Reciprocating screw vacuum compressor

A vacuum compressor, reciprocating technology, applied in liquid variable capacity machinery, mechanical equipment, machine/engine, etc., can solve the problems of uncompact structure, high power consumption, vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

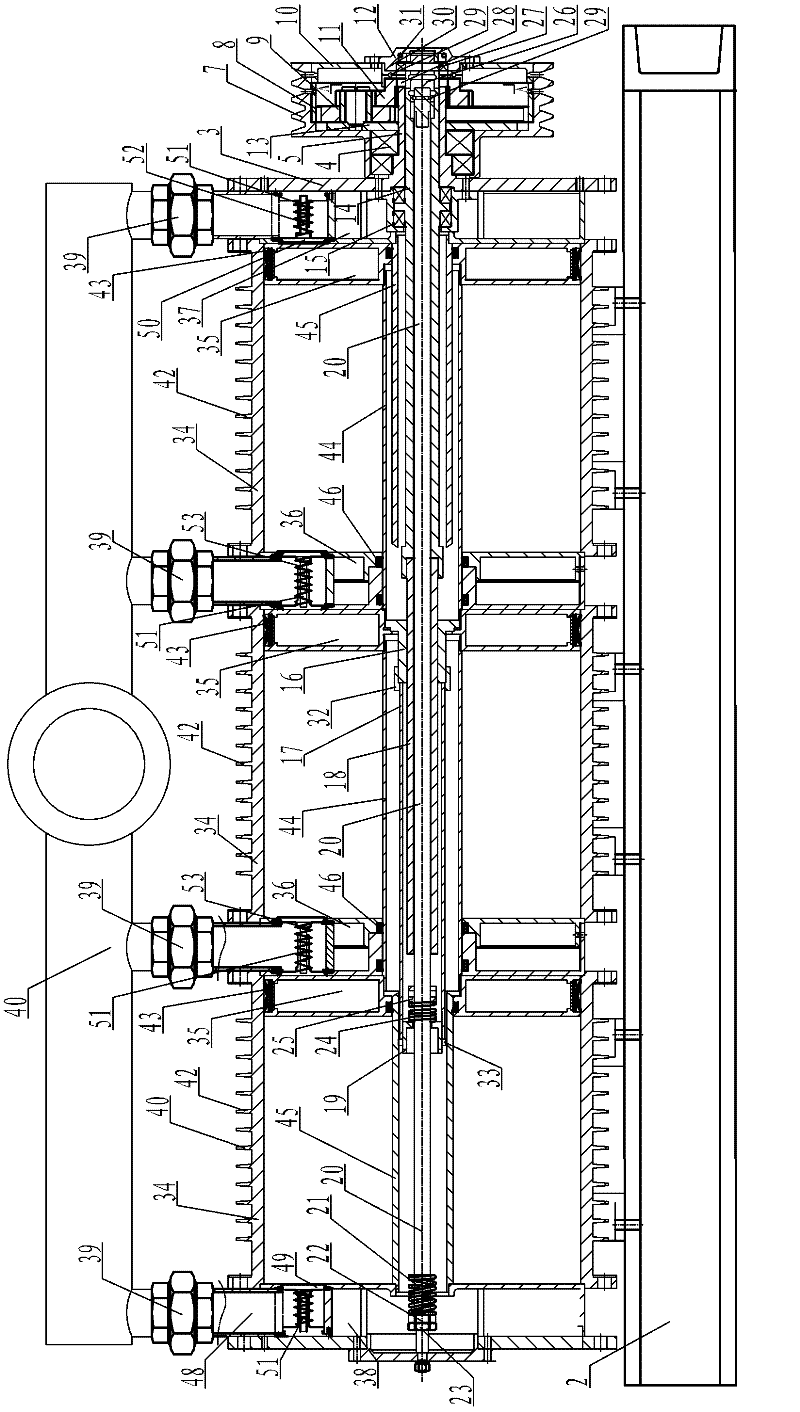

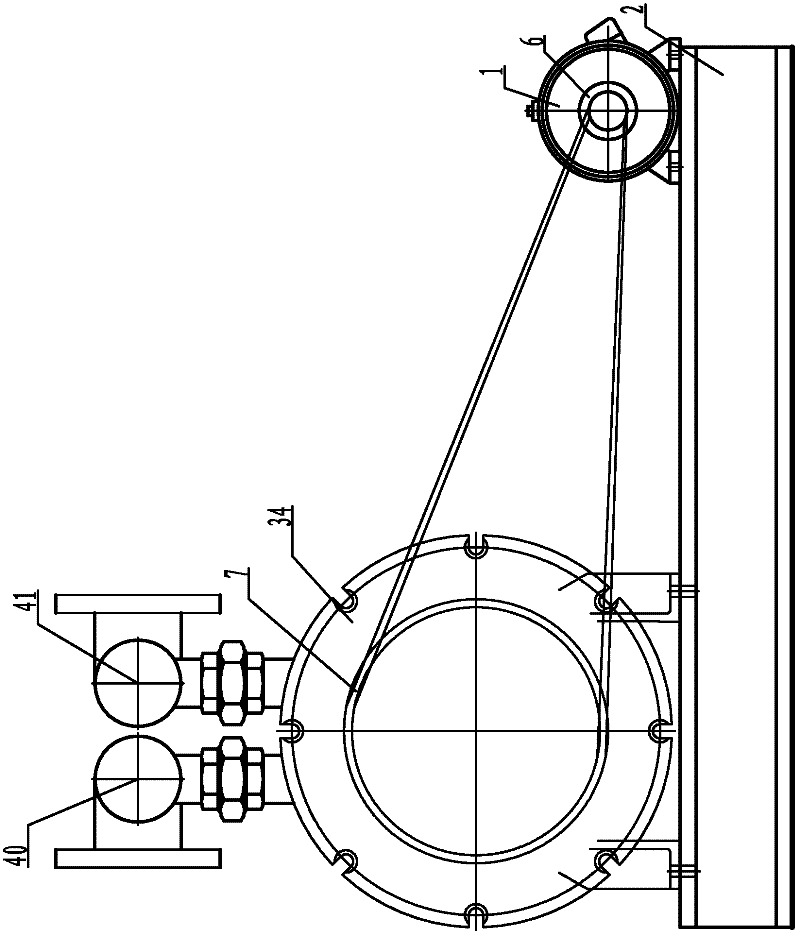

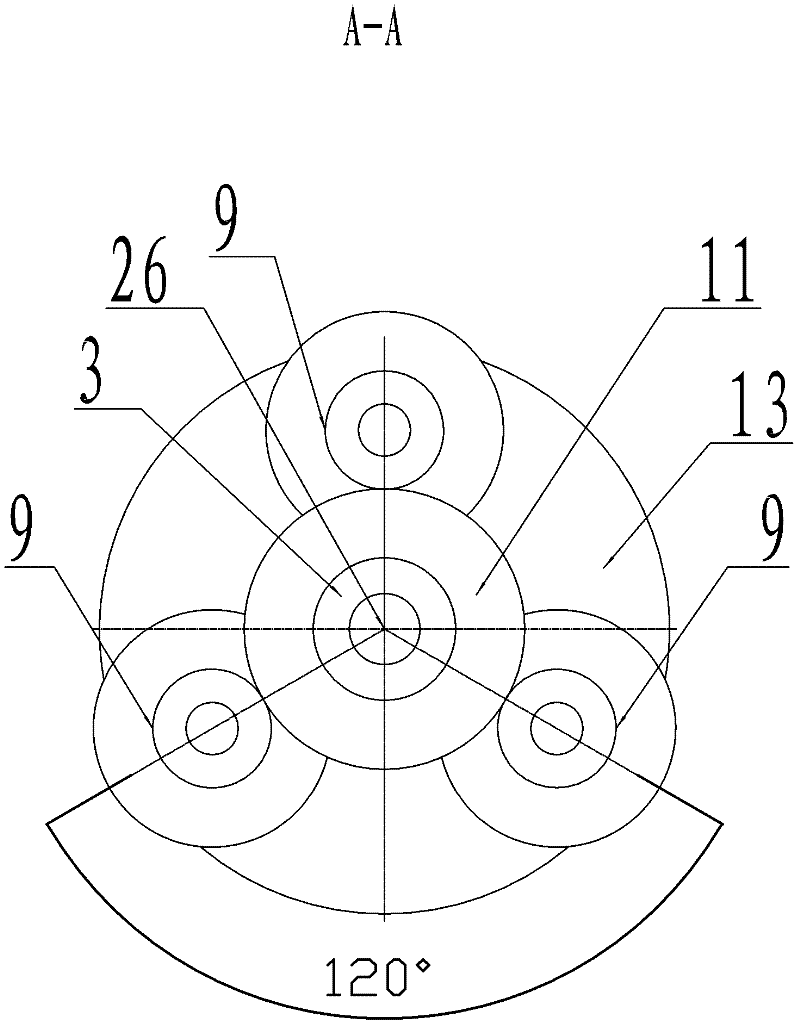

[0018] figure 1 , 2Shown in , 3 is the specific embodiment of the present invention, and it is a kind of spiral reciprocating vacuum compressor of three-piston series group type; Its structure comprises support 2, motor 1, is characterized in that: the motor in support 2 1 is equipped with a pulley type driven wheel 7 driven by a pulley type driving wheel 6, and a driven wheel support shaft, a gear drive reversing system, a hollow shaft 14, a bearing seat 15, and a hollow shaft are installed on the pulley type driven wheel 7. Lead screw 18, screw nut 16, screw nut sleeve pipe 17, connecting sleeve 32, reversing lever 20, spring mechanism and jaw type clutch form the spiral reciprocating transmission mechanism, through the changeover in the described spiral reciprocating transmission mechanism The forward and reverse reversing rotation of the rod 20 drives the piston series group in the vacuum compression device to continuously move back and forth in the cylinder body, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com