Patents

Literature

189 results about "Methenamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An anti-infective agent most commonly used in the treatment of urinary tract infections. Its anti-infective action derives from the slow release of formaldehyde by hydrolysis at acidic pH. (From Martindale, The Extra Pharmacopoeia, 30th ed, p173)

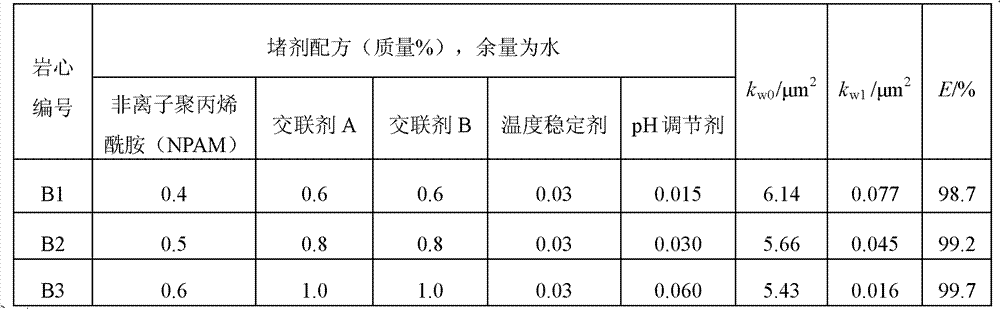

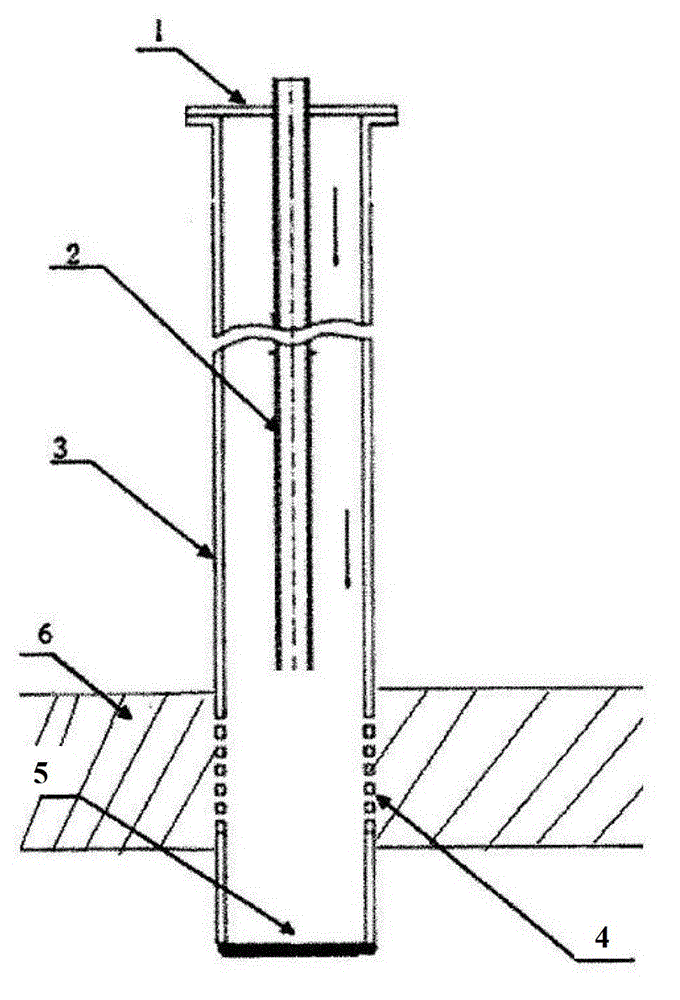

Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

ActiveCN102807849AImprove temperature resistanceGelation time is shortDrilling compositionSodium bicarbonateCross-link

The invention relates to a gel plugging agent for deep profile control of a higher temperature oil reservoir, and a preparation method of the gel plugging agent. The gel plugging agent comprises 0.3-0.8 percent of nonionic polyacrylamide, 0.6-1.3 percent of a cross-linking agent A, 0.45-1.44 percent of a cross-linking agent B, 0.02-0.04 percent of a temperature stabilizer and 0.01-0.08 percent of a pH value regulator, wherein the cross-linking agent A is methenamine; the cross-ling agent B is hydroquinone or resorcinol; the temperature stabilizer is sodium thiosulfate, sodium bisulfite or sodium sulfite; and the pH regulator is sodium hydroxide, potassium hydroxide, sodium carbonate or sodium bicarbonate. The gel plugging agent disclosed by the invention has strong temperature resisting performance and can be used for the profile control operation of the high temperature oil reservoir with 100-160DEG C; the gel plugging agent has the characteristics of high strength after being gelatinized, stronger plugging capability for the stratum and favorable thermal stability; and in addition, after the gel plugging agent is stood at the temperature of 130 DEG C for 90 days, the strength change is little and gel breaking and hydration are avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing novel remover for heavy metal ion and application thereof

The invention provides a method for preparing a novel heavy metal ion remover and an application thereof, and relates to a method for preparing a raw material of the heavy metal ion remover, a process for synthesizing the heavy metal ion remover and an application thereof. The invention is characterized in that the method comprises the following steps that: methenamine and epoxy chloropropane react with carbon bisulfide after the methenamine and the epoxy chloropropane are subject to the cross linking reaction, thereby obtaining a quaternary ammonium salt xanthate chelating agent-the novel heavy metal ion remover. The prepared novel heavy metal ion remover can be used for treating wastewater containing heavy metal ions, and the dosage and the adding process of the novel heavy metal ion remover can be controlled through detecting changes of an oxidation-reduction reaction electrode potential (ORP), thereby achieving the aim of automatically treating the wastewater containing the heavy metal ions with high efficiency.

Owner:陈德琪

Modified melamine resin and production method thereof

The invention discloses a modified melamine resin and a production method thereof. The modified melamine resin comprises the following components in part by weight: 500 to 600 parts of formaldehyde, 5 to 9 parts of polyvinyl alcohol, 25 to 35 parts of methenamine, 70 to 80 parts of melamine, 180 to 250 parts of carbamide, 50 to 300 parts of methanol or ethanol, and 20 to 80 parts of polyethylene glycol or diethylene glycol. Due to the addition of raw materials of high aliphatic chain, the modified melamine resin and the production method thereof further prolong the storage life of the melamine resin, can meet the production requirements of enterprises on the long storage life, save production cost, improve working efficiency and save energy consumption.

Owner:SHENZHEN NEWCCESS IND

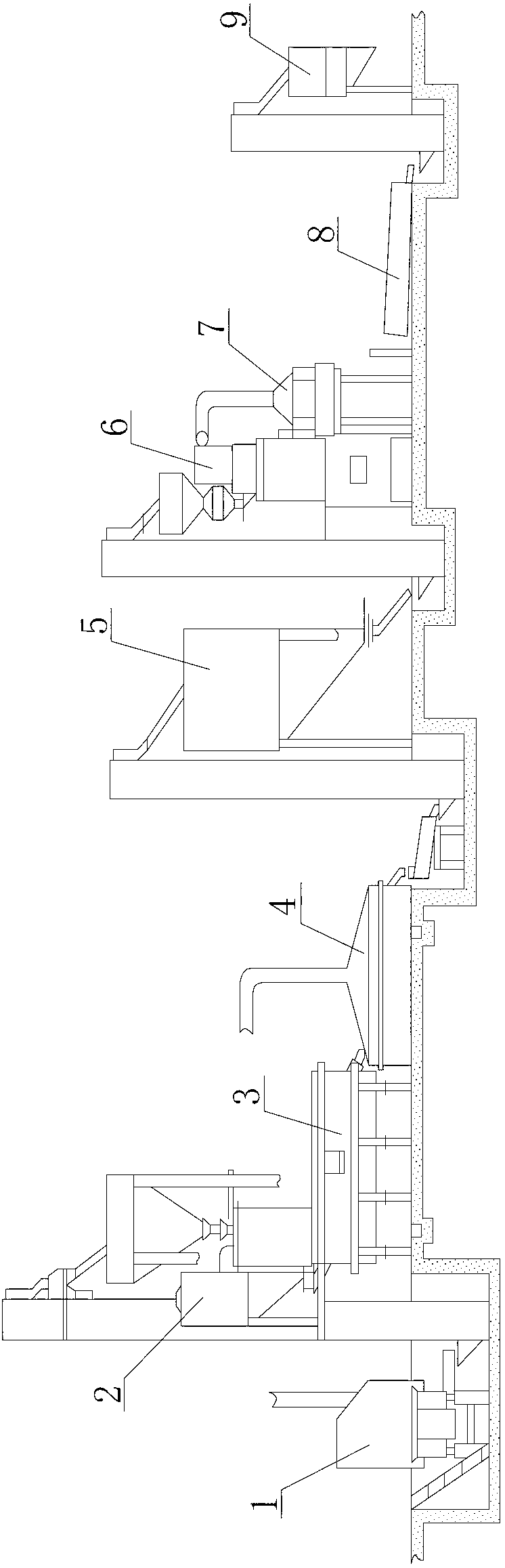

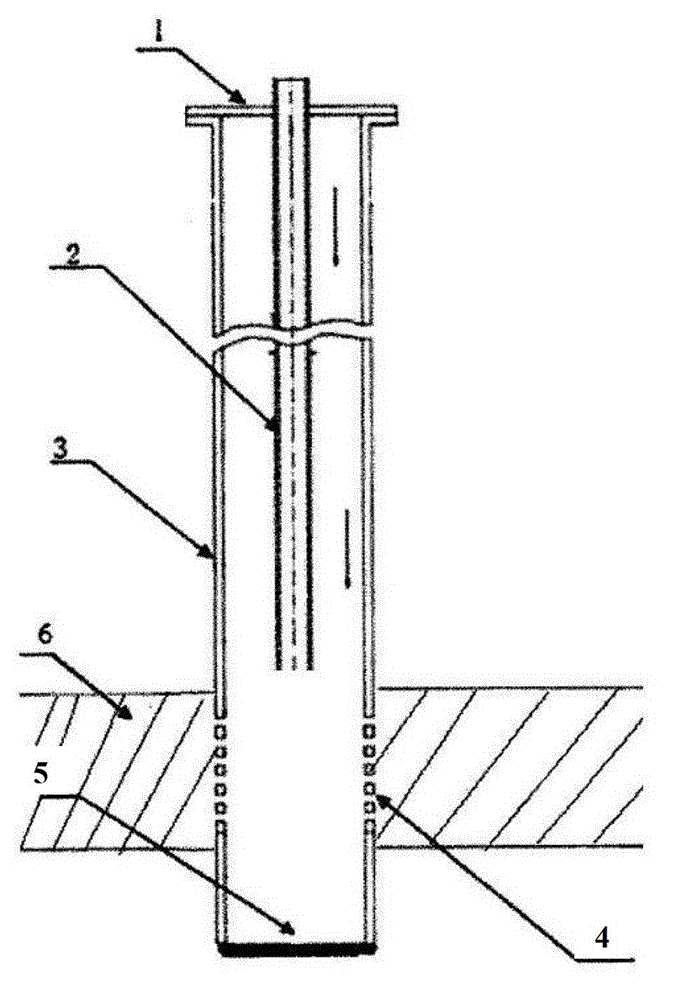

Waste sand recycling equipment and use method thereof

ActiveCN103317084AImprove recycling ratesEasy to operateMould handling/dressing devicesSilanesEngineering

The invention relates to waste sand recycling equipment which comprises a vibration crushing screening machine, an old sand lifting machine, a magnetic separation machine, a hot-method regeneration device, a cooling bed, a vibration screen and a new sand lifting machine which are connected in sequence. A use method of the waste sand recycling equipment comprises the following steps of: a, adding waste sand into the vibration crushing screening machine, crushing the waste sand into small particles, feeding the small particles into the old sand lifting machine, conveying the small particles to the magnetic separation machine, and removing iron materials; b, feeding preheated waste sand into the hot-method regeneration device for sintering; c, cooling the high-temperature sintered sand through the cooling bed, feeding the cooled sintered sand into the vibration screen, and enabling the sintered sand to pass through the new sand lifting machine to obtain regenerated sand; d, preparing materials according to the following formula: 1.6-1.7kg of a methenamine solution, 2.7-2.8kg of phenolic resin, 100-300g of calcium stearate, 60-100g of silane and 150kg of the regenerated sand and / or raw sand; e, adding the materials into a stirring kettle in sequence and uniformly stirring to obtain precoated sand. The waste sand recycling equipment has the beneficial effects of simplicity for operation, high old sand recycling rate and simplicity for popularization.

Owner:金丰(新乡)矽砂有限公司

Polypropylene hollow fiber ultrafiltration membrane coated with polymer composite coating

ActiveCN105080361AImprove antibacterial propertiesHigh strengthAntifouling/underwater paintsUltrafiltrationEpoxyFiber

The invention relates to a polypropylene hollow fiber ultrafiltration membrane coated with a polymer composite coating. The polypropylene hollow fiber ultrafiltration membrane comprises a water inlet surface and a water outlet surface which are respectively coated with a coating; the coating on the water inlet surface comprises the following raw materials: tricresyl phosphate, dioctyl phthalate, a modified polysiloxane polymer, polyether-ether-ketone (PEEK), methenamine and the like; and the coating on the water outlet surface comprises the following raw materials: allyl polyoxy alkyl epoxy ether, pentaerythritol, polyethylene glycol lauric acid diester, polyoxyethylene alkylamine, nano silver and the like. The polypropylene hollow fiber ultrafiltration membrane is capable of increasing the retention rate for macromolecular organic matter and emulsified oil, so that the COD removal rate of sewage is greatly increased, the electrostatic effect on the surface of the membrane is changed, the adsorption for contaminants of the surface of the membrane is prevented, the membrane can be continuously used for a long time under the condition of high membrane flux, and the service life of the membrane is prolonged. The addition of the nano silver effectively improves the antibacterial mildew properties of the membrane.

Owner:广州市纳清环保科技有限公司

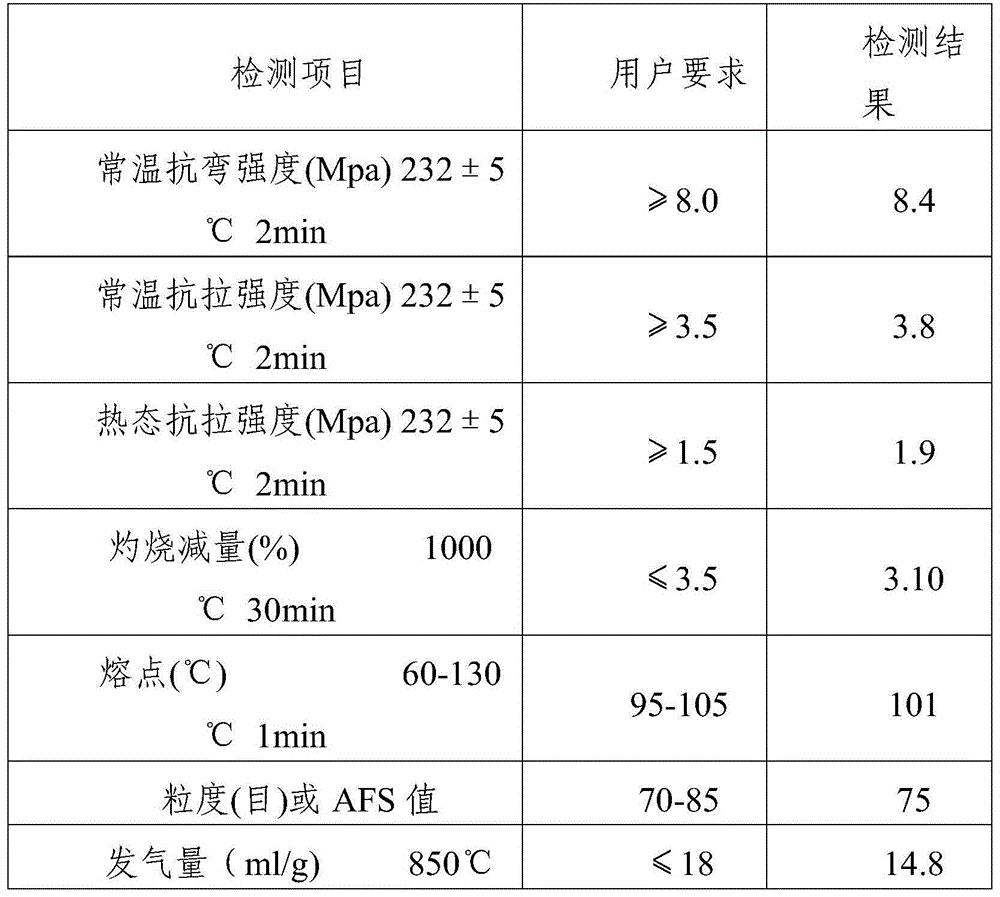

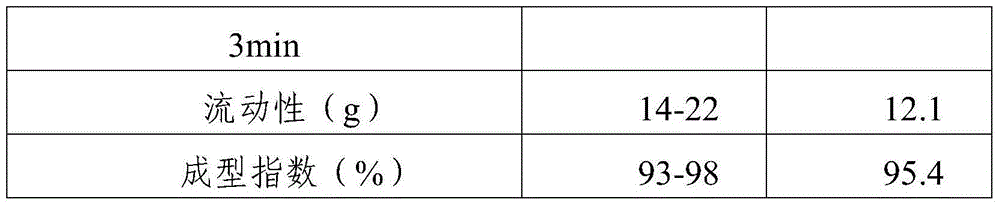

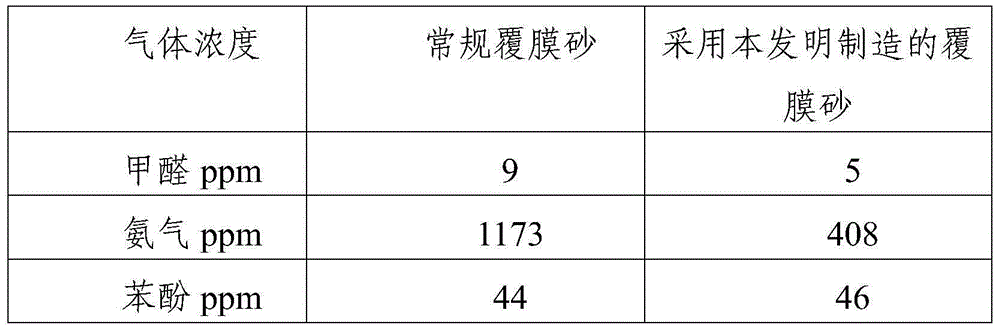

Coated sand preparation method

ActiveCN104889313AGuaranteed performanceEasy to useFoundry mouldsFoundry coresEnvironmental resistanceNitric oxide

The invention relates to the casting material technical field, and especially relates to a coated sand preparation method. According to the coated sand preparation method, in the manufacturing process, right amount of liquid phenolic resin is added, the content of added methenamine is reduced, because the main source of flue gas produced during combustion is methenamine combustion, and the liquid phenolic resin is added in the coated sand preparation method, coated sand performance can be ensured, at the same time the amount of the added methenamine is properly reduced, so that in the core making and the casting process of the coated sand, the quantity of generated ammonia, phenol, formaldehyde and nitric oxide and other harmful gases during coated sand combustion can be greatly reduced, the coated sand preparation method is more environmentally-friendly, and the use performance of the coated sand can be promoted.

Owner:通辽市仁创铸造材料有限公司

Environment-friendly bamboo charcoal composite ceramic brake

InactiveCN101709753AImprove protectionLarge effective braking areaFriction liningComposite ceramicHexamethylenetetramine

The invention relates to an environment-friendly bamboo charcoal composite ceramic brake which comprises the following raw materials in percentage by weight: 3-40 percent of floating bead, 3-35 percent of meerschaum, 4-30 percent of mica, 3-50 percent of plant fiber, 5-40 percent of barite, 2-30 percent of light weight calcium, 4-30 percent of molybdenum disulfide, 2-25 percent of titanium pigment, 1-10 percent of flame retardant, 2-25 percent of barium sulfate, 10-28 percent of 213 resin, 3-26 percent of methenamine, 5-30 percent of kaolin and 5-33 percent of figuline; the percentage sum by weight of the raw materials is 100 percent. The environment-friendly bamboo charcoal composite ceramic brake has the characteristics of good braking performance, long service life, low noise, little environment pollution and the like.

Owner:北京伟实节能科技发展有限责任公司

Synthetic method of silicon nitride nanopowder

InactiveCN101353160ALow costExpand production scaleNitrogen compoundsReaction temperatureNitrogen gas

The invention relates to a silicon nitride nano-powder synthesis method. Silica sol, urea and methenamine are evenly mixed to obtain solution, wherein the mol ratio of the urea to the methenamine is 4.7:3-5.6:3, the mol ratio of carbon to silicon is 2.5:1-4:1; the solution is added with cetyl trimethyl ammonium bromide and dilute sulfuric acid for addition reaction, and the acidity of a reaction medium is 6.5-7.5, and the reaction temperature is 50-60 DEG C; then condensation reaction is carried out for the mixture to generate a precursor, wherein the pH value is 3-4, the condensation temperature is 80-90 DEG C; the precursor is dried and ball-ground, and is positioned in a nitriding furnace for calcinations in 2-3L / min nitrogen flow at the temperature of 1480-1520 DEG C for 1.8-2.2 hours to synthesize Si3N4 powder; the silicon nitride nano-powder is prepared by decarbonizing the synthetic Si3N4 powder at the temperature of 570-630 DEG C for 3.7-4.2 hours. The silicon nitride nano-powder synthesis method takes organic carbon as a carbon source, organic nitrogen and nitrogen as a nitrogen source, and the silica sol as a silicon source, and has the advantages of high product quality, low production cost and large production scale. The average particle size of the prepared Si3N4 powder is 43-100nm, and the purity of the Si3N4 powder can be up to 100%.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

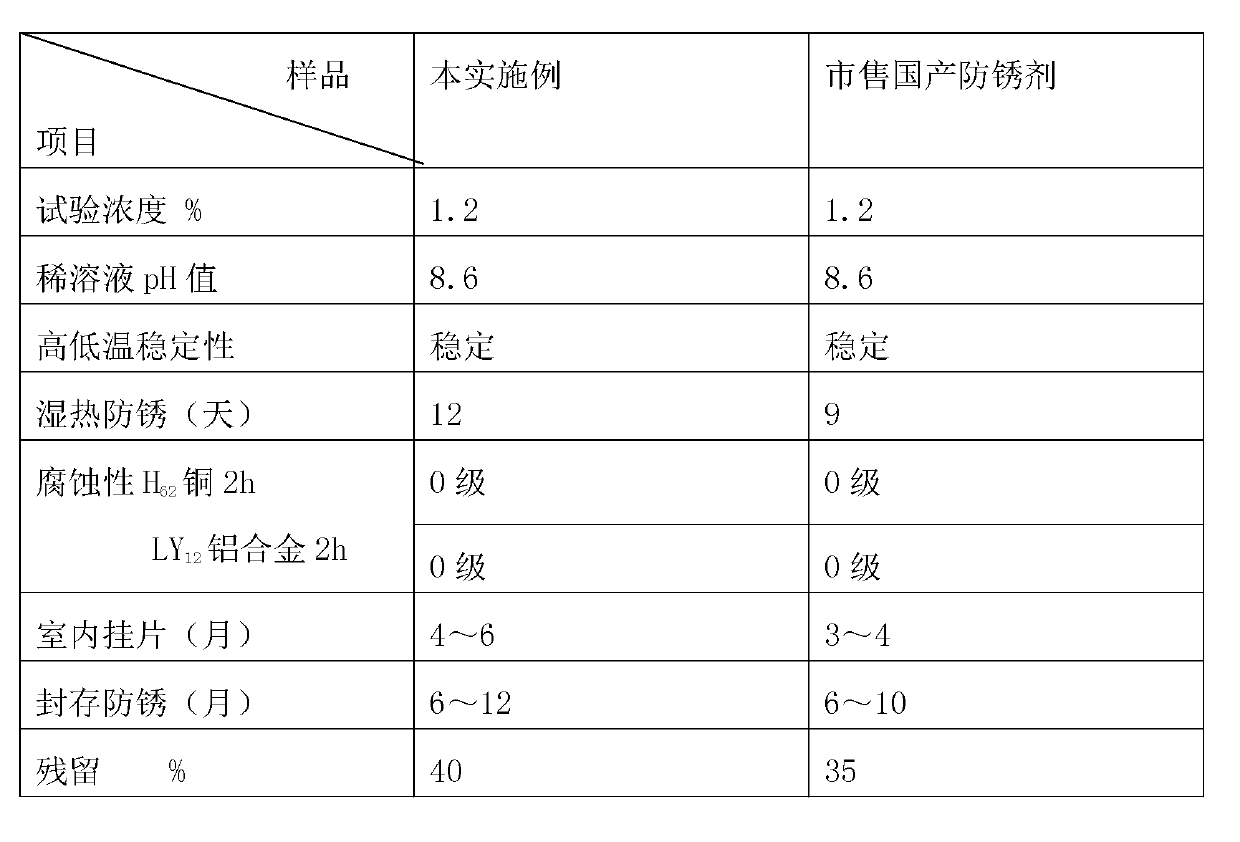

Corrosion and scale inhibitor for oil well in high water cut stage

ActiveCN102321464AExtend the pump inspection cycleDrilling compositionBorehole/well accessoriesThioureaEthylenediaminetetra(methylenephosphonic)acid

The invention relates to a corrosion and scale inhibitor for an oil well in a high water cut stage, which is applicable to corrosion and scale inhibition of an oilfield. The corrosion and scale inhibitor comprises the following components in percentage by weight: 3.25-4.0% of o-dimethyl thiourea, 12.5-13.5% of ethylenediamine tetramethylene phosphonate, 8.0-8.5% of dodecyl butylamine methyl sulfide, 3.0-3.25% of tetradecyl tributyl phosphonium chloride, 15.0-16.2% of DN-3212 acrylic acid, organic phosphine and sulfonic acid copolymer, 5.25-5.75% of M-505A corrosion inhibitor, 6.85-7.25% of SL-2 corrosion and scale inhibitor, 5.0-7.5% of methanol, 3.4-3.75% of methenamine, 0.05-0.055% of vitamin A and the balance of water, wherein the sum of the weight percentage of each component is100%. The corrosion and scale inhibitor has the effects that: when the addition amount of the corrosion and scale inhibitor is 50-60 mg / L, the corrosion inhibition rate of the oil well reaches more than 85%, and the scale inhibition rate reaches more than 90%; and the average pump examination period is prolonged by more than one time.

Owner:PETROCHINA CO LTD

Hydrogenation heat gas chemical yield increasing solution component for low-permeability carbonate reservoir oil well

ActiveCN102942914AImprove permeabilityImprove single well productivityFluid removalDrilling compositionHydrazine compoundAlkylphenol

The invention belongs to the technical field of oil exploitation, and particularly relates to a hydrogenation heat gas chemical yield increasing solution component capable of being used for increasing productivity of a low-permeability carbonate reservoir oil well. The solution component comprises first solution, second solution and third solution, the mass ratio of the first solution, the second solution and the third solution is 1:1:3, the first solution comprises urea CO(NH2)2, sodium nitrite NaNO2, hydrazine N2H4 and water H2O, the second solution comprises aluminum chloride AlCl3, sodium hydride NaH, ammonium chloride NH4Cl and tetrachloroethylene C2Cl4, and the third solution comprises hydrochloric acid HCl, methenamine (CH2)6N4 and alkylphenol ethoxylate C9H19C6H4O(C2H4O)nH. Compared with an acidizing and fracturing process, a hydrogenation heat gas chemical method is simple in process, has the advantage of combination of heat recovery, fracturing and acidizing, is long in yield increasing duration and high in recovery ratio, and can be applied to carbonate oil reservoir exploitation.

Owner:吉林贯通能源科技有限责任公司

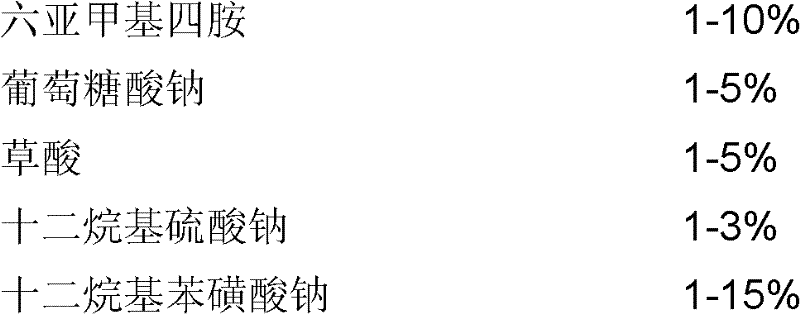

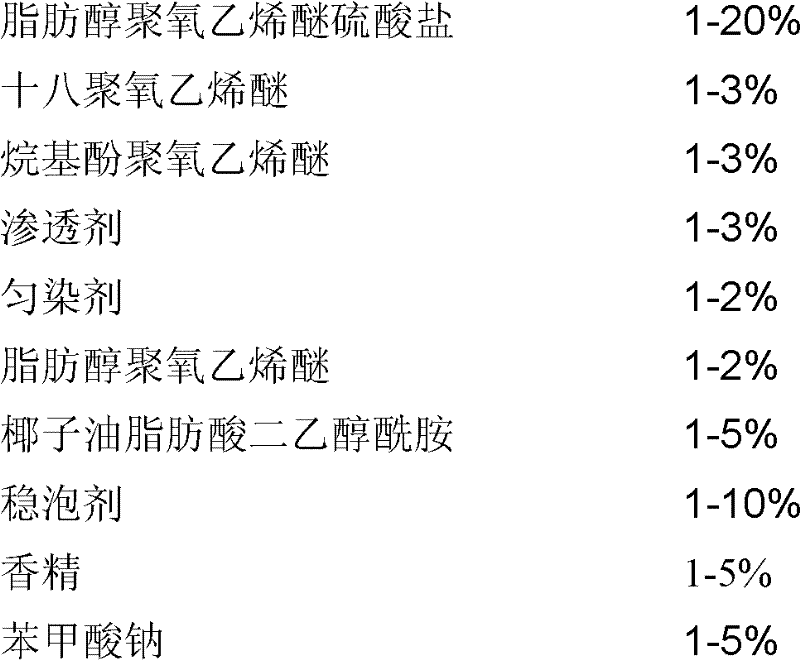

Acid-washing corrosion-inhibition fog inhibitor

The invention relates to an acid-washing corrosion-inhibition fog inhibitor, which achieves an effect of corrosion inhibition by using combination of methenamine, sodium gluconate and oxalic acid, prevents a steel base body from being subjected to acid corrosion and avoids an over-pickling phenomenon. In the acid-washing corrosion-inhibition fog inhibitor provided by the invention, foam can be generated by combination of dodecyl sodium sulfate, sodium dodecyl benzene sulfonate and AES (Sodium Alcohol Ether Sulphate) in the ingredients; and by using octadecyl polyoxyethylene ether, alkylphenolpolyoxyethylene ether, a penetrant, a leveling agent, fatty alcohol-polyoxyethylene ether, cocoanut fatty acid diethanolamide and a foam stabilizer in the ingredients, the form is promoted to be formed and time for forming the foam can be stabilized. The fog inhibitor prepared by the invention has the advantage of obvious acid fog inhibition effects with a fog inhibition rate of more than 80%, thereby obviously improving work condition of a production workshop and reducing damages to plants, equipment, workers and surrounding conditions of the acid fog.

Owner:TIANJIN JUNYITAI TECH DEV CO LTD

Manganese-containing low-zinc light-iron phosphating solution

InactiveCN101205610AImprove anti-pollution performanceImprove self-cleaning abilityMetallic material coating processesPhosphateHexamethylenetetramine

The invention discloses a normal-temperature manganese-containing low-zinc light-iron type phosphating liquid. The phosphating liquid comprising of phosphoric acid, nitric acid, fluorine ion, zinc ion, ammonia ion, sodium nitrate, sodium tungstate, copper nitrate, manganese dihydrogen phosphate, etc., complexing agent, and a plurality of composite oxidizing-reducing agents as well as buffer adjusting agent and so on, wherein, the mass fractions (expressed as g / L) of the compositions are respectively: phosphoric acid( 85 percent) of 8.0 to 29.0, nitric acid( 31 percent) of 2.5 to 6.6, fluorine ion: 0.55 to 3.35, zinc ion: 0.08 to 1.7), ammonia ion: 1.5 to 8.0, sodium tungstate : 0.6 to 4.5, sodium nitrate: 15 to 35, copper nitrate: 0.02 to 0.15, manganese dihydrogen phosphate: 6.0 to 16.5, tartaric acid: 1.5 to 7.22, and methenamine: 0.65 to 1.22. The normal-temperature manganese-containing low-zinc light-iron type phosphating liquid of the invention is used in various large, medium and small sized enterprises in recent years, and has the advantages of mature flow operation, wide process range, less pollution, low comprehensive cost, easy bath solution control, no need of promoters and so on.

Owner:北京冰石科技有限公司 +1

Energy-saving cooling fluid

The invention relates to an energy-saving cooling fluid which takes glycol as a base material, and has the following components according to mass percentage: 92 to 95 of the glycol, 1 to 3 of deionized water, 0.5 to 1.5 of decanedioic acid, 0.6 to 2 of n-octanoic acid, 0.4 to 1.5 of potassium hydroxide, and 0.3 to 0.8 of methenamine. The cooling fluid has low freezing point, wide boiling spread, excellent heat conductivility at high temperature, and energy-saving efficiency, prevents frozen injury and occurrence of steam blocking layer when the engine works, improves the thermal equilibrium temperature when the engine works, with the fuel completely combusted, reduces tail gas discharge, and obviously promotes the power.

Owner:周振华

Preparation method for chrome shaving and polyacrylamide composite gel

The present invention relates to a preparation method for a chrome shaving and polyacrylamide composite gel. The method comprises the following steps: (1) preparing polyacrylamide into a solution by water; (2) dissolving methenamine, sodium sulfite and chromic acetate in water to prepare a chrome cross-linking agent; (3) adding the chrome cross-linking agent to the polyacrylamide solution from the step (1), and uniformly stirring; (4) adding chrome shavings to the solution from the step (3), then adding a water-soluble phenolic resin, adjust the pH value to 6-9; placing the resulting solutionin a water bath with the temperature of 45-85 DEG C to carry out heating and waiting-on cementing to obtain the chrome shaving and polyacrylamide composite gel. According to the present invention, the chrome shavings are adopted as the cross-linking agent to prepare the gel, such that the problem of the chrome shaving pollutant treatment can be solved well, and the waste chrome shavings are subjected to resource utilization so as to turn waste into treasure.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Additive for pickling degreasing and derusting of steel

The invention relates to an additive for pickling degreasing and derusting of steel, which is mainly applied to pickling degreasing and derusting, corrosion inhibition and fog inhibition in the pretreatment process of plating and coating of a steel assembly. The additive comprises the components by weight percent: 0 to 2% of methenamine, 0 to 1% of oleic acid-based imidazoline corrosion inhibitor, 0 to 10% of JFC-M, 0 to 5% of degreasing agent, 0 to 4% of sodium dodecylsulfate and the balance of water. The additive has the advantages of simple preparation and low cost, and is characterized in that the additive is applicable to degreasing and derusting of the steel assembly in hydrochloric acid, sulfuric acid or mixing acid of hydrochloric acid and sulfuric acid and also has good corrosion inhibition and fog inhibition performance. The general addition quantity is 1% to 2% of acid solution quality. In use, the addition quantity can be properly regulated according to the real acid solution concentration and the surface condition of the assembly.

Owner:南通鑫凯界面工程科技有限公司

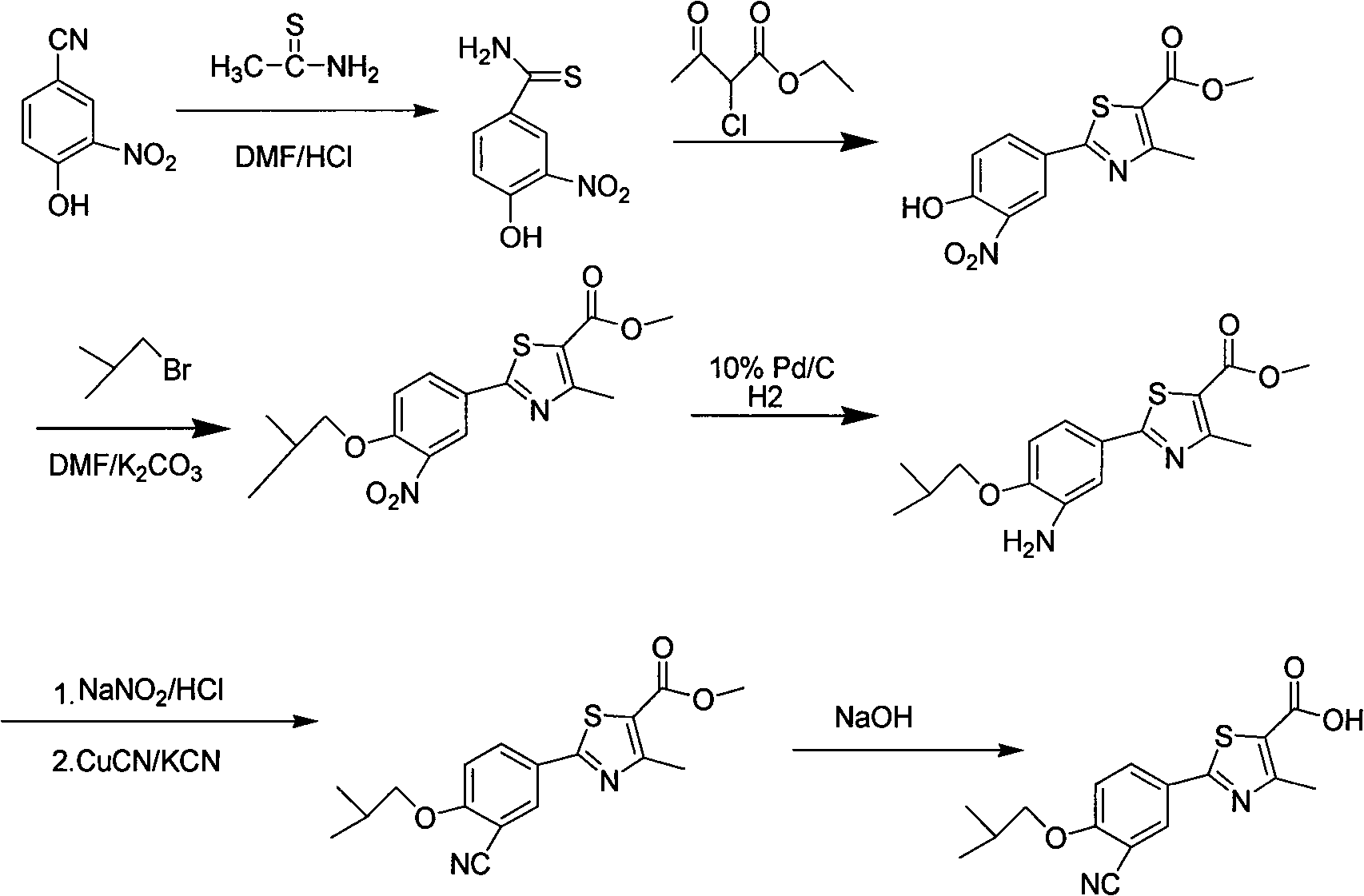

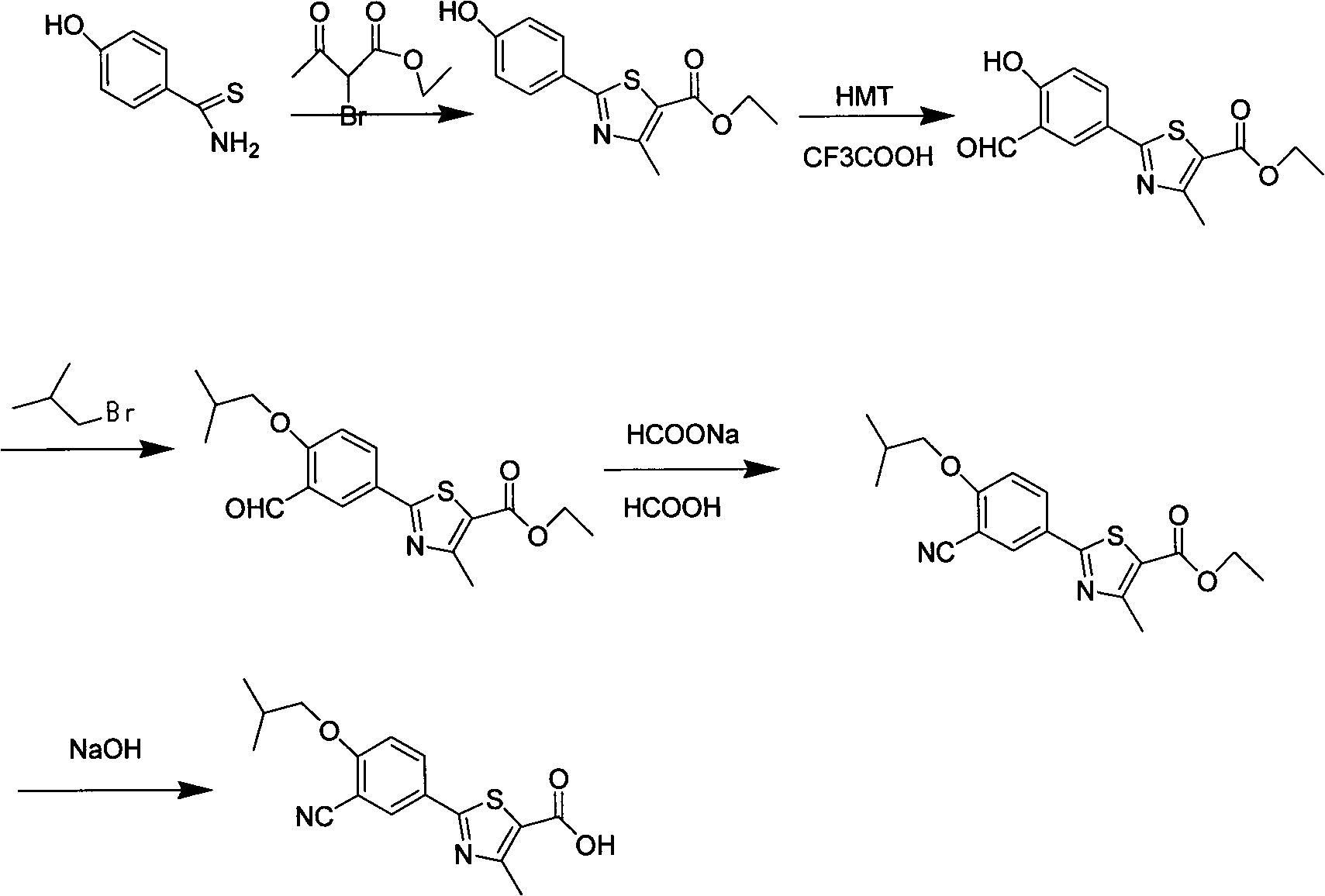

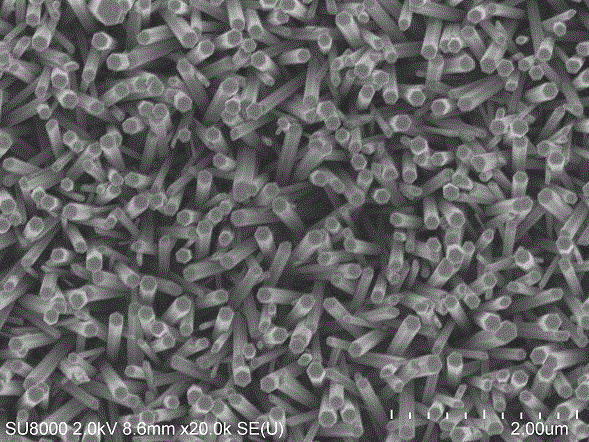

Preparation method of febuxostat intermediate

ActiveCN101665471AReduce usageEasy to industrializeOrganic chemistryHexamethylenetetramineFormylation reaction

The invention relates to the field of pharmaceutical chemistry, in particular to a preparation method of 2-(3-formoxyl-4-hydroxy phenyl)-4-methyl-thiazole-5-carboxylate as an intermediate of pharmaceutical febuxostat for treating gout; the invention is characterized in that the intermediate is prepared through the reaction of 2-(4-hydroxy phenyl)-4-methyl-thiazole-5-carboxylate and paraformaldehyde under the catalysis of tin tetrachloride. The preparation method avoids the use of trifluoroacetic acid and methenamine as corrosive reagents, the yield of a formylation reaction of the febuxostat and low toxicity paraformaldehyde in acetonitrile can reach more than 95 percent, and the preparation method is easy for industrialization.

Owner:CHINA PHARM UNIV +1

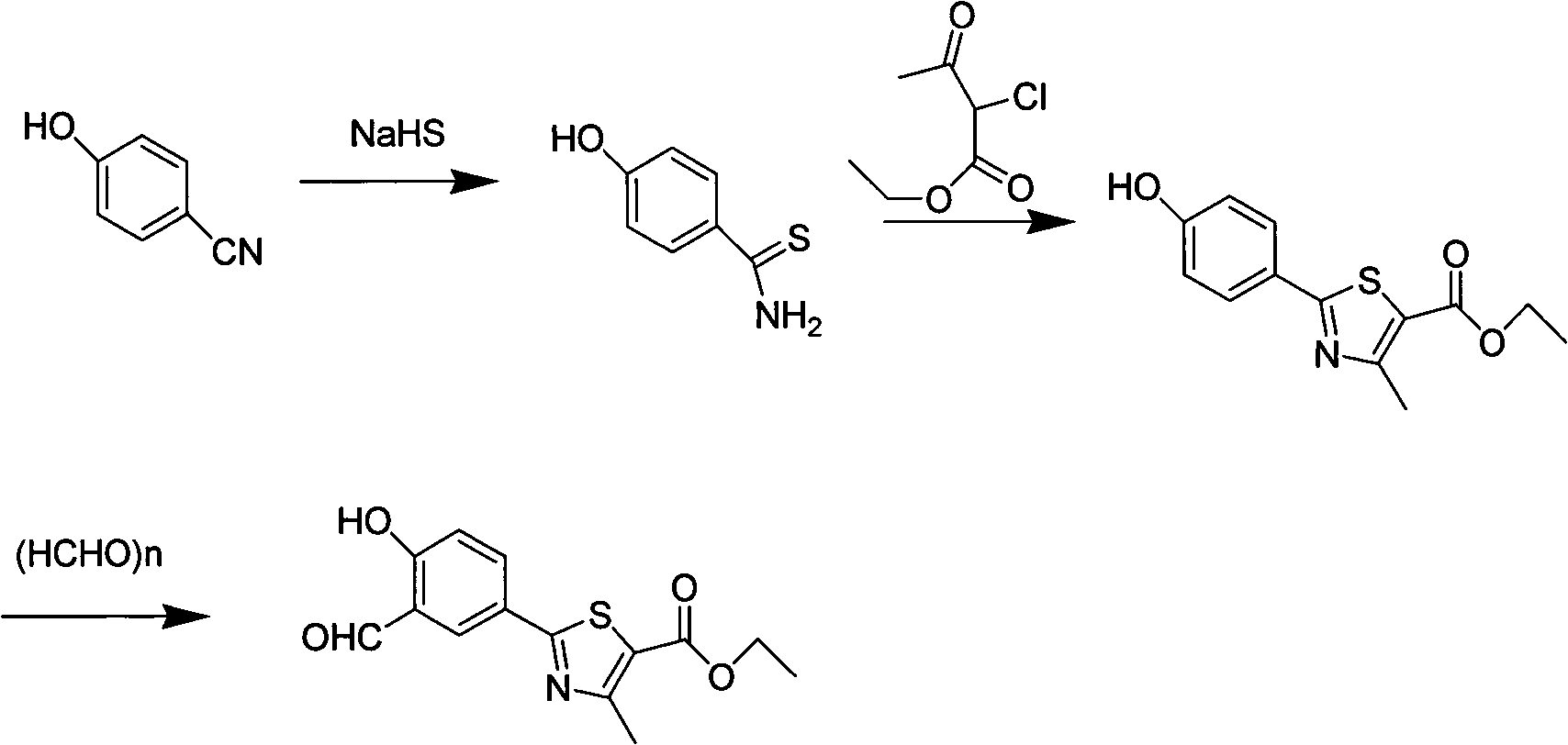

Pre-coated sand for casting and manufacturing method thereof

InactiveCN106807881AFill in the gapsReduce infiltrationFoundry mouldsFoundry coresHexamethylenetetramineRejection rate

The invention relates to pre-coated sand for casting, and aims to overcome the defects that the pre-coated sand is poor in high-temperature performance and casting sand adhering is easily produced. The invention provides the pre-coated sand for casting which comprises crude sand, phenolic resin, methenamine and calcium stearate; in addition, the pre-coated sand for the casting comprises ceramic glaze powder which is in the weight ratio of 0.1 to 0.6 to the phenolic resin. A manufacturing method for the pre-coated sand comprises the following steps: heating the crude sand, and pouring the heated crude sand into a sand mixer; adding the phenolic resin, the ceramic glaze powder and the methenamine in proportions in sequence, wherein the methenamine is added in an aqueous solution mode; after a material is crushed and broken after a coating is cured, stirring the calcium stearate uniformly in a proportion; cooling, screening and packaging. The pre-coated sand provided by the invention is high in high-temperature resistance; if the pre-coated sand for the casting used for high-temperature casting, the rejection rate and the defective rate of products are reduced.

Owner:LIUZHOU LIUJING TECH CO LTD

Electrical insulation compound adhesive for high voltage electrical apparatus

ActiveCN101368075AImprove heat resistanceImprove toughnessPlastic/resin/waxes insulatorsAldehyde/ketone condensation polymer adhesivesEpoxyAdhesive

The invention provides a high-voltage electrical apparatus insulated adhesive, which comprises the following components by weight portion: 150 to 160 portions of bakelite, 30 to 40 portions of epoxide resin, 10 to 12 portions of methenamine, 100 to 110 portions of nitrile latex, 5 to 8 portions of 2-mercaptobenzothiazole zinc salt, 2 to 4 portions of accelerant PX, 2 to 4 portions of zinc naphthenate, 30 to 35 portions of colophony, 200 to 220 portions of benzene, 100 to 120 portions of acetone, 20 to 22 portions of toluene diisocyanate, and 50 to 80 portions of mica powder. The high-voltage electrical apparatus insulated adhesive has excellent bonding properties, ageing resistance and chemical mediator resistance as well as excellent insulating properties, which is applicable for bonding metal units, and in particular applicable for manufacturing of high-voltage electrical apparatuses and equipment.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

Precoated sand and burn-free regeneration technology thereof

ActiveCN103341587AHigh heat tensile strengthLow gasFoundry mouldsMould handling/dressing devicesHexamethylenetetramineDolomite

The invention belongs to the field of new materials and discloses precoated sand. The precoated sand is prepared from silica sand, pyrite powder, phenolic resin, bisphenol-A epoxy resin, phenolsulfonic acid, short peptide, boric acid, molybdenum disulfide, a methenamine solution, zinc stearate, dolomite powder, talcum powder and graphite powder. The invention also discloses a burn-free regeneration technology of the used precoated sand. The precoated sand prepared by the technoloyg has relatively high hot tensile strength, low gas-forming property and stable storage property; and the rejection rate of castings is relatively low.

Owner:LINYI ZHUBAO WATER METER

Composite floor tiles having good stain resistance capacity

InactiveCN105384403AImprove the disadvantage that large holes are easily blocked by mudHigh strengthSodium sulfateStain

The invention discloses composite floor tiles having the good stain resistance capacity. The composite floor tiles are prepared from, by weight, 50-53 parts of desert sand, 4-5 parts of thermoplastic phenolic resin, 0.6-0.7 part of methenamine, 0.2-0.22 part of calcium stearate, an appropriate amount of water, 42-45 parts of Portland cement of the mark number 42.5, 5-6 parts of fly ash, 1.6-2 parts of sodium sulfate, 1.5-2 parts of polyvinyl alcohol, 4-5 parts of waterborne fluorocarbon emulsion, 40-44 parts of silica sand, 80-83 parts of waste ceramics, 19-23 parts of industrial smelting waste, 11-13 parts of nano titanium dioxide, 2-2.2 parts of melamine and 1.5-2 parts of an antioxidant 1010. The waterborne fluorocarbon emulsion, the nano titanium dioxide and the like are added in a surface material, the composite floor tiles have the good stain resistance performance and can overcome the defects of poor stain resistance, poor water permeability and the like of water-permeable floor tiles in the prior art, and the products made of the composite floor tiles have the excellent stain resistance capacity and good water permeability, are low in cost and are anti-slip.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

High-strength PCB conductive silver paste and preparing method thereof

ActiveCN104078093ALow costImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureEpoxyAntimony tin oxide

High-strength PCB conductive silver paste is prepared from, by weight, 10 parts to 20 parts of antimony tin oxide, 2 parts to 4 parts of calcium sulphate whisker, 50 parts to 60 parts of micron-order silver powder, 4 parts to 6 parts of tantalum carbide whisker, 1 part to 2 parts of methenamine, 7 parts to 10 parts of glass powder, 1 part to 2 parts of isopropyl tri(dioctylpyrophosphate)titanate, 8 parts to 12 parts of E-12 epoxy resin, 2 parts to 3 parts of isocyanate, 3 parts to 5 parts of diethylene glycol, 5 parts to 7 parts of glyceryl triacetate, 1 part to 2 parts of itaconic acid and 4 parts to 6 parts of terpineol. According to the silver paste, by adding the calcium sulphate whisker and the tantalum carbide whisker, the strength of a printed circuit is increased, and the printed circuit is not prone to falling off and being broken; by adding the antimony tin oxide, the using amount of the silver powder is reduced while the excellent conductivity is guaranteed, and the prepared silver paste is low in cost, excellent in conductivity and good in dispersibility; by using the glass powder, the high-strength PCB conductive silver paste is low in melting point and can be formed easily through curing, and the conductivity is not influenced.

Owner:乐凯特科技铜陵有限公司

Externally used urotropin nebula and preparing method thereof

InactiveCN1435174AEasy to usePrecise dosageAntibacterial agentsAntipyreticAlcoholHexamethylenetetramine

An exterior-applied urotropine spray for treating hand and foot hyperhidrosis and hircus is prepared from urotropine, alcohol, cosolvent, deodorant, antibacterial agent, antioxidizing agent, surfactant and water through proportional dissolving, stirring, regulating pH value to 4-11, filtering and loading in spray bottles.

Owner:彭红

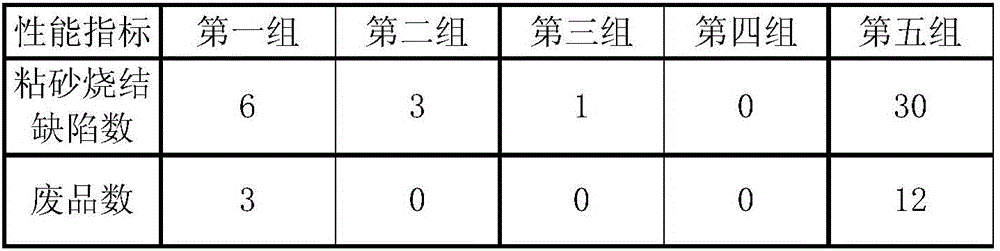

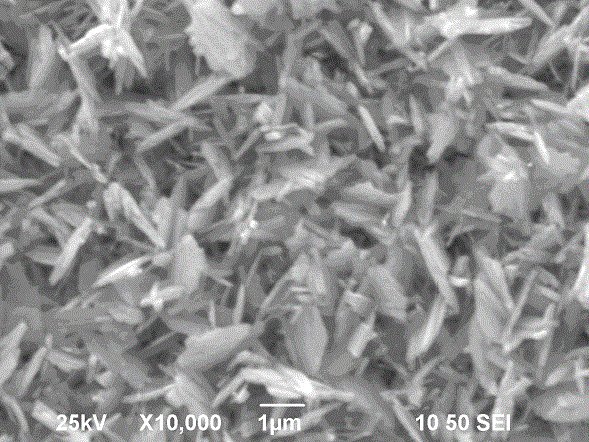

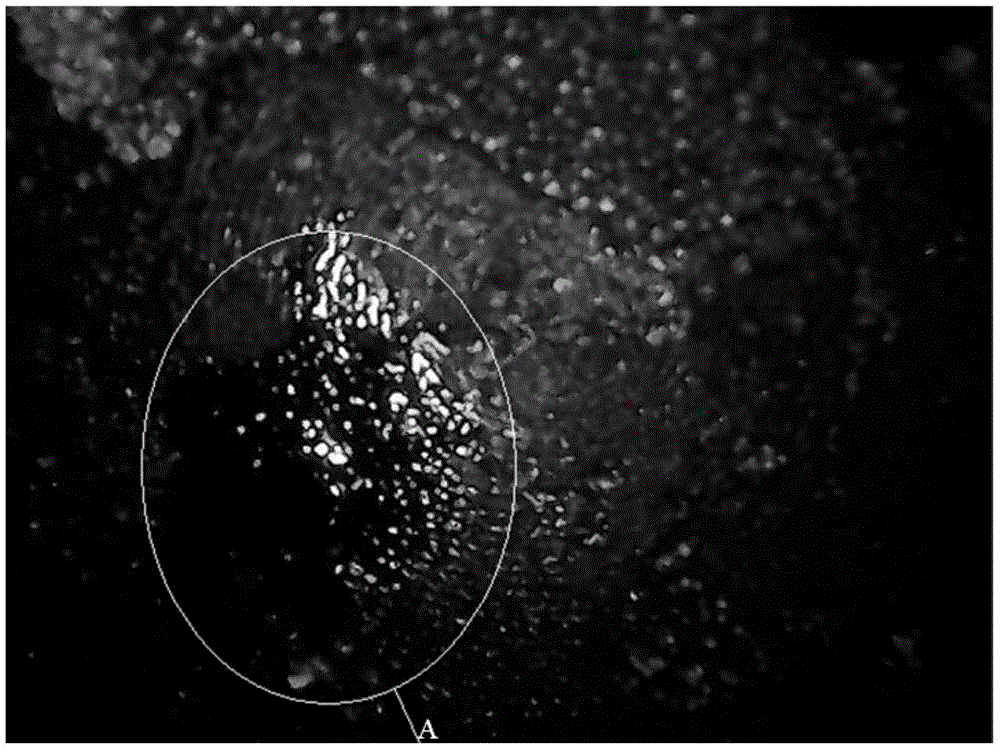

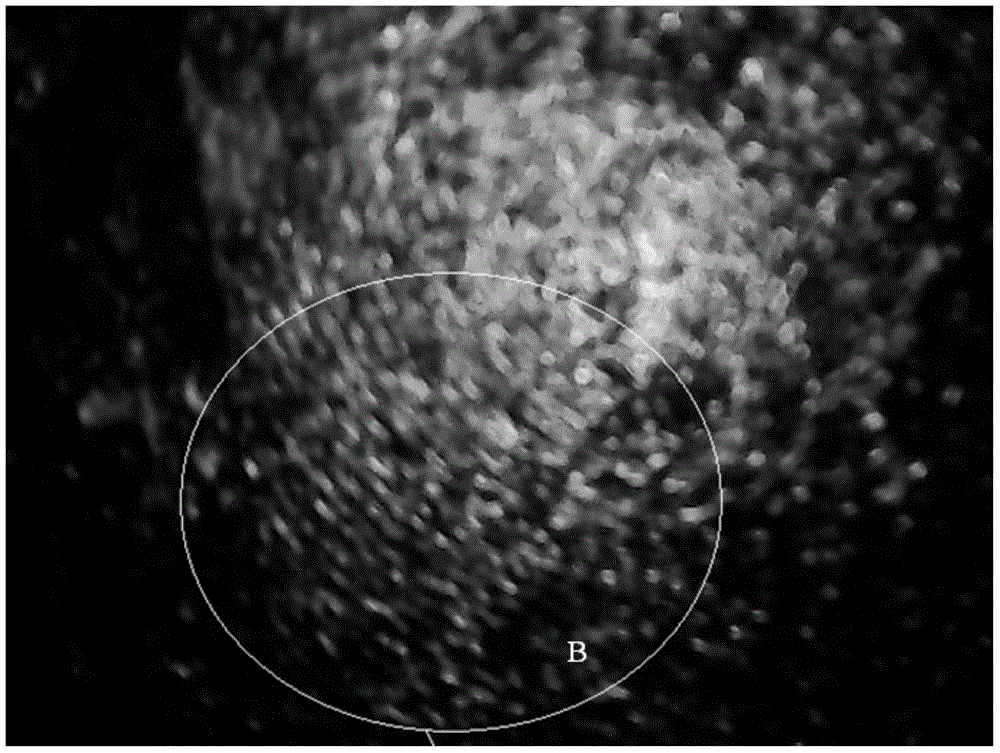

Synthetic method of ZnO/WO3 heterojunction arrays

ActiveCN106512985ALarge capture rangeSimple processMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionAmmonium paratungstate

The invention discloses a synthetic method of ZnO / WO3 heterojunction arrays. The synthetic method comprises the specific steps that 1, ZnO crystal seeds grow on an FTO substrate; 2, the FTO covered with the ZnO crystal seeds is placed into a container containing a mixed water solution of zinc acetate, polyethyleneimine and methenamine, and an oil bath heating reaction is carried out to obtain an FTO on which ZnO nanometer bar arrays grow; and 3, the FTO on which the ZnO nanometer bar arrays grow is placed into a hydrothermal reaction kettle containing an ethyl alcohol-water mixed solution of ammonium paratungstate, a concentrated hydrochloric acid solution and hydrogen peroxide, and a hydrothermal reaction is carried out to prepare the ZnO / WO3 heterojunction arrays. The synthetic method is simple in technology, environmentally friendly and beneficial for mass production.

Owner:HENAN NORMAL UNIV

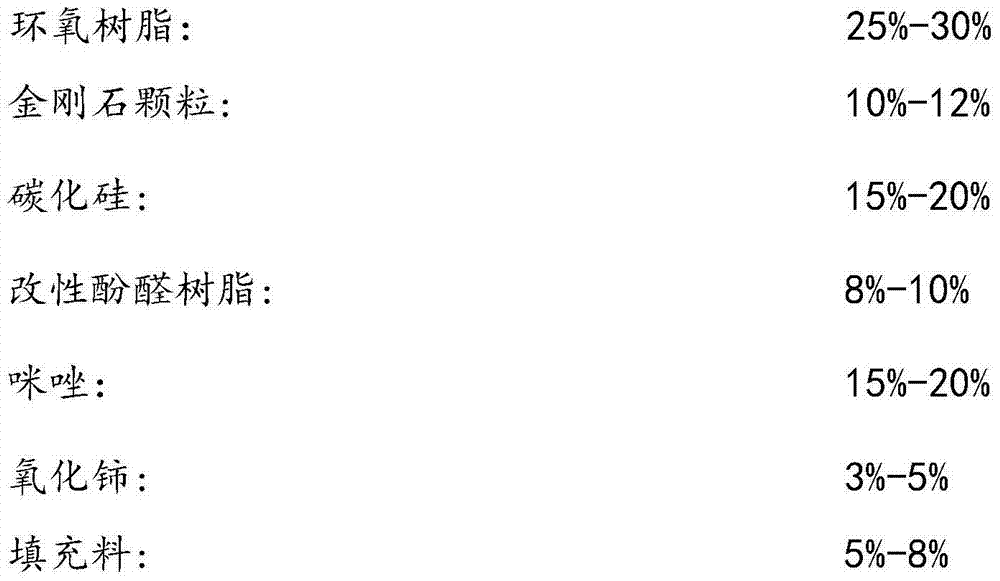

Recipe for manufacturing nylon grinding blocks and method for manufacturing nylon grinding blocks by adopting recipe

ActiveCN104325416AImprove wear resistanceExtended service lifeAbrasion apparatusGrinding devicesEpoxyWear resistant

The invention relates to a recipe for manufacturing nylon grinding blocks. The recipe consists of the following ingredients in percentage by weight: 25 percent to 30 percent of epoxy resin, 10 percent to 12 percent of diamond particles, 15 percent to 20 percent of silicon carbide, 8 percent to 10 percent of modified phenolic resin, 15 percent to 20 percent of imidazole, 3 percent to 5 percent of cerium oxide and 5 percent to 8 percent of filling materials, and the modified phenolic resin consists of 12 percent to 15 percent of methenamine, 3 percent to 5 percent of polyimide and 80 percent to 85 percent of phenolic resin. Through the combined action of the modified phenolic resin and the other ingredients, the integral wear-resistant performance and the heat resistance performance of the nylon grinding blocks are improved, and the holding force of grinding materials is improved. The invention also provides a method for manufacturing the nylon grinding blocks by adopting the recipe. The method comprises the steps of proportioning, material selection, soaking, piling lamination pressing, natural curing and drying curing. Through adopting the method, the holding force between the diamond particles and nylon fiber sheets can be well maintained, and the wear resistance of the nylon grinding blocks is enhanced.

Owner:福建易达新材料股份有限公司

Hydrogenation heat gas chemical yield increasing solution component applied to shallow well

ActiveCN102942913AHigh porosityImprove permeabilityFluid removalDrilling compositionPorosityAmmonium nitrate

The invention belongs to the technical field of oil exploitation, and relates to a hydrogenation heat gas chemical yield increasing solution component capable of increasing permeability of a shallow well and a near wellbore region. The solution component comprises first solution and second solution, the mass ratio of the first solution to the second solution is 1:1, the first solution comprises 37-43% of ammonium nitrate NH4NO3, 23-26% of urea CO(NH2)2, 5-8% of decaborane B10H14, 1-2% of glucose C6H12O6, 0.5-1.5% of methenamine (CH2)6N4 and 19.5-33.5% of water. The second solution comprises 44-48% of sodium nitrate NaNO3, 15-20% of sodium nitrite NaNO2, 17-21% of sodium aluminum hydride NaAlH4 and 15-19% of tetrachloroethylene C2Cl4. By the aid of the solution component, porosity of an ore bed can be increased, accordingly, permeability is increased, and the yield can be increased by 2-10 times.

Owner:吉林贯通能源科技有限责任公司

Metal rust inhibitor containing peregal O

InactiveCN102993817AGood compatibilityImprove adaptabilityAnti-corrosive paintsPotassium persulfateParaffin wax

The invention discloses a metal rust inhibitor containing peregal O. The metal rust inhibitor is prepared from the following raw materials in parts by weight: 2-5 parts of urea, 5-8 parts of liquefied paraffin, 3-5 parts of acetyl tri(2-ethylhexyl)ester citrate, 4-6 parts of acrylic acid, 0.2-0.3 part of zinc powder, 3-5 parts of epoxidized rice bran oil, 2-3 parts of dimethylbenzene, 3-5 parts of polyethylene wax, 0.2-0.3 part of potassium persulfate, 0.3-0.5 part of borax, 1-2 parts of zinc naphthenate, 0.5-0.9 part of 2-methylimidazole, 1.3-1.5 parts of benzotriazole, 0.5-1.5 parts of methenamine, 1.1-1.7 parts of 2-n-octyl-4-isothiazolinone, 1.2-1.9 parts of peregal O and 95-105 parts of water. The metal rust inhibitor has rust inhibiting time as long as 4-6 months, has better adaptability to copper and aluminium and can form films on the metal surfaces while carrying out slow release and rust inhibition, thus lengthening the rust inhibiting time.

Owner:ANHUI RONGDA VALVE

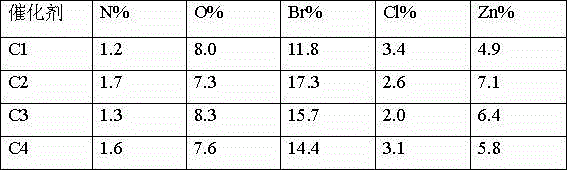

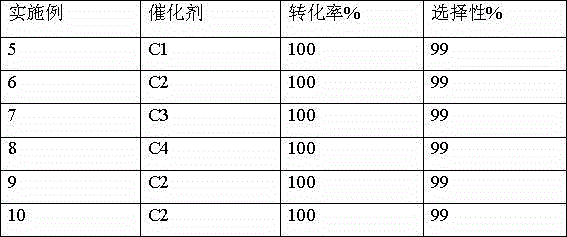

Preparation method of catalyst applied to preparation of propylene carbonate from CO2 and epoxypropane

ActiveCN104549513AImprove activity stabilityLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereHexamethylenetetramine

The invention discloses a preparation method of a catalyst applied to preparation of propylene carbonate from CO2 and epoxypropane. The preparation method comprises the following steps: (1) reflowing alkyl imidazole and chloromethyl polystyrene microspheres in a methylbenzene solvent for 12-36 hours, filtering, washing with methylbenzene and propylene carbonate respectively, performing vacuum drying for 12-24 hours at 60-80 DEG C to prepare an active component A; (2) crushing and mixing the active component A together with zinc salt, phenolic resin and methenamine to obtain powder, tabletting and moulding to obtain an active precursor B; (3) heating the active precursor B for 0.5-4 hours at 120-200 DEG C under the production of nitrogen, and crushing the active precursor B into 20-40-mesh particles to obtain a catalyst C. The catalyst prepared by the preparation method achieves catalytic reaction for stably synthesizing the propylene carbonate from CO2 and epoxypropane by a long period on a fixed bed reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reclaiming methenamine and glycin in glycin mother liquid by using nano-filtering technique

The invention belongs to the field of recycling resources in a glycin (amino acetic acid) production trade, and provides a method for separating and reclaiming methenamine and glycin in a glycin mother liquid by using a nano-filtering film. The molecular weight intercepted by the used nano-filtering film is 50-300 daltons; the operating pressure is 1.8-4.0MPa; the operating temperature is 20-50DEGC; and most of ammonium chloride in the glycin mother liquid enters a nano-filtering permeation liquid by penetrating through the nano-filtering film through the separation of the nano-filtering film, and the methenamine and most of the glycin are intercepted into an intercepting liquid. The methenamine and the glycin in the intercepting liquid are recycled.

Owner:刘长飞

Automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling automobile engine

ActiveCN104877831AReduce fuel consumptionIncrease motivationSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsCarbon deposit

The invention provides an automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling an automobile engine, relates to a carbon deposit cleaning agent and aims to solve the problem that the service life of an engine is shortened due to extremely high temperature in a cylinder when the conventional hydrogen method is used for removing carbon deposit. The automobile carbon deposit cleaning agent is formed by mixing dodecyl phenolsulfonic acid isopropylamine salt, nonylphenol polyglycol ether, ethylene glycol monopropyl ether, petroleum ether, petroleum hydrogenated light distillate, methenamine and deionized water. The cleaning agent has the advantages as follows: the automobile carbon deposit cleaning agent is gasified into nanoscale liquid drops through atomizing equipment to enter the engine along an engine gas inlet pipeline to achieve the purpose of cleaning, the interior of the engine, the pipeline and a three-element catalytic device can be cleaned without dismantling the engine. The invention is mainly used for preparing the automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling the automobile engine.

Owner:HARBIN INST OF TECH

Safe and environment-friendly concrete mold release agent and preparation method thereof

The invention discloses a safe and environment-friendly concrete mold release agent and a preparation method thereof. The concrete mold release agent comprises the following raw materials in parts by weight: 48-55 parts of modified waste oil, 3-4 parts of talc powder, 5-6 parts of sodium carboxymethyl cellulose, 0.6-0.8 part of alkylphenol polyoxyethylene ether, 4-5 parts of gypsum powder, 2-3 parts of urea, 0.5-0.6 part of methenamine, 2-4 parts of bamboo carbon powder, 0.1-0.3 part of hydroxyethyl acrylate, 0.3-0.8 part of methyl methacrylate, 1.0-1.2 parts of sodium petroleum sulfonate and 350-400 parts of deionized water. The mold release agent disclosed by the invention has the advantages of easiness in spraying, good adhesion, smoothness in exhausting and the like and is suitable for pouring concrete, the phenomena of pores, cracks and the like of concrete can be effectively decreased, the purpose of treating wastes with wastes is achieved, the full recycling of resources is realized and the concrete mold release agent has larger application values.

Owner:蒙城县科技创业服务中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com