Patents

Literature

1148 results about "Forming gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forming gas is a mixture of hydrogen (mole fraction varies) and nitrogen. It can also be manufactured by thermal cracking of ammonia, in an ammonia cracker or forming gas generator. Forming gas is used as an atmosphere for processes that need the properties of hydrogen gas. Typical forming gas formulations (5% H2 in N2) are not explosive. It is used in chambers for gas hypersensitization, a process in which photographic film is heated in forming gas to drive out moisture and oxygen and to increase the base fog of the film. Hypersensitization is used particularly in deep-sky astrophotography, which deals with low-intensity incoming light, requires long exposure times, and is thus particularly sensitive to contaminants in the film.

Layer member forming method

InactiveUS6984595B1No damageShort timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasGas phase

A vapor reaction method including the steps of providing a pair of first and second electrodes within a reaction chamber where the pair of electrodes are arranged substantially parallel with each other. The method further includes the steps of placing a substrate in the reaction chamber where the substrate is held by said first electrode so that a first surface of the substrate faces toward the second electrode. A first film forming gas is introduced into the reaction chamber through the second electrode. The first film forming gas is excited to form a first insulating film by vapor deposition. The first insulating film may be silicon nitride. The method may also include the step of introducing a second film forming gas into the reaction chamber through the second electrode to ultimately form a second film. After removing the substrate from the reaction chamber, a cleaning gas may then be introduced through the second electrode to remove unnecessary layers from the inside of the reaction chamber.

Owner:SEMICON ENERGY LAB CO LTD

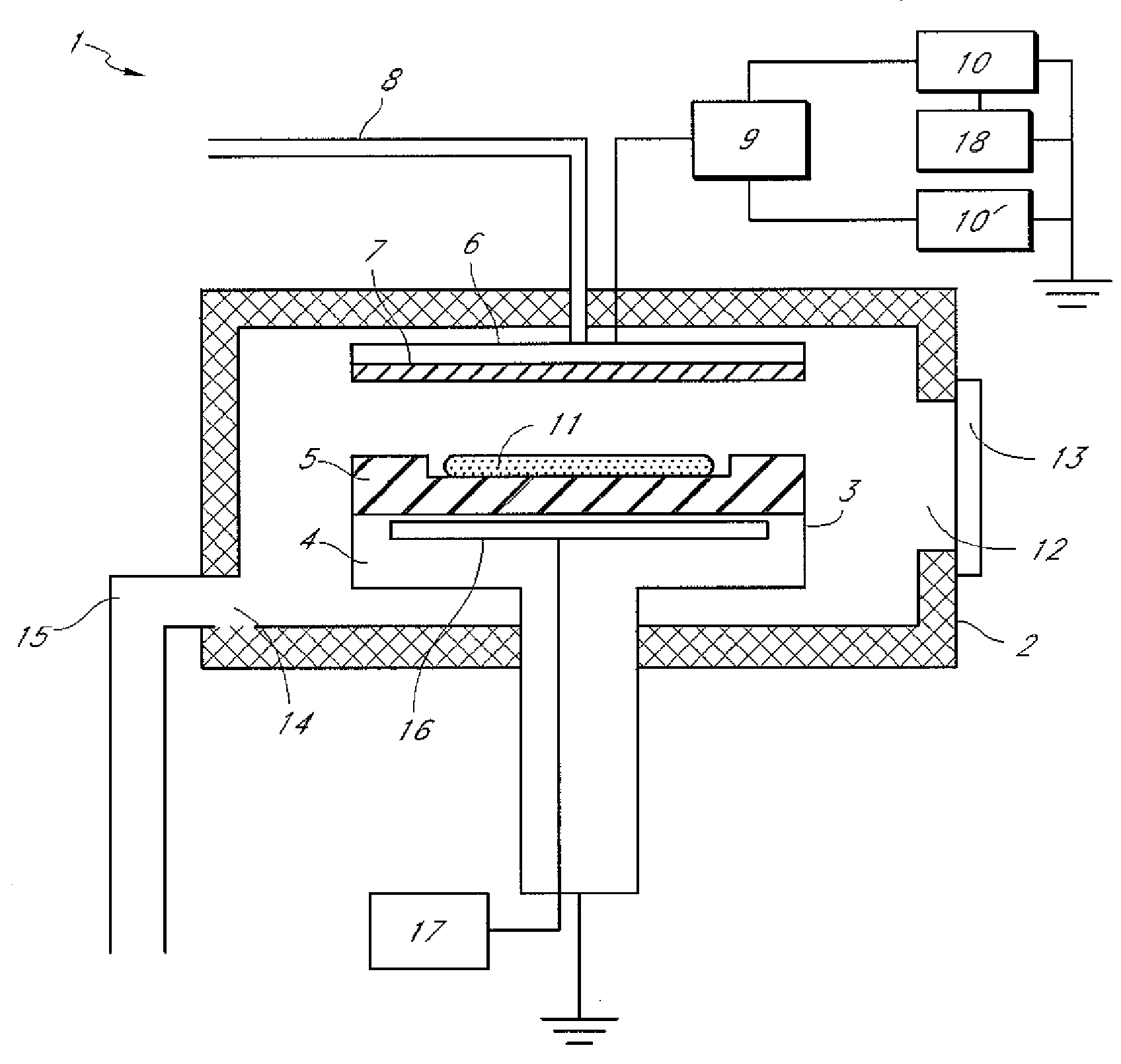

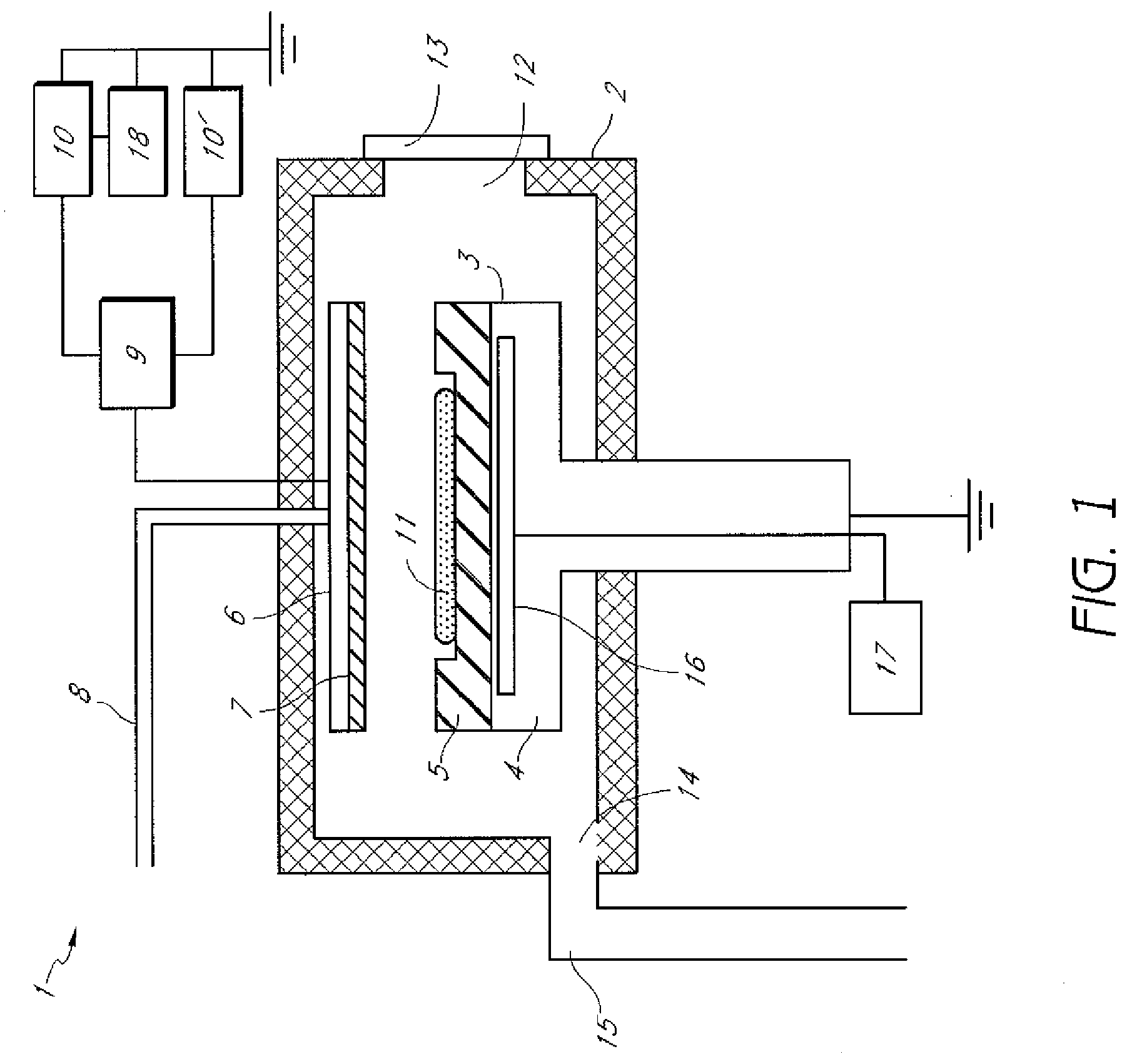

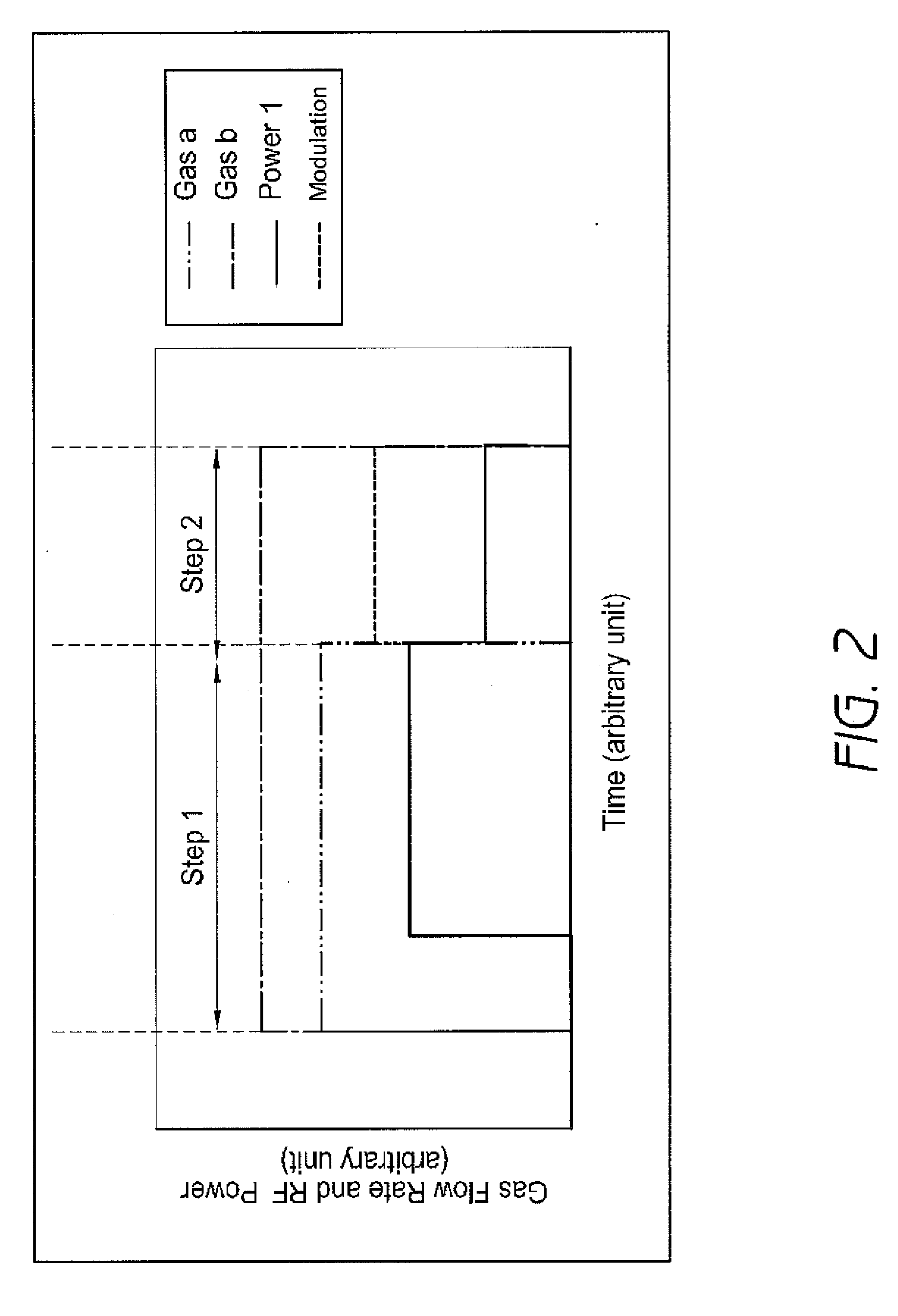

Method of plasma treatment using amplitude-modulated RF power

ActiveUS20090136683A1Reduce floating potentialSufficient voltageElectric discharge tubesVacuum evaporation coatingSusceptorForming gas

A method for processing a substrate by plasma CVD includes: (i) forming a film on a substrate placed on a susceptor by applying RF power between the susceptor and a shower plate in the presence of a film-forming gas in a reactor; and (ii) upon completion of step (i), without unloading the substrate, applying amplitude-modulated RF power between the susceptor and the shower plate in the absence of a film-forming gas but in the presence of a non-film-forming gas to reduce a floating potential of the substrate.

Owner:ASM JAPAN

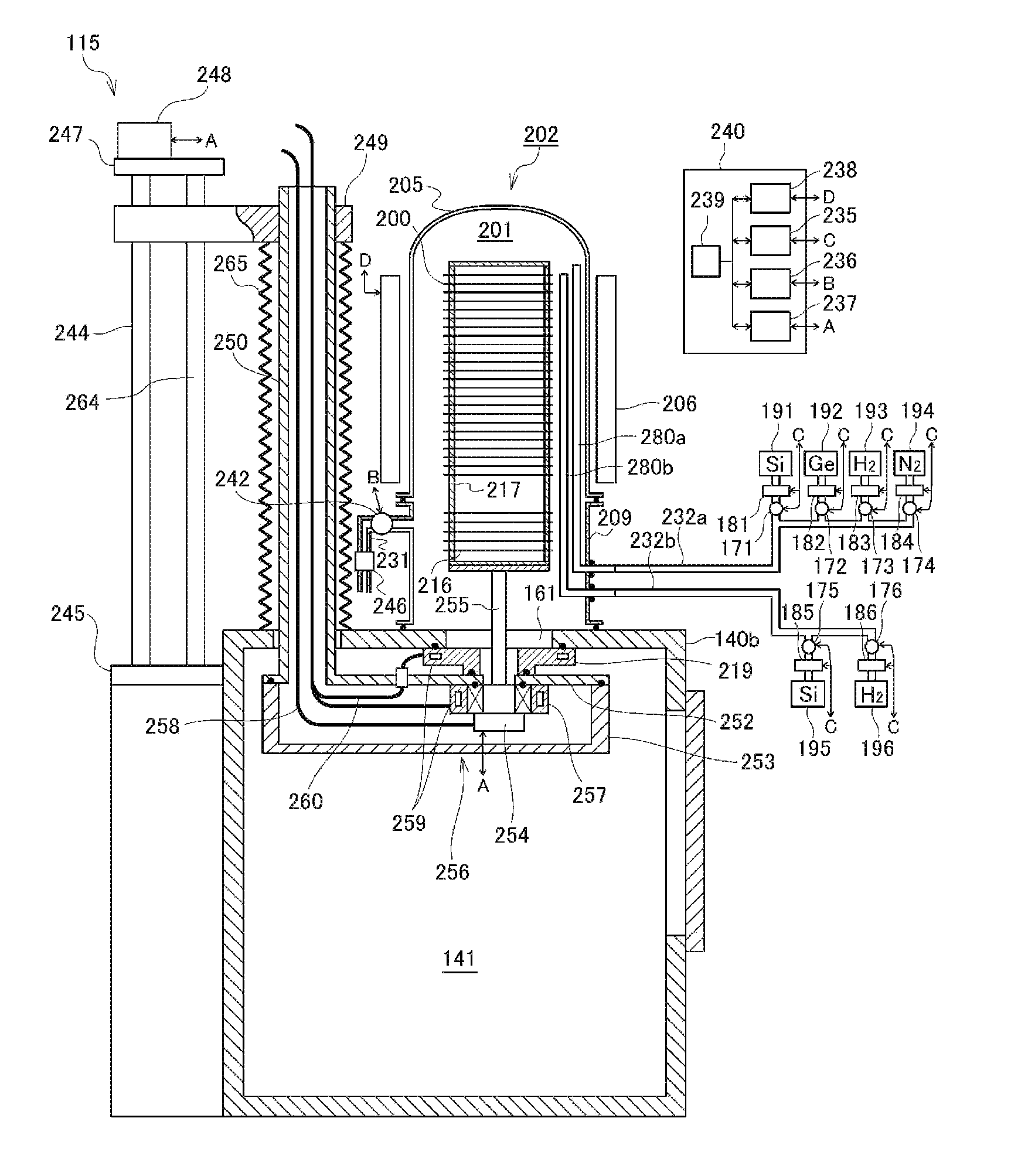

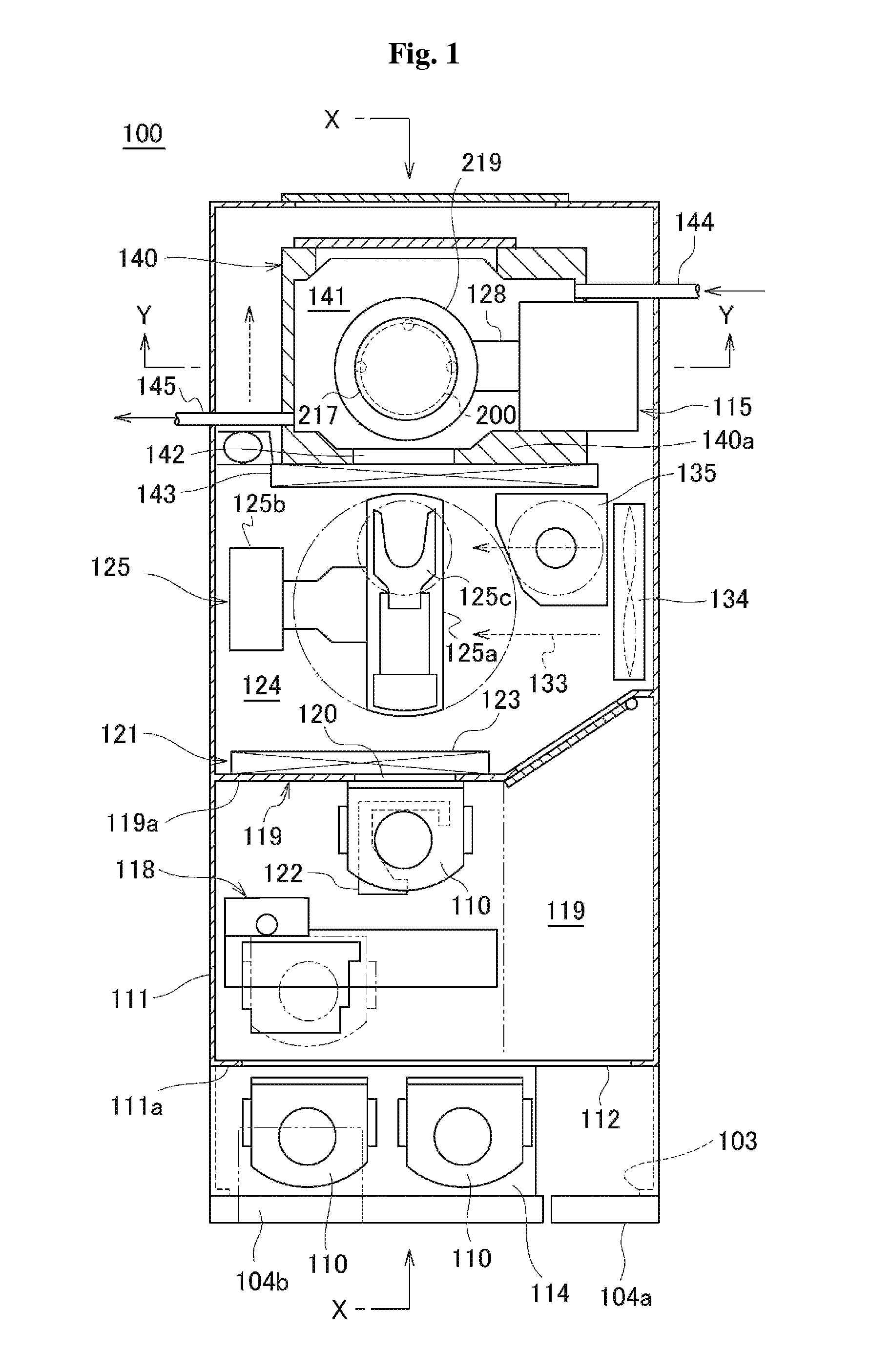

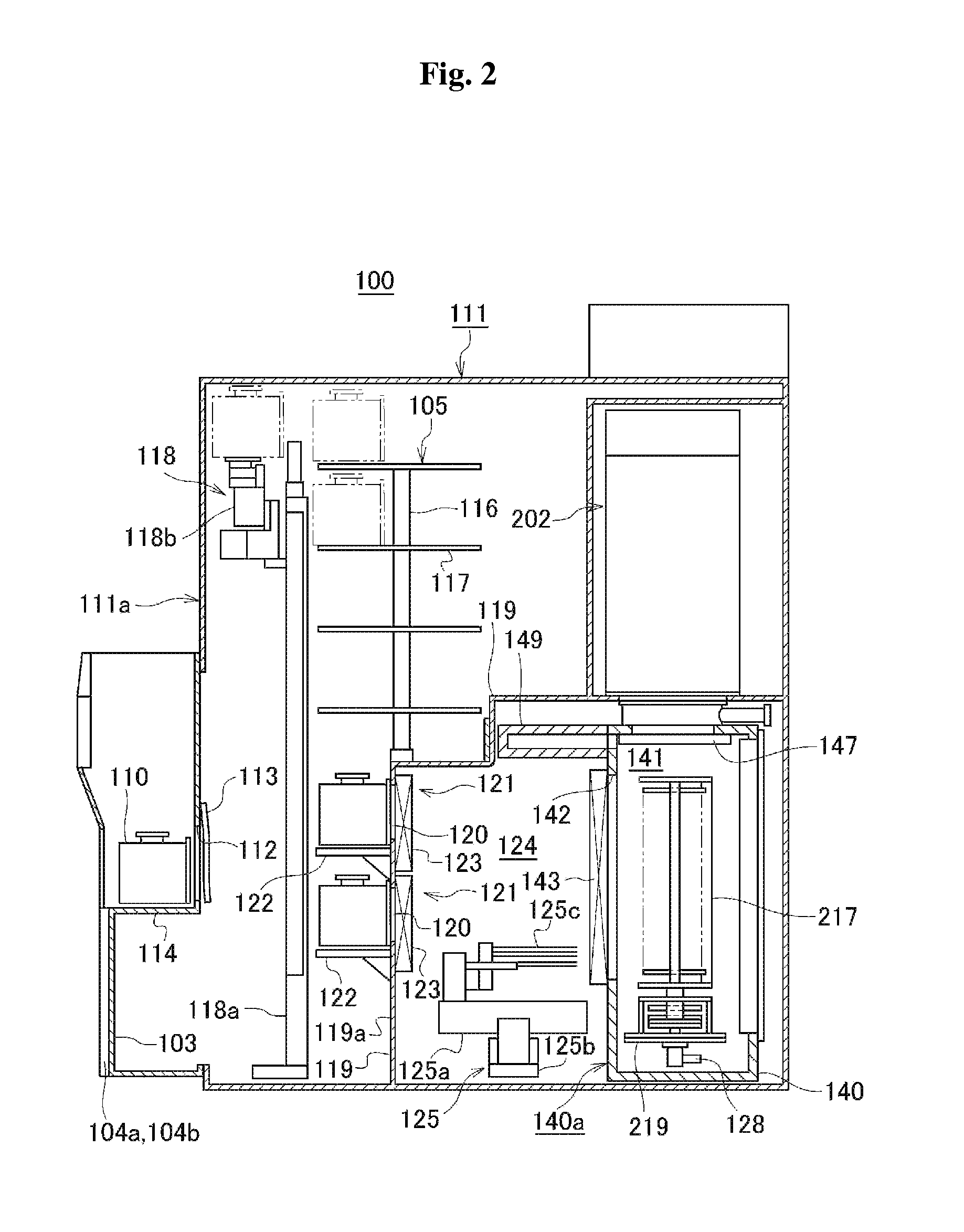

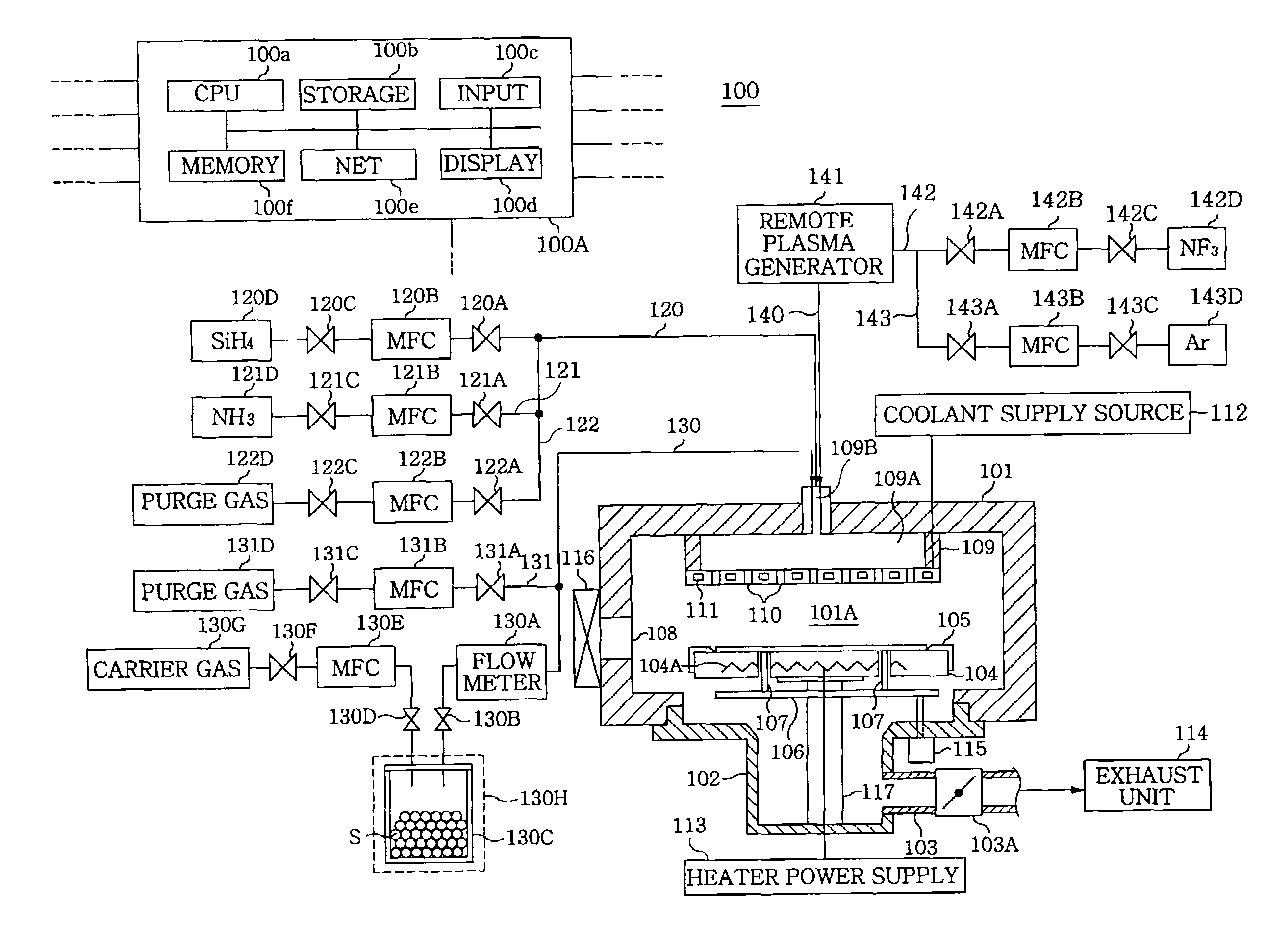

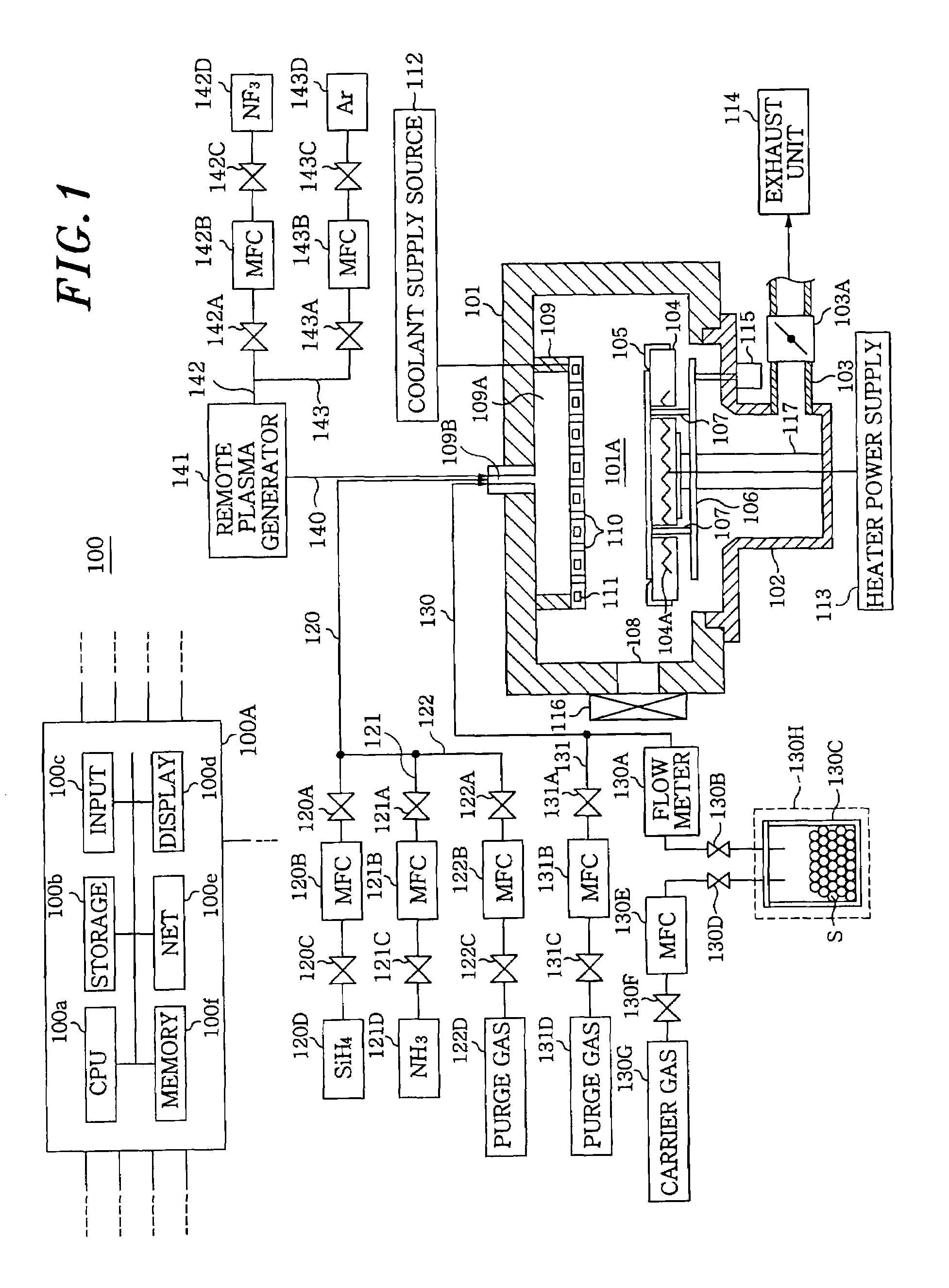

Substrate processing apparatus

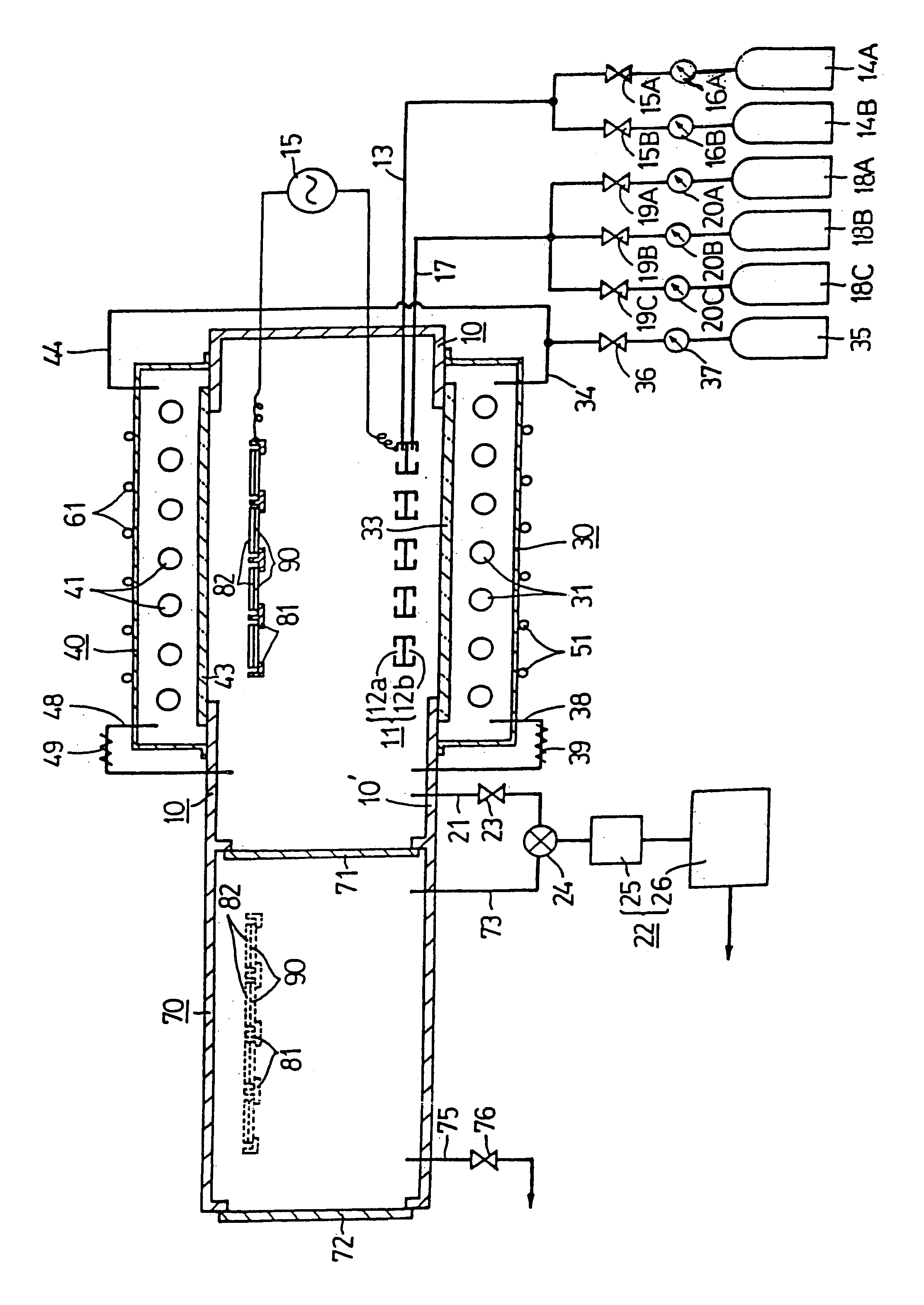

InactiveUS20100229795A1Suppress formationPolycrystalline material growthSemiconductor/solid-state device manufacturingProcess engineeringForming gas

Provided is a substrate processing apparatus that can suppress formation of an Si thin film on the inner wall of a film-forming gas supply nozzle. The substrate processing apparatus comprises a process chamber configured to process a substrate, a heating member configured to heat the substrate, a coating gas supply member including a coating gas supply nozzle configured to supply coating gas into the process chamber, a film-forming gas supply member including a film-forming gas supply nozzle supplying film-forming gas into the process chamber, and a control unit configured to control the heating member, the coating gas supply member, and the film-forming gas supply member. The control unit executes a control such that the coating gas supply nozzle supplies the coating gas to coat a quartz member in the process chamber and the film-forming gas supply nozzle supplies the film-forming gas to form an epitaxial film on the substrate.

Owner:KOKUSA ELECTRIC CO LTD

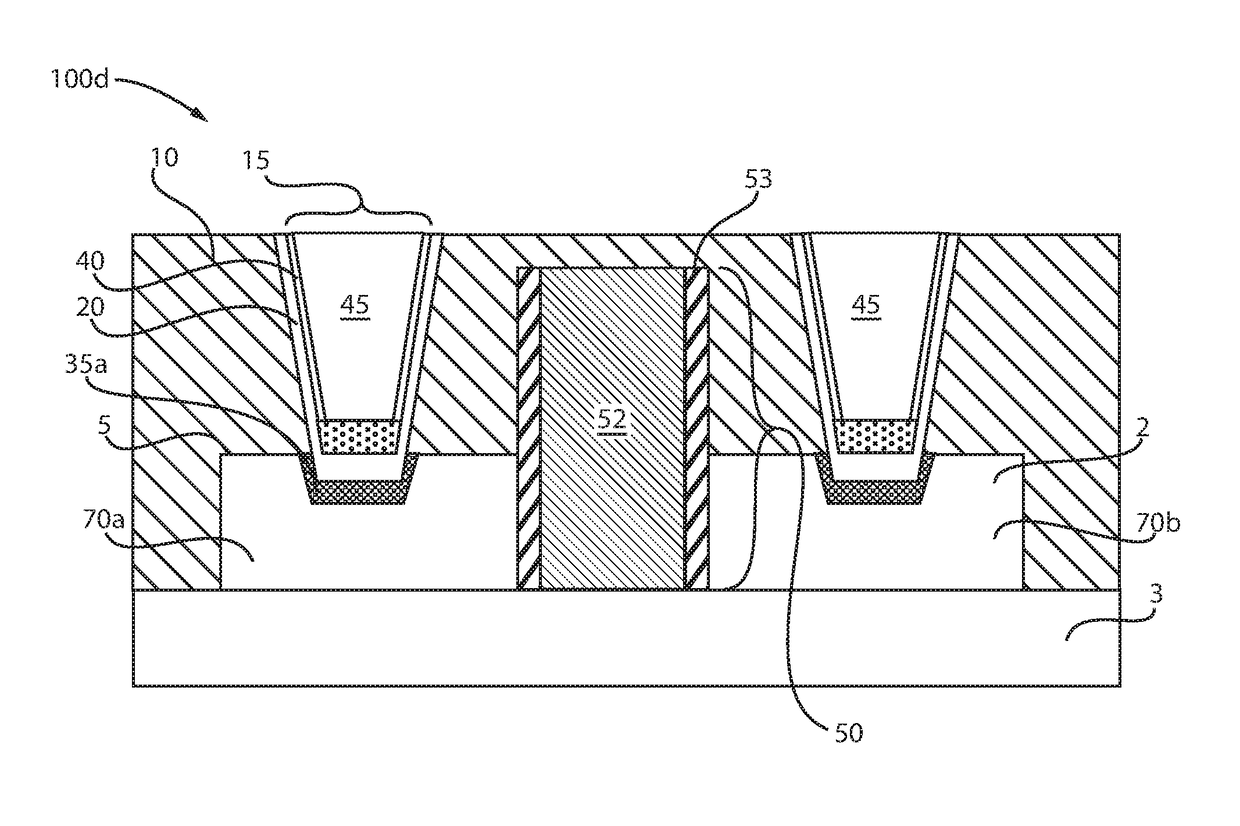

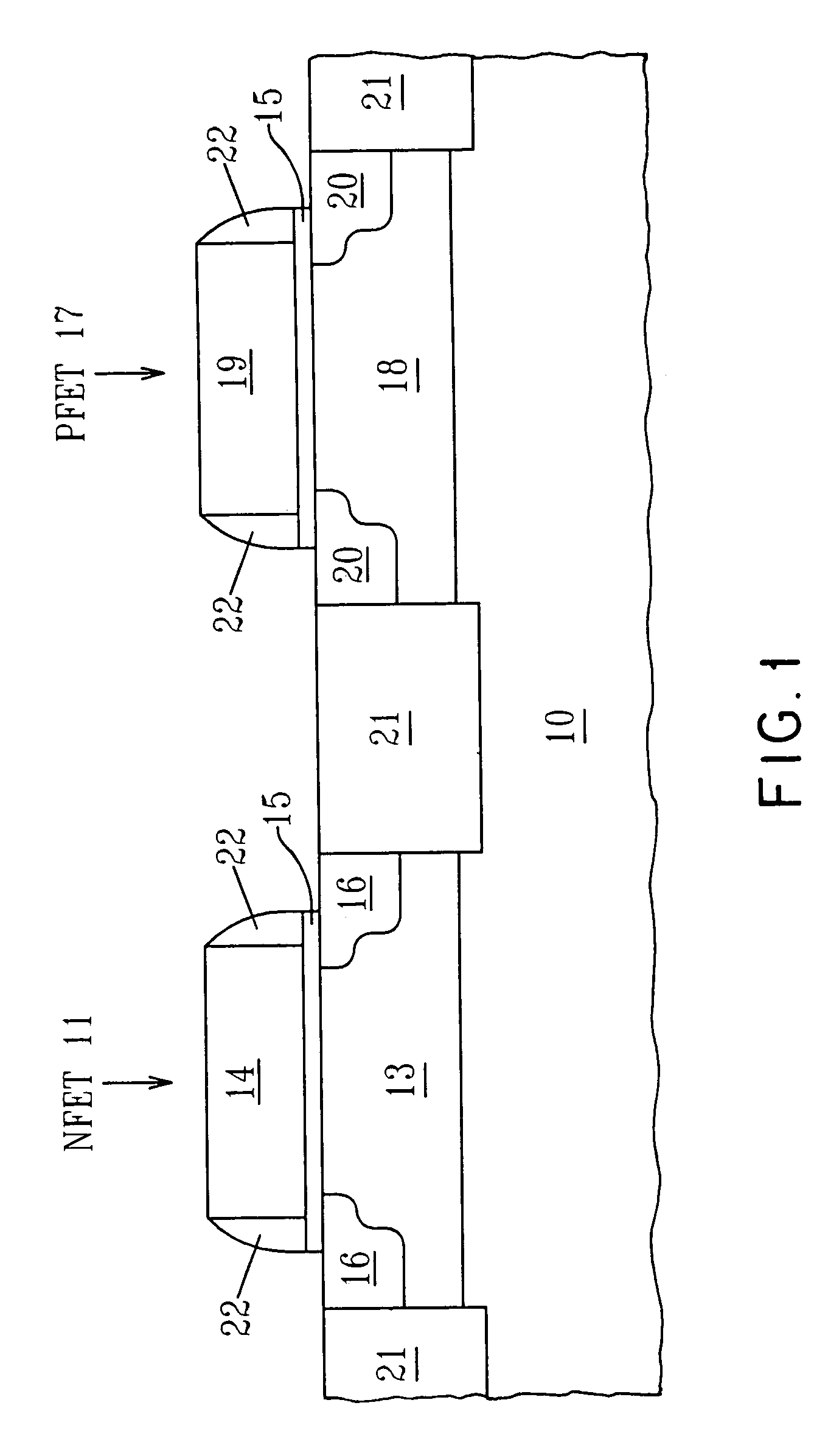

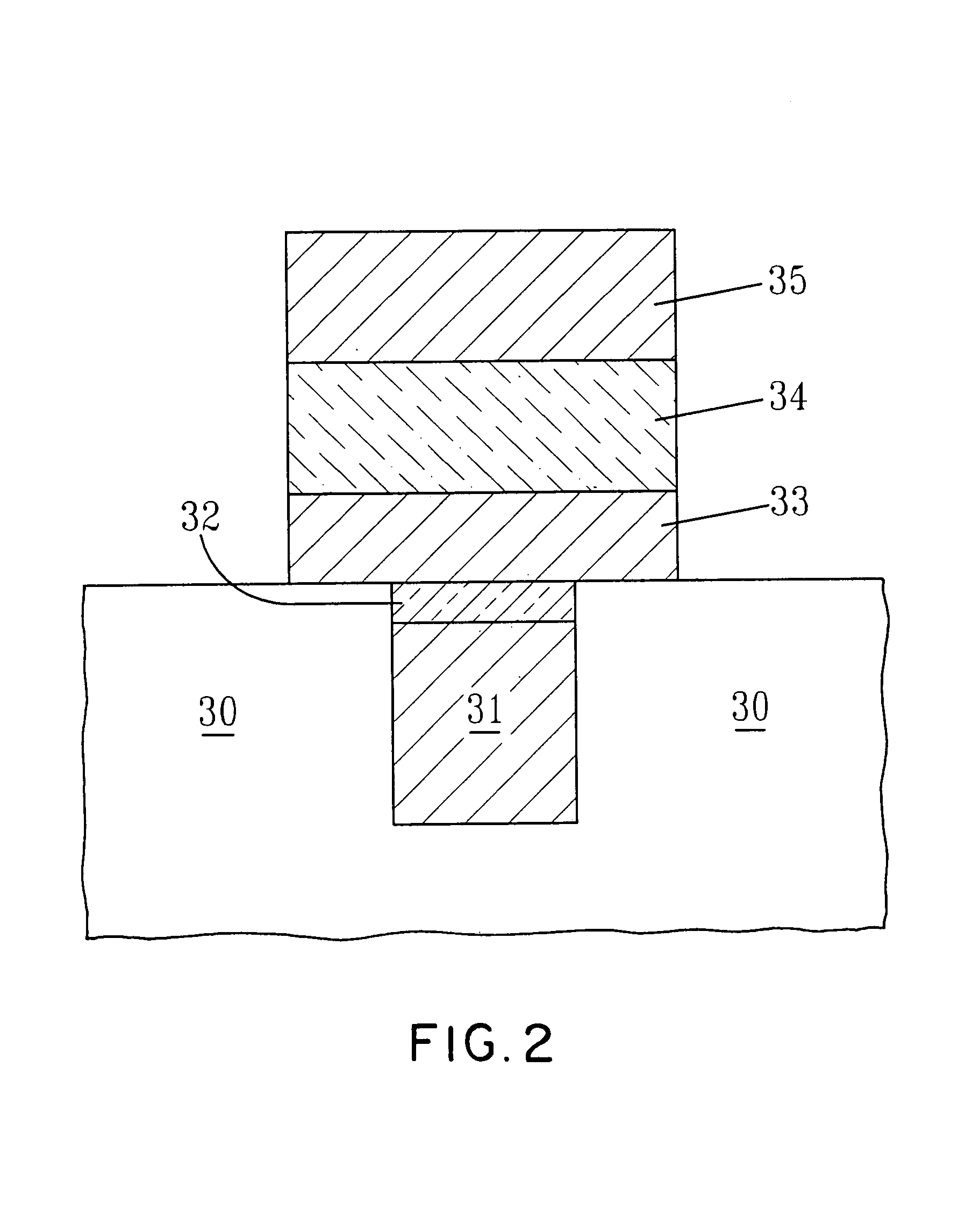

Low resistance contacts including intermetallic alloy of nickel, platinum, titanium, aluminum and type iv semiconductor elements

ActiveUS20180068950A1Semiconductor/solid-state device detailsSolid-state devicesPlatinumSemiconductor materials

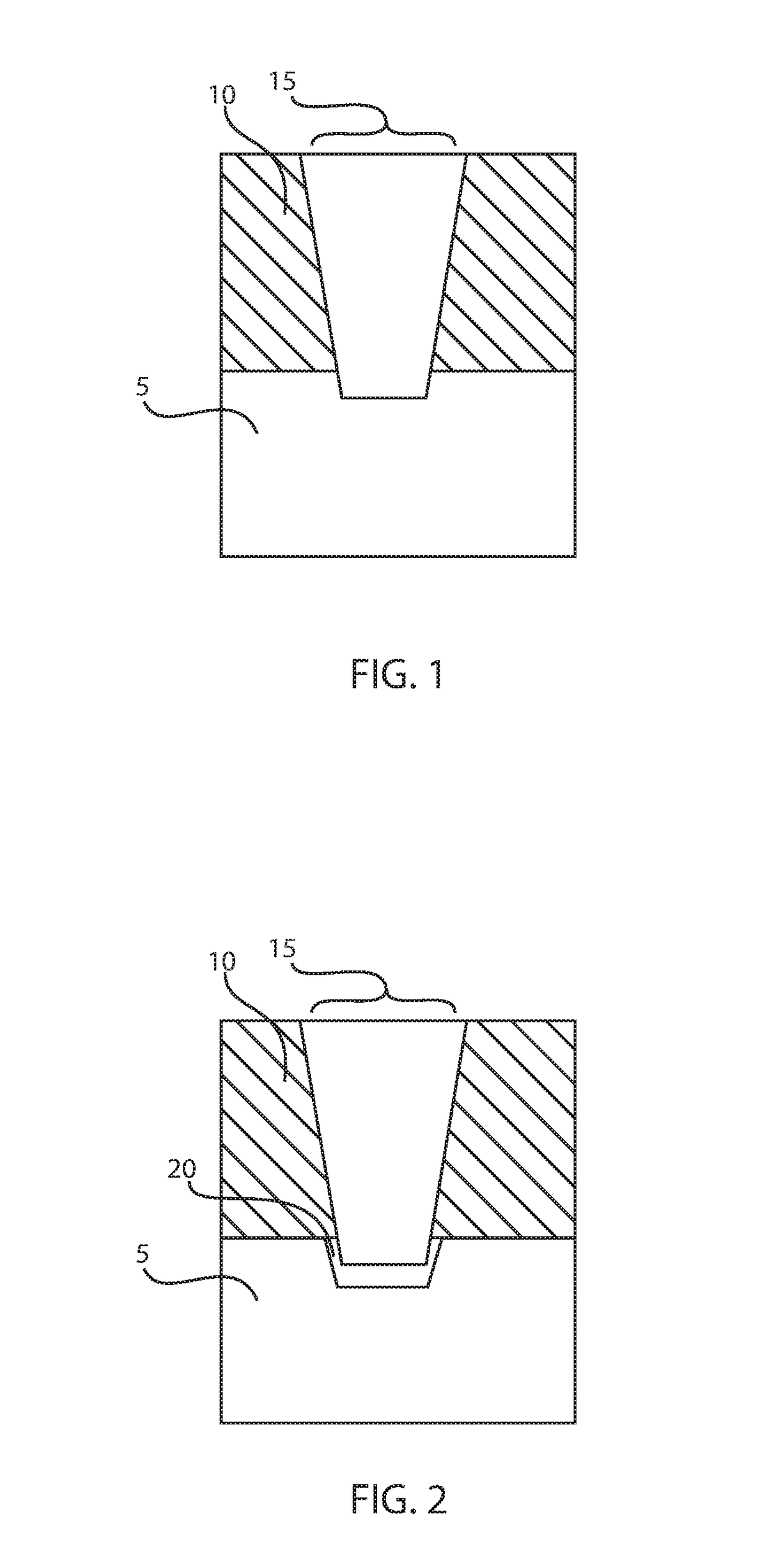

A method of forming a contact to a semiconductor device is provided that forms an alloy composed of nickel (Ni), platinum (Pt), aluminum (Al), titanium (Ti) and a semiconductor material. The methods may include forming a nickel and platinum semiconductor alloy at a base of a via. A titanium layer having an angstrom scale thickness is deposited in the via in contact with the nickel platinum semiconductor alloy. An aluminum containing fill is deposited atop the titanium layer. A forming gas anneal including an oxygen containing atmosphere is applied to the structure to provide a contact alloy comprising nickel, platinum, aluminum, titanium and a semiconductor element from the contact surface of the semiconductor device.

Owner:IBM CORP

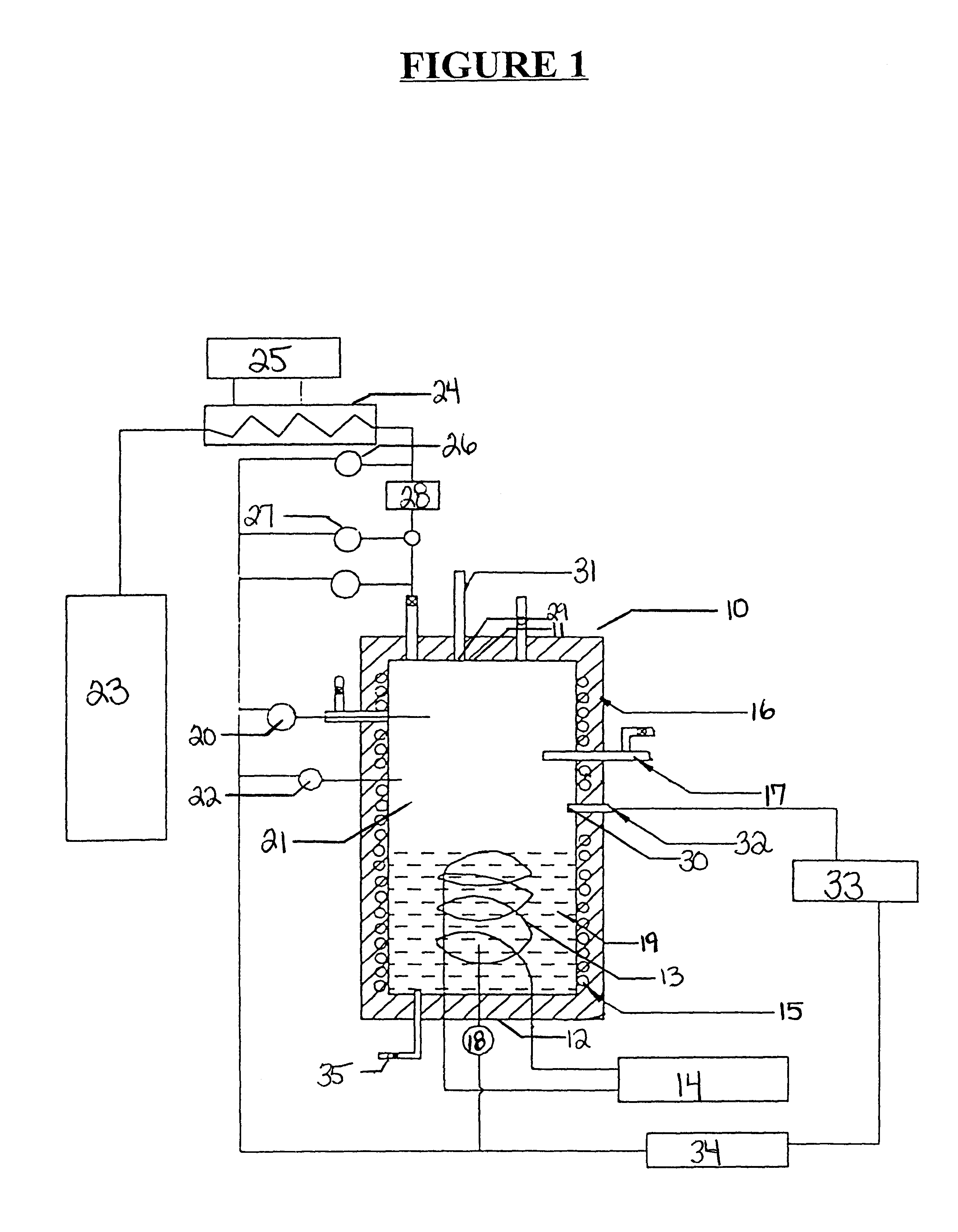

Reactor, system including the reactor, and methods of manufacturing and using same

ActiveUS20190287769A1Electric discharge tubesSemiconductor/solid-state device manufacturingForming gasContamination

A reactor for processing substrates and methods for manufacturing and using the reactor are disclosed. Specifically, the reactor can include a material that forms gas compounds. The gas compounds are then easily removed from the reactor, thus reducing or avoiding contamination of the substrates in the reactor that would otherwise arise.

Owner:ASM IP HLDG BV

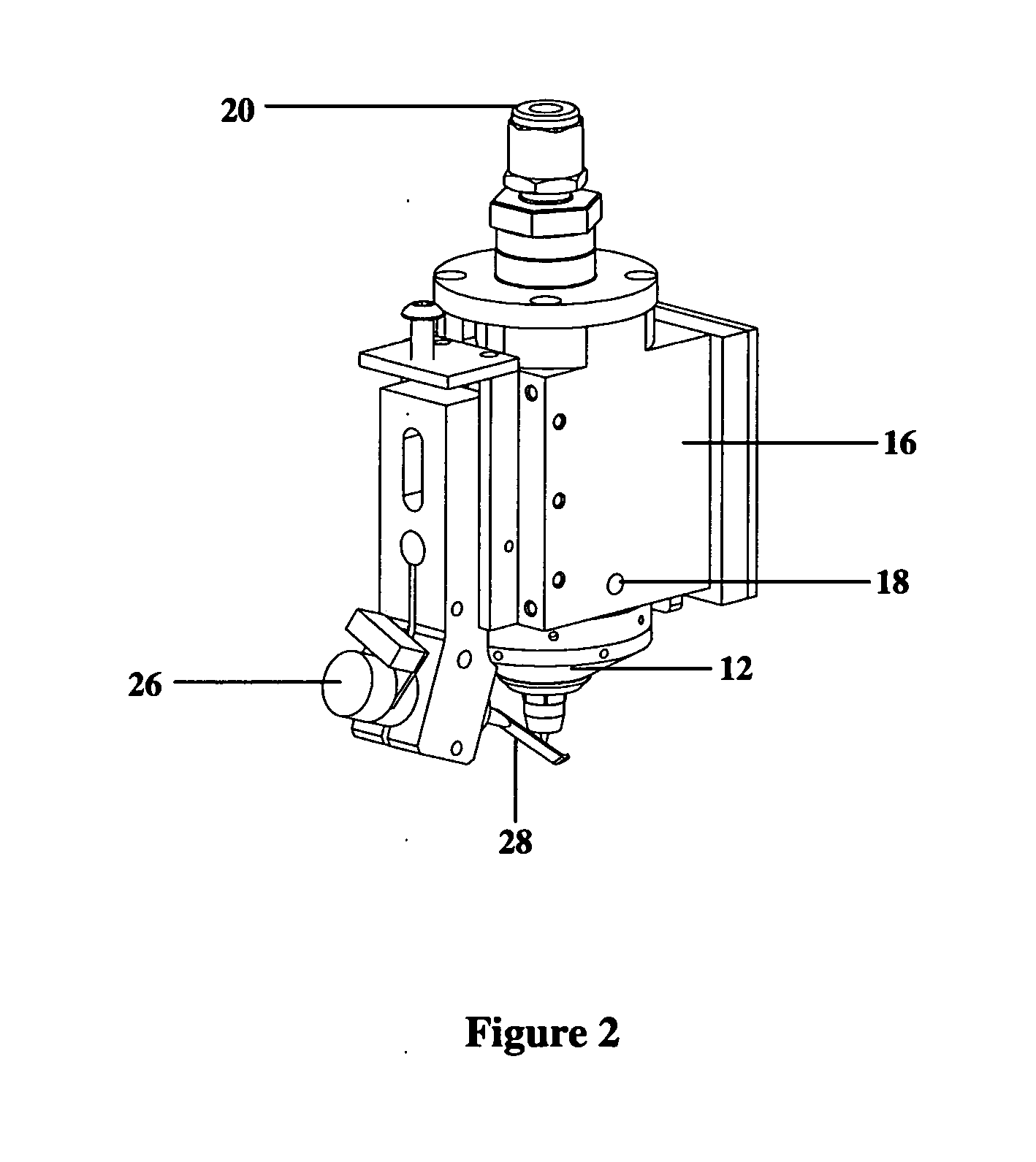

Method and apparatus for producing synthesis gas from carbonaceous materials

A method of producing syn gas from biomass or other carbonaceous material utilizes a controlled devolatilization reaction in which the temperature of the feed material is maintained at less than 450° F. until most available oxygen is consumed. This minimizes pyrolysis of the feed material. The method and apparatus utilizes the formed synthesis gas to provide the energy for the necessary gasification. This provides for a high purity syn gas and avoids production of slag.

Owner:JBK EXTRACTIONS

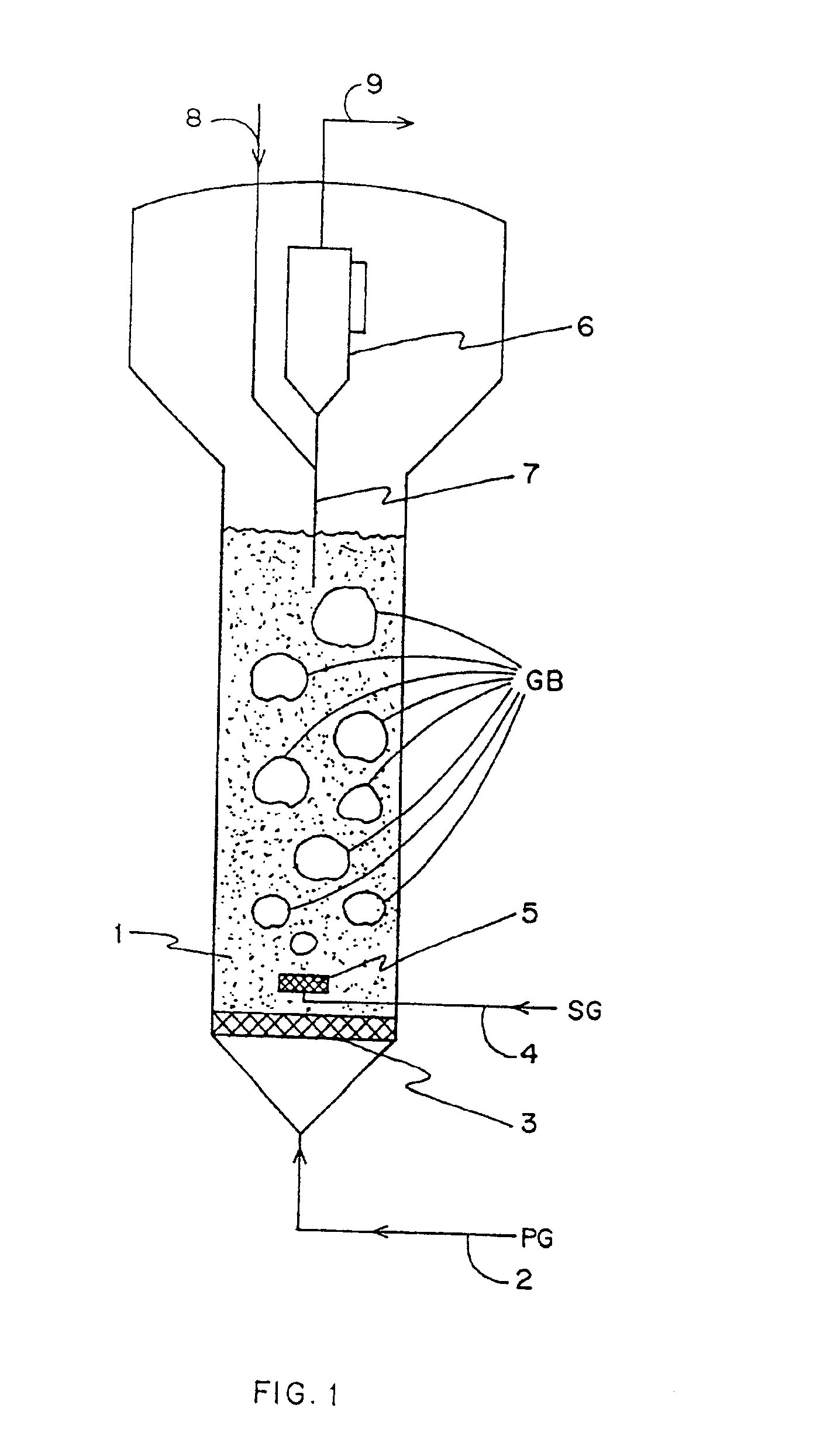

Method for gas-solid contacting in a bubbling fluidized bed reactor

InactiveUS6894183B2Eliminate and drastically reduce bypassEffective contactThermal non-catalytic crackingCatalytic crackingForming gasSolid particle

Owner:COUNCIL OF SCI & IND RES

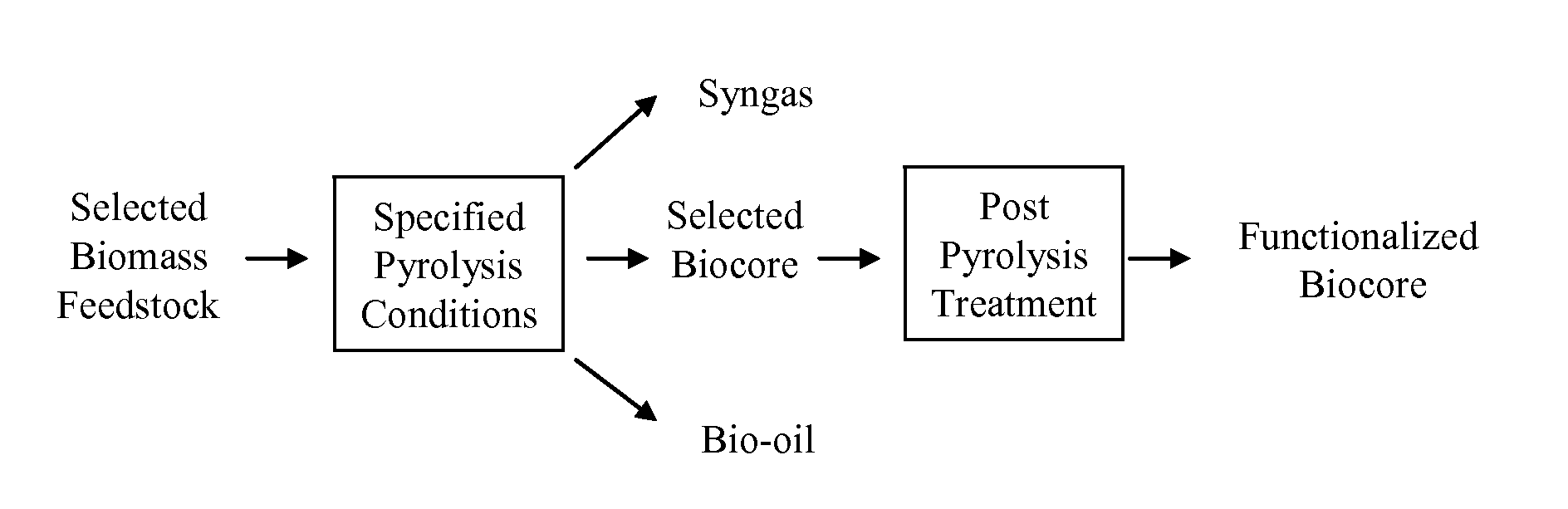

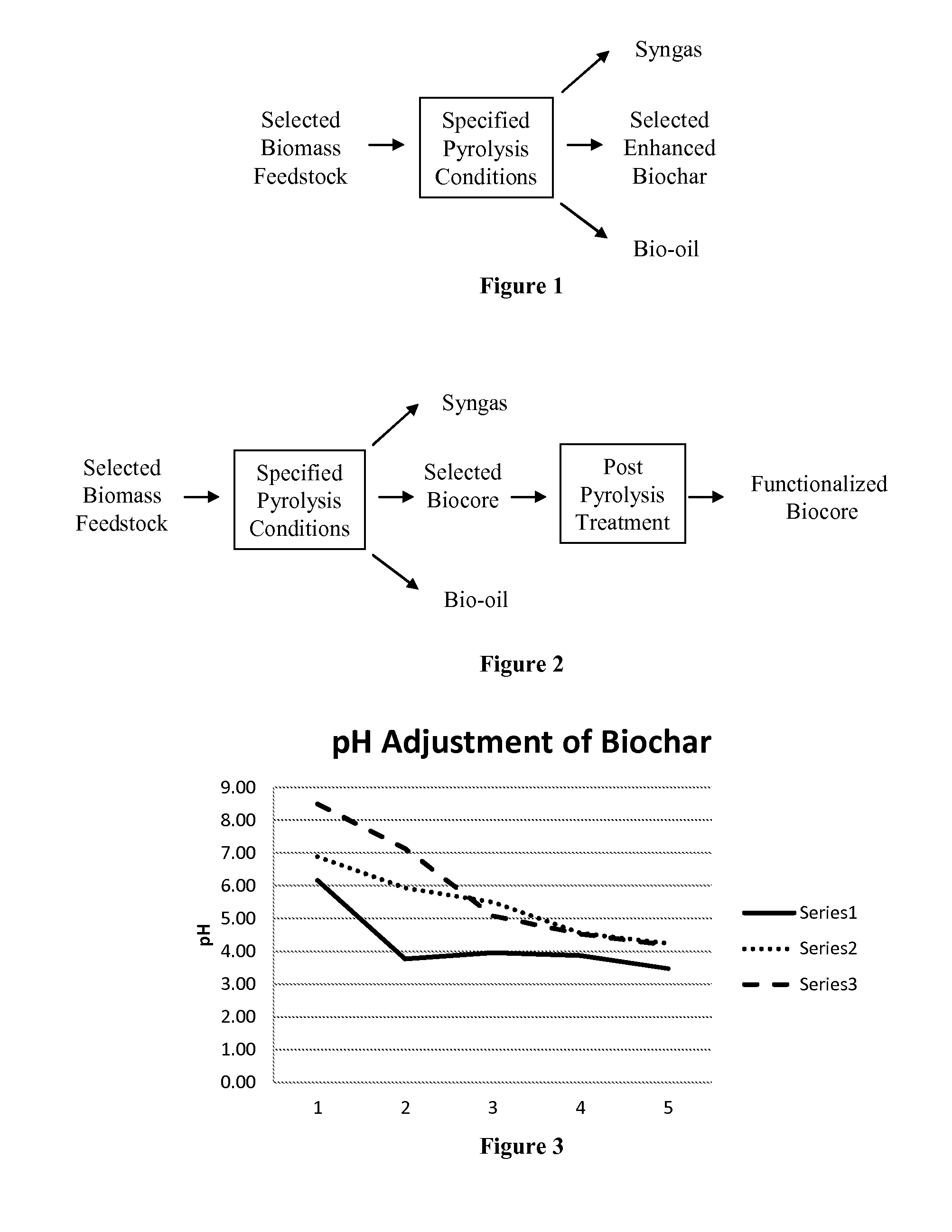

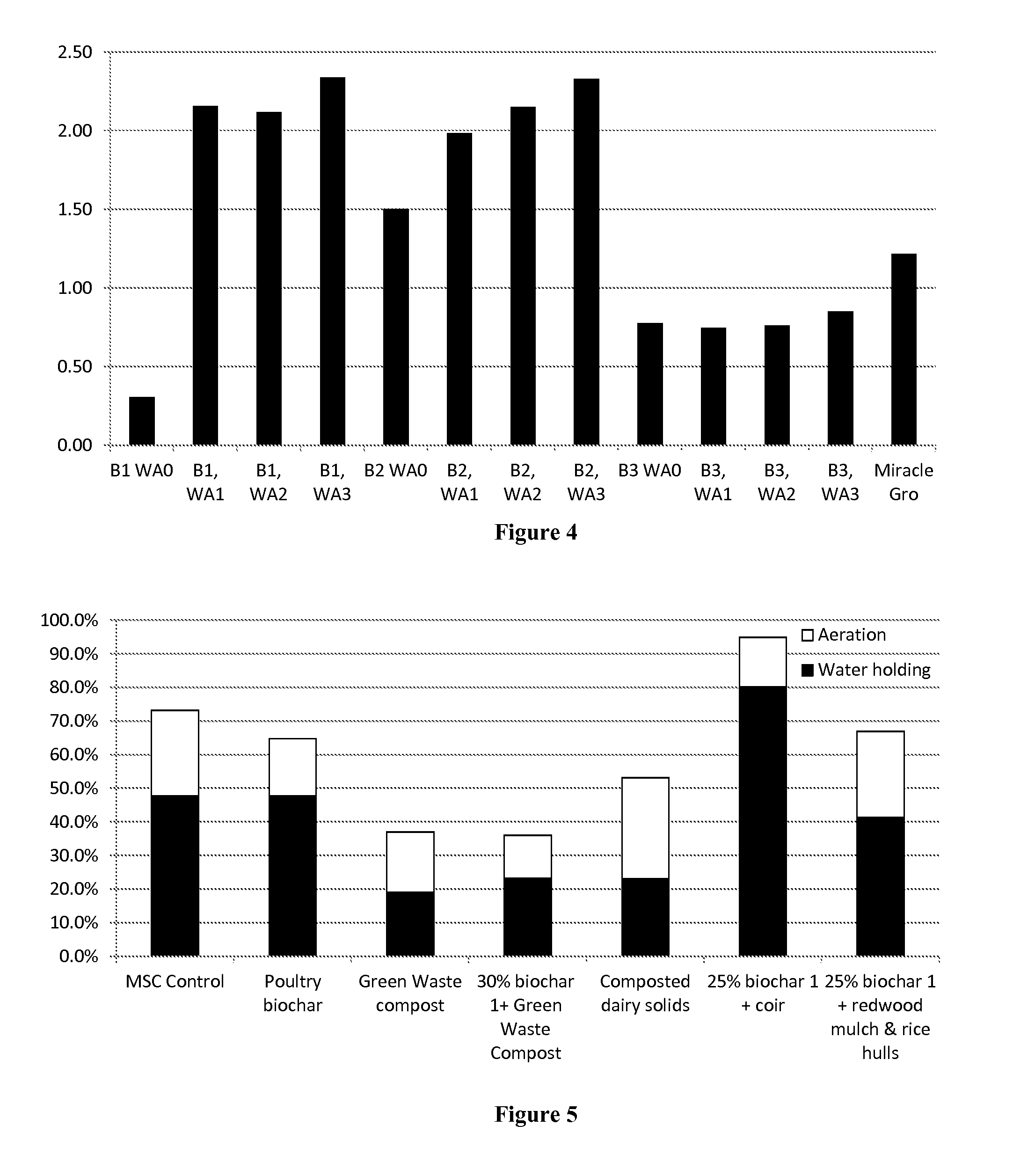

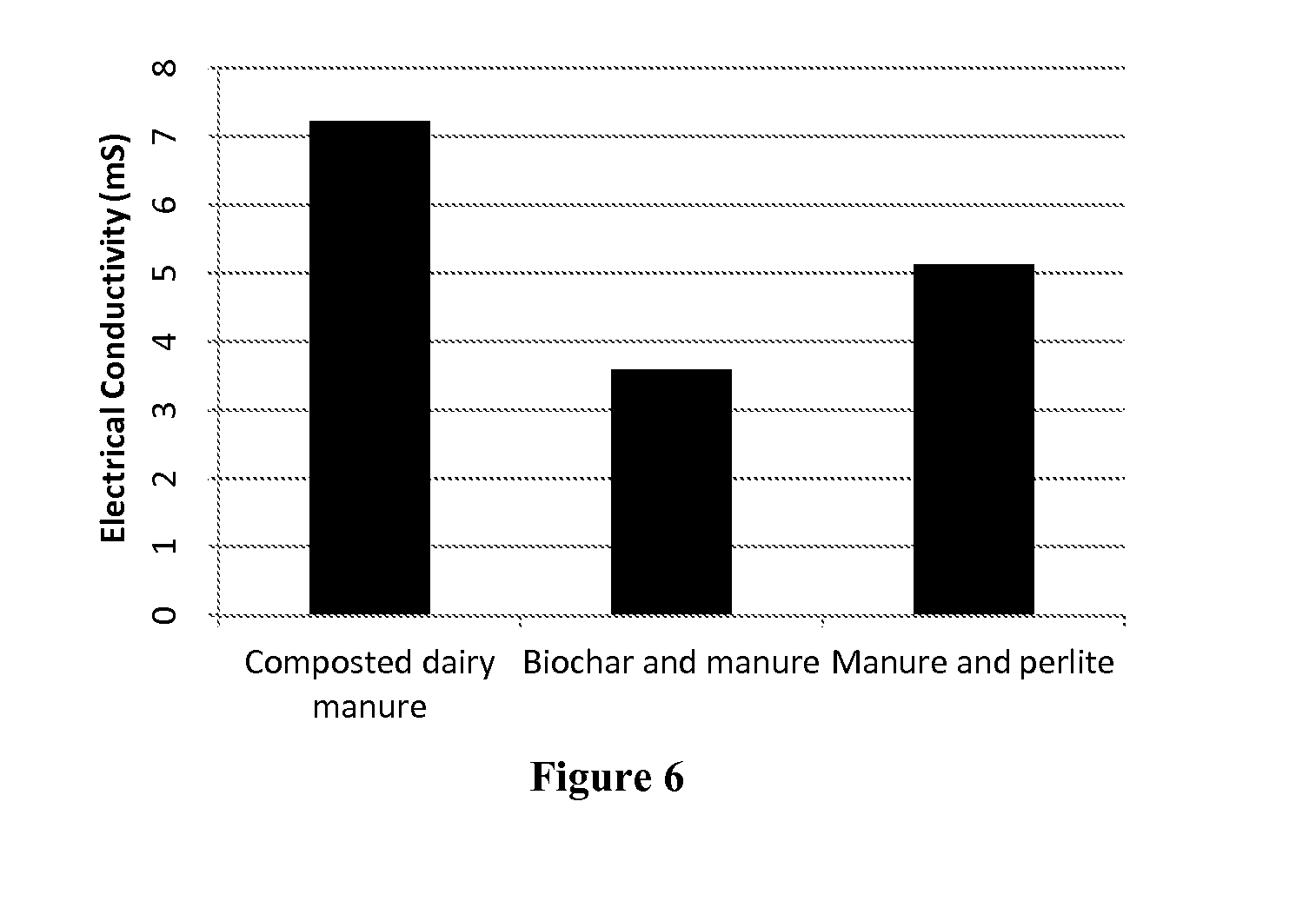

Biochar

ActiveUS8361186B1Enhanced and functionalizedCalcareous fertilisersMagnesium fertilisersForming gasBiological activation

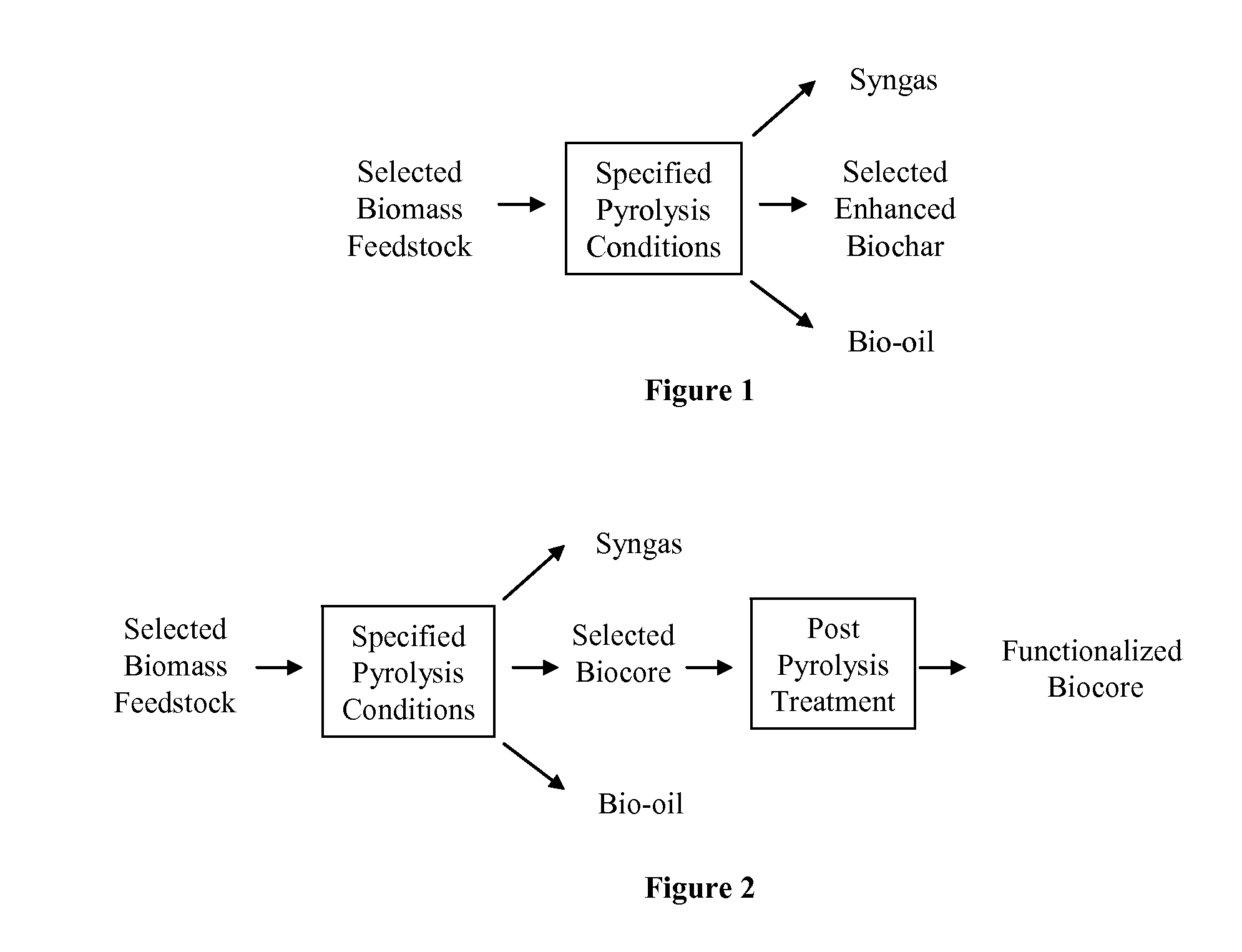

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalization can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

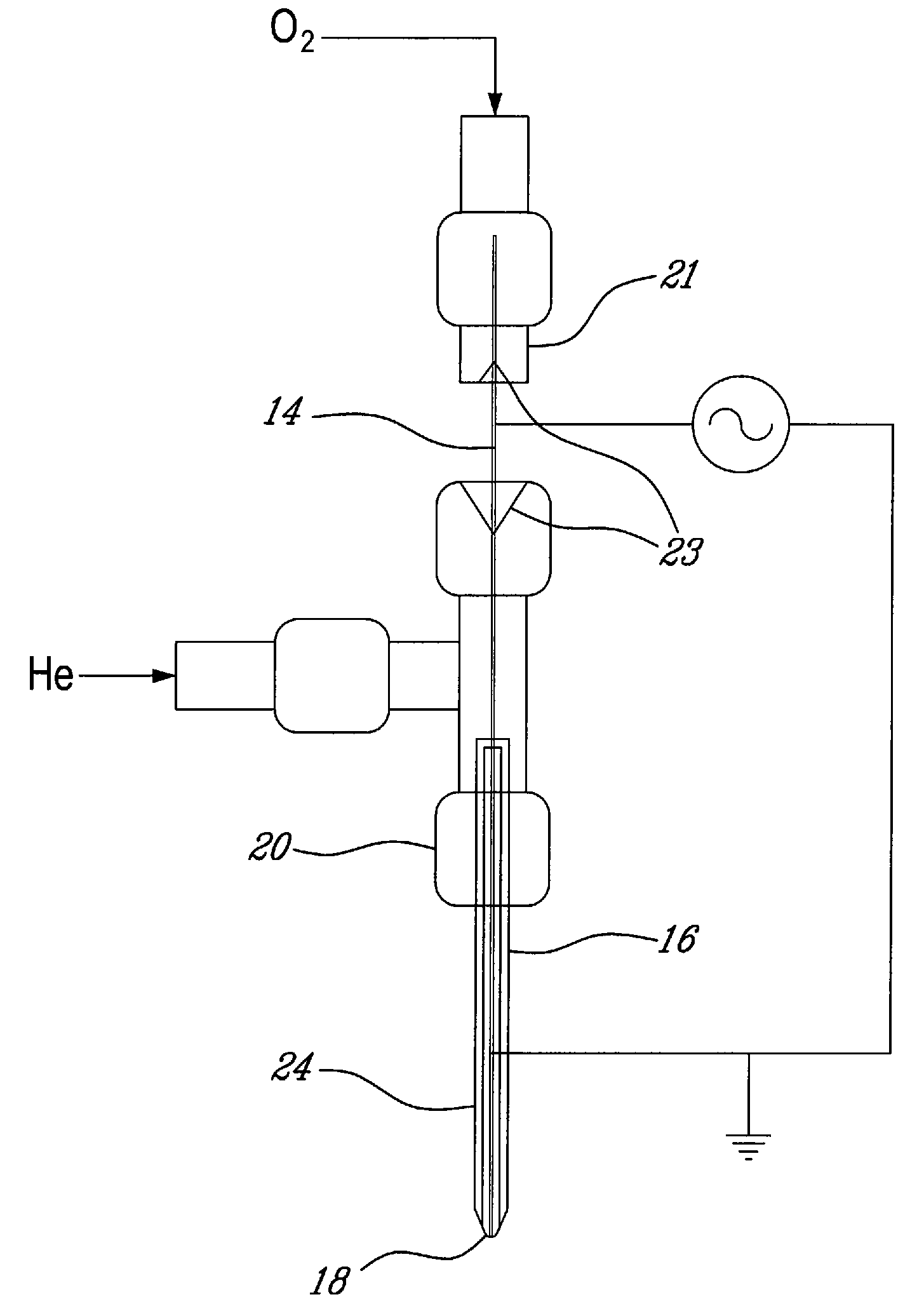

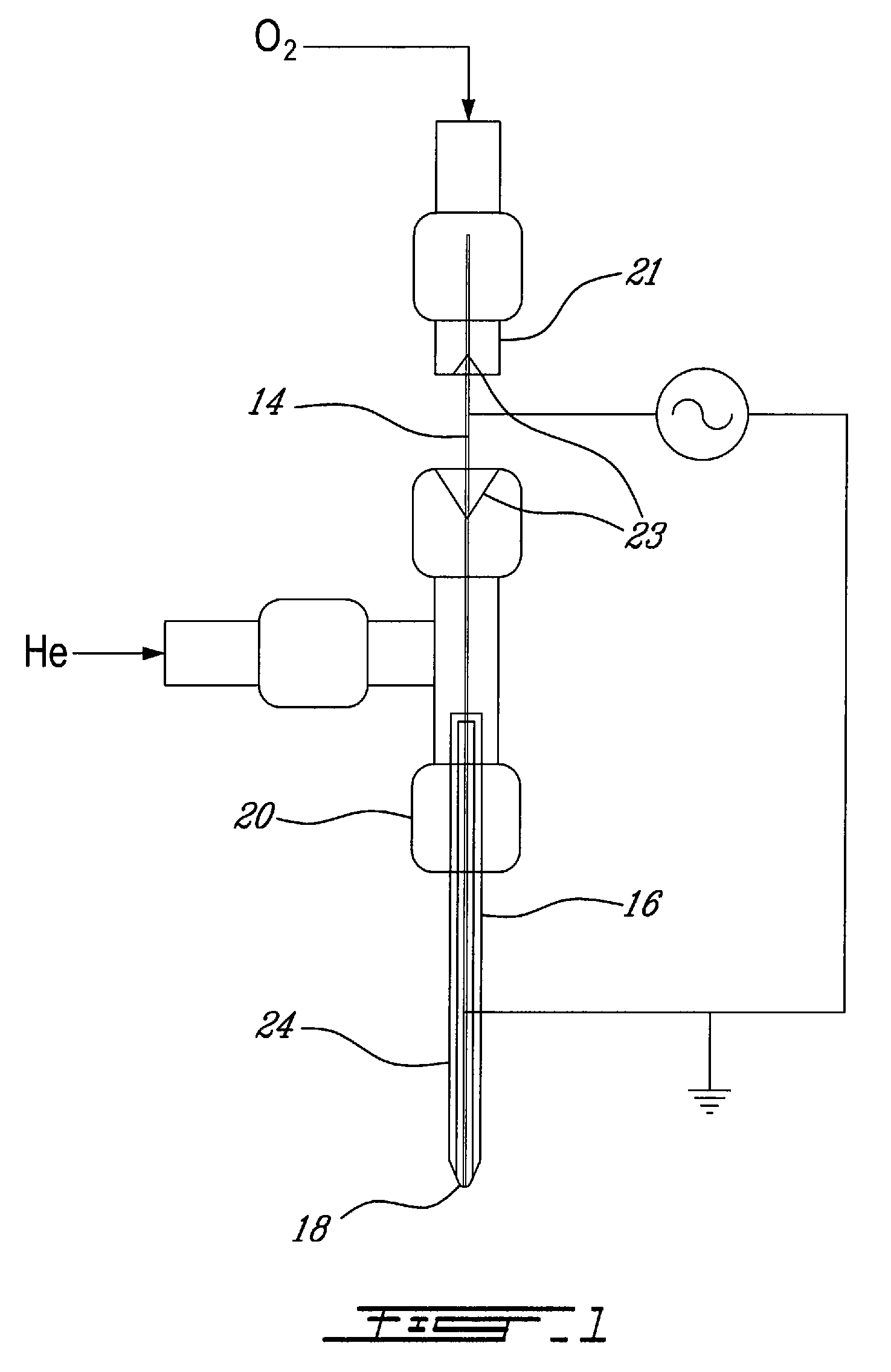

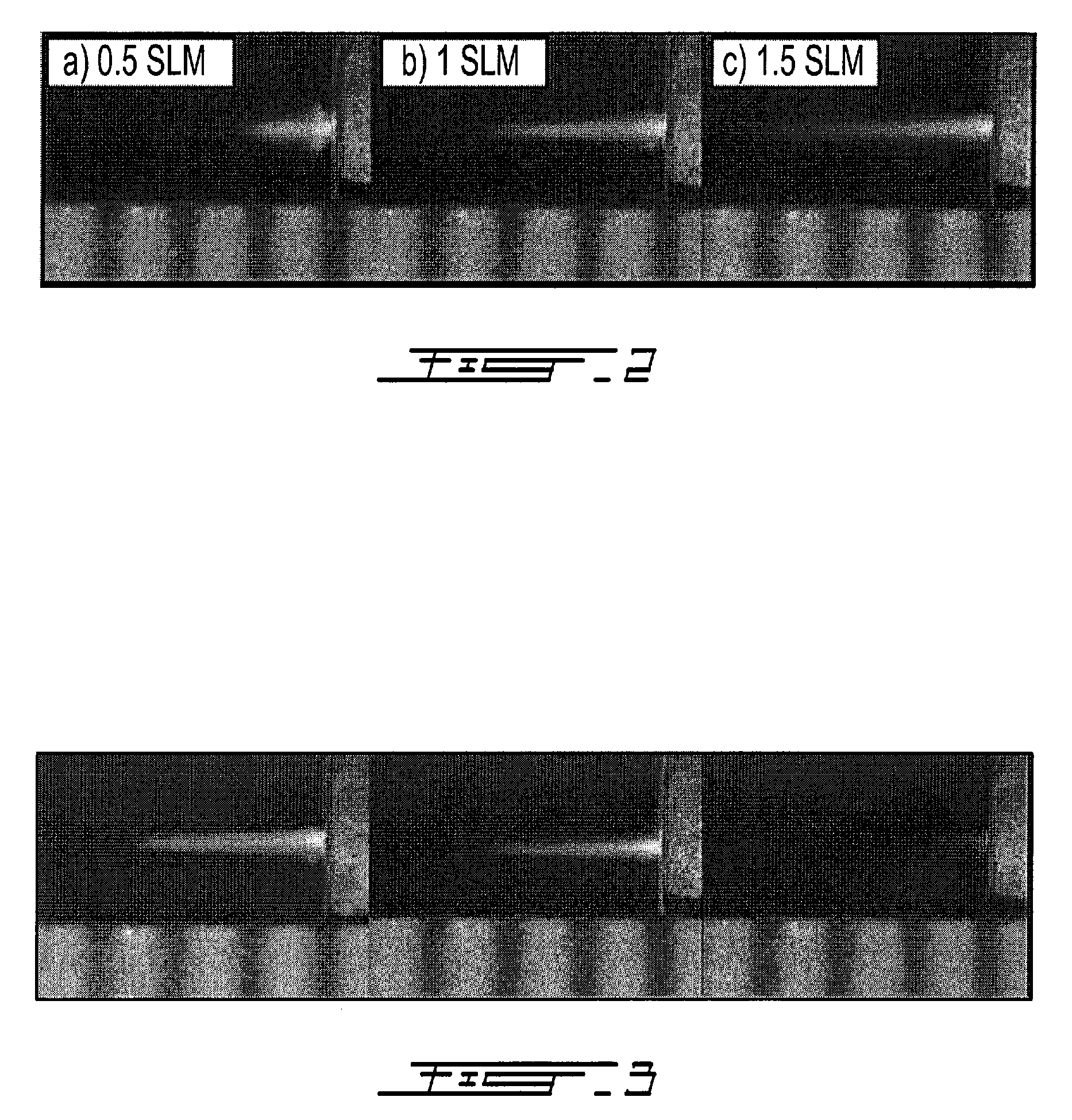

Plasma source and applications thereof

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may found applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

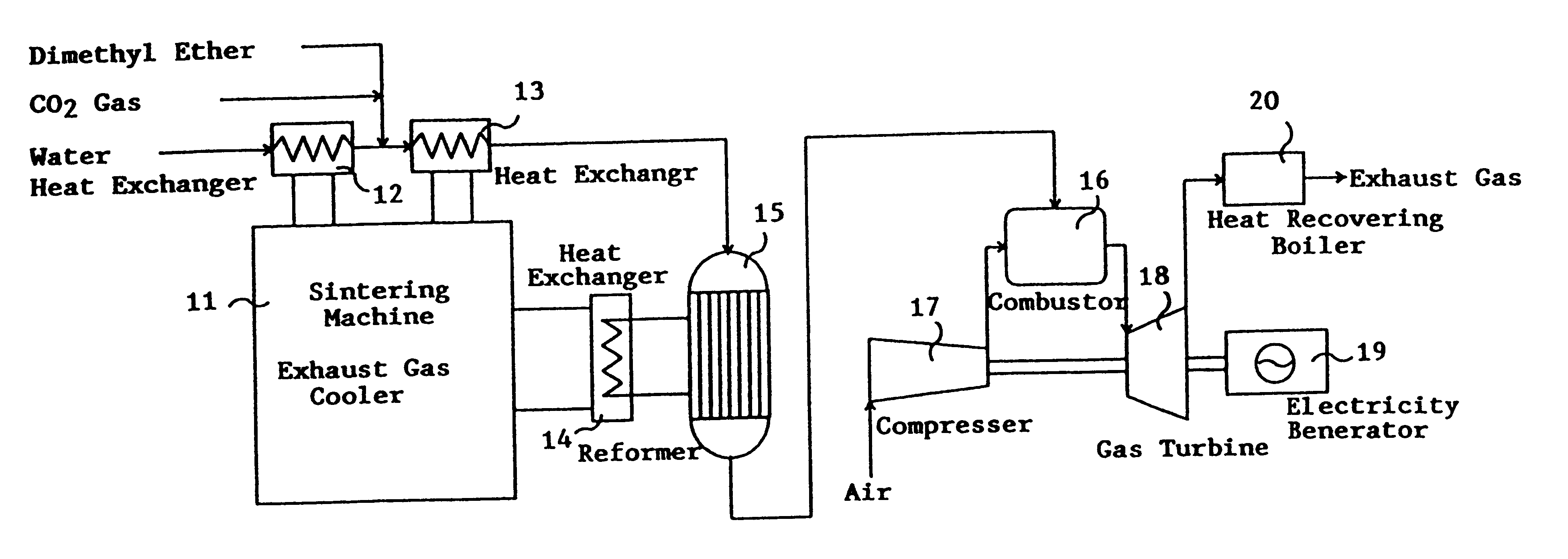

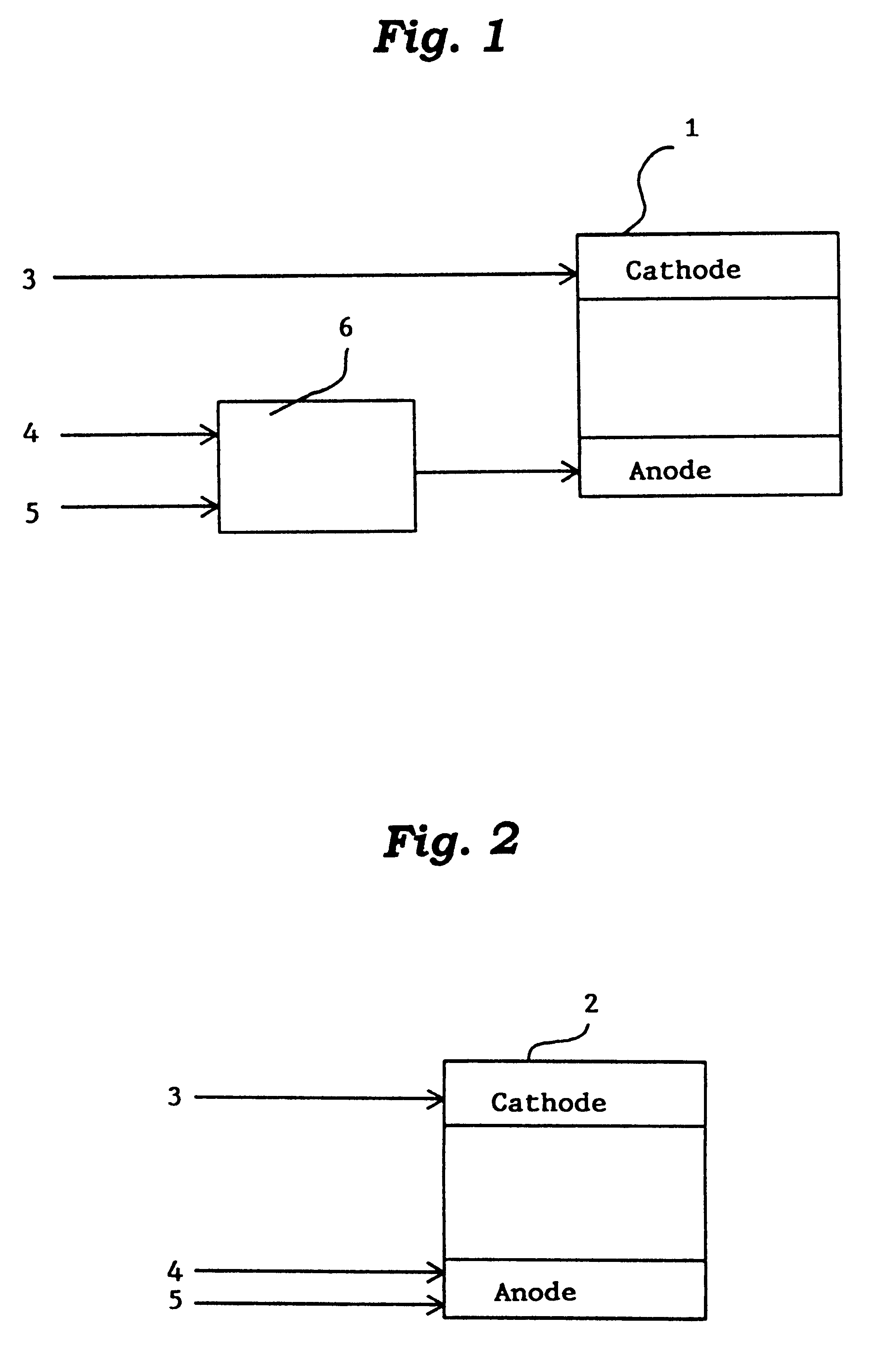

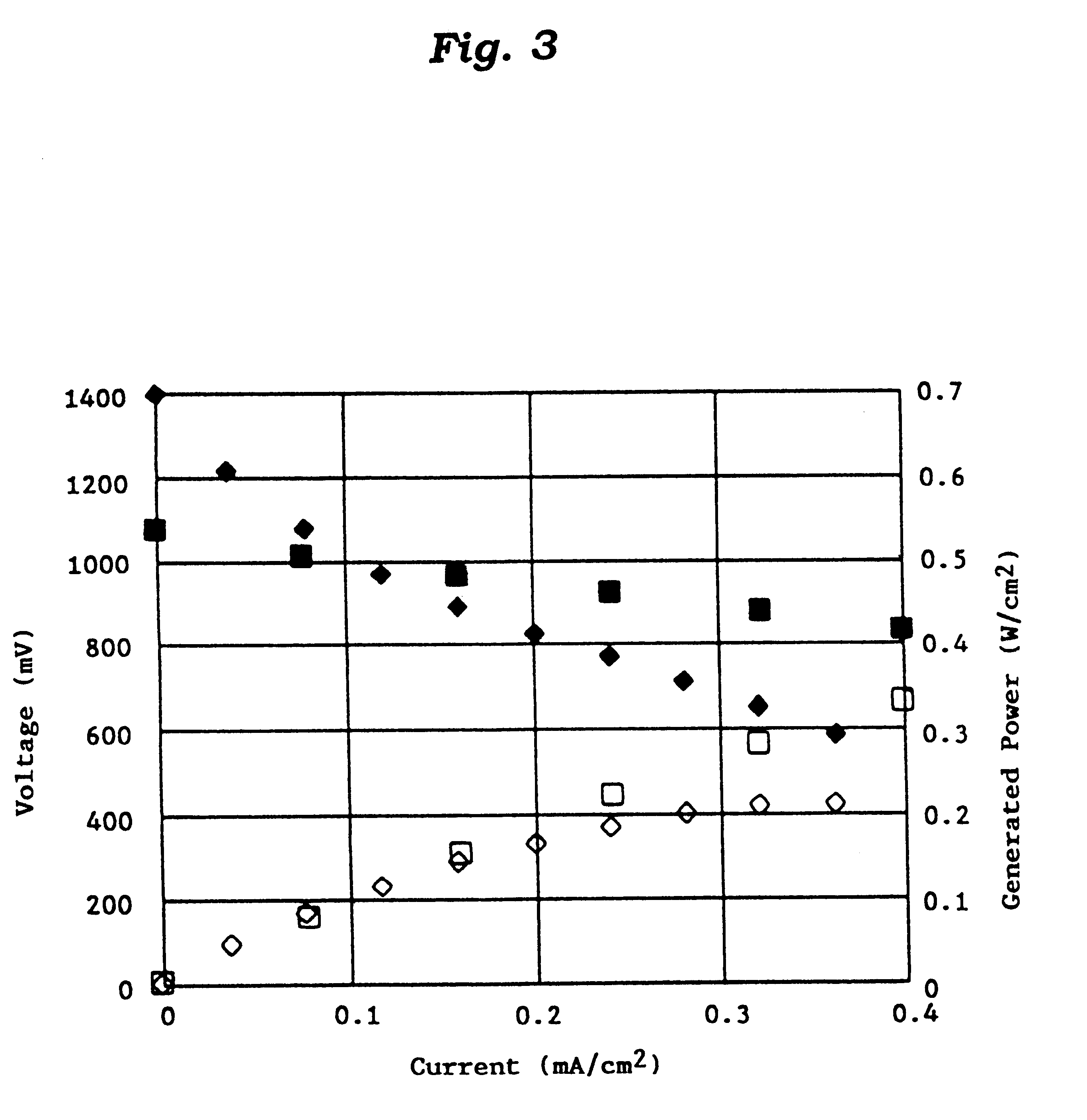

Catalyst for manufacturing hydrogen or synthesis gas and manufacturing method of hydrogen or synthesis gas

InactiveUS6361757B1Produce hydrogenEfficient productionIron compoundsCobalt compoundsIridiumForming gas

This invention provides a catalyst for producing hydrogen gas from a mixed gas comprising dimethyl ether and water vapor or carbon dioxide gas, which comprises copper, iron, cobalt, palladium, iridium, platinum, rhodium, or nickel as an active component, and a method of producing synthesis gas or hydrogen gas in a high yield at a low temperature. By using the catalyst, a fuel cell, electricity generation, reduction of iron ore and the like can be carried out.

Owner:NIPPON KOKAN KK

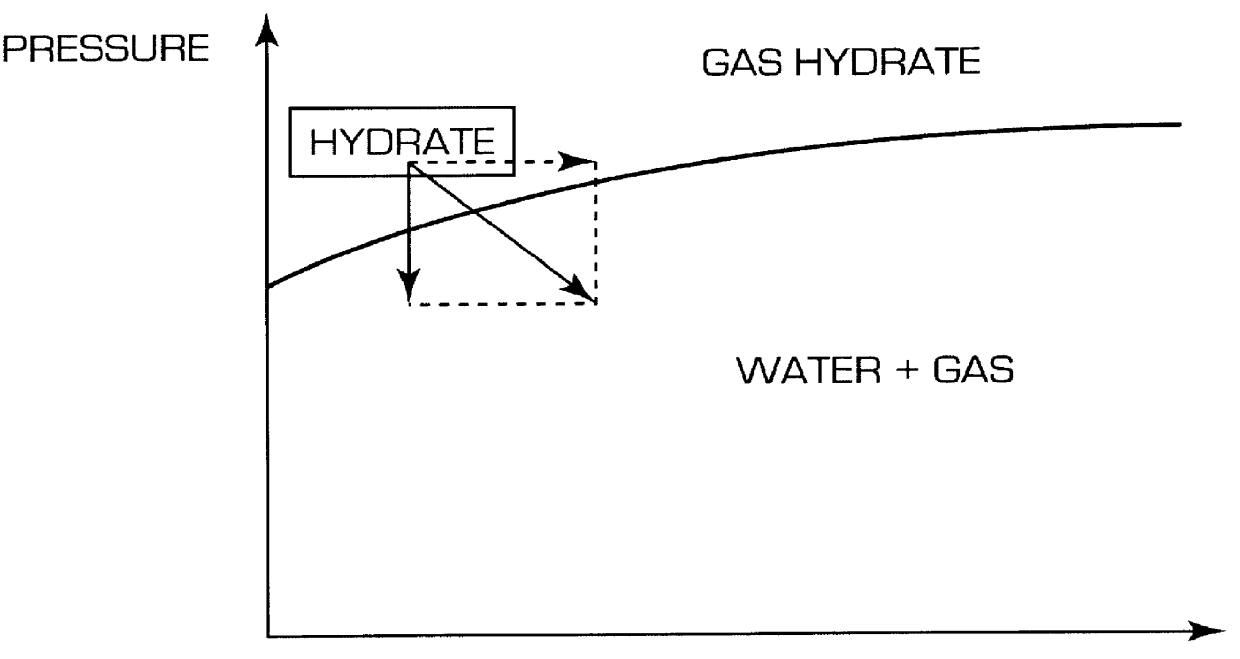

Surfactant process for promoting gas hydrate formation and application of the same

This invention relates to a method of storing gas using gas hydrates comprising forming gas hydrates in the presence of a water-surfactant solution that comprises water and surfactant. The addition of minor amounts of surfactant increases the gas hydrate formation rate, increases packing density of the solid hydrate mass and simplifies the formation-storage-decomposition process of gas hydrates. The minor amounts of surfactant also enhance the potential of gas hydrates for industrial storage applications.

Owner:MISSISSIPPI STATE UNIVERSITY

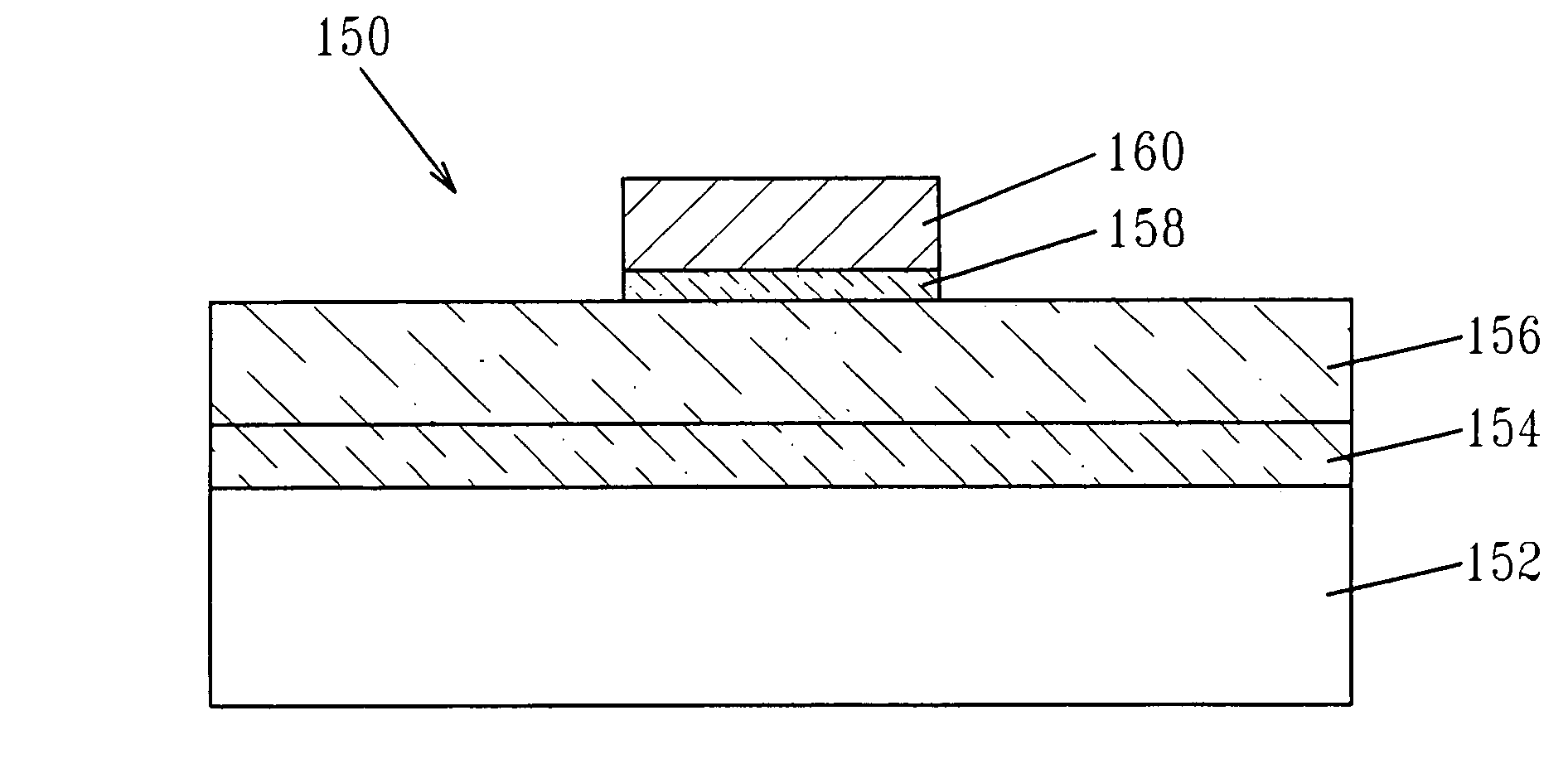

Deposition of hafnium oxide and/or zirconium oxide and fabrication of passivated electronic structures

InactiveUS6982230B2Stable to reducing condition necessaryImprove electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingElectronic structureHydrogen

A method of fabricating hafnium oxide and / or zirconium oxide films is provided. The methods include providing a mixture of Hf and / or Zr alkoxide dissolved, emulsified or suspended in a liquid; vaporizing at least the alkoxide and depositing the vaporized component at a temperature of greater than 400° C. The resultant film is dense, microcrystalline and is capable of self-passivation when treated in a hydrogen plasma or forming gas anneal.

Owner:GLOBALFOUNDRIES INC

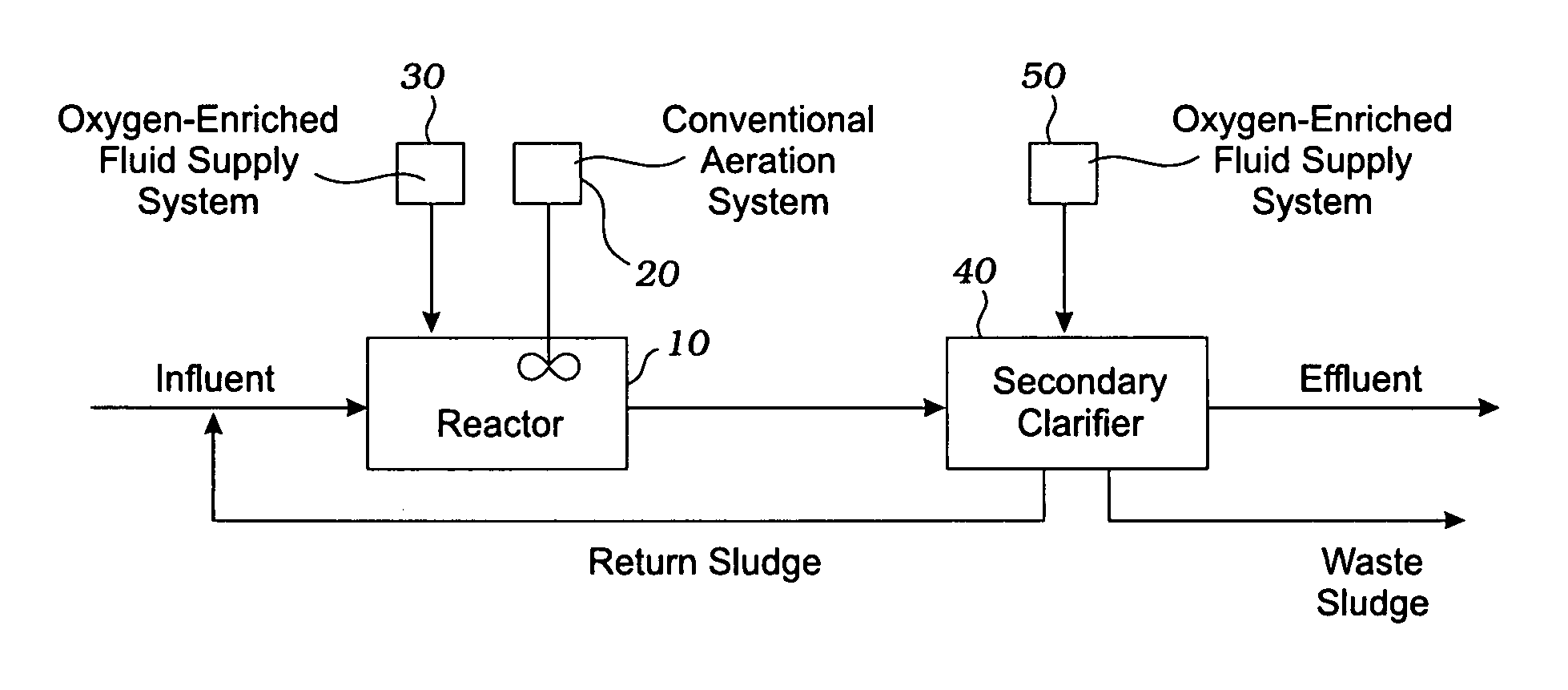

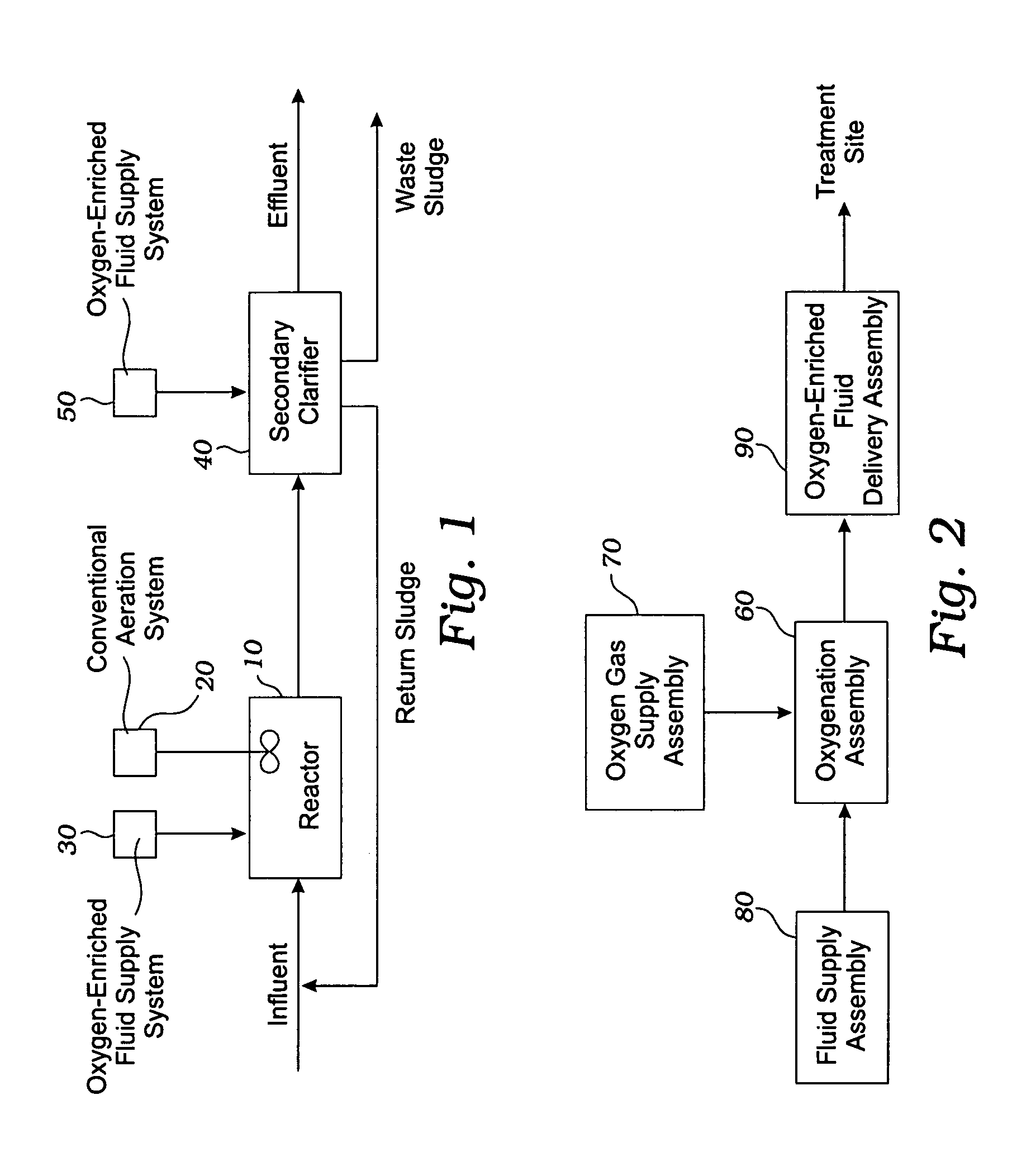

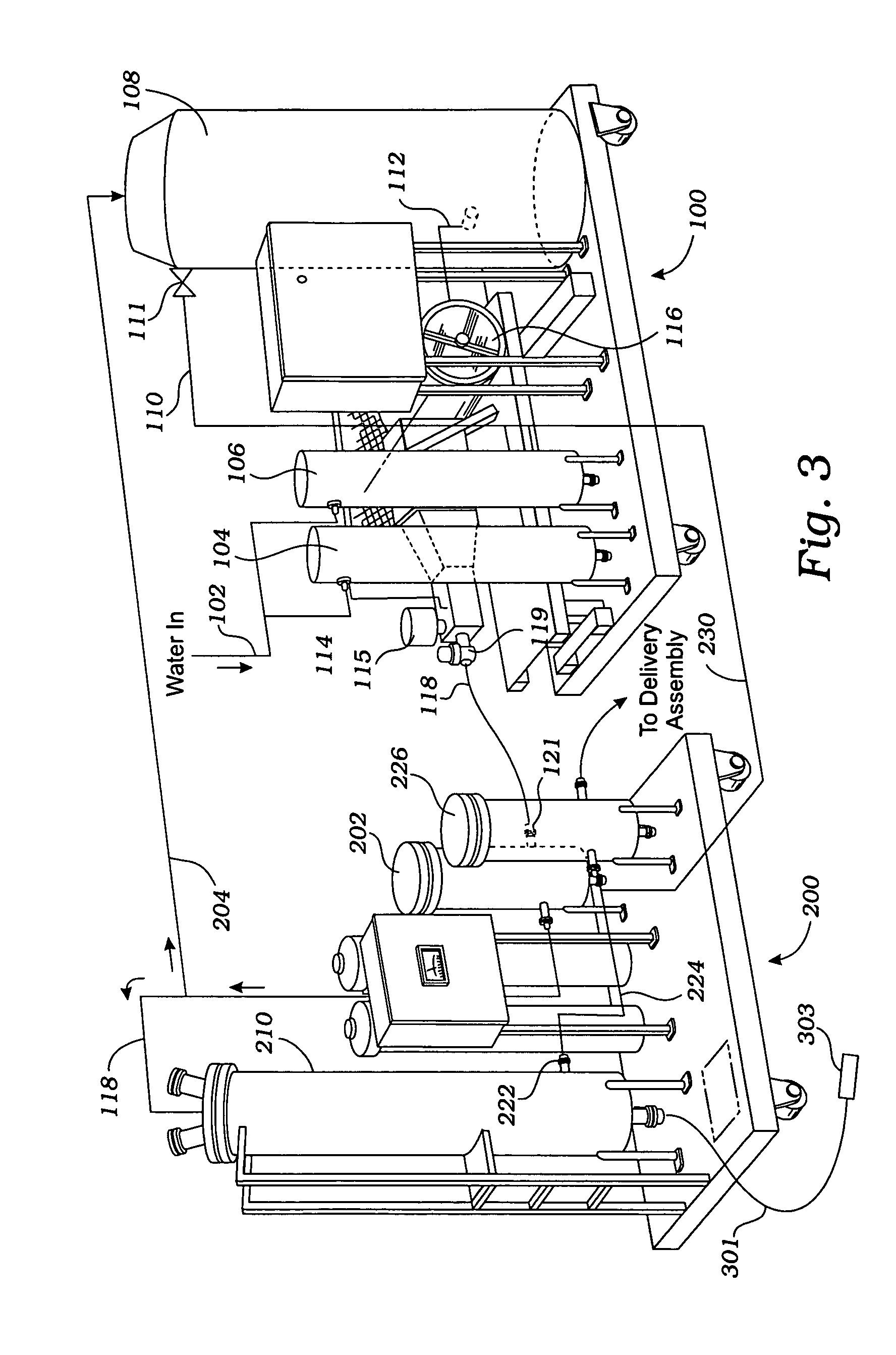

Apparatus for oxygenating wastewater

InactiveUS7008535B1Easy to assembleEasy to cleanTreatment using aerobic processesFlow mixersForming gasWastewater

A method and apparatus creates gas-enriched fluid that is used to treat wastewater. In one embodiment, the wastewater is withdrawn from a supply of wastewater to be treated, and the wastewater is delivered in an atomized manner to a vessel pressurized with gas to form gas-enriched wastewater. The gas-enriched wastewater is then delivered to the supply of wastewater to be treated.

Owner:WAYNE STATE UNIV +1

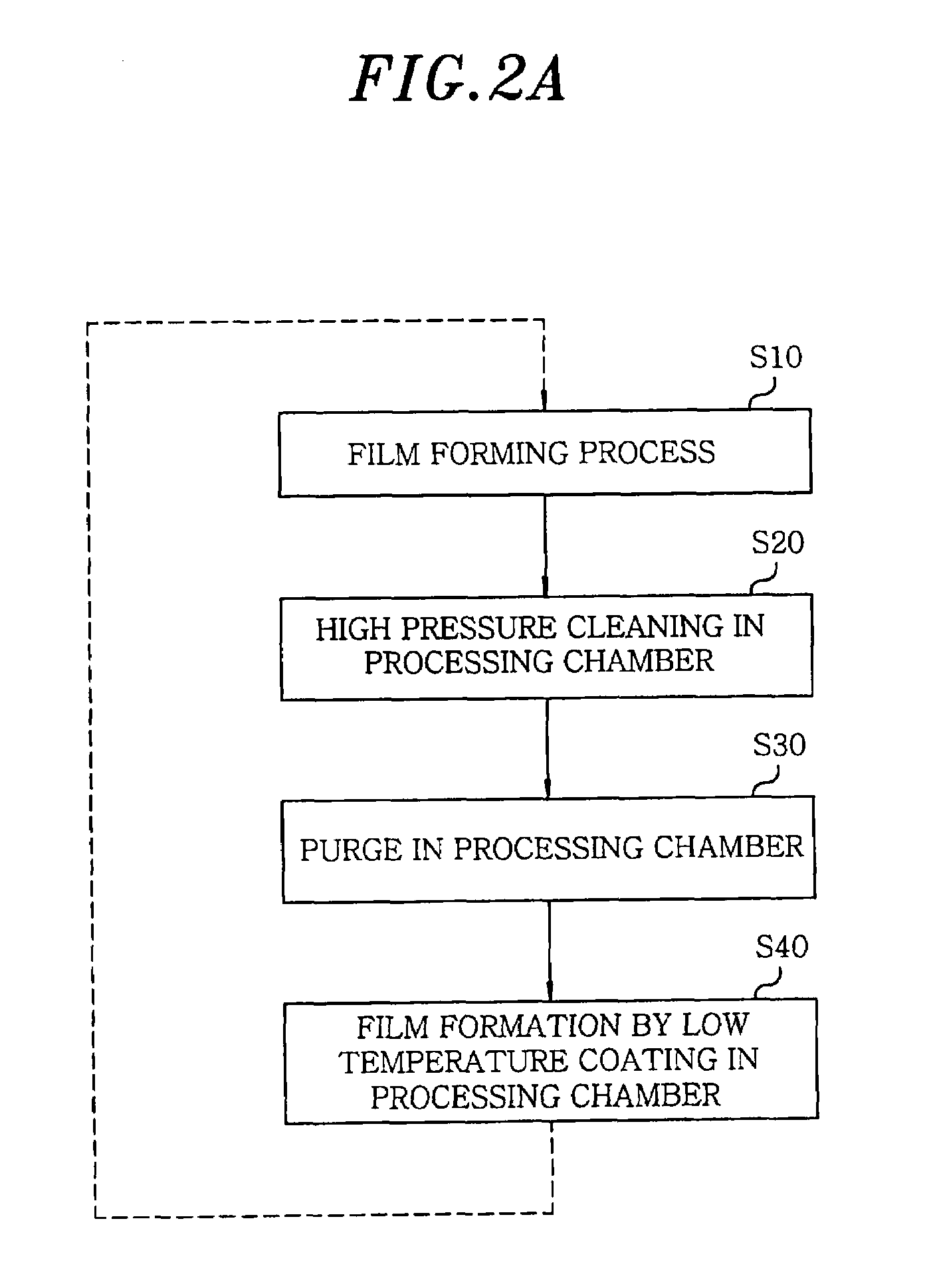

Method for treating substrate and recording medium

InactiveUS20090117270A1Efficient cleaning and maintenanceImprove productivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingForming gasEngineering

A method for processing a substrate includes a film forming step of supplying a film forming gas into the processing chamber to form a film on the substrate, a cleaning step of supplying a plasma-exited cleaning gas into the processing chamber after the film forming step to clean the inside of the processing chamber, and a coating step of forming a coating within the processing chamber after the cleaning step. The cleaning step includes a high pressure cleaning of regulating the pressure in the processing chamber so that cleaning is mainly performed by molecules formed by recombining radicals in the cleaning gas, and the coating step includes a low temperature film forming step of forming the coating film under the condition that the temperature of a substrate supporting table is set lower than that in the film formation on the substrate during the film formation step.

Owner:TOKYO ELECTRON LTD

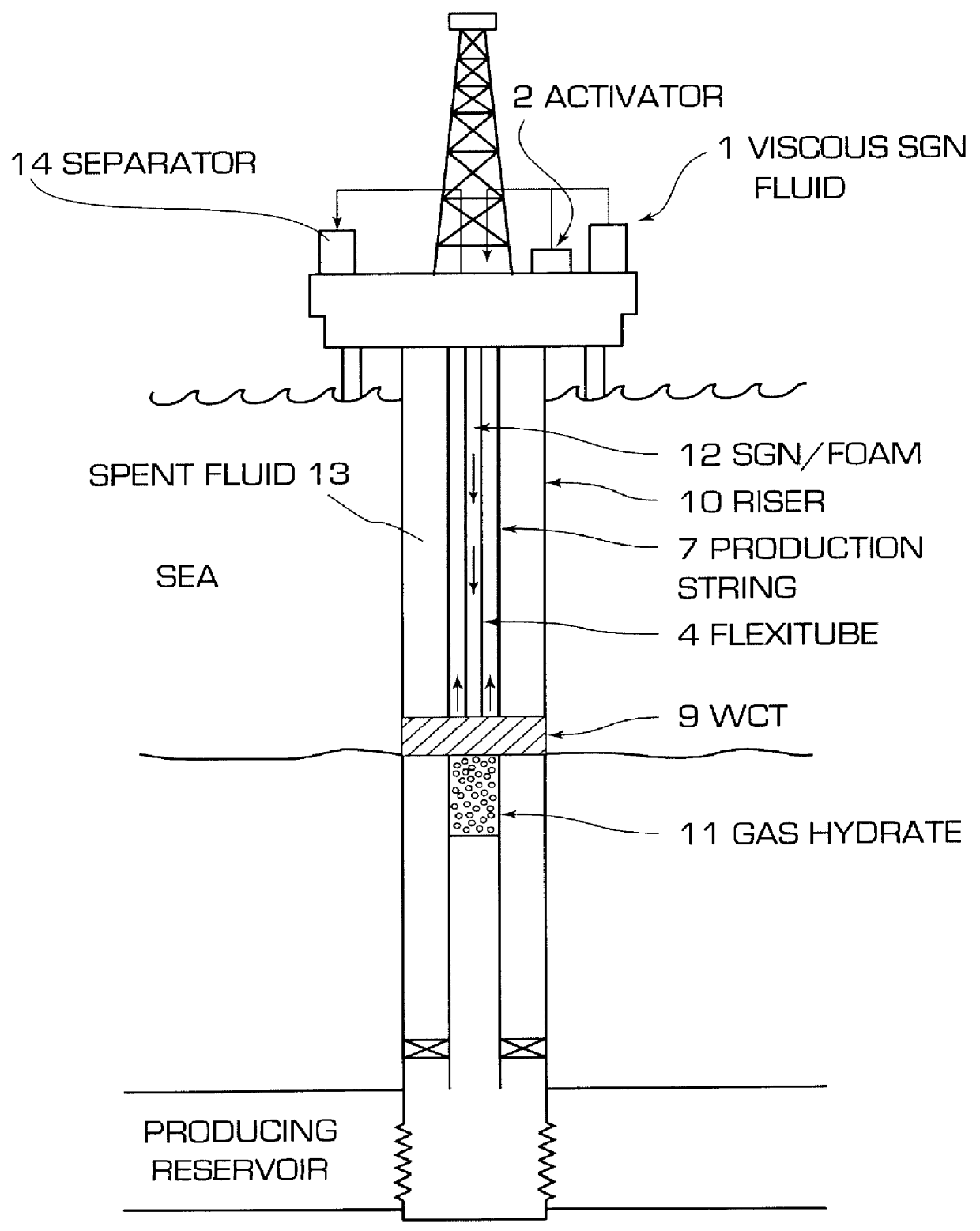

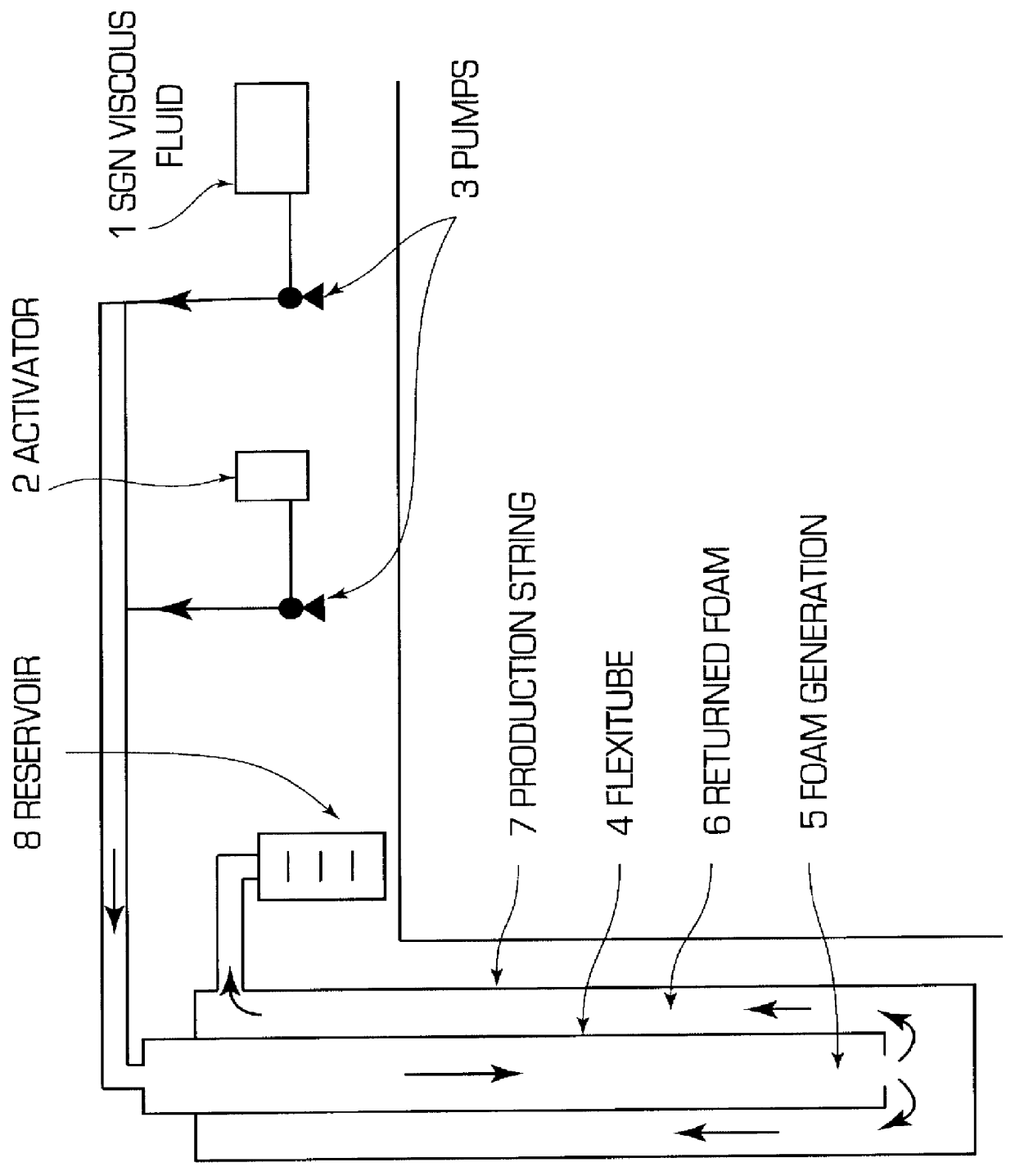

Process for the thermo-hydraulic control of gas hydrates

InactiveUS6035933AInhibition formationPipeline systemsDifferential sedimentationForming gasGas phase

A process for the thermo-hydraulic control of gas hydrates in subsea production and injection wells as well as pipelines which transport liquid or gaseous hydrocarbons is described, the process making use of a Nitrogen Generating System foamed or in solution. The control may signify the prevention of the formation of the gas hydrates or the dissolution of the gas hydrate plug already formed. Under conditions of use designed for the prevention of the formation of gas hydrates the SGN fluid prevents the thermal conditions leading to the gas hydrate plugs. Under conditions of use designed to dissolve the already formed gas hydrate plugs, the SGN fluid alters the thermo-hydraulic conditions which favor the gas hydrate plugs, so that they are dissolved and return to the water+gas phase.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

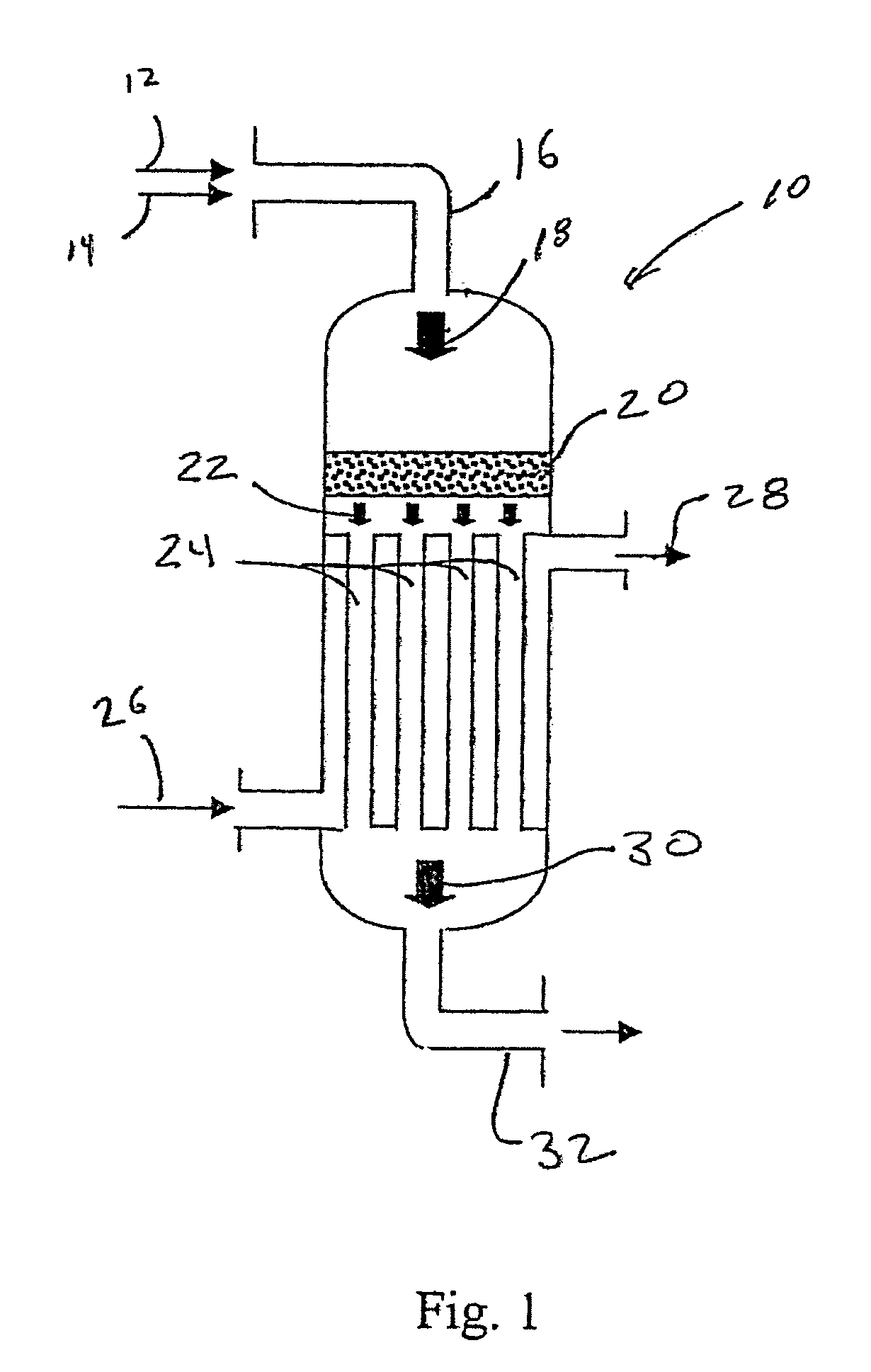

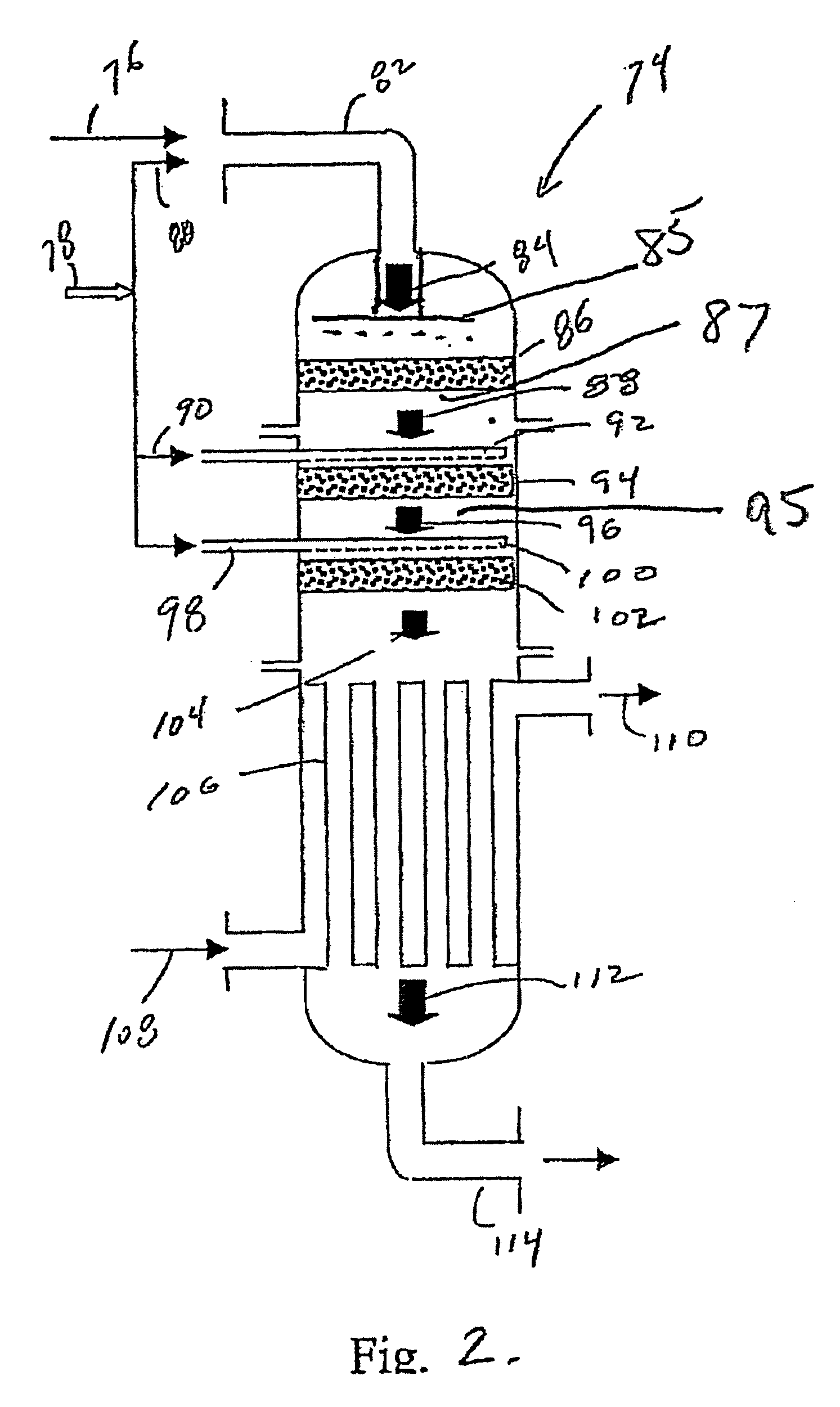

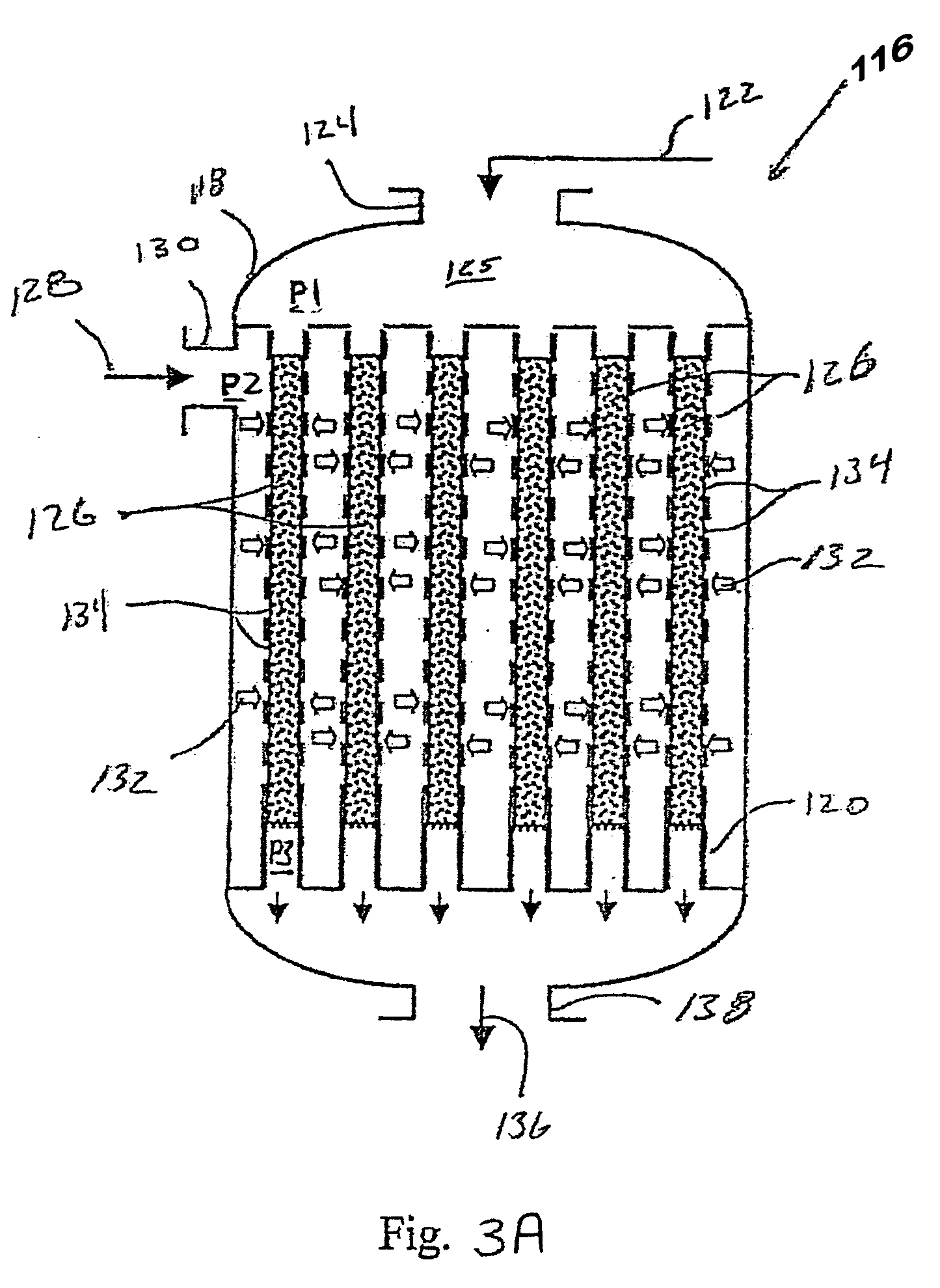

Synthesis gas process comprising partial oxidation using controlled and optimized temperature profile

ActiveUS20060029539A1Risk of explosion can be minimizedIncrease the molar ratioHydrocarbon from carbon oxidesCarburetting by solid carbonaceous material pyrolysisForming gasPartial oxidation

This invention relates to methods for reacting a hydrocarbon, molecular oxygen, and optionally water and / or carbon dioxide, to form synthesis gas. The preferred embodiments are characterized by delivering a substochiometric amount of oxygen to each of a multitude of reaction zones, which allows for optimum design of the catalytic packed bed and the gas distribution system, and for the optimization and control of the temperature profile of the reaction zones. The multitude of reaction zones may include a series of successive fixed beds, or a continuous zone housed within an internal structure having porous, or perforated, walls, through which an oxygen-containing stream can permeate. By controlling the oxygen supply, the temperatures, conversion, and product selectivity of the reaction can be in turn controlled and optimized. Furthermore the potential risks of explosion associated with mixing hydrocarbon and molecular oxygen is minimized with increased feed carbon-to-oxygen molar ratios.

Owner:PHILLIPS 66 CO

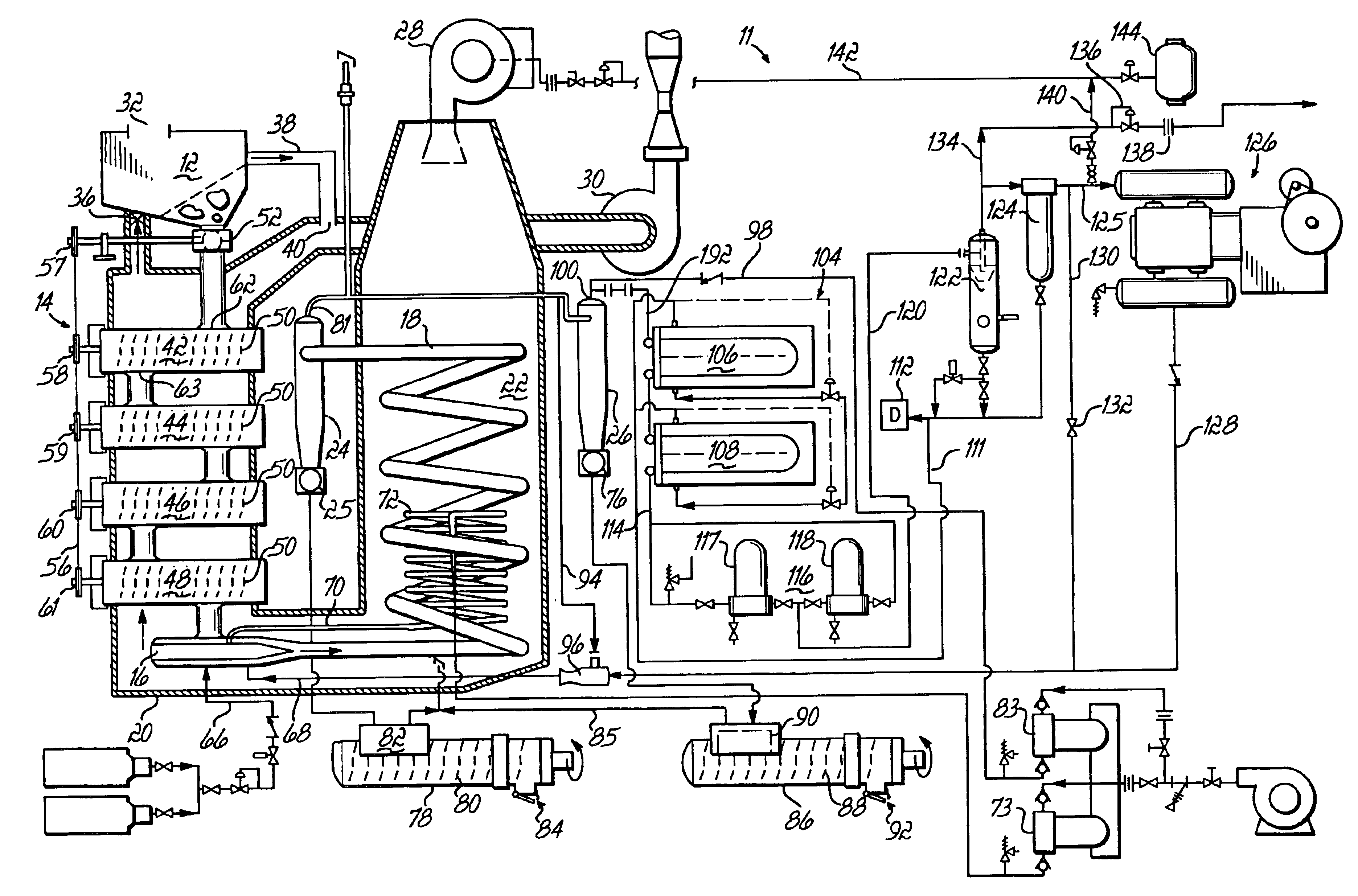

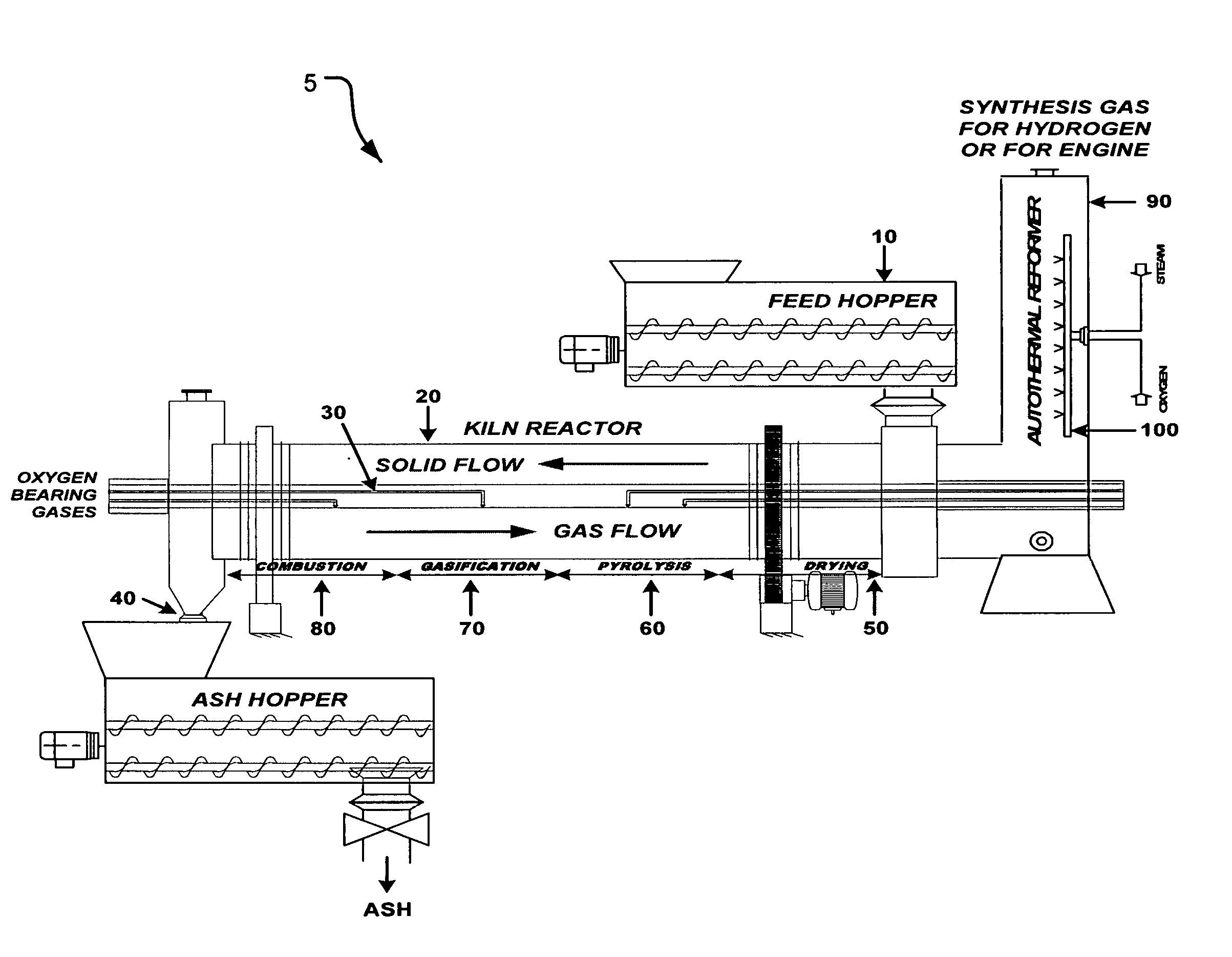

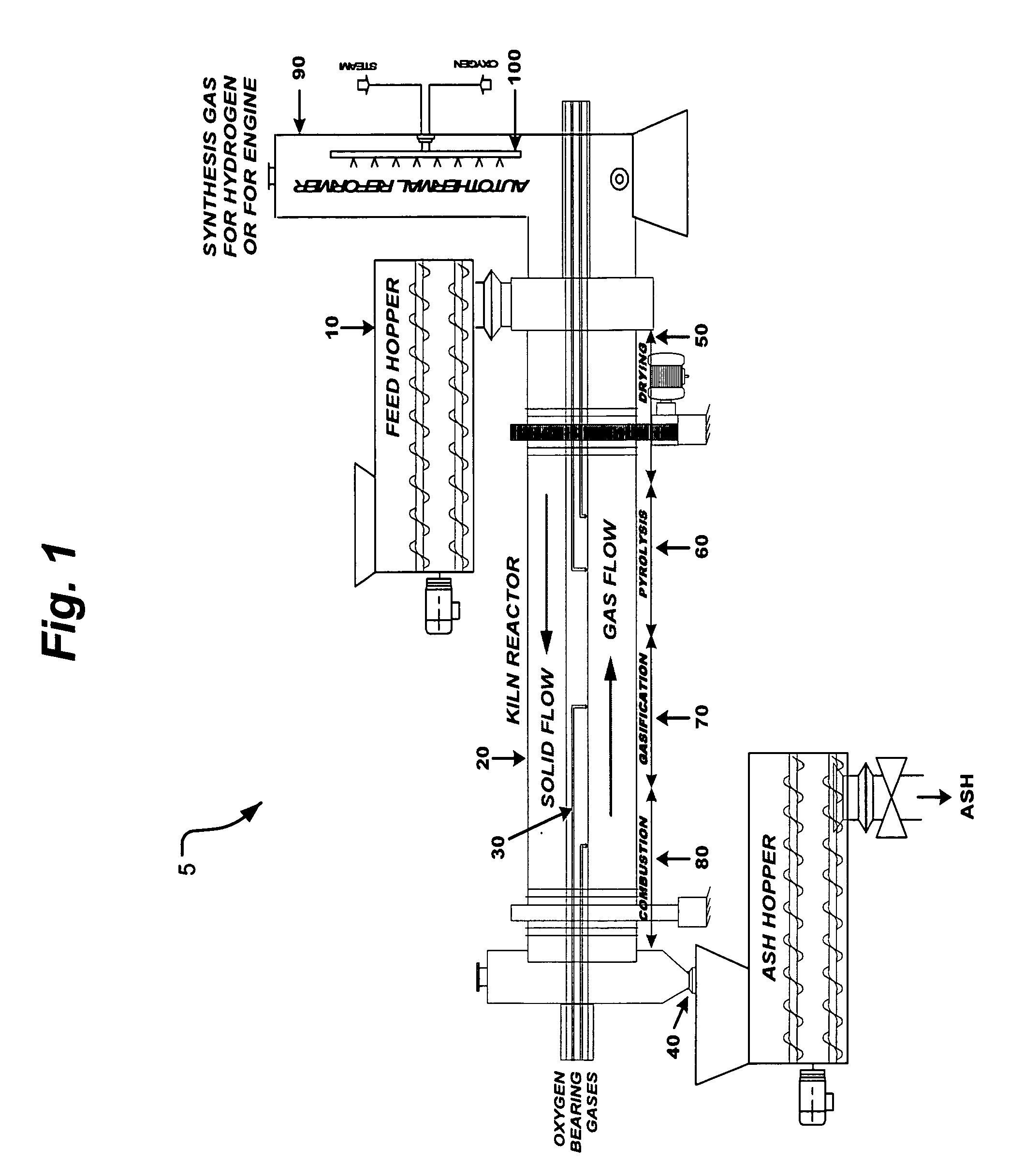

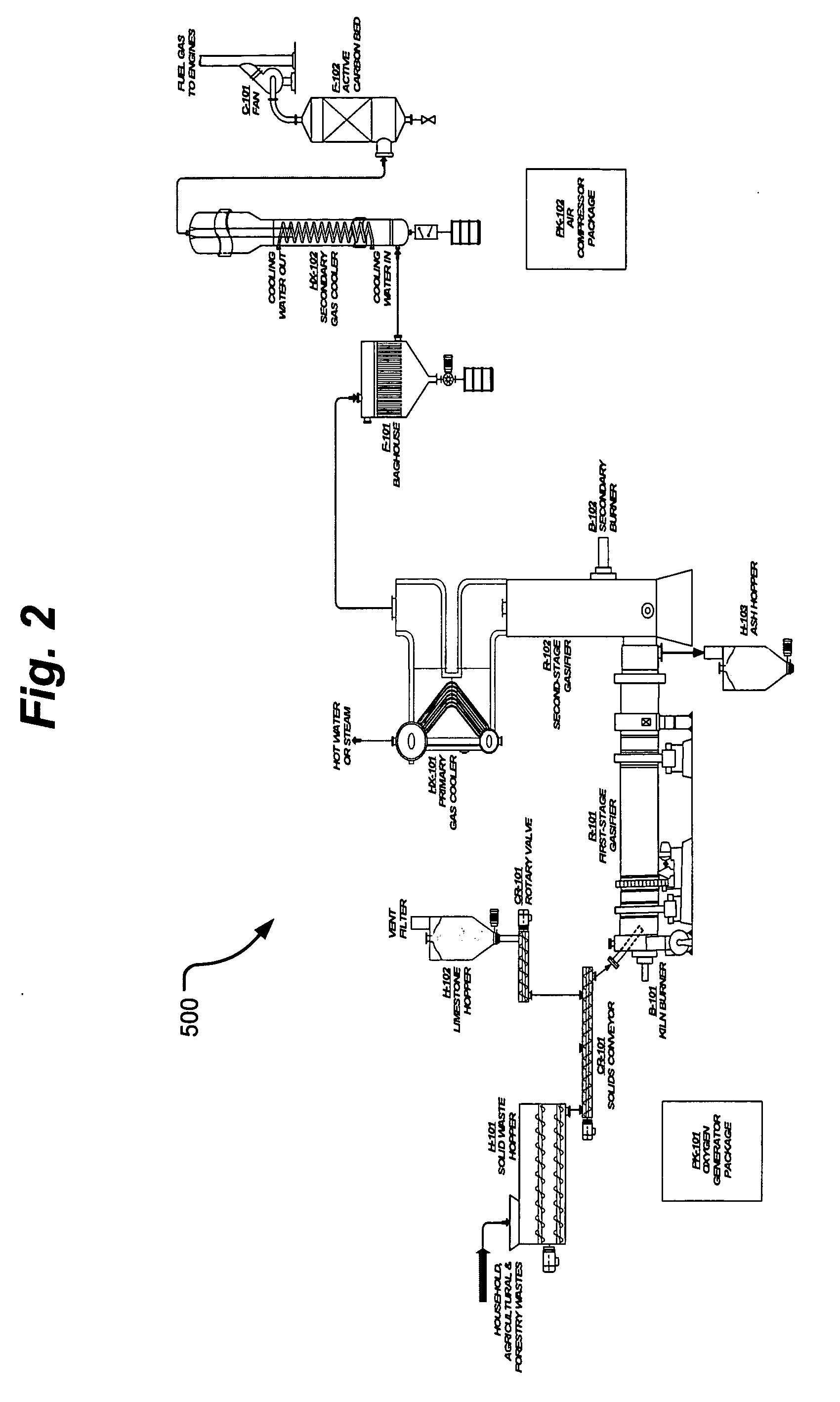

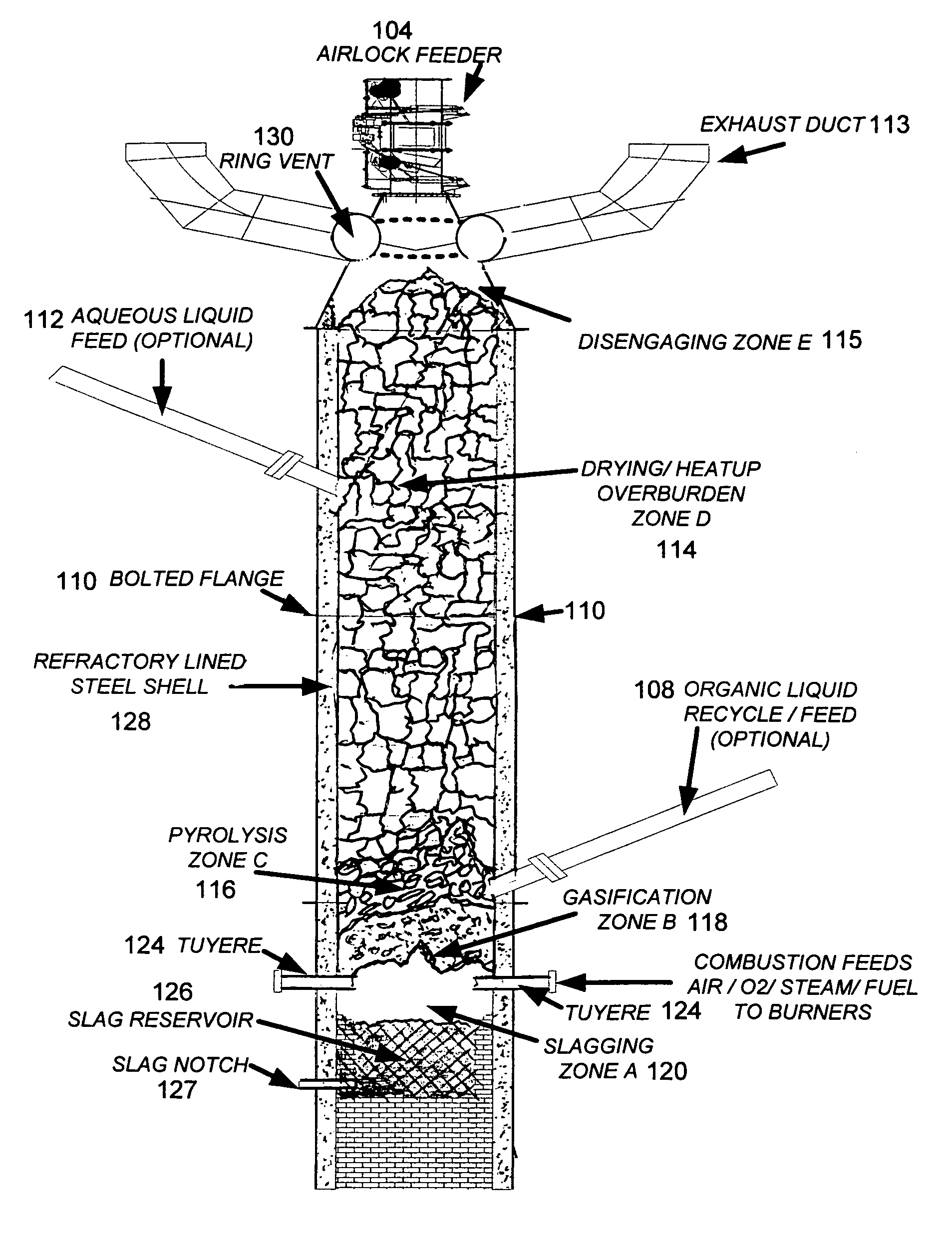

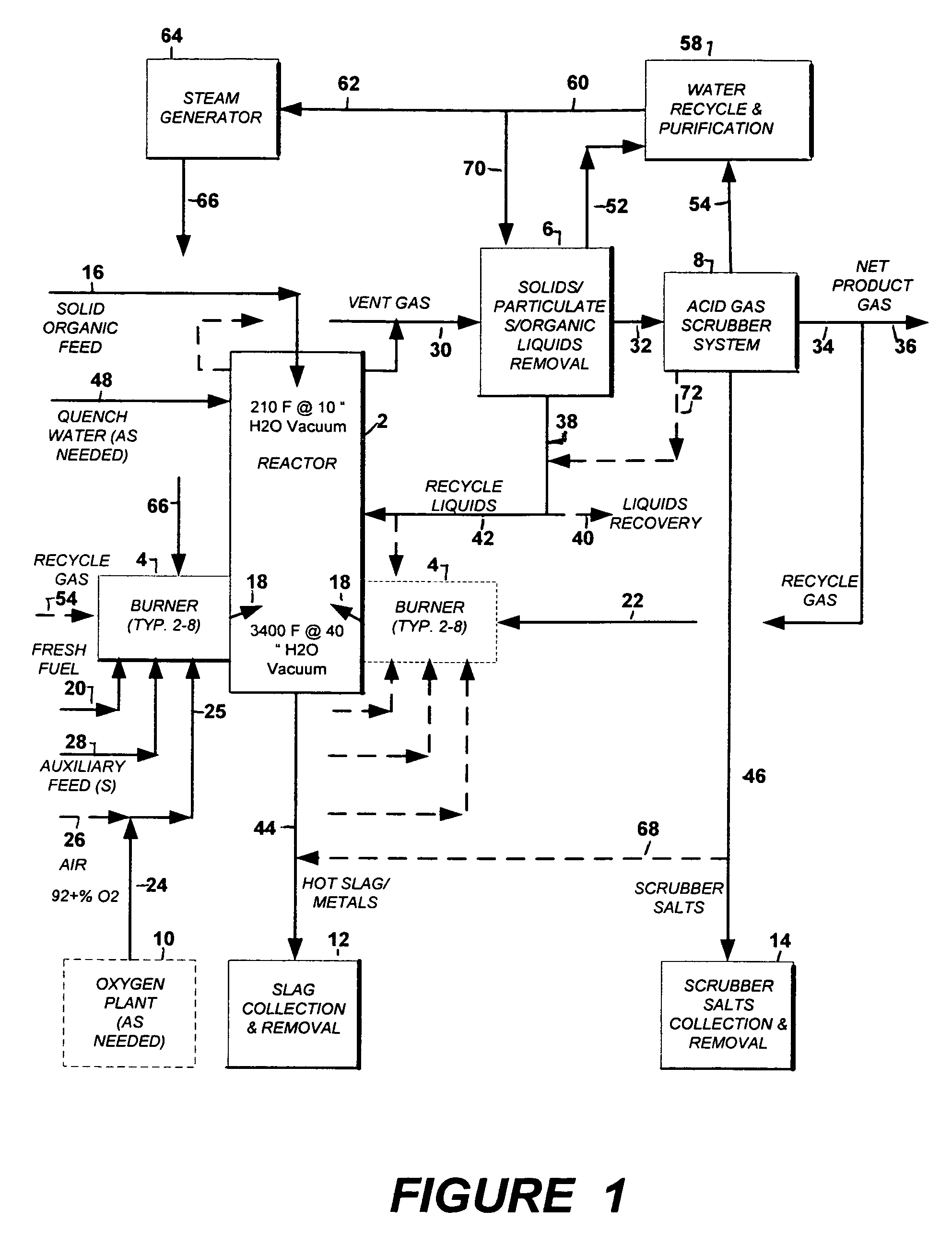

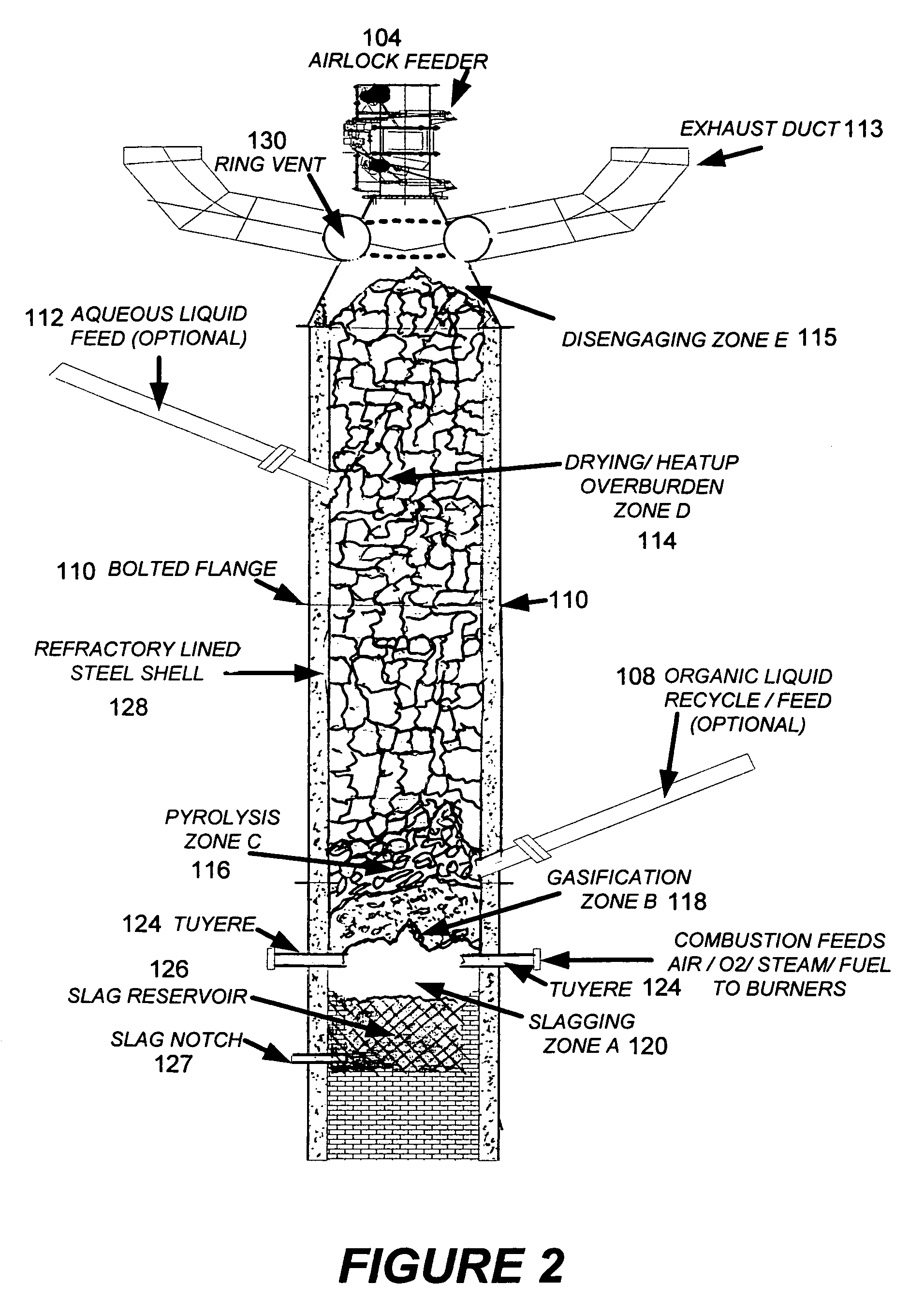

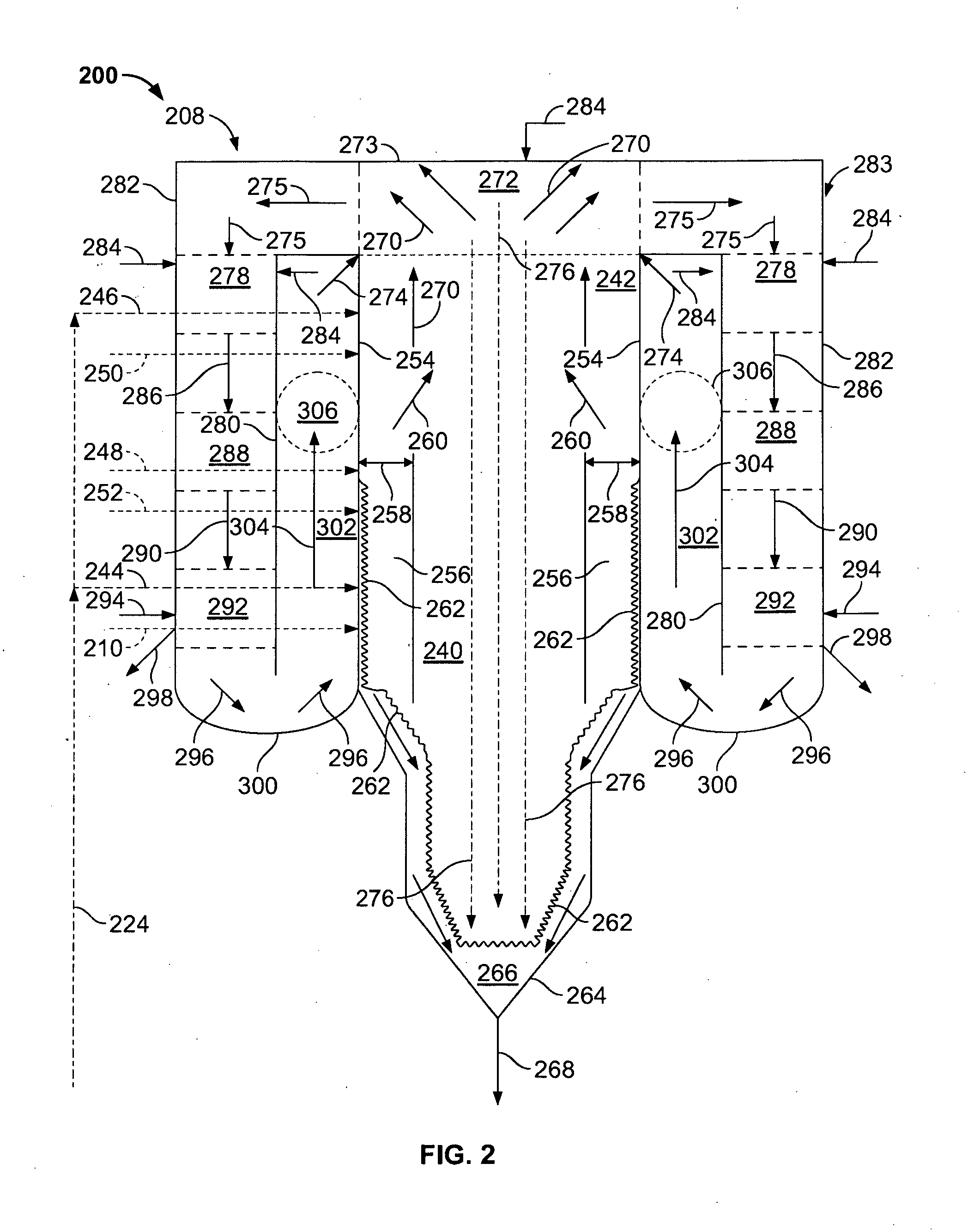

Process and apparatus for biomass gasification

InactiveUS20050095183A1Oxygen-containing compound preparationGasifier mechanical detailsForming gasTar

A waste-to-synthesis gas system including: a first gasifier for receiving biomass; a gas distributor for delivering reactant gas and oxygen into the first gasifier in a countercurrent direction to the biomass flow and to define a plurality of reaction regions including a drying region, a pyrolysis region, a gasification region and a combustion region; and, a second gasifier for receiving gases from the plurality of regions of the first gasifier and a gas distributor for delivering reactant gas and oxygen into the second gasifier in a concurrent direction to the flow of gases from the first gasifier. As a result, no carbon chars, oils or tars are expected to be present in the synthesis gas produced.

Owner:BIOMASS ENERGY SOLUTIONS

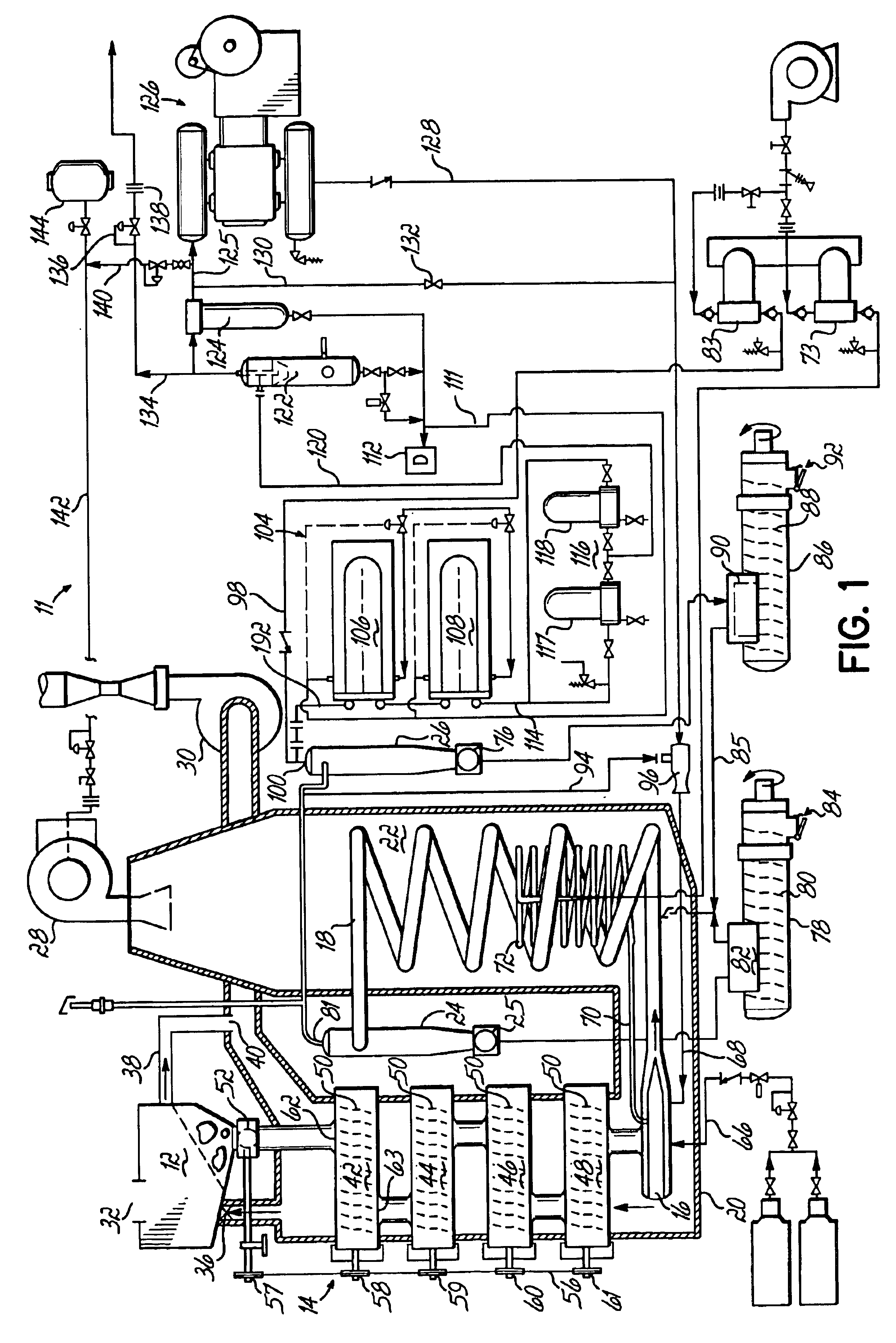

Process for pyrolytic heat recovery enhanced with gasification of organic material

InactiveUS7452392B2Improve throughputInhibition formationGas modification by gas mixingWaste based fuelThermal energyForming gas

This invention is a reactor and a process for the conversion of organic waste material such as municipal trash, sewage, post-consumer refuse, and biomass to commercially salable materials.The invention produces the following:1. Maximum energy conversion from the organic material2. High volume consumption of the organic feed material3. Less pollution of gaseous products than prior art systems4. Solid residuals for disposal are minimal and non-hazardous.The conversion is accomplished by combining anaerobic gasification and pyrolysis of the feed organic material and making it into synthetic gas. The synthetic gas is a mixture of hydrocarbons (CxHy), hydrogen, and carbon monoxide with small amounts of carbon dioxide and nitrogen. An essential feature of the invention is a hot driver gas, devoid of free oxygen and rich in water, which supplies the entire thermal and chemical energy needed for the reactions. This hot driver gas is produced by complete sub-stoichiometric combustion of the fuel (CxHy) before it enters the reactor.

Owner:NICK PETER A +4

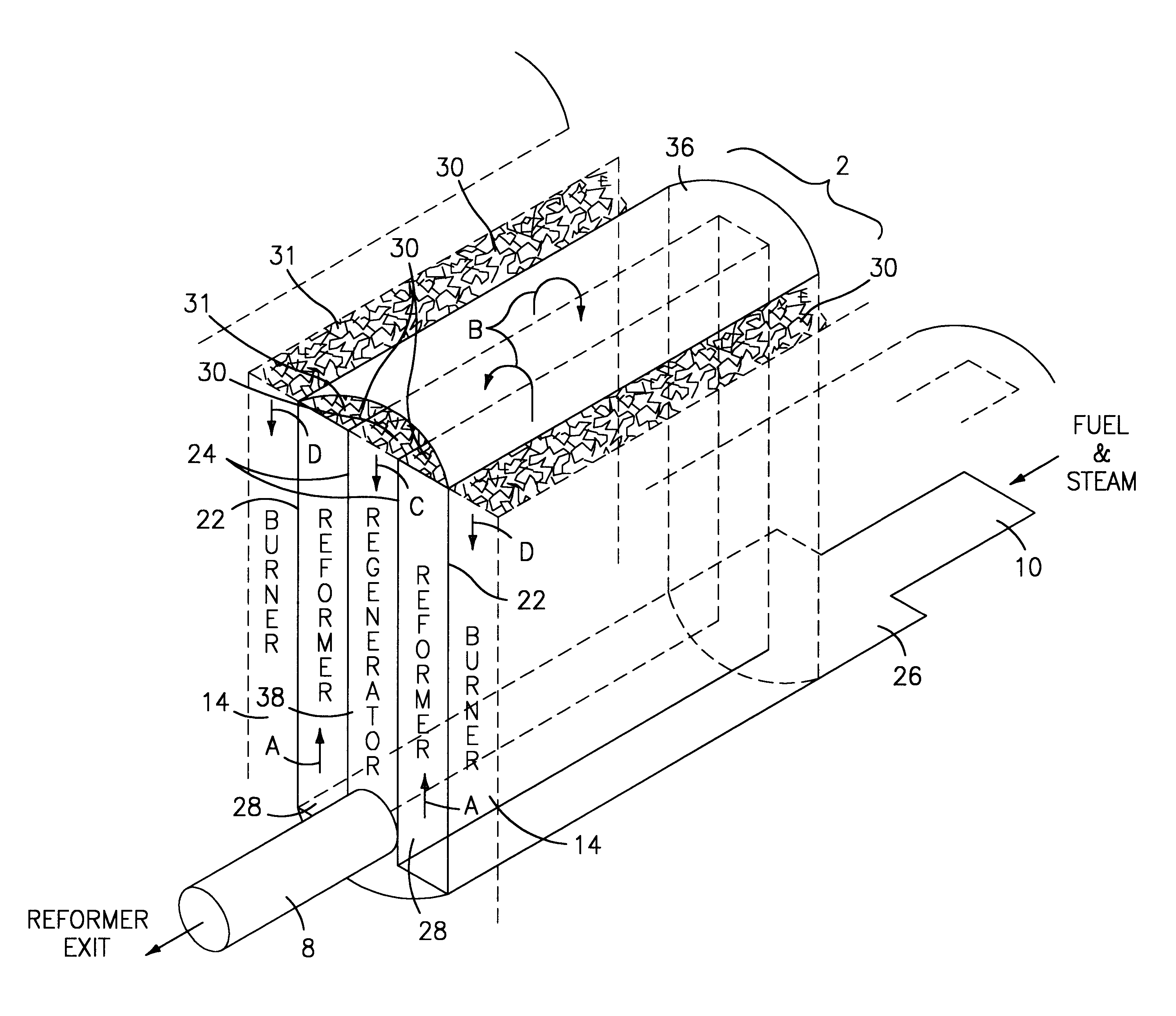

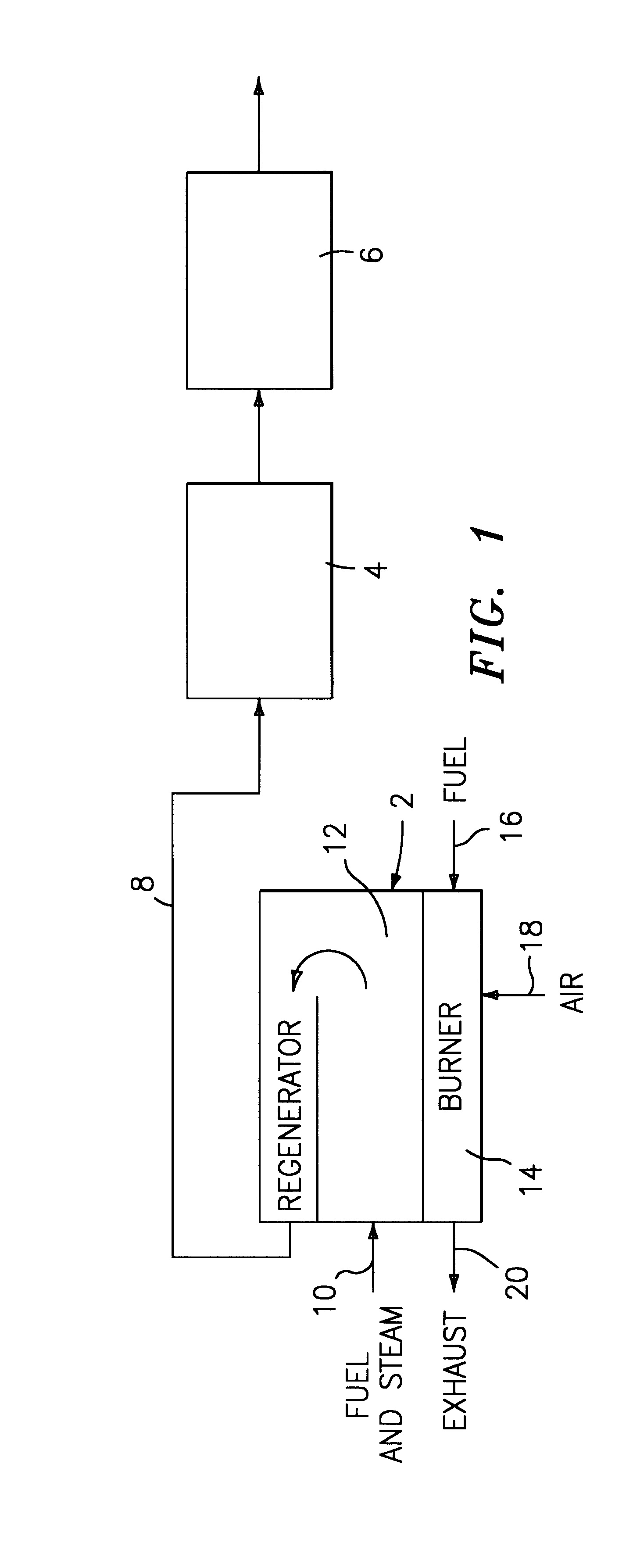

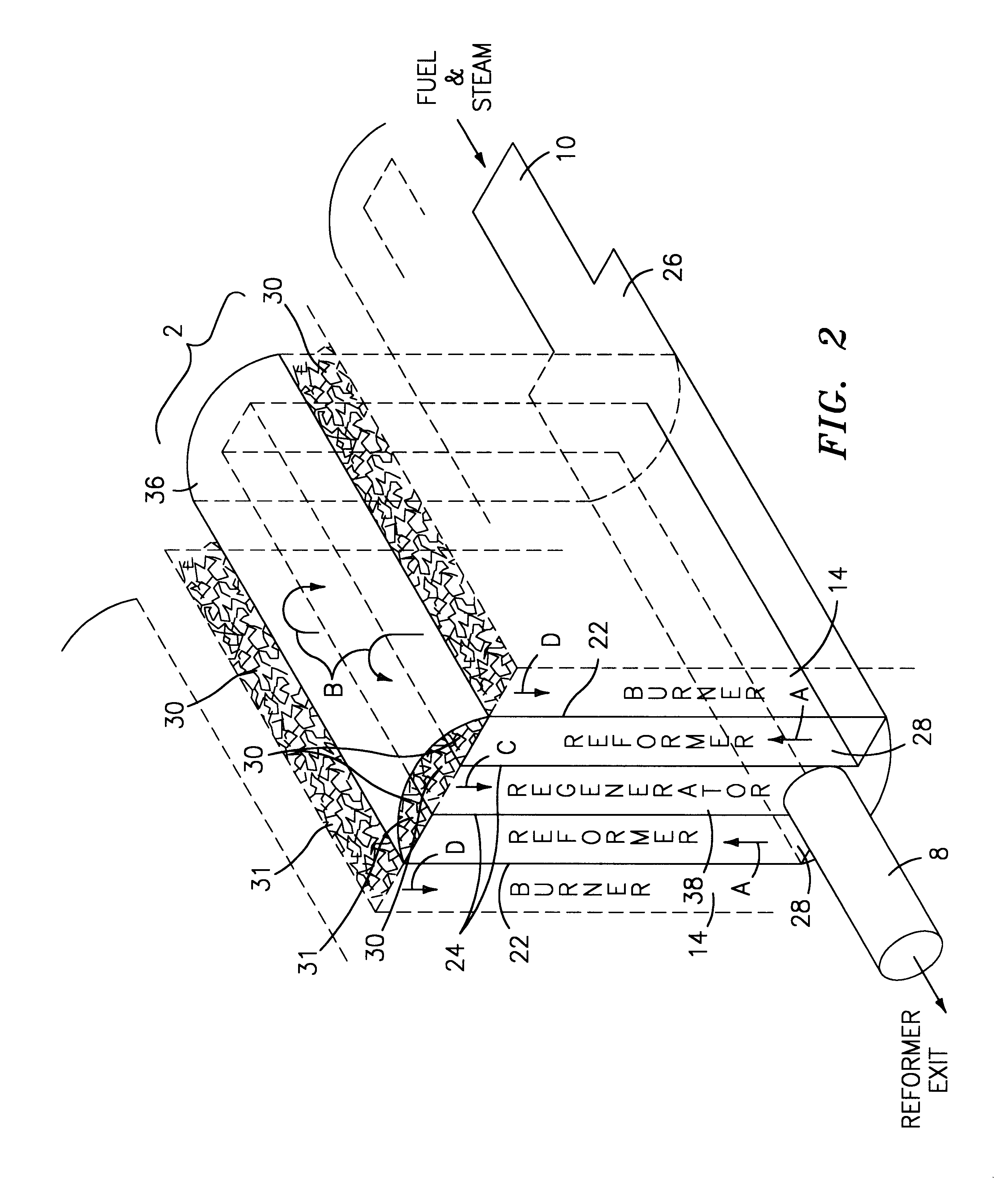

Compact fuel gas reformer assemblage

InactiveUS6203587B1Improve heat transfer performanceReduce the temperatureSemi-permeable membranesHydrogen separation using solid contactFuel cellsForming gas

A fuel gas reformer assemblage for use in a fuel cell power plant is formed from a composite plate assembly which includes spaced-apart divider plates with interposed monolithic open cell sponge-like members which form gas passages. The monolithic members have a lattice of internal open cells which are both laterally and longitudinally interconnected so as to provide for a diffuse gas flow. The entire surface area of the monolithic components is wash coated with a porous alumina layer, and selected areas of the wash coat are also catalyzed. The reformer assemblage is constructed from a series of repeating sub-assemblies, each of which includes a core of separate regenerator / heat exchanger gas passages. The core in each sub-assembly is sandwiched between a pair of reformer gas passage skins, which complete the subassembly. Adjacent reformer gas / regenerator / reformer gas passage sub-assemblies in the composite plate assembly are separated from each other by burner gas passages. The regenerator / heat exchanger gas passages and the reformer gas passages in each sub-assembly are connected by gas flow return manifolds which form a part of each sub-assembly. The fuel gases flow in one end of the assemblage, through the reformer gas passages, and then reverse their direction of flow in the return manifolds so as to exit the reformer assemblage through the regenerator gas flow passages. The burner gases flow in one end of the reformer assemblage and out the other end.

Owner:INT FUEL CELLS

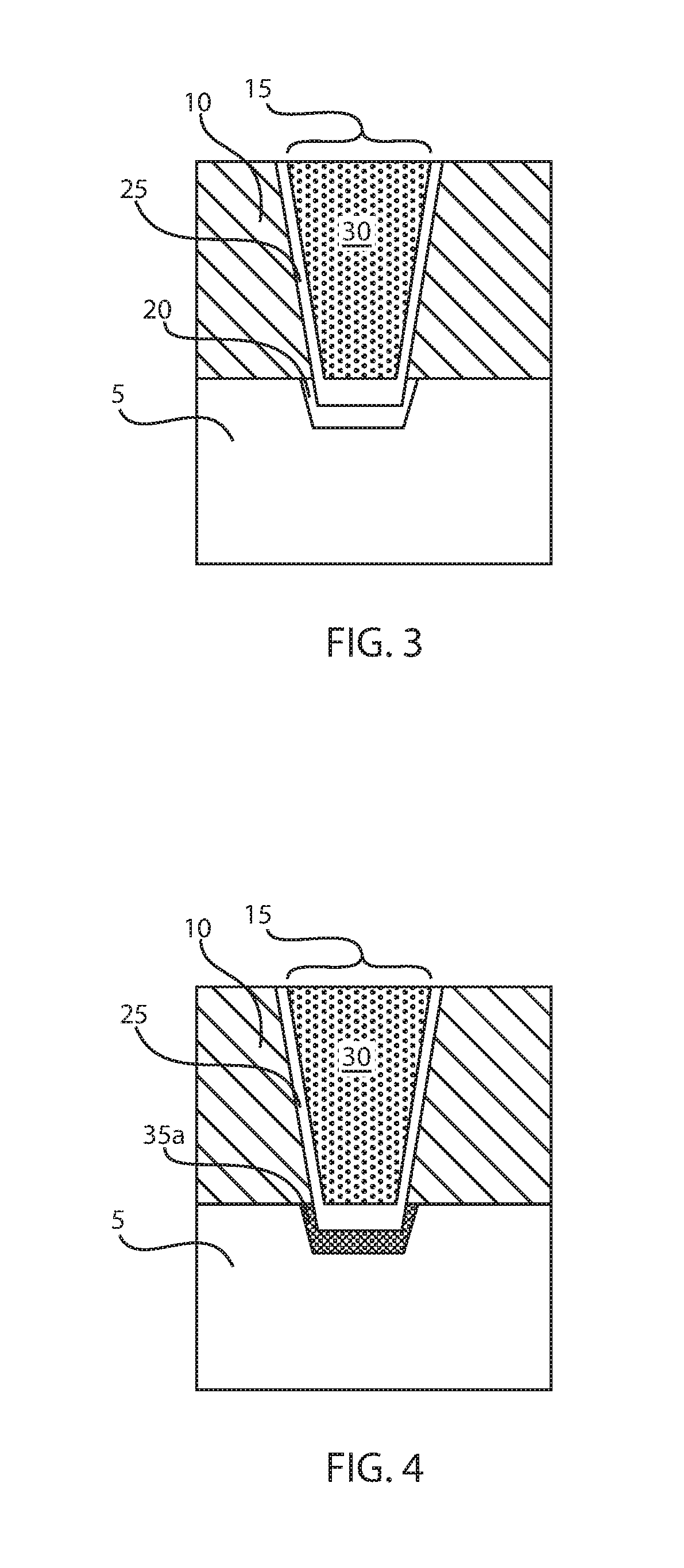

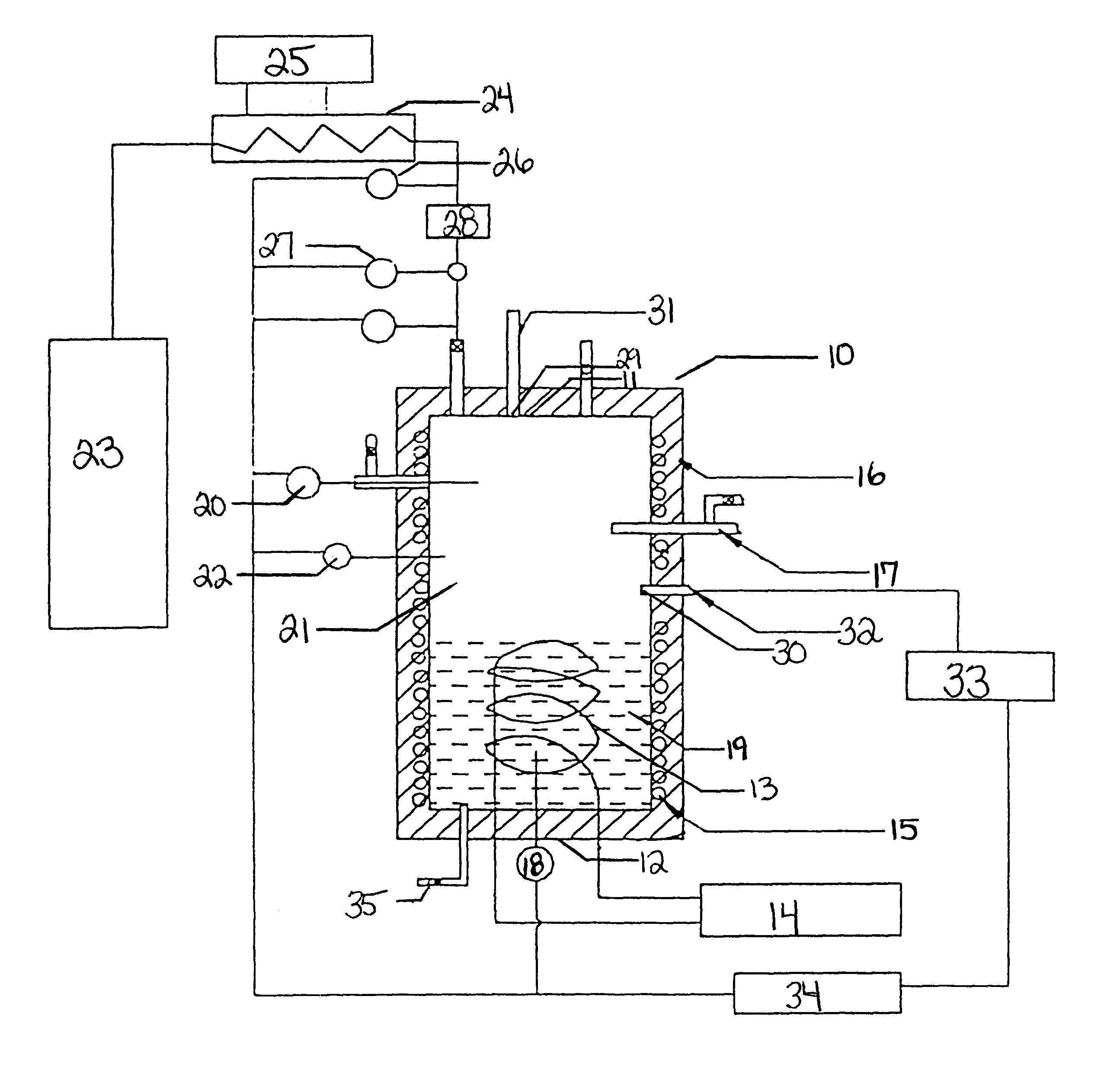

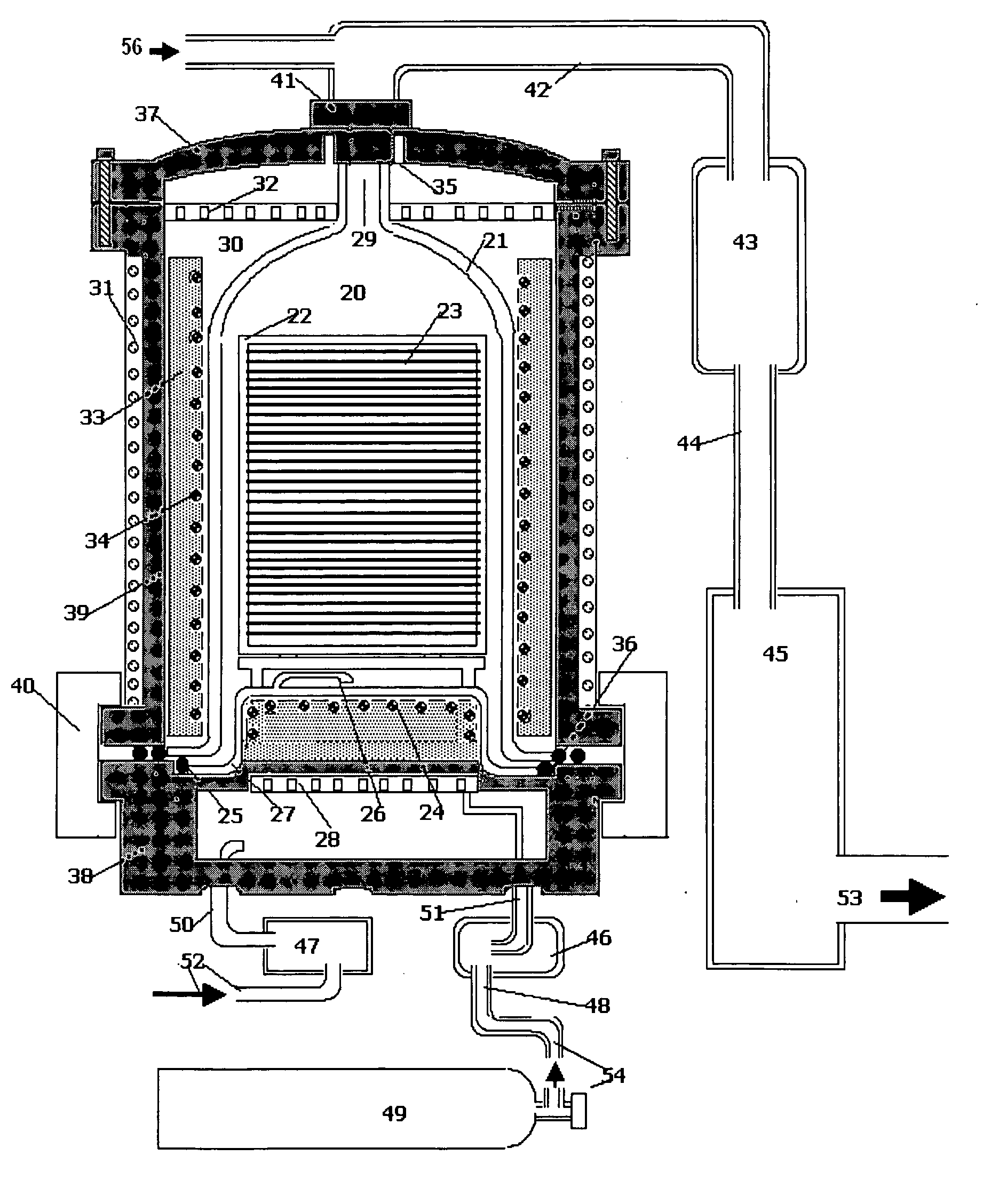

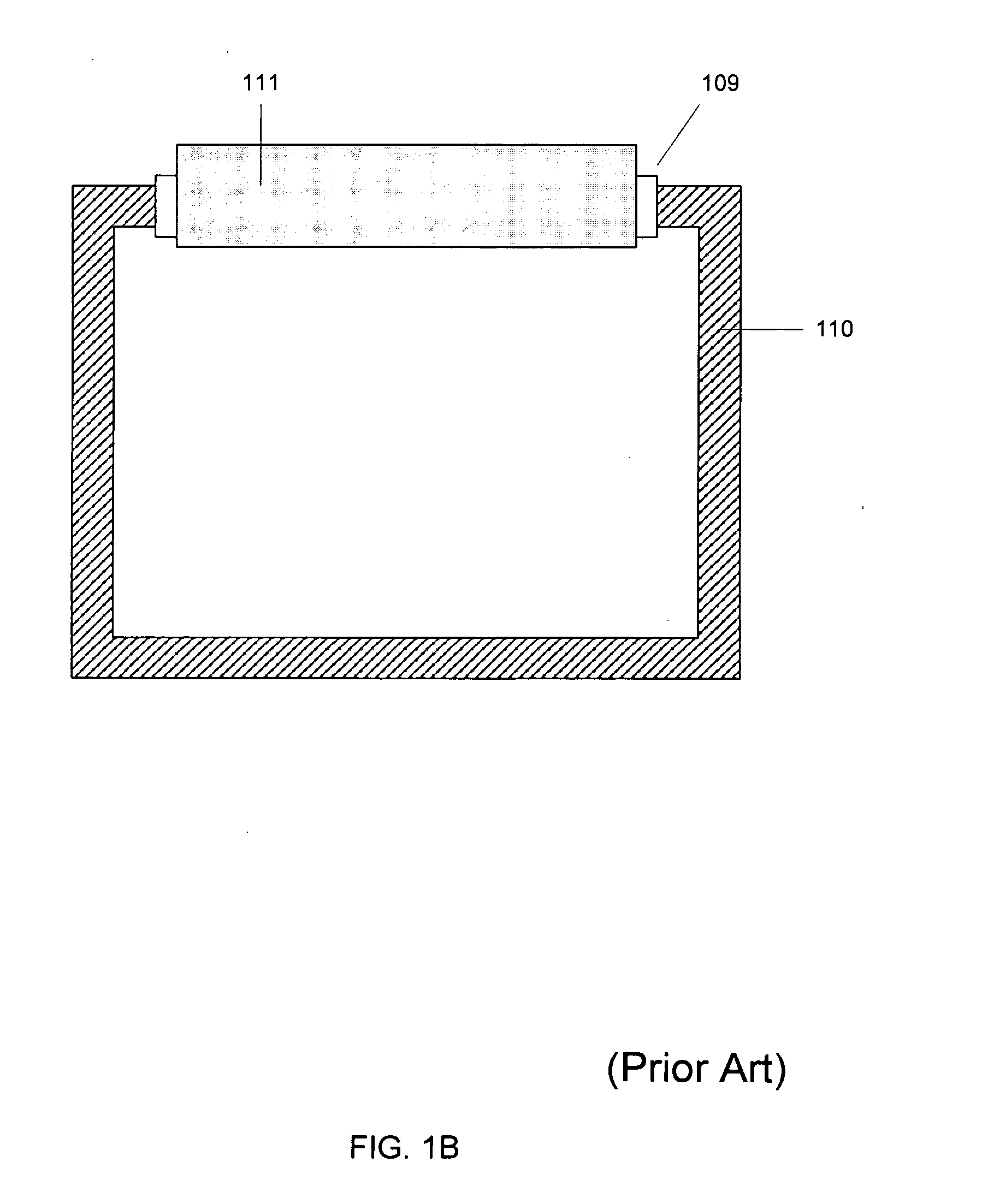

Methods and apparatuses for high pressure gas annealing

InactiveUS20070187386A1Improve device performanceIncrease device 's lifetimeSemiconductor/solid-state device testing/measurementSolid-state devicesForming gasGate dielectric

Novel methods and apparatuses for annealing semiconductor devices in a high pressure gas environment. According to an embodiment, the annealing vessel has a dual chamber structure, and potentially toxic, flammable, or otherwise reactive gas is confined in an inner chamber which is protected by pressures of inert gas contained in the outer chamber. The incoming gas delivery system and exhaust gas venting system are likewise protected by various methods. Embodiments of the present invention can be used, for example, for high-K gate dielectric anneal, post metallization sintering anneal, and forming gas anneal in the semiconductor manufacturing process.

Owner:PSMC

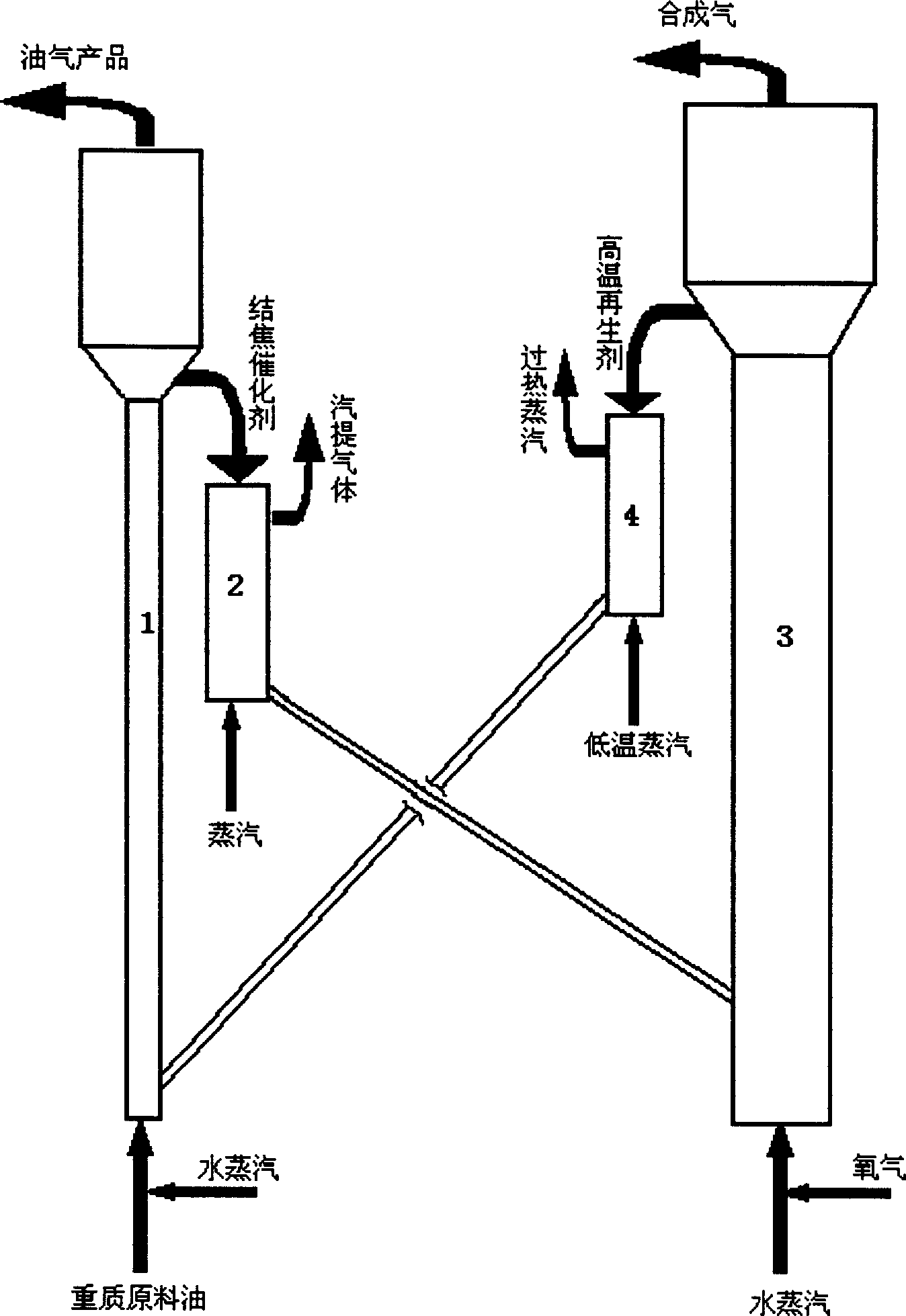

Process combined oil refining and gasification

A process of oil refining and gasification comprising the steps of, (1) petroleum hydrocarbon and coke transfer agent contacting and reacting in reactor, (2) separating produced reaction oil gas and residual coke transfer agent after reaction, (3) coke transfer agent contacting water vapor and oxygen-containing gas under gasification condition to produce formed gas, (4) returning the regenerated coke transfer agent back to reactor in step (1) for circulation use. The process by the invention can not only improve the quality of heavy petroleum hydrocarbon, but also provide cheap raw material gas for hydrogen production process or C1 chemistry.

Owner:CHINA PETROLEUM & CHEM CORP +1

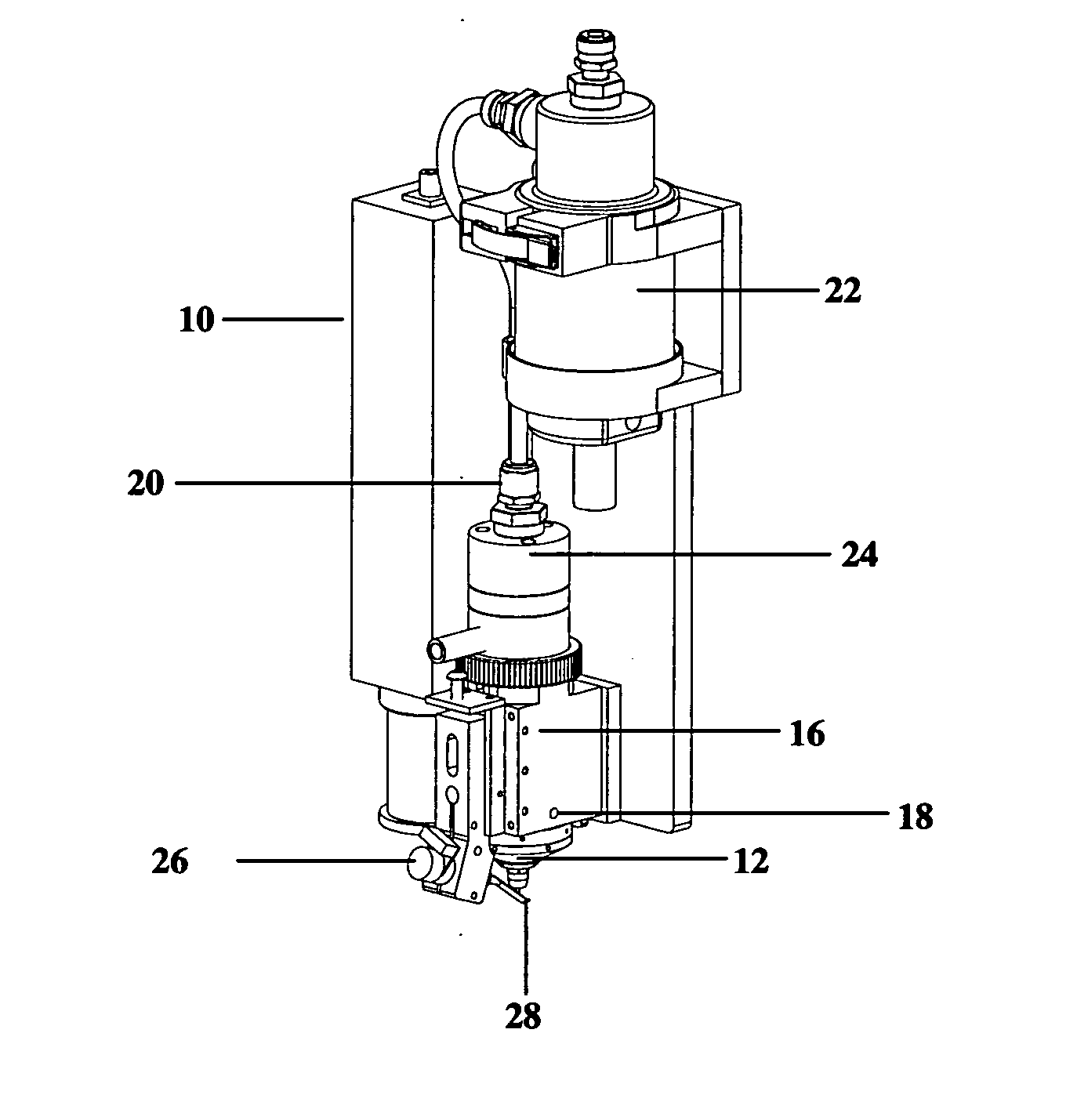

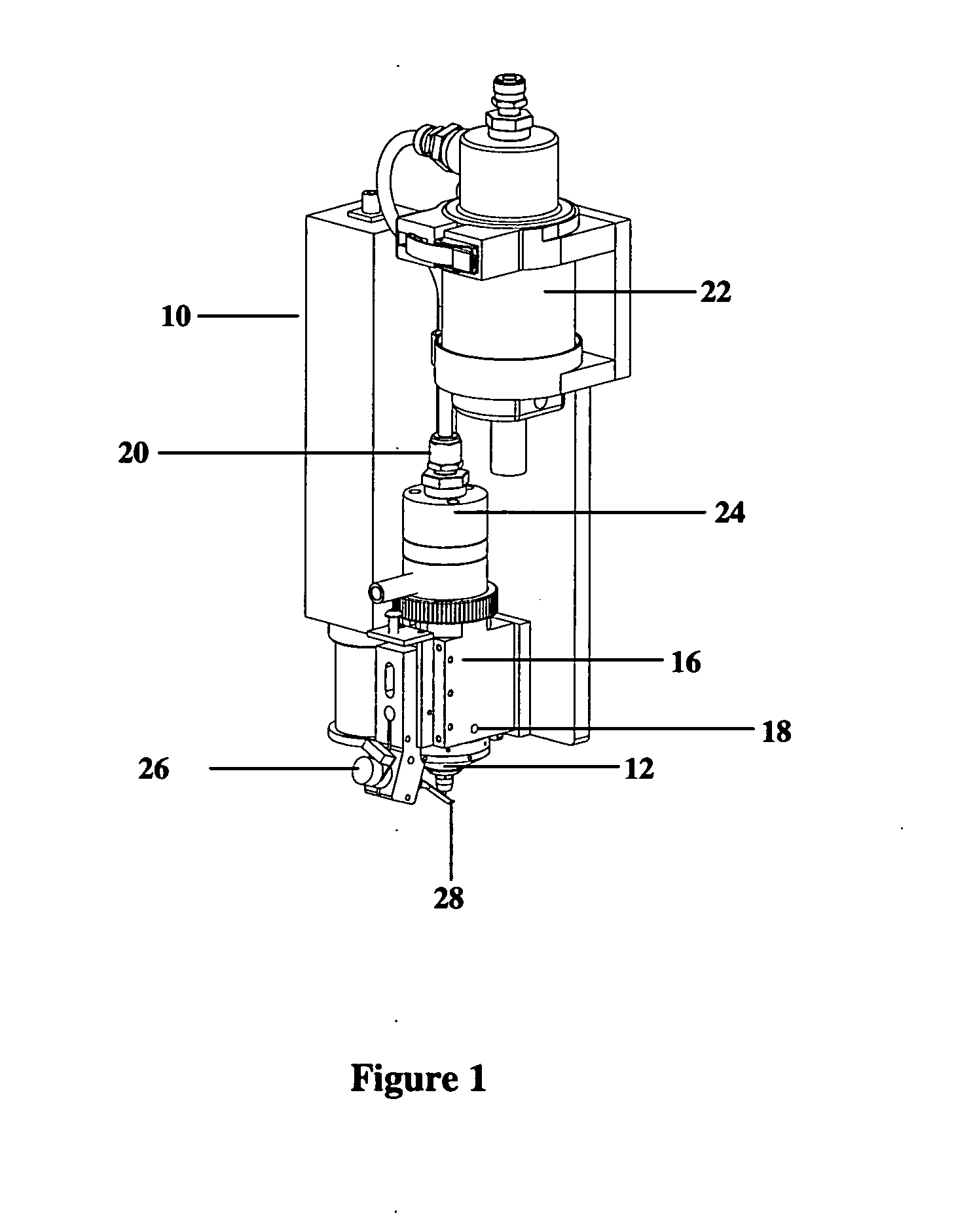

Laser processing for heat-sensitive mesoscale deposition of oxygen-sensitive materials

InactiveUS20070019028A1Damage to materialRadiation applicationsPretreated surfacesForming gasHeat sensitive

A method of depositing various materials onto heat-sensitive targets, particularly oxygen-sensitive materials. Heat-sensitive targets are generally defined as targets that have thermal damage thresholds that are lower than the temperature required to process a deposited material. The invention uses precursor solutions and / or particle or colloidal suspensions, along with optional pre-deposition treatment and / or post-deposition treatment to lower the laser power required to drive the deposit to its final state. The present invention uses Maskless Mesoscale Material Deposition (M3D™) to perform direct deposition of material onto the target in a precise, highly localized fashion. Features with linewidths as small as 4 microns may be deposited, with little or no material waste. A laser is preferably used to heat the material to process it to obtain the desired state, for example by chemical decomposition, sintering, polymerization, and the like. This laser processing may be performed in an ambient environment with laser powers of less than 100 milliwatts. Cover gases and / or forming gases may be used during thermal processing to change the material properties, for example by preventing oxidation.

Owner:OPTOMEC DESIGN CO

Biochar Compositions and Methods of Use Thereof

ActiveUS20150128672A1Enhanced and functionalizedNitrogenous fertilisersOrganic fertilisersForming gasBiological activation

The invention provides for methods, devices, and systems for pyrolyzing biomass. A pyrolysis unit can be used for the pyrolysis of biomass to form gas, liquid, and solid products. The biomass materials can be selected such that an enhanced biochar is formed after pyrolysis. The biomass can be pyrolyzed under specified conditions such that a selected biochar core is formed. The pyrolysis process can form a stable biochar core that is inert and / or resistant to degradation. The biochar or biochar core can be functionalized to form a functionalized biochar or functionalized biochar core. Functionalized can include post-pyrolysis treatments such as supplementation with microbes or physical transformations including annealing and / or activation.

Owner:FULL CIRCLE BIOCHAR

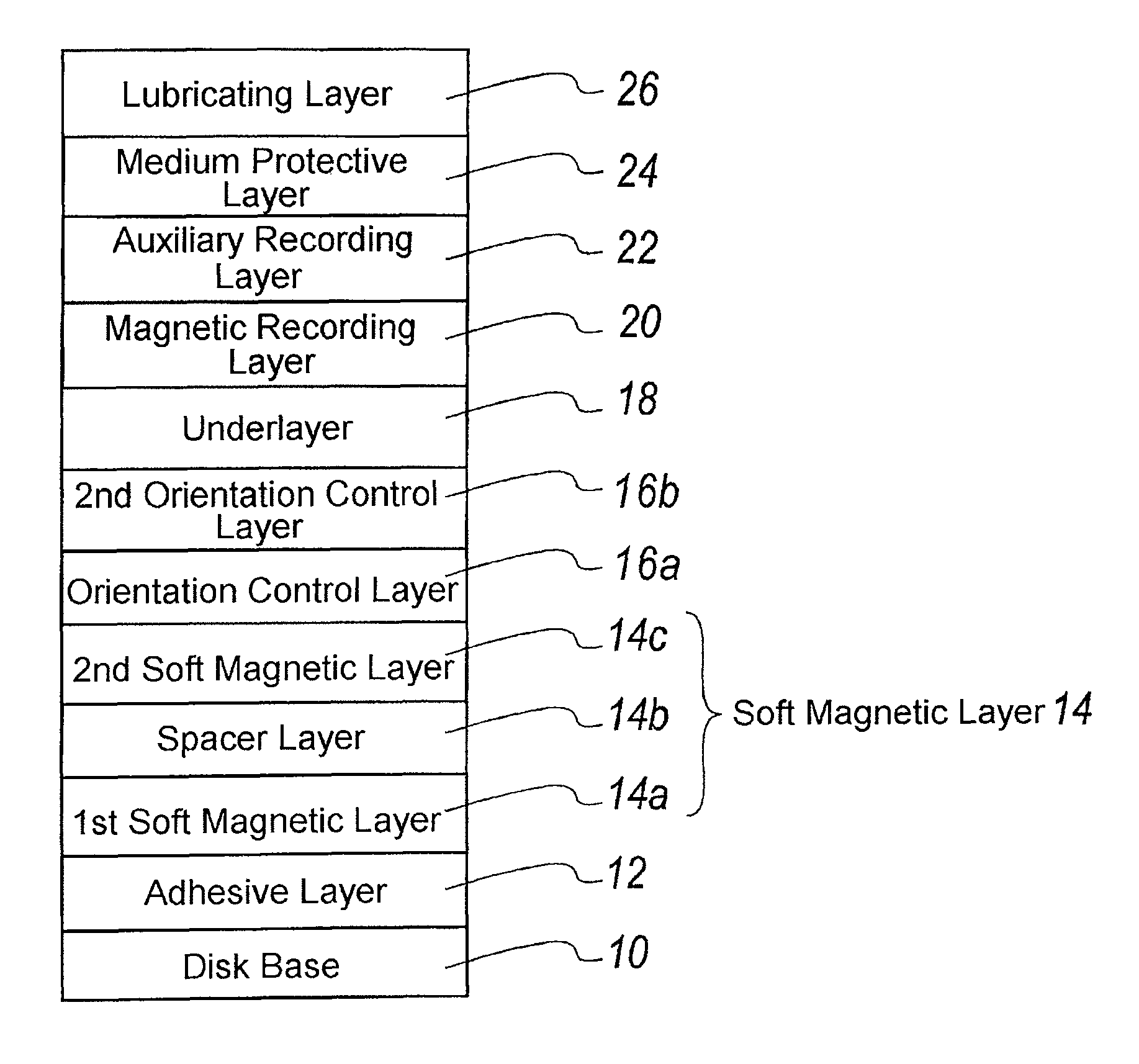

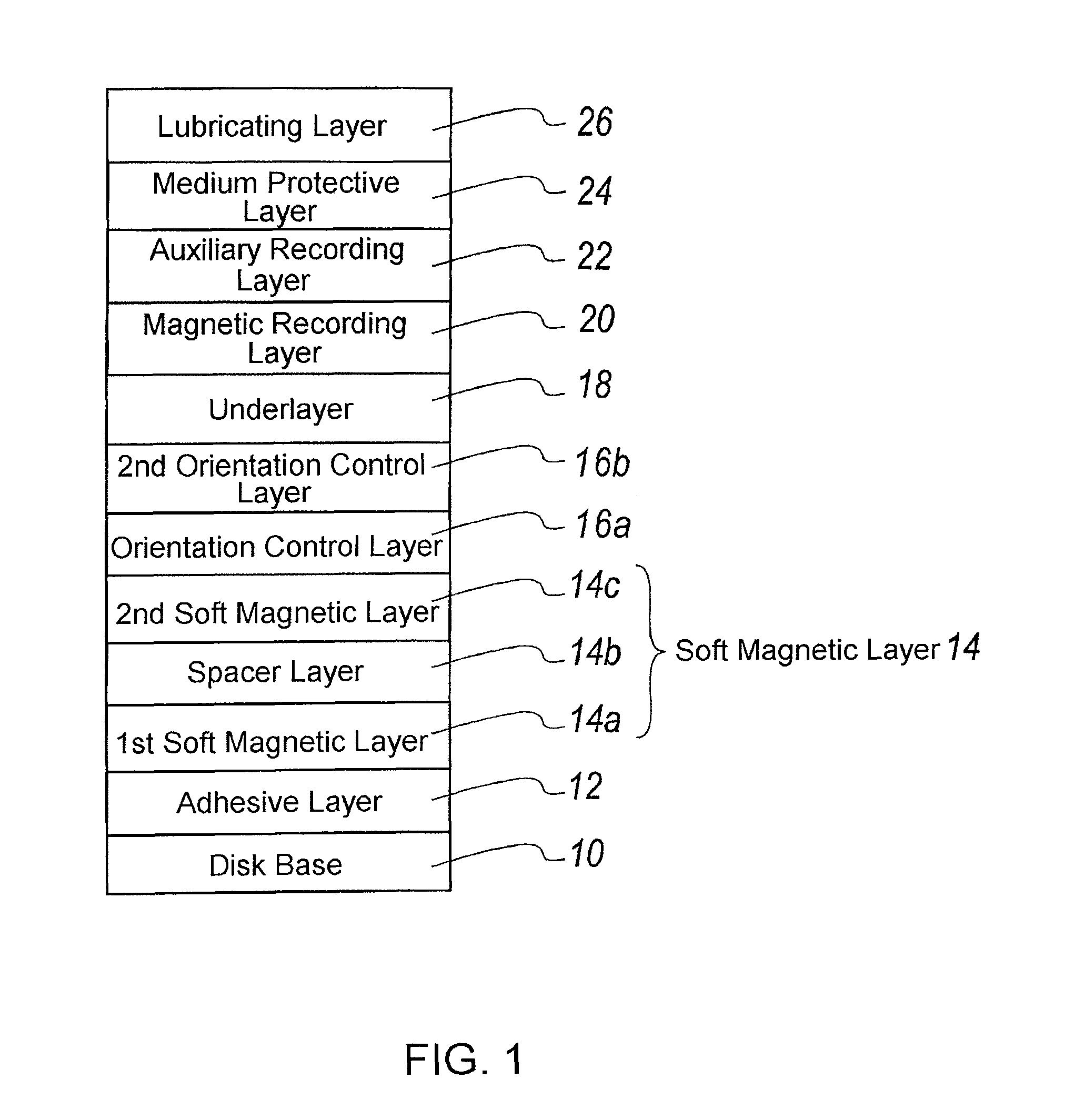

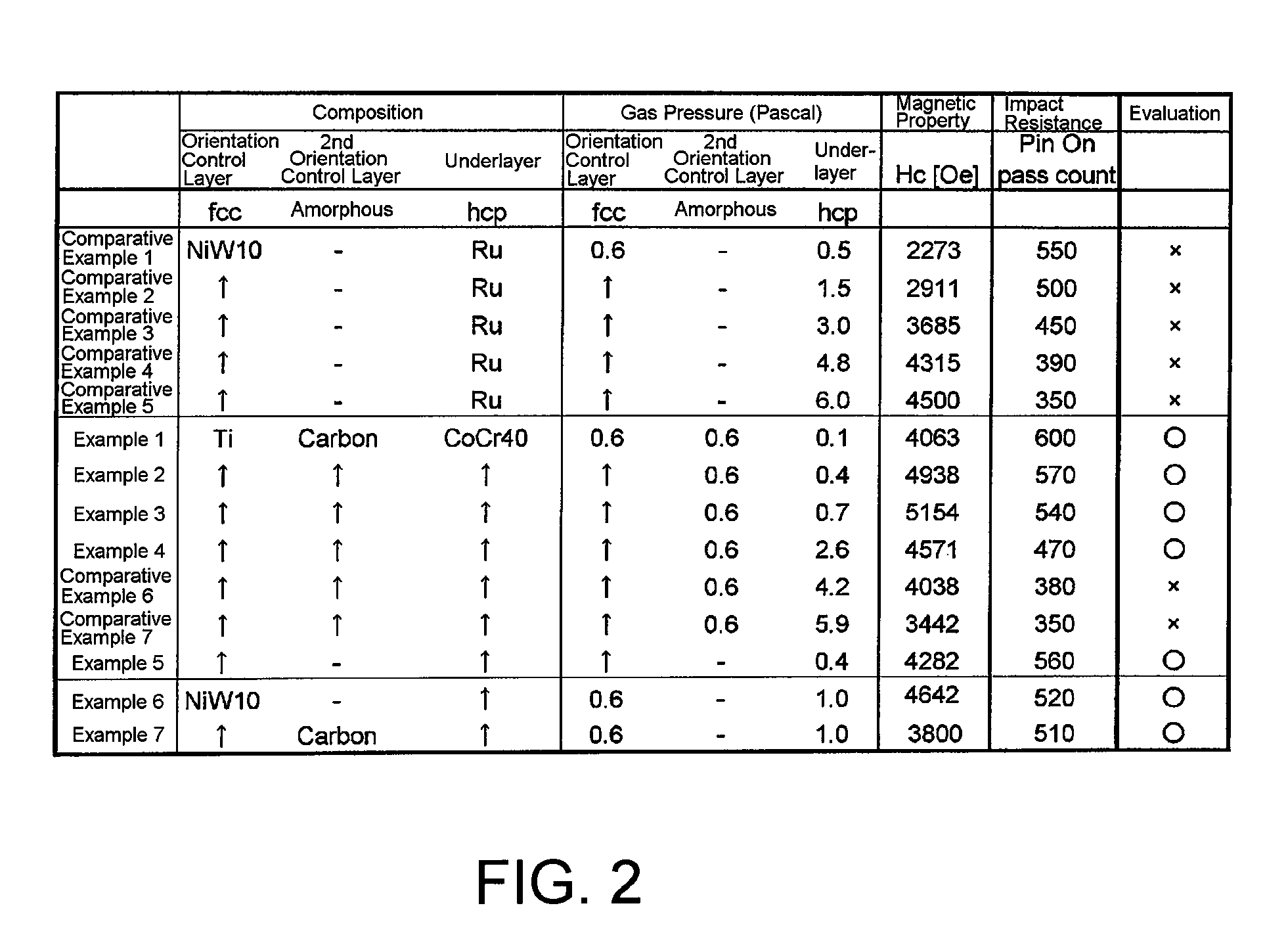

Method of manufacturing a perpendicular magnetic recording medium

ActiveUS8298689B2Improve coercive forceImprove recording densityRecord information storageCoating by sputteringForming gasRecording layer

Owner:WESTERN DIGITAL TECH INC

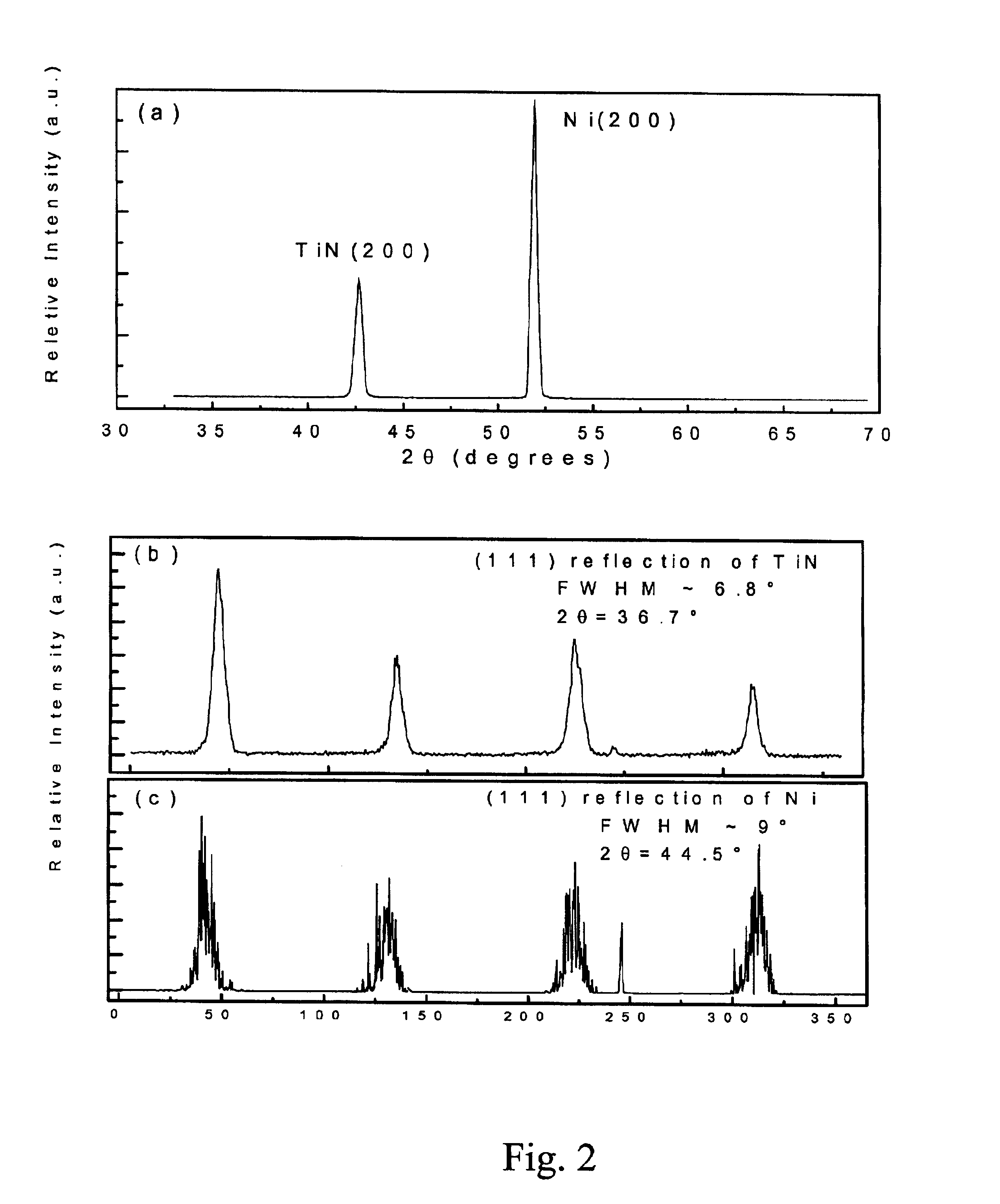

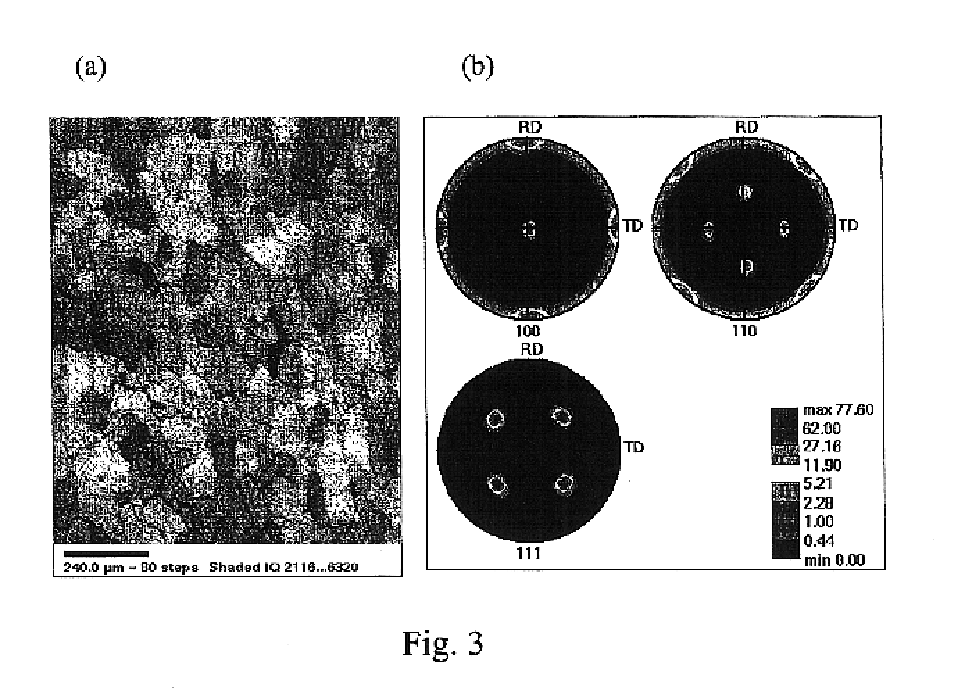

Conductive and robust nitride buffer layers on biaxially textured substrates

InactiveUS6784139B1Wide range of ingredientsReduce interface stressSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentForming gasAlloy

The present invention relates to epitaxial, electrically conducting and mechanically robust, cubic nitride buffer layers deposited epitaxially on biaxially textured substrates such as metals and alloys. The invention comprises of a biaxially textured substrate with epitaxial layers of nitrides. The invention also discloses a method to form such epitaxial layers using a high rate deposition method as well as without the use of forming gases. The invention further comprises epitaxial layers of oxides on the biaxially textured nitride layers. In some embodiments the article further comprises electromagnetic devices which may be super conducting properties.

Owner:APPL THIN FILMS INC +1

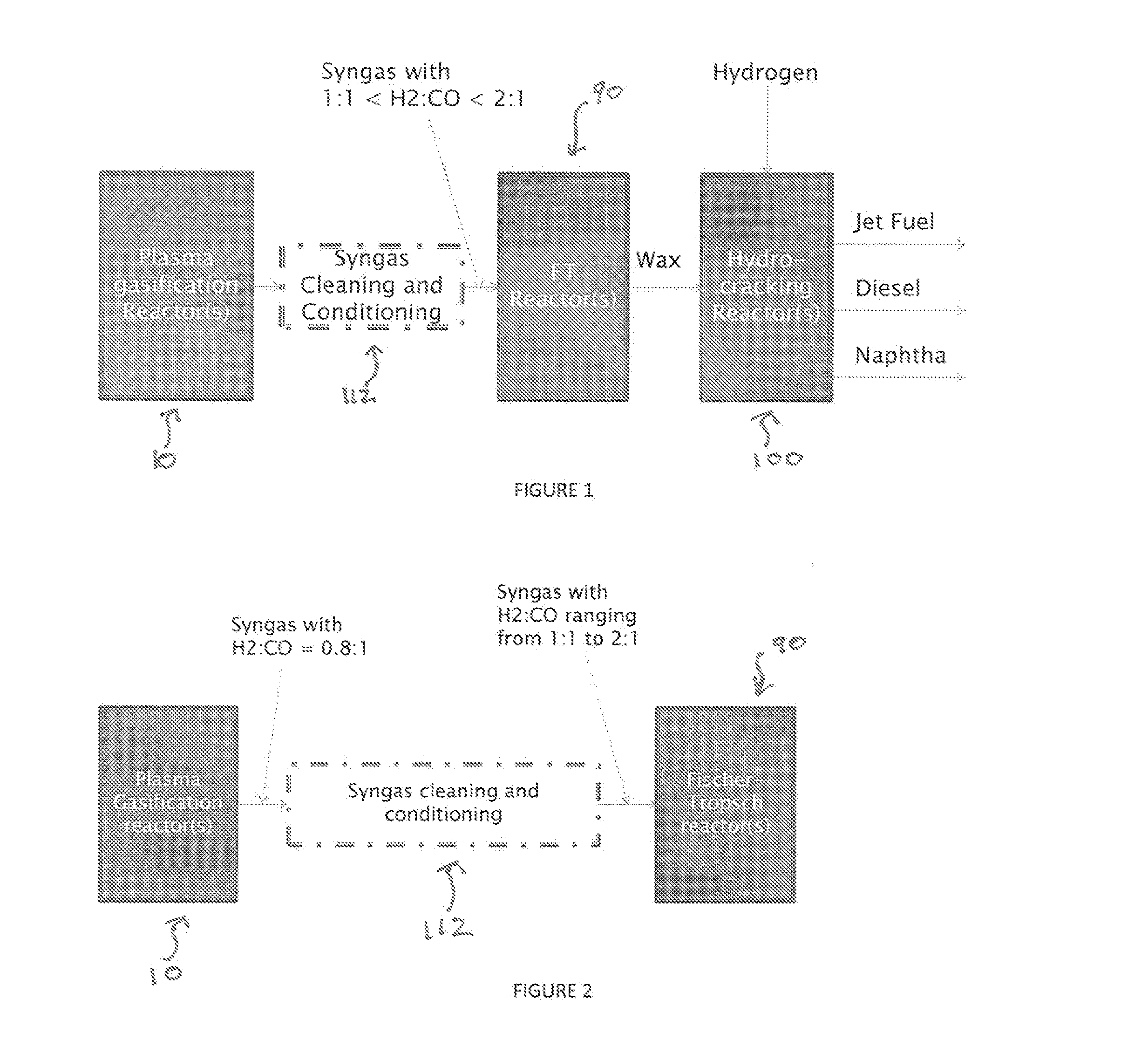

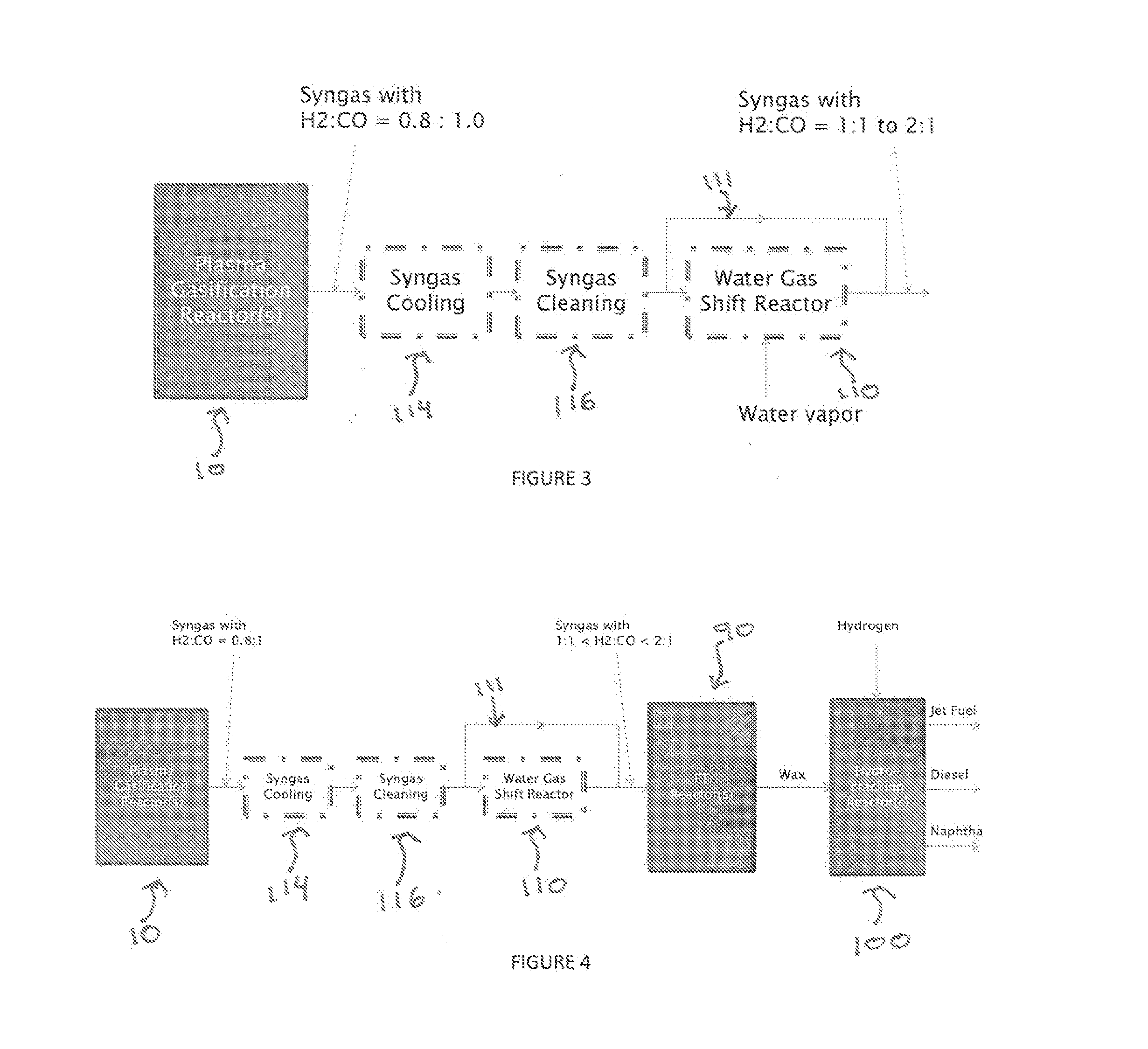

Producing Liquid Fuel from Organic Material such as Biomass and Waste Residues

InactiveUS20140224706A1Combustible gas catalytic treatmentGas modification by gas mixingWaxForming gas

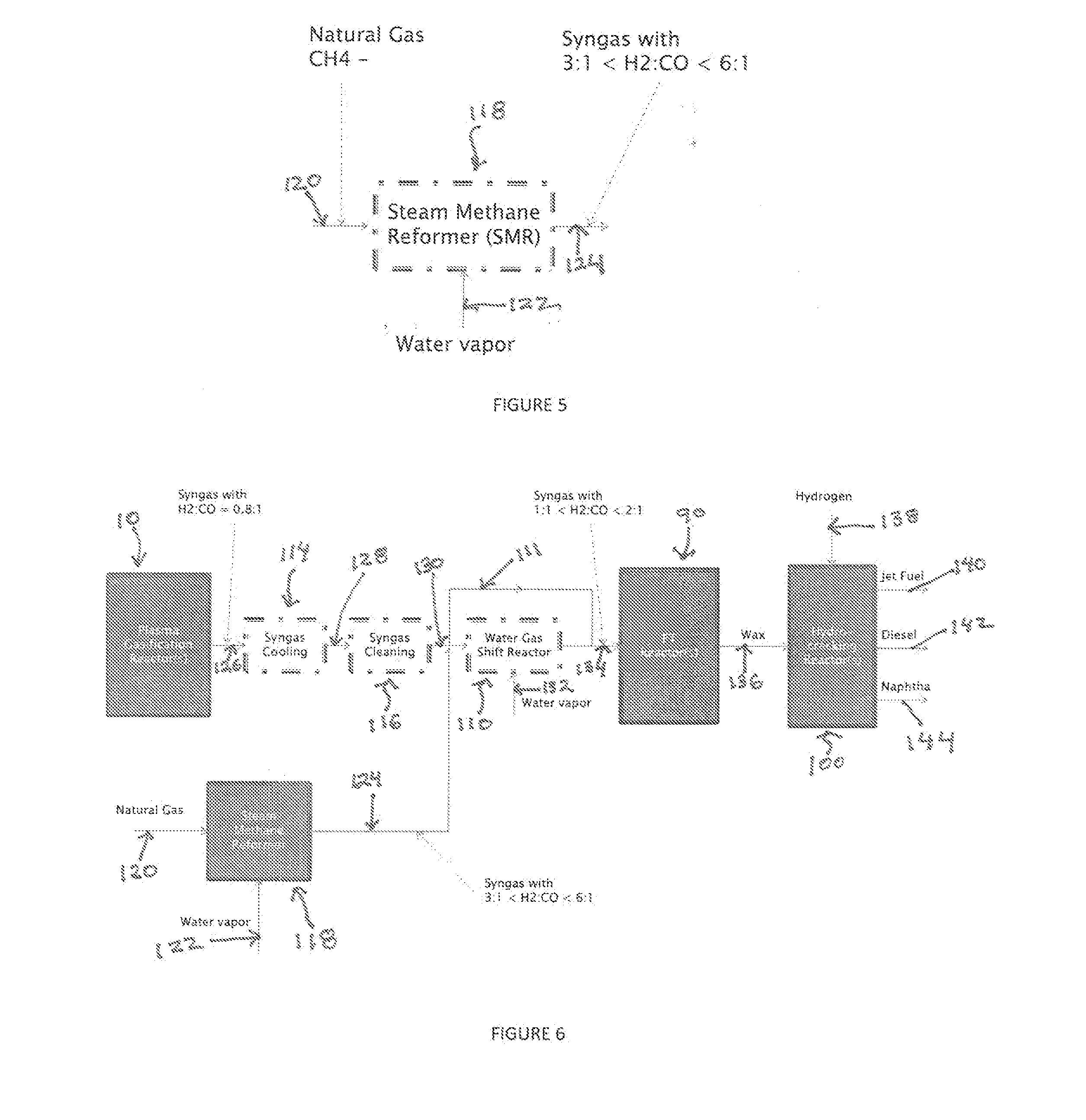

A process for producing liquid fuel from biomass feed stock comprising feeding a biomass feedstock into a one stage atmospheric pressure thermo-catalytic plasma gasifier, contacting the feedstock with oxygen or steam or both to obtain a syngas stream; splitting the syngas stream into first and second streams; conveying the first stream to a water gas shift reactor for producing a modified syngas stream containing CO and hydrogen; the second stream bypassing the water gas shift reactor and being added to the modified syngas steam; optionally reforming natural gas by steam methane reforming to produce a synthetic gas and optionally adding the synthetic gas to the water gas shift reactor; thereby obtaining a syngas having a H2:CO ratio of about 1:1 to about 2:1; subjecting the syngas to a Fischer Tropsch reaction thereby producing a wax product; and subjecting the product to a hydrogen cracking process to produce liquid fuel; and apparatus therefore.

Owner:SOLENA FUELS CORP

LED device and method by which it is produced

InactiveUS20080283849A1Inhibit deteriorationIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingForming gasOptoelectronics

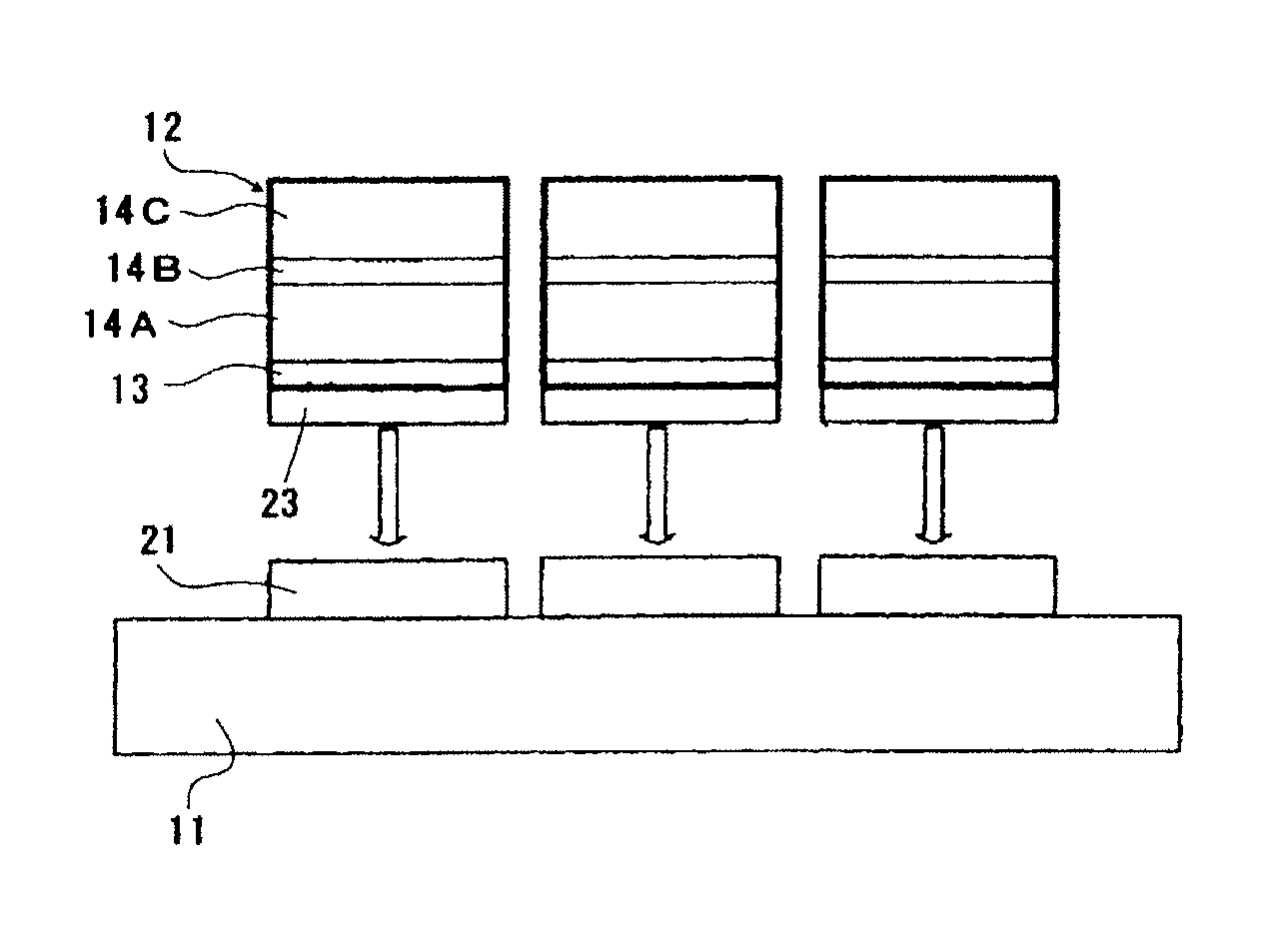

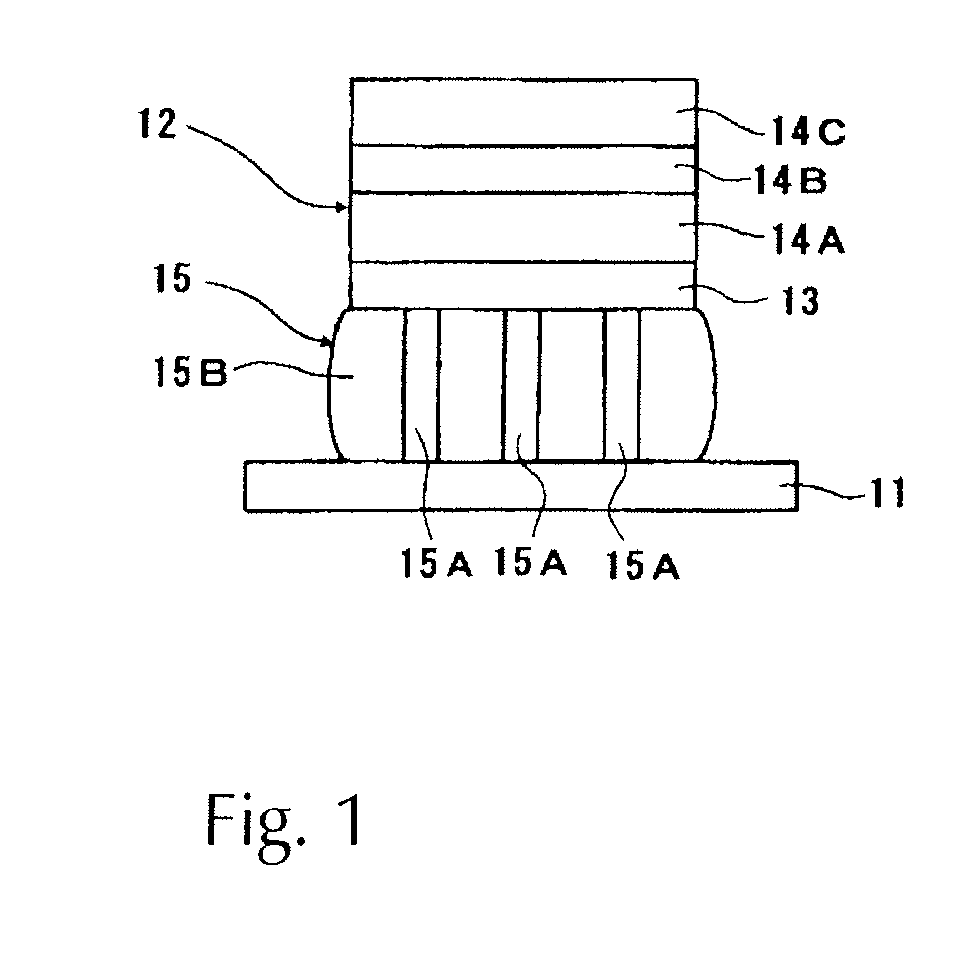

A LED device formed of LED chips bonded to an exoergic member by the LED chips being bonded to an Au—Sn alloy layer formed on an upper surface of the exoergic member with columnar crystals being formed within the Au—Sn alloy layer extending in a direction perpendicular to the upper surface of the exoergic member. The method of producing the LED device forms an Sn film directly on the upper surface of the exoergic member, an Au film on a lower surface of the LED chips, mounts the LED chips with the Au film thereon onto the Sn film formed on the upper surface of the exoergic member, and the exoergic member with LED chips mounted thereon is heated in an atmosphere in which a forming gas flows, so that the LED chips are bonded to the exoergic member.

Owner:USHIO DENKI KK

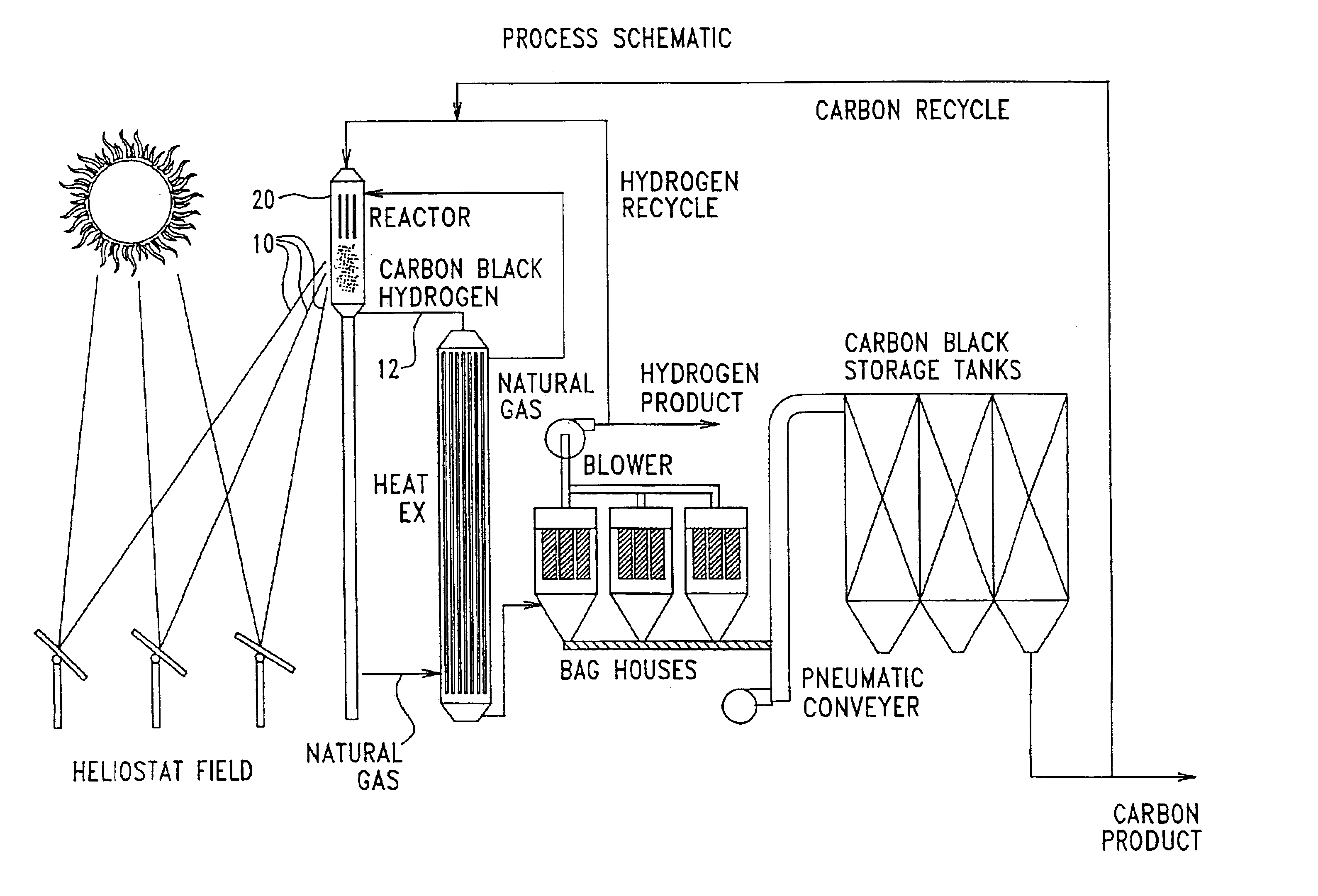

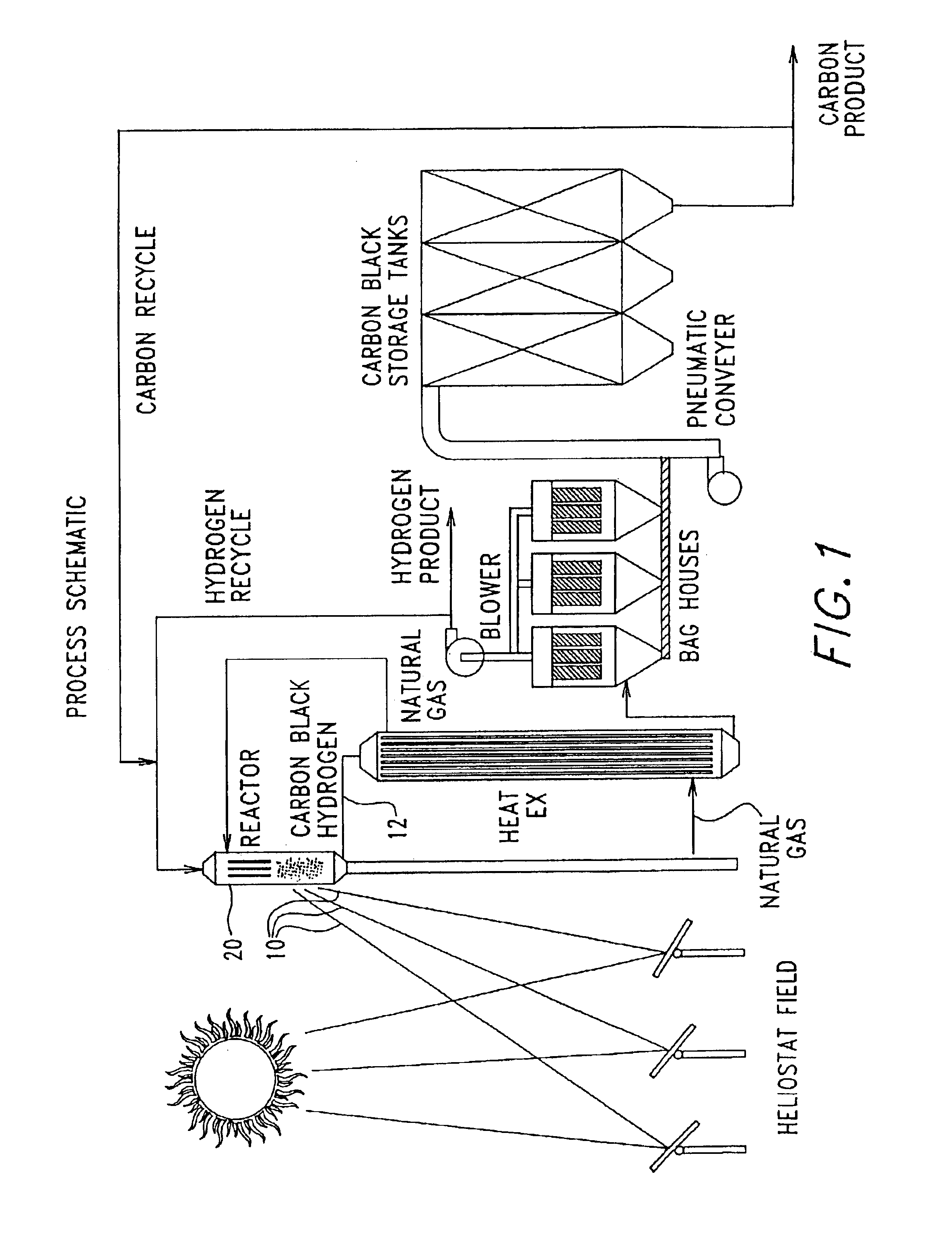

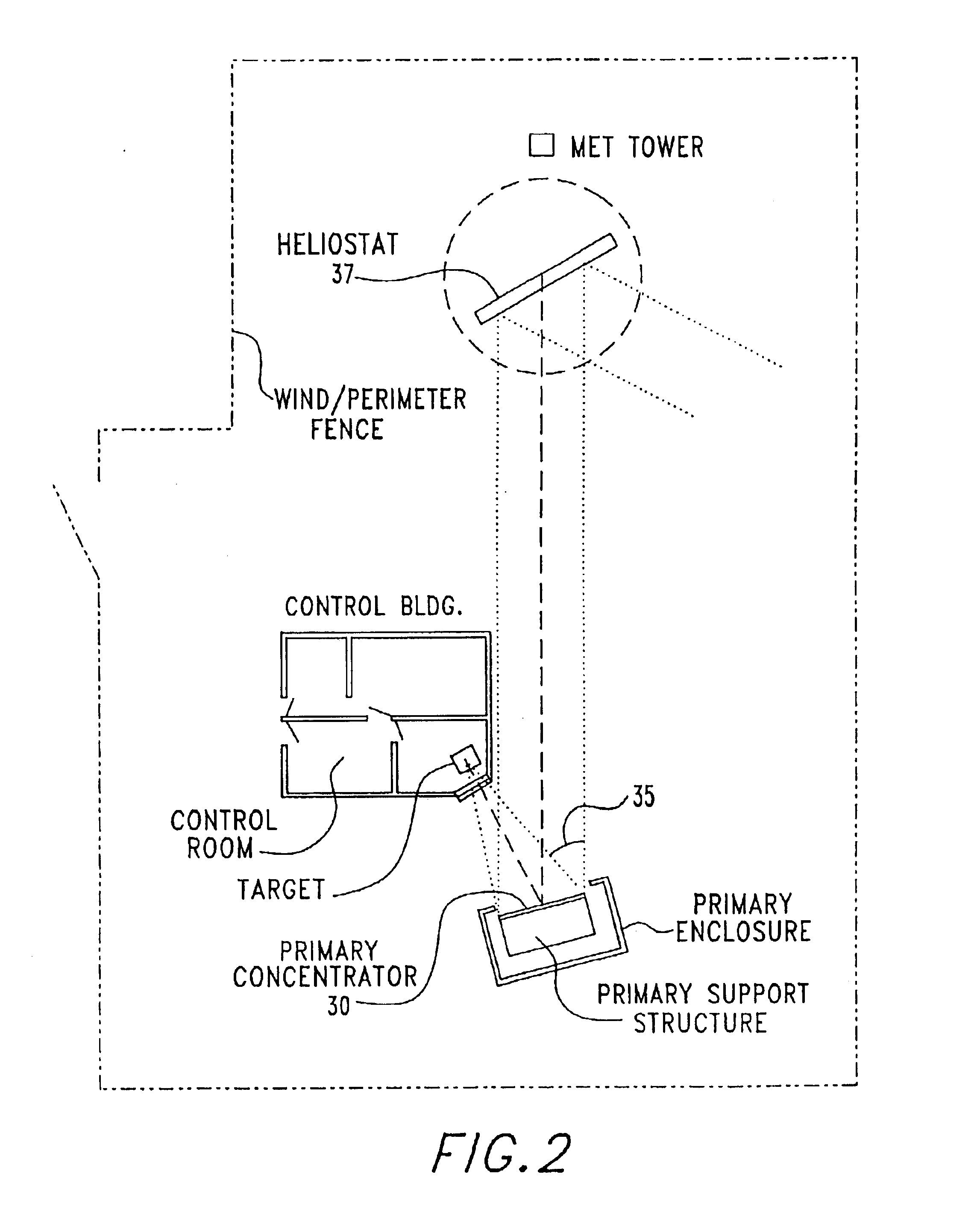

Solar thermal aerosol flow reaction process

InactiveUS6872378B2Short stayCost-effectiveSolar heating energyHydrocarbon from carbon oxidesForming gasChemical reaction

Owner:UNIV OF COLORADO THE REGENTS OF +1

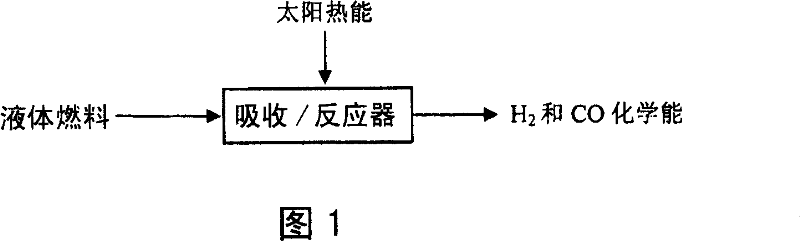

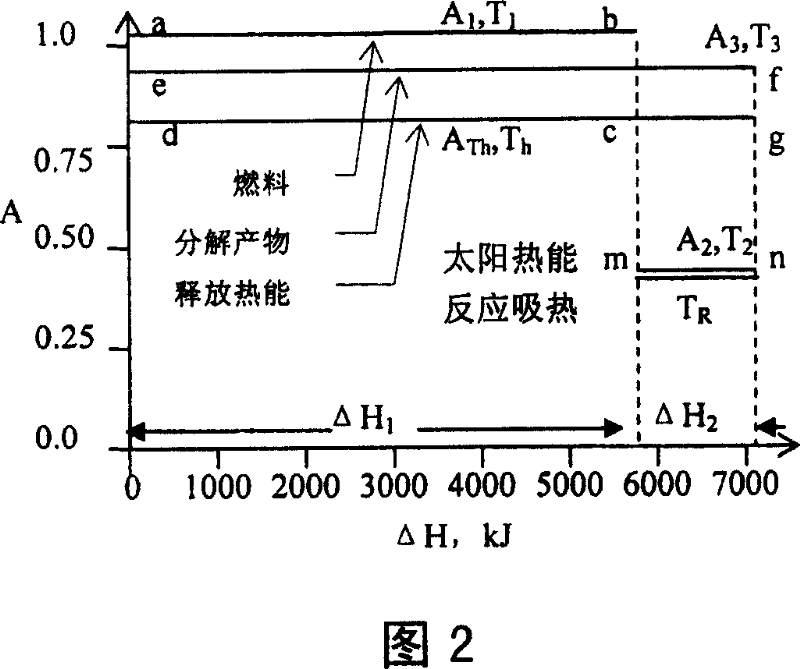

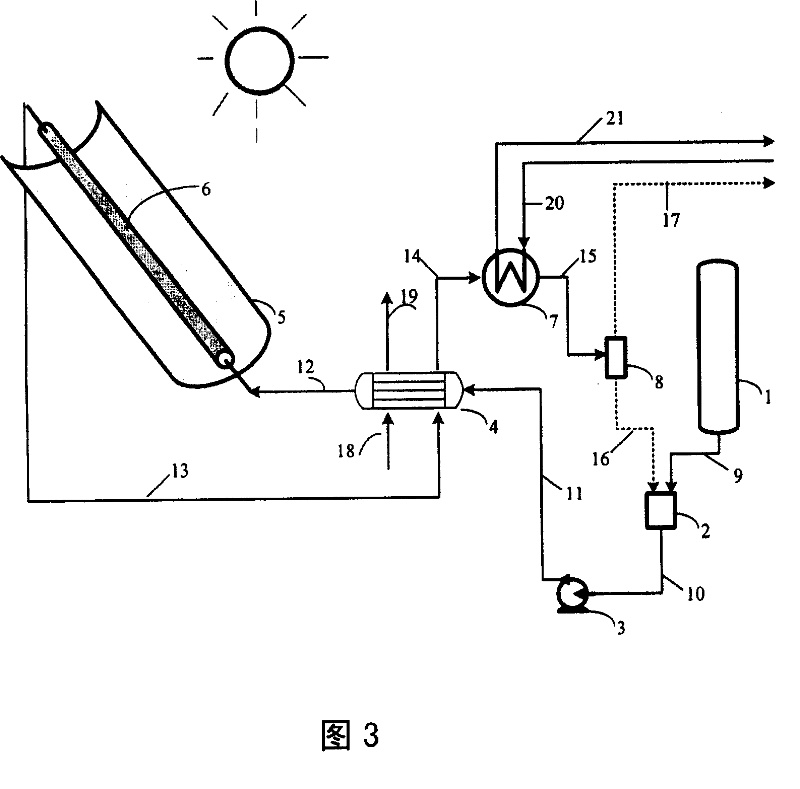

Method and apparatus for converting solar energy into fuel chemical energy

It relates to a method and device of changing solar energy to chemical energy. It accumulates the solar energy and changing it to heat energy ranging from 150deg.C-300deg.C, providing reaction heat for the liquid fuels, allowing the middle and low level solar energy changing and stored into high level chemical energy, with the liquid being carbinol or dimethyl ether synthetic fuel, with the catabolite being hydrogen and monoxide formed gas. It can be used for multi purposes, providing fine synthetic fuel and material for customers.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

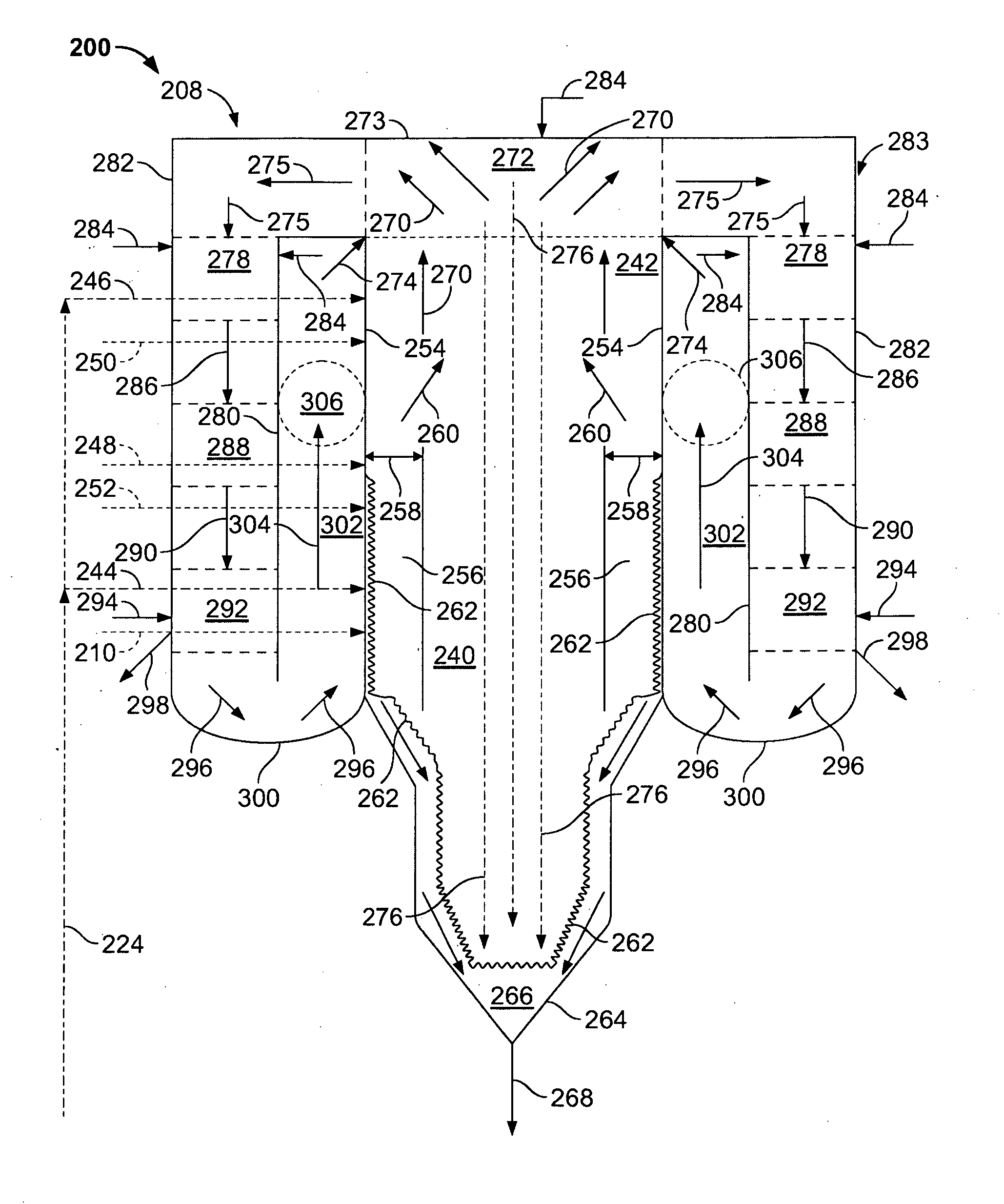

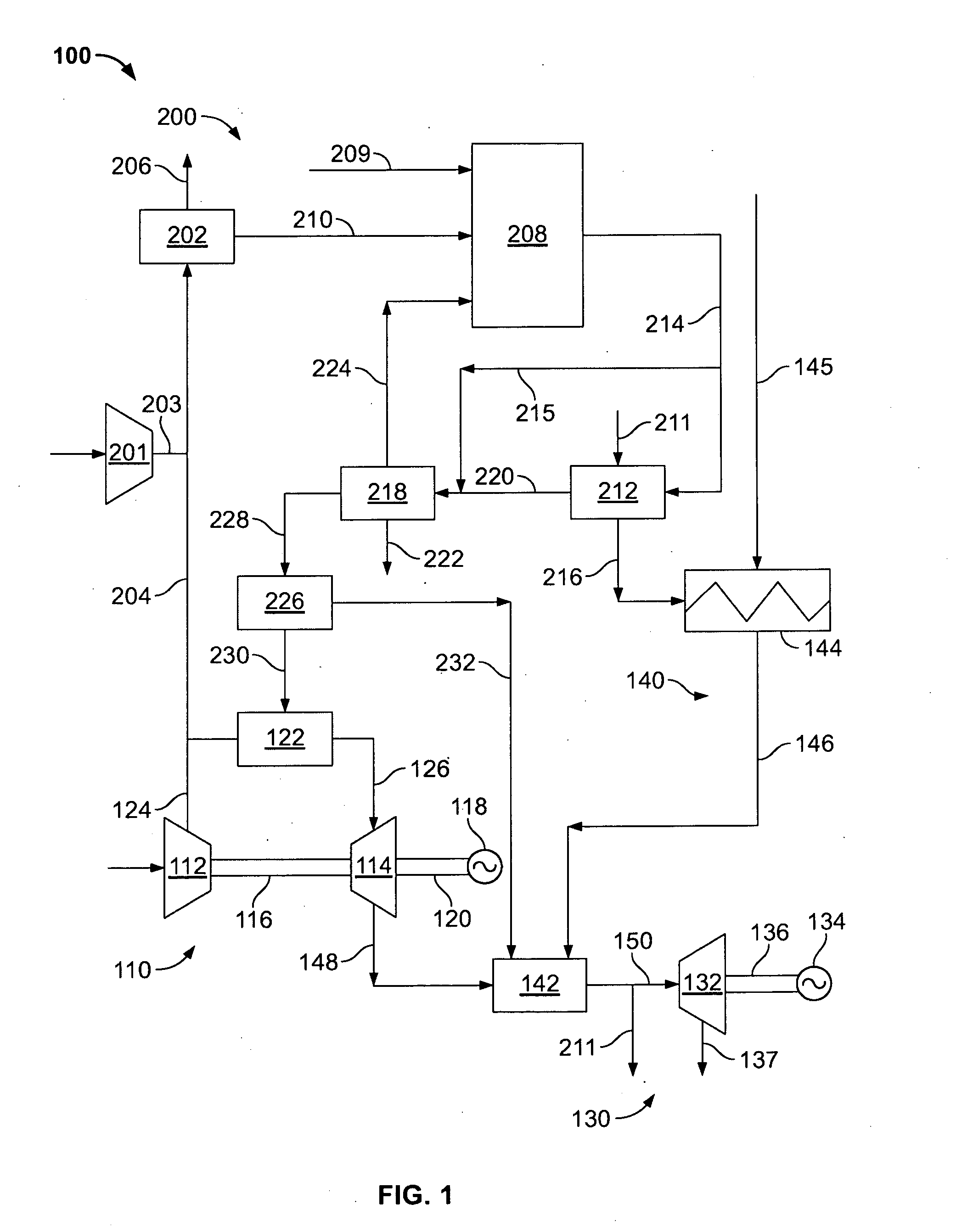

Method and apparatus to facilitate substitute natural gas production

ActiveUS20100018115A1Easy to operateReduce installationMuffle furnacesGasifier mechanical detailsForming gasProduct gas

A method of producing substitute natural gas (SNG) includes providing a gasification reactor having a cavity defined at least partially by a first wall. The reactor also includes a first passage defined at least partially by at least a portion of the first wall and a second wall, wherein the first passage is in heat transfer communication with the first wall. The reactor further includes a second passage defined at least partially by at least a portion of the second wall and a third wall. The method also includes coupling the cavity in flow communication with the first and second passages. The method further includes producing a first synthetic gas (syngas) stream within the cavity. The method also includes channeling at least a portion of the first syngas stream to the first and second passages.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com