Sulfur containing cage-like organic phosphate/ammonium polyphosphate compounded polyolefin fire retardant and preparation method thereof

An organic phosphate and ammonium polyphosphate technology, applied in the field of polyolefin flame retardants, can solve the problems of a large amount of inorganic flame retardants, human health and environmental hazards, and the decline of the mechanical properties of the matrix, and achieves high flame retardant efficiency, Good moisture absorption and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

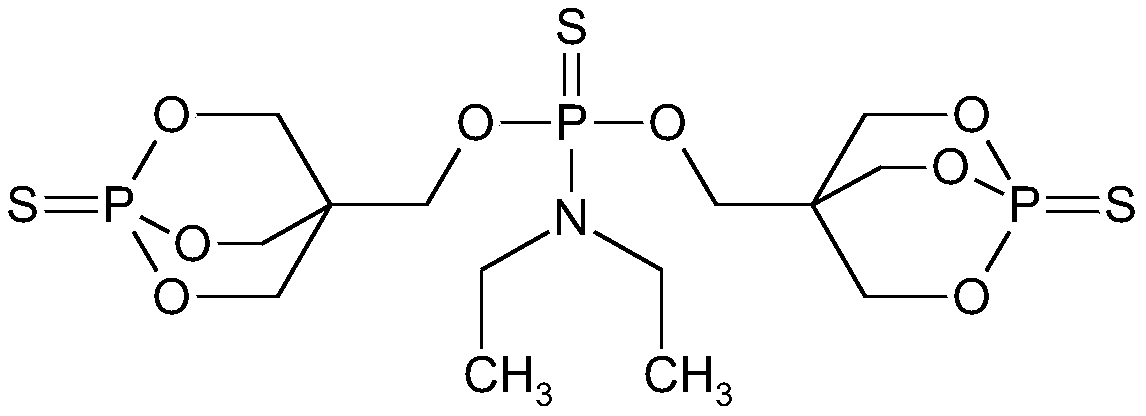

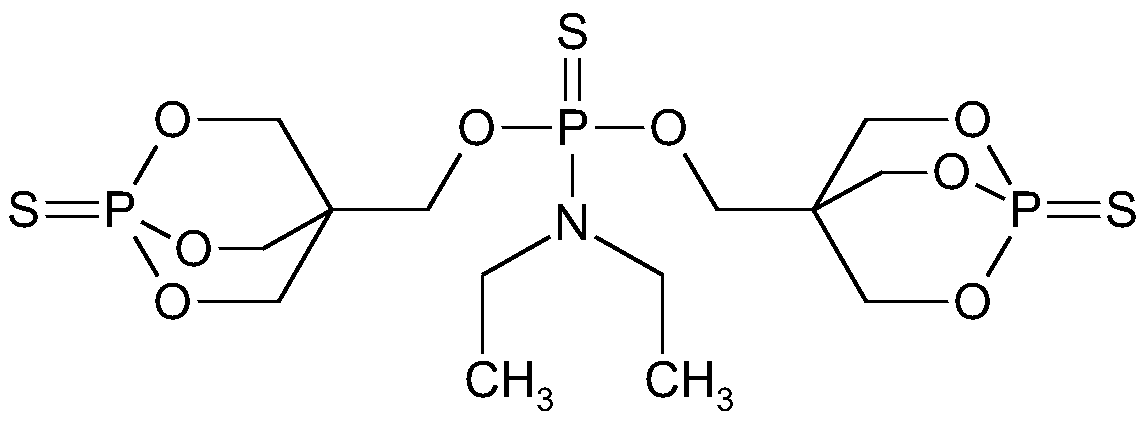

Image

Examples

Embodiment 1

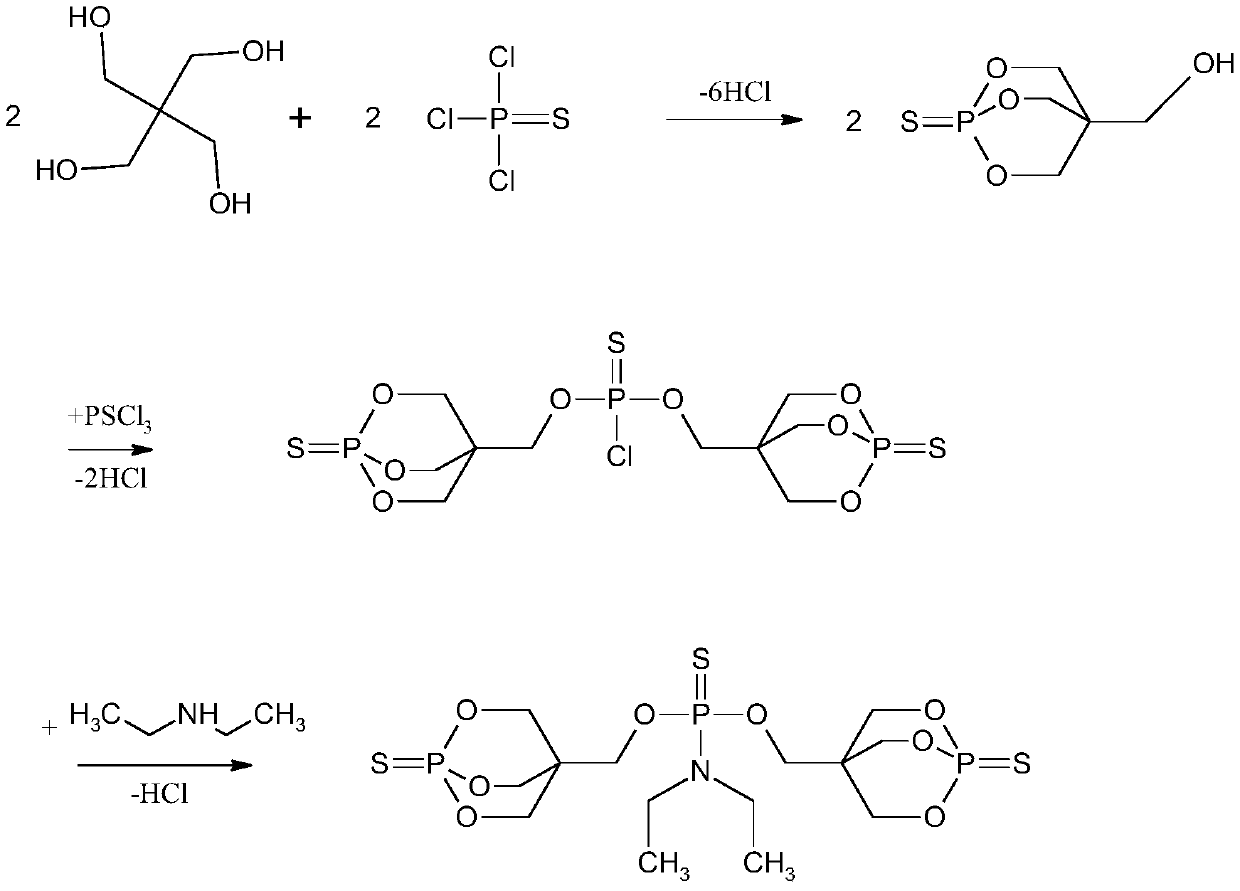

[0031] Step 1: Add 54.46 g (0.4 mol) of pentaerythritol and 100 mL of solvent benzene into a four-neck flask equipped with stirring, thermometer, and condenser, stir and heat to reflux temperature (90°C) under nitrogen protection, and weigh sulfur trichloride Phosphorus 42.42mL (0.4mol), quickly drop half of the weighed amount of phosphorus trichloride, and slowly add the other half dropwise from the addition funnel, stir and react for about 7 hours until the white solid product is completely precipitated. Cool to room temperature, filter the product with dichloromethane or chloroform, wash, and then dry in a vacuum oven at 80°C to obtain white powdery intermediate A.

[0032] Step 2: Add 21.21 g (0.2 mol) of phosphorus trichloride and 100 mL of anhydrous acetonitrile into a four-necked flask equipped with stirring, a thermometer, and a condenser, mix at room temperature until the system is stable, and then add the first step 78.42g (0.4mol) of the synthesized intermediate A w...

Embodiment 2

[0045] Step 1: Add 44.93g (0.33mol) of pentaerythritol and 100mL of solvent benzene into a four-neck flask equipped with a stirring, thermometer, and condenser tube, stir and heat to reflux temperature (80°C) under nitrogen protection, and weigh sulfur trichloride Phosphorus 67.76g (0.4mol), quickly drop half of the weighed amount of phosphorus trichloride, and slowly add the other half dropwise from the addition funnel, stir and react for about 7 hours until the white solid product is completely precipitated. Cool to room temperature, filter the product with dichloromethane or chloroform, wash, and then dry in a vacuum oven at 80°C to obtain white powdery intermediate A.

[0046] Step 2: Add 33.88 g (0.2 mol) of phosphorus trichloride and 100 mL of anhydrous acetonitrile into a four-necked flask equipped with stirring, a thermometer, and a condenser, mix at room temperature until the system is stable, and then add the first step 64.69g (0.33mol) of the synthesized intermediat...

Embodiment 3

[0058] Step 1: Add 49.01 g (0.36 mol) of pentaerythritol and 100 mL of solvent benzene into a four-necked flask equipped with stirring, thermometer, and condenser, stir and heat to reflux temperature (80°C) under nitrogen protection, and weigh sulfur trichloride Phosphorus 67.76g (0.4mol), quickly drop half of the weighed amount of phosphorus trichloride, and slowly add the other half dropwise from the addition funnel, stir and react for about 7 hours until the white solid product is completely precipitated. Cool to room temperature, filter the product with dichloromethane or chloroform, wash, and then dry in a vacuum oven at 80°C to obtain white powdery intermediate A.

[0059] Step 2: Add 33.88 g (0.2 mol) of phosphorus trichloride and 100 mL of anhydrous acetonitrile into a four-necked flask equipped with stirring, a thermometer, and a condenser, mix at room temperature until the system is stable, and then add the first step 70.57g (0.36mol) of the synthesized intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com