Patents

Literature

436results about How to "Reduce olefin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

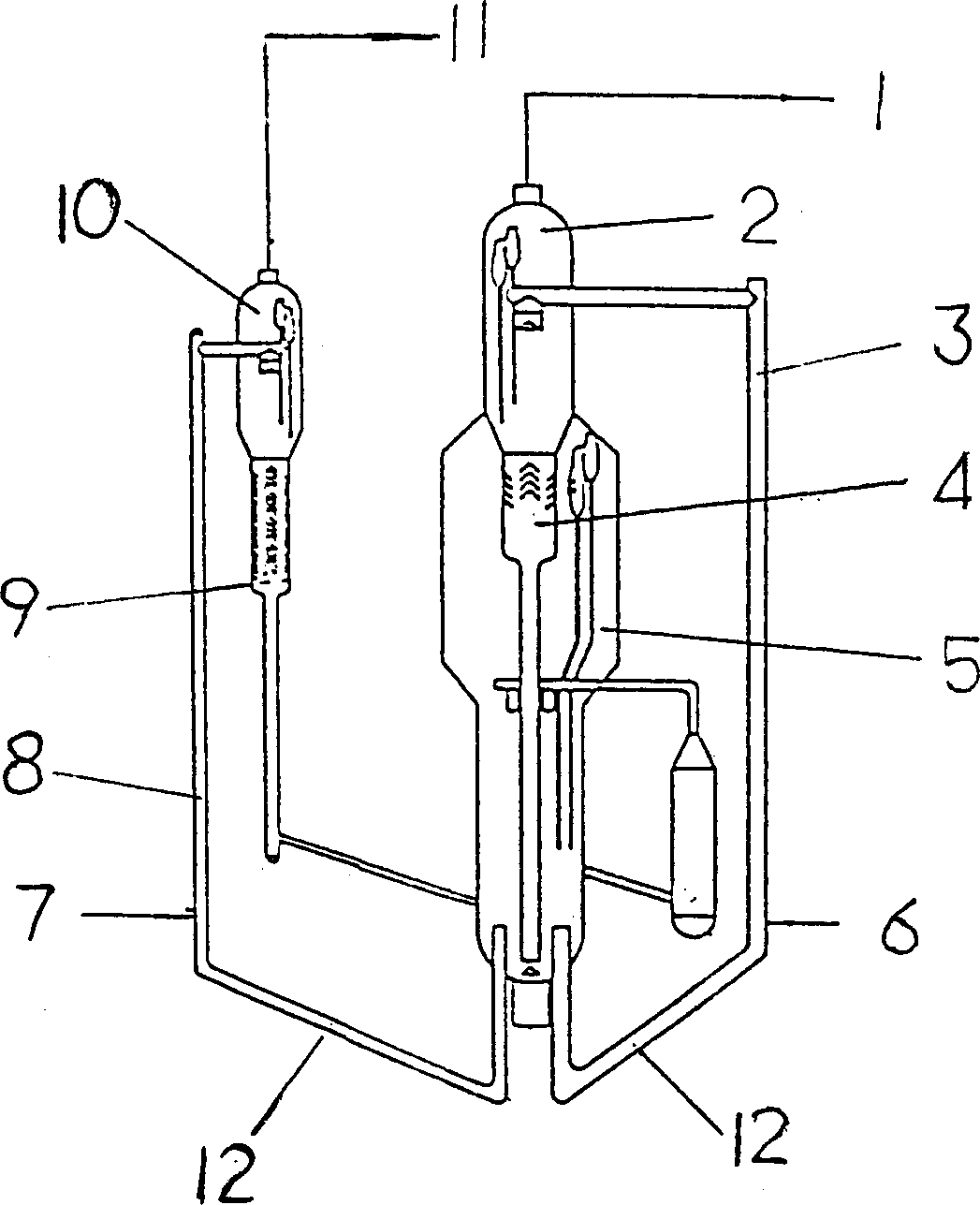

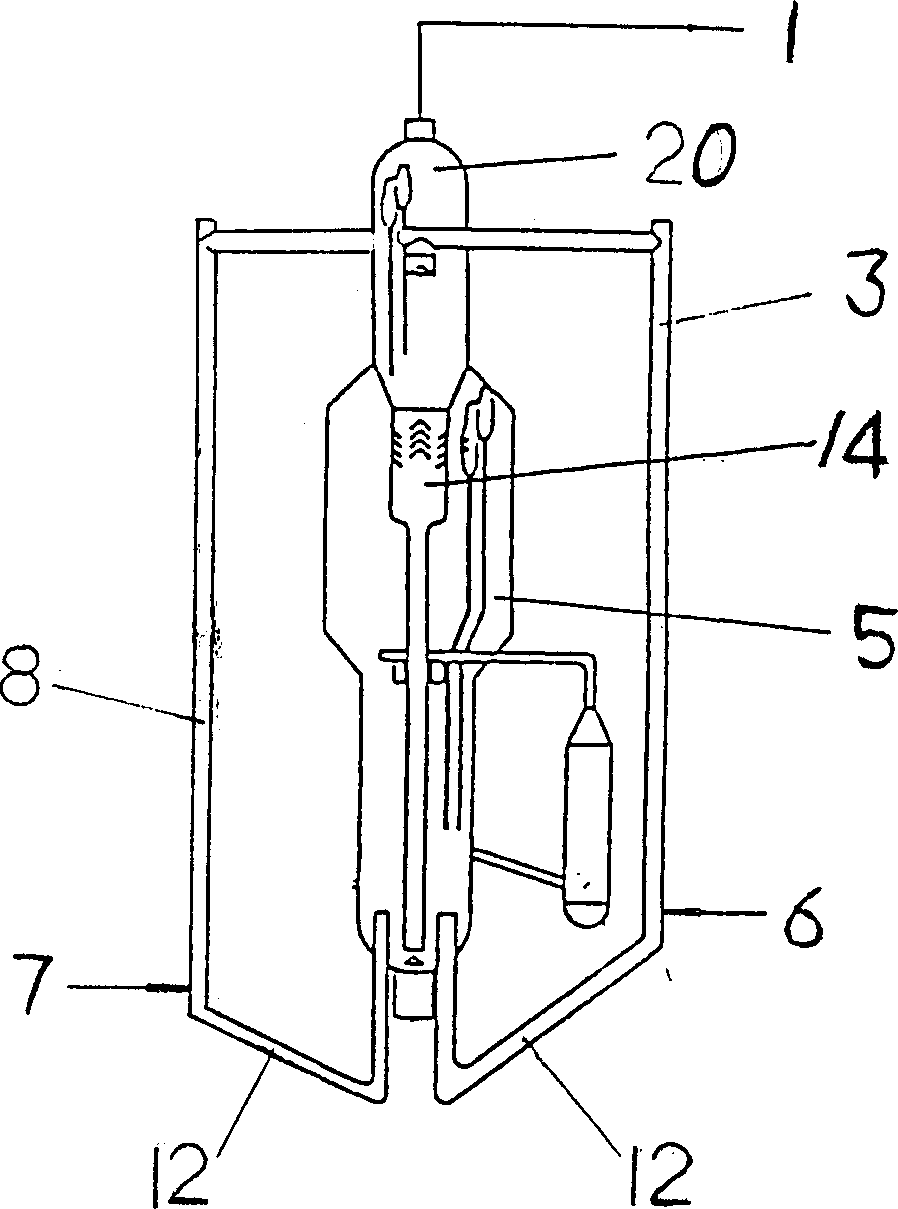

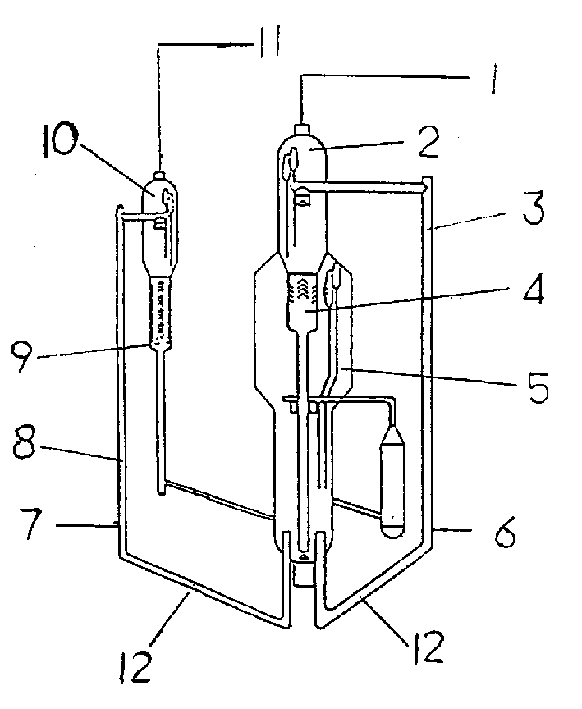

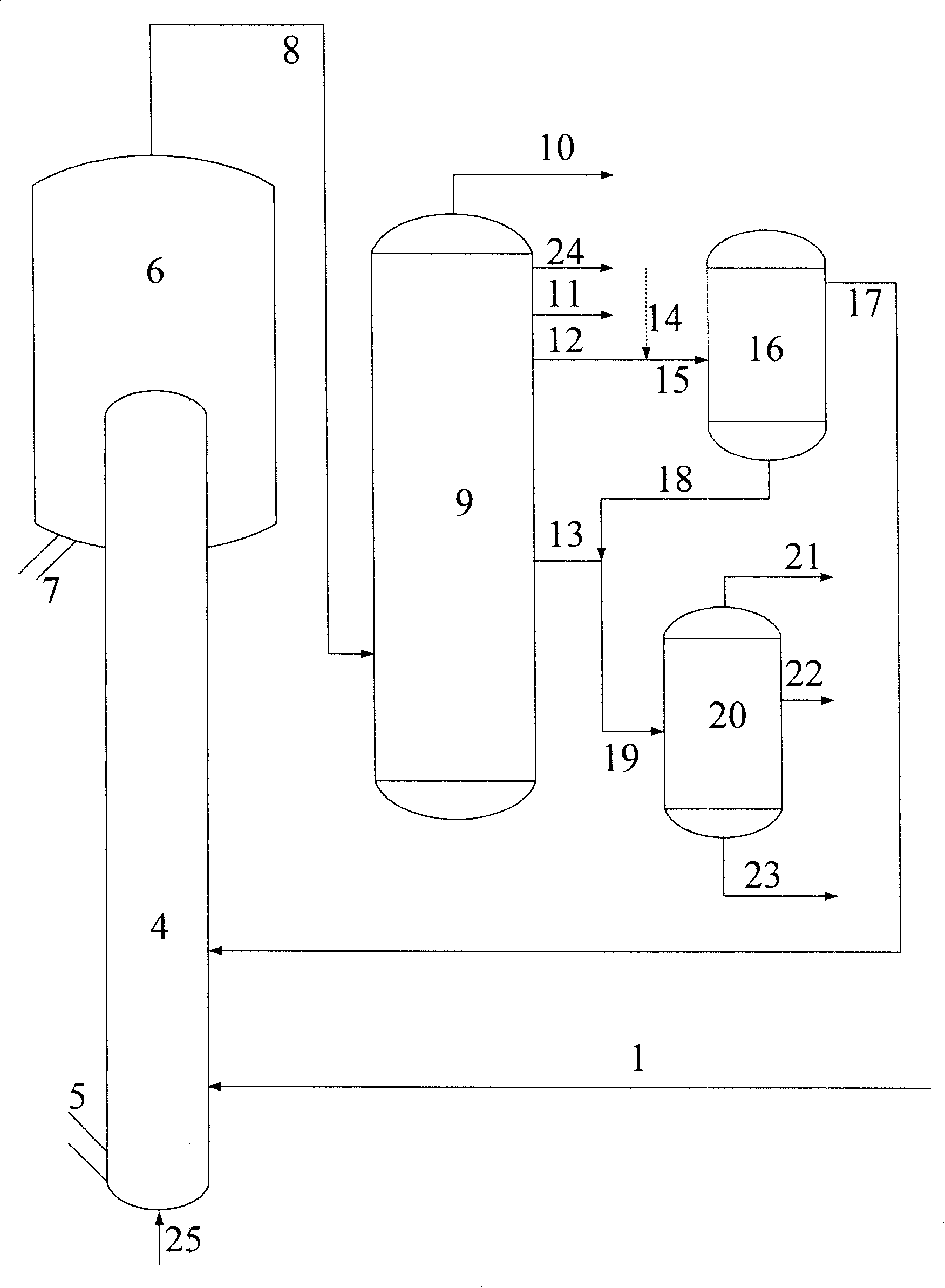

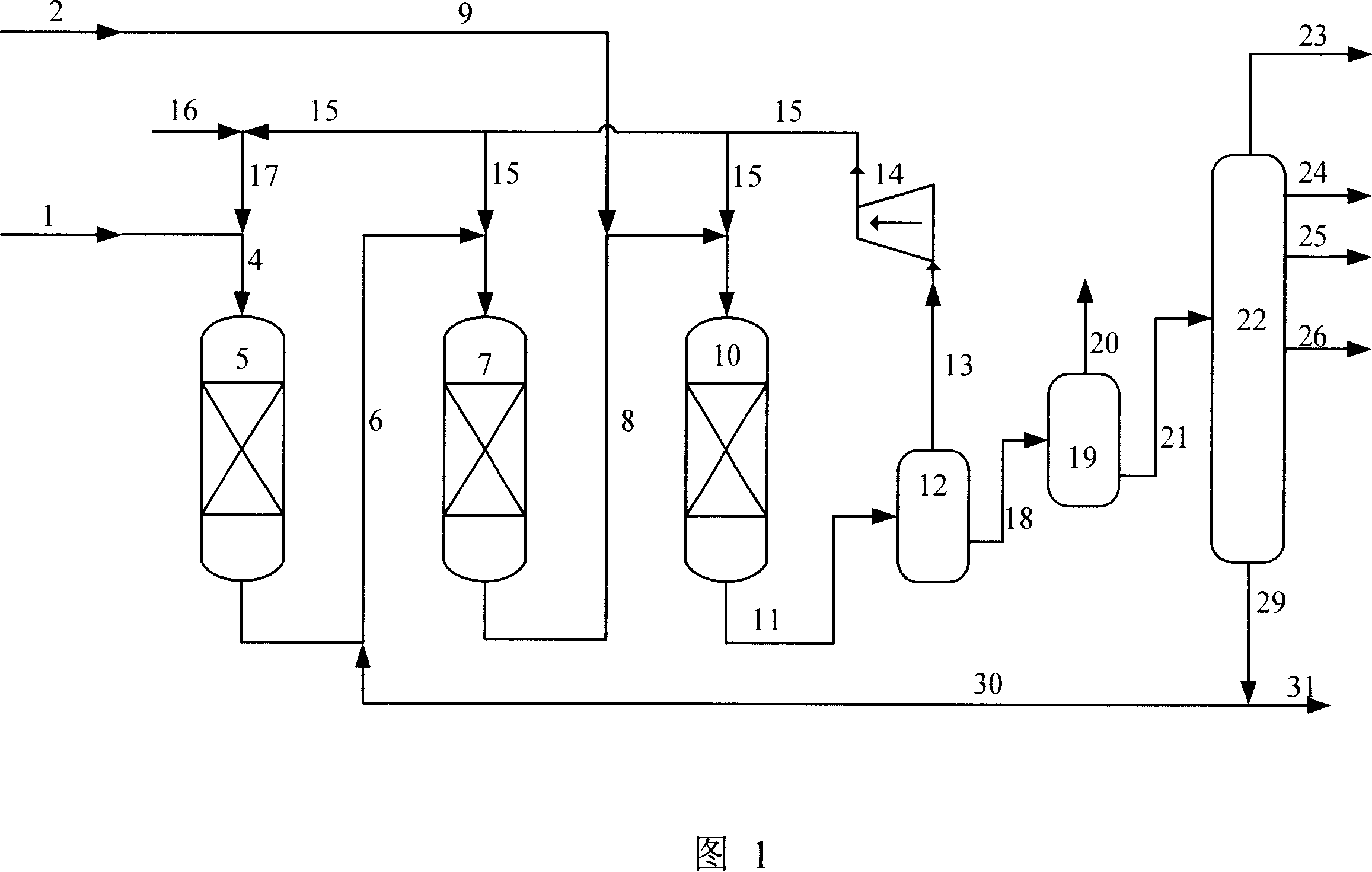

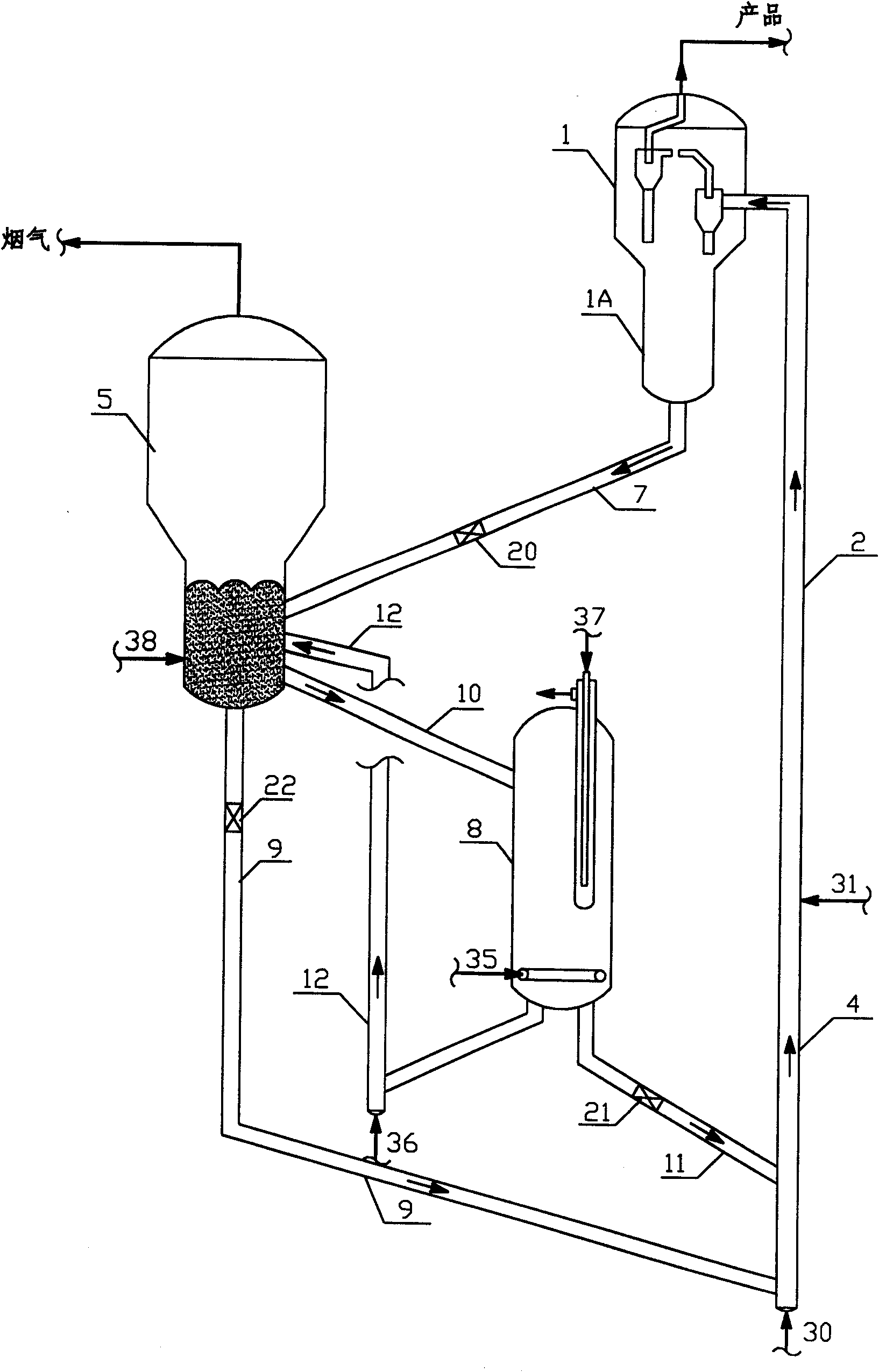

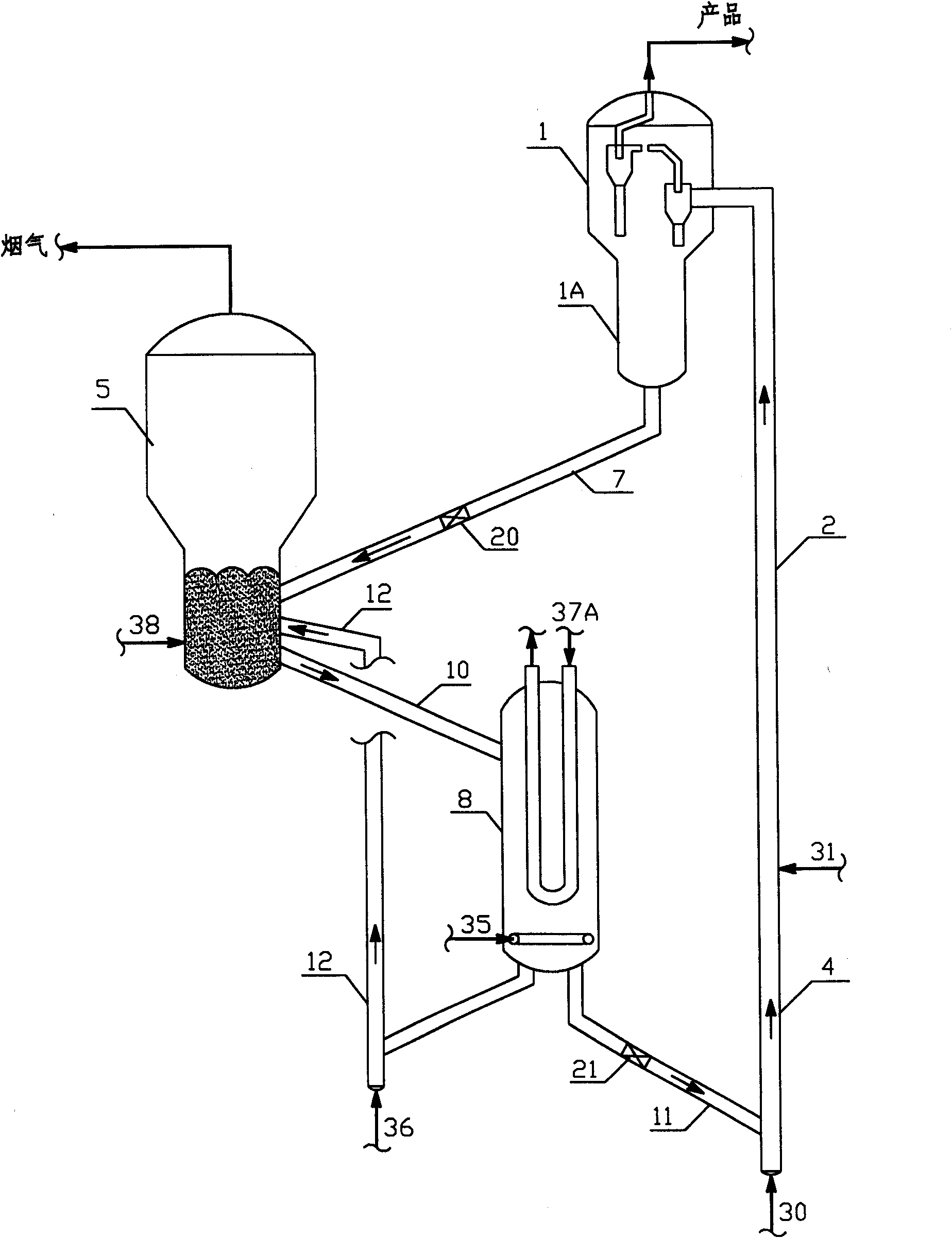

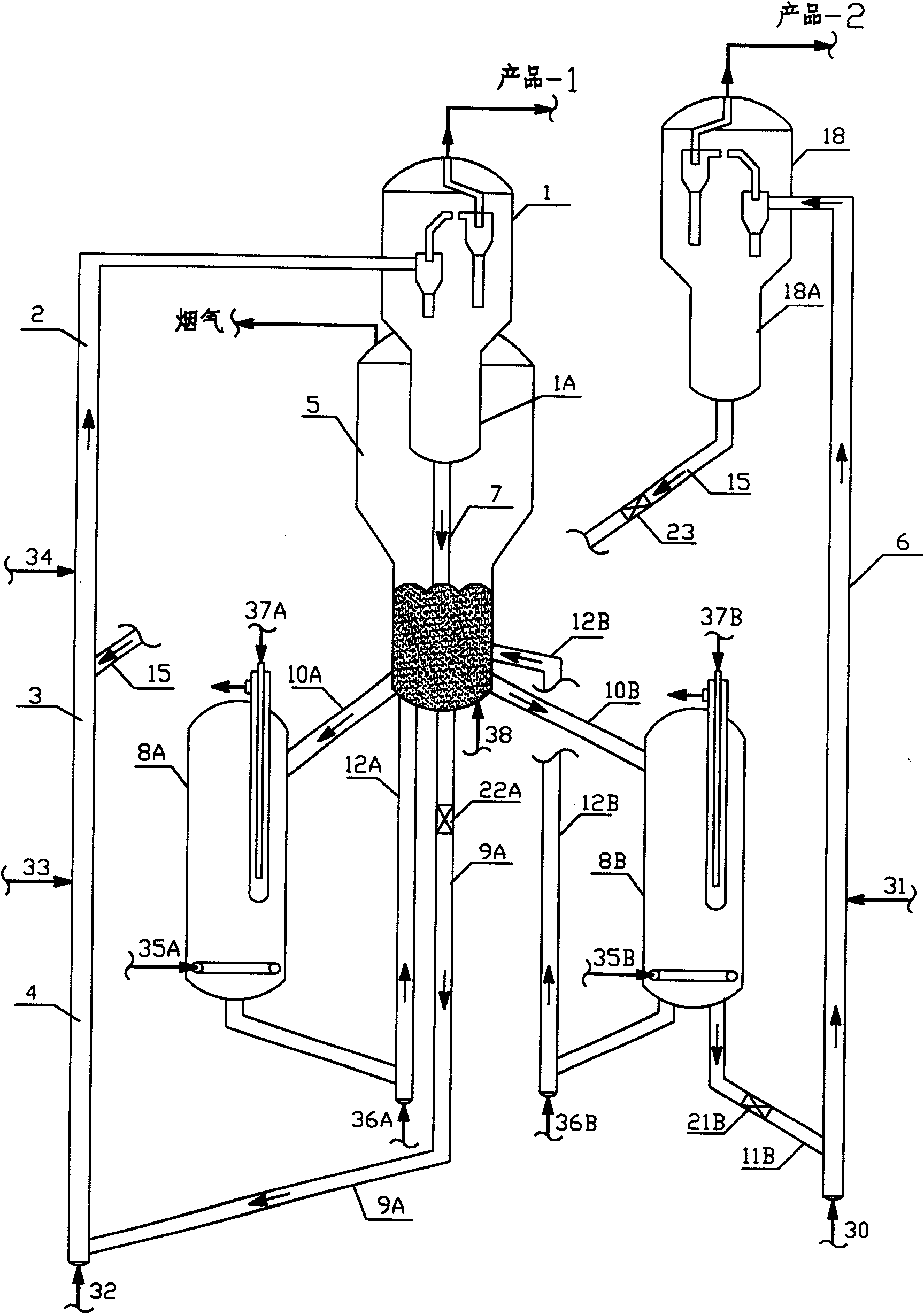

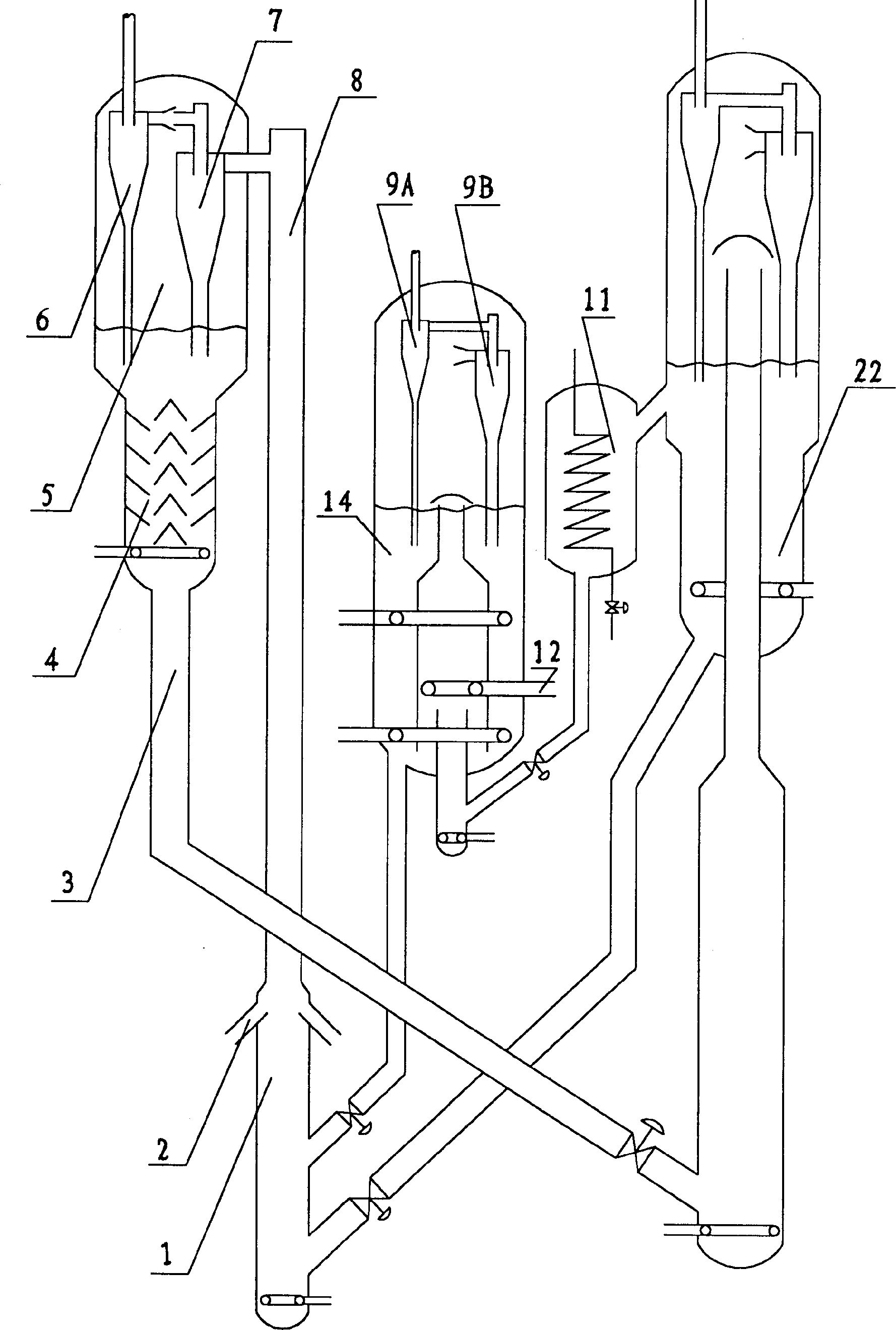

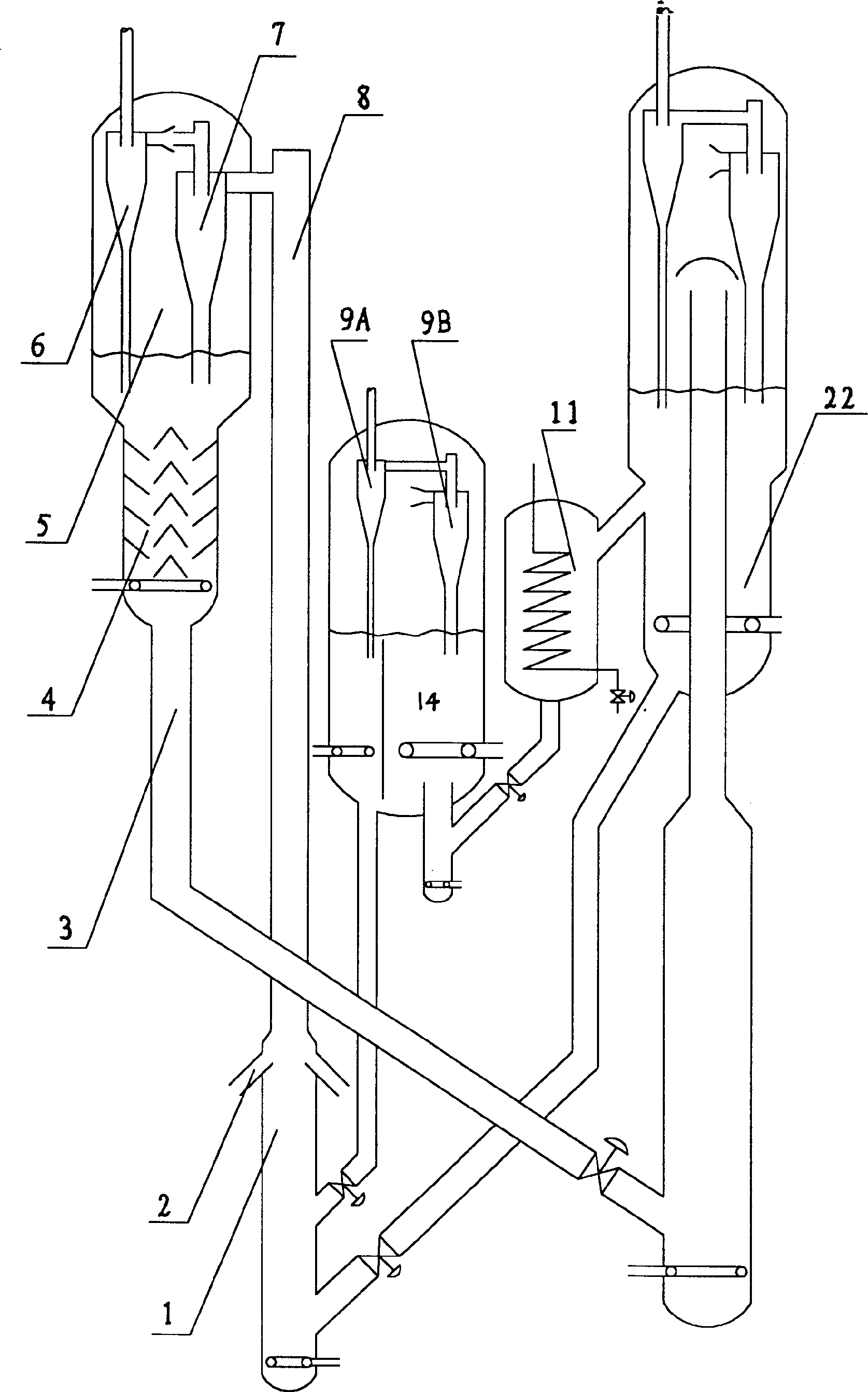

Catalytic conversion method and apparatus for upgrading poor gasoline

InactiveCN1401740AReduce olefin contentReduce sulfur contentTreatment with plural serial stages onlyCatalytic transformationFuel oil

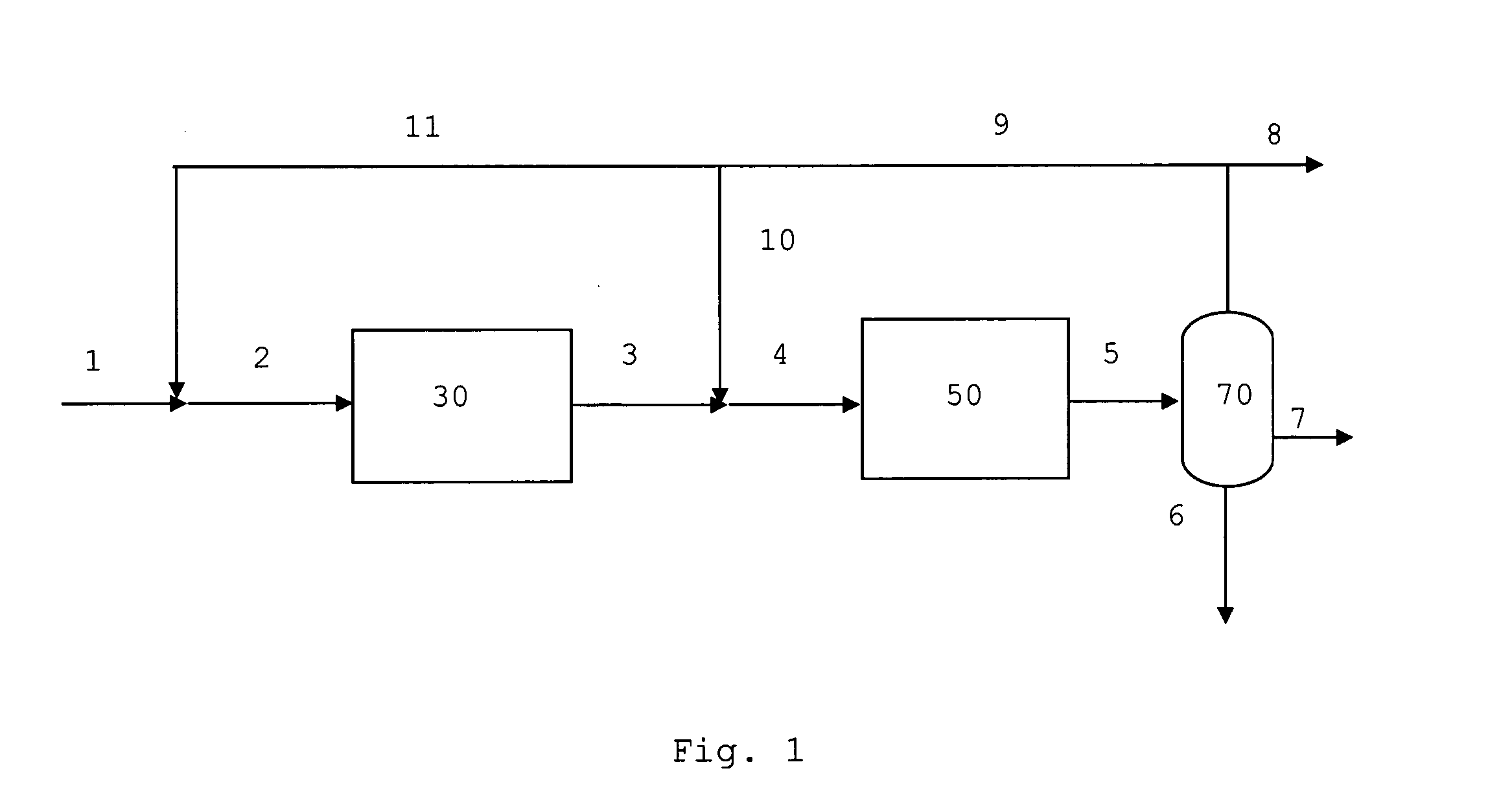

A catalytic converting process for upgrading poor-quality gasoline with high olefine content incldues a conventional catalytic cracking step for heavy oil and a catalytic converting step for upgrading said gasoline. It is characterized by in that two steps a common catalyst regenerator and a same catalyst are used. It can decrease olefine content by 15-50 vol% and S content by 5-30% and increase RON by 0.2-2 units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

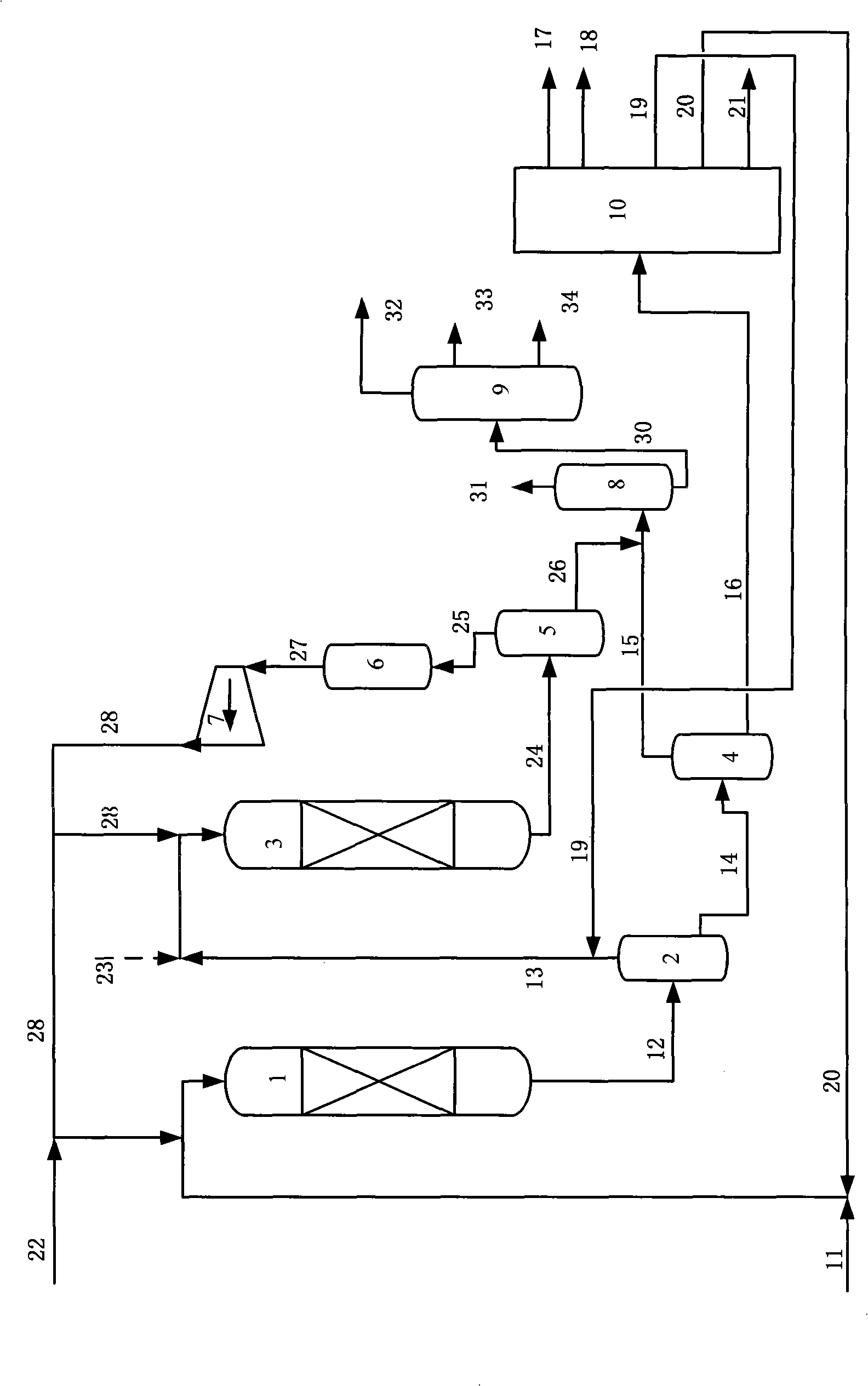

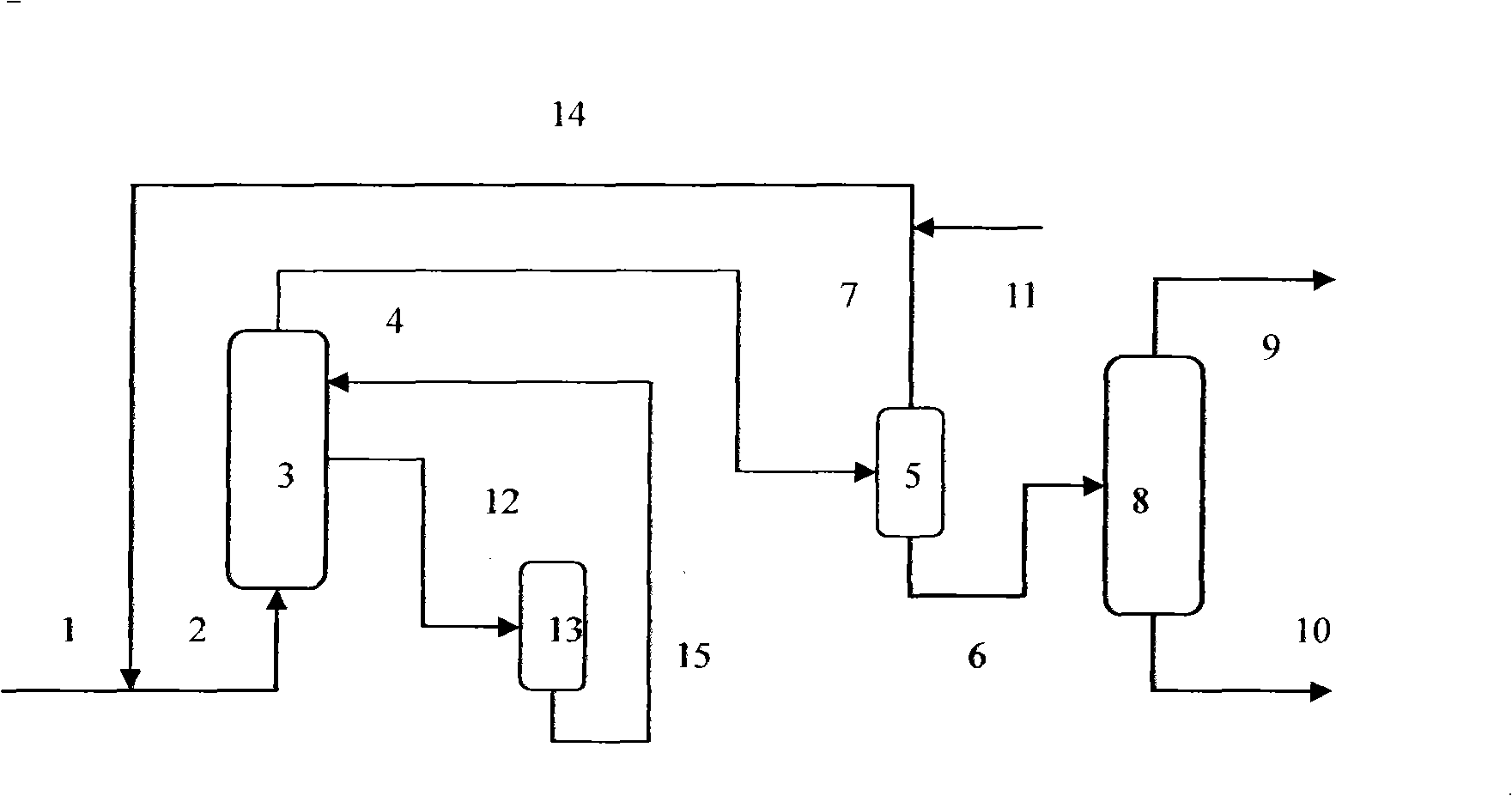

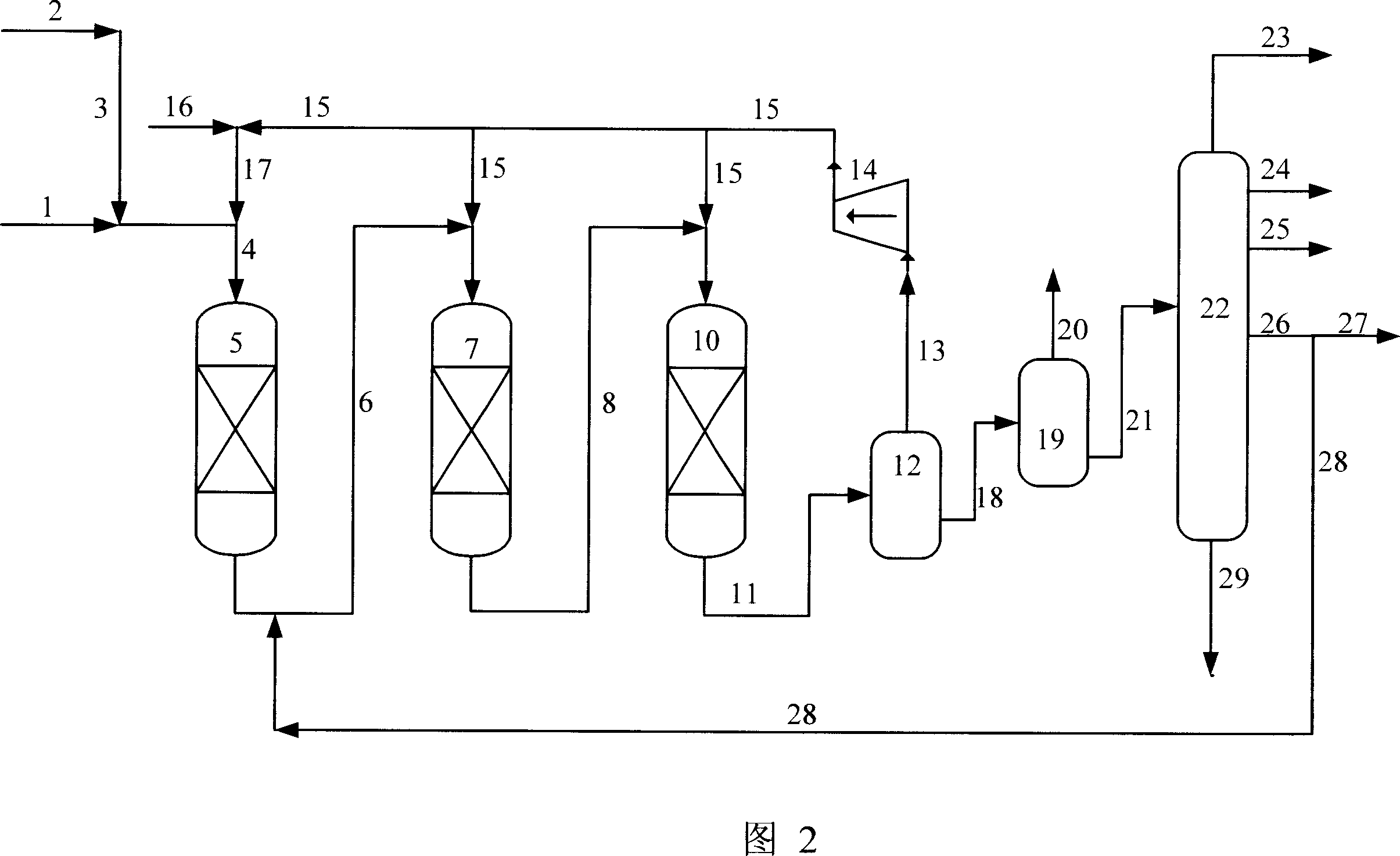

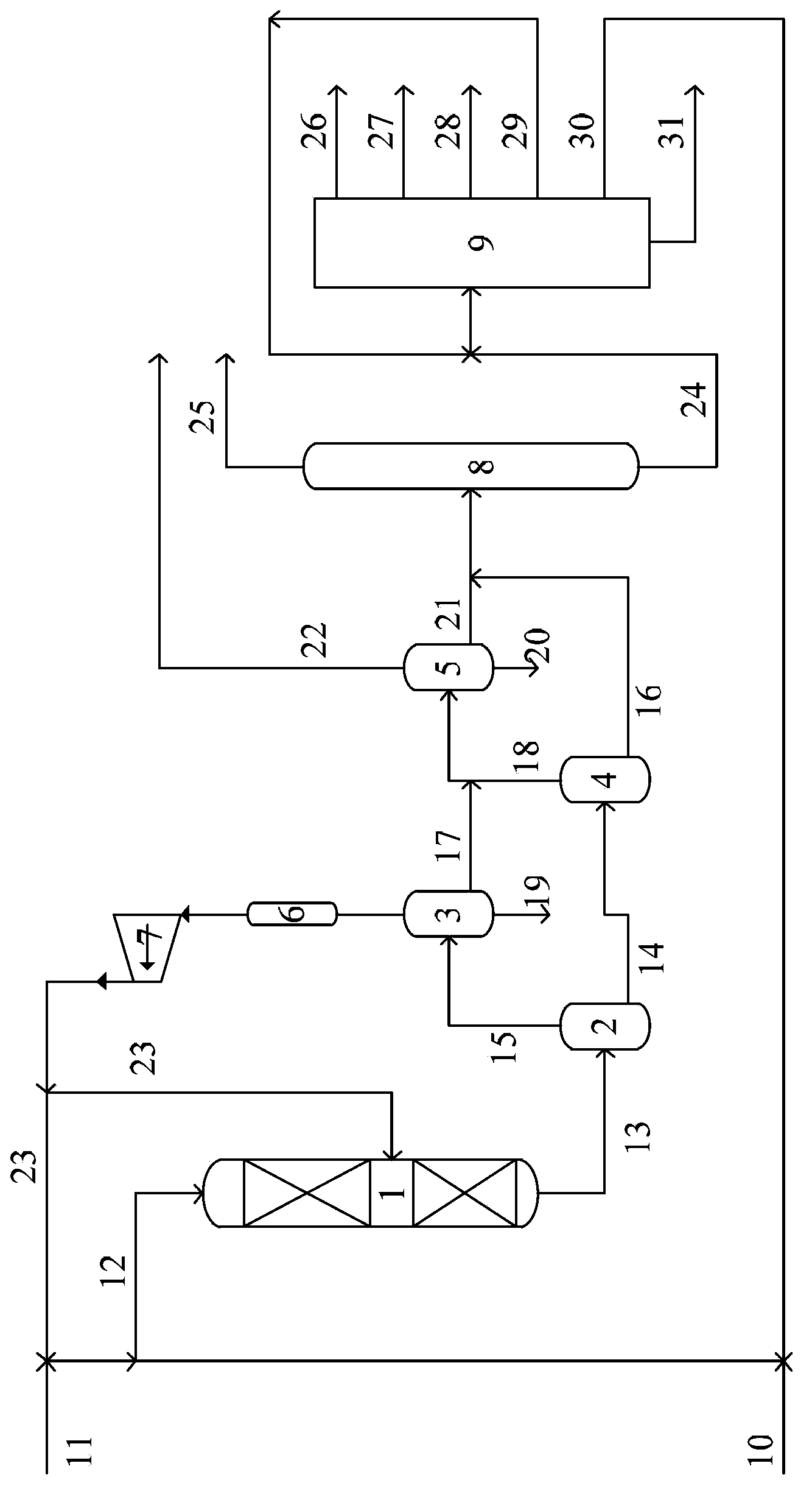

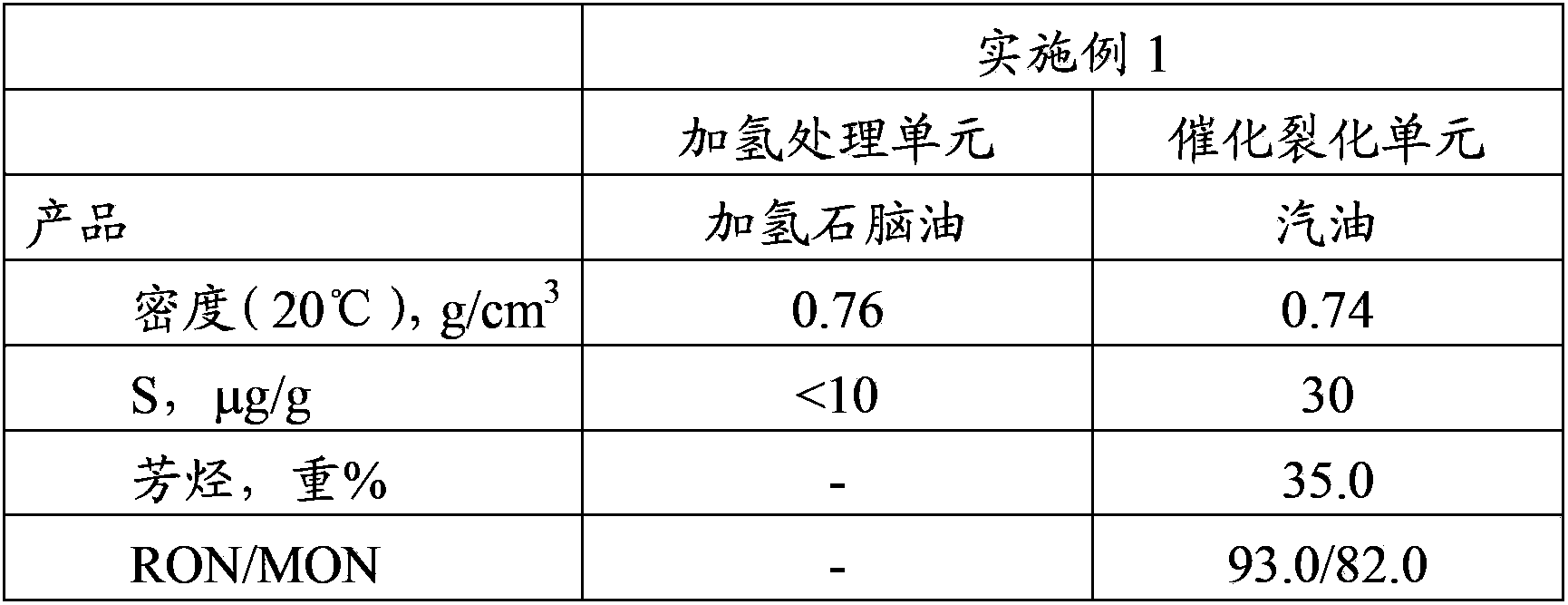

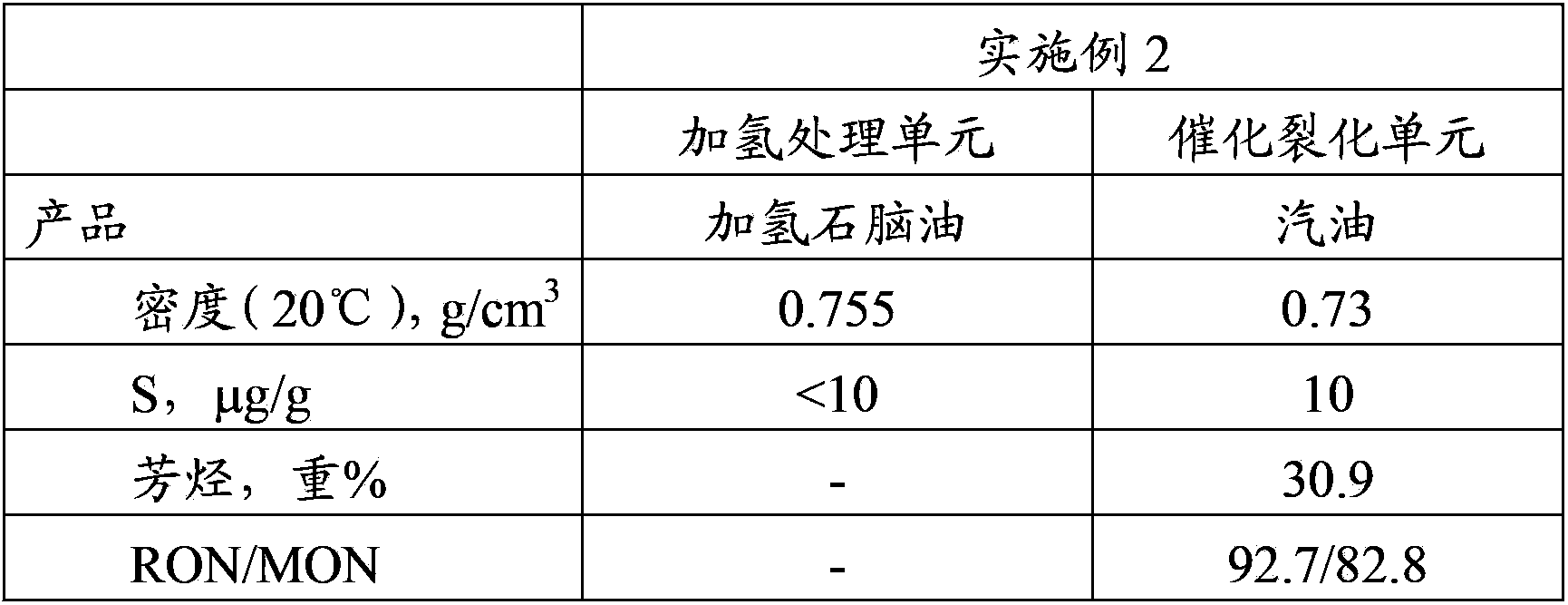

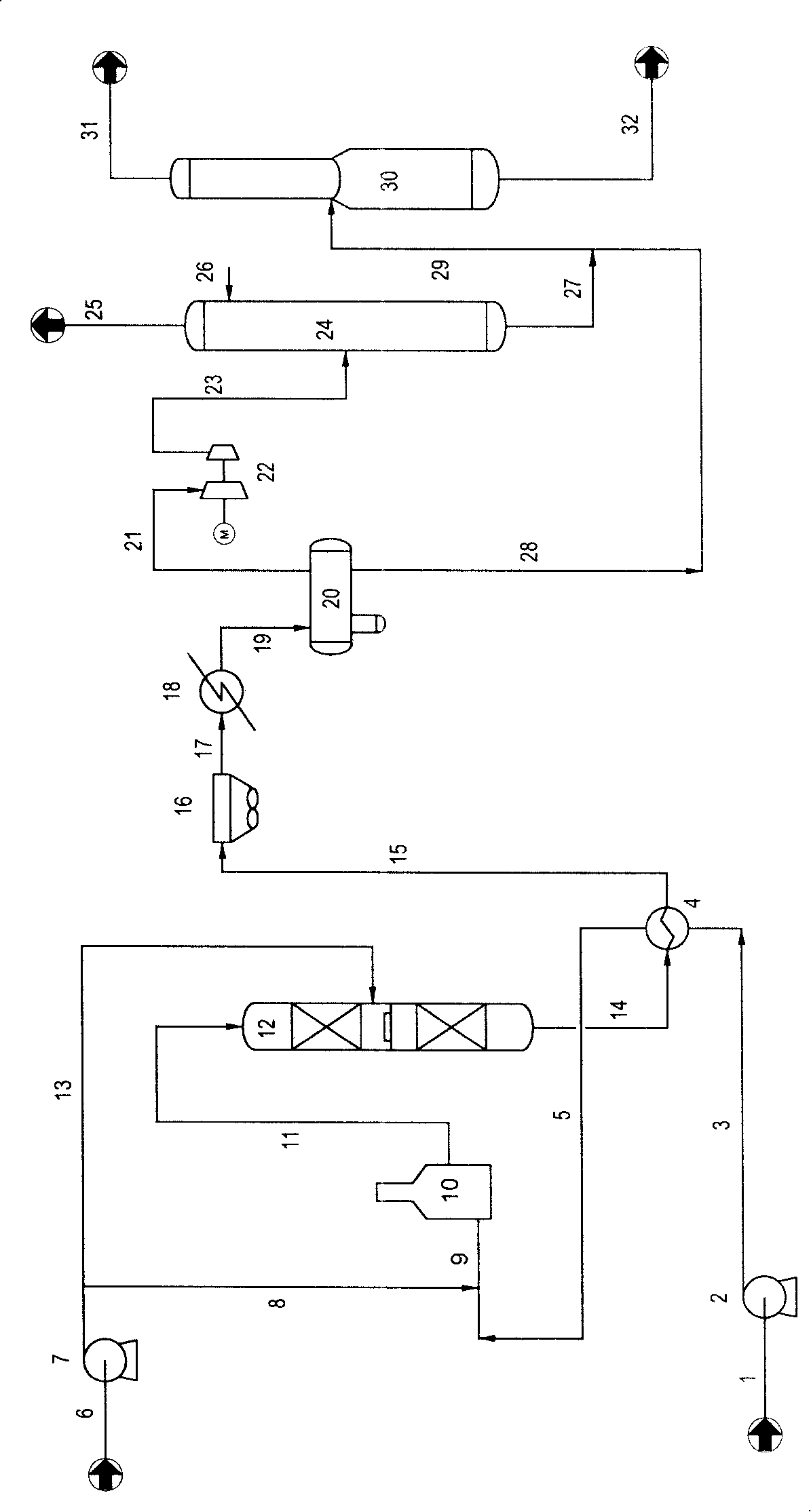

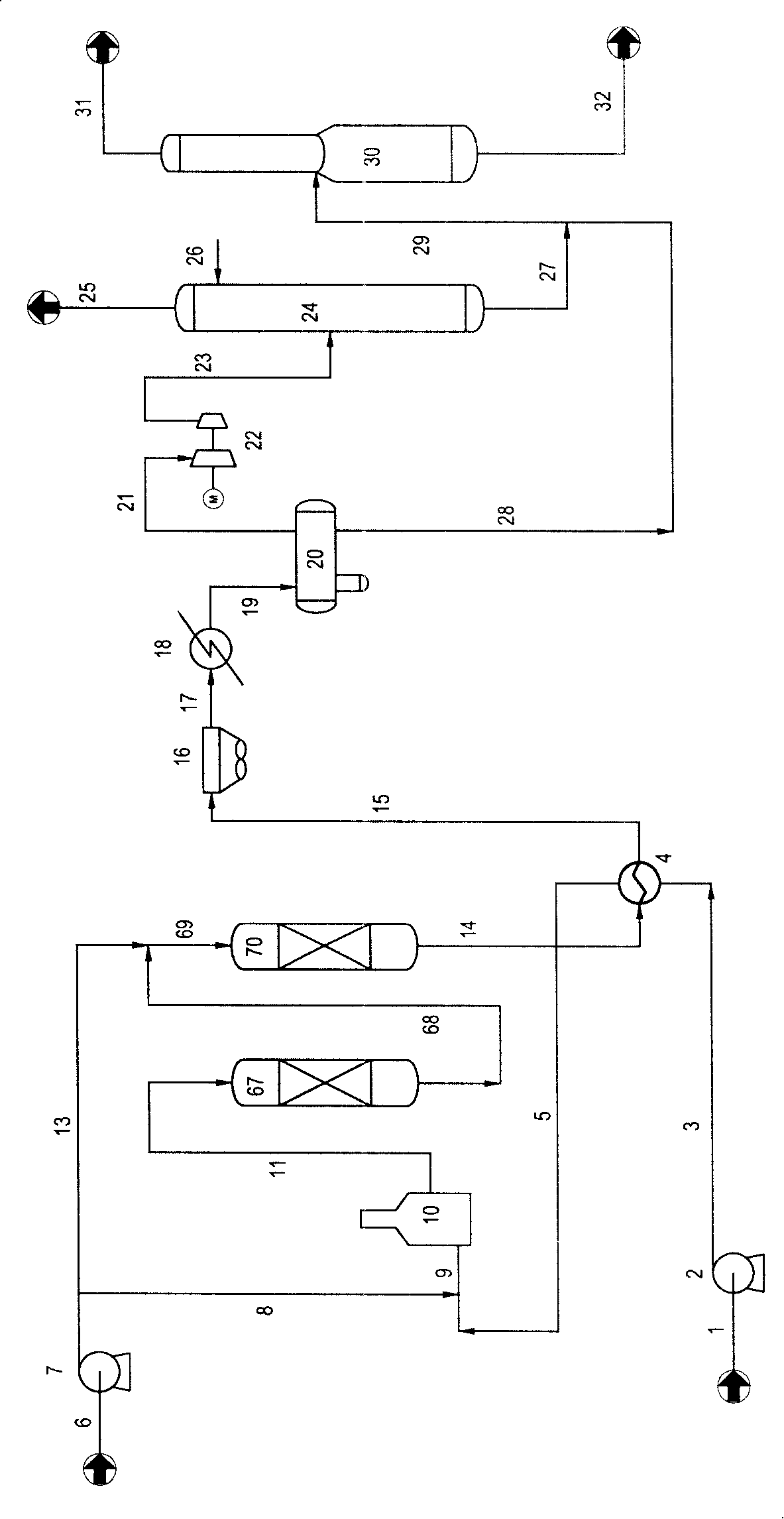

Optimized hydrogenation-catalytic cracking combination process

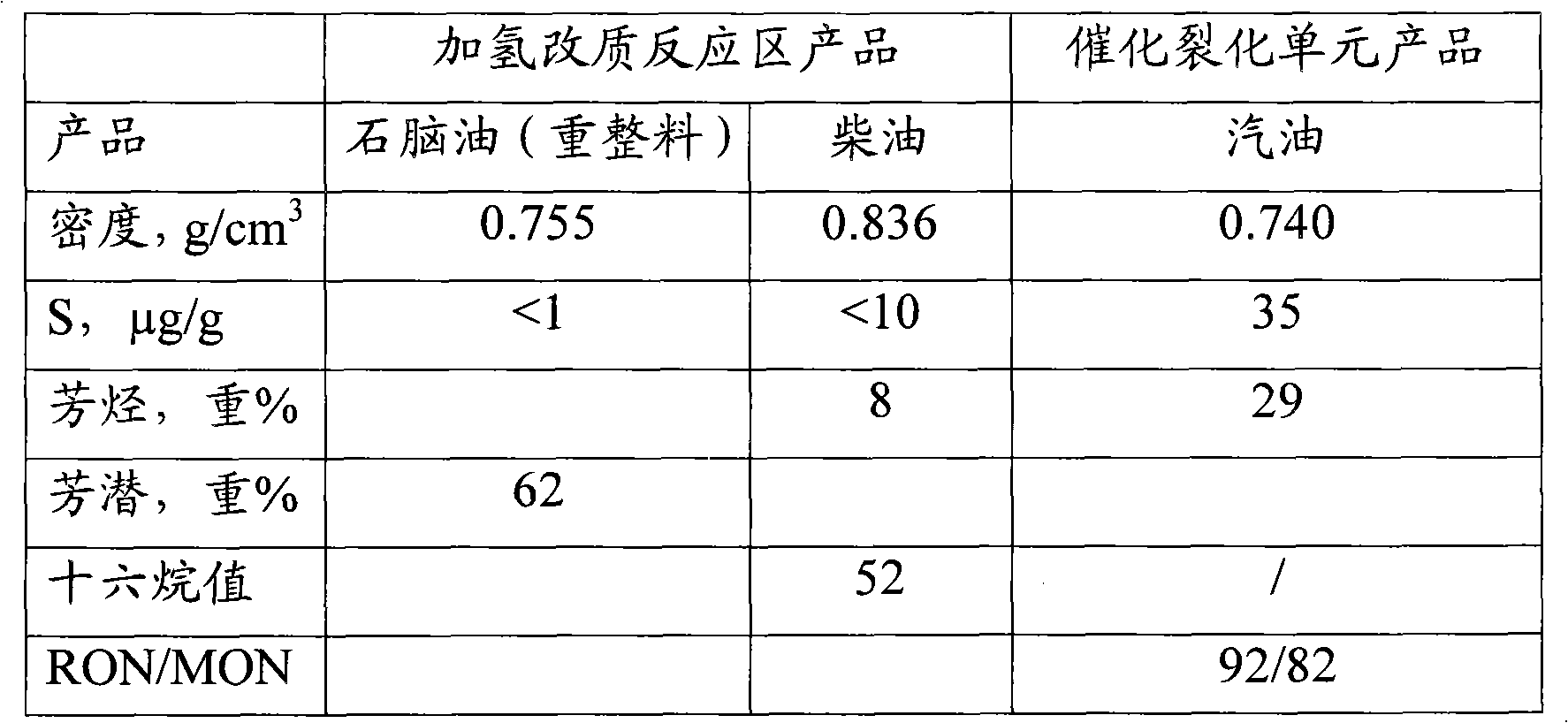

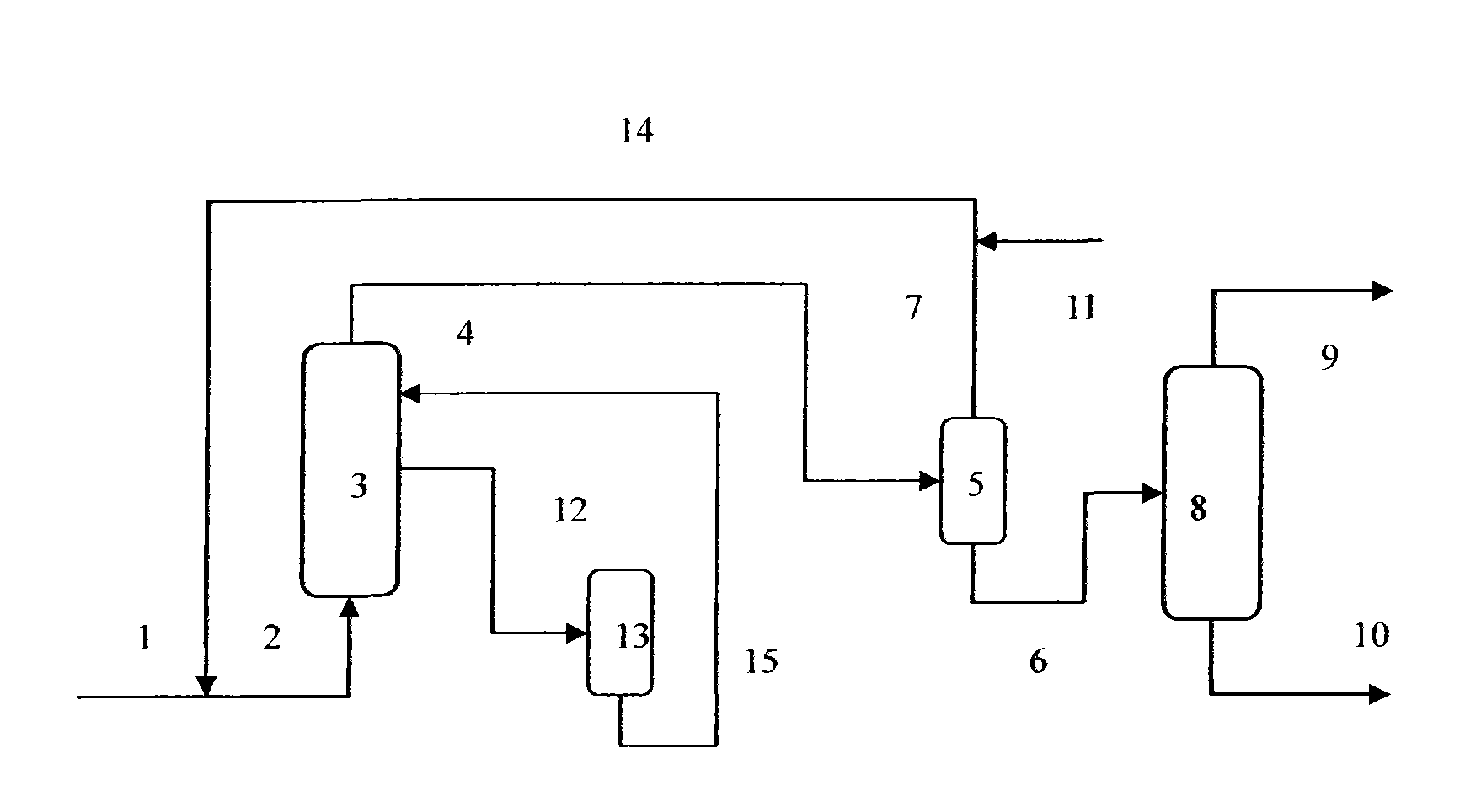

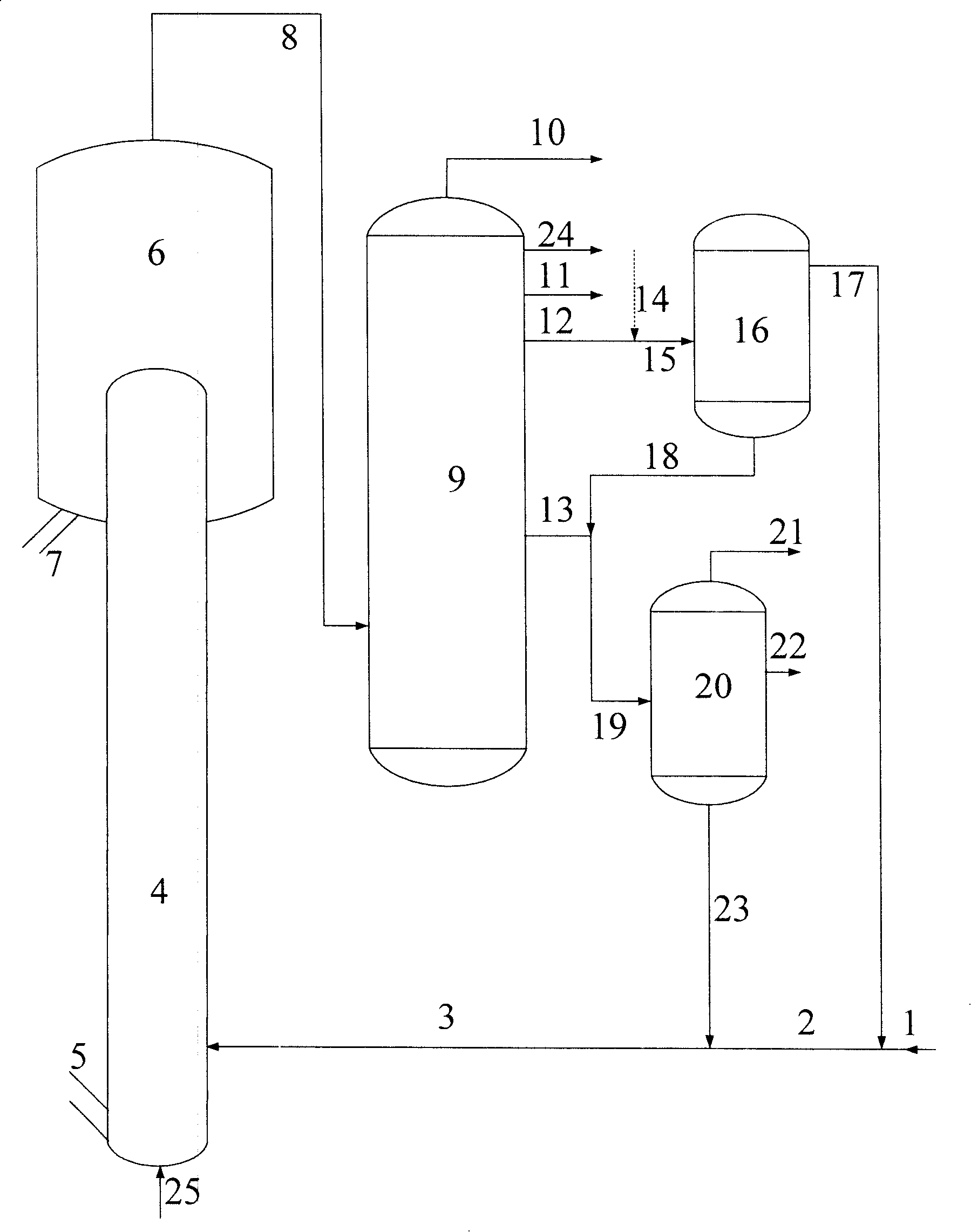

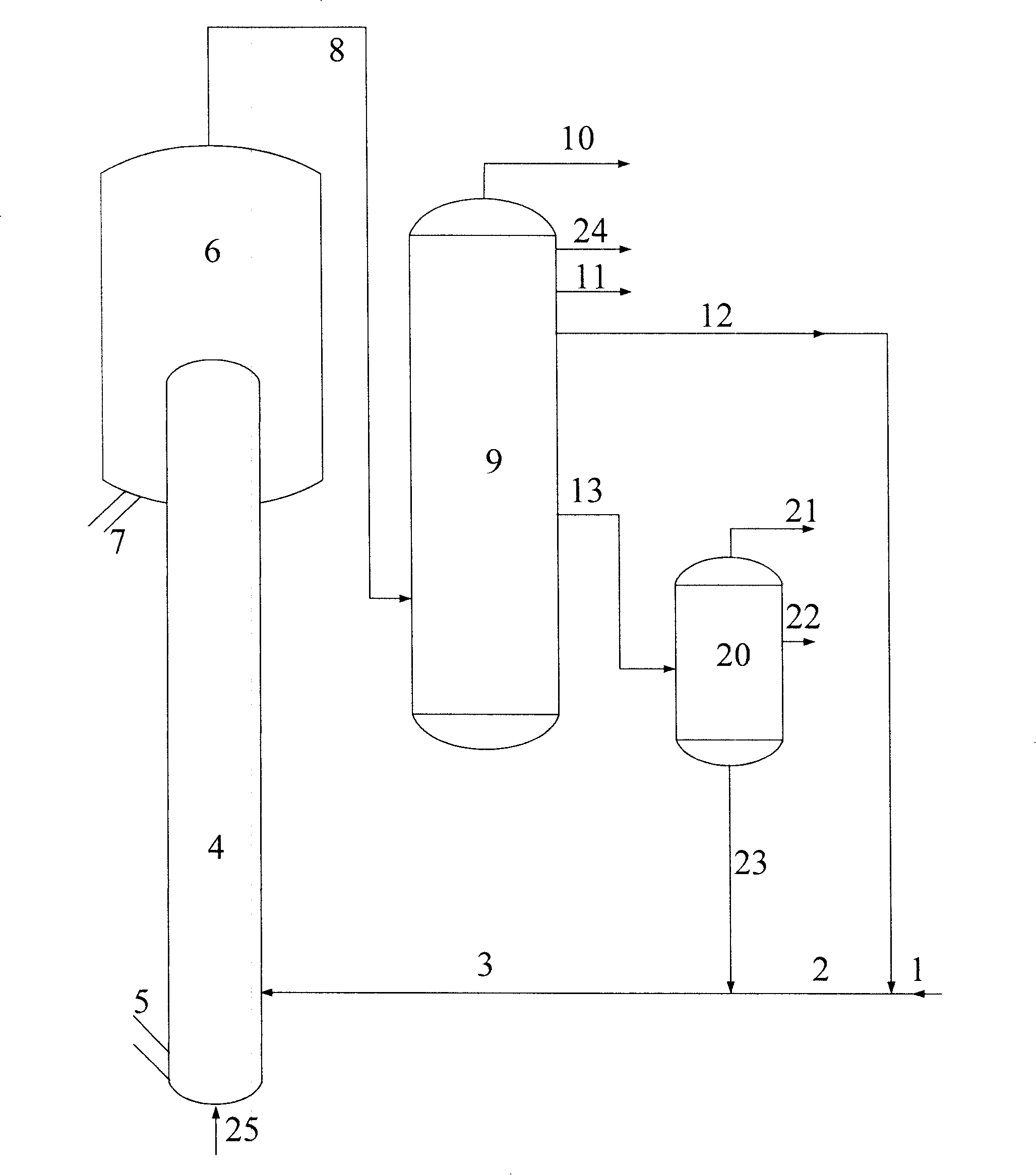

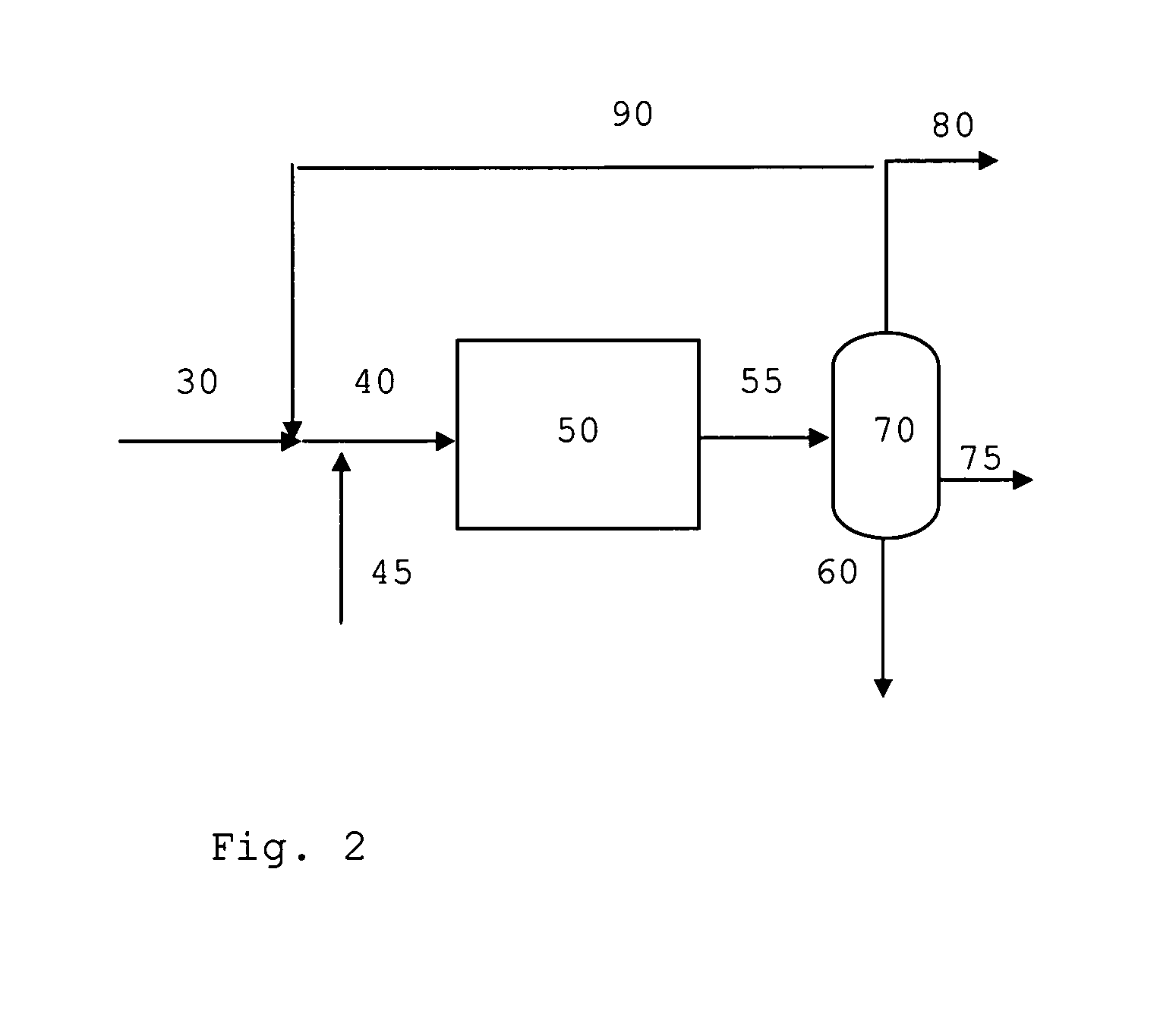

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced atthe same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

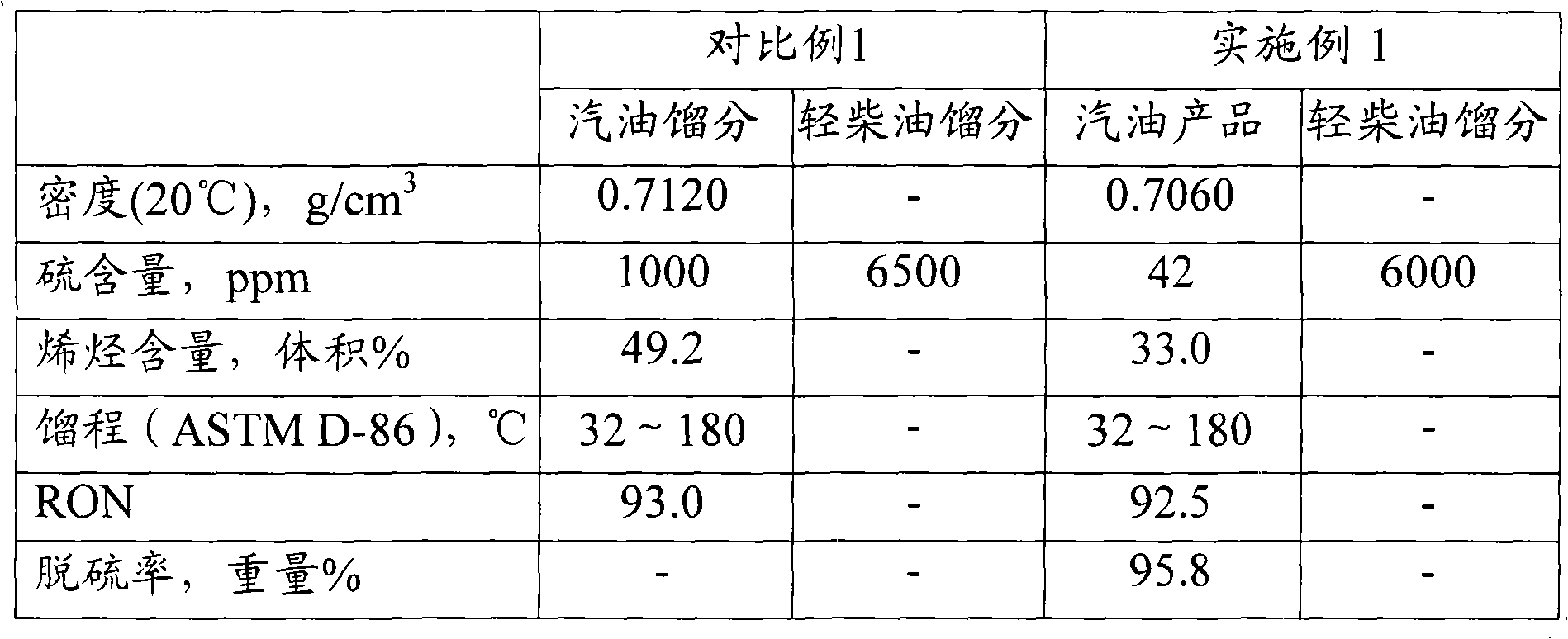

Method for deep desulfurization olefin hydrocarbon reduction of inferior gasoline

ActiveCN101492608AStructuring reaction does not affectReduce olefin contentRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the gasoline product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

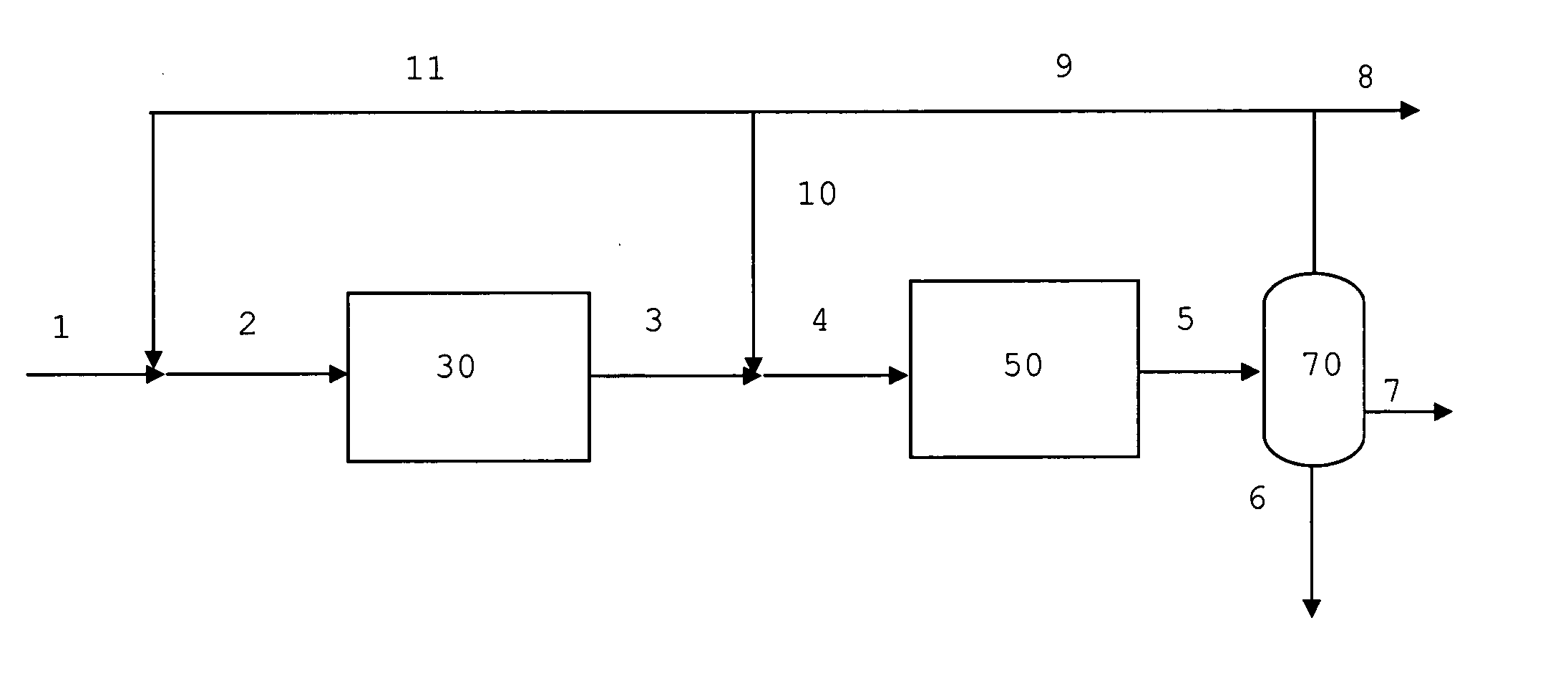

Catalytic conversion method for hydrocarbon oil raw material

ActiveCN101191081AReduce olefin contentBoost octaneTreatment with hydrotreatment processesLiquid gasRaw material

The invention discloses a catalytic conversion method for a hydrocarbon oil raw material. The hydrocarbon oil raw material contacts the catalytic cracking catalyst in a catalytic cracking reactor, the reaction oil gas and a spent catalyst are separated, then the spent catalyst is made steam stripping and regeneration and then returns to the catalytic cracking reactor for repeated use, the reaction oil gas is fractionated to obtain dry gas, liquefied gas, gasoline, light circulating oil, heavy circulating oil and heavy oil; the light circulating oil and any diesel fraction are cut into the light fraction of the light circulating oil and the heavy fraction of the light circulating oil; the heavy fraction of the light circulating oil is mixed with the heavy circulating oil and contacts the hydrogen and the hydrorefining catalyst, the reaction effluent is separated to obtain gas, naphtha and hydrogenated diesel, the hydrogen is reclaimed and then is circularly used; the light fraction of the light circulating oil independently or the light fraction of the light circulating oil along with the hydrogenated diesel returns to the catalytic cracking reactor. The method converts the catalytic cracking circulating oil into the gasoline with low olefin content and high octane value, and improves the yield of the gasoline and the yield of the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing rare-earth ultrastable Y-type zeolite

ActiveCN1676463AImprove exchange efficiencyEfficient removalCatalytic crackingMolecular sieve catalystsActive componentGasoline

The present invention relates to a preparation method of rare earth overstable Y zeolite. It is characterized by that said method includes the following steps: using mixed solution formed from rare earth salt and citric acid or mixed solution formed from inorganic ammonium salt, rare earth salt and citric acid to treat zeolite. Said zeolite can be used as active component of cracking catalyst, and has the advantages of reducing olefin content of catalytic cracked gasoline and obviously raising catalytic cracked light oil yield.

Owner:CHINA PETROLEUM & CHEM CORP

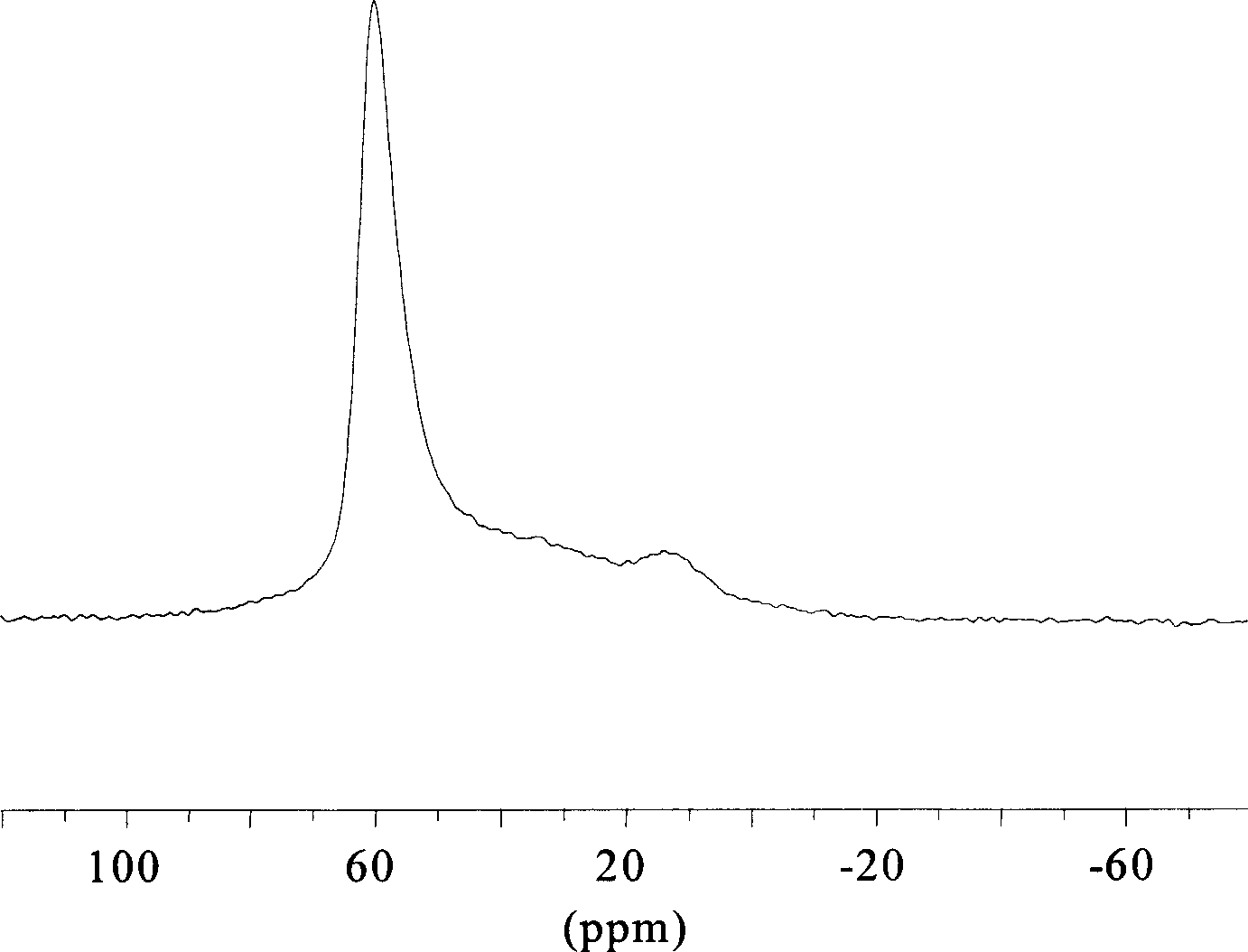

Cracking catalyst for reducing alkene content in catalytically cracked gasoline

ActiveCN1733363AReduce olefin contentStrong ability to convert heavy oilCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth ions

This invention discloses crack catalyst to decrease olefin content in catalytic cracking gasoline, which is characterized in that there is 10~50 w.t% CDY molecular sieve in the catalyst that is prepared by exchanging method of solid-liquid combination; the rare earth content is 12~22 w.t% considering the quantity of rare earth oxide; all rare earth ion is in molecular sieve small cage; there is no peak at 0ppm in 27Al M AS NMR spectrogram. The catalyst can decrease olefin content in catalytic cracking gasoline greatly with well heavy oil conversion ability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatization catalyst for catalytic gasoline and its use

InactiveCN1488728AReduce sulfur contentReduce olefin contentTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The present invention relates to an aromatization catalyst for gasoline and its application process. Said catalyst composition includes (by using weight percentage of catalyst as reference) 0.1m%-1.0m% of noble metal content, 50.0m%-90m% of K-type zeolite content, 1.0m%-5.0m% of K2O content and the rest is adhesive. Said catalyst can be used in the hydrodesulfurization process for catalyzing gasoline so as to attain the goal of desulfurization and reducing olefin content, and at same time obtaining less antiknock index loss of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for deep desulfurization olefin hydrocarbon reduction of gasoline

ActiveCN101492609AStructuring reaction does not affectReduced responseRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization catalyst and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Depth hydrogenation treatment method of faulty gasoline

ActiveCN1718687AReduce saturation rateLow desulfurization activityTreatment with hydrotreatment processesOrganic sulfide compoundHydrodesulfurization

A process for deeply hydrorefining poor-quality gasoline includes such steps as removing biolefine from FCC full-fraction gasoline at lower temp, and modifying (arylisomerizing) and hydrodesulfurizing at higher temp. The hydrodesulfarizing catalyst is the hydrorefining catalyst containing copper oxide and / or zinc oxide.

Owner:CHINA PETROLEUM & CHEM CORP +2

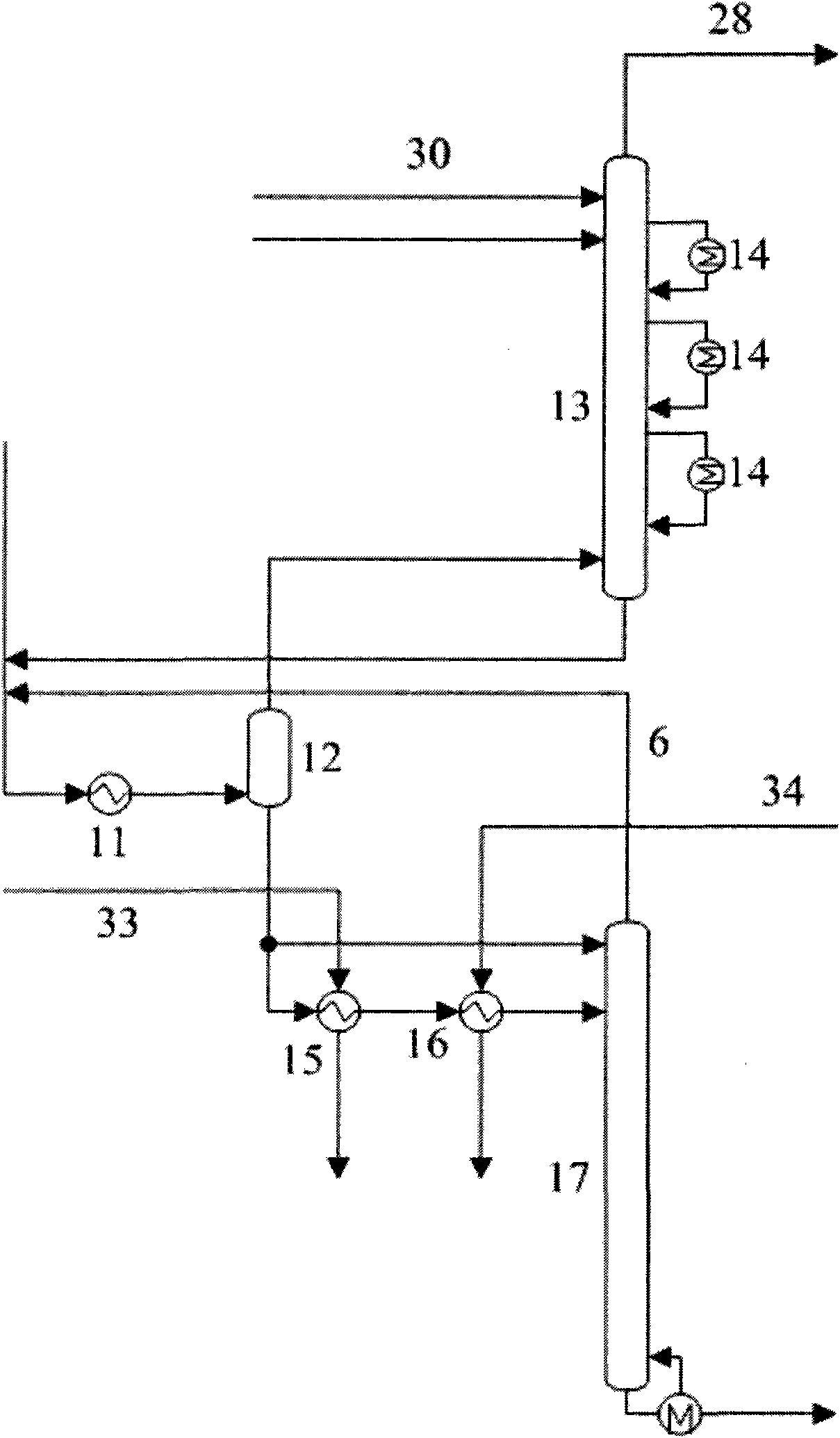

Hydrogenation method capable of producing diesel oil and chemical materials flexibly

ActiveCN101117596AMeet specificationsFlexible adjustment and operationTreatment with hydrotreatment processesNaphthaHydrogen

The present invention relates to a hydrogenation method for flexible production of diesel oil and chemical raw material, heavy raw material and optional light raw material mix with hydrogen, and enter into a first hydrogenation reaction area and a second hydrogenation reaction area, and contact with hydrogenation treatment catalyst I and hydrogenation cracking catalyst respectively and perform reaction. Without separation, the reactant mixes with the light raw material and enters into a third hydrogenation reaction area, under the action of hydrogenation treatment catalyst II, the mixture performs the reaction, through the reactant is cooled, separated and fractionated, the light naphtha distillate, the heavy naphtha distillate, the diesel oil distillate and the tail oil distillate can be got. The method provided by the present invention combines the hydrogenation treatment and the hydrogenation cracking organically, the heavy distillates such as decompression gas oil, etc. and the ungraded light distillate got from the second time processing are used as raw material, the operation can be adjusted flexibly according to the market demand, so as to produce high quality diesel oil or chemical raw material in the maximum volume, wherein the diesel oil can meet the requirement of Europe IV fuel specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

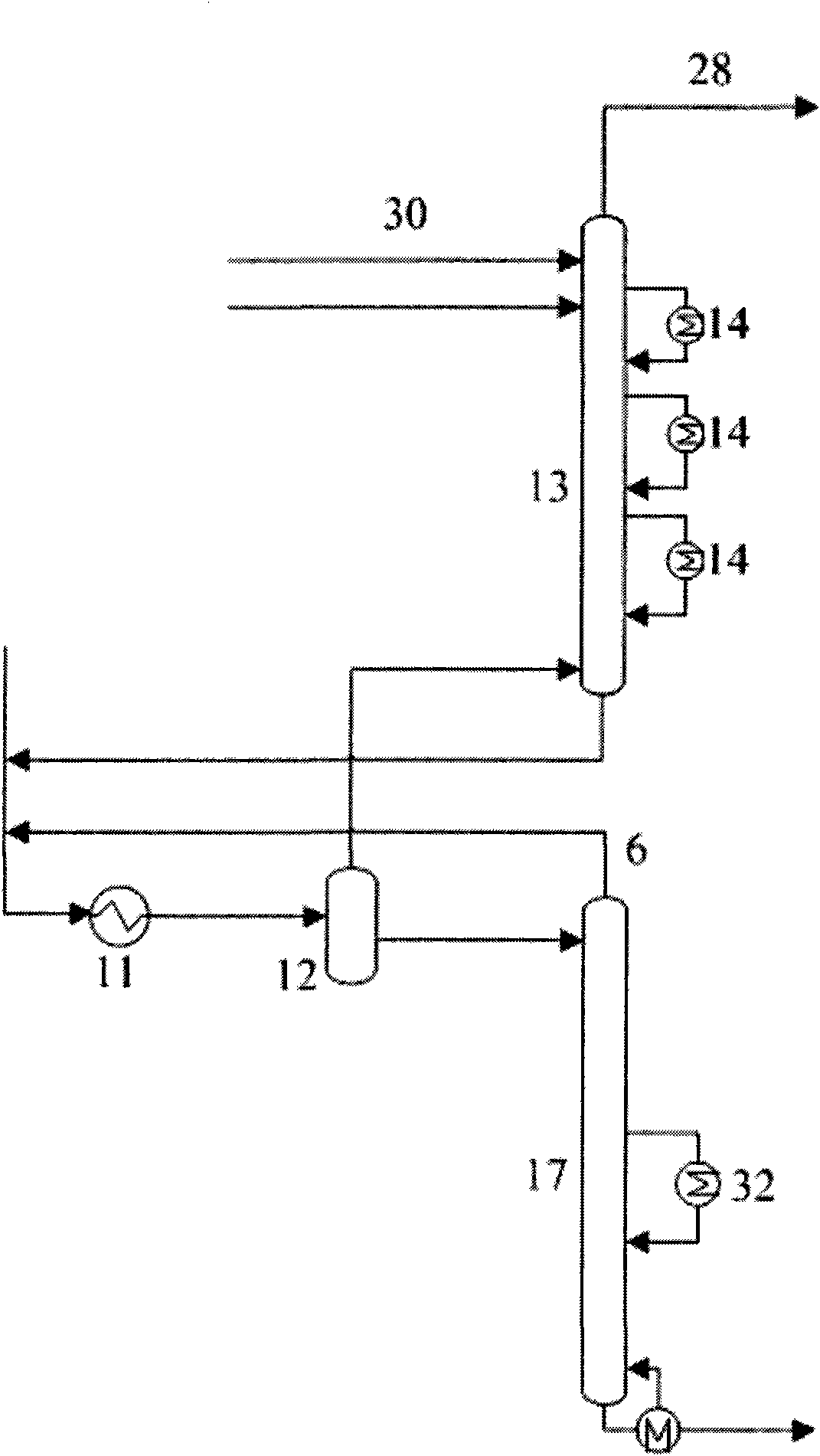

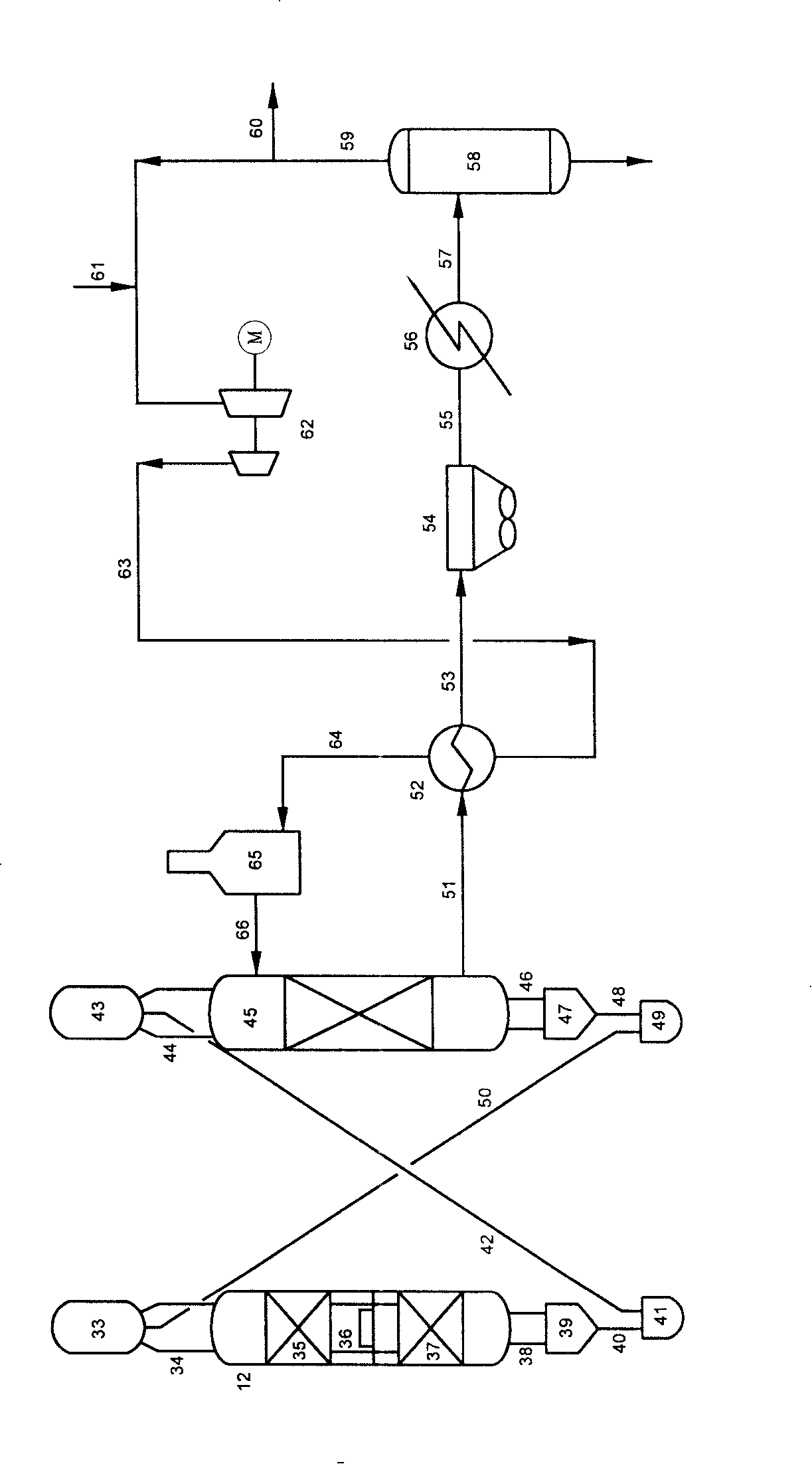

Method for saving energy and producing more propylene in absorption-stabilization system by catalytic cracking

ActiveCN101659876AReduce olefin contentTo achieve the goal of producing more propyleneOrganic chemistryCatalytic crackingGasolineEngineering

The invention relates to a method for saving energy and producing more propylene in an absorption-stabilization system by catalytic cracking. A liquid phase of a vapor-liquid equilibrium tank exchanges heat with stable gasoline on the bottom of a desorber T305 through a heat exchanger E301, exchanges heat with stable gasoline on the bottom of a stabilization tower T304 through a heat exchanger E302, and then enters a desorber T302; deethanized gasoline on the bottom of the desorber T302 exchanges heat with the stable gasoline on the bottom of a stabilization tower T304 through a heat exchanger E305, and then enters the stabilization tower T304; the stable gasoline on the bottom of the stabilization tower T304 is cooled by the heat exchanger E305 and the heat exchanger E302, a part of the stable gasoline enters a reaction-regeneration system for recycling, the rest stable gasoline is cooled by a heat exchanger E303, and a part of the rest stable gasoline enters an absorption tower T301; and the stable gasoline on the bottom of the desorber T305 is subjected to two-stage cooling of the heat exchanger E301 and a heat exchanger E304, serves as a stable gasoline product and is discharged from the device. The thermal load is reduced by 15.8 to 17.7 percent; and the alkene content in the stable gasoline product is reduced by 34.3 percent.

Owner:PETROCHINA CO LTD

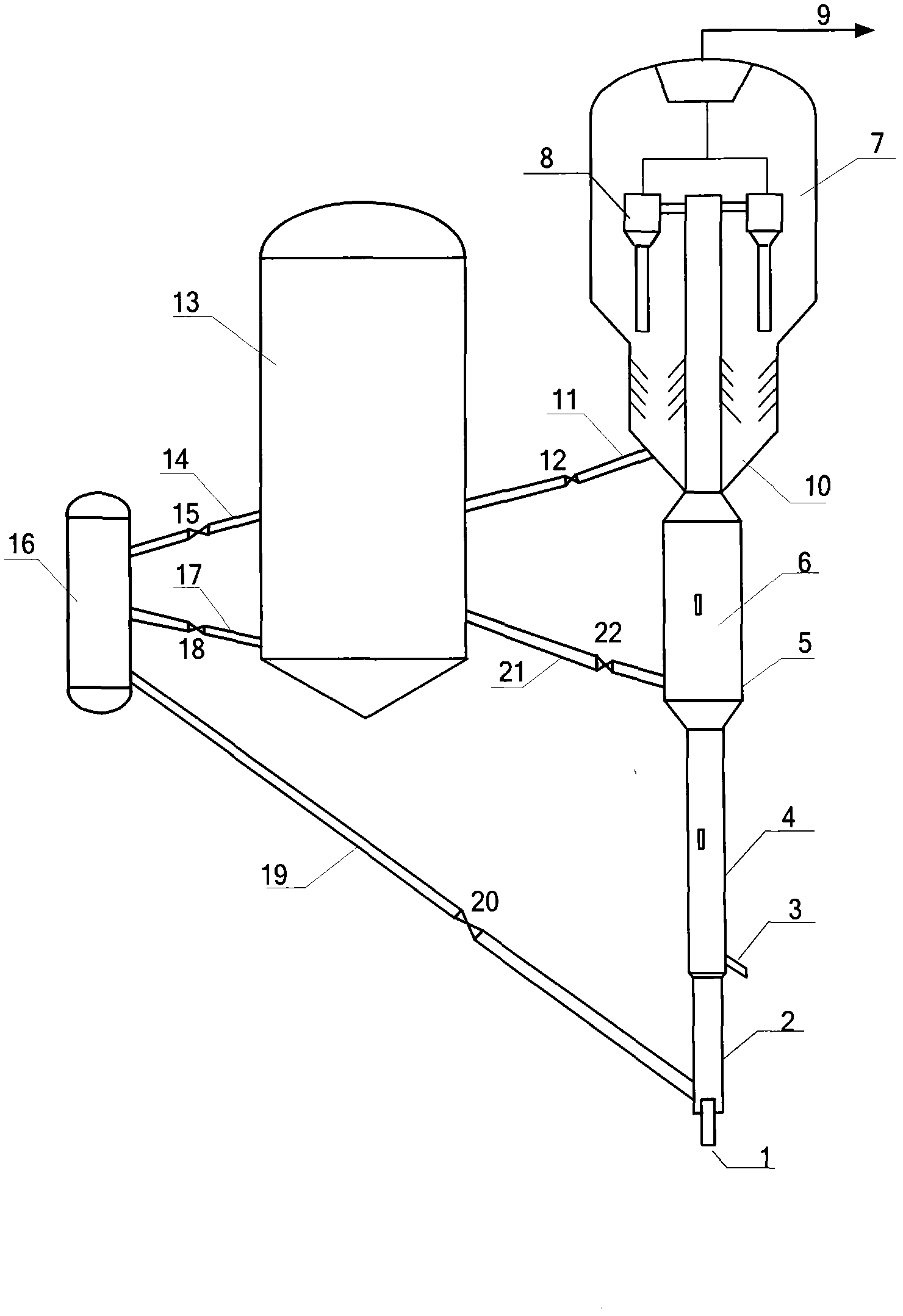

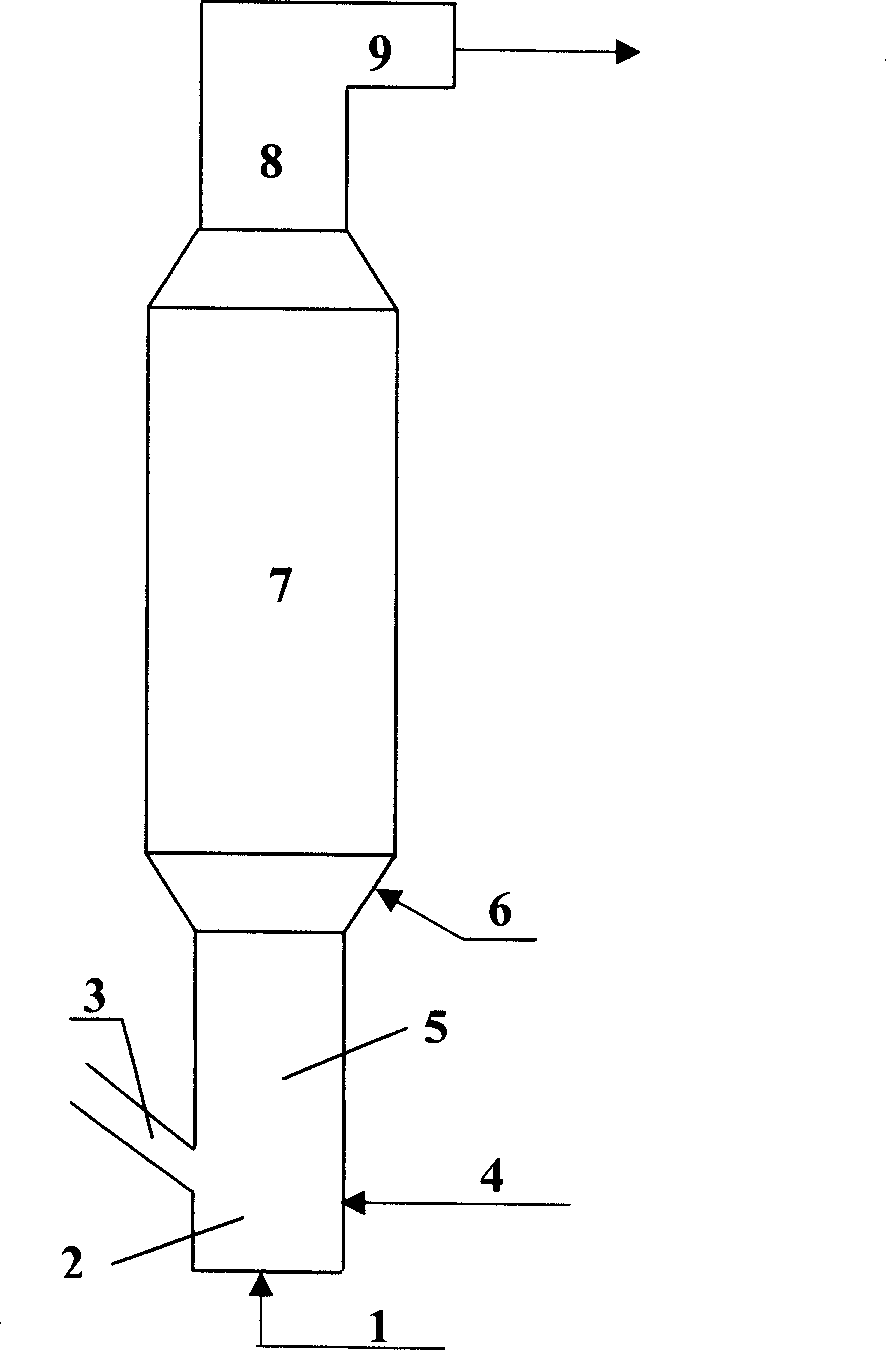

Catalytic conversion method for processing high-nitrogen raw material

ActiveCN103031147AReduce olefin contentImprove conversion rateTreatment with plural serial stages onlyChemistryHigh nitrogen

A catalytic conversion method for processing a high-nitrogen raw material is characterized in that a regenerated catalyst having a lower temperature enters the pre-lift section of a reactor, upward flows under the action of a pre-lift medium, enters a first reaction zone, contacts with the high-nitrogen raw material, adsorbs and reacts at the lower portion of the first reaction zone, and upward flows; the formed oil agent mixture enters a second reaction zone, contacts with a regenerated catalyst having a higher temperature in the second reaction zone, and continuously and fully reacts; and the oil agent mixture from the second reaction zone goes through the outlet of the reactor and undergoes gas-liquid separation, the carbon-containing catalyst obtained after the separation is stripped, scorched and regenerated for cycle use, and the separated reaction oil gas is sent to a subsequent product separating system. The method can be used to directly process the high-nitrogen raw material, and improves the conversion rate of the high-nitrogen raw material. The method is simple to operate, and a routine catalytic cracking device can be simply reconstructed to carry out the operation of the method. Gasoline produced through the method has a low olefin content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of lowering olefine content in gasoline

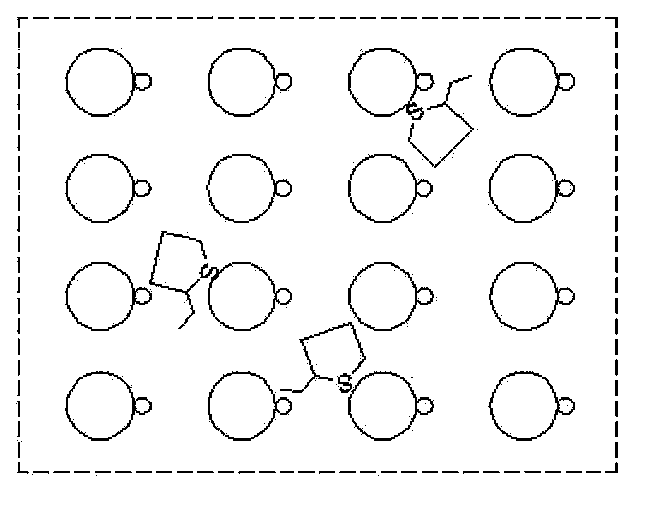

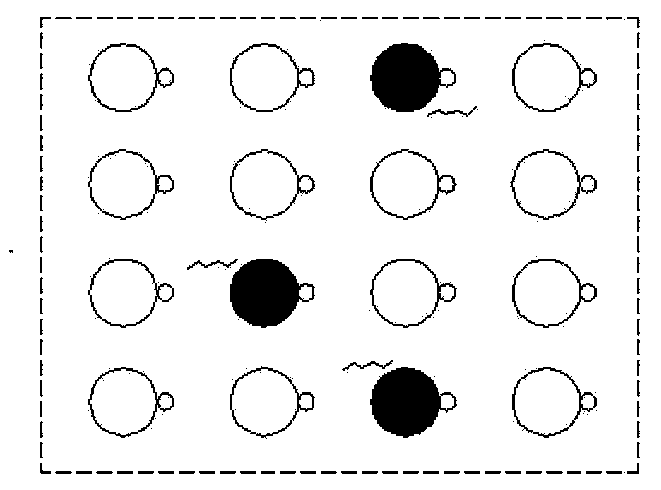

ActiveCN100448947CReduce olefin contentEasy to separateCatalytic crackingMolecular sieveActive component

The method of lowering olefin content in gasoline is to contact gasoline containing olefin with water and catalyst to obtain gasoline product with lowered olefin content. The catalyst is regular catalyst comprising carrier in regular structure and active component coating distributed in the inner surface and outer surface of the carrier, and active component is composition containing molecular sieve. The method of the present invention can lower the olefin content in gasoline from 51.9 wt% to 22.28 wt% and convert olefin into propylene and ethylene in the yield as high as 18 % and 2 % separately.

Owner:CHINA PETROLEUM & CHEM CORP +1

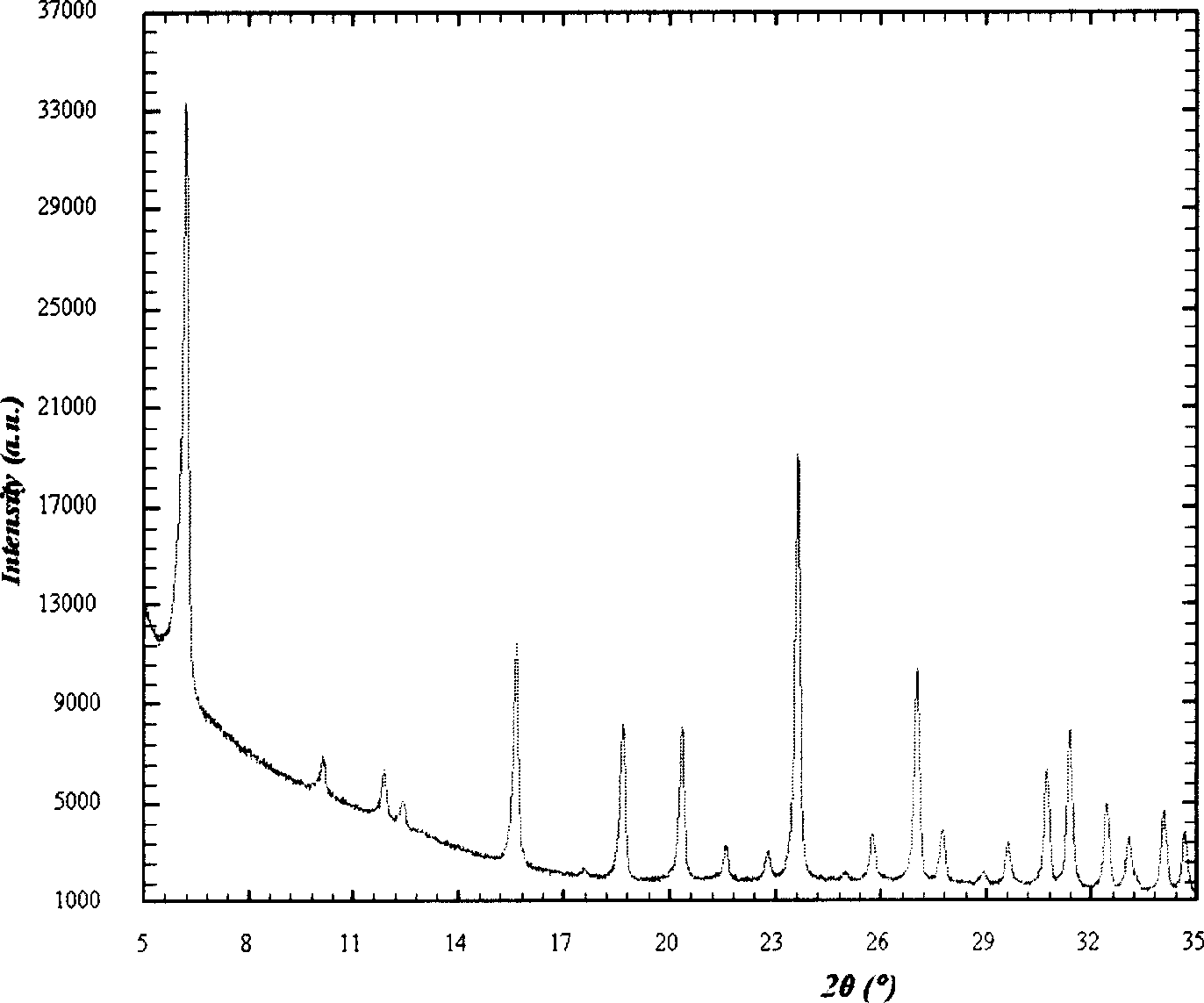

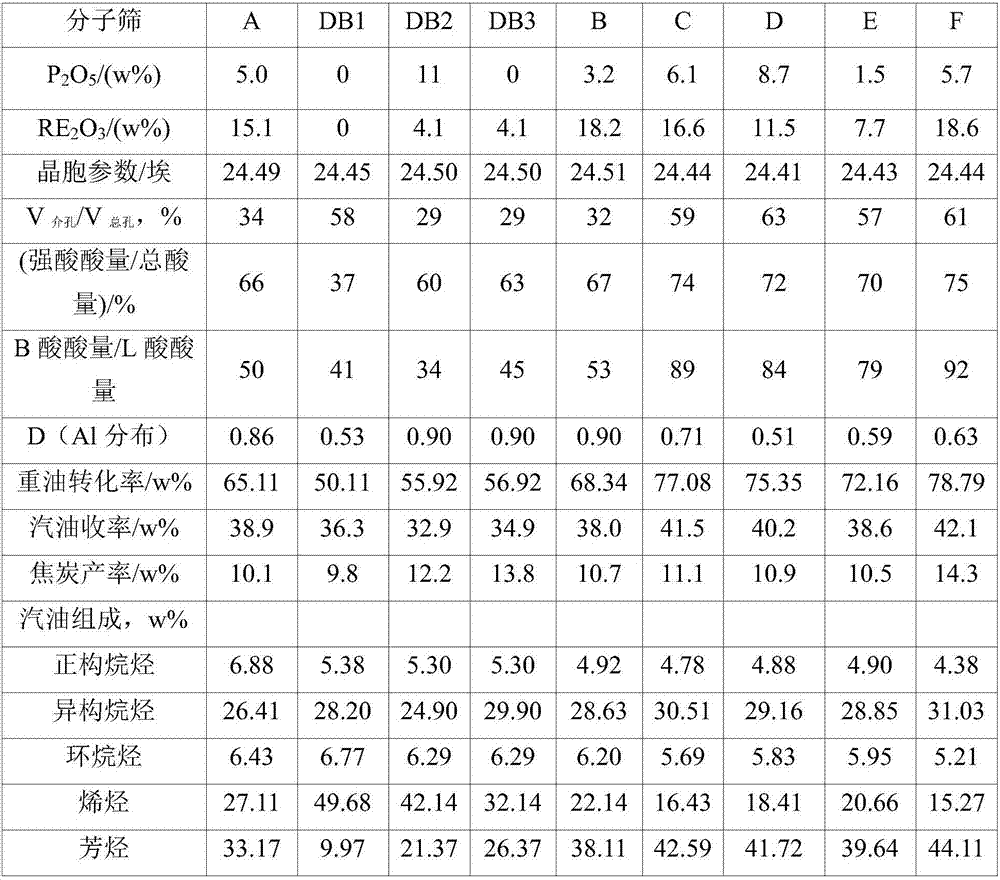

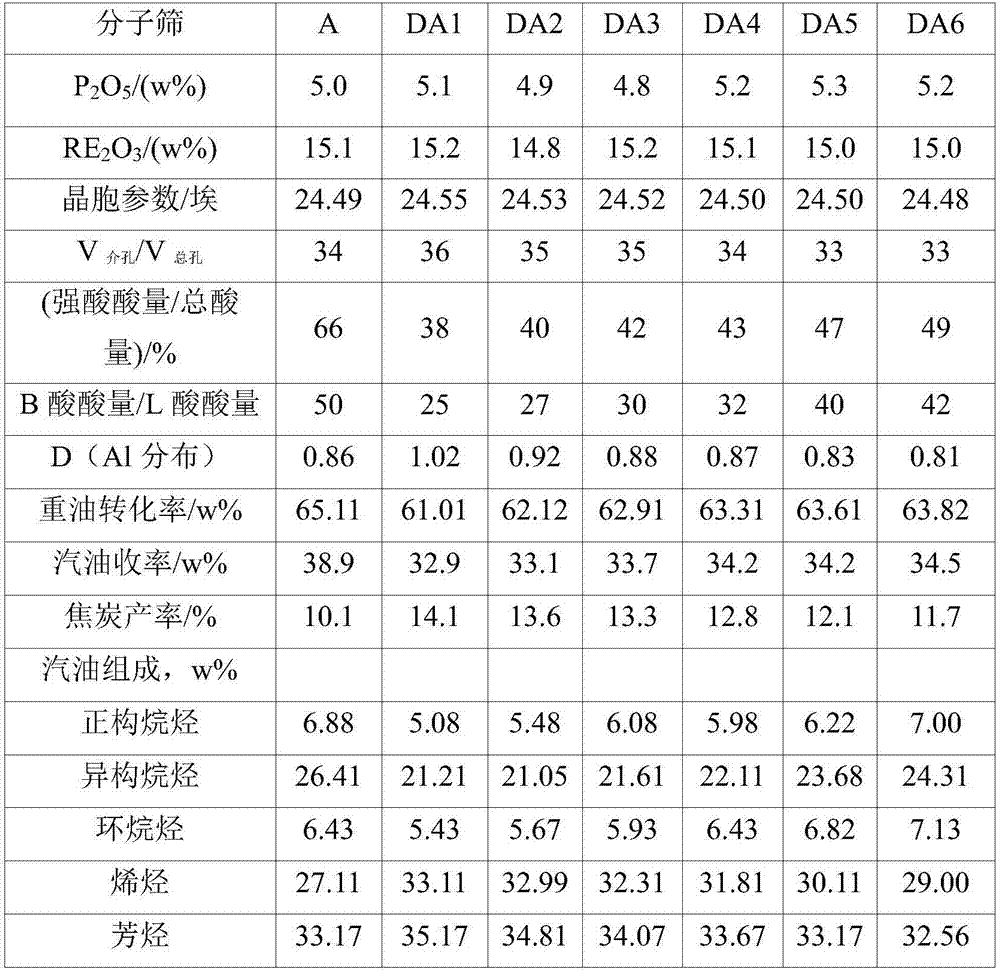

Phosphorus-containing and rare earth-containing Y molecular sieve and preparation method thereof

ActiveCN107973314APromote cracking reactionImprove conversion rateMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a phosphorus-containing and rare earth-containing Y molecular sieve and a preparation method thereof, wherein the unit cell parameter of the molecular sieve is 24.35-24.55 angstrom, the phosphorus content (calculated as P2O5) of the molecular sieve is 0.3-10.0 wt% by using the dry base weight of the molecular sieve as the reference, the rare earth content (calculated as RE2O3) of the molecular sieve is 0.5-19 wt% by using the dry base weight of the molecular sieve as the reference, the Al distribution parameter D of the molecular sieve is more than or equal to 0.4 and is less than or equal to 0.9, the volume of the mesopores of the molecular sieve accounts for 25-65% of the total pore volume, the amount of the strong acid of the molecular sieve accounts for 65-78% of the total acid amount, and a ratio of the acid B to the acid L is 21-98. According to the present invention, the catalyst prepared by using the phosphorus-containing and rare earth-containing Y molecular sieve as the active component can have advantages of excellent heavy oil conversion capacity, high gasoline yield, low coke yield and low olefin content in gasoline in the heavy oil cracking reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

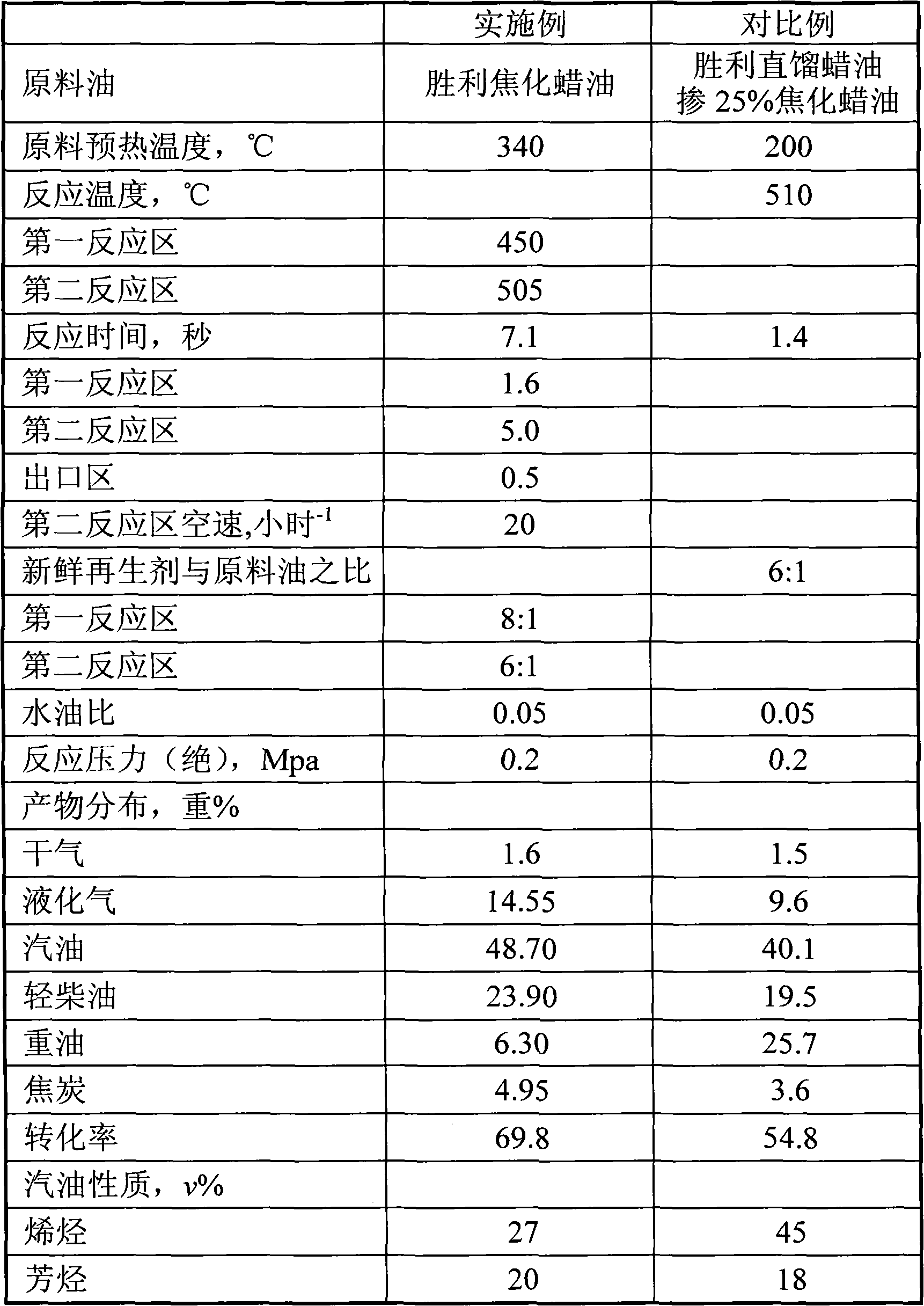

Method for catalytic cracking petroleum hydrocarbons

This invention discloses a method for catalytically pyrolyzing petroleum hydrocarbons. The method comprises: (1) introducing preheated petroleum hydrocarbons into a pyrolysis reactor containing two reaction zones; (2) catalytically pyrolyzing in the presence of water vapor and a hot catalytically pyrolyzing in the presence of water vapor and a hot catalyst in the first and the second reaction zones sequentially. The reaction temperature and time in the first reaction zones are 495-550 deg.C and 0.5-20 s, and those in the second reaction zone are 460-495 deg.C and 2-30 s. The catalyst comprises: Y-type zeolite modified with Zn and rare earth metals 25-50 wt.%, clay 20-50 wt.%, and inorganic oxides 20-50 wt.%. The contents of the Y-type zeolite are 0.5-10 wt. %, respectively. The method can lower the olefin content, and increase the lightweight oil yield in the products.

Owner:CHINA PETROLEUM & CHEM CORP +1

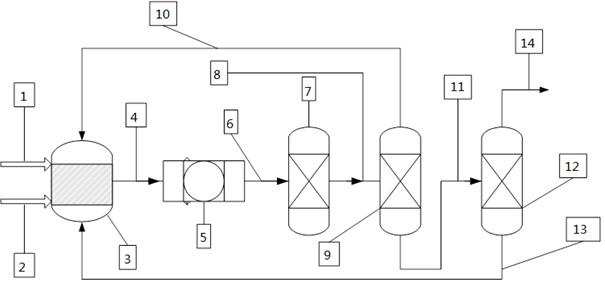

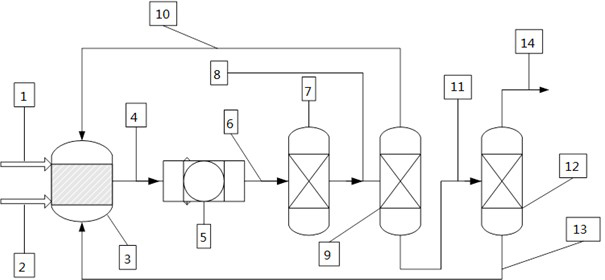

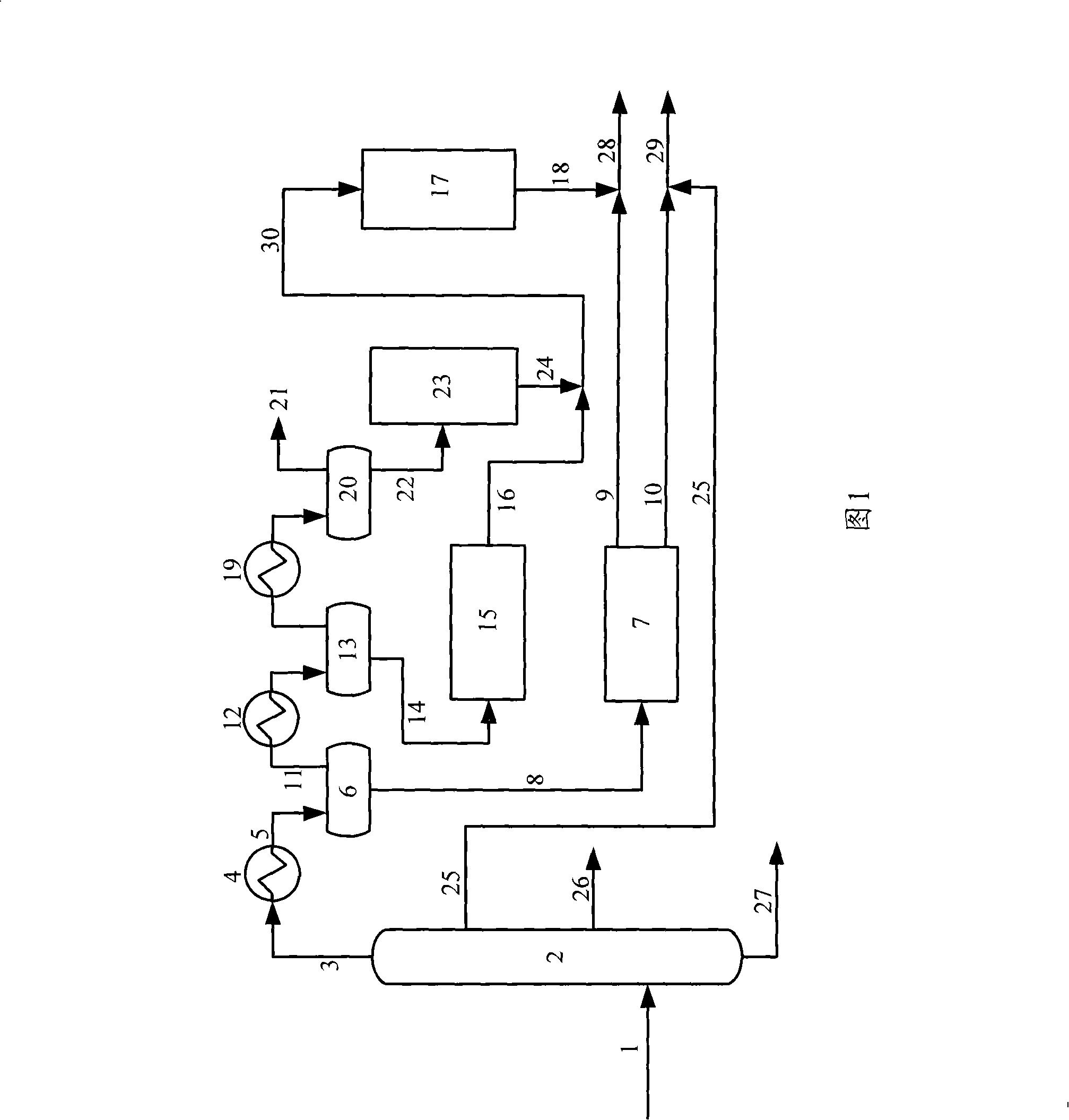

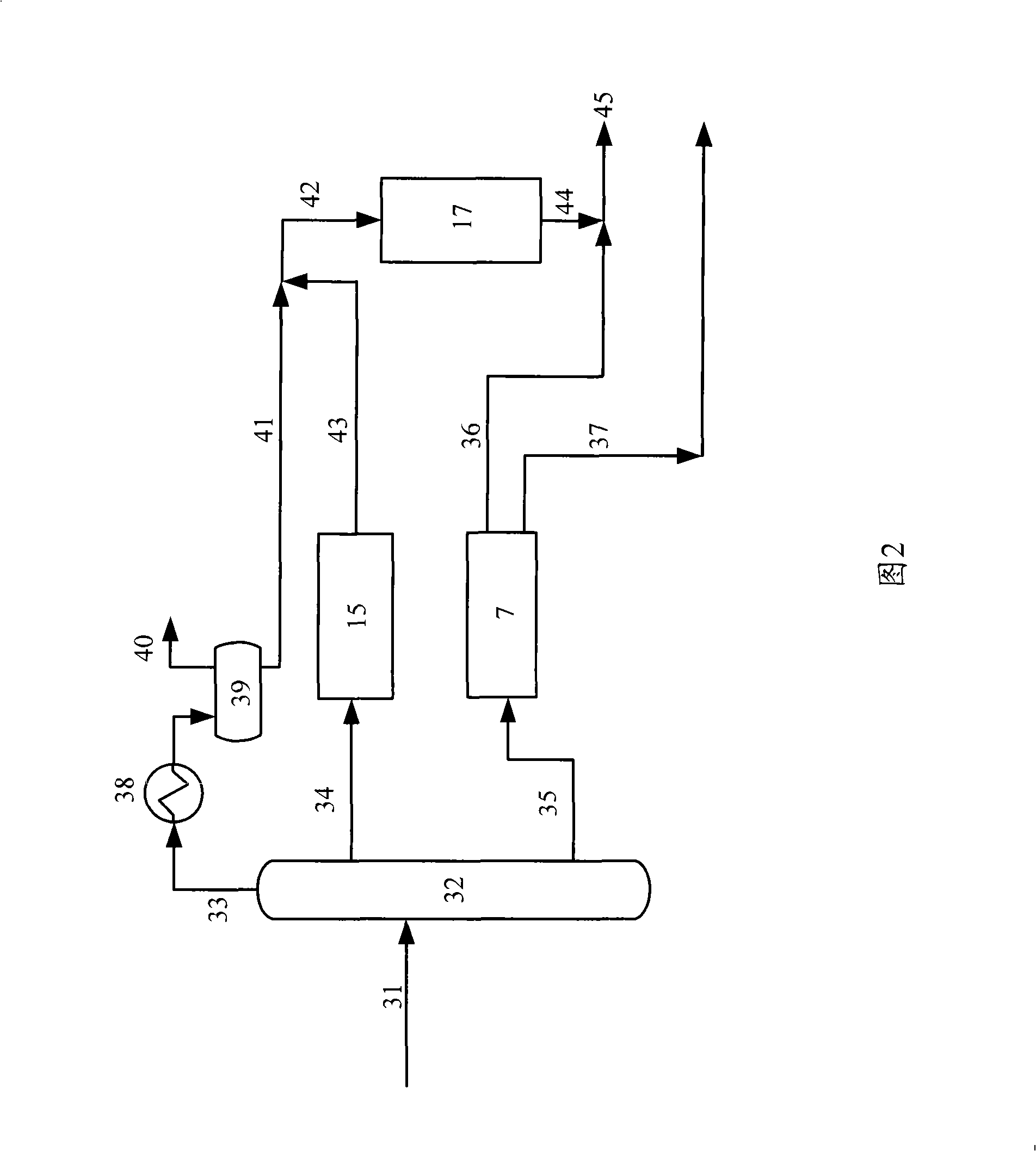

Hydrotreatment-catalytic cracking combination process method

ActiveCN103773495AReduce SOx contentImprove quality and yieldTreatment with hydrotreatment processesCycle oilChemistry

Provided is a hydrotreatment-catalytic cracking combination process method. Wax oil and catalytic cracking circulation oil go to a hydrotreatment reaction zone together, and are subjected to reactions of hydrodemetallization, hydrodesulfurization, hydrodenitrification, aromatic hydrogenation saturation and the like in the presence of hydrogen and hydrogenation catalysts. The obtained hydrogenated tail oil goes to a catalytic cracking device, a cracking reaction is carried out in the presence of catalytic cracking catalysts. Dry gases, liquefied gases, catalytic cracking gasoline, catalytic cracking light diesel oil, catalytic cracking circulation oil and slurry oil are obtained after separation, the catalytic cracking light diesel oil is subjected to self-circulation in the catalytic cracking device and the catalytic cracking circulation oil is circulated to the hydrotreatment reaction zone. The method can raise yield and quality of gasoline products greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-polymerization-degree polyformaldehyde dialkyl ether from petroleum fractions and application

ActiveCN102173984AHigh CN valueApparent output ratioOrganic chemistryOrganic compound preparationDistillates petroleumChemical industry

The invention belongs to the technical fields of energy chemical industry and clean diesel components and in particular relates to a method for preparing low-polymerization-degree polyformaldehyde dialkyl ether from main raw materials such as a petroleum C4 component, an alkadiene-removed petroleum C5 component, a catalytic cracking light petroleum 30-90-DEC C fraction low-carbon monoolefine and the like. The structural general formula of the low-polymerization-degree polyformaldehyde dialkyl ether is CnH2n+1O(CH2O)mCnH2n+1, wherein m is an integer from 1 to 5; and n is an integer from 2 to 5. The low-polymerization-degree polyformaldehyde dialkyl ether prepared by the method has a higher CN value, can be applied to diesel fuel widely and effectively without high polymerization degree andhas a relatively simple preparation process. The byproducts petroleum C4 and C5 in the petroleum cracking ethylene process and the catalytic cracking petroleum 30-90-DEC C light fraction serve as theraw materials, so production cost is greatly saved by using low-carbon olefin in the raw materials, a good technical route is provided for comprehensive utilization of a large number of byproducts inthe petroleum cracking process, and remarkable economic significance is achieved.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

Production of liquefied gas cracking catalyst with gasoline olefin content decreasement

It is a sort of cracking catalyst for reducing alkene content in gasoline and increasing liquid gas yield and the preparation method. It includes the following steps: clay, de-ionized water and phosphorus-containing compound were mixed up to form clay serosity ; molecular screen, de-ionized water and phosphorus-containing compound and rare earth compound were mixed up to form molecular screen serosity; agglomerant, de-ionized water and any mineral acid were mixed up to form agglomerant serosity. The above three agglomerants were mixed up and dried. Cracking catalyst made by this method has high liquid gas yield and it maintains high octane level in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

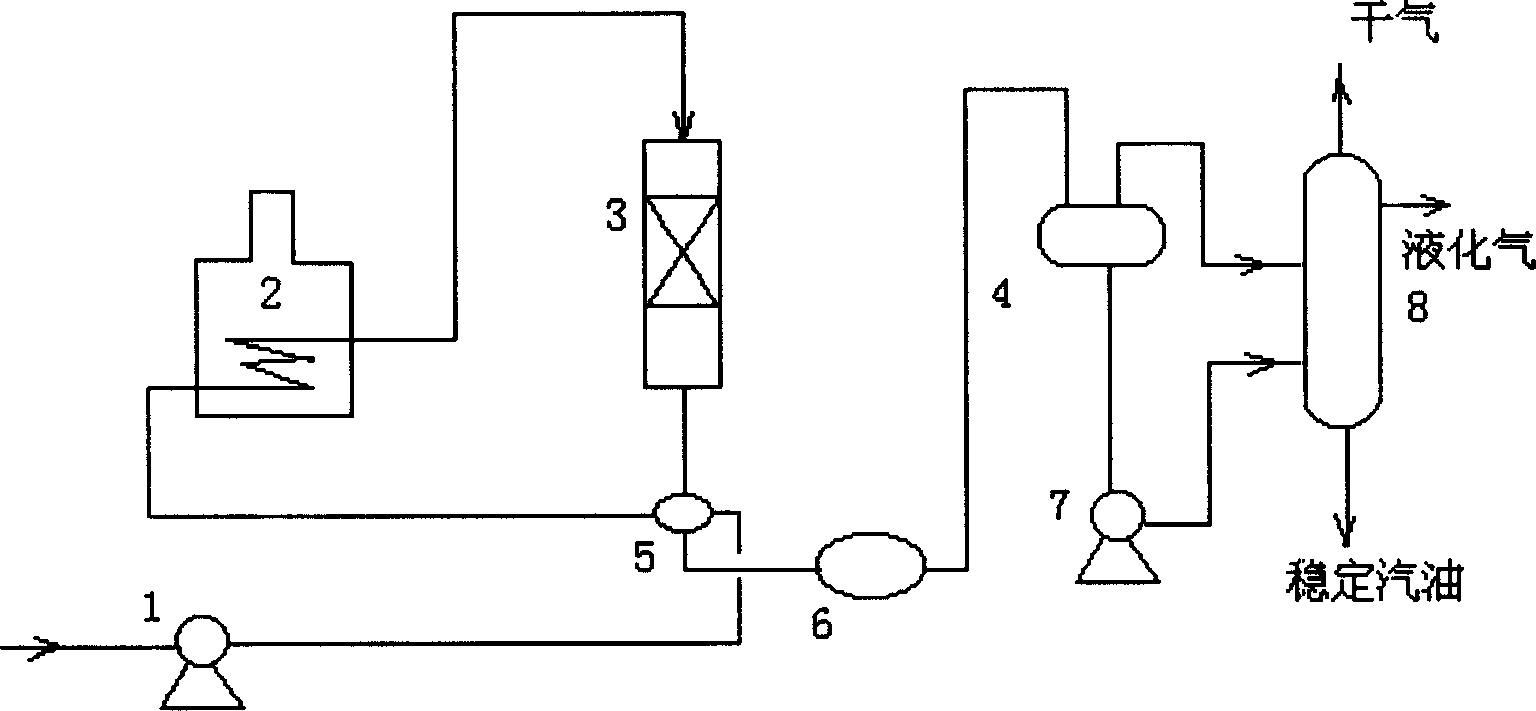

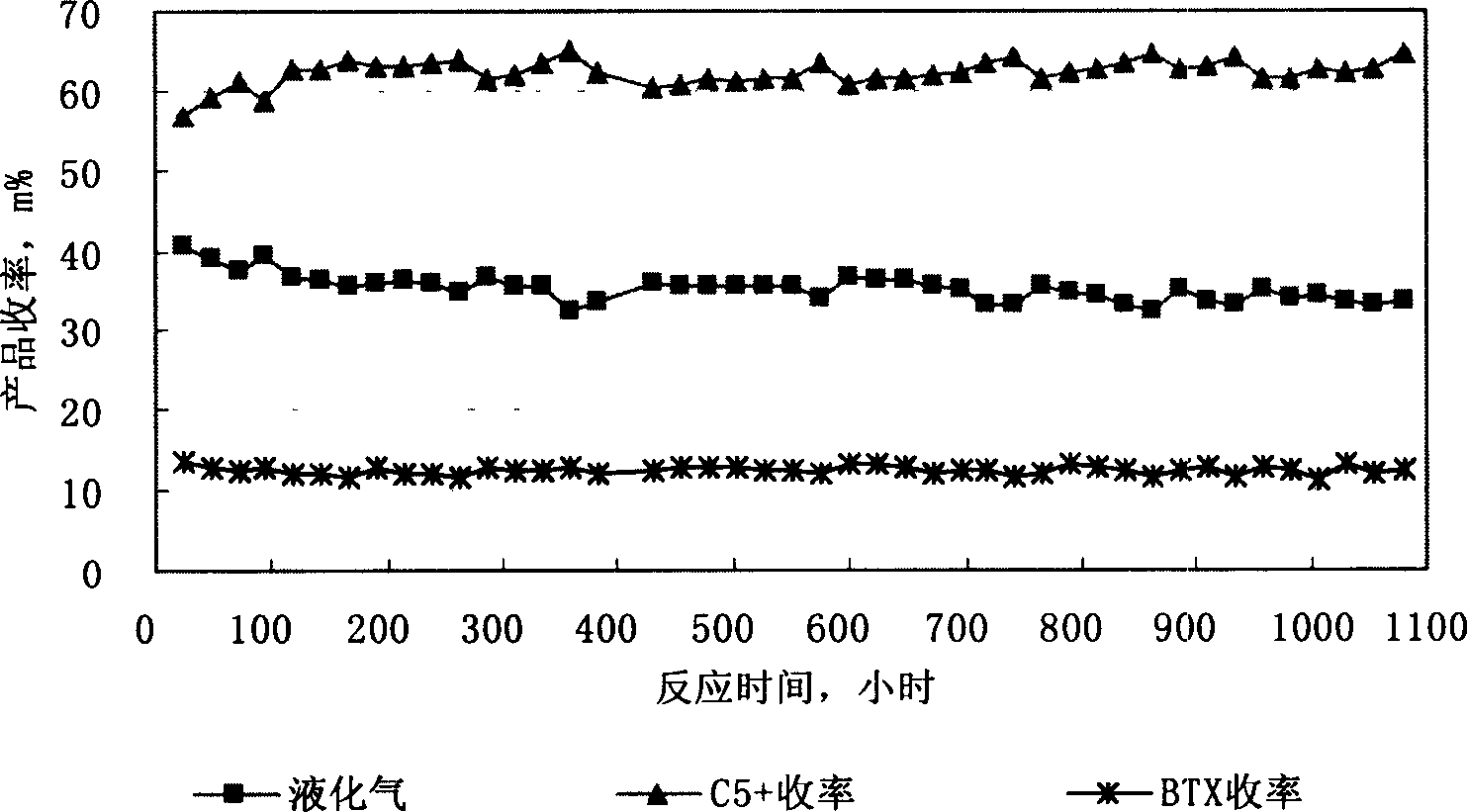

Catalyst continuous reproducible low octane rating gasoline modifying method

The invention discloses a catalyst continuous regeneration low-octane gasoline upgrading method. The low-octane gasoline raw material and the light hydrocarbon raw material are mixed, then enter into a gasoline upgrading reactor, contact and react with the upgrading catalyst in the reactor, the reactant is separated to obtain dry gas, liquefied gas and upgrading gasoline products; the deactivated catalyst in the reaction system is lifted and conveyed to a regeneration system, contacts with the regeneration gas to be burned in a regenerator, the burned regeneration catalyst is lifted and conveyed to the reaction system. The method greatly improves the octane value of the gasoline, and the olefin content in the upgrading gasoline is very low; the continuous regeneration of the deactivated catalyst ensures that the activity and the selectivity of the catalyst in the reactor are both maintained at higher levels; compared with the conventional reactor switching regeneration way, the dry gas yield of the upgrading reaction is obviously decreased, the upgrading gasoline and the liquefied gas as the target products are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Superfine granular zeolite aromatizing catalyst and its preparation and use

InactiveCN1552821AStrong anti-coking abilityImprove stabilityTreatment with hydrotreatment processesLanthanideRare earth

Preparation of micro-size particle zeolite catalyst for aromatization and its application in complete fractional FCC gasoline hydrogenation-aromatization composite process are disclosed. The catalyst consists of: transition metal oxide and lanthanide metal oxide is 1.0wt% - 10.0wt%, micro-size particle zeolite of 20nm-800nm 50.0wt% - 90.0wt%, and balanced inorganic oxide binder. Its advantages include low total and L acidity, unblocked pore canal, good stability and strong anticoking ability, low antiknock index ((R+M) / 2) loss of gasoline product with reduced S and olefin contents of FCC gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

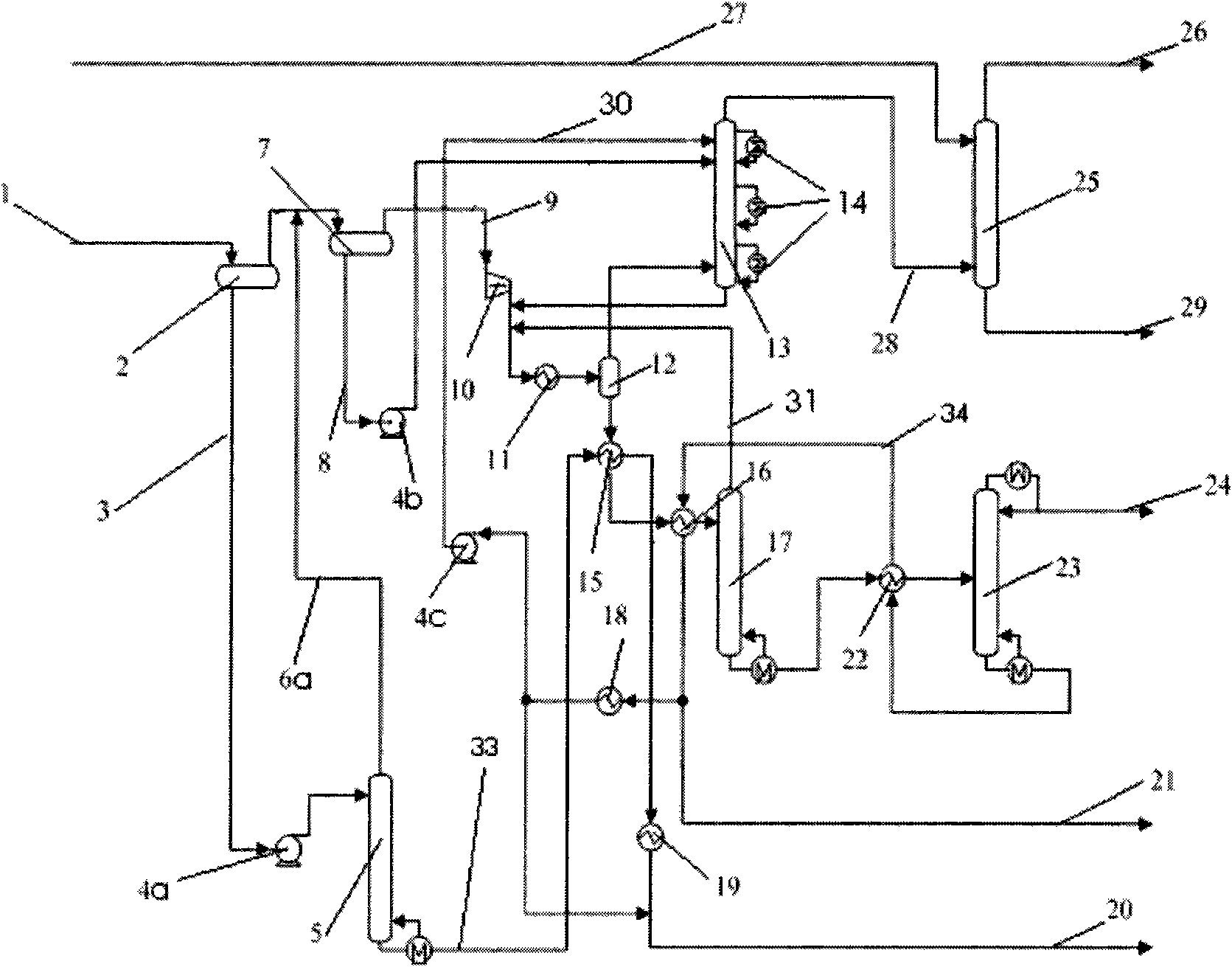

Method for reducing sulfur content of catalytically cracked gasoline

ActiveCN101275084AReduce sulfur contentReduce olefin contentTreatment with hydrotreatment processesHydrodesulfurizationEnergy consumption

The present invention provides a method of reducing sulfur content in fcc gasoline, the fraction below 250 DEG C from the main fractionator top of the catalytic cracking unit is stepped cooled to obtain a light gasoline fraction, a middle gasoline fraction and a heavy gasoline fraction, the light gasoline fraction enters in an alkali washing sweetening unit by a absorption and stabilization system of the catalytic cracking unit; the middle gasoline fraction processes selective hydrodesulfurization in a first hydrogenation region, the obtained hydrogenation middle gasoline fraction enters in the alkali washing sweetening unit to process deodorization; the heavy gasoline fraction processes hydrodesulfurization and octane number recovery reaction in a second hydrogenation region, the hydrodesulfurization heavy gasoline fraction is mixed with the light gasoline fraction after deodorized and the hydrodesulfurization middle gasoline fraction, a clean gasoline product is obtained. The method of the invention greatly reduces the sulfur content and the alkene content in fcc gasoline, the sulfur content of the product meets the need of sulfur in Europe IV discharging standard, the device has less investment, lower energy consumption because of the simple process of fcc gasoline hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline deep etherification modification method

ActiveCN103509591AIncrease the etherification contentIncrease liquid collectionTreatment with hydrotreatment processesHydrocarbon oils refiningAlcoholHeat resistance

The invention relates to a gasoline deep etherification modification method which comprises the following steps: an olefin-containing raw material and methanol are mixed; and in the presence of a solid strongly-acidic catalyst under the olefin etherification reaction condition of 95 DEG C above, secondary carbon olefin and tertiary carbon olefin in the gasoline and methanol are subjected to etherification reaction to obtain etherified gasoline, wherein the solid strongly-acidic catalyst is a high-temperature-resistant strongly-acidic catalyst, of which the heat resistance temperature is 125-250 DEG C and the acid core strength is greater than H0=-8.According to the method provided by the invention, the tertiary carbon olefin participates in the etherification reaction, and the secondary carbon olefin also participates in the etherification reaction, thereby greatly enhancing the etherified substance content in the gasoline, lowering the olefin content, enhancing the octane number, indirectly adding more cheap alcohols into the gasoline in a mode of etherified substances, increasing the liquid yield of the gasoline and lowering the gasoline cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light hydrocarbon non-hydrogenation modified catalyst, preparing process and application thereof

InactiveCN1524930AGood selective cleavage activityImprove stabilityTreatment with hydrotreatment processesPolymer scienceHydrocarbon mixtures

A modified catalyst of C3-C11 petroleum spirit, comprising 0.1-5.0 mass% of mixed rare-earth oxide or antimony trioxide, 95.0-99.1 mass% of carrying agent, wherein the carrying agent comprises 50-80 mass% of HZSM-5 zeolite and 20-50 mass% of gamma-aluminum oxide. The catalyst fits for low octane rating gasoline modification for boosting the octane and lowering olefin content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process For Converting Difficultly Convertible Oxygenates to Gasoline

InactiveUS20080228021A1Few propensityLong cycle timeOrganic compound preparationHydroxy compound preparationSyngasOxygenate

Process for converting oxygenate compounds to hydrocarbons comprising the steps: (a) introducing a feed stream of synthesis gas to a synthesis section for the production of easily convertible oxygenates, (b) passing the effluent stream from said synthesis section containing easily convertible oxygenates to a gasoline synthesis section, (c) passing the effluent of said gasoline synthesis section to a separator and withdrawing from said separator hydrocarbons boiling in the gasoline boiling range, (d) admixing a recycle stream from the separator containing unconverted synthesis gas volatile hydrocarbons with the feed stream of synthesis gas of step (a), (e) introducing a feed containing difficulty convertible oxygenates to the synthesis section of step (a).

Owner:HALDOR TOPSOE AS

Petroleum hydrocarbon cracking catalys containing rare earth superstable Y-type zeolite

This invention discloses a petroleum hydrocarbon cracking catalyst, including Y-shaped zeolite, clay and inorganic oxide agglomerant. The characteristic is that the Y-shaped zeolite contains 30-100 weight % rare earth super-stable Y-shaped zeolite, and the preparation method of the rare earth super-stable Y-shaped zeolite includes that the mixing solution of rare earth salt and citric acid or mixing agent of inorganic ammonium salt, rare earth salt and citric acid treat the zeolite. This catalyst can effectively decrease the content of olefin hydrocarbon in catalyzing cracking petroleum and increase the yield of light petroleum.

Owner:CHINA PETROLEUM & CHEM CORP

Method of lowering olefine content in gasoline

ActiveCN1986742AReduce olefin contentEasy to separateCatalytic crackingMolecular sieveActive component

The method of lowering olefin content in gasoline is to contact gasoline containing olefin with water and catalyst to obtain gasoline product with lowered olefin content. The catalyst is regular catalyst comprising carrier in regular structure and active component coating distributed in the inner surface and outer surface of the carrier, and active component is composition containing molecular sieve. The method of the present invention can lower the olefin content in gasoline from 51.9 wt% to 22.28 wt% and convert olefin into propylene and ethylene in the yield as high as 18 % and 2 % separately.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy-oil catalytic-cracking catalyst and preparing method

ActiveCN1814705AHigh yieldImprove gasoline qualityCatalytic crackingNaphtha reformingMolecular sieveGasoline

This invention relates to a catalytic cracking catalyst of heavy oil, which includes Al2O and molecular sieves and clays or not, in which, said Al2O is eta or chi, or mixture of eta and / or chi and gamma-Al2O, said catalyst contains P and rare earth metal, the content of eta-Al2O and / or chi-Al2O is 0.5-50 weight%, that of the gamma-Al2O is 0-50weight% and that of the clay is 0-75% taking the gross of the catalyst as the primary standard, content of P is 0.1-8weight % counted in P205, the rare earth is 0.1-2% and the molecular sieve is 10-70% counted in oxide and the molecular sieve is Y- type zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing contents of sulfur and olefin in catalytically cracked gasoline

ActiveCN104277875AReduce processingReduce olefin contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenHydrodesulfurization

The invention discloses a method for reducing the contents of sulfur and olefin in catalytically cracked gasoline. The method comprises the following steps: by using catalytic gasoline as a raw material, firstly, cutting and fractionating by virtue of a fractionating tower to obtain light gasoline and heavy gasoline, wherein the light gasoline enters into a fixed bed reactor for physical absorption desulfurization without hydrogen, the content of olefin is not reduced by physical absorption desulfurization, and the octane number of the light gasoline is not damaged; mixing the heavy gasoline with hydrogen and feeding the mixture into a selective hydrogen desulfurization fixed bed reactor, wherein the reaction product further enters into a hydro-upgrading fixed bed reactor and the modified heavy gasoline is mixed with a physical absorption desulfurization product without hydrogen of the light gasoline; and carrying out hydrogen desulfurization and hydro-upgradation on the heavy gasoline. As the olefin content of the heavy gasoline is less and the octane number of the light gasoline is low, the octane number of the heavy gasoline is less in loss under the condition that a relatively high desulfurization rate is maintained. The method disclosed by the invention can be used for producing clean gasoline which meets the sulfur requirements of European IV and European V, and the equipment investment is saved, the adsorbent is convenient to fill and the loss of the octane number is less.

Owner:PETROCHINA CO LTD

Method and device for catalytic conversion of light dydrocarbon

ActiveCN101665710AReduce olefin contentLow impurity contentCatalytic crackingIsomerizationFluidized bed

The invention provides a method for catalytic conversion of light dydrocarbon, which comprises that: a light dydrocarbon raw material (gaseous or liquid) enters a riser, is mixed with a cold regenerated catalyst from a pre-lifting zone of the light dydrocarbon riser, and then enters a light dydrocarbon riser reactor or a fluidized bed reactor to mainly undergo light dydrocarbon catalytic conversion reactions such as catalytic cracking, isomerization and aromatization and the like under the operating conditions that the reaction temperature is between 350 and 650DEG C, the absolute pressure is between 0.11 and 0.4MPa, and the contact time is 0.5 to 30 seconds to achieve the aims of reducing olefin, sulfur and nitrogen content and improving octane number.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Catalytic cracking combined process

InactiveCN1428402AReduce olefin contentInhibit excessive crackingTreatment with plural serial stages onlyFluidized bedGasoline

The catalytic cracking combination process includes the following steps: cooling 10-80 wt% of regenerative agent, feeding it into reaction zone of circulating fluidized bed reactor and making it contact with gasoline to make reaction; then feeding the produced reaction oil-gas into the subsequent gasoline conversion product separation system; feeding the catalyst after which is reacted into stripper zone of the circulating fluidized bed reactor to make stripping; back returning 40-80 wt% of stripped catalyst into reaction zone for circulating use and feeding residual portion into lift pipe reaction and making it mix with non-cooled regenerative agent and can be upward flower along lift pipe under the action of prelift medium; injecting hydrocarbon raw material into lift pipe and making it contact with catalyst, react, and making reactant flow through lift pipe outlet and come into the settler.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com