A kind of shaped molecular sieve catalyst and its preparation method and application

A molecular sieve and catalyst technology, which is applied in the field of shaped molecular sieve catalysts and their preparation, to achieve the effects of improving performance, simplifying operating procedures, and improving anti-coking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment HZ1-HZ4

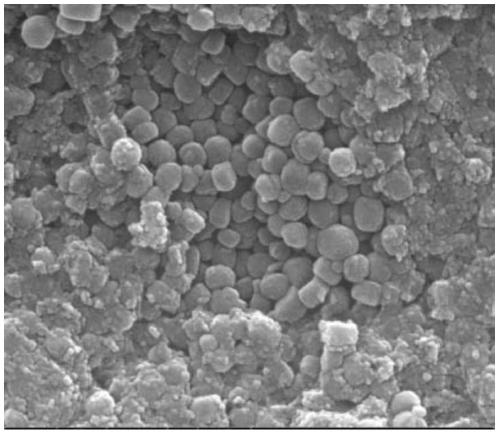

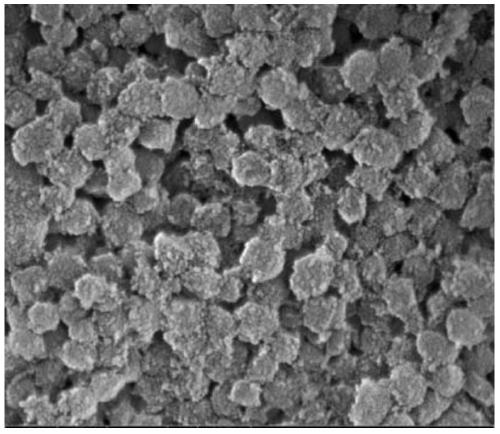

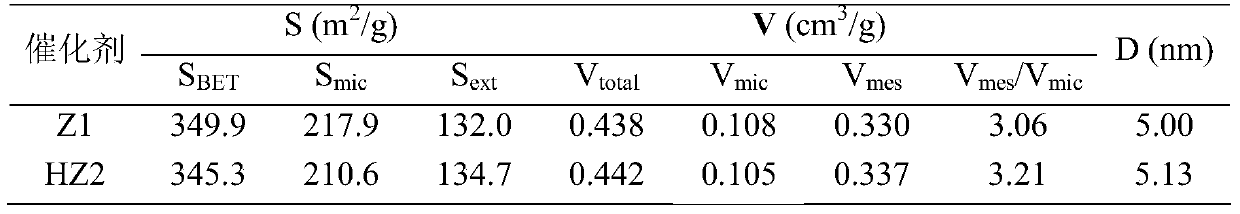

[0061] Select the molecular sieve solution with a silicon-aluminum ratio of 200 and a particle size of about 150nm after crystallization and perform membrane filtration. After the pH of the filtrate is between 7-8, the water content is 10%, 25%, respectively. 35%, 50% molecular sieve slurry, mix the slurry with pseudo-boehmite, nitric acid solution and safflower powder according to the following mass ratio, the mass ratio of molecular sieve dry base to pseudo-boehmite is 7:3, nitric acid solution (containing The mass of water in the molecular sieve solution is 50% of the total mass of molecular sieve dry base and pseudo-boehmite, and the mass of safflower powder is 1% of the total mass of molecular sieve dry base and pseudo-boehmite. Stir evenly and carry out extrusion molding , After drying at 100°C, bake at 600°C for 6 hours. The obtained sample was treated with 1mol / L NH 4 Cl was exchanged at 90°C for 2 hours, and then dried and calcined under the same conditions. After t...

Embodiment HZ5-HZ7

[0063] Select a molecular sieve slurry with a silicon-aluminum ratio of 500, a particle size of 50nm, a water content of 10%, and a pH between 7-8, and mix the slurry with kaolin, nitric acid solution, and scallion powder according to the following mass ratios. Molecular sieve dry basis The mass ratio of kaolin is 8:2, 7:3, 6:4, the mass of nitric acid solution (including water in molecular sieve slurry) is 50% of the total mass of molecular sieve dry basis and pseudo-boehmite, and the mass of squid powder is molecular sieve Dry basis and 1% of the total mass of pseudo-boehmite, stirred evenly, extruded, dried at 100°C, and then calcined at 600°C for 6 hours. The obtained sample was treated with 1mol / L NH 4 Cl was exchanged at 90°C for 2 hours, and then dried and calcined under the same conditions. After two exchanges, shaped molecular sieve catalysts HZ5-HZ7 are finally obtained.

Embodiment HZ8-HZ9

[0065] Select the molecular sieve slurry with a silicon-aluminum ratio of 100, a particle size of 500nm, a water content of 25%, and a pH between 7-8 (the slurry is mixed with activated alumina, kaolin, nitric acid solution and scallop powder according to the following mass Proportional mixing, the mass ratio of molecular sieve dry basis to binder is 7:3, the mass of nitric acid solution (including water in molecular sieve slurry) is 50% of the total mass of molecular sieve dry basis and binder, and the mass of squid powder is molecular sieve dry basis 1% of the total mass of the binder, stirred evenly and extruded, dried at 100°C and then roasted at 600°C for 6 hours. The obtained sample was mixed with 1mol / L NH 4 Cl was exchanged at 90°C for 2 hours, and then dried and calcined under the same conditions. After two exchanges, shaped molecular sieve catalysts HZ8-HZ9 are finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com