Patents

Literature

428results about How to "Long catalyst life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the manufacture of 1, 1, 1, 3, 3-pentachloropropane

InactiveUS6313360B1Improve degradation rateShorten the timeOrganic chemistry methodsHalogenated hydrocarbon separation/purificationChlorideOrganic phosphates

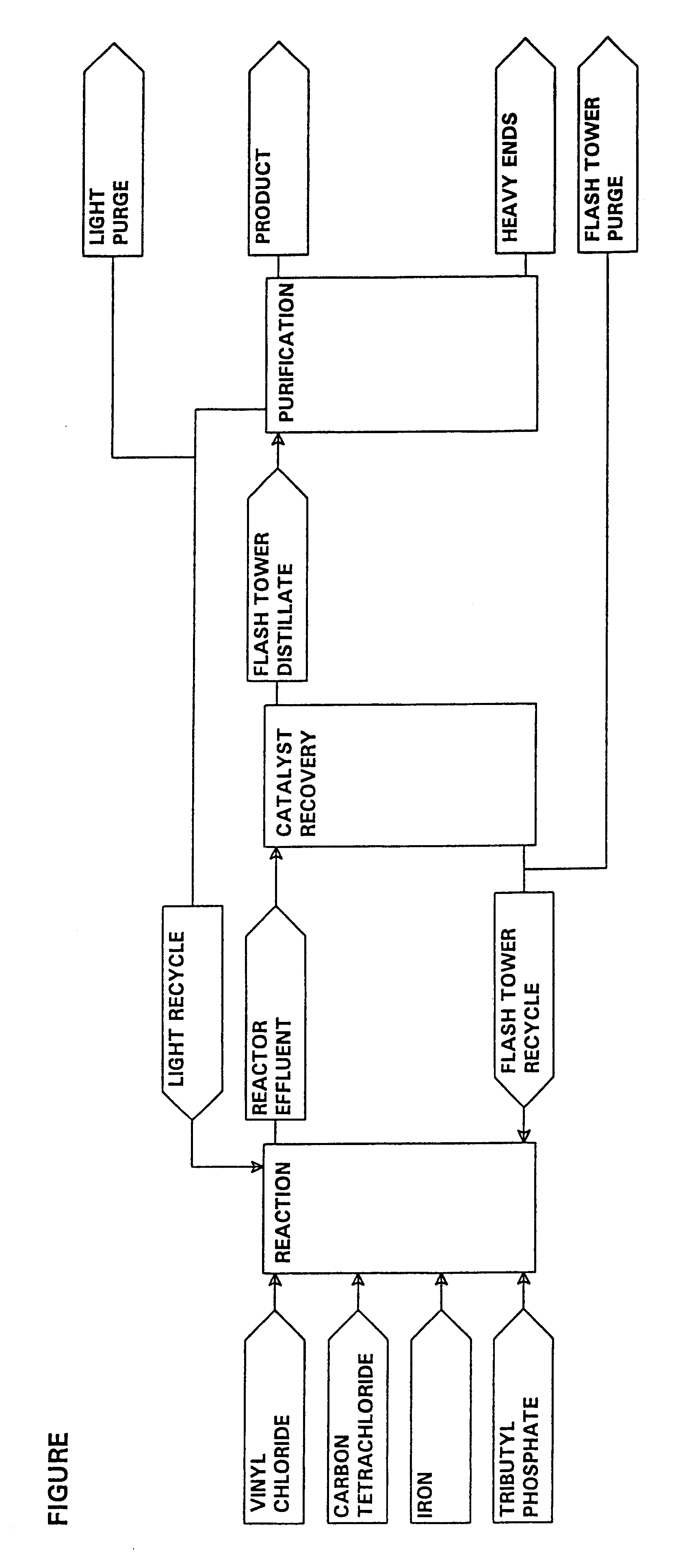

A process is provided for the production of 1,1,1,3,3-pentachloropropane. The process comprises: (a) producing a product mixture in a reactor by reacting carbon tetrachloride and vinyl chloride in the presence of a catalyst mixture comprising organophosphate solvent, iron metal and ferric chloride under conditions sufficient to produce 1,1,1,3,3-pentachloropropane; (b) subjecting the 1,1,1,3,3-pentachloropropane containing product mixture from step (a) to evaporation such that a fraction enriched in 1,1,1,3,3-pentachloropropane is separated from the product mixture and a bottoms fraction results which comprises the iron metal / ferric chloride catalyst components and heavy end by-products; and (c) recycling at least a portion of the bottoms fraction from step (b) to the reactor.

Owner:OCCIDENTAL CHEM CORP

Method for manufacturing cleaner fuels

InactiveUS6248230B1Long catalyst lifeReduce hydrogen consumptionLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesBoiling pointGasoline

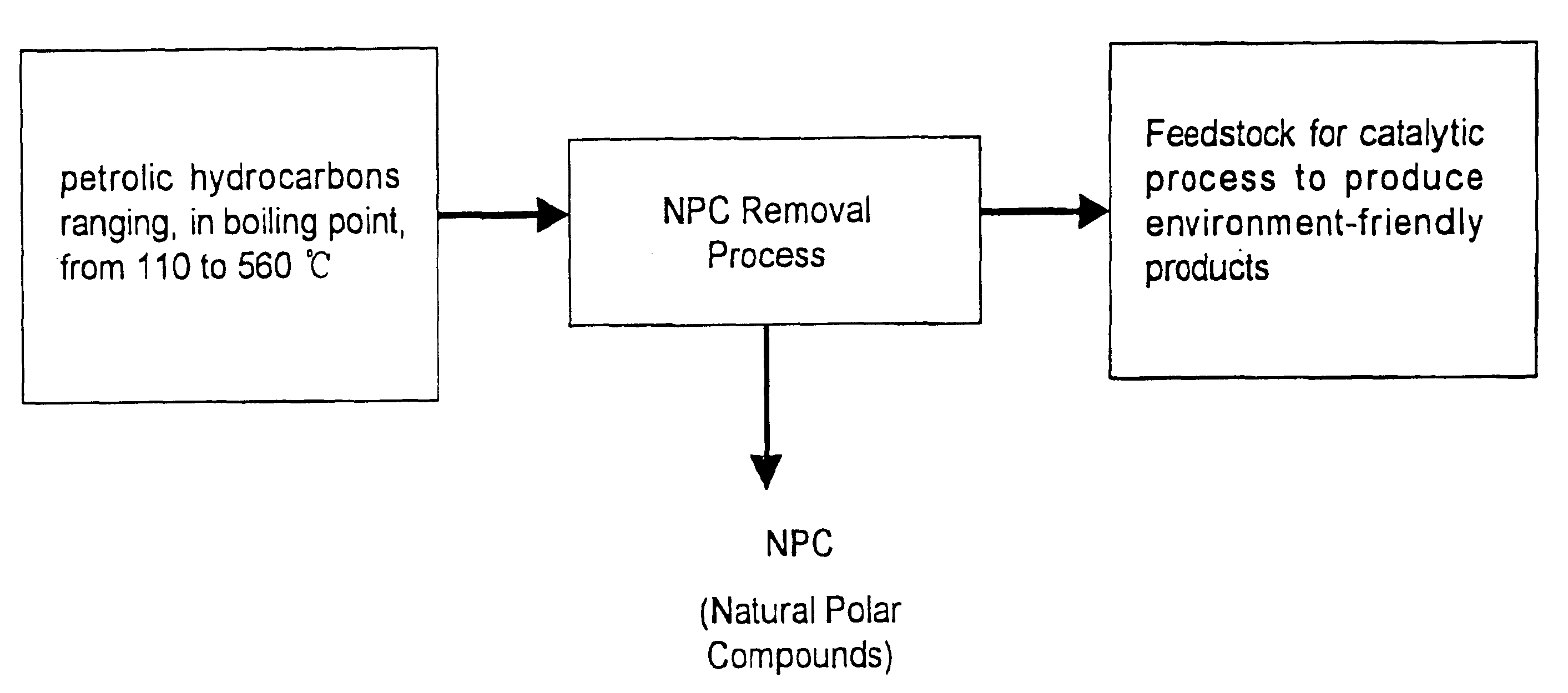

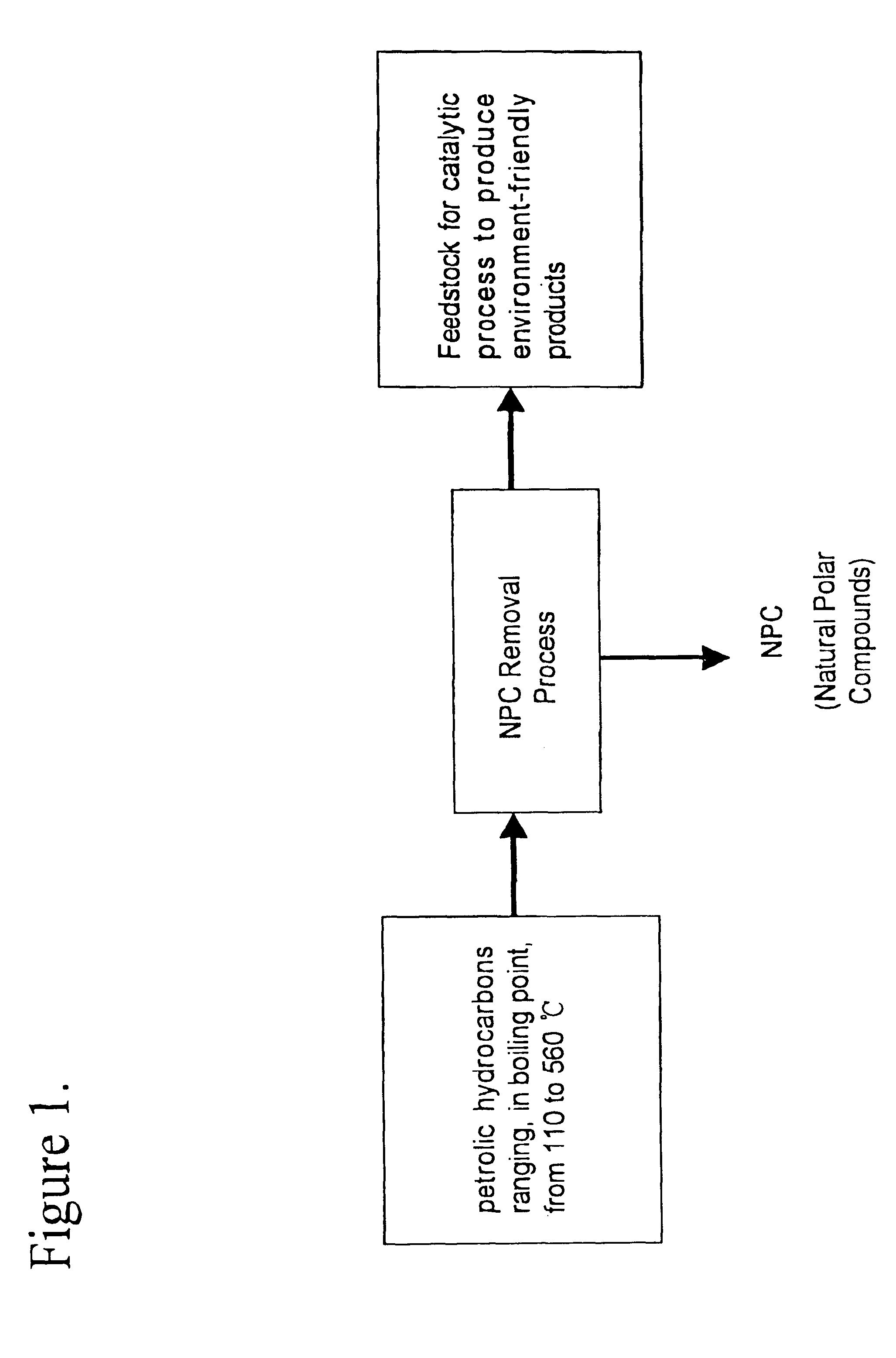

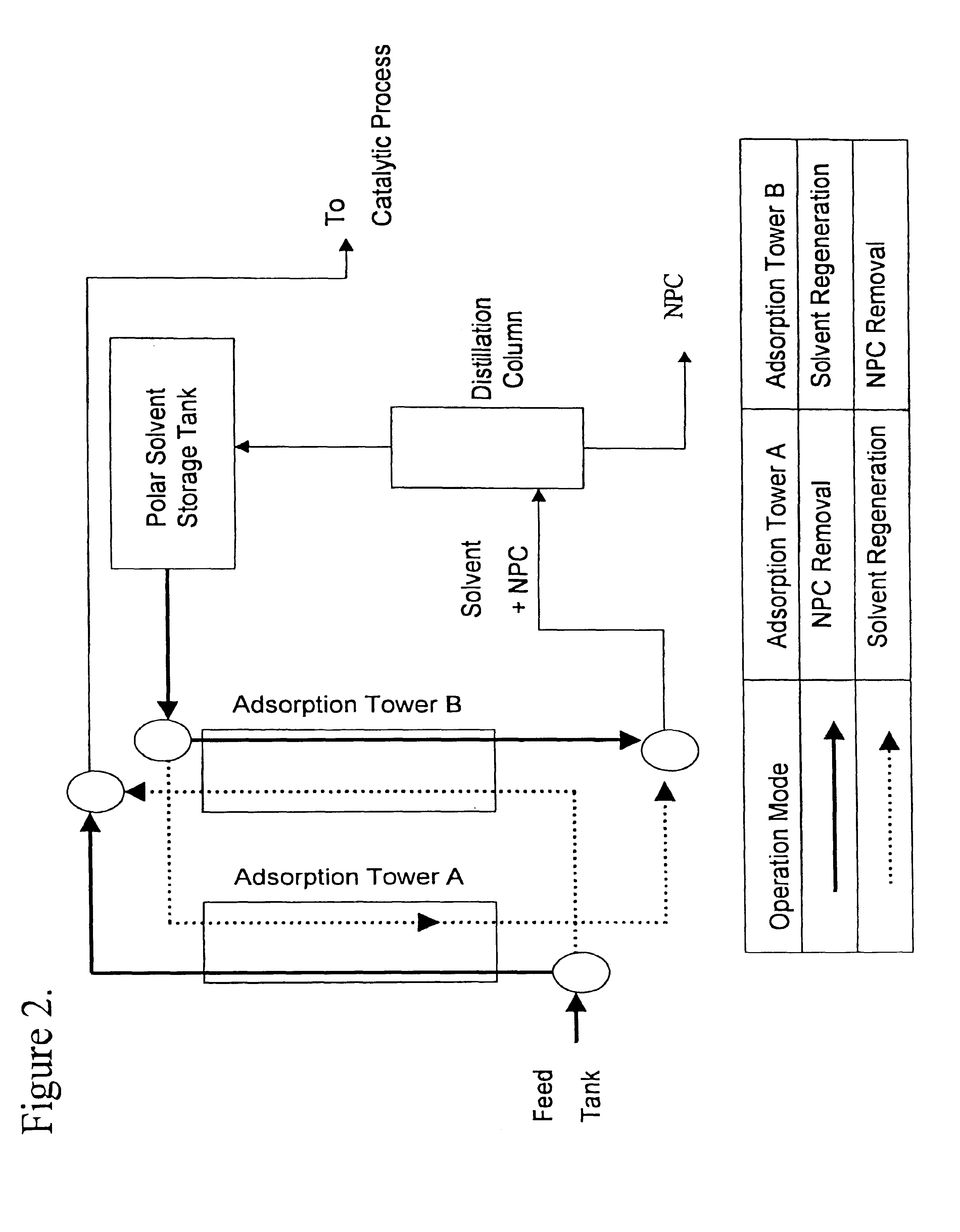

A method is provided for manufacturing cleaner fuels, in which NPC (Natural Polar Compounds), naturally existing in small quantities within various petrolic hydrocarbon fractions, are removed from the petrolic hydrocarbon fractions ranging, in boiling point, from 110 to 560° C. and preferably from 200 to 400° C., in advance of catalytic hydroprocessing. The removal of NPC improves the efficiency of the catalytic process and produces environment-friendly products, such as diesel fuel with a sulfur content of 50 ppm (wt) or lower. Also, the NPC can be used to improve fuel lubricity.

Owner:SK ENERGY CO LTD (KR)

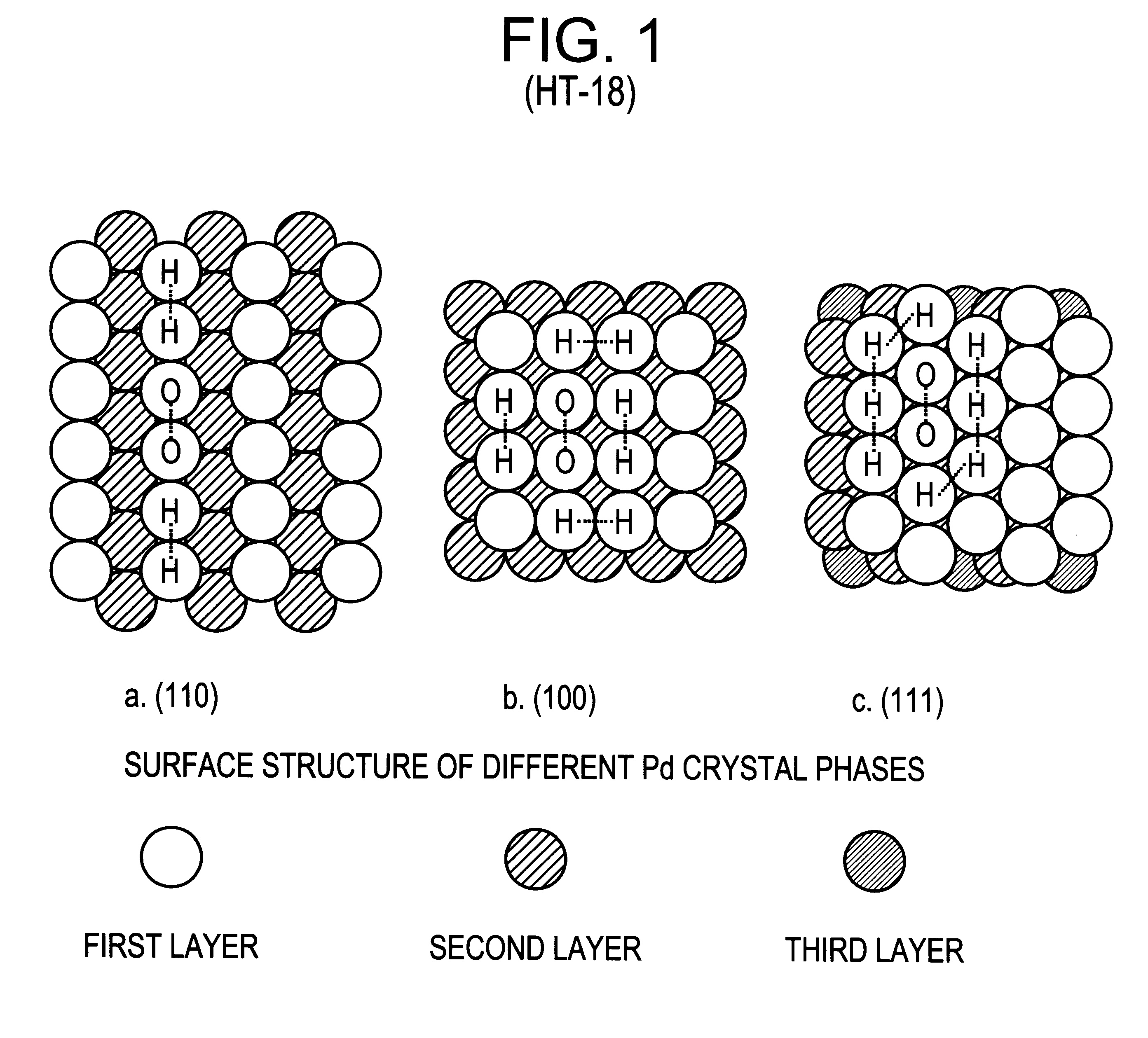

Noble metal support

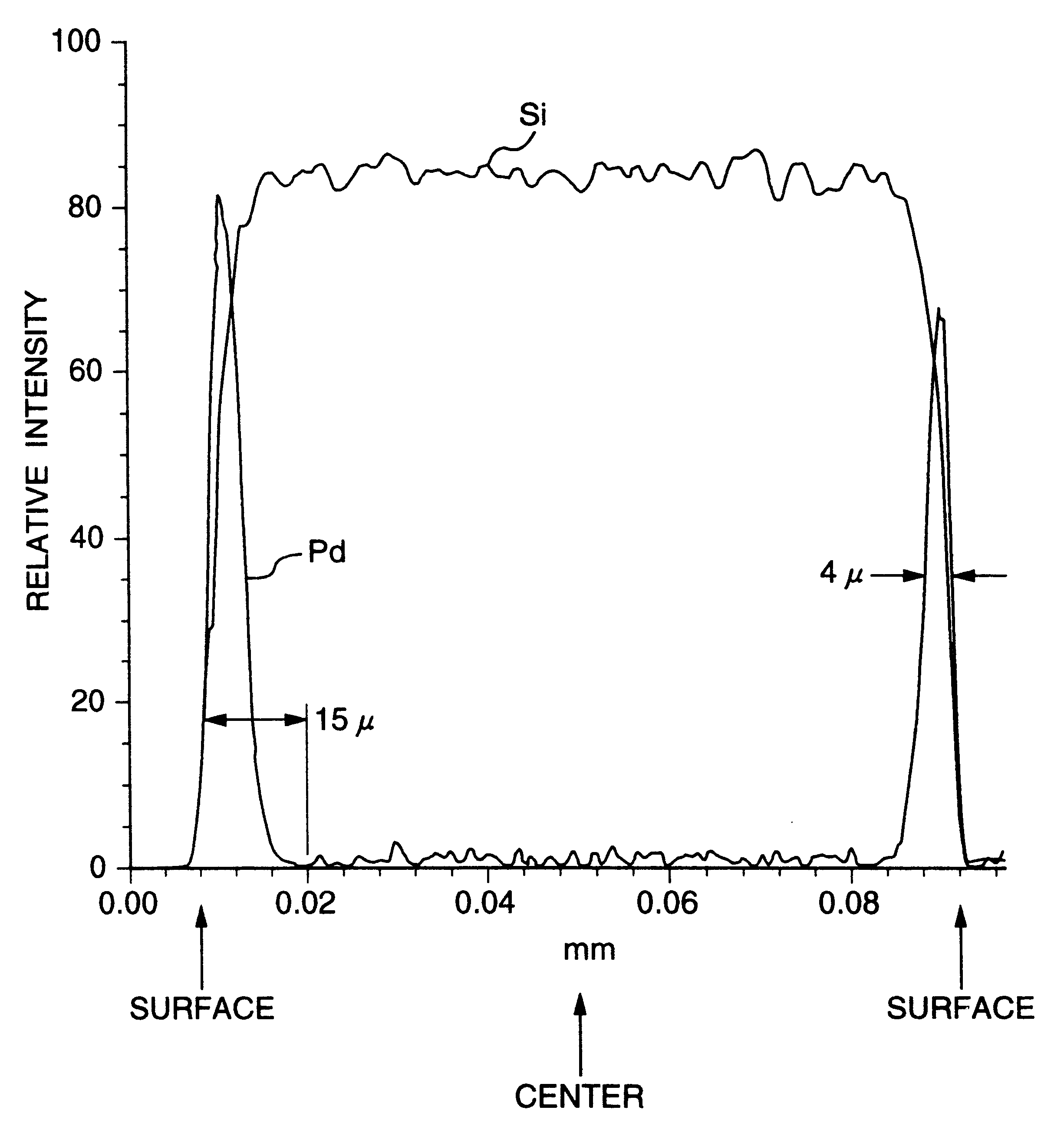

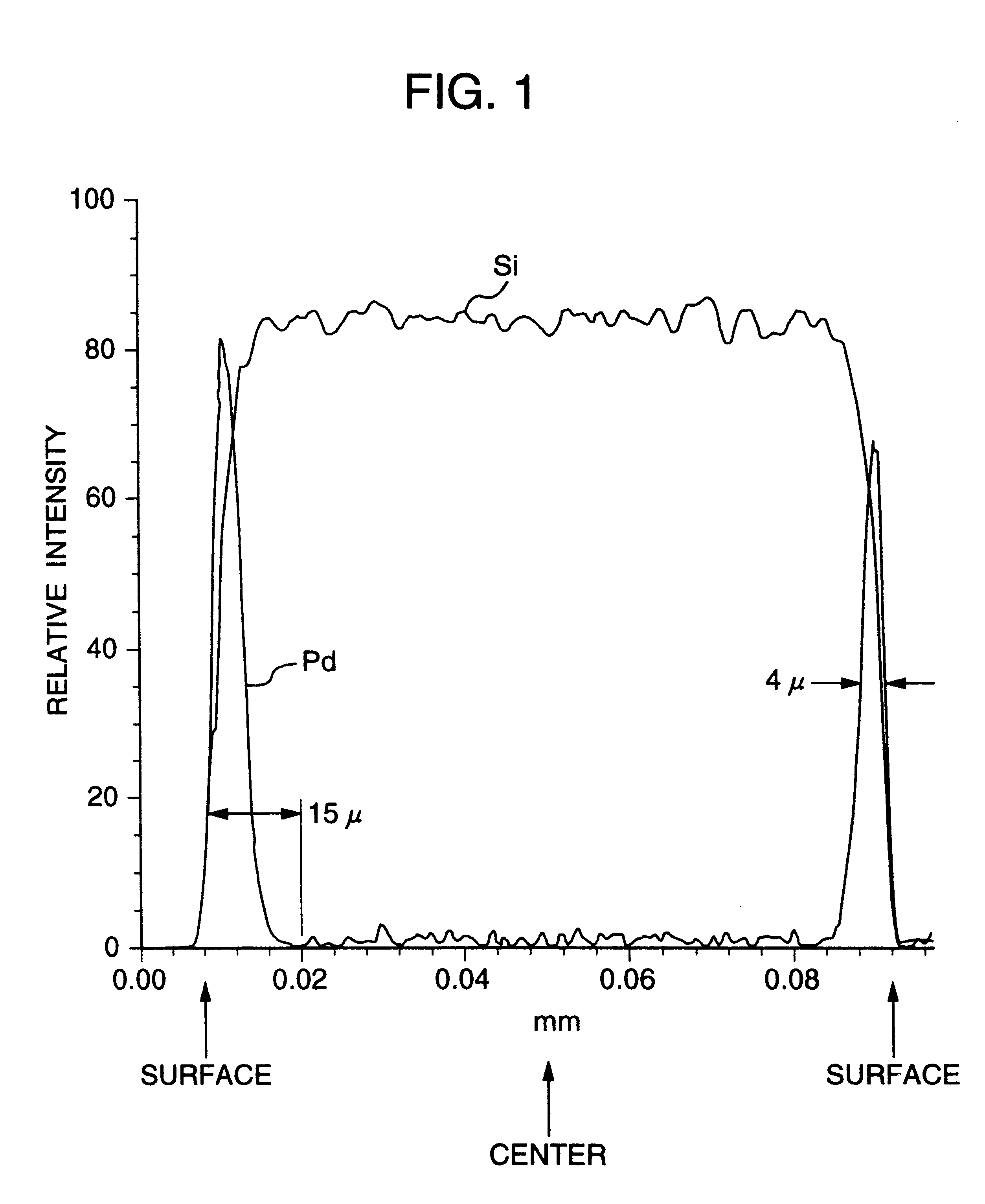

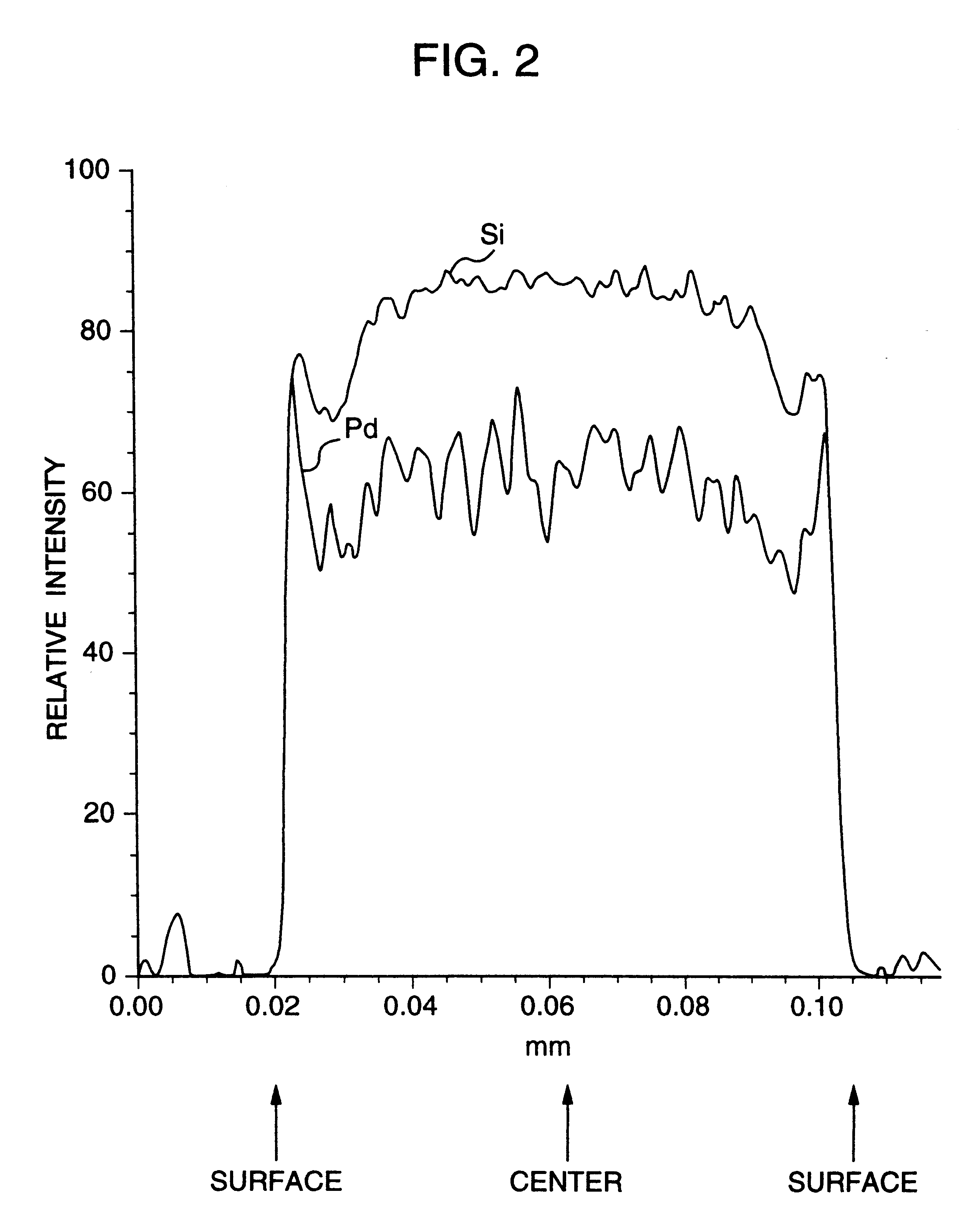

InactiveUS6228800B1Efficient use ofLong catalyst lifeOrganic compound preparationCatalyst activation/preparationPalladiumChemistry

A noble metal-supported article which comprises a carrier and a palladium-containing metal component supported on the carrier, which article has (A) a layer in which substantially no palladium is supported in the interior of the carrier and (B) a layer in which palladium is supported in the region from the outer surface to a depth of less than 100 mum of the carrier.

Owner:ASAHI KASEI KK

Oxide catalyst composition

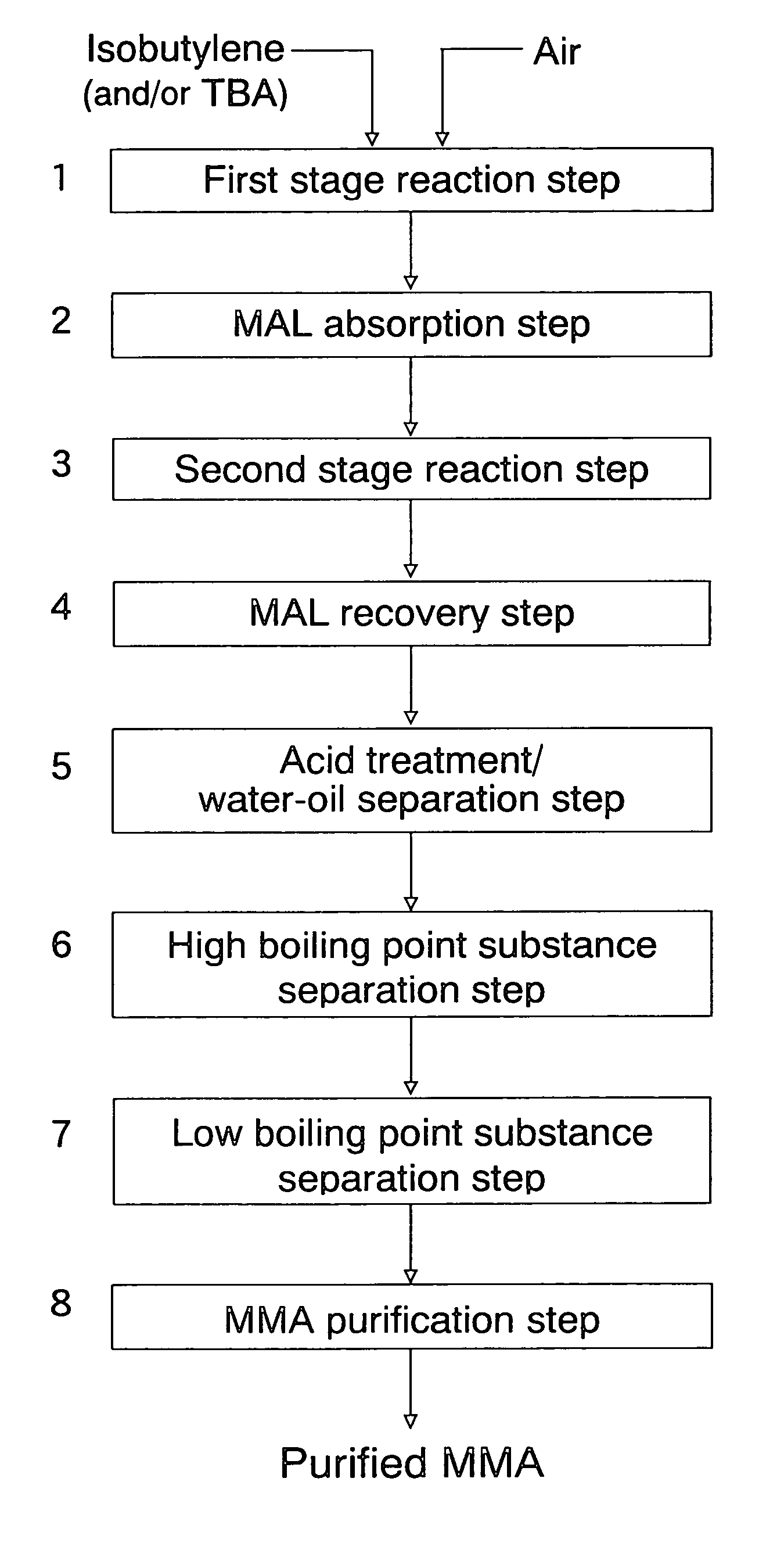

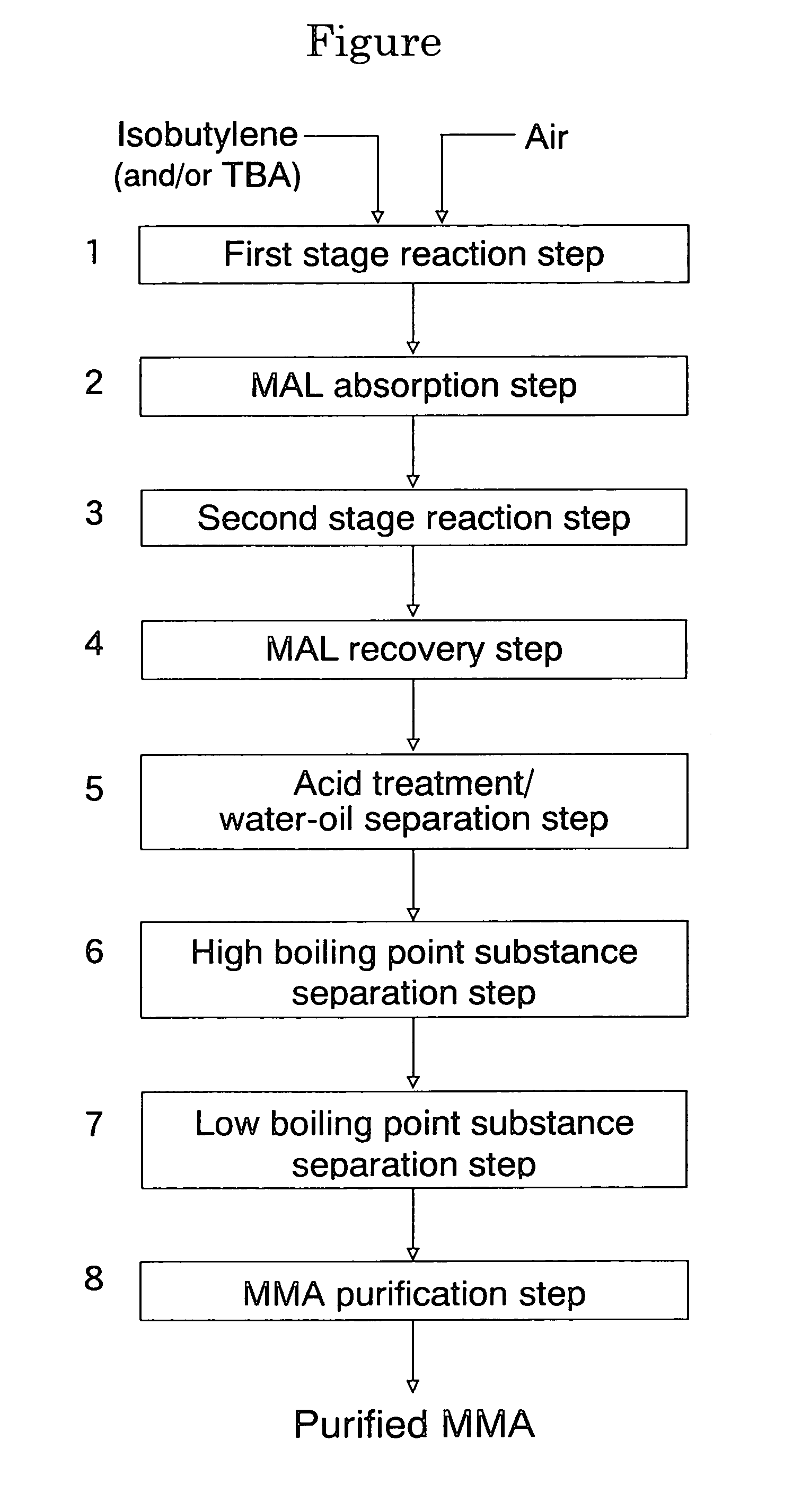

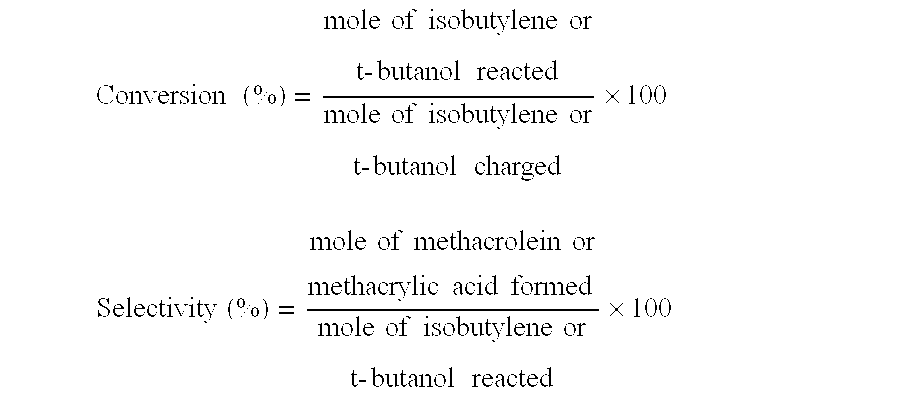

InactiveUS7012039B2High selectivityLow selectivityOrganic compound preparationCarboxylic acid esters preparationLanthanideMethacrolein

An oxide catalyst composition for use in producing methacrolein or a mixture of methacrolein and methacrylic acid, wherein the oxide catalyst composition is represented by the formula (Mo+W)l2BiaAbBcFedXeSbfOg, wherein: A is at least one member selected from the group consisting of Y and the elements of the lanthanoid series exclusive of Pm; B is at least one member selected from the group consisting of K, Rb and Cs; X is Co solely, or a mixture of Co and at least one member selected from the group consisting of Mg and Ni; and a, b, c, d, e, f and g are, respectively, the atomic ratios of Bi, A, B, Fe, X, Sb and O, relative to twelve atoms of the total of Mo and W, wherein the atomic ratios (a to f) of the elements and the relationship between the amounts of the elements are chosen so as to satisfy specific requirements.

Owner:ASAHI KASEI CHEM CORP

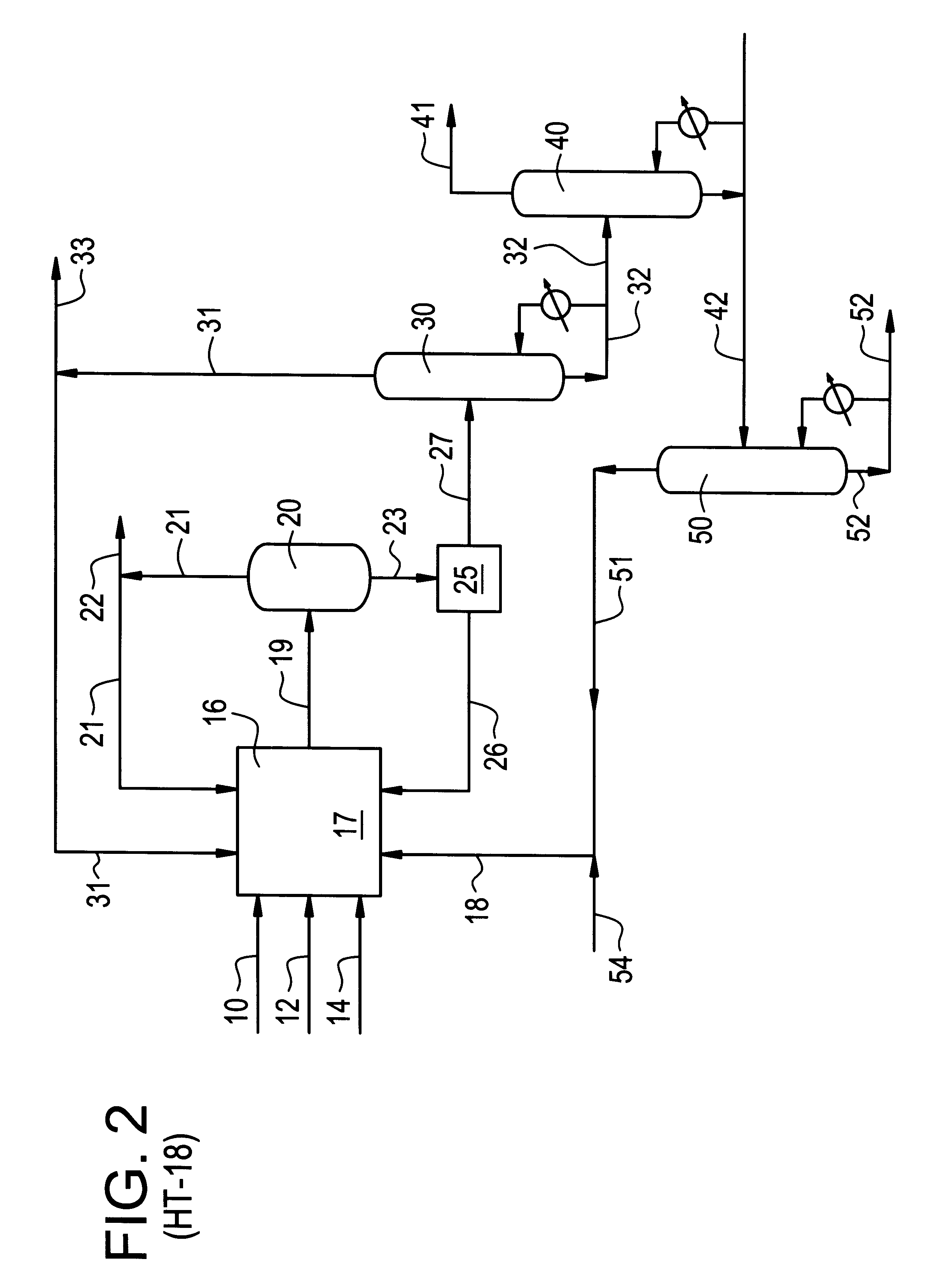

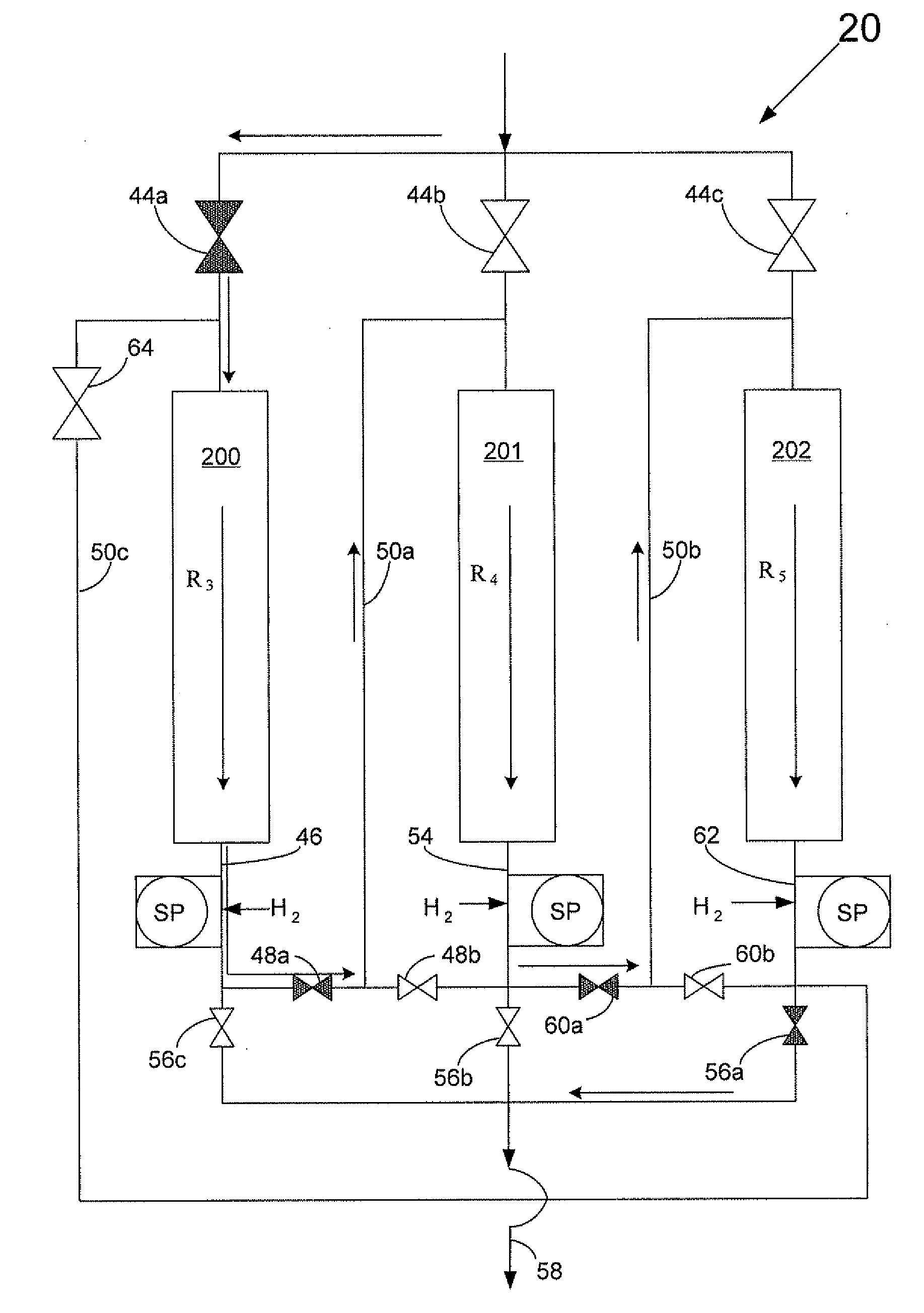

Integrated process and dual-function catalyst for olefin epoxidation

The invention discloses a dual-functional catalyst composition and an integrated process for production of olefin epoxides including propylene oxide by catalytic reaction of hydrogen peroxide from hydrogen and oxygen with olefin feeds such as propylene. The epoxides and hydrogen peroxide are preferably produced simultaneously in situ. The dual-functional catalyst comprises noble metal crystallites with dimensions on the nanometer scale (on the order of <1 nm to 10 nm), specially dispersed on titanium silicalite substrate particles. The dual functional catalyst catalyzes both the direct reaction of hydrogen and oxygen to generate hydrogen peroxide intermediate on the noble metal catalyst surface and the reaction of the hydrogen peroxide intermediate with the propylene feed to generate propylene oxide product. Combining both these functions in a single catalyst provides a very efficient integrated process operable below the flammability limits of hydrogen and highly selective for the production of hydrogen peroxide to produce olefin oxides such as propylene oxide without formation of undesired co-products.

Owner:HEADWATERS TECH INNOVATION GRP

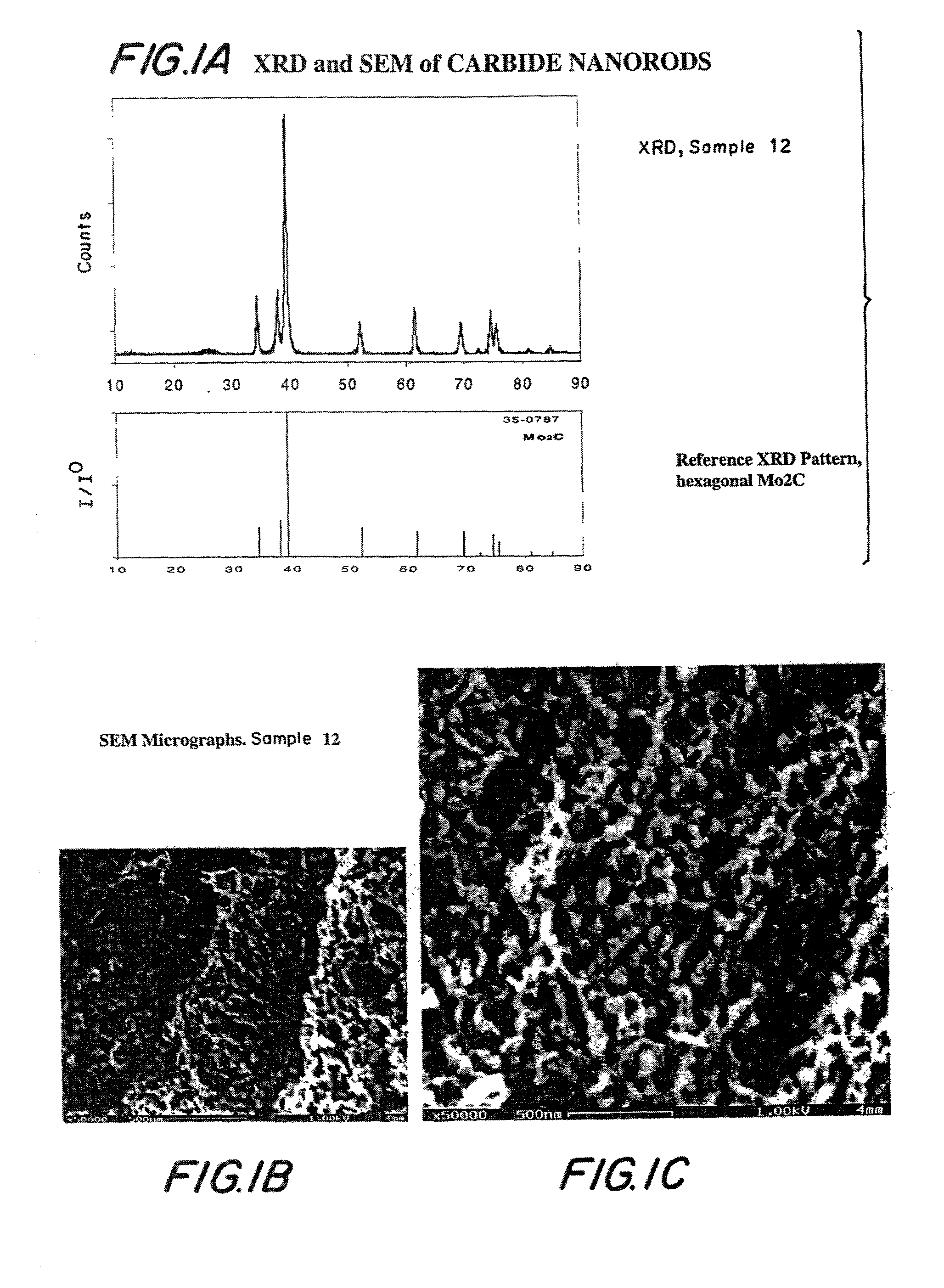

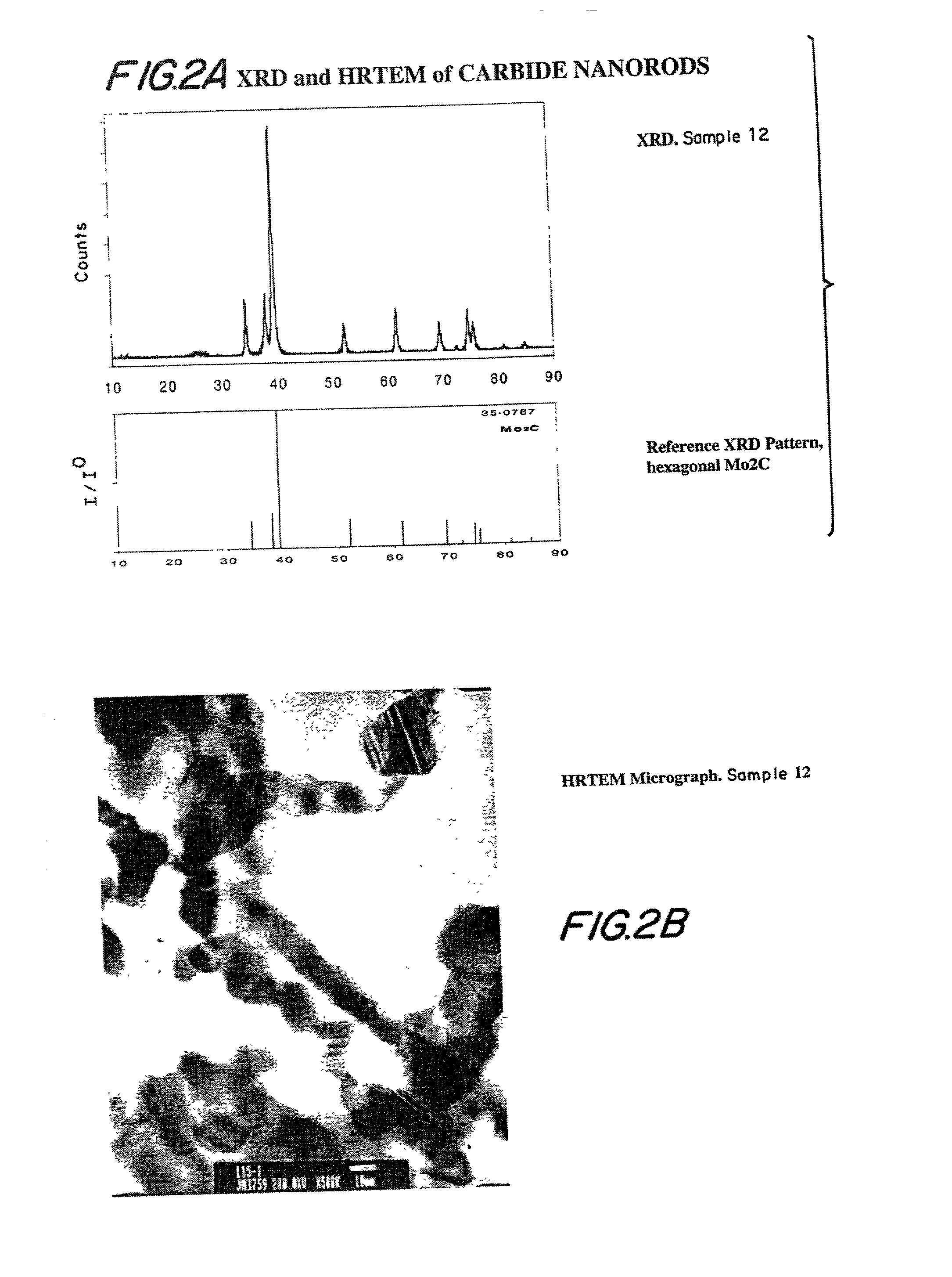

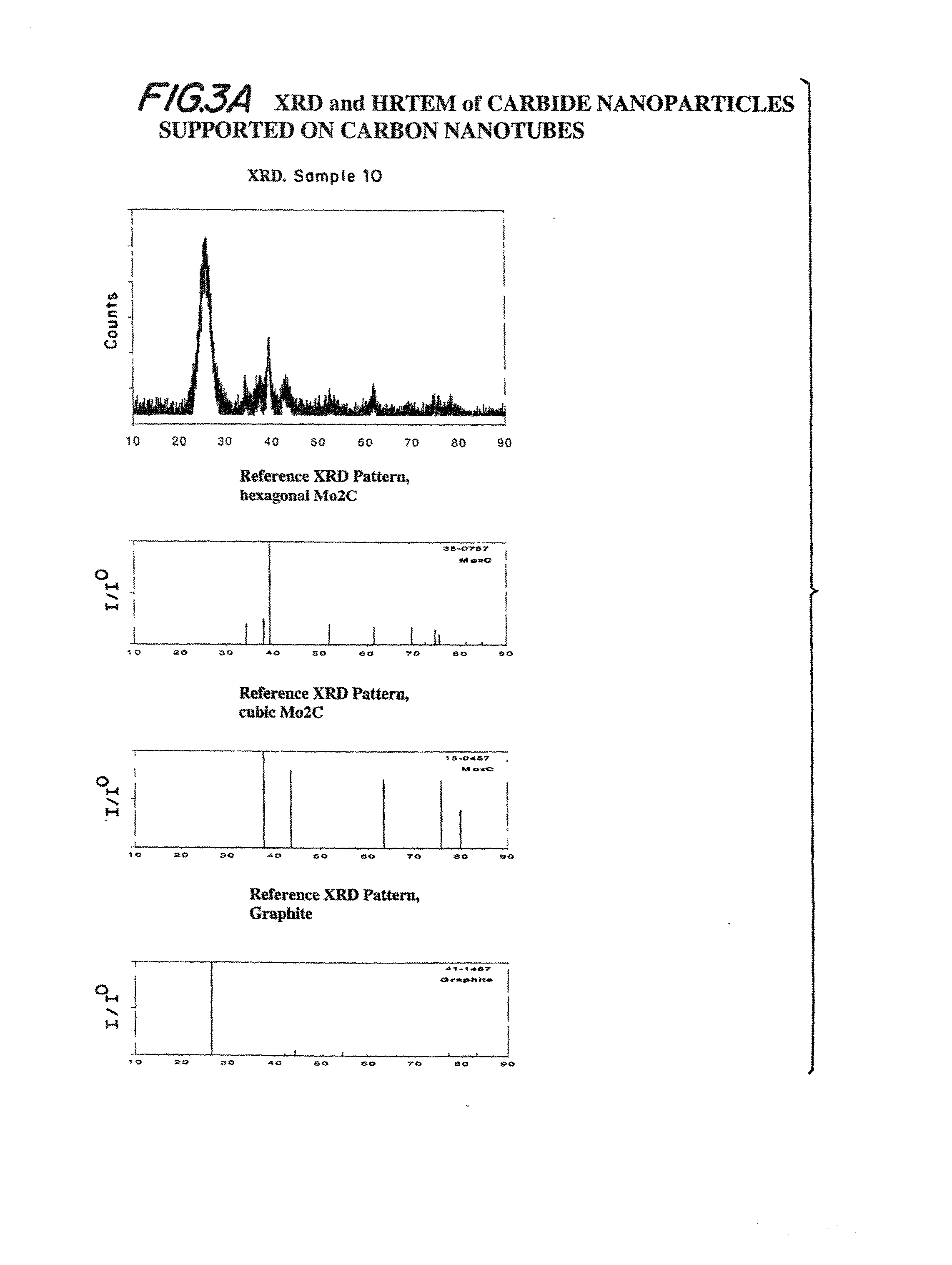

Method of using carbide and/or oxycarbide containing compositions

InactiveUS20020121460A1Facilitated DiffusionHigh porosityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

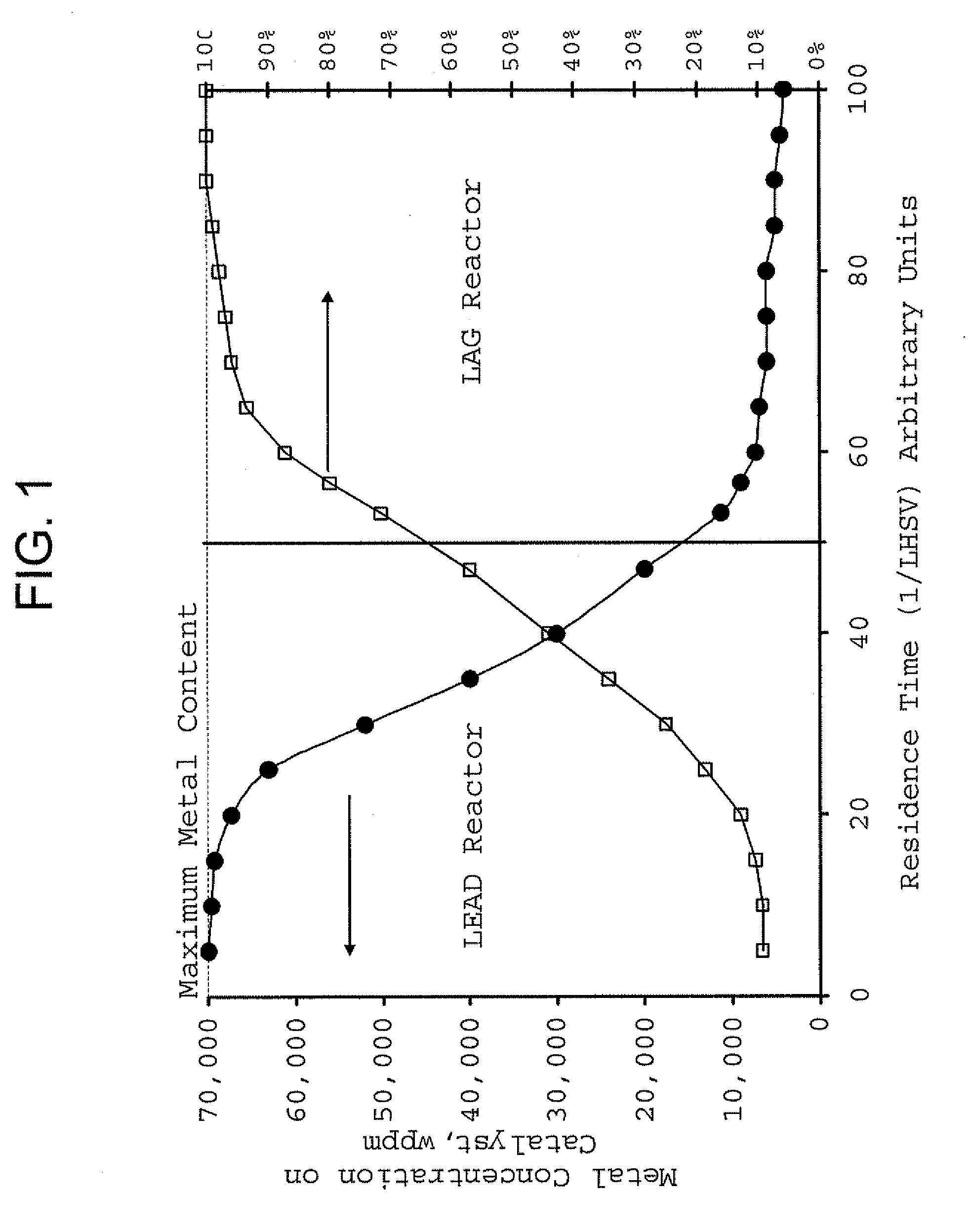

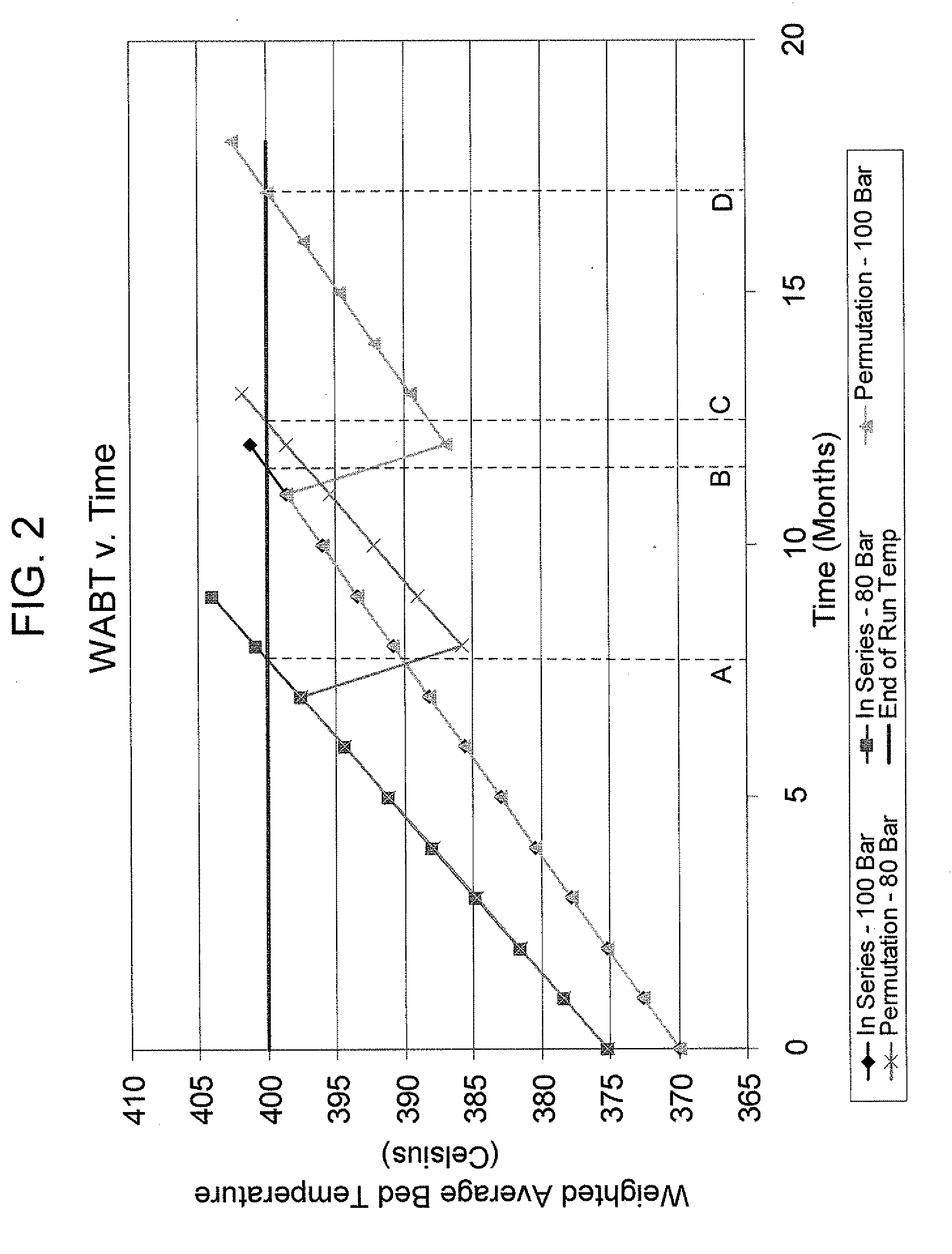

Process for catalytic hydrotreating of sour crude oils

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

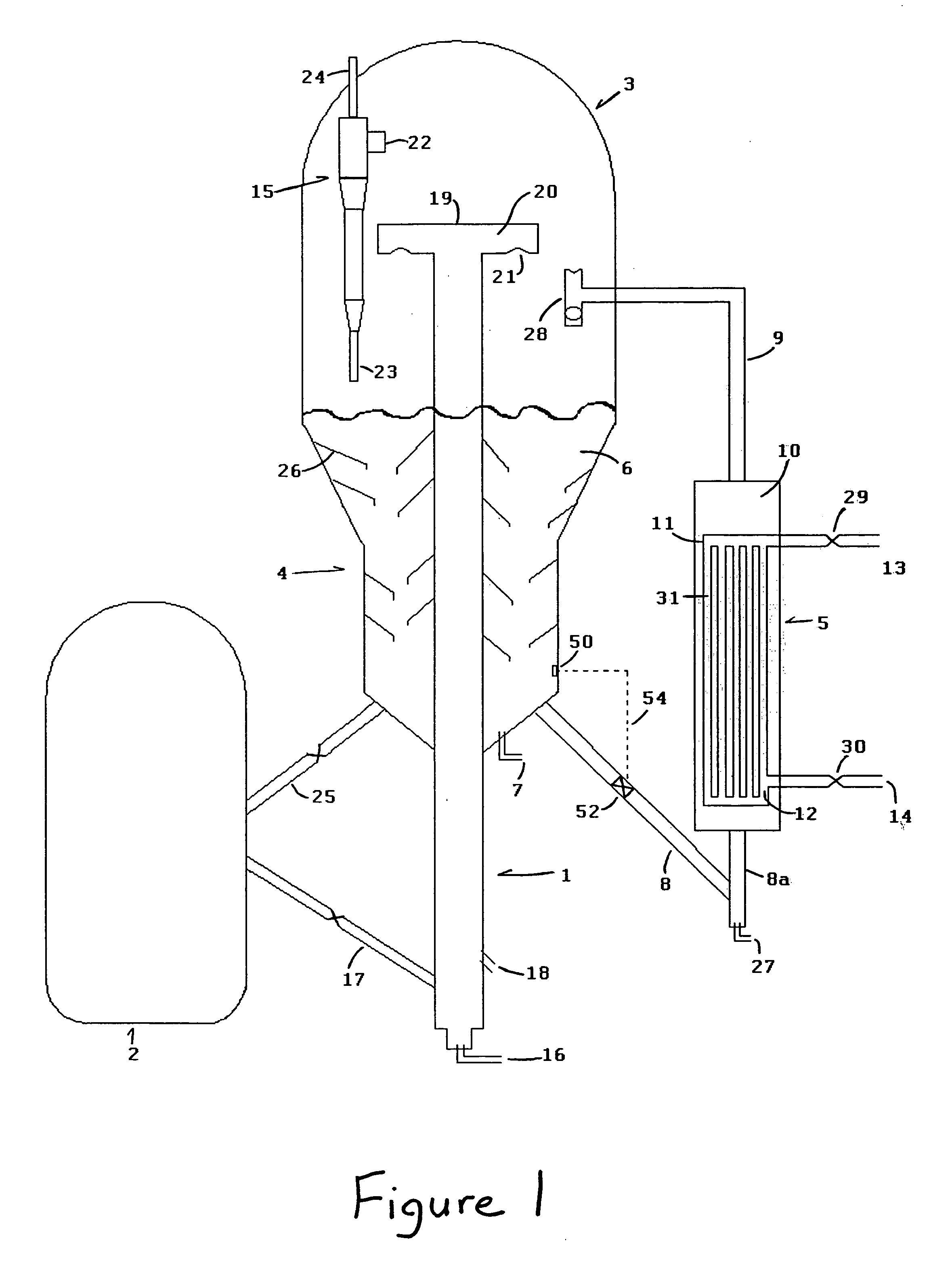

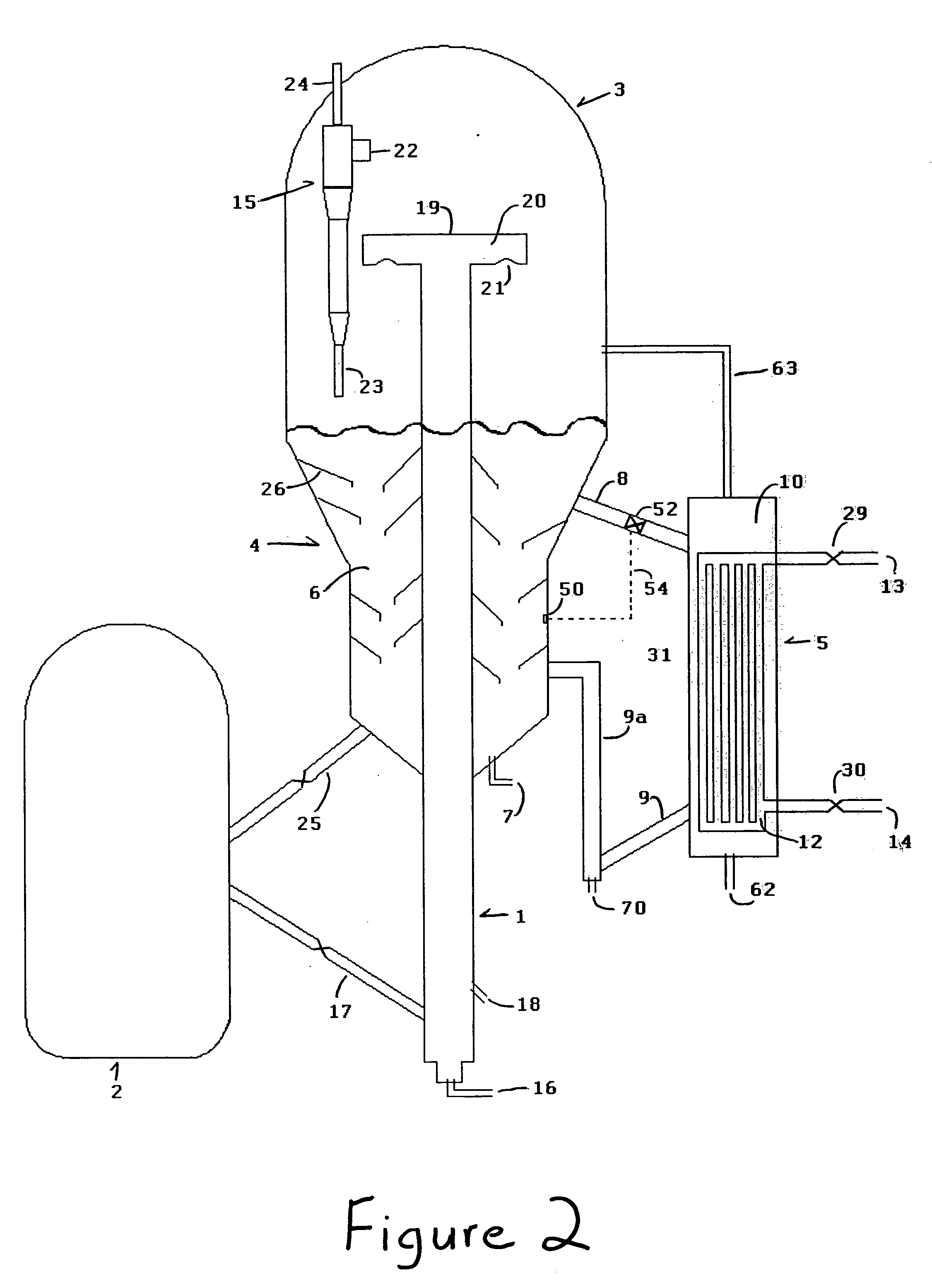

Process and apparatus for controlling catalyst temperature in a catalyst stripper

ActiveUS20050029163A1Easy constructionLong catalyst lifeCatalytic crackingCatalytic naphtha reformingHydrocarbonChemistry

A process and an apparatus for catalytic cracking a hydrocarbon feed to lighter hydrocarbon employing a catalyst cooler in flow communication with a catalyst stripper is disclosed.

Owner:TECH PRECESS TECH INC

Catalyst activation and resins therefrom

InactiveUS20050192177A1Improve responseHigh activityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsBlow moldingCompound (substance)

The present invention relates to the removal of hydrocarbon residues from a catalyst and more specifically the air activation of a catalyst containing hydrocarbon residues. It also relates to extruded pipe and utility conduit resins comprising polyethylene, household / industrial chemicals container resins, and to a polyethylene resin particularly suitable for large parts by blow molding and sheet extrusion procedures, wherein the resin is made by a process using an activated chromium and titanium-based catalyst.

Owner:EXXONMOBIL CHEM PAT INC

Dehydrogenation process with water and temperature control

ActiveUS7687676B1Long catalyst lifeLower inlet temperatureHydrocarbon by hydrogenationCatalytic naphtha reformingTemperature controlAlkane

The activity of a dehydrogenation catalyst is improved by increasing the water concentration maintained in the reactants toward the start of the catalyst's life, but after the catalyst has deactivated to the extent that the temperature required to maintain the conversion per pass of paraffinic hydrocarbon through the reaction zone increases by at least 2° C.

Owner:UOP LLC

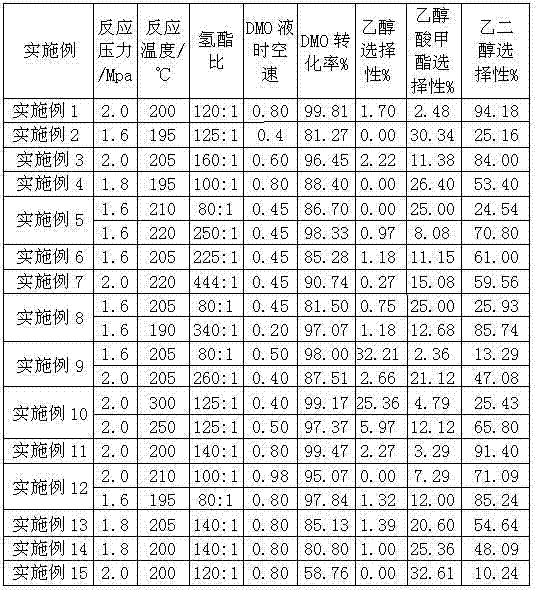

High-efficiency hydrogenation catalyst and method for preparing same

ActiveCN102764656AHigh catalytic activityLong catalyst lifeOrganic compound preparationCarboxylic acid esters preparationPtru catalystManganese

The invention discloses a high-efficiency hydrogenation catalyst and a method for preparing the high-efficiency hydrogenation catalyst. The high-efficiency hydrogenation catalyst comprises the following components by weight: 5-30% of active metal, 0-20% of auxiliary metal and 40-85% of carrier. The active metal is copper or copper oxide; the auxiliary metal is the composition of one or more than two of the sodium, aluminum, nickel, zinc, cobalt, manganese, cerium, lanthanum and strontium; and the carrier the silicon dioxide of silica sol or the aluminum oxide of pseudo-boehmite or aluminum salt. The high-efficiency hydrogenation catalyst is prepared by adopting the impregnation or precipitation method, and the urea is used as the precipitating agent. Compared with the prior art, the catalyst prepared under the condition that the content of the active metal and the auxiliary metal is low has high catalytic activity and long life. In addition, the catalyst has low preparation and production cost and can be universally used for preparing methyl glycolate, ethylene glycol and ethanol by catalytic hydrogenation and preparing 1,2-glycol from glycerin by hydrogenation.

Owner:久泰能源(鄂尔多斯)有限公司

Catalytic conversion of oxygenates to olefins

InactiveUS20070043250A1Coke selectivity of be improveLow coke selectivityLiquid hydrocarbon mixture productionEthylene productionOxygen compoundMolecular sieve

An oxygenate conversion catalyst useful in the conversion of oxygenates such as methanol to olefinic products may be improved by the use of a catalyst combination based on a molecular sieve in combination with a co-catalyst comprising a mixed metal oxide composition which has oxidation / reduction functionality under the conditions of the conversion. This metal oxide co-catalyst component will comprise a mixed oxide of one or more, preferably at least two, transition metals, usually of Series 4, 5 or 6 of the Periodic Table, with the metals of Series 4 being preferred, as an essential component of the mixed oxide composition. The preferred transition metals are those of Groups 5, especially titanium and vanadium, Group 6, especially chromium or molybdenum, Group 7, especially manganese and Group 8, especially cobalt or nickel. Other metal oxides may also be present. The preferred molecular sieve components in these catalysts are the high silica zeolites and the SAPOs, especially the small pore SAPOs (8-membered rings), such as SAPO-34. These catalyst combinations exhibit reduced coke selectivity have the potential of achieving extended catalyst life. In addition, these catalysts have the capability of selectively converting the hydrogen produced during the conversion to liquid products, mainly water, reducing the demand on reactor volume and product handling.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst for the preparation of carboxylic esters and method for producing carboxylic esters

InactiveUS7326806B2Good activityHigh levelOrganic compound preparationCarboxylic acid esters preparationCarboxylic esterAldehyde

It is an object of the present invention to provide a catalyst for manufacturing a carboxylic ester, which has superior catalytic activity. The present invention relates to a catalyst for preparing a carboxylic ester, used in a) a reaction for preparing a carboxylic ester by reacting oxygen, an aldehyde, and an alcohol, or b) a reaction for manufacturing a carboxylic ester by reacting oxygen and one or more types of alcohol, comprising a carrier and 1) ultrafine gold particles and / or 2) ultrafine metal particles containing gold and a second element other than gold, having an average particle diameter of not more than 6 nm, are supported on the carrier.

Owner:NIPPON SHOKUBAI CO LTD

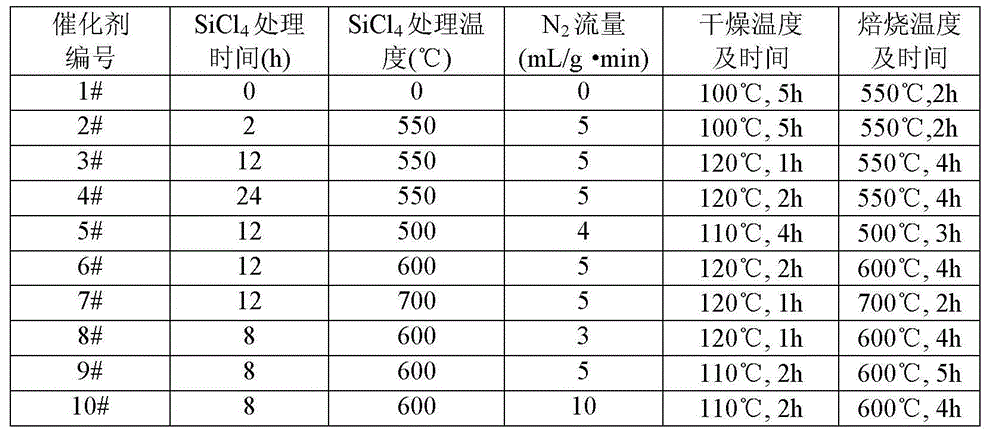

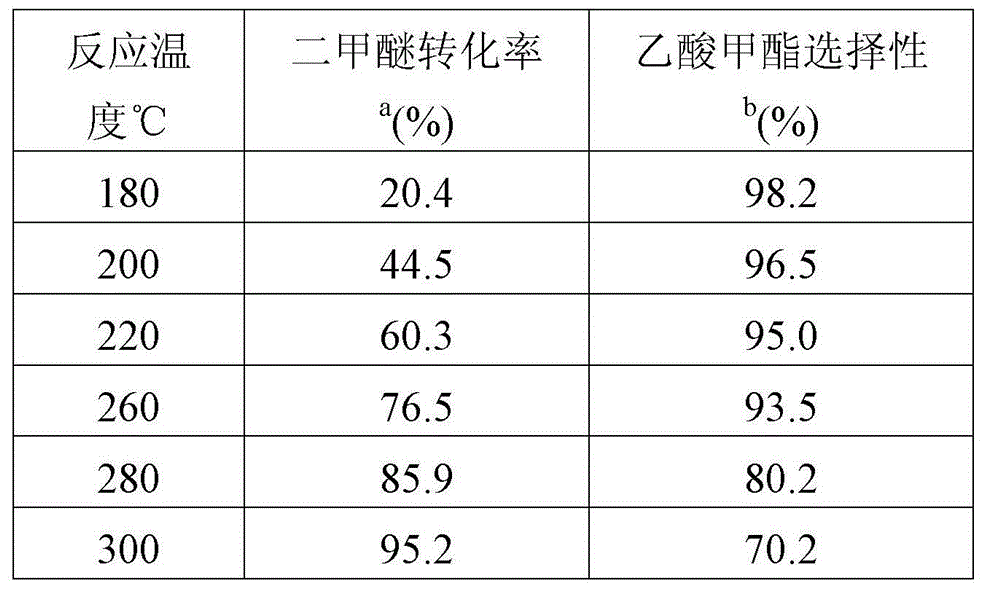

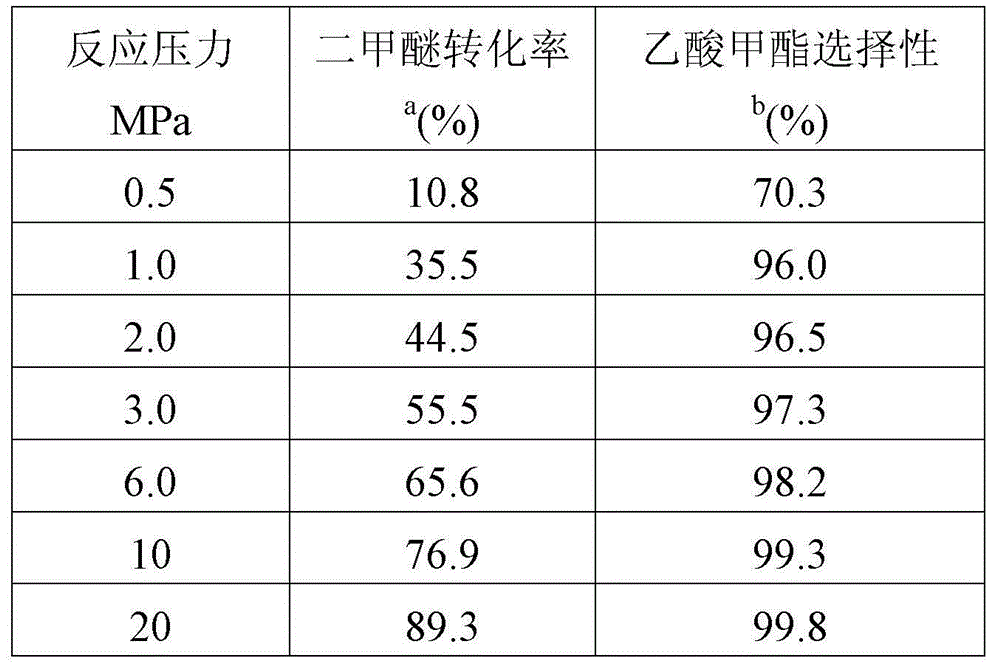

Catalyst used for preparing methyl acetate through dimethyl ether carbonylation, preparation method and application thereof

ActiveCN104689845AHigh product selectivityLong catalyst lifeMolecular sieve catalystsPreparation by carbon monoxide or formate reactionProtein carbonylMolecular sieve

The invention provides a catalyst used for preparing methyl acetate through dimethyl ether carbonylation, a preparation method and an application thereof, more specifically, the invention provides the catalyst used for preparing methyl acetate through dimethyl ether carbonylation, the catalyst contains a silicon tetrachloride steam dealuminated hydrogen-mordenite molecular sieve, and silicon and aluminum atomic ratio is 3: 1-20: 1. According to the invention, silicon tetrachloride steam is contacted to mordenite for effecting acid site in 12-membered ring tunnel without influence of acid site in 8-membered ring tunnel, aluminum in 12-membered ring tunnel is selectively removed, and acid site in 12-membered ring tunnel is kept, so that life and selectivity of catalyst in a reaction for preparing methyl acetate through dimethyl ether carbonylation are increased, and reaction yield is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

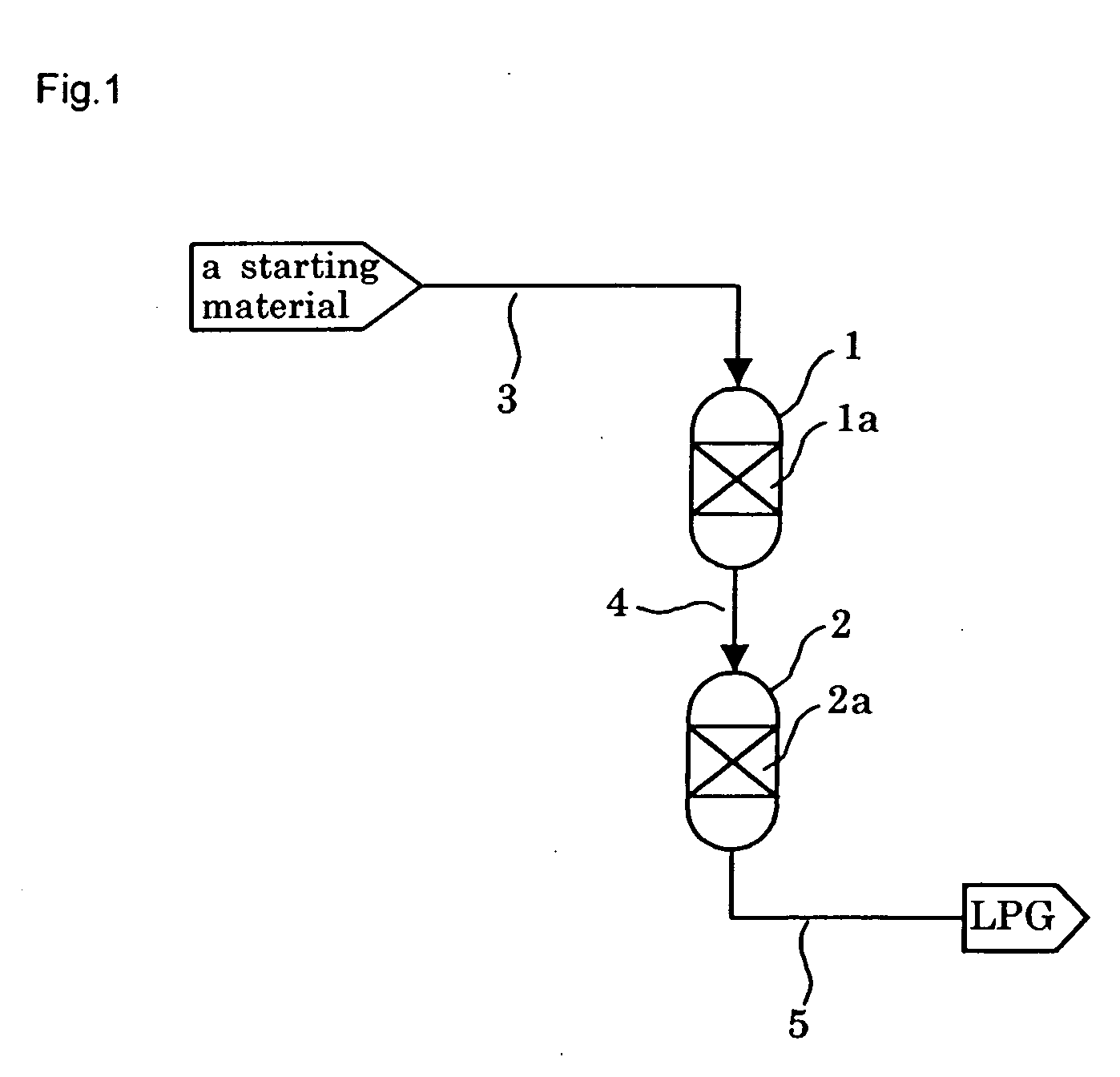

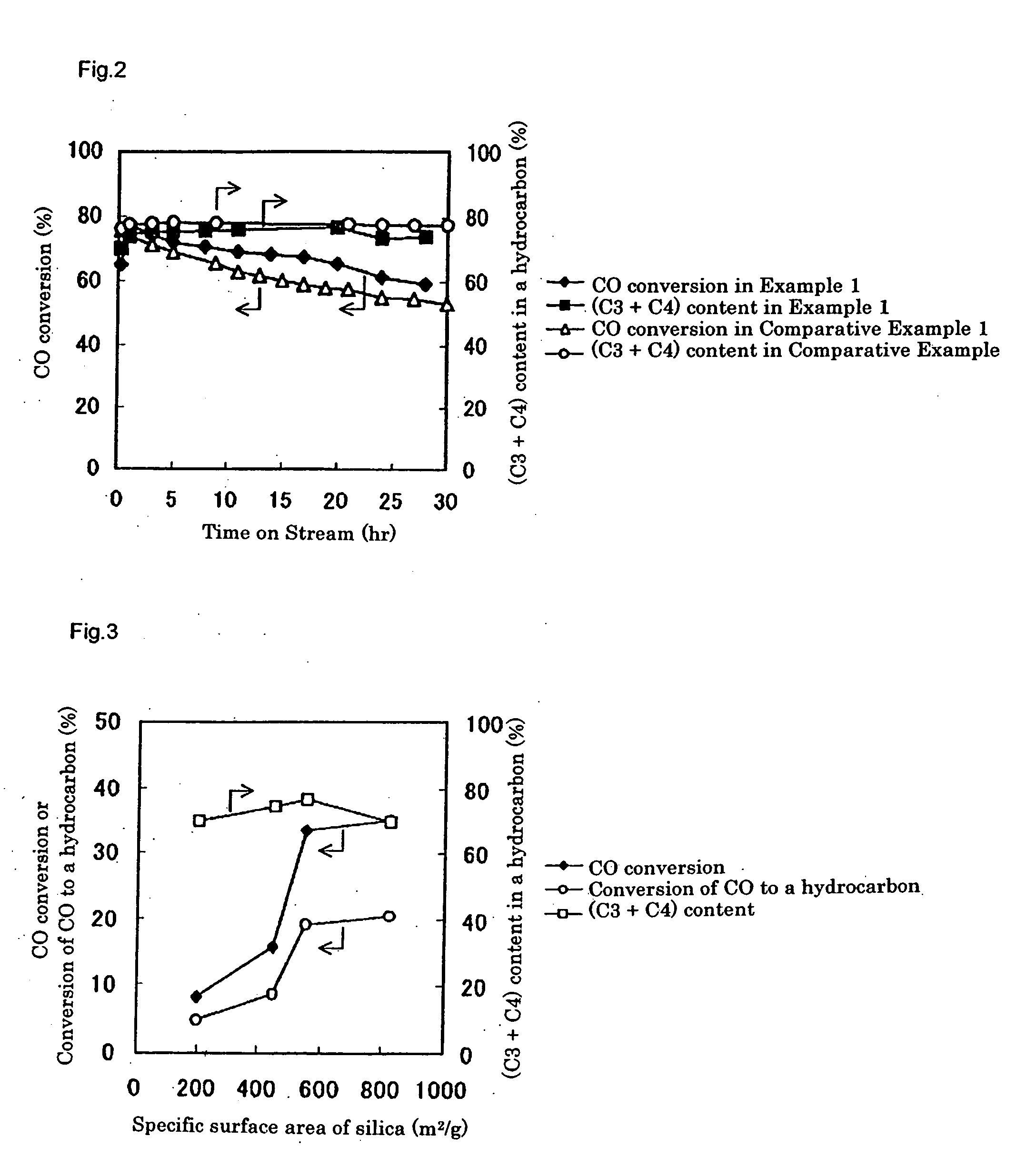

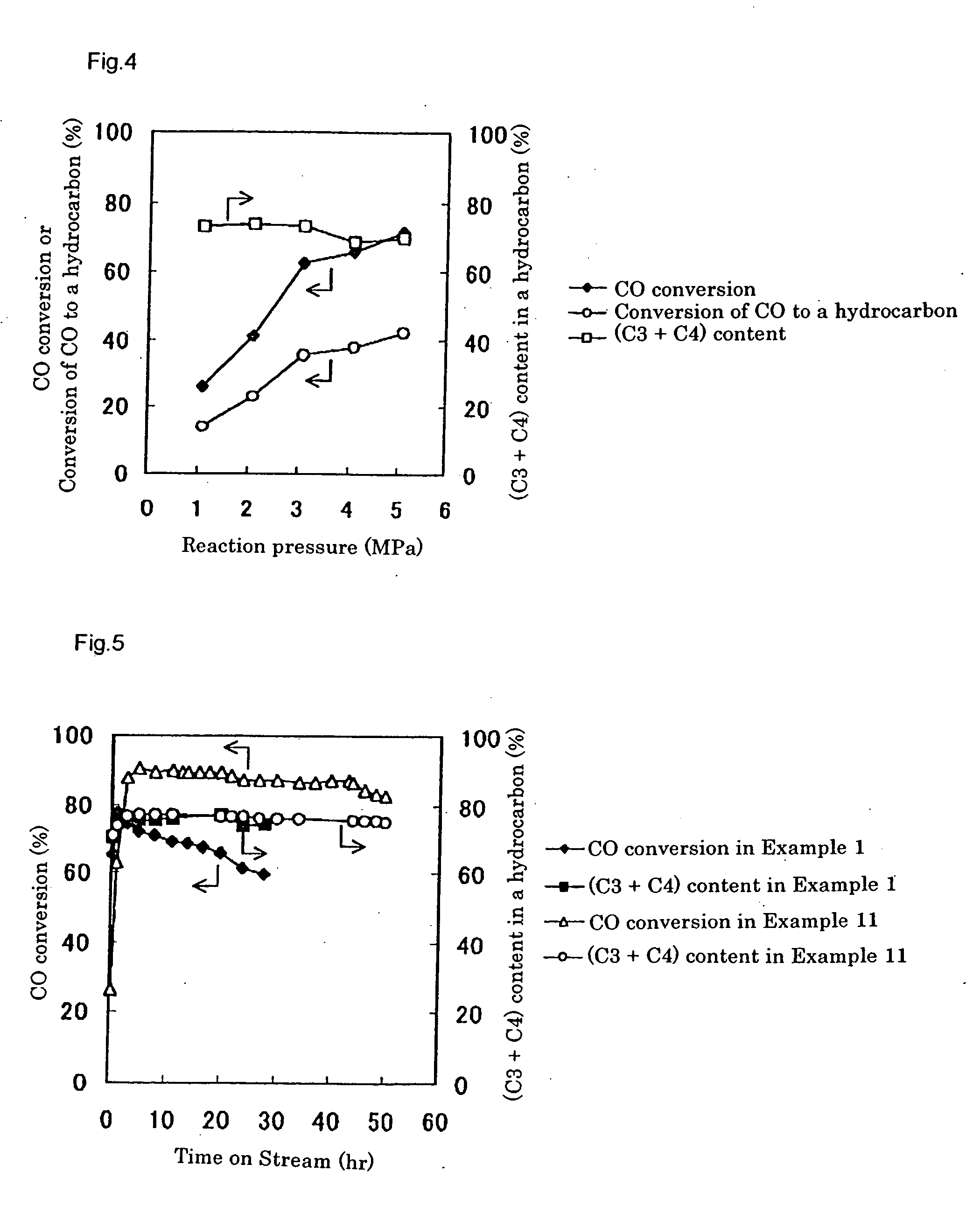

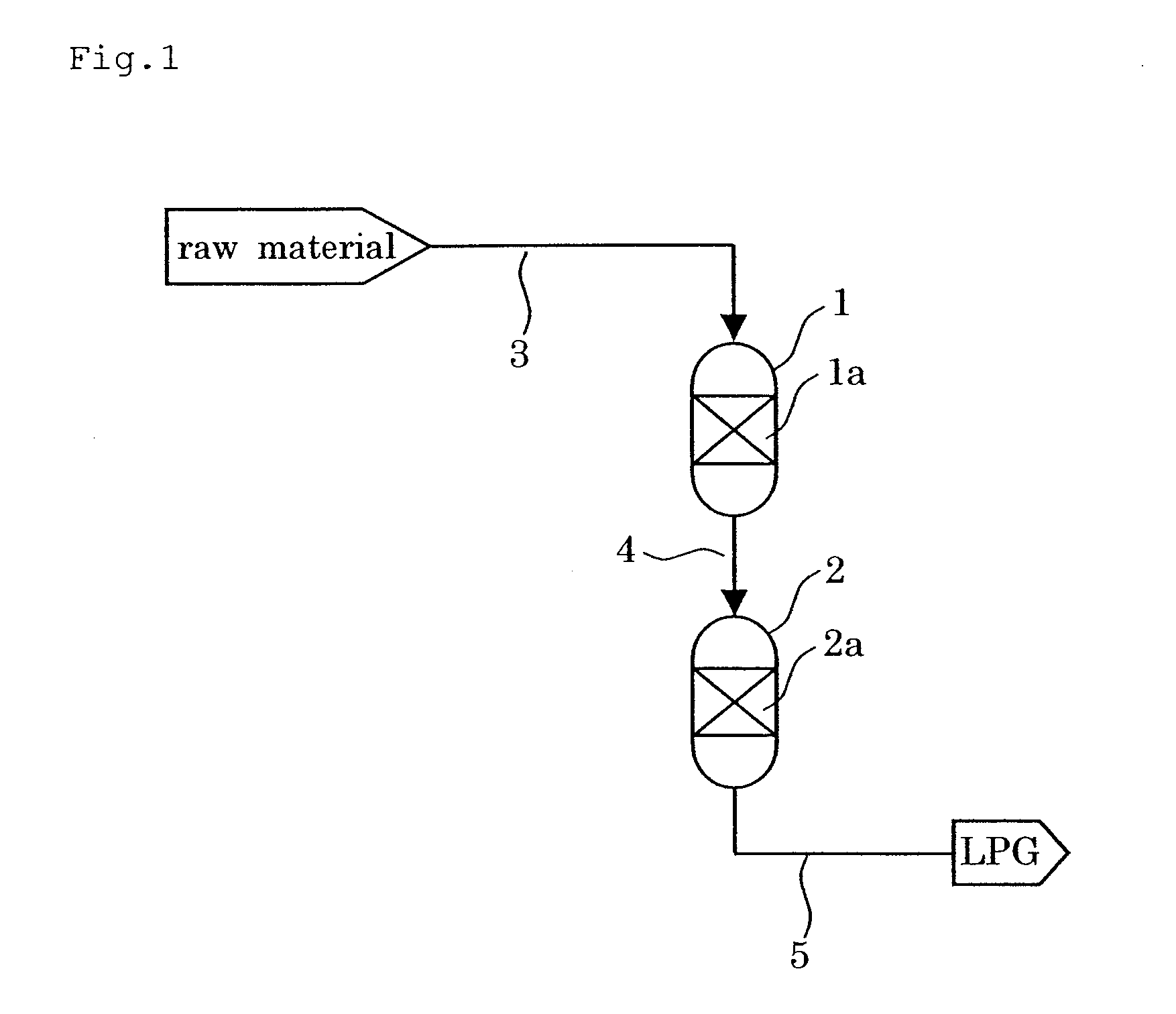

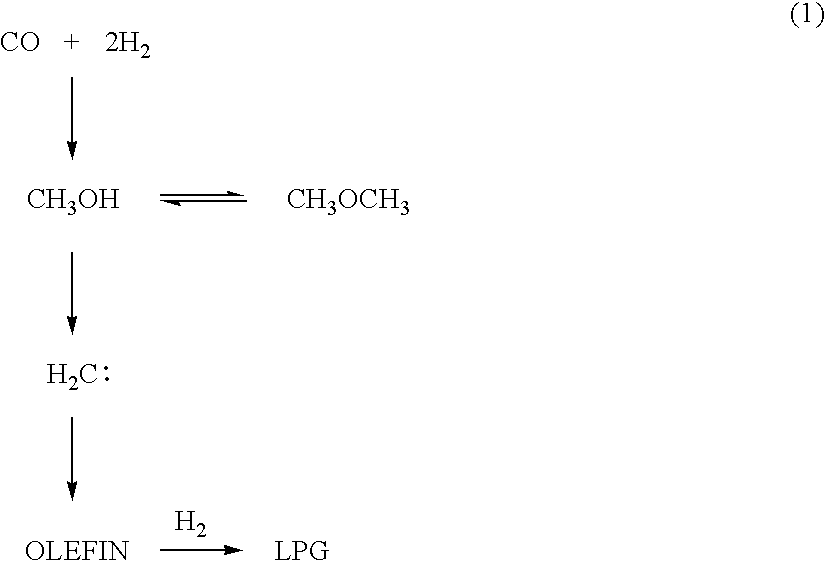

Catalyst and process for LPG production

InactiveUS20060009349A1Less deteriorationHigh activityMolecular sieve catalystsOrganic compound preparationHydrogenHigh activity

A catalyst for producing a liquefied petroleum gas according to the present invention comprises a Pd-based methanol synthesis catalyst component and a β-zeolite catalyst component. It can be used in a reaction of carbon monoxide and hydrogen to give a hydrocarbon containing propane or butane as a main component, i.e., a liquefied petroleum gas, with high activity, high selectivity and high yield. Furthermore, the catalyst has a longer catalyst life with less deterioration.

Owner:JAPAN GAS SYNTHESIZE

Catalytic conversion of oxygenates to olefins

InactiveUS7700816B2Low coke selectivityLong catalyst lifeLiquid hydrocarbon mixture productionEthylene productionLiquid productManganese

An oxygenate conversion catalyst useful in the conversion of oxygenates such as methanol to olefinic products may be improved by the use of a catalyst combination based on a molecular sieve in combination with a co-catalyst comprising a mixed metal oxide composition which has oxidation / reduction functionality under the conditions of the conversion. This metal oxide co-catalyst component will comprise a mixed oxide of one or more, preferably at least two, transition metals, usually of Series 4, 5 or 6 of the Periodic Table, with the metals of Series 4 being preferred, as an essential component of the mixed oxide composition. The preferred transition metals are those of Groups 5, especially titanium and vanadium, Group 6, especially chromium or molybdenum, Group 7, especially manganese and Group 8, especially cobalt or nickel. Other metal oxides may also be present. The preferred molecular sieve components in these catalysts are the high silica zeolites and the SAPOs, especially the small pore SAPOs (8-membered rings), such as SAPO-34. These catalyst combinations exhibit reduced coke selectivity have the potential of achieving extended catalyst life. In addition, these catalysts have the capability of selectively converting the hydrogen produced during the conversion to liquid products, mainly water, reducing the demand on reactor volume and product handling.

Owner:EXXONMOBIL CHEM PAT INC

One-step preparation method for hydrogen type multistage pore molecular sieve with SAPO-5 and SAPO-34 symbiosis

InactiveCN103011195ASlow down the rate of carbonizationLong catalyst lifeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesHydrogenSurface-active agents

The invention belongs to the technical field of preparation of inorganic multistage pore materials, and relates to a one-step preparation method for a hydrogen type multistage pore molecular sieve with SAPO-5 and SAPO-34 symbiosis. According to the invention, tetraethylammonium hydroxide (TEAOH) is used as atemplate agent, and an organic silicon surface active agent (STSAC) is used at the same time to prepare a hydrogen type micropore-mesopore composite molecular sieve with SAPO-5 and SAPO-34 symbiosis in one step through the hydrothermal method, so that the acid exchange step is avoided, and the cost is reduced. The molecular sieve is used as catalyst for preparing low-carbon olefin with methanol, so that the limitations to aspects of dispersion and mass transfer can be overcome, the caking speed is reduced, the catalysis life is possibly prolonged, and wide application foreground is anticipated in industrial catalysis.

Owner:JILIN UNIV

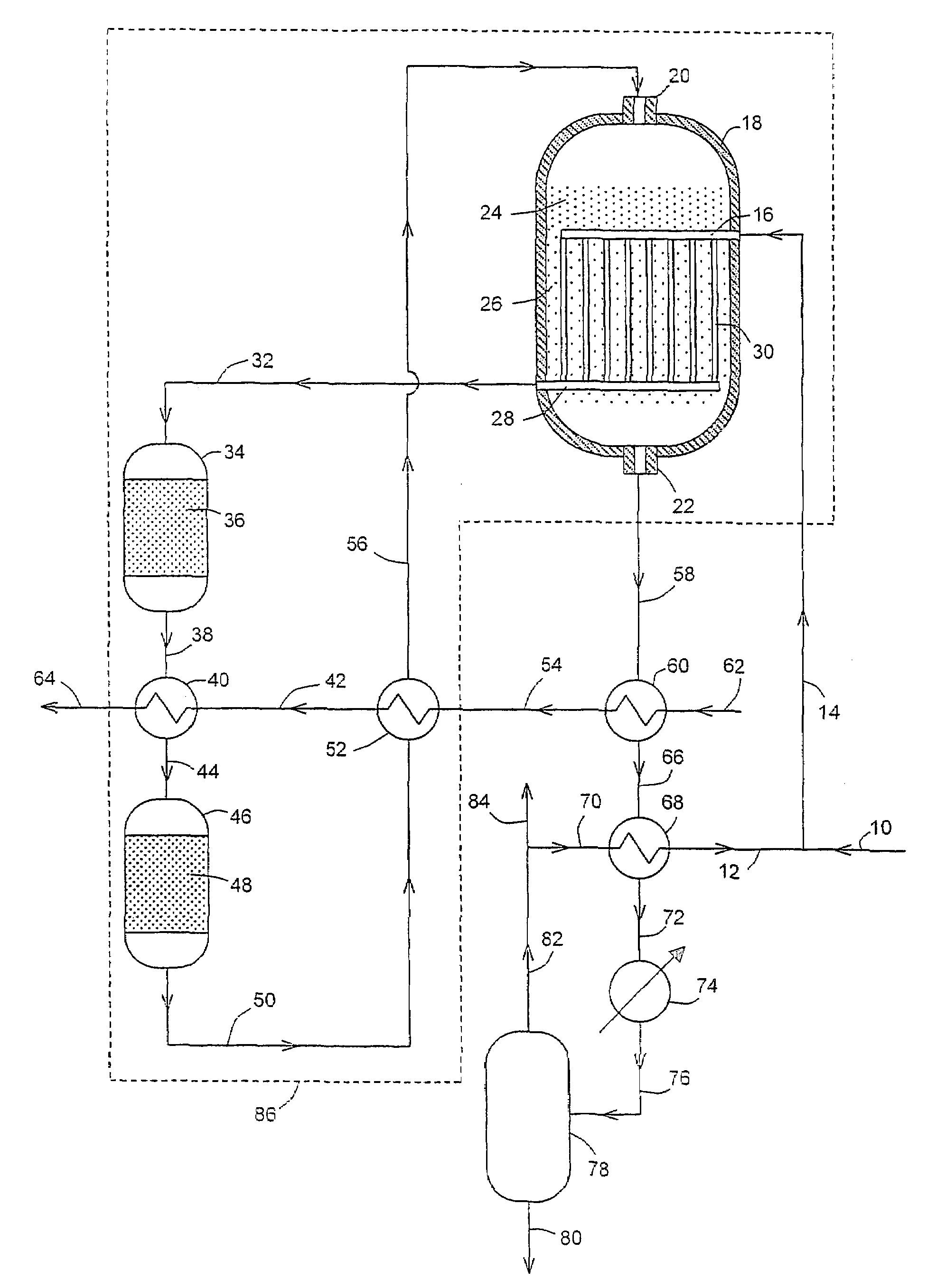

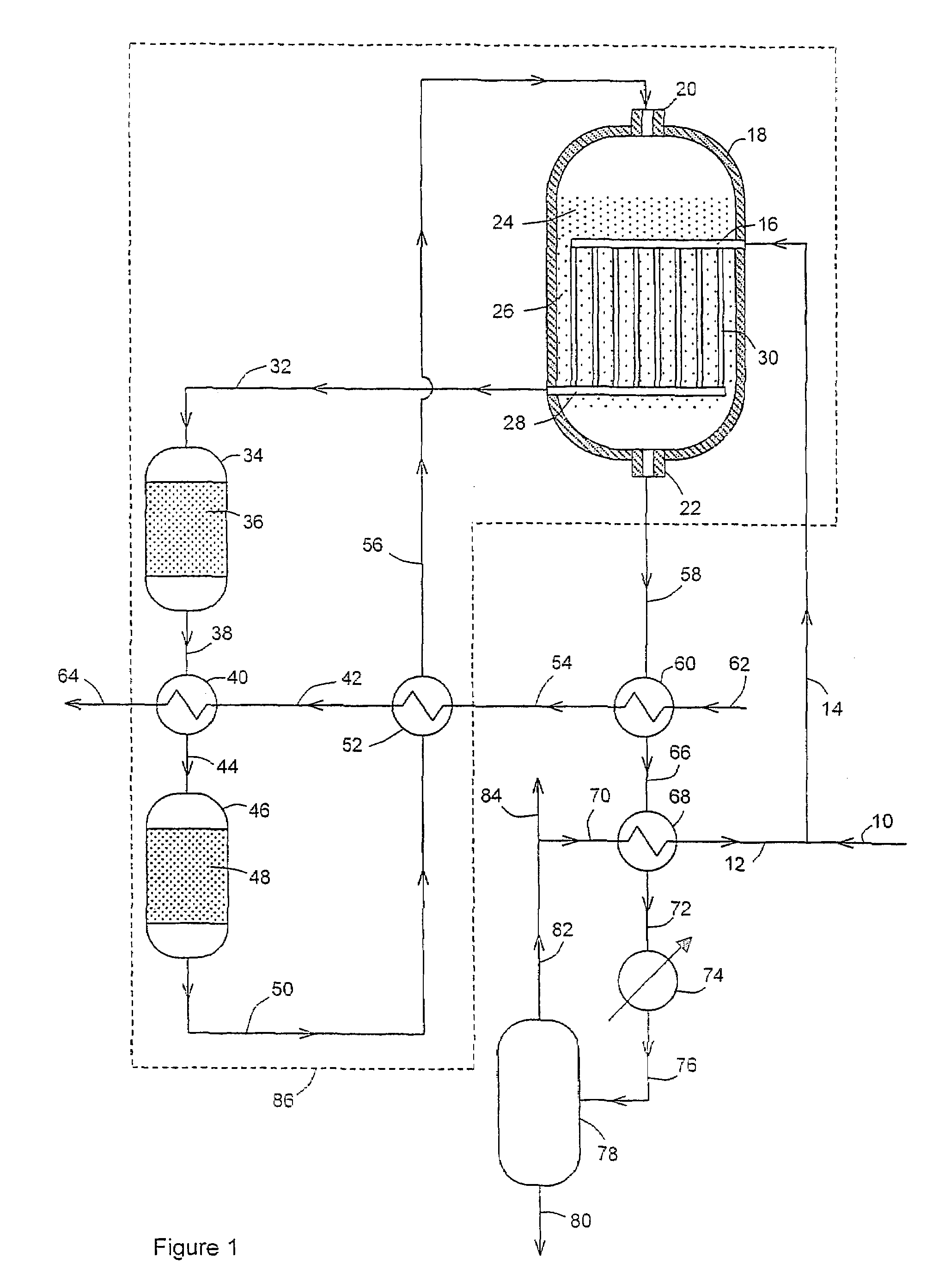

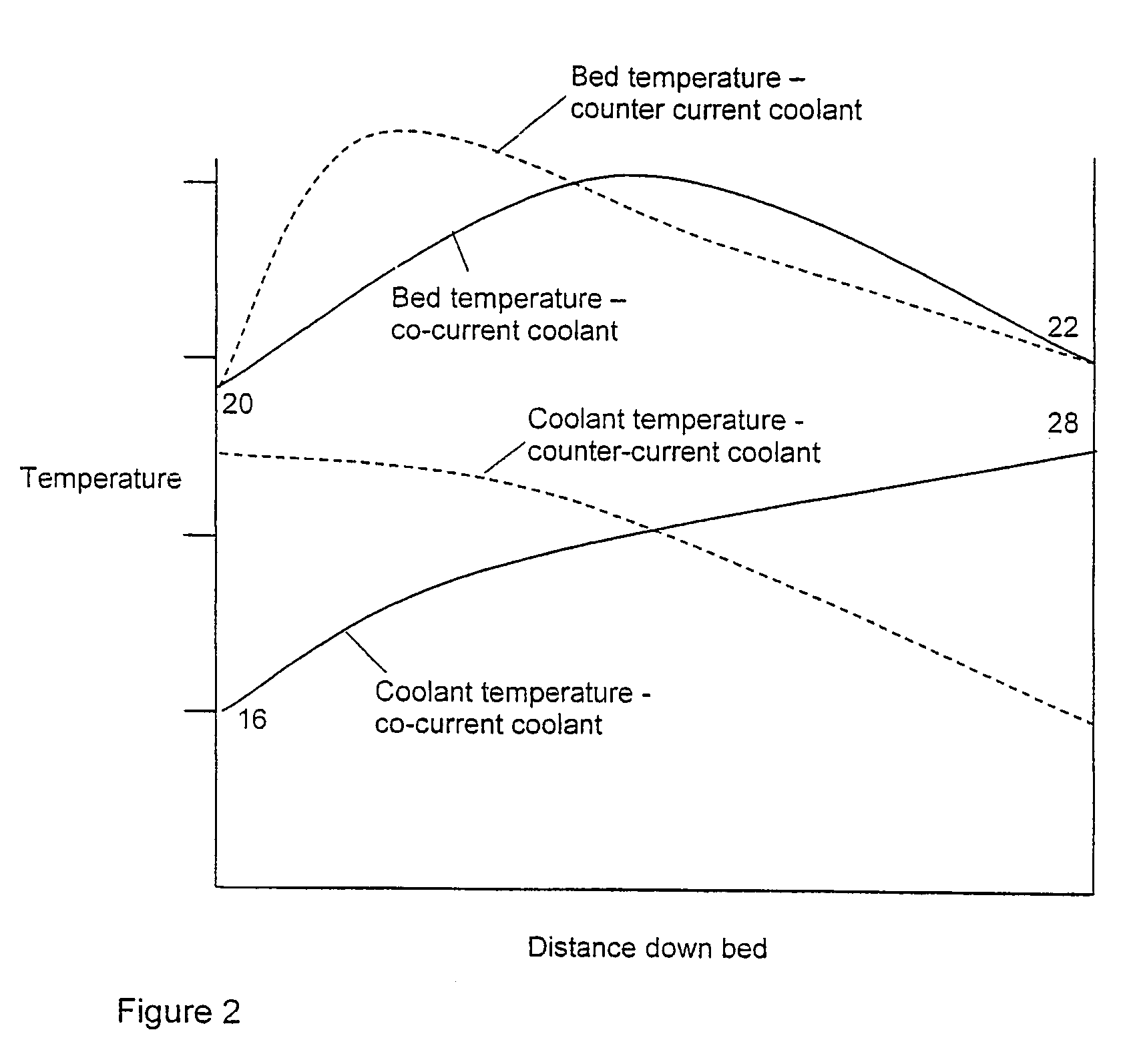

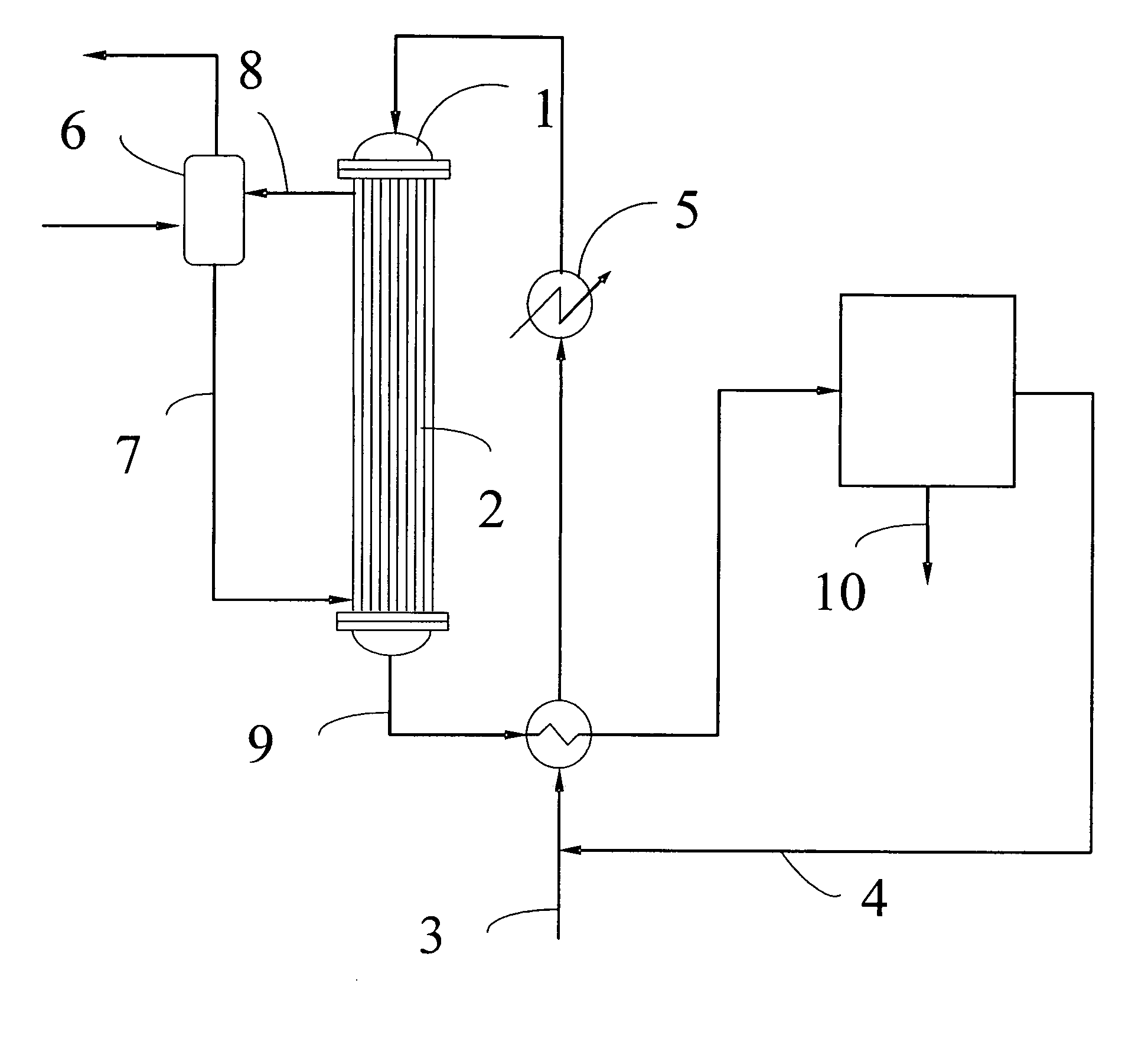

Methanol synthesis

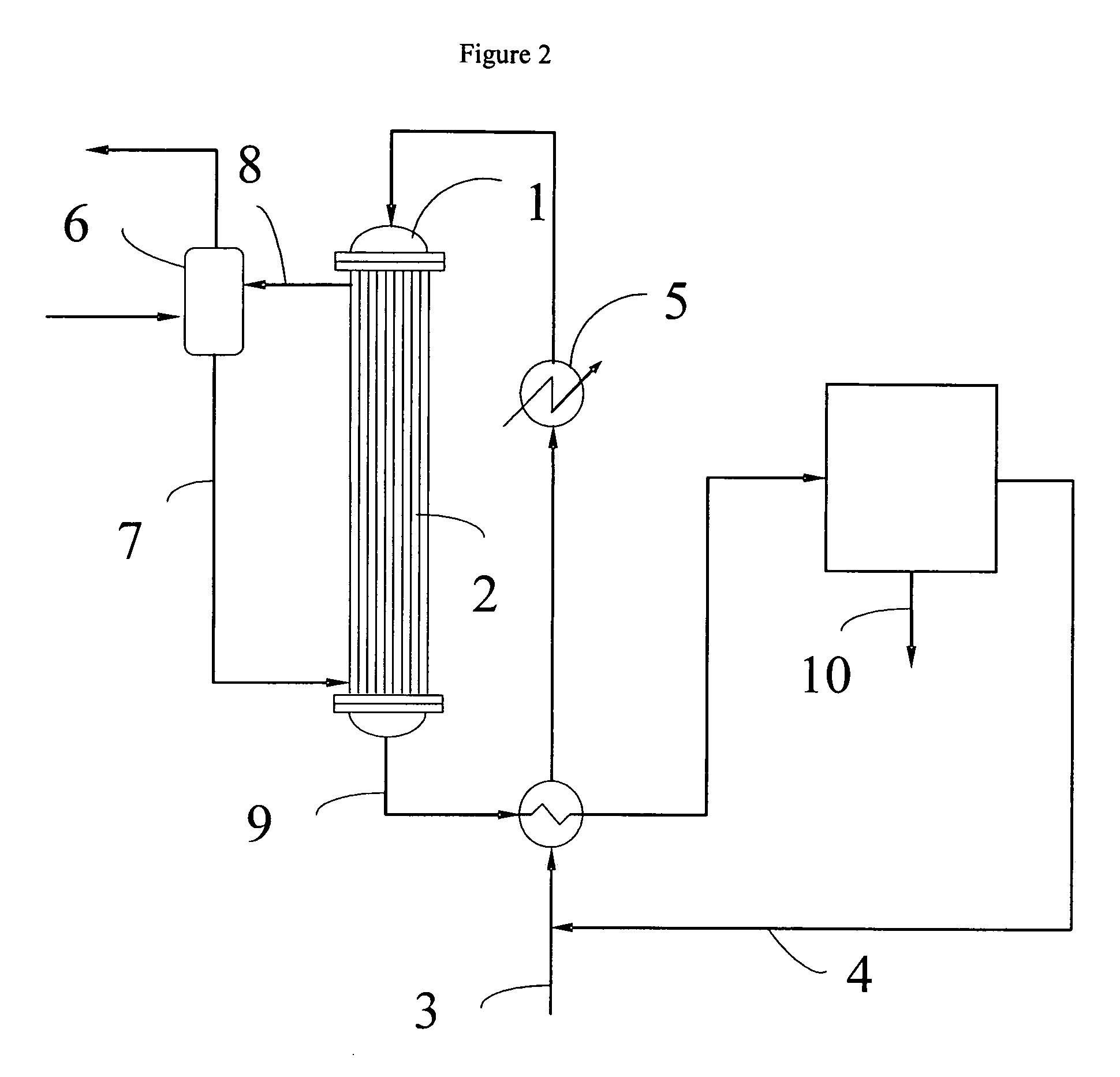

InactiveUS7144923B2Easy temperature controlEfficient heat recoveryOrganic compounds purification/separation/stabilisationOrganic compound preparationSyngasCoolant flow

Methanol is synthesized from pre-heated methanol synthesis gas in one or more adiabatic synthesis stages with cooling of the resultant gas after each stage. Further methanol synthesis is then effected on the resultant partially reacted synthesis gas in a bed of synthesis catalyst cooled by means of a coolant flowing co-currently through tubes disposed in the catalyst bed. After cooling methanol is separated from the unreacted gas. Part of the unreacted gas is combined with make-up gas and used as the coolant fed to the aforesaid tubes, thus producing the pre-heated synthesis gas to be fed to the adiabatic synthesis stages.

Owner:JOHNSON MATTHEY PLC

Homogenous process for the hydrogenation of carboxylic acids and derivatives thereof

InactiveUS7709689B2Improve economyLong catalyst lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenCarboxylic acid

A homogenous process for the hydrogenation of the carboxylic acids and / or derivatives thereof in the presence of a catalyst comprising ruthenium, rhodium, iron, osmium or palladium, and an organic phosphine is described in which the hydrogenation is carried out in the presence of at least about 1% by weight water. A process for regenerating a catalyst comprising ruthenium, rhodium, iron, osmium or palladium and an organic phosphine is also described in which the regeneration is carried out in the presence of hydrogen and water.

Owner:JOHNSON MATTHEY DAVY TECH LTD

Process for preparing bisphenol A

InactiveUS6329556B1Long catalyst lifeHigh strengthCation exchanger materialsOrganic chemistryDivinylbenzenePhenol

This invention relates to a process for preparing bisphenol A by the condensation of phenol with acetone in the presence of cation exchange resin obtained by sulfonating copolymers of monovinyl monomers mainly consisting of styrenes and divinyl monomers as crosslinking agent while using divinylbiphenyl and divinylbenzene mainly as said divinyl monomers and controlling the molar ratio of divinylbiphenyl to divinylbenzene at 10 / 0-2 / 8. The cation exchange resin to be used as catalyst in the condensation reaction shows a long life, maintains the production of bisphenol A over a long period of time, possesses high strength and is useful for economical and advantageous production of bisphenol A.

Owner:NIPPON STEEL CHEMICAL CO LTD

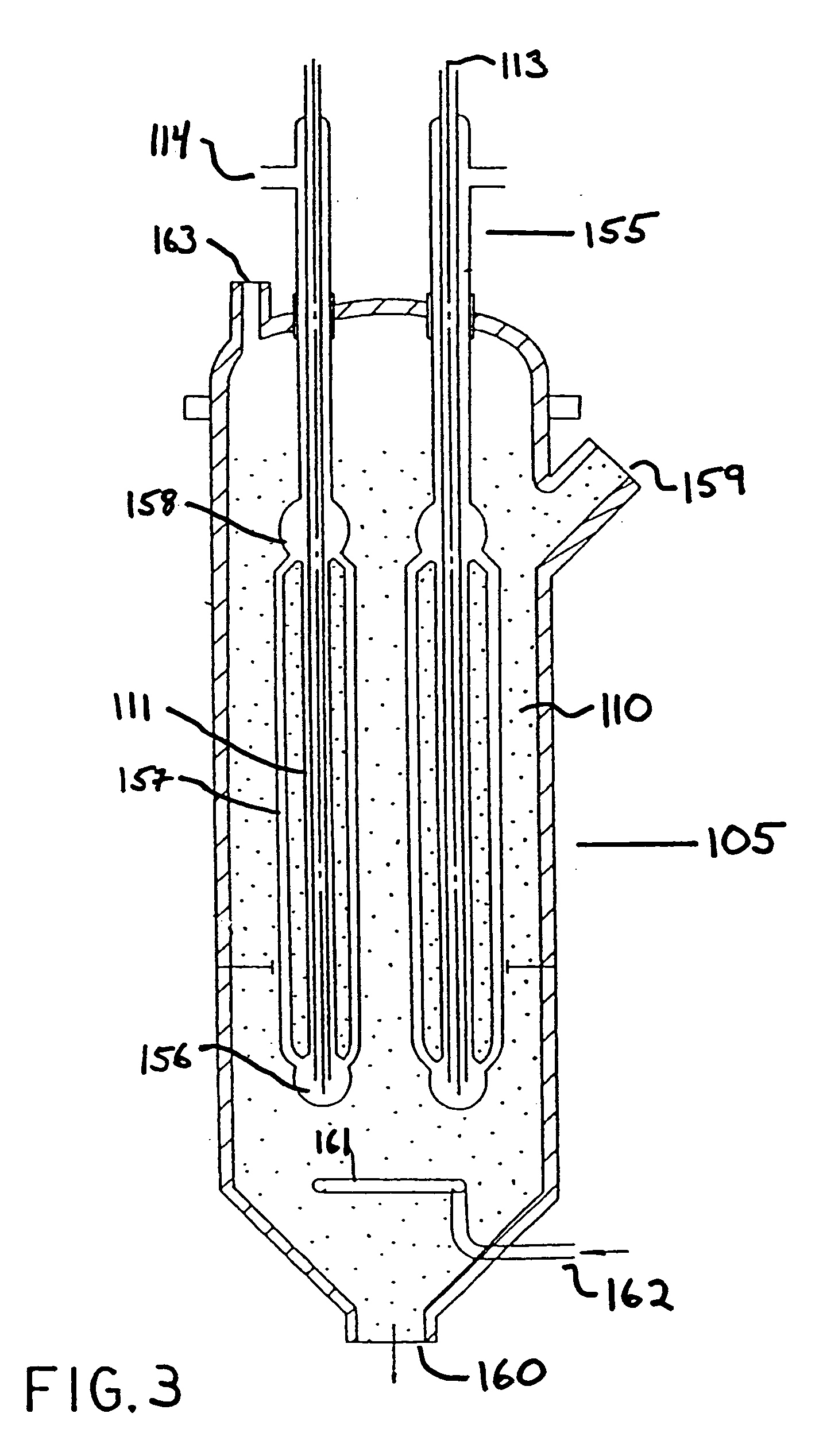

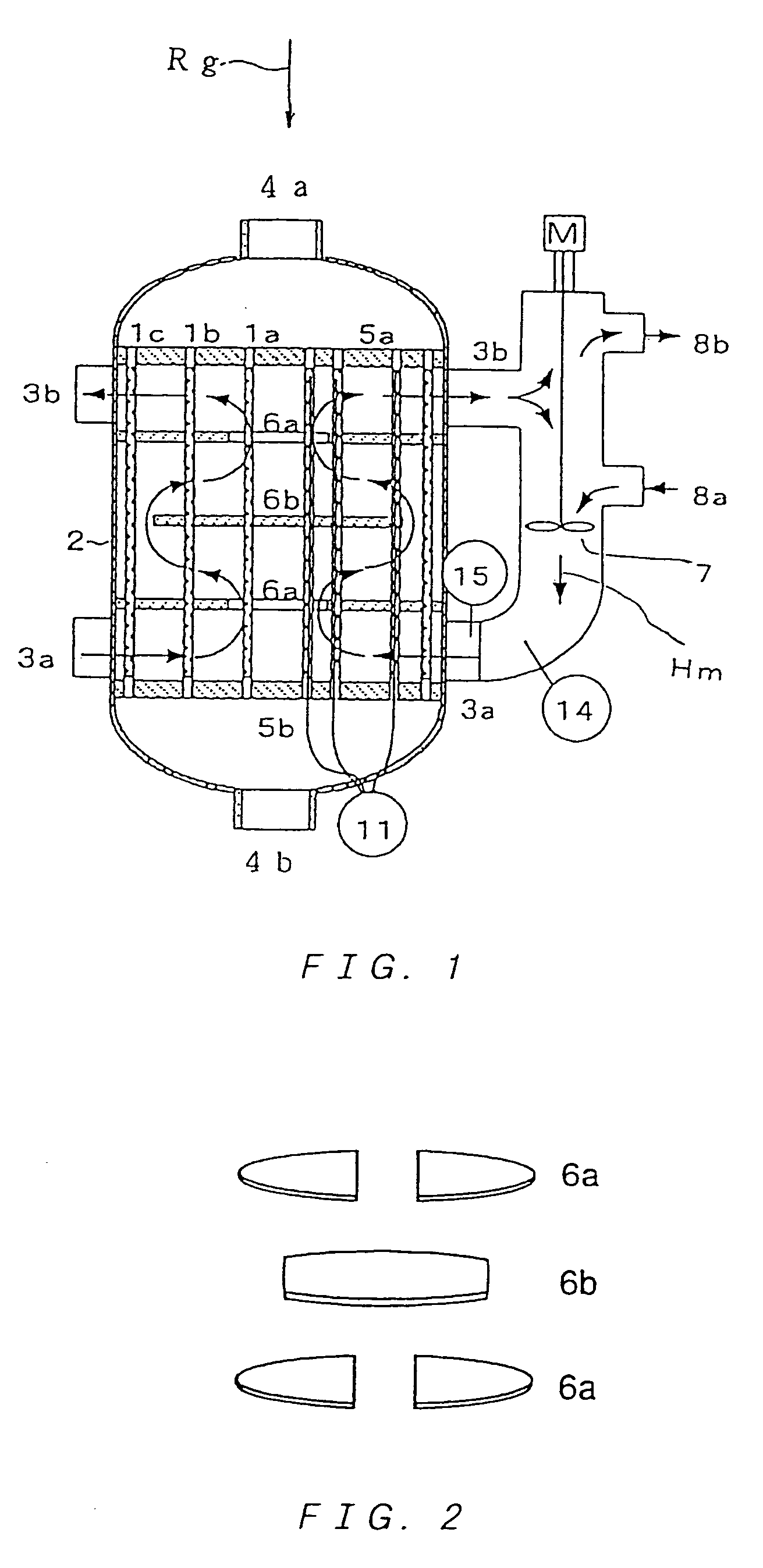

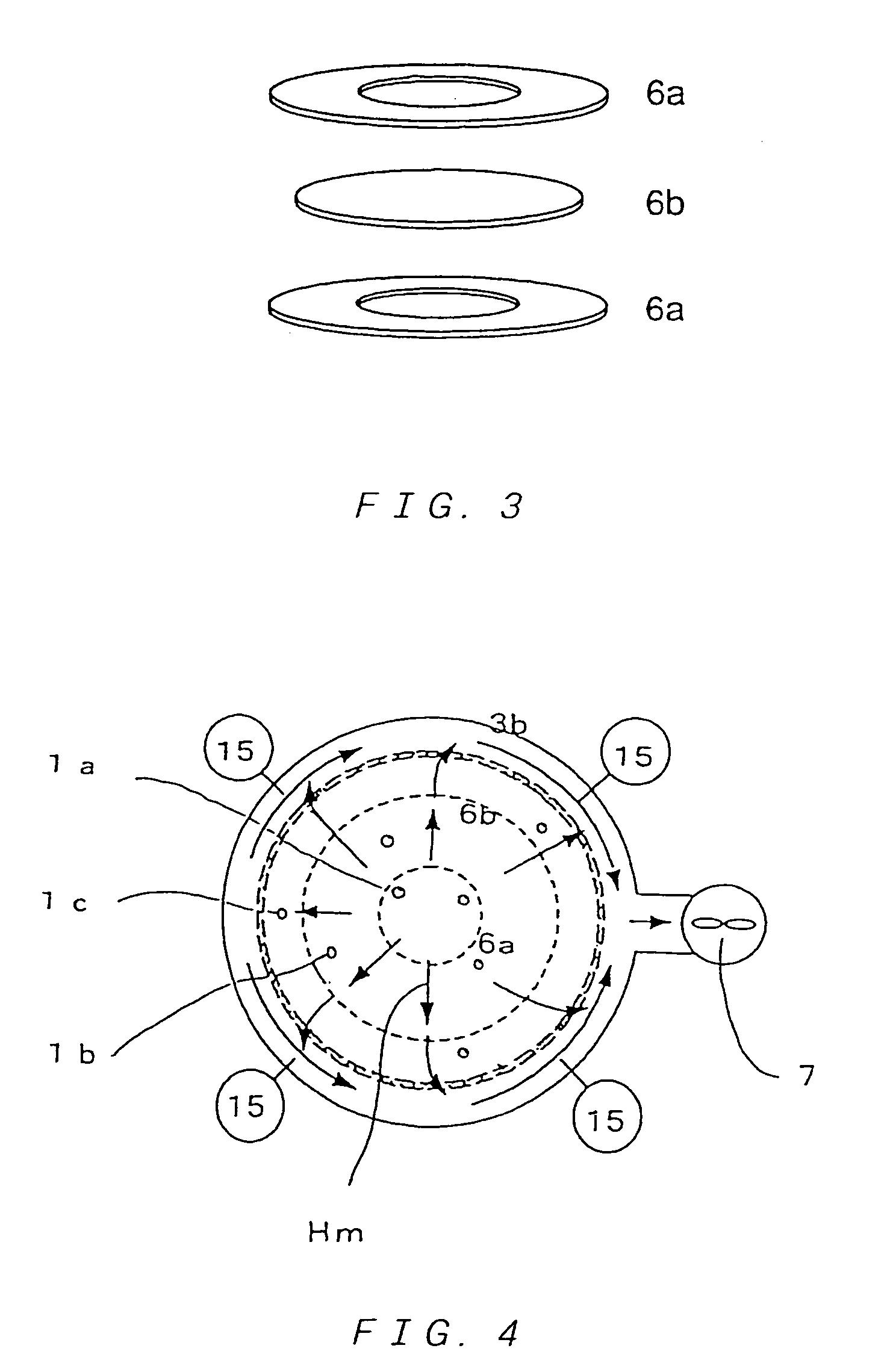

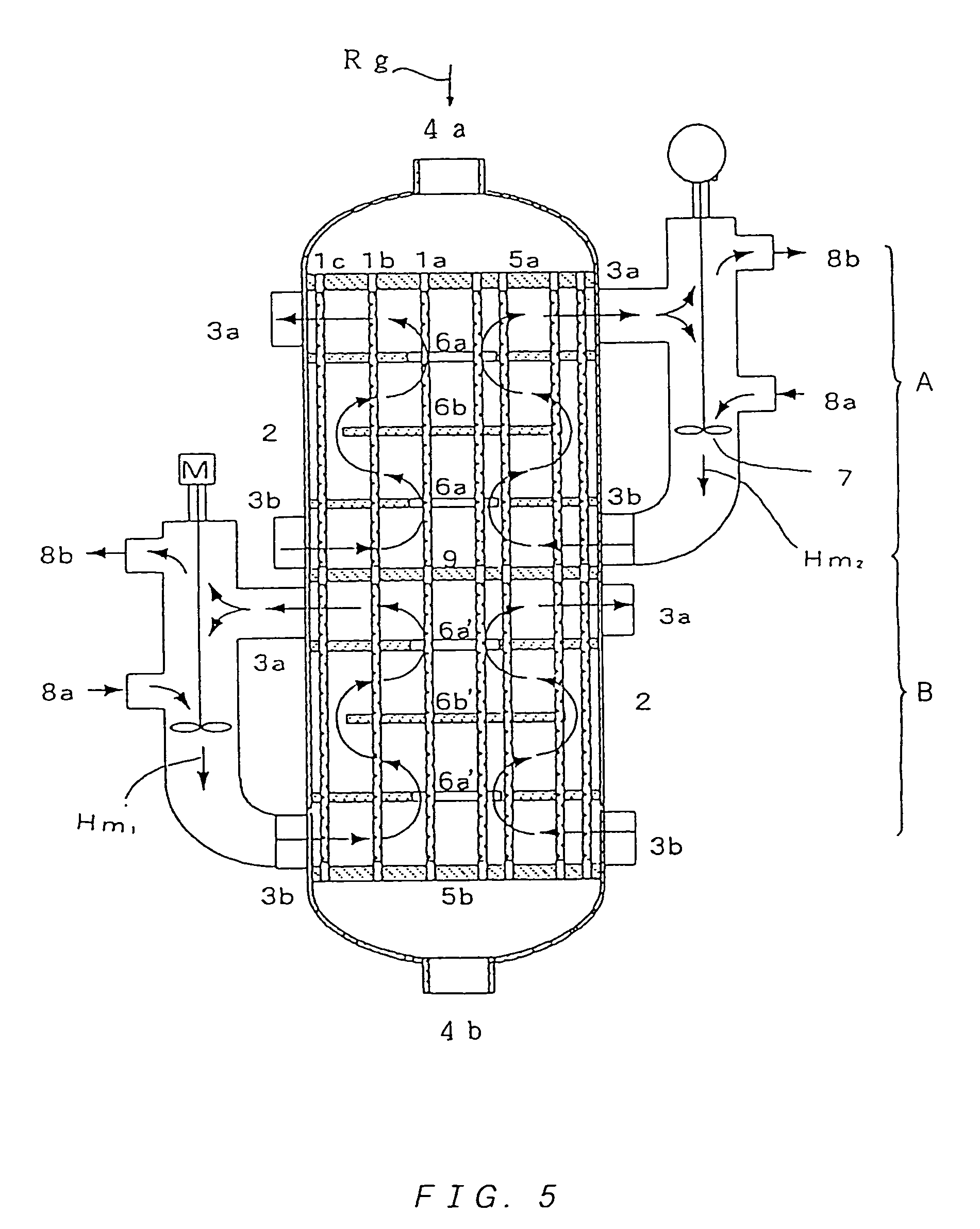

Multitube reactor, vapor phase catalytic oxidation method using the multitube reactor, and start up method applied to the multitube reactor

InactiveUS7144557B2Long catalyst lifeAvoid YieldOrganic compound preparationSafety devices for heat exchange apparatusCatalytic oxidationNominal size

Owner:MITSUBISHI CHEM CORP

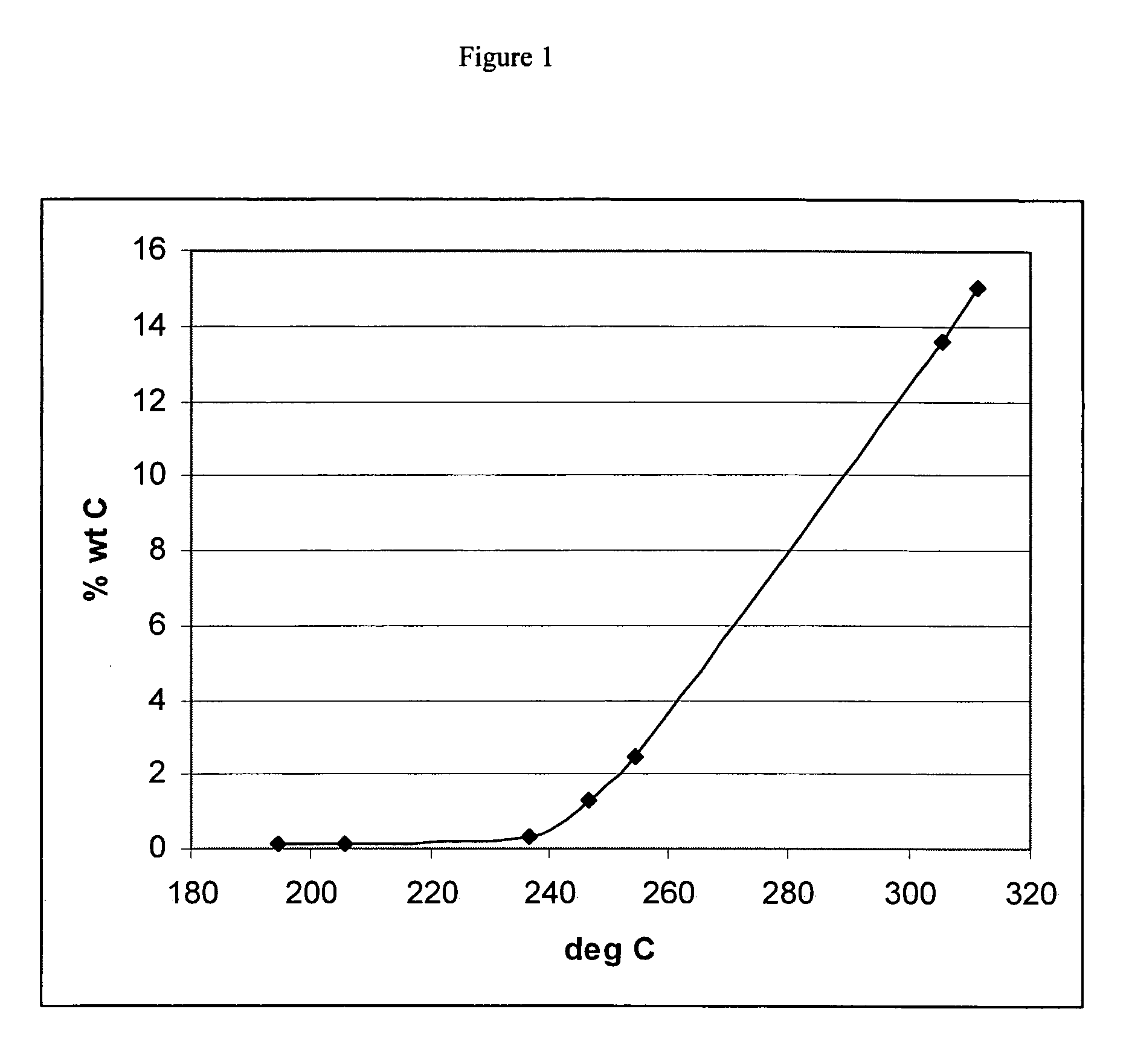

Oligomerisation of Olefins

ActiveUS20090221862A1Not to damageImprove cooling effectHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsPhosphoric acidAlkene

Olefin feeds with high olefin content and / or containing a substance that generates water when contacting the catalyst, are oligomerised over solid phosphoric acid catalyst in tubular reactors by introducing the olefin feed into the reactor and maintaining the reacting mixture under conditions whereby the peak temperature is controlled to be below 265° C. and preferably a single liquid or dense phase is maintained and the average temperature throughout the reactor is maintained in the range 190° C. to 260° C.

Owner:EXXONMOBIL CHEM PAT INC

Sulfur tolerant zeolite catalyst

InactiveUS6063723AHigh yieldHigh selectivityAluminosilicate zeolite type ZSM-12SilicaSulfurDehydrogenation

A process is provided for catalyst dehydrogenation of light paraffinic hydrocarbons using a catalyst comprising a noble metal and an intermediate pore size zeolite having a specified alkali content. The catalyst is sulfur tolerant, so that the dehydrogenation process can be carried out in the presence of sulfur or with periodic exposure to sulfur.

Owner:CHEVROU USA INC

Heavy lube oil from Fischer-Tropsch wax

InactiveUS20080083648A1High product yieldLess of the desirable heavy lubricant base stock oilHydrocarbon oil crackingLiquid hydrocarbon mixture productionWaxFuel oil

A heavy lubricant base stock is made by (a) producing a synthesis gas from natural gas, (b) reacting the H2 and CO in the gas in the presence of a cobalt Fischer-Tropsch catalyst, at reaction conditions effective to synthesize waxy hydrocarbons boiling in the heavy lubricant oil range, which are hydrodewaxed it at least two stages, with interstage separation and removal of the lighter material.

Owner:BISHOP ADEANA RICHELLE +4

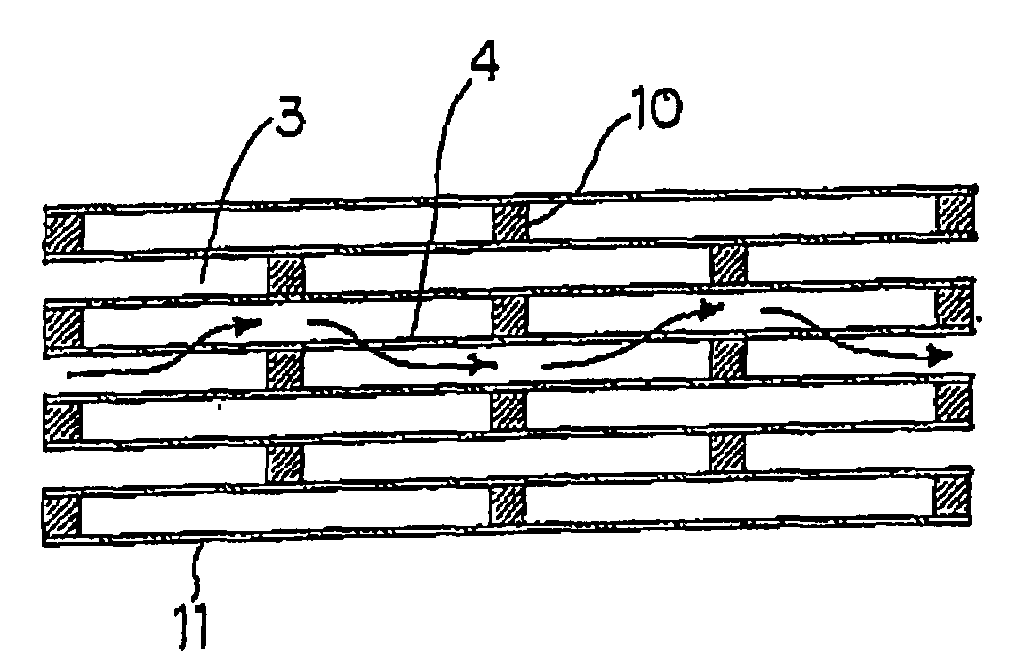

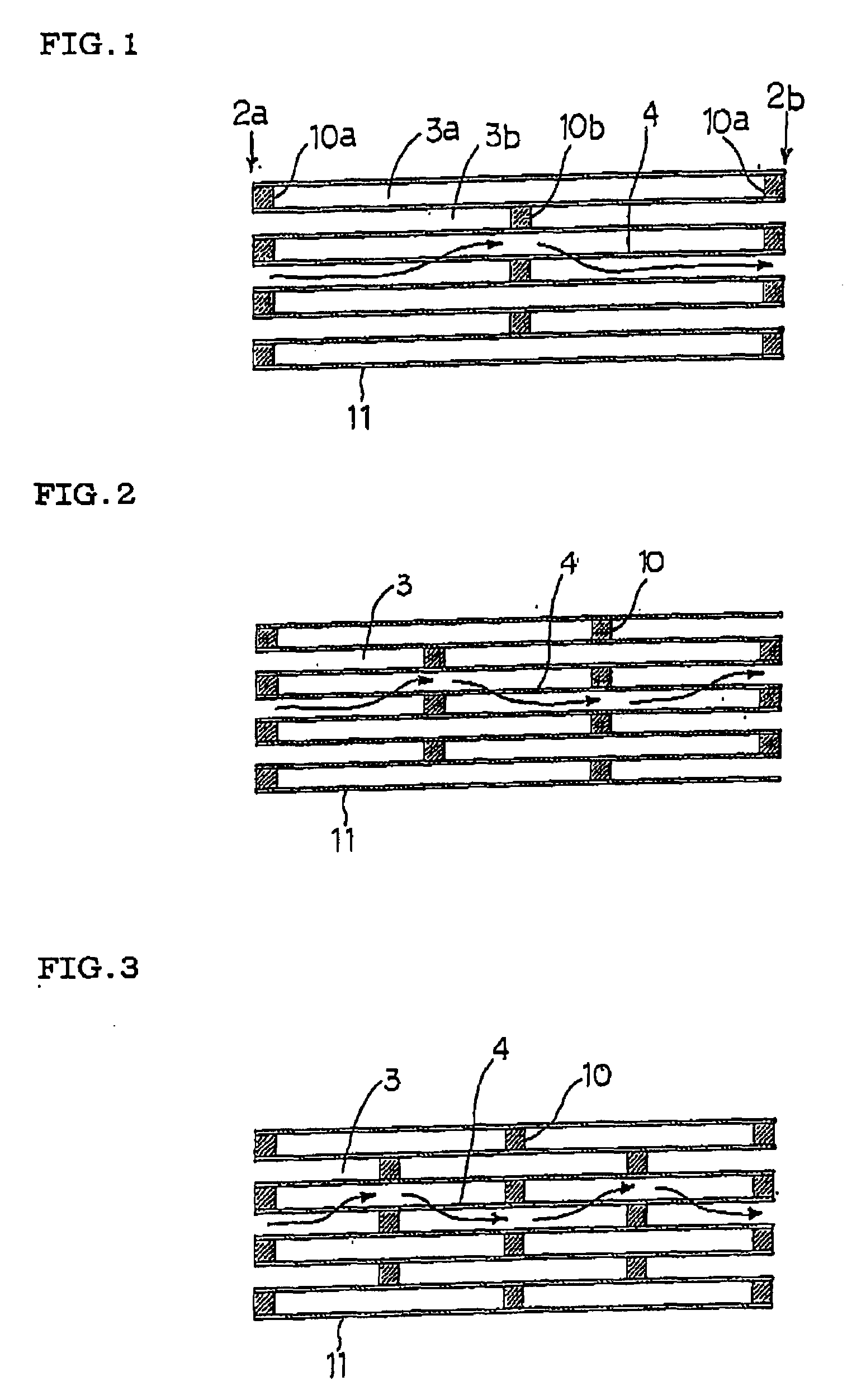

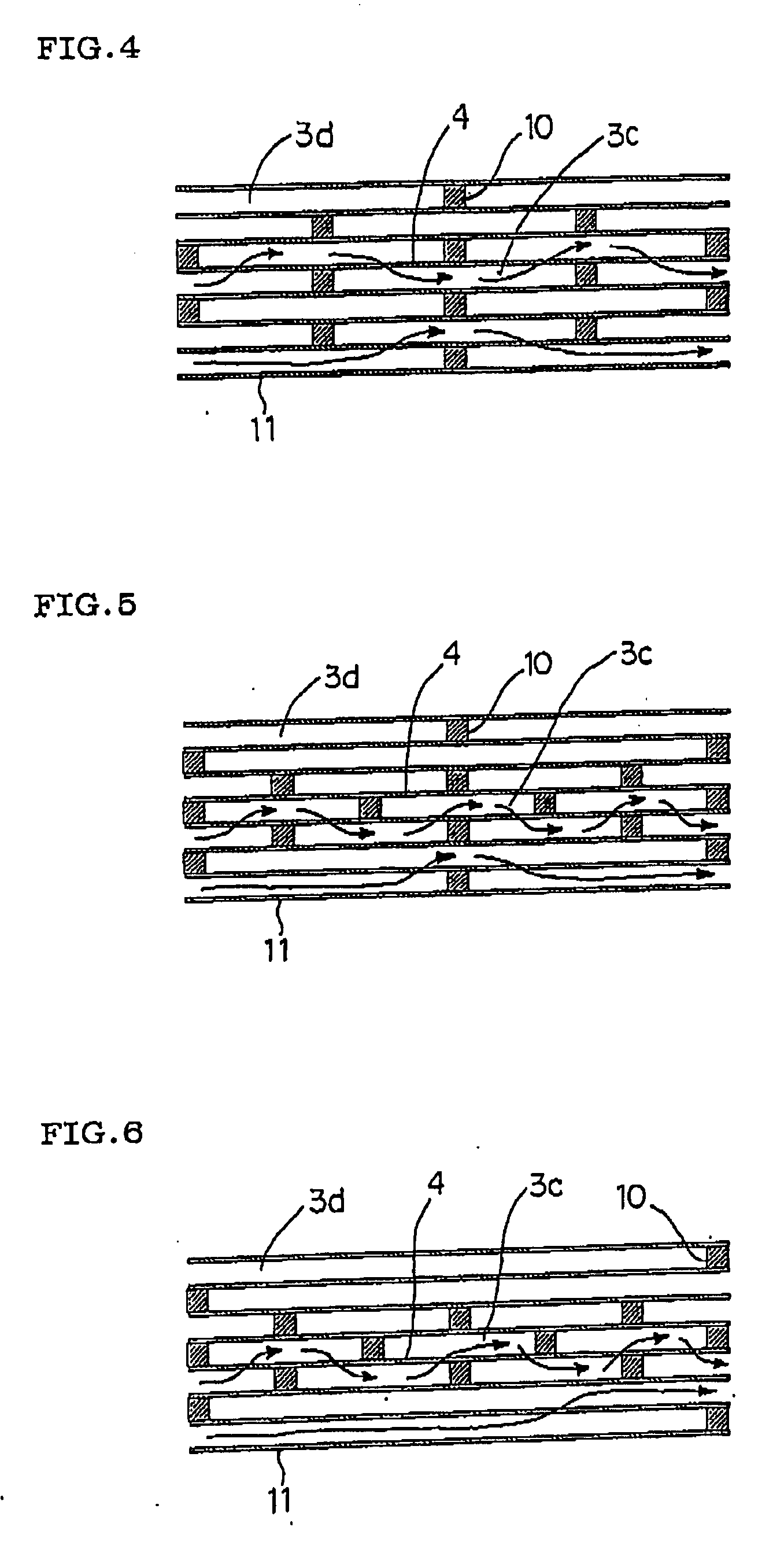

Honeycomb structure and honeycomb catalytic body

InactiveUS20070231539A1High contact efficiencyAmount of catalyst can be reducedInternal combustion piston enginesDispersed particle filtrationStructural engineeringHoneycomb like

There are disclosed a honeycomb catalytic body to which a wall flow structure is applied so that a fluid such as an exhaust gas passes through a partition wall twice or more, and a honeycomb structure for use as a catalyst carrier of the honeycomb catalytic body in which a pore characteristic and the like are appropriately adjusted as the catalytic body. In a honeycomb structure 11 including porous partition walls 4 arranged so as to form a plurality of cells 3 which communicate between two end surfaces of the honeycomb structure and having a large number of pores; and plugging portions 10 arranged so as to plug at least a part of the plurality of cells 3 at any position in a length direction of the cells, an average maximum image distance of the partition walls is larger than 40 μm, and the plugging portions 10 are arranged so that at least a part of a fluid which has entered the cells from one end surface passes through the partition wall 4 twice or more, and is then discharged from the other end portion.

Owner:NGK INSULATORS LTD

Catalyst, process for preparing the catalyst and process for producing lower hydrocarbon with the catalyst

InactiveUS20070032379A1High yieldLow hydrocarbonMolecular sieve catalystsOrganic chemistry methodsAlkaline earth metalDimethyl ether

An alkaline earth metal-containing MFI zeolite catalyst is used when synthesizing a lower hydrocarbon from dimethyl ether and / or methanol, which has a Si / Al atomic ratio ranging from 30 to 400, an alkaline earth metal / Al atomic ratio ranging from 0.75 to 15, and an average particle diameter ranging from 0.05 to 2 μm.

Owner:JGC CORP

Vertically aligned layered double hydroxides (LDHs) film and application thereof in structured catalysis

ActiveCN102343283AAvoid churnControl shapeOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningThiolCatalytic oxidation

The invention discloses a vertically aligned layered double hydroxides (LDHs) film and a preparation method thereof, and belongs to the technical field of an inorganic functional material and controlled preparation thereof. The vertically aligned LDHs film has the characteristics of good stability, high catalysis efficiency, longer catalysis life, easy regeneration procedure and the like in the event that the film is applied to structured catalytic oxidation deodorization of mercaptan. The preparation method of a structured catalyst comprises the following steps: preparing vertically aligned binary and ternary LDHs films on a pure aluminum substrate by an in-situ growth method; calcining the obtained LDHs films at the temperature of 400-500 DEG C to obtain a complex metal oxide film; and then loading cobalt sulfonated phthalocyanine (CoSPc) on the complex metal oxide film to obtain the structured catalyst. The obtained catalyst can be applied to catalytic oxidation of mercaptan and shows the advantages of high catalytic activity and longer catalysis life, thus having potential application prospect in deodorization in petroleum industry.

Owner:BEIJING UNIV OF CHEM TECH

Nanocrystalline accumulation meso-microporous ZSM-5 catalyst and preparation and application

ActiveCN104525245APropylene selectivity is highLong catalyst lifeMaterial nanotechnologyMolecular sieve catalystsMolecular sieveCrystallite

The invention provides a nanocrystalline accumulation meso-microporous ZSM-5 catalyst and preparation and application thereof. The catalyst is aggregated by small grains with particle sizes of 20-100 nm to an aggregation state with a particle size of 200-2000 nm, the aggregation state forms the catalyst, the specific surface area of the catalyst is 350-420 m<2> / g, and the pore volume of the catalyst is 0.25-0.35 cm<3> / g. According to the invention, a mesoporous-microporous composite nanocrystalline accumulation state ZSM-5 molecular sieve is directly synthesized; under the condition of adding no second template, a solid silicon source is pretreated to generate different degrees of depolymerization, the material ratio of the synthesis system is further adjusted, a sodium salt is added to adjust the growth speed in a crystallization process of the molecular sieve, and meanwhile, a two-stage crystallization method is adopted to promote the generation of a crystal nucleus at a low temperature and promote the growth of a crystal at a high temperature, so as to synthesize a serial grain aggregation state ZSM-5 molecular sieve.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Supported advanced oxidation catalyst material and preparation method thereof

ActiveCN107029720APromote engineering applicationOvercoming the problem of weak bindingMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsChemical platingOrganic solvent

The invention belongs to the field of catalyst materials for waste water treatment, and provides a supported advanced oxidation catalyst material and a preparation method thereof. The method includes the steps: (1) pre-treating carrier materials; (2) placing the pretreated carrier materials into plating solution with a pH (potential of hydrogen) value of 3-13, stirring mixture for at least 5 minutes at the temperature ranging from 30 DEG C to 90 DEG C, performing solid-liquid separation, cleaning a solid phase by the aid of water and organic solvents, and drying the cleaned solid phase to chemically-plated carrier materials; (3) aerobically roasting the chemically-plated carrier materials for 1-8 hours at the temperature ranging from 200 DEG C to 1000 DEG C to obtain the catalyst material. According to the catalyst material, metal oxides are uniformly loaded on the surfaces of the carrier materials, binding force among the loaded metal oxides and the carrier materials can be effectively improved, loading capacity is improved, the service life of the catalyst material is prolonged, catalytic activity is improved, and secondary pollution caused by metal ion leaching is effectively relieved.

Owner:成都柏溪环境科技有限公司

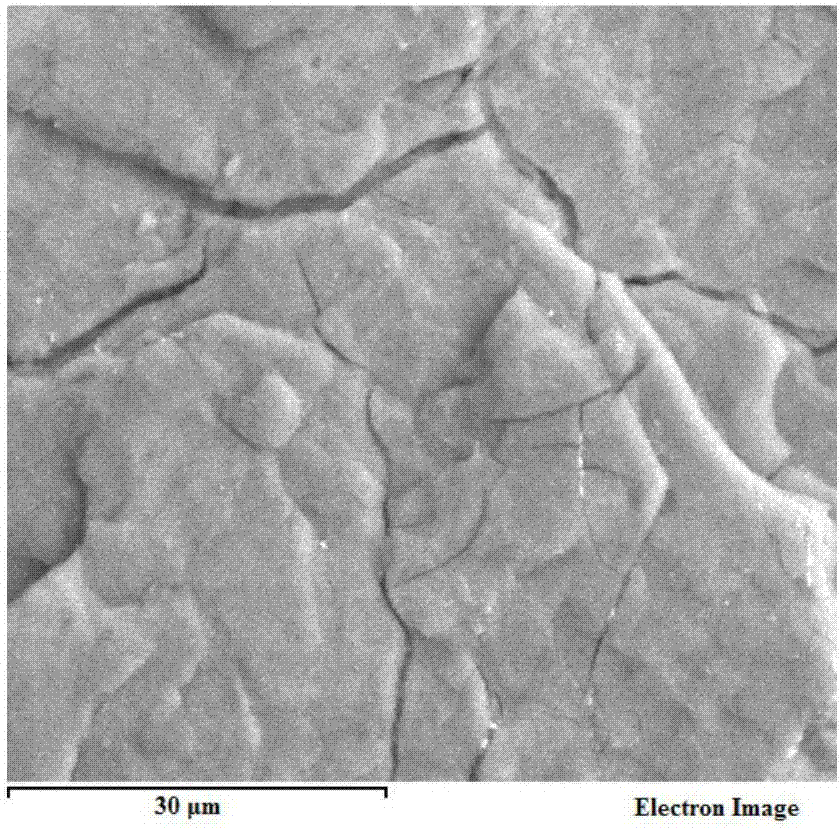

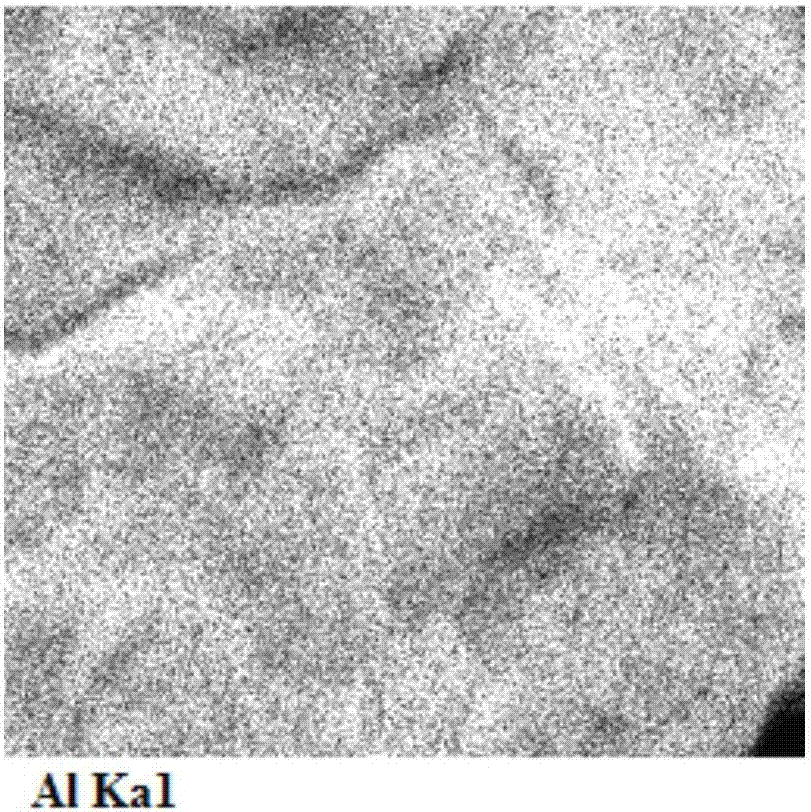

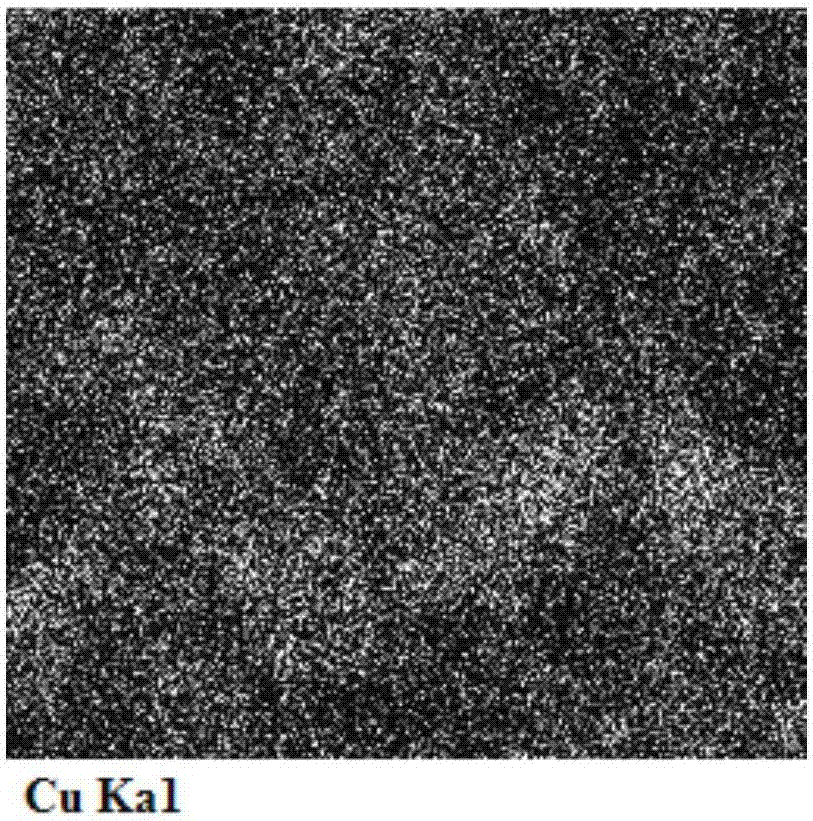

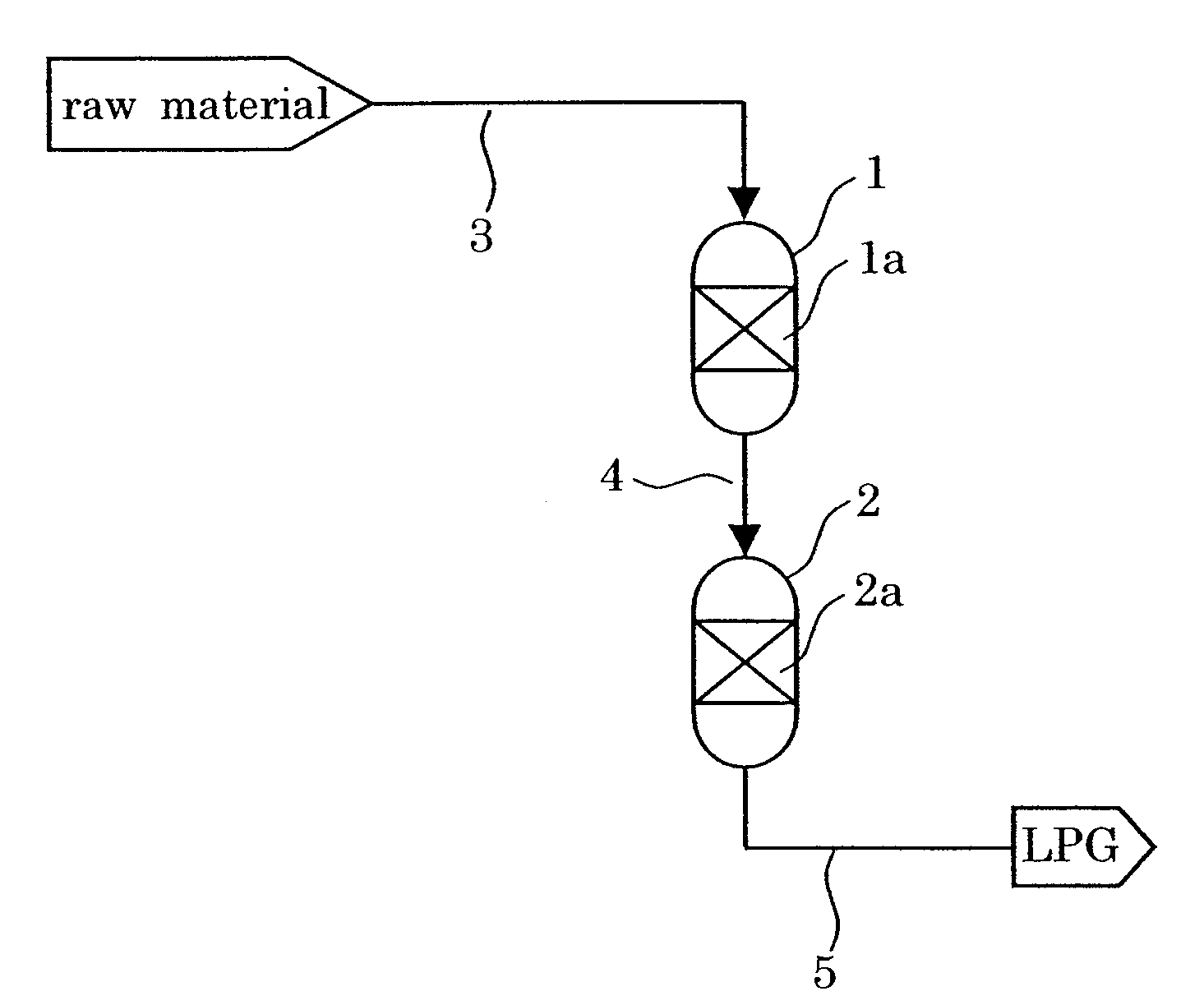

Catalyst and Process for Producing Liquefied Petroleum Gas

InactiveUS20080319245A1Long catalyst lifeLess deteriorationMolecular sieve catalystsGaseous fuelsHydrogenHigh activity

A catalyst for producing a liquefied petroleum gas according to the present invention comprises a methanol synthesis catalyst component in which an olefin-hydrogenation catalyst component is supported on a Zn—Cr-based methanol synthesis catalyst, and a zeolite catalyst component. It can be used in a reaction of carbon monoxide and hydrogen to give a hydrocarbon containing propane or butane as a main component, i.e., a liquefied petroleum gas, with high activity, high selectivity and high yield. Furthermore, the catalyst has a longer catalyst life with less deterioration.

Owner:JAPAN GAS SYNTHESIZE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com