Pot casting mold assembly and pot casting method

A technology for die-casting molds and pots, which is applied in the fields of pot casting and pot casting mold components, can solve the problems of difficult discharge of air bubbles, leakage of liquid at the edge of the pot, and achieve the effects of improving quality and yield and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

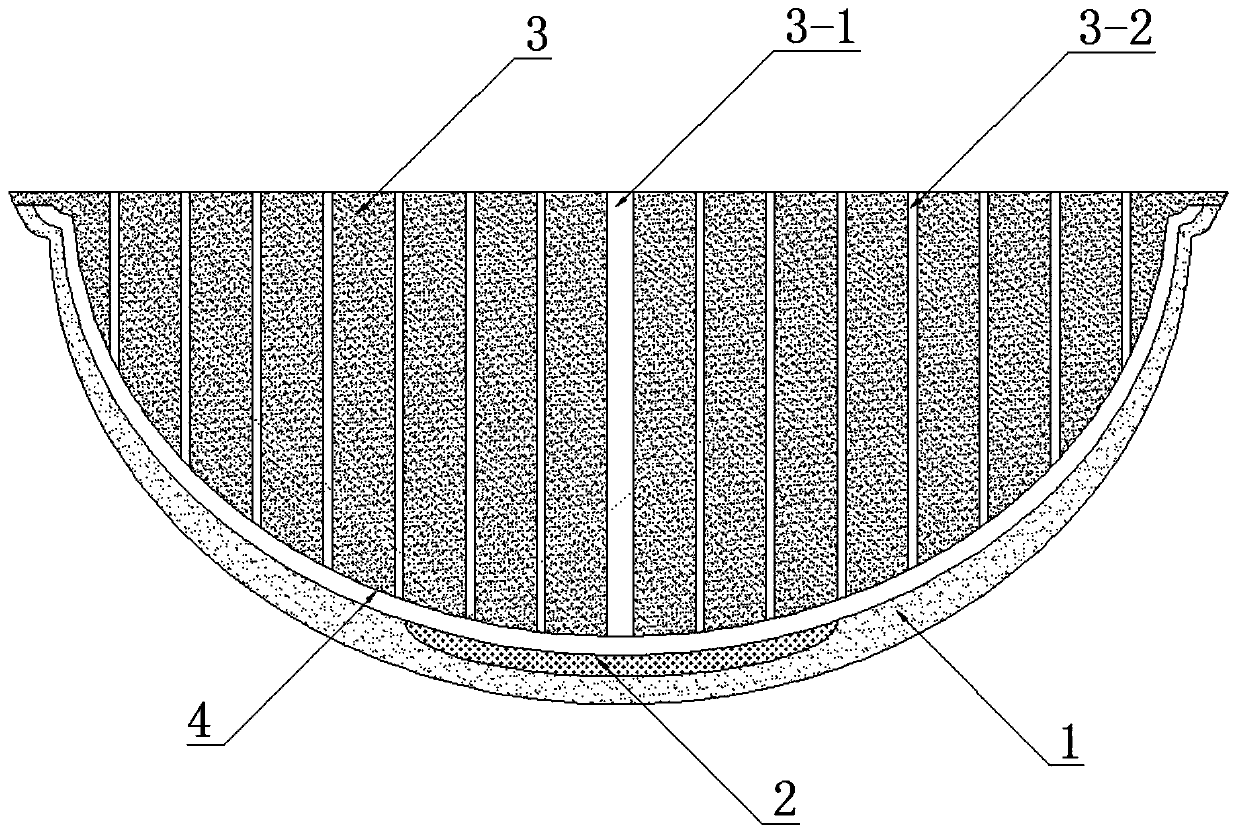

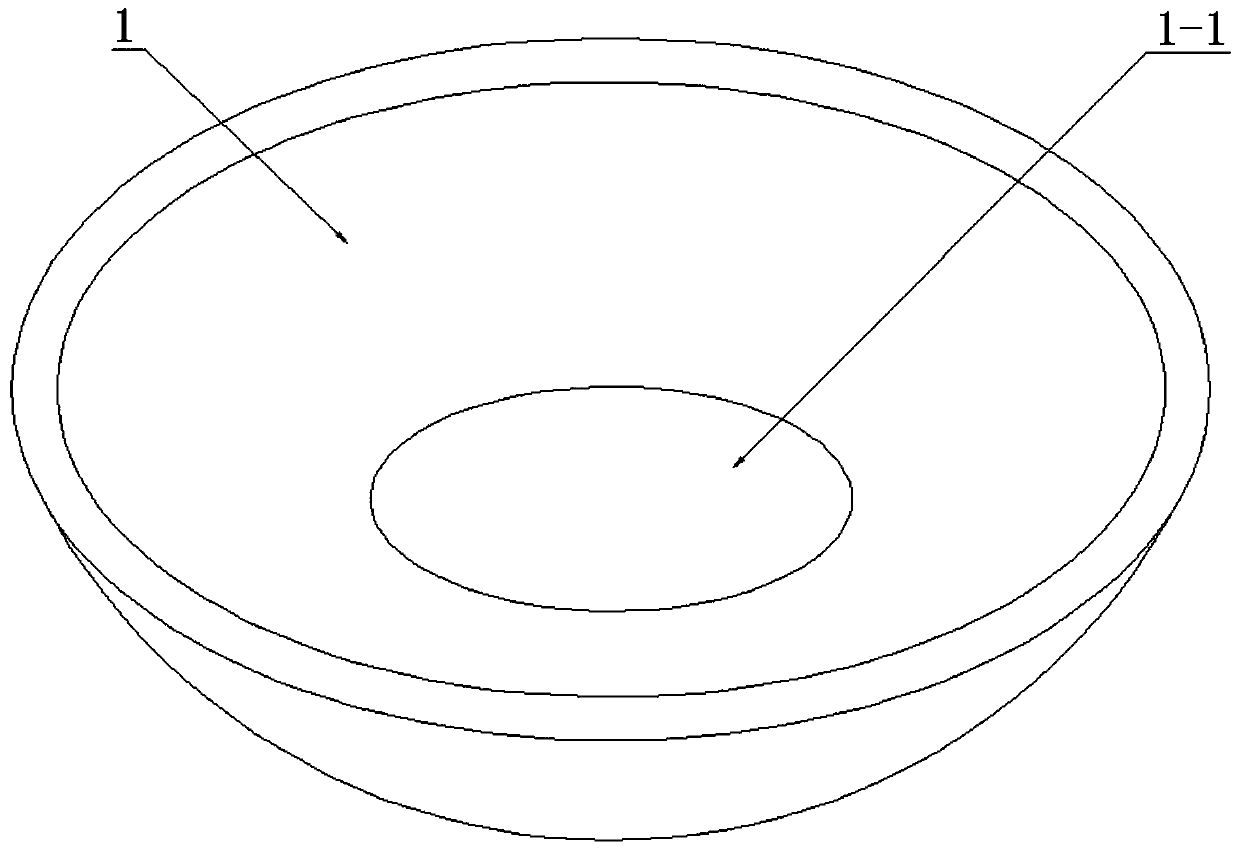

[0019] Such as figure 1 , 2 As shown in and 4, a pot casting mold assembly includes a bottom mold 1, a fin mold 2 and an upper mold 3, the bottom mold 1 and the upper mold 3 are mud molds or metal molds, and the fin mold 2 is a film-coated sand mold , the bottom mold 1 is a semi-ellipsoidal cavity, the bottom center of the bottom mold 1 cavity is provided with a slot 1-1, the fin mold 2 can be movably embedded in the slot 1-1, the upper surface of the fin mold 2 and the bottom The surface of the mold 1 cavity is bonded, the upper surface of the finned mold 2 is provided with fin patterns 2-1, the upper mold 3 is semi-ellipsoidal, and the center is provided with a casting channel 3-1 perpendicular to its upper surface, and the upper mold 3 There are air-dispersing micropores 3-2 parallel to the sprue 3-1 evenly distributed inside, and an annular flange is provided on the edge of the upper mold 3, and the annular flange is pressed against the edge of the bottom mold 1, and the ...

Embodiment 2

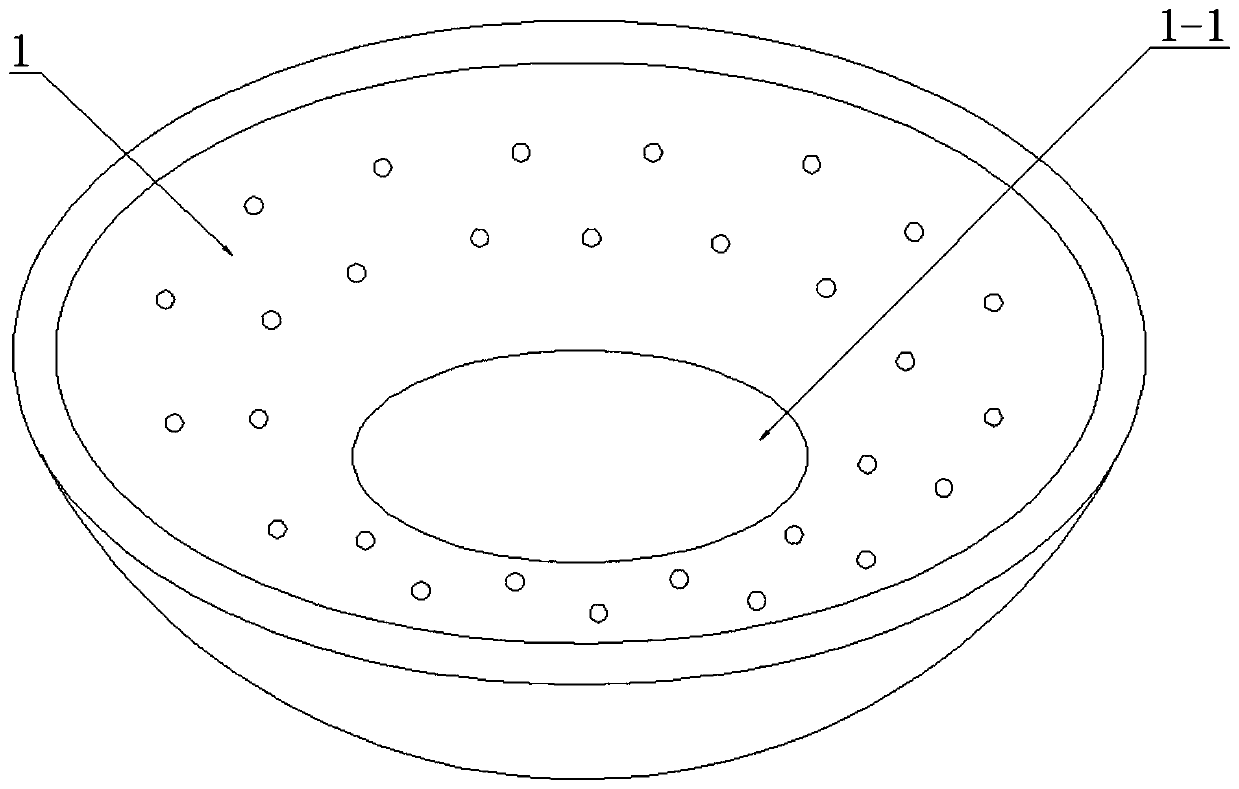

[0021] Such as figure 1 , 3 As shown in and 4, a pot casting mold assembly includes a bottom mold 1, a fin mold 2 and an upper mold 3, the bottom mold 1 and the upper mold 3 are mud molds or metal molds, and the fin mold 2 is a film-coated sand mold , the bottom mold 1 is a semi-ellipsoidal cavity, evenly distributed with air holes penetrating the bottom mold 1, the bottom center of the bottom mold 1 cavity is provided with a slot 1-1, and the fin mold 2 can be movably embedded in the slot 1-1 Inside, the upper surface of the fin mold 2 is attached to the surface of the cavity of the bottom mold 1, the upper surface of the fin mold 2 is provided with fin patterns 2-1, the upper mold 3 is semi-ellipsoidal, and the center is provided with The casting path 3-1 of the upper mold 3 is evenly distributed with air-dispersing micropores 3-2 parallel to the casting path 3-1, and the edge of the upper mold 3 is provided with an annular flange, which is connected to the edge of the bott...

Embodiment 3

[0023] Such as figure 2 , 4 As shown in and 5, a pot die-casting mold assembly includes a bottom mold 1, a fin mold 2 and an upper mold 3, the bottom mold 1 is a semi-ellipsoidal cavity, and the bottom center of the bottom mold 1 cavity is provided with a slot 1 -1, the fin mold 2 can be movably embedded in the slot 1-1, the upper surface of the fin mold 2 is attached to the cavity surface of the bottom mold 1, and the upper surface of the fin mold 2 is provided with fin patterns 2-1; The mold 3 is in the shape of a semi-ellipsoid, and there are evenly distributed air-dispersing micropores 3-2 perpendicular to the upper surface of the upper mold 3 and passing through the upper mold 3, and a connecting piece 3-3 is arranged at the center of the upper surface of the upper mold 3; the bottom mold 1 and the upper mold 3 are mud molds, and the fin mold 2 is a coated sand mold.

[0024] The invention also discloses a pot casting method. In addition to the above-mentioned pot die-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com