Method and device for producing calcium ammonium nitrate

A technology of calcium ammonium nitrate and calcium nitrate, which is applied in the production field of calcium ammonium nitrate, can solve problems such as easy agglomeration and blockage, impossibility of granulation, continuous production limitation, etc., and achieve the effect of easy agglomeration and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

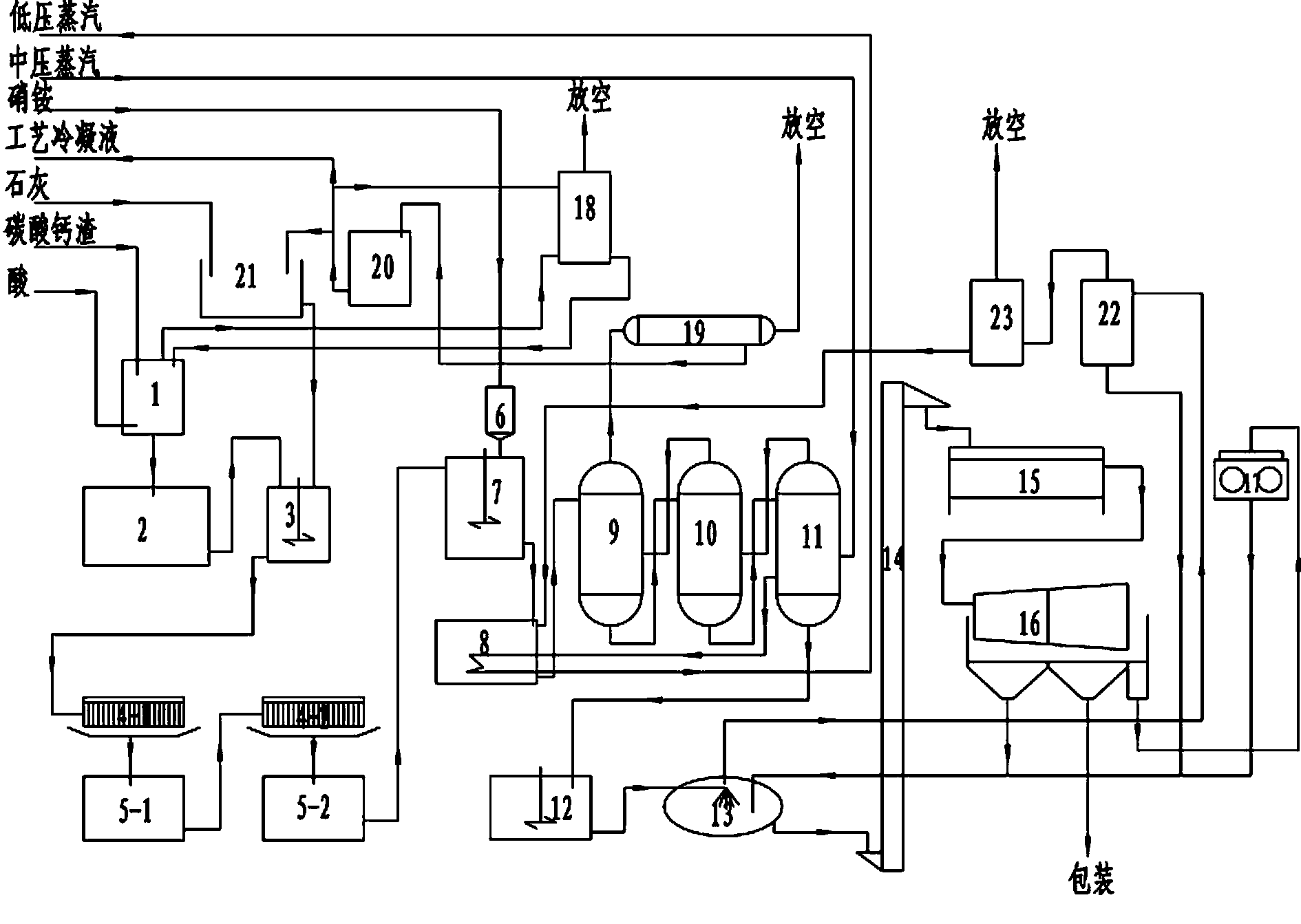

[0031]The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] Pour calcium carbonate waste slag into neutralization tank 1, and nitric acid enters neutralization tank 1 from the bottom of neutralization tank 1, so that nitric acid can fully react with calcium carbonate waste slag in neutralization tank 1 from bottom to top, and calcium nitrate waste slag is continuously discharged from top to bottom. In addition, nitric acid reacts with calcium carbonate waste residue to form calcium nitrate liquid, which flows out from the overflow pipe and enters the settling tank 2. Calcium nitrate liquid is produced in the neutralization tank 1, and waste gas such as carbon dioxide and water are also generated, and the waste gas is sucked in by negative pressure. After being washed and purified in the tail gas treatment device 18, it is discharged into the air, and the washing water reaches a certain concentration and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com