Vapor deposition apparatus having pretreatment device that uses plasma

a vapor deposition and film-forming technology, applied in the direction of plasma technique, vacuum evaporation coating, coating, etc., can solve the problems of poor film homogeneity, low thin-film forming rate, poor yield, etc., to achieve low plasma output, improve film-forming speed, and reliably and effectively implant plasma on the substrate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

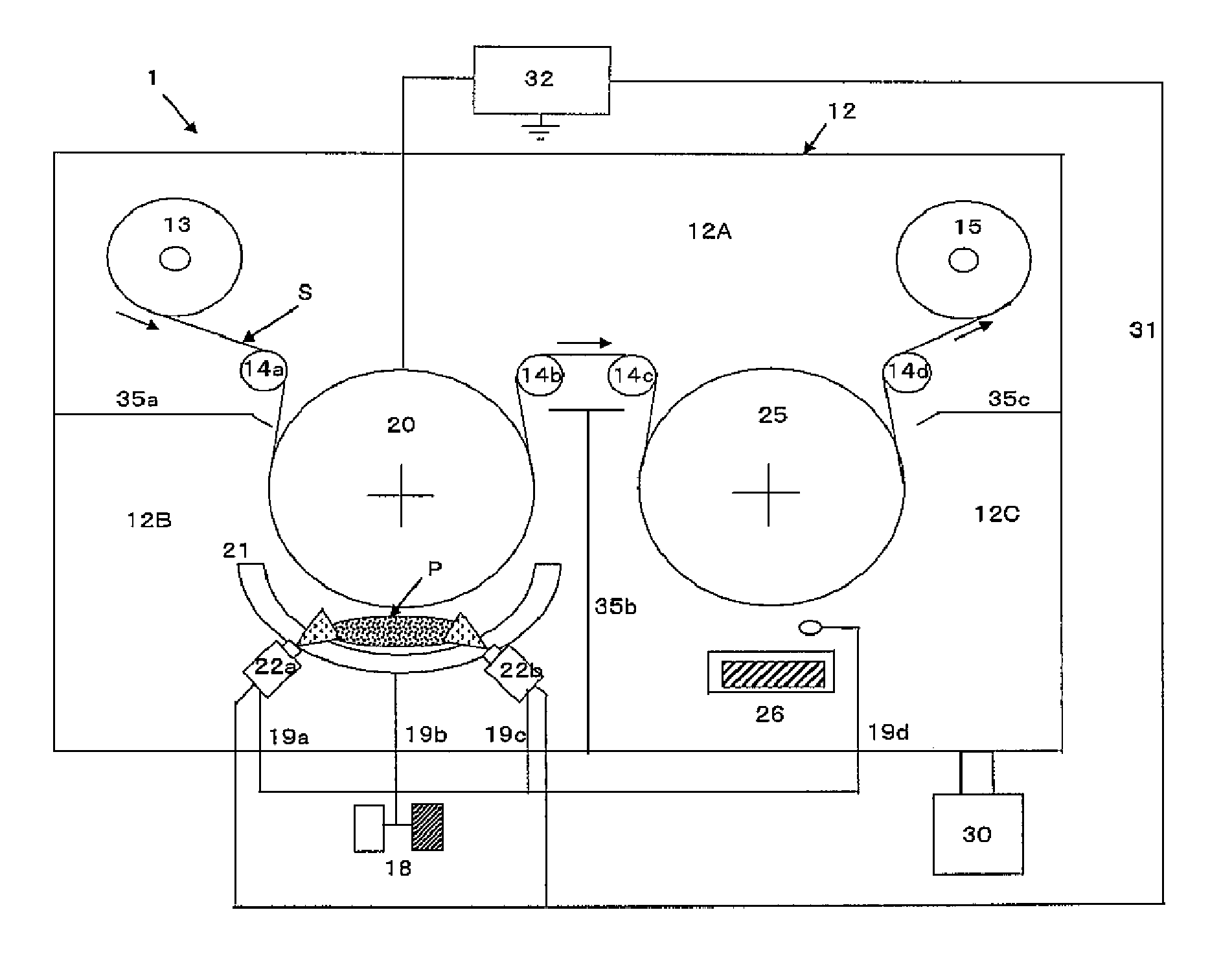

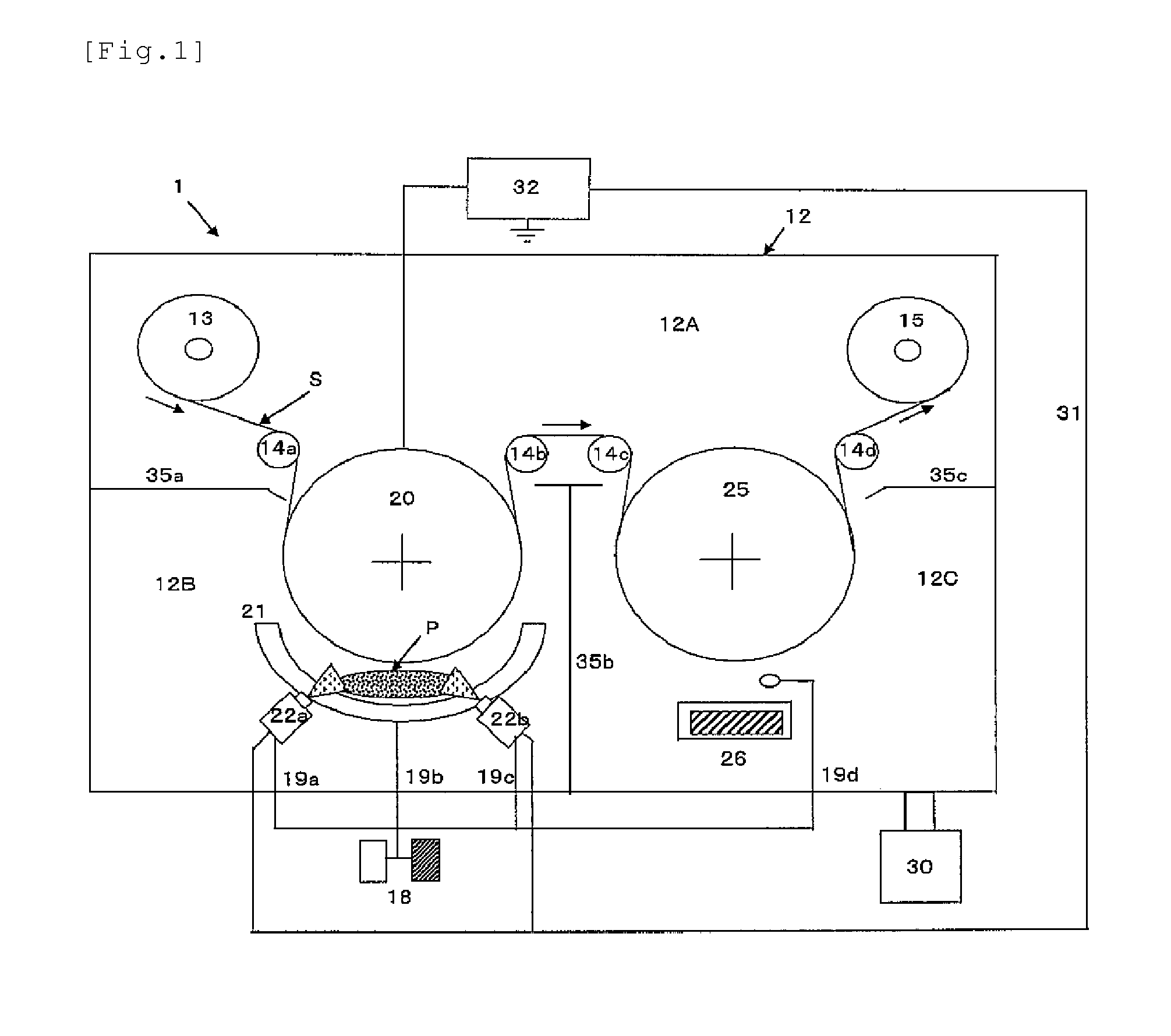

[0134]Using a plasma pretreatment device of the invention, plasma was introduced from plasma supply nozzles onto one side of a substrate of PET (by Nan Ya Plastics Corp.) with a thickness of 12 μm and a width of 1000 mm, under the following plasma conditions, for plasma pretreatment of the PET substrate at a conveying speed of 480 m / min, by passing it through plasma at a density of 550 W·sec / m2 in a gap formed by the pretreatment drum, the magnetic field-forming means 21 and the plasma supply nozzles.

[0135]Next, on the continuously conveyed substrate in the film formation compartment there was formed a vapor deposited thin-film layer (thickness: 10 nm) made of aluminum oxide, using aluminum metal as the target, by vacuum vapor deposition based on resistance heating.

[0136]The plasma pretreatment conditions were as follows.

Plasma Pretreatment Conditions:

[0137]High-frequency power source output: 4 (2+2) kw

[0138]Plasma density (Ed value): 550 W·sec / m2

[0139]Plasma-forming gas: Plasma-fo...

example 2

[0154]Plasma pretreatment was carried out under the same conditions as Example 1, except for using a plasma output of 12 (6+6) kw, to form a vapor deposited thin-film layer (thickness: 10 nm) comprising aluminum oxide by vacuum vapor deposition on the plasma pretreated side.

[0155]The evaluation method was the same as in Example 1.

example 3

[0156]Using a plasma pretreatment device of the invention, in the same manner as Example 1, plasma was introduced from plasma supply nozzles onto one side of a substrate of PET (by Nan Ya Plastics Corp.) with a thickness of 12 μm and a width of 1000 mm, under the following plasma conditions, for plasma pretreatment of the PET substrate at a conveying speed of 480 m / min, by passing it through plasma at a density of 550 W·sec / m2 in a gap formed by the pretreatment drum, the magnetic field-forming means 21 and the plasma supply nozzles.

[0157]Next, on the continuously conveyed substrate in the film formation compartment there was formed a vapor deposited thin-film layer (thickness: 10 nm) made of aluminum oxide, using aluminum metal as the target, by vacuum vapor deposition based on resistance heating.

[0158]The plasma pretreatment conditions were as follows. Plasma pretreatment was carried out under the same conditions as Example 1, with a plasma output of 12 (6+6) kw, and a plasma-form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com