Technology for producing methane through low-rank coal

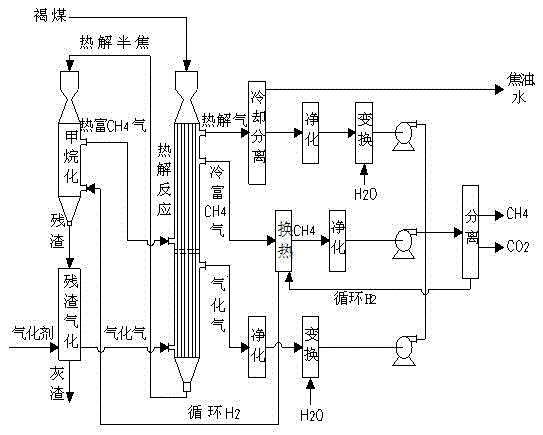

A technology of low-rank coal and methane production, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of low thermal energy utilization rate and large hydrogen consumption, and achieve the effect of high thermal efficiency and low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Implement the technology of a kind of low-rank coal methane production provided by the present invention, take the technological process of producing 1,100,000,000 cubic meters of methane as an example, and its described specific technology is to carry out according to the following steps:

[0029] In this embodiment, lignite is used as raw material, and the basic coal quality analysis of the lignite used is shown in Table 1. 17,800 tons / day lignite raw coal was crushed, sieved to 3-6mm, and dried and dehydrated at 150°C to obtain dry lignite with a moisture content of 8% (wt%). The amount of dry lignite in the pyrolysis reactor is 16,000 tons / day. Dried lignite stays in the pyrolysis reactor at a pyrolysis temperature of 600°C for 1.5 hours, and the products obtained are pyrolysis semi-coke and pyrolysis gas containing tar, of which the output of pyrolysis semi-coke at 600°C is 10,000 tons / day, the pyrolysis gas is cooled and separated to obtain about 1900 tons / day o...

Embodiment 2

[0046] Implement a process for producing methane from low-rank coal provided by the present invention, a process flow with an annual output of 600 million cubic meters of methane. Its described specific technique is carried out according to the following steps:

[0047] In this embodiment, long-flame coal is used as raw material, and its specific analysis is shown in Table 5. The long-flame coal with a particle size of 5-10mm is fed into the pyrolysis reactor, and the feeding amount is 5000 tons / day. The residence time of long-flame coal in the pyrolysis reactor is 2.5 hours. After pyrolysis, 650°C pyrolysis semi-coke and pyrolysis gas containing tar are obtained. The output of 650°C pyrolysis semi-coke is 4028 tons / day. After cooling and separating the pyrolysis gas, about 273 tons / day of low-temperature fuel-type tar can be obtained. The purified pyrolysis gas is 500,000 Nm3 of pyrolysis gas. The composition and volume content are shown in Table 6.

[0048] The pyrolysis s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com