Patents

Literature

535results about How to "Reduce hydrogen consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

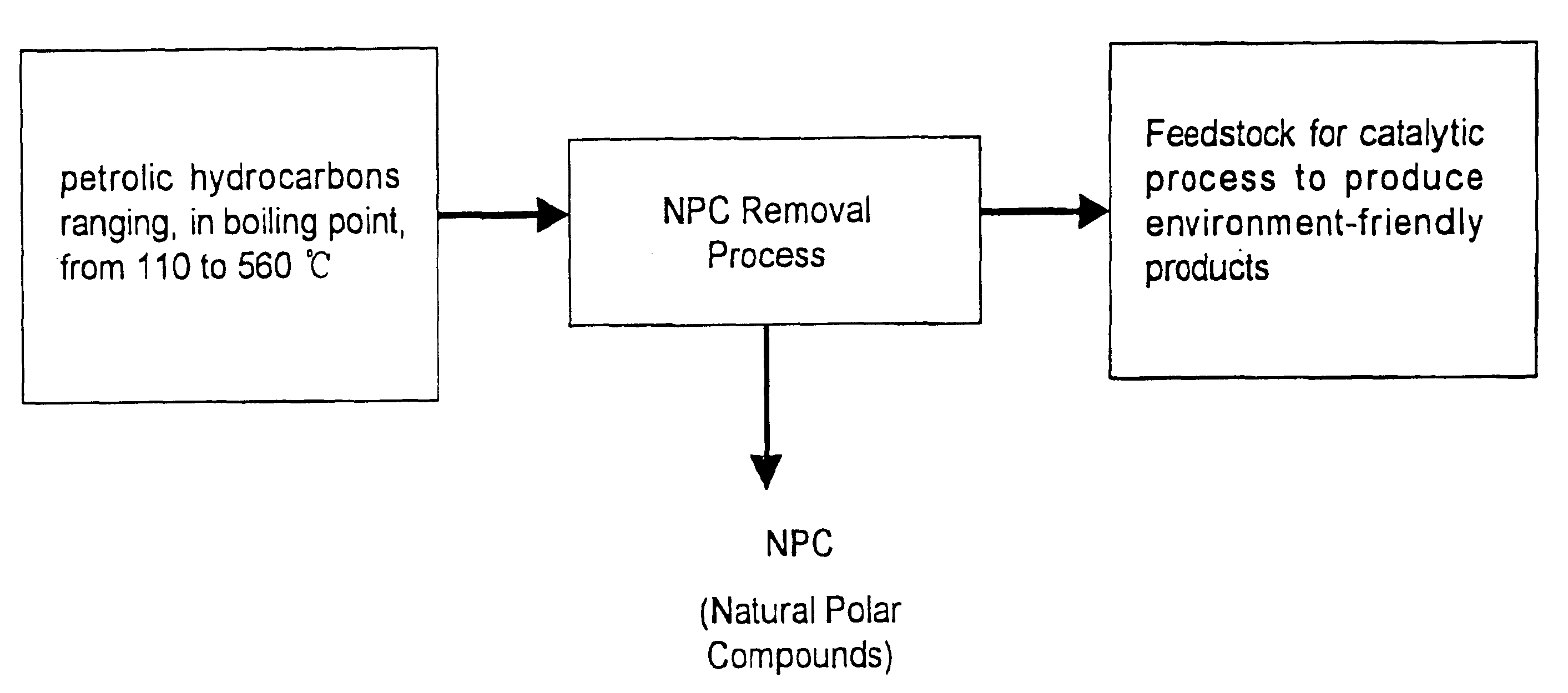

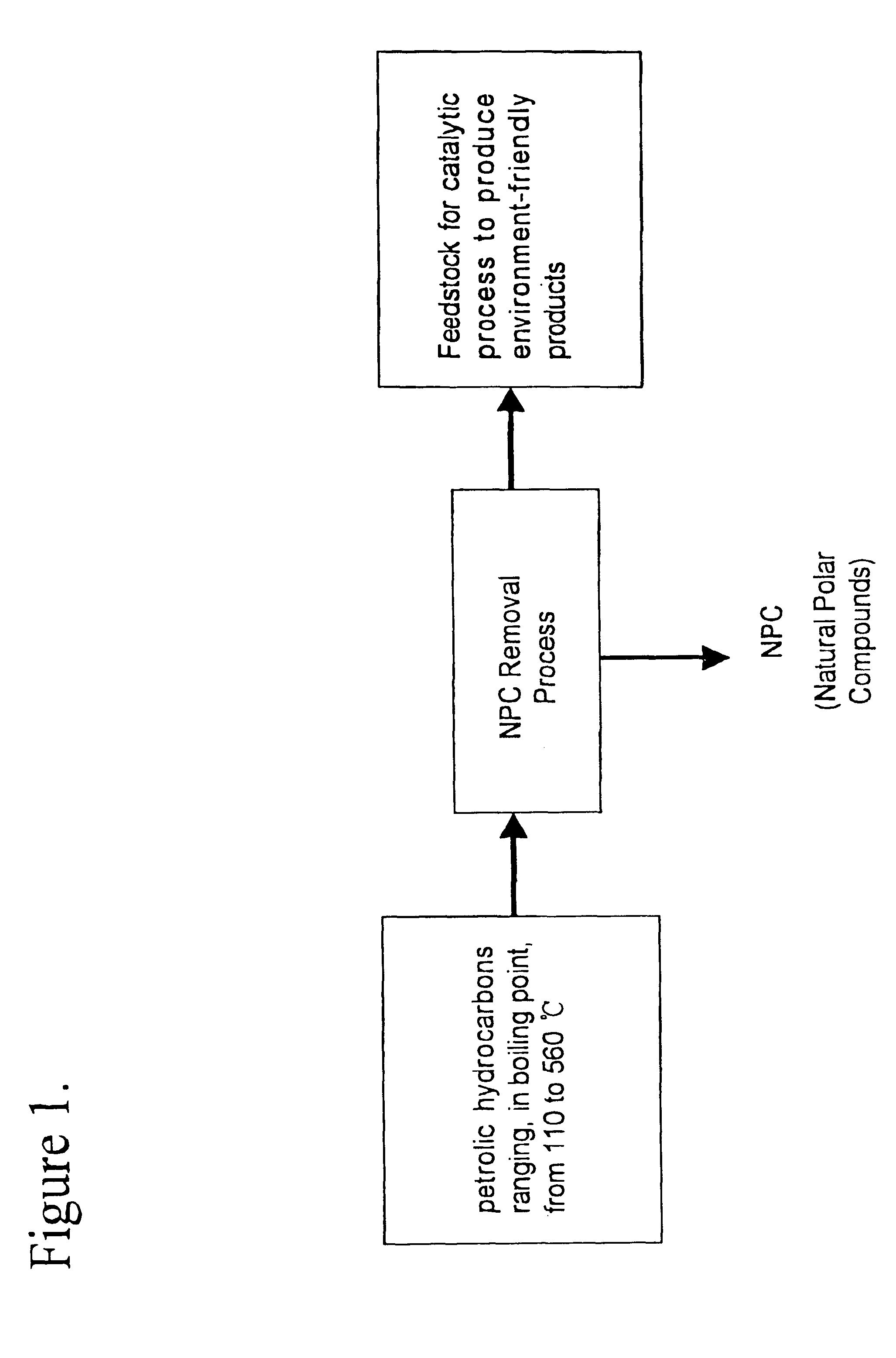

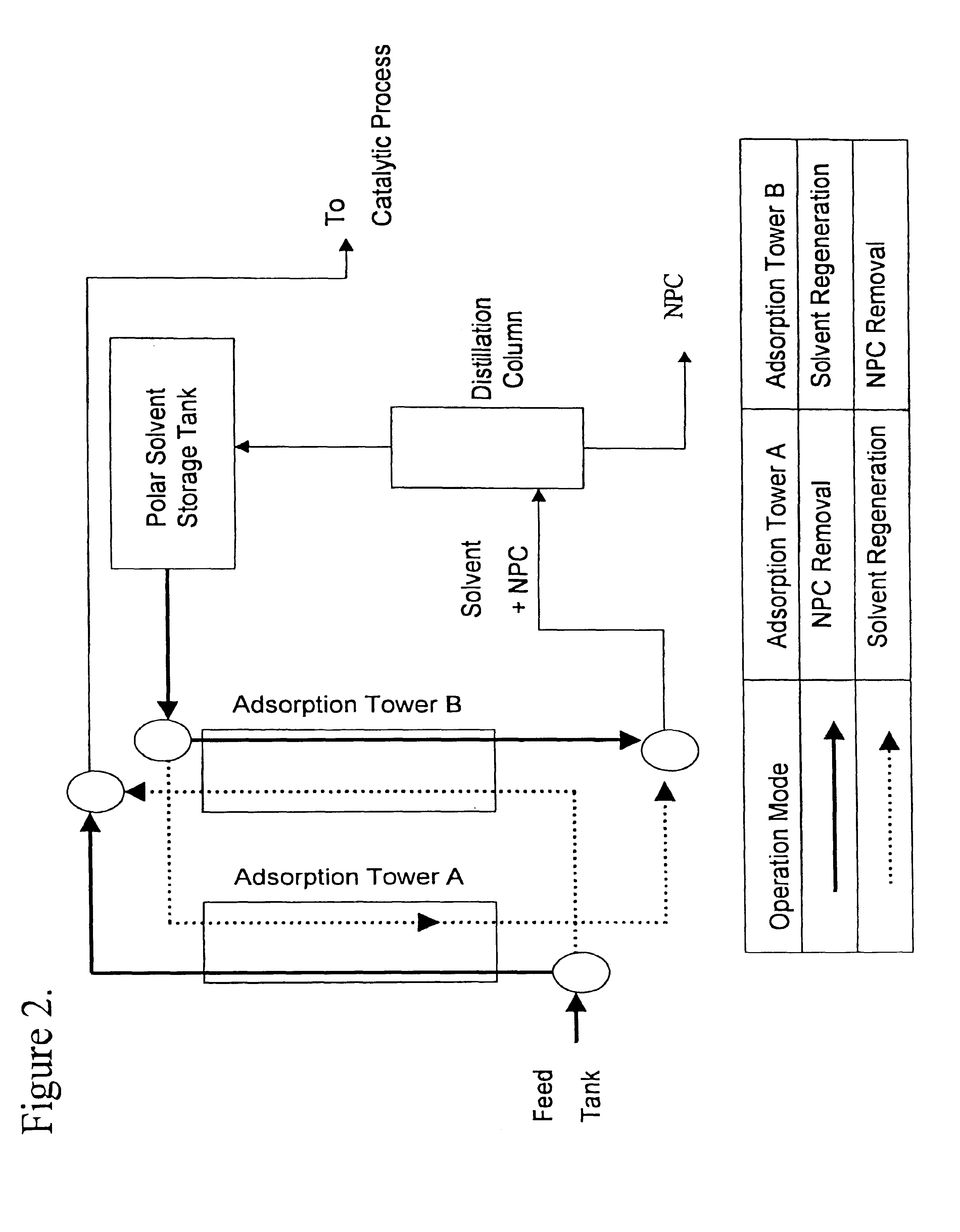

Method for manufacturing cleaner fuels

InactiveUS6248230B1Long catalyst lifeReduce hydrogen consumptionLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesBoiling pointGasoline

A method is provided for manufacturing cleaner fuels, in which NPC (Natural Polar Compounds), naturally existing in small quantities within various petrolic hydrocarbon fractions, are removed from the petrolic hydrocarbon fractions ranging, in boiling point, from 110 to 560° C. and preferably from 200 to 400° C., in advance of catalytic hydroprocessing. The removal of NPC improves the efficiency of the catalytic process and produces environment-friendly products, such as diesel fuel with a sulfur content of 50 ppm (wt) or lower. Also, the NPC can be used to improve fuel lubricity.

Owner:SK ENERGY CO LTD (KR)

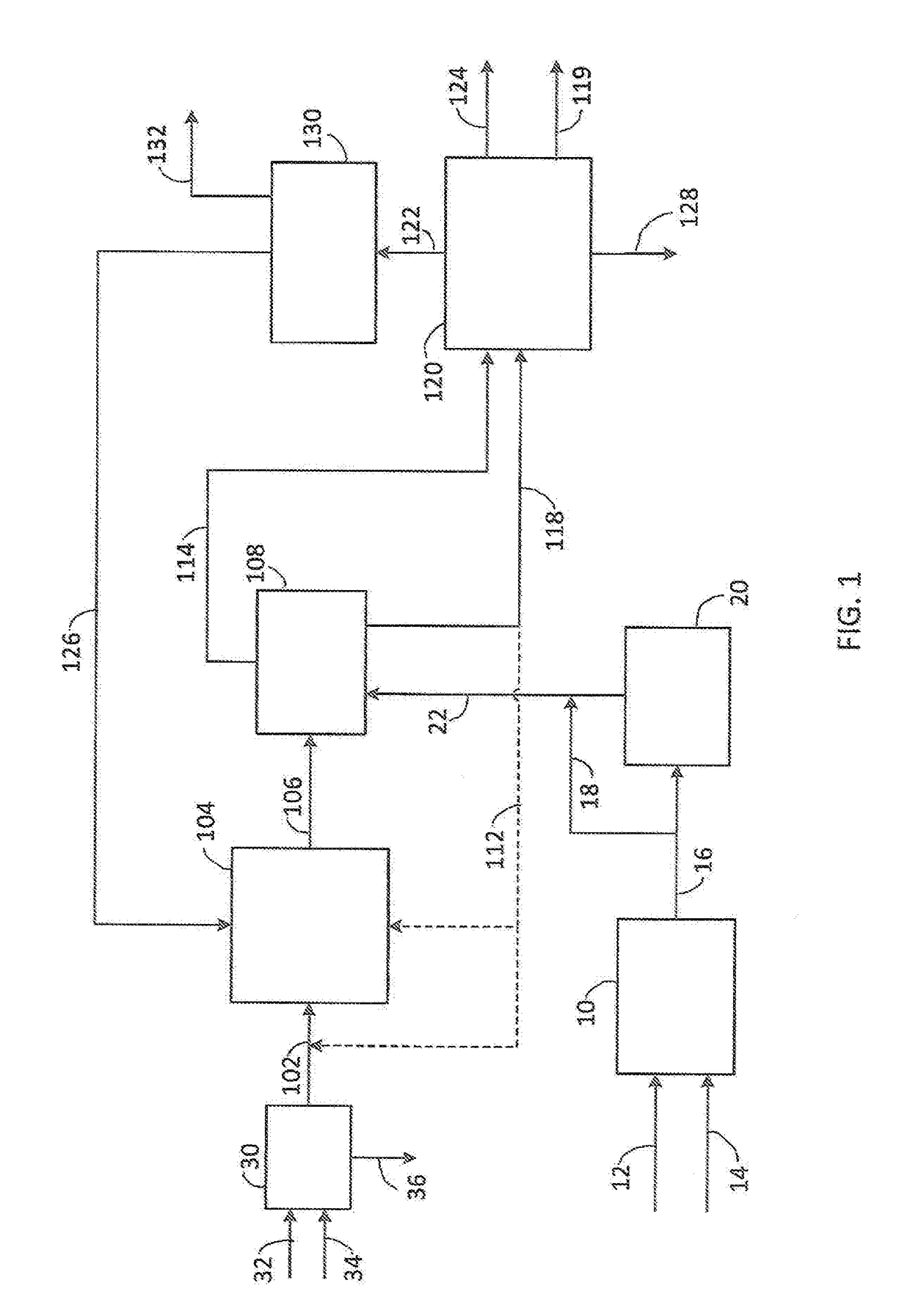

Method for the manufacture of hydrocarbons

ActiveUS7491858B2Reduce hydrogen consumptionMaterial nanotechnologyRefining to change hydrocarbon structural skeletonHydrogenDistillation

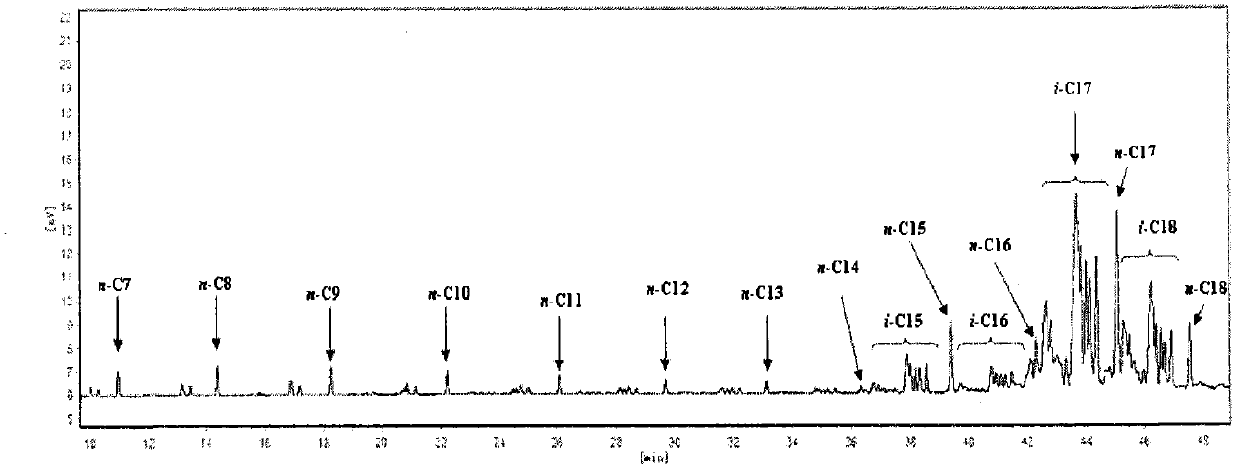

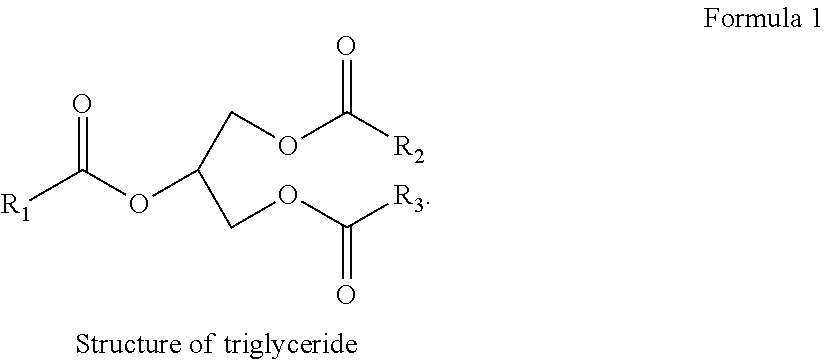

Feedstock originating from renewable sources is converted to hydrocarbons in diesel fuel distillation range by contacting with a supported catalyst comprising VIII group metal / metals, whereby the consumption of hydrogen is decreased.

Owner:NESTE OIL OY

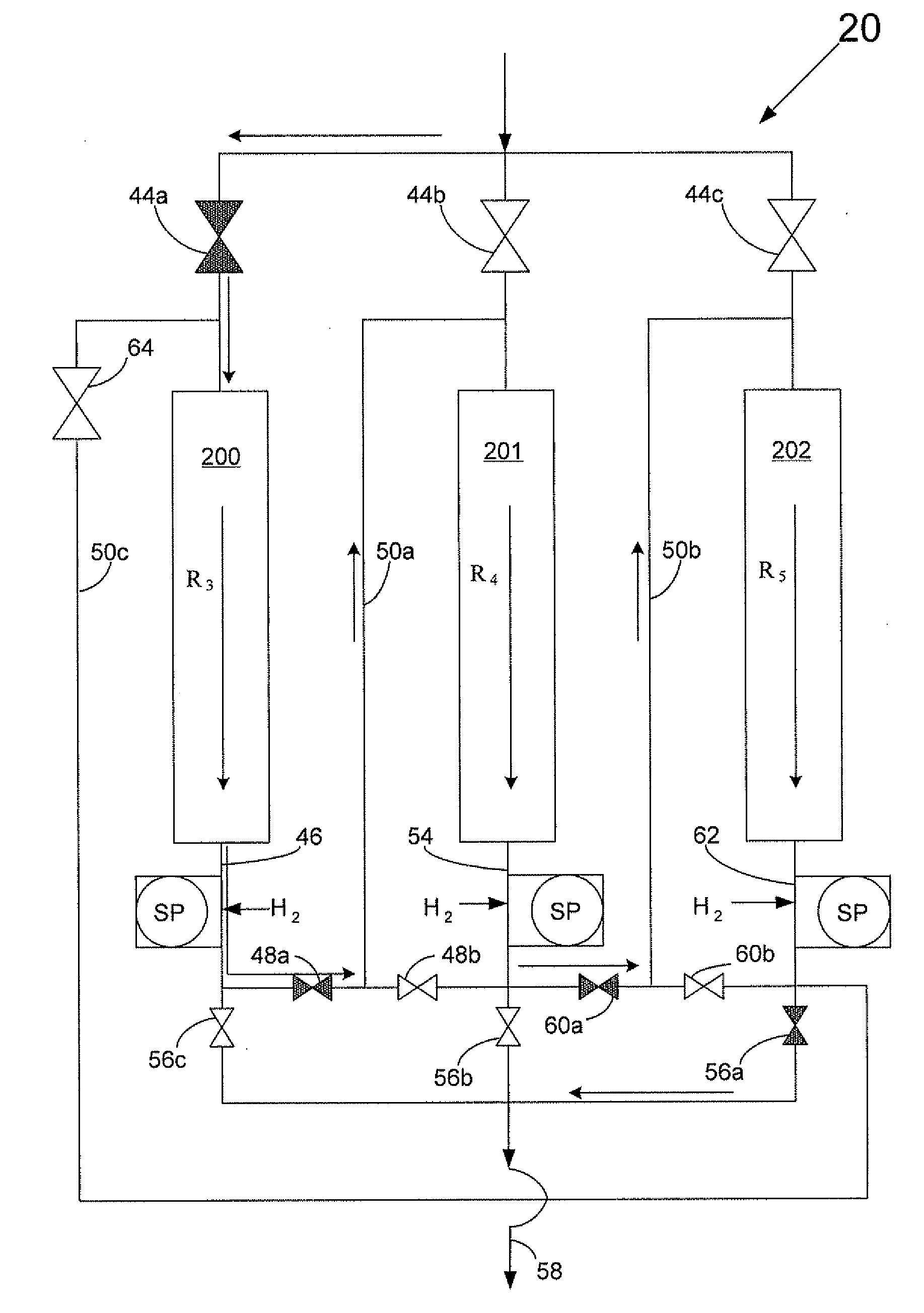

Process for catalytic hydrotreating of sour crude oils

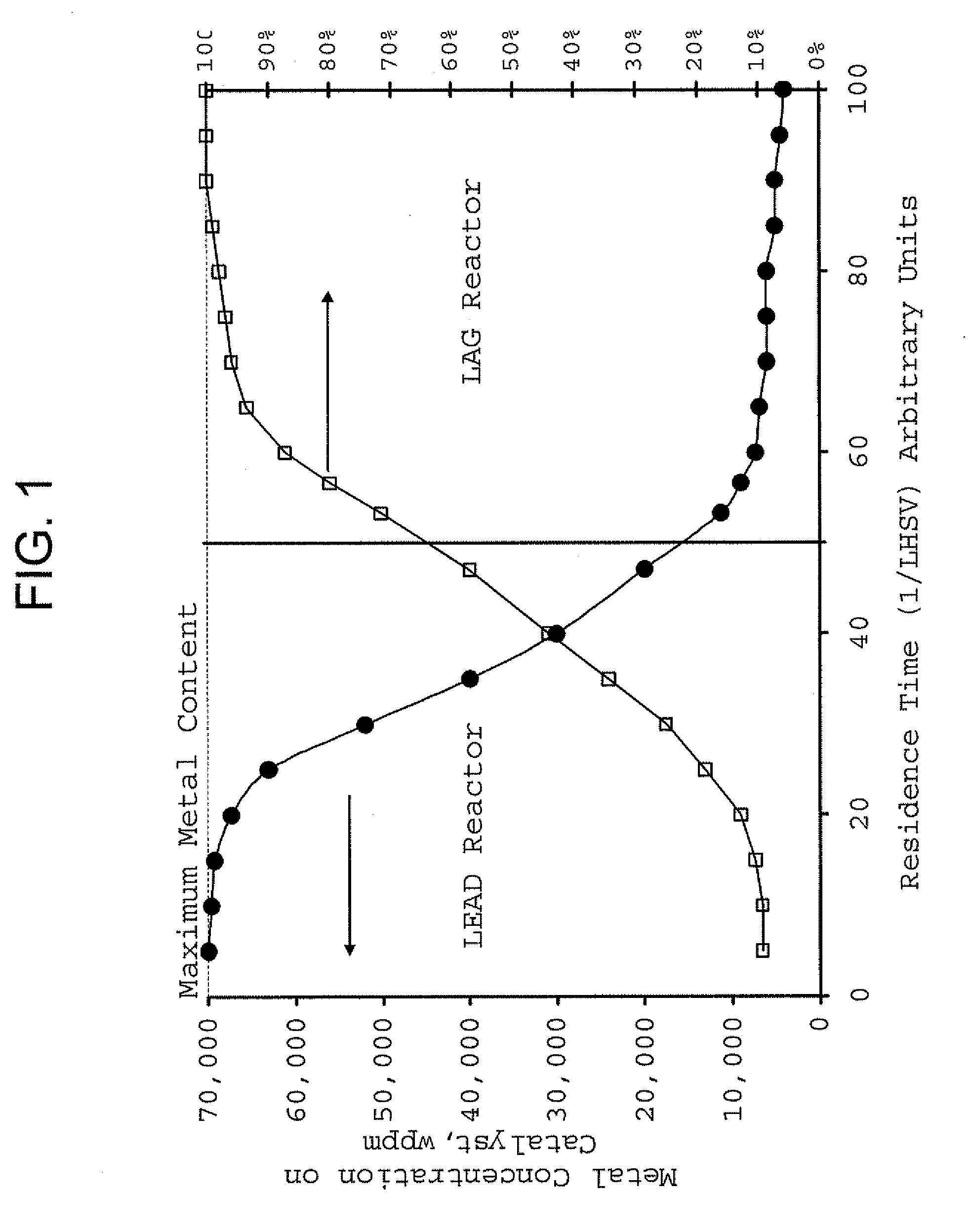

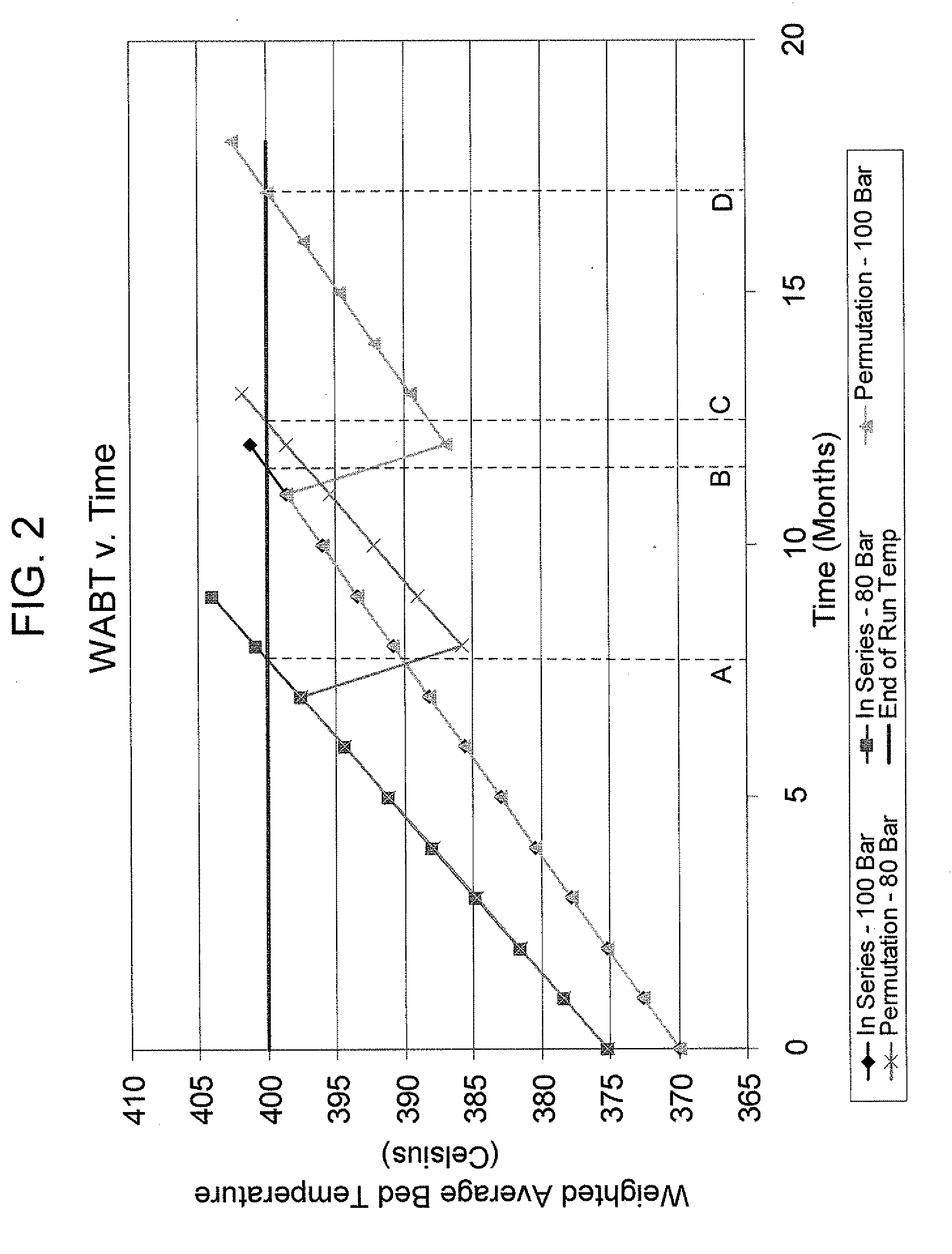

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

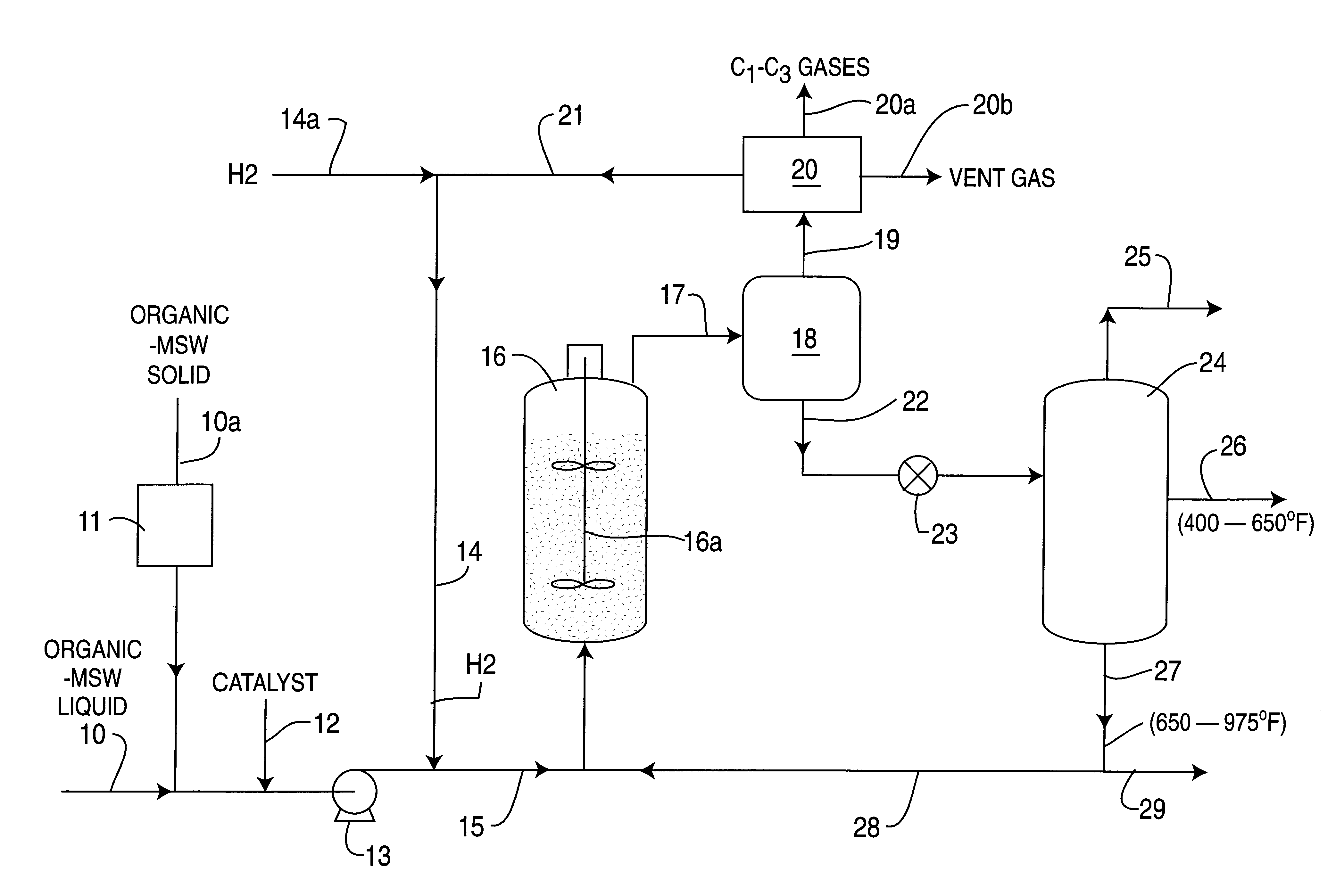

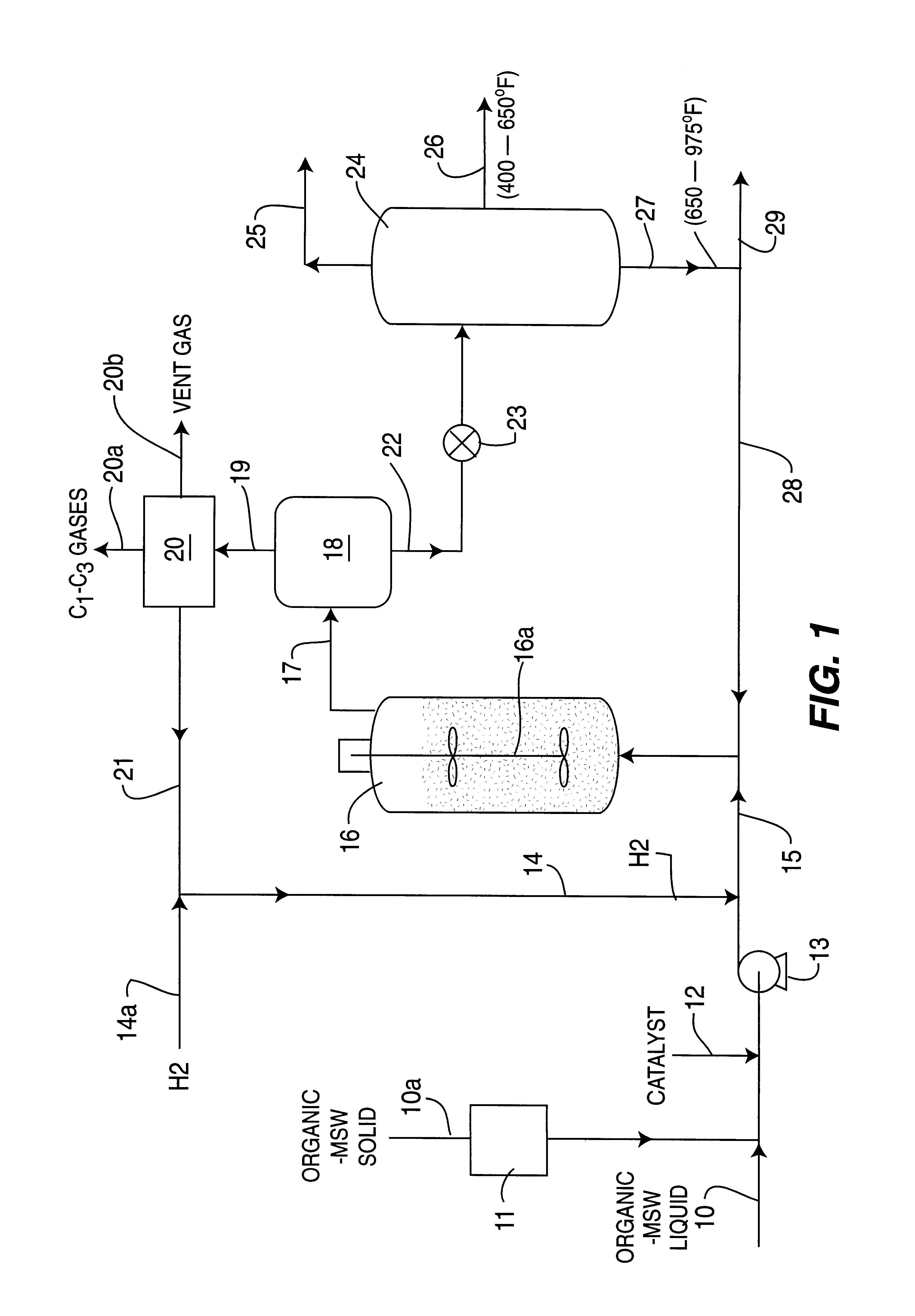

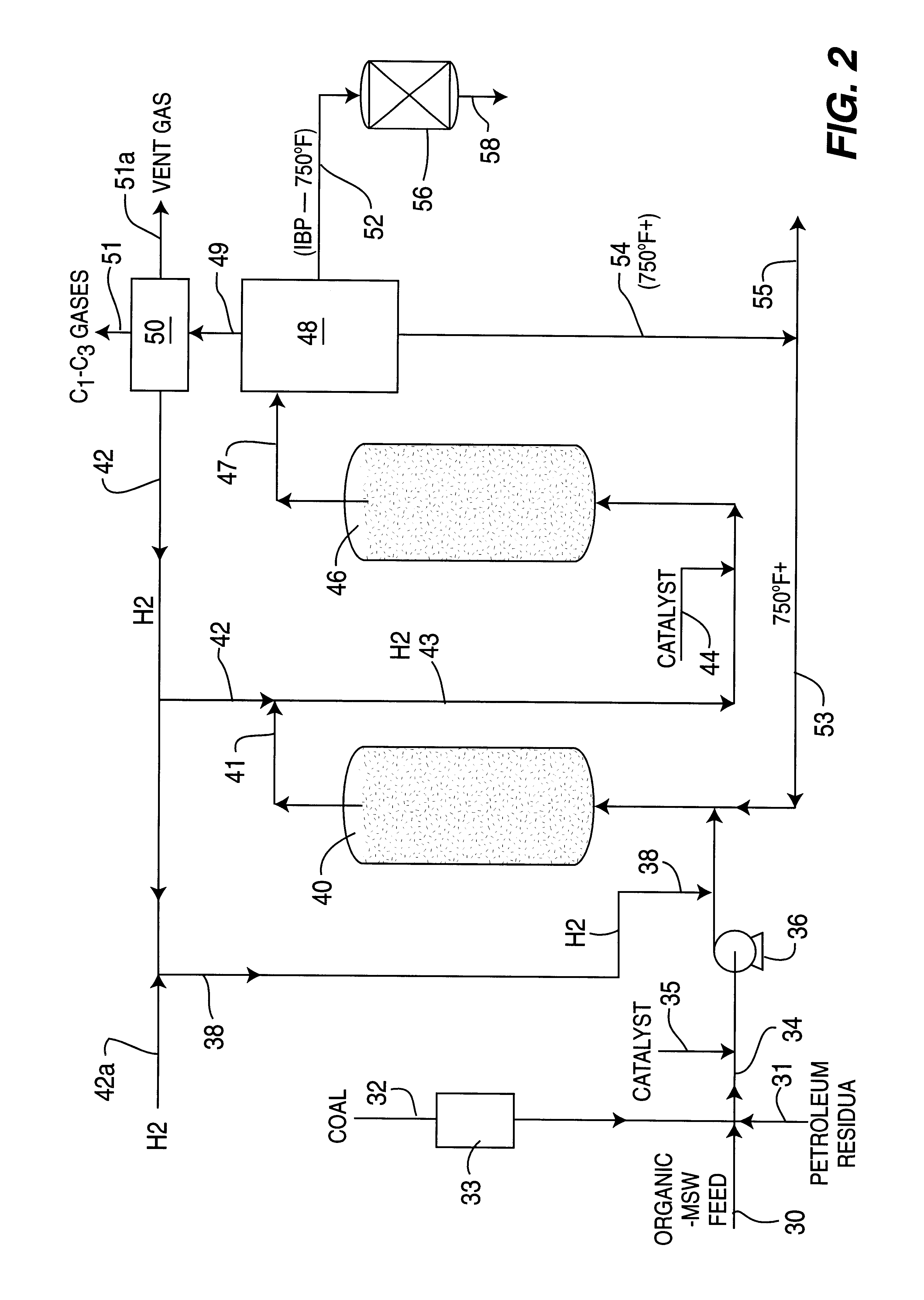

Catalytic hydroconversion of chemically digested organic municipal solid waste materials

InactiveUS6270655B1Increase surface areaReduce total nitrogenLiquid hydrocarbon mixture productionHydrocarbon oil crackingParticulatesLiquid product

A hydrocarbon liquid feedstock containing at least 50 wt. % chemically digested organic-MSW material is catalytically hydroconverted utilizing either a single stage or two-stage catalytic reaction process to produce desirable lower-boiling hydrocarbon liquid products. The catalyst can be either a particulate supported type catalyst such as containing cobalt and / or molybdenum and / or nickel on alumina support, or a dispersed slurry type catalyst containing mainly iron oxide with anions of molybdate, phosphate, sulfate or tungstate, and combinations thereof. Broad useful reaction conditions are 600-860° F. (315-460° C.) temperature, 1000-3000 psi hydrogen partial pressure, and fresh feed rate of 20-60 pounds / hr / ft3 reactor volume. Effluent material from the final stage catalytic reactor is phase separated and the resulting liquid portion is fractionated to produce the desired low-boiling hydrocarbon liquid products particularly useful as transportation fuels. If desired, the chemically digested organic-MSW feedstock can be blended with petroleum residua and / or particulate coal and / or mixed waste plastics and the blended feed material processed in catalytic two-stage reactors to produce similar desirable low-boiling hydrocarbon liquid products.

Owner:HYDROCARBON TECH

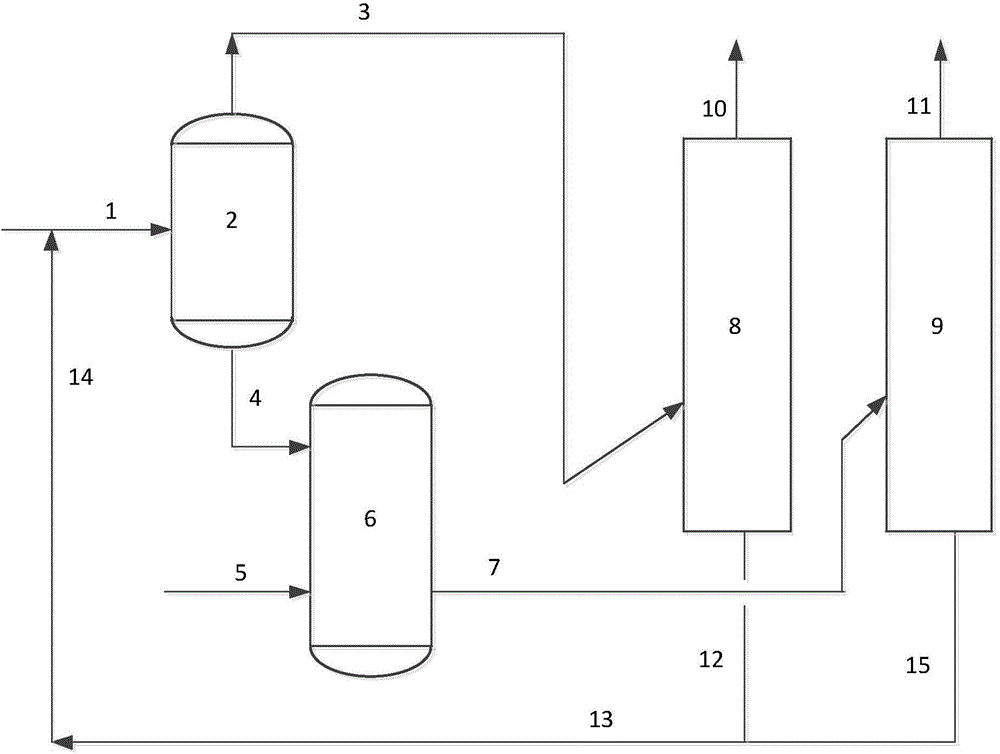

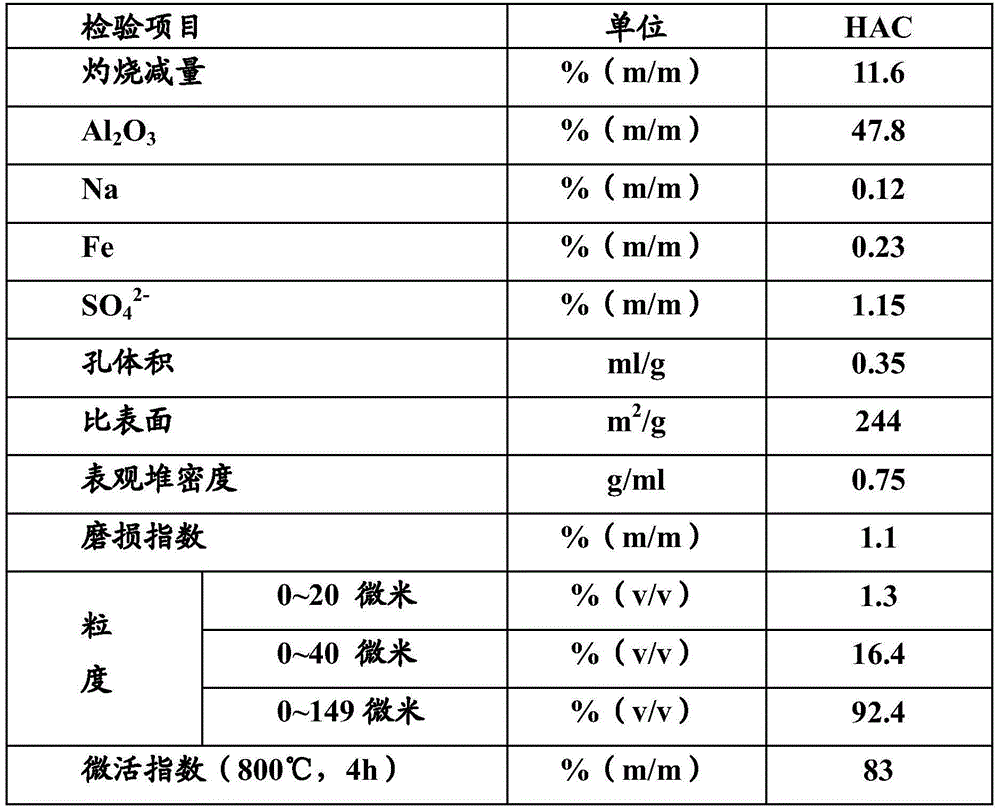

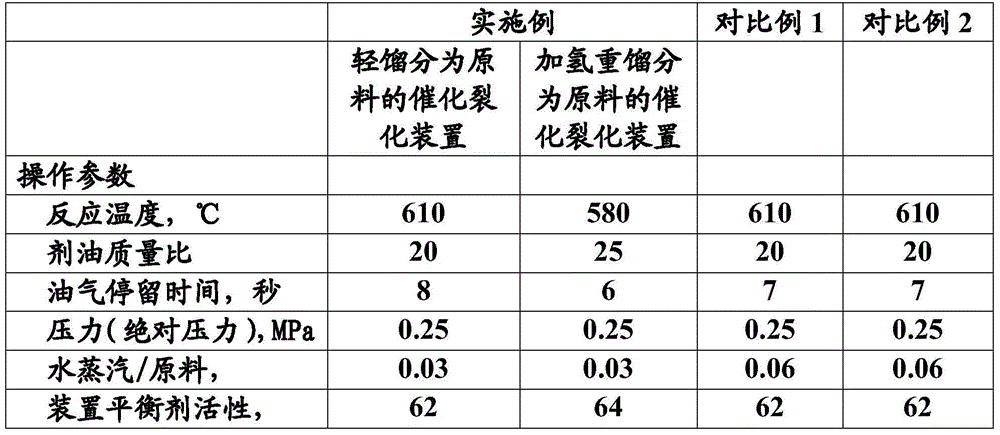

Catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon

ActiveCN104560187AReduce hydrogen consumptionImprove harsh conditionsTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonGasoline

The invention provides a catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon. The catalytic conversion method comprises the following steps: cutting catalytic cracking light cycle oil to obtain a light fraction and a heavy fraction, performing hydrogenation treatment on the heavy fraction to obtain a hydrogenated heavy fraction, singly and respectively conveying the light fraction and the heavy fraction into different riser reactors of catalytic cracking devices, performing a cracking reaction in the presence of a catalytic cracking catalyst, and separating reaction products to obtain a product containing the gasoline which contains rich aromatic hydrocarbon and the light cycle oil. According to the method, single catalytic cracking devices are used for processing the light fraction and the hydrogenated heavy fraction of the light cycle oil to satisfy harsh conditions necessary for the catalytic cracking reaction of different fractions of the light cycle oil to the maximum, so as to produce catalytic gasoline containing rich benzene, toluene and xylene to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

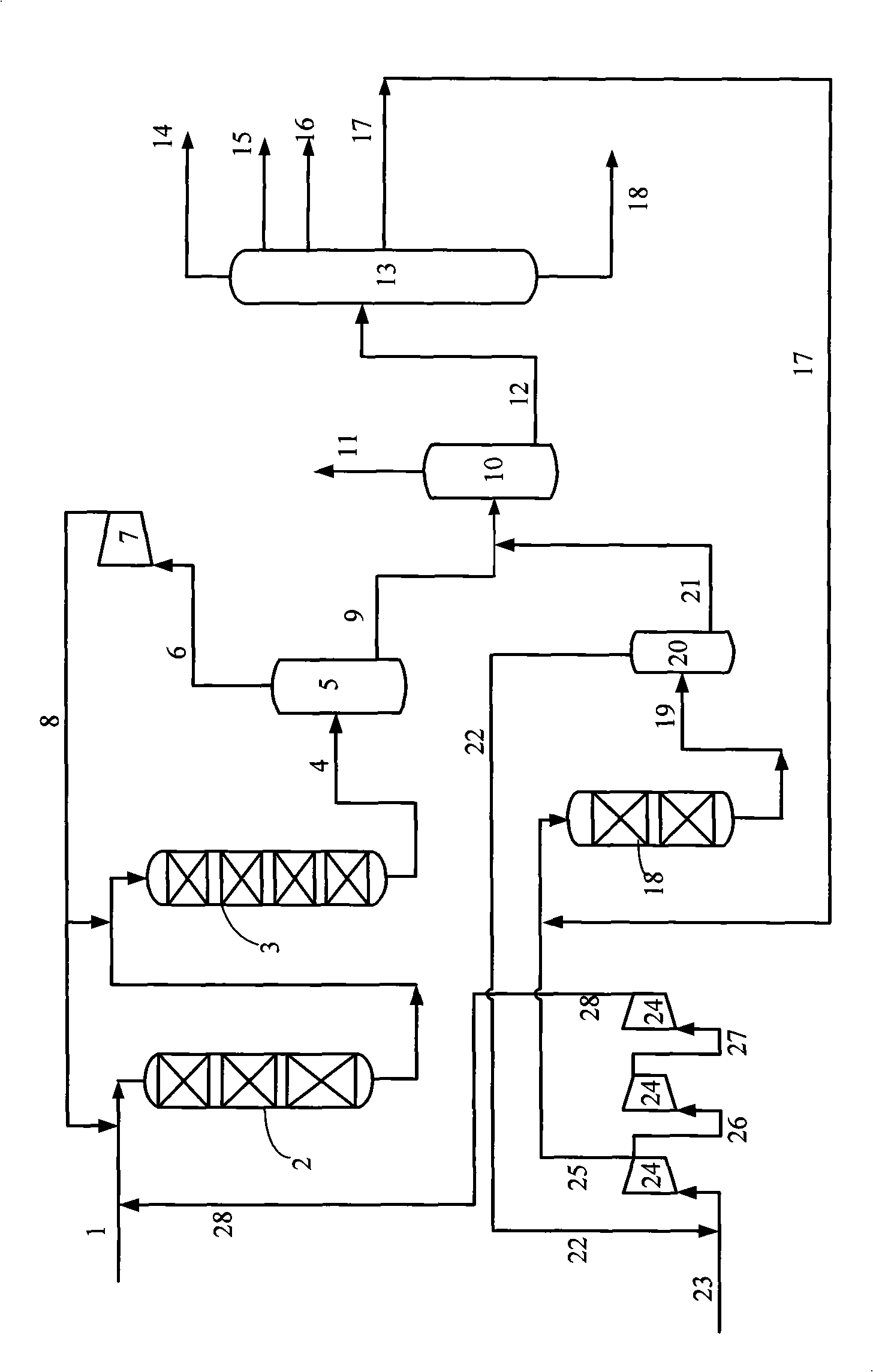

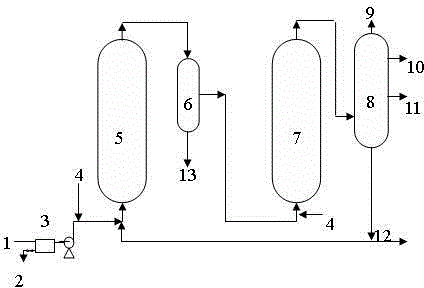

Hydrocracking method for producing chemical materials to maximum with low cost

ActiveCN101684415AReduce hydrogen consumptionLow investment costHydrocarbon oil crackingNaphthaFractionation

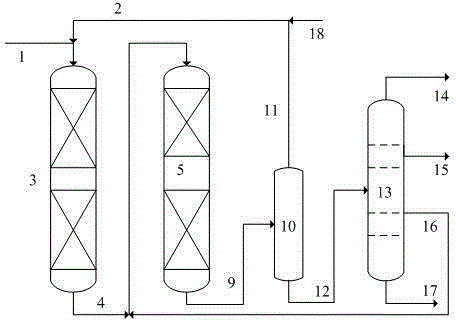

The invention relates to a hydrocracking method for producing chemical materials to the maximum with low cost, comprising the following steps: mixing raw oil and hydrogen gas , entering a first reaction area, sequentially contacting with hydrofining catalyst and hydrocracking catalyst, reacting under the pressure of 6.0-16.0 MPa; carrying out oil-gas separation and fractionation on the reaction products thereof to obtain liquefied gas, light naphtha fractions, heavy naphtha fractions, middle fractions and tail oil fractions; mixing the middle fractions and the hydrogen gas and enteringa second reaction area, contacting with the hydrocracking catalyst under the pressure of 1.0-5.5 MPa to react; and carrying out oil-gas separation on the reaction products thereof and entering a fractionation system . By adopting the method, heavy raw materials such as vacuum gas oil, coking gas oil and the like are treated to obtain more than 98 weight percent chemical materials. In the invention, themiddle fractions are wholly converted into the chemical materials in the low pressure condition, and low hydrogen consumption, low investment cost and low operation cost are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

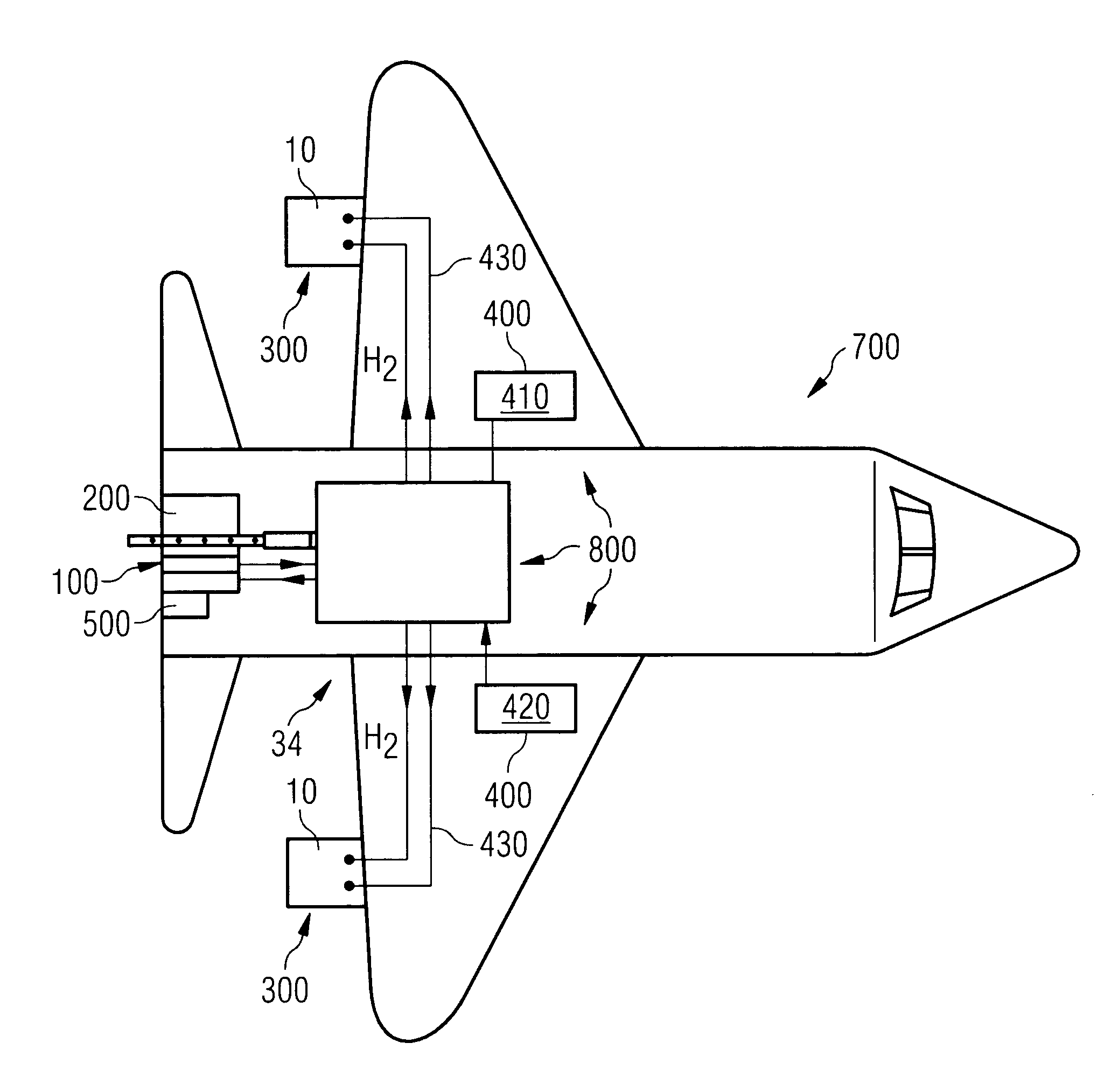

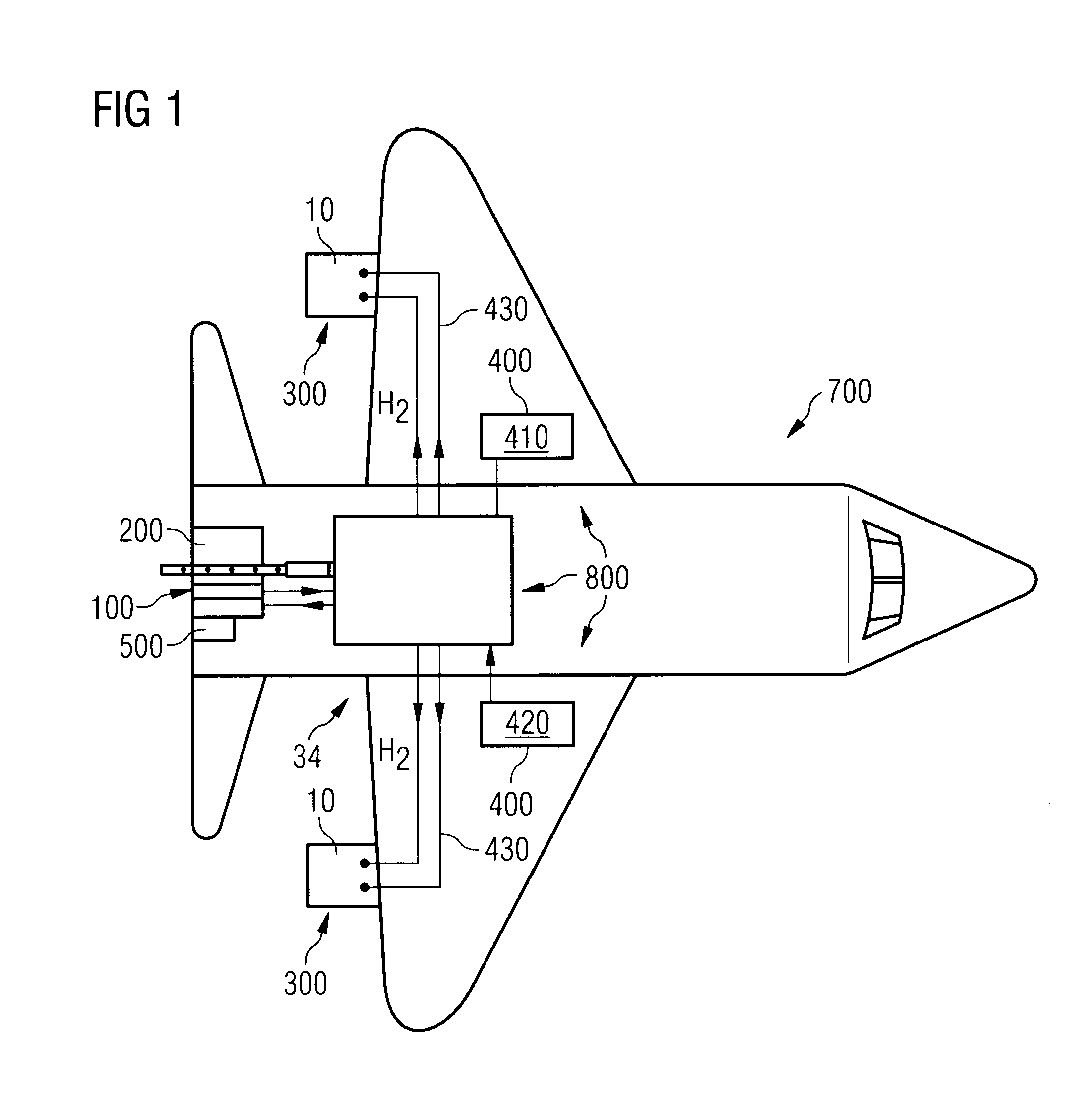

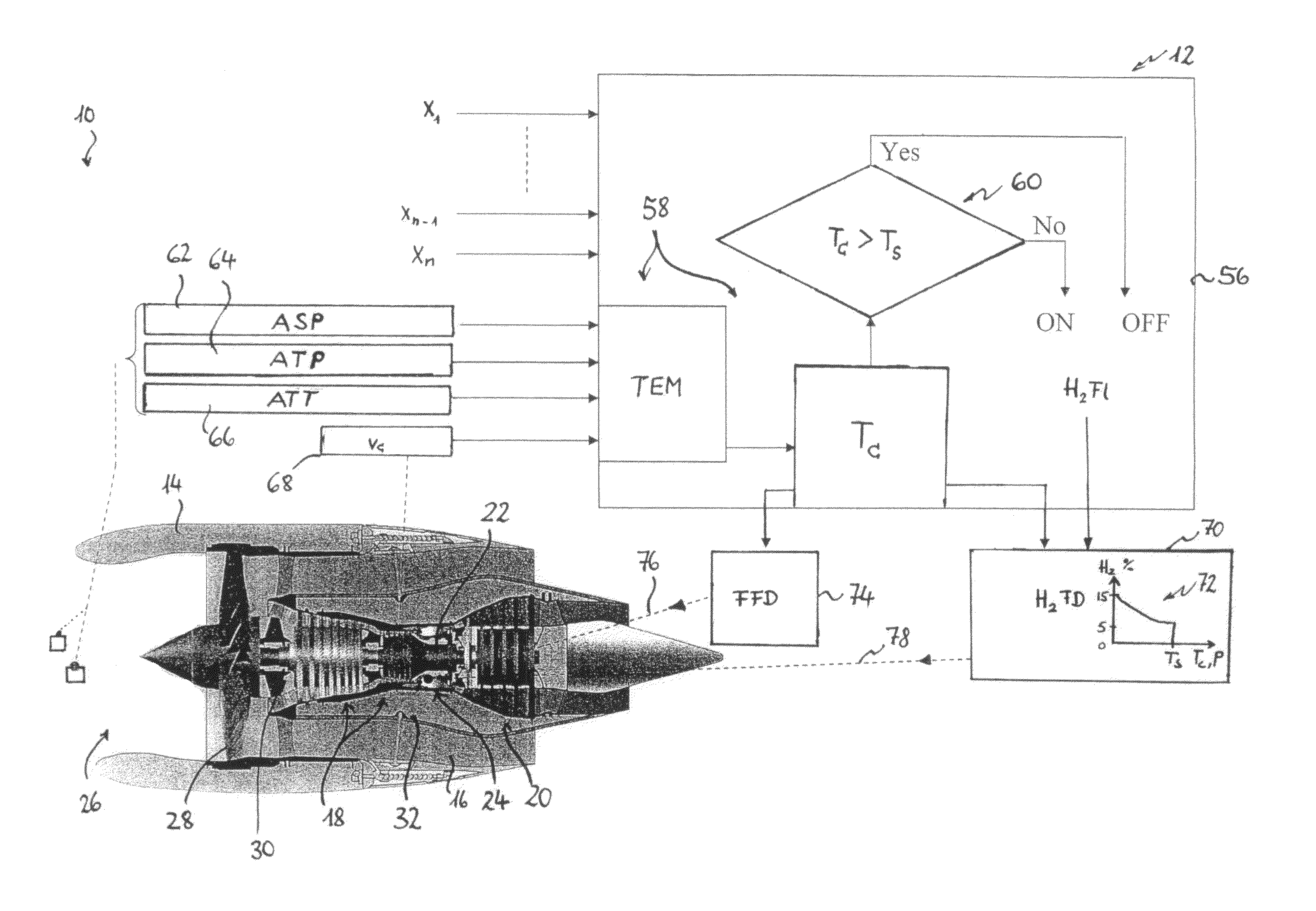

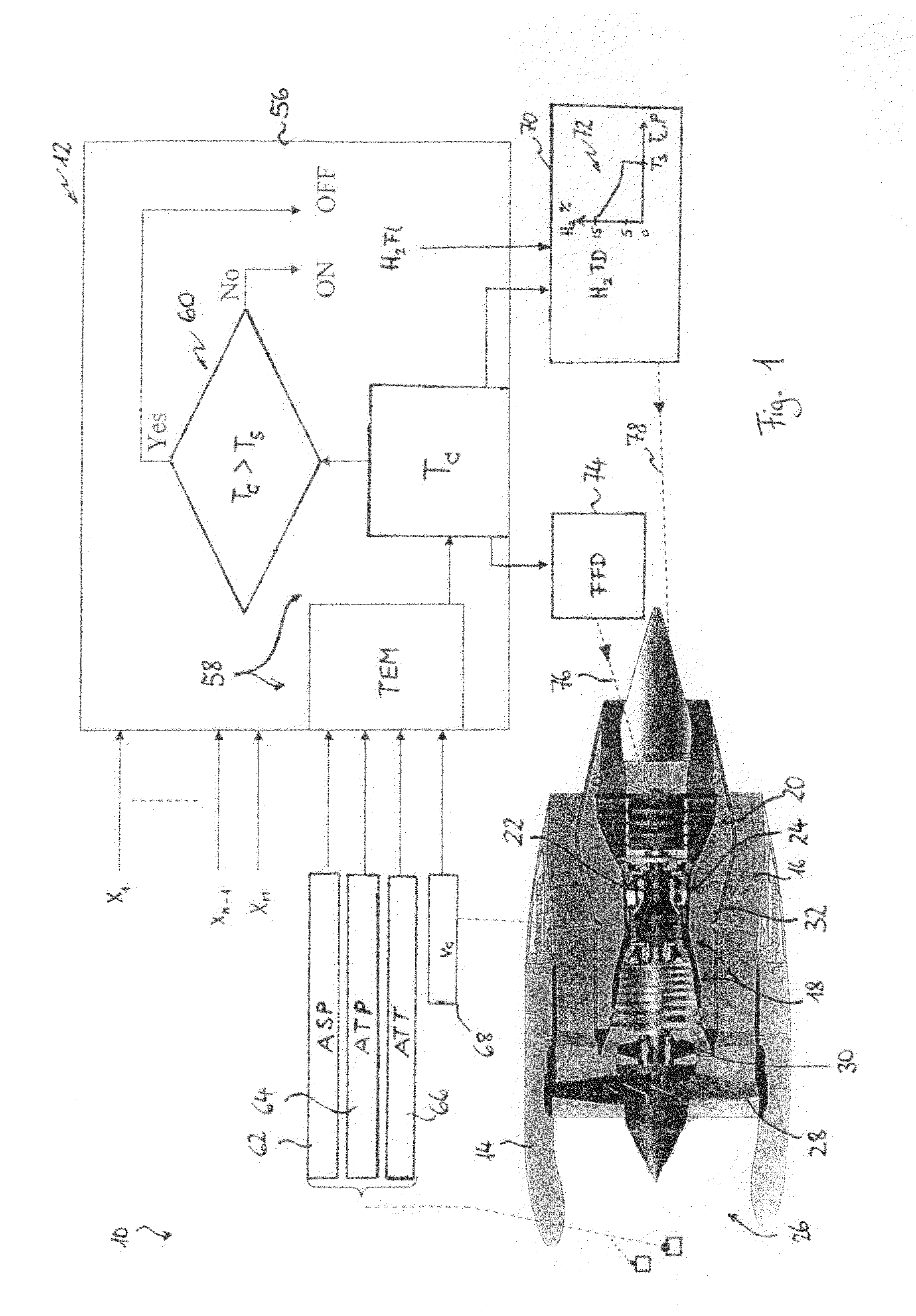

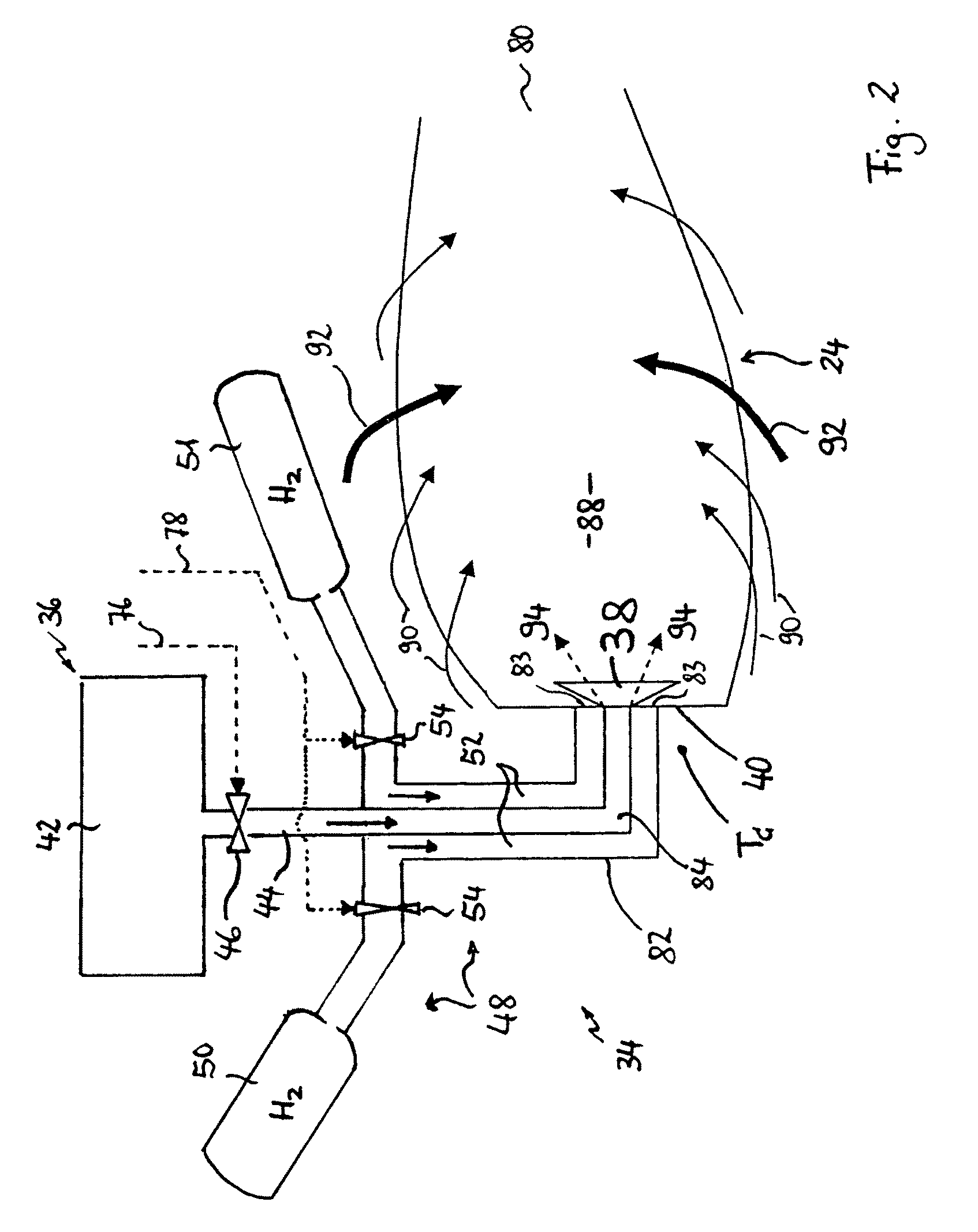

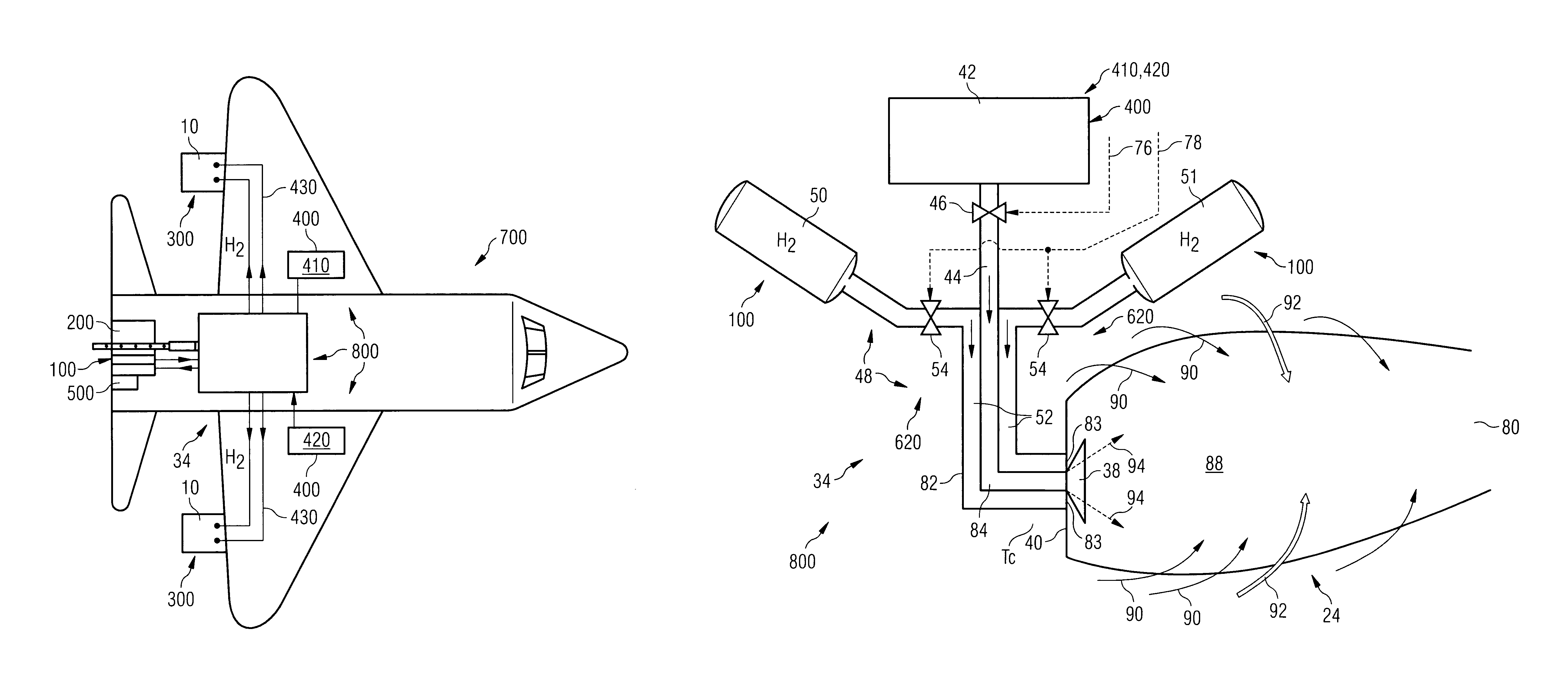

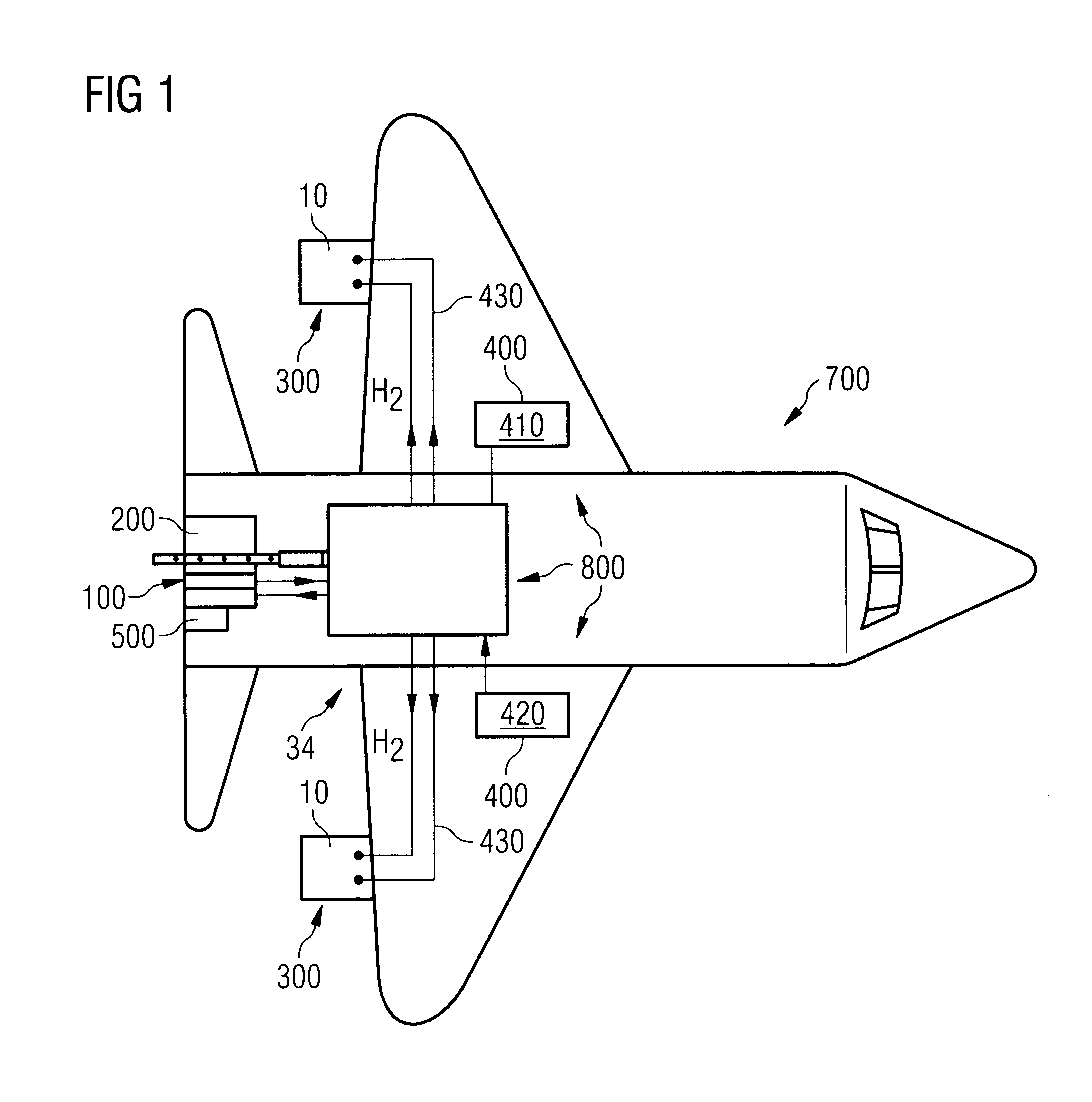

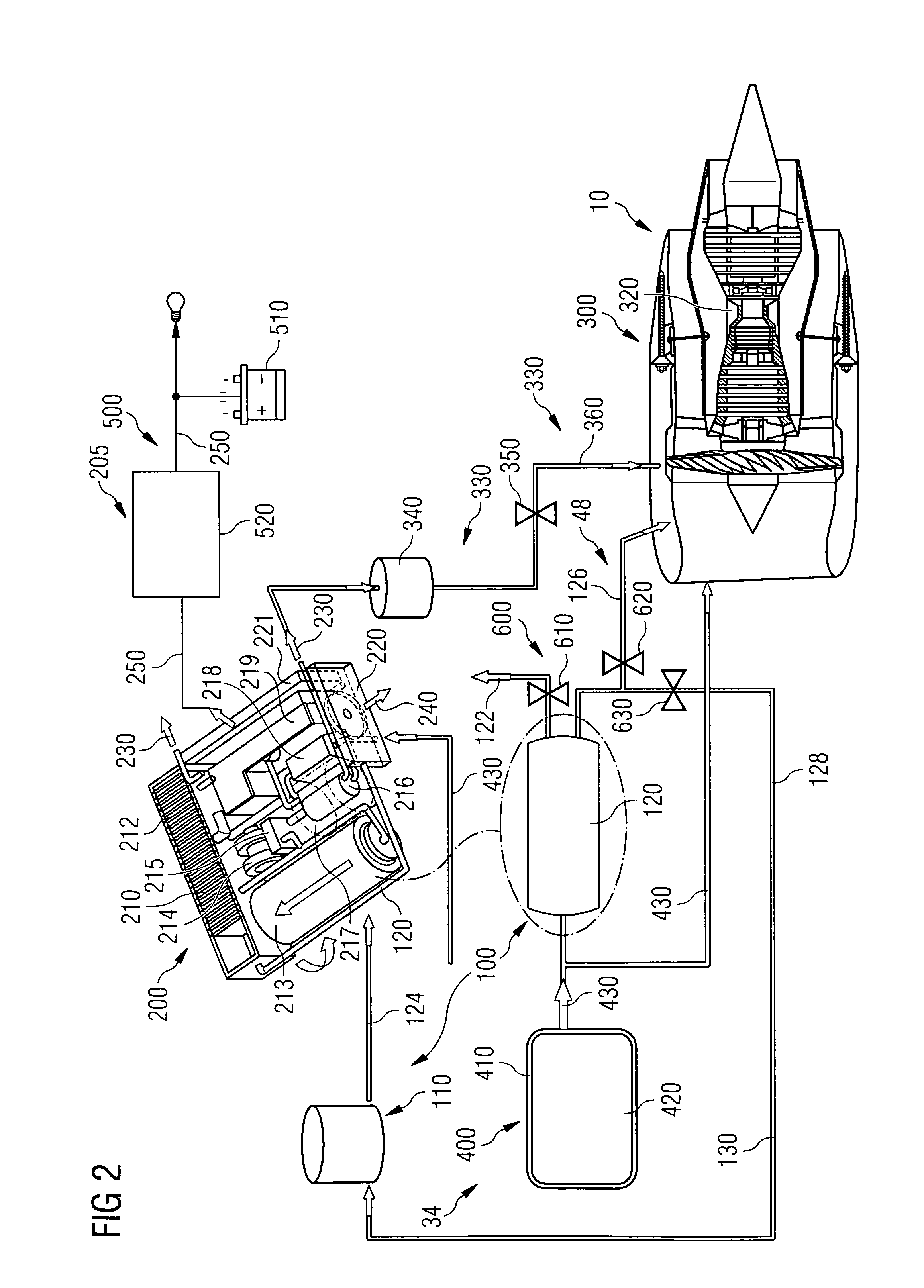

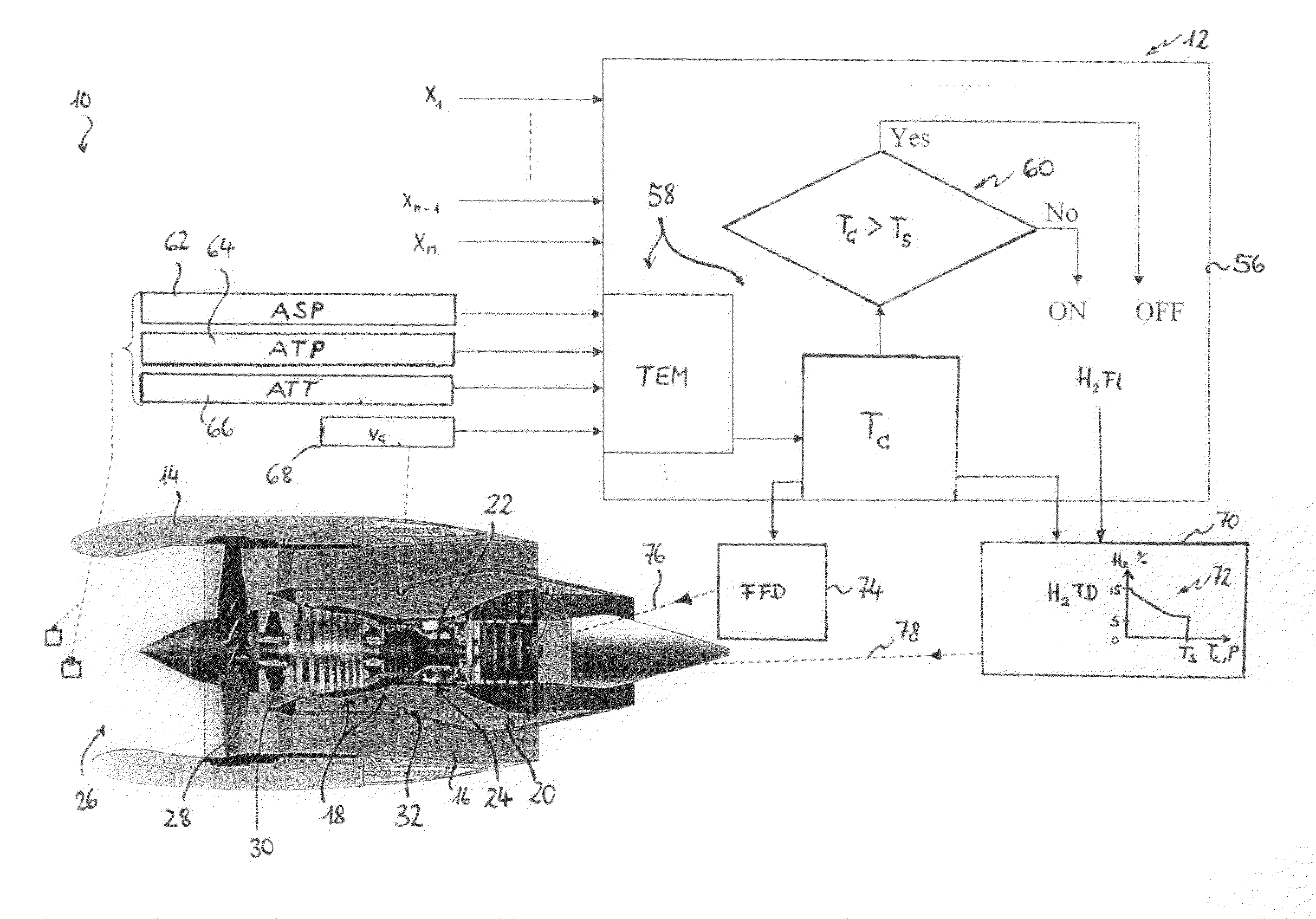

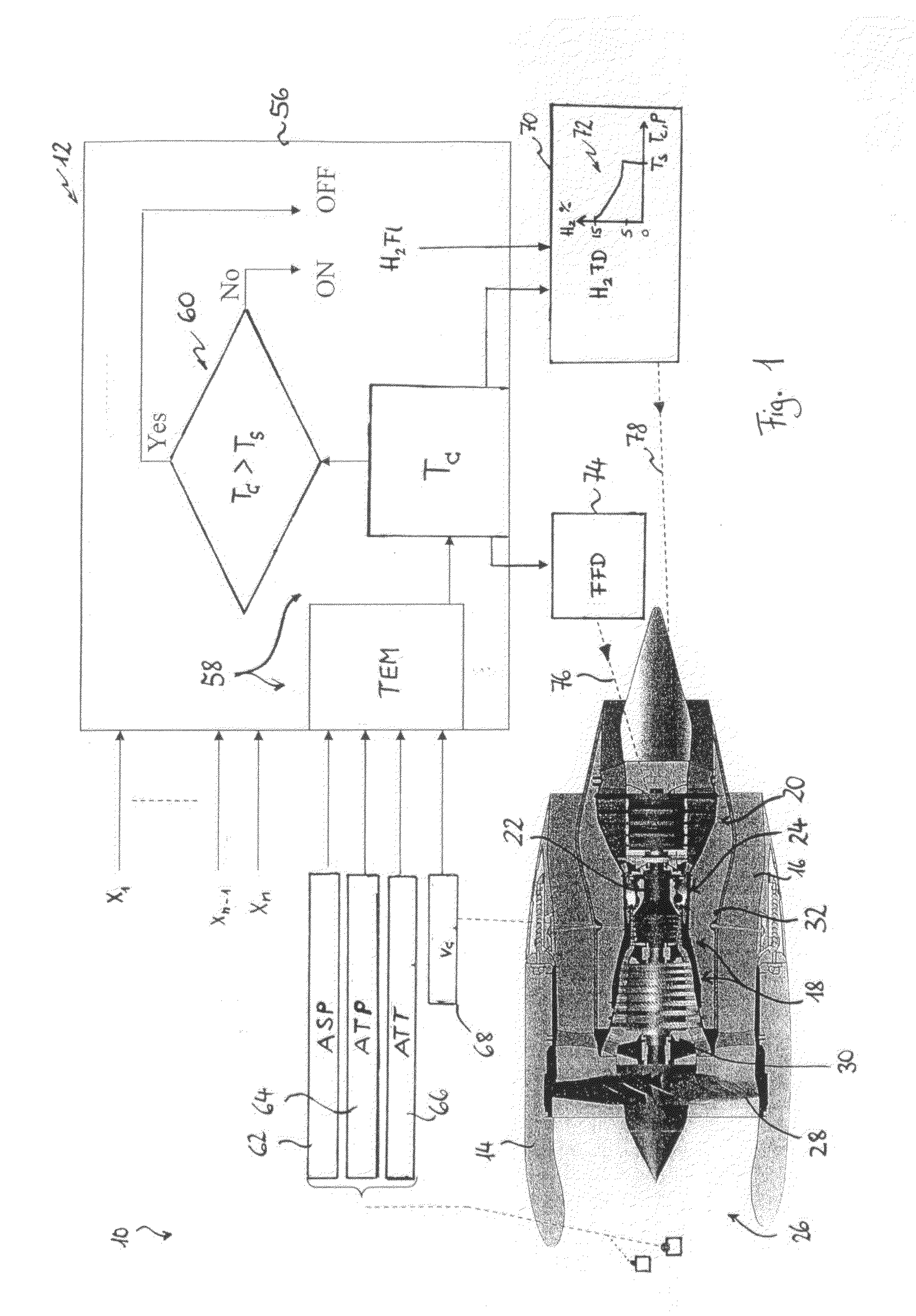

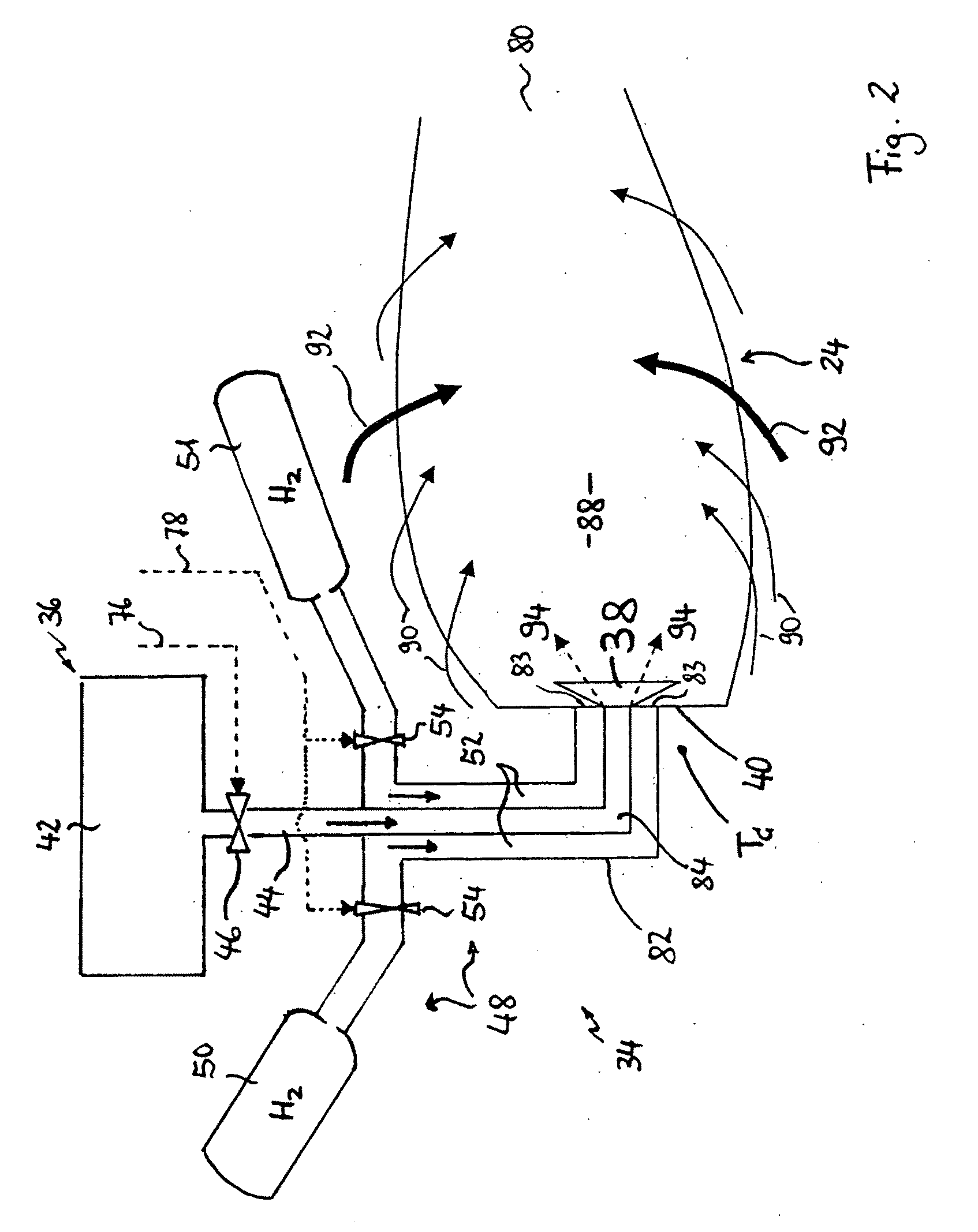

Method for Operating a Gas Turbine Engine, Power Supplying Device for Conducting such Method and Aircraft using such Method

ActiveUS20100293959A1Emission reductionReduce hydrogen consumptionContinuous combustion chamberTurbine/propulsion engine ignitionAviationCombustion chamber

A power supply device or system for aeronautics, having a hydrocarbon supply for supplying an engine with hydrocarbon fuel and a hydrogen supply having a fuel reformer for producing hydrogen from hydrocarbon fuel from said hydrocarbon supply. The hydrogen supply is connected to a hydrogen-powered fuel cell for producing electric power and to a hydrogen injecting system for injection of hydrogen into a combustion chamber of the engine. Further, the invention relates to an aircraft having an engine that can be supplied by that power supplying device or system, and to a method for operating said engine.

Owner:AIRBUS SAS

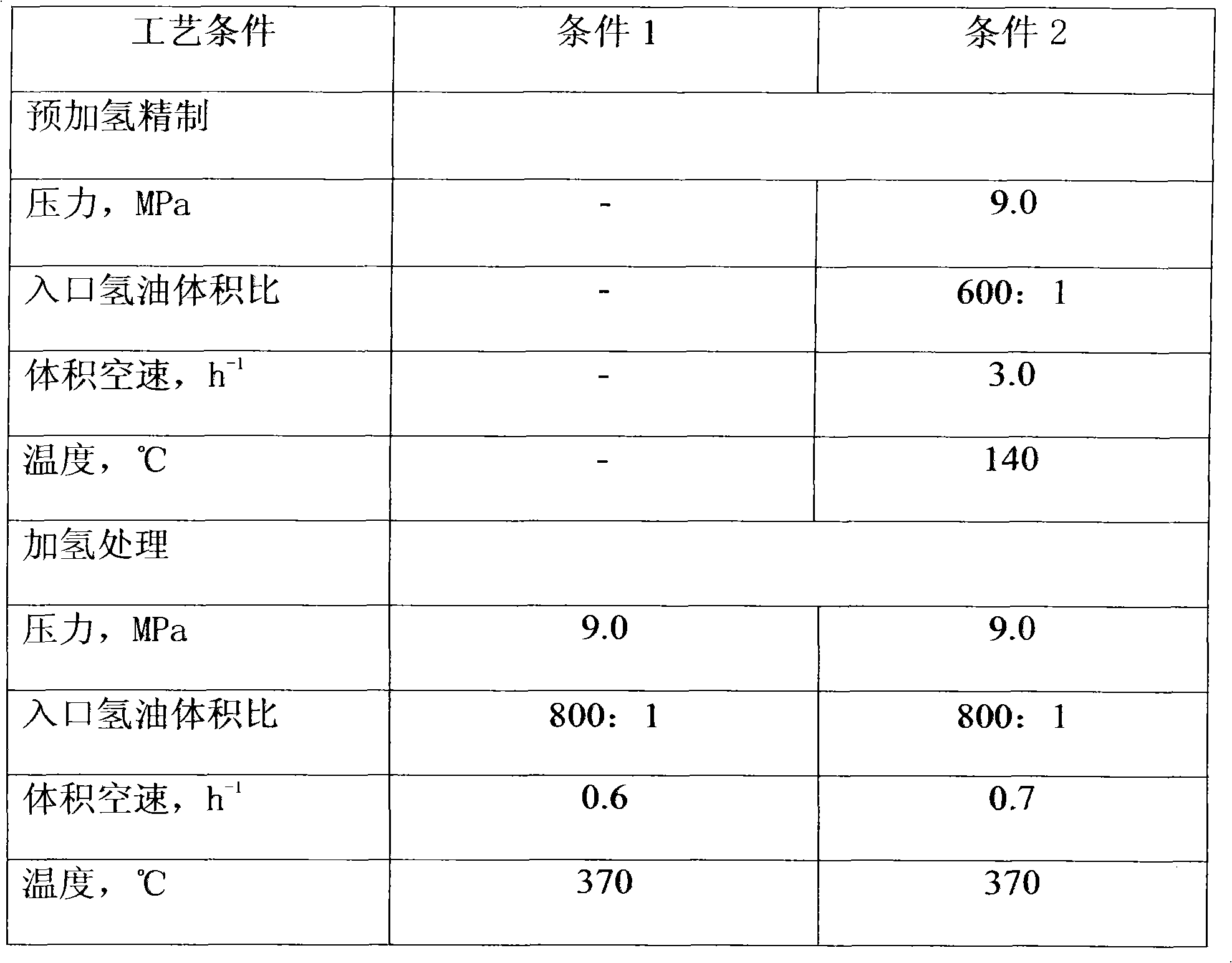

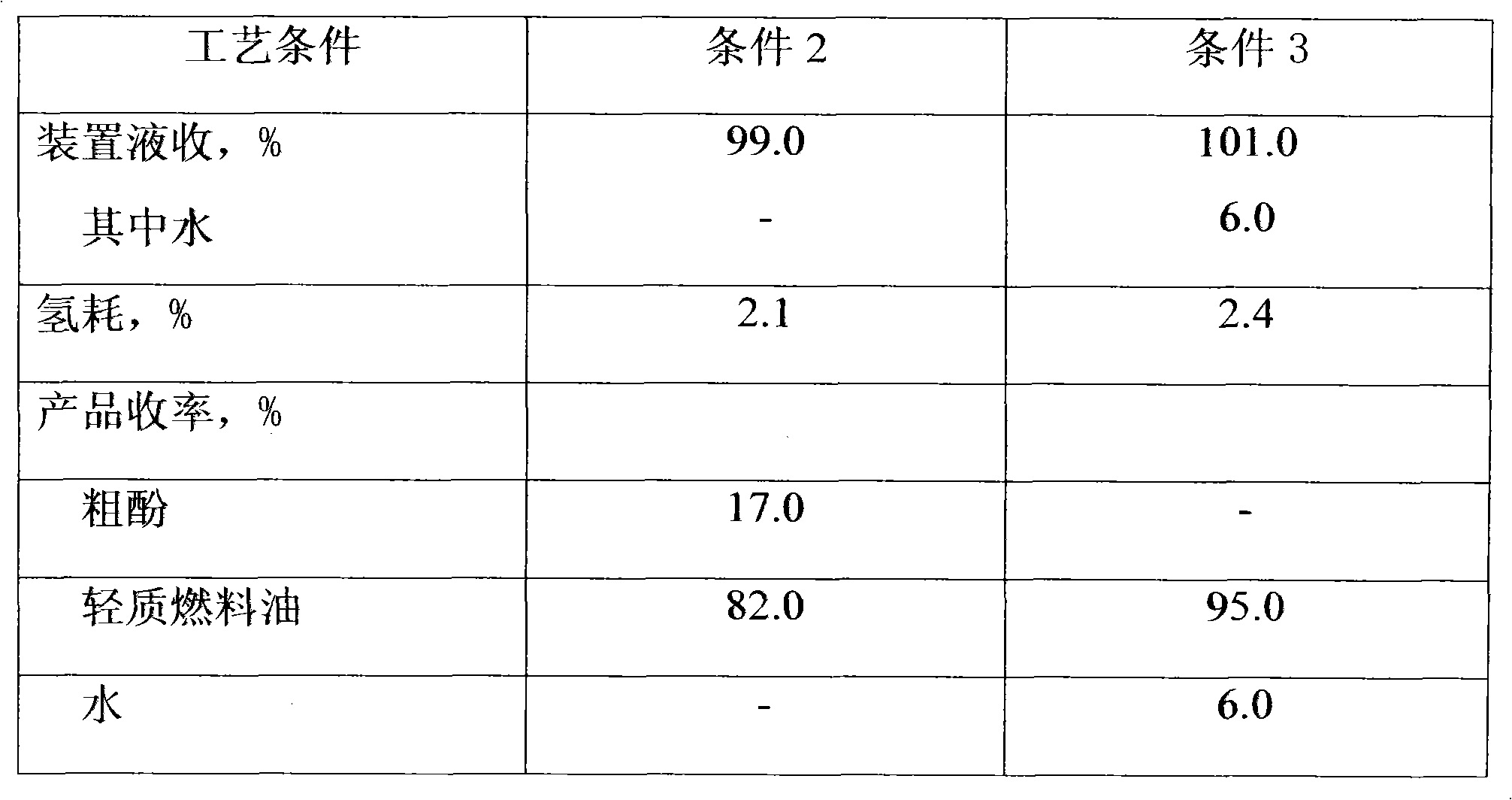

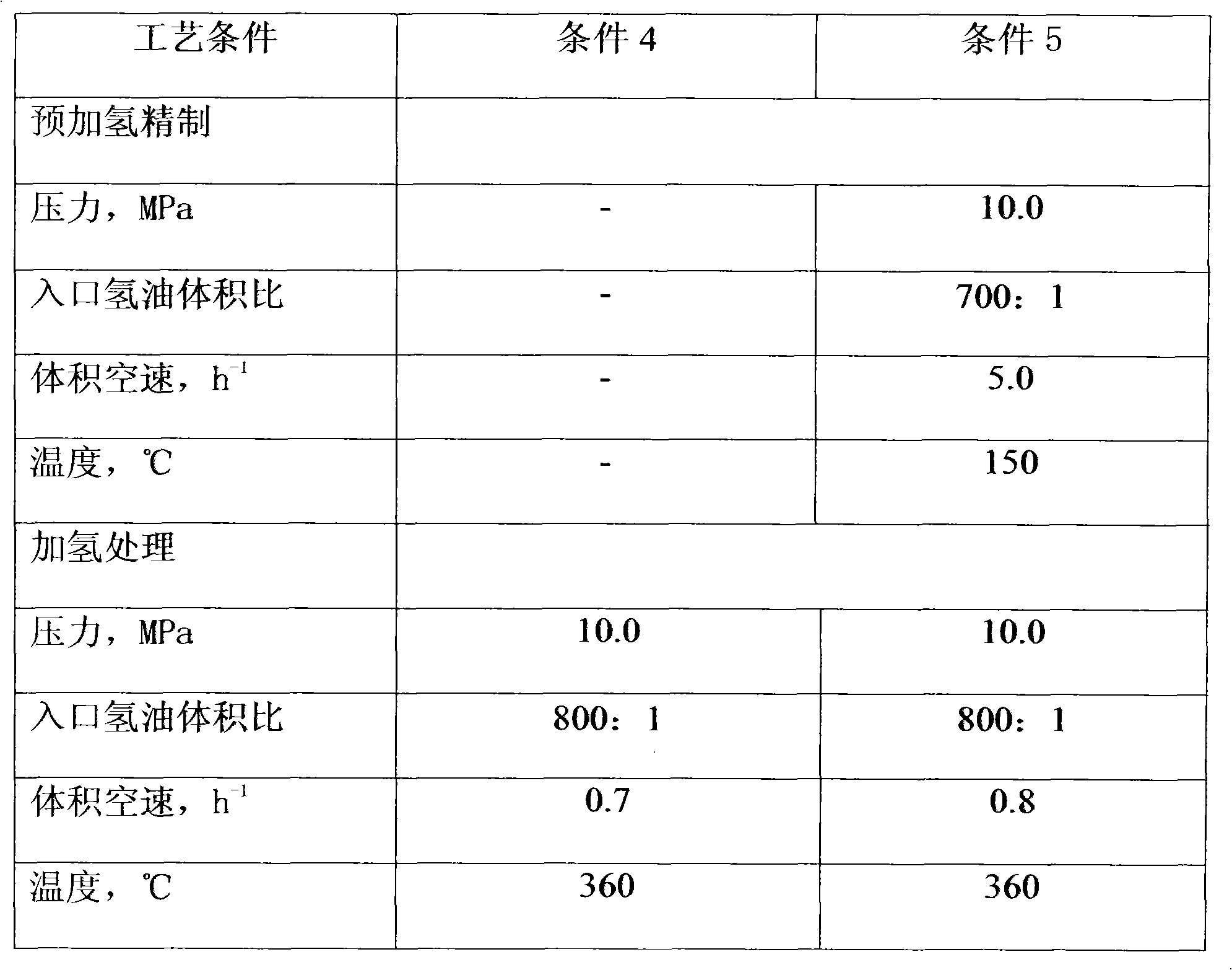

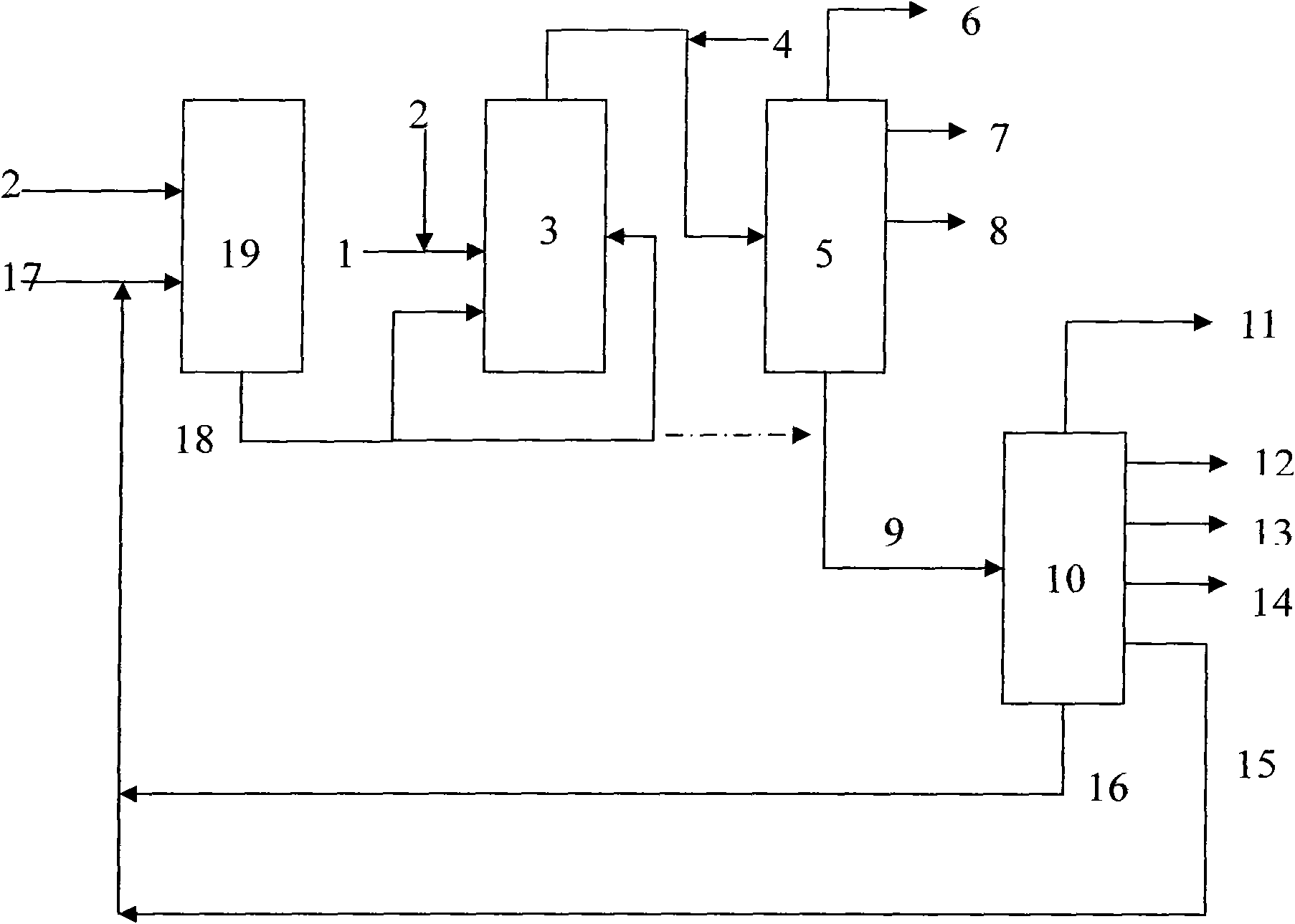

Diesel fuel fraction hydrotreating method

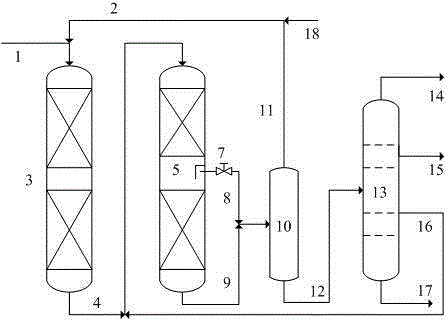

ActiveCN1769387AHigh gross airspeedImprove efficiencyTreatment with hydrotreatment processesLiquid productHydrogen

The invention discloses the diesel oil distillate hydrotreating method. The method comprises the following steps: dividing the raw oil into light cut and heavy cut, entering the light cut into the first reaction area to touch the hydrofining catalyst, entering the heavy cut into the second reaction area to touch the hydrofining catalyst, mixing the liquid product of the two reaction areas to prepare the refined distillate oil. The first reaction area uses the hydrogenation catalyst which possesses high desulfurizing activity, and the second reaction area uses hydrogenation catalyst which possesses the high hydrogenation activity. Comparaed with the general diesel oil refined process, the said method can realize the deep hydrogenation and desulfuration. The method possesses the characteristics of simple process flow and easy operation. The said method can be used for various hydrotreating processes containing the diesel oil fraction raw oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

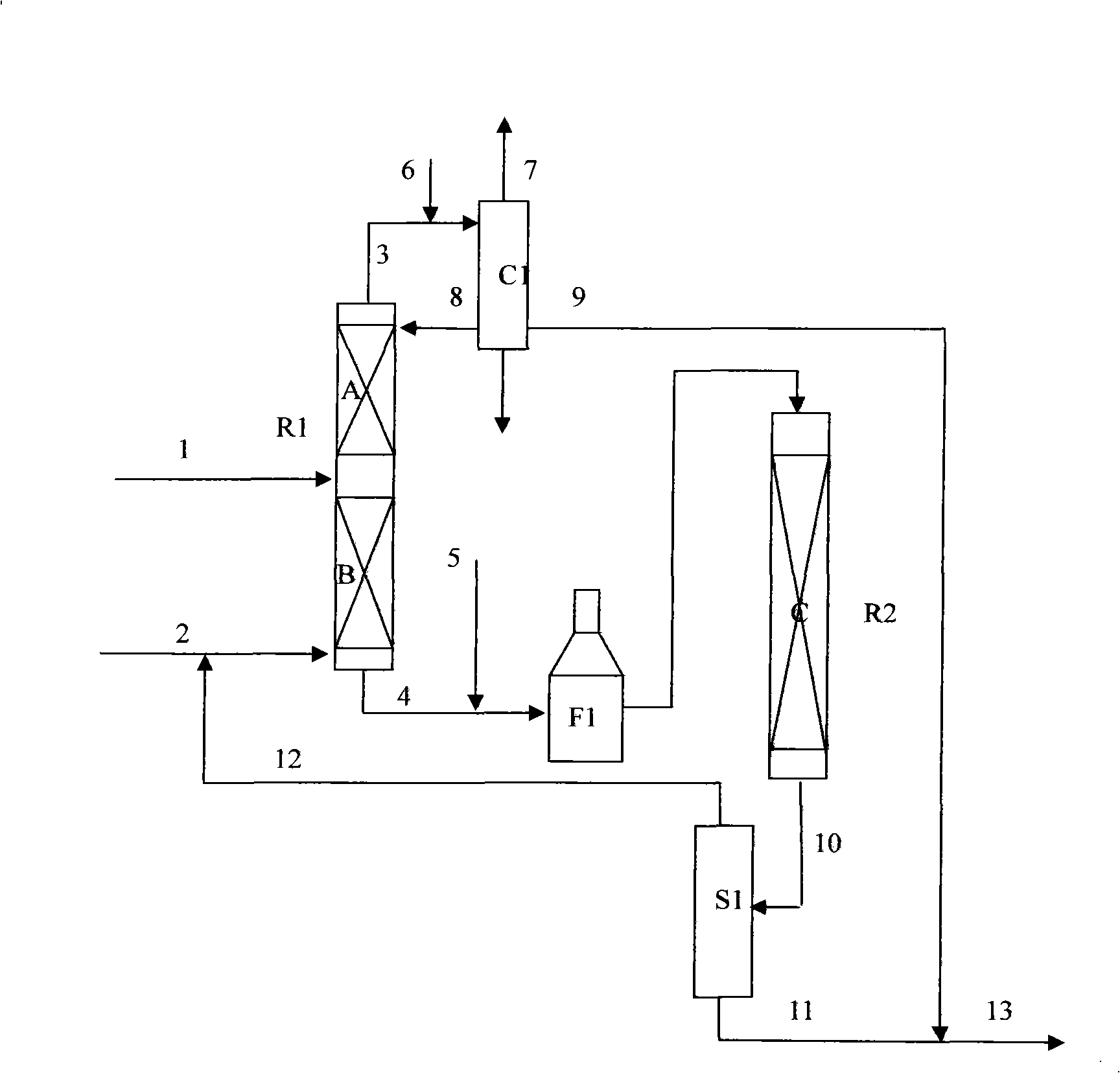

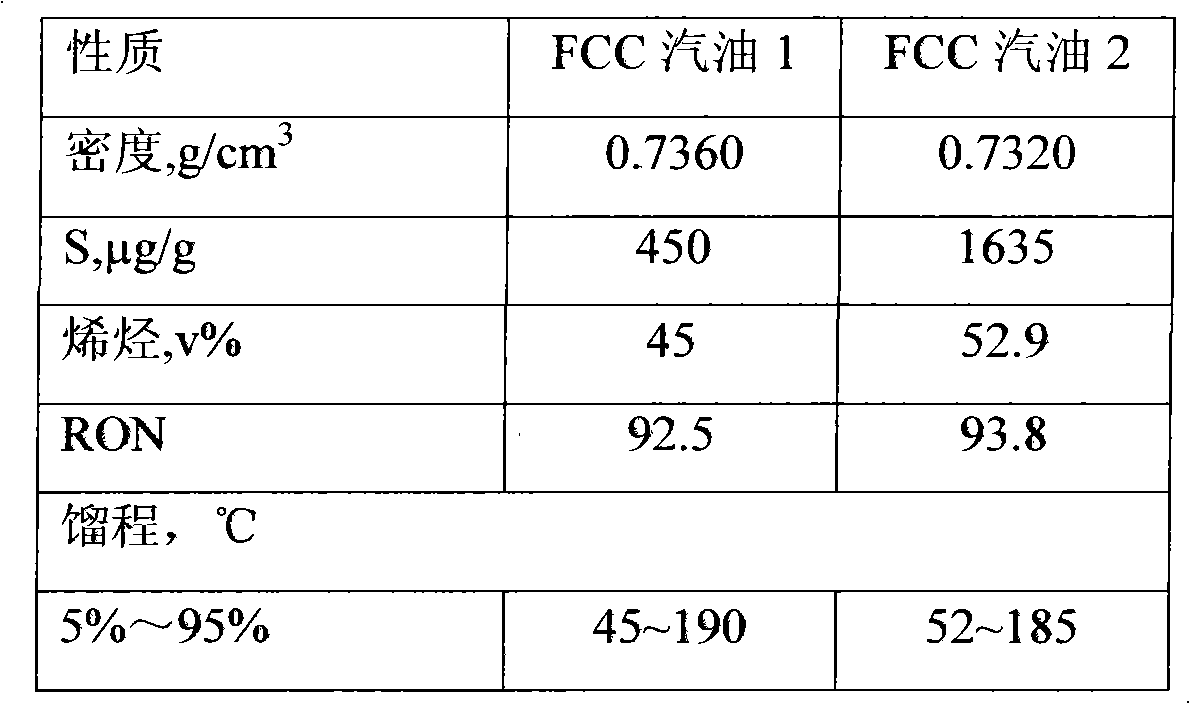

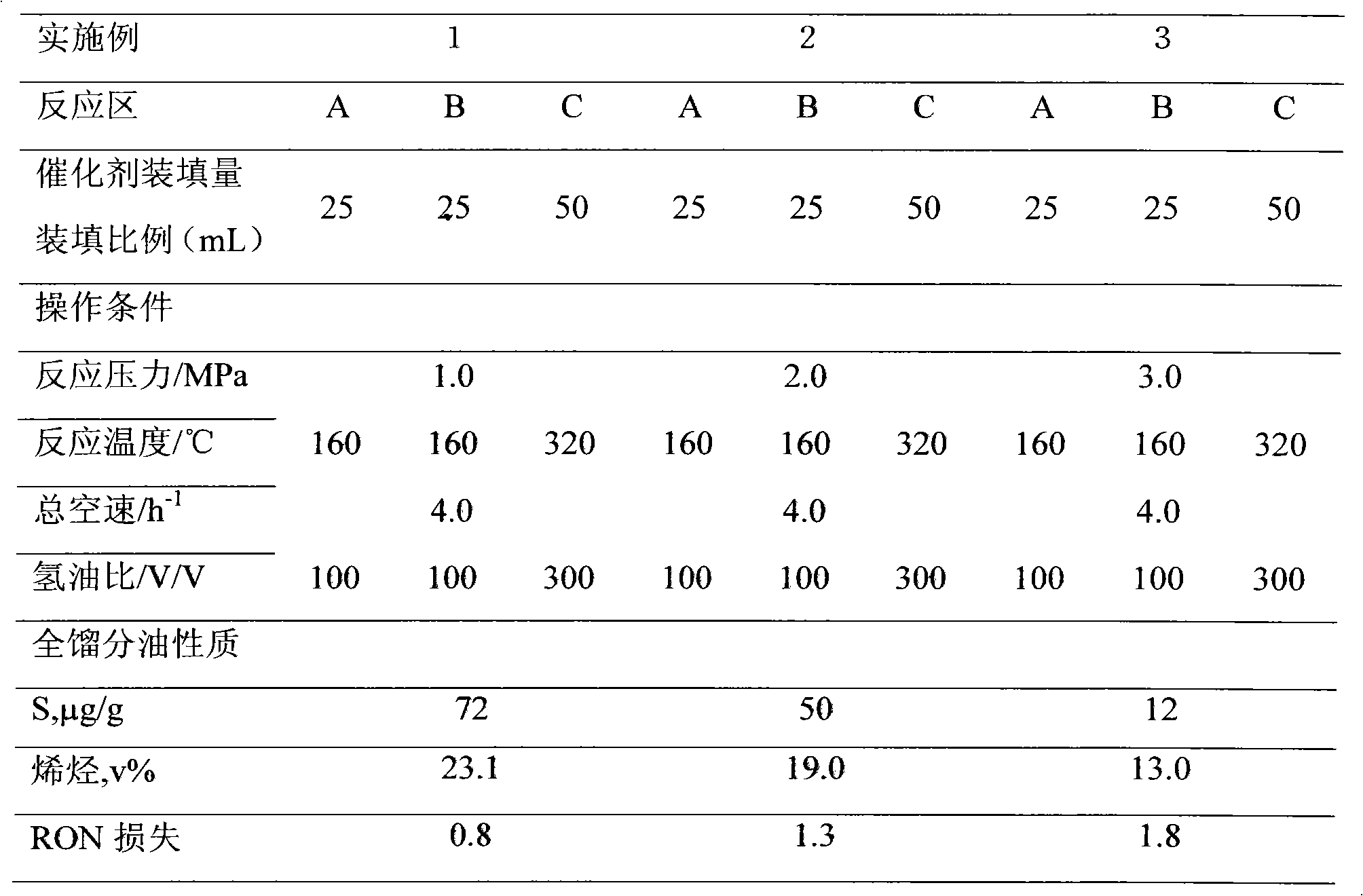

Hydrotreating process for light hydrocarbons

ActiveCN101343563AReduce saturationReduce cokingTreatment with hydrotreatment processesIsomerizationGas phase

The invention discloses a lightweight hydrocarbon hydrogenising method, which adopts a first stage countercurrent hydrogenising reactor and a conventional co-current hydrogenising reactor connected in series. The raw material enters into a flash evaporation area of the countercurrent hydrogenising reactor at a lower temperature, gas-phase hydrocarbon flows upwards and performs a reaction of diene and mercaptan producing sulfide and a diene hydrogenising reaction at the upper part of the countercurrent hydrogenising reactor, high boiling sulfide generated by the upper part reaction and liquid-phase hydrocarbon after the raw material flash evaporation flow downwards together, and an alkylation reaction of thiophene sulfur and olefin is generated; Hydrogen enters at the bottom of the countercurrent hydrogenising reactor and flows upwards. Liquid phase discharged at the bottom of the countercurrent hydrogenising reactor and new hydrogen are mixed and enter into the co-current hydrogenising reactor to perform the reactions, such as deep hydrodesulfurization, selective cracking or isomerization and the like after being heated. The method has the advantages that the technological process is simple, the desulphurization effect is good, the octane value loss is low, the product yield is high, and the required equipment is few. The method is mainly used for the secondary processing the poor-quality gasoline, namely, the upgrading process of catalytic cracking gasoline, coking gasoline or thermal cracking gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

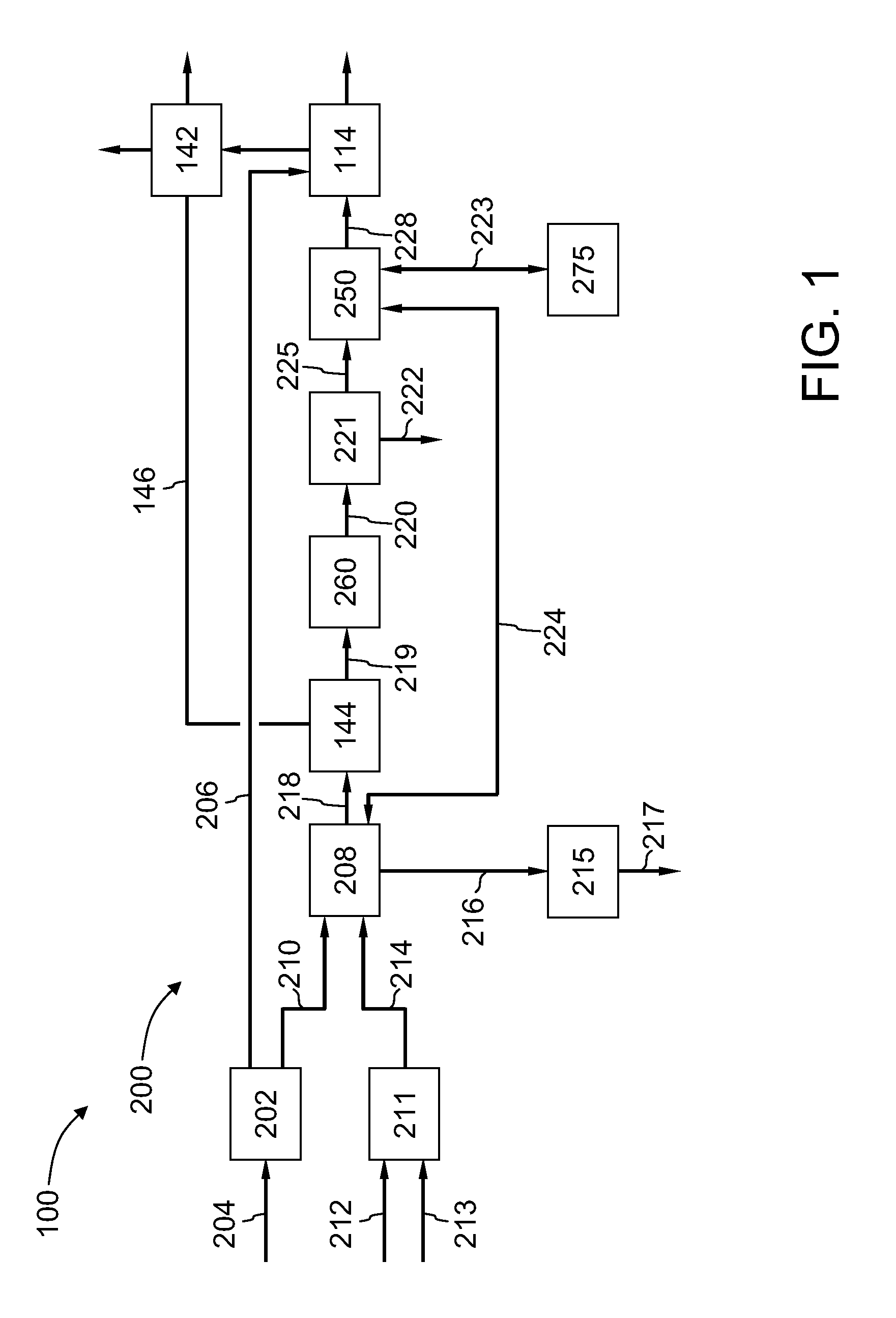

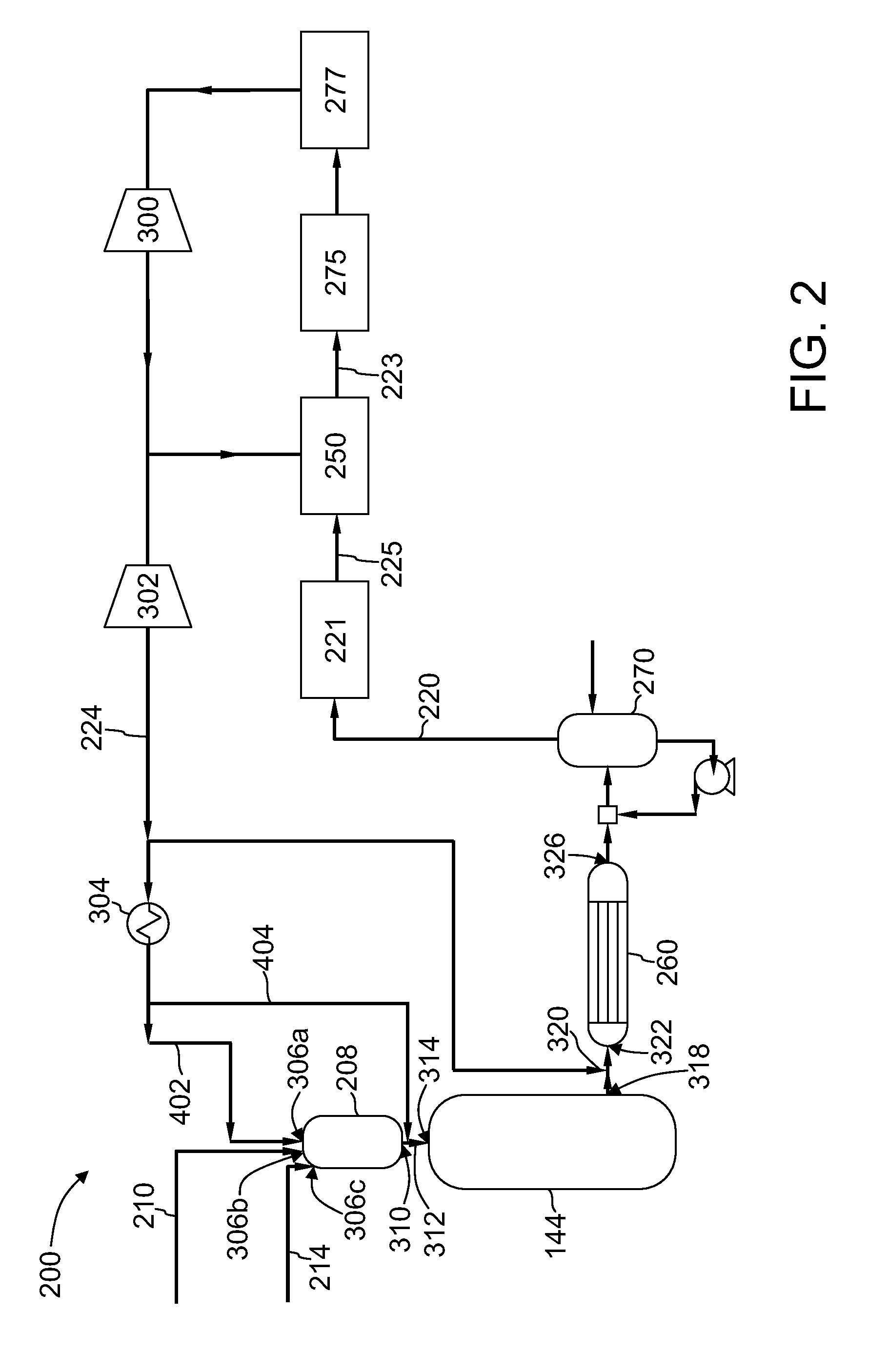

Methods of recycling carbon dioxide to the gasification system

ActiveUS20100324156A1Improve cooling effectEasy to produceUsing liquid separation agentGas modification by gas mixingSyngasChiller

Method of producing syngas in an IGCC system, comprising compressing and heating carbon dioxide-rich gas to produce heated compressed carbon dioxide-rich gas, mixing the heated compressed carbon dioxide-rich gas with oxygen and feedstock to form a feedstock mixture, subjecting the feedstock mixture to gasification to produce syngas, cooling the syngas in a radiant syngas cooler, contacting syngas cooled in the radiant syngas cooler with compressed carbon dioxide-rich gas to further cool the syngas, and removing an amount of carbon dioxide-rich gas from the product mixture and compressing the removed carbon dioxide-rich gas prior to mixing with oxygen and feedstock.

Owner:AIR PROD & CHEM INC

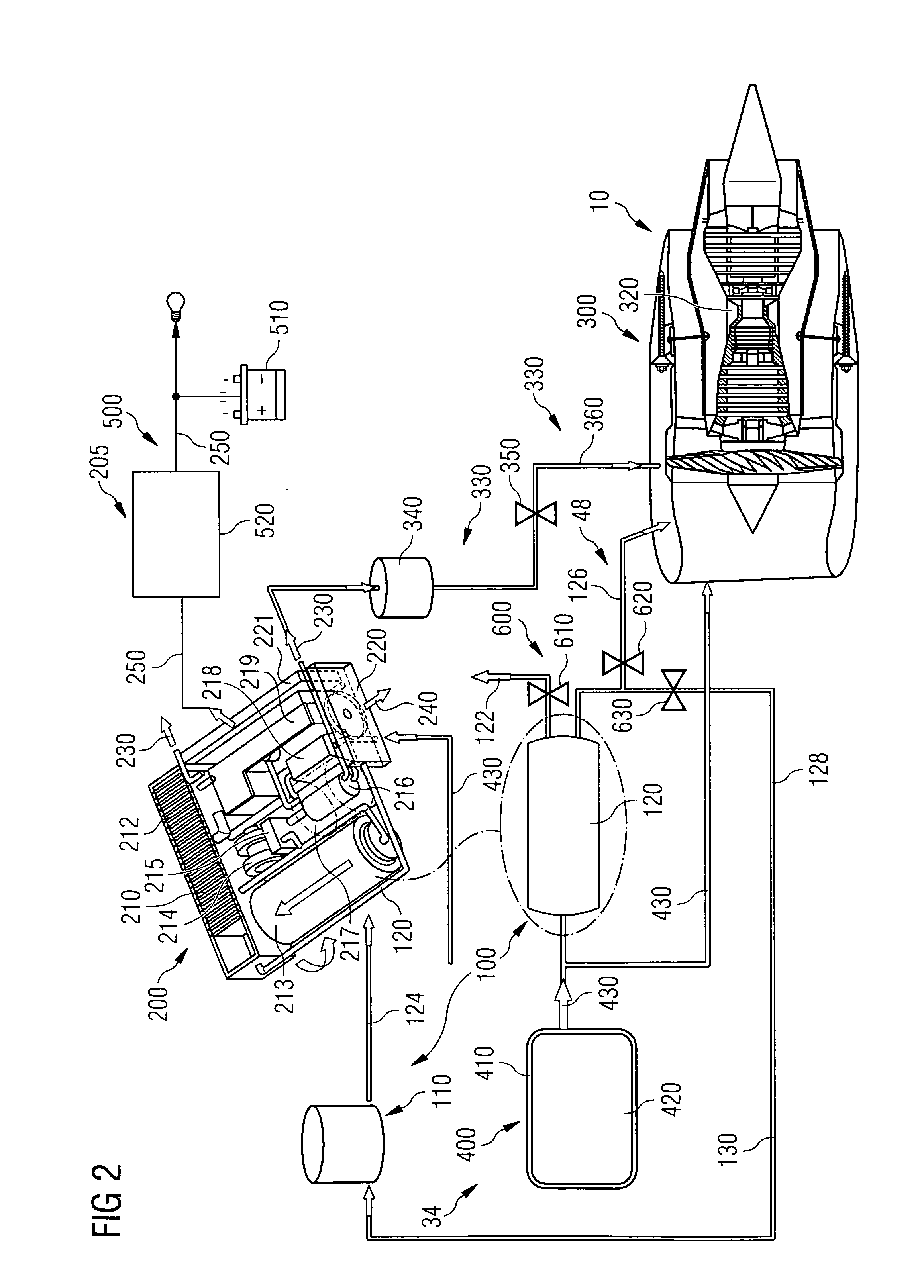

Gas turbine engine and method for reducing turbine engine combustor gaseous emission

ActiveUS8056344B2Reduce hydrogen consumptionSmall sizeAnalogue computers for vehiclesFuel supply regulationCombustorGaseous hydrogen

Owner:AIRBUS SAS

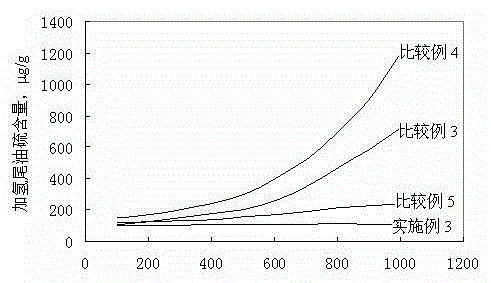

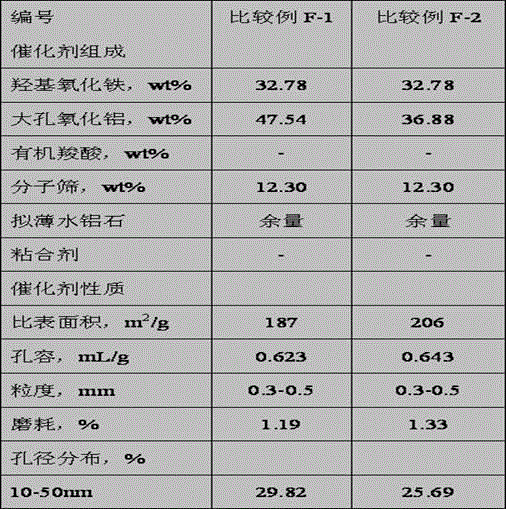

Method for hydrogenation of coal tar via fluidized bed

ActiveCN104593060AConsistent activityEasy to removeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a method for hydrogenation of coal tar via a fluidized bed. The method comprises the following steps: subjecting a coal tar raw material to hydro-upgrading; carrying out separation to remove water; and then carrying out hydrorefining and fractionation so as to obtain a gasoline fraction, a diesel fraction and hydrogenation tail oil. A hydro-upgrading catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite; and a hydrofining catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina and a binder. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, the hydro-upgrading catalyst and the hydro-refining catalyst are graded, so cost is low. According to the invention, moderate cracking of coal tar is carried out before refining of coal tar, so impurities in coal tar are effectively removed, product distribution and product quality are adjusted, and the running period of a device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

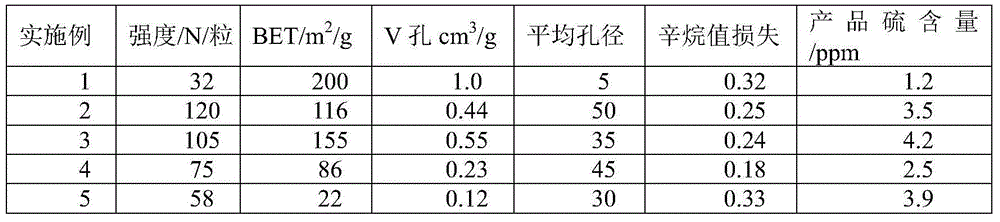

Fuel oil deep-adsorption desulfurizationn catalyst, preparation method and application thereof

ActiveCN104056632ALarge specific surface areaReduce hydrogen consumptionOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSorbent

The invention discloses a fuel oil deep-adsorption desulfurizationn catalyst. The desulfurizationn catalyst is characterized by consisting of an active component, a sulfur adsorbent and an adhesion agent, wherein the active component refers to one or more of Ni, Co, Cu, W and Mo oxides; the sulfur adsorbent refers to at least one of Mg, Ca, Zn, Ce, Fe, Mn and Ti oxides; the mass percent content of the active component is 2wt%-50wt%, the mass percent content of the sulfur adsorbent is 20wt%-90wt%, and the mass percent content of the rest components is the adhesion agent. The adhesion agent is one or a mixture of more than one of aluminium oxide, pseudo-boehmite, kaolin, imvite, bentonite, Yunmeng soil, kieselguhr, silica sol, silica gel and expanded perlite. The catalyst has the advantages of high specific surface area, moderate reaction, high intensity and low hydrogen consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

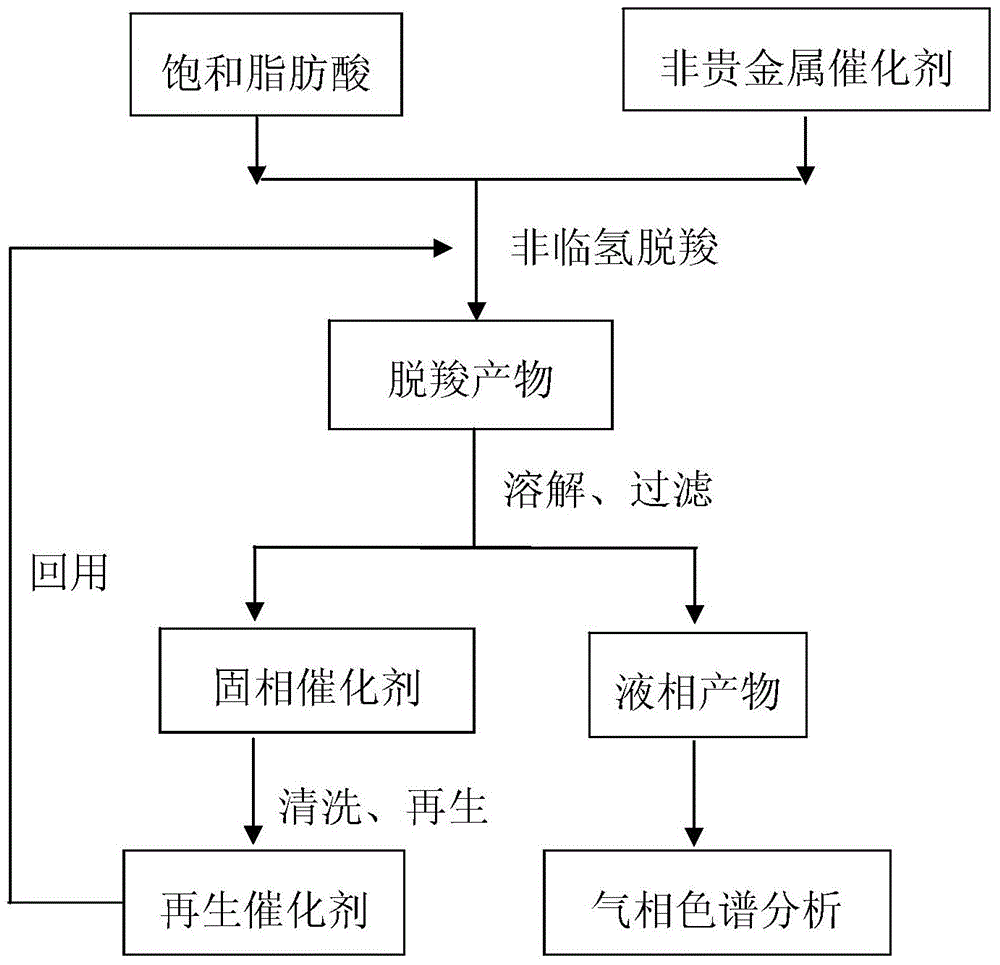

Method for using non-noble metal catalyst to catalyze decarboxylation of saturated fatty acid to prepare long-chain alkane

InactiveCN104403683AEasy to separateIncrease the rate of the decarboxylation reactionFatty acid chemical modificationMolecular sieve catalystsLiquid productAlkane

The invention discloses a method for using non-noble metal catalyst to catalyze decarboxylation of saturated fatty acid to prepare long-chain alkane. The method includes: 1) adding saturated fatty acid and a non-noble metal catalyst into a high-temperature and high-pressure reaction kettle; 2) conducting heating to 300-390DEG C to carry out decarboxylation for 0.5-8h; 3) cooling the decarboxylation product, conducting dissolving by an organic solvent, and performing filtering to obtain a liquid product and a solid catalyst; and 4) cleaning and regenerating the non-noble metal catalyst for reuse. The non-noble metal catalyst is prepared by a co-precipitation method or impregnation method, and the catalyst is regenerated through reductive calcination in hydrogen. The reaction process involved in the invention has the characteristics of no need for a solvent, low energy consumption, and zero emission. The non-noble metal catalyst can effectively catalyze decarboxylation, the catalyst is low in cost and is easy to recover, and the process is simple and green.

Owner:ZHEJIANG UNIV +1

Processing method of medium-low temperature coal tar

ActiveCN102465033AImprove economyOperation cycle solutionOrganic chemistryOrganic compound preparationSlagFuel oil

The invention discloses a processing method of medium-low temperature coal tar. According to the method, whole fraction of the medium-low temperature coal tar which has been undergone dehydration and slag removal is firstly distilled to obtain a light fraction and a heavy fraction. The heavy fraction is used as modified asphalt or heavy fuel oil and the like. A phenolic compound is separated from the light fraction by an acid-base extraction method so as to obtain a crude phenol product. Hydrogenation saturation of alkene from dephenolized raw oil is carried out by a hydro-pretreating method. The prehydrogenation raw oil contacts with a main hydrofining catalyst for desulphurization, nitrogen removal, aromatic saturation and other reactions. In comparison with the prior art, by the adoption of the method provided by the invention, components which influence long-term operation of a hydrogenation device can be fundamentally removed; the operation period of the device can be obviously prolonged; the crude phenol product can be obtained; and the utilization rate of raw materials and the whole economy of a processing device can be raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

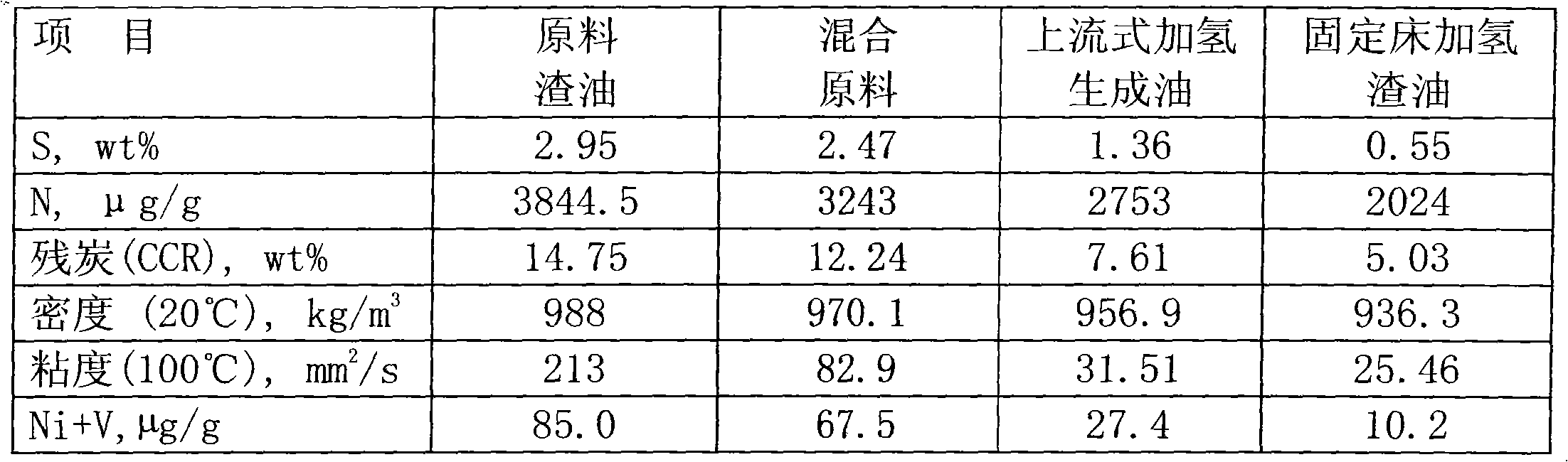

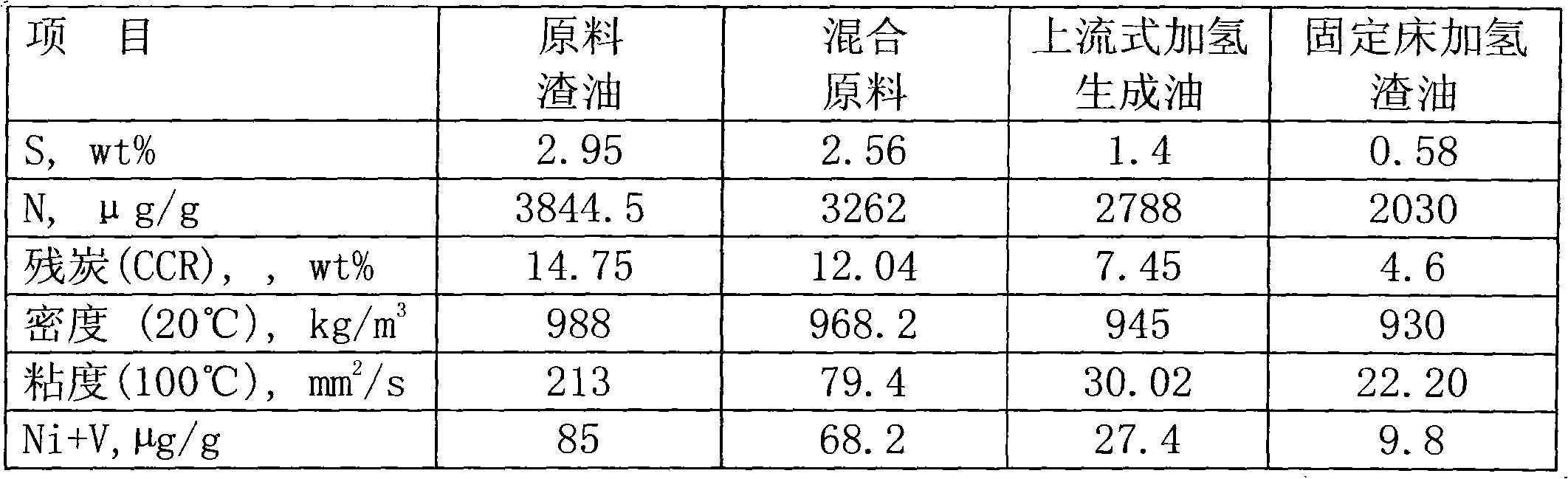

Method for hydrotreating heavy hydrocarbon

InactiveCN101942332AExtended service lifeImprove operational stabilityTreatment with hydrotreatment processesHydrogenation reactionReaction zone

The invention discloses a method for hydrotreating heavy hydrocarbon. A hydrotreatment process comprises a pre-hydrogenation reaction zone, an up-flow hydrogenation reaction zone and a fixed bed-trickle bed reaction zone. The method comprise the following steps that: catalytic cracking slurry oil and / or catalytic cracking heavy cycle oil pass / passes through the pre-hydrogenation reaction zone; the pre-hydrogenation reaction zone adopts a fixed bed-trickle bed operation mode; both the reaction effluent of the pre-hydrogenation reaction zone and a residual oil raw material are jointly introduced into the up-flow hydrogenation reaction zone and the fixed bed-trickle bed reaction zone in turn; and the final reaction effluent is separated. The method of directly taking the catalytic cracking residual oil, the catalytic cracking heavy cycle oil and the like as fluxing oil of the residual oil raw material is changed, and the catalytic cracking residual oil and the catalytic cracking heavy cycle oil are pretreated to retard the coking of a catalyst and effectively prevent the generation of a bed layer hot point, so that stable operation of an up-flow reactor is guaranteed, the service life of the catalyst is prolonged, simultaneously the product quality is improved.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

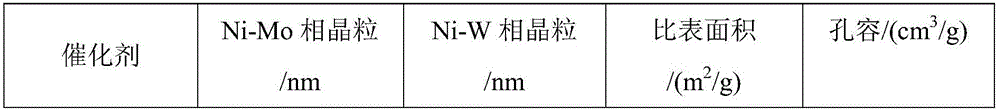

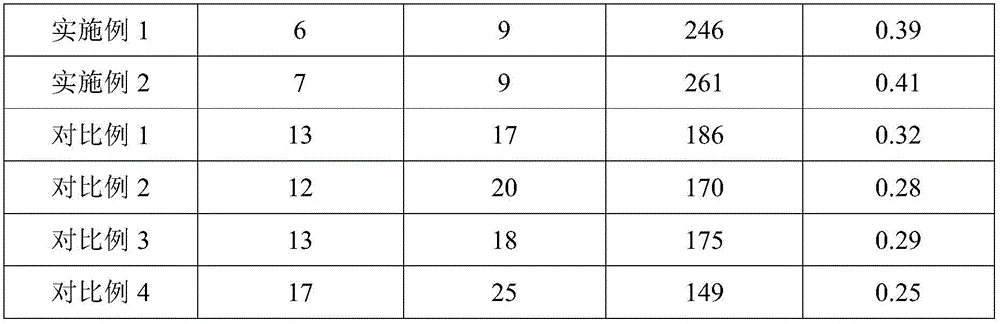

Preparation method of bulk-phase hydrofining catalyst

ActiveCN106513006AExcellent hydrodesulfurization performanceReduce utilizationHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive phaseSulfur containing

The invention relates to a preparation method of a bulk-phase hydrofining catalyst. The method comprises steps as follows: an Ni-containing compound and deionized water are mixed and pre-dispersed in an ultrasonic environment, a Mo-containing compound is added, an Ni-Mo fine grain structure is formed by adjusting the ultrasonic frequency and in combination with a surfactant and ammonia water, a W-containing compound and a complexing agent are added for a hydrothermal reaction, spray drying and roasting are performed, and active component powder is obtained; an active component and aluminum hydroxide dry glue are mixed, kneaded and extruded, and the catalyst is obtained through drying and roasting. According to the catalyst prepared with the method, grains of active phases are fine, grains of different active phases are uniformly dispersed, the utilization rate of active metal is high, the catalyst has an excellent pore structure property, the removal efficiency of complicated sulfur-containing compounds in inferior diesel oil is improved, hydrogen consumption is reduced, and the use cost of the catalyst is reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Method for producing super-low sulfur gas oil blending component or super-low sulfur gas oil composition, and super-low sulfur gas oil composition

InactiveUS7938955B2Reduce sulfur contentLow aromatic contentRefining with metalsLiquid carbonaceous fuelsAdverse effectFuel injection

Provided are a method for producing a super-low sulfur gas oil blending component or a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm, under relatively mild conditions, without greatly increasing the hydrogen consumption and without remarkably decreasing the aromatic content; and a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm which exhibits a high heating value, is excellent in fuel economy and output power, and is free from an adverse effect on a sealing rubber member or the like used in the fuel injection system and thus does not cause the leakage of a fuel. A method for producing a super-low sulfur gas oil blending component or a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm is also disclosed.

Owner:JAPAN ENERGY CORP

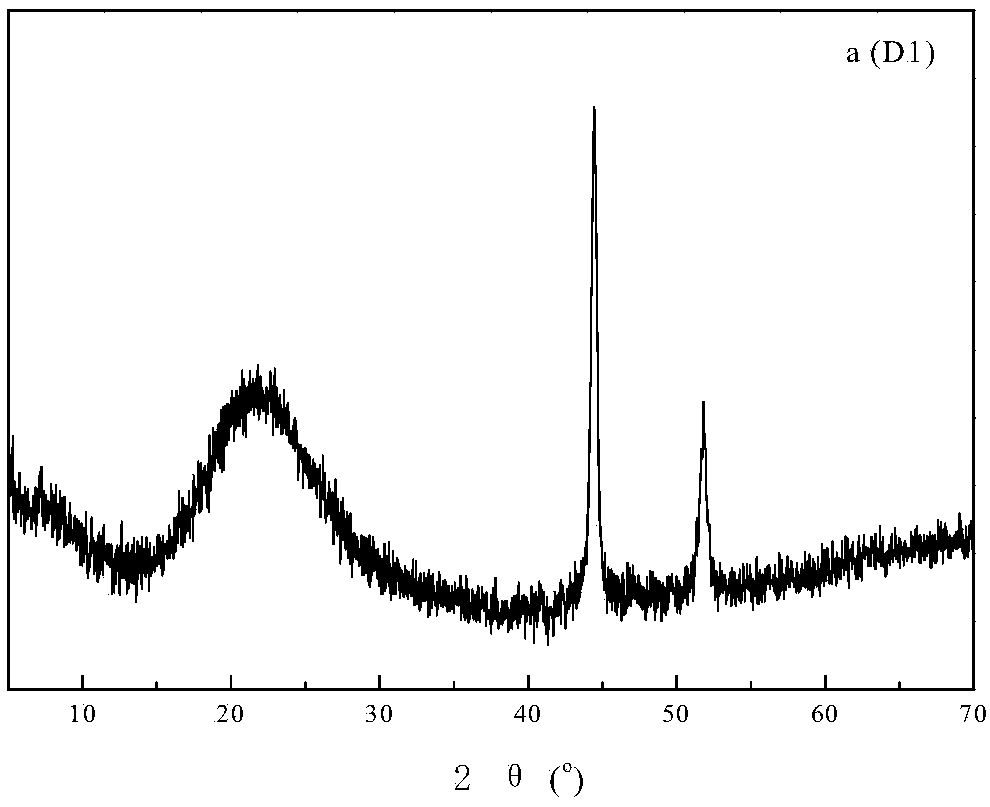

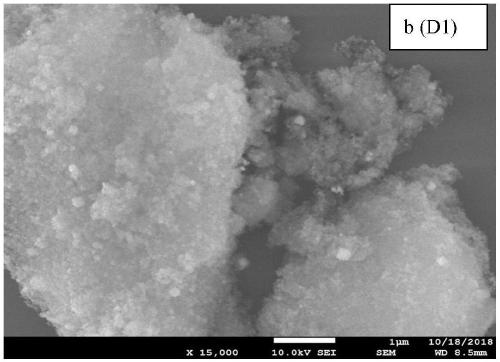

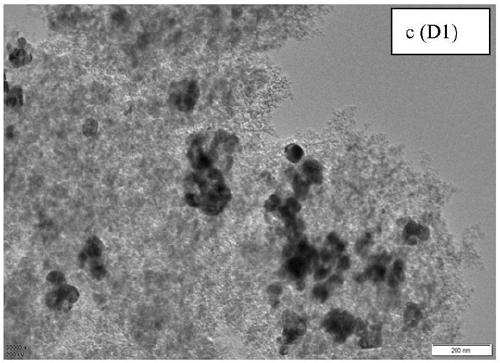

Pure silicon S-1 molecular sieve catalyst for packaging metal nanoparticles and preparing method and application of catalyst

ActiveCN109647493AEvenly distributedUniform particle sizeMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMetal catalyst

The invention relates to a pure silicon S-1 molecular sieve catalyst for packaging metal nanoparticles and a preparing method and application of the catalyst. By means of the catalyst, a metal precursor is added in the pure silicon S-1 molecular sieve in-situ synthesis process, and the metal nanoparticles are packaged by a pure silicon S-1 molecular sieve through a one-step method. The packaging catalyst is neat in morphology, and the metal nanoparticles are uniform in distribution and particle size and have the size of 1-10 nm. The metal content in the pure silicon S-1 molecular sieve for packaging the metal nanoparticles is 0.1-20 wt%. The packaging catalyst is applied in the phenol catalysis reaction; compared with a metal catalyst synthesized through a traditional wet impregnation method, the phenol conversion rate, the phenol selectivity and the catalysis stability are remarkably improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for operating a gas turbine engine, power supplying device for conducting such method and aircraft using such method

ActiveUS9464573B2Reduce hydrogen consumptionSmall sizeContinuous combustion chamberTurbine/propulsion engine ignitionAviationCombustion chamber

A power supply device or system for aeronautics, having a hydrocarbon supply for supplying an engine with hydrocarbon fuel and a hydrogen supply having a fuel reformer for producing hydrogen from hydrocarbon fuel from said hydrocarbon supply. The hydrogen supply is connected to a hydrogen-powered fuel cell for producing electric power and to a hydrogen injecting system for injection of hydrogen into a combustion chamber of the engine. Further, the invention relates to an aircraft having an engine that can be supplied by that power supplying device or system, and to a method for operating said engine.

Owner:AIRBUS SAS

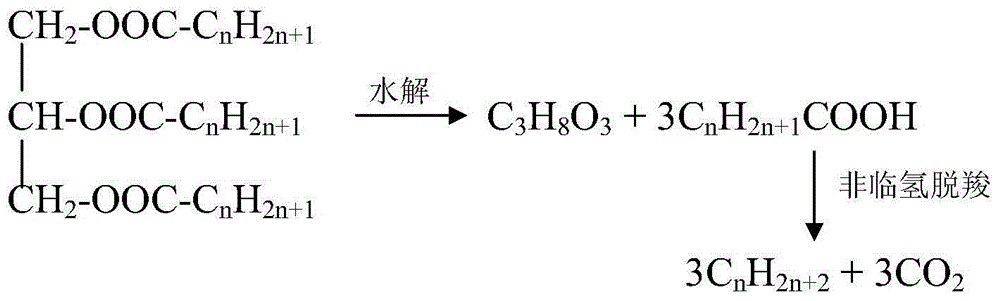

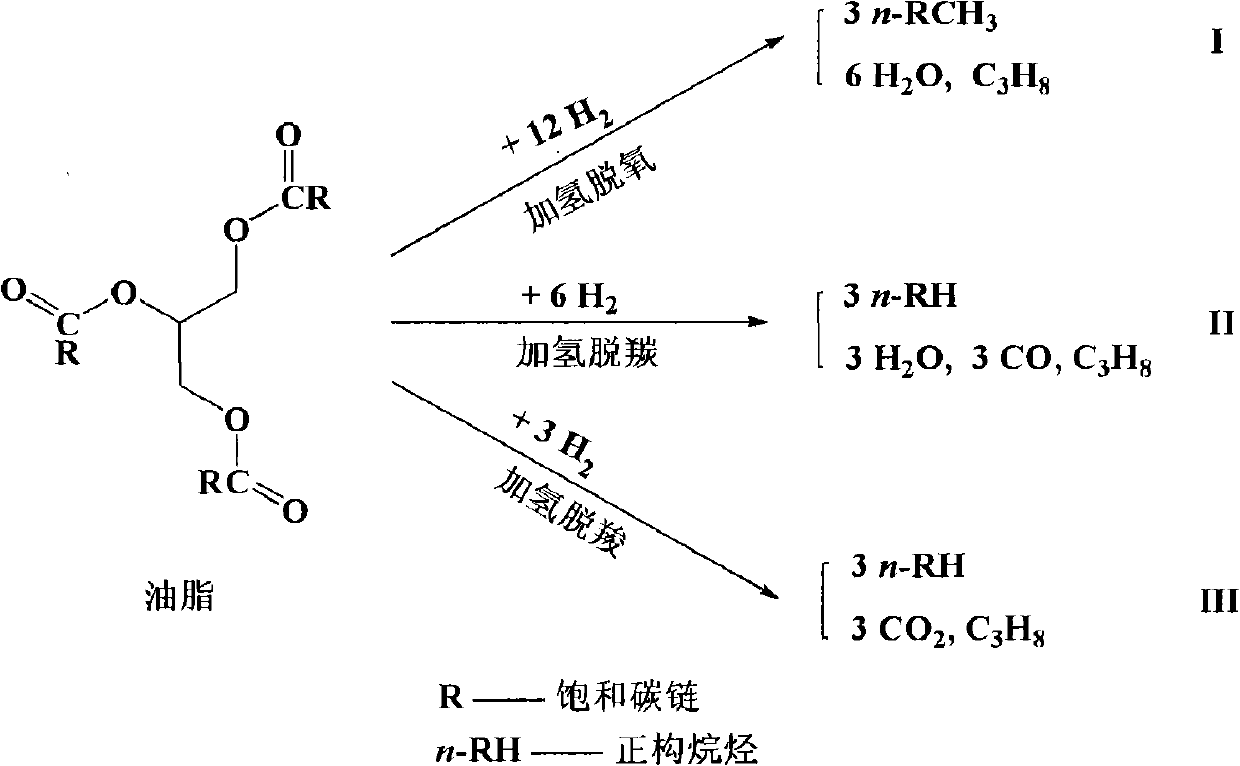

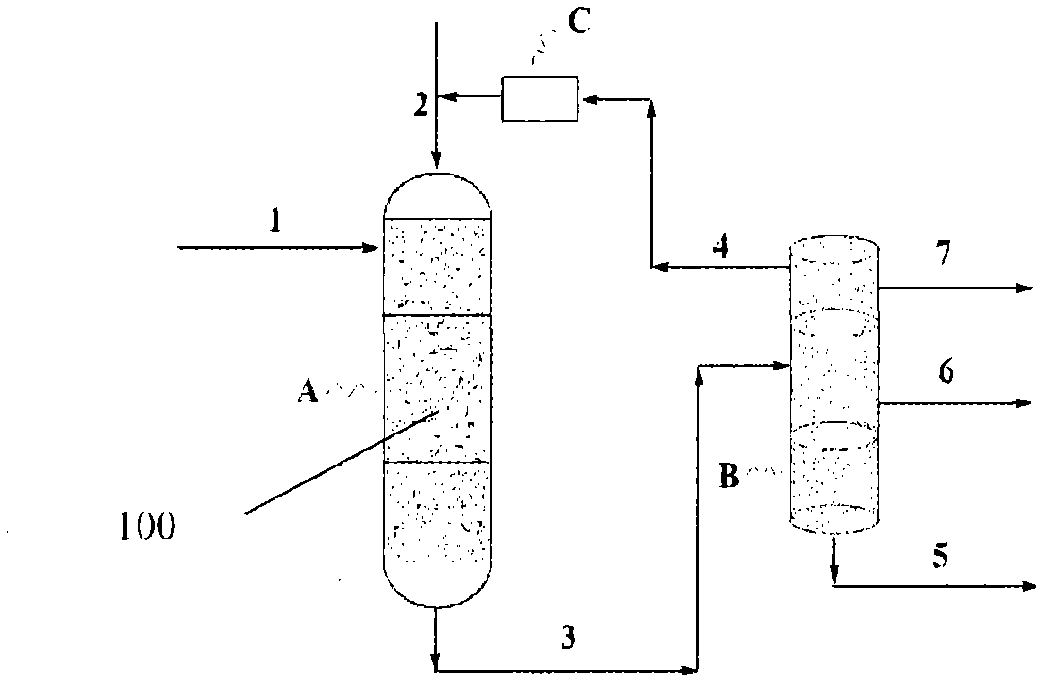

Conversion process of grease

ActiveCN103289824AReduce hydrogen consumptionHigh selectivityFatty acid hydrogenationMolecular sieve catalystsChemistryAlkane

The invention relates to a process of preparing hydrocarbon compounds. According to the process, grease is used as a raw material, the raw material contacts with hydrogen on a catalyst, and a hydrocarbon compound is generated through one-step catalytic reaction. The catalyst involved in the process is a supported metal / carrier catalyst M1-[Sup], and has catalytic activity for converting the grease into the hydrocarbon compounds through one-step reaction, wherein in the composition of the catalyst, M1 is an active metal component, and [Sup] is an acid carrier component. The process can be used for producing the hydrocarbon compounds which have high cetane values, low freezing points, and main components of C11-C24 isoparaffin by using the grease as the raw material, and the hydrocarbon compounds can be used as diesel oil and / or aviation kerosene. In the process provided by the invention, the yield of converting the grease into C11-C24 alkanes is more than 70wt.%, wherein the selectivity of the isoparaffin is more than 60wt.%.

Owner:PETROCHINA CO LTD +2

Deoxygenation of materials of biological origin

ActiveUS20110087058A1Quality improvementReduce hydrogen consumptionHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsIridiumRhenium

The present invention relates to a method for the deoxygenation of materials of biological origin and particularly to the removal of oxygen from biomass derived organic compounds with carbon monoxide, to yield linear and branched hydrocarbons suitable as biofuels or as blending stocks or components for biofuels, such as gas, gasoline, diesel fuel and aviation fuel, as well as solvents. The method comprises contacting a feedstock with carbon monoxide in the presence of a catalyst comprising a metal selected from a group consisting of ruthenium, manganese, rhodium, rhenium, osmium, iridium, molybdenum, copper, zinc, palladium, platinum and cobalt, in the presence of water, under alkaline conditions at a temperature from 150 to 350° C. and under a pressure from 0.1 to 150 bar, to produce hydrocarbons.

Owner:NESTE OIL OY

Hydrocracking method

ActiveCN104611040AReduce overhydrogenationReduce hydrogen consumptionTreatment with hydrotreatment processesProcess engineeringNaphtha

The present invention discloses a hydrocracking method. According to the method, heavy distillate oil and hydrogen gas are mixed and then enter a hydrorefining reactor to carry out a hydrorefining reaction; the hydrorefining reaction effluent directly enters a hydrocracking reactor and is subjected to a contact reaction with grading catalyst bed layers in the hydrocracking reactor, wherein at least two cracking catalyst bed layers are arranged inside the hydrocracking reactor, and the hydrogenation activity of the hydrocracking catalyst presents the decrease tendency according to the reaction material flowing direction; and the hydrocracking reaction effluent is subjected to separation and fractionation to obtain the hydrocracking products including heavy naphtha and tail oil. With the method of the present invention, the heavy component hydrocracking effect can be ensured while the excessive hydrogenation and the excessive cracking of the heavy naphtha are reduced, and the chemical hydrogen consumption is reduced, such that the aromatic potential and the selectivity of the heavy naphtha are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas Turbine Engine and Method for Reducing Turbine Engine Combustor Gaseous Emission

ActiveUS20090301096A1Emission reductionReduce hydrogen consumptionAnalogue computers for vehiclesFuel supply regulationAviationCombustor

The invention relates to turbine engines used in aeronautics, but also for industrial and marine turbine engines. To reduce turbine engine combustor gaseous emissions at given combustor sizes or to reduce combustor sizes at given combustor gaseous emissions, the invention proposes the injection of hydrogen into the combustor in response to a power output level. According to a preferred embodiment, gaseous hydrogen is always injected at low-power operations and switched off at mid-power and high-power operations.

Owner:AIRBUS SAS

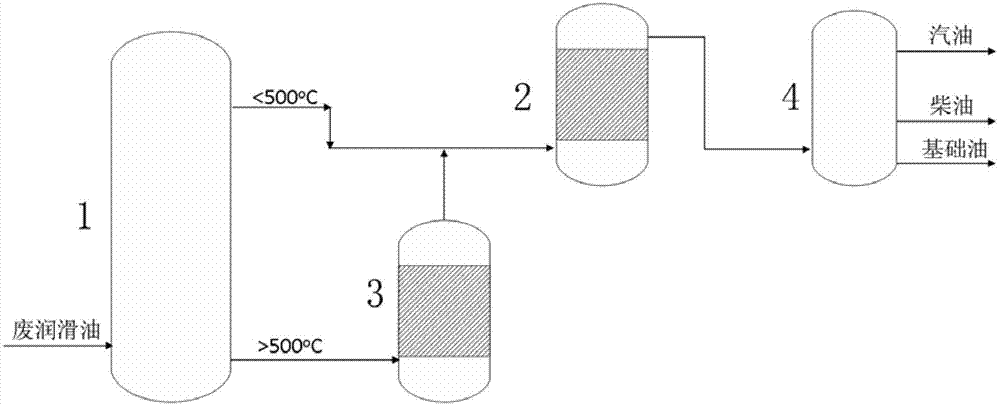

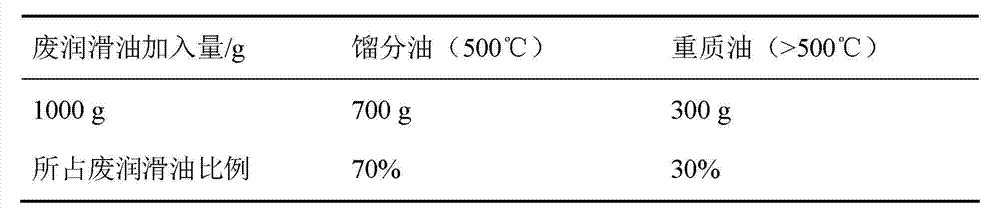

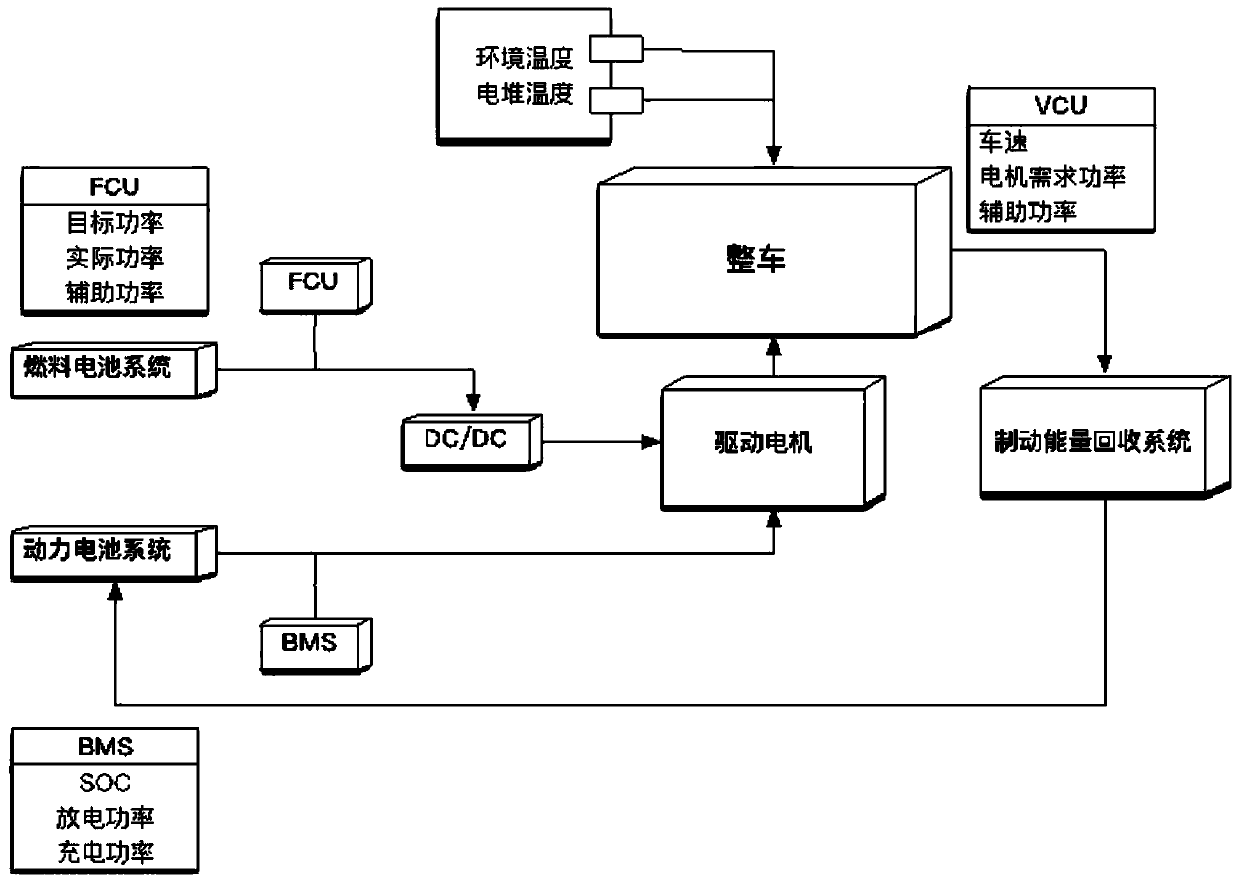

Resource utilization method for waste lubricating oil

ActiveCN102786985AFlexible operationSimple and fast operationTreatment with hydrotreatment processesLubricant compositionResource utilizationEngineering

The invention discloses a resource utilization method for waste lubricating oil and belongs to the fields of environmental protection and energy technology. The method is characterized in that the waste lubricating oil is used as the raw material, is distilled and then is hydrofined to produce high-quality gasoline, diesel and base oil, and comprises the steps that the waste lubricating oil is firstly distilled to obtain a fraction with the temperature lower than 500 DEG C and a fraction with the temperature higher than 500 DEG C, then the fraction with the temperature lower than 500 DEG C is reacted in a manner of hydrofining on a sulfide catalyst, a monoene compound is removed by monoolefine hydrostturation reaction, desulfuration, denitrification, deoxygenation and colloid removal are carried out to produce odorless high-quality mixed oil of the gasoline, the diesel and the base oil, and then the mixed oil is distilled to obtain distillate oil of the gasoline, the diesel and the base oil. The distilled fraction with the temperature higher than 500 DEG C is hydrofined after being reactively distilled. The method disclosed by the invention has the advantages of simple process, high catalyst activity and selectivity, and good economic benefits and industrial application prospects.

Owner:河北镕达环保科技有限公司

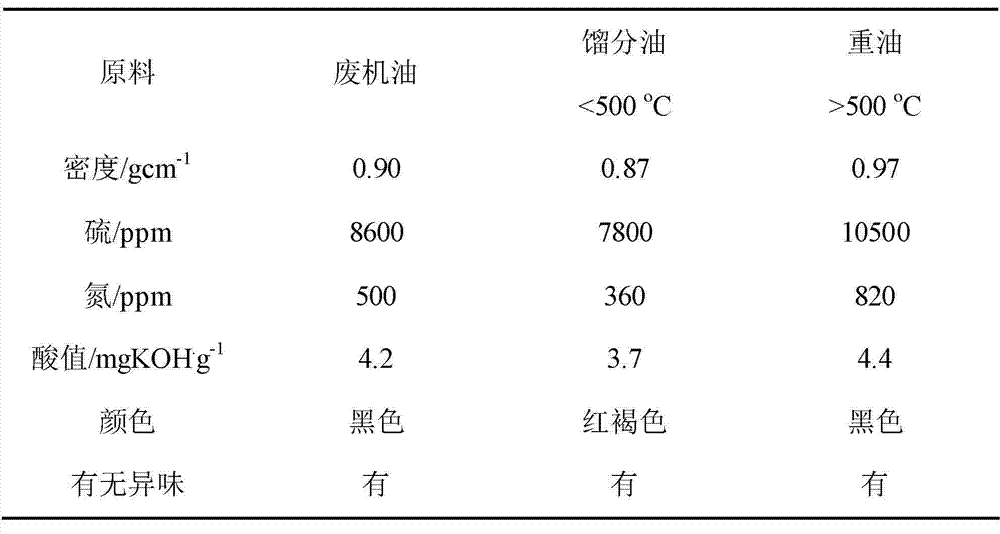

Method for producing cyclohexanone by using coked benzene

ActiveCN101628862AHave resourcesHas costOrganic compound preparationCarbonyl compound preparationCyclohexanoneHydration reaction

The method for producing cyclohexanone by using coked benzene is implemented according to the following steps: A. hydrogenation of the coked benzene to prepare cyclohexene; B. extraction and rectification; C. hydratization of the cyclohexene to prepare cyclohexanol; D. separation and extraction of the cyclohexanol; E. dehydrogenation of the cyclohexanol to prepare the cyclohexanone; and F. refining of alcohol and ketone. The method has the advantages that 1. as the coked benzene, the product of the coal chemical industry, is used as the raw material, the method has resource advantage and cost advantage and saves 15-20 percent of resource and cost when compared with a cyclohexane method; 2. the method has high comprehensive yield rate and low hydrogen consumption, almost 99 percent of the coked benzene is converted into usable products, namely the cyclohexanone and the cyclohexane, the ratio between the cyclohexanone and the cyclohexane is 1:0.25, and the hydrogen consumption is reduced by two thirds; 3. the method is environment friendly; a small amount of waste gas and waste liquid is generated, and the investment in waste disposal is small, therefore the method is a clean production technology; and 4. the method is safer; the hydrogenation reaction and the hydratization reaction are both carried out in liquid, conditions are mild, and the method is safer when compared with a traditional oxidation technology, prevents the corrosion and the byproduct blockage and has high operation stability.

Owner:HEBEI SHIJIAO CHEM

Loading method of hydroprocessing catalyst

ActiveCN1609172AIncreased average macroporosityIncrease the porosityRefining to eliminate hetero atomsNitrogenEngineering

The present invention is loading method of hydroprocessing catalyst. Unlike conventional grading loading scheme, The hydrogenating and denitrogenating reaction region is loaded with the catalyst in antitone grading mold, in which the activity of the hydrogenating and denitrogenating catalyst in the downstream bed side is slightly lower than that in the upstream bed side, and the pore size of the catalyst in the downstream bed side is slightly greater than that in the upstream bed side. The said loading method can control the temperature raise of hydrogenating and denitrogenating catalyst bed, reduce cold hydrogen amount to lower the hydrogen consumption of the apparatus, reduce the carbon deposit speed in the catalyst bed to reduce bed pressure drop of bed, and prolong the service life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

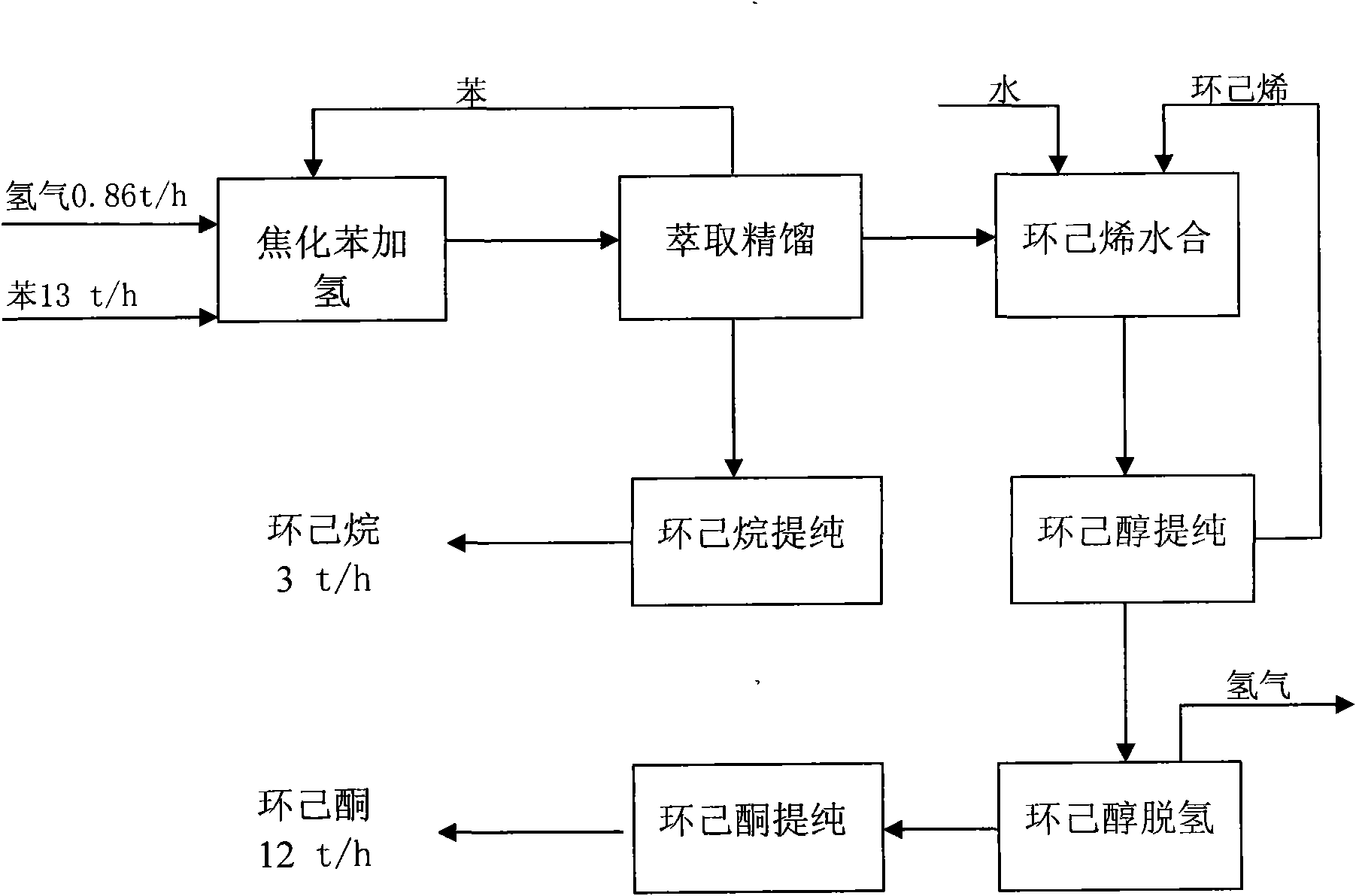

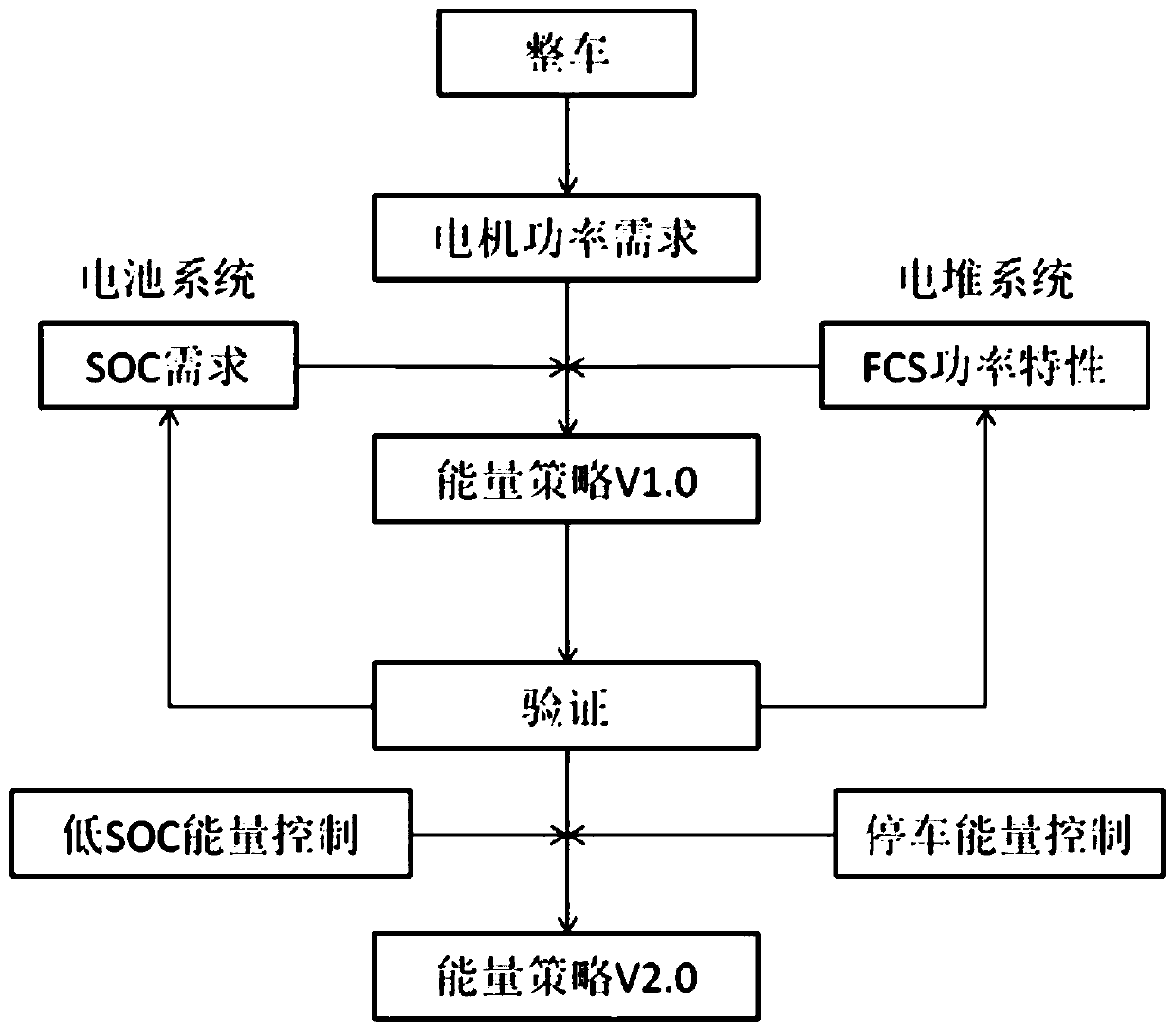

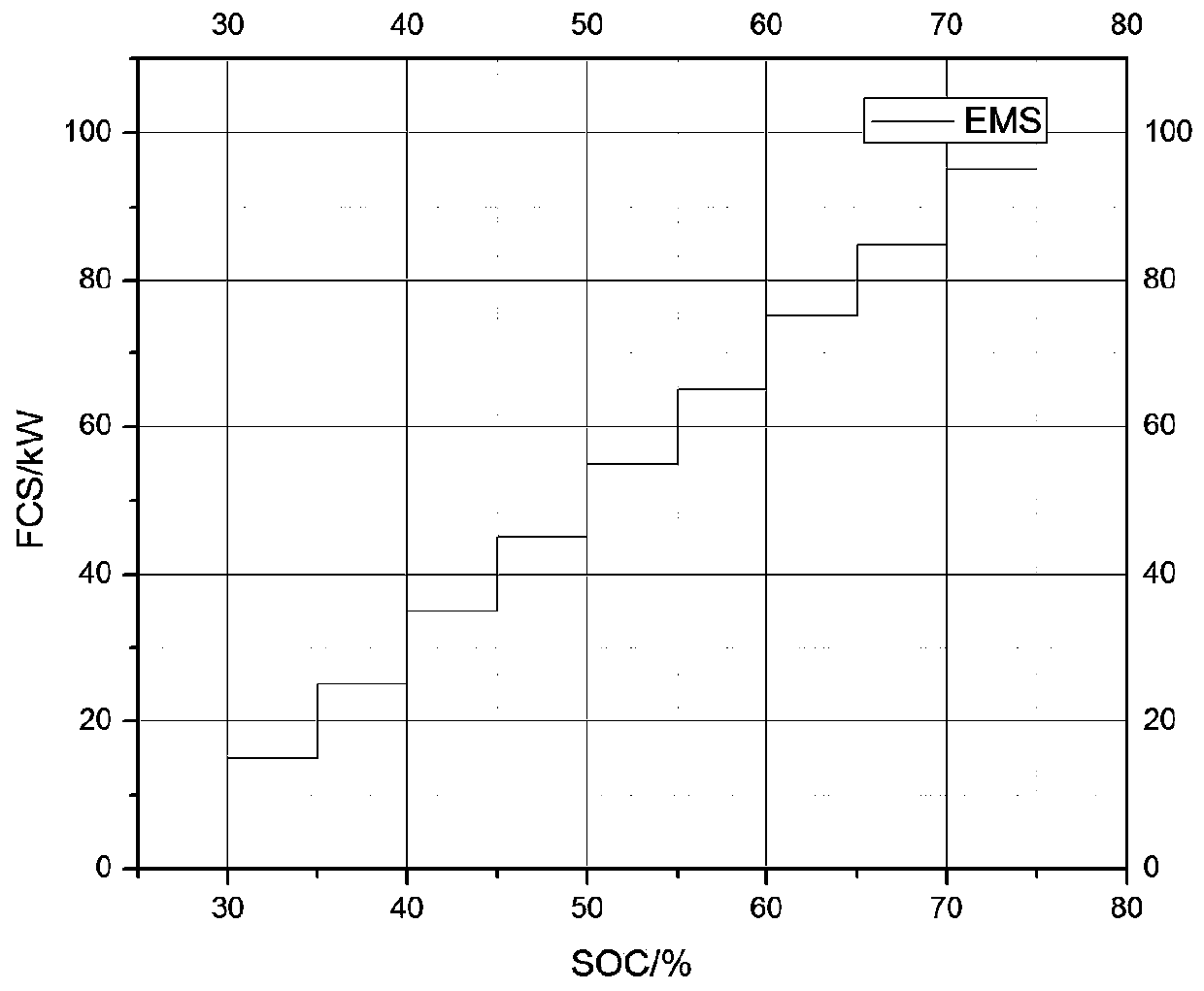

Energy control method of hydrogen fuel cell and power cell hybrid power bus

ActiveCN111055728AGuaranteed lifeExtend your lifeElectric devicesOperating modesPower batteryElectrical battery

The invention discloses an energy control method of a hydrogen fuel cell and power cell hybrid power bus. The method comprises the following steps of: collecting motor power data, selecting SOC valueswithin a certain range around the average power value of the motor, and conducting interpolation distribution on the power range of a galvanic pile, increasing vehicle parking judgment, locking the variable-load frequency standard of the galvanic pile, and evaluating whether the variable-load frequency standard meets requirements or not, judging the SOH condition of the battery, and increasing the low SOC to forcibly start the reactor. Based on the galvanic pile system controller, the BMS and the whole vehicle controller system, energy control strategy assignment and optimization can be completed through real-time data. And the VCU is used for judging the power state of the whole vehicle, so that the low-power power supply and low-SOC forced starting operation of the parking galvanic pileare increased, and the healthy working states of the galvanic pile and the battery are further ensured. Therefore, the galvanic pile outputs as low as possible on the basis of meeting the power requirement of the whole vehicle as much as possible, and hydrogen consumption is reduced while the service life of the galvanic pile is ensured. And meanwhile, the battery can work in a relatively high and stable SOC interval, and the service life of the battery is prolonged.

Owner:HIGER

Method for producing micro crystal wax

InactiveCN1458244AHigh activitySolution to short lifePetroleum wax refiningState of artMicrocrystalline wax

The present invention discloses the hydrogenation process of producing white soft micro crystal wax. The said process has hydrodesulfurizing, dentrifying, deoxygenation and arene saturating reaction in optimal conditions to produce high quality white soft micro crystal wax product for food product and cosmetics. Compared with available technology, the said process is simple, long in operation period, and flexible in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

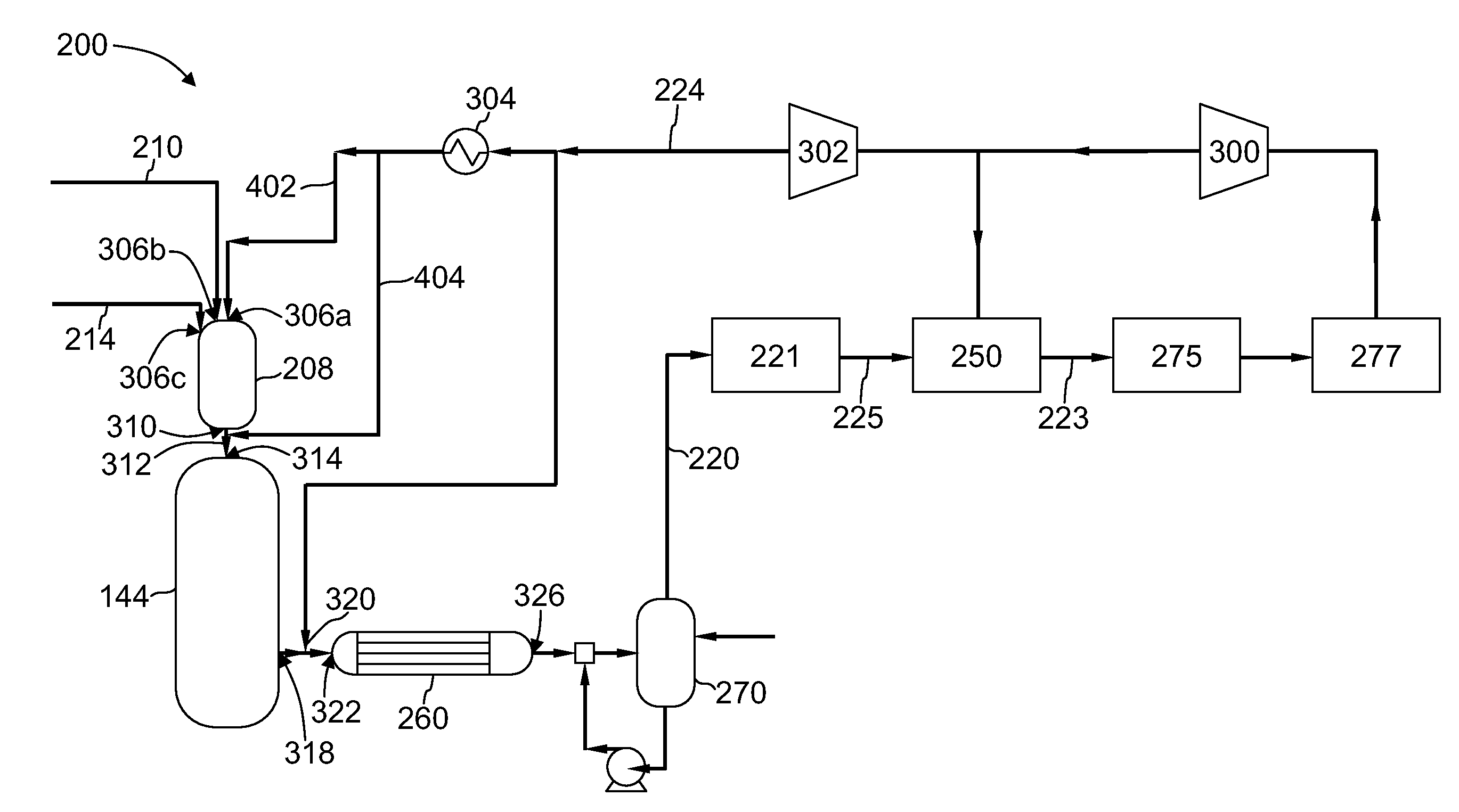

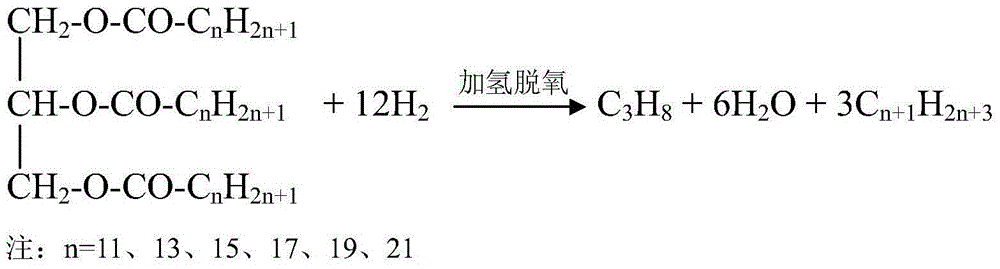

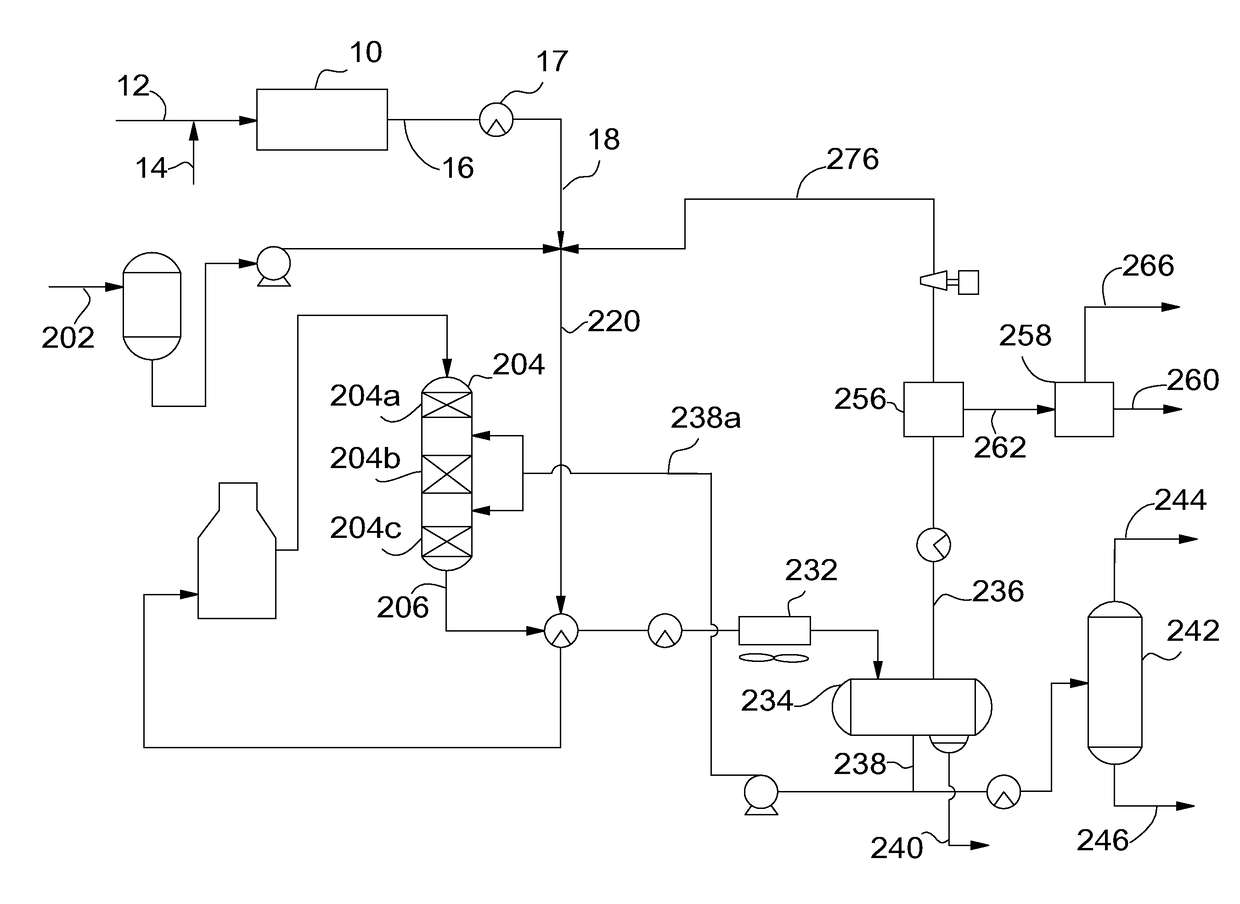

Process for producing diesel fuel and jet fuel from biorenewable feedstocks

InactiveUS20180216010A1Reduce hydrogen consumptionHydrocarbon distillationLiquid hydrocarbon mixture productionHigh pressure hydrogenGlycerol

A process has been developed for producing diesel fuel or jet fuel from renewable feedstocks such as fats and oils from plants and animals. The process involves producing a hydrogen-rich mixture in a reformer, hydrolyzing a renewable feedstock to produce a free fatty acid stream and a glycerol-containing stream, catalytically treating the free fatty acid stream by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel fuel or jet fuel. A selective separation such as a hot high pressure hydrogen stripper may be used to remove at least the carbon oxides from the reaction zone effluent and provide a liquid recycle stream at pressure and temperature. A vapor stream is separated from the effluent and at least carbon dioxide is removed using at least one amine absorber. The resulting hydrogen-rich stream is recycled to the reaction zone.

Owner:HONG JIANHUI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com