Patents

Literature

130 results about "Substitute natural gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Renewable Natural Gas (RNG), also known as Sustainable Natural Gas (SNG) or biomethane, is a biogas which has been upgraded to a quality similar to fossil natural gas and having a methane concentration of 90% or greater. A biogas is a gaseous form of methane obtained from biomass. By upgrading the quality to that of natural gas, it becomes possible to distribute the gas to customers via the existing gas grid within existing appliances. Renewable natural gas is a subset of synthetic natural gas or substitute natural gas (SNG).

Method and apparatus to facilitate substitute natural gas production

ActiveUS20100018115A1Easy to operateReduce installationMuffle furnacesGasifier mechanical detailsForming gasProduct gas

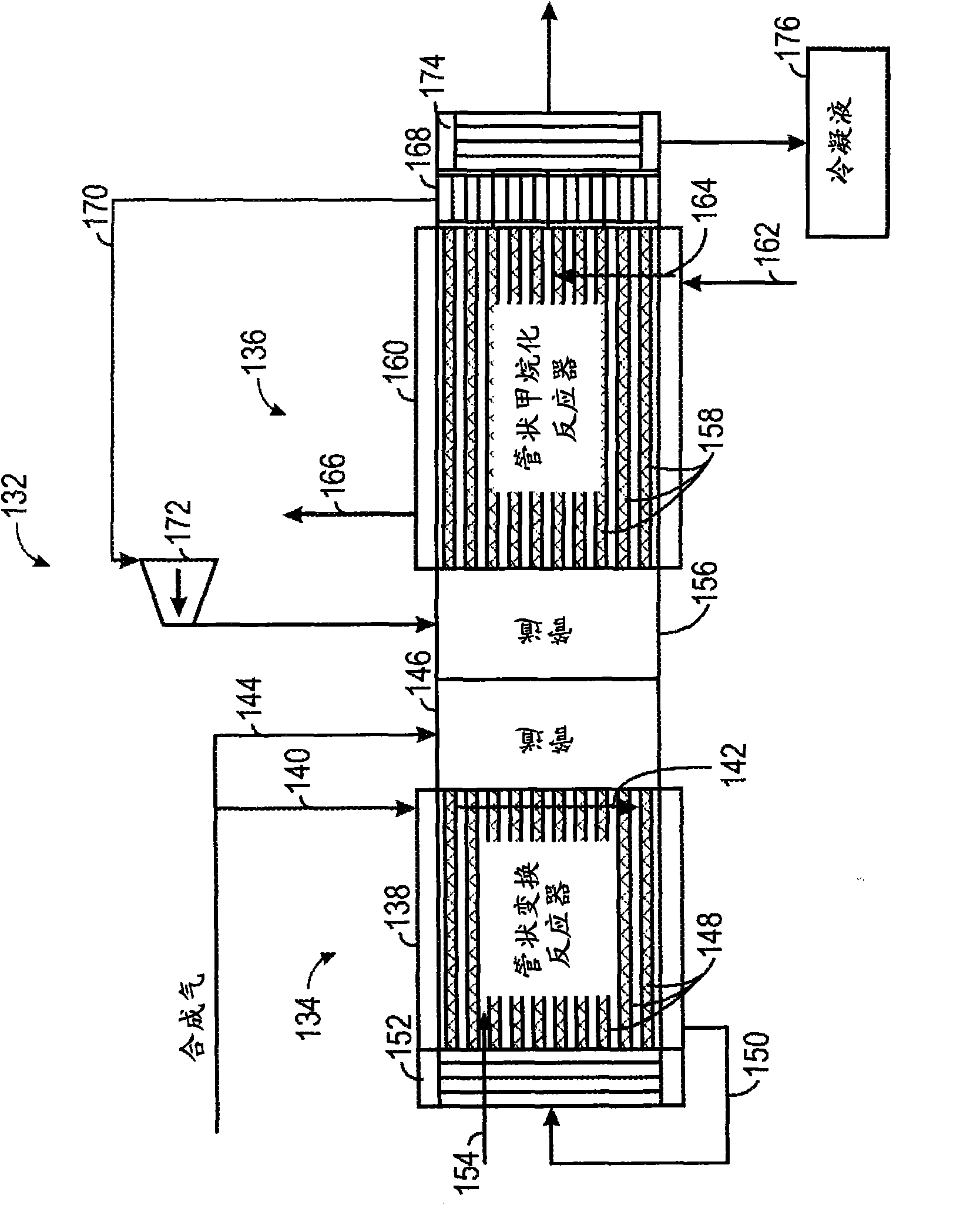

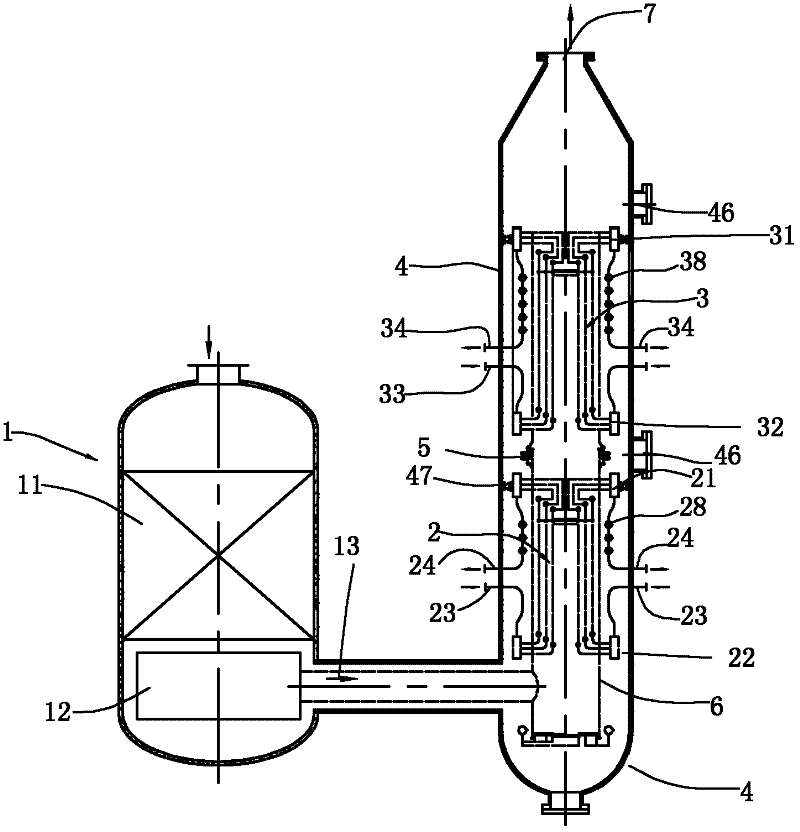

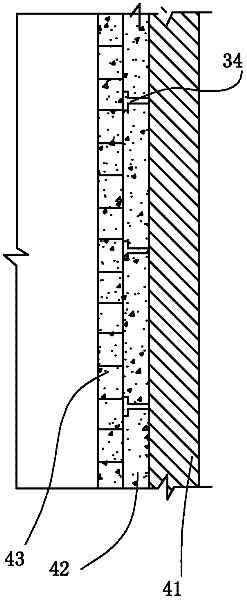

A method of producing substitute natural gas (SNG) includes providing a gasification reactor having a cavity defined at least partially by a first wall. The reactor also includes a first passage defined at least partially by at least a portion of the first wall and a second wall, wherein the first passage is in heat transfer communication with the first wall. The reactor further includes a second passage defined at least partially by at least a portion of the second wall and a third wall. The method also includes coupling the cavity in flow communication with the first and second passages. The method further includes producing a first synthetic gas (syngas) stream within the cavity. The method also includes channeling at least a portion of the first syngas stream to the first and second passages.

Owner:AIR PROD & CHEM INC

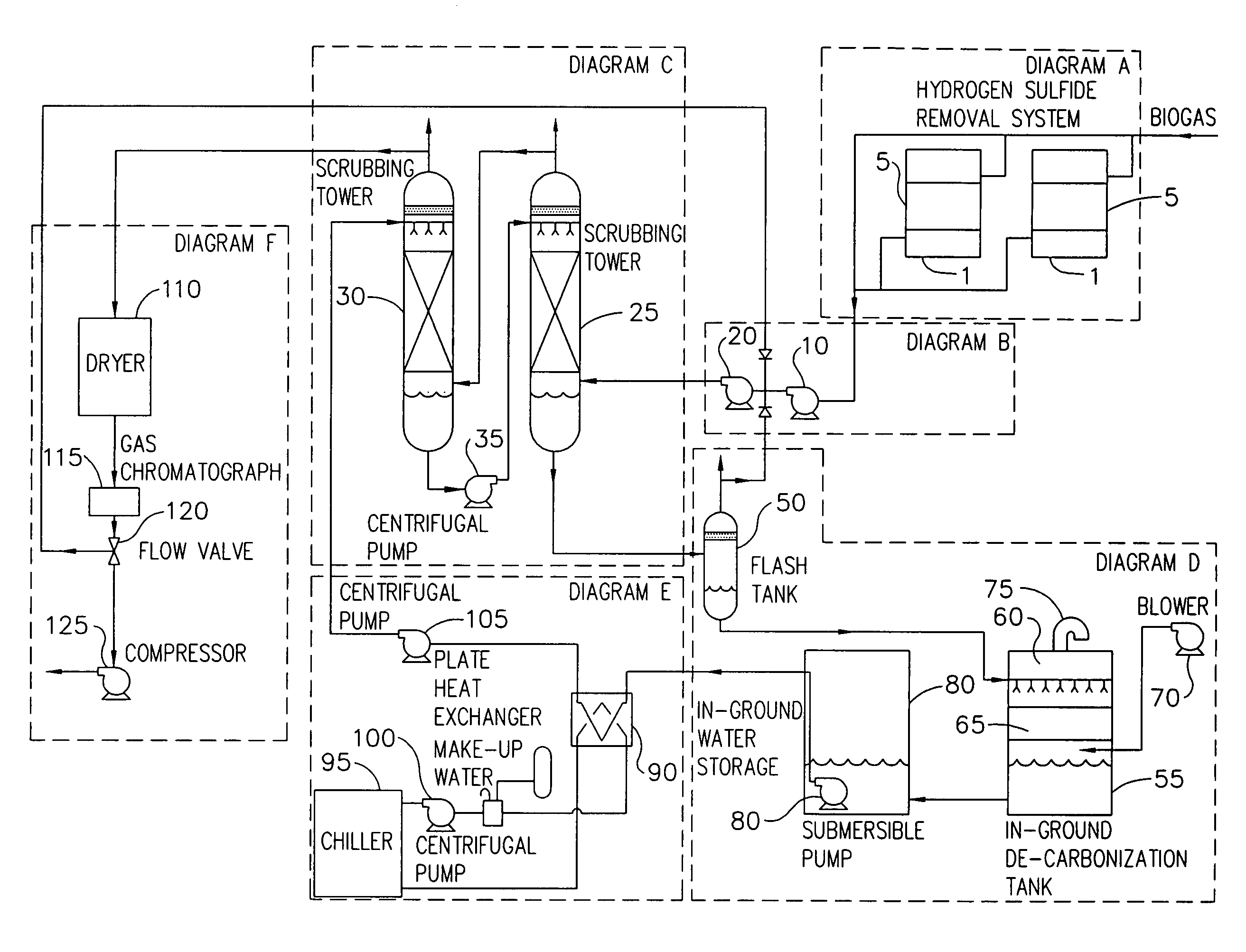

Process for converting biogas to a pipeline grade renewable natural gas

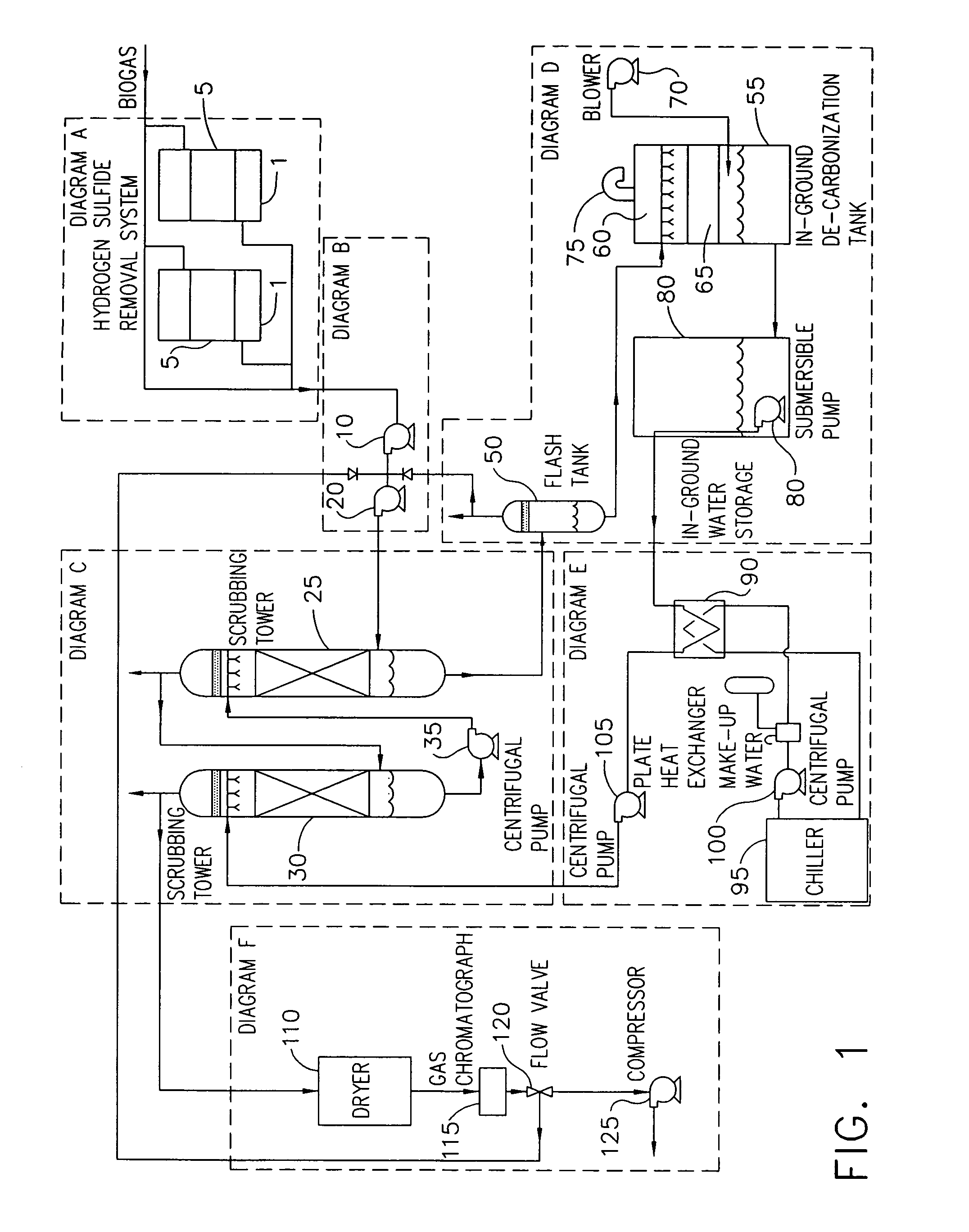

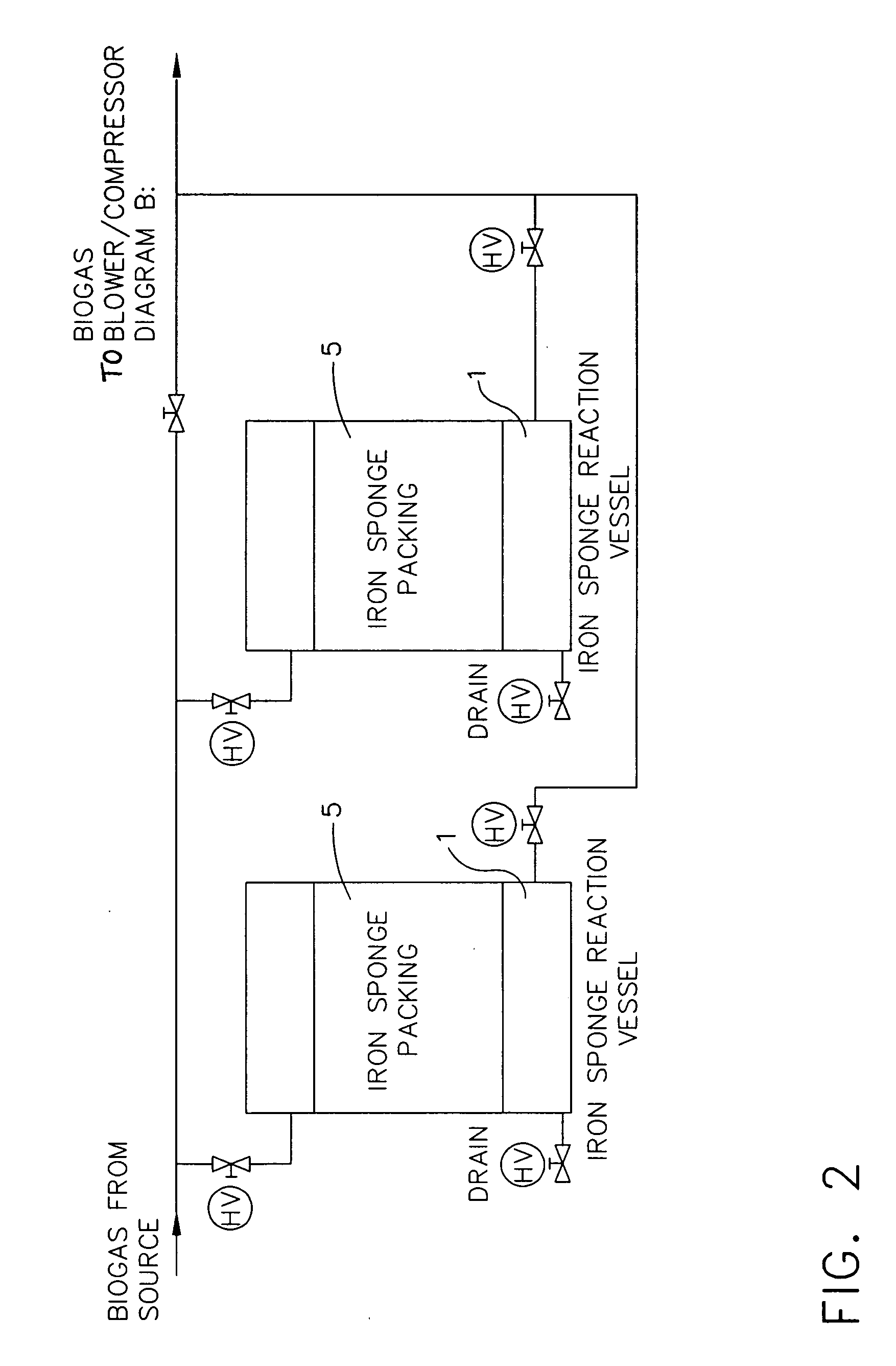

InactiveUS20080134754A1Minimize biogas pressureMinimize water flowGas treatmentSamplingExtreme weatherWater flow

A process purifies raw biogas created from a renewable source into pipeline grade natural gas and / or D.O.T. specification, or other predetermined specification, gas. The automated scrubbing processed employed and the particular attributes of the system allow the system to function under extreme weather conditions by employing specific tools to control the temperature of the scrubbing water to allow for efficient and effective removal of the carbon dioxide gas. The system also employs specific measures to use recycled scrubbing water, thus eliminating the need for excessive water generally needed to economically employ this type of scrubbing process. The recycled water is continuously de-carbonated to allow the recycled water stream to effectively scrub the raw biogas. Treated gas from the process is then dried, and compressed for introduction into storage tanks or a natural gas pipeline delivery system.

Owner:FUNK MICHAEL N

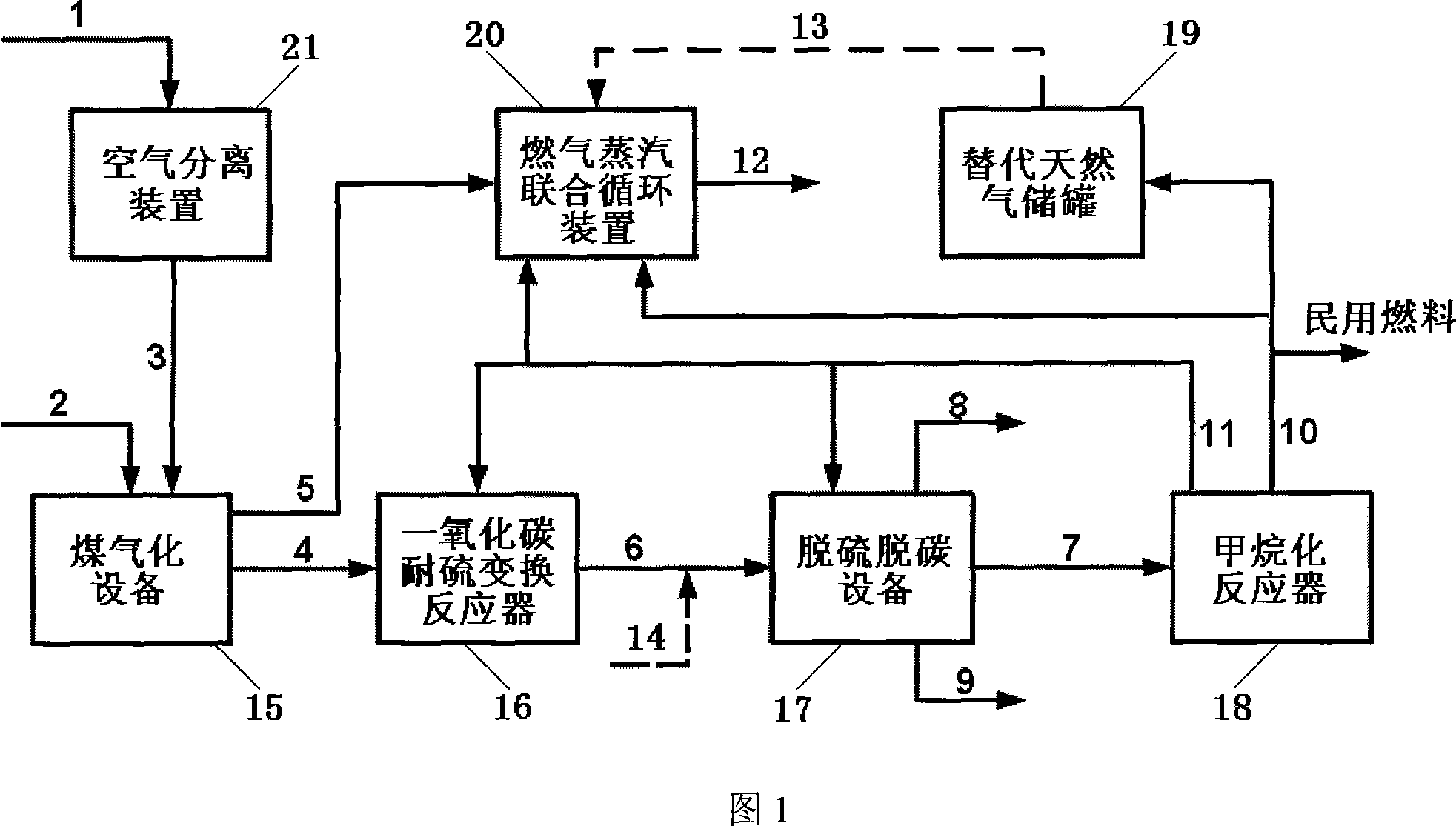

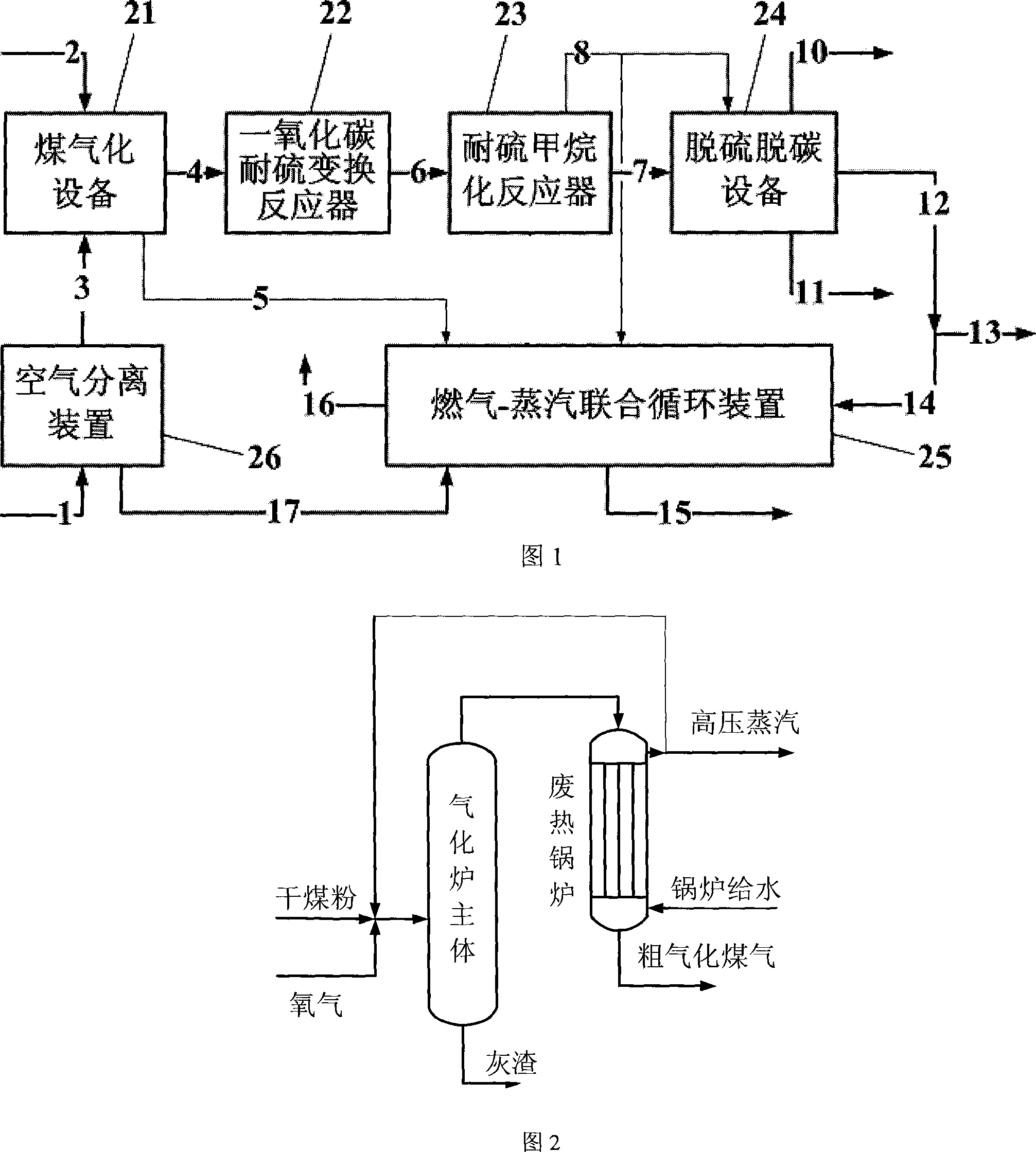

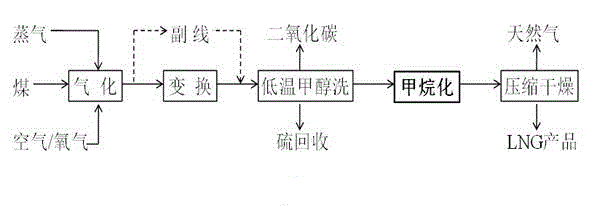

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

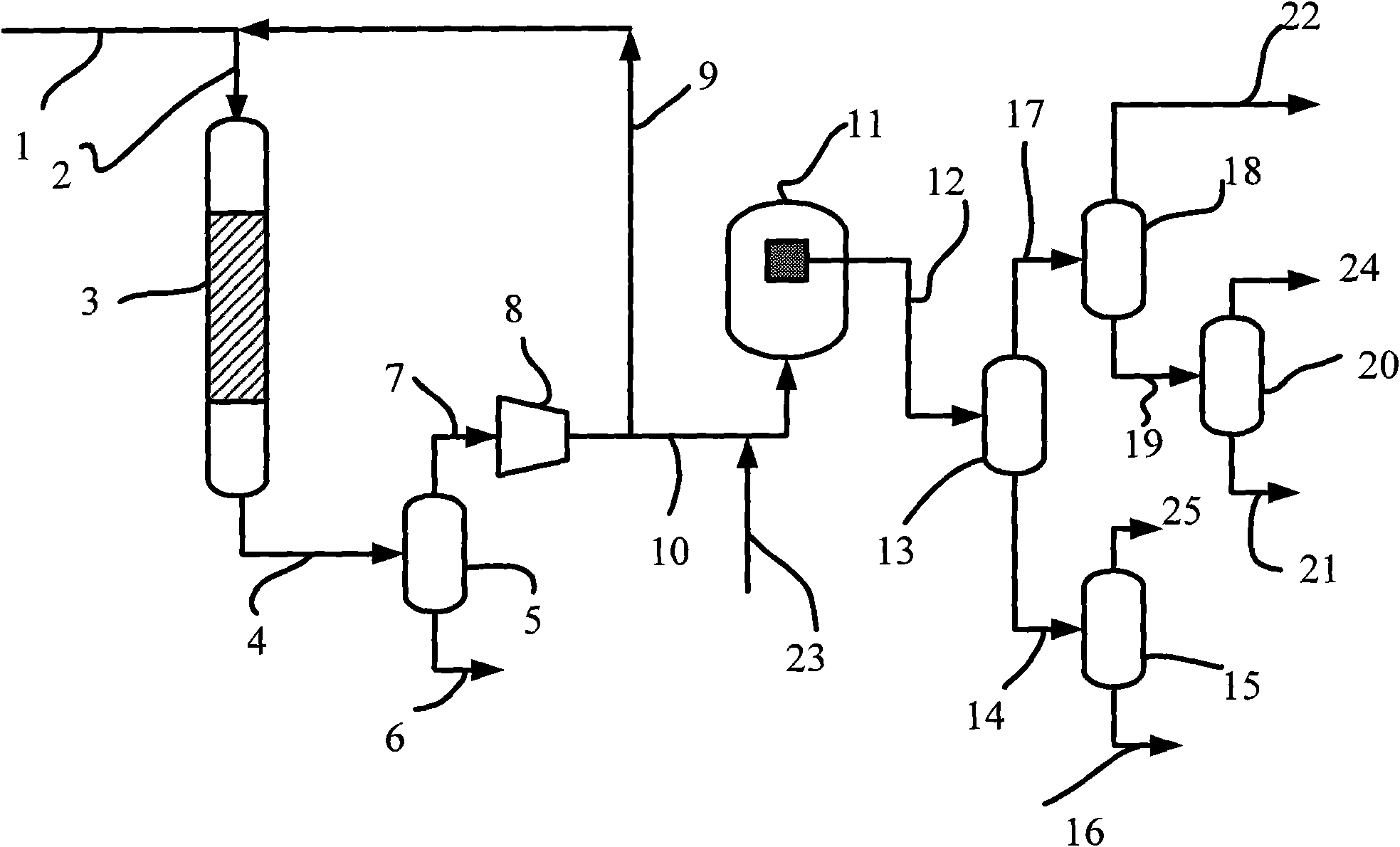

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

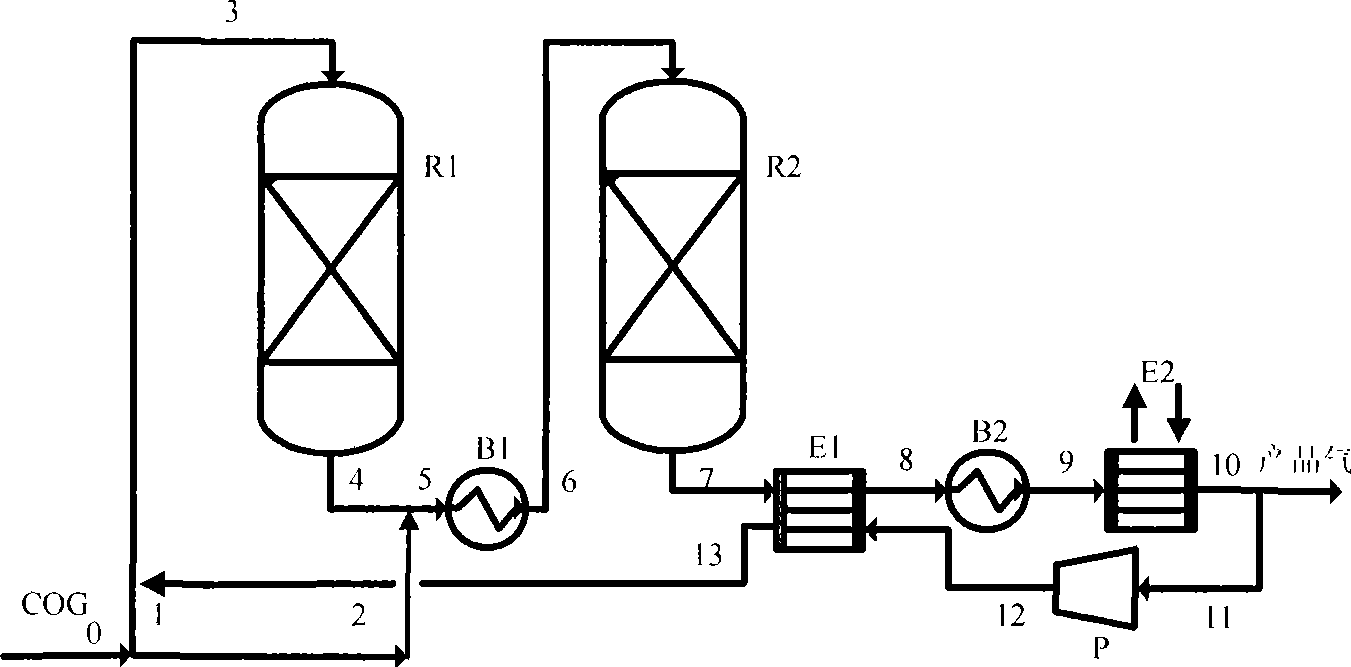

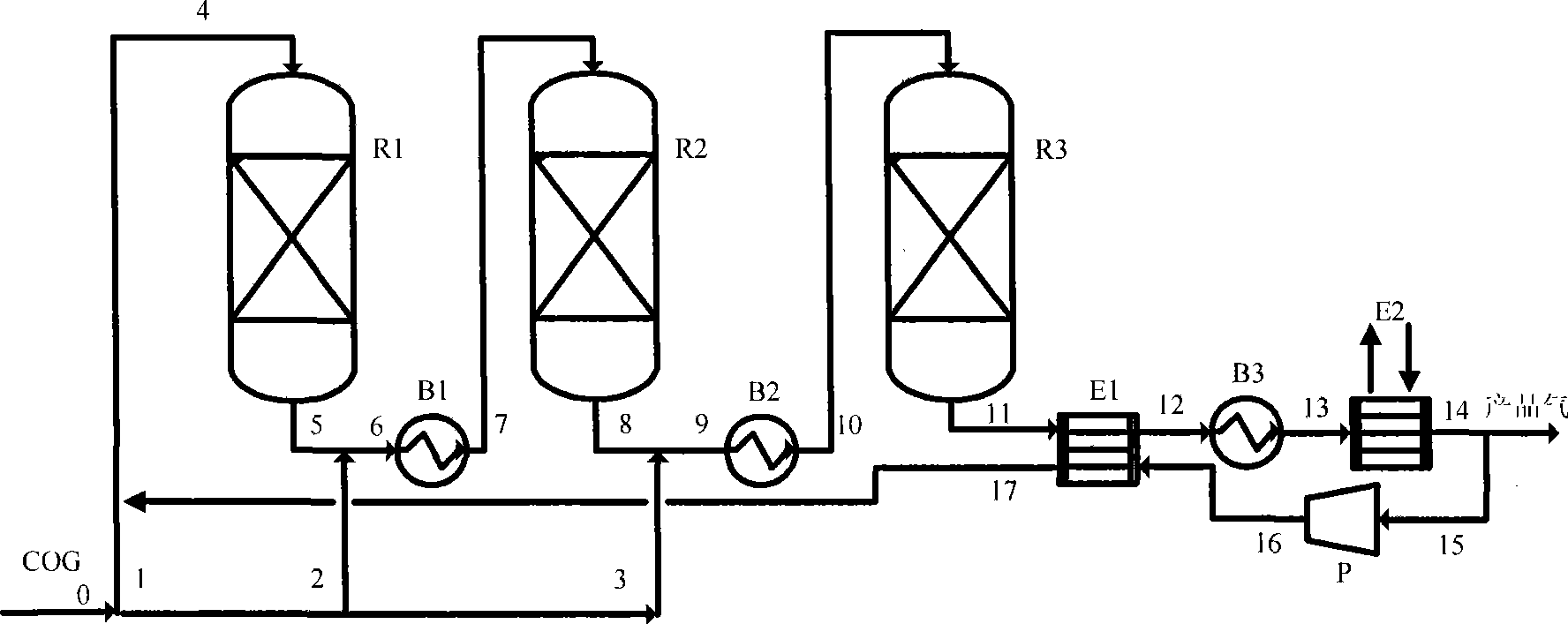

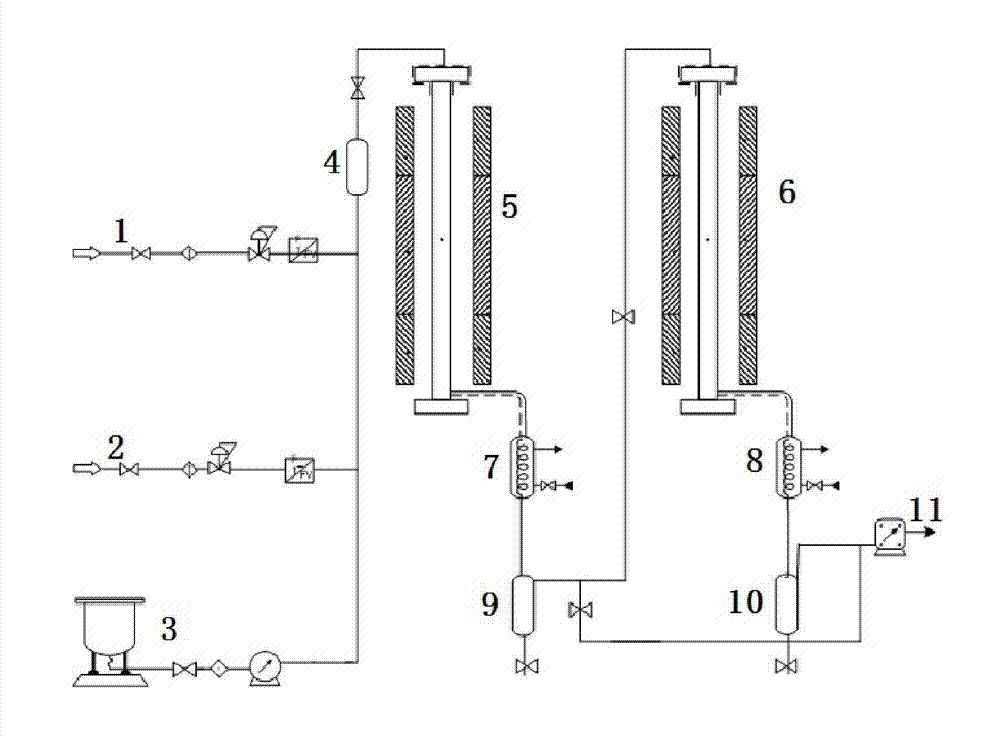

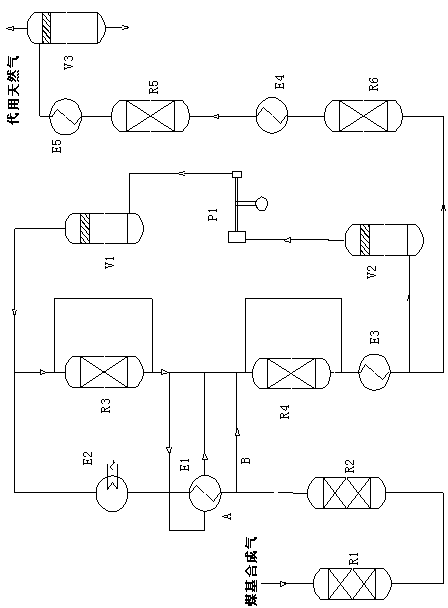

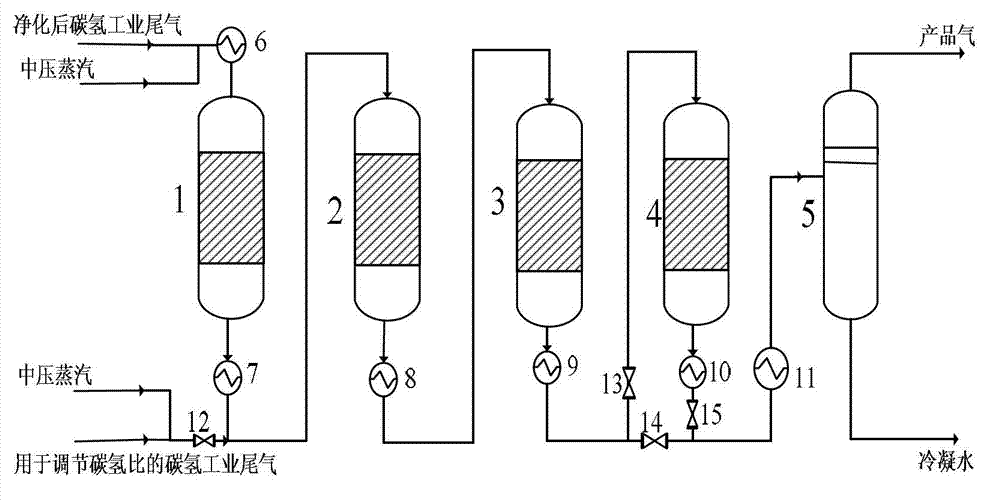

Methanation reaction process using oven gas to prepare substitute natural gas

The invention discloses a methanation reaction technique using oven gas for preparing synthetic natural gas. A multilevel methanation reactor is adopted to control the temperature of gas at the inlet of every level of methanation reactor and the total content of CO+CO2 in the gas at the inlet to be less than or equal to 3.5%, so as to ensure the temperature of gas at the outlet of every level of methanation reactor to be less than or equal to 450 DEG C after methanation. By adopting the technique, the quantity of the gas used for diluting CO+CO2 in the oven gas of the raw materials can be greatly reduced, and the energy consumption is remarkably lowered; meanwhile, the gas temperature at the outlet of the methanation reactor can be effectively controlled, thus being beneficial to methanation reaction and the selection of the materials of the reactor.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Gas-steam combined cycle system and technique based on coal gasification and methanation

ActiveCN101245262AReduce energy consumptionEasy to recycleNitrogen purification/separationCombustible gas chemical modificationMethanationSubstitute natural gas

A combined cycle system based on coal gasification and methanation gas-steam and a technique thereof, wherein, the method comprises the following steps: oxygen produced by an air separation unit and coal powder or water-coal-slurry are sent into coal gasification equipment, the produced crude gasification gas is sent to a carbon monoxide sulfur-tolerant shift reactor to adjust the ratio of hydrogen and carbon after the sensible heat recollecting, and is then sent into sulfur-tolerant methanation reactor to produce methane and carbon dioxide, then the reaction product is sent into desulfurization and decarbonization equipment so that element sulfur can be recovered and carbon dioxide can be separated so as to obtain substitute natural gas with high content of methane, part of which is sent to the gas-steam combined cycle equipment while the other part is sent to a urban gas system. The enriched CO2 density of the system can reach 50 to 60 percent, technical probability is provided for reasonably realizing low-energy-consumption reduced exhaust of CO2, no change needs to be done with gas turbines, each chemical unit operates according to established rated condition and needs not to change load owing to power conditioning so as to improve the economy of the operation of power plants; compared with the prior art, the energy utilization efficiency of the whole system is improved so as to realize the efficient clean utilization of coal.

Owner:TSINGHUA UNIV

Isothermal methanation process method for coal to substitute natural gas

InactiveCN102827657AExtended service lifeLow running costGaseous fuelsMethanationSubstitute natural gas

The invention discloses an isothermal methanation process method for coal to substitute natural gas. Specifically, upstream purified synthetic gas enters one or more methanation reactors after fine desulfurization for undergoing a methanation reaction, and two-stage methanation is adopted in the methanation reactor(s). At a first stage, methanation is performed in one or more isothermal methanation reactors; and at a second stage, methanation is performed in a heat-insulated methanation reactor. The isothermal methanation process method has the advantages of saving in energy, environment friendliness, small investment and easiness in localization.

Owner:EAST CHINA ENG SCI & TECH

Synthesis gas methanation catalyst and preparation thereof

InactiveCN102319574AEasy to passAvoid overheating and sinteringHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIridiumAlkaline earth metal

The invention relates to a synthesis gas methanation catalyst, which uses nickel oxide as active ingredients, uses cerium oxide modified medium-pore gamma-aluminum oxide as carriers and use oxide of transition metals of iridium, lanthanum, copper and ferrum or alkaline-earth metals of magnesium and calcium as auxiliary agents, wherein a preparation method of the medium-pore gamma-aluminum oxide adopts a hydrothermal synthesis method, and a nickel base catalyst is prepared by a soaking process, wherein the medium-pore gamma-aluminum oxide has the specific surface area being 200 to 400m<2> / g, the pore volume being 0.2 to 0.9cm<3> / g and the pore diameter being 2 to 15nm, the content of the active ingredients of the nickel oxide is 10 to 30 percent of the total weight of the catalyst, the content of the cerium oxide is 1 to 20 percent of the weight of the aluminum oxide, and the content of the auxiliary agents is 0.1 to 15 percent of the total weight of the catalysts. The synthesis gas methanation catalyst has the advantages that the preparation process is simple, the cerium oxide modified medium-pore gamma-aluminum oxide is used as the catalyst carriers, the obtained nickel base catalyst has good high-temperature resistance and anti-sintering resistance performance and has the advantages of high activity at low temperature, stability at high temperature and high methane selectivity, and the synthesis gas methanation catalyst has an important application value for synthesizing the substitute natural gas and solving the problem of natural gas shortage in the prior art.

Owner:TAIYUAN UNIV OF TECH

Apparatus and method for coal gasification

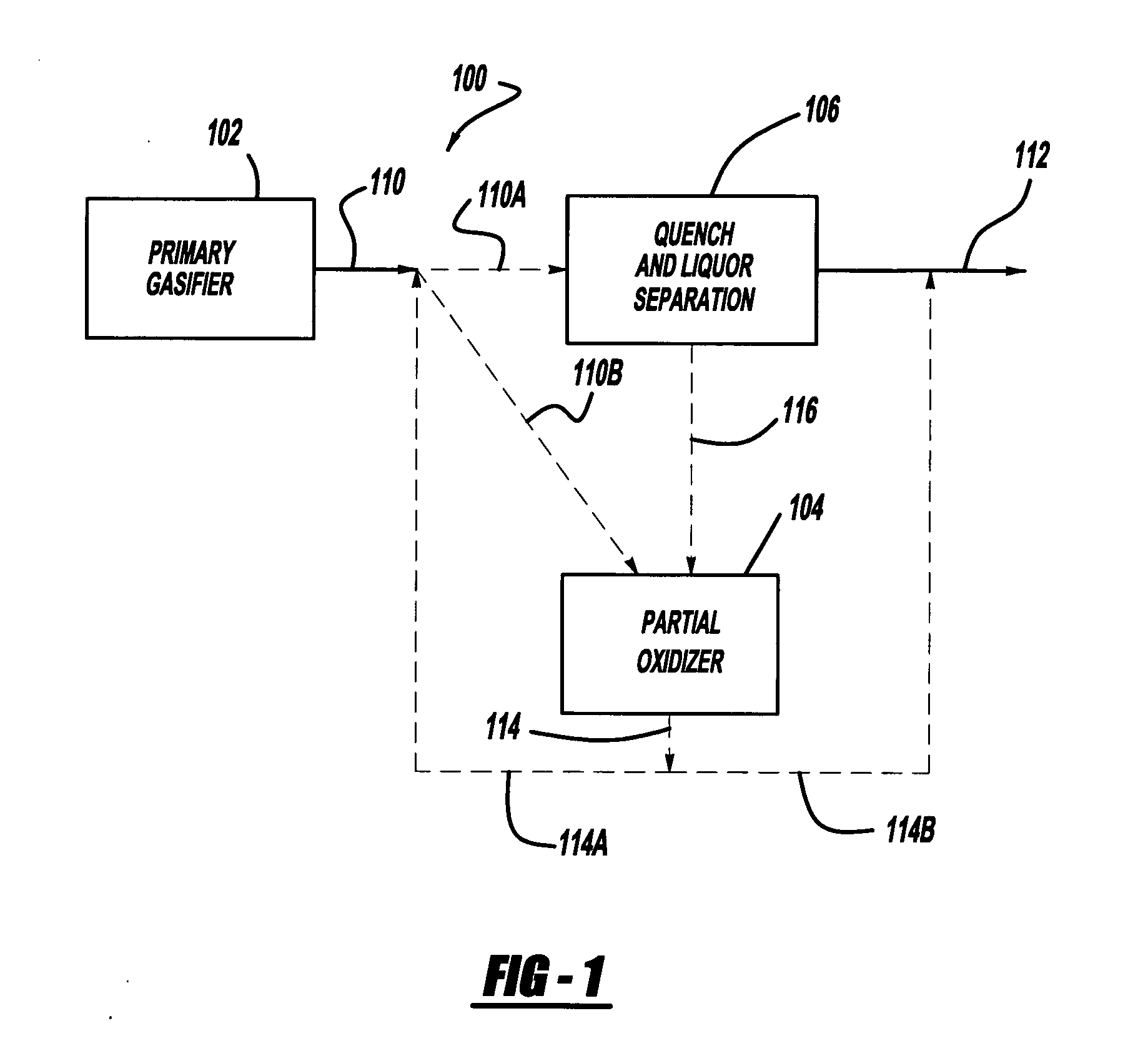

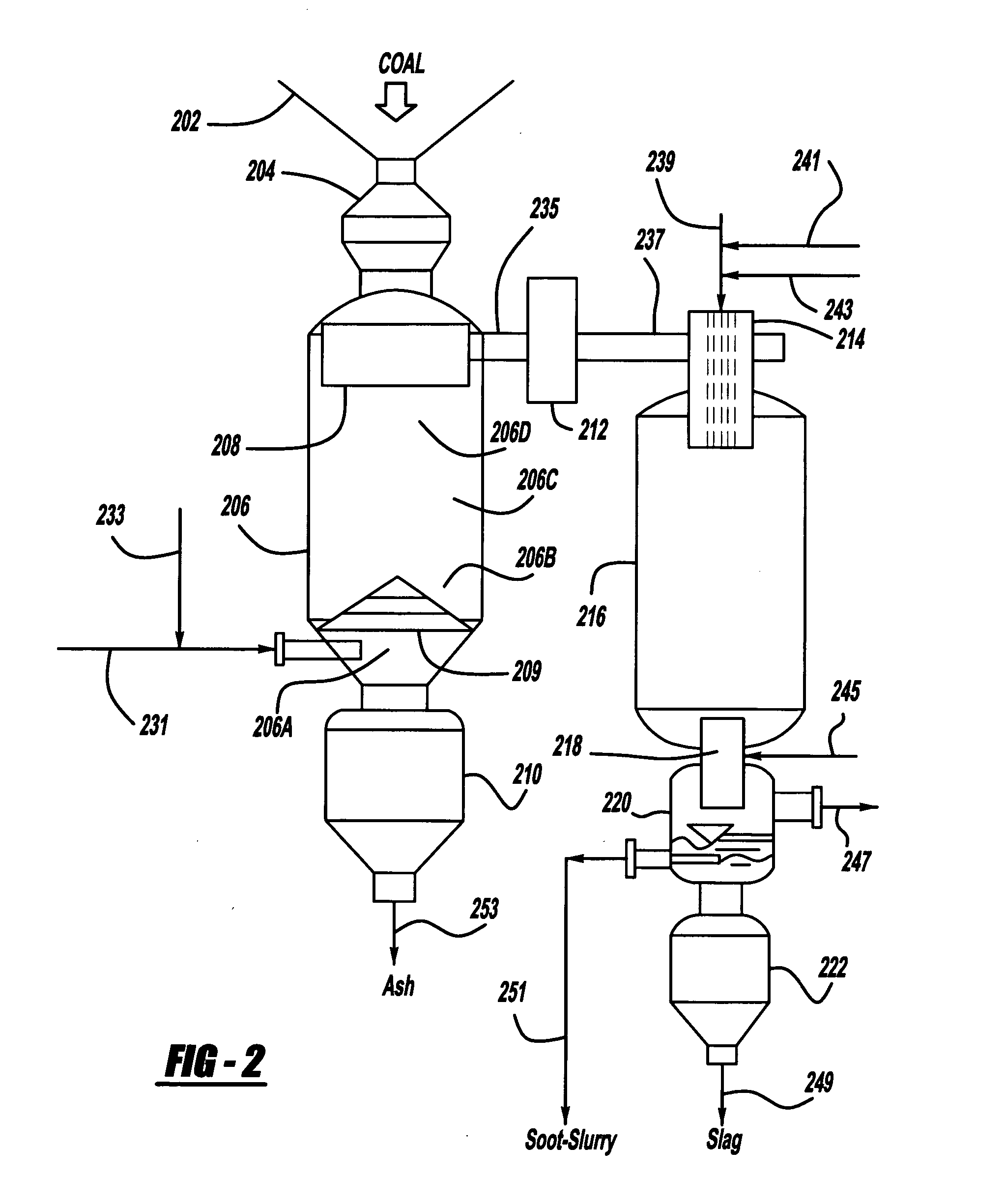

InactiveUS20060101715A1HydrogenGasification processes detailsPartial oxidationHydrocotyle bowlesioides

A process and apparatus for converting a coal into a substitute natural gas generates raw gas in a conventional coal gasification unit and passes at least a portion of the raw gas into a partial oxidation unit to convert the at least portion of the raw gas into a secondary raw synthesis gas substantially devoid of higher hydrocarbons. Optionally, the raw gas is quenched and only the resulting condensate is passed to the partial oxidation unit for conversion to the secondary raw synthesis gas.

Owner:COGAS LLC

Process for the production of substitute natural gas

InactiveUS20100286292A1Quality improvementHydrocarbon from carbon oxidesOrganic compound preparationMethanationProcess engineering

Process for the production of substitute natural gas (SNG) by the methanation of a synthesis gas derived from the gasification of a carbonaceous material together with water gas shift and carbon dioxide removal thereby producing a synthesis gas with a molar ratio (H2—CO2) / (CO+CO2) greater than 3.00. At the same time, a gas with a molar ratio (H2—CO2) / (CO+CO2) lower than 3.00 is added to the methanation section. The final product (SNG) is of constant high quality without excess of carbon dioxide and hydrogen.

Owner:HALDOR TOPSOE AS

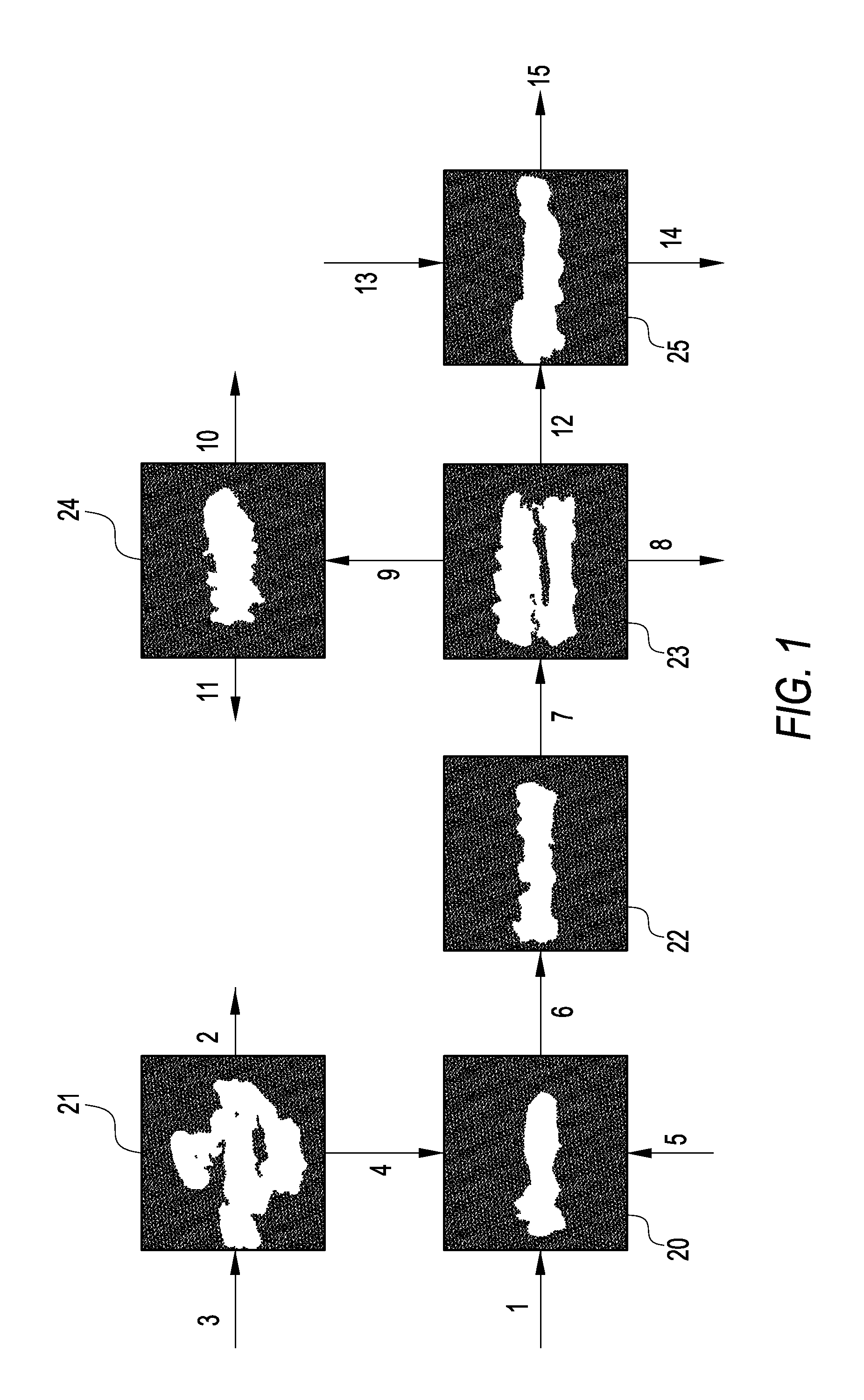

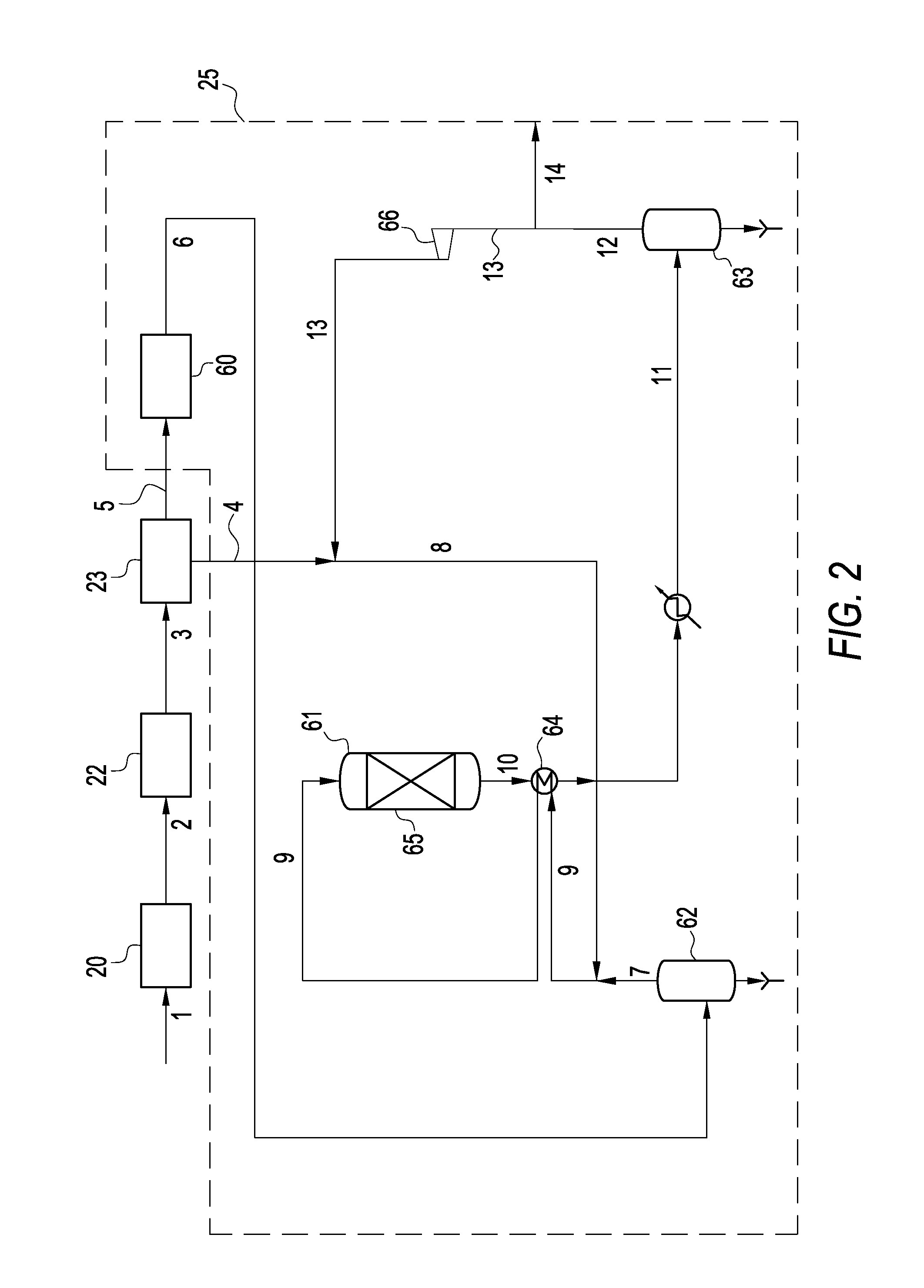

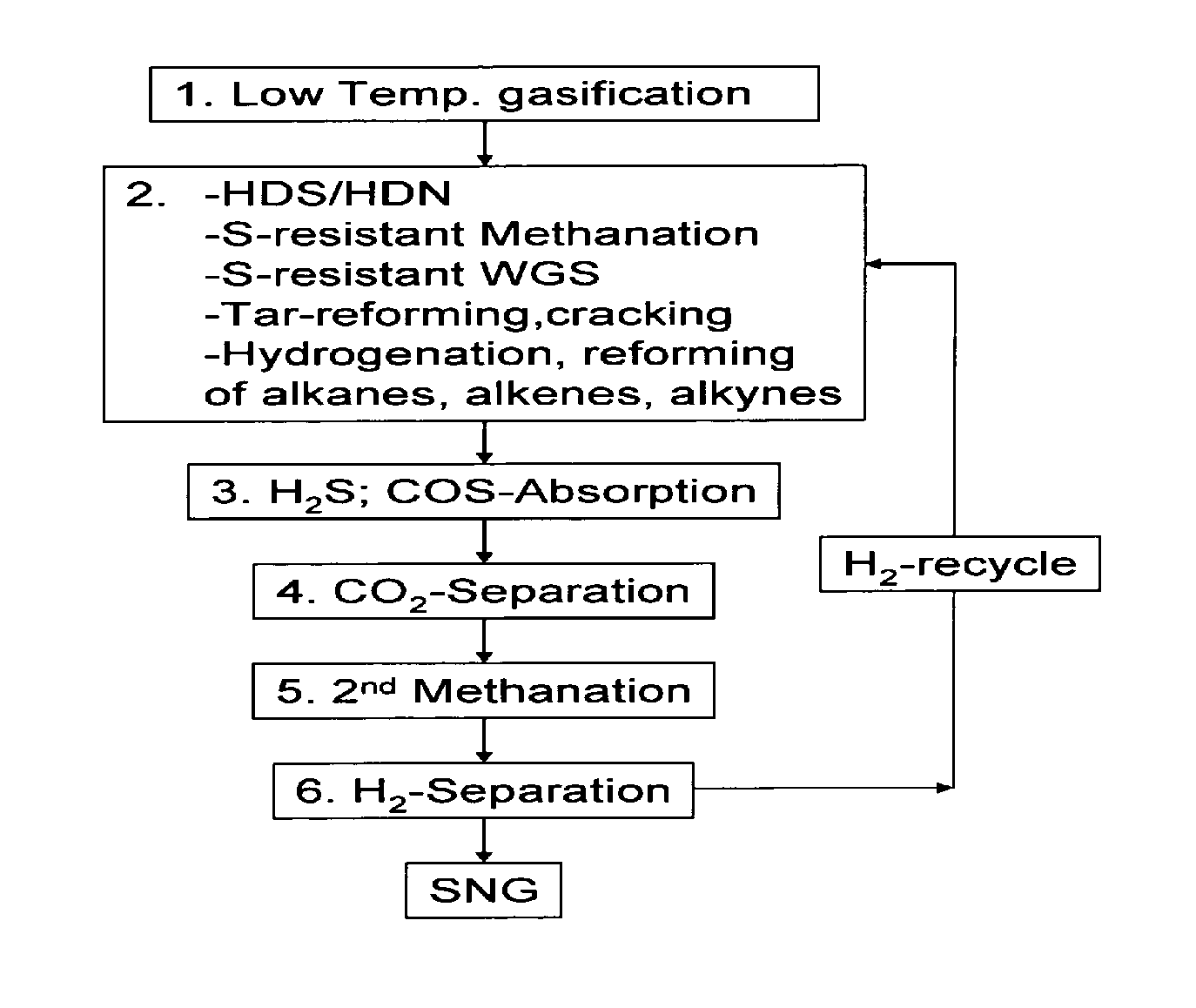

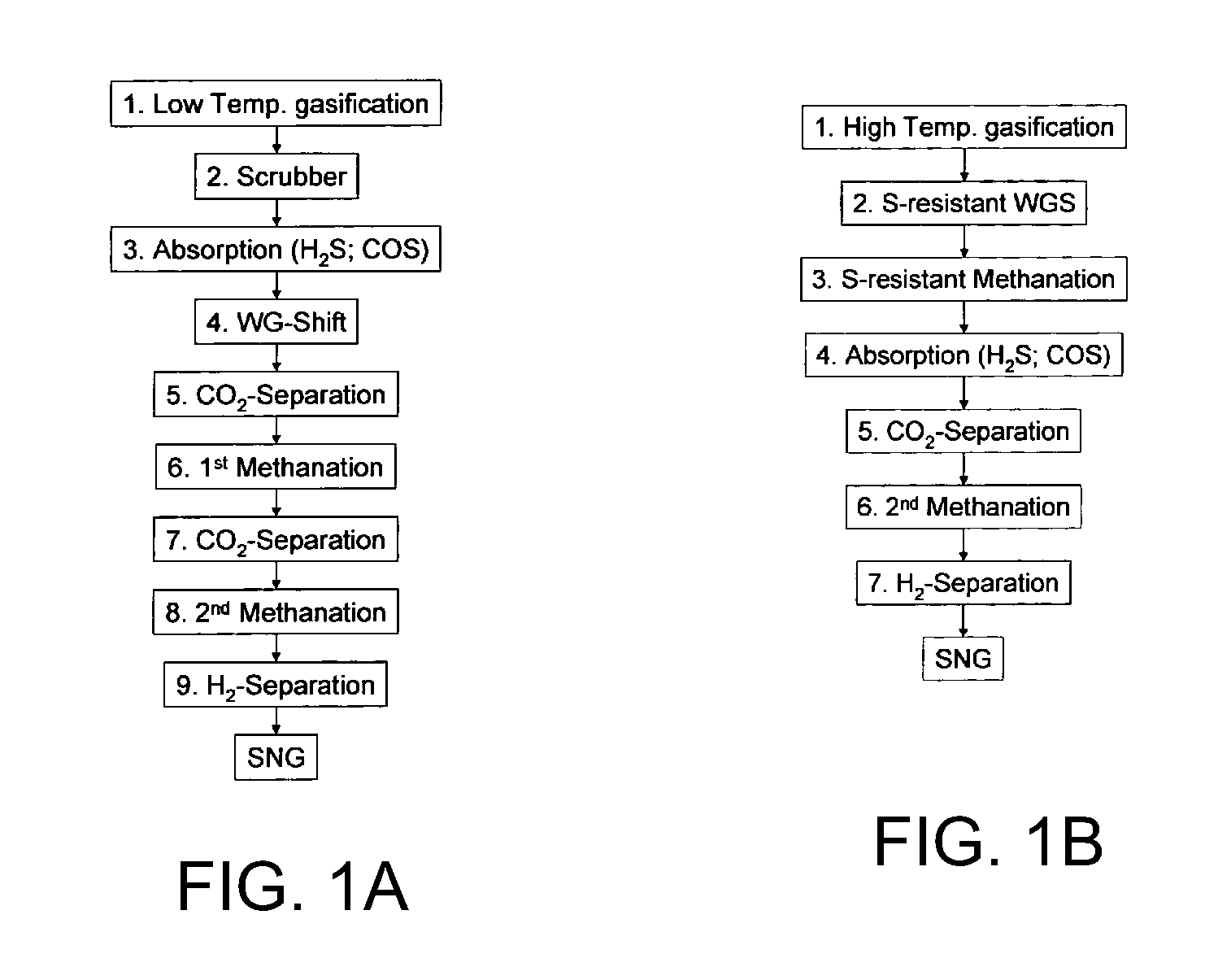

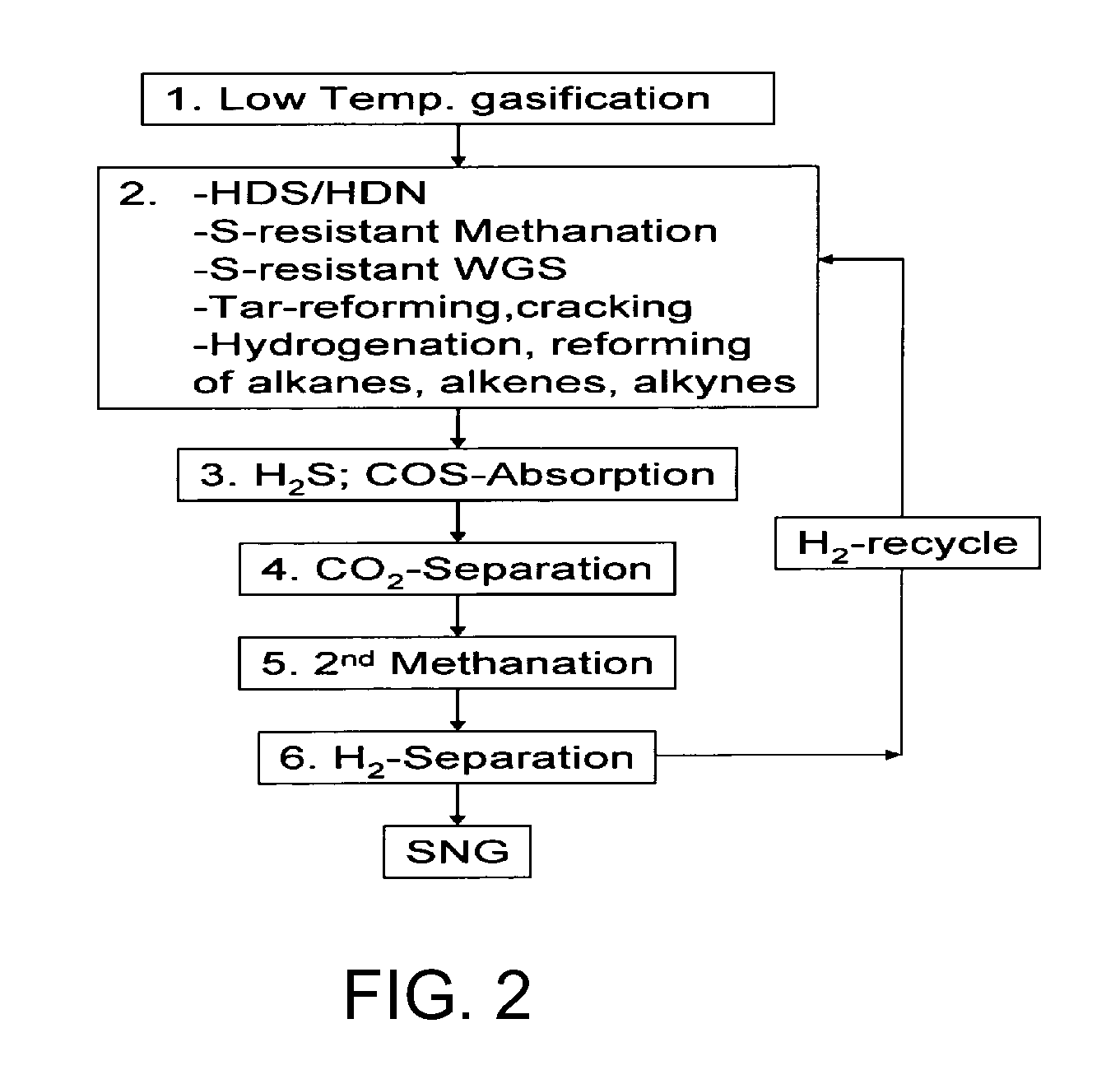

Process to Produce a Methane Rich Gas Mixture From Gasification Derived Sulphur Containing Synthesis Gases

A method for converting a raw gas into a methane-rich and / or hydrogen-rich gas includes the following steps: a) providing the raw gas stemming from a coal and / or biomass gasification process, thereby the raw gas comprising beside a methane and hydrogen content carbon monoxide, carbon dioxide, alkanes, alkenes, alkynes, tar, especially benzole and naphthalene, COS, hydrogen sulfide and organic sulfur compounds, especially thiophenes; thereby the ratio of hydrogen to carbon monoxide ranges from 0.3 to 4; b) bringing this raw gas into contact with a catalyst in a fluidized bed reactor at temperatures above 200° C. and at pressures equal or greater than 1 bar in order to convert the raw gas into a first product gas, thereby simultaneously converting organic sulfur components into hydrogen sulfide, reform tars, generate water / gas shift reaction and generate methane from the hydrogen / carbon monoxide content; c) bringing the first product gas into a sulfur absorption process to generate a second product gas, thereby reducing the content of hydrogen sulfur and COS from 100 to 1000 ppm down to 1000 ppb or less; d) optionally bringing the second product gas into a carbon dioxide removal process to generate a third product gas at least almost free of carbon dioxide; e) bringing the third product gas into a second methanation process to generate a fourth product gas having a methane content above 5 vol %; f) optionally bringing the fourth product gas into a carbon dioxide removal process to generate a fifth product gas at least almost free of carbon dioxide g) bringing the fifth product gas into an hydrogen separation process in order to separate a hydrogen rich gas from a remaining methane-rich gas, called substitute natural gas.

Owner:PAUL SCHERRER INSTITUT

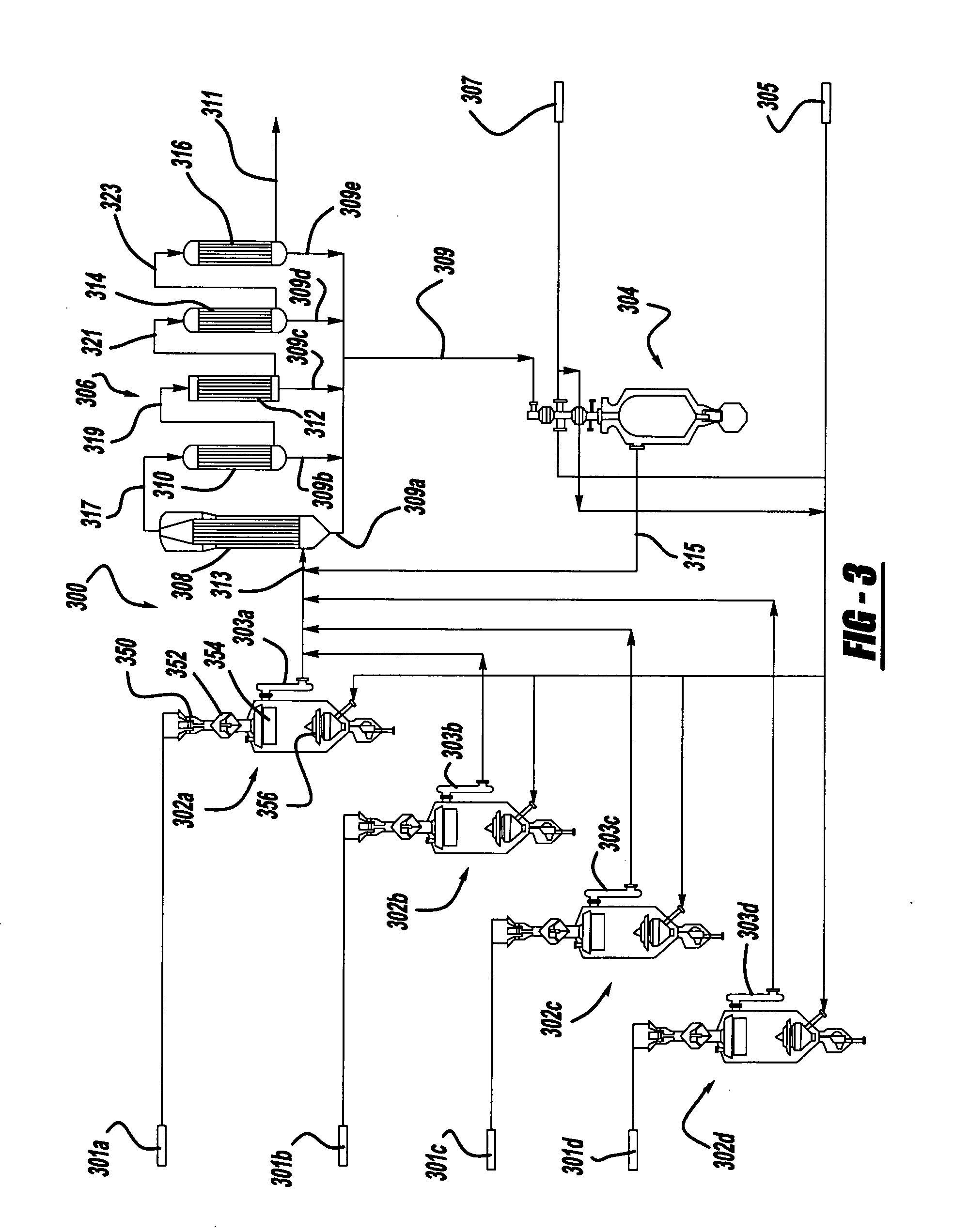

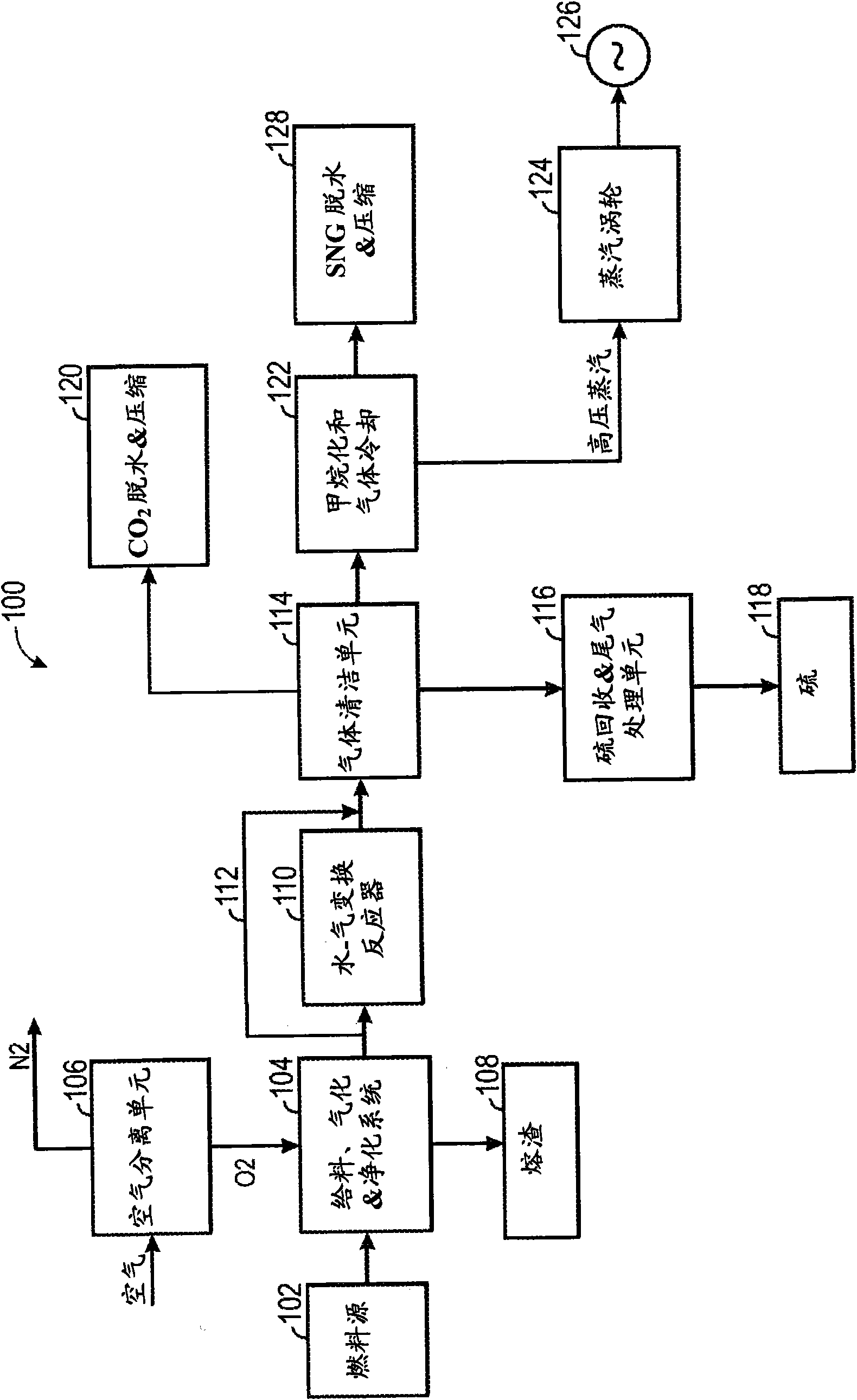

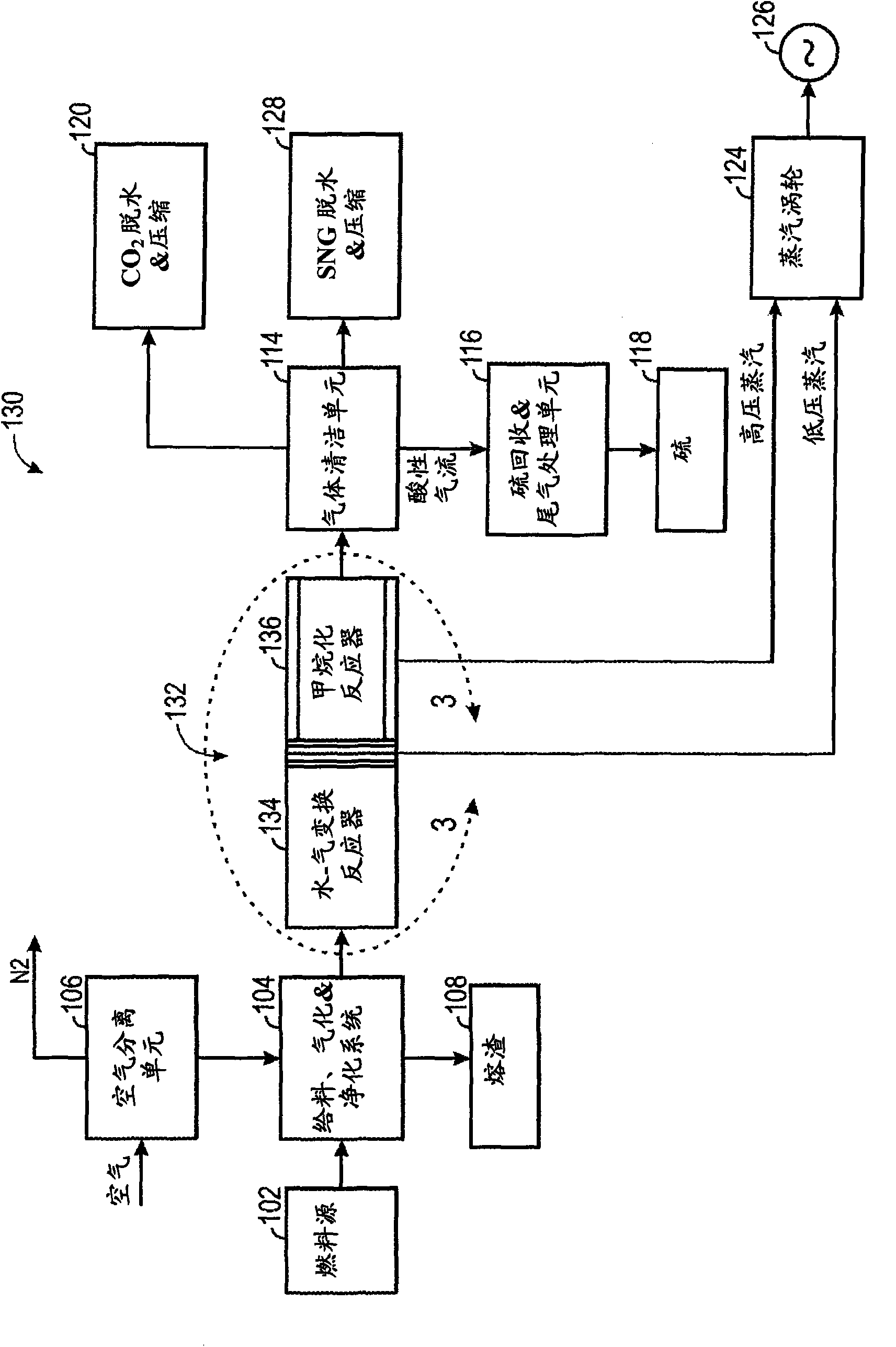

Method and apparatus for substitute natural gas generation

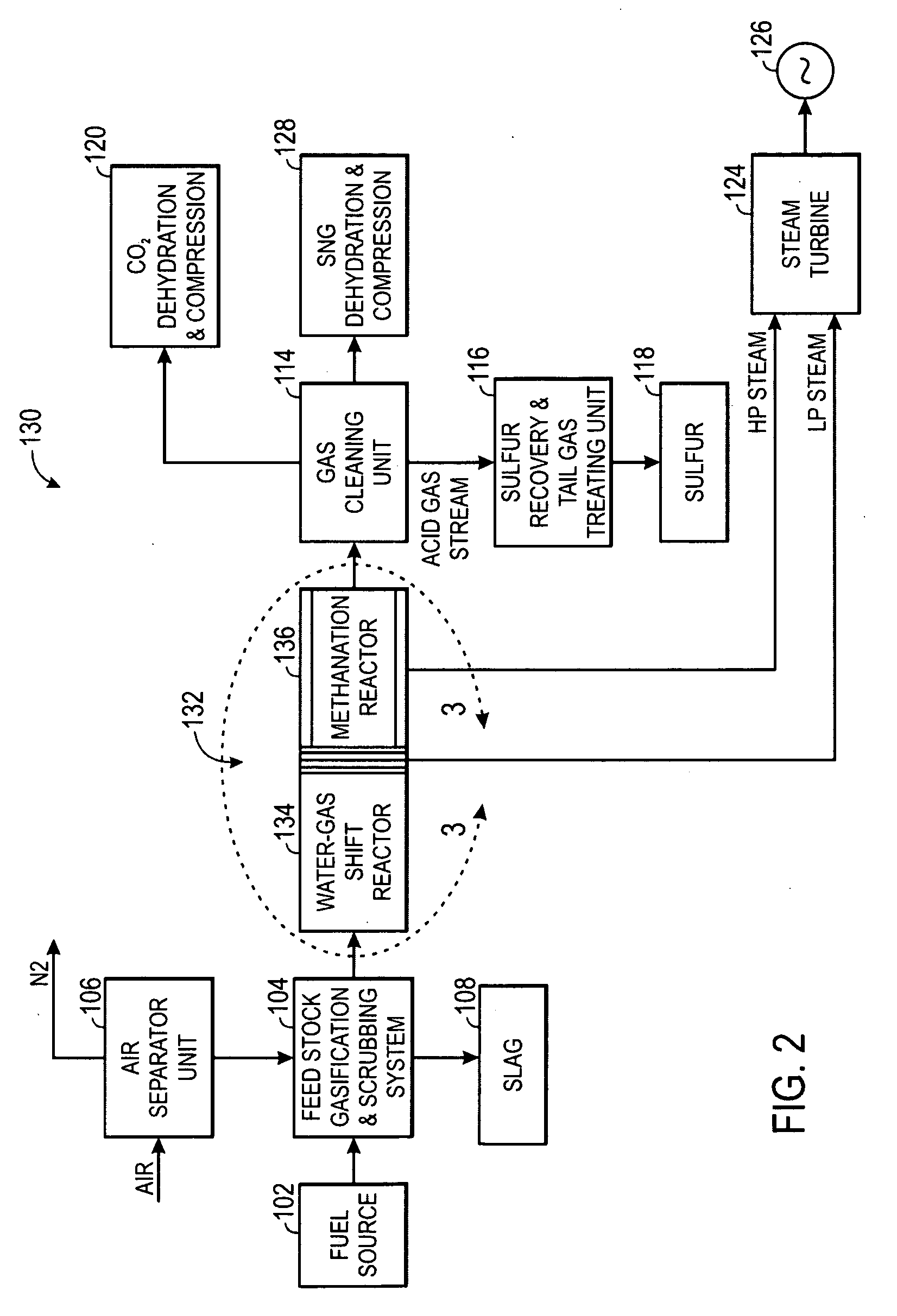

ActiveUS20100272619A1Combustible gas catalytic treatmentGas modification by gas mixingMethanationProduct gas

A system comprising a multi-stage reactor. The multi-stage reactor may include a water gas shift (WGS) reactor and a sour methanation reactor configured to generate methane without prior removal of acid gas. Furthermore, the multistage reactor may be a single unit having both the WGS reactor and the methanation reactor.

Owner:AIR PROD & CHEM INC

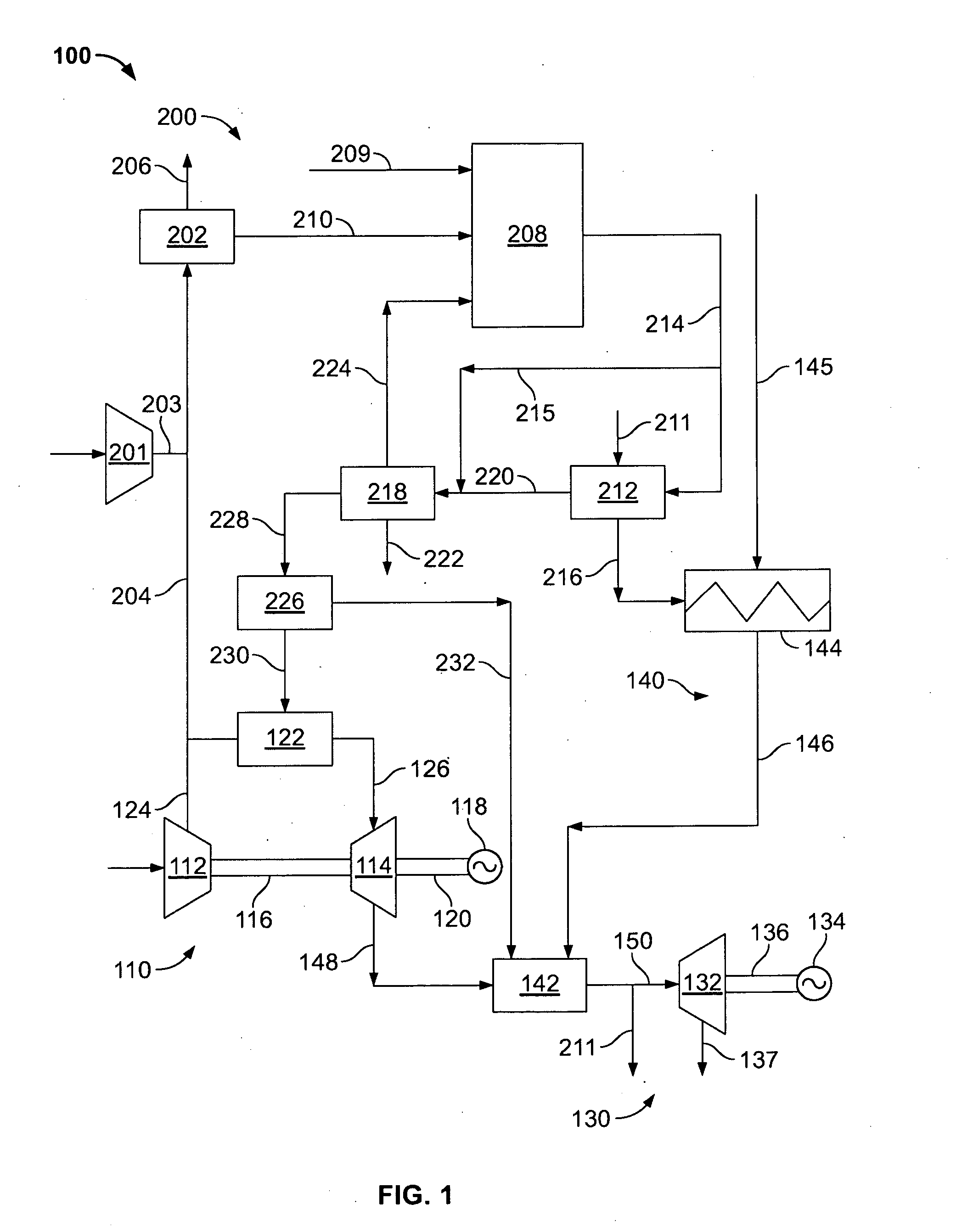

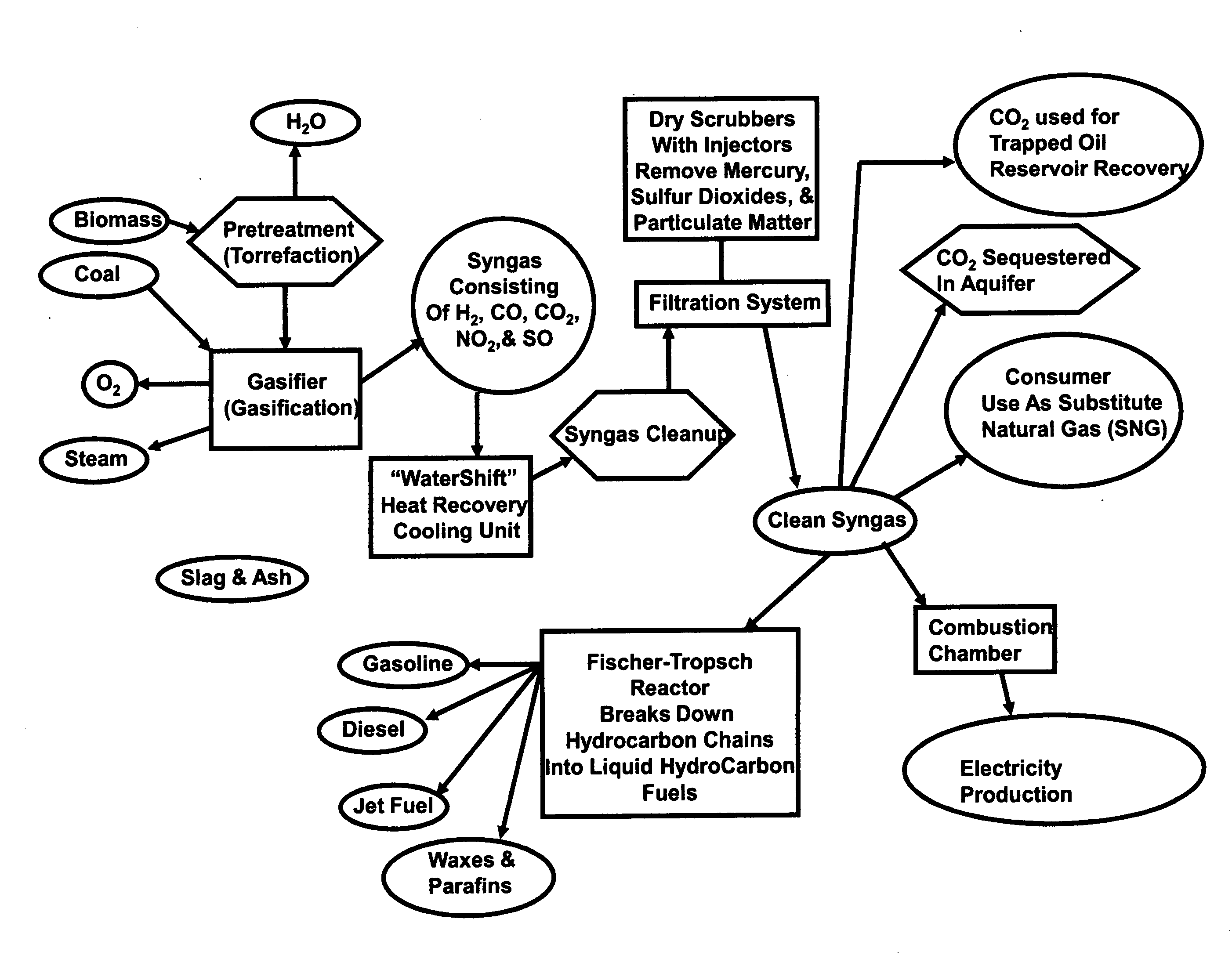

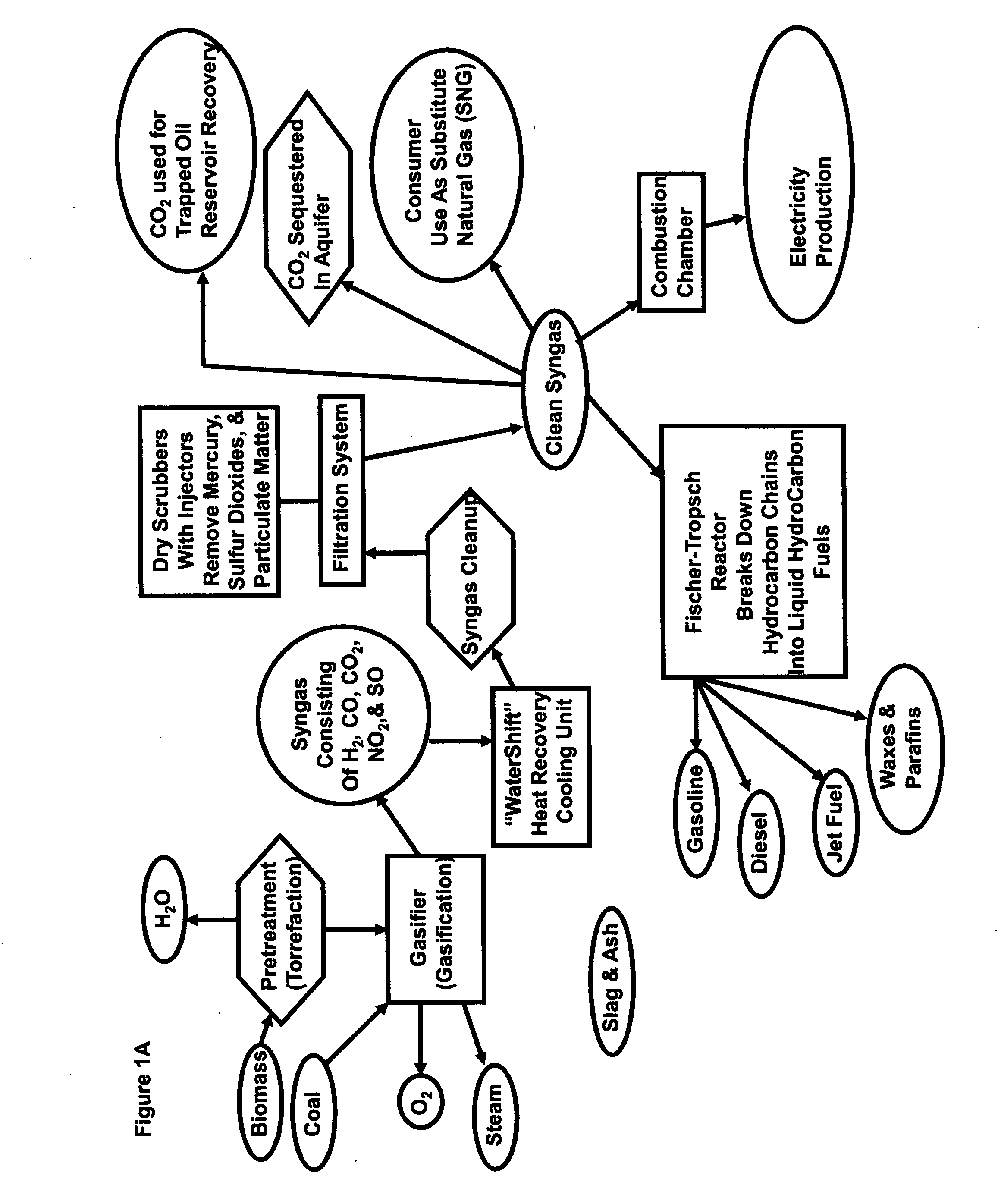

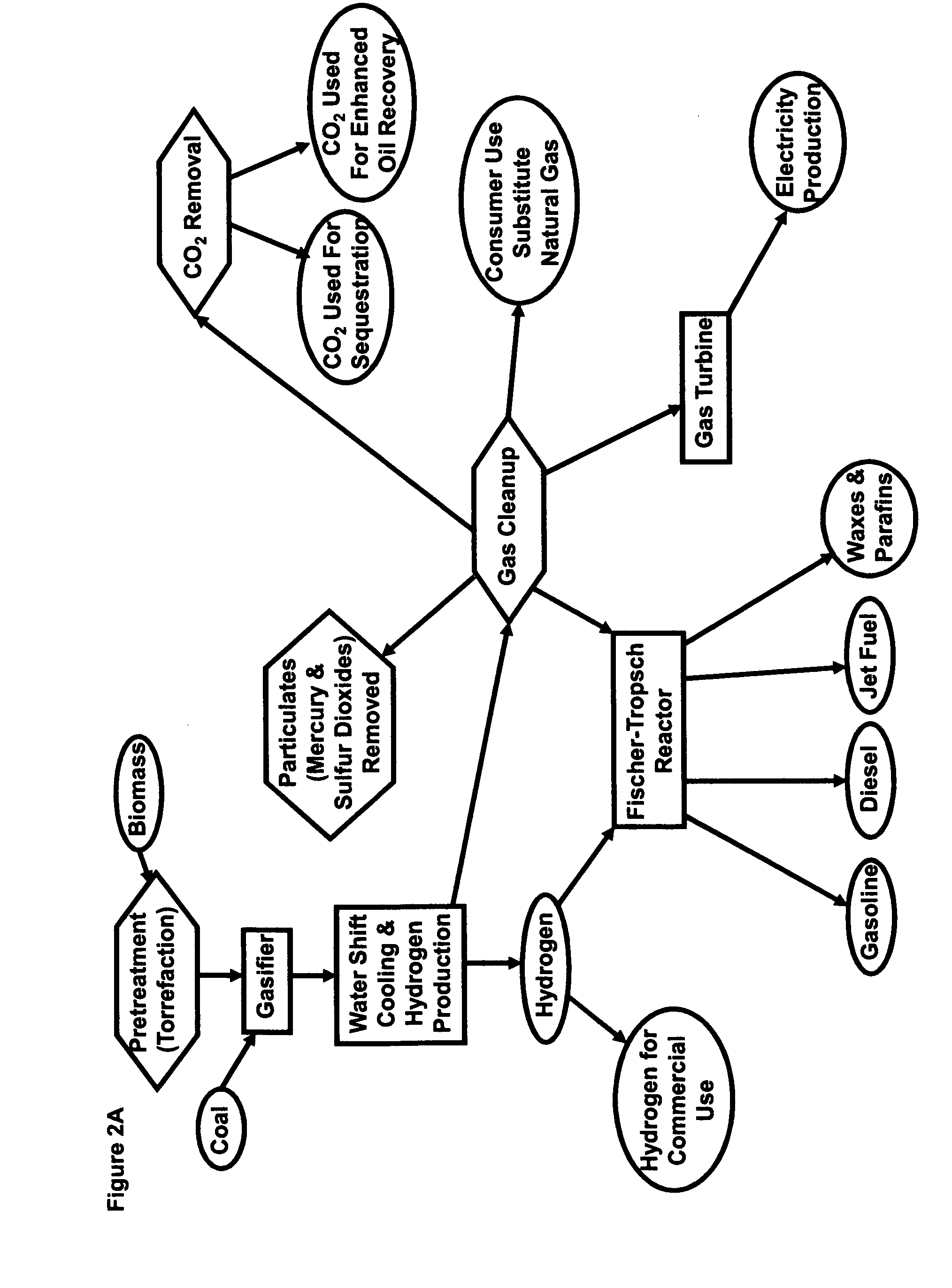

Coal and Biomass Conversion to Multiple Cleaner Energy Solutions System producing Hydrogen, Synthetic Fuels, Oils and Lubricants, Substitute Natural Gas and Clean Electricity

The system contained within this application for patent protection provides the ability to produce clean syngas, natural gas, synthetic fuels, electricity, hydrogen fuels, and oil substitutes using a variety of materials. These materials include, but are not limited to: coal, biomass (including but not limited to municipal solid wastes), and agricultural byproducts. The fuels and electricity generated by this system can immediately be utilized by existing power and transportation grids, and as such, allow for rapid integration into the nation's energy needs. The system also removes and sequesters carbon dioxide, creating a clean, environmentally responsible supply of multiple types of power. The overall process provides an alternative to current oil and power solutions, allowing for domestic production of various energy requirements, creating the possibility for the reduced dependence on foreign imports for energy needs.

Owner:KUKU MR LAI O

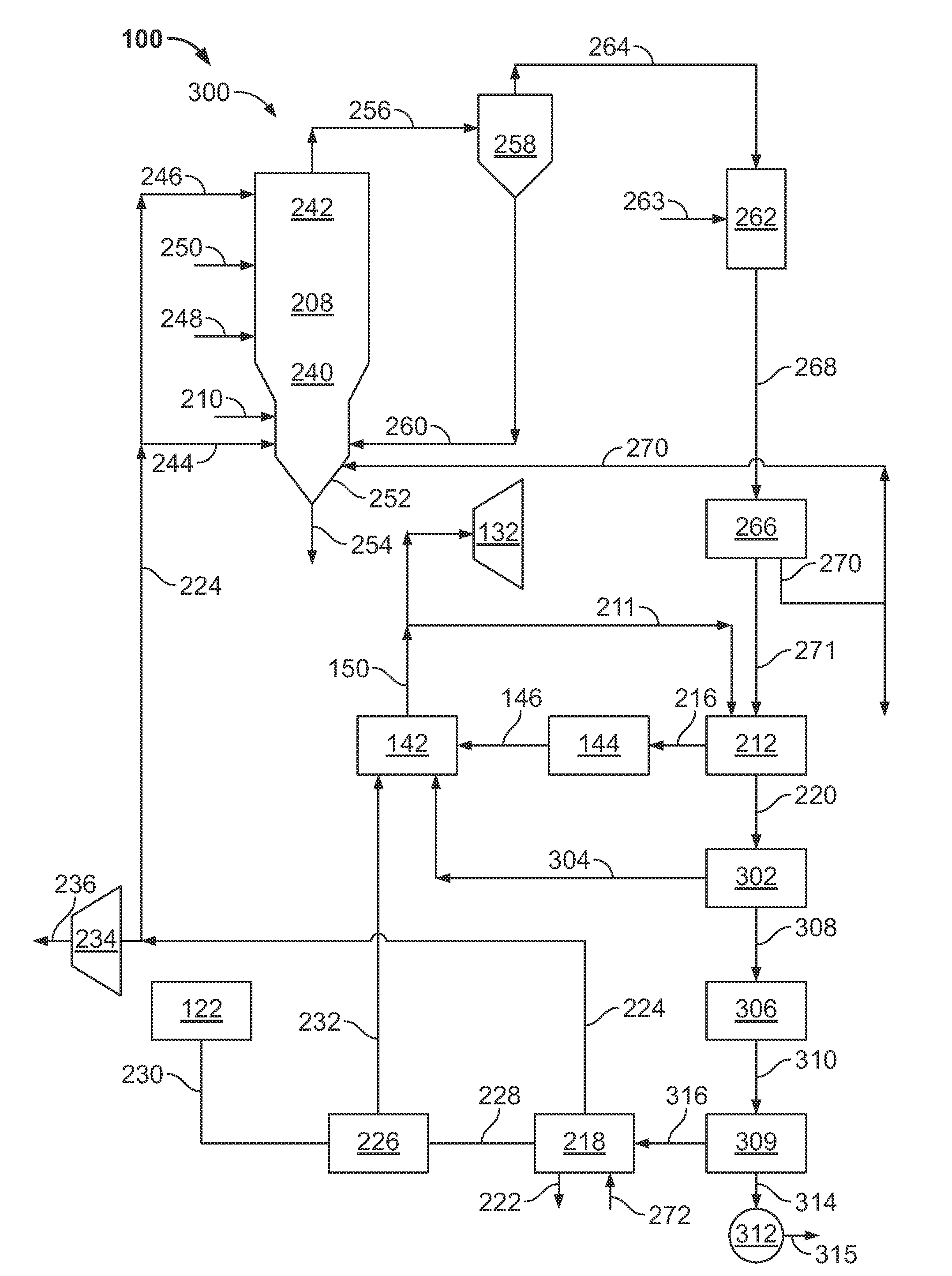

Method and apparatus for substitute natural gas generation

A system comprising a multi-stage reactor. The multi-stage reactor may include a water gas shift (WGS) reactor and a sour methanation reactor configured to generate methane without prior removal of acid gas. Furthermore, the multistage reactor may be a single unit having both the WGS reactor and the methanation reactor.

Owner:GENERAL ELECTRIC CO

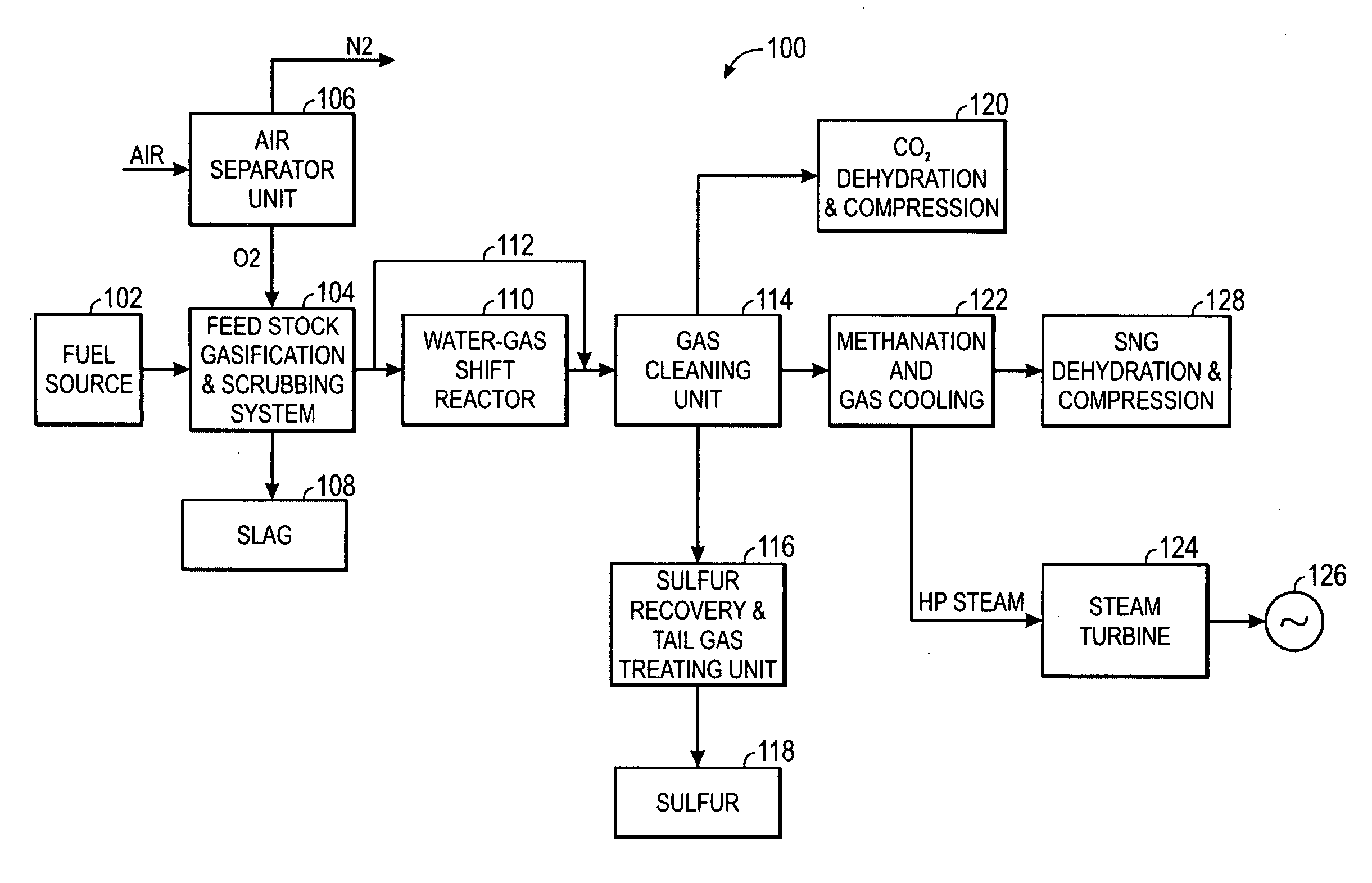

System and method for producing substittue natural gas from coal

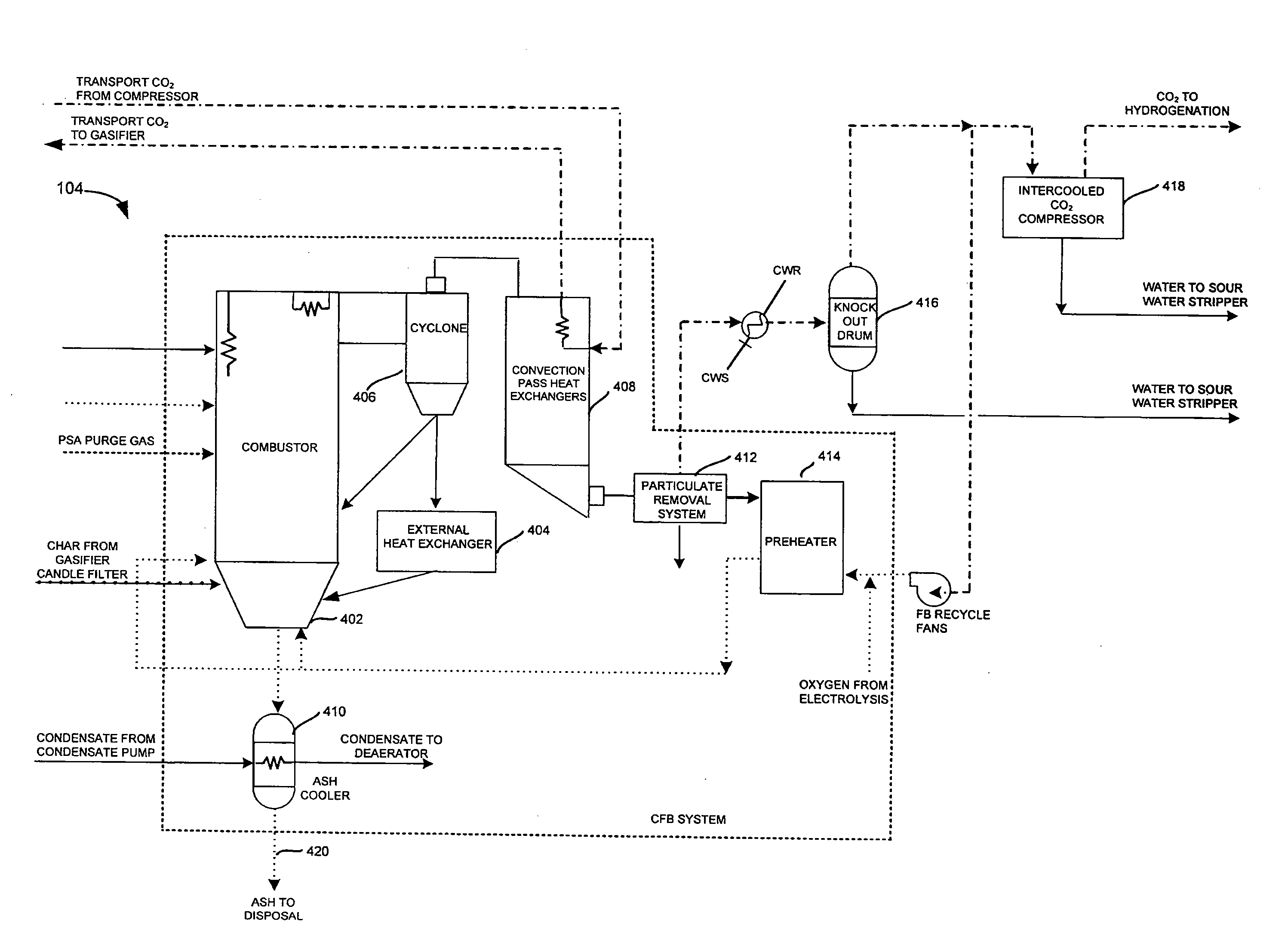

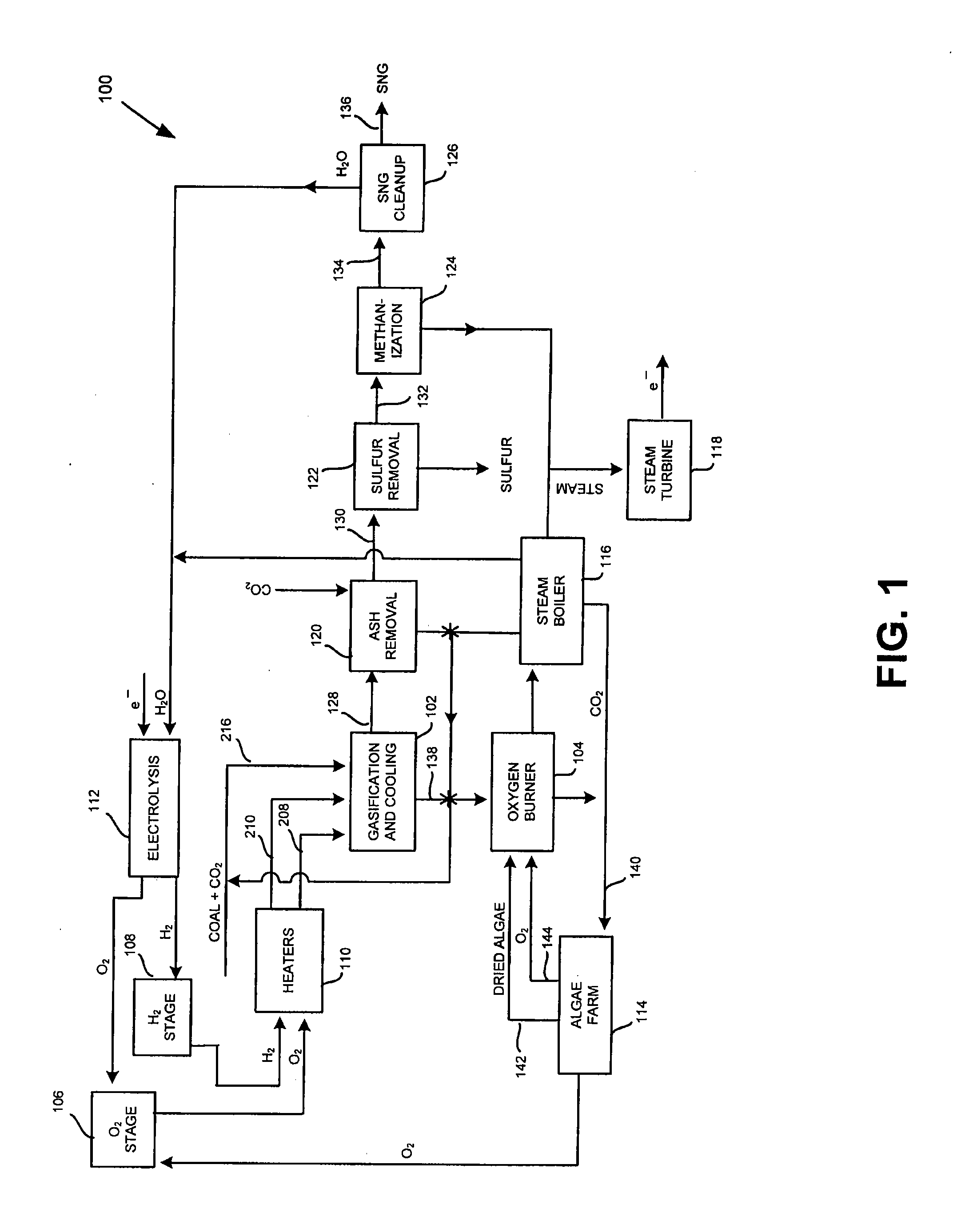

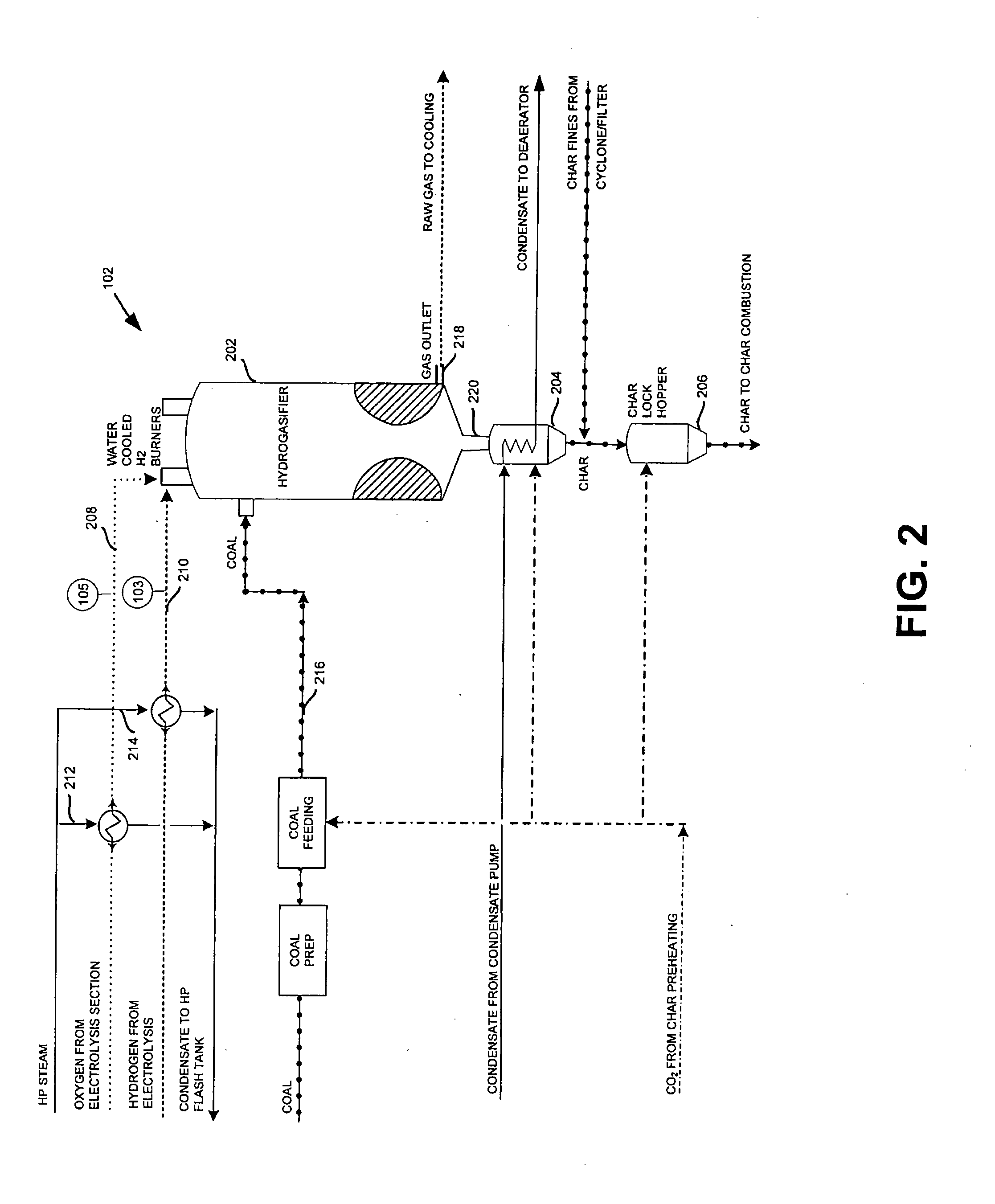

InactiveUS20080190024A1Produce electricityReduce productionBiofuelsGas modification by gas mixingElectricityCombustor

The present invention provides a system and method for producing substitute natural gas and electricity, while mitigating production of any greenhouse gasses. The system includes a hydrogasification reactor, to form a gas stream including natural gas and a char stream, and an oxygen burner to combust the char material to form carbon oxides. The system also includes an algae farm to convert the carbon oxides to hydrocarbon material and oxygen.

Owner:ARIZONA PUBLIC SERVICE

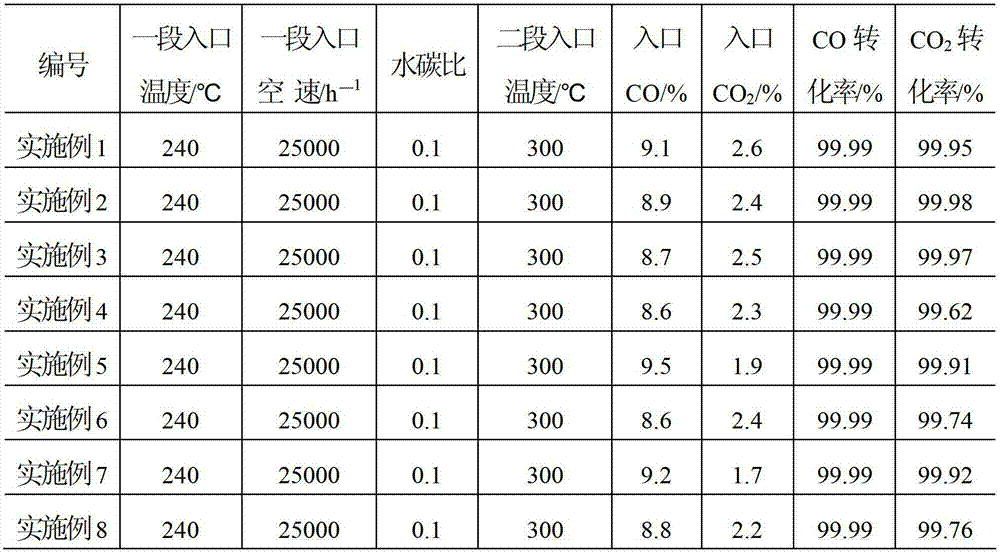

Methanation catalyst for synthesizing substitute natural gas and preparation method thereof

ActiveCN103191749ASimple structureImprove stabilityCatalyst carriersGaseous fuelsMethanationSpace velocity

The invention relates to a methanation catalyst for synthesizing substitute natural gas and a preparation method thereof. The methanation catalyst comprises Al2o3, MgO, NiO, La2O3, TiO2, CeO2 or ZrO2 and the mixture thereof. Compared with the existing methanation catalyst, the methanation catalyst prepared by using the method disclosed by the invention has high conversion ratio, great space velocity, high activity and good thermostability, so that the methanation catalyst and the preparation method thereof are suitable for the adiabatic non-circulation process and the adiabatic cycle process for synthesizing the substitute natural gas through the tail gas in hydrocarbon industries.

Owner:XIAN ORIGIN CHEM TECH

Synthesis gas methanation reaction method

ActiveCN103421561AReduce the temperatureReduce energy consumptionGaseous fuelsThermodynamicsPtru catalyst

The present invention relates to a synthesis gas methanation reaction method, wherein problems of low methanation reaction conversion rate, more heat exchange equipment, complex process and high compressor energy consumption in the prior art are mainly solved with the present invention. The method comprises the following steps that: at a temperature of 20-60 DEG C under a pressure of 3.0-5.5 MPa, synthesis gas is divided into a plurality of parts, the plurality of the parts are mixed with circulation gas from a methanation reactor, and the obtained mixing gases are introduced into various bed layers of a multi-stage fixed bed reactor filled with a methanation catalyst, wherein a temperature of the mixed gas is controlled to 300-400 DEG C, and the mixed gas comprises the mixing gas and the reaction gas discharged from various catalyst bed layers; outlet gas comprising CH4, H2O, unconverted CO, unconverted CO2 and unconverted H2 is obtained from the reactor outlet; the mixing gas entering the first stage catalyst bed layer and the outlet gas of the methanation reactor are subjected to heat exchange to be heated to a temperature of 260-450 DEG C; and the methanation reactor outlet gas is divided into two parts, the one part is adopted as the circulation gas, and the other part enters the next stage methanation reactor. With the technical scheme, the problems are well solved, and the method can be used for industrial production of substitute natural gas preparation through synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

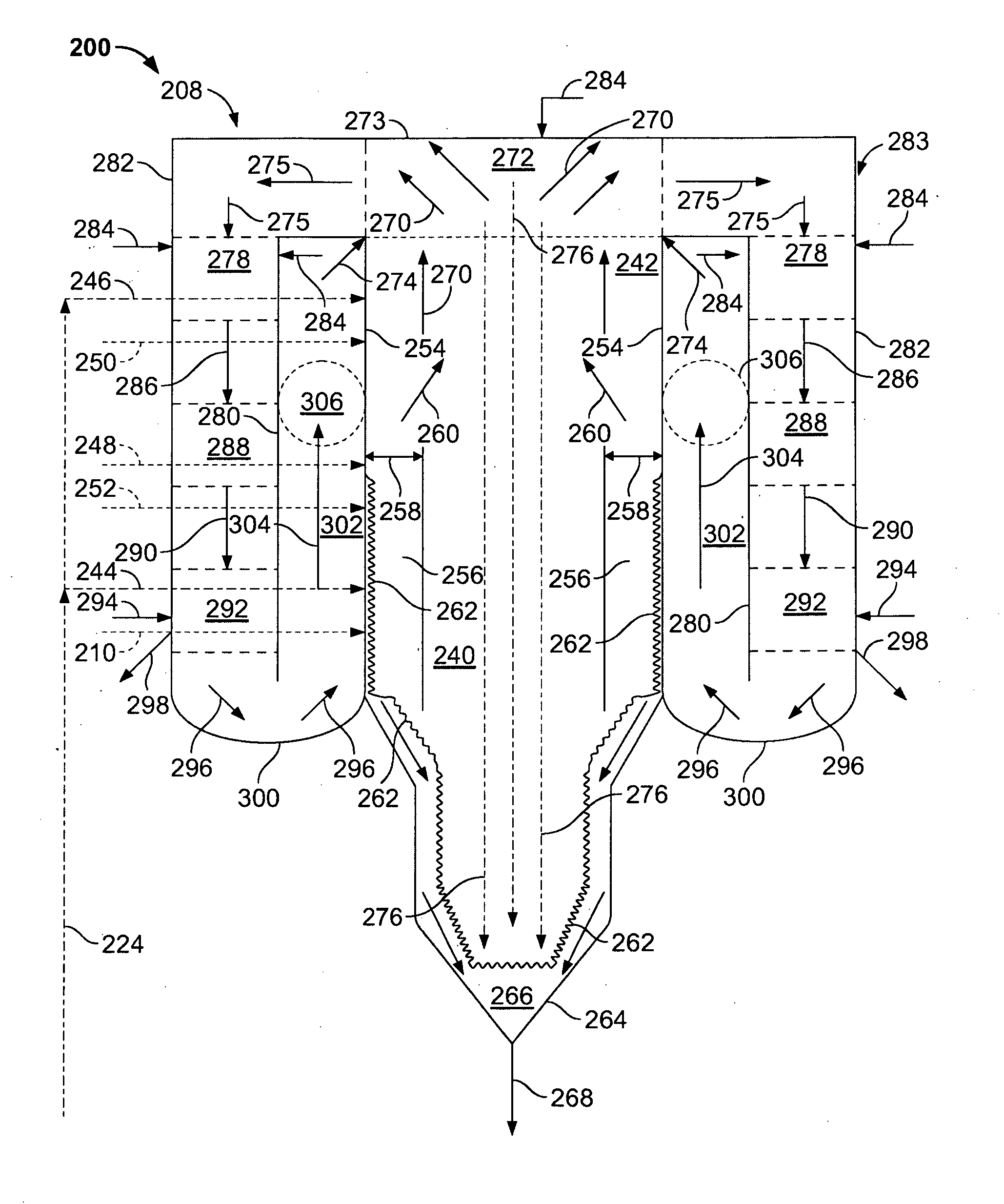

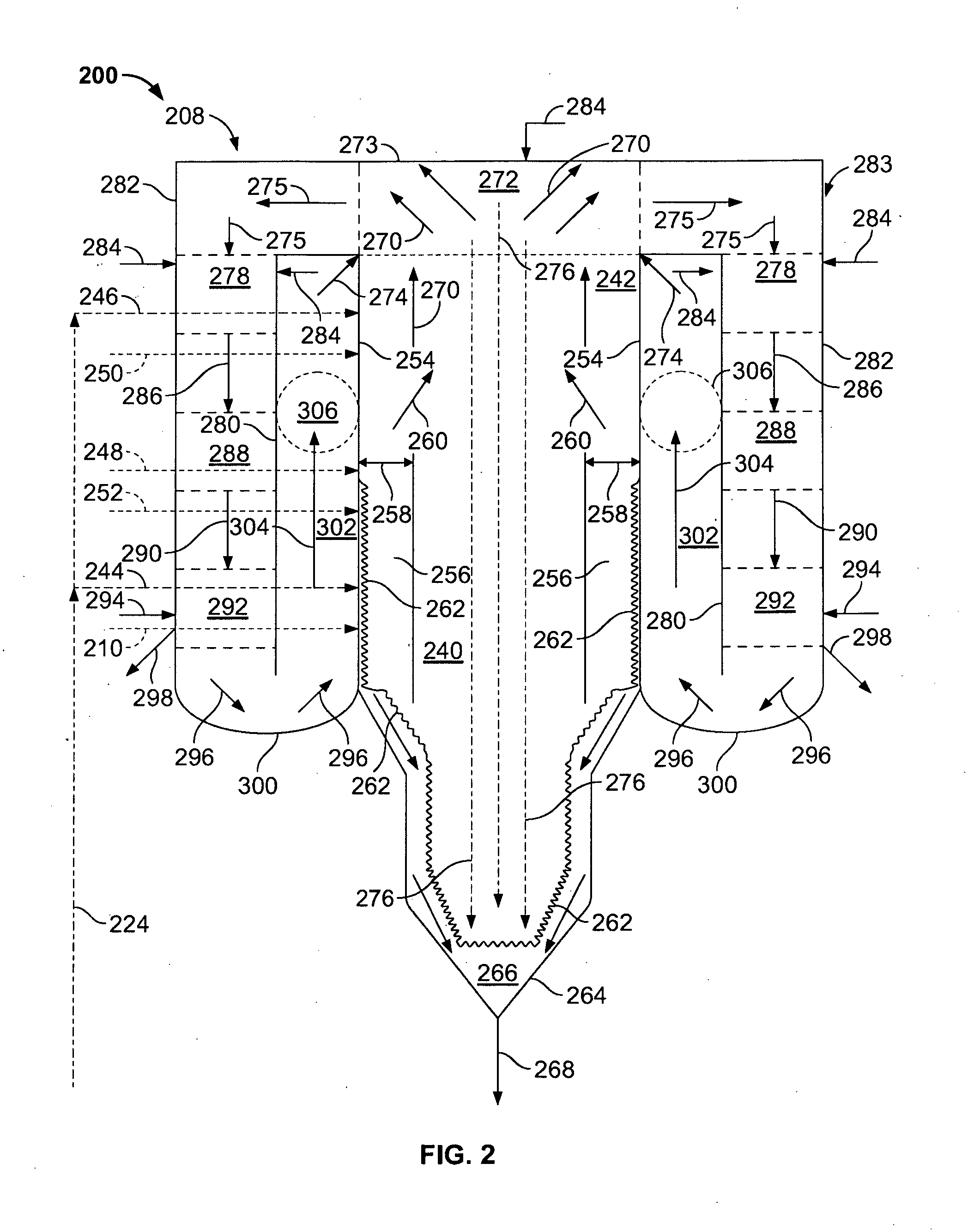

Method and apparatus to facilitate substitute natural gas production

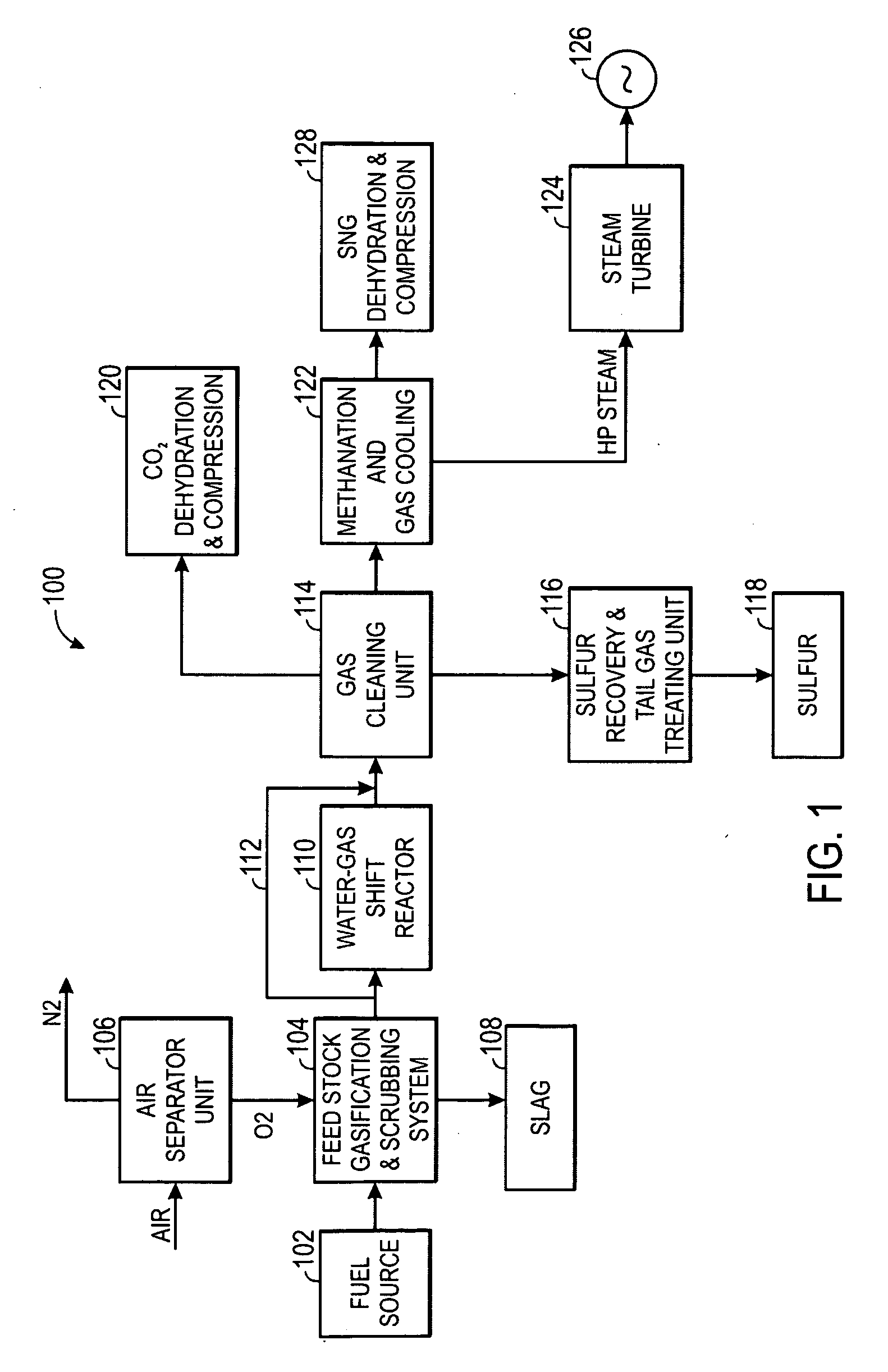

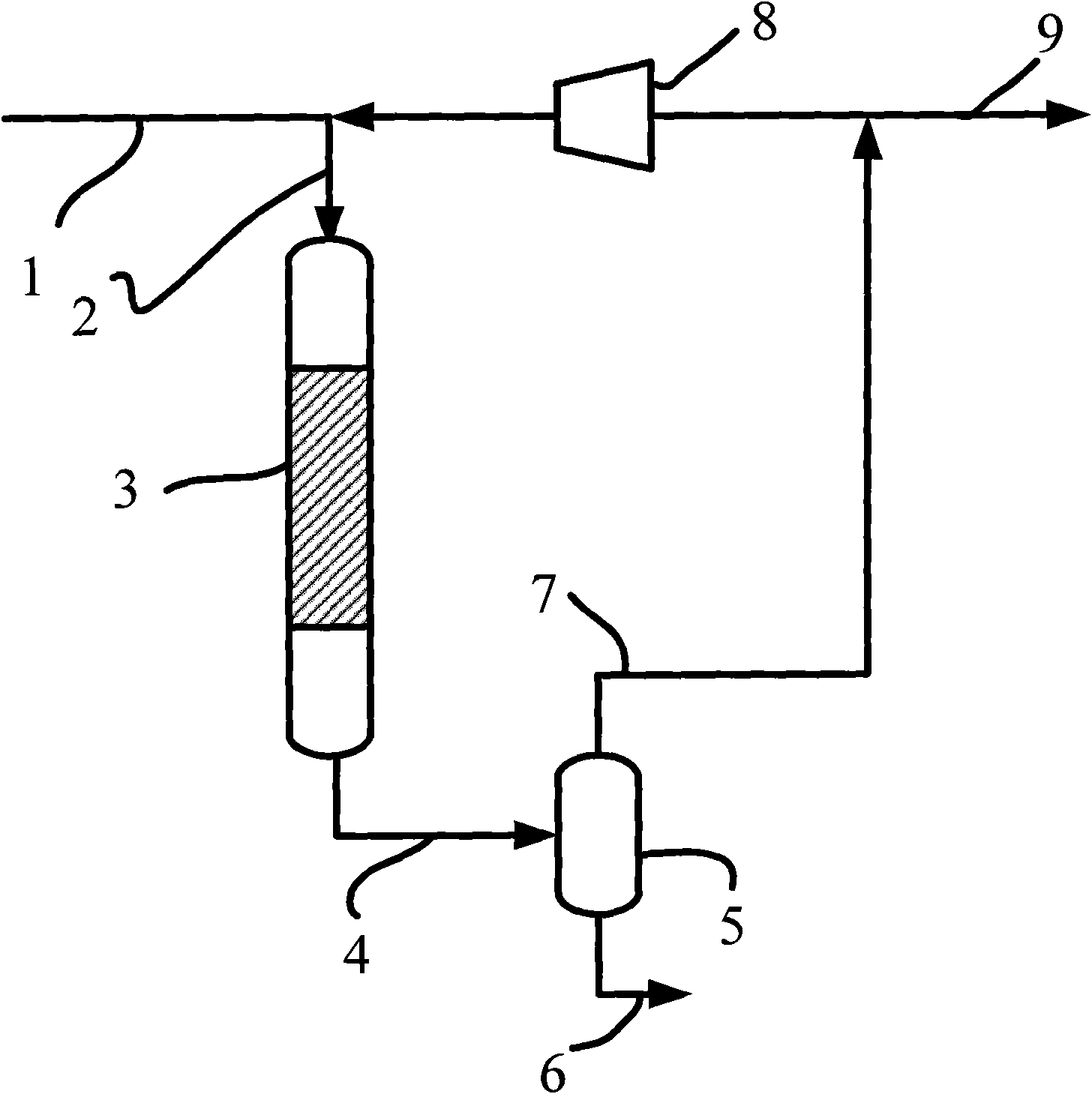

InactiveUS20090173081A1Facilitate channelingGas turbine plantsHydrogen/synthetic gas productionSubstitute natural gasSulfur hydride

A method of producing substitute natural gas (SNG) includes providing a syngas stream that includes at least some carbon dioxide (CO2) and hydrogen sulfide (H2S). The method also includes separating at least a portion of the CO2 and at least a portion of the H2S from at least a portion of the syngas stream provided. The method further includes channeling at least a portion of the CO2 and at least a portion of the H2S separated from at least a portion of the syngas stream to at least one of a sequestration system and a gasification reactor.

Owner:GENERAL ELECTRIC CO

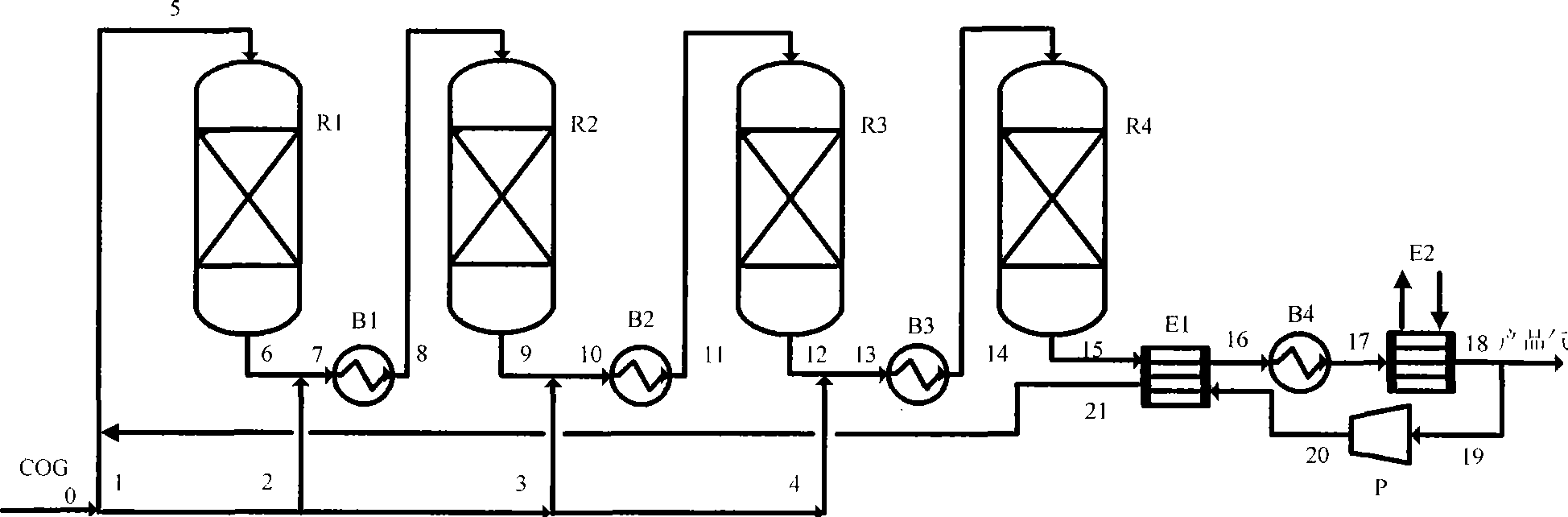

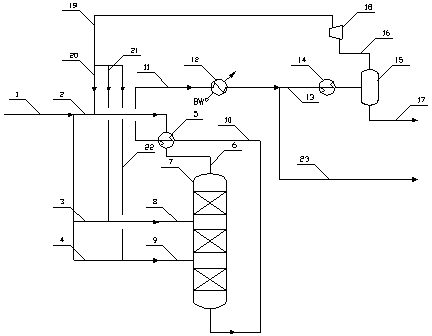

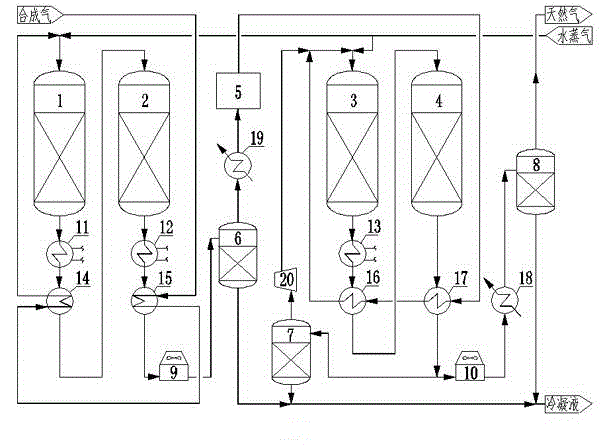

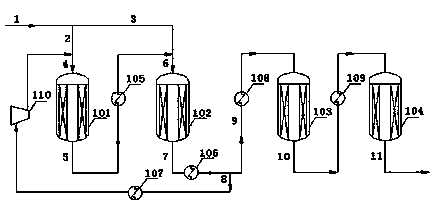

Methanation technology

The invention discloses a methanation technology for preparing substitute natural gas by using coal based syngas, and belongs to the technical field of new energy utilization. The coal based synthetic gas undergoes fine desulfurization, the obtained fresh gas is divided into two parts comprising a fresh gas A and a fresh gas B, the fresh gas A is mixed with recycle gas, the obtained gas mixture enters a first methanation reactor, the total concentration of CO and CO2 is not greater than 11%, the obtained first reaction product gas is mixed with the fresh gas B, the obtained mixed gas enters a second methanation reactor, the total concentration of CO and CO2 is not greater than 12%, parts of the above obtained second reaction product gas is recycled by a recycle compressor and returns to the inlet of the first methanation reactor, the rest of the second reaction product gas sequentially enters a third methanation reactor and a fourth methanation reactor for a methanation reaction, and the obtained fourth reaction product gas is condensed and separated to obtain the substitute natural gas with the methane content of 95% or less.

Owner:CHINA PETROLEUM & CHEM CORP +1

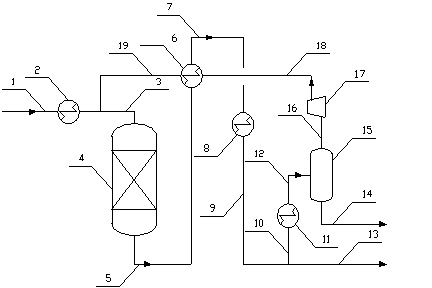

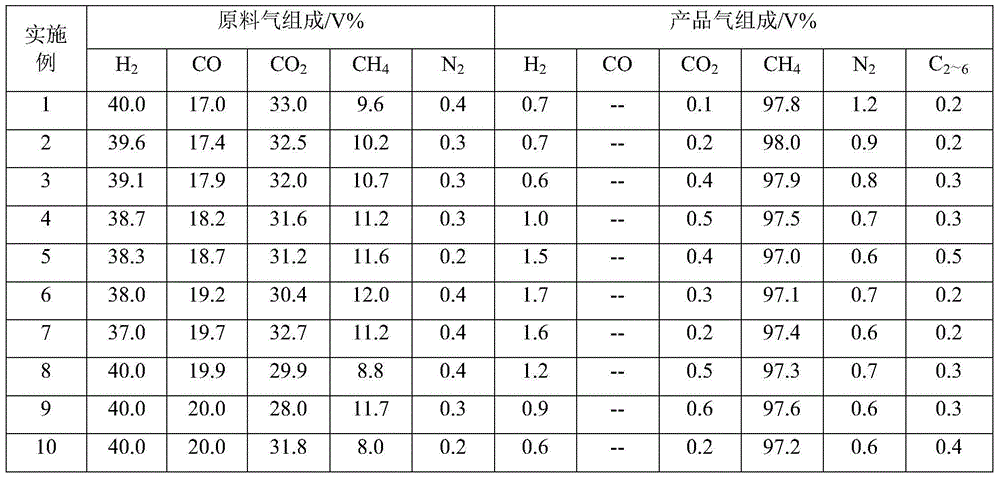

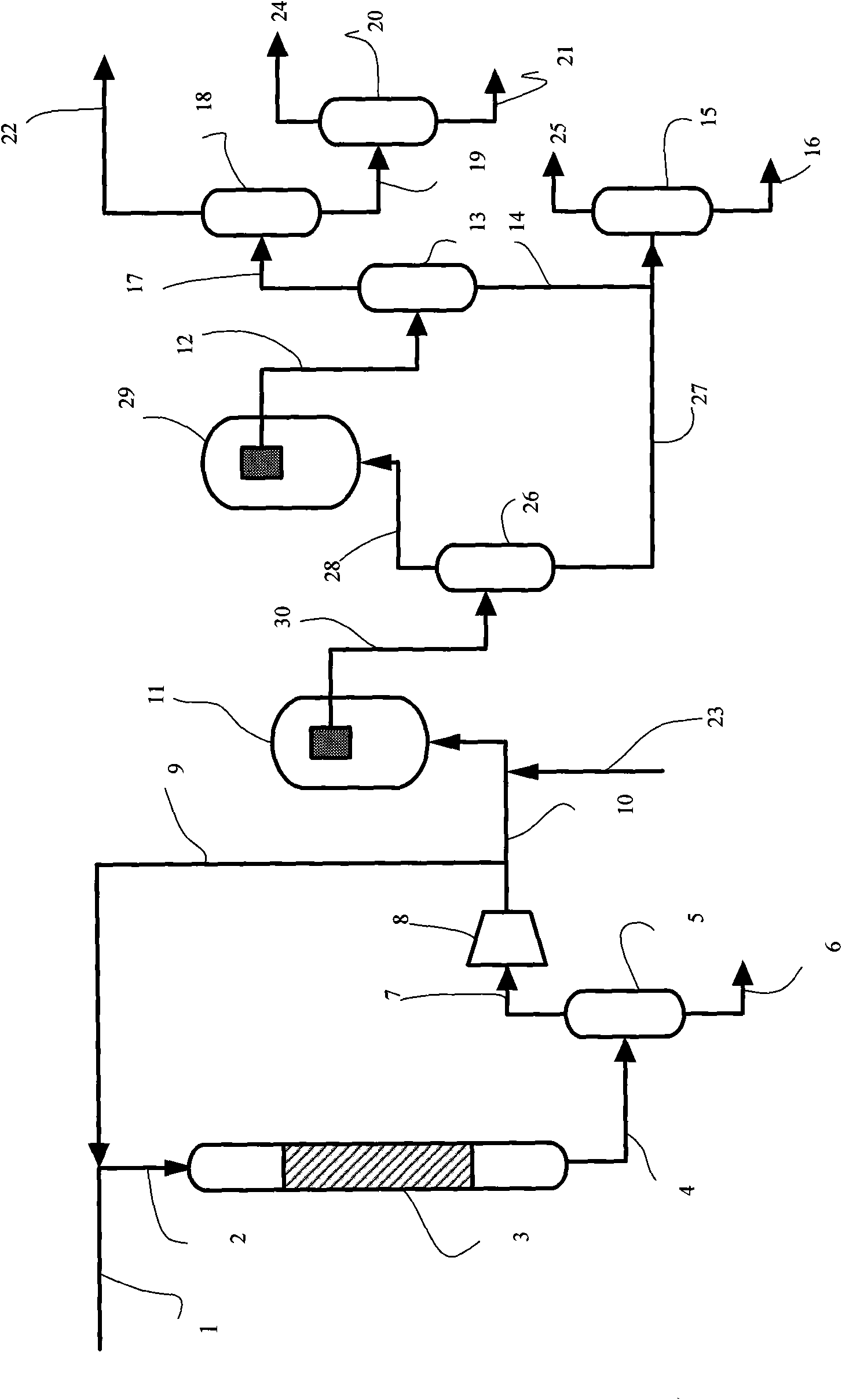

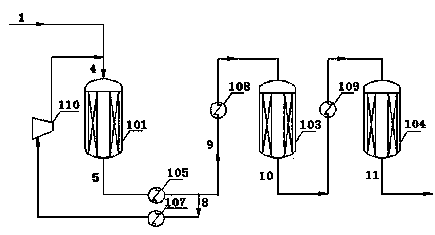

Process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas

ActiveCN104164262AWith characteristicsHave made significant progressGaseous fuelsMethanationWater vapor

The invention provides a process for preparing substitute natural gas through sulphur-tolerant methanation of coal synthesis gas. The process is characterized in that the synthesis gas enters sulphur-tolerant methanation reactors I and II in sequence, and the mixed gas of the synthesis gas and water vapor enters a rectisol system so as to remove the impurities such as CO2, H2S and the like in the gas after undergoing sulphur-tolerant shift and sulphur-tolerant methanation reaction on a molybdenum-based bifunctional catalyst and then undergoes methanation reaction in methanation reactors I and II in sequence under the action of Ni-based methanation catalysts, thus obtaining the natural gas product. The process has the advantages of simple process flow, small equipment investment, low comprehensive energy consumption and excellent natural gas products.

Owner:SEDIN ENG +1

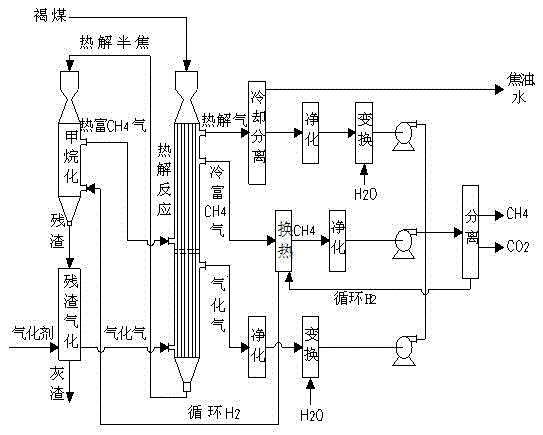

Technology for producing methane through low-rank coal

InactiveCN102911756AReduce hydrogen consumptionImprove thermal efficiencyGaseous fuelsWater vaporMethanation

A technology for producing methane through low-rank coal is that the low-rank coal is pyrolyzed so as to obtain pyro-char and pyrolysis gas which contains tar. The pyrolysis gas which contains the tar is cooled and separated so as to obtain the tar, water and the pyrolysis gas; the pyro-char is fed into a methanator, the easily reactive pyro-char is reacted with circulated hydrogen at a high temperature and a high pressure so as to obtain methanation gas, and the difficult reactive pyro-char is fed into a gasification reactor to be reacted with water vapor and oxygen, so that gasification gas is produced. The methanation gas and the gasification gas are used as heat sources to directly supply heat for the pyrolytic reaction of feed coal in a pyrolysis reactor. The pyrolysis gas and the gasification gas are separated or mixed to be converted, decarbonized and separated, so that hydrogen-rich gas is obtained, and the pyrolysis gas and the methanation gas are subjected to heat exchange, purified and separated to obtain the hydrogen-rich gas, so that hydrogen sources are provided for a methanation unit. The substitute natural gas which is produced by the technology has the advantages of high thermal efficiency, low hydrogen consumption, quick methanation reaction speed and the like.

Owner:TAIYUAN UNIV OF TECH

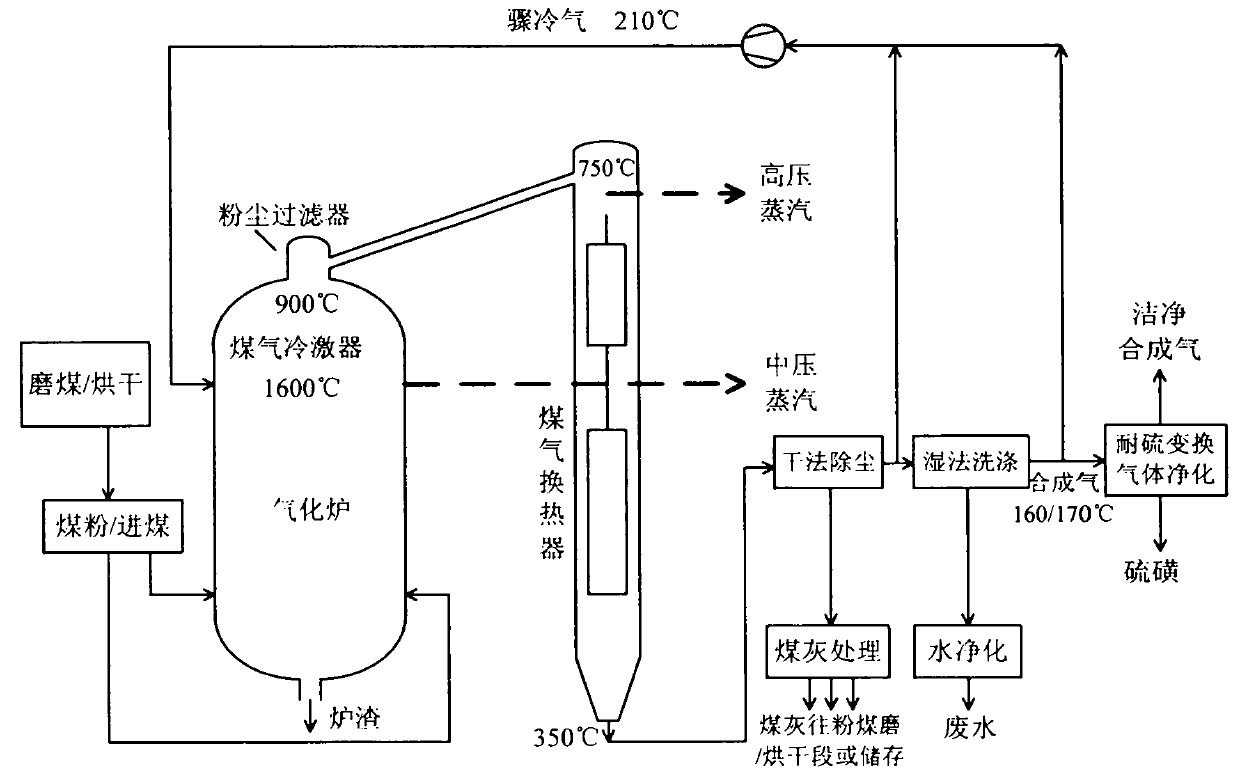

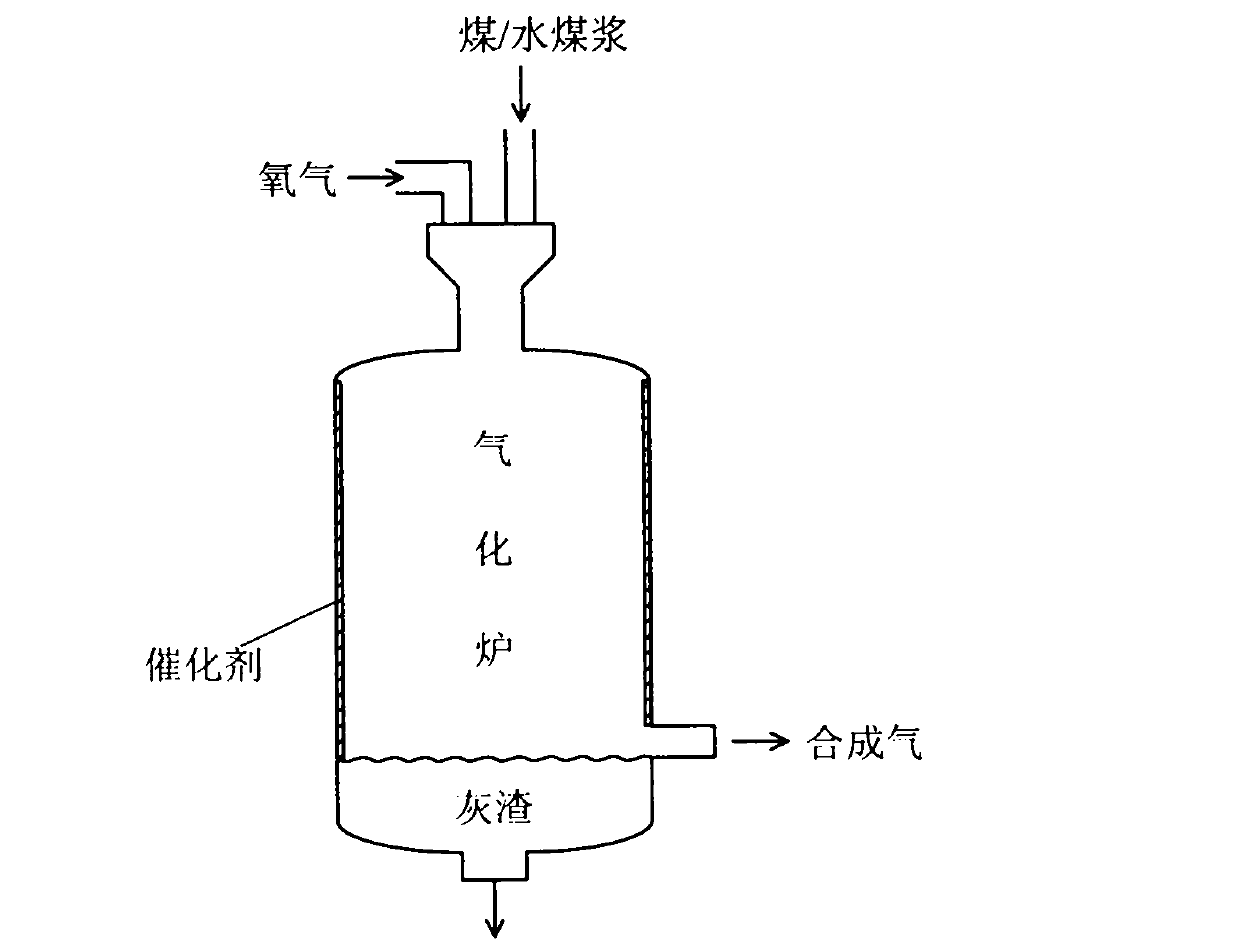

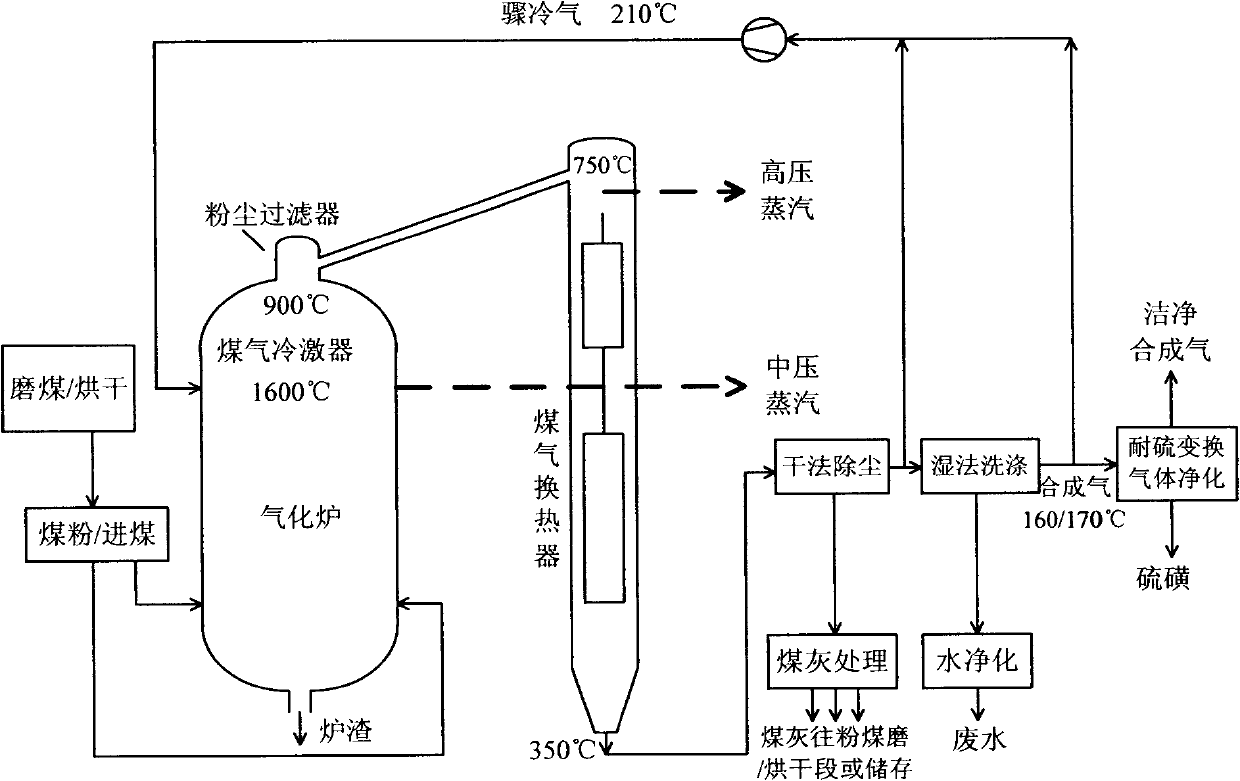

Process and device for integrally producing substitute natural gas by coal gasification and methanation

InactiveCN101906339AWide adaptabilityIncrease flexibilityGaseous fuelsGranular/pulverulent flues gasificationPartial oxidationMethanation

The invention relates to a process and a device for integrally producing substitute natural gas by coal gasification and methanation, which comprises the following steps: manufacturing the raw material coal into pulverized coal or coal water slurry; feeding the raw materials into a gasification furnace for partial oxidation reaction to generate a gas mixture; and enabling the gas mixture to enter a subsequent device for processing to obtain the substitute natural gas, wherein the gasification furnace and / or the subsequent device are subject to methanation catalysis and strengthen process, and the gas mixture generates a methanation reaction in the gasification furnace and / or the subsequent device. The devices comprise the following equipments: the gasification furnace, a dust filter, a gas chiller and / or a coal gas heat exchanger, wherein one or more of the devices are subject to the methanation catalysis and the strengthen process. The process and the device for integrally producing the substitute natural gas through the coal gasification and methanation provided by the invention has high cost efficiency and competitiveness.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

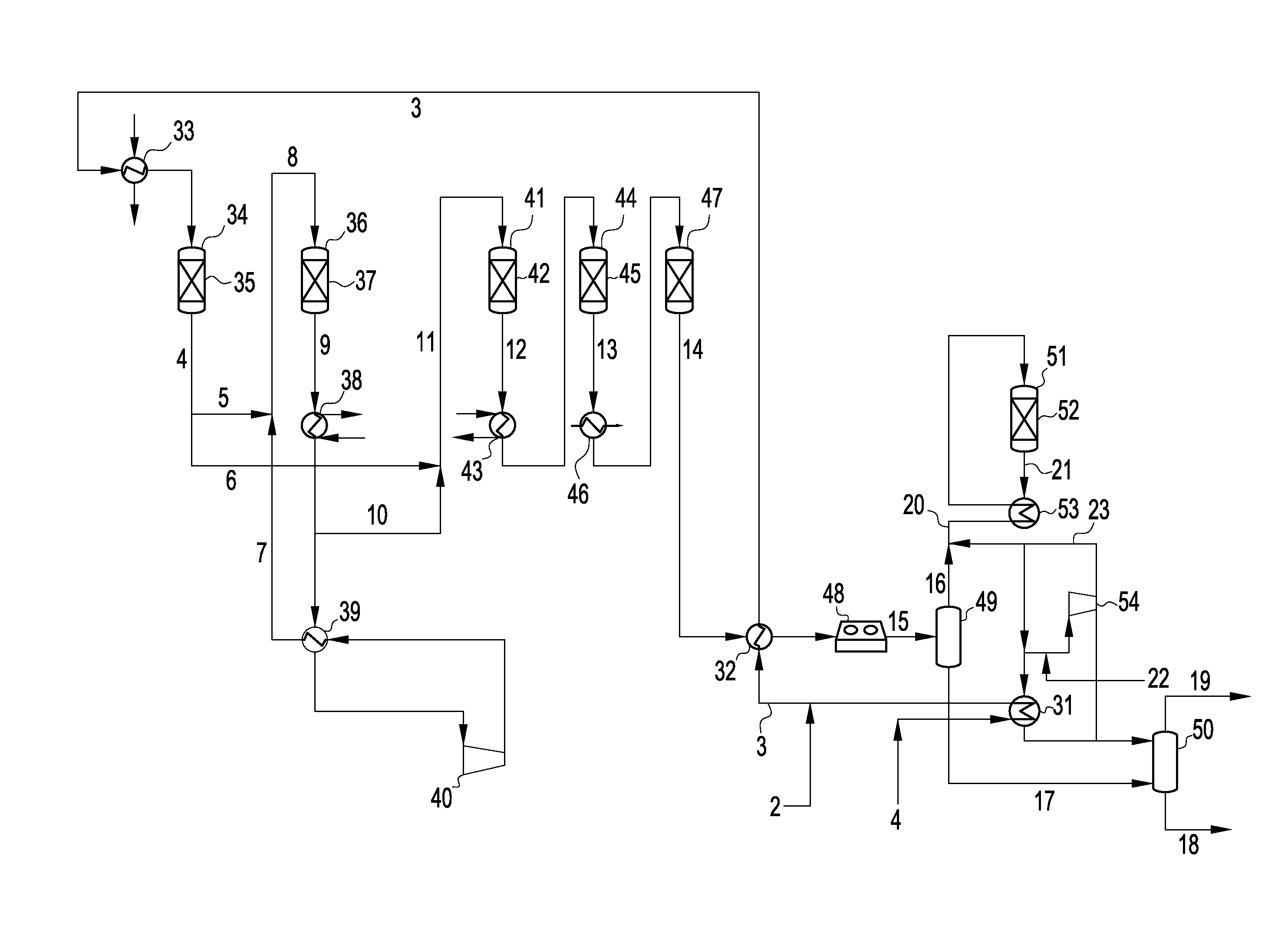

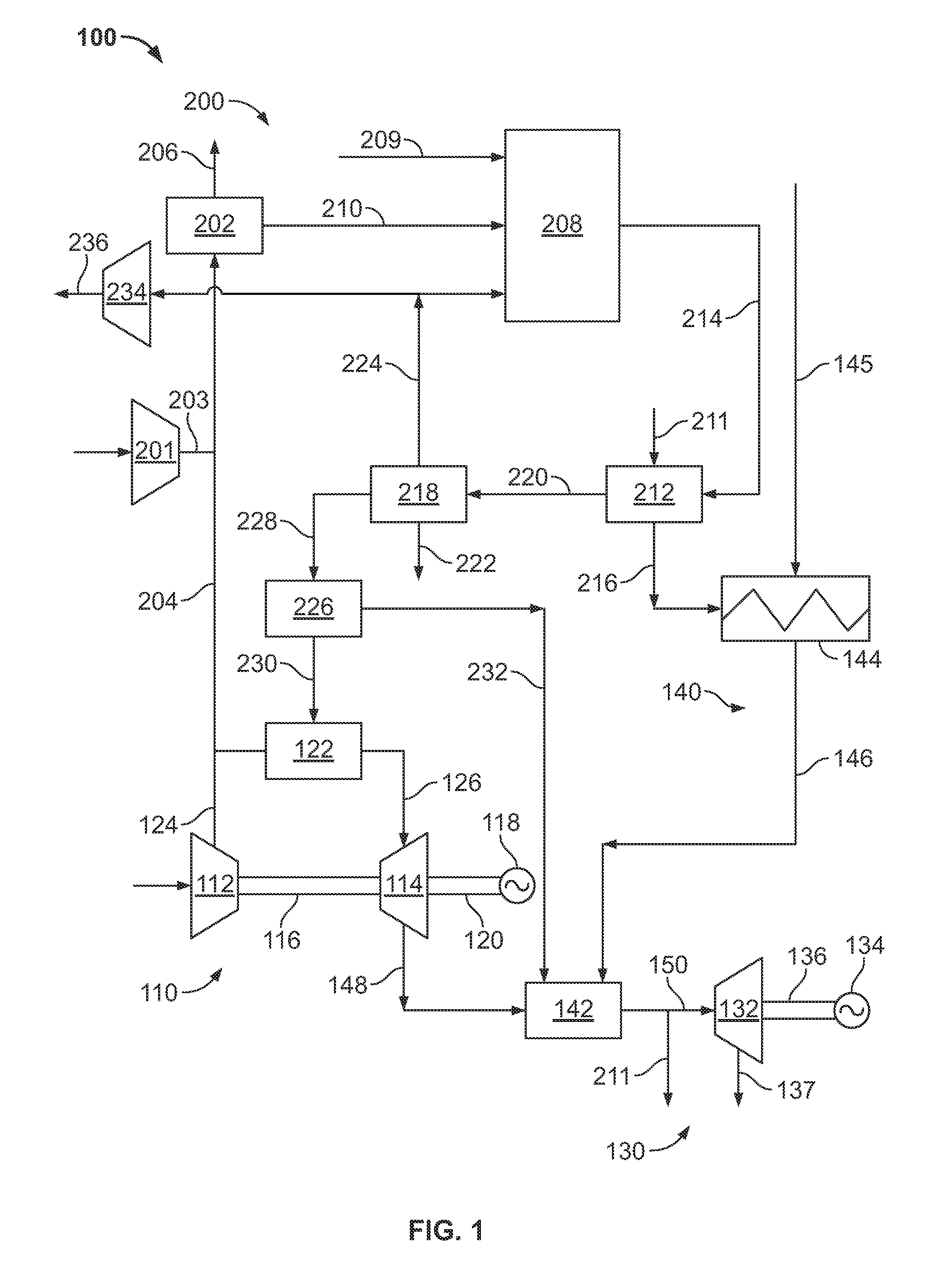

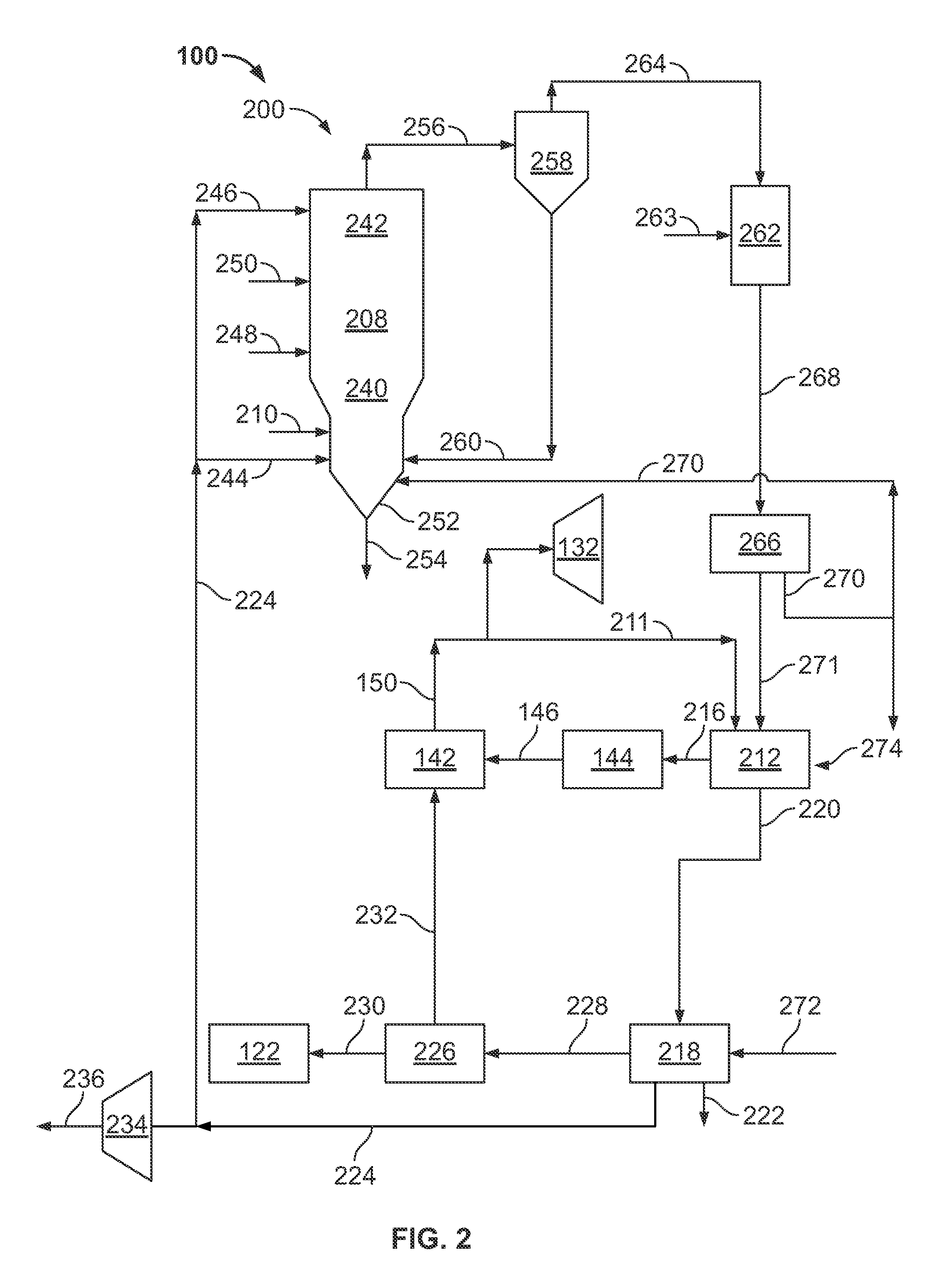

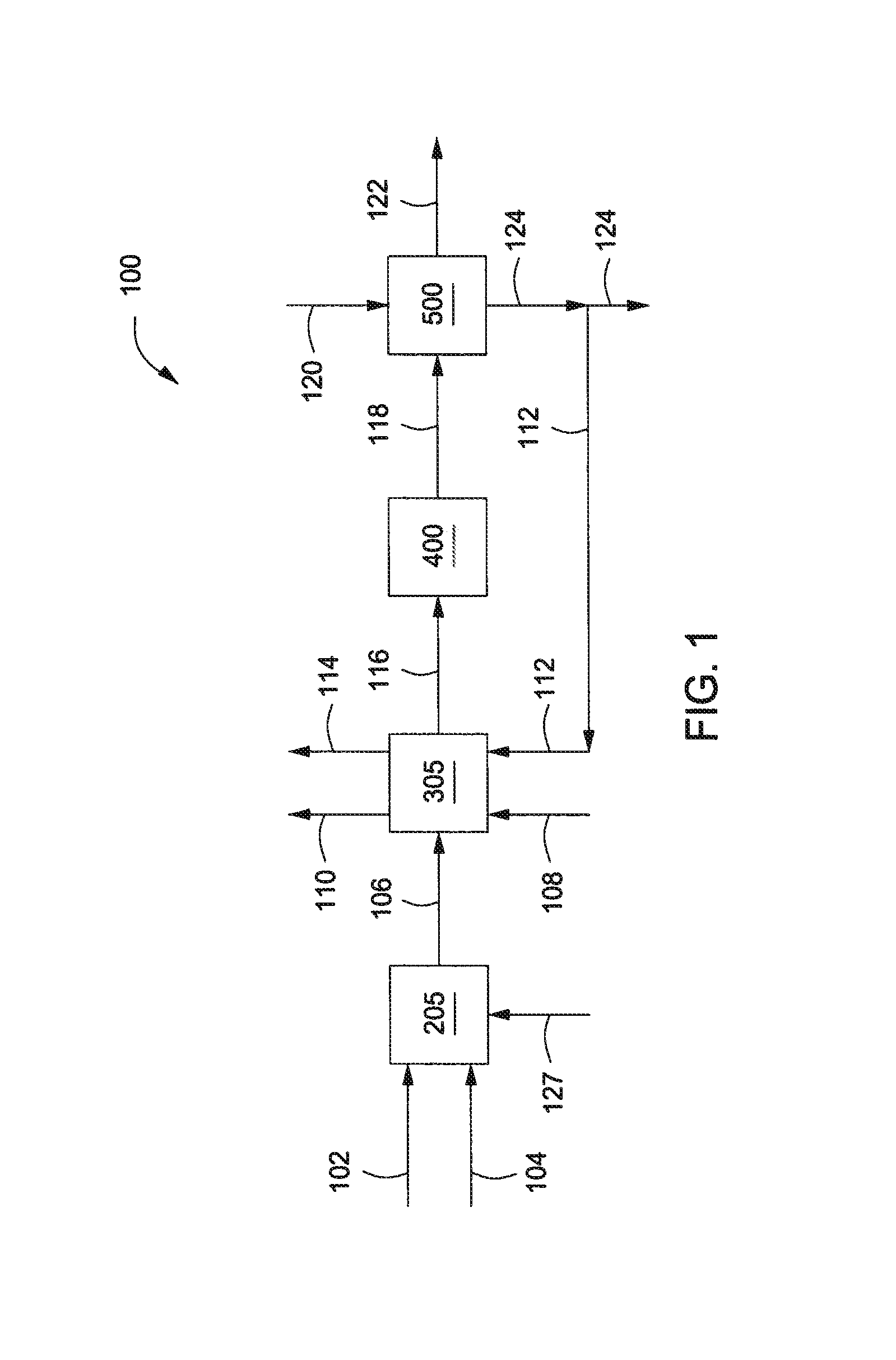

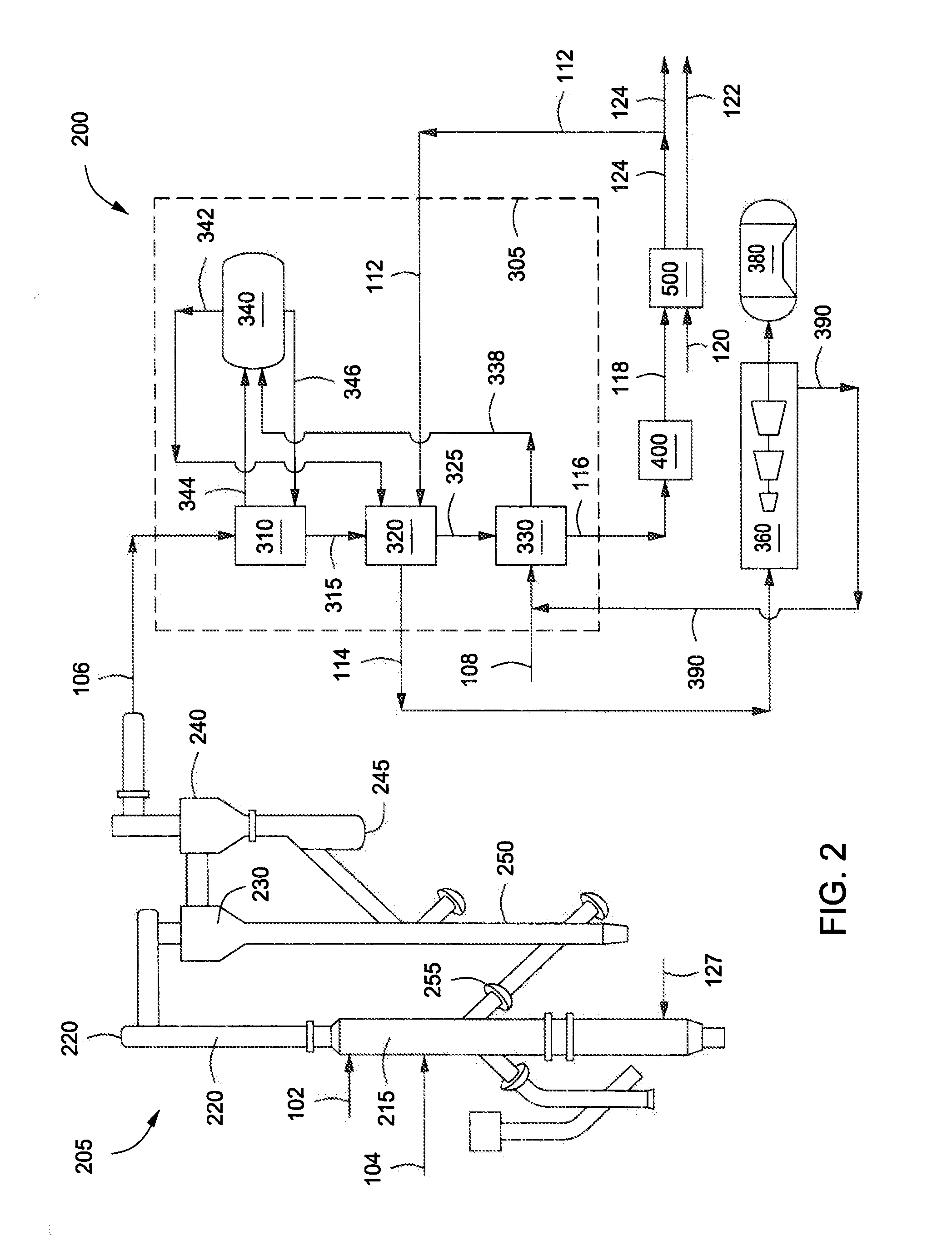

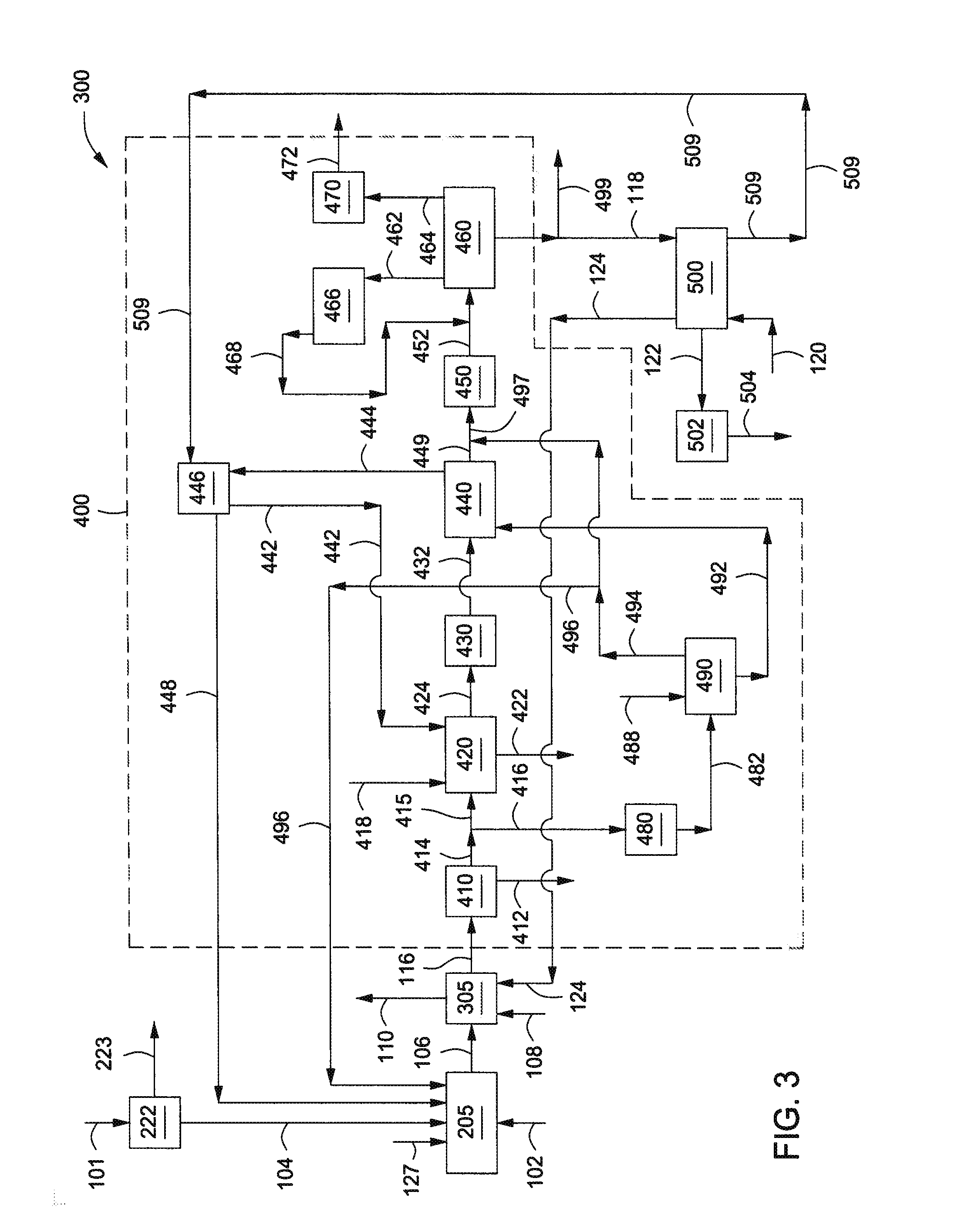

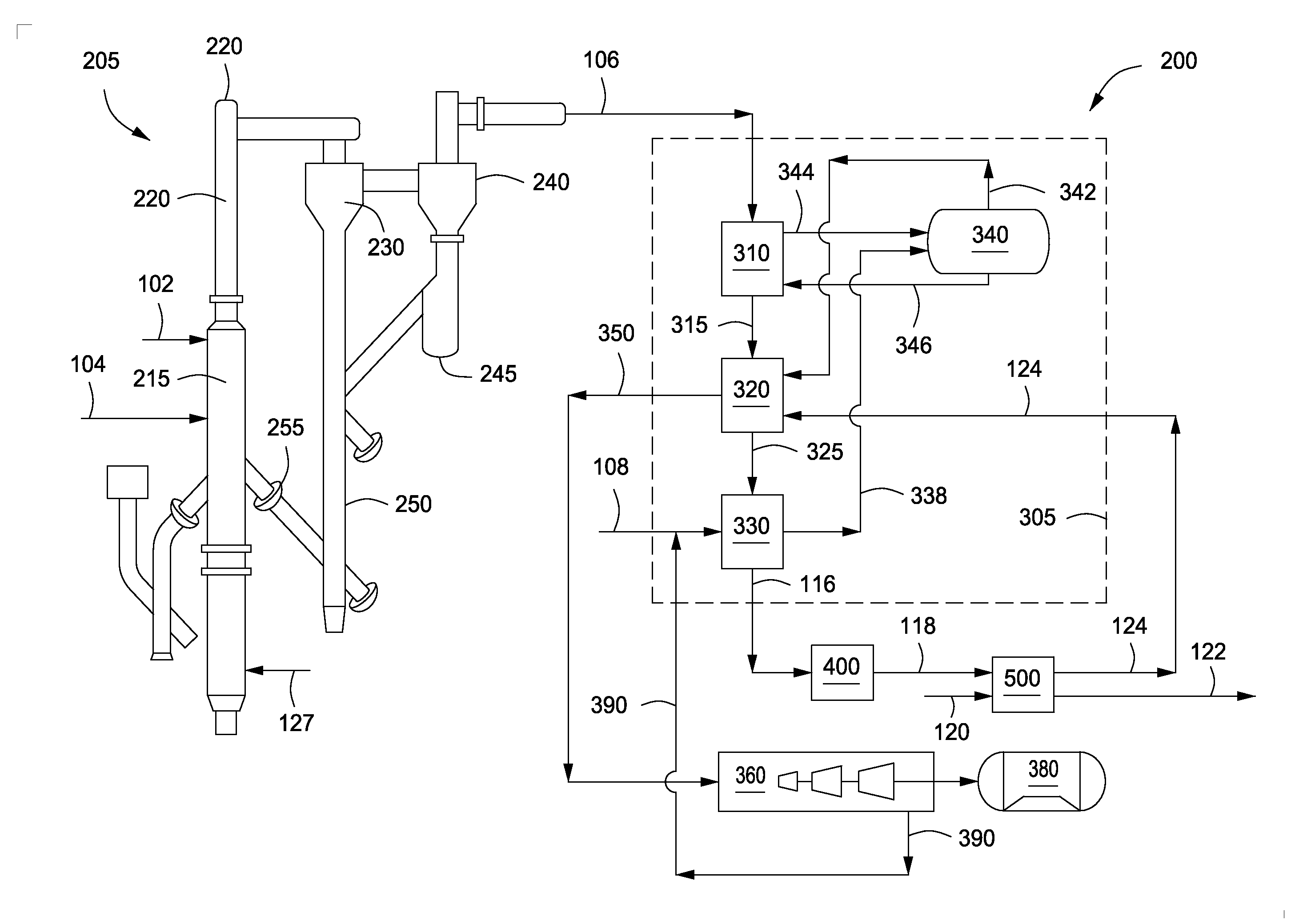

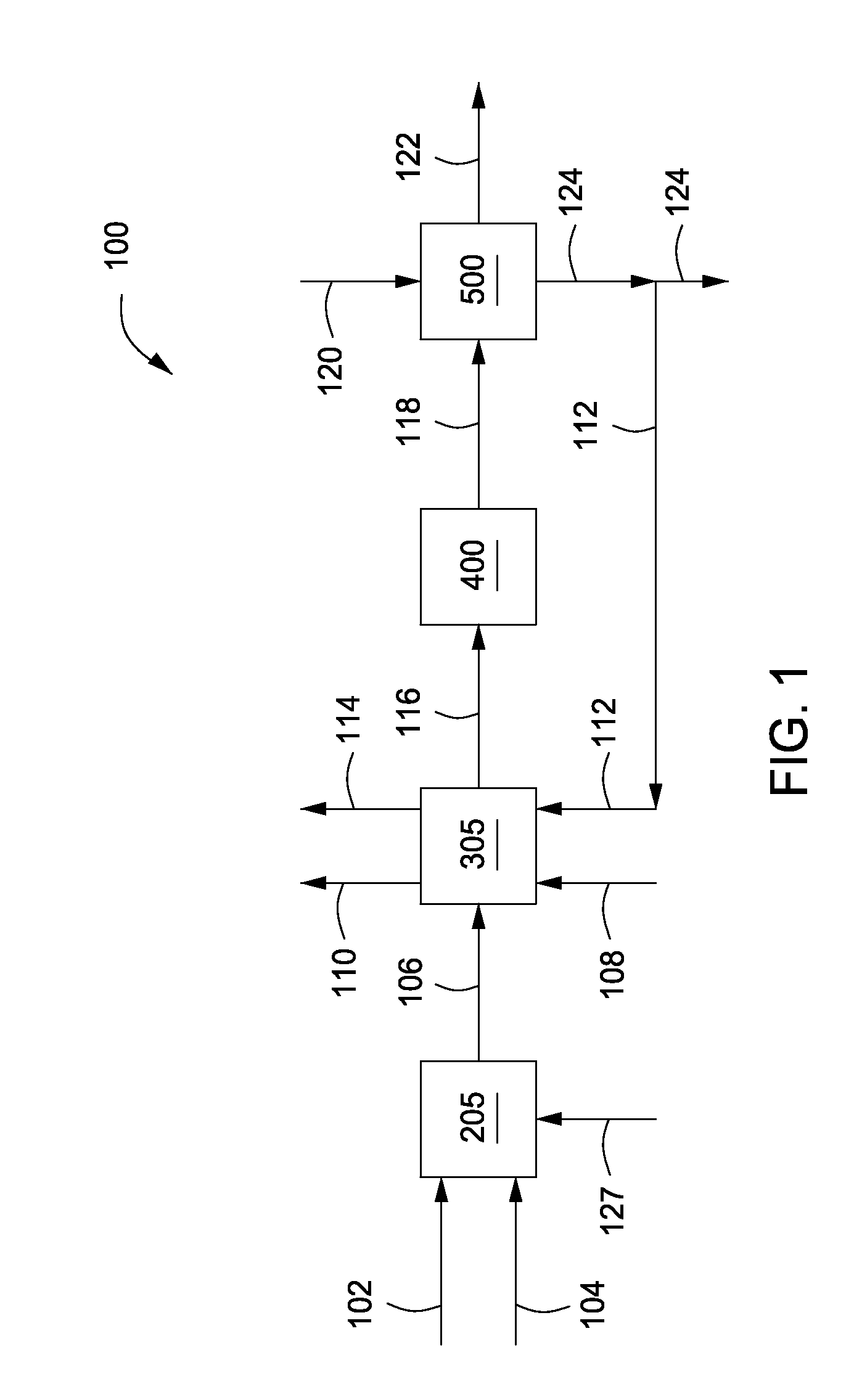

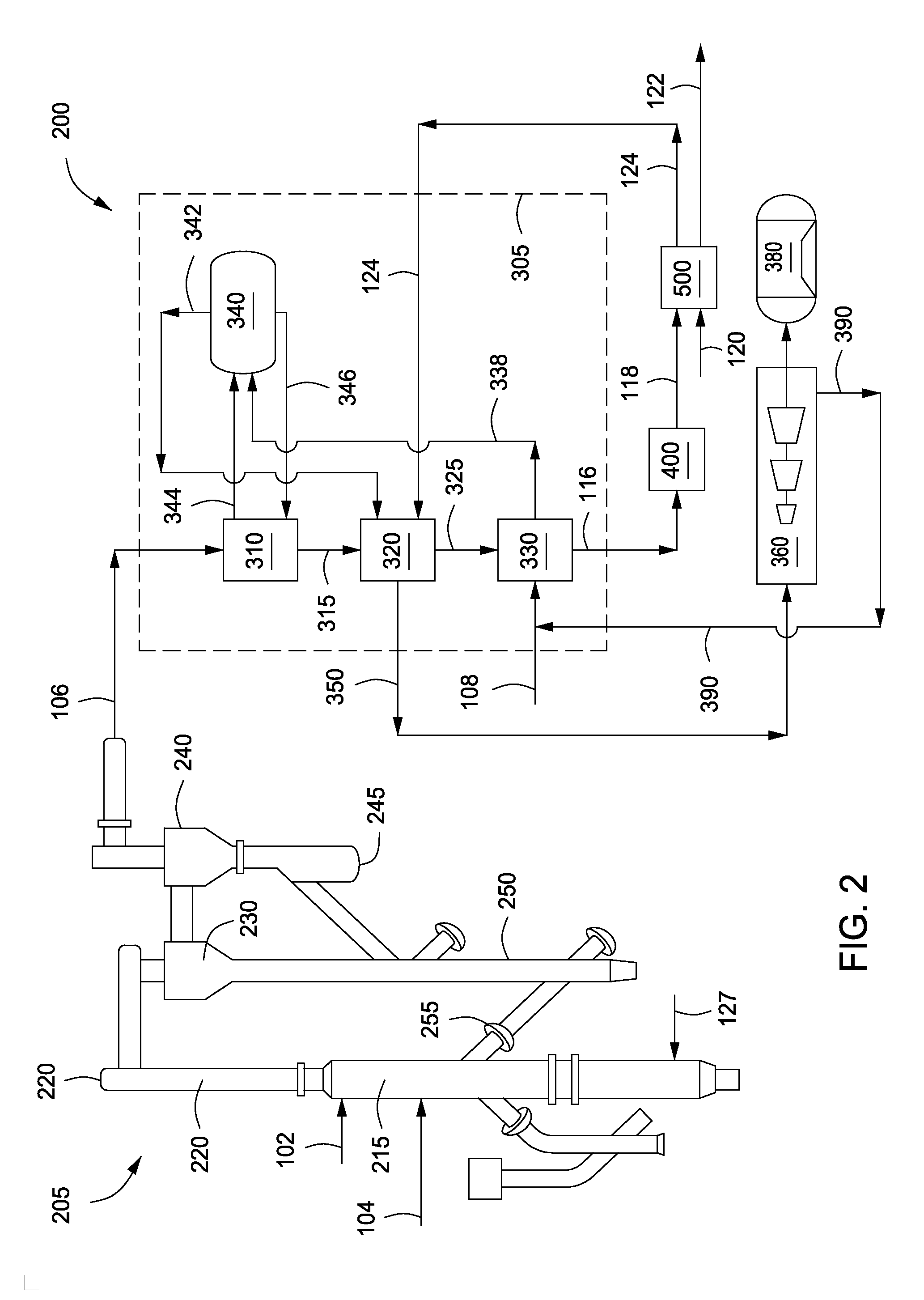

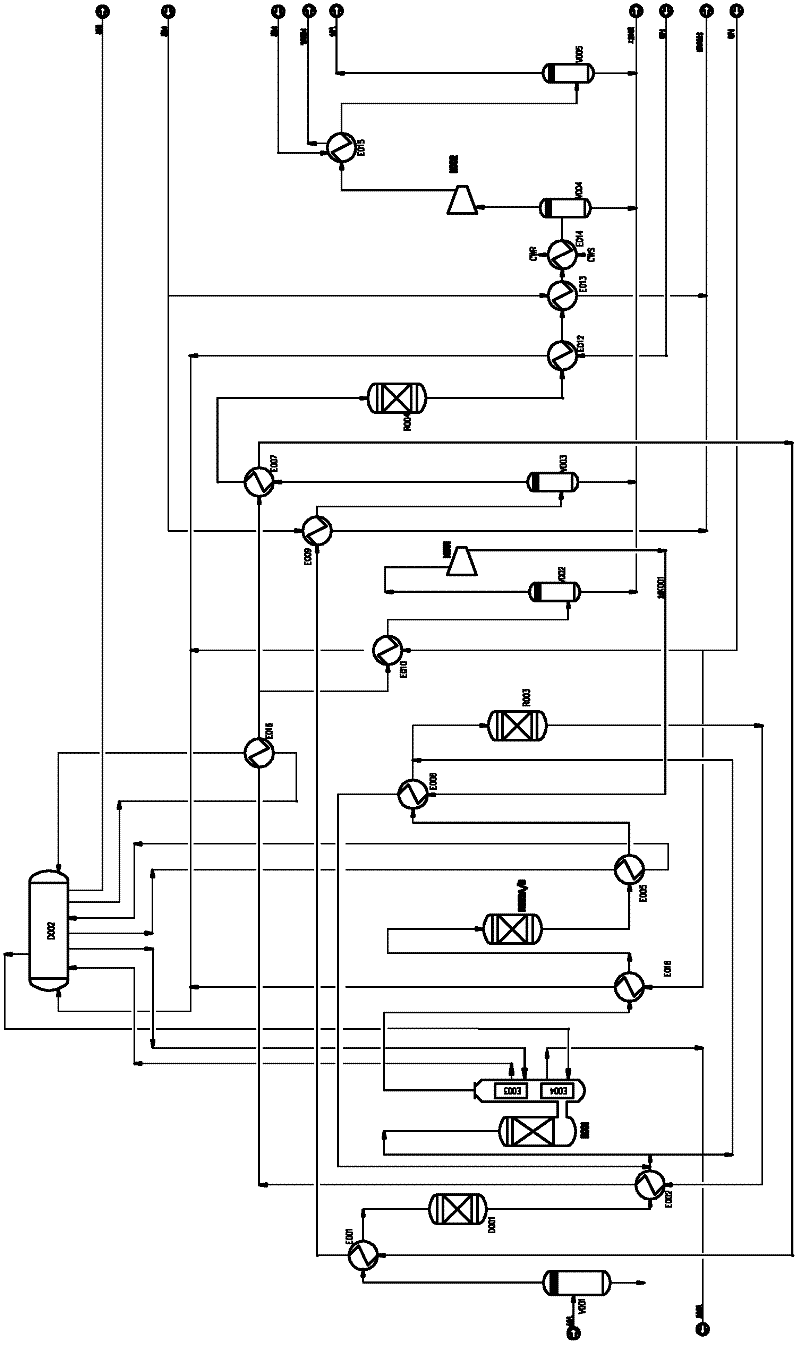

Systems And Methods For Producing Substitute Natural Gas

ActiveUS20140117287A1Hydrocarbon from carbon oxidesCombustible gas catalytic treatmentForming gasMethanation

Systems and methods for producing synthetic gas are provided. The method can include gasifying a carbonaceous feedstock in the presence of an oxidant within a gasifier to provide a raw syngas. The raw syngas can be cooled within a cooler to provide a cooled syngas. The cooled syngas can be processed within a purification system to provide a treated syngas. The purification system can include a saturator adapted to increase a moisture content of the cooled syngas. The treated syngas and a first heat transfer medium can be introduced to a methanator to provide a synthetic gas, a second heat transfer medium, and a methanation condensate. At least a portion of the methanation condensate can be recycled from the methanator to the saturator.

Owner:KELLOGG BROWN & ROOT LLC

Systems and methods for producing substitute natural gas

ActiveUS20120101323A1Combustible gas catalytic treatmentHydrocarbon purification/separationMethanationFlash-gas

Systems and methods for producing synthetic natural gas are provided. The method can include gasifying a carbonaceous feedstock within a gasifier to provide a raw syngas. The raw syngas can be cooled to provide a cooled raw syngas. The cooled raw syngas can be processed in a purification system to provide treated syngas. The purification system can include a flash gas separator in fluid communication with the gasifier and a saturator. The treated syngas can be converted to synthetic natural gas to provide steam, a methanation condensate, and a synthetic natural gas. The methanation condensate can be introduced to the flash gas separator.

Owner:KELLOGG BROWN & ROOT LLC

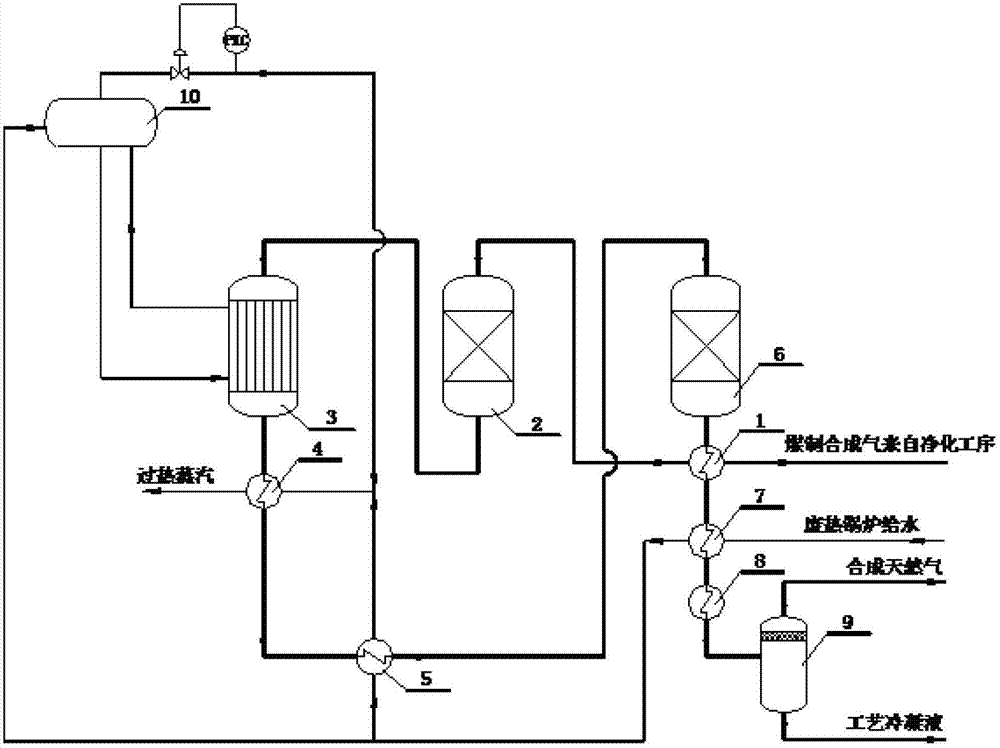

Process for preparing substitute natural gas from synthesis gas

ActiveCN102585949AExtended service lifeReduce manufacturing difficultyGaseous fuelsMethanationReaction temperature

The invention relates to a process for preparing substitute natural gas from synthesis gas, which comprises the following steps that: after being subjected to detoxification and desulfuration, the raw materials are subjected to heat exchange and are mixed with recycle gas from a third methanator and the obtained mixture is divided into two strands, wherein the first strand enters a first methanator to be subjected to the methanation reaction; all high-temperature first synthesis gas obtained after the first strand of raw material gas reacts in the first methanator is sequentially fed into a steam superheater and a first waste heat boiler to be subjected to heat exchange and then is fed into a second methanator to be subjected to the further methanation reaction to obtain second synthesis gas; after being subjected to heat exchange, the second synthesis gas is mixed with the second strand of raw material gas, and then the mixture is fed into the third methanator; and third synthesis gas discharged out of the third methanator is divided into two strands after being subjected to heat exchange compression, one strand of the third synthesis gas serving as the recycle gas is mixed with the raw material gas, the rest of the third synthesis gas enters a fourth methanator to enable the unreacted raw material gas to be synthesized into methane so as to obtain the synthesis gas capable of replacing the natural gas. The process has the characteristics that the reaction temperature rise is easy to control; the utilization of system energy is optimized; and the like.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for coproducing substitute natural gas through coal liquefaction

ActiveCN102041019AReduce riskLow investment costGaseous fuelsLiquid hydrocarbon mixture productionMethanationProduct gas

The invention relates to a method for coproducing substitute natural gas through coal liquefaction. Synthetic gas obtained by gasifying coal enters a methanation reactor, water generated in the methanation process is separated out of a material flow at the outlet of the methanation reactor through gas-liquid separation, the gas is partially circulated back to the inlet of the methanation reactor to further participate in the reaction, and the uncirculated gas enters a Fischer-Tropsch synthesis reactor. Synthetic oil and gas are obtained through the cooling and the gas-liquid separation of thematerial flow at the outlet of the methanation reactor, the CH4 in the gas is further separated out, and the gas rich in the CH4 is used as the substitute natural gas to be output. The synthetic oil and the substitute natural gas are simultaneously produced by the coal, and thereby the invention not only solves the problem of difficult control for the temperature of the Fischer-Tropsch synthesis reactor, but also saves a circulating compressor of a Fischer-Tropsch synthesis device. The product distribution of Fischer-Tropsch synthesis is not changed while the substitute natural gas is coproduced, and the high-proportion heavy hydrocarbon can also be obtained through the Fischer-Tropsch synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

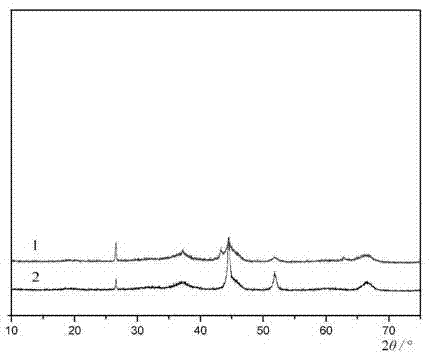

Methanation catalyst used for preparing substitute natural gas from synthesis gas, and preparation method and application thereof

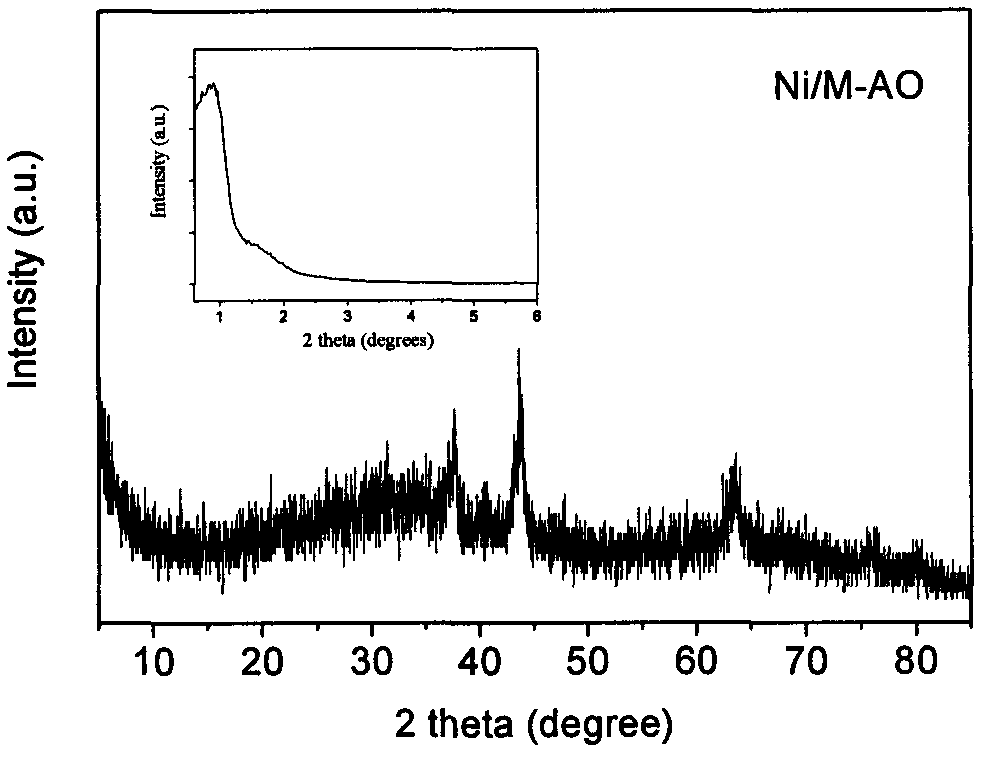

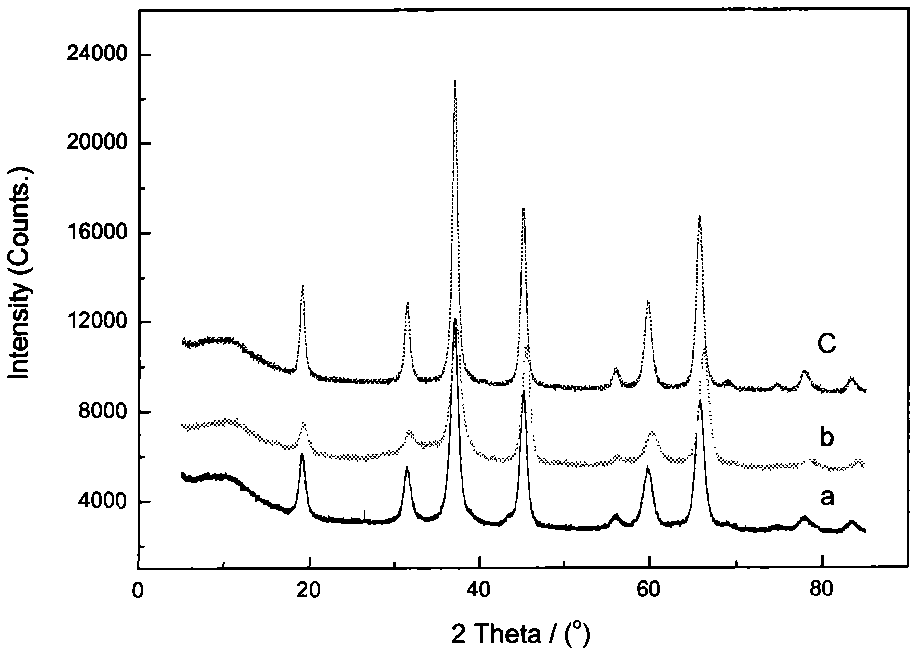

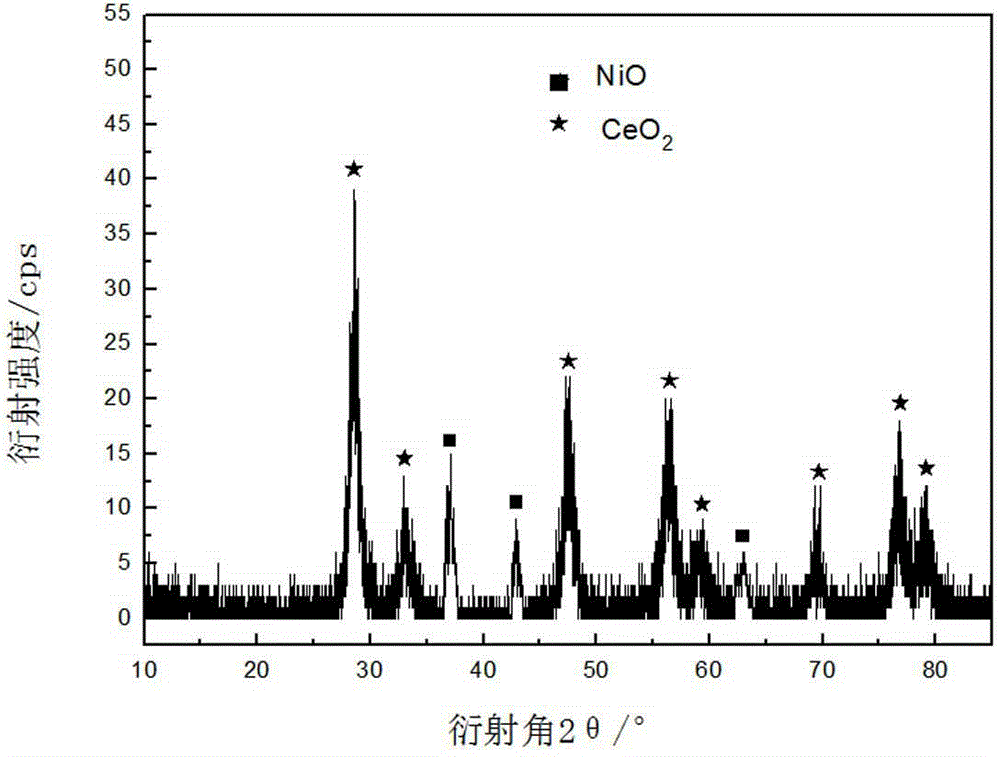

InactiveCN103055874AImprove thermal stabilityPrevent solid phase reactionHydrocarbon from carbon oxidesGaseous fuelsMethanationX-ray

The invention discloses a methanation catalyst. The methanation catalyst comprises a. 5-30wt% of nickel by metallic element, b. 0-30wt% of magnesium and / or calcium by metallic element, c. 0-5.0wt% of lanthanide series metals by metallic element, d. 5-30wt% of magnesium aluminate spinel by magnesium element and e. the balance of Al2O3. A preparation method of the catalyst comprises the following steps of: adhering a water-soluble salt containing magnesium to Al2O3 and roasting the components so that a magnesium aluminate spinel structure is generated on the surface of a catalyst support; dipping water-soluble salts of the components a, b and c on the support; and drying and roasting the support, thus obtaining the catalyst. On the XRD (X-ray diffraction) spectrogram of the catalyst support, a group of obvious magnesium aluminate spinel characteristic diffraction peaks exist between 10 degrees and 80 degrees (angle 2theta). The catalyst has the characteristics of high low-temperature methanation activity, good heat stability, good anti-carbon deposition property and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of synthetic gas methanation catalyst

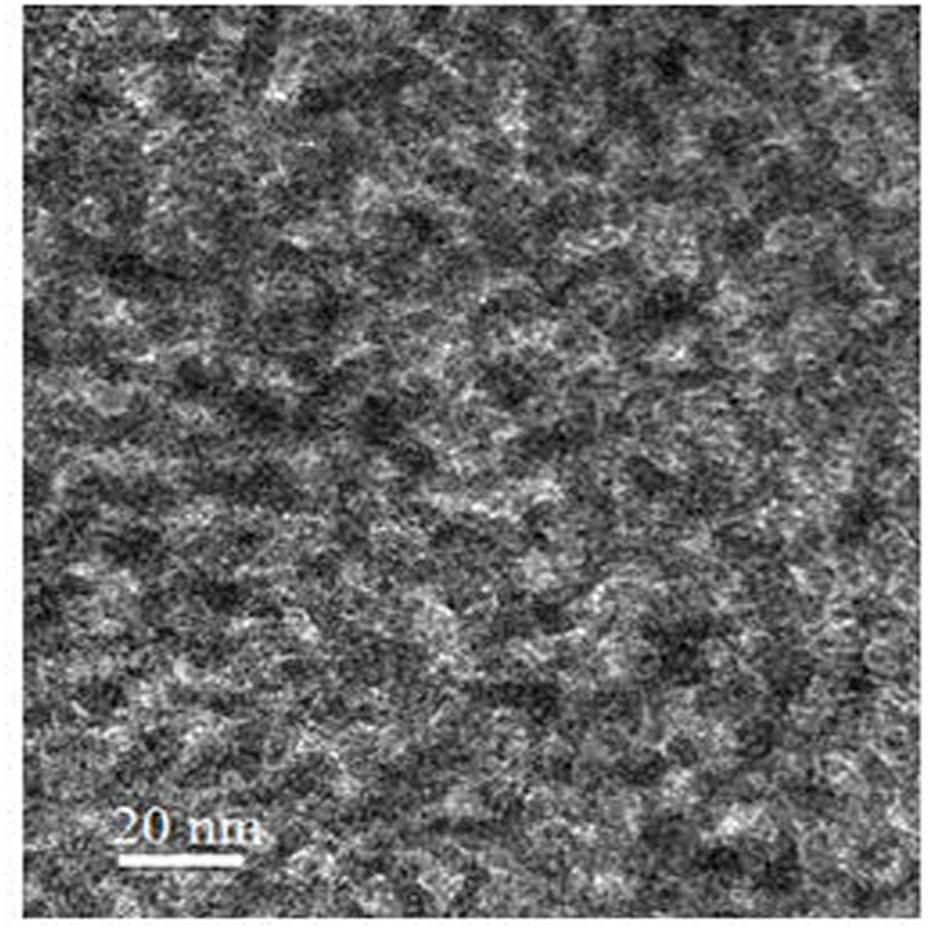

InactiveCN102626628AImprove stabilityLimit anchorHydrocarbon from carbon oxidesGaseous fuelsPtru catalystMethanation

The invention discloses a preparation method of a synthetic gas methanation catalyst. The preparation method is characterized in that a polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer, one or more aluminum sources, nickel nitrate and one or more auxiliaries as raw materials undergo a one-step synthesis reaction according to a certain ratio by a solvothermal method to produce a desired product. The preparation method has simple processes. The synthetic gas methanation catalyst obtained by the preparation method has a mesoporous structure and controllable aperture sizes and catalyst particle dispersity, can show good sintering resistance, high activity at a low temperature, stability at a high temperature and high methane selectivity in methanation, and has important application values in synthesis of substitute natural gas and solution of the existing natural gas shortage problem.

Owner:TAIYUAN UNIV OF TECH

Method of producing substitute natural gas by methanation of synthesis gas

The invention relates to a method of producing substitute natural gas by methanation of synthesis gas, mainly solving problems, namely large using amount of recycle gas and high energy consumption of compressors, of high-temperature methanation reactions in the prior art. According to the technical scheme adopted by the method, the method comprises: a) a step of providing a high-temperature methanation reaction zone including n-stage series-connected reactors, with the n being not less than 2; b) a step of dividing the synthesis gas raw materials containing H2, CO, CO2 and H2O into n sections and respectively feeding the n sections of the synthesis gas raw materials into inlets of the reactors at all stages in the high-temperature methanation reaction zone, wherein a stream flowing out of an outlet of each of the reactors except the reactor at the final stage enters the inlet of the reactor at the next stage, the stream Vn flowing out from the reactor at the final stage is divided into Vn' and Vn'', and the stream Vn' is condensed and circulated to the inlet of the reactor at the first stage; c) a step of providing a low-temperature methanation reaction zone including m-stage series-connected reactors, with the m being not less than 2; and d) a step of feeding the stream Vn'' into the low-temperature methanation reaction zone, and substitute natural gas is obtained after the reaction. By the technical scheme, the problems are solved well and the method can be used in industrial production of the substitute natural gas from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

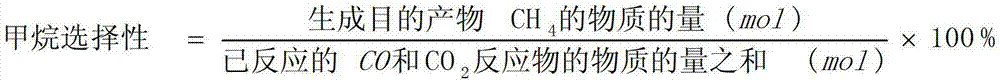

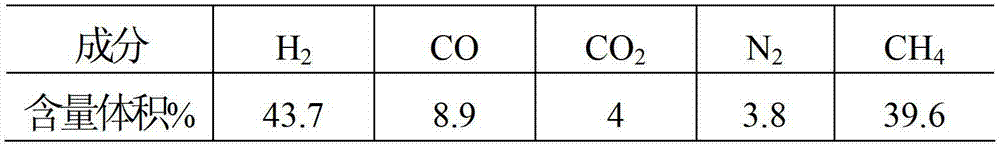

Methanation method for synthesizing substitute natural gas by using industrial hydrocarbon exhaust gas

ActiveCN103194286AAchieving zero emissionsLow investment costGaseous fuelsCompressed natural gasMethanation

The invention relates to a methanation method for synthesizing substitute natural gas by using industrial hydrocarbon exhaust gas. The methanation method comprises the following steps of: carrying out third-order or fourth-order methanation reaction on the feed gas of the industrial hydrocarbon exhaust gas; thermally recycling; and cooling and separating to produce a qualified synthetic natural gas product. CO and CO2 in the industrial hydrocarbon exhaust gas are completely converted into methane to achieve the purpose of zero emission of CO2. According to the methanation method, the gas passes through a multistage methane reactor once, CO conversion and CO2 separation are not needed, meanwhile, a segmented cycle and a compressor are not needed for the process gas, thus the investment cost and the operation cost can be greatly reduced; the process flow is simple, reliable and efficient; the operation is convenient and stable, the temperature is easy to control; the energy consumption is low; and the economic benefit is obvious. The synthetic natural gas produced by using the industrial hydrocarbon exhaust gas meets the international standards, and can be directly used for producing compressed natural gas and liquefied natural gas.

Owner:THE NORTHWEST RES INST OF CHEM IND

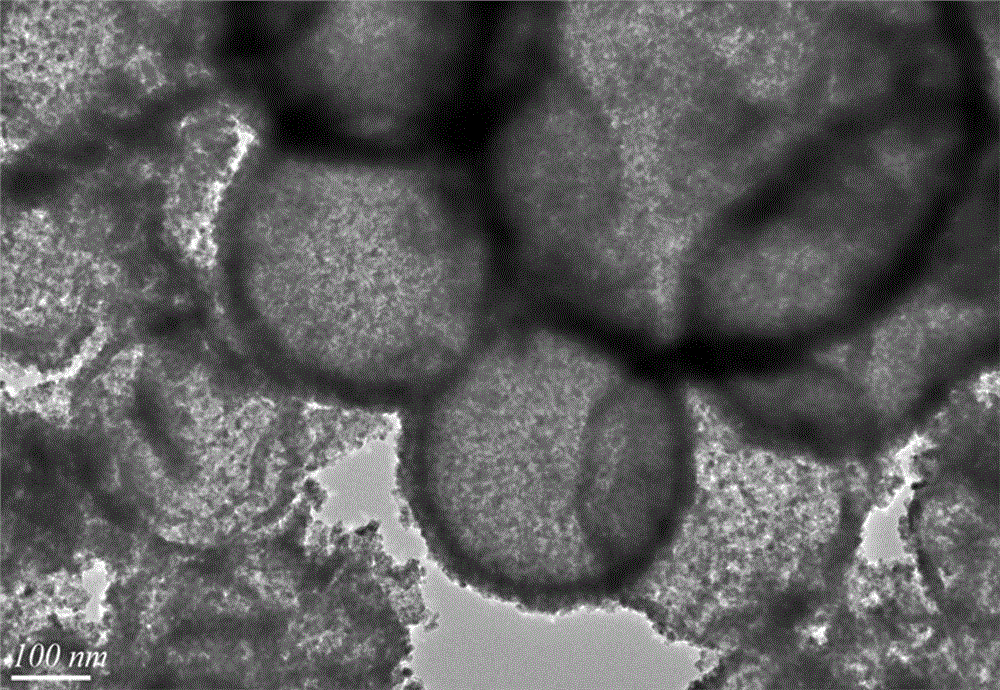

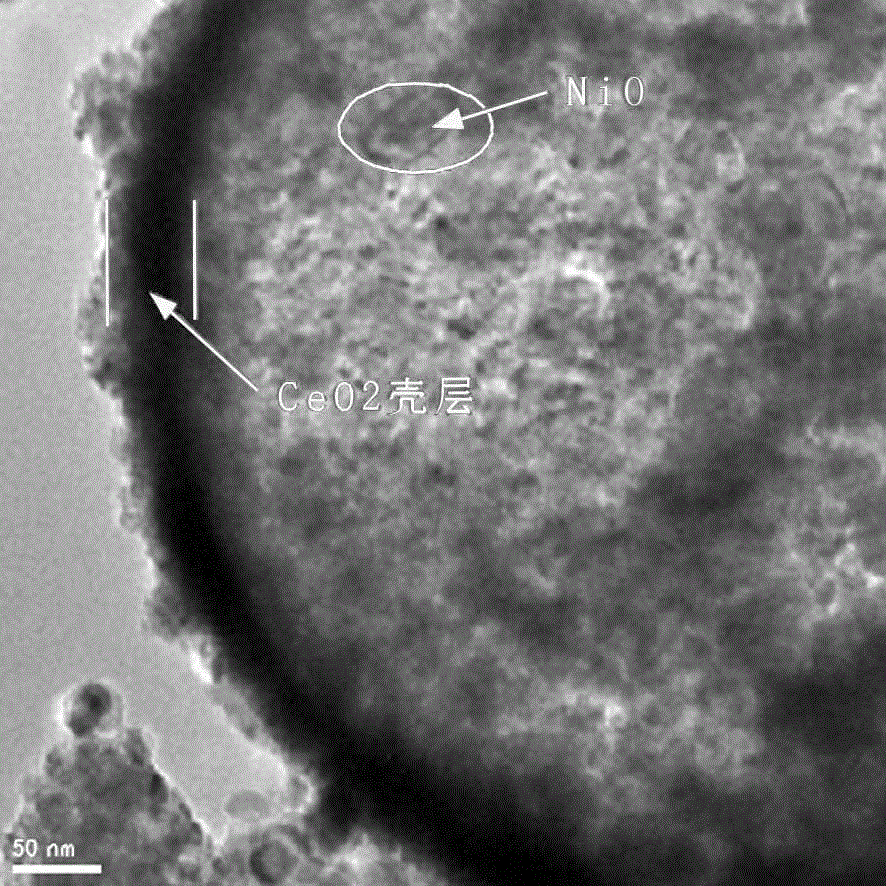

Core-shell cerium oxide-coated nickel catalyst for methanation, and preparation method and application thereof

ActiveCN104971728AHigh selectivityQuality improvementHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationCarbon deposit

The invention specifically relates to a core-shell cerium oxide-coated nickel catalyst for methanation, and a preparation method and application thereof, belonging to the field of preparation and application of methanation catalysts used for synthesis of substituted natural gas. The preparation method comprises the following steps: (1) preparation of core-shell nickel oleate-coated HPS sphere; (2) preparation of a precursor solution capable of forming a cerium oxide shell layer; and (3) preparation of a Ni-coated HPs-coated CeO2 precursor. The preparation method for the core-shell cerium oxide-coated nickel catalyst used for methanation is advanced, has accurate and detailed data and produces the catalyst with high quality and high purity, as high as 98%; the produced catalyst can effectively inhibit migration, agglomeration and sintering of the active component Ni at high temperature through confinement effect of the shell layer, prevents growth of Ni crystal grains to inhibit carbon deposit and has high catalytic activity, high methane selectivity and good stability; and the preparation method is an ideal method for preparation of the anti-sintering and anti-carbon deposit methanation catalyst.

Owner:DATONG COAL MINE GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com