Roller combined gyration-type used sand reconditioning system

A technology of used sand regeneration and treatment system, which is applied in the direction of cleaning/processing machinery for casting materials, casting molding equipment, removing smoke and dust, etc. It can solve the problem of incomplete fault feedback system, troublesome and inconvenient operation, and increase investment and manufacturing. cost and other issues, to achieve the effect of improving the intensification of technology and equipment, compact and efficient configuration, and expanding use and scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

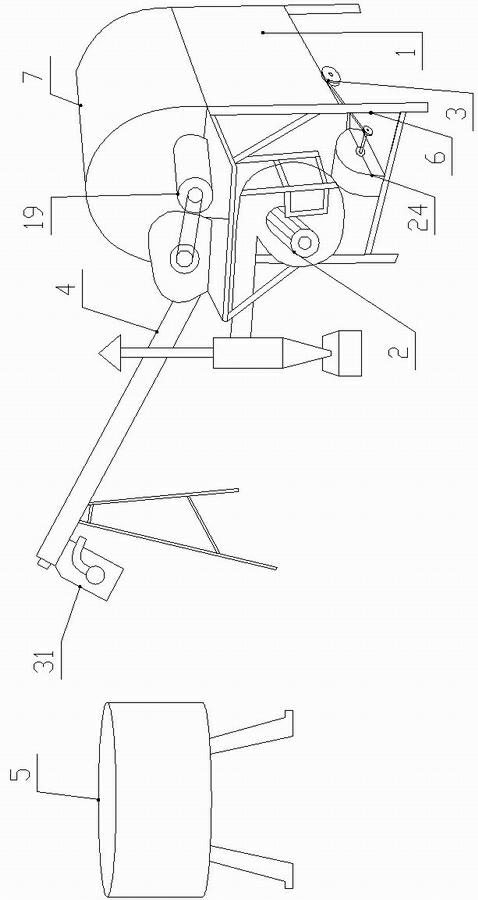

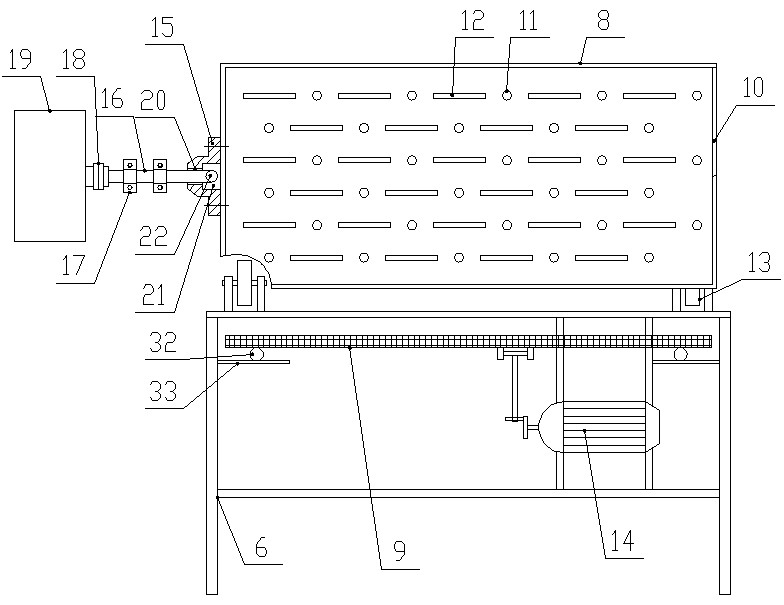

[0026] Such as Figure 1 to Figure 5 As shown, the drum combined rotary type used sand regeneration treatment system of the present invention includes a drum reclaimer 1, a dust removal device 2, a secondary demoulding device 3, a conveying device 4 and a sand mixer 5, and the drum reclaimer 1 The discharge port of the secondary demoulding device 3 is connected to the feed port of the secondary demoulding device 3, the dust removal device 2 is located at the side of the drum recycler 1, the discharge port of the secondary demoulding device 3 is connected to the conveying device 4, and the sand mixer 5 is located at the At the outlet of the conveying device 4.

[0027] The drum type recycling machine 1 includes a frame 6, a casing 7 arranged on the frame 6, a drum 8 inside the casing 7, an unbalanced power drive device connected to the drum 8 and a vibrating screen 9 below the drum 8, One end of the drum 8 is provided with a feeding port 10, and the inner wall of the drum 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com