Patents

Literature

227 results about "Phosphorus chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

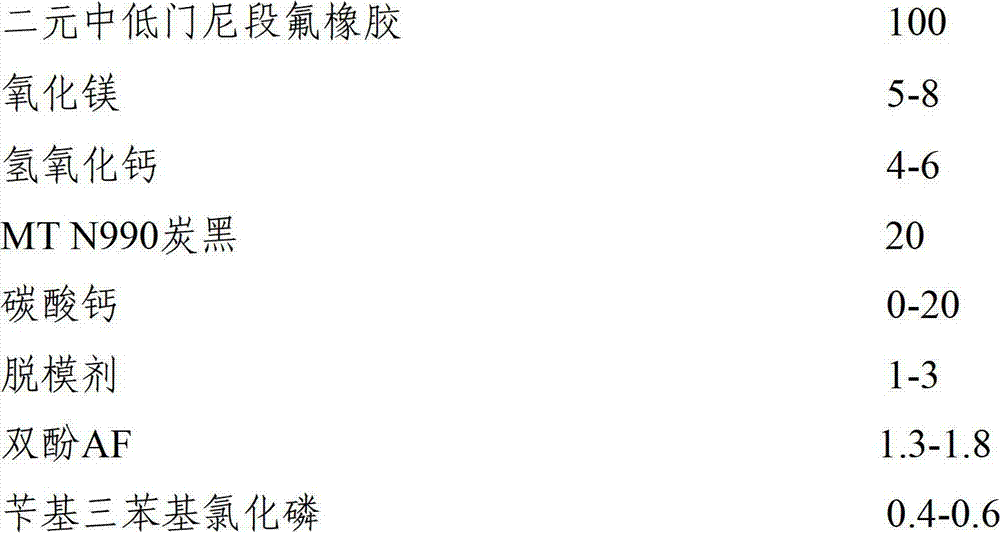

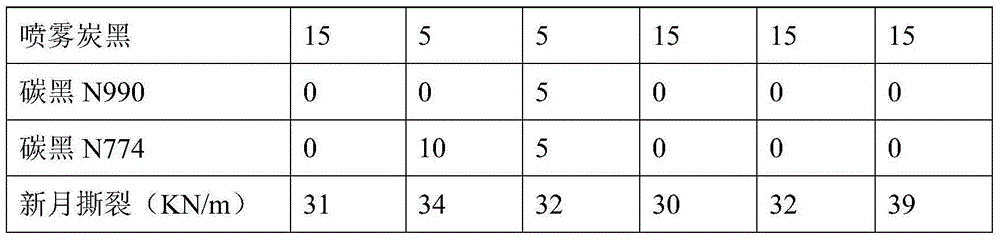

Fluororubber rubber compound and preparation method thereof

The invention provides a fluororubber rubber compound and a preparation method thereof. The fluororubber rubber compound is prepared by mixing binary intermediate-low monney sectional fluororubber rubber, reinforcing system (MT N990 carbon black and inorganic filler), acid absorbing system (active magnesium oxide and superfine calcium hydroxide), vulcanizing system (benzyl triphenyl phosphorus chloride and bisphenol AF), releasing agent (alfux and / or carnauba wax), and multifunctional bisphenol vulcanizing composite assistant vulcanizing agent L; the obtained fluororubber rubber compound has high stretching strength, and high extending rate, increases the scorching time by improving the liquidity of the rubber, therefore, high adaptability of the rubber to different manufacture technical environments and the vulcanizing environments can be ensured, the safety in vulcanizing can be improved, and as a result, the rejection rate of the products can be reduced. The fluororubber rubber compound provided by the invention is applicable to industries such as aerospace, aviation, car, metallurgy, petrochemical industry and electron and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

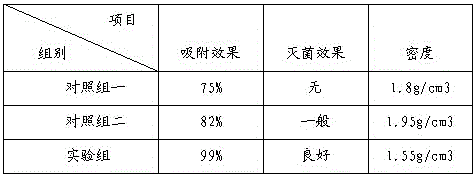

Antibacterial polypropylene block copolymer and preparation method thereof and modified material containing block copolymer

The invention relates to an antibacterial polypropylene block copolymer and a preparation method thereof and a modified material containing the antibacterial polypropylene block copolymer. The general formula of the antibacterial polypropylene block copolymer is S-I-S, wherein I is a hydrophilic matrix polypropylene chain segment, and S is an antibacterial functional chain segment; the antibacterial functional chain segment is quaternary ammonium polymethacrylate, chitosan polyacrylate, polypara-vinylbenzyltributyl phosphorus chloride or polyvinylpyridine quaternary ammonium; and the molecular weights of the hydrophilic matrix polypropylene chain segment and the antibacterial functional chain segment are 1,000-20,000g / mol respectively. According to the antibacterial polypropylene block copolymer and the preparation method thereof provided by the invention, the hydrophilic matrix polypropylene chain segment is combined with the specific antibacterial functional chain segment to form the antibacterial polypropylene block copolymer, thus the problems of the prior art are solved; the process is simple, and the cost is low; and in the obtained modified material, the adhesion of the copolymer is greatly improved, and the copolymer does not drop easily and has good durability, thus the antibacterial property is long-lasting while the mechanical properties of the matrix material are not influenced.

Owner:汕头市康家宝塑料制品实业有限公司

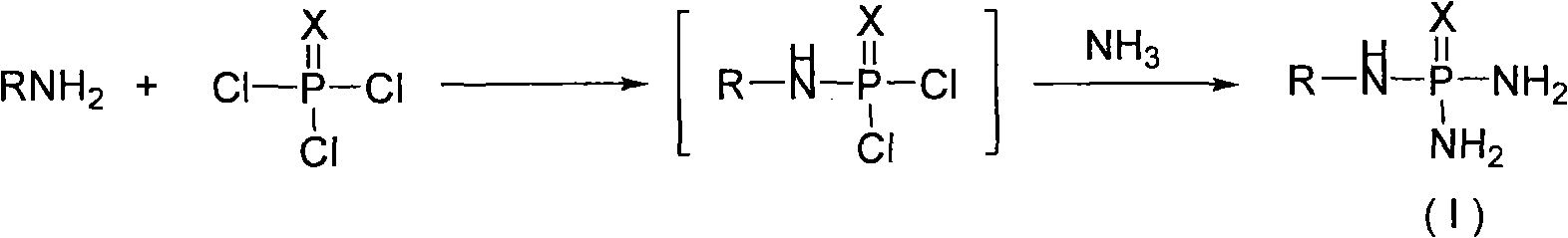

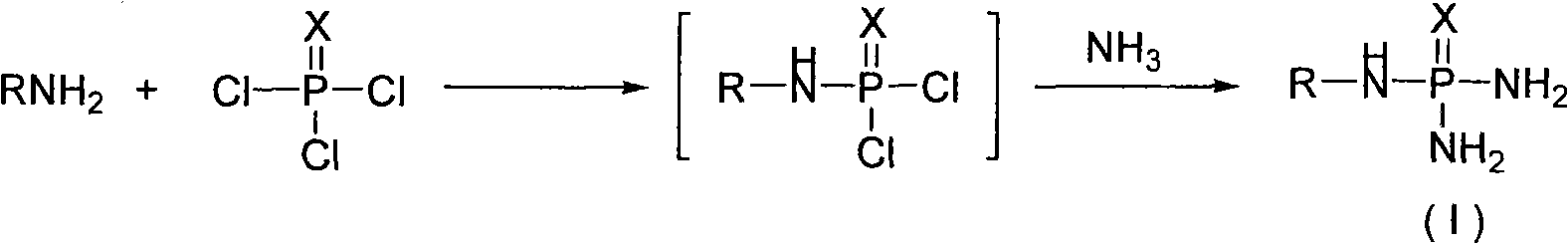

Method for industrialized production of N-alkyl substituted phosphoric triamide

InactiveCN101525348ARecyclingReduce the difficulty of operationGroup 5/15 element organic compoundsOrganic phosphatic fertilisersPhosphoric acidUrokinase inhibitor

The invention relates to a preparation method of N-alkyl substituted phosphoric triamide, in particular to a method for industrialized production of the N-alkyl substituted phosphoric triamide. The preparation method mainly solves technical problems of the existing synthetic method such as severe production process requirements and great separation difficulty of products caused by taking triethylamine as an acid-binding agent and the like. The technical proposal of the invention is as follows: the method for industrialized production of the N-alkyl substituted phosphoric triamide comprises the following steps: allowing phosphorus chloride solution to react with excessive alkylamine, using up the excessive alkylamine as the acid-binding agent, and introducing ammonia gas to obtain the N-alkyl substituted phosphoric triamide. The N-alkyl substituted phosphoric triamide is an efficient urokinase inhibitor.

Owner:林文斌 +1

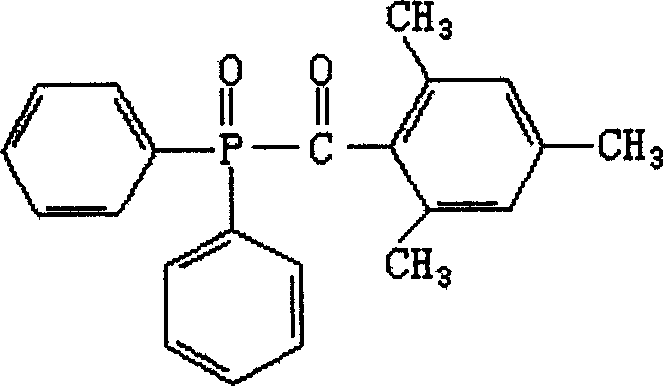

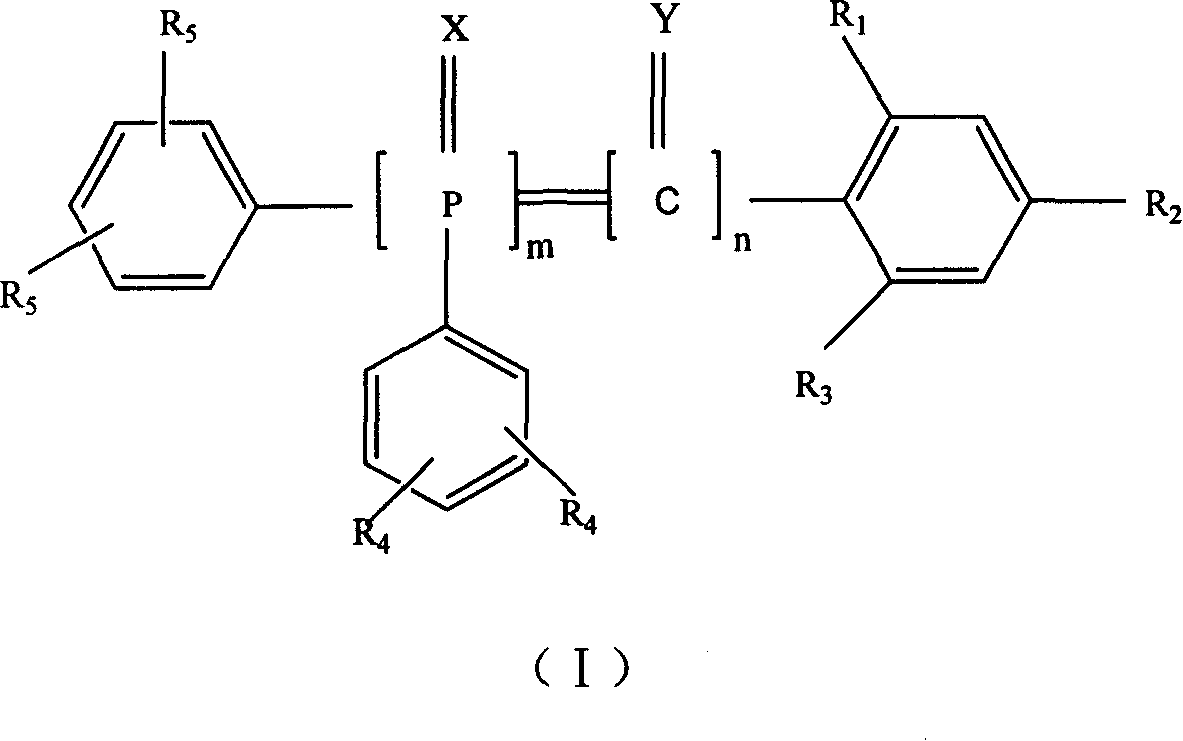

Method for preparing acyl and bisacyl phosphine oxide or acyl and bisacyl sulfur phosphines

InactiveCN101200475AReduce manufacturing stepsReduce decreaseGroup 5/15 element organic compoundsCoatingsBenzaldehydePhosphine oxide

The invention relates to a preparation method of single acyl or two acyl phosphine oxide and single acyl or two acyl sulfur phosphine compound, in particular to a preparation method of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide of the photoinitiator. The addition reaction is carried out between Trimethyl benzaldehyde and diphenyl phosphorus chloride and then the mixture is oxidized by tert-butyl alcohol peroxide. The invention adopts the addition reaction of aldehyde and halogenated phosphorus and replaces the original process of acyl chloride and halogenated phosphorus, and has the advantages of greatly shortening the preparation procedures, low cost, easy operation and quick production. The compound prepared by the invention has more than 98 percent of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide and can be served as the photoinitiator for solid for producing the solidification product with the performance of paint, varnish, porcelain glaze, paint, pigment or ink, and can better satisfy the increasing market demand.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

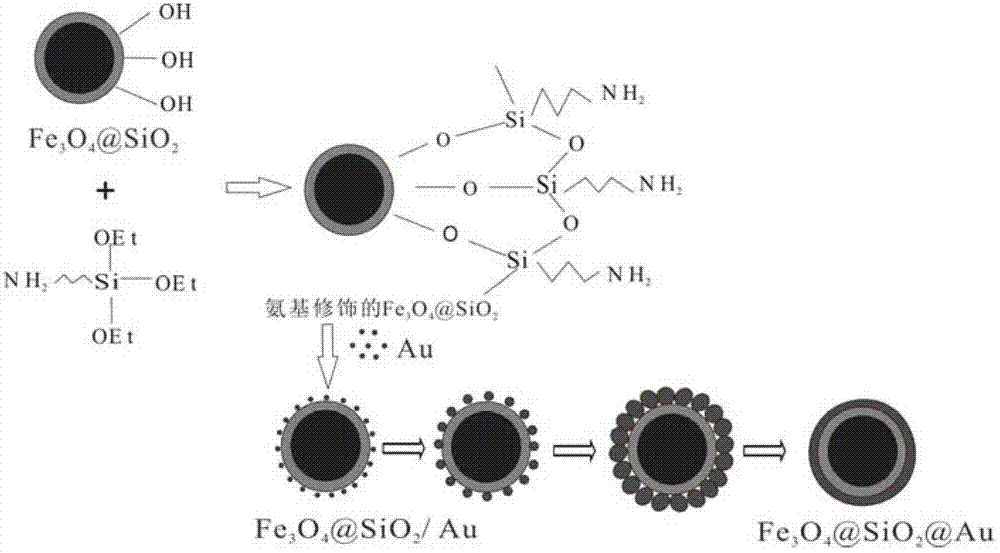

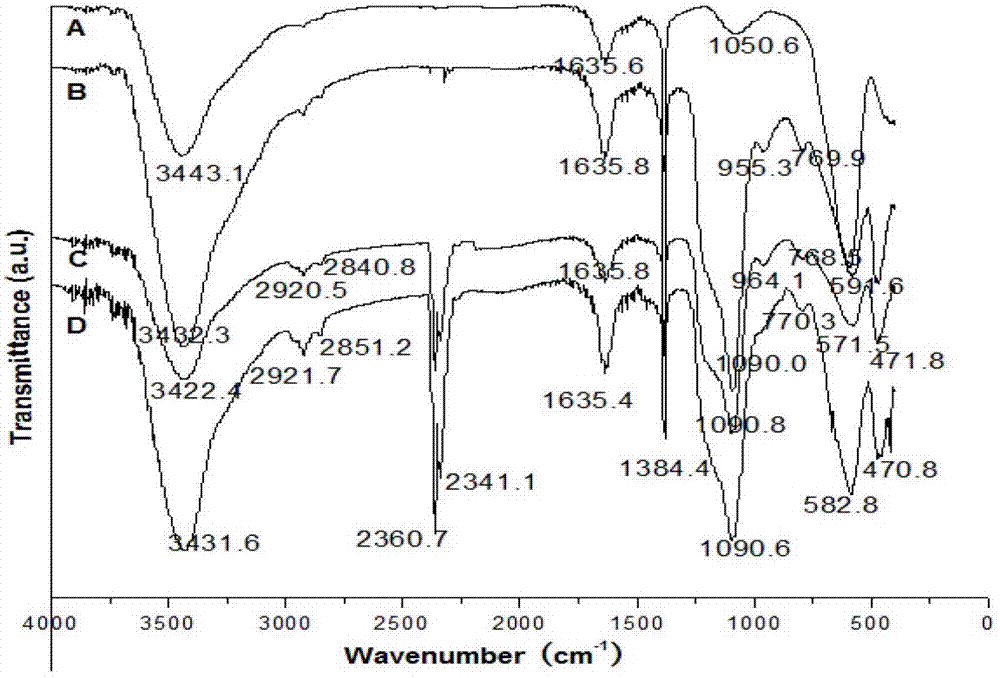

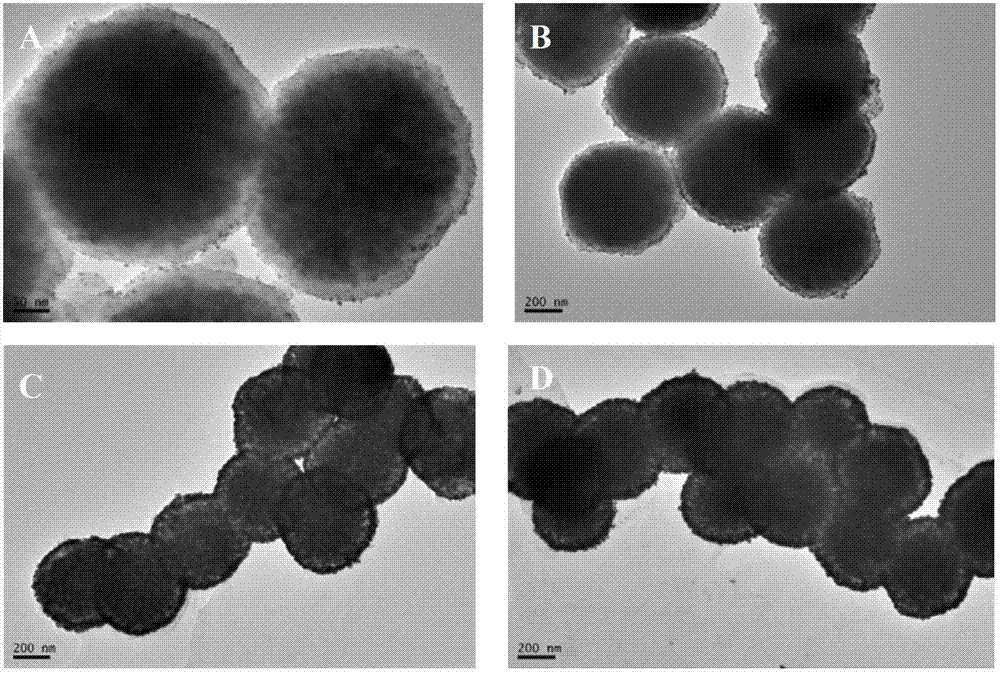

Method for preparing three-layer core-shell structural gold magnetic nano particles

ActiveCN102764618AComplete Particle Size DistributionUniform particle size distributionInorganic material magnetismMicroballoon preparationGold particlesNanoparticle

The invention discloses a method for preparing three-layer core-shell structural gold magnetic nano particles. The method comprises the following steps of: preparing amino modified core-shell structural Fe3O4 coated SiO2 particles; reducing chloroauric acid by using tetra-hydroxymethyl phosphorus chloride (THPC), wherein the obtained particles carry negative charge and are easily adsorbed to the surfaces of the amino modified Fe3O4 coated SiO2 particles; mixing and stirring suspension of the amino modified Fe3O4 coated SiO2 particles and nano gold suspension, and thus obtaining assembled gold magnetic composite particles Fe3O4 coated SiO2 / Au; and performing multi-step reduction on the surfaces of the THPC reduced nano gold particles which are adsorbed to the surfaces of the Fe3O4 coated SiO2 particles and used as crystal nuclei by using formaldehyde to obtain complete gold shells, and thus obtaining the three-layer core-shell structural gold magnetic nano particles Fe3O4 coated SiO2 coated Au. The prepared particles are uniform in particle diameter distribution and high in dispersibility, stability, magnetic responsibility and biocompatibility.

Owner:SOUTHEAST UNIV

Preparation method of sulfadoxine

A preparation method of sulfadoxine belongs to the field of sulfanilamide antimicrobial drug preparation. Cyclization reaction comprises the following steps of: firstly pouring a sodium methoxide solution into a reactive pan, then successively adding methanamide and methyl ethyl methoxymalonate, keeping warm, recovering methanol, cooling for crystallization, drying by centrifugation, discharging,and drying to obtain 5-methoxy-4,6-disodium dihydroxypyrimidine; Chlorination reaction comprises the following steps of: firstly putting phosphorus oxychloride into a reaction vessel for heating, adding 5-methoxy-4,6-disodium dihydroxypyrimidine into the reaction vessel to react, decompressing and recovering phosphorus oxychloride until the material is dry, cooling, adding trichloro ethylene withuniformly stirring, putting into a hydrolysis pan for hydrolyzation, collecting a trichloro ethylene layer after standing and delaminating, followed by a neutralization reaction, controlling pH value, washing, removing a water layer, recovering trichloro ethylene, and releasing crystals to obtain 5-methoxy-4,6-dichloropyrimidine. The preparation method provided by the invention can be used to guarantee the product purity, prolong the service life of equipment, avoid the damage to the environment and human body, reduce emission, and save energy, and accords with foreign pharmacopoeia standard requirements.

Owner:CHANGSHU JINSHEN MEDICAL PROD CO LTD

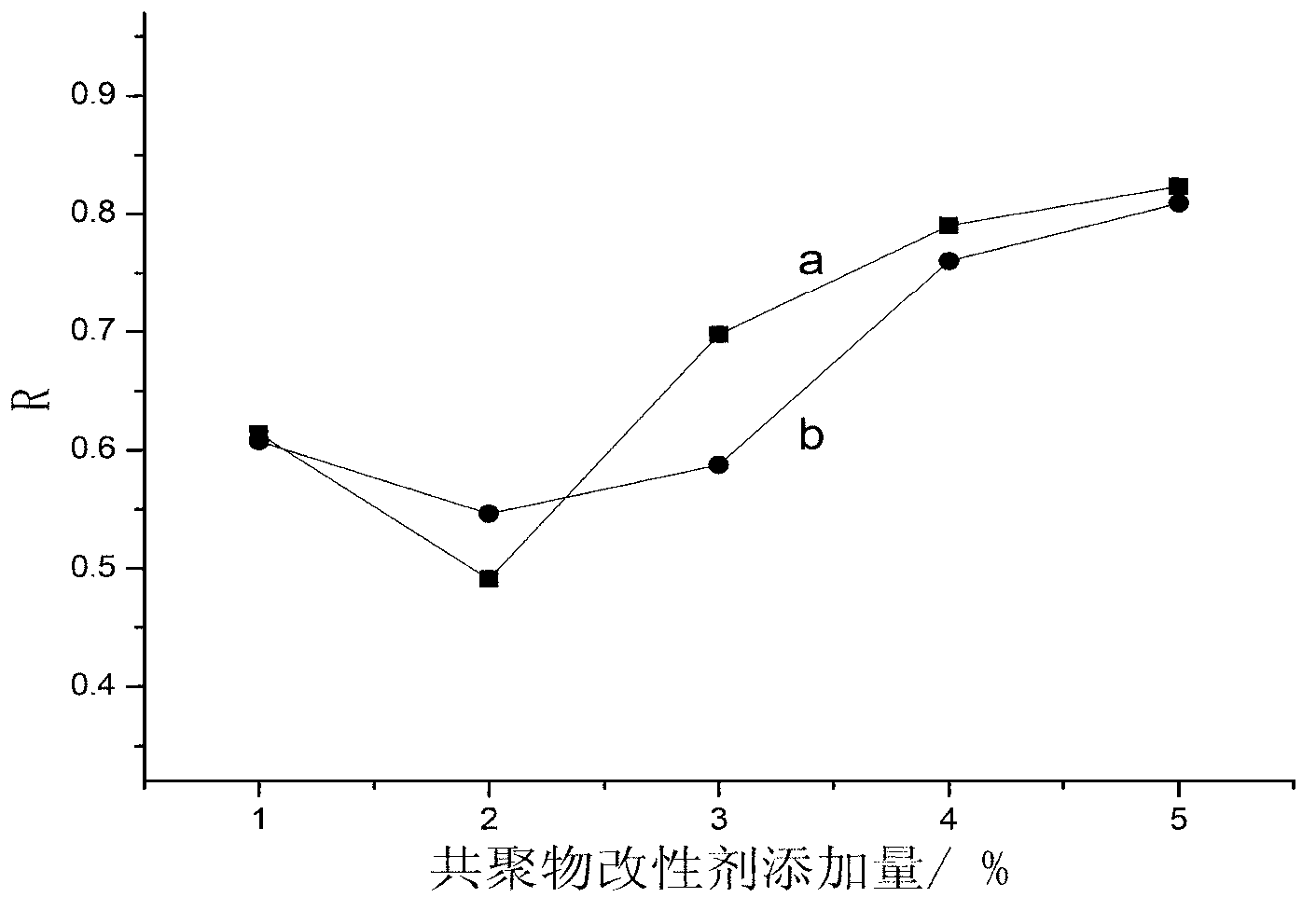

Organic polymer flocculant and its prepn. and application in water treatment

InactiveCN1336391ALess drug consumptionGood processing effectWater/sewage treatment by flocculation/precipitationWater chlorinationPhosphorus trichloride

The present invention relates to preparation of organic polymer coagulant and its application in water treatment. Said method incldues condensation polymerization, inorganic ammonium salt is dissolved in a reactor containing aliphatic aldehyde and water, reaction temp. is 60-95 deg.C, reaction time is controlled at 0.5-3 hr., proceed hydrolysis and esterification, reduce the temp. of reaction liquid to 20-70 deg.C., and phosphorus trichloride, raise temp. to 90-120 deg.C, react for 2-9 hr., then reduce temp. of 45-85 deg.C, and additive, continue reaction 1-3 hr. cool to room temp. to obtain product. The invented product is ideal in waste water treatment, good in stability, non-toxic etc..

Owner:FUZHOU UNIV

Low-temperature-resistant low-compressive deformation seal gasket material for intake manifolds and preparation method thereof

The invention discloses a low-temperature-resistant low-compressive deformation seal gasket material for intake manifolds and a preparation method thereof. The material comprises, by weight, 60-70% of raw fluororubber, 5-15% of calcium silicate, 5-20% of diatomite, 3-15% of barium sulfate, 3-10% of polytetrafluoroethylene powder, 2-5% of cerium oxide, 2.4-4.5% of calcium hydroxide, 1.5-2.8% of magnesium oxide, 0.5-2% of lubricant, 0.6-1.4% of 2, 2-bis(4-hydroxyphenyl)hexafluoropropane, 0.3-0.7% of benzyl triphenyl phosphorus chloride, and 0.5-2% of auxiliary material. The low-temperature-resistant low-compressive deformation seal gasket material for intake manifolds and the preparation method thereof have the advantages that the preparation method is simple and easy to operate, the material has good processability, low compression set and excellent low temperature resistance, and an intake manifold seal gasket made of the material has good comprehensive properties and long service life.

Owner:ANHUI ZHONGDING SEALING PARTS

Method for preparing flame-retardant fabric finishing agent

InactiveCN103790006AExcellent flame retardant effectGood flame retardancyFibre treatmentAmezinium methyl sulfateFire resistance

The invention discloses a method for preparing a flame-retardant fabric finishing agent. The method comprises the following steps: (1) grinding 2-3 weight parts of diammonium hydrogen phosphate, 15-17 weight parts of borax, 8-9 weight parts of trimethylol tripolyamide , 2-3 weight parts of tetrakis hydroxyethyl phosphorus chloride and 6-7 weight parts of sodium silicate, and uniformly mixing; (2) simultaneously adding 2-3 weight parts of dodecyl trimethyl ammonium sulfate, 5-6 weight parts of magnesium chloride, 150-180 weight parts of deionized water and 10-15 weight parts of tricresyl phosphate, finishing batching within 15-20 minutes, and uniformly stirring and mixing at the temperature of 60-65 DEG C; and (3) cooling to room temperature, sequentially adding 2-3 weight parts of hydroxypropyl methyl cellulose, 12-14 weight parts of triethanolamine and 8-9 weight parts of urea, uniformly stirring and mixing to obtain the flame-retardant fabric finishing agent. The invention provides a method for preparing the flame-retardant fabric finishing agent, and the fabric finished by the flame-retardant fabric finishing agent has high fire resistance and hidden combustion property, can prevent molten drops and is resistant to washing and dry cleaning.

Owner:CHANGSHU YAOU IMPORTS & EXPORTS TRADE

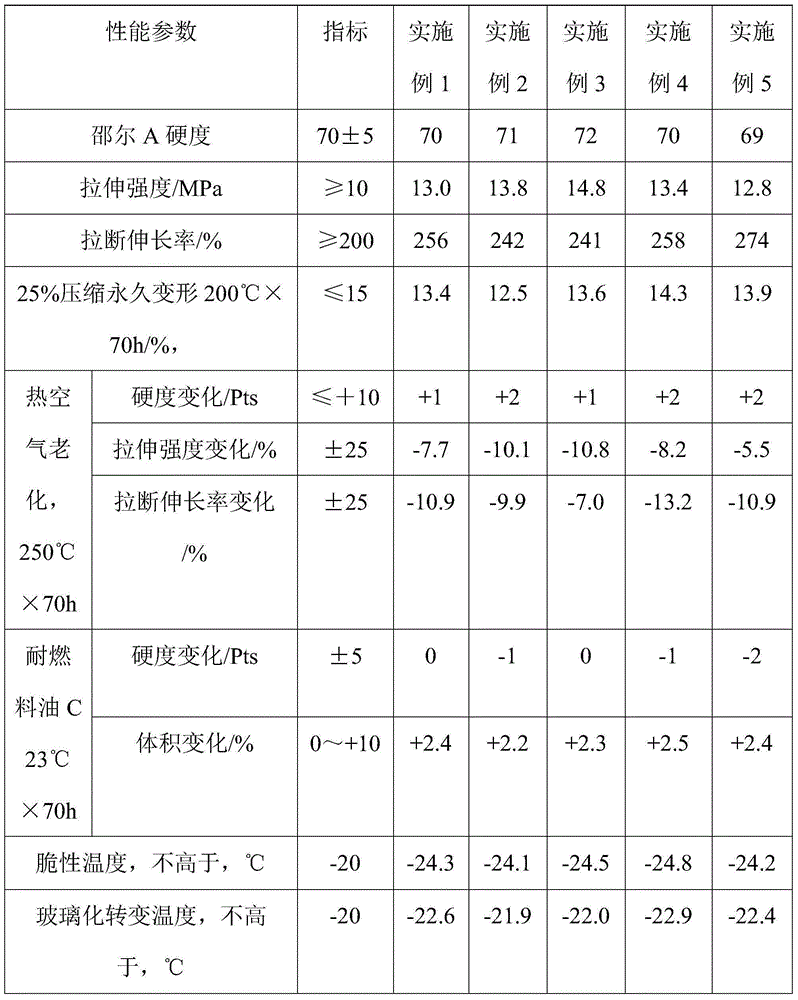

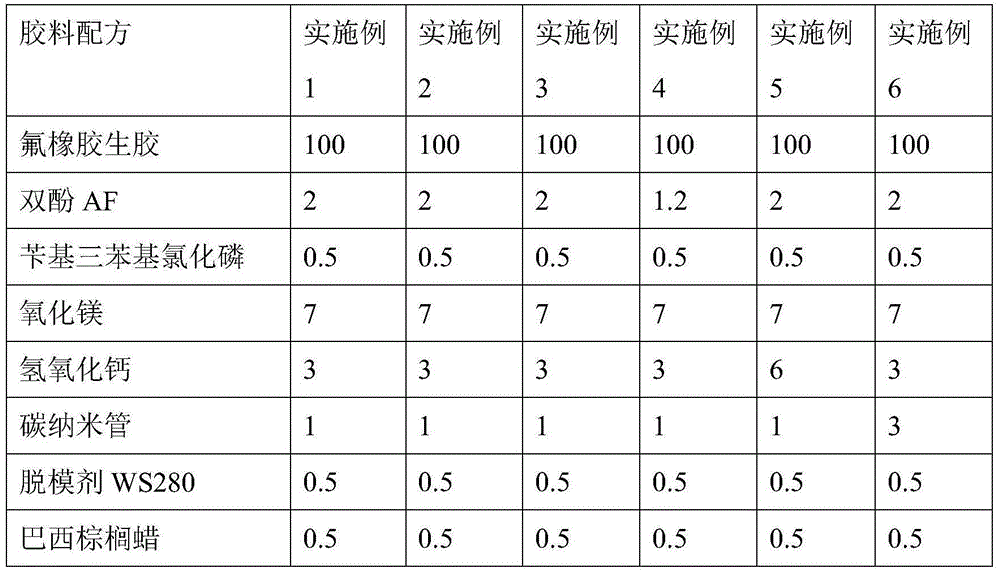

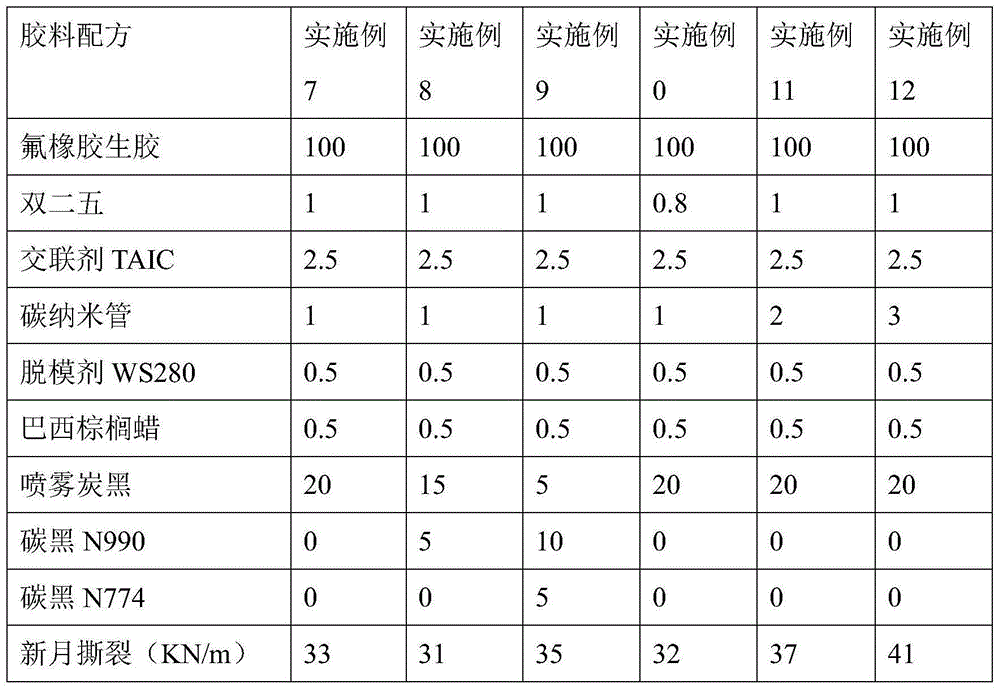

Tear-resistant fluoro-rubber mixed compound and preparation method thereof

The invention provides a tear-resistant fluoro-rubber mixed compound and a preparation method thereof, which belong to the filed of mixed compound application. The tear-resistant fluoro-rubber mixed compound is formed by mixing a binary fluoro-rubber, a ternary fluoro-rubber, active magnesium oxide, calcium hydroxide, a vulcanization system (bisphenol vulcanization system: bisphenol AF, benzyl triphenyl phosphorus chloride or peroxide vulcanization system: DBPH, TAIC), a carbon nanotube, a releasing agent, a reinforcing agent, and the like. The mixed compound prepared according to the invention is good in tear resistance, and can be widely used in rubber products.

Owner:NANJING ORIENTLEADER TECH CO LTD

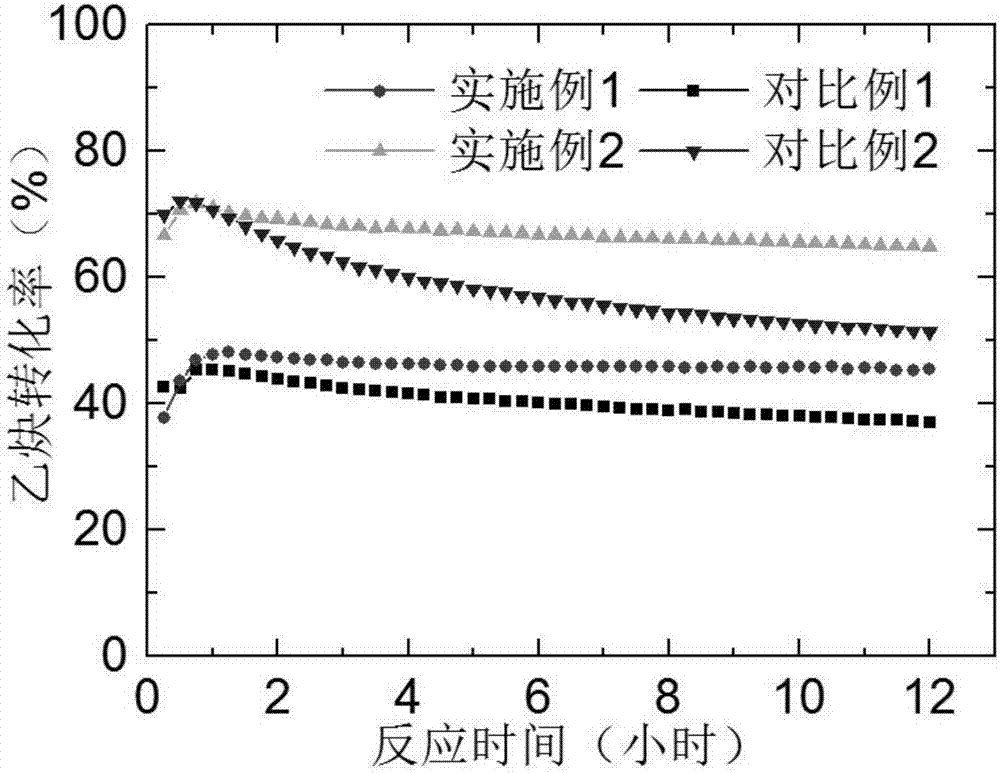

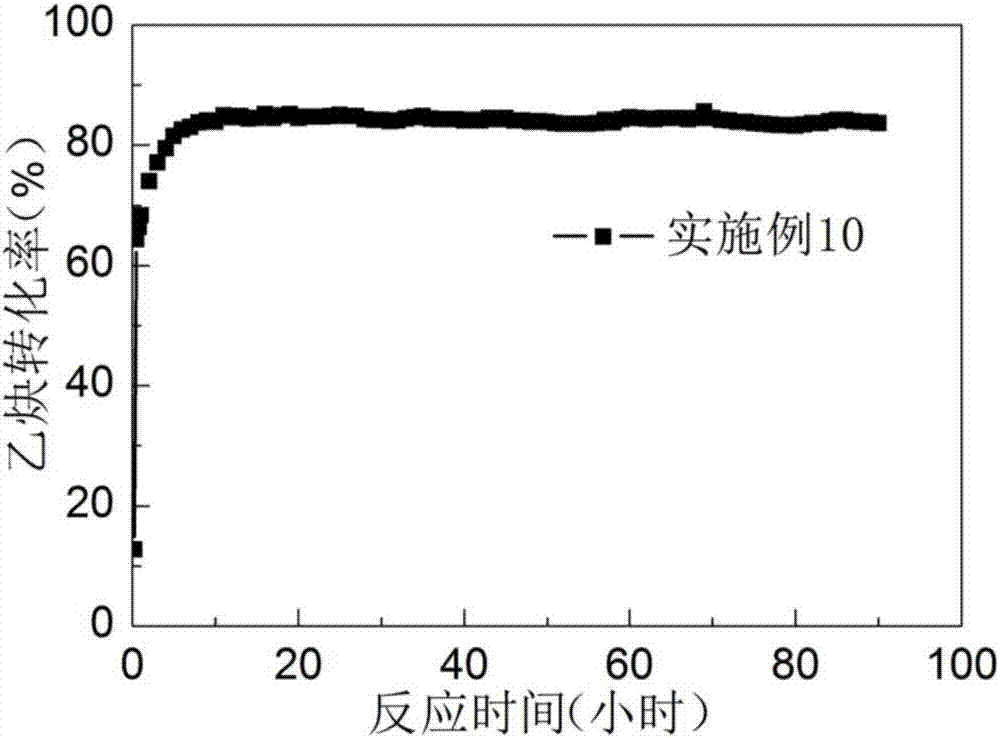

Copper-based catalyst with high activity and stability for acetylene hydrochlorination

ActiveCN107008465ALow costIncrease costPhysical/chemical process catalystsPreparation by halogen halide additionSteam pressurePhosphate

The invention relates to a copper-based catalyst with high activity and stability for acetylene hydrochlorination. According to the copper-based catalyst, a copper salt is taken as an active component, wherein the copper salt is selected from one or more of copper chloride, copper nitrate, copper sulfate and copper phosphate. The copper-based catalyst is characterized in that a stabilizer is introduced into the copper-based catalyst; and the stabilizer is selected from one or more of guanidine hydrochloride, tetramethylethylenediamine hydrochloride, tetramethylammonium chloride, tetraethylammonium chloride, benzyltrimethylammonium chloride, benzyl triethyl ammonium chloride, tetramethyl phosphorus chloride, tetrabutyl phosphorus chloride, methyl triphenyl phosphorus chloride and 1-butyl triphenylphosphonium. Through introducing the stabilizer has the advantages of being low in cost, low in toxicity, good in heat stability and small steam pressure into the catalyst, and the stability of the copper-based catalyst for acetylene hydrochlorination is significantly improved.

Owner:TSINGHUA UNIV

Metallic paint

InactiveCN103122159AEasy to useImprove corrosion resistanceAnti-corrosive paintsTetrafluoroboratePotassium hydroxide

The invention discloses a metallic paint which comprises the following raw materials in parts by mass: 1-4 parts of potassium hydroxide, 2-3 parts of benzotriazole, 1-2 parts of melamine, 2-6 parts of 12-hydroxystearic acid, 3-5 parts of methyl methacrylate, 2-5 parts of sodium lauryl sulfate, 3-7 parts of p-tert-pentyl phenol, 1-3 parts of tetraethylammonium tetrafluoroborate, 2-4 parts of benzyltriphenyl phosphorus chloride, 1-2 parts of trifluoroacetylacetone cobalt and 3-6 parts of methylene bromide. The metallic paint disclosed by the invention has the advantages of stable use effect, strong corrosion resistance, low surface damage tendency, favorable wear resistance and favorable punching property, can obviously prolong the service life, and is safe and nontoxic for the human body.

Owner:NANTONG HAISHUN CHEM

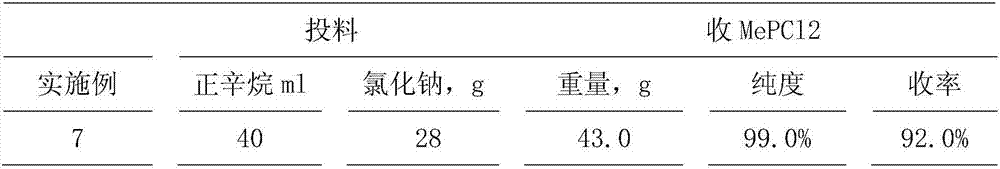

Method for preparing dichloro monoalkyl phosphine

The invention discloses a method for preparing dichloro-alkylphosphine, which uses sodium chloride to decomplex the binary complex of dichloro-alkylaluminum or alkyl aluminum sesquichloride and phosphorus trichloride When adding the alkane solvent, the free dichloro-alkylphosphine enters the alkane solvent, and the alkane solution of the dichloro-alkylphosphine is separated from the newly generated sodium tetrachloroaluminate NaAlCl by solid filtration; the target product dichloro-alkyl The mixture of phosphine and alkane solvent can be separated by distillation, or directly enter the next application process without separation. The decomposition of the traditional dichloro-alkylphosphine high-temperature distillation is avoided, the yield is increased and the waste residue is reduced.

Owner:南京奥格美化学研究所有限公司

Processing method of exhaust gas in sodium hypophosphite production course

ActiveCN101224378AFeel goodImprove flame retardant performanceDispersed particle separationPhosphorus compoundsPolyesterPhosphonium

The invention relates to an exhaust gas disposal method in the sodium hypophosphite preparation process. The technique includes the following steps: phosphine is collected and stored; formaldehyde, vitriol or hydrochloric acid are prepared into water solutions according to molar ratio of 8.1 to 8.2:1; the water solution is pumped into an absorbing tower by an anti-corrosion pump and then is sprayed downwards from the tower top, and the phosphine in a gas tank is filled into the absorbing tower by a gas pump, and the reaction compounding happens under the temperature of 40 - 50 DEG C to obtain tetramethylol phosphonium sulfate or tetramethylol phosphorus chloride water solution. The invention has the advantages that the prepared tetramethylol phosphonium sulfate (THPS) is phosphonium actericide bactericidal algicide and generates no pollution to environment; the prepared tetramethylol phosphorus chloride (THPC) can be synthesized with urea to generate THPC-Urea which can be used for pure cotton or polyester cotton and other fabrics as permanent flame retardant, and the phosphine can be thoroughly absorbed by formaldehyde, vitriol or hydrochloric acid so as to realize a zero emission of poison gases.

Owner:江苏和纯化学工业有限公司

Waterproof building-out cable

InactiveCN105860371AHigh temperature resistantOil resistantRubber insulatorsInsulated cablesCarvacryl acetateBisphenol AF

The invention discloses a waterproof building-out cable which comprises a cable core and a sheath. The sheath is made from a modified fluororubber composite material. The modified fluororubber composite material comprises fluororubber, methyl vinyl silicone rubber, ethylene-propylene-diene monomer rubber, epichloro-hydrin rubber, an ethylene-vinyl acetate copolymer, fluororubber graft vinyl triethoxy silane, alumina, stearic acid, bisphenol AF, benzyl triphenyl phosphorus chloride, ethylidene thiourea, modified nano-silica, carbon black N550, silica powder, rectorite powder, talcum powder, calcined kaolin, barium sulfate, an accelerant PPD, an accelerant ZBPD, an accelerant CZ, dioctyl phthalate, epoxy fatty acid butyl ester, dibutyl sebacate, erbium oxide, lanthanum stearate, an anti-aging agent 2246 and 2,2'-ethylidene bis(4,6-di-tert-pentylphenol). The waterproof building-out cable is high in strength, good in water resistance and excellent in aging resistance.

Owner:ANHUI HUAYU CABLE GRP

High-performance natural rubber/butadiene styrene rubber composite material

The invention discloses a high-performance natural rubber / styrene-butadiene rubber composite material. The raw materials include: natural rubber, styrene-butadiene rubber, rare-earth isoprene rubber, zinc oxide, stearic acid, sulfur, benzoyl peroxide, and an accelerator CZ, accelerator DM, accelerator NOBS, antioxidant, light calcium carbonate, magnesium oxide, calcium hydroxide, graphene oxide, bamboo charcoal powder, aluminum silicate, diatomaceous earth, sodium montmorillonite, benzyl triphenyl Phosphorous chloride, polyethylene glycol. The high-performance natural rubber / styrene-butadiene rubber composite material proposed by the invention has high strength, good heat resistance and wear resistance, can meet the use requirements of various fields, and has a long service life.

Owner:合肥市再德高分子材料有限公司

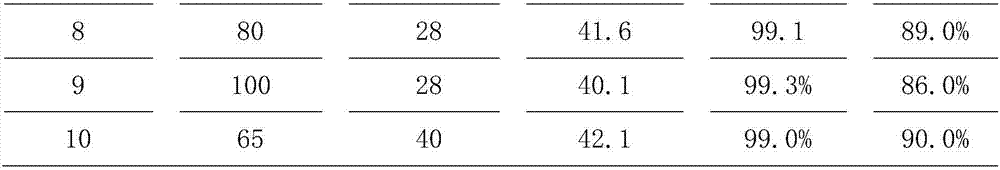

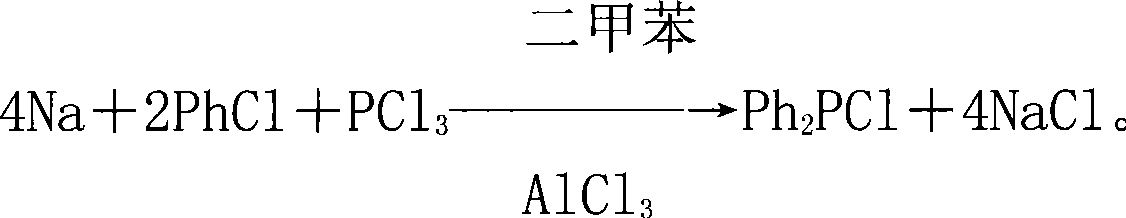

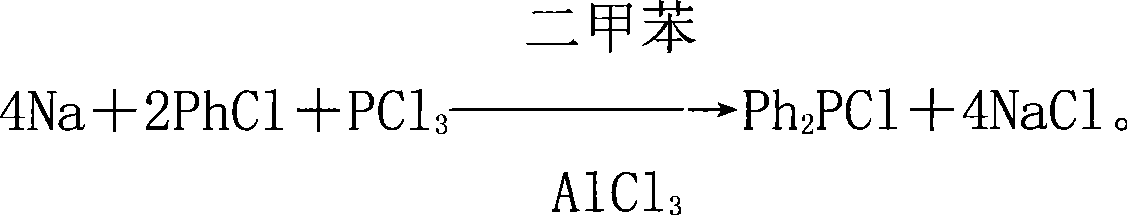

Raw material components and production method of diphenyl phosphorus chloride

InactiveCN101481390AShort reaction timeLess side effectsGroup 5/15 element organic compoundsChemical productsSolvent

The invention relates to raw material components and a production method of chlorodiphenylphosphine, and belongs to the technical field of chemical product formulas and production methods. Based on mass part, the raw material components are as follows: 0.8-1.5 parts of an active metal, 1-4 parts of benzene halide, 1-3 parts of phosphorus trichloride, 1-8 parts of an organic solvent and 0.03-0.1 part of a catalyst. The production method comprises the following steps: 1. mixing and adding the organic solvent and the active metal to a dispersing kettle based on the mass part, heating and stirring to disperse the active metal, and adding the benzene halide for a first initiation; 2. cooling the materials after dispersion, adding the same amount of the benzene halide for a second initiation, cooling and adding the remaining benzene halide and the phosphorus trichloride; 3. allowing reaction, adding the catalyst, and heating for reaction; 4. filtering through a press filter cone when the materials are hot; and 5. putting the filter pressed materials in a rectifying still and stirring, distilling off the solvent at normal pressure, rectifying a finished chlorodiphenylphosphine product at negative pressure, checking and packaging. The raw material components and the production method have the advantages of 1. shortening the reaction time, reducing the side reaction and improving the yield; and 2. avoiding a hydrolysis procedure, eliminating sewage discharge and reducing the raw material consumption.

Owner:ZHAOYUAN SONGHE CHEM

Method for producing dichlorophenylphosphine

InactiveCN105732708ALow costAvoid generatingGroup 5/15 element organic compoundsDichlorophenylphosphineWastewater

The present invention relates to a kind of method of producing phenyl phosphorus dichloride. Its technical scheme is: use chlorinated benzene, elemental phosphorus, and phosphorus trichloride as raw materials, and adopt reaction in a tubular reactor to prepare phenylphosphorus dichloride. The reaction equation is as follows: P 4 + 6C 6 h 5 Cl + 2PCl=6C 6 h 5 PCl. The beneficial effect is: since the main reaction of this method is carried out in a tubular reactor, without using a catalyst, the materials can directly reach the reaction conditions according to the ratio for rapid reaction, shorten the production cycle, and avoid the generation of a large number of by-products; at the same time It solves the potential safety hazards caused by high-temperature and high-pressure reactions in the past by using autoclaves; and there is no waste gas, waste residue, and waste water in the production process. Compared with the current process for preparing phenylphosphorus dichloride, it has greater cost advantages and environmental protection advantages.

Owner:东营美利达新型材料科技有限公司

Adsorption preparation for wastewater treatment and preparation method thereof

PendingCN106669633AImprove adsorption capacityDestabilizingOther chemical processesAlkali metal oxides/hydroxidesAluminateManganese oxide

The invention discloses an adsorption preparation for wastewater treatment. The adsorption preparation for the wastewater treatment is prepared from the following raw materials in parts by weight: 14-18 parts of aluminum sulfate, 19-20 parts of oxalic acid, 22-25 parts of polyacrylamide, 16-18 parts of sodium carbonate, 9-17 parts of activated carbon, 10-16 parts of calcium aluminate, 5-8 parts of ammonium sulfate, 4-11 parts of sodium metaaluminate, 12-14 parts of calcium disodium versenate, 9-16 parts of potassium ferrate, 8-10 parts of polyvinylpyrrolidone, 3-4 parts of sodium carbonate, 9-14 parts of ferric citrate, 8-10 parts of polysulfide ferric chloride, 2-5 parts of cellulose powder, 3-8 parts of sodium lignosulphonate, 1-2 parts of dibenzoyl peroxide, 7-14 parts of nano-manganese oxide, 16-24 parts of guanidine sulfate, 22-25 parts of dodecyl triphenyl phosphorus chloride and 9-16 parts of isopropanol. The adsorption preparation for the wastewater treatment provided by the invention has a sterilizing function, and has the advantages of small material density and high processing efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Preparation method of high-performance fluoride rubber/silicone rubber cable sheath material

InactiveCN105802090AGood weather resistanceAccelerated corrosionRubber insulatorsInsulated cablesElastomerCalcium silicate

The invention discloses a preparation method of a high-performance fluoride rubber / silicone rubber cable sheath material. The preparation method comprises the following steps of performing primary mixing on fluoride rubber, silicone rubber, epoxy acrylate elastomer, hydrogenated butadiene-acrylonitrile rubber, maleic anhydride grafted polyethylene and methyl vinyl silicone rubber grafted methacrylic acid-2,2,2-trifluoroethyl to obtain a primary rubber compound; adding carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofibers, sepiolite fibers and calcium hydroxide, and mixing for 1 to 5 minutes; adding 2,6-di-tert-butyl paraaminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane, 5,5'- dimethyl-5,10-dihydracridine, and mixing for 3 to 8 minutes; adding stearic acid, inositol hexaphosphate, epoxidized linseed oil, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, N,N'-meta phenylene bismaleimide, phenolic resin and an accelerator, mixing for 5 to 10 minutes and then vulcanizing for two times.

Owner:ANHUI HUAYU CABLE GRP

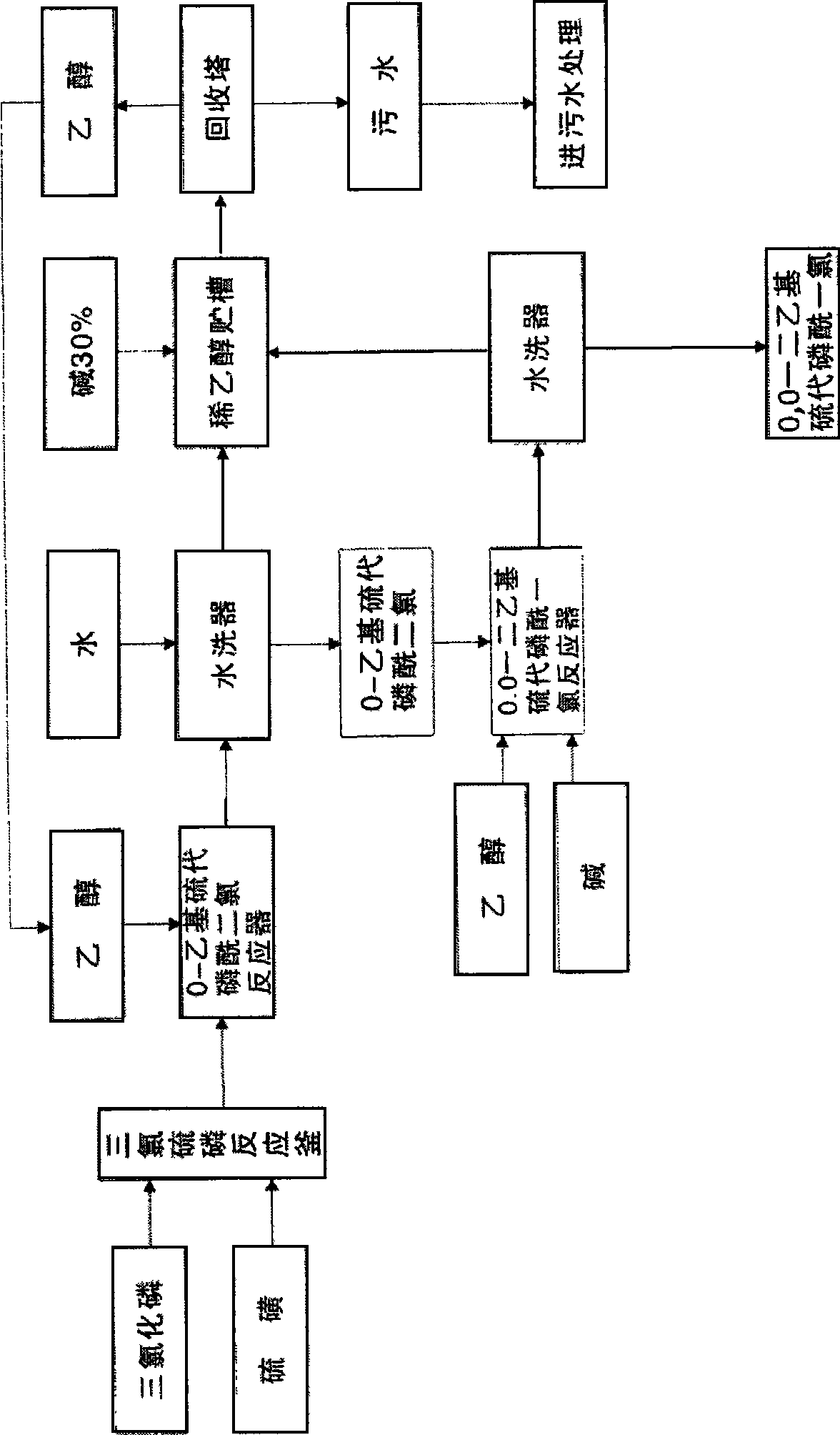

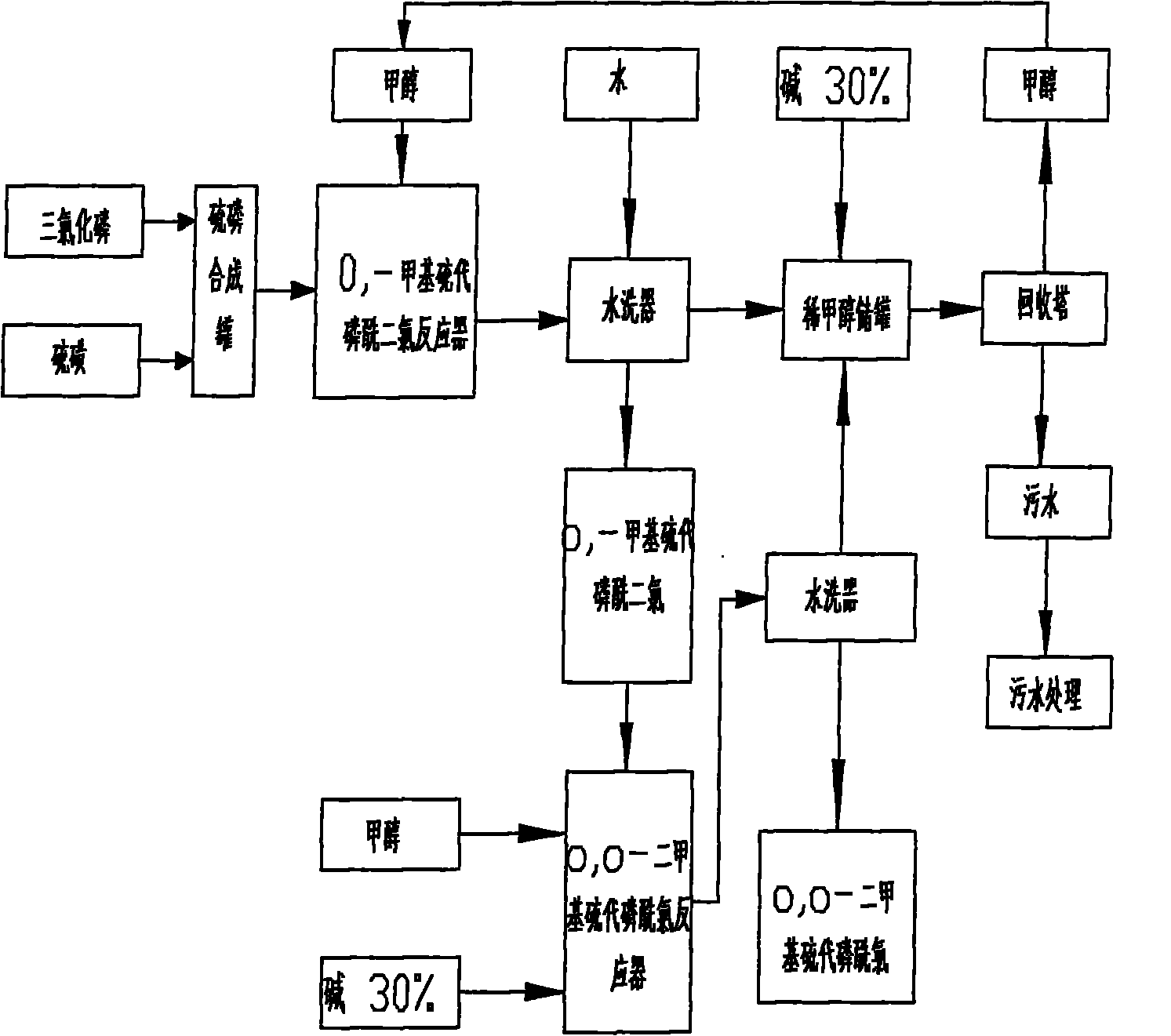

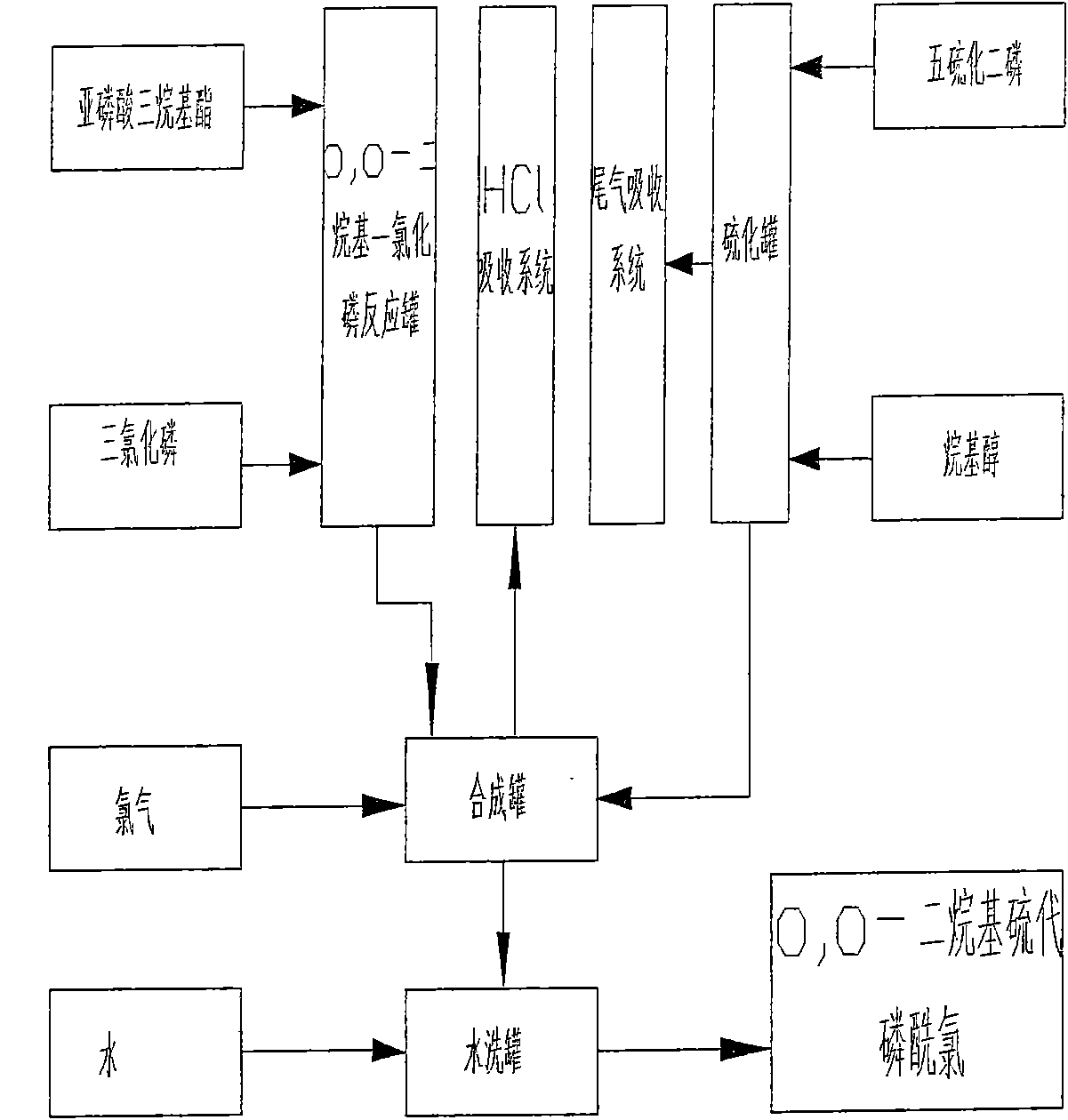

Production method of O, O-dialkyl thiophosphoryl chloride

ActiveCN101486729AQuality improvementReduce energy consumptionGroup 5/15 element organic compoundsPhosphorous acidAlcohol

The invention discloses a manufacturing method of O, O-dialkyl thiophosphoryl chloride; the manufacturing method comprises the steps that phosphorus trichloride, alcohol, sulfur and the like are taken as raw materials, wherein, the phosphorus trichloride reacts with alcohol in a trialkyl synthesis kettle to produce phosphorous acid trialkyl ester; then, the phosphorous acid trialkyl ester reacts with the phosphorus trichloride in a chlorinator to produce O, O-dialkyl phosphorus chloride; and the O, O-dialkyl phosphorus chloride reacts with sulfur in a vulcanizing apparatus to produce the crude products of O, O-dialkyl thiophosphoryl chloride which then is processed to obtained the refined products of the O, O-dialkyl thiophosphoryl chloride. The overall yield of the manufacturing method can be up to 94 percent, the content of the O, O-dialkyl thiophosphoryl chloride can reach 99 percent, and the manufacturing method is characterized by safe production, low energy consumption and no pollution.

Owner:荆州市沙市东方有机化工研究所

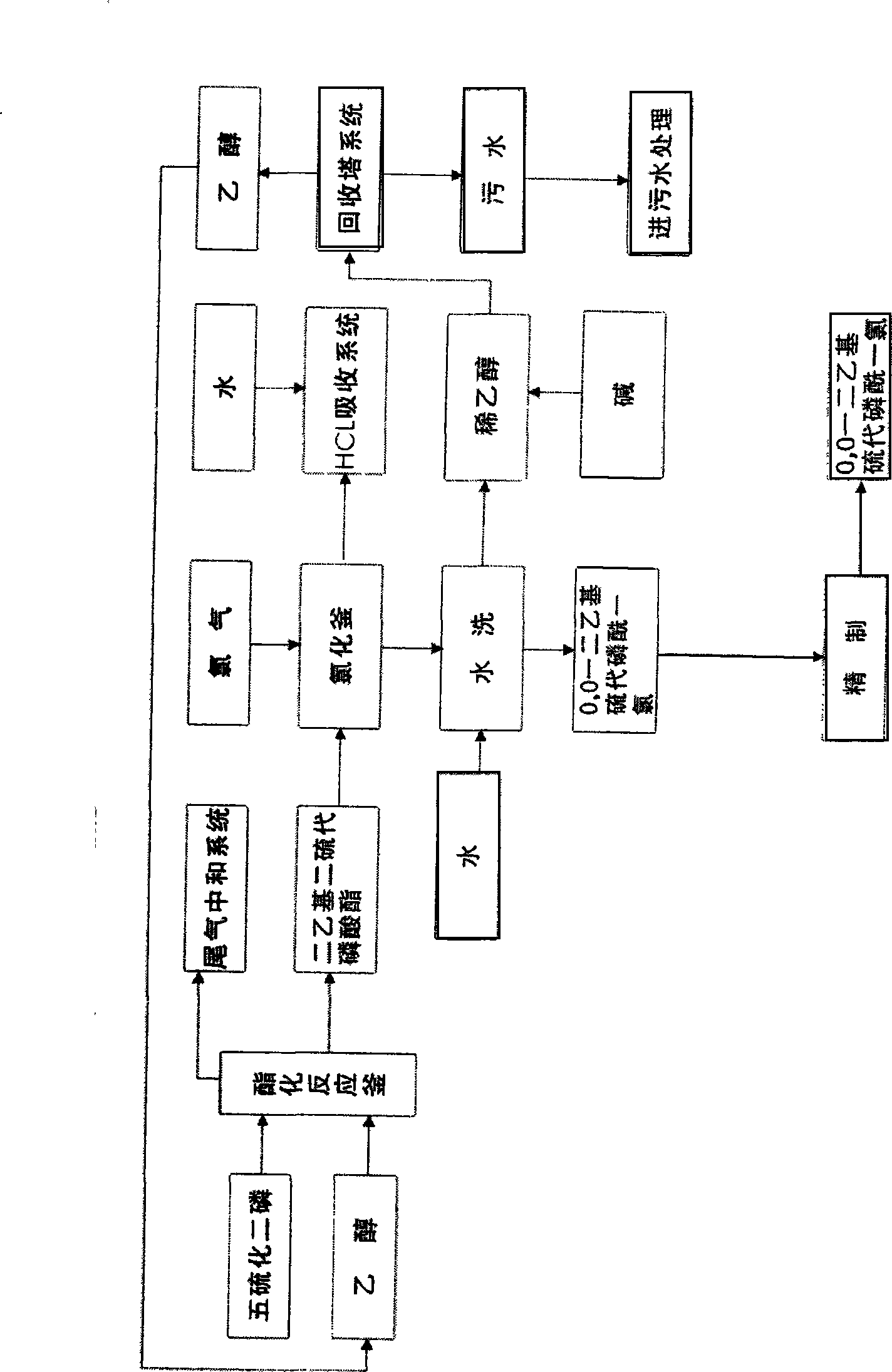

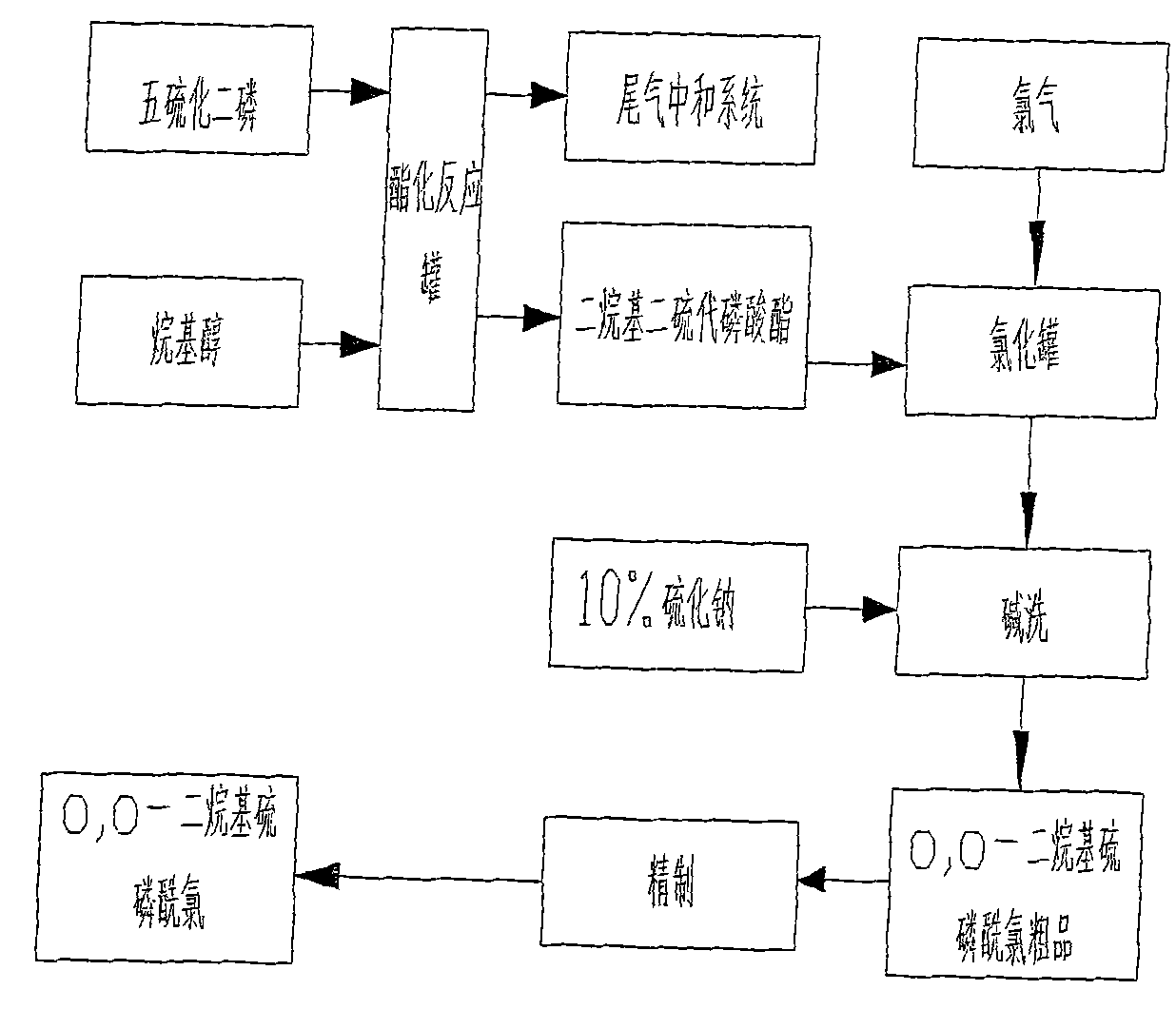

Production process of O, O-dialkyl thiophosphoryl chloride

ActiveCN101830925AReduce energy consumptionIncrease consumptionGroup 5/15 element organic compoundsPhosphorus pentasulphidePhosphorus trichloride

The invention relates to a production process of O, O-dialkyl thiophosphoryl chloride, which improves the production process of the O, O-dialkyl thiophosphoryl chloride produced by a phosphorus pentasulfide method. An O, O-dialkyl thiophosphoryl chloride product is synthesized by adding a by-product obtained by reacting phosphorus pentasulfide with alkanol and introducing chlorine to O, O-dialkyl phosphorus chloride obtained by reacting trialkyl phosphite with phosphorus trichloride. The invention can achieve the total yield of the trialkyl phosphite by 94 percent and the total yield of the phosphorus pentasulfide more than 95 percent and has safe production, little energy consumption and pollution without generating sulphur residues.

Owner:荆州三才堂化工科技有限公司

Fluororubber material used for seal gaskets of engines

The invention discloses a fluororubber material used for seal gaskets of engines. The fluororubber material is characterized by comprising the following raw materials in parts by weight: 30-80 parts of binary fluororubber, 40-60 parts of modified fluororubber, 10-20 parts of ethylene propylene diene monomer, 1-3 parts of dicumyl peroxide, 1-3 parts of 1,3-bis(tert-butylperoxyisopropyl)benzene, 1-3 parts of triallyl isocyanurate, 1-2.5 parts of magnesium oxide, 1-3 parts of triallyl cyanurate, 0.5-2.5 parts of caprolactam, 1-3 parts of (hexafluoroisopropylidene)diphenol, 0.5-2.5 parts of benzyl triphenyl phosphorus chloride, 1-3 parts of chelating titanate coupling agent, 40-60 parts of nano silica, 5-13 parts of barium sulfate, 40-60 parts of carbon black, 15-35 parts of calcined kaolin, 5-15 parts of molybdenum disulfide, 0.5-1.5 parts of sodium stearate, 1.5-4 parts of palm wax and 0.1-0.9 part of dilauryl thiodipropionate. The product has good toughness and excellent high temperature and wear resistance.

Owner:ANHUI JINYANG FLUORINE CHEM

Method for producing dichloropropanol

InactiveCN101397238AOvercome the priceOvercome efficiencyPreparation by halogen introductionPhosphorous acidOrganic acid

The invention provides a method for producing dichloropropanol, a chlorination agent and glycerol are adopted for reaction, and water generated by the reaction is continuously removed under the condition of taking a phosphorous acid derivative or a phosphoric acid derivative or a phosphorus chloride derivative as a catalyst, thereby obtaining the dichloropropanol. The method overcomes the shortcomings of product pollution, great separation difficulty and impact on yield which are caused by volatilization of carboxylic acid catalysts and the shortcomings of high price and lower catalytic efficiency of non-volatile organic acid catalysts in the prior art, reduces the using amount of the catalyst and simultaneously improves the product yield.

Owner:南通凯塔化工科技有限公司

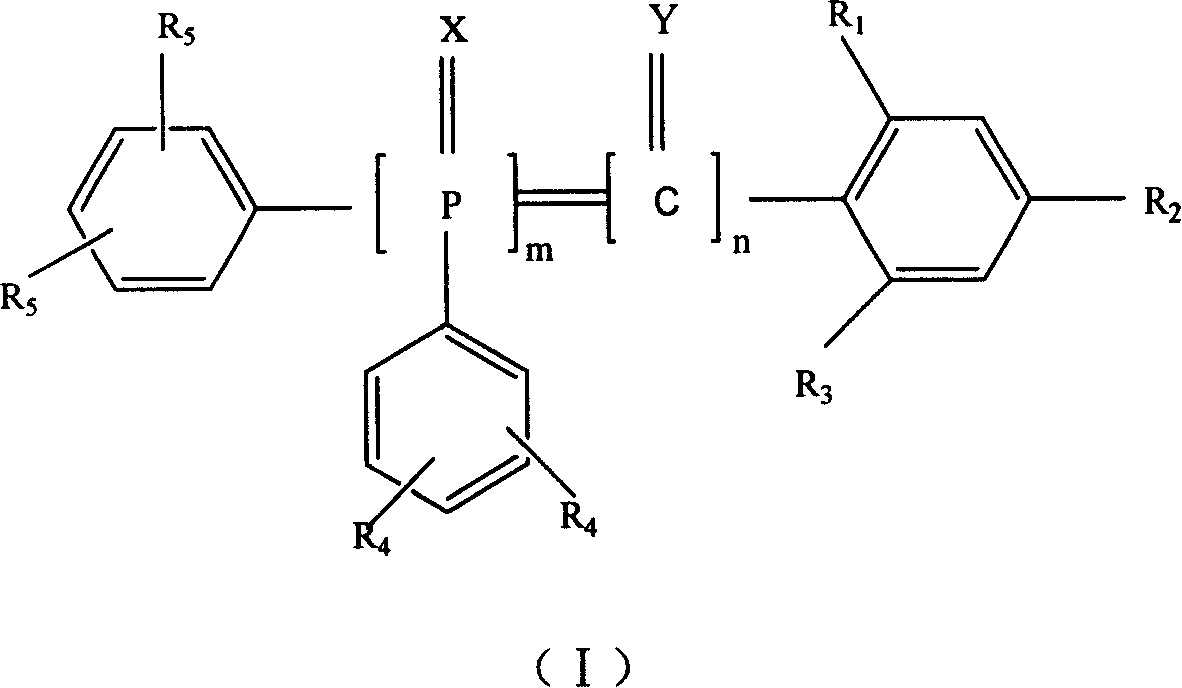

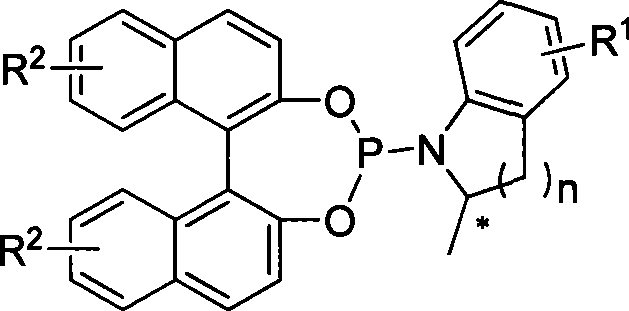

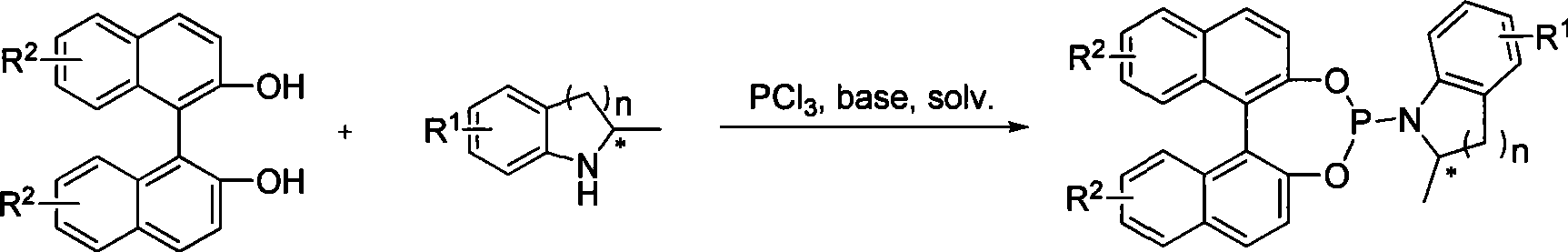

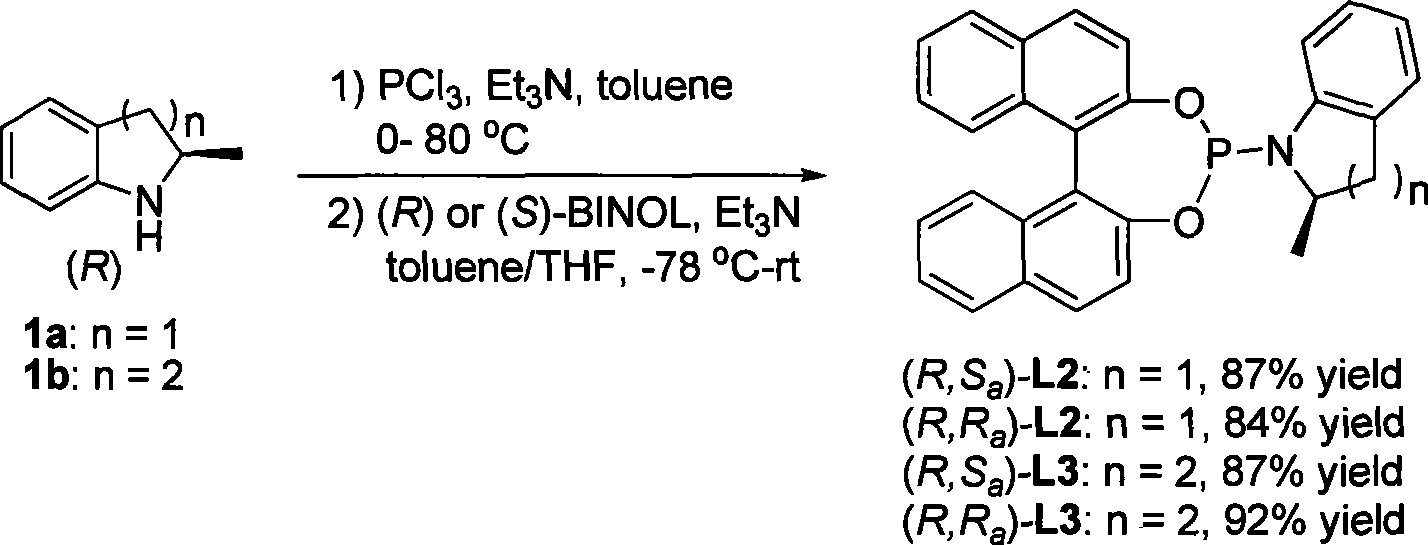

Tetrahydroquinoline and indoline derivative phosphor nitrogen ligand, synthesis and uses thereof

ActiveCN101508702AImprove efficiencyHigh enantioselectivityGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsIridiumSynthesis methods

The invention provides a phosphorus-nitrogen compound based on a binaphthol framework and a synthesis method thereof. The synthesis method is an effective method for synthesizing the optically pure phosphorus-nitrogen compound by taking chiral binaphthol compound, phosphorus trichloride, chiral tetrahydroquinoline and indoline as raw materials under the action of alkali. The method has available raw materials, mild reaction condition and easily separated and purified products. The phosphorus-nitrogen compound which is synthesized by the method based on the binaphthol framework can be effectively applied to an allylic substitution reaction catalyzed by metal iridium, and the product can be obtained at high enantioselectivity and regioselectivity, which greatly expands substrate range of the reaction.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Silicone rubber cable sheath material with high flame resistance

InactiveCN106349706AImprove stabilityHigh tensile strengthRubber insulatorsInsulated cablesPolymer scienceBisphenol AF

The invention discloses a silicone rubber cable sheath material with high flame resistance. The silicone rubber cable sheath material comprises the following raw materials: silicone rubber, MQ silicon resin, Ethylene Propylene Diene Monomer, butadiene rubber, zinc oxide, stearic acid, 2,4-dichlorobenzoyl peroxide, trimethylolpropane trimethacrylate, benzyl triphenyl phosphorus chloride, bisphenol AF, alumina silicate fiber, ferric oxide, nano titanium dioxide, magnesium hydroxide modified by stearic acid, ammonium polyphosphate, aluminum nitride, nanometer silicon carbide, epoxidized soybean oil, dibutyl phthalate, trioctyl trimellitate, an accelerator, an anti-aging agent and modified beta-cyclodextrin. The silicone rubber cable sheath material has the advantages of high strength and good heat resistance and flame resistance.

Owner:ANHUI LAND GRP

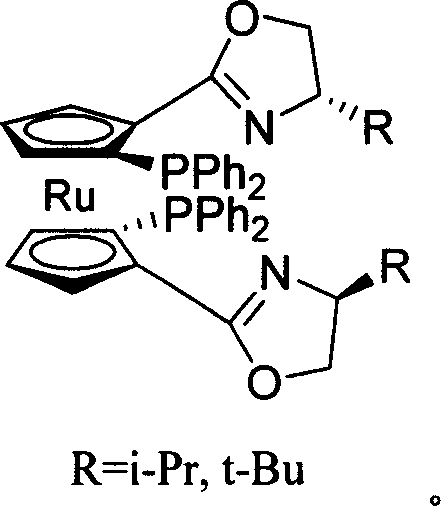

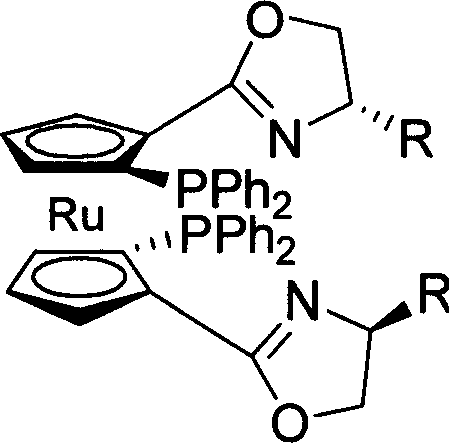

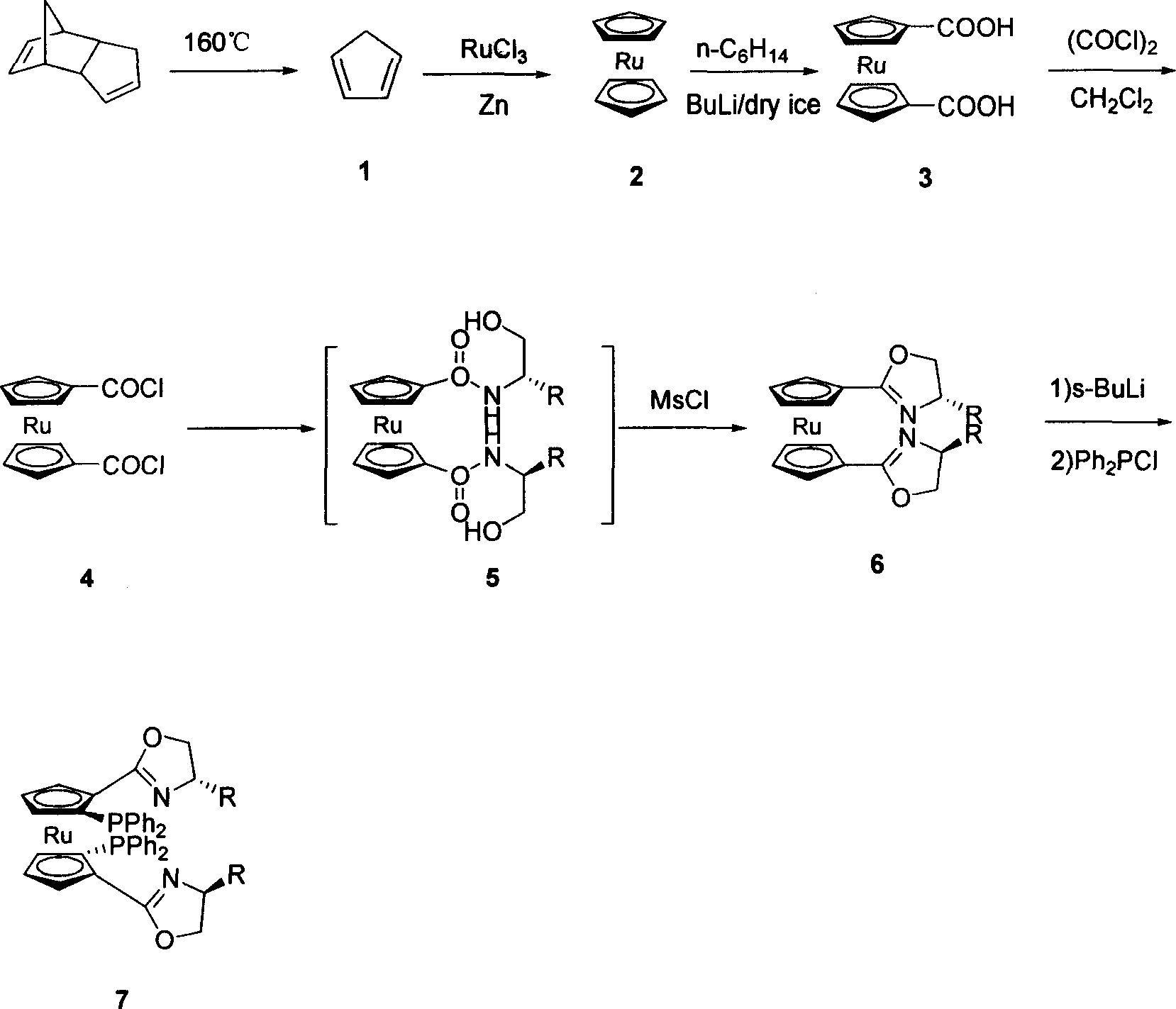

C2-symmetrical chirality bis ruthenium ligand and its synthesis method

ActiveCN1876666AHigh reactivityHigh stereoselectivityGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsButyl lithium

The invention relates the synthesis of C2-symmetry chirality bis ruthenium ligand. The method comprises the following steps: 1 using dicyclopentadiene as raw material, carrying out depolymerisation, and getting cyclopentadiene; 2 carrying out reaction of cyclopentadiene and ruthenic chloride, and getting bis ruthenium; 3 getting 1, 1' - dicarboxyl bis ruthenium; 4 the dicarboxyl bis ruthenium and oxalyl chloride reacting in carrene, and getting 1, 1'- dichloro carbonyl bis ruthenium; 5 1, 1'- dichloro carbonyl bis ruthenium and beta- amino alcohol reacting, getting acidamide compound, then it reacting with methane sulfonyl chlo-ride, and getting 1, 1'- dioxazoline bis ruthenium; 6 1, 1'- dioxazoline bis ruthenium and secondary butyl lithium reacting, then them reacting with biphenyl phosphorus chlorides, and getting C2- dioxazoline 2, 2'- biphenyl phosphino bis ruthenium. The ligand from the invention can be used in metallic catalysis asymmetric reaction, and the ligand has the good reaction active and stereoselectivity.

Owner:SHANGHAI JIAO TONG UNIV

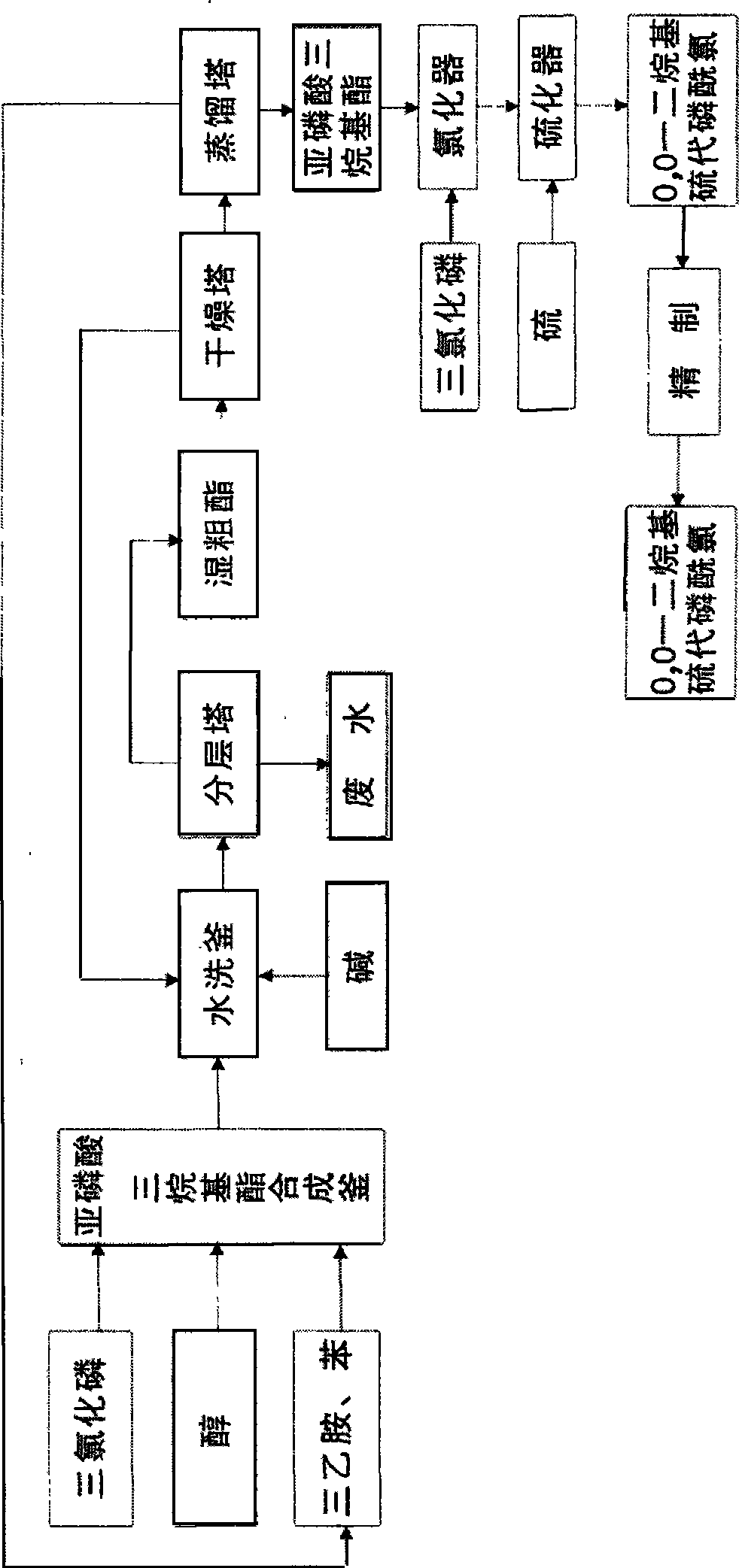

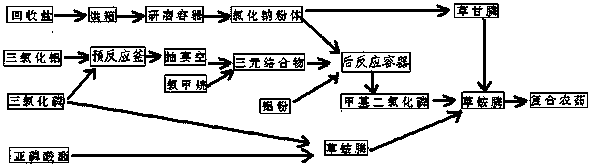

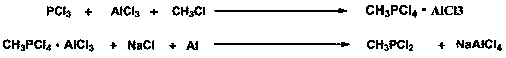

Method and apparatus to prepare glufosinate ammonium composite pesticide via recovered salts containing glufosinate ammonium and trimethyl phosphite

PendingCN107912446ARealize resource utilizationEmission reductionBiocideGroup 5/15 element organic compoundsPhosphorous acidAluminium chloride

The invention provides a method and apparatus to prepare glufosinate ammonium composite pesticide via recovered salts containing glufosinate ammonium and trimethyl phosphite. Chloromethane, aluminum trichloride and phosphorus trichloride are subjected as raw materials to reaction to generate a ternary complex; the ternary complex is distilled under the catalytic reduction of aluminum powder and double decomplexing action of sodium chloride to obtain methylphosphorus dichloride that is further used to synthesize the glufosinate ammonium composite pesticide. The method and apparatus according tothe scheme have the advantages that industrially-produced recovered salt wastes such as glufosinate ammonium and trimethyl phosphite are resourcefully utilized and the composite pesticide is more effective than common glufosinate ammonium.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

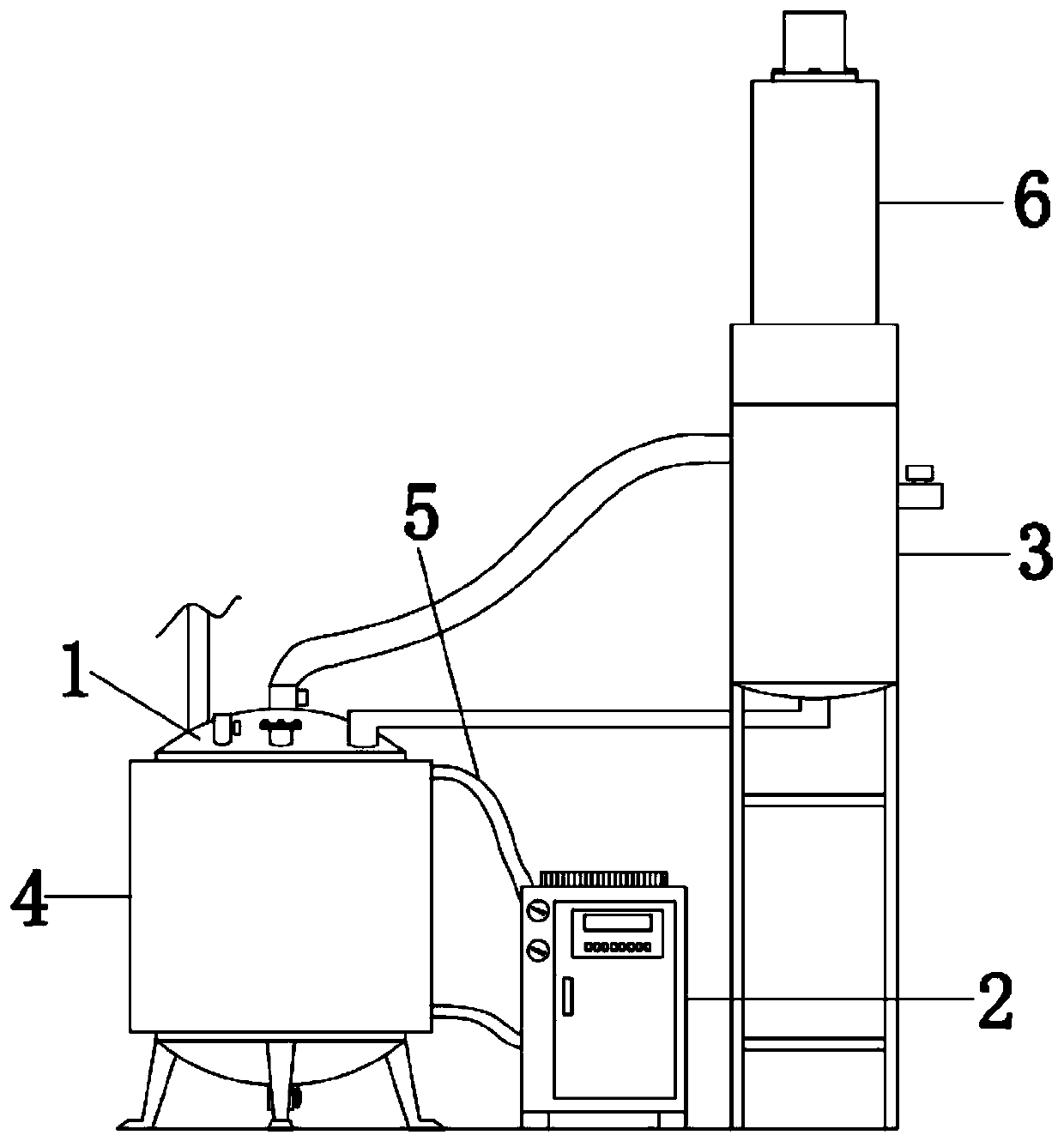

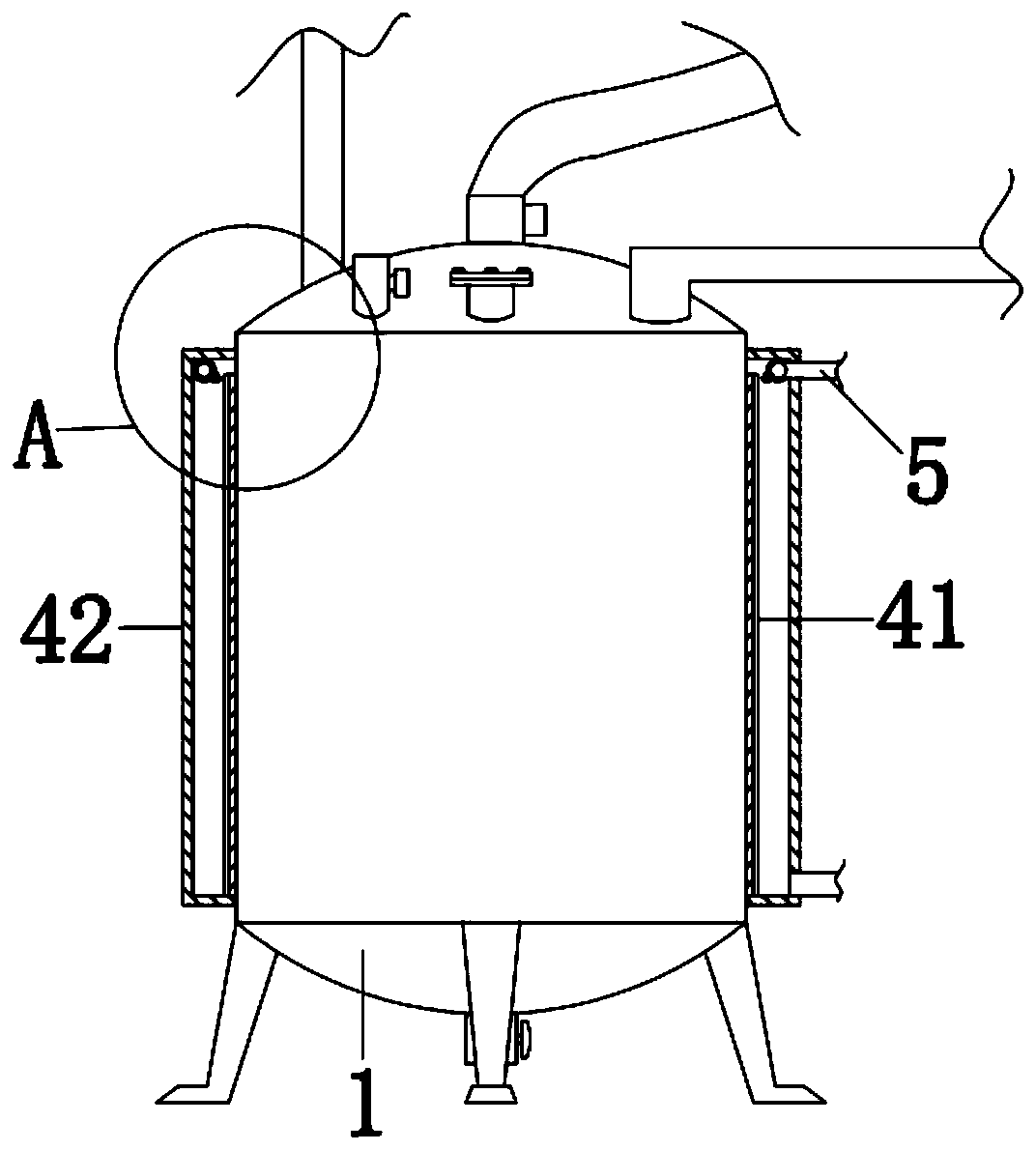

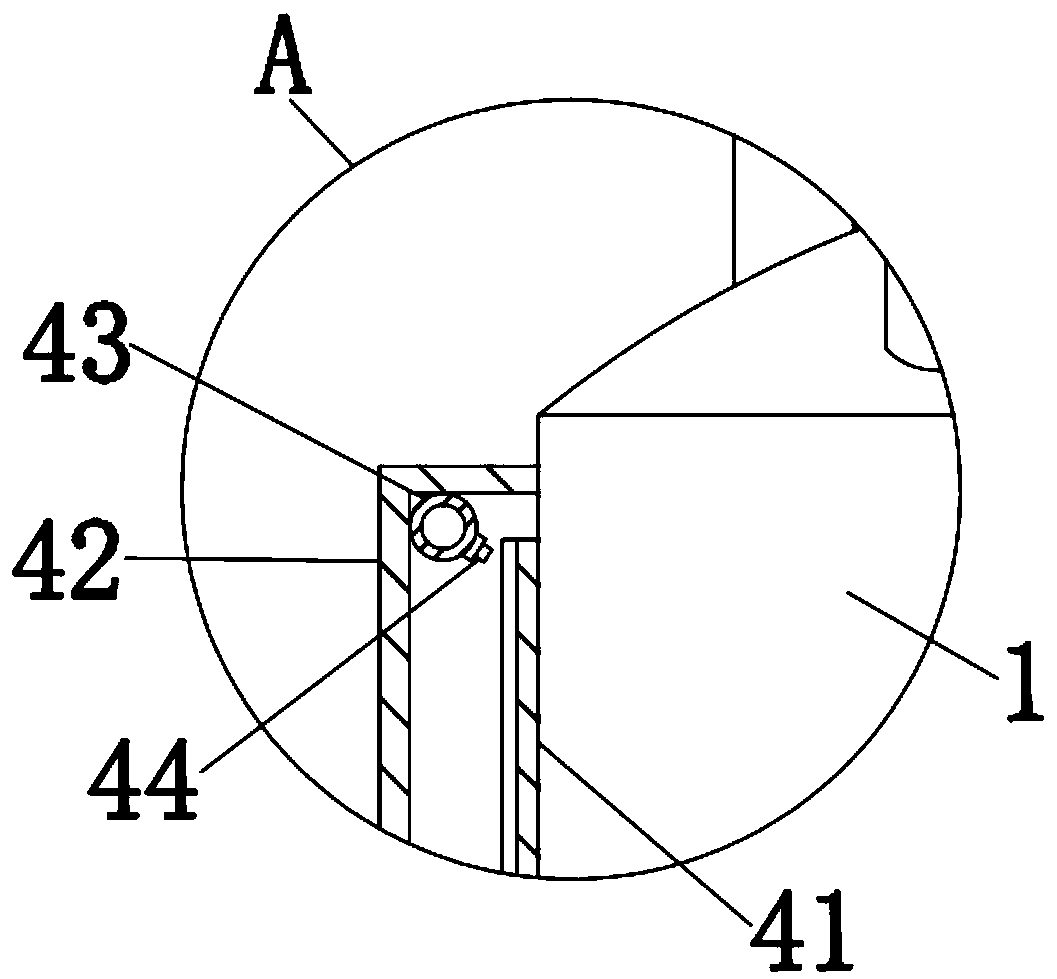

Refining equipment and refining process for phosphorus trichloride

InactiveCN110898455AAvoid explosionAvoid hanging onHollow article cleaningChemical/physical/physico-chemical processesPhysical chemistryWater chlorination

The invention discloses refining equipment and a refining process for phosphorus trichloride. The refining equipment comprises a reaction kettle, a cooling-water machine and a rectifying tower which are arranged from left to right, and also comprises: a cooling mechanism, which is detachably arranged on the outer wall of the reaction kettle; cold water pipes, one ends of which are respectively connected to a water inlet and a water outlet of the cooling-water machine, and the other ends of which are connected to the cooling mechanism; and a scrubbing mechanism, which is detachably arranged atthe top of the rectifying tower. The refining equipment can enable a heat dissipation cylinder to perform heat absorption comprehensively on the reaction kettle, avoids explosion caused by too high temperature during use of the reaction kettle, in addition, the inner wall of the rectifying tower can be comprehensively scrubbed to prevent free phosphorus impurities from hanging on the inner wall ofthe rectifying tower, and influence on the re-rectifying effect of phosphorus trichloride can be prevented, therefore the equipment is beneficial to the production and use of phosphorus trichloride.

Owner:FUTONG CHEM

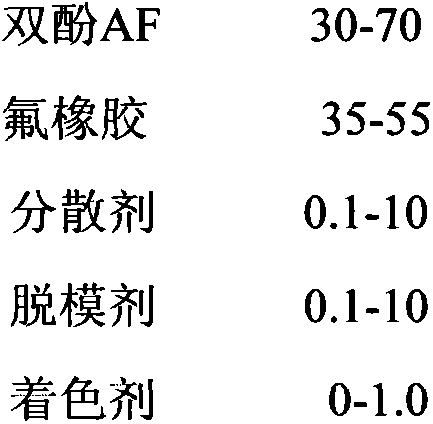

Fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula

The invention discloses a fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula prepared from the following raw materials by mass: 30-70 parts of bisphenol AF; 35-55 parts of fluorubber; 0.1-10 parts of a dispersant; 0.1-10 parts of a release agent; and 0-1 parts of a colorant. The fluorubber as a carrier is cooperated with the dispersant and the release agent, the bisphenol AF curing agent is mixed into the fluorubber on an open blending machine, so that the bisphenol AF is fully dispersed uniformly in the fluorubber, the bisphenol AF curing agent has excellent curing properties in the fluorubber, and can meet the use requirements. The fluorubber use bisphenol AF pre-dispersion mother colloidal particle formula can improve the dispersion of the fluorubber curing agent bisphenol AF (2, 2-bis-(4-hydroxy phenyl) hexafluoropropane) and BPP (tri phenyl phosphorus chloride) in the fluorubber, and overcomes the problems of the poor dispersion and mutual smelting of a traditional curing agent in the fluorubber.

Owner:SHANGHAI PINKE RUBBER & PLASTIC MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com