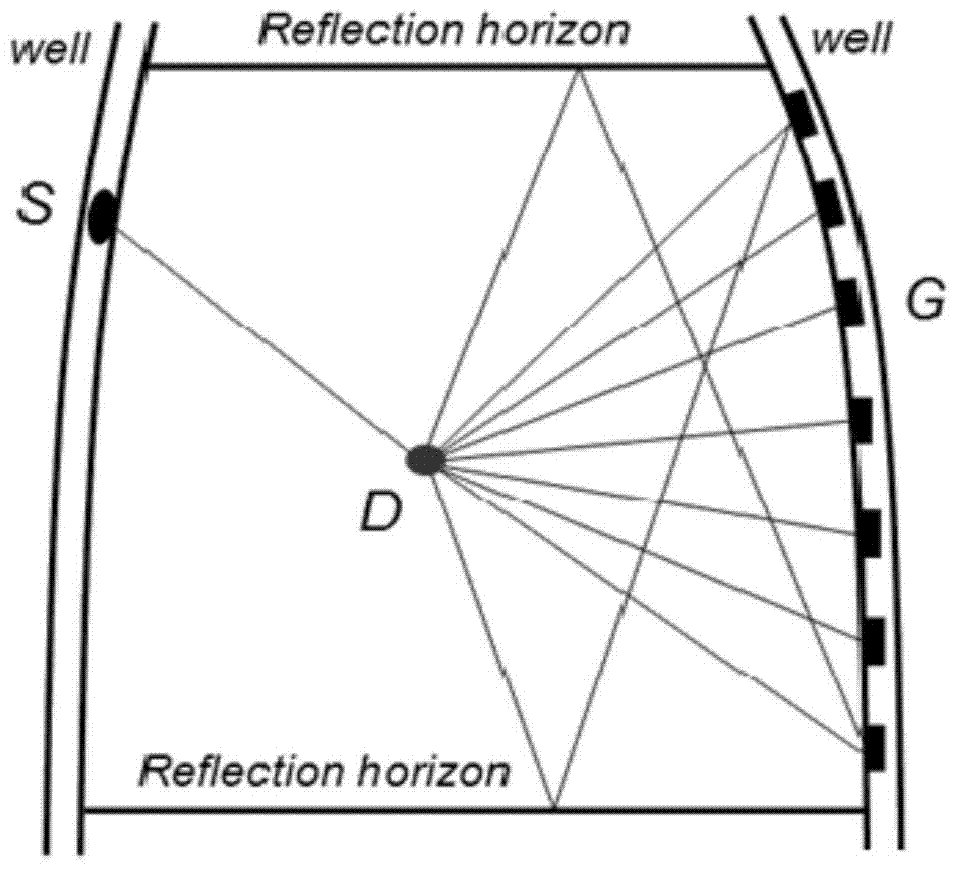

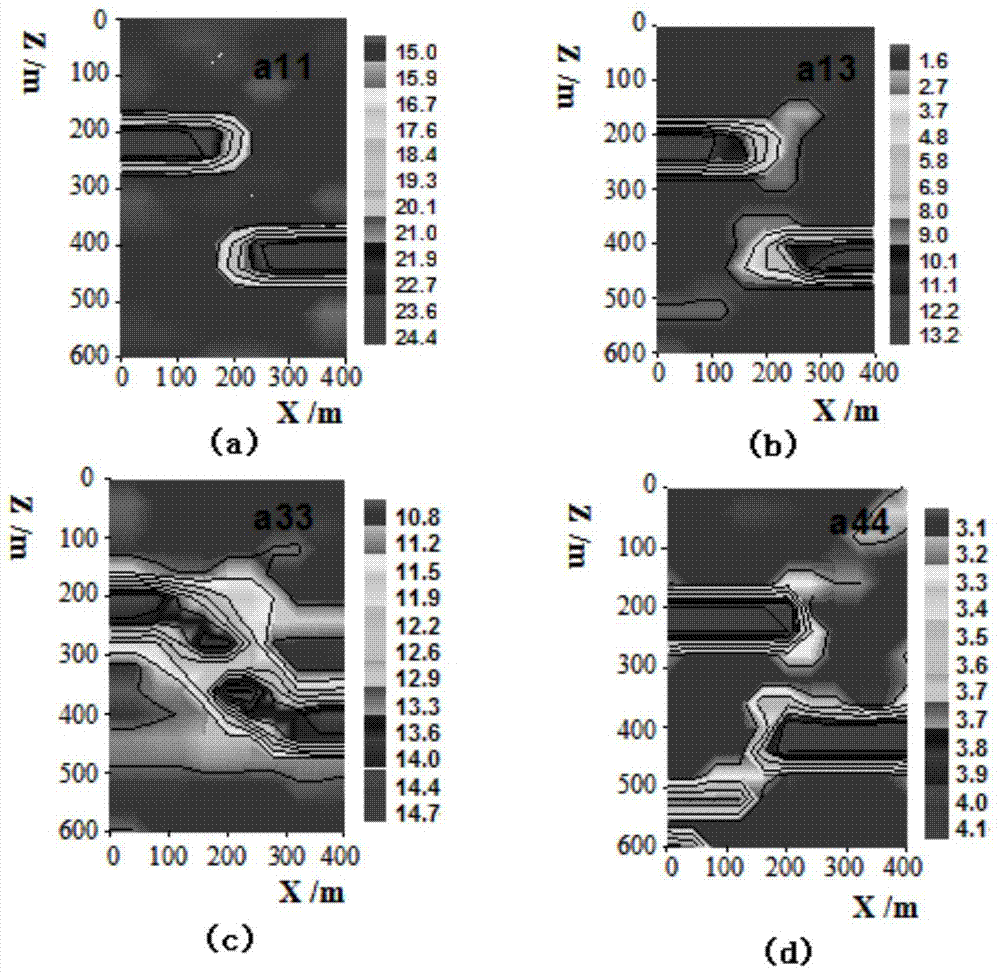

Well-to-well seismic pre-stack reverse-time depth migration imaging method for sea deviated well

ActiveCN104391327AMaintain propertiesMaintain Imaging Accuracy RequirementsSeismology for water-loggingReverse timeContinuation

The invention relates to a well-to-well seismic pre-stack reverse-time depth migration imaging method for a sea deviated well. The method includes the following steps: 1) collecting or having field construction acquisition for gathering the well-to-well seismic data of deviated well; 2) taking TTI medium chromatography inversion on the seismic data to obtain the two-dimension TTI medium offset model; 3) taking wave field treatment on the well-to-well seismic data of deviated well to obtain the converted wave field and reflection wave field used for imaging; 4) taking mesh generation on the two-dimension TTI medium offset model; 5) adopting the first-motion wave ray tracing method for calculating the first-motion wave time for each grid; 6) having wave field inverse continuation calculation on the seismic data based on the two-dimension TTI medium offset model to obtain the wave field value of the seismic data at different instants of time; 7) adopting the image-forming condition on the wave field value of the seismic data at different instants of time for imaging in each grid to obtain well-to-well seismic depth migration imaging section of deviated well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

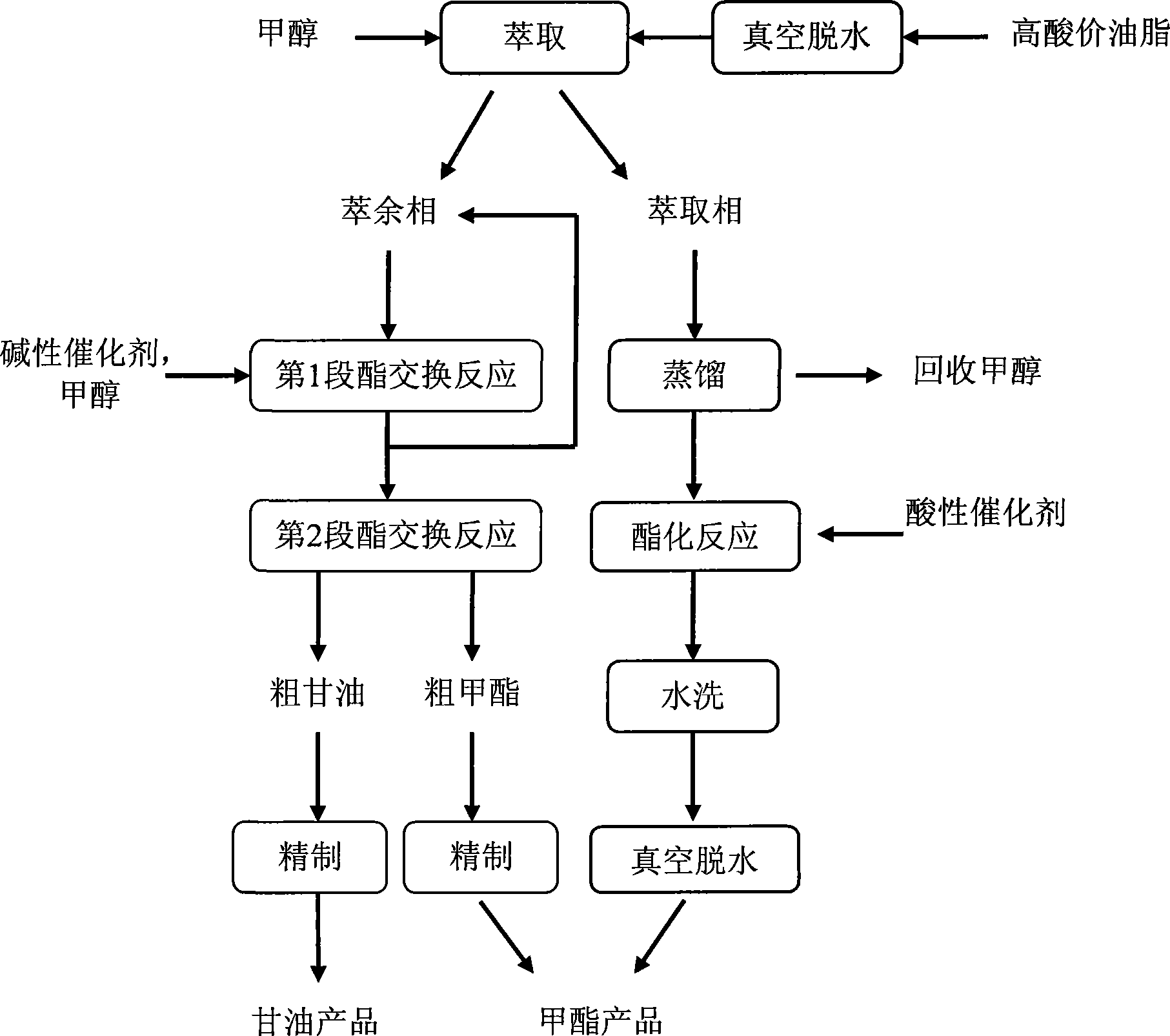

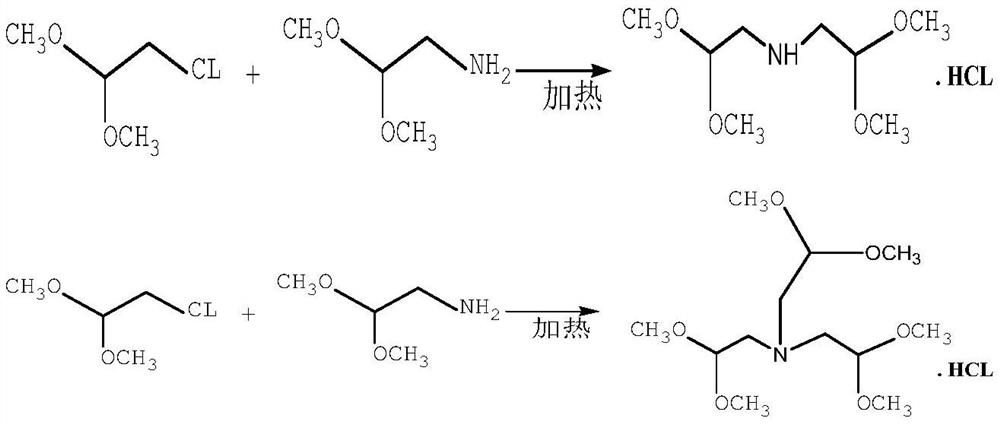

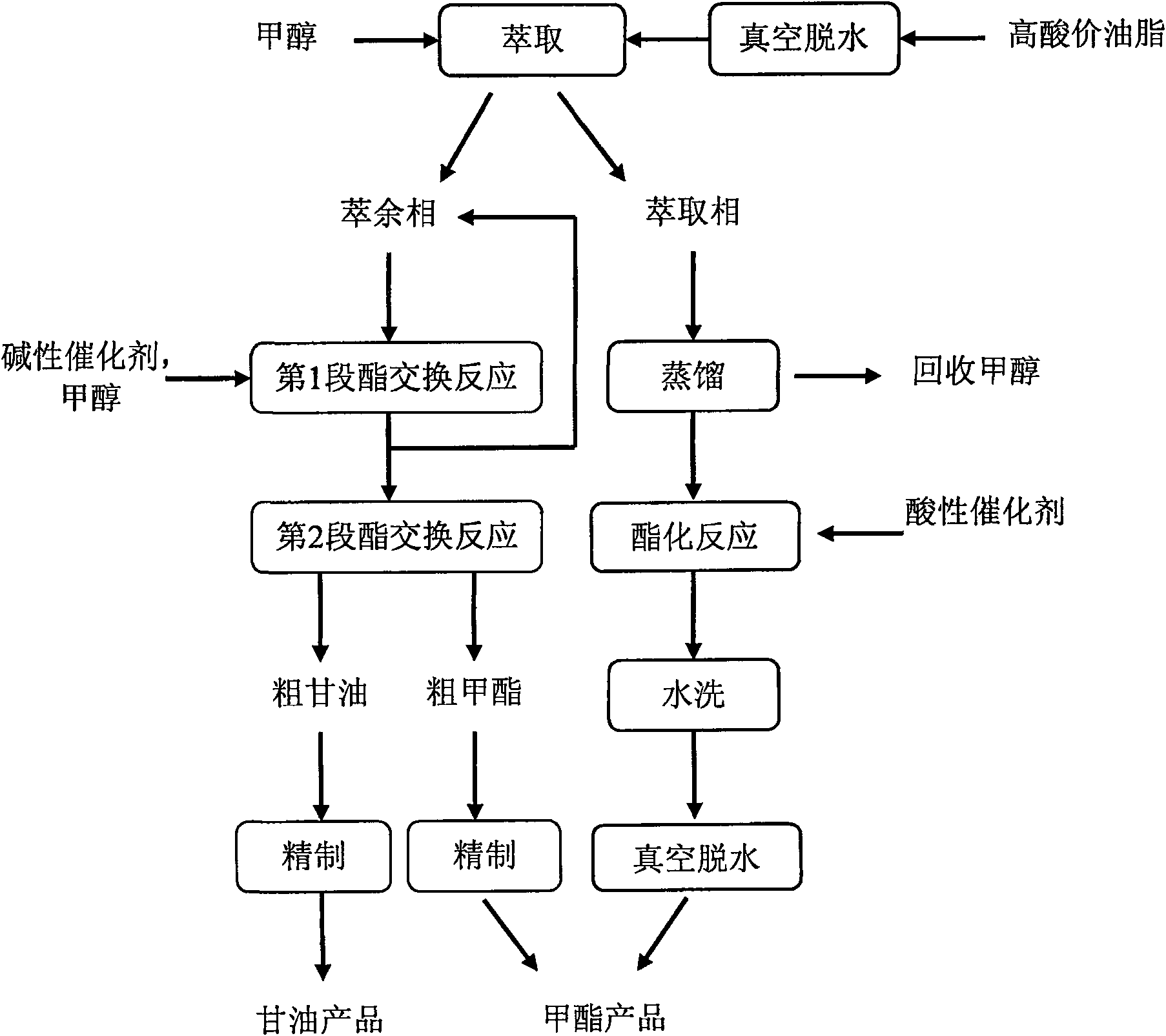

Parallel methyl ester method for fats and oils in high acid value

InactiveCN101050399AReduce dosageEmission reductionFatty acid esterificationMonoglyceridePresent method

This invention discloses a method for producing fatty acid methyl ester from high-acid-value grease by parallel methyl esterification. The method solves the problems of large raw material loss, low reaction efficiency, low apparatus utility and large wastewater discharge faced by present methods. The method comprises: (1) extracting high-acid-value grease with methanol; (2) performing parallel methyl esterification and interesterification reactions to obtain crude fatty acid methyl ester; (3) refining crude fatty acid methyl ester. A mixture of fatty acid methyl ester, fatty acid monoglyceride, and fatty acid diglyceride can be added during the interesterification reaction to prevent mass transfer hindrance. The method has such advantages as low raw material loss, high reaction efficiency, and high apparatus utility, and can be used to produce fatty acid methyl ester from restaurant waste oil, food processing waste oil and acidified oil from refinery plants.

Owner:WUHAN POLYTECHNIC UNIVERSITY

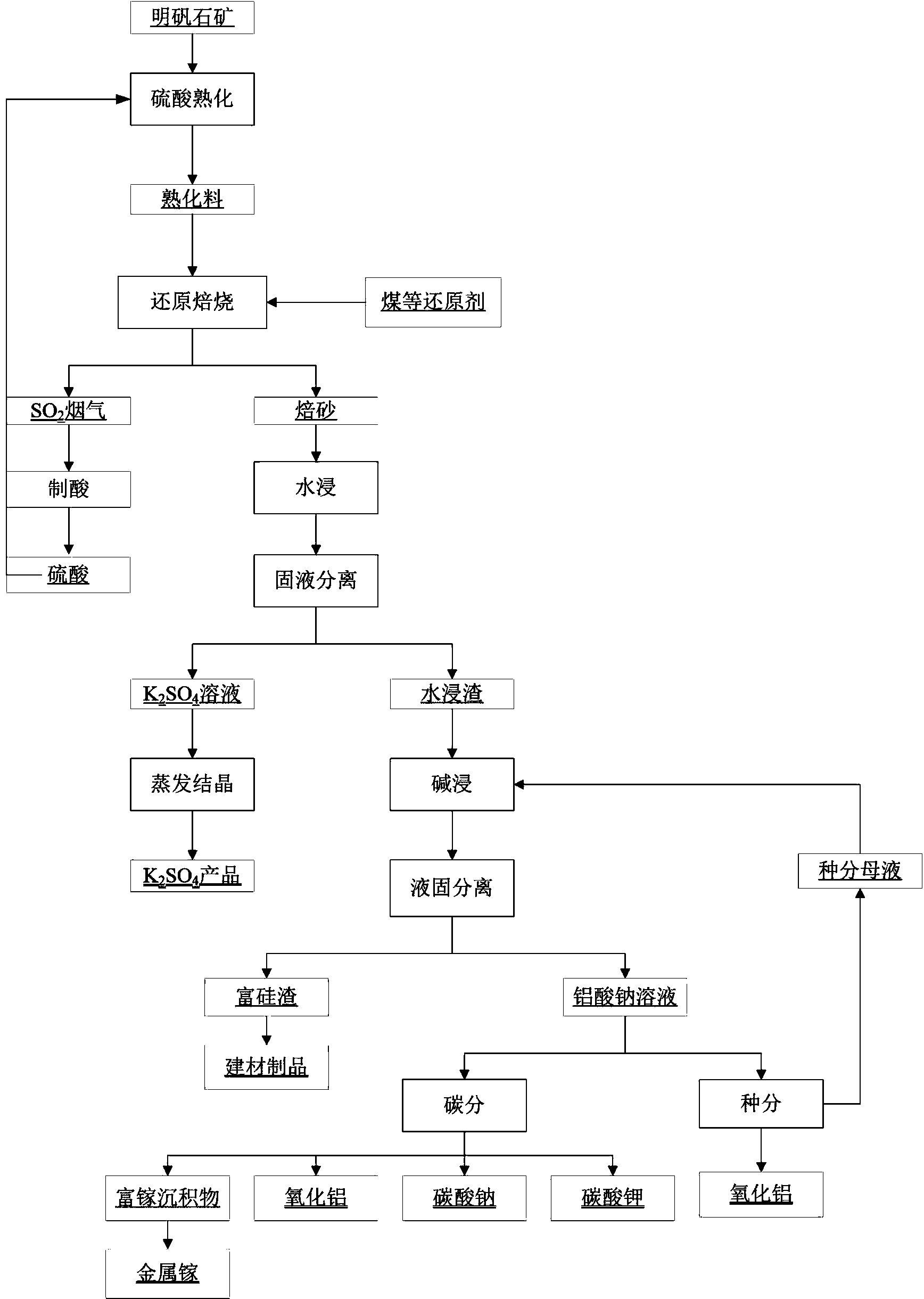

Acid-alkali combination method for extraction of aluminum, potassium and gallium from alunite concentrate

ActiveCN104313304AAvoid separation difficultiesSolve the problem of utilization of flue gas acid production outletProcess efficiency improvementChemistryDecomposition

The invention discloses an acid-alkali combination method for extraction of aluminum, potassium and gallium from alunite concentrate. The method comprises the following steps: uniformly mixing the alunite concentrate with a proper amount of concentrated sulfuric acid, curing, carrying out fast high-temperature reduction roasting to realize desulfuration; performing acid-making on sulfur-containing smoke to realize regeneration cycle utilization of sulfuric acid; carrying out water leaching on reduced calcine to extract potassium, carrying out alkaline leaching to produce aluminium oxide, and enriching and recycling gallium. According to the method, the advantages in a traditional alkaline method for extraction of aluminium oxide from alunite, and a concentrated sulfuric acid high-temperature reaction is effectively utilized to strengthen decomposition of alunite mineral, so that the recycling rate of aluminium oxide is improved, meanwhile the problem that acid produced in the alkaline method cannot be utilized is solved, and recycling of sulfuric acid is realized. The produced aluminium oxide product is good in quality, high in recycling rate, low in energy consumption, low in equipment corrosion, and easy in implementation of large-scale industrialization.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

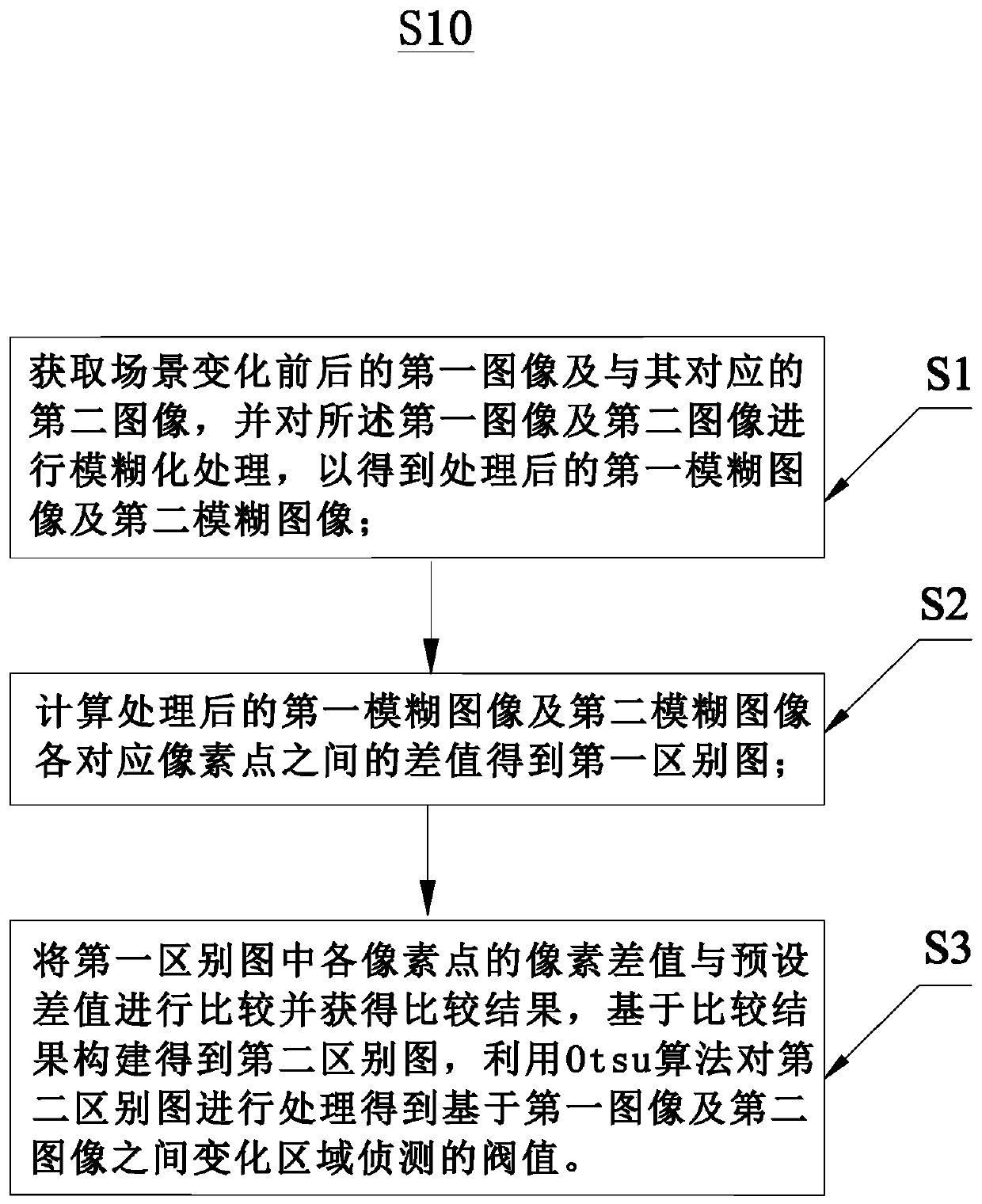

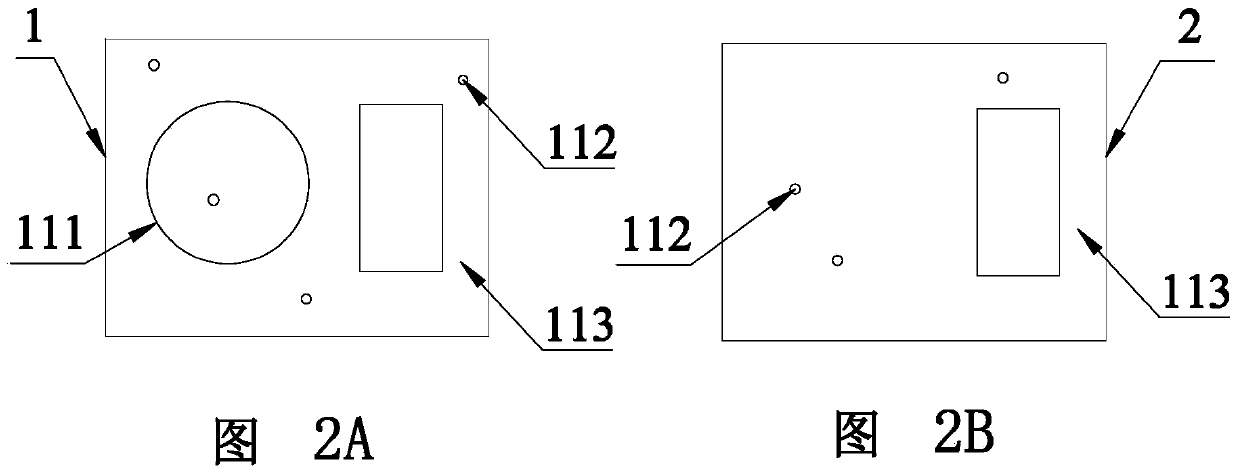

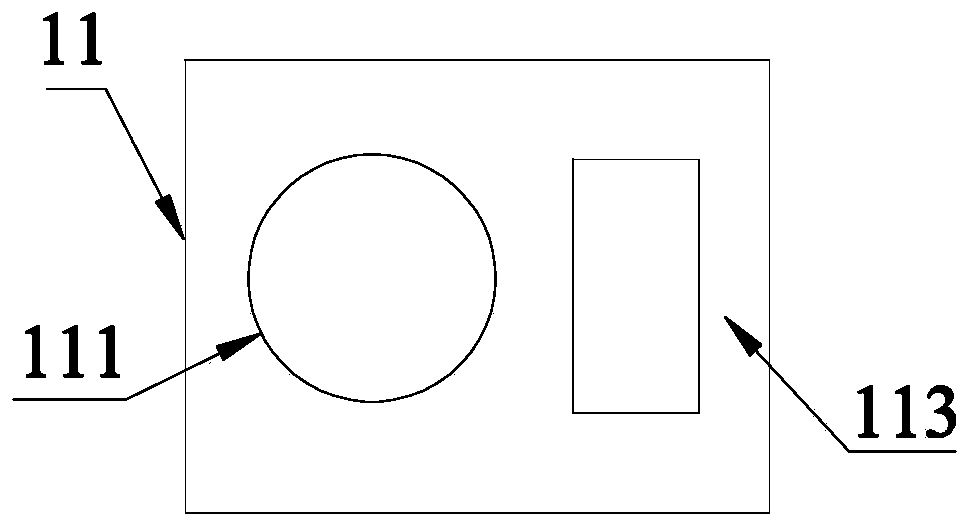

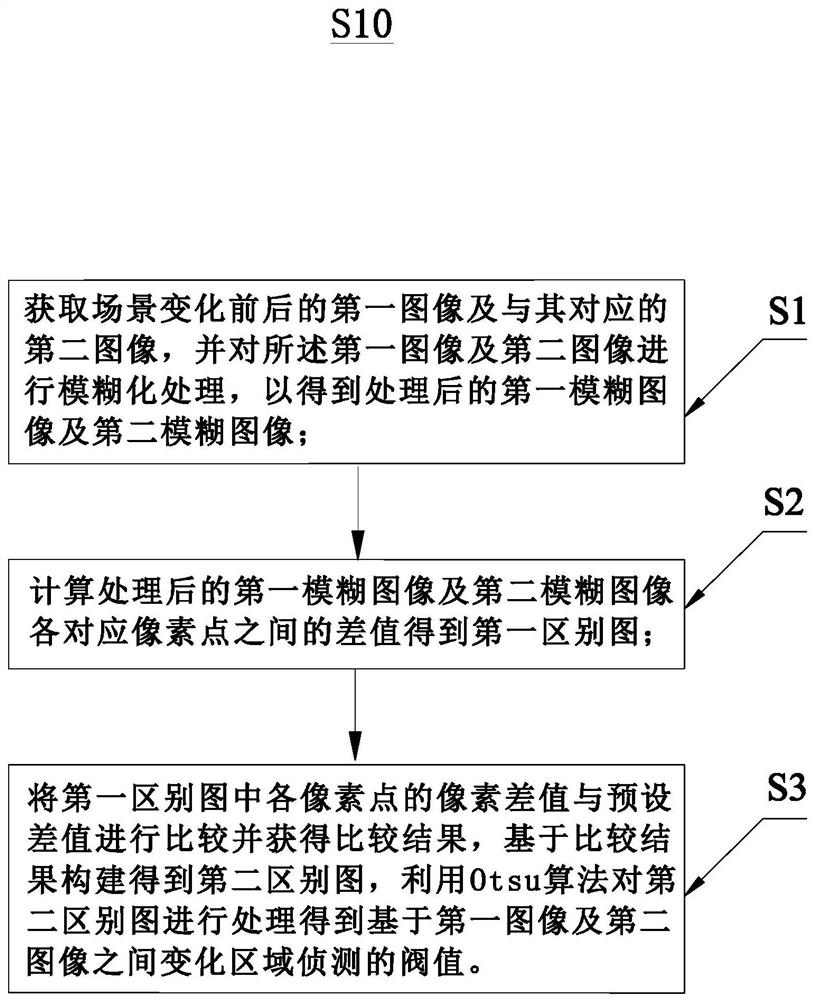

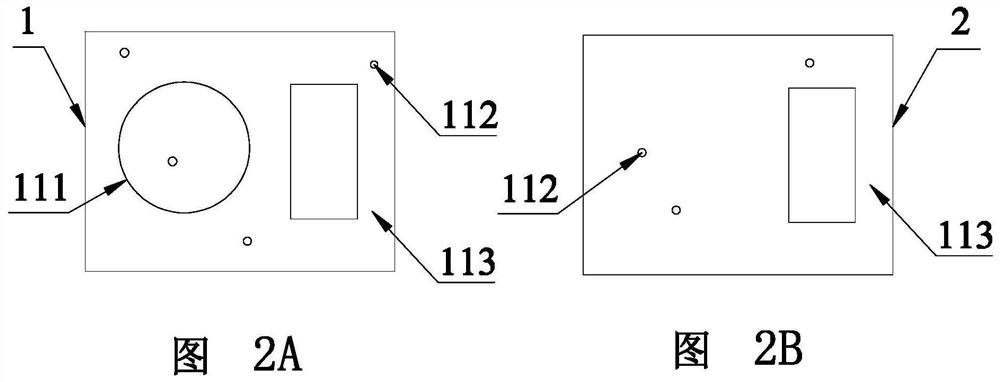

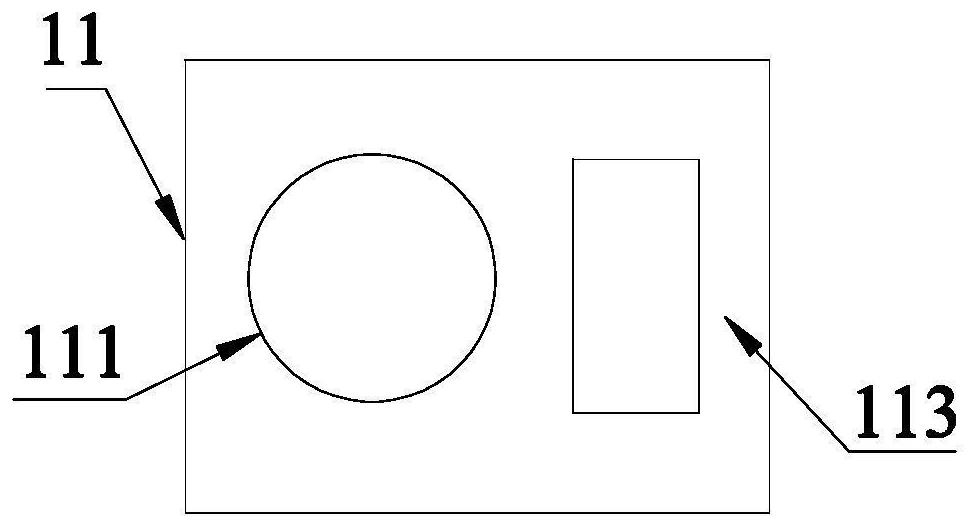

Image change area detection threshold setting method and system and electronic device thereof

ActiveCN109903265AFast and precise identificationHigh precisionImage enhancementImage analysisVisual recognitionDetection threshold

The invention relates to the field of intelligent visual recognition, in particular to an image change area detection threshold setting method and system and an electronic device thereof. The method comprises the steps of obtaining a first image before and after scene change and a second image corresponding to the first image, and performing fuzzification processing on the first image and the second image to obtain a processed first blurred image and a processed second blurred image; Calculating a difference value between corresponding pixel points of the first blurred image and the second blurred image to obtain a first difference image; And further optimizing the first difference image to obtain a second difference image, and processing the second difference image by using an Otsu algorithm to obtain a threshold value detected based on a change area between the first image and the second image. According to the method, the image change area can be accurately and efficiently detectedby obtaining the threshold value, environmental interference is prevented from influencing the image change detection precision, and the use requirements of the field of contemporary intelligent containers are met. The image change area detection threshold setting system and the electronic device thereof have the same beneficial effects as the method.

Owner:创新奇智(南京)科技有限公司

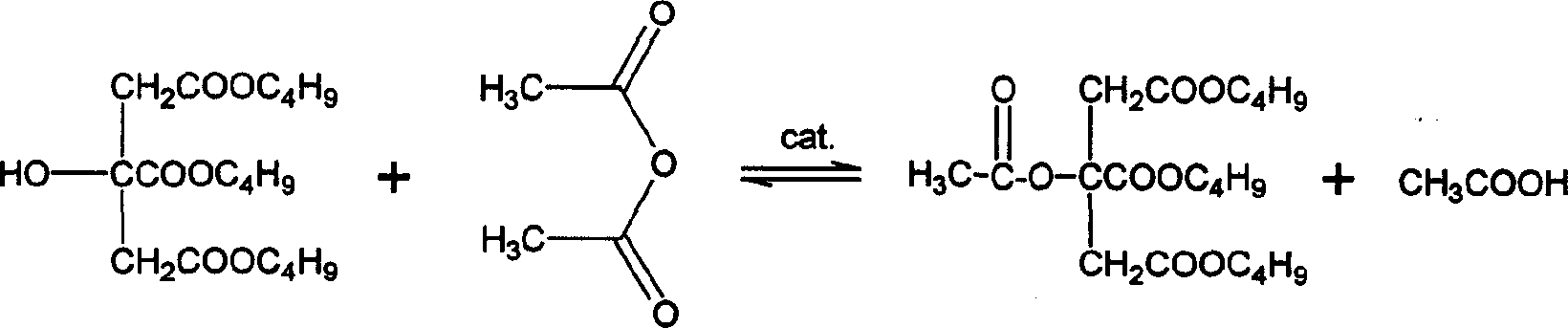

Catylatic synthesizing method of acetyl tri-in-butyl citrate

InactiveCN1709854AHigh purityAvoid separation difficultiesOrganic chemistryChemical recyclingWater bathsAcetic anhydride

This invention has disclosed a kind of catalyzed synthesis method for acetyl tri-n-butyl citrate; its step is as follows: -Join tri-n-butyl citrate and acetic anhydride, catalyst in three-necked flask, which is in water bath, mix and react, gain acetyl tri-n-butyl citrate; -Recover catalyst from above-mentioned coarse product, distill acetic anhydride and acetic by pressure reduction, wash by deionized water and alkaline solution, then bath to water-phase to neutrality, distill water off by pressure reduction. This method is simple and the catalyst used is choiceness recyclable, and easy to gain. In agreeable condition, this method can make tri-n-butyl citrate complete liquefaction basically, have prevented tributyl citrate and acetyl tri-n-butyl citrate from separating problem, the purity of acetyl tri-n-butyl citrate is above 99% analysed by gas chromatography.

Owner:ZHEJIANG UNIV

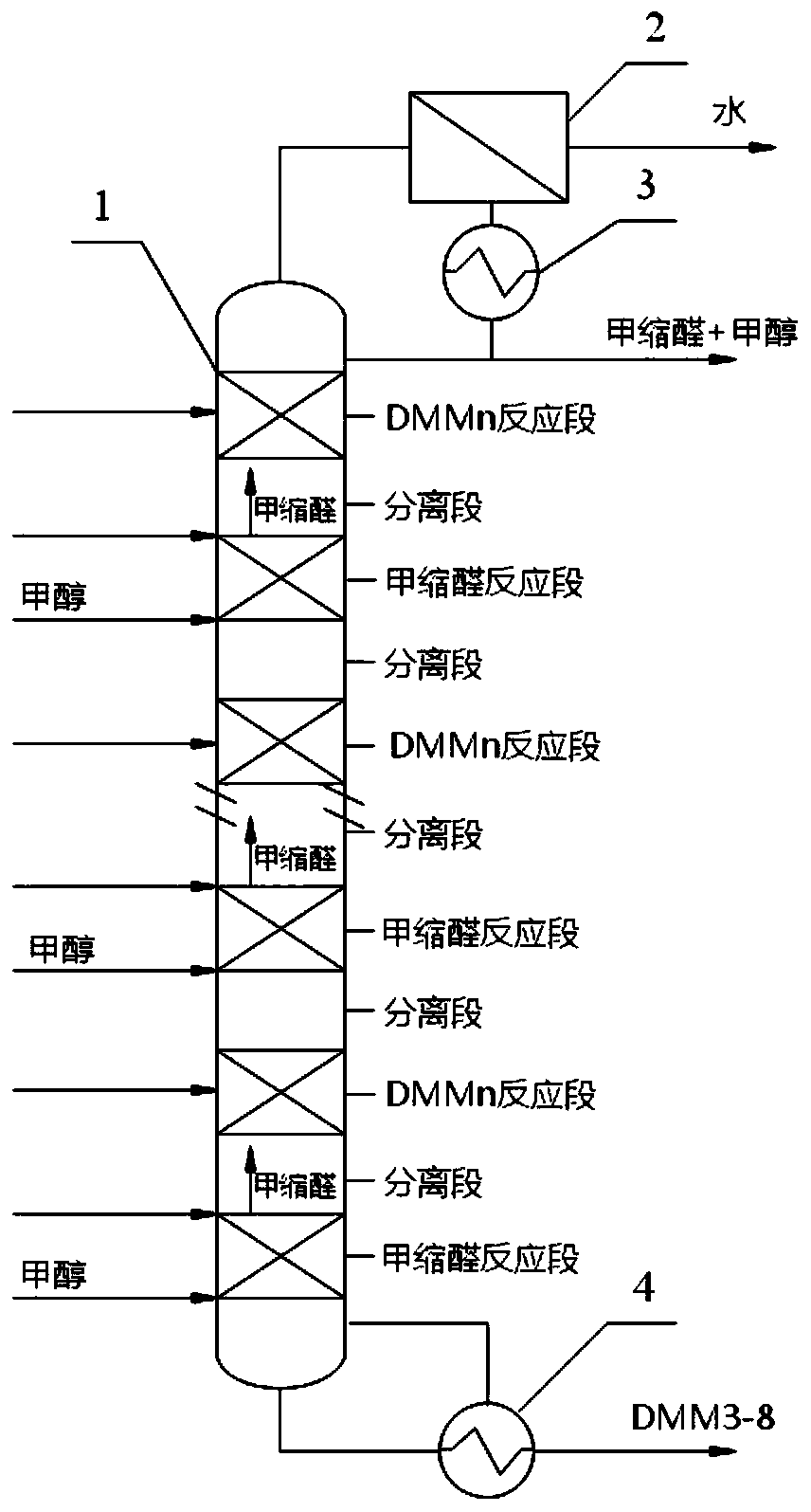

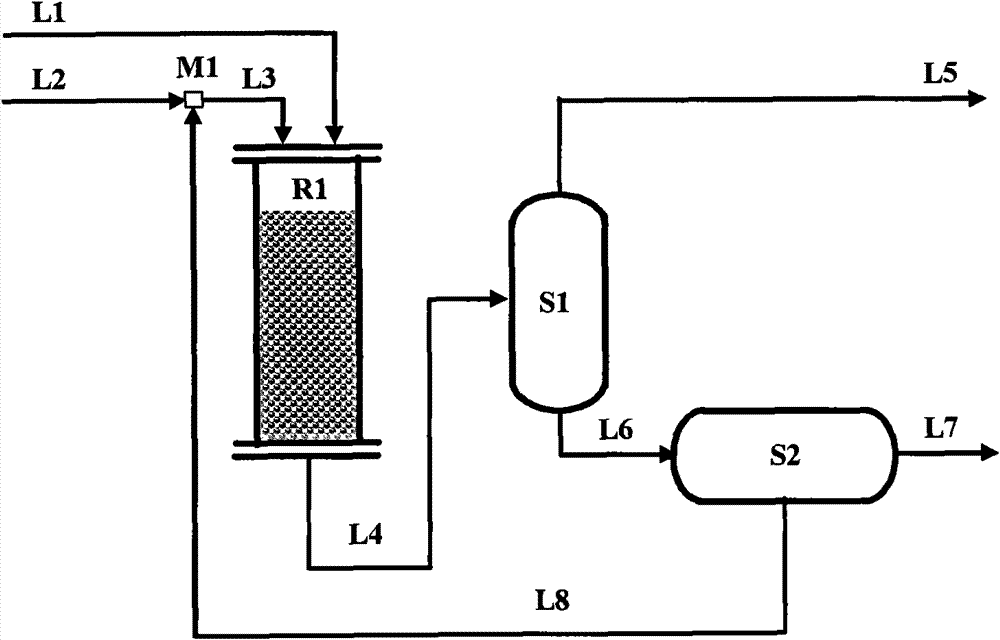

Multi-stage reactive distillation synthesis technique and device of PODEn (polyoxymethylene dimethyl ethers)

ActiveCN110078598ALow priceImprove processing economyOrganic chemistryOrganic compound preparationCouplingStream flow

The invention provides a multi-stage reactive distillation synthesis technique and device of PODEn (polyoxymethylene dimethyl ethers). According to the technique, industrial methanol and a formaldehyde solution are taken as raw materials, a methylal reactive distillation column and a PODEn reactive distillation column are combined in one set of equipment, two reaction processes are combined by sufficient use of advantages of the reactive distillation columns and equipment coupling advantages, the reaction conversion rate and the target product yield are effectively increased, the circular stream flow is reduced, and the equipment efficiency is improved. According to the technique, the cost of used raw materials is low, the reaction process is controllable, the investment and the cost are low, no other substances are introduced, the process is environmentally friendly, and the technique has good application prospects.

Owner:TIANJIN UNIV

Organic electroluminescence material and device

InactiveCN1367223AAvoid control difficultyAvoid separation difficultiesEnergy efficient lightingLuminescent compositionsElectricityLuminescent polymers

The present invention relates to an organic electroluminescence material and its electroluminescence device. This invention adopts the introduction of group into 5-position of quinoline ring of aluminium 8-hydroxyquinolinate to design and synthesize the aluminium 8-hydroxyquinoliate derivative bioluminescence material which not only possesses good luminescence property and electronic transmissioncapacity, but also can be uniformly dissolved in organic polymer. According to luminescent colour it can be compounded and made into new luminescence material capable of giving various colour lights,including white light. This invented device is a single-layer compound functional film luminescent device.

Owner:SICHUAN UNIV

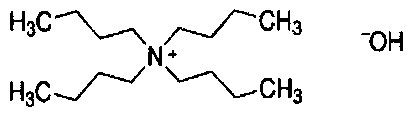

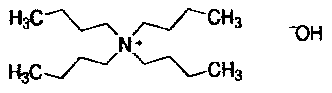

Method for improving enzymatic hydrolysis efficiency by adopting hydrothermal-microwave approach combined with ionic liquid for two-step pretreatment of lignocellulose raw material

The invention relates to the field of biomass pretreatment and provides a method for improving the enzymatic hydrolysis efficiency by adopting a hydrothermal-microwave approach combined with an ionicliquid for two-step pretreatment of a lignocellulose raw material. The method can effectively improve the enzymatic hydrolysis efficiency of the lignocellulose raw material. The pretreatment method aims to achieve the effects that the method is environmentally friendly, the material is recyclable and the energy consumption and the cost are low, and the use rate of the ionic liquid is increased. Byadopting the hydrothermal-microwave approach combined with the ionic liquid tetrabutylammonium hydroxide [TBA][OH] for carrying out pretreatment sequentially on the lignocellulose raw material, the lignocellulose raw material is effectively destructed, the wetting effect of tetrabutylammonium hydroxide [TBA][OH] on lignocellulose is enhanced, more tetrabutylammonium hydroxide [TBA][OH] enters thelignocellulose through destroyed gaps in the surface of the lignocellulose, structures of hemicellulose and lignin are broken, depolymerization among the hemicellulose, the lignin and cellulose occurs, and correspondingly the solubility degree of tetrabutylammonium hydroxide [TBA][OH] on the cellulose is increased.

Owner:SOUTH CHINA AGRI UNIV

Iron symbiotic non-ferrous metal copper-lead-zinc comprehensive recovery process

ActiveCN112619878AReduce the difficulty of separationAvoid separation difficultiesFlotationProcess efficiency improvementOre concentrateNon-ferrous metal

The invention relates to an iron symbiotic non-ferrous metal copper-lead-zinc comprehensive recovery process. The process comprises the following steps of carrying out medium-weak activation and weak collection on copper-lead-zinc mixed flotation, strongly removing chemicals, separating low-concentration copper from lead and zinc, and separating lead and zinc minerals by using a small-stroke large-stroke-frequency micro-fine mud shaking table. By means of hydrophobicity of copper-lead-zinc minerals after iron separation, copper-lead-zinc weak activation and weak collection complete mixed separation is achieved, the agent cost is saved, and the problems that due to strong activation and strong collection of a traditional process, the technical index of copper and lead-zinc separation is poor, and concentrates are high in mutual content are solved; copper is separated from lead and zinc by adopting low-concentration strong reagent removal, and copper and lead and zinc minerals are separated by utilizing the natural floatability of copper minerals on the basis of cleaning and activation of dilute sulfuric acid and pyrosulphurous acid; and lead-zinc concentrate adopts the micro-fine mud shaking table, the separation process of micro-particle lead-zinc minerals is strengthened by small stroke, large stroke-frequency and no flushing water, single lead concentrate and zinc concentrate are obtained, and the problems that the single lead concentrate and zinc concentrate cannot be obtained through iron-symbiotic copper-lead-zinc separation, the separation efficiency is low, the concentrate mutual content is high, and the concentrate value is low are solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

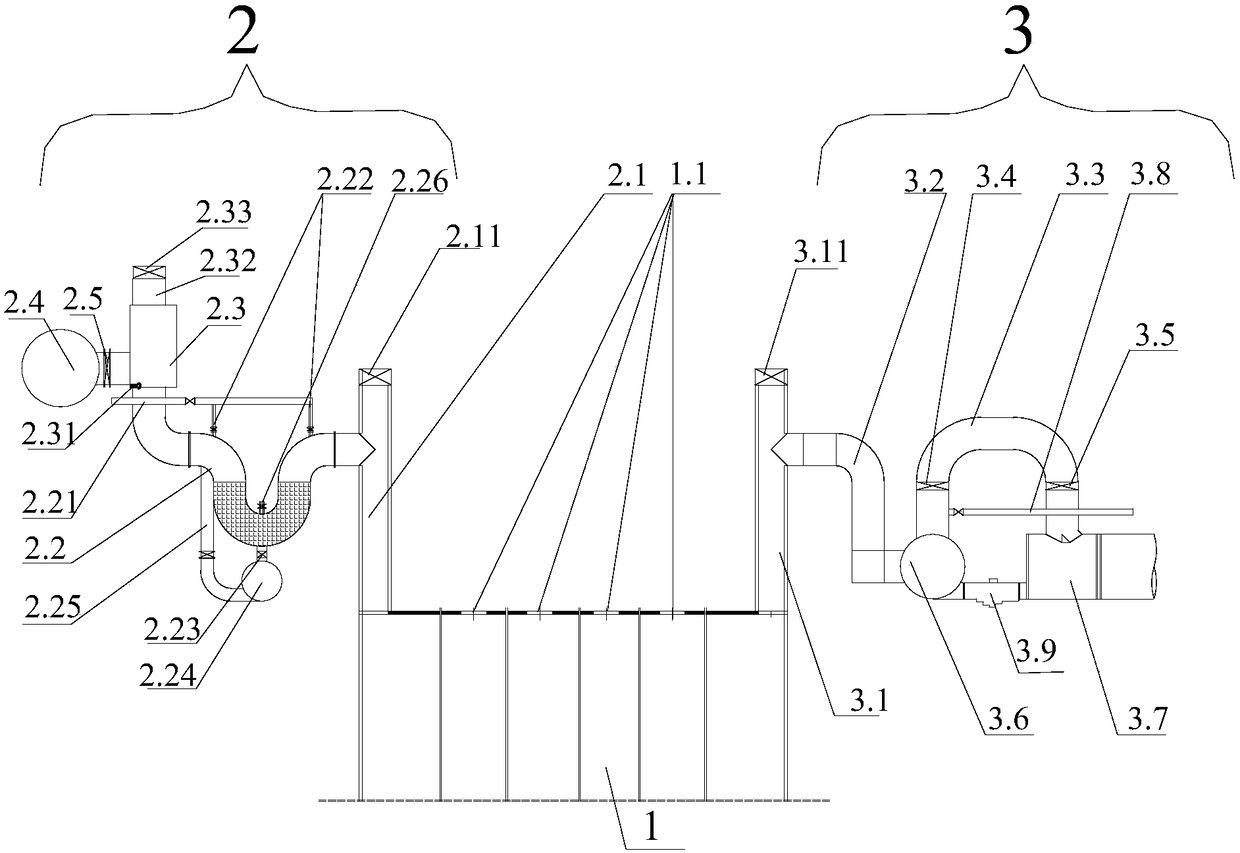

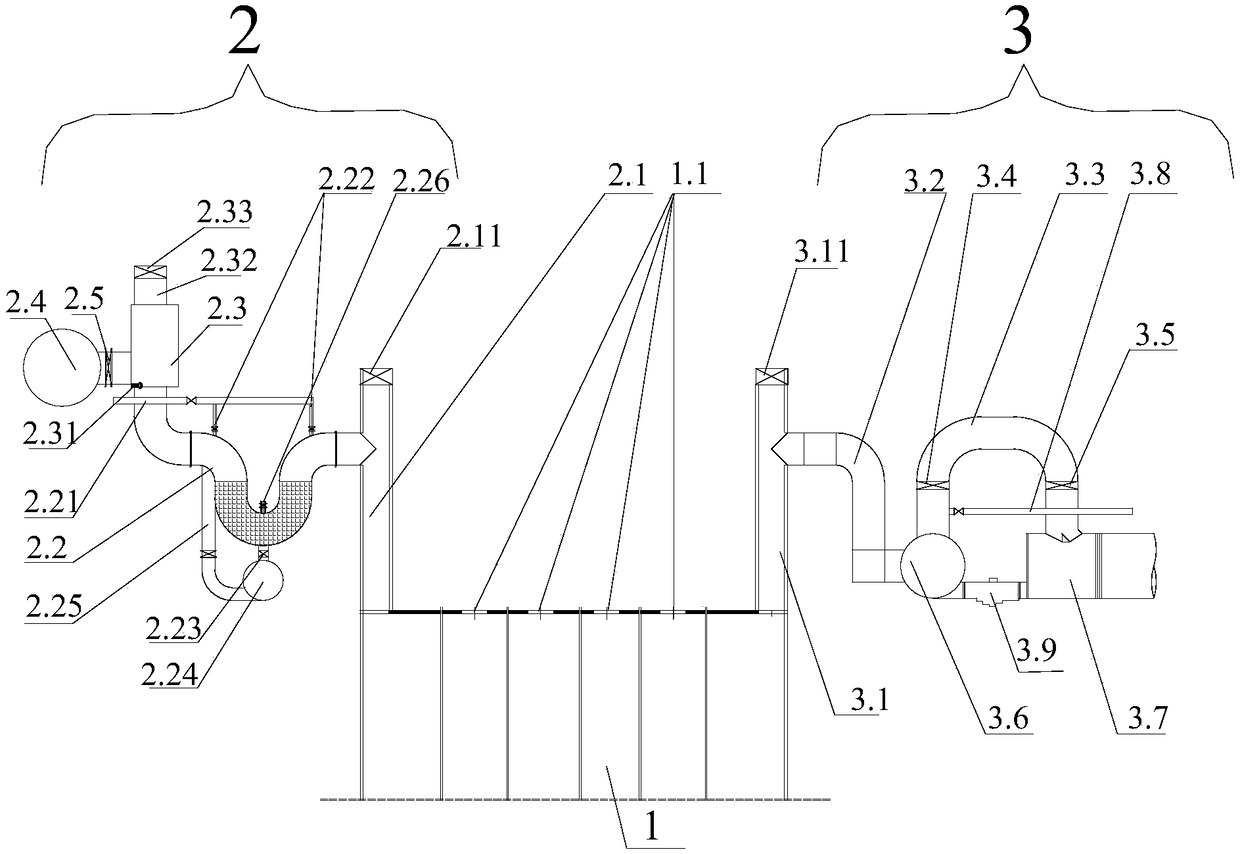

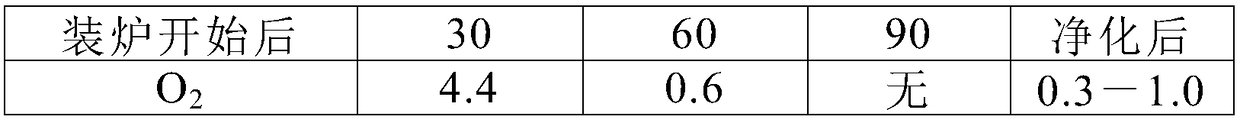

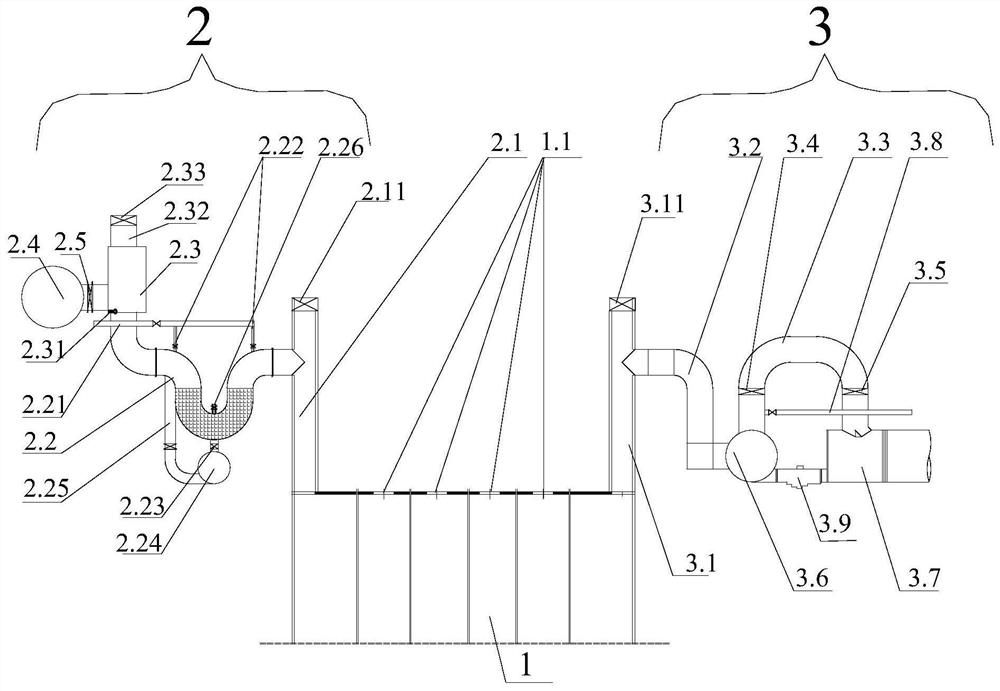

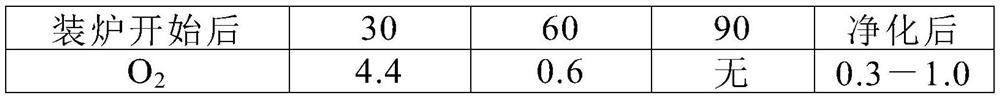

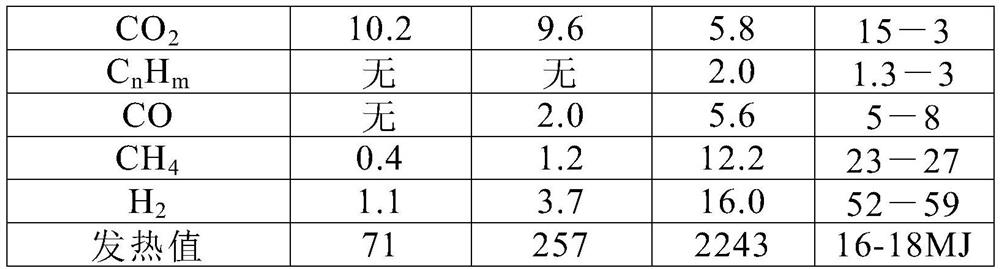

Coke oven carbonization chamber fume and dust treatment system based on gas separate recycling

ActiveCN108504370AImprove qualityAvoid separation difficultiesEnergy inputOven incrustations prevention/removalGas collecting tubeCombustion chamber

The invention discloses a coke oven carbonization chamber fume and dust treatment system based on gas separate recycling, and belongs to the technical field of coking industry energy conservation andenvironmental protection. The system comprises a machine side coke oven gas recycling system which is arranged on the machine side of a coke oven carbonization chamber and used for recycling raw gas generated by coking coal in the mid-term of coking and a coke side coaling fume and dust recycling system which is arranged on the coke side of the coke oven carbonizatin chamber and used for recyclingcoaling fume and dust generated in the coaling process and raw gas generated by the coking coal in the initial stage and terminal stage of coking, the coke side coaling fume and dust recycling systemcomprises a water-sealed valve, a coaling fume and dust combustion chamber connected with one end of the water-sealed valve and a coke side gas collecting tube used for conveying the fume and dust toa coke oven combustion chamber, the coaling fume and dust combustion chamber is further internally provided with an automatic igniter and a combustion emission opening kept to be communicated with the outside atmosphere. According to the system, waste heat recycling in the coaling process and the coking process can be achieved simultaneously, and the occurrence rate of accidents is reduced.

Owner:武汉钢铁有限公司

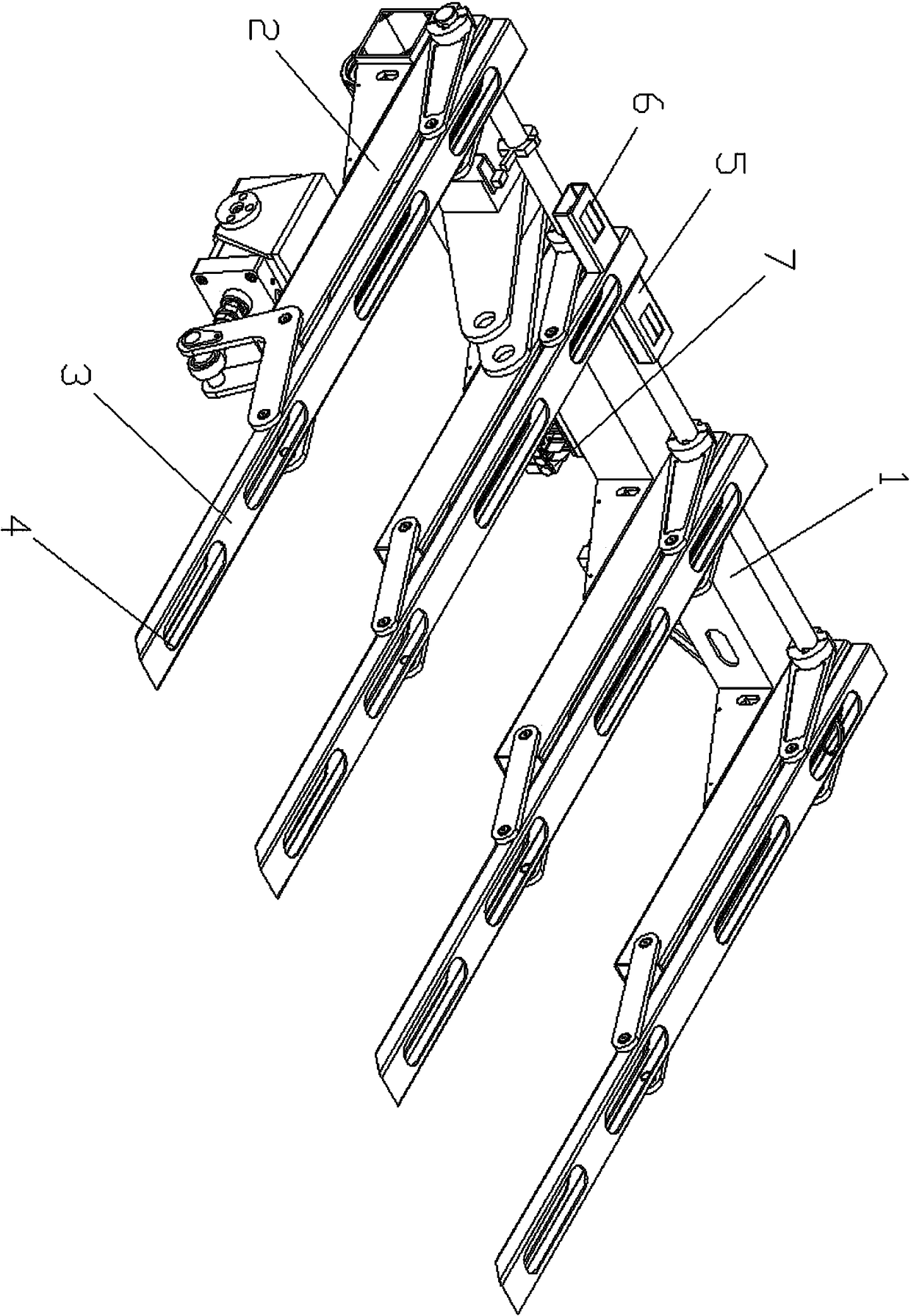

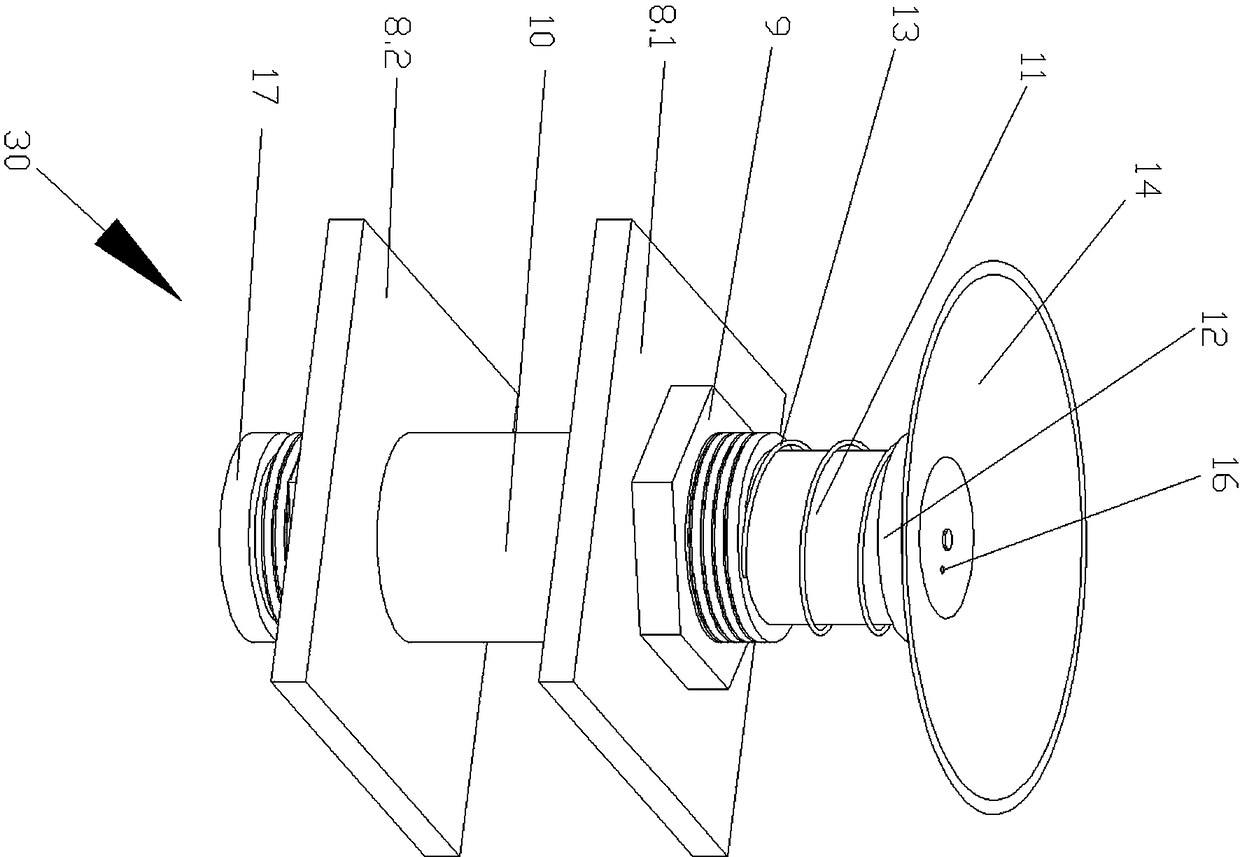

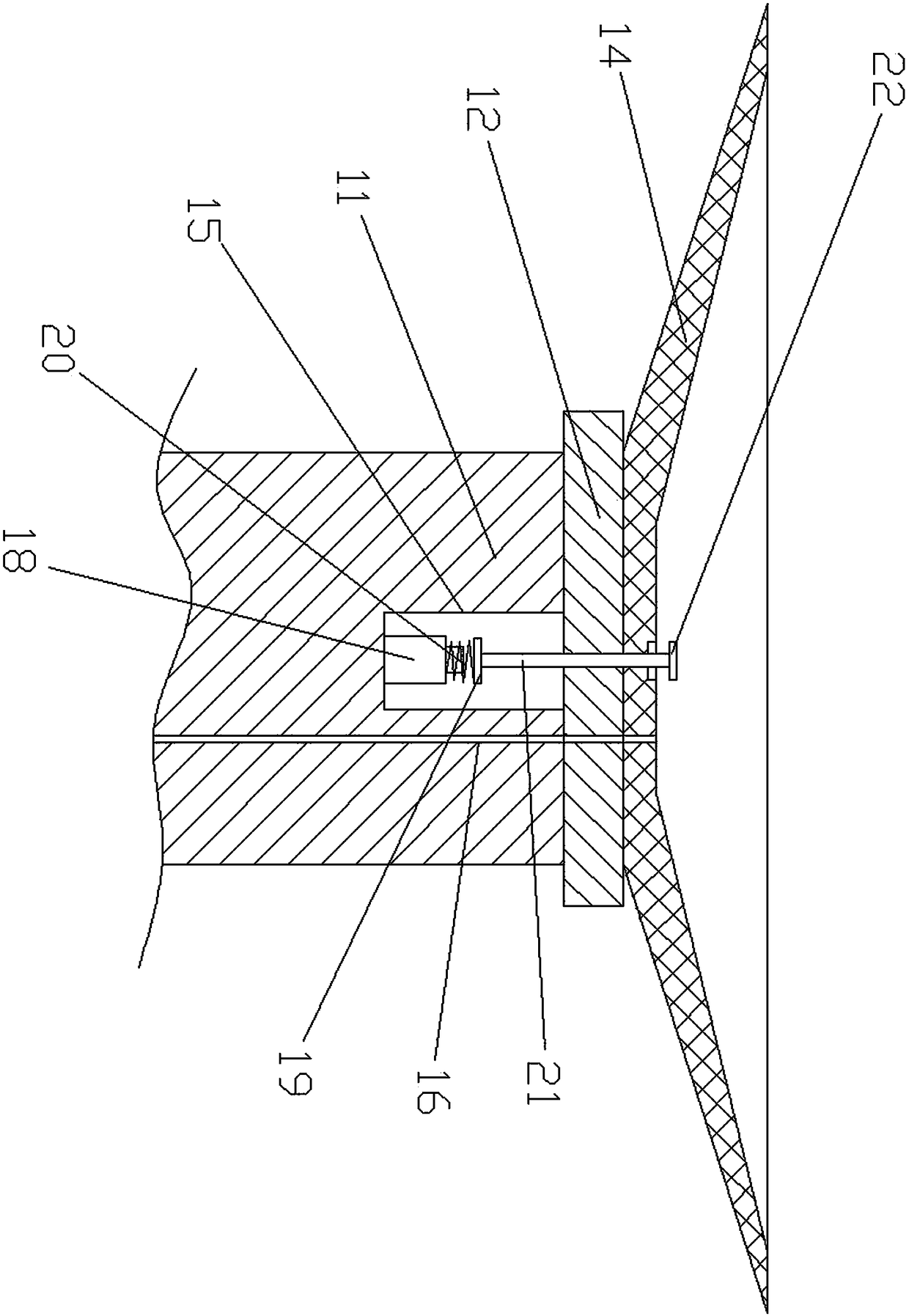

Glass feeding device capable of achieving automatic discharging

InactiveCN109132557AAvoid separation difficultiesPrevent security incidentsCharge manipulationConveyor partsEngineeringVacuum pump

The invention discloses a glass feeding device capable of achieving automatic discharging. The glass feeding device comprises a turnover shaft. A set of turnover arms are evenly and fixedly connectedto the upper side of the turnover shaft. A square pipe is arranged on the upper side of each turnover arm. A set of first straight circular grooves are evenly arranged on the upper side of each squarepipe at intervals. An auxiliary suction cup is mounted on each fixed plate. Each glass suction cup is connected with a vacuum pump through an air pipe, a solenoid valve is mounted on each air pipe, and the solenoid valves are evenly fixed to the lower side of the turnover shaft. Mounting grooves are arranged on the upper sides of sliding shafts, a travel switch is arranged in each mounting groove, a first pressing plate is further arranged in each mounting groove, each first pressing plate is located above the corresponding travel switch, and a second spring is arranged between each first pressing plate and the corresponding travel switch. The glass feeding device has the advantages that whether discharging of the suction cups succeeds or not can be detected through the travel switches, safety accidents caused by suction cup discharging failures are effectively avoided, and the problem that suction cups and glass plates are hard to separate due to water spots is avoided.

Owner:蚌埠贝特智能科技有限公司

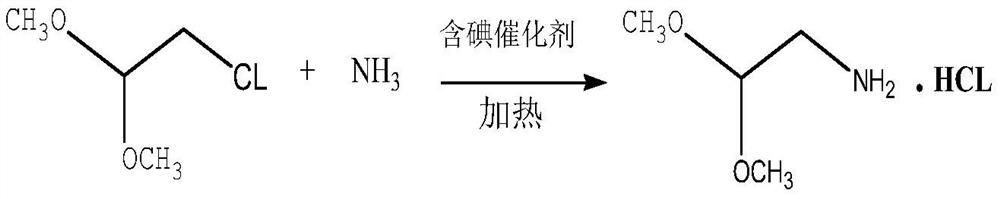

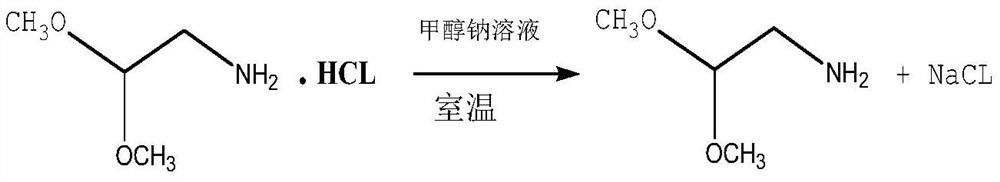

Production process of high-purity aminoacetaldehyde dimethyl acetal

PendingCN112375003AAvoid separation difficultiesHigh purityOrganic compound preparationAmino-hyroxy compound preparationPtru catalystDimethyl acetal

The invention discloses a production process of high-purity aminoacetaldehyde dimethyl acetal. The process comprises the following steps: proportionally mixing chloroacetaldehyde dimethyl acetal withanhydrous liquid ammonia to react, and carrying out ammoniation, deamination recovery, alkali neutralization desalination, distillation and rectification in the presence of an iodine-containing catalyst to obtain the high-purity aminoacetaldehyde dimethyl acetal. According to the method, chloroacetaldehyde dimethyl acetal is innovatively used as a main raw material, anhydrous liquid ammonia is used as a solvent and a reaction raw material, an iodine-containing catalyst is added, and the anhydrous high-purity aminoacetaldehyde dimethyl acetal is obtained through ammoniation, deamination, alkalineutralization desalination, distillation and rectification. In practice, the technical process can reduce the generation of by-product conjugates, can realize higher conversion rate than the traditional process under the condition of higher catalytic effect, and simultaneously reduces the requirements on organic solvents and energy sources; and under the condition of the same proportion, the single-batch feeding amount and the product yield of the novel process are improved by 50% or above, the yield is about 20% higher than that of a traditional process, and the effects of saving energy, improving quality, reducing cost and reducing consumption can be achieved.

Owner:INNER MONGOLIA SAINTCHEM CHEM

Parallel methyl ester method for fats and oils in high acid value

InactiveCN100572517CReduce dosageEmission reductionFatty acid esterificationMonoglyceridePresent method

Owner:WUHAN POLYTECHNIC UNIVERSITY

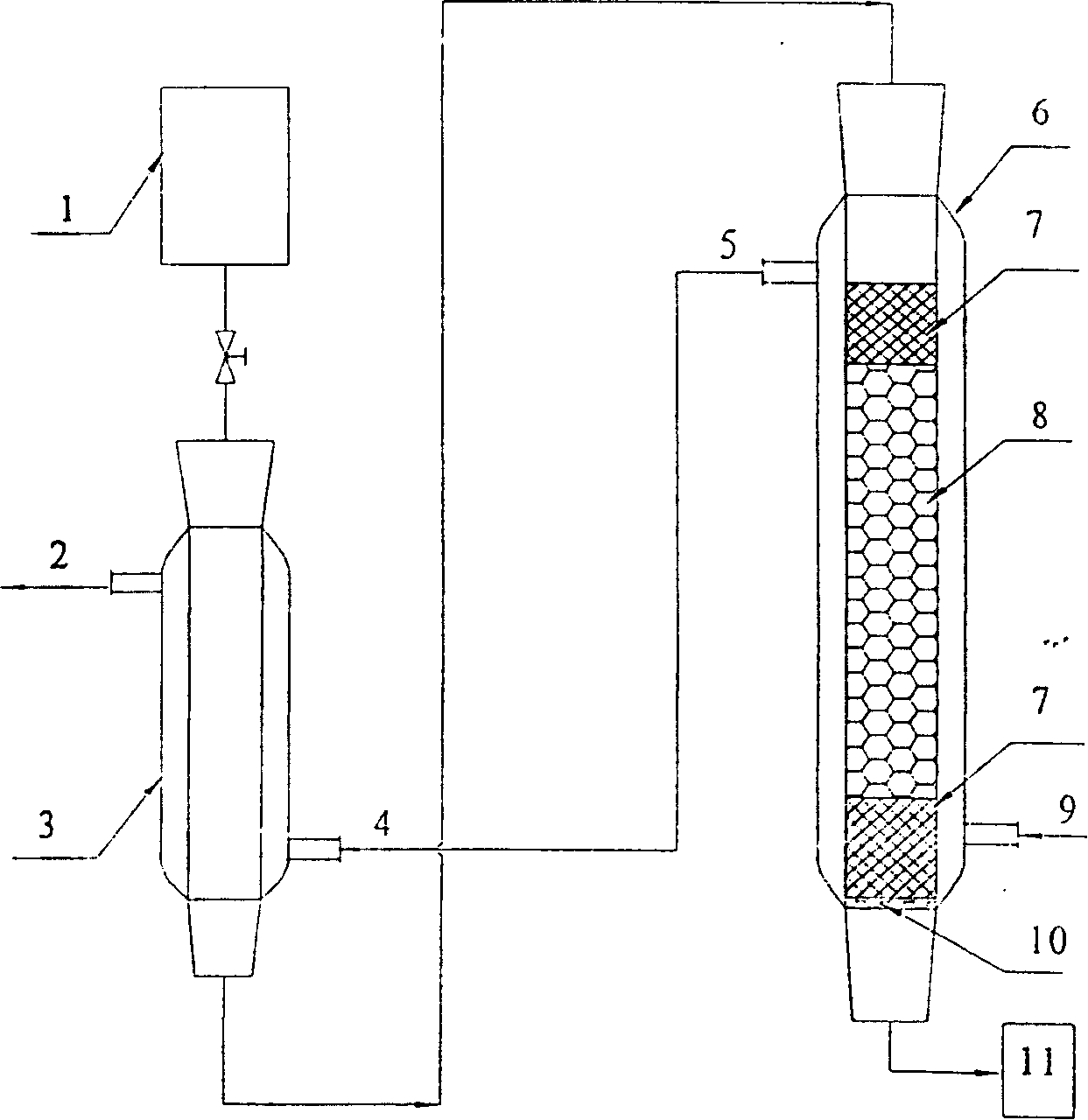

Device and method for catalytic synthesis of acetyl tri-n-butyl citrate by fixed bed reactor

InactiveCN100387569CSolution to short lifeHigh purityOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The invention discloses a method and setting of acetyl tributyl that is catalytic synthesized by solid-bed reactor. The steps are as follows: 1) adding accelerant and filler in solid-bed reactor according to priority by direct filling method, preheating and keeping constant temperature by constant temperature water; 2) preheating acetyl tributyl and acetic anhydride by preheating section, and then entering pipe fixed bed for reaction, getting acetyl tributyl crude product; 3) vacuum distilling the mention crude product to recover acetic anhydride and ethyl acetate, washing by aqueous alkali, and then rinshing to water phase show neutral, removing moisture by vacuum distillation, getting the acetyl tributyl. This invention is easy to accomplish, the setting is few, the operating condition is easy to control, the used accelerant is cheap and easy getted, the catalysis performance is good, the agelimit is long and regenaration is easy. The getted acetyl tributyl is more than 99% by gas-chromatography analysis.

Owner:ZHEJIANG UNIV

Preparation method of 2,3,6-trichloropyridine

The invention discloses a preparation method of 2,3,6-trichloropyridine. The method comprises the following steps: taking a pyridine solution as a raw material, carrying out preheating and gasifying,and sending the gasified pyridine solution to a fixed bed reactor by using a carrier gas, and carrying out a reaction on pyridine with chlorine under the action of a molecular sieve catalyst to generate the 2,3,6-trichloropyridine, wherein the molecular sieve catalyst is an HZSM-5 molecular sieve, the molar ratio of the pyridine to the chlorine is 1:(3-12), the weight hourly space velocity of thepyridine is 0.12-2 h<-1>, and the reaction temperature is 200-450 DEG C. The method disclosed by the invention is short in technological process, low in raw material cost and simple in post-treatment;the highest selectivity of the 2,3,6-trichloropyridine can reach 95% or above; and the highest yield can reach 90% or above.

Owner:CHONGQING ZHONGBANG TECH CO LTD

Printing machine with discharging and static electricity removing device

InactiveCN109986879AAvoid separation difficultiesEliminate static electricityPrinting press partsElectrostatic chargesElectricityPower flow

The invention discloses a printing machine with a discharging and static electricity removing device. The printing machine comprises a printer; a discharging device is fixedly installed on one side ofthe printer, the top of the discharging device is fixedly connected with the bottom of a supporting column, the top of the supporting column is fixedly connected with the bottom of a static electricity removing device; the static electricity removing device comprises a box body, a containing cavity is formed in the box body, and a conductive plate is placed at the bottom of the inner wall of thecontaining cavity. According to the invention, a power supply device, an electrode plate and a needle-shaped electrode are matched; the power supply device provides power, therefore, current is generated on a motor plate; therefore, the needle-shaped electrode generates corona to generate electric ions, the electric ions can neutralize charges on the surface of a printing paper, so the static electricity on the surface of the paper is eliminated, and the effects that the static electricity on the surface of the paper is eliminated are realized, the problem that the paper is difficult to separate due to electrostatic bonding is solved, and the printing work is more convenient and faster.

Owner:天津市慧翔实业集团有限公司

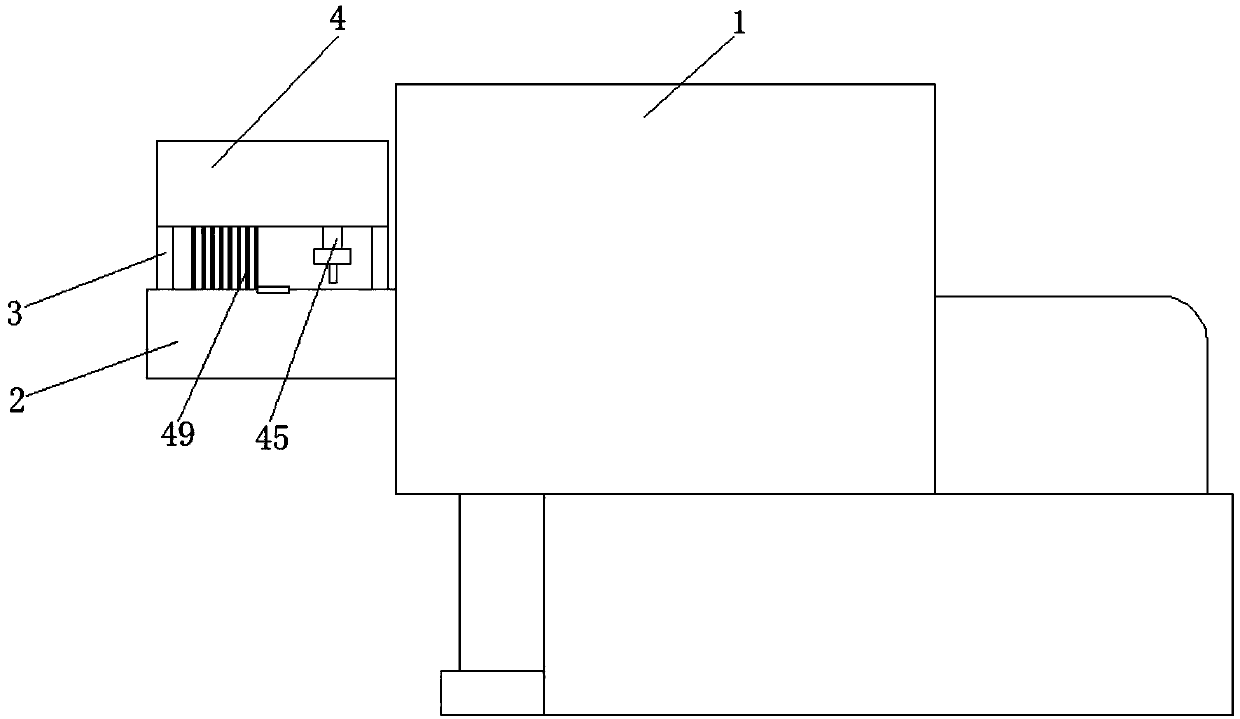

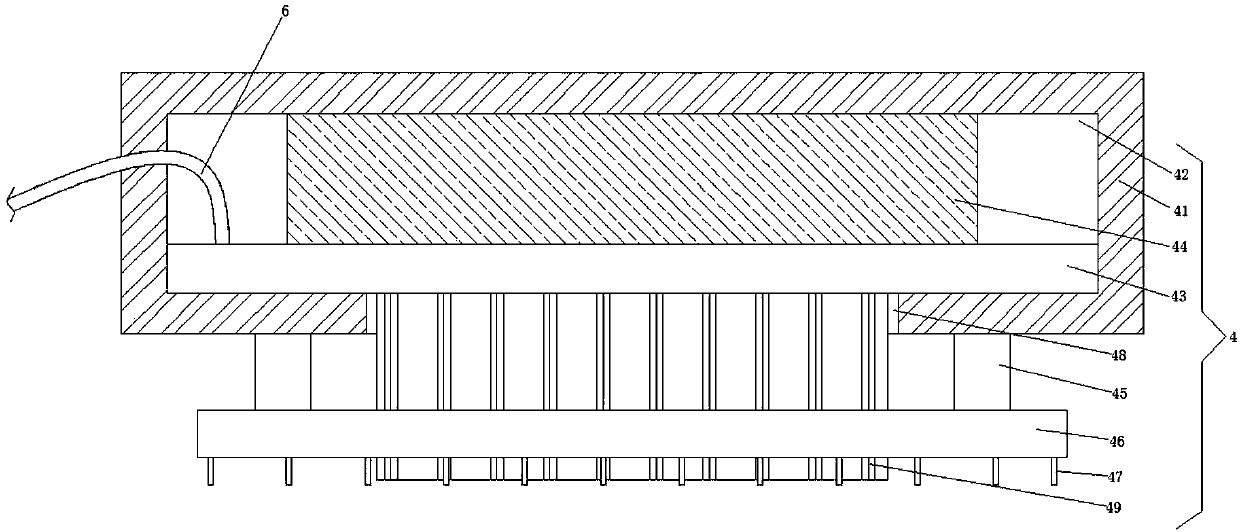

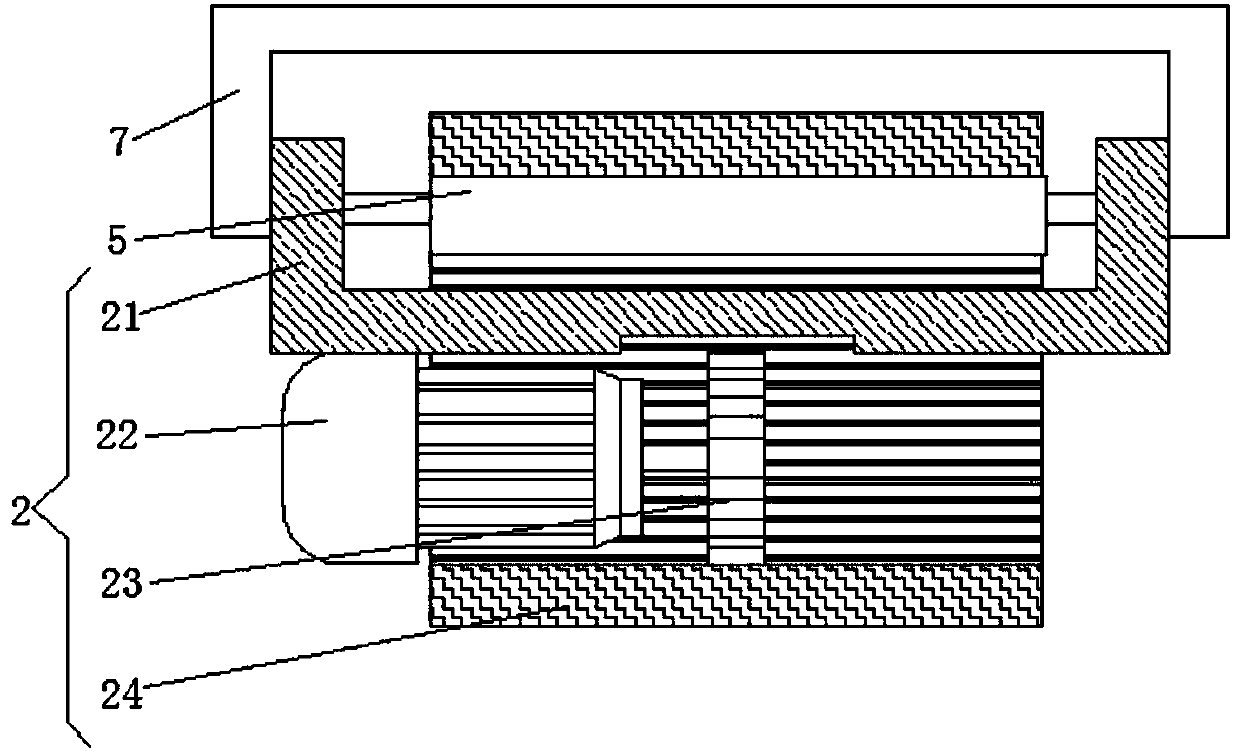

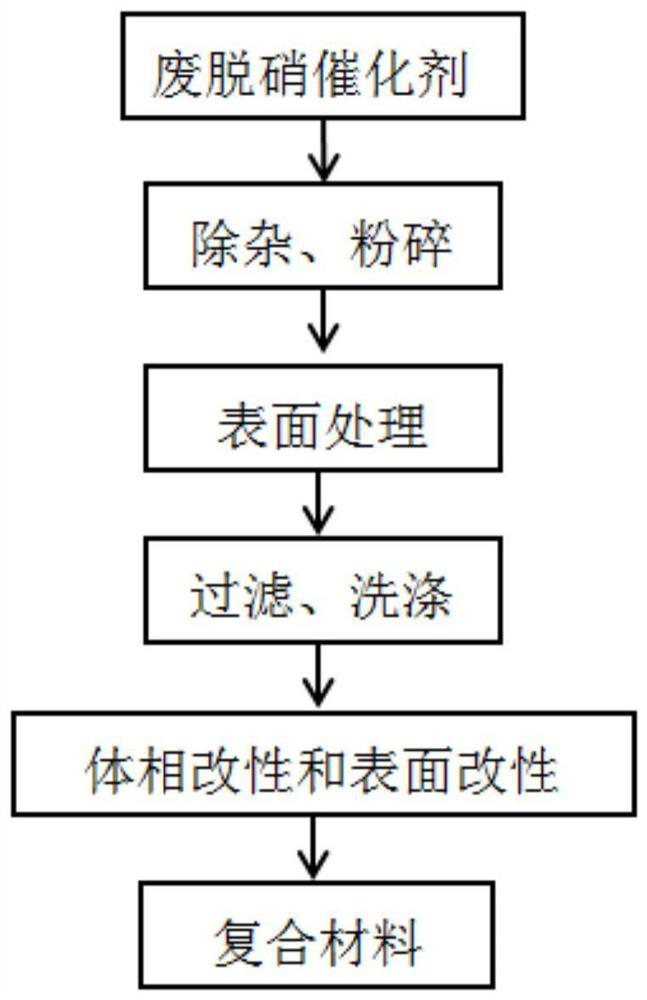

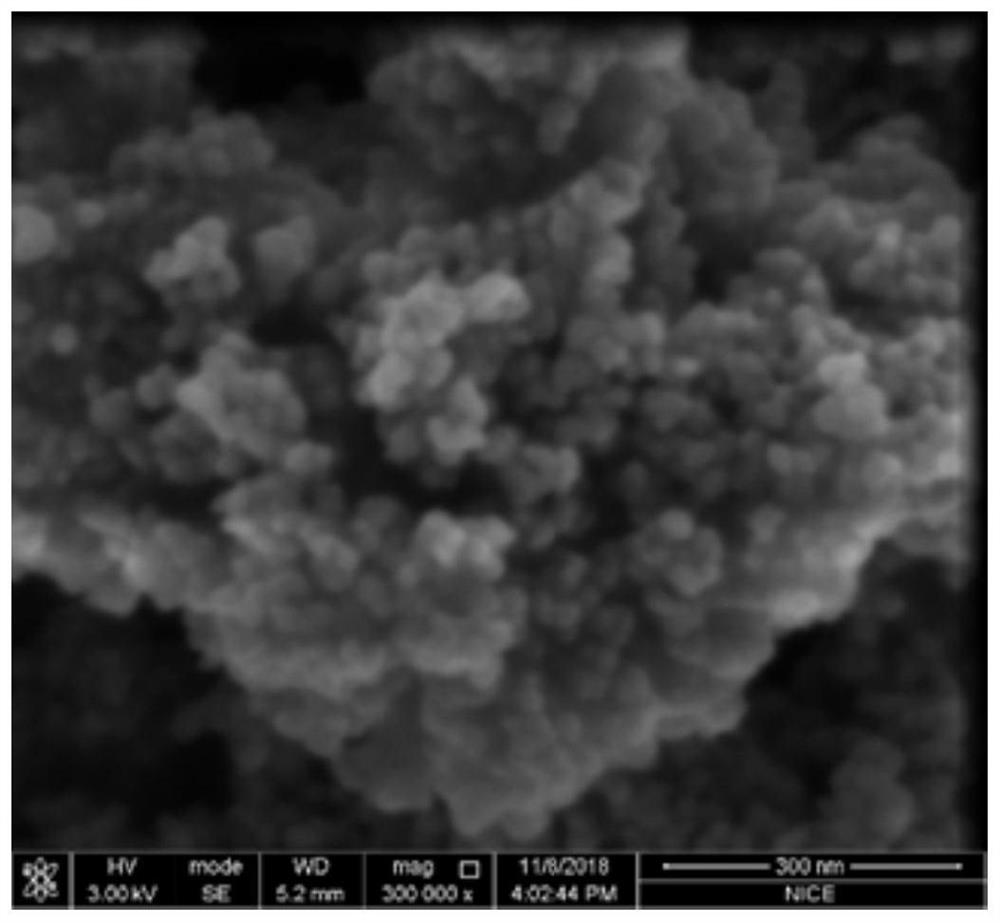

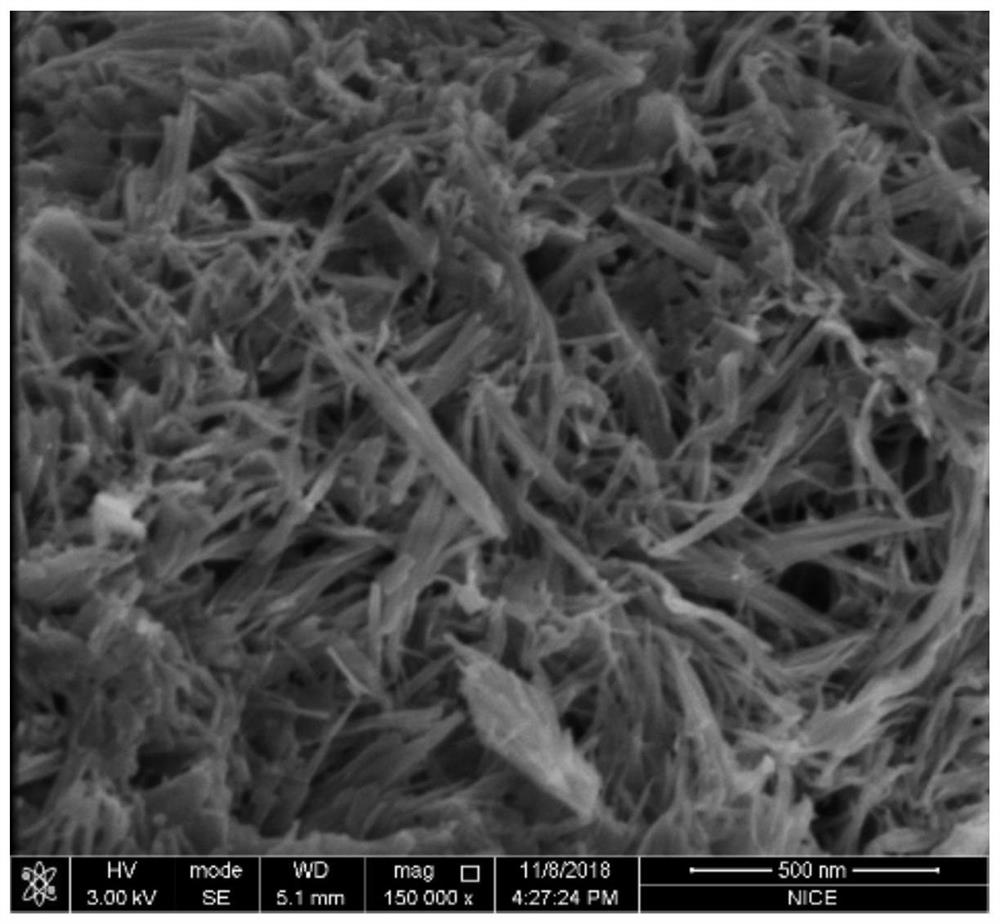

Composite material as well as preparation method and application thereof

PendingCN112156816ALarge specific surface areaReduce moisture contentDispersed particle separationCatalyst regeneration/reactivationPtru catalystAlkali metal

The invention relates to the field of waste catalyst treatment, and discloses a composite material as well as a preparation method thereof, wherein the composite material comprises a spherical inner layer and a coating layer coating at least part of the outer surface of the spherical inner layer, the coating layer is whisker-shaped and / or columnar, and the content of the coating layer is 5-30 wt%based on the total weight of the composite material. The composite material has high specific surface area and low water content; the content of harmful elements such as alkali metal, arsenic, iron and phosphorus in the composite material is remarkably reduced. When the composite material provided by the invention is used for preparing the denitration catalyst, roasting is not needed, and therefore the investment and the operation cost are remarkably reduced. Meanwhile, according to the method provided by the invention, valuable elements in the waste catalyst do not need to be respectively extracted, so that the technological process is simplified, the emission of waste byproducts is reduced, and the secondary pollution is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

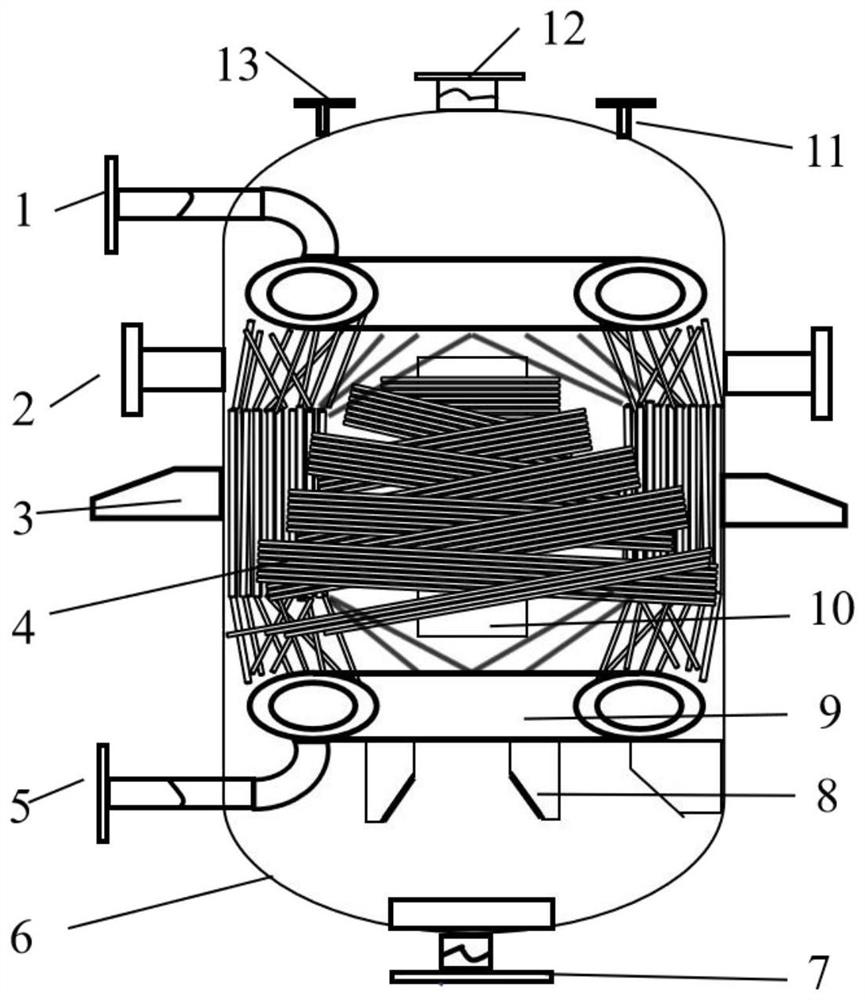

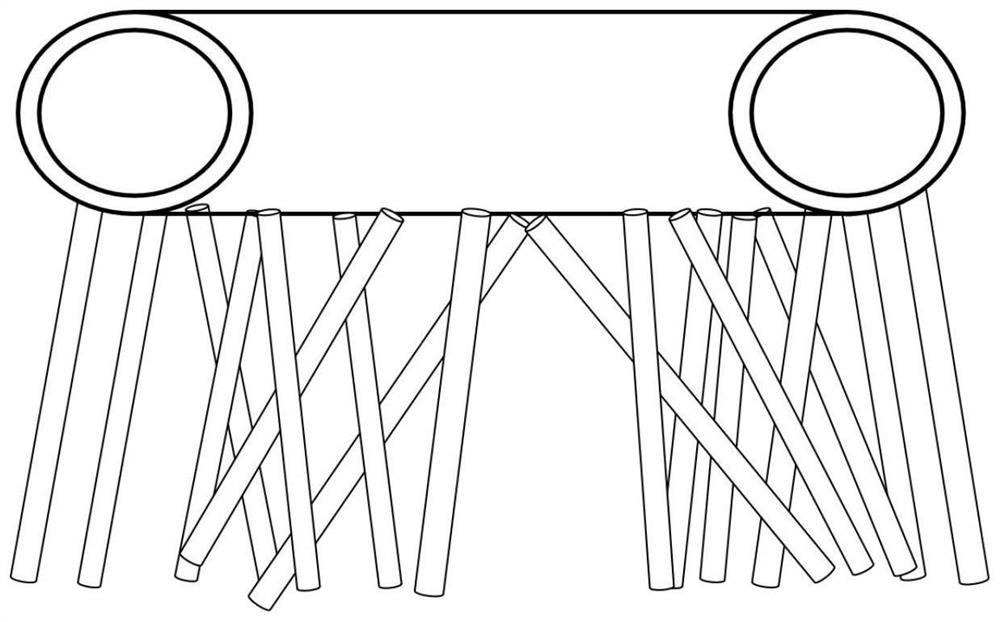

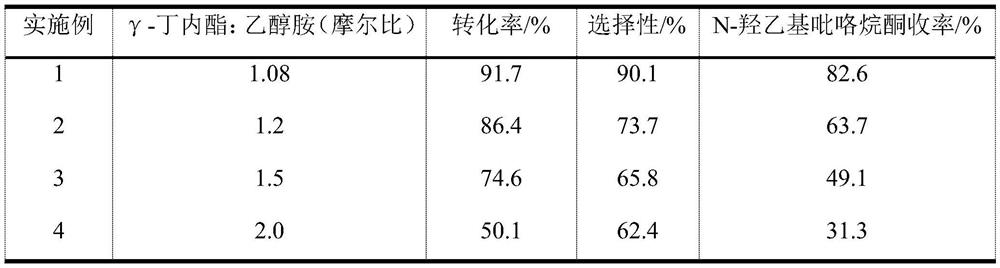

Method for preparing pyrrolidone and derivatives thereof by continuous tubular reactor

InactiveCN113527169AEasy to operateAvoid separation difficultiesOrganic chemistryProcess engineeringPerylene derivatives

The invention relates to a method for preparing pyrrolidone and derivatives thereof by a continuous tubular reactor. According to the method, a vertical winding tubular reactor is adopted, gamma-butyrolactone, ethanol amine and other organic amines are taken as raw materials, water is taken as a solvent, no catalyst participates, and the defects of complex technological process, low equipment utilization rate and difficulty in improving the production efficiency in an intermittent kettle reaction process are overcome. According to the method, automation and continuity of the production process can be achieved, meanwhile, the product selectivity is greatly improved, the technological operation is simple, and the process is convenient to regulate and control.

Owner:HEBEI UNIV OF TECH

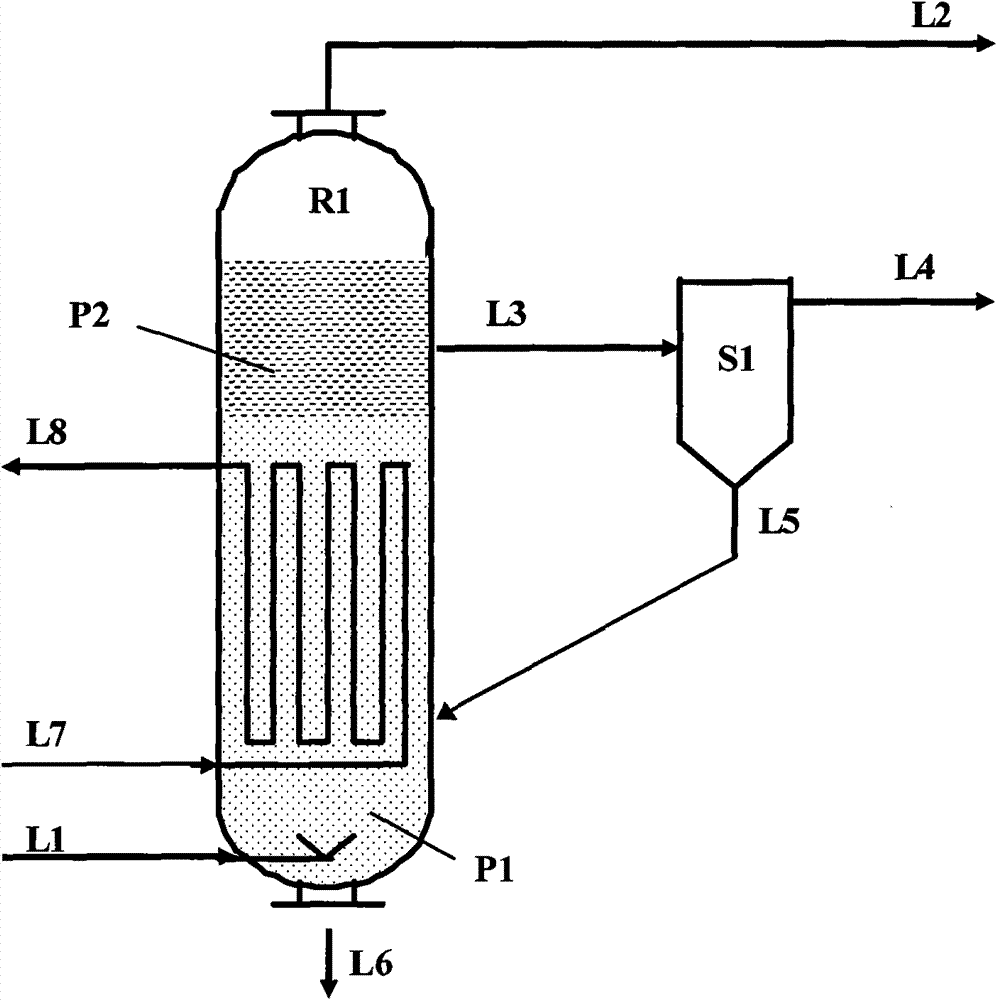

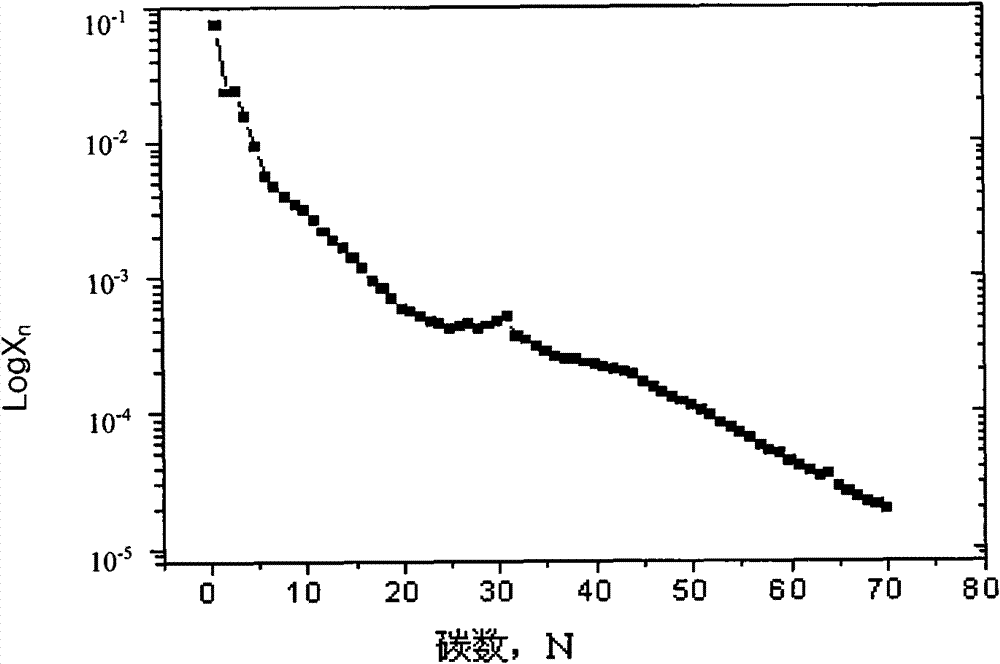

Method for producing linear alpha-olefins (LAOs) through Fischer-Tropsch synthesis of solvent phase

ActiveCN102408908BHigh activityDiffusion rate is fastHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionPtru catalystCombinatorial chemistry

The invention discloses a solvent phase Fischer-Tropsch synthesis method. The method is characterized in that a Fischer-Tropsch synthesis reaction is carried out in a heterogeneous reaction system; a polar solvent is taken as the reaction medium; a traditional granular Fischer-Tropsch synthesis catalyst is suspended or soaked in the polar solvent phase to carry out the Fischer-Tropsch synthesis reaction; and as the generated hydrocarbon products are insoluble in the polar solvent, the phases are voluntarily split. The method can be used for producing linear alpha-olefins (LAOs) with various carbon numbers. By applying the method, the reaction products can rapidly leave the inner and outer surfaces of the catalyst to reduce the probability of readsorption and secondary reaction, thus improving the yield of the LAOs. The Fischer-Tropsch synthesis reaction can be carried out in the conventional Fischer-Tropsch synthesis reactor by using the common catalyst. By applying the method, the mass content of the LAOs in the reaction products is more than 70%, thus being very beneficial to separation and purification. Meanwhile, by applying the method, the CO conversion rate can be improved, the methane selectivity can be reduced and the yield of heavy hydrocarbons can be greatly increased.

Owner:SYNFUELS CHINA TECH CO LTD

Method for purifying and recycling coaling smoke dust of coke oven

ActiveCN108707466AEliminate pollutionQuality improvementCombustible gas coke oven heatingOven incrustations prevention/removalCombustion chamberCoal dust

The invention belongs to the technical field of energy conservation and environmental protection of the coking industry, and specifically discloses a method for purifying and recycling coaling smoke dust of a coke oven. According to the method, the coaling smoke dust generated during coaling of the coke oven is sucked by a coke-side heat-resisting blower, cooled by a water-sealed valve and then allowed to enter a coaling dust combustion chamber to have mixed oxygen burned out, then a coaling dust collecting head tube is introduced into a combustion chamber of the coke oven to supply supplementary fuel for coke oven heating, and accordingly coaling dust is recycled, dust capacity of a crude gas system of the coke oven is decreased, and quality of tar is improved. Additionally, the method for purifying and recycling the coaling smoke dust of the coke oven has the advantages that crude gas diffusion under emergency conditions is eliminated substantially, quality of crude gas under diffusing conditions is improved, and atmosphere quality around the coke oven is improved.

Owner:武汉钢铁有限公司

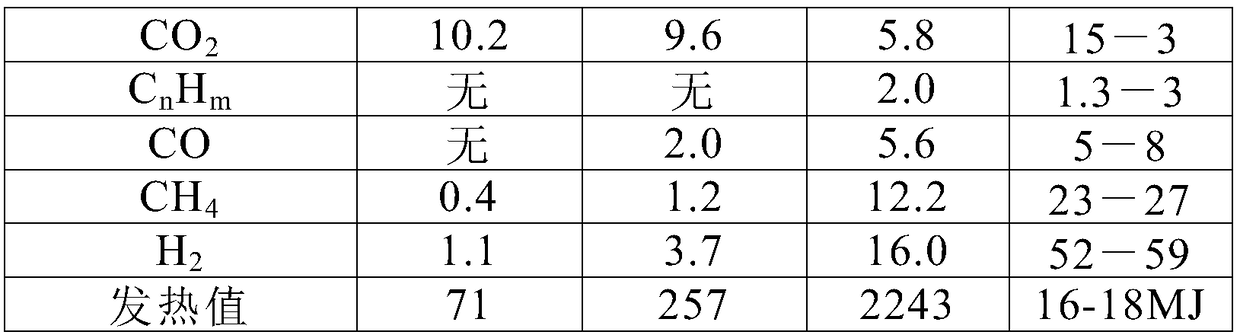

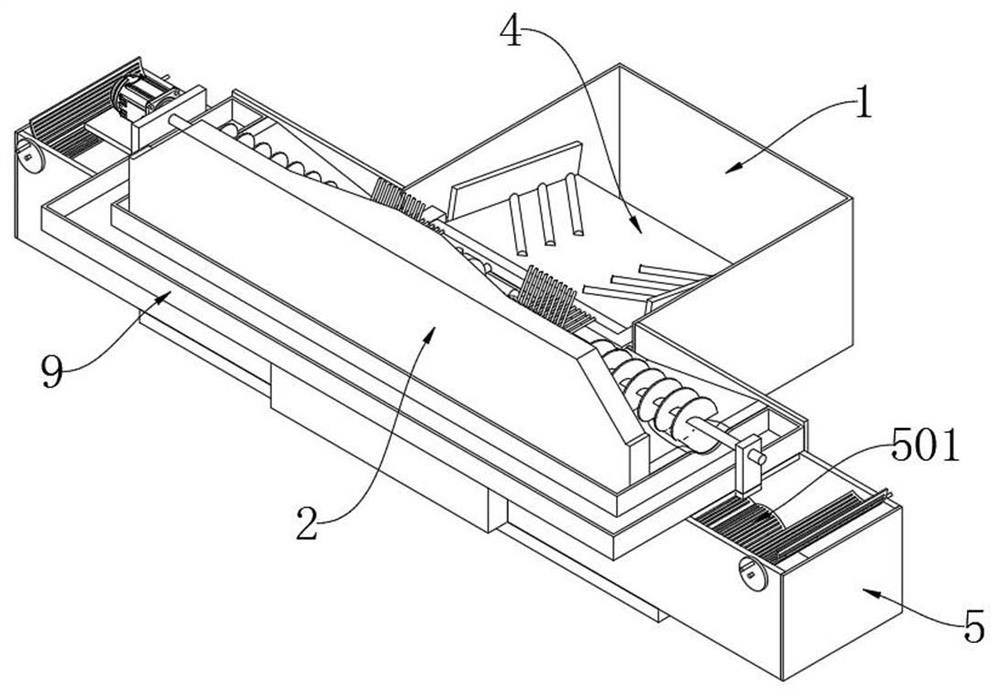

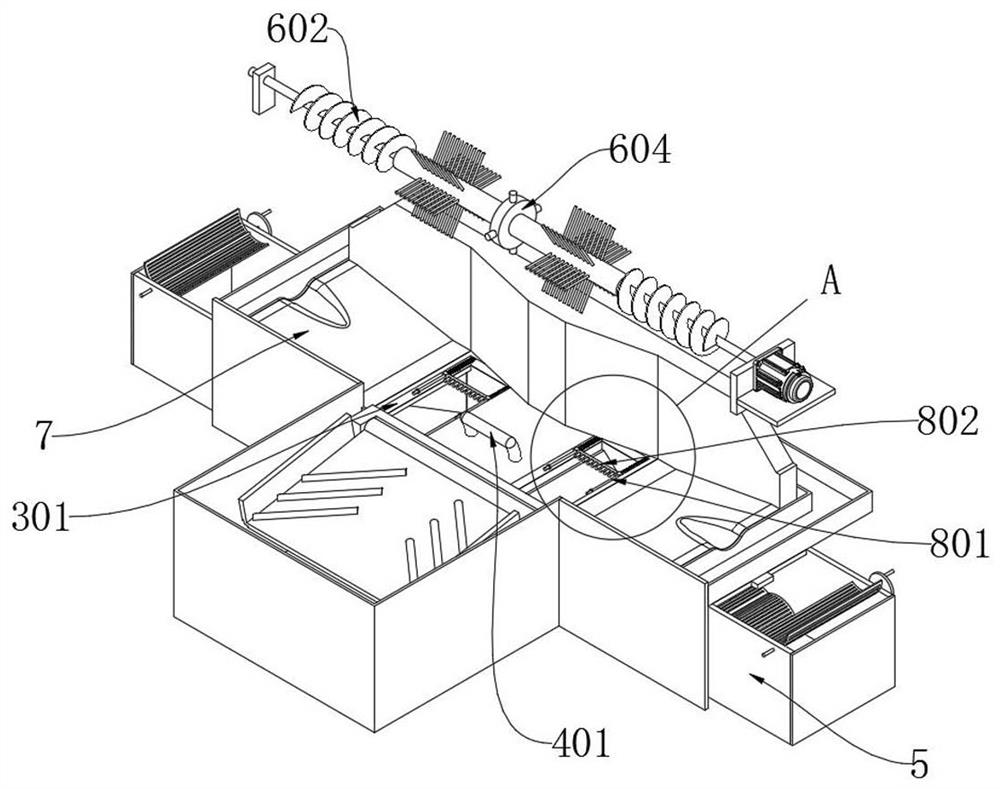

Waste wool processing and recycling device for garment production

ActiveCN113385296AAvoid separation difficultiesClear division of laborWet separationProcess engineeringMechanical engineering

The invention provides a waste wool processing and recycling device for garment production, and relates to the technical field of garment production. The problems that in the waste wool processing and recycling process, waste wool and high-quality wool cannot be distinguished and the recycling success ratio is low due to the fact that the waste wool and the high-quality wool are liable to be wound together in the cleaning process in the recycling process, and in addition, impurities contained in the waste wool are carried together due to mechanical stirring inclination can be solved. The waste wool processing and recycling device comprises a wool inlet box, the wool inlet box is of a T-shaped structure, and the rear end of the wool inlet box is transversely in butt joint with a flow dividing box. A retaining wall is fixedly mounted at the rear end of the flow dividing box in a transverse, vertical and upward manner; and the left end and the right end of the flow dividing box are fixedly connected with cleaning boxes in a butt joint mode. A wool inlet tongue plate is rotationally mounted at the position, corresponding to the wool inlet box, of the edge of the front end of the flow dividing box. A bent spring is arranged on a guide inner rod in a sleeving mode, the poking action is generated through the guide inner rod and the bent spring, the poking bionic action can be formed, and wool clustering and separation difficulty caused by wool clustering are avoided.

Owner:南通衣之韵服饰有限公司

Coke Oven Charging Dust Purification and Recycling Method

ActiveCN108707466BEliminate pollutionQuality improvementCombustible gas coke oven heatingOven incrustations prevention/removalCombustion chamberCoal dust

The invention belongs to the technical field of energy conservation and environmental protection of the coking industry, and specifically discloses a method for purifying and recycling coaling smoke dust of a coke oven. According to the method, the coaling smoke dust generated during coaling of the coke oven is sucked by a coke-side heat-resisting blower, cooled by a water-sealed valve and then allowed to enter a coaling dust combustion chamber to have mixed oxygen burned out, then a coaling dust collecting head tube is introduced into a combustion chamber of the coke oven to supply supplementary fuel for coke oven heating, and accordingly coaling dust is recycled, dust capacity of a crude gas system of the coke oven is decreased, and quality of tar is improved. Additionally, the method for purifying and recycling the coaling smoke dust of the coke oven has the advantages that crude gas diffusion under emergency conditions is eliminated substantially, quality of crude gas under diffusing conditions is improved, and atmosphere quality around the coke oven is improved.

Owner:武汉钢铁有限公司

NaY molecular sieve modifying method

InactiveCN102502695BImprove purification effectReduce the modification effectFaujasite aluminosilicate zeoliteSlurryCrystallinity

A NaY molecular sieve modifying method includes: adding mixed acid into mixed liquid of NaY molecular sieve, buffer solution and water and beating uniformly, using the buffer solution to adjust pH to be 4.0-6.5, and performing exchange reaction at the temperature ranging from 70 DEG C to 95 DEG C; filtering the exchanged slurry to obtain a filter cake, washing the filter cake with deionized water, drying, adding starch, adding water, stirring, leaching and drying. Using the NaY molecular sieve modifying method can realize ammonia (ammonium)-free emission, and on one hand, the service life of equipment is prolonged, on the other hand, environment pollution can be reduced while the problem of waste water treatment of the ammonium salt method can be solved. Na2O content of a product obtained by the method can be reduced smaller than 0.5%, and crystallinity of the product can reach more than 85%.

Owner:HUNAN UNIV

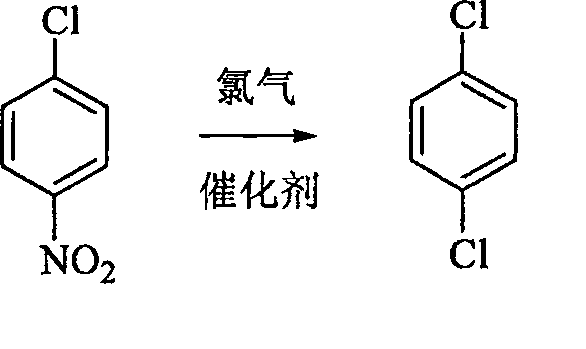

Method for synthesizing p-dichlorobenzene

InactiveCN100537502CMild reaction conditionsEasy to operateHalogenated hydrocarbon preparationPeroxideP-dichlorobenzene

Owner:淮安嘉诚高新化工股份有限公司

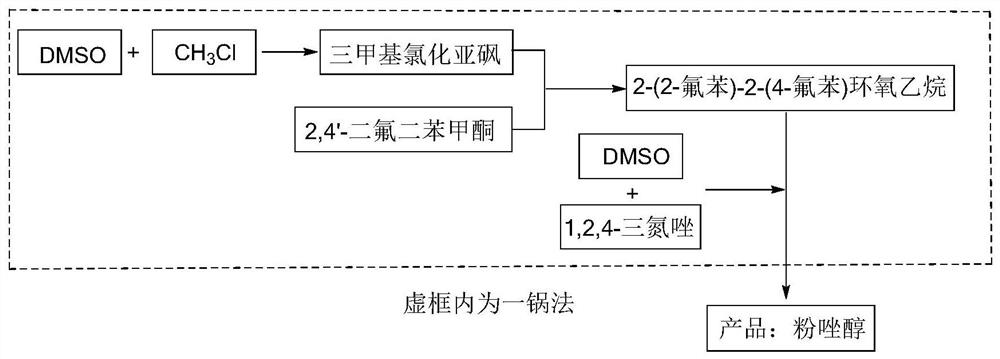

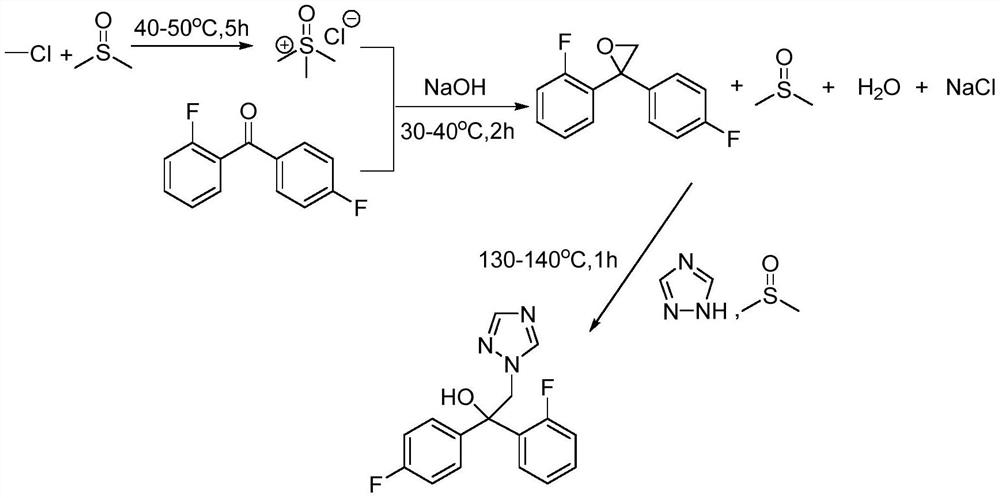

A kind of synthetic method of fuconazole

ActiveCN108997237BAvoid separation difficultiesImprove economic efficiencyOrganic chemistryHalomethaneToxic chemical

The invention relates to a method for synthesizing triazolol, which comprises reacting methyl halide and dimethyl sulfoxide at 0-120°C for 1-48 hours; adding solid base and 2,4'-difluorobenzophenone, the temperature Control at 0-80°C, react for 1-25h; add triazole, control the temperature at 50-200°C, react for 1-20h, after the reaction, filter, remove the solvent, wash, and crystallize to obtain the triazole . Dimethyl sulfoxide in the present invention is not only used as a reaction raw material, but also as a solvent, which avoids the difficulty of separation of mixed solvents, and dimethyl sulfoxide and methyl halide replace the dimethyl sulfoxide that has a large environmental pressure in the prior art. Sulfur ether and highly toxic chemical dimethyl sulfate, so that the present invention is environmentally friendly. In addition, the present invention has mild reaction conditions, short reaction time, high yield, high product quality, low discharge of three wastes, and only produces a single inorganic salt , thus the present invention has high production capacity and good economic efficiency.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

Method, system and electronic device for setting image change region detection threshold

ActiveCN109903265BFast and precise identificationHigh precisionImage enhancementImage analysisComputer graphics (images)Radiology

The invention relates to the field of intelligent visual recognition, in particular to a method, system and electronic device for setting an image change region detection threshold. This method obtains the first image before and after the scene change and the corresponding second image, and performs blurring processing to obtain the processed first blurred image and the second blurred image; The difference between the pixels is obtained as the first difference map; the first difference map is further optimized to obtain the second difference map, and the Otsu algorithm is used to process the second difference map to obtain the change area based on the first image and the second image detection threshold. Obtaining the threshold value through the above method can accurately and efficiently detect the image change area, prevent environmental interference from affecting the image change detection accuracy, and meet the use requirements of the contemporary intelligent container field. The image change area detection threshold setting system and its electronic device have the same beneficial effect as the above method.

Owner:创新奇智(南京)科技有限公司

A Prestack Reverse Time Depth Migration Imaging Method for Interwell Seismic Offshore Inclined Wells

ActiveCN104391327BMaintain propertiesMaintain Imaging Accuracy RequirementsSeismology for water-loggingImaging conditionData acquisition

Owner:CHINA NAT OFFSHORE OIL CORP +1

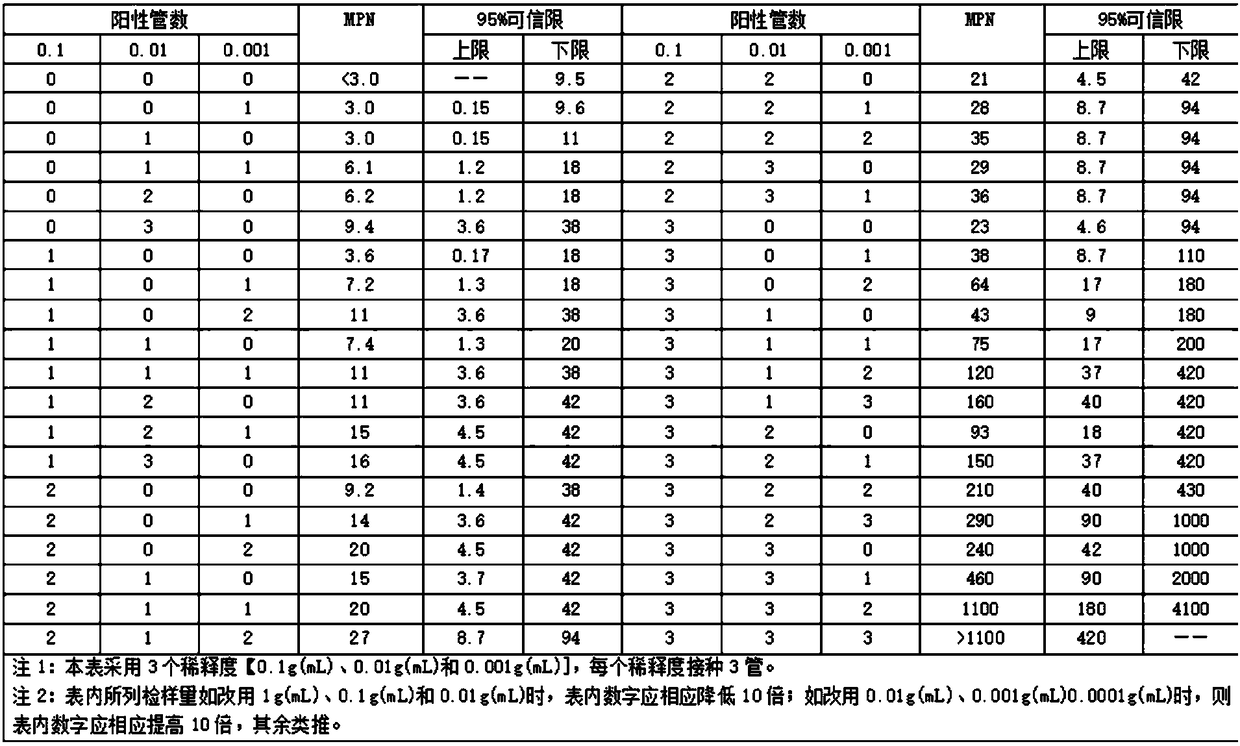

Method for detecting gas forming microorganisms contaminated in milk

ActiveCN108570489AAvoid separation difficultiesQuick judgment typeMicrobiological testing/measurementBiological material analysisTest tubeMilk sample

Owner:BRIGHT DAIRY & FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com