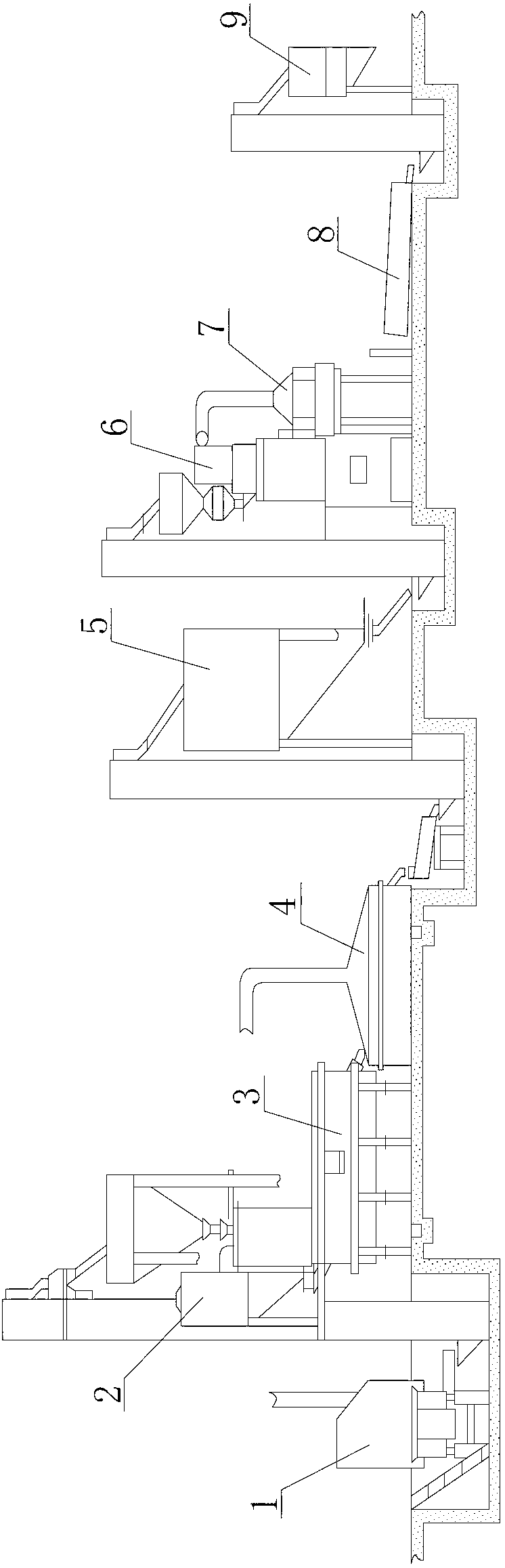

Waste sand recycling equipment and use method thereof

A technology of equipment and used sand, applied in the field of waste sand recycling equipment, can solve the problem of occupying waste sand sites, etc., and achieve the effects of high recycling rate, simple operation and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Hexatropine solution (hexamethamine: water = 1:3) 1.6kg, phenolic resin 2.7kg, calcium stearate 100g, silane 60g, the rest is recycled sand and / or original sand, the total amount is 150kg.

[0031] The recovery rate of the waste sand obtained according to the above-mentioned usage method is 85%.

Embodiment 2

[0033] Hexamethamine solution (hexamethamine: water = 1:3) 1.7kg, phenolic resin 2.8kg, calcium stearate 300g, silane 100g, the rest is recycled sand and / or original sand, the total amount is 150kg.

[0034] The recovery rate of the waste sand obtained according to the above-mentioned usage method is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com