Nanocrystalline accumulation meso-microporous ZSM-5 catalyst and preparation and application

A ZSM-5 catalyst technology, applied in the field of nanocrystalline stacked mesoporous ZSM-5 catalyst and its preparation and application, can solve the problems of cumbersome overall steps and achieve good filtration effect, large specific surface area and pore volume, The effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

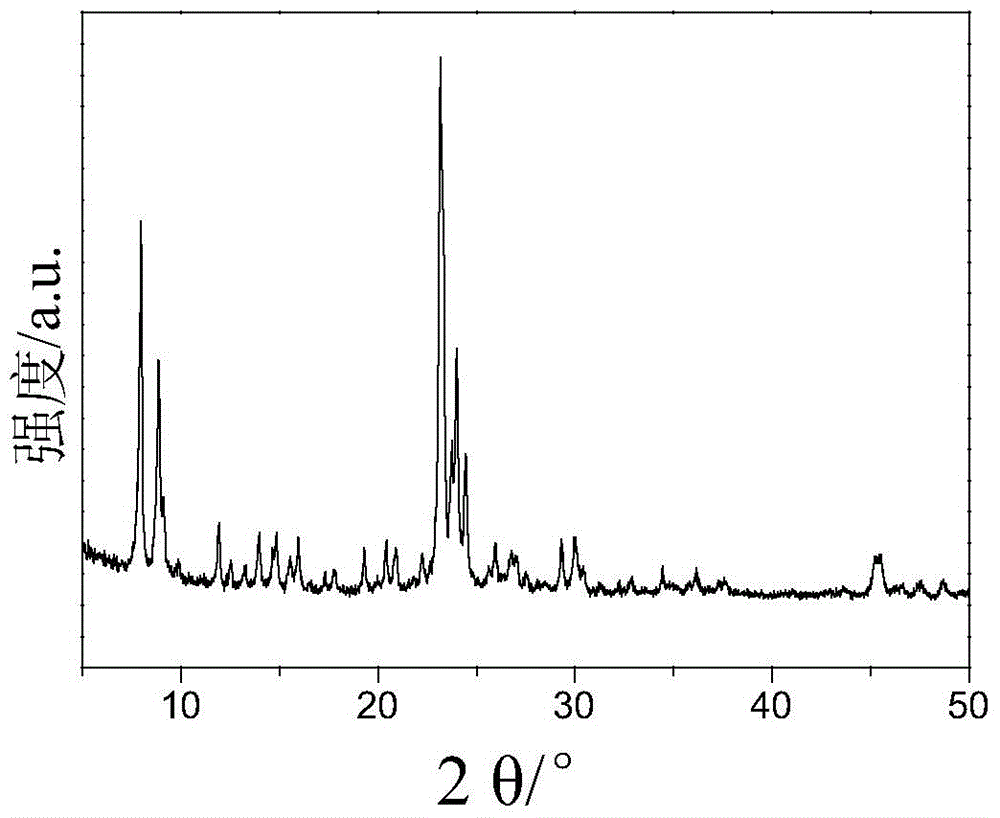

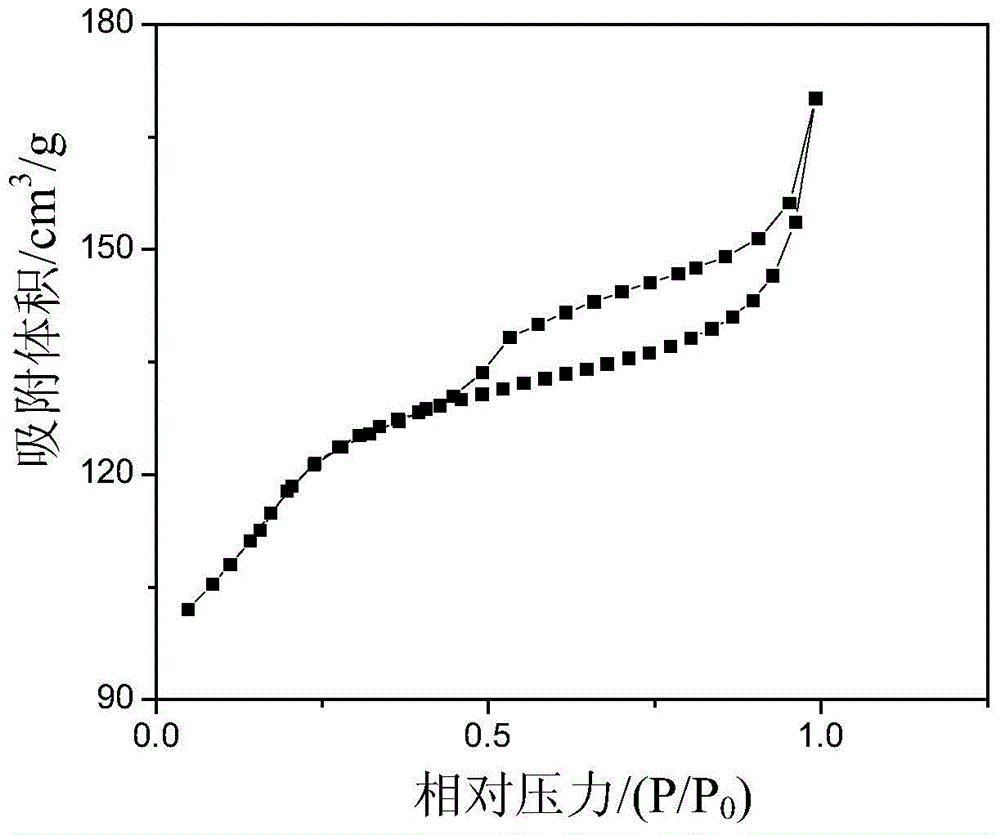

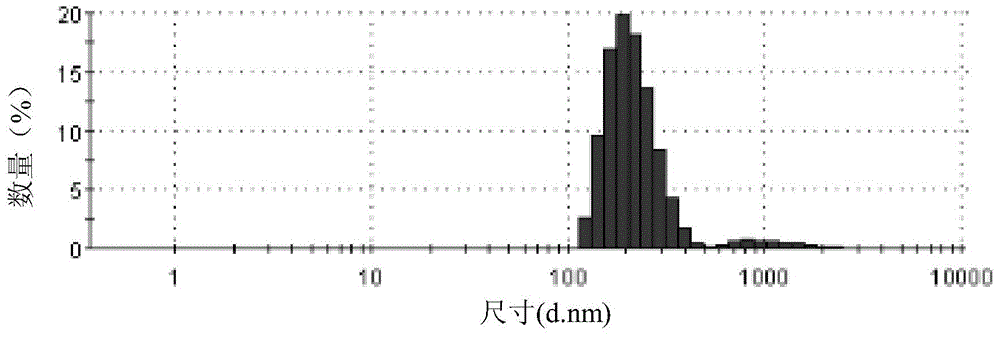

[0116] Add solid sodium silicate and sodium hydroxide to a part of deionized water in sequence, the molar ratio of sodium hydroxide to water is 0.025, mix and stir at 20°C for 2 hours to prepare liquid A. Afterwards, tetraethylammonium bromide, aluminum hydroxide, sodium chloride and the remaining deionized water were thoroughly mixed at 20°C for 2 hours to prepare liquid B. Slowly add liquid B to liquid A, mix well and stir at 20°C for 24h. Among them, based on molar ratio, in the synthesis initial gel system, OH - :Al 2 o 3 : SiO 2 :H 2 O: Na + :TPA + =0.1:0.005:1:5:0.05:0.1. The mixed gel was crystallized in an oven. The crystallization condition of the first stage was crystallization at 100°C for 1 day, and the crystallization condition of the second stage was crystallization at 170°C for 1 day. After the product is filtered, washed and dried, the ZSM-5 molecular sieve raw powder with high crystallinity and mesoporous composite state with a silicon-aluminum ratio o...

Embodiment 2

[0118] Add white carbon black and sodium hydroxide to a part of deionized water in turn, the molar ratio of sodium hydroxide to water is 0.016, mix and stir at 10°C for 4 hours to prepare liquid A. Afterwards, tetraethylammonium bromide, aluminum hydroxide, sodium bromide and the remaining deionized water were thoroughly mixed at 10°C for 2 hours to prepare liquid B. Slowly add liquid B to liquid A and mix evenly at 10°C for 12 hours. Among them, based on molar ratio, in the synthesis initial gel system, OH - :Al 2 o 3 : SiO 2 :H 2 O: Na + :TPA + =0.2:0.002:1:15:0.1:0.3. The mixed gel was crystallized in an oven. The crystallization condition of the first stage was crystallization at 100°C for 1 day, and the crystallization condition of the second stage was crystallization at 170°C for 2 days. After the product is filtered, washed and dried, the ZSM-5 molecular sieve raw powder with high crystallinity and mesoporous composite in a nanocrystalline stacked state with a s...

Embodiment 3

[0120] Add coarse-porous silica gel and sodium hydroxide to a part of deionized water in sequence, the molar ratio of potassium hydroxide to water is 0.015, mix and stir at 12°C for 6 hours to prepare liquid A. Afterwards, tetraethylammonium bromide, aluminum hydroxide, sodium sulfate and the remaining deionized water were thoroughly mixed at 12°C for 2 hours to prepare liquid B. Slowly add liquid B to liquid A and mix evenly at 12°C for 16 hours. Among them, based on molar ratio, in the synthesis initial gel system, OH - :Al 2 o 3 : SiO 2 :H 2 O: Na + :TPA + =0.3:0.00125:1:25:0.15:0.5. The mixed gel was crystallized in an oven. The crystallization condition of the first stage was crystallization at 100°C for 3 days, and the crystallization condition of the second stage was crystallization at 170°C for 3 days. After the product is filtered, washed and dried, the ZSM-5 molecular sieve raw powder with high crystallinity and mesoporous composite in a nanocrystalline stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com