Patents

Literature

114 results about "Thiophosphoryl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiophosphoryl chloride is an inorganic compound with the formula PSCl₃. It is a colorless liquid with a pungent odor that fumes in moist air. It is synthesized from phosphorus chloride and used to thiophosphorylate organic compounds, such as to produce insecticides.

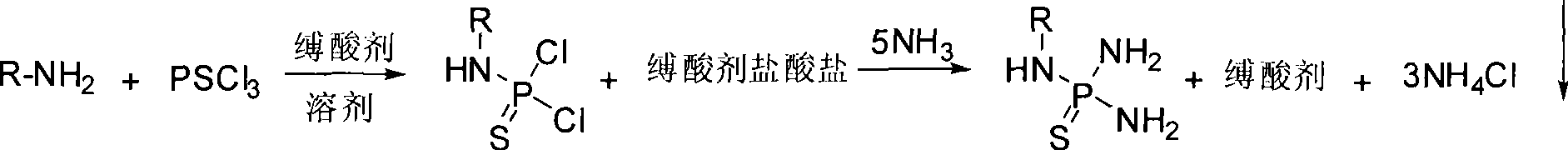

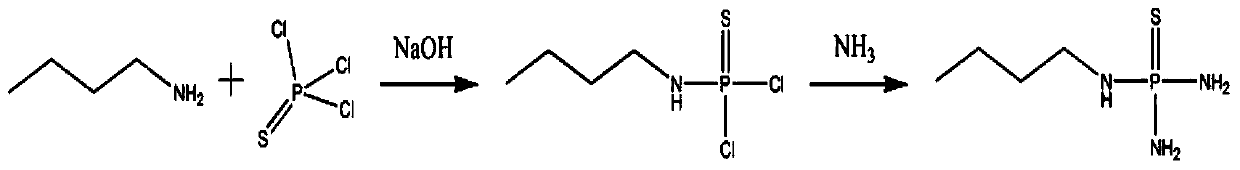

Process for preparing N-(hydrocarbyl) phosphoric or thiophosphoric triamides

The invention provides a process for preparing N-(hydrocarbyl)phosphoric or thiophosphoric triamides with substantially improved yields and purity. Two equivalents of hydrocarbylamine are used in the reaction with phosphoryl or thiophosphoryl chloride and then with ammonia in an aromatic solvent. The invention further relates to N-(hydrocarbyl)phosphopric or thiophosphoric triamides having the purity of at least 98% wherein R is a hydrocarbyl group and X is O or S.(RNH)(NH2)2P=X (I).

Owner:AGRA GROUP AS

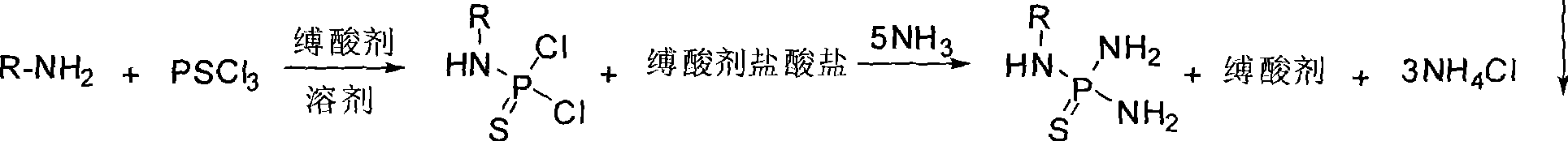

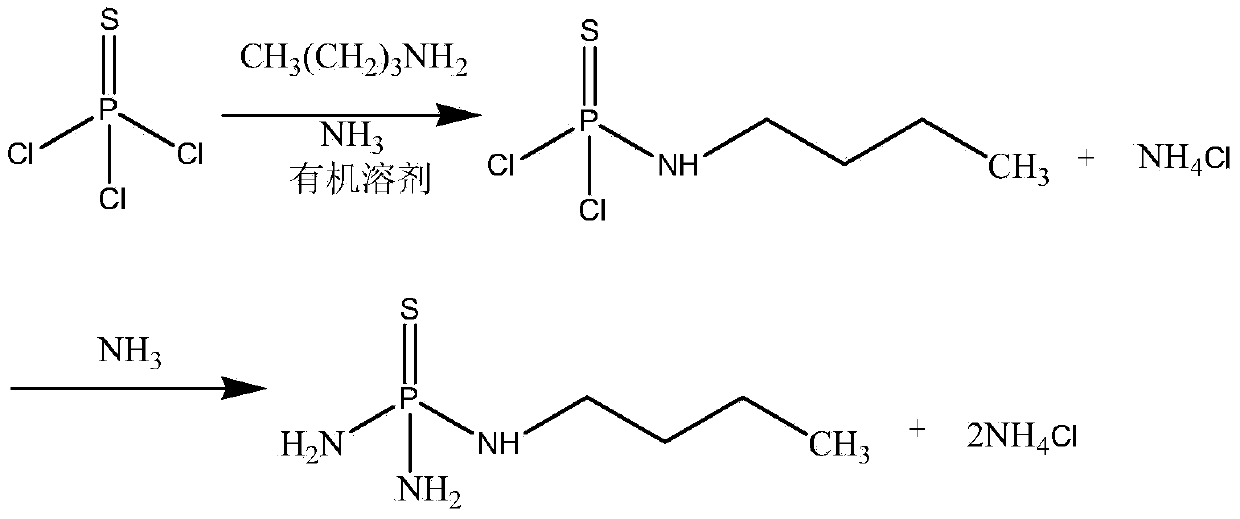

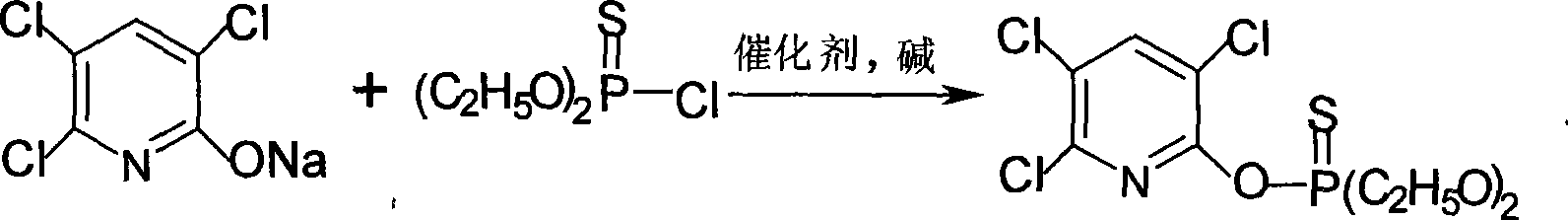

Preparation of N-alkyl thiophosphoryl triamide by one-pot method

InactiveCN101412733AModerate reaction conditionsSimple processGroup 5/15 element organic compoundsOrganic solventReaction temperature

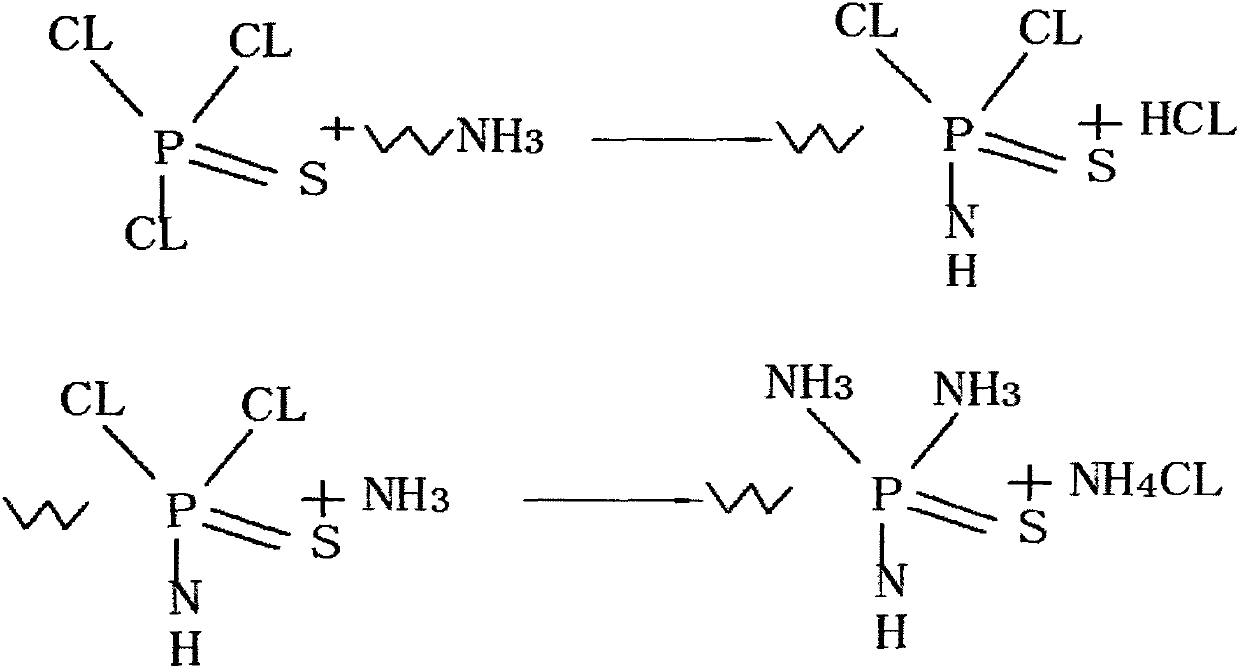

The invention discloses a method for preparing N-alkyl thiophosphoryl triammonium through a favorable one-pot method in industry. The method is characterized in that in an organic solvent, in the presence of a tertiary amine acid-binding agent, and at an reaction temperature of between 10 below zero and 50 DEG C, thiophosphoryl chloride and alkyl primary amine react to generate N-alkyl thiophosphoryl bichloride and tertiary amine acid-binding agent hydrochloride as intermediate products; the generated intermediate products continuously react with ammonia gas in the same reaction system without purification and separation to generate the N-alkyl thiophosphoryl triammonium, the acid-binding agent and ammonium chloride as target products; the target products are filtered and condensed to obtain the product (as the right upper formula); and the yield of the N-alkyl thiophosphoryl triammonium is more than or equal to 85 percent. The method has the advantages of compact preparation process, low cost, high yield and suitablility for scale industrialized production.

Owner:DALIAN UNIV OF TECH

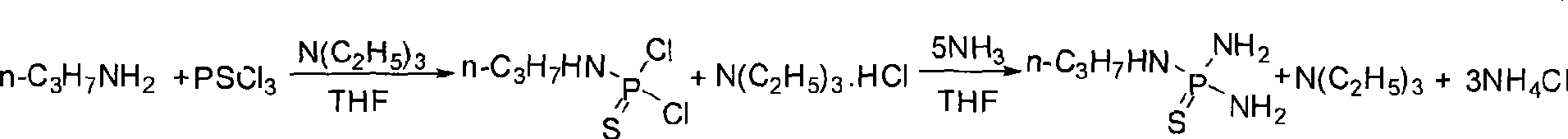

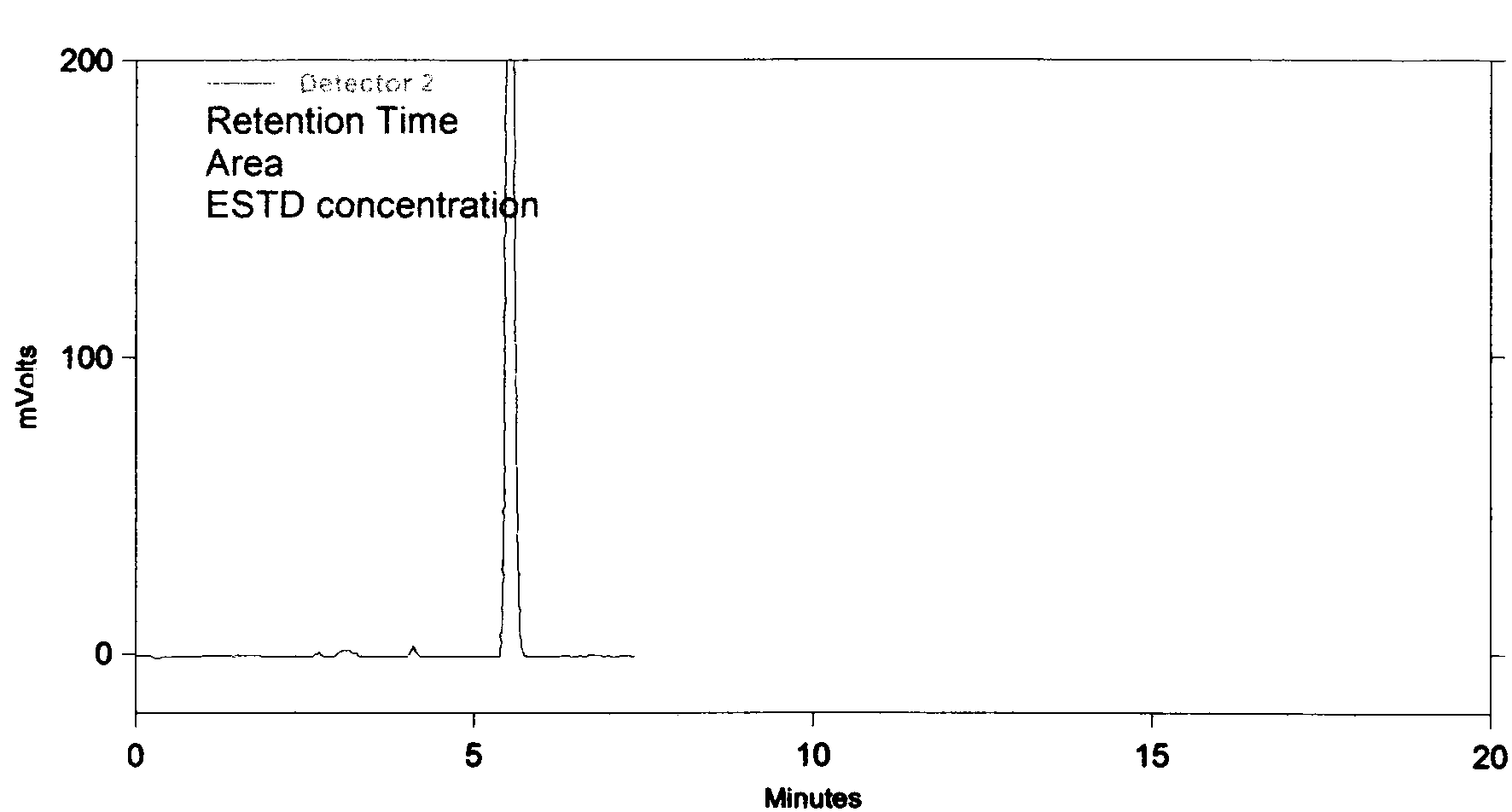

Method for producing N-butyl-phosphorothioic triamide n-(n-butyl)thiophosphoric triamide

ActiveCN101503424AEasy to operateLow costGroup 5/15 element organic compoundsFertilizer mixturesReaction temperatureSolvent

The invention relates to a production method of N-normal-butyl thiophosphoryl triamine, comprising the following steps: dehydrating raw materials to control the water content to be within a required range, mixing phosphorus thiochloride with tetrahydrofuran, stirring the mixture, lowering the temperature, adding a mixture of n-butylamine, triethylamine and tetrahydrofuran in the mixture of the phosphorus thiochloride and the tetrahydrofuran by means of slow dripping, keeping a certain reaction temperature for 1-8h to obtain a white turbid liquid; leading ammonia gas into the a reaction system under the normal atmosphere, controlling the lead-in speed of ammonia gas, and keeping the temperature of the reaction system for 1-5h; centrifugating the reaction liquid to separate solid generated in the reaction system, distilling an obtained organic liquid in a decompression mode to remove most of the solvent and obtain a crude product, recrystallizing and refining the crude product to obtain a refined product with the purity higher than 99 percent. The invention has the advantages of wide raw material source, short process, simple operation, low cost, no three waste discharge, high economical benefit, applicability for industrial production, and the like.

Owner:NORTH HUAJIN CHEM IND GRP

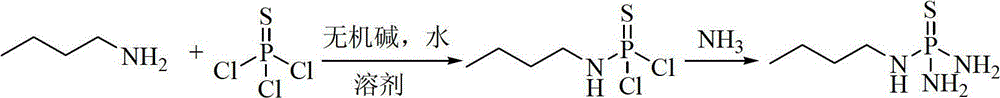

Synthetic method of N-(n-butyl) thiophosphoric triamide

ActiveCN102746333AImprove solubilityMild conditionsGroup 5/15 element organic compoundsInorganic saltsOrganic solvent

The invention discloses a synthetic method of N-(n-butyl) thiophosphoric triamide (NBPT), comprising the following steps: at a certain temperature, respectively adding n-butyl amine and organic alkaline solution dropwisely to a mixed solution of thiophosphoryl chloride and organic solvent; after the reaction, separating water phase, at the constant temperature, introducing ammonia gas into the organic phase, after detection reaction, filtering to remove the generated ammonium chloride, recovering most solvent from the filtrate, cooling, conducting crystallization, filtering, and drying to obtain a final product of NBPT. According to the invention, by using the organic alkaline solution as an acid binding agent, the disadvantage of complicated recovery of organic alkali is overcome, and inorganic salts can be directly removed after the reaction; the method has the advantages of easy obtainment of raw materials, cheap raw materials, simple operation steps, and high yield and high purity of products, and is suitable for industrial production.

Owner:SHANGYU SUNFIT CHEM

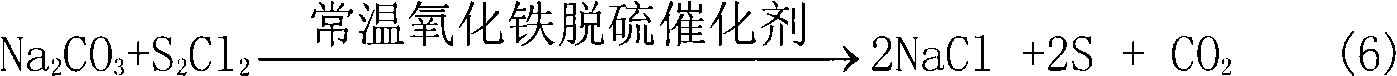

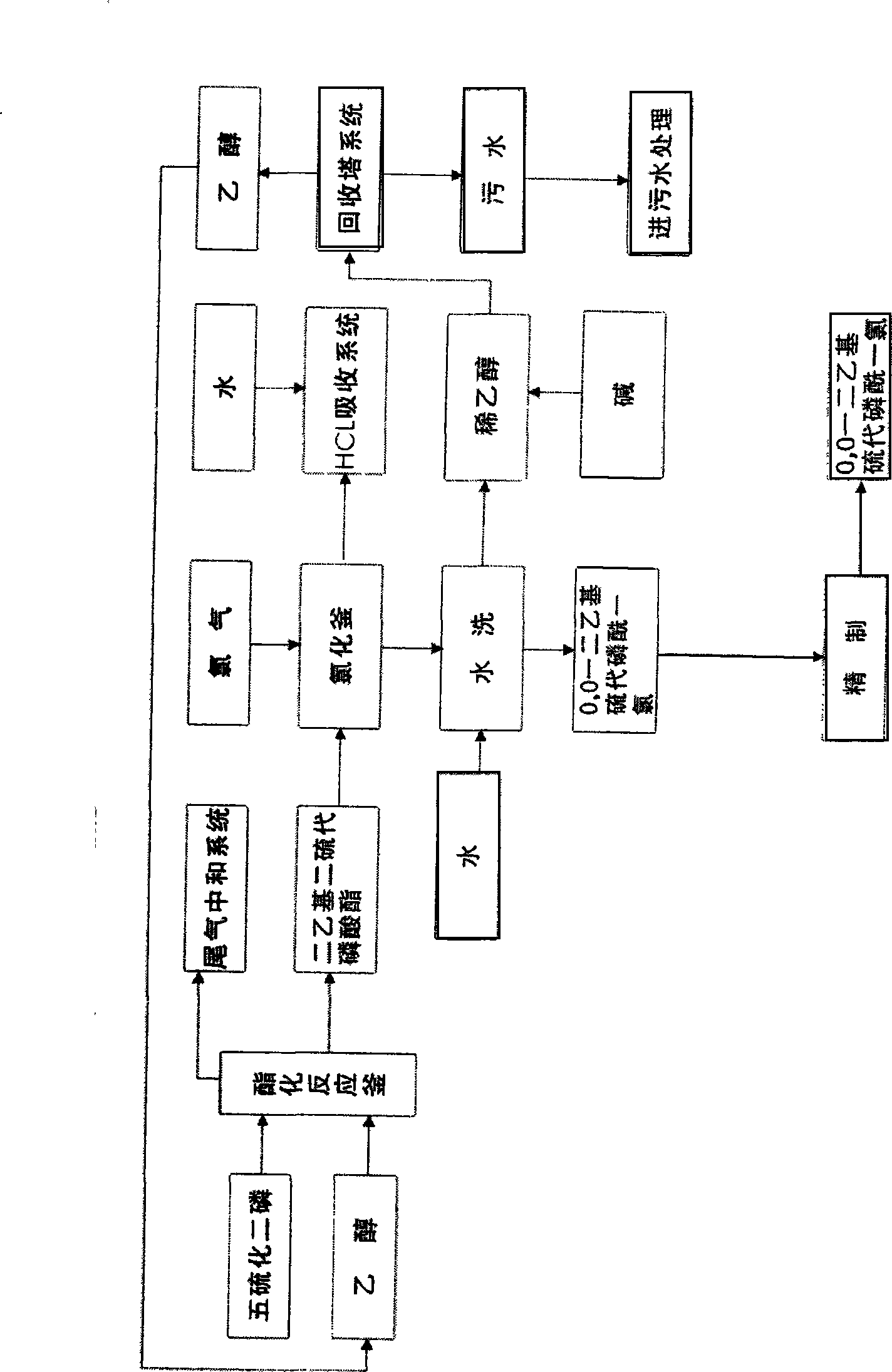

Method for preparing O,O-ethyl thioether substituted phosphorus oxychloride

InactiveCN101293897AMild desulfurization conditionsAchieve friendlyGroup 5/15 element organic compoundsPhosphorus pentasulfideSulfide

The invention relates to a method for preparing O,O-diethyl thiophosphoryl chloride (DETC), comprising the steps of reacting the raw material of phosphorus pentasulfide with anhydrous alcohol to obtain O,O-diethyl phosphorodithioate (referred to as ethyl sulfide); reacting with chlorine gas to obtain crude O,O-diethyl thiophosphoryl chloride; performing desulfuration of the crude O,O-diethyl thiophosphoryl chloride with ferric oxide desulfuration catalyst at room temperature to obtain desulfurized O,O-diethyl thiophosphoryl chloride and crystalline sulfur; and refining the desulfurized O,O-diethyl thiophosphoryl chloride by the steam distillation method to obtain O,O-diethyl thiophosphoryl chloride with high purity (over 99.5%). The method has the advantages of environmentally friendly production process, and high product purity.

Owner:湖北蕲农化工有限公司

Continuous production method for N-NBPT

InactiveCN103755739AHigh yieldHigh purityGroup 5/15 element organic compoundsN-ButylamineRaw material

The invention relates to a production method for chemical fertilizer urease inhibitors, in particular to a continuous production method for N-NBPT. The continuous production method comprises the following steps: mixing thiophosphoryl chloride and dichloromethane for stirring; cooling; then dropwise adding a mixed solution of n-butylamine and dichloromethane, and acid bounded reaction agents simultaneously; preserving heat for 0.5-6 hours after dropwise adding to obtain a reaction solution, wherein the acid bounded reaction agents are ammonium hydroxides or ammonia gases; filtering and layering the obtained reaction solution; introducing the ammonia gases into the underlayer reaction solution for an ammonolysis reaction; centrifuging, filtering and concentrating the reaction solution obtained after the ammonolysis reaction; recrystallizing to obtain the product. According to the invention, other auxiliary raw materials are not needed except for raw materials used for producing the product; the continuous production method needs no purification in the tremendously optimized reaction process, has a mild reaction condition and no other by-products, and has the advantages of high production efficiency, mild reaction condition, high yield, good quality, less three wastes, fully utilized resources and the like.

Owner:CANGZHOU JINCANG FINE CHEM CO LTD

Microchannel synthesis technology for N-(n-Butyl)thiophosphoric triamide

InactiveCN104370957AOvercome difficultyOvercome the disadvantages of increasing investment in equipment and facilitiesGroup 5/15 element organic compoundsChemical industryProcess engineeringEnergy consumption

The invention discloses a microchannel synthesis technology for N-(n-Butyl)thiophosphoric triamide. The microchannel synthesis technology comprises the following steps: evenly mixing thiophosphoryl chloride and dichloromethane as well as n-butyl amine and dichloromethane, respectively injecting the two mixtures in a feed inlet of a Corning microchannel reactor simultaneously by a metering plunger pump, injecting 10% NaOH solution into another feed inlet through a metering plunger pump, regulating the value of a back pressure valve, controlling the reaction time of materials, evenly using up the three materials, reacting through four modules, receiving the materials at an outlet, performing gas-liquid separation to the materials, standing and separating an inorganic layer, evaporating a part of dichloromethane from an organic layer, cooling and crystalizing, and filtering to obtain NBPT products. The microchannel synthesis technology has the characteristics of being simple and convenient to operate, fewer in side products, low in energy consumption, high in yield, low in cost and suitable for continuous industrial production.

Owner:ZHEJIANG AOFUTUO CHEM

Continuous production process of N-normal-butyl thiophosphoryl triamide

ActiveCN103524551AEasy accessReduce lossesGroup 5/15 element organic compoundsAmmonium halidesThio-Reaction temperature

The invention discloses a continuous production process of N-normal-butyl thiophosphoryl triamide. Mixture of thiophosphoryl chloride and organic solvent and mixture of n-butyl amine, tertiary amine acid-binding agent and organic solvent are respectively input in a Y-type jet flow mixing device to be rapidly mixed, then the mixture enters a first tubular reactor and an amination reaction is conducted, an obtained reaction solution is pre-heated, and enters a second tubular reactor, ammonia gas is added, the amination reaction is conducted, and finally the N-normal-butyl thiophosphoryl triamide is obtained through separation and purification. According to the continuous production process of the N-normal-butyl thiophosphoryl triamide, proper solvent and acid-binding agent are selected, proper reaction temperature is selected, and therefore the purpose that the amination reaction is continuously conducted in a pipeline without added pressure is achieved. The continuous production process of the N-normal-butyl thiophosphoryl triamide has the advantages that production efficiency is high, reaction condition can be controlled easily, yield is high, quality is high, discharge amount of the three wastes is small, resources are sufficiently used, and the continuous production process of the N-normal-butyl thiophosphoryl triamide is suitable for large-scale industrialized production.

Owner:江西吉翔医药化工有限公司

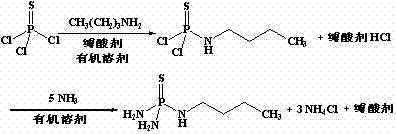

Preparation of O,O-diethyl-O-(3,5,6- trichloro-2-pyridinyl)thiophosphate

InactiveCN101372497ASave the recycling processEasy to operateGroup 5/15 element organic compoundsThiophosphateEthanol

The invention provides a method for preparing O, -O diethyl-O-(3, 5, 6-trichloro-2-pyridyl) thiophosphate, comprising the following steps: O, -O diethyl thiophosphoryl chloride is added into the mixed solution of 3, 5, 6-trichloropyridine-2-ethanol-sodium and water in a dripping way at the temperature of 45-70 DEG C under the condition that a catalytic amount of phase transfer catalyst exists for reaction, and then the target product which is dursban is collected from resultant of reaction; the pH value of a reaction system ranges from 10 to 12, the phase transfer catalyst is a multivariant compound phase transfer catalyst which is formed by 4-dimethylamino naphthyridine and more than one of trialkyl phenmethyl ammonium halide, tetra-allkyl ammonium halide, triethylene diamine or 4-methyl drewamine. The method adopts water as solvent, eliminates the recycling process of organic solvent, is simple and safe to operate, has little waste water, is easy to process and has high yield and product purity.

Owner:SHANGHAI SHENGLIAN CHEM

Synthesizing method of active compound of chlorpyrifos

InactiveCN102993236AReduce harmReduce pollutionGroup 5/15 element organic compoundsChlorpyrifosPtru catalyst

The invention provides a synthesizing method of chlorpyrifos primary drugs. The method comprises the following steps of: dosing 2,3,5,6-tetrachloropyridine and NaOH with the volume concentration of 30% into a high-pressure autoclave in one time, insulating the reacting materials at a temperature of between 145 and 155 DEG C for 5 hours, and cooling and crystallizing to obtain a 3,5,6-trichloropyridin-2-ol sodium; injecting water into another reaction kettle, and dosing an emulsifier which accounts for 0.1 to 0.15 percent of the mass of the water, and catalyst 4-dimethylaminopyridine which accounts for 0.1 percent of the mass of the water into the water, stirring for 15 minutes, dosing the 3,5,6-trichloropyridin-2-ol sodium which is in a ratio of 1:(2.8-3.0) with the water mass into the reaction kettle, and dripping O,O-diethyl thiophosphoryl chloride until the reaction is completed. The synthesizing method has the advantages of simple process, small hurt to human, small environment pollution, high yield and purity, and the like, the technical problems of low content and low yield of a traditional aqueous phase process for synthesizing chlorpyrifos crude oil can be solved, and the environment can be effectively protected.

Owner:HUBEI XIANLONG CHEM IND

Flame-retardant acrylonitrile copolymer and preparation method thereof

The invention discloses a flame-retardant acrylonitrile copolymer and a preparation method thereof. The flam-retardant acrylonitrile copolymer comprises the following structural formula: in the structural formula, X is R2OP(O)-substitutional group or R2OP(S)-substitutional group and R is methyl or ethyl. The preparation method adopts the following steps of: (1) co-polymerization: preparing an acrylonitrile-vinyl acetate copolymer; (2) hydrolyzation: preparing a neutral acrylonitrile-vinyl alcohol colymer generated by hydrolyzing a vinyl acetate unit; and (3) flame-retardant modification: adding a flame-retardant modifying agent for modifying reaction to obtain the copolymer, wherein the flame-retardant modifying agent is dimethoxy phosphoryl chloride, diethoxy phosphoryl chloride, dimethoxy thiophosphoryl chloride or diethoxy thiophosphoryl chloride.

Owner:TIANJIN POLYTECHNIC UNIV

Phosphorus and nitrogen flame retardant and preparation method thereof

InactiveCN104341612AImprove flame retardant performanceReduce dosageGroup 5/15 element organic compounds1-PropanolSolvent

The invention discloses a phosphorus and nitrogen flame retardant and a preparation method thereof. A structural formula of the flame retardant is shown in the specification. The preparation method comprises the following steps: firstly dissolving 2,2-dihydroxymethyl-3-nitro-1-propanol and an acid-binding agent in a solvent and adding 2,2-dihydroxymethyl-3-nitro-1-propanol and the acid-binding agent to a three-neck flask, then dropping thiophosphoryl chloride, stirring the materials uniformly, regulating the temperature to 0-50 DEG C and carrying out thermostatic reaction for 5-8 hours, evaporating the solvent at reduced pressure after the reaction is completed, washing the residual solid with distilled water and filtering the residual solid, and carrying out vacuum drying on the product, thus obtaining the phosphorus and nitrogen flame retardant. The synthetic process is simple and is mild in conditions. Nitro functional groups in the molecules of the phosphorus and nitrogen flame retardant can be easily transformed to amino with higher activity, can serve as intermediates for developing novel flame retardants, more importantly, can directly react on polymers or raw materials of the polymers after being reduced to amino, and can be widely applied to the polymers of various base materials.

Owner:NANYANG INST OF TECH

Method for synthesizing chlopyrifos in water medium

ActiveCN1858055AEasy to operateHigh yieldGroup 5/15 element organic compoundsSURFACTANT BLENDReaction system

The method of synthesizing chlorpyrifos in water medium features that through adding water into reaction kettle, adding surfactant, 3,5,6-trichloro pyridyl -2-sodium alcoholate and O, O-diethyl thiophosphoryl chloride via stirring for emulsifying and dispersing in water, adding composite catalyst, adding pH regulator to regulate system pH value to 9-10, reaction at 25-65 deg.c, lowering temperature to crystallize, suction filtering, water washing and drying, chlorpyrifos is prepared. The present invention features using water as medium to form high dispersed reaction system, simple and reliable synthesis process, easy operation, high product yield and purify, low production cost and environment friendship.

Owner:SHANDONG TIANCHENG BIOTECH

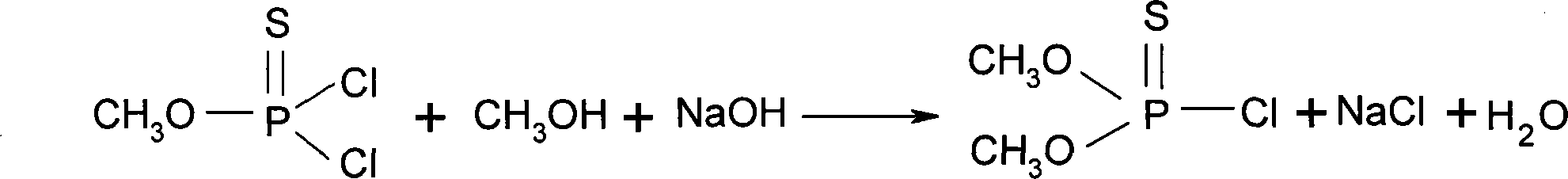

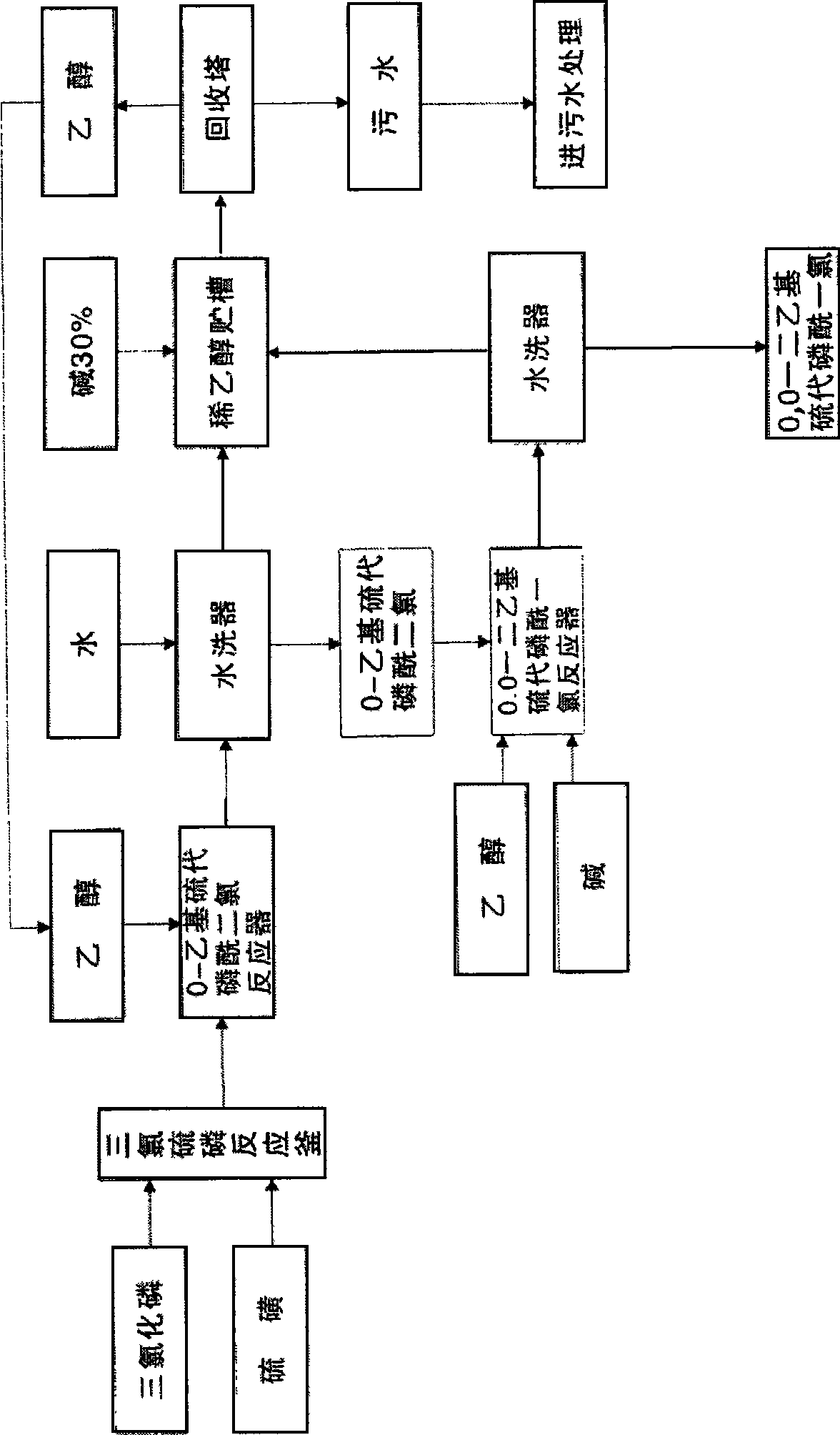

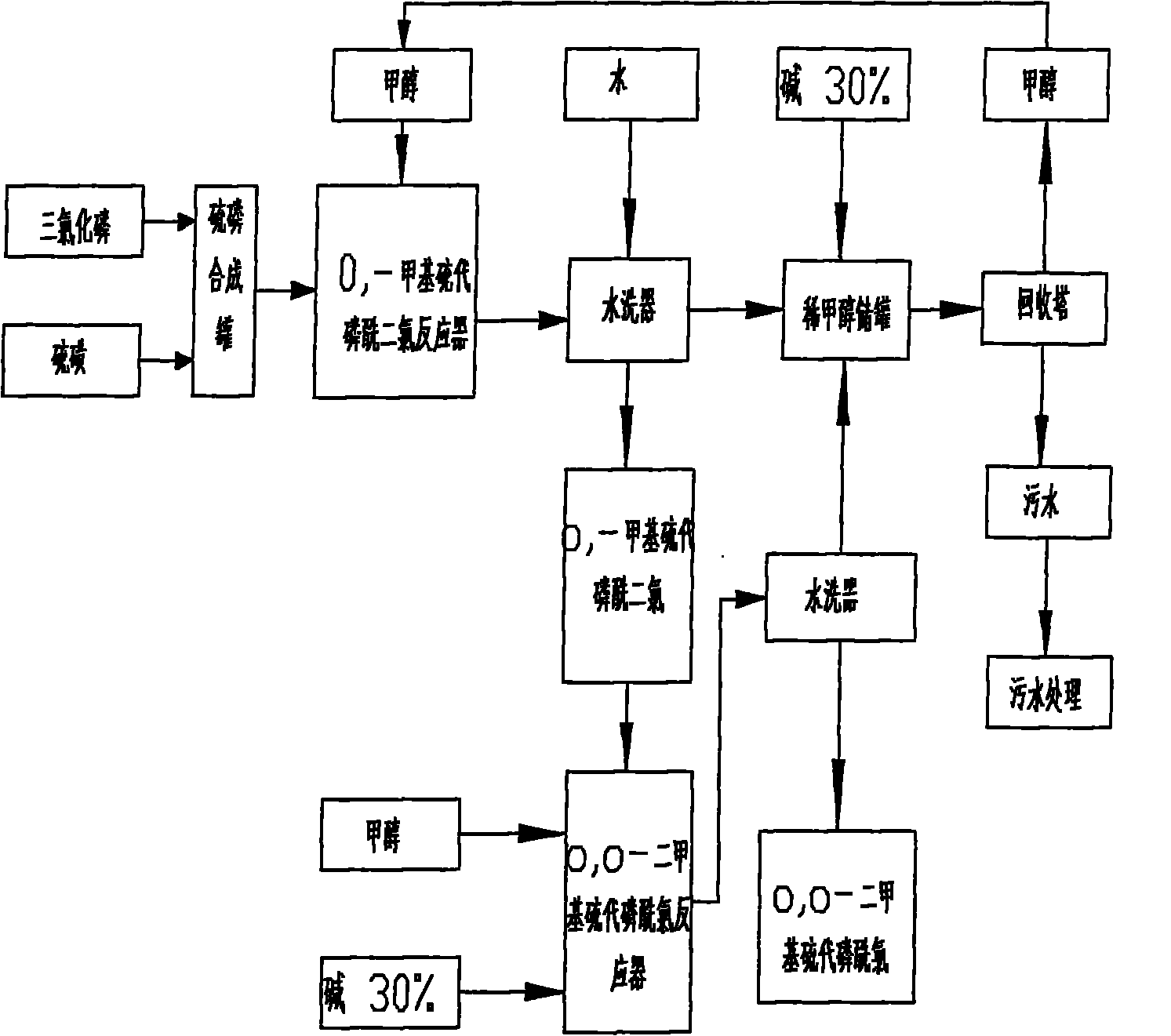

Method for continuous production of 0,0-dimethyl thiophosphoryl chloride

ActiveCN101195640AReduce labor intensityHigh yieldGroup 5/15 element organic compoundsWastewaterOil phase

The invention relates to a continuous preparation method of O, O-dimethyl thiophosphoryl chloride, which comprises adding O-methyl thiophosphoryl chloride, methanol and alkali continuously into a combination reactor composed of serial multistage reactors, adding alkali into the reactor at each stage, using a hydraulic cyclone to separate the material continuously flown outside the reactor, using the oil phase as product, and feeding water phase into a settler to further separate residual O, O-dimethyl thiophosphoryl chloride, recovers methanol in the water phase, and removes waste water. The invention has high reaction yield and equipment utilization, high product quality, short reaction time and reduced production cost, which can continuously prepare O, O-dimethyl thiophosphoryl chloride.

Owner:XIANGTAN UNIV +1

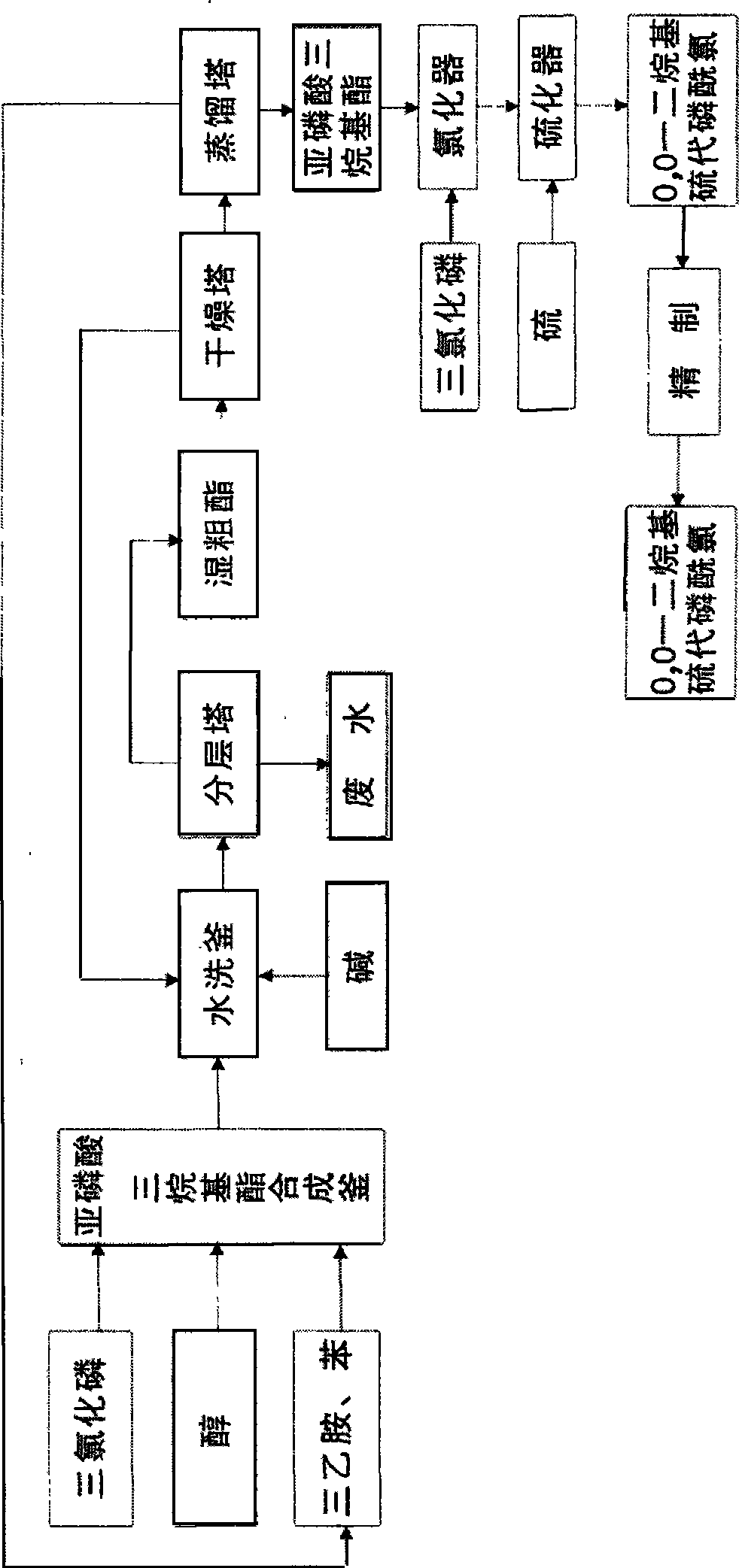

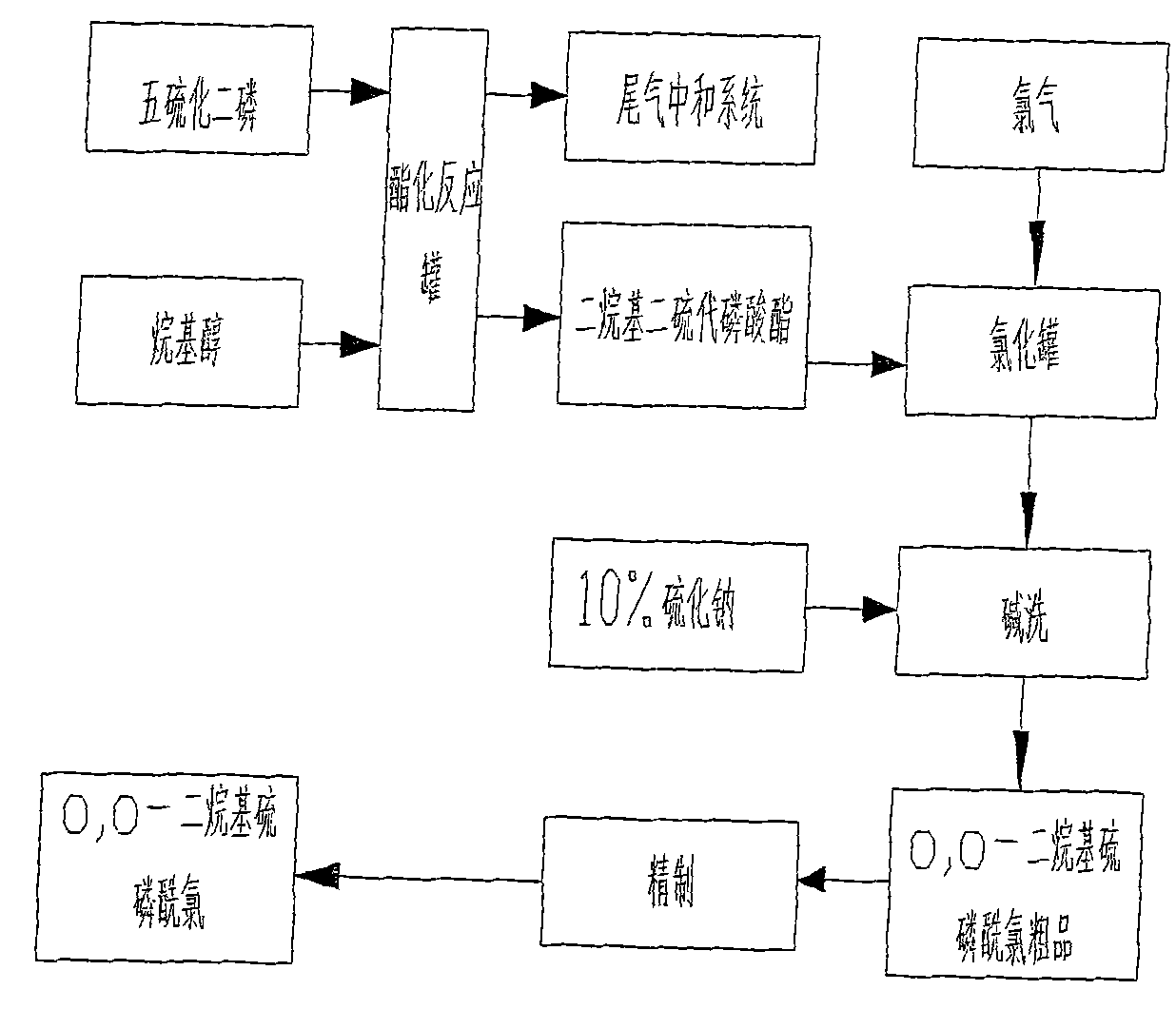

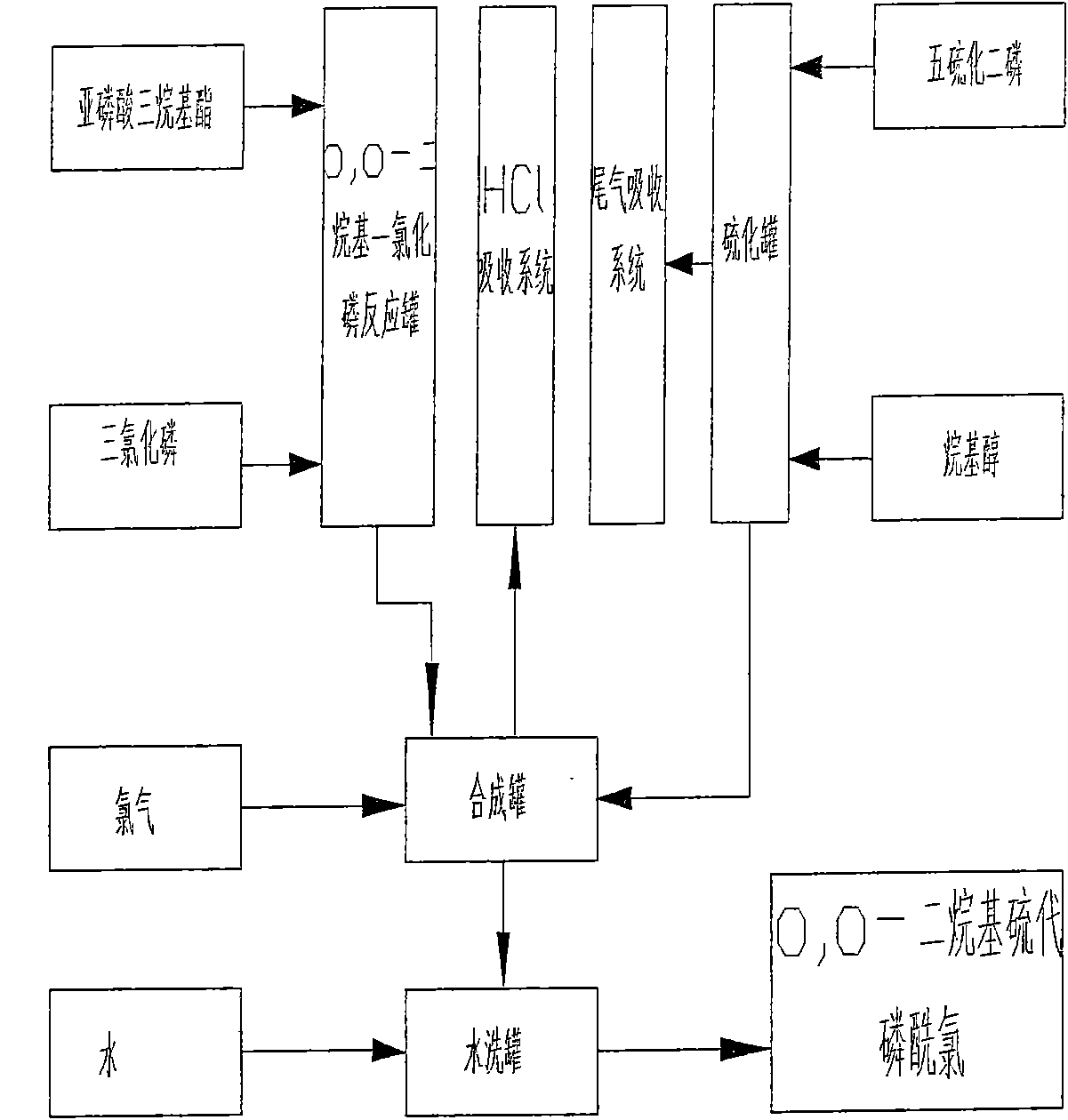

Production method of O, O-dialkyl thiophosphoryl chloride

ActiveCN101486729AQuality improvementReduce energy consumptionGroup 5/15 element organic compoundsPhosphorous acidAlcohol

The invention discloses a manufacturing method of O, O-dialkyl thiophosphoryl chloride; the manufacturing method comprises the steps that phosphorus trichloride, alcohol, sulfur and the like are taken as raw materials, wherein, the phosphorus trichloride reacts with alcohol in a trialkyl synthesis kettle to produce phosphorous acid trialkyl ester; then, the phosphorous acid trialkyl ester reacts with the phosphorus trichloride in a chlorinator to produce O, O-dialkyl phosphorus chloride; and the O, O-dialkyl phosphorus chloride reacts with sulfur in a vulcanizing apparatus to produce the crude products of O, O-dialkyl thiophosphoryl chloride which then is processed to obtained the refined products of the O, O-dialkyl thiophosphoryl chloride. The overall yield of the manufacturing method can be up to 94 percent, the content of the O, O-dialkyl thiophosphoryl chloride can reach 99 percent, and the manufacturing method is characterized by safe production, low energy consumption and no pollution.

Owner:荆州市沙市东方有机化工研究所

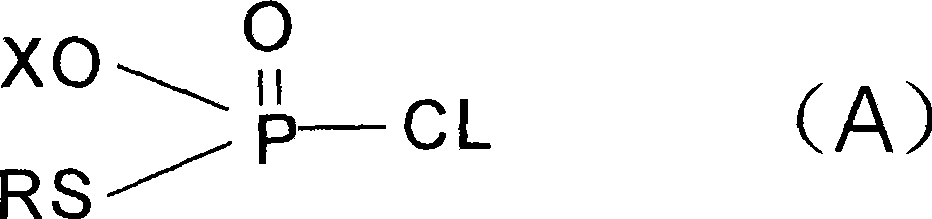

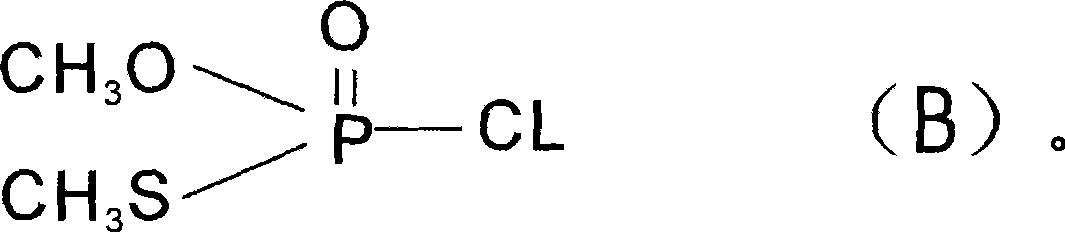

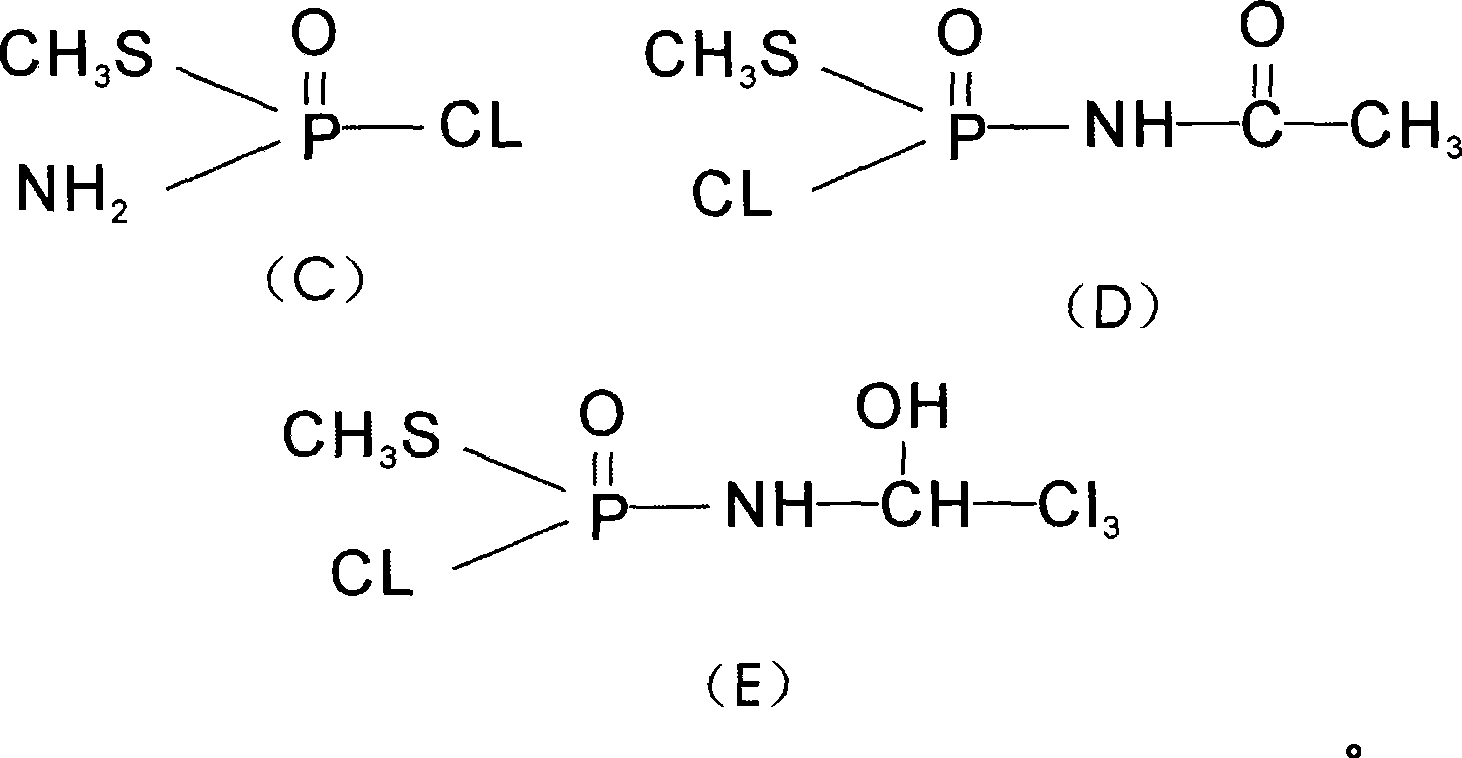

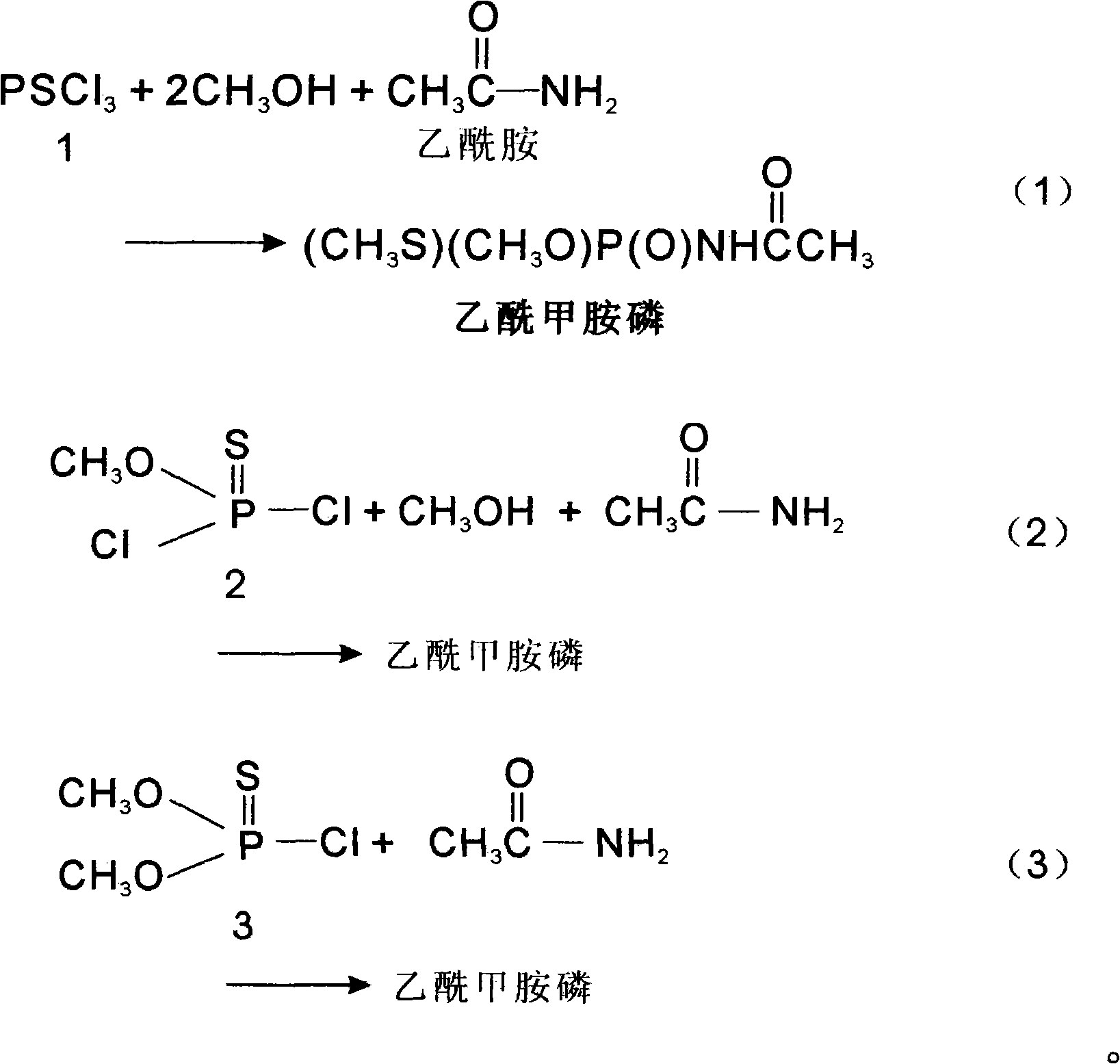

O,S-dimethyl thiophosphoryl chloride, preparation and uses thereof

InactiveCN101429213AEmission reductionReduce the cost of protection and governanceGroup 5/15 element organic compoundsChloramine BWater discharge

The invention relates to a novel compound of O, S-dimethyl thiophosphoryl chloride, a preparation method and application as intermediate or raw material of pesticide thereof. The novel compound can be used to prepare pesticide products, such as acephatemet, orthene and chloramine phosphorus. Compared with the prior process for preparing the acephatemet and the orthene, the method has the advantages that dislocation isomerism yield is improved by 15 percent; production cost is reduced by 10 percent and 20 percent; waste water discharge is reduced by 80 percent; and the cost for environmental protection and control is reduced by 60 percent.

Owner:李坚

Production process of O, O-dialkyl thiophosphoryl chloride

ActiveCN101830925AReduce energy consumptionIncrease consumptionGroup 5/15 element organic compoundsPhosphorus pentasulphidePhosphorus trichloride

The invention relates to a production process of O, O-dialkyl thiophosphoryl chloride, which improves the production process of the O, O-dialkyl thiophosphoryl chloride produced by a phosphorus pentasulfide method. An O, O-dialkyl thiophosphoryl chloride product is synthesized by adding a by-product obtained by reacting phosphorus pentasulfide with alkanol and introducing chlorine to O, O-dialkyl phosphorus chloride obtained by reacting trialkyl phosphite with phosphorus trichloride. The invention can achieve the total yield of the trialkyl phosphite by 94 percent and the total yield of the phosphorus pentasulfide more than 95 percent and has safe production, little energy consumption and pollution without generating sulphur residues.

Owner:荆州三才堂化工科技有限公司

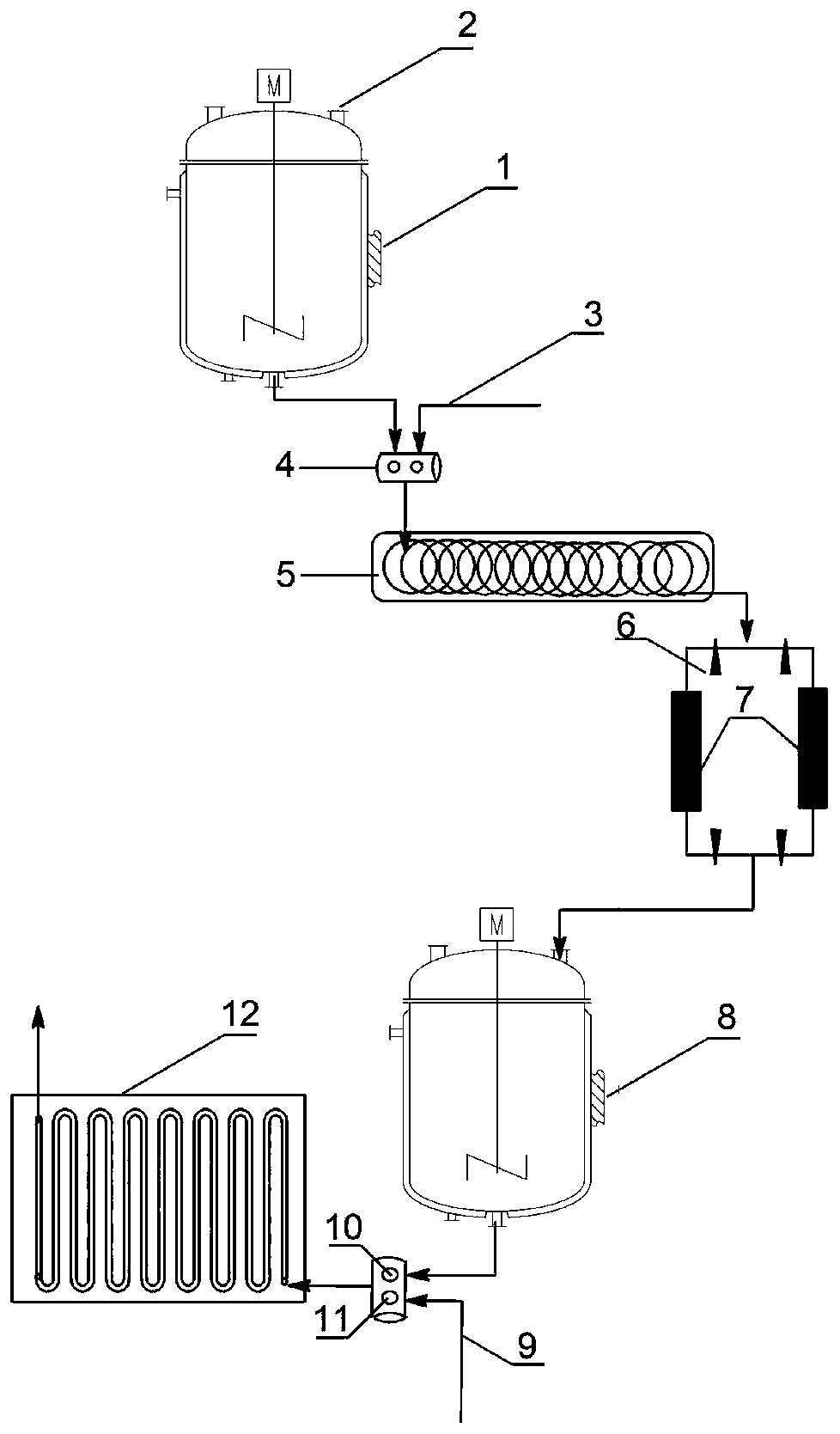

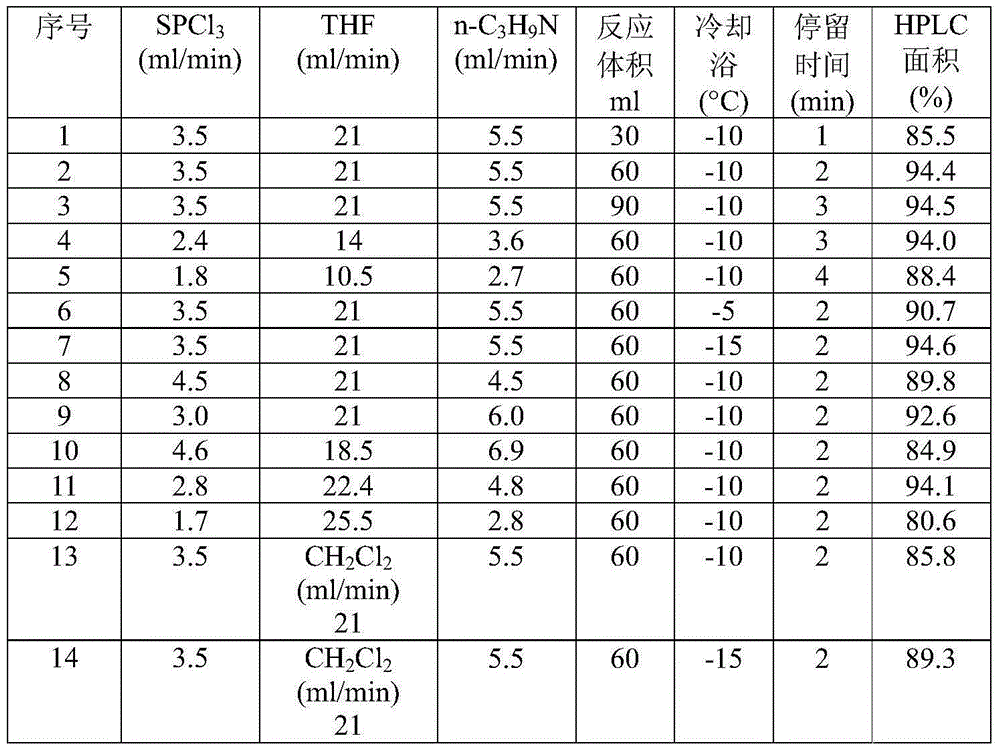

Method for continuously synthesizing N-butylthiophosphoric triamide by microreactors

InactiveCN108084224AEvenly dispersedImprove solubilityGroup 5/15 element organic compoundsChemical/physical/physico-chemical processesSolventDistributor

The invention discloses a method for preparing N-butylthiophosphoric triamide by continuous reaction in microreactors. The method comprises the following steps: uniformly mixing n-butylamine and triophosphoryl chloride with a solvent respectively at first, then adding a mixture into a membrane dispersion microreactor through a charging pump, dispersing the n-butylamine into a mixture solution of the triophosphoryl chloride in a micro-droplet form, performing reaction at certain temperature to obtain N-butylthiophosphoric dichloride, and simultaneously introducing ammonia as an acid binding agent of hydrogen chloride; delivering the reactant to a tubular microreactor, and continuously introducing ammonia into the reactor through a gas distributor to obtain the N-butylthiophosphoric triamideand ammonium chloride; finally collecting a product through a collection kettle, and executing operations of crystallization, filtering, drying and the like to obtain a product. The method has the advantages of short processing flow, mild reaction condition, simplicity for process operation, few byproducts, low energy consumption, high yield, low cost and the like, and is suitable for large-scaleindustrial production.

Owner:NORTH HUAJIN CHEM IND CO LTD

Preparation of N-alkyl thiophosphoryl triamide by one-pot method

InactiveCN101412733BModerate reaction conditionsSimple processGroup 5/15 element organic compoundsReaction temperatureReaction system

The invention discloses a method for preparing N-alkyl thiophosphoryl triammonium through a favorable one-pot method in industry. The method is characterized in that in a tetrahydrofuran solvent, in the presence of a tertiary amine acid-binding agent, and at an reaction temperature of between 10 below zero and 50 DEG C, thiophosphoryl chloride and alkyl primary amine react to generate N-alkyl amino thiophosphoryl bichloride and tertiary amine acid-binding agent hydrochloride as intermediate products; the generated intermediate products continuously react with ammonia gas in the same reaction system without purification and separation to generate the N-alkyl thiophosphoryl triammonium, the acid-binding agent and ammonium chloride as target products; the target products are filtered and condensed to obtain the product; and the yield of the N-alkyl thiophosphoryl triammonium is more than or equal to 85 percent. The method has the advantages of compact preparation process, low cost, high yield and suitablility for scale industrialized production.

Owner:DALIAN UNIV OF TECH

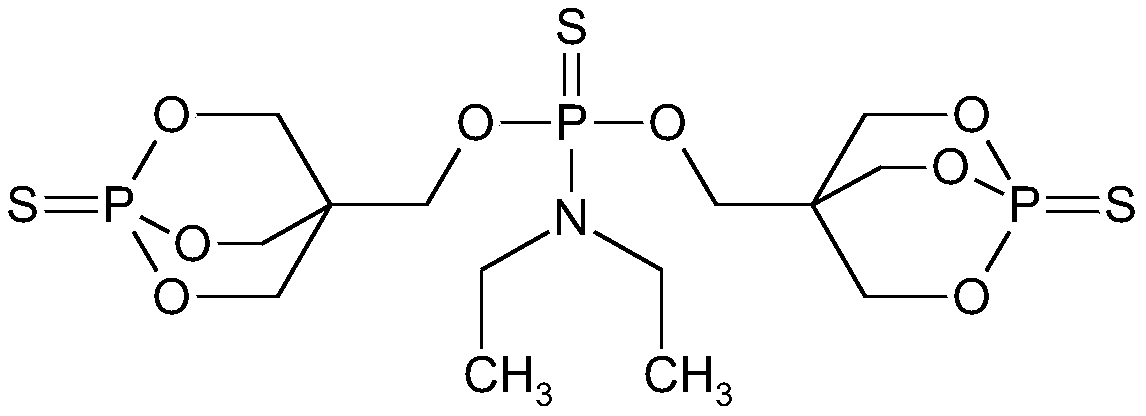

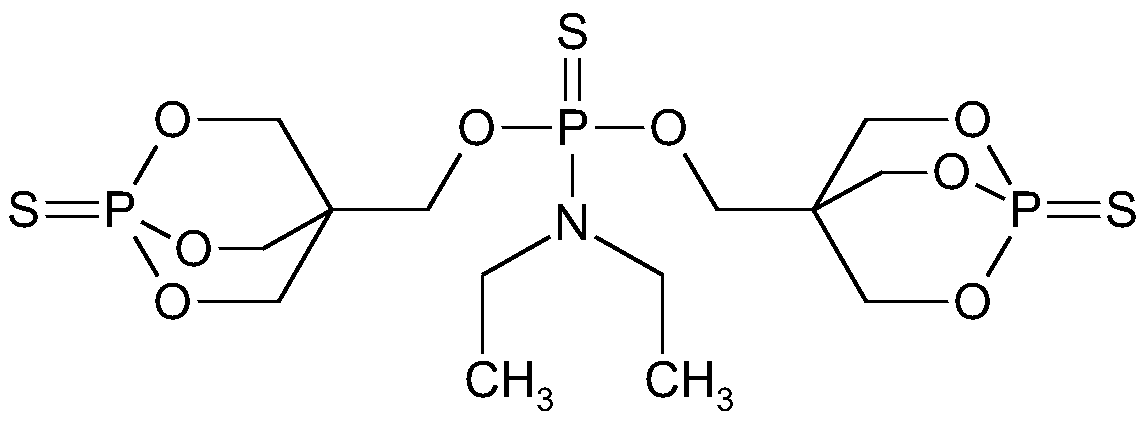

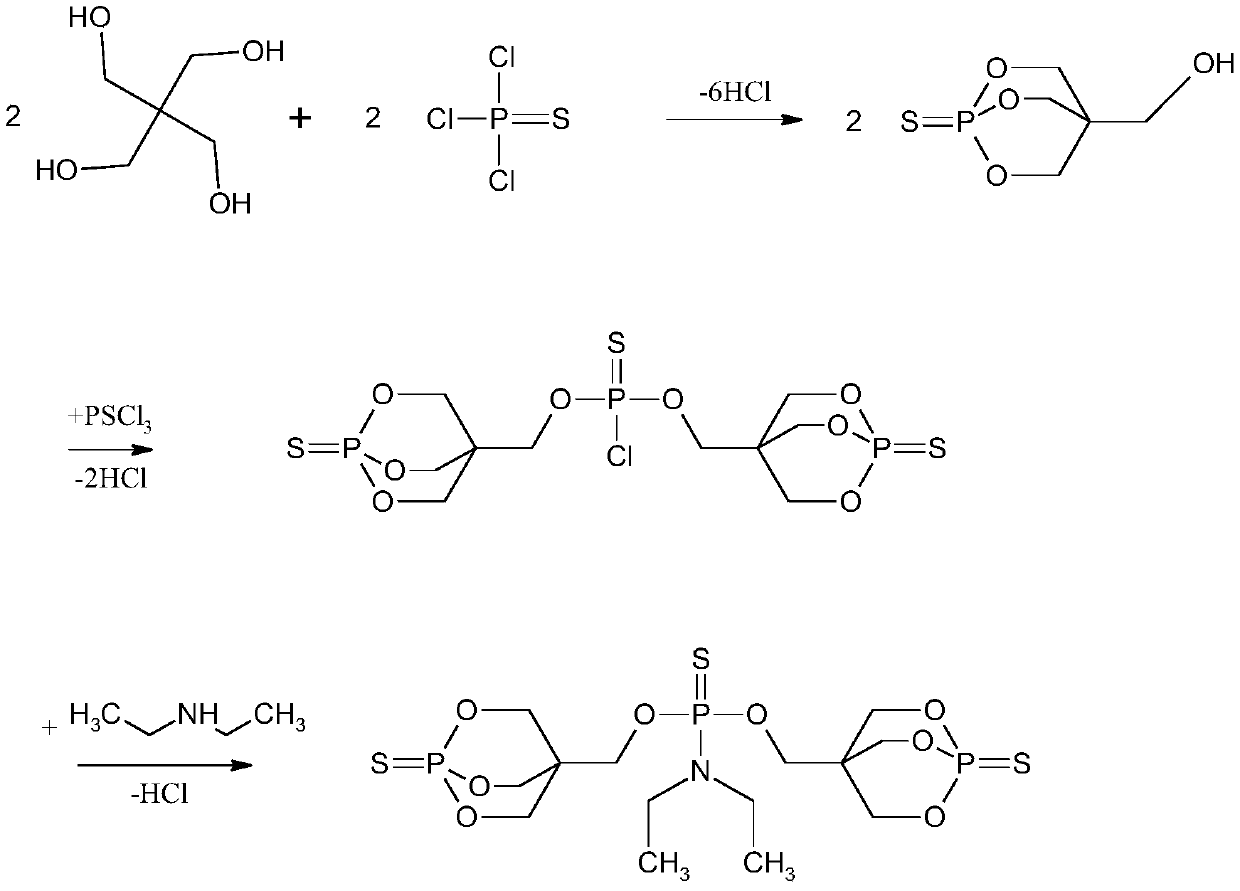

Sulfur containing cage-like organic phosphate/ammonium polyphosphate compounded polyolefin fire retardant and preparation method thereof

ActiveCN110804208AMeet environmental protection requirementsImprove flame retardant performanceGroup 5/15 element organic compoundsPhosphoric Acid EstersPolymer science

The invention relates to a sulfur containing cage-like organic phosphate / ammonium polyphosphate compounded polyolefin fire retardant and a preparation method thereof. The preparation method comprisesfollowing steps: reacting pentaerythritol with thiophosphoryl chloride under certain conditions, and after reactions, filtering, washing, and drying the reaction product to obtain a white powdery intermediate A; reacting the intermediate A with thiophosphoryl chloride under certain conditions for a while, cooling, carrying out rotary evaporation and drying to obtain a white powdery intermediate B;reacting the intermediate B with diethylamine under certain conditions, filtering, washing, and drying to obtain a white powdery product namely sulfur containing cage-like organic phosphate; compounding the white powdery product namely sulfur containing cage-like organic phosphate with ammonium polyphosphate according to a certain ratio t obtain a white solid namely the sulfur containing cage-like organic phosphate / ammonium polyphosphate compounded polyolefin fire retardant. The fire retardant is prepared by compounding a nitrogen fire retardant, a phosphorus fire retardant, and a sulfur fireretardant, the synergistic fire-retardant effect is excellent, and the fire retardant is not dissolved by water and most of organic solvents, and has a good fire retardant effect on multiple polyolefin materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

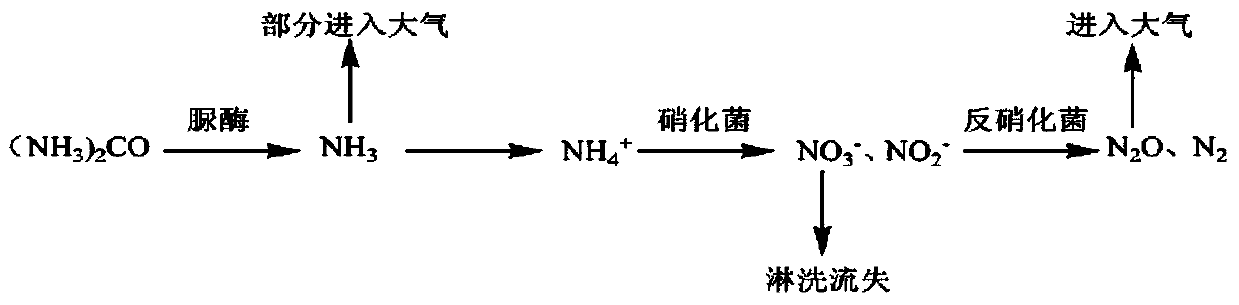

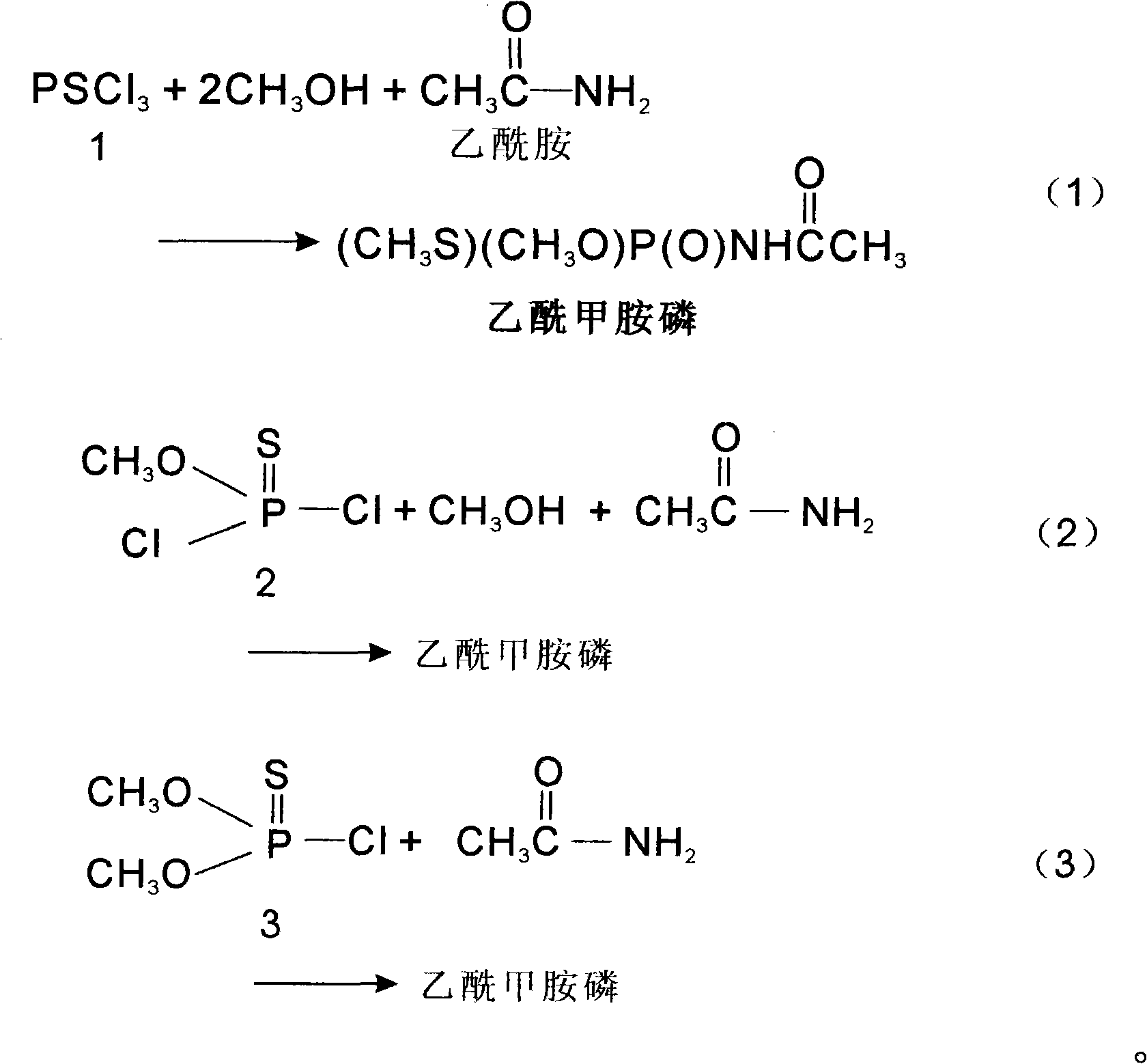

Method for synthesizing oxydemeton-methyl by taking phosphorus oxychloride as raw material through reaction in one step

The invention relates to a new method for synthesizing oxydemeton-methyl by taking combined thiophosphoryl chloride or other phosphorus oxychloride, carbinol and acetamide as raw materials only through one step of serial-connected pericyclic reaction. Compared with the prior art, the preparation cost of the oxydemeton-methyl is reduced by more than 50%, and cleaner production industrial design standards of zero discharging of waste water can be realized.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Aqueous phase method for synthesis of chlorpyrifos

PendingCN103467515AEasy to operateHigh yieldGroup 5/15 element organic compoundsChlorpyrifosSynthesis methods

The invention relates to an aqueous phase method for synthesis of chlorpyrifos. The method is characterized by: adding water into a reaction kettle, adding a surfactant under stirring to make 3, 5, 6-trichloropyridine-2-sodium alkoxide and O, O-diethyl thiophosphoryl chloride emulsified and dispersed in water, then adding a compound catalyst, and a pH regulator to make the pH value of the system reach 9-10, then leaving the materials to react fully at 25-65DEG C, carrying out cooling crystallization, pumping filtration, washing, and drying, thus obtaining a chlorpyrifos original drug product. The main technical features of the invention lie in that: water is adopted as a solution, reactants are added in one time, and by means of the action of the surfactant, a highly dispersed system is formed to undergo reaction. The synthesis method is simple and reliable, and is easy to operate, the product yield and purity are both improved and both can reach over 98%. The production cost is low, and the environment is improved.

Owner:SHANDONG TIANCHENG BIOTECH

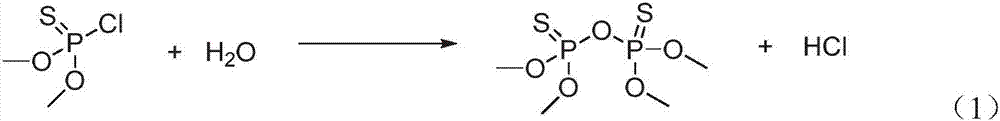

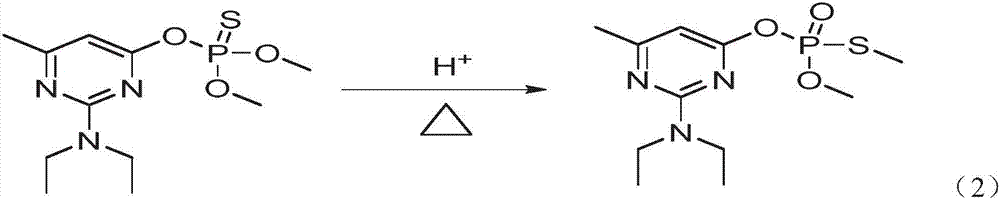

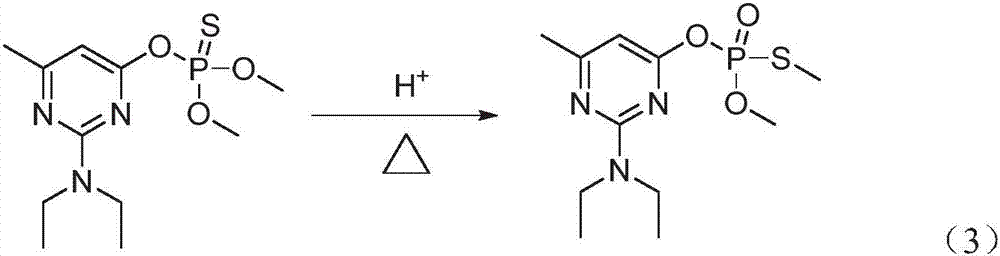

Method of controlling harmful impurities during pirimiphos-methyl synthesis

ActiveCN107011381ALow in MethylthiotropinLow in teppGroup 5/15 element organic compoundsOrganic solventLimited concentration

The invention discloses a method of controlling harmful impurities during pirimiphos-methyl synthesis. The method includes following steps: adding 2-N, N-diethylamino-6-methyl-4-hydroxy pyrimidine metal salt and a catalyst into an organic solvent; dropwise adding O, O-dimethyl thiophosphoryl chloride for condensation reaction; after-treating obtained reaction liquid to obtain pirimiphos-methyl to complete control on harmful impurities. By the method, content of the harmful impurities can be controlled effectively, and amounts of the harmful impurities like methyl sulfotepp (<0.06%) and iso-pirimiphos-methyl (<0.2%) are far lower than FAO limited concentration standards.

Owner:HUNAN CHEM RES INST

Green synthesis technology of O,O-diethyl thiophosphoryl chloride

InactiveCN109369708AAvoid generatingReduce processing costsGroup 5/15 element organic compoundsChemical synthesisPollution

The invention provides a green synthesis technology of O,O-diethyl thiophosphoryl chloride and relates to the field of chemical synthesis. The green synthesis technology comprises the following steps:taking O,O-diethyl dithiophosphate to react with chlorine gas at low temperature, so as to obtain a crude product of the O,O-diethyl thiophosphoryl chloride; then transferring the crude product to react at high temperature; enabling the residual O,O-diethyl dithiophosphate to further completely react with the chlorine gas. Meanwhile, in a high-temperature reaction process, a polymeric compound isprevented from being generated when a compound catalyst is used and sulfur monochloride impurities are completely removed through reaction, so that a byproduct sulfur has a crystalline state and a product more easily separated and purified. Moreover, HCl and sulfur-containing odorous gas are pumped away through applying negative pressure and the tail gas is absorbed to prevent air pollution. In awhole reaction process, technological water does not need to be added, so that wastewater is not generated and the treatment cost of sulfur-containing and phosphorus-containing wastewater is reduced.The technology has the advantages of simplicity in operation, easiness for obtaining raw materials, moderate reaction conditions, small pollution and environment friendliness.

Owner:CHONGQING HUAGE BIOCHEM

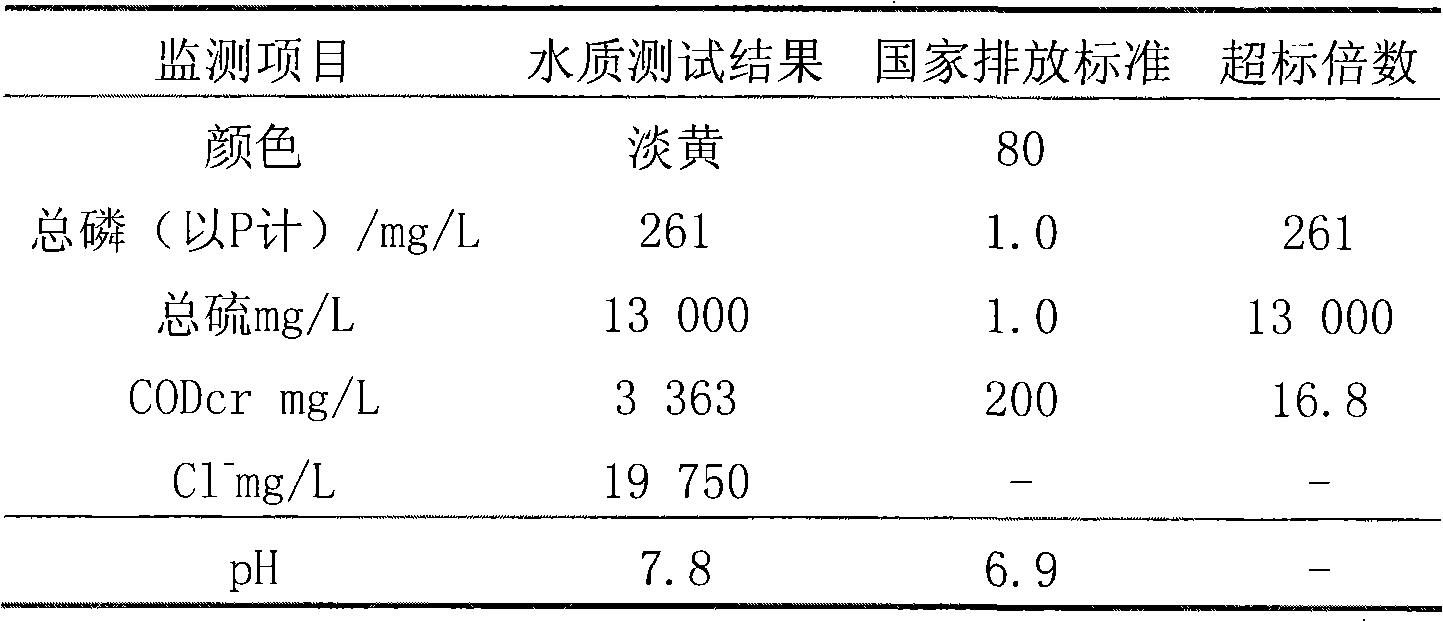

Phosphorus thiochloride production waste water emission reduction and purification treatment method

InactiveCN106007048AHigh removal rateSimple processWater contaminantsWaste water treatment from gaseous effluentsFiltrationWastewater

The invention provides a phosphorus thiochloride production waste water emission reduction and purification treatment method. The method is characterized in that phosphorus thiochloride storage tank absorption water is cyclically used as reaction kettle pot washing water and reaction kettle tail gas alkali absorption water; the reaction kettle pot washing water and the reaction kettle tail gas alkali absorption water are mixed to produce waste water; oxidizing agents are added into production waste water to perform oxidation reaction; filtration is performed to obtain production waste water filter liquid; a phosphorus removing agent is added into obtained production waste water filter liquid to perform deep dephosphorization; the obtained purification standard reaching production waste water is discharged. The method provided by the invention has the advantages that the technical flow process is simple; the speed is high; the operation is convenient; the cost is lower; the contaminant removal rate is high; therefore the method provided by the invention has good popularization values. The contaminants in the waste water can be effectively removed by the method; the treated waste water does not contain S<2-> ions; the mass concentration of the phosphorus, Al<3+> and COD is reduced; the water quality is clear and transparent; the national discharge standard is reached.

Owner:荆州沙隆达控股有限公司

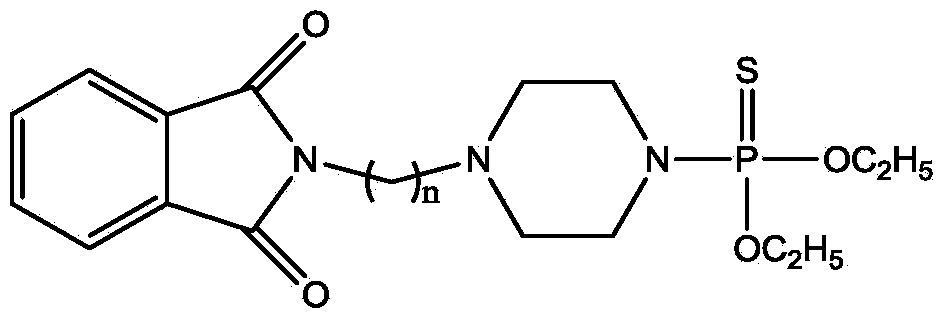

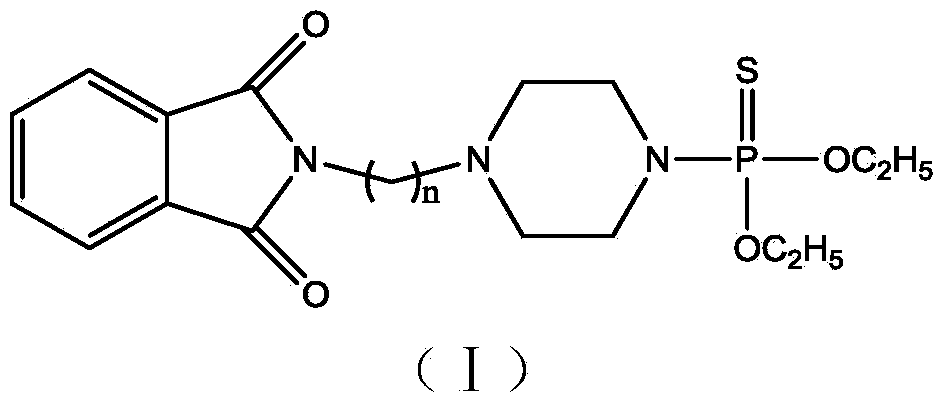

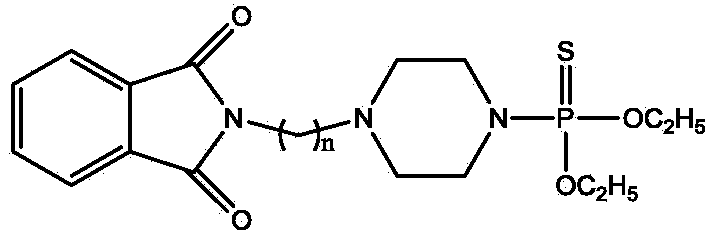

N-alkylation phthalimide piperazine derivatives as well as preparation method and application thereof

InactiveCN103923123AReduce manufacturing costGood synergyBiocideGroup 5/15 element organic compoundsAlkaneAlkyl transfer

The invention discloses N-alkylation phthalimide piperazine derivatives as well as a preparation method and an application thereof. The structural formula of the N-alkylation phthalimide piperazine derivatives is shown in descriptions, and in the structural formula, n is 1 or 2 or 3. The preparation method of the N-alkylation phthalimide piperazine derivatives comprises the following steps: dissolving phthalimide potassium salt in acetone, then adding dibromine alkane to the acetone, and reacting for 5-12 hours at the temperature of 45-65 DEG C so as to obtain a first intermediate; dissolving piperazine in dichloromethane, adding diethyl thiophosphoryl chloride to the dichloromethane at the temperature of -5 to 5 DEG C, and reacting for 0.1-1 hour at the temperature of -5 to 5 DEG so as to obtain a second intermediate; and dissolving the first intermediate in N,N-dimethylformamide, adding monovalent carbonate and the second intermediate to the N,N-dimethylformamide, and reacting for 1-5 hours at the temperature of 50-80 DEG C. The N-alkylation phthalimide piperazine derivatives provided by the invention have high effect on prevention and treatment of invertebrate insect pests. Serving as arthropod killing agents, the N-alkylation phthalimide piperazine derivatives are capable of reducing production cost and environmental load.

Owner:GUILIN JIQI BIOCHEM

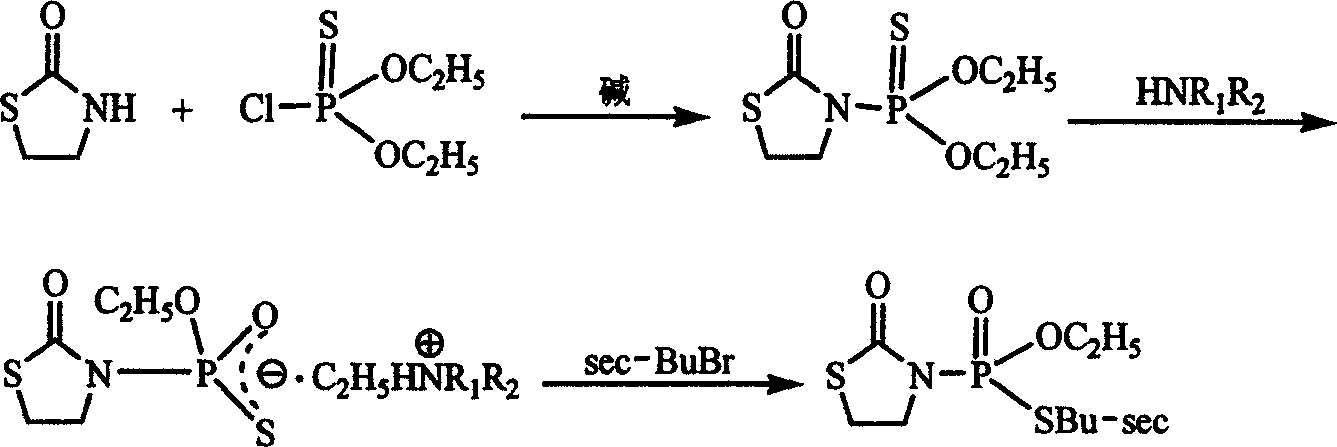

Synthesis method of (R,S)-S-secondary butyl o-ethyl-2-oxo-1,3-thiazolidine-3-thiosulphate

InactiveCN1752093AAvoid participationSimple processGroup 5/15 element organic compoundsSynthesis methodsSolvent

A process for preparing (R, S)-S-parabutyl-O-ethyl-2-oxy-1, 3-thiazolidine-3-yl thiophosphate includes such steps as reaction between 2-thiazolidinone and O, O'-diethyl thiophosphoryl chloride in arylhydrocarbon under the action of organic alkali to obtain O, O'-diethyl-2-oxy-1,3-thiazolidine-3-yl thionphosphate, reflux reaction on the aqueous solution of excessive lipoamine to obtain ammonium thiophosphate, reflux reaction on bromoparabutane in arylhydrocarbon-water system, and post-treating.

Owner:ZHEJIANG UNIV OF TECH

Continuous preparation method and preparation device of N-n-butyl thiophosphoric triamide

ActiveCN110950904AAchieve serializationOvercoming the Insufficiency of Intermittent OperationGroup 5/15 element organic compoundsThio-Phosphoramide

The invention relates to a continuous preparation method and a preparation device of N-n-butyl thiophosphoric triamide. The preparation method comprises the following steps: (1) adding a thiophosphoryl chloride toluene solution and n-butylamine into a micro-channel reactor for substitution reaction to obtain an N-n-butyl dichloro thioxophosphamide toluene solution, treating the N-n-butyl dichlorothioxophosphamide toluene solution with an anion exchange resin, and feeding the treated N-n-butyl dichloro thioxophosphamide toluene solution into a storage tank; (2) adding the solution in the storage tank and ammonia gas into a tubular reactor for reaction to obtain an N-n-butyl thiophosphoric triamide toluene solution; and (3) carrying out extraction washing, organic phase concentration recrystallization, separation and drying on the obtained solution to obtain the high-purity N-n-butyl thiophosphoric triamide. According to the continuous preparation method and the preparation device disclosed by the invention, the continuity of the production process of the N-n-butyl thiophosphoric triamide is realized, the defect of intermittent operation of a kettle type reactor is avoided, the process is simplified, the reaction selectivity is improved, and the purposes of clean production, shortening of the production period and reduction of the production cost are achieved.

Owner:武威金仓生物科技有限公司

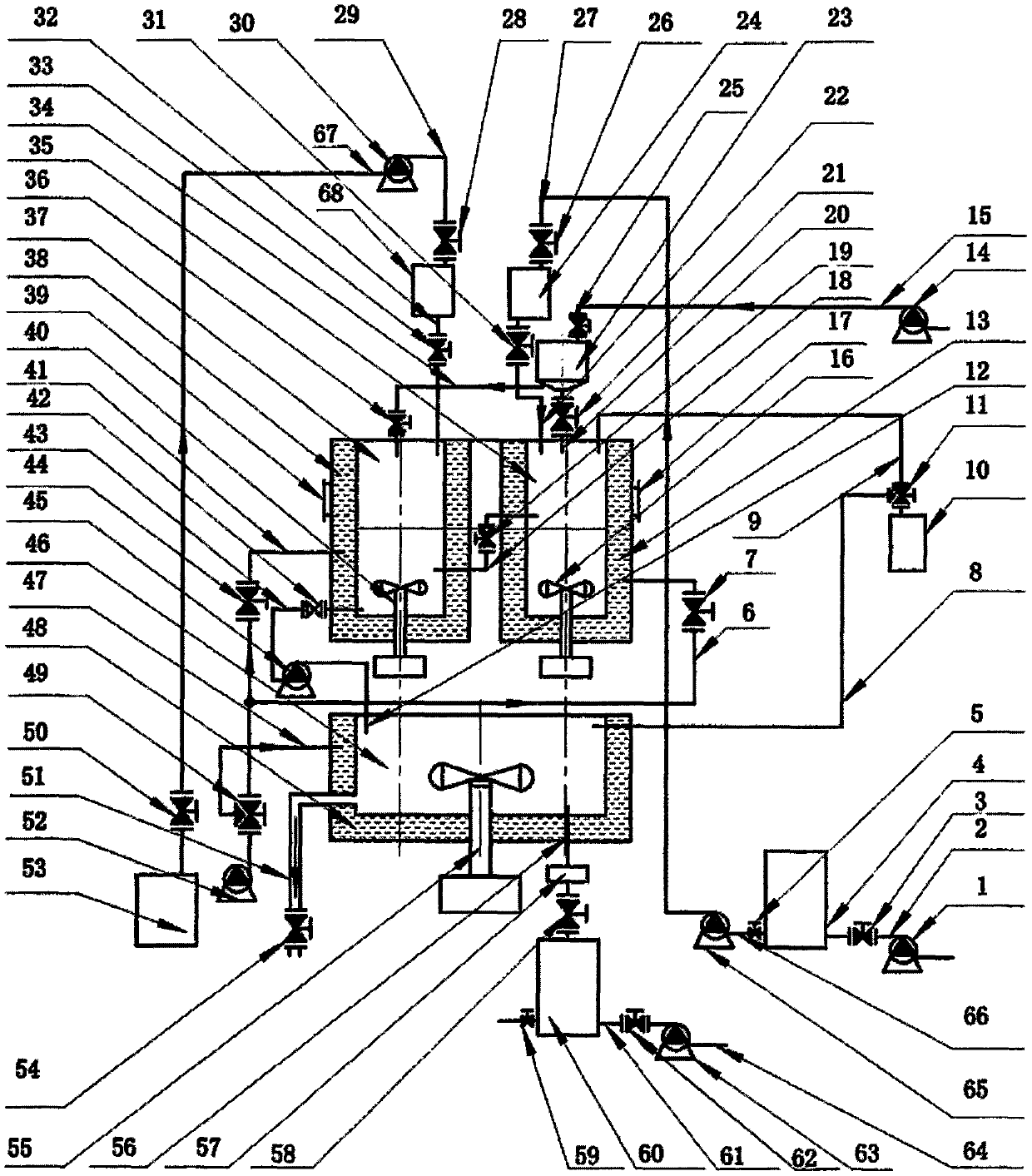

Method for synthesizing N-alkylthiophosphoryl triamide through continuous reaction

ActiveCN105131031AHigh yieldIncrease productivityGroup 5/15 element organic compoundsChemical industryMicroreactorOrganic solvent

The invention discloses a method for synthesizing N-alkylthiophosphoryl triamide through a continuous reaction. The method comprises the following steps: 1, mixing thiophosphoryl chloride with an organic solvent, pre-cooling the obtained mixture in a heat exchanger to -5-0DEG C, mixing the material with an aminated compound pre-cooled to -5-0DEG C, and reacting the obtained mixture in a micro-reactor to obtain N-alkylthiophosphoryl dichloride at the outlet of the reactor; and 2, allowing N-alkylthiophosphoryl dichloride to directly enter an ammoniation reactor, carrying out an ammoniation reaction on N-alkylthiophosphoryl dichloride and ammonia gas, and post-processing after the ammoniation reaction is completed to obtain N-alkylthiophosphoryl triamide. N-alkylthiophosphoryl triamide is synthesized through a micro-reaction technology with high mass transfer and heat transfer efficiency, so conversion of intermittence to continuity is realized, the operating step is simplified, and the reaction yield is improved.

Owner:SHANGYU SUNFIT CHEM

Method for preparing n-butyl thiophosphoric triamide and integrated device thereof

PendingCN111138490AReasonable process designLower unit costGroup 5/15 element organic compoundsThio-Biochemical engineering

The invention discloses a method for preparing n-butyl thiophosphoric triamide and an integrated device of the n-butyl thiophosphoric triamide and belongs to the technical field of production of efficient green slow-release fertilizer synergists, liquid crystal intermediates and medical intermediates. The method mainly comprises the following steps: carrying out a reaction between thiophosphoryl chloride and n-butylamine to generate N-n-butyl thiophosphoryl dichloride; and carrying out a reaction between N-n-butyl thiophosphoryl dichloride with liquid ammonia to generate a target product, namely n-butyl thiophosphoric triamide. The invention specifically relates to a method and a device for preparing thiophosphoryl chloride. The core content and the technical scheme are as follows: a novelammoniation production process flow is adopted on the basis of the existing method for preparing the n-butyl thiophosphoric triamide; a liquid ammonia introduction and restriction orifice plate is added, so that the flow of ammonia introduced into an ammonia introduction kettle is effectively controlled; as a liquid ammonia metering tank is added, the mass of ammonia introduced into the ammonia introduction kettle is effectively controlled; since a batching kettle is added, materials in the batching kettle are pre-cooled, the reaction temperature in a n-butyl kettle is effectively controlled,and the purposes of complete process reaction, good product stability and low unit cost are achieved.

Owner:安徽中枨信息科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com