Patents

Literature

73results about How to "Improve quality and yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

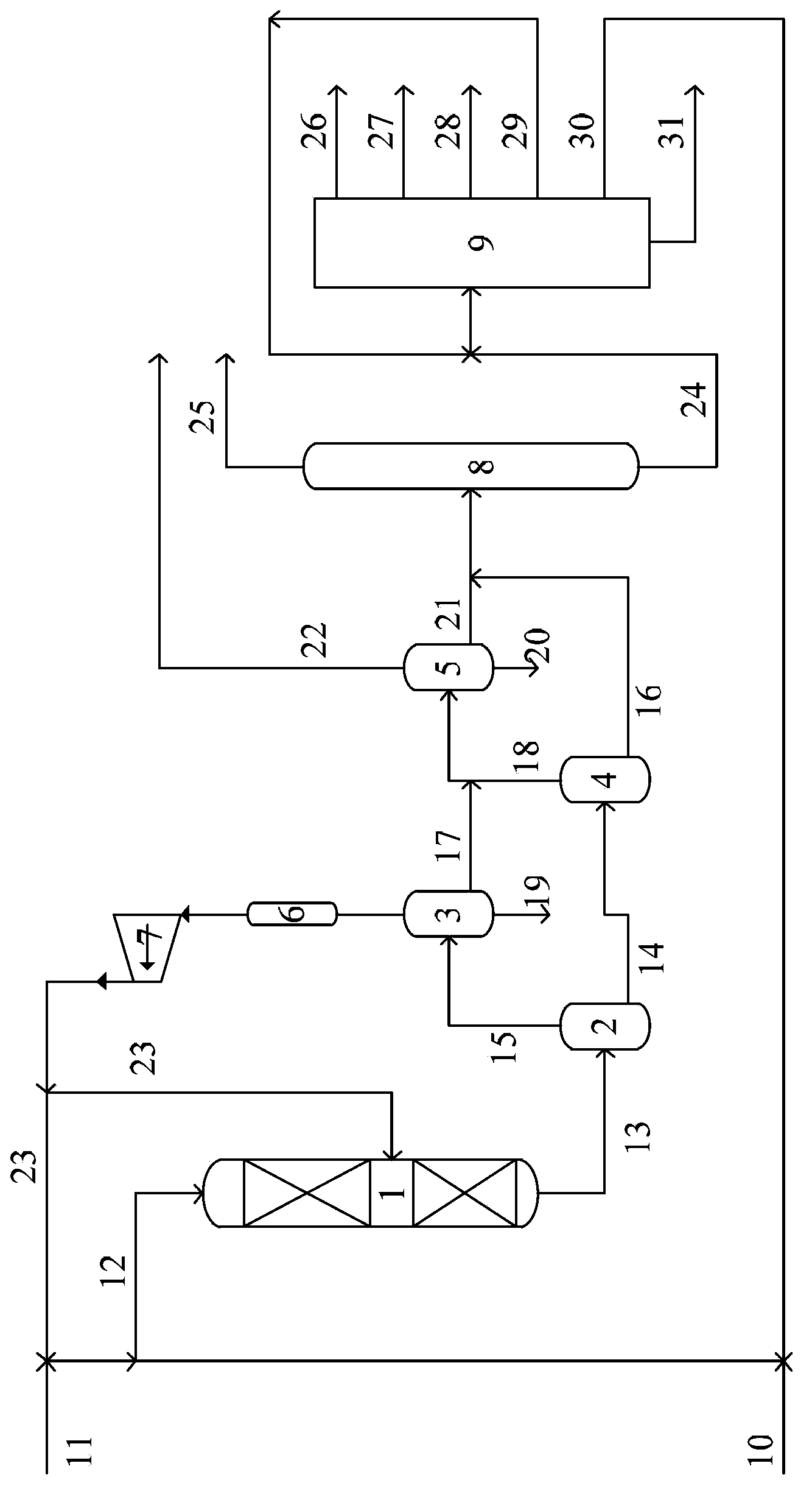

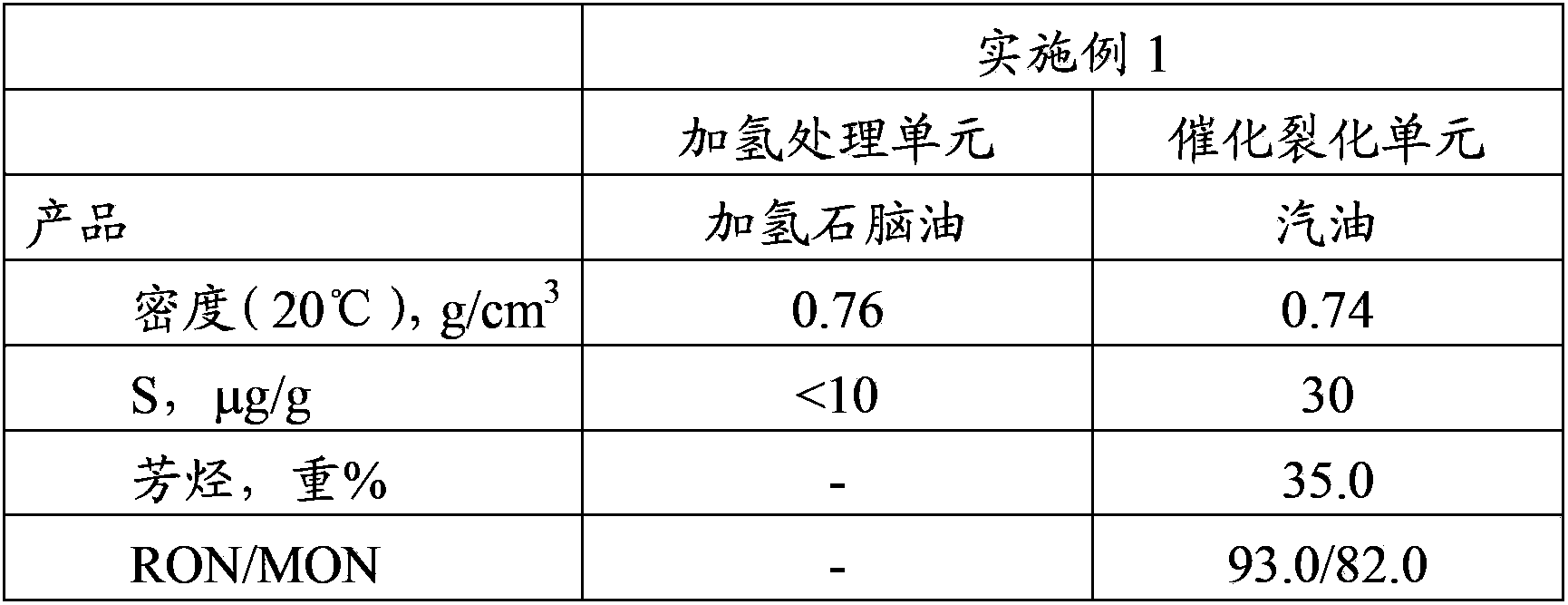

Hydrotreatment-catalytic cracking combination process method

ActiveCN103773495AReduce SOx contentImprove quality and yieldTreatment with hydrotreatment processesCycle oilChemistry

Provided is a hydrotreatment-catalytic cracking combination process method. Wax oil and catalytic cracking circulation oil go to a hydrotreatment reaction zone together, and are subjected to reactions of hydrodemetallization, hydrodesulfurization, hydrodenitrification, aromatic hydrogenation saturation and the like in the presence of hydrogen and hydrogenation catalysts. The obtained hydrogenated tail oil goes to a catalytic cracking device, a cracking reaction is carried out in the presence of catalytic cracking catalysts. Dry gases, liquefied gases, catalytic cracking gasoline, catalytic cracking light diesel oil, catalytic cracking circulation oil and slurry oil are obtained after separation, the catalytic cracking light diesel oil is subjected to self-circulation in the catalytic cracking device and the catalytic cracking circulation oil is circulated to the hydrotreatment reaction zone. The method can raise yield and quality of gasoline products greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

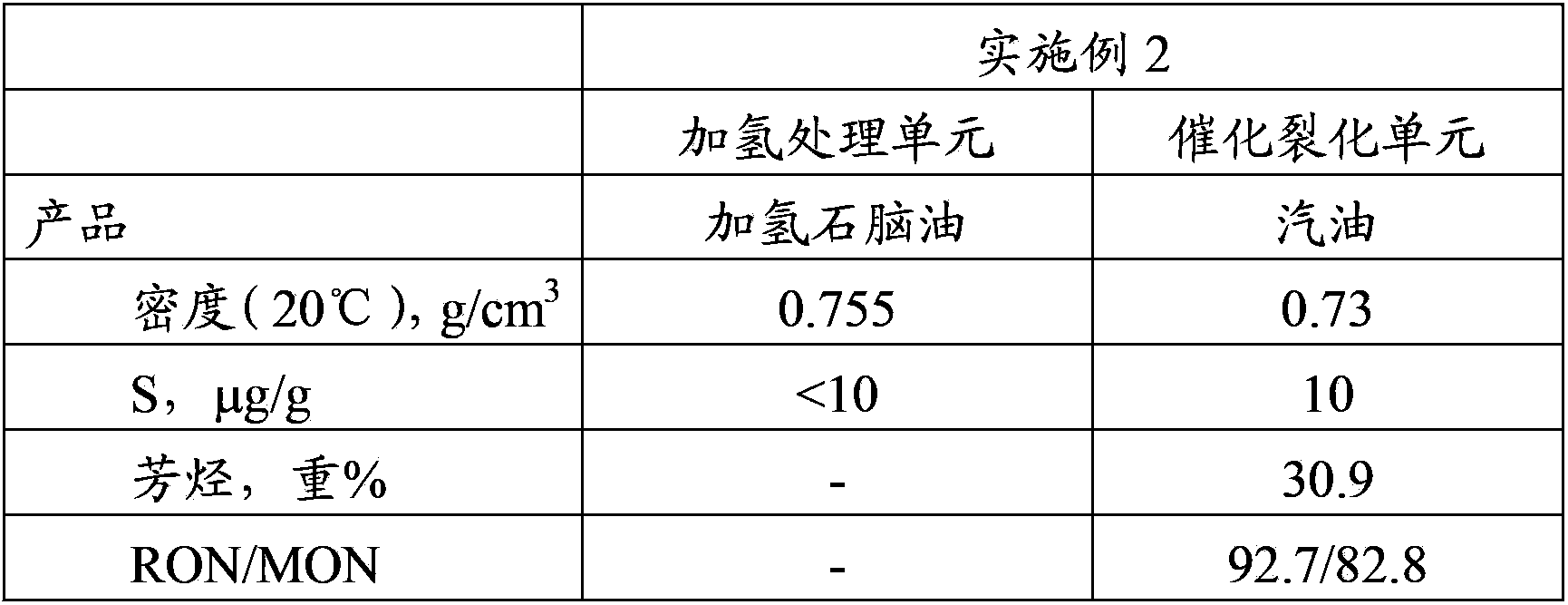

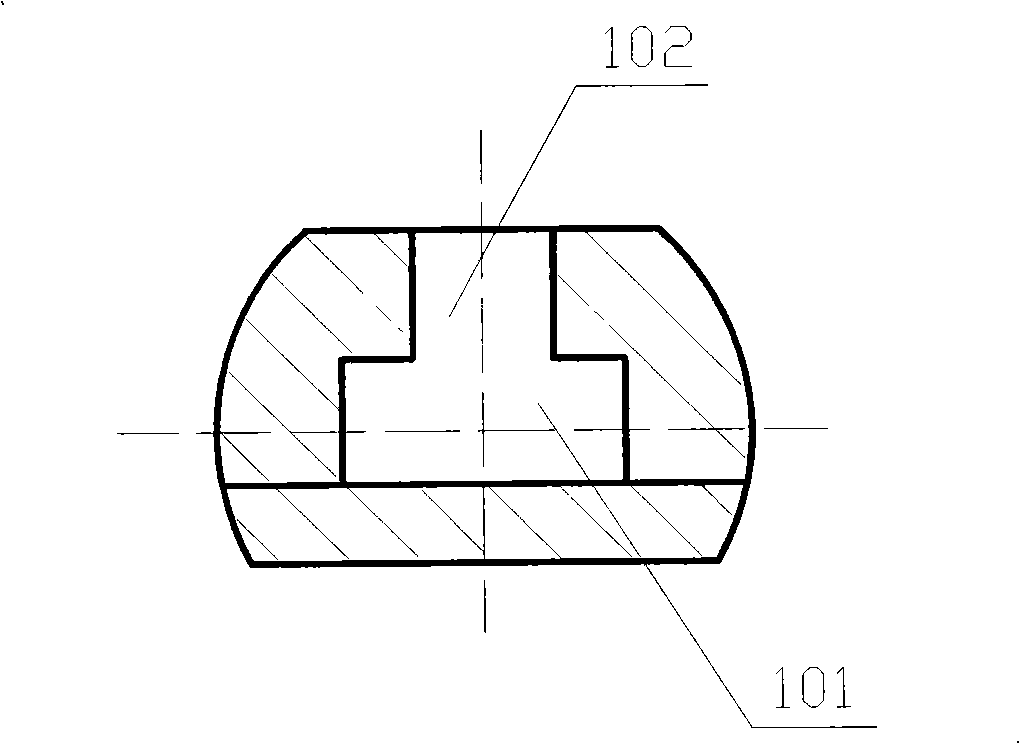

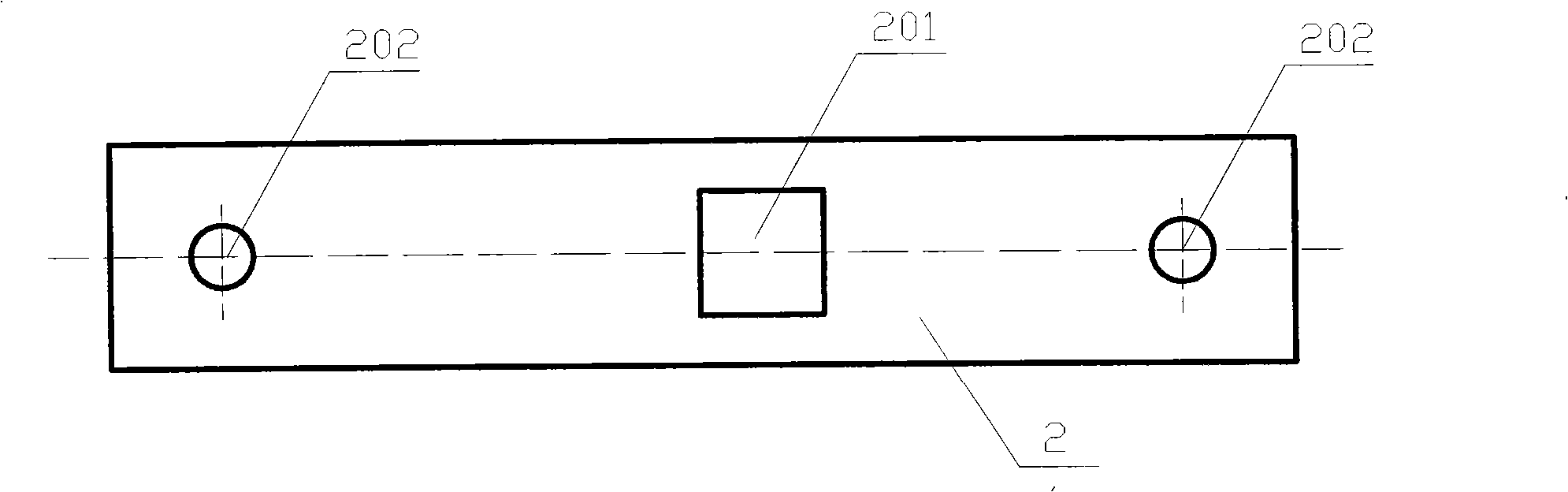

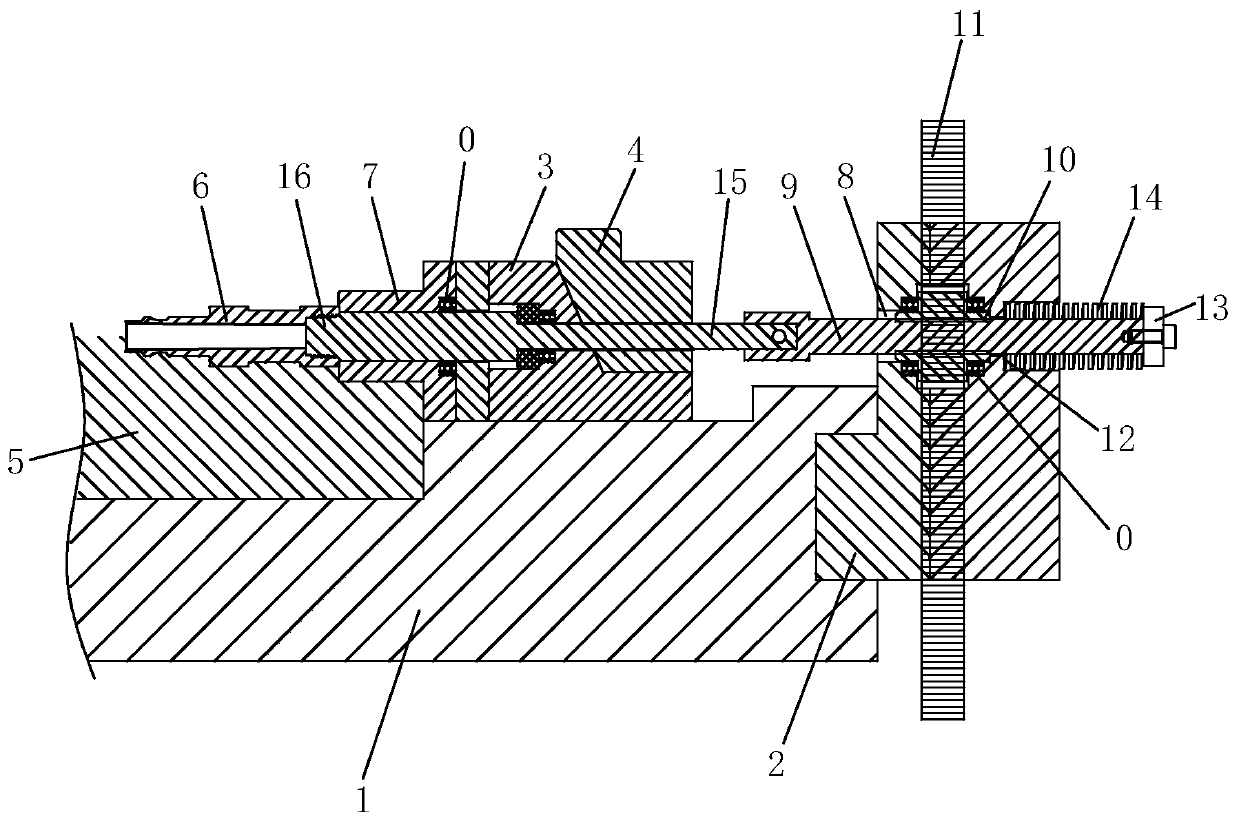

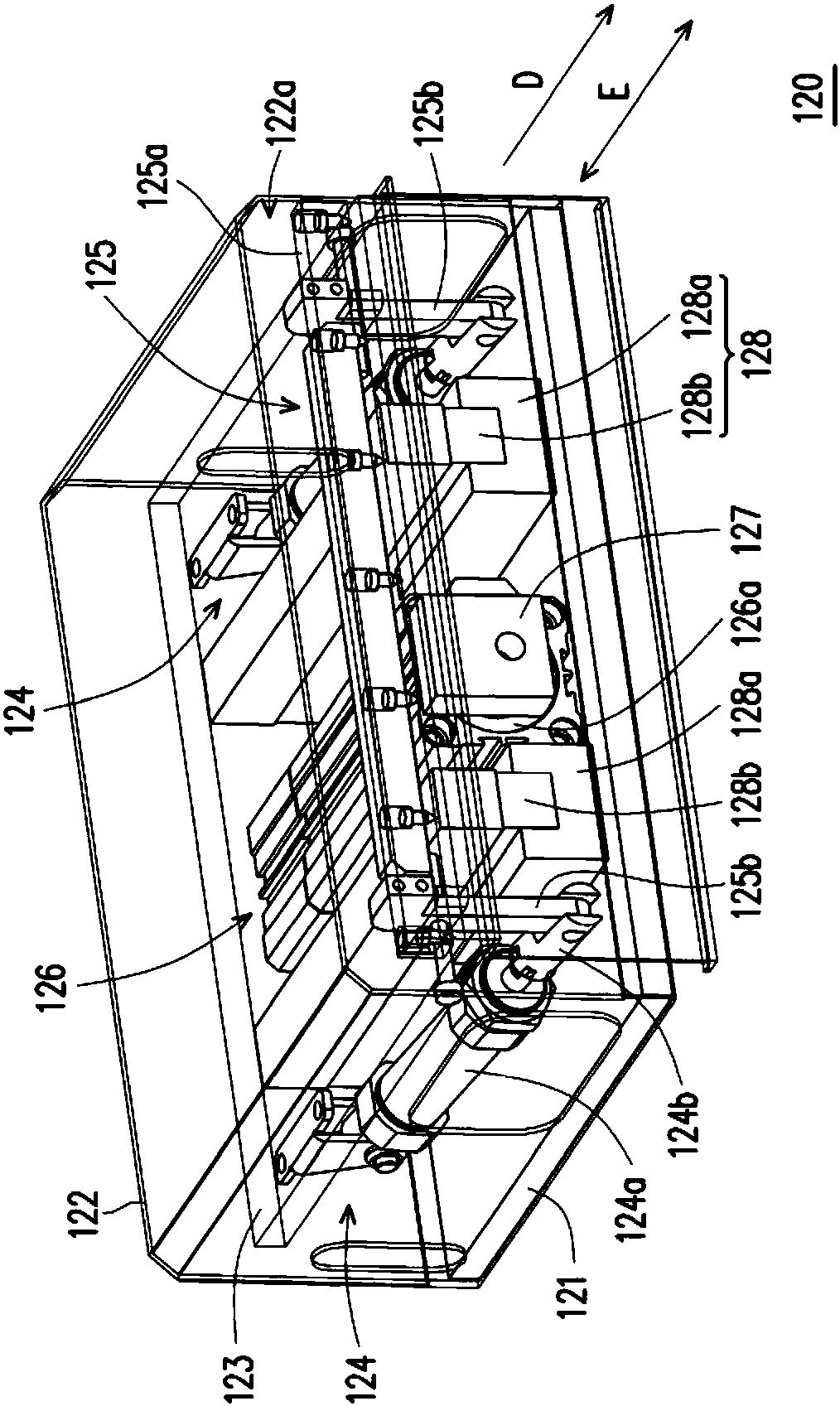

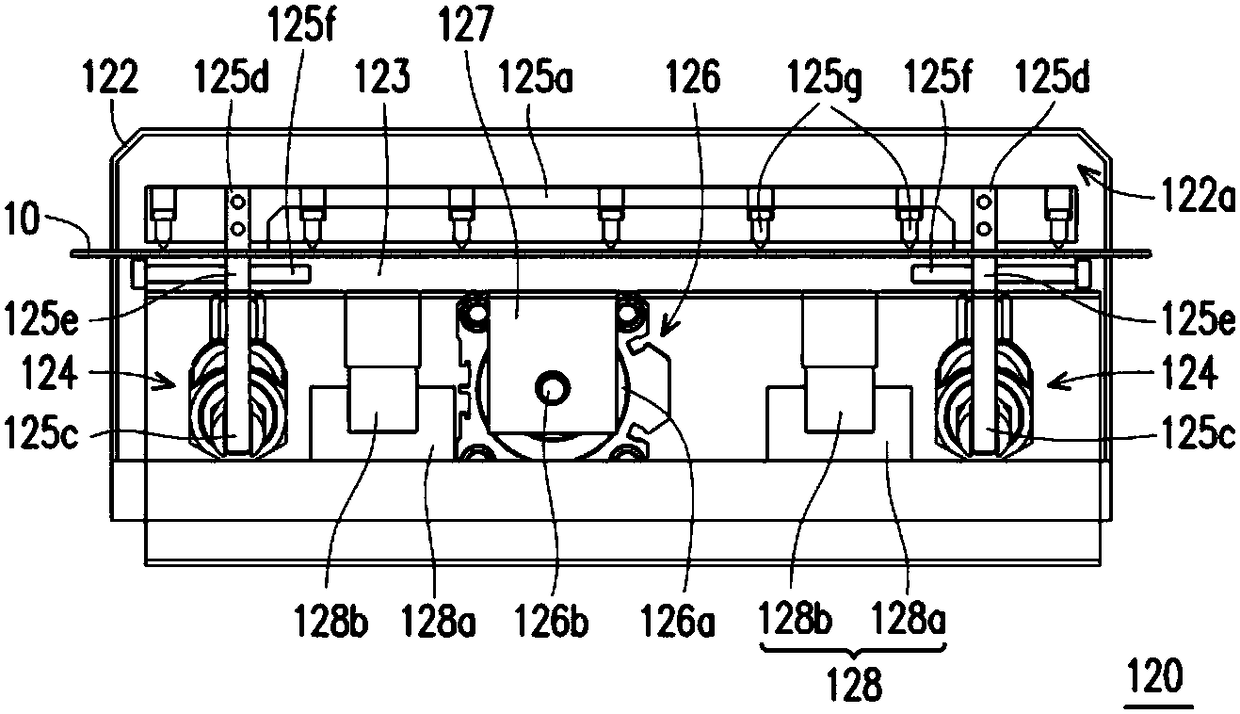

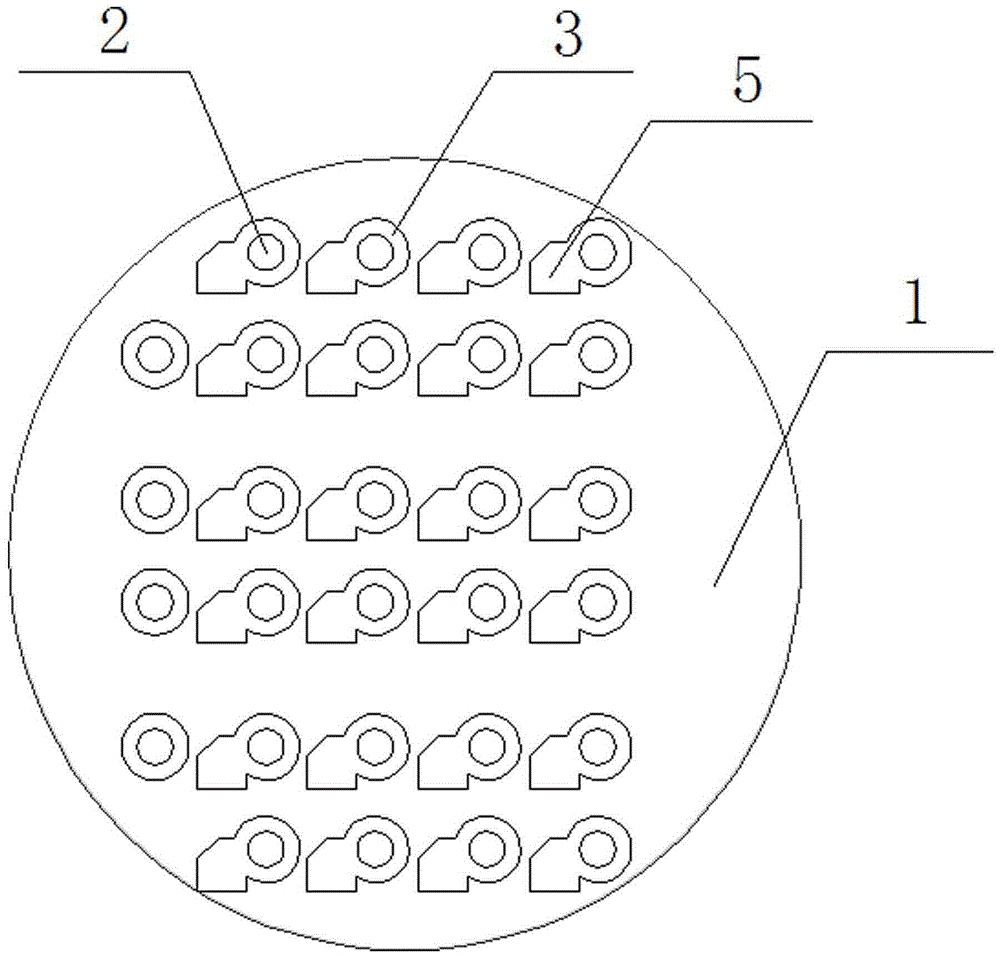

Tunneling type graphite boat for semi-conducting material liquid phase epitaxial growth

InactiveCN101353812AResidue reductionImprove quality and yieldLiquid-phase epitaxial-layer growthFilm materialMother liquor

The invention discloses a tunnel-typed graphite boat applied to liquid phase epitaxial growth of semi-conductive material. The graphite boat comprises: a boat body with tunnels, a slider matched with the dimension of cross-section of the tunnels, a cover and a graphite pad. The top surface of the tunnel is provided with a plurality of mother liquid square holes equal spaced and loading with mother liquid of different integrants, the center of the slider is provided with a substrate square hole with the same dimension of an epitaxial substrate, the graphite pad is arranged in the substrate square hole to regulate height between the substrate and the square hole mouth, and the substrate is arranged on the graphite pad. The mother liquid is contacted with the substrate through sliding the slider, and a layer of film material epitaxially grows on the substrate. The method has the advantages that: a substrate groove of the graphite boat is replaced by the substrate square hole, the bottom of the boat body is taken as the backing plate for installing the graphite pad and the substrate to cause that in the graphite boat processing, vertical degree in the hole and flatness of the bottom are guaranteed and the height of the substrate can be adjusted by the graphite pad. The characteristics can effectively reduce residual quantity of the mother liquid and improve quality and yield rate of single crystal films.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

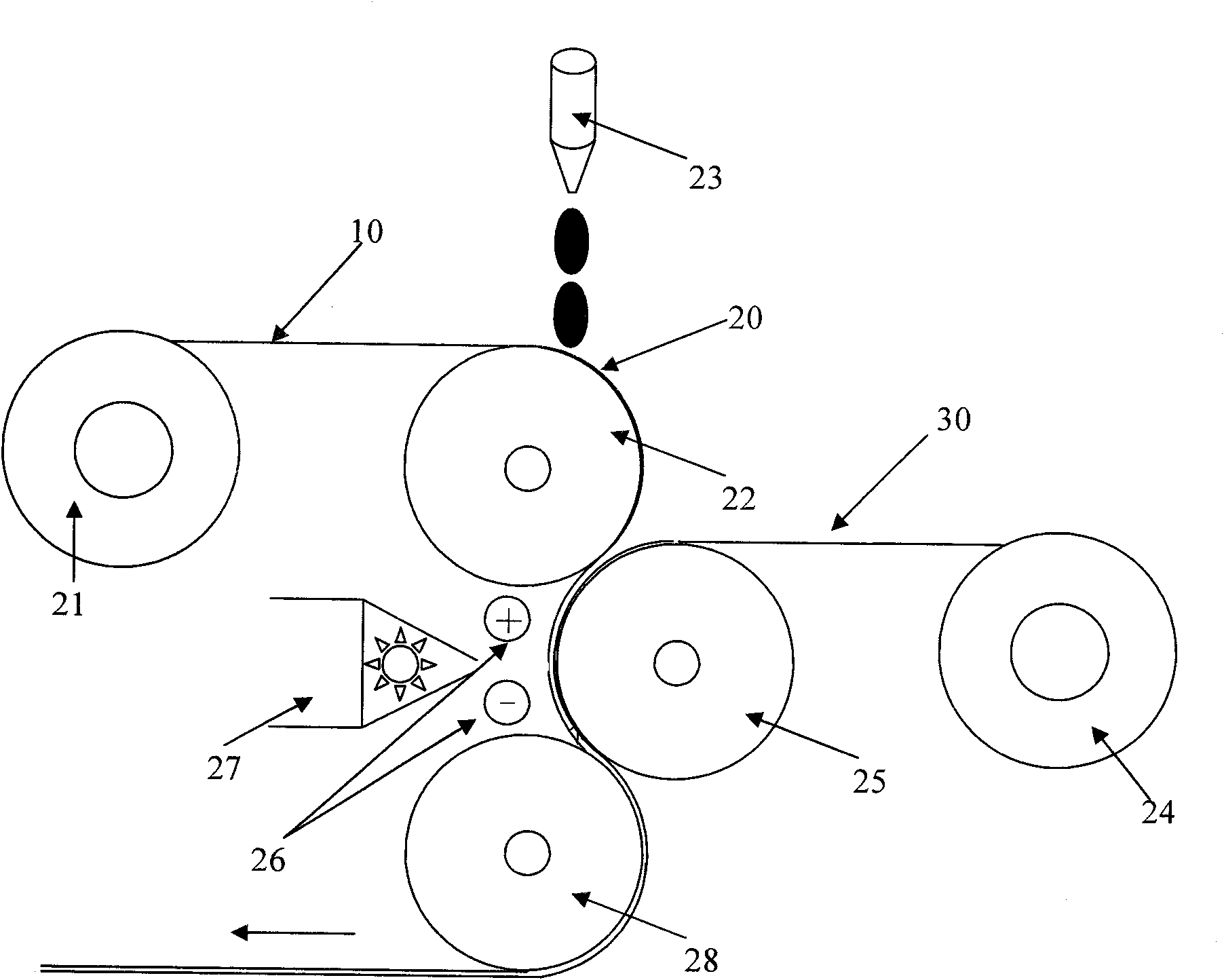

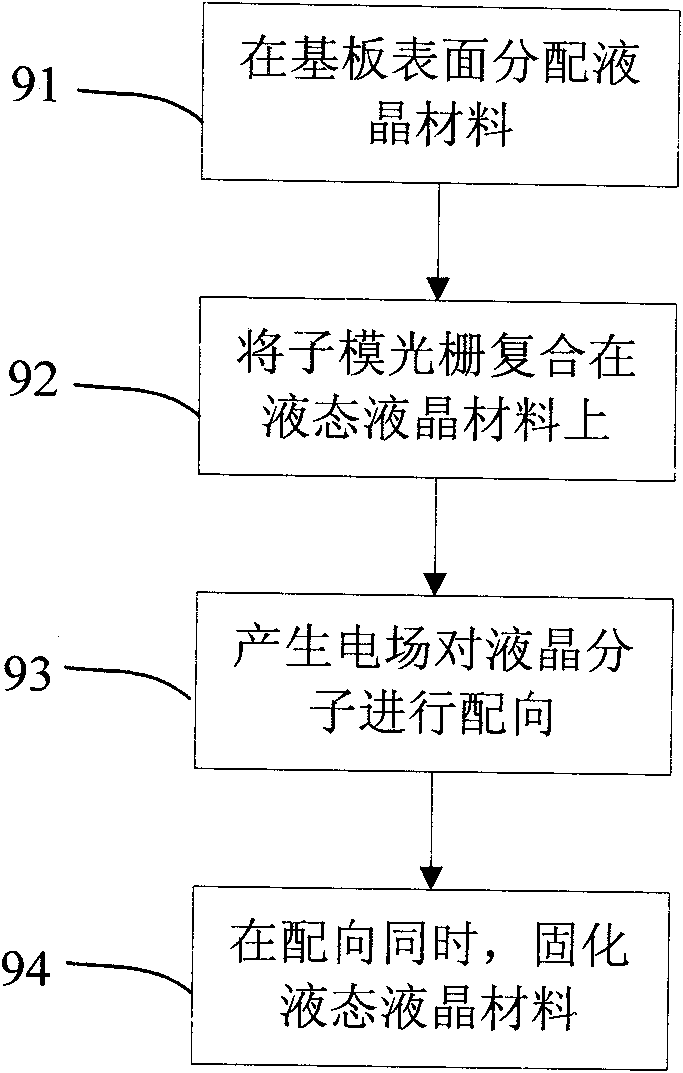

Equipment and method for manufacturing liquid crystal optical element

ActiveCN101893778AEliminate dust and static electricityImprove quality and yieldNon-linear opticsElectric fieldEngineering

The invention provides equipment and a method for manufacturing a liquid crystal optical element. The manufacturing equipment comprises a first transmitting device used for transmitting a substrate, a liquid crystal distribution device used for distributing liquid-state liquid crystal materials for the surface of the substrate, an electric field generating device used for generating an electric field so as to distribute directions for liquid crystal molecules in the liquid-state liquid crystal materials, and a curing device used for curing the liquid-state liquid crystal materials when the electric field generating device distributes directions for the liquid crystal molecules. Due to the mode, in the process of manufacturing the liquid crystal optical element, by performing non-contact direction distribution on the liquid crystal molecules by using the electric field, dust and static generated due to friction in a friction method can be effectively eliminated, and the finished product ratio and quality of the liquid crystal optical element are improved.

Owner:SUPERD CO LTD

M12 large-size silicon wafer cutting process

ActiveCN111531733AImprove quality and yieldReduce thicknessWorking accessoriesFine working devicesWire cuttingSilicon chip

The invention relates to an M12 large-size silicon wafer cutting process, and belongs to the technical field of crystalline silicon processing. The M12 large-size silicon wafer cutting process comprises the following steps of performing rod adhesion, namely fixing a silicon rod and a workpiece plate; performing feeding, namely assembling the silicon rod and the workpiece plate into a cutting machine to be cut; adding cutting fluid, namely adding the cutting liquid into the cutting machine; performing preheating before cutting, namely opening the cutting liquid and a wire net, and performing reciprocating wiring; cutting, namely setting cutting parameters and cutting the silicon rod; and performing blanking, namely setting retracting parameters, and enabling the silicon rod to be graduallyseparated from the wire net. According to the M12 large-size silicon wafer cutting process, a wear condition of a diamond wire can be reduced, the abnormal and bad edge breakage of the adhesive surface of the silicon wafer is effectively reduced, the diamond wire consumption is reduced, and the M12 large-size silicon wafer cutting process has the characteristics that the phenomenon of edge breakage of the silicon wafer is remarkably reduced and the slicing cost is reduced.

Owner:乐山高测新能源科技有限公司

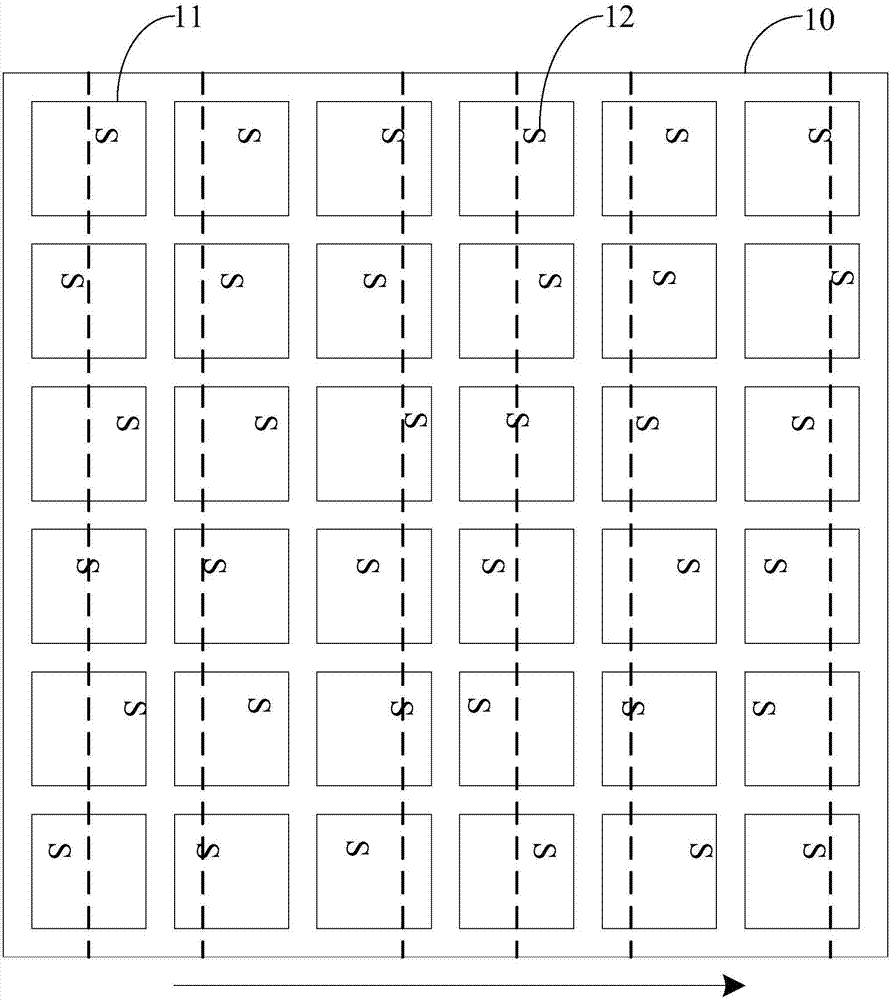

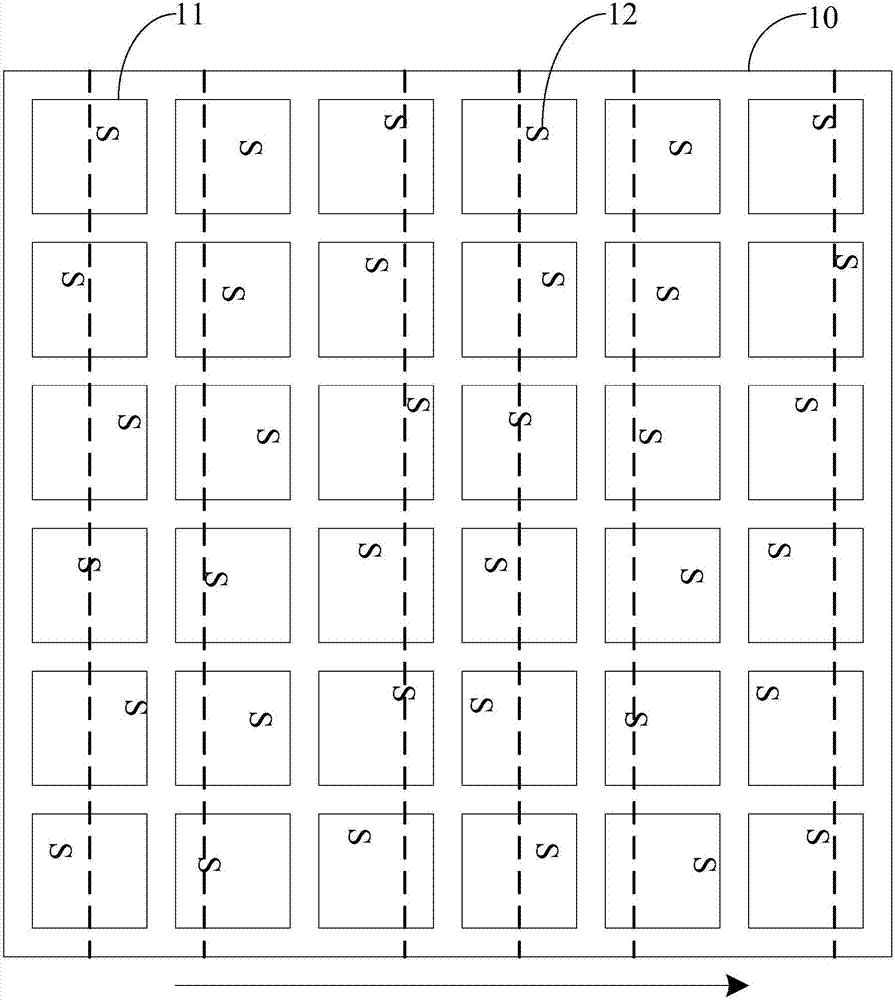

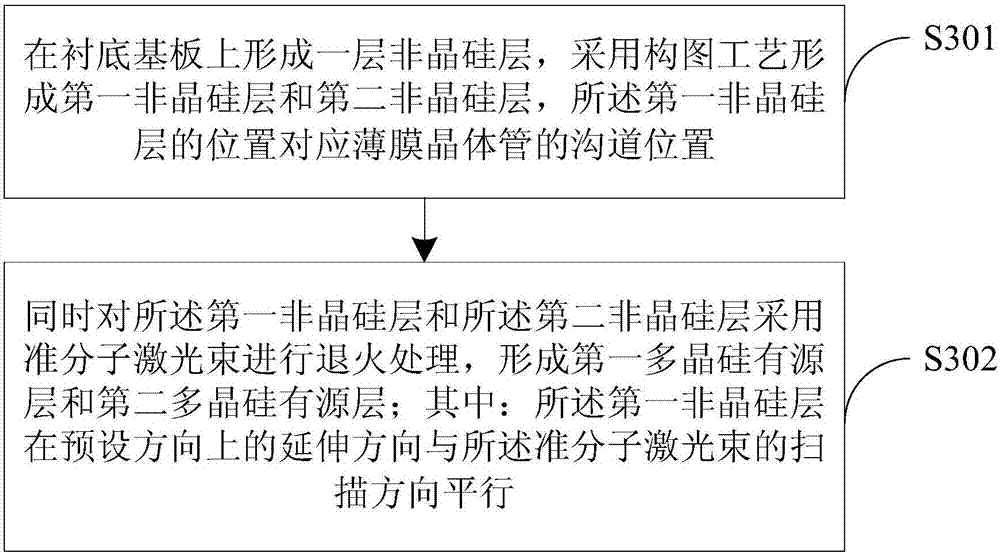

Array substrate and preparation method thereof, display panel, and display equipment

InactiveCN107104112AReduce visual defectsImprove quality and yieldSolid-state devicesSemiconductor/solid-state device manufacturingPolycrystalline siliconEngineering

The invention discloses an array substrate and a preparation method thereof, a display panel, and a display equipment, is used for reducing a visual defect for displaying Mura, and is used for improving the quality and the yield of the array substrate. The array substrate comprises pixel units arranged in several arrays on the substrate; each pixel unit includes a thin film transistor; the thin film transistor includes a polysilicon active layer; the length extending direction of a channel of the thin film transistor is parallel to a presetting direction; and the presetting direction is a scanning direction of an excimer laser beam used when the polysilicon active layer is formed.

Owner:BOE TECH GRP CO LTD

Circuit board pattern electroplating clamping film remover and pattern electroplating clamping film removing process

ActiveCN114126245ARemove completelyEasy to operatePrinted circuit liquid treatmentPrinted circuit secondary treatmentPhysical chemistryPrinted circuit board

The invention discloses a circuit board pattern electroplating sandwich film remover, and relates to the technical field of printed circuit board production, and the sandwich film remover is composed of the following components by the mass percentage: 5-20% of an organic alkali, 0.2-3% of a penetrant, 0.2-5% of a softening material, 0.05-10% of an accelerator, 0.05-1% of a tin surface bank protection agent, and the balance water. The sandwiched film remover can reduce the surface tension of a dry film, quickly permeate into a sandwiched film layer, soften and dissolve part of dry film slag, accelerate the fracture of a bond bridge between the dry films, enable the adhesive force of the dry films and a copper layer to disappear, and achieve the purpose of quickly and thoroughly removing the sandwiched film.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

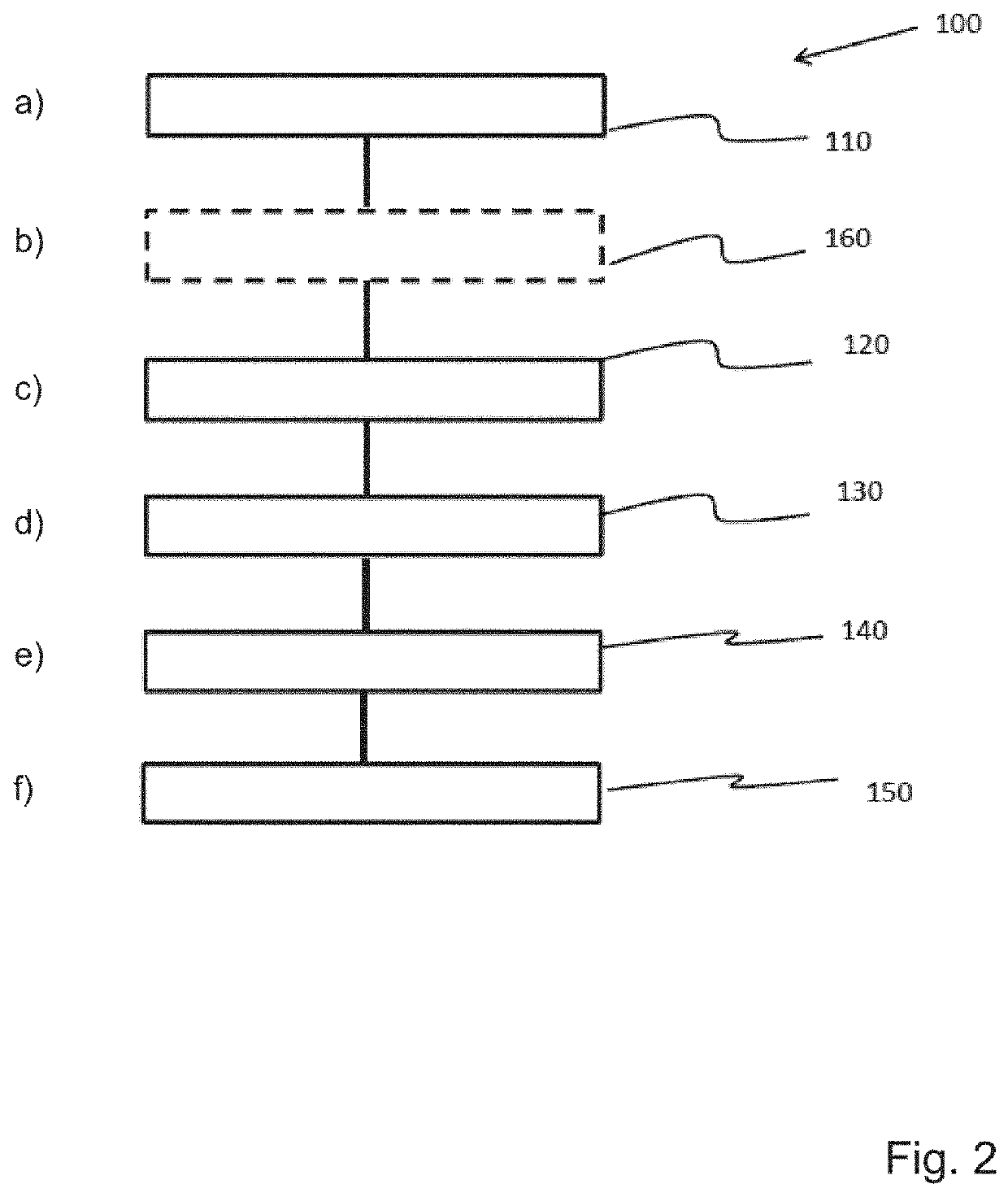

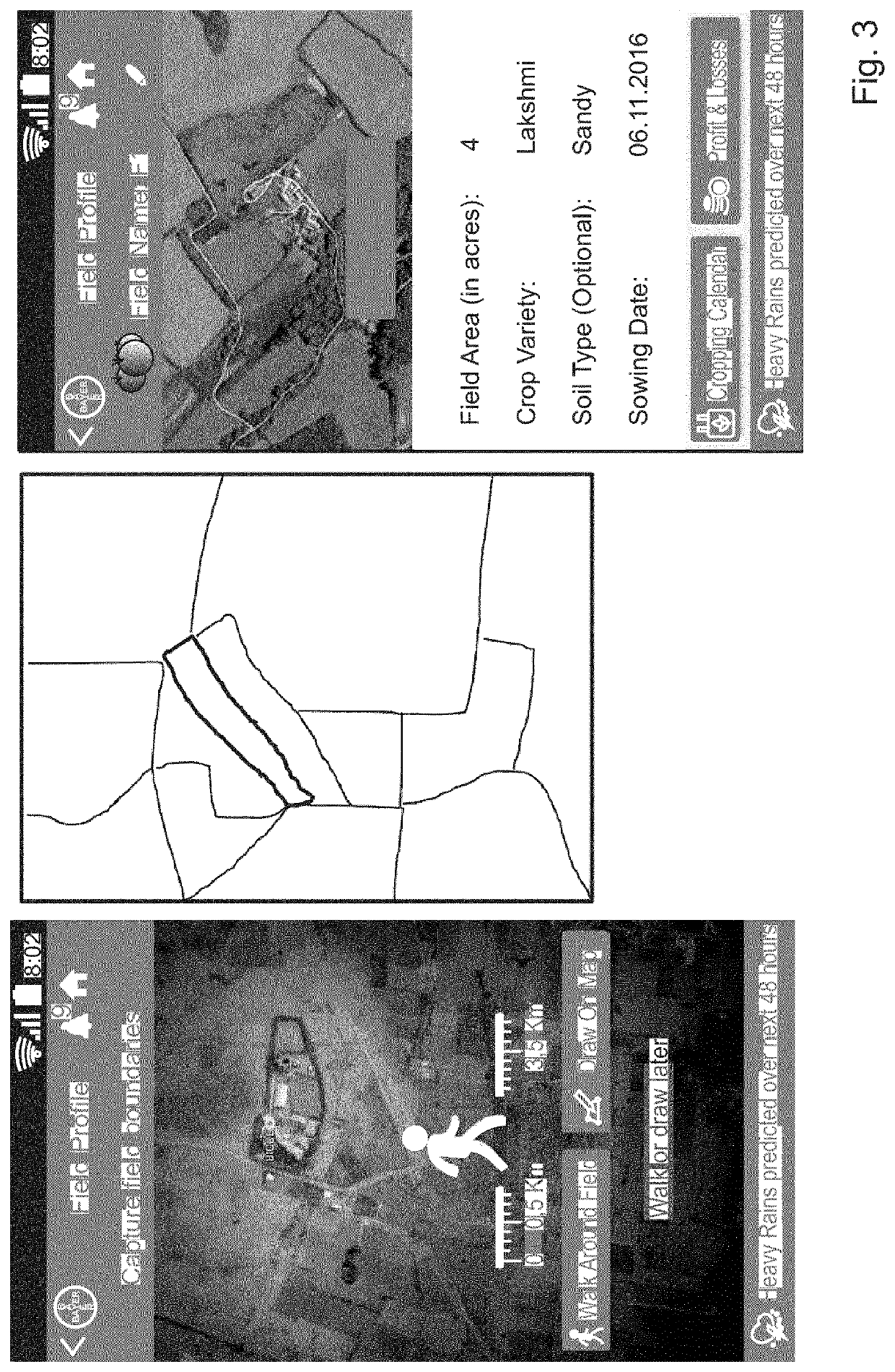

A hand held device for economic agricultural management

InactiveUS20200311828A1Improve quality and yieldLow priceMarket predictionsSeed and root treatmentAgricultural engineeringAgricultural science

A hand held device for economic agricultural management is described for a user of the device to provide agricultural information relating to a field, wherein the agricultural information includes information on at least one crop. A transmitter of the device transmits information including the agricultural information relating to the field. A receiver of the device receives agricultural data that includes economic information relating to the at least one crop. A processing unit of the device determines economic agricultural management information on the basis of the agricultural data. An output unit of the device outputs the economic agricultural management information to the user of the device.

Owner:BAYER BUSINESS SERVICES

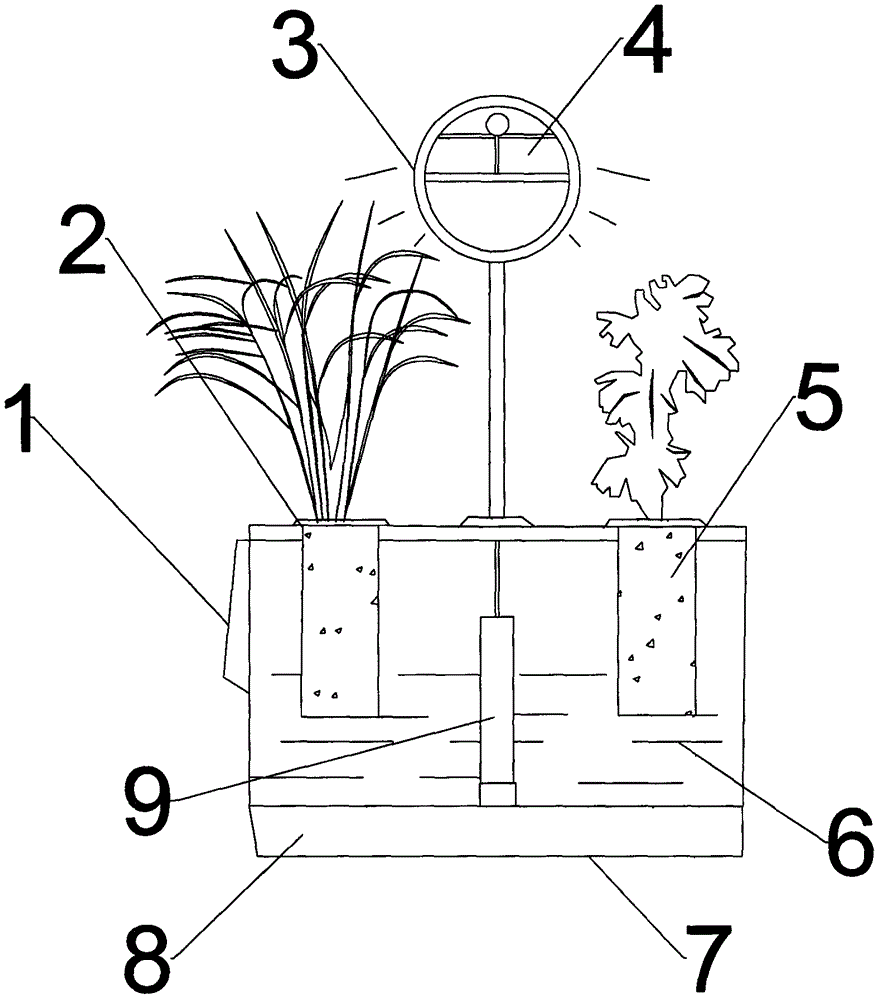

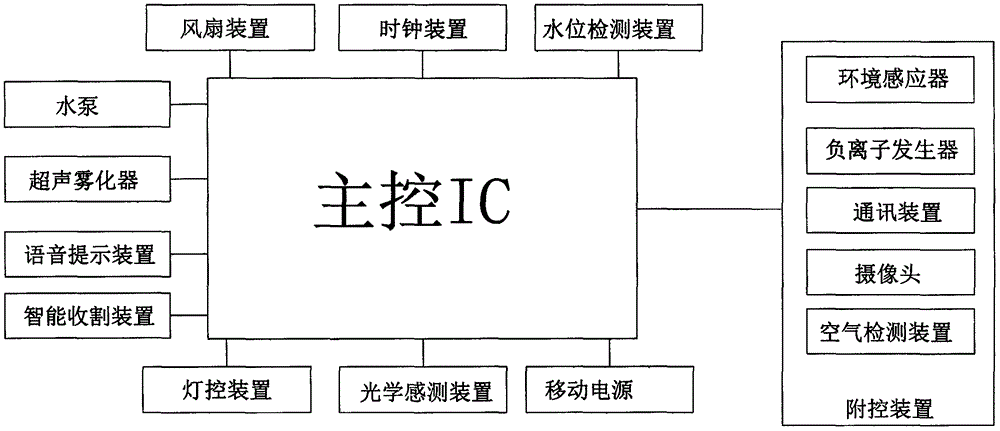

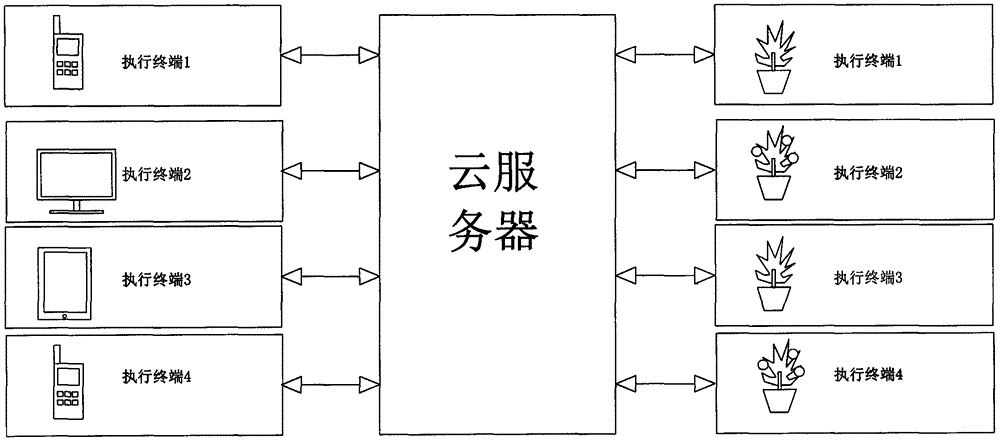

Intelligent cloud technology based plant growth mechanism control system and control method thereof

InactiveCN106227280AImprove quality and yieldRealize automatic plantingSimultaneous control of multiple variablesGrowth plantControl system

The invention relates to an intelligent cloud technology based plant growth mechanism control system and a control method thereof. The intelligent cloud technology based plant growth mechanism control system comprises an executing terminal, a control terminal and a cloud server, wherein the executing terminal is a plant growth mechanism body, responds to an instruction of the control terminal and executes a corresponding action, the control terminal comprises an externally connected communication device, can access server data and can also send the instruction to the executing terminal, the cloud server is used for establishing a database, a virtual community and an interactive platform, and communication between the executing terminal and the control terminal is performed through the cloud server. The intelligent cloud technology based plant growth mechanism control system achieves automatic planting, sowing in all seasons, improvement of plant quality and yield and real organic environmental protection. In addition, the intelligent cloud technology based plant growth mechanism control system achieves remote real-time monitoring, control and harvesting, interactivity improvement and planting fun increase based on an intelligent cloud technology. Furthermore, WeChat friends can operate similar happy farms on line, executes one-key planting, one-key watering, one-key fertilization, one-key harvesting and other functions and performs corresponding actions on offline executing terminals.

Owner:宁波率健环保科技有限公司

Injection mold automatic thread twisting device

PendingCN109719905AReach the effect of mechanical automatic tooth extractionRealize automated productionGear driveGear wheel

The invention relates to the technical field of molds, in particular to an injection mold automatic thread twisting device. Compared with the prior art, the injection mold automatic thread twisting device uses opening and closing of a mold, a rack installed on a front template drives a gear, then the gear drives a connecting rod and a screw thread core to rotate, so that the screw thread core screws in and screws out along the screw thread shape, during molding, the screw thread core screws in along the screw thread shape so that a screw thread can be molded on the upper side surface of a molding product, after the product is molded, the screw thread core is driven by the gear to screw out along the screw thread shape, then elastic force of a spring is used for separating the screw threadcore from the product, at the same time, a sliding block further moves backwards synchronously, and finally, a mechanical automatic thread disengaging effect is achieved. Full-automatic production ofproducts with screw threads on the side surfaces of molds can be realized, the production efficiency is greatly improved, and moreover, the advantages of safer structure, higher quality yield and thelike are achieved.

Owner:XIAMEN SUNZONE PRECISION TECH

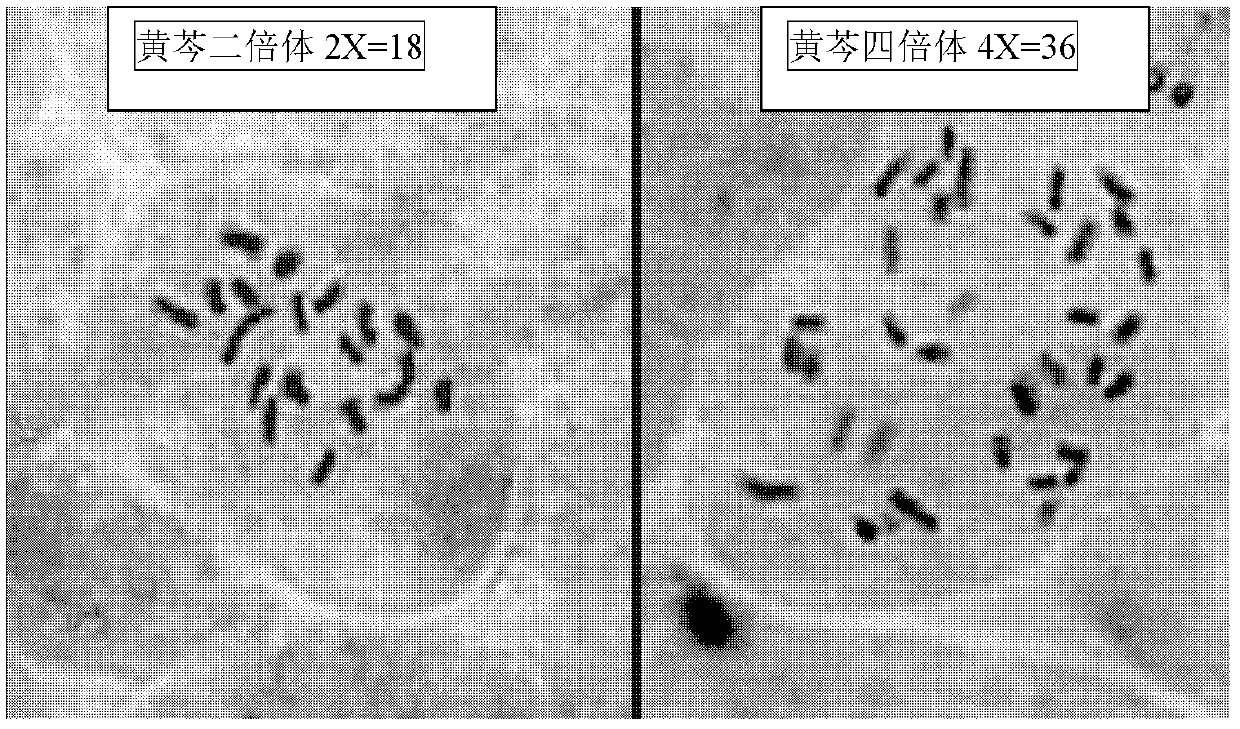

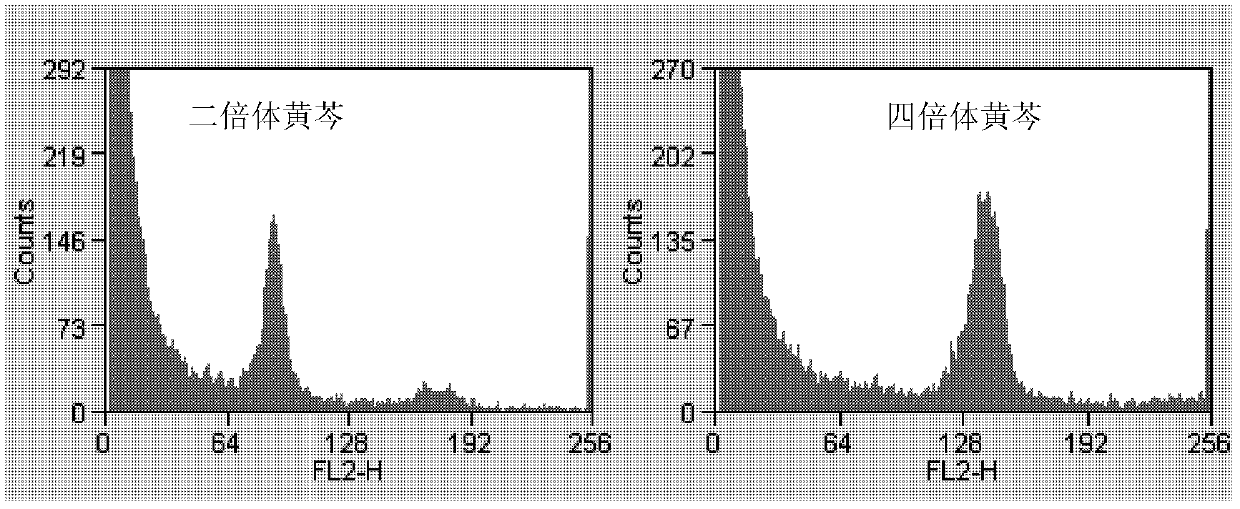

Technical flow applicable to mass production of polyploidy radix scutellariae excellent variety

InactiveCN102511387AQuality improvementEasy to shapePlant tissue cultureHorticulture methodsCataphyllFertility

The invention provides a technical flow applicable to the mass production of tetraploid radix scutellariae, which is characterized in that: radix scutellariae is used as a breeding material, a tetraploid radix scutellariae seedling with excellent and consistent characters can be rapidly obtained through the plant polyploidy breeding technology, the tissue culture and rapid propagation technology and the stem cuttage technology. The tetraploid radix scutellariae seedling belongs to the KT optimization, height of the tetraploid radix scutellariae seedling is 1.84 times of a reference, length of a leaf is 1.50 times of the reference, width of the leaf is 2.14 times of the reference, yield of a single plant is high, the yield of a single root is 1.70 times of a diploid reference, content of baicalin is improved by 1.86 percent compared to the reference, the fertility of the polyploidy radix scutellariea excellent variety is sterile, the entire growth period is 25 to 30 days longer than the reference, the tissue culture and rapid propagation technology is used for propagating the polyploidy radix scutellariea excellent variety to obtain original seedlings, and then the original seedlings are made into seedlings through the stem cuttage technology, the seedlings are transplanted to a field to be planted, about 5000 seedlings per Mu are planted, leaves and roots can be harvested in current year, about 40 to 50 kilograms of radix scutellariae tea can be produced per Mu, about 350 to 450 kilograms of roots can be produced, the content of the baicalin can reach 13.5 to 16.56 percent which is far higher than the requirement of pharmacopoeia that the content of the baicalin is not less than 8 percent, and the quality of the radix scutellariae is excellent.

Owner:SINOBIOWAY BIO AGRI GRP CO LTD

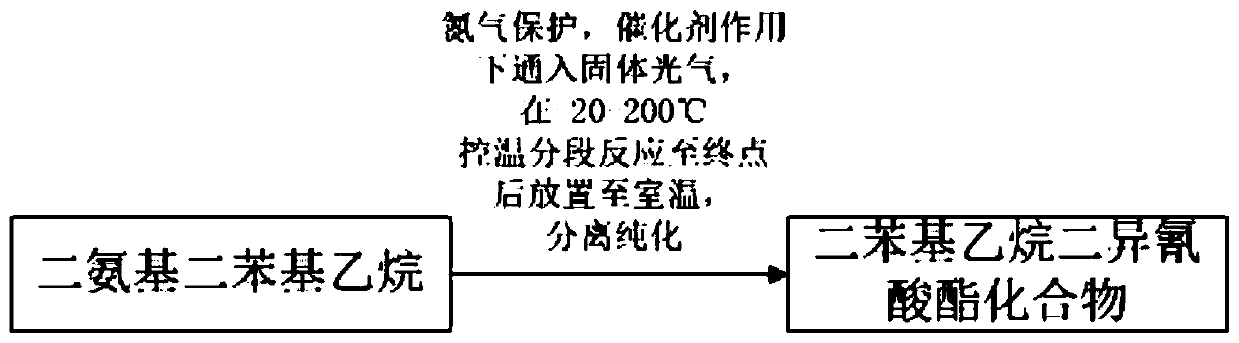

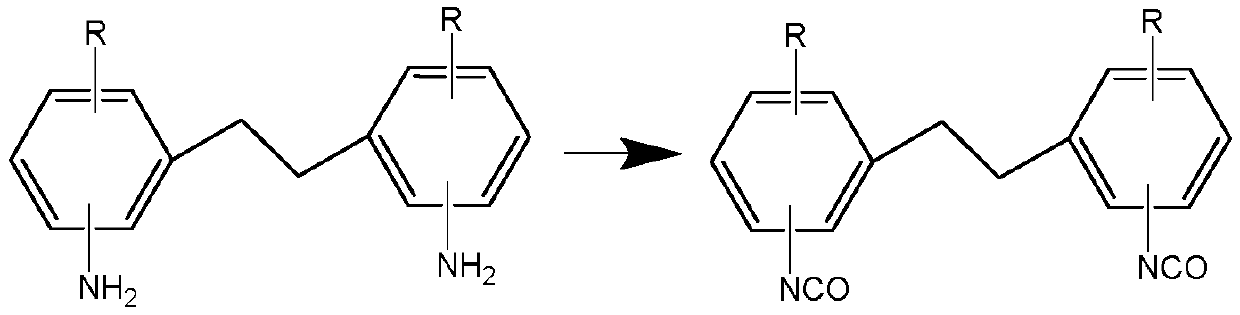

Diphenylethane diisocyanate prepared by a solid phosgene method and application thereof

InactiveCN110903216AImprove working conditionsImprove quality and yieldIsocyanic acid derivatives preparationOrganic compound preparationPolymer chemistryDi-isocyanate

Owner:山东华阳农药化工集团有限公司

Film stripping process of high-precision circuit board

ActiveCN114554707AReduce surface tensionRemove completelyPrinted circuit secondary treatmentConductive material chemical/electrolytical removalOrganic filmAmmoniacal nitrogen

The invention relates to a film stripping process of a high-precision circuit board, and relates to the technical field of printed circuit board processing. The film stripping process of the high-precision circuit board sequentially comprises a bulking section, a film stripping section I and a film stripping section II, the bulking section adopts an inorganic film stripping solution with the mass concentration of 3-5% or an organic film stripping solution with the mass concentration of 10-12%, the film stripping section I adopts an environment-friendly high-precision circuit film stripping solution with the mass concentration of 10-12%, and the film stripping section II adopts an inorganic film stripping solution with the mass concentration of 3-5% or an organic film stripping solution with the mass concentration of 10-12%. According to the film stripping process, the film stripping speed is high, and the service life of the bath solution is long; film stripping is clean, no dry film residue is caused, and a copper surface and a tin surface are not corroded; the film removing device is suitable for film removing of fine lines, IC carrier plates and MSAP manufacturing procedures; and the film stripping liquid basically does not contain ammonia nitrogen and is very environment-friendly.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

Vacuum sintering anti-bending method for hard alloy round bar material

The invention discloses a vacuum sintering anti-bending method for a hard alloy round bar material. The vacuum sintering anti-bending method comprises the following processing steps: a, pressing and forming by an extruding machine; b, pressing graphite boat loaded blank for natural drying; c, trimming the blank; d, putting the blank in a degumming furnace along with a degumming presintering graphite boat for degumming presintering; e, machining the blank; f, coating anti-sticking coatings on the surface of the cover plate V-shaped groove of a graphite cover plate and the surface of the base plate V-shaped groove of a graphite base plate; g, naturally drying the anti-sticking coatings; h, sintering and loading the graphite boat loaded blank, and clamping the blank between the base plate V-shaped groove and the cover plate V-shaped groove; i, putting the blank in a vacuum sintering furnace along with the sintering loading graphite boat, and vacuumizing after the furnace door is closed; j, vacuum-sintering the blank; k, cooling to room temperature along with the furnace, so that the preparation of the round bar material is completed. Through the design of the processing steps, the bending rate can be effectively reduced, the phenomenon of bonding can be avoided, and the quality and the yield of the hard alloy round material can be effectively improved.

Owner:DONGGUAN UNIV OF TECH +8

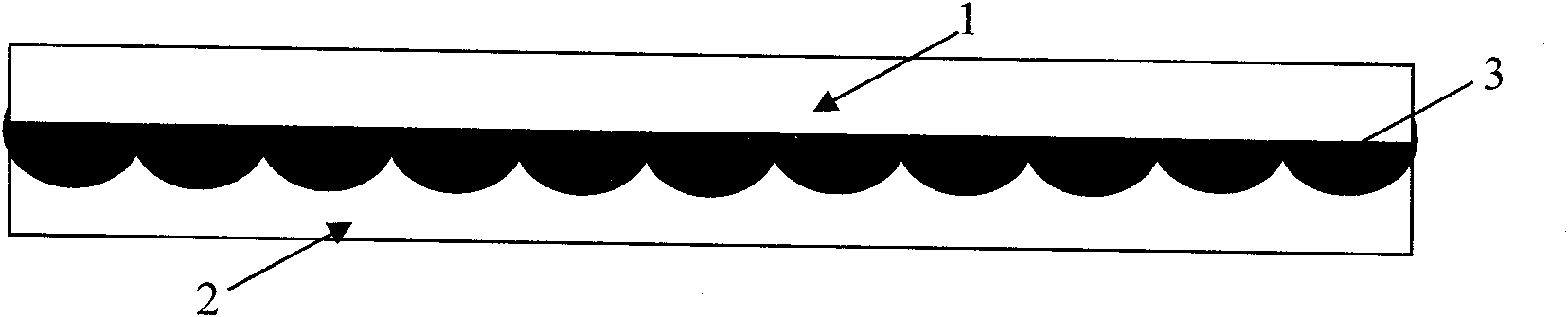

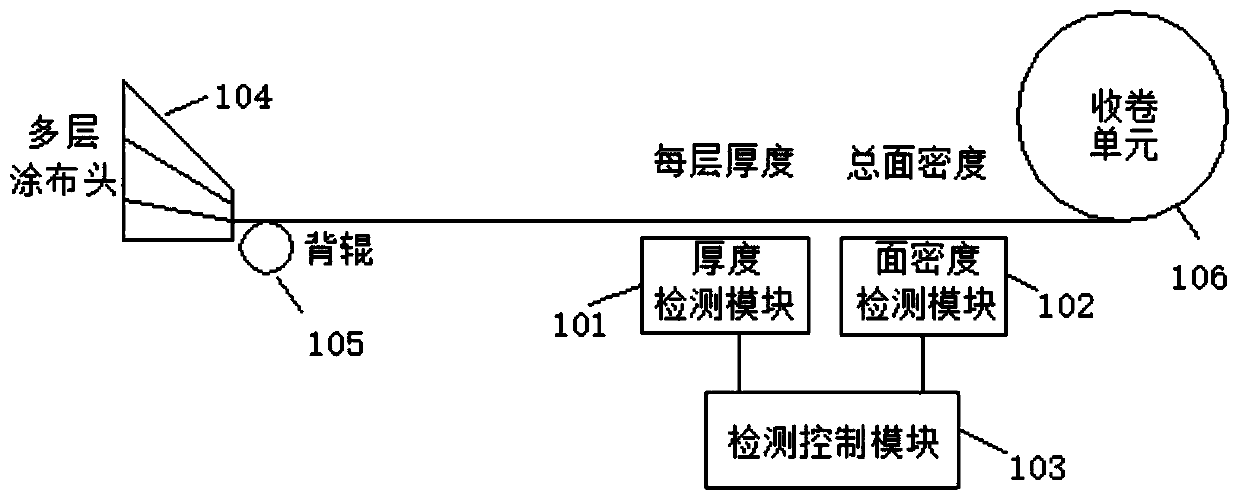

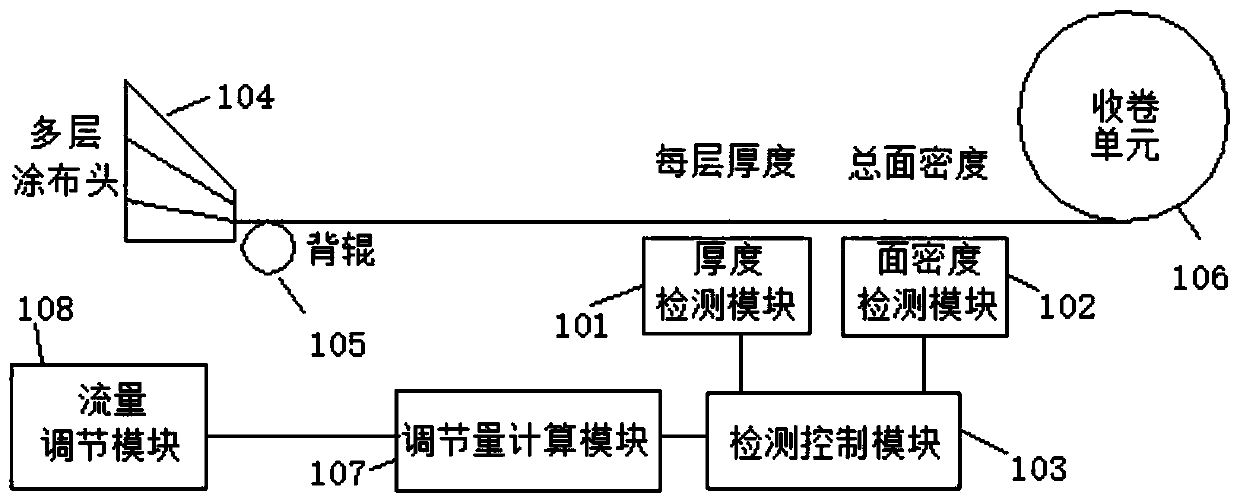

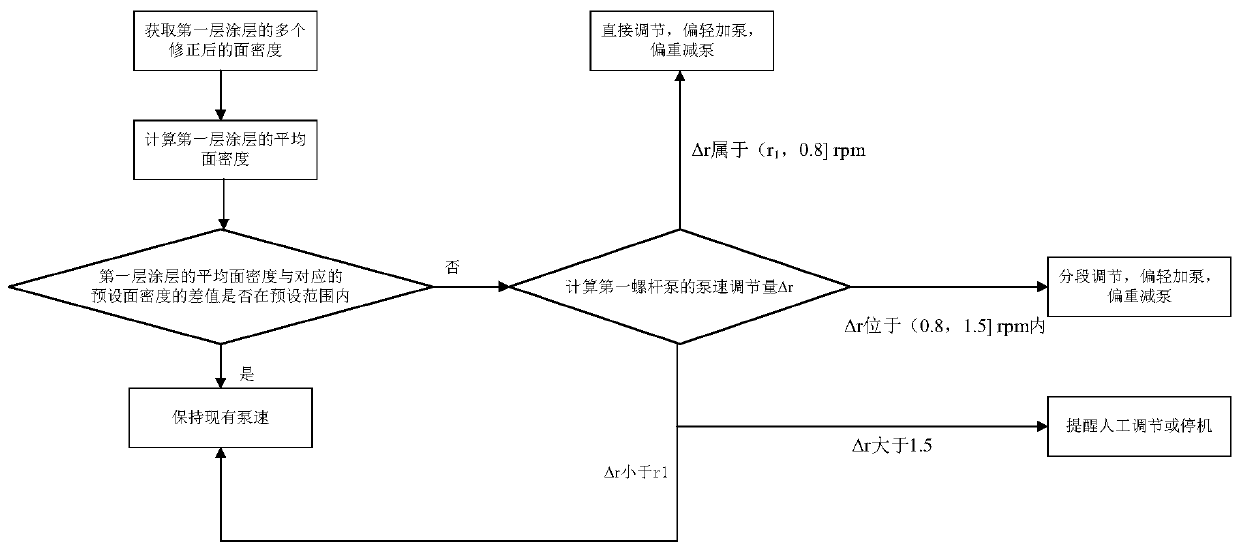

Coating surface density detection device and method

ActiveCN111103213AMonitor qualityImprove quality and yieldUsing subsonic/sonic/ultrasonic vibration meansSpecific gravity measurementMaterials sciencePhysics

The invention discloses a coating surface density detection device and method. The device comprises a thickness detection module used for detecting the total thickness of a to-be-detected multi-layercoating; a surface density detection module, used for detecting the total surface density of the multi-layer coating to be detected; and a detection control module, used for calculating the surface density of each coating in the to-be-detected multi-layer coating based on the total thickness and the total surface density. According to the embodiment of the invention, the detection of the surface density of each coating layer can be realized.

Owner:CONTEMPORARY AMPEREX TECH CO

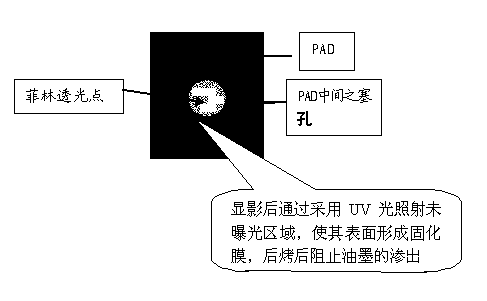

Method for solving problem of oil bleeding of anti-welding plug hole in single-side windowed PCB (printed circuit board)

InactiveCN103687334AImprove efficiencySimple processPrinted element electric connection formationPrinting inkThermal expansion

The invention discloses a method for solving the problem of oil bleeding of an anti-welding plug hole in a single-side windowed PCB (printed circuit board). The method includes the steps: performing development processing on the single-side windowed PCB, performing light-sensitive curing on unexposed printing ink in the anti-welding plug hole in the single-side windowed PCB, and forming a layer of light-sensitive cured film so as to prevent oil bleeding in the subsequent curing process. In other words, the anti-welding plug hole is prevented from post-curing thermal expansion as a result of oil bleeding, so that quality and yield are improved. In addition, for the PCB, hardness of the printing oil is improved after one more time of UV (ultraviolet) curing, and the board is prevented from being scratched caused by carrying before post curing.

Owner:SHENZHEN KINWONG ELECTRONICS

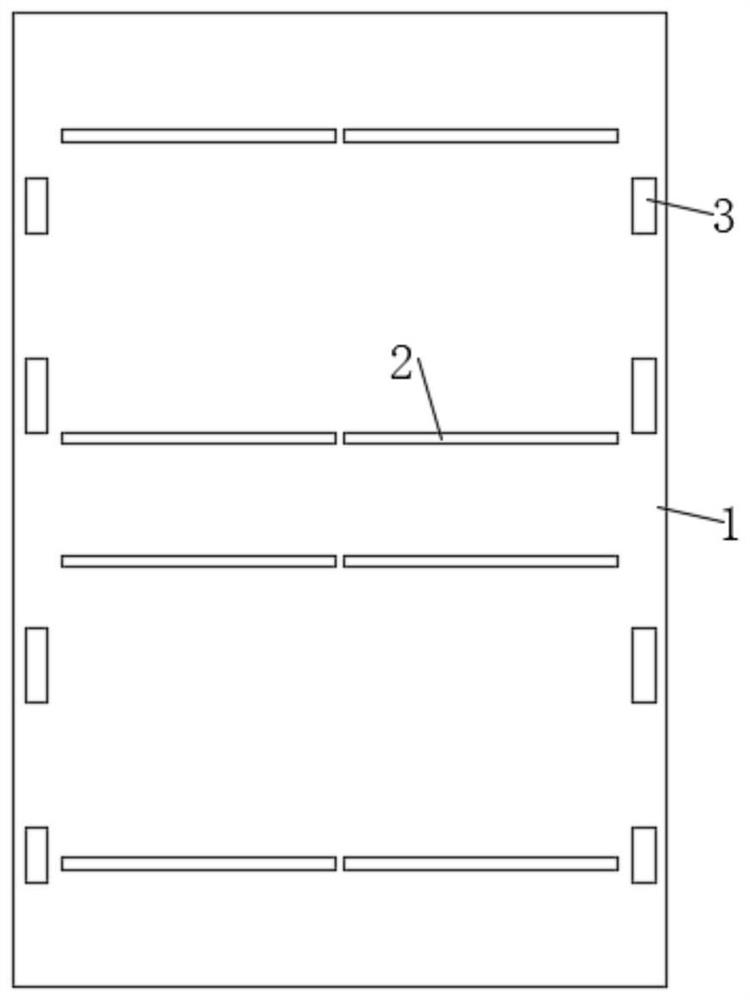

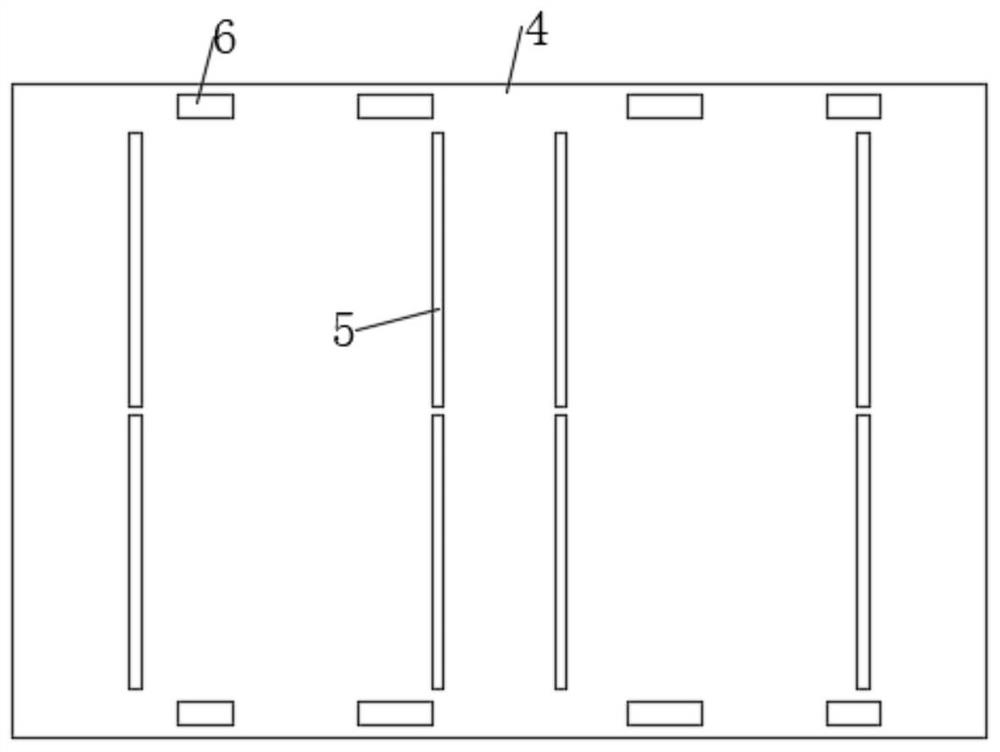

Z-shaped slotted hole machining method

ActiveCN111787698AAvoid formingAvoid the problem of manual repair of burrsPrinted element electric connection formationPhysicsDrill hole

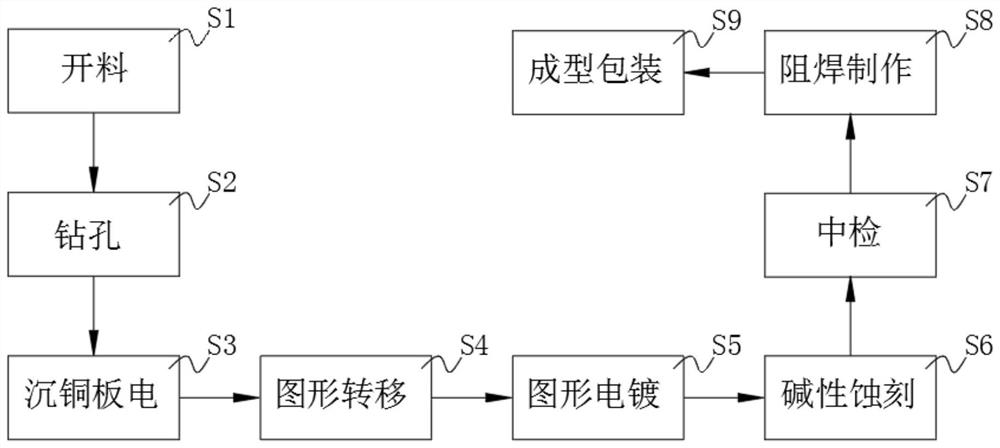

The invention discloses a Z-shaped slotted hole machining method which specifically comprises the following steps that S1, cutting is carried out by cutting an FR4 board by using a full-automatic cutting machine, and cutting the FR4 board into the designed size; and S2, drilling is conducted, specifically, a drilling machine is used for drilling the cut FR4 board, during drilling, a red hole stacking area is machined firstly, the machining sequence is from left to right, then a green area 2 is machined to remove burr holes, then a blue hole stacking area 3 is machined, and the machining sequence is from left to right. According to the Z-shaped slotted hole machining method, the drill point rotates in the forward direction during drilling, and drilling needs to be carried out from a hangingposition to an entity position; according to mechanical stress analysis, burrs can be prevented from being formed at edge difference sets of stacked holes, so that the quality yield of products is greatly improved, the problem of manual burr repairing is avoided, the production efficiency of the products is improved, and the production cost of the products is greatly reduced finally.

Owner:黄石星河电路有限公司

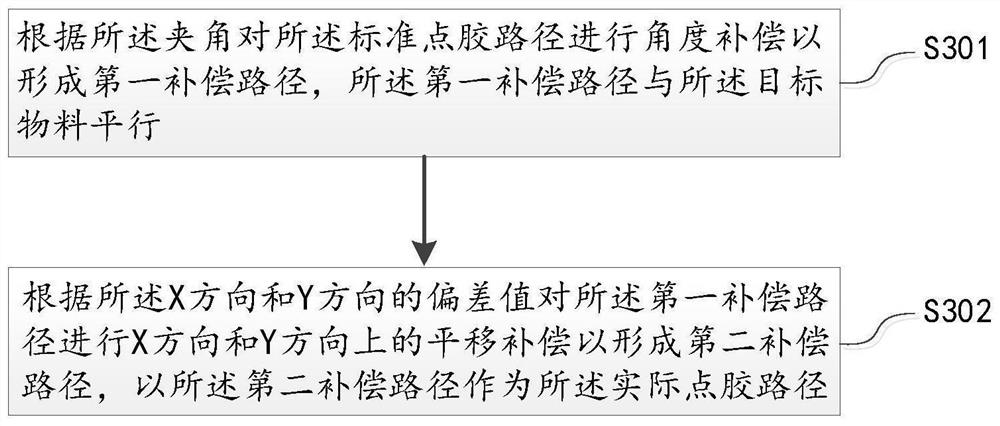

Dynamic dispensing compensation method and device, computer device and computer storage medium

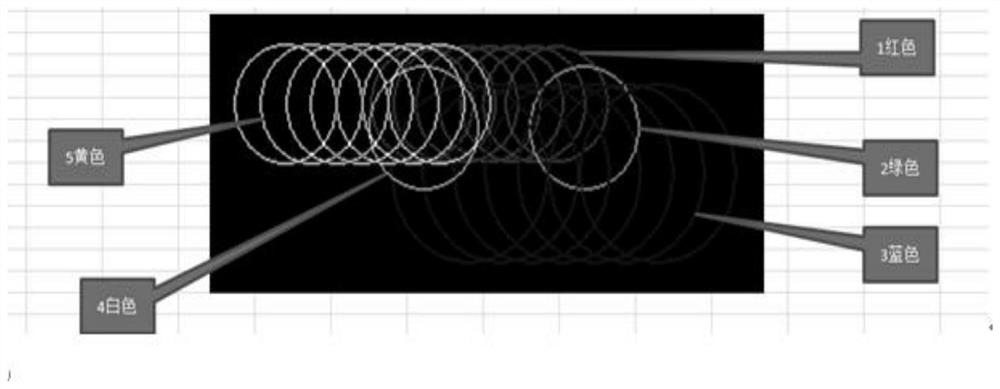

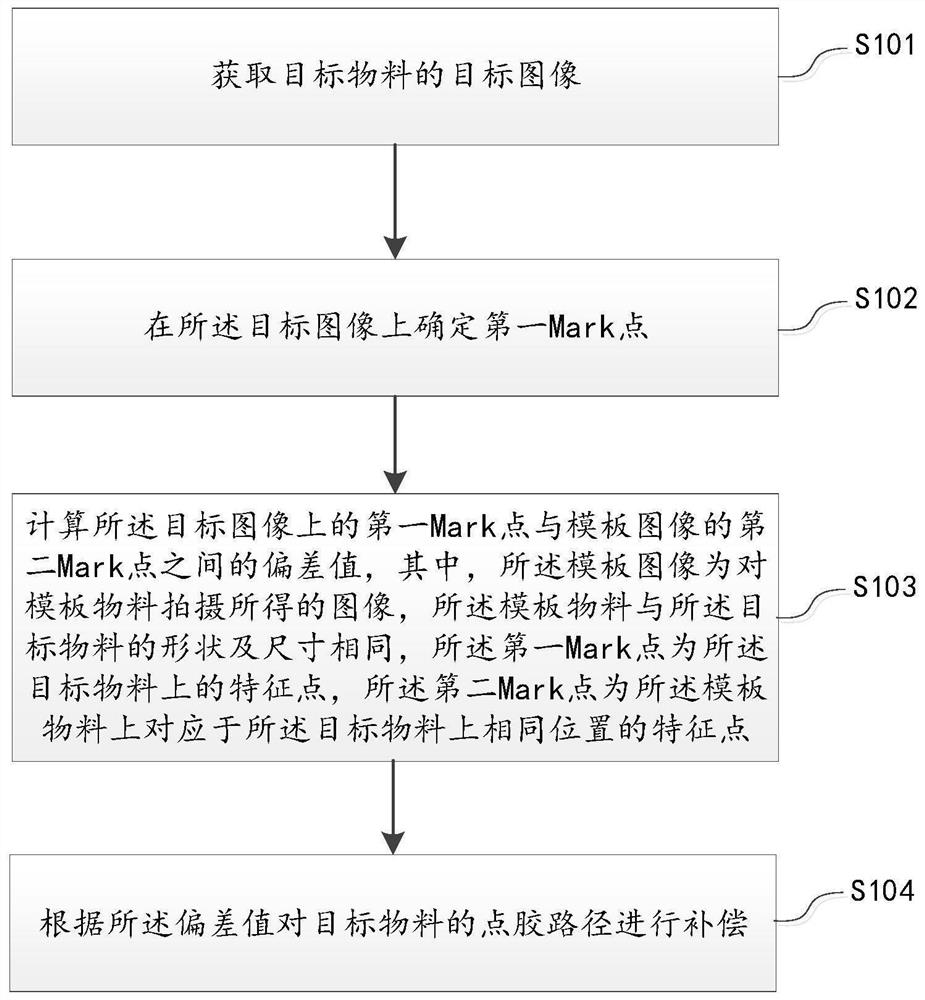

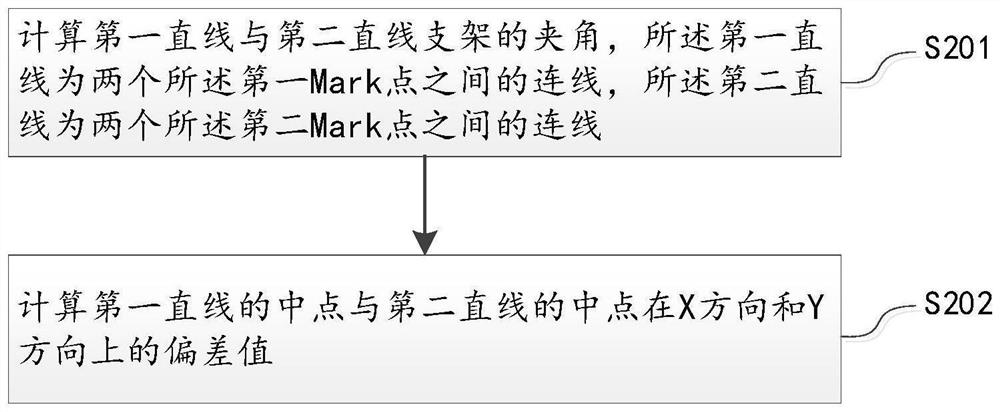

PendingCN113304966AAccurate and reliable dispensing pathStable dispensing effectLiquid surface applicatorsCoatingsEngineeringCharacteristic point

The invention discloses a dynamic dispensing compensation method and device, a computer device and a computer storage medium. The method comprises the following steps: acquiring a target image of a target material; determining a first Mark point on the target image; calculating a deviation value between the first Mark point on the target image and a second Mark point of a template image, wherein the template image is an image obtained by shooting a template material, the template material and the target material are the same in shape and size, the first Mark point is a feature point on the target material, and the second Mark point is a feature point, corresponding to the same position on the target material, on the template material; and compensating the dispensing path of the target material according to the deviation value. According to the dynamic dispensing compensation method and device, the computer device and the computer storage medium, it can be ensured that the dispensing path of the target material is accurate and reliable, the angle difference existing in the target material can be corrected through compensation and deviation correction of the dispensing path, then the dispensing effect is more stable, and the quality yield can be remarkably improved.

Owner:SHENZHEN SHIZONG AUTOMATION EQUIP CO LTD

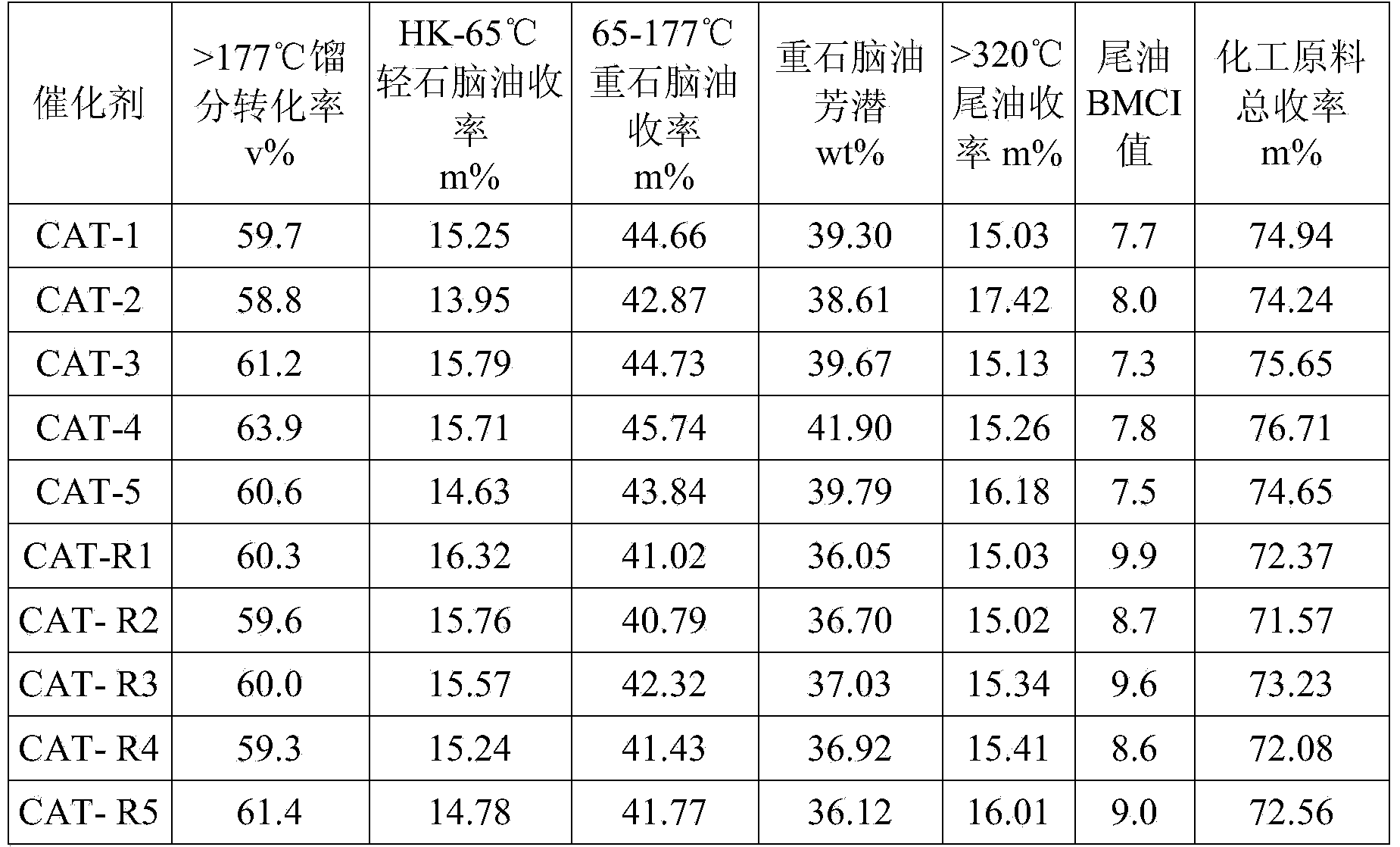

Hydrocracking catalyst containing Ti-P-Y molecular sieve and preparation method of hydrocracking catalyst

ActiveCN103521255AImprove quality and yieldPromote sulfur reductionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHigh potential

The invention provides a hydrocracking catalyst containing a Ti-P-Y molecular sieve and a preparation method of the hydrocracking catalyst. The preparation method comprises the following steps: mixing and forming amorphous silica and alumina, a Beta molecular sieve and a tungsten-loaded Ti-P-Y molecular sieve prepared by the method, thus obtaining a catalyst carrier, wherein the weight percents of the amorphous silica and alumina, the Beta molecular sieve and the tungsten-loaded Ti-P-Y molecular sieve are respectively 30-70%, 5-15% and 10-30%; loading tungsten and nickel on the catalyst carrier, thus obtaining the hydrocracking catalyst, wherein the weight percents of NiO and WO3 are respectively 1-10% and 10-29%. The hydrocracking catalyst is prepared by the preparation method provided by the invention. The catalyst has relatively high hydrocracking activity and stability, can be used for preparing heavy naphtha with high potential aromatic content and tail oil with low BMCI (Bureau of Mines Correlation Index) and has relatively high chemical material total recovery.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

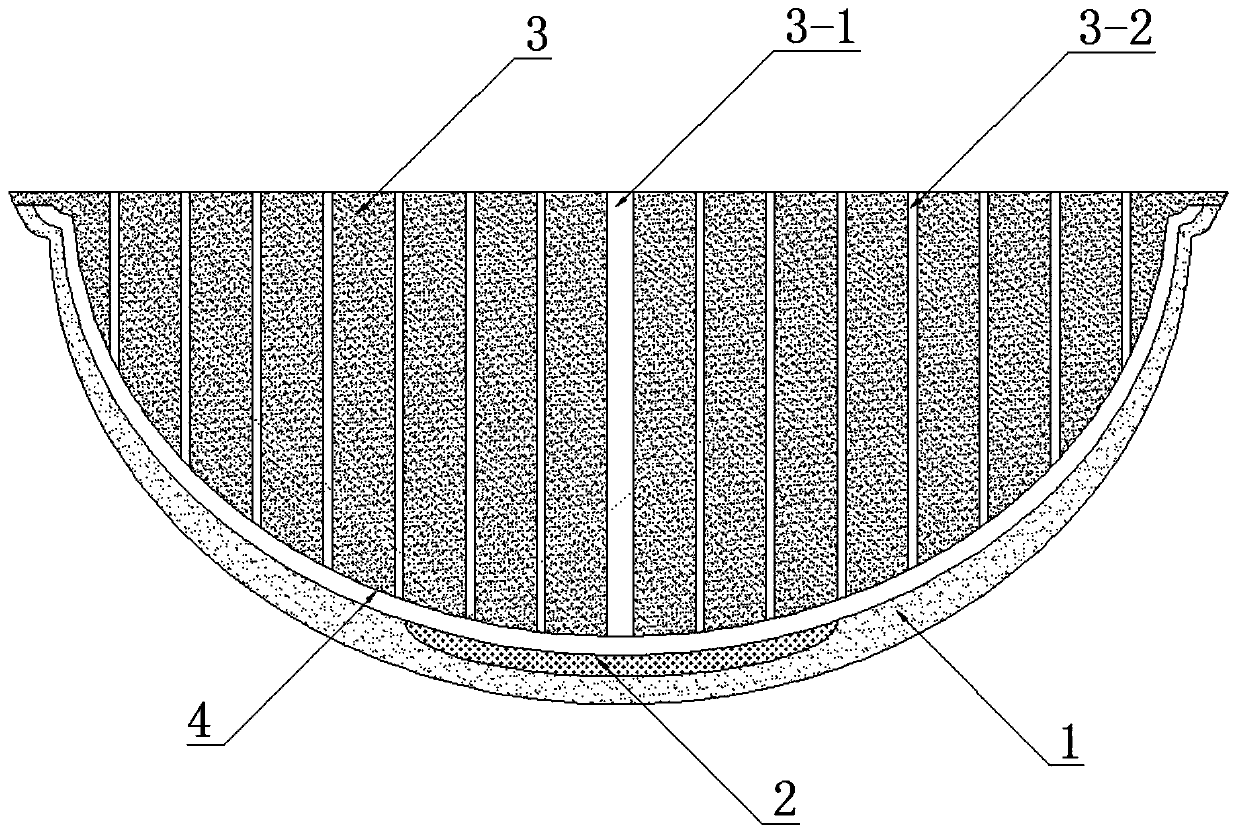

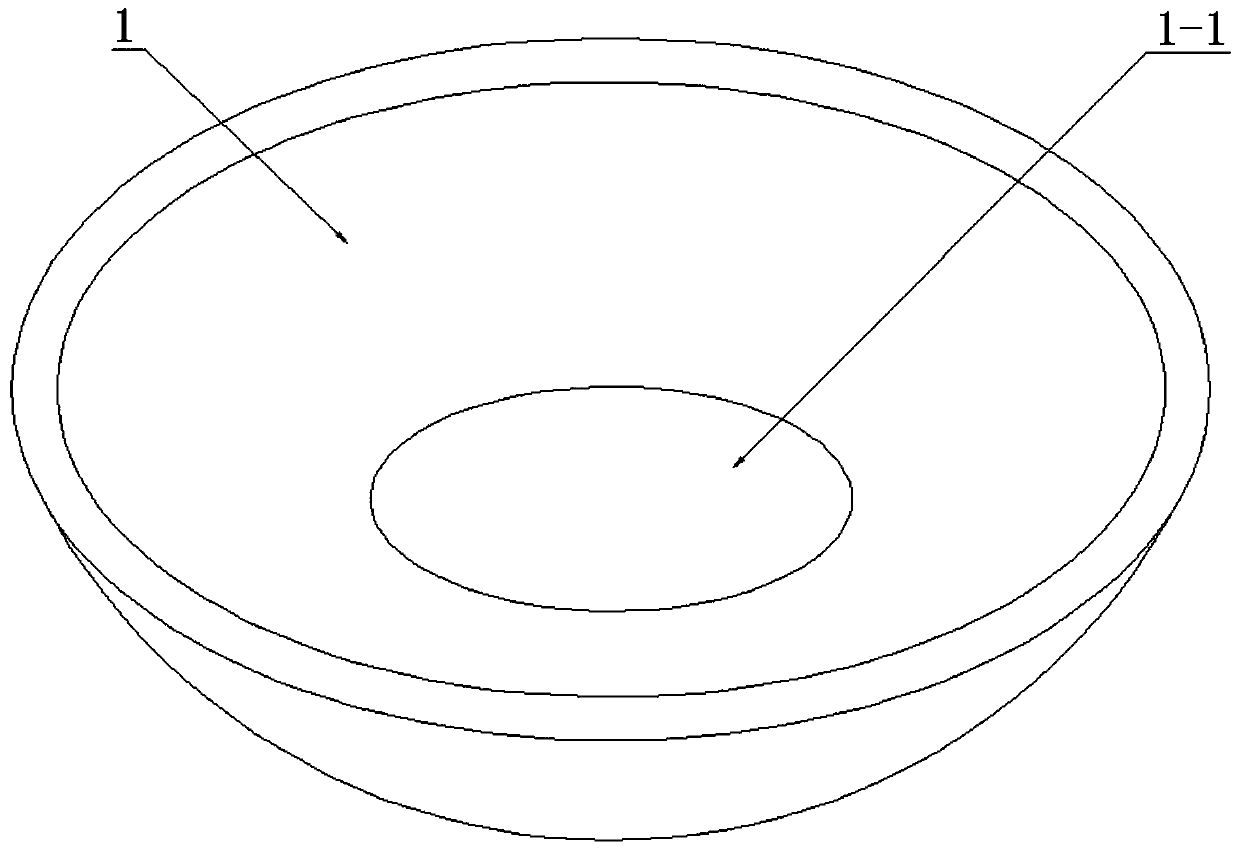

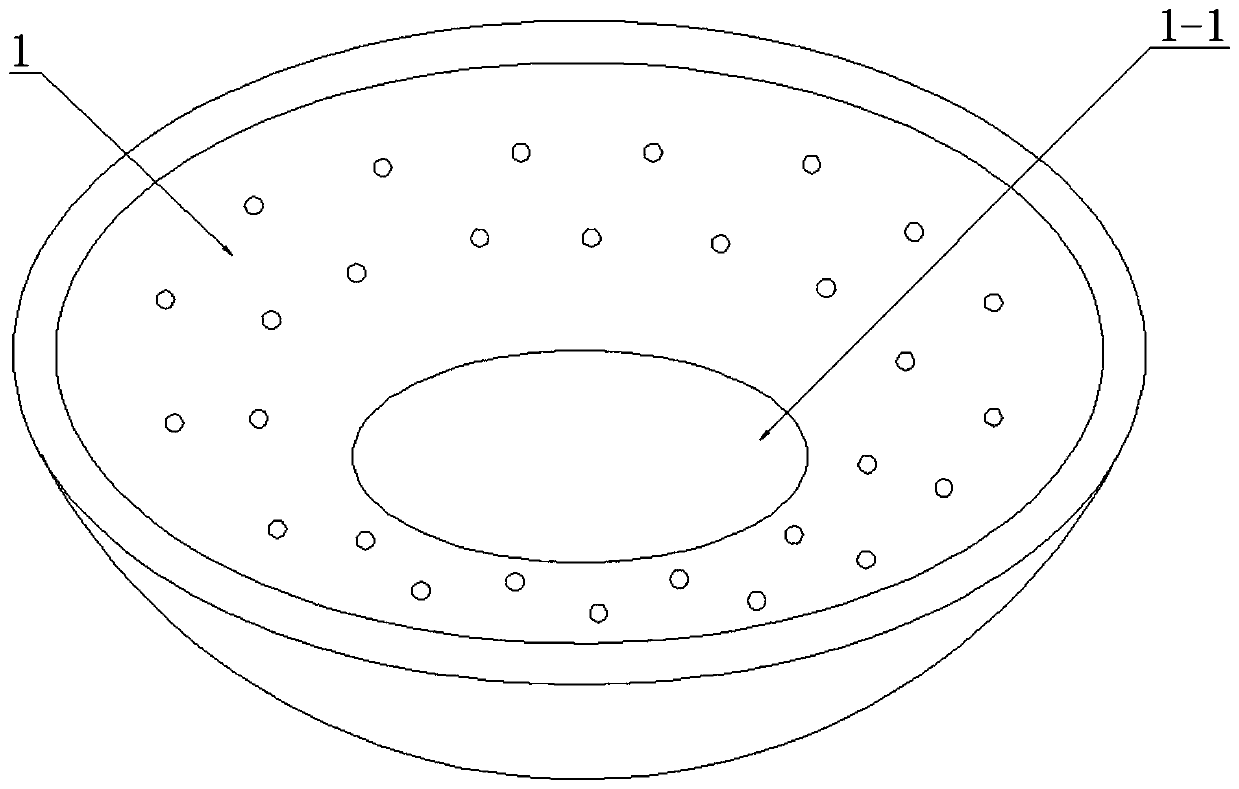

Pot casting mold assembly and pot casting method

The invention discloses a pot casting mold assembly. The pot casting mold assembly comprises a bottom mold, a fin mold and an upper mold. The bottom mold is a semi-ellipsoidal cavity. An embedding groove is formed in the center of the bottom of the bottom mold cavity. The fin mold is movably embedded in the embedding groove. The upper surface of the fin mold is bonded to the surface of the bottommold cavity. The upper surface of the fin mold is provided with fin patterns. The upper mold is semi-ellipsoidal, and a casting path perpendicular to the upper surface of the upper mold is formed in the center of the upper mold. Exhaust micropores parallel to the casting path are uniformly distributed in the upper mold. The edge of the upper mold is provided with an annular flange. The annular flange is press-fitted with the edge of the bottom mold. A casting cavity is formed among the bottom mold, the fin mold and the upper mold. The casting path and the exhaust micropores communicate with the casting cavity. According to the pot casting mold assembly, when an iron pot is cast, a pot opening faces upwards, the pot bottom faces downwards, casting liquid is gathered at the bottom, the liquid level gradually rises as the casting liquid increases, the liquid level discontinuity phenomenon is avoided, and the casting liquid does not produce a large number of bubbles; and since the bottom mold is intact, connection of different casting molds is avoided, and the casting liquid does not overflow.

Owner:YANTAI ZHONGDE ENVIRONMENTAL PROTECTION EQUIPTECH

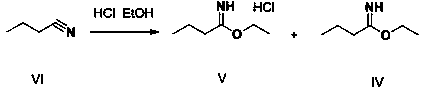

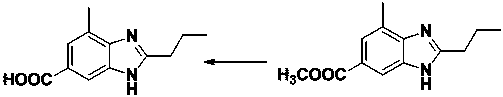

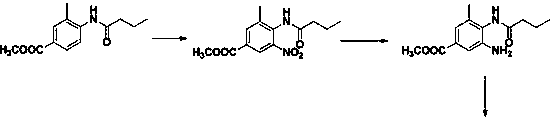

Preparation method of telmisartan intermediate

ActiveCN109320461AImprove quality and yieldAvoid carboxyl esterificationOrganic chemistryHydrogen chlorideP-Aminobenzoic acid

The invention relates to a preparation method of a telmisartan intermediate, namely 2-n-propyl-4-methyl-6-Benzimidazolecarboxylic acid. The preparation method of the 2-n-propyl-4-methyl-6-Benzimidazolecarboxylic acid comprises the following steps: firstly, ethanol hydrochloride acts with butyronitrile and anhydrous hydrogen chloride within the range of 0-35 DEG C; the mixture obtained in the firststep reacts with 3-methyl-4-aminobenzoic acid and ice vinegar within the range of pH 5.0-11.0 at the controlled temperature of 10-40 DEG C, and an intermediate shown in the formula II is obtained; and then the intermediate shown in the formula II reacts with a sodium hypochlorite solution, and the 2-n-propyl-4-methyl-6-Benzimidazolecarboxylic acid is obtained. The intermediate preparation processis suitable for industrial production, and meanwhile the product quality is improved.

Owner:迪嘉药业集团股份有限公司

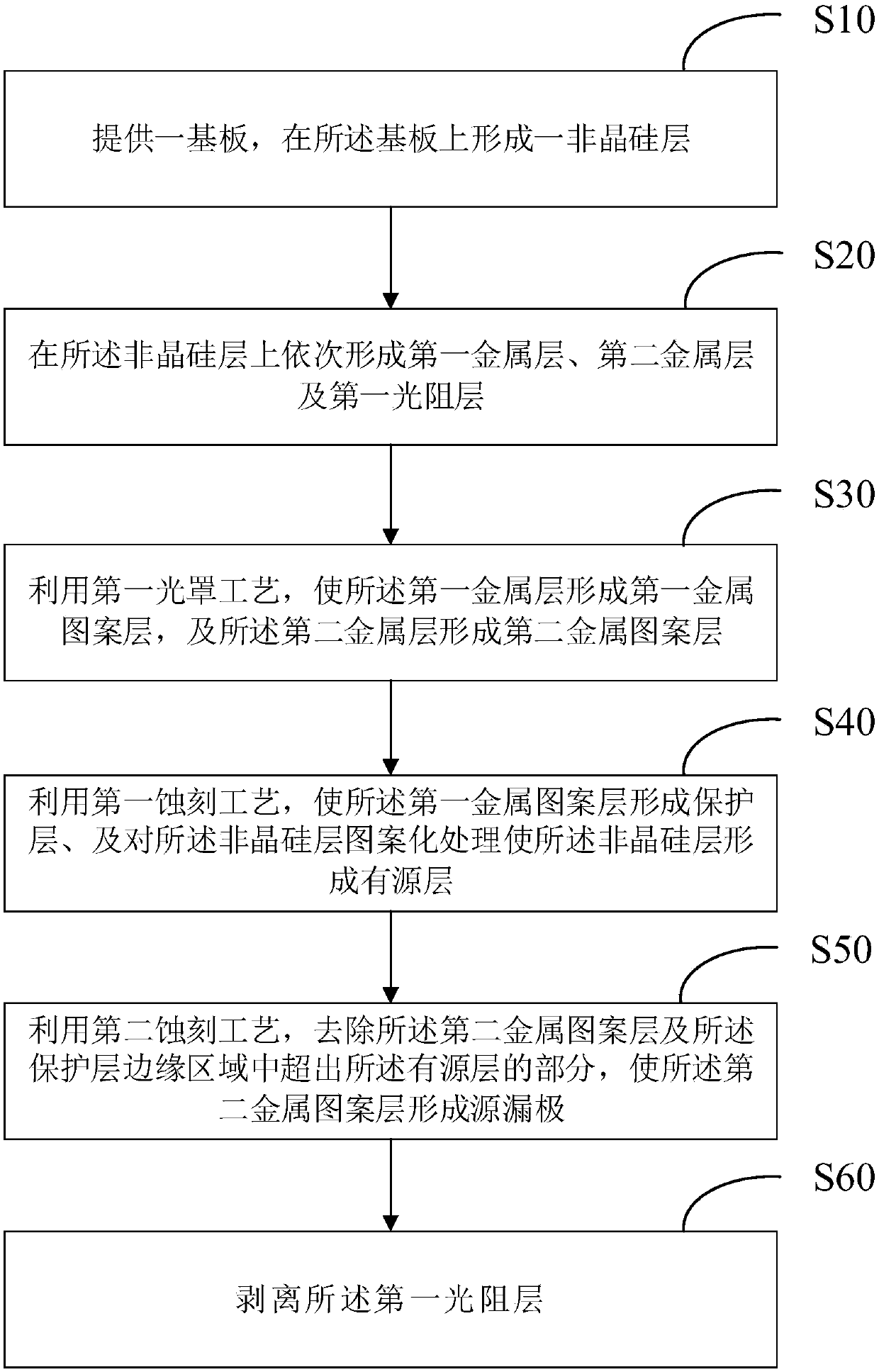

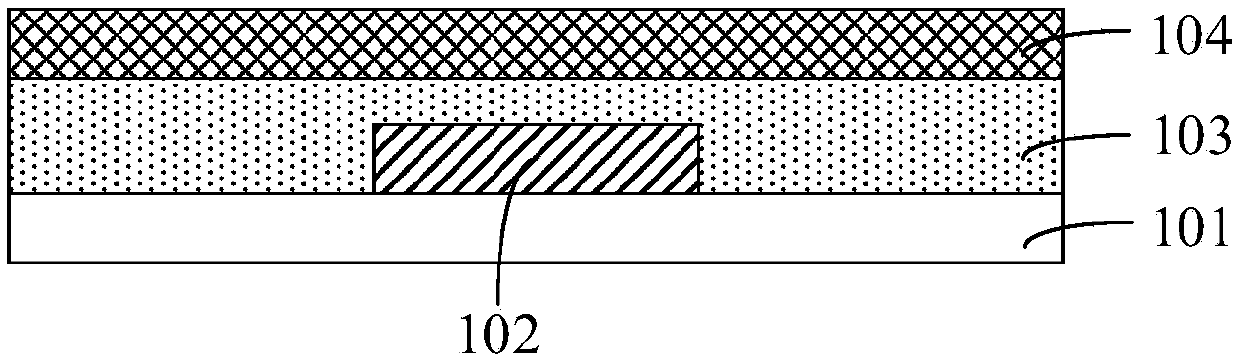

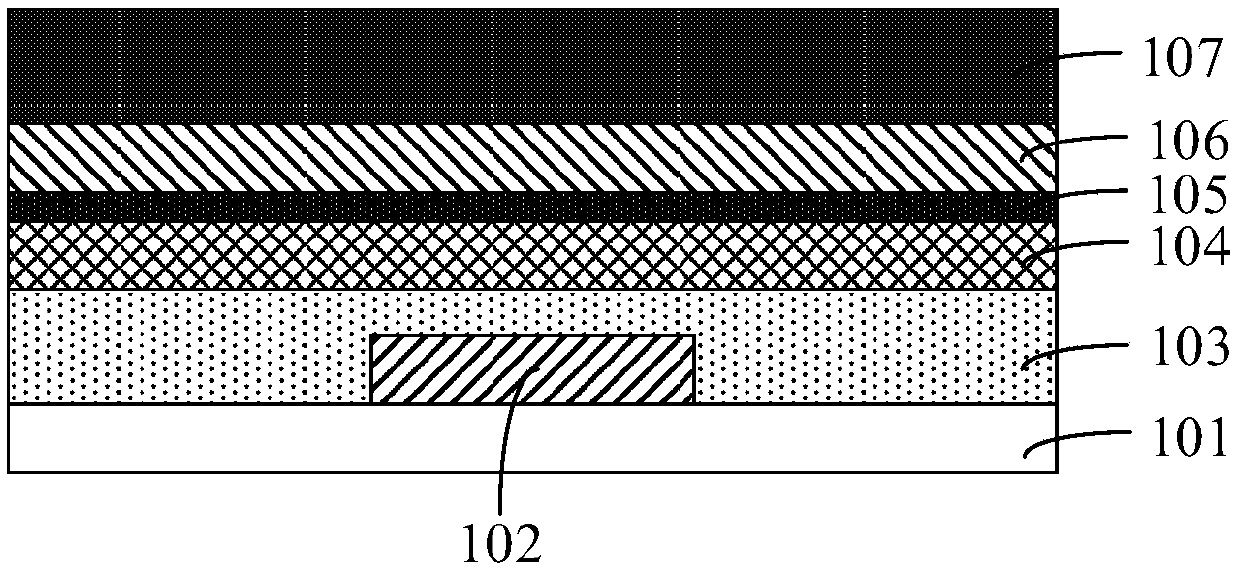

Display panel and manufacturing method thereof

ActiveCN109659276AImprove quality and yieldAvoid etchingTransistorSolid-state devicesPhotoresistOptoelectronics

The invention provides a display panel and a manufacturing method thereof. The manufacturing method of the display panel comprises the steps of: providing a substrate, wherein an amorphous silicon layer, a first metal layer, a second metal layer, and a first photoresist layer are sequentially formed on the substrate; utilizing a first mask process, thus the first metal layer forms a first metal pattern layer, and the second metal layer forms a second metal pattern layer; utilizing a first etching process to make the first metal pattern layer form a protective layer, and performing patterning processing on the amorphous silicon layer so that the amorphous silicon layer forms an active layer; and utilizing a second etching process to remove portions exceeding the active layer in edge regionsof the second metal pattern layer and the protective layer, so that the second metal pattern layer forms a source and a drain. Through forming the protective layer between the active layer and the source and the drain, the active layer under the source and the drain is avoided from being etched when performing patterning processing on the source and the drain, thereby improving the yield and quality of the product.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Cleaning liquid used for surface treatment of black silicon battery sheet

InactiveCN108559639AImprove cleanlinessImprove quality and yieldInorganic/elemental detergent compounding agentsCationic surface-active compoundsIonChemistry

The invention discloses cleaning liquid used for surface treatment of a black silicon battery sheet. The cleaning liquid is prepared from, by mass, 8-25% of fluorine compound, 5-30% of alcohol additive, 2-6% of complexing agent, 4-15% of dispersant, 5-10% of surfactant and 14-76% of deionized water, and made by mixing the materials. According to the provided cleaning liquid used for surface treatment of the black silicon cell sheet, metal contaminants on the surface of the black silicon battery sheet are rapidly decomposed, spots on the surface of the silicon sheet can be efficiently removed,the cleanliness of the surface of the black silicon battery sheet is greatly improved, correspondingly the yield of texture surface making of the black silicon battery sheet is increased, and the quality of texture surface making of the black silicon battery sheet is improved. At the same time, the product yield of an enterprise is increased, and the cost of the enterprise is reduced.

Owner:JIANGSU RONGMA NEW ENERGY

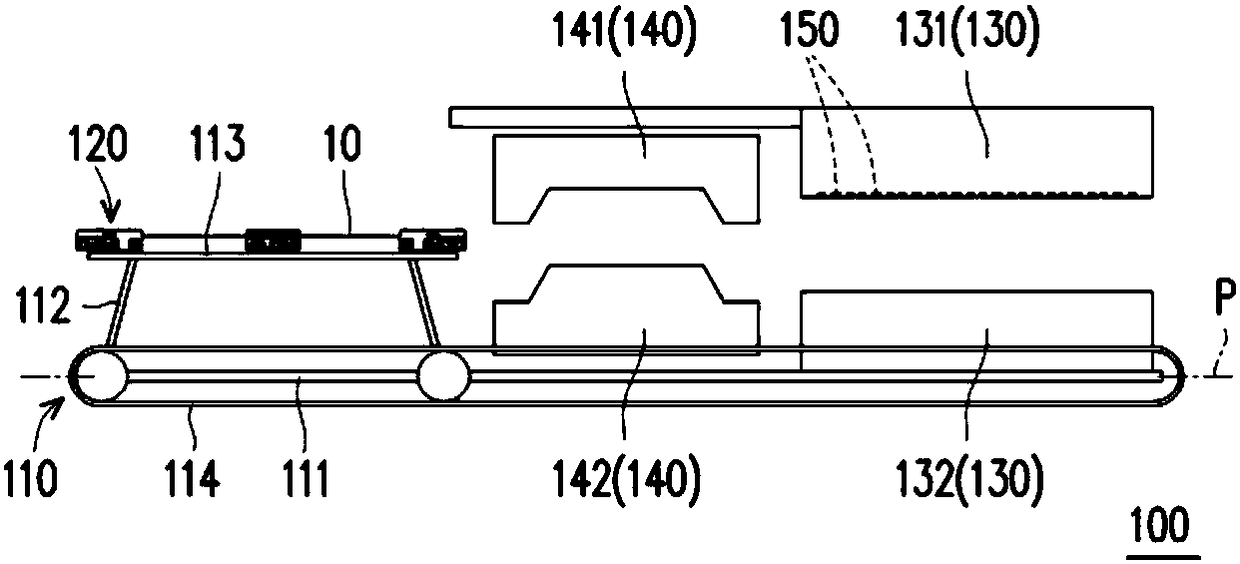

Manufacturing apparatus and manufacturing method of plastic component

InactiveCN108215133ANot easy to wrinkleImprove quality and yieldMechanical conveyorsMoulding deviceEngineering

Owner:SWANCOR INDSWANCOR IND CO LTD +1

Purifying method for calcium gluconate solution

InactiveCN106008196AAvoid low product yieldsImprove quality and yieldCarboxylic compound separation/purificationUltrafiltrationEnvironmental chemistry

The invention discloses a method for purifying calcium gluconate solution. The key points of the technology are: the calcium gluconate solution is first ultrafiltered through a membrane device to filter out macromolecular impurities such as pigments, proteins and polysaccharides in the solution, and then the ultrafiltered solution is nanofiltered through a membrane device to filter Remove most of the water therein and make the concentration of the solution reach 10%, then crystallize smoothly and generate solid calcium gluconate at one time. Due to the concentration and removal of impurities of calcium gluconate solution under normal temperature conditions, the quality and yield of the product are effectively improved; and under the premise of not increasing power consumption, the coal consumption of steam concentration and the cost of impurity cleaning are eliminated. Water consumes two costs, and the filtered water is of good quality, so there will be no waste water pollution. In addition, the process of the present invention is simple, the equipment cost is low, and the operation is easy.

Owner:韦彩勇

Method for improving orifice burrs after mechanical drilling of rigid-flex board with height difference on board surface

The invention discloses a method for improving orifice burrs after mechanical drilling of a rigid-flex board with a height difference on a board surface. The method comprises the following steps: S1,preparing a cold punching board consistent with the rigid-flex board in size before drilling; S2, correspondingly designing the windowing of the cold punching plate according to the position of a convex part on the surface of the rigid-flex board and the position of a heat capacity block on the edge of the board, and manufacturing the windowing cold punching plate for later use; S3, during mechanical drilling, mechanically drilling below the rigid-flex board by using the windowed cold-punched board clamping pad, enabling the back surface of the drilling position of the rigid-flex board to be in complete contact with the windowed cold-punched board, replacing the drilling base plate by the windowed cold-punched board, and correspondingly stacking the non-porous bulge part position and the board edge heat capacity block position of the rigid-flex board at the windowed position. The invention has the beneficial effects that the problem of a gap between the rigid-flex board and the drilling base plate is solved, orifice burrs after mechanical drilling of the rigid-flex board with height difference on the board surface are effectively improved, the quality yield is improved, the qualityscrap rate is reduced, and the product processing material cost is reduced.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD +1

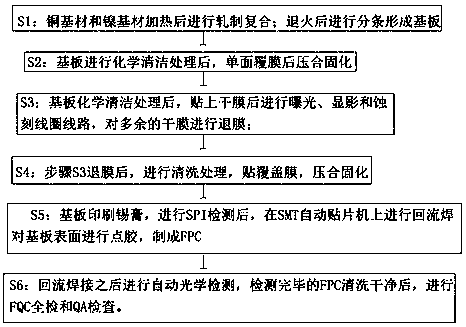

Manufacturing method of novel FPC

PendingCN110087398ASave human effortSave costsPrinted circuit aspectsConductive material chemical/electrolytical removalEtchingCopper

The invention discloses a manufacturing method of a novel FPC. The manufacturing method of the novel FPC comprises the following steps: S1: a copper base material and a nickel base material are heatedand rolled and clad; stripping is performed after annealing so as to form a substrate; S2: after the substrate is chemically cleaned, single-sided film coating is performed and then pressing and solidifying are performed; S3: after the substrate is chemically cleaned, a dry film is adhered, and exposing, developing and etching of a coil line are performed and the excess dry film is removed; S4, after the film is removed in the step S3, cleaning is performed, a covering film is adhered and pressed and solidified; S5, the substrate is baked and then the solder paste is printed, SPI detection isperformed and then reflow soldering is performed on an SMT automatic mounting machine, and glue dispensing is performed on the surface of the substrate and then the FPC is prepared. The aluminum material is directly soldered with the FPC so that the original bridging processing through the nickel sheet can be simplified, a large amount of manpower and processing cost can be saved, the productionefficiency can be improved, the quality and the yield rate can be improved and safety and reliability can be improved.

Owner:奕东电子科技股份有限公司

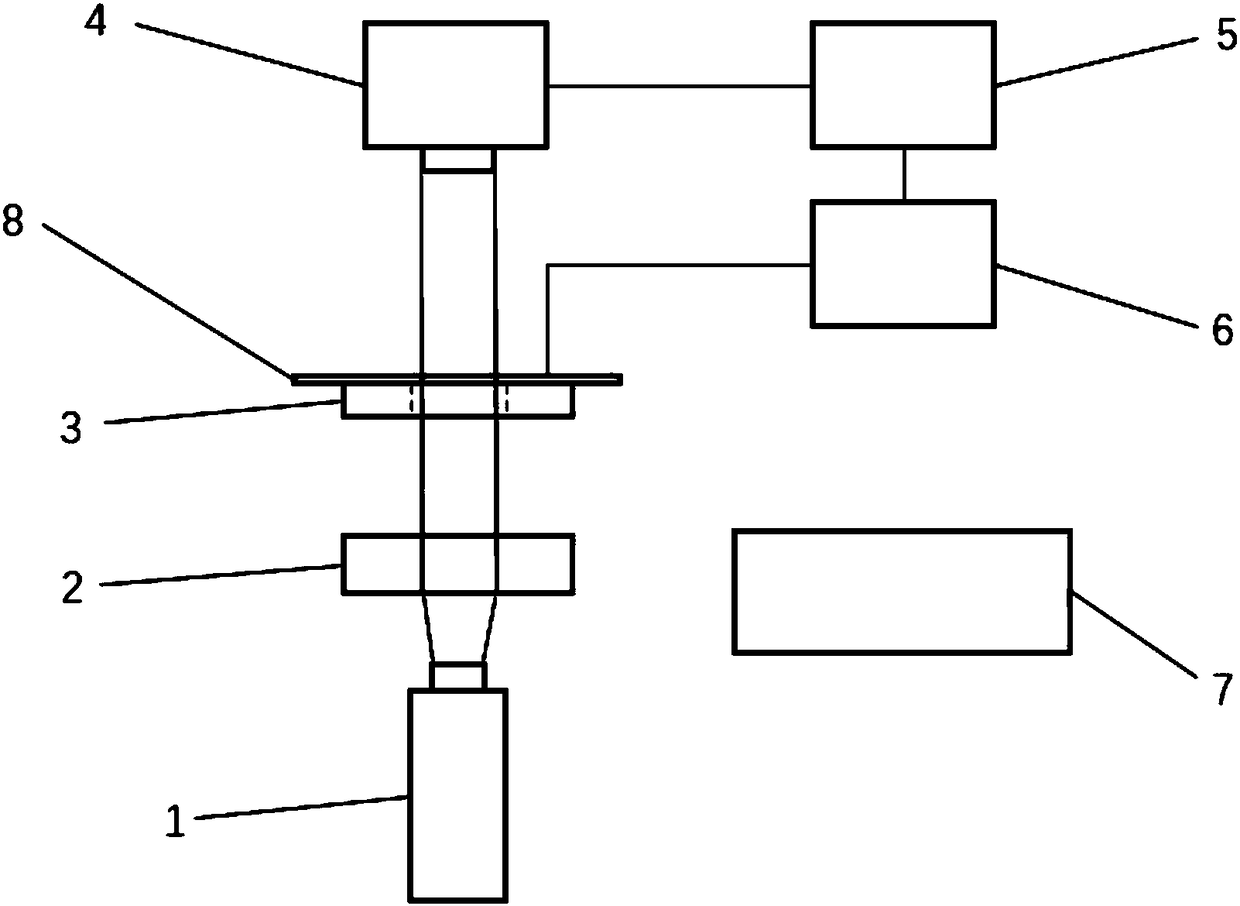

Device for nondestructively detecting resistivity of silicon wafer by terahertz and application method of device

PendingCN108226099AImprove quality and yieldNon-destructive measurementResistance/reactance/impedenceTransmissivity measurementsPhysicsTerahertz nondestructive evaluation

The invention provides a device for nondestructively detecting the resistivity of a silicon wafer by terahertz and an application method of the device and relates to the technical field of terahertz.The device comprises a terahertz radiation source, a collimation and beam expanding system, a sample platform, a terahertz detector, a computer, a mechanical suction disc and a reworking sheet collection box, wherein the terahertz radiation source is arranged at the lowest side; the terahertz radiation source is used for vertically and upward radiating terahertz waves; the collimation and beam expanding system is arranged just above the terahertz radiation source; the terahertz detector is arranged just above the collimation and beam expanding system; a certain distance is formed between the terahertz detector and the collimation and beam expanding system; a probe of the terahertz detector is arranged downward and is used for receiving terahertz radiation; the sample platform is arranged between the terahertz detector and the collimation and beam expanding system and can move along the horizontal plane; the computer is connected with the terahertz detector through a data line; the mechanical suction disc is connected with the computer through the data line; the reworking sheet collection box is independent. According to the device provided by the invention, the resistivity of the silicon wafer can be nondestructively measured under the condition that the silicon wafer is not touched, and the silicon wafer is not damaged.

Owner:BEIJING UNIV OF TECH +1

Mini-LVDS connecting wire and manufacturing method of mini-LVDS connecting wire

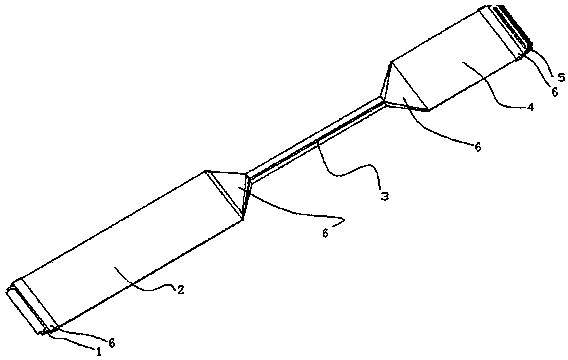

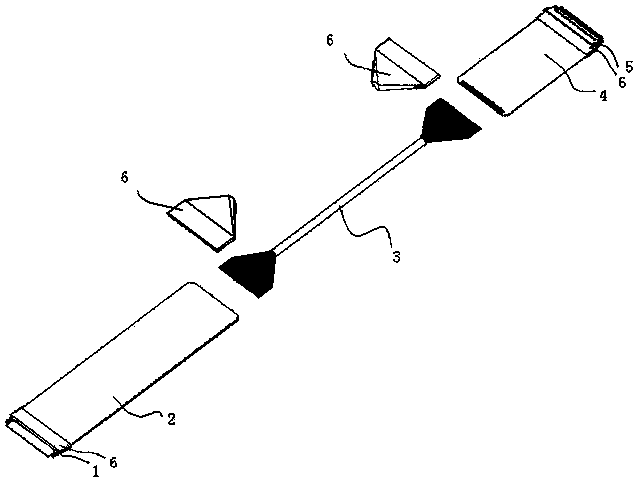

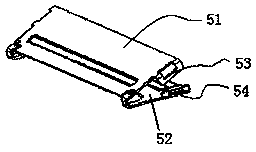

InactiveCN103401114AImprove qualityReduce manufacturing costLine/current collector detailsCoupling contact membersCopper wireEngineering

The invention provides a Mini-LVDS (Low Voltage Differential Signaling) connecting wire and a manufacturing method of the Mini-LVDS connecting wire. The Mini-LVDS connecting wire comprises a first LVDS connector, a first FFC (Flexible Flat Cable), a Teflon wire, a second FFC and a second LVDS connector, wherein the first FFC as well as the second FFC comprises an upper-layer insulating leather film, a plurality of flat copper wires arranged side by side and a lower-layer insulating leather film, which are jointed together; the ends of the flat copper wires are exposed; the ends of the flat copper wires are welded with the Teflon wire; the other ends of the flat copper wires are assembled with the first LVDS connector and the second LVDS correspondingly; the middle parts of the core wires of the Teflon wire are wrapped to form a cylinder; the ends of the core wires are exposed and are respectively welded with the first FFC and the second FFC. According to the Mini-LVDS connecting wire, the Teflon wire adopts the smallest length, so that the production cost is greatly reduced; the integrated LVDS connectors are adopted so as to improve the quality and yield of products, simplify the manufacture process, reduce manual operation and greatly improve the production efficiency.

Owner:SHENZHEN DEREN ELECTRONICS

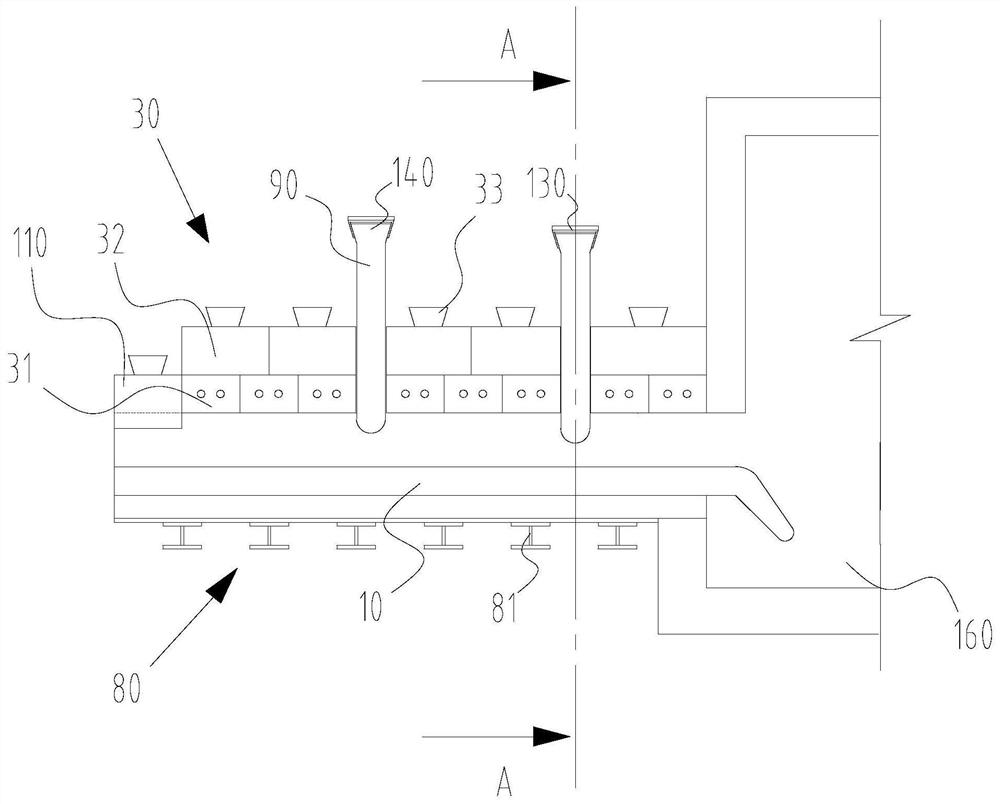

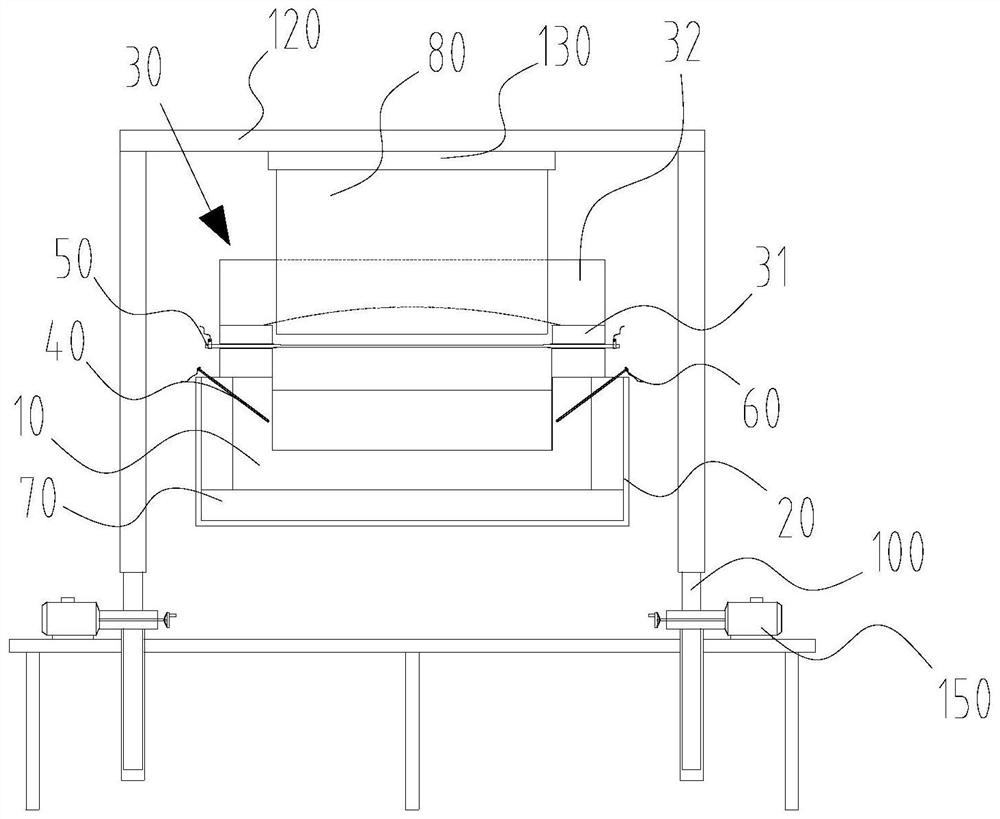

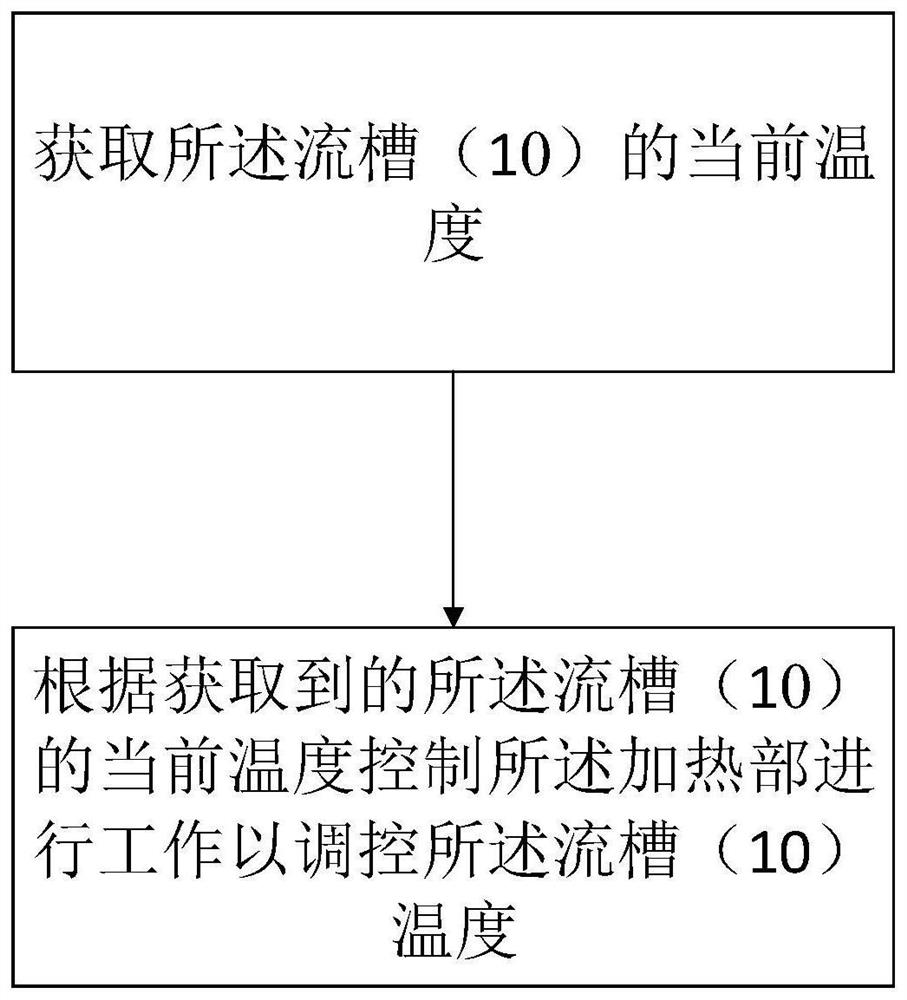

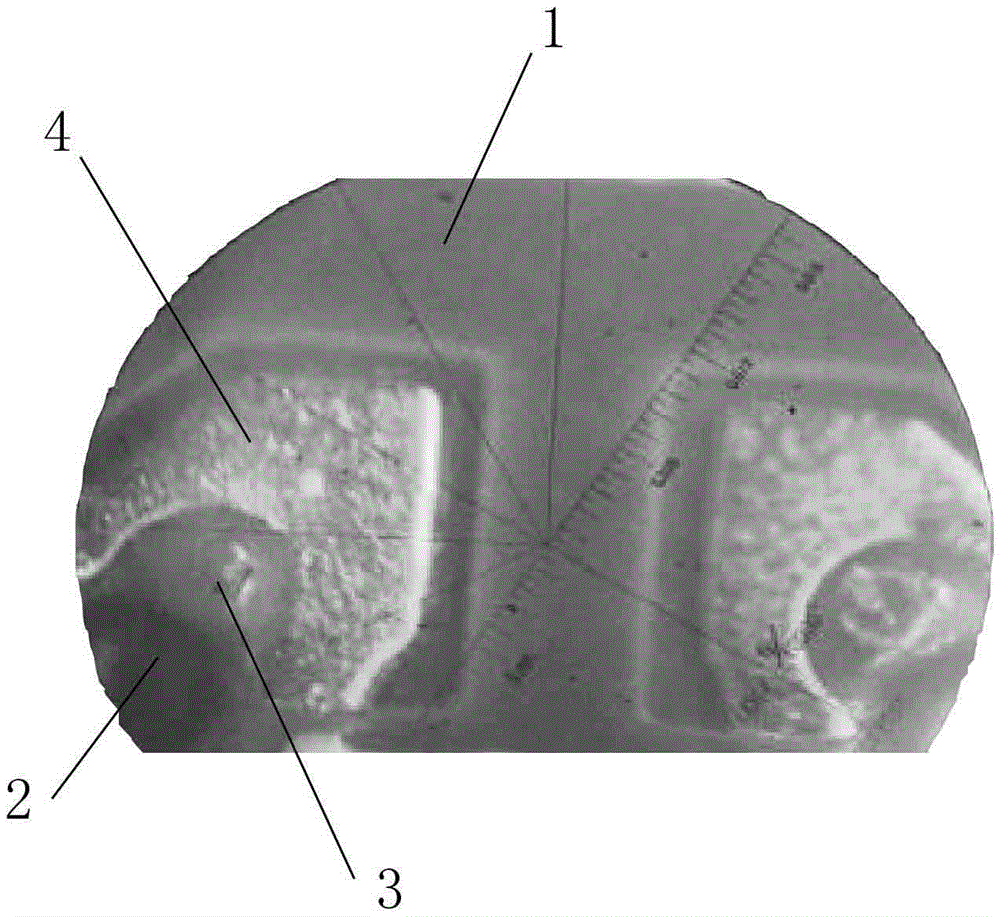

Launder device and launder temperature control method

The invention relates to a launder device and a launder temperature control method. The launder device comprises a launder for molten glass to flow and a steel tank for mounting the launder, the launder device further comprises a heating part used for heating the molten glass, a temperature measuring part used for measuring the temperature of the launder, a control part used for controlling the heating part to work according to feedback information of the temperature measuring part and an upper enclosure used for forming a sealed heating space on the upper portion of the launder, and the heating part is arranged in the heating space and spaced from the molten glass; a plurality of blind holes which are concave inwards are formed in the outer side wall of the launder at intervals, the temperature measuring parts are arranged in the blind holes, the upper enclosure is arranged on the upper portion of the launder and connected with the two side walls of the launder in a sealed mode, and the upper enclosure and the launder are combined to form a heating space. During use, the control part controls the heating part according to the temperature of the launder measured by the temperature measuring part, and the temperature of the launder is adjusted by changing the heating power of the heating part, so that the temperature uniformity of molten glass is ensured, and the yield and the quality of glass are improved.

Owner:河南旭阳光电科技有限公司 +1

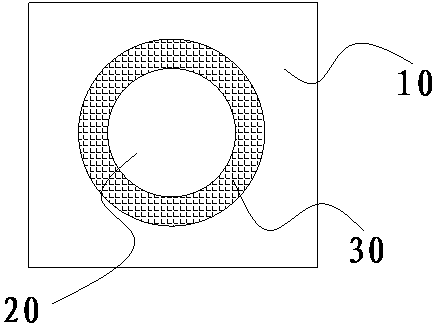

PCB BGA area zero-distance through hole design method

InactiveCN105282971AImprove quality and yieldLow costPrinted circuit aspectsElectrical connection printed elementsPrinting inkEngineering

The invention discloses a PCB BGA area zero-distance through hole design method. The design method includes that a BGA area is displayed on the spherical contact of a PCB board, a plurality of through holes are arranged as needed, a pad is arranged at the outer sides of the through holes and deviates from the through holes at a certain distance, and an oil cover ring is arranged in the deviation distance, the oil cover ring is a recess ring surrounding the outer sides of the through holes, and the outer sides of the oil cover ring is contacted with the edge of the pad. Compared with the prior art, the PCB BGA area zero-distance through hole design method can prevent the pad from being subjected to oil explosion through the BGA through holes and effectively improves the production yield rate and quality of the PCB board by modifying the PCB design and additionally arranging the oil cover ring; and through the modification of the PCB design, printing ink plug holes can be continuously used, the cost is effectively saved, the application is wide, the practicality is high, and the popularization is easy.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com