Patents

Literature

370results about How to "Continuous and stable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

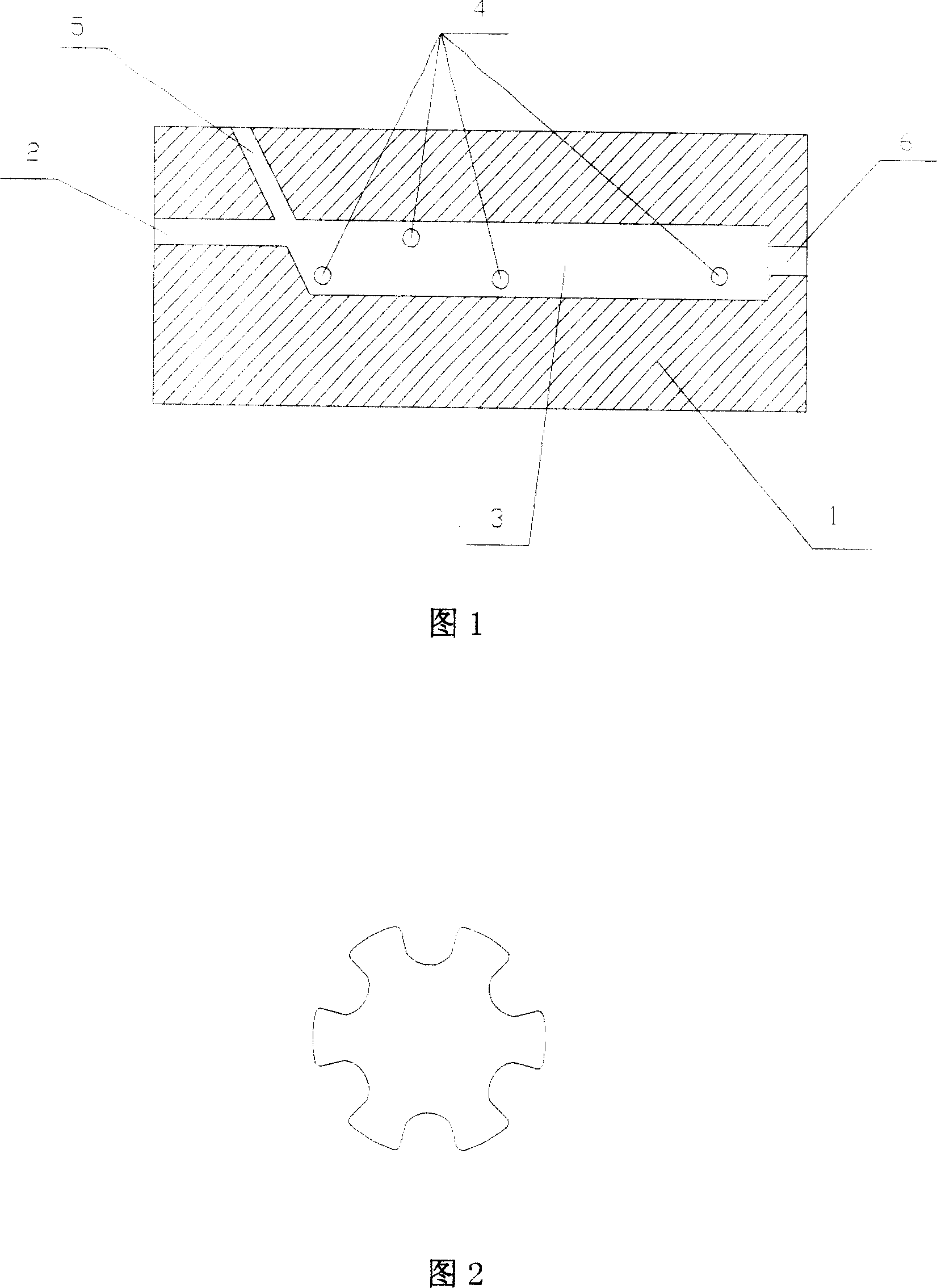

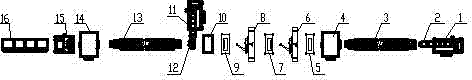

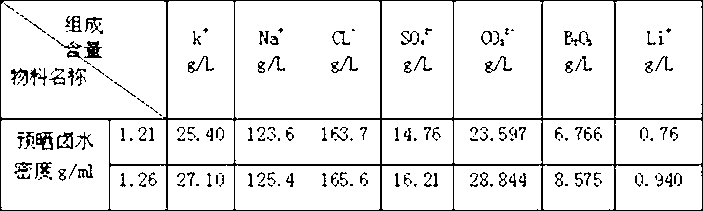

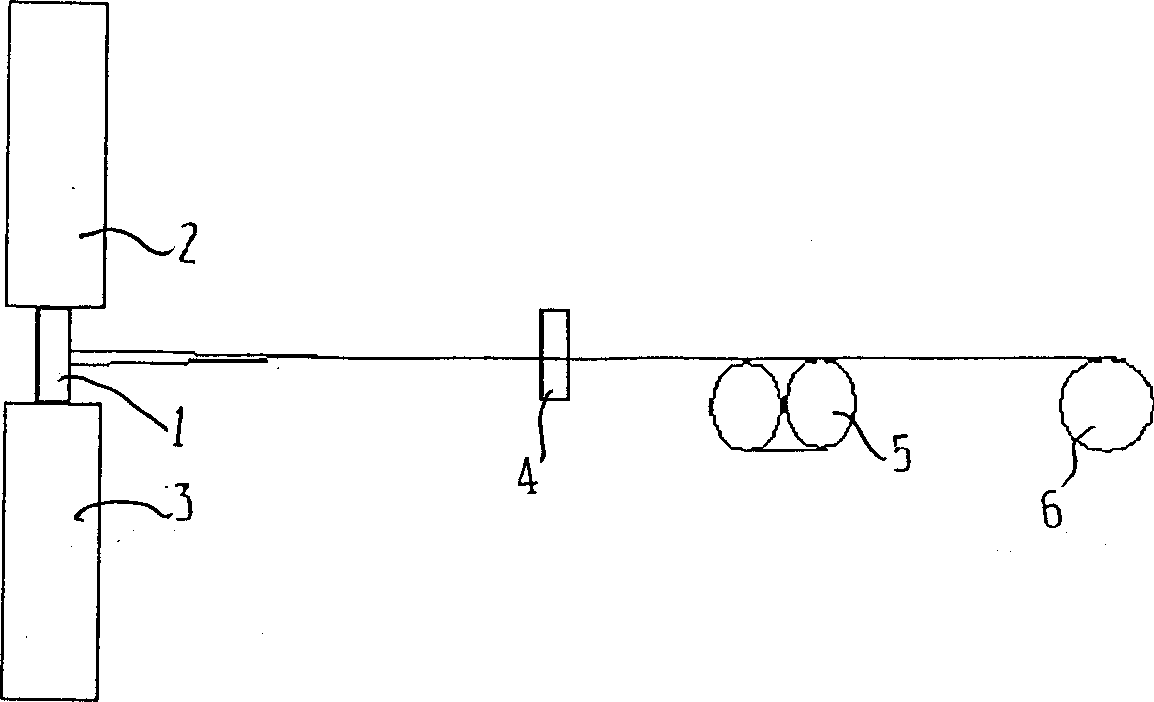

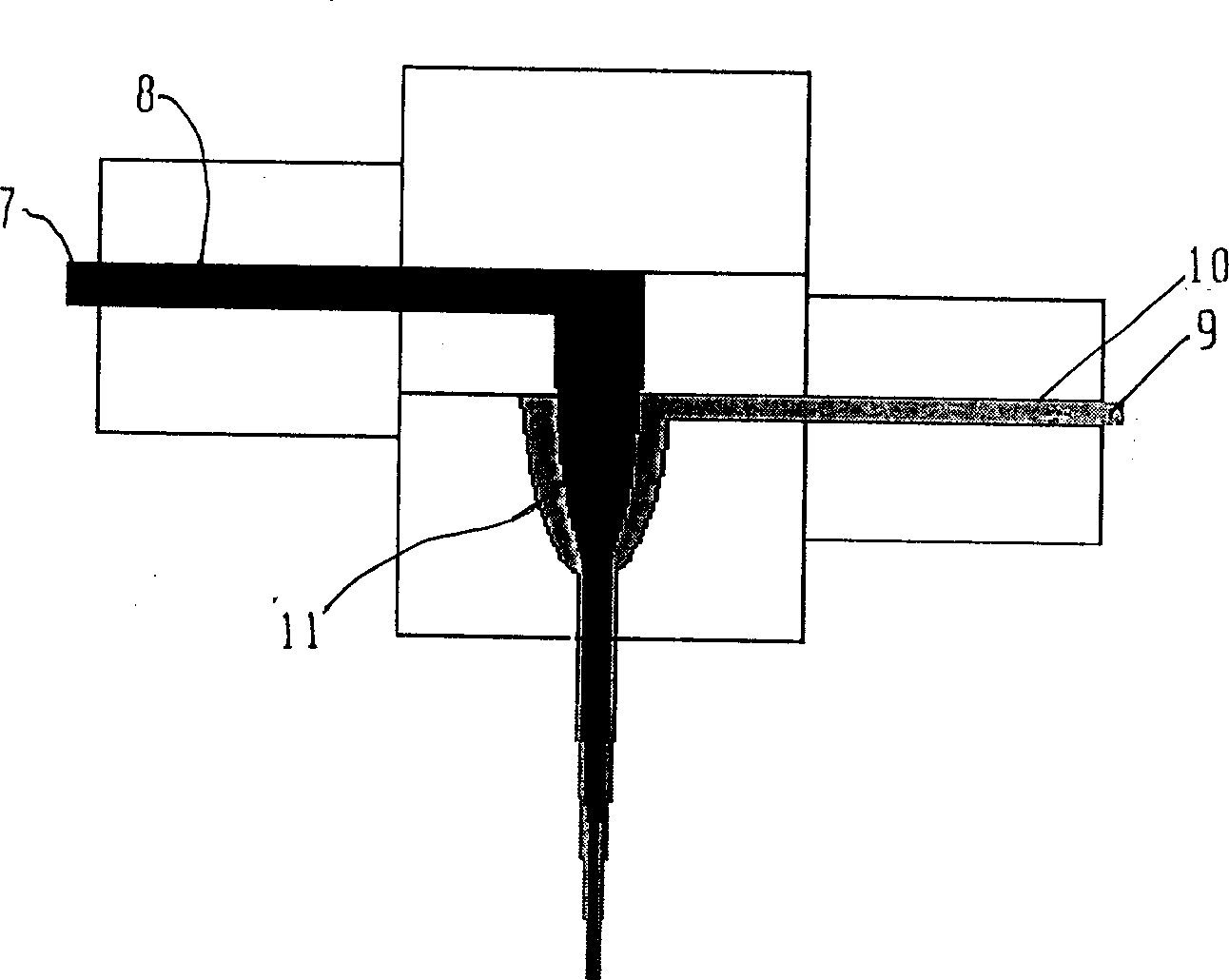

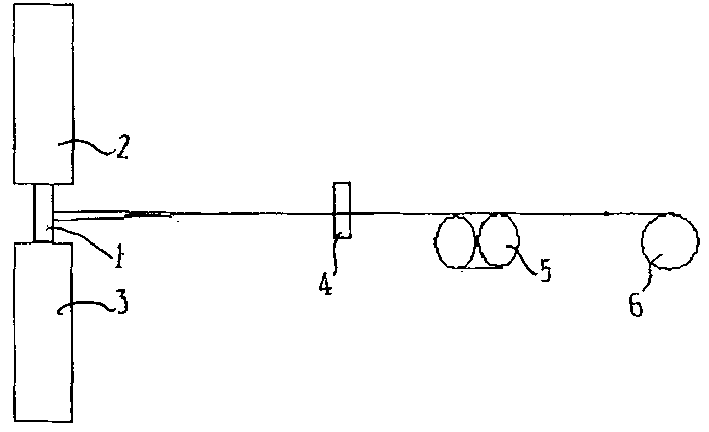

Method for shaping continuous fiber reinforced thermoplastic resin and shaping equipment thereof

ActiveCN101152767AAvoid mutual interferenceContinuous and stable productionFiber bundleFree rotation

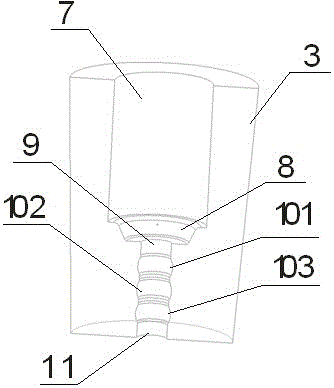

The present invention discloses a molding method and molding equipment for a continuous fiber reinforced thermoplastic resin. The molding equipment of the present invention comprises a melting soakage mould. The melting soakage mould comprises a soakage mould outer body and a thermoplasticity resin fused mass crack flow passage, a soakage independent flow passage, a continuous fiber inlet passage and a soakage outlet which are arranged in the soakage mould outer body. The thermoplasticity resin fused mass crack flow passage is arranged on upstream end and forms an angle with the continuous fiber inlet passage. The thermoplasticity resin fused mass crack flow passage and the continuous fiber inlet passage are both communicated with the soakage independent flow passage. The soakage outlet is arranged on downstream end and is communicated with the end of the soakage independent flow passage. The soakage independent flow passage is also provided with at least one tension roller group which is capable to rotate freely. Using the molding equipment of the present invention for manufacturing continuous fiber reinforced thermoplastic resin avoids the interference and impairment between fiber bundles, guarantees the stable and continuous production and improves the dipping effect, so fiber reinforced thermoplastic resin with excellent performance can be obtained.

Owner:KINGFA SCI & TECH CO LTD +1

Device and method for continuously synthesizing amine-terminated polyether by utilizing fixed bed

ActiveCN103524725AGood effectContinuous and stable productionChemical recyclingVapor–liquid separatorAlcohol

The invention provides a device and a method for continuously synthesizing amine-terminated polyether by utilizing a fixed bed. The device for continuously synthesizing amine-terminated polyether by utilizing the fixed bed comprises a fixed bed reactor, a preheater, two gas-liquid separators, a compressor, a circulating compressor, a raw material pump, a liquid ammonia pump and two buffer tanks, hydrogen is preheated by virtue of the preheater and is fed into the fixed bed reactor with raw material and liquid ammonia; the amine-terminated polyether is synthesized in a hydrogen atmosphere of the fixed bed; the fixed bed reactor is at the temperature of 150-300 DEG C and the pressure of 1-20MPa, ammonia alcohol ratio is 1-15, and unreacted hydrogen and ammonia are recycled. The device and method for continuously synthesizing amine-terminated polyether by utilizing the fixed bed overcome the defects of tedious operation, unstable product quality, low synthesis efficiency and the like of the existing technology as a batch-type operation is adopted, a continuous reaction technological design is adopted, a technology is simple, performance is stable, yield is high, excessive ammonia and hydrogen are recycled, pollution to the environment is reduced, production cost is reduced, and energy is saved; conversion rate of hydroxyl-terminated polyether or derivative thereof and selectivity of the amine-terminated polyether product are obviously improved, so that production cost of the amine-terminated polyether product is obviously reduced.

Owner:康达新材料(集团)股份有限公司

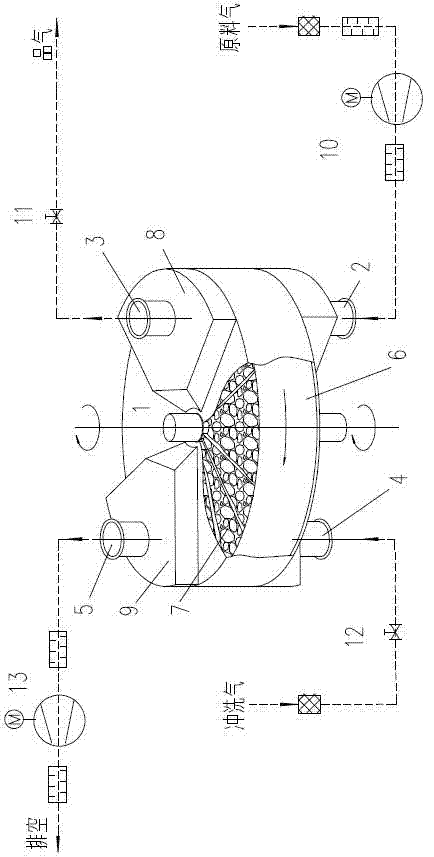

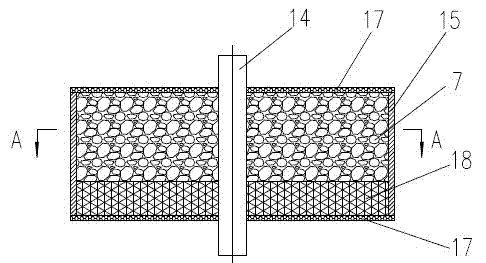

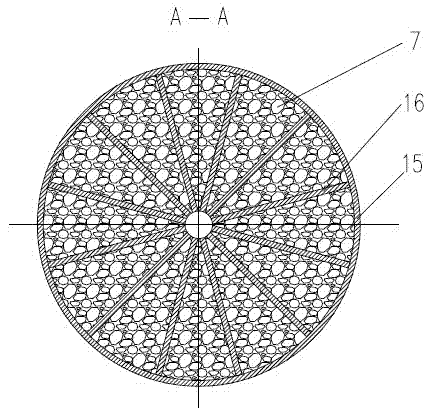

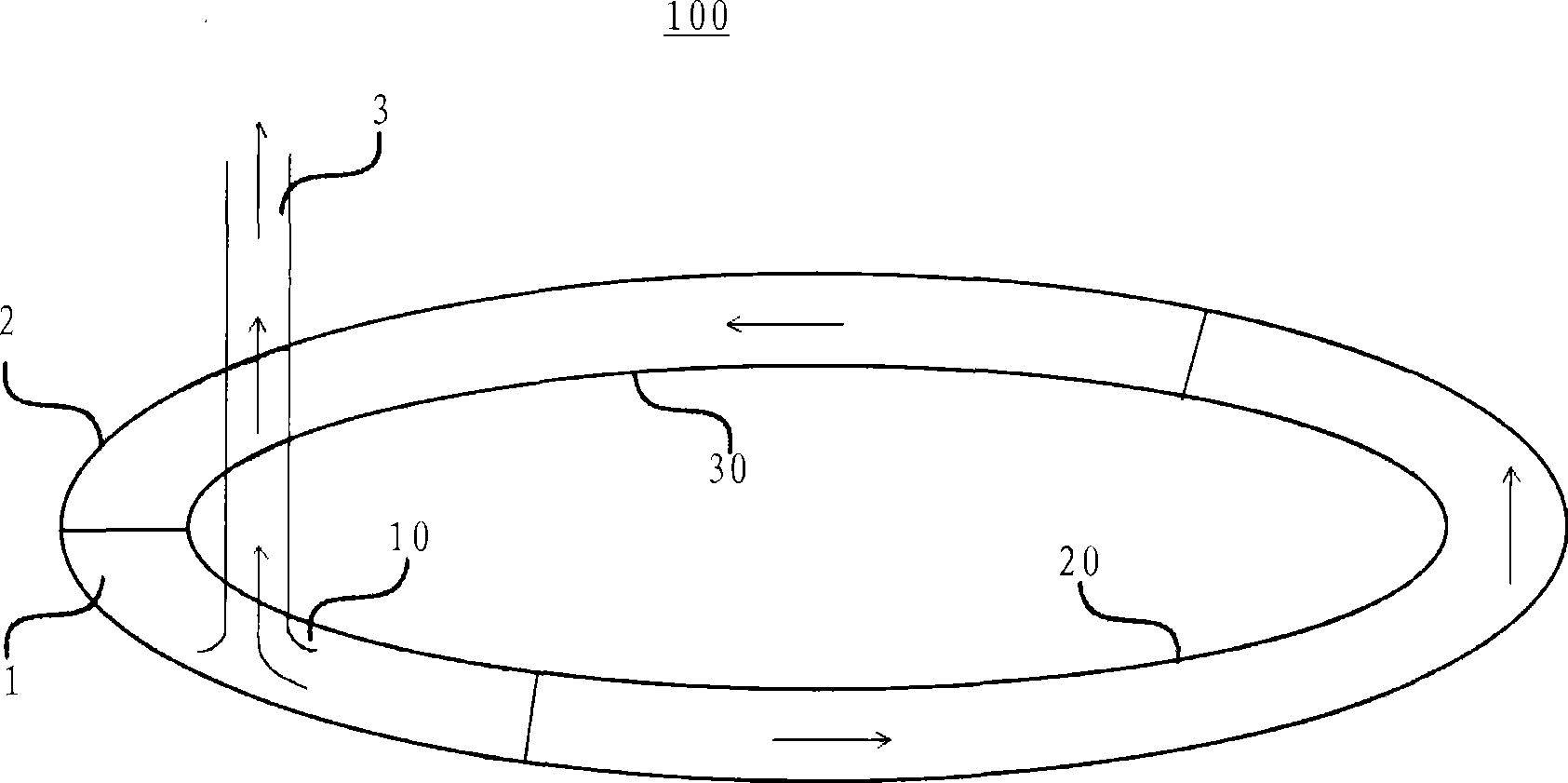

Rotor type pressure swing adsorption gas separation device

InactiveCN102755810AReduce dosageLess investmentGas treatmentOxygen/ozone/oxide/hydroxideSorbentDesorption

The invention discloses a rotor type pressure swing adsorption gas separation device, wherein a rotor is arranged in a shell; an adsorption region and a desorption region are divided according to formed different pressures; the rotor comprises a disc with a plurality of empty grids which is formed by a plurality of partition plates; the empty grids are filled with an adsorbent and are sealed by using porous plates or nets at the two ends in the axial direction; during work, the rotor rotates, an adsorbent is driven to continuously move and circulate at the adsorption region and the desorption region; feed gas and / or flushing gas regionally pass (passes) through the adsorbent layer in direction crossed with the adsorbent movement direction, so that the feed gas is continuously separated and purified at the adsorption region; and saturated adsorbent is continuously decompressed or / and flushed and regenerated at the desorption region, so that product gas is continuously and stably produced. The rotor type pressure swing adsorption gas separation device has the advantages of overcoming the defect of frequent switching of an adsorption tower existing in the conventional pressure swing adsorption gas separation device, low energy consumption, high yield, easiness in running and operation, small land occupation and small using amount of the adsorbent, is extremely suitable for the fields of oxygen enriched combustion, oxygen enriched and pure oxygen application of industrial kilns and can also be used for separation and purification industries of other gases.

Owner:南京圣火环境科技有限公司

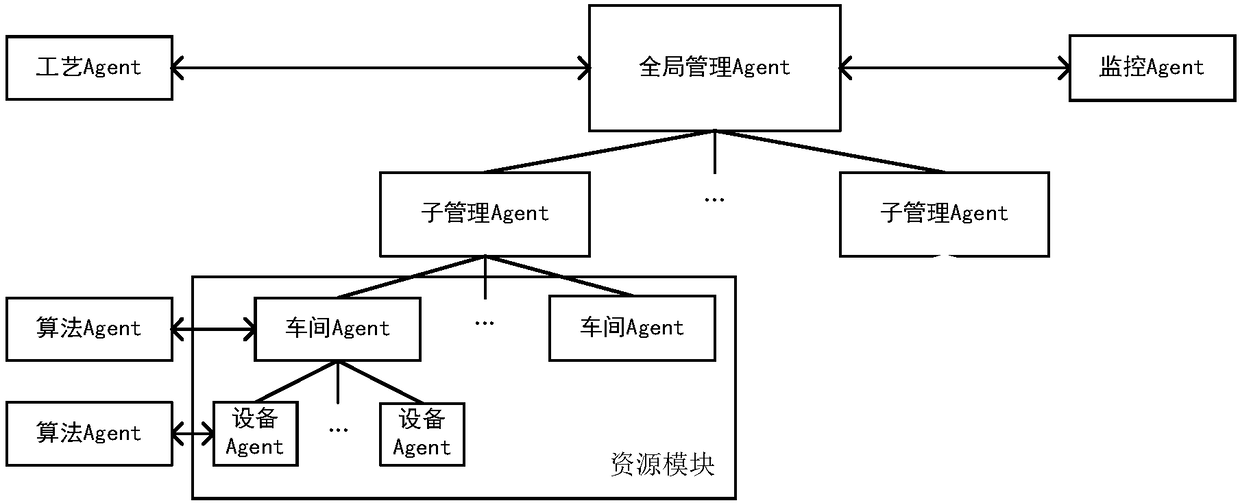

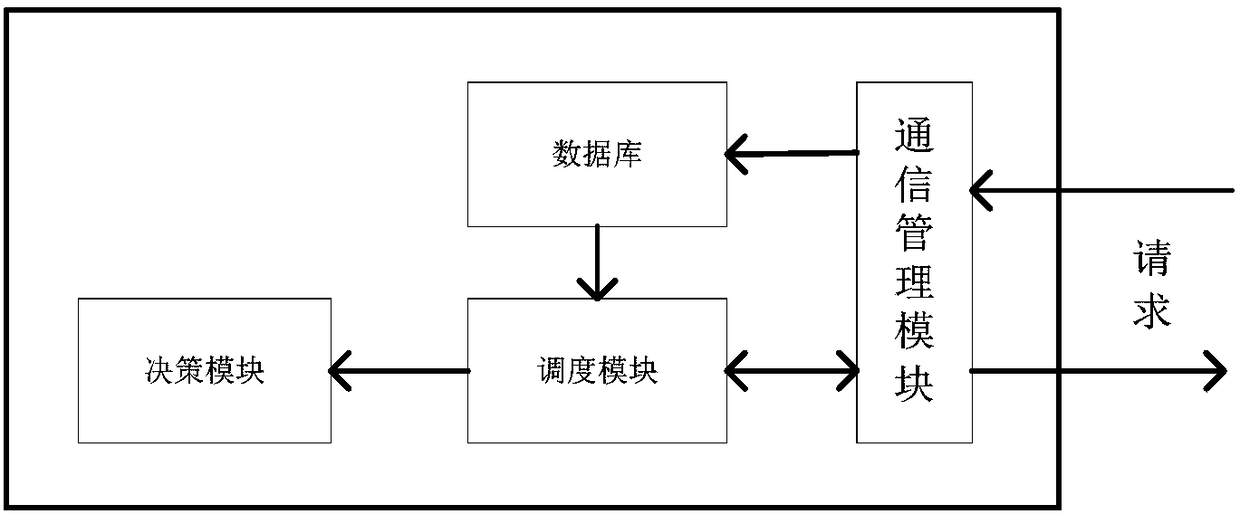

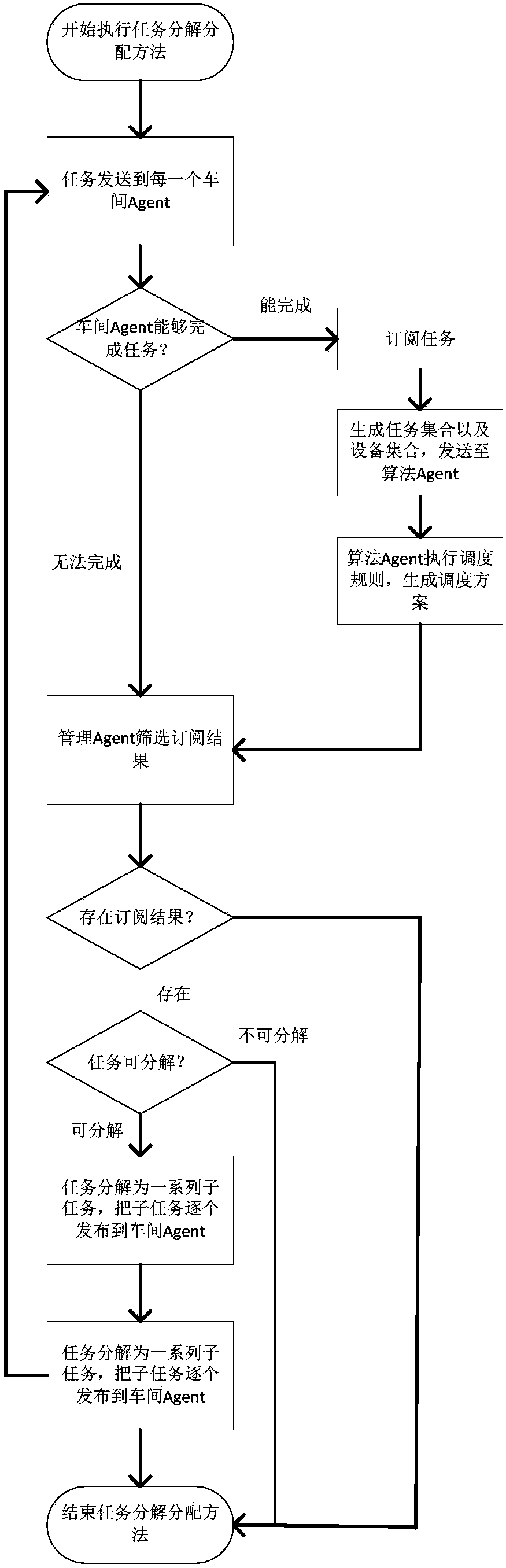

Order-oriented flexible production dynamic scheduling system based on multi-agent

ActiveCN108549977AQuickly complete the decomposition assignmentQuick responseResourcesManufacturing computing systemsProcedure AgentsOrder form

The invention provides an order-oriented flexible production dynamic scheduling system based on multi-agent; the system comprises a process Agent, a monitoring Agent, a management Agent, a resource module and an algorithm Agent; the process Agent is used for managing product process information of the system, and providing data check services for other Agents; the monitoring Agent is used for gathering equipment work state information and analyzing faults; the management Agent is a message transfer station of the system, and used for managing all Agents; the resource module has a workshop Agent and an equipment Agent, wherein the equipment Agent is used for simulating the working progress of the equipment, and the workshop Agent is used for managing the equipment Agent that belongs to theworkshop Agent; the scheduling method and re-scheduling method of an algorithm Agent packaging system can provide computing service for other Agents. The scheduling system and method can improve the utilization rate and management level of the manufacture resources in the manufacturing industry, can fast response to abnormity factors, thus ensuring the manufacture process to be continuous, stableand efficient.

Owner:SOUTH CHINA UNIV OF TECH

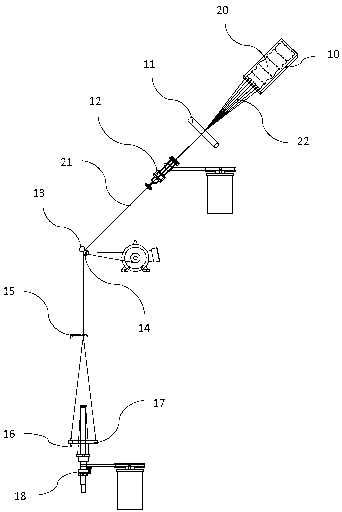

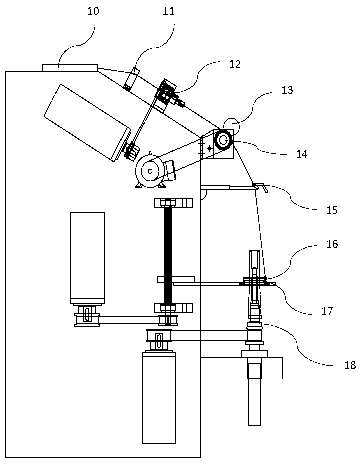

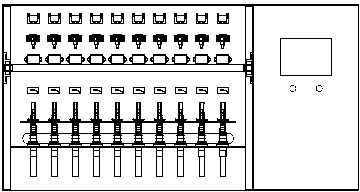

Carbon nanotube spinning machine and method for preparing carbon nanotube yarns by use of same

InactiveCN102953171AContinuous and stable productionContinuous wound-up machinesCarbon nanotube yarnCollection system

The invention discloses a carbon nanotube spinning machine which is used for spinning carbon nanotube films pulled out of a carbon nanotube array into carbon nanotube yarns. The spinning machine comprises a storage device, a soaking device, a false twisting device, a drafting system, a twisting collection system and a rack, wherein the storage device is used for placing the carbon nanotube array; the soaking device is used for soaking the films for shrinkage; the false twisting device performs false twisting of the carbon nanotube films; the drafting system is used for pulling the carbon nanotube films out of the carbon nanotube array; and the rack is integrated with a power system of the carbon nanotube spinning machine. According to the carbon nanotube spinning machine disclosed by the invention, the carbon nanotube films are subjected to false twisting by use of the false twisting principle of the false twisting device, and relatively long carbon nanotube yarns with better mechanical properties can be obtained; and meanwhile, large-batch industrial production can be realized.

Owner:SUZHOU CREATIVE CARBON NANOTECH

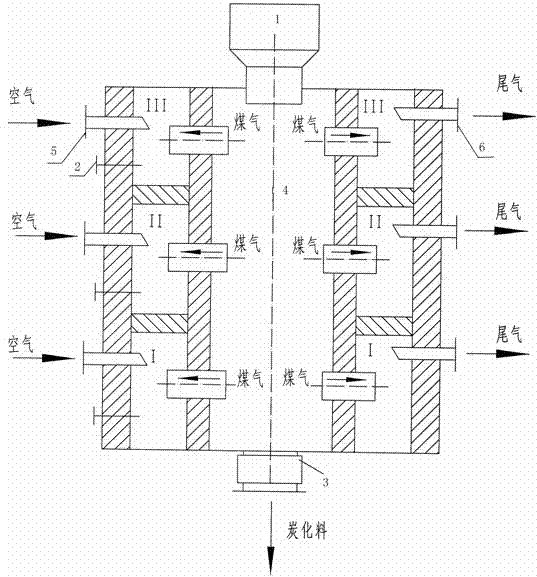

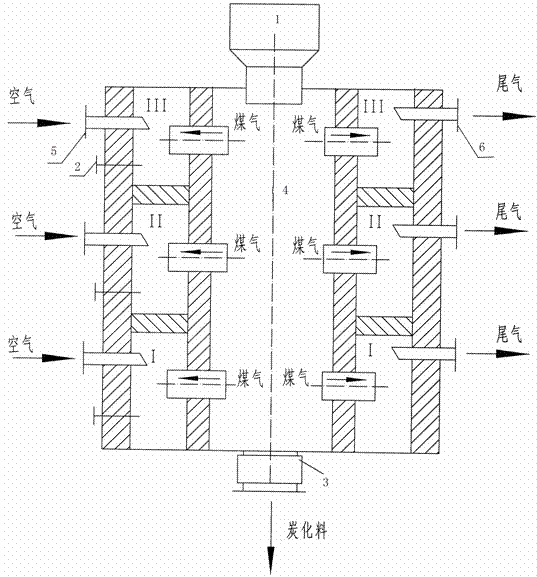

External heating biomass pyrolysis gasification furnace and method for preparing charcoal by continuous pyrolysis gasification

InactiveCN102260507AReduce ignition lossHigh yieldCoke quenchingBiofuelsCombustion chamberHeat energy

The invention discloses an external heating type biomass pyrolysis gasification furnace and a method for preparing charcoal by continuous pyrolysis gasification. The pyrolysis gasification furnace is composed of a silo, a combustion chamber, a trough and a carbonized material cooling section. There is a silo on the trough, a carbonized material cooling section under the trough, and a carbonized material outlet in the carbonized material cooling section. , there is a biomass raw material inlet on the silo, an air inlet and an exhaust gas outlet on the combustion chamber, and three independent annular combustion chambers are arranged on the outer periphery of the trough from top to bottom. An air inlet and an exhaust gas outlet are respectively provided, and a gas overflow pipe is provided on the inner wall, and the gas overflow pipe communicates with the trough. The pyrolysis and dry distillation gas enters three independent annular combustion chambers respectively through the overflow pipe, and undergoes combustion reaction with air, and the heat energy generated is used to maintain the pyrolysis temperature of the biomass material layer. Using the heat energy provided by it, the biomass in the furnace is pyrolyzed and dry-distilled to decompose the dry distillation gas to obtain charcoal. The charcoal has high yield, good quality, and the device occupies less land.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

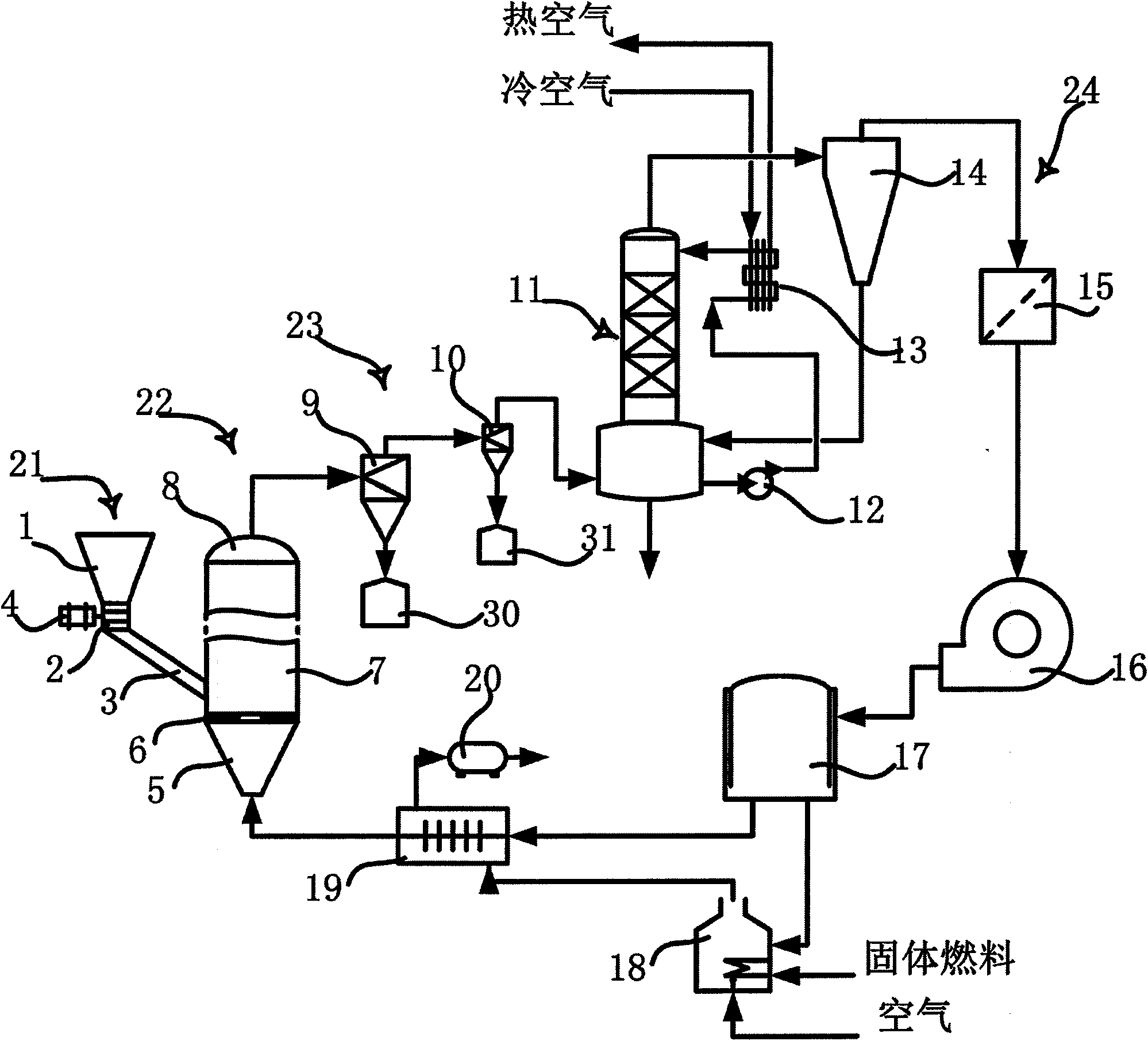

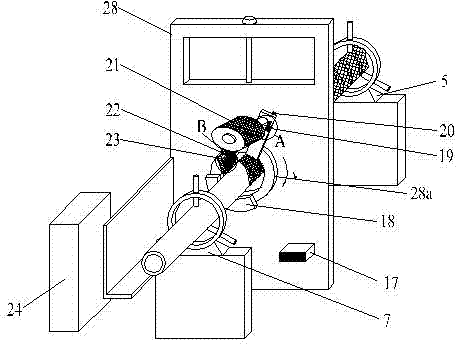

Miniature movable type agricultural and forest biomass fast pyrolysis device

InactiveCN101671570AHeight adjustableAdjust process parametersBiofuelsLiquid hydrocarbon mixture productionCombustionBuffer tank

The invention discloses a miniature movable type agricultural and forest biomass fast pyrolysis device. The device comprises a traveling mechanism (25), a combustion furnace (18), a feeder (21), a fast pyrolysis reactor (22), a gas solid separator (23), a gas condenser (11), a non-condensable gas purifier (24), a fan (16), a gas buffer tank (17) and a gas preheater (19); the height of the fast pyrolysis reactor (22) can be adjusted, the device can be suitable for various agricultural and forest biomass raw materials, and the fluidization quality in the reactor is better due to the arrangementof an inverted-cone-shaped gas flow stabilizer in a top cover of the reactor; the non-condensable gas is taken as gas sources of spouting gas and fluidized gas and heat supply fuel, the entire deviceis simple in structure, small in volume and stable in running, can be hauled to the agricultural and forest biomass for production intensively and has lower production cost; the small-scale movable type operating mode also avoids the problem that the industrial enlargement of a fluid bed reactor is not easy; and the industrial production of agricultural and forest biomass fast pyrolysis is realized in a disguised form.

Owner:BEIJING FORESTRY UNIVERSITY

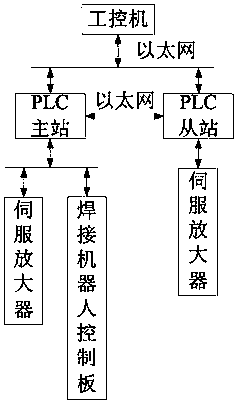

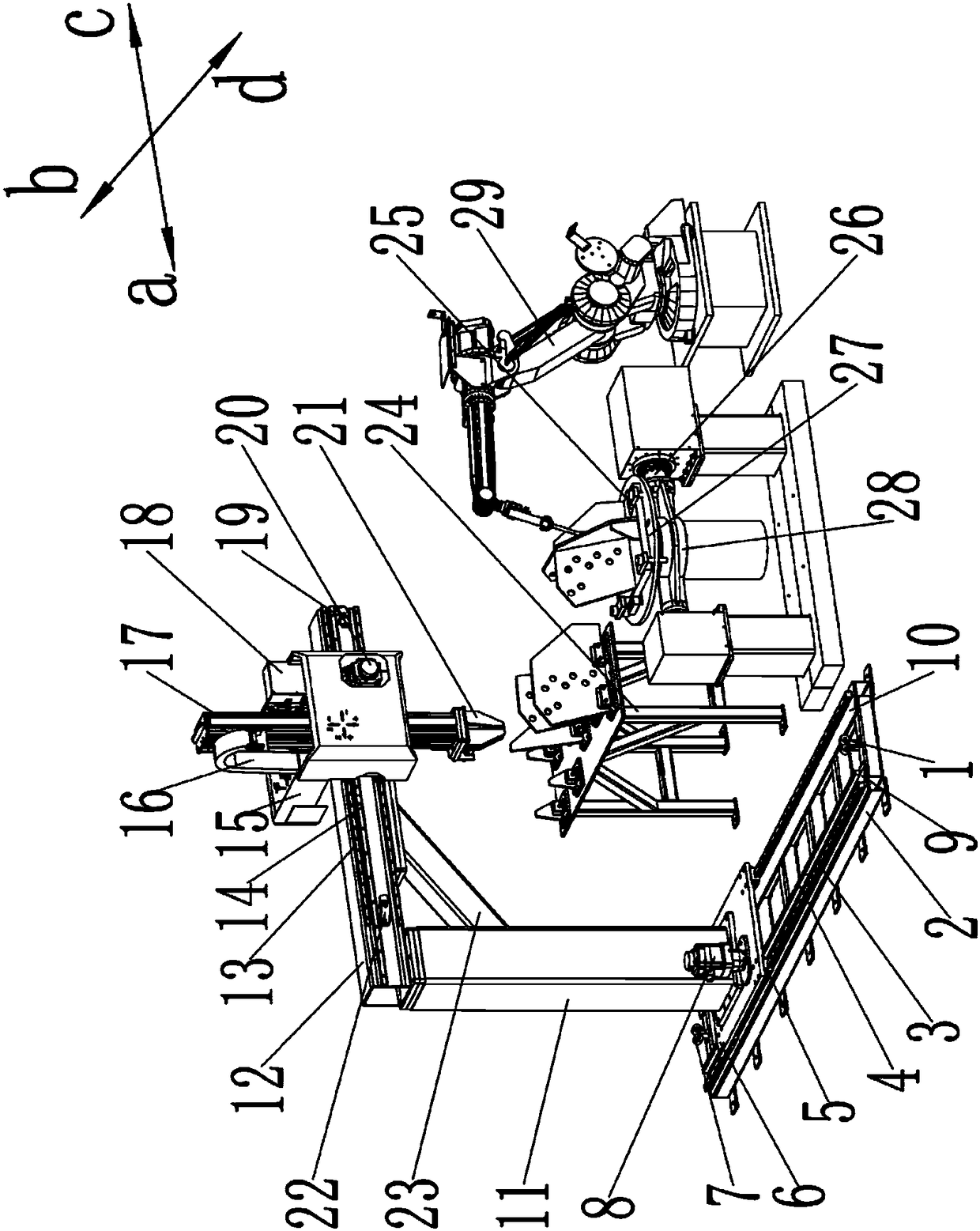

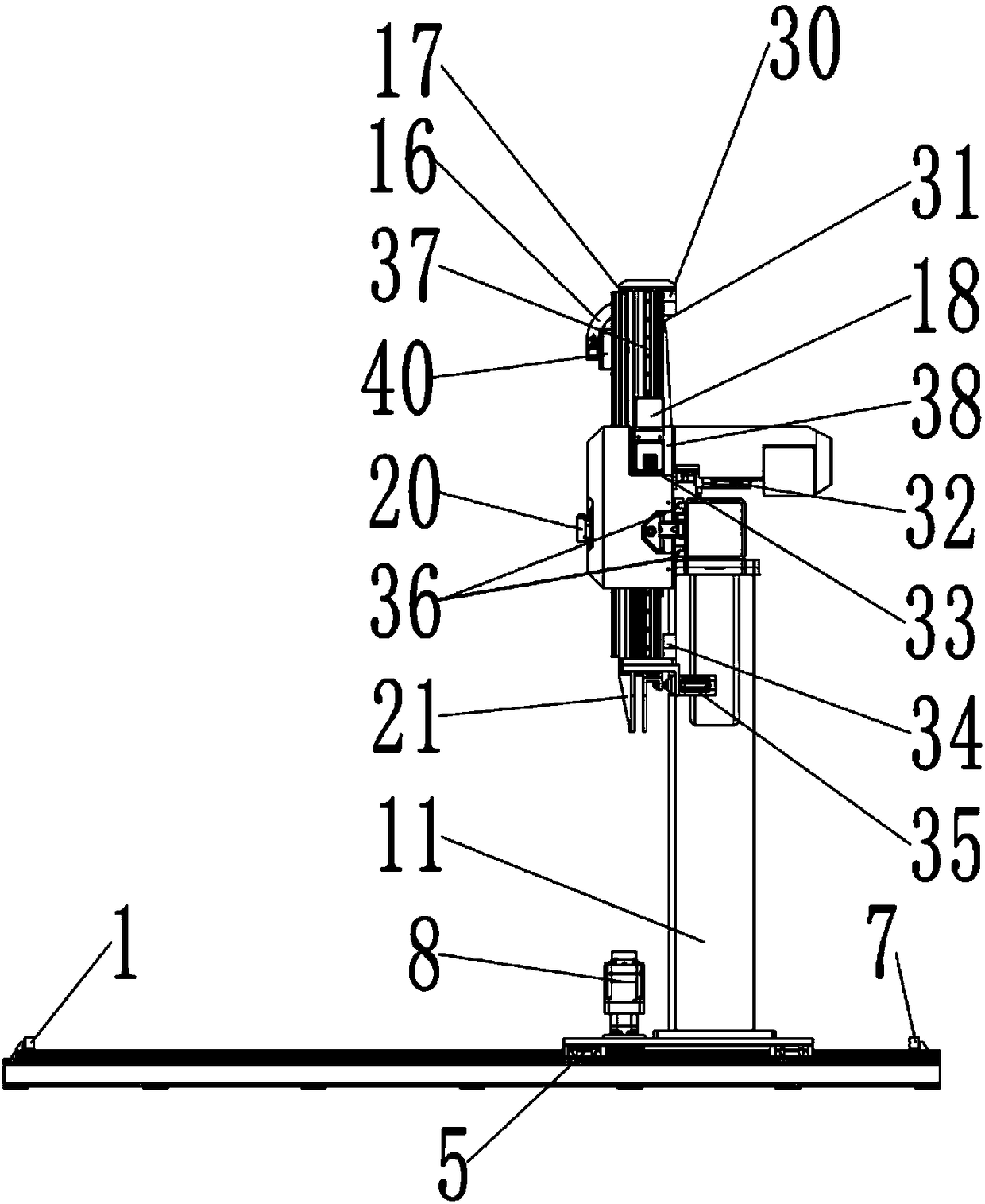

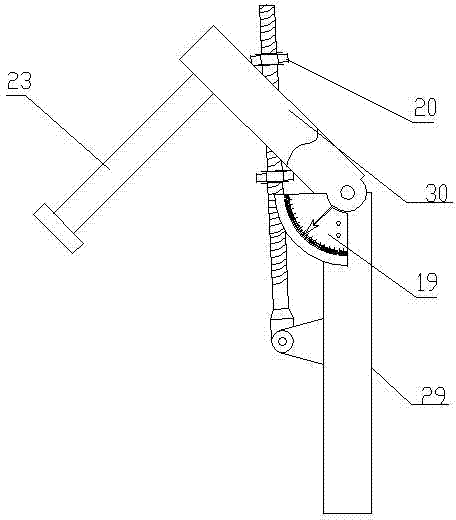

Flexible automatic welding system for tower foot of communication tower and control method thereof

ActiveCN108326476AReduce laborRealize automatic assembly and weldingWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyElectrical control

The invention discloses a flexible automatic welding system for a tower foot of a communication tower and a control method thereof, and relates to the technical field of equipment manufacturing. The flexible automatic welding system for the tower foot of the communication tower comprises a plate taking robot, a positioning table, a positioner, a welding robot and an electrical control system; theplate taking robot comprises a ground rail mechanism, a vertical beam mechanism, a cross beam mechanism and a material taking mechanism; the positioner comprises a turning shaft, a rotating shaft, a rotating platform and a positioning device; and the electrical control system comprises an industrial personal computer, a PLC master station, a PLC slave station, a servo amplifier and a welding robotcontrol panel. The plate taking robot sequentially conveys tower foot plates placed on the positioning table to a tower foot bottom plate fixed on the rotating platform according to the assembly sequence of the tower foot, and the positioner is in linkage with the welding robot to carry out spot welding and then carry out full welding. According to the system, automatic assembling and welding ofthe tower feet with multiple types and different inclination angles can be realized, the labor amount of workers is reduced, and the welding quality and efficiency are improved.

Owner:河北省机电一体化中试基地有限公司

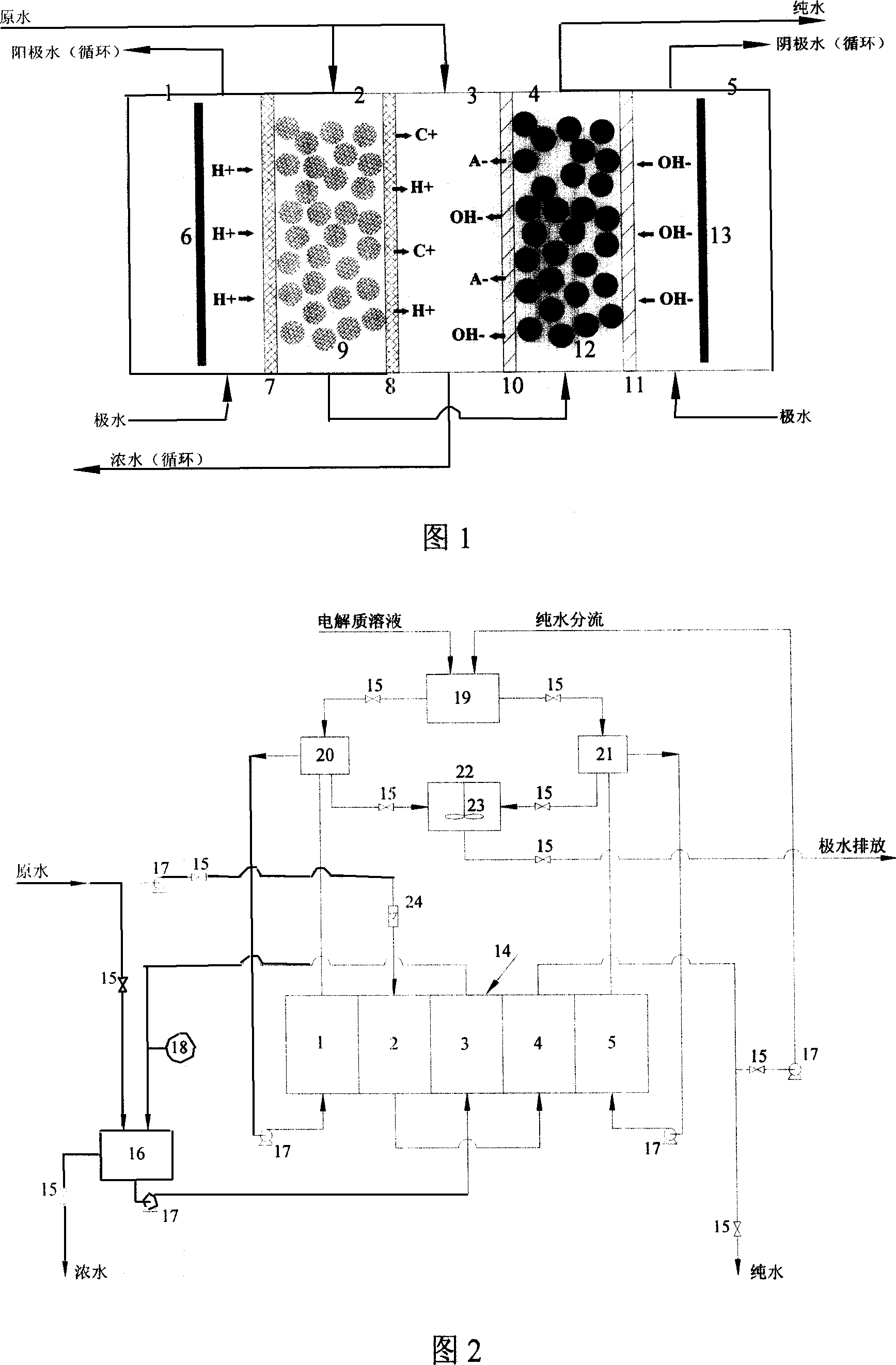

Electrodeionization water-purifying device and method for recovering cation and anion without scaling

ActiveCN101007663APrevent scalingEasy to operateDispersed particle separationWater/sewage treatment by ion-exchangeWater flowIon-exchange membranes

The invention discloses an electric ion-removing water purifying device and method without scaling to recycle anion and cation, which comprises the following parts: anode chamber with anode, first dilute and first condense chambers with cation exchange resin, second dilute chamber with anion exchange resin, anode chamber with anode, wherein two side of first dilute chamber is separated by two cation exchange films, which separates anode chamber and condense chamber separately; two sides of the second dilute chamber is divided by two anion exchange films, which separates condense chamber from cathode chamber; the pressure is added between anode and cathode to circulate anode water, cathode water and condense water periodically; the original water flows through the first and second dilute chambers, which produces pure water.

Owner:吴祖成

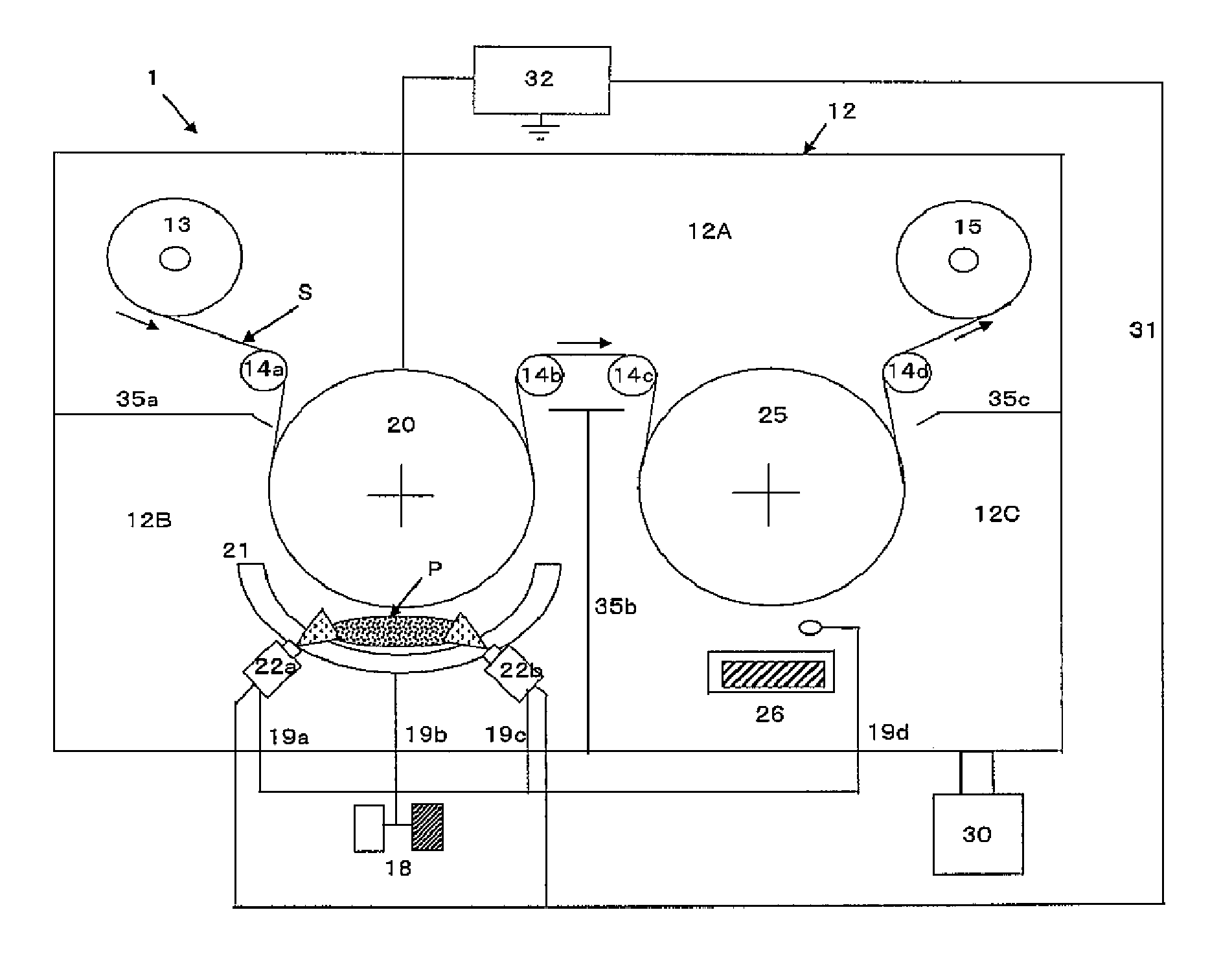

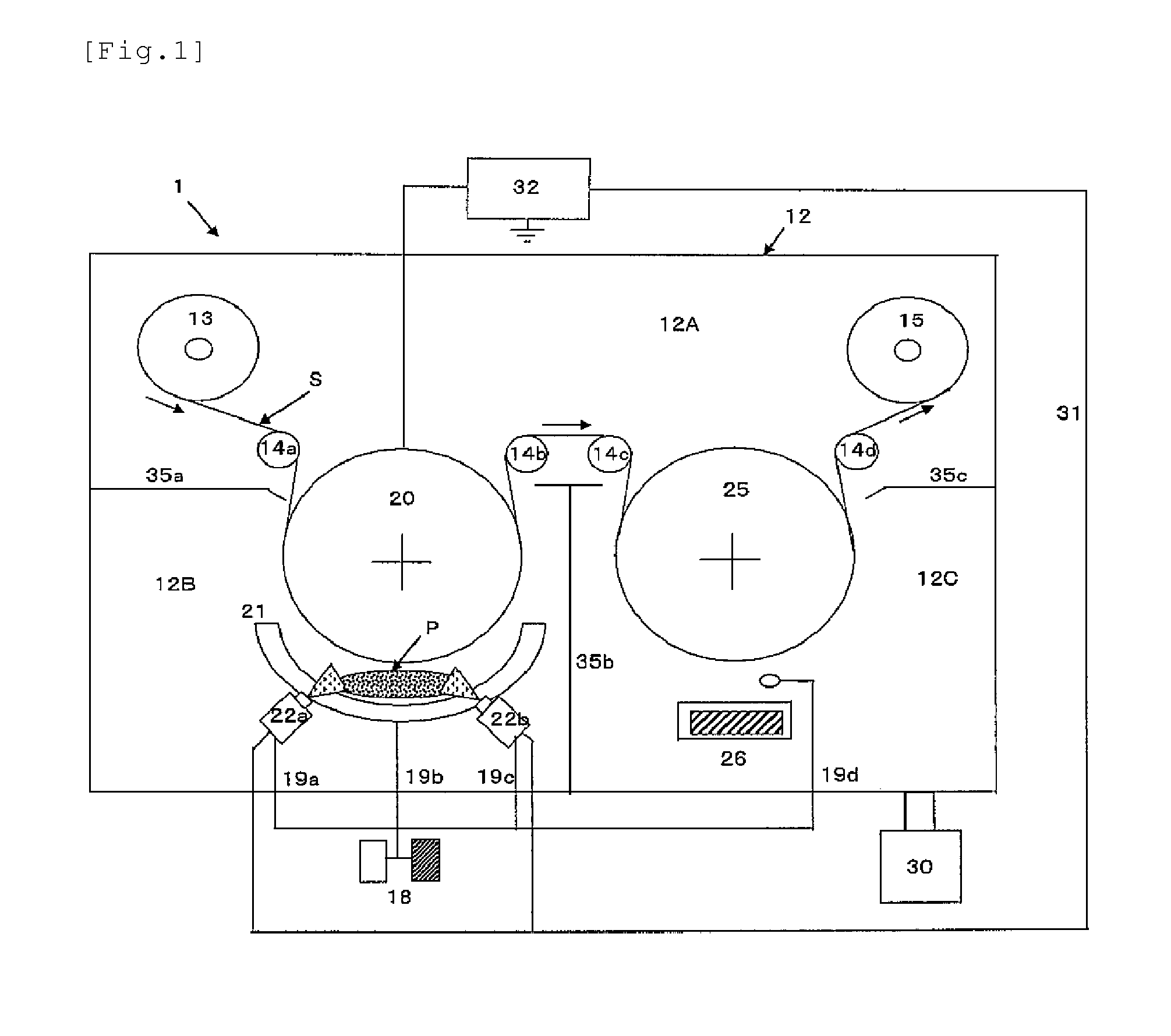

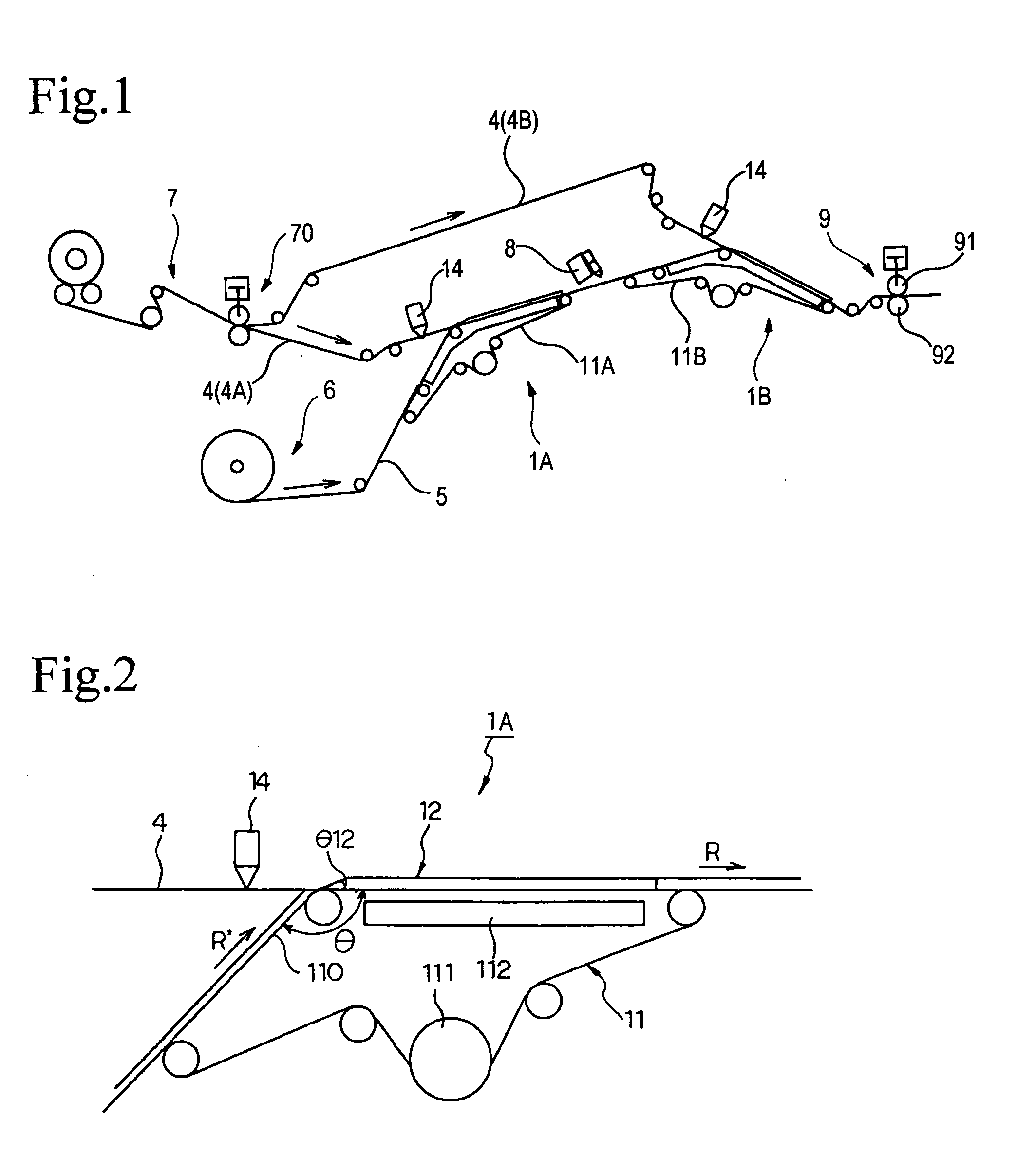

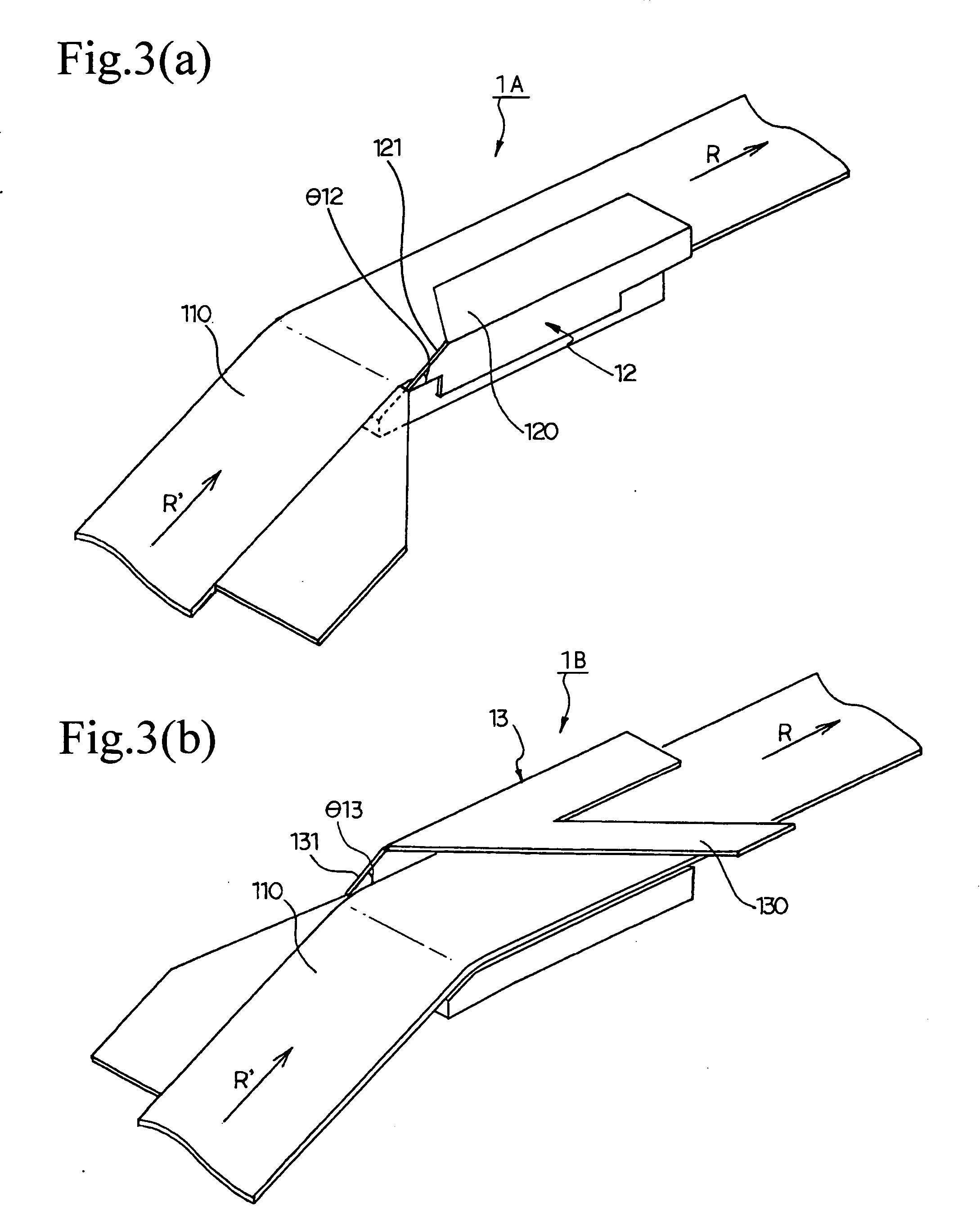

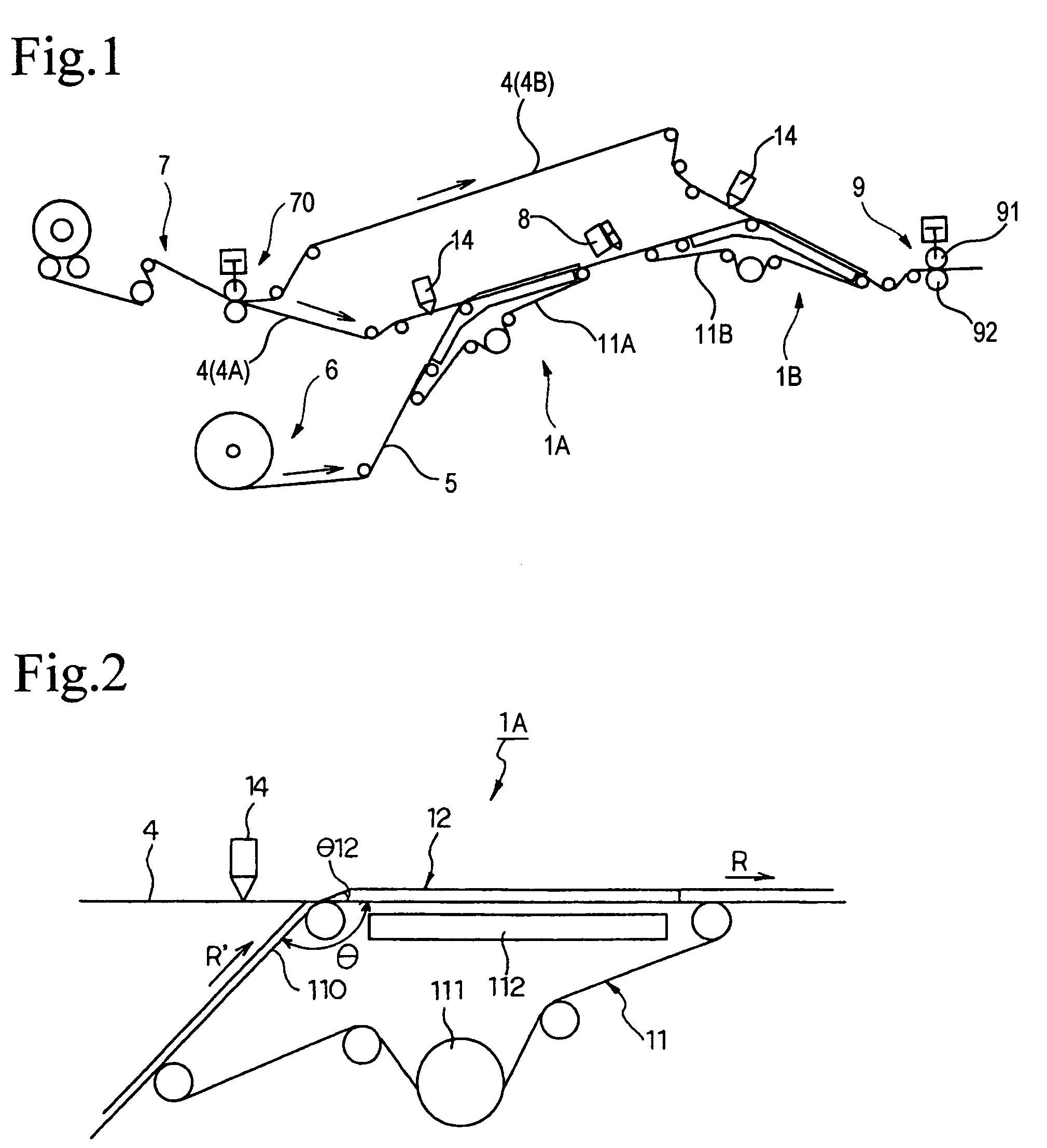

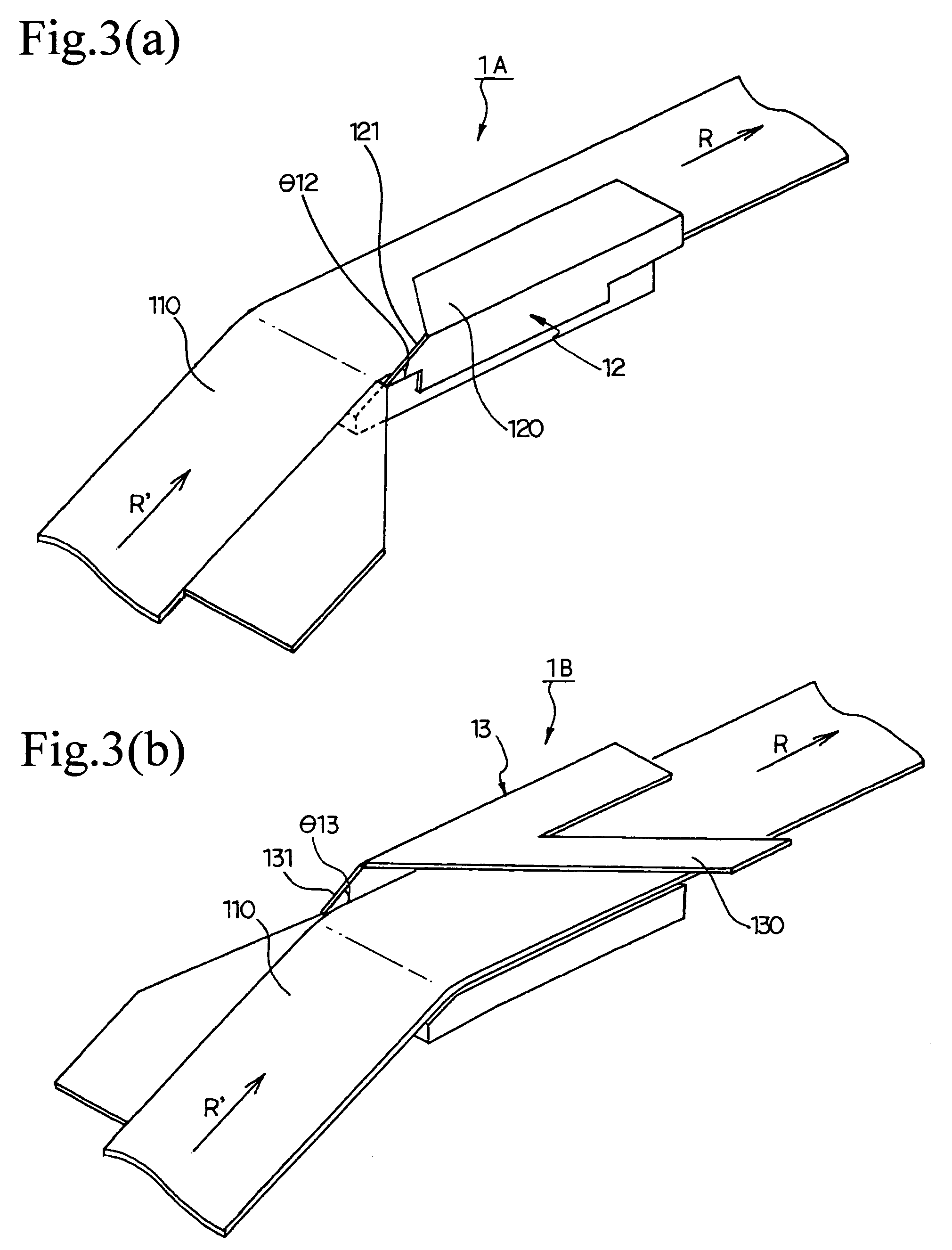

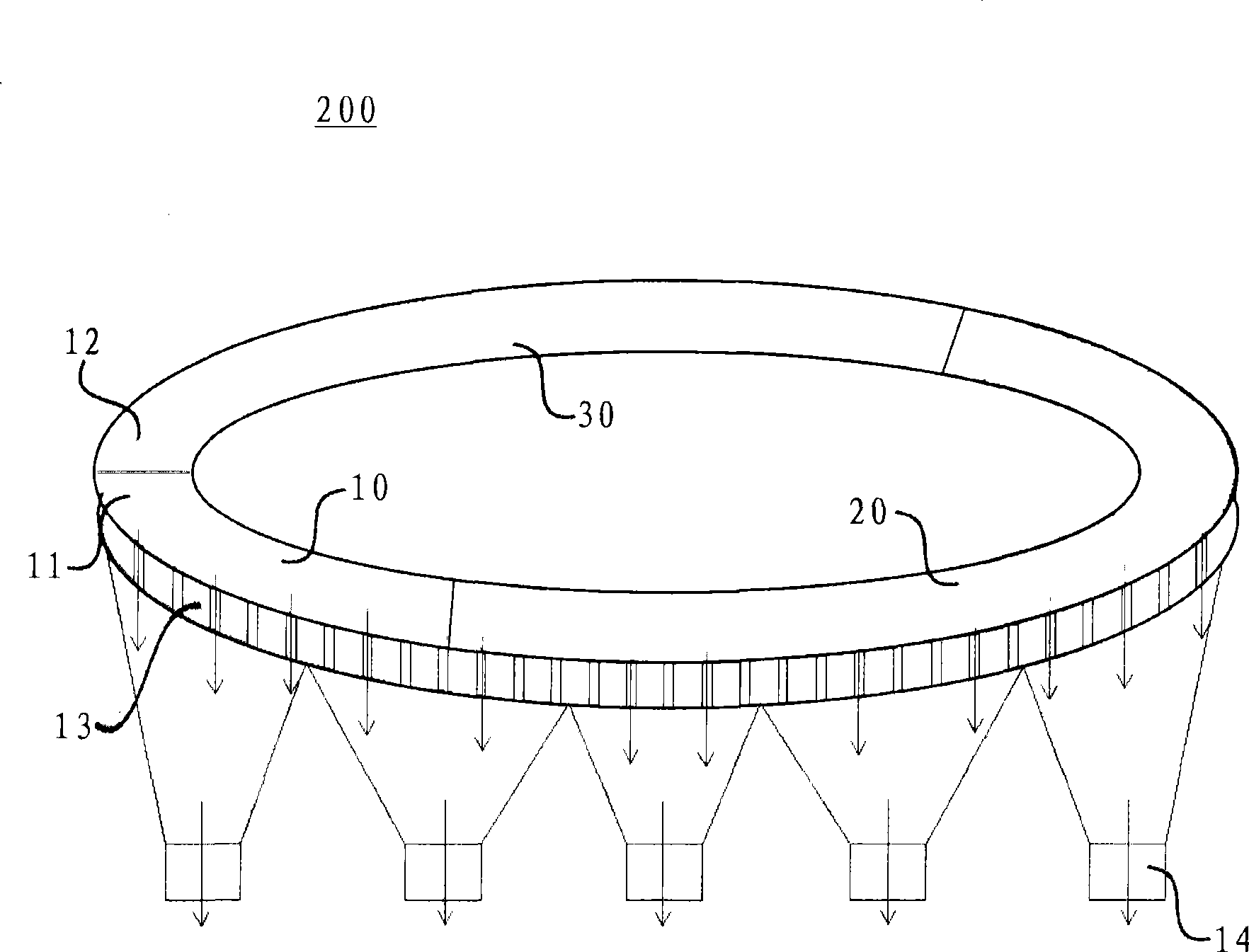

Vapor deposition apparatus having pretreatment device that uses plasma

InactiveUS20140311409A1Formed rapidly and stablyImprove adhesionElectric discharge tubesVacuum evaporation coatingForming gasGas phase

A roller-type continuous vapor deposition film-forming apparatus for a substrate that is to be conveyed at high speed, comprising a plasma pretreatment device and a film-forming apparatus provided in series, wherein a substrate conveying compartment 12A, a pretreatment compartment 12B and film formation compartment 12C are formed inside a chamber 3; and a substrate S is wound from an unwinding roller 13 onto a plasma pretreatment roller 20 and film formation roller 25, which are provided in series, via guide rollers 14a-14d, and is taken up by a take-up roller 15. In the pretreatment device, plasma P is supplied toward the substrate S inside a gap, wherein a plasma-forming gas to be supplied from plasma supply nozzles 22a, 22b is surrounded by the pretreatment roller, the plasma supply nozzles and a magnet 21, as magnetic forming means, and the plasma is electrically set to a positive electrical potential, power is supplied between the electrodes positioned on the substrate surface side, the plasma P is generated and an active pretreatment surface is formed on the surface of the substrate S. An inorganic oxide can be formed at high speed by the film formation device by physical vapor deposition or the like on a pretreatment surface of a substrate that has been subjected to the pretreatment.

Owner:DAI NIPPON PRINTING CO LTD

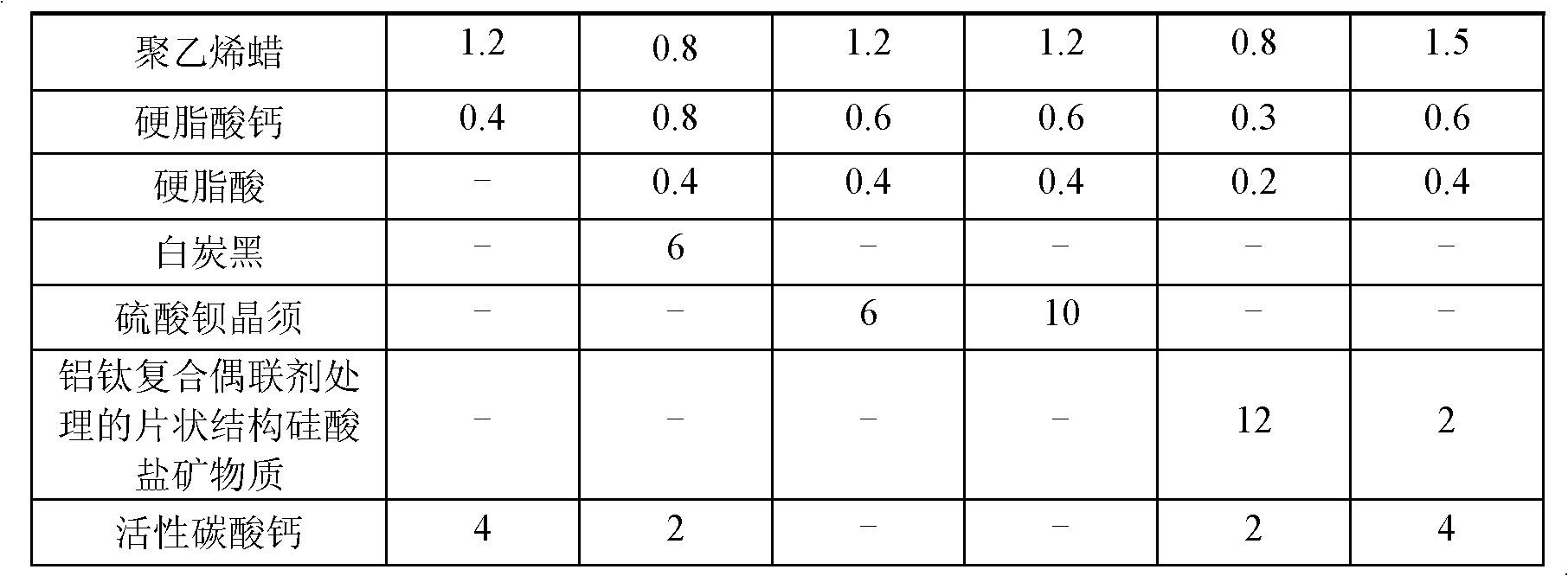

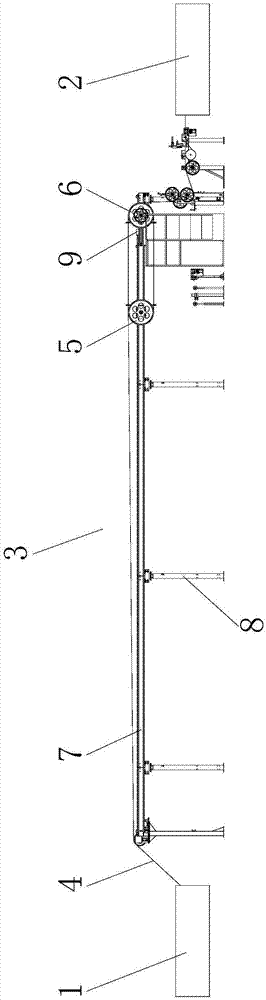

Production apparatus and extrusion technology of novel clad pipe

The invention relates to a production apparatus and an extrusion technology of a novel clad pipe. The production apparatus comprises an extrusion production line apparatus for production of an inner layer and an external layer of an enhanced clad pipe, winders for winding and preheating a long fiber strip, a center locating frame for controlling a fibrous strip winding to cause tilt of an inner pipe, and a heating box for heating the inner pipe wound with the fibrous strip. According to the invention, two winders are configured between an inner pipe extrusion line and an external layer extrusion cladding die head and used alternately; when a fibrous strip on one winder is using up, the other winder is initiated rapidly to ensure continuous and stabilized production of the enhanced clad pipe. In the invention, a winding packaging technology is upgraded and reconstructed to combine with a cladding double-layer extrusion technology. A foreign complex technology requiring a special windercan be substituted to raise operation convenience, promote generalization of the technology and fill domestic technical blank of continuous fiber winding enhanced clad pipe. Therefore, the technologyof the invention is suitable for industrialized popularization.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

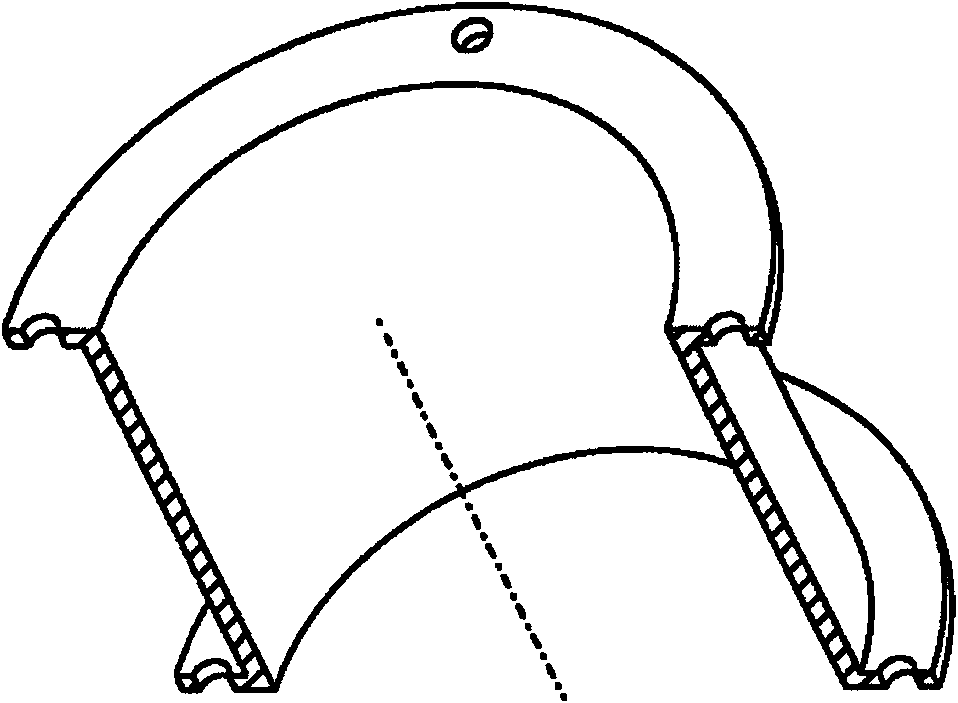

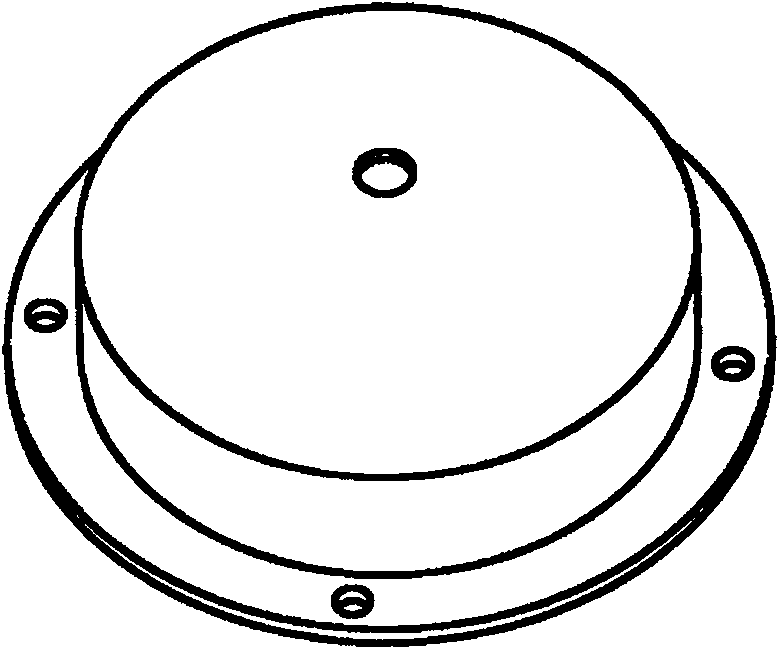

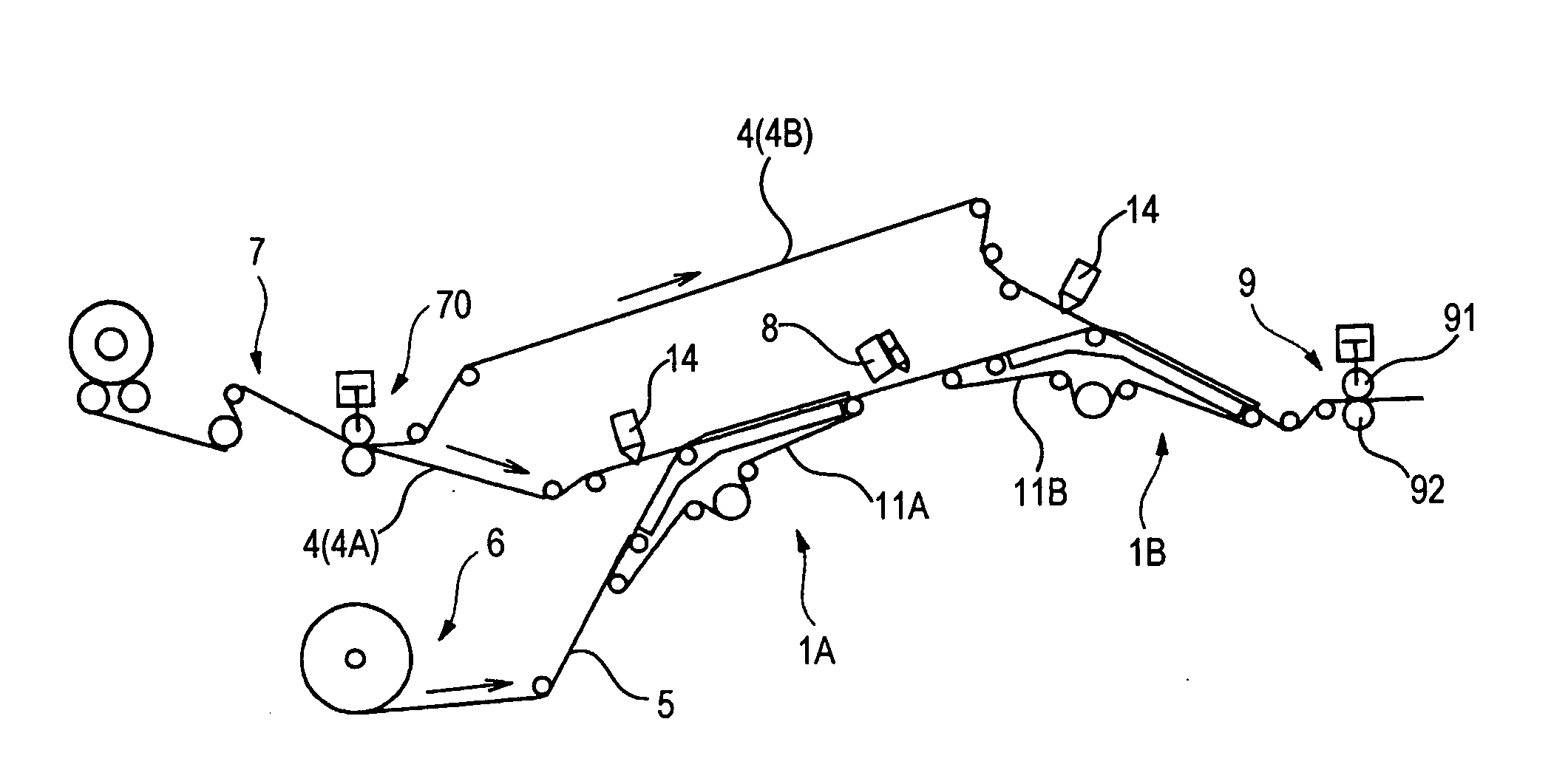

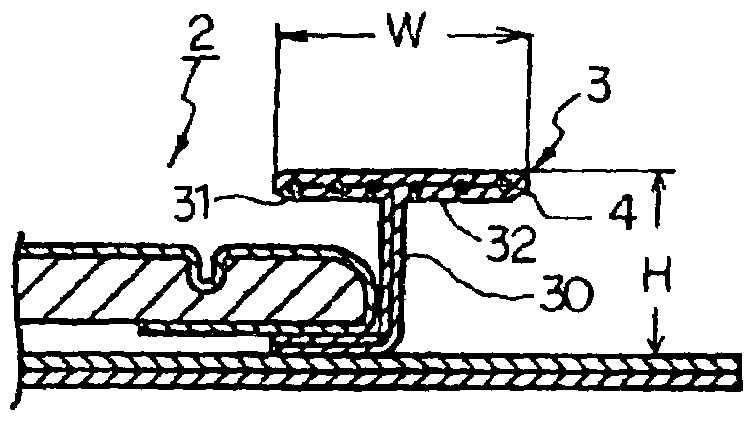

Method of manufacturing solid gather forming member

InactiveUS20060151091A1Reliable leakReliable protection against leakageMechanical working/deformationLaminationEngineeringMechanical engineering

A method of making a standing gather-forming member having a basal wall and first and second overhangs on both sides of the basal wall. Elastic members are disposed in their stretched state on the inner surface of a middle portion of a continuously running strip-shaped sheet. One of side portions extending on both longitudinal sides of the middle portion is Z-folded to cover a part of the width of the middle portion thereby to form the first overhang. The other side portion is then folded inward along the longitudinal direction to cover the part of the middle portion that remains uncovered with the first-mentioned side portion and to overlay the Z-folded portion of the first-mentioned side portion thereby to form the second overhang and the basal wall.

Owner:KAO CORP

Method of manufacturing solid gather forming member

InactiveUS7435309B2Reliable protection against leakageContinuous and stable productionMechanical working/deformationLaminationEngineeringMechanical engineering

A method of making a standing gather-forming member having a basal wall and first and second overhangs on both sides of the basal wall. Elastic members are disposed in their stretched state on the inner surface of a middle portion of a continuously running strip-shaped sheet. One of side portions extending on both longitudinal sides of the middle portion is Z-folded to cover a part of the width of the middle portion thereby to form the first overhang. The other side portion is then folded inward along the longitudinal direction to cover the part of the middle portion that remains uncovered with the first-mentioned side portion and to overlay the Z-folded portion of the first-mentioned side portion thereby to form the second overhang and the basal wall.

Owner:KAO CORP

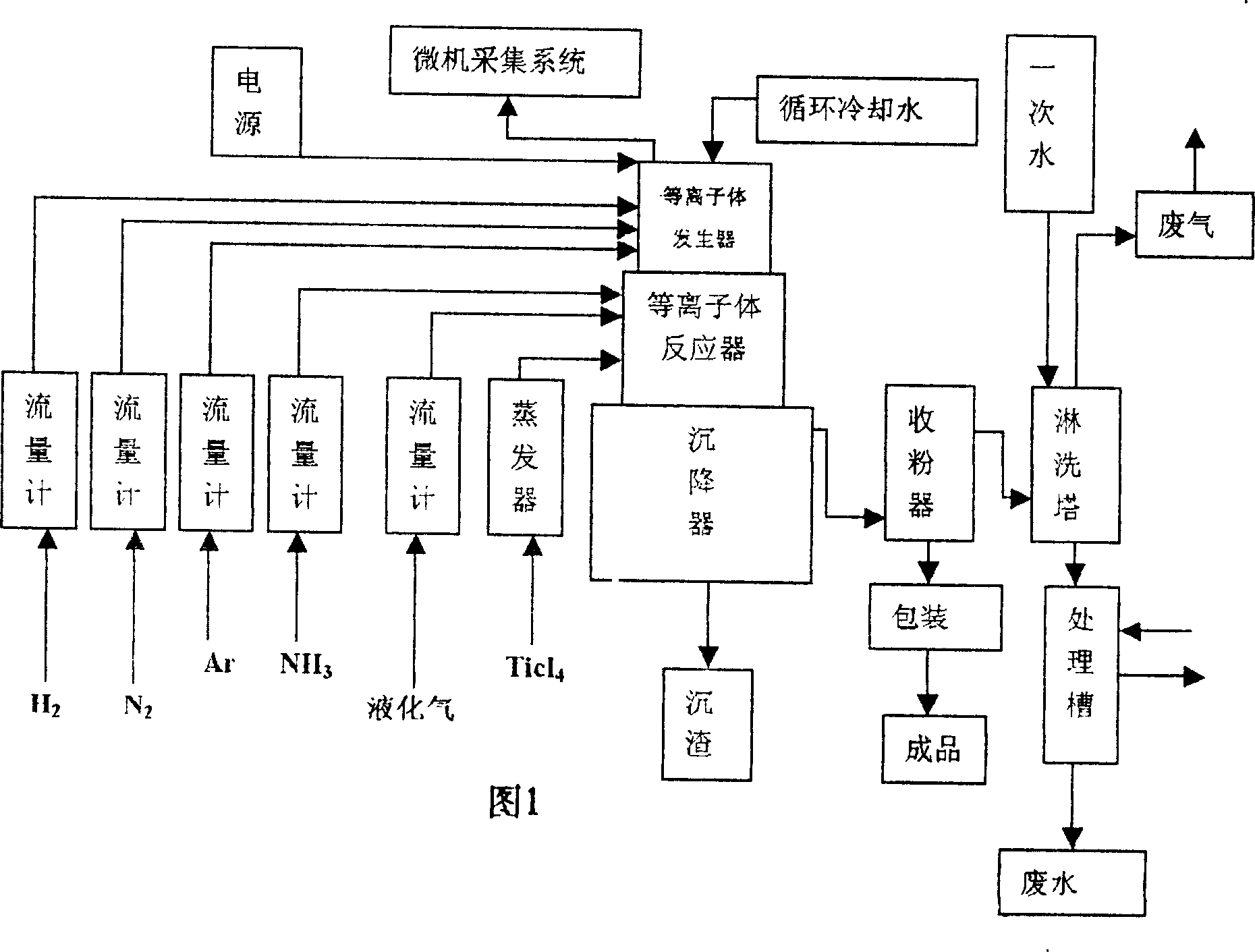

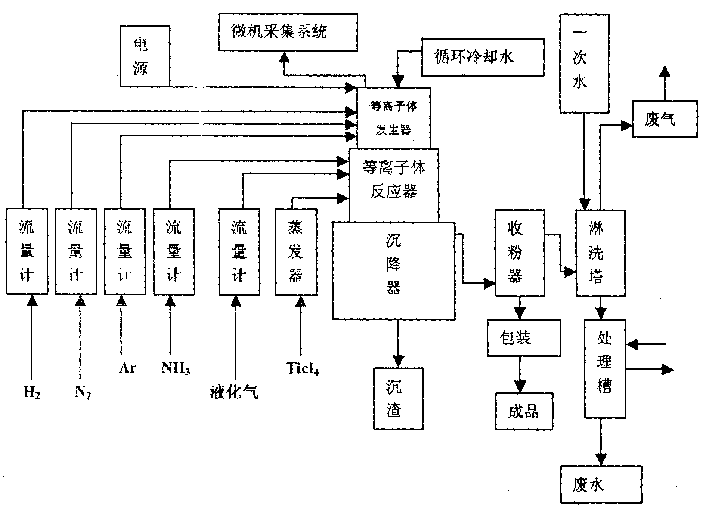

Process for preparing titanium carbonitride ceramic powder body by utilizing plasma chemial gas phase synthesis method

The process for preparing titanium carbonitride ceramic powder body by using plasma chemical gas-phase synthesis method is characterized by utilizing the D.C. electric arc plasma as heat source, heating the gas N2-H2-Ar flowing through electric arc to high temp. of 4800-5200 deg.C and feeding said gas and liquefied gas heating-evaporated by evaporator, TiCl4 and NH3 gases into plasma reactor together to make them quickly produced decomposition and synthesis reaction of titanium carbonitride, and making the TiCN formed at 1200-1300 deg.c in reactor undergo the processes of crystallization, growth, cooling and gas-solid separation so as to obtain the invented nano-grade titanium carbonitride ceramic powder body.

Owner:白万杰

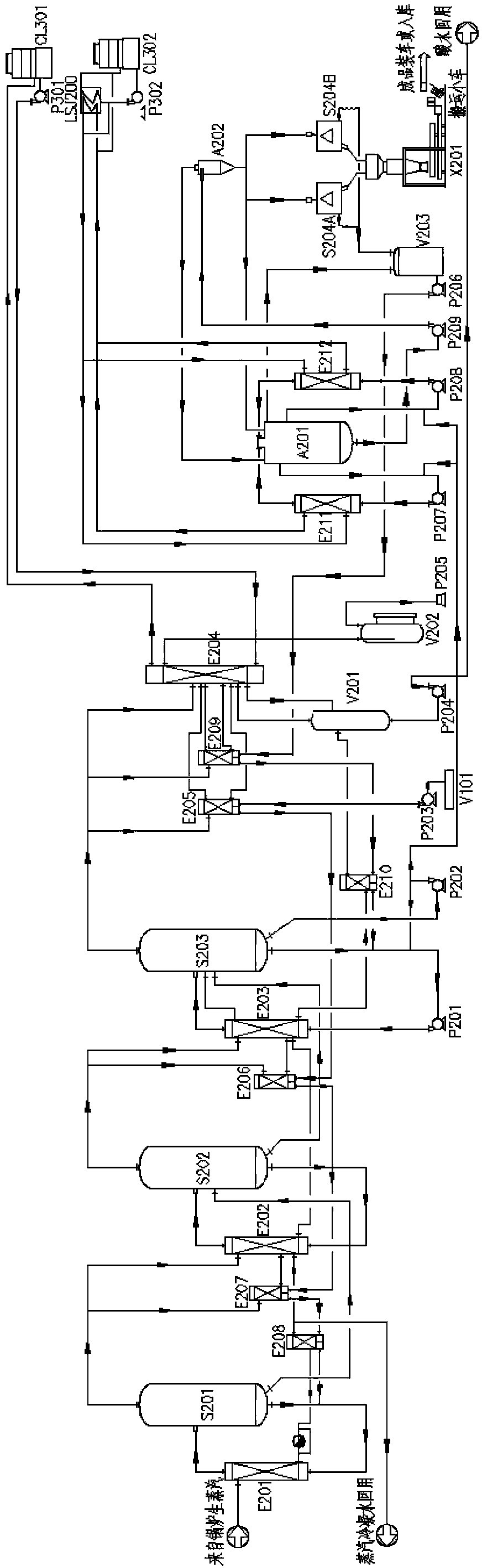

High-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer

ActiveCN103394206AIncrease profitImprove economySolution crystallizationMultiple-effect evaporationLiquid wasteSolvent

The invention discloses a high-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer, belonging to the field of pickling waste liquoir treatment. The evaporation crystallizer disclosed by the invention comprises an evaporation concentration unit, a feed unit, a gas condensation unit, a cooling crystallization unit, a solid-liquid separation unit, a mother liquor circulating unit and a vacuum unit. The hydrochloric acid pickling waste liquor is heated in a vacuum state, so that volatile chlorine hydride and water in the solution are evaporated together, and are condensed through the gas condensation unit to form reusable clean hydrochloric acid; and the concentration of the nonvolatile metal salt in the solution is continuously increased to form a metal salt supersaturated solution, and the metal salt supersaturated solution is cooled by the cooling crystallization unit, so that part of metal salts are precipitated in the crystalline-state hydrous crystal, thereby achieving the goal of separating the solute and solvent in the solution. The invention mainly aims to provide a high-efficiency energy-saving hydrochloric acid pickling waste liquor triple-effect negative-pressure graphite evaporation crystallizer which has the advantages of favorable antiseptic property, high recovery ratio and low treatment cost.

Owner:常州泰特环境设备工程有限公司

Process for preparing power transmission composite cross arm with electric mark corrosion tolerance and high hydrophobic property

The invention relates to a process for preparing a power transmission composite cross arm with electric mark corrosion tolerance and high hydrophobic property, which comprises preparation of a core rod and preparation of a climb increasing parachute cluster. The process is characterized in that: the core rod of the cross arm is a high-strength epoxy resin composite core rod; and the climb increasing parachute cluster is an electric mark tolerant aliphatic epoxy resin climb increasing parachute cluster at the end part of the core rod. The preparation process has the characteristics of simple and quick operation and the like; the prepared insulated cross arm has good hydrophobic property, mechanical property, chemical corrosion resistance, fatigue resistance, fouling and flashing resistance and the like besides excellent electric mark corrosion tolerance, continuous and stable production and physical and chemical stability; and the application range of the composite in the insulating field is further broadened.

Owner:CHINA ELECTRIC POWER RES INST +1

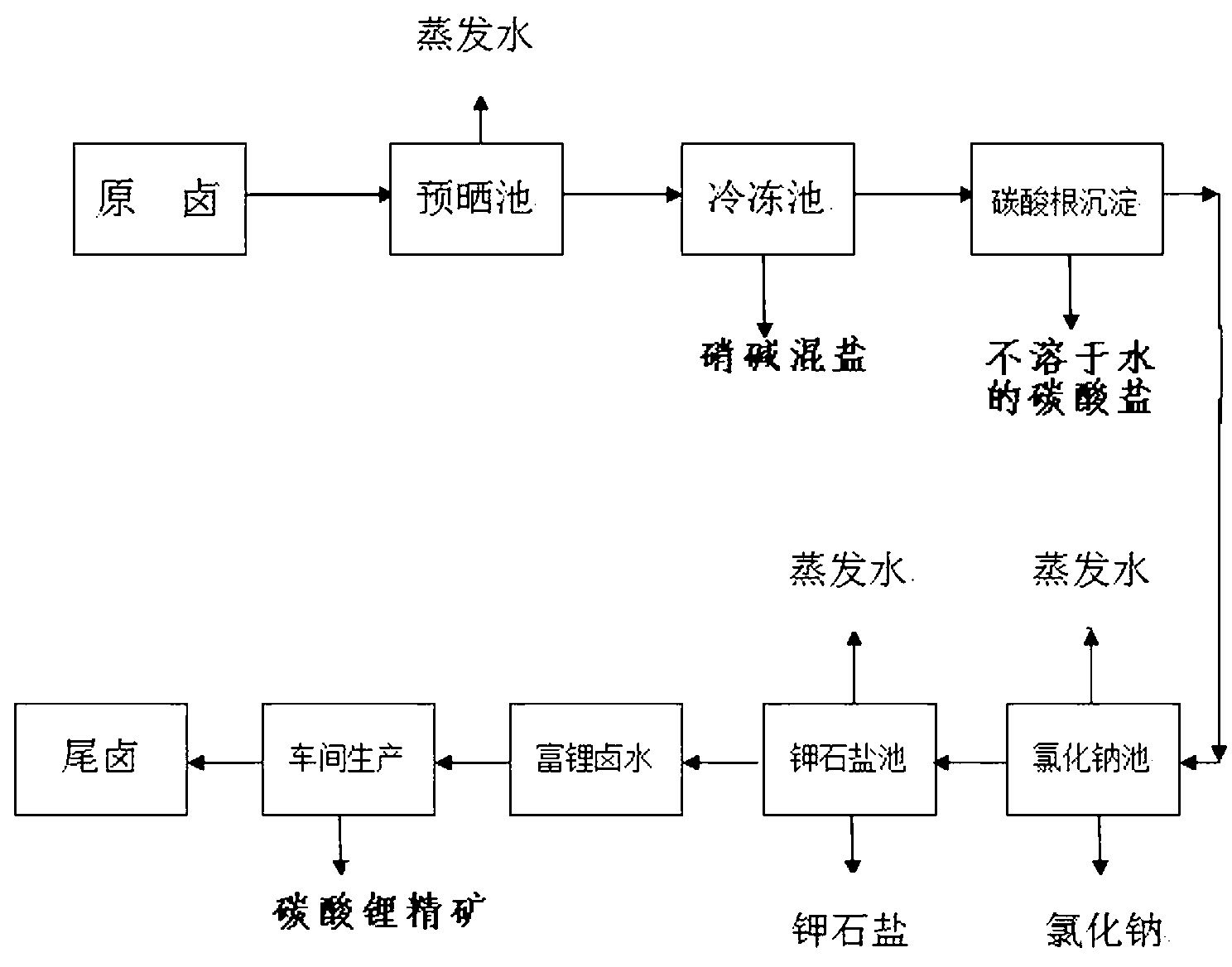

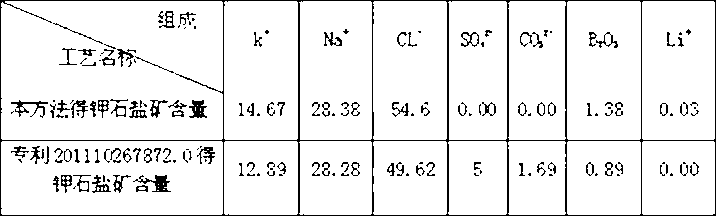

Method for separating carbonate from carbonate bittern containing lithium and potassium to prepare sylvinite ore and lithium carbonate concentrate

InactiveCN103058232AEfficient use ofPrevent precipitationAlkali metal chloridesLithium carbonates/bicarbonatesSylviniteLithium carbonate

The invention discloses a method for separating carbonate from carbonate bittern containing lithium and potassium to prepare sylvinite ore and lithium carbonate concentrate, wherein the carbonate bittern containing lithium and potassium is pre-concentrated, the carbonate is separated from the carbonate bittern containing lithium and potassium by means of combination of frozen alkaline and a precipitant so as to prepare the concentrated bittern with the content of carbonate reduced, then the concentrated bittern is further concentrated, the sylvinite ore separated out by evaporative crystallization is separately collected and prepared after the content of the potassium ion in the bittern is up to 51.70g / L, the lithium enrichment bittern with the content of the lithium ion being 4-26g / L is prepared, and the lithium enrichment bittern is guided into a crystallizer, added with sodium carbonate, and separated in a centrifugal way to obtain the lithium carbonate concentrate. Compared with the prior art, the method provided by the invention has the following advantages: the lithium enrichment concentration is increased because the carbonate in the bittern is removed; the purity of the obtained lithium carbonate and the overall recovery of the lithium ion are high; continuous industrialization and automated production of the preparation of the lithium carbonate concentrate can be implemented; high-grade sylvinite can be prepared from a salt pan, and the potassium ion recovery of the salt pan is increased; and the residual bittern of which the lithium is extracted can be comprehensively developed conveniently so as to further extract substances like boron, rubidium, cesium bromine.

Owner:TIBET XUSHENG MINING DEV

Circular disc shear blade space control method

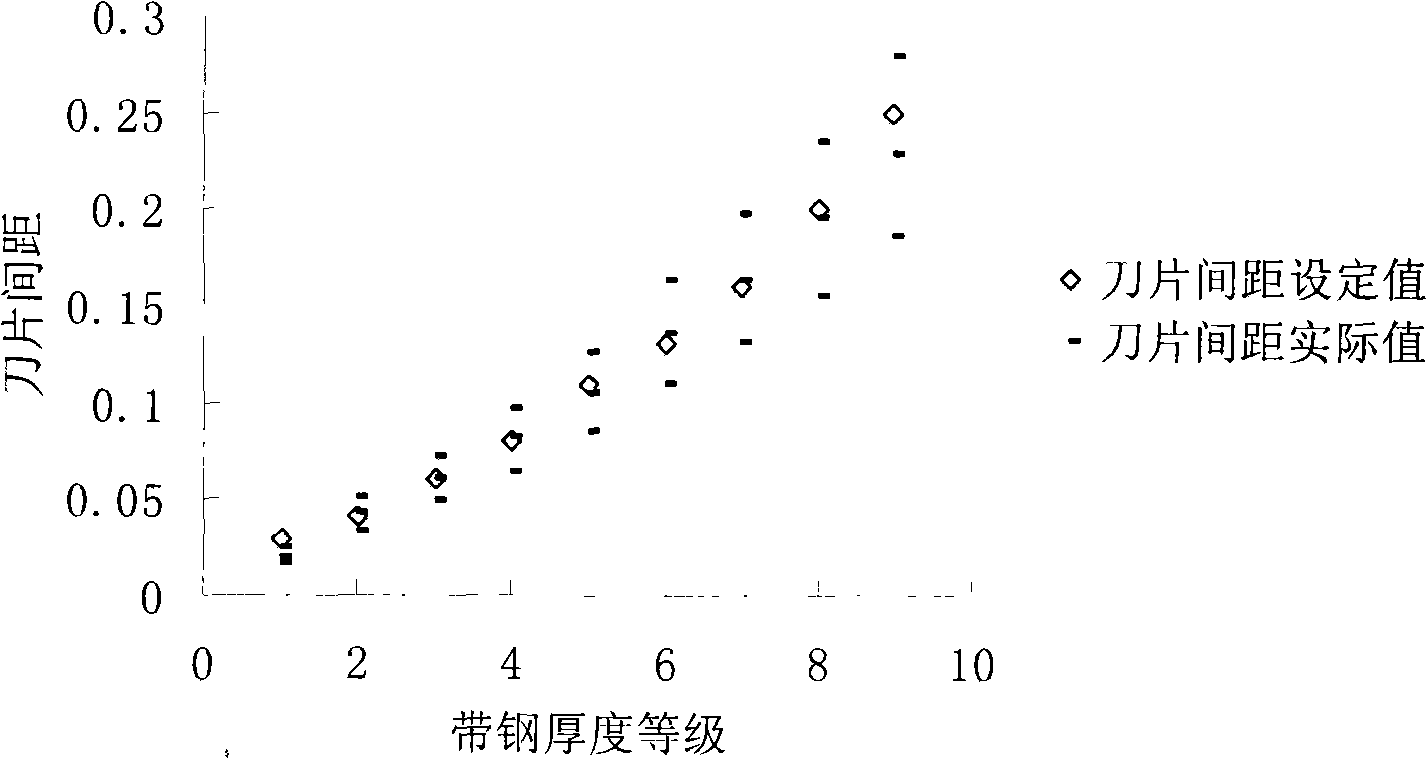

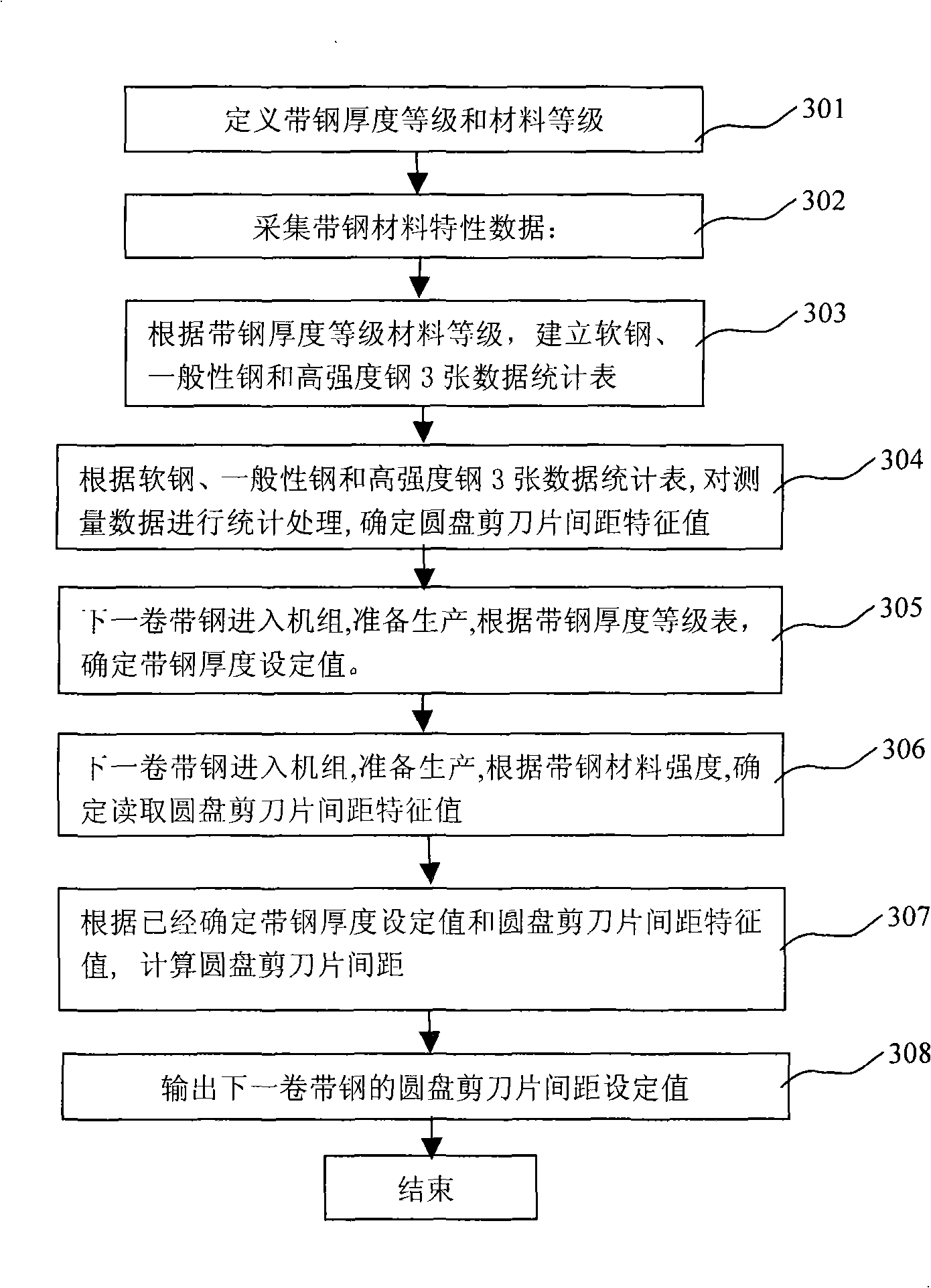

ActiveCN101266465ATarget control with high precisionSimple and fast operationShearing machinesProgramme control in sequence/logic controllersCircular discTarget control

The invention relates to a circular disc shear blade space length control method. The method includes the following steps: dividing band steel thickness gradation and material strength gradation; capturing band steel material characteristic data; establish three sheets of mild steel, general steel and high-duty steel data statistical tables according to band steel thickness gradation and material strength gradation; executing statistical processing to the measured data according to the data statistical tables, and determining circular disc shear blade space length eigen value; cutting a reel band steel to enter into train for produce, determining the band steel thickness setting value according to band steel thickness gradation table; cutting a reel band steel to enter into train for produce, determining the reading circular disc shear blade space length eigen value according to band steel material strength table; and calculating the circular disc shear blade space length setting value, according to the already determined band steel thickness setting value and circular disc shear blade space length eigen value. The invention has high target control accuracy, easy operation, furthermore wide range of adaptability and improved band steel synthetic sawn goods rate.

Owner:BAOSHAN IRON & STEEL CO LTD

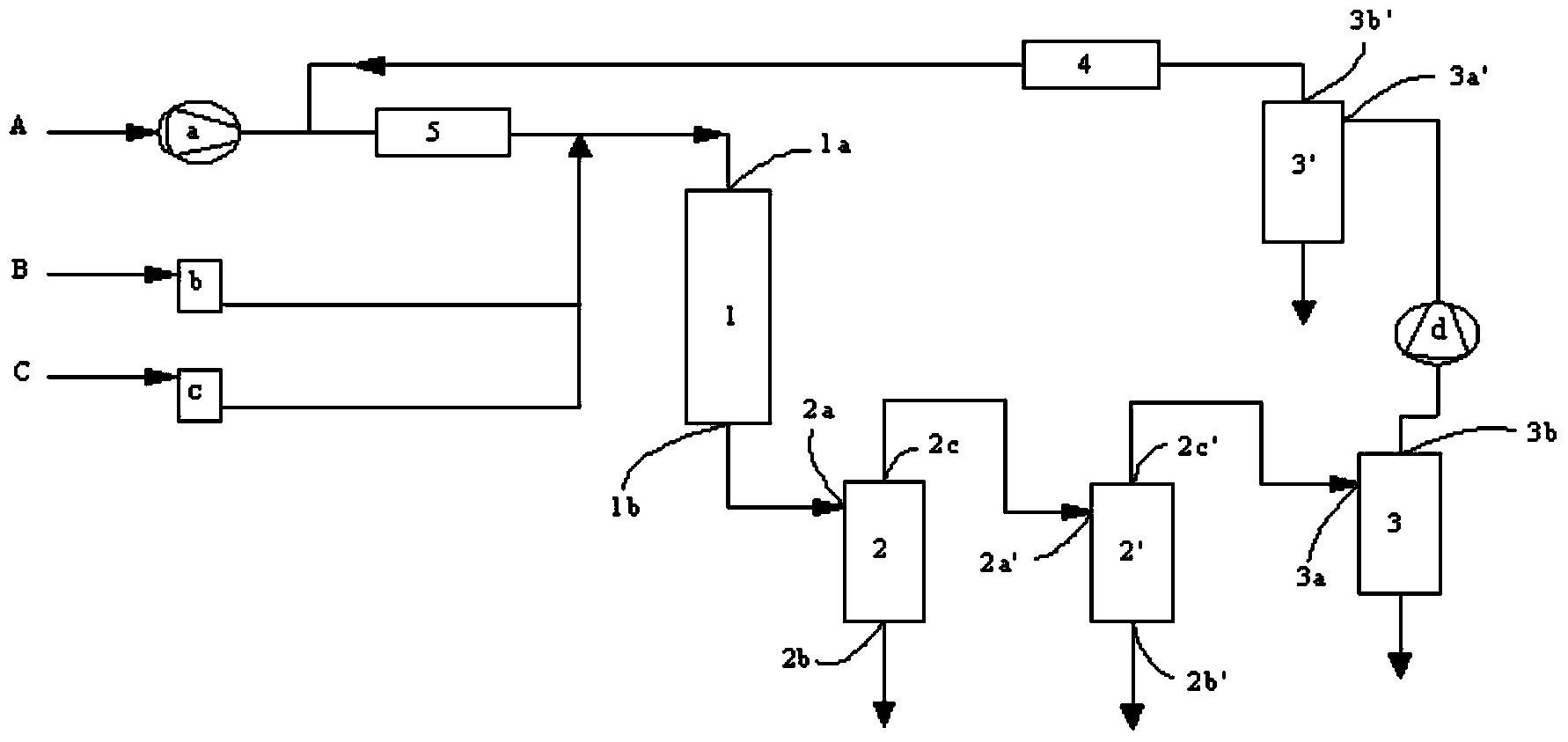

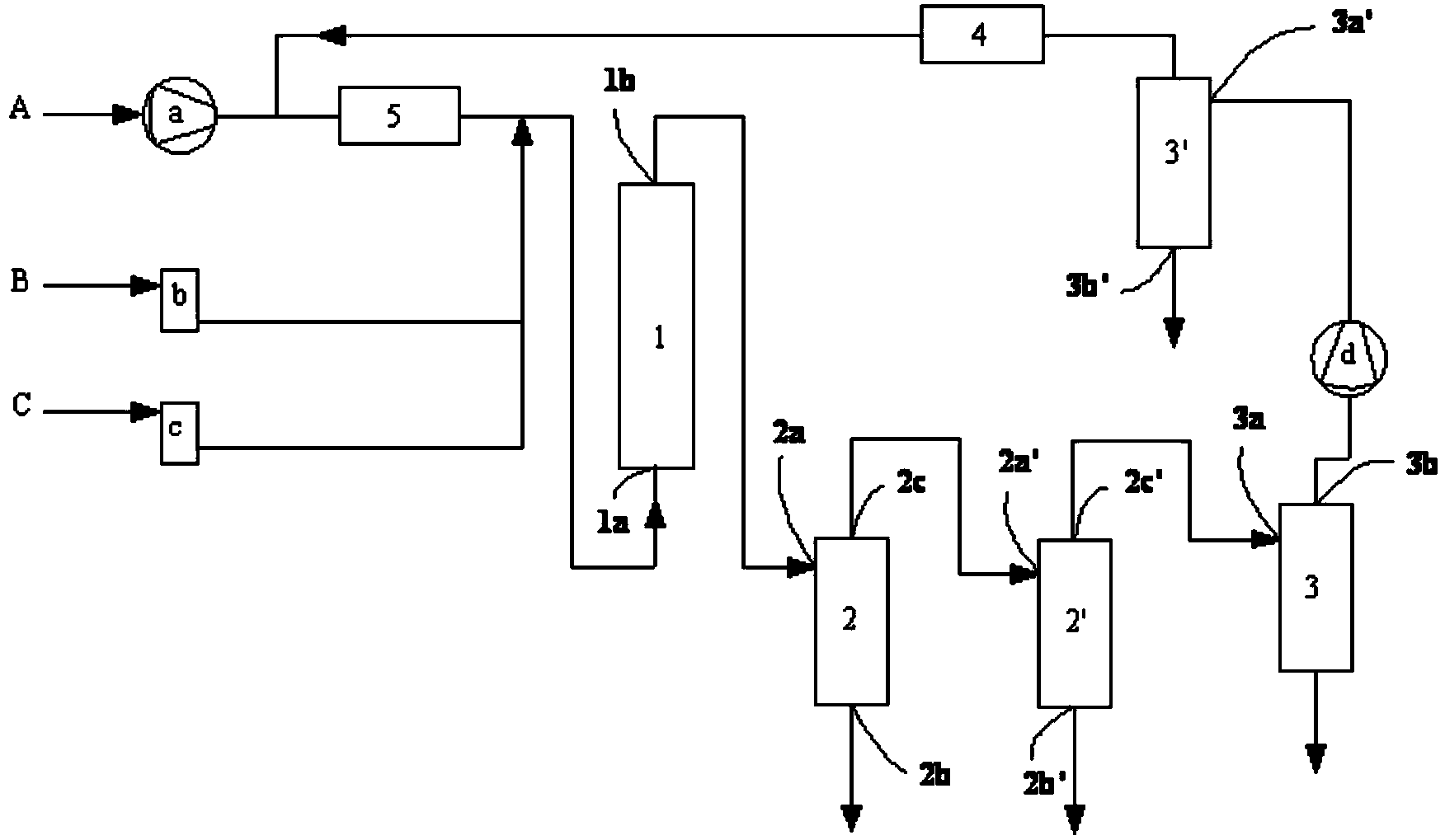

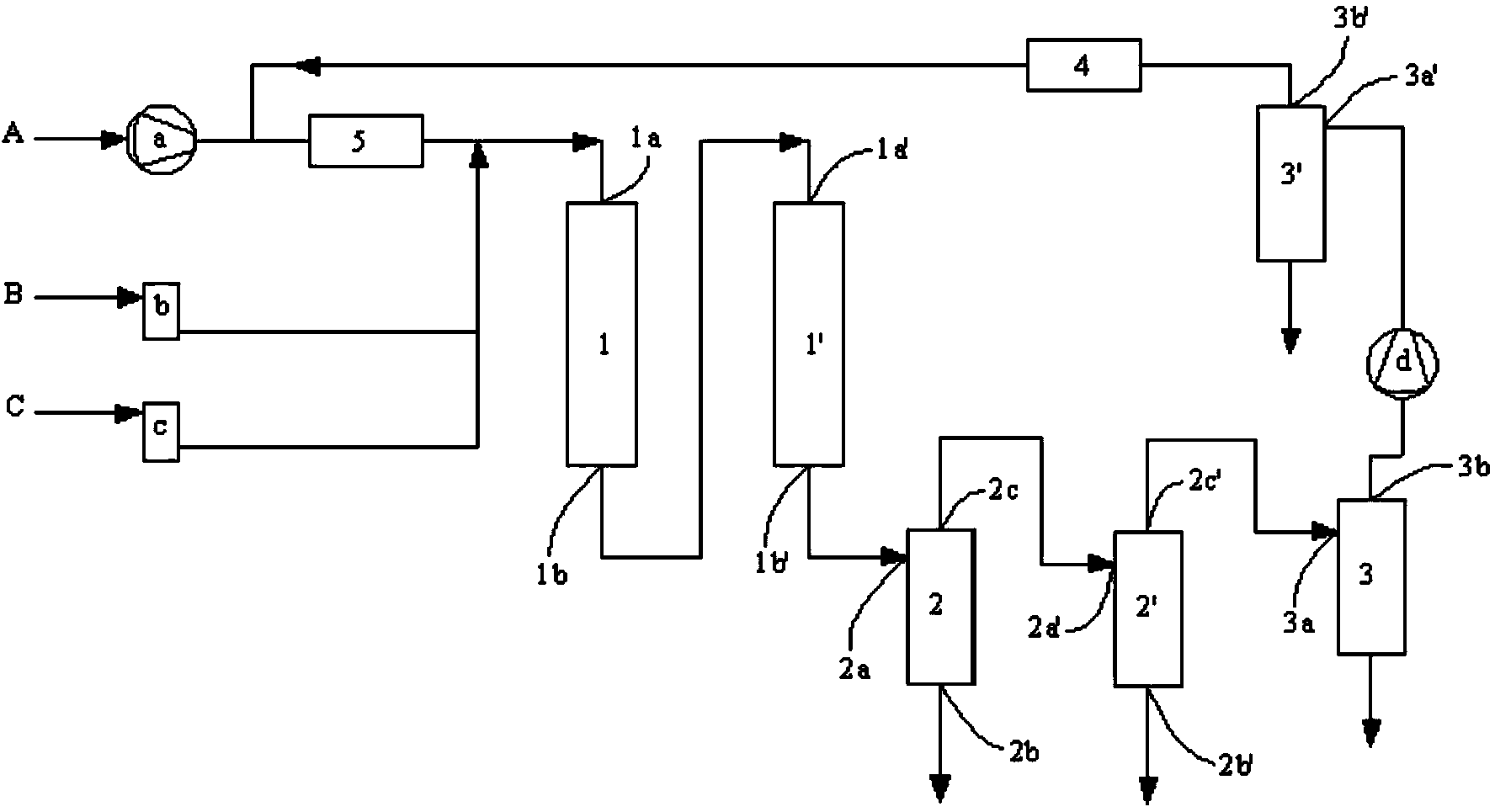

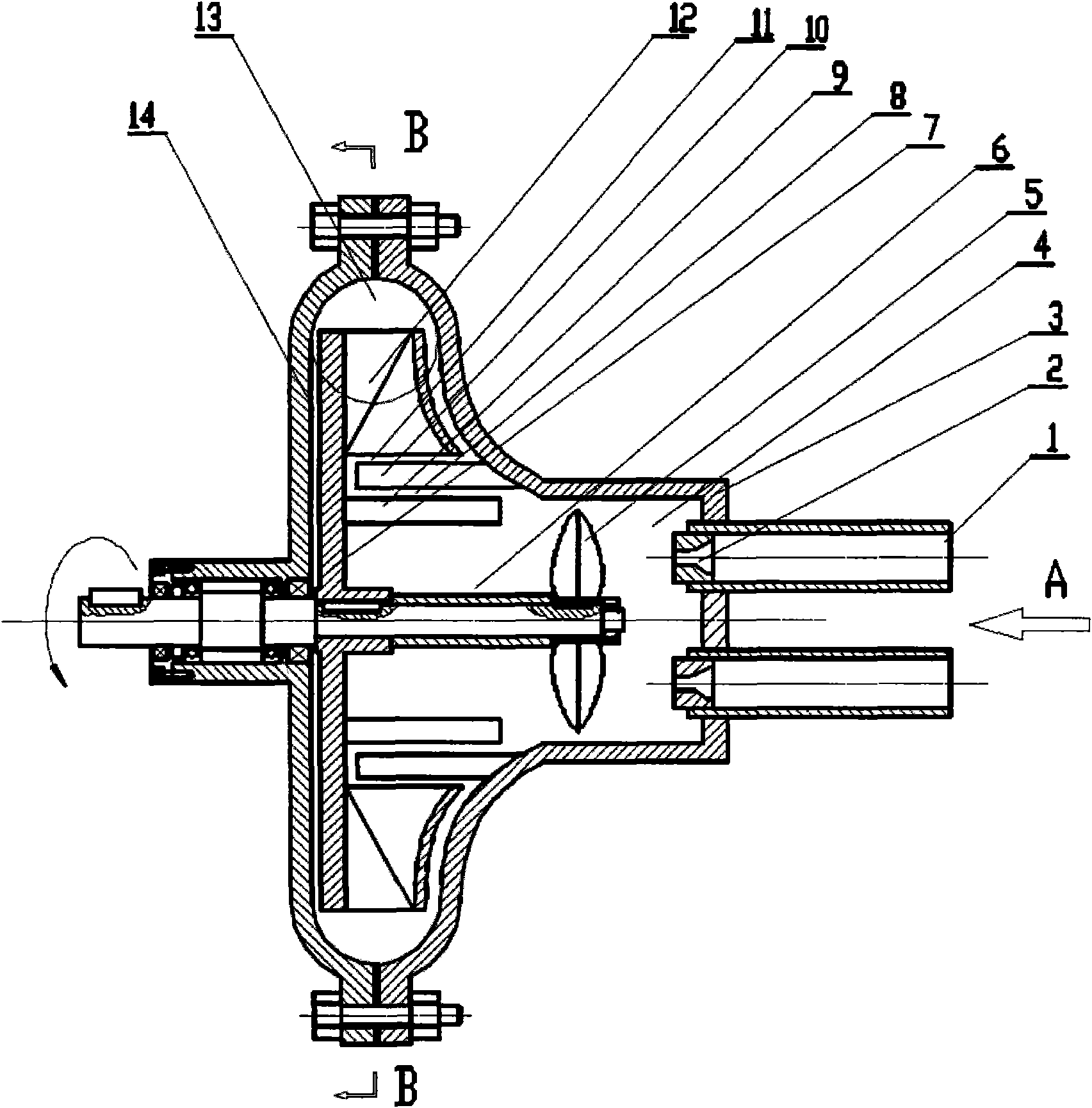

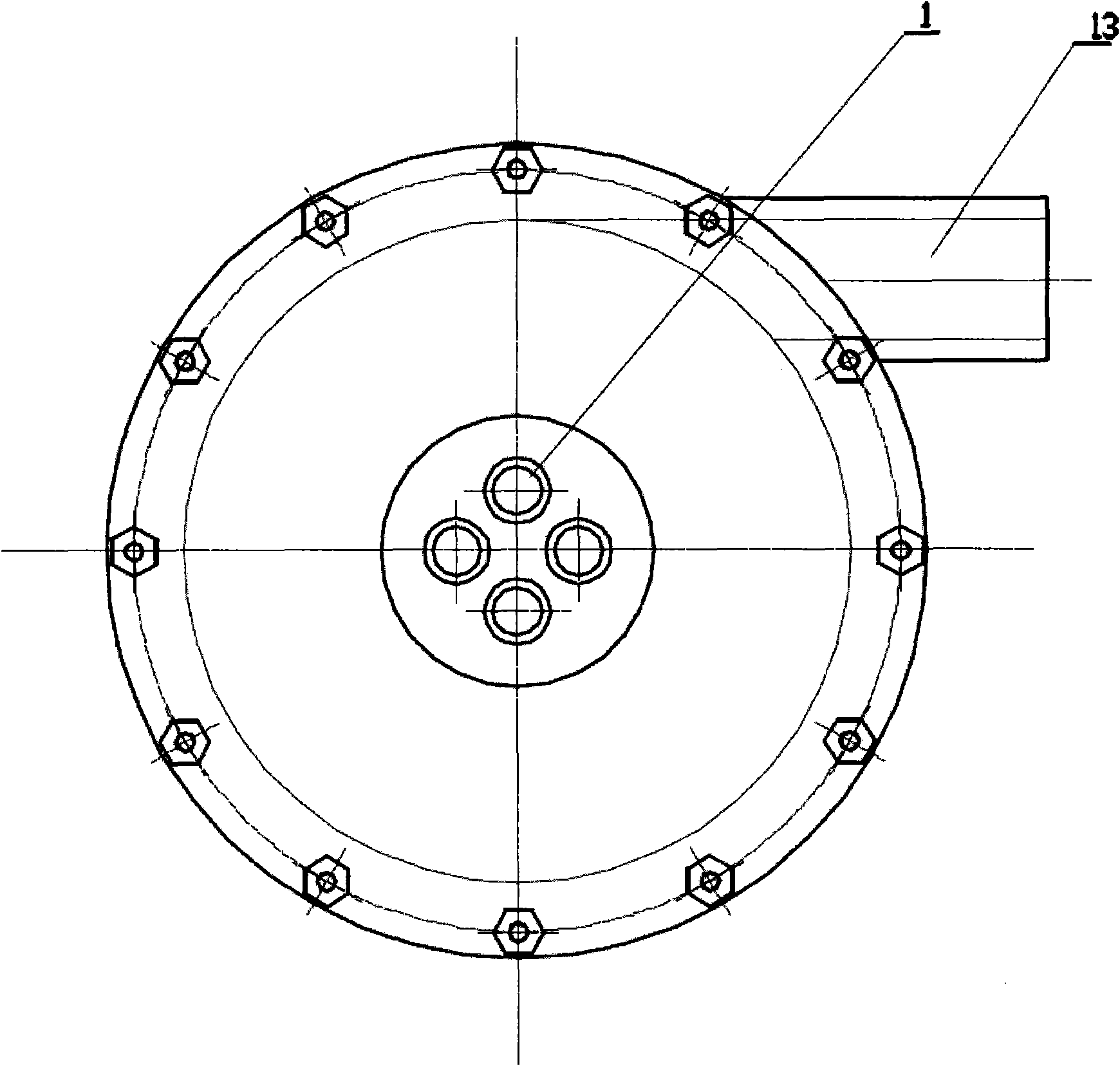

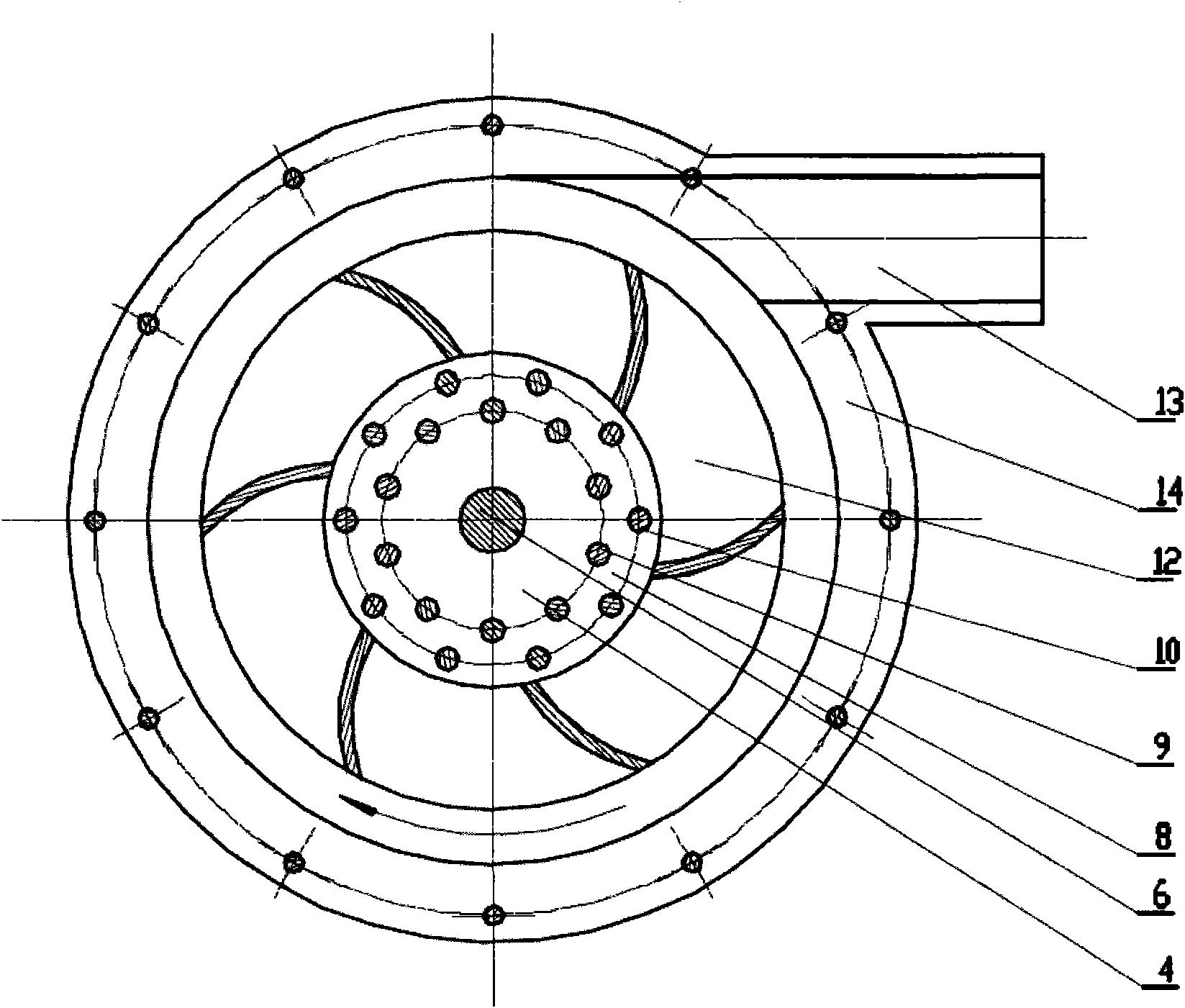

Fluid continuous reactor and application thereof

ActiveCN101850230AImprove uniformityWell mixedChemical/physical/physico-chemical stationary reactorsLiquid-liquid reaction processesImpellerContinuous reactor

The invention discloses a fluid continuous reactor and application thereof. The fluid continuous reactor comprises a cavity consisting of a front shell (3) and a rear shell (14), a feed pipe (1) opened on the front shell and a power input main shaft (6) arranged on the rear shell, wherein the front shell is raised to form a cavity which is a quick mixing chamber (4); the front end of the main shaft extends into the quick mixing chamber (4); the front end of the main shaft (6) is provided with a mixing blade (5); a rotor (7) is arranged on the main shaft on one side of the rear shell in the cavity, the rotor (7) is a round pad consisting of rotor teeth (9) and a centrifugal impeller (12) thereon, the rotor teeth (9) are mutually engaged with stator teeth (10) arranged on the front shell (3), and the clearance of the rotor teeth and the stator teeth forms a pulverizing chamber (8), and the cavity where the centrifugal impeller (12) is positioned is a conveying chamber (11); and an output pipe (13) is tangentially arranged on the outer edge of the shell of the conveying chamber (11) and communicated with the conveying chamber (11). The fluid continuous reactor provided by the invention is suitable for a reaction process of generating high-viscosity colloid product with sediment and floccules by quick reaction of liquid raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

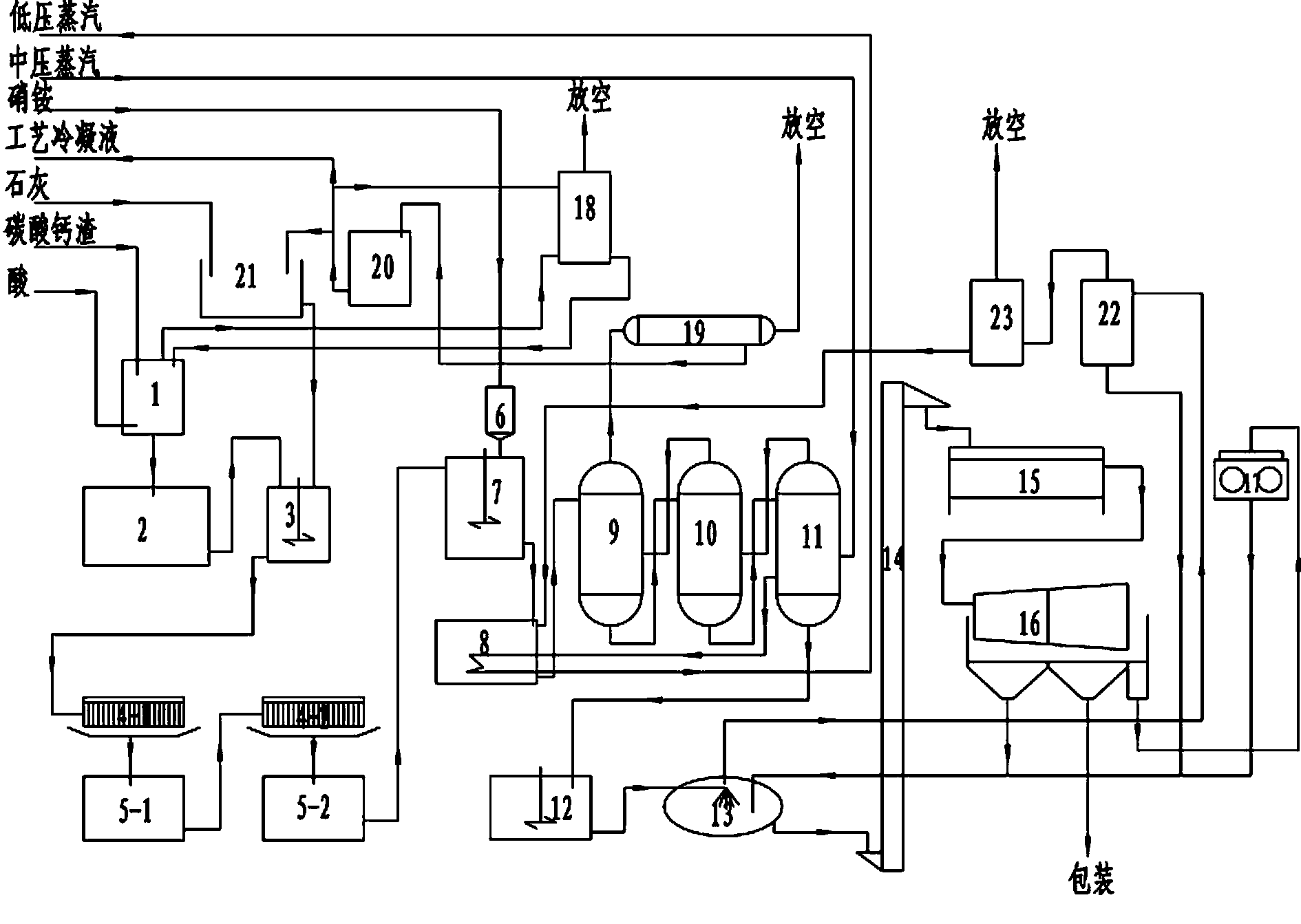

Method and device for producing calcium ammonium nitrate

ActiveCN103936466ASolve easy caking blockageEfficient productionNitrate fertilisersSlagCarbon dioxide

The invention relates to a method for producing calcium ammonium nitrate. The method comprises the following steps: carrying out a reaction on nitric acid and calcium carbonate slag to generate calcium carbonate, water and carbon dioxide, and feeding into a filter press to filter acid non-soluble substances and particle impurities; after mixing the generated calcium carbonate liquor and calcium carbonate liquor in a certain proportion, carrying out intermediate-pressure steam distillation and concentration; and pelleting by using a disc pelleting machine, and then, cooling, screening and packaging to obtain finished-product calcium ammonium nitrate. The invention further relates to a device for producing calcium ammonium nitrate by production waste calcium carbonate slag of nitric phosphate. The device is additionally provided with a settling tank for preventing slag from entering into the system. By adopting a disc pelleting technology, continuous and stable production of excellent calcium ammonium nitrate is realized, and problems that a conventional pelleting technology is easy to agglomerate and block, and the finished product is less in particle quantity and the like are solved.

Owner:TIANJI COAL CHEM IND GROUP +1

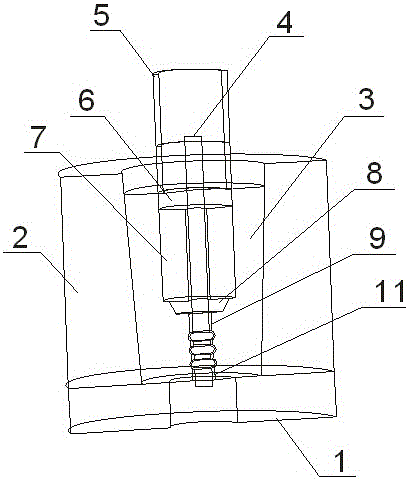

Forming mold and method for ultra-fine grain hollow magnesium alloy profile

The invention discloses a forming mold and method for an ultra-fine grain hollow magnesium alloy profile. The forming mold comprises a base, a concave die outer sleeve, a concave die inner sleeve, an extruding needle, an extruding shaft and an extruding pad, wherein the concave die inner sleeve is provided with a forming concave die. The forming method the following steps: (1) fixedly connecting the extruding pin and the extruding shaft with an inner sliding block and an outer sliding block of a double-acting extruding machine; (2) heating an ultra-fine grain hollow cylinder blank above a re-crystallization temperature; (3) putting the heated blank into a feeding section of the forming concave die; (4) starting the double-acting extruding machine to position the extruding needle, and pushing the extruding shaft and the extruding pad through the outer sliding block to extrude the blank; and (5) finally forming a tubular product by virtue of the extrusion of the outer sliding block of the extruding machine. According to the forming mold and method, the continuous plasticity of the magnesium alloy tubular product in the machining process can be effectively improved, the mechanical property can be enhanced, and the large-batch production machining can be realized.

Owner:重庆昱华新材料科技有限公司

Reactor and method for producing particle materials

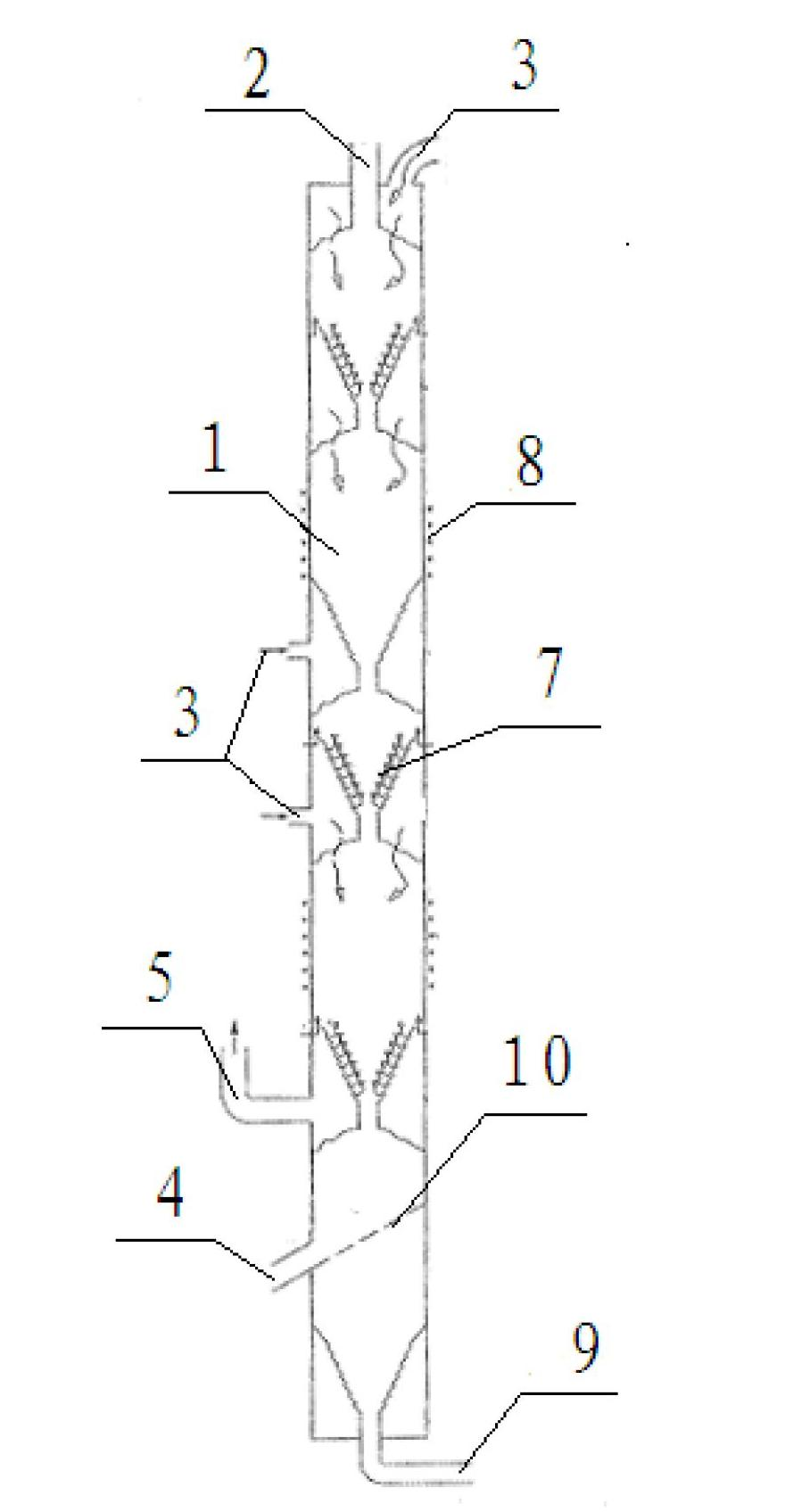

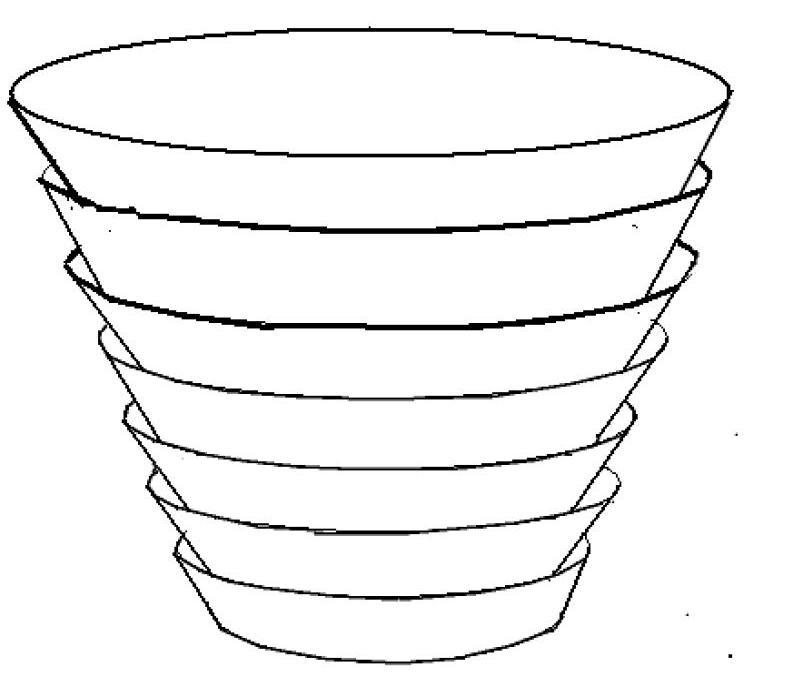

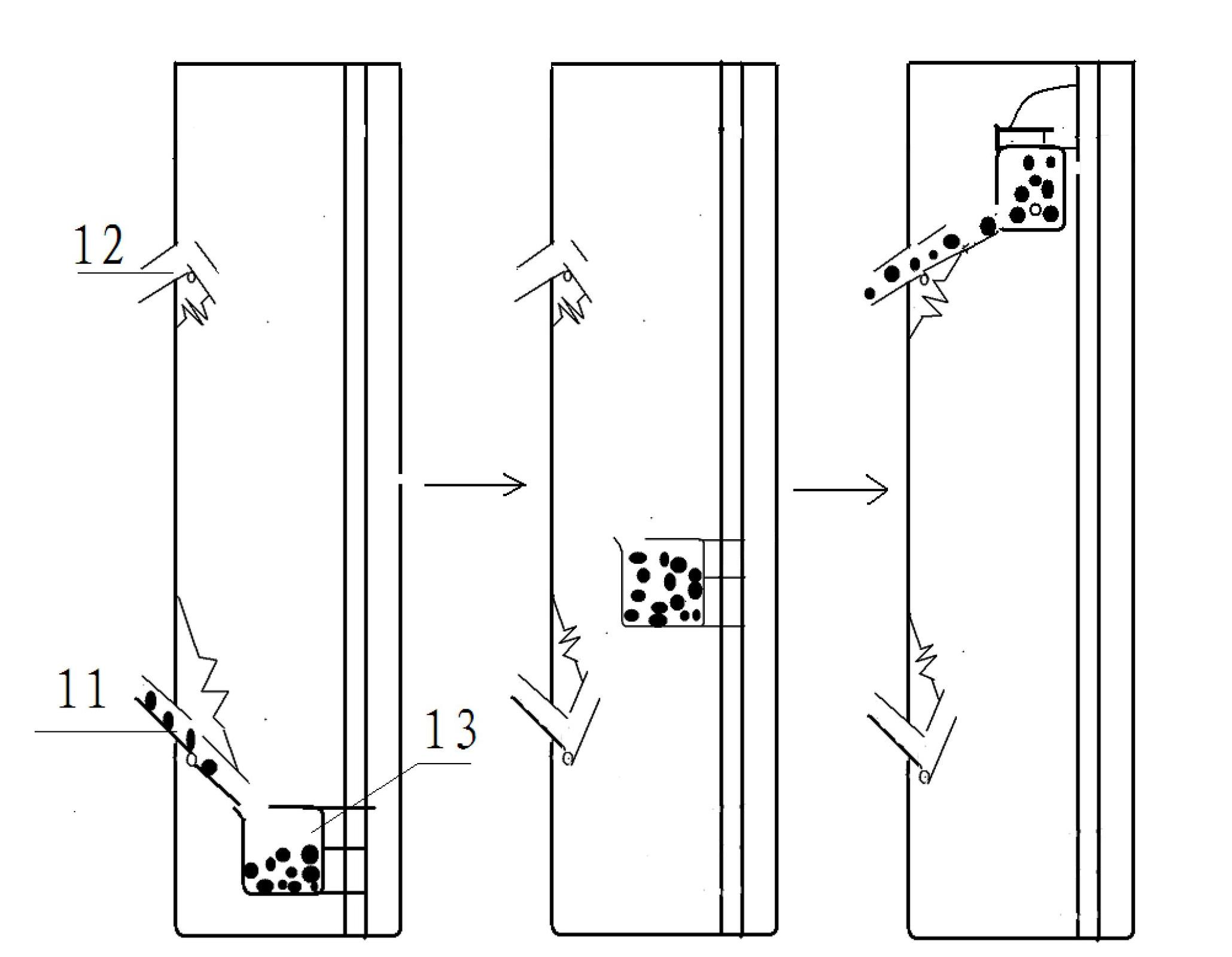

ActiveCN102671582AGuarantee continuous and stable operationFully contactedSiliconCarbon preparation/purificationExhaust gasNuclear engineering

The invention discloses a reactor and a method for producing particle materials. The reactor comprises a reactor cavity which is at least provided with a particle feeding hopper, a raw gas inlet, a particle product discharging port and a tail gas outlet, wherein the reactor cavity is internally provided with at least one conical distributor; the position of the tail gas outlet is higher than that of the conical distributor; the particle feeding hopper is arranged at the upper part of the reactor cavity; the particle product discharging port is arranged at the lower part of the reactor cavity; the reactor cavity also comprises an air curtain mechanism which can realize the blocking action between the reaction material and the inner wall of the reactor cavity; the reactor cavity is also provided with an internal or external mechanism for heating a reaction area; and the reactor cavity is also provided with an internal or external dynamic generation mechanism. The invention also discloses the method for producing the particle materials. According to the invention, the defects in the prior art are overcome, and the high-efficiency, energy-saving, long-term stable, safe and reliable production of the particle materials is realized.

Owner:储晞

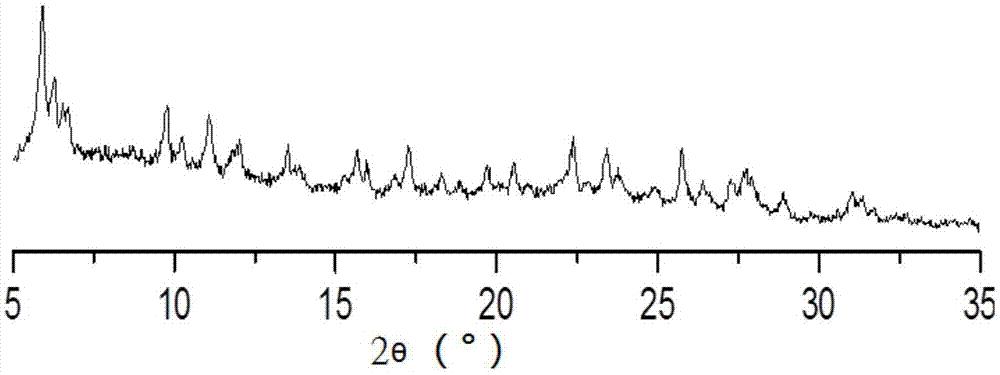

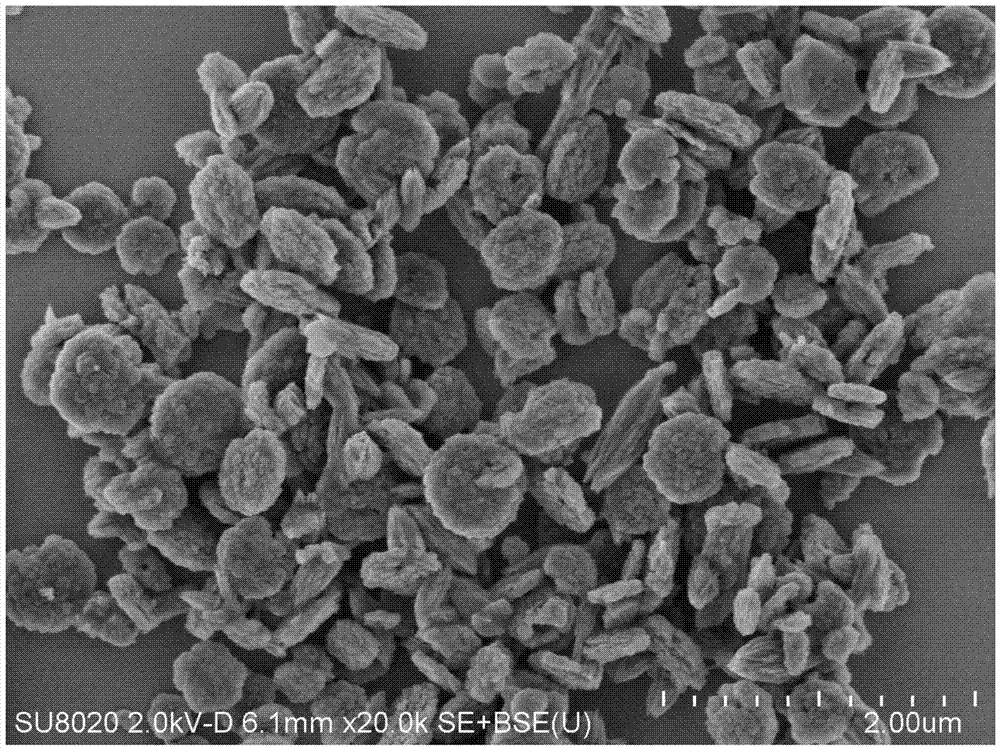

Catalyst for production of methyl acetate through carbonylation of dimethyl ether and application thereof

ActiveCN106890665AHigh selectivityContinuous and stable productionMolecular sieve catalystsPreparation by carbon monoxide or formate reactionMolecular sieveActive component

The invention discloses a catalyst for production of methyl acetate through carbonylation of dimethyl ether. The catalyst is characterized by containing an EMT molecular sieve, wherein the median particle diameter D50 of the EMT molecular sieve is not greater than 6 micrometers. By using the EMT molecular sieve as an active component, the methyl acetate selectivity and the catalyst stability can be greatly improved; and after continuously reacting on a fixed bed for 100 hours, the methyl acetate selectivity in the product can still be kept at 91-98.3%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Continuous reaction and coextrusion process of preparing stepped plastic fiber

InactiveCN1486835AReduce lossAdjust numerical apertureCladded optical fibreOptical waveguide light guidePolymer scienceOligomer

The continuous reaction and coextrusion process of preparing stepped plastic fiber includes purifying monomer, compounding polymer solution, heating or microwave prepolymerization, extrusion with one continuous reaction extruder, exhausting and recovering unreaced monomer and oligomer, forming transparent polymer melt or cooling and cutting into grains; extruding transparent polymer core and transparent coating with two continuous reaction extruders; and fusing and combining in a coextruding mold, drawing, tensing and cooling to form the stepped plastic fiber.

Owner:四川汇源光通信股份有限公司

Rotary hearth furnace and rotary hearth furnace waste gases utilization method

The invention discloses a rotary hearth furnace and a waste gas utilization method thereof. The invention is characterized in that, a waste gas utilization apparatus is arranged at the bottom of the rotary hearth furnace, namely, an air extractor and gas permeable bricks are arranged at the bottom of the rotary hearth furnace; when the rotary hearth furnace is working, hot waste gas generated by the rotary hearth furnace is extracted by the air extractor, therefore convection heat transferring by hot waste gas is formed in the materials in the rotary hearth furnace, a forced pre-heating of the materials is performed and heat quantity is provided for material reduction, therefore, the reduction of the materials at the reduction segment can be promoted, and the thickness of material layer is up to 100mm-300mm.By adopting the rotary hearth furnace and the waste gas utilization method of the invention, exhaust heat of the waste gas generated by a rotary hearth furnace can be utilized efficiently, heat transmission speed of the materials is fast and the material layer is thick, therefore, a stable continuous production with a high production efficiency can be realized.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

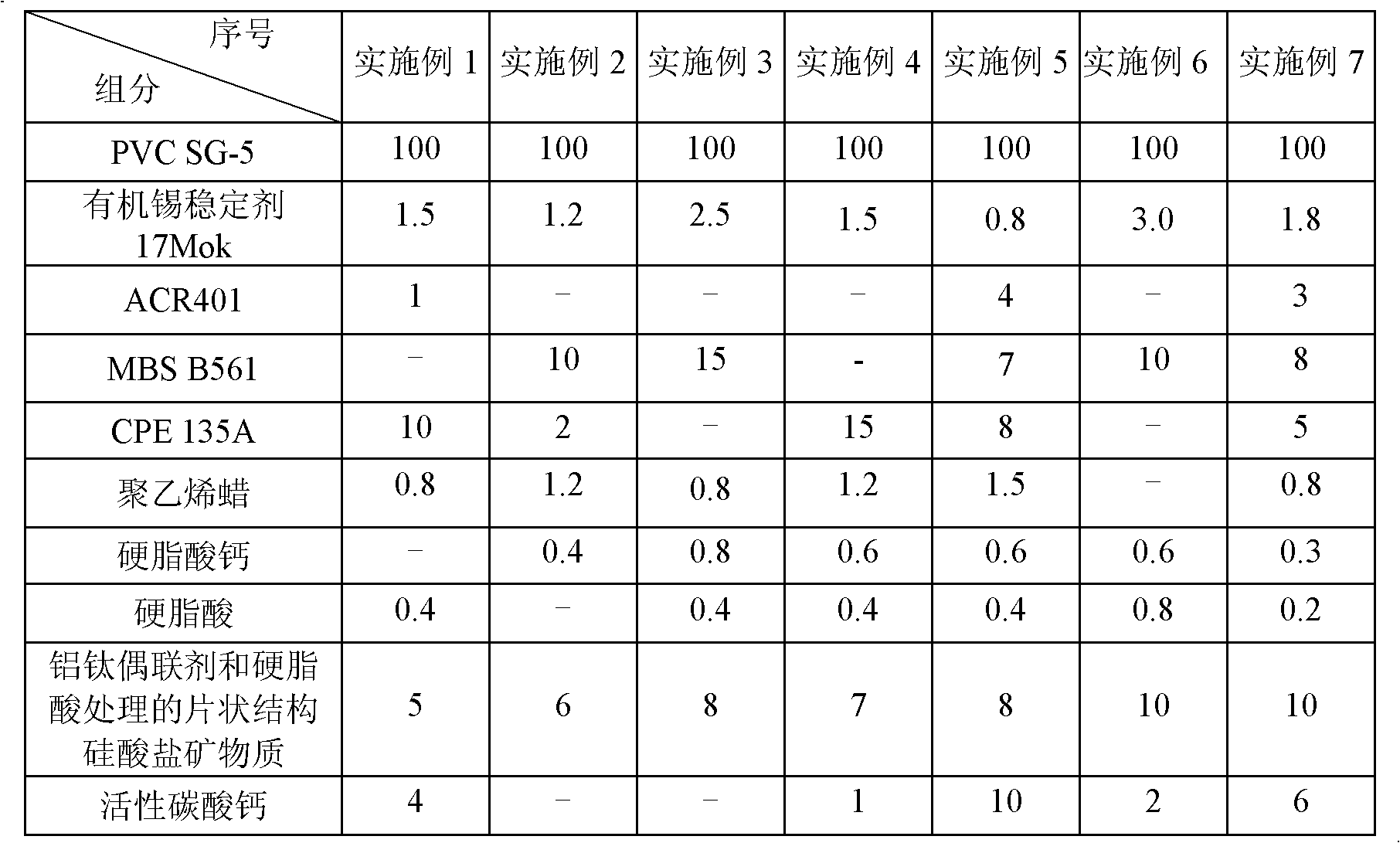

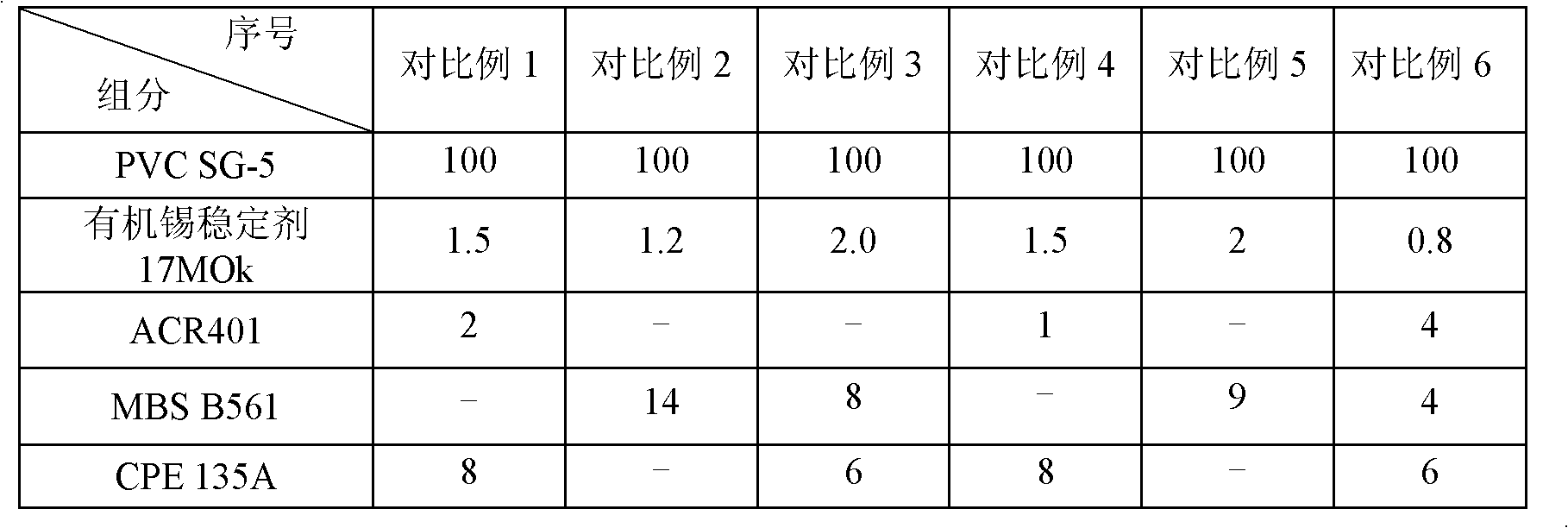

Scraping and wear-resistant impact-resistant polyvinyl chloride tube material and preparation method

A scraping and wear-resistant impact-resistant polyvinyl chloride tube material belongs to the field of polymer materials. The tube material is prepared by the following components by weight: 100 parts of PVC resin, 0.8-3 parts of a stabilizing agent, 1-4 parts of a processing additive, 10-15 parts of a impact-resistant modifier, 1.2-2.5 parts of a lubricant, 0-10 parts of a filler, and 5-10 parts of a wear-resistant modifier. The wear-resistant modifier is a sheet-structure silicate mineral substance with a jade structure and treated by a coupling agent. The sheet-structure silicate mineral substance is from debris of jade processing, is grinded and screened, and is treated by the coupling agent, which enhances the connection strength and interface compatibility between the silicate mineral substance and polyvinyl chloride molecules. The appropriate adding amount of the wear-resistant modifier improves the scraping and wear resistance of the material of the invention, and also reduces the influence on other performance of the polyvinyl chloride tube material as much as possible. The polyvinyl chloride tube material of the invention is prepared by general processing technology, and has excellent scraping and wear resistance, good impact resistance and processing performance.

Owner:CHINA PETROLEUM & CHEM CORP

Integrated production device of cabling and sheathing optical cable

PendingCN106950672AIncrease productionReduce demandFibre mechanical structuresMechanical engineeringElectrical and Electronics engineering

The invention discloses an integrated production device of cabling and sheathing an optical cable. The device comprises a cabling device and a sheathing device. The device is characterized in that the cabling device and the sheathing device are connected through a cable storage holder, and after cable cores processed by the cabling device are conveyed to the cable storage holder to be stored on-line, the cable cores are directly conveyed to the sheathing device to be sheathed. The conventional cabling device and the conventional sheathing device are effectively connected to realize integrated continuous production, a conventional semi-finished product transferring procedure enabling the cabling device to be connected with the sheathing device is removed, semi-finished products do not need to be rolled, places and spaces for storing semi-finished products are saved, and semi-finished products do not need to be transported. Therefore, the labor intensity is reduced, the number of needed workers is reduced, the time for transferring is reduced, the production efficiency is effectively improved, and the production output of optical cables is increased.

Owner:CHENGDU SEI FUTONG OPTICAL CABLE

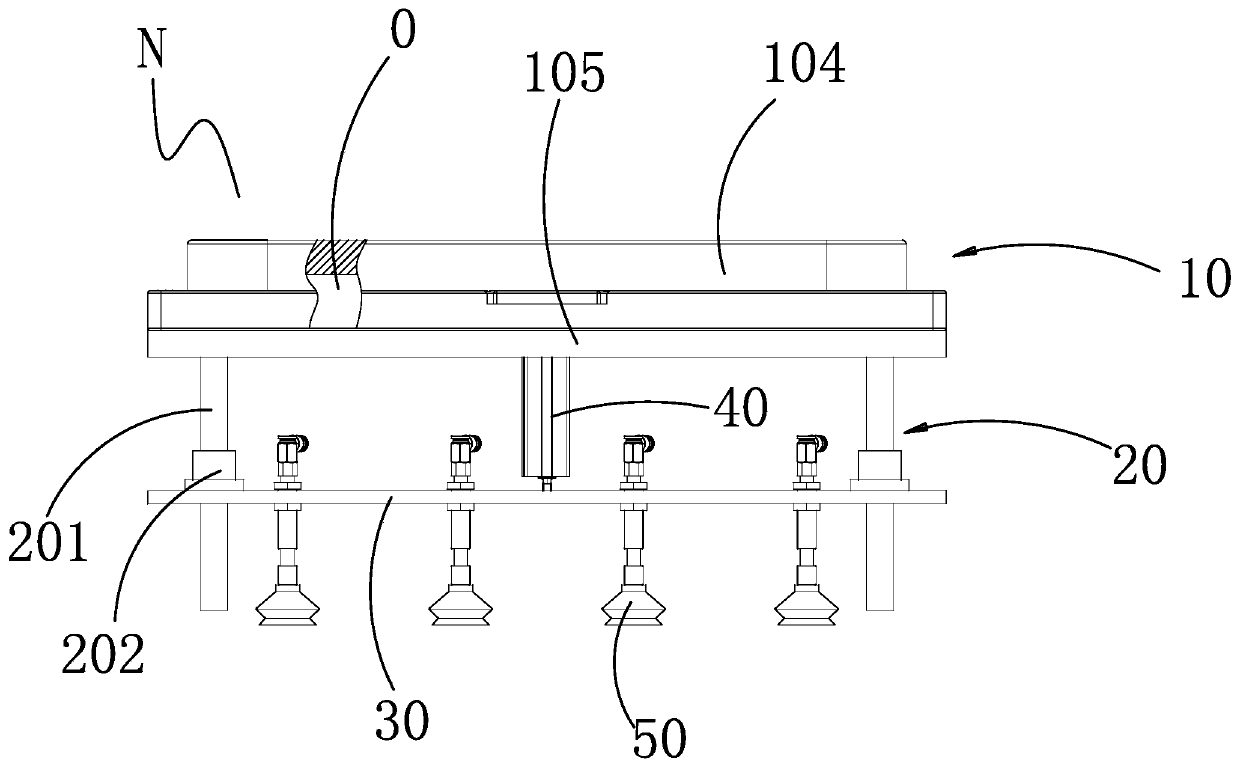

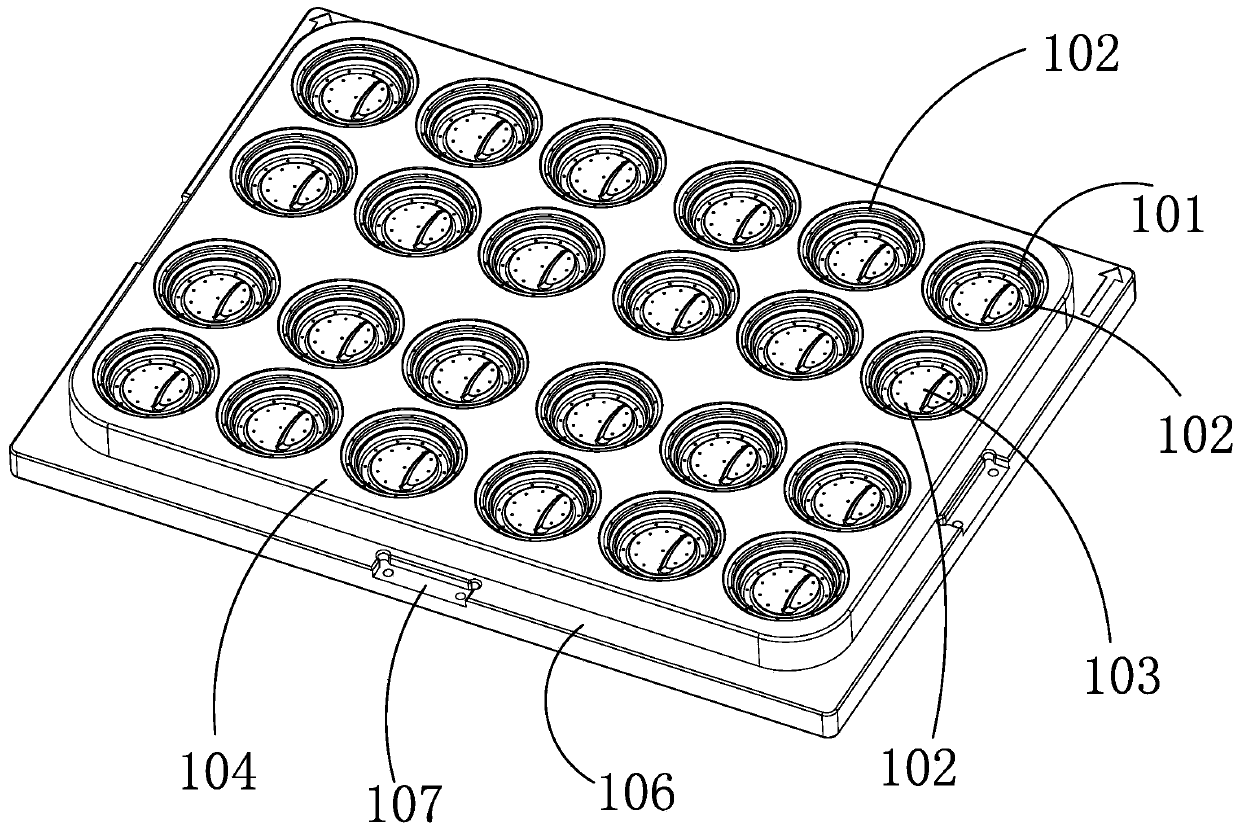

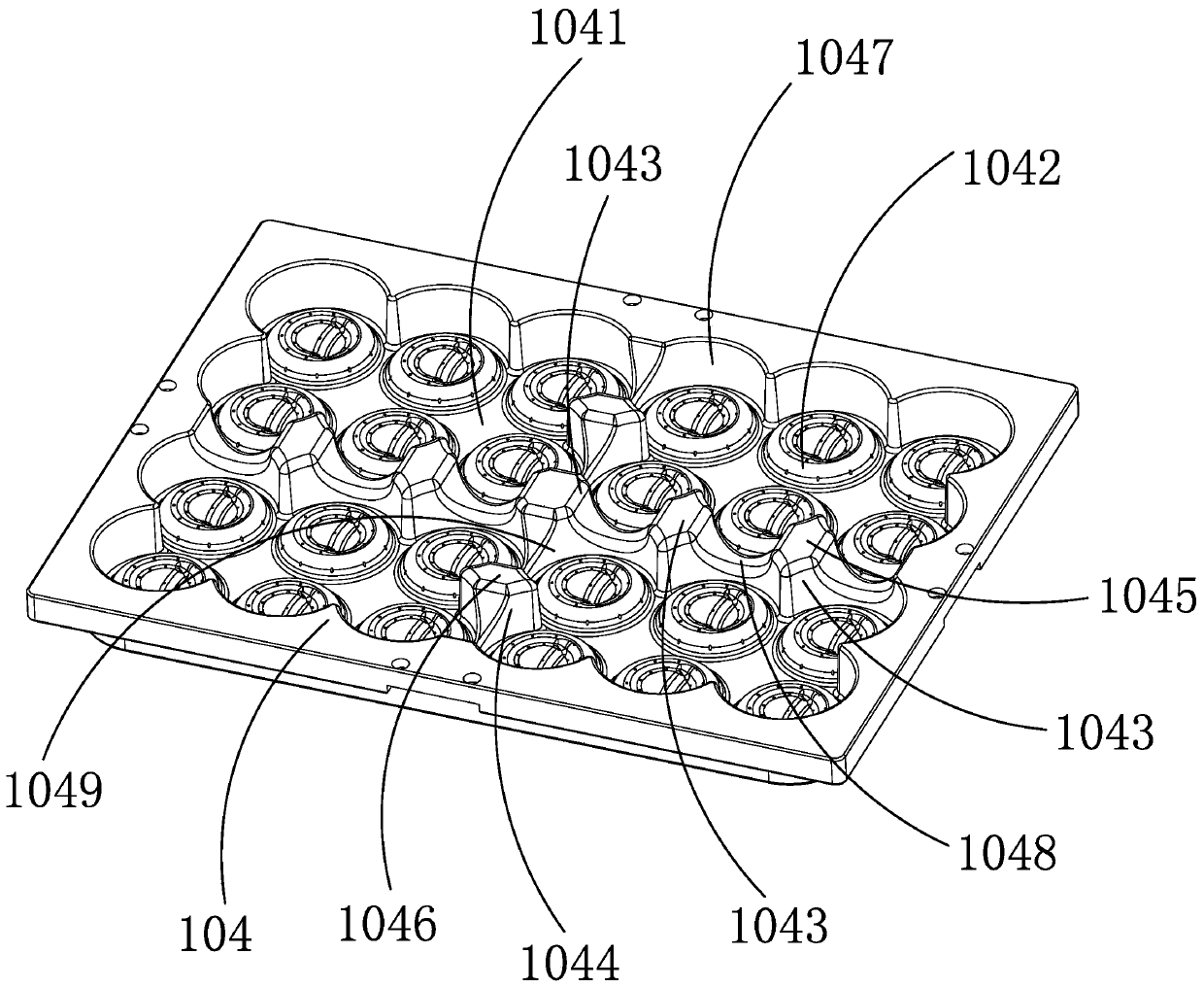

Pulp molding production line and processing method

PendingCN110219210AIncrease productivitySimple structureMachine wet endPress sectionProduction lineMolding machine

A pulp molding production line includes at least one molding machine, a pulp molding manipulator and at least one press which are arranged in this order. A transfer device is mounted on the pulp molding manipulator, and includes a wet blank transfer mold having a sealed gas chamber inside. The front surface of the wet blank transfer mold is provided with at least one concave matching mold cavity capable of sleeving a pulp wet blank product and being concaved towards the sealed gas chamber side, with the concave matching mold cavity being matched with the pulp wet blank product. The inner walland the bottom of each concave matching mold cavity are respectively provided with a plurality of communicating holes communicating the concave matching mold cavity with the sealed gas chamber. The back surface of the wet blank transfer mold is connected, through a guide mechanism, to a movable rack parallel to the wet blank transfer mold. A driver is connected between the back surface of the wetblank transfer mold and the movable rack, and drives the movable rack to move relative to the wet blank transfer mold. The movable rack is provided with a plurality of evenly spaced vacuum suction disks.

Owner:ZHEJIANG SHURCON MFG

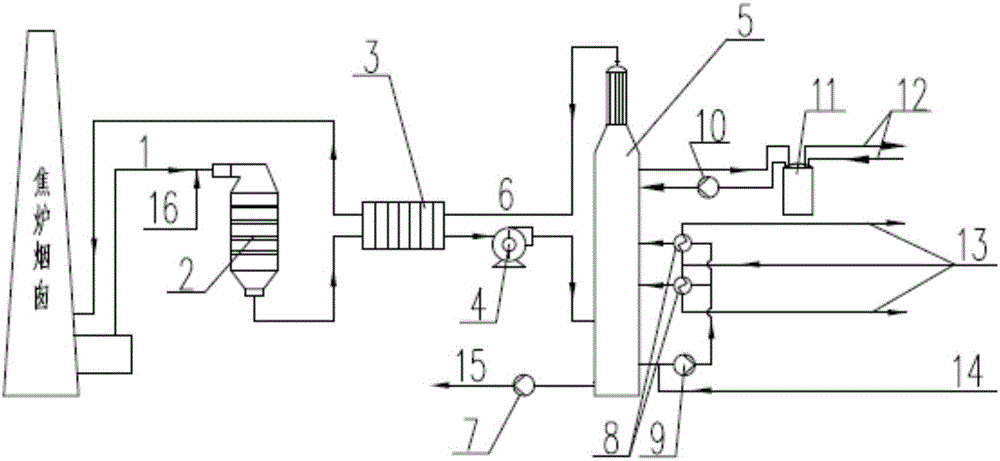

Low-temperature denitration and desulfurization device for coking furnace flue gas and process

InactiveCN106178864AContinuous and stable productionHigh denitrification and desulfurization efficiencyGas treatmentDispersed particle separationFlue gasCoke oven

The invention discloses a low-temperature denitration and desulfurization device for coking furnace flue gas and a process and belongs to the technical field of pollutant treatment of flue gas of a coking furnace in the coking industry. The device mainly comprises a denitration reactor, a reheater, an induced draft fan, a desulfurizing tower, a desulfurization absorption liquid heat exchanger, an ammonium sulfate mother liquor tank, an ammonium sulfate mother liquor circulating pump, a desulfurizing liquid circulating pump and a desulfurizing liquid metering and conveying pump. The coking furnace flue gas is denitrated by the denitration reactor, heat exchange of high and low temperature coking furnace gas is performed by the aid of the reheater, desulfurization is performed by the aid of a desulfurization absorption, and finally, low-temperature denitration and desulfurization purification treatment of the coking furnace flue gas is completed. The low-temperature denitration and desulfurization device has the advantages as follows: resources of a coking plant are sufficiently utilized, the idea of treating waste with waste is realized, and continuous and stable production of the coking furnace is guaranteed while the working condition of the coking furnace flue gas and the denitration and desulfurization requirements are met through a pilot plant test and an industrialized application test.

Owner:BEIJING SHOUGANG INT ENG TECH

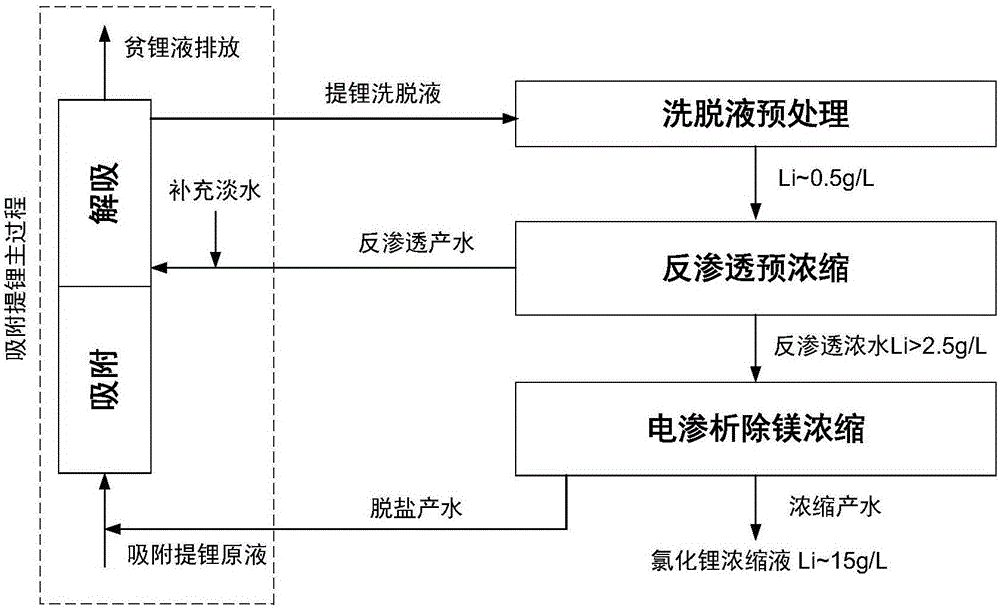

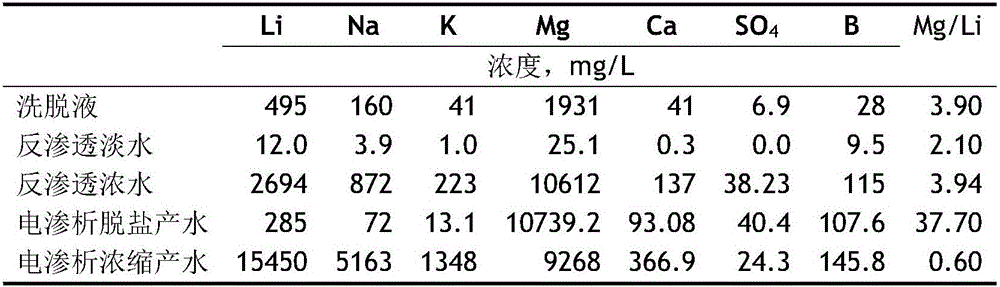

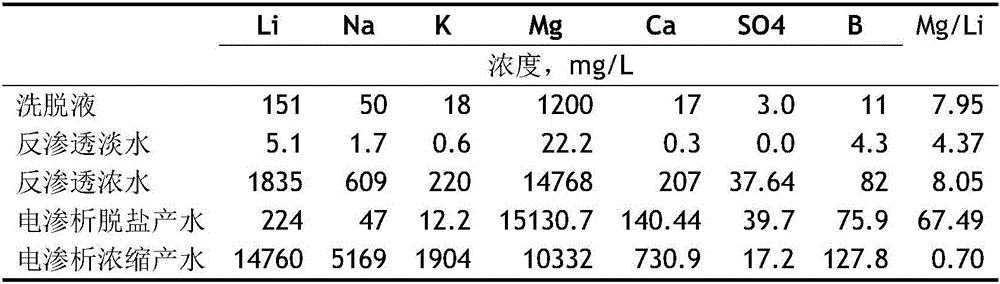

Method for preparing lithium chloride concentrate by using eluent of adsorptive lithium extraction as raw material

ActiveCN106492639AAchieve reuseContinuous and stable productionGeneral water supply conservationReverse osmosisHigh magnesiumLithium chloride

The invention relates to a method for preparing lithium chloride concentrate by using eluent of adsorptive lithium extraction as raw material; adsorptive lithium extraction eluent having magnesium-lithium ratio of 0.5-10 and lithium content of 150-2500 mg / L is used as a raw liquid, the raw liquid is subjected to reverse osmosis, pre-concentration is then carried out to obtain lithium content of 1700-7000 mg / L, reverse osmosis concentrate is used as electrodialysis desalination stock liquid, the stock liquid is treated with a monovalent ion selective exchange membrane to obtain lithium chloride concentrate having lithium content of 14 g / L and magnesium-lithium ratio of 0.1-1 and suitable for high-purity lithium salts, such as lithium carbonate and lithium chloride; reverse osmosis fresh water is reclaimed for cyclic use in the desorption step of adsorptive lithium extraction; electrodialysis desalination produced water is returned for cyclic use in the adsorbing step, and therefore concentrative enrichment of lithium in eluent and full reclaiming of water are achieved. The method is simple to perform, has a continuous process and is low in investment and low in cost, and the bottleneck problem with magnesium removal and concentration of salt lake adsorptive lithium extraction eluent with high magnesium-lithium ratio is basically solved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com