Patents

Literature

527results about How to "No overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

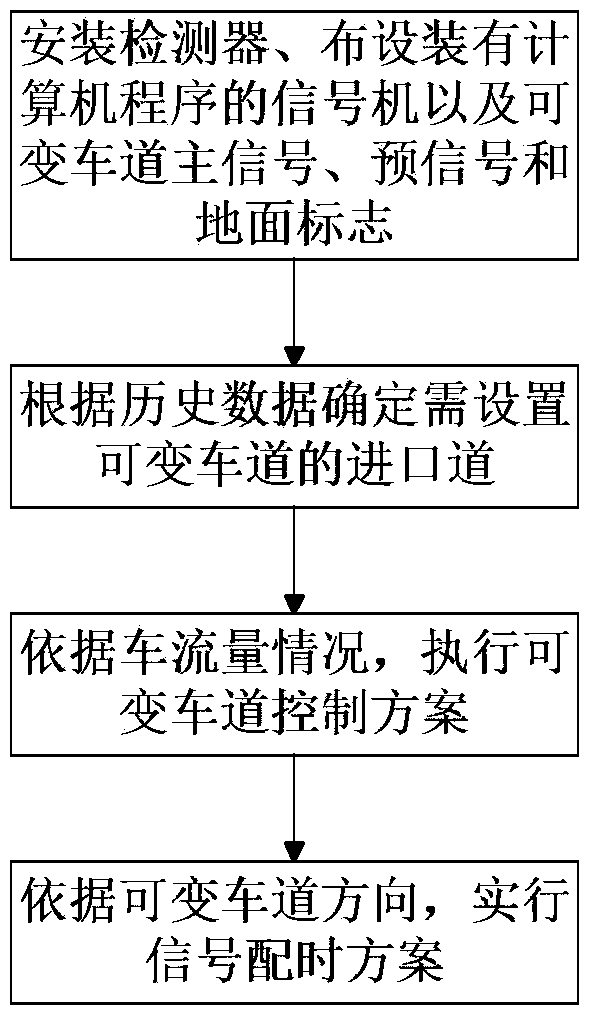

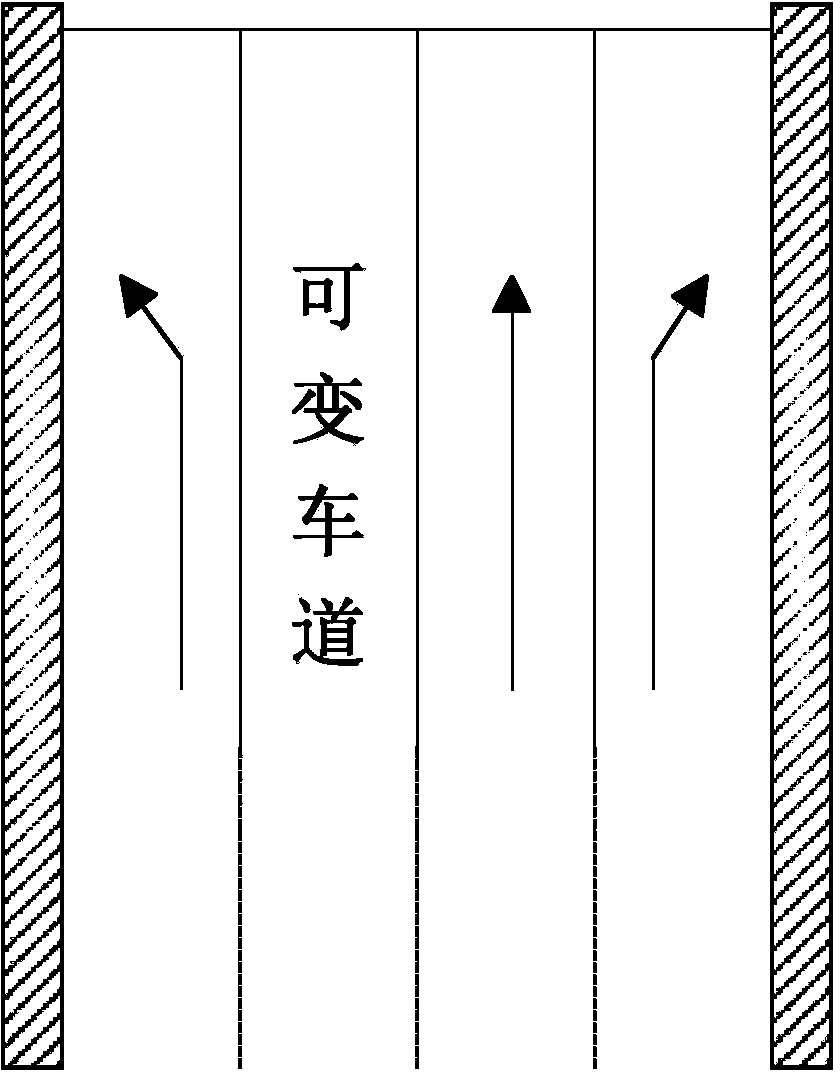

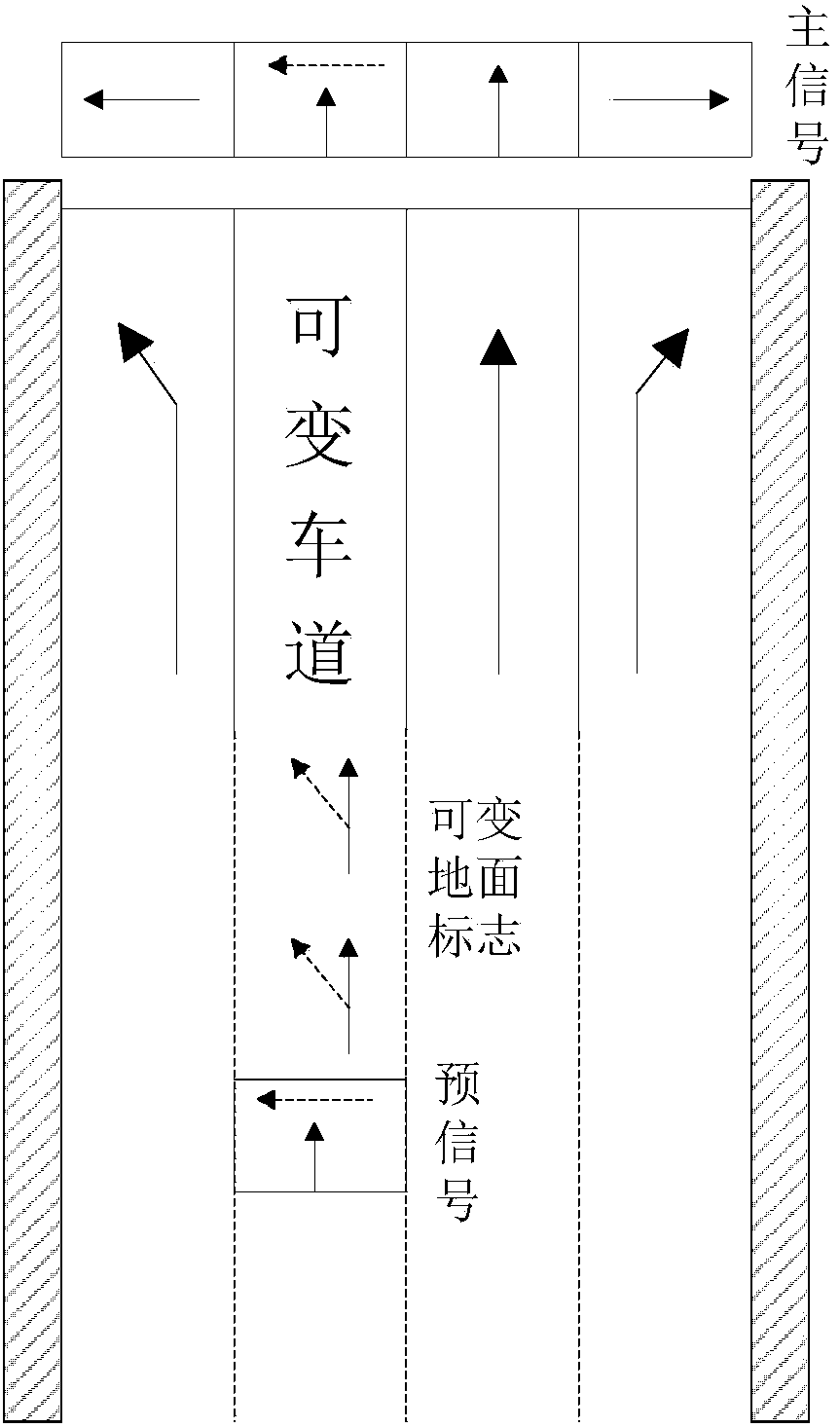

Reversible-lane-based intersection signal control method

InactiveCN104036645APass smoothlyBalance traffic loadControlling traffic signalsTraffic capacitySignal light

The invention discloses a reversible-lane-based intersection signal control method. The method comprises the following steps of, firstly, at eligible intersections, mounting detectors, and laying annunciators, main signal lights, pre-signal lights, reversible lane dynamic signs, wherein the annunciators are provided with computer programs, and the main signal lights, the pre-signal lights and the reversible lane dynamic signs are associated with reversible lanes; secondly, according to historical data, determining approaches where the reversible lanes can be arranged, and starting reversible lane control schemes; thirdly, according to the left turn and straight traffic flow of the approaches and the relation between the number of lanes and the saturation flow, judging the operating directions of the reversible lanes; lastly, according to the directions of the reversible lanes, determining appropriate signal matching schemes. The reversible-lane-based intersection signal control method can improve the traffic capacity of the intersections, reduce delay at the intersections and guarantee vehicle driving safety of the intersections.

Owner:SOUTHEAST UNIV

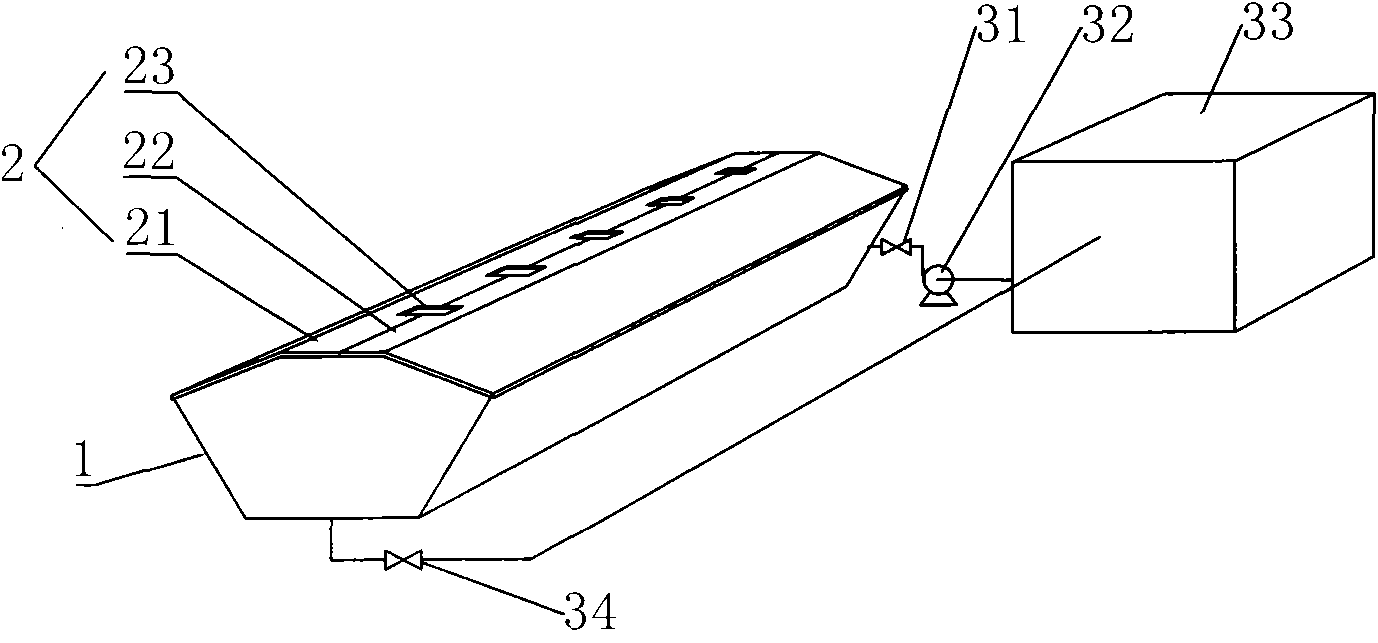

Multifunctional matrix soilless culture method and device

InactiveCN102210254ASuitable for growthPromote absorptionAgriculture gas emission reductionCultivating equipmentsNutrient solutionPlant growth

The invention discloses a multifunctional matrix soilless culture method and device. The method comprises the following steps of: filling culture matrix into a porous culture container; placing the porous culture container filled with the culture matrix into a culture bed groove; reserving gaps between the inner wall of the culture bed groove and the porous culture container to form a root exogenous space; planting plants on the porous culture container with the culture matrix; covering the upper opening of the culture bed groove with a covering substance; reserving a plant fixing hole or growth port at the position, wherein the plant is planted, on the covering substance, so that a heat-preserving, a humidity-preserving and black environment is formed in the culture bed groove; and supplying water or nutrient solution to the culture matrix in the porous culture container, wherein in the growth process of the plant, the root grows to permeate the gaps of the porous gap culture container to grow into and out of the culture container and in the space in the bed groove. By the soilless culture method and the soilless culture device, good growth environment and balanced supply of nutrients and water of the root can be guaranteed; and different irrigation modes are suitable, such as the soilless culture method for culturing various crops, the matrix culture method and the matrix and water composite culture method.

Owner:北京绿东国创农业科技有限公司

Anhydrous albany grease and preparation method thereof

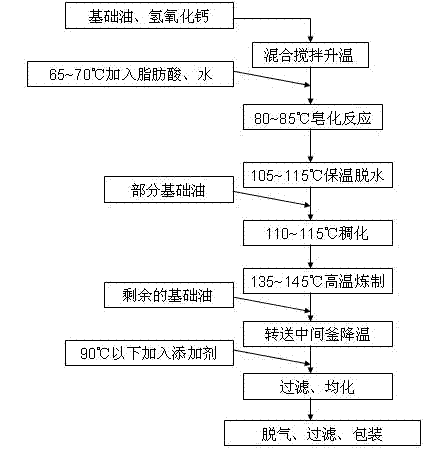

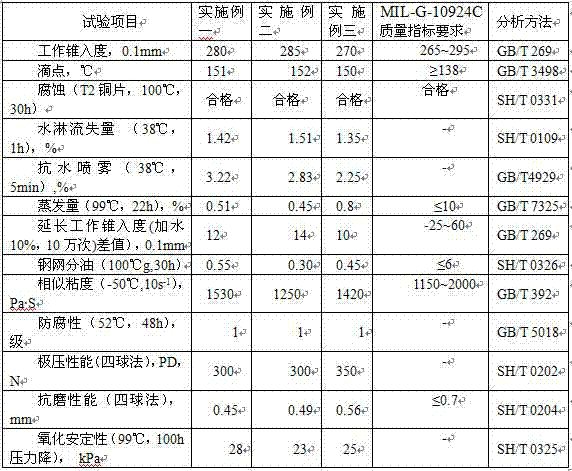

ActiveCN102757847AMeet the requirements of wide temperature rangeExcellent water shear stabilityLubricant compositionChemical industryCalcium hydroxide

The invention belongs to the technical field of the chemical industry, and relates to grease and a preparation method thereof, in particular to anhydrous albany grease and the preparation method thereof. The anhydrous albany grease and the preparation method comprises the following components by weight: 82-90% of base oil, 1-4% of calcium hydroxide, 6-15% of fatty acid, 0.3-1% of antioxygen, 0.5-1.5% of rust inhibitor, and 0.5-3% of extreme pressure antiwear additive. The anhydrous albany grease and the preparation method have the benefits as follows: the grease is simple in preparation process and easy to control; and the prepared product has better water erosion resistance, favorable metal adhesivity and extreme pressure abrasion resistance, and can provide outstanding lubrication and abrasion resistance protection for wheel bearings and chassis.

Owner:JIANGSU LOPALTECH

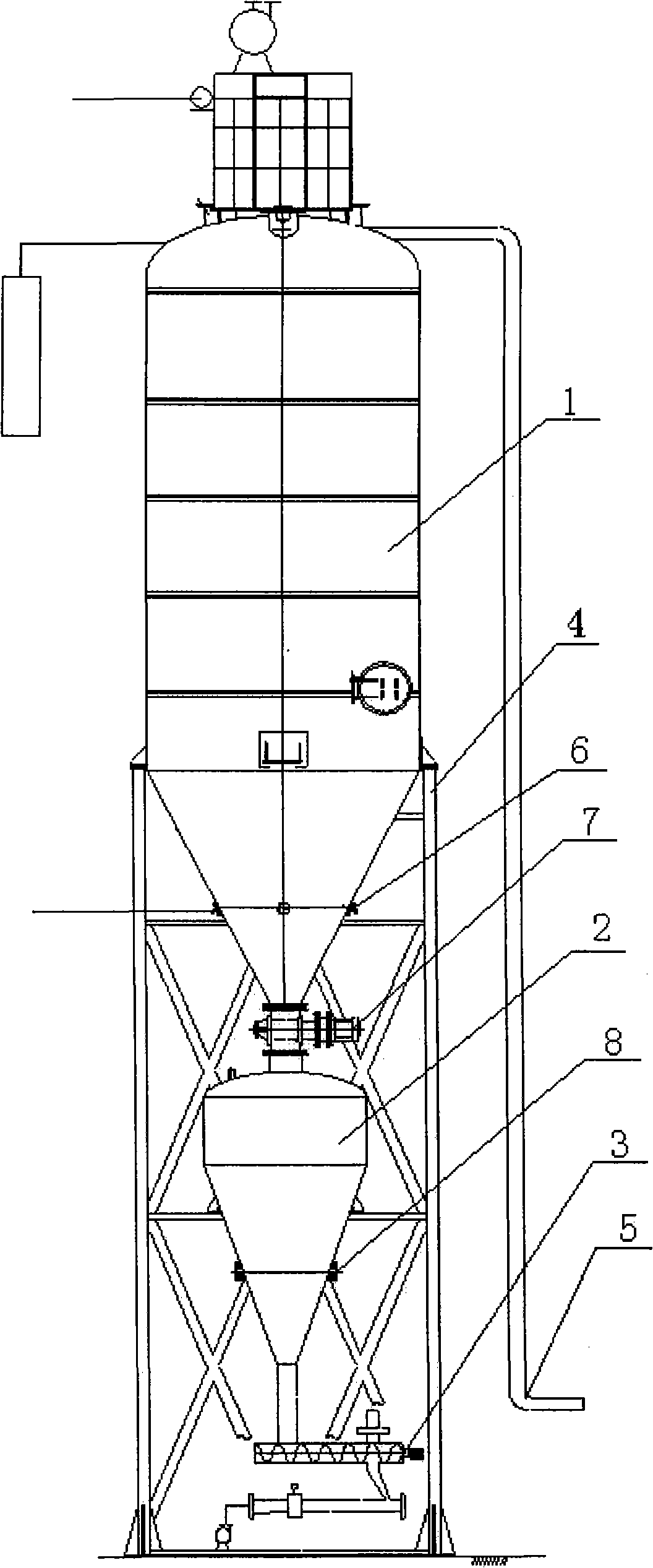

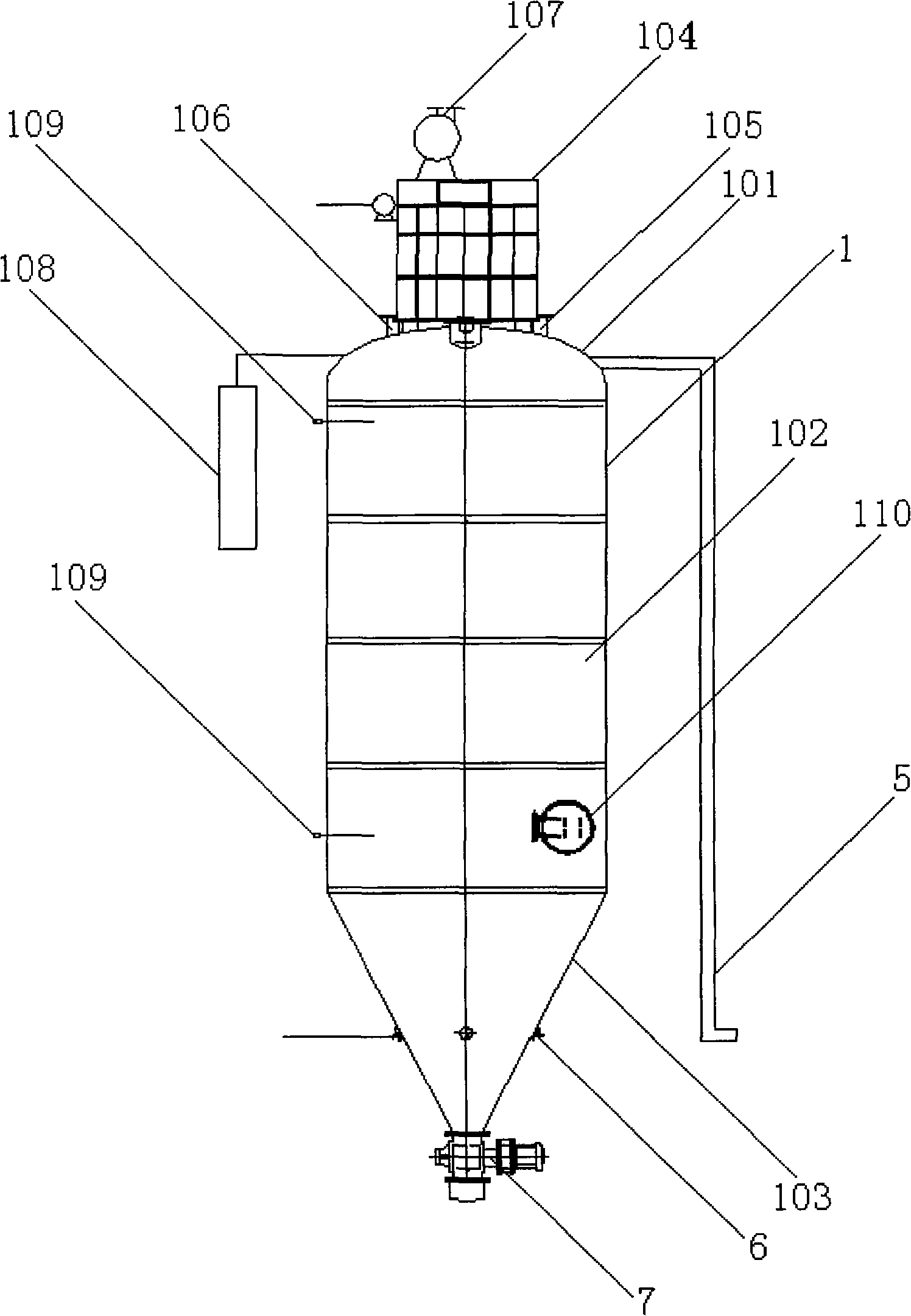

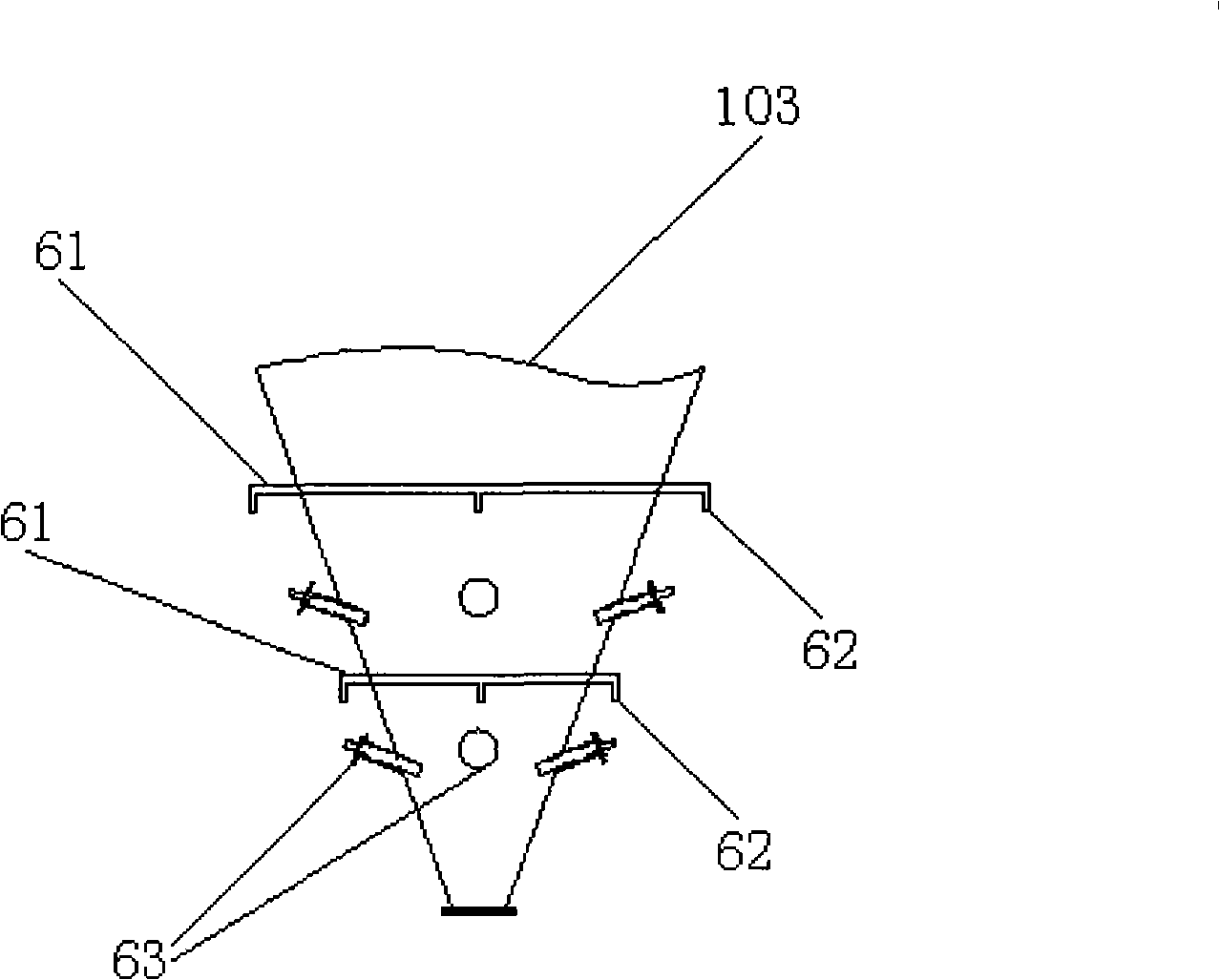

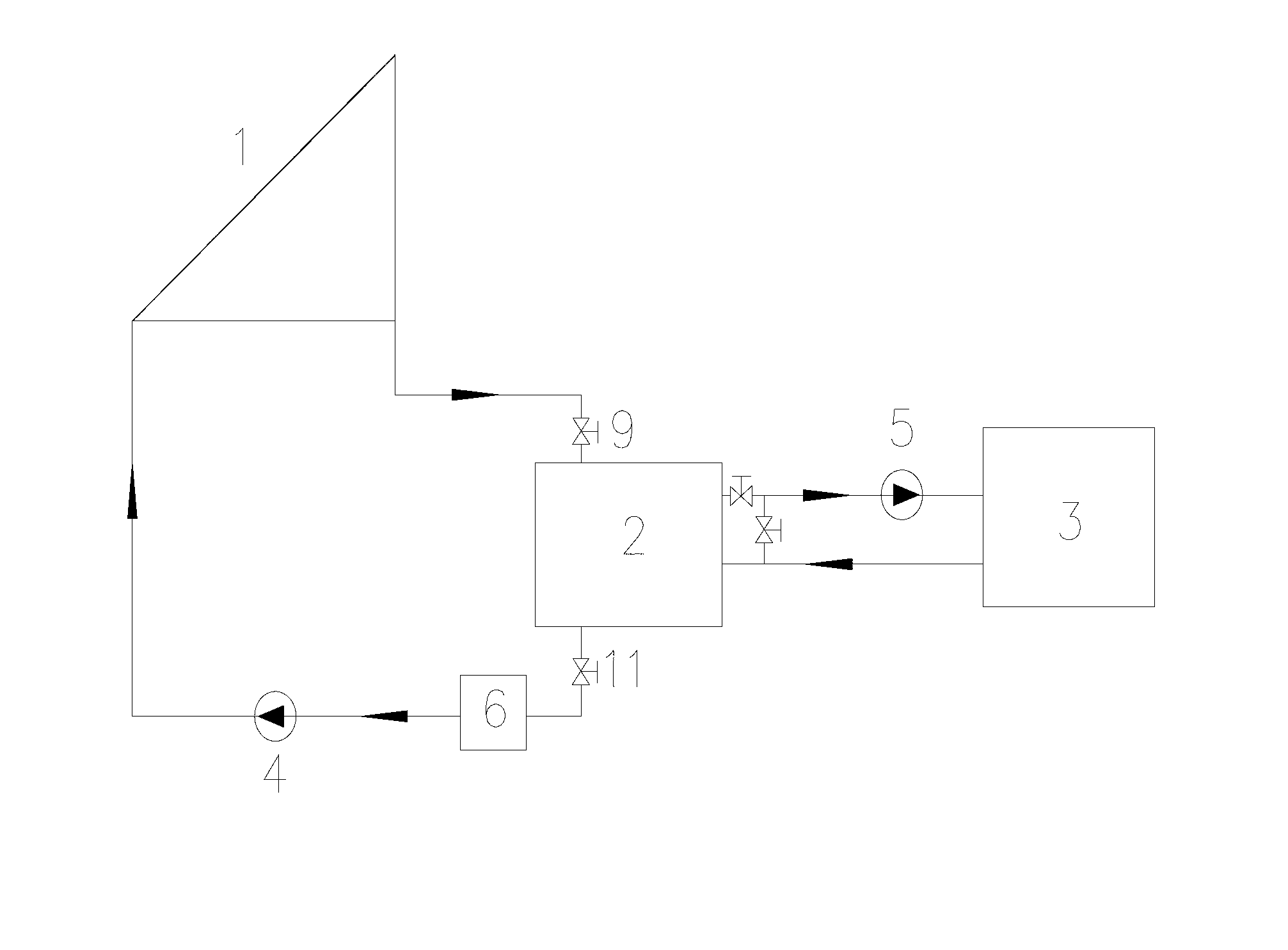

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

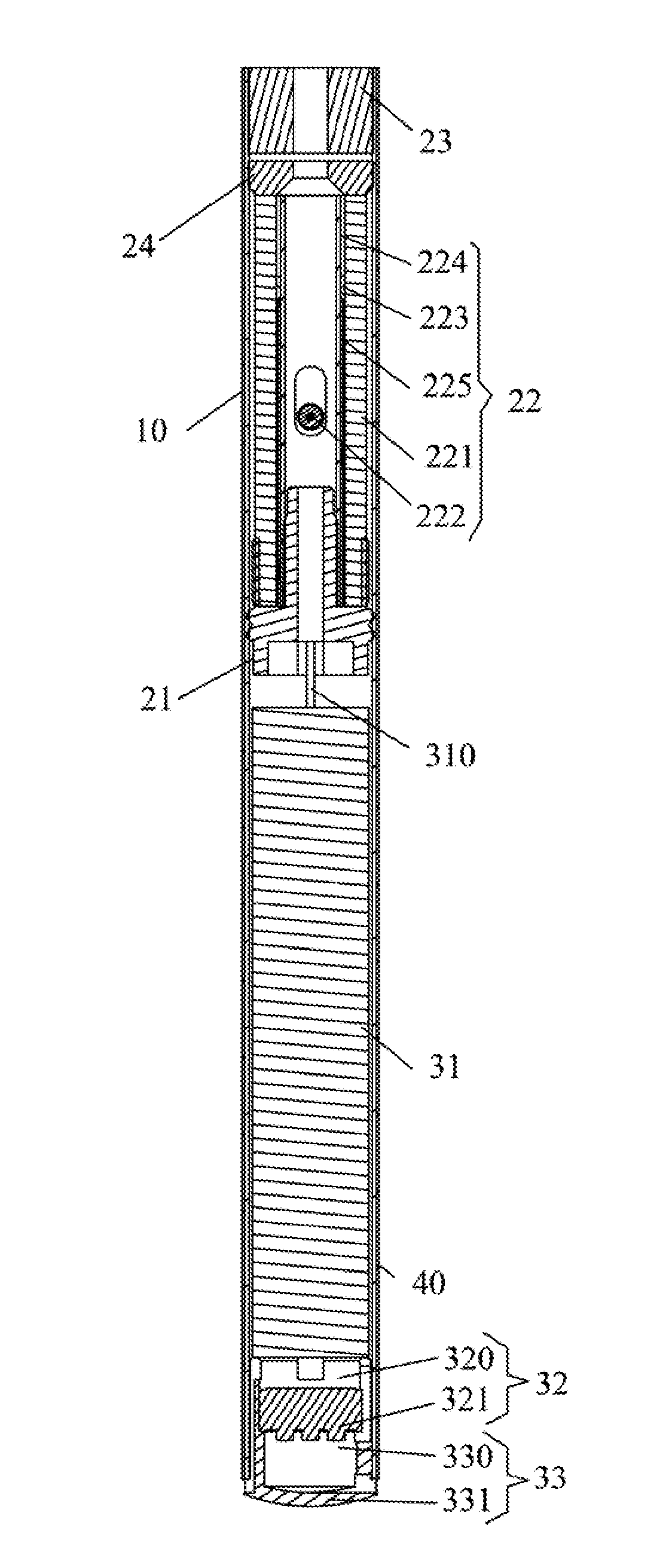

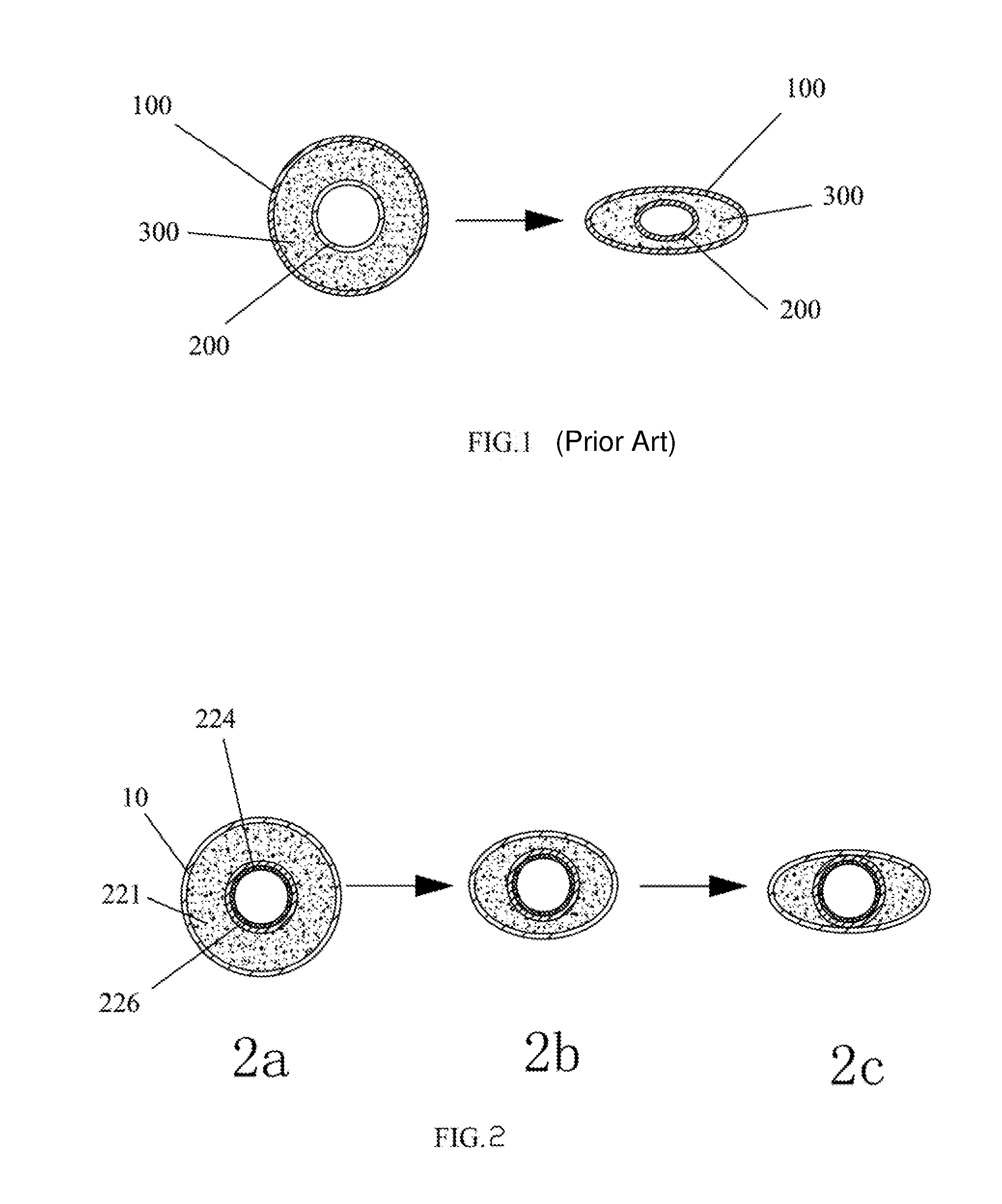

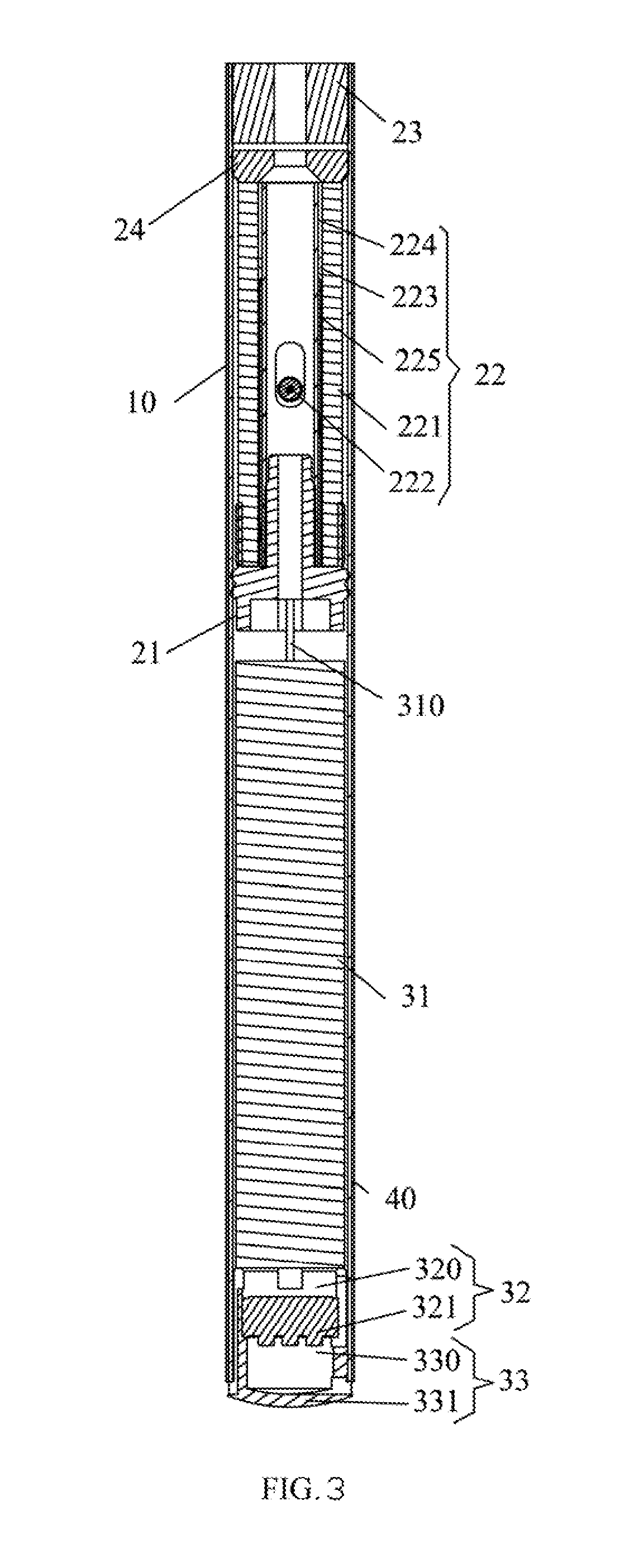

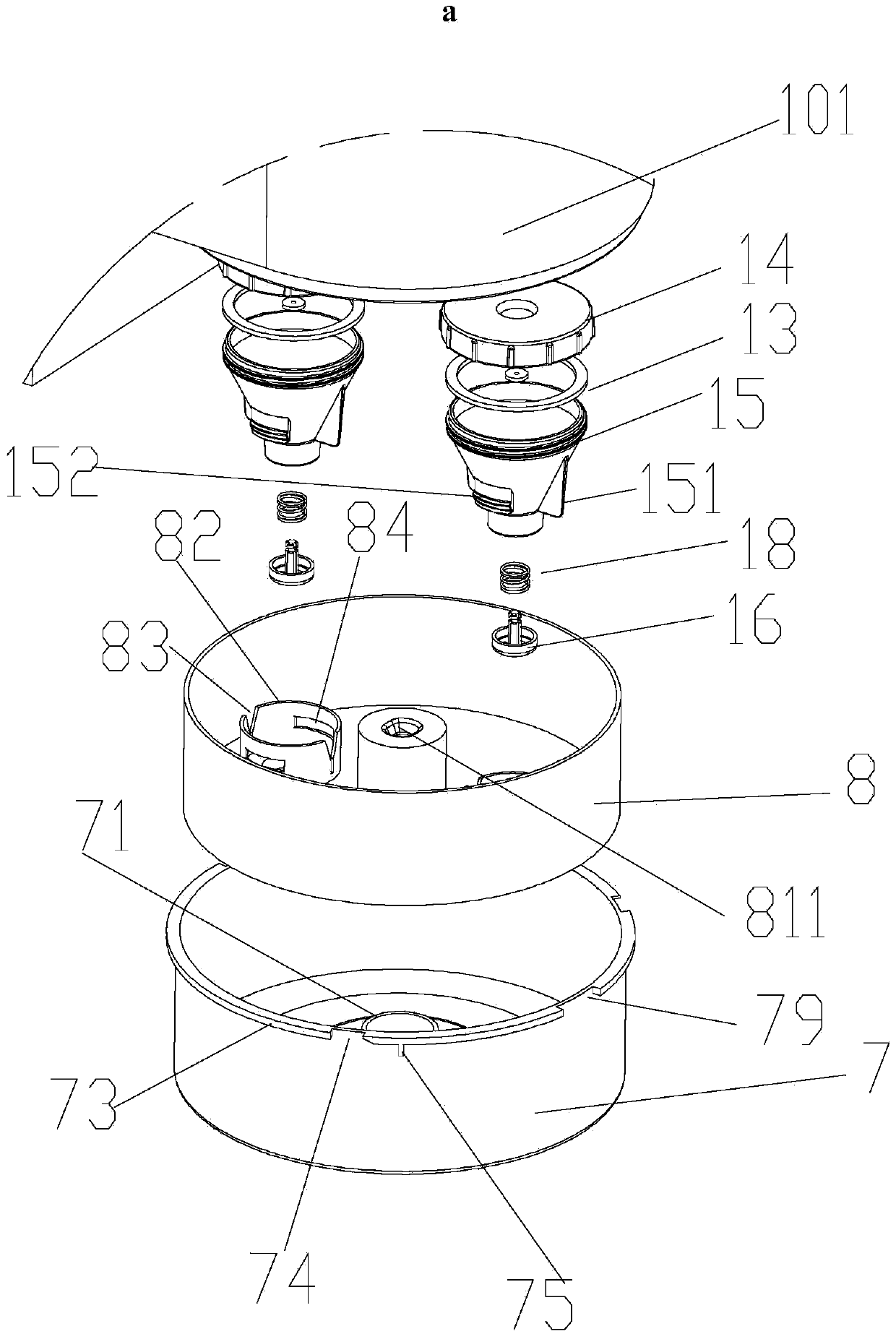

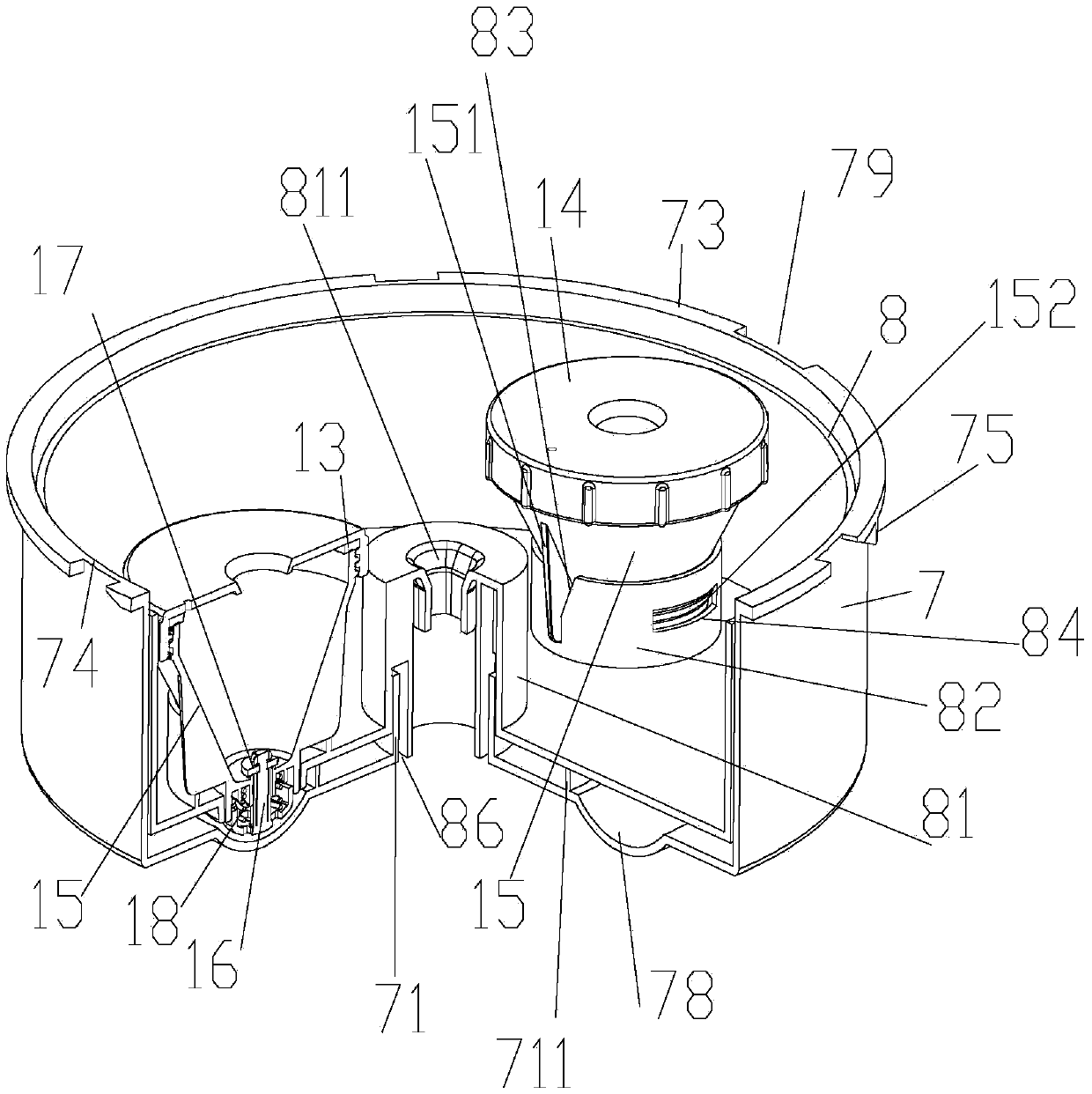

Electronic cigarette

InactiveUS20160128388A1Add support functionSolve the lack of spaceTobacco devicesHand ironElectronic cigaretteSmoke

Disclosed is an electronic cigarette, comprising a tube sleeve and an atomizer assembly which is provided in the tube sleeve and is used for producing smoke, wherein the atomizer assembly comprises an oil storage space which is mainly composed of a liquid storage part; the atomizer assembly is provided with a support mechanism which prevents the oil storage space from deforming excessively when the oil storage space is pressed. By means of the support mechanism, the electronic cigarette can achieve the technical effects of no overflow of cigarette oil after the electronic cigarette is pressed, a robust structure and stable and reliable quality.

Owner:KIMREE HI TECH

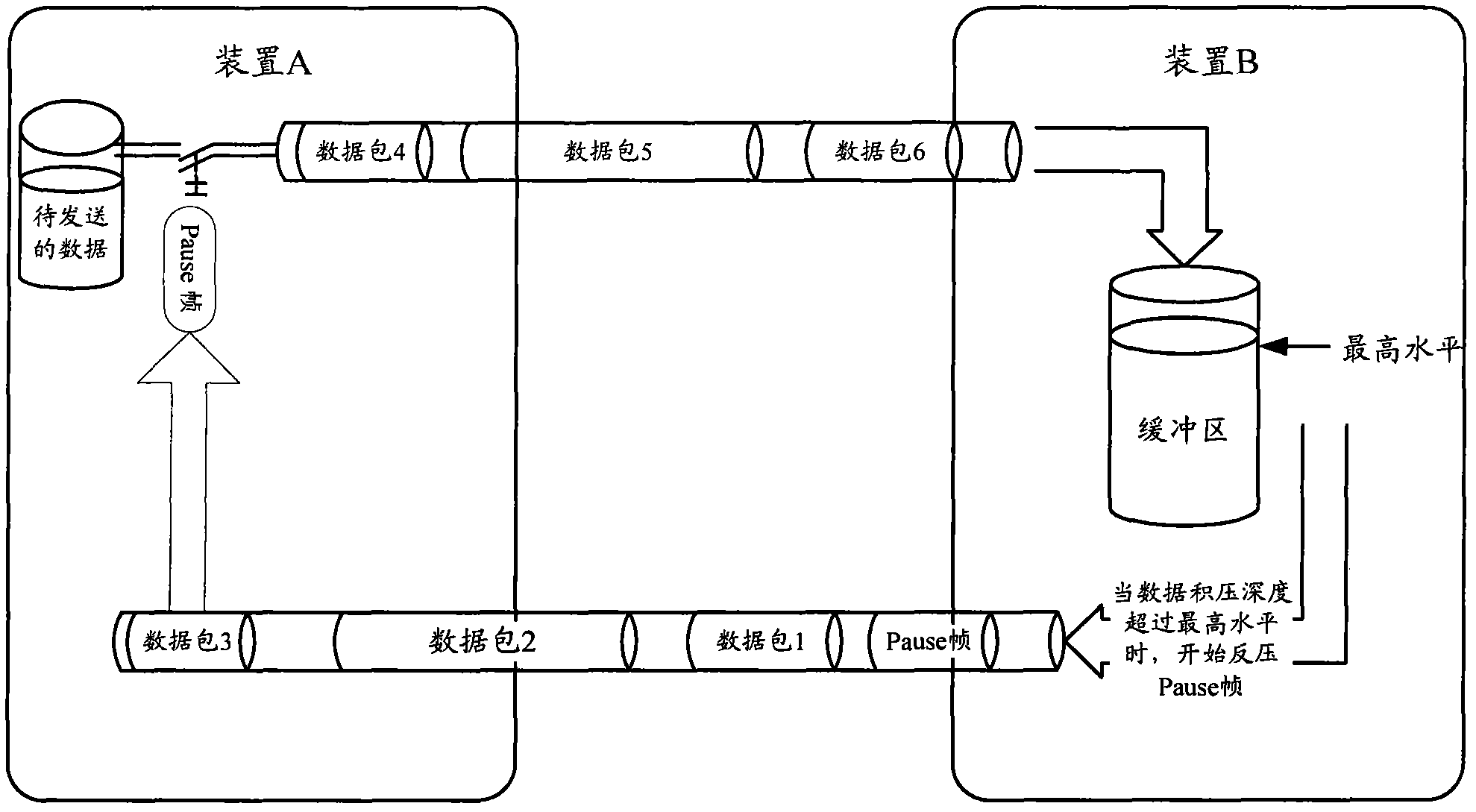

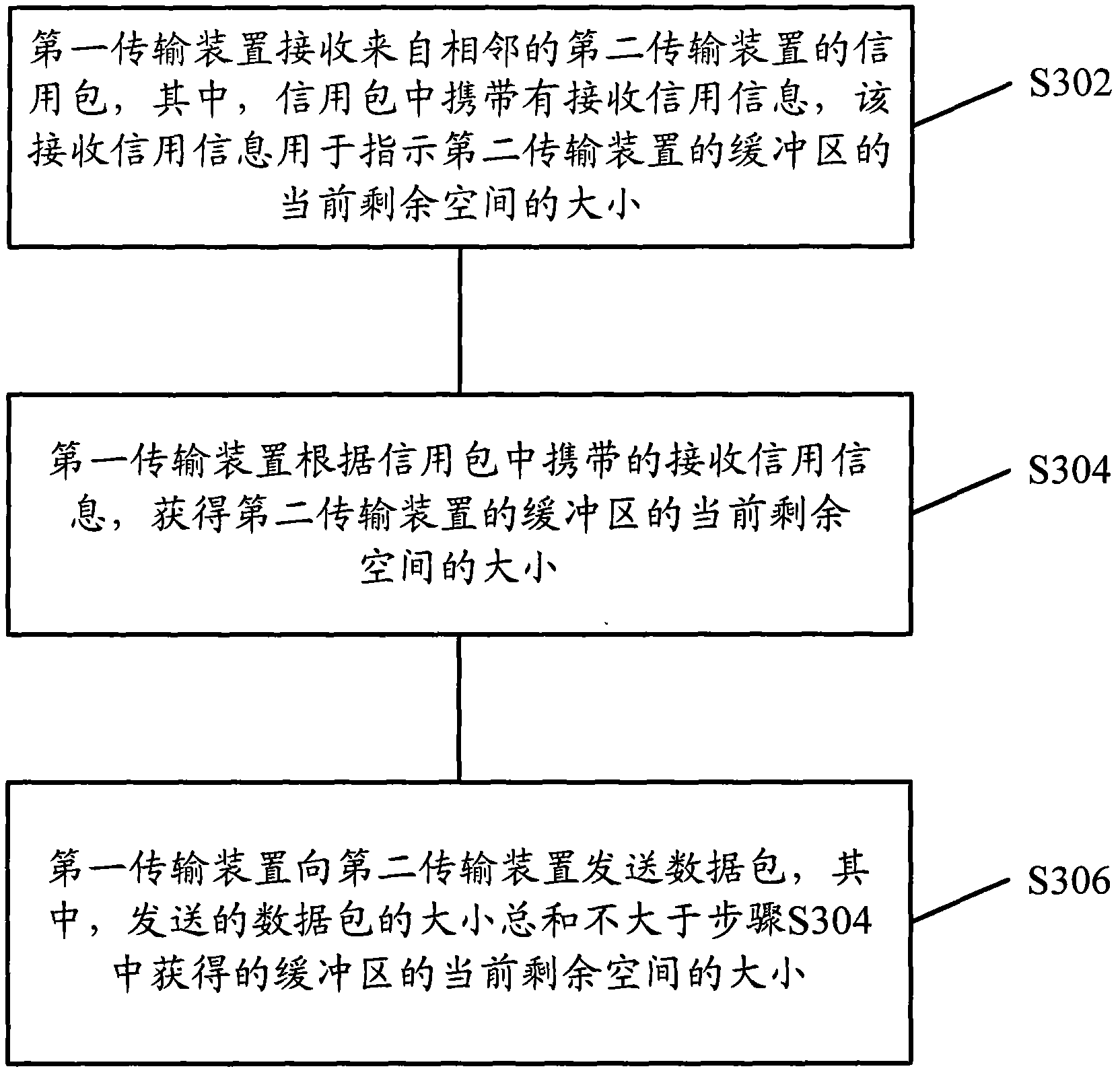

Ethernet, and data transmitting method and device thereof

ActiveCN102075436ANo overflowHigh data transmission reliabilityError preventionData switching networksPacket lossData transmission

The embodiment of the invention provides Ethernet, and a data transmitting method and a device thereof, which are used for the technical field of communication, wherein the data transmitting method of the Ethernet comprises the following steps that: a first transmitting device receives a credit packet from an adjacent second transmitting device, wherein the credit packet carries receiving credit information which is used for indicating the current rest space size of a buffer region of the second transmitting device; the first transmitting device obtains the current rest space size of the buffer region according to the receiving credit information; and the first transmitting device transmits data packets to the second transmitting device, wherein the total size of the transmitted data packets is not greater than the obtained current rest space size of the buffer region. The embodiment of the invention ensures that the receiving buffer of receivers can not generate overflow phenomena, so the occurrence of packet loss is avoided, and the data transmission reliability of the Ethernet is improved.

Owner:CHENGDU HUAWEI TECH

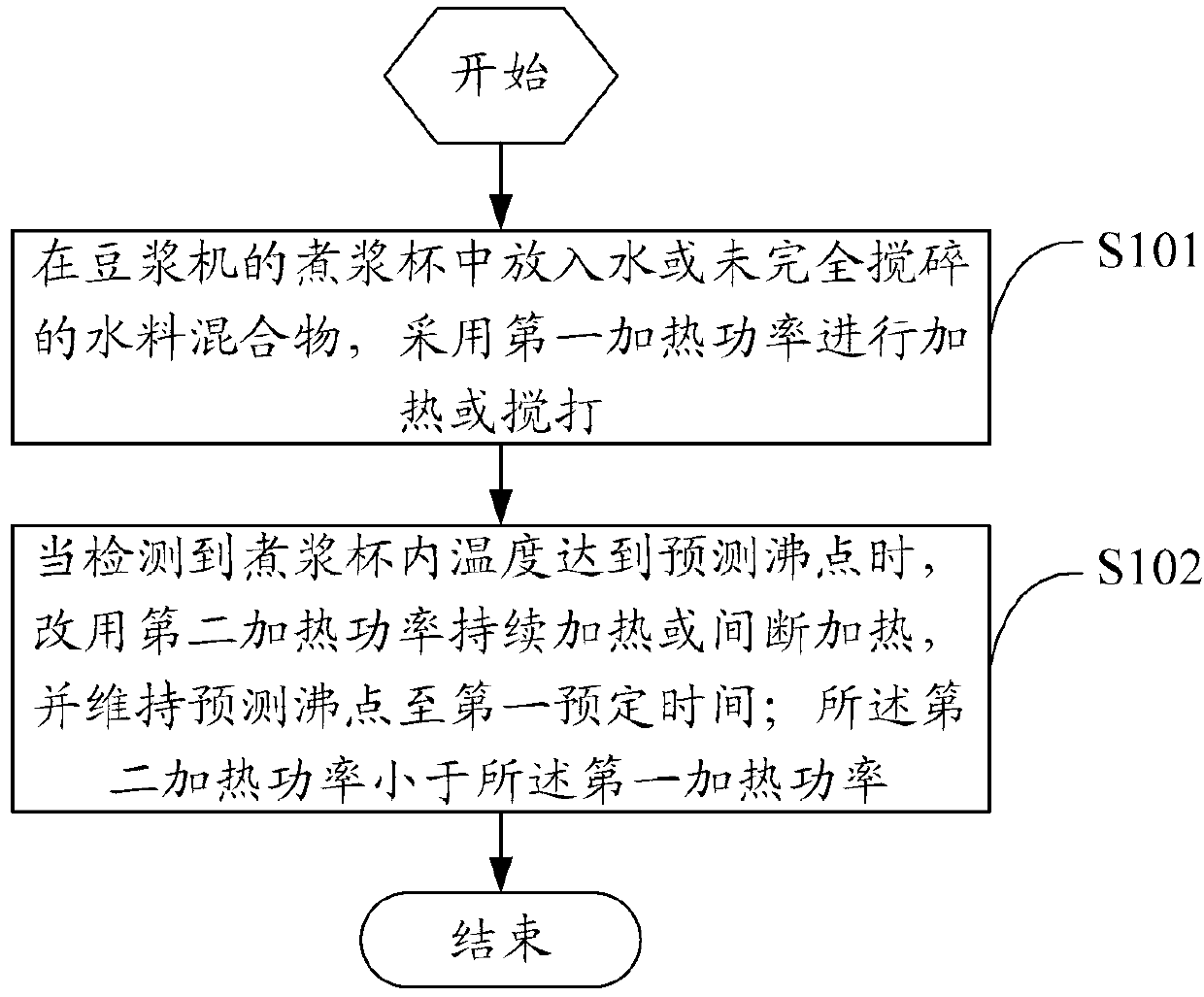

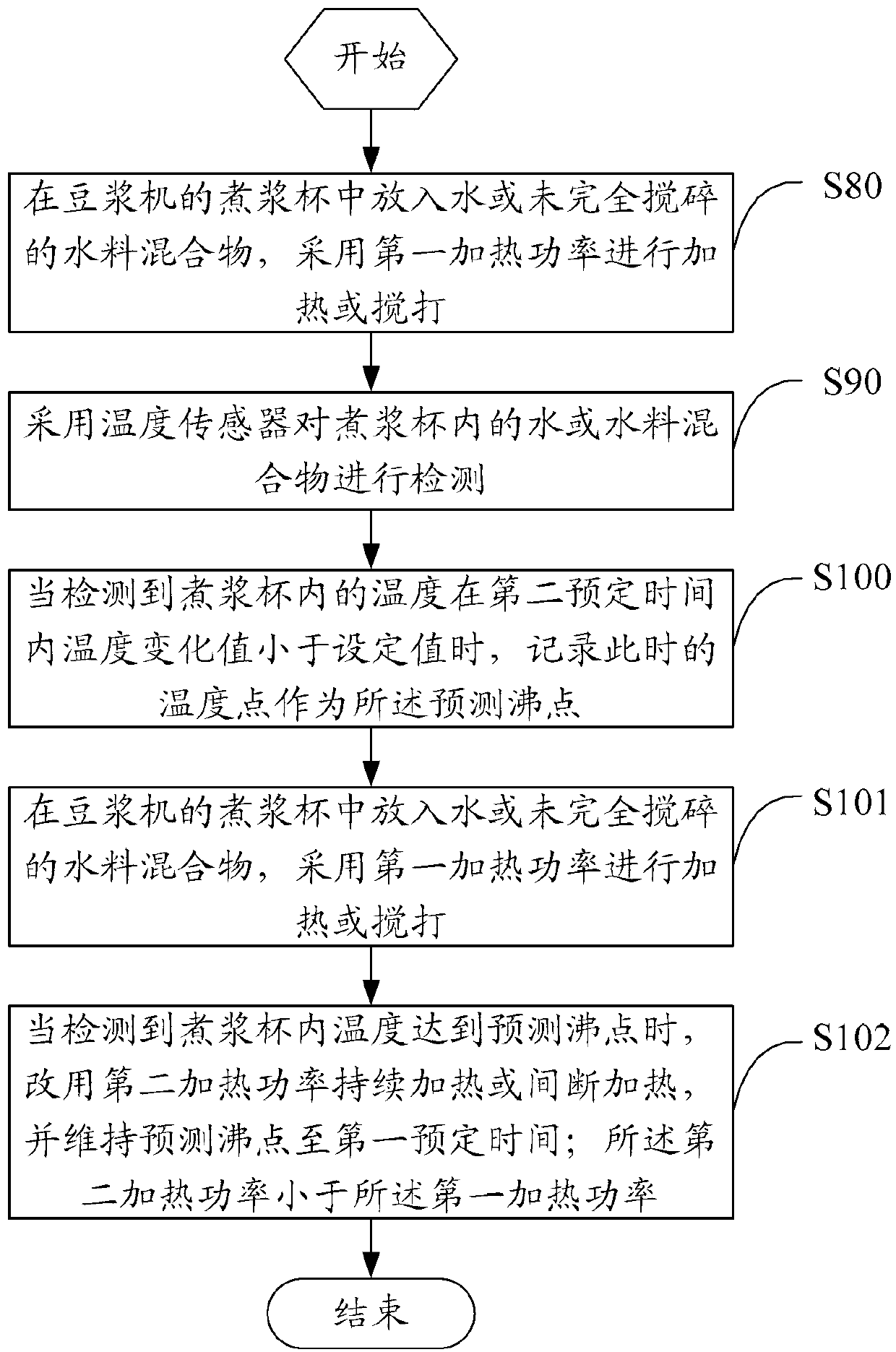

Spill-proof control method of soybean milk maker and soybean milk maker

ActiveCN102987925ANo overflowSimple structureBeverage vesselsMilk substitutesBoiling pointEngineering

The invention discloses a spill-proof control method of a soybean milk maker and the soybean milk maker. The spill-proof control method comprises the following steps of: putting water or a water-material mixture in a soybean milk cooking cup of the soybean milk maker and heating or stirring by adopting a first heating power; and when detecting that the temperature in the soybean milk cooking cup reaches a predicted boiling point, continuously heating or intermittently heating by adopting a second heating power and maintaining the predicted boiling point for a first preset time, wherein the second heating power is lower than the first heating power. According to the invention, a temperature sensor is used for acquiring data and judging the current boiling point through analysis and calculation according to the temperature data, so that soybean milk can be cooked thoroughly by taking the current boiling point as a parameter standard for subsequent program control, and no spillage phenomenon can be caused. According to the spill-proof control method disclosed by the invention, the capabilities of saving a spill-proof device of the traditional soybean milk maker, simplifying the structure, saving the cost and solving the problem of large effect difference of soybean milk caused by different elevations in different places can be realized.

Owner:MIDEA GRP CO LTD

Two-component solar sealant and preparation method thereof

InactiveCN101851486AFast curingCuring Speed AdjustmentNon-macromolecular adhesive additivesOther chemical processesCross-linkSolar battery

The invention relates to a two-component solar sealant for assembling solar battery assemblies and a preparation method thereof. The sealant of the invention comprises a component A and a component B, wherein the component A comprises 0-100 parts of basic polymer, 10-50 parts of plasticizing agent, 50-100 parts of padding and 1-10 parts of reinforcing agent; and the component B comprises 0-100 parts of terminal alkoxy polysiloxane, 0-100 parts of dimethyl silicon oil, 5-30 parts of pigment, 50-100 parts of cross-linking agent, 5-30 parts of coupling agent and 0.001-5 parts of catalyst. The invention has the advantages that (1) the curing speed is high and can be adjusted according to the ratio of the component A to the component B; (2) the sealant can be stored stably, the component A and the component B are separately packaged, and the cross-linking agent and the catalyst are not in contact with the basic materials; and (3) the 'sealant overflowing' phenomenon can not occur in practical use.

Owner:JIANGSU TIANCHEN NEW MATERIALS

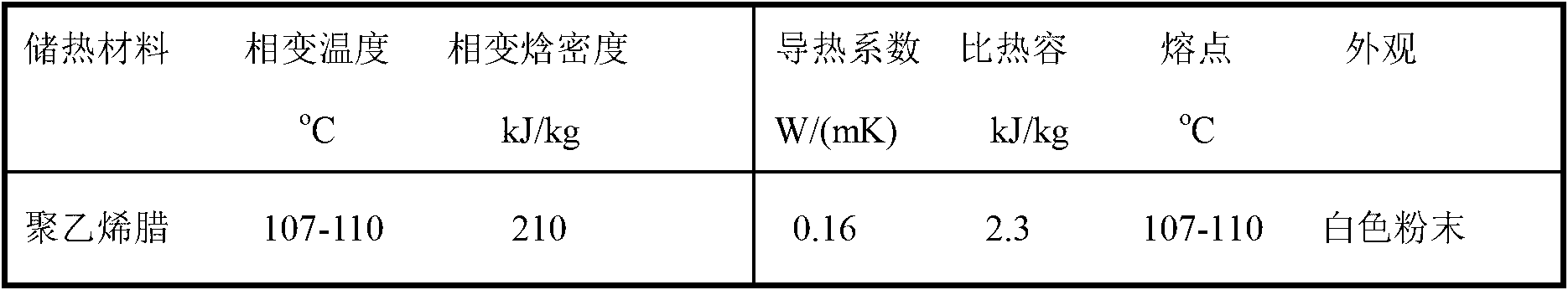

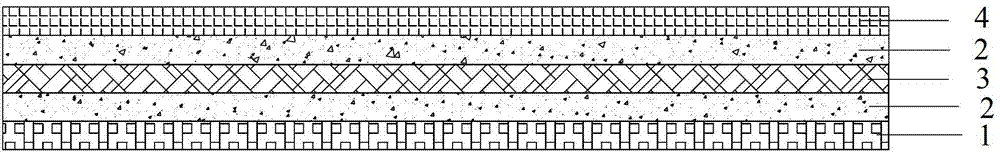

Constructional phase change energy storage plate and manufacturing method thereof

InactiveCN103015540APrevent leakageNo overflowLaminationLamination apparatusEnvironmental resistanceAlcohol

The invention discloses a constructional phase change energy storage plate, consisting of an upper cover plate, a lower bottom plate and a phase change material, wherein the phase change material is a mixture of fatty acid and high carbon alcohols; the fatty acid is n-decylic acid, lauric acid, myristic acid, palmitic acid and stearic acid; the alcohols are dodecanol, tetradecanol, hexadecanol and octadecanol; and the mass percent of the fatty acid to the mass percent of the high carbon alcohols is 46.4%: 53.6% to 97.5%: 2.5%. With the adoption of the constructional phase change energy storage plate and a manufacturing method thereof, the problems such as damages to mechanical performances, environmental protection, safety and the like are fundamentally solved, and meanwhile, the risks existing in actual application are prevented; the constructional phase change energy storage plate is stable in structure; the phase change material is not easy to leak; no irritant gas overflows; the appearance is attractive; and therefore, besides application onto constructed walls, the constructional phase change energy storage plate also can be used as an interior decoration, a suspended ceiling and a laid floor board.

Owner:TIANJIN UNIV

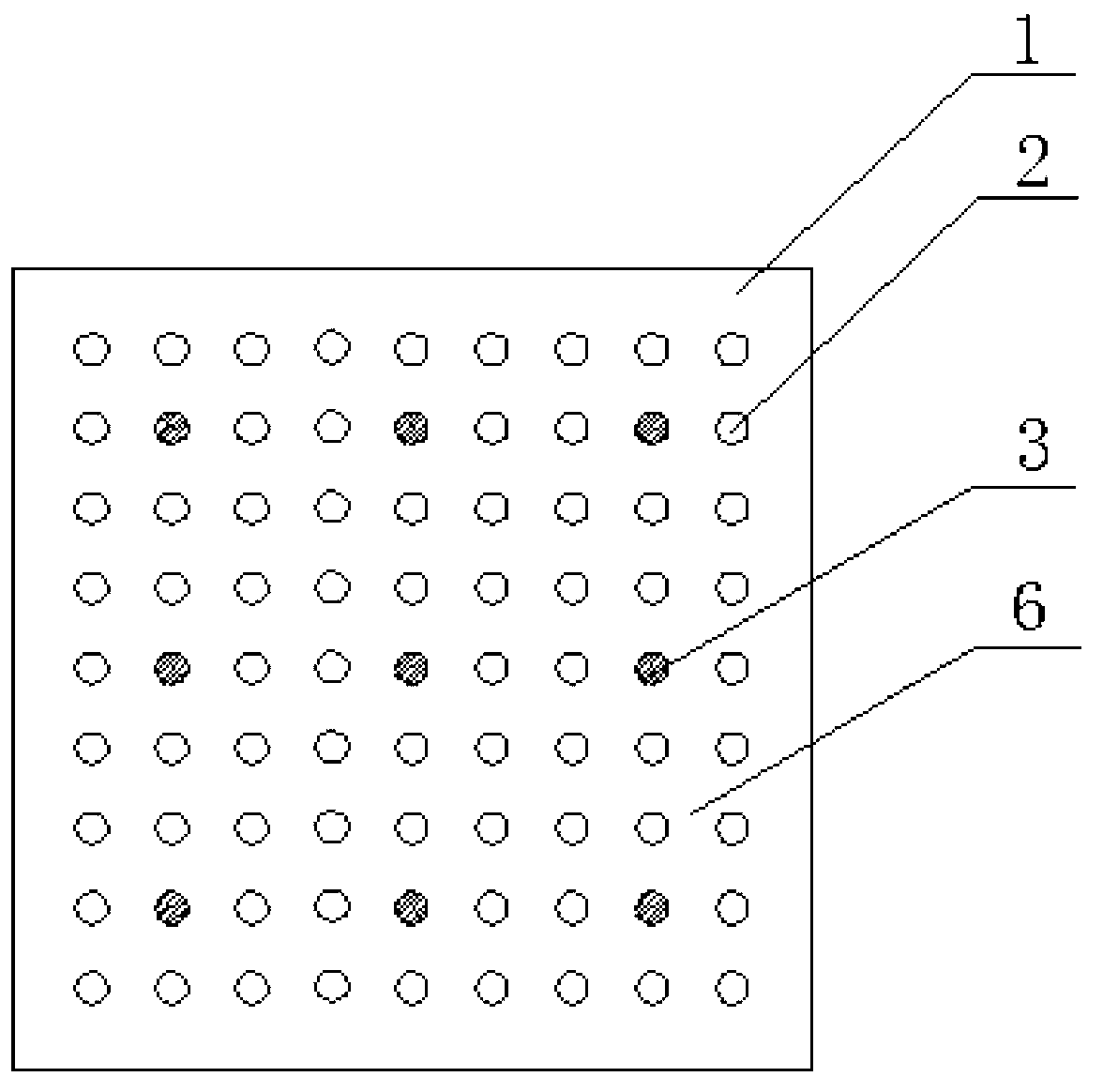

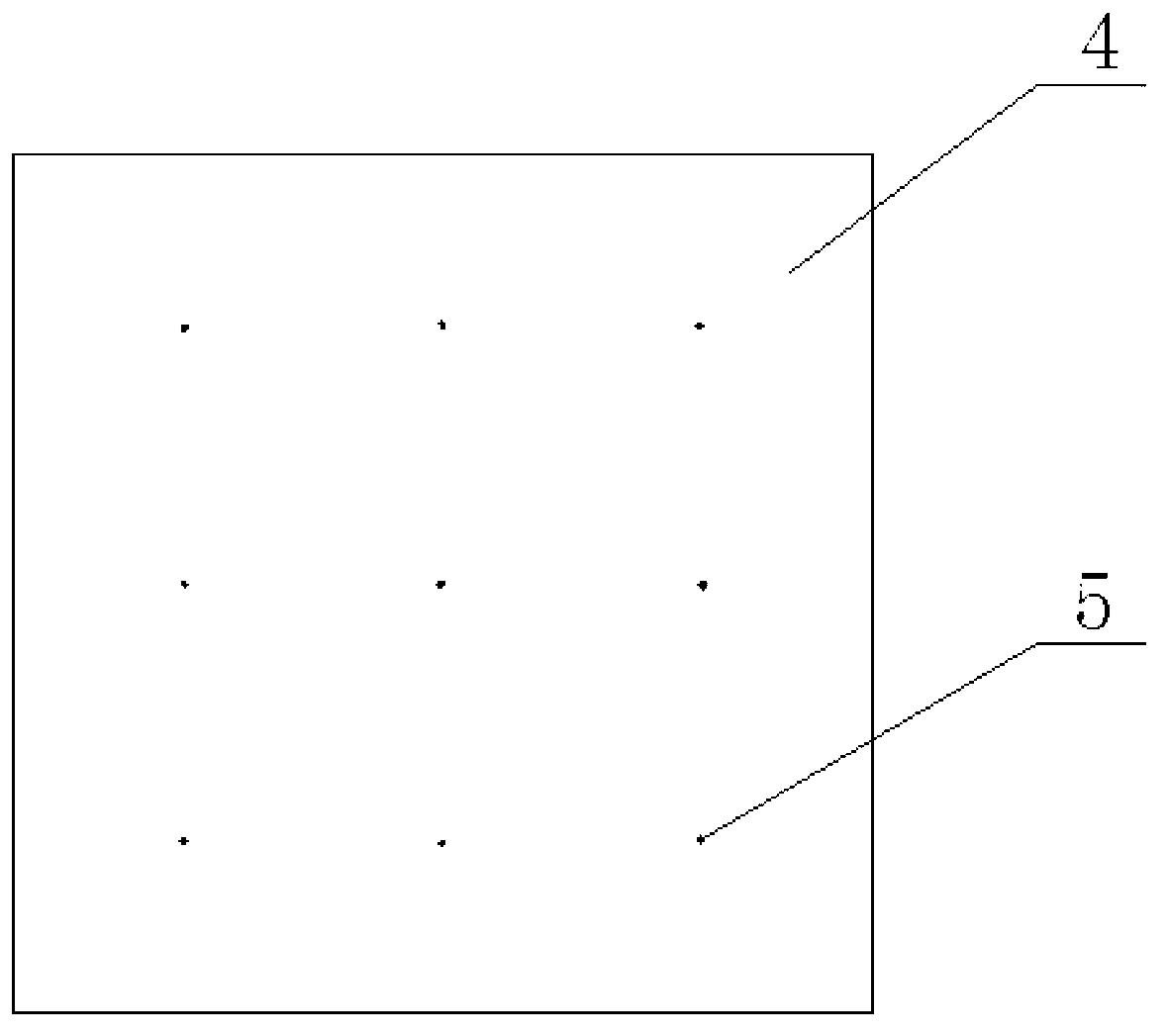

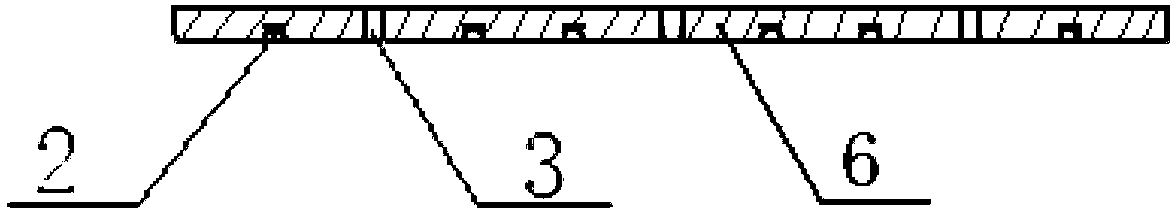

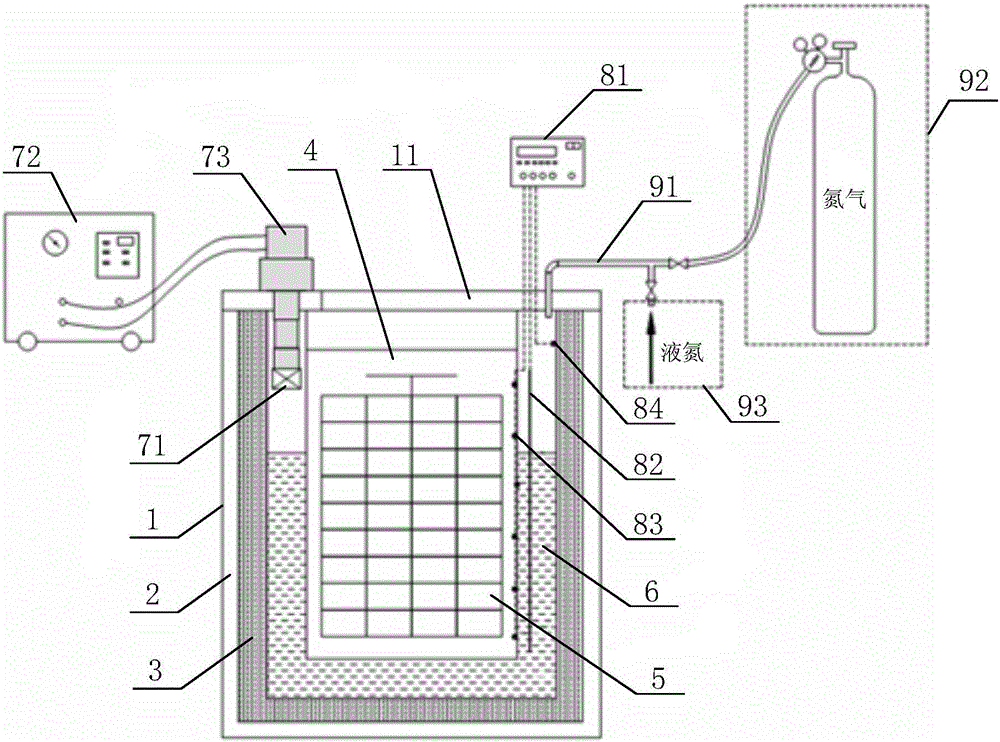

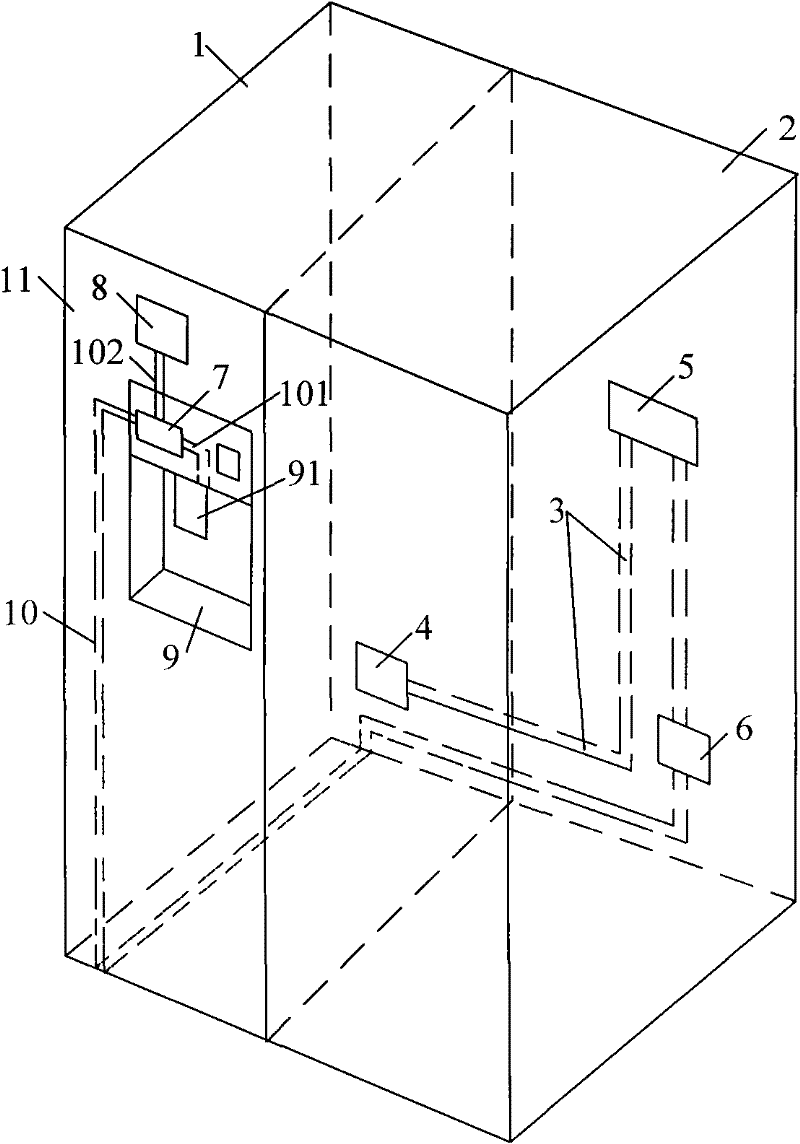

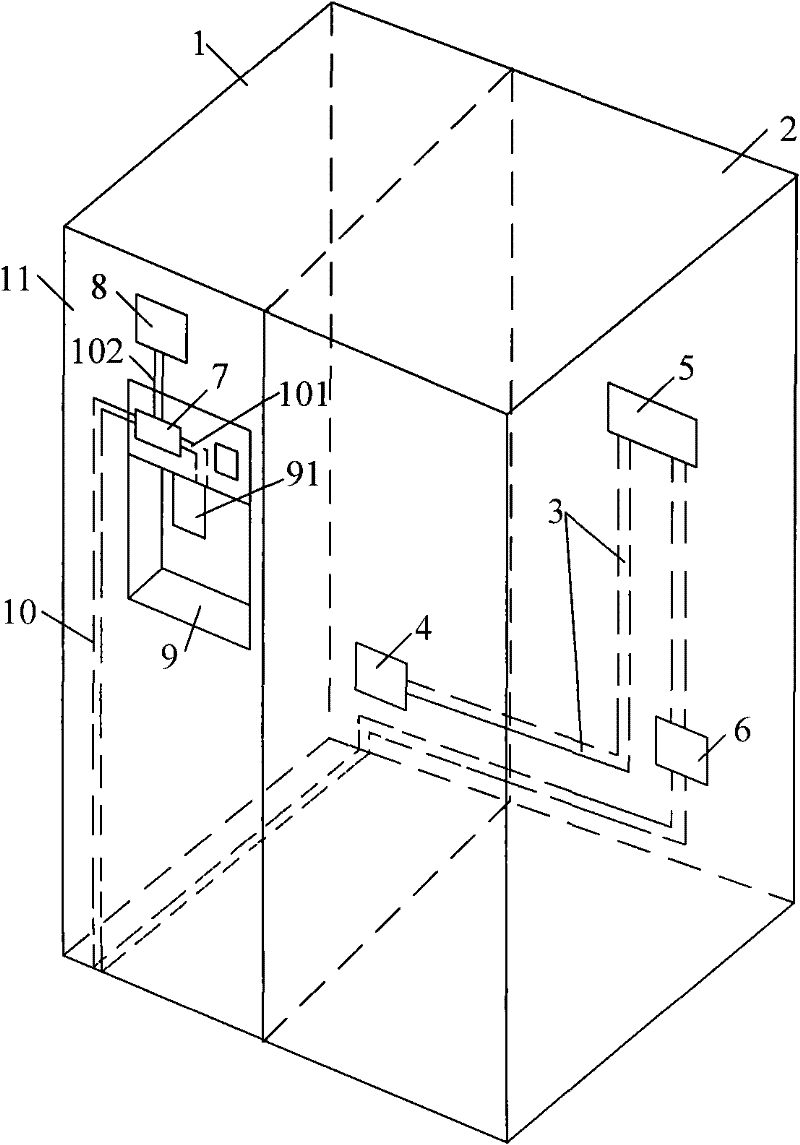

Liquid nitrogen zero-loss biology sample low-temperature storage device

ActiveCN106081363AAchieve zero lossRealized lossLiving organism packagingDomestic cooling apparatusHeat conductingProcess engineering

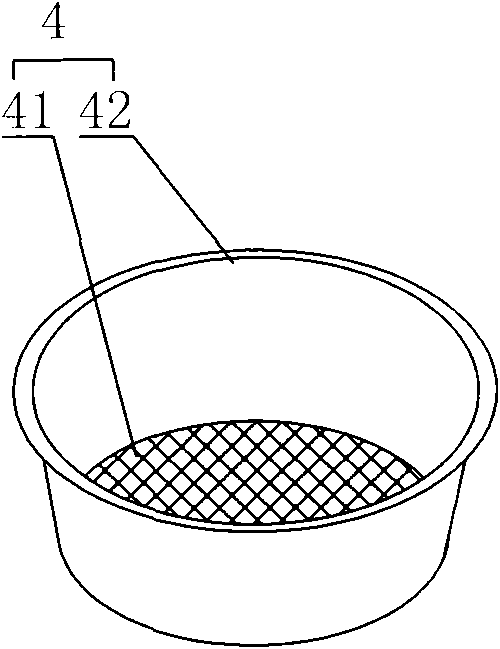

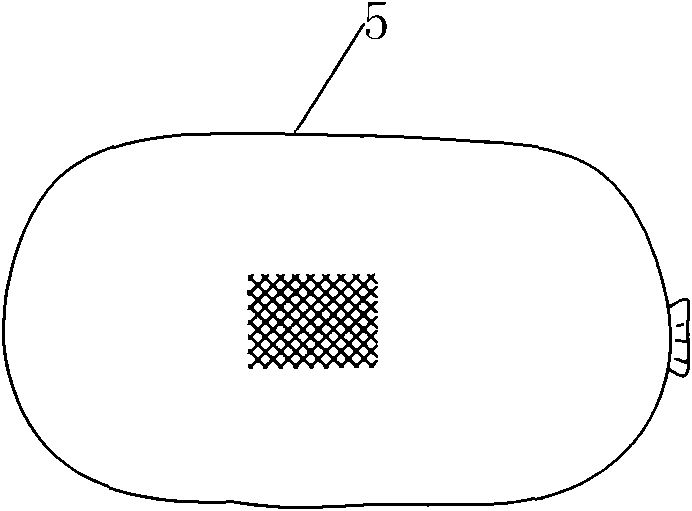

The invention discloses a liquid nitrogen zero-loss biology sample low-temperature storage device which comprises a storage cylinder provided with a top cover (11), a heat-conducting inner container (4) and liquid nitrogen refrigerating equipment. The wall of the storage cylinder comprises an outer cylinder (1), a vacuum layer (2) and a heat-insulating layer (3). The heat-insulating layer (3) is arranged in the outer cylinder (1). The vacuum layer (2) is arranged between the outer cylinder (1) and the heat-insulating layer (3). Liquid nitrogen (6) is contained in the storage cylinder. The heat-conducting inner container (4) is soaked in the liquid nitrogen (6). A biology sample (5) is arranged in the heat-conducting inner container (4). The liquid nitrogen refrigerating equipment comprises a condensing heat exchanger (71) and a refrigerator (72). The condensing heat exchanger (71) is arranged between the heat-insulating layer (3) and the heat-conducting inner container (4). A refrigerating head (73) of the refrigerating machine (72) is connected with the condensing heat exchanger (71). The situation that in the running process, a large amount of cool air flows out is avoided, the liquid nitrogen zero loss is achieved, liquid nitrogen does not need to be supplemented, and the device is easy to maintain and suitable for places where no liquid nitrogen is supplied.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Heat conductive phase-change material and production method thereof

The invention relates to a heat conductive phase-change material which consists of the following components in percentage by weight: 75-90% of heat conductive filler, 2-8% of low-melting-point solid resin, 5-15% of liquid resin, 0.01-1% of an antioxidant and 0.02-2% of a coupling agent, and the phase-change material is prepared through a production method of mixing raw materials, mixing the heat conductive filler, pressing and forming, and cooling. The heat conductive phase-change material, which is prepared by mixing the heat conductive filler, the low-melting-point solid resin, the liquid resin, the antioxidant and the coupling agent, disclosed by the invention has the advantages that the phase-change material is in a shape of flaky solid at room temperature, so that the material is convenient in using and operation and can be directly attached on the surface of a heat-radiating component; when the component runs to the working temperature of the heat conductive phase-change material, phase change occurs and the material becomes soft, so as to wet the surface of the component to a great extent, and contact thermal resistance is reduced to the lowest so as to guarantee a heat conductive interstitial property better than that of heat conductive grease or a graphite flake; in addition, with excellent thixotropy, the material, when being used in a vertical direction, is protected away from circumstance of overflow or flowing.

Owner:PINGHU ALLIED IND

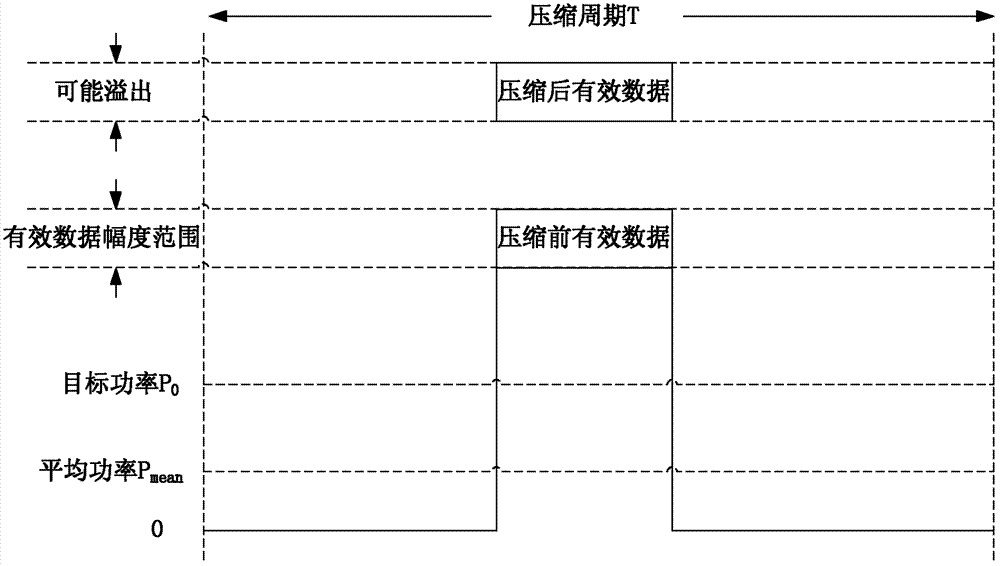

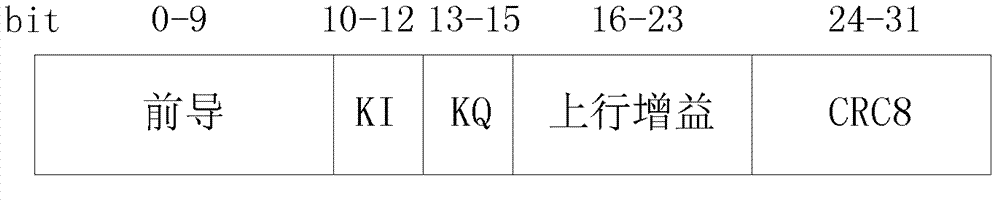

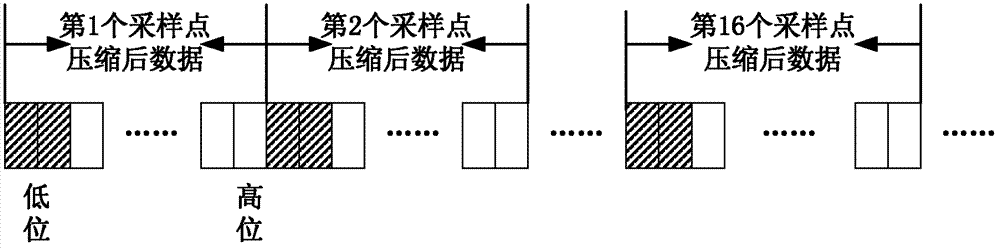

Data compression, transmission, receiving and uncompressing method and corresponding device

ActiveCN102790999AAchieve compressionNo overflowError preventionNetwork traffic/resource managementData compressionCompression method

The invention discloses a data compression, transmission, receiving and uncompressing method and a corresponding device, can achieve IQ data compression with low complexity and small error, and can achieve transmission of IQ data compressibility factors with fewer resources. The data compression method comprises reading data to be compressed, finding I data and Q data with maximum absolute values from a group of data to be compressed, determining an effective bit number M of the I data with the maximum absolute value and an effective bit number N of the Q data with the maximum absolute value, generating a first digital automatic gain control (DAGC) factor for compressing the I data according to the effective bit number M and a compressed target bit wide number X, generating a second DAGC factor for compressing the Q data according to the effective bit number N and the compressed target bit wide number X, using the first DAGC factor to compress each I datum in the group of data to be compressed, and using the DAGC factor to compress each Q datum in the group of data to be compressed.

Owner:ZTE CORP

Synthetic method for preparing colorless transparent alkyl polyglucoside

InactiveCN101696226AQuick responseGood emulsification and dispersionSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsGlycosideGlucose polymers

The invention relates to a synthetic method for preparing colorless transparent alkyl polyglucoside, which comprises the following steps: adding glucosum anhydricum or glucose containing one crystal water and aliphatic alcohol with 8 to 20 carbon atoms into a reaction kettle in the weight ratio of 1:2.8-6.5; adding a composite catalyst containing dodecyl benzene sulfonic acid under the agitation of an emulsifying agitator; after undergoing a reaction for 4 to 8 hours at a temperature of between 80 and 120 DEG C under the vacuum condition of between -0.093 and -0.098 MPa, reducing the temperature to between 70 and 80 DEG C; adding neutralizer alkaline hydroxide, adjusting the pH value between 6 and 8 to obtain a flaxen mixture of alkyl polyglucoside and the aliphatic alcohol; and performing dealcoholization and blanching on the mixture to obtain a product of the colorless transparent alkyl polyglucoside. The method has a simple process and convenient operations. The process of the method not only can use the glucosum anhydricum, but also can use the glucose containing one crystal water, has a low cost and good quality; and the method adopts the composite catalyst, has a mild temperature, smooth water yielding and no phenomenon of foam overflow.

Owner:石家庄金莫尔化学品有限公司

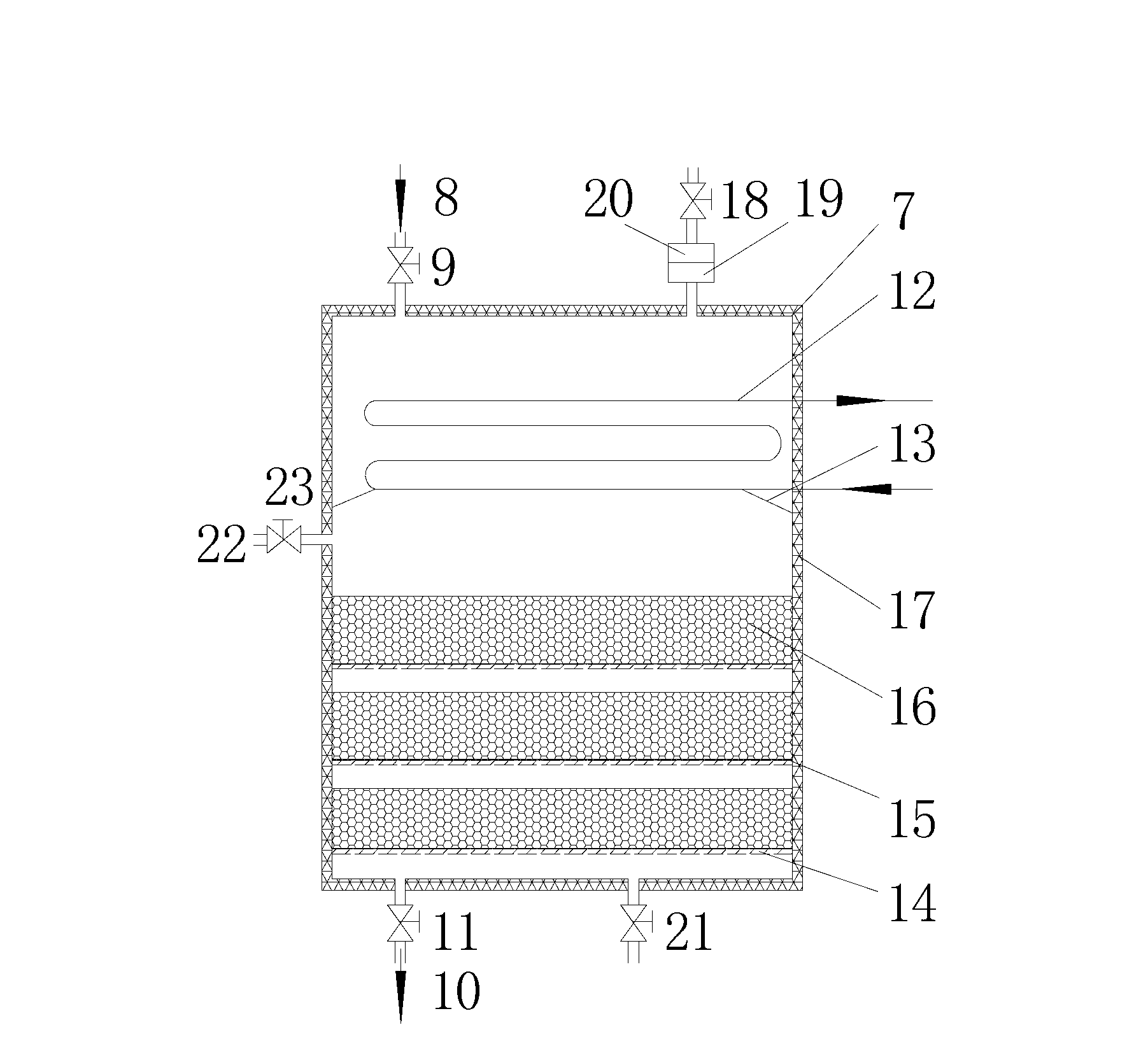

Phase-change heat transfer type intermediate temperature heat reservoir as well as manufacturing and application thereof

InactiveCN103017368AImprove heat transfer effectImprove heat transfer coefficientSolar heat devicesHeat storage plantsHeat conductingWater vapor

The invention discloses a phase-change heat transfer type intermediate temperature heat reservoir and an intermediate temperature solar air-conditioning system formed by the phase-change heat transfer type intermediate temperature heat reservoir. The phase-change heat transfer type intermediate temperature heat reservoir is a closed pressure container and comprises a box body, a plurality of ring frames, screens, heat accumulation layers and heat exchanging tubes, wherein the plurality of ring frames are respectively and horizontally fixed on the inner wall at the lower part of the box body, a plurality of screens are respectively arranged on each ring frame, the heat accumulation layers are respectively paved on each sieve screen, each heat accumulation layer is formed by mixing a composite phase-change heat accumulation material and grains of sand, the heat exchanging tubes are arranged in an inner cavity in the upper part of the box body, a tube cavity of each heat exchanging tube is isolated from the inside of the box body and is communicated with the outside of the box body, wherein a heat conducting device flows in the tube cavity, the intermediate temperature heat accumulation device takes water and water vapor as phase-change heat transfer working mediums, and the phase-change heat transfer mediums are directly evaporated or condensed on the surface of the granular composite phase-change heat accumulation material to realize phase-change heat exchange. The phase-change heat transfer type intermediate temperature heat reservoir and the intermediate temperature solar air-conditioning system have the advantages of excellent heat exchange capability, high solar utilization ratio, simple structure, easy manufacture and long service life.

Owner:SHANGHAI JIAO TONG UNIV +1

Photovoltaic backplane adhesive and preparation method thereof

ActiveCN102887988AImprove hydrolysis resistanceImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterHexafluoropropylene

The invention discloses a photovoltaic backplane adhesive which comprises a component A and a component B, wherein the component A contains hydrolysis resistant polyester polyol, and component B comprises an isocyanate curing agent; and the molar ratio of the isocyanate group in the isocyanate curing agent and the hydroxyl in the hydrolysis resistant polyester polyol is (0.9-1.3):1. The photovoltaic backplane adhesive adopts the hydrolysis resistant polyester polyol and the isocyanate curing agent, and the molar ratio of the isocyanate group and the hydroxyl in the hydrolysis resistant polyester polyol is (0.9-1.3):1, so that the hydrolysis resistance, the adhesive property and the weather fastness of the prepared photovoltaic backplane adhesive are improved. The photovoltaic backplane adhesive can be used for interlamination compounding of a film, and is especially suitable for the interlamination compounding of a photovoltaic backplane, thus being suitable for splicing and compounding the photovoltaic backplanes made of polyethylene terephthalate (PET), polyvinylidene fluoride (PDVF), tetrafluoroethylene-hexafluoropropylene-vinylidene fluoride (THV), polyvinyl fluoride (PVF), polyethylene (PE) and other films.

Owner:CSI SOLAR POWER GROUP CO LTD +1

Refrigerator with water dispenser

InactiveCN102455109AShorten the lengthReduce usageDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses a refrigerator with a water dispenser, comprising one water dispenser and one ice maker which are respectively arranged on a refrigerator door, a connecting pipe communicated with external water for leading-in the external water, and a water distribution valve arranged in the refrigerator door, wherein the water distribution valve is provided with a water inlet, a first water outlet and a second water outlet, the water inlet is communicated with the connecting pipe, the first water outlet is communicated with the water dispenser, and the second water outlet is communicated with the ice maker. By adopting the invention, the installation is convenient, the using length of a water pipe can be shortened, the using cost of the water pipe is saved, and water in the water pipe connected to the water dispenser is ensured to flow smoothly.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

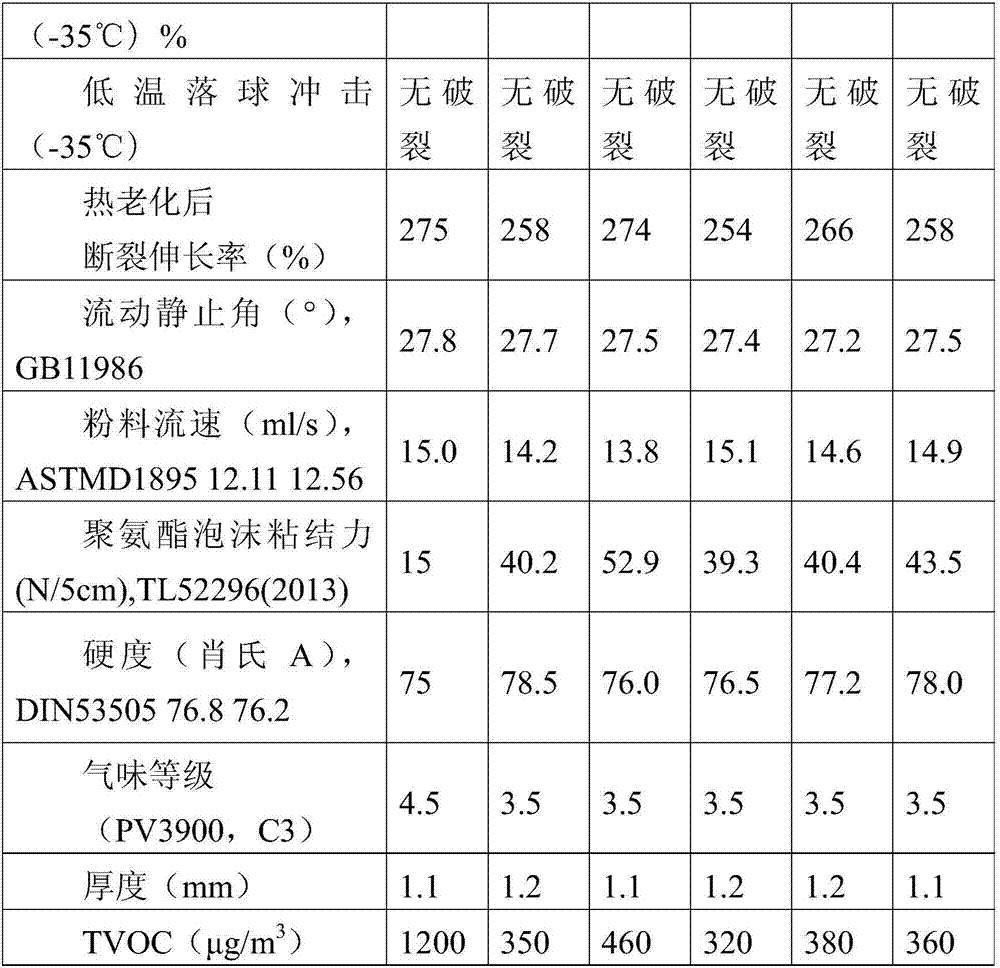

Low-odor PVC powder for automotive upholstery and preparing method thereof

The invention relates to low-odor PVC powder. The low-odor PVC powder comprises 100 parts of PVC resin, 35-50 parts of plasticizer, 5-10 parts of heat stabilizer, 0.2-1.0 part of light stabilizer, 0.3-1.0 part of antioxidant, 3-5 parts of dispersant and 1-5 parts of deodorant. The deodorant is formed by at least one of nano calcium carbonate, nano zinc oxide, fumed silica, precipitated silica and hot-melt rubber powder. The low-odor PVC powder further comprises a coupling agent formed by at least one of an aluminate coupling agent, a borate coupling agent, an aluminum-titanium coupling, a titanate coupling and dispersible rubber powder, and the mass ratio of the coupling agent to the deodorant is (1-5):100. The invention further provides a preparing method of the low-odor PVC powder. The surface of the deodorant is modified by the coupling agent, and the compatibility between the deodorant and the PVC matrix is improved.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

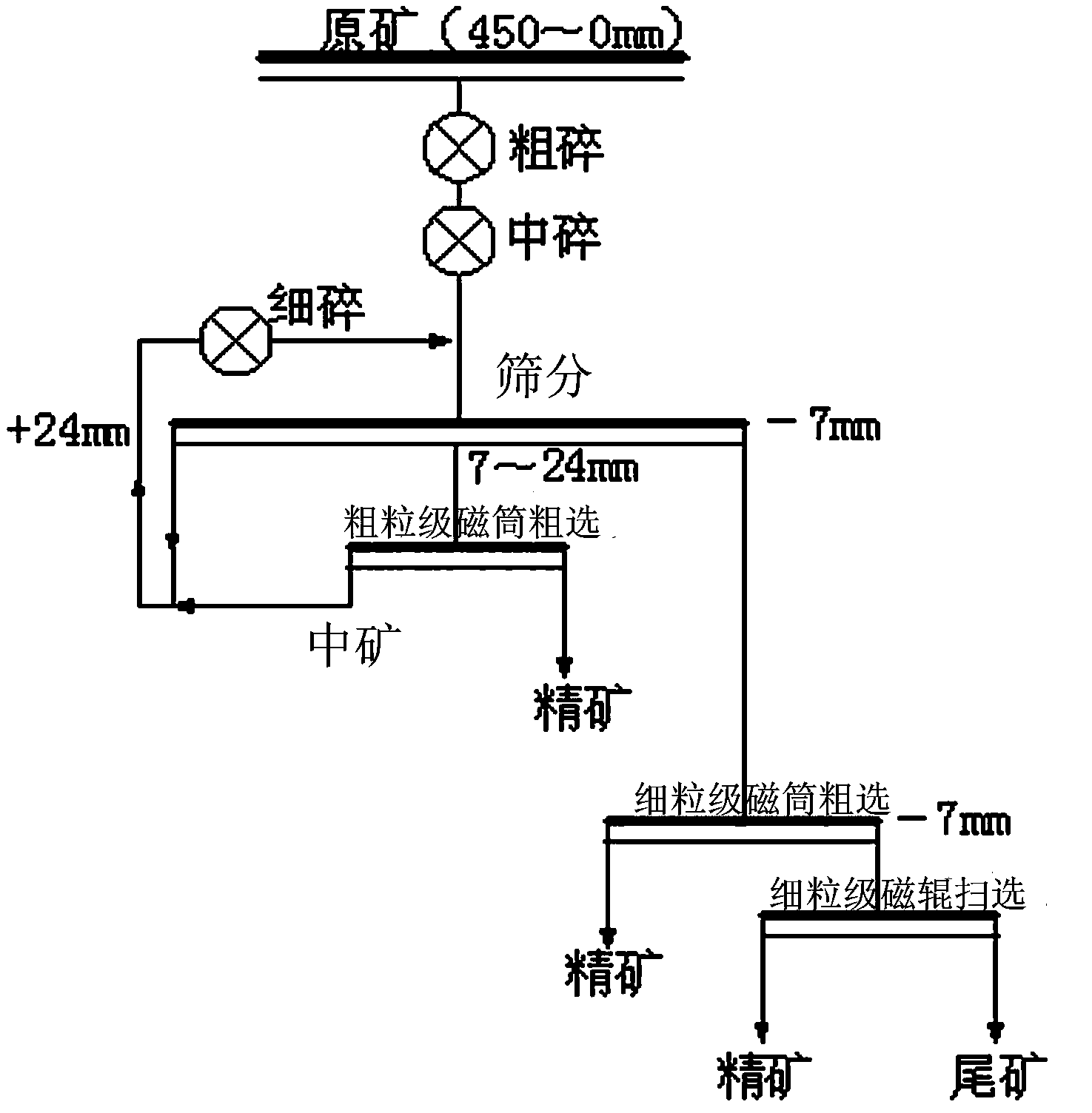

Dry separation method of manganese carbonate ore

ActiveCN103639027AHigh recovery rateIdeal beneficiation technical indicatorsSievingScreeningBrickEconomic benefits

The invention discloses a dry separation method of manganese carbonate ore. The dry separation method comprises the following steps: feeding raw manganese carbonate ore into a crushing system for crushing; screening the crushed ore through a double-layer dry-type screening system; according to the screen hole size of the screening system, performing coarse-fraction magnetic separation on the screened ore through a coarse-fraction dry-type magnetic separation system to obtain coarse-fraction concentrate and middling, and performing fine-fraction magnetic separation on the screened ore through a fine-fraction dry-type magnetic separation system to obtain fine-fraction concentrate and tailings, wherein the obtained middling is returned to the crushing system. The dry separation method has the beneficial effects that (1) the process flow is simplified, the ore separation efficiency is improved, and the recovery rate of manganese ore is improved; (2) on the basis of cost reduction, the grading index of concentrate grade is not reduced; (3) energy is saved, consumption is reduced, clean production is realized, and economic benefits are improved; (4) overflowing is avoided, the storage capacity pressure of a tailings pond can be released fundamentally, and meanwhile, final manganese carbonate tailings (waste sands) can be applied to paving or brick-making after being treated.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

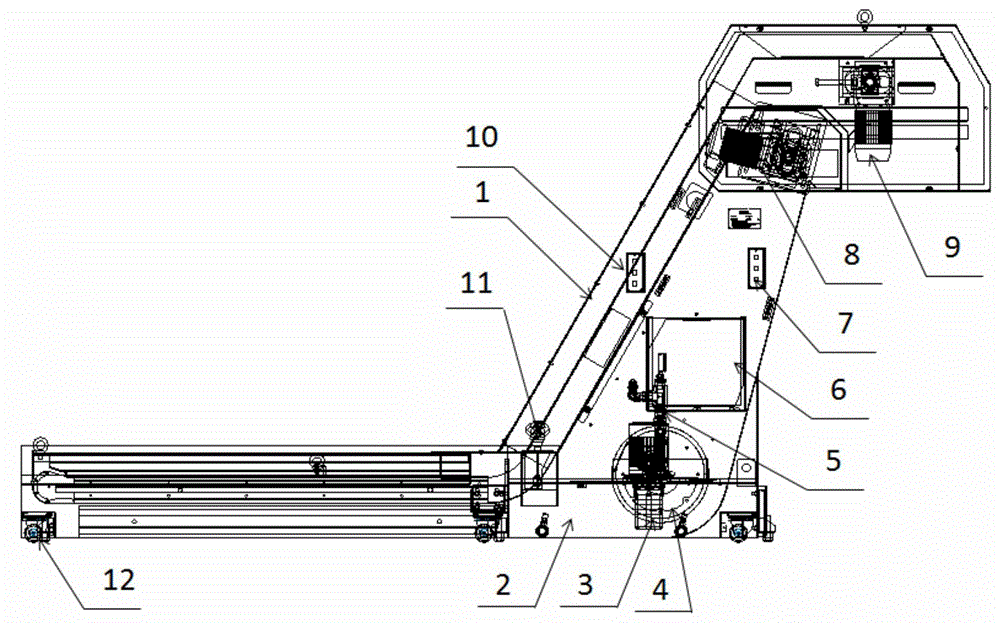

Chip removal and cutting fluid purification device for machine tool

InactiveCN103551909AReduce wasteReduce manufacturing costMaintainance and safety accessoriesMoving filtering element filtersEngineeringControl switch

The invention relates to a chip removal and cutting fluid purification device, in particular to a chip removal and cutting fluid purification device for a machine tool. The chip removal and cutting fluid purification device for the machine tool is characterized by being formed by movably connecting and assembling an upper layer chain board chip remover and a bottom layer recoil roller scraper chip remover by a middle part, wherein the upper layer chain board chip remover is controlled by an upper layer control switch and is driven by an upper layer chip remover speed reduction motor; the bottom layer recoil roller scraper chip remover is controlled by a bottom layer control switch and is driven by a bottom layer chip remover speed reduction motor. The invention provides the chip removal and cutting fluid purification device for the machine tool, which is suitable for turning and milling composite wet machining, can greatly reduce waste of cutting fluid and reduce production cost, can replace a plurality of machines to work, reduces an occupied space, reduces energy consumption, is clean in removing chips and has no pollution to a factory.

Owner:KOCEL GROUP +1

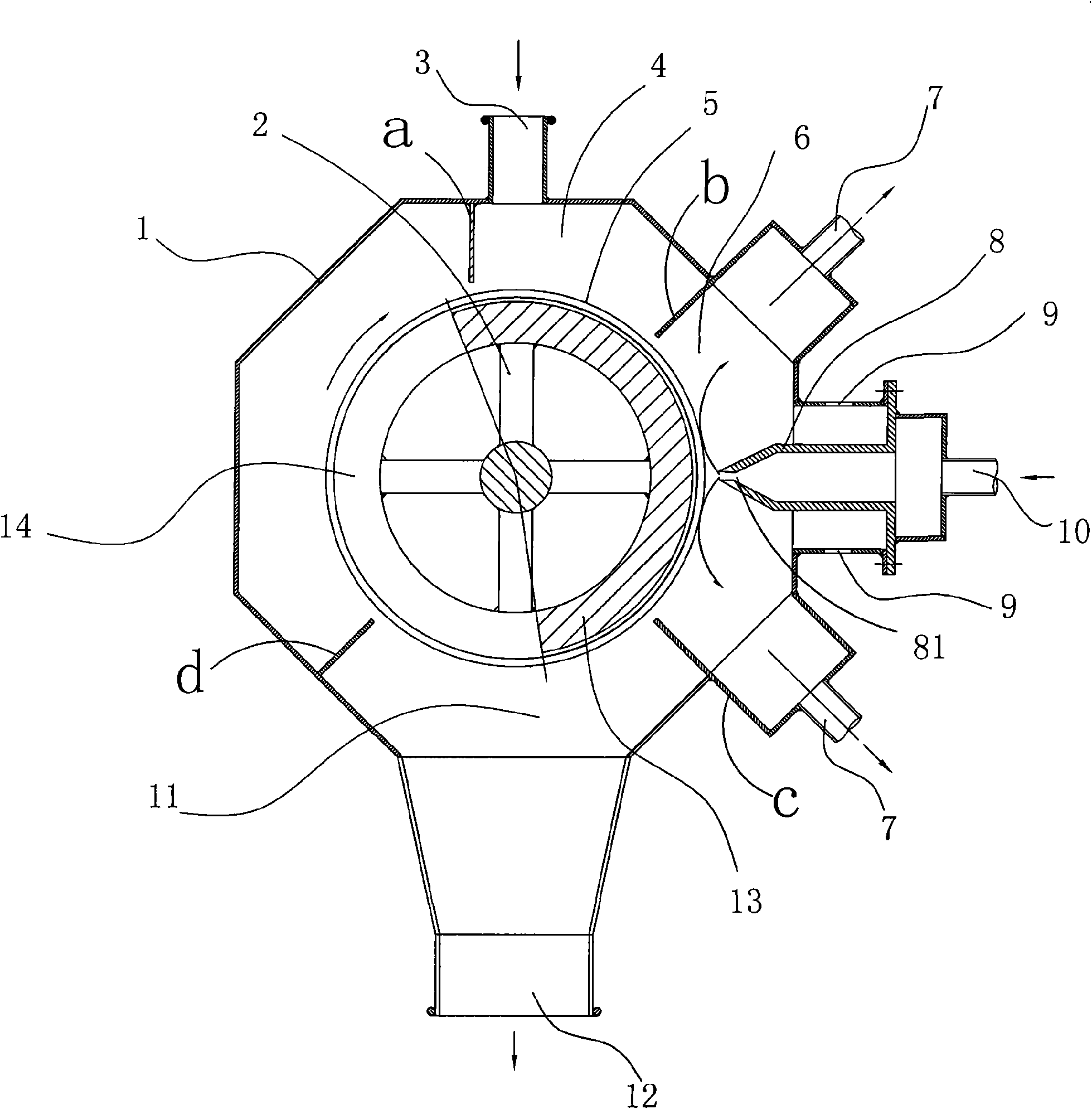

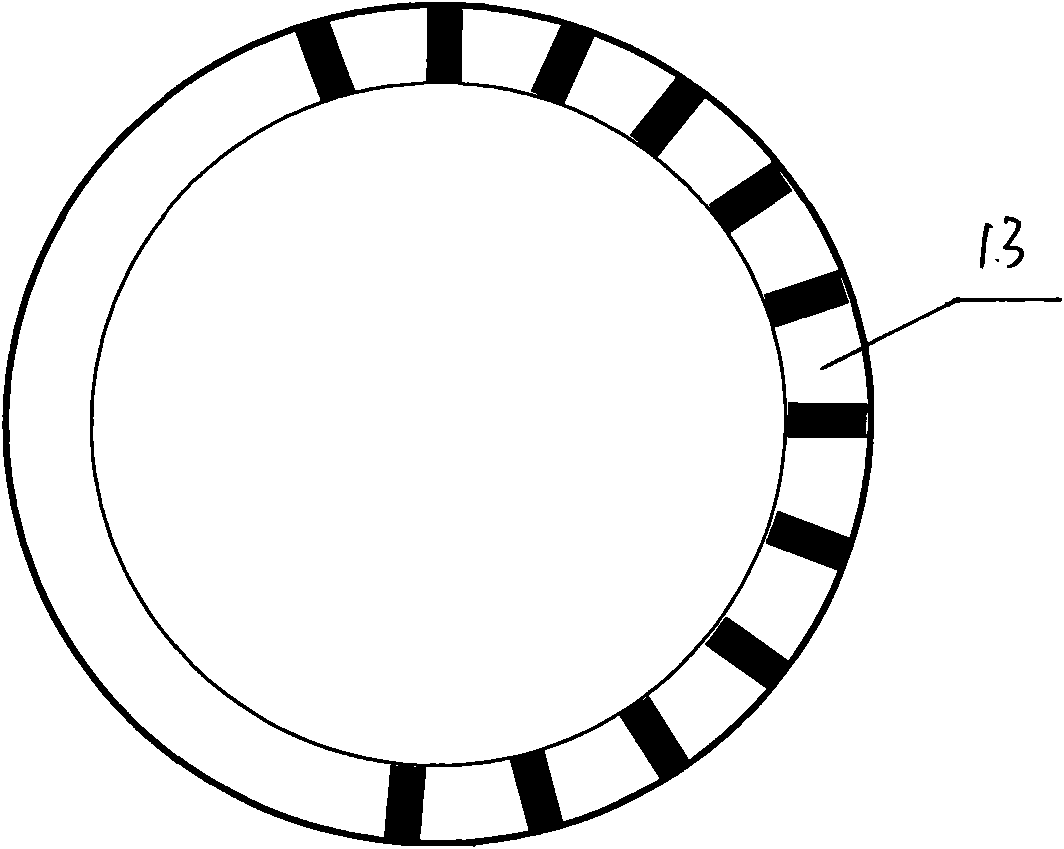

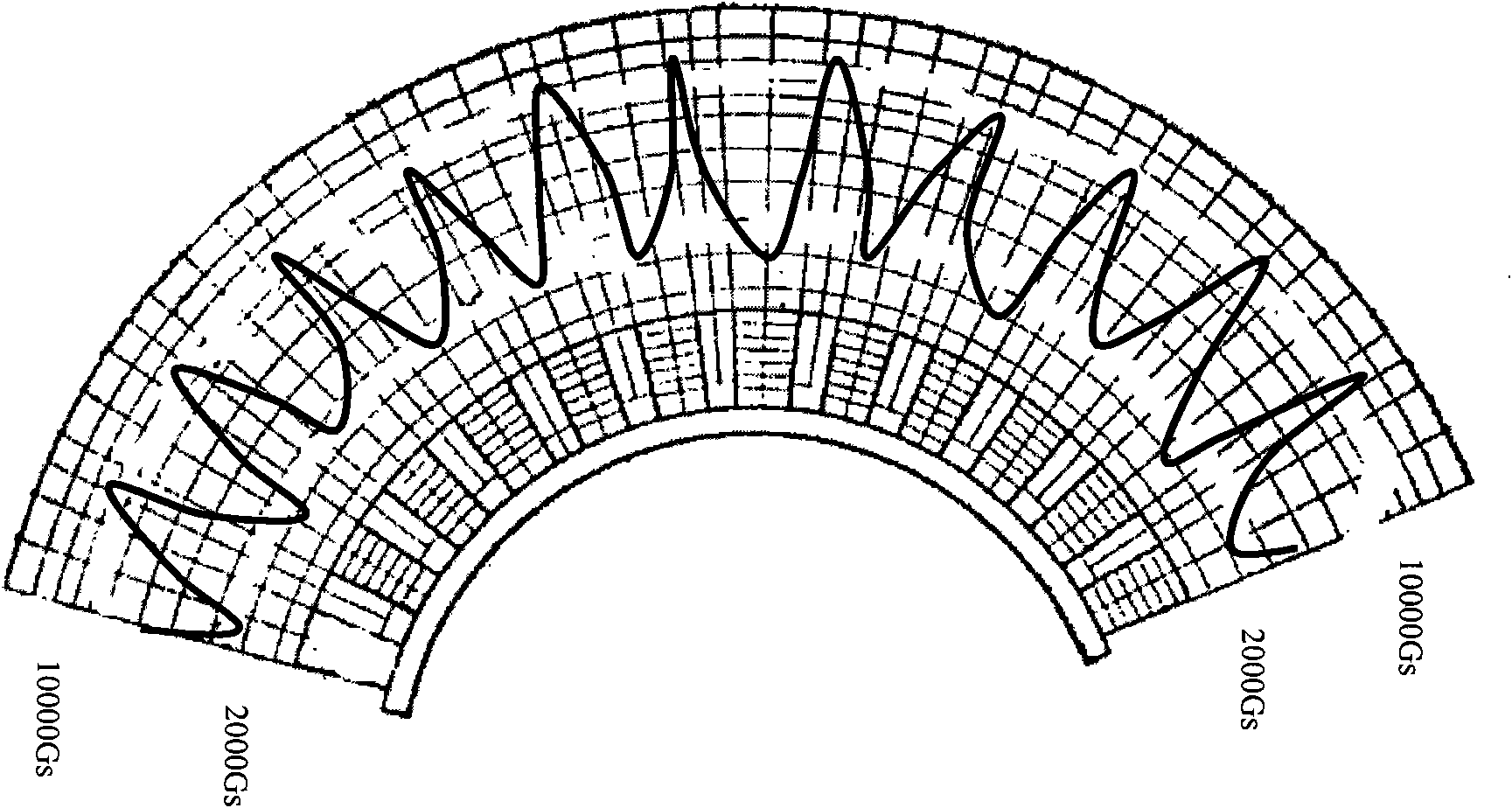

Dry-method air-separation strong permanent magnetic separator

InactiveCN101612609AReduce energy consumptionReduce production and operation costsMagnetic separationEngineeringIon

The invention provides a dry-method air-separation strong permanent magnetic separator, belongs to the technical field of dressing equipment, and is particularly suitable for regenerating an ion-containing fly ash resource produced in a smelting process for making ion and steel. The dry-method air-separation strong permanent magnetic separator comprises a machine body and a magnetic roller arranged in the machine body, wherein the machine body is provided with a feeding hole, a discharge hole and an exhaust and air discharge hole; the magnetic roller comprises a fixedly arranged roller core and a roller sheet which surrounds the roller core and can rotate around the roller core; the internal space formed by the machine body and a semi-circumferential surface, provided with a magnetic area, of the roller core is divided into a material distribution area, a separation area and a blanking area by baffle plates from top down, and the material distribution area, the separation area and the blanking are mutually communicated; the machine body is provided with a nozzle device spraying air flow toward the separation area, the nozzle device is at least provided with a nozzle, and the tail end of the nozzle device is provided with an air inlet; and the roller core is divided into the magnetic area and a nonmagnetic area, and the magnetic area and the material distribution area and the separation area are arranged correspondingly. The separator overcomes the drawback that the prior art is incapable of directly and effectively separating fine weak magnetic ferric oxide mineral powder, and is low in energy consumption, low in productive operation cost, high in sorting purity, simple and reasonable in structure, and convenient in operation. In the separation process, the inside of the machine body is constantly kept in a negative pressure state so as to avoid dust overflow and secondary environmental pollution.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

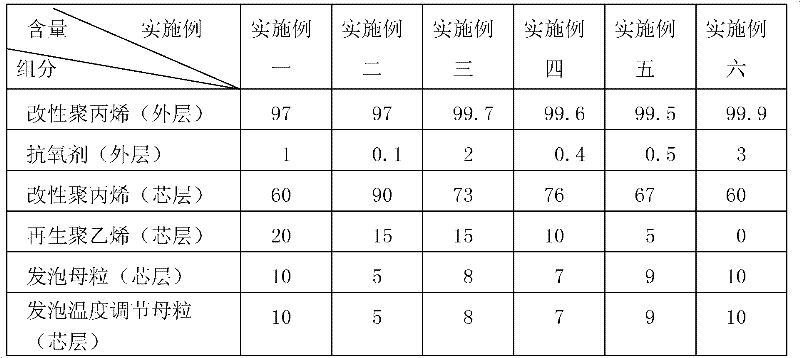

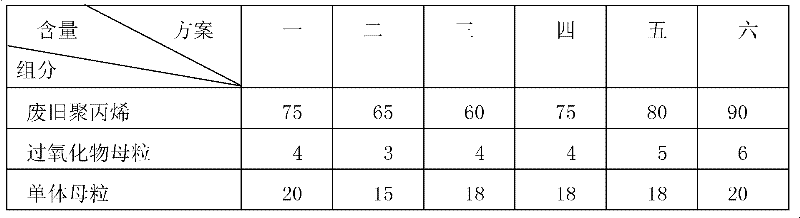

Waste polypropylene-modified foaming plate and manufacturing method thereof

ActiveCN102218879AImprove toughnessHigh strengthSynthetic resin layered productsFlat articlesMasterbatchPolypropylene

A waste polypropylene-modified foaming plate comprises a core foaming layer and an outer layer covering the upper and the lower surfaces of the core foaming layer; the outer layer is prepared by mixing the following components and performing melt extrusion, wherein the components comprises by weight: 97-99.9 parts of modified polypropylene, 0.1-3 parts of anti-oxidants; the core foaming layer is prepared by mixing the following components and performing melt foaming, wherein the components comprises by weight: 60-90 parts of modified polypropylene, 0-20 parts of regenerated polyethylene, 5-10parts of foaming masterbatches, and 5-10 parts of foaming temperature adjusting masterbatches; the manufacturing method of the foaming plate comprises the following steps: preparing activated inorganic powder, preparing a modified auxiliary agent peroxide masterbatch, preparing a modified auxiliary agent monomer masterbatch, preparing the foaming masterbatch, preparing the foaming temperature adjusting masterbatch, and preparing the core foaming plate. The waste polypropylene-modified foaming plate has high melt strength, and the manufacturing method has the characteristics of low production cost and no environment pollution.

Owner:NANTONG SUDONG NEW EXTERNAL WALL INSULATION BOARDCO

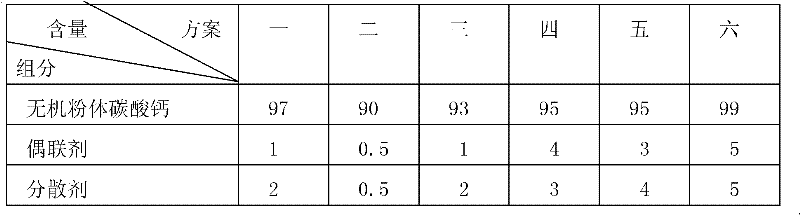

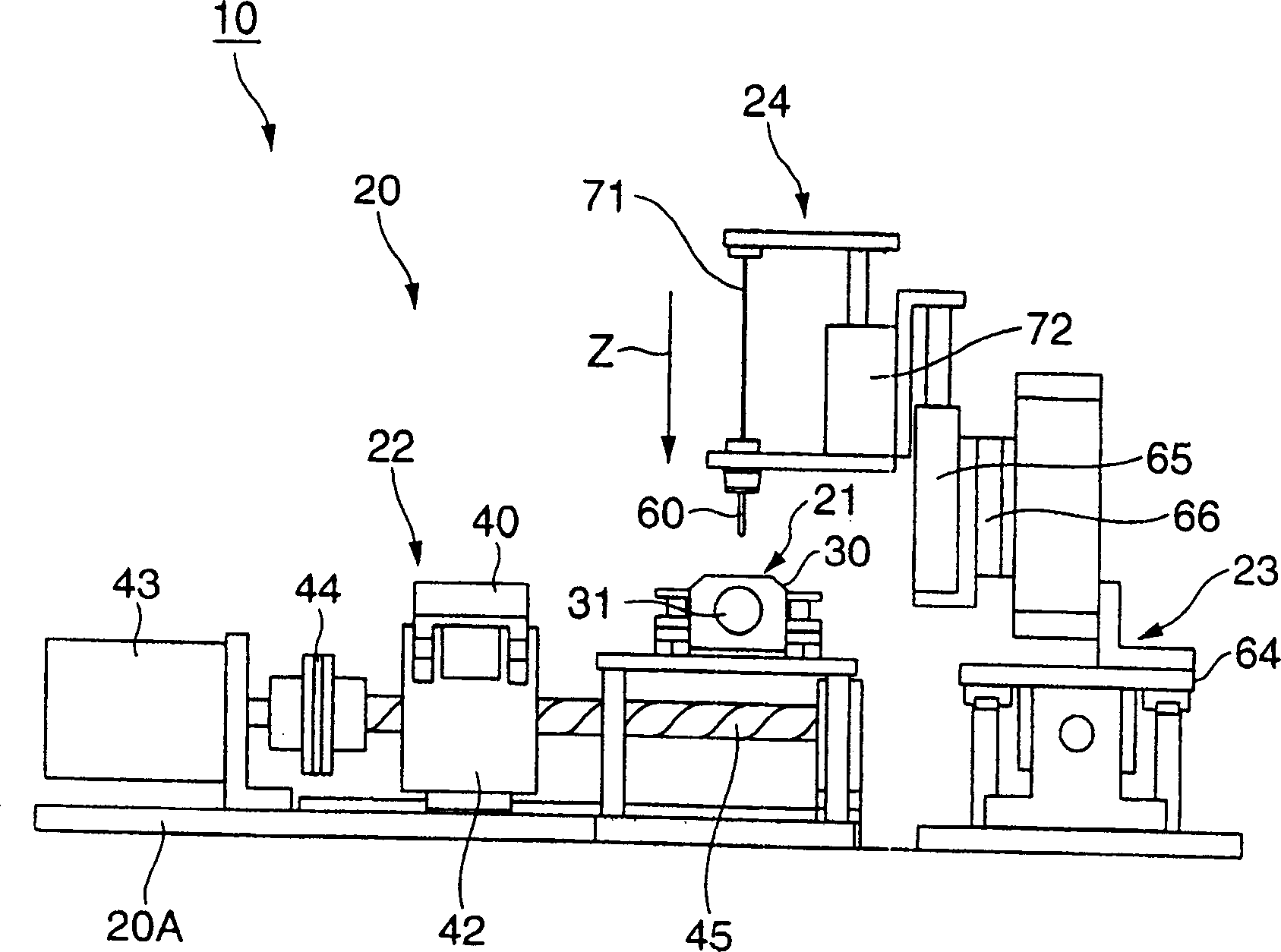

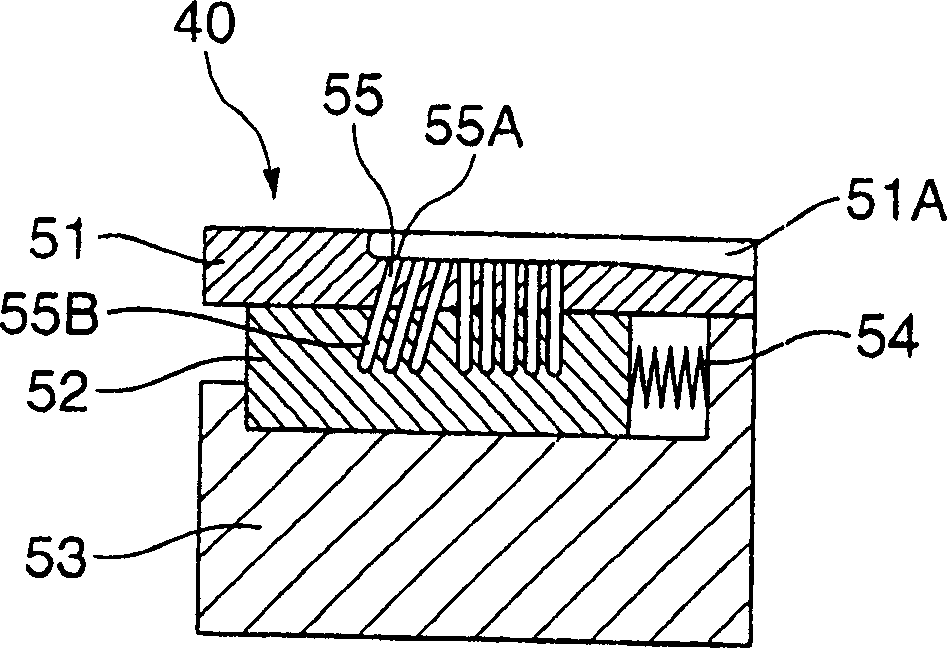

Brush making method and apparatus

InactiveCN1399928APrevent overflowImprove insertion accuracyBrush bodiesBristleBristleBiomedical engineering

A manufacturing method of a brush 6 including of inserting bristles 2 into a bristles insertion hole 55, and thereafter implanting the bristles in a resin base plate. Further, each individual sleeve 60 is prepared in correspondence to cross sectional shapes and cross sectional areas in the bristles insertion hole 55, the bristles 2 are introduced to the sleeves 60, and each of the bristle 2 in the sleeves 60 is inserted to the corresponding bristles insertion holes 55 by an extrusion pin 71.

Owner:KAO CORP

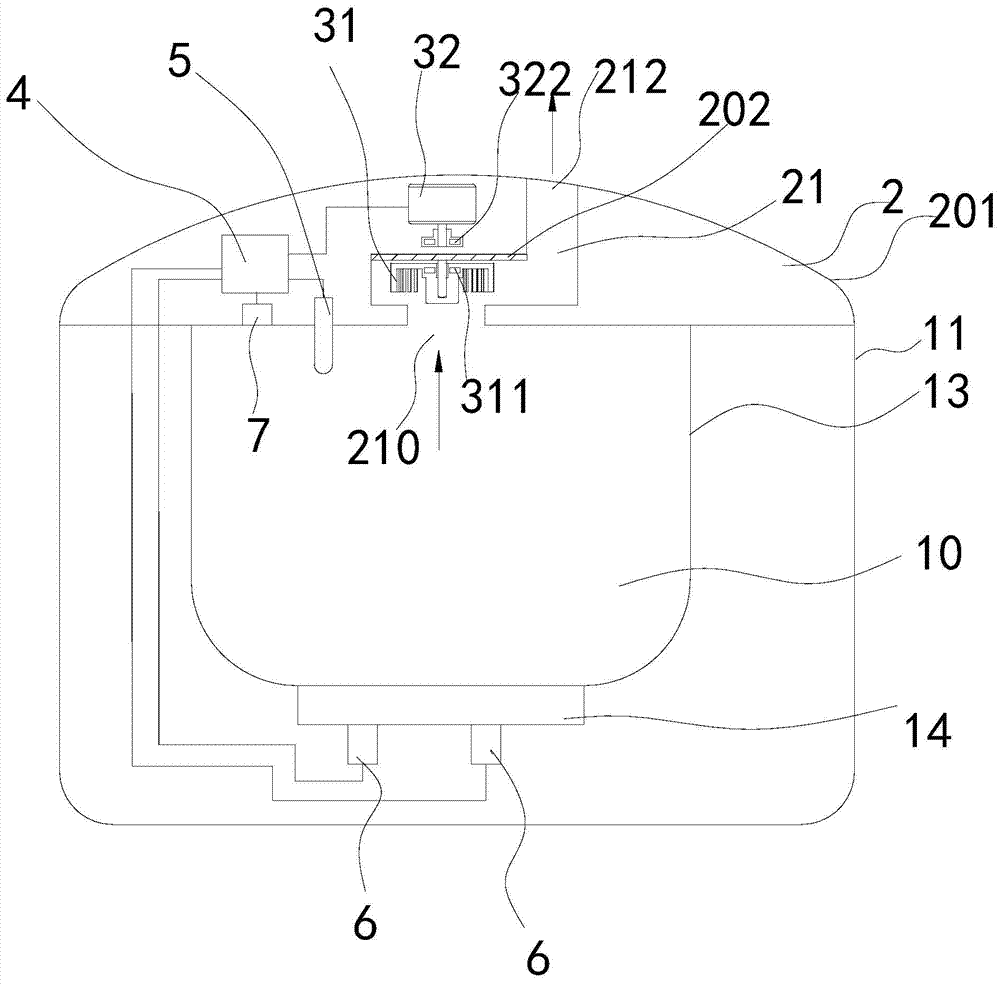

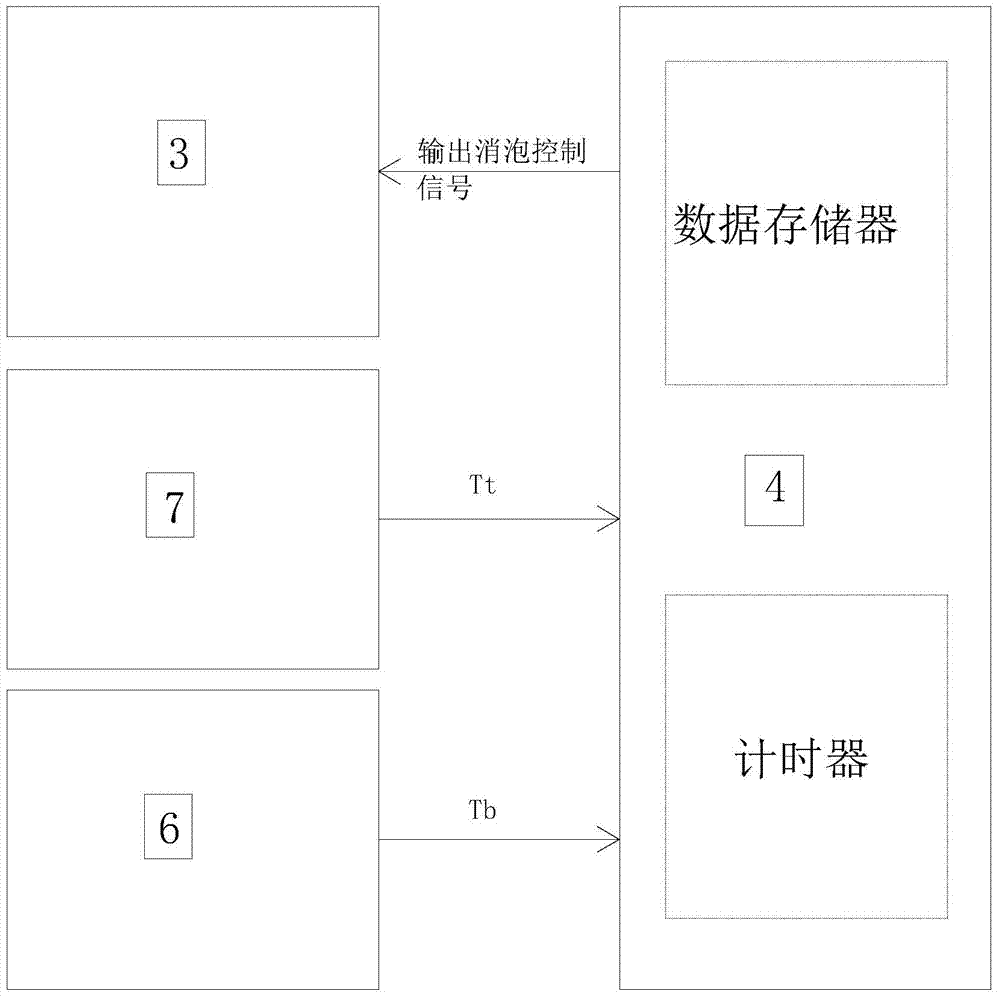

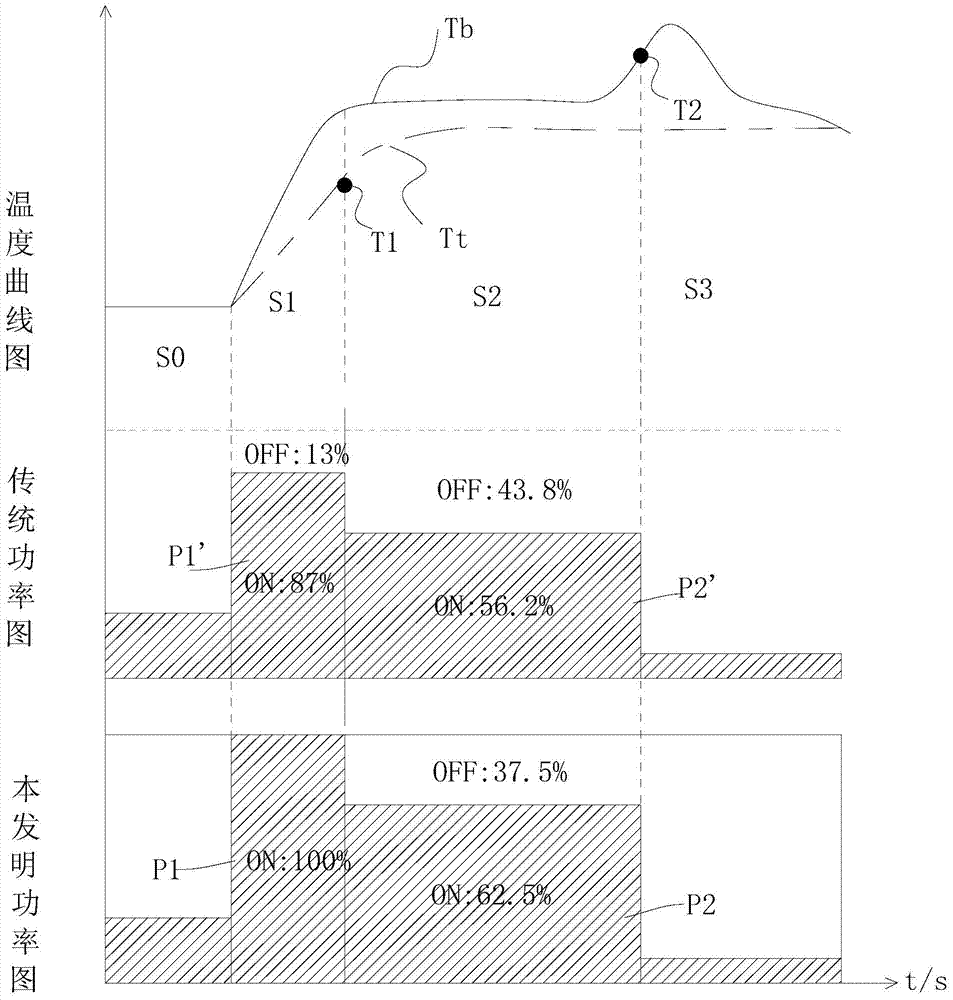

Electric cooker and control method thereof

InactiveCN104510325AWill not affect hygieneDoes not affect cleanlinessSteam cooking vesselsEngineeringCooker

The invention discloses an electric cooker and a control method thereof. The electric cooker comprises a cooker body in which a heater is arranged, a cover which covers the cooker body to limit a cooking cavity with the cooker body, a foam breaking device for breaking foam generated in the cooking cavity, and a controller which is connected with the heater and the foam breaking device to control the foam breaking device to break foam as well as heating the heater to heat in a full-power heating mode at the heating stage of the electric cooker. According to the electric cooker, the foam breaking device is additionally arranged to break the foam generated in the cooking cavity, and synchronously the heater can heat with full power in the heating state, so that the phenomenon that foam overflows can be avoided; the cooking time is decreased, and the cooked rice or porridge tastes great.

Owner:MIDEA GRP CO LTD +1

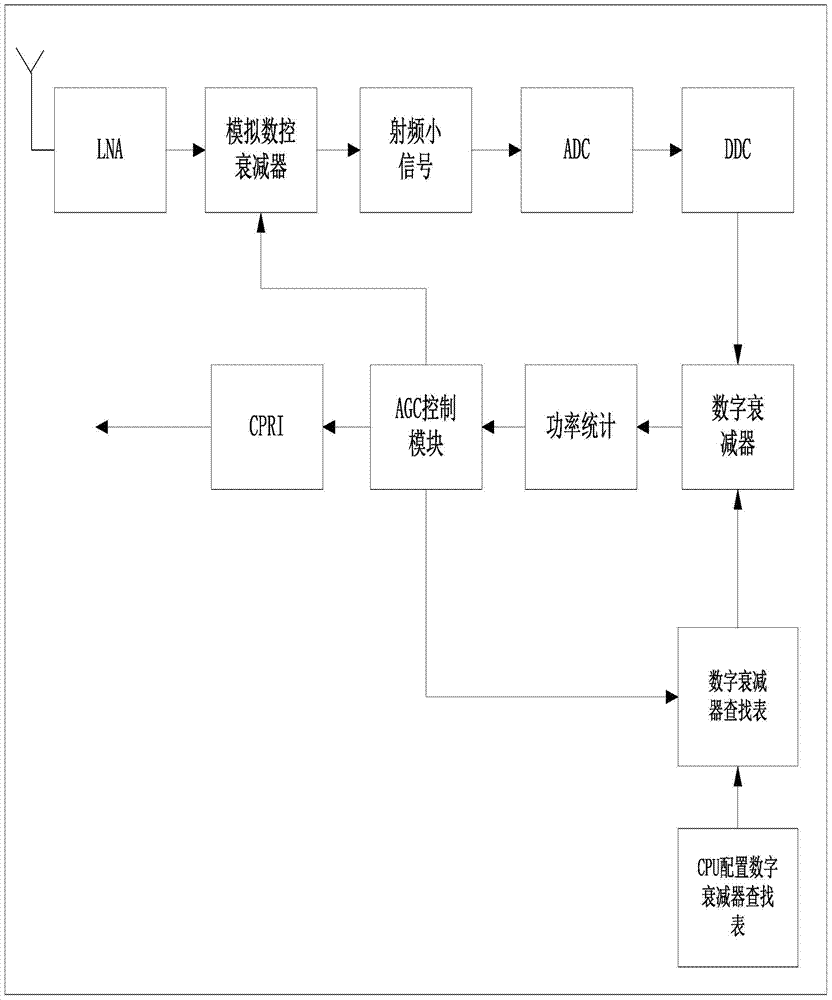

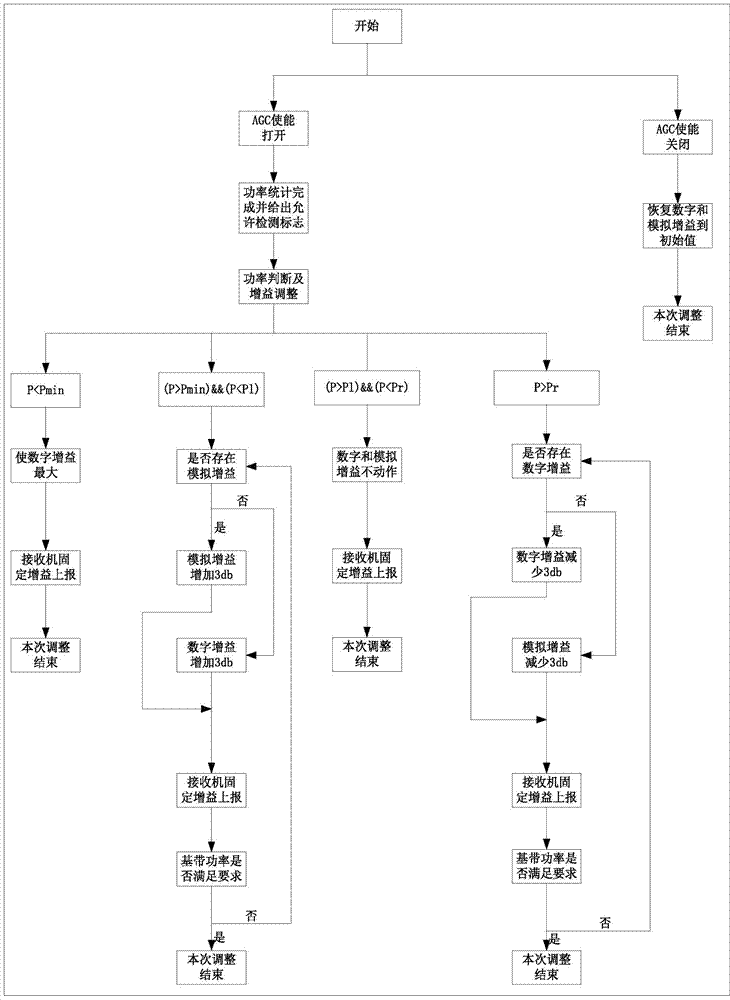

Automatic LTE terminal receiver gain control achieving method

ActiveCN104768216ANo overflowLarge dynamic rangePower managementSoftware engineeringAutomatic gain control

The invention discloses an automatic LTE terminal receiver gain control achieving method. According to the method, an FPGA controls an analog attenuator and a digital attenuator to adjust the input signal power to be within the target range, and a CPU configures and adjusts the stepping value and all power gates; the AGC function is enabled, the FPGA conducts statistics on the baseband data power of one frame and sends the power to an AGC control module, and the AGC control module judges the segment of the power range according to the current statistics power value, so that operation of the analog attenuator or operation of the digital attenuator is conducted at the beginning of one frame, one stepping value is adjusted at a time, and the final target power is reached through multiple adjustment.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Sesquiterpene-containing film-forming resin and positive 248 nm photoresist thereof

ActiveCN103387636AHigh transparencyIncrease photosensitivityPhotomechanical apparatusPolymer scienceSesquiterpene

A sesquiterpene-containing film-forming resin and a positive 248 nm photoresist thereof are characterized in that: the film-forming resin is a copolymer prepared by copolymerization of comonomers in a solvent in the presence of a radical initiator, and the comonomers mainly comprise 5-40 parts by weight of substituted styrene and 10-60 parts by weight of a sesquiterpene-containing constitutional unit; and the positive 248 nm photoresist mainly consists of 10-35 parts by weight of the film-forming resin, 0.5-6 parts by weight of a photoinduced acid, 70-90 parts by weight of a solvent and 0.01-0.5 part by weight of an organic base. The film-forming resin of the invention is a new modified film-forming resin prepared by introducing a polymerisable monomer containing a natural product sesquiterpene to a conventional poly(p-hydroxystyrene)-based film-forming resin. The new film-forming resin is capable of increasing transparency of the photoresist at exposure wavelength of 248 nm, improving photosensitivity of the photoresist, increasing adhesive property between HMDS-treated silicon chips, having no influence on photo-etched pattern and no damage to expensive lens of an exposure machine, improving heat resistance of the photoresist and substantially improving anti-etching performance of the photoresist.

Owner:昆山西迪光电材料有限公司

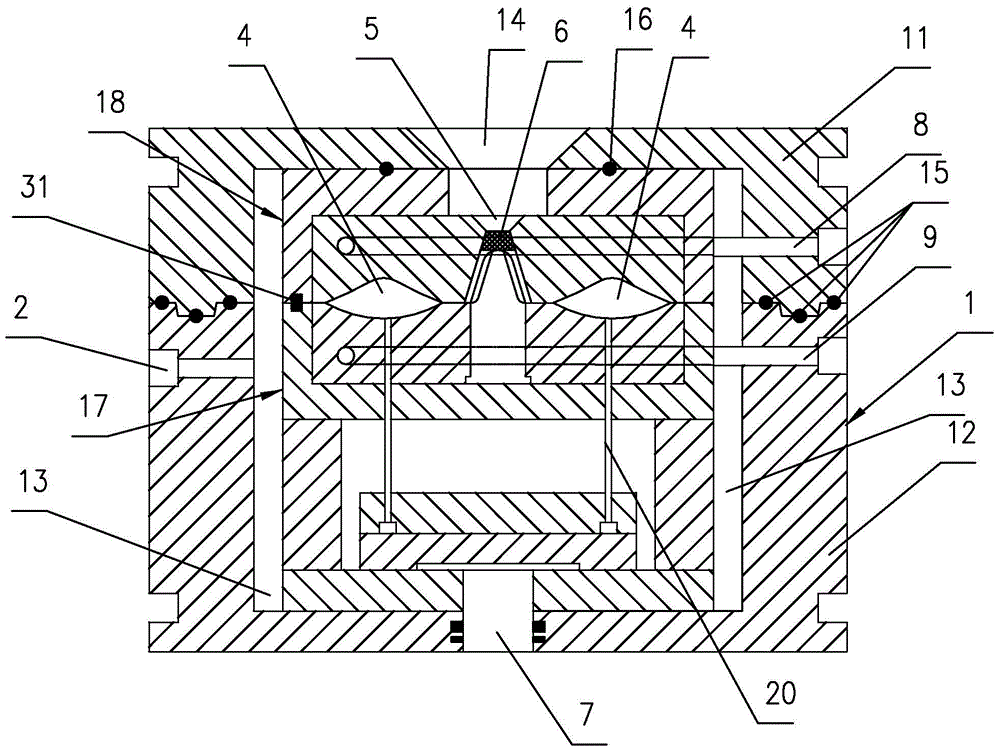

Full sealing thermal type vacuum die-casting die assembly

The invention discloses a full sealing thermal type vacuum die-casting die assembly, which comprises a die consisting of a moving die and a fixed die, a pushing mechanism, a cooling system and a pouring system are arranged on the die, the die is provided with a vacuumizing hole passage communicated with the cavity of the die, a sealing box is additionally arranged outside the die, the sealing box is formed by docking a sealing front cover and a sealing rear cover to cause the die to be positioned in an airtight space of the sealing box, and the sealing box is provided with a bleeder hole communicated with the airtight space, so that the die is positioned in a vacuum environment after vacuumizing is performed through the bleeder hole; ports, positioned in the die, of the outer parts of the pushing mechanism, the cooling system and the pouring system extend to and penetrate through the sealing box. According to the full sealing thermal type vacuum die-casting die assembly, the vacuum degree in the cavity of the die is obviously improved, mobility of molten metal or plastic liquid in the cavity of the die is accelerated, tiny gaps between the casting thimble of a casting machine and the hole wall of a thimble hole in the moving die are in the vacuum state, no airflows impact the molten metal or plastic liquid in the cavity of the die, no oxidation occurs and product quality is improved.

Owner:GUANGZHOU CITY CONSTR COLLEGE +1

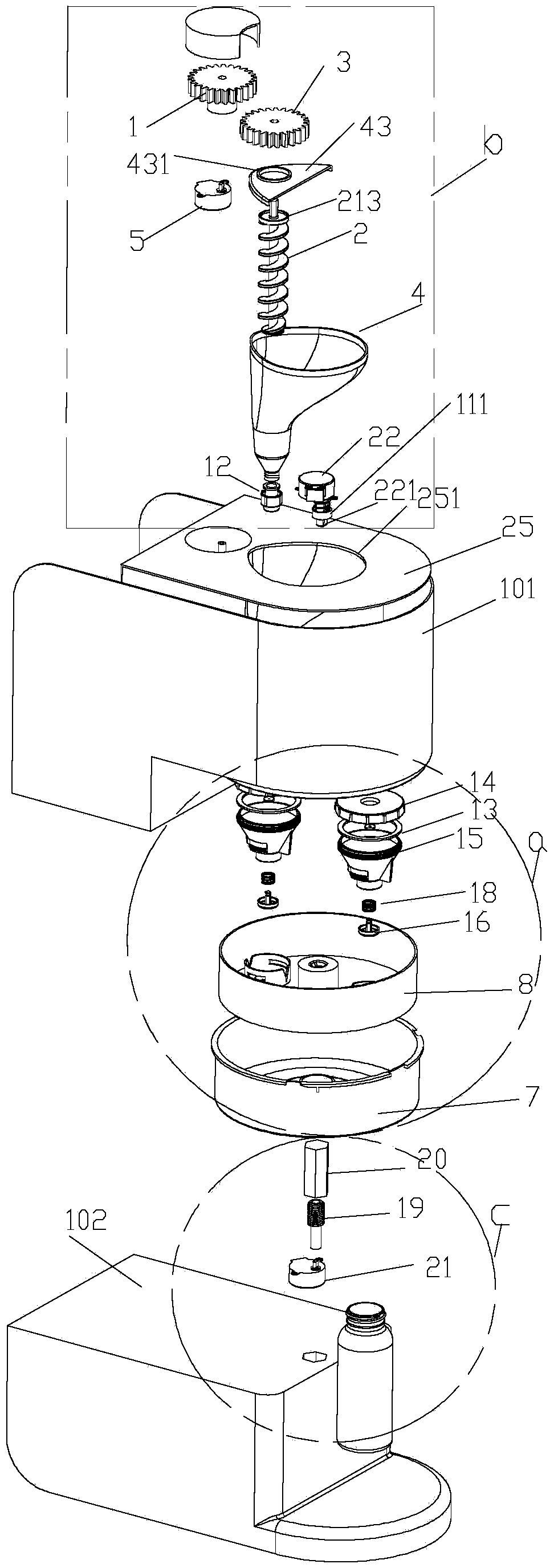

Milk making machine

PendingCN105361703ACause health problemsProblems in preventing moisture deteriorationBeverage vesselsInjection portTorque transmission

The invention discloses a milk making machine, which comprises a machine shell, a water supply unit, a milk supply unit and mixing containers, and further comprises a container fixing base and a rotation driving mechanism, wherein the water supply unit is arranged on the machine shell and is used for controlling water temperature and a water supply amount; the milk supply unit is used for controlling a milk amount; and the mixing containers are used for mixing milk powder with warm boiled water, so that milk liquid is formed, and is exported to a milk bottle; the mixing containers are centrifugally installed on the container fixing base; the rotation driving mechanism is arranged on the machine shell and is connected to the container fixing base by virtue of a torque transmission structure; the rotation driving mechanism is used for driving the container fixing seat to rotate for rotating the mixing container to various stations; an injection port for injecting water and milk powder is arranged in the top surface of the mixing container, and a milk liquid outlet, which is controlled by a valve, is additionally arranged at the bottom of the mixing container; the milk outlet of the milk supply unit and the water outlet of the water supply unit are respectively aligned with the injection ports of the mixing containers on different stations; and a milk outlet station of the milk making machine is located below the water outlet. The milk making machine disclosed by the invention can be used for effectively protecting the milk powder from being affected with damp.

Owner:GUANGDONG SHUNDE CHINNO IND DESIGN

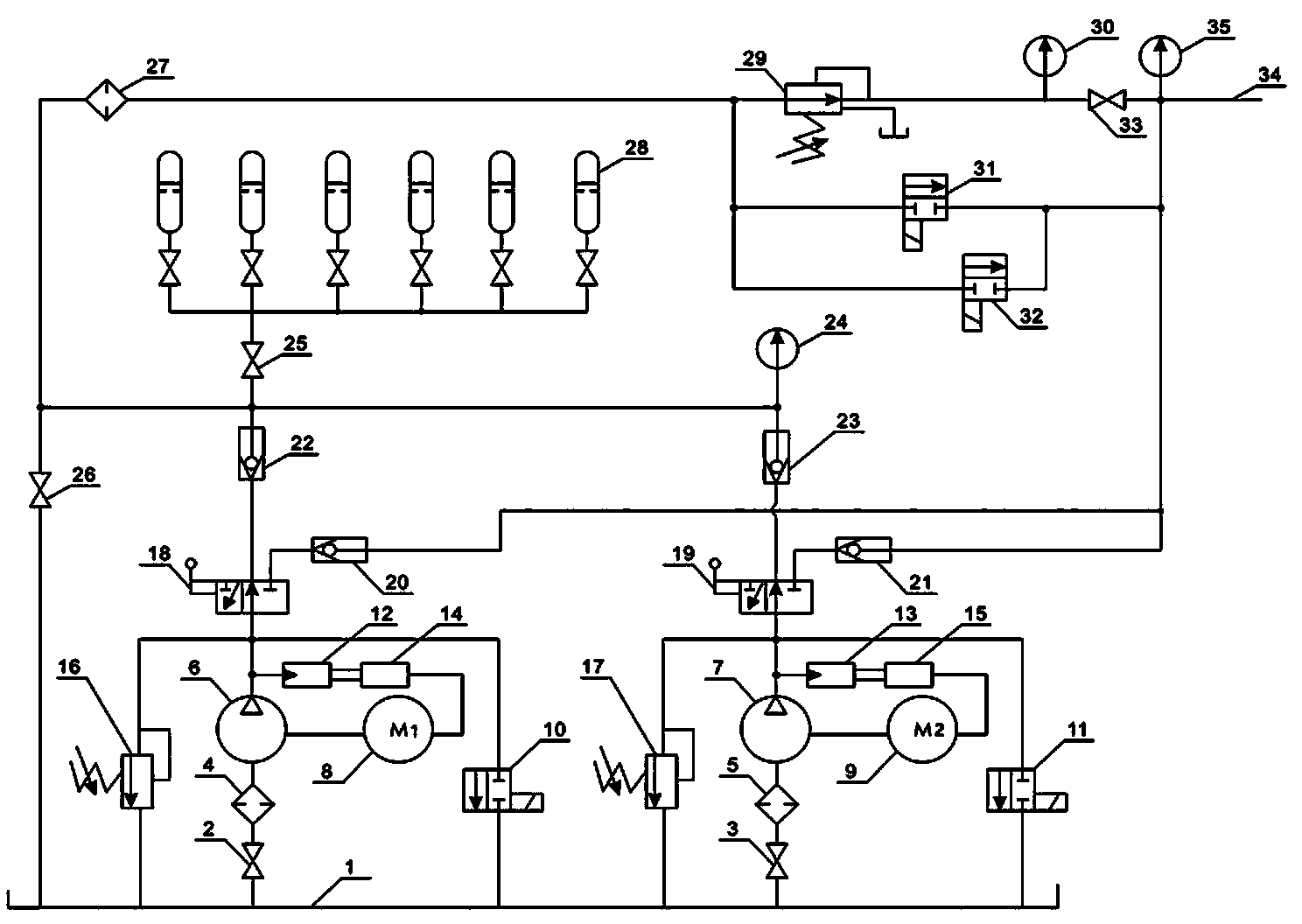

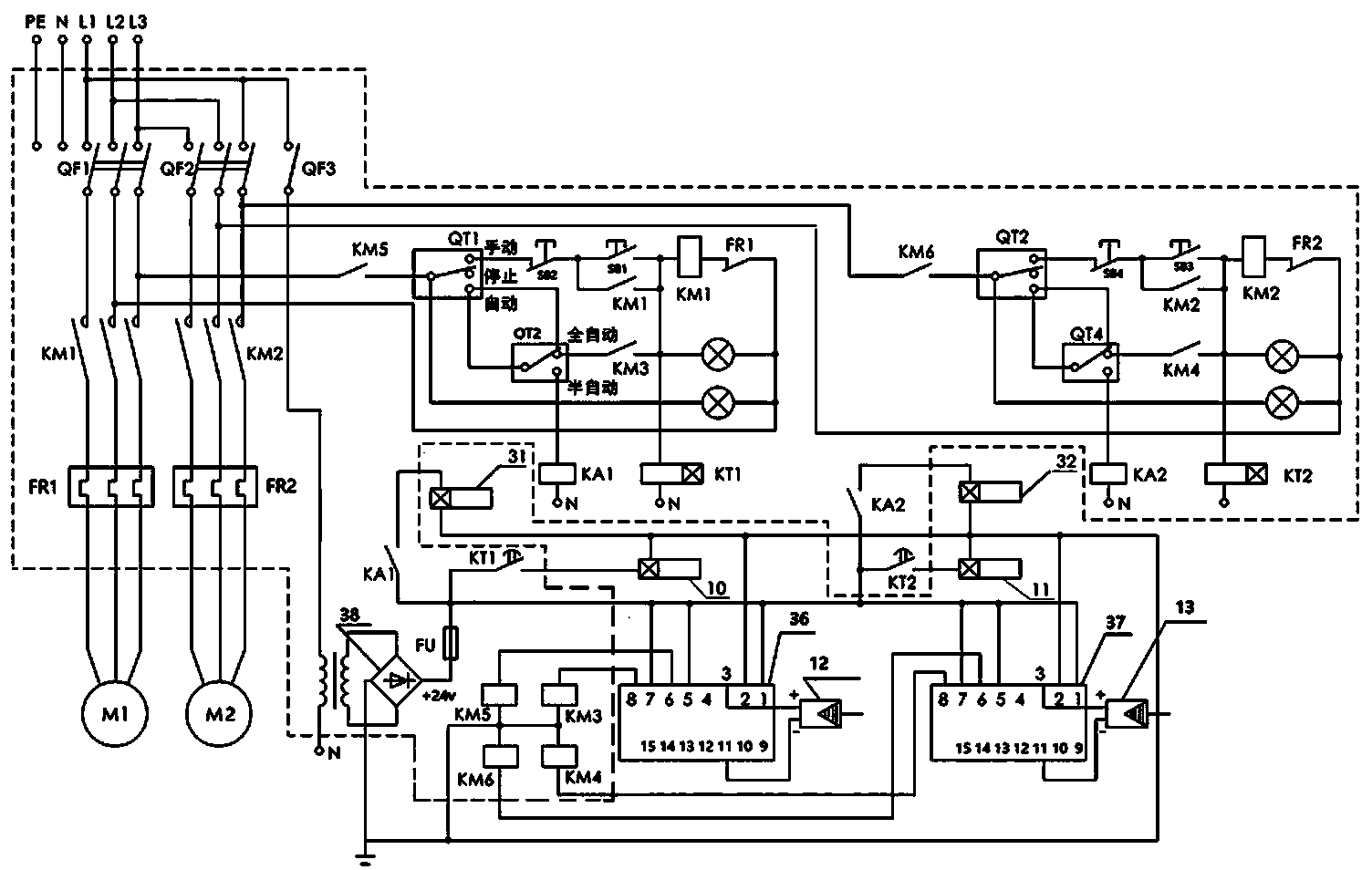

Multifunctional hydraulic power station

ActiveCN104389827ALower skill requirementsRelieve stressServomotorsEnergy industryAutomatic controlPower station

The invention relates to a multifunctional hydraulic power station, which mainly consists of two pump groups, an electric cabinet, a hand-operated direction valve, a check valve, an overflow valve, an energy accumulator, a manual pressure-reduction pressure-regulation overflow valve, a normally-closed solenoid valve, a normally-opened solenoid valve, a stop valve, a high-pressure oil output end and an automatic control device. On the basis that the hydraulic power station has an original function, the defects and the deficiencies of an original hydraulic power station are overcome, and functions, such as free regulation of oil pressure, optimal torque control, energy saving and accumulation, multifunctional changeover, no-load time delay startup and automatic control, which are provided for a load, are increased. The multifunctional hydraulic power station is simple in operating, saves electric energy by more than 50%, can provide hydraulic power for various petroleum drilling tools, is also suitable for other industries to provide hydraulic power for hydraulic tools by taking high-pressure hydraulic oil as mediums, and can achieve the effects of energy saving, energy accumulation and controllable torque.

Owner:范清云 +1

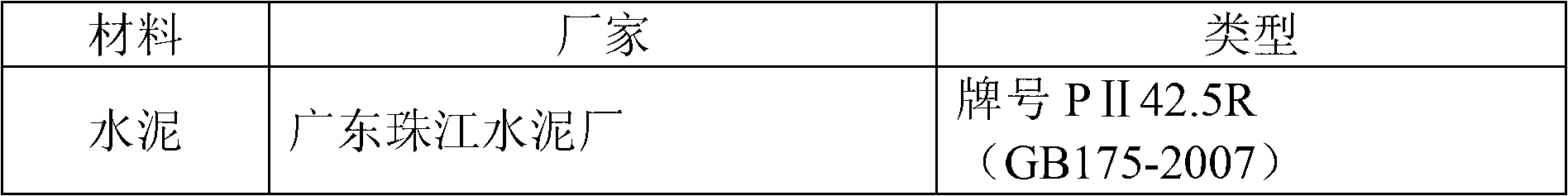

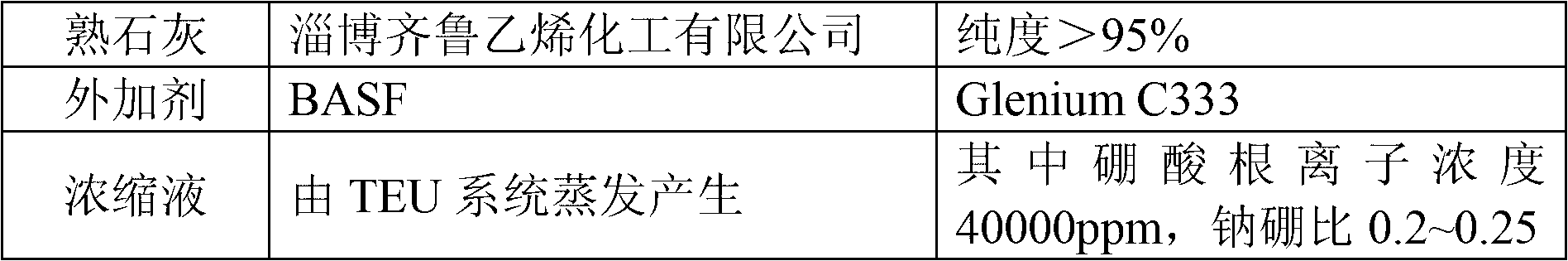

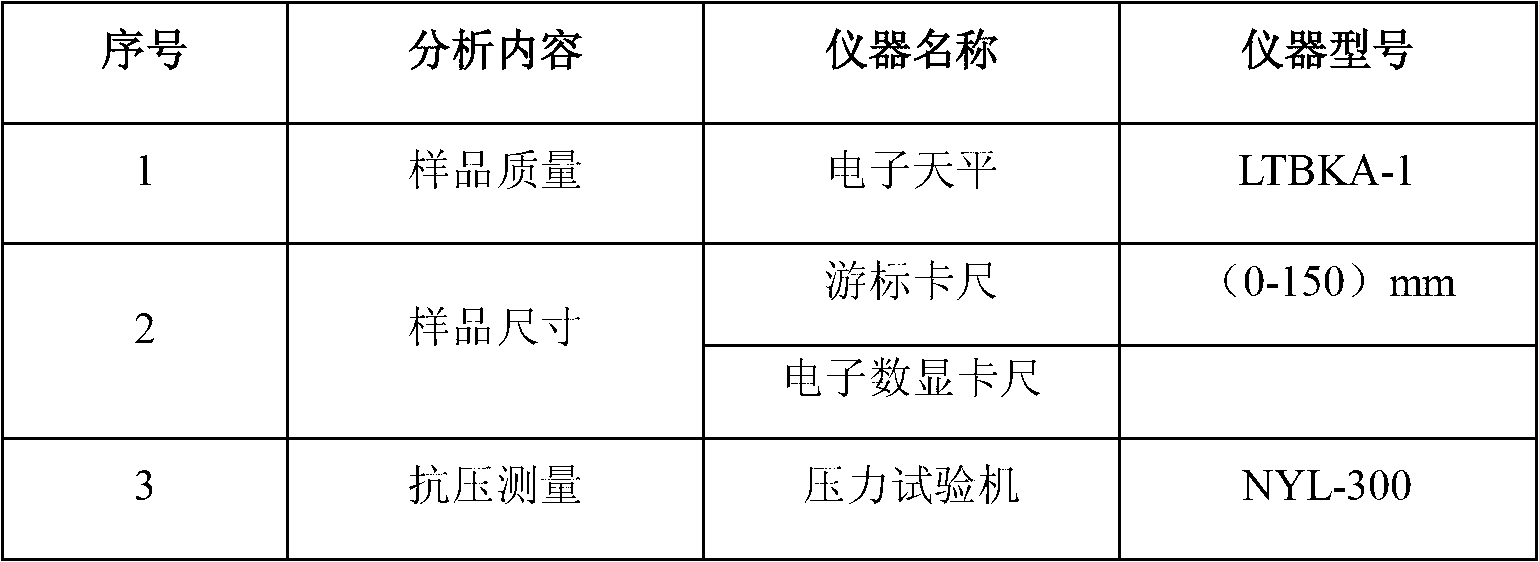

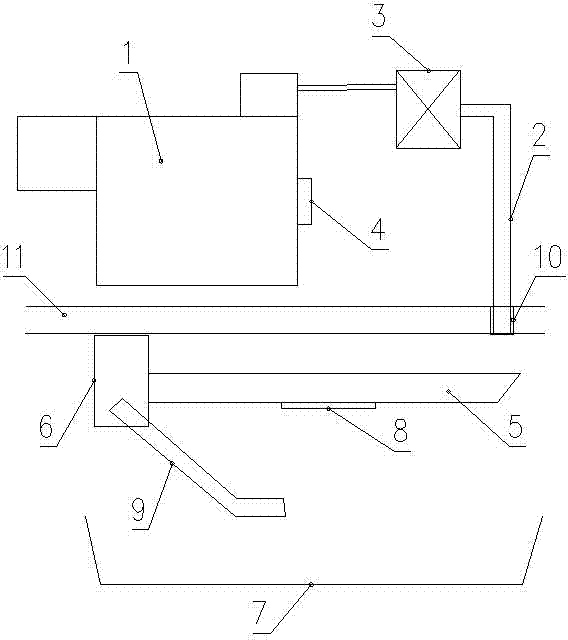

Cement solidification method of nuclear power wastes

ActiveCN102800377AReduce volumeHigh inclusion rateSolid waste managementRadioactive decontaminationSulfate radicalsPhosphate ion

The invention discloses a cement solidification method of nuclear power wastes. The cement solidification method comprises the steps of taking cement, lime and an additive as raw materials of a curing agent; detecting the density of concentrated solution, the concentration of boric acid radical ions, total salt content, the concentration of phosphate radical ions, and the concentration of sulfate radical ions in nuclear power waste concentrated solution; determining the weight of the needed cement, additive and lime; sequentially adding the additive, the lime and the cement in the nuclear power waste concentrated solution, and stirring; and standing and curing slurry to obtain the cement solidification body. According to the cement solidification method of the nuclear power wastes provided by the invention, the volume of the cement solidification body is reduced, the containing rate of the nuclear power waste is increased, and the processing process is safe and reliable.

Owner:中广核工程有限公司 +1

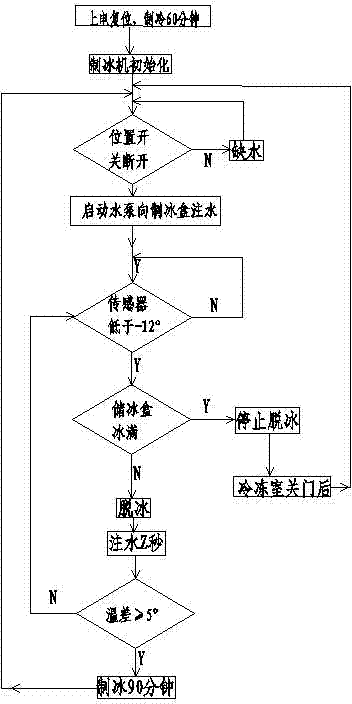

Ice machine for air-cooled refrigerator and control method of ice machine for air-cooled refrigerator

ActiveCN103940184ASimple structural designGood action coordinationDomestic cooling apparatusLighting and heating apparatusIcemakerIce storage

The invention discloses an ice machine for an air-cooled refrigerator and a control method of the ice machine for the air-cooled refrigerator. The ice machine comprises a water storage device and an ice making device. The control method of the ice machine includes the steps that a switch signal of the position of a water storage device body is firstly detected, then a water pump is controlled by an electric control device to be started for Z seconds, whether ice making is completed or not is detected, whether an ice storage box is filled with ice or not is detected, deicing is carried out if the ice storage box is not filled with the ice, then water injection is carried out, whether the rising temperature is higher than 5 DEG C or not after water injection is carried out is judged, if the rising temperature is lower than or equal to 5 DEG C, the ice making process is restarted, and if the rising temperature is higher than 5 DEG C, the ice making process is restarted after the ice making state is kept for 90 minutes. According to the ice machine for the air-cooled refrigerator and the control method, the amount of the supplied water is accurate, ice making completing conditions can be accurately judged, whether the ice storage box is filled with ice blocks or not is accurately detected through fewest elements, structural design is optimized, the motion matching effect is good, the manufacturing cost is reduced, and a water injection pipe is prevented from being blocked by freezing.

Owner:河南新飞制冷器具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com