Patents

Literature

562 results about "Mechanical products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

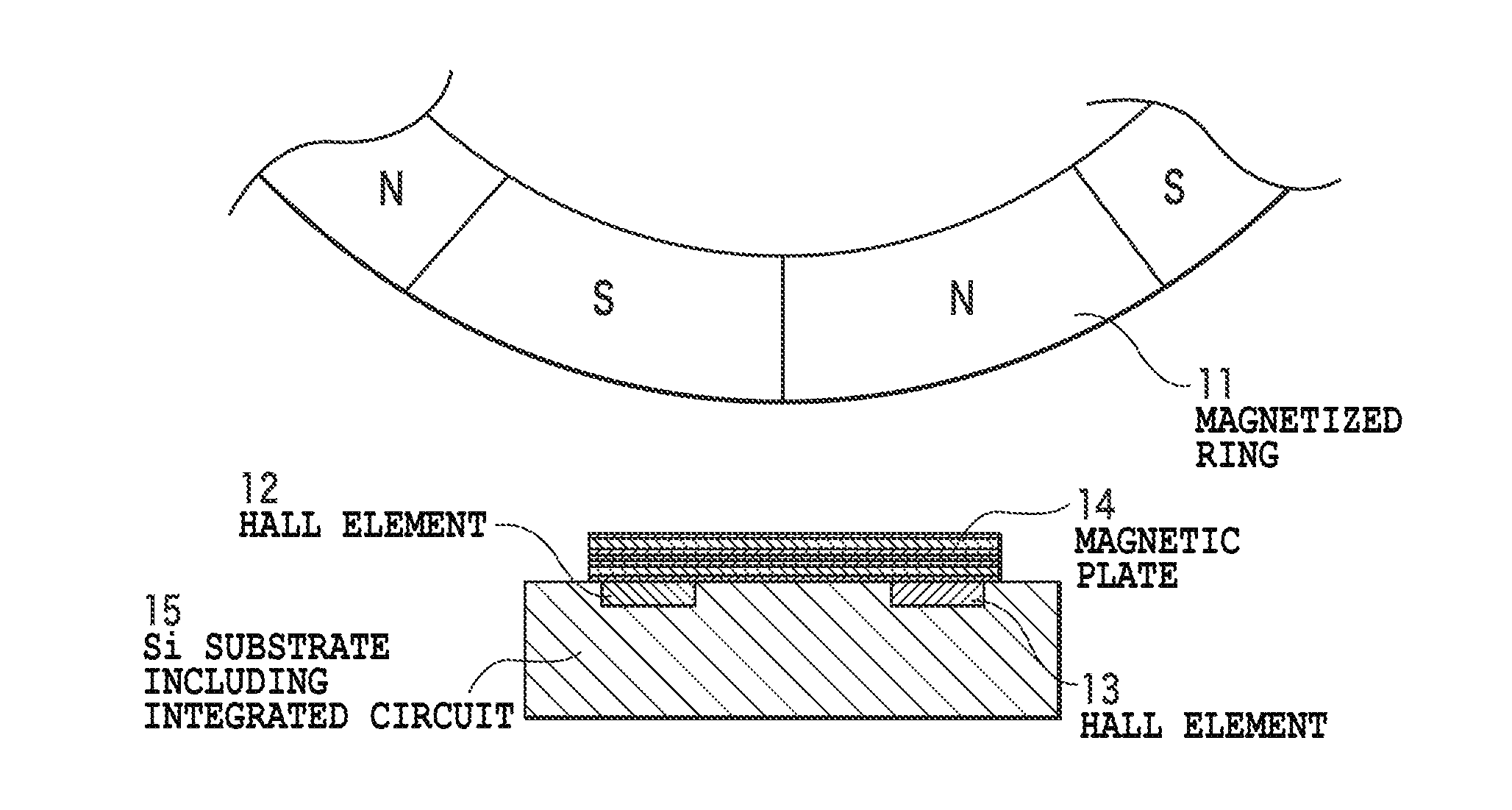

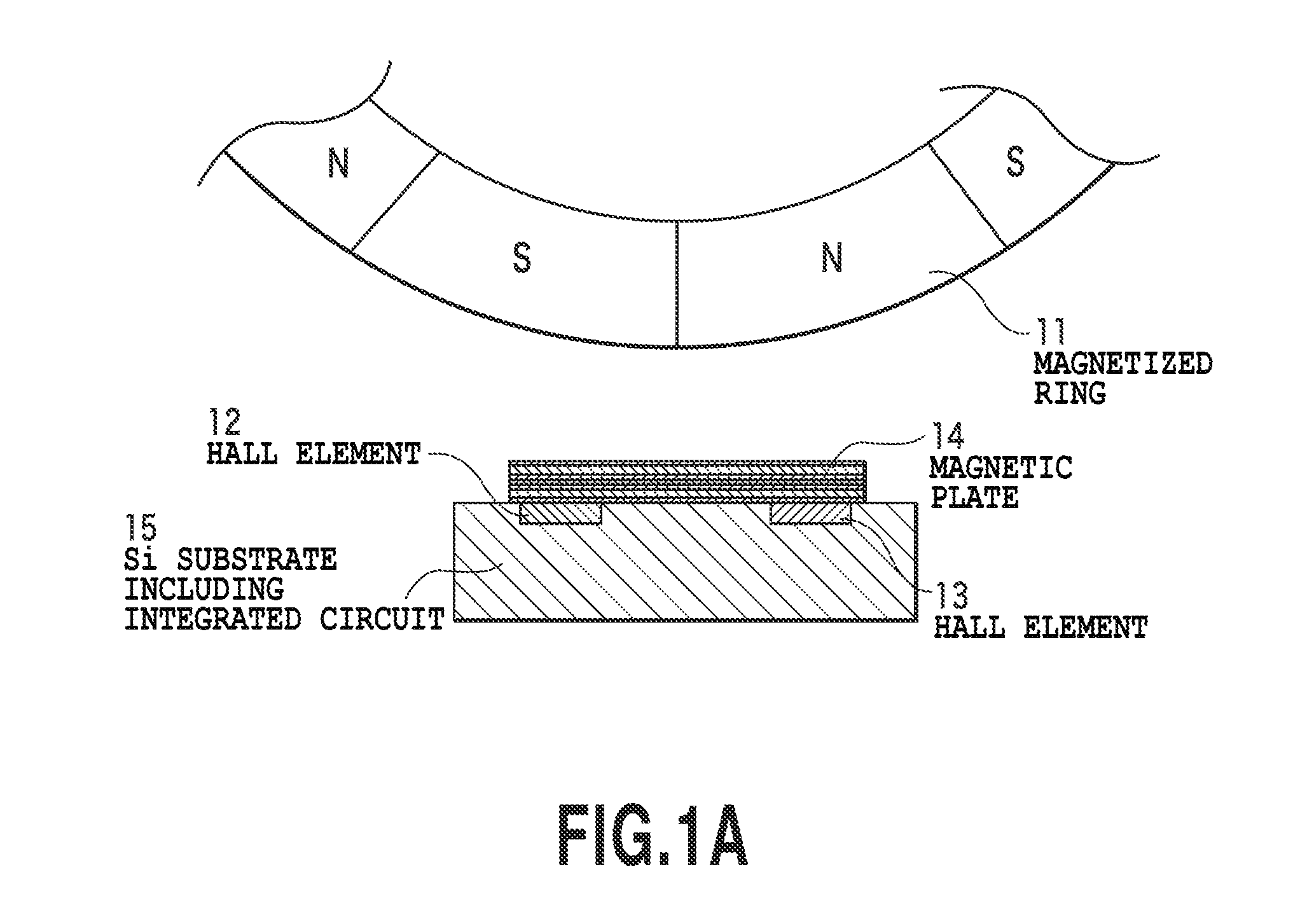

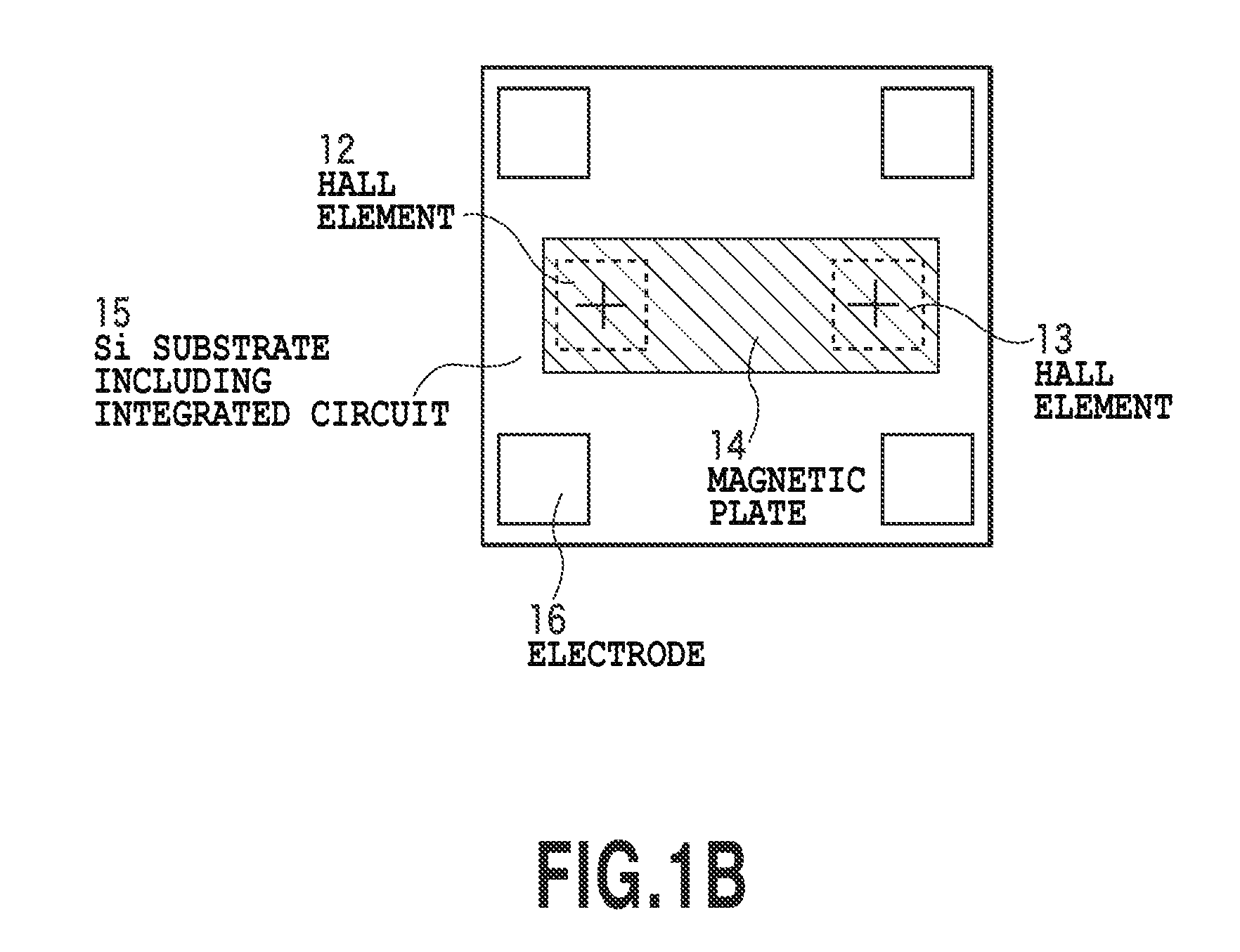

Position detecting apparatus

ActiveUS20120007589A1High sensitivitySmall sizeSolid-state devicesMagnetic field measurement using galvano-magnetic devicesLocation detectionPhase difference

The present invention provides a single component implementing highly precise pulse detection for rotational or liner position detecting apparatuses for jog dials and mechanical products. Focusing on the fact that the phase difference between the magnetic fields in circumferential and radial directions generated by a magnetized ring is precisely 90 degrees, a position detecting apparatus of the present invention includes two Hall elements placed at a distance; a protective film provided on magnetic sensitive portions of the two Hall elements to cover the magnetic sensitive portions; a thin-film magnetic plate placed on the protective film to cover the magnetic sensitive portions of the two Hall elements; and further a processing circuit calculating the sum and difference of the signals from the two Hall elements to generate signals having an accurate phase difference of 90 degrees. The position detecting apparatus can therefore detect the rotation direction and precise rotation angle.

Owner:ASAHI KASEI ELECTRONICS CO LTD

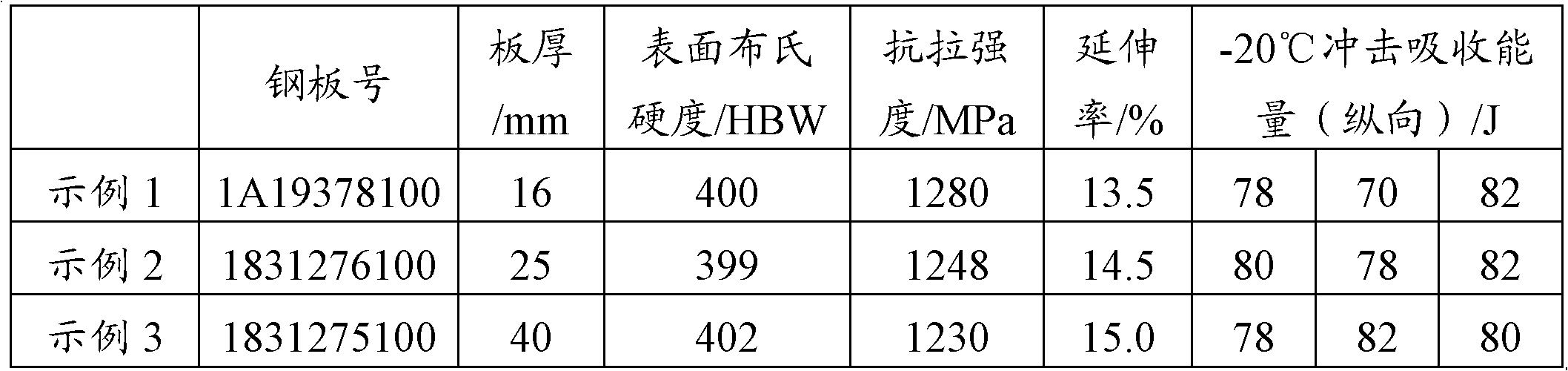

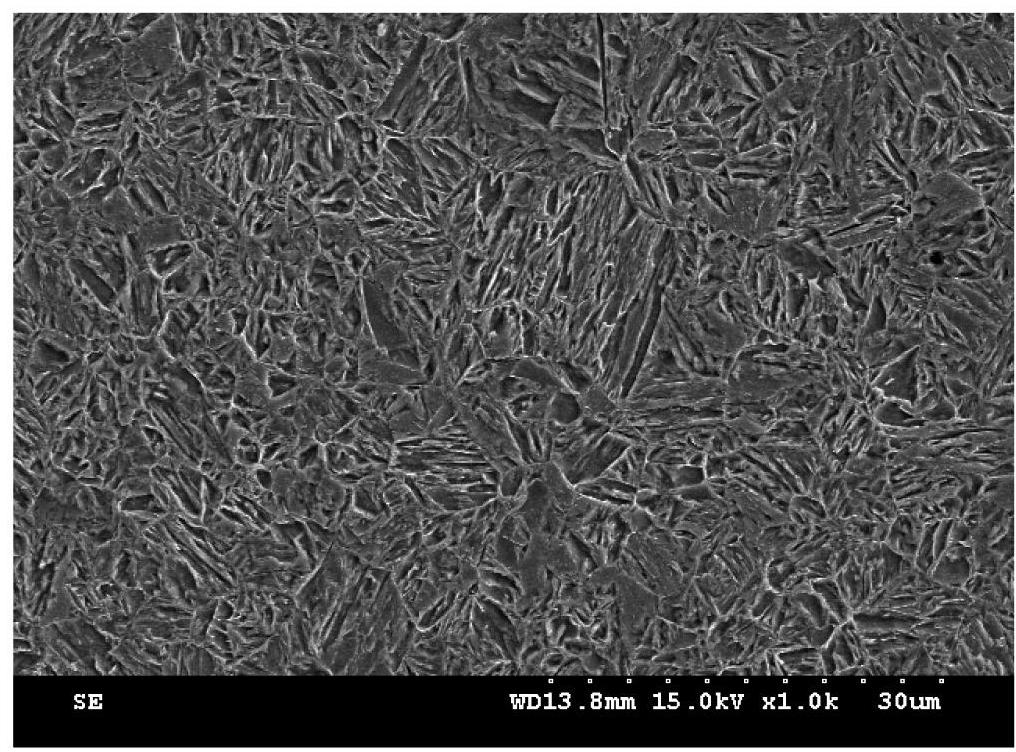

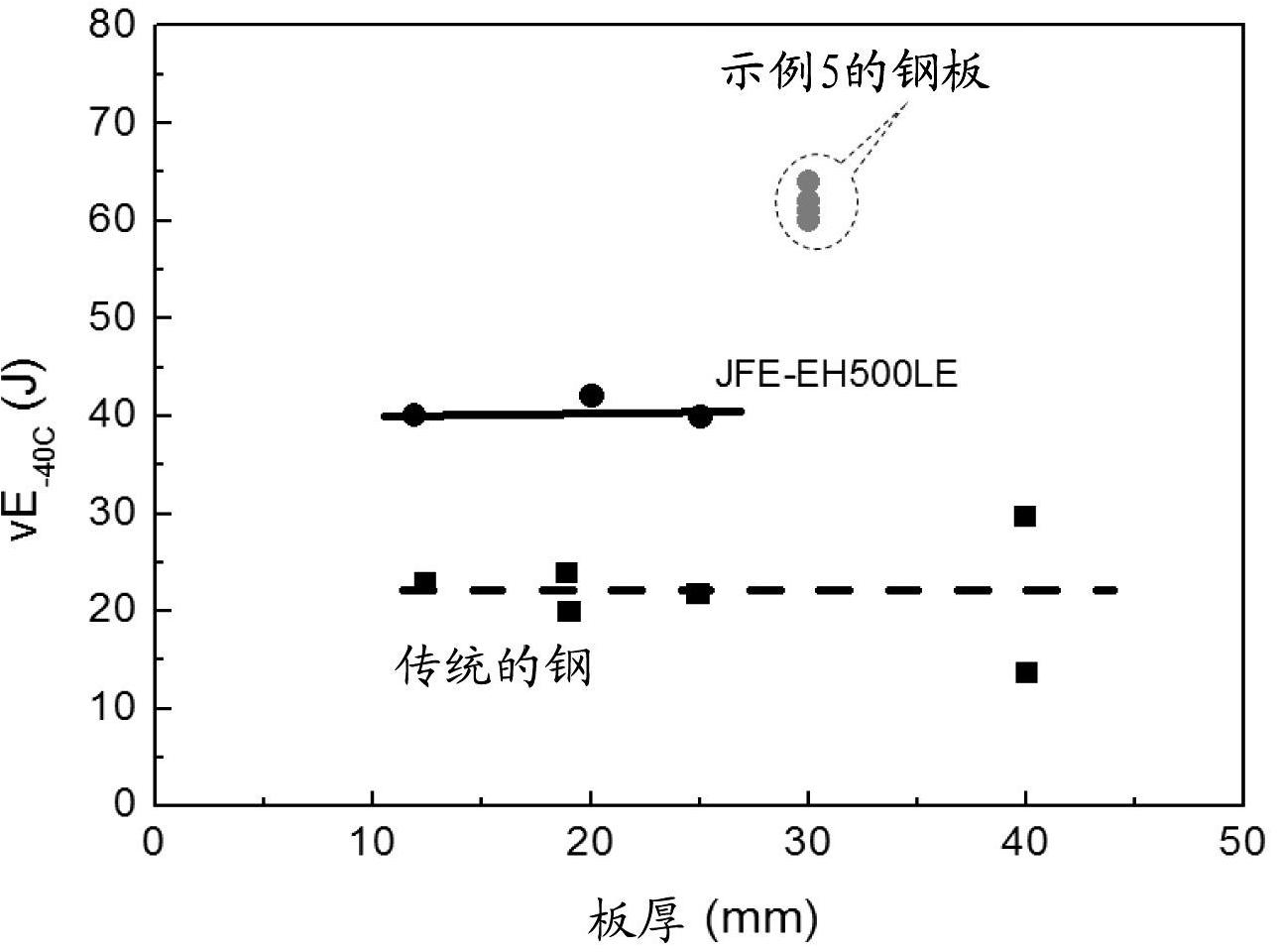

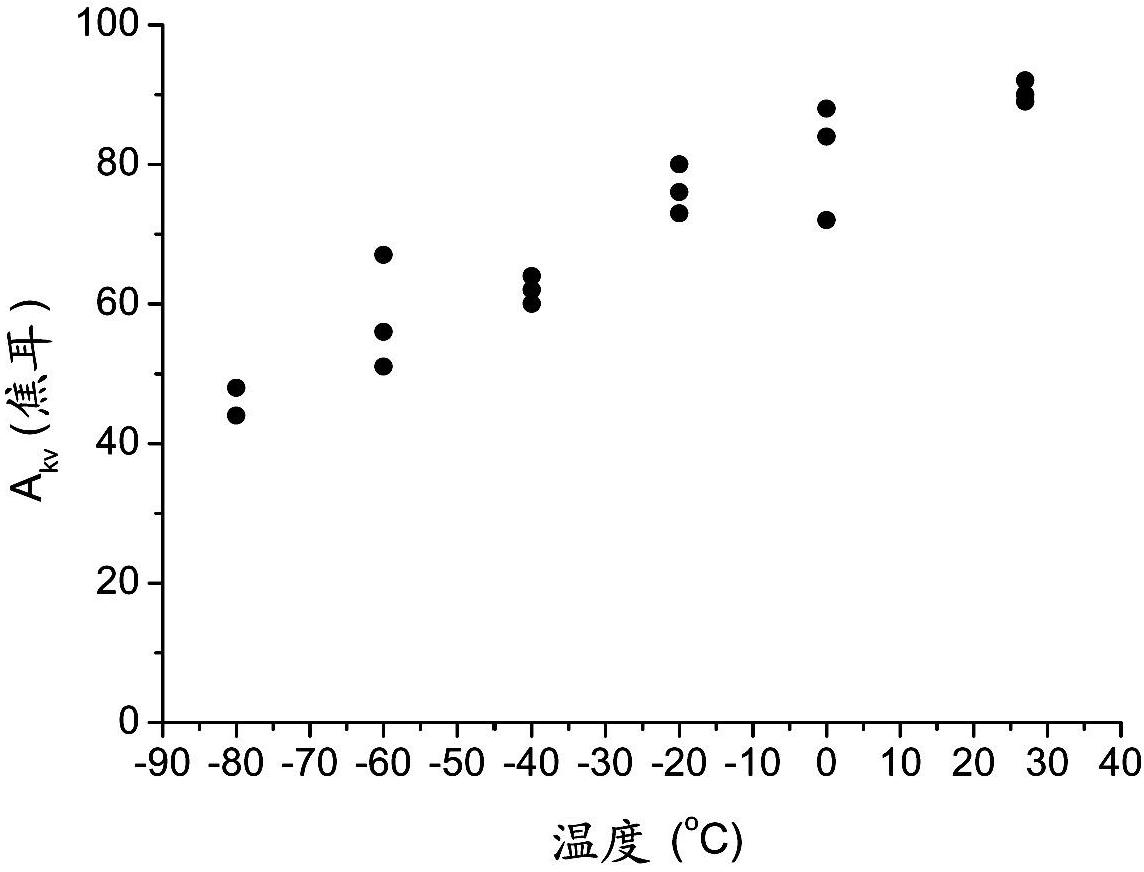

High-strength abrasion-resistant steel for engineering machinery and manufacturing method thereof

InactiveCN102618792ALow costWith superficial Brinell hardnessHigh wear resistanceMechanical products

The invention discloses high-strength abrasion-resistant steel for engineering machinery and a manufacturing method thereof. Components of the steel includes, by weight, 0.05-0.30% of C, 0.20-0.65% of Si, 1.20 to 1.60% of Mn, S<=0.010%, P<=0.020%, 0.0010-0.0040% of B, 0.30-1.00% of Cr, 0.030-0.080% of V, 0.015-0.050% of Al, [N]: 80-(200*10-6), [H]<=2*10-6, [O]<=40*10-6, and the balance Fe and inevitable impurities. The steel has surface brinell hardness no less than 395HBW, tensile strength no less than 1220 MPa, elongation after fracture no less than 13% and -20 DEG C shock absorption energy no less than 70J and is low in cost and capable of being used for manufacturing high-strength and high-abrasion resistance mechanical products in the industries of engineering, mining, building, agriculture, cement production, harbors, electric power and metallurgy. For example, the steel can be used as steel balls and lining plates of a ball grinder, bucket teeth of an excavator, rolling mortar walls, toothed plates and hammers of various crushers, track shoes of a tractor and a tank, scraper knives and relieving teeth for a bulldozer and the like.

Owner:LAIWU IRON & STEEL GRP +1

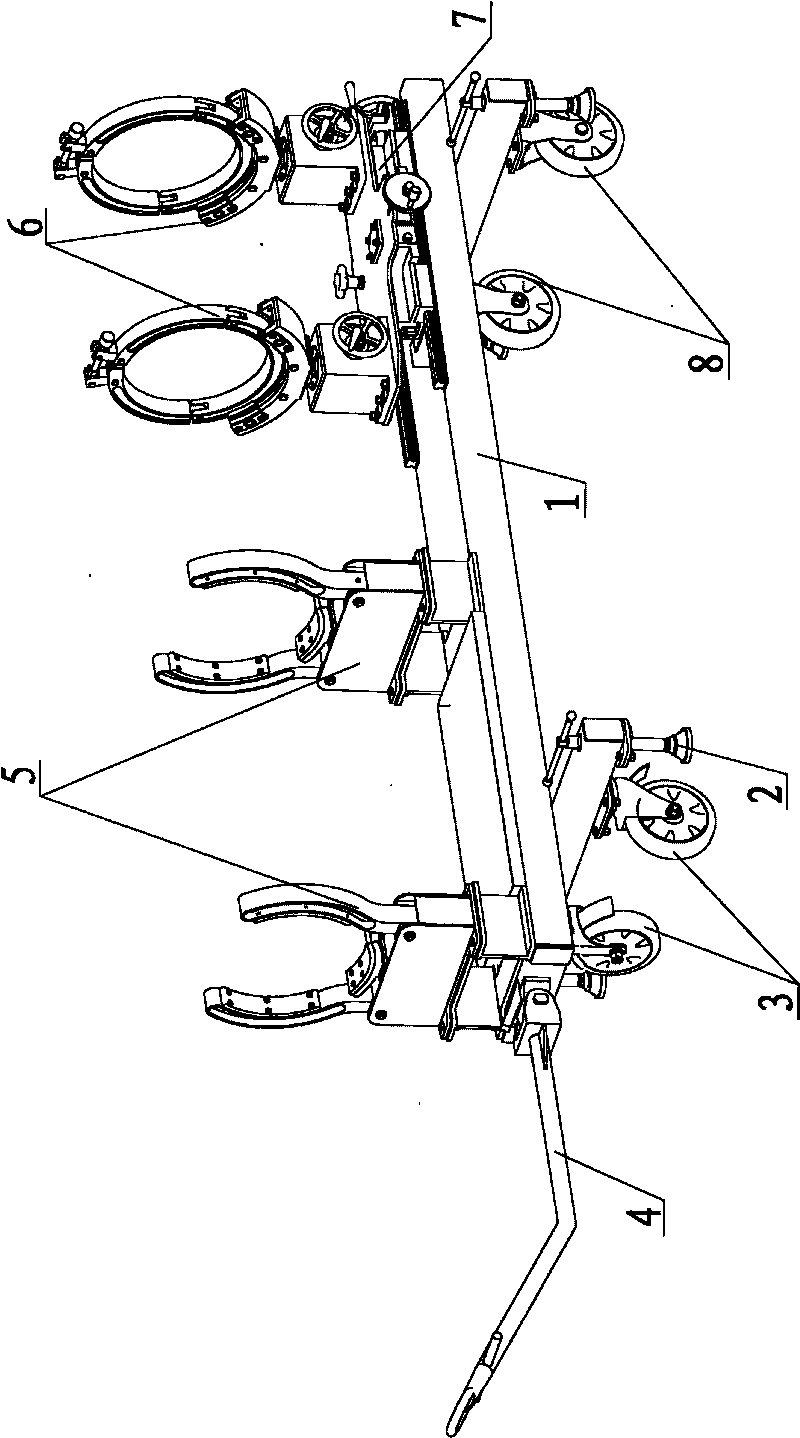

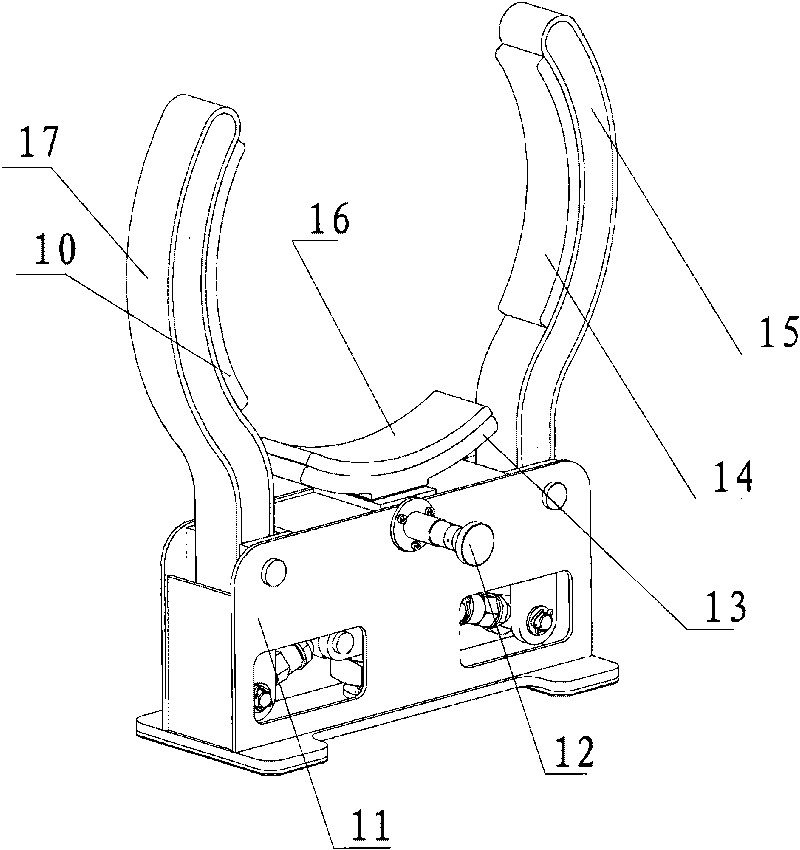

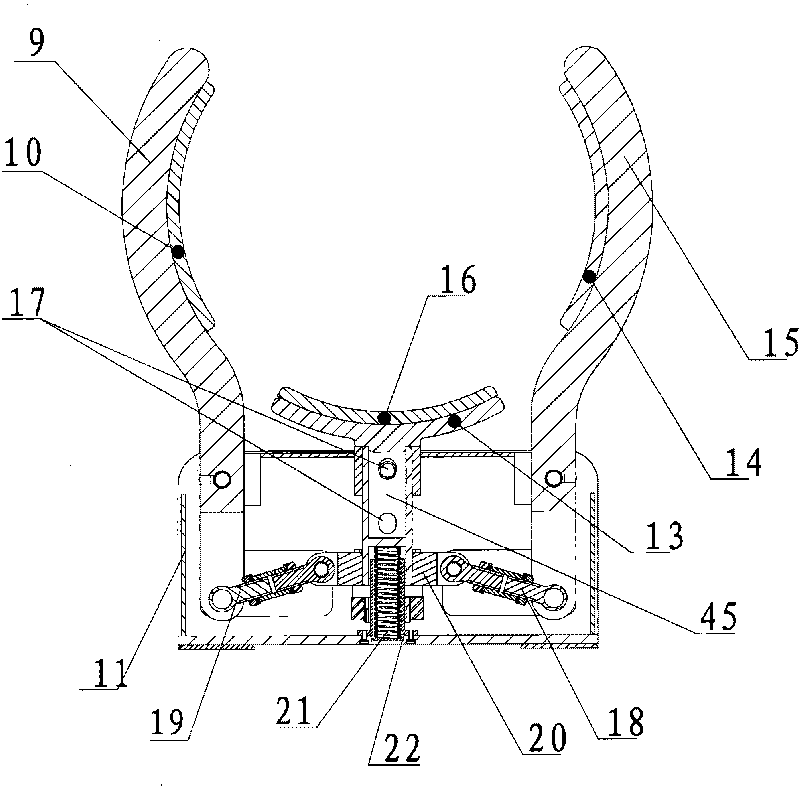

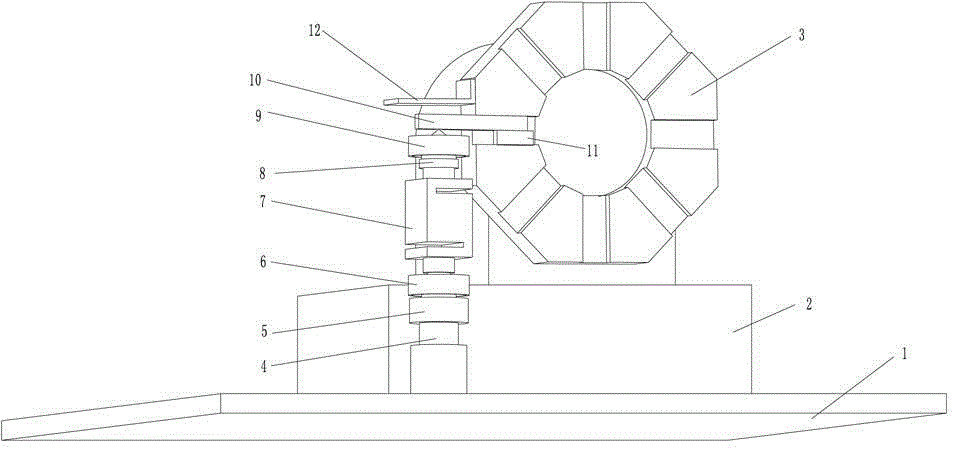

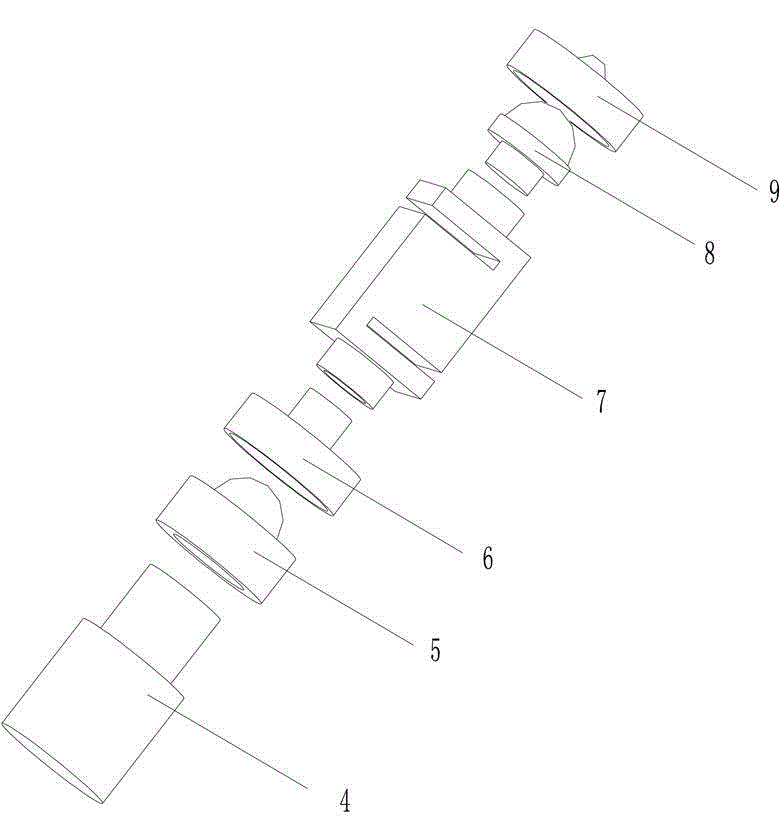

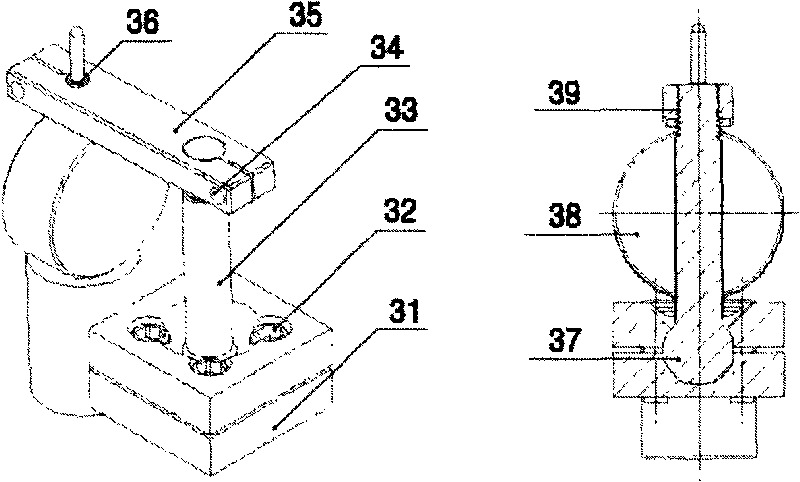

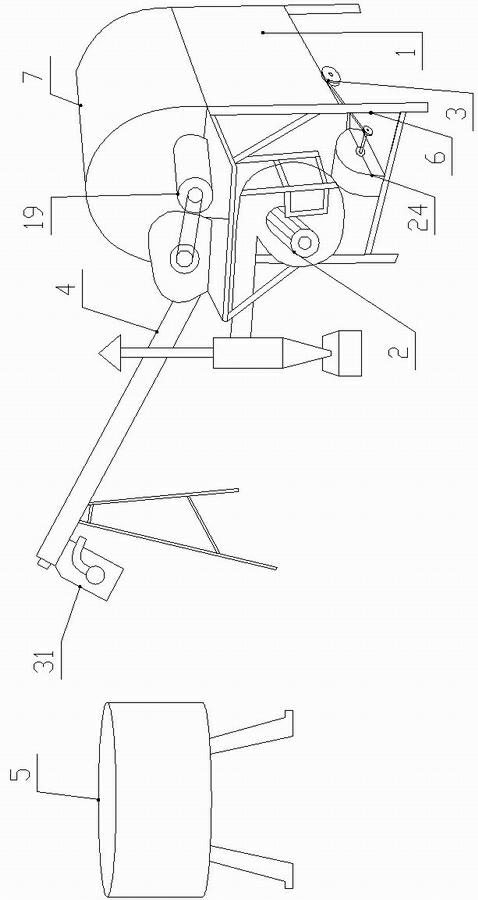

Mechanical product assembly stand

ActiveCN101712150AEasy loading and unloading of workpiecesLower the altitudeWork holdersWork benchesEngineeringMechanical products

The invention relates to a mechanical product assembly stand which comprises a stand body, wherein an adjusting platform is arranged at one end of the upper part of the stand body; a roll clamping device is arranged on the adjusting platform; a self-enclasping device is arranged at the other end of the stand body; the self enclasping device comprises an installing shell; a first cambered enclasping claw and a second cambered enclasping claw which are used for enclasping a workpiece are oppositely articulated at two sides of the installing shell; a supporting rod for supporting the workpiece is arranged vertically in a sliding way between the two cambered enclasping claws on the installing shell; the first cambered enclasping claw and the second cambered enclasping claw are respectively connected with the supporting rod through articulated connecting rods in a transmission way; and the supporting rod and the cambered enclasping claws form a plane connecting rod structure which converts the vertical movement of the supporting rod into the opposite opening and closing swinging movement of the cambered enclasping claws through the articulated connecting rods. In the invention, because the first cambered enclasping claw and the second cambered enclasping claw are respectively connected with the supporting rod through the articulated connecting rods in a transmission way, after the workpiece is put on the supporting rod, the supporting rod moves downwards under the action of gravity and acts on the two cambered enclasping claws through the connecting rods, and the two cambered enclasping claws enclasp the workpiece.

Owner:凯迈(洛阳)测控有限公司

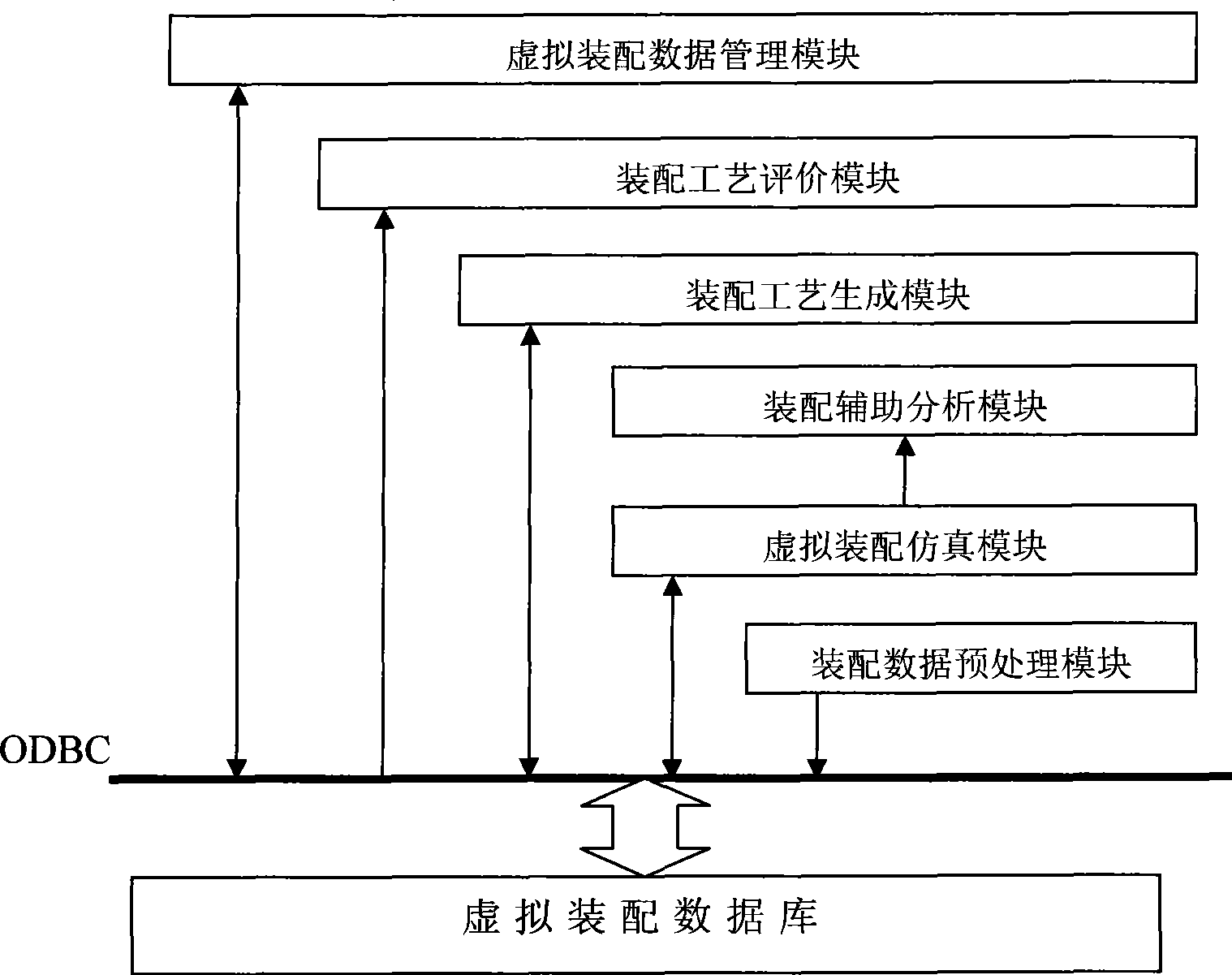

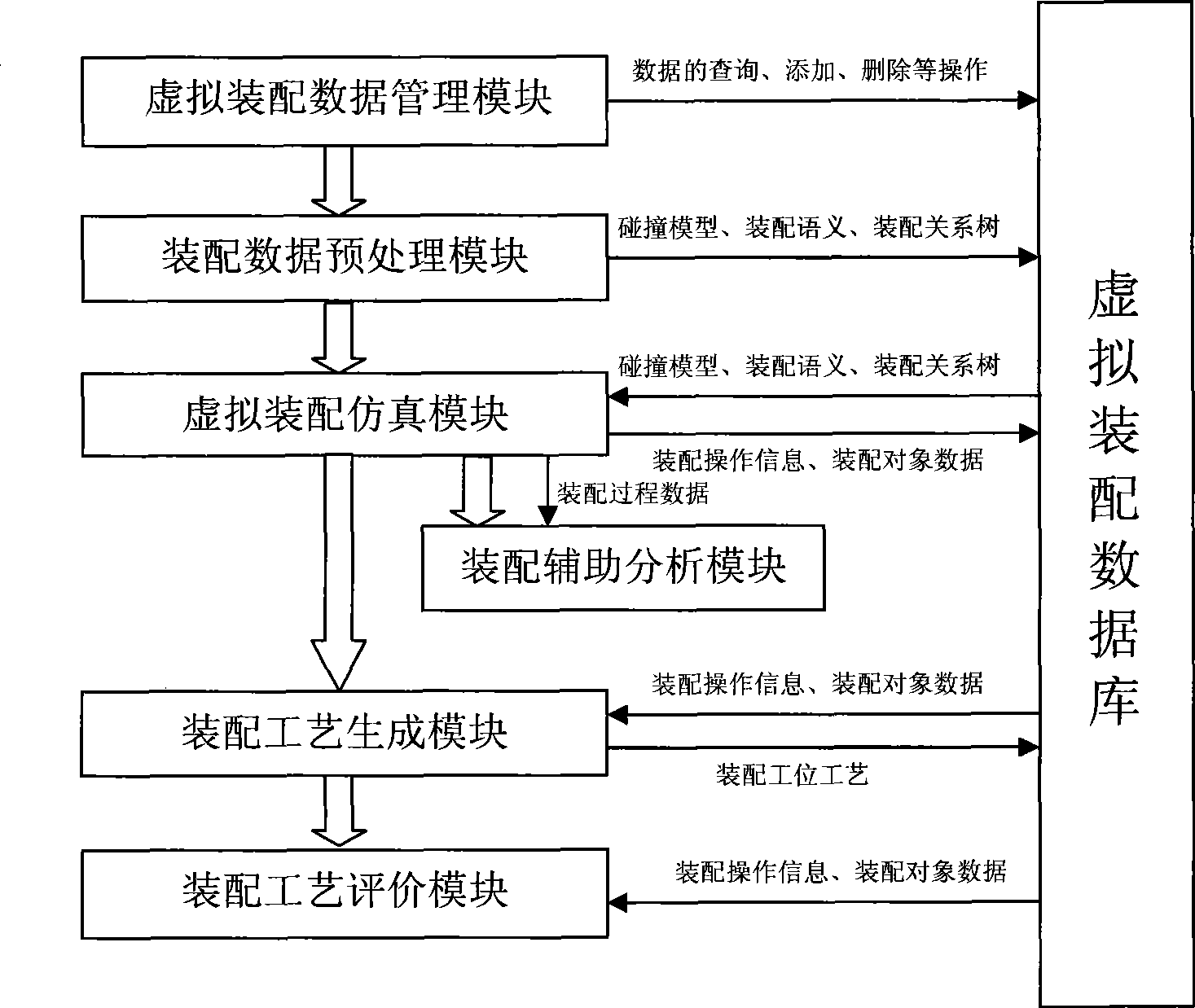

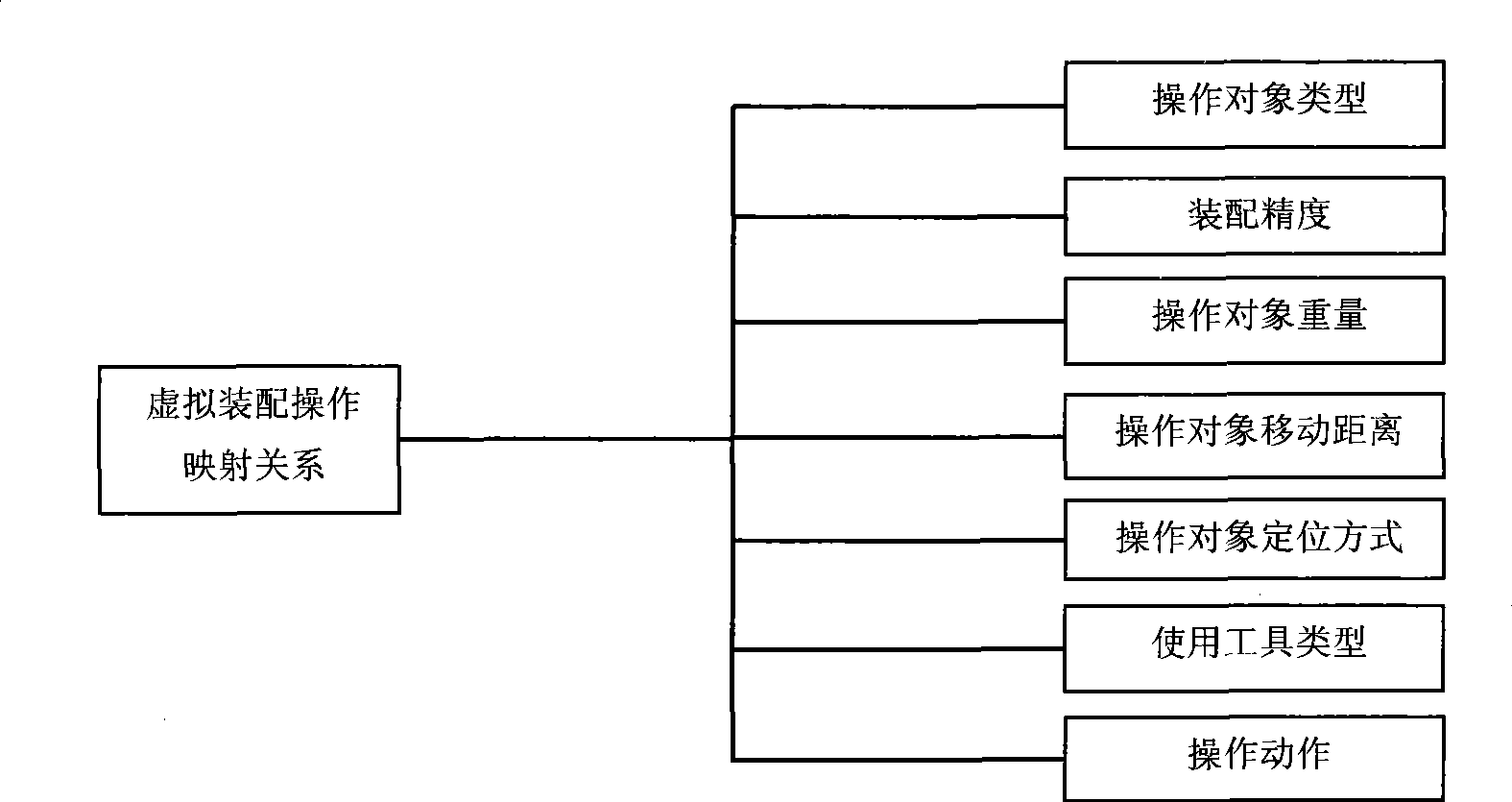

Human-machine interactive assembly process planning system

InactiveCN101414179AShorten the design cycleSave the cost of sweet-scented osmanthusTotal factory controlProgramme total factory controlAnalysis dataCollision detection

The invention discloses a human-machine interactive assembly process planning system of the manufacturing field. In the system, an assembly data preprocessing module establishes a corresponding collision detection model corresponding to a CAD geometric model of each part, designates an assembly constraint element, and establishes an assembly relation tree; a virtual assembly simulation module extracts data required by the virtual assembly to establish a virtual assembly simulation scene; an assembly auxiliary analysis module achieves dynamic playback of an assembly procedure, statically displays an assembly track of the part, and computes a distance between the models; an assembly process generation module acquires assembly procedure data from a virtual assembly database, generates an assembly process by reference to entries of a standard assembly process in the database, and divides service positions; an assembly process evaluation module reads an assembly operation action and operation object data, computes the efficiency of the assembly procedure to obtain ergonomic analysis data; and a virtual assembly data management module executes a data maintenance task. The assembly process planning system achieves dynamic assembly and process planning functions of mechanical products in a virtual environment.

Owner:SHANGHAI JIAO TONG UNIV

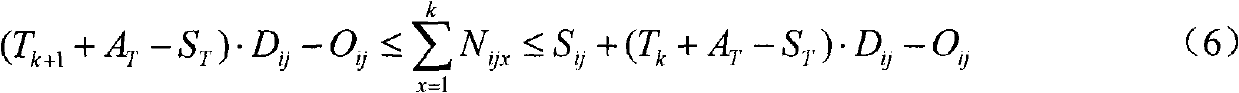

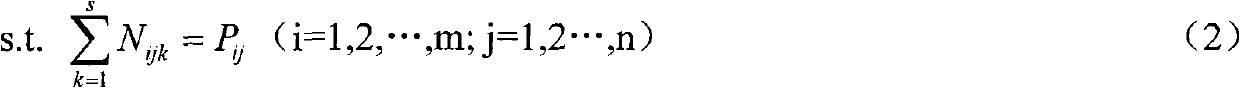

Real-time material distribution method in mechanical product assembling process

InactiveCN101950387AEasy to manage on siteNo stack pressureLogisticsMaterial consumptionMaterial distribution

The invention discloses a real-time material distribution method in a mechanical product assembling process, which is characterized in that: according to the production plan on the same day, calculating to obtain all required parts; by considering the storage capability, the existing amount, the material lead time and the product cycle time of each part on each station, calculating a material distribution scheme; distributing the parts in time on small batches according to the obtained distribution scheme; simultaneously, tracking the on-site production situation by an MES system in real time; recording manufacturing product situation and the material consumption situation of each station; and timely feeding back production plan information and station inventory information. The method of the invention can realize on-time material distribution, feeds back and adjusts the distribution scheme in time according to real-time working condition, can improve production efficiency and lowers product cost.

Owner:HEFEI UNIV OF TECH

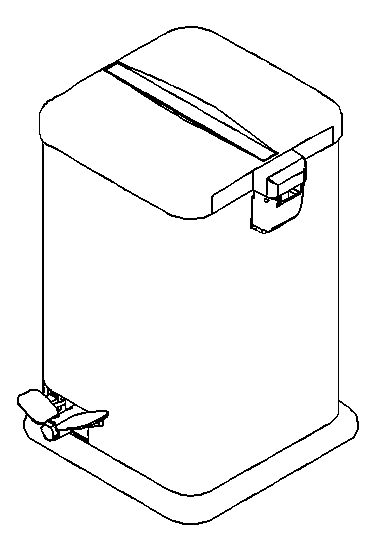

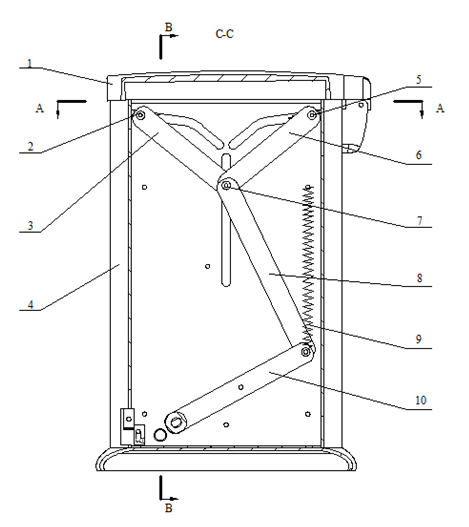

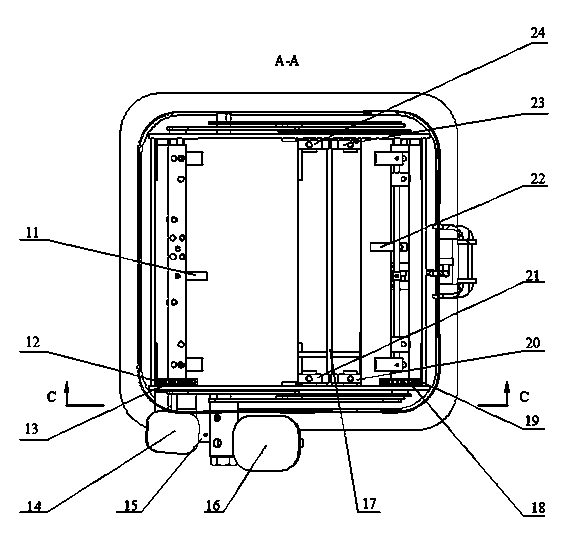

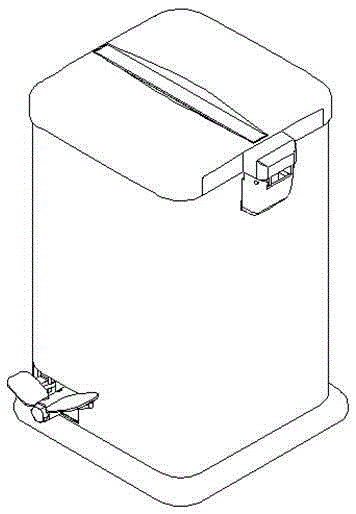

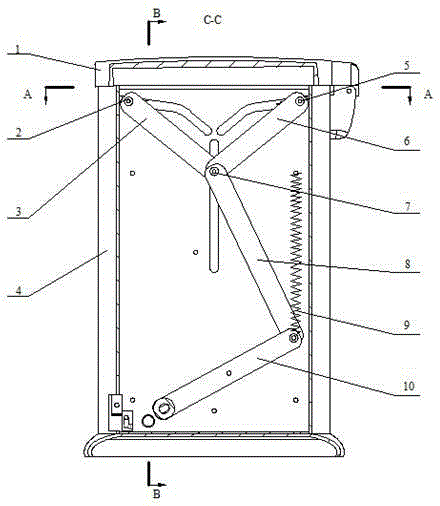

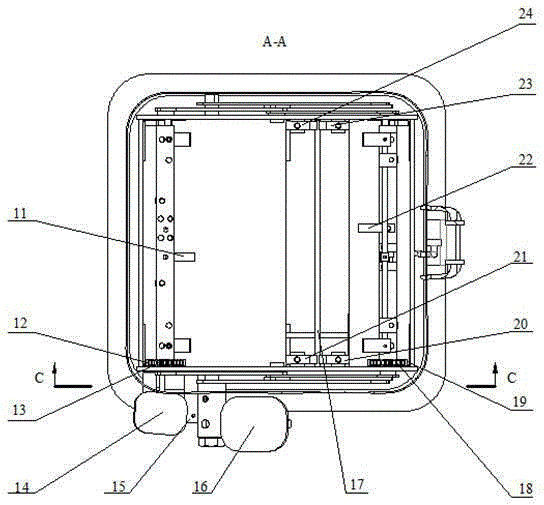

Convenient bagging garbage can and using method thereof

The invention belongs to the technical field of mechanical product design, and relates to a convenient bagging garbage can and a using method thereof, in particular to a convenient bagging garbage can widely applicable to public places and outdoor or household use. The convenient bagging garbage can is characterized in that a process of convenient bagging of the garbage can is realized mainly through a connecting rod combination mechanism, a spring contact block mechanism, a gear rack and the like, and a series of problems of insanitation in bag taking, trouble in bag tearing, difficulty in bagging and the like in the garbage can bagging process are solved. Compared with an existing automatic bagging garbage can, the convenient bagging garbage can is simpler and more ingenious in used mechanisms, high in space utilization rate, more convenient in bagging process, high in bagging success rate and widely applicable to public places and outdoor or household use.

Owner:陕西皇城大唐维修安装有限公司

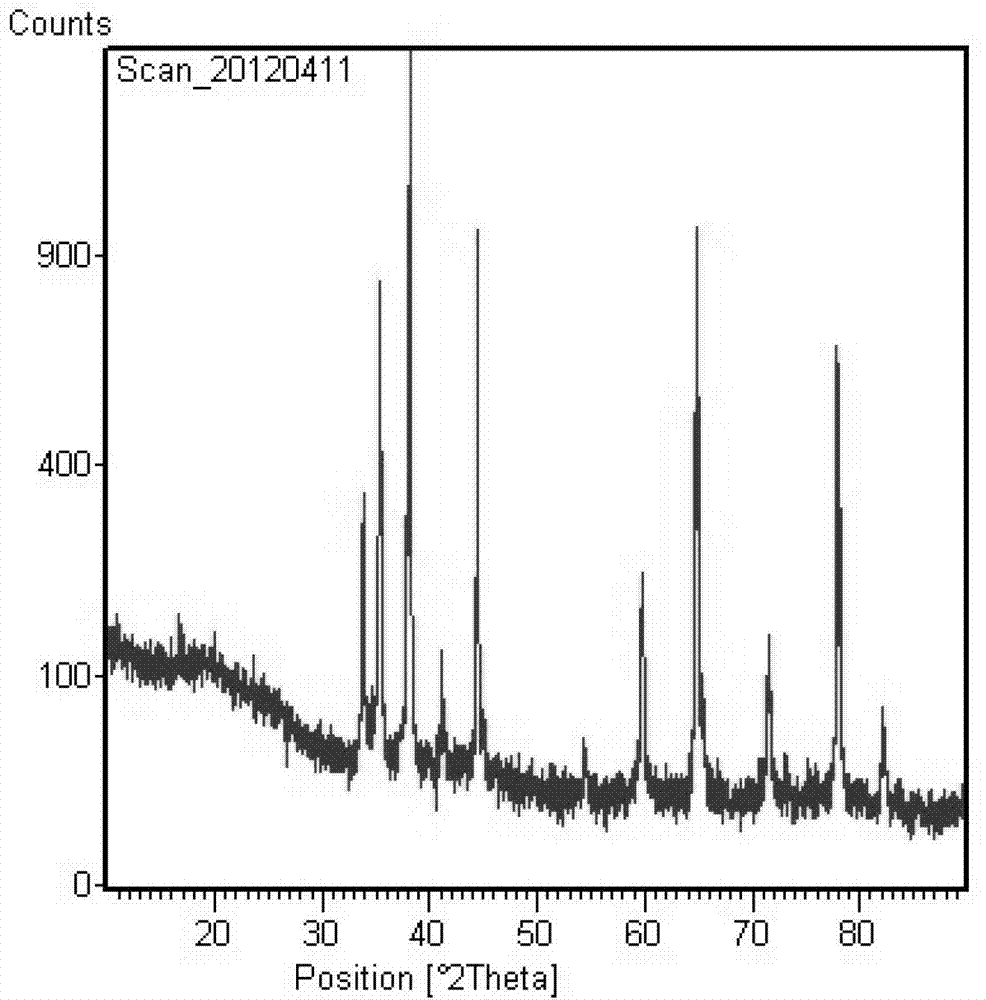

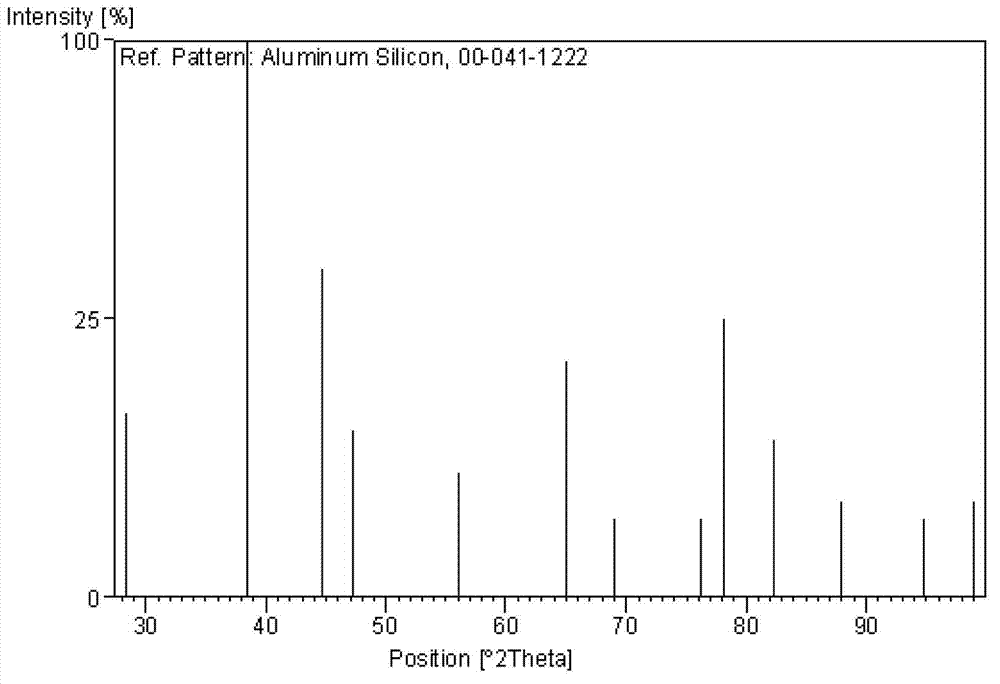

Low-alloy wear-resistant steel and manufacturing method thereof

The invention discloses low-alloy wear-resistant steel and a manufacturing method thereof. The low-alloy wear-resistant steel comprises the following components in percentage by weight: 0.13-0.50 percent of C, 0.10-0.50 percent of Si, 0.30-1.50 percent of Mn, 0.125-0.40 percent of V, 0.05-0.30 percent of Mo, less than 0.020 percent of P, less than 0.010 percent of S and the balance of Fe and inevitable impurities. The low-alloy wear-resistant steel has the advantages of low cost, series strength, excellent low-temperature toughness and low welding carbon equivalent weight, and can be widely applied to mechanical products with high requirements on strength and wear resistance in engineering, ore mining, buildings, cement production, ports, electric power, metallurgy and the like.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

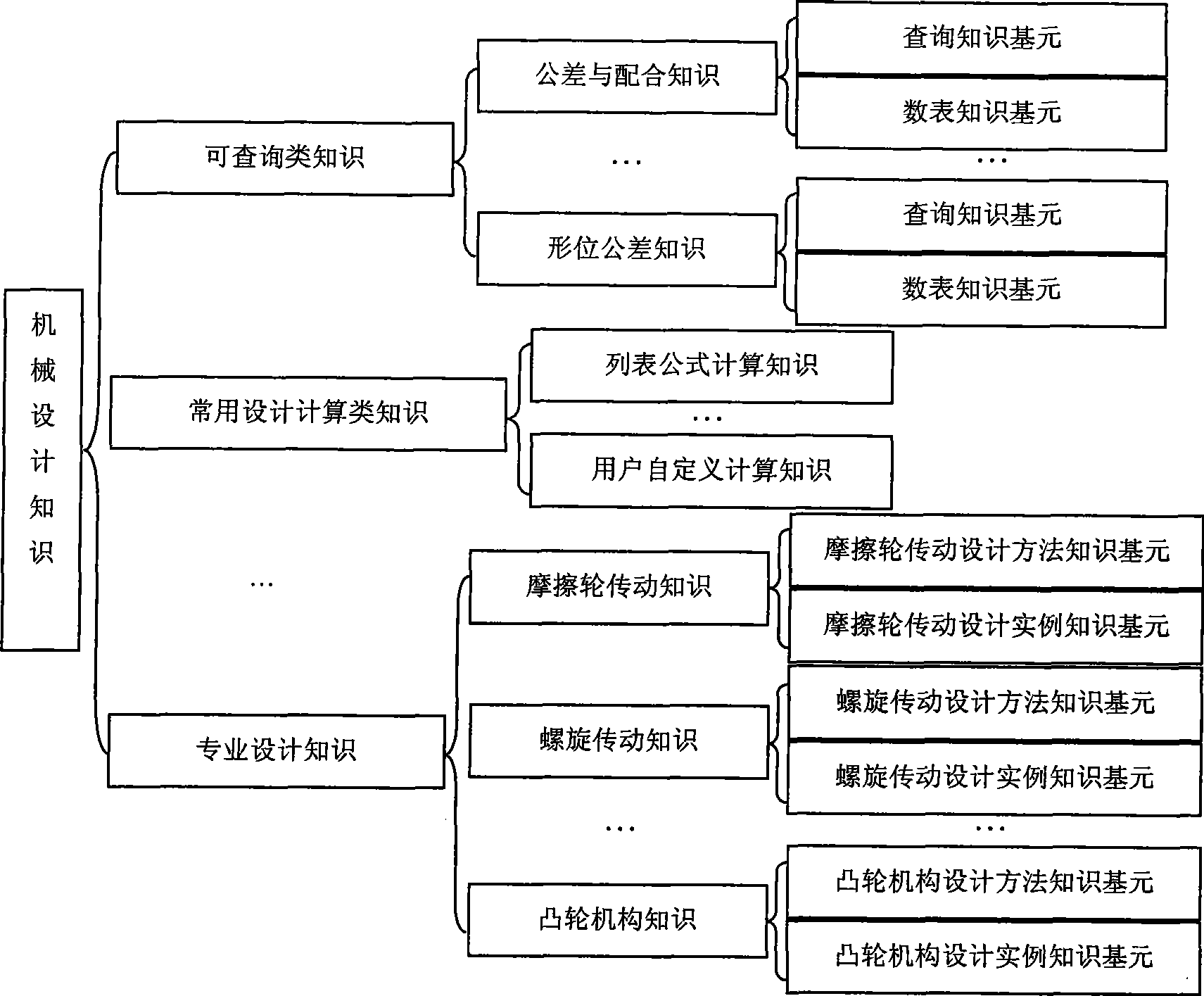

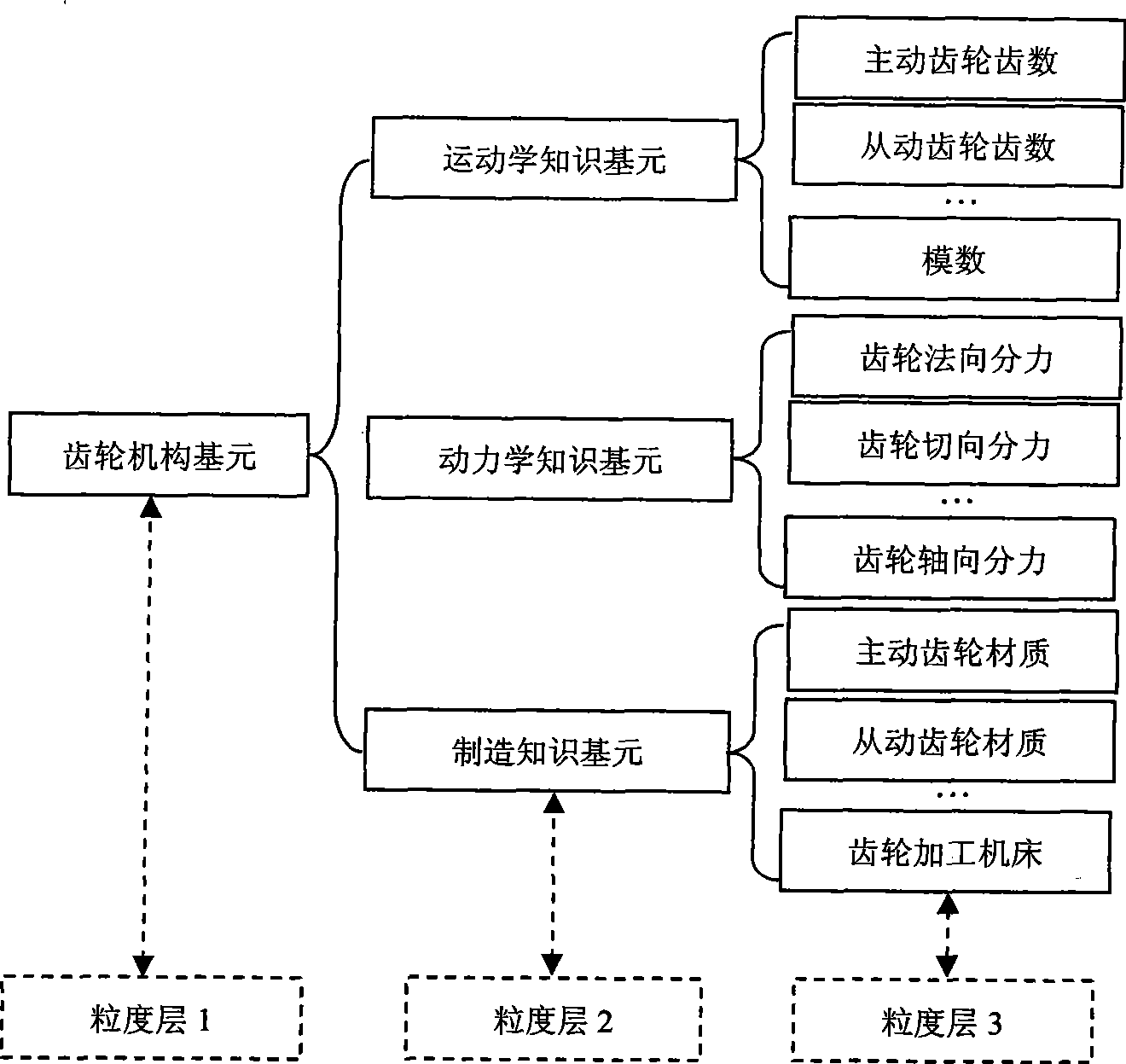

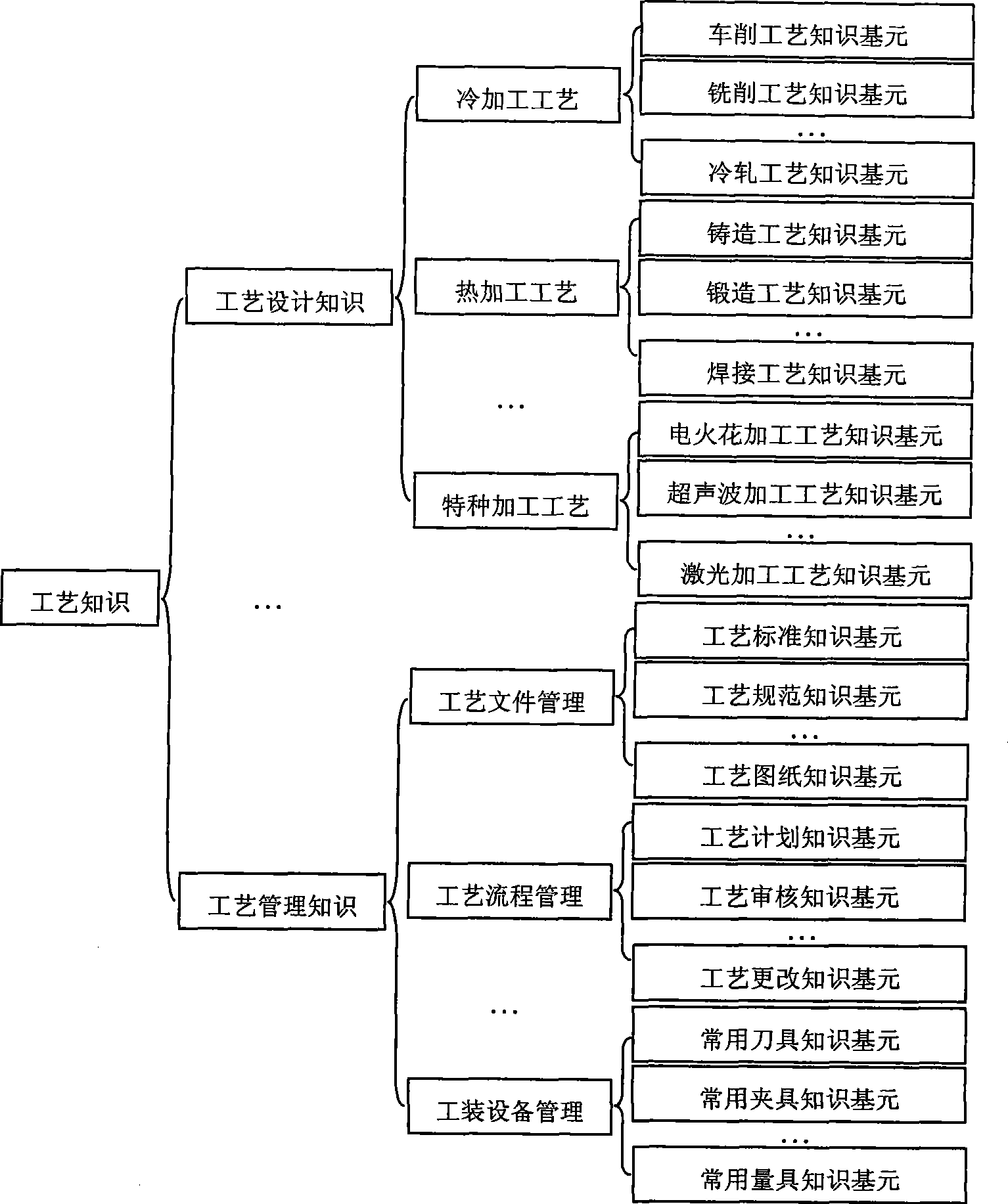

Non-standard knowledge acquisition method used for constructing mechanical product design knowledge base

InactiveCN101477521AEliminate transmissionEliminate DiffusionSpecial data processing applicationsInformation processingInformatization

The invention discloses a method for obtaining irregular knowledge used for constructing a mechanical product design knowledge base. Aiming at the requirements for knowledge processing and knowledge base system development in the mechanical product design field, the invention defines the irregular knowledge, discloses a computation module for dividing irregular knowledge granularity by adopting granularity calculation principle, studies mechanical product design irregular knowledge base structure system and basic format, discloses an irregular knowledge base display method based on metadata, and invents a method for obtaining semantic matching, irregular knowledge base in serial data source, and multi-mode irregular knowledge based on irregular example knowledge obtaining of cluster analysis; and on the basis, designs a system frame and a prototype software system for mechanical product design knowledge base system construction and application. The invention can be used to solve the technical problem of treating irregular knowledge in an information processing system such as CAD (computer-aided design), CAM (computer-aided manufacturing), CAE (computer-aided engineering) or PDM (products data management) in manufacturing industry, so as to satisfy the requirements for the deepening development of the manufacturing industry information project technology.

Owner:SICHUAN UNIV

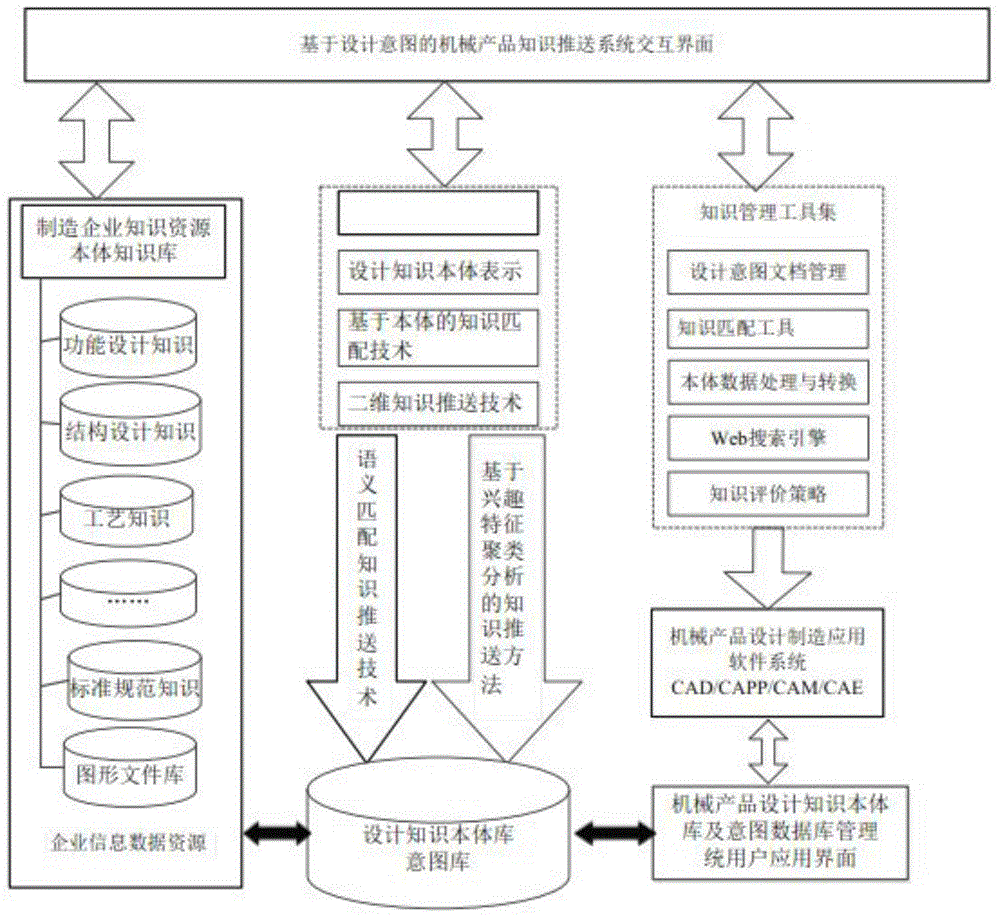

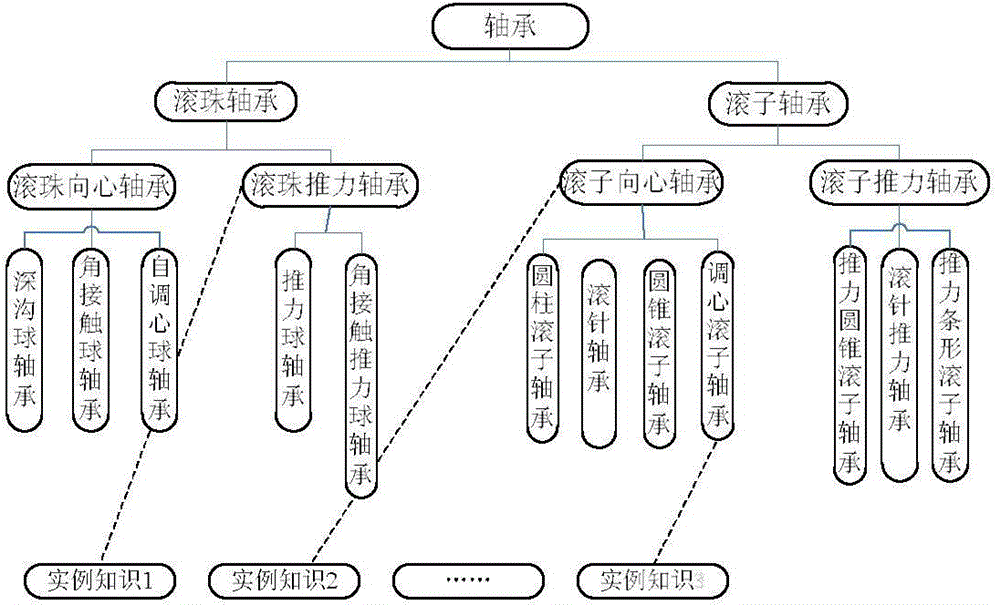

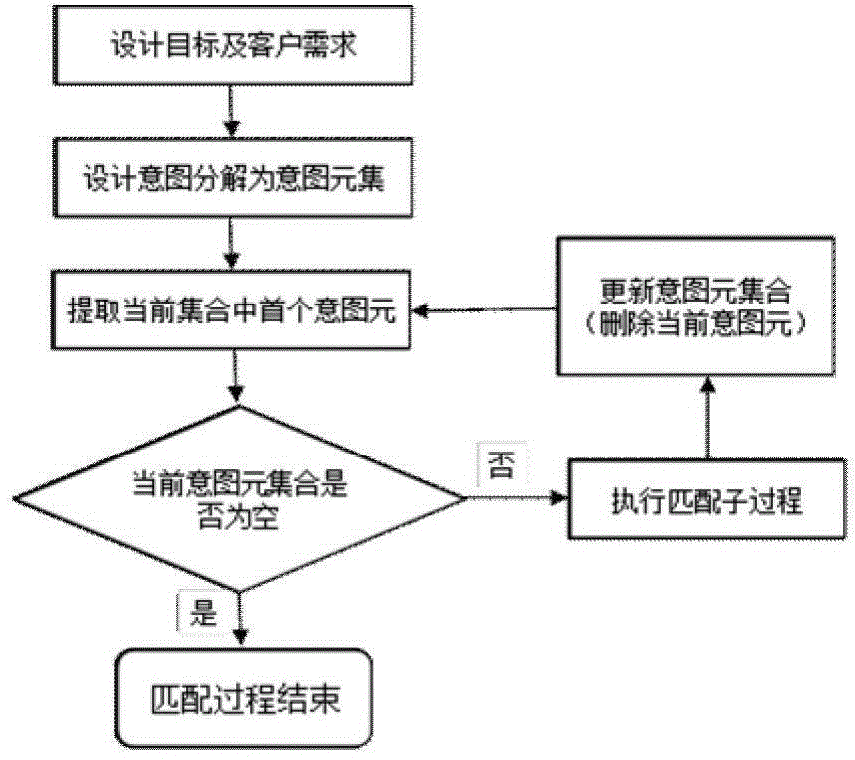

Mechanical product design two-dimensional knowledge pushing method based on design intent

ActiveCN104899242ARich knowledge push resultsAdapt to the needs of deepening developmentSpecial data processing applicationsInformatizationConcept Attribute

The present invention discloses a mechanical product design two-dimensional knowledge pushing method based on design intents. The mechanical product design two-dimensional knowledge pushing method mainly comprises: establishing a mechanical product design intent database, establishing a design intent acquisition and decomposition method, constructing a design intent attribute table by a rough set theory and performing reduction to obtain the simplest design intent set; establishing a mechanical product design knowledge ontology database; and calculating similarity degrees between intent elements and a compared knowledge ontology in a sequential traversing manner by using an improved similarity degree matching algorithm based on a knowledge ontology concept semantic distance and a concept attribute, sequentially carrying out matching on each intent element, of which the similarity degree is greater than a threshold value, in an intent element set from large to small according to the similarity degrees until completing all the matching, and completing matching of the knowledge ontologies by utilizing a text semantic similarity degree calculating method. The mechanical product design two-dimensional knowledge pushing method can solve the problem of low knowledge intelligent degree of knowledge pushing in the mechanical product design, can improve efficiency of mechanical product design and is suitable for the requirement of the manufacturing information engineering technology for deepening development.

Owner:SICHUAN UNIV

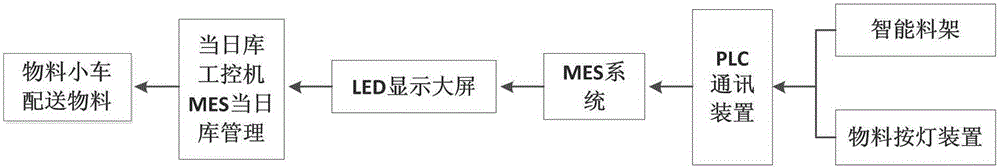

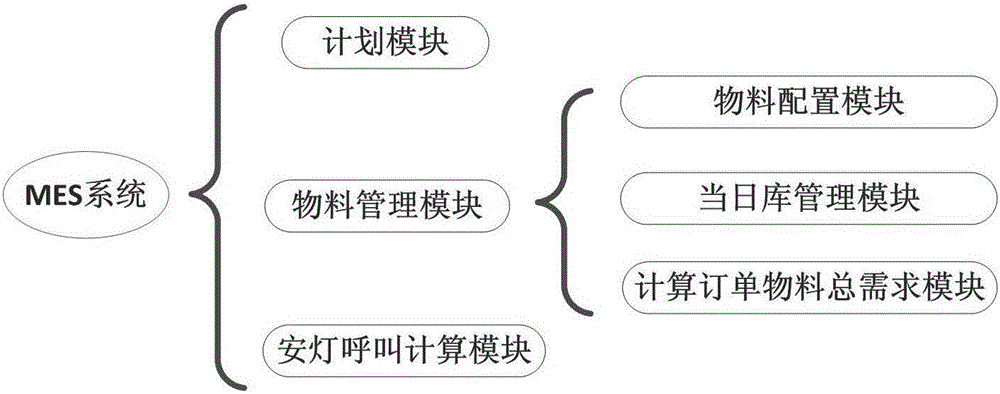

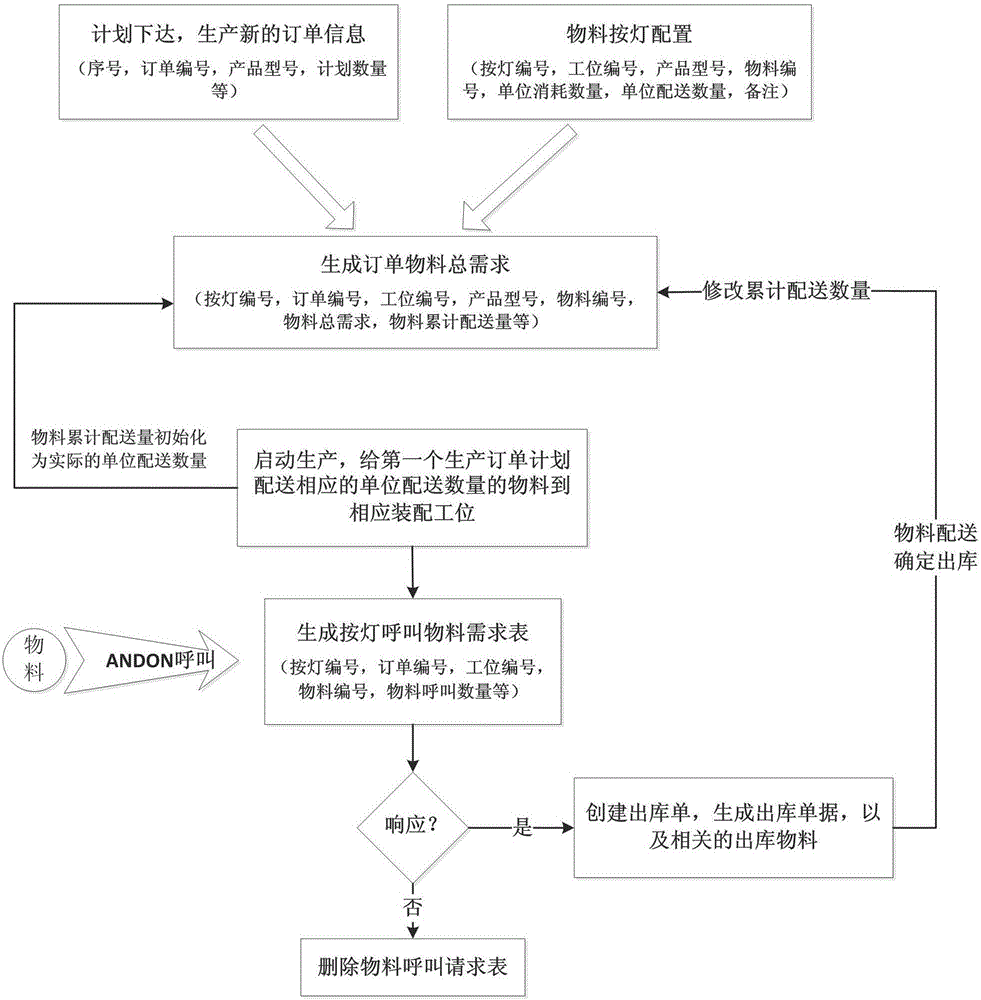

Mechanical product assembly workshop material calling and dispensing management system and method based on MES system

InactiveCN106094748AReliable deliveryReliable management effectTotal factory controlProgramme total factory controlProduction lineProgram planning

The invention discloses a mechanical product assembly workshop material calling and dispensing management system and method based on an MES system. The system comprises a planning module, a material management module, an andon calling calculating module and a visualization monitoring module. By employing the planning module and the material management module as configuration prerequisites, the andon calling calculating module generates a production line assembly station material calling request according to concrete steps, including calling for the required quantity of material kind and response; meanwhile, the retrieval of materials on that day is connected in real time with tracking assembly station material calling so as to perform better material management. The management system and method can timely and accurately generate material dispensing demands according to real production processes, and perform effective warehouse management on that day so as to create more scientific and effective material dispensing management environment, and to increase an enterprise material dispensing management level.

Owner:HEFEI UNIV OF TECH

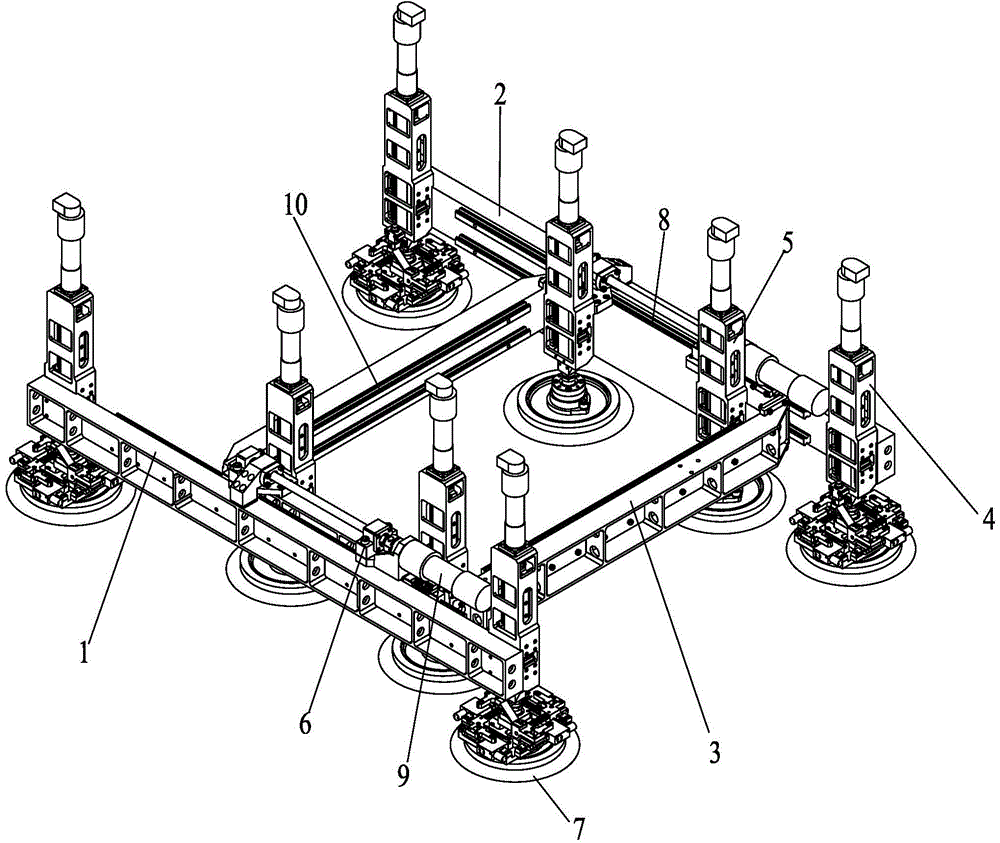

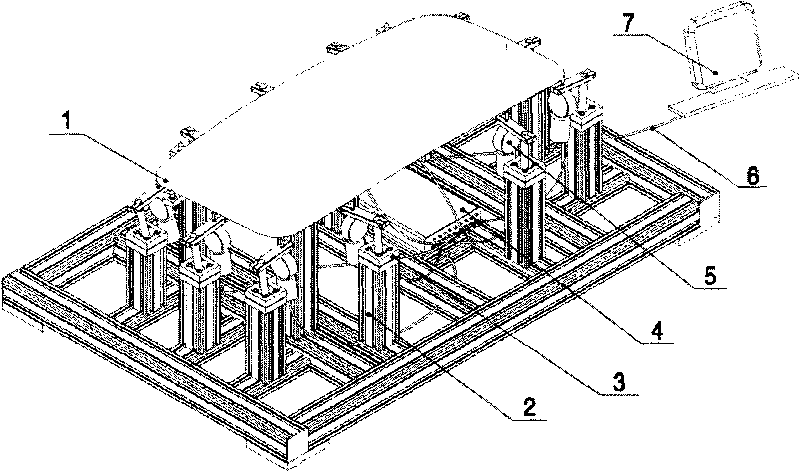

Crawling robot worktable

The invention relates to an automatic walking mechanical product and particularly relates to a crawling robot worktable. The crawling robot worktable comprises a first outer frame and a second outer frame which are parallel to each other, wherein a guide rail is fixedly arranged on each of faces opposite to the first outer frame and the second outer frame; a rectangular inner frame is slidingly connected with the guide rails; an inner frame retractable leg is arranged at each of four vertex angle positions of the inner part of the inner frame; each inner frame retractable leg comprises a framework which is fixedly connected with the inner frame, and a retractable leg motor which is fixedly arranged at the top of the framework; the output end of each retractable leg motor is fixedly connected with a feeding screw rod; retractable leg guide rails are arranged on middle discs of the frameworks. The crawling robot worktable is simple, reasonable and compact in stricture; the aim of frontward alternating movement is realized by the inner frame and the outer frames, which are mutually matched, and suction discs arranged at the bottoms of the inner frame and the outer frames; the manpower can be effectively saved in a working process and the working efficiency is improved.

Owner:WUXI BEST PRECISION MACHINERY

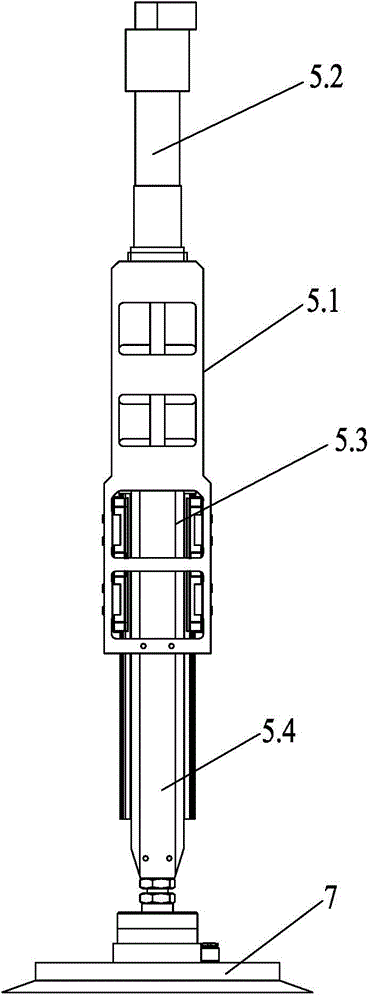

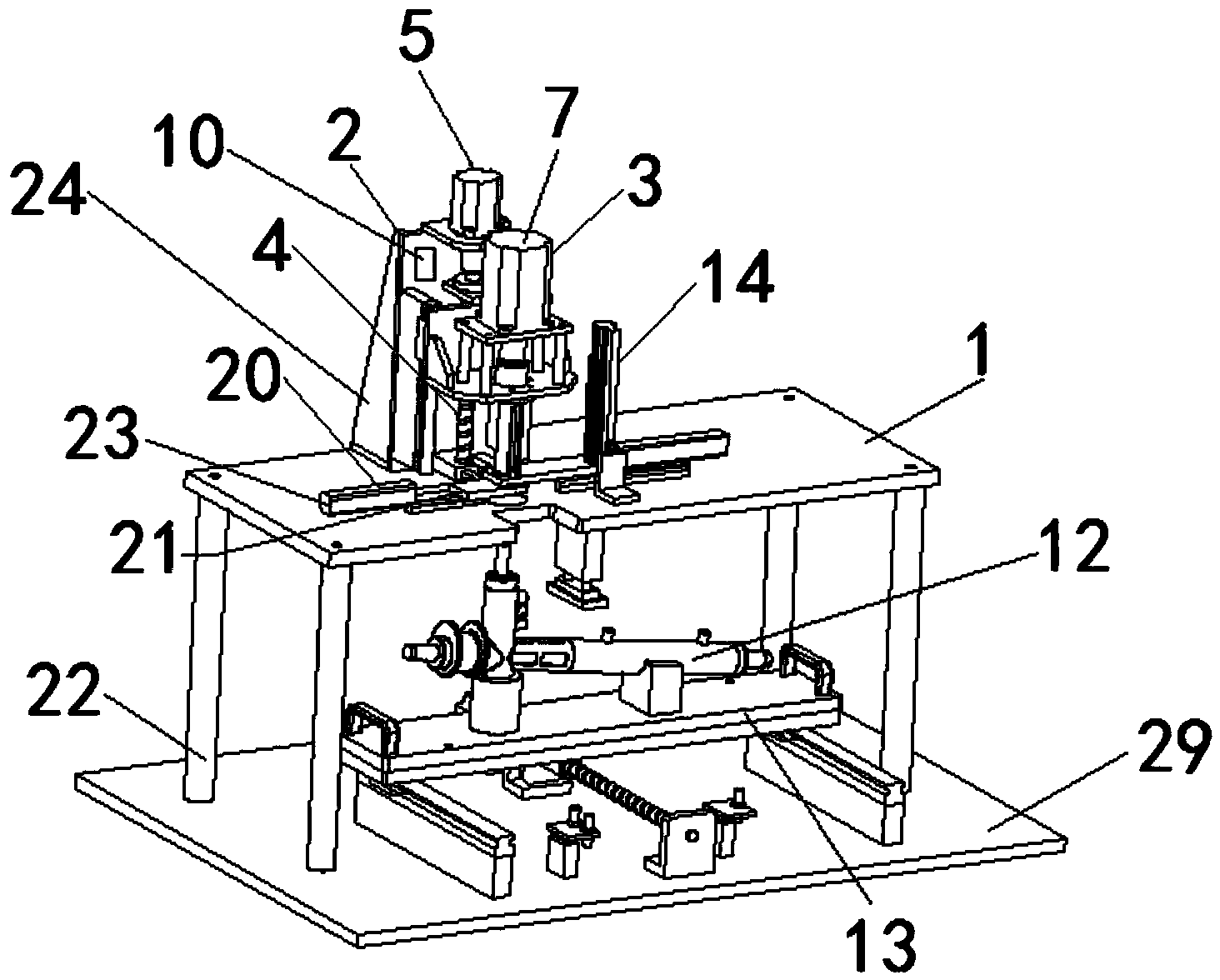

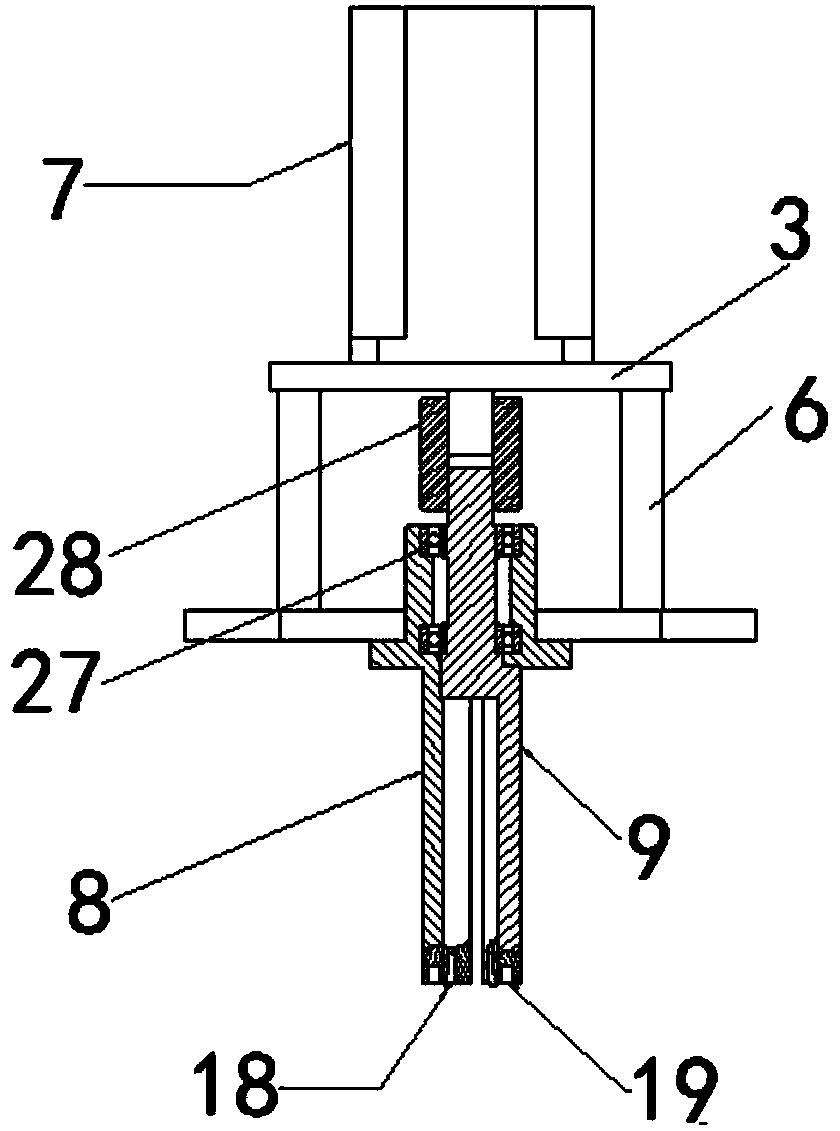

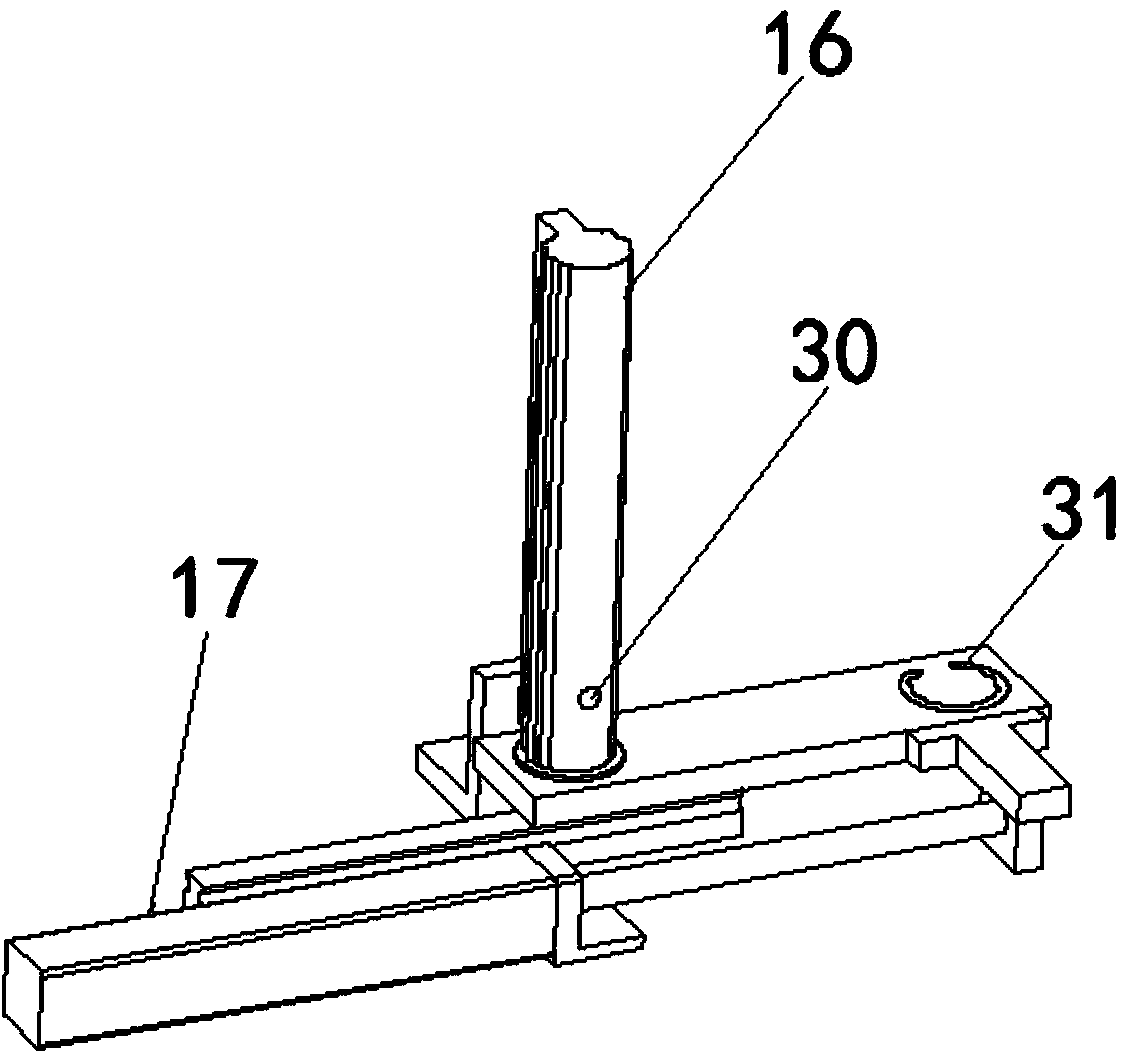

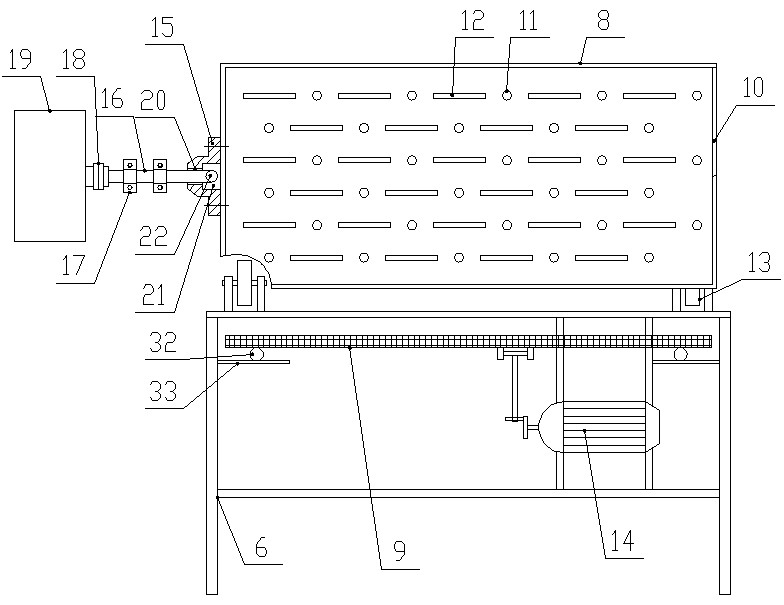

Snap spring pressing machine

InactiveCN103447801AEasy to assembleQuick assemblyMetal working apparatusElectric machineEngineering

The invention provides a snap spring pressing machine applied to the producing and assembling field of the mechanical product. The frame (1) of the snap spring pressing machine is provided with a snap spring loading mechanism (2) and a snap spring angle shrinking mechanism (3), wherein the servo motor (5) of the snap spring loading mechanism (2) is set into a structure capable of driving a lead screw (4) to rotate; the mechanism body part (6) of the snap spring angle shrinking mechanism (3) is sheathed on the lead screw (4); a fixed semicircle part (8) and a rotary semicircle part (9) are in a circular rod structure after being buckled; a stepping motor (7) is set into a structure capable of driving the rotary semicircle part (9) to rotate; the servo motor (5) and the stepping motor (7) are connected with a control component (10). The pressing machine disclosed by the invention has a simple structure, the snap spring can be conveniently, quickly and accurately installed in a product trough, the snap spring assembling efficiency is improved, the snap spring assembling quality can be guaranteed, and the integral quality of a snap spring installation part is improved.

Owner:WUHU HENGLONG AUTO STEERING SYST

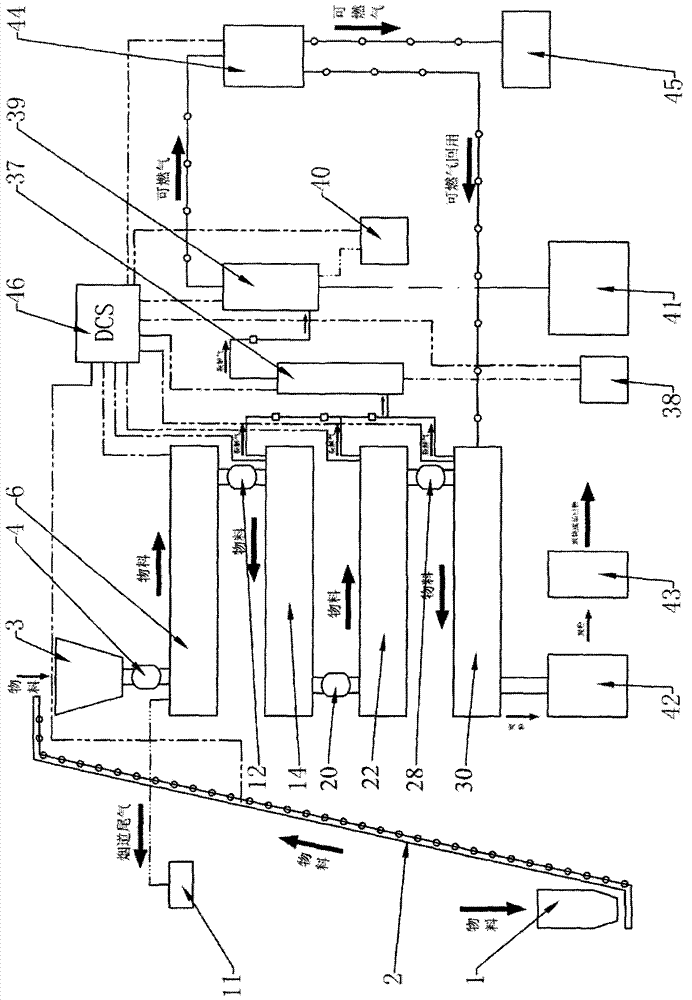

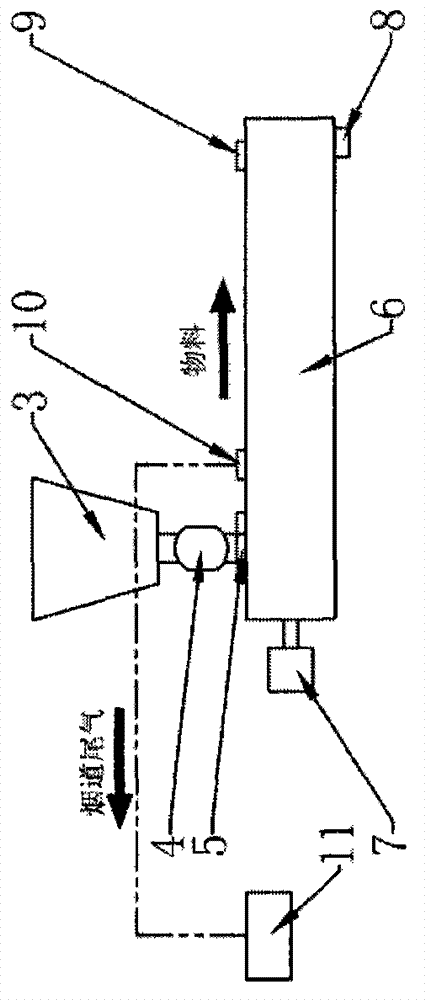

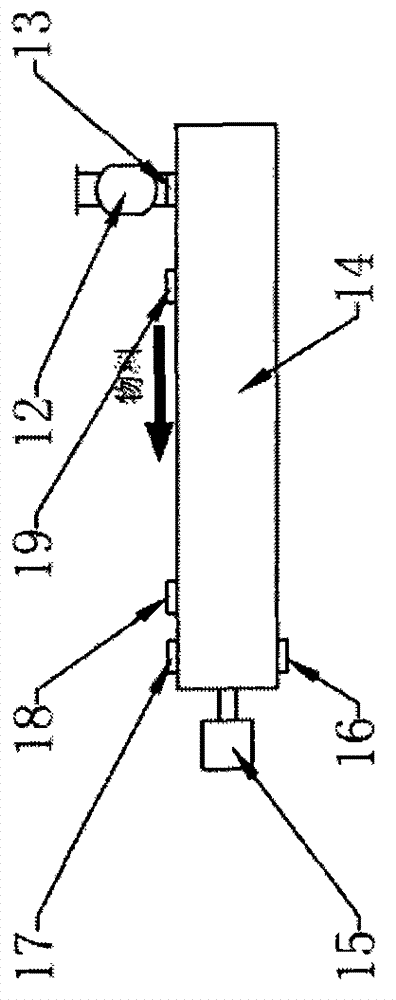

Apparatus and process for destructive distillation and cracking of biomass

ActiveCN102816575AShort processReduce energy consumptionMechanical conveying coke ovensCombustible gas coke oven heatingReactive distillationProcess engineering

The invention discloses an apparatus and a process for destructive distillation and cracking of biomass, belonging to the technical field of industrial processing apparatus structures and processes for mechanical products. The apparatus comprises an input part, a reaction vessel part, a control part and a processing output part. Self-balancing of energy in the process of production is realized through utilization of the destructive distillation and cracking process for biological garbage. According to the invention, the destructive distillation and cracking process for biomass has the advantages of short process flow, little equipment and low energy consumption, and the apparatus has the advantages of safe and convenient operation, easy maintenance and repair, etc.

Owner:上海清平环保科技有限公司

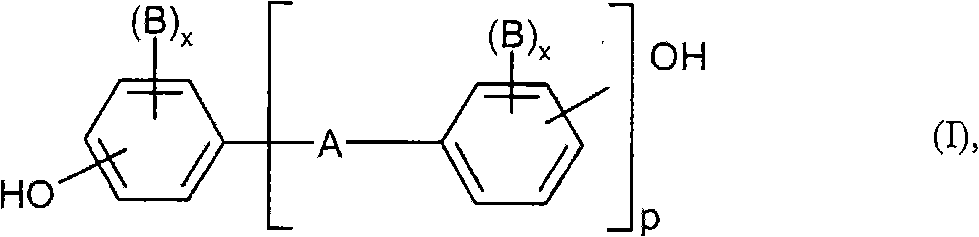

Blend of aromatic polycarbonate and polylactic acid, preparation method and application thereof

InactiveCN101671476AImprove mechanical propertiesImprove hot workabilityTrans esterificationPolymer science

The invention relates to a blend of aromatic polycarbonate and polylactic acid, a preparation method and application thereof. According to the method, an ester exchange reaction catalyst is added in the process of preparing the blend of the aromatic polycarbonate and the polylactic acid so as to improve the compatibility of each composition in the blend. The blend of the aromatic polycarbonate and the polylactic acid has excellent mechanical performance, hot-working character and flame retardant property, and can be widely applied to mechanical products or parts, electrical and electronic products or parts, building materials and daily necessities.

Owner:COVESTRO POLYMERS CHINA CO LTD +1

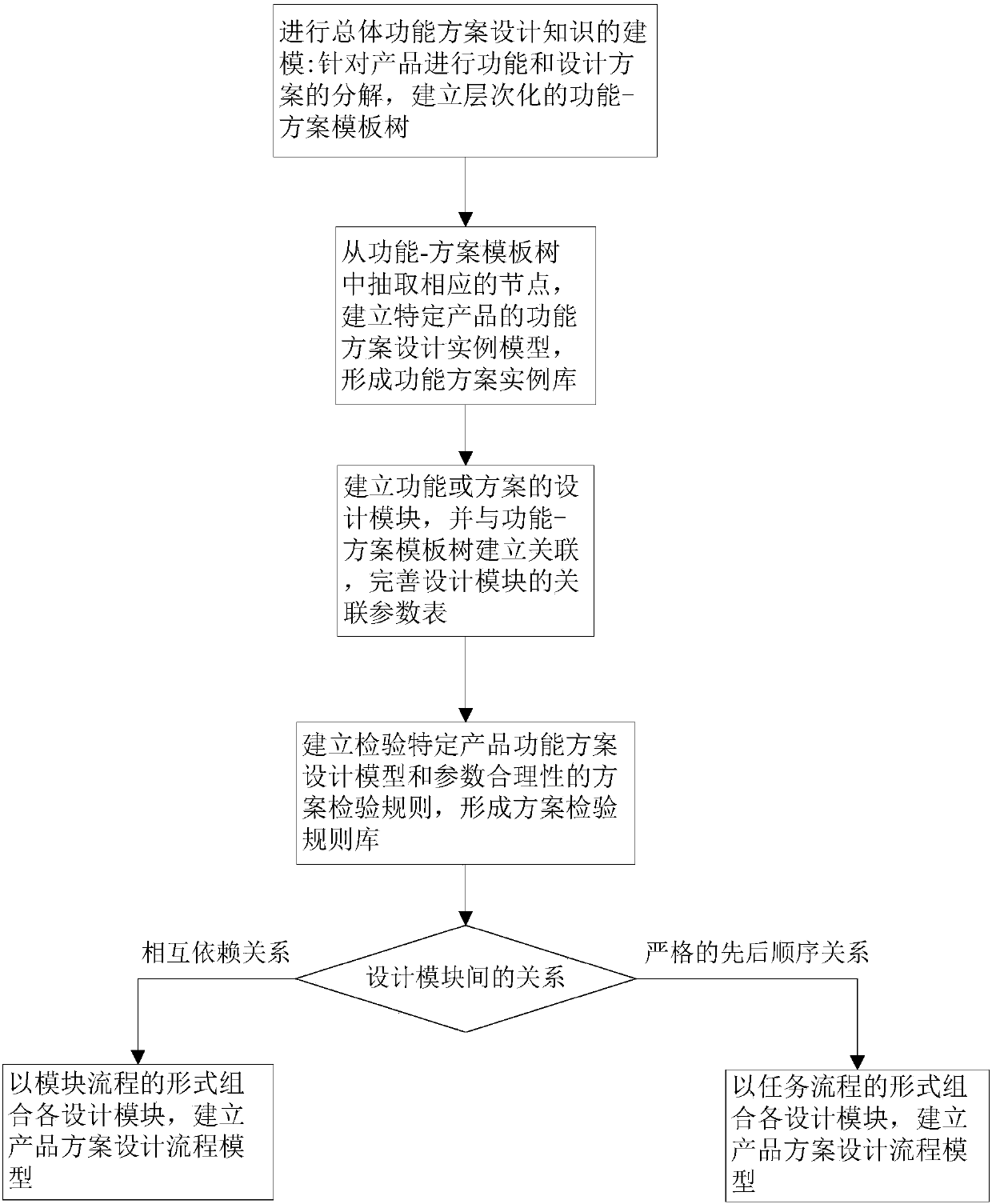

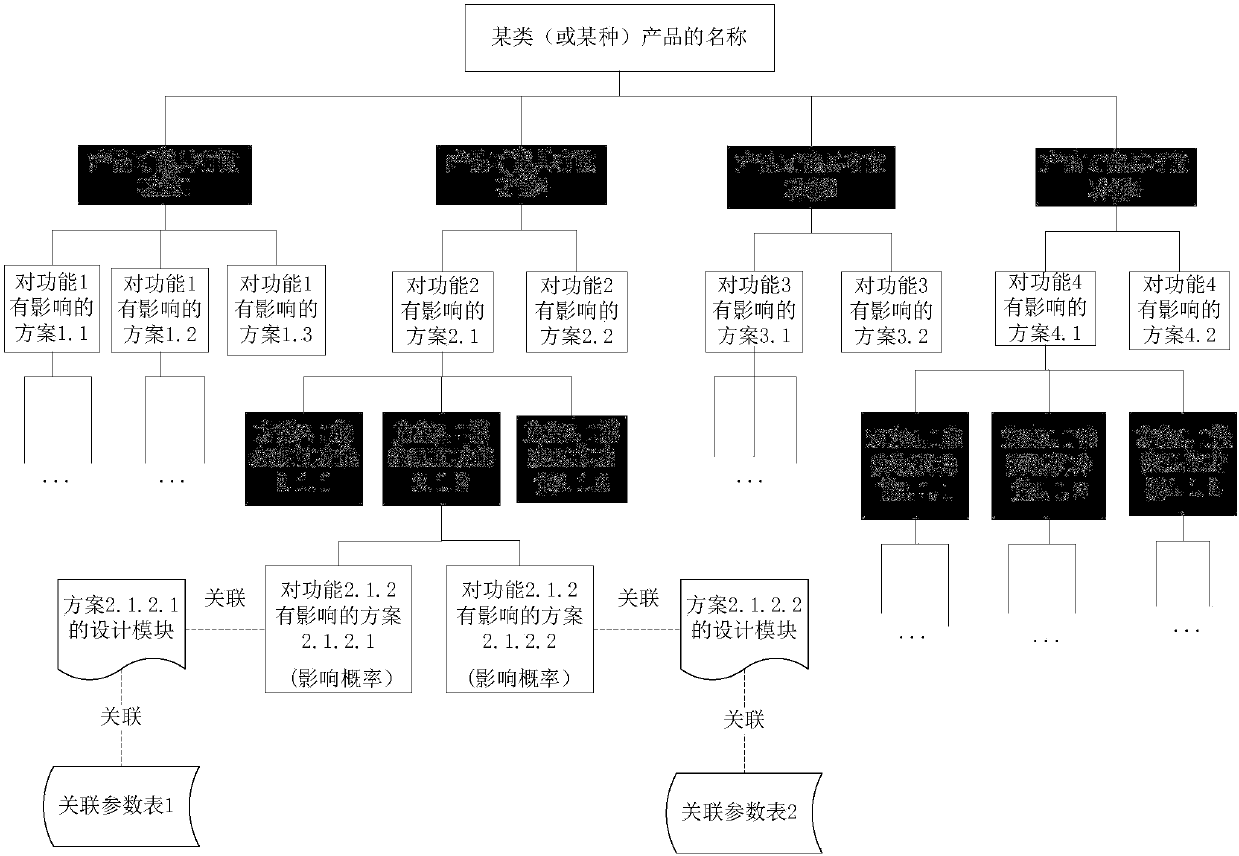

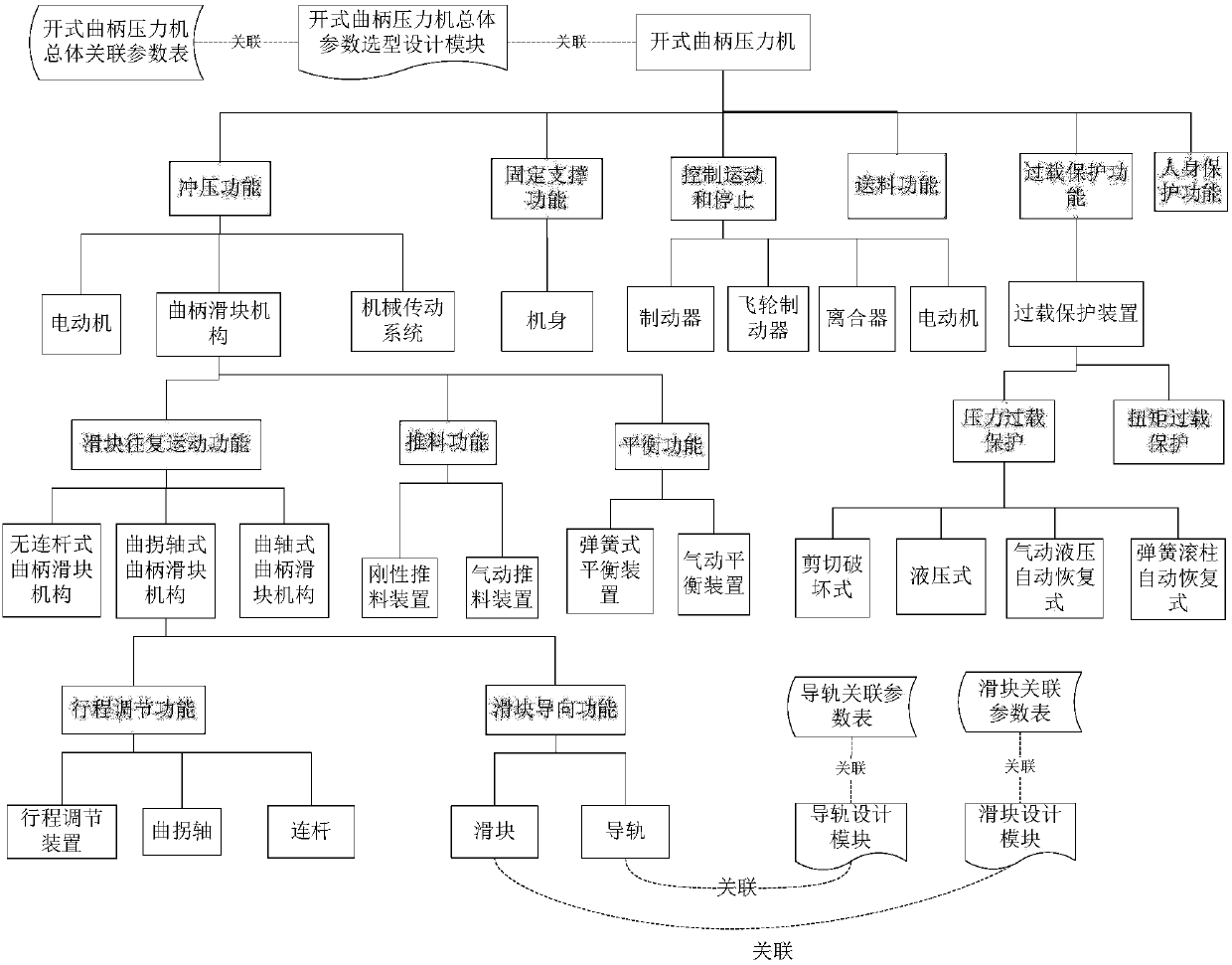

Knowledge modeling method and system used for aided design of mechanical product scheme

ActiveCN107590319AReduce modeling difficultyImprove reusabilitySpecial data processing applicationsAutomatic transmissionHabit

The invention discloses a knowledge modeling method and system used for aided design of a mechanical product scheme. The method comprises the steps of firstly performing overall function scheme designknowledge modeling to build a function-scheme template tree knowledge model and a function scheme design example model; and secondly establishing function or scheme design modules, establishing association with a function-scheme template tree, building a check function scheme design model and a parameter reasonability scheme check rule, combining the design modules in the form of a reconfigurablemodule process or task process, building a scheme design process model, and realizing parameter value automatic transmission and design process guide functions. The system comprises a function schemeaided design module, a module process aided design module, a task process aided design module, a design module control module and a system main control module. According to the method and the system,the knowledge modeling difficulty can be lowered; and the knowledge modeling method and the corresponding aided design system which conform to thinking habits of engineers and are reusable are provided.

Owner:NANJING UNIV OF SCI & TECH

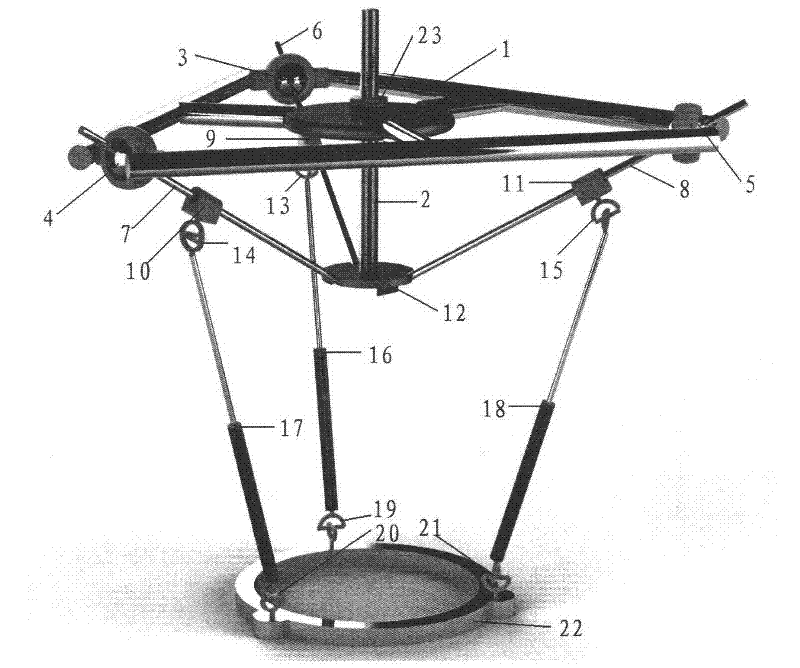

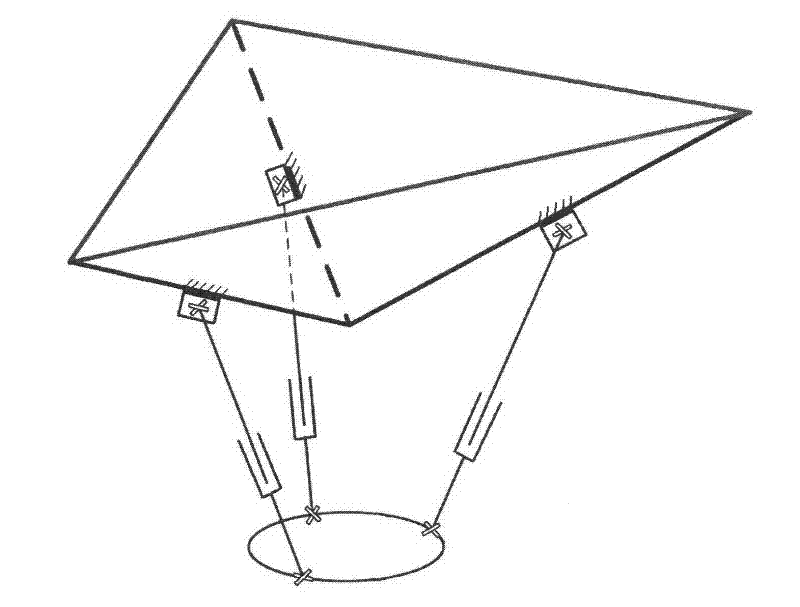

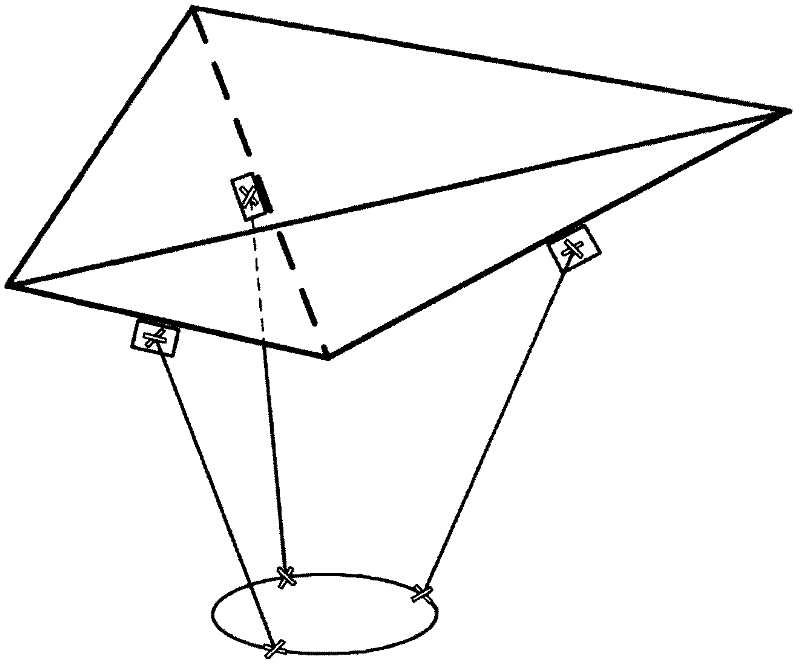

Device capable of realizing combinatorial motion output of 3PUU (three-prismatic-universal-universal) mechanism and 3UPU (three-universal-prismatic- universal) mechanism

InactiveCN102488557AAdjustable working spaceEasy to assembleProgramme-controlled manipulatorDiagnosticsBall screwPrecision surgery

The invention discloses a device which is applied to medical mechanical products for precision surgeries and minimally invasive surgeries and the like and other occasions requiring to realize two compound motion modes (macroscopic motion and fine motion adjustment). The device is composed of a working space adjusting mechanism, a 3-DOF (degree of freedom) fine motion mechanism and a 3-translational-motion parallel mechanism, and can realize the motion output of a 3PUU (three-prismatic-universal-universal) mechanism and a 3UPU (three-universal-prismatic- universal) mechanism. A rack (1) of a main body part and a movable operator platform (22) are connected by three branch chains. The structures of the branch chains are exactly same, in case of taking one branch chain for example, from the rack (1), the branch chain connects a spherical swinging block I (3), a sliding channel I (6), a slide block I (9), a hooke hinge I (13), a linear driver I (16), a hooke hinge IV (19) and the movable operator platform (22) together, thereby realizing the function of the whole device. In the process of realizing the motion output of a 3-DOF parallel mechanism, the linear driver I(16), a linear driver II (17) and a linear driver III (18) are the driving devices of the mechanism, and the linear drive-mode input is realized in a hydraulic or ball-screw mode; in the process of realizing the motion output of the 3-DOF fine motion mechanism, the slide block I (9), a slide block II (10) and a slide block II (11) are the driving devices of the mechanism, and the linear drive-mode input is realized in a ball-screw mode; and in the process of realizing the function of the working space adjusting mechanism, an adjusting nut (23) is the driving device of the mechanism, and the rotary drive-mode input is realized through a servo motor.

Owner:EAST CHINA JIAOTONG UNIVERSITY

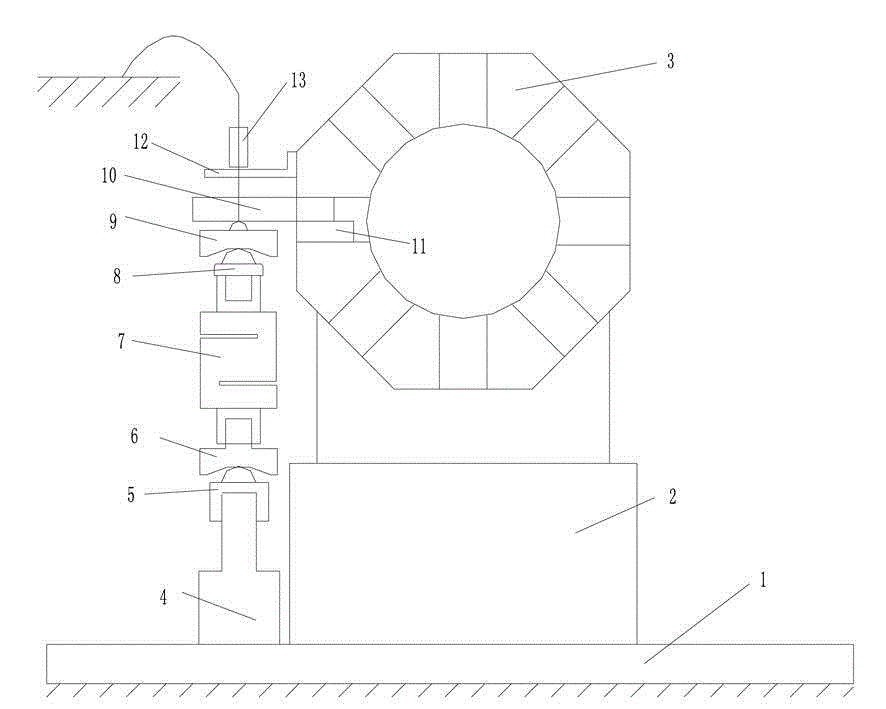

Loading force direction self-balanced loading device and force direction self-controlled numerical control knife rest static rigidity test platform

ActiveCN104568424AGuaranteed accuracyGuaranteed verticalityMachine part testingNumerical controlEngineering

The invention discloses a loading force direction self-balanced loading device and a force direction self-controlled numerical control knife rest static rigidity test platform, belonging to the field of test of basic performance parameters of functional parts of numerical control machine tools. The loading device is fixedly arranged on a test bed rack, and the loading force direction is always perpendicular to a cutter bar by virtue of self-balance of a ball pair and does not deviate; single-point centralized loading of the force is realized, and the accuracy of the loading position is guaranteed; according to the test device, the ground is taken as the reference, a designed cutter head bearing plate is selected as a measuring point, the measuring point and the load point are positioned on the same vertical line, and the test error caused by deformation of other functional parts of the machine tool is overcome. The device and the test scheme have the greatest advantages that the accuracy of the direction and position of the loading force is guaranteed. The loading device also can be applied to the static rigidity test of other functional parts of the machine tool and other mechanical products.

Owner:SOUTHEAST UNIV

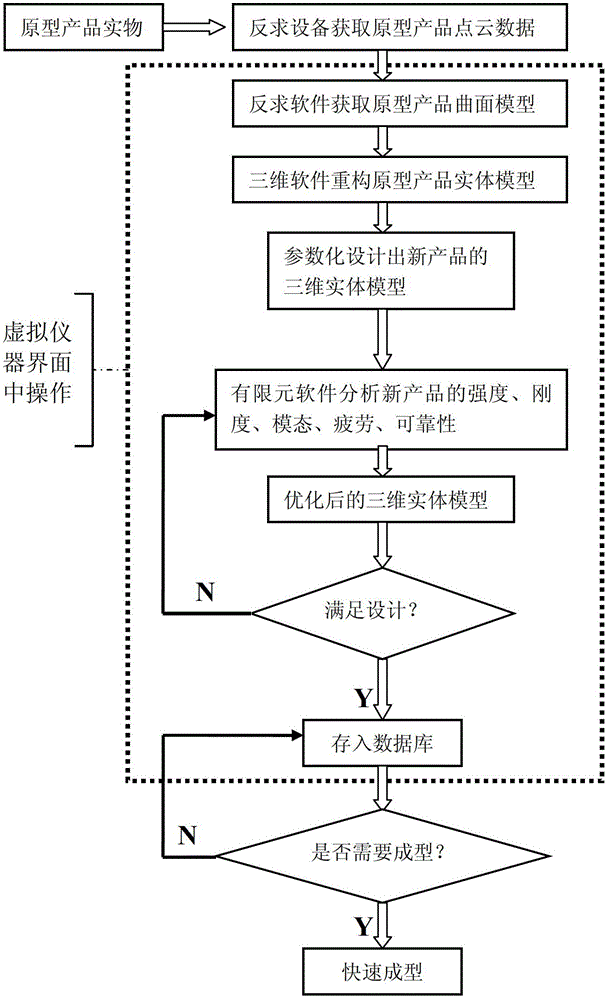

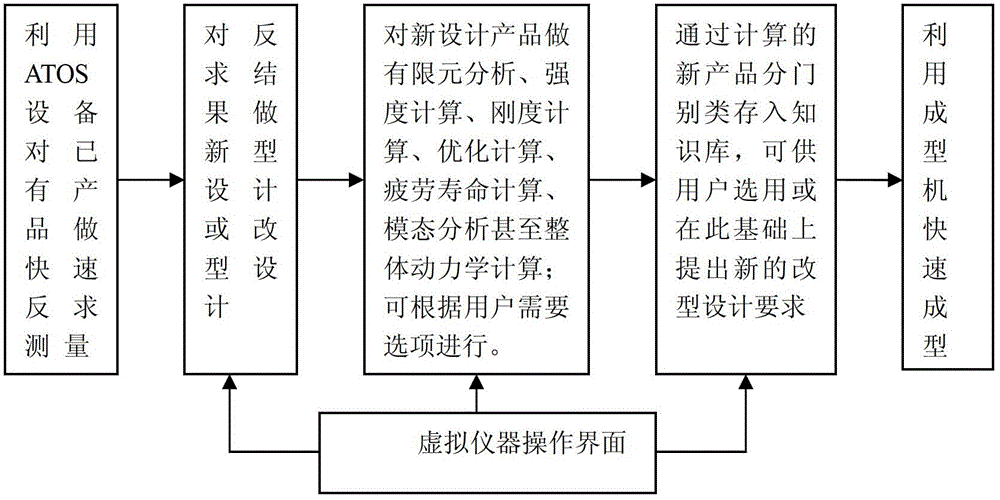

Method for quickly designing mechanical products based on virtual instruments and reverse engineering

InactiveCN103150447AAchieve innovative designFast reverse measurementSpecial data processing applicationsMeasuring instrumentSoftware engineering

The invention relates to a method for quickly designing mechanical products based on virtual instruments and reverse engineering. The method comprises the following steps of: acquiring the point cloud data through a prototype product model at first, obtaining a prototype product curved surface model through utilizing an imageware software according to the obtained point cloud data, utilizing CATIA software to form a prototype product solid model of the curved surface model, using a parametrization design to obtain a new product solid model, analyzing and computing the new model through utilizing ANSYS software so as to obtain a new product model which satisfies requirements, and finally, storing the model into a database and quickly forming through a quick forming machine. The method consists of a prototype product model data acquiring part, a data processing, analyzing and managing part with a computation and analysis software and a quick forming part. The data acquiring part is an optical measuring instrument, data measurement and acquisition can be realized through scanning, and the point cloud data of the model can be obtained.

Owner:HANGZHOU DIANZI UNIV

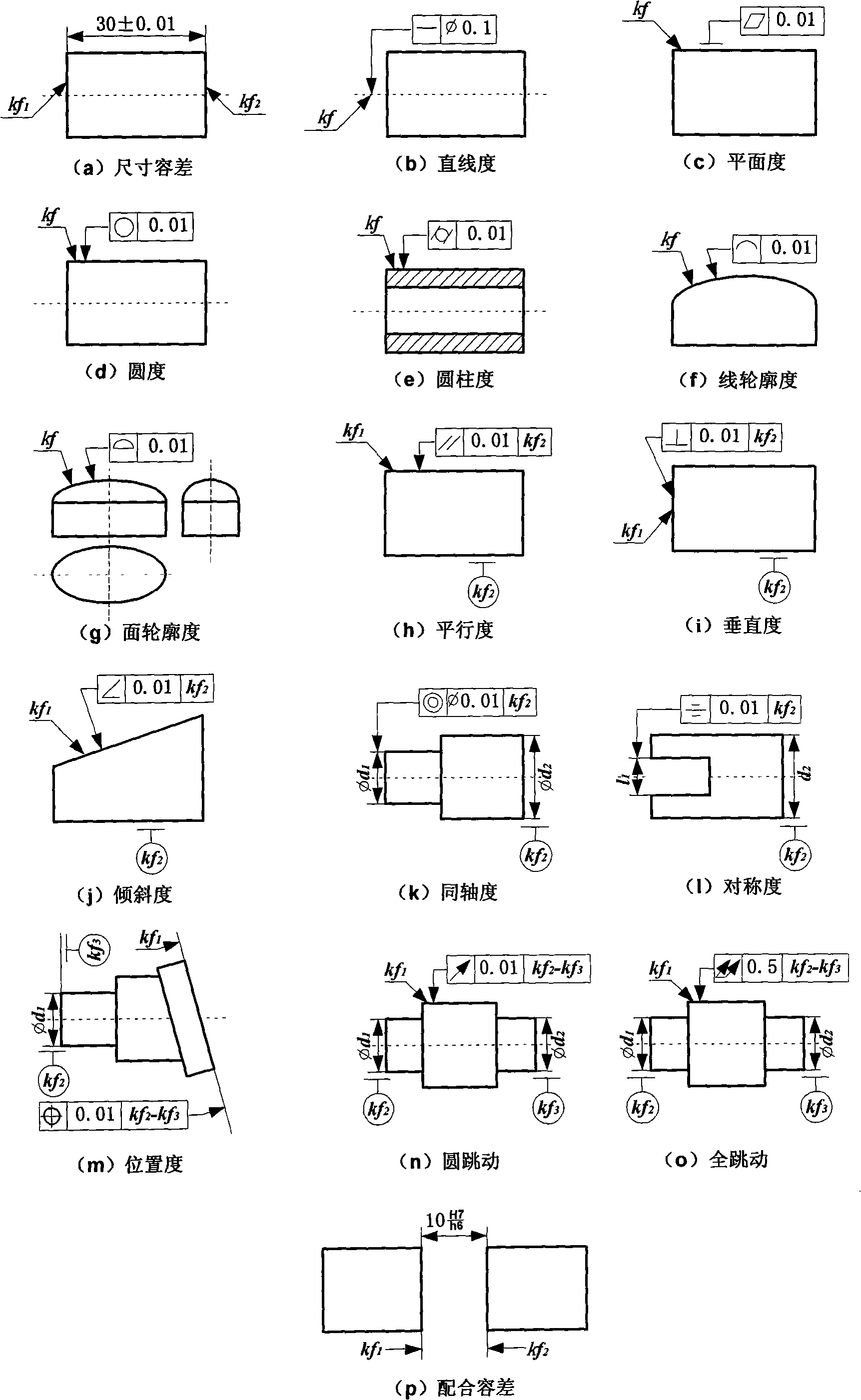

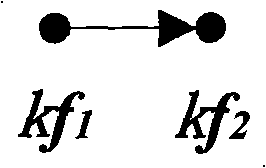

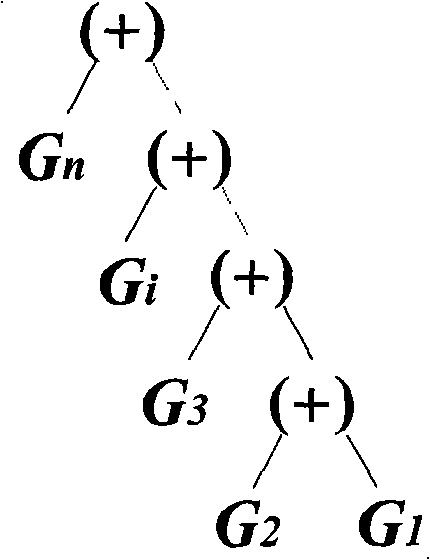

Unified modeling method of mechanical product tolerance

InactiveCN101271479AReduce diversityReduce ambiguitySpecial data processing applicationsPosition toleranceElement model

The invention relates to a tolerance unified modeling method for a mechanical product, which adopts technologies of graph theory, vectors and characteristics, etc., and implements part tolerance element modeling, part tolerance modeling, assembly fit tolerance modeling and assembly body tolerance modeling layer by layer from bottom to top according to an assembly decomposition structure of the product, thereby realizing the unified modeling of product tolerances. The tolerance unified modeling method of the invention is characterized in that: the part tolerance element model is firstly established; each part tolerance element modeling built by extended directed graphs is adopted, and all the part tolerance element modeling are adopted to establish the part tolerance element models by a summation operation of the extended directed graphs; and each assembly fit tolerance modeling built by the extended directed graphs is adopted to establish a produc tolerance unified modeling. The tolerance unified modeling method for the mechanical product has the advantages of realizing the unified modeling of a dimension tolerance, a shape tolerance, a position tolerance and an assembly matching tolerance of the mechanical product. First, the diversity and the ambiguity of the tolerance models are eliminated; second, an assembly dimension chain and error accumulation analysis can be established conveniently.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

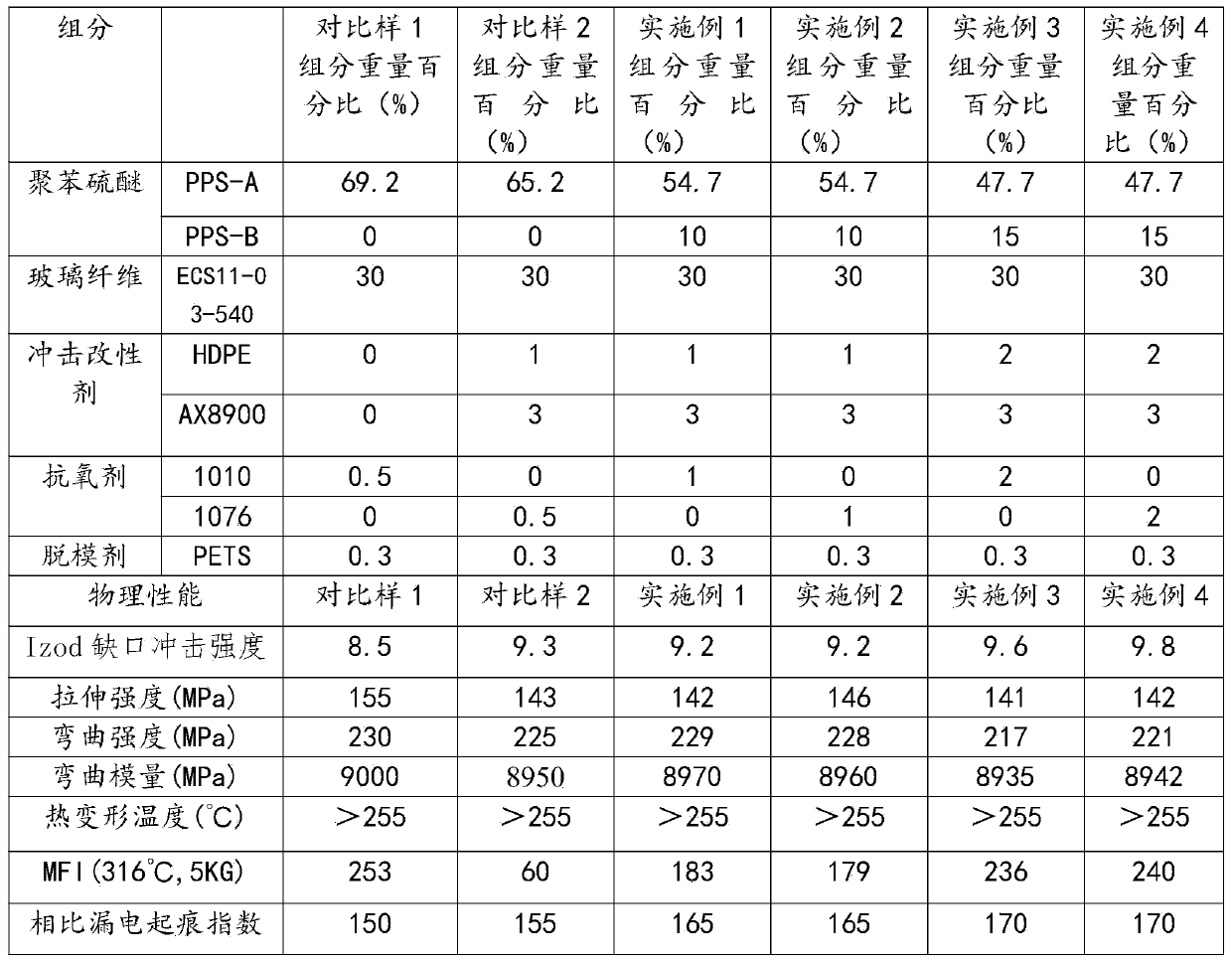

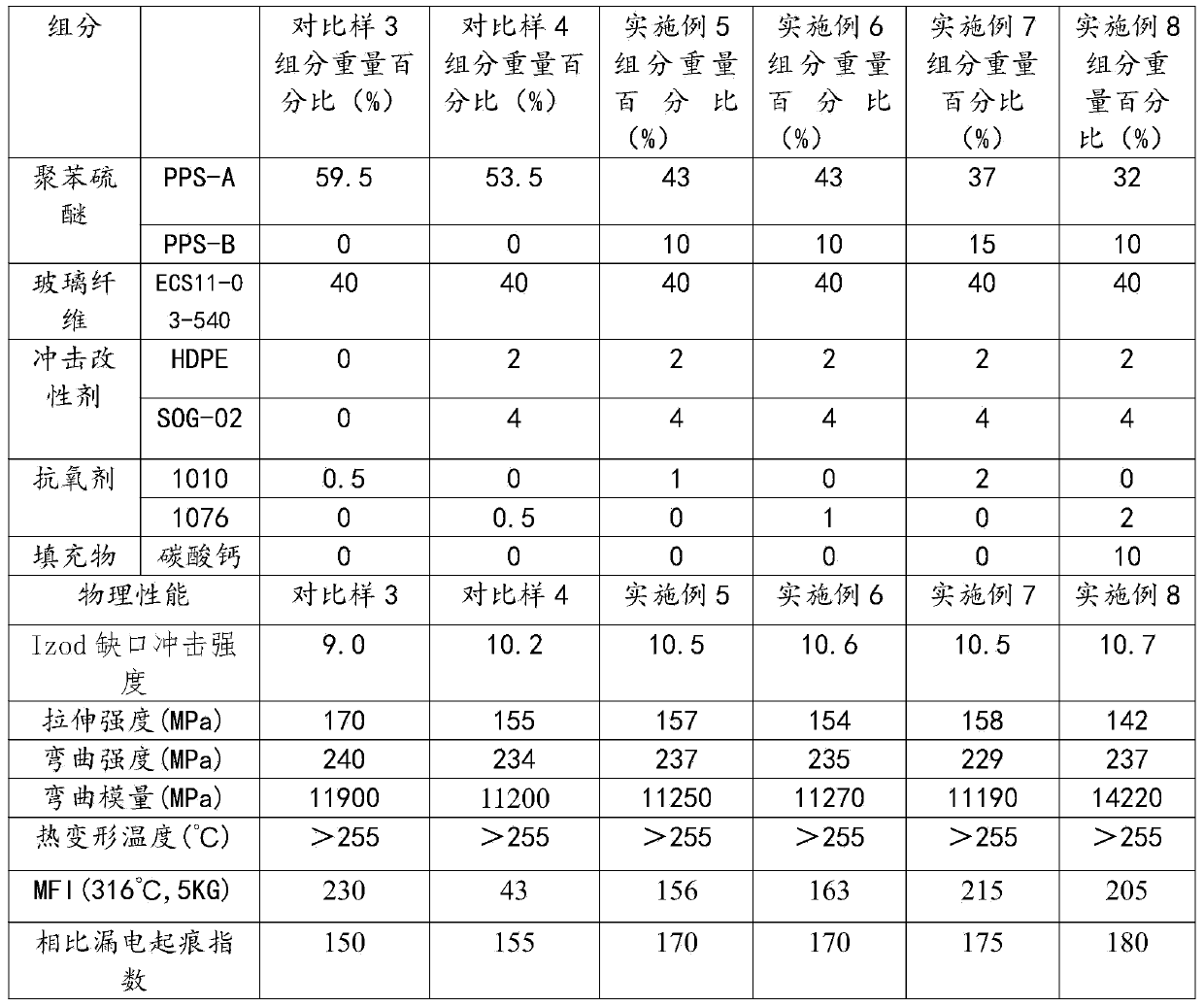

Composite polyphenyl thioether material

The invention provides a composite polyphenyl thioether material. The composite material consists of the following components by weight percent: 40-80% of polyphenyl thioether, 20-50% of glass fiber, 3-10% of an impact modifier, and 1-2% of an antioxidant. The composite polyphenyl thioether material has favorable impact property, heat resistance and higher comparative tracking index, at the same time, the composite polyphenyl thioether material has higher flowability, and the composite polyphenyl thioether material is suitable for manufacturing electrical and electronic products, mechanical products, automobile parts and other heat-resistant and corrosion-resistant products.

Owner:南京真宸科技有限公司

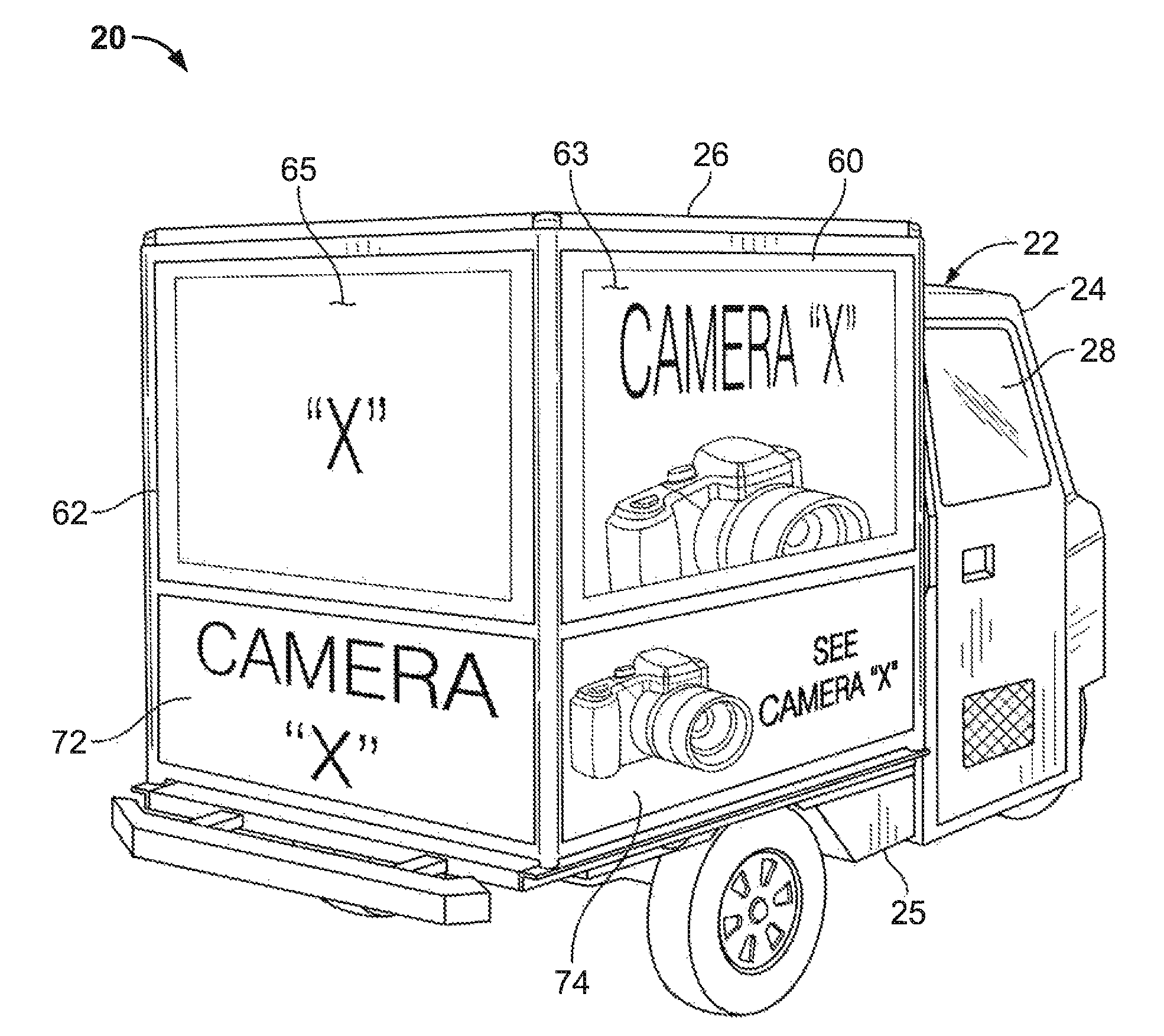

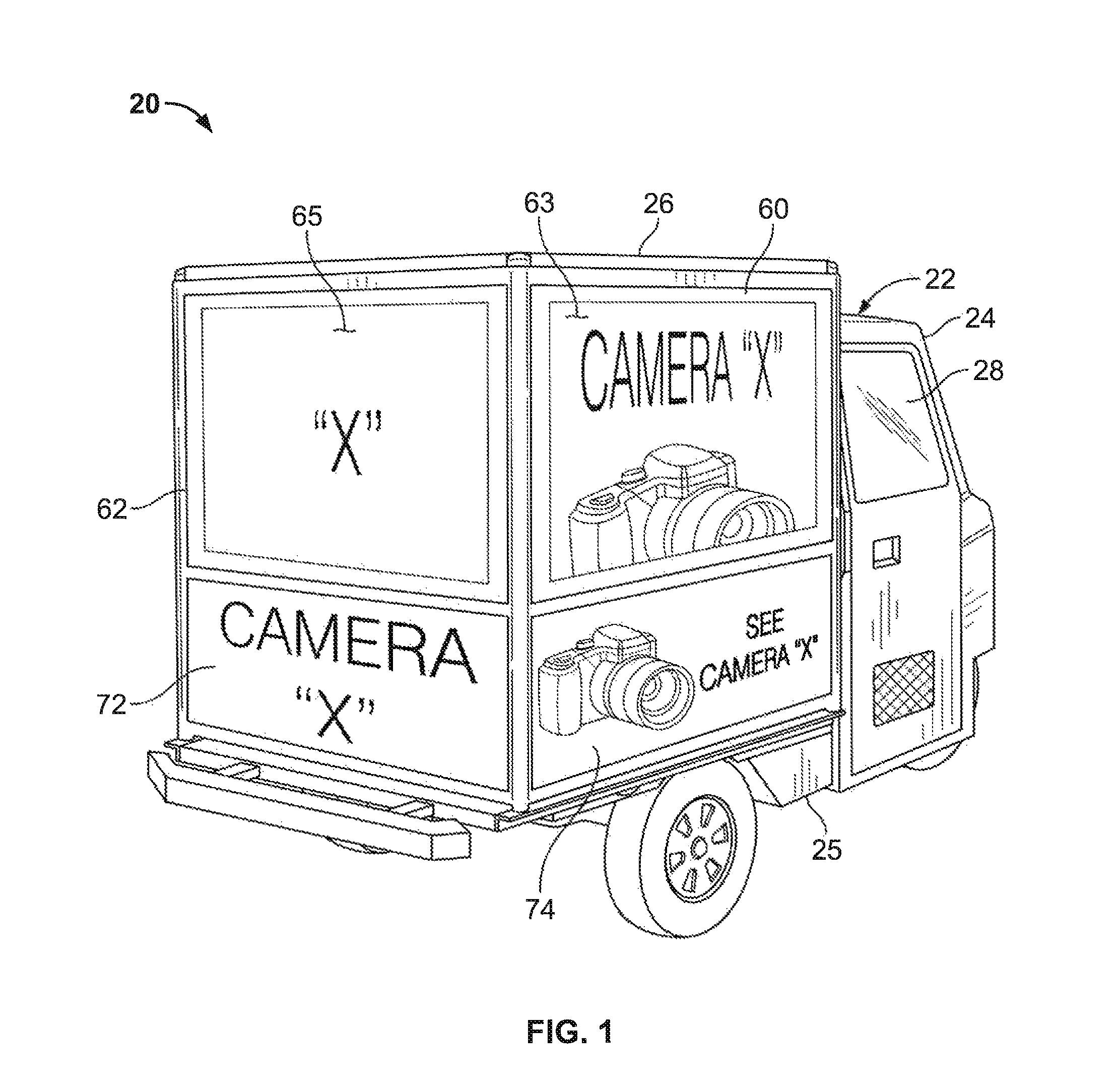

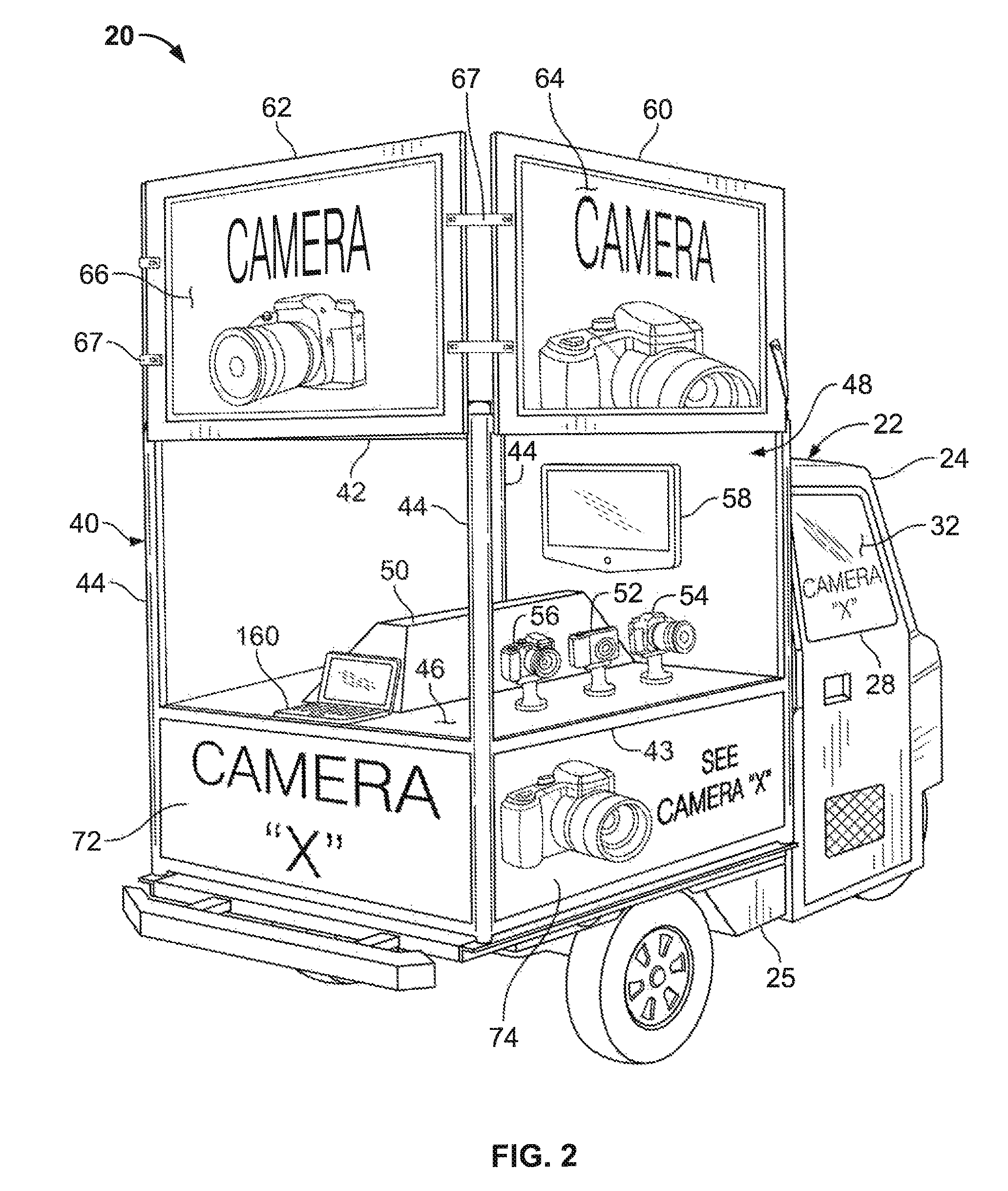

Method and apparatus for selling consumer products

ActiveUS7942461B2Easily and efficiently demonstrateMobile visual advertisingMonocoque constructionsMobile vehicleElectrical devices

Owner:BOBCAR MEDIA

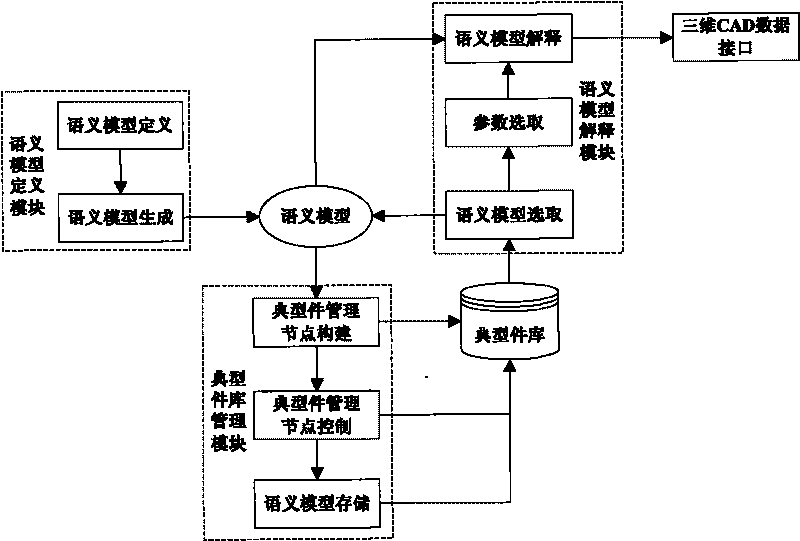

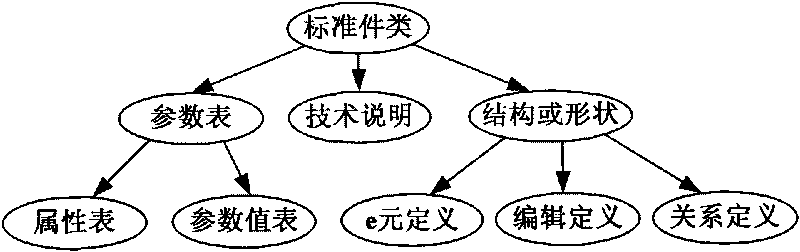

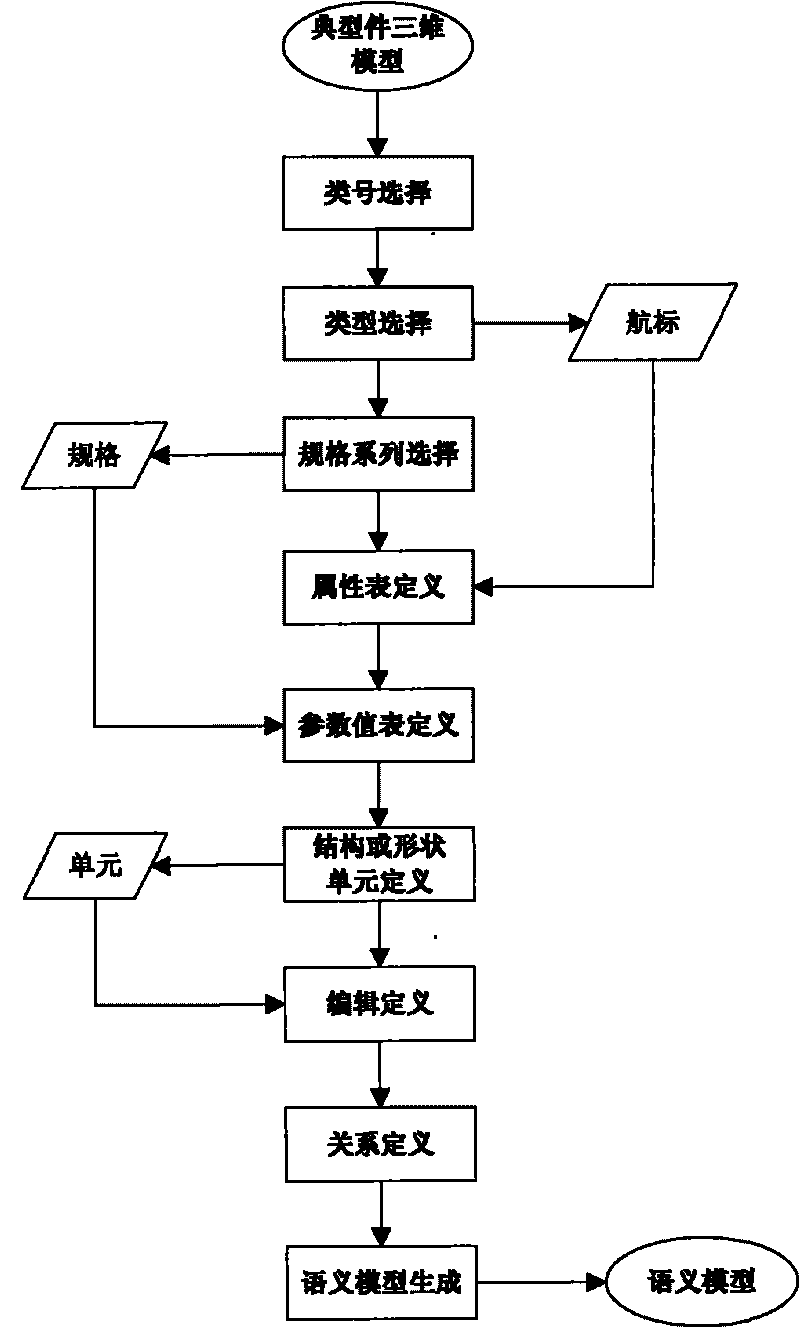

Management system of numerical control machining tool typical parts of complex parts of airplane and method

InactiveCN101763066AImprove design efficiencyImprove design qualityProgramme controlComputer controlNumerical controlPart type

The invention provides a management system of numerical control machining tool typical parts of complex parts of an airplane and a method. The system comprises a semantics model defining module facing to the three-dimensional parameterization of the typical parts, a typical parts storeroom management module and a semantics model explaining module. The method comprises the processes of defining, memorizing and explaining the semantics model. The invention can effectively manage the parts type and the assembled parts type typical parts of the numerical control machining tool of the complex parts of the airplane, provides support to quickly design the numerical control machining tool, and can be popularized and applied to the design field of the other mechanical products.

Owner:SHENYANG AIRCRAFT CORP +1

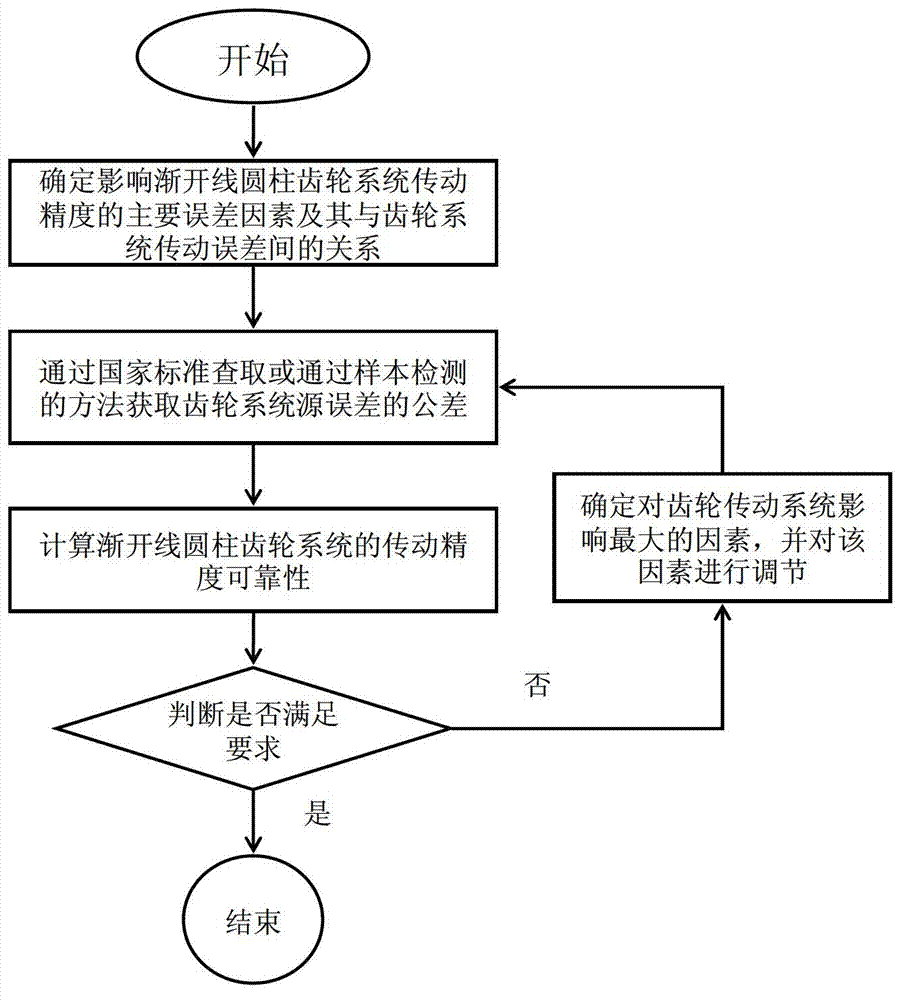

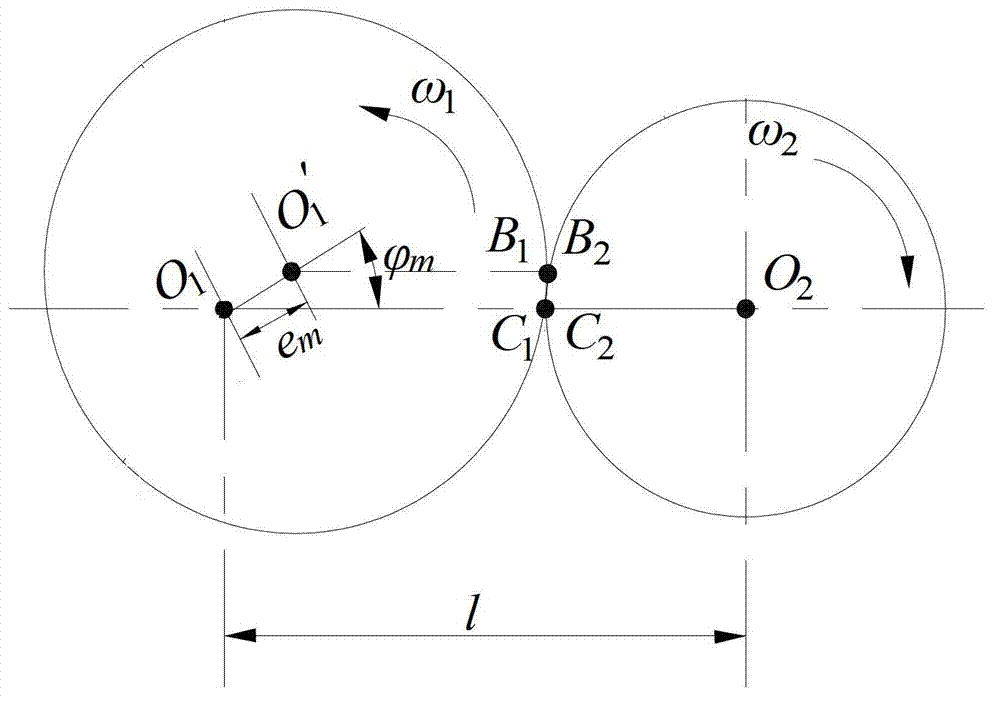

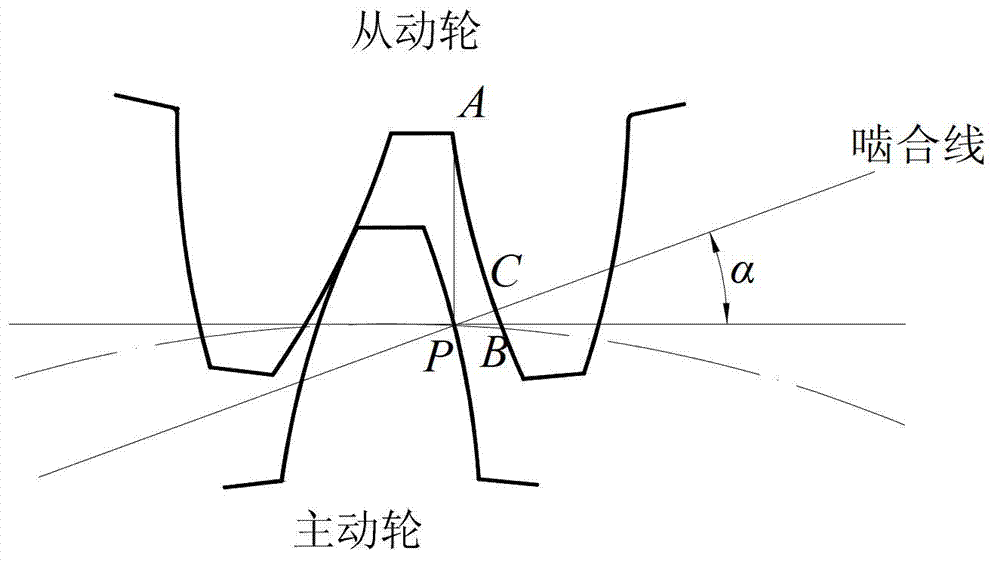

Involute cylindrical gear system transmission accuracy reliability determining and controlling method

The invention provides an involute cylindrical gear system transmission accuracy reliability determining and controlling method and belongs to the technical field of mechanical product design. According to the national standard, the involute cylindrical gear system transmission accuracy reliability determining and controlling method can help an enterprise to forecast failure probability of a gear system and make a reasonable improved plan to improve product reliability through detection of original errors of the gear system and analysis and control of transmission accuracy reliability of an involute cylindrical gear system, thereby saving cost and preventing resource waste and failure occurrence.

Owner:NORTHEASTERN UNIV

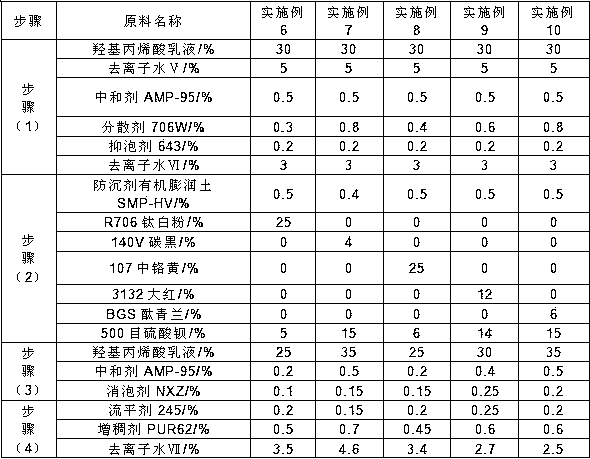

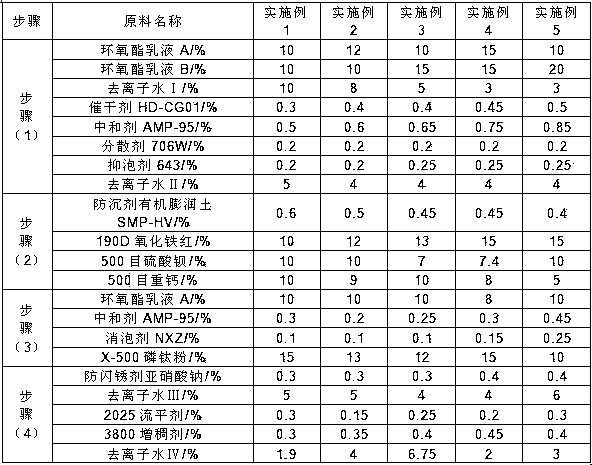

Water-based coating for surface of mechanical product

ActiveCN103468092AWater-basedFast dryingAnti-corrosive paintsEpoxy resin coatingsWeather resistanceEmulsion

The invention relates to a water-based coating for the surface of a mechanical product and belongs to the technical field of painting. The coating comprises a water-based primer coat layer and a water-based top coat layer, the water-based primer coat used in the water-based primer coat layer comprises the following components in percentage by mass: 30-40% of epoxy-ester emulsion, 10-15% of pigment, 10-15% of environment-protecting anti-rust pigment, 15-20% of filler, 3-4% of assistant and 13-22% of de-ionized water; the water-based top coat used in the water-based top coat layer comprises the following components in percentage by mass: 55-65% of hydroxyl acrylic emulsion, 4-25% of pigment, 5-15% of filler, 2.5-3.5% of assistant and 10.5-12.6% of de-ionized water. The coating product is water-based and environment-friendly, has very high drying speed and high gloss of the top coat, also has excellent chemical property and excellent weather resistance, and the corrosion resistance of the coating in combination with the primer coat and the top coat is more than 2000h.

Owner:JIANGSU HUAXIA PAINT MAKING

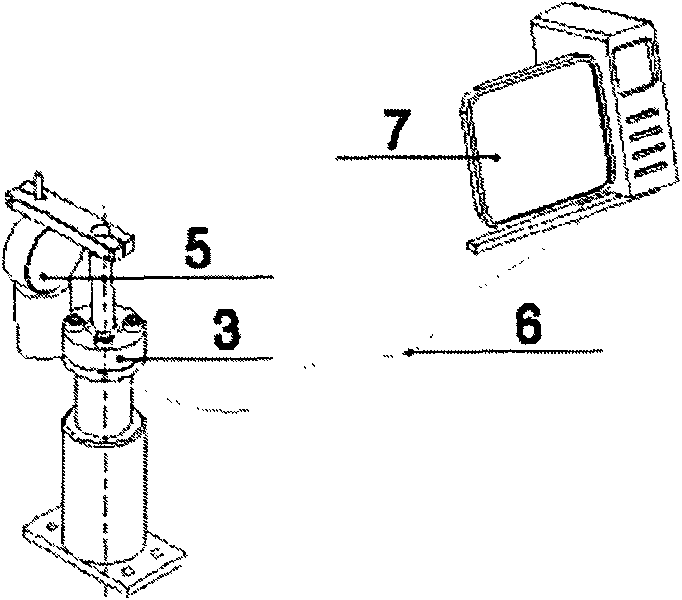

Detection system of automatic flexible checking tool based on contact measuring head

InactiveCN101750005AMature technologyEasy to installUsing electrical meansCommunication interfaceMechanical products

The invention discloses a detection system of an automatic flexible checking tool based on a contact measuring head, which comprises an adjustable tool, a measuring head seat, the contact measuring head, a controller, software and a main control computer, wherein the system uses the adjustable flexible tool to fix a workpiece and uses a contact measuring head with a communication interface to measure a relative dimension error. The measuring head is mounted on the measuring head seat capable of freely adjusting the gesture of the measuring head. Through the controller, one or more measuring heads are connected with the main control computer which controls the collection and treatment of measured data and realizes the automatic detection of the workpiece error. The system software makes statistic of the measured data, provides the information needed for controlling a statistic process and realizes the self-adapting calibration of the system. The invention has the advantages of good adjustability, low cost, high precision, fast speed, full automation, measures of quantization and the like, is an effective alternative scheme of current manual visual mechanical checking tool, and is also an excellent on-line detection scheme for dimension error of mechanical products.

Owner:涂成生

Roller combined gyration-type used sand reconditioning system

The invention discloses a roller combined gyration-type used sand reconditioning system, which comprises a roller reconditioning device, a dust removing device, a secondary demoulding device, a conveying device and a sand mixing device. A discharging port of the roller reconditioning device is connected with a feeding port of the secondary demoulding device. The dust removing device is located on the lateral portion of the roller reconditioning device. A discharging port of the secondary demoulding device is connected with the conveying device. The sand mixing device is located at the position of a discharging port of the conveying device. The roller combined gyration-type used sand reconditioning system integrates the basic functions of smashing, demoulding, dust removing, conveying and the like in an identical machine body, removes intermediate links to the maximum degree and preferably chooses the process scheme of jump running on the condition of gear shifting. The jump running process technology on the condition of gear shifting not only can be used in the sand reconditioning system but also can be used in other fields or other mechanical products. The jump running process technology is of special significance.

Owner:PUYANG LONGHAO MACHINERY

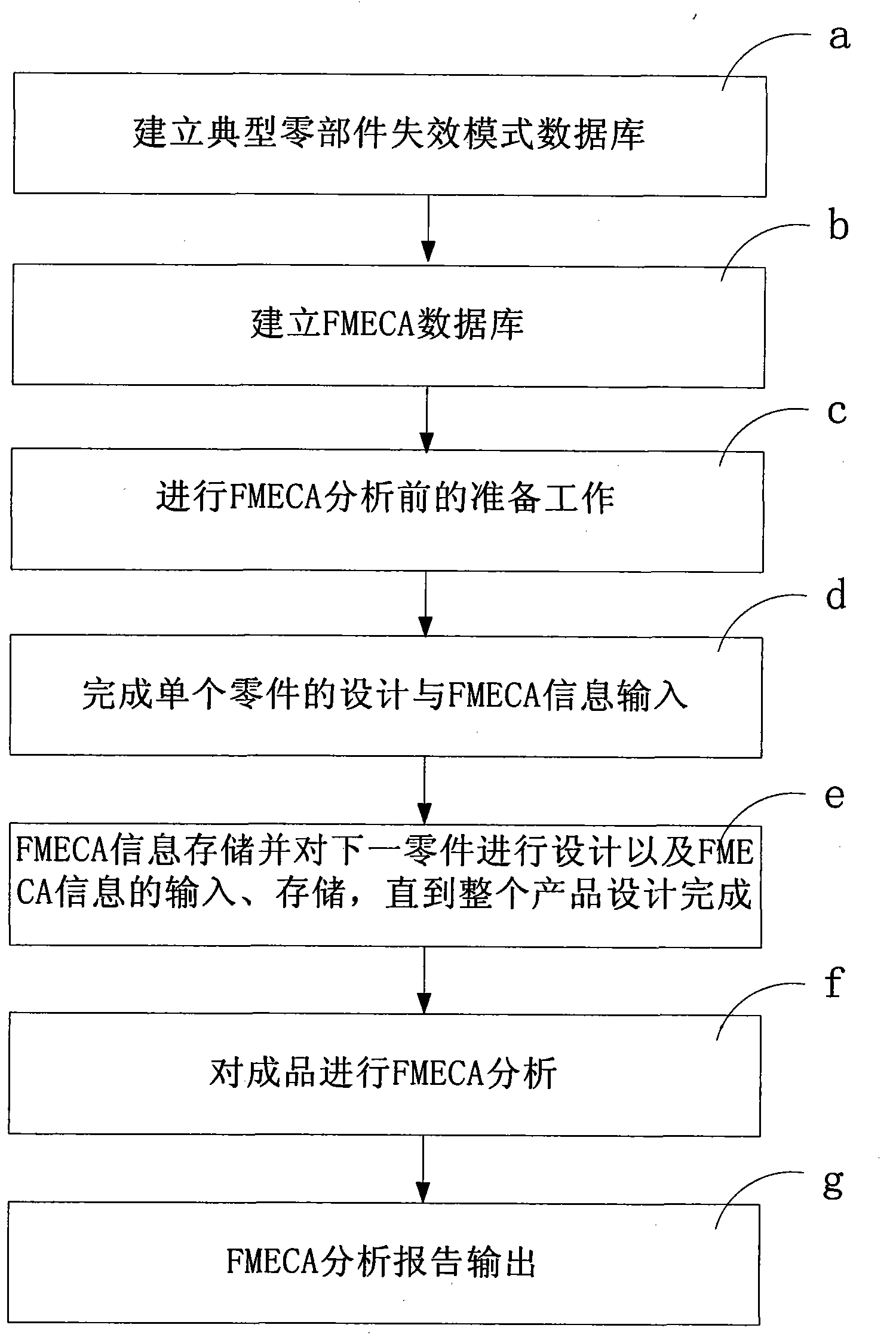

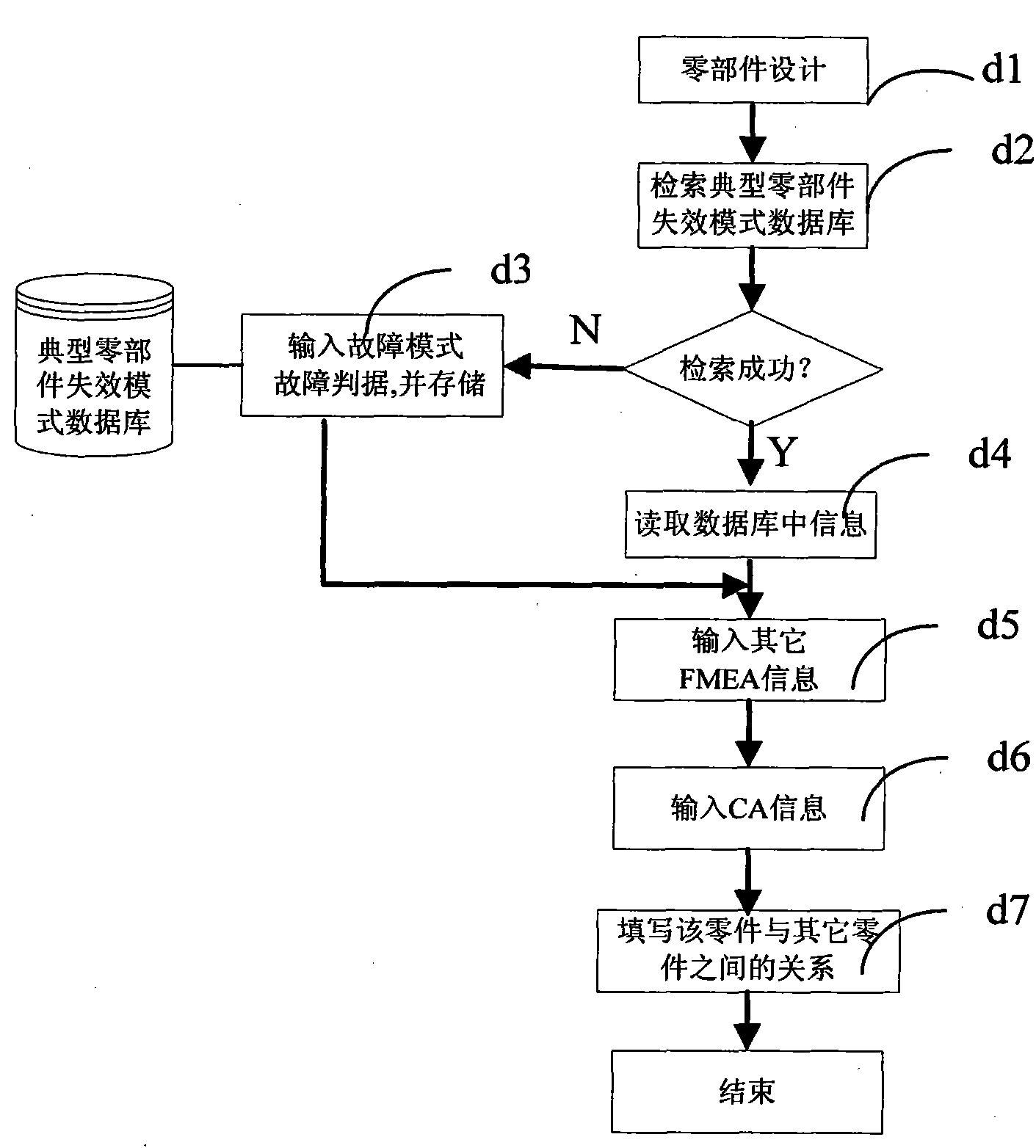

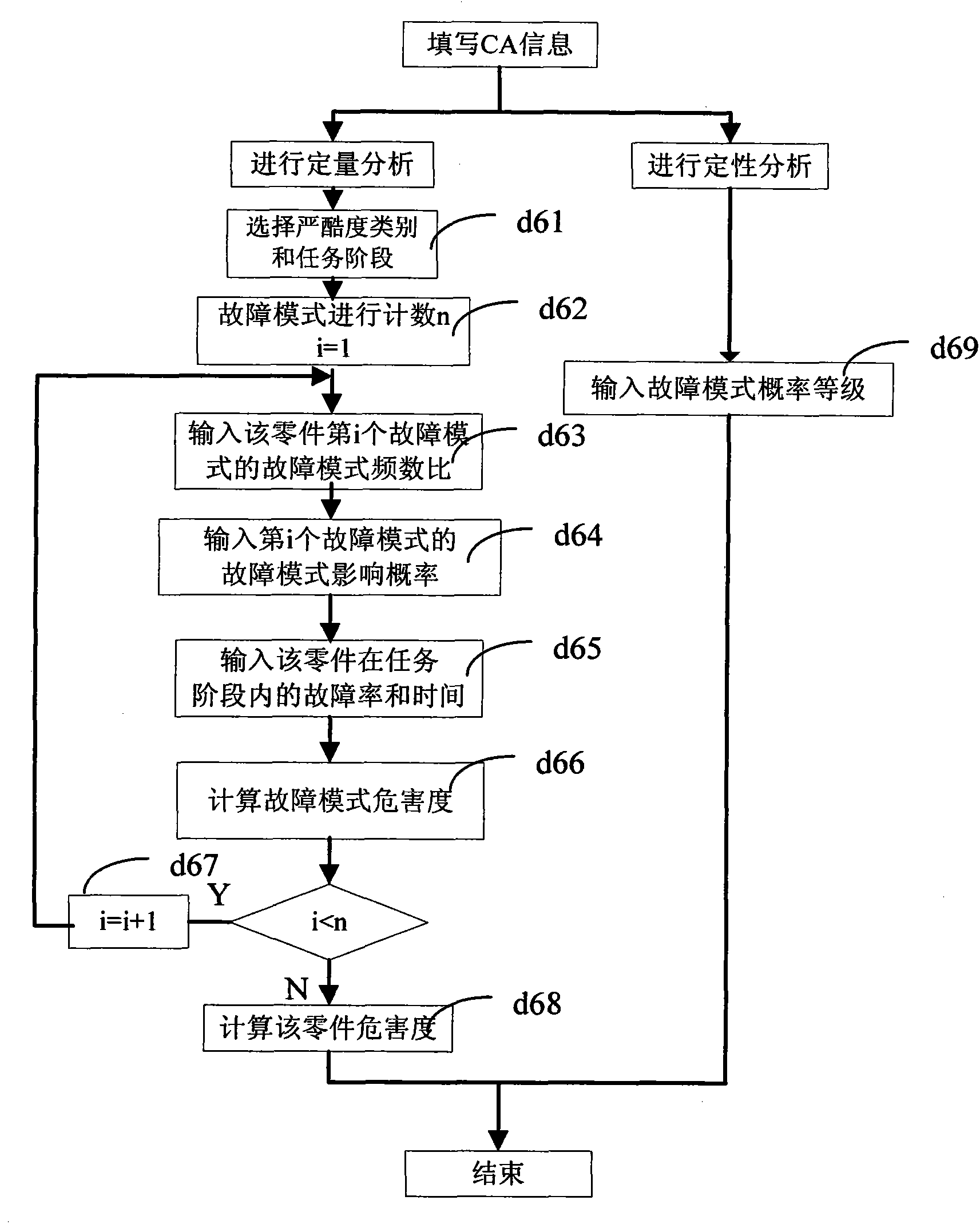

FMECA analysis method of aviation onboard mechanical products

InactiveCN104021248AAvoid confusionEasy to checkSpecial data processing applicationsAviationMechanical products

The invention relates to an FMECA analysis method of aviation onboard mechanical products. The FMECA analysis method of the aviation onboard mechanical products comprises the steps that step a, a typical part failure mode database is built; step b, an FMECA database is built; step c, preparation work before FMECA analysis is carried out; sep d, the design and input of FMECA information of a single part are finished; step e, the FMECA information is stored, the next part is designed, the FMECA information is input and stored until the design of a whole product is finished; step f, FMECA analysis is carried out on the product; step g, an FMECA analysis report is output. The FMECA analysis method of the aviation onboard mechanical products can achieve tight combination of product design and FMECA analysis of the product, systemically manage the FMECA information of each part and clearly reflect the hierarchical relation of the parts of the product.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

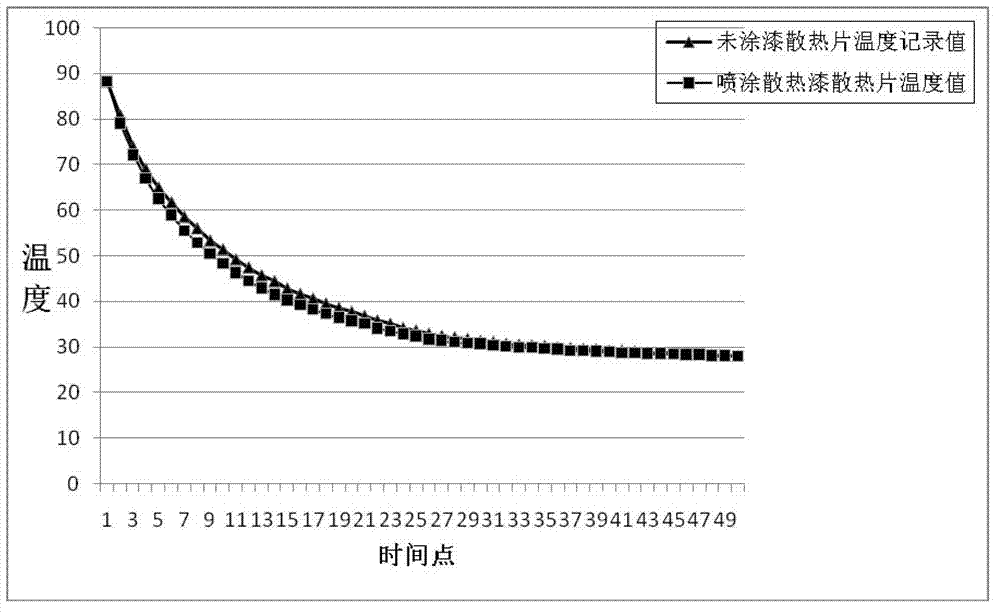

Radiating paint, and preparation method and application thereof

The invention discloses a radiating paint, and a preparation method and an application of the radiating paint. The radiating paint comprises the following components: nano alloy powder, polyvinyl butyral, organic solvent, and cross linking agent. The invention further discloses a preparation method of the radiating paint, and an application of the radiating paint in reducing temperature of electronic products and / or mechanical products, and components of the electronic and / or mechanical products. The radiating paint has high radiance; and within the temperature range from 0 EDG C to 200 DEG C, the emissivity of wavelength of 1micro m is 0.91-0.95, and the emissivity of wavelength of 8micro m-14micro m is 0.92-0.98. The coefficient of heat conductivity of the radiating coat is 143W / m. DEG C, so the paint has excellent heat conducting property. According to the radiation application effect tests, the radiating effect of the radiators is greatly enhanced by the radiating paint, so the electronic products or components of the products are prevented from each danger caused by the excess temperature.

Owner:鹤山市顺鑫实业有限公司

A kind of convenient bagged trash can and its use method

InactiveCN103832743BImprove automationImprove space utilizationRefuse receptaclesLidsPublic placeGear wheel

The invention belongs to the technical field of mechanical product design, and relates to a convenient bagging garbage can and a using method thereof, in particular to a convenient bagging garbage can widely applicable to public places and outdoor or household use. The convenient bagging garbage can is characterized in that a process of convenient bagging of the garbage can is realized mainly through a connecting rod combination mechanism, a spring contact block mechanism, a gear rack and the like, and a series of problems of insanitation in bag taking, trouble in bag tearing, difficulty in bagging and the like in the garbage can bagging process are solved. Compared with an existing automatic bagging garbage can, the convenient bagging garbage can is simpler and more ingenious in used mechanisms, high in space utilization rate, more convenient in bagging process, high in bagging success rate and widely applicable to public places and outdoor or household use.

Owner:陕西皇城大唐维修安装有限公司

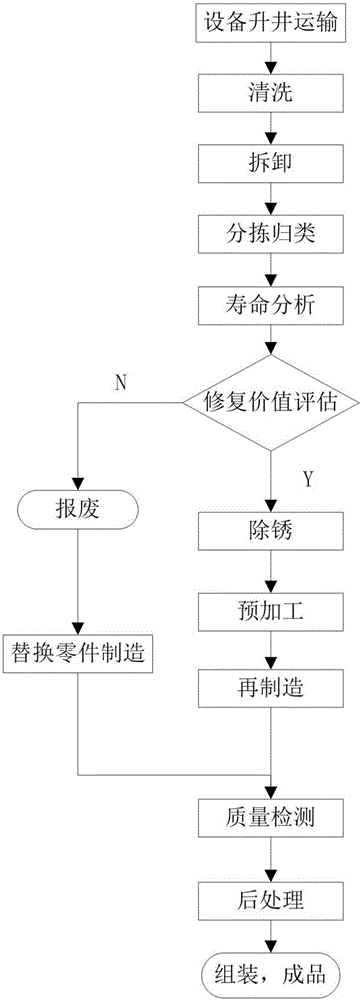

Mine waste machine repair process

InactiveCN106624626AReduce usageReduce maintenance costsWelding apparatusSurface engineeringQuality control

The invention discloses a mine waste machine repair process, and belongs to the field of machine remanufacturing. The process comprises the steps of: cleaning and sorting, analysis and estimation, derusting and premachining, repair and remanufacturing, quality inspection and assembly. The mine waste machine repair process uses waste mine mechanical products as blanks, uses the remanufacturing quality control and the advanced surface engineering technology for repairing failed surfaces to recover geometric sizes, reduces the use of new materials in the remanufacturing process to the greatest extent, recovers and promotes the product quality and performances, prolongs the product service life, improves the product reliability, reduces the maintenance costs of remanufactured products, reduces the energy consumption and the pollution emission generated in chain production, realizes the equipment performance promotion and great-leap-forward development requirements under lower cost, and excavates additional values contained in waste parts to the greatest extent.

Owner:甘肃兰煤机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com