Rotor type pressure swing adsorption gas separation device

A pressure swing adsorption and gas separation technology, which is applied in the direction of dispersed particle separation, gas treatment, separation methods, etc., can solve the problems of increased investment, increased sulfur dioxide emissions, increased energy consumption, etc., and achieves easy operation, small amount of adsorbent, Effect of reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

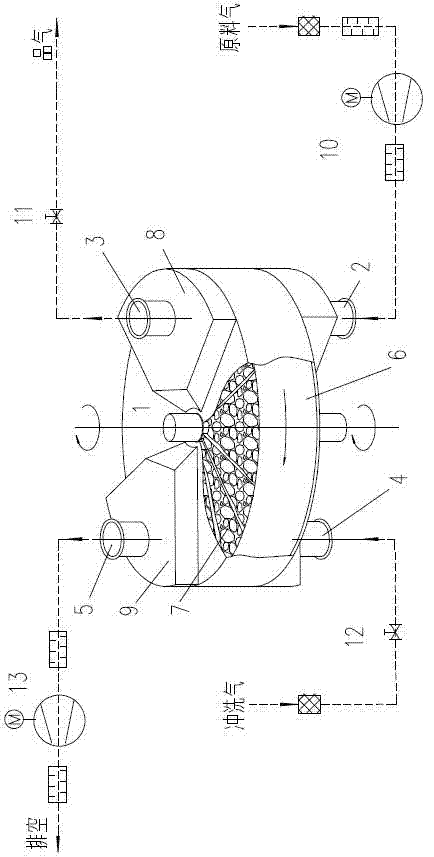

[0013] Control attached figure 1 , its structure includes a housing and a rotor 6,

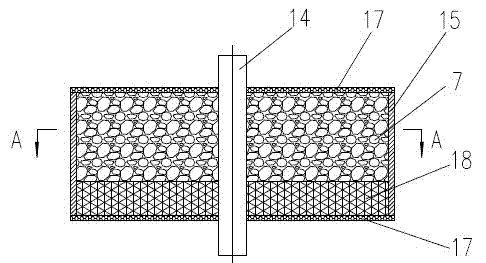

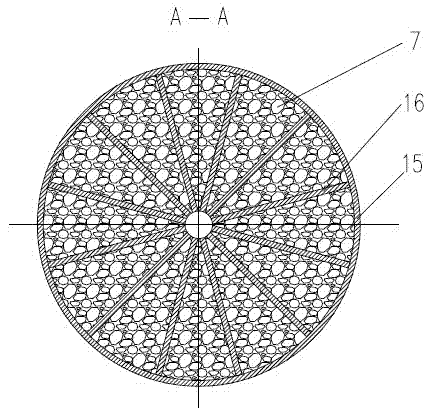

[0014] The rotor 6 is installed in the housing, and is divided into an adsorption zone 8 and a desorption zone 9 according to the different pressures formed; the rotor 6 is composed of a rotating shaft 14 and a hollow disc 15 fixed on the rotating shaft, and the disc 15 is composed of several The separator 16 forms a plurality of spaces, and the spaces are filled with the adsorbent 7 and closed with porous plates or nets 17 at both ends along the axial direction. In order to make the air flow evenly distributed and protect the adsorbent from strong air flow impact, a flow equalization layer 18 is provided on the air intake side of the space, so that the rotor disk is air-permeable in the axial direction and can rotate with the rotating shaft.

[0015] Raw gas inlet 2, product gas outlet 3, flushing gas inlet 4, and waste gas discharge port 5 are installed on the housing.

[0016] The rotor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com