Patents

Literature

1055 results about "Tert-Butyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tert-Butyl alcohol (TBA), also called tert-butanol or t-butanol, is the simplest tertiary alcohol, with a formula of (CH₃)₃COH (sometimes represented as t-BuOH). It is one of the four isomers of butanol. tert-Butyl alcohol is a colorless solid, which melts near room temperature and has a camphor-like odor. It is miscible with water, ethanol and diethyl ether.

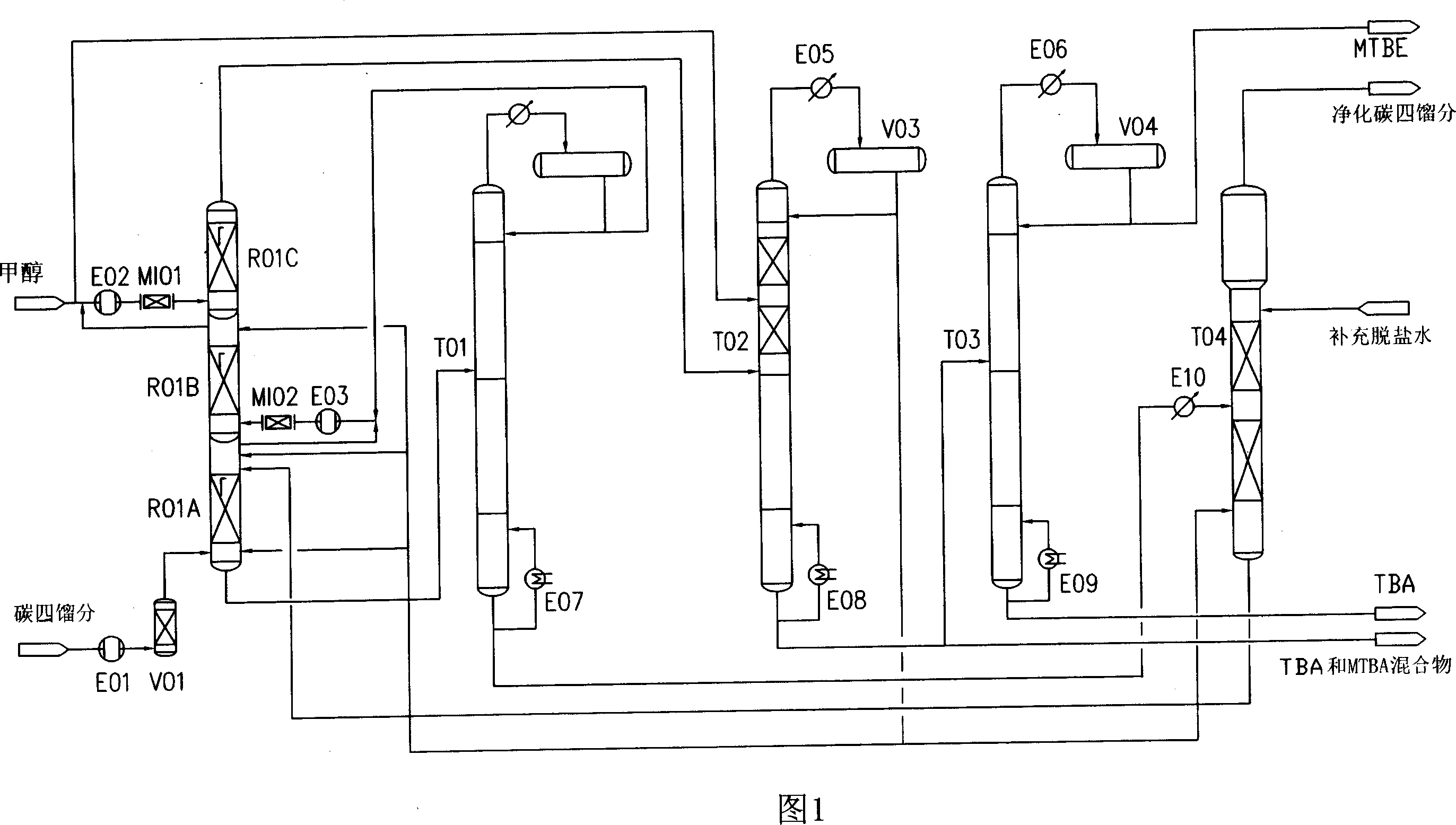

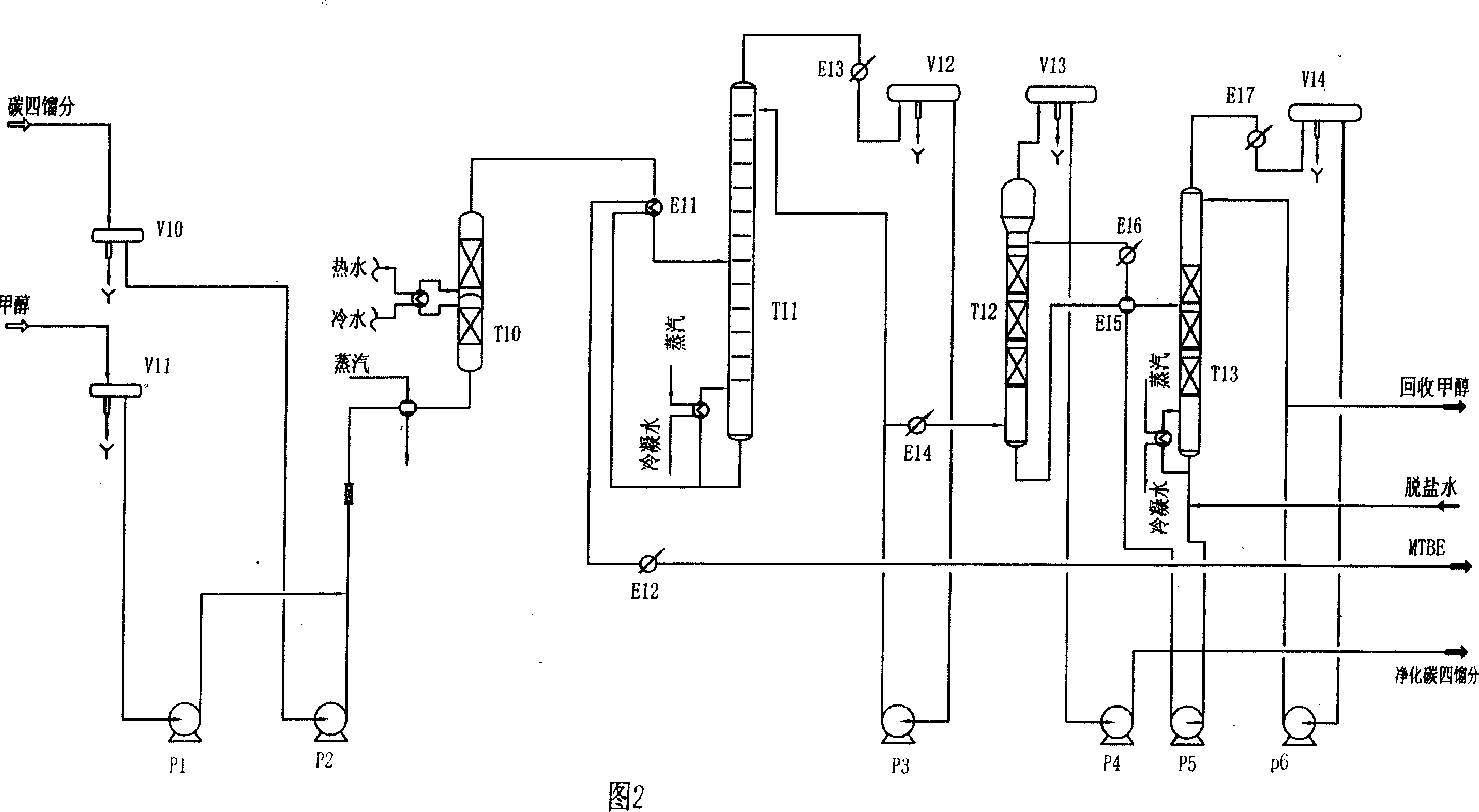

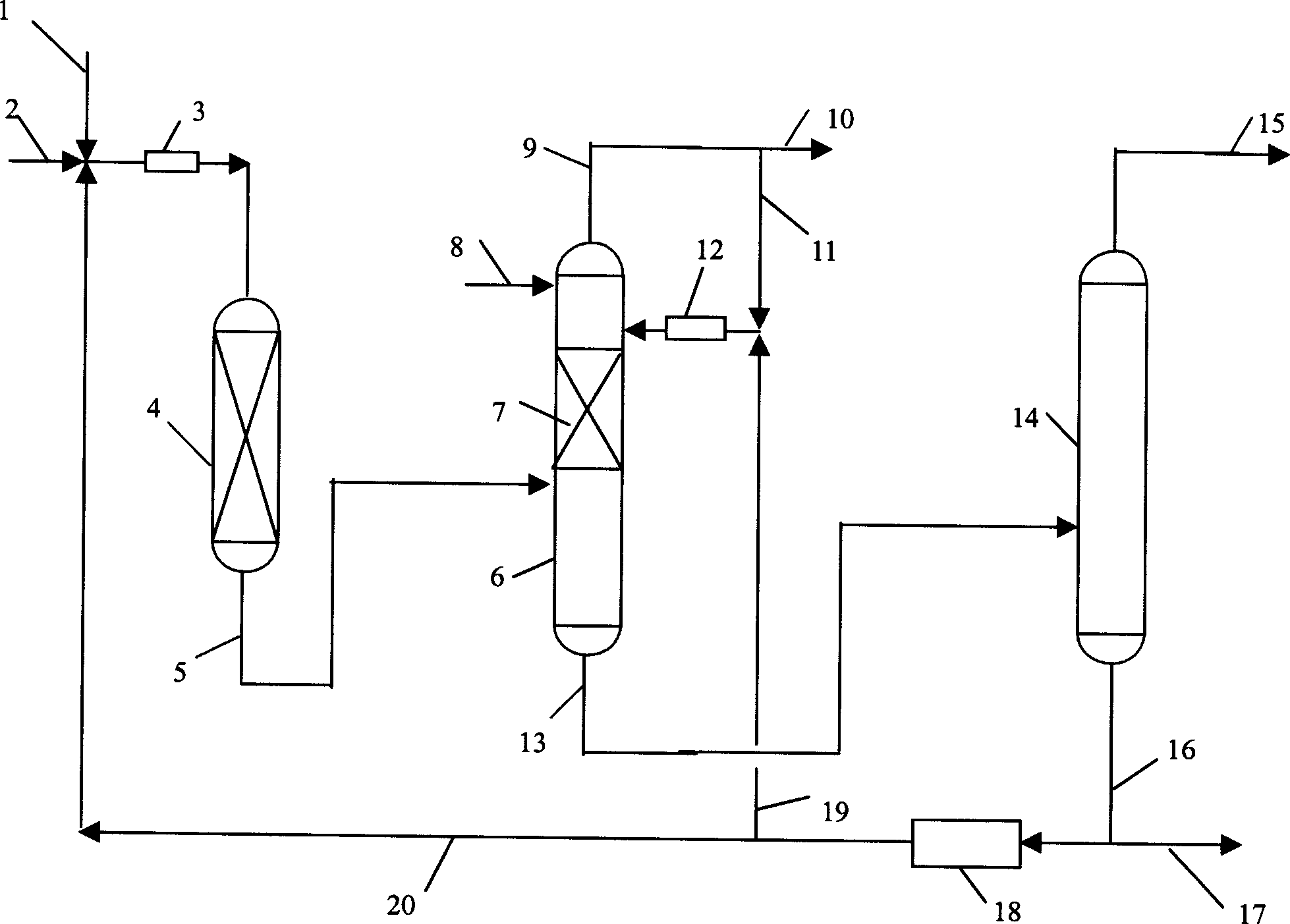

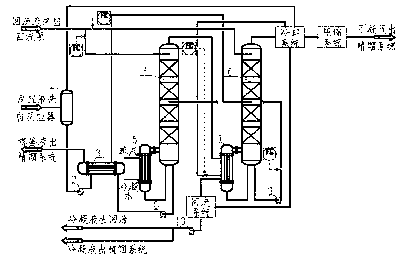

Phrcess of coproducing methyl tert-butyl ether and tert-butyl alcohol

InactiveCN101020622ASave energyLess investmentPreparation by hydroxy group additionEther preparation by compound additionMethanol waterMethyl t-butyl ether

The present invention relates to process of co-producing methyl tert-butyl ether and tert-butyl alcohol with isobutene and methanol in C4 fraction. The present invention features that two kinds of product are produced in an identical equipment with reduced investment, and that separation is completed through several reactions, resulting in simplified equipment and facilitated separation.

Owner:西安道特石化工程有限公司

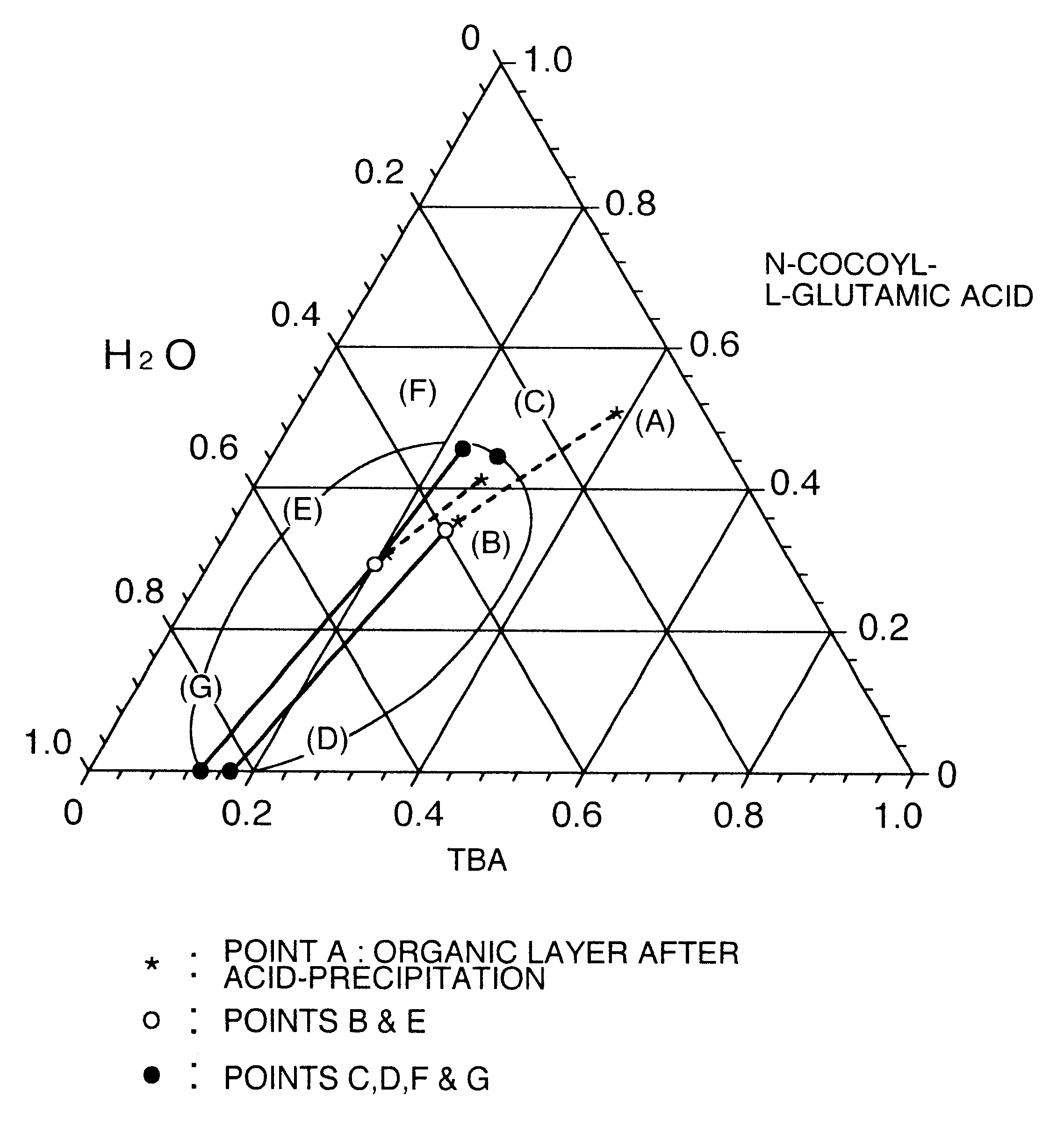

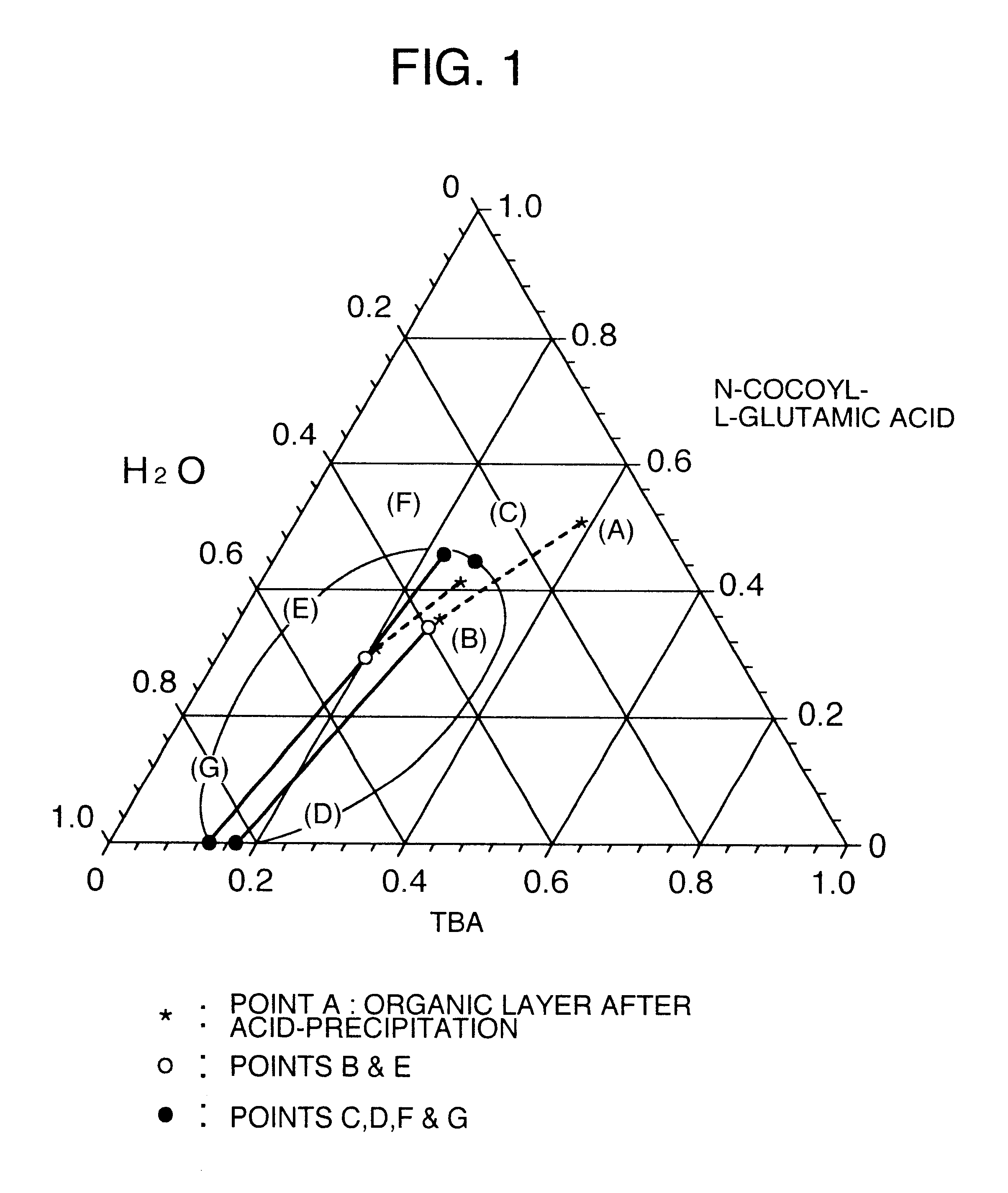

Process for producing long chain N-acyl acidic amino acid

A process for producing a long chain N-acyl acidic amino acid removes impurities by separating a mixture composed of a long chain N-acyl acidic amino acid containing an inorganic salt and a medium containing water and tertiary butanol into an aqueous layer and an organic layer containing the long chain N-acyl acidic amino acid at a temperature of from 35 to 80° C.

Owner:ASAHI KASEI FINECHEM CO LTD

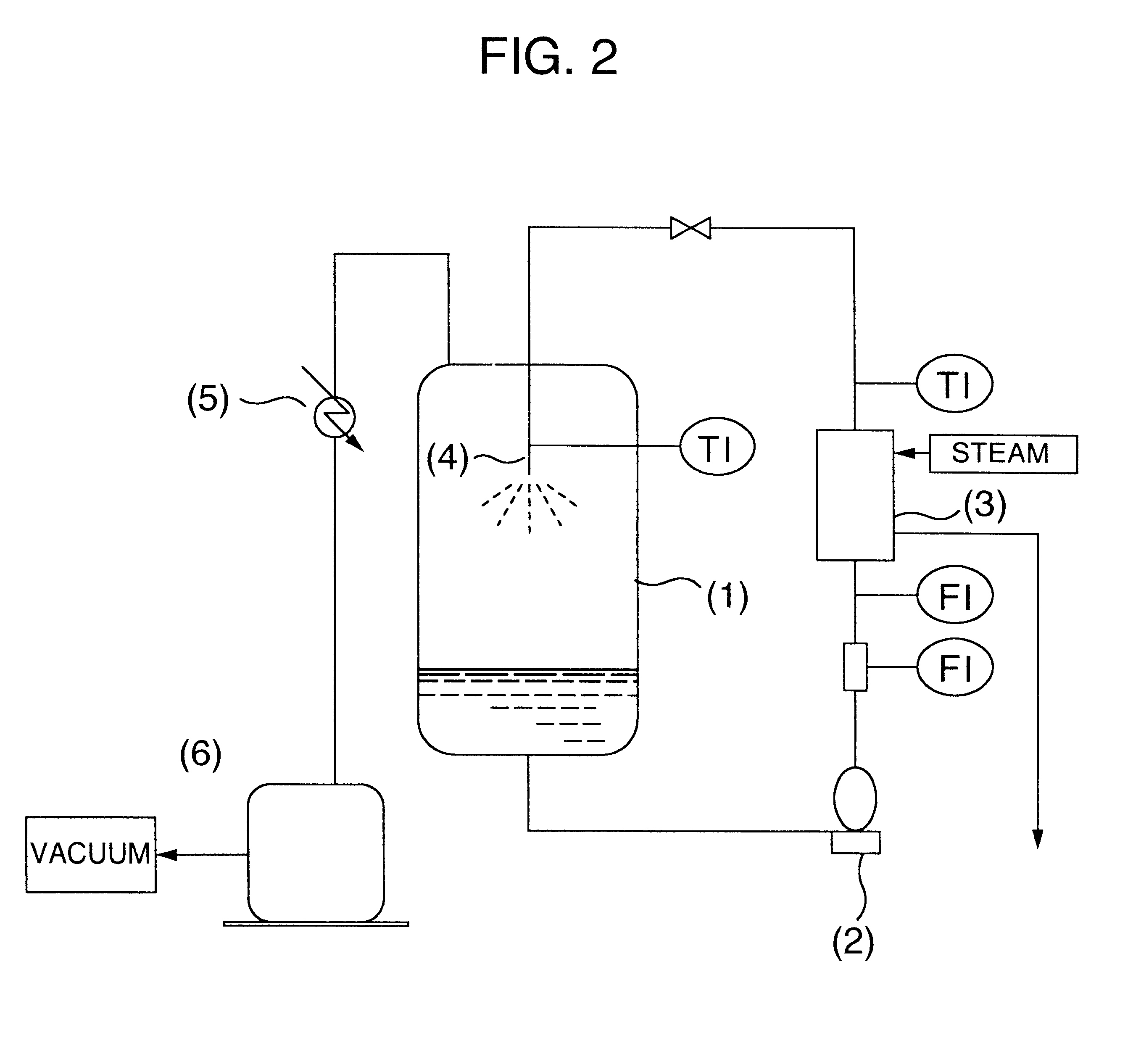

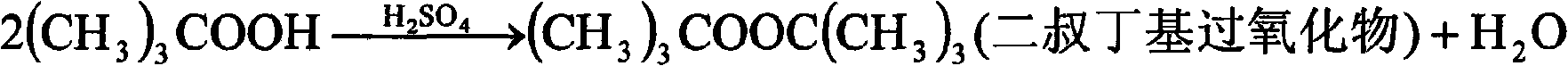

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

ActiveCN101298429AMild reaction conditionsHigh yieldOrganic chemistryDi-tert-butyl peroxideOil phase

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

Particulate porous ammoxidation catalyst

ActiveUS7473666B2High yieldIncrease productionOrganic compound preparationHeterogenous catalyst chemical elementsPore distributionNiobium

A particulate porous ammoxidation catalyst for use in producing acrylonitrile or methacrylonitrile by reacting propylene, isobutene or tert-butyl alcohol with molecular oxygen and ammonia in a fluidized-bed reactor, the catalyst comprising a metal oxide and a silica carrier having supported thereon the metal oxide, wherein the metal oxide contains at least two elements selected from the group consisting of molybdenum, bismuth, iron, vanadium, antimony, tellurium and niobium, and the catalyst having a particle diameter distribution wherein the amount of catalyst particles having a particle diameter of from 5 to 200 μm is from 90 to 100% by weight, based on the weight of the catalyst, and having a pore distribution wherein the cumulative pore volume of pores having a pore diameter of 80 Å or less is not more than 20%, based on the total pore volume of the catalyst and wherein the cumulative pore volume of pores having a pore diameter of 1,000 Å or more is not more than 20%, based on the total pore volume of the catalyst. A method for efficiently producing this catalyst.

Owner:ASAHI KASEI CHEM CORP

Catalyst for selectively oxidizing tertiary butanol or isobutene to synthesize methyl acrylic aldehyde and its use

ActiveCN1647853AHigh activityImprove thermal conductivityPhysical/chemical process catalystsOrganic compound preparationGas phaseCatalytic oxidation

The present invention provides a kind of catalyst for selectively oxidizing tertiary butanol or isobutene to synthesize methyl acrolein and its preparation process and application in gas phase catalytic oxidizing synthesis of methyl acrolein. The catalyst of the present invention is one kind of composite oxide containing Mo, Bi, Fe, Co, Sb, Pb, Yb, etc. and has high catalytic activity and stability, long service life, isobutene converting rate higher than 95 % and methyl acrolein selectivity over 86 % in the presence of molecular oxygen.

Owner:SHANGHAI HUAYI NEW MATERIAL

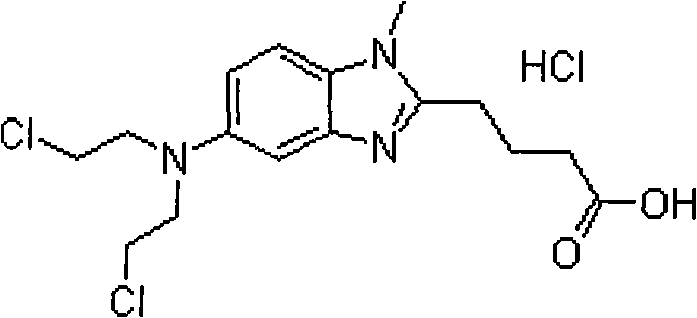

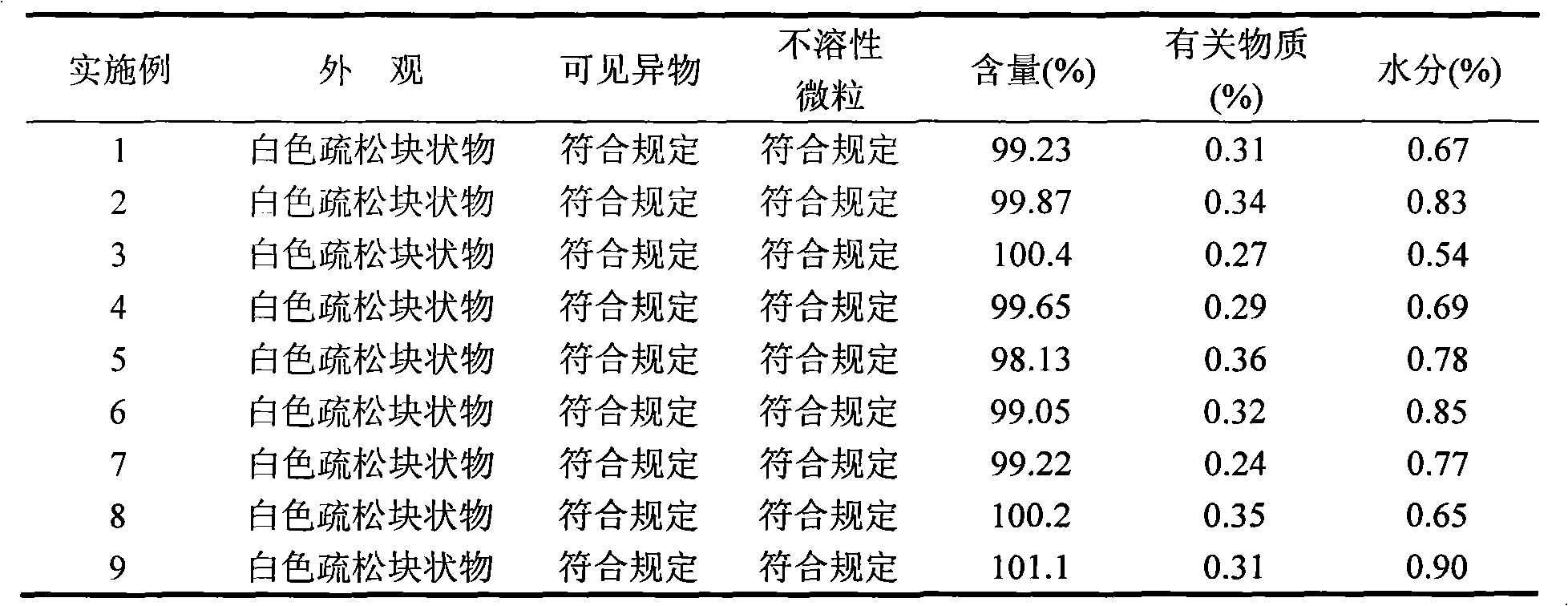

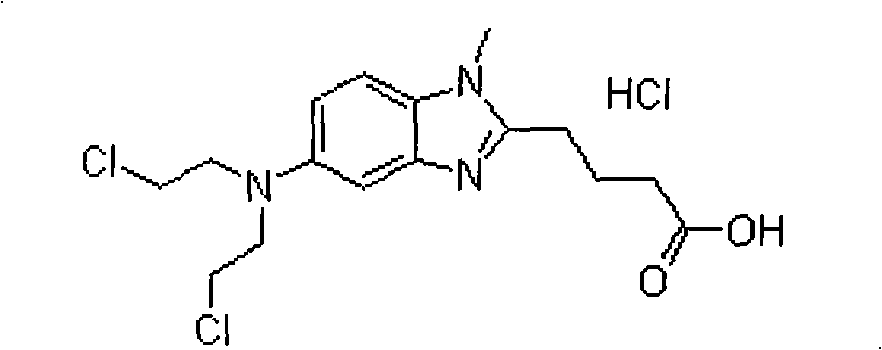

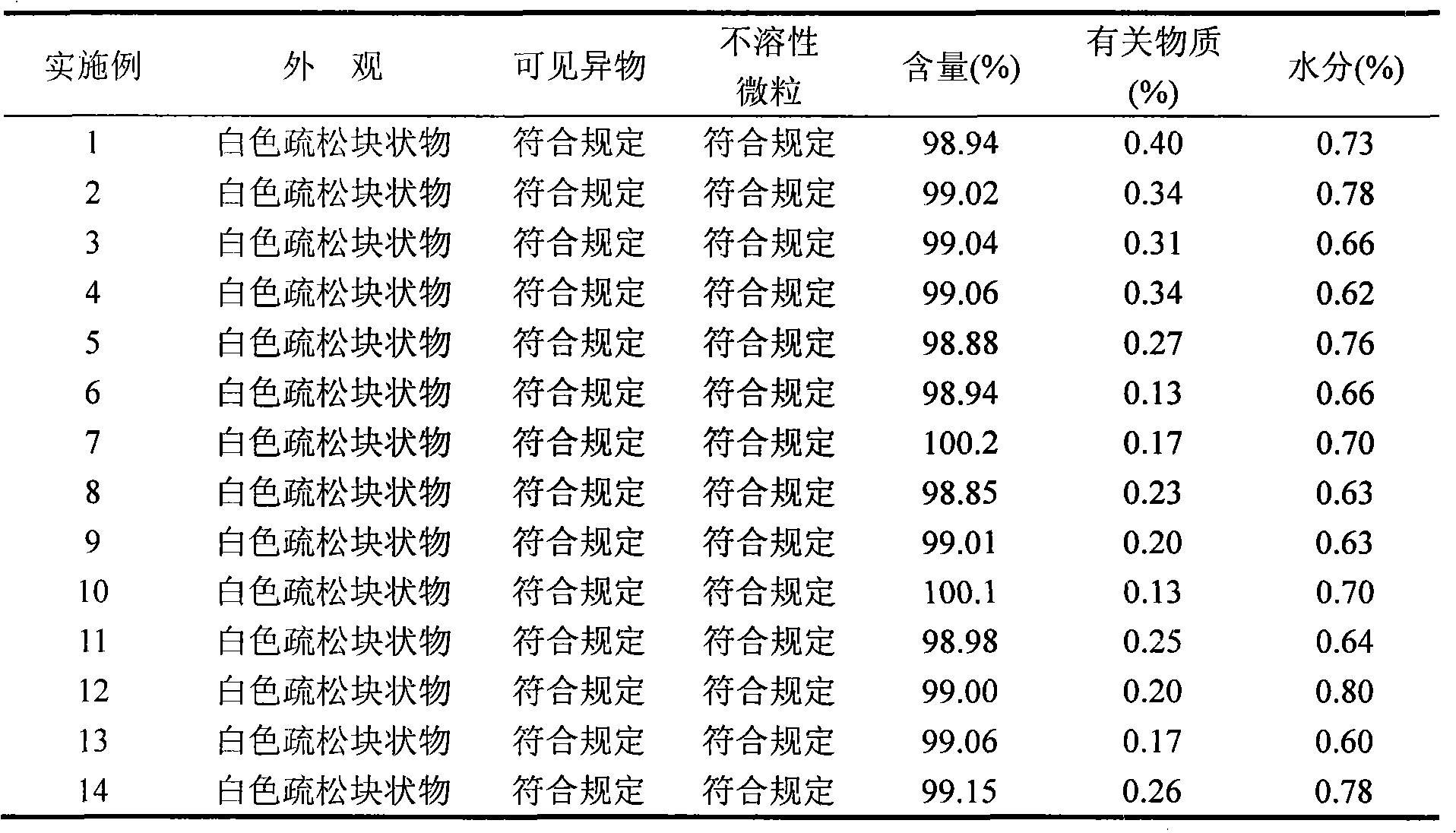

Bendamustine hydrochloride freeze-dried powder injection

InactiveCN101584668AImprove stabilityReduced stabilityPowder deliveryOrganic active ingredientsBendamustine hydrochlorideFreeze-drying

The invention relates to a bendamustine hydrochloride freeze-dried powder injection and its preparing method. The prepared bendamustine hydrochloride freeze-dried powder injection is used for chronic lymphocytic leukemia (CLL) and in the treating process of rituximab / MabThera or containing the same, or for inert B cell non hodgkin lymphoma (B-NHL) patients whose illness state still deteriorates during the treatment period in six months. The bendamustine hydrochloride freeze-dried powder injection contains bendamustine hydrochloride and uses the mixed solvent composed of the tertiary butanol and the injection water in the preparation process. The concentration of the bendamustine hydrochloride in the mixed solvents is 5-10 mg / ml. The volume ratio of the solvents is: 5-50% of tertiary butanol and the balance of injection water. The preparation process is that: measuring the tertiary butanol, adding injection water, mixing evenly, cooling to 2-15 DEG C, heat preserving, then adding the bendamustine hydrochloride, stirring to dissolve, filtering, filling, plugging, disking, freeze-drying, pressing the plug, out box, tying and packing.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Blocking remover for reservoir of oil well

The invention discloses a blocking remover for a reservoir of an oil well. The blocking remover is applied to the technical field of oil extraction in an oil field, comprises an agent A and an agent B, and is characterized in that the weight percentage of the agent A is 25-35%; the weight percentage of the agent B is 65-75%; the agent A comprises the following components by weight: 45-50% of petroleum mixed xylene, 1-2% of nonyl phenol polyoxyethylene (4) ether, and the balance of 0# diesel oil; the agent B comprises the following components by weight: 6-10% of glacial acetic acid or sulfamic acid, 2-2.5% of ammonium bifluoride, 2% of ammonium chloride, 1-2% of citric acid, 1.5-2% of corrosion inhibitor 7801, 3-5% of tertiary butanol, 0.5-1% of octyl phenol polyoxyethylene (10) ether and the balance of water. The blocking remover has the following effects that: the agent A and the agent B are respectively prepared so as to be beneficial to storing the blocking remover for a long time, the agent A of the blocking remover has strong dissolving capacity on crude oil heavy components, such as wax colloid asphalt, and the washing oil efficiency on oil sand is more than 90%. The dissolving rate of the agent B of the blocking remover on carbonate is more than 80%, and the corrosion speed on N80 steel is low and is smaller than 2 g / m<2>.h.

Owner:PETROCHINA CO LTD

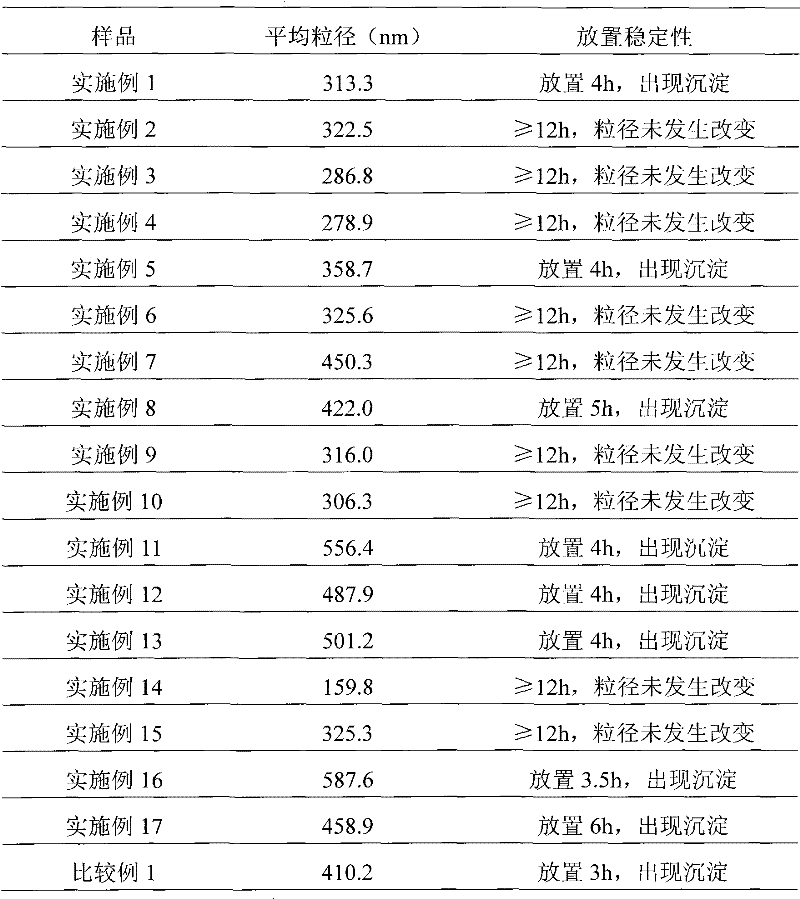

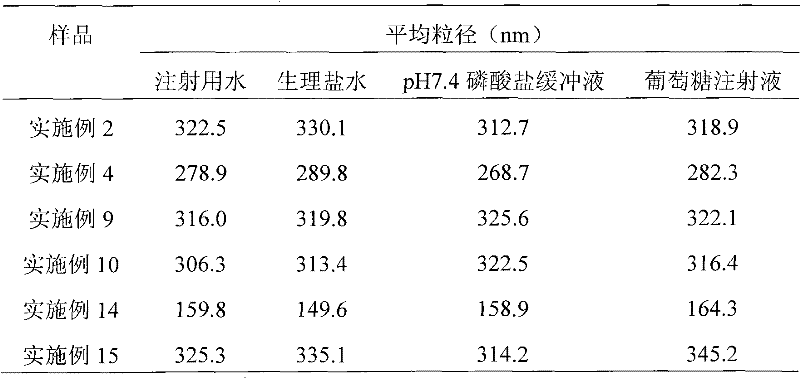

Paclitaxel albumin subparticles for injection and preparation method thereof

ActiveCN102274190ADenaturation does not produceMeet the requirements of clinical useOrganic active ingredientsPowder deliveryOrganic solventFreeze-drying

The invention discloses a paclitaxel alhumin submicron for injection. The paclitaxel alhumin submicron comprises 1-10% (W / W) of paclitaxel, 10-80%(W / W) of alhumin and 10-85% (W / W) of freeze-drying protective agent. The invention also discloses a preparation method of the paclitaxel alhumin submicron. The method comprises the following steps of 1) adding paclitaxel into tert-butyl alcohol, stirring and dissolving to be used as an organic phase; 2) adding the alhumin and the freeze-drying protective agent to water or a buffer with a pH within 6.0-8.5, stirring and dissolving to be used as a water phase; 3) adding the organic phase into water with stirring, stirring and dissolving, filtering and degerming through a millipore filtration method, and placing in a clean container; 4) freezing at-30- -50 DEG C, removing tert-butyl alcohol and water through freeze-drying by a lyophilizer to obtain freeze-drying powder with good profile and loosening quality. During usage, the freeze-drying powder is added to a solvent for injection and redissolved, so that paclitaxel alhumin submicrons with an average particle size of 100-600nm are formed. The paclitaxel alhumin submicron for injection ofthe invention has advantages of a simple preparation technology, no high toxic organic solvent and long-term storage, etc.

Owner:SHANGHAI MODERN PHARMA ENG INVESTIGATION CENT

Catalyst for tert-butyl alcohol cleavage reaction and preparation method thereof

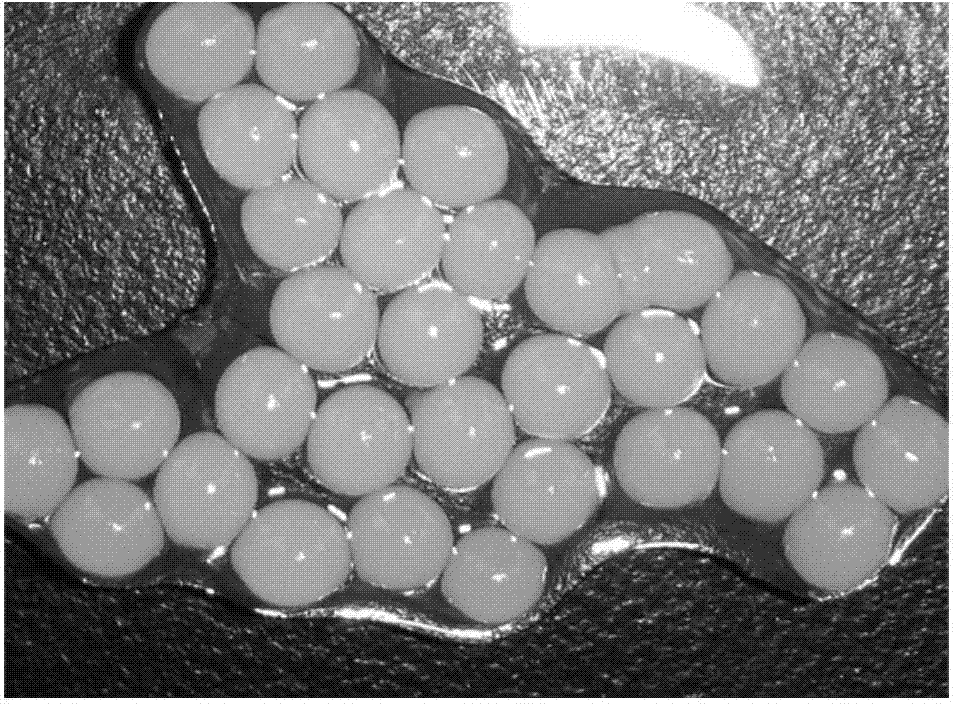

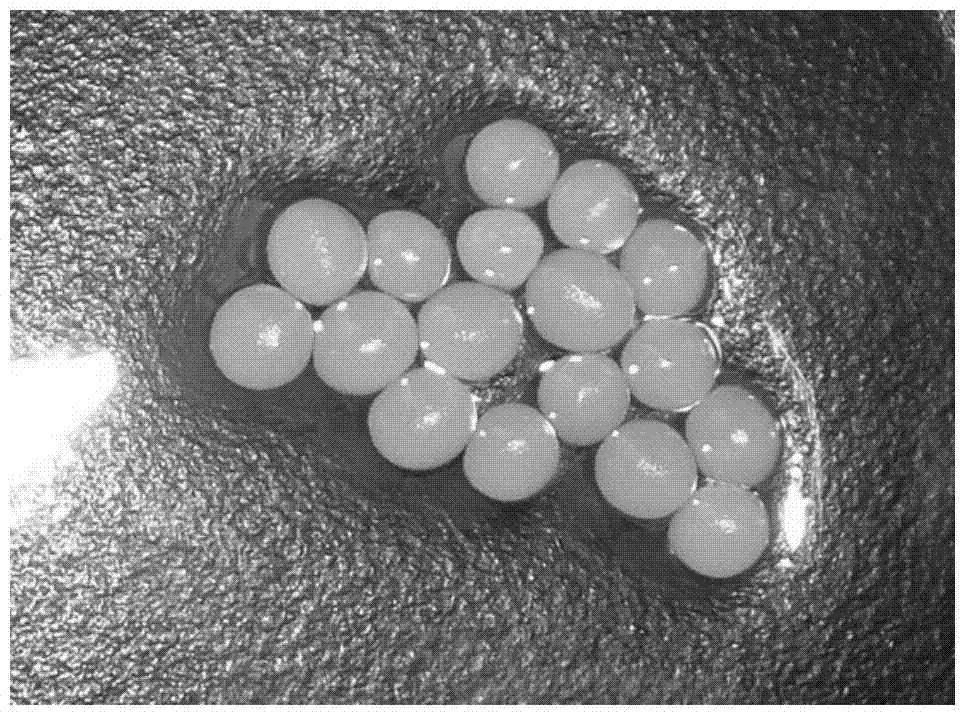

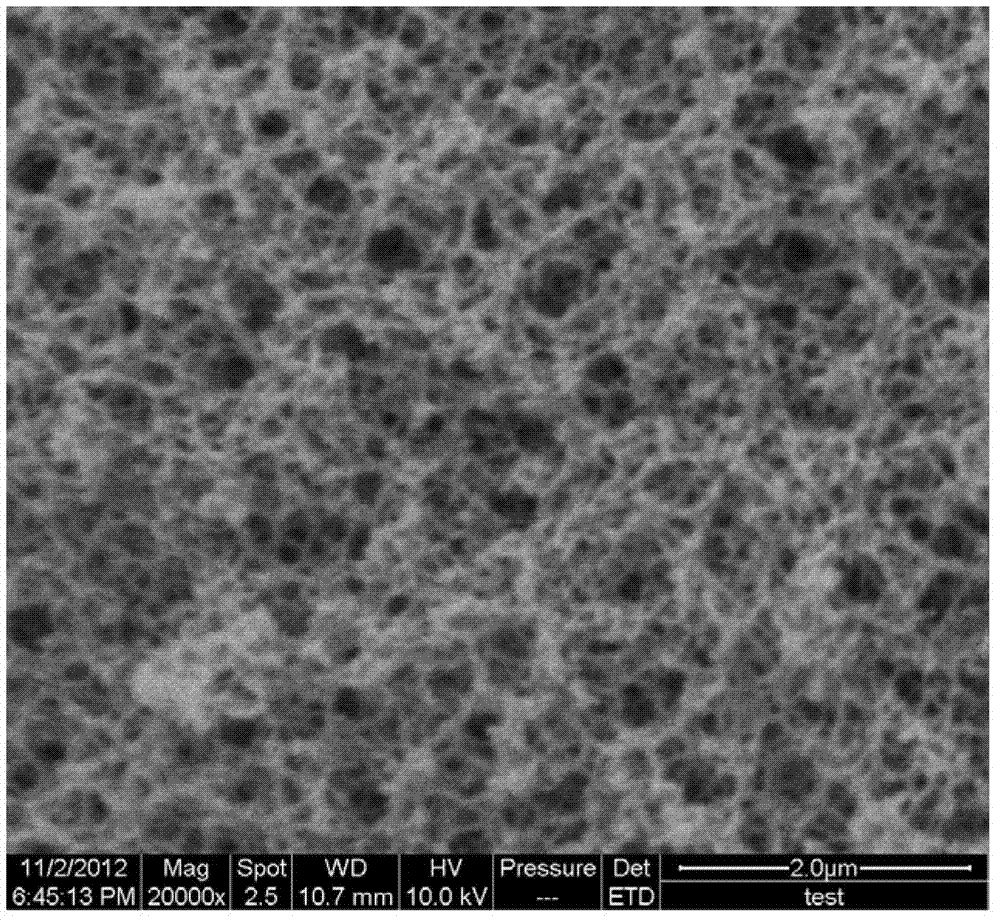

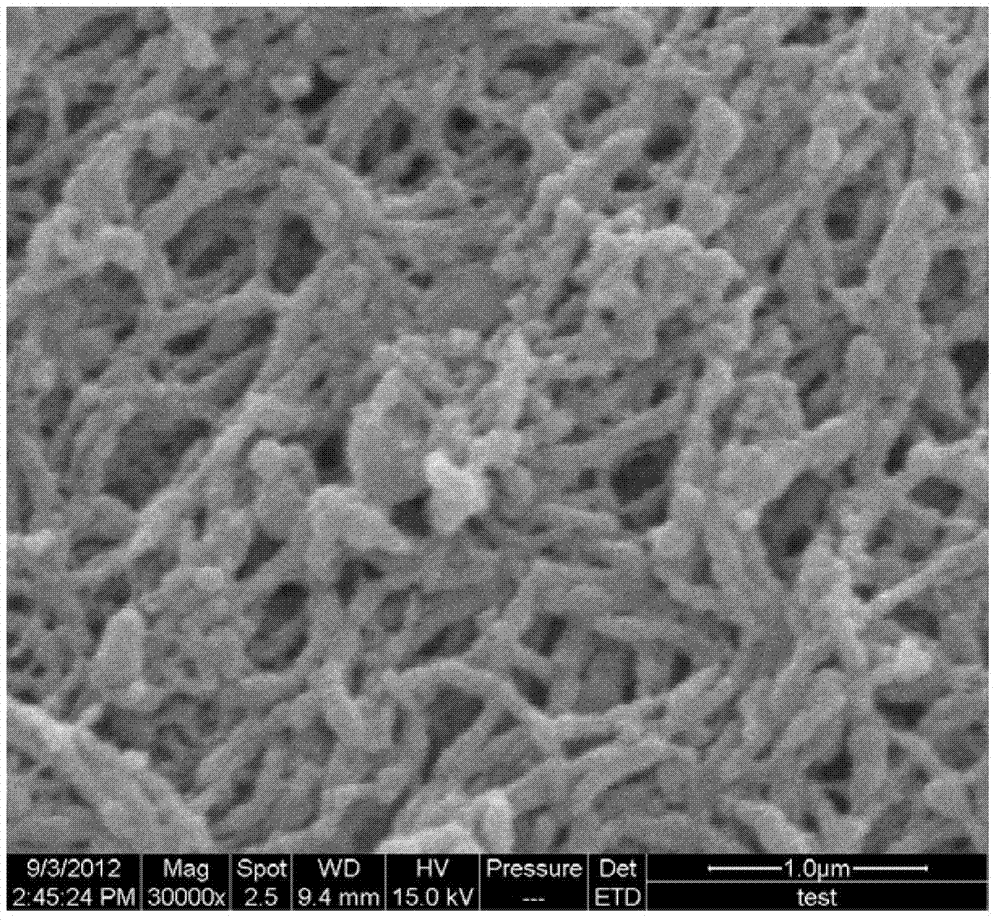

ActiveCN103611572AIncreased intermolecular attractionNot easy to fall offOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsChlorinated polyvinyl chloridePolystyrene

The invention provides a catalyst for tert-butyl alcohol cleavage reaction, which is prepared by the following steps: by using a melt granulation process, blending and melting polystyrene, chlorinated polyvinyl chloride, polytrifluorochloroethylene and polyvinylidene fluoride, and granulating; and carrying out sulfonation reaction on the granulation product in the fixed bed and sulfur trioxide to obtain the catalyst. When being used for tert-butyl alcohol cleavage reaction, the catalyst has the advantages of high selectivity for technique reaction, fewer side reactions and low shedding tendency of sulfo-group under high-temperature conditions. The invention also provides a preparation method of the catalyst.

Owner:南通灵润医用新材料有限公司

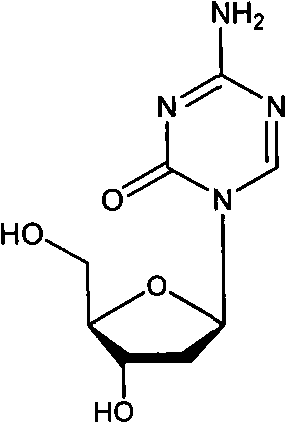

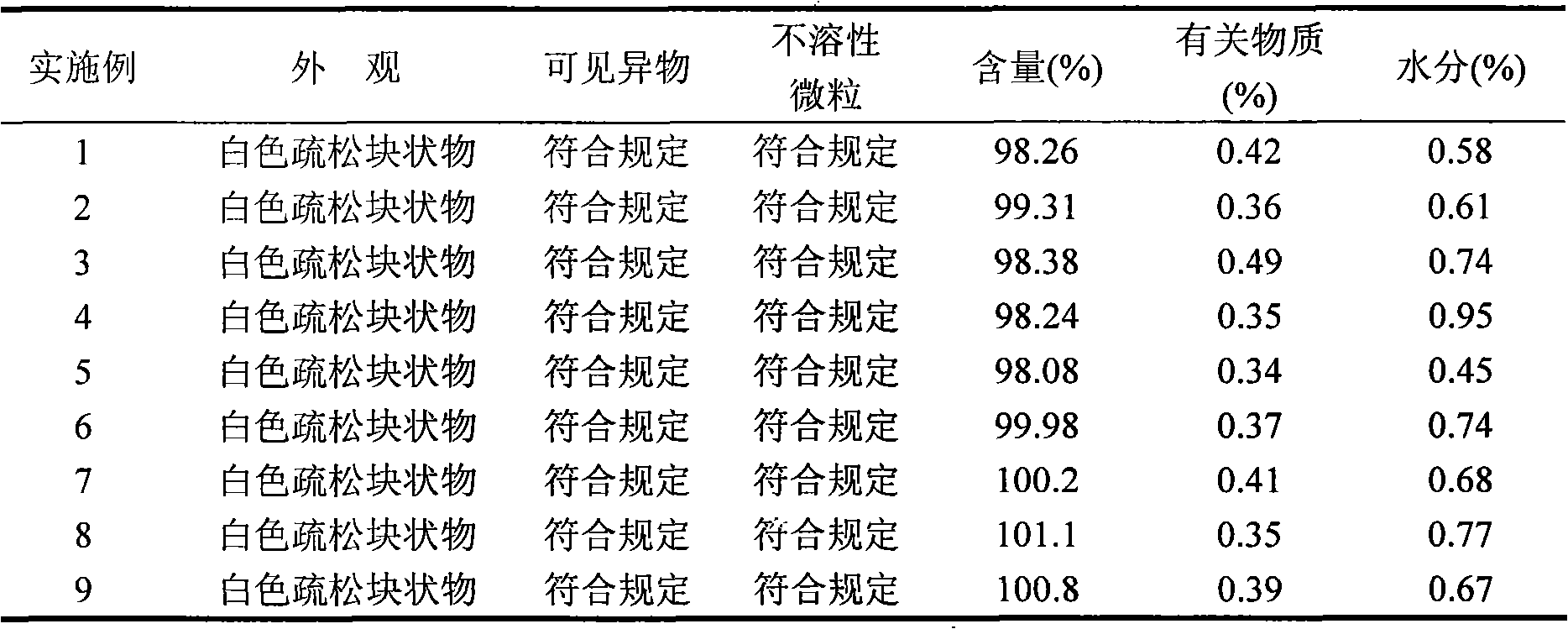

Decitabine freeze-dried powder injection

ActiveCN101584670AImprove stabilityLow content of related substancesOrganic active ingredientsPowder deliveryPhosphateFreeze-drying

The invention relates to a decitabine freeze-dried powder injection and a preparing method thereof. The prepared decitabine freeze-dried powder injection is used for treating myelodysplastic syndrome (MDS). The decitabine freeze-dried powder injection contains decitabine, utilizes the mixed solvent composed of the tert-butyl alcohol and the injection water in the preparation process, wherein the concentration of the decitabine in the mixed solvents is 2.5-5 mg / ml; and the volume ratio of the solvents is: 5-50% of tert-butyl alcohol and the balance of injection water. The potassium dihydrogen phosphate and the sodium hydroxide may be added for the pH regulator. The preparation process comprises the following steps: measuring tert-butyl alcohol, adding injection water, potassium dihydrogen phosphate and sodium hydroxide, stirring and mixing evenly, cooling to 2-15 DEG C, heat preserving, adding decitabine, stirring to dissolve, filtering, filling, plugging, disking, freeze-drying, pressing plug, out box, tying and packing after quality test qualification.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

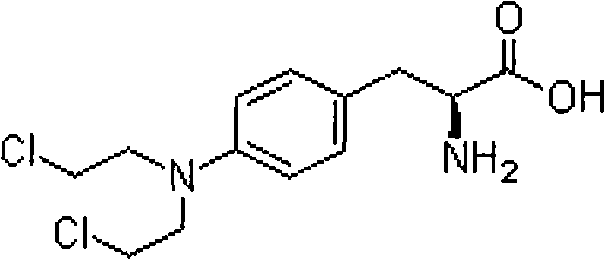

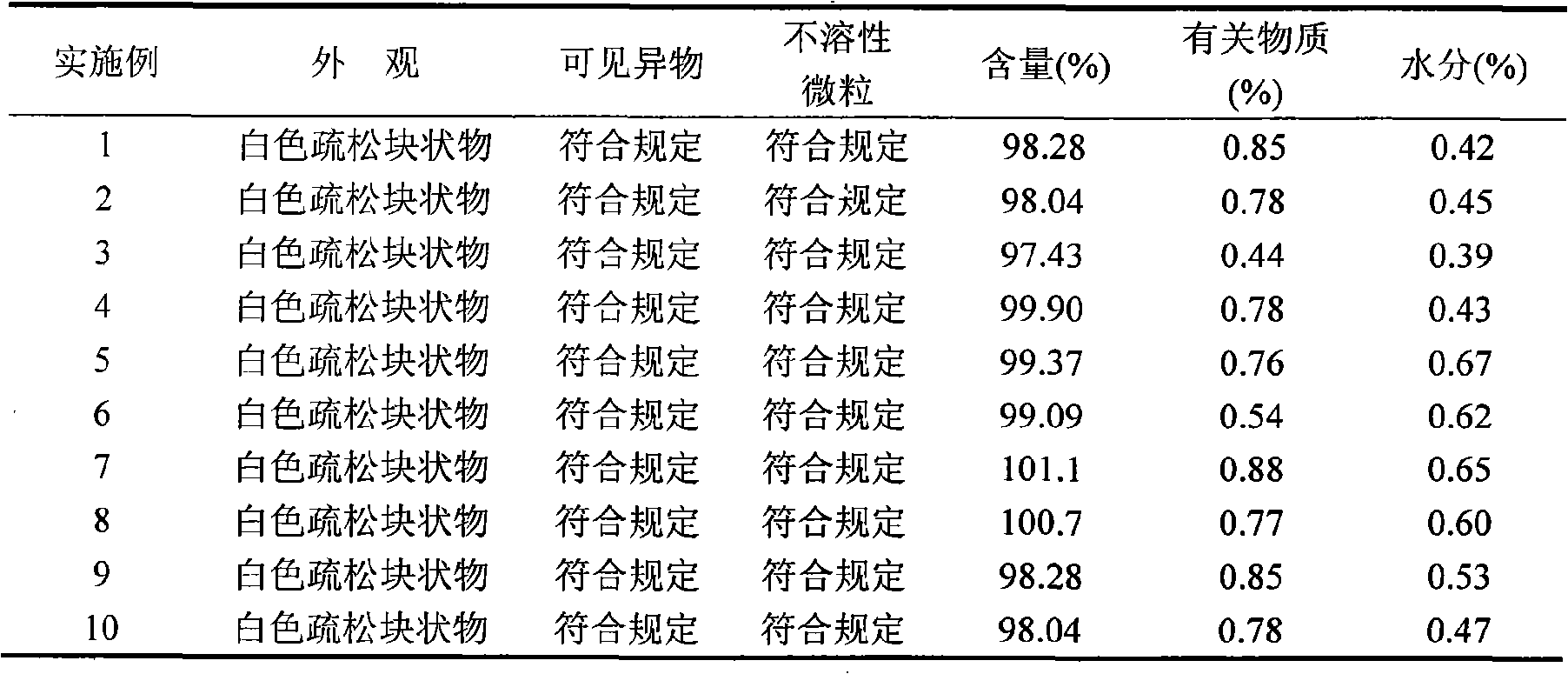

Melphalan freeze-dried powder injection

InactiveCN101584669AImprove stabilityLow content of related substancesOrganic active ingredientsPowder deliveryFreeze-dryingMedicine

The invention relates to a melphalan freeze-dried powder injection and a preparing method thereof. The prepared melphalan freeze-dried powder injection is used for treating multiple myeloma, oophoroma, polycythemia vera, local malignant melanoma and soft tissue sarcoma. The melphalan freeze-dried powder injection contains melphalan, utilizes the mixed solvent composed of the tert-butyl alcohol and the injection water in the preparation process, wherein the concentration of the melphalan in the mixed solvents is 10-25 mg / ml; and the volume ratio of the solvents is: 5-50% of tert-butyl alcohol and the balance of injection water. The preparation process comprises the following steps: measuring tert-butyl alcohol, adding injection water, mixing evenly, cooling to 2-15 DEG C, heat preserving, adding melphalan, stirring and dripping 0.5 mol hydrochloric acid to dissolve, filtering, filling, plugging, disking, freeze-drying, pressing plug, out box, tying and packing after quality test qualification.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

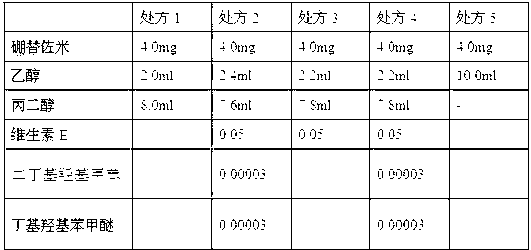

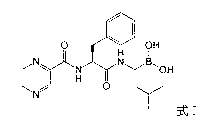

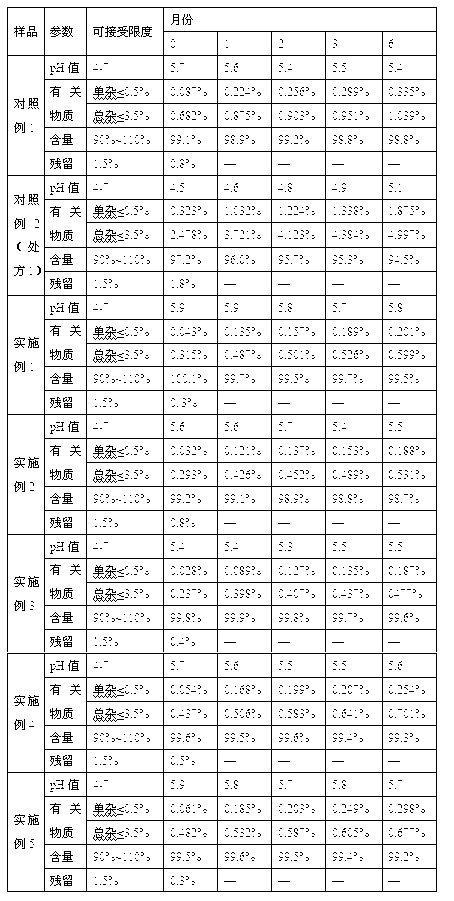

Freeze-dried composition containing bortezomib and preparation method of freeze-dried composition

ActiveCN103070835AReduce preparation timeEasy to producePowder deliveryDipeptide ingredientsMANNITOL/SORBITOLFreeze-drying

The invention belongs to the technical field of medicine, in particular to the field of chemical pharmacy, and particularly relates to a freeze-dried composition containing bortezomib and a preparation method of the freeze-dried composition. The freeze-dried composition and the preparation method aim at overcoming main medicine dissolution difficulty and oxygen environment sensitivity in an environment. A mixed solvent comprising mannitol and tert butyl alcohol is used, so that a dissolution rate of bortezomib is increased significantly, and the dissolution rate of bortezomib can be increased further through an addition sequence of materials. A nitrogen filled environment is used, so that liquid preparation time is shortened greatly, the contact of main medicine components with an aerobic environment is avoided effectively, and contents of relevant substances and total impurities in a final finished product are reduced.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Preparation method of tert-butyl hydroperoxide

ActiveCN103204792AHigh hydrogen peroxide yieldHigh yieldOrganic compound preparationPeroxy compound preparationMolecular sieveHeteroatom

The invention discloses a preparation method of tert-butyl hydroperoxide. Under oxidation reaction conditions, tert-butyl alcohol, an oxidant, a solvent and a catalyst are subjected to mixed contact. The method is characterized in that the catalyst is a soluble zinc salt modified heteroatom molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst and preparation method thereof as well as method for preparing methylacrolein with catalyst

ActiveCN102211027AHigh selectivityHigh activityOrganic compound preparationCarbonyl compound preparationMethacroleinHigh activity

The invention discloses a catalyst for preparing methylacrolein, a preparation method thereof as well as a method for preparing methylacrolein by catalyzing tert butyl alcohol or isobutene with the catalyst. The catalyst comprises a composite metal oxide which is expressed by the following general formula: (Mo12BiaFebCocCudCseVfNbiWjPbk): n carriers. The catalyst disclosed by the invention has the characteristics of high activity, high methylacrolein selectivity, high yield and the like. Finally, the conversion rate of the tert butyl alcohol or isobutene can be bigger than 95%, the methylacrolein selectivity can be bigger than 90%, and the single period yield of the methylacrolein can exceed 90%. The catalyst has the advantages of simple preparation technology and low production cost and is suitable for large-scale industrial application.

Owner:WANHUA CHEM GRP CO LTD +1

Prepn process of nanometer crystal titania aerogel with high photocatalysis activity

InactiveCN1810356ALarger than surfaceSmall grain sizeCatalyst activation/preparationSupercritical dryingMicro structure

The preparation process of aerogel TiO2 with high photocatalysis activity includes the following steps: dissolving non-titanium alkoxide and titanium source in alcohol-water mixture solution through stirring; adding metered epoxide to obtain translucent lumpy alcohol gel of titanium oxide in minutes; ageing, supercritical drying and roasting to obtain nanometer crystal aerogel TiO2 block or powder with adjustable micro structure and specific surface area greater than 100 sq m / g. Where, the titanium source is titanium tetrachloride, titanium trichloride or titanium sulfate; the epoxide is ethylene oxide, propylene oxide, chloropropylene oxide or butylenes oxide; and the organic alcohol solvent is methanol, ethanol, isopropanol or tert-butyl alcohol. When used in degrading nitrobenzene and other sewage treatment, the aerogel TiO2 has photocatalysis activity as high as three times that of commercial P-25 photocatalyst.

Owner:FUDAN UNIV

Preparation method of tert-butyl peroxide

InactiveCN104557652AStrong acidPore structure highOrganic compound preparationPeroxy compound preparationPtru catalystDi-tert-butyl peroxide

The invention provides a method for preparing tert-butyl peroxide by using a heterogeneous catalyst. The method comprises the following steps: by using tert-butyl alcohol and oxydol as raw materials and an acidic ion exchange resin as a catalyst, reacting under reflux, cooling, standing, and separating to obtain an oil phase and a water phase; and washing the oil phase with alkali and water to obtain a di-tert-butyl peroxide solution (DTBP), wherein the oil phase water washing solution and water phase are the tert-butyl hydroperoxide water solution (TBHP). Since the ion exchange resin has the advantages of large pore structure, high acidity and high catalysis efficiency and the large pore structure can not be destroyed in reaction, the catalyst can be easily separated from the reaction product and can be recycled repeatedly, thereby having higher economic value. Besides, no sulfuric acid or any other strong acid is used in the production process, so the method has the advantages of low corrosion to equipment and no environment pollution, and has higher environmental benefit.

Owner:NORTHWEST NORMAL UNIVERSITY

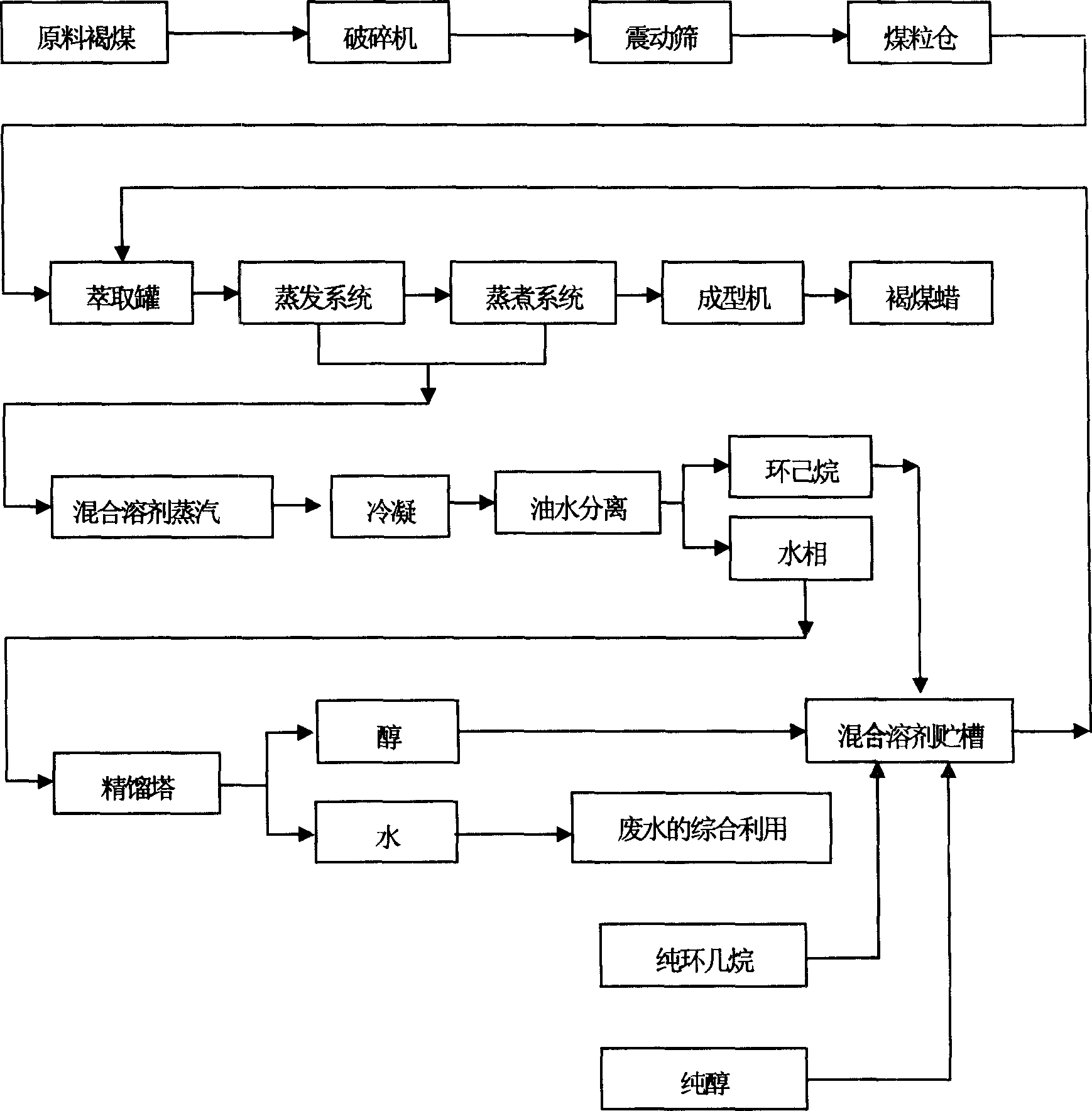

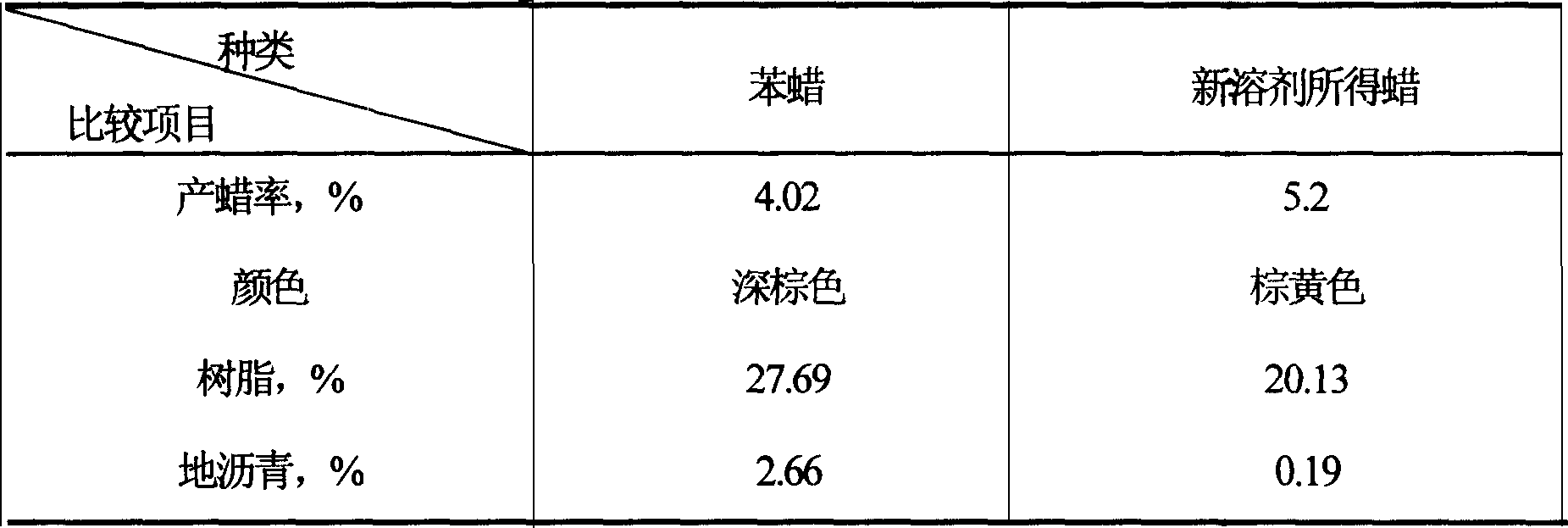

Brown-coal green extractive solvent and its production

InactiveCN101029255ALow asphalt contentImprove product qualityMineral wax recovery/refiningBrown coalWax

A lignite wax green extractive solvent and its production are disclosed. The process is carried out by taking mixed solvent of cyclohexane and alcohol, crushing for lignite, screening, putting lignite coal grain into extractor, mixing with solvent in proportion of 1:1-1:4 while extracting, flash evaporating, recovering solvent, evaporating for residual mixed solvent by stewing system to obtain crude lignite wax, condensing for mixed solvent steam by heat exchanger, oil-water separating, delivering cyclohexane to solvent trough, separating tert-butyl from water while rectifying, inducing tert-butyl into solvent trough, inspecting cyclohexane or tert-butyl content, supplement cyclohexane and alcohol, mixing proportionally and using. It's cheap, simple reliable, and economical, it has more wax yield and no environmental pollution.

Owner:CHINA UNIV OF MINING & TECH

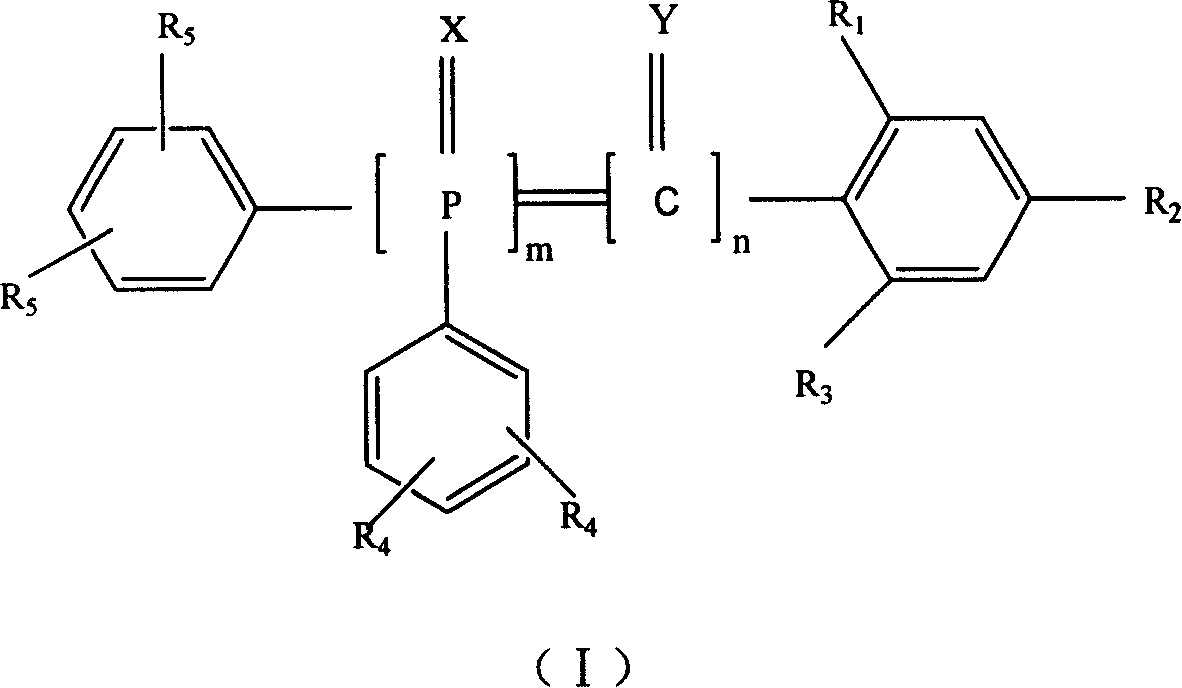

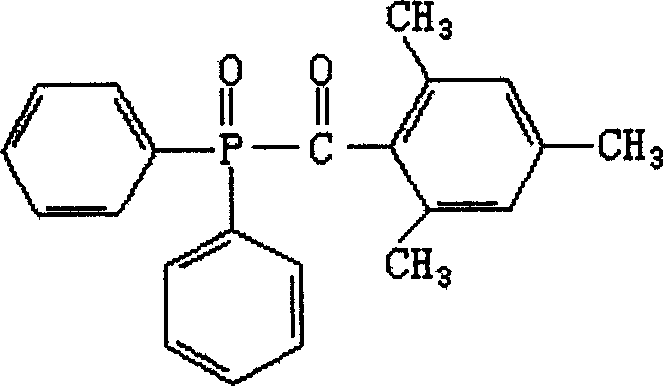

Method for preparing acyl and bisacyl phosphine oxide or acyl and bisacyl sulfur phosphines

InactiveCN101200475AReduce manufacturing stepsReduce decreaseGroup 5/15 element organic compoundsCoatingsBenzaldehydePhosphine oxide

The invention relates to a preparation method of single acyl or two acyl phosphine oxide and single acyl or two acyl sulfur phosphine compound, in particular to a preparation method of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide of the photoinitiator. The addition reaction is carried out between Trimethyl benzaldehyde and diphenyl phosphorus chloride and then the mixture is oxidized by tert-butyl alcohol peroxide. The invention adopts the addition reaction of aldehyde and halogenated phosphorus and replaces the original process of acyl chloride and halogenated phosphorus, and has the advantages of greatly shortening the preparation procedures, low cost, easy operation and quick production. The compound prepared by the invention has more than 98 percent of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide and can be served as the photoinitiator for solid for producing the solidification product with the performance of paint, varnish, porcelain glaze, paint, pigment or ink, and can better satisfy the increasing market demand.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

Method for preparing tert-butyl hydrogen peroxide and tert-butyl alcohol by oxidating isobutane

InactiveCN102391167AImprove conversion rateHigh selectivityPreparation by oxidation reactionsOrganic compound preparationCatalytic oxidationSolvent

The invention discloses a method for preparing tert-butyl hydrogen peroxide and tert-butyl alcohol by oxidating isobutene. Molecular oxygen is taken as an oxygen source; N-hydroxy phthalimide (NHPI) or a derivative thereof is taken as a catalyst; in the presence of a polar solvent, carrying out catalytic oxidation on the liquid phase of the isobutane to prepare the tert-butyl hydrogen peroxide and the tert-butyl alcohol; after finishing the reaction and rapidly cooling, the catalyst and the products are subjected to solid-liquid separation; and the catalyst is recycled through centrifugal sedimentation and washing. Compared with the existing process without catalytic optimization, the method disclosed by the invention has mild reaction conditions, the temperature and the pressure needed in the reaction can be remarkably lowered; and in addition, under the condition of having higher rate of conversion of the isobutane, the high selectivity of the tert-butyl hydrogen peroxide and the tert-butyl alcohol can be maintained.

Owner:XIANGTAN UNIV

Method for preparing regenerated cellulose spherical aerogel modified through carboxylation

InactiveCN103570967AImprove permeabilityAvoid gatheringOther chemical processesChemical recyclingFreeze-dryingSolvent

The invention relates to a method for preparing regenerated cellulose spherical aerogel modified through carboxylation, which aims at the problem of poor adsorptive property of the cellulose aerogel prepared by the existing methods. The method comprises steps of firstly, mixing sodium hydroxide, urea and deionized water, then adding into a cellulose raw material, preparing a cellulose solution, adding the cellulose solution into a regeneration solution for solidifying, washing and obtaining spherical hydrogel; and secondly, dissolving TEMPO (tetramethyl-piperidin-1-oxyl) and sodium bromide into deionized water, adding the spherical hydrogel, then adding a sodium hypochlorite solution, regulating pH value of a system through a sodium hydroxide solution, steeping, exchanging the collected solid phase objects sequentially through absolute ethyl alcohol and a tertiary butanol solvent, then cooling, finally, freeze drying so as to finish preparing the cellulose spherical aerogel. The largest capacity of the obtained spherical aerogel in adsorbing metal ions Cu<2+> reaches 0.55m mol / g, and the adsorptive property is good.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Method for preparing inorganic oxide aerogel by taking biomass nanometer fibrillation cellulose as template

InactiveCN103112830AReduce pollutionWide variety of sourcesMaterial nanotechnologyOxide/hydroxide preparationCelluloseAqueous solution

The invention relates to a method for preparing inorganic oxide aerogel by taking biomass nanometer fibrillation cellulose as a template, relating to a preparation method of the inorganic oxide aerogel. The method aims at solving the problems of complex process, high cost and low yield of the traditional method for preparing the inorganic oxide aerogel. The method comprises the following steps of: 1, preparing a biomass nanometer fibrillation cellulose water solution; 2, preparing a biomass nanometer fibrillation cellulose absolute ethyl alcohol solution; 3, mixing to obtain an inorganic / biomass nanometer fibrillation cellulose mixed solution; 4, preparing an inorganic / biomass nanometer fibrillation cellulose composite material dispersion solution; 5, displacing and concentrating to obtain an inorganic / biomass nanometer fibrillation cellulose composite material / tert-butyl alcohol suspension; 6, carrying out drying treatment to obtain a tert-butyl alcohol / inorganic / biomass nanometer fibrillation cellulose composite material; and 7, carrying out template stripping treatment to obtain the inorganic oxide aerogel. The method disclosed by the invention is mainly used for preparing the inorganic oxide aerogel.

Owner:NORTHEAST FORESTRY UNIVERSITY

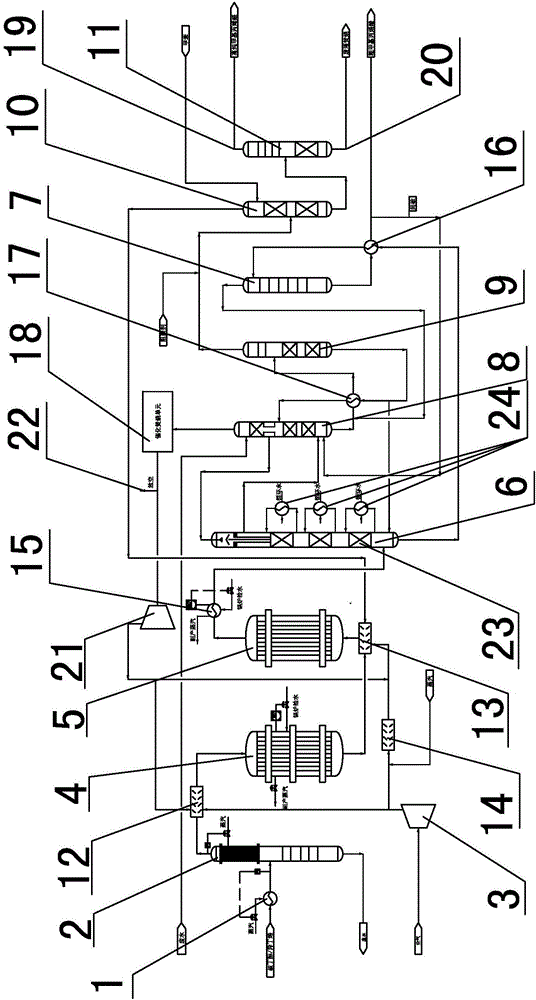

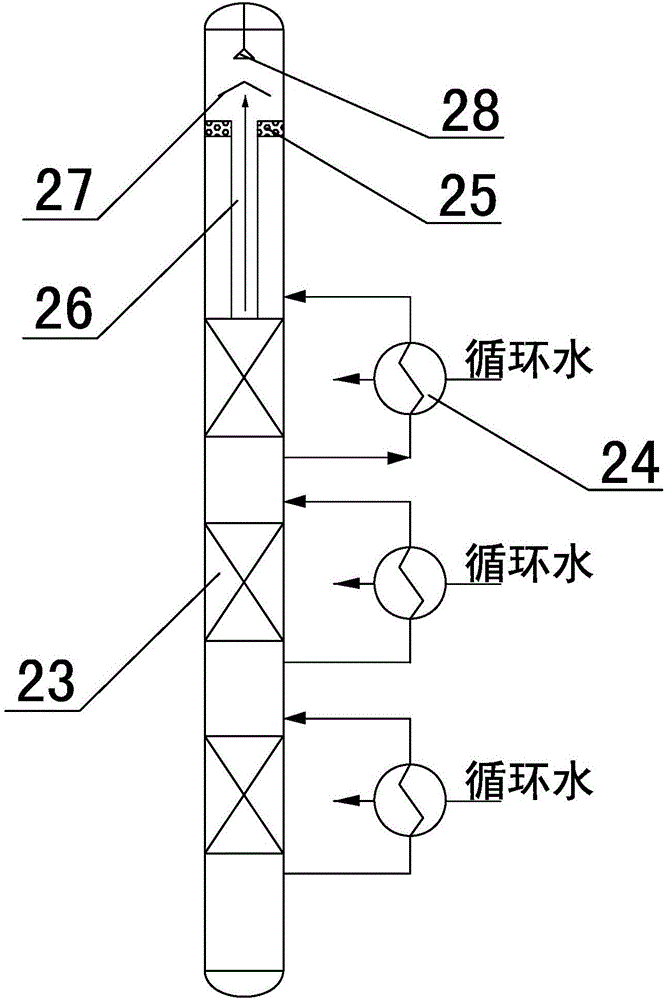

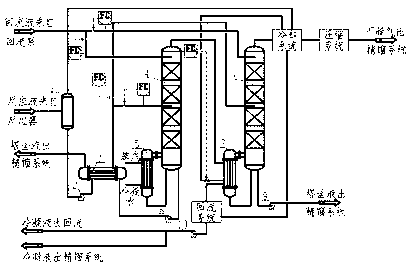

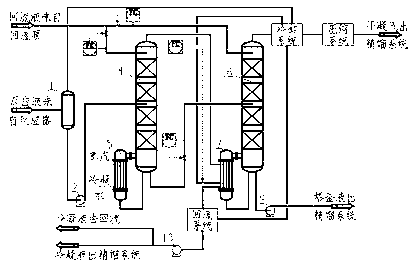

System and method for simultaneously producing methacrylic acid and methacrolein

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

Process for preparing tertiary butanol

InactiveCN1511815AImprove conversion rateHigh selectivityChemical industryPreparation by hydroxy group additionHydration reactionCatalytic distillation

The present invention relates to preparation process of tertiary butanol with C4 mixture containing isobutylene as material and through hydration reaction. The present invention features that isobutylene in C4 mixture fraction and water produce hydration to produce tertiary butanol inside catalytic distillation tower in the presence of catalyst and non-ionic surfactant. The said preparation process has high isobutylene converting rate, high tertiary butanol selectivity and low tertiary butanol producing cost.

Owner:QILU PETRO CHEM - SINOPEC

Preparation method of proton exchange film fuel cell film electrode

The invention provides a preparation method of a proton exchange film fuel cell film electrode. Pt / C catalyst layers are coated on two sides of a proton exchange film respectively to obtain a CCM filmsemi-finished product, and anti-reverse pole slurry layers are coated on peripheral edges of anode surfaces of the CCM film semi-finished product; the preparation process of the anti-reverse pole slurry specifically comprises steps of adding an antipole substance into deionized water, uniformly mixing the mixture to form mixed solution, adding mixed solution of organic solvent and proton exchangefilm resin solution into the mixed solution, and uniformly mixing the mixture to obtain anti-reverse pole slurry; the solid content of the anti-reverse pole slurry is controlled to be 1-4%, the anti-reverse pole substance is one or more of iridium, rubidium, tin, cobalt metal and metal oxide thereof, and the organic solvent is one or more of ethanol, isopropanol, tert-butyl alcohol and n-propyl alcohol. The method is simple in process, can reduce the probability of occurrence of a reverse pole phenomenon of a fuel cell in the operation process, and reduces a perforation phenomenon.

Owner:先进储能材料国家工程研究中心有限责任公司

Prepn process of cyclodextrin inclusion for lipophilic medicine

InactiveCN1706501AImprove solubilityImprove stabilityMacromolecular non-active ingredientsSolubilityCyclodextrin

The present invention is the preparation process of new cyclodextrin inclusion of lipophilic medicine, and solves the problem in preparing inclusion of lipophilic medicine with poor water solubility and lower stability. The preparation process completed inside co-solvent system of tert-butyl alcohol and water includes the following steps: dissolving the lipophilic medicine and cyclodextrin as including material separately in tert-butyl alcohol and water, mixing the obtained two kinds of solution to obtain single phase solution, and drying the mixed solution to obtain powder of cyclodextrin inclusion of lipophilic medicine. The present invention may prepare powder for injection, injection, tablet, capsule or other form. The present invention has simple preparation process, easy operation, short preparation period, low power consumption and no organic solvent residue, and is suitable for industrial production.

Owner:SHENYANG PHARMA UNIVERSITY

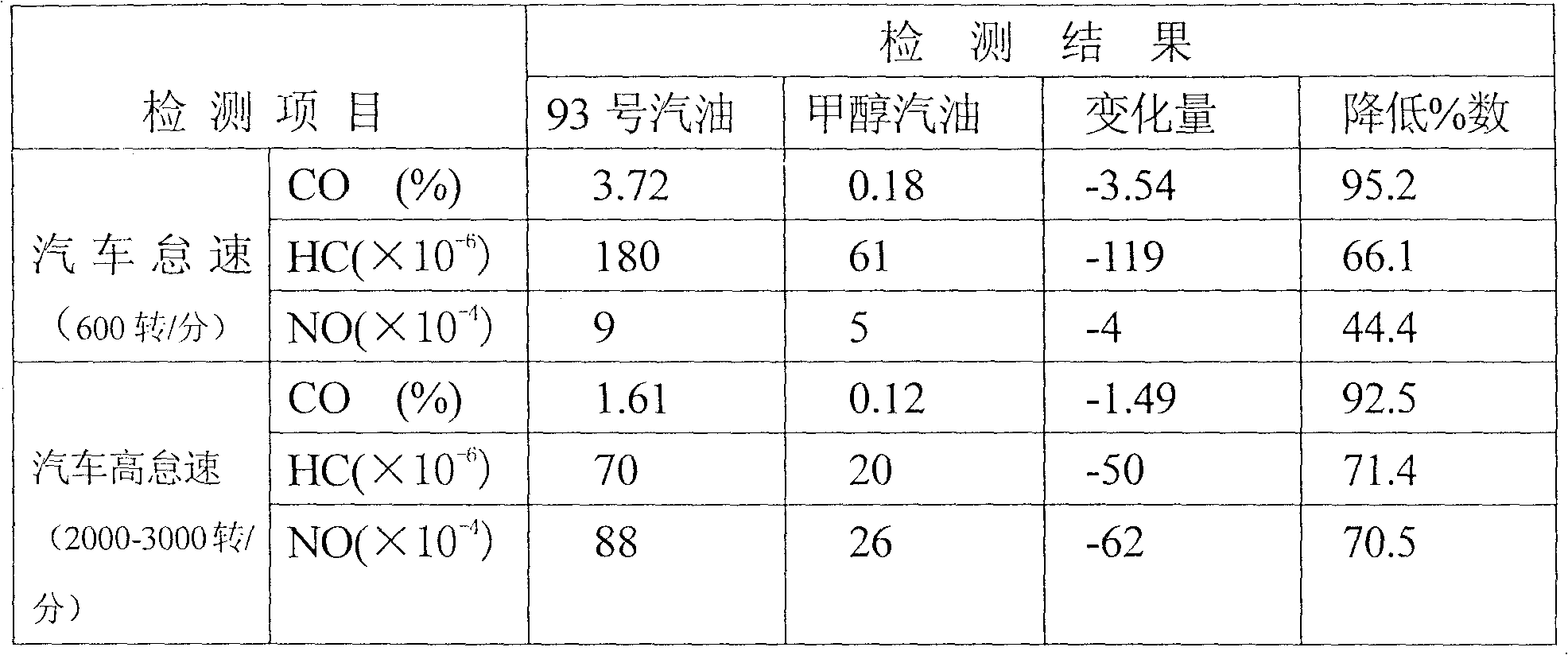

Environmental-friendly methanol gasoline multifunctional synergist

The invention provides an environmental-friendly methanol gasoline multifunctional synergist which comprises the following components in parts by weight: 35-45 parts of methyl tertiary butyl ether, 20-30 parts of methyl formate, 20-30 parts of dimethylbenzene, 10-20 parts of alkyl isopropanol, 3-20 parts of tertiary butanol, 0.1-0.5 part of dicyclopentadienyl iron, 0.05-0.1 part of hydroxy benzotriazole, 0.5-1 part of dodecyl 2-ethylhexanoate and 0.1 part of triethanolamine. The synergist has low cost, easy obtaining of raw materials and remarkable synergizing effect; the mixed methanol gasoline has power equal to No.93 gasoline and the addition amount of commonly 3-5 in the methanol gasoline, and ensures that the emission of Co in the tail gas is greatly reduced; and the methanol gasoline after the addition has good stability and comprehensive cost reduced by over 30 percent, and is mainly used as a methanol gasoline additive.

Owner:李珍发

Bendamustine hydrochloride compound

InactiveCN101606934AStable and uniform qualityImprove stabilityOrganic active ingredientsPharmaceutical product form changeBendamustine hydrochlorideFreeze-drying

The invention relates to a bendmustine hydrochloride compound and a method for preparing the same. The bendmustine hydrochloride compound prepared by the method can be used for treating chronic lymphocytic leukemia (CLL) and inertia B-cell non-Hodgkin's lymphoma (B-cell NHL). The bendmustine hydrochloride compound contains bendmustine hydrochloride and hydroxyproyl beta-cyclodextrin, wherein the mass ratio of bendmustine hydrochloride to hydroxyproyl beta-cyclodextrin is 1:1-20. During the preparation process, mixed solvent of tertiary butanol and water for injection can be used, wherein the concentration of bendmustine hydrochloride in the mixed solvent is 5-10mg / mL; the ratio in the solvent (100%) by volume is as follows: 5-50% of tertiary butanol and the balance of water. The preparation process comprises the following steps of: weighing the tertiary butanol, sequentially adding the solvent and the hydroxyproyl beta-cyclodextrin, dissolving, evenly mixing and cooling the mixture to 2-15 DEG C, maintaining the temperature, then adding the bendmustine hydrochloride, stirring until bendmustine hydrochloride dissolves, filtering, filling, stoppering, dishing-up, freeze-drying, corking, out-box, covering and packaging, and finally, the bendmustine hydrochloride compound is obtained.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Batch extractive distillation separation method of methylal-methanol azeotropic mixture

InactiveCN102627536AReduce energy consumptionFlexible operationOrganic compound preparationHydroxy compound preparationSeparation technologyExtractive distillation

Belonging to separation technologies of methylal-methanol azeotropic mixtures, the invention discloses a batch extractive distillation separation method of a methylal-methanol azeotropic mixture. The method takes propanol, isopropanol, butanol, tert-butyl alcohol, 1, 3-propylene glycol or dimethyl sulfoxide as the extracting agent. An extractive distillation tower are operated according to the operation conditions that, under normal pressure or reduced pressure, the extracting agent and an overhead product are in a mass ratio of 0.5:1-10:1, the feed temperature of the extracting agent is 20-40DEG C, and the extractive distillation tower top is controlled at different temperatures and reflux ratios, so that a methylal product, a methylal-methanol transition section I, a methanol product and a methanol-extracting agent transition section II can be obtained from the extractive distillation tower top respectively. When composition of the extracting agent of a heating kettle meets requirements, the extracting agent is pumped into a high storage tank, and feeding is conducted for next batch of extractive distillation separation. The method of the invention has the advantages of low cost of single-tower equipment, flexible operation, adoption of an extracting agent to destroy a methylal-methanol azeotropic system, and can obtain high purity methanol and methylal products.

Owner:UNIV OF JINAN

Synthesis method for pyridone

InactiveCN104030972AOptimize the synthetic routeReduce manufacturing costOrganic chemistrySynthesis methodsMorpholine

The invention discloses a synthesis method for pyridone, and relates to the technical field of synthesis of a heterocyclic compound containing three heterocyclic rings one of which takes nitrogen and oxygen as the only one heteroatom. The synthesis method comprises the following steps: reacting tetrahydrofuran, ursol, triethylamine and 5-chlorin valeryl chloride which are taken as raw materials, and after the reaction, adding potassium tert-butoxide for reacting again, thereby obtaining a monomer 1 after reaction; reacting the monomer 1 with phosphorus pentachloride in a dichloromethane solvent, thereby obtaining a monomer 2 after reaction; reacting the monomer 2 with morpholine to obtain a final product I. The synthesis method has the advantages that the raw materials are cheap and easily available, and the reaction process is greatly shortened in comparison with that of the prior art, and the synthesis method is mild and safe in reaction conditions, good in reaction reproducibility, low in cost, and high in efficiency, and has simple and easy operations in the reaction.

Owner:河北序能生物技术有限公司

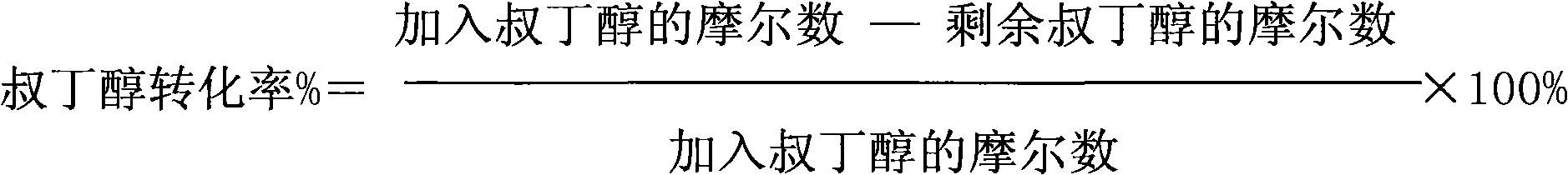

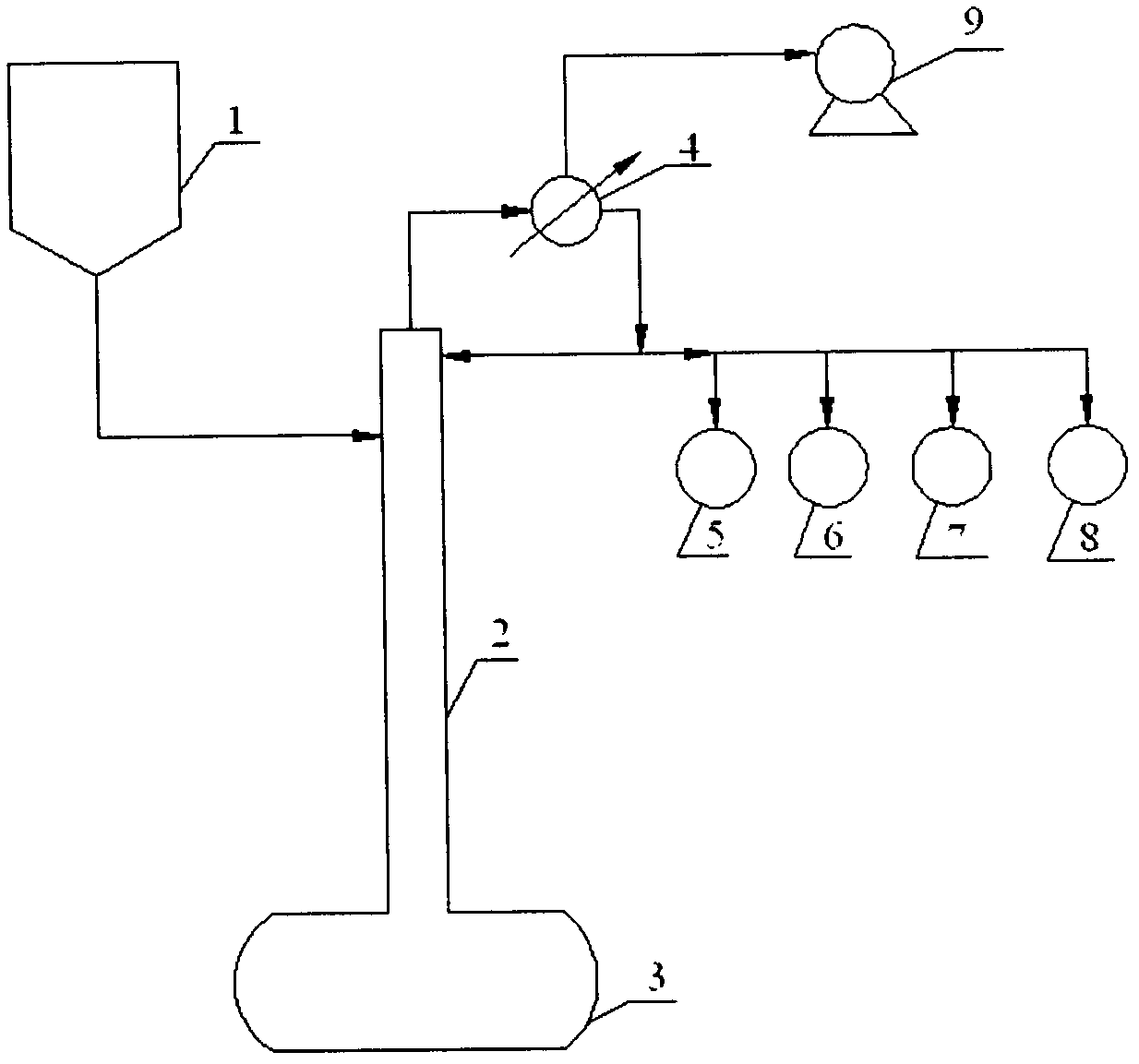

Recovering process of solvent tertiary butanol in production process of ammoximation

InactiveCN103214346AReduce consumptionTake advantage ofOrganic compound preparationHydroxy compound preparationGas phaseTower

The invention discloses a recovering process of a solvent tertiary butanol in a production process of ammoximation. The process comprises the following steps of: combining a rectifying system by a plurality of rectifying towers and configuring corresponding re-boiler, cooling system, reverse-flow system and compressing system; recovering ammonia and tertiary butanol in a reaction liquid of a reactor by a double-effect or multi-effect rectifying tower; using the overhead gas phase of the previous rectifying tower as a heat source of the re-boiler of the next rectifying tower by setting different operating pressures of the rectifying towers so as to utilize the previous gas phase condensing heat energy, wherein the operating pressure of one rectifying tower is 0.08-0.6MPa (absolute pressure) while the operating pressure of the last rectifying tower is 0.001-0.1MPa (absolute pressure), the overhead temperature of one rectifying tower is 60-140 DEG C, while the overhead temperature of the previous rectifying tower is 10-40 DEG C higher than that of the next rectifying tower; condensing the overhead gas phases by the cooling system, controlling the discharge temperature at 10-80 DEG C, the condensate enters into the reverse-flow system, and is pressurized by a pump, and part of the condensate is fed to the rectifying tower to reverse-flow, while the other condensate is fed outside the rectifying system; and feeding noncondensable gases in the cooling system to the compressing system to be compressed and feeding outside the rectifying system. According to the tertiary butanol recovering process flow, steam consumed is just 45-65% of that consumed by a single rectifying tower.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com