Phrcess of coproducing methyl tert-butyl ether and tert-butyl alcohol

A technology for the production of methyl tert-butyl ether and its production method, which is applied in the field of co-production of methyl tert-butyl ether and tert-butanol, can solve the problems of insufficient refinement of the process flow, inability to borrow equipment, increase in equipment and investment, etc. Achieve the effect of saving equipment investment, avoiding separation difficulty, and saving separation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

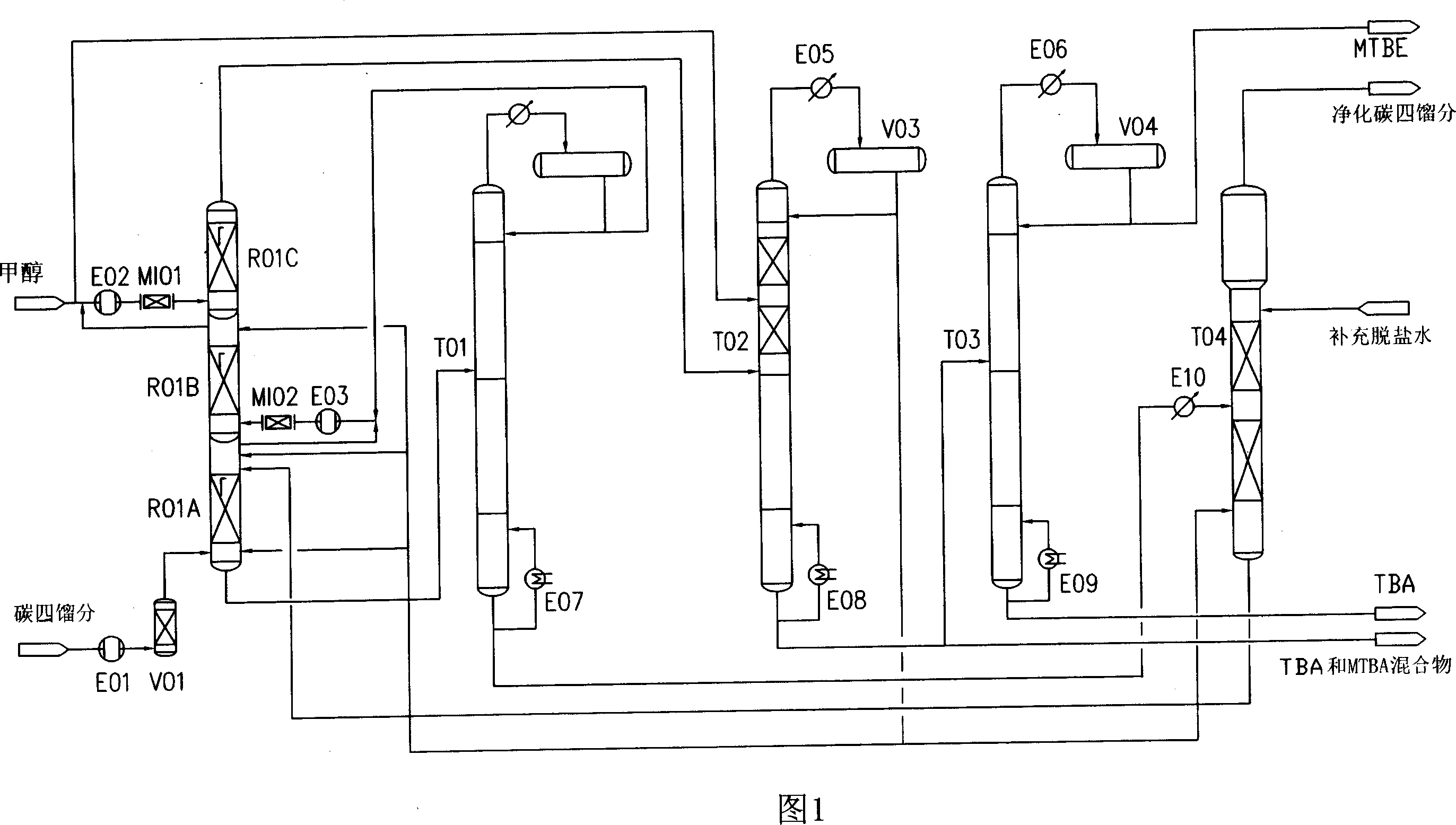

[0027] Referring to Fig. 1, the production method of the present invention operates in the system shown in the figure, and this system comprises front, middle and rear reactor R01A, R01B, R01C, tert-butanol rectification tower T01, catalytic rectification tower T02, extraction Tower T04 and separation tower T03 and their corollary equipment, the specific implementation steps of the present invention are as follows:

[0028] 1. Utilizing the principle that isobutene in the C4 fraction reacts preferentially with methanol in methanol water (where the methanol content is 6±4%), the C4 fraction is preheated to 80±5°C through the preheater E01, and then pretreated After the reduction of device V01, it enters the lower part of the pre-reactor R01A, and returns the methanol water from the bottom of the extraction tower T04 to the upper part of the pre-reactor, and contacts with the C4 cut countercurrently. Under the action of the catalyst (the catalyst usually adopts acid resin ), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com