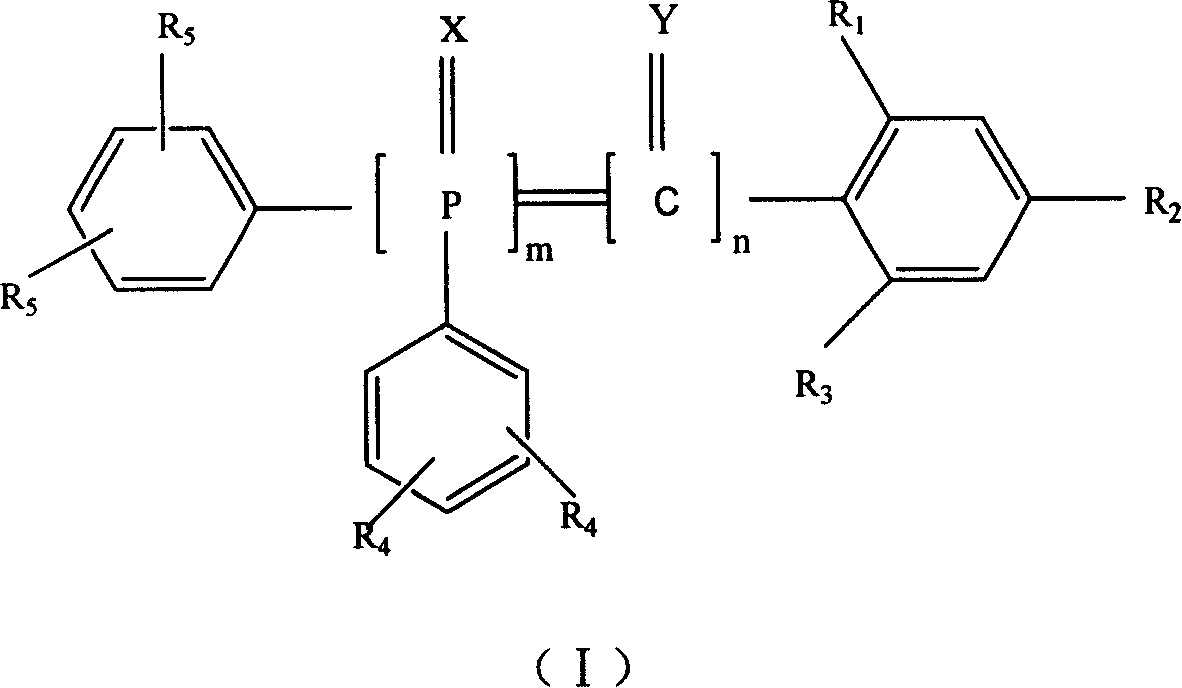

Method for preparing acyl and bisacyl phosphine oxide or acyl and bisacyl sulfur phosphines

A bisacylphosphine oxide and compound technology, which is applied in the field of preparation of acylphosphine and its derivatives, can solve the problems of many steps, low yield, high cost of raw materials, etc., and achieve the effects of low cost, fast finished product and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

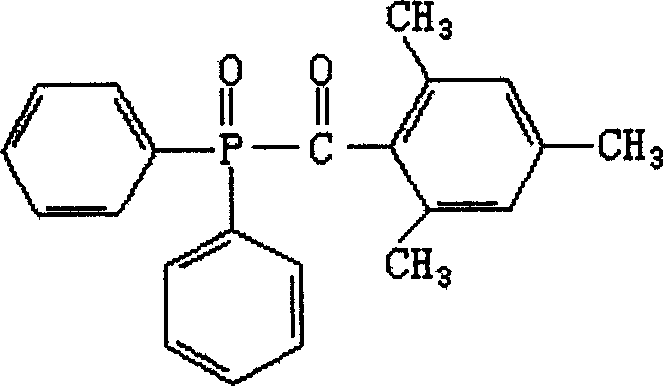

Examples

Embodiment

[0033] 880kg chlorobenzene, 20kg water and 175kg2,4,6-trimethylbenzaldehyde (TPO-A: 2,4,6-trimethylbenzaldehyde alias: rice aldehyde Mesitoldehyde) were dropped into a 3000L reactor, stirred, and Condensed water was passed into the jacket to reduce the temperature of the reactor to below 5°C. Add 230kg phenyl phosphorus chloride, the temperature in the reactor remains on room temperature or below room temperature (reaction solution becomes turbid) all the time in the process of adding. After the addition was complete, the reactor was allowed to heat up naturally. After rising to room temperature, react for 1-2 hours. Then, feed condensed water into the reactor jacket, lower the temperature of the reactor to below 10° C., and adjust the pH value to 1-2 with 20% NaOH aqueous solution.

[0034] The temperature of reactor remains on below 10 ℃, adds 12kg catalyst (vanadium catalyst: V 2 o 5 ) and 190kg tert-butanol peroxide, the temperature during the reaction was no more than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com