Patents

Literature

2277results about "Mould handling/dressing devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

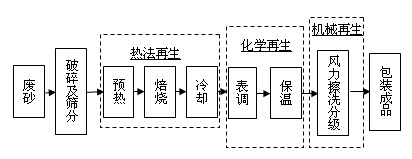

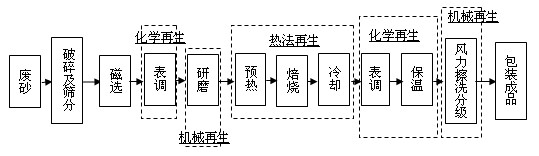

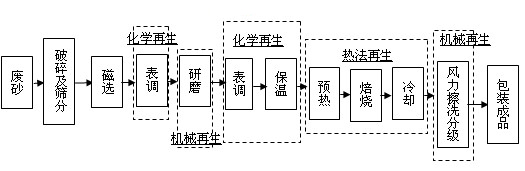

Chemical regeneration method in casting waste sand disposing process

InactiveCN102000764AGood regeneration performanceSolve sinteringMould handling/dressing devicesChemical treatmentDie casting

The invention provides a chemical regeneration method in the casting waste sand disposing process, relating to a process for performing surface chemical processing on various impurities which are attached on the surface of waste sand and are better not be reused in casting-form sand materials. During the chemical regeneration, chemical surface conditioning liquid I or / and chemical surface conditioning liquid II is or are used, and the disposing sand temperature is not more than 400 DEG C. The chemical regeneration method in the invention is carried out before or after the hot-method regeneration disposing or mechanical regeneration disposing of the casting waste sand disposing processing, and the chemical disposing technique is combined with the traditional hot-method regeneration and mechanical friction regeneration. The regeneration new sand formed in the method has better quality of the new sand, can better meet the application requirement on multi-form sand producing technique (hot core box, warm core box and cold core box) for recycling different casting waste sands (hot core box resin casting waste sand, warm core box resin casting waste sand, gas or / and organic fat hardening cold core box resin casting waste sand and profile damp die casting sand), and has better economical efficiency.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Rapid manufacturing method for sprayed and cured molding sand

InactiveCN104999031AReduce distortionImprove assembly qualityFoundry mouldsMould handling/dressing devicesCasting moldUltimate tensile strength

The invention discloses a rapid manufacturing method for sprayed and cured molding sand. The rapid manufacturing method is characterized by comprising the following steps: molding sand is mixed with a curing agent in advance, and diluted resin is sprayed onto the molding sand mixed with the curing agent through a spray; through powder layering and resin spraying, the molding sand with sprayed resin is cured, and then adhesive forming is realized; the formed layers are heated for drying; the entity of a casting mold is formed through layer-by-layer printing, stacking and curing, and then the strength of the casting mold is improved through further drying. Through adoption of the rapid manufacturing method, the problem that the amount of gas evolution of the casting mold is overlarge can be solved through reduction of the resin consumption, the spray is protected from blockage, the curing speed is increased, the assembly quality of the casting mold and a mold core is improved, and finally the casting mold with relatively high strength is obtained.

Owner:宁波高新区多维时空科技有限公司

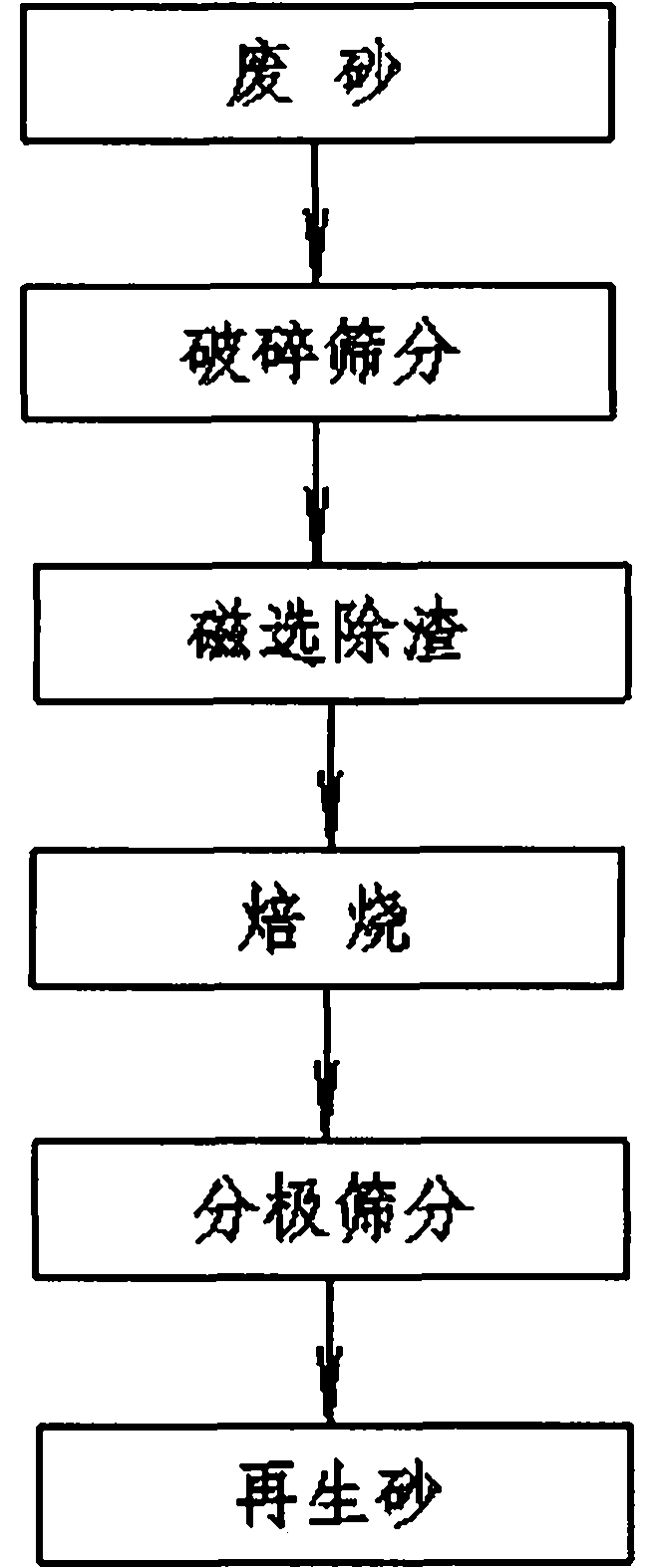

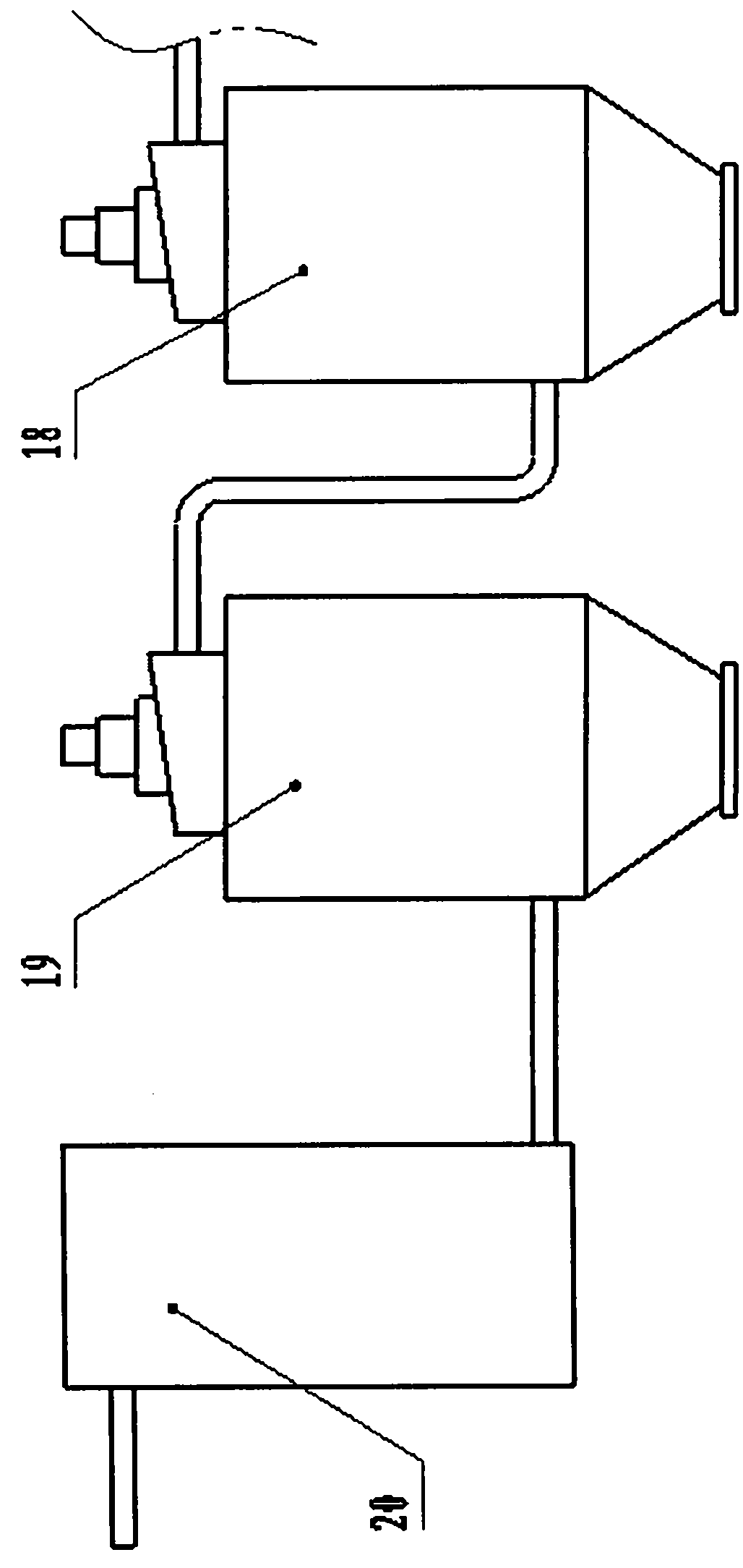

Waste foundry sand regenerating process method

InactiveCN102009122AReduce roasting energy consumptionMould handling/dressing devicesFoundryCombustor

The invention discloses a waste foundry sand regenerating process method, which comprises the processes of crashing and screening, magnetic separation, roasting and graded screening. The roasting process particular comprises the following steps of: preheating waste sand which does not enter a furnace and air for combustion by using the heat of hot sand which is discharged from the furnace; controlling the roasting temperature of a roasting furnace to be between 780 and 850 DEG C by controlling a roasting furnace burner and the flow of the waste sand entering the furnace; separating roasted waste sand from waste gas by using a cyclone dust collector, a spraying dust collector and a bag type dust collector; and exhausting the separated waste gas to the atmosphere after passing through an alkali liquor washing tank and an adsorption tank, wherein the bag type dust collector has a high-pressure air flow blowback control bag dust-removing structure; and the dust-removing process and the normal operation of a system are maintained by controlling the bag dust-removing cycle of the bag type dust collector. Compared with the conventional method, the waste foundry sand regenerating process method has the advantages of greatly reducing energy consumption and guaranteeing the cleaness of the exhausted waste gas.

Owner:LIUZHOU AOKAI ENG MACHINERY

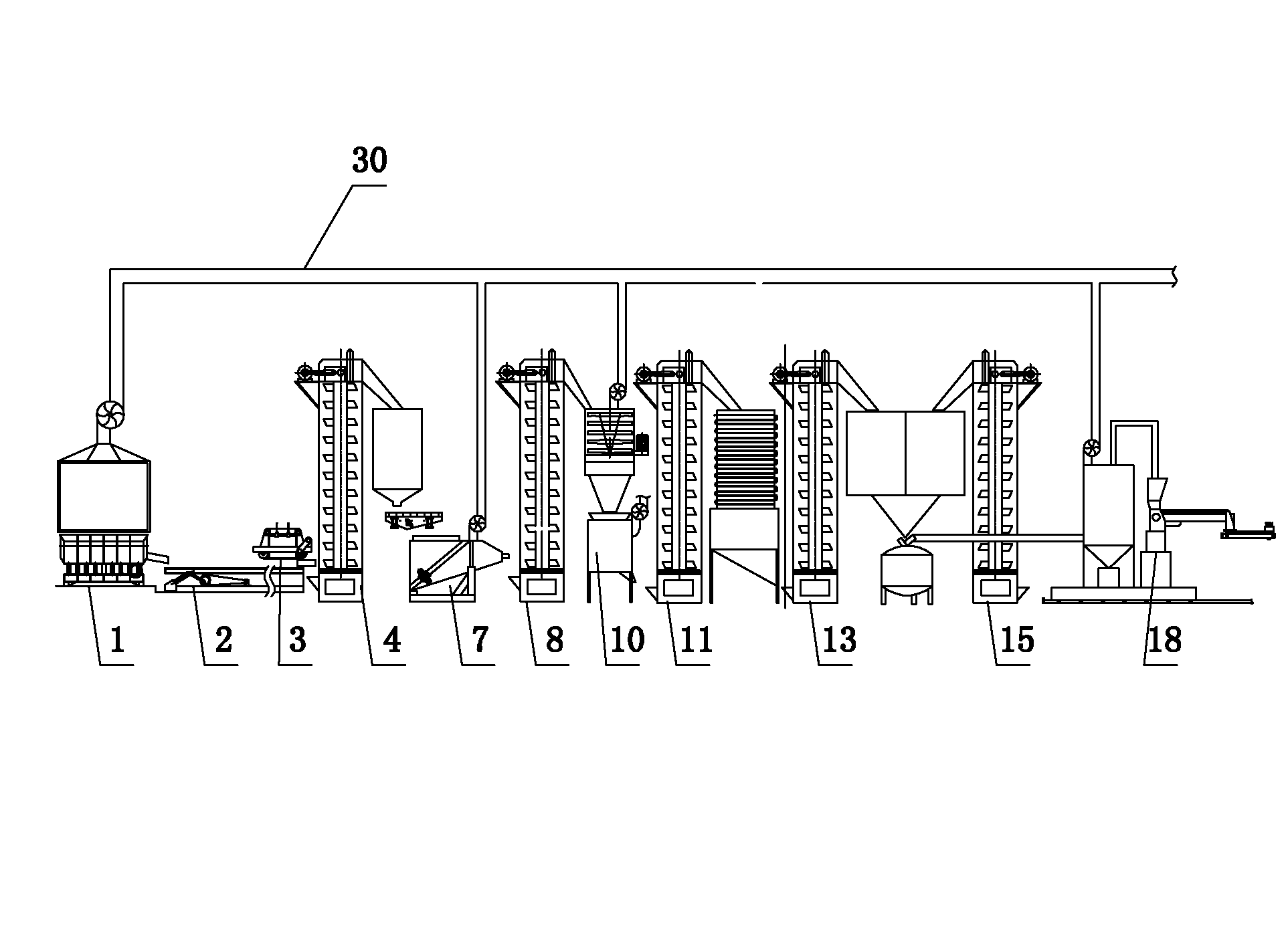

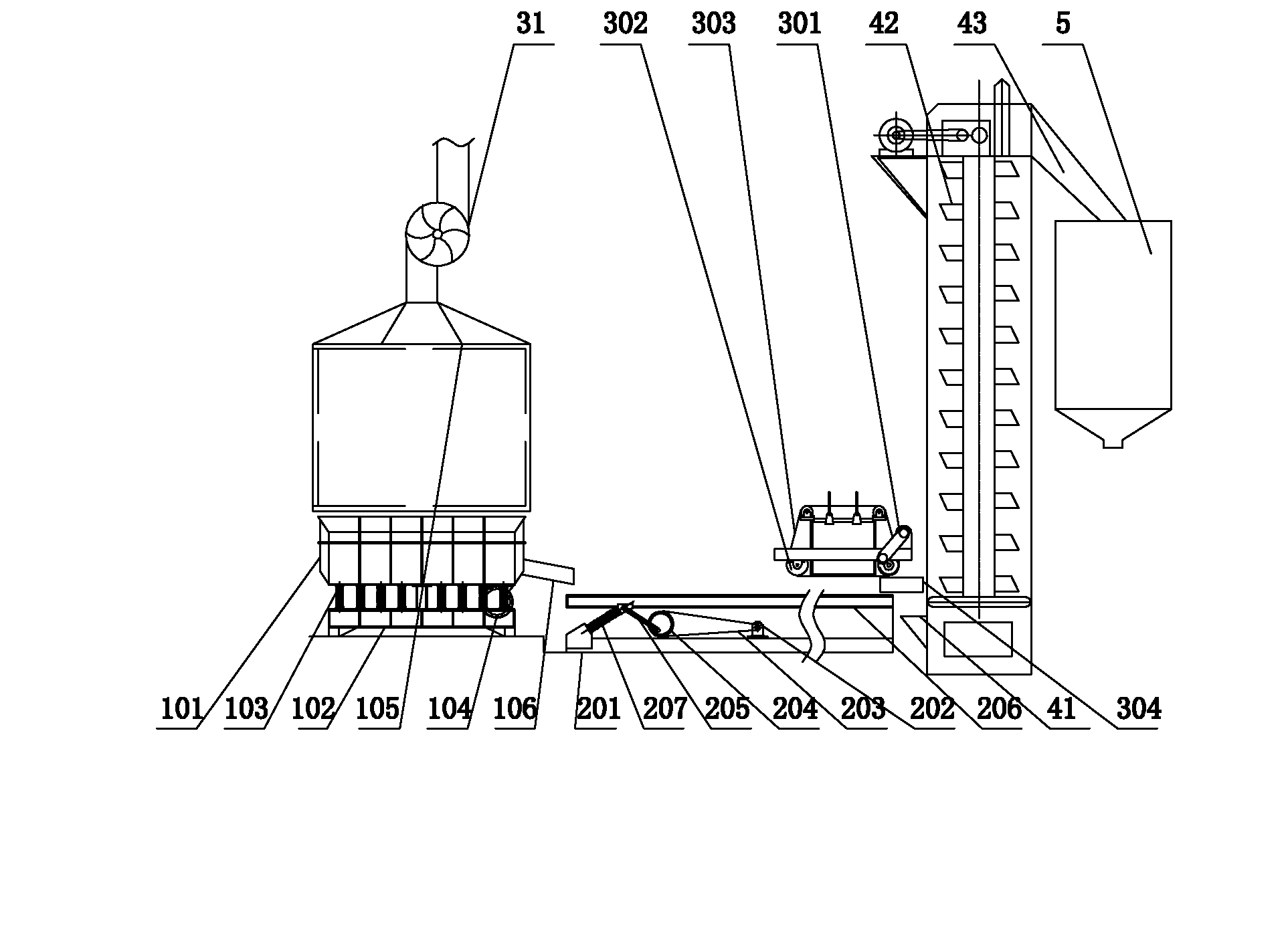

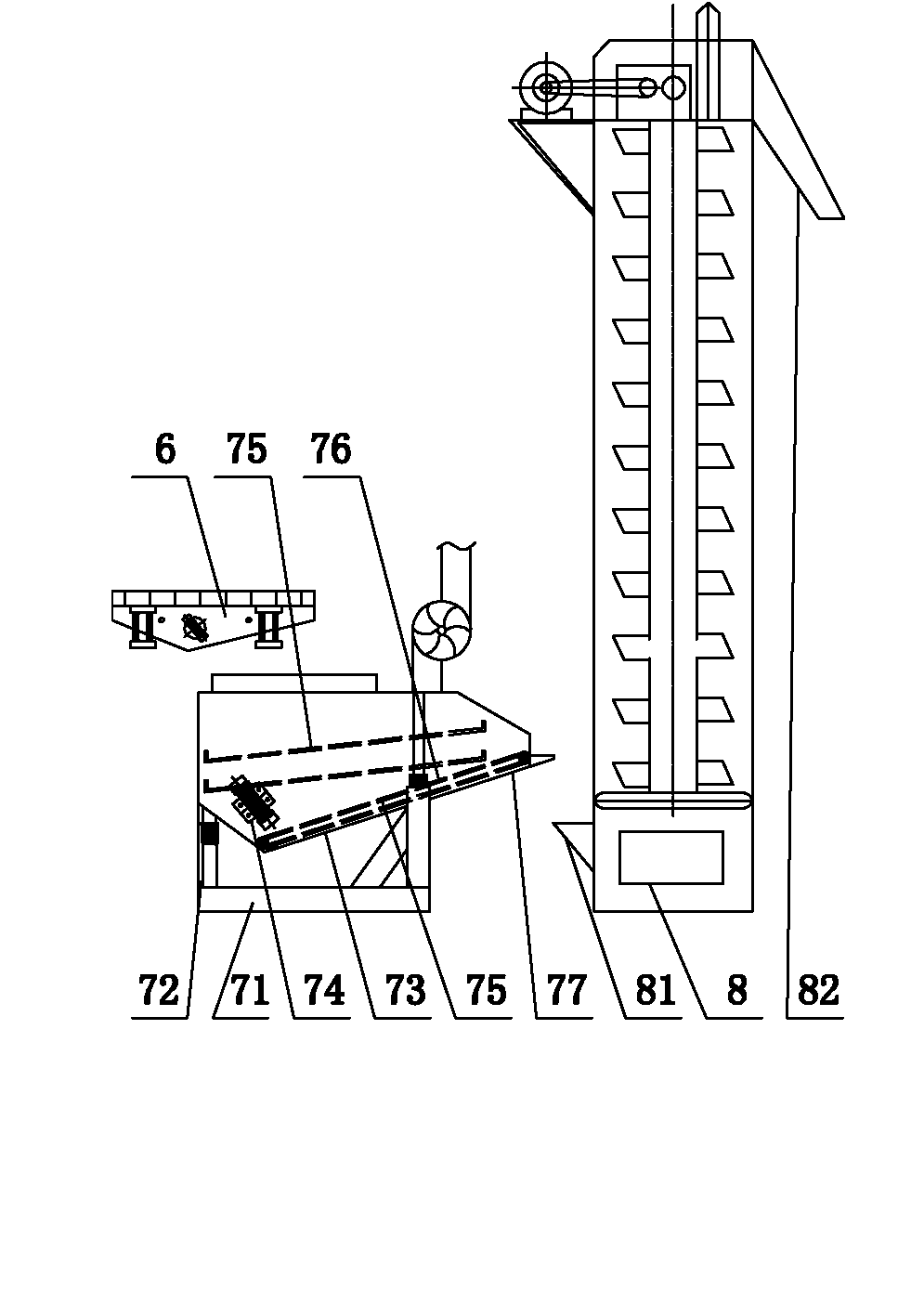

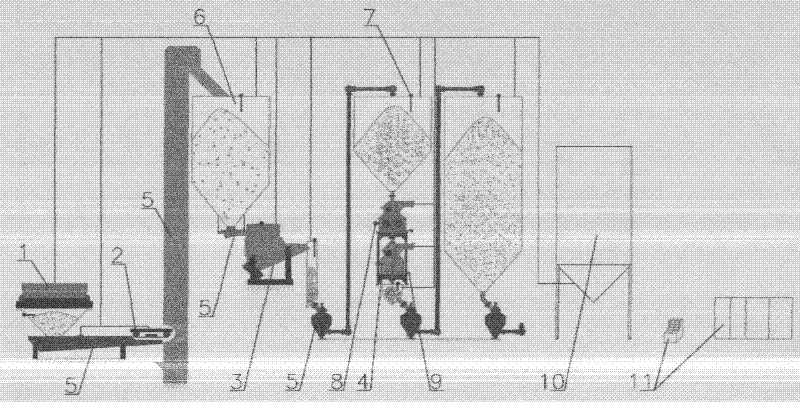

Full-automatic reprocessing line of casting-purpose resin sand

InactiveCN102909315AReduce manufacturing costImprove recycling efficiencyMould handling/dressing devicesProduction lineTemperature control

A full-automatic reprocessing line of casting-purpose resin sand comprises a shakeout system, a shakeout machine, a suspended magnetic separator, a crusher, a reprocessing machine, a winnower, a double-cavity sand bin, a material mixing hopper, a sand mixer and the like. The reprocessing line of the resin sand is low in production cost, high in recycling efficiency and small in pollution. By the reprocessing line, procedures such as shakeout, crushing, reprocessing, winnowing, temperature control, material mixing, dust removing and the like can be finished automatically. The reprocessing machine is used for reprocessing by unique collision, extrusion and centrifuging ways; little binder is remained on used sand, reprocessed sand is high in quality; because sliding rails are arranged at the bottom of the sand mixer, a plurality of sand molds can be molded conveniently; deformation or damage of the sand mould due to transportation are prevented; and the full-automatic reprocessing line of the casting-purpose resin sand is suitable for large-scale production and has high promotional value.

Owner:HUBEI JIANGHAN HEAVY IND

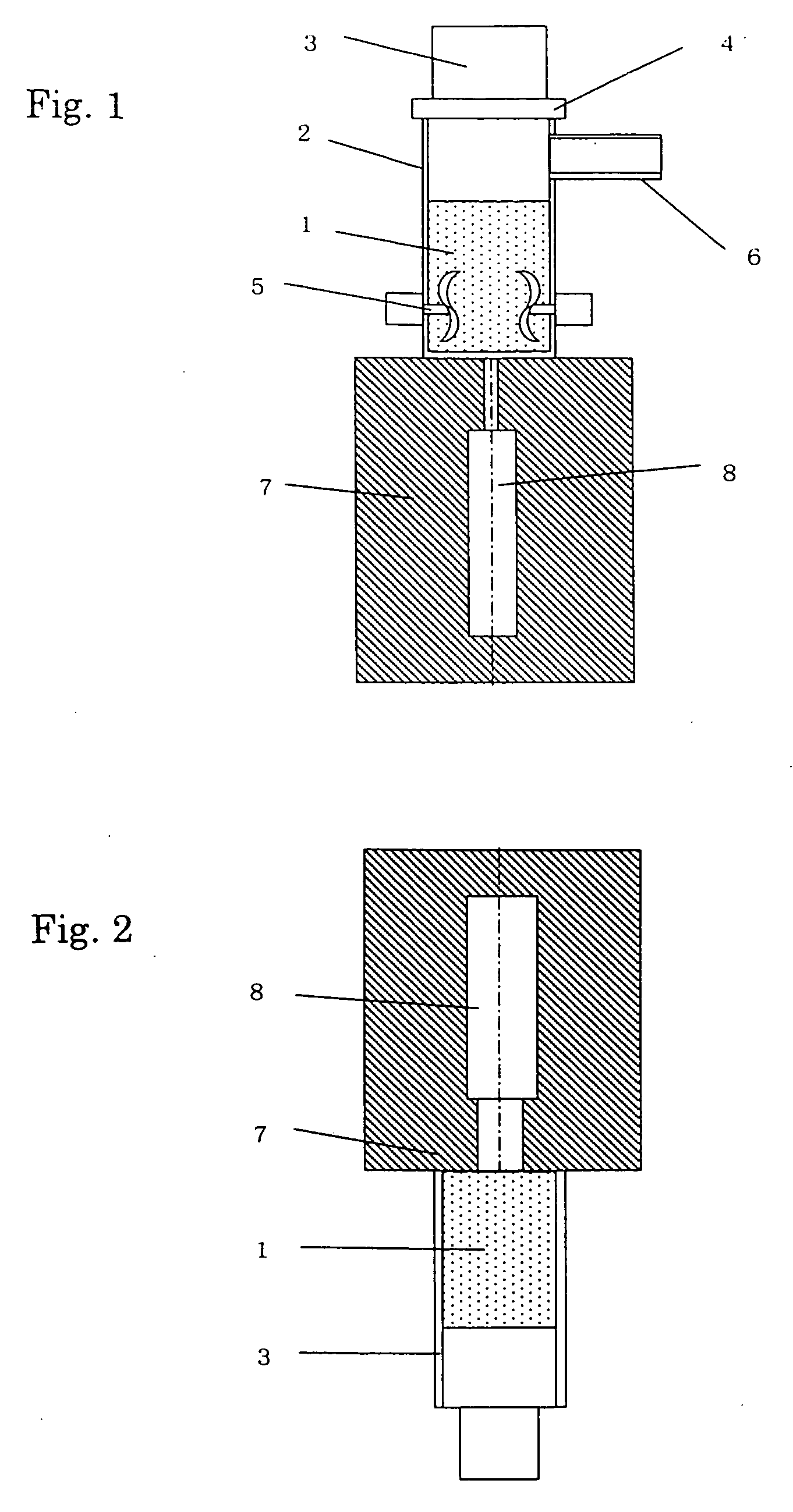

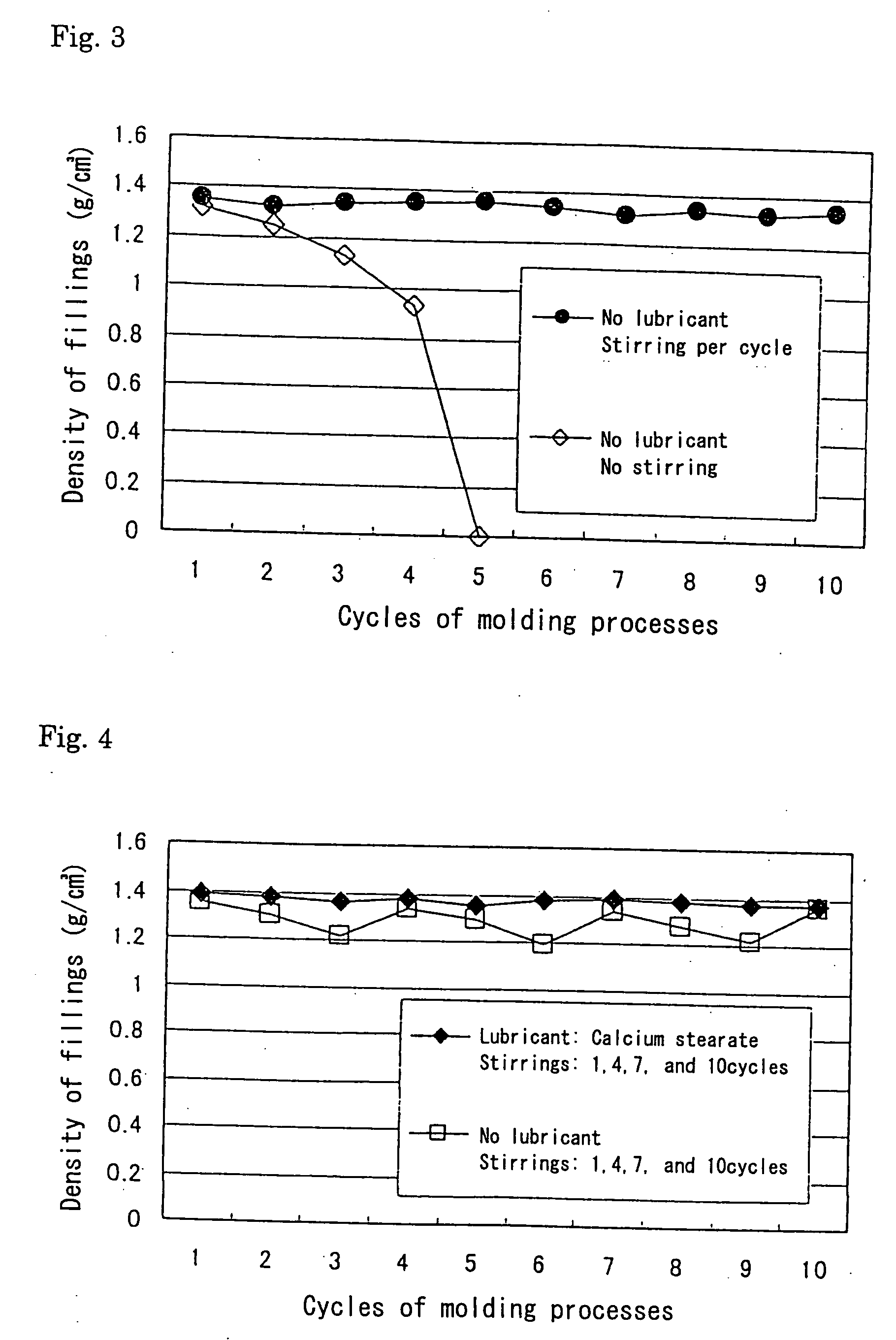

Dry aggregate mixture, method of foundry molding using dry aggregate mixture and casting core

InactiveUS20060071364A1Avoid concentrationEasy constructionMovable spraying apparatusFoundry mouldsFoundryHigh humidity

There are provided a dry aggregate mixture wherein the binder, even when heated, does not evolve unpleasant odor or gas hazardous to human health; a method of foundry molding wherein a space for foundry molding, up to minute portion thereof, can satisfactorily be filled with an aggregate mixture composed of a binder and granular aggregate; and a method of foundry molding wherein the mold used in molding of an aggregate mixture composed of a binder and granular aggregate can retain satisfactory properties even in high humidity. In the method of foundry molding, a mold is formed by the use of a dry mixture obtained by providing an aggregate mixture composed of granular aggregate, a water soluble binder and water and evaporating the water contained in the aggregate mixture through heating, pressure reduction or aeration while mixing so as to effect separation into single granules, or with the addition of a lubricant and a crosslinking agent thereto.

Owner:SINTOKOGIO LTD

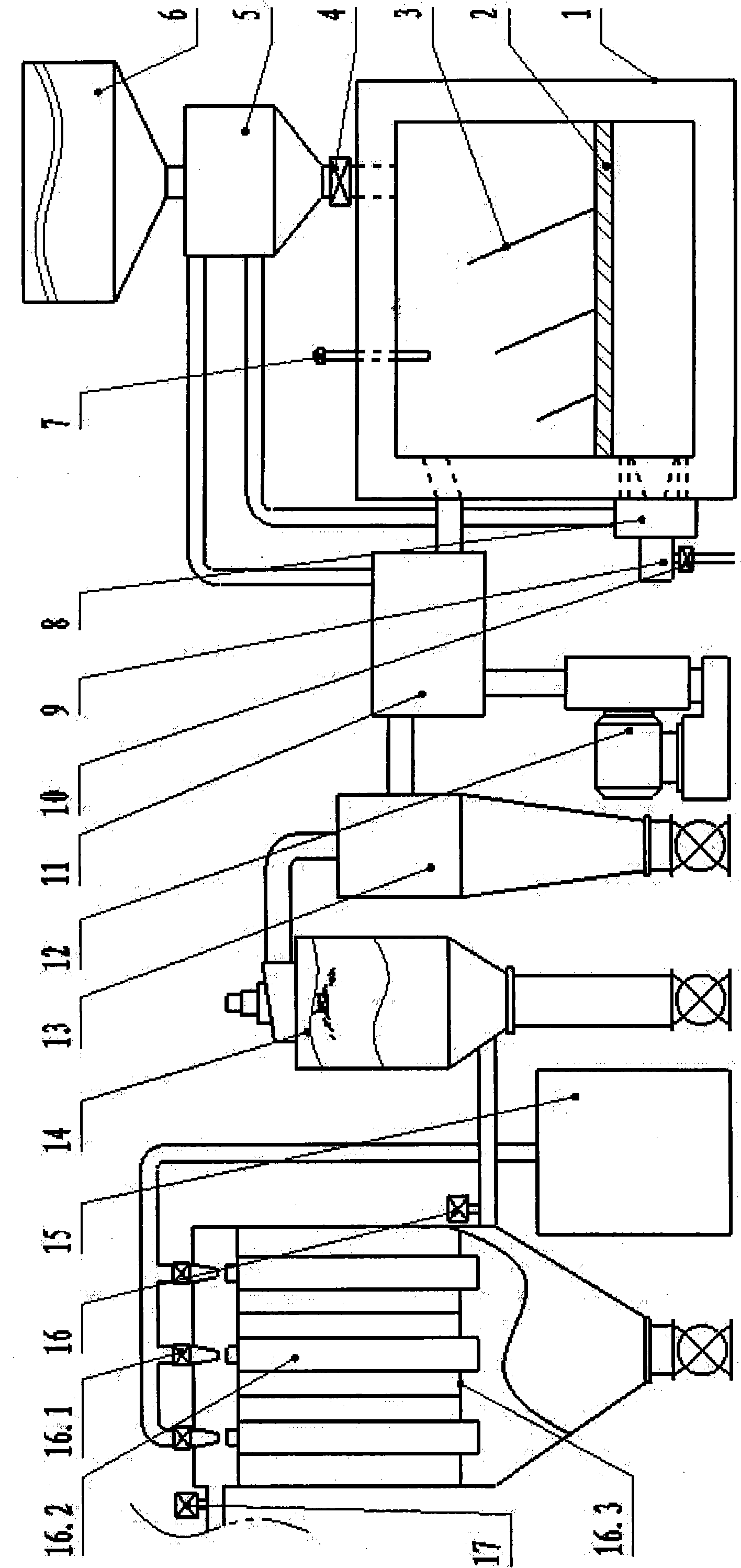

Used sand reclamation method and used sand reclamation thereof

InactiveCN101209485AQuality improvementStrong ability to remove inert film on sand surfaceMould handling/dressing devicesSodium silicateHeat flow

The invention discloses a used sand regeneration method and a used sand regeneration system thereof. The sodium silicate used sand is positioned in a heat flow used sand regeneration machine 1 for being heated and cleaned, an inert membrane at the surface of the used sand is dissolved, the sewage passes through a used sand layer, the fine powder in the sewage is retained in the regeneration sand,and the sodium silicate flows into a storage water tank with water. The regeneration sand is then sent to a dry regeneration machine 18 for dedusting after being sent to a dryer 10 for drying, and then the clean regeneration sand is obtained. Liquid in the storage water tank can be repeatedly reused for cleaning the used sand. When the sodium silicate content is too high to be reused, concentration and recycling can be done to solution. The invention can not only produce the high quality regeneration sand, but also can realize zero discharge of the sewage.

Owner:河南省巨辉机械设备有限公司

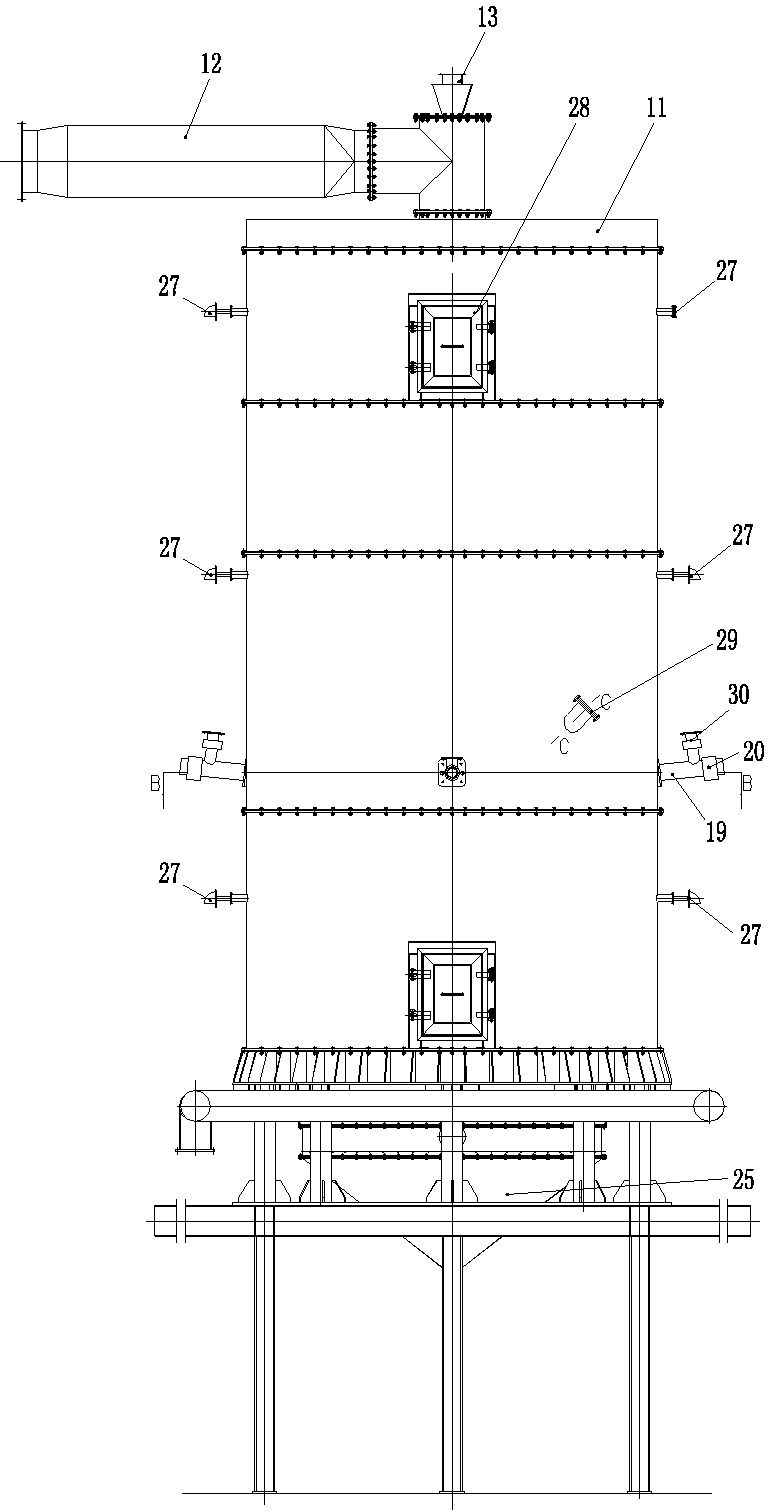

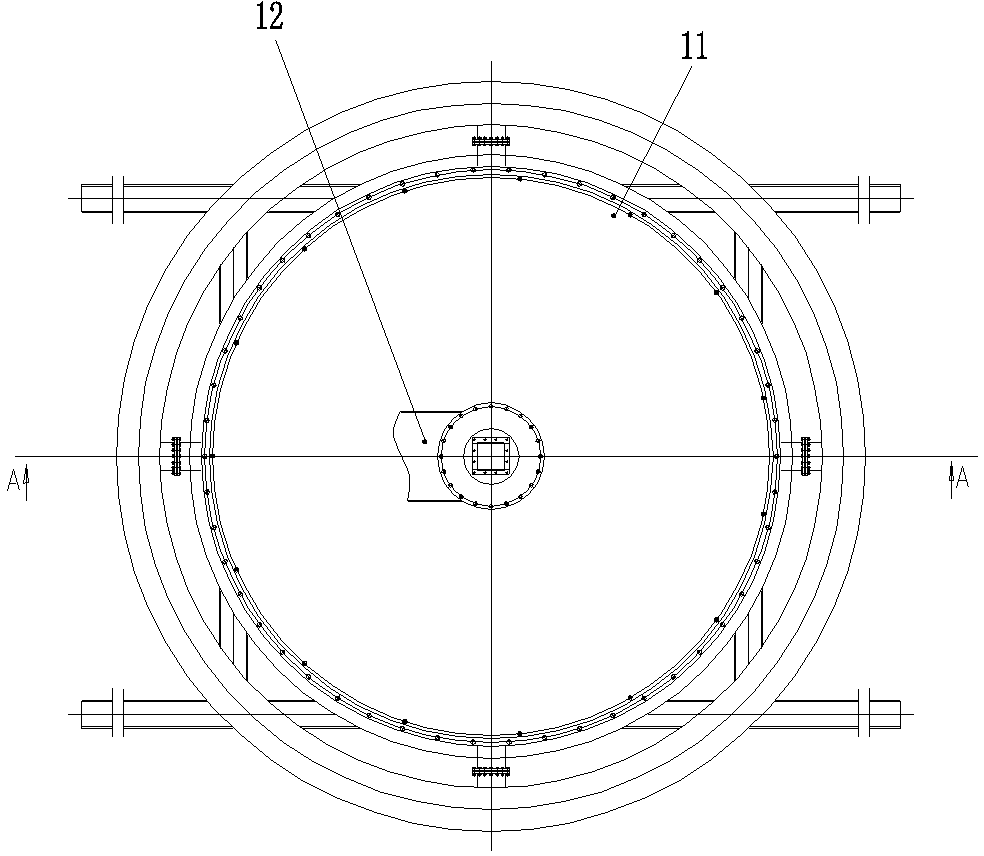

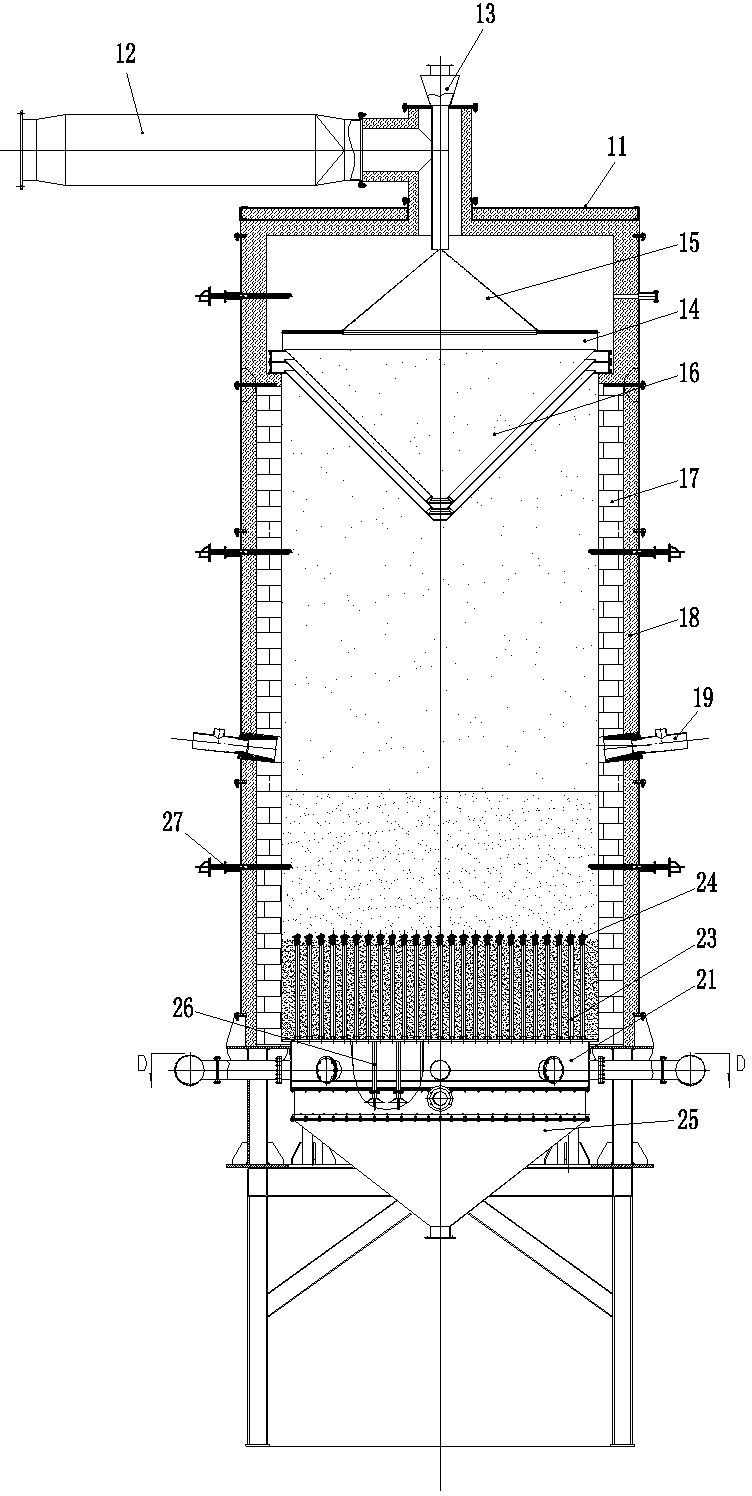

Boiling fluidizing roasting furnace

ActiveCN102914154AImprove collection efficiencySpeed up coolingMould handling/dressing devicesFluidised-bed furnacesCombustorCooling rate

The invention relates to a waste moulding sand or core sand reproducing device, in particular to a boiling fluidizing roasting furnace which comprises a furnace body. The furnace body is internally provided with a distributing heating chamber on the upper part and a roasting heating chamber on the lower part; the wall of the roasting heating chamber is provided with a burner; and the upper part of the distributing heating chamber is provided with a distributing cone. The boiling fluidizing roasting furnace is characterized in that: the bottom of the heating chambers is provided with a heat exchanging area, the burner is arranged above the heat exchanging area, an air collecting chamber with more than one air inlet is fixedly arranged below the furnace body, an air pipe is fixedly arranged on the top wall of the air collecting chamber, the lower end of the air pipe is arranged in the air collecting chamber, and the upper end of the air pipe is arranged in the heat exchanging area and provided with an air hood. The speed of cooling the roasted material is increased under the premise that the energy is fully utilized, so that the work efficiency of the existing waste moulding sand or core sand reproducing device is improved.

Owner:SCIVIC ENGINNEERING +1

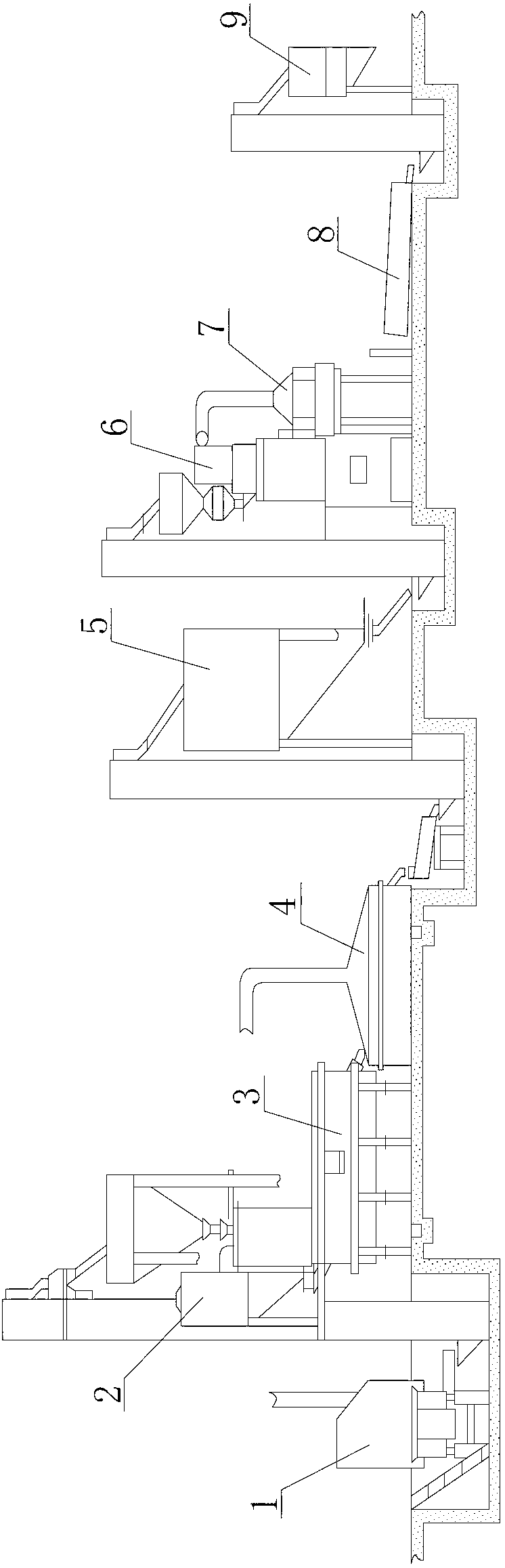

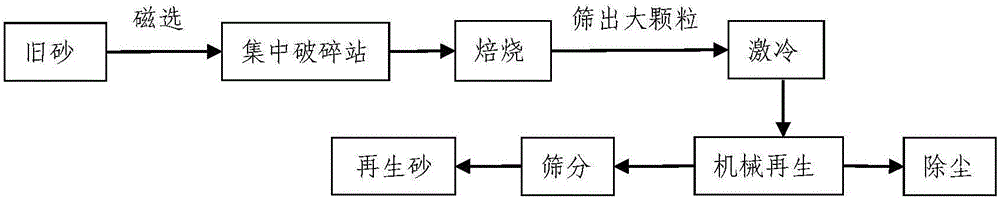

Waste sand recycling equipment and use method thereof

ActiveCN103317084AImprove recycling ratesEasy to operateMould handling/dressing devicesSilanesEngineering

The invention relates to waste sand recycling equipment which comprises a vibration crushing screening machine, an old sand lifting machine, a magnetic separation machine, a hot-method regeneration device, a cooling bed, a vibration screen and a new sand lifting machine which are connected in sequence. A use method of the waste sand recycling equipment comprises the following steps of: a, adding waste sand into the vibration crushing screening machine, crushing the waste sand into small particles, feeding the small particles into the old sand lifting machine, conveying the small particles to the magnetic separation machine, and removing iron materials; b, feeding preheated waste sand into the hot-method regeneration device for sintering; c, cooling the high-temperature sintered sand through the cooling bed, feeding the cooled sintered sand into the vibration screen, and enabling the sintered sand to pass through the new sand lifting machine to obtain regenerated sand; d, preparing materials according to the following formula: 1.6-1.7kg of a methenamine solution, 2.7-2.8kg of phenolic resin, 100-300g of calcium stearate, 60-100g of silane and 150kg of the regenerated sand and / or raw sand; e, adding the materials into a stirring kettle in sequence and uniformly stirring to obtain precoated sand. The waste sand recycling equipment has the beneficial effects of simplicity for operation, high old sand recycling rate and simplicity for popularization.

Owner:金丰(新乡)矽砂有限公司

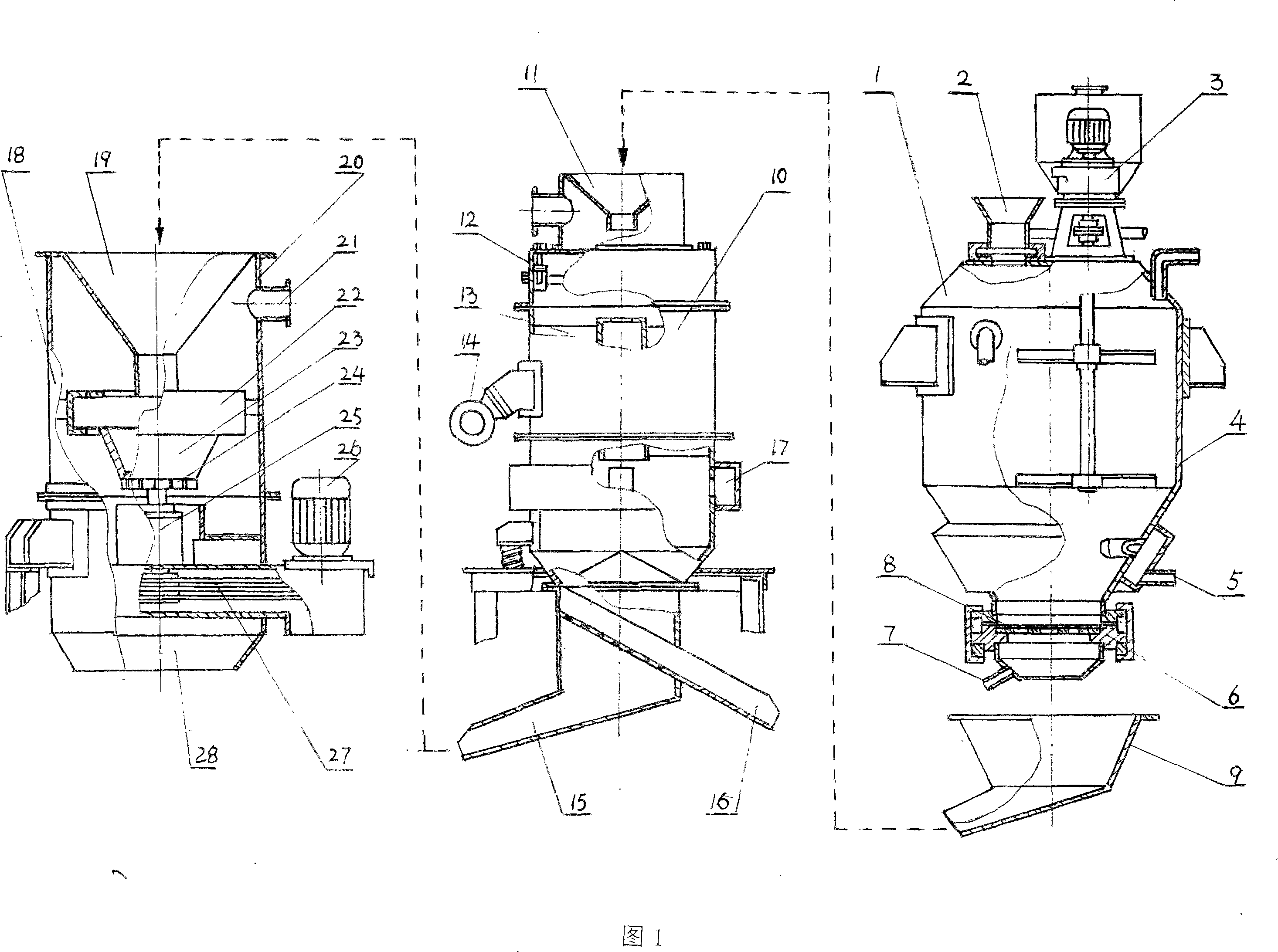

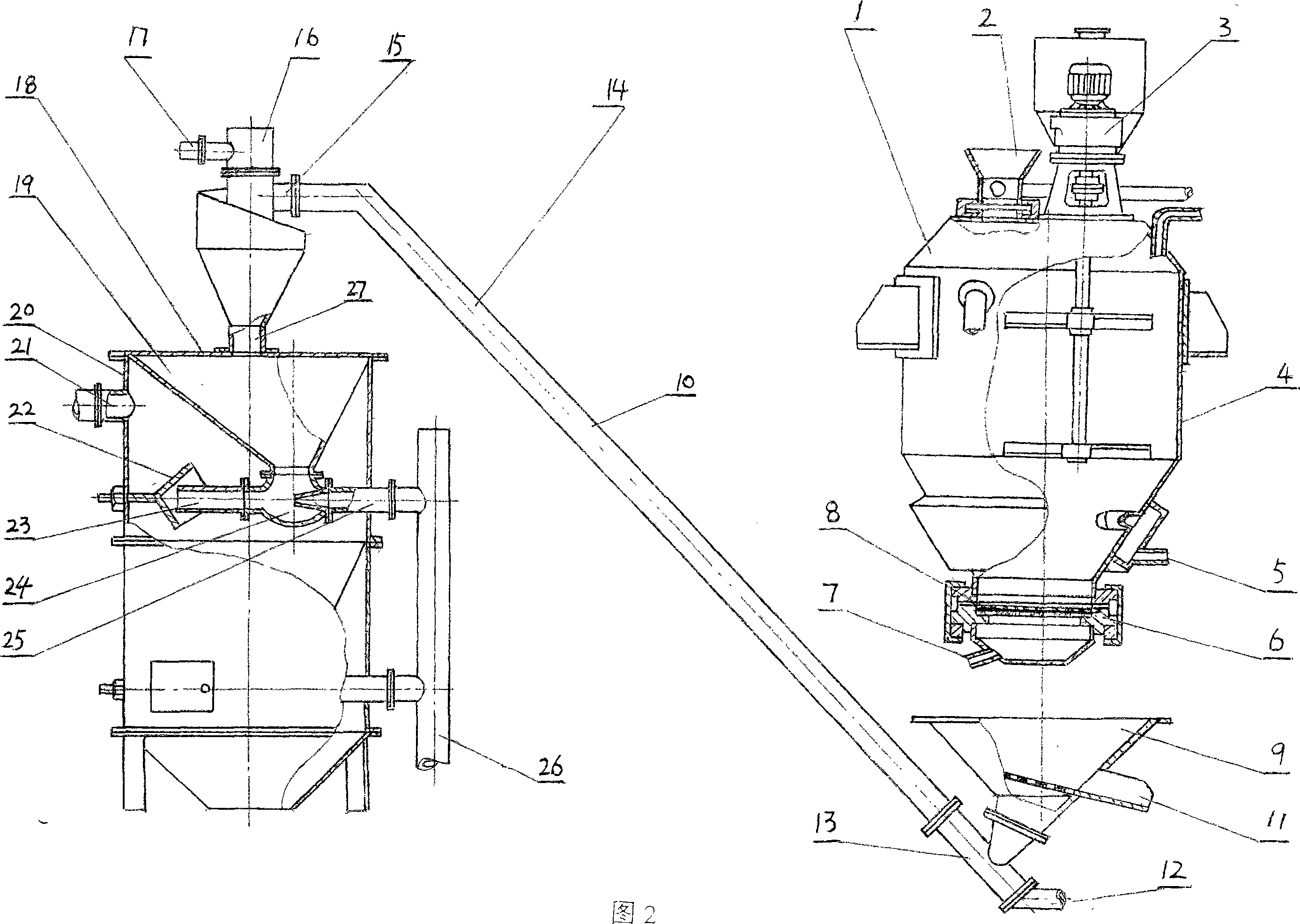

Foundry self-hardening sand recycling system process

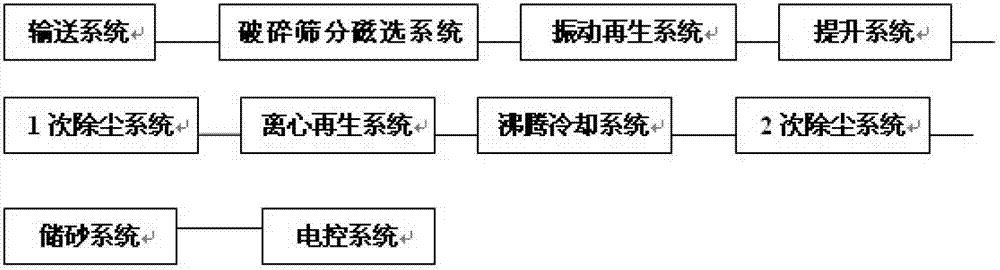

ActiveCN102873268AReduce manufacturing costSimple processMould handling/dressing devicesFoundryElectric control

The invention discloses a foundry self-hardening sand recycling system process, which comprises a delivery system, a crushing, screening and magnetic separation system, a vibrating regeneration system, a hoisting system, a primary dedusting system, a centrifugal regeneration system, a boiling cooling system, a secondary dedusting system, a sand storage system and an electric control system. The invention overcomes the defects of the prior art, waste sand is recycled, the production cost is saved, energy is saved, emission is reduced, environment is protected, and the pollution is avoided.

Owner:ANHUI CHENGUANG HIGH WEAR RESISTANCE TECH CO LTD

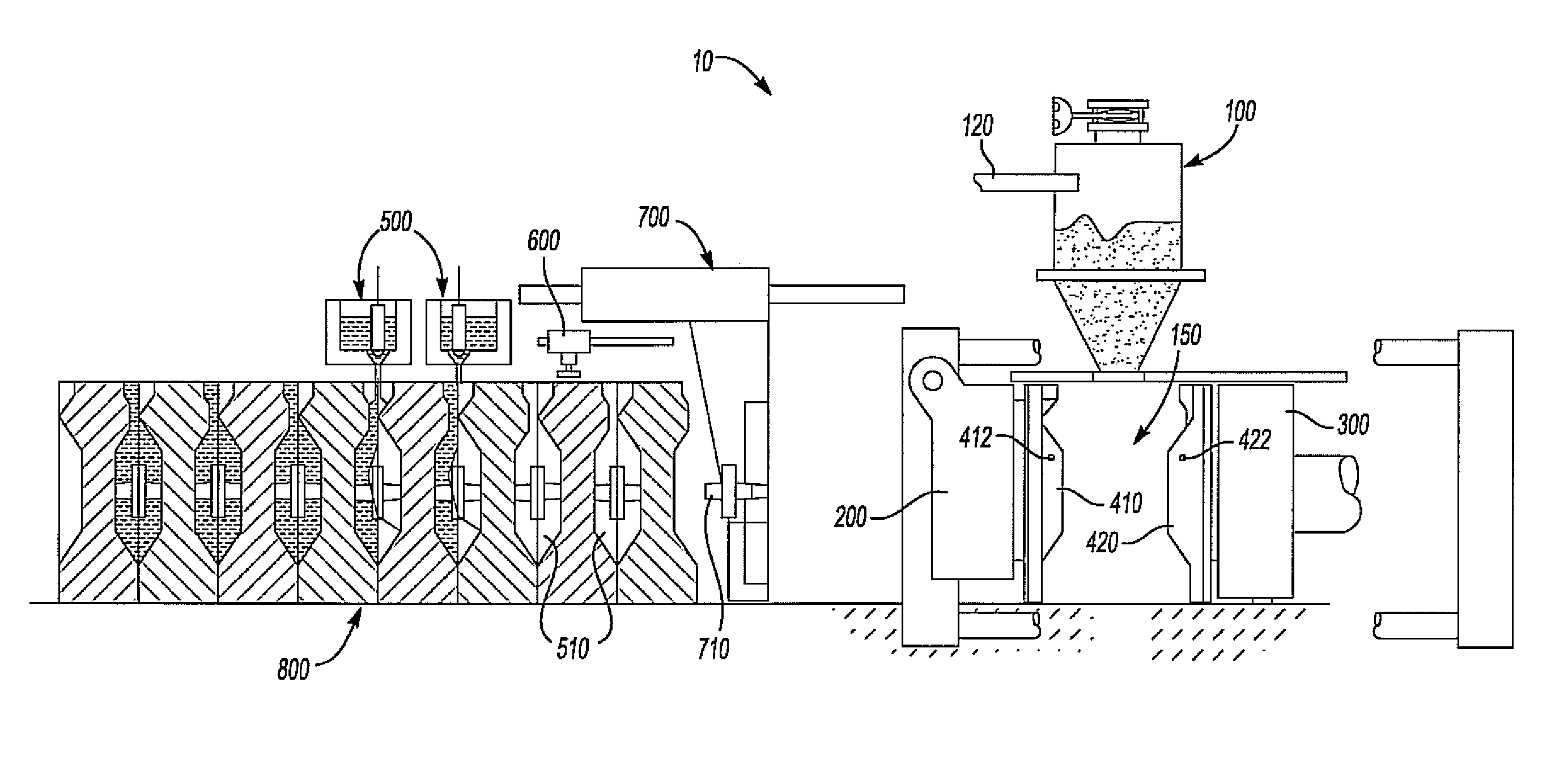

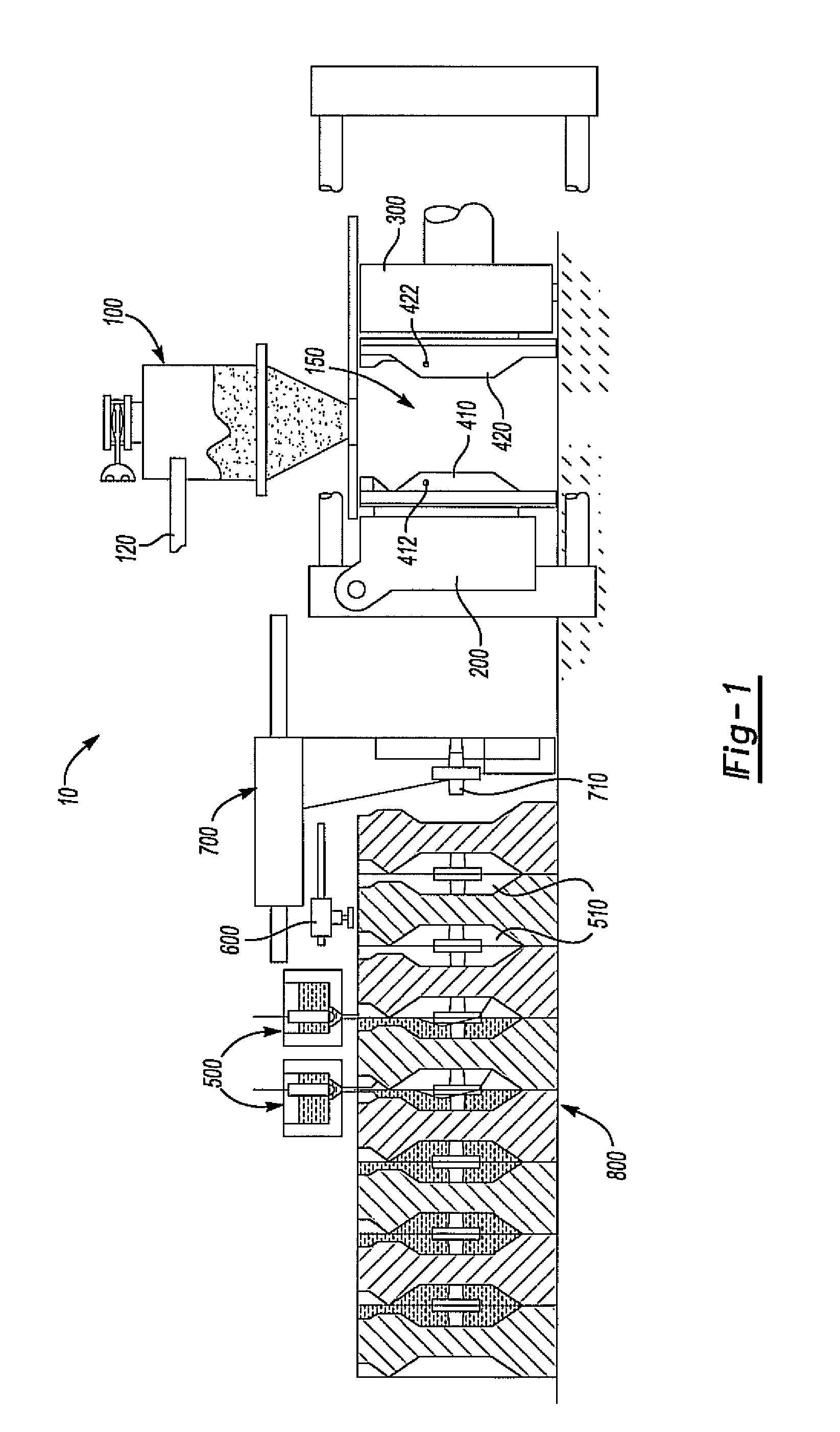

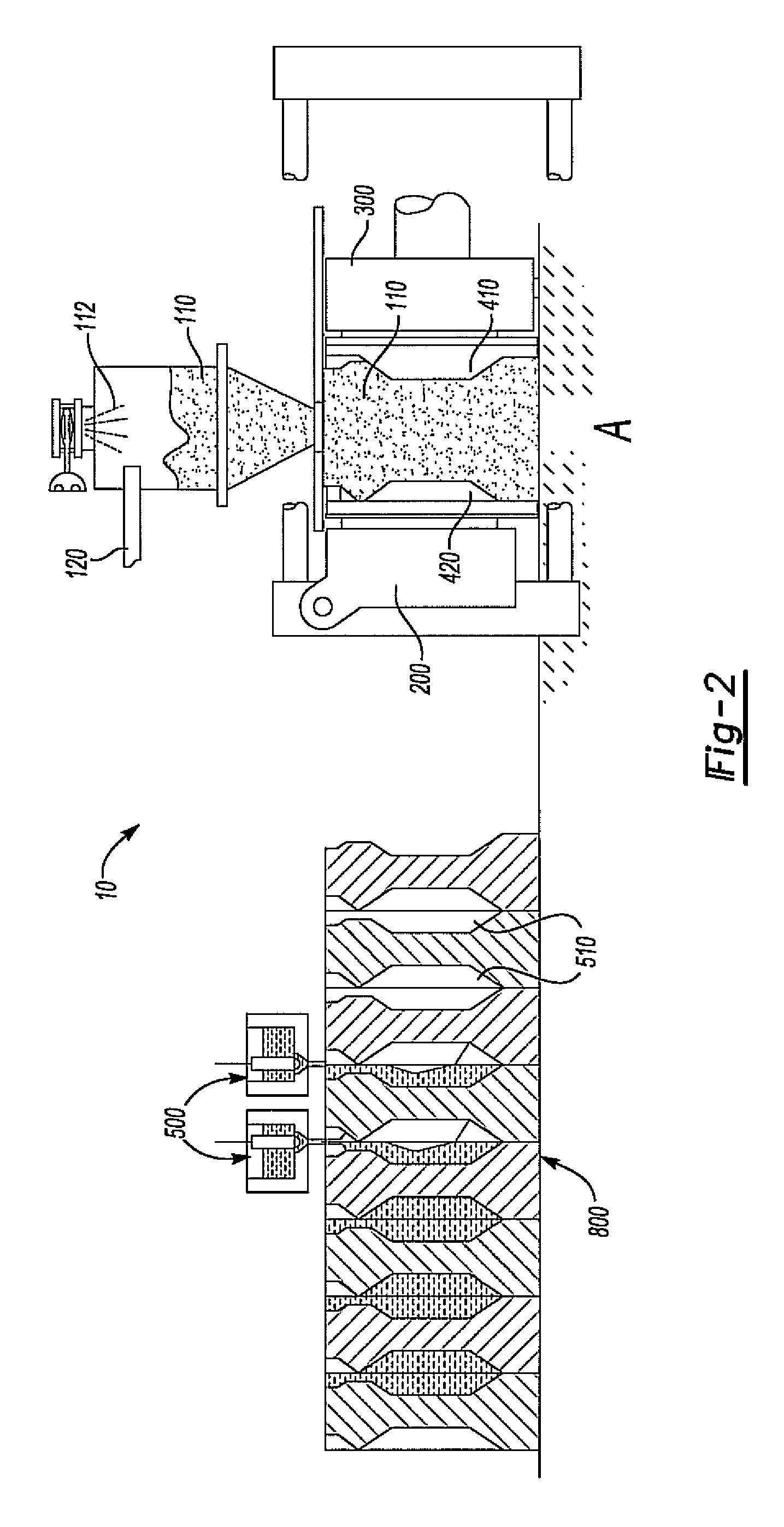

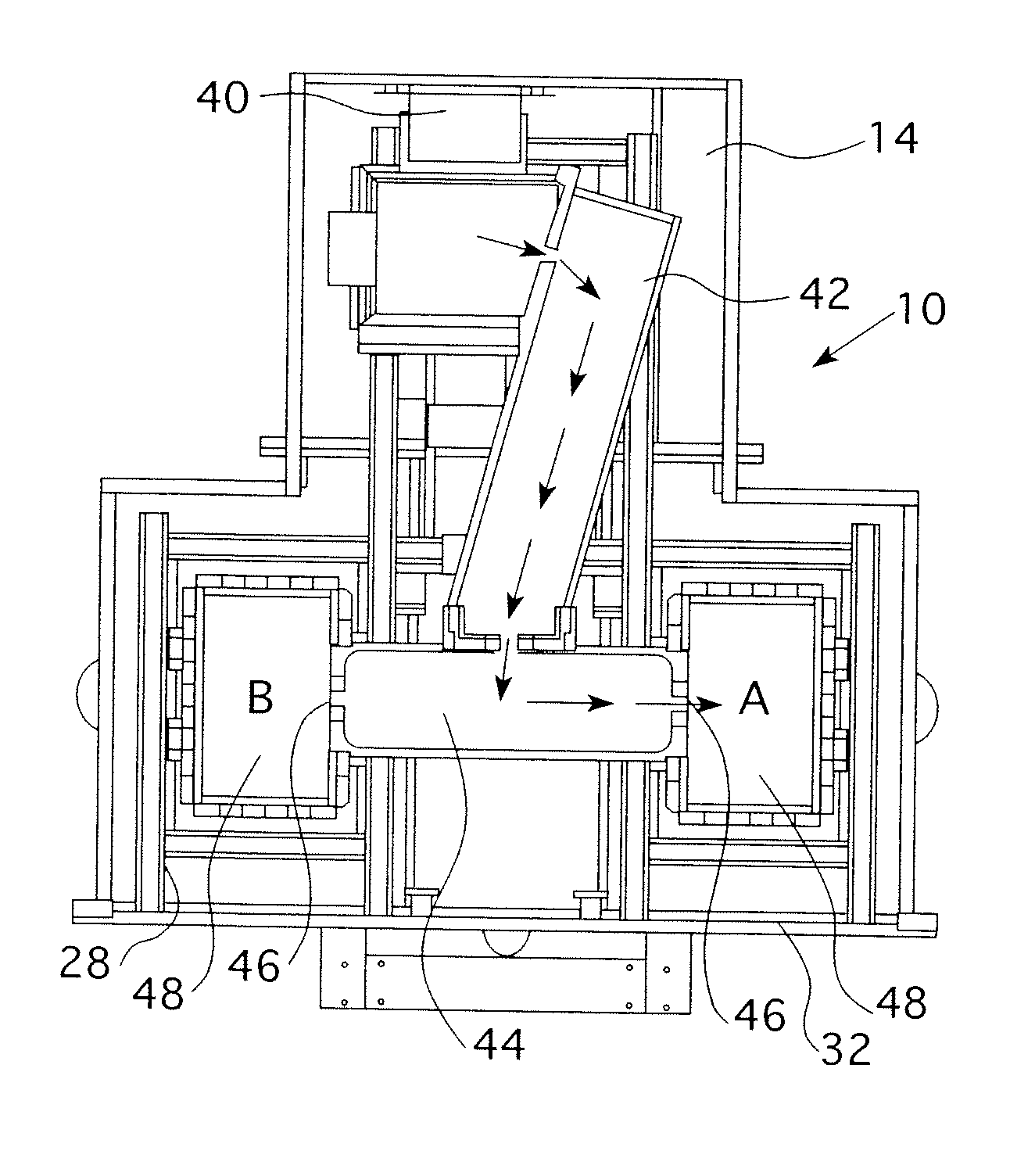

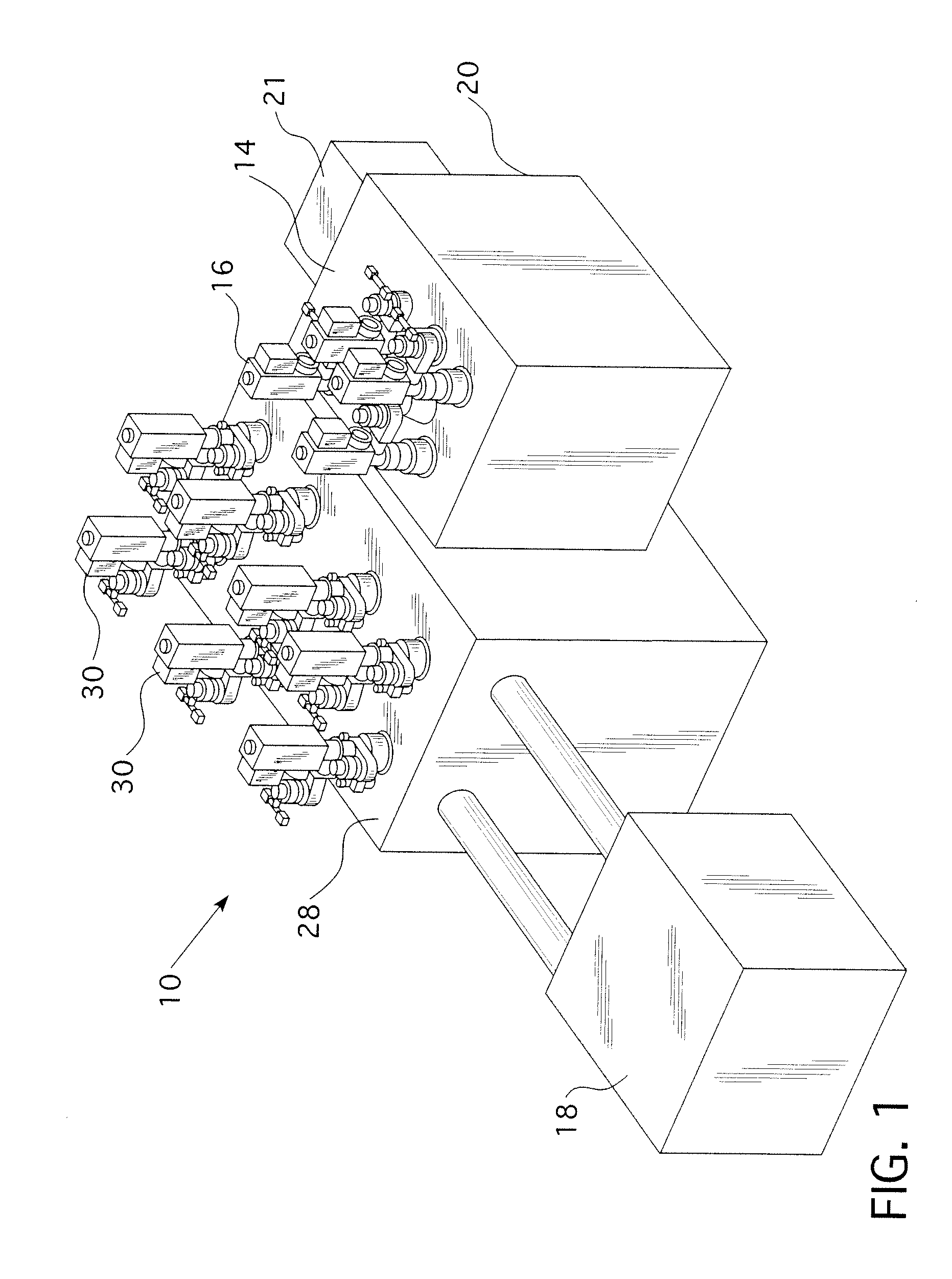

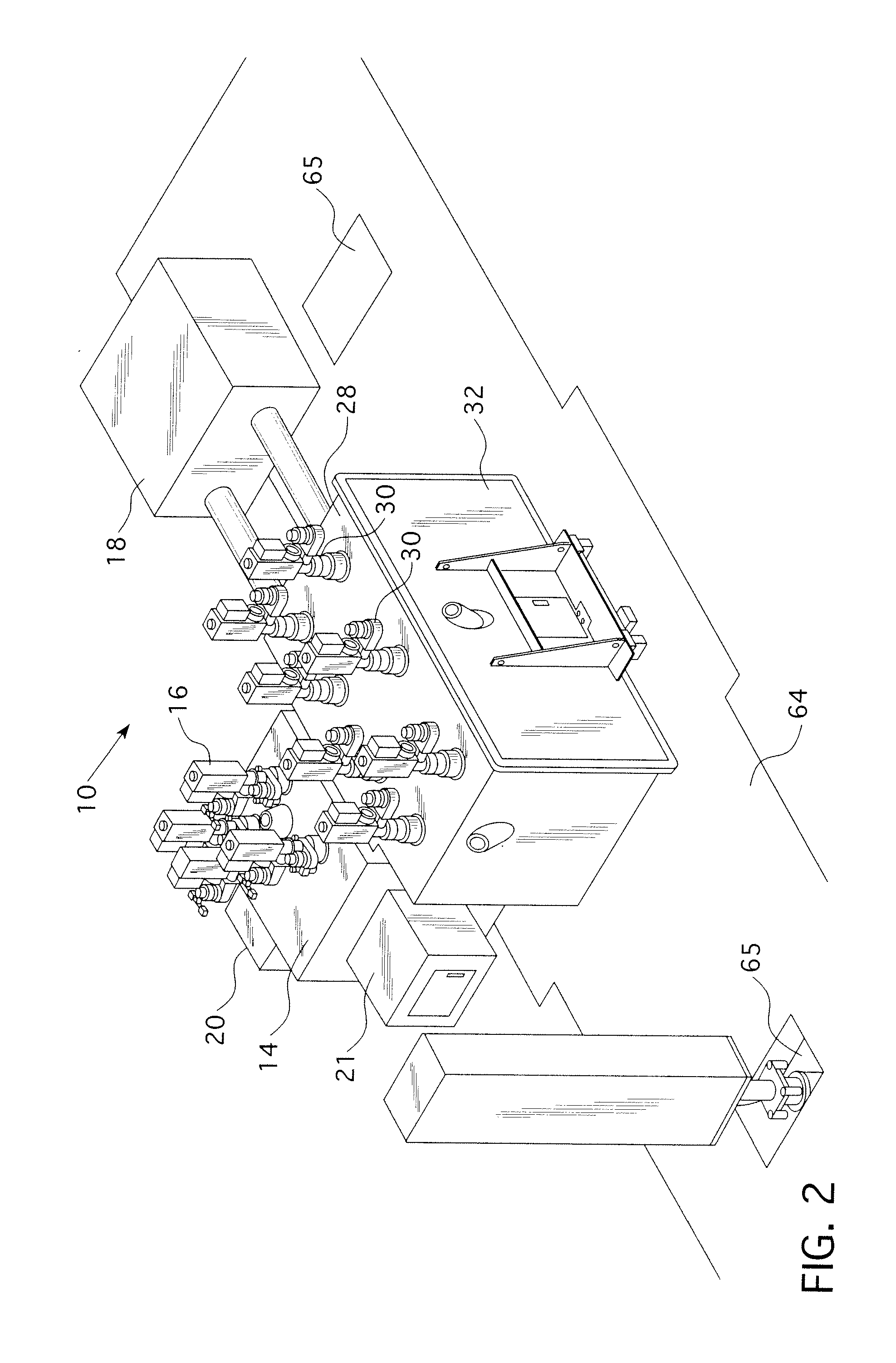

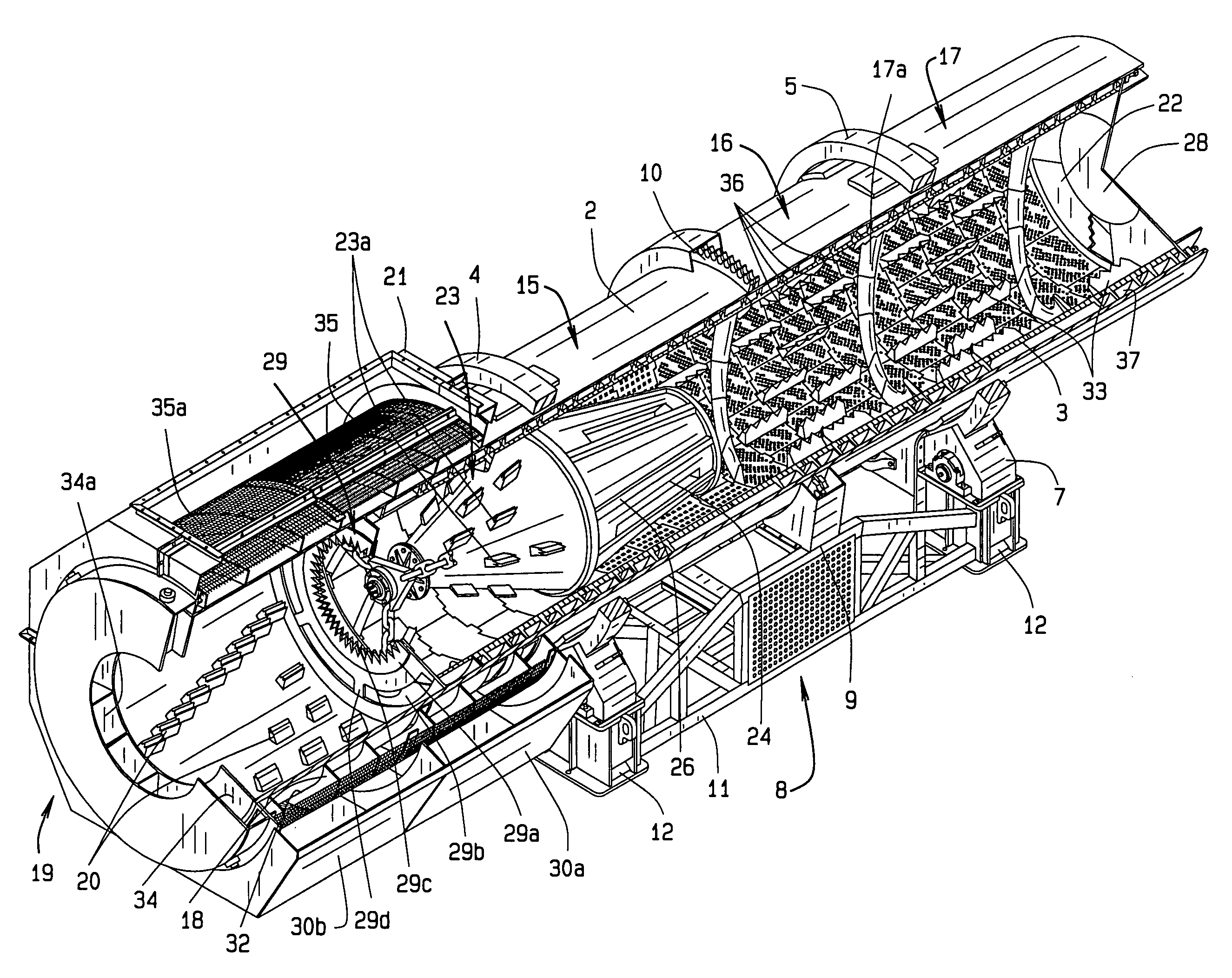

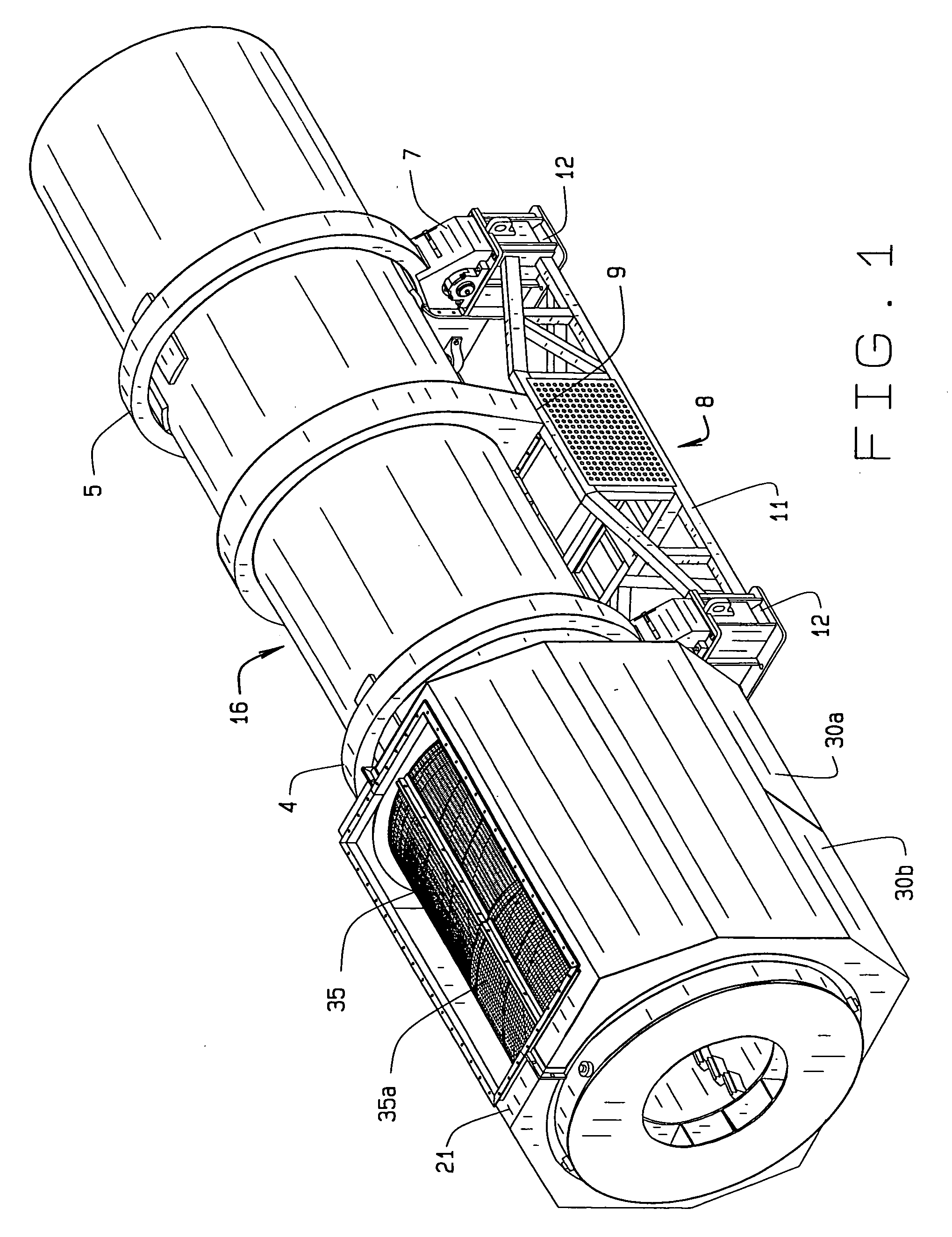

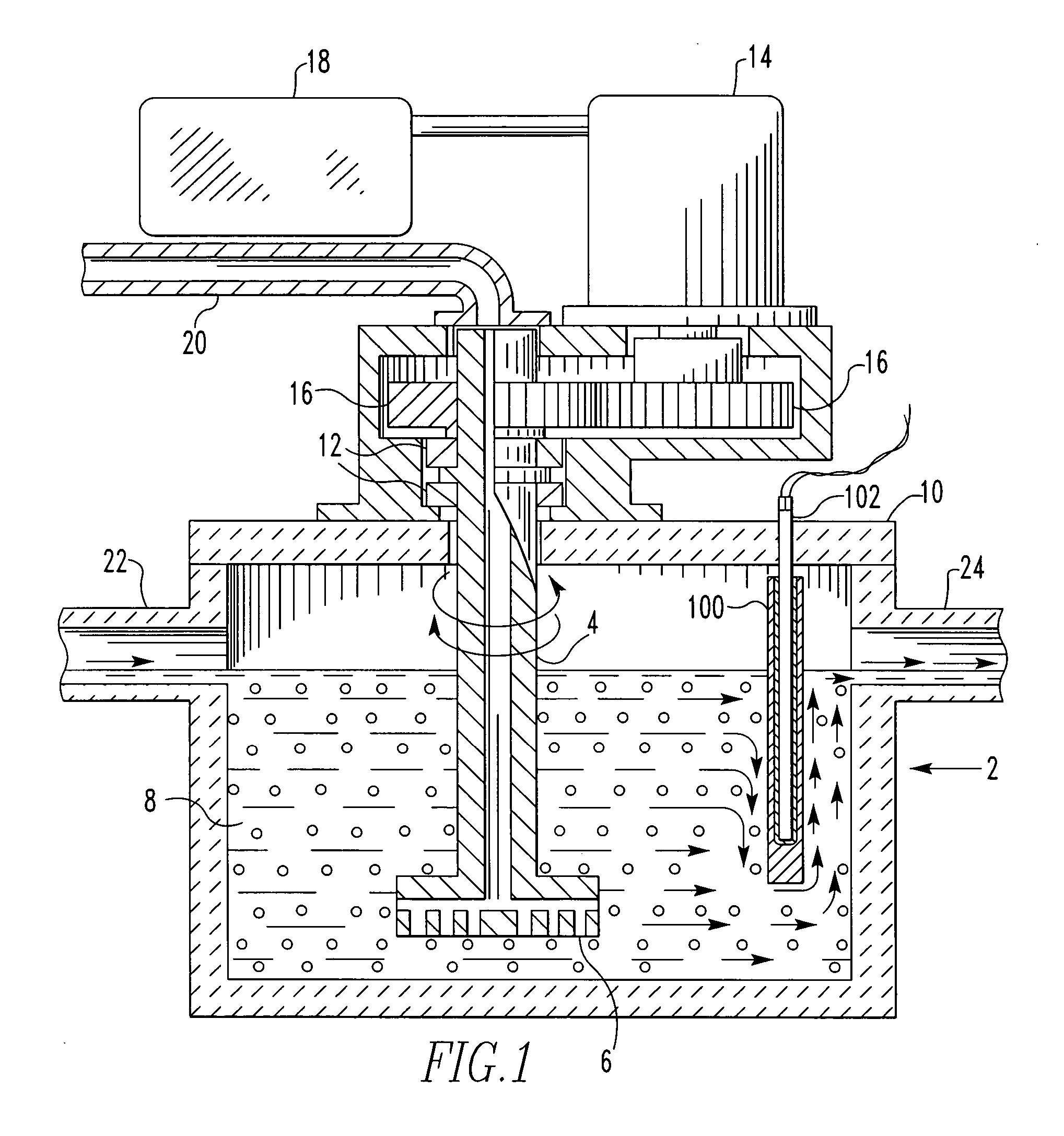

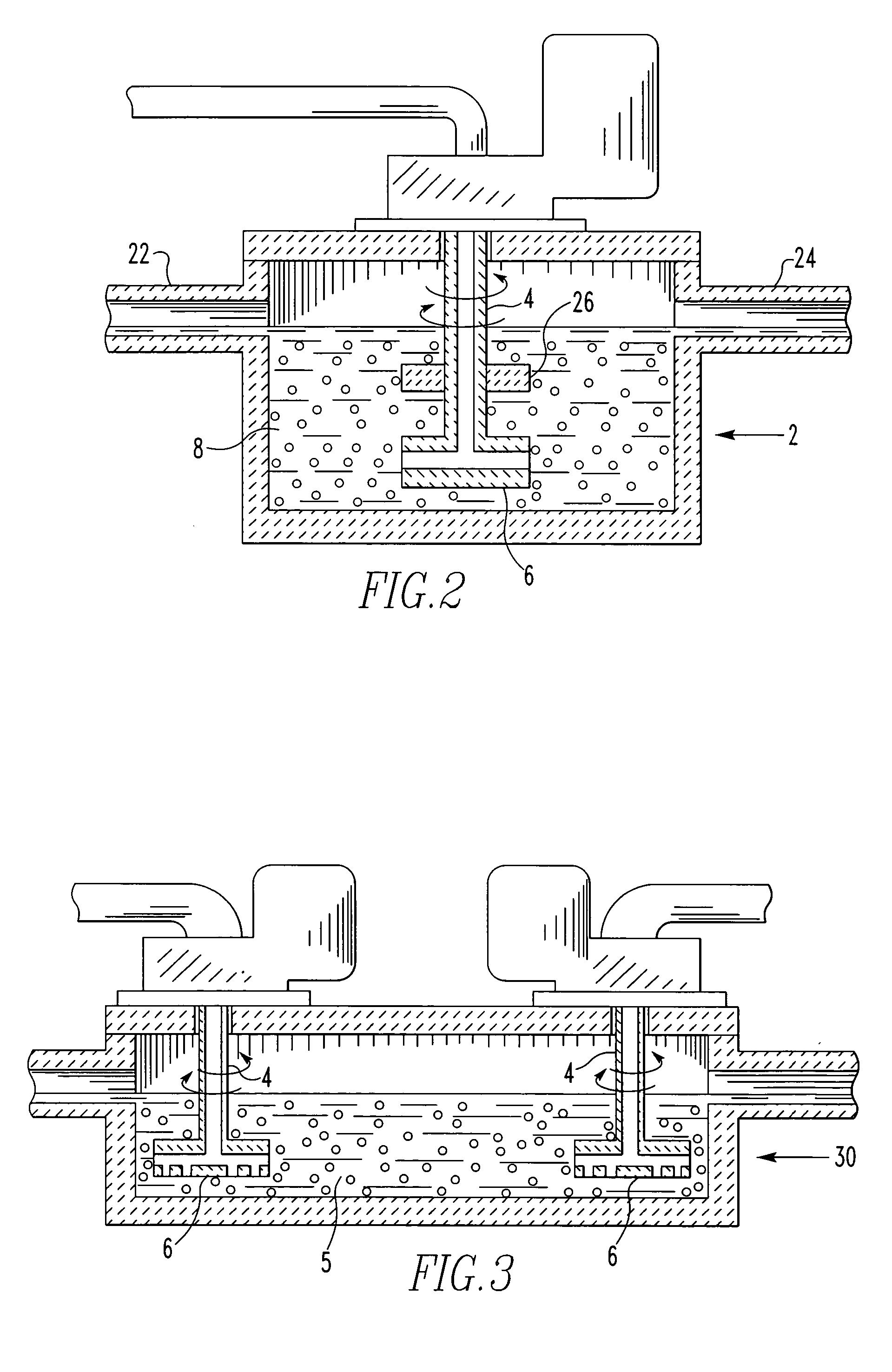

Molding and casting machine

ActiveUS7806161B2Easy to moveEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

Used water glass sand regeneration method

InactiveCN102078915AEfficient removalReduce intensityMould handling/dressing devicesSludgeWastewater

The invention discloses a used water glass sand regeneration method which mainly comprises the steps of: (1) adding wastewater to used water glass sand for pulverization, separating the used sand by using a crusher, and recovering with a dry process; (2) in the dry-process recovering process, removing sodium oxide in the used sand, and simultaneously separating out dust and sinter in the used sand together; (3) in a wet-process regeneration process, washing the used sand recovered with the dry process with water, scrubbing and removing the sodium oxide again; and (4), dehydrating the regenerated water glass sand, drying, cooling, modeling facing sand, and delivering to a sand warehouse for storage for later use. In the invention, the technologies of dry-processing recovering, wet-process regeneration and facing sand modeling are comprehensively utilized to regenerate the used water glass sand and collect and comprehensively utilize sludge generated after precipitation and wastes generated from other regenerated sands, thereby the purposes of saving energy, reducing energy consumption, lightening pollution, reducing cost, improving quality and realizing green casting are achieved.

Owner:TIANJIN AUKANG BUILDING DECORATION ENG

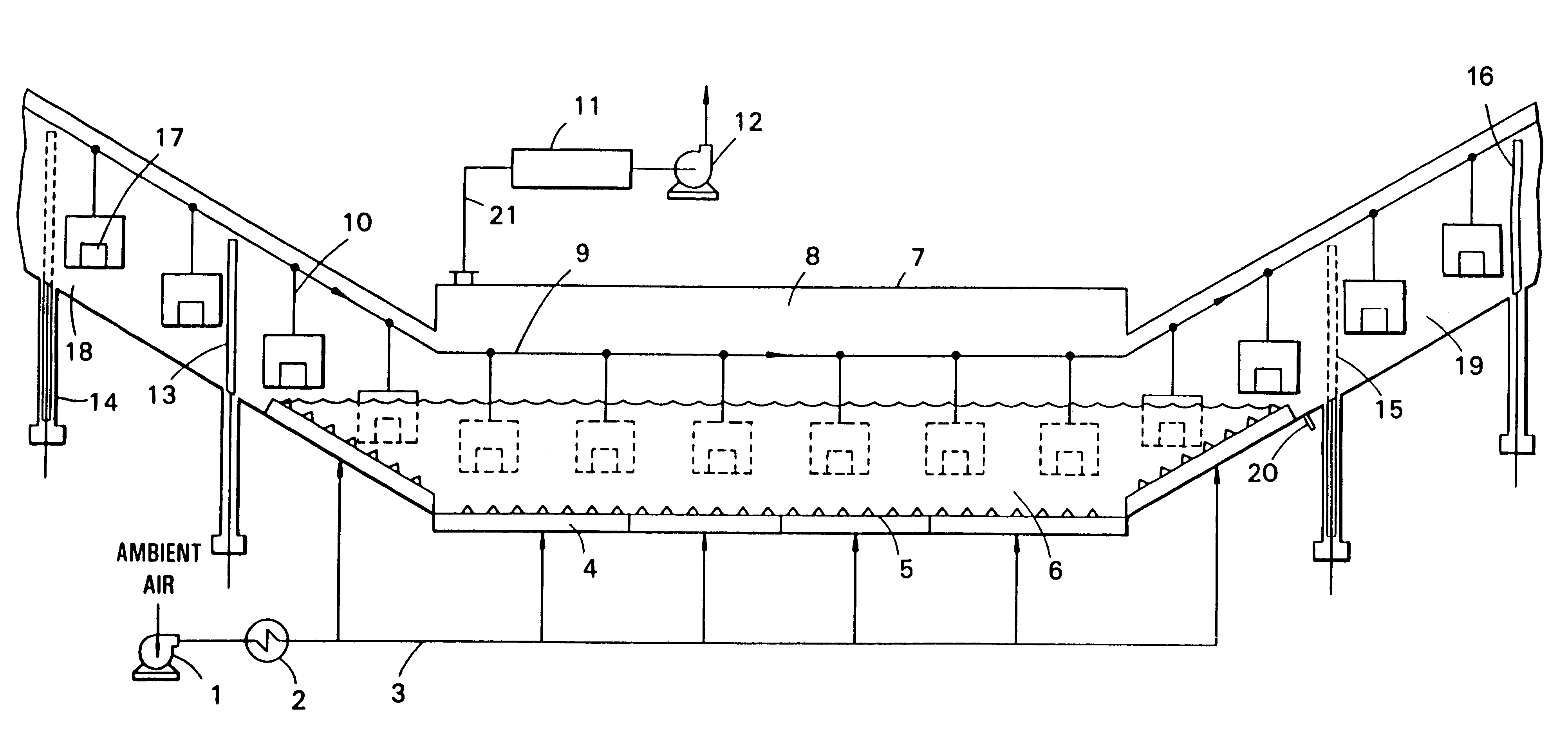

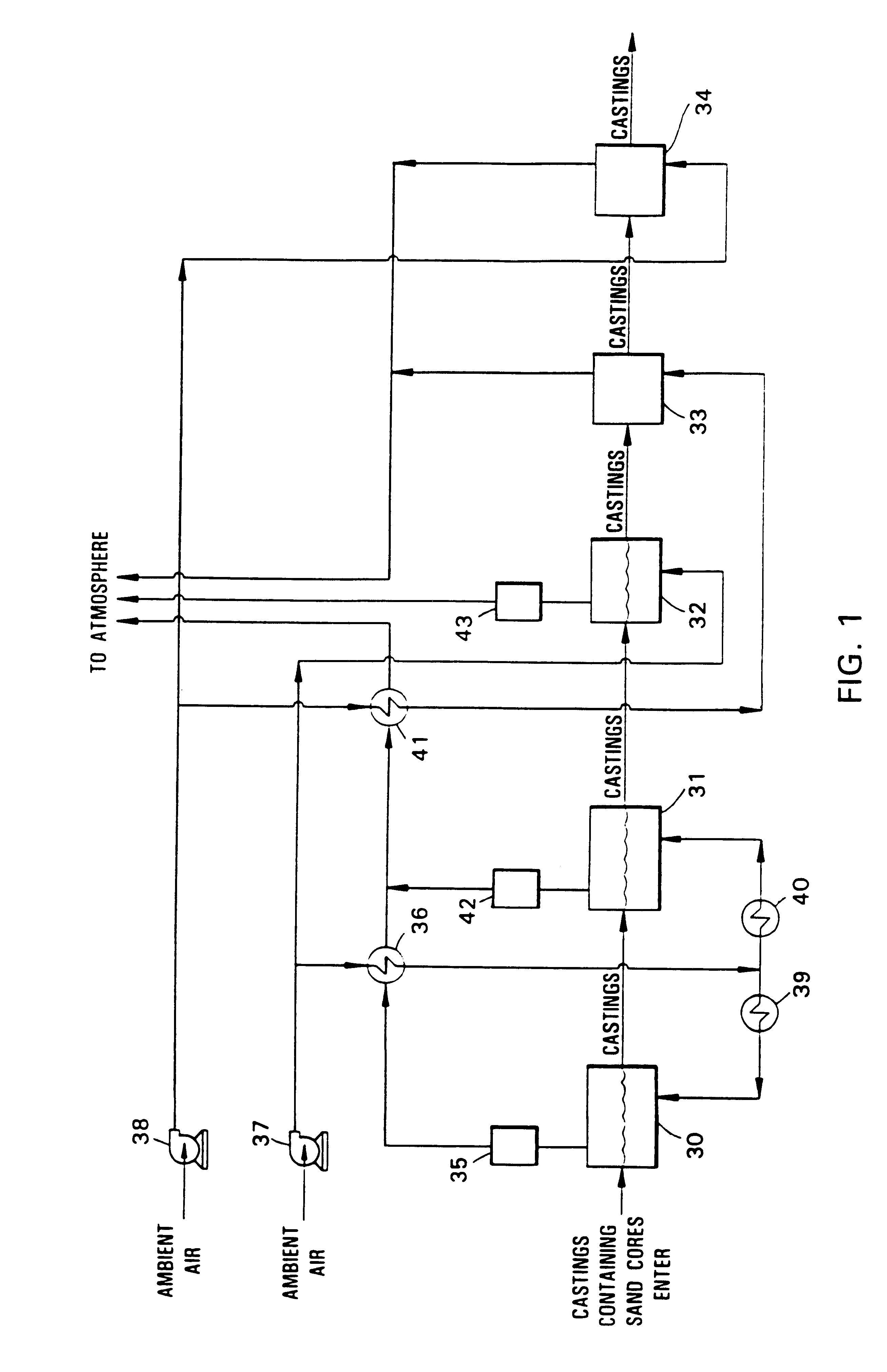

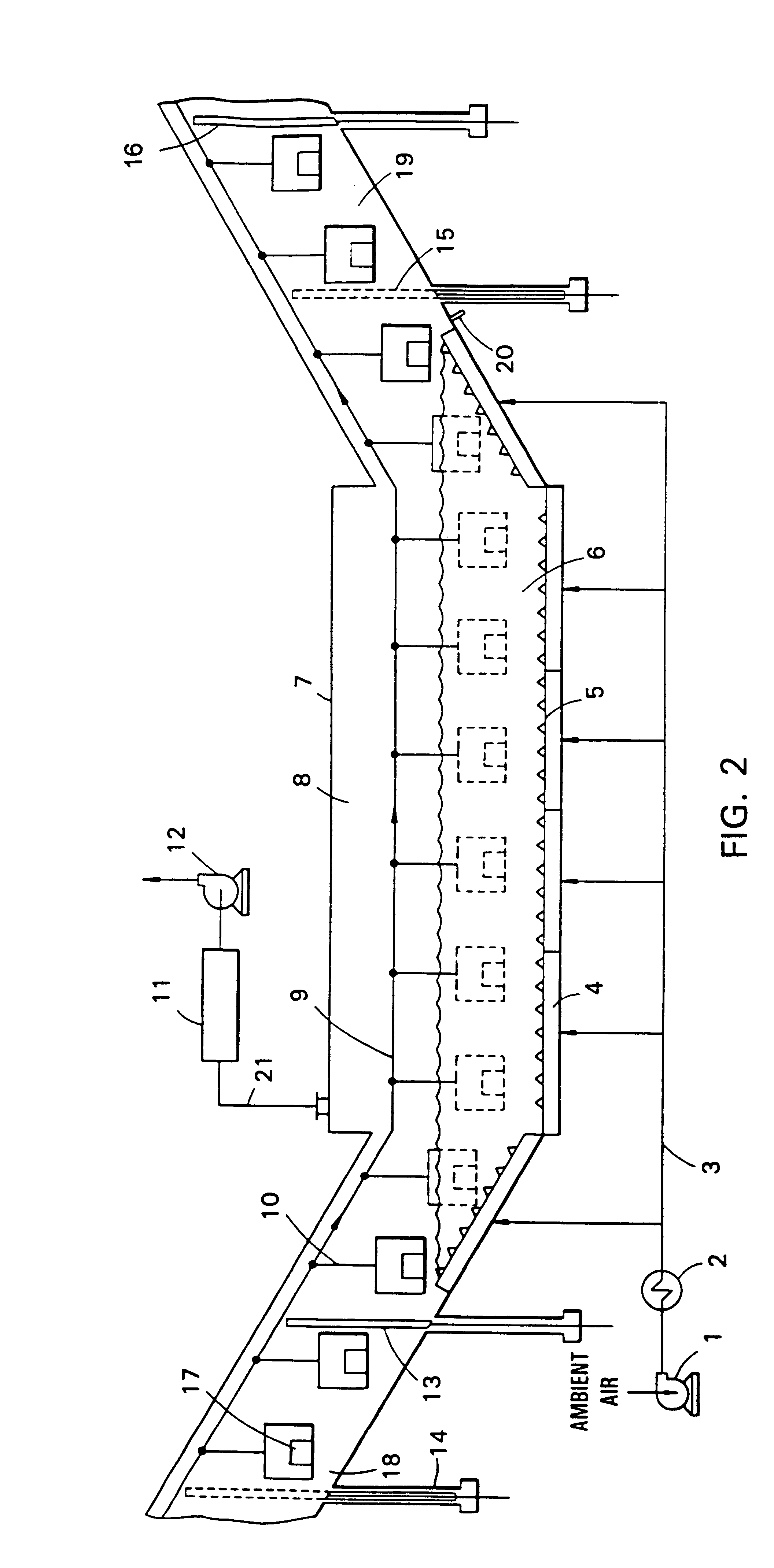

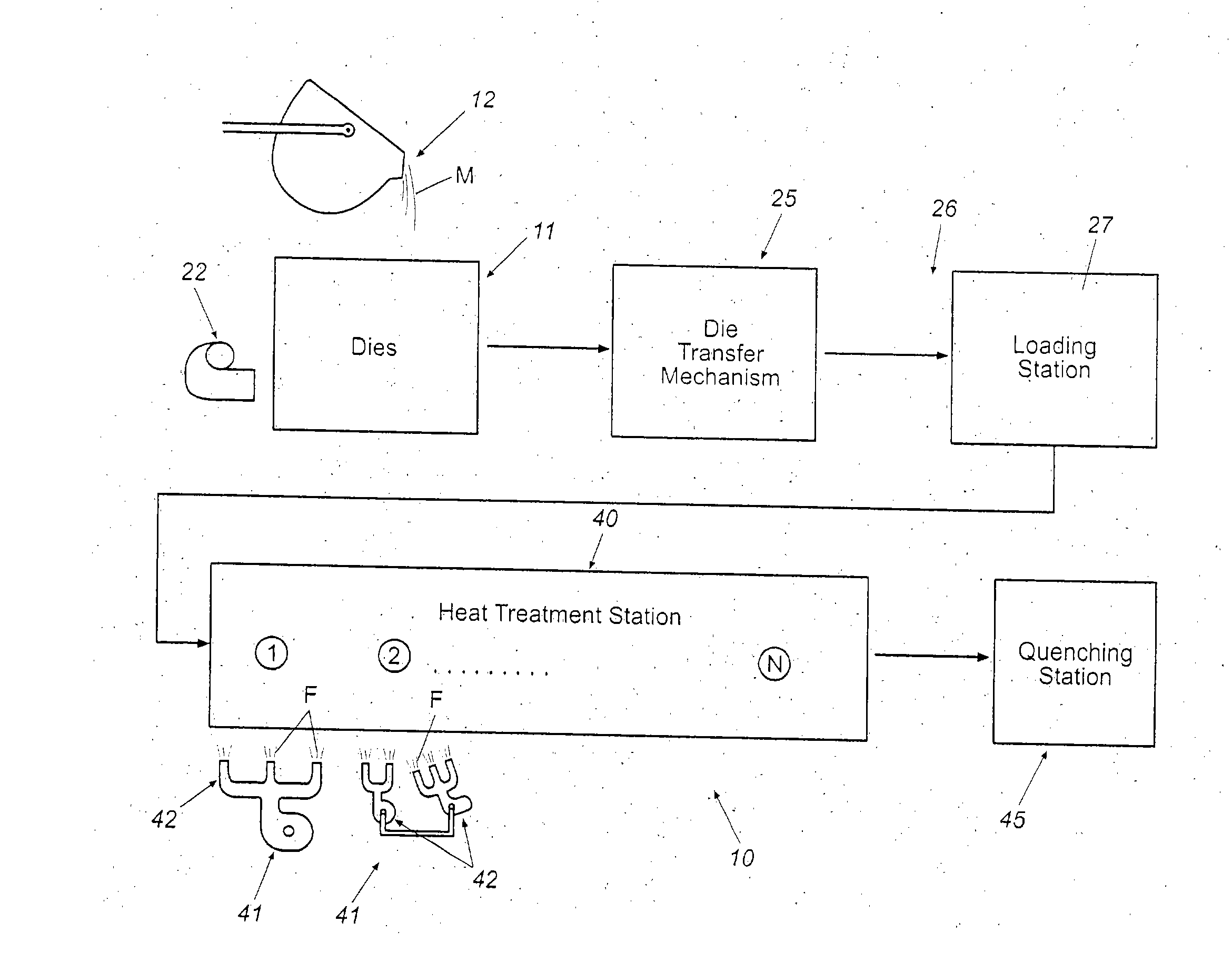

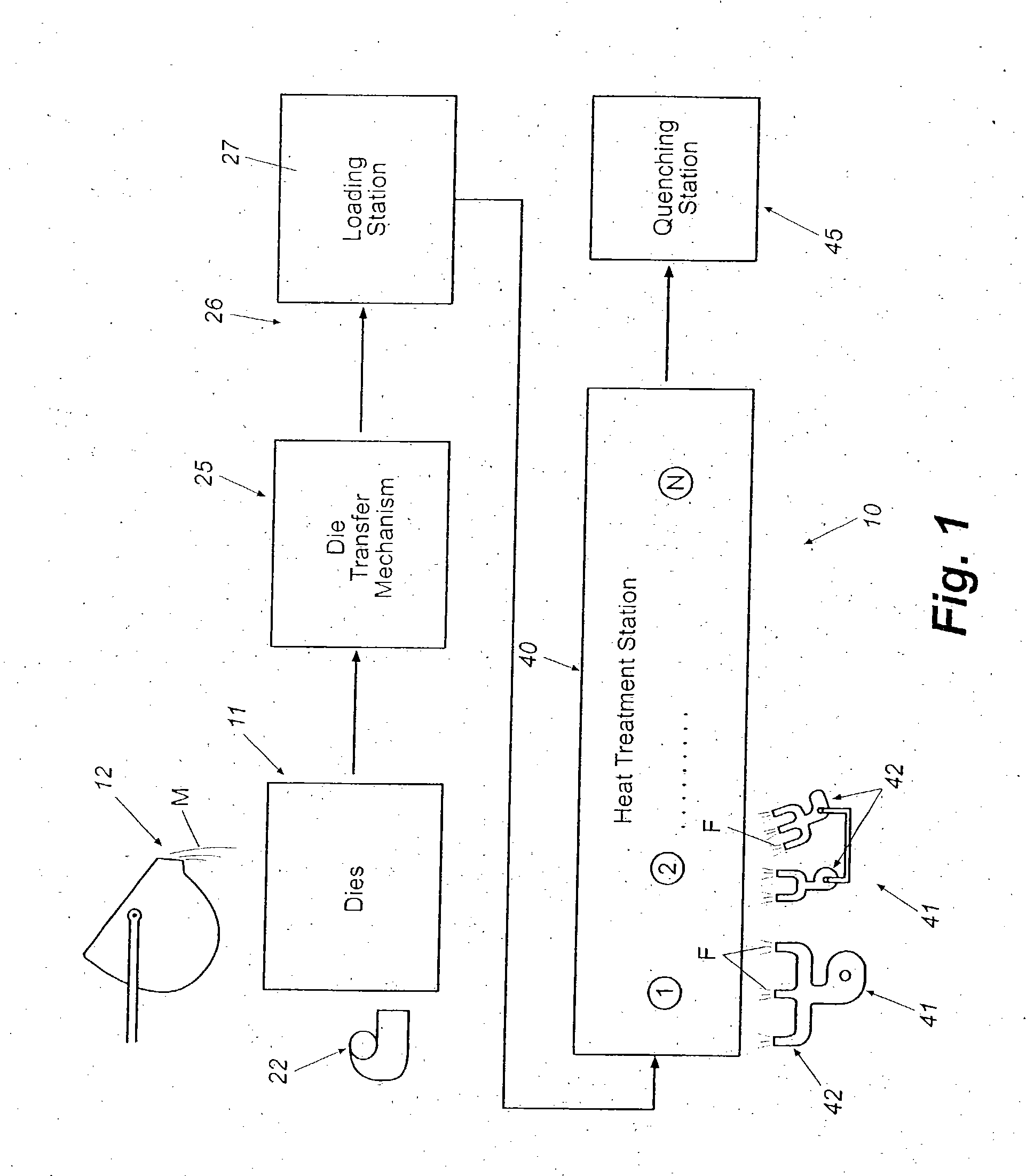

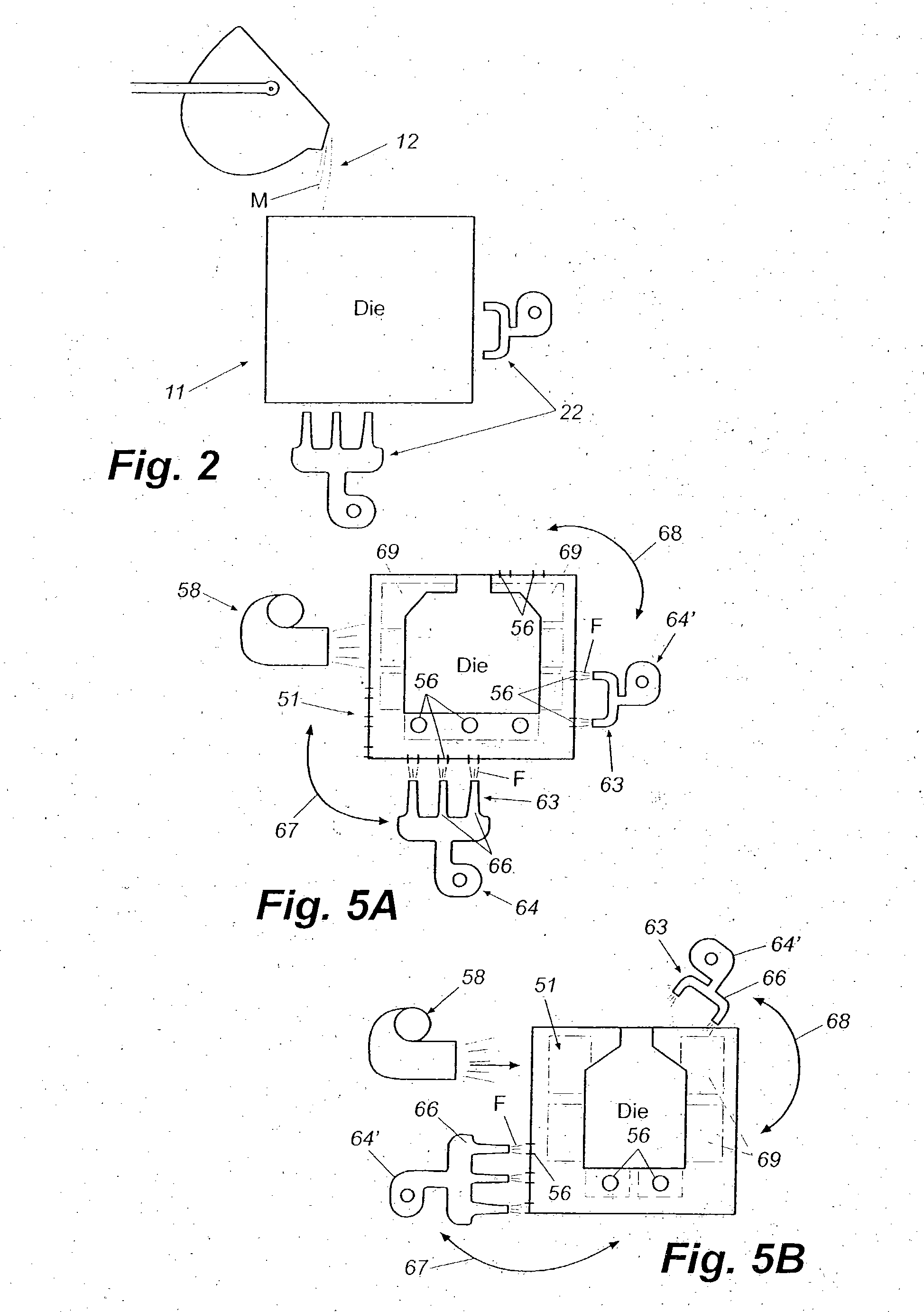

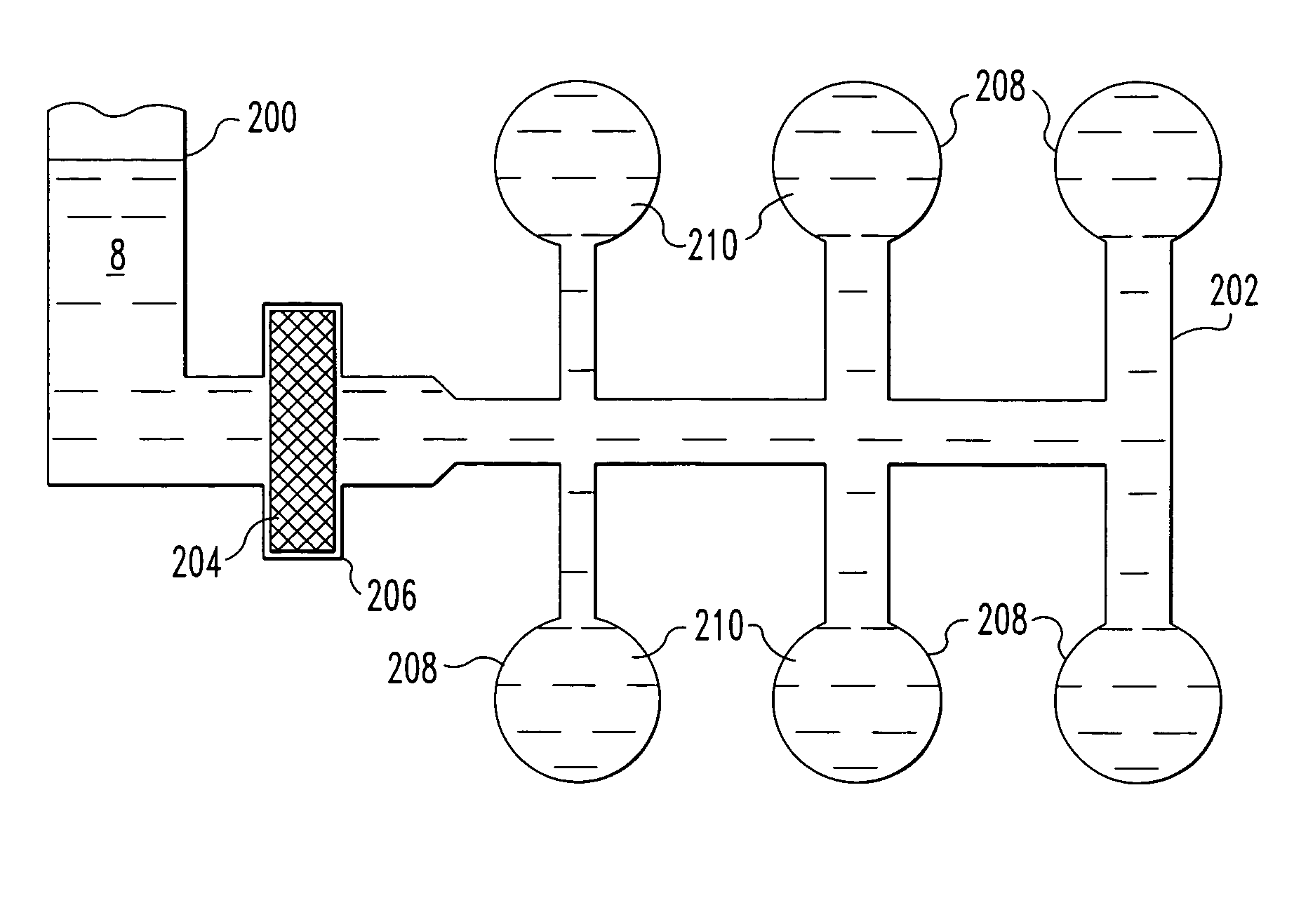

Methods and apparatus for heat treatment and sand removal for castings

InactiveUS20050022957A1Efficient removalEasy to handleFoundry mouldsFurnace typesMaterials scienceHeat treating

A system and method for heat treating castings and removing sand cores therefrom. The castings are initially located in indexed positions with their x, y, and z coordinates known. The castings are passed through a heat treatment station typically having a series of nozzles mounted in preset positions corresponding to the known indexed positions of the castings passing through the heat treatment station. The nozzles apply fluid to the castings for heat treating the castings and degrading the sand cores for removal from the castings.

Owner:CONSOL ENG

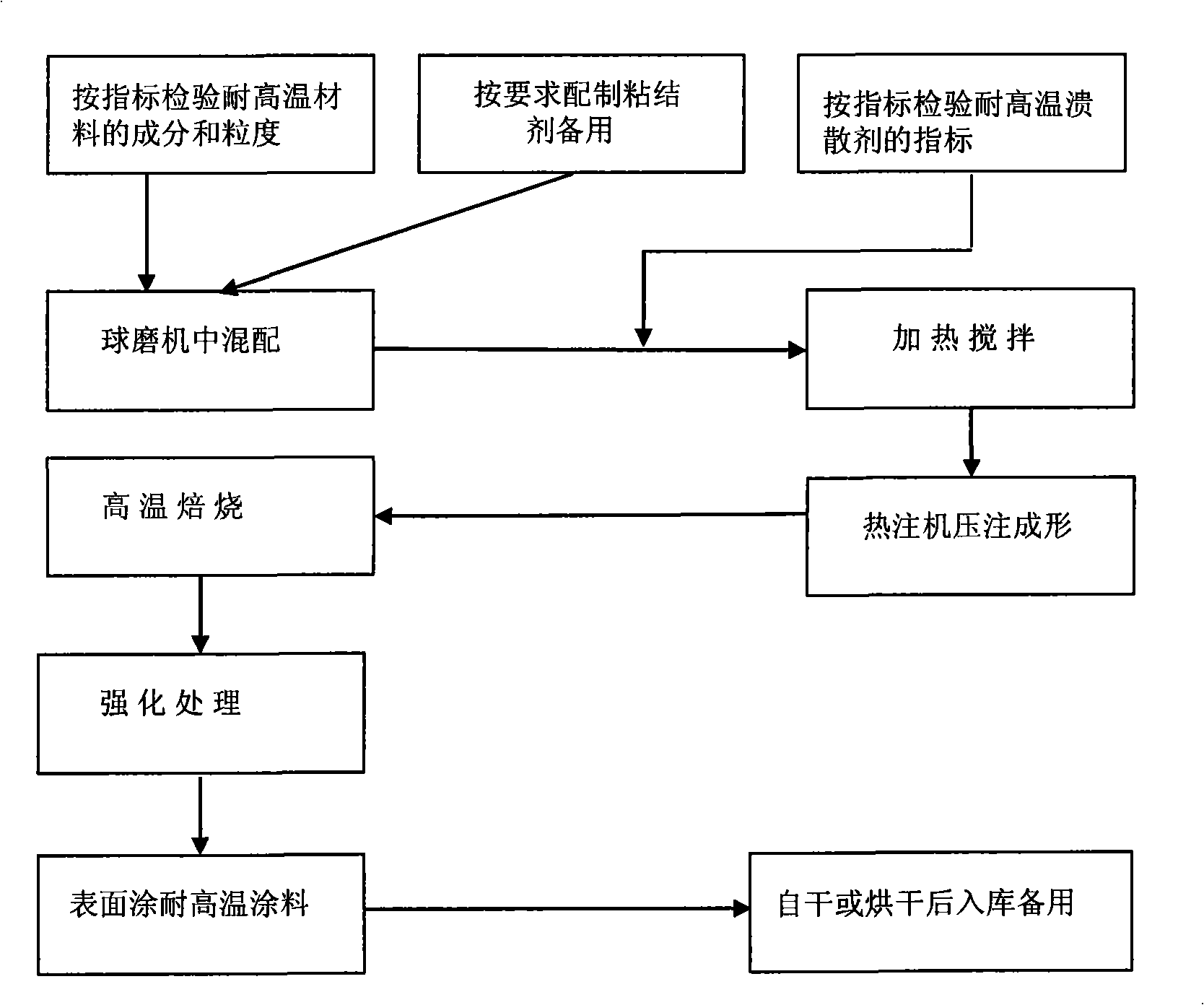

Ceramic core for silica sol precision casting and manufacturing process thereof

InactiveCN101537473AShorten roasting timeLow firing temperatureFoundry mouldsMould handling/dressing devicesTemperature resistanceChoice making

The invention discloses a ceramic core for silica sol precision casting and a manufacturing process thereof. Main body components of the ceramic core comprise refined quartz powder and a proper amount of collapsing agent, and the surface of the ceramic core is coated with high-temperature resistant paint with a thickness of 0.1 to 0.2 millimeter; and at the same reasonable manufacturing processes such as mixing, core making and roasting are adopted. In the ceramic core for casting, the unique material mixing and manufacturing processes are adopted, and the reasonable use of the refined quartz powder and the collapsing agent improves the collapsibility of the ceramic core after casting considerably, the high-quality high-temperature resistant material in ingredients enables the core to resist the erosion of high-temperature molten metals, and the high-temperature resistant paint on the surface of the ceramic core not only improves the high temperature resistance during casting, but also increases the cooling speed of the molten metal.

Owner:上海市机械制造工艺研究所有限公司

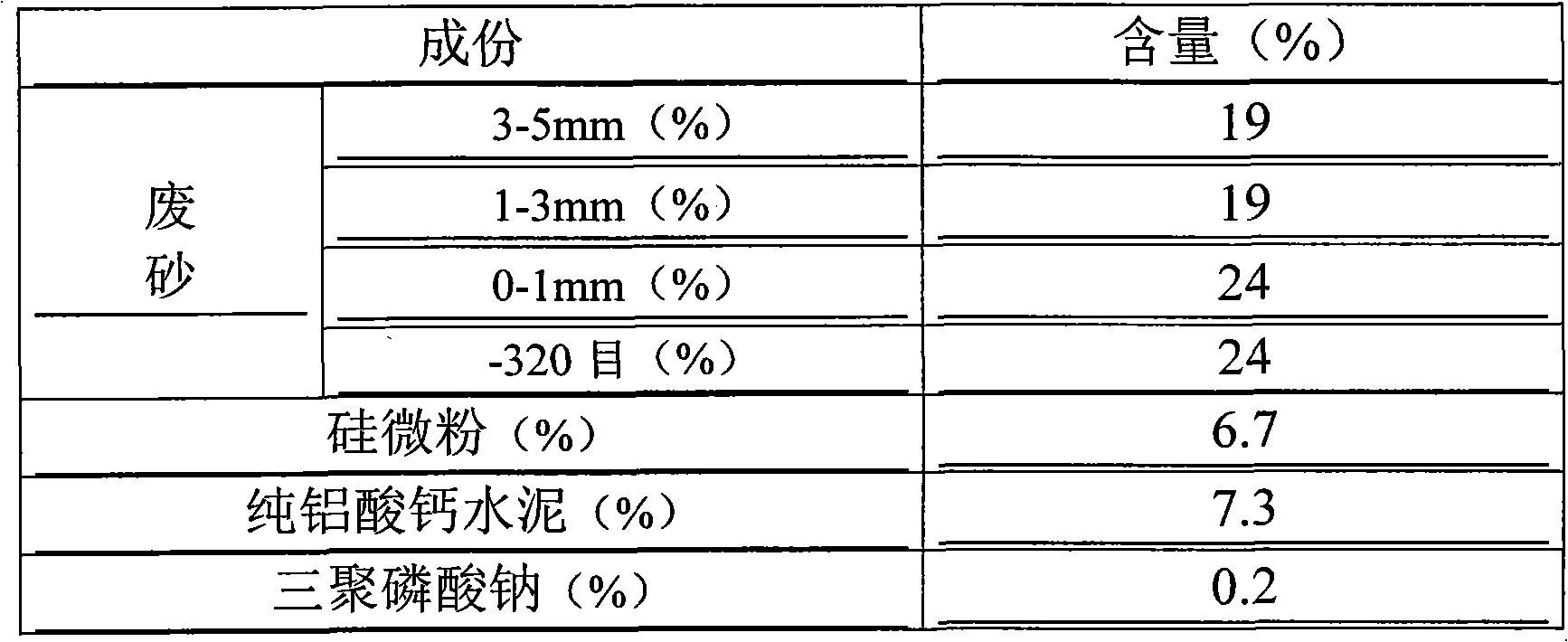

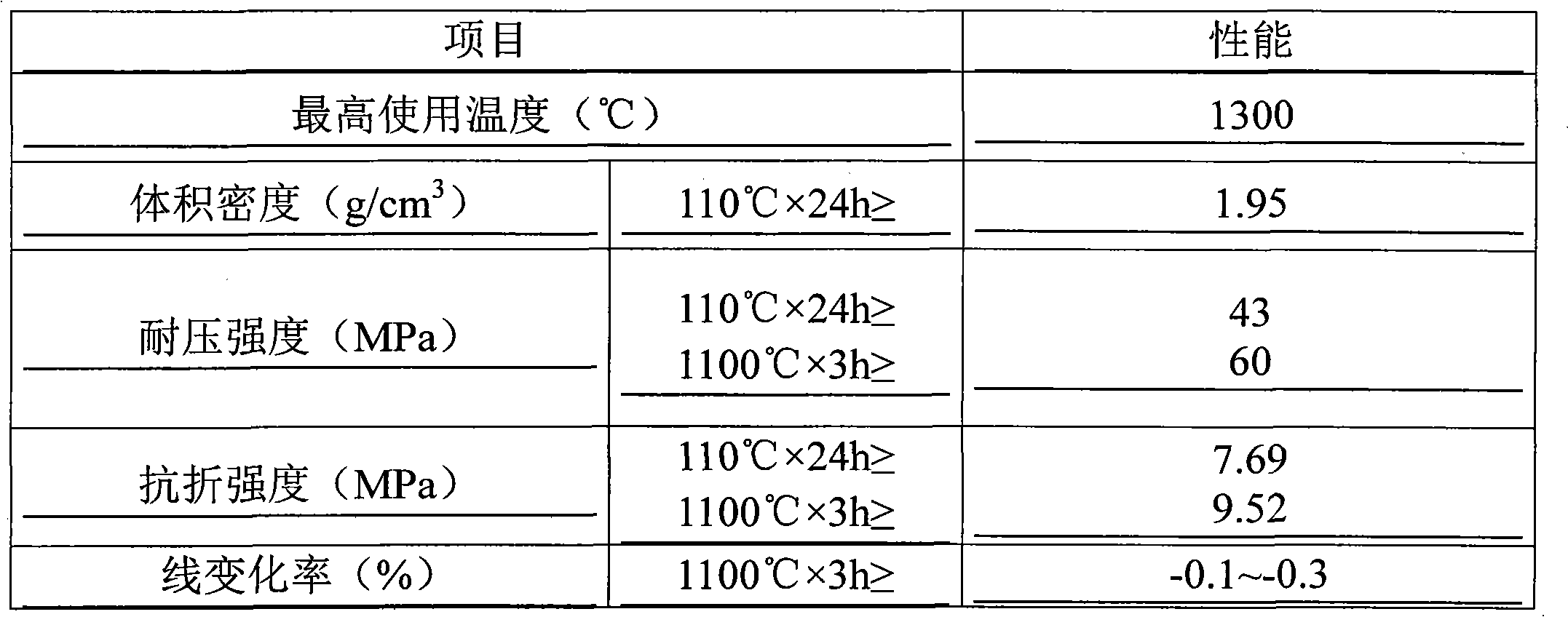

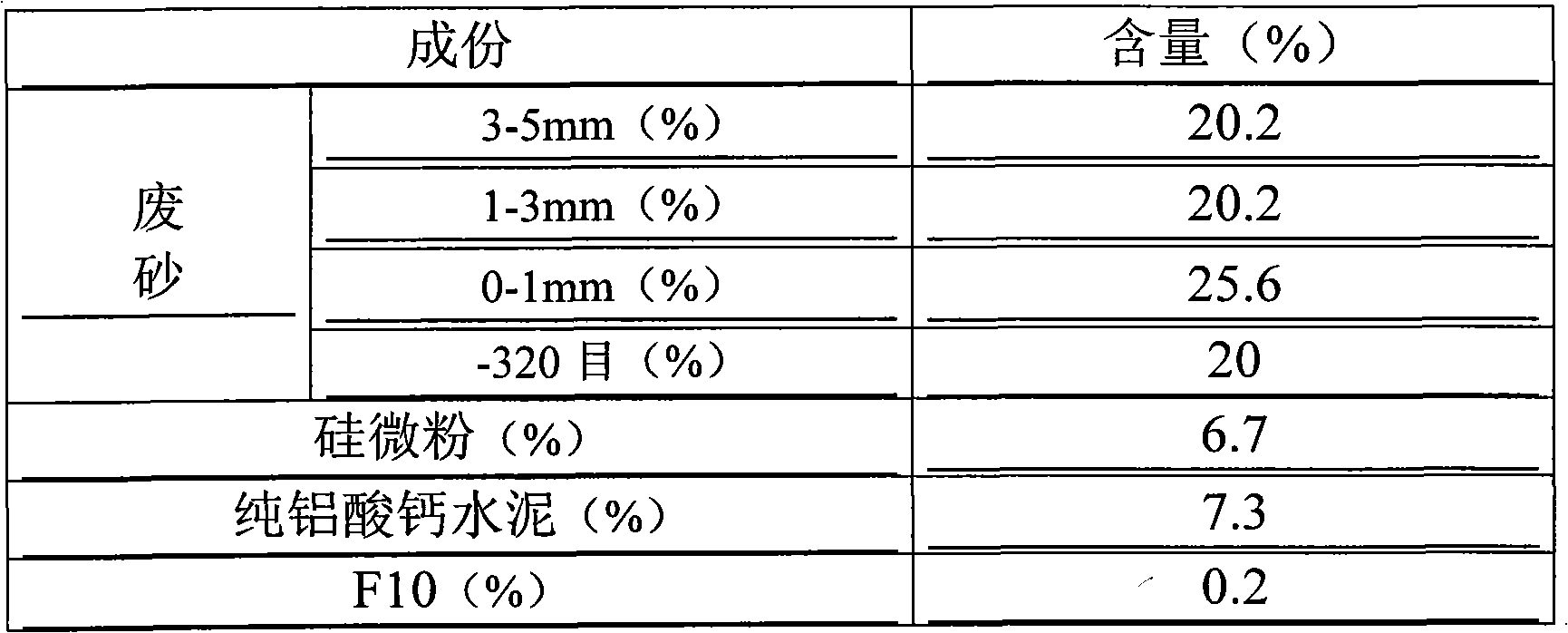

Precision casting waste sand reusing method

ActiveCN101870562AReduce manufacturing costSolve pollutionSolid waste managementSolid waste disposalMulliteRefractory

The invention relates to the waste reusing technology, in particular to a precision casting waste sand reusing method. The precision casting waste sand contains mullite, mullite sand, zirconite and zircon sand. The precision casting waste sand is cleaned, dried, crushed and screened to form aggregate and powder for a fireproof casting material; and a bonding agent and an admixture are added into the aggregate and the powder, and the components are mixed and homogenized to form the fireproof casting material. The method solves the problem that the conventional precision casting waste sand pollutes the environment.

Owner:泰州枫叶冶金设备有限公司

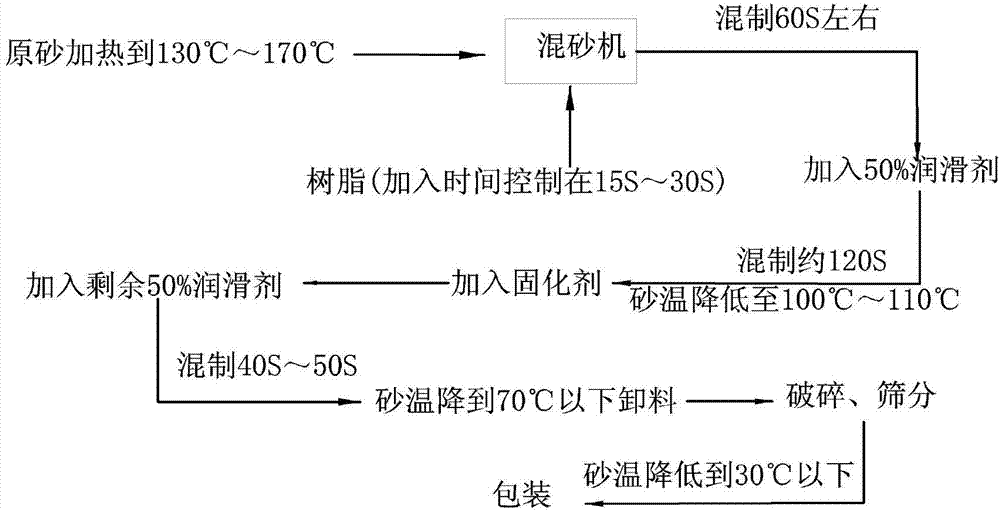

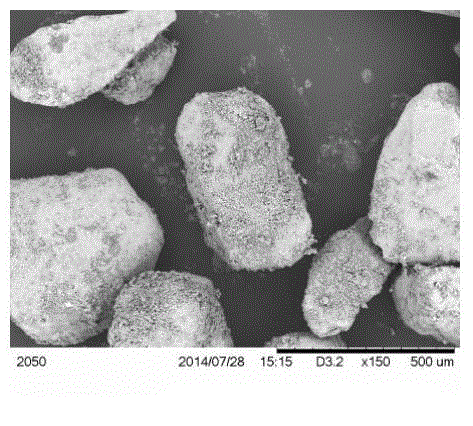

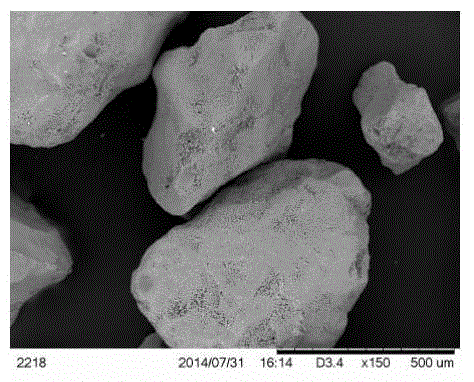

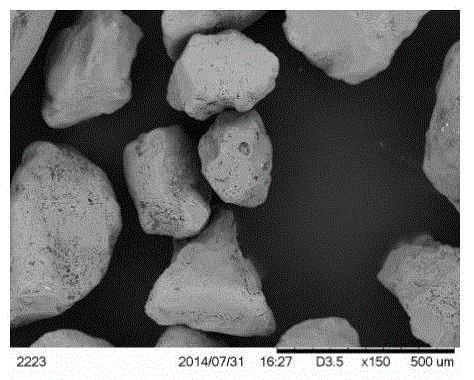

Easy-to-fill precoated sand and preparation process thereof

ActiveCN103658506AHigh molding strengthHigh temperature strengthFoundry mouldsMould handling/dressing devicesUltimate tensile strengthHot Temperature

The invention discloses easy-to-fill precoated sand and a preparation method thereof. Raw materials comprise roughing sand, phenolic resin, curing agents, lubricating agents and additives. The preparation method comprises the following steps that the roughing sand is heated to 130 to 170 DEG C, then, the phenolic rein, a half quantity of the lubricating agents, the curing agents and the rest half quantity of lubricating agents are sequentially added, finally, the discharging is carried out, and then, crushing, sieving and package are carried out. Through the improvement on the raw material ingredients and the preparation process, the forming intensity of the precoated sand is high, the high-temperature intensity is high, the deformation quantity is small, the flowability is good, complicated sand cores can be produced, the surface smoothness of the molding sand is good, the collapsibility performance is excellent, castings can be easily subjected to the vibration sand falling treatment, the precoated sand gas producing quantity is reduced, and the high-temperature performance and other casting performance of the precoated sand are improved.

Owner:ANSHUN UNIV

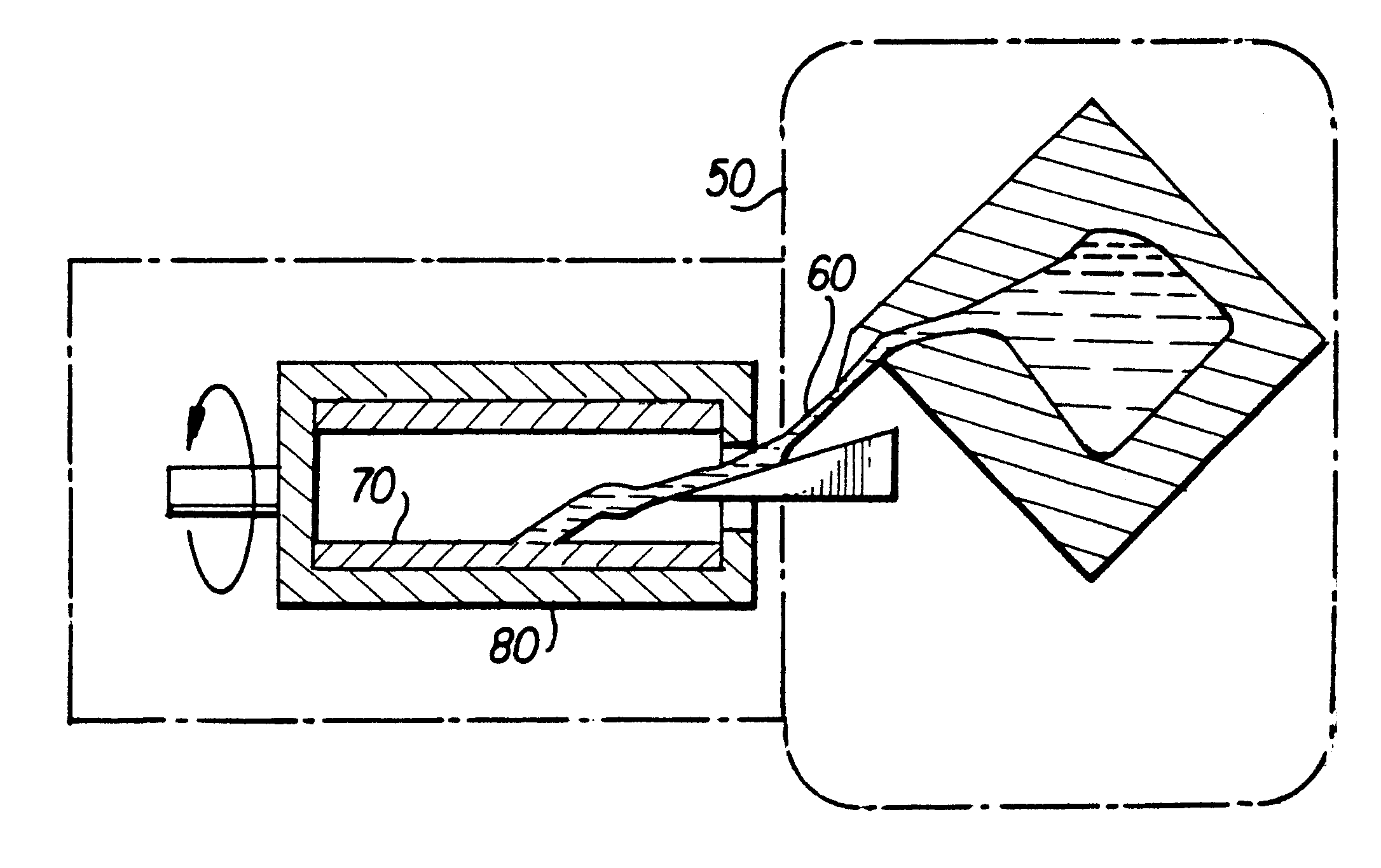

Systems and methods for casting metallic materials

Certain embodiments of a melting and casting apparatus comprising includes a melting hearth; a refining hearth fluidly communicating with the melting hearth; a receiving receptacle fluidly communicating with the refining hearth, the receiving receptacle including a first outflow region defining a first molten material pathway, and a second outflow region defining a second molten material pathway; and at least one melting power source oriented to direct energy toward the receiving receptacle and regulate a direction of flow of molten material along the first molten material pathway and the second molten material pathway. Methods for casting a metallic material also are disclosed.

Owner:ATI PROPERTIES LLC

Process for regenerating forced scrubbing water glass used sand through wet method

InactiveCN101780521ANovel structureThe composition is compact and reasonableMould handling/dressing devicesMagnetic separatorEnvironmental engineering

The invention discloses a process for regenerating forced scrubbing water glass used sand through a wet method, which comprises the following steps of: firstly, loading collected old sand into a jaw crusher to perform crushing, and conveying the crushed old sand into a magnetic separator to perform magnetic separation; secondly, putting sand grains after the magnetic separation into a first stage spiral sand-water separator, a first stage wet method regenerator and a second stage spiral sand-water separator to perform sand-water separation on the old sand; thirdly, neutralizing the sand after the separation by a neutralizing sedimentation basin; fourthly, performing sand-water separation for the second time through a second stage wet method regenerator and a third stage spiral sand-water separator to ensure that water glass existing in the old sand can be thoroughly eliminated cleanly; and finally, performing dust elimination and drying to obtain sand grains namely the finished products which are put into a sand storage. The process adopts a device with a simple and novel structure, a compact and reasonable system composition and fewer wear-out parts. The process has a high elimination ratio of Na2O in the old sand, and the regenerated sand is good in quality and can be recycled repeatedly for use; besides, the process has small water consumption, realizes recycling by using water and plays a positive role in protecting the environment.

Owner:YIXING AOXING GANISTER SAND PROCESSING

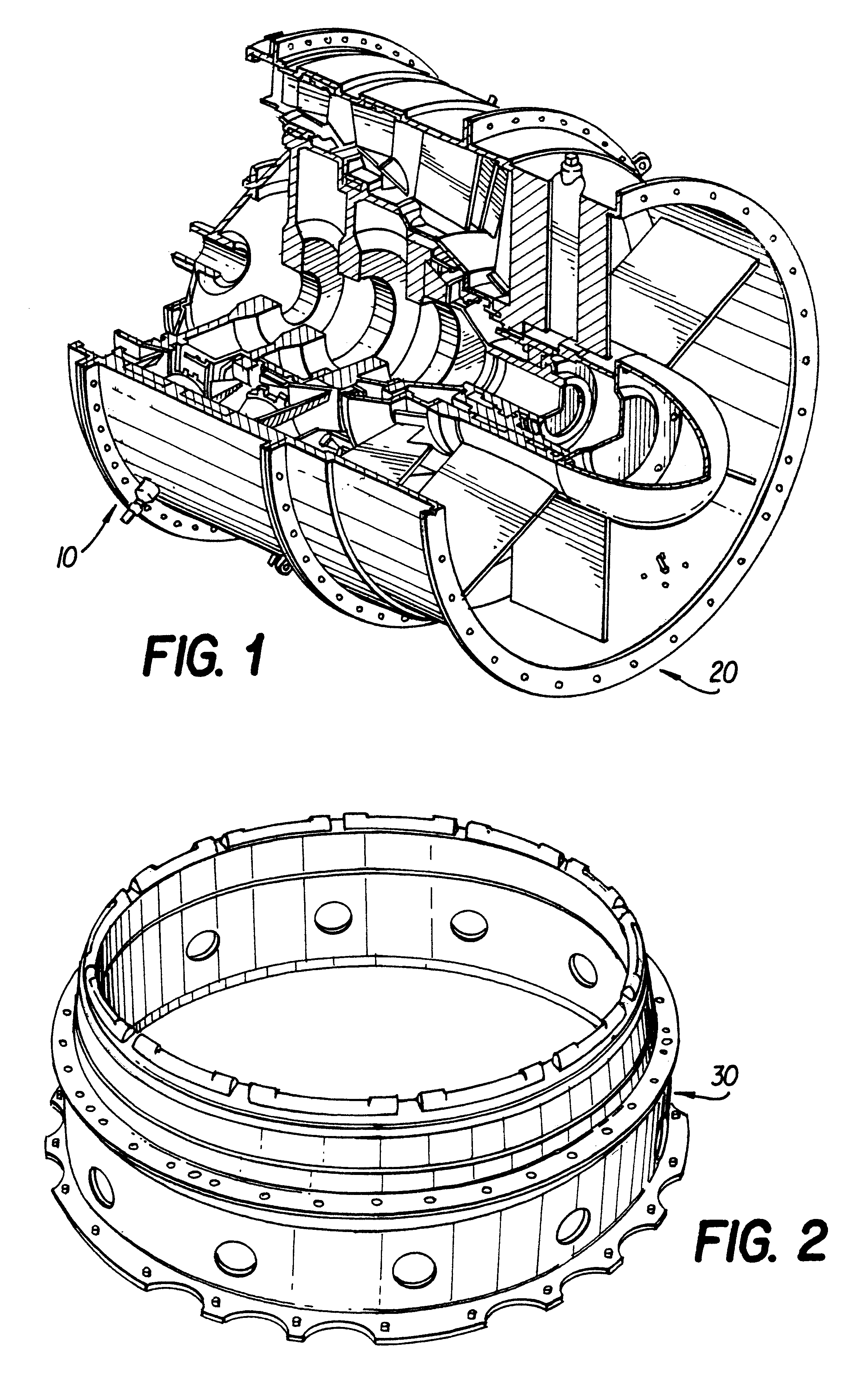

Centrifugal casting of nickel base superalloys in isotropic graphite molds under vacuum

InactiveUS6634413B2Eliminate needImprove qualityFoundry mouldsPretreated surfacesHigh densityShell molding

Methods for making various nickel based superalloys into engineering components such as rings, tubes and pipes by melting of the alloys in a vacuum or under a low partial pressure of inert gas and subsequent centrifugal casting of the melt in the graphite molds rotating along its own axis under vacuum or low partial pressure of inert gas are provided. The molds have been fabricated by machining high density, high strength ultrafine grained isotropic graphite, wherein the graphite has been made by isostatic pressing or vibrational molding.

Owner:SANTOKU CORP

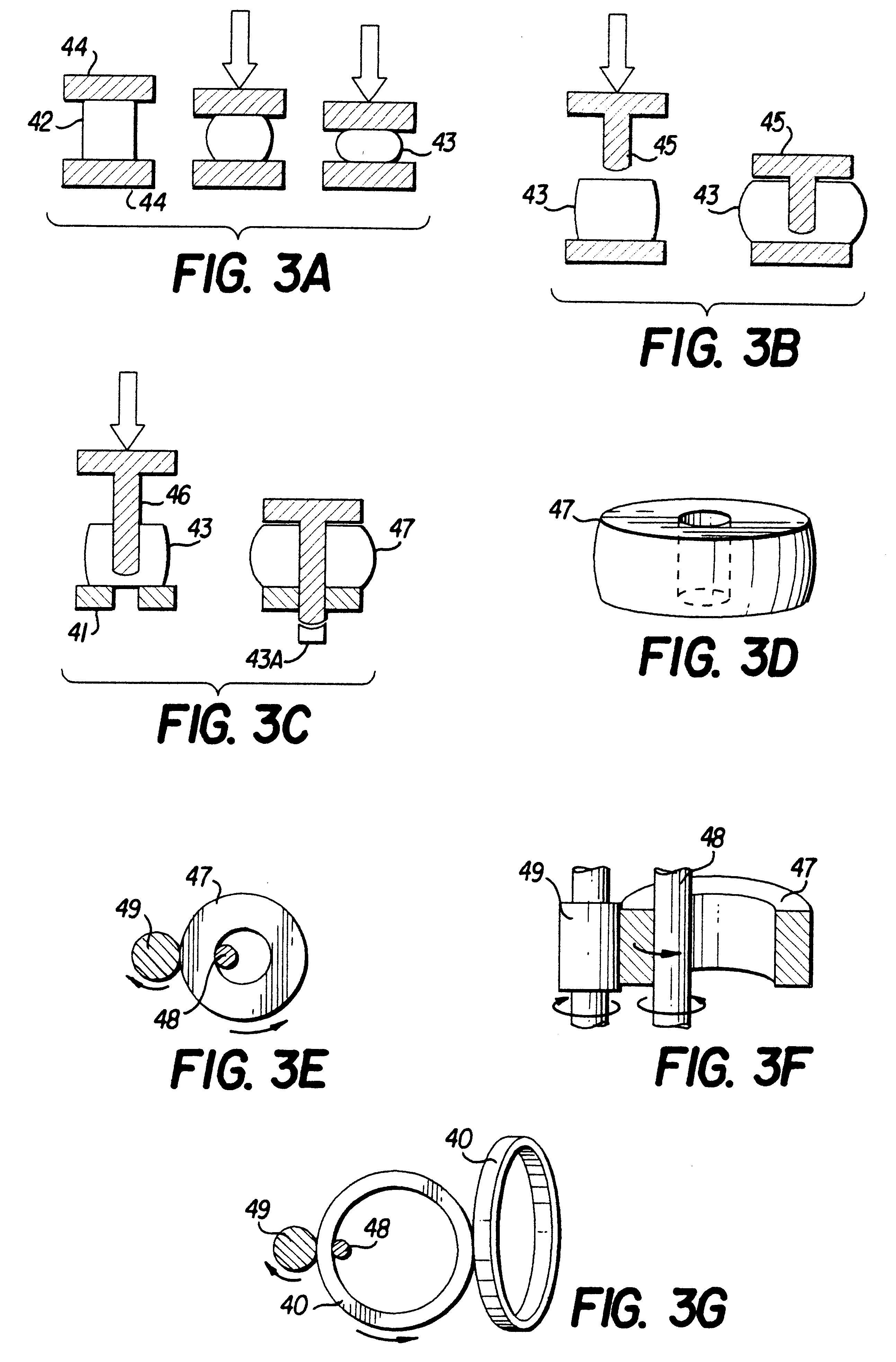

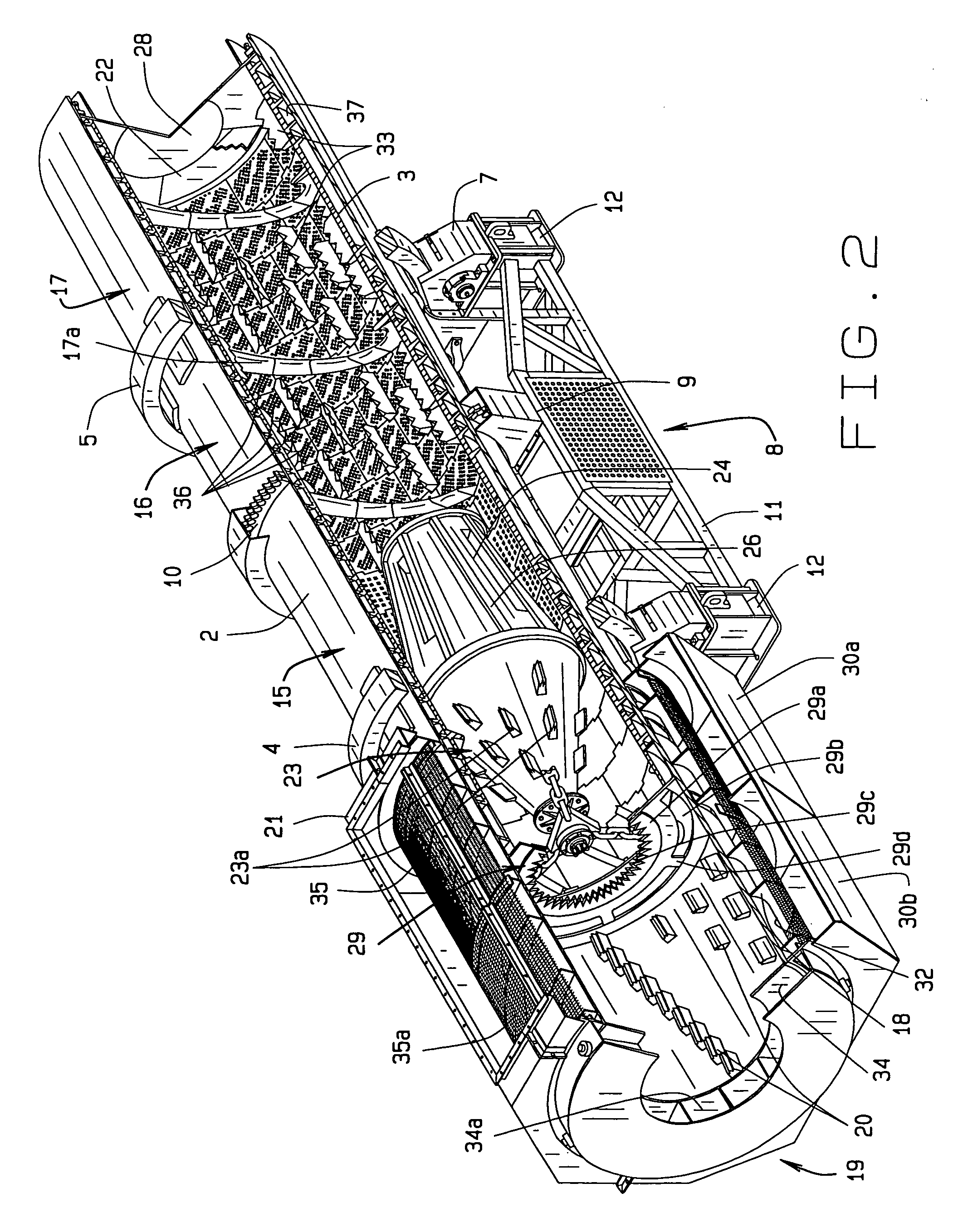

Rotary tumbler and metal reclaimer

A rotary tumbler metal reclaimer includes an inner cylinder and a concentric outer cylinder that rotate simultaneously. The inner cylinder includes a first compartment that intakes material for breaking by teeth, a second compartment that receives broken material from the first compartment and crushes the material into smaller particles, and a third compartment wherein particulate material enters the space between the inner cylinder and the outer cylinder by attrition through perforated screens. The second compartment includes a crusher having various features for crushing lump material as it rotates. The third compartment provides further breakage and conveyance of particulate material. Particulate material then returns proximate the intake for screening into fine and coarse sizes and then collecting for reuse. Metallics and metallic oxides exit the tumbler through apertures in the rear of the third compartment for collection. The tumbler reclaims metals, metallic oxides, sands, and other materials for reuse.

Owner:DIDION TECHNOLOGIES LLC

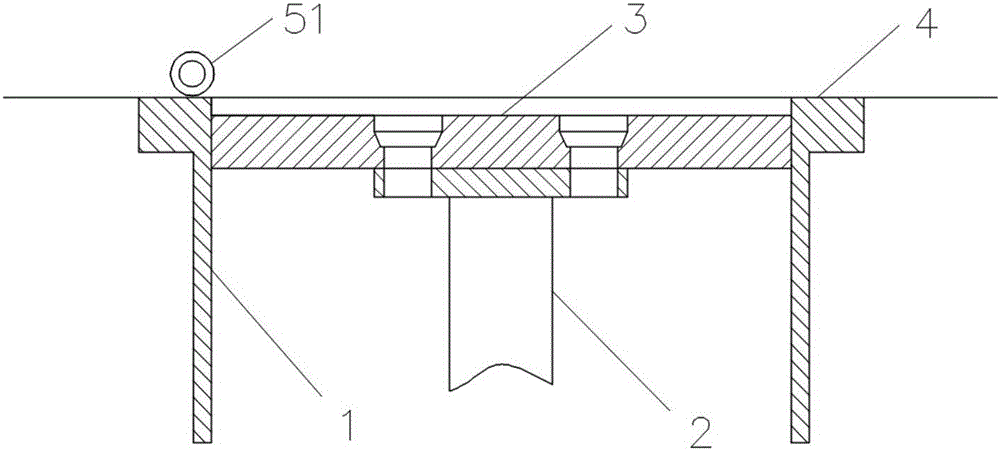

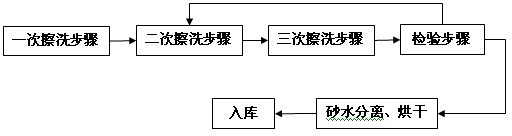

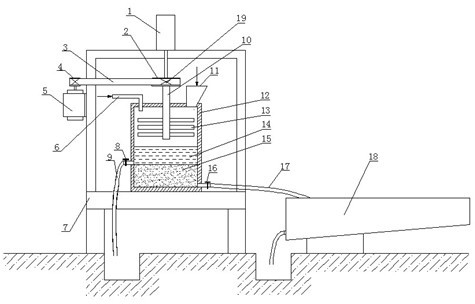

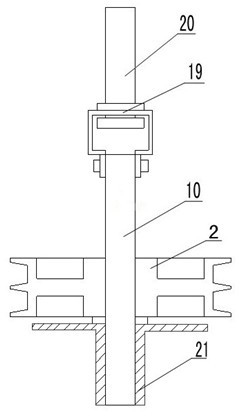

Foundry used sand wet intermittent regeneration method and equipment thereof

ActiveCN102615243AHigh removal rateQuality improvementMould handling/dressing devicesFoundryAcid washing

A foundry used sand wet intermittent regeneration method and equipment thereof belong to a foundry used sand regeneration method and equipment thereof, aim to solve the problem of complicated process and narrow application scope of the conventional foundry used sand wet regeneration method, and further solve the problem of relatively complicated structure of the conventional regeneration equipment. The regeneration method comprises a scrubbing step, a second scrubbing step, a third scrubbing step and a checking step. The regeneration equipment comprises a stirrer and a sand-water separation device, wherein the stirrer comprises a support frame, a scrubbing cylinder, a drive cylinder, a motor and a main shaft, and the scrubbing cylinder is provided with a sand inlet and a water inlet and further provided with a water drainage valve and a sand discharge valve. By integrating the combined actions of mechanical stirring, water washing and acid cleaning, the regeneration method provided bythe invention has the advantages of convenience in control, low water consumption, high residual adhesive removal ratio and good sand regeneration quality; the regeneration equipment has the advantages of simple structure, low energy consumption, convenience in control and good sand regeneration quality; and the regeneration method and equipment are suitable for large-scale wet regeneration of used clay sand, used water glass sand and used alkaline phenolic resin sand.

Owner:包头市晟裕机械制造有限责任公司

Waste foundry sand regeneration method

InactiveCN107983907AQuality improvementHigh regeneration rateMould handling/dressing devicesEnvironmental resistanceRecovery method

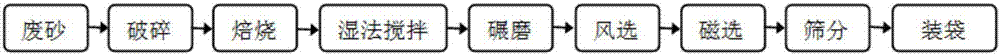

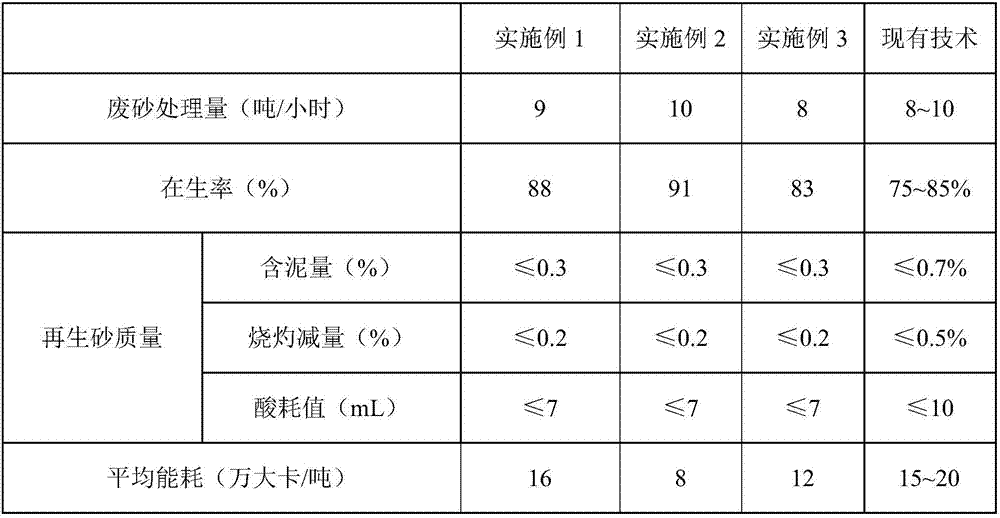

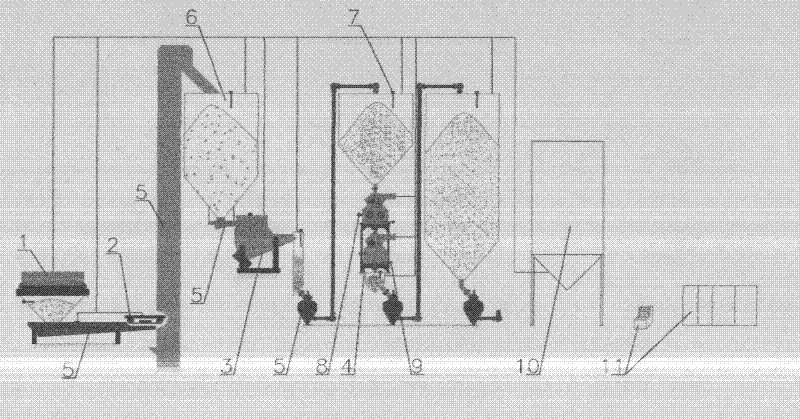

The invention provides a waste foundry sand regeneration method, belongs to the field of environment-friendly regeneration, and particularly relates to a recovery method for waste casting materials. According to the waste foundry sand regeneration method, procedures are successive and reasonable, operation is easy and convenient, and the regeneration rate is high. The waste foundry sand regeneration method comprises the steps of (1) breaking of waste foundry sand, (2) roasting, (3) wet stirring, (4) grinding, and (5) winnowing and magnetic separation. According to the waste foundry sand regeneration method, the heating procedure, the wet stirring procedure and the mechanical grinding procedure are more successive and reasonable, sand reclaimed through the method is high in quality, the regeneration rate is high, and thus, the waste foundry sand regeneration method has good technical feasibility and applicability; and by adoption of the waste foundry sand regeneration method, no poisonous and harmful waste is discharged in the treatment process, zero emission is achieved, and the purpose of environmental protection is achieved.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

Digital resin sand regeneration system

InactiveCN102233405AMeet the needs of productionAutomatic production controlMould handling/dressing devicesEngineeringElectric control

A digital resin sand regeneration system comprises a vibrating knockout device, a magnetic separation device, a vibrating crushing device, an intermittent grinding regeneration unit, a conveying device, a sand storehouse, a dedusting device, a computer control system, etc. The main working principle is as follows: waste sand blocks are vibrated and crushed into smaller blocks and scattered sand by the knockout device; magnetic separation is performed to remove iron beans and flash; crushing is performed by the crushing device to obtain granular scattered sand; stripping, grading and temperature adjustment are performed by the intermittent grinding regeneration unit to remove micro powder included in the sand, and the sand temperature is adjusted to a temperature required by the process; and the sand is conveyed to the sand storehouse to keep in reserve. Through the additionally installed computer control system which comprises a material level sensor, a temperature sensor, a pressure sensor, and a corresponding electric control component, the whole production line can realize the target control of technological parameters and stock sand amounts; mainly-controlled technological parameters are: stripping rate (loss on ignition, LOI), micro powder content, sand temperature and sand amount; and technical guarantee is provided for the digital production management of the whole factory. Digital control of molding resin amount, hardening stripping time, and sand using amount is basic guarantee for solving energy saving and consumption reduction, improving productivity, and increasing yield.

Owner:于彦奇

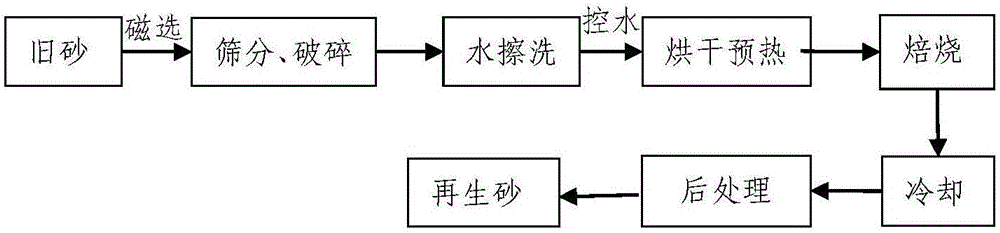

Regeneration method of casting wet type mixed old sand

ActiveCN105728641ASolve industry problemsLow gas productionMould handling/dressing devicesSocial benefitsPerformance index

The invention relates to a regeneration method of casting wet type mixed old sand. The regeneration method comprises the following steps: preprocessing casting wet type mixed old sand; wiping with water; drying; preheating; roasting; and post-processing. In the invention, components, such as bentonite, coal dust and ashes, in wet type old sand are effectively removed by a water wiping process, and a residual resin film in mixed old sand is thoroughly decomposed by a roasting process. The regeneration cost is low, and the regeneration effect is great. Actual production and verification show that the performance indexes of regenerated sand reach or surpass those of new sand. The regeneration method is successively applied to the core making production of cold boxes and has remarkable economical and social benefits.

Owner:WEICHAI POWER CO LTD

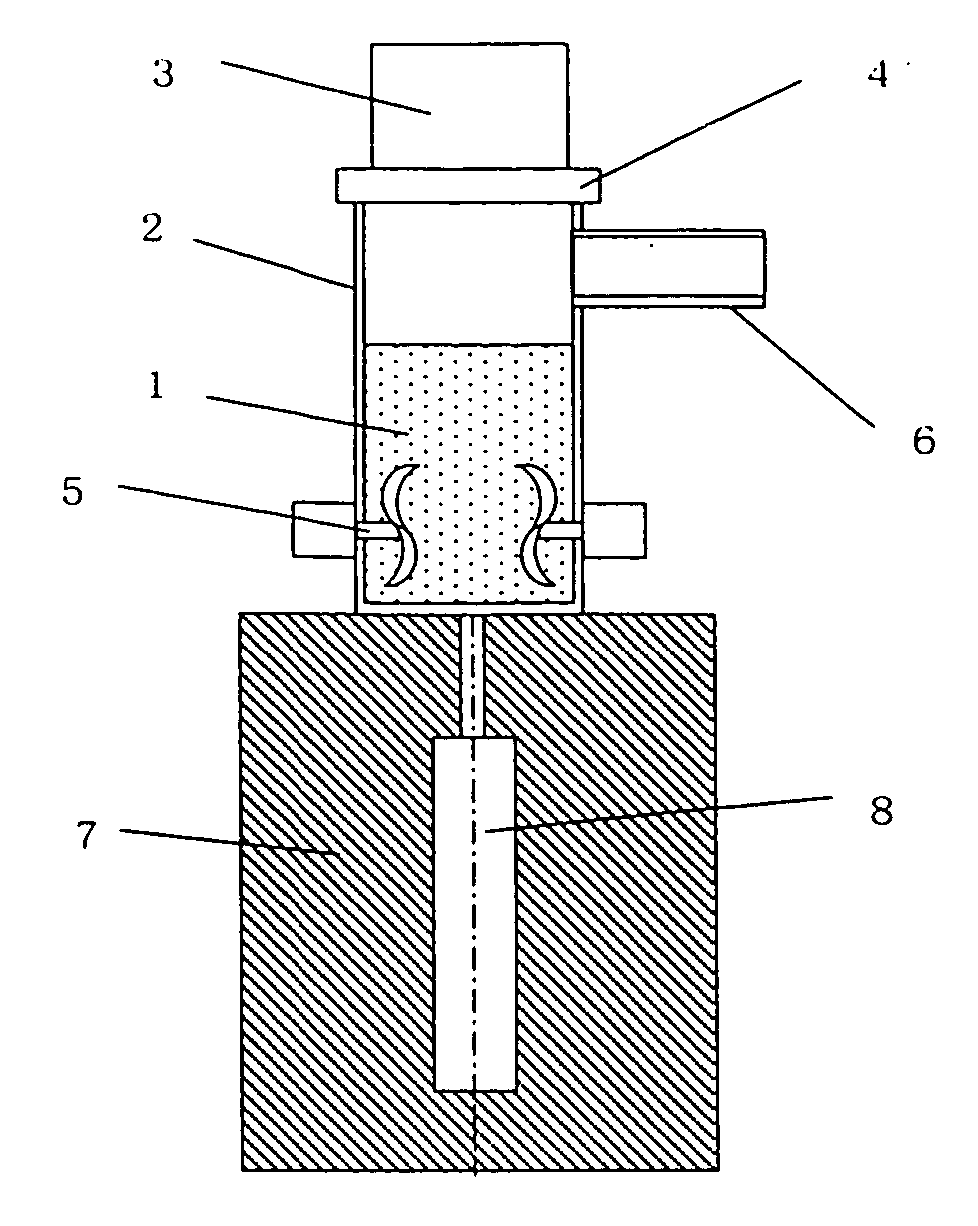

Method utilizing ultrasonic technology to regenerate used sodium silicate sand

ActiveCN104399876ALow costReduce recycling costsMould handling/dressing devicesSodium silicateUltrasonic technology

The invention discloses a method utilizing an ultrasonic technology to regenerate used sodium silicate sand. The method comprises the following steps: soaking used sodium silicate sand in a prepared sodium hydroxide solution, then separating the sodium silicate sand from the sodium hydroxide solution, placing the soaked sodium silicate sand in clean water or an alkali solution with a mass concentration of 0 to 20%; then subjecting the solution to an ultrasonic treatment by ultrasonic waves with a frequency of 20 to 200 kHz, then separating the sodium silicate sand from the waste liquid so as to obtain sodium silicate sand and waste liquid containing waste residues; washing the obtained sodium silicate sand, and drying so as to obtain regenerated sodium silicate sand with a demoulding rate more than 95%. The provided method has the advantages of high regeneration demoulding rate, no pollution, and good usability of regenerated sand.

Owner:天津众智科技有限公司

Preparation method for sodium silicate sand used for casting

ActiveCN102366812AHigh strengthGood collapsibilityFoundry mouldsMould handling/dressing devicesPolypropylene glycolNano al2o3

The invention discloses a preparation method for sodium silicate sand used for casting. The method comprises the steps of preparing modified sodium silicate and preparing molding sand, wherein, the modified sodium silicate is prepared by using a composite modifier which comprises 35 to 50% of talcum powder, 6 to 12% of starch, 14 to 18% of polypropylene glycol and 25 to 35% of nanometer alumina powder on the basis of the total amount of the composite modifier. The molding sand in the invention enhances strength and improves collapsibility of the sodium silicate sand.

Owner:江苏龙欧新型建材科技有限公司

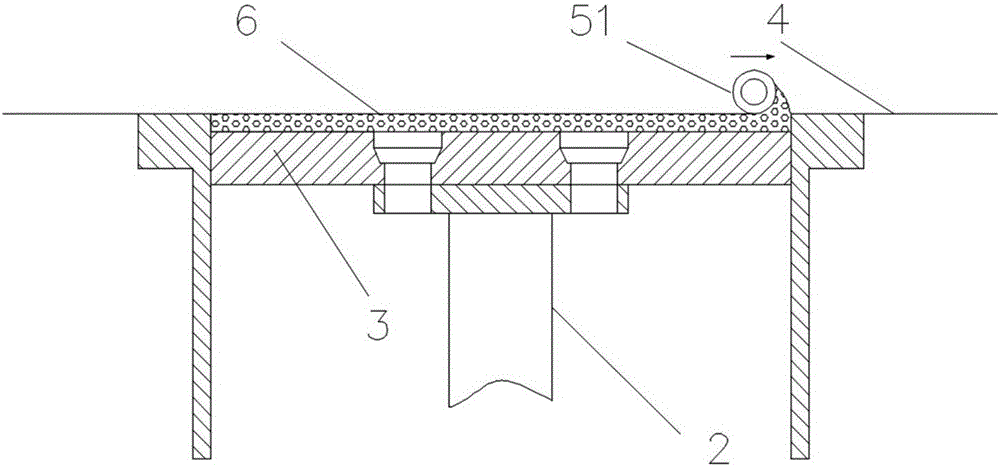

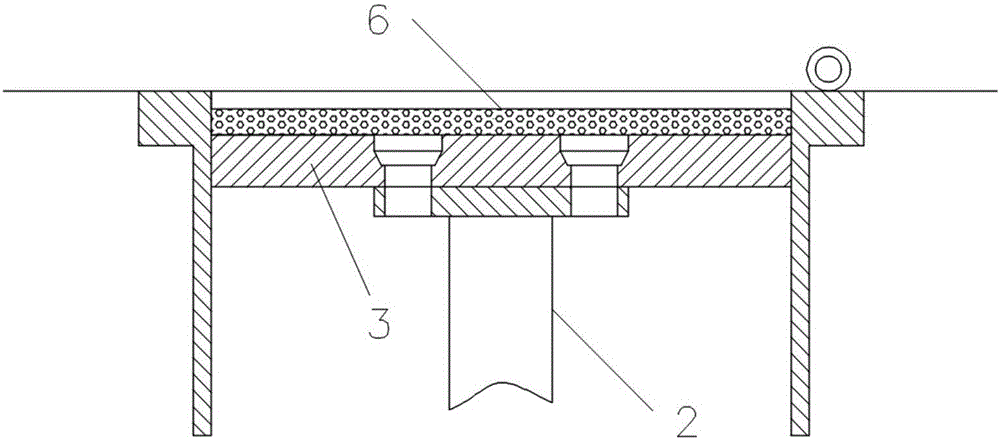

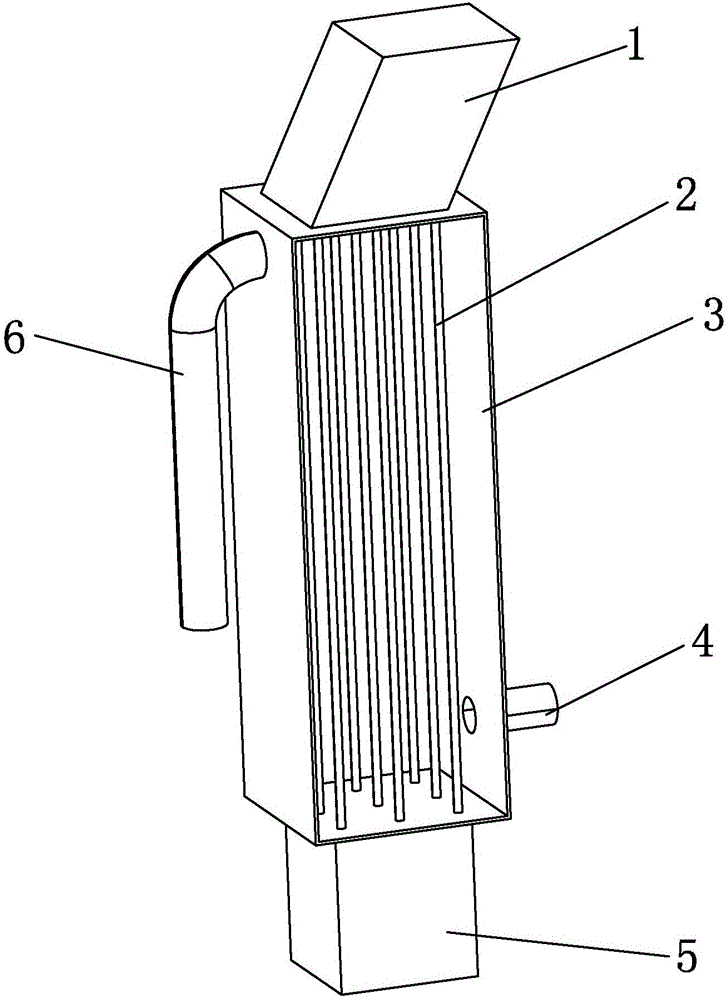

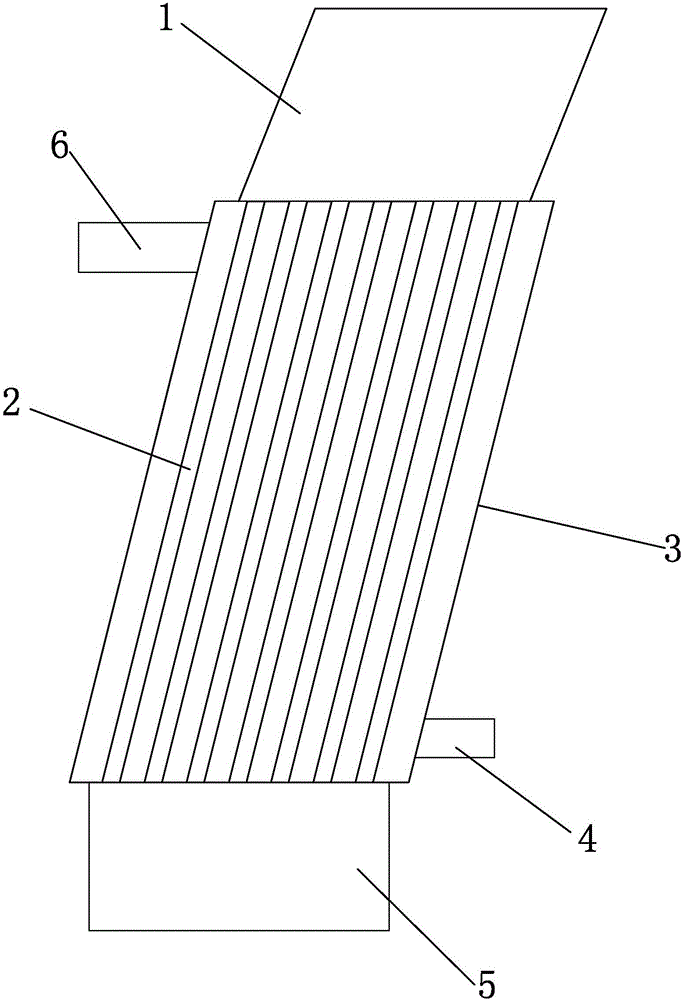

Quick cooling device for sand of lost-foam production line

InactiveCN106077451AImprove thermal conductivityReduce manufacturing costMould handling/dressing devicesProduction lineCooling effect

The invention discloses a quick cooling device for sand of a lost-foam production line, and relates to a cooling device. The quick cooling device comprises a cooling water tank, sand cooling metal tubes, a sand inlet hopper and a sand outlet hopper; the tank wall, close to the top end, of the cooling water tank is connected with a water outlet tube which extends into the cooling water tan; the tank wall, close to the bottom end, of the cooling water tank is connected with a water inlet tube which extends into the cooling water tank; the sand inlet hopper is connected with the outer surface of the tank wall at the top end of the cooling water tank; the sand outlet hopper is connected with the outer surface of the tank wall at the bottom end of the cooling water tank; the plurality of sand cooling metal tubes are uniformly arranged in the cooling water tank; the top end of each sand cooling metal tube is connected with the tank wall at the top end of the cooling water tank in a sealing manner; the top end of each sand cooling metal tube passes through the tank wall at the top end, and communicates with an inner cavity of the sand inlet hopper; the bottom end of each sand cooling metal tube is connected with the tank wall at the bottom end of the cooling water tank in the sealing manner; and the bottom end of each sand cooling metal tube passes through the tank wall at the bottom end, and communicates with the inner cavity of the sand outlet hopper. The quick cooling device has the advantages of being small in size, simple in structure, good in cooling effect, low in energy consumption, and the like.

Owner:LIUZHOU ZHIBAO MACHINERY

Molten aluminum filtration

InactiveUS20050167075A1Smooth connectionIncrease shear forceMolten metal pouring equipmentsMolten metal supplying equipmentsFiltrationFilter material

A filter material for molten aluminum, the material subsequently dissolvable in molten aluminum to recover aluminum captured therein.

Owner:ECKERT C EDWARD

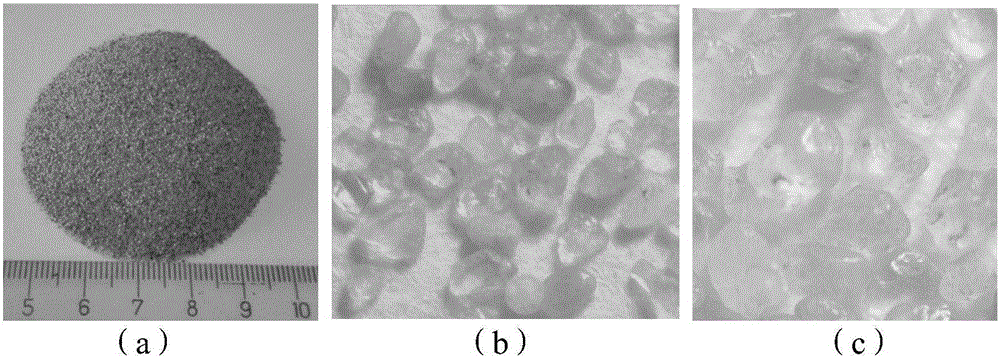

Regeneration technology of foundry used sand

ActiveCN104858362AImprove qualityReduce pollutionMould handling/dressing devicesFoundryResin coating

The invention relates to a regeneration technology of foundry used sand. The technology comprises the following steps that (1), initial magnetic separation is carried out on broken used sand; (2) the broken used sand obtained after initial magnetic separation is roasted; (3), roasted sand grains are cooled, and under the negative pressure condition, blast grinding is carried out on the sand grains; and (4), the ground sand grains are screened, magnetic separation is carried out again, and regeneration sand is obtained. The quality of the regenerated sand obtained through the technology treatment is further improved, the acid consumption value and the ignition losses of the sand are obviously reduced, the sand grain and the resin coating effect is better, the strength is higher, the pollution of the used sand to the environment is reduced, the cost of core making materials of a casting enterprise is saved, and a hot core box and a cold core box made of original sand can be completely replaced.

Owner:南阳仁创再生资源有限公司

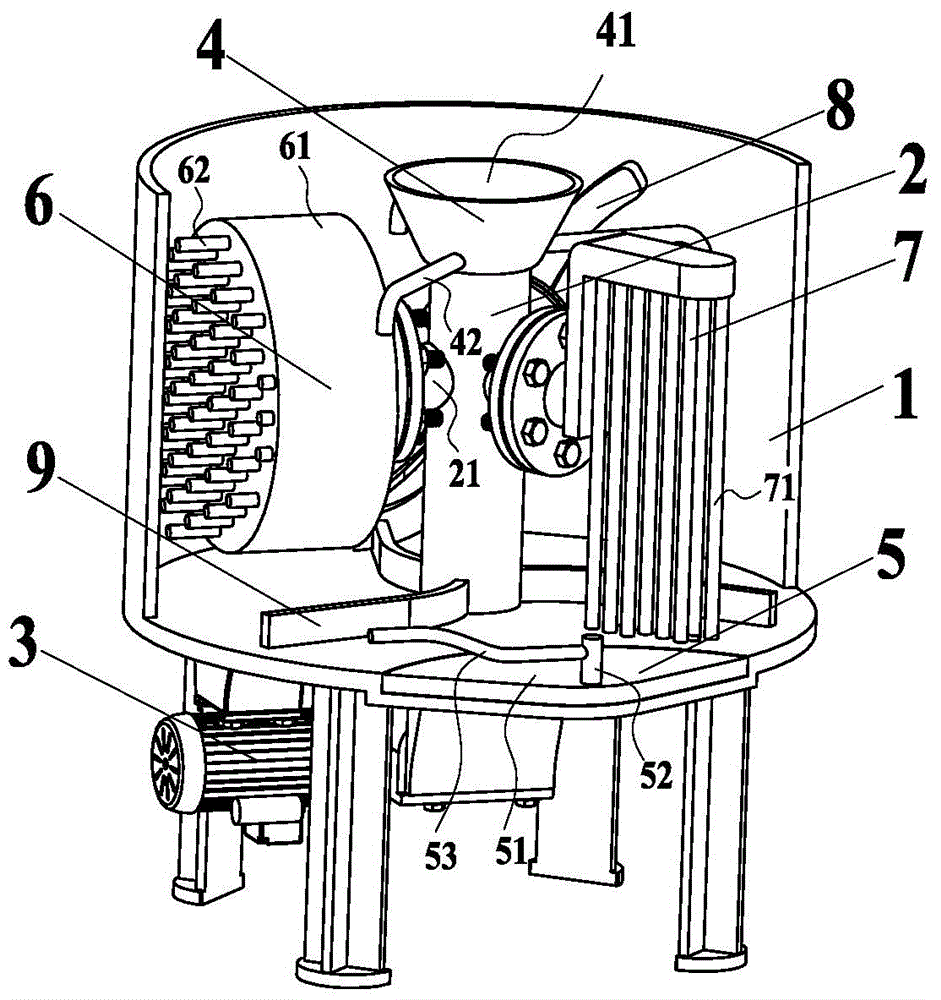

Sand mixing equipment

ActiveCN104815950AAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorEngineering

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com